Page 1

Operating Instructions

VEGASON 54P … 56P (Profibus PA)

Level and Pressure

PROF I

PROCESS FIELD BUS

BUS

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function ................................................................................. 4

1.2 Application features ............................................................. 5

1.3 Profibus output signal .......................................................... 6

1.4 Adjustment ............................................................................ 7

1.5 Type survey ........................................................................ 11

1.6 Type code ........................................................................... 12

2 Mounting and installation

2.1 Mounting ............................................................................. 13

2.2 General installation instructions ........................................ 15

2.3 Measurement of liquids ..................................................... 17

2.4 Measurement of solids ...................................................... 19

2.5 Socket extensions ............................................................. 20

2.6 False echoes ...................................................................... 21

2.7 Installation mistakes ........................................................... 23

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGASON 54P … 56P

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the operating instructions and come with the Ex approved instruments.

Page 3

Contents

3 Electrical connection

3.1 Connection .......................................................................... 26

3.2 Connection cables and bus configuration ....................... 26

3.3 Sensor address ................................................................. 29

3.4 Connection of the sensor .................................................. 31

3.5 Connection of the external indicating instrument ............ 32

3.6 Bus configuration ............................................................... 33

4 Setup

4.1 Adjustment media .............................................................. 38

4.2 Adjustment with the PC ...................................................... 39

4.3 Adjustment with the adjustment module MINICOM ........ 39

5 PA function diagram and parameters

5.1 PA function diagram........................................................... 46

5.2 Status bytes ....................................................................... 50

5.3 Parameter listing ................................................................ 51

6 Diagnosis

6.1 Simulation ............................................................................ 56

6.2 Error codes ........................................................................ 56

7 Technical data

7.1 Data ..................................................................................... 57

7.2 Data format of the output signal ........................................ 62

7.3 Approvals ........................................................................... 63

7.4 Dimensions ......................................................................... 63

VEGASON 54P … 56P 3

Page 4

1 Product description

1.1 Function

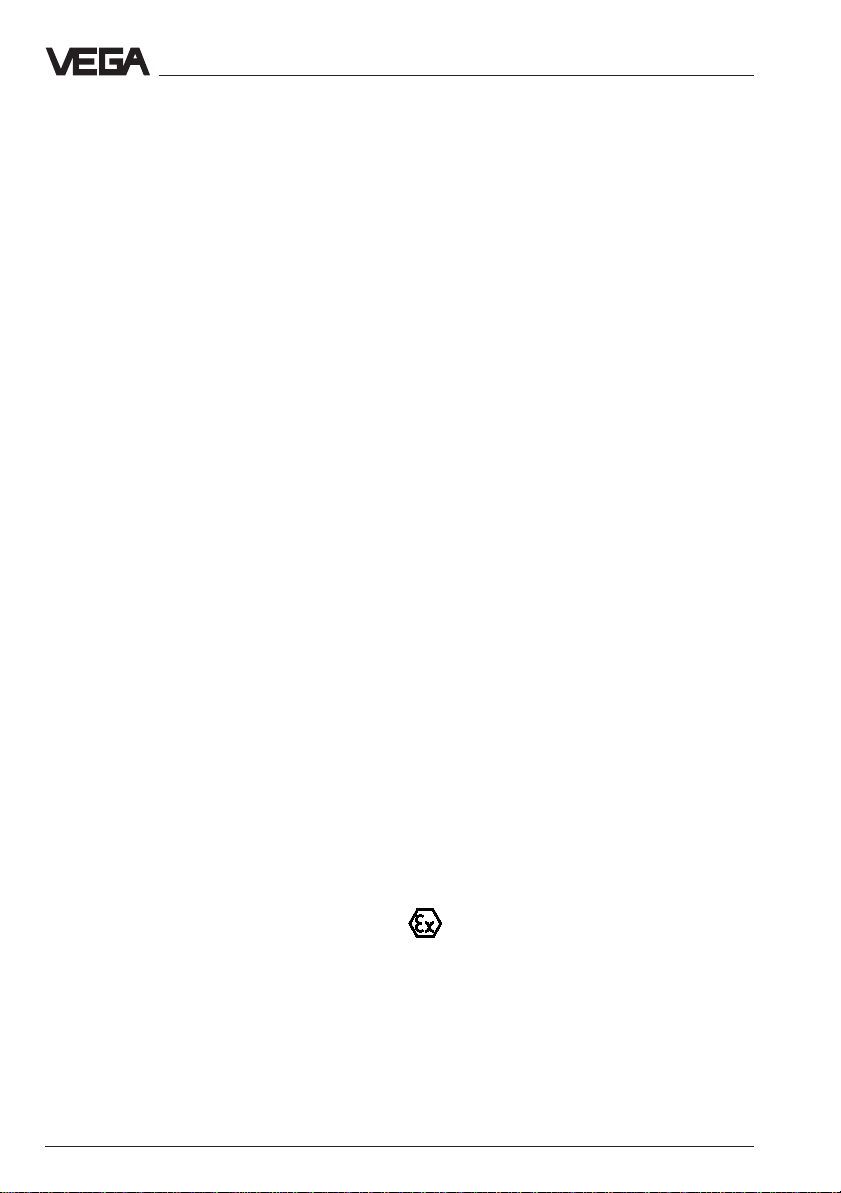

Continuous level measurement with ultrasonic

sensors is based on the running time measurement of ultrasonic pulses.

Product description

VEGASON 54 … 56 sensors are a newly

developed generation of extremely compact

ultrasonic sensor for level measurement.

They were developed for liquids and

especially for solids and larger measuring

distances. They are the right choice for

applications in silos, bunkers and material

dumps.

Due to small housing dimensions and process fittings, the compact sensors are an

unobtrusive, and most of all, very costeffective solution for your level measurement

applications. With the integrated display and

a special sensor intelligence in conjunction

with large measuring ranges, they enable

high-precision level measurement and can

be used for applications in which the advantages of non-contact measurement could

never before be realised.

The outputs generate a digital Profibus PA

signal as output, i.e. measurement signal.

Measuring principle

High-performance piezoceramic transducers

emit focused ultrasonic pulses which are

reflected by the product surface. The measurement electronics prepares a precise image of the environment from the reflected

ultrasonic pulses. The transducers work both

as transmitter and receiver. As receiver, the

transducers are high-sensitivity piezo microphones.

Meas.

distance

emission - reflection - reception

The measurement electronics precisely calculates the distance between transducer and

medium from the speed of sound and the

measured running time of the emitted sound

impulse. The distance is then converted into

a level-proportional signal and, in conjunction

with the sensor parameter settings, made

available as a precise, calibrated level value.

Since the speed of sound is subject to temperature influence, the transducer also continuously detects the ambient temperature, so that the level is precisely measured

even in case of varying ambient temperature.

4 VEGASON 54P … 56P

Page 5

Product description

Output signal

The level-proportional Profibus PA measurement signal is processed and outputted

completely digitally. Digital processing of the

measurement signal ensures an accuracy

which could be never reached by an analogue measurement signal, as the digital

signal is always transmitted error-free right

up to the last decimal position. Varying

resistances or tiny leakage currents do not

influence the accuracy of digital technology.

The digital signal is always clear and unambiguous.

The digital signal, giving a faithful representation of the adjusted measuring range of the

sensor, can be modified by various parameter settings.

Measured value display

As an option, the series 50 ultrasonic sensors

can be equipped with an indicating instrument for direct, local level survey. The indicating instrument shows the precise level by

means of the analogue bar graph and the

digital number value. In addition to the indication in the sensor, you can have the level

displayed with the VEGADIS 50 external

indicating instrument at a distance of up to 25

m from the sensor. The external measured

value display operates, like the integrated

display, independently of the PA output signal

and can be modified through individual parameter settings.

1.2 Application features

Two-wire technology

• Power supply and output signal on one

two-wire cable.

• Output signal and signal processing completely digital, therefore maximum accuracy.

• Profibus profile 3 – sensor.

Applications

• Level measurement of solids, liquids and

pastes.

• Gauge measurement, distance measurement, object monitoring and conveyor belt

monitoring.

Rugged and precise

• Measurement unaffected by substance

properties such as density, conductivity,

dielectric constant…

• Suitable for corrosive substances.

• Measuring range 0.8 m … 70 m.

Adjustment options

• With adjustment software VEGA Visual

Operating (VVO) on the PC.

• With detachable adjustment module

MINICOM.

Measured value display

• Measured value display integrated in the

sensor.

• Optional display separate from sensor.

• Adjustment module MINICOM in sensor.

Connection to any process

• G 1 A, DN 50, DN 80, DN 200, DN 250

Approvals

• CENELEC, ATEX, PTB

VEGASON 54P … 56P 5

Page 6

Product description

1.3 Profibus output signal

PROPRO

PROcess

PROPRO

sult of a joint project of thirteen companies

and five universities. The companies Bosch,

Klöckner-Möller and Siemens played a decisive role. The specifications of the bus are

described in the protocol layers 1, 2 and 7 of

the ISO/OSI reference model and are available from the PNO (Profibus user organisation). Layers 3 … 5 have not yet been

developed as a standard, leaving Profibus

with far-reaching perspectives for the future.

Today approx. 600 companies make use of

Profibus technology and belong to the PNO.

Profibus

Specification, Profibus

Periphery and Profibus

mation.

As a process automation bus, Profibus PA

enables power supply over the bus. Up to 32

sensors can be operated on a shielded twowire cable that carries both power supply

and measurement signal. In Ex areas, up to

ten sensors can be connected from the PA

level to one two-wire cable (EEx ia).

Bus structure

The Profibus DP and PA network consists of

up to 126 master and slave participants.

Data are always exchanged from point to

point, with the data traffic being exclusively

controlled and checked by master devices.

Communication is carried out according to

the Token-Passing procedure. This means

that the master holding the Token can contact

the slaves, give instructions, enquire data

and cause the slaves to receive and transmit

data. After the work is done or after a predetermined time interval, the Token is passed

on by the master to the next master.

FIFI

BUSBUS

FIeld

BUS (PROFIBUS) is the re-

FIFI

BUSBUS

FMSFMS

FMS stands for Fieldbus Messaging

FMSFMS

DPDP

DP for Decentralised

DPDP

PP

AA

P

A for Process Auto-

PP

AA

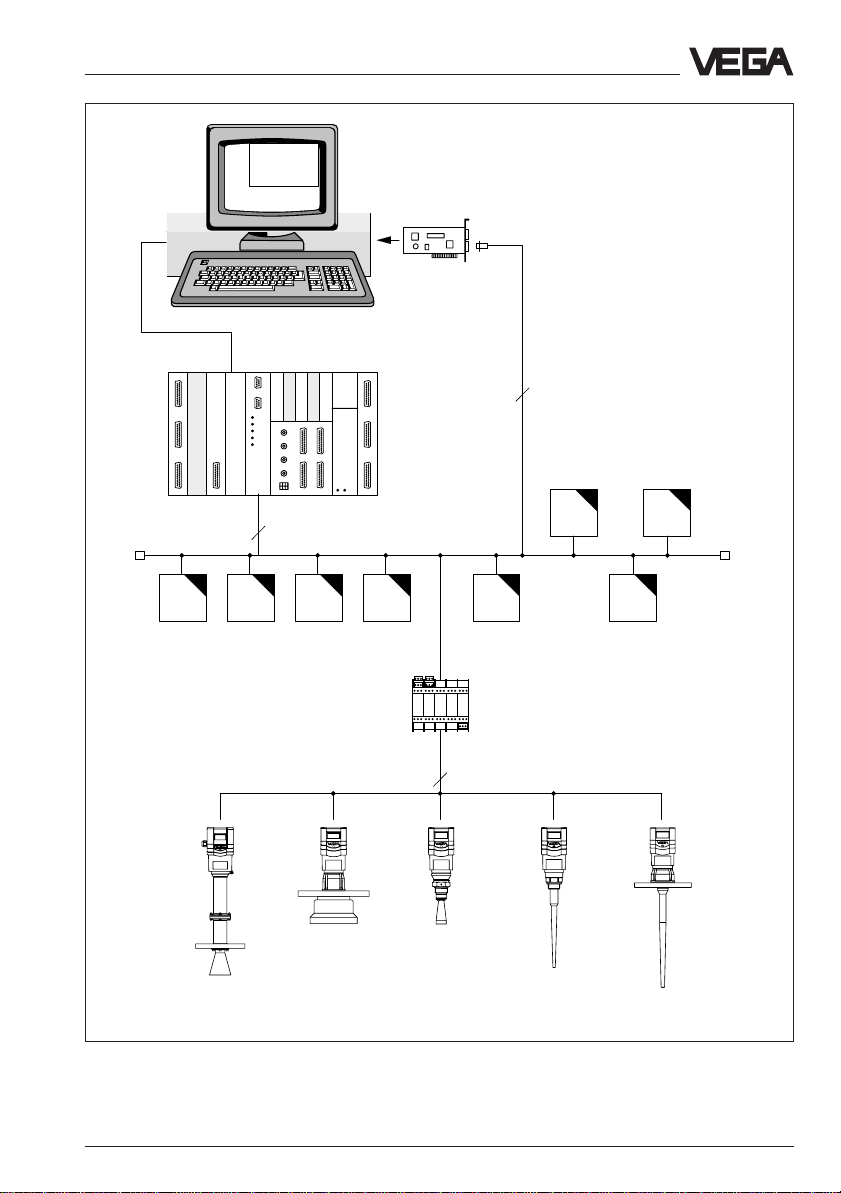

Master-Class 1

is the actual automation system, i.e. the process control computer or the PLC that enquires and processes all measured values.

Master-Class 2

One or several Master-Class 2 can operate in

a Profibus network. As a rule, Master-Class 2

devices are engineering, adjustment or visualisation stations. The VEGA adjustment software VVO (VEGA Visual Operating) operates

as Master-Class 2 participant on the DP bus

and can work on an engineering PC, on an

adjustment PC or on the process control

computer and can access any VEGA sensor

on the PA level.

Instrument master file

A so-called GSD file is delivered with every

VEGASON Profibus sensor. This file is necessary for integrating the sensor into the bus

system. The GSD file (instrument master file)

contains, beside the sensor name and the

manufacturer, the sensor-specific communication parameters which are necessary for a

stable integration of the sensor in the bus.

Load the GSD file belonging to the sensor

into your bus configuration program. If the

GSD file is not available, it can be loaded

from the VEGA homepage:

http://www.vega.com.

Do not confuse the GSD file with the EDD

(Electronic Device Description), a file necessary for the PDM environment (this can be

also found on the VEGA homepage).

6 VEGASON 54P … 56P

Page 7

Product description

1.4 Adjustment

Each measuring situation is unique. For that

reason, every ultrasonic sensor needs some

basic information on the application and the

environment, e.g. which level means "empty"

and which level "full". Beside this "empty and

full adjustment", many other settings and

adjustments are possible with VEGASON

ultrasonic sensors. The output of echo

curves or the calculation of vessel linearisation curves by means of vessel dimensions are only two examples.

Profibus adjustment scheme

In the Profibus environment, there are different adjustment concepts and adjustment

tools which often differ considerably from

manufacturer to manufacturer. From the user’s point of view, a manufacturer-independent adjustment program which could be

operated directly on the Profibus DP, as well

as at any system node (e.g. the engineering

station or the process control), would be

ideal.

In the past, only the program "SIMATIC PDM",

based on the HART® adjustment scheme,

could fulfil this wish (though with the limitations common to HART®). As with HART®, the

availability of an instrument-specific database

for a comprehensive adjustment with PDM

(Process Device Managing) is a requirement.

Otherwise, only the basic instrument functions, such as adjustment, are available. In

the PDM environment, this instrument-specific database is called EDD (Electronic Device Description), in perfect analogy to the

HART® environment which also requires,

except for the VEGA HART® instruments, a

DD (Device Description) for each sensor.

We are aware of the disadvantages of the

HART® environment: for each sensor/participant, an individual DD must be loaded, which

in addition, must always be the latest and

most up-to-date DD. Special adjustment

options such as e.g., the output of an echo

curve, are available neither with HART® nor

with PDM. User-friendly adjustment is out of

the question. With VEGA’s adjustment program VVO, those restrictions belong to the

past.

The legitimate wish of many Profibus users

for a manufacturer-independent adjustment

tool without EDD has been realised in the

form of PACTware

TM 1)

. An association of a

number of process technology companies

developed PACTwareTM: a Process Automation Configuration Tool that can run different

manufacturer software tools under a standardised user interface and adjustment

scheme. Specialists call this technology Field

Device Transcription. Just as different Windows printer drivers enable operation of

completely different printers under a single

user interface, PACTware

TM

enables operation

of all field instruments under a single user

interface. Instrument-specific databases

(EDD), like those required for SIMATIC PDM,

are not necessary.

As a result of this development, four adjustment media are available for VEGA Profibus

sensors:

- adjustment with the PC and the adjustment

program VVO (VEGA Visual Operating) as

stand-alone tool, on the segment coupler

or directly on the sensor.

- adjustment with the detachable adjustment

module MINICOM in the sensor

- adjustment with the SIMATIC PDM adjust-

ment program (requires EDD instrument

databases) from the control room

- adjustment with the manufacturer-inde-

pendent user interface PACTwareTM on the

sensor, from the control room or on the

segment coupler.

VEGASON 54P … 56P 7

Page 8

Product description

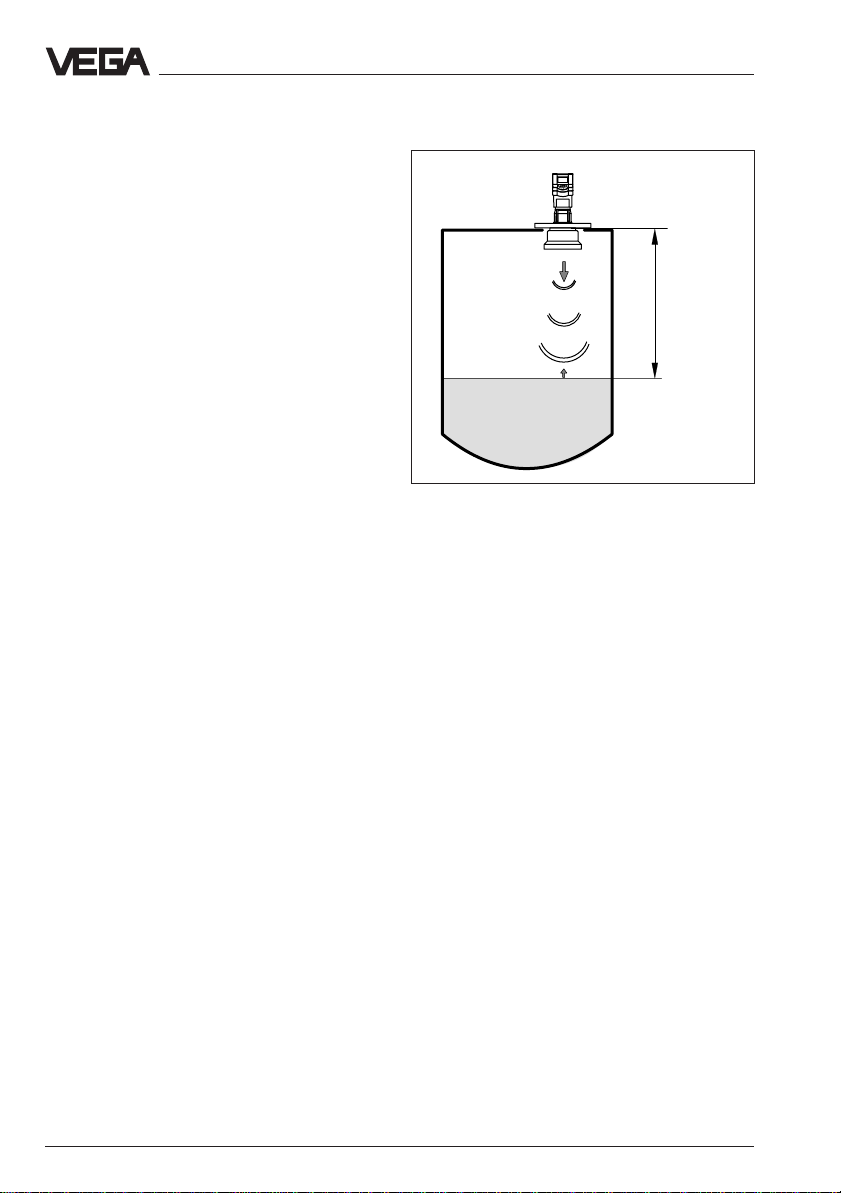

Adjustment with the adjustment program VVO - VEGA Visual Operating

The setup and adjustment of the ultrasonic

sensors is generally done on the PC with the

adjustment program VEGA Visual Operating

(VVO) under Windows®. The program leads

quickly through adjustment and parameter

setting by means of pictures, graphics and

process visualisations.

Note:

The adjustment program VVO must be available in version 2.70 or higher.

The VEGA adjustment software VVO (VEGA

Visual Operating) operates either as a

subprogram of the host program PACTware

acc. to the FDT concept (Field Device Tool) or

as an independent adjustment program on

any PC, engineering station or process control computer.

The adjustment program recognises the sensor type

Visualised input of a vessel linearisation curve in the

adjustment program VVO

VEGA’s adjustment program VVO can access the adjustment options of VEGA sensors in their entirety and, if necessary, can

update the complete sensor software. For

communication with Profibus sensors, the

adjustment program either requires a

Profibus-Master-Class2 interface card or the

interface adapter VEGACONNECT 3.

The PC with the Profibus interface card can

be connected directly to any point on the DP

bus with the standard RS 485 Profibus cable.

In conjunction with the adapter

VEGACONNECT, the PC can be connected

directly to the sensor. VEGACONNECT communicates via a small plug directly with the

respective sensor.

The adjustment and parameter data can be

TM

saved at any time on the PC with the adjustment software and can be protected by

passwords. If necessary, the adjustments

can be transferred quickly to other sensors.

In practice, the adjustment program VVO is

often installed as a tool on an engineering

station or an operating station. VVO then

accesses all VEGA sensors directly over the

bus via the Profibus interface card (e.g. from

Softing) as Master Class 2, from the DP level

to the PA level (via segment coupler) right

down to the individual sensor.

Beside the instrument master file (GSD), with

which a sensor is logged into the Profibus

system, the majority of all Profibus sensors

requires for adjustment, beside the specific

adjustment software, also a so-called EDD

(Electronic Device Description) for each

sensor, in order to access and adjust the

sensor from the bus levels. This is not the

case with VVO. The adjustment software

VVO can communicate at any time with all

VEGA sensors without the help of a special

database. Of course, all other non-Profibus

VEGA sensors can be adjusted with the

adjustment software as well (4 … 20 mA

sensors or VBUS sensors). With VEGA sensors, it is not necessary to go looking for the

latest EDD. This is the essential requirement

for a manufacturer-independent adjustment

program, like PACTwareTM, anticipated by

many users, see following pages.

8 VEGASON 54P … 56P

Page 9

Product description

Adr. 21

SPS

Adr. 22

VVO

3

PA-

Adr. 23

Bus

Master-Class 1

Adr. 1

DP-Bus

Adr. 24

Adr. 10

Adr. 25 … 56

2

Profibus DP interface card as

Master-Class 2 (e.g. Softing)

3

Adr. 58

Adr. 57

Segment coupler

(max. 32 participants)

Adr. 60

Adr. 59

Adr. 26

Adr. 25

Adr. 27

Adr. 28

Adr. 29

Adjustment of the VEGASON ultrasonic sensors from process control via a Profibus interface card in the process control computer or in an additional PC. The adjustment software VEGA Visual Operating (VVO) accesses

the sensors bidirectionally via the interface (interface card).

VEGASON 54P … 56P 9

Page 10

Product description

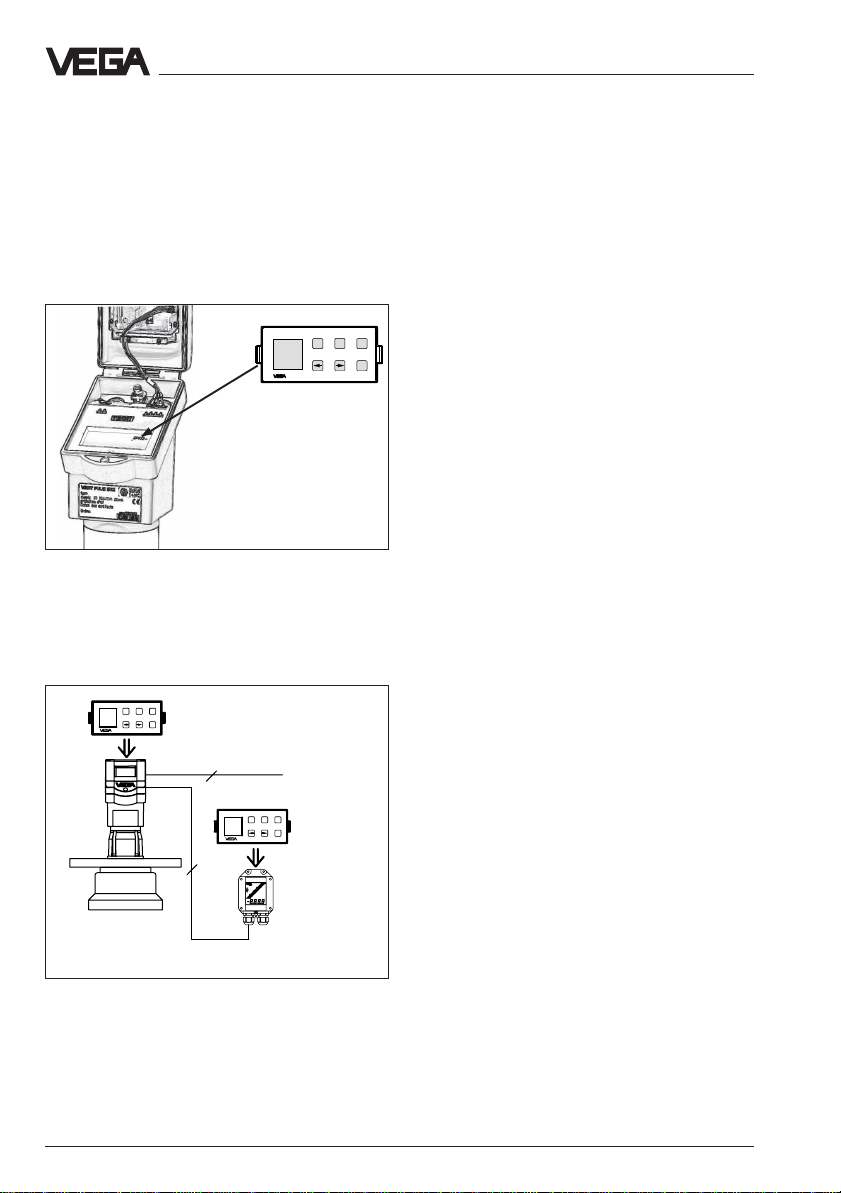

Adjustment with adjustment module

MINICOM

With the small (3.2 cm x 6.7 cm) 6-key adjustment module with display, you carry out

the adjustment in clear text dialogue. The

adjustment module can be plugged into the

ultrasonic sensor or into the optional, external

indicating instrument.

Tank 1

m (d)

12.345

Detachable adjustment module MINICOM

The adjustment module can be easily removed to prevent unauthorised sensor adjustment.

ESC

+

-

Tank 1

m (d)

12.345

OK

2

Tank 1

m (d)

12.345

4

PA-Bus

ESC

+

-

OK

ESC

+

-

OK

Adjustment with the SIMA TIC PDM

adjustment program

To adjust all essential functions of the VEGA

sensor with the adjustment station SIMATIC

PDM from Siemens, a so-called EDD is required. Without this EDD, only the basic functions such as min./max. wet adjustment or

integration time can be adjusted with the

PDM adjustment program. Further important

adjustment functions, such as input of the

measuring environment or false echo storage, are not available without EDD. After

integration of the EDD files in the Simatic PDM

adjustment software, all important adjustment

functions are accessible. If it is not at hand,

the obligatory GSD (instrument master file)

as well as the EDD (Electronic Device Description) necessary for PDM can be

downloaded from the VEGA homepage

(http://www.vega.com).

Adjustment with PACTware

PACTwareTM is a manufacturer-independent

automation/configuration tool through which

access to instruments of different manufacturers (Krohne, Pepperl + Fuchs, VEGA,

WIKA-, Bürkert…) is possible. The VEGA

adjustment software VVO works as a

subprogram/menu. PACTwareTM activates the

required menu options for the sensor/instrument being accessed.

PACTwareTM looks different than VVO and is

designed with a tree structure. Operating

instructions for PACTwareTM can be found in

the PACTware

described in this operating instructions

manual.

TM

documentation. They are not

TM

max. 2.5 m

Adjustment with detachable adjustment module. The

adjustment module can be plugged into the ultrasonic

sensor or into the external indicating instrument

VEGADIS 50.

10 VEGASON 54P … 56P

Page 11

Product description

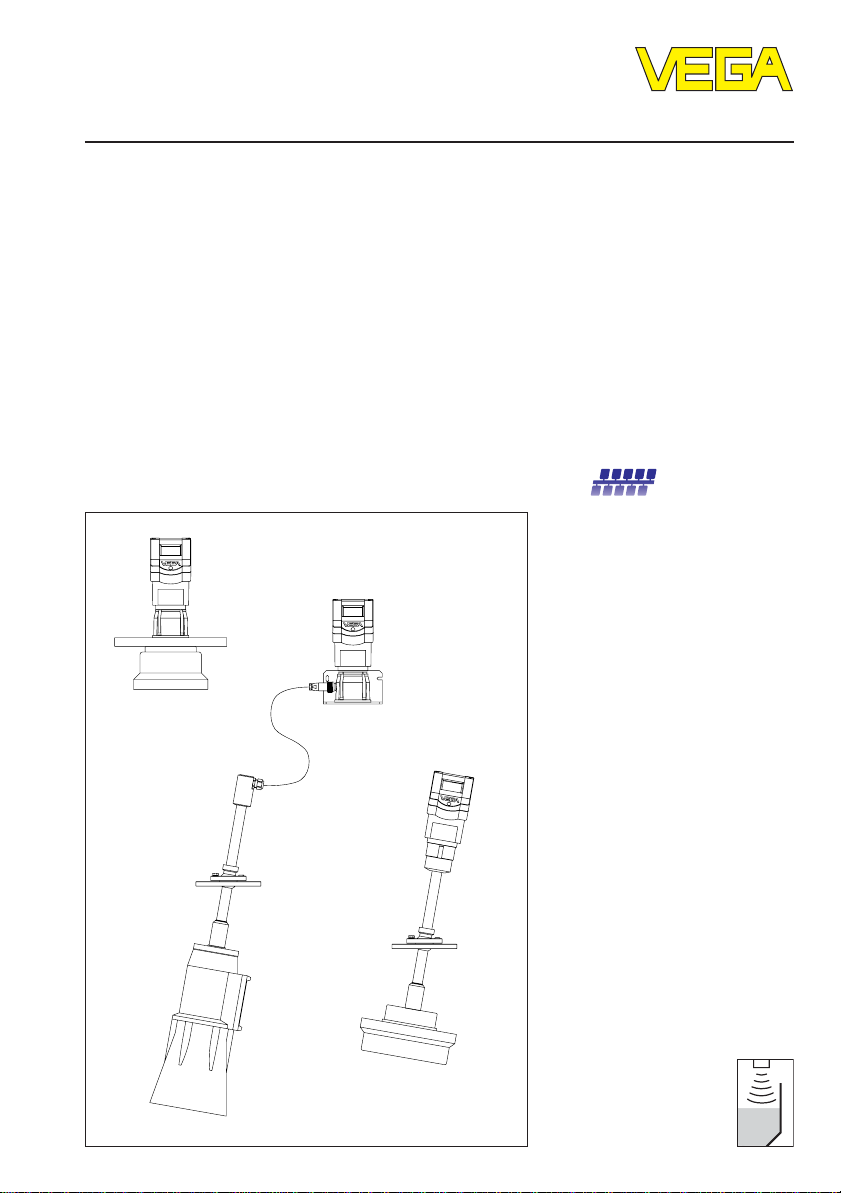

1.5 T ype survey

VEGASON 54 … 56 sensors are a newly

developed generation of very compact ultrasonic sensors for large measuring ranges.

For shorter measuring ranges, VEGASON

51 … 53 sensors are used.

Thanks to the small housing dimensions and

process fittings, the compact sensors are a

very cost-effective solution for your level

measurement applications. Swivelling holders

enable quick orientation of the transducers to

the liquid or solid surface. Because the sensor electronics and transducer can be separated, installation is very simple. It is possible

to separate the sensor electronics up to

300 m from the transducer. As a result, the

transducer can handle ambient temperatures

up to 150°C (VEGASON 56).

General features

• Application in solids and liquids.

• Measuring range 0.8 m … 70 m.

• Ex-approved in Zone 10 (IEC) or Zone 11

(ATEX) classification mark EEx ia [ia] IIC T6

or Zone 20/21/22, VEGASON 56 also

Zone 1.

• Integrated measured value display in the

sensor or in the external indicating instrument which can be mounted up to 25 m

away from the sensor.

VEGASON 54

Version A Version B Version C Version D

VEGASON 55

Version A Version B Version C Version D

VEGASON 56

Version A Version B Version C Version D

VEGASON 54P … 56P 11

Page 12

1.6 Type code

Product description

VEGASON 54 K EX.XX X X X X X X X

K - Plastic housing PBT, M20 x 1.5 cable entry

N - Plastic housing PBT,

A - Aluminium housing, M20 x 1.5 cable entry

FEP - Version A, flange DN 200 (PP)

FEA - Version A, flange DN 200 (Aluminium)

FLP - Version A, flange 8" (PP)

FLA - Version A, flange 8" (Aluminium)

SAS - Version B, flange swivelling holder DN 50

SBS - Version B, flange swivelling holder DN 80

GAS - Version C, flange swivelling holder DN 50

GBS - Version C, flange swivelling holder DN 80

RGS - Thread G 1 A

YYY - Other process fittings

X - without display

A - with integrated display

X - without adjustment module MINICOM

B - with adjustment module MINICOM (mounted)

A - 20 … 72 V DC; 20 … 250 V AC; 4 … 20 mA (four-wire)

B - 20 … 72 V DC; 20 … 250 V AC; 4 … 20 mA, HART

(four-wire)

E - Power supply via signal conditioning instrument

G - Segment coupler for Profibus PA

P - 90 … 250 V AC (only in USA)

N - 20 … 36 V DC, 24 V AC (only in USA)

Z - Supply via signal conditioning instrument (only in USA)

.X - without approval

EXS.X - StEx Zone 10

K - Analogue 4 … 20 mA output signal (two-wire or

four-wire technology)

V - Digital output signal (two-wire technology)

P - Profibus

Type 54 - Measuring range 1.0 … 25 m

Type 55 - Measuring range 0.8 … 45 m

Type 56 - Measuring range 1.6 … 70 m

Measuring principle (SON for ultrasonic)

½" NPT cable entry

®

12 VEGASON 54P … 56P

Page 13

Mounting and installation

2 Mounting and installation

2.1 Mounting

Version A

Sensors in version A (flange version) are

supplied completely assembled and ready

for operation. Immediately after mounting on

the vessel and electrical connection, they are

ready for operation.

Version B

Sensors in version B are supplied in two

parts (transducer and sensor electronics).

First of all, mount the transducer on the vessel or above the medium. There is a four-pole

jack at the end of the transducer tube. The

respective counterpart to the jack protrudes

out of the lower side of the sensor electronics. Insert the plug of the sensor electronics

(only possible in one position) into the jack of

the transducer tube. Continue pushing the

electronics housing onto the transducer tube,

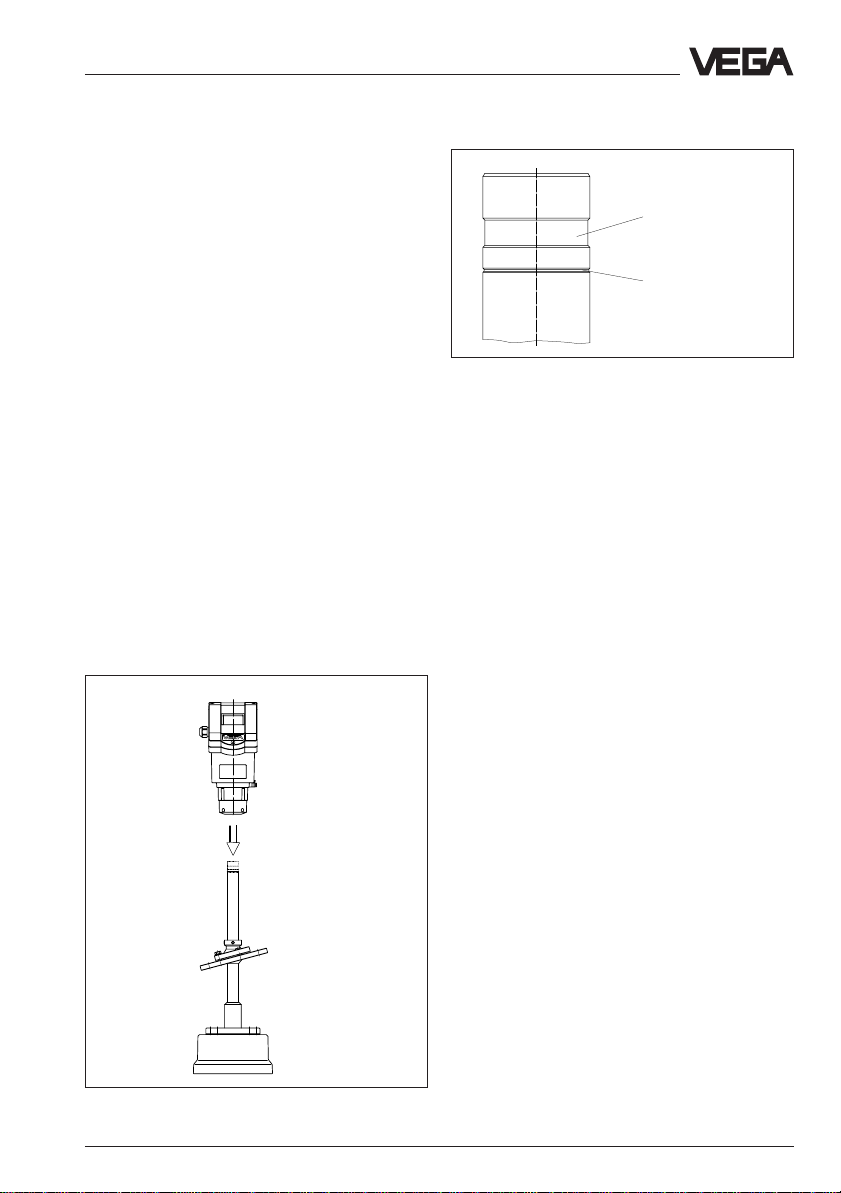

on which there is a wide and a narrow

groove.

Groove for locking the

headless screw

Mounting groove (must

no longer be visible after

mounting)

The wide groove is used for locking the

headless screws. The narrow groove is an

assembly mark. Move the electronics housing farther down over the transducer tube

until the mounting groove is no longer visible.

Fasten the housing with the headless screws

to the transducer tube. Use a 5 mm hexagon

screwdriver (or Allen wrench).

VEGASON 54P … 56P 13

Page 14

Mounting and installation

Ver sion C and D

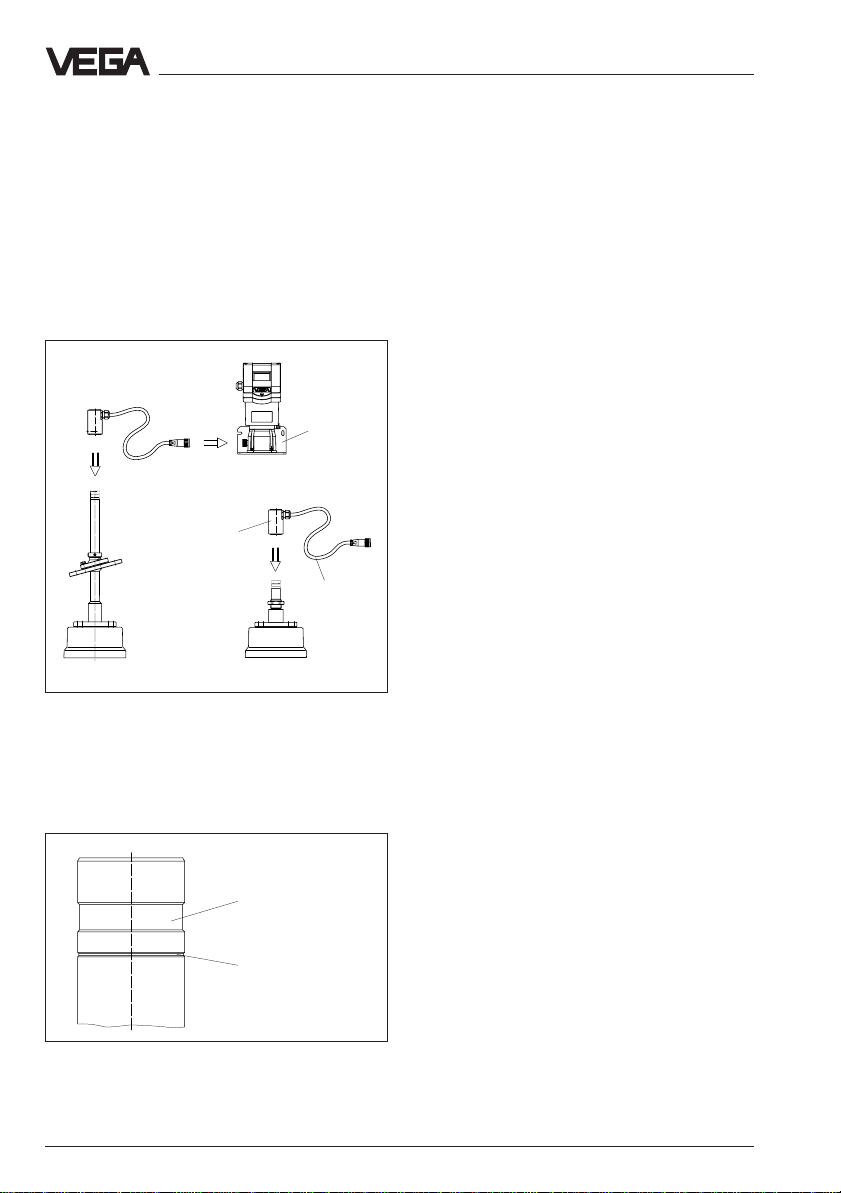

The sensors in version C and D are supplied

in three parts (transducer, sensor electronics

and transducer cable). First mount the transducer (see version B). There is a four-pole

jack at the transducer tube end. A respective

counterpart to the jack is provided in the

connection cylinder of the transducer cable.

Insert the connection cylinder plug into the

jack of the transducer tube. S

Connection

cylinder

Mounting

bracket

Connection

cylinder

Transducer

cable

On the end of the transducer tube you find a

wide and a narrow groove. The wide groove

is used for locking the cylinder with the headless screws. The narrow groove is the assembly mark.

Then push the connection cylinder onto the

transducer tube (with a slight swivelling motion) until the assembly mark is no longer

visible.

When the assembly mark is covered by the

cylinder, fasten the cylinder with the two

headless screws. Use a 5 mm hexagon

screwdriver (or Allen wrench).

Now mount the sensor electronics at the

requested location. The sensor electronics is

fastened to a mounting bracket so that it can

be mounted on a plain surface or on a wall.

Make sure that the sensor electronics is

mounted in such a way that there is enough

space above the electronics to open the

cover.

Now insert the plug at the other end of the

transducer cable into the jack on the electronics housing.

Note:

Avoid bending the transducer cable too

sharply when laying it out. This is a special

cable which could otherwise be damaged.

In addition, make sure that the cable cannot

be damaged during operation. A signal with

a voltage of approx. 1 kV is transmitted

(which could be a danger in Ex areas if the

cable is damaged) via the shielded cable

cores.

Groove for locking the

headless screws

Mounting groove (must

no longer be visible after

mounting)

14 VEGASON 54P … 56P

Page 15

Mounting and installation

2.2 General installation instructions

Measuring range

version, the instrument flange (version A).

Please note the information on the reference

Beside other criteria, you select your instrument according to the required measuring

range. The reference plane for the min. and

planes in chapter "7.4 Dimensions". The max.

filling depends on the required min. distance

and the mounting location.

max. distance to the liquid or solids is the

transducer end, or for instruments in flange

Reference plane

min. distance

1.0 m

100 %

0 %

Span

Min. distance, max. measuring range, span and reference plane

0 %

max. meas. range

max. meas. distance 25 m (type 54), 45 m (type 55), 70 m (type 56)

min. distance 0.8 m

100 %

Span

Reference plane

min. distance 1.4 m

100 %

0 %

Span

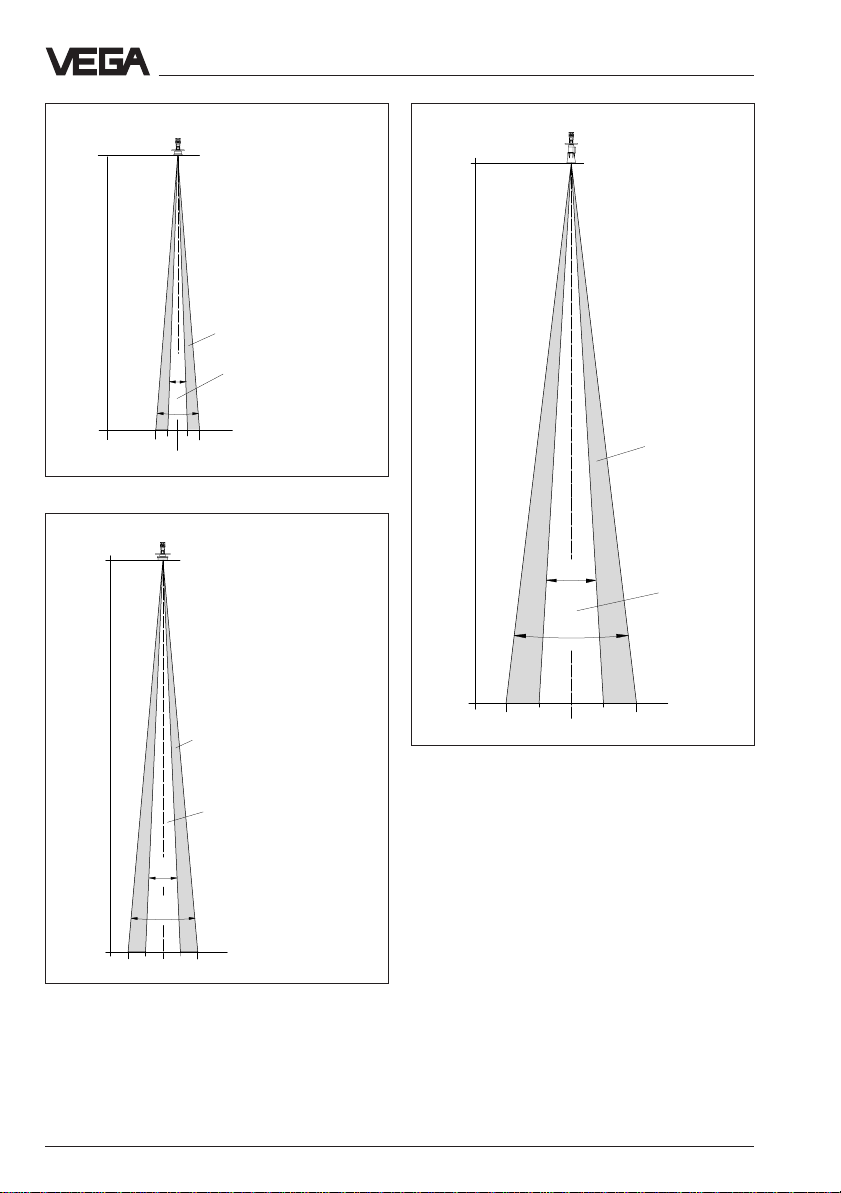

Beam angle and false echoes

At greater distance, the energy of the ultrasonic impulses distributes over a large area,

The ultrasonic impulses are focused by the

transducers. The impulses leave the transducer in a conical form similar to the beam

pattern of a spotlight. The beam angle is 4°

thus causing weaker echoes from obstructing surfaces. The interfering signals are

therefore less critical than those at close

range.

(VEGASON 54), 5° (VEGASON 55) and 6°

(VEGASON 56) at -3 dB emitted power.

Any object, e.g. tubes or struts inside this

emission cone will cause a large false echo.

Especially within the first few meters of the

If possible, orient the sensor axis perpendicularly to the product surface and avoid

vessel installations (e.g. pipes and struts)

within the 100 % area of the emission cone.

emission cone, pipes, struts, or other installations can interfere with the measurement. At a

distance of 6 m, the false echo of a strut has

an amplitude nine times greater than at a

distance of 18 m.

VEGASON 54P … 56P 15

The following illustration of the ultrasonic

beams is simplified and represents only the

main beam - a number of additional weaker

beams exists.

Page 16

0 m

Meas.

distance

Mounting and installation

VEGASON 56VEGASON 54

0 m

Emitted power

50 %

100 %

4˚

Emitted power

25 m

Meas.

distance

45 m

0 m

4

0,9

2,0

5˚

10˚

242

0

8˚

m

0,9

2,0

0

VEGASON 55

50 %

Emitted power

100 %

m

Emitted power

Meas. distance

50 %

Emitted power

6˚

100 %

Emitted power

12˚

70 m

3,7

7,5

3,7

0

m

7,5

Therefore, in practical application, the transducer has to be oriented so that the lowest

possible false echo signal strength is

achieved. Only giving attention to the size of

the useful echo is usually not adequate under

difficult measuring conditions. In most cases,

a low false echo level enables the sensor to

reliably pick up the useful echo. With the

adjustment software VVO on the PC, you can

view the echo image (see manual VVO "Sensor optimisation".

16 VEGASON 54P … 56P

Page 17

Mounting and installation

2.3 Measurement of liquids

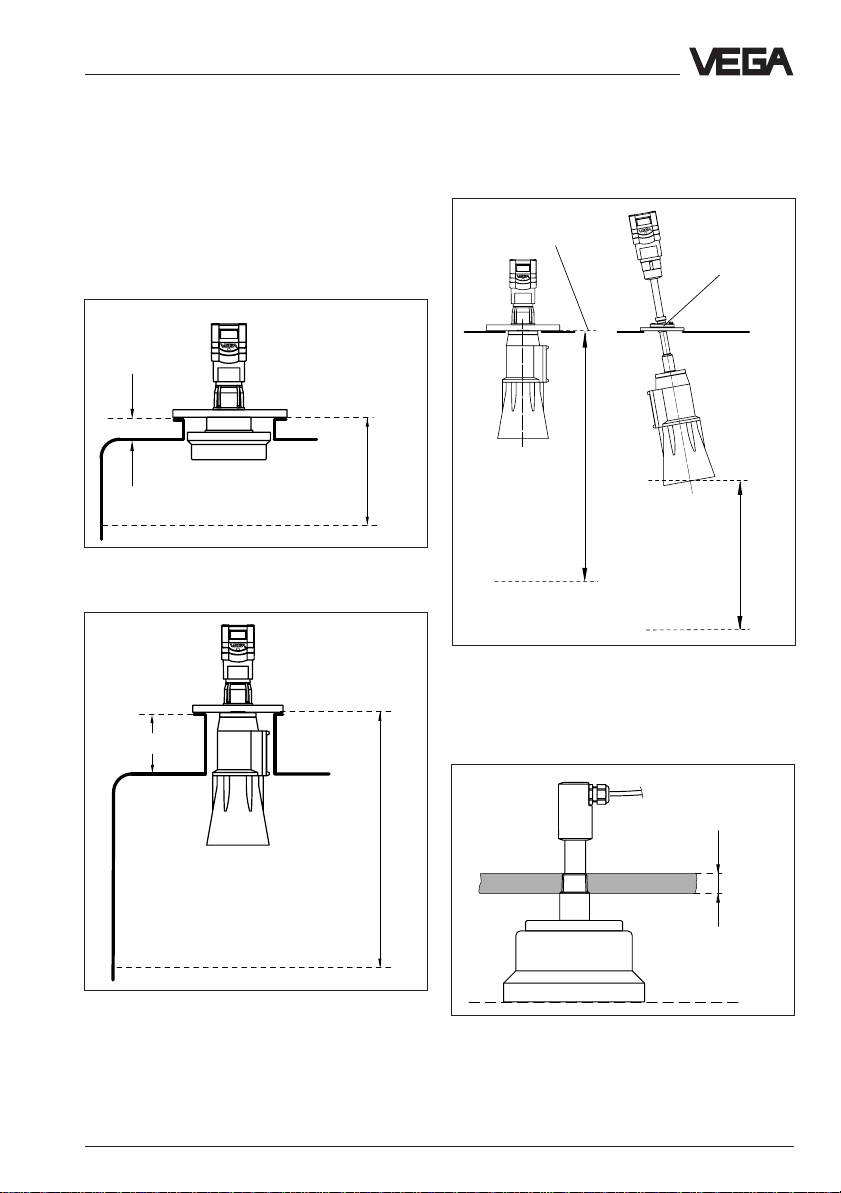

Flat vessel top

On flat vessels, mounting is usually done on

a very short DIN socket piece. The lower

side of the flange is the reference plane. The

transducer should protrude out of the flange

pipe.

< 100 mm

VEGASON 55 in flange version on short DIN socket

piece

< 400 mm

Reference plane

Min. distance

Type 54: 1 m

Type 55: 0.8 m

Reference plane

A mounting location directly on the vessel top

is ideal. A round opening in the vessel top is

sufficient to fasten the sensor with the flange

or version B and C with the swivelling holder.

Reference

plane

Min. meas. distance

1.8 m

Swivelling

holder

Min. meas. dis-

tance 1.4 m

Reference

plane

Flange version and swivelling holder on flat vessel

top

It is also possible to mount version C sensors

in a 1" thread.

Min. distance

1.8 m

< 60 mm

Reference plane

VEGASON 56 in flange version on short DIN socket

piece

Mounting of the transducer in a 1" thread

VEGASON 54P … 56P 17

Page 18

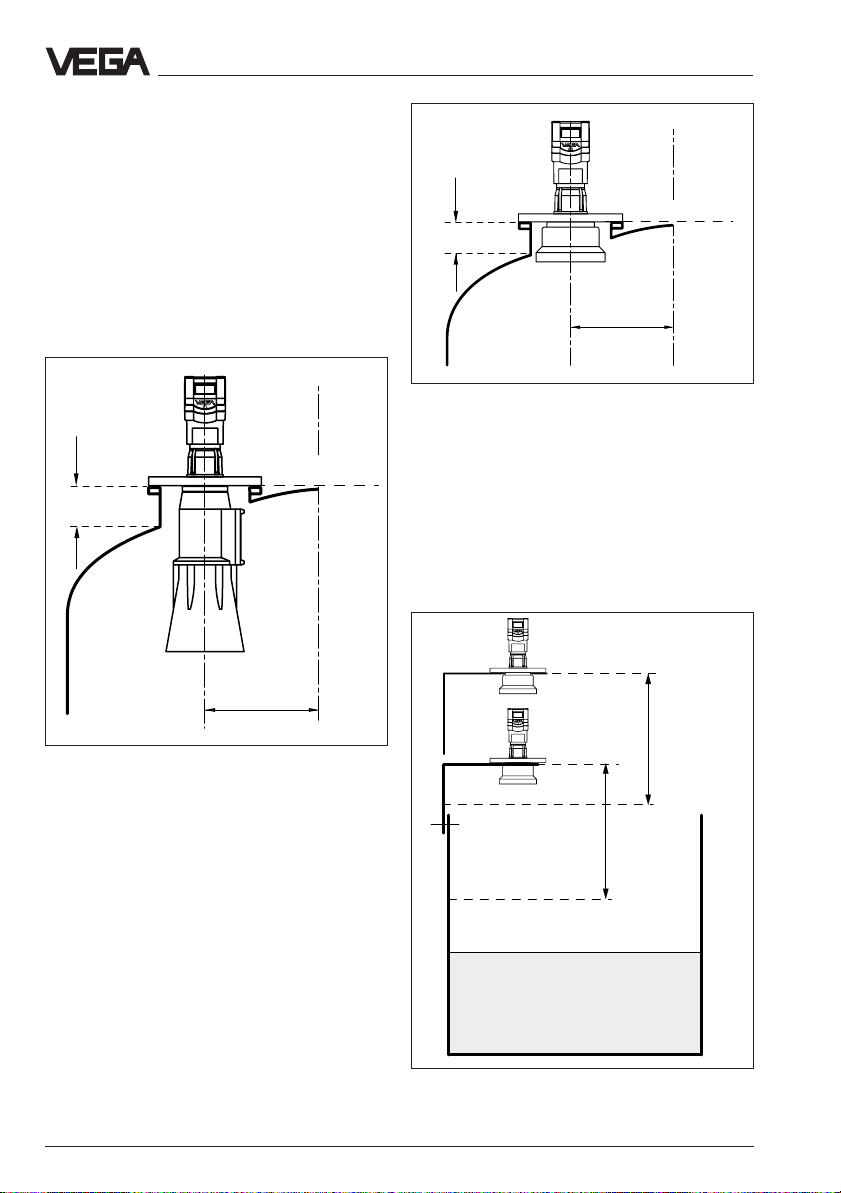

Dished tank top

On dished tank tops, please do not mount

the instrument in the centre or close to the

vessel wall, but approx. ½ vessel radius from

the centre. Dished tank ends can act as

paraboloidal reflectors. If the transducer is

placed in the focal point of the parabolic tank,

the ultrasonic sensor receives amplified false

echoes. The transducer should be mounted

outside the focal point. Parabolically amplified

echoes can be thereby avoided.

Mounting and installation

Reference plane

< 100 mm

½ vessel radius

VEGASON 54 on dished tank top; applies also to

VEGASON 55

< 400 mm

1

/2 vessel radius

VEGASON 56 on dished tank top

Reference plane

Open vessels

On open vessels, the sensors can be readily

installed on extended mounting brackets.

Mount the low-weight sensor onto such a

bracket and ensure a sufficient distance from

the vessel wall.

Reference plane

Min. meas.

Min. meas.

distance

distance

Reference plane

Open vessel

18 VEGASON 54P … 56P

Page 19

Mounting and installation

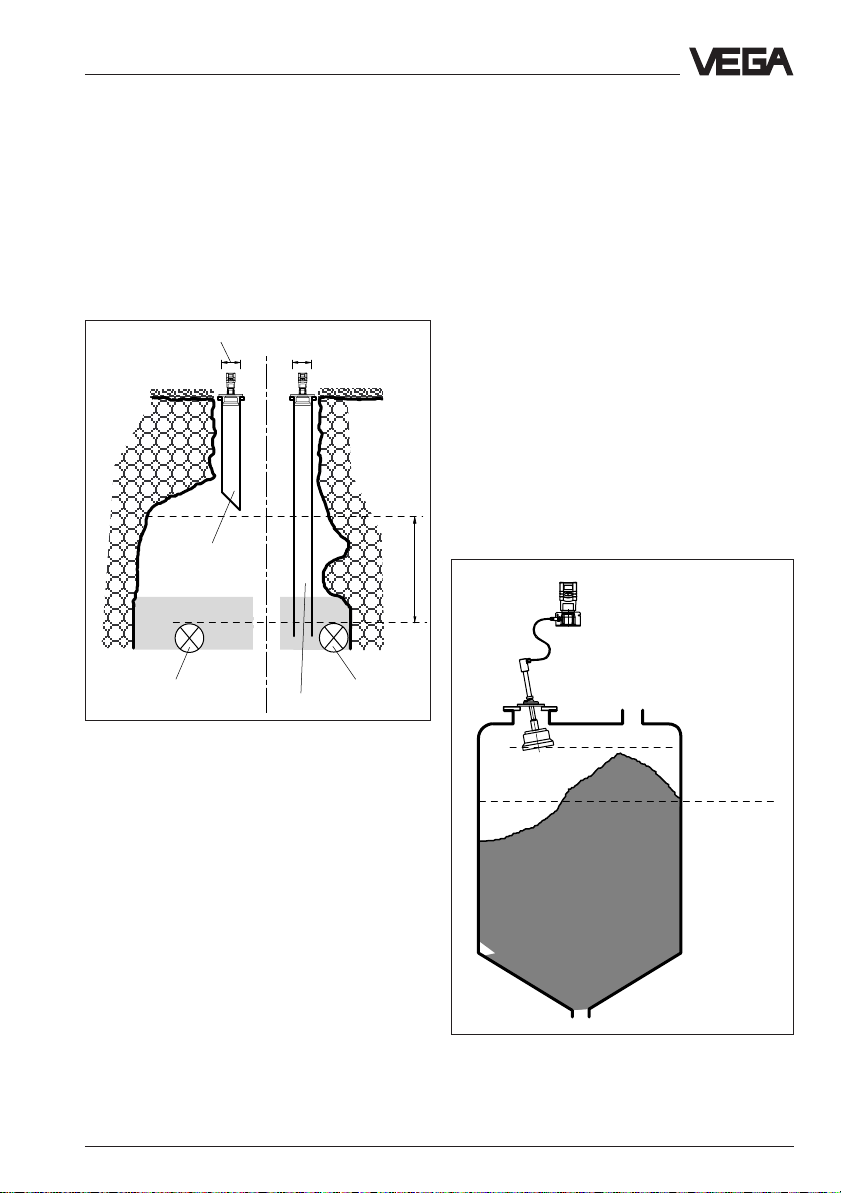

Pump shaft

Narrow, uneven shafts, wells and vessel

openings with very rough walls and shoulders make ultrasonic measurements extremely difficult due to strong false echoes.

This problem can be overcome by using an

extended socket piece or a complete measuring tube (see chapter "2.5 Socket extension").

see "2.5 Socket extensions"

Socket piece

Shaft pump

Measuring tube socket or measuring tube in a shaft

≥ 250 mm

Shaft pump

Measuring tube

min.

distance

Meas. range

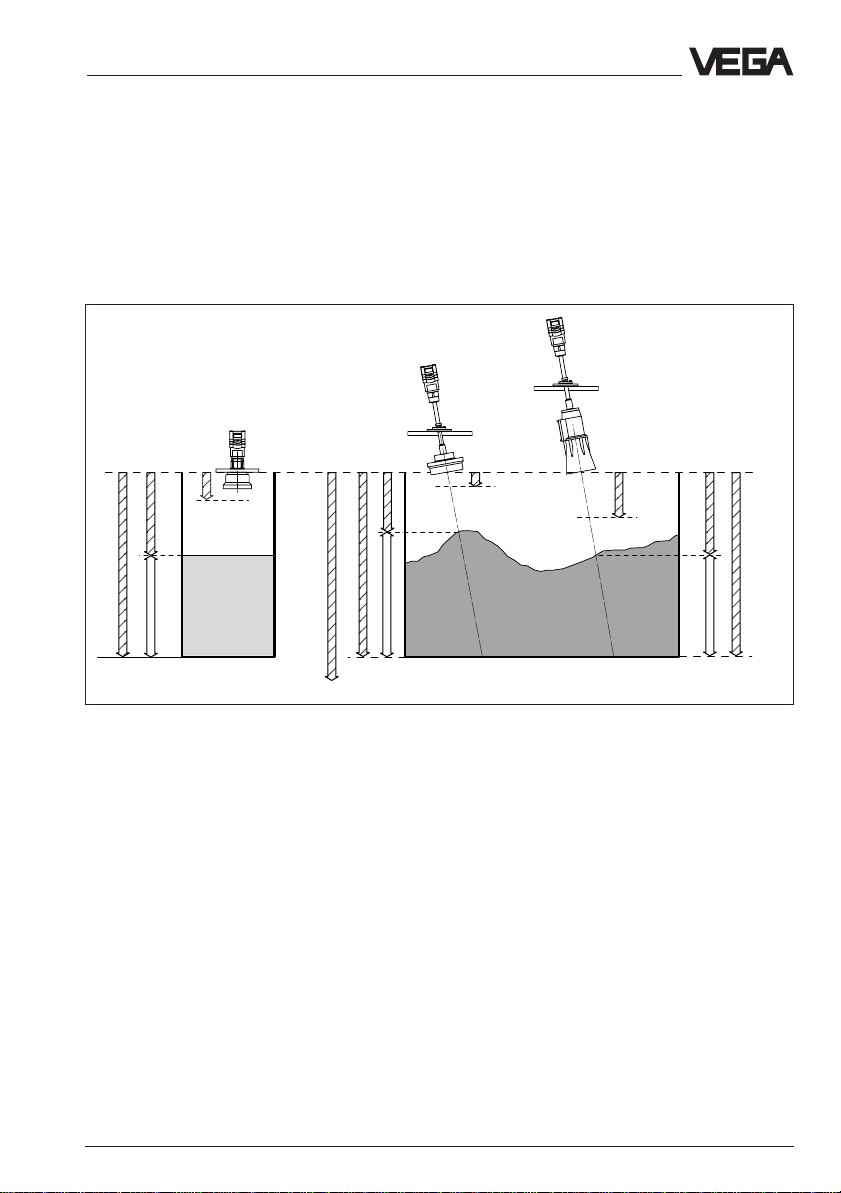

2.4 Measurement of solids

Flange mounting

For containers with solids, as with applications for liquids, the instrument can be

mounted on a short DIN socket piece. The

transducer end should protrude out of the

socket so that it does not interfere with ultrasonic signals. The swivelling holder enables

not only correct orientation to the product

surface but also minimisation of possible

false echoes.

Different filling conditions often lead to a varying product surface orientation. This causes

the useful echo to vary in quality. For this

reason, the transducer should be mounted in

such a way that, even in an empty vessel, the

false echo intensity remains as low as possible. You can view the echo curve on the PC

with the adjustment program VVO.

Reference plane

Shaft

Min. distance

Very good measuring results can be attained

with a measuring tube in continuous narrow

shafts, see illustration. The applied measuring tube must have smooth walls inside (e.g.

PE sewage pipe) and a diameter ≥ 200 mm.

This arrangement works well as long as the

inside of the measuring tube collects no dirt

or buildup (cleaning necessary). You might

want to consider using hydrostatic pressure

transmitters or capacitive measuring probes.

The measuring tube should either be never

immersed in the medium, or always immersed, making the measurement take place

exclusively in the tube.

VEGASON 54P … 56P 19

VEGASON 54C with adapter flange on a DN 200

vessel flange

Page 20

Mounting and installation

Mounting boss

Reference plane

Min. distance

VEGASON 56 in 1" mounting boss.

The socket axis should be oriented to the

product surface. More suitable is the use of a

swivelling holder version (type B, C), as

described on previous pages.

Material heaps

2.5 Socket extensions

Ultrasonic sensors require a min. distance to

the liquid or solid. Take the min. distance into

account in your planning. In some situations,

it is possible to reach the required min. distance, and hence the desired filling height

with a socket extension. However, the socket

piece increases the noise level of the ultrasonic signal at the extension outlet and can

interfere with the measurement. Only use a

socket extension if all other possibilities have

to be excluded. Carry out the extension as

shown in the following illustration.

Socket extensions for liquids

Chamfer and deburr the socket carefully and

make sure that it has a smooth inner surface.

The socket should not protrude into the

measured product, in case buildup can form

on the socket through dirt or product

residues.

For non-adhesive measured products, a

socket extension in the form of a measuring

tube can be permanently submerged in the

product. The ultrasonic measurement is then

made exclusively in the measuring tube and

works very well without interference from

other vessel installations (see "Pump shaft").

Large material heaps are usually measured

with several instruments, which can be

mounted on e.g. traverse cranes. If material

cones form, we recommend orienting the

sensors to the solid surface.

Socket piece should not be immersed into adhesive

products (figure: VEGASON 54)

Transducer on traverse crane above a material heap

20 VEGASON 54P … 56P

Page 21

Mounting and installation

The socket diameter should be as large and

the socket length as small as possible. To

minimise false echoes, make sure that the

socket outlet is burr-free.

Typ e 5 4

L

45˚

ø

Socket extensions not immersed into the medium

Typ e 5 5

L

45˚

ø

Max. socket length in relation to socket

diameter

ø in mm L in mm

Type 54 Type 55 Type 56

200 400 – – ––

250 500 500 500

300 –– –– 600

2.6 False echoes

The mounting location of the ultrasonic sensor

must be selected such that no installations or

inflowing material are in the path of the ultrasonic impulses. The following examples and

instructions show the most frequent measuring problems and how to avoid them.

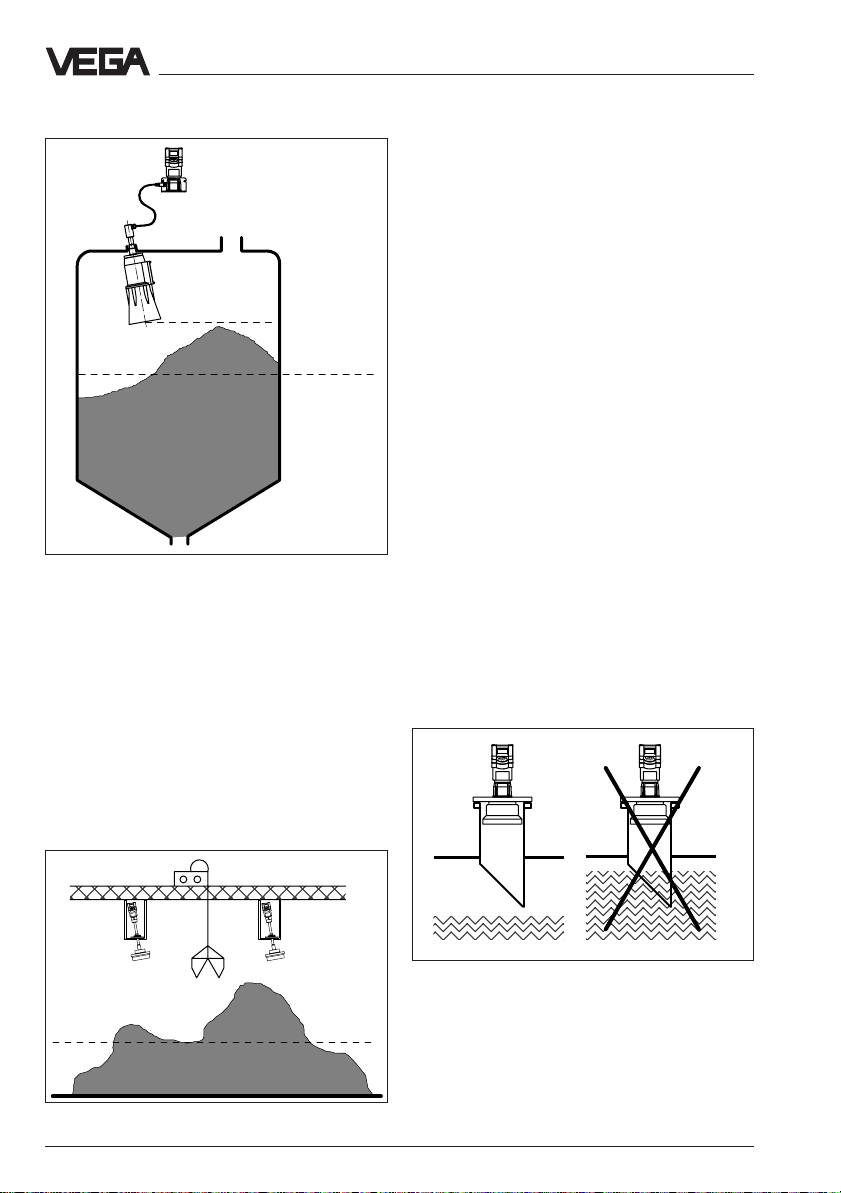

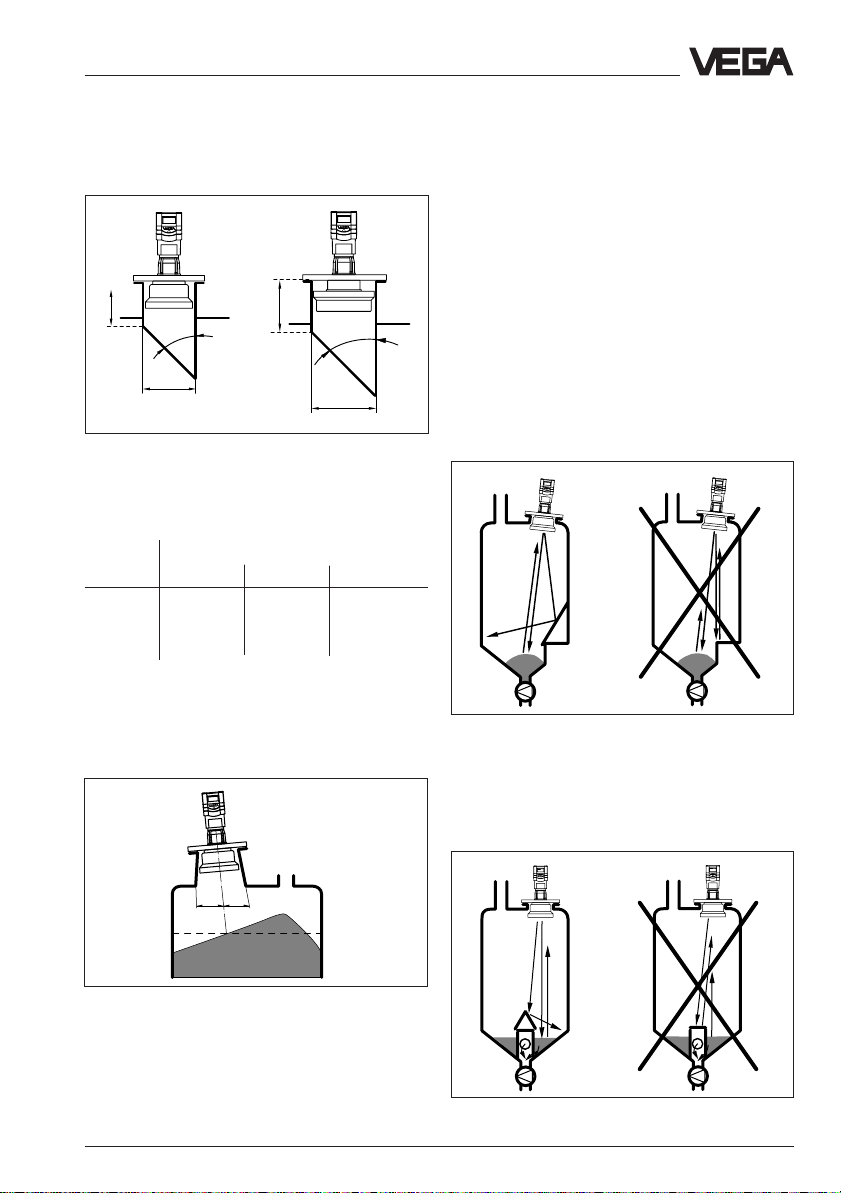

Vessel protrusions

Vessel forms with flat protrusions can, due to

their strong false echoes, adversely effect

the measurement. Shields above these flat

protrusions scatter the false echoes and

guarantee a reliable measurement.

Correct Incorrect

Socket extension in solids

For solids, use a conical socket extension

with a taper of at least 15° … 20°.

Vessel protrusions (slope)

Intake pipes, e.g. for the mixing of materials,

with a flat surface directed towards the sensor should be covered with a sloping shield.

The shield will scatter the false echo.

Correct Incorrect

15˚ 15˚

Socket extension in solids

Vessel protrusions (intake pipe)

VEGASON 54P … 56P 21

Page 22

Mounting and installation

Vessel installations

Vessel installations such as, for example, a

ladder, often cause false echoes. Make sure

when planning your measurement loop that

the ultrasonic signals have free access to the

measured product.

Correct Incorrect

Ladder

Vessel installations

Ladder

Struts

Struts, like other vessel installations, can

cause strong false echoes that are superimposed over the useful echo signal. Small

shields effectively hinder a direct false echo

reflection. The false echoes are scattered

and diffused in the area and are then filtered

out as "echo noise" by the measuring electronics.

Inflowing material

Do not mount the instrument in or above the

filling stream. Ensure that you detect the

product surface and not the inflowing material.

Correct

Correct

Inflowing material

Incorrect

Incorrect

Buildup

Correct Incorrect

If the sensor is mounted too close to the

vessel wall, residues or buildup of the measured product on the vessel wall can cause

false echoes. Position the sensor at a sufficient distance from the vessel wall. Please

Shields

also note chapter "2.2 General installation

instructions".

Struts

22 VEGASON 54P … 56P

Page 23

Mounting and installation

Correct

Buildup

Incorrect

Strong product movements

Strong turbulence in the vessel, e.g. caused

by powerful stirrers or intense chemical reactions, seriously interfere with the measurement. A surge or bypass tube of sufficient

size (DN 200, DN 250) always allows, provided the product causes no buildup in the

tube, a reliable measurement even with

strong turbulence in the vessel.

100 %

2.7 Installation mistakes

Foam generation

Thick foam on the product can cause incorrect measurements. Take measures to avoid

foam, carry out the measurement in a bypass

tube, or use a different measurement technology, e.g. capacitive probes or hydrostatic

pressure transmitters.

Foam generation

Wrong orientation to the product

Weak measuring signals are the result if the

sensor is not directly oriented to the product

surface. Orient the sensor axis perpendicularly to the product surface to achieve optimum measuring results.

60 %

0 %

Strong turbulence

Orient the sensor perpendicularly to the product

surface

VEGASON 54P … 56P 23

Page 24

Mounting and installation

Strong temperature fluctuations

Strong temperature fluctuations, e.g. caused

by the sun, cause measuring errors. Please

provide a sun shield.

Sun shield

Strong heat fluctuations

Min. distance to the medium

If the min. distance to the medium is not maintained, the instruments show wrong measured values. Mount the instrument at the

required min. distance.

Sensor too close to vessel wall

Correct Incorrect

If the sensor is mounted too close to the

vessel wall (dimension A in diagram), strong

false echoes can be caused. Buildup, rivets,

screws or weld joints on the vessel wall superimpose their echoes on the product, i.e.

the useful echo. Please ensure a sufficient

distance from the sensor to the vessel wall

depending on the maximum measuring distance (dimension B in diagram). In case of

good reflecting conditions (liquids, no vessel

installations), we recommend determining the

sensor distance according to Diagram curve

1. At a max. measuring distance of e.g. 10 m,

the distance of the transducer (acc. to curve

1) should be approx. 1.5 m. In case of solids

with poor reflective properties, determine the

distance to the vessel wall according to Dia-

gram curve 2. Under very bad measuring

conditions (rough vessel walls, struts), it

might be necessary to increase the distance

to the vessel wall, or to also filter out the false

echoes by storing them in memory, thereby

adapting the sensor more precisely to the

environment.

Distance from the

transducer to the

vessel wall

A

2 m 4 m 6 m 8 m

Curve 1 (liquids)

10 m

B

20 m

Sensor too close to the vessel wall

24 VEGASON 54P … 56P

30 m

max. meas.

distance

Curve 2 (solids)

Page 25

Mounting and installation

Parabolic effects of rounded or arched

vessel tops

Round or parabolic tank tops act like a parabolic mirror on the signals. If the sensor is

placed at the focal point of such a parabolic

tank top, the sensor receives amplified false

echoes. The optimum location is generally in

the area of half the vessel radius from the

centre.

Correct

< 100 mm

~ ½

vessel

radius

Incorrect

Socket piece too long

If the sensor is mounted in a socket piece

that is too long, strong false echoes are generated and measurement is made more difficult. Make sure that the transducer protrudes

at least 30 mm out of the socket piece.

Reference plane

< 100 mm

Incorrect

Correct and wrong length of socket piece

Mounting on a vessel with parabolic tank top

VEGASON 54P … 56P 25

Page 26

3 Electrical connection

Electrical connection

3.1 Connection

Safety information – Qualified personnel

Instruments which are not operated with

protective low voltage or DC voltage must

only be connected by qualified personnel.

This also applies to the configuration of

measuring systems planned for Ex environment.

As a rule, do all connecting work in the complete absence of line voltage. Always switch

off the power supply before you carry out

connecting work on the ultrasonic sensors.

Protect yourself and the instruments.

Note, important for connection to an EP

card

If VEGASON 54P … 56P sensors are operated on Profibus input cards (EP cards) in

the VEGALOG 571 processing system, each

card must be powered individually with an

own power supply unit. For power supply of

an EP card, use the power supply unit "ASIInterface SLA 3.100" from Puls which is available from VEGA.

By this measure, the signal circuits are galvanically separated. This avoids possible

crosstalks between the EP cards.

3.2 Connection cables and bus configuration

Note the Profibus specification. The connection cables must be specified for the expected operating temperatures in the plant

and must have an outer diameter of

6 … 12 mm, to ensure the seal effect of the

cable entry on the sensor.

For power supply and bus communication, a

two-wire cable acc. to the Profibus specification (up to max. 2.5 mm2 cross-section area

of conductor) is used. The electrical connection on the sensor is made by spring-loaded

terminals.

In a laboratory setup, a Profibus system will

also work with standard, unshielded two-wire

cable. In practice however, an automation

network and bus system can only be protected reliably against electromagnetic interference with screened cable. Acc. to the

Profibus specification (IEC 1158-2),

screened and twisted cables are prescribed.

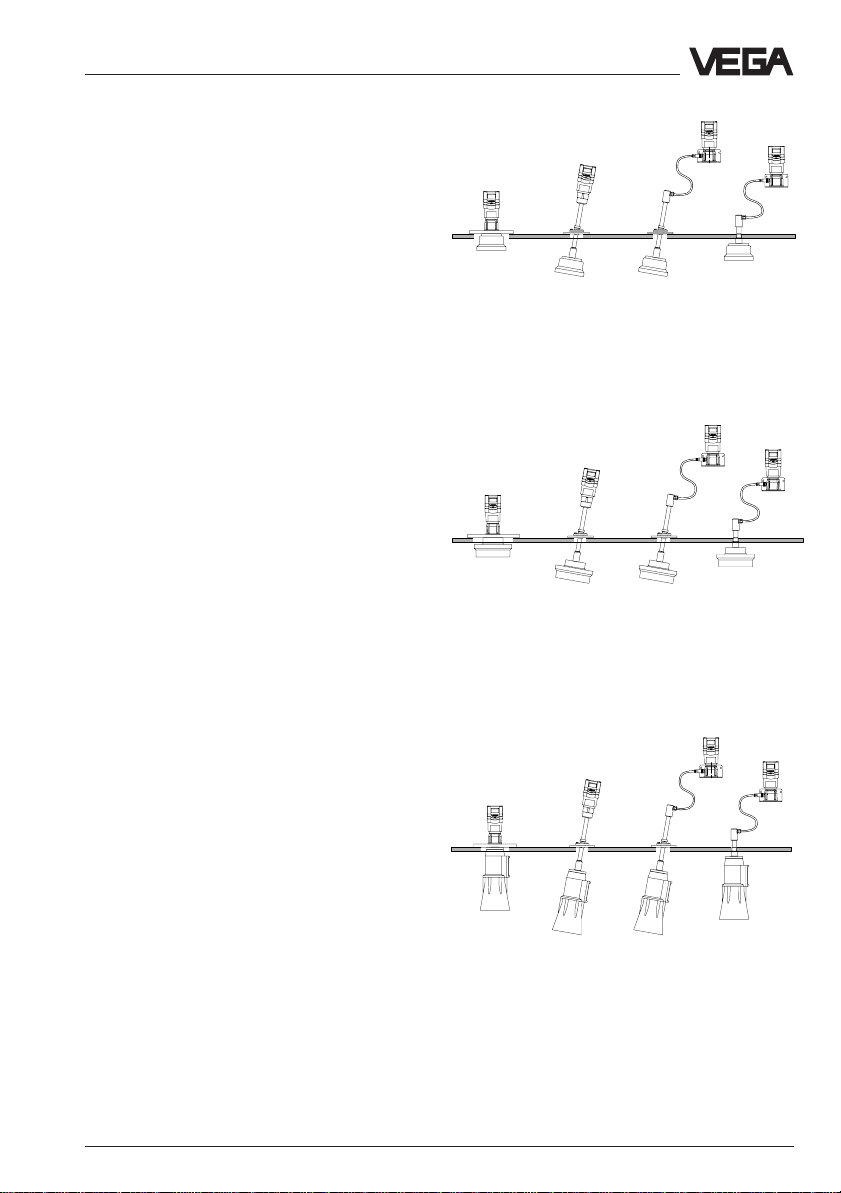

All participants are connected in one line

(serially). At the beginning and end of the

bus segment, the bus is terminated by an

active bus termination. On the DP bus level,

most participants already have a bus termination implemented. With more than 32 participants on the DP level, a so-called repeater

must be used to open and combine another

DP level with a max. of 32 additional participants. On the PA bus branch of the segment

coupler, the PA ultrasonic sensors also work

with a maximum of 32 participants (Ex max.

10 participants).

A PA sensor can work only in conjunction with

a Profibus DP system, to which a Profibus PA

subsystem is connected. A PA Profibus participant must consume min. 10 mA supply

current.

26 VEGASON 54P … 56P

Page 27

Electrical connection

Cable length

Connection cables must correspond to the

Profibus specification and the FISCO model.

The sensor cable must be in conformity with

the values of the reference cable acc. to

IEC 61158-2:

0.8 mm2; R

Z

= 80 … 120 Ω; damping = 3 dB/km;

31.25kHz

C

asymmetric

The max. cable length first of all depends on

the transmission speed:

up to 32 kbit/s: 1900 m Prup to 32 kbit/s: 1900 m Pr

up to 32 kbit/s: 1900 m Pr

up to 32 kbit/s: 1900 m Prup to 32 kbit/s: 1900 m Pr

up to 94 kbit/s: 1200 m Profibus DP

up to 188 kbit/s: 1000 m Profibus DP

up to 500 kbit/s: 500 m Profibus DP

up to 1500 kbit/s: 200 m Profibus DP

up to 12000 kbit/s: 100 m Profibus DP

The distributed resistance of the cable, in

conjunction with the output voltage of the

segment coupler and the current requirement

(VEGASON 10 mA) or the voltage requirement (VEGASON 9 V) of the sensors, determines the max. length of the cable.

In a practical application of a PA bus branch,

the max. length of the cable is also determined (beside the required supply voltage

and max. current consumption of all participants on the PA bus branch) by the bus

structure and the type of segment coupler

used.

The cable length results from the sum of all

cable sections and the length of all stubs.

The length of the individual stubs must not

exceed the following lengths:

1 … 12 stubs 120 m (Ex: 30 m)

13 … 18 stubs 60 m (Ex: 30 m)

19 … 24 stubs 30 m (Ex: 30 m)

More than 24 stubs are not permitted,

whereby each branch longer than 1.2 m is

counted as a stub. The total length of the

cable must not exceed 1900 m (in Ex version

1000 m).

= 44 Ω/km;

DCmax.

= 2 nF/km.

ofibus Pofibus P

ofibus P

ofibus Pofibus P

AA

A

AA

Ground terminal

The electronics housings of the sensors have

a protective insulation. The ground terminal in

the electronics is galvanically connected with

the metallic process connection. For sensors

with a plastic thread as process fitting, the

sensor must be grounded by connecting a

ground cable to its external ground terminal.

Screening

"Electromagnetic pollution" caused by electronic actuators, energy cables and transmitting systems has become so pervasive that

shielding for normal two-wire bus cable is

usually a necessity. According to the Profibus

specification, the screening should be made

on both ends. To avoid potential equalisation

currents, a potential equalisation system

must be provided in addition to the screening.

According to specification, we recommend

the use of twisted and screened two-wire

cable, e.g.: SINEC 6XV1 830-5AH10 (Siemens), SINEC L26XV1 830-35H10 (Siemens),

3079A (Belden).

Alternatively, when grounding at both ends in

non-Ex areas, the cable shielding can be

connected on one ground side (in the switching cabinet) via an YC-capacitor (e.g. 10 nF,

1500 V) to the ground potential. Make sure

that the ground connection has the lowest

possible resistance (foundation, plate or

mains earth).

Profibus PA in Ex environment

When used in Ex area, a PA bus with all connected instruments must be carried out in

intrinsically safe protection class "i". Four-wire

instruments requiring separate supply must

at least have an intrinsically safe PA connection. VEGA sensors for PA-Ex environment

are generally "ia” two-wire instruments.

VEGASON 54P … 56P 27

Page 28

Electrical connection

In the so-called Fieldbus Intrinsically Safe

Concept (FISCO), the general conditions for

an Ex safe bus configuration have been laid

down. Therein, the electrical data of the

participants and the bus cable have been

determined, so that the linking of these components always meets Ex requirements. This

makes the otherwise time-consuming Ex

calculation unnecessary. You can build your

Ex bus according to the IEC standard

1158-2.

The Ex segment coupler delivers a controlled

power supply to the PA bus. It acts as

source in the PA branch. All other components (field instruments and bus terminators)

are only consumers. A field instrument must

consume at least 10 mA. Ideally, an individual

sensor should not consume more than

10 mA, so that the number of instruments can

be as large as possible.

VEGA PA sensors, whether Ex or non Ex,

consume a constant current of 10 mA. According to the Profibus specification, this is

the minimum participant current. With VEGA

sensors it is therefore possible to connect 10

sensors (also in Ex environment) even with a

limited energy supply from the Ex segment

couplers.

Watch out for potential losses

Due to potential transfer, earthing on both

sides without a potential equalisation system

is not allowed in Ex applications. If an instrument is used in hazardous areas, the required regulations, conformity and type

approval certificates for systems in Ex areas

must be noted (e.g. DIN 0165). Please also

note the approval documents with the safety

data sheet attached to the Ex sensors.

Electrical data of the cables

R

DC

No. of A in Z

cores mm

2

31.25kHz

C in Damping Screen

nF/km

SINEC 6XV1 44 Ω/km 2 0.75 100 Ω < 90 < 3 dB/km Cu braiding

830-SEH10 +/- 20 Ω 39 kHz

(Siemens)

SINEC L26XV1 44 Ω/km 2 0.75 100 Ω < 90 < 3 dB/km Cu braiding

830-SFH10 +/- 20 Ω 39 kHz

(Siemens)

3079A 105 Ω/km 2 0.32 150 Ω 29.5 < 3 dB/km Foil

(Belden) 39 kHz

28 VEGASON 54P … 56P

Page 29

Electrical connection

3.3 Sensor address

In a Profibus system composed of Profibus

DP and Profibus PA subsystem, each participant must have a unique address. Each

participant, whether master or slave, is

accessed by means of its own address in

the bus system. The address of a participant, whether on DP or PA level, should be

assigned before connecting to the bus, because an address can be used only once. If

an address is used twice, interference in the

bus will be caused.

The address of an ultrasonic sensor can be

set in two ways:

- with the adjustment software VVO (software addressing) or

- with the DIP switch block in the sensor

(hardware addressing).

VEGA Profibus sensors are delivered with

the address set at 126 (all DIP switches to

"ON").

Remember, in a Profibus system there are

max. 126 participants possible. When the

DIP switch is set to address 126 (or higher),

the address can be adjusted with the adjustment software VVO, the adjustment module

MINICOM or another configuration tool (e.g.

PDM). However, there can be only one sensor on the bus with address 126 (delivery

status) during address assignment via software. For that reason, hardware addressing

(DIP switch) before connection to the bus is

recommended.

Hardware addressing

The DIP switches generate an address

number in the binary system. This means

that, from right to left (ascending), any switch

represents a number twice as high as the

previous switch on the right. The corresponding number in the decimal system

results from the sum of all switches set to

"ON". In the illustration, you see the decimal

number that corresponds to each individual

DIP switch.

DIP switch 8 corresponds to the number 128,

switch 1 corresponds to the number 1 and

switch 3 corresponds to the decimal number

4.

1

2

8765 4

128

64

32

Example 1

The switches 3, 5 and 7 are set to "ON". The

address is then:

DIP switch 3 to "ON" means 4

DIP switch 5 to "ON" means 16

DIP switch 7 to "ON" means 64

The sum is:

4 + 16 + 64 = Address 84

3

1

2

4

8

16

ON

1

2

8765 4

64

64 + 16 + 4 = 84

VEGASON 54P … 56P 29

3

16

4

Page 30

Electrical connection

Example 2

You want to set address 27.

16 + 8 + 2 + 1 = 27

You must set the DIP switches

5 = 16

4 = 8

2 = 2

1 = 1

to "ON".

Example 3

You want to set address 99

64 + 32 + 2 + 1 = 99

You must set the DIP switches

7 = 64

6 = 32

2 = 2

1 = 1

to "ON".

Software addressing

The DIP switches must be set to an address

of 126 … 255, i.e.

- either all DIP switches are set to "ON",

corresponding to address 255 (delivery

status)

OFF

1

2

64

3

ON

8765 4

32

16

1

2

3

1

2

4

8

8765 4

Addr.

- or only DIP switch 8 is set to "ON", corresponding to address 128.

128

Of course, software addressing is also possible, if the switches 7 … 2 are set to "ON"

(address 126).

The adjustment of the address with software

VVO is described in chapter "6.2 Adjustment

with VVO" under the heading "Software addressing" or in chapter "6.3 Sensor adjustment with the adjustment module MINICOM".

30 VEGASON 54P … 56P

Page 31

Electrical connection

3.4 Connection of the sensor

After mounting the sensor at the measurement location according to the instructions in

chapter "4 Mounting and installation", loosen

the closing screws on top of the sensor. The

sensor lid with the optional indication display

can then be opened. Unscrew the sleeve nut

and slip it over the connection cable (after

removing about 10 cm of insulation). The

sleeve nut of the cable entry has a self-locking ratchet that prevents it from opening on

its own.

Version with Aluminium housing

Power supply and

Profibus signal

+

To the indicating instrument in the

sensor lid or to the external

indicating instrument VEGADIS 50

–

M20x1.5 (diameter of the

connection cable

6…9 mm)

Now insert the cable through the cable entry

into the sensor. Screw the sleeve nut back

onto the cable entry and clamp the stripped

wires of the cable into the proper terminal

positions.

The terminals hold the wire without a screw

(spring-loaded terminals). Press the white

opening tabs with a small screwdriver and

insert the copper core of the connection

cable into the terminal opening. Check the

hold of the individual wires in the terminals by

lightly pulling on them.

Version with plastic housing

Power supply and

Profibus signal

M20x1.5 (diameter of the

connection cable

6…9 mm)

+

To the indicating display

in the sensor lid or to the

external indicating

instrument

–

Spring-loaded terminals

(max. 2.5 mm2 wire

cross-section)

1

2

3

87654

+1 2- 5 6 7 8

Addr.

Bus

Display

ON

ESC

-

+

OK

1

2

3

8 765 4

Opening tabs

Pluggable

adjustment

module

MINICOM

+1 2- 5 6 7 8

Addr.

Bus

Tank 1

m (d)

12.345

Display

ON

ESC

+

-

OK

VEGASON 54P … 56P 31

Page 32

3.5 Connection of the external indicating instrument

Loosen the four screws of the housing lid on

VEGADIS 50.

The connection procedure can be facilitated

by fixing the housing cover during connection work with one or two screws on the right

of the housing.

Adjustment

module

OUTPUT

(to the sensor)

3

2

1

4

5

8

6

7

VEGADIS 50

+

-

Tan k 1

m (d)

12.345

Electrical connection

ESC

OK

Voltage supply and

digital meas. signal

-

+

8 7654

+1 2- 5 6 7 8

Addr.

Bus

Tank 1

m (d)

12.345

DISPLAY

(in the lid of the

indicating

instrument)

1

2

3

Display

ON

ESC

+

-

OK

Screws

32 VEGASON 54P … 56P

Page 33

Electrical connection

3.6 Bus configuration

The type of ultrasonic sensor you use depends on the process requirements and

mounting conditions, as well as on the requirements of your control, regulative, or

process control system.

VEGASON 54 … 56 Profibus sensors are

sensors for use in Profibus PA environment.

Profile 3 has been implemented in the sensors. A measuring system consists of one or

several sensors, one or several segment

couplers and one DP master computer, such

as e.g. a S7 PLC with Profibus interface or a

process control system with Profibus DPMaster-Slot. The processing unit, e.g. the

PLC, evaluates the level-proportional, digital

measuring signals in a number of evaluation

routines and puts them to use process-specifically.

On the following four pages you will see

schematic illustrations of the bus configuration.

The automation system as Master-Class 1

takes over the complete bus control. It reads

out all signals cyclically and, if necessary,

gives instructions to the participants (e.g.

sensors). Additional master systems (e.g.

visualisation systems or adjustment tools)

can also be connected to the DP bus. These

systems operate as so-called Master-Class 2

participants. Like the Master-Class 1 system,

they can read out signals, give instructions

and operate in the acyclical mode.

Each participant on the bus must have an

unambiguous address. The addressing

covers both bus levels. A Profibus DP network can have max. 126 participants, including all participants on the PA level. In

practice, each Master-Class 1 computer gets

address 1 and the Master-Class 2 computers address 10 … 20. As a rule, the slaves or

participants get the addresses 21 … 126. On

the Profibus PA network segment, a max. of

32 sensors can be connected on one PA

segment coupler.

Ex environment

In Ex environment, intrinsically safe (EEx ia)

PA sensors are used with Ex segment couplers. Generally, the number of PA sensors

on a segment coupler (Ex or non Ex) depends on the current requirement of the

sensors and on the current supplied by the

segment coupler. Segment couplers for

EEx ia environment provide 90 … 110 mA.

The number of sensors results from the sum

of:

- the basic current intake of all sensors

- plus 9 mA communication signal

- plus the leakage currents of all sensors

- plus a recommended current reserve

(approx. 10 mA)

A DP bus does not allow power supply via

signal cable, whereas the PA bus does. Both,

DP and PA, require at least one screened

two-wire cable. The DP bus can additionally

have up to 8 cores (screened), some of

which can be supply cables (see also "Installation Guides PA + DP" of the Profibus User

Organisation (PNO).

VEGASON 54P … 56P 33

Page 34

Profibus PA sensors on the Profibus network

1

Electrical connection

Master-Class 1

Bus terminator

3...9

Profibus PA (31,25 kBit/s)

Profibus DP

21

Profibus interface

card

RS 232

22...54

3

RS 485

10

Master-Class 2

Segment coupler

Bus terminator

2

22

23

24

53

54

VEGACONNECT 3

PA segment on segment coupler:

1 … 32 sensors on one two-wire cable

(Ex: 10 sensors)

34 VEGASON 54P … 56P

Page 35

Electrical connection

Profibus DP segment level

1 … 126 participants including all DP and PA participants.

Through segment couplers and PA segments, the transmission rate, also on the DP level, is determined by the

slowest coupler/participant on the Profibus DP and PA

network.

Bus terminator

3...9

M

Segment coupler

3...9

3~M

89

90

Bus terminator

2

55

56...88

2

Profibus PA

56

57

87

88

PA segment:

1 … 32 sensors on one two-wire cable

(Ex: 10 sensors)

VEGASON 54P … 56P 35

Page 36

Electrical connection

Profibus PA sensors with 4 … 20 mA sensors on the Profibus network

1

Master-Class 1

Bus terminator

VEGALOG

Profibus PA (31,25 kBit)

3~M

3…9

Profibus DP

Profibus interface

card

21

3

RS 485

22

10

Master-Class 2

VEGACONNECT 3

4

RS 232

1

2

3

5

11

4

1 … 15 PA sensors per two-wire cable

13

12

15

14

with independent address zone

(Ex: 10 sensors)

36 VEGASON 54P … 56P

Page 37

Electrical connection

Profibus DP segment level

1 … 126 participants including all DP and PA participants.

Up to 12 MBit/s transmission rate on DP level.

In the PA segments 31.25 kBit/s transmission rate.

VEGACONNECT 3

4 … 20 mA (HART )

2

4

4

4

2

2

2

Profibus PA (31,25 kBit)

3…9

23

M

3…9

24

25

VEGALOG

VBUS

Outputs

2

2

2

2

®

2

2

2

2

2

0/4…20 mA

0…10 V

2

VBUS

Bus terminator

Profibus PA:

1 … 15 sensors per two-wire cable

(Ex: 10 sensors) with independent address zone

VBUS:

1 … 15 sensors per twowire cable

Exd: also 15

Ex ia: 5 sensors

VEGASON 54P … 56P 37

Page 38

4 Setup

4.1 Adjustment media

Adjustment with PACTware

Setup

TM

In chapter "1.4 Adjustment" the Profibus adjustment scheme was briefly explained and

the adjustment media for VEGA Profibus

sensors were shown. All VEGA Profibus

sensors operate in profile 3 and can be adjusted with:

- the adjustment program VVO on a PC with

Profibus card

- the adjustment program PACTwareTM, under

which VVO runs as a subprogram

- the Siemens software PDM in conjunction

with an EDD (Electronic-Device-Description)

- the adjustment module MINICOM in the

sensor.

Adjustment with VV O on the PC

The adjustment program VVO enables userfriendly adjustment of VEGA Profibus PA

sensors. All functions and options relating to

the sensor adjustment are accessible. The

program runs under Windows® on a PC with

a Profibus-Master-Class 2 interface card on

Profibus DP level as Master-Class 2 tool. The

VVO program accesses the VEGA PA sensors via the DP bus, the segment coupler

and the PA bus.

The adjustment with PACTwareTM corresponds to VVO adjustment. In this case,

VVO runs as a subprogram of PACTwareTM.

The adjustment instructions can be found in

the documentation of PACTwareTM.

Adjustment with PDM

The sensors can be adjusted completely with

PDM. However, some convenient functions

and many special features, like e.g. display

of an echo curve, are not available. In addition to the PDM software, an EDD (available

upon request from VEGA) is required for

each sensor type. The adjustment instructions for PDM are described in the PDM

documentation.

Adjustment with the adjustment module

MINICOM

With the adjustment module MINICOM, you

adjust the individual sensor directly in the

sensor or in the external indicating instrument

VEGADIS 50. The adjustment module

MINICOM enables (with the 6-key adjustment

field with text display) all essential functions

of parameter setting and adjustment.

Note:

Please note that for adjustment with VVO,

version 2.70 or higher is required.

38 VEGASON 54P … 56P

Page 39

Setup

4.2 Adjustment with the PC

The instructions for the adjustment with the

PC and the adjustment program VVO can be

found in the manual "VEGA Visual Operating

(VVO)" which is supplied with the latest adjustment software.

Beside the adjustment of ultrasonic sensors,

the manual "VEGA Visual Operating (VVO)"

also describes the setup of all other VEGA

sensors with the PC.

4.3 Adjustment with the adjustment module MINICOM

In addition to the PC, you can adjust the

sensor with the small, detachable adjustment

module MINICOM. The adjustment module is

plugged into the sensor or into the external

indicating instrument (optional).

ESC

+

-

Tank 1

m (d)

12.345

OK

2

Tank 1

m (d)

12.345

4

All sensor versions (adjustment options)

provided by a PC with the adjustment program VVO are also available with the adjustment module MINICOM. However, the

adjustment with MINICOM looks different.

+

-

4 ... 20 mA

ESC

OK

You can carry out all adjustment steps with

the 6 keys of the adjustment module. A small

display shows you, apart from the measured

value, a short message on the menu item or

an entered numerical value.

Although the volume of information of the

small display cannot be compared with that

of the adjustment program VVO, you will be

able to carry out your settings quickly and

efficiently with the small MINICOM.

VEGASON 54P … 56P 39

Page 40

Setup

Error codes:

E013 No valid measured value

- sensor in the warm-up phase

- loss of the useful echo

E017 Adjustment span too small

E036 Sensor program not operating

- sensor must be reprogrammed

(service)

- fault signal also appears during

programming

E040 Hardware failure, electronics

defective

E113 Hardware failure

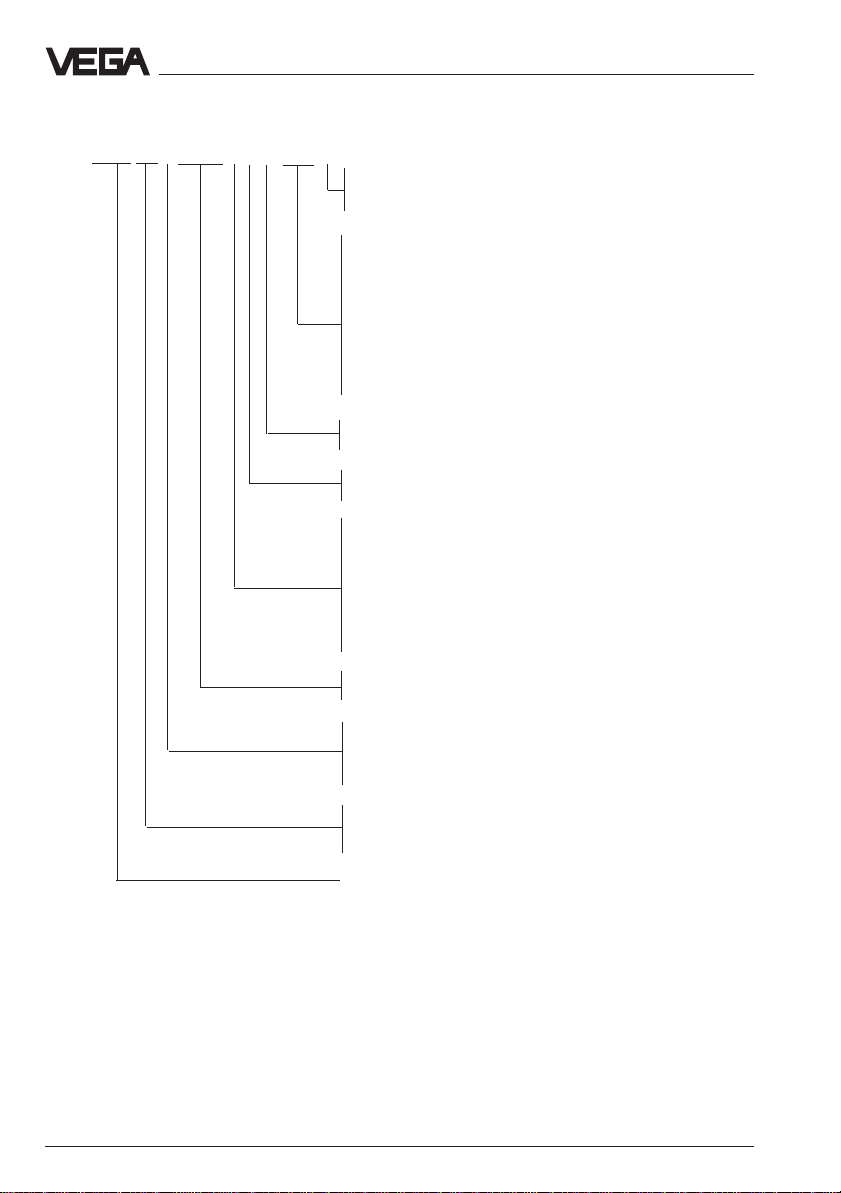

Adjustment steps

On the following pages, you will find the complete menu schematic of the adjustment module MINICOM.

Set up the sensor in the numbered sequence:

1. Address

2. Measurement in gases

3. Operating range

4. Adjustment

5. Conditioning

6. Meas. conditions

7. False echo storage (only required if errors

occur during operation).

8. Indication of the useful level and noise level

9. Outputs

Below you will find short explanations to

setup steps 1 … 9.

3. Operating range

Without special adjustment, the operating

range corresponds to the measuring range.

The measuring range was already entered

with the min./max. adjustment. Generally, it is

useful to choose a slightly wider range

(approx. 5 %) for the operating range than

for the measuring range.

Example:

Min./Max. adjustment: 0.300 … 5.850 m;

adjust operating range to approx.

0.250 … 6.000 m.

4. Adjustment

Max.

Min.

Under the menu item "

the sensor of the measuring range.

100 % (1.270 m) correspond

to 1200 liters

Span (4.58 m)

0 % (5.850 m) correspond

to 45 liters

Adjustment

", you inform

1. Address

Choose a free bus address with the DIP

switch (see chapter "4.2 Sensor address").

You can carry out the adjustment with or

without medium. Generally, you will carry out

the adjustment without medium, as you can

then adjust without a filling/emptying cycle.

2. Measurement in gases

Adjustment is only necessary if the measurement is made in gases other than air (CO2,

He, etc.). When measuring in gases, sound

the distance from the sensor to the product

surface and enter this in the menu item

"

Measurement in gases

take the altered (compared to air) sonic velocity into account and output correct levels.

40 VEGASON 54P … 56P

". The sensor can then

Page 41

Setup

Adjustment without medium

(adjustment independent of the actual level)

Key Display indication

Sensor

m(d)

4.700

Parameter

OK

OK

OK

OK

+

adjustment

Adjustment

w.o.

medium

Adjustment

in

m(d)

(min. adjustment)

The distance indication flashes

and you can choose "feet" and

"m".

OK

+ –

or

Confirm the setting with "OK".

m(d)

0.0%

at

m (d)

XX.XXX

Adjustment

in

With "+" and "–" you set the

percentage value for the min.

value or the lower level (example 0.0 %).

OK

The entered percentage value

is written in the sensor and the

distance corresponding to the

percentage value begins

flashing.

+ –

or

With the "+" or "–" key you can

assign a level distance (example 5.85 m) to the previously

adjusted percentage value. If

you do not know the distance,

you have to measure it by

sounding.

OK

The entered product distance

is written in the sensor and the

display stops flashing.

You thereby adjusted the lower product distance as well as the percentage filling value

corresponding to the lower product distance.

100.0%

at

m (d)

XX.XXX

(max. adjustment)

Enter the max. adjustment (upper product

distance) in the same manner (example:

100 % and 1.270 m).

Note:

The difference between the adjustment values of the lower product distance and the

upper product distance should be as big as

possible, preferably at 0 % and 100 %. If the

values are very close together, e.g. lower

product distance adjustment at 40 %

(3.102 m) and upper product distance adjustment at 45 % (3.331 m), the measurement

will be inaccurate. A characteristics curve is

generated from the two points. Even the

smallest deviations between actual product

distance and entered product distance will

considerably influence the slope of the characteristics curve. If the adjustment points are

too close together, small errors inflate to

considerably larger ones when the 100 % or

the 0 % value is outputted.

VEGASON 54P … 56P 41

Page 42

Setup

Adjustment with medium

with

medium

Max.

Min.

adjust at

adjust

%

at %

XXX.X

XXX.X

Fill the vessel e.g. to 10 % and enter 10 % in

the menu "

Min. adjust

" with the "+" and "–"

keys. Then fill the vessel, e.g. to 80 % or

100 % and enter 100 % in the menu "

adjust

" with the "+" and "–" keys.

Max.

5. Conditioning

Signal

conditioning

Scaling

0 %

100 %

Deci-

prop.

corres-

corresponds

XXXX

mal

point

888.8

Conditioning

ponds

XXXX

Under the menu item "

assign a product distance at 0 % and at 100

% filling. Then you enter the physical quantity

and the physical unit as well as the decimal

point.

to

Mass

Unit

Kg

", you

With the "—>" key you change to the 100 %

menu. Enter here the numerical value of your

parameter corresponding to a 100 % filling.

In the example 1200 for 1200 liters.

• Confirm with "OK".

If necessary, choose a decimal point. However, note that only max. 4 digits can be

displayed. In the menu "

prop. to

", you choose

the physical quantity (mass, volume, distance…) and in the menu "

Unit

" the physical