PH - PH1

Istruzioni per l’installazione

Installation instructions

Instructions pour l’installation

Installationsanleitung

Instrucciones para la instalación

SCOPO DEL MANUALE

Questo manuale è stato redatto dal costruttore ed è parte integrante

del prodotto.

In esso sono contenute tutte le informazioni necessarie per:

• la corretta sensibilizzazione degli installatori alle problematiche

della sicurezza;

• la corretta installazione del dispositivo;

• la conoscenza approfondita del suo funzionamento e dei suoi limiti;

• il corretto uso in condizioni di sicurezza;

La costante osservanza delle indicazioni fornite in questo manuale,

PURPOSE OF THE MANUAL

This manual was drawn up by the manufacturer and is integral part

of the product.

It contains any useful information:

• to draw the attention of the installers to safety related problems;

• to install the device properly;

• to know its operation and limits in depth;

• to use the device under safe conditions.

BUT DU MANUEL

Ce manuel a été réalisé par le constructeur et fait partie intégrante du produit.

Il contient toutes les informations nécessaires pour:

• sensibiliser les installateurs aux problèmes liés à la sécurité;

• installer le dispositif de manière correcte;

• connaître le fonctionnement et les limites du dispositif;

•

utiliser correctement le dispositif dans des conditions de sécurité optimales.

Le respect des indications fournies dans ce manuel garantit la

sécurité personnelle, une économie de fonctionnement et une

ZWECK DES HANDBUCHS

Dieses Handbuch wurde vom Hersteller verfasst und ist ein

ergänzender Bestandteil des Produkts.

Es enthält alle nötigen Informationen für:

• die richtige Sensibilisierung der Monteure für Fragen der Sicherheit;

• die vorschriftsmäßige Installation der Vorrichtung;

• die umfassende Kenntnis ihrer Funktionsweise und ihrer Grenzen;

• die vorschriftsmäßige und sichere Benutzung.

Die ständige Beachtung der in diesem Handbuch gelieferten

OBJETO DEL MANUAL

Este manual ha sido redactado por el constructor y forma parte

integrante del producto.

Contiene todas las informaciones necesarias para:

• la correcta sensibilización de los instaladores hacia los problemas

de la seguridad;

• la correcta instalación del dispositivo;

• el conocimiento en profundidad de su funcionamiento y de sus límites;

cod. LBT0008 - 09/2007

• el correcto uso en condiciones de seguridad;

garantisce la sicurezza dell’uomo, l’economia di esercizio ed una

più lunga durata di funzionamento del prodotto.

Al fi ne di evitare manovre errate con il rischio di incidenti, è

importante leggere attentamente questo manuale, rispettando

scrupolosamente le informazioni fornite.

Le istruzioni, i disegni, le fotografi e e la documentazione contenuti

nel presente manuale sono di proprietà VDS e non possono essere

riprodotti in alcun modo, né integralmente, né parzialmente.

The strict observance of the instructions of this manual grants safety

conditions as well as effi cient operation and a long life to the product.

To prevent operations that may result in accidents, read this manual

and strictly obey the instructions provided.

Instructions, drawings, photos and literature contained herein

are exclusive property of VDS and cannot be reproduced by any

means.

longue durée de vie du produit.

Afi n d’éviter des opérations incorrectes et de ne pas risquer

des accidents sérieux, lire attentivement ce manuel et respecter

scrupuleusement les informations fournies.

Les instructions, les dessins, les photos et la documentation

contenus dans ce manuel sont la propriété de la société VDS et

ne peuvent être reproduits sous aucune forme, ni intégralement,

ni partiellement.

Hinweise gewährleistet die Sicherheit der Personen, wirtschaftlichen

Betrieb und eine lange Lebensdauer des Produkts.

Zur Vermeidung fehlerhafter Manöver mit Unfallgefahr ist es

wichtig, dieses Handbuch aufmerksam durchzulesen und die darin

enthaltenen Informationen genauestens zu beachten.

Die Anleitungen, Zeichnungen, Fotos und Dokumentationen in

diesem Handbuch sind Eigentum von VDS und dürfen in keiner

Weise ganz oder teilweise reproduziert werden.

La constante observación de las indicaciones suministradas en

este manual, garantiza la seguridad del hombre, la economía del

ejercicio y una mayor duración de funcionamiento del producto.

Con el fin de evitar maniobras equivocadas con riesgo de

accidente, es importante leer atentamente este manual, respetando

escrupulosamente las informaciones suministradas.

Las instrucciones, los dibujos, las fotografías y la documentación

que contiene este manual son propiedad de VDS y no pueden

ser reproducidas en ninguna manera, ni integral ni parcialmente.

Italiano

EnglishFrançais

Deutsch

Español

English

Contents / Characteristics

Characteristics of the operator

1

1.0 General characteristics ................................................................................................................................... 15

1.1 Technical data ................................................................................................................................................15

1.2 Choosing the type of automation.................................................................................................................... 15

Description of the automation system

2

2.0 Components layout ........................................................................................................................................16

2.1 System electrical connection ......................................................................................................................... 16

Checks and operations prior to the operator installation

3

3.0 Checking the gate .......................................................................................................................................... 17

3.1 Checking the operator components ............................................................................................................... 17

3.2 Mounting tools ................................................................................................................................................ 18

Installing the operator

4

4.0 Positioning the mountings .............................................................................................................................. 18

4.1 Prepping the rear operator mounting ............................................................................................................. 19

4.1.1 Operator fi xed on iron posts .............................................................................................................................................. 19

4.1.2 Operator fi xed on wooden posts ....................................................................................................................................... 19

4.1.3 Operator fi xed on masonry posts ...................................................................................................................................... 19

4.1.4 Rear operator mounting - special cases............................................................................................................................ 20

4.2 Fixing the rear operator mounting .................................................................................................................. 21

4.3 Temporary installation of the operator ............................................................................................................ 21

4.4 Positioning the front operator mounting ......................................................................................................... 22

4.5 Final installation of the operator .................................................................................................................... 23

4.5.1 Mechanical fi xing ............................................................................................................................................................... 23

4.5.2 Checking the motion.......................................................................................................................................................... 23

4.5.3 Electrical connection ......................................................................................................................................................... 23

4.5.4 Fitting the protection casing and removing the bleed screw ............................................................................................ 23

4.5.5 Bleeding ............................................................................................................................................................................ 24

Checks and adjustments

5

5.0 Checking and adjusting the thrust force ......................................................................................................... 24

Emergency manoeuvre

6

6.0 Emergency manoeuvre - use of the manual release .................................................................................... 24

Notes for the installer

7

7.0 Maintenance ...................................................................................................................................................25

7.1 Troubleshooting .............................................................................................................................................. 25

- 14 -

Characteristics / Preliminary operations

1. CHARACTERISTICS OF THE OPERATOR

1.0 GENERAL CHARACTERISTICS

• Hydraulic swing gate operator, specially designed for residential use.

• The operator, if installed correctly, conforms to the current safety standards.

List of versions:

PH1: Hydraulic lock for closing only (with lock inaccessible when the gate is open)

PH: No hydraulic lock - braking action (the gate leaf can be moved by hand with a minimum of resistance, if moved

slowly; there is also a release device to facilitate opening -needs an electric lock)

• The version with hydraulic closing lock does not require the use of the electric lock and keeps gate leaves of

less than 1.8 m in closed position.

• The emergency release (to be used in the event of a power failure) is safe to use and easily manoeuvrable and

enables the user to move the gate by hand using the triangular key provided. The release is easily accessible

via a hatch on the upper cover of the operator.

• Safety against entrapment risks is guaranteed by sensing valves, settable during installation.

English

B

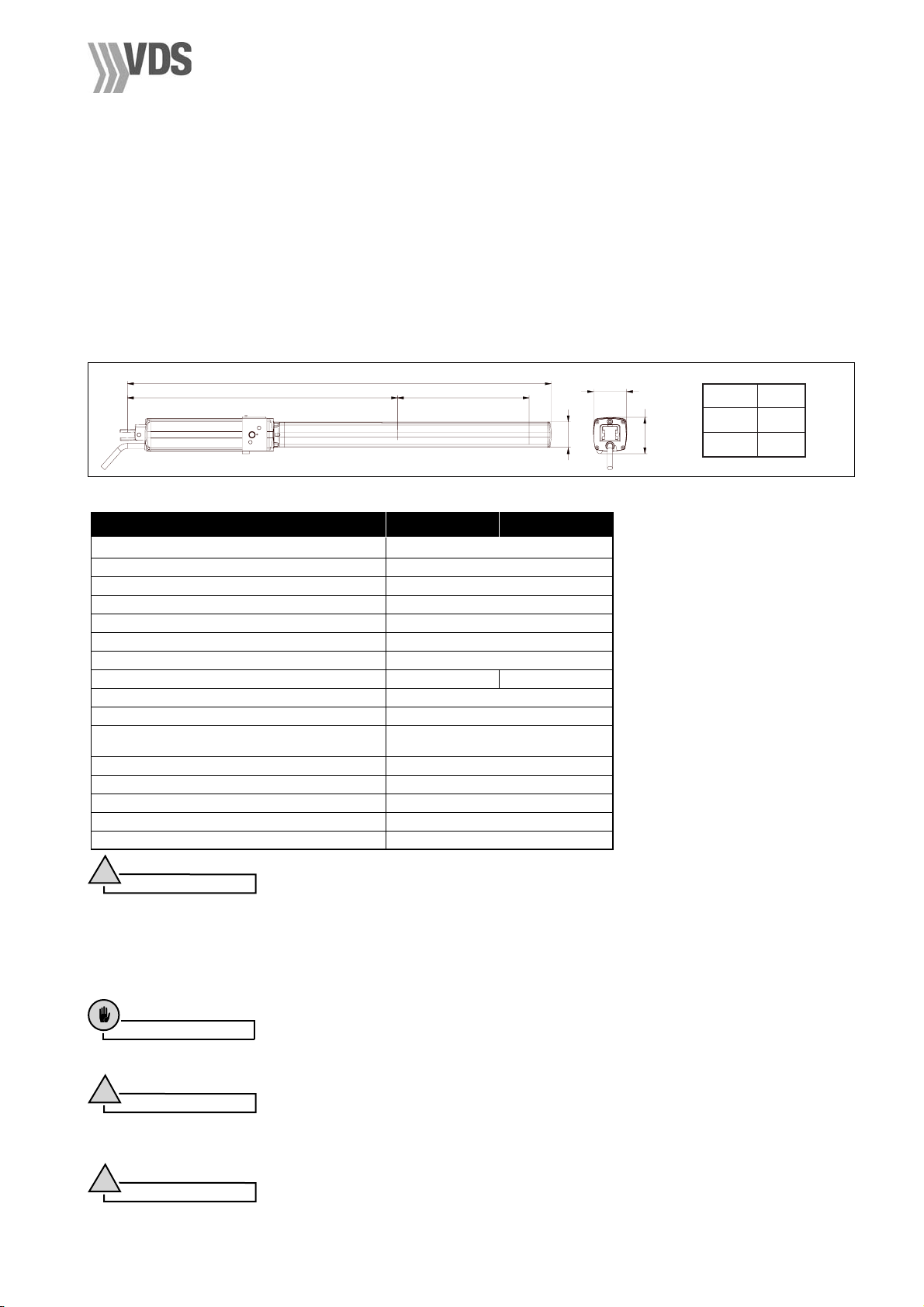

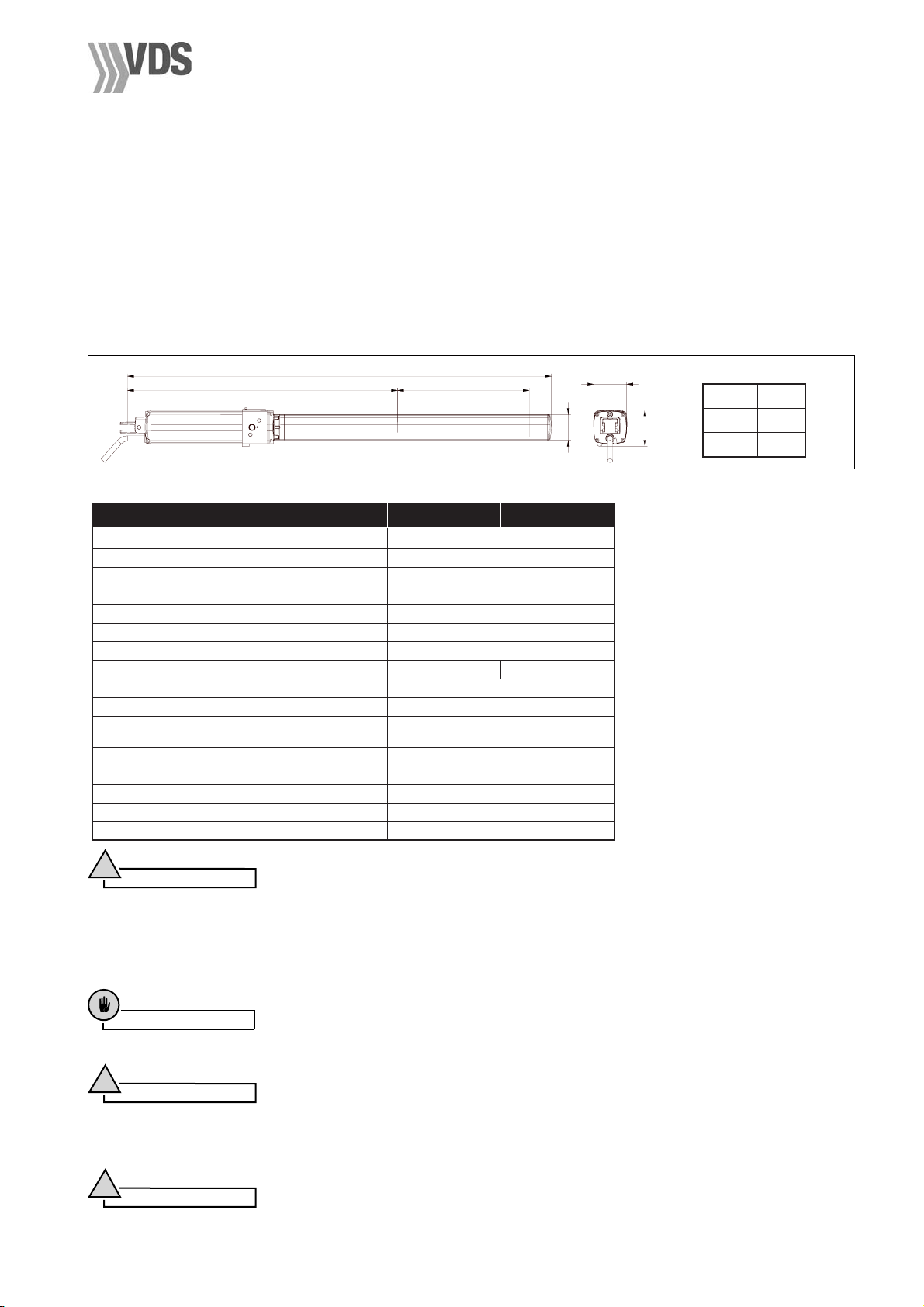

1.1 TECHNICAL DATA

FEATURES

Single-phase system voltage

Power absorption

Mean pressure

Thrust force at 10 bar

Traction force at 15 bar

Rod retraction time (max. stroke)

Rod extension time

Max leaf length

Min leaf length

Operating temperature range

Max distance between centres for

mounting holes with fully extended rod

Max stroke - standard arm

Weight with oil

Oil quantity

Oil type

Protection degree

A

C

PH1

230 V±10% 50 Hz

250W

30 bar

962 N

1140 N

22 sec ±2

22 sec ±2

1.8 m 3 m

1.2 m

-20° / + 70°C

1002 mm ± 5

270 mm

8 Kg

0.6 lt.

AprimOil HC13

IP 55

PH

70

90

A (mm)

B (mm)

97,5

C (mm)

1060

698

274

!

Warning

The noise level of the above models, referred to the working of the operator, independently of the gate leaf

and the post, falls within the maximum limits set by EEC standards.

1.2 CHOOSING THE TYPE OF AUTOMATION

Before mounting, choose the type of automation on the basis of the characteristics and dimensions of the element

to be operated.

Caution

• The choice of the most suitable type of automation assures an effi cient operation of the unit and minimises

the possibility of failures.

!

Warning

• The versions listed above are also recommended for use with solid gate leaves (with the operator

inaccessible when the gate is open).

• The PH1 model, suitable for use in windy areas, must not be fi tted to gate leaves of up to 1.8 m.

!

Warning

The peripheral speed of the gate leaf must always fall within the limits of the current safety regulations.

Also, it is important to avoid the use of high-speed operators on wide gate leaves, as this could cause the

leaves to bang violently against the gate stop (see the “Technical Data”).

- 15 -

English

Preliminary operations

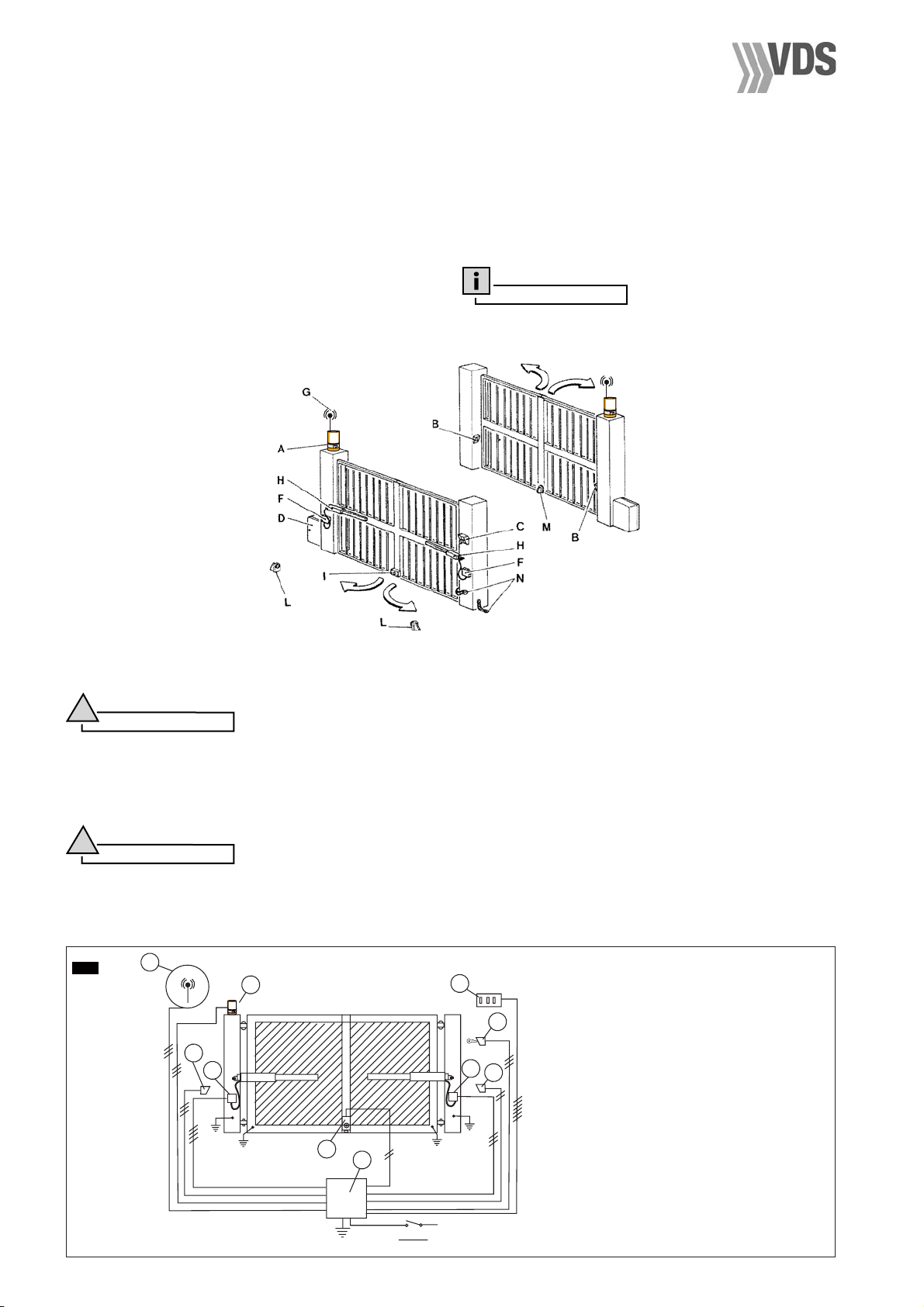

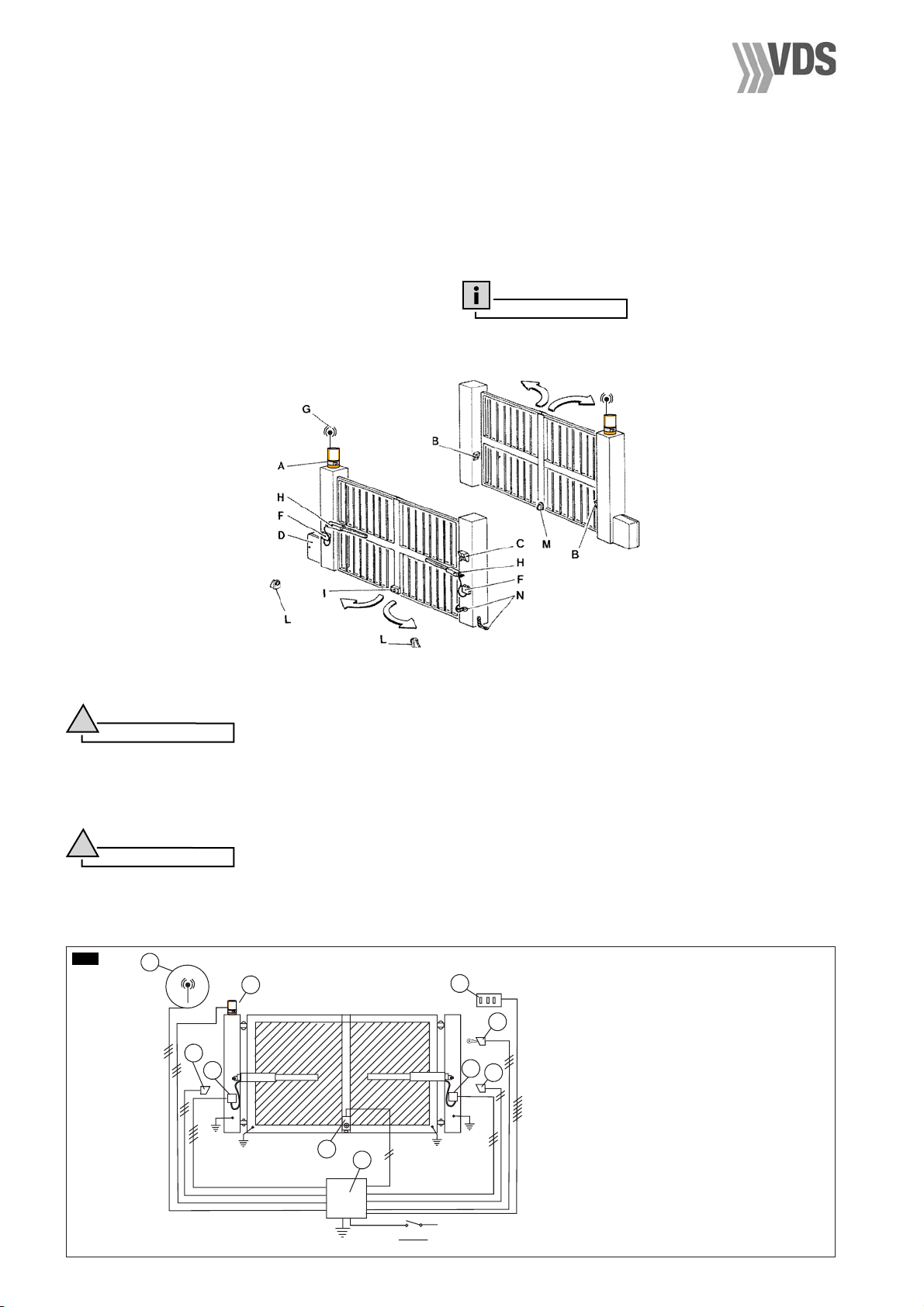

2. DESCRIPTION OF THE AUTOMATION SYSTEM

2.0 COMPONENTS LAYOUT

A - Flashing warning/courtesy lamp (to be positioned

at a point clearly visible from both approaches)

B - Safety photocell

C - Manual key-operated control unit (magnetic, digital,

keyboard combination lock, mechanical, etc.)

D - Microprocessor control unit in watertight container

(if possible, to be fi tted in a position sheltered from

atmospheric agents)

F - Watertight operator electricity supply junction box

(recommended),

to be positioned so that cables are not

subject to dangerous stretching during the gate motion

G - Antenna

H - Aprimatic PH series operators

I - Electric lock (optional)

L - Open position gate stop

M - Close position gate stop

N - Ground connection for metal framework

Consult the price-list for additional (optional) safety

devices.

Information

2.1 SYSTEM ELECTRICAL CONNECTION

- When making the electrical connections,carefully follow the instructions for each of the components, referring

to the wiring diagram D1.

!

Warning

• Make the electrical connection of the single components after having completed their installation.

• The entire circuit must be made consistent with the current safety regulations.

• Use cables with a cross-section of 1.5 mm

2

for the wiring.

• Protect the operator power cable with a sheath if necessary; do this before connecting the cable to the

junction boxes.

!

Warning

• Every operator comes complete with a pickup capacitor. During installation, connect the capacitor to

the electrical equipment according to the wiring diagram supplied.

- After making the electrical connections, check the thrust force at the end of the gate leaf; if necessary, adjust

the pressure of the operator according to the procedure described in the specifi c paragraph.

D1

1

2

5

6

1 Antenna

2 Flashing lamp

3

9

9

4

3 Receiver photocell

4 Transmitter photocell

5 Internal control panel

6 Key control

7

8

7 Electrical lock

8 Electronic control unit

9 Junction box

6A

0,030 A

- 16 -

Preliminary operations

3. CHECKS AND OPERATIONS PRIOR TO THE INSTALLATION OF THE OPERATOR

3.0 CHECKING THE GATE

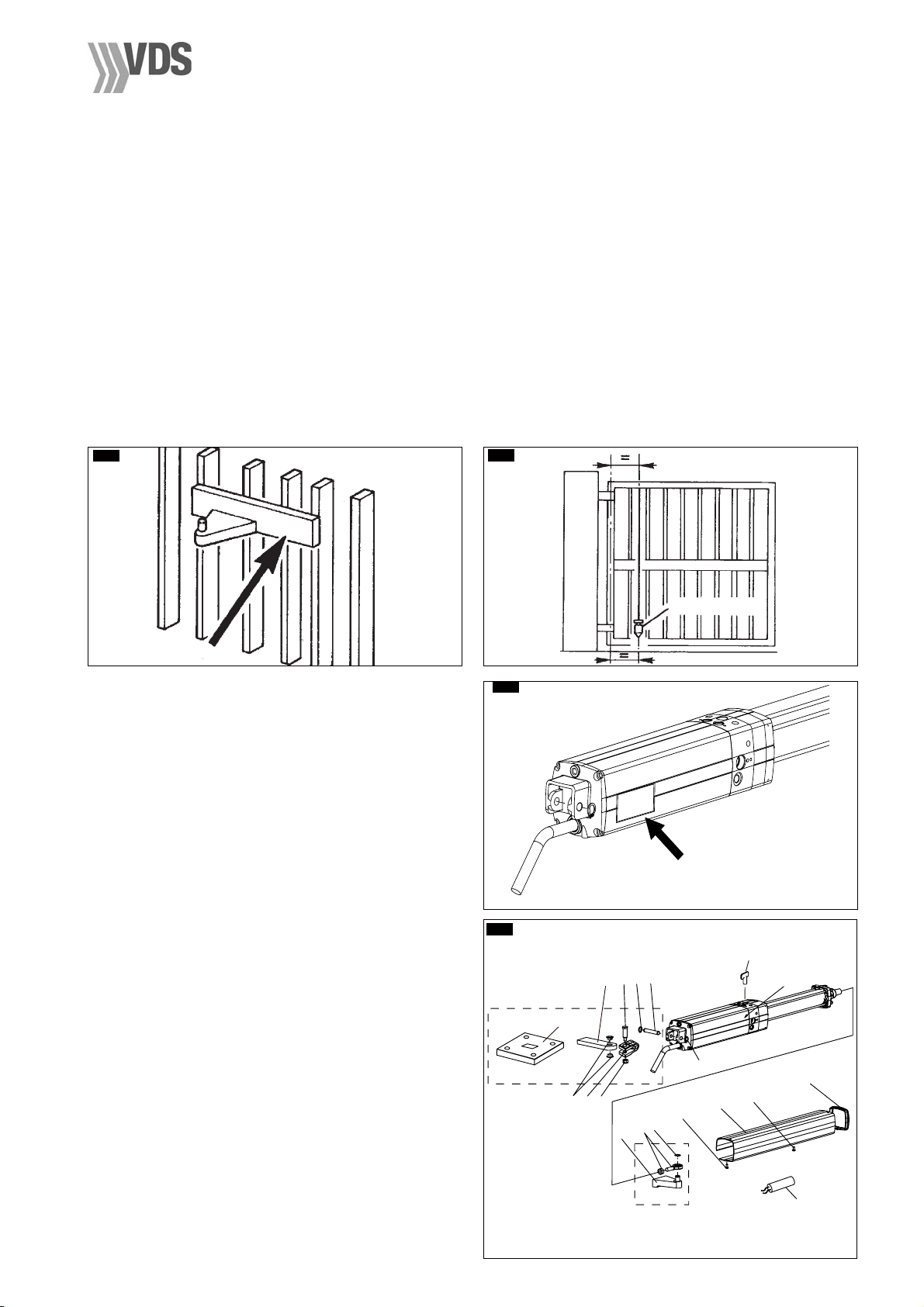

• Before proceeding with the mounting, do a complete check on the gate leaves making sure that they are in good

condition and not broken or damaged in any way.

• Ensure the motion of the gate leaves is uniform and the hinges have no play and do not rub.

Otherwise, hinges must be repaired so that the gate leaves can be moved easily by hand or, if repair is impossible,

hinges must be replaced.

• Check that the gate leaves are plumb (when perfectly still at any point in the swing) (B1B); when the gate leaves

are completely closed, check that the closure is even throughout the whole height of the gate leaves.

• Using a dynamometer, check that the opening and closing effort of the gate, to be measured from the end of the

gate leaf, does not exceed 15 kg. (147 N).

Before deciding on the fi nal position of the mountings, it is necessary to:

• Choose the most suitable height on the gate leaf for the operator front mounting. If possible, it should be positioned

halfway up the gate leaf. As a rule, the ideal point is always in the strongest area where the fi xing of the gate leaf

has the least effect. If there is not a broad strip of steel in the gate framework, then a suitable support needs to

be welded on in the area where the front mounting is to be positioned in order to spread the load over a wide

zone (B1A).

• Check whether the chosen area needs reinforcing or strengthening in any way. Make the same check on the

gate leaf support posts.

English

B1A

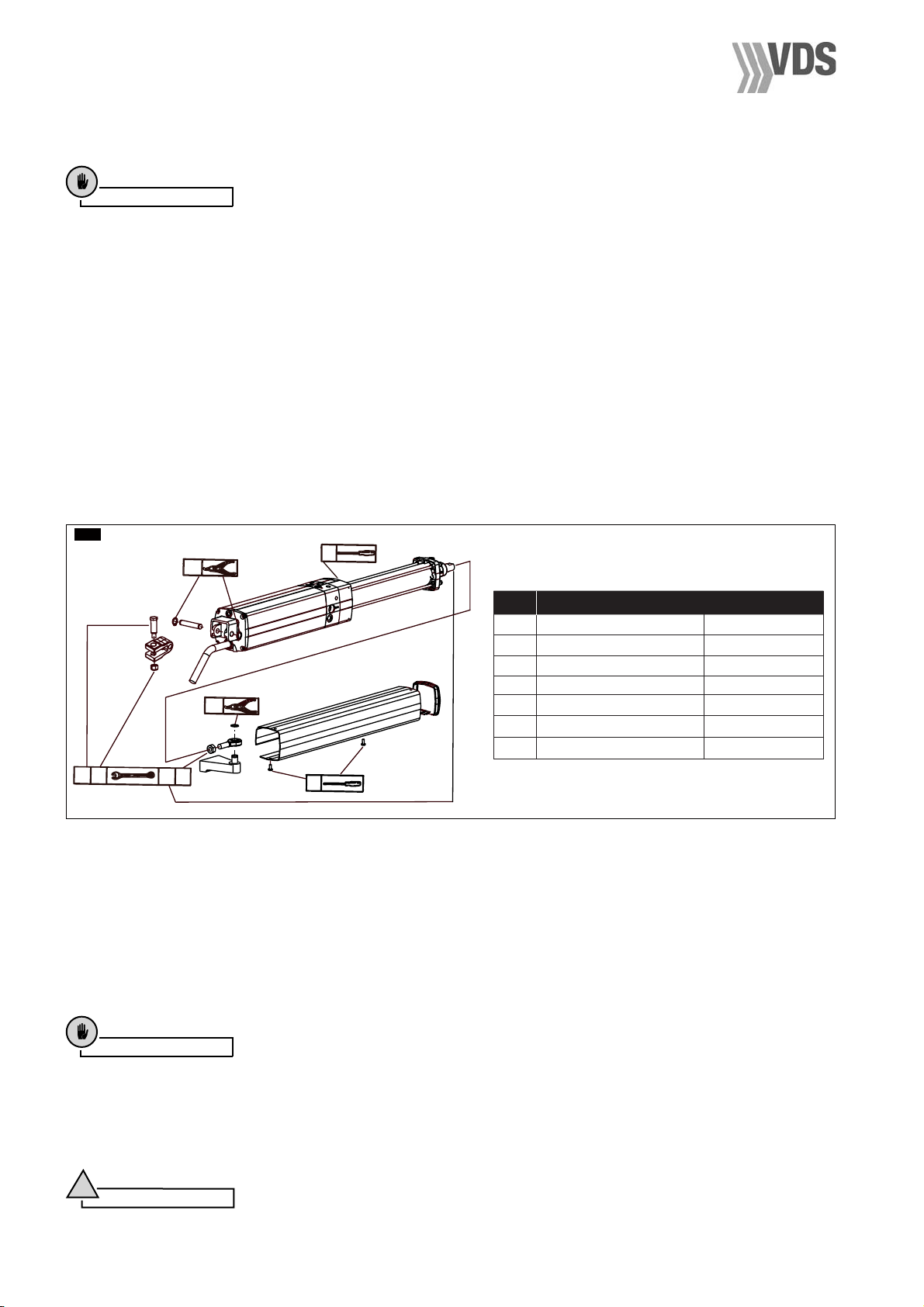

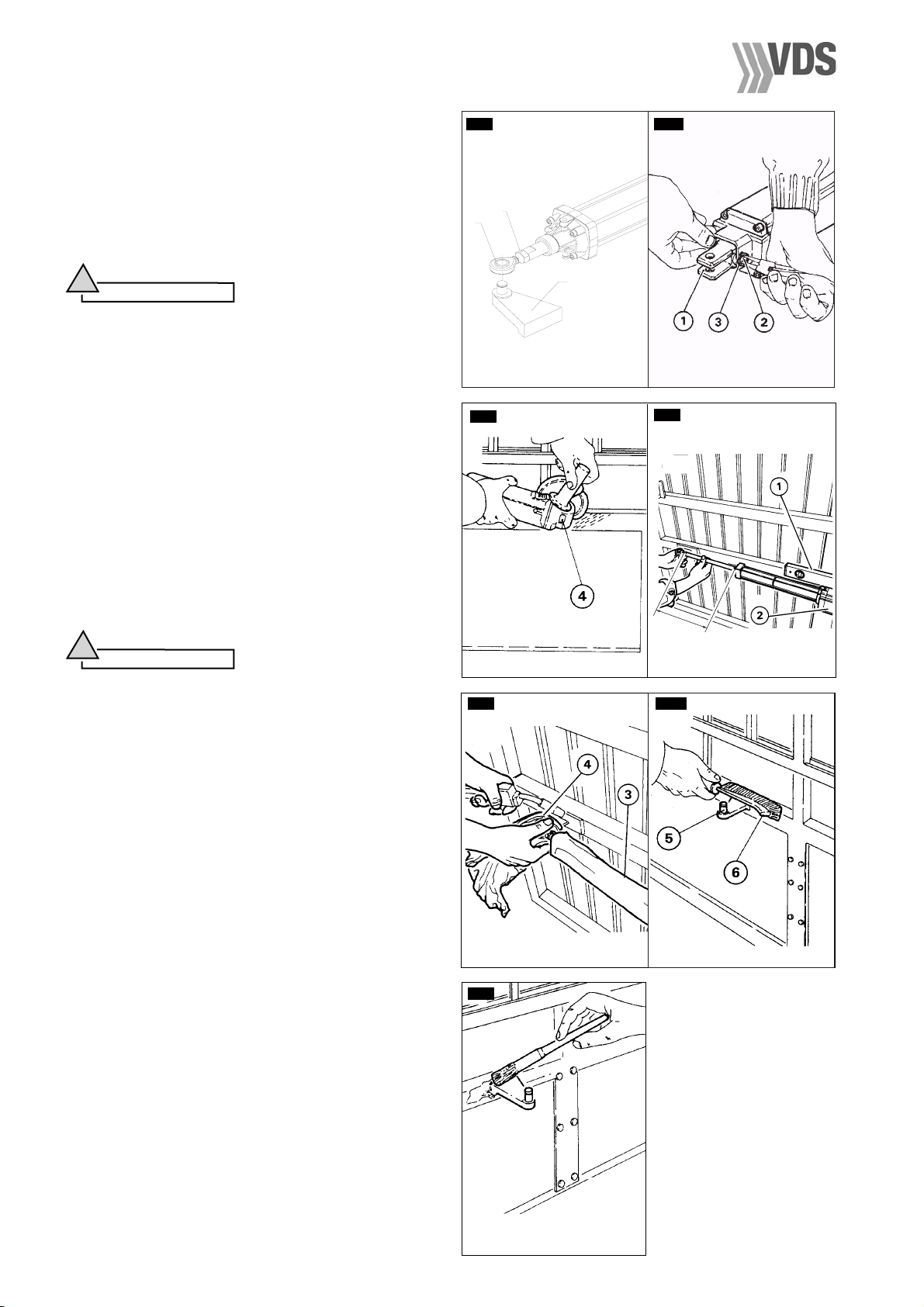

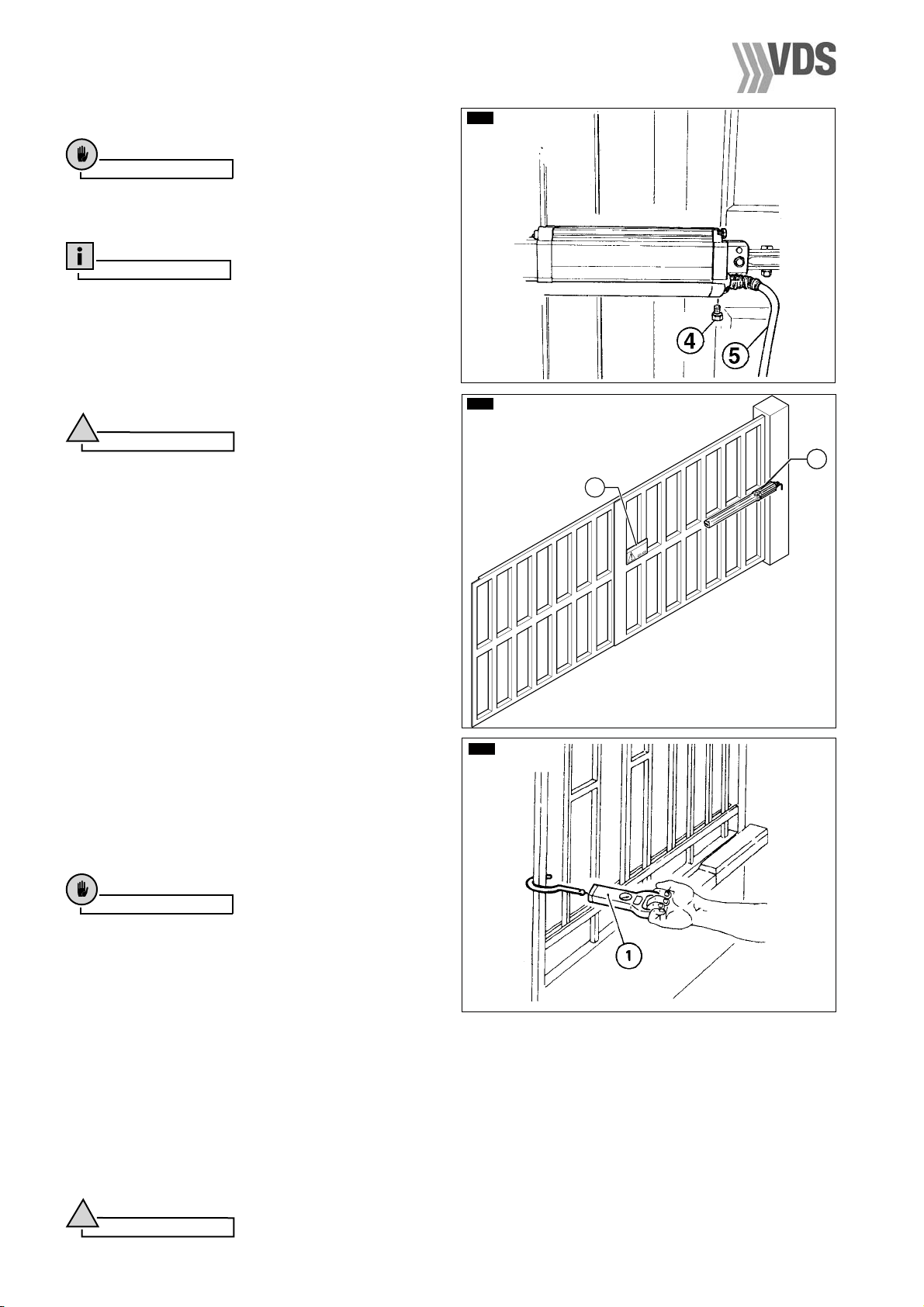

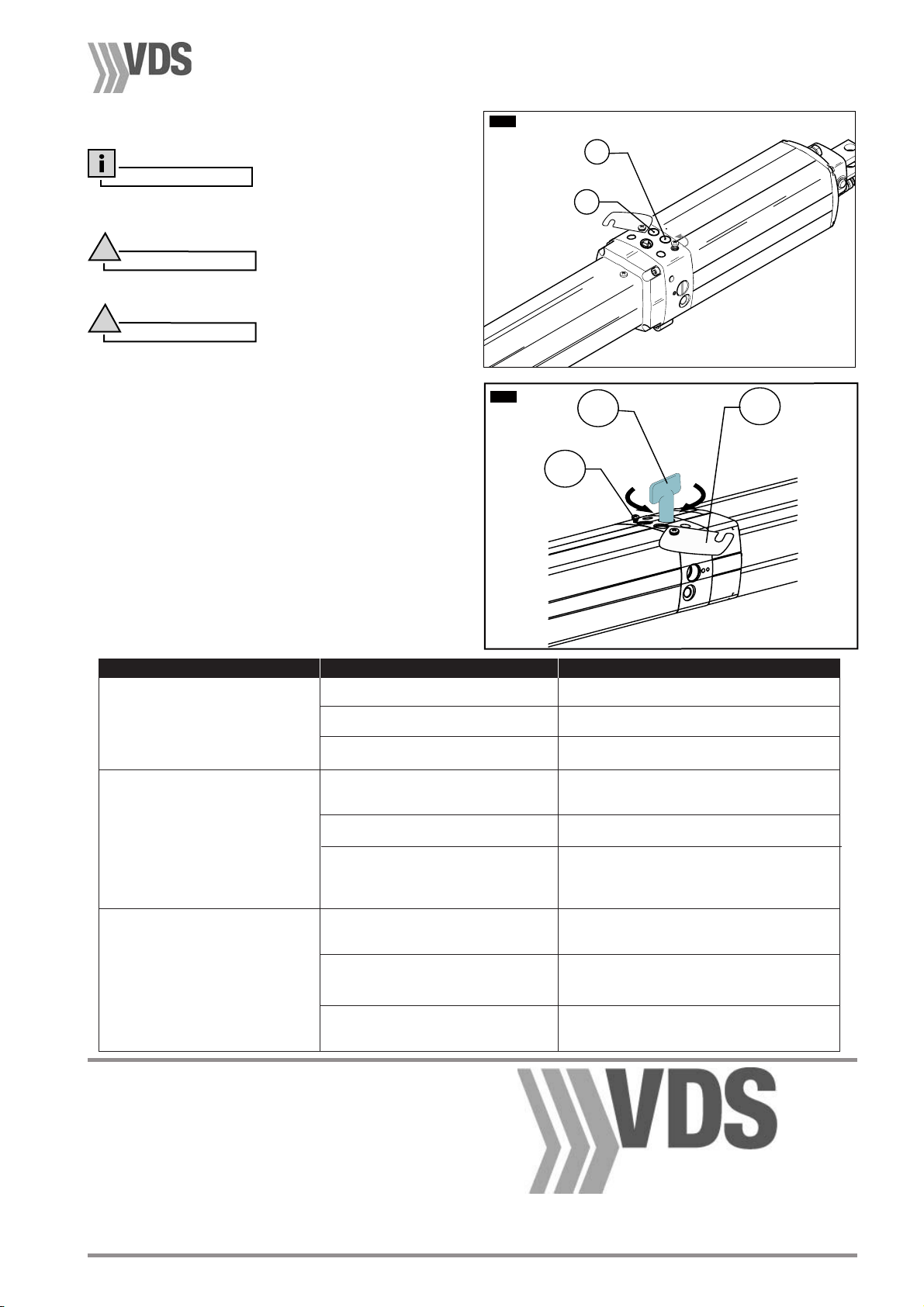

3.1 CHECKING THE OPERATOR COMPONENTS

Check that the model code displayed on the operator

packaging corresponds to the code on the identifi cation

plate on the operator itself (B3).

Also,before starting with the mounting procedure, check

that the packaging contains all the components listed

below (B4) and that none of them is damaged.

1 - Operator

2 - Rod protection casing

3 - Rod proctection casing cover

4 - Rear mounting

5 - Bushes

6 - Fork

7 - Rear pin

8 - Locknut

9 - Fork pin

10 - Snap ring

11 - Front mounting

12 - Ball joint with nut

13 - Snap ring

14 - Capacitor

15 - Self-threading screw

16 - Release key

17 - Plate for rear mounting

A - Complete front mounting assembly

B - Complete rear mounting assembly

B1B

B3

B4

B

PLUMMET

eee eee

eee eee

x eee

............

16

9

10

7

4

17

10

5

8

6

13

12

11

2

15

1

3

15

- 17 -

A

14

Installation

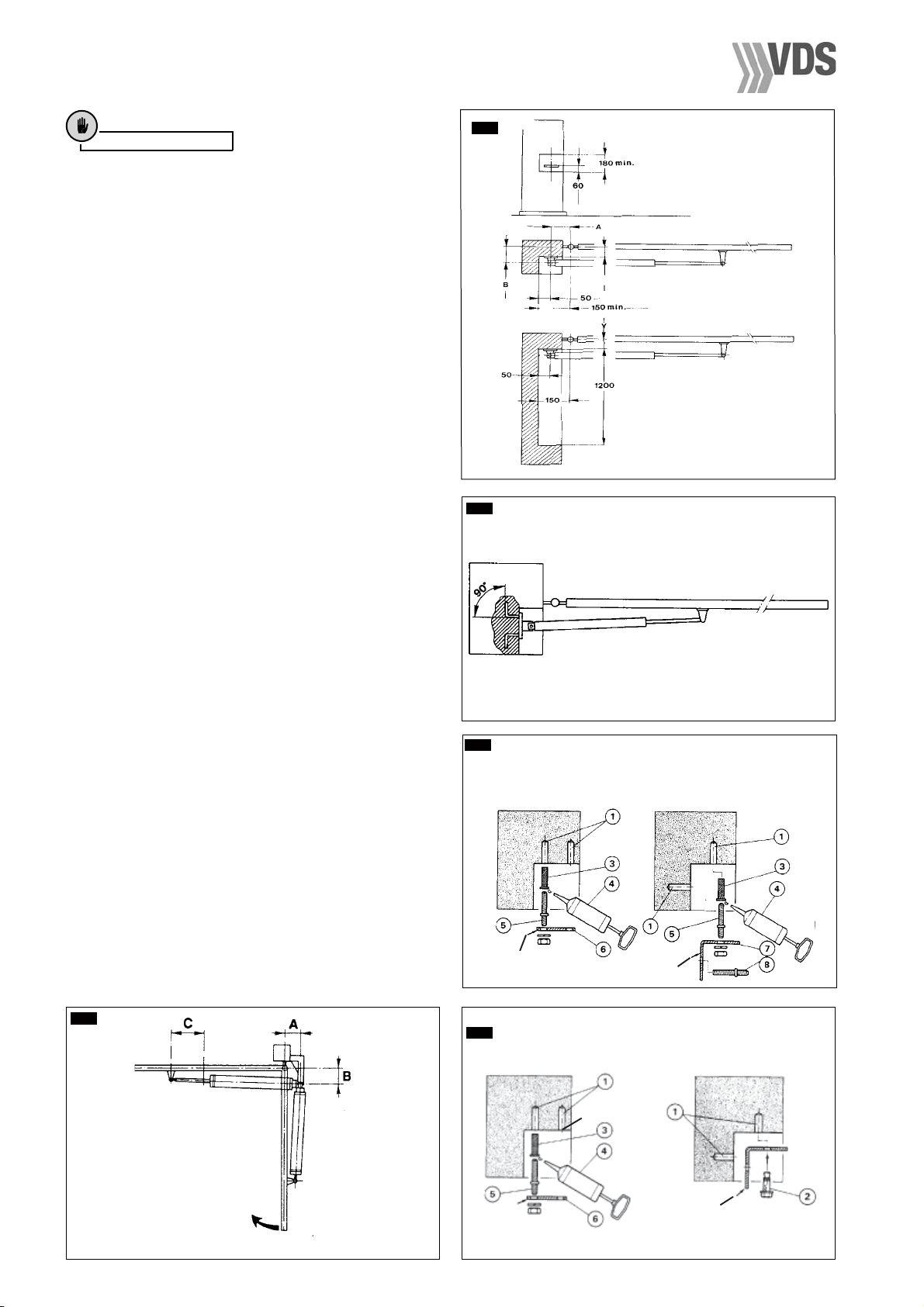

3.2 MOUNTING TOOLS

To mount the operator, a number of preparatory on-site jobs need to be done on the structure that is to be moved;

for this, it is better to be equipped with the correct tools, so that the installer is able to work independently.

English

Caution

The list of required tools is shown in the illustration and table (B5).

Electric disk grinder - 230 V

Protective goggles

Electric welder - min. power 230 V/100 amp.

Protective mask

Electrodes - min. ø 2

Soldering iron

Suitably powered electric drill - 230 V

Drill bits

Hollow cutter ø 67 for photocells and control panel

mounting holes

Extension cable for welder

Electric cable, cross-section 1.5 mm

2

, various colours +

various types of terminals

Electrical scissors

Pliers for cable terminals

Tester

1/20 gauge

Rule

Goniometer

B5

1

2

2

Dynamometer

Plumb line

Spirit level (3-D)

Graphitized grease

Oil - AprimOil HC 13 (specially formulated)

Zinc-spray cylinder

Anti-rust paint

Paintbrushes

Thinner for cleaning paintbrushes

Wire brush

Files

Hacksaws

Scribers

Hammer

Chisel for steel and masonry

Detergent wipes

Paper hand-towels

First aid kit

POS.

TOOL

Screwdriver

1

Gripper for snap ring on shaft

2

Screwdriver TC

3

Combined wrench 12

4

Combined wrench 13

5

6

Combined wrench 14

7

Combined wrench 17

USAG 326/5x150

USAG 128 P/1025

USAG 326 TC/2

USAG 285/12

USAG 285/13

USAG 285/14

USAG 285/17

65

47

3

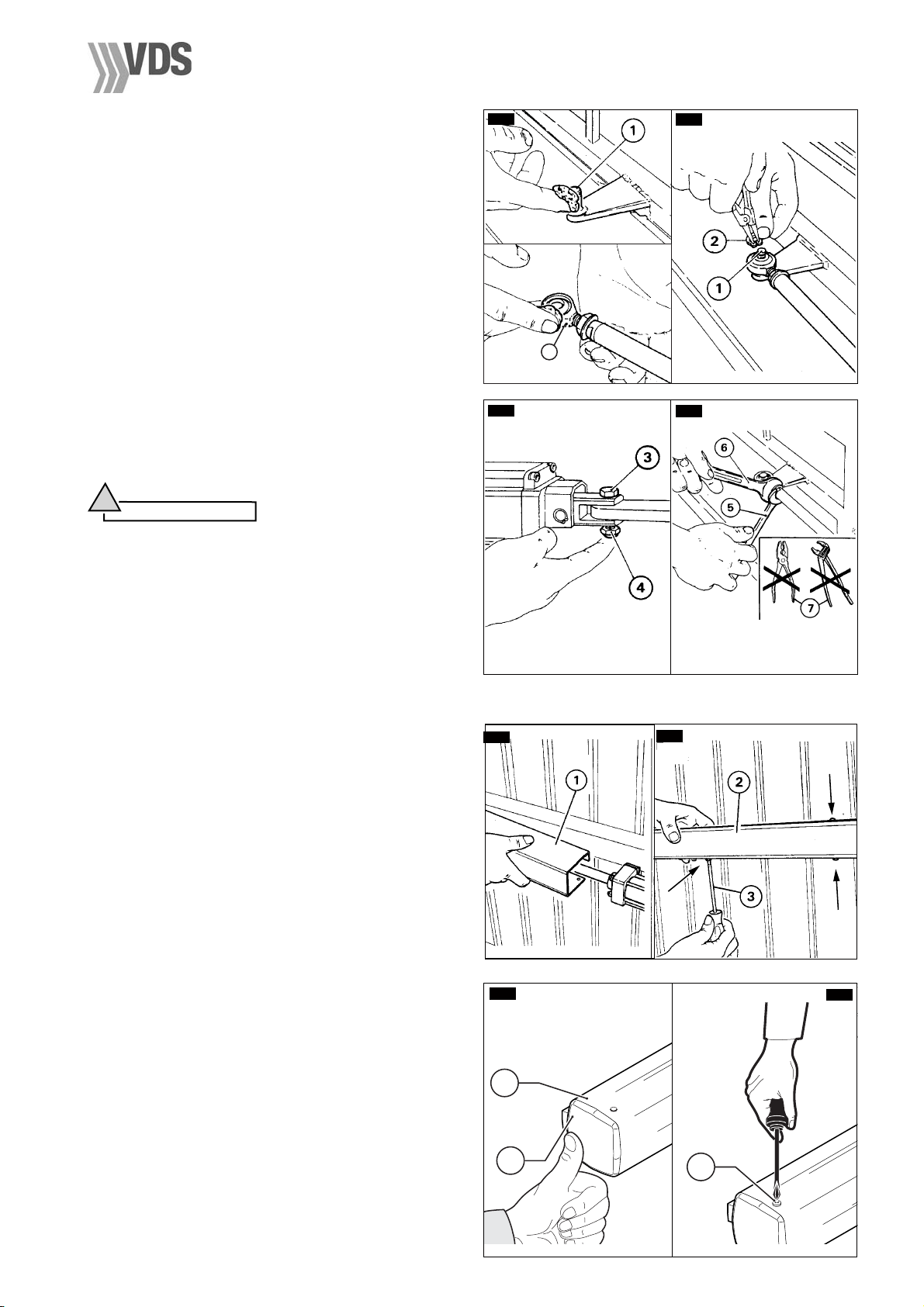

4. INSTALLING THE OPERATOR

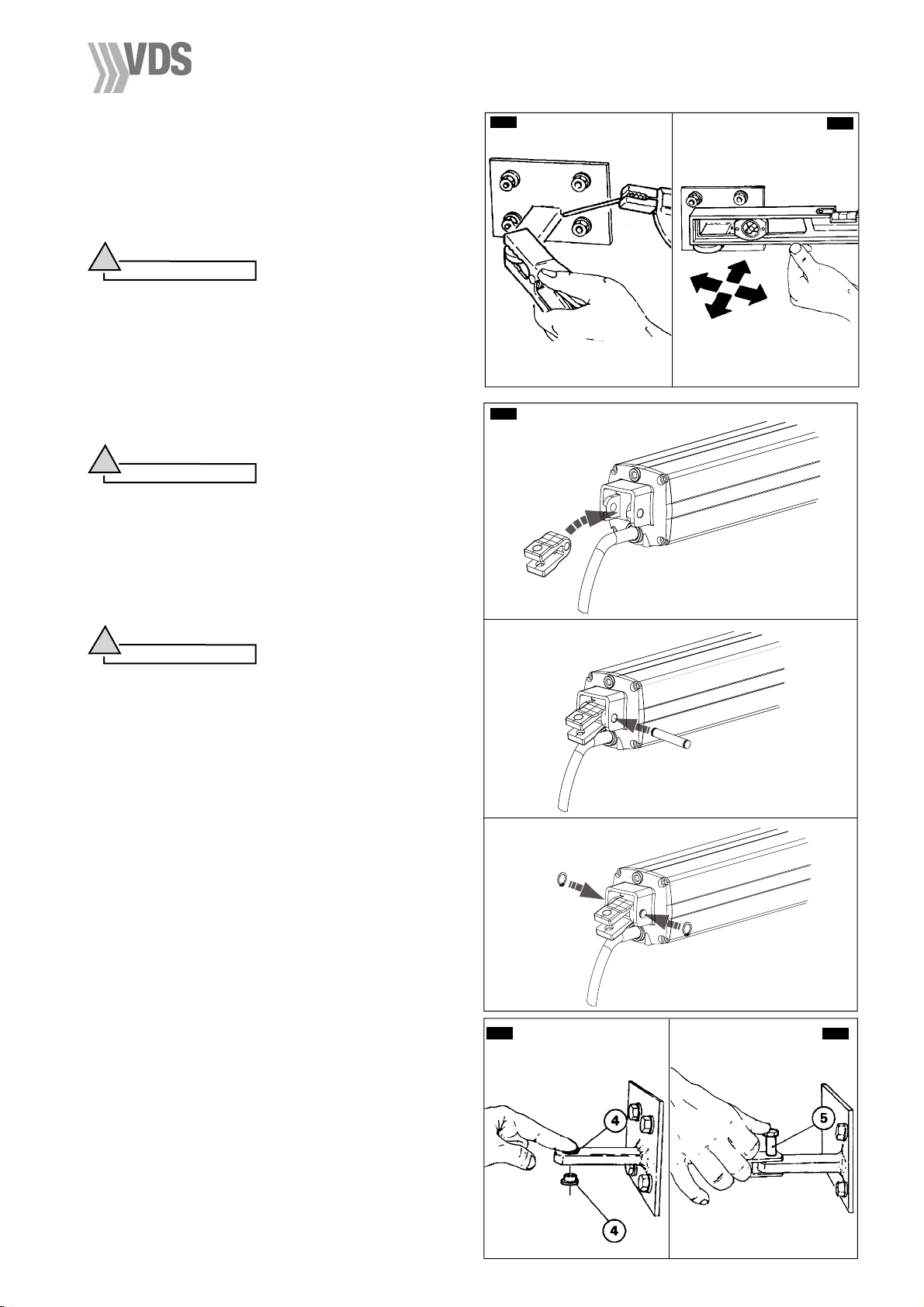

4.0 POSITIONING THE MOUNTINGS

The following table (C1) indicates the recommended data for defi ning the position of the operator mountings in

relation to the centre of rotation of the gate leaf.

The distances A and B will give:

• The useful stroke length (C) of the piston

• The peripheral velocity of the gate leaf

• The angle of maximum opening of the gate leaf

• The holding capacity of the lock in relation to distance E (which must always be less than B when the operator

is fi tted with a hydraulic lock); the distance E is obtained, in practice, by measuring the distance between front

mounting fulcrum and gate hinge axis (see fi g. C1).

Caution

• The sum A+B corresponds to the useful stroke length of the piston (C) for a 90° opening of the gate leaf.

• The minimum value of distances A and B is 70 mm; the maximum one is indicated in column B of the

table (see fi g. C1).

• Distances A and B must be as equal as possible in order to have a uniform peripheral velocity.

• If the gate leaf shall be opened by more than 90°, fi rst of all fi nd the best A and B measurements for

mounting, then reduce distance B to the desired opening angle, making sure, by checking the distance

Y, that the corner of the post does not interfere with the operator action.

!

Warning

• The greater the distance B in relation to E, the more effi cient the holding capacity of the hydraulic lock

(for all types of operator).

• If the gate leaf is closed with an electric lock, then E must always be less than or equal to B (never greater).

- 18 -

Installation

C1

1

2

1) Wing rotation axis

2) Operator centre of rotation

4.1 PREPPING FOR THE REAR MOUNTING

4.1.1 Operator fi xed on iron posts

If the gate supporting posts are made of iron, it is necessary to fi t a reinforcing plate for welding the rear operator

mounting.

Perfectly clean the welding zone for the rear mounting with the special tool (C2 pos.1); make sure to remove any

traces of paint or zinc coating.

Position the reinforcing plate (C3 pos. 2) in the rear mounting welding zone and weld it on the column, covering

it from edge to edge.

The size of the reinforcing plate must be in proportion to the size of the column.

VALUES IN MILLIMETRES

C

L

1200

÷

3000

B

A

140 275 90

130

YMax.

English

!

Warning

• If the size of the column allows for it, use the

standard plate provided.

4.1.2 Operator fi xed on wooden posts

If the gate supporting posts are made of wood, it is

necessary to fit a reinforcing plate on the column,

covering it from edge to edge, in the rear mounting

welding zone. The plate shall be fi xed fi rmly on the

column by means of fi xing screws (C4).

The size of the reinforcing plate must be in proportion

to the size of the column.

!

Warning

• If the size of the column allows for it, use the

standard plate provided.

4.1.3 Operator fi xed on masonry posts

If the supporting posts for the gate leaves are made of

masonry, fi x the special metal plate complete with anchor

bolts used to weld on the rear mounting of the operator

to each of them.

Preparing the insets

If mounting insets have to be made in the posts for

the rear operator mounting with metal plates, the

measurements shown in fi g.C6 must be adhered to.

C2

C4

C3

3

2

!

Warning

Remember that the inset is necessary when the distance

between the edge of the post and the centre of rotation of

the gate leaf is greater than the distance Y (C1), or when

the gate leaf is anchored to a continuous wall.

Fixing the anchoring plates

Fig. C5 shows some fi xing examples by means of

different types of plates:

A - Plate with hooked fi tting

B - Plate with stud bolts, either glued or pressure-

fi tted

C - L-plate with stud bolts, either glued or pressure-

fi tted

- 19 -

C5

A

(optional)

(standard)

min 5 mm

B

C

*

min 5 mm

min 5 mm

* CUT TO MEASURE

(not supplied)

Installation

Y

max. from hinge axis

to plate edge

English

Caution

• The size of the plates must be proportioned to the

size of the columns.

• If the A-type plate is used and has to be positioned

in line with the operator axis, the hook fi ttings

must be modifi ed as shown in fi g. C7.

Clean out any traces of cement or sand.

Drill four holes (C8 pos. 1), after marking the position of

the holes, using the anchorage plate itself as a drilling

guide mask.

Attach the plate with “FISCHER” expansion anchors of

minimum ø 15 with M8 steel or cast iron screws (C8 pos.

2) (if the material the column is made of is able to hold

the screws), or, if not, attach with glue as follows:

- Insert the mesh sheaths (C8 pos. 3) into the holes

and inject the quick-dry glue (C8 pos. 4); see attached

instructions for application method and quantity.

If the B-type plate is used:

- Insert the stud bolts (C8 pos. 5) into the sheaths (if

the B-type plate is used).

- Fit the anchoring plate (C8 pos. 7) to the stud bolts.

If, on the contrary, the C-type plate is used:

- Insert the stud bolts (C8 pos. 5) into one of the two

sides of the inset.

- Fit the anchoring plate (C8 pos. 7) to the stud bolts.

- Insert the two remaining stud bolts (C8 pos. 8).

At this point, if plates B or C are used, screw in all the

fi ttings, nuts and washers by hand, without tightening;

after about half an hour tighten up the stud bolts with a setscrew

wrench.

When fi nished, cut off the protruding parts of the stud

bolts using the correct tool.

C6

C7

4.1.4 Rear operator mounting - special cases

For outward-opening gate leaves, the rear mounting has

to modifi ed using an L-plate as shown in (C9).

C9

For dimensions A,B and C

consult table C1

C8

Type B plate

C8

RECOMMENDED GLUE FITTING

(other glue fitting systems

are available on the market)

Type C plate

PRESSURE FITTING

Type B plate

Inside entrance

Type C plate

- 20 -

Installation

4.2 FIXING THE REAR OPERATOR MOUNTING

Position the rear mounting (B4 pos. 4) at the height

previously measured and weld it on the anchorage plate

with two weld points (C9).

Check the lengthwise and crosswise alignment of the

mounting (C10) with a water level.

Complete the welding and clean away the residues with

a wire brush.

!

• Before welding, ensure that there are no bushes

(B4 pos. 5) in the mounting, and that the fi tting

hole is properly protected from weld residues.

• When the welded zone has cooled down, apply a

coat of anti-rust paint.

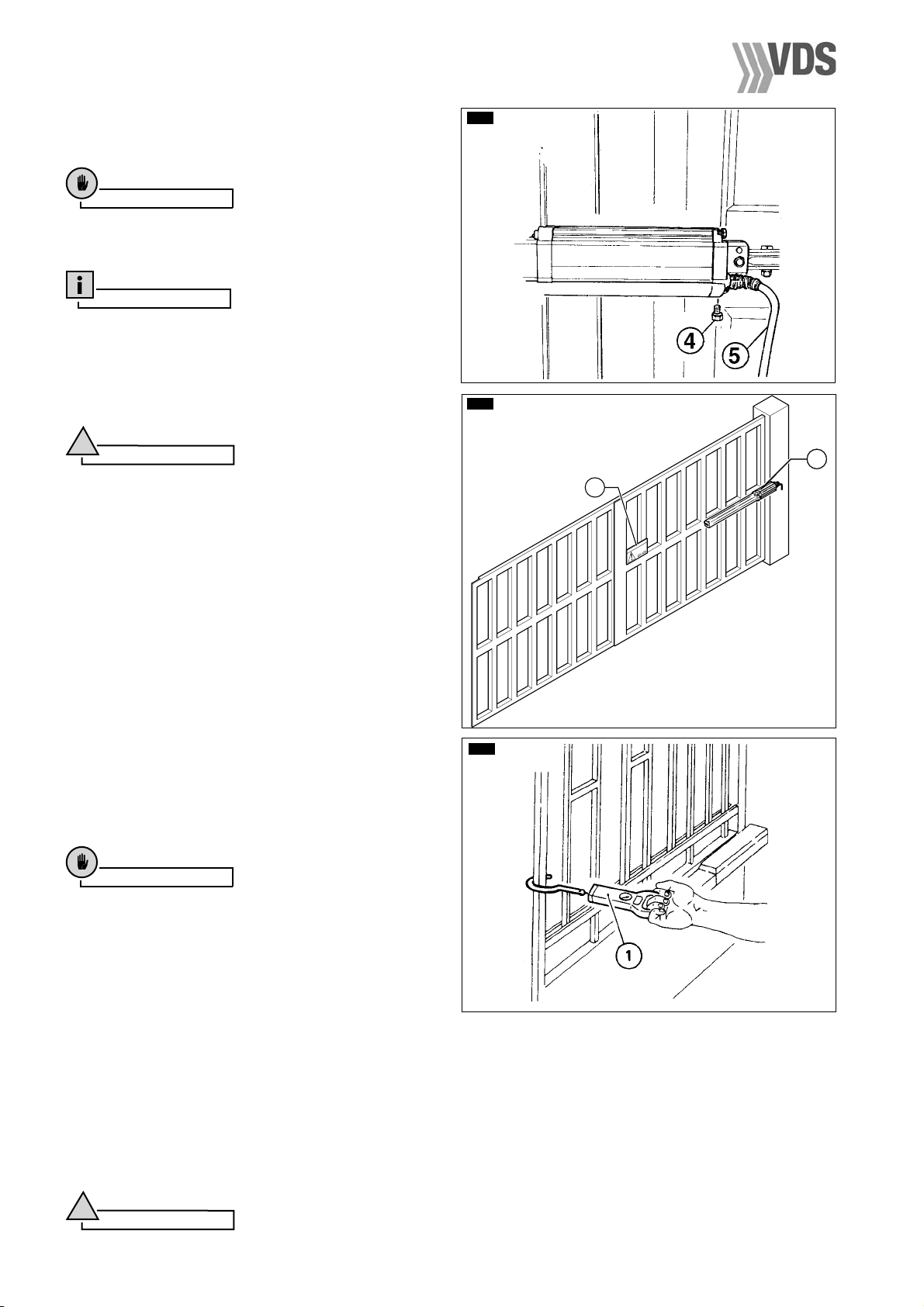

4.3 TEMPORARY INSTALLATION OF THE

OPERATOR

Temporarily mount the operator to fi nd the correct fi xing

position of the front mounting.

!

Handle the operator with care during assembly.

Fit the fork (C11 pos. 1) to the operator bottom. Lock the

fork with the special pin (C11 pos. 2) and fi x both with

the two snap rings (C11 pos. 3).

Fit the two vibration damping bushes (C12 pos. 4) above

and below the mounting.

Position the fork of the operator on to the mounting and

lock it with the vertical pin (C13 pos. 5) after greasing

abundantly.

Warning

Warning

C9

C11

C10

English

1

!

Grease both the pin and the housings abundantly.

Warning

C12

2

3

3

C13

- 21 -

Installation

English

4.4 POSITIONING THE FRONT MOUNTING

Spread grease on the threaded stem of the ball joint (C14

pos.1), fi t the ball joint, along with its nut (C14 pos.2) and

to the operator arm, screwing on to about halfway along

the thread. Insert the pin (C14 pos. 4) into the ball joint,

without fi tting the snap ring.

Fit the fork (C14b pos.1) to the base of the operator with

its pin (C14b pos.2) and fi x in place with the two snap

rings (C14b pos.3).

!

• Check the strength of the mounting zone;

if necessary, fit a strengthening plate of the

correct size; the strengthening plate is especially

important with gate leaves made from thin sheet

steel.

• When cleaning the mounting zone for the operator

front mounting, remove the operator and protect

it from fl ying sparks.

Rest a water level (C16 pos.1) on the operator body

(C16 pos.2) and level the operator.

Weld the front mounting of the rod to the gate leaf with

two weld-points, protecting the rod from weld residues

with a clean cloth (C17 pos.4).

Withdraw the jointed head of the operator from the front

mounting; completely remove the operator itself from its

temporary mountings, close off the fl ange with the correct

plug; complete the welding, covering the pin - using a

clean cloth or adhesive tape (C20 pos.5) - to protect it

from weld residue, and then clean off the residue with a

wire brush (C20 pos.6).

Warning

C14

1

C15

C14b

2

4

C16

300 mm

!

Warning

• While welding the points on the front mounting

with the electrode, always cover the rod with a

clean cloth; a splinter of molten metal can cause

irreparable damage to the machined surface and

make the operator unusable.

• During welding, the operator must be disconnected

from the electricity supply.

After cooling, apply a coat of rustproof paint to the welded

zone (C19).

C17

C19

C18

- 22 -

Installation

4.5 FINAL INSTALLATION OF THE OPERATOR

4.5.1 Mechanical fi xing

Fix both ends of the operator to the respective

mountings.

Front fi xing

Spread graphitized-type grease on to the frontal

anchorage pin of the ball joint (C20 pos.1).

Spread graphitized-type grease on to the ball joint (C20

pos.2).

Fit the jointed head to the pin (C21 pos.1) and fi x in place

with the snap ring (C21 pos.2).

Rear fi xing

Fit the operator to the rear mounting with the fork pin

(C22 pos.3) and its locknut (C22 pos.4).

With the gate leaf fully closed, re-check that the rod

comes out from the operator of the defi ned measure;

then tighten up the ball joint fi tting to the rod using a

CH 12 hexagonal wrench (C23 pos.5) and a CH 17

hexagonal wrench (C23 pos.6).

4.5.2 Checking the motion

!

Warning

• When the mounting is completed, neutralize the

hydraulic lock (if present in the operators) by

turning the correct key through 180° counterclockwise, and move the gate-leaves manually

to check on the smoothness of the movement;

this should be done very slowly, otherwise the

operators will take in air and, consequently, will

have to be bled.

• Open and close the gate leaf to check that the

operator can move freely without rubbing and

without going against either the gate leaf or the

gate post.

• After making the checks, reset the hydraulic lock

by turning the release key fully in a clockwise

direction.

4.5.3 Electrical connection

Make the electrical connection according to the wiring

diagram (D1) - see paragraph “System electrical

connection”.

Connect the supplied capacitor (B4 pos. 12) to the

electric control unit according to the wiring diagram of

the unit itself.

C20

C22

E1

C21

English

2

C23

E2

4.5.4 Fitting the protection casing and removing

the bleed screw

Fit the protective casing (E1 pos. 1) to rod and insert

into the operator.

Hold the casing bottom (E2 pos. 2) in position with a

cross-head screwdriver (E2 pos. 3).

Fit the push-on cover (E3 pos. 2) on to the protective

casing (E3 pos.1).

Tighten the fi xing screw of the protective casing (E4

pos.1).

On completion of the assembly, remove the bleed screw

- 23 -

E3

E4

1

2

1

Final operations

English

(E5 pos. 4) using a CH7 hexagonal wrench.

Fit the protective sheath to the power supply cable (E5

pos. 5) if necessary.

Caution

One drop of hydraulic oil coming out of the duct

created by the screw elimination (E5 pos. 4) is

normal.

Information

After installation, an appropriate warning sign must

be attached to the gate (E6 pos. 2.)

When completely assembled, the operator should

appear as shown in the fi gure (E6 pos. 1).

4.5.5 Bleeding

!

Warning

Before proceeding in setting the operator, bleed it.

Start the operator after having checked the setting of the

pressure relief valves and move it to stroke end either in

open or close position. Rotate on the key (see paragraph

6) and lock and unlock the operator a dozens of times.

E5

E6

1

2

c

i

t

a

c

i

t

im

c

ma

pr

i

i

t

a

pr

A

A

m

i

c

pr

i

t

a

A

m

i

r

p

A

c

i

t

a

m

i

r

p

A

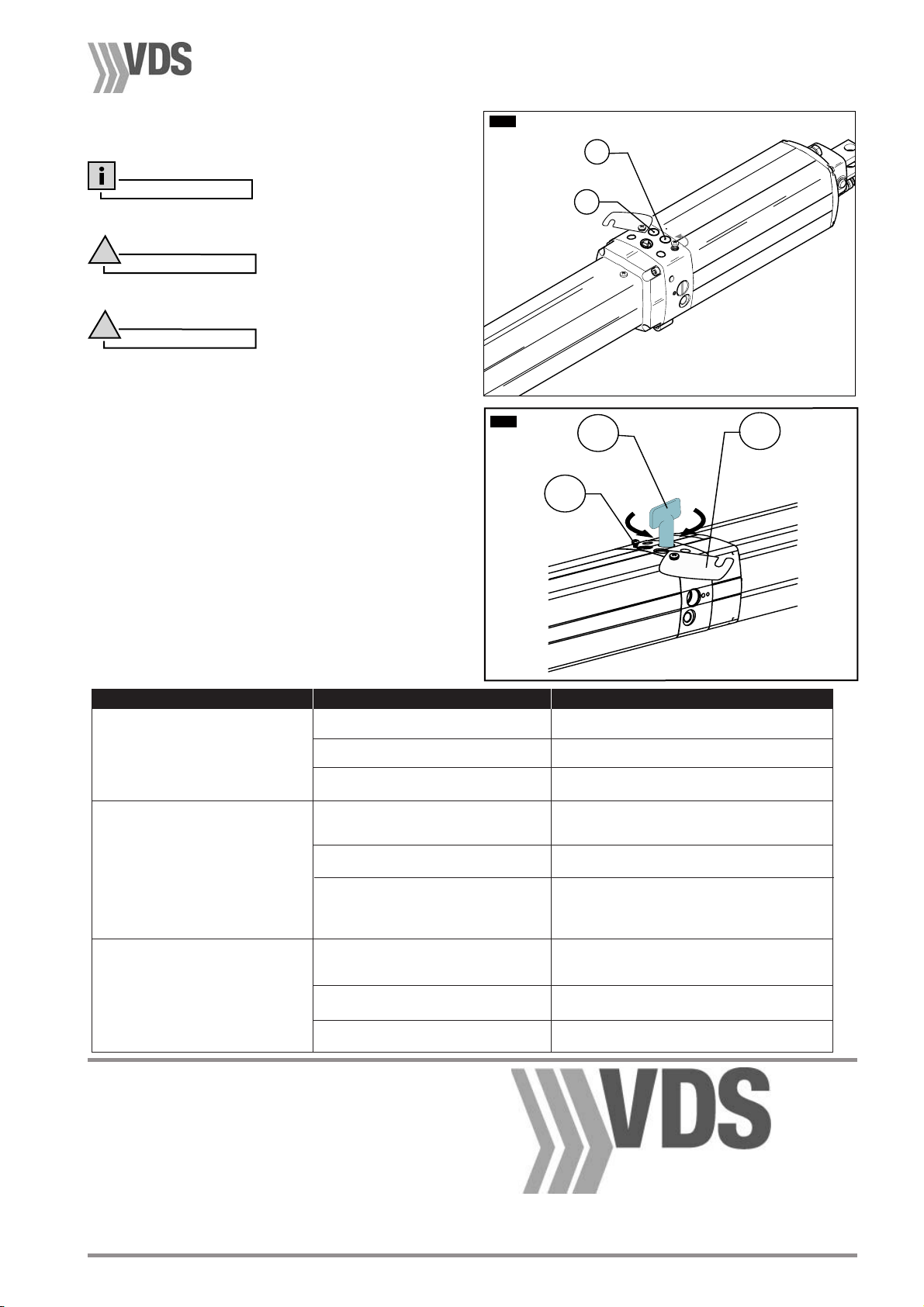

5. CHECKS AND ADJUSTMENTS

5.0 CHECKING AND ADJUSTING THE THRUST

FORCE

With the gate leaf moving, measure the thrust force

at the end of the gate leaf, using a dynamometer (E7

pos. 1).

The thrust force must never exceed 15 Kg (147 N).

If necessary, adjust the working pressure of the

operator.

Using a broad, fl at-headed screwdriver, turn the control

valves clockwise to increase the pressure and counterclockwise to reduce it.

Adjust both opening (silver - E8 pos. 2) and closing

pressure (gold - E8 pos. 1).

Caution

• The opening thrust of the gate leaf should be set

slightly higher than the closing thrust.

• After making the settings, make another check

with the dynamometer to see if the thrust force

corresponds to the setting; if it doesn’t, then the

setting needs to adjusted again.

• If the gate leaf requires an excessively high

pressure to move it, then make another thorough

check of the mechanical parts, the plumb and the

free movement of the gate leaf itself.

E7

6.0 EMERGENCY MANOEUVRE - USE OF THE MANUAL RELEASE

In the event of a power failure, release the operator in order to open the gate by hand.

To gain access to the release valve, it is enough to loosen the screw (E9 pos. 2) and open the small cover (E9

pos. 3) by rotating it.

Unlock the operator by turning the triangular key provided (E9 pos. 1) counter-clockwise.

After the operation, re-lock the operator by turning the key clockwise.

!

Warning

After locking and releasing operations, remember to re-close the cover.

- 24 -

2

1

3

Notes for the user

7. NOTES FOR THE INSTALLER

7.0 Maintenance

Information

Periodically check the proper functioning of the

operator. Do this check at least every 12 months

!

Warning

Maintenance must be performed only by skilled

technicians.

!

Warning

Before doing any maintenance job, turn the operator

off by means of the differential switch of the electric

system.

• Grease the joints with graphitized grease every

year.

• Check the general condition of the gate structure.

• Check the mechanical resistance of hinges, operator

mountings and stops.

• Ensure the installed safety devices are in working

order (photocells, rubber barriers,…) and adjust the

thrust force at the end of the gate leaf (max. 147 N).

• Ensure the electrical system and the differential switch

are effi cient.

• Check the setting of the pressure relief valve.

• Check the tightening of the safety lock.

• Depending on the use of the operator, check the oil

level of the system.

E8

1

2

English

E9

7.1 Troubleshooting

Fault type

By operating the opening control, the

leaf does not move and the electric

motor of the operator does not run.

By operating the opening control, the

electric motor of the operator runs but

the leaf does not move.

During the motion, the operator jerks.

SPACE RESERVED FOR INSTALLER

PLEASE GIVE A COPY OF THIS PAGE TO THE USER

Probable cause

No power supply.

Defective fuse.

The power cable of the operator is damaged.

If the operator has a hydraulic release,

check that the release valve setting is

closed.

If the operator doesn't have a hydraulic

release, adjiust the opening pressure setting.

If the operator has been exposed to the sun for

a long period, with the gate closed, check that

the operator piston is not in the fully advanced

position, i.e. with the rod completely out.

Probably air in the cylinder.

Oil in the cylinder not enough.

The front and rear operator mountings

move or have been fitted incorrectly.

Solution

Turn the power on.

Replace the defective fuses with new ones having

the same amperage.

Replace the power cable and find and rectify

the fault.

Turn the valve fully in a clockwise direction (E9 pos.1).

Screw the pressure setting valve clockwise

(par.5 - E8 pos.2)

Check the operator mounting, as described in

this manual.

Check the measure of the piston stroke.

Detach the operator from its front mounting

and make a few opening and closing movements;

then re-fit to the front mounting.

Check for oil leaks; if any, address to a Repair Centre.

Repair or strengthen the mountings.

Via Circolare, sn

65010 Santa Teresa di Spoltore - Pescara

Tel. 085/4971946 - Fax 085/4973849

- 25 -

Français

Index / Caractéristiques

Caractéristiques de l’automatisme

1

1.0 Caractéristiques générales ............................................................................................................................. 27

1.1 Données techniques ....................................................................................................................................... 27

1.2 Vérifi cation de l’automatisme choisi .............................................................................................................. 27

Description du système d’automatisation

2

2.0 Disposition des composants ........................................................................................................................... 28

2.1 Branchement electrique du système ............................................................................................................. 28

Contrôles et opérations précédant l’installation de l’automatisme

3

3.0 Contrôles sur le portail ................................................................................................................................... 29

3.1 Vérifi cation des composants de l’automatisme .............................................................................................. 29

3.2 Outils nécessaires pour le montage ............................................................................................................... 30

Installation de l’automatisme

4

4.0 Mise en place des connexions ....................................................................................................................... 30

4.1 Préparation pour la fi xation arrière ................................................................................................................ 31

4.1.1 Automatisme fi xé sur des piliers en fer ............................................................................................................................. 31

4.1.2 Automatisme fi xé sur des piliers en bois ........................................................................................................................... 31

4.1.3 Automatisme fi xé sur des piliers en maçonnerie ............................................................................................................... 31

4.1.4 Cas particuliers de fi xation arrière de l’automatisme......................................................................................................... 32

4.2 Fixation de la patte arrière de l’automatisme ................................................................................................. 33

4.3 Installation provisoire de l’automatisme .........................................................................................................33

4.4 Mise en place de la patte de fi xation avant .................................................................................................... 34

4.5 Installation fi nale de l’automatisme ...............................................................................................................35

4.5.1 Fixation mécanique ........................................................................................................................................................... 35

4.5.2 Contrôle du mouvement .................................................................................................................................................... 35

4.5.3 Branchement électrique .................................................................................................................................................... 35

4.5.4 Montage du carter de protection et démontage de la vis de purge ................................................................................... 35

4.5.5 Purge de l’air ..................................................................................................................................................................... 36

Contrôles et réglages

5

5.0 Contrôle et réglage de la force de poussée ................................................................................................... 36

Manœuvre d’urgence

6

6.0 Manœuvre d’urgence - utilisation du déblocage manuel .............................................................................. 36

Notes pour l’installateur

7

7.0 Entretien ......................................................................................................................................................... 37

7.1 Recherche des pannes .................................................................................................................................. 37

- 26 -

Caractéristiques / Opérations préliminaires

1. CARACTERISTIQUES DE L’AUTOMATISME

1.0 CARACTERISTIQUES GENERALES

• Automatisme oléo-hydraulique pour portails à battant conçu pour des zones résidentielles.

• L’automatisme, si installé correctement, est conforme aux normes de sécurité actuellement en vigueur.

Liste des versions:

PH1: Blocage hydraulique seulement en fermeture (avec automatisme inaccessible lorsque le vantail est ouvert)

PH: Sans blocage hydraulique - freiné (vantail actionnée lentement à la main, avec une petite résistance; il est

doté d’un dispositif de déblocage pour faciliter l’ouverture - électro-serrure nécessaire).

• La version avec blocage hydraulique en fermeture évite l’installation de l’électro-serrure, car il assure la fermeture

des vantaux jusqu’à 1,8 mètres de long.

• Le déblocage d’urgence (à utiliser en cas de panne de courant) permet une commande manuelle aisée du

portail par la clé triangulaire très simple à utiliser. Le dispositif de déblocage est facilement accessible à travers

un petit couvercle placé sur le coffret supérieur de l’automatisme.

• La protection anti-écrasement est assurée par des clapets très sensibles, réglables en phase d’installation

.

B

1.1 DONNEES TECHNIQUES

CARACTÉRISTIQUES

Tension d'alimentation monophasée

Puissance

Pression moyenne de service

Force de poussée à 10 bar

Force de traction à 15 bar

Temps d'entrée tige (course maximale)

Temps de sortie tige

Longueur max. vantail

Longueur min. vantail

Température de fonctionnement

Ecartement maximal des trous de fixation

avec tige sortie

Course maximale tige standard

Poids avec huile

Quantité huile

Huile type

Degré de protection

A

C

PH1

230 V±10% 50 Hz

250W

30 bar

962 N

1140 N

22 sec ±2

22 sec ±2

1,8 m 3 m

1,2 m

-20° / + 70°C

1002 mm ± 5

270 mm

8 Kg

0,6 lt.

AprimOil HC13

IP 55

PH

70

90

A (mm)

B (mm)

97,5

C (mm)

1060

698

274

Français

!

Attention

Le niveau de bruit des modèles décrits auparavant rentre dans les limites maximales établies par les

normes CEE pour le fonctionnement d’automatismes non fi xés à portails ou piliers.

1.2 VERIFICATION DE L’AUTOMATISME CHOISI

Avant de procéder au montage, il faut vérifi er le type d’automatisme choisi par rapport aux caractéristiques et aux

dimensions de l’élément à actionner.

Prudence

• Le choix d’un automatisme correct assure un fonctionnement correct du groupe et réduit la possibilité

de pannes.

!

Attention

• Les versions décrites auparavant peuvent être utilisées même en cas de vantaux pleins (avec l’automatisme

inaccessible lorsque le vantail est ouvert).

• Le modèle PH1 est adapté pour une utilisation dans des zones venteuses et ne doit pas être installé sur des

vantaux supérieurs à 1,8 m de long.

!

Attention

La vitesse périphérique du vantail doit toujours être conforme aux limites des normes de sécurité en vigueur. Ne pas

installer d’automatismes rapides sur des vantaux larges afi n d’éviter des chocs violents contre les arrêts du portail

(voir tableau “Données techniques” ).

- 27 -

Français

Opérations préliminaires

2. DESCRIPTION DU SYSTEME D’AUTOMATISATION

2.0 DISPOSITION DES COMPOSANTS

A - Clignotant (à placer dans un point bien visible des deux

côtés de passage)

B - Photocellule de sécurité

C - Dispositif de commande manuelle à clé (magnétique,

numérique, par clavier, mécanique, etc.)

D - Dispositif de contrôle à microprocesseur placé dans une

boîte étanche (à placer, si possible, à l’abri des intempéries)

F - Boîte de dérivation étanche pour l’alimentation de

l’automatisme (conseillée) à placer de façon à ce que

les câbles ne soient pas sujets à des efforts dangereux

lors du mouvement

G - Antenne

H - Automatismes série PH

I - Electro-serrure (optionnelle)

L - Arrêt mécanique pendant l’ouverture

M - Arrêt mécanique pendant la fermeture

N - Mise à la terre des structures métalliques

Informations

Pour d’autres dispositifs de sécurité (optionnels), voir

le tarif.

2.1 BRANCHEMENT ELECTRIQUE DU SYSTEME

- Pour effectuer les branchements électriques, respecter rigoureusement les instructions fournies avec les

composants en suivant le schéma indiqué en D1.

!

Attention

• Effecteur le branchement électrique de chaque composant après l’installation.

• L’installation doit être conforme aux normes de sécurité en vigueur.

• Pour la connexion, utiliser des câbles électriques avec une section de 1,5 mm2.

• S’il s’avère nécessaire de protéger le câble d’alimentation de l’automatisme avec une gaine de protection,

effectuer l’opération avant de raccorder le câble aux boîtes de dérivation.

!

Attention

• Chaque automatisme est fourni complet avec condensateur de courant. Lors de l’installation, relier le

condensateur à l’intérieur de l’équipement électrique en suivant le schéma fourni.

- Une fois les branchements électriques effectués, vérifi er la force de poussée à l’extrémité du vantail et, si

nécessaire, régler les pressions comme indiqué dans le paragraphe spécifi que.

D1

1

2

5

6

1 Antenne

3

9

9

4

2 Clignotant

3 Photocellule récepteur

4 Photocellule émetteur

5 Tableau à boutons-poussoirs intérieur

6 Bouton-poussoir à clé

7

8

7 Electro-serrure

8 Appareil électronique

9 Boîte de dérivation

6A

0,030 A

- 28 -

Opérations préliminaires

3. CONTROLES ET OPERATIONS PRECEDANT L’INSTALLATION DE L’AUTOMATISME

3.0 CONTROLES SUR LE PORTAIL

• Avant de procéder au montage défi nitif, vérifi er que les vantaux sont en bonne condition et qu’ils ne sont pas

endommagés ou cassés.

• Vérifi er que le mouvement des vantaux est uniforme et que les charnières correspondantes n’ont pas de jeu et

ne frottent pas.

Dans le cas contraire, réparer les charnières de façon à ce que les vantaux peuvent être actionnés à la main ou,

dans le pire des cas, remplacer les charnières.

• Vérifi er que les vantaux sont “à plomb” (parfaitement stables dans tout point de rotation) (B1B). Avec vantaux

complètement fermés, contrôler qu’ils coïncident de manière uniforme tout au long de leur hauteur.

• A l’aide d’un dynamomètre, vérifi er que l’effort d’ouverture et de fermeture calculé à l’extrémité du vantail, ne

dépasse pas 15 kg (147 N).

Avant de défi nir le positionnement des pattes de fi xation, il faut:

• Choisir la position la plus appropriée, sur le vantail, pour positionner en hauteur la patte antérieure de l’automatisme.

Si possible, placer cette patte à mi-hauteur sur le vantail. En général, la position optimale correspond toujours

à la zone du vantail la plus solide et moins sujette aux déformations. Si la structure du portail n’est pas dotée

d’une bande en profi lé, souder un support dans la zone de positionnement de la patte antérieure afi n de répartir

la charge sur une surface plus étendue (B1A).

• Vérifi er si la position choisie doit être renforcée. Répéter ce contrôle même sur les piliers soutenant les

vantaux.

Français

B1A

3.1 VERIFICATION DES COMPOSANTS DE

L’AUTOMATISME

Vérifier que le sigle du modèle sur l’emballage de

l’automatisme correspond à celui indiqué sur la plaque

de l’automatisme lui-même (B3).

Avant de commencer le montage, vérifi er que l’emballage

contient tous les composants indiqués ci-après (B4) et

qu’ils ne sont pas endommagés.

1 - Automatisme

2 - Carter de protection tige

3 - Couvercle carter de protection tige

4 - Patte arrière

5 - Bagues

6 - Fourche

7 - Goujon arrière

8 - Ecrou de sûreté

9 - Axe fourche

10 - Anneau de retenue Seeger

11 - Patte avant

12 - Rotule avec son écrou

13 - Anneau de retenue Seeger

14 - Condensateur

15 - Vis auto-taraudeuse

16 - Clé de déblocage

17 - Plaque pour patte arrière

A - Groupe fi xation avant complet

B - Groupe fi xation arrière complet

B1B

B3

B4

B

FIL À PIOMB

eee eee

eee eee

x eee

............

16

9

10

7

4

17

10

5

8

6

13

12

11

2

15

1

3

15

- 29 -

A

14

Installation

3.2 OUTILS NECESSAIRES POUR LE MONTAGE

Le montage de l’automatisme nécessite une série de travaux de préparation du groupe à déplacer à effectuer

directement sur le lieu d’installation; par conséquent, l’installateur doit se doter avant des outils adaptés pour

pouvoir travailler en autonomie.

Français

Prudence

La liste des outils nécessaires est indiquée dans la fi gure complète avec tableau (B5).

Meule-disque électrique - alimentation 230 V

Lunettes de protection

Soudeuse électrique - alimentation 230V/100 amp. minimum

Masque de protection

Electrodes ø 2 minimum

Soudeur à l’étain

Perceuse électrique de puissance adaptée alimentation

230V

Jeu de forets

Fraise à godet ø 67 pour trous de logement photocellules

et tableaux à poussoirs

Câble de rallonge pour équipement électrique

Câble électrique section 1,5 mm2 de différentes couleurs

et cosses de type différent

Ciseaux pour électricien

Pinces pour cosses

Tester

Jauge vingtième

Mètre

B5

1

2

2

Goniomètre

Dynamomètre

Fil à plomb

Niveau à bulle d’aire (tridimensionnel)

Graisse graphitée

Huile type AprimOil HC 13 (formulée expressément)

Bombe Zincspray

Peinture anti-rouille

Brosses pour peinture

Solvant pour le nettoyage des brosses

Brosse métallique

Limes

Scies à fer

Pointes à tracer

Marteau

Boucharde pour acier et maçonnerie

Serviettes

Papier pour les mains

Trousse de premiers soins

POS.

OUTIL

Tournevis

1

Pince pour seeger sur axe

2

Tournevis TC

3

Clé combinée 12

4

Clé combinée 13

5

6

Clé combinée 14

7

Clé combinée 17

USAG 326/5x150

USAG 128 P/1025

USAG 326 TC/2

USAG 285/12

USAG 285/13

USAG 285/14

USAG 285/17

65

47

3

4. INSTALLATION DE L’AUTOMATISME

4.0 MISE EN PLACE DES FIXATIONS

Le tableau suivant (C1) illustre les données conseillées pour défi nir la position des fi xations de l’automatisme par

rapport au centre de rotation du vantail.

En déterminant les valeurs A et B, on obtient:

• la course utile (C) du piston

• la vitesse périphérique du vantail

• l’angle d’ouverture maximale du vantail

• la résistance du blocage par rapport à la valeur E (qui doit toujours être inférieure à B si l’automatisme est doté

de blocage hydraulique); la valeur E est obtenue en mesurant la distance du point d’appui de la fi xation avant

jusqu’à l’axe de la charnière du portail (voir fi g. C1).

Prudence

• La somme de A+B correspond à la course utile du piston (C) pour obtenir une ouverture du vantail de

90°.

• La valeur minimale de A et B est 70 mm; la valeur maximale est indiquée dans la colonne B du tableau

de la fi gure C1.

• Afi n d’obtenir des vitesses périphériques uniformes, les cotes A et B doivent être égales entre elles

autant que possible.

• Pour dépasser les 90° d’ouverture du vantail, après avoir trouvé les valeurs optimales de A et B pour le

montage, réduire la valeur B jusqu’à obtenir l’angle d’ouverture désiré en faisant toujours attention à la

valeur Y pour éviter toute interférence de l’automatisme avec le coin du pilier.

!

Attention

• Plus grande est la valeur B par rapport à E, plus effi cace est la résistance du blocage hydraulique (si installé).

• Si le portail est doté d’une électro-serrure, la valeur E doit être inférieure ou égale à la valeur B (jamais supérieure).

- 30 -

Installation

C1

1

COTES EN MILLIM˚TRES

C

B

A

140 275 90

130

2

1) Point de rotation du vantail

2) Point de rotation de l’opérateur

L

1200

÷

3000

4.1 PREDISPOSITIONS POUR LA FIXATION ARRIERE

4.1.1 Automatisme fi xé sur des piliers en fer

Lorsque les piliers de soutien des vantaux du portail sont en fer, il faut réaliser une plaque de renforcement pour

le soudage de la patte de fi xation arrière de l’automatisme.

Nettoyer parfaitement la zone de soudage de la patte arrière à l’aide de l’outil prévu à cet effet (C2 pos. 1); en

particulier, enlever toute trace de peinture ou de zincage.

Souder la plaque de renforcement (C3 pos. 2), d’un coin à l’autre du pilier, dans la zone préparée pour le soudage

de la fi xation arrière (C3 pos. 3).

Les dimensions de la plaque de renforcement doivent être proportionnées aux dimensions du pilier.

!

Attention

C2

• Si les dimensions du pilier sont adaptées, utiliser

la plaque standard fournie.

Y Max.

C3

Français

4.1.2 Automatisme fi xé sur des piliers en bois

Si les piliers soutenant les vantaux du portail sont en

bois, il faut appliquer une plaque de renforcement d’un

coin à l’autre du pilier afi n de pouvoir souder la fi xation

arrière de l’automatisme. La plaque doit être fixée

solidement sur le pilier avec des vis de fi xation (C4) .

Les dimensions de la plaque de renforcement doivent

être proportionnées aux dimensions du pilier.

!

Attention

• Si les dimensions du pilier sont adaptées, utiliser

la plaque standard fournie.

4.1.3 Automatisme fi xé sur des piliers en maçonnerie

Si les piliers de soutien des vantaux du portail sont en

maçonnerie, il faut fi xer sur chaque pilier une plaque

métallique dotée d’ancrages sur laquelle souder la patte

arrière de l’automatisme.

Réalisation des niches

S’il s’avère nécessaire de réaliser des niches de logement

dans les piliers pour la fi xation arrière de l’automatisme à

l’aide des plaques métalliques, respecter les dimensions

indiquées sur la fi gure (C6).

!

Nous rappelons que la niche est nécessaire quand la

distance entre le coin du pilier et le centre de rotation

du vantail dépasse la cote Y (C1) ou quand le vantail

est fi xé à un mur continu.

Attention

C4

C5

A

(en option)

B

(standard)

3

2

C

*

Fixation des plaques d’ancrage

Nous indiquons quelques exemples de réalisation avec

utilisation de types de plaques différents (C5):

A - Plaque avec connexion à agrafes

B - Plaque avec connexion par goujons à fixation

chimique ou mécanique

C - Plaque en “L” avec connexion par goujons à fi xation

chimique ou mécanique

- 31 -

min 5 mm

min 5 mm

min 5 mm

*À RÉALISER SUR MESURE

(non fournie)

Installation

Y

max. de l’axe de la charnière

au deébut de la patte

Français

Prudence

• Les dimensions des plaques doivent être

proportionnées aux dimensions des piliers.

•

Lorsque l’on utilise la plaque du type A et qu’elle

doit être alignée à l’automatisme, il est nécessaire

de modifi er les agrafes comme indiqué à la fi g.C7.

Eliminer de la surface tous résidus de ciment ou de

sable.

Effectuer quatre trous (C8 pos. 1), après avoir marqué

leur position en utilisant la plaque d’ancrage comme

gabarit de perçage.

Fixez mécaniquement la plaque avec des chevilles

d’expansion “FISCHER” ø 15 minimum, vis M8 (C8 pos.

2), en acier ou fonte (le matériel dont le pilier est réalisé

le permettant), ou bien procéder à la fi xation chimique

comme suit:

-

Introduire dans les trous les gaines tramées (C8 pos. 3)

et y injecter le ciment-colle à durcissement rapide (C8

pos. 4) comme indiqué dans les instructions fournies.

Si l’on utilise une plaque du type B :

- Insérer les goujons (C8 pos. 5) dans les gaines (quand

l’on utilise le type B).

- Monter la plaque d’ancrage (C8 pos. 7) sur les

goujons.

Si, au contraire, l’on utilise une plaque du type C :

- Insérer les goujons (C8 pos. 5) dans un de deux côtés

de la niche.

Monter la plaque d’ancrage (C8 pos. 7) sur les

-

goujons.

- Insérer les deux autres goujons (C8 pos. 8).

Maintenant, soit que l’on utilise la plaque B ou la plaque

C, fi xer le tout à la main, sans serrer, à l’aide des écrous

et des rondelles prévus à cet effet. Après environ une

heure et demi, serrer les goujons à l’aide d’une clé à

tête hexagonale.

Une fois l’opération terminée, éliminer les parties

saillantes à l’aide de l’outil prévu à cet effet.

4.1.4 Cas particuliers de fi xation arrière de

l’automatisme

Pour les vantaux avec ouverture vers l’extérieur, il faut

modifi er la patte de fi xation arrière en utilisant un profi l

en “L” comme indiqué en C9.

C7

C8

C6

FIXATION CHIMIQUE CONSEILLE

(d'autres systèmes de fixation chimique

sont disponibles sur le marche)

C9

Pour le cotes A,B et C,

voir le tableau C1

Côte interne entrée

- 32 -

Patte type B

C8

Patte type C

FIXATION MECANIQUE

Patte type B

Patte type C

Installation

4.2 FIXATION DE LA PATTE ARRIERE DE

L’AUTOMATISME

Placer la patte arrière (B4 pos. 4) aux cotes défi nies

avant et la fi xer à la plaque d’ancrage avec deux points

de soudure (C9).

A l’aide d’un niveau à bulle d’air, vérifi er l’alignement

longitudinal et transversal (C10) de la patte de fi xation.

Terminer la soudure et éliminer les résidus avec une

brosse métallique.

!

• Avant tout soudage, s’assurer que sur la patte

il n’y a pas de bagues (B4 pos. 5) et que le trou

de logement est protégé contre les résidus de

soudure.

• Après le refroidissement, recouvrir la zone de

soudage avec de la peinture anti-rouille.

4.3 INSTALLATION PROVISOIRE DE

L’AUTOMATISME

Il est nécessaire d’installer provisoirement l’automatisme

pour déterminer la position correcte de la patte de

fi xation antérieure.

!

Manier l’automatisme avec soin pendant les phases

de montage.

Insérer sur le fond de l’automatisme la fourche (C11

pos. 1). Bloquer la fourche avec le goujon spécial (C11

pos. 2) et fi xer le tout avec les deux anneaux Seeger

(C11 pos. 3).

Appliquer les deux bague anti-vibration (C12 pos. 4) sur

la patte en haut et en bas.

Placer la fourche de l’automatisme sur la patte de fi xation

et la fi xer

Attention

Attention

avec l’axe vertical (C13 pos. 5) bien graissée.

C9

C11

C10

Français

1

!

Graisser abondamment tant l’axe que les logements

correspondants.

Attention

C12

2

3

3

C13

- 33 -

Installation

Français

4.4 MISE EN PLACE DE LA FIXATION AVANT

Etalez de la graisse sur la tige fi letée de la rotule (C14

pos.1), introduisez dans la tige de l’opérateur la rotule avec

l’écrou (C14 pos.2) et vissez-le jusqu’à la moitié du fi let.

Introduisez dans la rotule le pivot (C14 pos.4) de l’opérateur

avant, sans le serrer, avec le seeger correspondant.

Dans le fond de l’opérateur, introduisez la fourche

correspondante (C14b pos.1) à l’aide de l’axe prévu

à cet effet (C14b pos.2) et fi xez tout ça au moyen des

deux seegers (C14b pos.3).

!

• Vérifi er la résistance de la zone de fi xation et,

s’il est nécessaire, appliquer un gousset de

renforcement de dimensions adaptées. Le gousset

est indispensable si les tôles des vantaux ne sont

pas de forte épaisseur.

• Pendant le nettoyage de la zone de fi xation de

la patte avant, éloigner l’automatisme de la zone

d’intervention et le protéger contre les étincelles.

Appuyez un niveau (C16 pos.1) sur le corps de

l’automatisme (C16 pos.2) et niveler l’automatisme.

Fixer la patte avant de la tige au vantail avec deux points

de soudure en protégeant la tige contre les résidus de

soudage avec un chiffon propre (C17 pos.4).

Enlevez la rotule de la patte avant. Enlevez complètement

l’opérateur des fi xations provisoires et fermez la bride

de déblocage à l’aide du sous-bouchon correspondant.

Complétez le soudage, protégez (à l’aide d’un chiffon

propre ou d’un ruban adhésif) le pivot (C18 pos.5) contre

les résidus et enlevez-les au moyen d’une brosse

métallique (C18 pos.6).

Attention

C14

1

C15

C14b

2

4

C16

300 mm

!

Attention

• Lors du soudage par points de la patte avant,

toujours protéger la tige avec un chiffon. En

effet, une éclaboussure de métal fondu pourrait

endommager la surface rectifi ée aussi bien que

l’automatisme.

• Pendant le soudage, l’automatisme doit être

débranché du réseau électrique.

Après le refroidissement, recouvrez la zone de soudure

avec de la peinture anti-rouille (C19).

C17

C19

C18

- 34 -

Installation

4.5 INSTALLATION FINALE DE L’AUTOMATISME

4.5.1 Fixation mécanique

Fixer les deux extrémités de l’automatisme aux pattes

correspondantes.

Patte de fi xation avant

Lubrifi ez avec de la graisse graphitée le pivot d’ancrage

avant de la rotule (C20 pos.1).

Lubrifi ez avec de la graisse graphitée la rotule (C20

pos.2).

Introduisez la rotule dans le pivot (C21 pos.1) et fi xez-la

à l’aide du seeger correspondant (C21 pos.2).

Patte de fi xation arrière

A l’aide du pivot de la fourche (C22 pos.3) et de l’écrou

auto-bloquant (C22 pos.4), fixez l’opérateur à la

fi xation.

Avec le vantail fermé, contrôlez avec le gabarit que la

tige sort de l’opérateur de la valeur établie.

Après ça, bloquez la rotule sur la tige à l’aide d’une clé

hexagonale CH14 (C23 pos.5) et d’une clé hexagonale

CH19 (C23 pos.6).

4.5.2 Contrôle du déplacement

!

Attention

• Une fois le montage effectué, déplacer

manuellement les vantaux pour en vérifier le

glissement, après avoir désactivé (si présent) le

blocage hydraulique en tournant la clé spéciale

de 180° dans le sens anti-horaire. Effectuer cette

opération très lentement afi n d’éviter que les

automatismes aspirent de l’air, ce qui rendrait

nécessaire leur purge.

• En ouvrant et en fermant le vantail, vérifi er que

l’automatisme se déplace librement sans frotter

ou toucher ni le vantail ni le pilier.

• Après le contrôle, réactiver le blocage hydraulique

en tournant la clé de déblocage dans le sens

horaire.

4.5.3 Branchement électrique

Pour le branchement électrique, voir le schéma (D1) du

paragraphe “Branchement électrique du système”.

Relier le condensateur fourni (B4 pos. 12) à l’appareil

électrique de commande en se rapportant au schéma

électrique de l’appareil lui-même,

4.5.4 Montage du carter de protection et

démontage de la vis de purge

Monter le carter de protection (E1 pos.1) sur la tige et

l’encastrer sur l’automatisme.

Bloquer le carter (E2 pos. 2) dans la zone inférieure à

l’aide d’un tournevis à lame cruciforme (E2 pos. 3).

Insérer à pression le petit couvercle (E3 pos. 2) sur le

carter de protection (E3 pos. 1).

Serrer la vis de fi xation du carter de protection (E4

pos. 1).

Une fois l’assemblage terminé, enlever la vis de purge

C20

C22

E1

E3

C21

2

C23

E2

E4

Français

- 35 -

1

2

1

Opérations fi nales

Français

(E5 pos. 4) à l’aide d’une clé hexagonale CH7.

Si nécessaire, protéger le câble d’alimentation (E5 pos.

5) avec une gaine de protection.

Prudence

Il est normal qu’une goutte d’huile hydraulique sorte

de l’ouverture créée par l’élimination de la vis (E5

pos. 4).

Informations

A la fi n de l’installation, appliquer sur le portail la

pancarte de signalisation prévue (E6 pos. 2.)

L’automatisme complètement assemblé doit se présenter

comme montré sur la fi gure (E6 pos. 1).

4.5.5 Purge de l’air

!

Attention

Avant d’effectuer le réglage de l’automatisme, il est

nécessaire de le purger.

Actionner l’automatisme, vérifi er le réglage des clapets

de pression et, par la suite, le déplacer jusqu’en fi n de

course en ouverture ou en fermeture. Agir sur la clé (voir

paragraphe 6) pour bloquer et débloquer l’automatisme

une dizaine de fois.

E5

E6

1

2

c

i

t

a

c

i

t

im

c

ma

pr

i

i

t

a

pr

A

A

m

i

c

pr

i

t

a

A

m

i

r

p

A

c

i

t

a

m

i

r

p

A

5. CONTROLLI E REGOLAZIONI

5.0 CONTROLE ET REGLAGE DE LA FORCE DE

POUSSEE

Avec le vantail en mouvement, vérifi er à l’aide d’un

dynamomètre la force de poussée à l’extrémité du

vantail (E7 pos. 1).

Cette force ne doit jamais être supérieure à 15 Kg (147

N).

Dans le cas contraire, effectuer le réglage de la pression

de fonctionnement de l’automatisme.

Agir sur les clapets avec un tournevis à lame plate large

en tournant dans le sens horaire pour augmenter la

pression ou dans le sens contraire pour la réduire.

Le réglage doit être effectué sur le clapet de pression

en ouverture (argent - E8 pos. 2) qu’en fermeture (or

- E8 pos. 1).

Prudence

• La force de poussée en ouverture doit être

légèrement supérieure à celle en fermeture.

• Après le réglage, vérifier à nouveau avec

le dynamomètre que la valeur de la force

de poussée correspond à celle prévue.

Dans le cas contraire, régler à nouveau.

• Si le mouvement du vantail demande une pression

trop élevée, vérifi er le fonctionnement, l’aplomb

et les frottements du vantail.

E7

6.0 MANŒUVRE D’URGENCE - UTILISATION DU DEBLOCAGE MANUEL

Lors d’une panne de courant, il faut débloquer l’automatisme pour pouvoir ouvrir à la main le portail.

Pour accéder à la soupape de déblocage, il suffi t de desserrer la vis (E9 pos. 2) et ouvrir le petit volet

en le tournant (E9 pos. 3).

Débloquer l’automatisme en tournant la clé triangulaire fournie (E9 pos. 1) dans le sens anti-horaire.

A la fi n de l’opération, bloquer à nouveau l’automatisme en tournant la clé dans le sens horaire

!

A la fi n des opération de blocage ou de déblocage, se rappeler de fermer le petit volet.

Attention

.

- 36 -

Notes pour l’itilisateur

2

1

3

7. NOTES POUR L’INSTALLATEUR

7.0 Entretien

Informations

Vérifi er régulièrement le fonctionnement correct de

l’automatisme. Effectuer ce contrôle au moins une

fois tous les 12 mois.

!

Attention

Les opérations d’entretien doivent être confi ées

uniquement à du personnel spécialisé.

!

Attention

Avant d’effectuer toute opération d’entretien,

débrancher l’automatisme du réseau d’alimentation

à l’aide de l’interrupteur différentiel de l’équipement

électrique.

• Graissage des joints tous les ans avec de la graisse

graphitée.

• Contrôle de l’état général de la structure du portail.

• Contrôle de la résistance mécanique des charnières,

des fi xations de l’automatisme et des butées d’arrêt.

• Contrôle du fonctionnement correct des dispositifs

de sécurité installés (photocellules, barrières à

microrupteurs, etc.) et réglage de la force de poussée

à l’extrémité du vantail (max. 147 N).

• Contrôle de l’effi cacité de l’équipement électrique et

de la protection de l’interrupteur différentiel.

• Contrôle du réglage du clapet de pression.

• Contrôle de la résistance du blocage de sûreté.

• Contrôle, en fonction de l’utilisation de l’automatisme,

du niveau d’huile de l’installation.

E8

E9

1

2

Français

7.1 Recherche des pannes

Type de panne

Lorsqu'on active la commande d'ouverture,

le vantail ne bouge pas et le moteur

électrique de l'opérateur ne marche pas.

Lorsqu'on active la commande d'ouverture,

le moteur électrique de l'opérateur marche,

mais le vantail ne bouge pas.

Pendant le mouvement, l'opérateur

fonctionne à-coup.

ESPACE RÉSERVÉ À L’INSTALLATEUR

VEUILLEZ DONNER UNE COPIE DE CETTE PAGE À L’UTILISATEUR

Cause probable

La centrale de l'automatisme n'est pas

alimentée.

Le fusible est grillé.

Le câble d'alimentation de l'opérateur est

endommagé.

Si l'opérateur est doué de déblocage

hydraulique, contrôlez que le clapet de

déblocage est fermé.

Si l'opérateur n'est pas doué de déblocage

hydraulique, réglez la pression d'ouverture.

Si l'opérateur, à portail fermé, a été exposé au

soleil pendant longtemps, contrôlez que le

piston ne se trouve pas

course en sortie.

Possible présence d'air dans le cylindre.

Quantité d'huile insuffisante dans le piston.

Les fixations avant et arrière de l'opérateur ne

sont pas fixés d'une façon correcte.

complètement à fin de

Solution

Rétablir la tension.

Remplacer les fusibles grillés avec d'autres ayant le

même ampérage.

Remplacer le câble et rechercher et éliminer la cause

du dommage.

Vissez le clapet de pression dans le sens horaire, par.5

(E8 pos. 2).

Vissez complètement le clapet en sens horaire (E9 pos.

1).

Vérifiez l'installation de l'opérateur comme indiqué dans

ce manuel.

Contrôlez la mesure de la course du piston.

Détachez l'opérateur de la fixation avant et effectuez

quelque opération d'ouverture et fermeture; après ça

rétablissez la fixation avant.

Vérifiez s'il y a des pertes d'huile; dans ce cas,

contactez le Centre de Réparation.

Réparez ou renforcez les fixations.

Via Circolare, sn

65010 Santa Teresa di Spoltore - Pescara

Tel. 085/4971946 - Fax 085/4973849

- 37 -

Deutcsh

Inhaltsverzeichnis / Merkmale

Merkmale des Antriebs

1

1.0 Allgemeine Merkmal ............................................................................................................................... 39

1.1 Technische Daten ................................................................................................................................... 39

1.2 Prüfen der Antriebsversion .....................................................................................................................39

Beschreibung des Automatiksystems

2

2.0 Anordnung der Bauteile ......................................................................................................................... 40

2.1 Elektroanschluss des Systems ............................................................................................................. 40

Kontrollen und Vorarbeiten für die Installation des Antriebs

3

3.0 Kontrollen am Tor ...................................................................................................................................41

3.1 Prüfen der Antriebsteile ..........................................................................................................................41

3.2 Für die Montage erforderliche Ausrüstung und Werkzeuge ...................................................................42

Installation des Antriebs

4

4.0 Positionierung der Drehpunkte ...............................................................................................................42

4.1 Vorbereitung für die Befestigung hinten ................................................................................................. 43

4.1.1 An Eisenpfosten befestigter Antrieb ......................................................................................................................... 43

4.1.2 An Holzpfosten befestigter Antrieb ........................................................................................................................... 43

4.1.3 An gemauerten Pfeilern befestigter Antrieb.............................................................................................................. 43