Vaisala HMT370EX Installation Manual

M212306EN-B

EN

Installation and

Safety Guide

Intrinsically safe humidity and temperature

transmitter series

HMT370EX

DE

FR

NL

ES

PT

IT

HU

CS

PL

FI

ET

SV

NO

DA

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala Oyj 2021

No part of this document may be

reproduced, published or publicly

displayed in any form or by any means,

electronic or mechanical (including

photocopying), nor may its contents be

modified, translated, adapted, sold or

disclosed to a third party without prior

written permission of the copyright holder.

Translated documents and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject

to change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this document.

Vaisala makes no representations on this

document’s compliance with the local

rules and regulations applicable at any

given time, and hereby disclaims any and

all responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

exclusively in the applicable supply

contract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

B C

G

D

E

F

H

1

35.5

[1.4]

141 [5.5]

I

J

A

160 [6.3]

124.5 [4.9]

115 [4.53]

HMP378

HMP377

HMP375

HMP374

HMP373

HMP371

59 [2.3]

56.5 [2.2]

115 [4.53]

141 [5.5]

mm

[in]

2

1

2

3

5

mA

V

Test Points

6

7

CH1

4

V

CH2

mA

2 × Ø 5.5 mm

1

3

M20×1.5

V

CH1

mA

Test Points

mA

V

CH2

M20×1.5

Do not remove this cover

!

A

2

Service Port

Use only in safe area

3

CH 1

4 ... 20 mA

12 ... 28 V

−

+

4

−

+

CH 2

4 ... 20 mA

4

3.5 Nm

5

6

7

4 mm2

Table of contents

Table of contents

English.............................................................................................................................................5

Deutsch......................................................................................................................................... 21

Français........................................................................................................................................39

Nederlands.................................................................................................................................. 57

Español.........................................................................................................................................75

Português.................................................................................................................................... 93

Italiano.......................................................................................................................................... 111

Magyar........................................................................................................................................ 129

Čeština........................................................................................................................................ 147

Polski........................................................................................................................................... 165

Suomi.......................................................................................................................................... 183

Eesti.............................................................................................................................................201

Svenska.......................................................................................................................................217

Norsk...........................................................................................................................................233

Dansk..........................................................................................................................................249

3

M212306EN-B

4

Chapter – Introduction to HMT370EX Series

1 Introduction to HMT370EX Series

Vaisala HUMICAP® Humidity and Temperature Transmitter Series HMT370EX is the ideal

solution for measuring humidity in hazardous areas. Intrinsically safe and robust, HMT370EX

operates safely and reliably even in the most hazardous areas, such as Zone 0. The nextgeneration HMT370EX transmitter can be used as a replacement for the long-running HMT360

transmitter series in all HMT360 applications.

HMT370EX can be installed directly in explosive areas. It can withstand continuous exposure to

potentially explosive environments that contain flammable gases or dust, and requires no

additional protective enclosures for operation in either gas or dust environments.

HMT370EX oers several probe options for dierent applications. Thanks to the detachable

probe module, probes can be easily replaced and removed for calibration outside the

hazardous area without removing the entire transmitter.

The transmitter has 2 analog current output channels (4 … 20 mA) for connection via safety

barriers. For easy-to-use access to configuration, diagnostics, and calibration and adjustment

functionalities, the probe and transmitter body can be connected to Vaisala Insight PC

software for configuration either together as one unit or separately.

1.1

Basic features and options

• Available measurement parameters: relative humidity (RH) and temperature (T)

•

Calculated measurement parameters include 1) : dew point temperature, wetbulb

temperature, absolute humidity, mixing ratio, water concentration, water mass

fraction, water vapor pressure, enthalpy, and oil/fuel moisture with special models

• Ex classification: IECEx and ATEX certified for use in Zone 0 and Zone 20 environments:

for full Ex classifications, see Table 1 (page 6).

• 2 analog outputs (4 … 20 mA, scalable, isolated)

• Display options: graphical LCD display or non-display model

• Power supply input: 12 … 28 V

• Compatible with Vaisala Insight PC software

ENGLISH

1.2

More information

For further information on using, configuring, and maintaining the transmitter after

installation, see HMT370EX User Guide (available at www.vaisala.com/HMT370EX).

1) Additional calculated parameters available: see product information at vaisala.com

5

M212306EN-B

2 Using HTM370EX Series transmitters in

hazardous locations

WARNING!

mandatory in a hazardous environment.

In hazardous environments, always connect the transmitters via galvanic isolators or Zener

barriers. A galvanic isolator or Zener barrier must also be used when the transmitter and probe

body are in a safe area, but the probe head is installed in a hazardous environment. For wiring

information, see the galvanic isolator and Zener barrier wiring diagrams included in this

document.

HMT370EX does not include a galvanic isolator or a Zener barrier. They can be ordered as

optional accessories from Vaisala.

WARNING!

hazardous locations as specified by the product classification. The personnel

installing, using, or maintaining HMT370EX transmitters are responsible for

determining the appropriate protection concept for the specific application

HMT370EX is used in, and that the hazardous area classification of the device

meets the requirements of the application.

WARNING!

protection provided by the equipment may be impaired.

HMT370EX series transmitters are certified for use in hazardous areas as defined by the

following classifications:

Table 1 HMT370EX series hazardous area classifications

Protected installation using galvanic isolators or Zener barriers is

HMT370EX series transmitters have been designed for use in

If the equipment is used in a manner not specified by Vaisala, the

Certification HMT370EX classification

IECEx 1) / ATEX

1) International certification

2) EU certification

6

2)

II 1 G Ex ia IIC T4 Ga

II 1 D Ex ia IIIC T

-40 °C ≤ T

≤ +60 °C

amb

200

85 °C Da

HMT370EX

1 2 31a

M20x1.5 M20x1.5

Chapter – Using HTM370EX Series transmitters in hazardous locations

CAUTION!

transmitters must have the required competencies for working in the hazardous

location, as defined by the applicable standards.

For information on the standards that apply to using HMT370EX based on the classification of

the device, see HMT370EX certification documentation and the declarations of conformity

related to HMT370EX at www.vaisala.com/declarationofconformity.

The personnel installing, operating, and maintaining HMT370EX

2.1 Guidelines for safe use in hazardous conditions

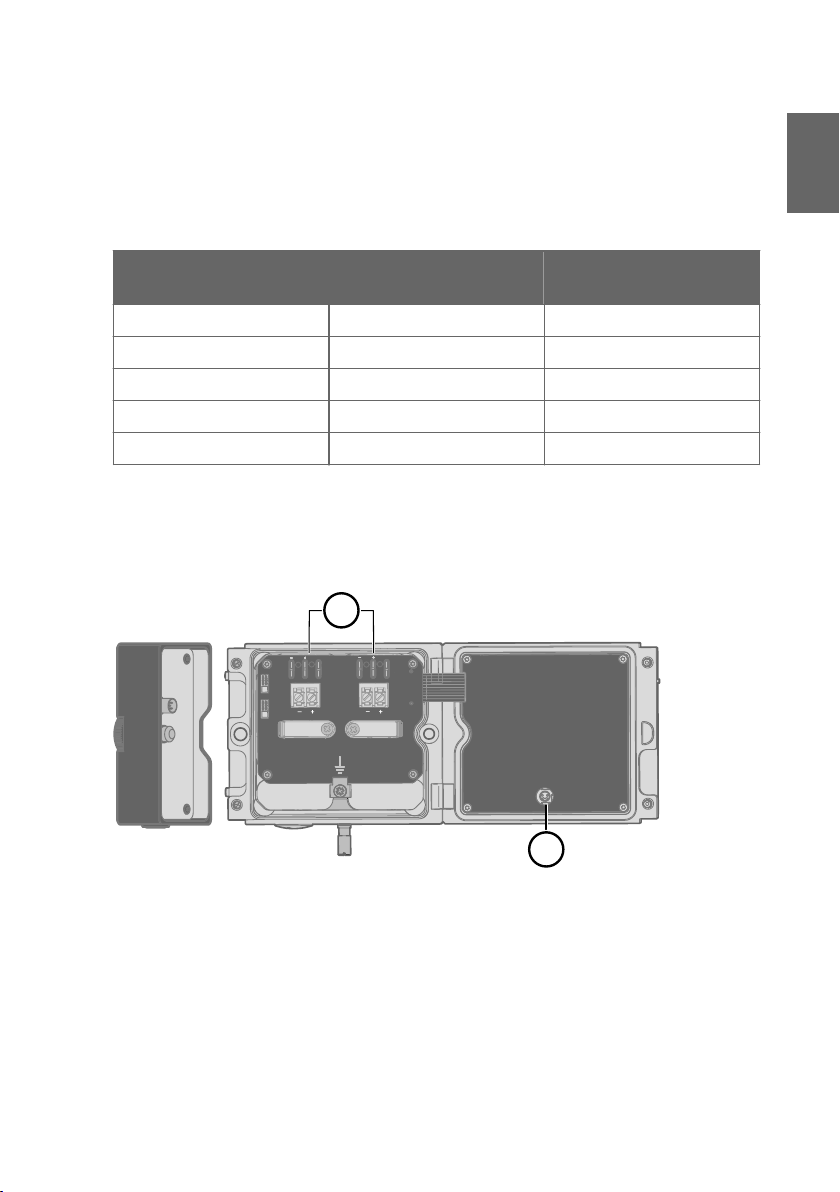

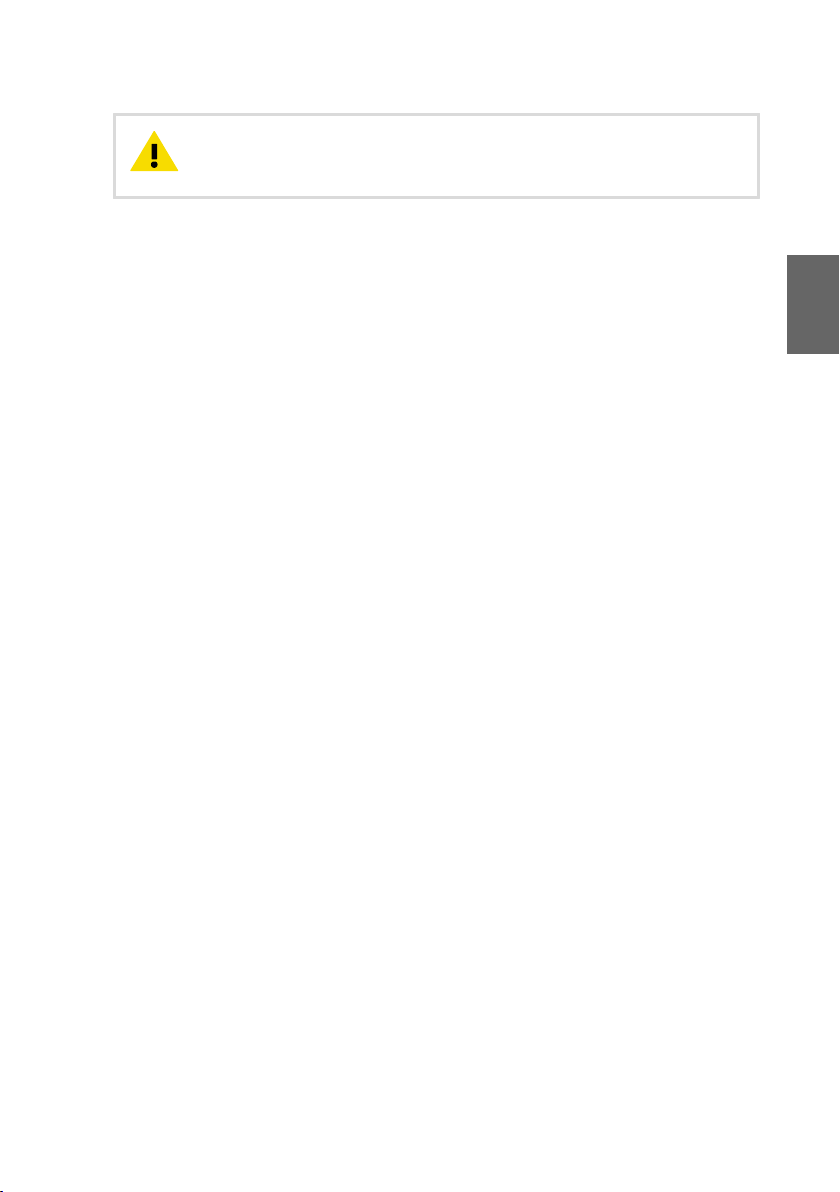

HMT370EX Series parts overview

ENGLISH

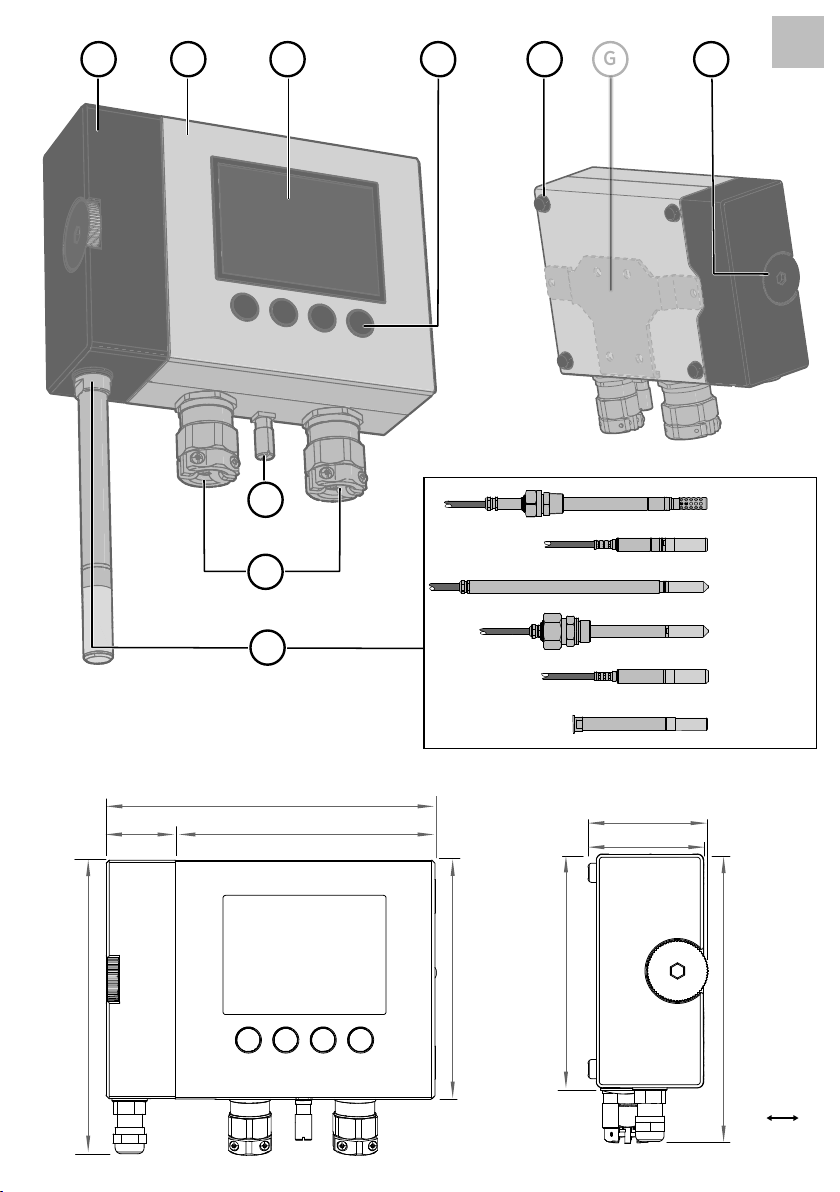

Figure 1 HMT370EX parts overview

HMT370EX Series transmitters consist of 3 main parts: the transmitter body, a detachable

probe body, and a probe head attached to the probe body, either directly or using a cable.

Figure 1 (page 7) shows the main parts.

Probe heads (for variant descriptions, see HMT370EX User Guide)

1

1a Probe head filters

2 Probe body

3 Transmitter body

7

M212306EN-B

The dierent probe head variants are designed for a range of applications, and have their own

specifications. Ensure that the transmitter body, probe body, and probe head are each placed

in an environment that matches the specification of the part. For allowed ambient temperature

ranges, see Table 2 (page 8).

Table 2 Allowed ambient temperature ranges

Equipment part Allowed ambient temperature range

Transmitter body -40 °C … +60 °C (-40 … +140 °F)

Probe body -40 °C … +60 °C (-40 … +140 °F)

Probe heads HMP374, HMP375, HMP377, and

HMP378

Probe head HMP371 Temperature class T4:

Probe head HMP373 Temperature class T4:

Temperature class T4:

-70 °C … +120 °C (-94 … +248 °F)

Temperature class T3:

-70 °C … +180 °C (-94 … +356 °F)

-40 °C … +60 °C (-40 … +140 °F)

Rubber cable version:

-40 °C … +80 °C (-40 … +176 °F)

FEP cable version:

-40 °C … +120 °C (-40 … +248 °F)

2.1.1 Specific conditions of use

CAUTION!

to be ensured that sparks due to impact or friction do not occur.

Wiring requirements

• The cable glands and cables used for wiring the device must not impair the Ex protection.

• Unused lead-throughs must be sealed using Ex compliant plugs.

• Select a strain relief option that suits the application (either use cable glands that include

strain relief or install separate clamps: see IEC 60079-14).

CAUTION!

input before completing the wiring and closing the transmitter body.

8

With the installation of the equipment in Zone 0 Group II area it has

Connect only de-energized wires. Never switch on the power supply

mA

V

mA

V

CH1

CH2

A

Service Port

Use only in safe area

!

Do not remove this cover

1

2

Test Points

Chapter – Using HTM370EX Series transmitters in hazardous locations

Intrinsic safety

The overvoltage category of HMT370EX transmitters is I (non-mains equipment), and ambient

pollution degree is 4, as specified in IEC 60664-1. For intrinsically safe input parameters, see

Table 3 (page 9) .

Table 3 Intrinsically safe input parameters

Parameter Value Associated apparatus entity

parameters

U

i

I

i

P

i

C

i

L

i

28 VDC Uo ≤ U

100 mA Io ≤ I

700 mW Po ≤ P

i

i

i

12.1 nF Co ≥ Ci + C

16 µH Lo ≥ Li+ L

cable

cable

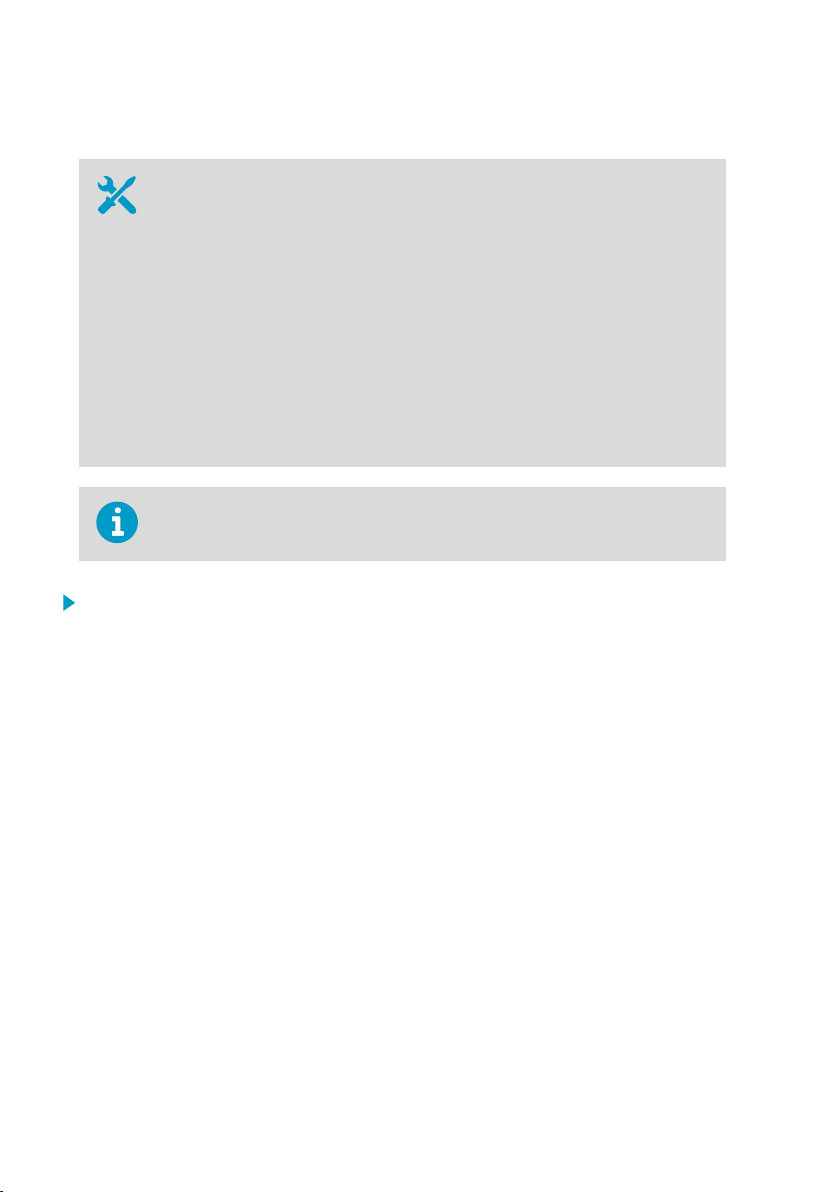

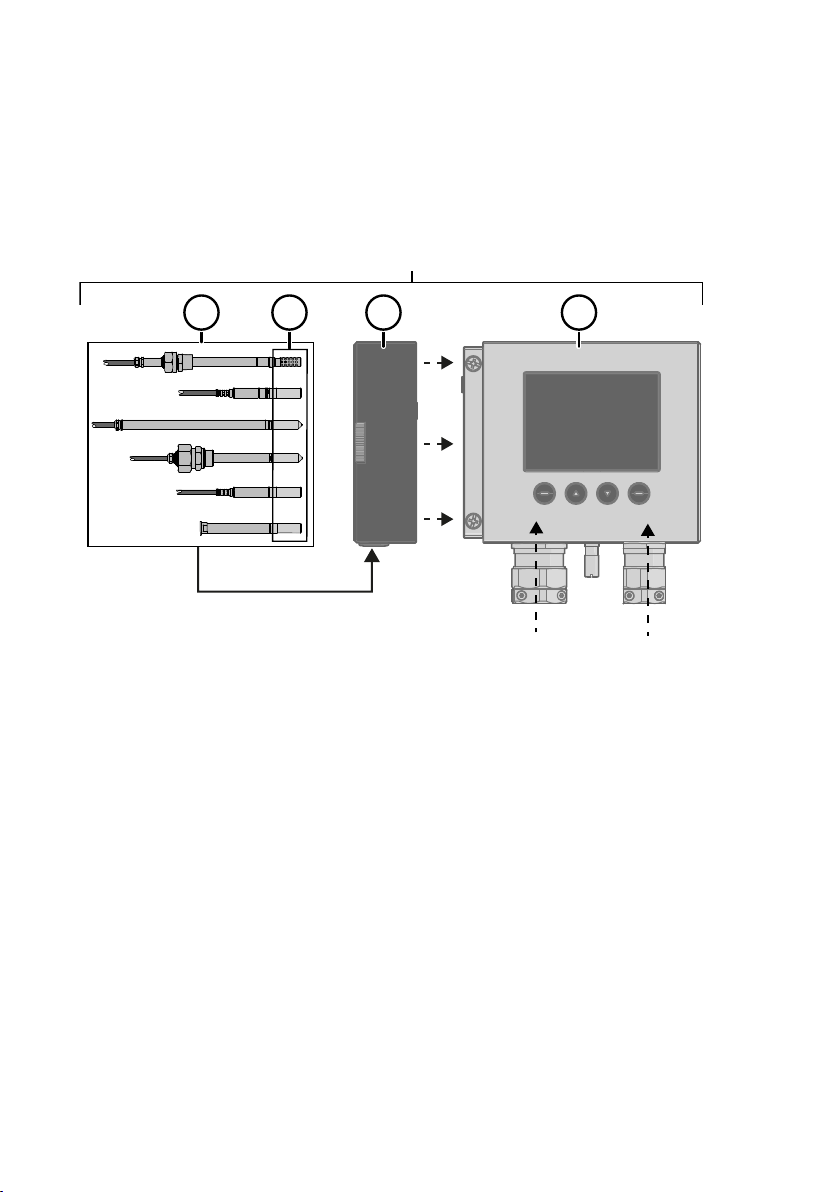

Using analog output test points

There are test points for measuring the voltages and currents of the analog outputs, located

above each screw terminal block as shown in Figure 2 (page 9). Accessing the test points on

the component board requires opening the transmitter enclosure.

ENGLISH

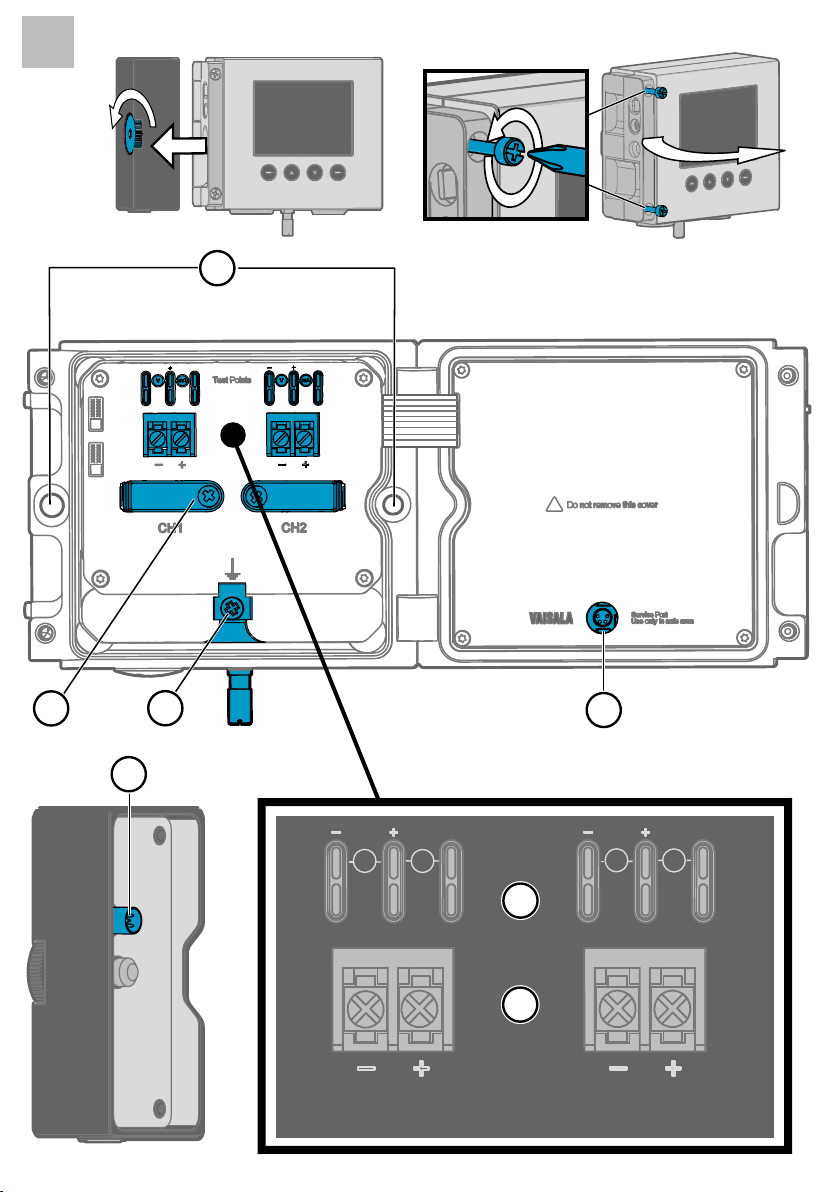

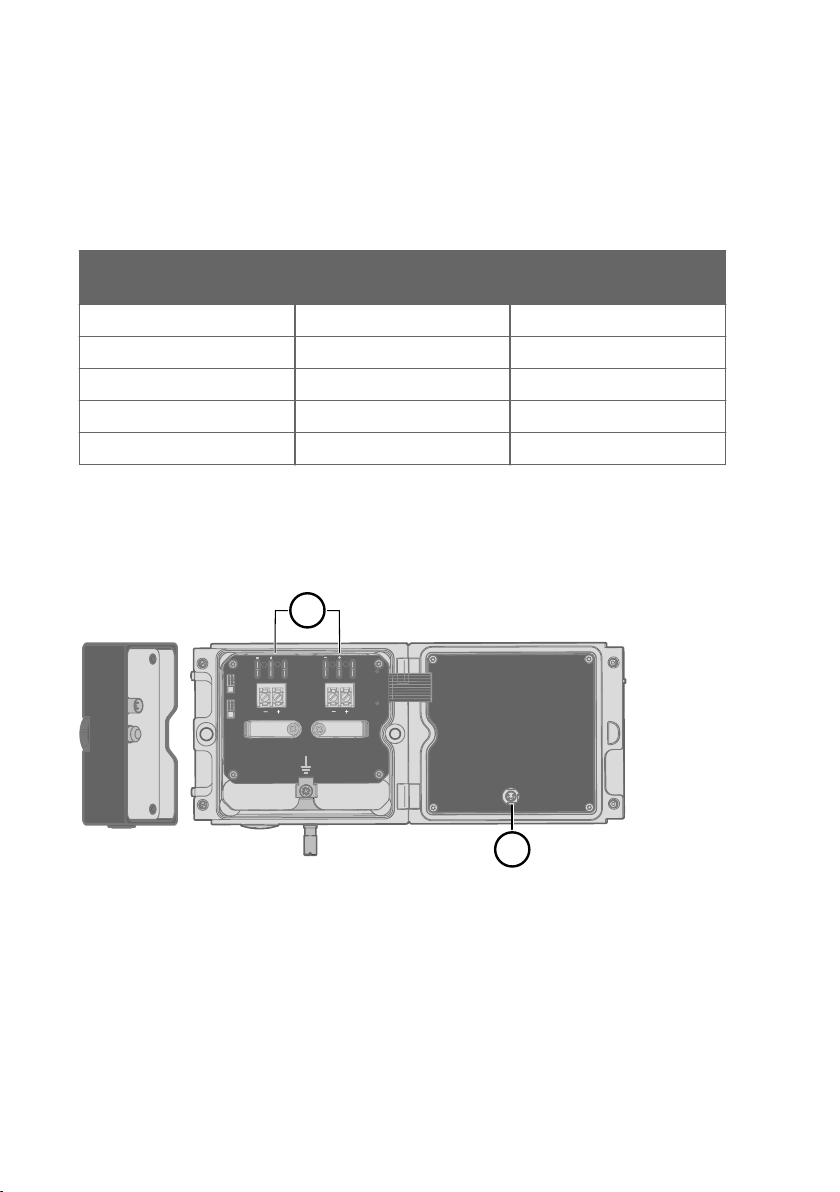

Figure 2 Location of test points and service port

Multimeter test points for analog output channels 1 and 2

1

2 Service port for PC connection

9

M212306EN-B

CAUTION!

The transmitter body enclosure must not be opened in an explosion

hazardous area, unless a safe work permit has been issued in accordance with

the standard IEC 60079-14. Either remove the transmitter from the hazardous

area before opening the enclosure, or ensure that an IEC 60079-14 compliant

safe work procedure has been implemented in the hazardous area.

Use an intrinsically safe multimeter that won't cause the intrinsically safe input parameters

listed in Table 3 (page 9) to be exceeded when it is connected in series (current measurement)

or parallel (voltage measurement) to the associated apparatus.

Using the service port

The service port (see Figure 2 (page 9)) must only be used in a safe area. Either remove the

transmitter from the hazardous area or ensure that a safe work procedure has been

implemented in the hazardous area. Only use the Vaisala accessory PC connection cable with

the service port.

Maintenance

The probe (includes probe body and head) can be detached and replaced by the user. The

probe head filter (see Figure 1 (page 7)) is also user-replaceable. For other maintenance

requirements, contact Vaisala.

CAUTION!

The probe can be detached and changed when HMT370EX is

powered. Any other live maintenance, including changing the probe head filter,

is not allowed.

The content in this chapter is maintained in the following separately tracked document:

Document ID: M212506EN Revision: A (25 Feb 2021)

10

Chapter – HMT370EX parts

3 HMT370EX parts

External parts

Items A … J refer to the external parts illustration page 1 in the beginning of the

document. Items 1 … 7 refer to the internal parts illustration page 2 in the

beginning of the document.

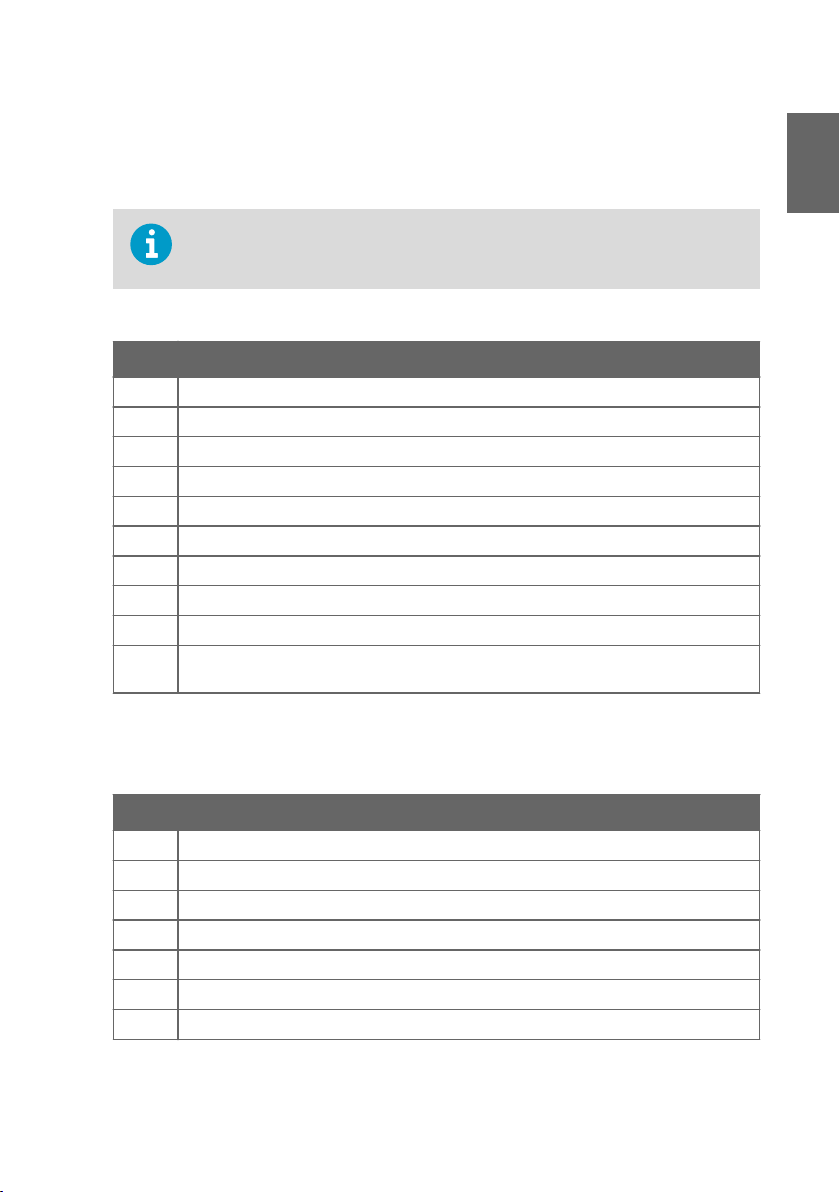

Table 4 External parts

Item Description

A Probe head (for HMP370EX probe head variant options, see HMT370EX User Guide)

B Detachable probe body

C Transmitter body (see Internal parts table)

D LCD display (in optional display model)

E Display user interface buttons (display model only)

F Wall pads (4 pcs)

G Mounting plate (optional)

H Probe body locking wheel

I Grounding terminal

J Lead-throughs for wiring (for cable gland and conduit options, see HMT370EX User

Guide)

ENGLISH

Internal parts

Table 5 Internal parts

Item Description

1 Holes for mounting screws

2 Cable fastening clamps

3 Transmitter grounding terminal

4 Transmitter service port (M8, requires Vaisala USB connection cable)

5 Probe body service port (M12, requires Vaisala USB connection cable)

6 Analog output channel 1 and 2 multimeter test points for current and voltage

7 Screw terminals for wiring analog output channels 1 and 2

11

4 Installation and wiring

M212306EN-B

WARNING!

ensure that an IEC 60079-14 compliant safe work procedure has been

implemented in the hazardous area.

WARNING!

be opened in a hazardous area. The probe can be detached and changed

when HMT370EX is powered. Any other live maintenance, including changing

the probe head filter, is not allowed.

The installation must be carried out in a safe area, or you must

When HMT370EX is powered, the transmitter enclosure must not

4.1 Installation preparations

Before starting the installation, check the following:

• Make sure that your installation site suits the Ex classification of the transmitter: see Table

1 (page 6).

• Review the hazardous area information in Guidelines for safe use in hazardous conditions

(page 7) for further information on Ex safety requirements related to HMT370EX and

specific conditions of use.

• Review the wiring diagrams included in this document for information on wiring using

either a galvanic isolator or a Zener barrier.

• Wiring with galvanic isolators (page 17)

• Wiring with Zener barriers (page 18)

• When selecting the cable glands and plugs for your application, make sure they are Ex

compliant. The glands and plugs must be water and dust tight.

Wiring information

WARNING!

mandatory in a hazardous environment.

CAUTION!

(CH1) must always be wired. The transmitter receives power through the

Channel 1 screw terminals, and does not power on if only Channel 2 (CH2) is

wired.

12

Protected installation using galvanic isolators or Zener barriers is

When planning the wiring of your application, note that Channel 1

1

2

Chapter – Installation and wiring

CAUTION!

minimum voltage in all conditions, measured at the transmitter screw terminals.

If the supply voltage is less than 12 VDC, the analog output current can be

erroneous.

It is recommended to use ferrules on the stripped wires to help ensure a secure

connection with the screw terminals.

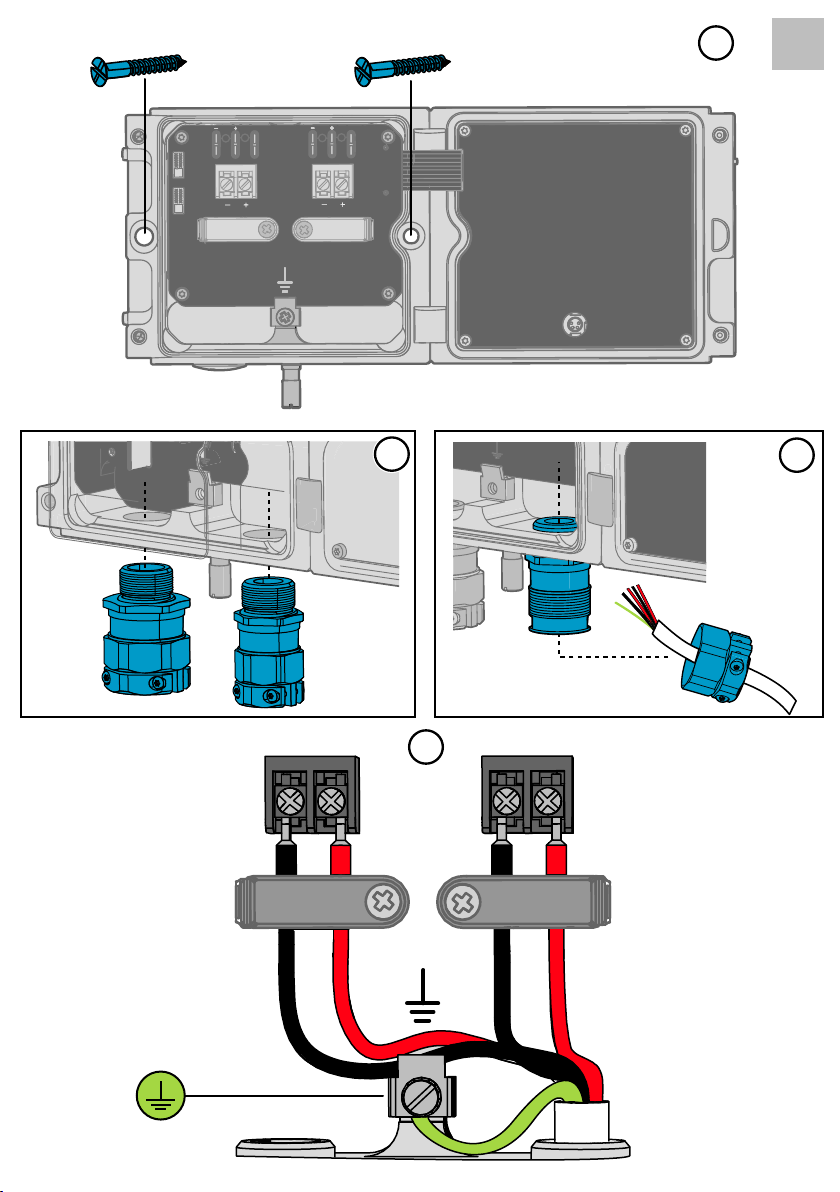

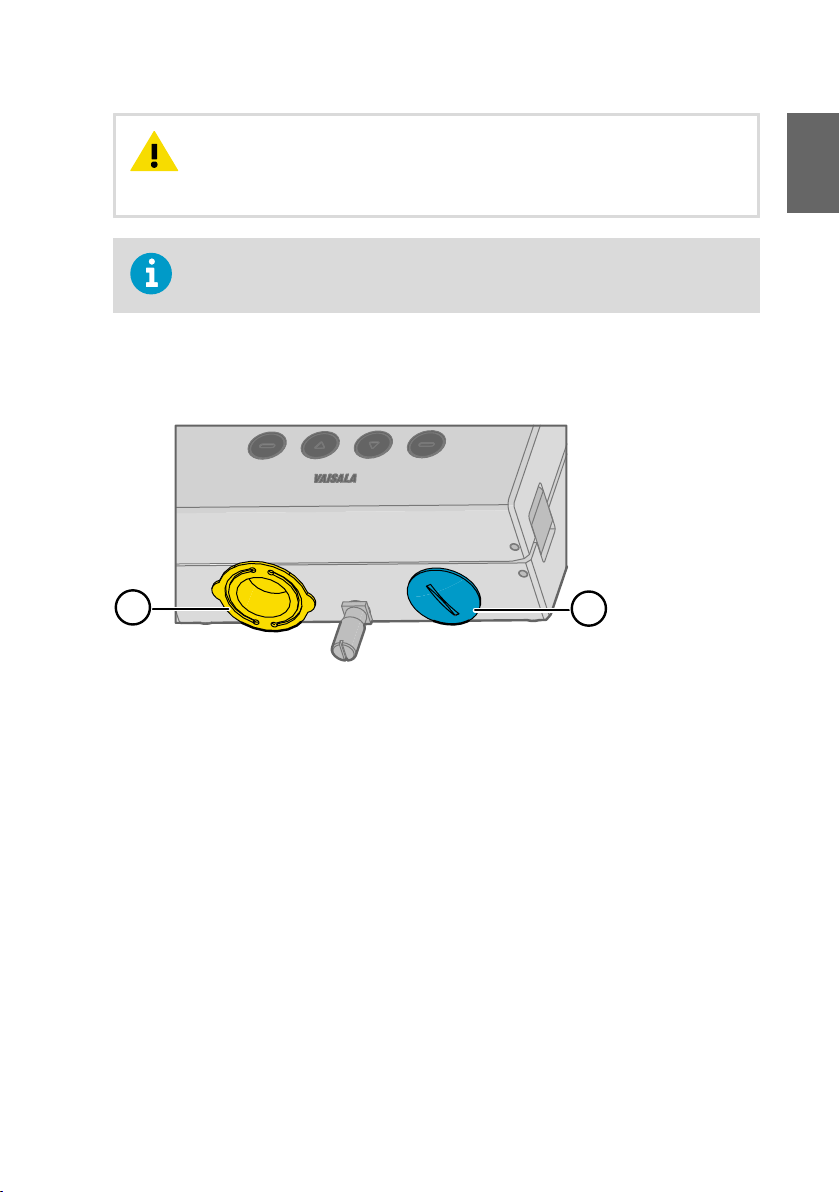

Lead-through selection and default plugs

HMT370EX comes delivered with 2 dierent plug types on the transmitter lead-throughs, as

shown in Figure 3 (page 13).

Figure 3 Default plugs in HMT370EX lead-throughs

Ensure that the transmitter is powered correctly. 12 VDC is the

ENGLISH

Removable plastic transport cover: must be replaced (fold sides of transport cover

1

together and pull out)

2 Metal sealing plug: can be used in final installation

The plastic transport cover (1) must always be replaced with an Ex compliant cable gland,

conduit, or seal when wiring HTM370EX. The metal sealing plug (2) can be left in place and

used in the final installation, if the right-hand lead-through is not used. For cable gland and

conduit options, see HMT370EX User Guide.

13

M212306EN-B

4.2 Installing HMT370EX

• Screws for mounting the transmitter:

• Installation directly through the transmitter body: 2 pcs Ø 5.5 mm screws

• Installation with optional mounting plate: 4 pcs Ø 5.5 mm screws and 2 pcs

M6 Allen screws

• Crosshead screwdriver for transmitter cover captive screws and wiring screw

terminals

• Flathead screwdriver for the grounding terminal

• Cable glands, conduits, and plugs as required in your application, and suitable

tools for attaching and tightening them

• Wire-cutting pliers

Optional:

• Crimping tool and wire ferrules

• Allen key (5 mm) for probe body locking wheel

• Ex-compliant multimeter for testing analog outputs

Steps 1 … 7 refer to illustrations 1 … 7 on illustration pages 3 and 4 in the beginning

of the document.

1. Select a surface (for example, a wall) for installing the transmitter. You can mount the

transmitter directly to the installation surface with 2 screws, or use an optional mounting

plate that attaches to the back of the transmitter.

a. Installation without mounting plate: attach the transmitter body directly to the

installation surface with 2 Ø 5.5 mm screws. The left-hand screw hole has extra

vertical space for adjusting the position of the transmitter after you have attached the

right-hand screw.

b. Installation with mounting plate: attach the mounting plate to the installation surface

with 4 Ø 5.5 mm screws, and then attach the transmitter to the mounting plate with 2

M6 Allen screws.

2. Attach cable glands (1 or 2) to the wiring lead-throughs as required in your application.

Note the cable gland requirements listed in Specific conditions of use (page 8).

• Both lead-throughs have M20x1.5 threads.

• Plug possible unused lead-throughs with Ex compliant seals.

• The glands and plugs must be water and dust tight.

14

Chapter – Installation and wiring

3. Prepare the cabling wires as required in your application (cabling either through 1 or 2

lead-throughs).

a. Strip the cable wires: it is recommended to attach ferrules to the contact ends of the

wires.

b. Open the cable gland and insert a suitable length of the cable inside the transmitter

through the cable gland.

c. Tighten the cable gland: refer to the instructions of the glands used in your

application for maximum tightness.

d. If your installation does not require using both lead-throughs, plug the unused lead-

through with an Ex compliant seal.

4. Connect the screw terminal wiring as required in your application. For protected

installation wiring diagrams, see Wiring with galvanic isolators (page 17) and Wiring with

Zener barriers (page 18).

a. Open the cable fastening clamps below the screw terminals and lead the cables to the

terminals through the clamps.

b. Connect the wires to the screw terminals.

Note that Channel 1 (CH1) must always be wired. The transmitter receives

power through the CH1 screw terminals, and does not power on if only

Channel 2 (CH2) is wired.

c. Adjust the length of the wires and close the cable fastening clamps so that they hold

the cables in place.

Optional: For instructions on testing the analog output level with a multimeter, see step 8.

5. Close the transmitter body cover and tighten the captive screws, and then attach the

probe body to the transmitter.

ENGLISH

It is sucient to tighten the probe body to finger tightness with the locking

wheel. To prevent detaching the probe body without tools, you can tighten

the locking wheel further with an Allen key (5 mm).

6. Mount the probe head to the area you want to measure in.

HMT370EX Series probes are designed for a variety of applications with

dierent installation requirements. For probe-specific installation

instructions, see HMT370EX User Guide.

7. Connect the grounding terminal on the bottom of the transmitter to the grounding

element of the installation site with a 4 mm2 grounding wire. After grounding the

transmitter, switch on the power supply input.

15

mA

Test Points

CH1

CH2

mA

V

V

+

−

20.0 mA

M212306EN-B

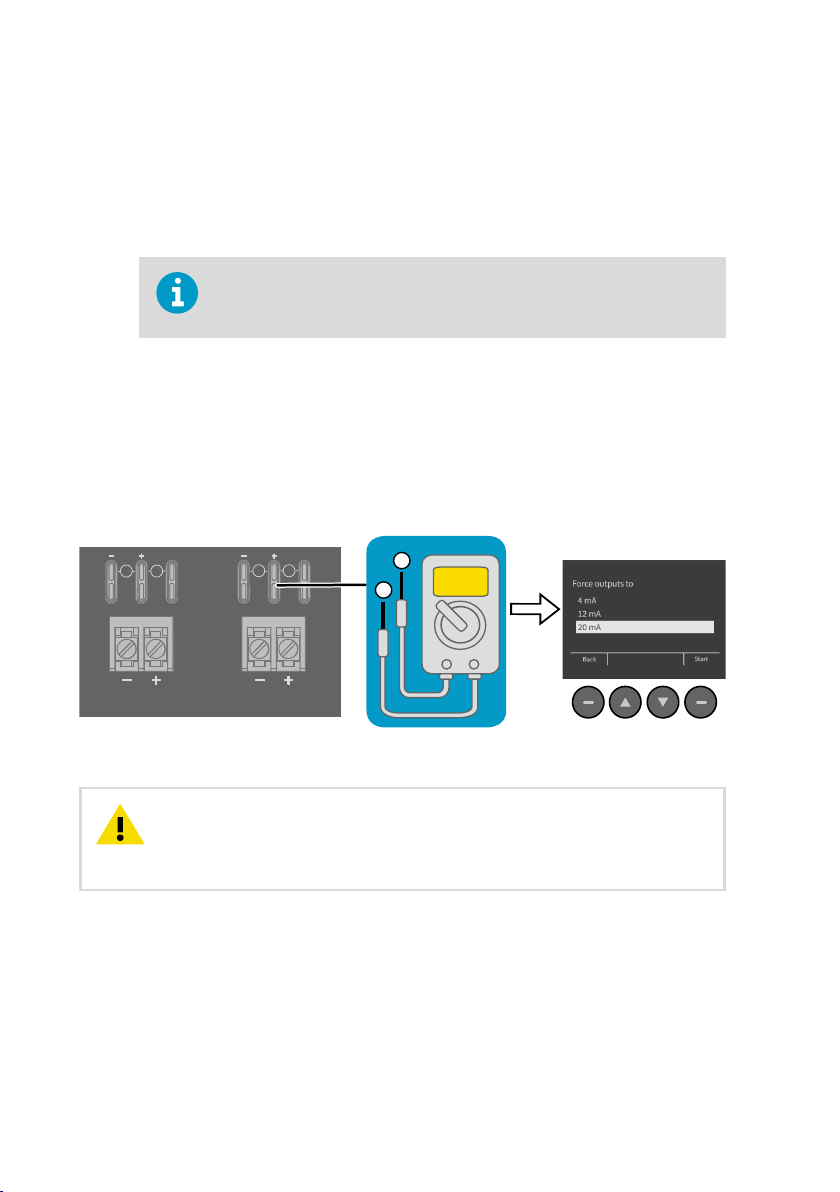

8. Optional: if you want to verify the output level of the analog output channels, test the

connection as follows:

a. Detach the probe body and open the transmitter cover.

b. Connect a multimeter to the mA testing points located above the output screw

terminals on the transmitter component board (see illustration page 2 in the

beginning of the document for the location of the terminals).

Always use an Ex compliant multimeter. The output parameters of the

multimeter must be compatible with the input parameters of the

transmitter.

c. Start the output test mode either by using the transmitter display interface, or, if

using a transmitter without a display, by connecting the transmitter to Insight PC

software. For instructions on using the output test mode with the display interface

and Insight PC software, see HMT370EX User Guide.

d. After verifying the output, remove the multimeter, close the transmitter cover, and

reattach the probe body.

Figure 4 Multimeter test point overview

CAUTION!

The service port (see Figure 2 (page 9)) must only be used in a safe

area. Either remove the transmitter from the hazardous area or ensure that a

safe work procedure has been implemented in the hazardous area. Only use the

Vaisala accessory PC connection cable with the service port.

16

mA

Test Points

mA

V

V

HAZARDOUS AREA

External

grounding

terminal

SAFE AREA

4 ... 20

mA

+

-

+

-

4 ... 20

mA

+

-

+

-

L

L

+

-

L

L

+

-

Intrinsically

safe certified

galvanic isolators

Controller

DC power supply

+

-

If the controller

uses voltage input,

use a shunt resistor:

+

-

4 ... 20 mA

Controller

U = I*RI

RI

+

-

+

-

Chapter – Installation and wiring

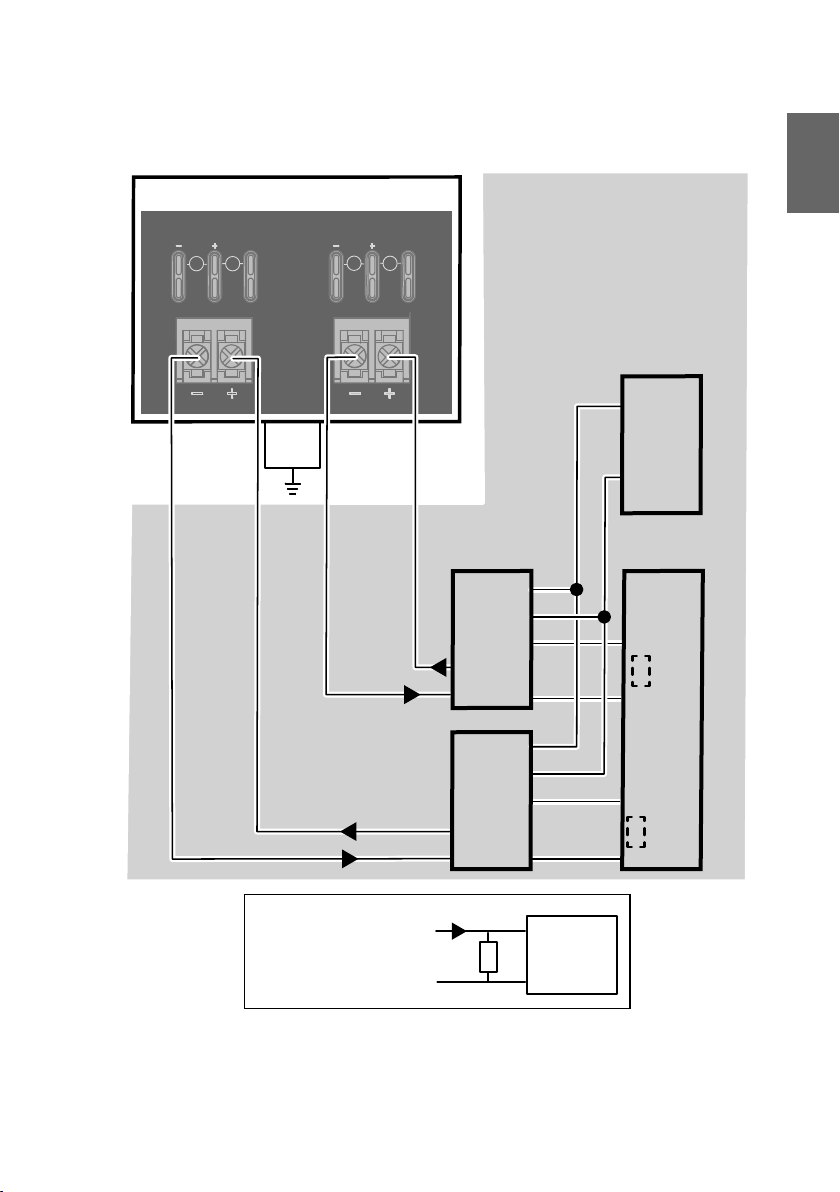

4.3 Wiring with galvanic isolators

ENGLISH

Figure 5 Wiring diagram with galvanic isolators

17

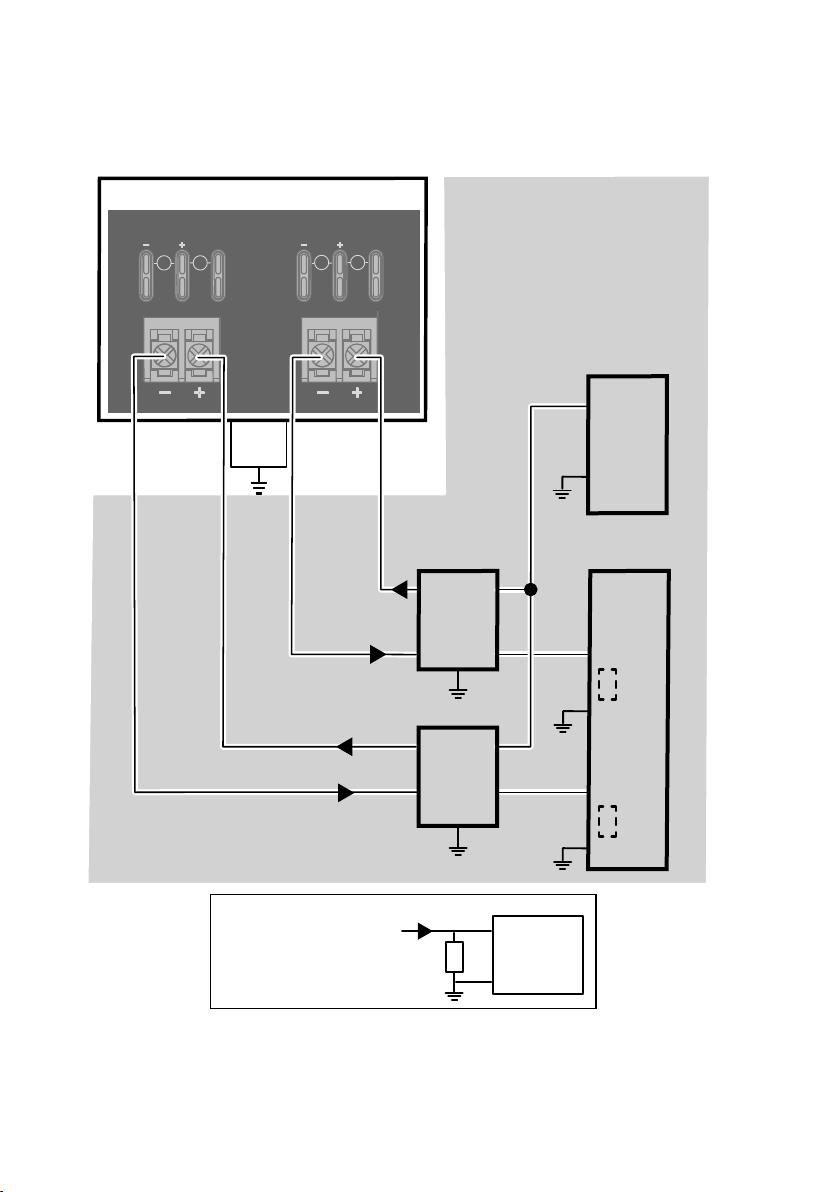

4.4 Wiring with Zener barriers

mA

Test Points

mA

V

V

HAZARDOUS AREA SAFE AREA

4 ... 20

mA

+-+

-

4 ... 20

mA

Intrinsically

safe certified

Zener barriers

Controller

DC power supply

+

-

+

-

If the controller

uses voltage input,

use a shunt resistor:

+

-

4 ... 20 mA

Controller

U = I*RI

RI

+-+

-

4 ... 20

mA

+

-

External

grounding

terminal

M212306EN-B

Figure 6 Wiring diagram with Zener barriers

18

Chapter – Installation and wiring

Maintenance and calibration services

Vaisala oers comprehensive customer care throughout the life cycle of our

measurement instruments and systems. Our factory services are provided

worldwide with fast deliveries. For more information, see www.vaisala.com/

calibration.

• Vaisala Online Store at store.vaisala.com is available for most countries. You

can browse the oering by product model and order the right accessories,

spare parts, or maintenance and calibration services.

• To contact your local maintenance and calibration expert, see

www.vaisala.com/contactus.

Warranty

For standard warranty terms and conditions, see www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of damage due to normal wear

and tear, exceptional operating conditions, negligent handling or installation, or unauthorized

modifications. Please see the applicable supply contract or Conditions of Sale for details of the

warranty for each product.

Technical support

Contact Vaisala technical support at helpdesk@vaisala.com. Provide at least the

following supporting information as applicable:

• Product name, model, and serial number

• Software/Firmware version

• Name and location of the installation site

• Name and contact information of a technical person who can provide further

information on the problem

For more information, see www.vaisala.com/support.

ENGLISH

Recycling

Recycle all applicable material.

19

M212306EN-B

Follow the statutory regulations for disposing of the product and packaging.

20

Kapitel – Einführung zur Serie HMT370EX

1 Einführung zur Serie HMT370EX

Die Vaisala HUMICAP® Feuchte- und Temperaturmesswertgeber der Serie HMT370EX eignen

sich besonders zur Feuchtemessung in Gefahrenbereichen. Der eigensichere und robuste

HMT370EX arbeitet auch in stark explosionsgefährdeten Bereichen (z. B. Zone 0) sicher und

zuverlässig. Der Messwertgeber HMT370EX der neuen Generation kann in allen HMT360

Anwendungen als Ersatz für die Geräte der Messwertgeberbaureihe HMT360 verwendet

werden.

Der HMT370EX kann direkt in explosionsgefährdete Bereiche eingebaut werden. Er ist für den

dauerhaften Einsatz in explosionsgefährdeten Umgebungen geeignet, die entflammbare Gase

oder Stäube enthalten. Für den Betrieb in solchen Umgebungen sind keine zusätzlichen

Schutzgehäuse erforderlich.

Für den HMT370EX sind verschiedene Sonden für unterschiedliche Anwendungen erhältlich.

Dank des abnehmbaren Sondenmoduls lassen sich die Sonden einfach austauschen, um sie

außerhalb des Gefahrenbereichs kalibrieren zu können, ohne den Messwertgeber vollständig

ausbauen zu müssen.

Der Messwertgeber verfügt über 2 analoge Stromausgangskanäle (4 … 20 mA), die über

Sicherheitsbarrieren angeschlossen werden. Sonde und Messwertgebergehäuse können zur

Konfiguration zusammen als Einheit oder separat mit der Software Vaisala Insight PC

verbunden werden, die den benutzerfreundlichen Zugri auf Konfigurations-, Diagnose-,

Kalibrier- und Justierfunktionen ermöglicht.

1.1

Grundlegende Merkmale und Optionen

DEUTSCH

• Verfügbare Messgrößen: Relative Feuchte (rF) und Temperatur (T)

• Berechnete Messgrößen:1): Taupunkttemperatur, Feuchttemperatur, absolute Feuchte,

Mischungsverhältnis, Wasserkonzentration, Wassermassenanteil, Wasserdampfdruck,

Enthalpie und Feuchtegehalt in Öl/Kraftsto mit Spezialmodellen

• Ex-Klassifizierung: IECEx- und ATEX-zertifiziert für Umgebungen der Zonen 0 und 20:

vollständige Ex-Klassifizierungen siehe Tabelle 6 (Seite 22).

• 2 Analogausgänge (4 ... 20 mA, skalierbar, isoliert)

• Displayoptionen: Grafisches LC-Display oder Modell ohne Display

• Versorgungsspannungsbereich: 12 … 28 V

• Kompatibel mit der PC-Software Vaisala Insight

1.2

Weitere Informationen

Weitere Informationen zu Verwendung, Konfiguration und Wartung des Messwertgebers nach

dem Einbau enthält das HMT370EX User Guide (verfügbar unter www.vaisala.com/

HMT370EX).

1) Zusätzlich verfügbare berechnete Größen: siehe Produktinformationen unter vaisala.com

21

M212306EN-B

2 Verwenden von Messwertgebern der

Serie HMT370EX in Gefahrenbereichen

WARNUNG

Trennstufen oder Sicherheitsbarrieren erfolgen.

Schließen Sie die Messwertgeber in Gefahrenbereichen immer über Ex-i-Trennstufen oder

Sicherheitsbarrieren an. Eine Ex-i-Trennstufe oder Sicherheitsbarriere muss auch verwendet

werden, wenn sich Messwertgeber und Sondenkörper in einem sicheren Bereich befinden, der

Sondenkopf jedoch in einen Gefahrenbereich eingebaut wird. Informationen zur Verdrahtung

enthalten die Schaltpläne in diesem Dokument zu Ex-i-Trennstufen und Sicherheitsbarrieren.

Der HMT370EX enthält keine Ex-i-Trennstufe und keine Sicherheitsbarriere. Diese

Komponenten können als optionales Zubehör bei Vaisala bestellt werden.

WARNUNG

Gefahrenbereichen (gemäß Produktklassifizierung) entwickelt. Das für Einbau,

Nutzung und Wartung der HMT370EX Messwertgeber zuständige Personal ist

für die Einhaltung der erforderlichen Sicherheitsvorkehrungen im jeweiligen

Anwendungsbereich des HMT370EX verantwortlich und muss sicherstellen,

dass die Gefahrenbereichsklassifizierung des Geräts der betreenden

Anwendung entspricht.

WARNUNG

Weise verwendet wird, ist der ausrüstungsseitige Schutz möglicherweise

beeinträchtigt.

Messwertgeber der Serie HMT370EX sind gemäß den folgenden Klassifizierungen für den

Einsatz in Gefahrenbereichen zertifiziert:

In Gefahrenbereichen muss eine geschützte Installation mit Ex-i-

Messwertgeber der Serie HMT370EX wurden für den Einsatz in

Wenn die Ausrüstung in einer von Vaisala nicht aufgeführten

Tabelle 6 Gefahrenbereichsklassifizierungen für Serie HMT370EX

Zertifizierung HMT370EX Klassifizierung

IECEx 1)/ATEX-

1) Internationale Zertifizierung

2) EU-Zertifizierung

22

2)

II 1 G Ex ia IIC T4 Ga

II 1 D Ex ia IIIC T

–40 °C ≤ T

≤ +60 °C

amb

200

85 °C Da

Kapitel – Verwenden von Messwertgebern der Serie HMT370EX in Gefahrenbereichen

ACHTUNG

Das für Einbau, Verwendung und Wartung der HMT370EX

Messwertgeber zuständige Personal muss gemäß den einschlägigen Normen

und Vorschriften für die Arbeit in Gefahrenbereichen qualifiziert sein.

Informationen zu den einschlägigen Normen und Vorschriften für die Verwendung der Serie

HMT370EX basierend auf ihrer Klassifizierung enthalten die HMT370EX

Zertifizierungsdokumente sowie die Konformitätserklärungen zur Serie HMT370EX unter

www.vaisala.com/declarationofconformity.

DEUTSCH

23

HMT370EX

1 2 31a

M20x1.5 M20x1.5

M212306EN-B

2.1 Leitlinien für die sichere Nutzung unter gefährlichen Bedingungen

Teileübersicht für Serie HMT370EX

Abbildung 7 HMT370EX Teileübersicht

Messwertgeber der Serie HMT370EX bestehen im Wesentlichen aus 3 Komponenten:

Messwertgebergehäuse, abnehmbarer Sondenkörper und an diesem angebrachter

Sondenkopf (direkt oder über ein Kabel). Abbildung 7 (Seite 24) zeigt die Hauptkomponenten.

Sondenköpfe (Variantenbeschreibungen siehe HMT370EX User Guide)

1

1a Sondenkoplter

2 Sondenkörper

3 Messwertgebergehäuse

Die verschiedenen Sondenkopfvarianten wurden mit jeweils eigenen Spezifikationen für

unterschiedliche Anwendungen entwickelt. Achten Sie darauf, Messwertgebergehäuse,

Sondenkörper und Sondenkopf jeweils in für die Komponente geeigneten Umgebungen

einzusetzen. Zulässige Umgebungstemperaturbereiche siehe Tabelle 7 (Seite 25).

24

Kapitel – Verwenden von Messwertgebern der Serie HMT370EX in Gefahrenbereichen

Tabelle 7 Zulässige Umgebungstemperaturbereiche

Komponente Zulässiger Umgebungstemperaturbereich

Messwertgebergehäuse –40 °C … +60 °C

Sondenkörper –40 °C … +60 °C

Sondenköpfe HMP374, HMP375, HMP377 und

HMP378

Sondenkopf HMP371 Temperaturklasse T4:

Sondenkopf HMP373 Temperaturklasse T4:

Temperaturklasse T4:

−70 °C … +120 °C

Temperaturklasse T3:

−70 °C … +180 °C

–40 °C … +60 °C

Gummikabelversion:

–40 °C … +80 °C

FEP-Kabelversion:

–40 °C … +120 °C

2.1.1 Spezifische Nutzungsbedingungen

DEUTSCH

ACHTUNG

Bei Installation des Geräts in einem Bereich der Zone 0,

Gerätegruppe II muss sichergestellt werden, dass es nicht aufgrund von

Aufschlägen oder Reibung zu Funkenbildung kommt.

Anforderungen an die Verdrahtung

• Die Kabelverschraubungen und Anschlusskabel für die Sonde dürfen den Ex-Schutz nicht

beeinträchtigen.

• Ungenutzte Kabeldurchführungen müssen mit Ex-konformen Stopfen verschlossen

werden.

• Wählen Sie eine für die Anwendung geeignete Zugentlastung (entweder eine mit

Zugentlastung ausgeführte Kabeldurchführung oder separate Schellen: siehe IEC

60079-14).

ACHTUNG

Schließen Sie nur spannungsfreie Kabel an. Schalten Sie die

Spannungsversorgung niemals ein, bevor die Verdrahtung fertiggestellt und das

Messwertgebergehäuse geschlossen wurde.

25

mA

V

mA

V

CH1

CH2

A

Service Port

Use only in safe area

!

Do not remove this cover

1

2

Test Points

M212306EN-B

Eigensicherheit

HMT370EX Messwertgeber entsprechen der Überspannungskategorie I (nicht mit dem

Stromnetz verbundene Komponente) und Verschmutzungsgrad 4 gemäß IEC 60664-1. Zu den

Parametern für eigensichere Eingänge siehe Tabelle 8 (Seite 26).

Tabelle 8 Parameter für eigensichere Eingänge

Messgröße Wert Elektrische Daten Versor-

gungsstromkreise

U

i

I

i

P

i

C

i

L

i

28 VDC Uo ≤ U

100 mA Io ≤ I

700 mW Po ≤ P

i

i

i

12,1 nF Co ≥ Ci + C

16 µH Lo ≥ Li + L

Kabel

Kabel

Verwenden der Analogausgangstestpunkte

Über jedem Schraubklemmenblock befinden sich Testpunkte zum Messen der Spannungen

und Ströme der Analogausgänge, siehe Abbildung 8 (Seite 26). Um an die Testpunkte auf der

Platine zu gelangen, müssen Sie das Messwertgebergehäuse önen.

Abbildung 8 Position der Testpunkte und der Serviceschnittstelle

Multimetertestpunkte für Analogausgangskanäle 1 und 2

1

2 Serviceschnittstelle für PC-Verbindung

26

Loading...

Loading...