Page 1

Operating Instructions

Radar sensor for continuous level

measurement of liquids

VEGAPULS 66 standpipe version

Foundation Fieldbus

Document ID: 36526

Page 2

Quick start

Mounting

Connect electrically

Quick start

The quick start enables a quick setup with many applications. You

can nd further information in the respective chapters of the operating

instructions manual.

1. In case of turbulences or strong product movement in the vessel,

long standpipe antennas should be fastened to the vessel wall.

2. The measurement is only possible inside the tube, the standpipe

antenna must hence reach up to the requested min. level

For further information see chapter "Mounting".

1. Make sure that the power supply corresponds to the specications on the type label.

2. Connect the instrument according to the following illustration

2

0

1

1

0

Bus

( )

(-)

1

+

2

5

678

1

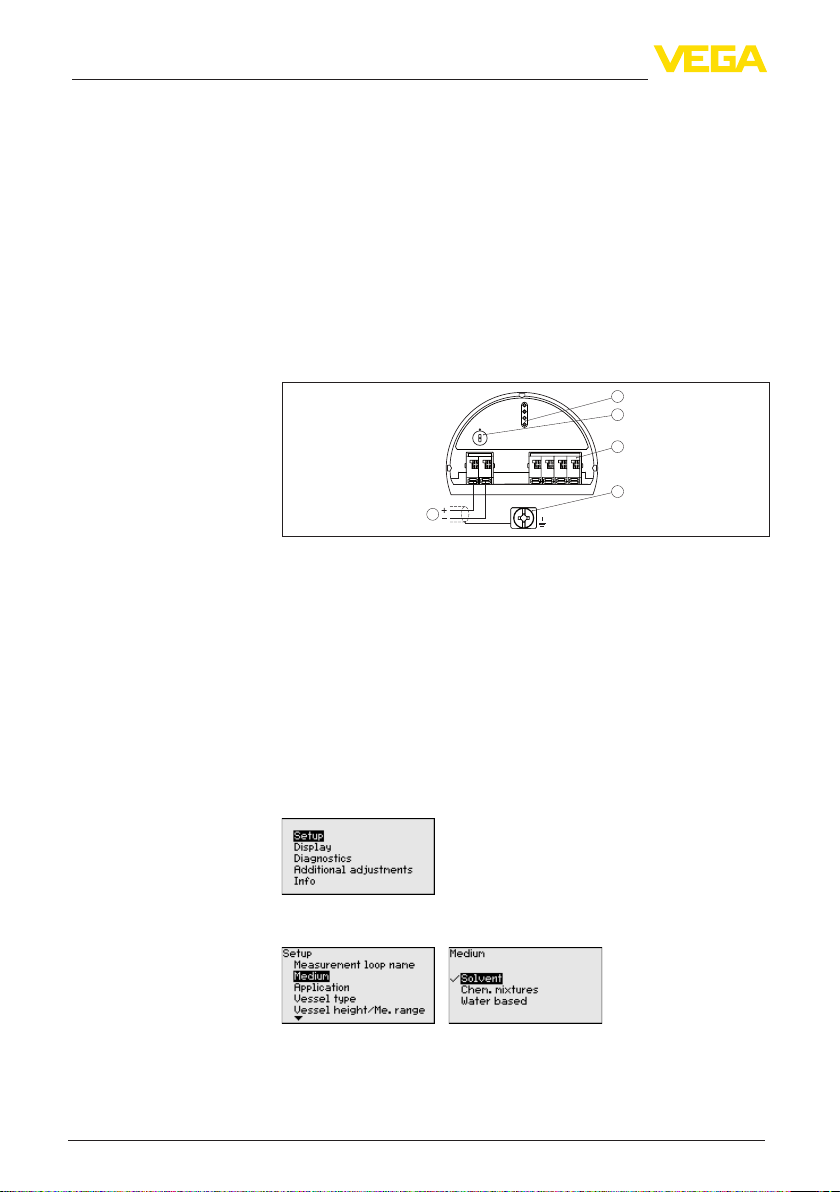

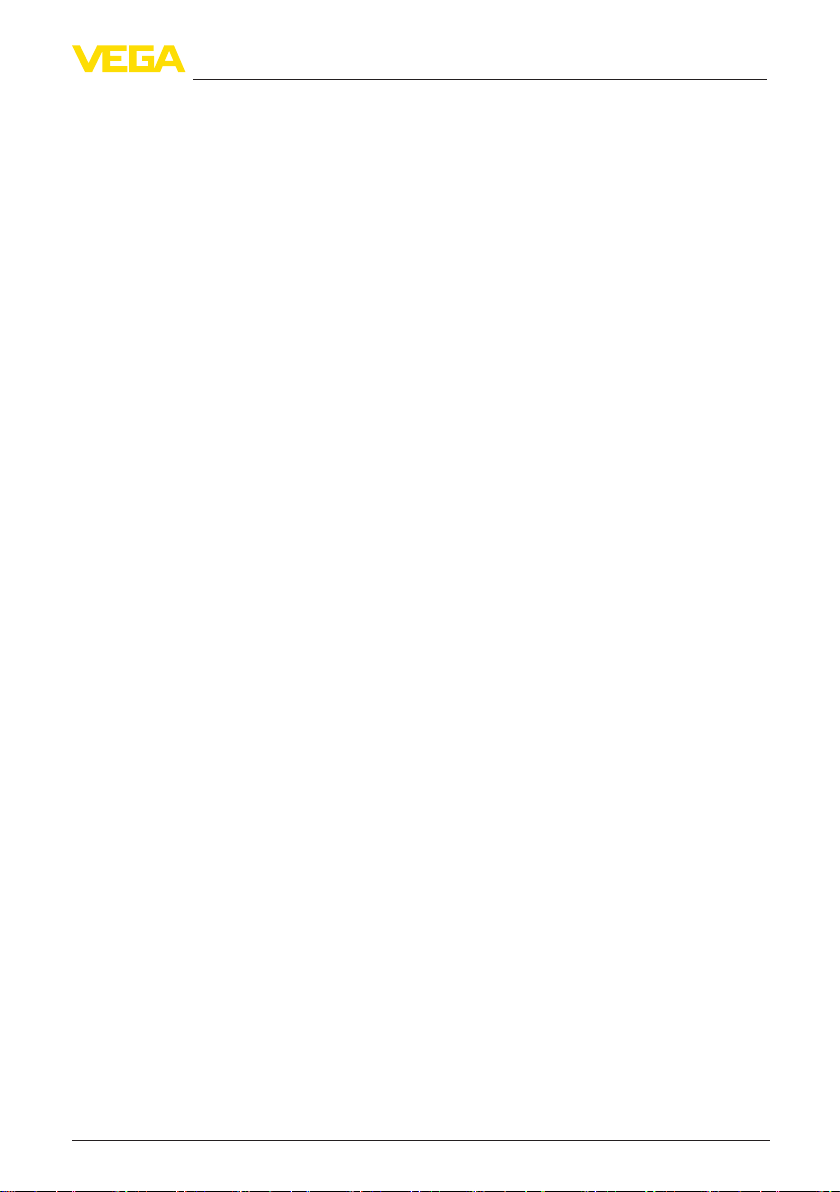

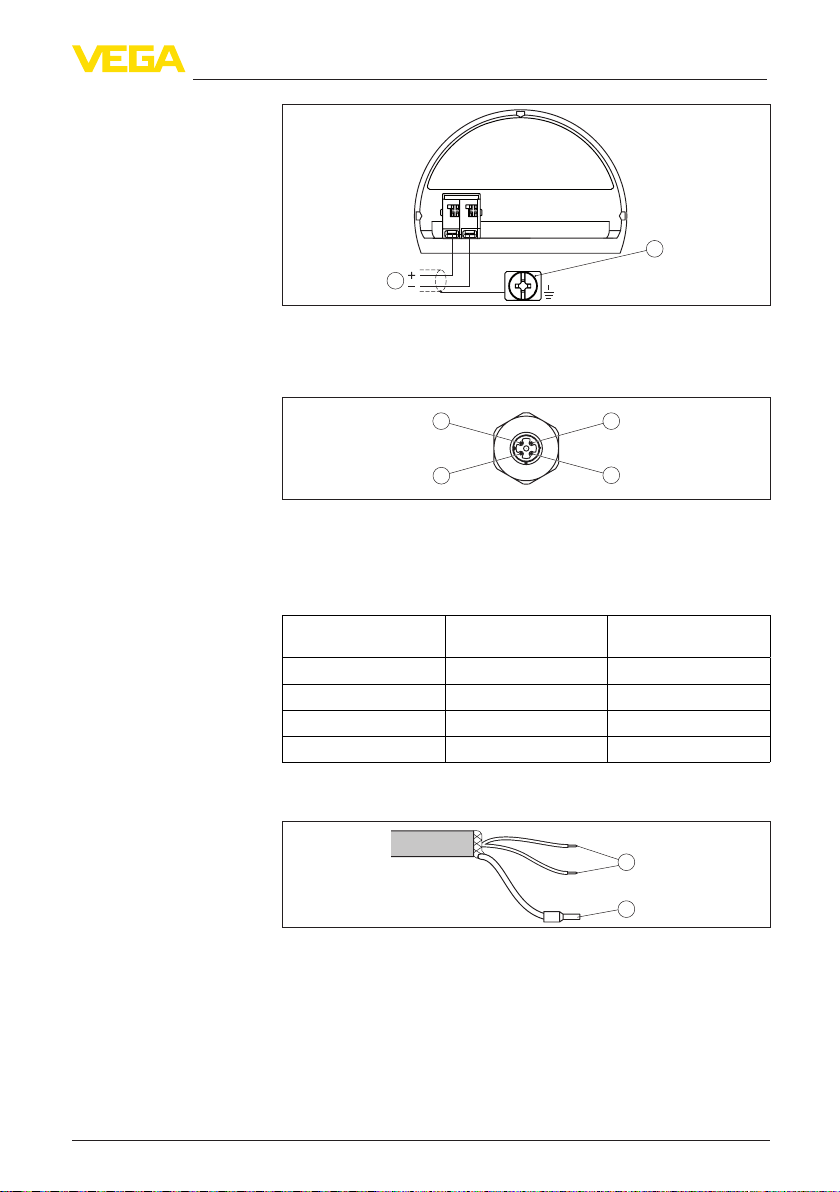

Fig. 1: Electronics and connection compartment, single chamber housing

1 Voltage supply, signal output

2 Contact pins for the indicating and adjustment module or interface adapter

3 Simulation switch ("1" = mode for simulation release)

4 For external indicating and adjustment unit

5 Ground terminal for connection of the cable screen

For further information see chapter "Connecting to power supply".

3

4

5

Set parameters

Further steps

2

The instrument is preset by default with the suitable parameters for

"Application", "Min. adjustment" and "Max. adjustment".

For adaptation of the parameter "Medium" you have to proceed as

follows:

1. Go via the indicating and adjustment module to the menu "Setup".

2. In the menu item "Medium"you select the medium of your application, for example "Solvent".

36526-EN-121011

1. In the menu "Additional settings", menu item "Damping" you have

to adjust the requested damping of the output signal.

2. Select the output characteristics in the menu item "Current out-

put".

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 3

Quick start

The quick start is then nished. For further information see chapter

"Parameter adjustment".

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

3

Page 4

Contents

Contents

1 About this document

1.1 Function ............................................................................. 6

1.2 Target group ....................................................................... 6

1.3 Symbolism used ................................................................. 6

2 For your safety

2.1 Authorised personnel ......................................................... 7

2.2 Appropriate use .................................................................. 7

2.3 Warning about incorrect use ............................................... 7

2.4 General safety instructions ................................................. 7

2.5 CE conformity ..................................................................... 8

2.6 NAMUR recommendations ................................................ 8

2.7 Radio license for Europe .................................................... 8

2.8 Radio license for USA/Canada ........................................... 8

2.9 Environmental instructions ................................................. 9

3 Product description

3.1 Conguration .................................................................... 10

3.2 Principle of operation ........................................................ 11

3.3 Packaging, transport and storage ..................................... 11

3.4 Accessories and replacement parts ................................. 12

4 Mounting

4.1 General instructions ......................................................... 14

4.2 Instructions for installation ................................................ 14

5 Connecting to the bus system

5.1 Preparing the connection ................................................. 15

5.2 Connecting ....................................................................... 16

5.3 Wiring plan, single chamber housing ................................ 17

5.4 Wiring plan, double chamber housing .............................. 17

5.5 Wiring plan, double chamber housing Ex d ...................... 18

5.6 Wiring plan - version IP 66/IP 68, 1 bar ............................. 19

5.7 Switch-on phase ............................................................... 19

6 Set up with the indicating and adjustment module

6.1 Insert indicating and adjustment module .......................... 21

6.2 Adjustment system ........................................................... 22

6.3 Parameter adjustment ...................................................... 23

6.4 Saving the parameter adjustment data ............................. 31

7 Setup with PACTware

7.1 Connect the PC ................................................................ 32

7.2 Parameter adjustment with PACTware .............................. 32

7.3 Saving the parameter adjustment data ............................. 33

8 Set up with other systems

8.1 DD adjustment programs ................................................. 34

8.2 Communicator 375, 475 ................................................... 34

9 Diagnosis, Asset Management and service

9.1 Maintenance .................................................................... 35

9.2 Measured value and event memory ................................. 35

36526-EN-121011

4

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 5

9.3 Asset Management function ............................................. 36

9.4 Rectify faults ..................................................................... 39

9.5 Exchanging the electronics module .................................. 41

9.6 Software update ............................................................... 42

9.7 How to proceed in case of repair ...................................... 42

10 Dismounting

10.1 Dismounting steps ............................................................ 44

10.2 Disposal ........................................................................... 44

11 Supplement

11.1 Technical data .................................................................. 45

11.2 Supplementary information Foundation Fieldbus ............. 51

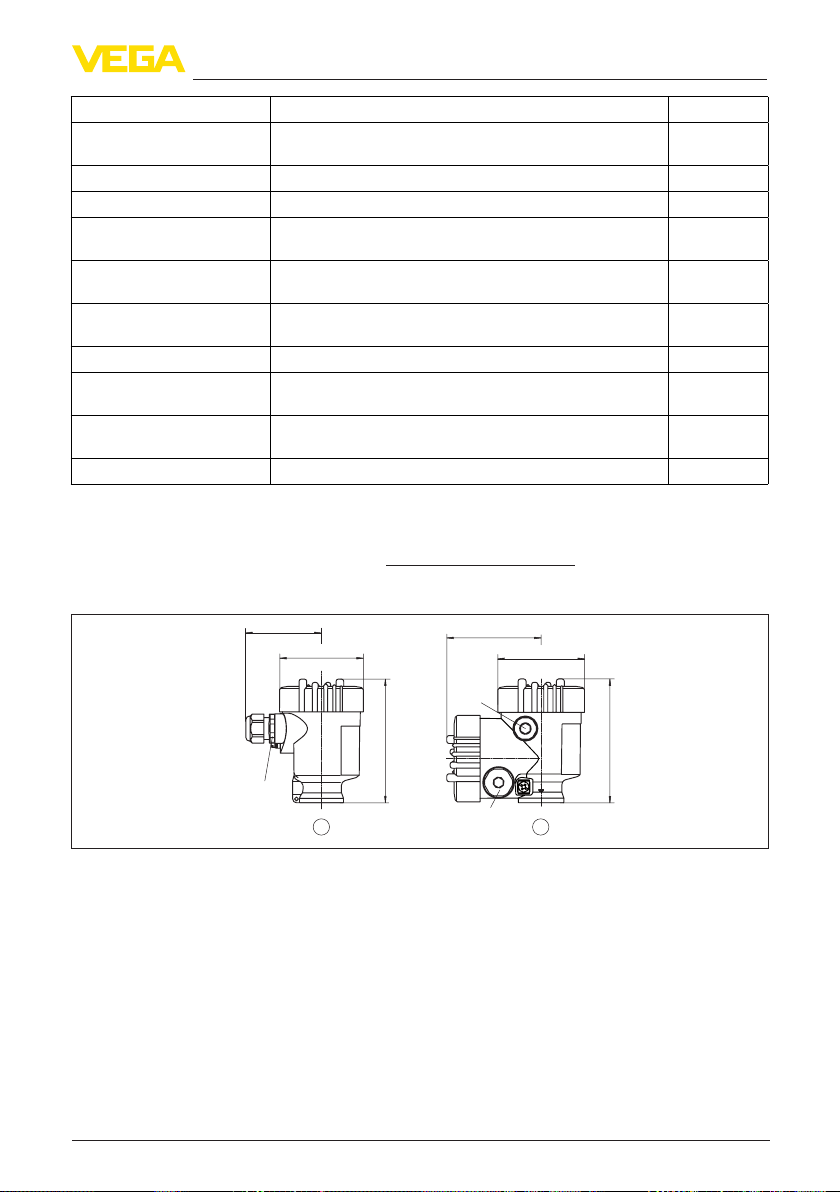

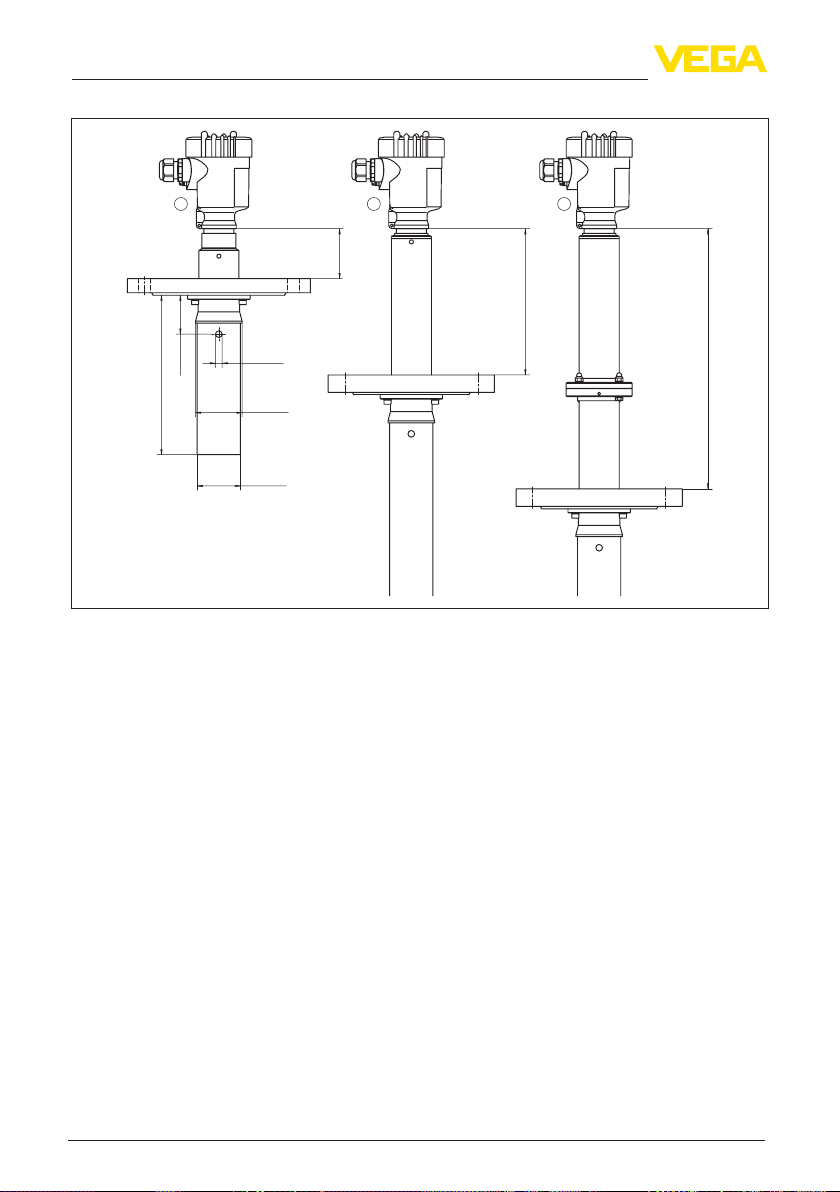

11.3 Dimensions ...................................................................... 59

Contents

Safety instructions for Ex areas

Please note the Ex-specic safety information for installation and operation in Ex areas. These safety instructions are part of the operating

instructions manual and come with the Ex-approved instruments.

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

Editing status: 2012-09-27

5

Page 6

1 About this document

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important instructions for maintenance and fault rectication. Please read this information before putting the instrument into operation and keep this manual

accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained qualied

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

List

•

The dot set in front indicates a list with no implied sequence.

Action

→

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of batteries and accumulators.

36526-EN-121011

6

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 7

2 For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must

be carried out only by trained specialist personnel authorised by the

plant operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

VEGAPULS 66 is a sensor for continuous level measurement.

You can nd detailed information on the application range in chapter

"Product description".

Operational reliability is ensured only if the instrument is properly

used according to the specications in the operating instructions

manual as well as possible supplementary instructions.

2.3 Warning about incorrect use

Inappropriate or incorrect use of the instrument can give rise to

application-specic hazards, e.g. vessel overll or damage to system

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a state-of-the-art instrument complying with all prevailing

regulations and guidelines. The instrument must only be operated in a

technically awless and reliable condition. The operator is responsible

for the trouble-free operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the necessary occupational safety measures with the

current valid rules and regulations and also take note of new regulations.

The safety instructions in this operating instructions manual, the national installation standards as well as the valid safety regulations and

accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbitrary conversions or modications are explicitly forbidden.

The safety approval markings and safety tips on the device must also

be observed.

Depending on the instrument version, the emitting frequencies are in

the C or K band range. The low emitting frequencies are far below the

internationally approved limit values. When used correctly, there is no

danger to health.

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

7

Page 8

2 For your safety

2.5 CE conformity

The device fullls the legal requirements of the applicable EC guidelines. By axing the CE marking, we conrm successful testing of the

product.

You can nd the conformity certicate in the download section of our

homepage.

Only with Ex-d-ia version

The instrument is designed for use in an industrial environment.

Nevertheless, electromagnetic interference from electrical conductors

and radiated emissions must be taken into account, as is usual with a

class A instrument according to EN 61326-1. If the instrument is used

in a dierent environment, its electromagnetic compatibility with other

devices must be ensured by suitable measures.

2.6 NAMUR recommendations

NAMUR is the automation technology user association in the process

industry in Germany. The published NAMUR recommendations are

accepted as the standard in eld instrumentation.

The device fullls the requirements of the following NAMUR recom-

mendations:

NE 21 – Electromagnetic compatibility of equipment

•

NE 43 – Signal level for malfunction information from measuring

•

transducers

NE 53 – Compatibility of eld devices and indicating/adjustment

•

components

NE 107 - Self-monitoring and diagnosis of eld devices

•

For further information see www.namur.de.

2.7 Radio license for Europe

The instrument is approved according to EN 302372-1/2 (2006-04)

for use in closed vessels.

2.8 Radio license for USA/Canada

The instrument is in conformity with part 15 of the FCC regulations.

Take note of the following two regulations:

The instrument must not cause any interfering emissions

•

The device must be insensitive to interfering immissions, including

•

those that may cause undesirable operating conditions

Modications not expressly approved by the manufacturer will lead to

expiry of the operating licence according to FCC/IC.

The instrument is in conformity with RSS-210 of the IC regulations.

The instrument may only be used in closed vessels made of metal,

concrete, or bre-reinforced plastic.

8

VEGAPULS 66 standpipe version • Foundation Fieldbus

36526-EN-121011

Page 9

2 For your safety

2.9 Environmental instructions

Protection of the environment is one of our most important duties.

That is why we have introduced an environment management system

with the goal of continuously improving company environmental protection. The environment management system is certied according

to DIN EN ISO 14001.

Please help us full this obligation by observing the environmental

instructions in this manual:

Chapter "Packaging, transport and storage"

•

Chapter "Disposal"

•

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

9

Page 10

3 Product description

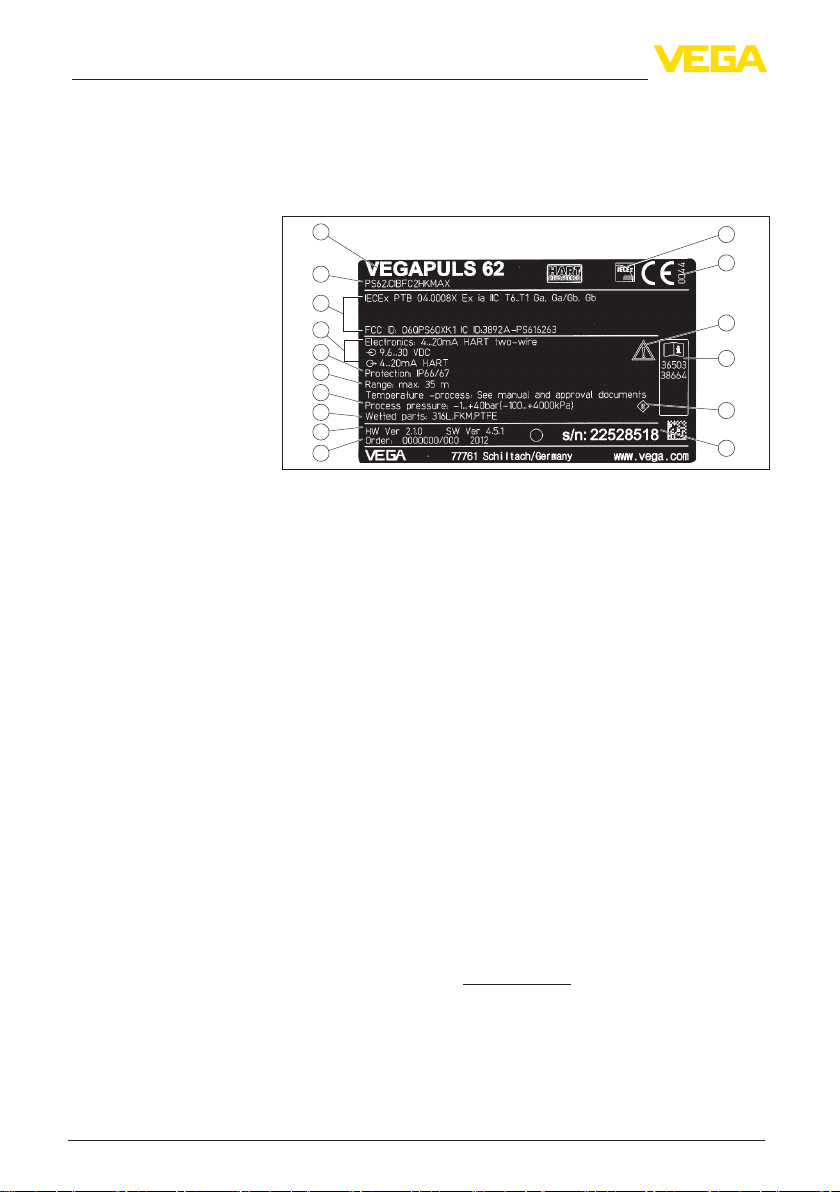

Type label

3 Product description

3.1 Conguration

The type label contains the most important data for identication and

use of the instrument:

1

2

3

4

5

6

7

8

9

10

Fig. 2: Layout of the type label (example)

1 Instrument type

2 Product code

3 Approvals

4 Power supply and signal output, electronics

5 Protection rating

6 Measuring range

7 Process and ambient temperature, process pressure

8 Material, wetted parts

9 Hardware and software version

10 Order number

11 Serial number of the instrument

12 Symbol of the device protection class

13 ID numbers, instrument documentation

14 Note to observe the instrument documentation

15 NotiedauthorityforCEmarking

16 Approval directive

16

15

14

13

12

11

Serial number

Scope of this operating

instructions manual

10

With the serial number of the instrument on the type label you have

access to the following data on our homepage:

Article number of the instrument (HTML)

•

Delivery date (HTML)

•

Order-specic instrument features (HTML)

•

Operating instructions at the time of shipment (PDF)

•

Order-specic sensor data for an electronics exchange (XML)

•

Test certicate "Measuring Accuracy" (PDF)

•

For this purpose, move to www.vega.com and "VEGA Tools".

This operating instructions manual applies to the following instrument

versions:

Hardware from 2.1.1

•

Software from 4.5.0

•

VEGAPULS 66 standpipe version • Foundation Fieldbus

36526-EN-121011

Page 11

3 Product description

Versions

Scope of delivery

Application area

The instrument is available in two dierent electronics versions. Each

version can be identied via the product code on the type label as

well as on the electronics.

Standard electronics type PS60FFC.-

•

Electronics with increased sensitivity type PS60FFS.-

•

The scope of delivery encompasses:

Radar sensor

•

Documentation

•

– this operating instructions manual

– Test certicate Measurement accuracy, depending on the

instrument VEGAPULS 66 (optional)

– Operating instructions manual "Indicating and adjustment mod-

ule PLICSCOM" (optional)

– Supplementary instructions "GSM/GPRS radio module"

(optional)

– Supplementary instructions manual "Heating for indicating and

adjustment module" (optional)

– Supplementary instructions manual "Plug connector for con-

tinuously measuring sensors" (optional)

– Ex-specic "Safety instructions" (with Ex versions)

– if necessary, further certicates

3.2 Principle of operation

The instrument is suitable for the measurement of liquids under difcult and extreme process conditions. Application possibilities can

be found in the chemical industry, in environmental and recycling

technology as well as in the petrochemical industry.

The version with standpipe antenna is particularly suitable for

measurement of solvents and liquid gases, for vessels with foam

generation or for measurement of products with low dielectric values

(DK > 1.6).

Measurement in a standpipe is not recommended for extremely

adhesive products.

The instrument can be used with products with an ε

actually achievable value depends on the measuring conditions, the

antenna system, the standpipe or bypass.

value ≥1.8. The

r

Functional principle

The antenna of the radar sensor emits short radar pulses with a

duration of approx. 1 ns. These pulses are reected by the product

and received by the antenna as echoes. The transit time of the radar

pulses from emission to reception is proportional to the distance and

hence to the level. The determined level is converted into an appropriate output signal and outputted as measured value.

3.3 Packaging, transport and storage

Packaging

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

11

Page 12

3 Product description

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE

foil is also used. Dispose of the packaging material via specialised

recycling companies.

Transport

Transport inspection

Storage

Storage and transport

temperature

Indicating and adjustment module

Transport must be carried out under consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or concealed defects must be appropriately dealt with.

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

Not in the open

•

Dry and dust free

•

Not exposed to corrosive media

•

Protected against solar radiation

•

Avoiding mechanical shock and vibration

•

Storage and transport temperature see chapter "Supplement -

•

Technical data - Ambient conditions"

Relative humidity 20 … 85 %

•

3.4 Accessories and replacement parts

The indicating and adjustment module PLICSCOM is used for measured value indication, adjustment and diagnosis. It can be inserted

into the sensor and removed at any time.

You can nd further information in the operating instructions "Indicat-

ing and adjustment module PLICSCOM" (Document-ID 27835).

Interface adapter

External indicating and

adjustment unit

12

The interface adapter VEGACONNECT enables the connection of

communication-capable instruments to the USB interface of a PC. For

parameter adjustment of these instruments, an adjustment software

such as PACTware with VEGA-DTM is required.

You can nd further information in the operating instructions "Interface

adapter VEGACONNECT" (Document-ID 32628).

VEGADIS 61 is an external indicating and adjustment unit for sensors

with single chamber housing and Ex-d double chamber housing.

It is suitable for measured value indication and adjustment of plics

sensors and is connected to the sensor with a four-wire standard

cable up to 50 m long.

You can nd further information in the operating instructions "VE-

GADIS 61" (Document-ID 27720).

VEGAPULS 66 standpipe version • Foundation Fieldbus

®

36526-EN-121011

Page 13

3 Product description

External radio unit

Flanges

Protective cover

Electronics module

The PLICSMOBILE T61 is an external GSM/GPRS radio unit for

transmission of measured values and for remote parameter adjustment of plics® sensors. The adjustment is carried out via PACTware/

DTM by using the integrated USB connection.

You can nd further information in the supplementary instructions

"PLICSMOBILE T61" (Document-ID 36849).

Screwed anges are available in dierent versions according to the

following standards: DIN 2501, EN 1092-1, ANSI B 16.5, JIS B 22101984, GOST 12821-80.

You can nd additional information in the supplementary instructions

manual "Flanges according to DIN-EN-ASME-JIS" (Document-ID

31088).

The protective cover protects the sensor housing against soiling and

intense heat from solar radiation.

You will nd additional information in the supplementary instructions

manual "Protective cover" (Document-ID 34296).

The electronics module VEGAPULS series 60 is a replacement part

for radar sensors of VEGAPULS series 60. There is a dierent version

available for each type of signal output.

You can nd further information in the operating instructions "Elec-

tronics module VEGAPULS series 60" (Document-ID 36801).

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

13

Page 14

4 Mounting

Screwing in

4 Mounting

4.1 General instructions

With instruments with threaded process tting, suitable tools must be

applied for tightening the hexagon.

Warning:

The housing must not be used to screw the instrument in! Applying

tightening force can damage internal parts of the housing.

Moisture

Suitability for the process

conditions

Installation

Use the recommended cables (see chapter "Connecting to power

supply") and tighten the cable gland.

You can give your instrument additional protection against moisture

penetration by leading the connection cable downward in front of the

cable entry. Rain and condensation water can thus drain o. This applies mainly to outdoor mounting as well as installation in areas where

high humidity is expected (e.g. through cleaning processes) or on

cooled or heated vessels.

Make sure that all parts of the instrument exposed to the process, in

particular the active measuring component, process seal and process

tting, are suitable for the existing process conditions. These include

above all the process pressure, process temperature as well as the

chemical properties of the medium.

You can nd the specications in chapter "Technical data" and on the

type label.

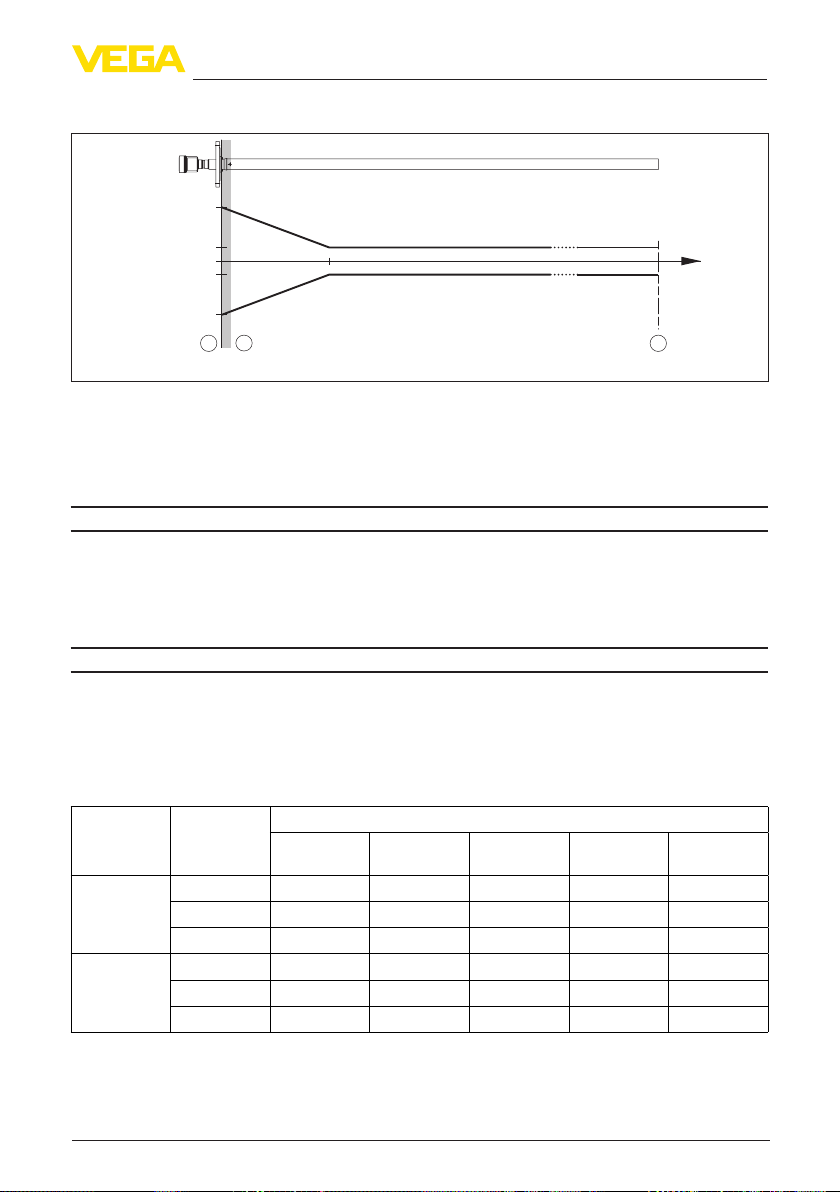

4.2 Instructions for installation

By using the standpipe version, the inuence of turbulence and vessel installations, such as e.g. heating spirals or agitators, is excluded.

If turbulence or vigorous product movement occurs in the vessel, long

standpipe antennas should be fastened to the vessel wall.

The standpipe antenna must extend all the way down to the requested min. level, as measurement is only possible within the tube. If a

good mixing of the product is important, you should use a version with

perforated surge pipe.

14

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 15

Safety instructions

5 Connecting to the bus system

5 Connecting to the bus system

5.1 Preparing the connection

Always keep in mind the following safety instructions:

Connect only in the complete absence of line voltage

•

If overvoltage surges are expected, overvoltage arresters should

•

be installed

Voltage supply

Connection cable

Cable gland ½ NPT

Cable screening and

grounding

The instrument requires a operating voltage of 9 … 32 V DC. Operating voltage and the digital bus signal are carried on the same two-wire

connection cable. Power is supplied via the H1 power supply.

Connection is carried out with screened cable according to Fieldbus

specication.

Use cable with round cross-section. A cable outer diameter of

5 … 9 mm (0.2 … 0.35 in) ensures the seal eect of the cable gland.

If you are using cable with a dierent diameter or cross-section,

exchange the seal or use a suitable cable gland.

Make sure that the entire installation is carried out according to the

Fieldbus specication. In particular, make sure that the bus is terminated with suitable terminating resistors.

With plastic housing, the NPT cable gland or the Conduit steel tube

must be screwed without grease into the threaded insert.

Max. torque for all housings see chapter "Technical data"

Make sure that the cable screening and ground is executed according to the Fielbus specication. If electromagnetic interference is

expected which is above the test values of EN 61326-1 for industrial

areas, we recommend to connect the cable screen on both ends to

ground potential.

With systems with potential equalisation, connect the cable screen

directly to ground potential at the power supply unit, in the connection

box and at the sensor. The screen in the sensor must be connected

directly to the internal ground terminal. The ground terminal outside

on the housing must be connected to the potential equalisation (low

impedance).

In systems without potential equalisation with cable screening on

both sides, connect the cable screen directly to ground potential at

the power supply unit and at the sensor. In the connection box or

T-distributor, the screen of the short stub to the sensor must not be

connected to ground potential or to another cable screen. The cable

screens to the power supply unit and to the next distributor must be

connected to each other and also connected to ground potential via a

ceramic capacitor (e.g. 1 nF, 1500 V). Low-frequency potential equalisation currents are thus suppressed, but the protective eect against

high frequency interference signals remains.

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

15

Page 16

5 Connecting to the bus system

Connection technology

5.2 Connecting

The voltage supply and signal output are connected via the springloaded terminals in the housing.

The connection to the indicating and adjustment module or to the

interface adapter is carried out via contact pins in the housing.

Information:

The terminal block is pluggable and can be removed from the electronics. To do this, lift the terminal block with a small screwdriver and

pull it out. When inserting the terminal block again, you should hear it

snap in.

Connection procedure

Proceed as follows:

1. Unscrew the housing cover

2. If an indicating and adjustment module is installed, remove it by

turning it slightly to the left.

3. Loosen compression nut of the cable entry

4. Remove approx. 10 cm (4 in) of the cable mantle, strip approx.

1 cm (0.4 in) of insulation from the ends of the individual wires

5. Insert the cable into the sensor through the cable entry

Fig. 3: Connection steps 5 and 6

6. Insert the wire ends into the terminals according to the wiring plan

Information:

Solid cores as well as exible cores with cable end sleeves are

inserted directly into the terminal openings. In case of exible cores

without end sleeves, press the terminal head with a small screwdriver;

the terminal opening is freed. When the screwdriver is released, the

terminal closes again.

You can nd further information to the max. wire cross-section under

"Technical data/Electromechanical data"

7. Check the hold of the wires in the terminals by lightly pulling on

them

36526-EN-121011

16

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 17

5 Connecting to the bus system

8. Connect the screen to the internal ground terminal, connect the

outer ground terminal to potential equalisation

9. Tighten the compression nut of the cable entry. The seal ring must

completely encircle the cable

10. Place probably existing indicating and adjustment module back

on

11. Screw the housing cover back on

The electrical connection is hence nished.

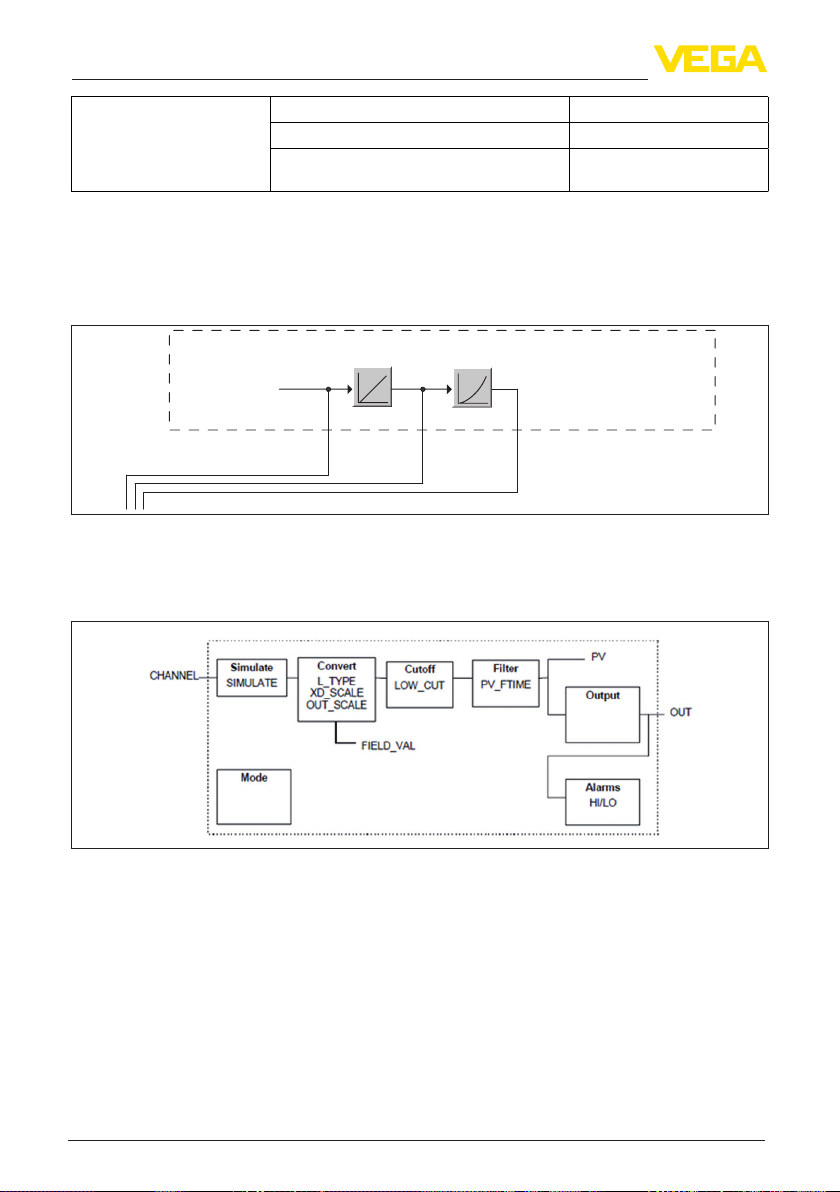

5.3 Wiring plan, single chamber housing

Electronics and connection compartment

Electronics compartment

2

3

0

1

1

0

Bus

( )

(-)

1

+

2

5

678

4

5

1

Fig. 4: Electronics and connection compartment, single chamber housing

1 Voltage supply, signal output

2 Contact pins for the indicating and adjustment module or interface adapter

3 Simulation switch ("1" = mode for simulation release)

4 For external indicating and adjustment unit

5 Ground terminal for connection of the cable screen

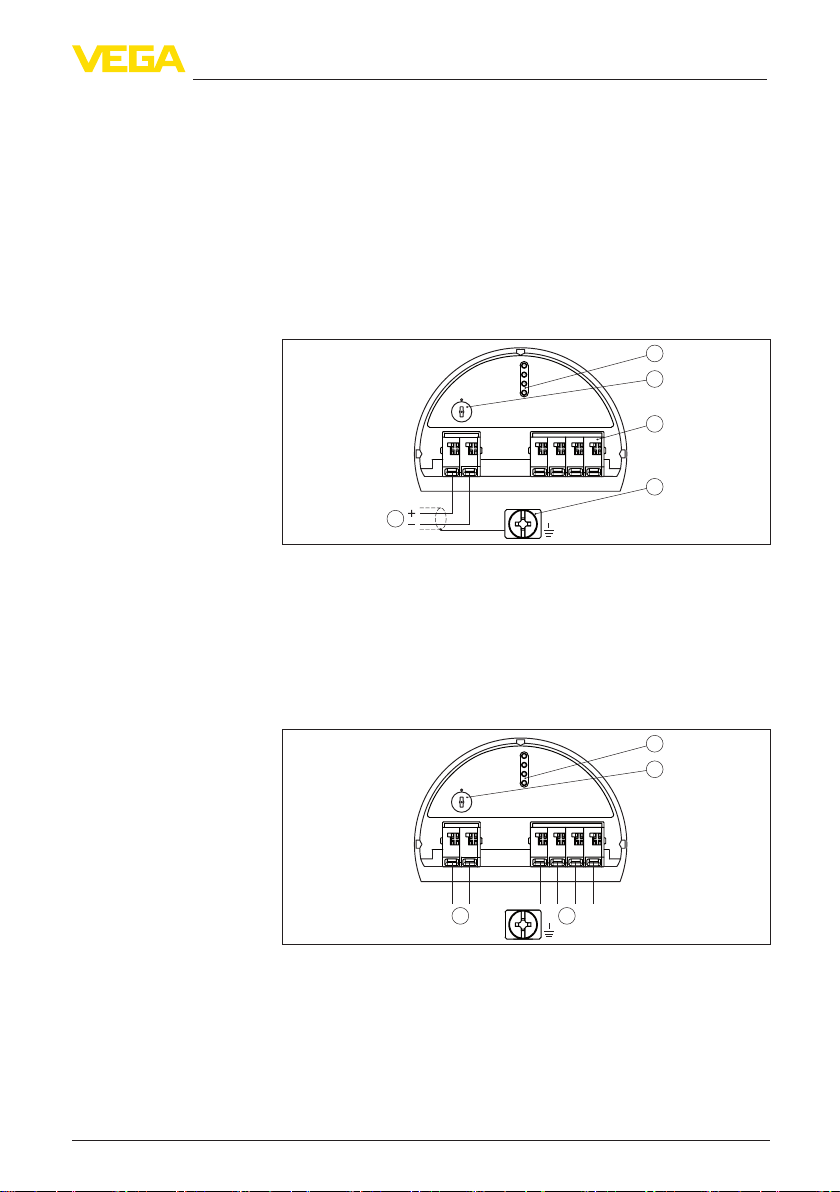

5.4 Wiring plan, double chamber housing

2

3

0

1

1

0

Bus

( )

(-)

+

1

2

5

678

11

Fig. 5: Electronics compartment, double chamber housing

1 Internal connection to the connection compartment

2 Contact pins for the indicating and adjustment module or interface adapter

3 Simulation switch ("on" = simulation mode)

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

17

Page 18

5 Connecting to the bus system

Connection compartment

Radio module PLICSMOBILE integrated in the

connection compartment

2

Bus

(-)

( )

+

1

2

3

1

Fig. 6: Connection compartment, double chamber housing

1 Voltage supply, signal output

2 For indicating and adjustment module or interface adapter

3 Ground terminal for connection of the cable screen

Status

SIM-Card

Test

Bus

( )

+

1

2

USB

(-)

1

Fig. 7: CConnection of the voltage supply of the radio module

1 Voltage supply

You can nd detailed information for connection in the supplementary

instructions "PLICSMOBILE GSM/GPRS radio module".

Electronics compartment

18

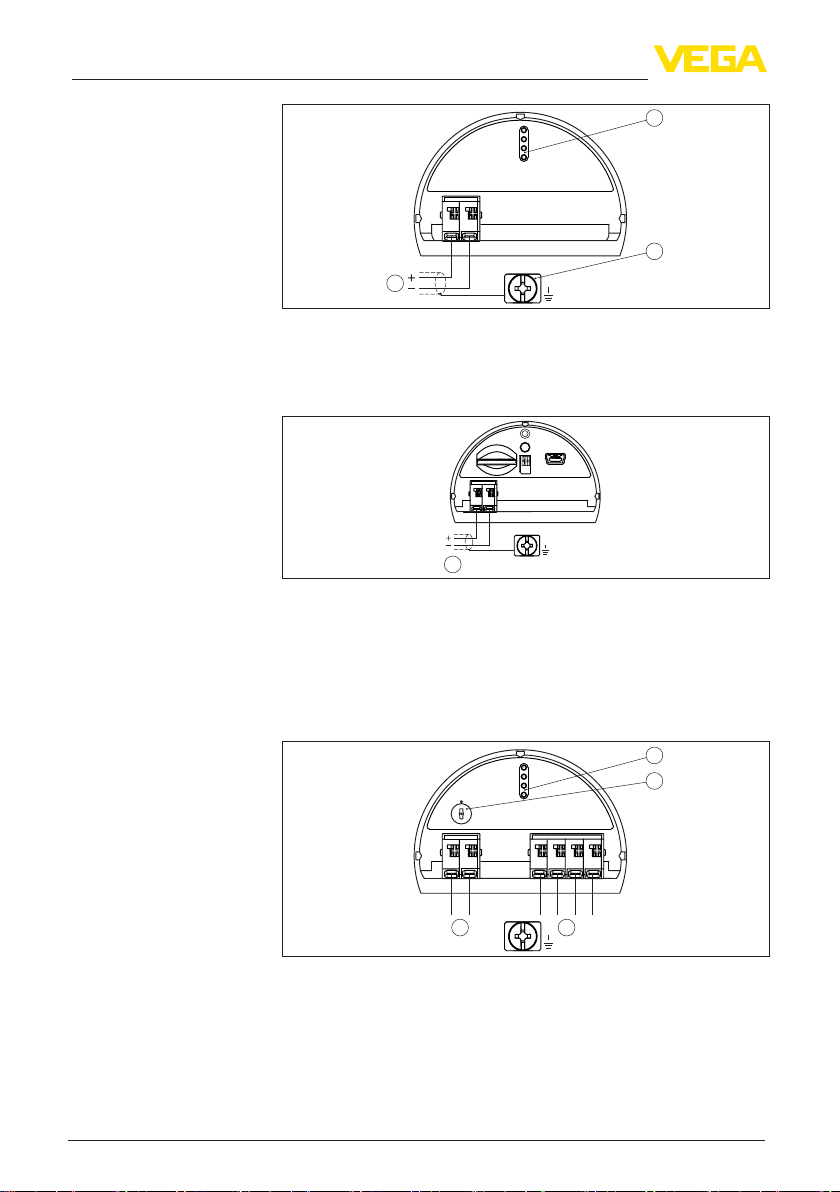

5.5 Wiring plan, double chamber housing Ex d

2

3

0

1

1

0

Bus

( )

(-)

+

1

2

Fig. 8: Electronics compartment, double chamber housing

1 Internal connection to the connection compartment

2 Contact pins for the indicating and adjustment module or interface adapter

3 Simulation switch ("on" = simulation mode)

VEGAPULS 66 standpipe version • Foundation Fieldbus

5

678

11

36526-EN-121011

Page 19

Connection compartment

5 Connecting to the bus system

Bus

( )

(-)

+

1

2

2

1

Fig. 9: Connection compartment, double chamber housing Ex d

1 Voltage supply, signal output

2 Ground terminal for connection of the cable screen

Plug M12 x 1 for external

indicating and adjustment unit

Wire assignment, connection cable

34

1

Fig. 10: Top view of the plug connector

1 Pin 1

2 Pin 2

3 Pin 3

4 Pin 4

Contact pin Colour connection ca-

ble in the sensor

Pin 1 Brown 5

Pin 2 White 6

Pin 3 Blue 7

Pin 4 Black 8

2

Terminal, electronics

module

5.6 Wiring plan - version IP 66/IP 68, 1 bar

1

2

Fig.11:Wireassignmentx-connectedconnectioncable

1 brown (+) and blue (-) to power supply or to the processing system

2 Shielding

5.7 Switch-on phase

After VEGAPULS 66 is connected to the bus system, the instrument

carries out a self-test for approx. 30 seconds. The following steps are

carried out:

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

19

Page 20

5 Connecting to the bus system

Internal check of the electronics

•

Indication of the instrument type, hardware and software version,

•

measurement loop name on the display or PC

Indication of the status message "F 105 Determine measured

•

value" on the display or PC

Status byte goes briey to fault value

•

As soon as a plausible measured value is found, it is outputted to the

signal cable. The value corresponds to the actual level as well as the

settings already carried out, e.g. factory settings.

20

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 21

6 Set up with the indicating and adjustment module

6 Set up with the indicating and adjustment

module

6.1 Insert indicating and adjustment module

The indicating and adjustment module can be inserted into the sensor and removed any time. Four positions displaced by 90° can be

selected. It is not necessary to interrupt the power supply.

Proceed as follows:

1. Unscrew the housing cover

2. Place the indicating and adjustment module in the requested

position onto the electronics and turn to the right until it snaps in

3. Screw housing cover with inspection window tightly back on

Removal is carried out in reverse order.

The indicating and adjustment module is powered by the sensor, an

additional connection is not necessary.

Fig. 12: Insertion of the indicating and adjustment module with single chamber

housing into the electronics compartment

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

21

Page 22

6 Set up with the indicating and adjustment module

1 2

Fig. 13: Insertion of the indicating and adjustment module with double chamber

housing

1 In the electronics compartment

2 In the connection compartment (with Ex-d-ia version not possible)

Note:

If you intend to retrot the instrument with an indicating and adjustment module for continuous measured value indication, a higher

cover with an inspection glass is required.

Key functions

22

6.2 Adjustment system

Fig. 14: Indicating and adjustment elements

1 LC display

2 Adjustment keys

[OK] key:

•

– Move to the menu overview

– Conrm selected menu

VEGAPULS 66 standpipe version • Foundation Fieldbus

1

2

36526-EN-121011

Page 23

6 Set up with the indicating and adjustment module

– Edit parameter

– Save value

[->] key:

•

– Presentation change measured value

– Select list entry

– Select editing position

[+] key:

•

– Change value of the parameter

[ESC] key:

•

– interrupt input

– Jump to next higher menu

Adjustment system

Main menu

The sensor is adjusted via the four keys of the indicating and adjustment module. The LC display indicates the individual menu items. The

functions of the individual keys are shown in the above illustration.

Approx. 10 minutes after the last pressing of a key, an automatic reset

to measured value indication is triggered. Any values not conrmed

with [OK] will not be saved.

6.3 Parameter adjustment

Through the parameter adjustment the instrument is adapted to the

application conditions. The parameter adjustment is carried out via an

adjustment menu.

The main menu is divided into ve sections with the following func-

tions:

Setup: Settings, e.g., for measurement loop name, medium, application, vessel, adjustment, signal output

Display: Settings, e.g., for language, measured value display, lighting

Diagnosis: Information, e.g. on the instrument status, pointer, reli-

ability, simulation, echo curve

Further settings: Instrument unit, false signal suppression, linearisa-

tion curve, reset, date/time, reset, copy function

Info: Instrument name, hardware and software version, calibration

date, instrument features

Information:

In this operating instructions manual, the instrument-specic parameters in the menu sections "Setup", "Diagnosis" and "Additional set-

tings" are described. The general parameters in these menu section

are described in the operating instructions manual "Indicating and

adjustment module".

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

23

Page 24

6 Set up with the indicating and adjustment module

You can nd in the operating instructions manual "Indicating and ad-

justment module" also the description of the menu sections "Display"

and "Info".

In the main menu point "Setup", the individual submenu points should

be selected subsequently and provided with the correct parameters

to ensure the optimum adjustment of the measurement. The procedure is described in the following.

Setup

Setup/Medium

Each medium has dierent reection properties. With liquids, further

interfering factors are uctuation product surface and foam generation. With bulk solids, these are dust generation, material cone and

additional echoes from the vessel wall.

To adapt the sensor to these dierent measuring conditions, the

selection "Liquid" or "Bulk solid" should be made in this menu item.

Through this selection, the sensor is adapted perfectly to the product

and measurement reliability, particularly in products with poor reective properties, is considerably increased.

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

Setup/Adjustment

24

Since a radar sensor is a distance measuring instrument, the distance

from the sensor to the product surface is measured. For indication of

the real level, an allocation of the measured distance to the percentage height must be carried out.

To perform the adjustment, enter the distance with full and empty vessel. For instruments with standpipe antenna, these values are already

preset by default, see the following example:

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 25

6 Set up with the indicating and adjustment module

")

0,5 m

(19.68

100%

2

")

5 m

(196.9

0%

1

Fig. 15: Parameter adjustment example min./max. adjustment

1 Min. level = max. meas. distance

2 Max. level = min. meas. distance

If these values are not known, an adjustment with the distances of for

example 10 % and 90 % is possible. Starting point for these distance

specications is always the seal surface of the thread or ange. By

means of these settings, the real level will be calculated.

The real product level during this adjustment is not important, because the min./max. adjustment is always carried out without changing the product level. These settings can be made ahead of time

without the instrument having to be installed.

Setup/Min. adjustment

Proceed as follows:

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "Min. adjustment" and conrm

with [OK].

2. Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3. Set the requested percentage value with [+] and save with [OK].

The cursor jumps now to the distance value.

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

25

Page 26

6 Set up with the indicating and adjustment module

4. Enter the suitable distance value in m for the empty vessel (e.g.

distance from the sensor to the vessel bottom) corresponding to

the percentage value.

5. Save settings with [OK] and move with [ESC] and [->] to the max.

adjustment.

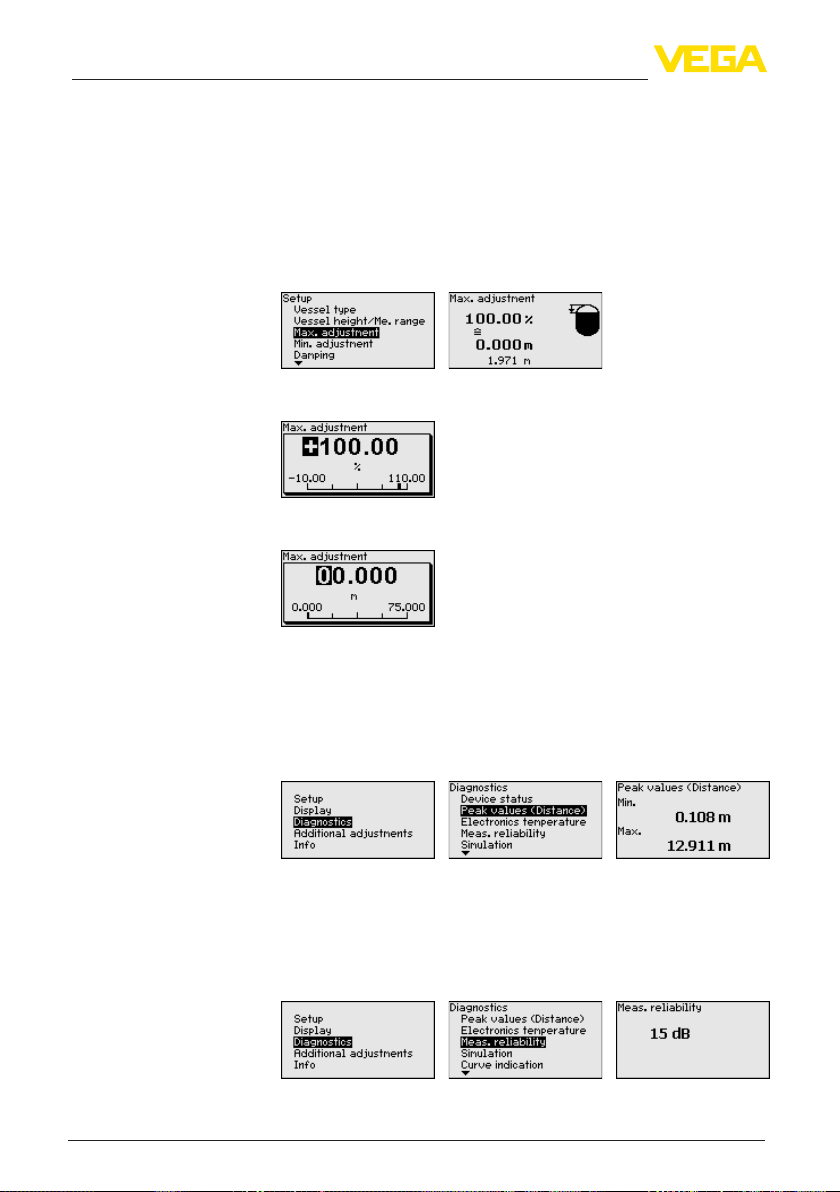

Setup/Max. adjustment

Diagnosis/Peak value

Proceed as follows:

1. Select with [->] the menu item max. adjustment and conrm with

[OK].

2. Prepare the percentage value for editing with [OK] and set the

cursor to the requested position with [->].

3. Set the requested percentage value with [+] and save with [OK].

The cursor jumps now to the distance value.

4. Enter the appropriate distance value in m (corresponding to the

percentage value) for the full vessel. Keep in mind that the max.

level must lie below the min. distance to the antenna edge.

5. Save settings with [OK]

The respective min. and max. measured value is saved in the sensor.

The values are displayed in the menu item "Peak values".

Diagnosis/Measurement

reliability

26

When non-contact level sensors are used, the measurement can be

inuenced by the respective process conditions. In this menu item,

the measurement reliability of the level echo is displayed as dB value.

The measurement reliability equals signal strength minus noise. The

higher the value, the more reliable the measurement. With a functioning measurement, the values are > 10 dB.

VEGAPULS 66 standpipe version • Foundation Fieldbus

36526-EN-121011

Page 27

6 Set up with the indicating and adjustment module

Diagnoses/Curve indication

The "Echo curve" shows the signal strength of the echoes over the

measuring range in dB. The signal strength enables an evaluation of

the quality of the measurement.

The "False signal suppression" displays the saved false echoes (see

menu "Additional settings") of the empty vessel with signal strength in

"dB" over the measuring range.

A comparison of echo curve and false signal suppression allows a

more accurate conclusion on measurement reliability. The selected

curve is continuously updated. With the [OK] key, a submenu with

zoom functions is opened:

"X-Zoom": Zoom function for the meas. distance

•

"Y-Zoom": 1, 2, 5 and 10x signal magnication in "dB"

•

"Unzoom": Reset the presentation to the nominal measuring range

•

with single magnication

Diagnostics/Echo curve

memory

Additional adjustments/

False signal suppression

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

With the function "Echo curve memory" the echo curve can be saved

at the time of setup. This is generally recommended; for using the Asset Management functions it is absolutely necessary. If possible, the

curve should be saved with a low level in the vessel.

With the adjustment software PACTware and the PC, the high resolution echo curve can be displayed and used to recognize signal

changes over the operating time. In addition, the echo curve of the

setup can be also displayed in the echo curve window and compared

with the actual echo curve.

The following circumstances cause interfering reections and can

inuence the measurement:

High sockets

•

27

Page 28

6 Set up with the indicating and adjustment module

Vessel installations such as struts

•

Agitators

•

Buildup or welded joints on vessel walls

•

Note:

A false signal suppression detects, marks and saves these false signals so that they are no longer taken into account for level measurement.

This should be done with the low level so that all potential interfering

reections can be detected.

Proceed as follows:

1. Select the menu item "Additional settins" with [->] and conrm

with [OK]. With [->] you have to select the menu item "False

signal suppression" and conrm with [OK].

2. Conrm again with [OK].

3. Conrm again with [OK].

28

4. Conrm again with [OK] and enter the actual distance from the

sensor to the product surface.

5. All interfering signals in this section are detected by the sensor

and stored after conrming with [OK].

Note:

Check the distance to the product surface, because if an incorrect

(too large) value is entered, the existing level will be saved as false

signal. The lling level would then no longer be detectable in this area.

If a false signal suppression has already been created in the sensor,

the following menu window appears when selecting "False signal

suppression":

VEGAPULS 66 standpipe version • Foundation Fieldbus

36526-EN-121011

Page 29

6 Set up with the indicating and adjustment module

The menu item "Delete" is used to completely delete an already created false signal suppression. This is useful if the saved false signal

suppression no longer matches the metrological conditions in the

vessel.

The menu item "Extend" is used to extend an already created false

signal suppression. This is useful if a false signal suppression was

carried out with a too high level and not all false signals could be detected. When selecting "Extend", the distance to the product surface

of the created false signal suppression is displayed. This value can

now be changed and the false signal suppression can be extended to

this range.

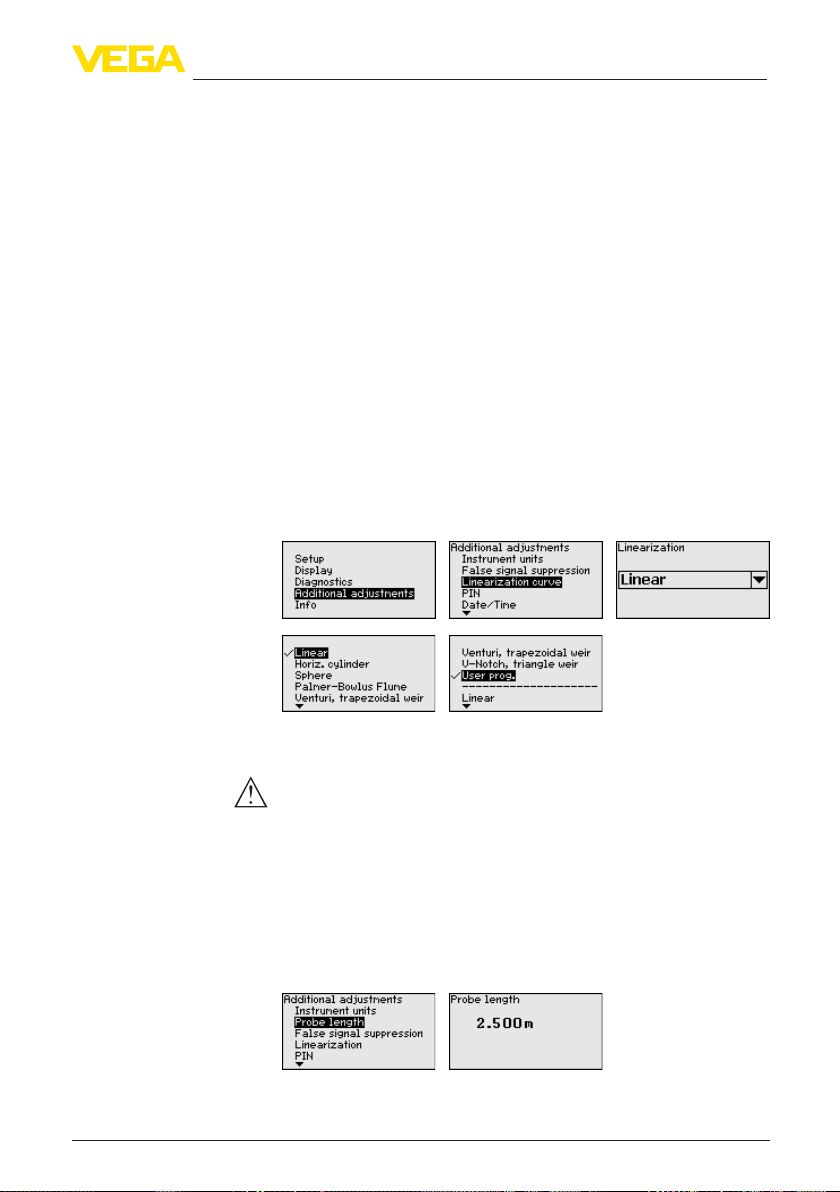

Additional adjustments/

Linearization curve

A linearization is necessary for all vessels in which the vessel volume

does not increase linearly with the level - e.g. in a horizontal cylindrical or spherical tank - and the indication or output of the volume is

required. Corresponding linearization curves are preprogrammed

for these vessels. They represent the correlation between the level

percentage and vessel volume.

By activating the appropriate curve, the volume percentage of the

vessel is displayed correctly. If the volume should not be displayed in

percent but e.g. in l or kg, a scaling can be also set in the menu item

"Display".

Enter the requested parameters via the appropriate keys, save your

settings and jump to the next menu item with the [ESC] and [->] key.

Caution:

Note the following if the instrument with corresponding approval is

used as part of an overll protection system according to WHG:

If a linearisation curve is selected, the measuring signal is no longer

linearly proportional to the level. This must be taken into consideration

by the user, particularly when setting the switching point on the level

switch.

Additional adjustments/

Probe length

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

With radar sensors with standpipe antenna, the sensor length is

already preset in this menu item. When shortening the standpipe

antenna afterwards, this value must be appropriately corrected.

29

Page 30

6 Set up with the indicating and adjustment module

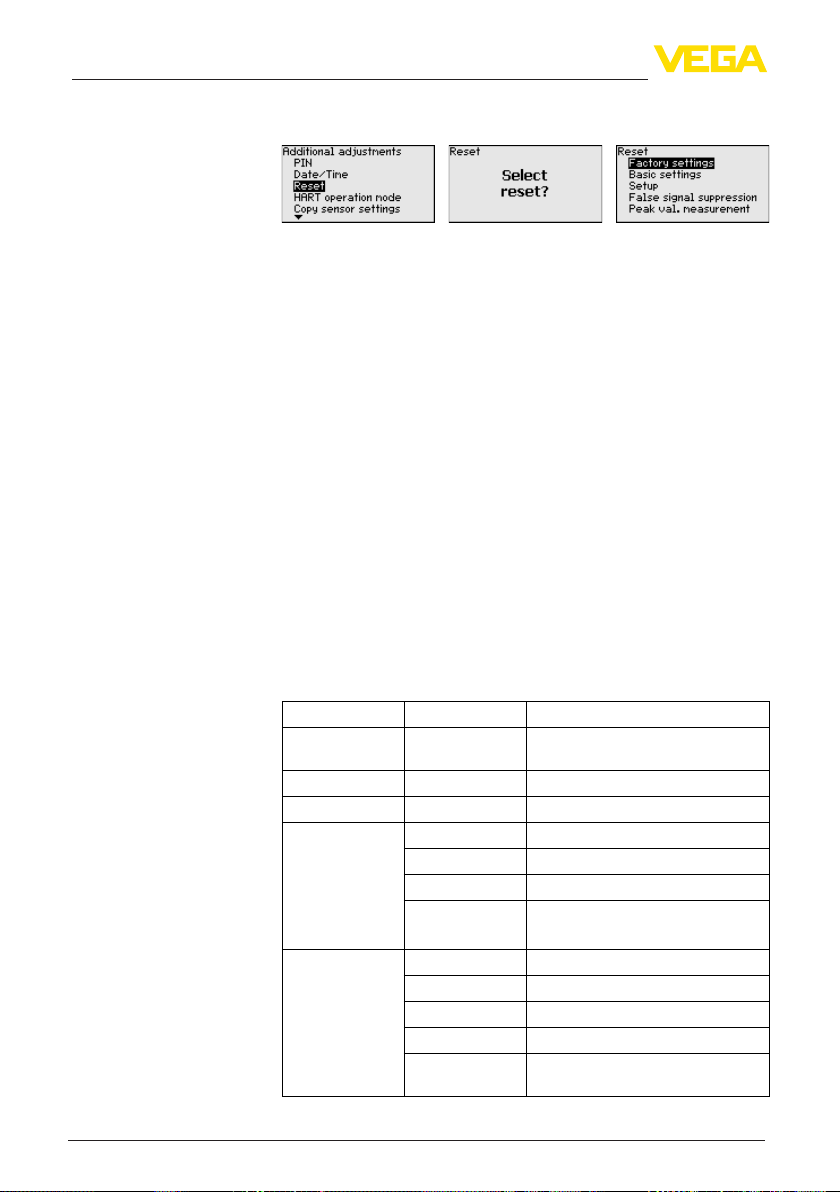

Additional adjustments/

Reset

When a reset is carried out, all settings (with only a few exceptions)

are reset. The exceptions are: PIN, language and lighting.

The following reset functions are available:

Delivery status: Restoring the parameter settings at the time of ship-

ment from the factory incl. the order-specic settings. A created false

signal suppression, user-programmable linearization curve as well as

the measured value memory will be deleted.

Basic settings: Resetting the parameter settings incl. special and

laboratory parameters to the default values of the respective instrument. A created false signal suppression, user programmable linearization curve as well as the measured value memory will be deleted.

Setup: Resetting of the parameter settings to the default values of the

respective instrument in the menu item Setup. Order-related settings

remain but are not taken over into the current parameters. Usergenerated false signal suppression, user-programmed linearization

curve, measured value memory as well as event memory remain

untouched. The linearization is set to linear.

False signal suppression: Deleting a previously created false signal

suppression. The false signal suppression created in the factory

remains active.

Peak values distance: Resetting the measured min. and max. distances to the actual measured value.

Select the requested reset function [->] and conrm with [OK].

The following table shows the default values of VEGAPULS 66:

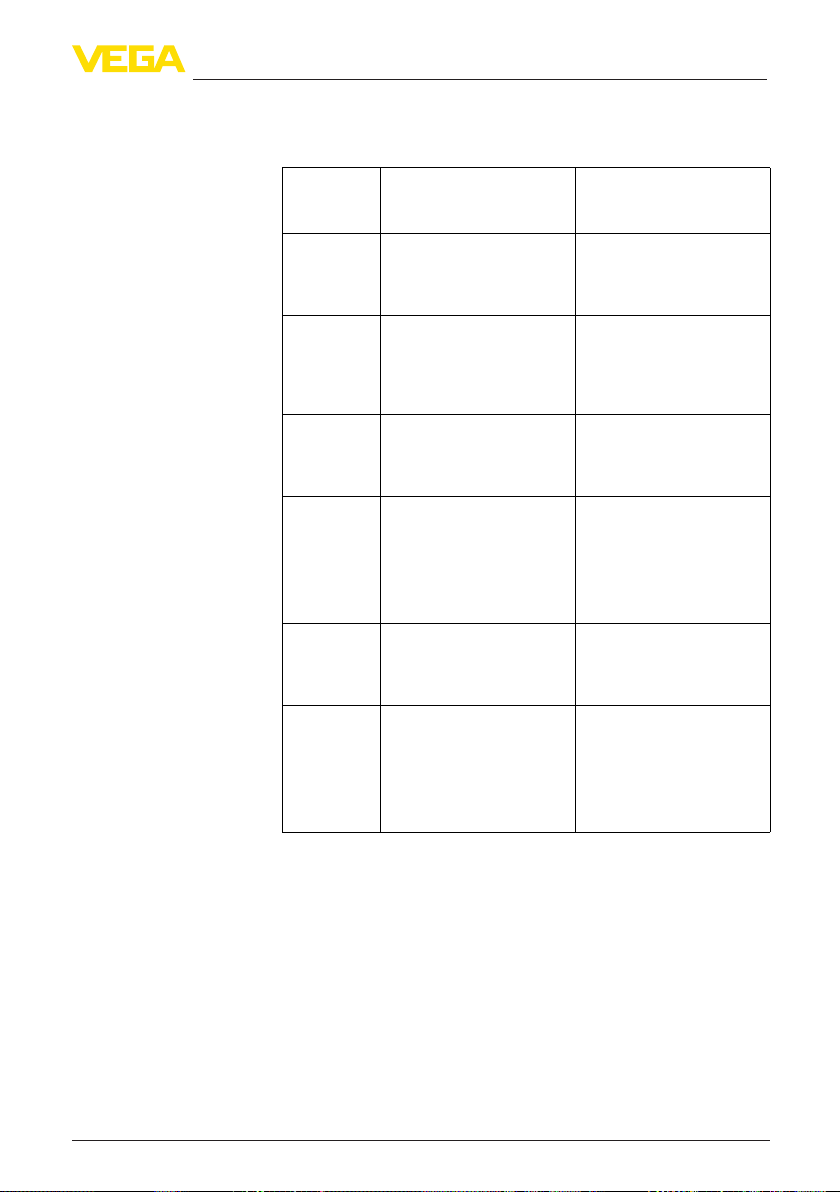

Menu section Menu item Default value

Setup Measurement

Display Language Like order

Additional adjust-

ments

loop name

Min. adjustment Length of the standpipe Ex factory

Damping 0.0 s

Displayed value Distance

Display unit m(d)

Scaling 0.00 %, 0 l

Distance unit m

Temperature unit °C

Unit SV2 m

Probe length Length of the standpipe Ex factory

Linearisation

curve

Sensor

100.00 %, 100 l

Linear

36526-EN-121011

30

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 31

6 Set up with the indicating and adjustment module

6.4 Saving the parameter adjustment data

We recommended noting the adjusted data, e.g. in this operating

instructions manual, and archiving them afterwards. They are thus

available for multiple use or service purposes.

If the instrument is equipped with an indicating and adjustment

module, the data in the sensor can be saved in the indicating and

adjustment module. The procedure is described in the operating

instructions manual "Indicating and adjustment module" in the menu

item "Copy sensor data". The data remain there permanently even if

the sensor power supply fails.

The following data or settings for adjustment of the indicating and

adjustment module are saved:

All data of the menu "Setup" and "Display"

•

In the menu "Additional adjustments" the items "Sensor-specic

•

units, temperature unit and linearization"

The values of the user programmable linearisation curve

•

The function can also be used to transfer settings from one instrument to another instrument of the same type. If it is necessary to

exchange a sensor, the indicating and adjustment module is inserted

into the replacement instrument and the data are likewise written into

the sensor via the menu item "Copy sensor data".

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

31

Page 32

7 Setup with PACTware

7 Setup with PACTware

7.1 Connect the PC

Via the interface adapter

directly on the sensor

Prerequisites

2

1

3

Fig. 16: Connection of the PC directly to the sensor via the interface adapter

1 USB cable to the PC

2 Interface adapter VEGACONNECT 4

3 Sensor

Information:

The interface adapter VEGACONNECT 3 is not suitable for connection to the sensor.

7.2 Parameter adjustment with PACTware

For parameter adjustment of the sensor via a Windows PC, the conguration software PACTware and a suitable instrument driver (DTM)

according to FDT standard are required. The up-to-date PACTware

version as well as all available DTMs are compiled in a DTM Collection. The DTMs can also be integrated into other frame applications

according to FDT standard.

Note:

To ensure that all instrument functions are supported, you should

always use the latest DTM Collection. Furthermore, not all described

functions are included in older rmware versions. You can download

the latest instrument software from our homepage. A description of

the update procedure is also available in the Internet.

Further setup steps are described in the operating instructions manual "DTM Collection/PACTware" attached to each DTM Collection and

which can also be downloaded from the Internet. Detailed descriptions are available in the online help of PACTware and the DTMs.

36526-EN-121011

32

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 33

Fig. 17: Example of a DTM view

7 Setup with PACTware

Standard/Full version

All device DTMs are available as a free-of-charge standard version

and as a full version that must be purchased. In the standard version,

all functions for complete setup are already included. An assistant for

simple project conguration simplies the adjustment considerably.

Saving/printing the project as well as import/export functions are also

part of the standard version.

In the full version there is also an extended print function for complete

project documentation as well as a save function for measured value

and echo curves. In addition, there is a tank calculation program as

well as a multiviewer for display and analysis of the saved measured

value and echo curves.

The standard version is available as a download under www.vega.

com/downloads and "Software". The full version is available on CD

from the agency serving you.

7.3 Saving the parameter adjustment data

We recommend documenting or saving the parameter adjustment

data via PACTware. That way the data are available for multiple use or

service purposes.

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

33

Page 34

8 Set up with other systems

8 Set up with other systems

8.1 DD adjustment programs

Device descriptions as Enhanced Device Description (EDD) are

available for DD adjustment programs such as, for example, AMS™

and PDM.

The les can be downloaded at www.vega.com/downloads under

"Software".

8.2 Communicator 375, 475

Device descriptions for the instrument are available as DD or EDD for

parameter adjustment with the Field Communicator 375 or 475.

The les can be downloaded at www.vega.com/downloads under

"Software".

34

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 35

9 Diagnosis, Asset Management and service

9 Diagnosis, Asset Management and service

9.1 Maintenance

If the device is used correctly, no maintenance is required in normal

operation.

9.2 Measured value and event memory

The instrument has several memories which are available for diagnosis purposes. The data remain even with voltage interruption.

Measured value memory

Event memory

Echo curve memory

Up to 60,000 measured values can be stored in the sensor in a ring

memory. Each entry contains date/time as well as the respective

measured value. Storable values are for example:

Distance

•

Filling height

•

Percentage value

•

Lin. percent

•

Scaled

•

Current value

•

Meas. reliability

•

Electronics temperature

•

When the instrument is shipped, the measured value memory is

active and stores distance, measurement certainty and electronics

temperature every 3 minutes.

The requested values and recording conditions are set via a PC with

PACTware/DTM or the control system with EDD. Data are thus read

out and also reset.

Up to 500 events are automatically stored with a time stamp in the

sensor (non-deletable). Each entry contains date/time, event type,

event description and value. Event types are for example:

Modication of a parameter

•

Switching on and o times

•

Status messages (according to NE 107)

•

Error messages (according to NE 107)

•

The data are read out via a PC with PACTware/DTM or the control

system with EDD.

The echo curves are stored with date and time and the corresponding

echo data. The memory is divided into two sections:

Echo curve of the setup: This is used as reference echo curve for

the measurement conditions during setup. Changes in the measurement conditions during operation or buildup on the sensor can thus

be recognized. The echo curve of the setup is stored via:

PC with PACTware/DTM

•

Control system with EDD

•

Indicating and adjustment module

•

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

35

Page 36

9 Diagnosis, Asset Management and service

Further echo curves: Up to 10 echo curves can be stored in a ring

buer in this memory section. Further echo curves are stored via:

PC with PACTware/DTM

•

Control system with EDD

•

9.3 Asset Management function

The instrument features self-monitoring and diagnostics according

to NE 107 and VDI/VDE 2650. In addition to the status messages in

the following tables there are more detailed error messages available

under the menu item "Diagnostics" via the indicating and adjustment

module, PACTware/DTM and EDD.

Status messages

The status messages are classied in the following categories:

Failure

•

Function check

•

Out of specication

•

Maintenance requirement

•

and explained by pictographs:

41 2 3

Fig. 18: Pictograms of the status messages

1 Failure - red

2 Function check - orange

3 Outofspecication-yellow

4 Maintenance - blue

Failure: Due to a malfunction in the instrument, a failure message is

outputted.

This status message is always active. It cannot be deactivated by the

user.

Function check: The instrument is in operation, the measured value

is temporarily invalid (for example during simulation).

This status message is inactive by default. It can be activated by the

user via PACTware/DTM or EDD.

Outofspecication: The measured value is unstable because the

instrument specication is exceeded (e.g. electronics temperature).

This status message is inactive by default. It can be activated by the

user via PACTware/DTM or EDD.

Maintenance: Due to external inuences, the instrument function

is limited. The measurement is aected, but the measured value is

still valid. Plan in maintenance for the instrument because a failure is

expected in the near future (e.g. due to buildup).

This status message is inactive by default. It can be activated by the

user via PACTware/DTM or EDD.

36526-EN-121011

36

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 37

9 Diagnosis, Asset Management and service

Failure (failure)

The following table shows the codes and text messages of the status

message "Failure" and provides information on causes as well as

corrective measures.

Code

Text message

F013

no meas-

ured value

available

F017

Adjustment

span too

small

F025

Error in the

linearization table

F036

No op-

erable

software

F040

Error in the

electronics

F080 – General software error – Separate operating

F105

Determine

measured

value

F113

Communi-

cation error

F125

Unper-

missible

electronics

temperature

Cause Rectication PA DevS-

– Sensor does not

detect an echo during

operation

– Antenna system con-

taminated or defective

– Adjustment not within

specication

– Index markers are not

continuously rising, for

examle unlogical value

pairs

– Failed or interrupted

software update

– Hardware defect – Exchanging the elec-

– The instrument is still

in the start phase, the

measured value could

not yet be determined

– Error in the internal

instrument communication

– Temperature of the

electronics in the nonspecied section

– Check or correct

installation and/or

parameter adjustment

– Clean or exchange

process component or

antenna

– Change adjustment

according to the limit

values (dierence

between min. and

max. ≥ 10 mm)

– Check linearization

table

– Delete table/Create

new

– Repeat software

update

– Check electronics

version

– Exchanging the elec-

tronics

– Send instrument for

repair

tronics

– Send instrument for

repair

voltage briey

– Wait for the warm-up

phase

– Duration depending

on the version and

parameter adjustment

up to approximately

3 min.

– Separate operating

voltage briey

– Send instrument for

repair

– Check ambient tem-

perature

– Isolate electronics

– Use instrument with

higher temperature

range

pec

Diagnosis

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

Bit 8

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

37

Page 38

9 Diagnosis, Asset Management and service

Function check

Code

Text message

F260

Error in the

calibration

F261

Error in the

conguration

F264

Installa-

tion/Setup

error

F265

Meas-

urement

function

disturbed

Cause Rectication PA DevS-

– Error in the calibra-

tion carried out in the

factory

– Error in the EEPROM

– Error during setup

– False signal suppres-

sion faulty

– Error when carrying

out a reset

– Adjustment not within

the vessel height/

measuring range

– Max. measuring range

of the instrument not

sucient

– Sensor no longer

carries out a measurement

– Operating voltage

too low

– Exchanging the elec-

tronics

– Send instrument for

repair

– Repeat setup

– Repeat reset

– Check or correct

installation and/or

parameter adjustment

– Use an instrument

with bigger measuring

range

– Check operating

voltage

– Carry out a reset

– Separate operating

voltage briey

pec

Diagnosis

Bit 9

Bit 10

Bit 11

Bit 12

The following table shows the error codes and text messages in the

status message "Function check" and provides information on causes

as well as corrective measures.

Code

Text message

C700

Simulation ac-

tive

Cause Rectication

– A simulation is active – Finish simulation

– Wait for the automatic end

after 60 mins.

Outofspecication

38

The following table shows the error codes and text messages in the

status message "Outofspecication" and provides information on

causes as well as corrective measures.

Code

Text message

S600

Unpermissi-

ble electronics

temperature

S601

Overlling

Cause Rectication

– Temperature of the elec-

tronics in the non-specied

section

– Danger of vessel overlling – Make sure that there is no

– Check ambient temperature

– Isolate electronics

– Use instrument with higher

temperature range

further lling

– Check level in the vessel

VEGAPULS 66 standpipe version • Foundation Fieldbus

36526-EN-121011

Page 39

9 Diagnosis, Asset Management and service

Maintenance

The following table shows the error codes and text messages in the

status message "Maintenance" and provides information on causes

as well as corrective measures.

Code

Text message

M500

Error with the

reset delivery

status

M501

Error in the

non-active

linearization

table

M502

Error in the

diagnosis

memory

M503

Reliability too

low

M504

Error on an

device inter-

face

M505

No echo avail-

able

Cause Rectication

– With the reset to delivery

status, the data could not

be restored

– Hardware error EEPROM – Exchanging the electronics

– Hardware error EEPROM – Exchanging the electronics

– The echot/noise ratio is the

small for a reliable measurement

– Hardware defect – Check connections

– Level echo can no longer

be detected

– Repeat reset

– Load XML le with sensor

data into the sensor

– Send instrument for repair

– Send instrument for repair

– Check installation and

process conditions

– Clean the antenna

– Change polarisation direc-

tion

– Use instrument with higher

sensitivity

– Exchanging the electronics

– Send instrument for repair

– Clean the antenna

– Use a more suitable

antenna/sensor

– Remove possible false

echoes

– Optimize sensor position

and orientation

9.4 Rectify faults

Reaction when malfunctions occur

Procedure for fault recti-

cation

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

The operator of the system is responsible for taking suitable measures to rectify faults.

The rst measures are:

Evaluation of fault messages, for example via the indicating and

•

adjustment module

Checking the output signal with 4 … 20 mA instruments

•

Treatment of measurement errors

•

Further comprehensive diagnostics options oer a PC with the software PACTware and the suitable DTM. In many cases, the reasons

can be determined in this way and faults can be rectied.

39

Page 40

9 Diagnosis, Asset Management and service

Treatment of measurement errors with standpipe versions

The below tables show typical examples of application-relevant measurement errors with standpipe versions. The measurement errors are

dierentiated according to:

Constant level

•

Filling

•

Emptying

•

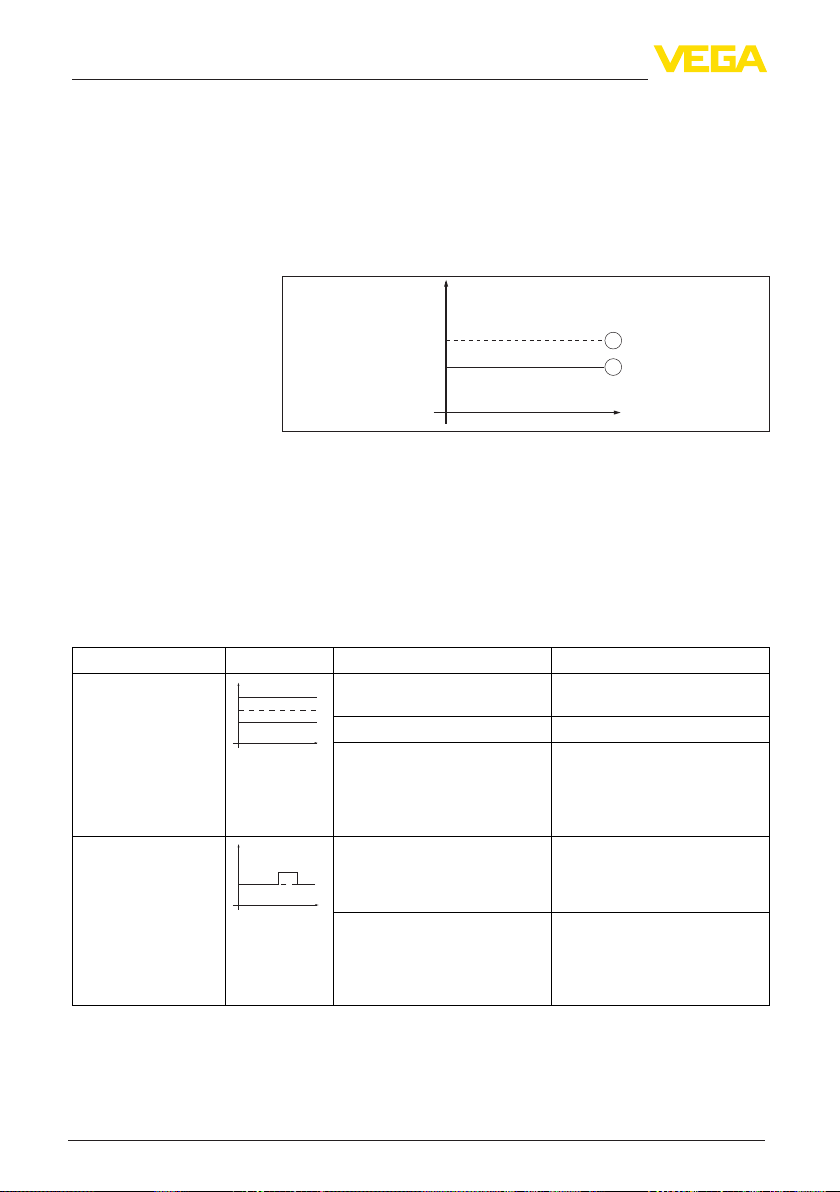

The images in column "Error pattern" show the real level with a broken line and the level displayed by the sensor as a continuous line.

Level

1

2

0

Fig. 19: The broken line 1 shows the real level, the continuous line 2 shows the

level displayed by the sensor

time

Instructions:

Wherever the sensor displays a constant value, the reason could

•

also be the fault setting of the current output to "Hold value"

In case of a too low level indication, the reason could be a line

•

resistance that is too high

9.4 Measurement error with constant level

Fault description Error pattern Cause Rectication

1. Measured value

shows a too low or too

high level

2. Measured value

jumps towards 100 %

Level

0

Level

0

– Min./max. adjustment not

correct

– Wrong linearization curve – Adapt linearization curve

time

– Installation in a bypass tube or

standpipe, hence running time

error (small measurement error

close to 100 %/large error close

to 0 %)

– Due to the process, the ampli-

tude of the product echo sinks

– A false signal suppression was

not carried out

time

– Amplitude or position of a

false echo has changed (e.g.

condensation, buildup); false

signal suppression no longer

matches

– Adapt min./max. adjustment

– Check parameter "Application"

with respect to vessel form,

adapt if necessary (bypass,

standpipe, diameter)

– Carry out false signal suppres-

sion

– Determine the reason for the

changed false echo, carry out

false signal suppression, e.g.

with condensation

36526-EN-121011

40

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 41

9 Diagnosis, Asset Management and service

9.4 Measurementerrorduringlling

Fault description Error pattern Cause Rectication

3. Measured value remains in the area of the

bottom during lling

4. Measured value

jumps to ≥ 100 % or

0 m distance

Level

– Echo from the tank bottom

larger than the product echo,

for example, with products with

0

Level

εr < 2.5 oil-based, solvents

time

– Level echo is no longer

detected in the close range

due to foam generation or false

echoes in the close range. The

sensor goes into overll protection mode. The max. level (0 m

distance) as well as the status

message "Overll protection"

– Check application parameters

Medium, Vessel height and

Floor form, adapt if necessary

– Check measuring site: Antenna

must protrude out of the socket

– Remove contamination on the

antenna

– Use a sensor with a more suit-

able antenna

are outputted.

9.4 Measurement error during emptying

Fault description Error pattern Cause Rectication

5. Measured value remains unchanged in

the close range during

emptying

6. Measured value

jumps towards 0 %

during emptying

Level

– False echo larger than the level

echo

– Level echo too small

0

time

Level

– Echo from the tank bottom

larger than the product echo,

for example, with products with

0

εr < 2.5 oil-based, solvents

time

– Remove false echoes in the

close range. Check: Antenna

must protrude out of the socket

– Remove contamination on the

antenna

– Minimize interfering instal-

lations in the close range by

changing the polarization

direction

– After removing the false ech-

oes, the false signal suppression must be deleted. Carry out

a new false signal suppression

– Check application parameters

Medium type, Vessel height and

Floor form, adapt if necessary

Reaction after fault recti-

cation

Depending on the reason for the fault and the measures taken, the

steps described in chapter "Setup" must be carried out again or must

be checked for plausibility and completeness.

24 hour service hotline

Should these measures not be successful, please call in urgent cases

the VEGA service hotline under the phone no. +49 1805 858550.

The hotline is also available outside the normal working hours on

seven days a week around the clock.

Since we oer this service worldwide, the support is in the English

language. The service itself is free of charge, the only costs involved

are the normal call charges.

9.5 Exchanging the electronics module

If the electronics module is defective, it can be replaced by the user.

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

41

Page 42

9 Diagnosis, Asset Management and service

In Ex applications only one instrument and one electronics module

with respective Ex approval may be used.

If there is no electronics module available on site, the electronics

module can be ordered through the agency serving you. The electronics modules are adapted to the respective sensor and dier in signal

output or voltage supply.

The new electronics module must be loaded with the default settings

of the sensor. These are the options:

In the factory

•

Or on site by the user

•

In both cases, the serial number of the sensor is needed. The serial

numbers are stated on the type label of the instrument, on the inside

of the housing as well as on the delivery note.

When loading on site, rst of all the order data must be downloaded

from the Internet (see operating instructions manual "Electronics

module").

9.6 Software update

The following components are required to update the sensor software:

Sensor

•

Voltage supply

•

Interface adapter VEGACONNECT 4

•

PC with PACTware

•

Current sensor software as le

•

You can nd the actual sensor software as well as detailed information of the procedure under "www.vega.com/downloads" and

"Software".

Caution:

Instruments with approvals can be bound to certain software versions. Therefore make sure that the approval remains eective with a

software update.

You can nd detailed information on www.vega.com/downloads and

"Approvals".

42

9.7 How to proceed in case of repair

You can nd a repair form as well as detailed information on how to

proceed under www.vega.com/downloads and "Formsandcerti-

cates".

By doing this you help us carry out the repair quickly and without having to call back for needed information.

If a repair is necessary, please proceed as follows:

Print and ll out one form per instrument

•

Clean the instrument and pack it damage-proof

•

Attach the completed form and, if need be, also a safety data

•

sheet outside on the packaging

VEGAPULS 66 standpipe version • Foundation Fieldbus

36526-EN-121011

Page 43

9 Diagnosis, Asset Management and service

Please contact for the return shipment the agency serving you. You

•

can nd the agency on our home page www.vega.com.

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

43

Page 44

10 Dismounting

10 Dismounting

10.1 Dismounting steps

Warning:

Before dismounting, be aware of dangerous process conditions such

as e.g. pressure in the vessel, high temperatures, corrosive or toxic

products etc.

Take note of chapters "Mounting" and "Connecting to power supply"

and carry out the listed steps in reverse order.

10.2 Disposal

The instrument consists of materials which can be recycled by specialised recycling companies. We use recyclable materials and have

designed the electronics to be easily separable.

Correct disposal avoids negative eects on humans and the environment and ensures recycling of useful raw materials.

Materials: see chapter "Technical data"

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/EG and

the respective national laws. Pass the instrument directly on to a specialised recycling company and do not use the municipal collecting

points. These may be used only for privately used products according

to the WEEE directive.

44

36526-EN-121011

VEGAPULS 66 standpipe version • Foundation Fieldbus

Page 45

11 Supplement

11 Supplement

11.1 Technical data

General data

316L corresponds to 1.4404 or 1.4435

Materials, wetted parts

Ʋ Process tting 316L, Hastelloy C22, Monell Alloy

Ʋ Process seal On site

Ʋ Antenna 316L, Hastelloy C22

Ʋ Antenna impedance cone PTFE, PP, PEEK, ceramic (99.7 % Al

Ʋ seal, antenna system FKM (A+P GLT FPM 70.16-06), FFKM (Kalrez 6375),

Standpipe 316L, Hastelloy C22

Materials, non-wetted parts

Ʋ Plastic housing plastic PBT (Polyester)

Ʋ Aluminium die-casting housing Aluminium die-casting AlSi10Mg, powder-coated - basis:

Ʋ Stainless steel housing 316L