Page 1

INSTRUCTION MANUAL

HYDRAULIC GAT E

PHV 240-PHV 360

Ed1. 14/12/09 (Italiano)

Page 2

Declaration of Conformity

Company Name: VDS, Internacional Co. Soc. Coop..

Address: Via Circolare P.I.P. Sn – 65010 Santa Teresa di Spoltore (PE)

National Identity Number (CIF/NIF): it 01807970684

C E R T I F I ES:

That the hydraulic equipment PHV240-PHV360 conforms to the following EU Directives:

89/392/EEC On the approximation of the laws of the Member States relating to machinery.

91/368/EEC Council Directive amending the previous Directive on the approximation of the laws of the Member States to

93/44/EEC Council Directive amending Directive 89/392/EEC on the approximation of the laws of the Member States to

93/68/EEC Regulating the Directive on simple pressurised containers, construction products, electromagnetic

2004/108/EEC Council Directive amending Directive 89/336/EEC on approximation of the laws of the Member States to

73/23/EEC On the approximation of the laws of the Member State son electrical material destined for use with specific

EU-EN 292-2/A1 Safety of machinery. Basic Concepts and general principles of design.

EU-EN 60204-1 Safety of machinery and electrical equipment of machinery.

EU-EN 292/1 Safety of machinery. Basic concepts and general principles of design.

EU-EN 418 Safety of machinery and emergency Shopping equipment, functional aspects.

EU-EN 982:96 Safety of machinery. Safety requirements for systems and components of hydraulic and pneumatic

This equipment bears the stamp of EEC conformity

Santa Teresa di Spoltore il 26 maggio del 2009

Company representative

GIUSEPPE DIODATO

machinery.

machinery.

compatibility, machinery, individual protection equipment, non automatic weighing machinery, terminal

telecommunication equipment and electrical material destined for use with specific voltage limits.

electromagnetic compatibility.

voltage limits.

transmissions Hydraulic.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

the following instructions.

.

inappropriate

the

environment. The presence of inflammable gases or smoke

it is also necessary to install

that will prevent any

es it is also necessary to install at least one light signal as well as a

The installation of this equipment, the electrical connections and maintenance of the equipment may only be

cause severe injury and/or death, for which

rential and a thermal

safety

es are properly working and that the pressure force is adjusted to the minimum according to regulations

and properly balanced. The

the equipment, contact a qualified technician. DO NOT try to repair the equipment

remote

you must learn how to use the manual release mechanism according to the

instructions in a safe place. Make sure that all persons who use the gates or who may be near

a copy of these safety

WARNING!

Incorrect installation or inappropriate use may cause serious personal injury.

This installation manual and safety instructions are an integral part of the product and must be supplied to the user

These instructions should be retained by the owner and/or operator of the gate.

This product has been designed and constructed exclusively for the use indicated in this manual. Any

use of this product may result in damage to the product and/or personal injury.

To ensure proper functioning of the product and personal safety only use the mounting equipment supplied and

spare parts and accessories supplied by the manufacturer.

Do not install this equipment in an easily flammable

are a serious threat to personal safety.

This equipment has an anti crushing safety device. In addition to this safety device

additional safety devices (for example: photo cells and/or pressure sensitive strips, etc.)

danger resulting from mechanical movement (for example crushing, pulling or ripping).

In addition to the above mentioned safety devic

printed notice fixed to the gate.

To reduce the risk of injury or death

it is important to closely follow all of

carried out by qualified technicians.

the manufacturer will not be held responsible.

For protection against electrical overload or short circuit, always install a 0.03 amp diffe

magnetic switch with a contact aperture of at least 3mm

This equipment must be earthed with a yellow/ green cable, connected to the earth terminal in the junction box.

The safety of this product is only guaranteed if the equipment is properly earthed.

Before operating this product you must ensure that all connections have been properly made, that the

devic

regarding automatic doors (EU Directive 89/392 and EN 12453 y EN 12445 norms).

Before installing this equipment, ensure that the structure of the gate is strong enough

gates

must work freely in both directions and have no friction points before the automatic operator is installed.

Failure to meet this requirement may

SAFETY INSTRUCTIONS FOR THE USER

In the event that a malfunction in

yourself.

Do not allow children or pets near the gate. Never allow children to play with the gate controls. Keep the

control in a safe place, out of reach of children and unauthorised persons.

In the event of a power cut or emergency,

procedures found in this installation manual

Keep these safety

the gates when they operate are aware of the dangers associated with automatic opening gates

If you sell or rent the property with this equipment installed, give the new owner or tenant

instructions

Ed1. 14/12/09 (English) 2 of 10

Page 4

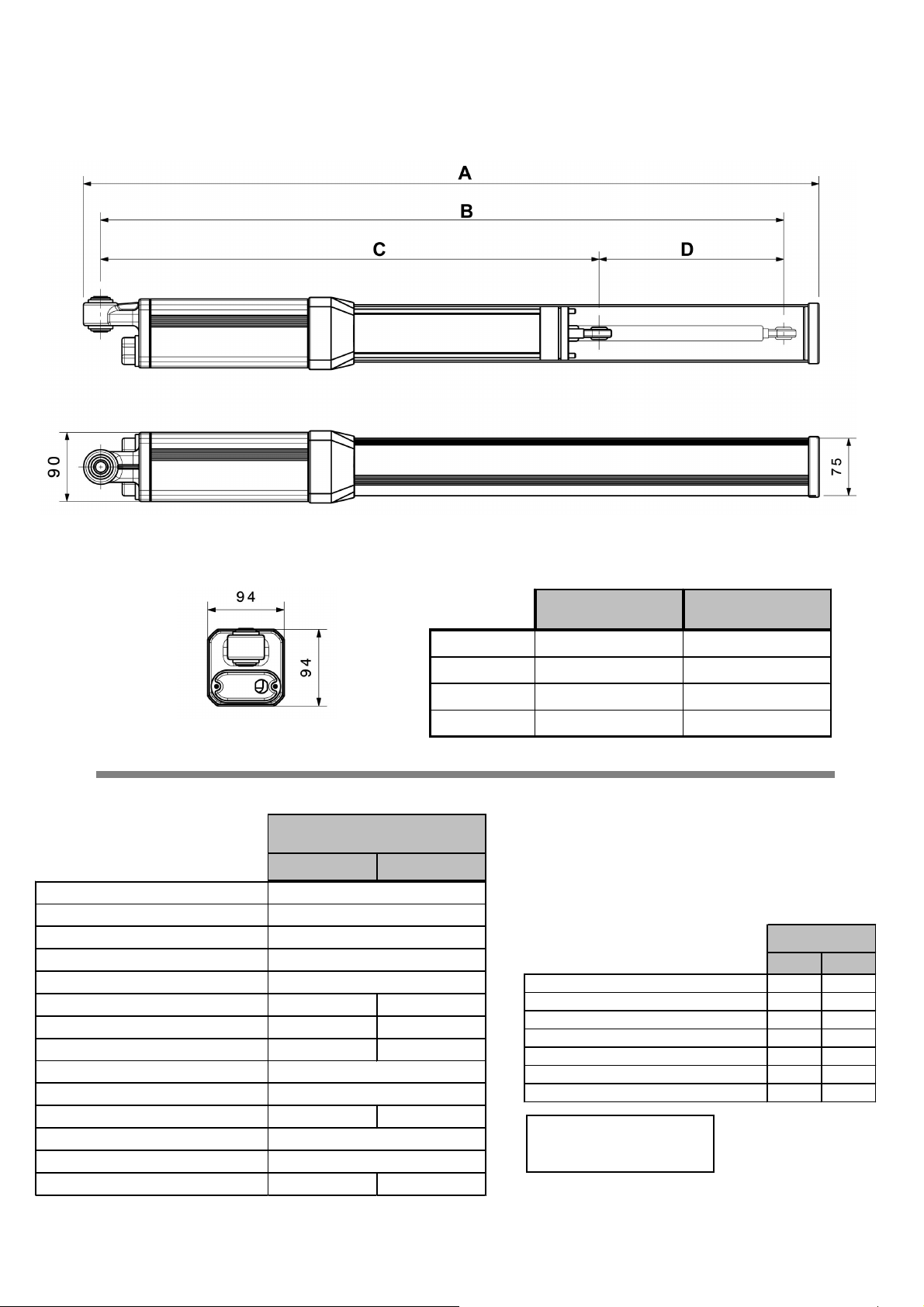

TECHNICAL DATA MODEL: PHV

●

●

●

●

●

●

●

●

●

●

PHV

TECHNICAL DATA

Current

Power

Consumption

Condenser

Maximum Pressure

Hydraulic Arm

Hydraulic arm exit time

Hydraulic arm entry time

Compression

Traction

Max. Length of gate leaf

Temperature Range

Thermic Protection

Weight

Dimensions

PHV

240 360

230V 50HZ

276 W

1,3 A

16 uf

50 bar

242 mm 362 mm

28 sec. 40 sec.

23 sec. 34 sec.

0 to 7793 N (795Kg)

0 to 6252 N (638Kg)

4 m 6 m

-15 to 80°C

100°C

11 Kg 12 Kg

A

B

C

D

PHV240PHV360

985 mm 1225 mm

915 mm 1155 mm

673 mm 793 mm

242 mm 362mm

FEATURES

SB BAC

HYDRAULIC LOCK OUT PUT

BLOCK OPEN & CLOSE

BLOCK CLOSE

BLOCK OPEN

REVERSABLE IN BOTH DIRECTIONS

ANTI-WIND REGULATION

BUFFER STOP CLOSE

SB = WITHOUT BLOCK

BAC = BLOCK, OPEN, CLOSE

Ed1. 14/12/09 (English)3 of 10

Page 5

FREQUENCY OF USE

The curve below allows calculation of the maximum working time (T) depending on the frequency of use (F).

To ensure correct operation of the equipment the working time should be within the shaded area.

These trials have been carried out at a temperature of 22ºC. If the equipment is operating at a higher temperature or is

exposed to direct solar radiation, the frequency of use can be reduced by 20%.

%F : use factor

Ta : opening time

Tc : closing time

Tp : pausing time

Ti : time between complete operations

E.G. Model 360

E.G. Model 240

%F= _______________ x100

WORK AREA

(F) Use Factor

(opening-closing)

Ta+Tc

Ta+Tc+Tp+Ti

(T) Time (Hours)

Graph.1

Note. 5 seconds more are needed to assure the complete opening and closing of the door.

There are heavy use times during the day where vehicle transit is higher. Calculations should be carried out during this

period of time.

E.G.

What is the maximum working time for a door that has a pause of 30 seconds and a time between cycles of 40

seconds?

CALCULATION FOR

PHV240

CALCULATION FOR

PHV360

Ta+Tc

%F= x100

Ta+Tc+Tp+Ti

Ta+Tc

%F= x100

Ta+Tc+Tp+Ti

%F= x100

%F= x100

28+33

28+33+30+40

39+45

39+45+30+40

46,5%

54.5%

2h

CONCLUSION: Once obtained data has been applied to

graph1, the maximum time of use for model 240 is 2h:15min

and for 360 is 1h:30min.

1h

Considering the quotas, model 240 should be used.

TIME (HOURS)

0

PHV240

Graph.2

PHV360

Ed1. 14/12/09 (English)

4 of 10

Page 6

MOUNTING HEIGHTS

MAX.

HEIGHT

LIGHT

400KG

MED.

600KG

HEAVY

800KG

Fig..1

PHV 240

110°

PHV 240

110°

PHV 240

110°

Max. 4m

PHV 240-95°

PHV 360-115°

PHV 240-95°

PHV 360-115°

PHV 360

115°

Max. 6mMax. 2m

PHV 360

95°

PHV 360

90°

Fig..2 Fig..3

INWARD OPENING (Fig.2)

M A B C

85° 195 185 90

90° 180 180 90

95° 165 180 90

100° 150 180 90

105° 140 180 90

110° 125 180 90

115° 115 180 90

120º 105 180 90

OUTWARD OPENING (Fig.3)

PHV 360

M A B C

85° 200 180 100

90° 180 180 100

95° 165 180 100

100° 150 180 100

105° 125 180 100

Ed1. 14/12/09 (English)5 of 10

INWARD OPENING (Fig.2)

M A B C

85° 130 125 70

90° 120 120 70

95° 110 120 70

100° 100 120 70

105° 93 120 70

110° 85 120 70

115º 85 115 70

OUTWARD OPENING (Fig.3)

PHV 240

ALL MEASUREMENTS IN MM FROM CENTER OF

HINGE

M A B C

85° 130 120 80

90° 120 120 80

95° 110 120 80

100° 100 120 80

Page 7

SPECIAL MEASUREMENTS INWARD OPENING (Fig.2)

MOUNTING QUOTAS 240 (C=70)

EXAMPLE (STANDARD)

EXAMPLE (SPECIAL DIMENSIONS)

MOUNTING QUOTAS 360 (C=90)

*measurements in mm.

In some cases it may be necessary to vary the standard dimensions, e.g., because of space restrictions in fixing the supports. The above

graphs show dimension ranges for inward opening 360 and 240 models.

At the top part of each graph are the range of gate opening angles and a series of diagonal lines from which the values of A and B may

be determined (fig.2 page 5 ). These values should be as near as possible to those determined by the thick vertical line.

The dimension for C is constant at C = 90 mm for model 360 and C = 70 mm for model 240.

Example: What should be the value for A and what model should be used for a gate with an opening angle of 100º where B = 140?

Answer: Model 360 where A =195 mm. See the example in the above graph shown by the dotted line for the 360 model : EXAMPLE

(SPECIAL DIMENSIONS))

Conclusion: It would not be possible to use the 240 model because the value for A would be outside the minimum for this model.

Ed1. 14/12/09 (English) 6 of 10

Page 8

MOUNTING INSTRUCTIONS

Fig.3Fig.2Fig.1

Fig.6Fig.5Fig.4

Fig.9Fig.8Fig.7

Fig.12Fig.11Fig.10

Ed1. 14/12/09 (English)

7 of 10

Page 9

1. Fix the pillar support (Fig.1 Page 7) shortening or lengthening the support according to the

dimensions A and B shown in the table on page 4. The support should be fixed at a height where the gate

has a sufficiently rigid surface to fix the gate support , bearing in mind that the gate support will be fixed

15 mm lower than the pillar support. (Fig.1 Page 5).

2. Shorten or lengthen the gate support according to the dimensions for C shown in the table on page 5.

Connect the gate opener to the gate support, with the rod completely extended (Fig.2 Page 7) and with

the swivel joint nut fully tightened (Fig.3 Page 7). Once this has been done use a spirit level (Fig.4

Page 7) to mark the position of the gate support on the gate. Dismantle the gate support and fix it to the

gate using the markings previously made.

3. Mount the motor and unscrew the swivel joint nut three turns to ensure closure. Attach the security

ring and the safety bolt supplied.(Fig.6 Page 7).

EARTH

4.Electrical connections: Unscrew the end cover and connect

the terminals according to the following diagram:

COMMON

CONDENSER

5. Open the door manually to the desired open position, slide the collar stopper along the arm (Fig.9

Page 7) up to the front cover plate, fixing its position with the Allen key. The hydraulic transmission can

then be plugged in and started. Re-position the collar stopper to the desired position if the angle of

opening is not the desired one.

6. Once the motor is working correctly the limit valves can be adjusted (Fig.10 Page 7). The limit valves

control the force and are independent in opening (blue limit valve) and closing (red limit valve) the gate.

The screws can be adjusted by turning them a maximum of 45º,and should be adjusted slightly above the

minimum possible, in this way the force of the hydraulic system is reduced thus increasing safety.

7. The closing buffer can then be adjusted (Fig.11 Page 7), thus avoiding the door banging closed.

To adjust the closing buffer turn the screw a maximum of 10º( If the buffer valve is completely closed

then 15mm of buffering will be lost) .

8.The aluminium arm cover can then be pressured into position (Fig.12 Page 7), followed by its plastic

cover and the end cover.

OPERATION OF THE HYRAULIC LOCK

With hydraulic powered gates it is necessary to consider the type of opening required:

- Inward opening (Fig.2, Page 5)

Kit ‘KM’ should be connected to

position 2 (see diagram).

- Outward opening (Fig.3, Page 5)

Kit ‘KM’ should be connected to

position 1 (see diagram).

Ed1. 14/12/09 (English)

2 1

8 of 10

Page 10

BLOCKING FUNCTION

Red closed - Blue open

The BAC system used in the

PHV range provides a wide range offeatures which can be adjusted

to ensure that the equipment may be adjusted for different requirements.

EMERGENCY RELEASE SYSTEM

This valve allows us to override the system in order to

operate the gate manually in the event of power cuts. To move

the gate manually , open the cover and turn the valve 360º

anti clockwise . To return to the automatic system turn the

valve clockwise.

IMPORTANT: If the valve is not tight the motor will not

function.

BAC AND ANTI-WIND SYSTEMS

Under view of motor.

By adjusting the red and blue valves (located under the

motor), gate actions can be reversed.

The options are as follows:

ADJUSTMENT OF BAC VALVES

Red open - Blue closed

Opening blocked and closing reversed

Opening reversed and closing blocked

Red closed - Blue closed

Opening and closing blocked

RED

BLUE

Red open - Blue open

Opening and closing reversed.

IMPORTANT: if these valves are slightly opened they serve as an excellent anti-wind system. The

pressure of the gate can be adjusted with the motor not working.

A lock is required for gates over 1.8m in length.

Ed1. 14/12/09 (English)

Under view of the motor.

9 of 10

Page 11

BOX CONTENTS

*

*only BAC system

SPARE PARTS ACCESSORIES

Nº Description Ref. Nº Description Ref.

PHV240SBA112.21100.009Allen key no. 680738

PHV240BACA112.21200.0010Strengthening block70141

1

PHV360SBA112.22100.0011Set up bolts - bag95008

PHV360BACA112.22200.0012Wire housing95107

Plastic cover 70284 13 Stopper collar 95020

2

Plastic cover BAC 95011 14 OILMEDVA-JV oil (1 Litre)

3 Installation Instructions 50171 15 Hingee set with nut A232.11003.K1

Aluminium cover

4

Aluminium cover

5 End cover for aluminium arm cover 70046 Door support kit 360 A232.11002.K1

Support 240 95006 18 Hydraulic lock A232.21002.00

6

Support 360 95037 19 Hydraulic piping (m) 80736

7 Electric cable 4x0,75 L1,5m 70055 20 Hydraulic piping mounting kit A232.22003.K1

8 Door support 240 95007

Door support 360 95036

PHV2407004416Condenser 16 Uf80497

PHV36070197Door support kit 240A232.11001.K1

17

70466

Ed1. 14/12/09 (English)

10 of 10

Loading...

Loading...