Electronic control board for sectional door operator

AT 7070

WARNING!! Before installing, thoroughly read this manual that is an integral

part of the pack

Our products if installed by qualified personnel capable to evaluate risks,

comply with norms UNI EN 12453, EN 12445

The CE mark conforms to European directive

EEC 89/336 + 92/31 + 93/68 D.L. 04/12/1992 N. 476.

1

Antenna

2

Start-stop-photocell common contact

1 mm²

3

Start contact N.O.

1 mm²

4

Photocell contact N. C. (put a jumper if nor used)

1 mm²

5

Stop contact N. C. (put a jumper if nor used)

1 mm²

6

Limit switches common contact

1 mm²

7

Closure limit switch contact N.C. (put a jumper if nor used)

1 mm²

9

Accessory power supply common

1 mm²

10

+ 12Vdc accessory power supply (photocells)

1 mm²

LAY OUT

RF CODE CLOSE OPEN PROG

1 2 3 4ON5 6 7 8

1 2 3 4

POWER

SLOW

SPEED

LED

TR2

FCC

+

LAMP

+12V

RELAY

COM

FCA

LED

10

ANT

+

TR1

LED

5 6 7 8 9

START

COM

PHOTO

COM

STOP

1 2 3 4 5 6 7 8 9 10 12

11 13

MOTOR

14

-

15

LED

10

SIG +5

16

17

24Vac

18

19

ELECTRICAL CONNECTION

8 Opening limit switch contact N.C. (put a jumper if nor used) 1 mm²

11-12 Flashing light free contact 1 mm²

13-14 Motor connection 24 Vdc

15 Encoder connection Negative

16 Encoder connection signal

17 Encoder connection +5V

18-19 Power Input 24 Vac (Transformer)

1 mm²

1 mm²

1 mm²

1 mm²

1,5 mm²

N.O. = Normally Open Contact N.C. = Normally Closed Contact

AUTOMATIC CLOSING:

Door closes automatically after waiting the a.c. time.

Door does not close automatically.

SAFETY FUNCTION (photocell):

ANALOG Contact (8.2KΩ)

N.C Contact (put a jumper if not used)

COURTESY LIGHT (LED 10):

Switched off

Switched on (with sthe START command, LED work for 30 sec)

FLASHING LIGHT OUTPUT (LAMP RELAY):

Light blinks until the operator is running or waiting for automatic closing.

It turns off after 30 seconds the operator stop.

Light is fix until the operator is running or waiting for automatic closing.

It turns off after 30 seconds the operator stop

SLOW START CLOSING

The automation during closing start at slow speed.

The automation during closing start at normal speed.

OPERATOR RUNNING DIRECTION:

Normale polarity

Reversed polarity

LED MEANINGS TABLE

N° LED

N° LED

1 RADIO

2 CLOSE

3 OPEN

4 PROGRAMMING

5 START

ON ON ON ON

1 2 3 4

DIP 1

ON

OFF

DIP 4

ON

ON ON ON ON

5 6 7 8

DESCRIPTION

DIP SWITCHES FUNCTIONS

DESCRIPTION

6 PHOTOCELL

7 STOP

8 CLOSURE LIMIT SWITCH

9 OPENING LIMIT SWITCH

10 COURTESY LIGHT

DIP 5

DIP 6

DIP 7

DIP 8

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

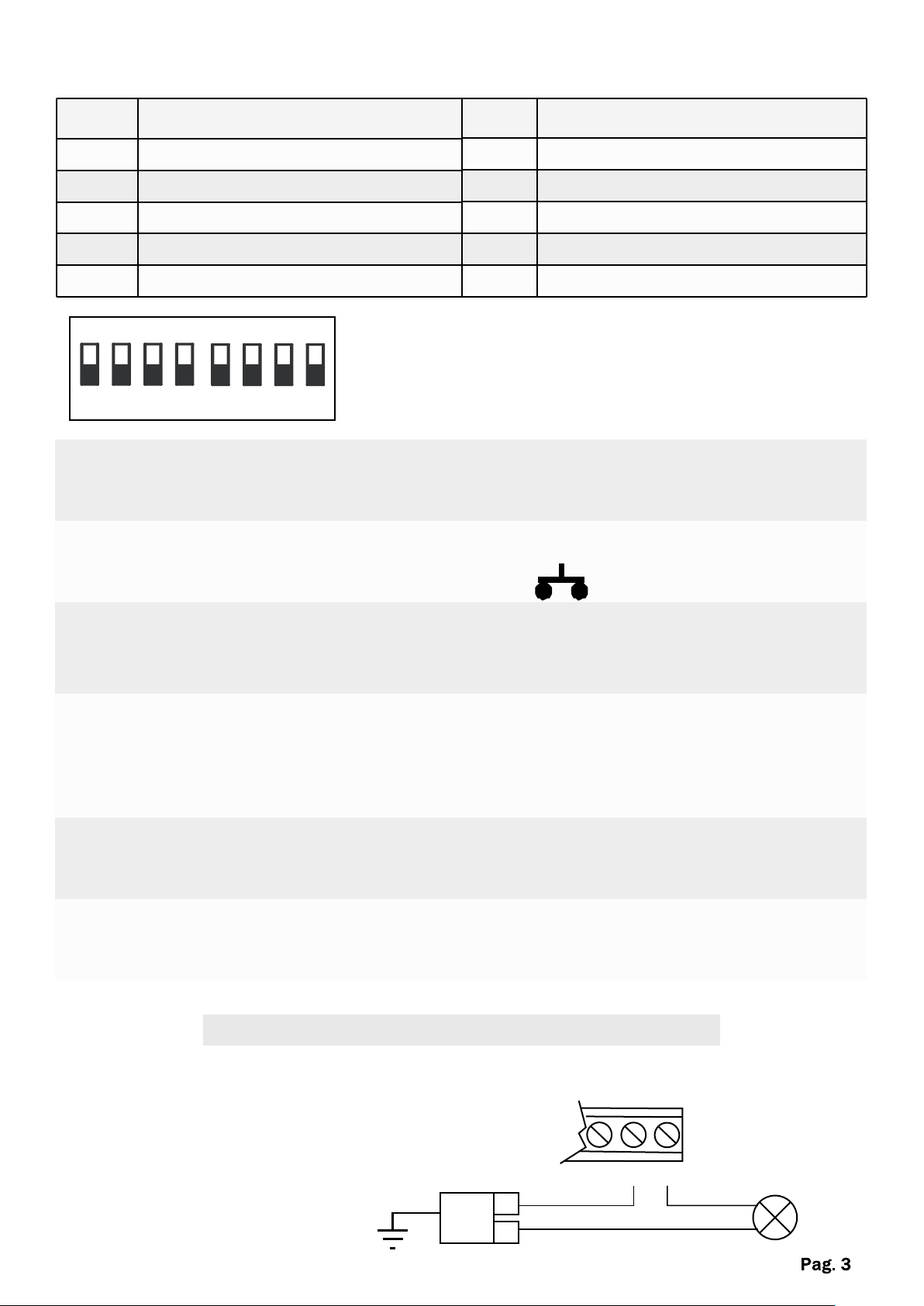

FLASHING LIGHT CONNECTION

Flashing light output relay (terminals 11-12)

Ground

Power supply

230V

L

N

+12V

11 12

LAMP

RELAY

LAMP

230V

AMPEROSTOP SENSIBILITY SETTING (ANTI CRUSHING)

To adjust the sensibility of the amperostop do the following :

Before programming stroke :

Ÿ Set the dip switch N ° 2-3 (look table)

- +

Ÿ Adjust the trimmer TR1 in halfway

Ÿ Program the stroke (see pag 5)

Ÿ Adjust trimmer TR1 so that the sensibility of the amperostop is adequate to the proper

functioning of the operator

Increase trimmer toward + to provide more

strength to the operator and less sensibility

- +

to the intervention of the amperostop

TR1

Increase trimmer toward - to provide less

strength to the operator and more sensibility

to the intervention of the amperostop

Sensibility amperostop Dip 2 Dip 3

100%

OFF OFF

TR1

75%

50%

25%

ON OFF

OFF ON

ON ON

SLOWING DOWN ADJUSTMENT

To adjust the slowing down speed :

Before programming stroke :

Ÿ Open the door with OPEN button and adjust trimmer TR2, to have the required speed.

Increase trimmer toward + to increase the

speed

- +

Increase trimmer toward - to decrease the

speed

TR2

RADIO TRANSMITTERS PROGRAMMING

Ÿ CODING : This control panel allows the storage of fix code and rolling code also simultaneously.

Ÿ PROGRAMMING:

Press RF-CODE button , LED lights for 10 seconds, press the transmitter button

you want to program. programming is completed.

Ÿ DELETING CODES:

To delete all codes in memory hold RF-CODE for 10 seconds until

LED begins to blink. the operation is completed

STROKE PROGRAMMING

WITH SLOW DOWN IN START CLOSING (DIP SWITCH 7 ON)

Ÿ Press OPEN button, bring the door to the desired opening and adjust the opening limit switch.

Ÿ Press CLOSE button, bring the door to the closure.

(NOTE : If connected, adjust the closure limit switch)

Ÿ Press PROG button for 2 seconds, LED blinks.

Ÿ Give a START impulse from button or radio transmitter, the door starts opening fast

Ÿ Give a second START imulse when you want to start the slowing down in opening, the door

stops once arrived to the opening limit switch.

Ÿ With automatic closure inserted, wait the desired time with the door open.

Ÿ Give a START impulse, door begins to close in slowing down

Ÿ Give a second START impulse, door begins to close faster.

Ÿ Give a third START impulse when you want to start the slowing down in closing

Ÿ Once arrived in closure the door memorizes the closed position.

WITHOUT SLOW DOWN IN START CLOSING (DIP SWITCH 7 OFF)

Ÿ Press OPEN button, bring the door to the desired opening and adjust the opening limit switch.

Ÿ Press CLOSE button, bring the door to the closure.

(NOTE : If connected, adjust the closure limit switch)

Ÿ Press PROG button for 2 seconds, LED blinks.

Ÿ Give a START impulse from button or radio transmitter, the door starts opening fast

Ÿ Give a second START imulse when you want to start the slowing down in opening, the door

stops once arrived to the opening limit switch.

Ÿ With automatic closure inserted, wait the desired time with the door open.

Ÿ Give a START impulse, door begins to fast close

Ÿ Give a second impulse when you want to start the slowing down in closing

Ÿ Once arrived in closure the door memorizes the closed position.

SAFETY DEVICES FUNCTION

PHOTOCELL (terminal 2-4)

Occupancy of photocell causes :

Ÿ Opening : no effect

Ÿ Closing : immediate stop and return to the opening operation.

AMPEROSTOP FUNCTION

Opening :

Ÿ Blocking the movement of the door

Closing :

Block ing and reverse in opening the movement of the door

START COMMAND FUNCTION

A START impluse by button or radio transmitter, with closed door, has the following function:

Ÿ STEP BY STEP: OPEN → STOP → CLOSE → STOP → OPEN

Ÿ AUTOMATIC: OPEN → STOP → AUTOMATIC CLOSURE O CLOSURE WITH IMPULSE →

STOP → OPEN

The data and images are for guidance only

reserves the right to change at any time characteristics of the products described in its sole

discretion, without notice.

CONTACTS :

Via Circolare p.i.p. N° 10

AUTOMAZIONE ACCESSI

MADE IN ITALY

65010 Santa Teresa di Spoltore (PE) - ITALY

Tel. +39 085 4971946 - FAX +39 085 4973849

www.vdsconsorzio.it - vds@vdsconsorzio.it

Loading...

Loading...