Page 1

Level and Pressure

Operating Instruction

Capacitive electrodes EL

4 … 20 mA - compact

Page 2

2 Capacitive electrodes EL 4 … 20 mA - compact

Safety information

Safety information

The described module must only be installed and

operated as described in this operating

instruction. Please note that other action can

cause damage for which VEGA does not take

responsibility.

Page 3

Capacitive electrodes EL 4 … 20 mA - compact 3

Contents

Safety information ......................................................................... 2

1 Product description

1.1 Function and configuration ................................................... 4

1.2 Types and versions ............................................................... 5

1.3 Technical data ....................................................................... 7

1.4 Approvals ............................................................................ 13

1.5 Dimensions ......................................................................... 14

1.6 Type plate ........................................................................... 16

2 Mounting

2.1 Mounting instructions .......................................................... 17

3 Electrical connection

3.1 Connection instructions ...................................................... 22

3.2 Wiring plan .......................................................................... 22

4 Set-up

4.1 General adjustment ............................................................ 26

4.2 Adjustment - Oscillators

CAP E32 Ex and CAP E32 H Ex ......................................... 27

4.3 Adjustment with VVO ............................................................ 30

4.4 Adjustment with HART®-handheld ..................................... 36

5 Diagnosis

5.1 Simulation ........................................................................... 44

5.2 Maintenance ....................................................................... 44

5.3 Repair ................................................................................. 44

5.4 Failure removal.................................................................... 45

Contents

Page 4

4 Capacitive electrodes EL 4 … 20 mA - compact

Product description

1 Product description

1.1 Function and configuration

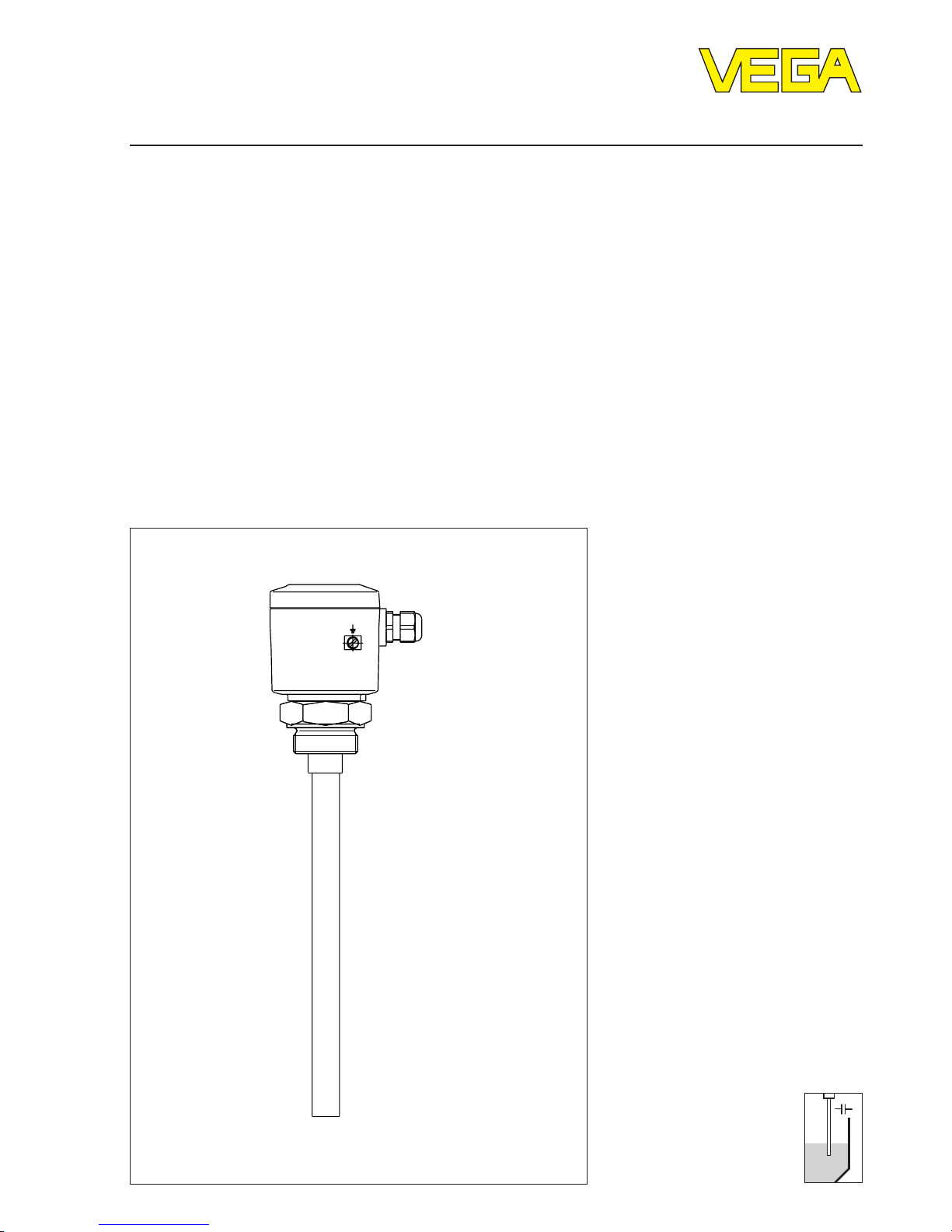

Capacitive electrodes series EL detect levels of

virtually any medium unaffected whether

liquids, powders or pastes. This is also valid for

adhesive products.

The electrode measures also the level

capacitance and the ohmic resistance

(admittance processing). Hence also

problematic medium and solids with fluctuating

humidity contents can be detected.

By the use of screening tubes and screen

segments, inactive areas can be provided on

the probe where pollution, condensation or

permanent build-up do not influence the

measuring result.

Measuring principle

Electrode, medium and vessel wall form an

electrical capacitor.

The capacitance of the capacitor is mainly

influenced by three factors:

- distance of the electrode plates (a)

- size of the electrode plates (b)

- kind of dielectricum between the electrodes

(c)

Fig. 1.1 Plate capacitor (schematic

demonstration)

Electrode and vessel wall are the capacitor

plates. The medium is the dielectricum. Due to

the higher dielectric constant figure (DK-value)

of the medium against air, the capacitance of

the capacitor increases with raising covering of

the electrode.

Fig. 1.2 Capacitance change with covered

electrode

a

b

c

The capacitance change is processed by the

oscillator and converted into a level proportional measured value. The measured value is

provided analogue as standardized, floating

4 … 20 mA-current signal, optionally also

digitally with the HART®-communication

protocol.

The sensor can be adjusted via the integral

oscillator. Optionally the adjustment with

HART®-handheld or PC with VVO-adjustment

software is also possible.

With the continuous level measurement the

appropriate level is continuously detected and

converted into a level proportional signal which

is either directly displayed or further processed.

You require a capacitive electrode series EL

with oscillator CAP E32 Ex or CAP E32 H Ex.

The continuous measurement assumes a

constant dielectric constant figure εr , i.e. the

medium should have steady features.

Page 5

Capacitive electrodes EL 4 … 20 mA - compact 5

Product description

*) also Ex 0

1) applied

2) 1.4435

3) 1.4571

4) 1.4401

5) For electrodes certified for Ex-Zone 0,only PTFE and FEP are approved as isolating material

1.2 Types and versions

Type EL EL EL EL EL EL EL EL EL

Version 11*

)

21*

)

24*

)

29 31*

)

33 42*

)

52 53

Continuous •••••••••

Partly-insulated • • •

Fully-insulated • • • • • •

Oscillators

CAP E32 EX •••••••••

CAP E32 H EX •••••••••

Approvals

PTB 98 ATEX 2086 • • • • •

PTB-no. Ex-98.E.2085 • • • • •

Overfill protection

acc. to WHG

1)

••••• •

German Lloyd

1)

•••••••••

Lloyds Register of Ship

1)

•••••••••

American Bureau of Ship

1)

•••••••••

Bureau Veritas

1)

•••••••••

RINA

1)

•••••••••

Mechanical connection

G 1 A • • • • • •

NPT 11/2" •• ••••••

G 11/2 A ••• •••••

Tri-Clamp 11/2“••

Tri-Clamp 2“ • • • • •

Bolting

DN 50 • • •

Flange • • • • ••••

Flange plated •

Screw adapter

PP ••• ••

PTFE • • • •

Electrode material

Steel • • • ••••

StSt •

2)

•

2)

•

2)

•

3)

•

3)

•

4)

•

2)

•

2)

Page 6

6 Capacitive electrodes EL 4 … 20 mA - compact

Type EL EL EL EL EL EL EL EL EL

Version 11*)21*

)

24*

)

29 31*

)

33 42*

)

52 53

Isolation material

5)

PTFE • • • • • •

PP • •

PE/PA 12 •

PFA •

FEP • •

PE •

Concentric tube

Steel • • •

StSt (1.4435) • • •

Screening tube (option)

Steel • • • • • • • •

StSt • • • • • • • •

Temperature

adapter (option)

Steel • • • • •

StSt (1.4435) • • • • •

PA • • • • • • •

Housing material

Plastic • • • • • • • • •

Aluminium • • • • • • • • •

Others

Adapter

6)

•• • •

Overvoltage protect.-option

CB-2-36 (integrated) • • • • • • • • •

Overvoltage arrester

7)

•• ••

Bending of

electrode

8)

••

9)

*) also Ex 0

1) applied

2) 1.4435

3) 1.4571

4) 1.4401

5) For electrodes certified for Ex-Zone 0, PTFE and FEP are only approved as isolation material

6) For combustible liquids in pressurized vessels, e.g. liquid gas, ammonia

7) For high electrostatic discharges, e.g. plastic granules

8) Bending max. 90°

9) EL 21 only with PTFE at 3,2 mm isolation thickness

Product description

Page 7

Capacitive electrodes EL 4 … 20 mA - compact 7

Product description

1.3 Technical data

Housing

Housing material plastic PBT (Polyester) or Aluminium

plastic coated

Protection

- plastic housing IP 66

- Aluminium housing IP 66/67 (meets both protections)

Cable entry 1 piece M20 x 1,5

Terminals for max. 1,5 mm2 cross-section area of conductor

Mechanical connection

Material galvanized steel (St 37), 1.4571 (StSt), Aluminium

Thread G 1

1/

2

A or 1

1/

2

" NPT

Flange flange versions

Electrode

Material EL 11 1.4435 (316 L)

EL 21 steel (St 37)

EL 31 1.4401 (316 L)

EL 24, 42 1.4571 (316 L)

Length

- rod max. 3 m

- cable max. 20 m

Isolation see "Isolation materials"

Max. tensile load (cable)

- EL 31 3 KN

- EL 33, 34, 42, 52, 53 3 KN

Ambient conditions

Ambient temperature on the housing -40°C … +80°C

Medium temperature see "Medium temperature and operating pressure"

Storage and transport temperature -40°C … +80°C

Operating pressure see "Medium temperature and operating pressure"

Oscillator CAP E32 Ex, CAP E32 H Ex

Protection class II

Overvoltage category III

Meas. frequency 300 KHz

Capacitance ranges 0 … 3000 pF

Page 8

8 Capacitive electrodes EL 4 … 20 mA - compact

Oscillators in two-wire technology for capacitive electrodes EL

Type Application Meas. range Freguency Signal cond.instr.

CAP E32 Compact electronics 4 … 20 mA for 0 - 3000 pF 300 KHz not required

Ex continuous level measurement,

according to the principle of

phase selective admittance processing

Parameter adjustment via

keys on the oscillator

CAP E32 H Compact electronics 4 … 20 mA for 0 - 3000 pF 300 KHz not required

Ex continuous level measurement,

according to the principle of

phase selective admittance processing

Parameter adjustment via

keys on the oscillator,

VVO from V. 2.30 or

HART®-handheld

Accessory

Straining spring of 1.4571

- length approx. 185 mm (stressed)

- tensile load approx. 200 N

Weight

Basic weight (e.g. EL 24) approx. 0,8 kg

Rod weight ø 6 mm - 0,23 kg/m

ø 10 mm - 0,62 kg/m

Product description

12

200

600

800

18 24 30 36

1000

Load in Ω

Supply

voltage in V

Supply voltage 12 … 36 V DC

for Ex-applications note the stated permissible

electrical connection values in the certificate.

Potential separation min. 500 V AC

Page 9

Capacitive electrodes EL 4 … 20 mA - compact 9

Product description

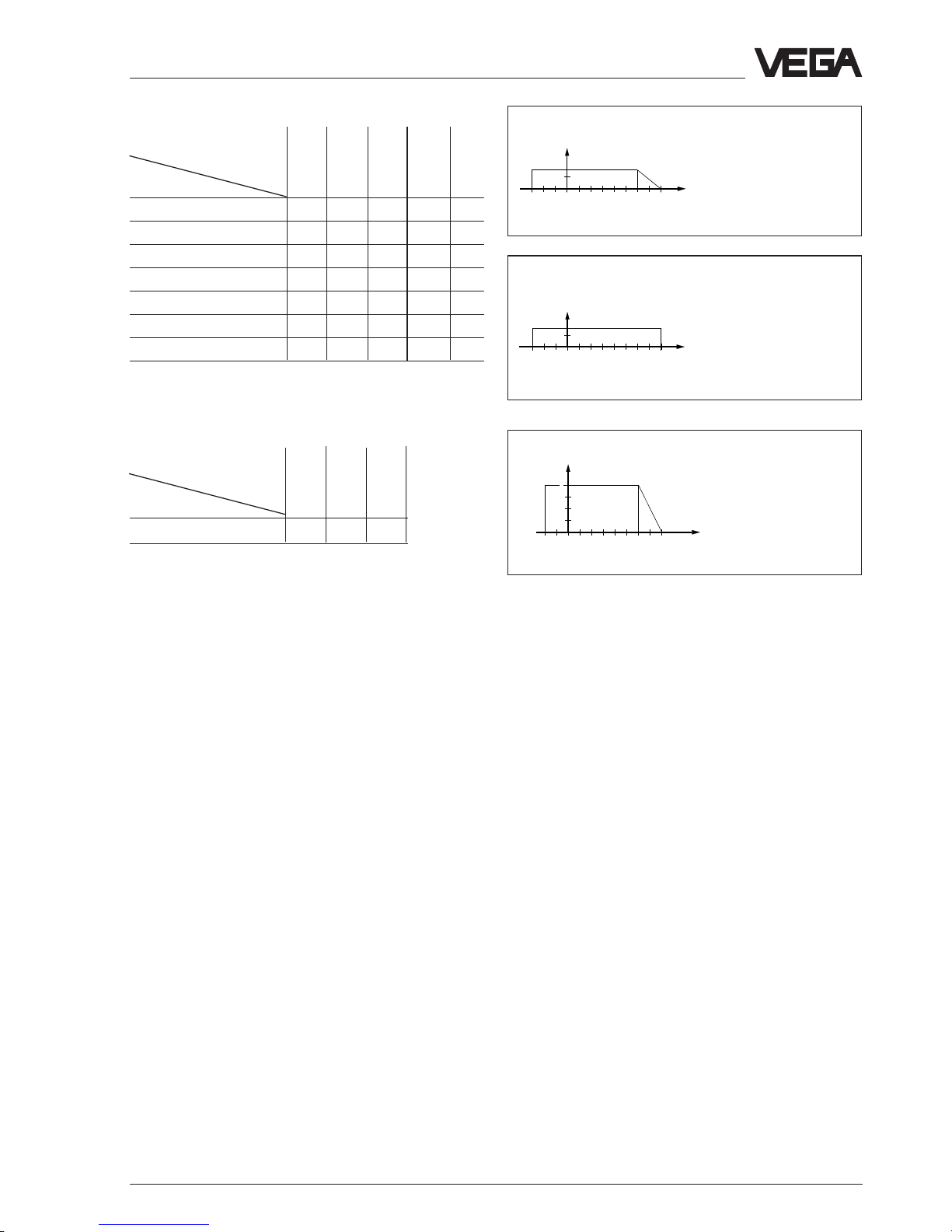

+

–

0 %

5 %

10 %

15 % vol.

fully insulated

electrode

partly

insulated

electrode

Solid

humidity (%)

Level

measured

value

Fig. 1.3 Humidity change

Oscillator

The oscillator CAP E32 (H) Ex with the patented

processing (phase selective admittance

processing) extends the application range of

capacitive level measurement technology. This

function can be switched on, see 4 Set-up.

In conjunction with a fully insulated rod

electrode, the oscillator compensates even

strong conductive build-up.

Mounted in an individual rod or cable electrode

type EL, this oscillator ensures also the exact

measurement in solids with varying humidity

contents.

The oscillator processes the measuring

currents according to the phase position.

Measuring currents with a defined phase

shifting as they occur with build-up or humidity

changes are filtered out.

Humidity change

A humidty change in solids causes a change of

the dielectric constant figure (εr). In parallel the

ohmic value of the medium changes. Due to the

change also a phase shifting of the measuring

currents is caused.

With a capacitive measurement already lowest

humidity changes cause measuring errors.

Typical products are, e.g. sand, aggregate in

the cement industry, hop or plastic granules

(after drying).

When using the oscillator CAP E32 (H) Ex

humidity changes of 15␣ % vol. do not influence

the accuracy of the measurement. Even

layering of product with different humidity do

not play a role for the measuring accuracy.

When the humidity contents exceeds 15␣ % vol.

1) Actual value level

1)

fully and partly insulated electrodes react

differently (see also “Fig. 1.3 Humidity

change“). Whereby the measured value on fully

insulated electrodes raises with steady level,

the measured value on partly insulated

electrodes drops.

Page 10

10 Capacitive electrodes EL 4 … 20 mA - compact

Product description

0

–10

60 80

40

°C

bar

16

0

–10

100

63

°C

bar

6

5

4

0

–10

100

63

200

°C

bar

25

EL 21, 53:

PE and PE / PA 12

up to 16 bar

Temperature

adapter

2)

EL 42:

up to 16 bar

EL 24:

up to 40 bar

from 100°C

unpressurized

max. 150°C for

30␣ min.

0

–50

100

63

200

°C

bar

25

0

–50

100

63

°C

bar

0

–30

60 80

40

bar

°C

16

3

2

1

EL 21, 53:

PE and PE / PA 12

up to 16 bar

Temperature

adapter

1)

EL 42:

up to 16 bar

EL 24:

up to 40 bar

from 100°C

unpressurized,

max. 150°C for

30␣ min.

1)

Temperature adapter of PA up to 150°C, from 100°C

unpressurized

Medium temperature1) and operating

pressure

1)

The figures in the tables relate to the figures on

this page. The statements on pressure are valid

for screw conenctions G 11/2 A, NPT 11/2“ and R

11/2.

Boltings DN 50 acc. to DIN 11␣ 851 only up to

max. 25 bar. With flange versions you have to

note their nominal pressure.

All electrodes are also suitable for vacuum

(-1␣ bar).

For electrodes certified for Ex-Zone 0, only

PTFE and FEP are approved as isolating

material.

Mechanical connection, 1.4571

Isolation

Electrode type

EL 11 - 1 3 - - EL 21 1-3-3EL 21 (flange) - - 2 - - EL 24 -----2

EL 29 - - 2 - - EL 31 - 1 3 - - EL 33 - - 3 - - EL 42 - - 2 - - EL 52 - - 3 - - EL 53 - - - 1 - -

Mechanical connection, steel (St 37)

Isolation

Electrode type

EL 11 - 4 6 - - EL 21 4-6-6EL 21 (flange) - - 5 - - EL 24 -----5

EL 31 - 4 6 - - EL 33 - - 6 - - EL 42 - - 5 - - EL 52 - - 6 - - EL 53 - - - 4 - -

PE

PP

PTFE

PE/PA 12

PFA

FEP

PE

PP

PTFE

PE/PA 12

PFA

FEP

Page 11

Capacitive electrodes EL 4 … 20 mA - compact 11

8

7

0

–30

100

16

°C

bar

0

–30

60 80

16

°C

bar

Mechanical connection, Aluminium

Isolation

Electrode type

EL 11 - 7 8 - EL 21 7 - 8 - 8

EL 31 - 7 8 - EL 33 - - 8 - EL 42 - - 8 - EL 52 - - 8 - EL 53 - - - 7 -

Mechanical connection, PP, PVC, PTFE,

screwed adapter

Isolation

Electrode type

EL 29 10 10 10

PE

PP

PTFE

PE/PA 12

PFA

1)

For Ex-applications the permissible temperatures and pressures stated in the certificate must be noted.

Additionally note the table on the following page.

2)

Temperature adapter of PA up to 150°C, from 100°C unpressurized

FEP

9

0

–20

60

°C

bar

2

45

1

PP

PTFE

PP: unpressurized up

to 80°C

PTFE: 3 bar,

-20␣ …␣ 100°C

Product description

Page 12

12 Capacitive electrodes EL 4 … 20 mA - compact

Product description

Electronics temperature

The following medium and ambient

temperatures must be kept, so that the limit

temperature on the electronics is not exceeded.

Temperature class T4 (or no Ex)

Without temperature adapter

- medium temperature -40°C … +135°C

- ambient temperature

1)

-40°C … +90°C

Temperature class T3

With temperature adapter

1) Ambient temperature on oscillator

Plastic housing Metal housing

Medium temperature -40°C … 180°C 200°C 150°C 175°C 200°C

Ambient temperature

1)

-40°C … 80°C75°C80°C69°C58°C

Product description

Page 13

Capacitive electrodes EL 4 … 20 mA - compact 13

Product description

1.4 Approvals

Explosion protection

Only certified capacitive electrodes EL** Ex 0

must be used in hazardous areas with

combustible gases, vapours or fog.

Capacitive electrodes EL** Ex 0 are suitable for

the use in hazardous areas of zone 1 and zone

0.

Proof for the explosion protection of these

instruments is the EC-type approval and the

conformity certificate possibly with national

zone 0 - annex issued by the approval

authority. These documents are generally

attached to the instruments.

When the capacitive electrodes are mounted

and operated in hazardous areas, the Exinstallation regulations must be noted.

The information and regulations of the supplied

certificates (EC-type approval, conformity

certificate) of the capacitive electrodes as well

as of the appropriate instrument (signal

conditioning instrument, separator, safety

barrier) must be noted.

• The mounting of Ex-systems must be

generally carried out by skilled staff.

• The capacitive electrodes must be powered

from an intrinsically safe circuit; the

permissible electrical values are stated in the

appropriate certificate.

• Capacitive electrodes with electrostatically

chargeable plastic parts are provided with a

warning label informing about measures

which must be taken to avoid dangers

caused by electrostatic discharges. Note the

contents of the warning label.

• The explosion protection of the instrument

used is only ensured when the limit

temperatures stated in the certificate are not

exceeded.

• In case of danger due to oscillation or

vibration, the appropriate parts of the

capacitive electrodes must be protected.

• After shortening of the electrode cable it

must be noted that the weight is sufficiently

secured by means of pins.

Overfill protection acc. to WHG

The information and regulations of the supplied

type approvals must be noted when a

capacitive electrode is used as overfill

protection for vessels storing water

endangering liquids. The general type approval

must be available on site.

Electrodes must be only used in such liquids

against which the materials of the wetted parts

of the capacitive electrodes are sufficiently

chemically resistant.

Ship approvals

For the use on ships, type approval certificates

are available of several ship classification

authorities (GL, LRS, ABS, BV, RINA).

CE-approval

The capacitive electrodes type EL meet the

protective regulations of EMVG (89/336/EWG)

and NSR (72/23/EWG). The conformity has

been judged acc. to the following standards:

EMVG Emission EN 50 081 - 1

Susceptibility EN 50 082 - 2

NSR EN 61 010 - 1

Zone 2

According to DIN VDE 0165, instruments can

be used in hazardous areas of zone 2 without

approval; they must meet the requirements in

section 6.3 of this VDE. The compliance of the

instruments with these requirements is

confirmed by Messrs. VEGA in a manufacturer

declaration.

Page 14

14 Capacitive electrodes EL 4 … 20 mA - compact

Product description

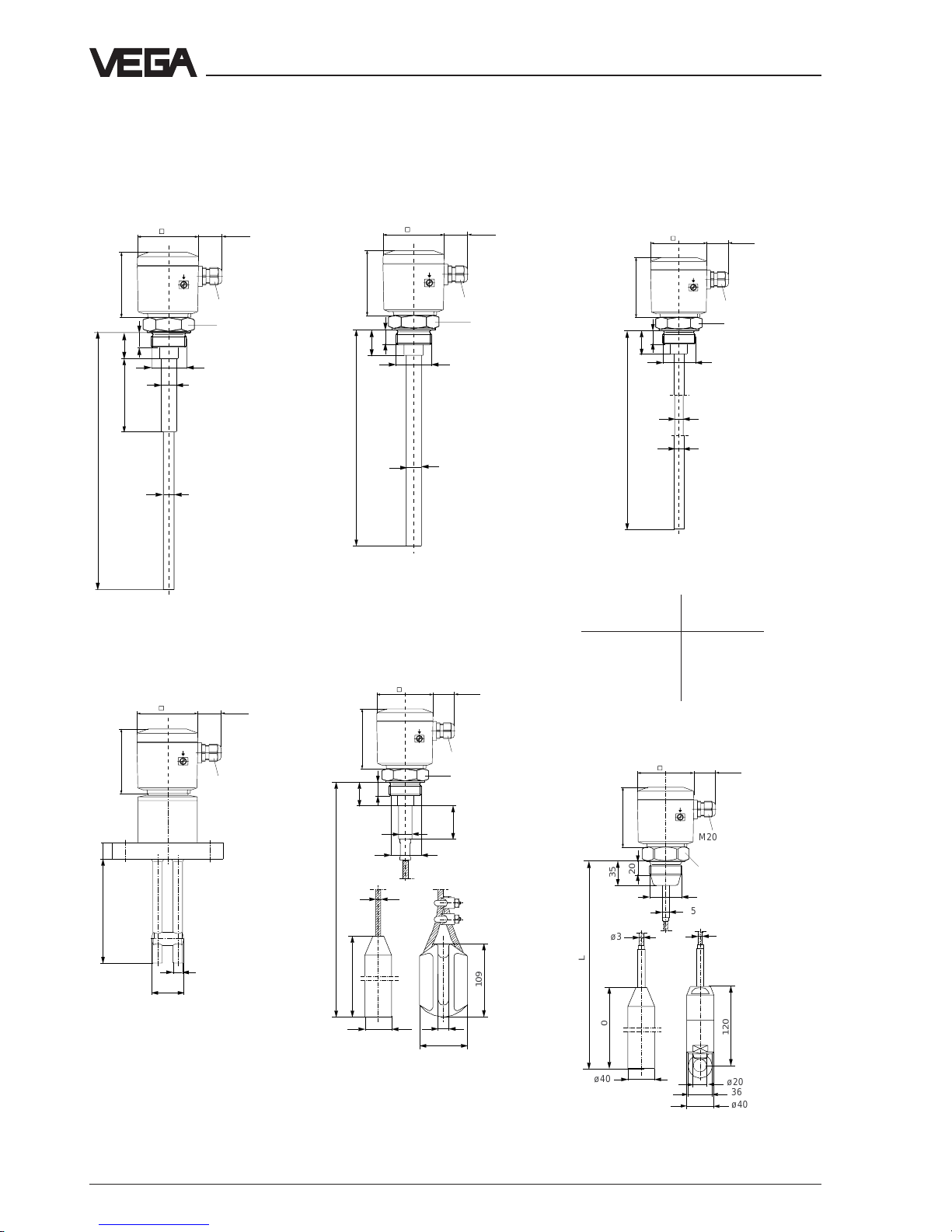

1.5 Dimensions

Dimensions of the capacitive electrodes type EL … Ex 0

Type EL 11

(partly insulated)

(Ex 0)

SW 60

M20x1,5

90

85

32,5

ø20

L1

ø15

35

L

20

G 11/2 A

L (min. 100 mm, max. 4000 mm)

Type EL 21 (fully insulated)

(Ex 0)

SW 60

35

A

L

20

M20x1,5

90

85

32,5

G 11/2 A

L (min. 100 mm, max. 4000 mm)

Isolation length L1:

PP: 100 mm

PTFE: 50 mm

StEx: max. 100 mm

Type EL 24 (fully insulated,

for adhesive products)

(Ex 0)

20

35

ø12

ø14

L

M20x1,5

90

85

32,5

SW 60

G 11/2 A

L (min. 120 mm, max. 4000 mm)

Type EL 29

(fully insulated)

25

ø14

48

L

M20x1,5

90

85

32,5

L (min. 120, max. 3000 mm)

Type EL 31 (partly insulated)

(Ex 0)

L (min. 400 mm, max. 25000 mm)

Isolation length L1:

PP: 100 mm

PTFE: 50 mm

StEx: max. 100 mm

,

109

200

35

L1

L

ø40

71

16

ø8

ø20

20

M20x1,5

90

85

32,5

Isolation A

outer-ø

PE 2,0 mm 20 mm

PTFE 2,0 mm 20 mm

PTFE 3,2 mm 16 mm

PFA 2,0 mm 20 mm

,,

,,

,,

ø3

,,

,,

,,

ø5

35

ø3

ø40

200

L

120

ø20

36

ø40

20

M20x1,5

90

85

32,5

Type EL 42 (fully insulated)

(Ex 0)

L (min. 400 mm, max. 25000 mm)

SW 60

SW 60

Page 15

Capacitive electrodes EL 4 … 20 mA - compact 15

Product description

Housing

Housing of plastic / Aluminium

M20x1,5

90

32,5

85

Temperature adapter

Adapter

for combustible liquids in pressurized

vessels, e.g. liquid gas, ammonia

Concentric tube

Screening tube

ø38

L

SW 60

of galvanized steel

or 1.4571

SW 60

ø45

54

ø60

ø60

70

Temperature adapter

10

ø38

L

of St or 1.4571 with

closing cone of PP or

PTFE

of St or 1.4571

of PA, for

temperatures up

to 150°C, from

100°C only

unpressurized

200

90

ø66

ø66

G 11/2 A

20

44

Screwed adapter of

PP or PTFE

Closing cone

Type EL 52 (fully insulated)

M20x1,5

90

85 32,5

125

35

L

ø40

ø40

ø20

36

ø15,5

ø8

200

20

M20x1,5

90

85 32,5

120

L

ø40

ø40

ø20

36

ø11

ø6

200

35

20

Type EL 53 (fully insulated)

L (min. 400 mm, max. 25000 mm)L (min. 400 mm, max. 25000 mm)

Page 16

16 Capacitive electrodes EL 4 … 20 mA - compact

ser. no. 10612892

Product description

1.6 Type plate

Before mounting and electrical connection

please check if you use the suitable instrument.

Therefore note the type plate which is located

as follows:

1 Master data of the order no.

2 Ex-certification number

Explosion protection version - note the

information and regulations of the certificate

3 Data of the electronics / Approvals

4 No. of the order confirmation /Pos.-no.

5 Number of the electrode type

6 Serial number

7 Test mark when used as part of an overfill

protection for vessels storing water

endangering liquids - note the information

and regulations in the general type approval

8 Manufacturing year

9 Number of the test authority

Type plate

The type plate contains important data required

for mounting and connection. The configuration

and components of the type plate are hence

explained in the following example.

Configuration of the type plate (example)

Order code

Detailled information on the order you will find

in the “Product Information Capacitive“ or in the

“VEGA-Pricelist“.

6

VEGA® EL 11

type EL11EXO.XGBVSTXXVKXX

see PTB Nr. EX-98.E.2085 EEx ia IIC T6 0032

PTB 98 ATEX 2086 II 1/2G EEx ia IIC T6

techn. data see document. / certificates 1998

protection: IP 66/67 Insp.

length: 400mm VVO: 02

Ord. no. 123456/000

3

1

4

2

®

D-77757 Schiltach

5

Z-65.13.XXX

7

9

8

Page 17

Capacitive electrodes EL 4 … 20 mA - compact 17

Mounting

Fig. 2.1 Lateral load

2 Mounting

2.1 Mounting instructions

General

Different mediums and requirements to the

measurement require various installations.

Hence the following instructions should be

noted.

Lateral load

Note that the electrode is not subjected to

strong lateral forces. Mount the electrode in a

position in the vessel where no interfering

influences such as e.g. stirrers, filling opening

etc. occur. This is mainly valid for very long rod

and cable electrodes.

Extraction forces

In case of strong extraction forces e.g. during

filling or settling of solids, high tensile loads can

be caused.

In these cases use for short measuring

distances a rod electrode, as a rod is generally

more stable. If due to the length or the

mounting position a cable electrode should be

necessary, the electrode should not be

strained, but only equipped with a gravity

weight as then the cable can more easily follow

the product movements. Note that the electrode

cable does not touch the vessel wall.

Pressure

In case of gauge or low pressure in the vessel,

the mounting boss must be sealed on the

thread. Use the attached seal ring. Check if the

seal ring is resistant against the medium.

Isolating measures such as e.g. the covering of

the thread with Teflon tape can interrupt the

electrical connection in case of metal vessels.

Hence earth the electrode on the vessel.

Page 18

18 Capacitive electrodes EL 4 … 20 mA - compact

Fig. 2.3 Humidity

Mounting

Fig. 2.2 Shortening of the electrode

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

,,,,,,

,

Shortening of the electrode

The dimensions of fully insulated electrodes are

fixed and must hence not be modified. Each

modification will destroy the instrument.

Partly insulated cable or rod electrodes can be

shortened afterwards.

The electrode basic capacitance is automatically compensated during adjustment. It is

hence possible to shorten the electrodes

individually.

Cable electrode EL␣ 31 can also be shortened

afterwards (see fig. 2.2). Loosen the two pins

on the gravity weight (hexagon) and remove the

two pins. Pull the cable out of the gravity

weight.

To avoid splicing of the steel cable (EL␣ 31)

during cutting, you have to tin the cable around

the cutting position with a copper bit or strongly

tighten the cable with a wire. Shorten the

electrode cable with a metal cutting saw or a

cutting-off wheel by the the requested length.

Carry out the adjustment. The instruction is

under “4.1 Adjustment“.

Filling opening

Install the electrode such that it does not

protrude directly into a strong filling stream.

Should such an installation place be necessary,

mount a suitable sheet above or in front of the

electrode e.g. L␣ 80␣ x␣ 8 DIN 1028, etc.

Humidity from outside

To avoid humidity ingress, loop the connection

line to the electrode housing on vertically

installed electrodes directly behind the cable

entry to the bottom so that rain and

condensation water can drain off.

This is mainly valid for mounting outside, in

areas where humidity must be expected (e.g.

by cleaning processes) or on cooled or heated

vessels (see fig. 2.3).

Cable entries

When mounting outside, on cooled vessels or in

humid areas where cleaning is made e.g. with

steam or high pressure, the seal of the cable

entry is very important.

Use cable with a round cross-section area of

conductor and tighten the cable entry. The

cable entry is suitable for cable diameters of

5␣ mm to 9␣ mm.

Metal vessels

Page 19

Capacitive electrodes EL 4 … 20 mA - compact 19

Mounting

Note that the mechanical connection of the

electrode is electrically conductive connected

with the vessel to ensure sufficient earth.

Use conductive seals such as e.g. copper, lead

etc. Isolating measures such as covering the

thread with Teflon tape can interrupt the

necessary electrical connection. In this case

use the earth terminal on the housing to

connect the electrode to the vessel wall.

Non-conductive vessels

In non-conductive vessels, e.g. plastic tanks,

the second pole of the capacitor must be

provided separately, e.g. by a concentric tube

or the use of a double rod electrode.

When using a standard electrode, a suitable

earth plate is necessary. Hence provide a

possibly large earth plate, e.g. wire braiding

laminated into the vessel wall or metal foil which

is glued to the vessel. Connect the earth plate

with the earth terminal on the housing.

Rod electrode

Mount the rod electrode such that the electrode

protrudes into the vessel. When mounting in a

tube or a socket, build-up can be caused which

can influence the measurement. This is particularly the case with viscous or adhesive

products.

Cable electrodes in solids

Dependent on the kind of solid and position or

kind of filling, the cable electrode can “float“

despite of the gravity weight. The electrode

(cable) is pushed by the solid to the vessel wall

or to the top and wrong measured values are

caused. This should be avoided with

continuous level measurement.

In this case use a fixing weight or a fixing

insulator to fasten the electrode (fig. 2.4).

When fastening the cable electrode avoid high

tensile strenghts. An appropriate fixing spring

avoiding overloading of the cable is listed in our

pricelist as accessory.

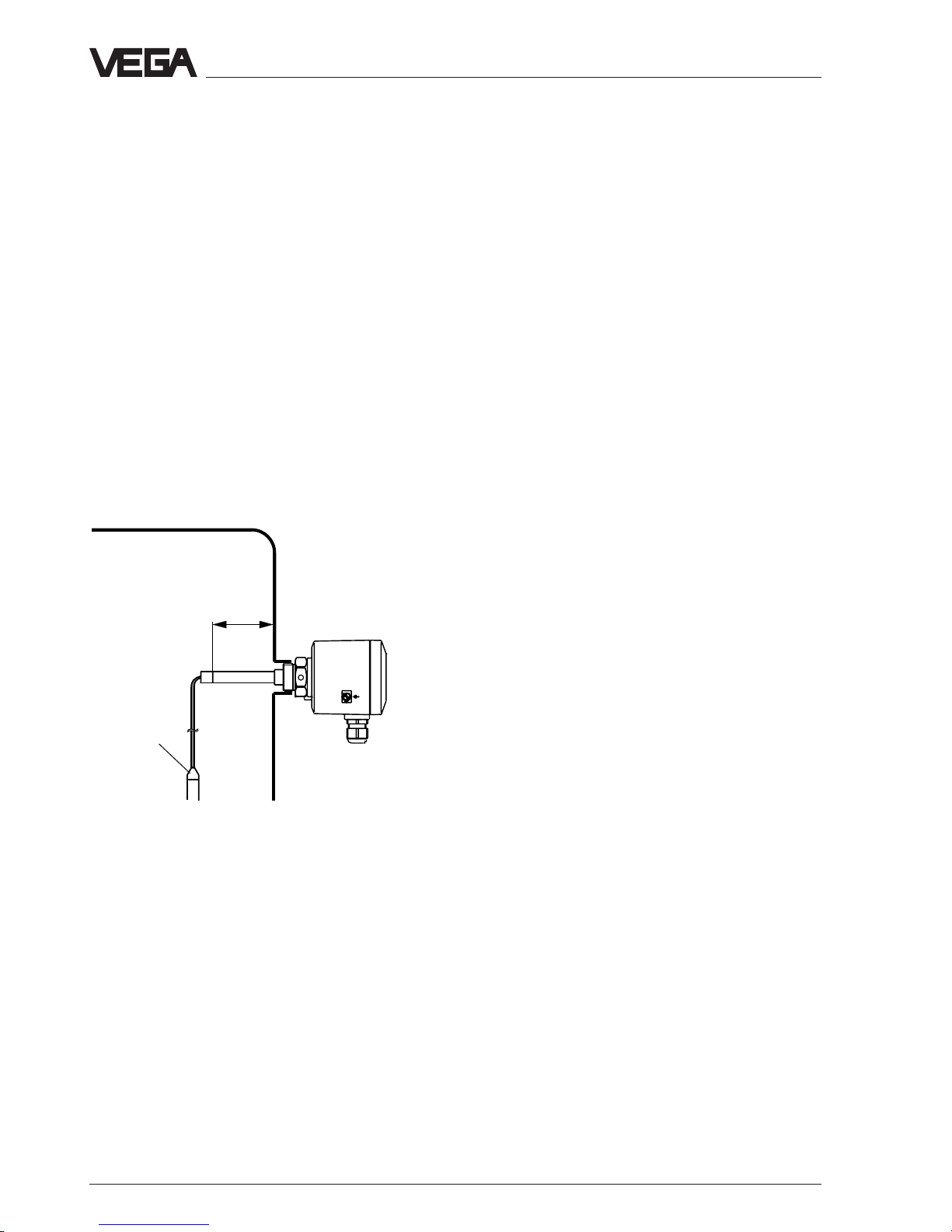

Lateral installation

Fig. 2.4 Cable electrode in solids

Page 20

20 Capacitive electrodes EL 4 … 20 mA - compact

L

Fixing weight

Mounting

With electrodes, delivering continuous

measured values, the electrode must only be

installed vertically. Should the installation from

top not be possible, the electrodes can also be

mounted laterally (fig. 2.5)

Under the accessory in our pricelist you find a

screening tube and a closing cone or a bent

rod electrode by which the electrode can be

also mounted laterally. Choose the length (L) of

the screening tube such that no product

bridges can be caused between cable and

vessel wall and that the electrode cable cannot

touch the vessel wall due to product

movements. Use a fixing weight or a fixing

insulator.

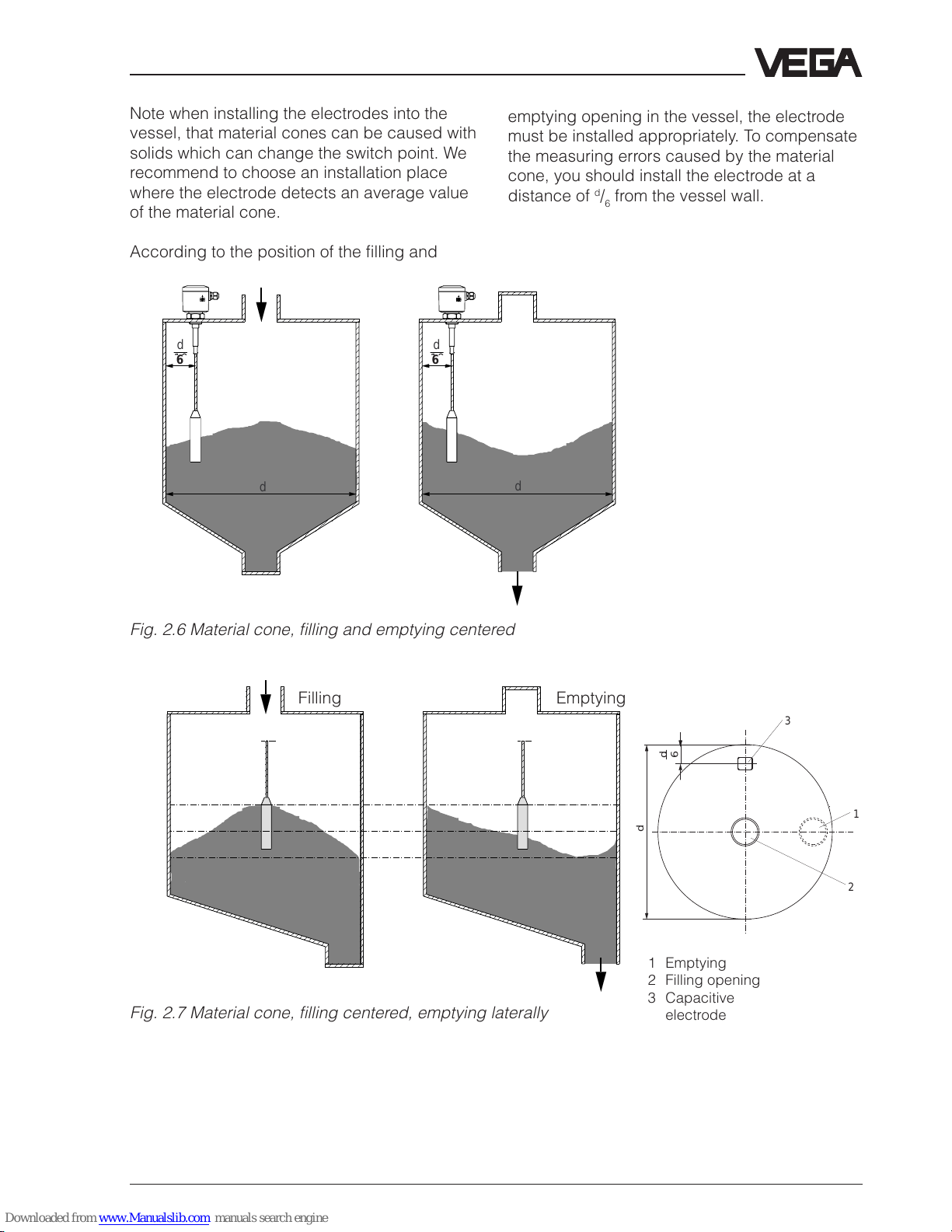

Material cone

Fig. 2.5 Continuous electrodes

Page 21

Capacitive electrodes EL 4 … 20 mA - compact 21

Mounting

Filling

Emptying

d

d

d

10

d

10

Fig. 2.6 Material cone, filling and emptying centered

d

3

1

2

d

6

Filling Emptying

1 Emptying

2 Filling opening

3 Capacitive

electrode

Fig. 2.7 Material cone, filling centered, emptying laterally

Note when installing the electrodes into the

vessel, that material cones can be caused with

solids which can change the switch point. We

recommend to choose an installation place

where the electrode detects an average value

of the material cone.

According to the position of the filling and

emptying opening in the vessel, the electrode

must be installed appropriately. To compensate

the measuring errors caused by the material

cone, you should install the electrode at a

distance of d/6 from the vessel wall.

6 6

Page 22

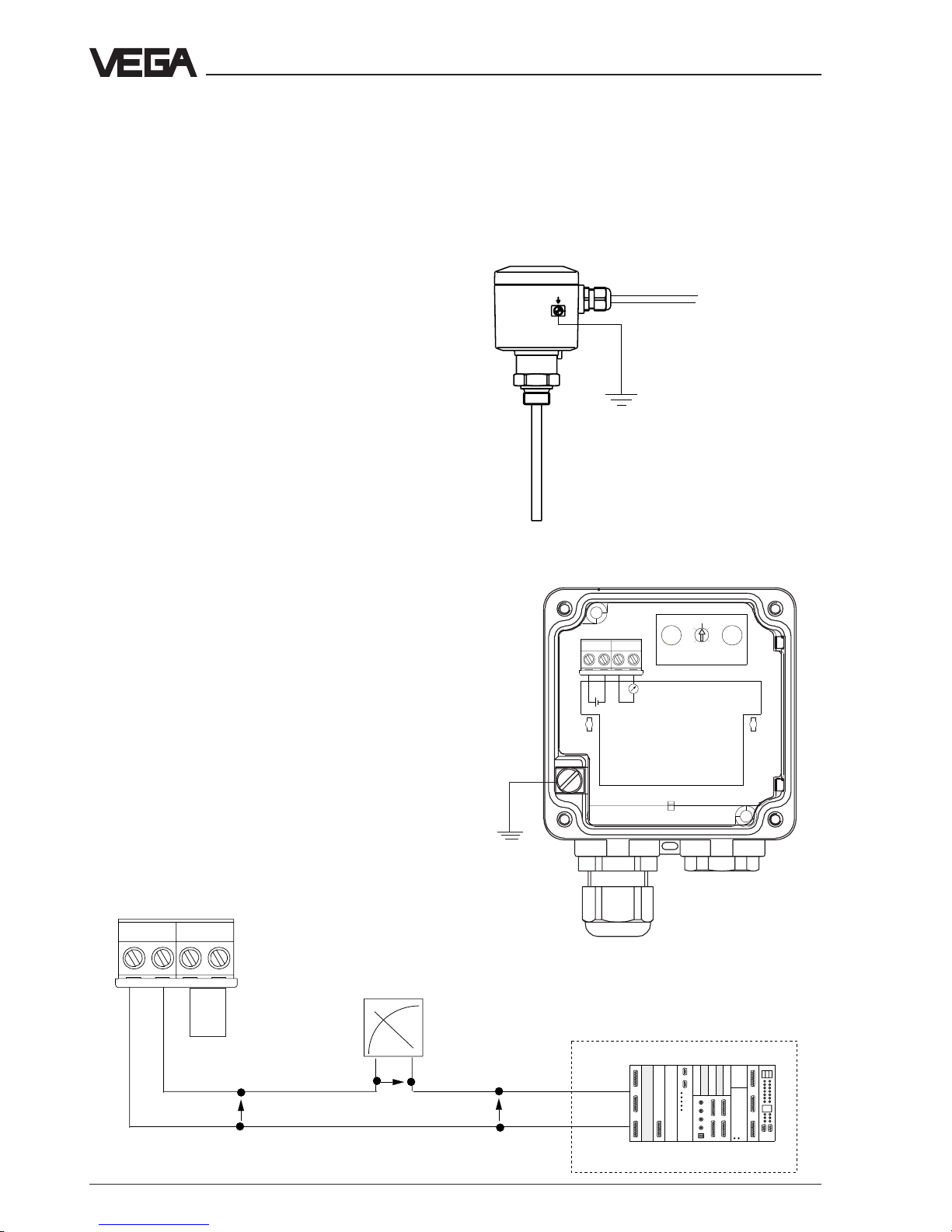

22 Capacitive electrodes EL 4 … 20 mA - compact

Note

The oscillator is independent of the electrode

and can be exchanged locally.

Electrical connection

3 Electrical connection

3.1 Connection instructions

Note

Switch off the power supply before starting

connection work.

Connect supply voltage according to the

following connection diagrams.

Note

If strong electromagnetic interferences have to

be expected, we recommend to use screened

cable. The screening of the cable should only

be earthed at one sensor end (electrode).

Generally connect the electrode with vessel

ground (PA). For this purpose there is a terminal

laterally on the housing. This connection is

additionally for the mass reference potential as

well as to drain off electrostatic charges.

3.2 Wiring plan

+

–

4 … 20 mA

Terminals

sensor

analogue / digital

indicating instrument

U

K

U

H

U

A

4 … 20 mA

U = 12 … 36 V

DCS

4

3

2

1

+ - + -

Ri < 250

+

–

with bridge:

12 …36 V

without

bridge:

13 … 36 V

4

3

2

1

+

-

8

0

2

6

4

+ - + -

mA

U = 12 … 36 V

Page 23

Capacitive electrodes EL 4 … 20 mA - compact 23

Electrical connection

Skilled staff

Instruments operated in Ex-areas must only be

mounted by skilled staff. They must note the

mounting regulations and the supplied EC-type

approvals and conformity certificates.

When capacitive electrodes are mounted on

vessels which must be protected according to

TRbF 100 no. 8, para.1 against inflammation

due to lightning, they have to be equipped with

the external overvoltage arrester type

B 62-36 G or the internal overvoltage protection

unit type CB 2-36.

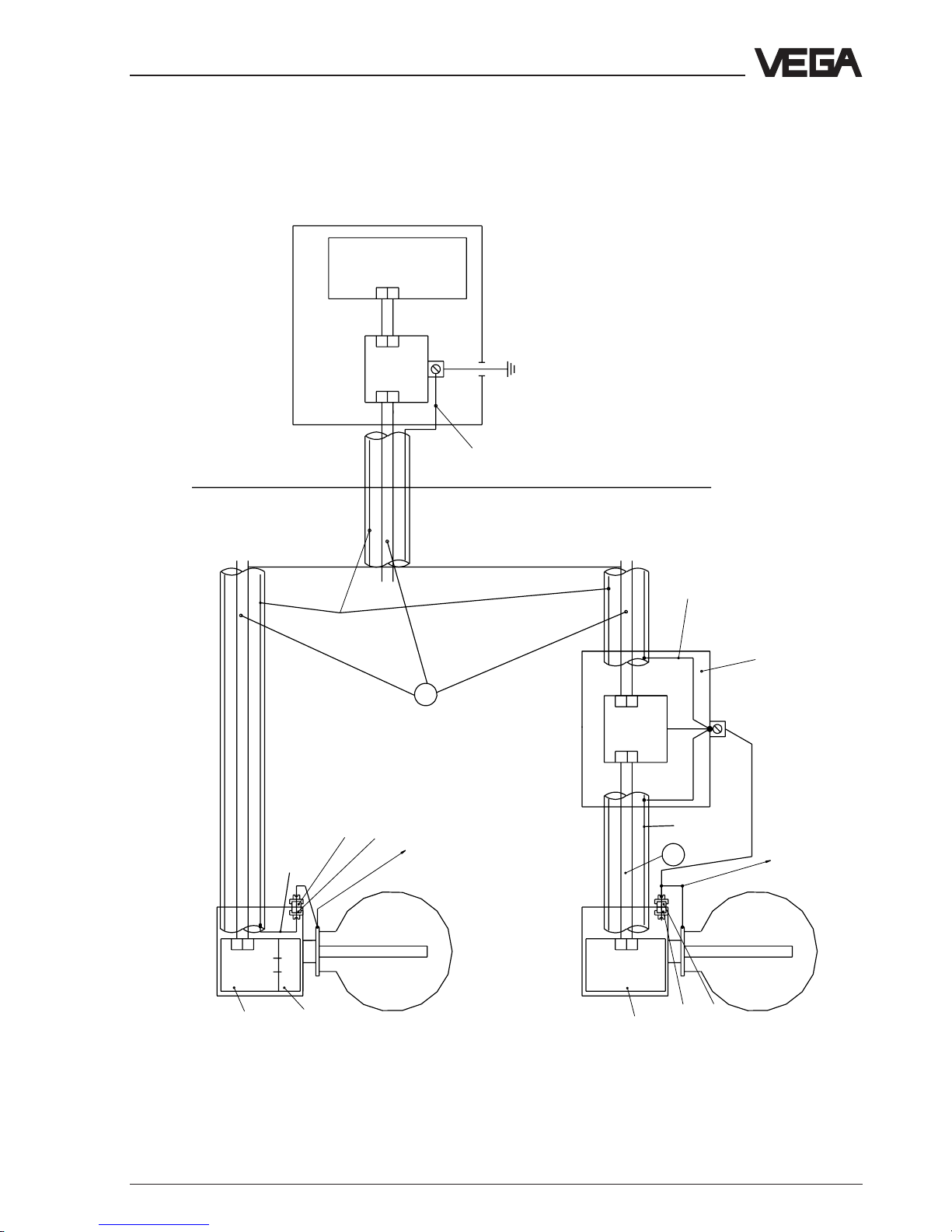

Page 24

24 Capacitive electrodes EL 4 … 20 mA - compact

Electrical connection

A

B

2

1

E2

E1

A2

A1

2

1

A2

A1

E2

E1

Vessel with cathodic corrosion protection

(Ex)-area Zone 1

Not (Ex)-area

overvoltage

protection unit

mounted on

oscillator

Oscillator

b)Capacitive electrodes with external overvoltage

protection unit

Screen

Cathodic tank protection

2 … 24 V (object voltage)

CB

2-36

CAP

E32(H)EX

External earth terminal

Internal earth terminal

Vessel

Zone 0

Li, Ci of the oscillator with

overvoltage protection unit

Li = 0,27 mH

Ci = 8,5 nF

Control room

either: Overvoltage

protection insert

Signal

cond.

instr.orsafety

barrier

Type B62-36G

Li=0,15 mH

Ci=2,5 nF

Overvoltage protection insert

Overvoltage protection

instrument in metal

housing or plastic

housing. The metal

housing must be

mounted earth free

External earth terminal

Internal earth terminal

Cathodic tank protection

2 … 24 V (object voltage)

Isolated line

min. 4 mm

2

Vessel

Zone 0

Oscillator

Li=0,12 mH

Ci=6 nF

Screen

CAP

E32

(H)Ex

Type

B62-36G

Li=0,15 mH

Ci=2,5 nF

Between control room and overvoltage protection

system a suitable cable must be used, if

necessary with metal cover or screen. Metal

cover or screen - if necessary - must be only

connected to the overvoltage protection system

on the electrode side. The cable must have an

outer isolation. Test voltage of the cable A: ≥ 500

V AC

Between overvoltage protection system and

capacitive electrode a suitable cable with metal

cover, screen or a suitable cable with metal

protection tube must be used (metal cover or

protection tube must not be earthed).

Test voltage of the cable B: ≥ 1500 V AC

a) Capacitive electrodes with integral overvoltage

protection unit type CB 2-36

A

B

Page 25

Capacitive electrodes EL 4 … 20 mA - compact 25

Electrical connection

Vessel without cathodic corrosion protection

A

B

A2

A1

E2

E1

2

1

2

1

E2

E1

A2

A1

Overvoltage

protection unit

mounted on

oscillator

Oscillator

CB

2-36

CAP

E32(H)EX

Vessel

Zone 0

Oscillator

Li=0,12 mH

Ci=6 nF

External earth terminal

Internal earth terminal

Vessel

Zone 0

CAP

E32

(H)Ex

External earth terminal

Internal earth terminal

Li, Ci of the oscillator with

overvoltage protection unit

Li = 0,27 mH

Ci = 8,5 nF

(Ex)-area Zone 1

Not (Ex)-area

Signal

cond.

instr.orsafety

barrier

Control room

either:

Overvoltage

protection unit

Type B62-36G

Li=0,15 mH

Ci=2,5 nF

Overvoltage protection unit

Type

B62-36G

Li=0,15 mH

Ci=2,5 nF

Isolated line

min. 4 mm

2

*

**

Screen

Between control room and overvoltage

protection system a suitable cable, if

necessary a metal cover or screen, must be

used. Metal cover or screen - if necessary -

must only be connected to earth or PA on

one line end.

Test voltage of the cable A: ≥ 500 V AC

Between overvoltage protection system

and capacitive electrode a suitable cable

with metal cover, screen or a suitable cable

with metal protection tube must be used

(metal cover or protection tube must be

connected with the potential equalisation).

Test voltage of the cable B: ≥ 1500 V AC

A

B

Overvoltage arrester type

B62-36 G in metal or plastic

housing

**

to potential

equalization line

Screen

to potential

equalization line

b)Capacitive electrodes with external

overvoltage protection unit

a)Capacitive electrodes with integral

overvoltage protection unit type CB 2-36

*

* either

screen only connected on one

line end to earth or PA

** either

screen only connected on one

line end with earth or PA

Page 26

26 Capacitive electrodes EL 4 … 20 mA - compact

Set-up

4 Set-up

4.1 General adjustment

The figures in brackets relate to the pictures

under chapter “3 Electrical connection“. With

the set-up the electrode must be adjusted with

the original medium.

In certain cases also a dry adjustment can be

carried out.

The electrode can be adjusted in three different

ways:

• with integrated oscillator

• with operating software VEGA Visual

Operating (VVO from V. 2.30)

• with HART®-handheld

CAP E 32 Ex

Adjustment - directly on the oscillator.

CAP E 32 H Ex

Adjustment - directly on the oscillator

- via PC with adjustment

program VVO

1)

- via HART®- handheld

Oscillator

The capacitive electrodes EL can be directly

adjusted on the oscillators CAP E32 Ex and

CAP E32 H Ex.

All sensor basic functions can be carried out

with the two keys and the rotating switch.

PC with adjustment program VVO

1)

With the adjustment program VVO V. 2.30

(VEGA Visual Operating) on the PC you can

adjust the capacitive electrode in conjunction

with oscillator CAP E 32 H Ex very comfortably.

Beside the sensor basic functions, also additional functions are available.

You require an interface adapter

VEGACONNECT 2, which you can connect to

any individual position of the signal line or

directly on the sensor.

System requirements:

- IBM-compatible PC with a free standard

interface. We recommend a PC with Pentiumprocessor with a clock frequency of

100 MHz.

- Memory: 16 MB

- Software requirements: Windows 95

HART®-handheld

The capacitive electrodes EL with oscillator

CAP E32 H Ex are suitable for HART®-protocols

and can be adjusted with a HART®-handheld.

All relevant sensor functions are possible with

the HART®-standard menus. A manufacturer

specific DDD (Data-Device-Description) is not

required.

1) When you want to adjust a sensor with the PC, you

have to connect the PC-lines on the signal line

outside the Ex-zone.

The intrinsic safety must be ensured with the

connection. Use a suitable interface converter e.g.

VEGACONNECT 2

Page 27

Capacitive electrodes EL 4 … 20 mA - compact 27

4

321

+

-

8

0

2

6

4

4.2 Adjustment Oscillators

CAP E32 Ex and CAP E32 H Ex

Set-up

Functional description

0 Operate

Basic position

The instrument should be in this position during

measurement. In mode Operate the actual

measured value is transmitted. The plus and

minus keys do not function.

1 Min. adjustment

This function is used to carry out the min.

adjustment. Empty the vessel to min. level

(0 % - level).

Push the plus and minus key together to set the

current value for the actual level to 4 mA.

When you want to coordinate a certain current

value to a known level, you can modify the

current with the plus and minus keys. Every

time you push the key, the current value will be

changed in 10 µA-steps. When you keep the

key pushed, the value modifies with increasing

speed.

Example: When you know that your vessel is

filled to 10 %, then you can enter under min.

adjustment a value of 5,6 mA.

20 mA - 4 mA = 16 mA

16 mA * 10% = 1,6 mA

1,6 mA + 4 mA = 5,6 mA

It is recommended to connect an amperemeter,

see 3.2 Electrical connection. You can monitor

the current value during modification. When you

keep the key pushed, the value changes

automatically and with increasing speed. The

difference between min. and max. adjustment

should be at least 20% or 3,2 mA.

(+/-) set 4 mA

(+) increase current

(-) lower current

2 Max. adjustment

You use this function to carry out the max.

adjustment. Fill the vessel to max. level (100 %

level). Push the plus and minus key together.

You can set the current value for the actual level

to 20 mA.

When you want to coordinate a certain current

Rotating switch (2)

With the rotating switch (10 steps) you choose

the appropriate mode.

As soon as you continue to turn the rotating

switch, the modified value is taken over.

0 Operate

1 Min. adjustment

2 Max. adjustment

3 Integration time

4 Reverse characteristics

5 Linearisation

6 Sensor optimization

7 Simulation current

8 Reset

9 Offset correction

Plus and minus keys (3 and 1)

With the keys + and - you can modify the

values of the parameters and choose out of

several possibilities.

When you push both keys together, the value of

the appropriately chosen function is reset to

factory setting

(except min./max. adjustment)

4

3

2

1

+ - + -

mA

U = 12 … 36 V

1

2

3

1 Minus switch

2 Rotating switch

3 Plus key

Page 28

28 Capacitive electrodes EL 4 … 20 mA - compact

Set-up

value to a known level, you can modify the

current with the plus and minus keys. Each time

you push the key, the current value changes in

10 µA-steps.

When you keep the key pushed, the value

changes with raising speed.

Example: When you know that your vessel is

filled to 90 % and should be filled to 100 %,

then you can enter under the min. adjustment a

value of 18,4 mA.

20 mA - 4 mA = 16 mA

16 mA * 90% = 14,4 mA

14,4 mA + 4 mA = 18,4 mA

It is recommended to connect an amperemeter,

see 3.2 Electrical connection. You can monitor

the current value during modification. When you

keep the key pushed, the value changes

automatically and with increasing speed. The

difference between min. and max. adjustment

should be at least 20% or 3,2 mA.

(+/-) set 20 mA

(+) increase current

(-) reduce current

3 Integration time

When you want to adjust the integration time

(damping), set the rotating switch to position 3.

With the plus and minus keys you can double

or halve the value of the integration time step

by step. As a standard feature an integration

time of 0,5 seconds is adjusted. Count how

often you have pushed the key, so that you can

adjust the time correctly. If you are not sure, set

the integration time to the preadjusted value of

0,5 s by pushing both keys together. Then

repeat the adjustment.

After the adjusted integration time 63 % of the

measured value change are available at the

output.

The following integration times can be chosen

on the oscillator: 0,5; 1; 2; 4; 8; 16; 32; 64;

128; 256 (s)

(+/-) 0,5 s

(+) increase time

(-) reduce time

Example: To adjust an integration time of 8

seconds, you have to push the key “+“ 4 times.

4 Reverse characteristics

With this function you can reverse the

characteristics of the current output. The

reverse characteristics is visible on the

amperemeter.

(+/-) 4 ... 20 mA

(-) 4 ... 20 mA

(+) 20 ... 4 mA

5 Linearisation

With this function you can activate the saved

linearisation curve. As a standard feature the

curve for cylindrical tank is saved.

On CAP E 32 H you can enter other

linearisation curves via VVO. In this case there

is no preadjustment necessary on the oscillator.

(+/-) linearisation off

(+) linearisation on

(-) linearisation off

6 Sensor optimization

Mode 1 = Phase angle 90°

Mode 1 is a pure capacitance measurement,

the ohmic resistance is not considered in the

measuring result.

Application:

- standard adjustment

- non-conductive liquids up to approx. 50 µS

- compensation of the resistance changes in

liquids

- generally on partly insulated electrodes in

liquids

- non-conductive solids without humidity

contents

- with bad product earth

- with electrodes in conjunction with a

concentric tube

- in non-conductive vessels with ground plate

provided from outside

Mode 2 = Phase angle 45°

The capacitance and the ohmic resistance are

Page 29

Capacitive electrodes EL 4 … 20 mA - compact 29

Set-up

measured separately, the capacitance value is

corrected by the calculation of the ohmic

resistance so that measuring errors due to

build-up or change in the product humidity are

compensated.

Application:

- high conductivity products

- adhesive, conductive products

- solids with fluctuating humidity contents

For the use in conductive, adhesive liquids, the

suitable electrode type EL 24 should be

applied.

(+/-) Mode 1 (90°)

(+) Mode 1 (90°)

(-) Mode 2 (45°)

7 Simulation current

With this function you can simulate the level. As

soon as you set the rotating switch to position 7,

the simulation is active. The actual current value

of the actual level is taken over for simulation.

With the plus and minus keys you can modify

the current value in a range of 3,8 mA to 22 mA.

Every time you push the key, the current value

changes in 10 µA-steps.

When you keep the key pushed, the value

modifies automatically and with increasing

speed.

(+) increase current

(-) reduce current

8 Reset

All adjusted values are reset to factory setting.

Note that also the adjustment is deleted. Tag

number, measurement loop designation etc.

from the HART® or VVO-adjustment however

remain unchanged.

(+/-) Factory setting

Factory setting

0 Operate ---

1 Min. adjustment 4 mA at 0 pF

2 Max. adjustment 20 mA at 3000 pF

3 Integration time 0,5 s

4 Reverse characteristics 4 ... 20 mA

5 Linearisation off

6 Sensor optimization mode 1 (90°)

7 Simulation current off

8 Reset --9 Offset correction already saved values

remain

9 Offset correction

This function is required when an adjustment

should be carried out in m. This is only possible

with an oscillator CAP E 32 H Ex. With this

function the initial capacitance in the

electronics is saved. Requirement is that the

electrode is mounted in the vessel and

completely uncovered.

On electrodes with concentric tube this function

is already carried out as factory setting as the

vessel does not influence the measurement.

The offeset correction must only be repeated

when exchanging the oscillator.

(+/–) Initial capacitance is saved

Page 30

30 Capacitive electrodes EL 4 … 20 mA - compact

4.3 Adjustment with VVO

When an oscillator CAP E 32 H Ex is mounted,

the electrode can be also adjusted via a PC

with adjustment software VVO (from version

2.30).

VVO determines automatically the kind of the

connected sensor and shows a little later to

which sensor the connection exists.

When you get no sensor connection, check the

following:

- The supply voltage must be at least 20 V.

- When VEGACONNECT 2 is directly

connected to the sensor line, the load resistor

must be 250 ... 350 Ohm.

- You have to use a VEGACONNECT 2. Older

versions of VEGACONNECT are not

compatible.

The following adjustment steps are described in

their sequence and should be carried out in this

sequence with the initial set-up.

Further information are stated in the operating

instruction of the adjustment program VEGA

Visual Operating (VVO).

Configuration

Display Diagnostics Instrument data Configuration Services Quit Help

Measuring

system

Measurement loop >

Program >

Language

User access

Communication

Under the menu point Configuration you can

choose the following functions:

• Measuring system

• Measurement loop

• Program

The electrode is preadjusted by VEGA. The

measuring system must only be re-configured

when the oscillator is exchanged.

Set-up

Note

When the resistance of the voltage supply is

less than 250 Ω, a resistor must be looped into

the signal/connection line during adjustment.

The digital adjustment and communication

signals would be shortcircuited via too small

resistors e.g. of the supply current source or the

processing system so that the sensor

communication would not be ensured. The

easiest way would be to connect the required

adjustment resistor in parallel to the connection

sockets of the HART®-handheld (see fig. 1).

• Switch on the power supply of the connected

sensor.

• Start the adjustment software VVO (VEGA

Visual Operating) on your PC.

• In the entrance window you choose with the

arrow keys or the mouse the point

Planning

and click to OK.

You should only choose

Planning

when you

are authorized to modify instrument

parameters. Otherwise choose

Operator

or

Maintenance

.

In the window User identification you are

asked for the name and the password.

• For set-up (

planning

) enter under name:

VEGA

and under password again:

VEGA

. It

does not matter if you use capital or small

letters.

4

3

2

1

+ - + -

PC with VVO

mA

approx.

250 Ω

Page 31

Capacitive electrodes EL 4 … 20 mA - compact 31

Measuring system

In this sensor you can choose your appropriate

electrode. You can see the electrode type on

the type plate of the instrument.

Choose the correct electrode out of the list, e.g.

EL 21 14 mm PTFE. In front of the listed

electrodes you see the number of the electrode

type. The number to your electrode is stated on

the type plate. See also 1.6 Type plate. When

your electrode is not stated in the list, choose

´not configured´

. Push the button for saving to

confirm the choice.

In this window you can carry out additionally a

reset. All adjusted values are then reset to

factory setting. Note that also the adjustment

will be deleted.

Tag number, measurement loop designation

etc. from the HART® or VVO-adjustment

however remain unchanged.

Factory Setting

0 Operate --1 Min. adjustment 4 mA at 0 pF

2 Max. adjustment 20 mA at 3000 pF

3 Integration time 0,5 s

4 Reverse characteristics 4 ... 20 mA

5 Linearisation off

6 Sensor optimization mode 1 (90°)

7 Simulation current off

8 Reset --9 Offset correction already saved values

remain

Measurement loop

In this window you can make the measurement

loop designation.

Measurement loop no. (Sensor-TAG)

In this field you can enter a measurement loop

number, e.g. Tank 15 - 3. Max. 16 positions are

available.

Measurement loop description

In this field you can specify your measurement

loop in detail, e.g. level measurement - cleaning

solution.

Up to 80 positions can be entered.

Application

For capacitive electrodes

Level measurement

is

fixed adjusted and cannot be modified.

Program

In this menu point you can modify the

adjustments for the program.

Language

Here you can modify the language of the program.

User access

With this function you can modify the user name

and the password or deactivate the password

request.

Set-up

Page 32

32 Capacitive electrodes EL 4 … 20 mA - compact

Communication

You can determine the adjustments for data

transmission.

Options

In this function, programm adjustments such as

activate sound, backup etc. are available.

Instrument data

Display Diagnostics Instrument data Configuration Services Quit Help

Parameter adjustment

Under the menu point instrument data you can

choose the function:

• Parameter adjustment.

Parameter adjustment

The following functions are available:

- adjustment

- conditioning

- outputs

- sensor optimization

- additional functions

Adjustment - Min./Max. adjustment

With this function you can adjust the electrode

(min./max. adjustment).

You can choose if you want to carry out the

adjustment with or without medium.

Adjustment with medium

Min. adjustment

There must be min. level in the vessel. When

you push the button

Save,

the current value for

the actual min. level is set to 4 mA. The read out

of the sensor value in pF is also possible.

You can also coordinate a certain percentage

value to a known level.

When you know e.g. that your vessel is filled to

10 %, this can be entered under min.

adjustment.

Max. adjustment

There must be max. level in the vessel. When

you push the button

Save,

the current value for

the actual max. level is set to 20 mA. The

sensor value can be also read out in pF.

You can also coordinate a certain percentage

value to a known level.

The difference between min. and max.

adjustment should be at least 20% or 3,2 mA.

Adjustment without medium (dry

adjustment)

By means of the adjustment software VVO you

can carry out under certain requirements an

adjustment without medium.

The requirements for an adjustment in m are:

In conductive medium:

- electrode is fully insulated

For conductivity the following criteria are valid:

Mode 1 (90°) Mode 2 (45°)

with conc.tube > 50 µS/cm >150 µS/cm

without conc. tube >100 µS/cm >300 µS/cm

In non-conductive medium:

- concentric tube electrode

- you know the DK-value of the medium

Set-up

Page 33

Capacitive electrodes EL 4 … 20 mA - compact 33

When you know already the electrode

capacitance of a second similar measurement

loop (same electrode, same installation

conditions, same medium) you can also carry

out the dry adjustment in pF.

First carry out an offset correction with

uncovered electrode (only with adjustment in m:

Instrument data - Parameter adjustment - Additional functions

).

Move to function

Adjustment without medium

.

You can choose if you want to carry out the

adjustment in pF or in m. When you have

chosen the adjustment in m, you have to enter

whether your medium is conductive or nonconductive. When the medium is nonconductive you must additionally enter the

dielectric constant figure.

In the previous table you can see which criteria

are valid for the conductivity with the capacitive

measurement and if you have to choose

Conductive

or

Non-conductive.

When you have chosen m, you can coordinate

to the current or percentage values an

appropriate value in metres.

Example

0% = 4,00 mA = 0,2 m

100 % = 20,00 mA = 3,2 m

When you have chosen pF, you can coordinate

to the current or percentage values an

appropriate value in pico-farad

Example

0% = 4,00 mA = 97,2 pF

100 % = 20,00 mA = 1428,0 pF

When you push the button OK, the values are

taken over for adjustment.

Conditioning

In this window the following functions are

available:

- scaling

- linearisation

- integration time

Scaling

With this command you can scale the

measured value for your indication.

You can choose out of 16 volume, height and

mass units or just dimensionless.

The indication values can be between -10000

and +10000.

Linearisation

In this window you can linearize unlinear

vessels such as e.g. cylindrical tanks.

The following linearisation curves are available:

- linear

- cylindrical tank

- spherical tank

- user programmable curve

On oscillator CAP E32 H you can enter under

“user programmable curve“ also own

linearisation curves for special vessels, e.g.

vertical cylindrical tanks with large conical

outlet.

Push the button

Edit.

You can enter the value

pairs (percentage value - volume value) for 32

index markers.

Push the button

Transfer

, to enquire further

linearisation curves.

Integration time

Choose this function when you want to adjust

an integration time (damping).

The possible integration time is between 0,5

and 300 seconds. As a standard feature an

integration time of 0,5 seconds is adjusted. For

an integration time of 0,5 s you have to enter

the value 0.

After the adjusted integration time, a measured

value change of 63 % is available on the

output.

Set-up

Page 34

34 Capacitive electrodes EL 4 … 20 mA - compact

Output - Current output

In this window you can change the

preadjustments for the current output. Push the

button

Save

to tranfer the modified values.

Failure mode

The capacitive sensor delivers in case of failure

generally 22 mA. This value cannot be

modified.

The current output corresponds to

The parameter of the current output is always

percent with capacitive electrodes.

Invert current output

With this function you can reverse the

characteristics of the current output (4 ... 20 or

20 ... 4 mA).

Sensor optimisation

In this window you can adjust the mode of the

sensor.

Hence the phase angle of the phase selective

admittance processing (PSA) is modified.

“Mode 1“ is preadjusted.

Mode 1 = Phase angle 90°

Mode 1 is a pure capacitance measurement,

the ohmic resistance is not considered in the

measuring result.

Application:

- standard adjustment

- non-conductive liquids up to approx. 500 µS

- compensation of resistance changes in

liquids

- generally with partly insulated electrodes in

liquids

- non-conductive solids without humidity

contents

- in case of bad earth of the medium

- with electrodes in conjunction with a

concentric tube

- in non-conductive vessels with earth plate

provided from outside.

Mode 2 = Phase angle 45°

The capacitance and the ohmic resistance are

measured separately, the capacitance value is

corrected by calculation with the ohmic

resistance, so that measuring errors by

conductive build-up or modifications of the

product humity are compensated.

Application:

- high conductivity products

- adhesive, conductive products

- solids with fluctuating humidity contents

Additional functions

Offset correction

This function is required when an adjustment

should be carried out in m. This is only possible

in conjunction with oscillator CAP E 32 H Ex.

With this function the initial capacitance is

saved in the electronics. Requirement is that

the electrode is mounted in the vessel and

completely uncovered.

The offset correction is necessary when an

adjustment should be carried out without

medium.

On electrodes with concentric tube, this

function is already carried out as factory setting

as the vessel does not influence the

measurement.

The offset correction must only be repeated

when the oscillator is exchanged.

Display

Display Diagnostics Instrument data Configuration Services Quit Help

Display of measured value

Under the menu point display you can choose

the function:

• Display of measured value.

Display of measured value

In this window the actual measured value is

displayed digitally and as bargraph.

The upper bar shows the actual measured

value in percent, pF or scaled in the

appropriate unit.

The lower bar shows the actual sensor current

value in mA.

Set-up

Page 35

Capacitive electrodes EL 4 … 20 mA - compact 35

Diagnostics

Display Diagnostics Instrument data Configuration Services Quit Help

Status

Si

mulation

Under the menu point diagnostics you can

choose the following functions.

• status

• simulation

Status

This function is not available.

Simulation

With this function you can simulate a level. Push

the start button to activate the simulation. Shift

the scrollbar to the requested current value or

enter a certain current value. The scaled

indication bar is modified in parallel.

Push the button

Stop

to interrupt the simulation.

When you quit the window

Simulation,

the

simulation is automatically interrupted.

Services

Display Diagnostics Instrument data Configuration Services Quit Help

Print

View

Backup >

Restore configuration >

Edit database

User level

Connection F8

Modem F7

Signal conditioning

instruments

Sensors

Under the menu point services you can choose

the following functions:

• print

• view

• backup

• restore configuration

• edit database

• user level

• connection

• modem

Set-up

Print

With this function you can print a protocol with

the adjustments of the sensor.

View

With this function you can have the protocol

with the sensor adjustments displayed.

Backup - Sensors

In this window you can save the adjustments of

the sensor in a database.

Restore configuration - Sensors

In this window you can enquire the adjustments

of the sensor from the database.

Edit database

In this window you can edit the saved sensor

data of the database.

User level

In this window you can choose the user level.

The following user levels are available:

- operator

- maintenance

- planning

Operator

This user level is for the operator. Indication

or print out of measured values and sensor

data. For this level there is no password

required.

Maintenance

When you use the level maintenance, you can

choose all functions except configuration.

The password for this level is: VEGA.

Planning

When you choose the level planning all

functions are accessible.

The passwords for the planning level are:

VEGA - VEGA.

Connection

Page 36

36 Capacitive electrodes EL 4 … 20 mA - compact

4.4 Adjustment with HART®handheld

The capacitive electrodes EL with oscillator

CAP E32 H Ex are suitable for HART®-protocols

and can be adjusted with a HART®-handheld.

All relevant sensor functions can be carried out

with the HART®-standard menus. A

manufacturer specific DDD (Data-DeviceDescription) is not necessary.

Connect the HART®-handheld to the signal line

after you have connected the sensor to the

supply voltage.

4

3

2

1

+ - + -

mA

250 Ω

HART®-handheld

With this function you can start a new

connection. This function can also be activated

with key F8.

Modem

This window enables the adjustments for data

transmission with a modem. This function can

also be activated with key F7.

No special requirements necessary for the

modem used.

Note

When the resistor of the supply voltage is less

than 250␣ Ω, a resistor must be looped into the

signal/connection line during adjustment. The

digital adjustment and communication signals

would be shortcircuited via too small resistors

e.g. of the current source or the processing

system so that the sensor communication

would no more be ensured. The easiest way

would be to connect the required resistor in

parallel to the socket of the HART®-handheld

(see fig. 1, page 38).

Set-up

Multidrop-operation

With the HART®-handheld the Multidropoperation can be chosen.

Hence several HART®-sensors can be

composed on one two-wire line.

The sensor provides beside the 4 … 20 mAsignal also a digital (HART®) level signal.

• When you enter address 0 (factory setting),

the sensors takes a level independent 4 …

20 mA-current and delivers a digital (HART®)

level signal. In this line e.g. also an indicating

instrument (4 … 20 mA) can be looped.

• When you enter an address from 1 to 15, the

sensor takes permanently a current of 4 mA

and delivers a digital (HART®) level signal.

Burst-operation

Normally the sensor signals the measured

values to the processing unit only on request.

When you switch on Burst-operation, the sensor

signals the measured values without request.

Page 37

Capacitive electrodes EL 4 … 20 mA - compact 37

Connection to a VEGA-signal conditioning

instrument

(fig. 3, page 38)

When you operate a sensor suitable for HART

®

on a VEGA-signal conditioning instrument, you

have to provide the sensor connection on the

signal conditioning instrument with a resistor of

the following table for the duration of the

HART®-adjustment.

VEGA-signal conditioning Rx

instrument

VEGAMET 513, 514, 515, 602

VEGATRENN 544

VEGATOR 521…527 50 … 100 Ω

VEGAMET 614 no additional

VEGADIS 371 resistor

required

VEGAMET 601 200 … 250 Ω

VEGASEL 643 150 … 200 Ω

VEGAMET 513 S4, 514 S4

515 S4 100 … 150 Ω

Set-up

Page 38

38 Capacitive electrodes EL 4 … 20 mA - compact

Ri > 250

+

–

Fig. 2

DCS

Fig. 3

+

–

VEGALOG VEGAMET

250

Ri < 250

+

–

Fig. 1

DCS

Set-up

250 Ω

Page 39

Capacitive electrodes EL 4 … 20 mA - compact 39

Set-up

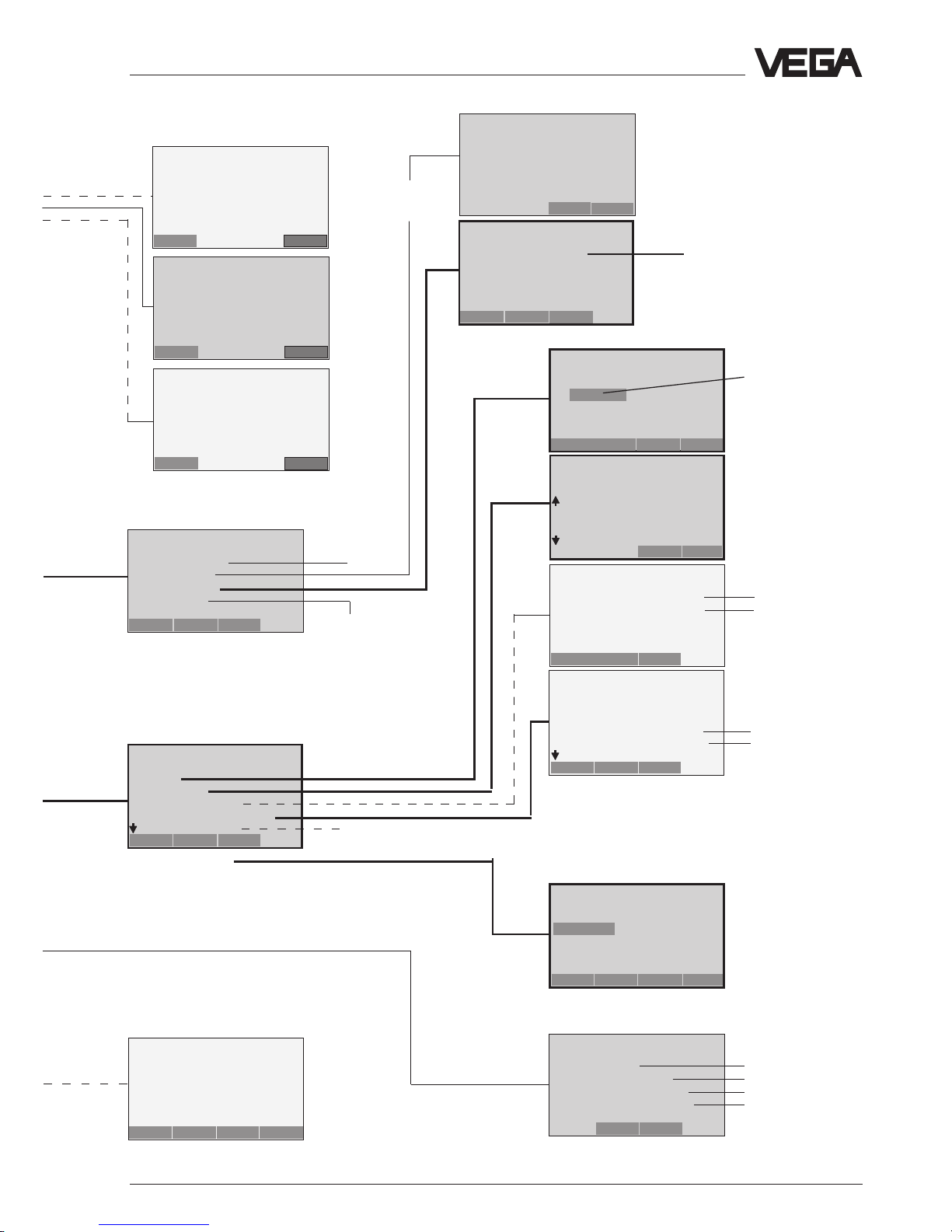

Adjustment steps

On the following pages you see the menu plan

to the HART®-handheld in relation with

capacitive electrodes.

The most important adjustment steps are

marked in the menu plan with the figures

A␣ …␣ D.

General information to the HART®-handheld:

When you enter or modify parameters, you

have to push the key “

ENTER

“. Hence the

adjustment is saved in the handheld but not in

the sensor itself.

After you have pushed “

ENTER

“, you have to

push “

SEND

“, to transfer the adjustment to the

sensor.

After pushing of “

SEND

“ a warning is

displayed.

When you push “OK“, the adjustment is

transmitted to the sensor.

Another safety enquiry asks you to switch over

your system from manual to automatic

operation. Push “

OK“

With

“HOME“

you reach again the initial menu.

Generic: SENSOR

PV LRV

0.000 m

10.000

HELP DEL ABORT ENTER

4.1

(5.1)

Empty adjustment without

medium

Generic: SENSOR

1PV LRV

2PV URV

HELP SEND HOME

Generic: SENSOR

- WARNINGPressing ”OK“ will

change device output.

Put loop in manual

ABORT OK

Generic: SENSOR

- WARNING-

Return control loop to

automatic control.

OK

Generic: SENSOR

1PV LRV

2PV URV

HELP HOME

Page 40

40 Capacitive electrodes EL 4 … 20 mA - compact

Set-up

HART®-menu plan

A

1

2

3

4

5

1.1

4.1

(5.1)

4.2

(5.2)

Less important

menu windows

Not required,

unimportant or blocked

menu windows

Important and

necessary menu

windows

B

Switch on:

after approx.

20 s

Set-up the sensor in the sequence of

the figures A, B, C and D (adjustment

without medium).

In case of adjustment with medium, setup the sensor in the sequence A1, B1,

C and D.

continue like under A

figure 4.1(5.1)

Empty adjustment

without medium

Full

adjustment

without

medium

continue like under

figure 4

Hart Communicator

Self Test

in Progress

Firmware Rev: F2.2

Module Rev: 3.6

01992-96 FRSI

Generic: Sensor

PV

2,56 m

HELP EXIT

Generic: Sensor

Device setup

1 Process variables

2 Diag/Service

3 Basic setup

4 Detailed setup

5 Review

SAVE HOME

Generic: Sensor

PV URV

100.000 m

90.300

HELP DEL ESC ENTER

Generic: Sensor

Process variables

1 Snsr 2,56 m

2 AI % rnge

3 AO1

HELP SAVE HOME

Generic: Sensor

Online(Generic)

1 Device setup

2PV

3PVAO

4PVLRV

5URV

HELP SAVE

Generic: Sensor

AO1

16.952 mA

HELP EXIT

Generic: Sensor

1 PV LRV

2URV

HELP SEND HOME

Generic: Sensor

PV LRV

0.000 m

10.000

HELP DEL ESC ENTER

Generic: Sensor

1 PV LRV

2URV

HELP SEND HOME

Page 41

Capacitive electrodes EL 4 … 20 mA - compact 41

Set-up

blocked menu.

6 PV Damping

1.1.3

1.2

1.3

1.4

1.5

1.1.2

1.1.1

1.3.1

1.3.2

1.3.3

1.3.4

1.3.6

6 Write protect None

7 Descriptor

8 Message

9 PV Snsr s/n

Final asmbly num

Revision’s

1.2.3

1.2.2

Individual current values for

test purposes (simulation of

measured values)

Empty and full

adjustment

with medium

(see next

page)

see

next

page

see next

page

C

D

new entered

measuring loop

designation to be

confirmed with

ENTER and SEND

}

}

see

next

page

}

Transmission function

(linear)

Confirm

safety

enquiry

A1

B1

}

Generic: Sensor

Detailed setup

1 Sensors

2 Signal condition

3 Output condition

4 Device information

SAVE HOME

Generic: Sensor

PV

0,2 m

HELP EXIT

Generic: Sensor

PV % rnge

8.945 %

HELP EXIT

Generic: Sensor

AO1

5.952 mA

HELP EXIT

Generic: Sensor

PV Snsr unit

m

m

bbl

in

cm

ESC ENTER

Generic. Sensor

Range values

1 PV LRV

2URV

3 PV LSL

4 USL

HELP HOME

Generic: Sensor

PV Damp

1.000 s

2 .000 s

HELP DEL ESC ENTER

Generic: Sensor

Basic setup

1Tag

2 PV Unit

3 Range values

4 Device information

5 PV Xfer fnctn

HELP SAVE HOME

Generic: Sensor

Review

Model

Generic

HELP PREV NEXT EXIT

Generic: Sensor

Calibration

1 Apply values

2 Enter values

HELP SAVE HOME

Generic: Sensor

Choose analog output

level

14 mA

2 20 mA

3 Other

4 End

ABORT ENTER

Generic: Sensor

Diag/Service

1 Test device

2 Loop test

3 Calibration

4 D/A trim

SAVE HOME

Generic: Sensor

Device information

1 Distributor

2 Model Generic

3 Dev id

4Tag

5 Date 10/01/97

HELP SAVE HOME

Generic: Sensor

Tag

Sensor

Sensor

HELP DEL ESC ENTER

Page 42

42 Capacitive electrodes EL 4 … 20 mA - compact

Set-up

1.3.3

1.3.4

6 Write protect None

7 Descriptor

8 Message

9 PV Snsr s/n

Final asmbly num

Revision’s

1.4

like menu 1.3.4

1.2.3.2

as display 4.1