Page 1

Operating Instructions

VEGASON 51K … 53K

Level and Pressure

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function ................................................................................. 4

1.2 Application features ............................................................. 5

1.3 Adjustment ............................................................................ 5

2 Types and versions

2.1 Type survey .......................................................................... 8

2.2 Configuration of meas. systems ....................................... 10

3 Technical data

3.1 Data ..................................................................................... 17

3.2 Approvals ........................................................................... 21

3.3 Dimensions ......................................................................... 22

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGASON 51K … 53K

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the operating instructions and come with the Ex approved instruments.

Page 3

Contents

4 Mounting and installation

4.1 General installation instructions ........................................ 24

4.2 Measurement of liquids ..................................................... 25

4.3 Measurement of solids ...................................................... 27

4.4 Socket extensions ............................................................. 29

4.5 Flow measurement ............................................................. 30

4.6 False echoes ...................................................................... 31

4.7 Installation error .................................................................. 33

5 Electrical connection

5.1 Connection and connection cable .................................... 36

5.2 Connection of the sensor .................................................. 37

5.3 Connection of the external indicating instrument

VEGADIS 50 ....................................................................... 38

6 Set-up

6.1 Adjustment structure ......................................................... 39

6.2 Adjustment with PC ............................................................ 39

6.3 Adjustment with the adjustment module MINICOM ........ 40

6.4 Adjustment with the HART®-handheld .............................. 46

7 Diagnosis

7.1 Simulation ............................................................................ 51

7.2 Error codes ........................................................................ 51

VEGASON 51K … 53K 3

Page 4

1 Product description

1.1 Function

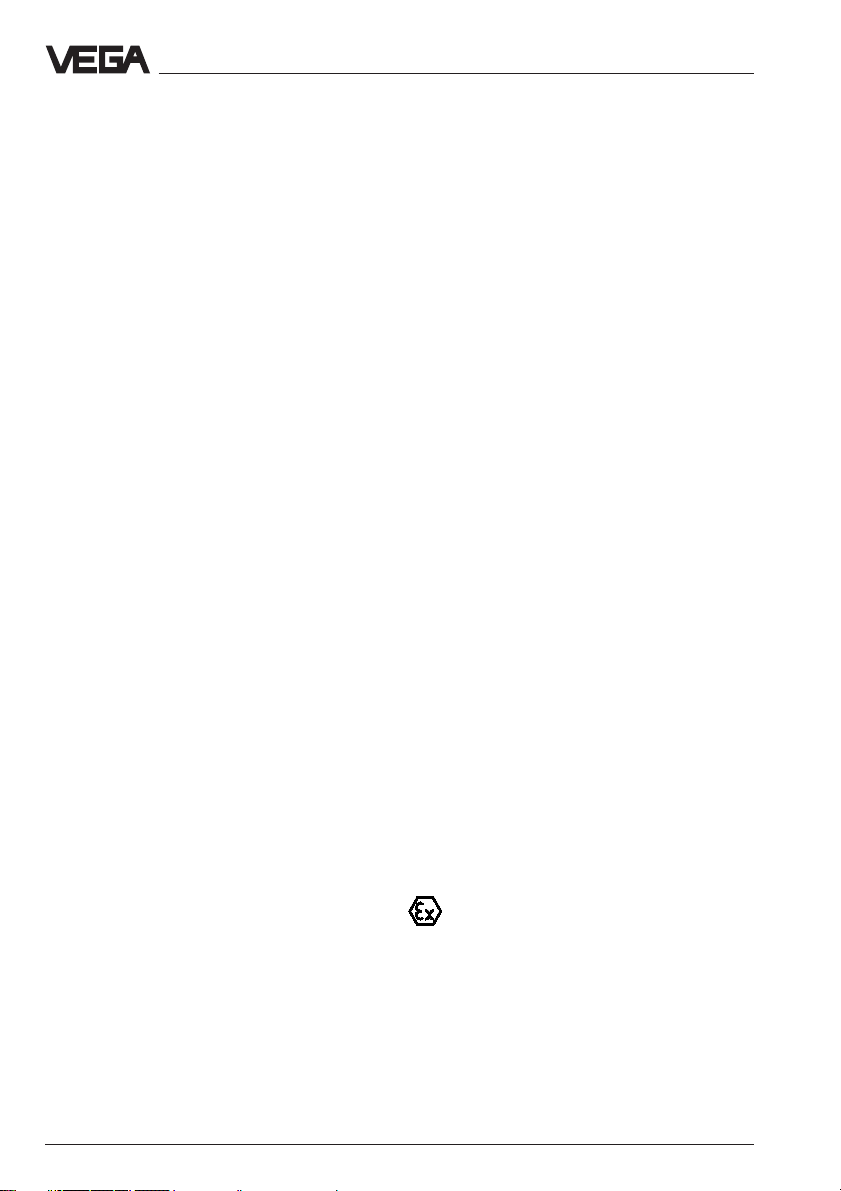

The continuous level measurement with ultrasonic sensors is based on the running time

measurement of ultrasonic pulses.

Measuring principle

Piezoceramic high performance transducers

emit focused ultrasonic pulses which are

reflected by the surface of solids and liquids.

The measuring electronics prepare a precise

picture of the environment from the running

time and the signal form of the reflected ultrasonic pulses. The transducers work as transmitter and receiver. As receiver the transducers are high sensitivity piezo-microphones.

Meas.

distance

Product description

In order to be prepared for the different

measuring distances and requirements, the

instruments operate with emitting frequencies

of 34 kHz up to 70 kHz.

As the sound velocity is subjected to a temperature influence, the transducer also continuously detects the ambient temperature so

that the level is precisely provided even in

case of varying ambient temperature.

Output signals

The level proportional measuring signal is

provided as 4 … 20 mA-output signal.

The parameter adjustment of the analogue

4 … 20 mA-signal is individually possible and

reflects the measuring range or the adjusted

adjustment range of the sensor.

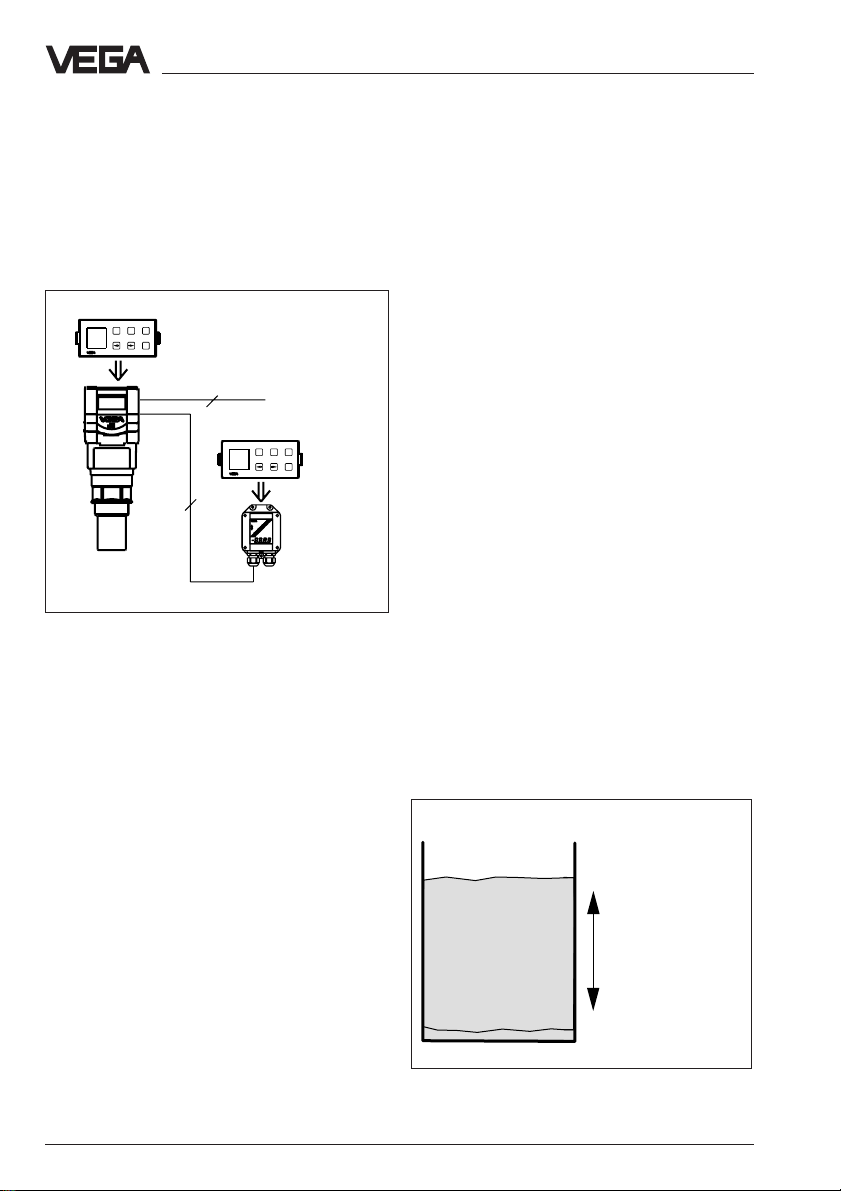

Measured value indication

If desired, an indicating instrument for direct

lobal survey can be mounted on to the series

50 ultrasonic sensors. The indicating instrument shows the precise level with the analogue bar-graph and with the digital figure. In

addition to the indication in the sensor itself,

you can have the level displayed with the

external indicating instrument VEGADIS 50

up to 25 m away from the sensor.

The external measured value indication oper-

emission - reflection - receipt

The measuring electronics precisely calculate

the distance between transducer and medium from the speed of sound and the actually detected running time of the emitted

sound impulse. The distance is then converted into a level proportional signal and

provided according to the sensor parameter

adjustment as precise scaled level.

4 VEGASON 51K … 53K

ates, like the integral indication, independent

of the 4 … 20 mA-output signal, and individual parameter adjustment is possible.

Page 5

Product description

1.2 Application features

Applications

• Level measurement of all liquids

• Level measurement of solids

(only short measuring distances) such as

e.g.:

coal, ore, stones, stone dust, cement,

gravel, crushed stones, sand, sugar, salt,

cereals, flour, granules, powder, dusts,

saw dust, wood chips

• Flow measurement on different flumes

• Gauge measurement, distance measurement, object monitoring and conveyor belt

monitoring

Two-wire technology

• Supply and output signal on one two-wire

line (Loop powered)

• 4 … 20 mA-output signal

Rugged and precise

• Unaffected by product features such as

density, conductivity, dielectric constant …

• Suitable for aggressive substances

• Measuring ranges 0,25 m … 15 m

Adjustment choice

• With adjustment software VEGA Visual

Operating (VVO) on PC

• With detachable adjustment module

MINICOM

• With the HART®-Handheld

• Measured value indication integrated in the

sensor

• Optional indication separate from the sensor

1.3 Adjustment

Each measuring distance is different, therefore each ultrasonic sensor must be given

some basic information on the application

and the environment, e.g. you need to inform

the sensor which level means “empty“ and

which level “full“. Apart from this “empty and

full adjustment“, a number of other adjustments can also be carried out with

VEGASON ultrasonic sensors.

The adjustment and parameter adjustment of

the ultrasonic sensors are carried out with

- the PC

- the detachable adjustment module MINICOM

- the HART®--Handheld

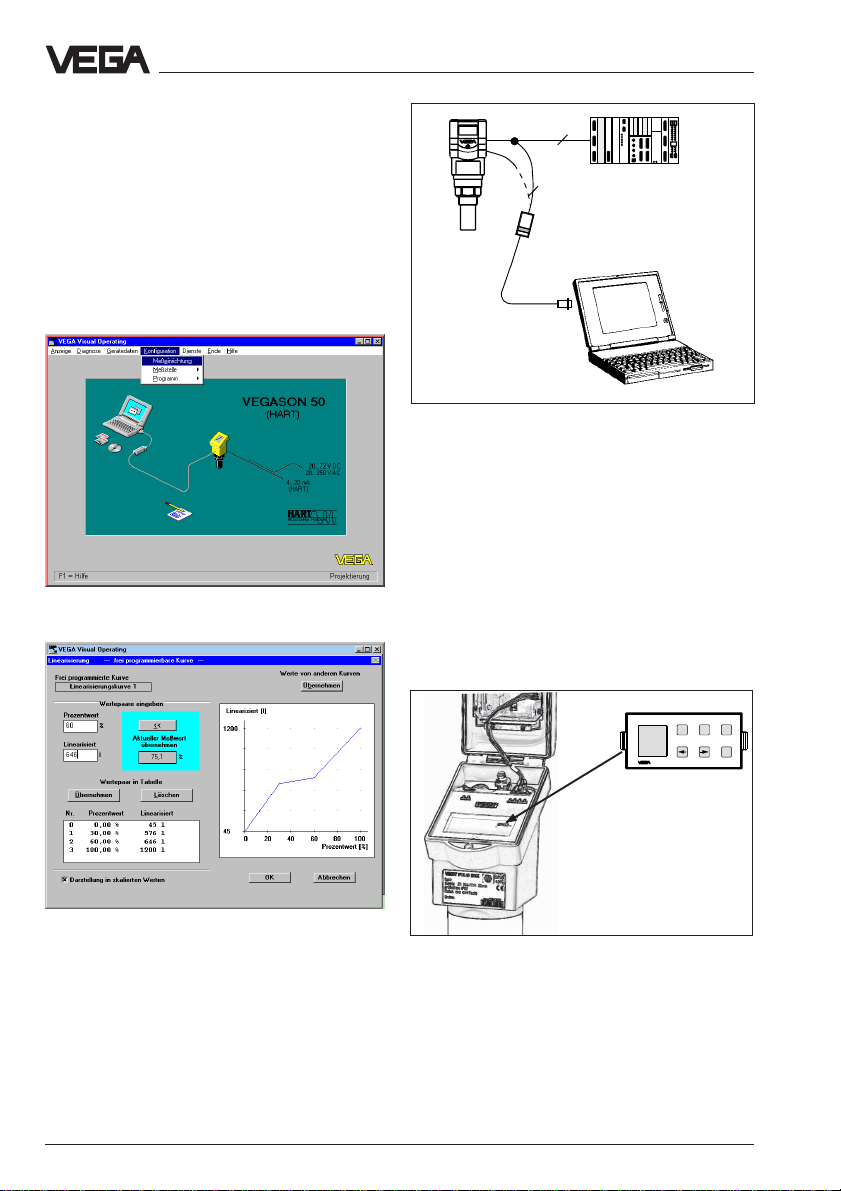

Adjustment with PC

The set-up and adjustment of the ultrasonic

sensors is generally made on the PC with the

adjustment program VEGA Visual Operating

(VVO) under Windows®.

The program leads quickly through the adjustment and parameter adjustment via pictures, graphics and process visualisations.

2

4 ...20 mA

2

Connection for each process

•G 11/2 A, 11/2" NPT

• G 2 A, 2" NPT

• Compression flange DN 100, ANSI 4"

Approvals

• CENELEC, ATEX, PTB, FM, CSA, ABS,

LRS, GL, LR, FCC

VEGASON 51K … 53K 5

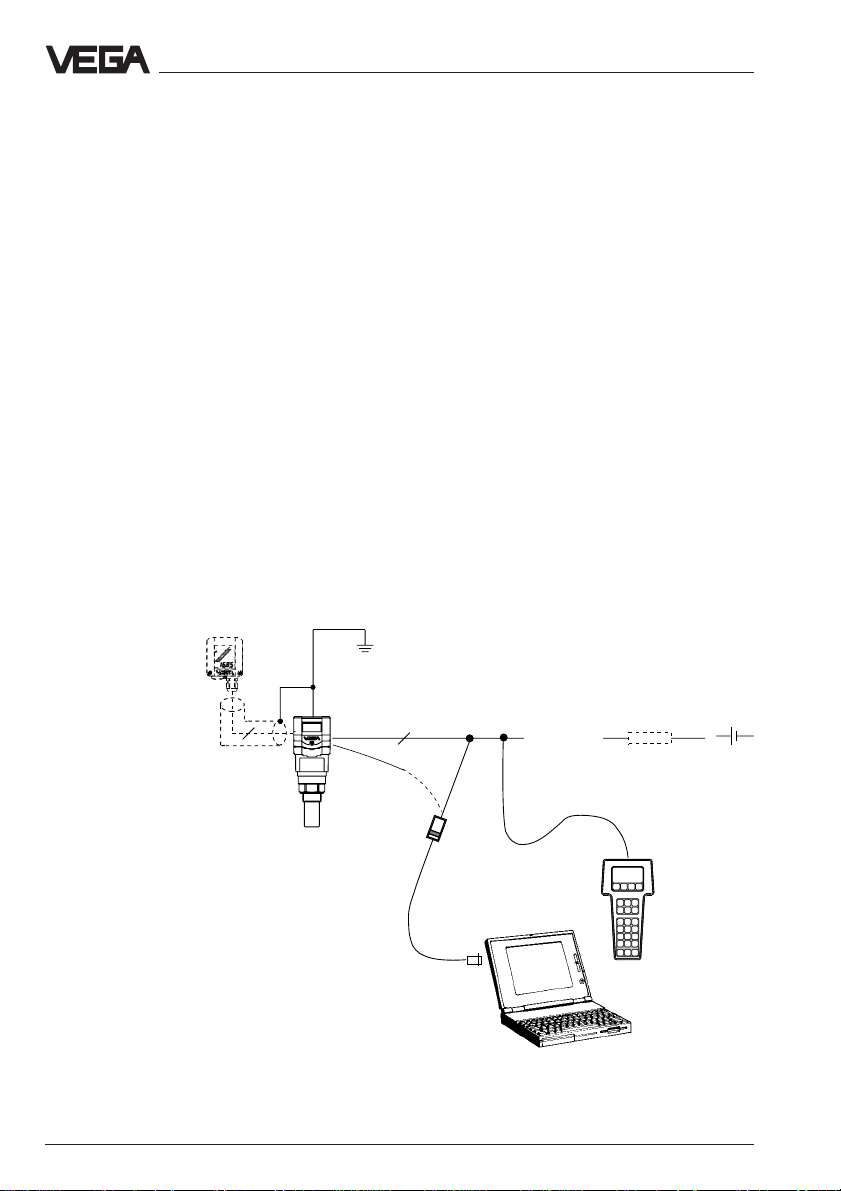

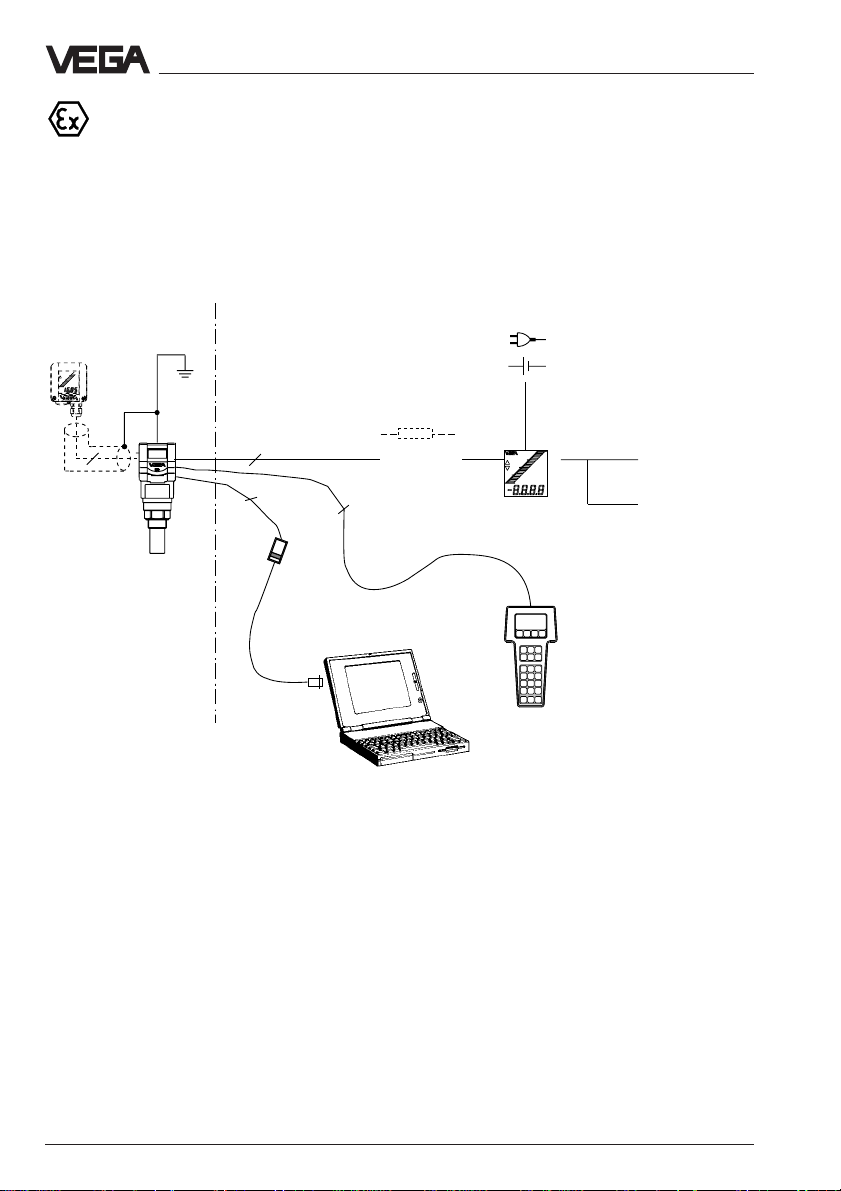

Adjustment with the PC on the analogue 4 … 20 mAsignal and supply line or directly on the sensor (fourwire sensor)

Page 6

The PC can be connected to any individual

position of the system or the signal line. It is

thereby connected with the two-wire PCinterface converter VEGACONNECT 2 to the

sensor or to the signal line.

The adjustment and parameter adjustment

data can be saved with the adjustment software on the PC and protected with passwords. If required, the adjustment can be

transmitted quickly to other sensors.

The adjustment program recognises the sensor type

Product description

2

DCS

2

Adjustment with the PC on the 4 … 20 mA signal and

supply line to the DCS or directly on the sensor (in

the figure a two-wire sensor)

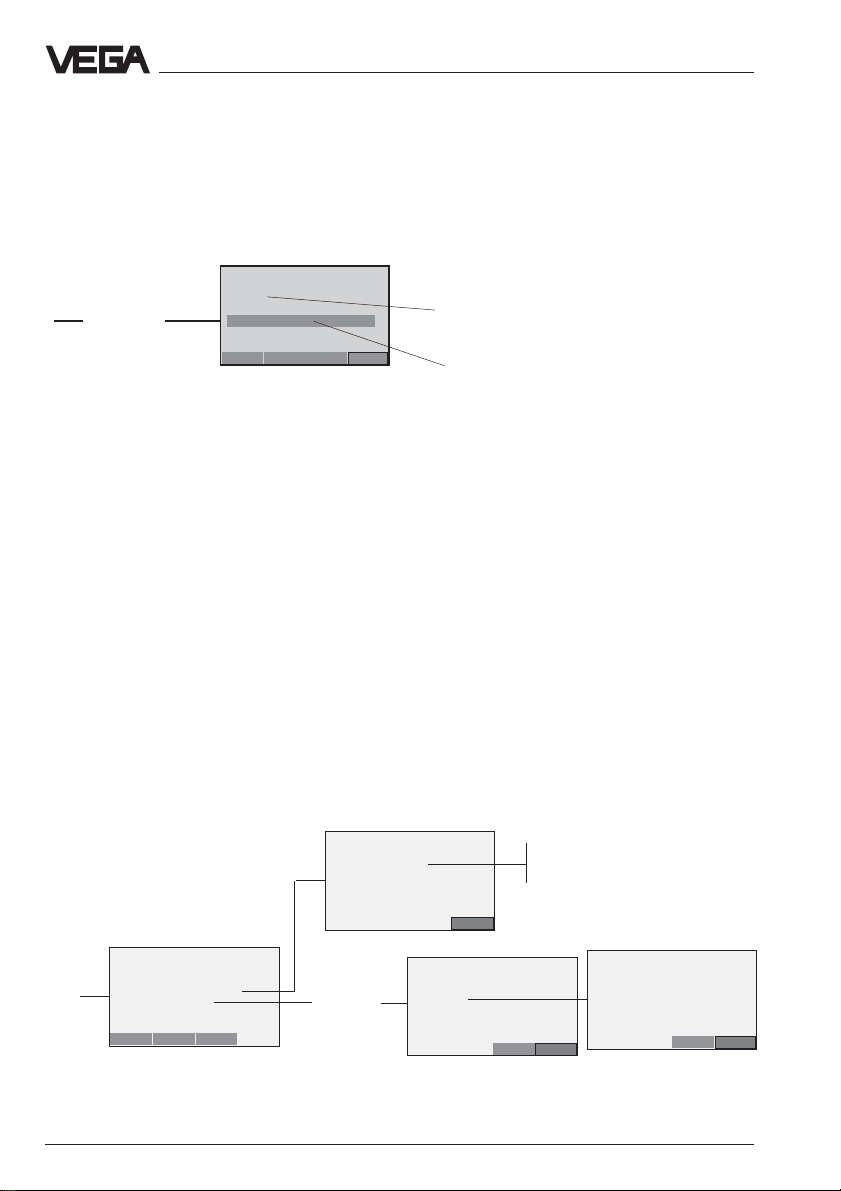

Adjustment with adjustment module

MINICOM

With the (3,2 cm x 6,7 cm) 6-key adjustment

module with display you can carry out the

adjustment in clear text.

The adjustment module can be plugged into

the ultrasonic sensor or into the optional

external indicating instrument.

Tank 1

m (d)

12.345

ESC

+

-

OK

Visualised input of a vessel linearisation curve

Detachable adjustment module MINICOM

By removing the adjustment module unauthorised adjustments are avoided.

6 VEGASON 51K … 53K

Page 7

Product description

ESC

+

-

Tank 1

m (d)

OK

12.345

2

4 ... 20 mA

ESC

+

-

Tank 1

m (d)

OK

12.345

4

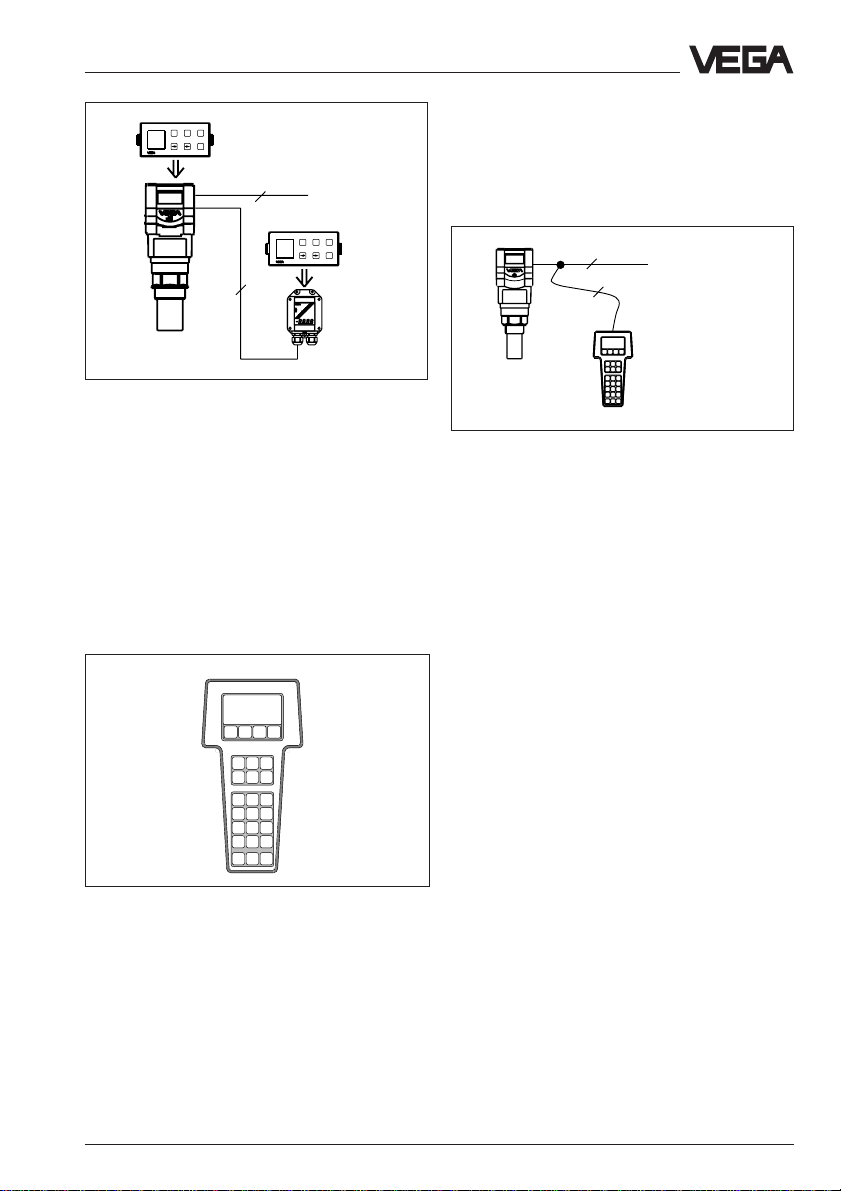

Adjustment with the detachable adjustment module.

The adjustment module can be plugged into the

ultrasonic sensor or the external indication instrument

VEGADIS 50.

Adjustment with HART®-Handheld

Series 50 sensors with 4 … 20 mA output

signal can also be adjusted with the HART®Handheld. A special DDD (Data-DeviceDescription) is not necessary as the sensors

can be adjusted with the HART®-standard

menus of the handheld.

For adjustment, just connect the HART®Handheld in any position of the 4 … 20 mAoutput signal line or insert the two communication lines of the HART®-handheld into the

adjustment sockets on the sensor.

2

4 ... 20 mA

2

HART®-handheld on the 4 … 20 mA-signal line

HART Communicator

HART®-handheld

VEGASON 51K … 53K 7

Page 8

2 Types and versions

Types and versions

VEGASON series 50 sensors are a newly

developed generation of very compact, small

ultrasonic sensors. With very narrow space

requirements, they are designed for short

meas. distances (0 … 15 m) and for standard applications such as storage tanks,

gauge measurement and buffer tanks.

Due to the small housing dimensions and

process connections, the compact sensors

monitor your levels very price favourably.

With the integral indication and the many

features of the “big brothers“ of VEGASON

series 80, they offer the advantages of an

ultrasonic level measurement for applications

where the special advantages of a non-contact measurement are not applicable for price

reasons.

VEGASON 50 ultrasonic sensors control the

two-wire technology perfectly. The supply

voltage and the output signal are transmitted

via a two-wire line. An analogue 4 ... 20 mAoutput signal is available as output or measuring signal.

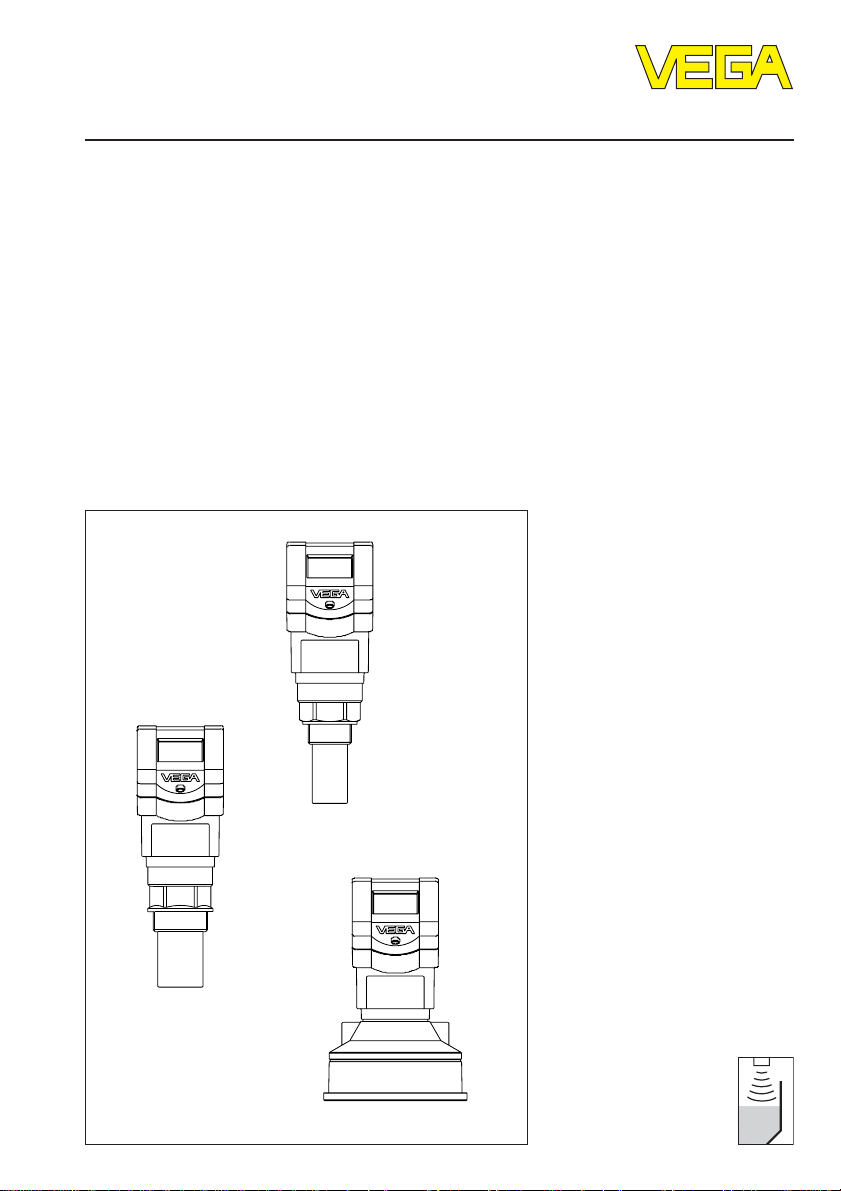

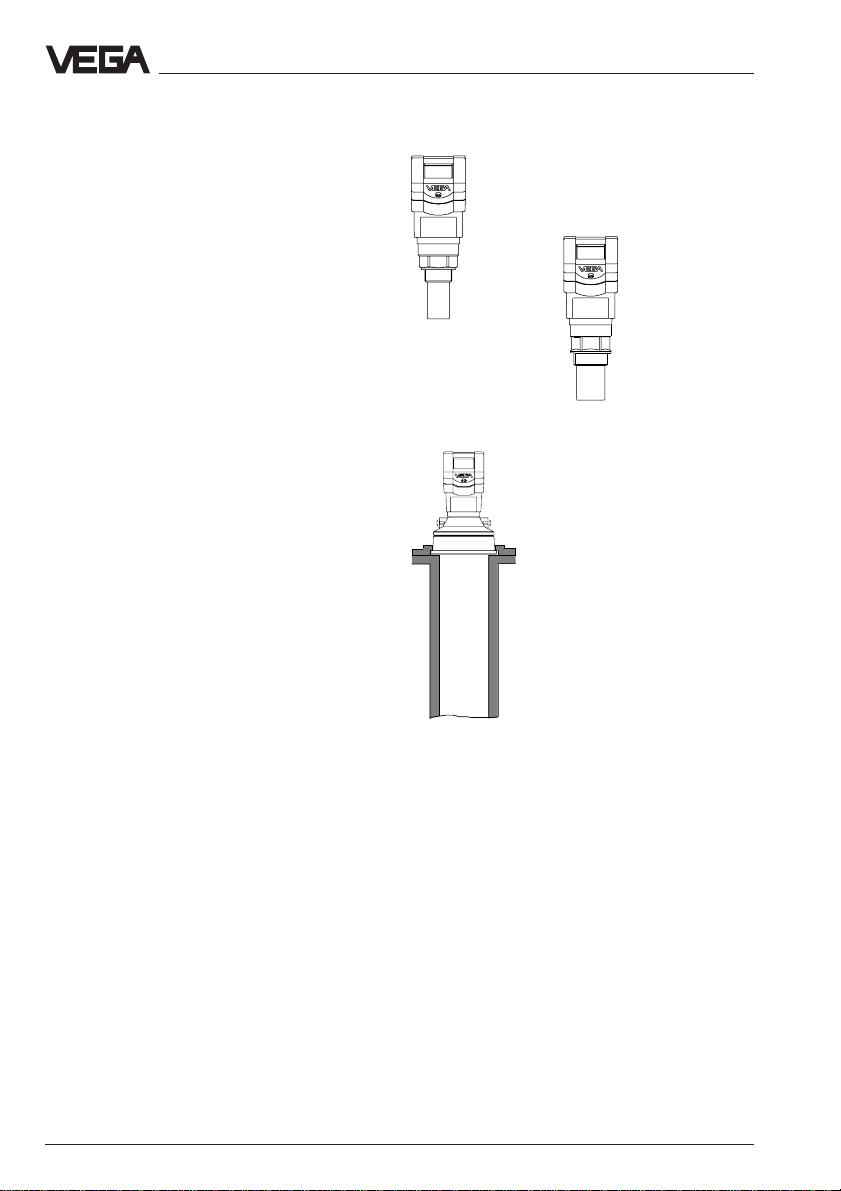

VEGASON 51

with 11/2“ thread

VEGASON 53

for mounting with holding strap or DN

100 compression flange (here on a

standpipe)

VEGASON 52

with 2“ thread

2.1 Type survey

General features

• Application in solids and liquids

• Measuring range 0,25 … 15 m

• Ex-approved in Zone 1 (IEC) or Zone 1 (ATEX) classification

EEx ia [ia] IIC T6

• Integral measured value indication

8 VEGASON 51K … 53K

Page 9

Types and versions

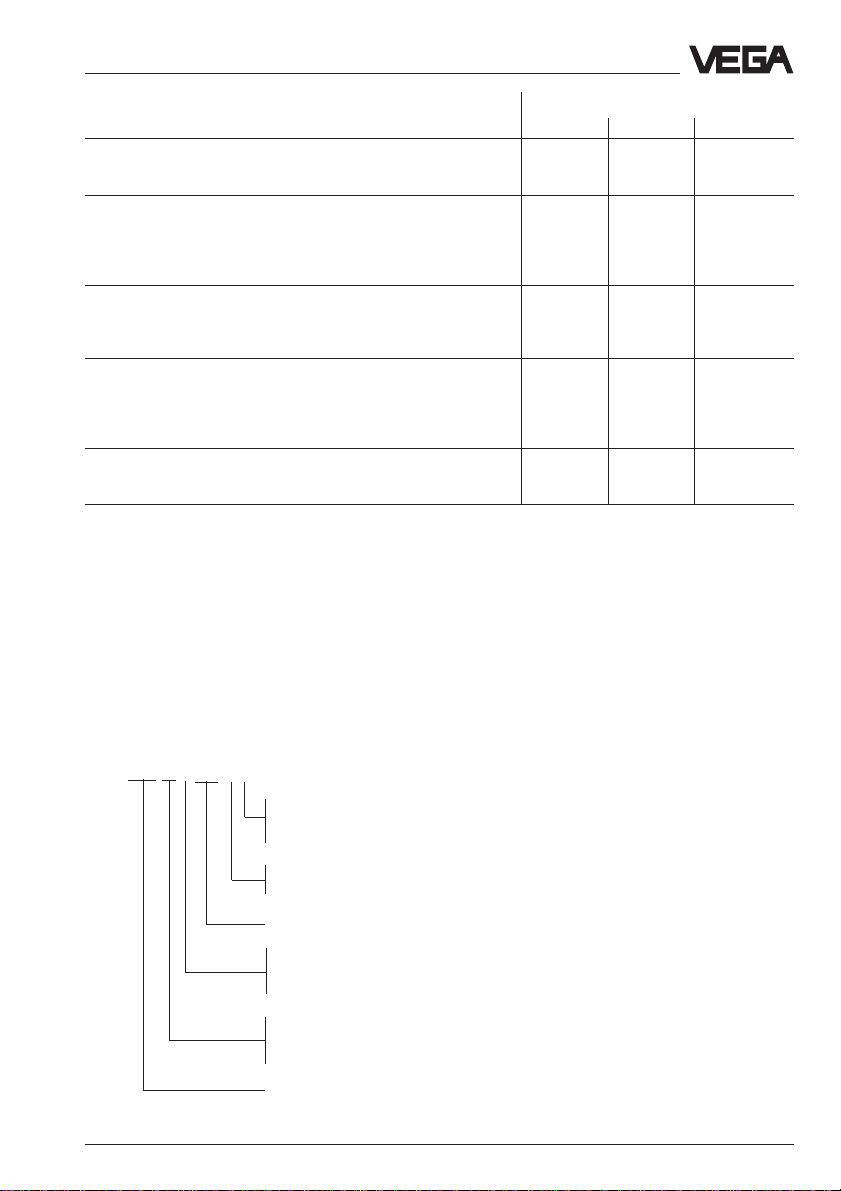

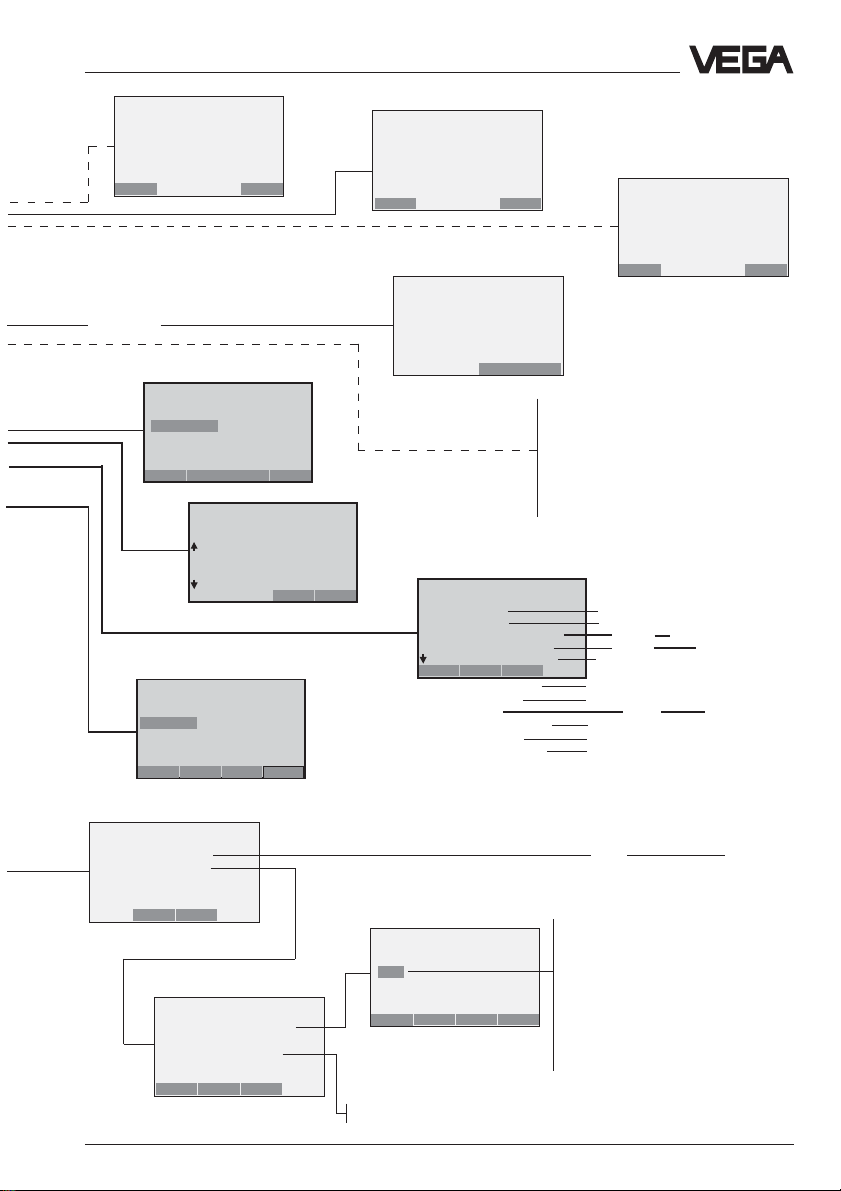

Survey VEGASON …

51K 52K 53K

Signal output

– active (4 … 20 mA) • • •

– passive (4 … 20 mA) • • –

Voltage supply

– two-wire technology (voltage supply and

signal output via a two-wire line) • • –

– four-wire technology (voltage supply separated

from the signal line) • • •

Process connection

1

–G1

/2 A; 11/2“ NPT • – –

– G 2 A; 2“ NPT – • –

– DN 100 compression flange – – •

Adjustment

–PC • • •

– adjustment module in the sensor • • •

– adjustment module in external indicating instrument • • •

– HART®-handheld • • •

Measuring range in m

– liquids 0,25 … 4 0,4 … 7 0,6 … 15

– solids 0,3 … 2 0,25…3,5 0,75 … 7

Type code

The second letter of the type designation e.g.

VEGASON 5[1]… differentiates the instruments acc. to process connection and measuring range.

The letter e.g. VEGASON 51[K] characterises

the output signal:

K stands for an analogue 4 … 20 mA output

signal (compact instrument).

VEGASON 51 K E X . X X (example)

P - 90 … 250 V AC (only in USA)

N - 20 … 36 V DC, 24 V AC (only in USA)

Z - supply via signal conditioning instrument (only in USA)

U - only in USA

X - outside the USA

Ex approved

K - Analogue 4 … 20 mA output signal

(two-wire or four-wire technology)

V - Digital output signal (two-wire technology)

Type 51: Measuring range 0,25 … 4 m

Type 52: Measuring range 0,4 … 7 m

Type 53: Measuring range 0,6 … 15 m

Measuring principle (SON for ultrasonic)

VEGASON 51K … 53K 9

Page 10

Types and versions

2.2 Configuration of meas. systems

Meas. systems in two-wire technology:

• 4 … 20 mA drawing without processing

unit,

A meas. system consists of a sensor with a

4 … 20 mA signal output and a unit evaluating or processing the level proportional current signal.

On the following pages you will see the instrument configurations called meas. system

which are shown in the following partly with a

signal processing.

(bottom)

• 4 … 20 mA on active DCS,

(page 12)

• 4 … 20 mA on active DCS (Ex-area),

(page 13)

• 4 … 20 mA on passive DCS,

(page 14)

• 4 … 20 mA on indicating instrument

VEGADIS 371 Ex,

(page 15)

Meas. systems in four-wire technology:

• 4 … 20 mA drawing without signal conditioning instrument, (page

16)

Meas. systems with VEGASON 51K … 53K

• Two-wire technology (loop powered), supply and output signal via a two-wire line

• Output signal 4 … 20 mA (passive)

• Optional external indicating instrument with analogue and digital indication (can be mounted

up to 25 m away from the sensor)

• Adjustment with PC, HART®-handheld or adjustment module MINICOM (can be plugged into

the sensor or in the external indicating instrument VEGADIS 50)

VEGADIS 50

4

2

VEGACONNECT 2

1)

If the resistors of the processing

systems connected to the

4 … 20 mA-signal output are less

than 200 Ω, a resistor of 250 Ω to

350 Ω must be connected to the

connection line during adjustment.

The digital adjustment signal would

be extremely damped or shortcircuited via too small input

resistors of the connected

processing system which means

that the digital communication with

the PC could no longer be

ensured.

10 VEGASON 51K … 53K

4 … 20 mA

1)

HART®-handheld

+

-

Page 11

Types and versions

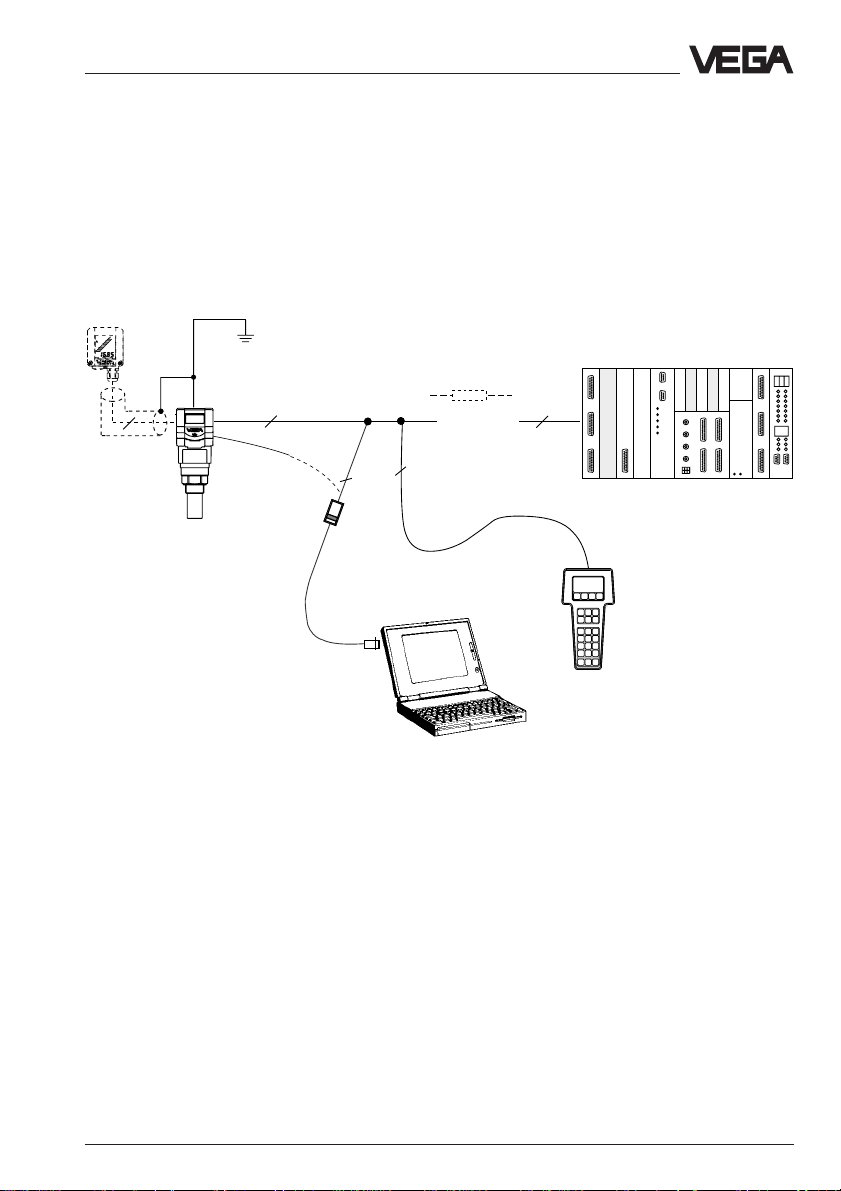

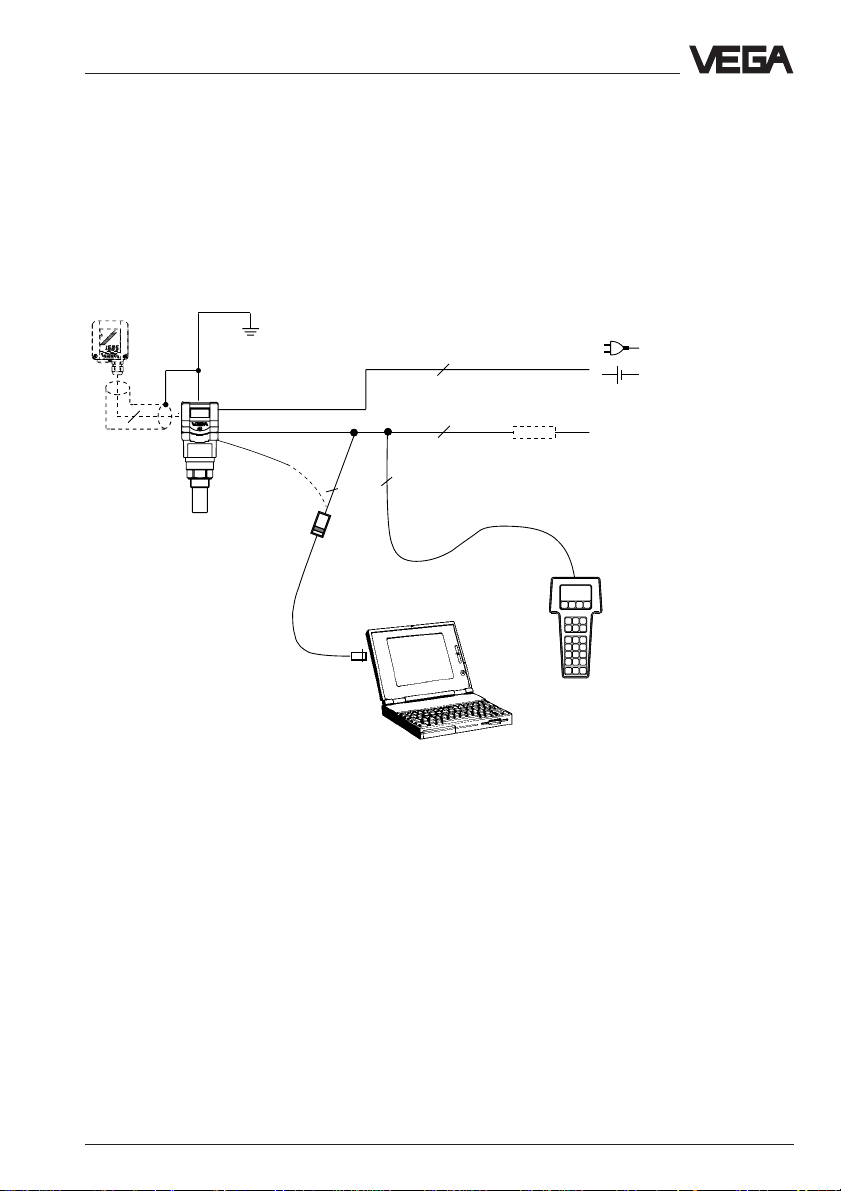

Measuring system with VEGASON 51K … 53K on active DCS

• Two-wire technology, supply on active DCS.

• Output signal 4 … 20 mA (passive).

• Measured value indication integrated in the sensor.

• Optional external indicating instrument (can be mounted up to 25 m away from the sensor

in Ex-area).

• Adjustment with PC, HART®-handheld or adjustment module (can be plugged in the sensor

or in the external indicating instrument).

VEGADIS 50

1)

4

2

VEGACONNECT 2

4 … 20 mA

2)

passive

2

2

2

DCS

HART®-handheld

1)

If the resistors of the processing systems

connected to the 4 … 20 mA-signal output are less

than 200 Ω, a resistor of 250 Ω to 350 Ω must be

connected to the connection line during adjustment.

The digital adjustment signal would be extremely

damped or short-circuited via too small input

resistors of the connected processing system

which means that the digital communication with

the PC could no longer be ensured.

2)

4 … 20 mA passive means that the sensor takes,

depending on the level a current of 4 … 20 mA.

The sensor therefore reacts electrically like a

resistor (consumer) on the DCS.

VEGASON 51K … 53K 11

Page 12

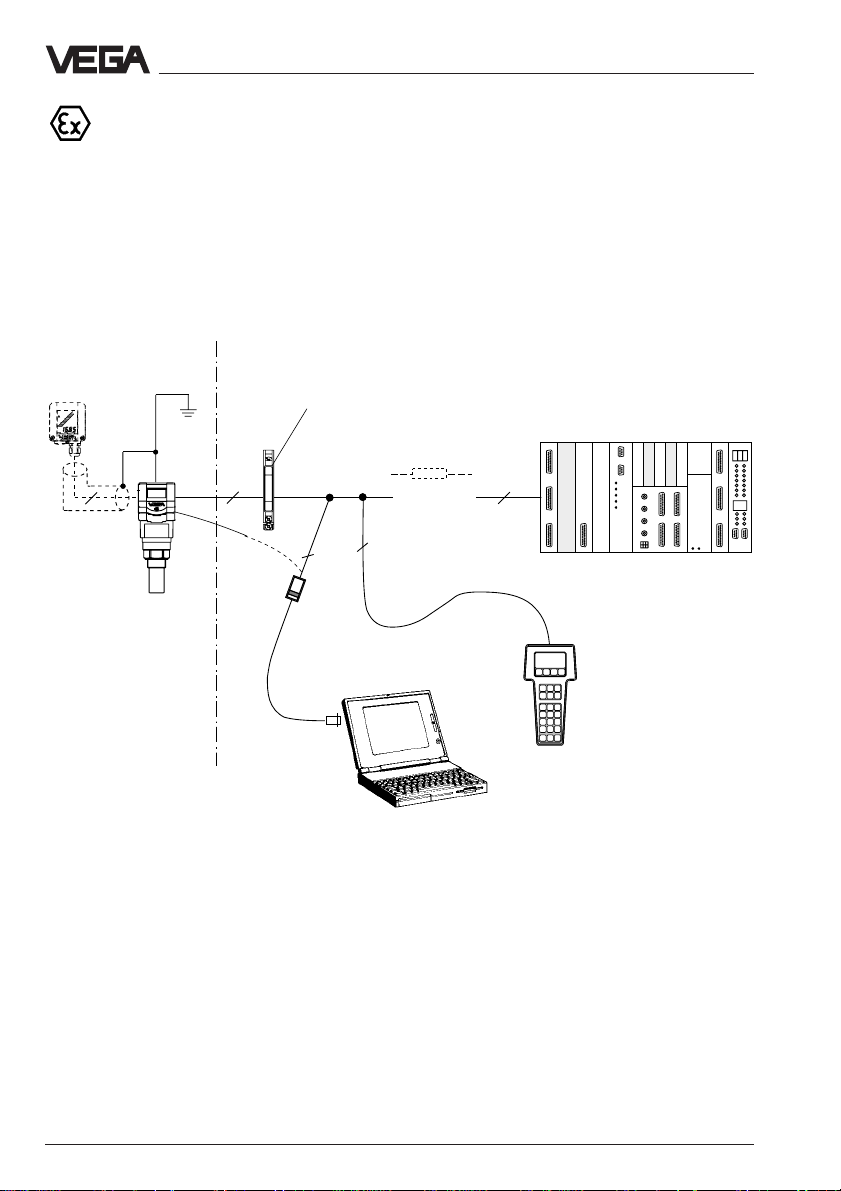

Types and versions

Measuring system with VEGASON 51K … 53K via separator in Ex-area on

active DCS

• Two-wire technology (loop powered), supply via the signal line on the DCS; output signal

4 … 20 mA (passive)

• Separator converts the not-intrinsically safe DCS-circuit into an intrinsically safe circuit, the

sensor can therefore also be used in Ex-zone 1

• Optional external indicating instrument with analogue and digital indication (can be mounted

up to 25 m away from the sensor)

• Adjustment with PC, HART®-handheld or adjustment module MINICOM (can be plugged in

the sensor or in the external indicating instrument VEGADIS 50)

Ex-area

VEGADIS 50

4

1)

If the resistors of the processing systems

Not Ex-area

2

Separator (e.g. Stahl)

(see "3.2 Approvals“)

2

2

VEGACONNECT 2

1)

4 … 20 mA

2)

passive

2

DCS active

HART®-handheld

connected to the 4 … 20 mA-signal output are less

than 200 Ω, a resistor of 250 Ω to 350 Ω must be

connected to the connection line during adjustment.

The digital adjustment signal would be extremely

damped or short-circuited via too small input

resistors of the connected processing system

which means that the digital communication with

the PC could no longer be ensured.

2)

4 … 20 mA passive means that the sensor takes a

current of 4 … 20 mA depending on the level. The

sensor, therefore, reacts electrically like a resistor

(consumer) on the DCS. The DCS operates

actively, i.e. as current or voltage supply.

12 VEGASON 51K … 53K

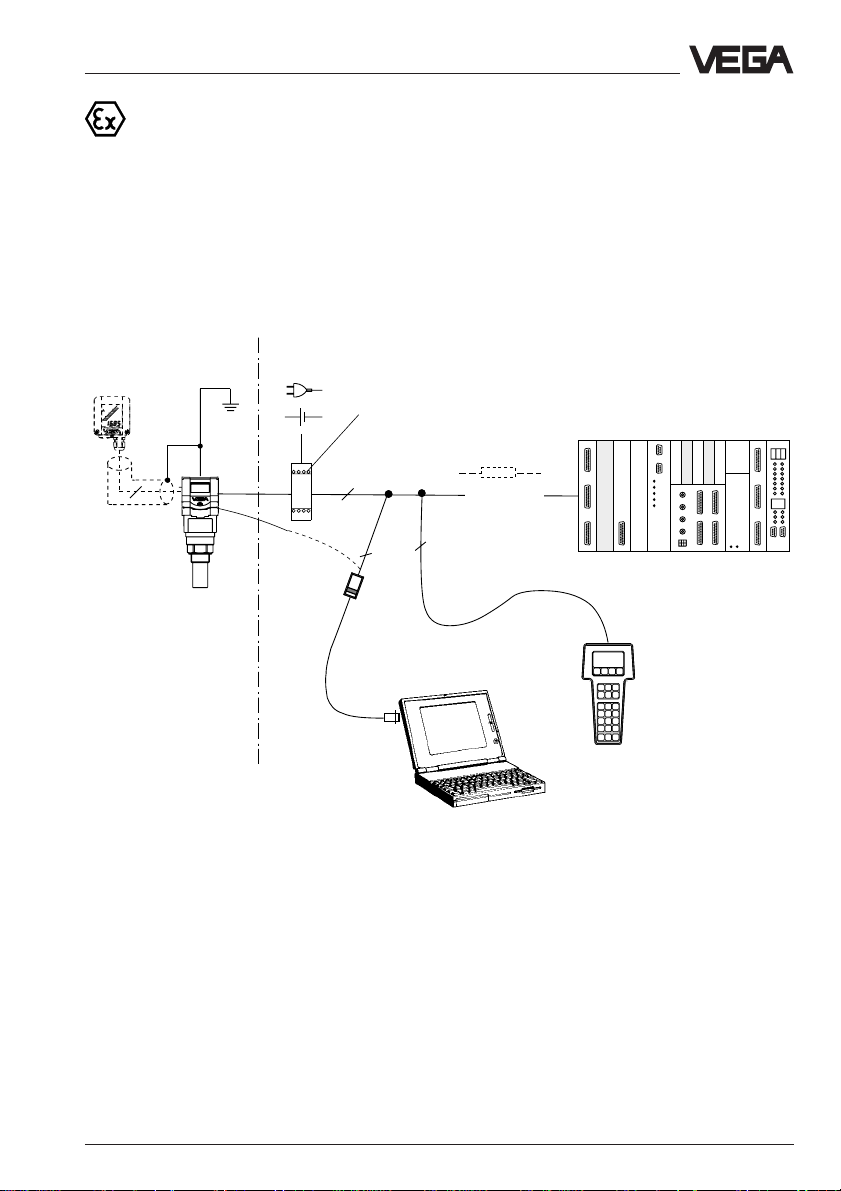

Page 13

Types and versions

Measuring system with VEGASON 51K … 53K vi a separator (Smart-Transmitter) on passive DCS

• Two-wire technology (loop powered), intrinsically ia-supply via the signal line from the separator for operation of the sensor in Ex-Zone 1

• Output signal sensor 4 … 20 mA passive

Output signal separator 4 … 20 mA active

• Optional external indicating instrument with analogue and digital indication (can be mounted

up to 25 m away from the sensor)

• Adjustment with PC, HART®-handheld or adjustment module MINICOM (can be plugged in

the sensor or in the external indicating instrument VEGADIS 50)

VEGADIS 50

4

Ex-area

Not Ex-area

-

+

Separator (e.g. VEGATRENN 149 Ex see

"3.2 Approvals“)

1)

2

2

VEGACONNECT 2

2

4 … 20 mA

2)

(active)

DCS (passive)

HART®-handheld

3)

1)

If the resistors of the processing systems

connected to the 4 … 20 mA-signal output are less

than 200 Ω, a resistor of 250 Ω to 350 Ω must be

connected to the connection line during adjustment.

The digital adjustment signal would be extremely

damped or short-circuited via too small input

resistors of the connected processing system

which means that the digital communication with

2)

4 … 20 mA active means that the separator

delivers level dependent a current of 4 … 20 mA.

The separator therefore reacts electrically against

the DCS like a current source.

3)

4 … 20 mA passive means that the sensor takes,

a current of 4 … 20 mA, depending on the level.

The sensor therefore reacts electrically like a

resistor (consumer) on the DCS.

the PC could no longer be ensured.

VEGASON 51K … 53K 13

Page 14

Types and versions

Measuring system with VEGASON 51K … 53K on the indicating instrument

VEGADIS 371 Ex with current and relay output

• Two-wire technology (loop powered), intrinsically safe ia-supply via the signal line from the

indicating instrument VEGADIS 371 Ex for operation of the sensor in Ex-zone 1

• Optional external indicating instrument with analogue and digital indication (can be mounted

up to 25 m away from the sensor)

• Adjustment with PC, HART®-handheld or adjustment module MINICOM (can be plugged in

the sensor or in the external indicating instrument VEGADIS 50)

Ex-area

VEGADIS 50

4

Not Ex-area

2

2

VEGACONNECT 2

4 ... 20 mA

2

1)

(passive)

-

+

VEGADIS

371 Ex

(see "3.2 Approvals“)

HART®-handheld

Relay

0/4 … 20 mA

1)

If the resistors of the processing systems

connected to the 4 … 20 mA-signal output are less

than 200 Ω, a resistor of 250 Ω to 350 Ω must be

connected to the connection line during adjustment.

The digital adjustment signal would be extremely

damped or short-circuited via too small input

resistors of the connected processing system

which means that the digital communication with

the PC could no longer be ensured.

14 VEGASON 51K … 53K

Page 15

Types and versions

Measuring system with VEGASON 51K … 53K in four-wire technology

• Four-wire technology, supply and output signal via two separate two-wire lines

• Output signal 4 … 20 mA active

• Optional external indicating instrument with analogue and digital indication (can be mounted

up to 25 m away from the sensor)

• Adjustment with PC, HART®-handheld or adjustment module MINICOM (can be plugged in

the sensor or in the external indicating instrument VEGADIS 50)

• Max. resistance on the signal output (load) 500 Ω

VEGADIS 50

2

-

4

2

2

2

VEGACONNECT 2

1)

> 200 Ω

+

4 … 20 mA

2)

(active)

HART®-handheld

1)

If the resistors of the processing systems

connected to the 4 … 20 mA-signal output are less

than 200 Ω, a resistor of 250 Ω to 350 Ω must be

connected to the connection line during adjustment.

The digital adjustment signal would be extremely

damped or short-circuited via too small input

resistors of the connected processing system

which means that the digital communication with

the PC could no longer be ensured.

2)

4 … 20 mA active means that the sensor delivers

a current of 4 … 20 mA (source) depending on the

level. The sensor, therefore, reacts electrically

against a processing system (e.g. indication) like a

current source.

VEGASON 51K … 53K 15

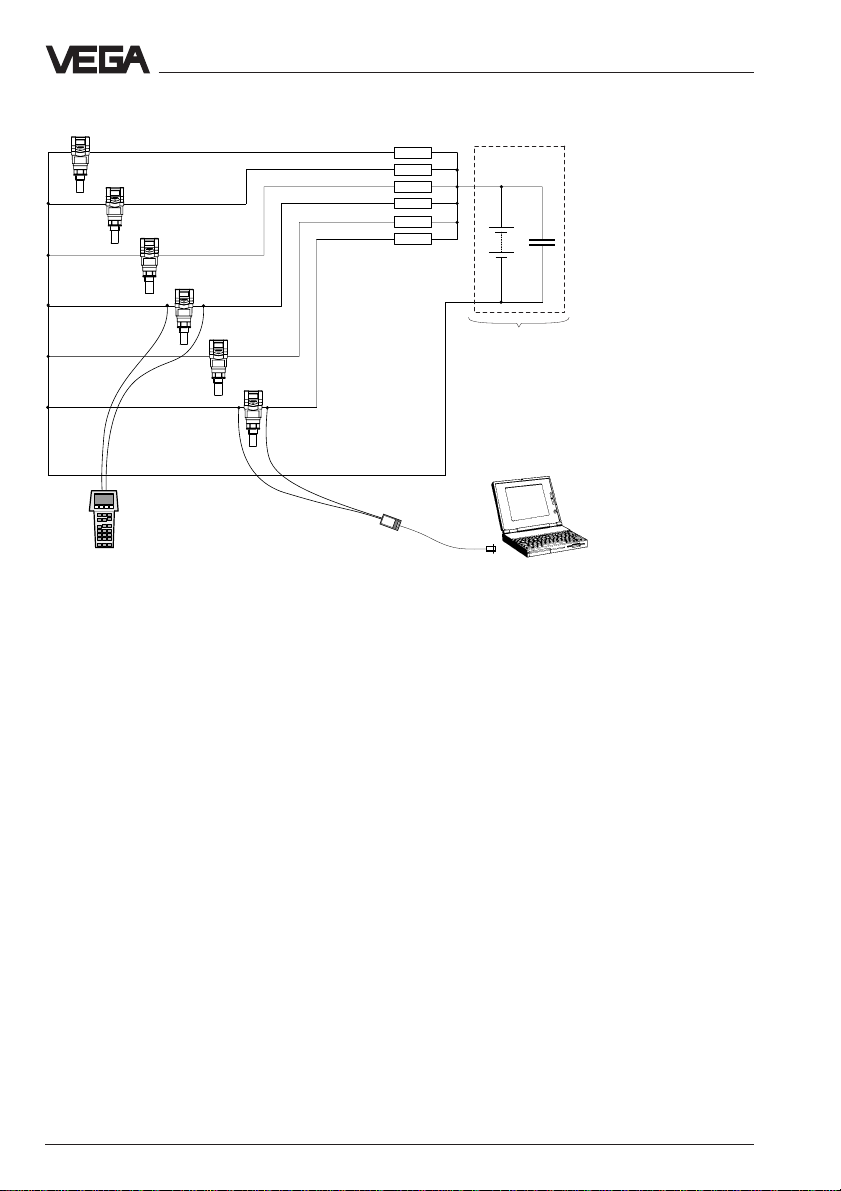

Page 16

Several sensors on a voltage source

250 Ω

250 Ω

250 Ω

250 Ω

250 Ω

250 Ω

Types and versions

C

R = 0…2 Ω

All sensors are dispatched with the same

communication address zero. If several sensors are operated on one voltage source, a

resistors avoid the adjustment signals of the

actually operated sensor from also being

short-circuited.

communication on the signal line with the PC

or with the HART®-handheld is no longer

possible, as in this case all sensors are addressed digitally at the same time.

With the PC and the adjustment software

VEGA Visual Operating (VVO) or with the

HART®-handheld, the sensors can be ad-

justed from the address zero to the address

To avoid this, 250 Ω … 350 Ω resistors must

be connected directly on the voltage source

in the sensor supply line. The inner resistance of the voltage source must be very

small. The digital communication signal (PC

or HART®-handheld) used on the sensor line,

1 … 15. If a sensor is adjusted to the ad-

dress 1 … 15, the sensor no longer delivers

a 4 … 20 mA-signal, but is frozen to 4 mA

(power supply). Nevertheless, the sensor will

continue to provide the measured value digit-

ally. This mode is called multidrop operation.

is then no longer transmitted to the other

sensors. You can then communicate with the

PC or HART®-handheld on the signal line of

the appropriate sensor without the participation of all other sensors in the communication

even though all sensors react to the address

zero. The low inner resistor (alternating load

resistor by filter capacitor) of the voltage

source short-circuits the signals before they

can cross over to the other sensor lines. The

16 VEGASON 51K … 53K

Page 17

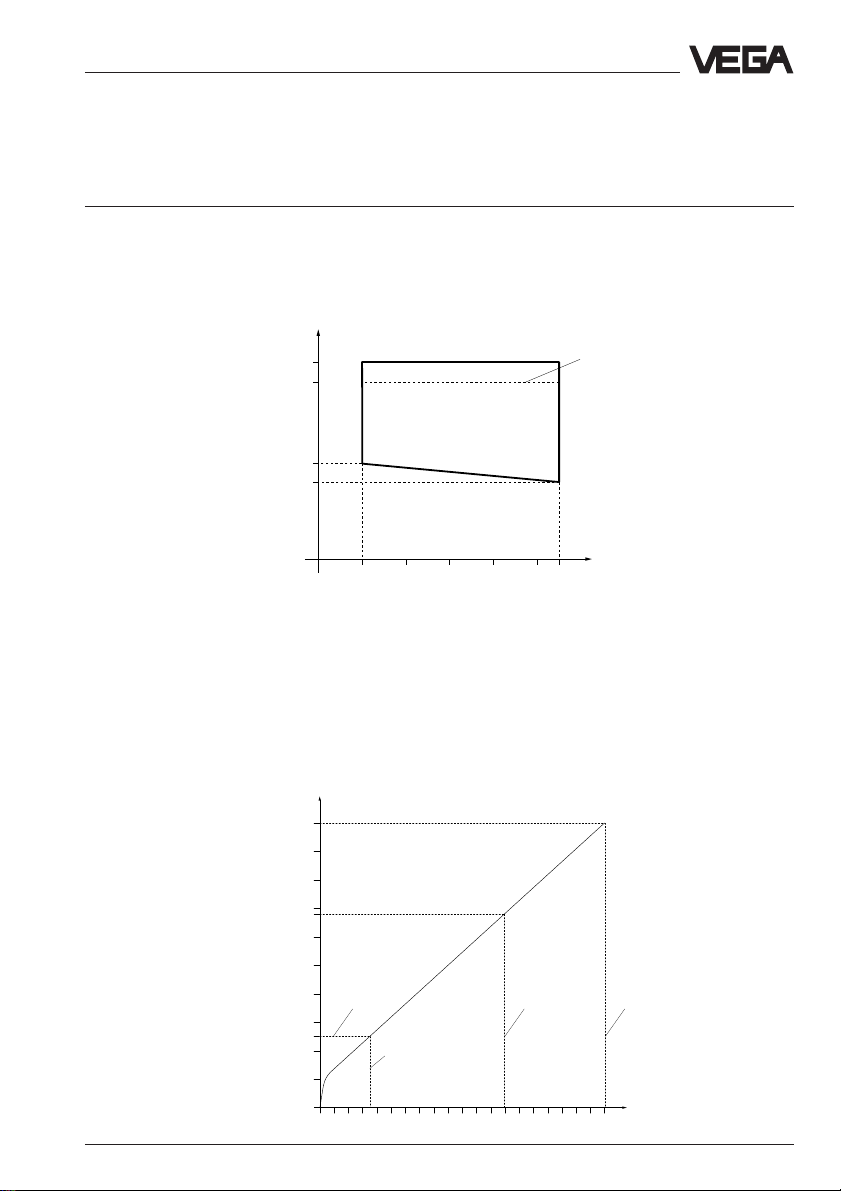

Technical data

3 Technical data

3.1 Data

Power supply

Supply voltage

- four-wire sensor 230 V AC (20 … 250 V AC), 50/60 Hz

- two-wire sensor 24 V DC (16 … 36 V DC); Sicherung 0,2 A TR

Diagram of the min. supply voltage dependent on the

V

sensor current (two-wire sensor)

36

29

16

14

24 V DC (20 … 72 V DC)

fuse 0,2 A TR

Range of the required and permissible terminal voltage

Ex-voltage limit

0

422

mA

Current consumption

- two-wire sensor max. 22,5 mA

- four-wire sensor max. 140 mA

Power consumption

- two-wire sensor max. 80 mW, 0,45 VA

- four-wire sensor max. 1,2 W, 2,50 VA

Load

- four-wire sensor max. 500 Ω

- two-wire sensor see diagram

Ω

Load diagram of the two-wire sensor

(loop resistor of processing unit, e.g. DCS and supply line)

1000

900

800

700

680

600

500

HART®-

400

load

300

250

200

100

0

16 20 25 30 35

min. voltage limit

by using the

HART®-load

17 18 19 29

VEGASON 51K … 53K 17

max. voltage

limit with

Ex-sensors

max. voltage limit

with not-Ex-sensors

V

36

Page 18

Technical data

Type 51… 52… 53…

Measuring range (relating to the transducer surface)

Liquid 0,25 … 4 m 0,4 … 7 m 0,6 … 15 m

Solid 0,30 … 2 m 0,5 … 3,5 m 0,75 … 7 m

Output signal

Analogue 4 … 20 mA-current signal

Adjustment

- PC with adjustment software VEGA Visual Operating

- adjustment module MINICOM

- HART®-handheld

Accuracy (typical values under reference conditions)

1)

Class accuracy (deviation in characteristics

including repeatability and hysteresis

acc. to the limit point method) < 0,1 % relating to max. measuring range

Temperature drift (relating to 20°C) < 0,015 %/10 K of measuring range

Accuracy of the 4 … 20 mAoutput signal 0,025 % (D/A-converter)

Resolution 1 mm

Characteristics

Min. span

(between empty and full adjustment) > 20 mm (recommended > 50 mm)

Ultrasonic frequency 70 kHz 55 kHz 34 kHz

Intervals 1,0 s 1,0 s 1,0 s

Beam angle

(at -3 dB emitted power) 5,5° 5,5° 3°

Response time

2)

2 … 20 s

(dependent on the factory setting)

Materials

Housing PBT (Valox)

Transducer, process connection thread PVDF

Compression flange PP or 1.4571

Transducer diaphragm (type 53) 1.4571

Weights

Weight incl. transducer

- VEGASON 51 1,2 kg

- VEGASON 52 1,6 kg

- VEGASON 53 2,3 kg

1)

Reference conditions acc. to IEC 770, e.g.: Temperature 18°C … 30°C etc.

2)

The response time is the time the sensor requires to provide the level correctly with a quick level change

(with max. 10 % deviation).

18 VEGASON 51K … 53K

Page 19

Technical data

Ambient conditions

Max. vessel pressure (gauge pressure)

- VEGASON 51 and 52 3 bar

- VEGASON 53 1 bar

Ambient temperature

- sensor (electronics) -20°C … +60°C

- process (transducer) -40°C … +80°C (StEx: -20°C … +75°C)

- storage and transport temperature -40°C … +80°C

Protection

- sensor IP 67

- transducer, process IP 68

Protection class

- two-wire sensor II

- four-wire sensor I

Overvoltage category III

Self-heating

at 40°C ambient temperature

- to sensor 45°C

- to transducer, process 55°C

Ex-technical data

Classification ia intrinsically safe (in conjunction with a safety

barrier or separator)

Temperature class (permissible ambient

temperature on the transducer when used

in Ex-areas)

- T6 42°C

- T5 58°C

- T4 60°C

- T3 60°C

Ex-approved in category or zone

- ATEX Zone 1 (II 2 G)

- IEC, CENELEC, PTB Zone 1 (II 2 G)

Classification mark EEx ia IIC T6

Process connections

VEGASON 51 G 11/2 A, 11/2" NPT

VEGASON 52 G 2 A, 2" NPT

VEGASON 53 DN 100 compression flange

Connection lines

Two-wire sensors supply and voltage via one two-wire line,

load dependent on the supply voltage

Four-wire sensor supply and signal separately, load of the

Cross-section area of conductor generally 2,5 mm

4 … 20 mA-signal line max. 500 Ω

Earth connection max. 4 mm

2

2

Cable entry, Pg 2 x M20 x 1,5 (cable diameter 5 … 9 mm)

VEGASON 51K … 53K 19

Page 20

Technical data

CE-conformity

VEGASON series 50 ultrasonic sensors meet the protective regulations of EMVG

(89/336/EWG) and NSR (73/23/EWG). The conformity has been judged acc. to the following

standards:

EMVG Emission EN 50 081 - 1: 1993

NSR EN 61 010 - 1: 1993

Susceptibility EN 50 082 - 2: 1995

Outputs and processings

Display indication

Indication - optional integrated in the sensor, scalable

Signal output

Signal output

- two-wire technology 4 … 20 mA (load dependent on supply

- four-wire technology 4 … 20 mA (load max. 500 Ω)

Resolution of the 20 mA-signal 0,025 % of operating range

Failure of the 20 mA-signal < 0,025 % of operating range

analogue and digital meas. value indication

- optional external meas. value indication,

powered by the sensor and up to 25 m away

from the sensor (also the adjustment module

MINICOM can be inserted)

voltage, see load diagram page 17)

Two-wire technology:

The analogue 4 … 20 mA-output signal (measuring signal) is transmitted together with the

power supply via a two-wire line.

Four-wire technology:

Separate power supply.

The analogue 4 … 20 mA-output signal (measuring signal) is looped by a line separated

from the supply voltage.

20 VEGASON 51K … 53K

Page 21

Technical data

3.2 Approvals

When using ultrasonic sensors in Ex-areas or

navigation, the instruments must be suitable

and approved for the explosion zones and

application areas. The suitability is checked

by approval authorities and certified by approval documents.

VEGASON 50 ultrasonic sensors are approved for Ex-zone 1. Please note the attached approval documents when using a

sensor in Ex-area.

Test and approval authorities

VEGASON ultrasonic sensors are tested and

approved by the following monitoring, test

and approval authorities:

- PTB

(Physikalisch Technische Bundesanstalt Physical Technical Test Authority)

- FM

(Factory Mutual Research)

- ABS

(American Bureau of Shipping)

- LRS

(Lloyds Register of Shipping)

- GL

(German Lloyd)

- CSA

(Canadian Standards Association)

Ex-area zone 1

Series 50 senors require special safety barriers and separators for operation in Ex-area

zone 1. The safety barriers and separators

provide intrinsically safe (ia) circuits. The

followes shows a choice of instruments with

which the series 50 sensors work reliably.

The signal line resistance must not exceed

15 Ω per wire.

Separators and signal conditioning instrument:

- VEGADIS 371 Ex

- A puissance 3 PROFSI 37-24070A

- VEGAMET 614 Ex

- Apparatebau Hundsbach

AH MS 271-B41EEC 010

Separators:

- VEGATRENN 149 Ex…

- Stahl 9303/15/22/11

- CEAG GHG 124 3111 C1206

Separators, safety barriers:

- Stahl 9001/01/280/110/10

- CEAG GHG 11 1 9140 V0728

- Type 9130 (VEGA)

- Stahl 9001/51/280/110/14

- MTL 787 S+

- CEAG CS 3/420-106

VEGASON 51K … 53K 21

Page 22

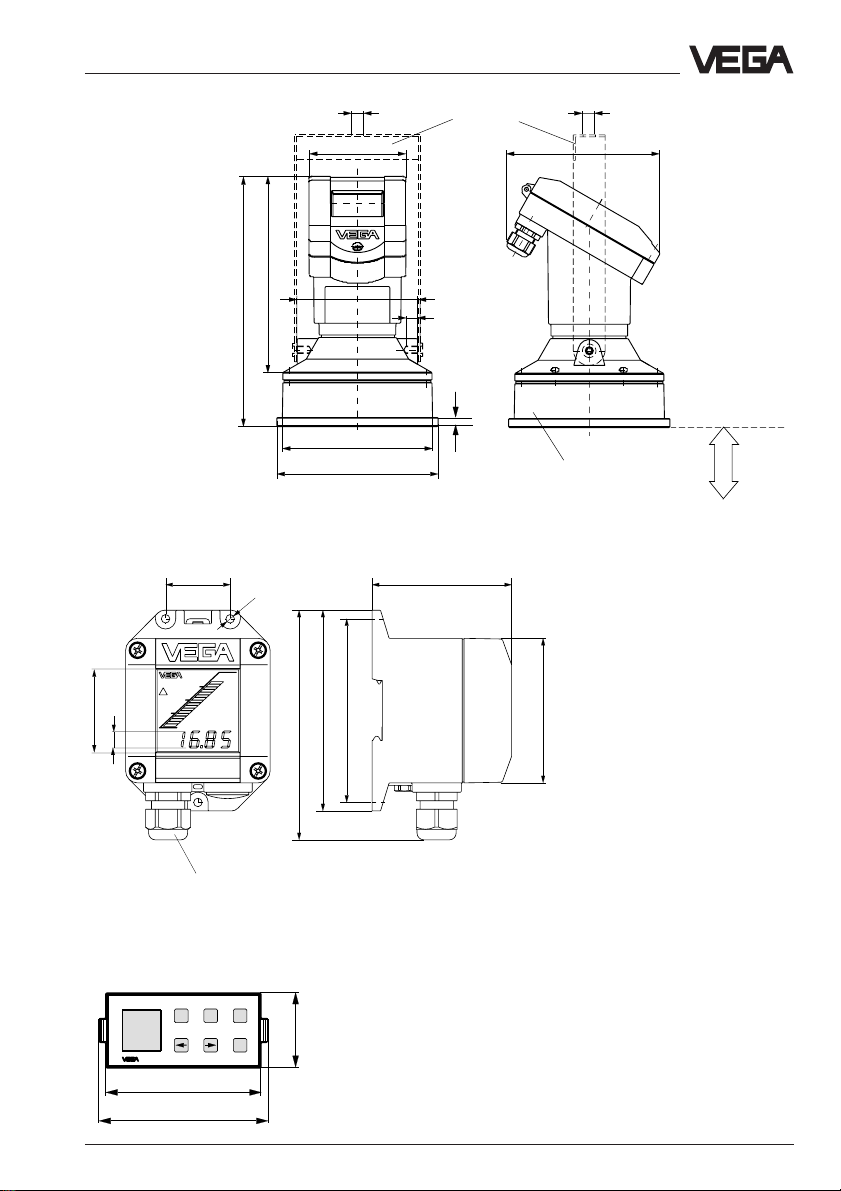

3.3 Dimensions

VEGASON 51

Technical data

95

152

VEGASON 52

206

202

22

65

2 x M20x1,5

Thread G 11/2 A or 11/2“

NPT

Reference plane

ø39

ø60

85

95

Min.-distance

to the medium

152

0,25 m

Thread G 2 A or 2" NPT

22

61

ø50

ø72

85

SW 60

Min.-distance

to the medium

Reference plane

0,4 m

22 VEGASON 51K … 53K

Page 23

Technical data

193

ø158

152

95

247

ø148

12

M8x10

ø12

ø12

120

0,6 m

VEGASON 53

External indicating instrument VEGADIS 50

38

5

ø

82

Mounting loop

suitable for compression

flange DN 100

Min.-distance

to the medium

48

10

135

118

108

85

Note:

Cable diameter of the connection cable min.

5 mm and max. 9 mm.

Otherwise the seal effect of the cable entry is

not ensured.

-

Pg 13,5

+

ESC

OK

Carrier rail mounting 35 x 7,5 acc. to EN 50 022 or flat

screwed

Adjustment module MINICOM

Tank 1

m (d)

12.345

32,5

Adjustment module for insertion into

VEGASON series 50 sensors or into the external indicating instrument VEGADIS 50

67,5

74

VEGASON 51K … 53K 23

Page 24

4 Mounting and installation

Mounting and installation

4.1 General installation instructions

Measuring range

You select your instrument according to the

required measuring range, as well as other

criteria. The reference planes for the min. and

on instruments with flange version, the instrument flange. (Note the information for the

reference planes in chapter "Dimensions“).

The max. filling is dependent on the required

min. distance of the instrument used (0,25 m

to 1,4 m) and the installation place of the

instrument or the transducer.

max. distance to the product or the solid is

either the transducer surface (diaphragm) or,

Typ e 5 1

Min.

distance

0,25 m 0,4 m

Min. distance, max. measuring range and span (example VEGASON 51, 52 and 53)

Full

1m

max. meas. range

4 m (type 51), 7 m (type 52), 15 m (type 53)

Empty

Min.

distance

0,75 m

Typ e 5 3 Typ e 52

Reference plane

Span

Min.

distance

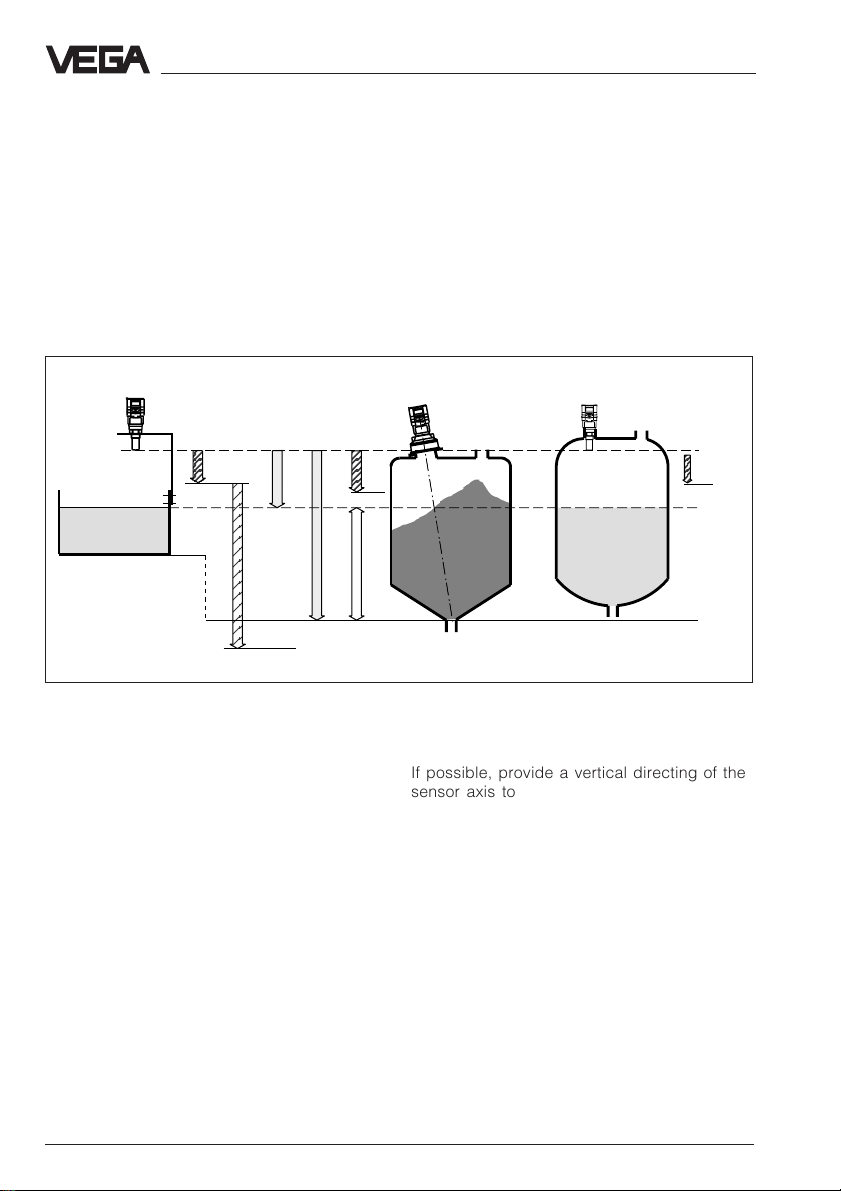

Beam angle and false echoes

If possible, provide a vertical directing of the

sensor axis to the product surface and

The ultrasonic impulses are focussed by the

transducer. The impulses leave the trans-

avoid, if possible, struts within the 100 %-

beam, e.g. by tubes and struts.

ducer in conical form similar to the beam

pattern of a spotlight. The beam angle is 5,5°

(VEGASON 51/52) or 3° (VEGASON 53) at

-3 dB emitted power.

Any object in this beam angle causes a false

echo. Within the first few metres of the beam

angle, tubes, struts or other installations

cause strong false echoes. At a distance of 6

m the false echo of a strut has 9-times more

amplitude than at a distance of 18 m.

24 VEGASON 51K … 53K

Page 25

Mounting and installation

Meas. distance

0 m

4 m

7 m

Meas. distance

0 m

VEGASON 51/52

0,4

VEGASON 53

4.2 Measurement of liquids

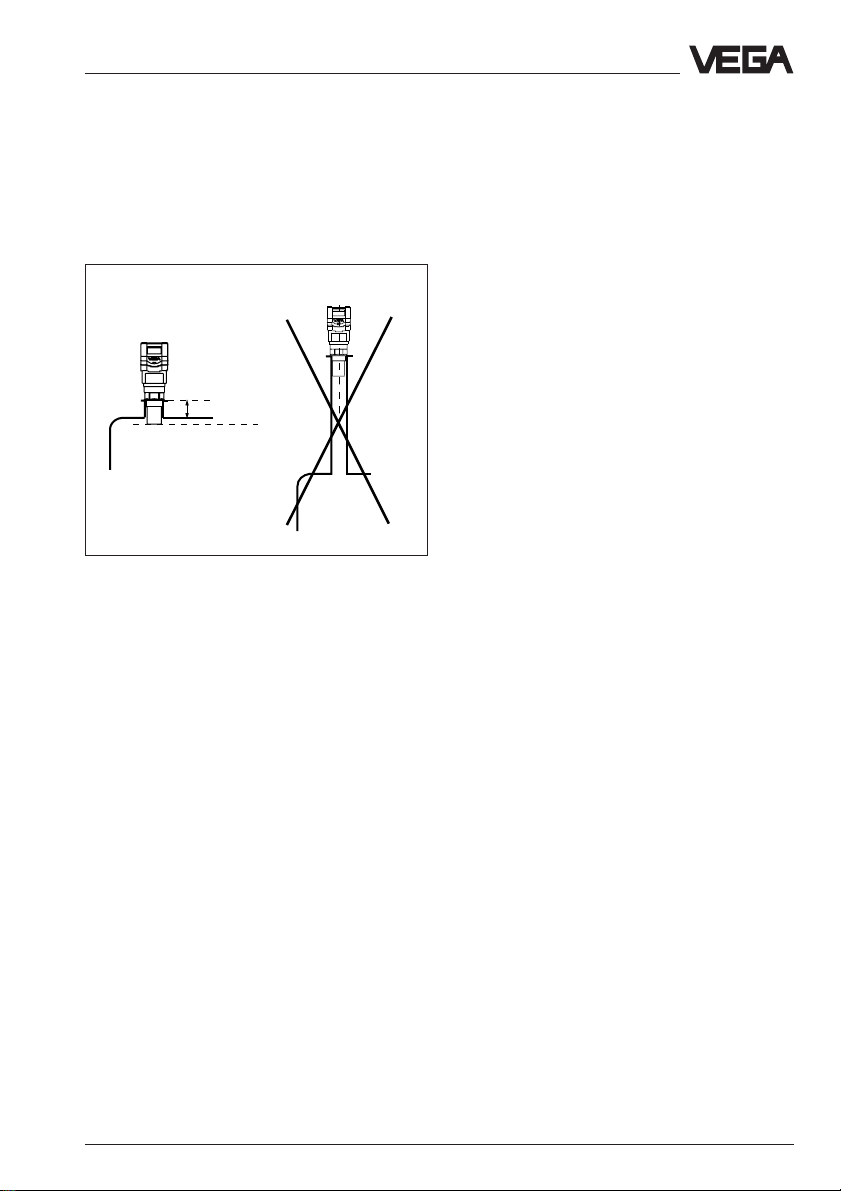

Flat vessel top

On flat vessels the mounting is mainly made

on a very short DIN-socket piece. Reference

5,5˚

12˚

50 %

emitted power

100 %

emitted power

0

1,21,2

0,4

3˚

8˚

emitted power

50 %

m

plane on flange versions is the instrument

flange. The transducer should protrude out of

the flange pipe.

Reference plane

≤ 60 mm

Min.

distance

Flange version on very short DIN-socket piece

Ideal is the mounting directly on the vessel

top. A round opening on the vessel is sufficient to fasten the VEGASON 53 sensor with

a compression flange.

emitted power

100 %

Reference plane

15 m

0,4

1,2

0,4

0

m

1,2

Flange version (compression flange) on flat vessel

top

VEGASON 51K … 53K 25

Page 26

You can also mount the sensors with 11/2“ or

2“ thread to short socket pieces.

≤ 60 mm

Reference plane

≤ 60 mm

Mounting and installation

Reference

plane

1

/2 vessel radius

Mounting on short 11/2“ or 2“ socket piece

Dished tank ends

On dished tank ends, please do not mount

the instrument in the centre but approx. 1/2

vessel radius from the centre. Dished tank

ends can act as paraboloidal reflectors for

the ultrasonic pulses. If the transducer is

placed in the "focus" of the parabolic tank

end, the transducer receives amplified false

echoes. The transducer should be mounted

outside the "focus". Parabolic amplified echoes are thereby avoided.

≤ 60 mm

Reference plane

1

/2 vessel radium

Flange on dished vessel ends

Open vessles

On open vessels the use of the instruments

on a mounting lever is recommended. Mount

the low-weight sensor to a mounting lever.

Reference plane

Min. meas.

distance

Open vessels

Mounting boss on dished tank ends

26 VEGASON 51K … 53K

Page 27

;;;;;;;;;;;;;

Mounting and installation

Pump shaft

Narrow shafts and shaft openings (vessel

openings) with very rough walls and shoulders aggravate an ultrasonic measurement

due to strong false echoes.

Shaft and vessel openings

Narrow, very rough shaft, well and vessel

openings can be overcome by a socket

piece as described under "4.4 Socket extensions“ (left lower half of the figure).

see also “4.4 Socket

extension“

Socket piece

> 100 mm

min.

distance

Measuring

Shaft

You can realise very good meas. results with

a meas. pipe in continous narrow shafts, see

figure. The meas. pipe used must have

smooth walls inside (e.g. PE-sewage pipe)

and a diameter of ≥100 mm. This coordination

works without problems as long as the inside

of the meas. pipe has no build-up (cleaning).

Also check the use of hydrostatic pressure

transmitters or capacitive electrodes.

4.3 Measurement of solids

Flange mounting

As with liquids, the instrument can also be

mounted on a short DIN-socket piece in solid

vessels. The socket axis must point to the

vessel outlet or should be directed vertically

to the product surface and must be very

short (< 100 mm).

Reference plane

range

Shaft pump

Meas. tube

Socket piece or meas. tube on the example of a shaft

VEGASON 51K … 53K 27

Shaft pump

VEGASON 53 on vessel flange

Min. distance

Page 28

Swivelling holder

The accessory programme offers a swivelling holder (mounting loop) for mounting of

the VEGASON 53. This facilitates the directing of the sensor to the product surface.

Reference plane

Min. distance

VEGASON 53 on swivelling holder

Mounting and installation

Reference plane

Min. distance

VEGASON 51 or 52 on the mounting boss. The socket

axis should point to the product surface

Material cones

Large material cones are detected with several instruments which can be fastened on

lifting beams.

Mounting boss

Reference plane

Max.

Transducer on lifting beam above material cone

VEGASON 52 on mounting boss

28 VEGASON 51K … 53K

Page 29

Mounting and installation

;

;

;

;

;

;

;

;

4.4 Socket extensions

The ultrasonic sensor requires a min. distance to the product or solid. Note this min.

distance in your planning.

In exceptions it is possible to reach the required min. distance and hence the desired

filling height with a socket piece. However,

the socket piece increases the noise level of

the ultrasonic signal and can interfere with the

measurement. Only provide the socket extension when there is no other possibility, and

carry out the extension as shown in the following figure.

Socket extension with liquids

Chamfer the socket carefully and ensure a

smooth inner side of the socket. The socket

should not protrude into the measured product when pollution or measured product

could stick to the socket.

;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;

For measurements in products which do not

cause any build-up, the socket extension, in

form of a meas. pipe, can be permanently

submerged into the measured product. The

ultrasonic mesurement is then only carried

out in the meas. pipe without being interfered

with by vessel installations (see page 28

"Pump shaft“).

Type 51/52

LL

45˚

ø

Socket extension with liquids

Typ e 5 3

45˚

ø

Max. socket length dependent on the socket

diameter

øL in mm

in mm Type 51 Type 52 Type 53

100 200 300 300

150 300 400 400

200 – 500 500

250 – – 600

Socket piece should not be submerged into the

adhesive product (figure: VEGASON 53)

Choose as large a socket diameter as possi-

Socket extension with solids

For solids provide a conical socket extension

with an angle of at least 15° … 20°.

ble and as small a socket length as possible.

Ensure that the socket opening is burr free to

minimise false echoes.

15˚

15˚

Socket extension with solids

VEGASON 51K … 53K 29

Page 30

Mounting and installation

4.5 Flow measurement

The short examples on this page only give

introductory information for your flow measurement. Planning information is given by the

flume manufacturers and in special literature.

Rectangular flume

- Installation of the sensor on the upstream

side

- Note distance to the overfall edge

(3 … 4 x h

- Installation centered to the flume

- Edge opening ≥ 2 x h

- Installation perpendicular to the liquid sur-

face

- Keep min. distance relating to h

- Min. distance of the edge opening of down-

stream water ≥ 50 mm

max

90°

)

from ground

max

max

≥ max.

distance

h

max

Khafagi-Venturi flume

- Installation of the sensor on the inlet side

- Note distance to the Khafagi-Venturi flume

(3 … 4 x h

- Installation perpendicular to the liquid surface

- Keep min. distance relating to the height of

damming h

Khafagi-Venturi flume

max

max

3 … 4 x h

90°

Sensor

)

max

h

max

B

≥ 2 x h

Overfall edge

max

Flow measurement on open flumes

Overfall edge

3 … 4 x h

max

90°

≥ 5 cm

Upstream water

Downstream water

Flow measurement on open flumes

30 VEGASON 51K … 53K

Page 31

Mounting and installation

4.6 False echoes

The placing of the ultrasonic senor must be

chosen so as to ensure that no mountings or

in-flowing filling material crosses with the

ultrasonic impulses. The following examples

and instructions show the most frequent

measuring problems and how to avoid them.

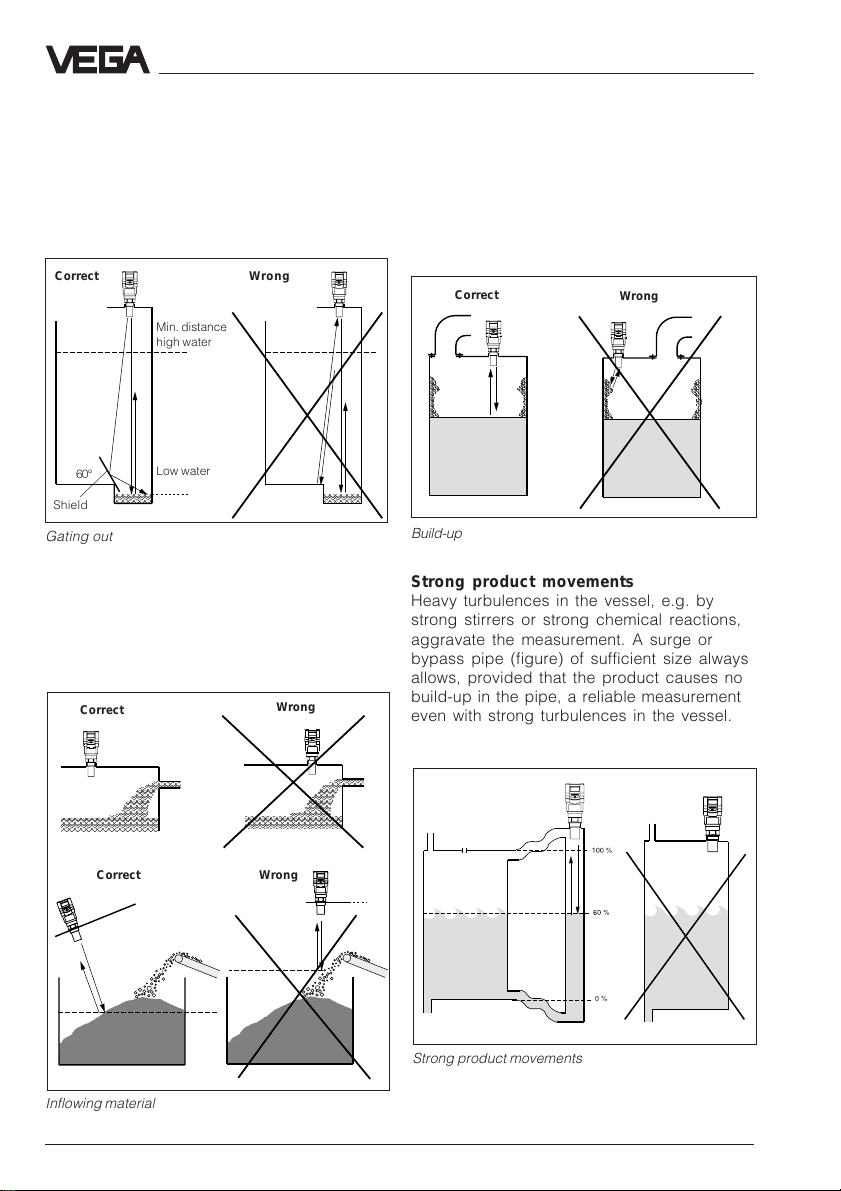

Vessel protrusions

Vessel forms with flat protrusions can, due to

their strong false echoes, greatly effect the

measurement. The placing of shields over

these flat protrusions scatter the false echoes

and guarantee a definite measurement.

Correct Wrong

Vessel protrusions (slope)

Intake pipes, i.e. for the mixing of materials with the flat top turned towards the sensor should be covered with an angular shield

with which the false echoes are then scattered.

Vessel mountings

Vessel mountings such as, for example, a

ladder often cause false echoes. When projecting the measuring point, please ensure

the free access of the ultrasonic signals to

the medium.

Correct Wrong

Ladder

Vessel mountings

Ladder

Vessel struts

Vessel struts, as with other vessel mountings,

can cause strong false echoes which superimpose the useful echoes. Small shields

effectively hinder a direct false echo reflection. The false echoes are scattered and

diffused in the area and are then filtered out

as "echo noise" by the measuring electronics.

Correct Wrong

Correct Wrong

Vessel struts

Vessel protrusions (intake pipe)

VEGASON 51K … 53K 31

Shields

Page 32

Mounting and installation

;;

;;

;;

Flood basin

The max. height of water to be expected

determines the installation height to keep the

min. distance of the transducer even with

highest high water. The low water edge

should be covered with a shield in the transducer range.

Correct Wrong

Min. distance

high water

60°

Shield

Low water

Gating out of an echo

Inflowing material

Do not mount the instrument in or above the

filling stream. Ensure that you detect the

product surface and note the inflowing material.

Correct

Wrong

Mounting on the vessel

If the sensor is mounted too close to the

vessel wall, build-up and adhesion of the

filling material to the vessel wall cause false

echoes. Please position the sensor at a sufficient distance from the vessel wall. Please

also note chapter "4.1 General installation

instructions".

Correct

Build-up

Wrong

Strong product movements

Heavy turbulences in the vessel, e.g. by

strong stirrers or strong chemical reactions,

aggravate the measurement. A surge or

bypass pipe (figure) of sufficient size always

allows, provided that the product causes no

build-up in the pipe, a reliable measurement

even with strong turbulences in the vessel.

Correct

Wrong

Strong product movements

Inflowing material

32 VEGASON 51K … 53K

Page 33

Mounting and installation

;

;

;

;

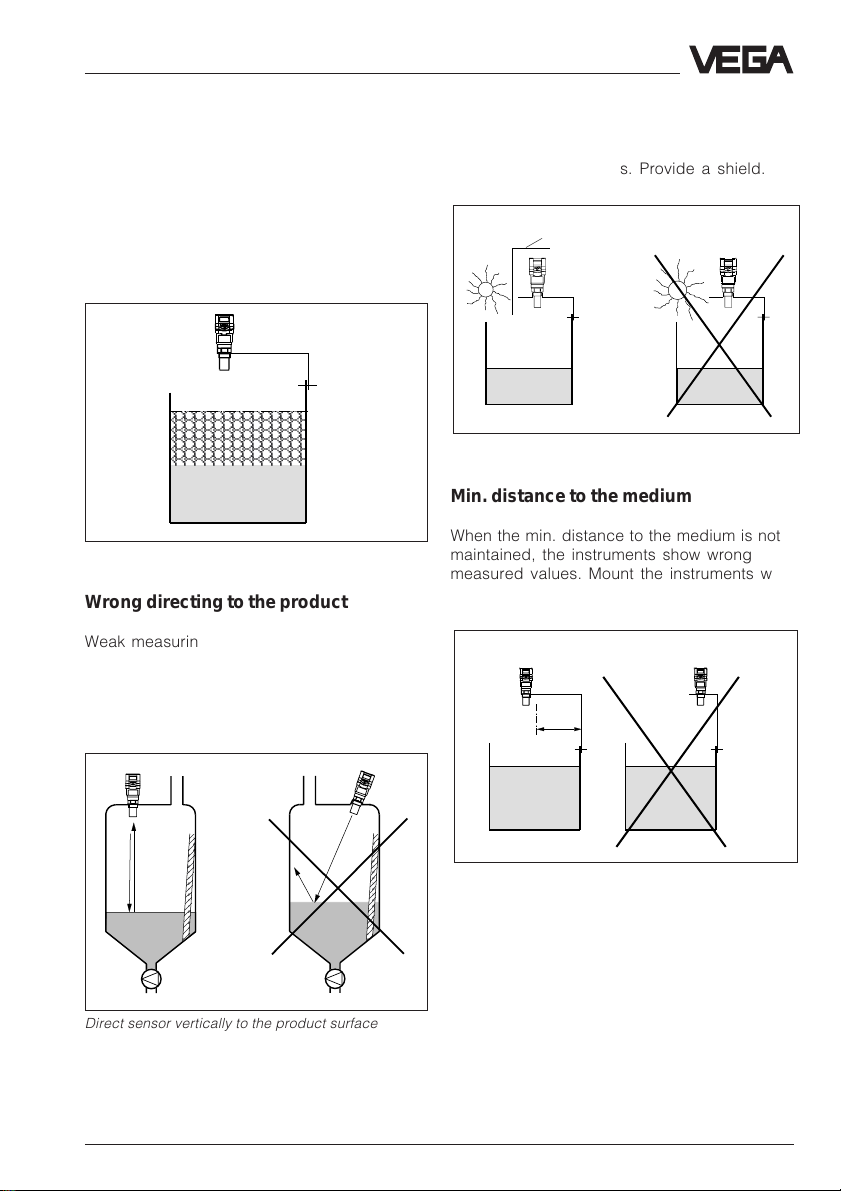

4.7 Installation error

Foam generation

Strong foam on the product can cause faulty

measurements. Provide measures to avoid

foam, measure in a bypass pipe or use another meas. principle, e.g. capacitive electrodes or hydrostatic pressure transmitters.

;;;;;;;;;;;;;

;;;;;;;;;;;;;

;;;;;;;;;;;;;

;;;;;;;;;;;;;

Foam generation

Wrong directing to the product

Weak measuring signals are caused if the

sensor is not directed to the product surface.

Direct the sensor axis vertically to the product surface to achieve optimum measuring

results.

Strong heat fluctuations

Strong heat fluctuations, e.g. due to the sun

cause measuring errors. Provide a shield.

Shield

Strong heat fluctuations

Min. distance to the medium

When the min. distance to the medium is not

maintained, the instruments show wrong

measured values. Mount the instruments with

the required min. distance.

Correct Wrong

Sensor too close to the vessel wall

Direct sensor vertically to the product surface

VEGASON 51K … 53K 33

Page 34

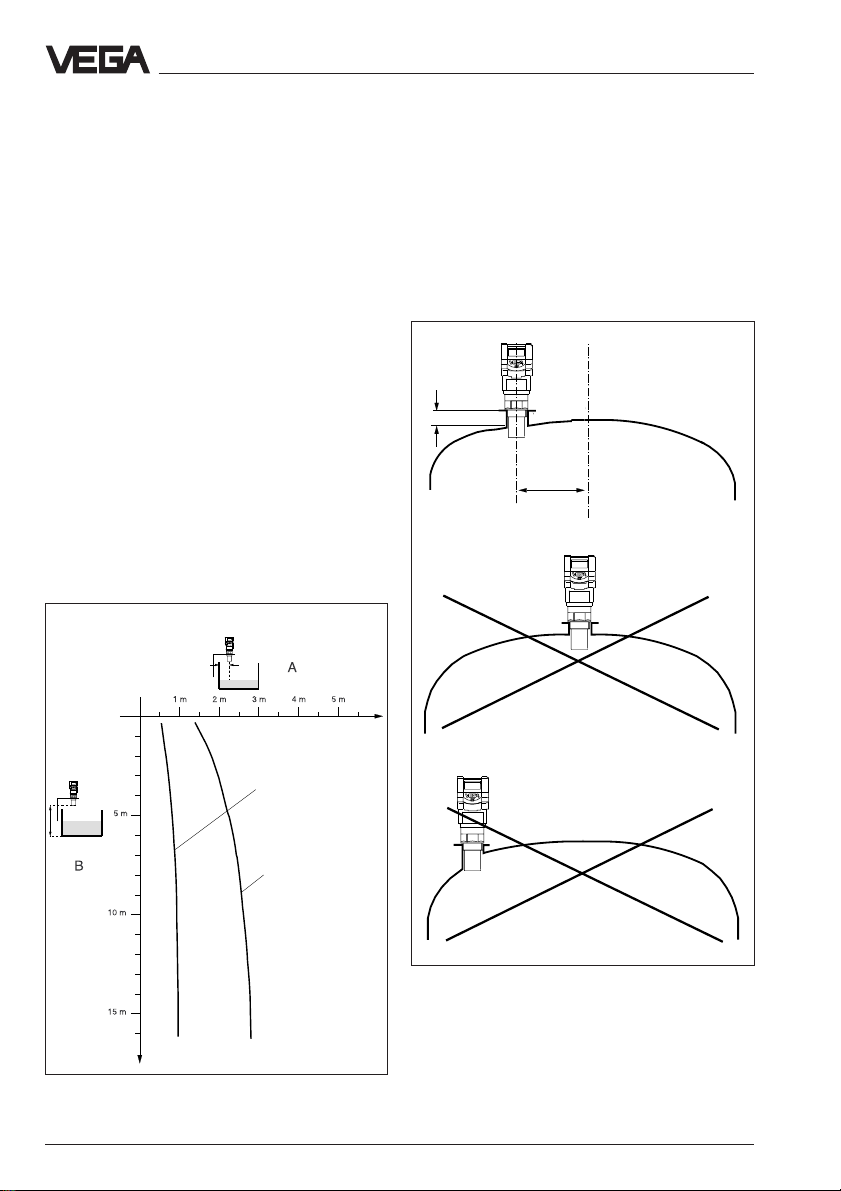

Mounting and installation

Sensor too close to the vessel wall

if the sensor is mounted too close to the vessel wall (dimension A in diagram) strong false

echoes can be caused. Build-up, rivets,

screws and weld joints superimpose their

echoes on the product echo or useful echo.

Please ensure the sufficient distance of the

sensor to the vessel wall depending on the

maximum measuring distance (dimension B

in diagram). In case of good reflection conditions (liquids, no vessel installation) we recommend the provision of the sensor distance

according to diagram curve 1. At a max.

meas. distance of, for example 10 m the

distance of the transducer, according to

curve 1, should be approx. 1 m. In case of

solids with bad reflection conditions provide

a distance to the vessel wall according to

diagram curve 2. With very bad meas. conditions it could be necessary to increase the

distance to the vessel wall or to gate out the

false echoes additionally by a false echo

storage and thereby adapt the sensor more

precisely to the environment.

Distance of the

transducer to the

vessel wall

Parabolic effects on dished boiler head

or basket arch vessels

Round or parabolic tank tops act like a parabolic mirror for the signals. If the sensor is

placed to the focus of such a parabolic tank

top the sensor receives amplified false echoes. The optimum mounting is generally in the

range of half the vessel radius from the centre.

Correct

> 60 mm

~ 1/

2

vessel

radius

Wrong

Curve 1 (liquids)

Curve 2 (solids)

Mounting on a vessel with parabolic tank top

Max. meas.

distance

34 VEGASON 51K … 53K

Wrong

Page 35

Mounting and installation

Socket piece too long

When mounting the sensor in a socket piece

which is too long, strong false echoes are

caused, aggravating the measurement.

Please ensure that the transducer protrudes

at least 30 mm out of the socket piece.

Wrong

Correct

> 60 mm

Reference plane

Correct and wrong length of socket piece

VEGASON 51K … 53K 35

Page 36

5 Electrical connection

Electrical connection

5.1 Connection and connection cable

Safety information

Ensure that the instrument is unpressurised

before you start work. Always switch off the

power supply before you carry out clamping

work on the ultrasonic sensors. Protect yourself and the instruments, especially when

using sensors which do not operarate with

low voltage.

Skilled staff

Instruments which are not operated with

protective low voltage or DC voltage must

only be connected by skilled staff.

Connection

A standard two or four-wire cable (sensors

with separate supply) with max. 2,5 mm2 can

be used as connection. Very often the "electromagnetic pollution“ by electronic actuators,

energy lines and transmitting stations is so

considerable that the two-wire line or fourwire line should be screened.

We recommend the use of screening. This

screening prevents future interferences. Only

earth the cable screens on both ends (on the

sensor and on the processing system) when

you have determined, by measurement, that

no or only lowest earth compensating currents flow via the screens. Use a very low

impedance earth connection (foundation,

plate or mains earth).

Ex-protection

If an instrument is used in hazardous areas,

the necessary regulations, conformity and

type approvals for systems in Ex-areas must

be noted (e.g. DIN 0165).

Intrinsically safe circuits with more than one

active instrument (instrument delivering

electrical energy) must not be connected.

Please note the special installation conditions

(DIN 0165).

Connection cable

Note that the connection cables are specified

for the expected operating temperatures in

your systems. The cable must have an outer

diameter of 5 … 9 mm to ensure the seal effect

of the cable entry. Cables for intrinsically safe

circuits must be marked blue and must not be

used for other circuits.

Earth conductor terminal

On VEGASON 51/52 sensors the earth conductor terminal is galvanically isolated. The

sensors are shockproof. On the VEGASON

53 sensor the earth conductor terminal is

galvanically connected to the metal transducer diaphragm.

36 VEGASON 51K … 53K

Page 37

Electrical connection

5.2 Connection of the sensor

After having mounted the sensor in the meas.

position according to the instructions in chapter 4 "Mounting and installation“, loosen the

closing screw on the top of the sensor. The

sensor cover with the optional indication

display can then be opened. Unscrew the

compression screw and shift the screw over

the approx. 10 cm dismantled connection

cable. The compression screw of the cable

entry is protected with a safety lock-in position against automatic loosening.

Supply voltage

4 … 20 mA (passive)

+

-

1)

To the indicating instrument in the

sensor cover or to the external indicating instrument VEGADIS 50

Now loop the cable through the cable entry

into the sensor. Screw the compression

screw on the cable entry and clamp the dismantled wires of the cable to the appropriate

terminal positions.

The terminals operate without terminal screw.

Press the white opening buckets with a small

screwdriver and insert the copper core of the

connection line into the terminal opening.

Check the position of the lines in the terminal

position by slightly pulling on the connection

lines.

Supply voltage

+

-

4 … 20 mA (active)

+

-

2)

Terminals

(max. 2,5 mm

12 C 567843

12 C 5678

Commu-

+-

nication

4...20 mA

+

-

Tank 1

m (d)

12.345

Tw o-wire technology

Display

ESC

OK

wire cross-section)

Sockets for connection of

the HART®-handheld or

the VEGACONNECT

pluggable

adjustment

module

MINICOM

(loop powered)

1)

4 … 20 mA passive means that the sensor takes a

current of 4 … 20 mA (consumer), depending on

the level.

2

12 C 567843

12 C 567843

Commu-

(+) (-)

L1 N

Tank 1

m (d)

12.345

nication

-

+ -

4...20 mA

+

Display

ESC

OK

Four-wire technology

(separate supply)

2)

4 … 20 mA active means that the sensor provides

a current of 4 … 20 mA (current source),

depending on the level.

Opening

buckets

VEGASON 51K … 53K 37

Page 38

Electrical connection

5.3 Connection of the external indicating instrument VEGADIS 50

Loosen the 4 screws of the housing cover on

VEGADIS 50.

You can facilitate the connection procedure

by fastening the housing cover during connection with one screw on the right of the

housing (figure).

OUTPUT

(to sensor)

3

2

1

4

5

8

6

7

DISPLAY

(in the cover of

the indicating

instrument)

VEGADIS 50

Adjustment

module

Tank 1

m (d)

12.345

+

ESC

-

OK

Screws

Voltage

supply

-

+

4 … 20 mA

active

12 C 567843

Commu-

(+) (-)

L1 N

Tank 1

m (d)

12.345

nication

+-

4...20 mA

+

-

Four-wire sensor

(separate supply)

4 … 20 mA

passive

+

-

to VEGADIS 50

12 C 567843

12 C 5678

Commu-

+-

Display

ESC

OK

4...20 mA

Tank 1

m (d)

12.345

nication

Display

+

ESC

-

OK

Tw o-wire sensor

(loop powered)

38 VEGASON 51K … 53K

Page 39

Set-up

6 Set-up

6.1 Adjustment structure

Series 50 ultrasonic sensors can be adjusted

with

- PC (adjustment program VVO)

- with the detachable adjustment module

MINICOM

- with the HART®-handheld.

The adjustment must only be carried out with

one adjustment medium. If, for example you

try the parameter adjustment with the

MINICOM and the HART®-handheld, the

adjustment will not be successful.

Adjustment program VVO

With the adjustment program VVO

Visual Operating System) on the PC you can

adjust the ultrasonic sensors very comfortably. The PC communicates via the interface

adapter VEGACONNECT 2 with the sensor. A

digital adjustment signal is therefore superimposed on the signal and supply line. The

adjustment can be carried out directly on the

sensor or on any individual position of the

signal line.

Adjustment module MINICOM

With the adjustment module MINICOM you

adjust in the sensor or in the external indicating instrument VEGADIS 50. The adjustment

module enables via the text display with 6key field the adjustment in the same functions

volume as with the adjustment program VVO.

(VEGA

6.2 Adjustment with PC

The instructions for the adjustment with the

PC and the adjustment program VVO can be

found in the manual "VEGA Visual Operating

(VVO)" which is supplied with the latest adjustment software.

Beside the adjustment of ultrasonic sensors,

the manual "VEGA Visual Operating (VVO)"

also describes the setup of all other VEGA

sensors with the PC.

PC on the sensor

For connection of the PC to the sensor you

need the interface adapter VEGACONNECT

2. Insert VEGACONNECT 2 into the

CONNECT-socket provided in the sensor.

PC on the signal line

Connect the two-wire line of VEGACONNECT

2 to the signal or supply line of the sensor.

When the resistors of the systems (DCS,

current source etc.,) connected to the signal/

supply line are less than 250 Ω, a resistor of

250 … 350 Ω must be connected to the signal/supply line during adjustment. The digital signals modulated to the signal line would

be considerably damped via the small system resistors or "shortcircuited" which means

that the communication with the PC would be

interfered with.

HART®-handheld

VEGASON 50 K ultrasonic sensors, like other

HART®-protocol capable instruments, can be

adjusted with the HART®-handheld. A manufacturer specific DDD (Data-Device-Description) is not required. The ultrasonic sensors

are adjusted with the HART®-standard

menus. All main functions are, therefore,

accessible.

Some functions which are rarely used such

as, for example the scaling of the A/D-converter for the signal output, or the adjustment

with medium, are not possible or are blocked

by the HART®-handheld. These functions

must be carried out with the PC or the

MINICOM.

VEGASON 51K … 53K 39

Page 40

Set-up

6.3 Adjustment with the adjustment module MINICOM

As with the PC, you can also adjust the sensor with the small detachable adjustment

module MINICOM. The adjustment module is

thereby plugged into the sensor or into the

external indicating instrument (optional).

ESC

+

-

Tank 1

m (d)

OK

12.345

2

4 ... 20 mA

ESC

+

-

Tank 1

m (d)

OK

12.345

4

For the adjustment with the adjustment module all sensor versions (adjustment options)

as with the PC and the adjustment program

VVO are available. The adjustment with

MINICOM, however, is different.

Error codes:

E Hardware failure, electronics defect

E013 No valid measured value

- Sensor in the feeding phase

- Loss of the useful echo

E017 Adjustment span too small

E036 Sensor program not operating

- Sensor must have a new program-

ming (service)

- Fault signal also appears during

programming

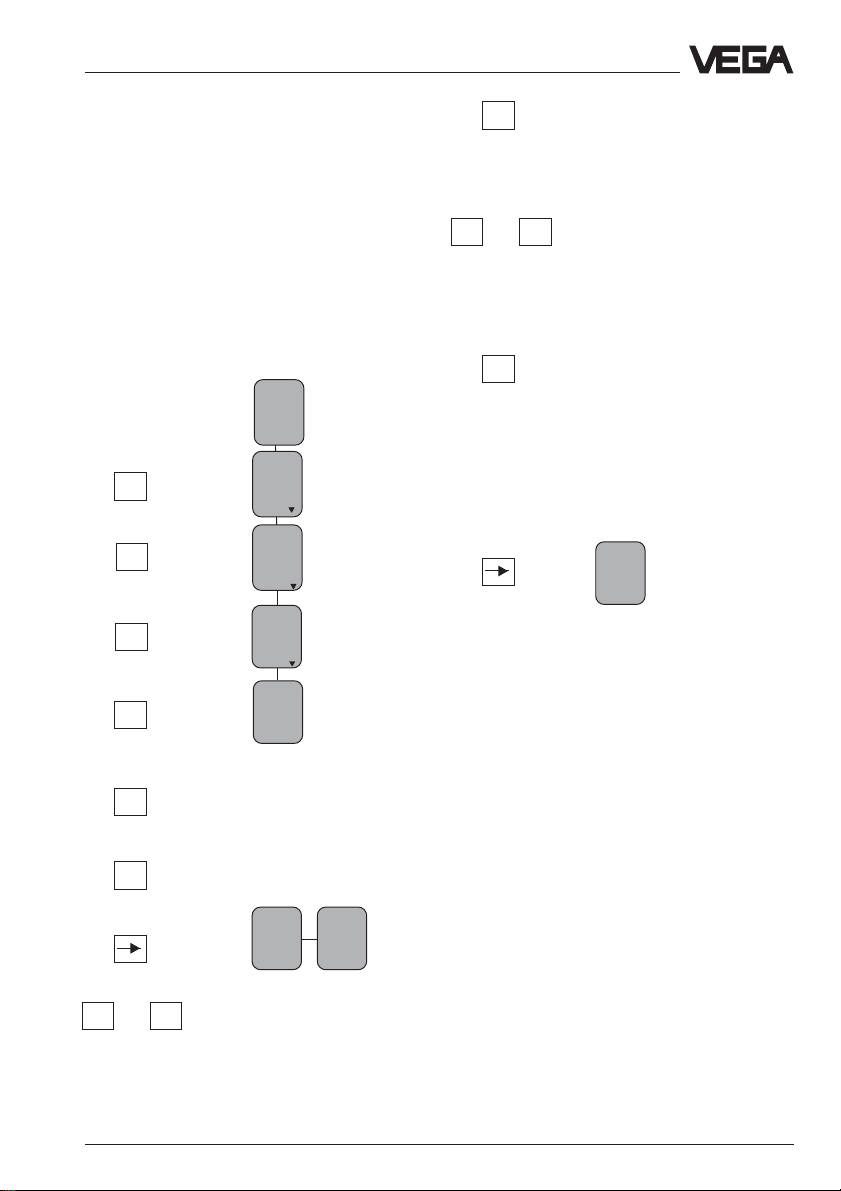

Adjustment steps

On pages 56 and 57 you can find the complete menu plan of the adjustment module

MINICOM.

Set-up the sensor in the numbered sequence:

1. Adjustment

2. Conditioning

3. Outputs

4. Operating range

5. Meas. conditions

6. Measurement in gases only necessary

when measuring gas compositions other

than air.

7. False echo memory (only required when

meas. errors occur during operation).

8. Indication of the useful and noise level

Short explanations to the set-up steps 1 … 8

follow:

You carry out all adjustment steps with the 6

keys of the adjustment module. A small dis-

1. Adjustment

play shows you, apart from the measured

value, a short message on the menu point or

on the figure of a menu adjustment.

The information volume of the small display

Max.

100 % (1,270 m) corresp. to

1200 l

however cannot be compared with that of the

adjustment program VVO, but you will soon

get used to it and will be able to carry out

your adjustments quickly and directly with

Span (4,58 m)

the small MINICOM.

Min.

40 VEGASON 51K … 53K

0 % (5,850 m) corresp. to

45 l

Page 41

Set-up

Under the menu point "

Adjustment

“ you inform the sensor with which meas. range it

should operate.

You can carry out the adjustment without and

with medium. Generally you will carry out the

adjustment without medium as you can then

adjust without filling cycle.

Adjustment without medium

(adjustment independent of the actual level)

Key Display

Sensor

m(d)

4.700

Parameter

OK

OK

OK

OK

+

The distance indication flashes

and you can choose "feet“ and

adjust

ment

Adjust

ment

w.out

medium

Adjust

ment

in

m(d)

(Min. adjustment)

"m“.

OK

+ –

or

Confirm the adjustment with

"OK“.

m(d)

0.0%

bei

m (d)

XX.XXX

Adjust

ment

in

With "+“ and "–“ you adjust the

percentage value for the min.

value or the lower level l (example 0,0 %).

OK

The adjusted percentage

value is written in the sensor

and the distance corresponding to the percentage value

flashes.

+ –

or

With the "+“ or "–“-key you can

co-ordinate a product distance (example 5,85 m) to the

previously adjusted percentage value. When you do not

know the distance, you have

to sound.

OK

The adjusted product distance is written in the sensor

and the indication stops flashing.

You have thereby adjusted the lower product

distance as well as the percentage filling

value corresponding to the lower product

distance.

100.0%

at

m (d)

XX.XXX

(Max-adjustment)

The max. adjustment (upper product distance) is made in the same way (example:

100 % and 1,270 m).

Note:

The difference between the adjustment values of the lower product distance and the

upper product distance should be as big as

possible, preferably at 0 % and 100 %. If the

values are very close together, e.g. lower

product distance at 40 % (3,102 m) and

upper product distance at 45 % (3,331 m),

the measurement will be inaccurate.

A level characteristic is generated from the

two points. Even with smallest deviations

between actual product distance and adjusted product distance, the slope of the

characteristics will be considerably influenced. Thereby small failures multiply with

the adjustment when the adjustment points

are too close together to more considerable

errors at the output of the 100 %-value or the

0 %-value.

VEGASON 51K … 53K 41

Page 42

Set-up

Adjustment with medium

with

medium

Max.

Min.

adjust

adjust

at %

at %

XXX.X

XXX.X

Fill the vessel, for example to 10 % and enter

10 % in the menu "

Min. adjust

“ with the "+“

and "–“ keys. Then fill the vessel, e.g. to 80 %

or 100 % and enter 80 % or 100 % in the

menu "

Max. adjust

“ with the "+“ and "–“ keys.

2. Conditioning

Signal

condit

ioning

Scal

ing

0 %

100 %

Deci-

prop.

corres

corres

ponds

XXXX

mal

point

888.8

Signal conditioning

ponds

XXXX

Under the menu point "

you choose the product distance at 0 % and

at 100 % filling. Then you enter the parameter

and the physical unit as well as the decimal

point.

Enter in the menu window "

0 % corresponds

the value of the 0 %-filling. In the example of

the adjustment with the PC and the adjustment software VVO this would be 45 for 45 l.

Unit

to

Mass

Kg

“

With the "—>“ key you change to the 100 %

menu. Enter here the figure of your parameter corresponding to a 100 %-filling. In the

example 1200 for 1200 l.

• Confirm with "OK“.

If necessary choose a decimal point. However note that only max. 4 digits can be displayed. In the menu "

Prop. to

“ you choose

the parameter (mass, volume, distance…)

and in the menu "

Unit

“ the physical unit (kg, l,

ft3, gal, m3 …).

Linearisation:

Adjust

ment

Signal

condit

ioning

Scal

ing

Lin.

curve

Linear

Integr

ation

time

0 s

A linear dependence between percentage

value of the product distance and the percentage value of the filling volume is

preadjusted. With the menu "Lin.curve“ you

can choose between linear, spherical tank

and cylindrical tank. The adjustment of one's

own linearisation curve is only possible with

the PC and the adjustment program VVO.

3. Outputs

Under the menu "

“

for example the current output should be

inverted or which parameter should be provided by the sensor display.

Outputs

“ you determine if,

• Confirm with "OK“.

42 VEGASON 51K … 53K

Page 43

Set-up

4. Operating range

Without special adjustment, the operating

range corresponds to the measuring range.

The measuring range has already been adjusted with the min./max. adjustment. Generally it is useful to choose a slightly bigger

(approx. 5 %) operating range than the

measuring range.

Example:

Set min./max. adjustment to: 0,300 … 5,850

m; operating range to approx. 0,250 … 6,000

m.

5. Meas. conditions

(see menu plan no. 5)

6. Measurement in gases

Adjustment is only necessary when the

measurement is made in gases (Co2, He,

etc.) deviating from air. In case of measurement in gases sound the distance of the

sensor to the product surface and enter in

the menu point "Measurement in gases“. The

sensor can then consider the modified sound

velocity in gases as opposed to air and provide correct levels.

7. False echo storage

A false echo storage is always useful when

false echo sources such as struts must be

reduced. With the creating of a false echo

storage, you authorise the sensor electronics

to note the false echoes and save them in an

internal database. The sensor electronics

treat these (false) echoes differently from the

useful echo and gates them out.

8. Useful and noise level

In the menu

you get important information on the signal

quality of the level echo. The higher the

"S-N“-value, the more reliable the measurement (menu plan MINICOM).

Ampl.: Means amplitude of the level echo in

S-N: Means Signal-Noise, i.e. the useful

The higher the "S-N“-value (distance of the

amplitude useful level to noise level), the

better the measurement:

> 50 dB Measurement excellent

40 … 50 dB Measurement very good

20 … 40 dB Measurement good

10 … 20 dB Measurement satisfactory

5 … 10 dB Measurement sufficient

< 5 dB Measurement poor

Example:

Ampl. = 68 dB

S-N = 53 dB

68 dB – 53 dB = 15 dB

53 dB signal distance means very good

reliability.

This means that the noise level is only

68 dB – 53 dB = 15 dB.

Ampl.:

XX dB

S-N:

XX

dB

dB (useful level)

level minus the level of the background noise

VEGASON 51K … 53K 43

Page 44

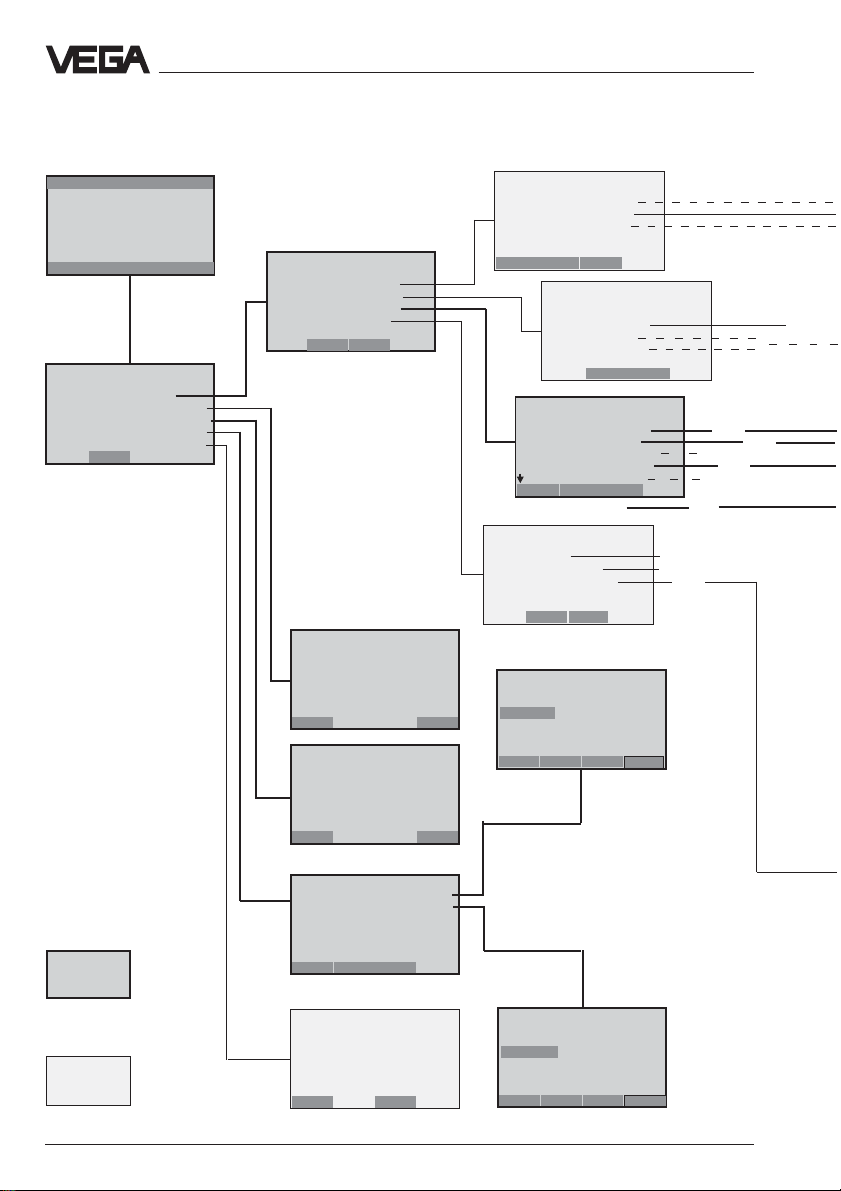

Menu plan of the adjustment module MINICOM

Set-up

Sensor

m(d)

4.700

Param

eter

adjust

ment

Sensor

optimi

sation

Sensor

Tag

Sensor

Meas.

enviro

nement

Operating

range

Begin

m (d)

0.50

SON 52

K

1.00

4.

When switching on, the sensor type and the

software version are displayed for a few seconds.

End

6.00

m (d)

Meas.

condit

ions

Condit

ion

liquid

5.

Fast

change

No

Measur

ing in

tube

Meas.

dist.

m (d)

4.700

Correction

Now!

Agitat

ed sur

face

No

OK?

6.

Foaming

prod.

No

High

dust

level

No

Large

angle

repose

No

Measur

ing in

tube

No

Vielfachechos

No

1. 2. 3.

Adjust

ment

w.out

medium

Adjust

ment

in

m(d)

with

medium

Min.

adjust

at %

XXX.X

0.0 %

at

m (d)

XX.XXX

Max.

adjust

at %

XXX.X

100.0%

at

m (d)

XX.XXX

Auswertung

Scaling

0 %

corres

ponds

XXXX

Lin.

curve

Linear

100 %

corres

ponds

XXXX

Integr

ation

time

Dezimal

point

888.8

0 s

prop.

to

Mass

Unit

Kg

Outputs

mAoutput

mAoutput

4-20mA

Failure

mode

22mA

Sensor

displ.

prop.

to

Distance

44 VEGASON 51K … 53K

Page 45

Set-up

With these keys you move in

the menu field to the left, right,

top and bottom

ESC

7. 8.

OK?

OK?

Distance

m (d)

4.700

Update

Meas.

dist.

m (d)

X.XX

Update

Now!

OK?

Learning!

Simulation:Simulation:

Simulation:

Simulation:Simulation:

One hour after the last simulation

adjustment the sensor returns automatically to normal operating condition.

Error codes:Error codes:

Error codes:

Error codes:Error codes:

E Hardware failure

E013 No va li d mea sure d val ue

E017 Adju st ment span too small

%

E036 No operating sensor program

False

echo

memory

Create

new

Meas.

dist.

m (d)

X.XX

Create

new

Now!

Learning!

Simulation

Simulation

Now!

Simulation

XXX.X

Add'l

functions

Ampl.:

XX dB

S-N:

XX

Delete

Delete

Now!

OK?

Deleting!

dB

Info

Sensor

Tag

Sensor

Reset

to de

fault

Reset

Now!

OK?

Reset

runs!

Sensor

type

SON52

K

- Sensor in feeding phase

- Loss of the useful echo

- Sensor must have a new

programming (service)

- Fault signal also appears during

programming

Language

English

Serial

number

1094

0213

Meas.

unit

Softw.

Vers.

0.40

Distance

m

X,XX

Heavy

dust

No

Fast

change

Yes

m (d)

Softw.

date

15.09.

1997

OK

max.

range

m (d)

7.000

Menu points in bold print provide

sensor and measured value

information and cannot be modified

in this position.

Light grey menu fields are only

displayed if required (depending on

the adjustments in other menus).

White menu points can be modified with the "+“ or "–“-key and

saved with the "OK“-key .

Distance

m (d)

4.700

Ampl.:

XX dB

S-N:

XX

dB

VEGASON 51K … 53K 45

Page 46

6.4 Adjustment with the HART®-handheld

With each HART®-handheld you can set-up

the VEGASON series 50K ultrasonic sensors

like all other HART®-capable sensors. A special DDD (Data Device Description) is not

necessary.

Just connect the HART®-handheld to the

signal line, after having connected the sensor

to power supply.

+

-

Set-up

Ri < 250 Ω

Note:

If the resistor of the power supply is less than

250 Ohm, a resistor must be looped into the

signal/connection line during adjustment.

250 Ω

Connection to a VEGA-signal conditioning instrument

When you operate a HART®-capable sensor

on a VEGA-signal conditioning instrument,

you have to connect the sensor via a resistor

according to the following table during the

HART®-adjustment, to reach together with the

inner resistor of the instruments the value of

250 Ohm required for the HART®-instrument.

The digital adjustment and communication

signals would be short-circuited via too small

resistors of the supply current source of the

processing system which means that the

sensor communication could not be ensured.

+

-

Ri < 250 Ω

VEGA-signal conditioning instr. Rx

VEGAMET 513, 514, 515, 602 50 … 100 Ohm

VEGAMET 614 no additional

VEGADIS 371 res istor

required

VEGAMET 601 200 … 250 Ohm

VEGASEL 643 150 … 200 Ohm

VEGAMET 513 S4, 514 S4

515 S4, VEGALOG EA-card 100 … 150 Ohm

46 VEGASON 51K … 53K

Page 47

Set-up

VEGALOG VEGAMET

Rx

The most important adjustment steps

On the following pages you see a menu plan

for the HART®-handheld in conjunction with

VEGASON 51K … 53K sensors. The most

important adjustment steps are marked in the

menu plan with the letters A … E. When entering parameters first of all the key "

must be pressed. The adjustment is thereby

saved in the handheld, but not in the sensor

itself.

Generic: SENSOR

PV URV

5.850 m

0.300 m

HELP DEL ESC ENTER

After having pressed "

ENTER

(here in the example for the min.-adjustment).

Generic: SENSOR

1 PV LRV 5.850 m

2 PV URV 0.300 m

HELP SEND HOME

After pressing "

SEND