Page 1

Operating Instruction

VEGASEL 643

12 43

Level and Pressure

–

–

max.

5

6

++

–

–

min.

5

3

++

on

VEGASEL 643

56 78

9 1011121314

out

in

Page 2

Contents

Safety information ........................................................................................ 2

1 Product description

1.1 Function and configuration ................................................................. 3

1.2 Approvals ............................................................................................ 3

1.3 Types and versions ............................................................................. 4

1.4 Technical data and dimensions .......................................................... 4

2 Mounting and installation instructions .......................................... 7

3 Electrical connection

3.1 Wiring instruction ................................................................................ 8

3.2 Wiring plan .......................................................................................... 8

4 Set-up

4.1 Indicating and operating elements ................................................... 10

4.2 Set-up sequence .............................................................................. 11

4.3 Switch point adjustment.................................................................... 11

Contents

5 Diagnosis

5.1 Maintenance ..................................................................................... 13

5.2 Repair ............................................................................................... 13

5.3 Failure removal ................................................................................. 13

Safety information

The described module must only be inserted and operated as described in this operating instruction. Please

note that other action can cause damage for which VEGA

does not take responsibility.

2 VEGASEL 643

Page 3

Product description

1 Product description

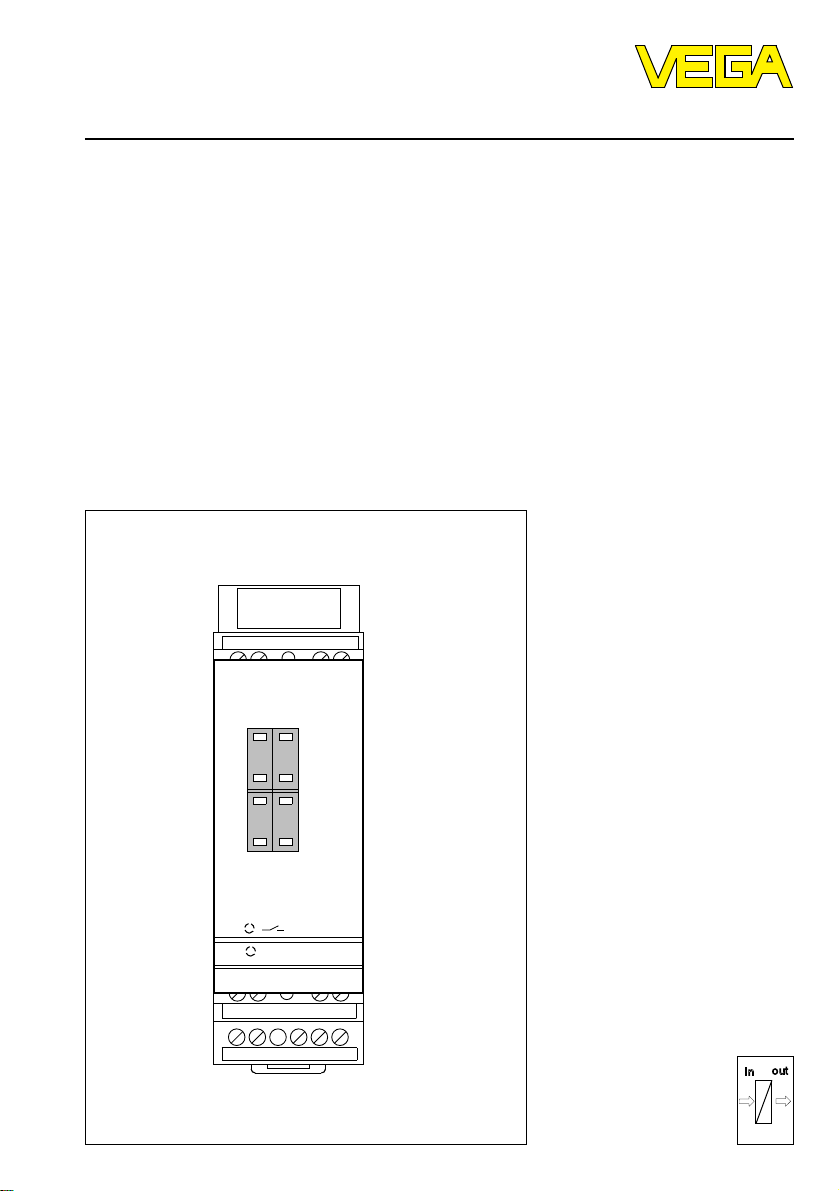

1.1 Function and configuration

VEGASEL 643 auxiliary level switch is a build-in instrument with terminal socket, suitable for carrier rail

mounting (DIN 46 277). Together with a sensor or a

VEGAMET… signal conditioning instrument it is used

for level detection.

Typical applications are two-point controls, e.g. pump

controls (ON/OFF) and monitoring functions such as

overfill protection and protection against dry running of

pumps.

The auxiliary level switch is provided with two passive

inputs, a current and a voltage input as well as additionally with an active current input. Hence VEGASEL

643 can be connected for control either with a

VEGAMET… or a sensor (4 … 20 mA).

12 43

–

–

max.

5

6

++

–

–

min.

5

3

++

on

VEGASEL 643

56 78

91011121314

Sensor

(4 … 20 mA)

Fig. 1.2 VEGASEL 643 with sensor

Function

VEGASEL 643, controlled by a VEGAMET…

- The continuous current or voltage course of the

VEGAMET… signal processing instrument is

processed into a switching command.

12 43

100

%

0/4 … 20 mA

50

0 … 10 V

0

!

on

VEGAMET 602EX

56 78

91011121314

Fig. 1.1 VEGASEL 643 on a VEGAMET

VEGASEL 643 with a 4 … 20 mA sensor

- VEGASEL 643 auxiliary level switch powers via the

active current input the sensors and processes its

continuous 4 … 20 mA current signal into a switching command.

12 43

–

–

max.

5

6

or

++

–

–

min.

5

3

++

on

VEGASEL 643

56 78

91011121314

p

p

In both cases a relay output is available for processing.

Configuration

With a VEGASEL 643 an available measuring system,

consisting of sensor and VEGAMET signal conditioning instrument can be extended by a level detection.

Or an own measuring system can be created with a

4 … 20 mA sensor.

1.2 Approvals

If measuring systems are created according to the

following approvals, the respective legal documents

and their regulations have to be observed. These

documents are supplied with the respective measuring system.

WHG-approval, VbF-approval

VEGASEL 643 auxiliary level switch together with a

measuring system (sensor and VEGAMET) as part of

an overfill protection acc. to WHG (test certificate

applied) or acc. to the regulations for combustible

liquids (test certificate applied).

CE-conformity

see „1.4 Technical data“.

VEGASEL 643 3

Page 4

Product description

off

on

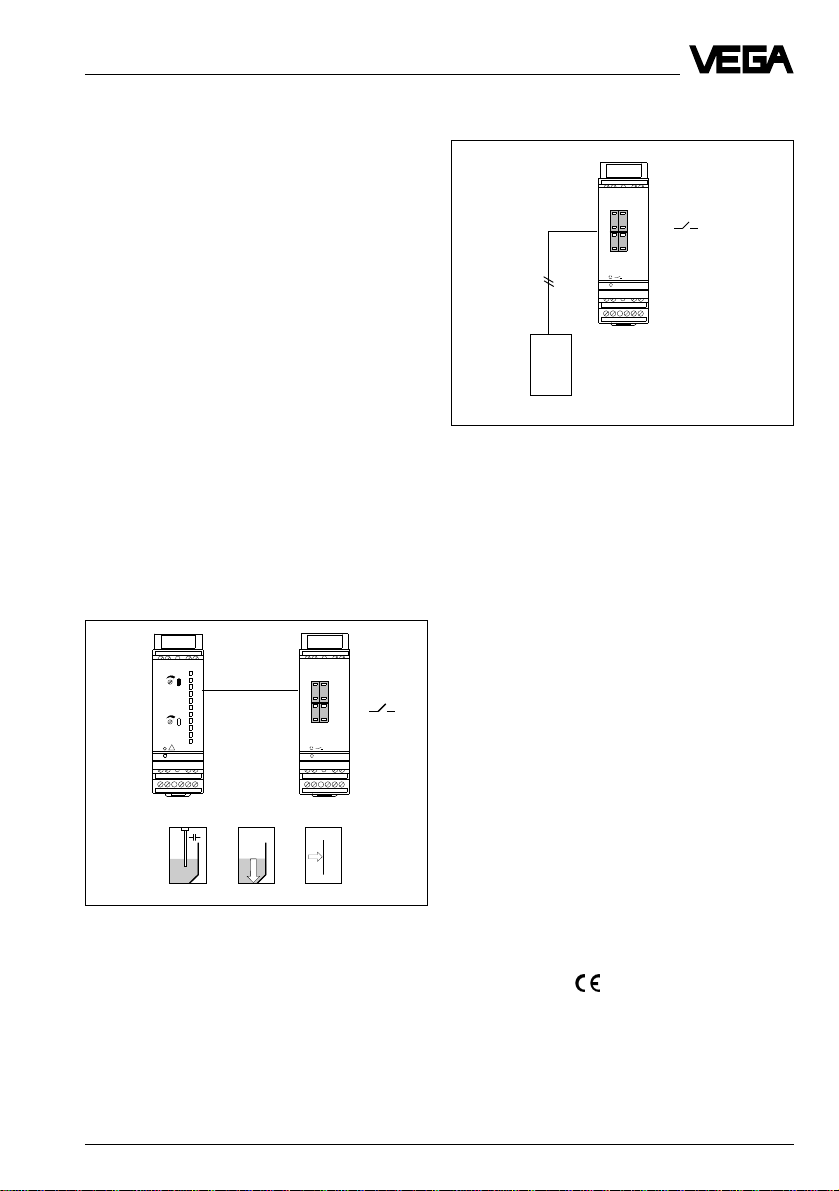

1.3 Types and versions

VEGASEL 643

Two-point auxiliary level switch with selectable mode; mode A (overfill

protection) or mode B (protection against dry running of pumps)

adjustable switching hysteresis

Inputs: - passive current input 0/4 … 20 mA

- active current input (connections of a sensor

4 … 20 mA)

- passive voltage input 0/2 … 10 V

Outputs: 1 relay (spdt)

Approvals: as part of an overfill protection acc. to WHG and

VbF

Application: level detection, overfill protection,

protection against dry running of pumps

Max.

Min.

Fig. 1.2 Two-point auxiliary level switch

VEGASEL 643

1.4 Technical data and dimensions

General data

Power supply

Operating voltage 20 … 250 V AC, 50/60 Hz

Power consumption max. 1,7 W (4,5 VA)

Fuse T 1 A, 250 V

Measuring data inputs

Input 1 1 current input

Kind of input active two-wire input analog

Range 4 … 20 mA

Application connection of sensors (4 … 20 mA)

Sensor supply voltage 16 … 24 V DC

Switching threshold adjustable via coded key

Min. hysteresis 1 %

Current limitation appr. 25 mA, permanently shortcircuit proof

Temperature error 0,05 %/10 K of range

Switch point error 0,5 % of adjusted switch point

Connection cable 2 wire (standard line)

Resistor per conductor max. 35 Ω

Interlock diode for connection of a measuring instrument

20 … 72 V DC

max. load 15 Ω

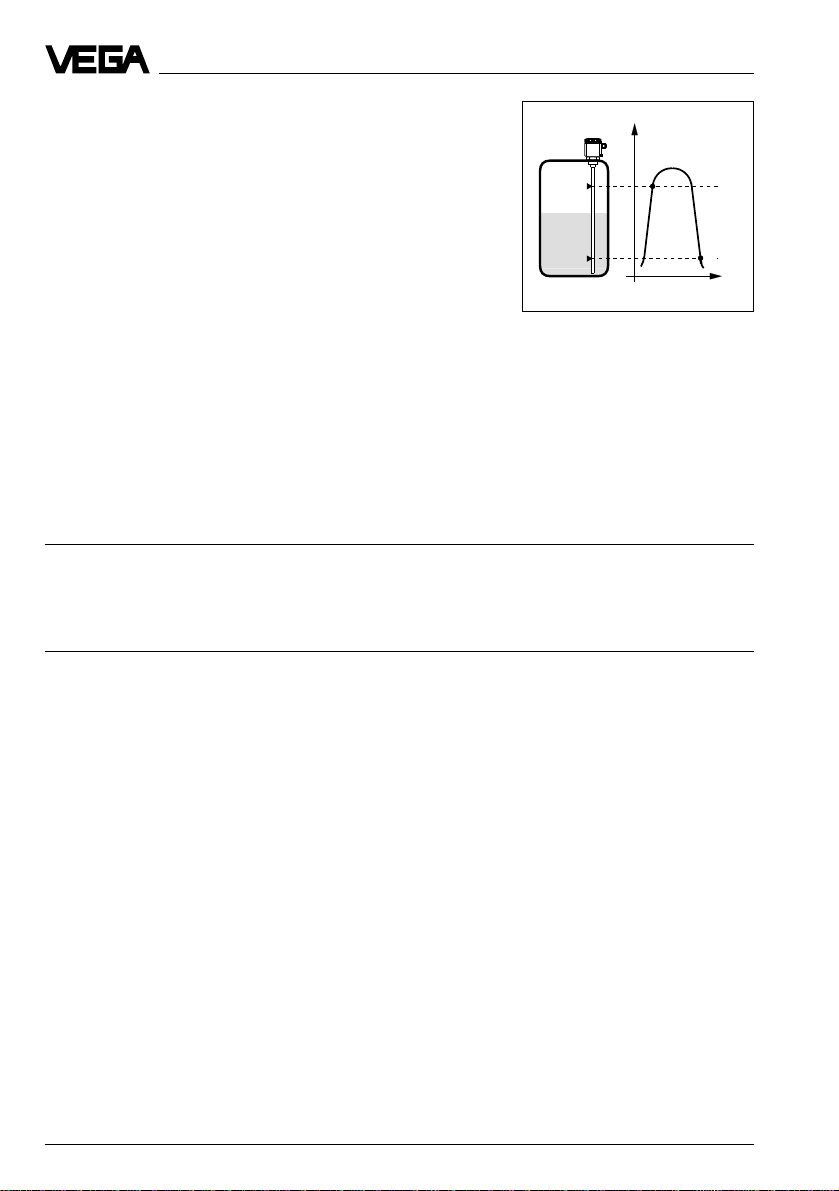

Level

Time t

Input 2 1 additional current input

Kind of input passive two-wire input analog

Range 0/4 … 20 mA

Inner resistor Ri = 50 Ω

Application direct connection to active current output of e.g.

VEGAMET 601, 602 Ex

Switching threshold adjustable via coded key

Min. hysteresis 1 %

Temperature error 0,05 %/10 K of range

Switch point error 0,5 % of adjusted switch point

4 VEGASEL 643

Page 5

Product description

Input 3 1 voltage input

Kind of input passive two-wire input analog

Range 0/2 … 10 V DC

Inner resistor Ri ≥ 100 kΩ

Application direct connection to active voltage output of

Switching threshold adjustable via coded key

Min. hysteresis 1 %

Temperature error 0,05 %/10 K of range

Switch point error 0,5 % of adjusted switch point

Connection cable 2-wire (standard line)

Resistor per conductor max. 100 Ω

Electrical connection

Screw terminal max. 1,5 mm

Electrical protective measures

Protection

- instrument IP 30

- terminal socket IP 20

Protection II

Overvoltage category II

Mechanical data

Series module instrument with terminal socket incl.

Mounting carrier rail mounting acc. to DIN 46 277, Bl. 3

Dimensions unassembled W = 36 mm, H = 118,5 mm, D = 134 mm

Weight appr. 170 g

e.g. VEGAMET 601, 602 Ex

2

transparent cover, cover of the sensor terminals,

coded pin, two connection bridges

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +70°C

Relay output

Number 1 output

Contact 1 spdt (open 12 - 13, closed 12 - 14)

AgCdO and Au plated

Turn-on voltage min. 10 mV DC

max. 250 V AC, 60 V DC

Switching current min. 10 µA DC

max. 2 A AC, 1 A DC

Breaking capacity max. 125 VA, 54 W

Indicating elements

LED in front plate green on: operating voltage on

yellow on: relay energized

Functions

Mode overfill protection (A)

protection against dry running of pumps (B)

Adjustments of the inputs 0 … 20 mA or 4 … 20 mA

0 … 10 V or 2 … 10 V

VEGASEL 643 5

Page 6

Product description

Operating elements

Front plate 2 coded key

Laterally on top 1 DIL-switch for adjustment

Electrical separating measures

Reliable separation acc. to VDE 0106, part 1 between power supply, meas. data inputs

- limit voltage 250 V

- isolation resistance 3 kV

CE-conformity

VEGASEL signal conditioning instruments meet the protective regulations of EMVG (89/336/EWG) and NSR

(73/23/EWG). The conformity has been judged acc. to the following standards:

EMVG Emission EN 50 081 - 1

Immission EN 50 082 - 2

NSR EN 61 010

Carrier rail 35 x 7,5 or

35 x 15 acc. to EN 50 022

Transparent cover

0 … 99 %

- mode A/B (overfill protection/protection against dry

running of pumps)

- adjustment possibility of the inputs

0 … 20 mA or 4 … 20 mA

0 … 10 V or 2 … 10 V

and level relais

12 4

3

118,5

54,5

134

VEGA

56 78

9 1011121314

36

6 VEGASEL 643

Page 7

Mounting and installation instructions

2 Mounting and installation instructions

Mounting

Each series 600 signal conditioning instrument consists of a terminal socket for carrier rail mounting DIN

46 277 and a module instrument.

The supply voltage can be connected to terminals 9

and 10.

For neighbouring series 600 signal conditioning

instruments it is possible to provide and loop the

connection L1 and N directly via the supplied bridges.

The same is valid for the connection VEGAMETvoltage output 0 … 10 V to VEGASEL-voltage input

0 … 10 V /terminals 7 and 8).

Note, danger!

Never use the bridges with single instrument or at the

end of an instrument row. They may come in touch

with the operating voltage or cause a shortcircuit.

Coding

The terminal socket must be provided with pins and

the signal conditioning instrument with appropriate

gaps (mechanical coding) to avoid interchanging of

the individual signal conditioning instruments.

An instrument coding ensures that interchanging

among the signal conditioning instruments is avoided

by differently positioned coded keys.

Instrument coding

VEGASEL 643 (pin 4)

Direct connection for

voltage input 0 … 10 V

Direct connection for

supply voltage

12 4

A o

B o

C o

1 o

2 o

3 o

o

o

o

7 o

8 o

9 o

o

o

o

3

VEGA

0…10 V

N

L1

56 78

9 1011121314

VEGASEL 643 7

Page 8

3 Electrical connection

Electrical connection

3.1 Wiring instruction

The following wiring plan and the extension examples

1 and 2 are valid for standard as well as for Ex-versions of the signal conditioning instruments. Please

note the following instructions:

- the relay contact is shown in unpressurized

condition

- if strong electromagnetic interferences are expected, we recommend to use screened cable for

the signal lines

- the screening must only be earthed at one sensor

side

- in case of overvoltages we recommend the use of

VEGA-overvoltage arresters

- the connection must be made according to the

appropriate national installation standards (e.g. in

Germany according to VDE-regulations).

3.2 Wiring plan

Sensor

+

+–

10 V

78

111213 14

–

43

–

+

12

VEGASEL 643

910

L1

N

+

–

Supply voltage

active current input for connection of a sensor (4 … 20 mA)

passive current input for

connection of a signal conditioning instrument

(VEGAMET…)

passive voltage input for

connection to the voltage

output of a signal conditioning

instrument (VEGAMET…)

Relay output

8 VEGASEL 643

Page 9

Electrical connection

Extension example 1

Instrument 1: VEGASEL 643 actively switched

Instrument 2 up to max. instrument 5: VEGASEL 643 passively switched

Note:

The voltage inputs (7, 8) must not be used when the current inputs are switched.

Sensor (4 … 20 mA)

active

–

+

12 43

+

VEGASEL

passive

–

Current

inputs

–

+

12

VEGASEL

–

+

Current

inputs

43

+

12

–

VEGASEL

+

passive

–

43

Current

inputs

Instrument 1 Instrument 2 .................... up to max. . instrument 5

Extension example 2

Instrument 1: VEGAMET 601 or 602 Ex

Instrument 2 up to max. instrument 10: VEGASEL 643 each switched to passive voltage input (parallel switching)

Note:

Current inputs (3, 4) must not be used when the voltage inputs are switched.

Sensor

10 V

+

+

–

43

–

87

Voltage input

–

+

12

10 V

VEGASEL

+

–

43

+

87

–

Voltage input

–

+

12

VEGAMET

10 V

+

+

–

43

–

87

Voltage input

–

+

12

VEGASEL

Instrument 1 Instrument 2 .................... up to max. . instrument 10

According to the extension examples it is possible to control several signal conditioning instruments with one

sensor and hence to detect different levels.

This kind of switching can be extended each up to 5 or 10 instruments.

VEGASEL 643 9

Page 10

4 Set-up

4.1 Indicating and operating elements

Set-up

1

2

3

4

5

6

VEGASEL 643

Top view, laterally

12 43

–

–

max.

5

6

++

–

–

min.

5

3

++

on

56 78

9 1011121314

7

8

9

10

11

12

1 Key for value falling

2 Coded key for max. switch point

3 Key for value raising

4 Coded key for min. switch point

5 Status indication of the output

6 LED-supply voltage

7 Separating wall

8 Terminals current input

9 Terminals voltage input

10 Terminals supply and relay output

11 Bar code, series number

12 DIL-switch block

13 Screws

14 Ventilation opening

15 Transparent cover

13

10 VEGASEL 643

14

15

Page 11

Set-up

Coded key

Coded keys (2 and 4) are located in the front plate by

which the switch point (with single point level

switches) as well as the switching hysteresis (with

double point level switches) can be adjusted.

The figures are given in % and relate to the current or

voltage input. By pushing the buttons „+“ or „–“ you

can adjust the requested values raising or falling in

1 % or 10 %-steps.

Signal lamps

Green (6)

- Supply voltage on, ready for operation

Yellow (5)

- Status indication of the relay output

(LED lights = relay energized,

LED extinguished = relay de-energized)

DIL-switch (13)

Laterally on top. When the signal conditioning instrument is mounted, covered by the terminal socket.

Description of the individual functions

2..10V

4..20mA

0..

A

B

Adjustment possibility

- Current input 0 … 20 mA or 4 … 20 mA

voltage output 0 … 10 V or 2 … 10 V

- Mode A or B

A = overfill protection, B = protection against dry

running of pumps

• Mount the terminal socket.

• Wire the input terminals of the terminal socket acc.

to the above mentioned conditions.

• Cover the input terminals with the separating

chamber.

• Switch the output of the auxiliary level switch acc. to

the technical requirements.

• Adjust on the DIL-switch (11) the range of the

inputs.

• When connecting a sensor to the active current

input (terminals 1 and 2) set the DIL-switch to

4 … 20 mA.

• Select on the DIL-switch (11) the desired mode.

• Adjust the switch points acc. to “section 4.3”.

• Mount the module unit to the terminal socket.

• Switch on the supply voltage, the green LED (6)

lights.

4.3 Switch point adjustment

Single point control

With a single point control it is possible to generate at

one point of the input signal (0…10 V or 0/4…20 mA) a

switching signal.

Coded key

max. 80

min. 79

t

12 13 14

12 13 14

Hysteresis

1 %

Mode A

Mode B

79/80

%

100

0

Procedure

4.2 Set-up sequence

• Adjust the switch point on both coded keys.

• As example min. = 79 %, max. = 80 %, with this

The following list states the essential set-up steps in

short

Pre-requirement:

adjustment there is a hysteresis of 1 %.

• Possible adjustment range 1 % … 99 %.

• The auxiliary level switch is hence ready for operation. Please cover with the transparent cover (15).

VEGASEL 643 auxiliary level switch is connected with

a measuring system (sensor and VEGAMET…) or

directly with a sensor (4 … 20 mA).

VEGASEL 643 11

Page 12

Set-up

Double point control

With a double point control it is possible to generate

switching signals at two different points of the input

signal (0/2 … 10 V or 0/4 … 20 mA).

Procedure

%

100

60

20

0

Mode A

Mode B

• Adjust the coded key with different values.

• Possible adjustment range 1 % … 99 %.

• As example min. = 20 %, max. = 60 %, with this

adjustment there is a hysteresis of 40 %.

• The auxiliary level switch is hence ready for operation. Please cover with the transparent cover (15).

Note:

Adjust the percentage values with the coded keys

which relate to the input signal.

Example 1

- Voltage input 0 … 10 V

- Two-point control

- Switch points min. = 20 %, max. = 60 %

0 … 10 V corresponds to 0 % … 100 %, ∆ = 10 V

20 % of 10 V = 2 V

60 % of 10 V = 6 V

Switch point 20 % corresponds to 2 V

Switch point 60 % corresponds to 6 V

Coded key

max. 60

min. 20

t

12 13 14

12 13 14

^ Hysteresis

40 %

Example 2

- Voltage input 2 … 10 V

- Two-point control

- Switch points min. = 20 %, max. = 60 %

2 … 10 V corresponds to 0 % … 100 %,

∆ = 10 V – 2 V = 8 V

20 % of 8 V = 1,6 V

60 % of 80 V = 4,8 V

Switch point 20 % corresponds to 1,6 V + 2 V = 3,6 V

Switch point 60 % corresponds to 4.8 V + 2 V = 6,8 V

Example 3

- Current input 0 … 20 mA

- Two-point control

- Switch points min. = 20 %, max. = 60 %

0 … 20 mA corresponds to 0 % … 100 %, ∆ = 20 mA

20 % of 20 mA = 4 mA

60 % of 20 mA = 12 mA

Switch point 20 % corresponds to 4 mA

Switch point 60 % corresponds to 12 mA

Example 4

- Current input 4 … 20 mA

- Two-point control

- Switch points min. = 20 %, max. = 60 %

4 … 20 mA corresponds to 0 % … 100 %,

∆ = 20 mA – 4 mA = 16 mA

20 % of 16 mA = 3,2 mA

60 % of 16 mA = 9,6 mA

Switch point 20 % corresponds to 3,2 mA + 4 mA =

7,2 mA

Switch point 60 % corresponds to 9,6 mA + 4 mA =

13,6 mA

The calculation and information examples are valid in

the same way for the single point control.

12 VEGASEL 643

Page 13

Diagnosis

5 Diagnosis

5.1 Maintenance

The instrument is maintenancefree.

5.2 Repair

For safety and guarantee reasons repairs on the

instrument must only be carried out by VEGA-staff.

In case of a defect please return the respective instrument along with a short description of the fault to our

repair department.

Occurring faults, possible reasons and their removals

are stated under „5.3 Failure removal“.

5.3 Failure removal

Failure Removal / Measure

Instrument does not

function, the green

mains control lamp

extinguishes Check the supply voltage and the mains connection by means of the „Connection

Instrument does not

switch correctly Check the position of the coded keys. The switch points for min. and max. must not

instructions“. When the instrument still does not function, contact our service

department.

be set to the same values. Correct if necessary the values.

Instrument does not

switch when using the

active input Check the connected measuring data input

VEGASEL 643 13

- Check wiring, see „3.3 Wiring plan and extension examples“

- Check voltage or current values on their nominal range, see „1.4 Technical data“.

- The auxiliary level switch is internally provided with an interlock diode. A measuring

instrument connected to terminal 2 and 3 is hence automatically switched into the

circuit of the measuring line (switching in series).

Hence it is possible to check the measuring line. The measuring instrument

indicates the actual current.

Load of the measuring

mA

instrument

max. 15 Ω

12 43

Page 14

Notes

14 VEGASEL 643

Page 15

Notes

VEGASEL 643 15

Page 16

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

Fax (0 78 36) 50 - 203

ISO 9001

Technical data subject to alterations 2.19 955 / Sept. 1996

Loading...

Loading...