Page 1

Operating Instructions

VEGAPULS 43

®

4 … 20 mA; HART

compact sensor

Page 2

Contents

Safety information ........................................................................ 3

Note Ex area ................................................................................ 3

1 Product description .................................................................. 4

1.1 Function................................................................................. 4

1.2 Application features ............................................................. 6

1.3 Adjustment ............................................................................ 7

2 Types and versions ................................................................... 9

2.1 Type survey .......................................................................... 9

2.2 Antenna ............................................................................... 10

3 Mounting and installation ..................................................... 11

3.1 General installation instructions ........................................ 11

3.2 Measurement of liquids ..................................................... 14

3.3 Measurement in standpipe (surge or bypass tube) ...... 15

3.4 False echoes ...................................................................... 21

3.5 Common installation mistakes ........................................... 22

Contents

4 Electrical connection .............................................................. 25

4.1 Connection and connection cable .................................... 25

4.2 Connection of the sensor .................................................. 27

4.3 Connection of the external indicating instrument

VEGADIS 50 ....................................................................... 31

4.4 Configuration of measuring systems ............................... 32

5 Set-up ........................................................................................ 40

5.1 Adjustment media .............................................................. 40

5.2 Adjustment with PC ............................................................ 40

5.3 Adjustment with adjustment module MINICOM ............... 42

5.4 Adjustment with HART® handheld ................................... 48

6 Diagnostics............................................................................... 50

6.1 Simulation ............................................................................ 50

5.2 Error codes ........................................................................ 50

2 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 3

Contents

7 Technical data .......................................................................... 51

7.1 Technical data ..................................................................... 51

7.2 Approvals ........................................................................... 56

7.3 Dimensions ......................................................................... 57

Supplement..................................................................................... 59

Safet y Manual ................................................................................. 59

1 General ............................................................................... 59

1.1 Validity ................................................................................. 59

1.2 Area of application ............................................................... 59

1.3 Relevant standards ............................................................. 59

1.4 Determination of safety-related characteristics .................. 60

2 Planning .............................................................................. 61

2.1 Low demand mode ............................................................... 61

2.2 High demand or continuous mode ....................................... 61

2.3 General ................................................................................ 61

3 Set-u p ................................................................................. 62

3.1 Mounting and installation..................................................... 62

3.2 Adjustment instructions and parameter adjustment ........... 62

3.3 Configuration of the processing unit ................................... 62

4 Reaction during operation and in case of failure ............. 63

5 Recurring function test ....................................................... 63

6 Safety-related characteristics ........................................... 64

SIL declaration of conformity .................................................... 65

CE conformity declaration......................................................... 66

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the operating instructions manual and come with the Ex

approved instruments.

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 3

Page 4

1 Product description

Product description

Sensors used in the food and pharmaceutical

industries must meet very high demands:

they must have long-term stability, they must

be accurate, robust, easy to set up, chemically resistant and flawlessly hygienic. Many

level sensors meet those demands only

halfway. Radar sensors, which are otherwise

widely used, are not usually found in hygienic

and sterile applications because their antennas are difficult to clean. The newly developed VEGAPULS 43 radar sensor was designed especially for areas of application in

hygienic and sterile production. Radar sensors are ideal because they operate without

touching the medium, are free of wear and

ageing, and perform well regardless of pressure (-1 … +40 bar) or temperature

(-40°C … +150°C). The new antenna design

of VEGAPULS 43, having no recesses or

gaps, presents a smooth surface (like a

smooth vessel wall) to CIP and SIP processes. It allows all the methods of modern,

environment-friendly system hygiene and

has, of course EHEDG, FDA and 3A approvals. The sensor faces the medium only with a

small, extremely dense TFM-PTFE surface

through which it transmits very small

(0.15 mW) radar pulses. A very fast, intelligent electronics creates from the resulting

echoes a precise image of the surroundings

and calculates from the pulse running time

the level in the vessel every 0.1 s. This value

is then outputted as a 4 … 20 mA signal.

Compared with the PTFE commonly used in

hygienic applications, the improved TFMPTFE has a far denser polymer structure and

a noticeably higher surface quality (Ra < 0.8).

As a result, proven radar technology is now

available for sterile production processes.

The spectrum of applications for the new

radar sensor is broad and varied: serum

production, face cream, fruit juice, etc.

Due to their small housing dimensions and

process fittings, the compact sensors are

unobstrusive and, above all, cost-effective

monitors of your product levels. With their

integrated display, they enable highprecision level measurements and can be

used for applications in which the

advantages of non-contact measurement

could never before be realized.

VEGAPULS radar sensors are perfectly

adapted to two-wire technology. The supply

voltage and the output signal are transmitted

via one two-wire cable. The instruments

produce an analogue 4 … 20 mA signal as

output, i.e. measurement signal.

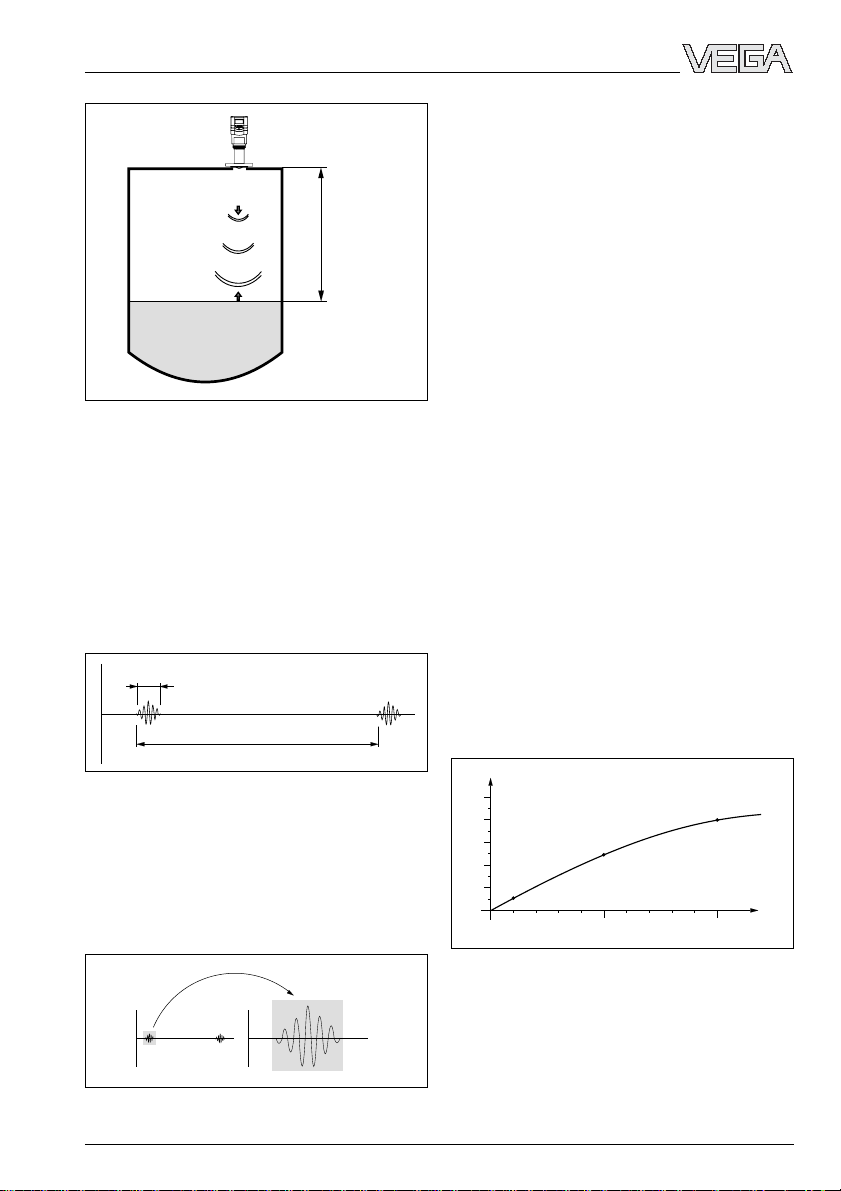

1.1 Function

Radio detecting and ranging: Radar.

VEGAPULS radar sensors are used for noncontact, continuous distance measurement.

The measured distance corresponds to a

filling height and is outputted as level.

Measuring principle:

emission – reflection – reception

Extremely small 26 GHz radar signals are

emitted from the antenna of the radar sensor

as short pulses. The radar pulses reflected

by the sensor environment and the product

are received by the antenna as radar echoes. The running period of the radar pulses

from emission to reception is proportional to

the distance and hence to the level.

4 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 5

Product description

Meas.

distance

emission - reflection - reception

The radar pulses are emitted by the antenna

system as pulse packages with a pulse

duration of 1 ns and pulse intervals of

278 ns; this corresponds to a pulse package

frequency of 3.6 MHz. In the pulse intervals,

the antenna system operates as a receiver.

Signal running periods of less than one billionth of a second must be processed and

the echo image evaluated in a fraction of a

second.

1 ns

278 ns

Hence, it is possible for the radar sensors to

process the slow-motion pictures of the sen-

sor environment precisely and in detail in

cycles of 0.5 to 1 second without using time-

consuming frequency analysis (e.g. FMCW,

required by other radar techniques).

Nearly all products can be measured

Radar signals display physical properties

similar to those of visible light. According to

the quantum theory, they propagate through

empty space. Hence, they are not depend-

ent on a conductive medium (air), and they

spread out like light at the speed of light.

Radar signals react to two basic electrical

properties:

- the electrical conductivity of a substance

- the dielectric constant of a substance.

All products which are electrically conductive

reflect radar signals very well. Even slightly

conductive products provide a sufficiently

strong reflection for a reliable measurement.

All products with a dielectric constant ε

greater than 2.0 reflect radar pulses suffi-

ciently (note: air has a dielectric constant εr of

1). Signal reflectivity grows stronger with

increasing conductivity or increasing dielec-

tric constant of the product. Hence, nearly all

substances can be measured.

r

Pulse sequence

VEGAPULS radar sensors can achieve this

through a special time transformation procedure which spreads out the more than 3.6

million echo images per second into a quasi

slow-motion picture, then freezes and processes them.

%

50

40

30

20

10

5 %

5

0

2

0

25 %

4 6 8 12 14 16 18

10

40 %

20

ε

Reflected radar power dependent on the dielectric

constant of the measured product

tt

Time transformation

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 5

r

Page 6

Product description

With standard flanges of DN 50 to DN 150,

ANSI 2“ to ANSI 6“ or G 1½ A and 1½“ NPT,

the sensor antenna systems can be adapted

to various products and measuring environments.

The high-quality materials can also withstand

extreme chemical and physical conditions.

The sensors deliver stable, reproducible

analogue or digital level signals with reliability

and precision.

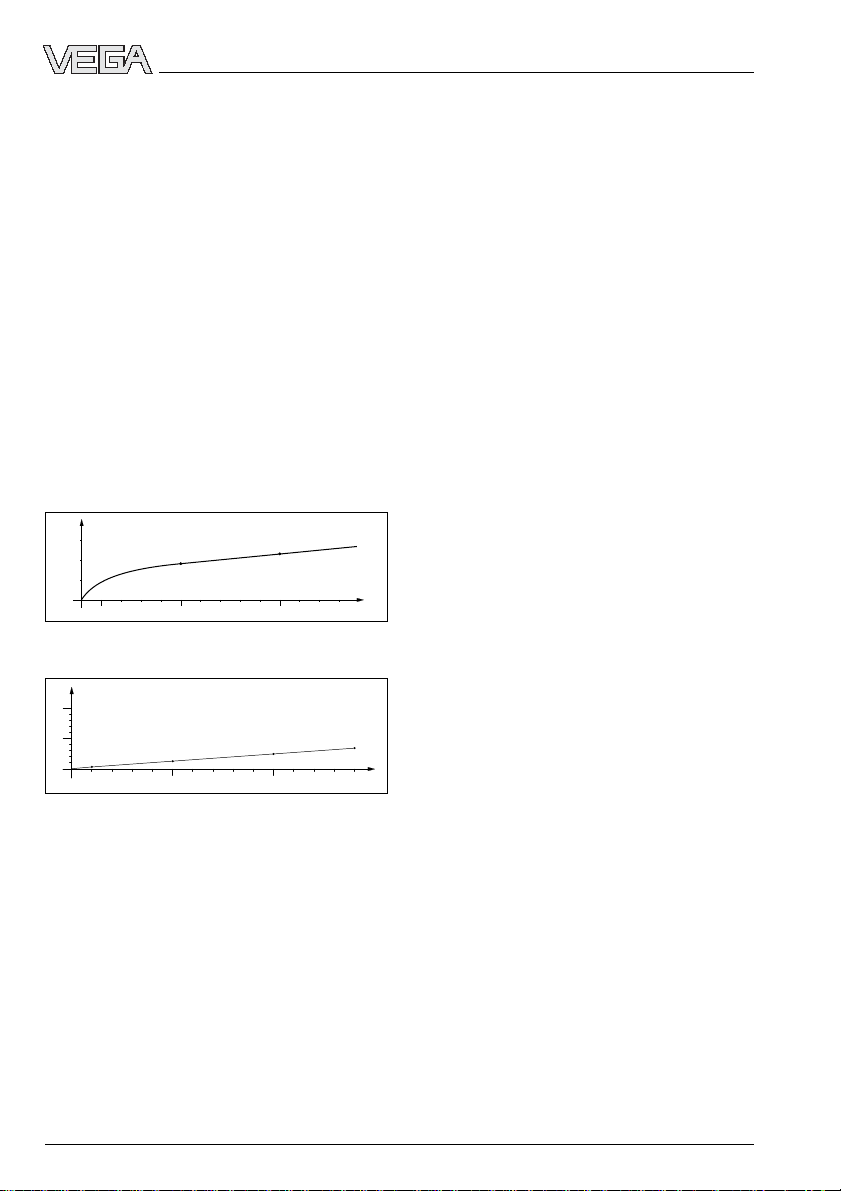

Continuous and reliable

Unaffected by temperature, pressure and

atmosphere content, VEGAPULS radar sensors are used for quick and reliable continuous level measurement of widely varying

products.

%

0,03

0,02

0,01

0

100 500 1000 1300 ˚C

0

0,018 %

Temperature influence: Temperature error absolutely

zero (e.g. at 500°C 0.018 %)

%

10

5

0,29 %

0

10

0

1,44 %

20 30 40 60

50

Pressure influence: Error with pressure increase very

low (e.g. at 50 bar 1.44 %)

0,023 %

2,8 %

70 80 90 110 120 130 140

100

3,89 %

bar

1.2 Application features

Applications

• level measurement of any liquid

• measurement also in vacuum

• all slightly conductive materials and all

substances with a dielectric constant > 2.0

• measuring range 0 … 10 m (DN 50).

measuring range 0 … 20 m (DN 80, DN

100, DN 150).

Two-wire technology

• power supply and output signal on one

two-wire cable (Loop powered)

• 4 … 20 mA output signal or HART

signal.

Rugged and abrasionproof

• non-contact

• high-resistance materials

Exact and reliable

• accuracy 0.05 %.

• resolution 1 mm

• unaffected by noise, vapours, dusts, gas

compositions and inert gas stratification

• unaffected by varying density and temperature of the medium

• measurement in pressures up to 16 bar

and product temperatures up to 150°C.

Communicative

• integrated measured value display

• optional display module separate from

sensor

• adjustment with detachable adjustment

module, pluggable in the sensor or in the

external display

• adjustment with HART

®

handheld

• adjustment with the PC.

®

output

Approvals

• CENELEC, ATEX, PTB, FM, CSA, ABS,

LRS, GL, LR, FCC.

6 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 7

Product description

1.3 Adjustment

Every measurement set-up is unique. For

that reason, every radar sensor needs some

basic information on the application and the

environment, e.g. which level means "empty“

and which level "full“. Beside this "empty and

full adjustment“, many other settings and

adjustments are possible with VEGAPULS

radar sensors.

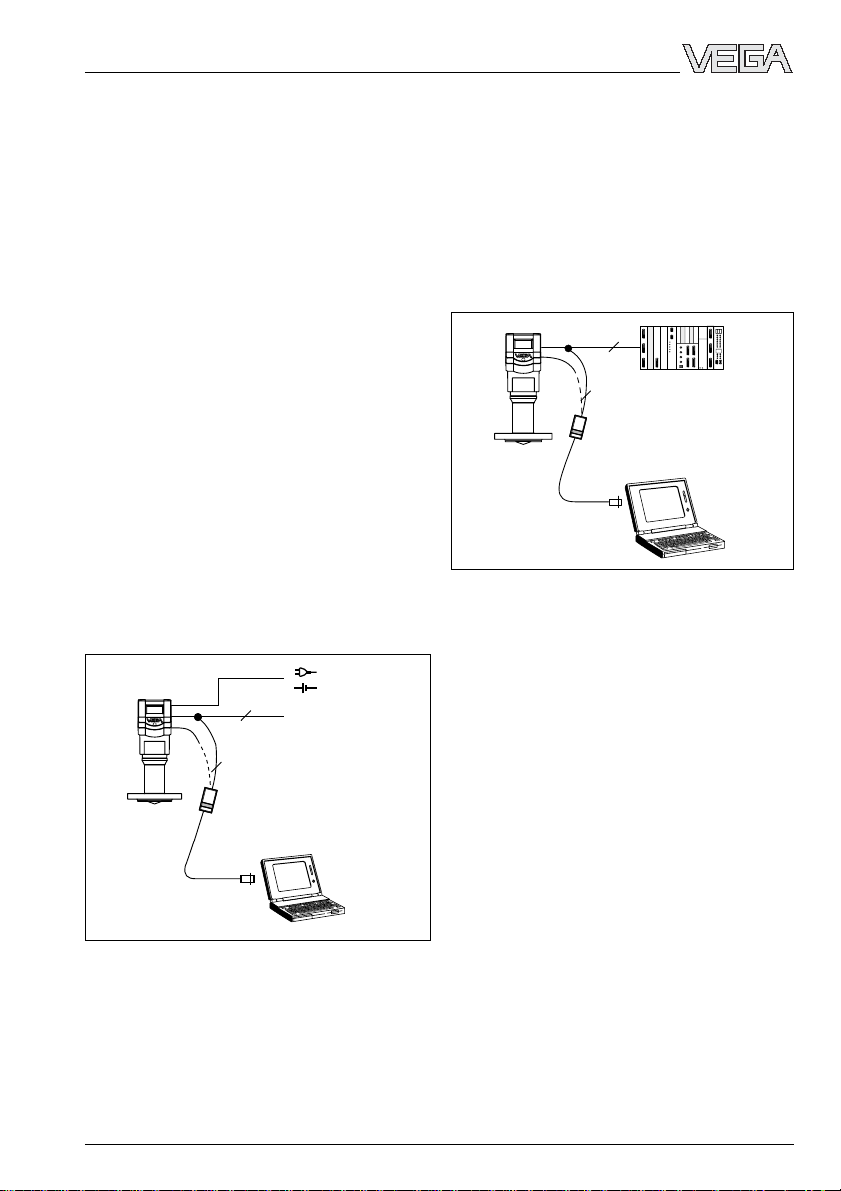

The adjustment and parameter setting of

radar sensors is carried out with

- the PC

- the detachable adjustment module MINICOM

- the HART

Adjustment with the PC

The set-up and adjustment of the radar sensors is generally done on the PC with the

adjustment software PACT

gram leads quickly through the adjustment

and parameter setting by means of pictures,

graphics and process visualisations.

®

handheld

ware

TM.

The pro-

The PC can be connected at any measuring

site in the system or directly to the signal

cable. It is connected by means of the twowire PC interface converter VEGACONNECT 3

to the sensor or the signal cable. The adjustment and parameter data can be saved with

the adjustment software on the PC and can

be protected by passwords. On request, the

adjustments can be quickly transferred to

other sensors.

2

PLC

2

Adjustment with the PC on the 4 … 20 mA signal and

supply cable or directly on the sensor (figure: a twowire sensor)

2

4 ...20 mA

2

Adjustment with the PC on the analogue 4 … 20 mA

signal and supply cable or directly on the sensor

(four-wire sensor)

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 7

Page 8

Product description

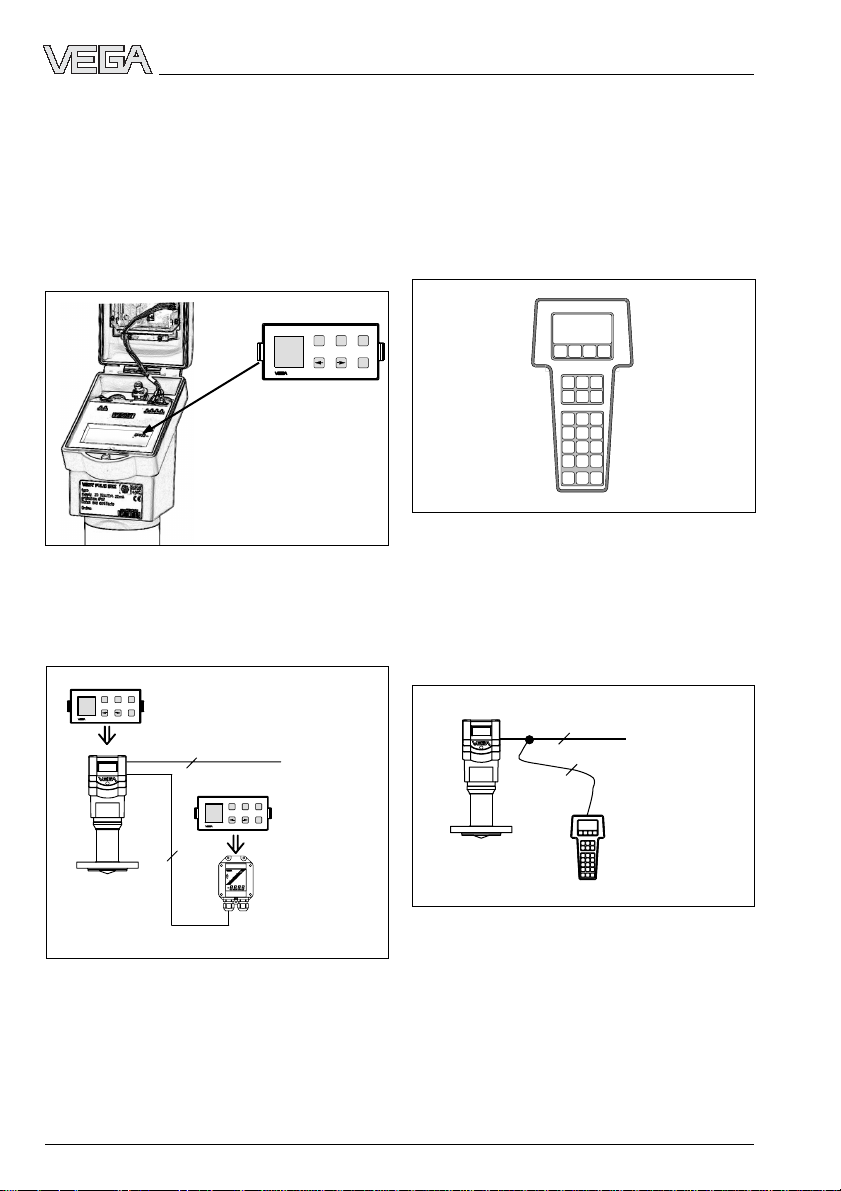

Adjustment with the adjustment module

MINICOM

The small (3.2 cm x 6.7 cm) 6-key adjustment

module with display allows the adjustment to

be carried out in clear text dialogue. The

adjustment module can be plugged into the

radar sensor or into the optional, external

indicating instrument.

Tank 1

m (d)

12.345

Detachable adjustment module MINICOM

Unauthorised sensor adjustments can be

prevented by removing the adjustment module.

ESC

+

-

OK

Adjustment with the HART® handheld

Series 40 sensors with 4 … 20 mA output

signal can also be adjusted with the HART

handheld. A special DDD (Data Device Description) is not necessary - the sensors can

be adjusted with the HART

®

standard menus

of the handheld.

HART Communicator

HART® handheld

To make adjustments, simply connect the

®

HART

handheld to the 4 … 20 mA output

signal cable or insert the two communication

cables of the HART

®

handheld into the ad-

justment jacks on the sensor.

®

ESC

+

-

Tank 1

m (d)

OK

12.345

2

-

Tank 1

m (d)

12.345

+

ESC

OK

4 ... 20 mA

2

4 ...20 mA

2

4

HART® handheld on the 4 … 20 mA signal cable

Adjustment with detachable adjustment module. The

adjustment module can be plugged into the radar

sensor or into the external indicating instrument

VEGADIS 50.

8 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 9

Types and versions

2 Types and versions

2.1 Type survey

VEGAPULS 43 sensors are manufactured

with three process connections:

- flange connections (block flanges) in

DN 50, 80, 100, 150, ANSI 2“, 3“, 4“, 6“

- TRI-Clamp 2“

- hygienic fitting DN 50.

Survey of features

General features

• Application preferably for liquids in storage tanks and process vessels with increased

accuracy requirements.

• Measuring range 0 … 10 m or 0 … 20 m.

• Ex approved in Zone 1 (IEC) or Zone 1 (ATEX) classification mark

EEx ia [ia] IIC T6.

• Integrated measured value display.

Survey

Signal outputs

- active (4 … 20 mA)

- passive (4 … 20 mA, loop powered)

Process fitting, optionally available with

- DN 50; ANSI 2“

- DN 80; ANSI 3“

- DN 100; ANSI 4“

- DN 150; ANSI 6“

- TRI-Clamp (50, 80)

- hygienic fitting (50, 80)

Adjustment

-PC

- adjustment module in the sensor

- adjustment module with external indicating instrument

- HART® handheld

Measuring range

- DN 50, ANSI 2“ 0 … 10 m

- DN 80, ANSI 3“ 0 … 20 m

- DN 100, ANSI 4“ 0 … 20 m

- DN 150, ANSI 6“ 0 … 20 m

- TRI-Clamp 50, 80 0 … 10 m

- hygienic fitting 50, 80 0 … 10 m

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 9

Page 10

Types and versions

2.2 Antenna

The antenna is the eye of the radar sensor.

The shape of the antenna, however, doesn’t

give a casual observer the slightest clue on

how carefully the antenna geometry must be

adapted to the physical properties of electromagnetic waves. The hygienic VEGAPULS 43

radar sensors are equipped with an antenna

that can be cleaned as easily as a smooth

vessel wall. The previously used horn and

rod antennas are gone. Only a small coneshaped bulge protrudes into the process

vessel. The small cone acts like a lens that

focuses the radar signals into a high-frequency beam. The relative dielectric constant

of the small 140° PTFE cone represents the

calculation index of the lens. The visible part

of the antenna (small cone), however, does

not give a clue as to how precisely the geometrical form of the antenna has to be

adapted to the physical properties of electromagnetic waves. The shape governs the

focusing of the waves and hence the sensitivity, just as shape governs the sensitivity of

a unidirectional microphone. The production

of such an electromagnetic lens requires

much empirical knowledge in the areas of

high-frequency physics and materials science.

Hygienic design

Beside the aforementioned geometry necessary for antennas used in the food and pharmaceutical industry, the choice of materials

for the newly developed VEGAPULS 43 sensors is critical for cleaning and sterilisation.

Fully automatic cleaning (CIP) and sterilisation (SIP) of entire production facilities (without disrupting production or having to

dismantle and disassemble parts of the

equipment) is, in practice, not an easy task.

Dirt and contaminants get trapped mechanically in pores, fissures, scratches and recesses, and even remain on smooth walls

due to electrostatic attraction.

PTFE is commonly found in hygienic applications. The small plastic cone of the sterile,

pharmaceutical VEGAPULS 43 radar sensor,

which is at the same time antenna and process seal, consists of a TFM-PTFE material.

This is a fluorothermoplastic which has additional distinct advantages compared to PTFE,

such as e.g., reduced load deformation,

denser polymer structure as well as

smoother surface (Ra < 0.8 µm). The other

known advantages of PTFE, such as, e.g.,

higher temperature resistance (< 200°C),

high chemical resistance as well as resistance to brittleness and ageing are still

present or have even been enhanced.

Perfluorelastomers and fluorthermoplasts are

resistant to virtually all chemical media, such

as e.g., amines, ketones, esters, acids (sulphuric acid, phosphoric acid, hydrochloric

acid, nitric acid), alkalis (caustic soda), oxidants, fuels and oils. Beside their use in the

chemical industry, these materials are being

applied more and more in sterilisation and

pharmaceutical technologies. The only limits

to these materials are in applications with

fluorine under high pressure or with liquid

alkali metals (sodium or potassium), where

explosive reactions may occur.

10 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 11

Mounting and installation

3 Mounting and installation

3.1 General installation instructions

Measuring range

The reference plane for the

measuring range of the sensor

is the lower edge of the flange.

Keep in mind that in measuring

environments where the medium can reach the sensor

flange, buildup may form on

the antenna and later cause

measurement errors.

Note: The series 40 sensors

are suitable for measurement

of solids only under certain

conditions.

full

Measuring range (operating range) and max. measuring distance

Note: Use of the sensors for applications with solids is limited.

Meas. range

Reference planeempty

max.

max.

min.

False echoes

If flat obstructions in the range of the radar

signals cannot be avoided, we recommend

Flat obstructions and struts cause strong

false echoes. They reflect the radar signal

with high energy density.

diverting the interfering signals with a deflector. The deflector prevents the interfering

signals from being directly received by the

radar sensor. The signals are then so lowInterfering surfaces with rounded profiles

scatter the radar signals into the surrounding

energy and diffuse that they can be filtered

out by the sensor.

space more diffusely and thus generate false

echoes with a lower energy density. Hence,

those reflections are less critical than those

from a flat surface.

Round profiles diffuse radar signals

Profiles with smooth interfering surfaces cause large

false signals

Cover smooth, flat surfaces with deflectors

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 11

Page 12

Mounting and installation

Emission cone and false echoes

The radar signals are focused by the antenna system. The signals leave the antenna

in a conical path similar to the beam pattern

of a spotlight. This emission cone depends

on the antenna used. Any object in this beam

cone will reflect the radar signals. Within the

first few meters of the beam cone, tubes,

struts or other installations can interfere with

the measurement. At a distance of 6 m, the

false echo of a strut has an amplitude nine

times greater than at a distance of 18 m.

At greater distances, the energy of the radar

signal distributes itself over a larger area,

thus causing weaker echoes from obstructing surfaces. The interfering signals are

therefore less critical than those at close

range.

If possible, orient the sensor axis perpendicularly to the product surface and keep

vessel installations (e.g. pipes and struts) out

of the emission cone.

The illustrations of the emission cones are

simplified and represent only the main beam

- a number of weaker beams also exist. Under difficult measuring conditions, the antenna location and alignment must be chosen

with the objective of reducing false echoes.

Only giving attention to the size of the useful

echo is not adequate when measuring conditions are unfavourable.

If possible, provide a "clear view“ to the

product inside the emission cone and avoid

vessel installations in the first third of the

emission cone.

Optimum measuring conditions exist when

the emission cone reaches the measured

product perpendicularly and when the emission cone is free from obstructions.

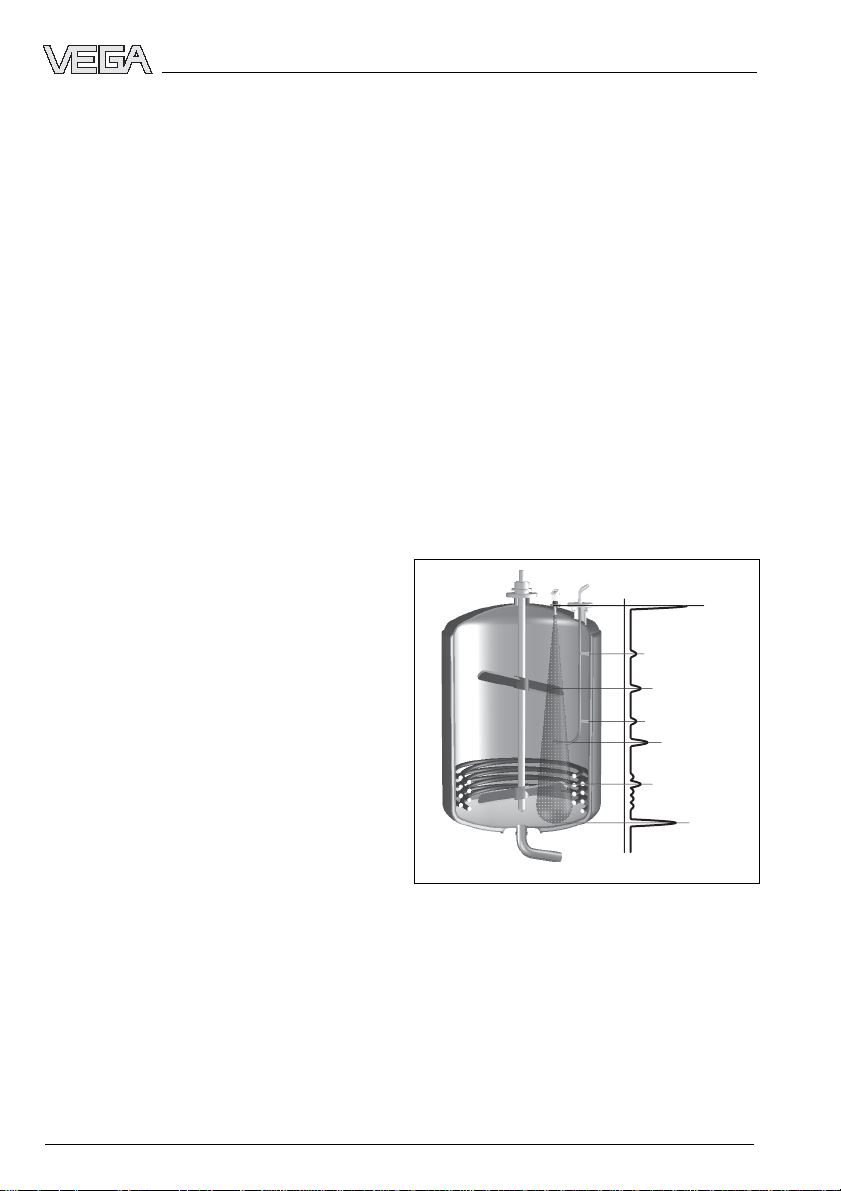

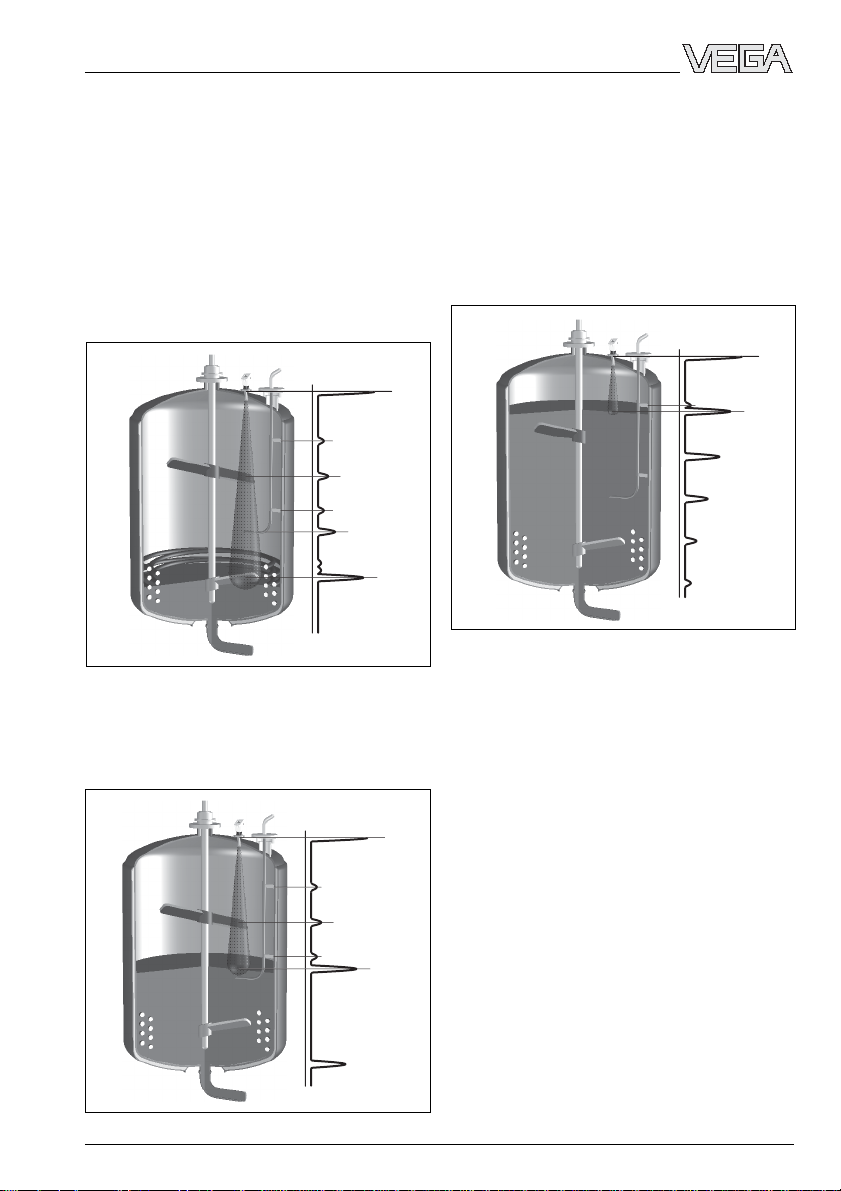

Examples of vessel echoes

The following vessel images show a typical

echo pattern in a vessel. The example shows

a process vessel with a slow double-bladed

stirrer. In the lower area, the vessel is

equipped with heating spirals. A thin, angled

inlet tube ends in the vessel centre between

the stirrer blades.

Empty vessel

In a difficult measuring environment, searching for a mounting location with the lowest

possible false echo intensity will bring the

best results. In most cases, the useful echo

will then be present with sufficient strength.

With the adjustment software PACT

the PC, you can have a look at the echo image and optimise the mounting location.

ware

TM

on

When the vessel is empty, you see the echoes of the vessel installations around the

emission cone. Beside the large bottom echo,

you see a number of additional false echoes.

The false echoes of the vessel installations

are saved during a false echo recording. For

this reason, the false echo recording must be

carried out when the vessel is empty.

12 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 13

Mounting and installation

False echoes from the top down:

- first inlet tube fastening

- upper stirrer blade

- second inlet tube fastening

- angled inlet tube

- upper heating tubes

- lower stirrer blade

- remaining heating tubes

- vessel bottom

¼ filling

After filling, the bottom echo is replaced by

the product echo.

The product echo moves to the centre of the

meas. range. At the end of the meas. range,

you now see an echo at a position where the

bottom echo previously was in the empty

vessel. This echo is a multiple echo of the

product echo and is located at twice the

distance of the product echo.

Filled vessel

When the vessel is completely filled, you see

additional multiple echoes at two, three or

four times the distance of the product surface

echo.

½ filling

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 13

Page 14

Mounting and installation

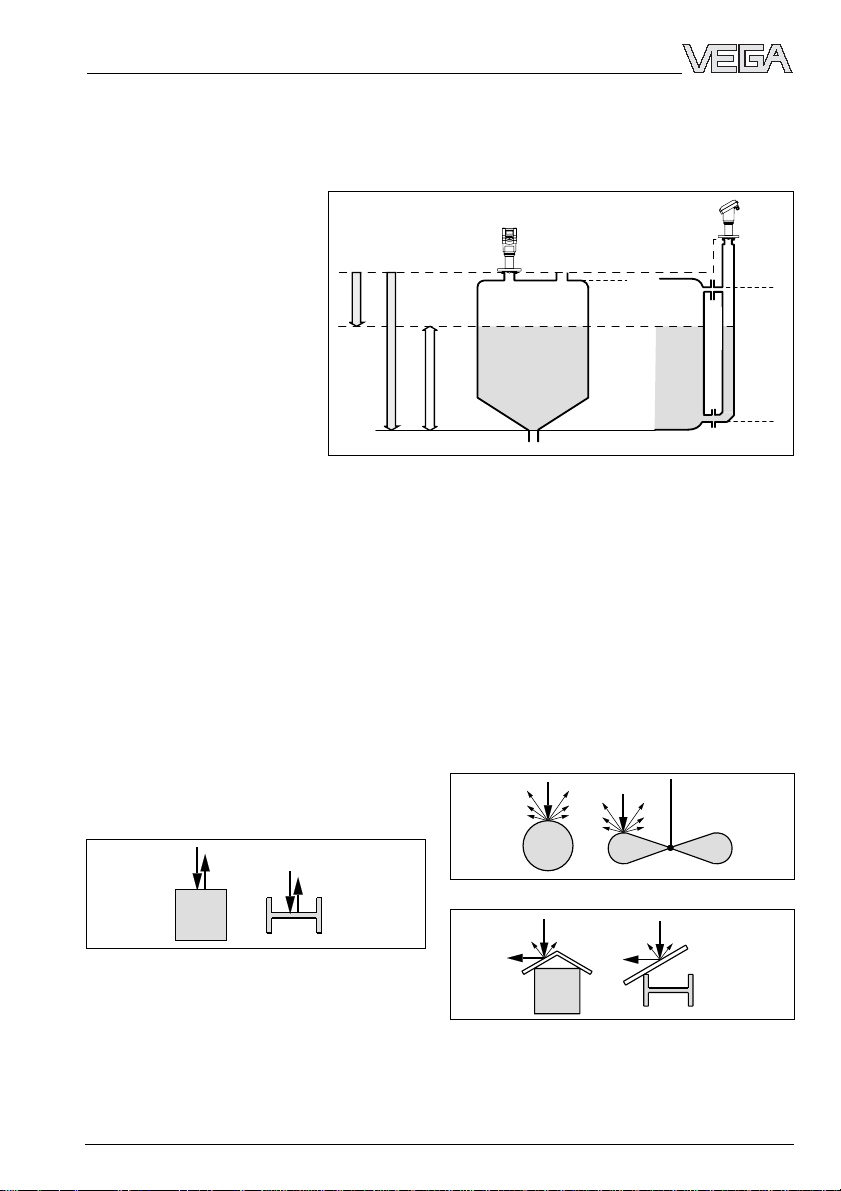

3.2 Measurement of liquids

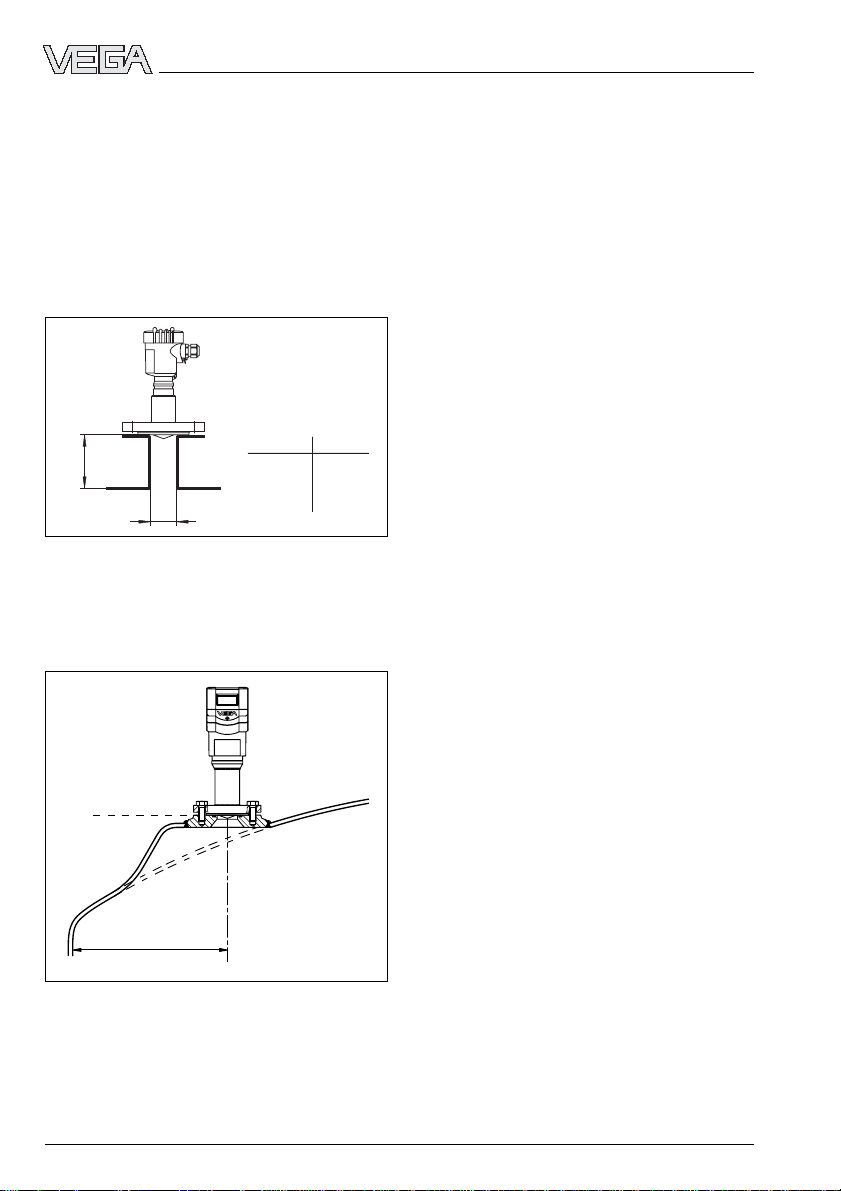

Flange antenna

Horn antenna on DIN socket piece

Radar sensors are usually mounted on short

DIN socket pieces. The lower side of the

instrument flange is the reference plane for

the measuring range. The socket piece

should be as short as possible.

d

h

max.

h

d

Deviating socket dimensions

50 mm/2"

80 mm/3"

100 mm/4"

150 mm/6"

Mounting on a block flange is especially

advantageous. Due to its very shallow recess, it is an ideal solution also for hygienic

and aseptic applications.

max.

100 mm

150 mm

250 mm

400 mm

The flange screws of VEGAPULS 43 must

always be tightened with a torque of approx.

60 Nm so that the PTFE seal is tight.

Dished tank tops can act as paraboloidal

reflectors. If the radar sensor is placed in the

focal point of the parabolic tank top, the radar

sensor receives amplified false echoes. The

radar sensor should be mounted outside the

focal point. Parabolically amplified echoes are

thereby avoided.

Horn antenna directly on the vessel top

If the stability of the vessel will allow it (sensor

weight), flat mounting directly on the vessel

top is a good and cost-effective solution. The

top side of the vessel is the reference plane.

> 400 mm

Mounting on dished tank end

In vessels with dished or rounded tops,

please do not mount the instrument in the

centre or close to the vessel wall.

14 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 15

Mounting and installation

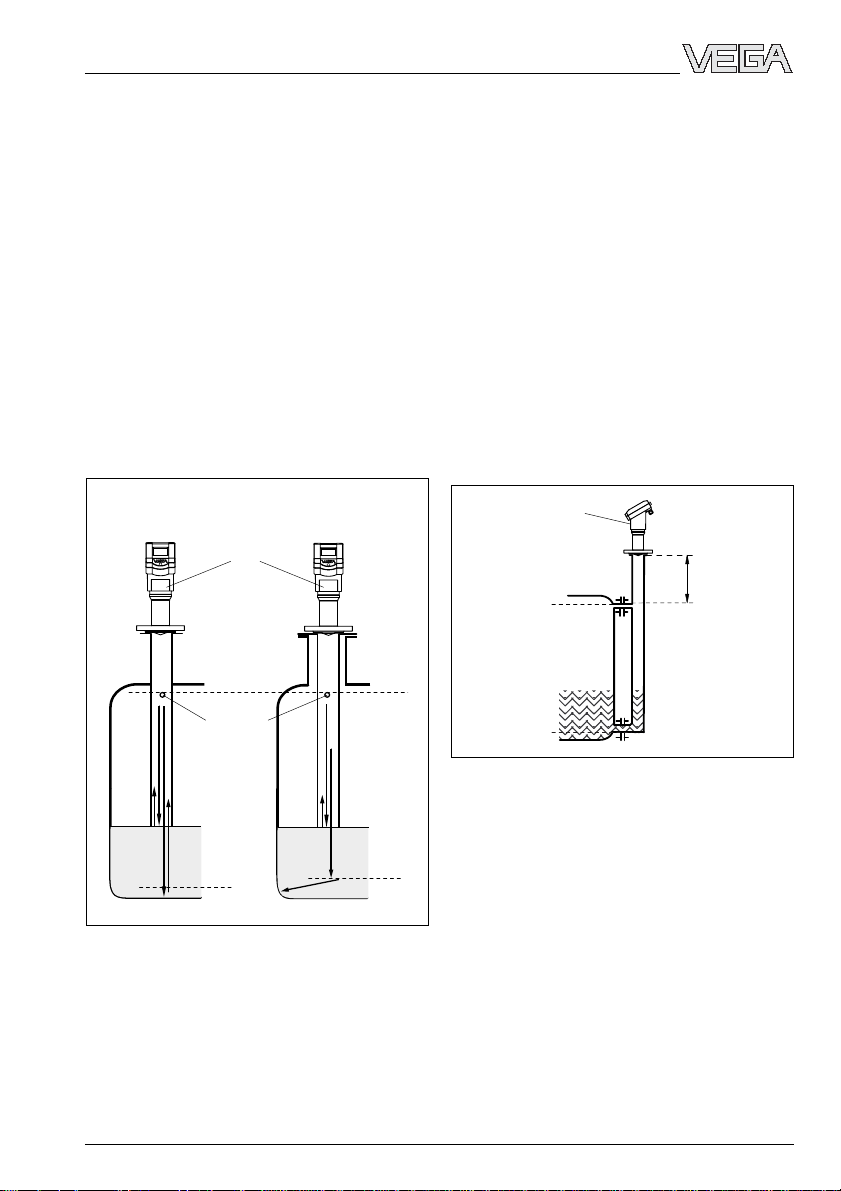

3.3 Measurement in standpipe (surge or bypass tube)

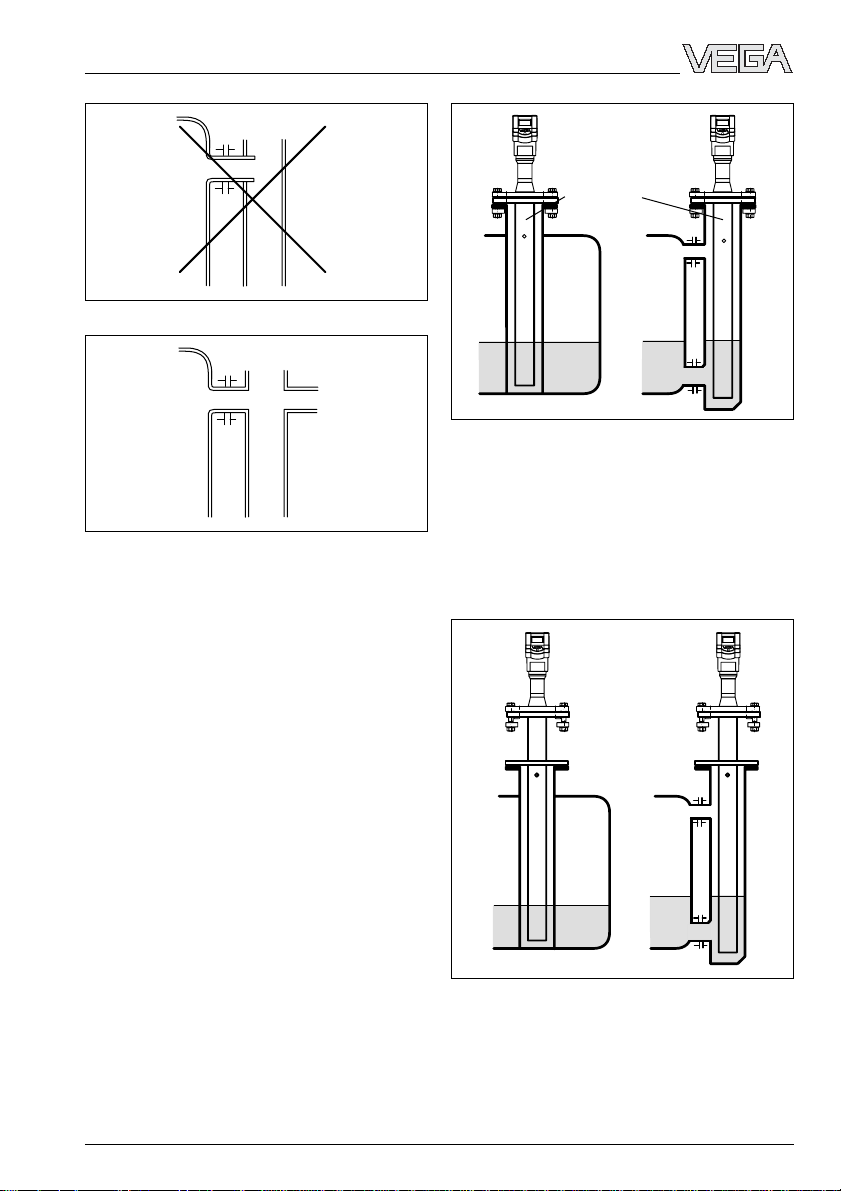

General instructions

Measurement in a standpipe is preferred in

vessels which contain many installations, e.g.

heating tubes, heat exchangers or fast-running stirrers. Measurement is then possible

when the product surface is very turbulent,

and vessel installations can cause no false

echoes.

Due to the concentration of the radar signals

within the measuring tube, even products

with small dielectric constants (ε

3) can be reliably measured in surge or by-

pass tubes.

Surge pipe welded

to the tank

Type label

= 1.6 up to

r

Surge pipe in the

socket piece

maxmax

Make sure the required upper vent hole in

the surge pipe is aligned with the sensor

type label.

As an alternative to a surge pipe in the vessel, a pipe antenna system outside the vessel in a bypass tube is also possible.

The surge and bypass tubes must generally

be made of metal. For plastic tubes, a

closed, conductive jacket is always required.

When using a metal tube with plastic inner

coating, make sure that the thickness of the

coating is minimal (approx. 2 … 4 mm).

Align the sensor so that the type label lies on

the same axis as the tube holes or the tube

connection openings. The polarisation of the

radar signals enables a considerably stabler

measurement with this alignment.

Type label

> 300 mm

100 %

Vent hole

ø 5 … 10 mm

Tube flange system as bypass tube

0 %

When mounting a VEGAPULS 43 on a bypass tube (e.g. on a previous floating or

displacer unit), the radar sensor should be

min

without deflector

Pipe antenna system in the tank

with deflector

min

placed approx. 300 mm or more from the

max. level.

Surge pipes which are open at the bottom

must extend over the full measuring range

(i.e. down to 0% level), as measurement is

only possible within the tube. The tube inner

diameter should be max. 100 mm or correspond to the size of the antenna horn.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 15

Page 16

Mounting and installation

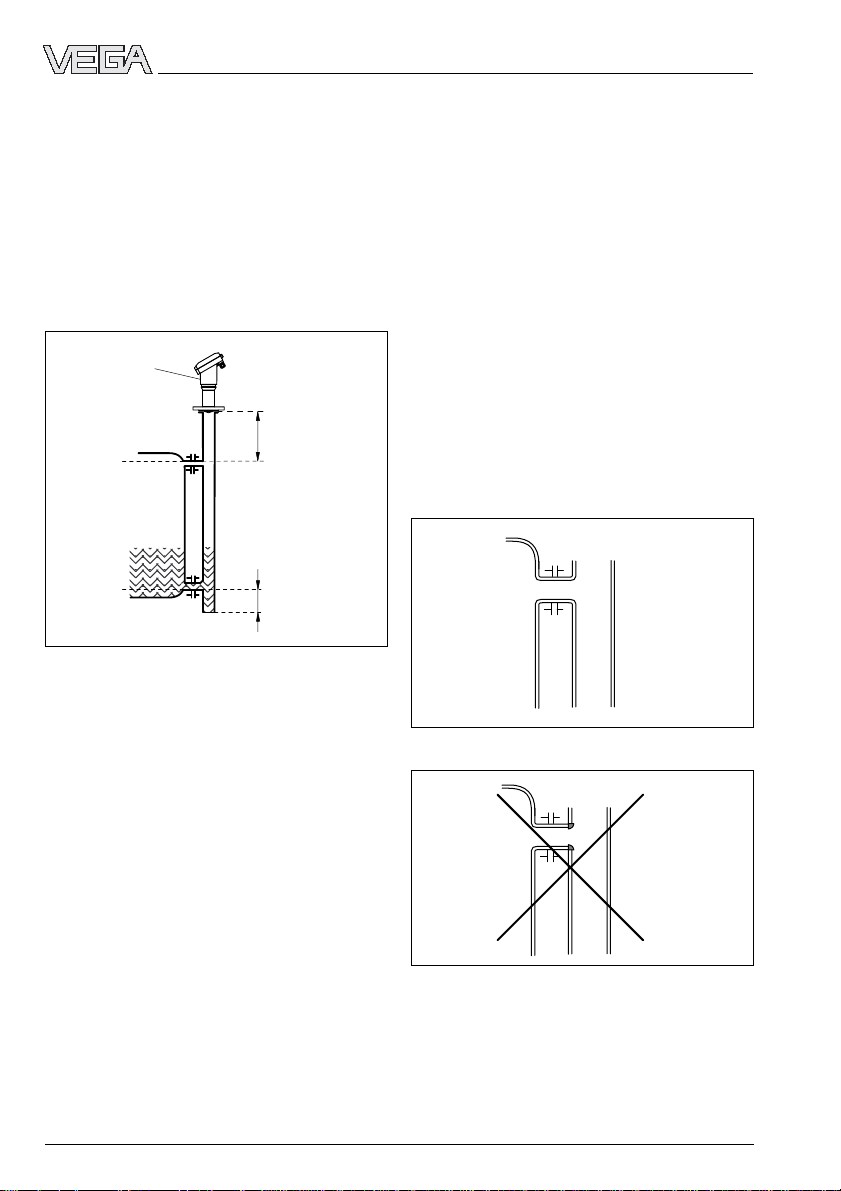

For products with small dielectric constants

(< 4), the bypass tube should have a length

greater than would normally be required for

the lower tube connection. Products with

small dielectric constants are partly penetrated by the radar signals, allowing the

tube bottom to produce a stronger echo than

the product (when the bypass tube is nearly

empty). By extending the tube downward,

some liquid remains at the bottom even when

the vessel is completely empty.

Type label

> 300 mm

100 %

0 %

Tube flange system as bypass tube

300 ... 800 mm

Connections to the bypass tube

The connections to the bypass tubes must

be fashioned in such a way that only minimal

reflections are caused by the walls of the

connecting tubes. This is especially important

for the breather connection in the upper part

of the tube. Observe the following points:

• Use small openings for the connection.

• The diameter of the connecting tubes

should not exceed 1/3 of the bypass diameter.

• The tube connections must not protrude

into the bypass tube.

• Large welding beads in the tubes should

be avoided.

• Additional connections to the bypass tube

must lie in the same plane as the upper

and lower vessel connection (above each

other or displaced by 180°).

If enough liquid (300 … 800 mm) remains in

the blind lower end of the tube, the portion of

the signal that penetrates the liquid and re-

Optimum connection to the bypass tube

flects from the tube bottom is sufficiently

damped - the sensor can then easily distinguish it from the echo of the liquid surface. In

cases where there is not enough liquid at the

bottom of the tube, a deflector situated there

will carry out the same function. It deflects

signals that reach the tube bottom into the

standard connection opening.

Welding beads too large

16 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 17

Mounting and installation

Tube connection protrudes

Additional connection in the bypass tube in one plane

Use of guide tubes

In case of very rough inner surfaces in existing bypass tubes (e.g. due to corrosion),

large connecting tube openings, as well as

bypass tubes with more than 100 mm inner

diameter, the use of a guide tube inside the

existing bypass tube is recommended. This

reduces the noise level and increases measurement reliability considerably. The flange of

the guide tube can be easily mounted as a

sandwich flange between vessel and sensor

flange.

Guide tube

Guide tube in existing surge or bypass tubes

To increase the min. distance, the guide tube

can project out of the surge or bypass tube.

This can be done by welding a flat welding

flange on the outside of the extended guide

tube. In both cases, an appropriate breather

hole is necessary.

Extended guide tube

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 17

Page 18

Mounting and installation

Seals on tube connections and tube extensions

Microwaves are very sensitive to gaps in

flange connections. If connections are made

without proper care, distinct false echoes as

well as increased signal noise can result.

Observe the following points:

• The applied seal should correspond to the

tube inner diameter.

• If possible, conductive seals such as conductive PTFE or graphite should be used.

• There should be as few seal positions as

possible in the guide tube.

Flange connections on bypass tubes

Adhesive products

With non-adhesive or slightly adhesive products, use a surge pipe with a nominal width of

e.g. 50 mm. VEGAPULS 43 radar sensors

with 26 GHz technology are for the most part

insensitive to buildup in the measuring tube.

Nevertheless, buildup should not block the

measuring tube.

For products with somewhat heavier buildup,

the use of a DN 80 to max. DN 100 standpipe

or surge pipe can make measurement possible despite buildup. But with extremely adhesive products, measurement in a standpipe

is not possible at all.

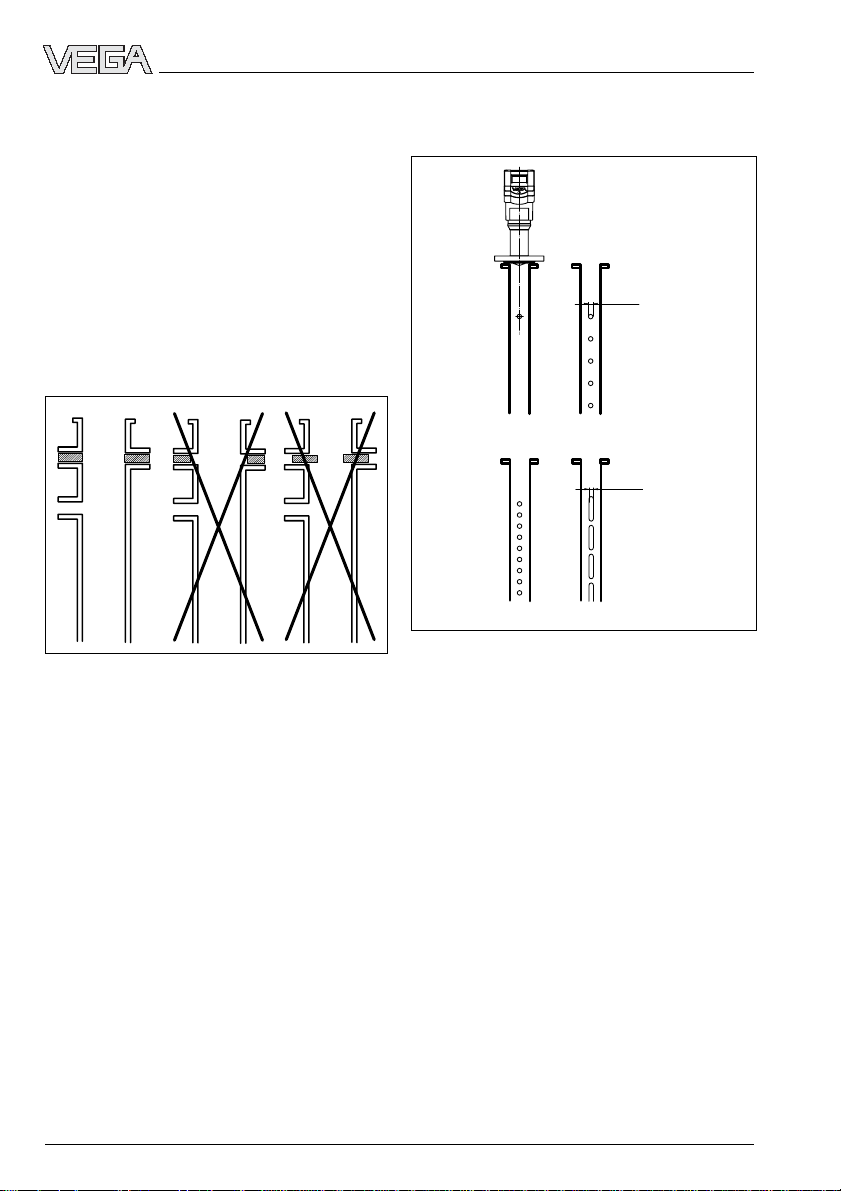

Standpipe measurement of inhomogeneous products

ø 5...15

homogeneous

liquids

inhomogeneous liquids

Openings in a surge pipe for mixing of inhomogeneous products

If you want to measure inhomogeneous or

stratified products in a surge pipe, it must

have holes, elongated holes or slots. These

openings ensure that the liquid is mixed and

corresponds to the liquid in the vessel.

The more inhomogeneous the measured

product, the closer the openings should be

spaced.

Due to radar signal polarisation, the holes or

slots must be positioned in two rows offset

by 180°. The radar sensor must then be

mounted so that the type label of the sensor

is aligned with the rows of holes.

Every wider slot causes a false echo. The

slots should therefore not exceed a width of

10 mm in order to keep the signal noise level

to a minimum. Round slot ends are better

than rectangular ones.

slightly inhomogeneous

liquids

ø 5...15

26626-EN-041227

18 VEGAPULS 43 – 4 … 20 mA

Page 19

Mounting and installation

Type label

ø 5...15

Row of holes in one axis with the type label

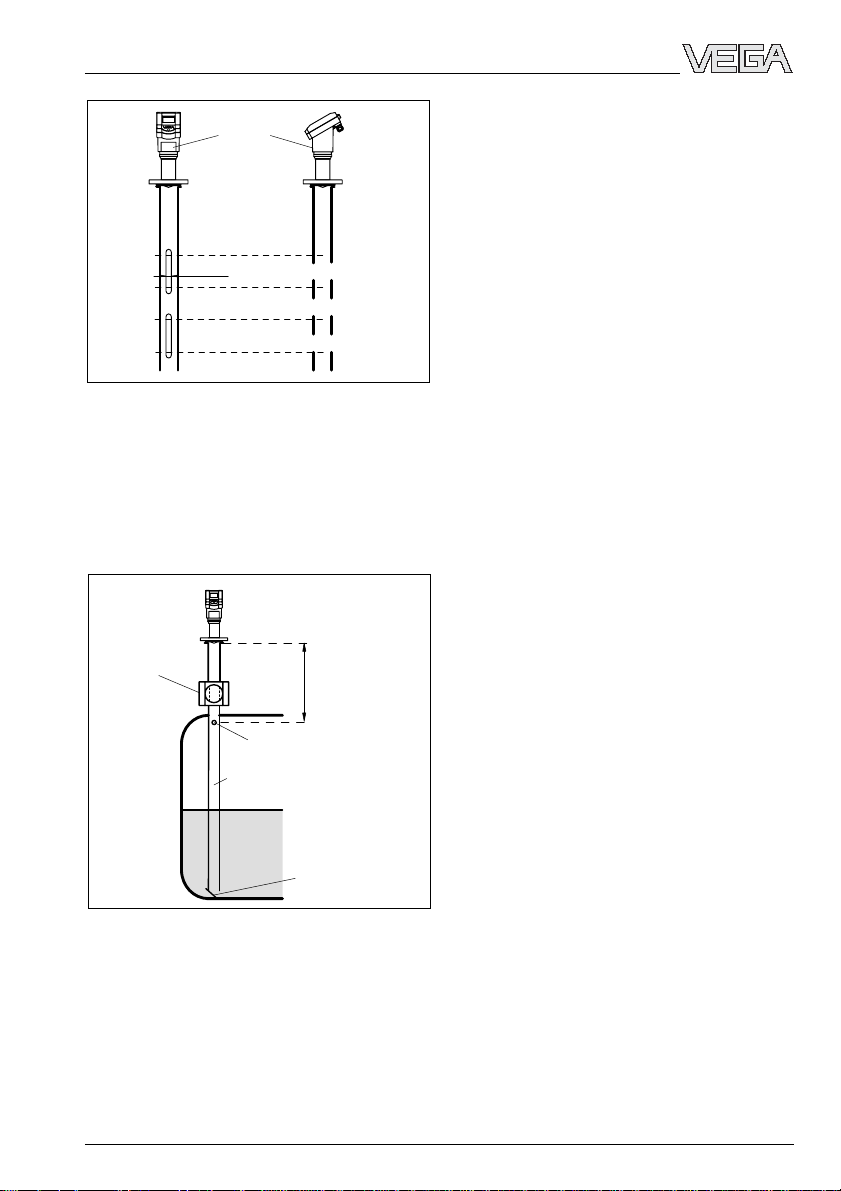

Surge pipe with ball valve

If a ball valve is mounted in the surge pipe,

maintenance and servicing can be carried

out without opening the vessel (e.g. if it contains liquid gas or toxic products).

Ball valve

> 300 mm

Vent hole

ø50

Deflector

Tube antenna system with ball valve cutoff in measuring tube

A prerequisite for trouble-free operation is a

ball valve throat that corresponds to the pipe

diameter and provides a flush surface with

the pipe inner wall. The valve must not have

any rough edges or constrictions in its channel. The distance to the sensor flange should

be at least 300 mm.

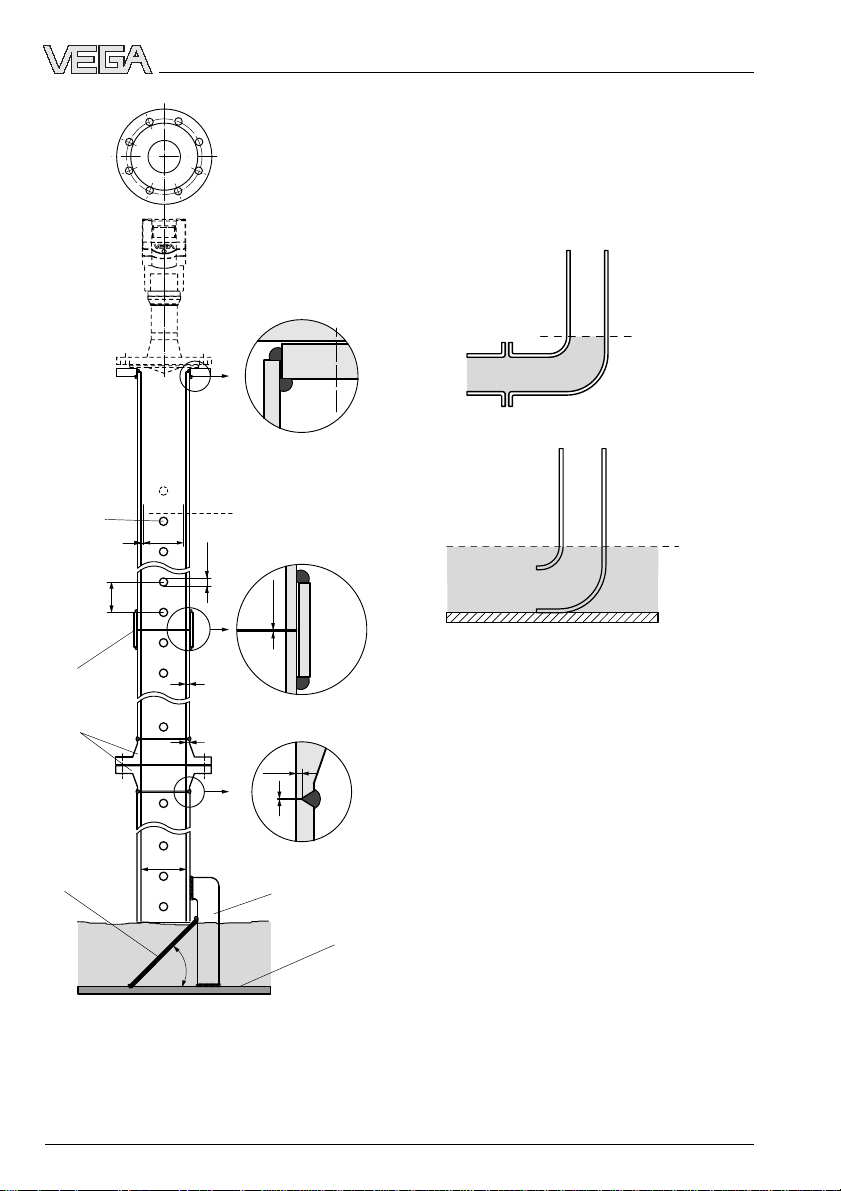

Guidelines for standpipe construction

The radar sensors with a DN 50 flange only

form a functioning measuring system in conjunction with a measuring tube.

The measuring pipe must be smooth inside

(average roughness Rz ≤ 30). Use stainless

steel tubing (drawn or welded lengthwise) for

construction of the measuring pipe. Extend

the measuring pipe to the required length

with weld-on flanges or with connecting

sleeves. Make sure that no shoulders or

projections are created during welding. Before welding, join pipe and flange with their

inner surfaces flush and exactly fitting.

Avoid welding through the pipe wall. The pipe

must remain smooth inside. Roughness or

welding beads on the inner surfaces must be

carefully removed and burnished, as they

cause false echoes and encourage product

adhesion.

If the vessel contains agitated products,

fasten the measuring pipe to the vessel bottom. Provide additional fastenings for longer

measuring pipes.

In products with lower dielectric values (< 4),

a part of the radar signal penetrates the

medium. If the vessel is nearly empty, echoes

are generated by both the product and the

vessel bottom. The echo from the vessel

bottom can in some cases be stronger than

the echo from the product surface. If a deflector is installed below the open end of the

measuring tube, the radar signals are scattered and prevented from reaching the vessel bottom. This ensures that, in nearly empty

vessels or with products of low dielectric

value, the product delivers a more distinct

echo than the vessel bottom.

Due to the deflector, the useful echo (and

thus the measured value) remains clearly

detectable in a nearly empty vessel, and the

0 % level can be reliably measured.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 19

Page 20

Mounting and installation

0 %

The standpipe or surge pipe can be

equipped with a quadrant pipe at its end

instead of a deflector. The quadrant pipe

reflects the radar signals that penetrate the

medium diffusely to the side and diminishes

strong echoes from the tube end or the vessel bottom.

Flange

DN 100

Deburr the

holes

150…500

Connecting

sleeve

Welding neck

flanges

Deflector

0 %

Quadrant pipe on the bypass tube end

Welding of the smooth

welding flange

100 %

ø 95

2

5…10

Welding of the connecting sleeves

0,0…0,4

Quadrant pipe on the standpipe end

3,6

Welding of the welding

neck flanges

3,6

1,5…2

0,0…0,4

ø 100,8

Meas. pipe fastening

0 %

~45û

Vessel

bottom

20 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 21

Mounting and installation

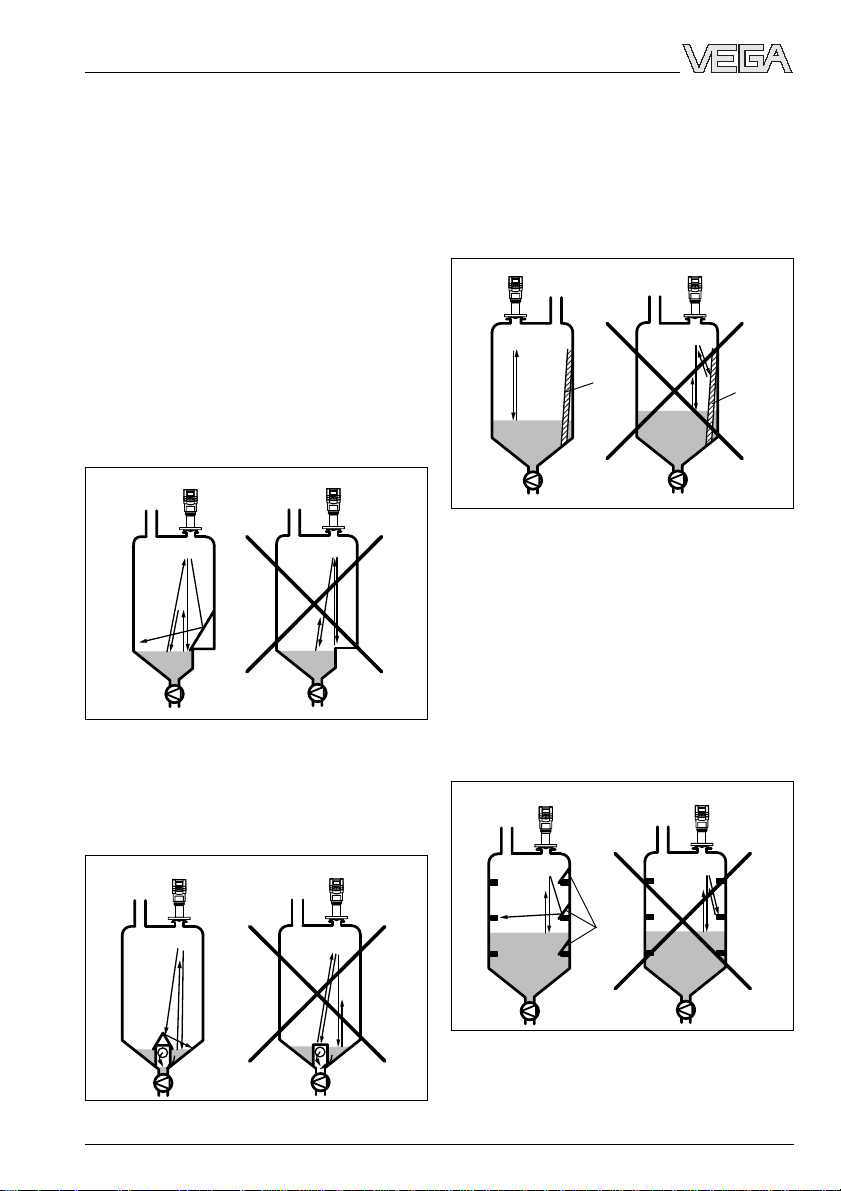

3.4 False echoes

The radar sensor must be installed at a location where no installations or inflowing material

cross the radar impulses. The following examples and instructions show the most frequent measuring problems and how to avoid

them.

Vessel protrusions

Vessel forms with flat protrusions can make

measurement very difficult due to their strong

false echoes. Baffles mounted above these

flat protrusions scatter the false echoes and

guarantee a reliable measurement.

Correct Incorrect

Vessel protrusions (ledge)

Intake pipes, i.e. for the mixing of materials with a flat surface directed towards the sensor - should be covered with an angled baffle

that scatters false echoes.

Vessel installations

Vessel installations, such as e.g. ladders,

often cause false echoes. Make sure when

planning your measuring location that the

radar signals have free access to the measured product.

Correct Incorrect

Ladder

Vessel installations

Ladder

Struts

Struts, like other vessel installations, can

cause strong false echoes that are superimposed on the useful echoes. Small baffles

effectively prevent a direct false echo reception. These false echoes are scattered and

diffused in the surrounding space and are

then filtered out as "echo noise“ by the measuring electronics.

Correct Incorrect

Correct Incorrect

Shields

Struts

Vessel protrusions (intake pipe)

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 21

Page 22

Mounting and installation

Inflowing material

Do not mount the instrument in or above the

filling stream. Ensure that you detect the

product surface and not the inflowing material.

Correct

Inflowing material

Incorrect

Buildup

If the sensor is mounted too close to the

vessel wall, product buildup and other deposits on the vessel wall cause false echoes.

Position the sensor at a sufficient distance

from the vessel wall. Please also note chapter

"3.1 General installation instructions“.

Correct

Incorrect

Strong product movements

Strong turbulence in the vessel, e.g. caused

by powerful stirrers or strong chemical reactions, can seriously interfere with the measurement. A surge or bypass tube (see

illustration) of sufficient size always enables

reliable and problem-free measurement even

if strong turbulence occurs in the vessel,

provided there is no product buildup in the

tube.

Correct Incorrect

100 %

75 %

0 %

Strong product movements

3.5 Common installation mistakes

Socket piece too long

If the sensor is mounted in a socket extension that is too long, strong false echoes

arise which interfere with the measurement.

Unfavourable

Correct

Buildup

Flange antenna: Correct and unfavourable socket

length

22 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 23

Mounting and installation

Wrong orientation to the product

Weak measuring signals are generated if the

sensor is not directly pointed at the product

surface. Orient the sensor axis perpendicularly to the product surface to achieve optimum measuring results.

Correct Incorrect

Ladder

Direct sensor vertically to the product surface

Ladder

Parabolic effects on dished or arched

vessel tops

Round or parabolic tank tops act on the radar

signals like a parabolic mirror. If the radar

sensor is placed at the focal point of such a

parabolic tank top, the sensor receives amplified false echoes. The optimum mounting

location is generally in the range of half the

vessel radius from the centre.

Correct

Unfavourable

Unfavourable

Mounting on a vessel with parabolic tank top

Sensor too close to the vessel wall

If the radar sensor is mounted too close to

the vessel wall, strong false echoes can be

caused. Buildup, rivets, screws or weld joints

superimpose their echoes onto the product

i.e. useful echo. Please ensure a sufficient

distance from the sensor to the vessel wall.

If there are good reflection conditions (liquid

medium, no vessel installations), we recommend locating the sensor where there is no

vessel wall within the inner emission cone. For

products in less favourable reflection environments, it is a good idea to also keep the

outer emission cone free of interfering installations. Note chapter "3.1 General installation

instructions“.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 23

Page 24

Mounting and installation

Foam generation

Conductive foam is penetrated to different

depths by the radar signals and generates a

number of individual (bubble) echoes. At the

same time, the signals are damped in foam,

similar to the way heat radiation is damped

by Styrofoam. Thick, dense, creamy and

conductive foam can cause incorrect meas-

urements.

Conductive

foam

Liquid

Foam generation

Provide preventative measures against foam

or measure in a bypass tube. Check, if necessary, the possibility of using a different

measurement technology, e.g. capacitive

electrodes or hydrostatic pressure transmitters.

In many cases, VEGAPULS 54 radar sensors

with 5.8 GHz operating frequency achieve

considerably better and more reliable measuring results in foam applications than series

40 sensors with 26 GHz technology.

Standpipe installation mistakes

Pipe antenna without ventilation hole

Pipe antenna systems must be provided with

a ventilation hole on the upper end of the

surge pipe. If this hole is absent, incorrect

measurements will result.

Type label

Incorrect

Incorrect

Correct

Pipe antenna: The surge pipe open to the bottom

must have a ventilation or equalisation hole at the

upper end

Wrong polarisation direction

When measuring in a surge pipe, especially if

there are holes or slots for mixing in the tube,

it is important that the radar sensor is aligned

with the rows of holes.

The two rows of holes (displaced by 180°) of

the measuring tube must be in the same

plane as the polarisation direction of the

radar signals. The polarisation direction is

always in the same plane as the type label.

Correct

VEGAPULS on the surge pipe: The sensor type plate

must be aligned with the rows of holes

24 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 25

Electrical connection

4 Electrical connection

4.1 Connection and connection cable

Safety information

As a rule, do all connecting work in the complete absence of line voltage. Always switch

off the power supply before you carry out

connecting work on the radar sensors. Protect yourself and the instruments, especially

when using sensors which do not operate

with low voltage.

Qualified personnel

Instruments which are not operated with

protective low voltage or DC voltage must

only be connected by qualified personnel.

Connection cable and screening

A standard two or four-wire cable (sensors

with separate supply) with max. 2.5 mm

cross-section can be used for connection.

Make sure that the connection cables are

specified for the expected application conditions in your systems. The cable must have

an outer diameter between 5 and 9 mm (1/2

to 1/3 inch), with NPT threads, 3.6 … 8.7 mm

(0.12 to 0.34 inch) and with threaded PG

cable entries, 5 … 10.5 mm. Otherwise, the

seal effect of the cable entry would not be

ensured.

2

wire

In critical systems, the signal cables are the

source of the problem. The signal cables

often act as antennas that pick up interfering

signals. The 4 … 20 mA signal lines are affected by earth equalisation currents and

especially by current peaks in the ms or µs

range (more so than digital signal lines). This

can be avoided with sophisticated wiring, of

which screening at both ends is a major

feature.

Circumspect system planning, however, will

take into account possible sources of interference from electromagnetic pollution. Due to

the complex interrelationships, it may be

difficult to decide whether measures against

such interference should be taken, and if so,

which ones. And in fact, it is extremely difficult

to describe in theoretical terms the actual

forces at work, since the effects depend

greatly on the frequency of the interfering

magnetic fields: what is very effective for one

frequency can produce completely opposite

results with other frequencies.

Experience has shown that even some relatively simple measures can protect the signal

current circuits against electromagnetic influence. As one of the more costly measures,

screening usually comes at the end of any

catalogue of preventive measures (interference suppression).

Quite often, the "electromagnetic pollution"

caused by electronic actuators, energy cables and transmitting stations is so considerable that measures against the effects of

electrical and magnetic fields can be necessary. This so-called "electromagnetic pollution" has increased considerably in the last

few years, caused e.g. by fast-cycle power

supply units and mobile phones, especially in

the high-frequency range. VEGAPULS radar

sensors take this into account. They are

generally insensitive to electromagnetic pollution.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 25

Page 26

Electrical connection

Wiring instructions

The signal cables should be wired close to

the ground potential. Wiring in well-grounded

metal cable channels is an effective protection against interference. Obviously, signal

cables should not be wired directly together

with high-energy cables, but should be separated from them, e.g., with sheet metal strips

in the cable channels. Twisted cable (twisted

pair) is especially suitable for signal circuits,

as it compensates coupled voltage vectors.

The distance between the outbound and the

return conductor is just as important as the

distance to ground when it comes to interference signal reception. For that reason, the

distance between the two conductors should

be as small as possible. Twisted pair cable

meets this requirement. These measures are

described by specialists with the expression

"wiring close to the structure". To wire the

signal cable still "closer to the structure", i.e.

even closer to the ground potential, the signal

cable can be provided with screening.

Earthing the screen only on one end is not

always effective, see the following table. The

table gives a simple overview of the effectiveness of the different protective measures

against electromagnetic pollution. In practice,

earthing of both sides is often useful. This

allows the option of earthing only one end

later by simply disconnecting the other earth

contact points of the screen. Why? Actual

interference only appears in the operating

environment. Earthing only one end of the

screen prevents interference, e.g. in the

100 kHz range, better than earthing both

ends, especially if there is insufficient potential equalisation. However, you must make

sure that no ground equalisation currents

flow through the cable screening. Ground

equalisation currents can be avoided by

ground potential equalisation systems. When

earthing on both ends, it is possible to connect the cable screen on one earth side (e.g.

in the switching cabinet) via a Y

the earth potential. Use a very low-resistance

capacitor1) to

C

earth connection (foundation, plate or mains

earth).

Screening magnetic low-frequency high-frequency Ground currents

fields electrical electrical and superimposed

fields fields potential currents

l < ––

λ

7

l > ––

λ

7

none – – – –

one end – ++ – –

both ends + + ++ ++

++ good protection against electromagnetic pollution

+ protection against electromagnetic pollution

– no protection against electromagnetic pollution

c

Note: λ (Lambda) =– – –

f

l cable length

c speed of light (300000 km/s)

f interference frequency

λ wave length

Example: Interference frequency approx. 100 kHz

m

1c 13 • 10

l < – • – = – • ––––––––– = 4285 m

7 f 7 100 • 10

9

–

s

1

3

–

s

This means that with an interference frequency of 100 kHz up to a cable length of approx.

4000 m, earthing the screen on only one end provides better protection than earthing on both

ends. However, with a cable length of more than 4000 m, earthing on both ends usually produces better results.

1)

max. 10 nF, e.g. voltage resistance 1500 V, ceramic

26 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 27

Electrical connection

Ex protection

If an instrument is used in hazardous areas,

the respective regulations, conformity certificates and type approvals for systems in Ex

areas must be noted (e.g. DIN 0165).

Intrinsically safe circuits with more than one

active instrument (instrument delivering electrical energy) are not allowed. Special installation regulations (DIN 0165) must be noted.

Note!

Due to the possibility of potential transfer,

earthing on both ends is prohibited in Ex

applications.

Ground terminals

On VEGAPULS 44/45 as well as on

VEGAPULS 42 sensors with metal thread, the

ground terminal is galvanically connected to

the flange or thread.

4.2 Connection of the sensor

After mounting the sensor at the measurement location according to the instructions in

chapter "3 Mounting and installation“, loosen

the closing screw on top of the sensor. The

sensor lid with the optional indication display

can then be opened. Unscrew the sleeve nut

and slip it over the connection cable (after

removing about 10 cm of cable mantle). The

sleeve nut of the cable entry has a self-locking ratchet that prevents it from opening on

its own.

Now insert the cable through the cable entry

into the sensor. Screw the sleeve nut back

onto the cable entry and clamp the stripped

wires of the cable into the proper terminal

positions.

The terminals hold the wire without a screw.

Press the white opening levers with a small

screwdriver and insert the copper core of the

connection cable into the terminal opening.

Check the hold of the individual wires in the

terminals by lightly pulling on them.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 27

Page 28

Version with plastic housing

Power supply

4 … 20 mA (passive)

+-

1)

To the indicating instrument in the

sensor lid or to the external indicating

instrument VEGADIS 50

Power supply

Cable entry

M20 x 1.5

+-

Electrical connection

4 … 20 mA (active)

+-

To the display in the lid or

the external indicating

instrument

2)

+

-

2

1

4-20mA

Tank 1

m (d)

12.345

Communication

5678

2.23272

Display

ESC

+

-

OK

Two-wire technology in

plastic housing

(loop powered)

1)

4 … 20 mA passive means that the sensor

consumes a level-dependent current of

4 … 20 mA (consumer).

Terminals

(max. 2.5 mm

wire cross-section)

Sockets for connection of

the HART

the VEGACONNECT

®

handheld or

Pluggable

adjustment

module

MINICOM

2

2)

Communication

4-+3

8765

4-20mA

Display

2.23274

Opening

ESC

+

-

OK

tabs

(+) L1

1

2

N

Tank 1

m (d)

12.345

Four-wire technology in

plastic housing

(separate supply)

4 … 20 mA active means that the sensor provides

a level-dependent current of 4 … 20 mA (current

source).

28 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 29

ESC

OK

ESC

OK

Electrical connection

Version with aluminium housing

Two-wire technology

(loop powered)

4 … 20 mA passive

+

-

1)

To the indicating instrument in the

sensor lid or to the external indicating

instrument VEGADIS 50

M20 x 1.5

(diameter of the

connection cable

5…9 mm)

Four-wire technology

4 … 20 mA active

Voltage supply

M20 x 1.5

(diameter of

the connection

cable

6…9 mm

+

-

+

-

To the indicating

instrument in the sensor

lid or to the external

indicating instrument

VEGADIS 50

2)

M20 x 1.5

12 C 567843

12 C 5 6 7 843

(+) (-)

Communication+-4...20mA

-

+

Display

ESC

OK

L1 N

1)

4 … 20 mA passive means that the sensor

consumes a level-dependent current of 4 … 20 mA

(consumer).

Sockets for connection of

VEGACONNECT

(communication

sockets)

2)

4 … 20 mA active means that the sensor provides

a level-dependent current of 4 … 20 mA (current

source).

12 C 567843

12 C 5 6 7 843

(+) (-)

Commu-

L1 N

nication+-4...20mA

Display

ESC

-

+

OK

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 29

Page 30

Electrical connection

ESC

OK

ESCESC

+

-

OKOK

12 C 5678

(+) (-)

L1 N

Communication

Display

12 C 5 6 7 8

Ver sion with aluminium housing and pressure-tight encapsulated terminal

compartment

Two-wire EEx d terminal compar tment

(opening in Ex atmosphere not allowed)

Power supply

-+

Locking of the cover

ser.no ********

R

FM

ATEX

APPROVED

Supply: 20...36V DC/4...20mA HART

R

-+

IS

21

GND

Exd terminal

compartment

1

/2“ NPT EEx d

diameter of the

connection cable

3.1…8.7 mm

(0.12…0.34 inch

Two-wire adjustment module terminal

compartment

(opening in Ex area permitted)

Exd safe connection to the

Exd terminal compartment

1

/2“ NPT EEx d

diameter of the

connection cable

to the Exd

terminal compartment

3.1…8.7 mm

(0.12…0.34 inch)

12 C 5678

12 C 5 6 7 8

(+) (-)

Communication

Display

ESC

-

+

OK

L1 N

Four-wire EEx d terminal compartment Four-wire adjustment module terminal

compartment

(opening in Ex area permitted)

Exd safe connection to the

Exd terminal compartment

1

Locking of the cove

12

+-

-+-+

Power supply

R

20...72V DC

HART

20...250V AC

ser.no ********

4 ... 20 mA

4...20mAsupply

543

R

IS

+-

GND

Exd terminal

compartment

1

/2“ NPT EEx d

diameter of the

connection cable

to the Exd

terminal compartment

3.1…8.7 mm

(0.12…0.34 inch)

30 VEGAPULS 43 – 4 … 20 mA

/2“ NPT EEx d

diameter of the

connection cable

to the Exd

terminal compartment

3.1…8.7 mm

(0.12…0.34 inch)

26626-EN-041227

Page 31

Electrical connection

ESC

OK

-

+

ESC

OK

Tank 1

m (d)

12.345

ESC

OK

4.3 Connection of the external indicating instrument VEGADIS 50

Loosen the four screws of the housing lid on

VEGADIS 50.

The connection procedure can be facilitated

by fixing the housing cover during connection work with one or two screws on the right

of the housing.

Four-wire sensor in aluminium housing

(separate supply)

OUTPUT

(to the sensor)

SENSOR

Power supply

+

-

DISPLAY

(in the lid of the indicating

instrument)

DISPLAY1234 56 78

4 … 20 mA

active

VEGADIS 50

Adjustment

module

Screws

Two-wire sensor in aluminium housing

(loop powered)

4 … 20 mA

passive

+

-

to VEGADIS 50 or to the

display in the sensor lid

12 C 567843

12 C 5 6 7 843

(+) (-)

Communication+-4...20mA

-

+

Display

ESC

OK

12 C 567843

12 C 5 6 7 843

(+) (-)

Communication+-4...20mA

-

+

Display

ESC

OK

L1 N

L1 N

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 31

M20x1.5

Page 32

Electrical connection

4.4 Configuration of measuring systems

A measuring system consists of a sensor

with 4 … 20 mA signal output and a unit that

evaluates and further processes the levelproportional current signal.

On the following pages, you will see a

number of instrument configurations, designated as "measuring systems“, some of

which are shown with signal processing

units.

Measuring systems in two-wire technology:

• 4 … 20 mA shown without processing unit

• 4 … 20 mA on active PLC

• 4 … 20 mA in Ex area on active PLC

• 4 … 20 mA in Ex area on passive PLC

• 4 … 20 mA in Ex area on indicating instrument VEGADIS 371 Ex

Measuring systems in four-wire technology:

• 4 … 20 mA shown without signal conditioning instrument

Measuring systems with VEGAPULS 43 connected to any 4 … 20 mA signal

processing unit

• Two-wire technology (loop powered), supply and output signal via one two-wire cable.

• Output signal 4 … 20 mA (passive).

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m away from the sensor).

• Adjustment with PC, HART

into the sensor or into the external indicating instrument VEGADIS 50).

®

handheld or the adjustment module MINICOM (can be plugged

VEGADIS 50

4

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 Ω, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 Ω.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Digital communication with the

PC would not be ensured.

32 VEGAPULS 43 – 4 … 20 mA

2

VEGACONNECT

4 … 20 mA

-

HART

+

®

handheld

1)

26626-EN-041227

Page 33

Electrical connection

Measuring system with VEGAPULS 43 on active PLC

• Two-wire technology, power supply from active PLC.

• Output signal 4 … 20 mA (passive).

• Measured value display integrated in the sensor.

• Optional external indicating instrument (can be mounted up to 25 m away from the sensor in

Ex area).

• Adjustment with PC, HART

into the sensor or into the external indication instrument).

VEGADIS 50

®

handheld or the adjustment module MINICOM (can be plugged

4

1)

If the resistance of the processing systems

2 2

VEGACONNECT

2

connected to the 4 … 20 mA signal output is less

than 250 Ω, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 Ω.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected processing

system. Digital communication with the PC would

not be ensured.

4 … 20 mA

passive

2

1)

2)

PLC (active)

HART® handheld

2)

4 … 20 mA passive means that the sensor

3)

consumes a level-dependent current of

4 … 20 mA. The sensor reacts electrically like a

varying resistor (consumer) to the PLC.

3)

Active means that the PLC powers the passive

sensor as voltage source.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 33

Page 34

Electrical connection

Measuring system with VEGAPULS 43 in fo ur-wire tec hnology

• Four-wire technology, power supply and output signal via two separate two-wire cables.

• Output signal 4 … 20 mA active.

• Optional external indicating instrument with analogue and digital indication (can be mounted

up to 25 m away from the sensor).

• Adjustment with PC, HART

the sensor or into the indicating instrument VEGADIS 50).

• max. resistance on the signal output (load) 500 Ω.

VEGADIS 50

4

VEGACONNECT

®

handheld or adjustment module MINICOM (can be plugged into

2

-

2

2

2

1)

≥ 250 Ω

+

4 … 20mA

2)

(active)

HART® handheld

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 Ω, a resistor must be connected to the

connection cable during adjustment to get a loop

2)

4 … 20 mA active means that the sensor delivers

a level-dependent current of 4 … 20 mA (source).

The sensor reacts electrically in the processing

system (e.g. indication) like a current source.

resistance of 250 Ω.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Digital communication with the

PC would not be ensured.

34 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 35

Electrical connection

Measuring system with VEGAPULS 43 via separator in Ex areas on active

PLC (Ex ia)

• Two-wire technology (loop powered), power supply via the signal line of the PLC; output

signal 4 … 20 mA (passive).

• Separator transfers the non intrinsically safe PLC circuit to the intrinsically safe circuit, so

that the sensor can be used in Ex zone 1 or Ex zone 0.

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m away from the sensor).

• Adjustment with PC, HART

the sensor or into the external indicating instrument VEGADIS 50).

®

handheld or adjustment module MINICOM (can be plugged into

VEGADIS 50

4

Zone 0 or

Zone 1

Ex area

EEx ia

Non Ex area

Separator (e.g. Stahl)

(see "7.2 Approvals“)

2

VEGACONNECT

1)

4 … 20 mA

passive

2

2)

2

2

PLC (active)

HART® handheld

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 Ω, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 Ω.

The digital adjustment signal would otherwise be

2)

4 … 20 mA passive means that the sensor or the

PLC consumes a level-dependent current of

4 … 20 mA. The PLC reacts electrically like a

varying resistor (consumer) to the PLC. The PLC

operates actively, i.e. as current or voltage

source.

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Digital communication with the

PC would not be ensured.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 35

Page 36

Electrical connection

Measuring system with VEGAPULS 43 via separator (Smart-Transmitter) on

passive PLC (Ex ia)

• Two-wire technology (loop powered), intrinsically safe ia supply via the signal cable of the

separator for operation of the sensor in Ex zone 1 or Ex zone 0.

• Output signal sensor 4 … 20 mA passive.

• Output signal separator 4 … 20 mA active

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m away from the sensor).

• Adjustment with PC, HART

the sensor or into the external indicating instrument VEGADIS 50)..

®

handheld or adjustment module MINICOM (can be plugged into

VEGADIS 50

4

Zone 0

or

Zone 1

Ex area

EEx ia

Non Ex area

Separator (e.g. VEGATRENN 149 Ex see

"7.2 Approvals“)

-

+

2

4 … 20 mA

(active)

2

2

VEGACONNECT

1)

2)

PLC (passive)

3)

HART® handheld

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 Ω, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 Ω.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Digital communication with the

2)

4 … 20 mA active means that the separator

delivers a level-dependent current of 4 … 20 mA

The separator reacts electrically to the PLC like a

current source.

3)

4 … 20 mA passive means that the PLC consumes

a level-dependent current of 4 … 20 mA. The PLC

reacts electrically like a varying resistor

(consumer).

PC would not be ensured.

36 VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Page 37

Electrical connection

Measuring system with VEGAPULS 43 on VEGADIS 371 Ex indicating

instrument with current and relay output (Ex ia)

• Two-wire technology (loop powered), intrinsically safe ia supply via the signal cable of the

VEGADIS 371 Ex indicating instrument for operation of the sensor in Ex zone 1 or Ex

zone 0.

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m away from the sensor).

• Adjustment with PC, HART

the sensor or into the external indicating instrument VEGADIS 50).

Ex area Non Ex area

VEGADIS 50

EEx ia

4

Zone 0 or

Zone 1

®

handheld or adjustment module MINICOM (can be plugged into

-

+

2

2

2

VEGACONNECT

1)

4 ... 20 mA

(passive)

VEGADIS

371 Ex

(see „7.2 Approvals“)

HART® handheld

Relay

0/4 … 20 mA

(active)

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 Ω, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 Ω.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Digital communication with the

PC would not be ensured.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 37

Page 38

Electrical connection

VEGAPULS 43 Ex (loop powered) with pressure-tight encapsulated

connection compartment on active PLC (Ex d)

• Two-wire technology, supply via the cable from active PLC to Exd connection housing for

operation in Ex-Zone 1 (VEGAPULS …Ex) or Ex-Zone 0 (VEGAPULS …Ex0).

• Output signal 4 … 20 mA (passive).

• Measured value display integrated in the sensor.

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m away from the sensor in Ex area).

• Adjustment with PC, HART

the sensor or into the external indicating instrument VEGADIS 50).

®

handheld or adjustment module MINICOM (can be plugged into

Ex area

VEGADIS 50 Ex

4

1)

If the resistance of the processing systems

Non Ex area

2

VEGACONNECT

2

2

connected to the 4 … 20 mA signal output is less

than 250 Ω, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance between 250 Ω.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Digital communication with the

PC or the HART

®

handheld would not be ensured.

4 … 20 mA

2)

passive

2

PLC (active)

®

HART

handheld

2)

4 … 20 mA passive means that the sensor

consumes a level-dependent current of

4 … 20 mA. The sensor reacts electrically like a

varying resistor (consumer) to the PLC.

26626-EN-041227

38 VEGAPULS 43 – 4 … 20 mA

Page 39

Electrical connection

VEGAPULS 41 Ex with pressure-tight encapsulated connection

compartment in four-wire technology (Ex d)

• Four-wire technology, supply and output signal via two separate two-wire cables for operation in Ex-Zone 1 (VEGAPULS …Ex) or Ex-Zone 0 (VEGAPULS …Ex0).

• Output signal 4 … 20 mA (active).

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m away from the sensor in Ex area).

• Adjustment with PC, HART

the sensor or into the external indicating instrument VEGADIS 50).

• Load max. 500 Ω.

®

handheld or adjustment module MINICOM (can be plugged into

Ex area

VEGADIS 50 Ex

4

1)

If the resistance of the processing systems

Non Ex area

VEGACONNECT

2

2

connected to the 4 … 20 mA signal output is less

than 250 Ω, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance between 250 Ω.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Digital communication with the

PC or the HART

®

handheld would not be ensured.

2

-

2

> 250 Ω

2)

4 … 20 mA active means that the sensor delivers

+

4 … 20mA

2)

active

HART® handheld

a level-dependent current of 4 … 20 mA (source).

The measuring signal of the sensor reacts

electrically to the processing system (e.g. display)

like a current source.

26626-EN-041227

VEGAPULS 43 – 4 … 20 mA 39

Page 40

5 Set-up

Set-up

5.1 Adjustment media

Radar sensors can be adjusted with the

- PC (adjustment software PACT

- detachable adjustment module

MINICOM

- HART

®

handheld.

The adjustment must be carried out with only

one adjustment device. If, for example, you

attempt to adjust the parameters with the

MINICOM and the HART

®

handheld at the

same time, the adjustment will not work.

PC

With the adjustment program PACT

the PC, you can adjust the radar sensors

quickly and conveniently. The PC communicates via the interface adapter

VEGACONNECT 3 with the sensor. During

the process, a digital adjustment signal is

superimposed on the signal and supply

cable. The adjustment can be carried out