Page 1

Ope

rating Instructions

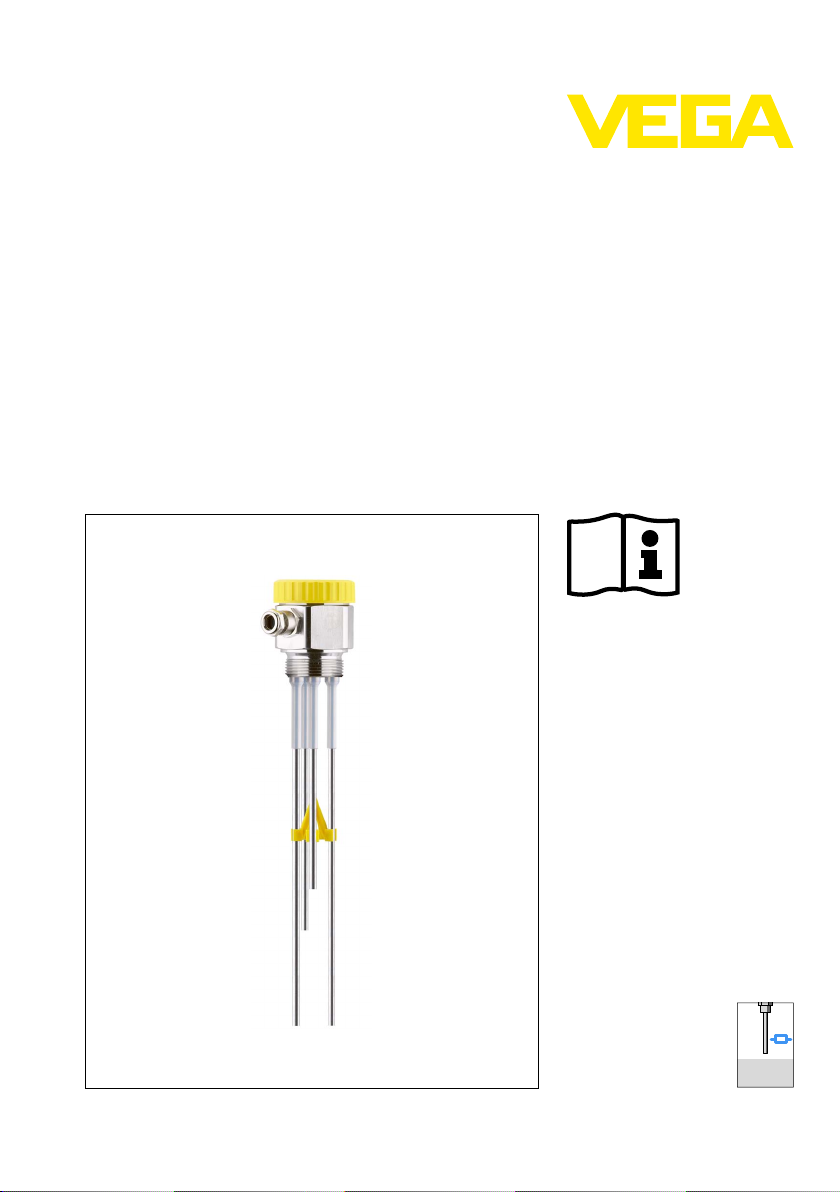

Conductive probe EL 3

Document ID:

32652

Cond

uctive

Page 2

Contents

Conten

1 About this document

2 For your safety

3 Product description

4 Mounting

5 Connecting to power supply

6 Set up

ts

1.1 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Symbolism used . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . .

2.4 General safety instructions . . . . . . . . . . . . . . . . . . . .

2.5 Safety instructions for Ex areas . . . . . . . . . . . . . . . . .

2.6 Environmental instructions. . . . . . . . . . . . . . . . . . . . .

3.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Storage and transport . . . . . . . . . . . . . . . . . . . . . . .

4.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Mounting instructions . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Preparing the connection . . . . . . . . . . . . . . . . . . . . .

5.2 Wiring plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 General information . . . . . . . . . . . . . . . . . . . . . . . . .

3

3

3

4

4

4

4

5

5

6

7

7

8

9

10

12

12

15

7 Maintenance and fault rectification

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Rectify malfunctions . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Shortening the probe . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Instrument repair . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Dismounting

8.1 Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Supplement

9.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Industrial property rights . . . . . . . . . . . . . . . . . . . . . .

9.4 Trademark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Cond

16

16

16

16

18

18

19

21

22

22

uctive probe EL 3

32652-EN-100208

Page 3

out this document

1 Ab

1 Abou

t this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important

instructions for maintenance and fault rectification. Please read this

information before putting the instrument into operation and keep this

manual accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained qualified

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Inform

ation, tip, note

This symbol indicates helpful additional information.

Cauti

on: If this warning is ignored, faults or malfunctions can

result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

applications

Ex

This symbol indicates special instructions for Ex applications.

32652-EN-100208

Condu

l List

The dot set in front indicates a list with no implied sequence.

à Action

Th

is arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

ctive probe EL 3 3

Page 4

2 For

your safety

or your safety

2 F

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

The EL 3 is a sensor for level detection.

You can find detailed information on the application range in chapter

"Product description".

Operational reliability is ensured only if the instrument is properly used

according to the specifications in the operating instructions manual as

well as possible supplementary instructions.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbitrary

conversions or modifications are explicitly forbidden.

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to system

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a high-tech instrument requiring the strict observance of

standard regulations and guidelines. The user must take note of the

safety instructions in this operating instructions manual, the countryspecific installation standards as well as all prevailing safety

regulations and accident prevention rules.

The instrument must only be operated in a technically flawless and

reliable condition. The operator is responsible for trouble-free

operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the required occupational safety measures with the

current valid rules and regulations and also take note of new

regulations.

4 Cond

32652-EN-100208

uctive probe EL 3

Page 5

2 For

your safety

2.5 Safety

Please note the Ex-specific safety information for installation and

operation in Ex areas. These safety instructions are part of the

operating instructions manual and come with the Ex-approved

instruments.

instructions for Ex areas

2.6 Environmental instructions

Protection of the environment is one of our most important duties. That

is why we have introduced an environment management system with

the goal of continuously improving company environmental protection.

The environment management system is certified according to DIN

EN ISO 14001.

Please help us fulfil this obligation by observing the environmental

instructions in this manual:

l Chapter "Packaging, transport and storage"

l Chapter "Disposal"

32652-EN-100208

Condu

ctive probe EL 3 5

Page 6

1

2

3

3 Produc

t description

Scope of delivery

Constituents

3 Produc

t description

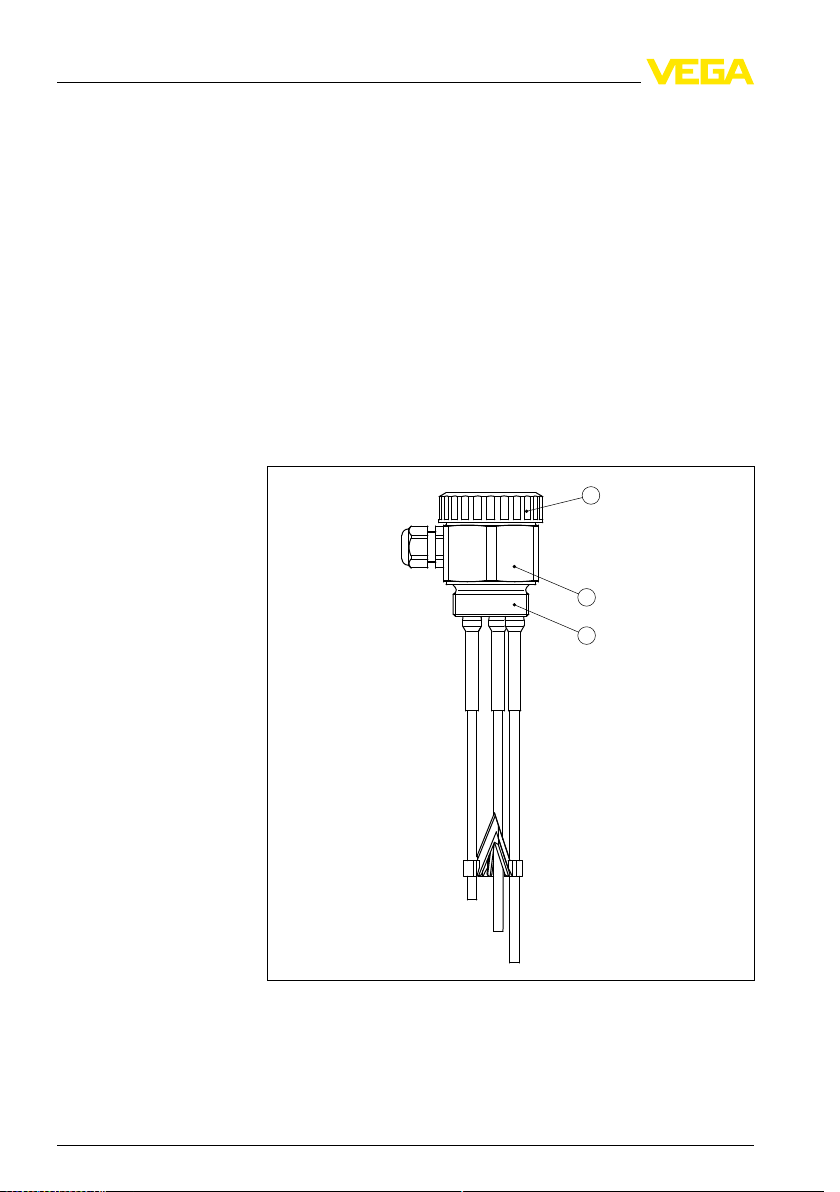

3.1 Configuration

The scope of delivery encompasses:

l EL 3 point level sensor

l Documentation

- this operating instructions manual

- Ex-specific "Safety instructions" (with Ex versions)

- if necessary, further certificates

The EL 3 consist of the following components:

l Housing cover

l Housing

l Process fitting with electrode

Fig. 1: Conductive

1 Housing cover

2 Housing

3 Process fitting

To create a measuring system you need one conductive probe and a

VEGATOR 256C, 532 or 631 signal conditioning instrument.

6 Cond

multiple rod electrode EL 3

32652-EN-100208

uctive probe EL 3

Page 7

Type label

3 Produc

e type label contains the most important data for identification a nd

Th

use of the instrument:

l Article number

l Serial number

l Technical data

l Article numbers, documentation

With the serial number, you can access the delivery data of the

instrument via

search". In addition to the type label outside, you can also find the

serial number on the inside of the instrument.

www.vega.com, "VEG

A Tools" and "serial number

t description

3.2 Principle of operation

Application area

Functional principle

Voltage supply

EL 3 is a point level sensor with partly insulated conductive electrode

for level detection.

EL 3 is very rugged and can be used in all areas of industrial process

technology.

The level switch can be used in conductive liquids such as e.g. water.

Typical applications are overfill and dry run protection.

The conductive measuring principle places no special requirements on

installation. Hence, many different applications can be equipped with

EL 3.

Conductive probes detect the product resistance when their electro-

des are covered by the product.

The switching signal is determined by the length or mounting position

of the respective electrode.

A low alternating current flows through the electodes, is measured for

amplitude and phase position by the electronics of the signal

conditioning instrument and converted into a switching command.

EL 3 is operated with an external processing unit. The connected

signal conditioning instrument powers EL 3 and provides a switching

signal. A connected device can be activated directly with this switching

command (e.g. a warning sys tem, a PLC, a pump, etc.).

You can find the exact range of the voltage supply in chapter

"Technical data" in the operating instructions manual of the signal

conditioning instrument.

32652-EN-100208

Condu

3.3 Operation

The probe does not have its own electronics. The measurement is

carried out via the connected signal conditioning instrument.

ctive probe EL 3 7

Page 8

3 Produc

t description

Packaging

Transport

Transport inspection

Storage

Storage and transport

temperature

3.4 Stora

ge and transport

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE foil

is also used. Dispose of the packaging material via specialised

recycling companies.

Transport must be carried out under consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or

concealed defects must be appropriately dealt with.

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

l Not in the open

l Dry and dust free

l Not exposed to corrosive media

l Protected against solar radiation

l Avoiding mechanical shock and vibration

l Storage and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

8 Cond

32652-EN-100208

uctive probe EL 3

Page 9

4 M

ounting

Switching point

Handling

Moisture

4 Moun

ting

4.1 General instructions

In general the level switch can be mounted in any position. The

instrument must be mounted in such a way that the probe is at the

height of the requested switching point.

The probe is provided with a special hexagon for tightening. Due to the

hexagon shape, the housing itself can be used to screw the instrument

in.

The wrench size is stated in chapter "Supplement" under "Dimen-

sions".

Use the recommended cables (see chapter "Connecting to power

supply") and tighten the cable gland.

You can give your EL 3 additional protection against moisture

penetration by leading the connection cable downward in front of the

cable entry. Rain and condensation water can thus drain off. This

applies mainly to outdoor mounting as well as installation in areas

where high humidity is expected (e.g. through cleaning processes) or

on cooled or heated vessels.

Transport

Pressure/Vacuum

32652-EN-100208

Condu

ctive probe EL 3 9

Fig. 2: Measures

Do not hold EL 3 on its electrode rods. Particularly with long rod

versions, the sensor can be damaged by the weight of the instrument.

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical data"

or on the type label of the sensor.

against moisture penetration

Page 10

1

2

1

2

4 M

ounting

Agitators and fluidization

4.2 Mount

Due to agitators, equipment vibration or similar, the level switch can be

subjected to strong lateral forces.

Extreme vibration caused by the system, e.g. due to agitators or

turbulence in the vessel from fluidization, can cause the probe of EL 3

to vibrate in resonance. If a longer rod version is necessary, you can

secure the probe by fastening a suitable insulating brace or guy

directly above the end of the rod.

Fig. 3: Fasten

1 Probe

2 Plastic sleeve at the probe end or laterally mounted

ing instructions

the probe

Inflowing medium

If EL 3 is mounted in the filling stream, unwanted false measurement

signals can be generated. For this reason, mount EL 3 at a position in

the vessel where no disturbances, e.g. from filling openings, agitators,

etc., can occur.

This applies particularly to instrument versions with a longer probe.

10 Cond

32652-EN-100208

uctive probe EL 3

Page 11

4 M

ounting

Socket

Ground connection

Fig. 4: Inflowing

medium

The probe should protrude into the vessel to avoid buildup. For that

reason, avoid using high mounting bosses for screw-in fittings. This

applies particularly to use in adhesive products.

Make su re that the mechanical connection of the probe to the vessel is

electrically conductive to ensure sufficient grounding.

Use conductive seals, such as those made of copper or lead, etc.

Insulating measures, such as covering the thread with Teflon tape, can

interrupt the necessary electrical connection with metal vessels. For

this reason, ground the probe on the vessel or use a conductive seal

material.

32652-EN-100208

Condu

ctive probe EL 3 11

Page 12

ecting to power supply

5 Conn

Note safety instructions

Voltage supply

Connection cable

Connection compart-

ment

5 Conn

ecting to power supply

5.1 Preparing the connection

Always keep in mind the following safety instructions:

l Connect only in the complete absence of line voltage

You can find the electrical connection of EL 3 in the operating

instructions manual of the corresponding signal conditioning instrument.

You can find suitable signal conditioning instruments in chapter

"Technical data".

The instrument is connected with standard two-wire cable without

screen. If electromagnetic interference is expected which is above the

test values of EN 61326 for industrial areas, screened cable should be

used.

Use cable with round cross-section. A cable outer diameter of 5 … 9 mm

(0.2 … 0.35 in) ensures the seal effect of the cable gland. If you are

using cable with a different diameter or cross-section, exchange the

seal or use a suitable cable gland.

5.2 Wiring plan

You can find the electrical connection of EL 3 in the operating

instructions manual of the corresponding signal conditioning instrument.

Line monitoring with

VEGATOR 631

12 Cond

To realize a line monitoring with a VEGATOR 631 signal conditioning

instrument, a resistor of 220 kΩ must be integrated in the connection

housing of the probe between terminal 1 and 2.

When a fault message is generated, the switching output is

simultaneously activated.

If a fault message is not wanted, a bridge must be provided on the

signal conditioning instrument instead of the resistor in the connection

housing of the probe.

The line monitoring is thus deactivated and the fault message

rendered invalid.

Take note of the operating instructions manual of the signal

conditioning instrument.

With Ex

the connection housing of the probe. The Ex measuring system (max.

and ground connection cable of the probe to the signal conditioning

instrument) is generally monitored for line break.

l Terminal 1 = longest rod (ground)

versions, this 220 kΩ resistor is already integrated ex factory in

32652-EN-100208

uctive probe EL 3

Page 13

1

2

3

4

5

4

3

2

1

2

3

1

1

2

2

2

3

4

1

2

3

4

1

5

2

3

1

1

A B

C D

ecting to power supply

5 Conn

Line monitoring with

VEGATOR 632

l Term

Fig. 5: Connection

terminals 1 and 2

1 Connection terminal 1 = longest rod

2 Connection terminal 2 = shortest rod

A Probe with 2 rods

B Probe with 3 rods

C Probe with 4 rods

D Probe with 5 rods

inal 2 = shortest rod (max.)

compartment of the probe - 220 kΩ resistance between

The line break monitoring or alarm function defines the function of the

signal conditioning instrument in case of failure.

To realize line monitoring with a signal conditioning instrument

VEGATOR 632, an additional component must be mounted in the

connection housing of the probe.

32652-EN-100208

Condu

Fig. 6: Component

ctive probe EL 3 13

for line break monitoring in conjunction with VEGATOR 632

Page 14

1

2

ecting to power supply

5 Conn

1 Connec

t the eyelet according to the following illustration.

Make sure that the eyelets have no contact to other metal parts.

2 Open one of the other terminals and attach the component.

3 Tighten the terminal.

Fig. 7: Mounting

1 Connection to terminal 1 (ground rod = longest rod)

2 Connection to terminal 2 (max. rod = shortest rod)

3 Component for line break monitoring with VEGATOR 632

of the component for line break monitoring

If you are using a probe without component for line break monitoring, a

fault signal will be triggered.

Keep in mind that in case of a fault signal also the switching output will

be activated.

Only failures of channel 1 are monitored.

Take note of the operating instructions manual of the signal

conditioning instrument.

14 Cond

32652-EN-100208

uctive probe EL 3

Page 15

6 Set

up

6 Set

up

6.1 General information

You can find the setup procedure for EL 3 in the operating instructions

manual of the corresponding signal conditioning instrument.

32652-EN-100208

Condu

ctive probe EL 3 15

Page 16

aintenance and fault rectification

7 M

Causes of malfunction

Fault rectification

24 hour service hotline

7 Maint

enance and fault rectification

7.1 Maintenance

When used as directed in normal operation, EL 3 is completely

maintenance free.

7.2 Rectify malfunctions

EL 3 offers maximum reliability. Nevertheless, faults can occur during

operation. These may be caused by the following, e.g.:

l Sensor

l Process

l Voltage supply

l Signal processing

You can find information on fault rectification in the operating

instructions manual of the corresponding signal conditioning instrument.

However, should these measures not be successful, call the VEGA

service hotline in urgent cases under the phone no. +49 1805 858550.

The hotline is available to you 7 days a week round-the-clock. Since

we offer this service world-wide, the support is only available in the

English language. The service is free of charge, only the standard

telephone costs will be charged.

7.3 Shortening the probe

The probe can be shortened by any amount.

Note:

ke note when shortening multiple probes that terminal 1 corre-

Ta

sponds to the longest probe and terminal 2 to the shortest probe.

7.4 Instrument repair

If a repair is necessary, please proceed as follows:

You can download a return form (23 KB) from our Internet homepage

www.vega.com

form".

By doing this you help us carry out the repair quickly and without

having to call back for needed information.

l Print and fill out one form per instrument

l Clean the instrument and pack it damage-proof

16 Cond

under: "Downloads - Forms and certificates - Repair

32652-EN-100208

uctive probe EL 3

Page 17

aintenance and fault rectification

7 M

ch the completed form and, if need be, also a safety data

l Atta

sheet outside on the packaging

l Please ask the agency serving you for the address of your return

shipment. You can find the respective agency on our website

www.vega.com under: "Company - VEGA worldwide"

32652-EN-100208

Condu

ctive probe EL 3 17

Page 18

8 Dismoun

ting

8 Dismou

nting

8.1 Dismounting steps

Warning:

Before dismounting, be aware of dangerous process conditions such

as e.g. pressure in the vessel, high temperatures, corrosive or toxic

products etc.

Take note of chapters "Mounting" and "Connecting to power supply"

and carry out the listed steps in reverse order.

8.2 Removal

The instrument consists of materials which can be recycled by

specialised recycling companies. We use recyclable materials and

have designed the electronics to be easily separable.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/EG and

the respective national laws. Pass the instrument directly on to a

specialised recycling company and do not use the municipal collecting

points. These may be used only for privately used products according

to the WEEE directive.

Correct disposal avoids negative effects to persons and environment

and ensures recycling of useful raw materials.

Materials: see chapter "Technical data"

If you have no possibility to dispose of the old instrument

professionally, please contact us concerning return and disposal.

18 Cond

32652-EN-100208

uctive probe EL 3

Page 19

9 Sup

plement

9 Supp

lement

9.1 Technical data

General data

Materials 316Ti corresponds to 1.4571, 316L corresponds to 1.4404 or 1.4435

Materials, wetted parts

- Process fitting 316Ti

- Process seal Klingersil C-4400

- insulation (partly insulated) PTFE

- Probe (rod partly PTFE insulated: ø 6 mm/

0.236 in)

Materials, non-wetted parts

- Housing 316Ti

- Housing cover PBT

- Seal between housing and housing

cover

- Cable gland brass, nickel-plated

Process fitting G1½ A (ISO 228 T1)

Weight

- with stainless steel housing 900 g (32 oz)

- Rod weight: ø 6 mm (0.236 in) 220 g/m (2.4 oz/ft)

Sensor length (L1 - L5) 0.1 … 6 m (0.328 … 19.69 ft)

Insulation length 78 mm (3.15 in)

316Ti, Hastelloy C4 (2.4610)

NBR

Output variable

Suitable signal conditioning instruments VEGATOR 256C, 532, 631

Ambient conditions

Ambient temperature on the housing -40 … +80 °C (-40 … +176 °F)

Storage and transport temperature -40 … +80 °C (-40 … +176 °F)

Process conditions

Process pressure -1 … 63 bar/-100 … 6300 kPa (-14.5 … 914 psig)

Process temperature EL 3 of 316L -50 … +130 °C (-58 … +266 °F)

Conductive of the medium min. 7.5 µS/cm

Electromechanical data

Cable entry 1 x cable gland M20 x 1.5 (cable: ø 5 … 9 mm/

32652-EN-100208

Condu

ctive probe EL 3 19

0.2 … 0.35 in)

Page 20

9 Suppl

Electri

Protection rating IP 66/IP 67

Approvals

Depending on the version, instruments with approvals can have different technical data.

For these instruments, the corresponding approval documents have to be taken into account.

These are part of the delivery or can be downloaded under

"serial number search" as well as via "Downloads" and "Approvals".

ement

cal protective measures

www.vega.com

via "VEGA Tools" and

20 Cond

32652-EN-100208

uctive probe EL 3

Page 21

9.2 D

M20x1,5

66mm (2 19/32")

57mm (2 1/4")

ø 6mm

(15/64")

59mm (2

21

/

64

") 80mm (3

5

/

32

")

SW 60mm

(2 23/64")

G1½A

20mm

(

25

/

32

")

L3

L1

L2

imensions

9 Sup

plement

Fig. 8: Conductive

multiple rod electrode EL 3

L1 Sensor length, see chapter "Technical data"

L2 Sensor length, see chapter "Technical data"

L3 Sensor length, see chapter "Technical data"

32652-EN-100208

Condu

ctive probe EL 3 21

Page 22

9 Suppl

ement

9.3 Indus

VEGA product lines are global protected by industrial property rights.

Further information see http://www.vega.com.

Only in U.S.A.: Further information see patent label at the sensor

housing.

VEGA Produktfamilien sind weltweit geschützt durch gewerbliche

Schutzrechte.

Nähere Informationen unter http://www.vega.com.

Les lignes de produits VEGA sont globalement protégées par des

droits de propriété intellectuelle.

Pour plus d'informations, on pourra se référer au site http://www.vega.

com.

VEGA lineas de productos están protegidas por los derechos en el

campo de la propiedad industrial.

Para mayor información revise la pagina web http://www.vega.com.

Линии продукции фирмы ВЕГА защищаются по всему миру

правами на интеллектуальную собственность.

Дальнейшую информацию смотрите на сайте http://www.vega.com.

VEGA系列产品在全球享有知识产权保护。

进一步信息请参见网站<http://www.vega.com>。

trial property rights

9.4 Trademark

All the brands as well as trade and company names used are property

of their lawful proprietor/originator.

22 Cond

32652-EN-100208

uctive probe EL 3

Page 23

9 Sup

plement

32652-EN-100208

Condu

ctive probe EL 3 23

Page 24

VEGA Grieshaber KG

ISO 9001

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

Printing date:

statements concerning scope of delivery, application,

All

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2010

Subject to change without prior notice 32652-EN-100208

Loading...

Loading...