查询UC1584供应商

Secondary Side Synchronous Post Regulator

UC1584

UC2584

UC3584

FEATURES

• Practical Operation at Switching

Frequencies up to 1MHz

• Wide Band Error Amplifier

• Undervoltage Lockout with Hysteresis

• Output Active Low During UVLO

• Soft Start/Maximum Duty Cycle

Control

• Trimmed Bandgap Reference

• Internally Regulated 15V Boost

Supply

• Short Circuit Protection with

Programmable Delay

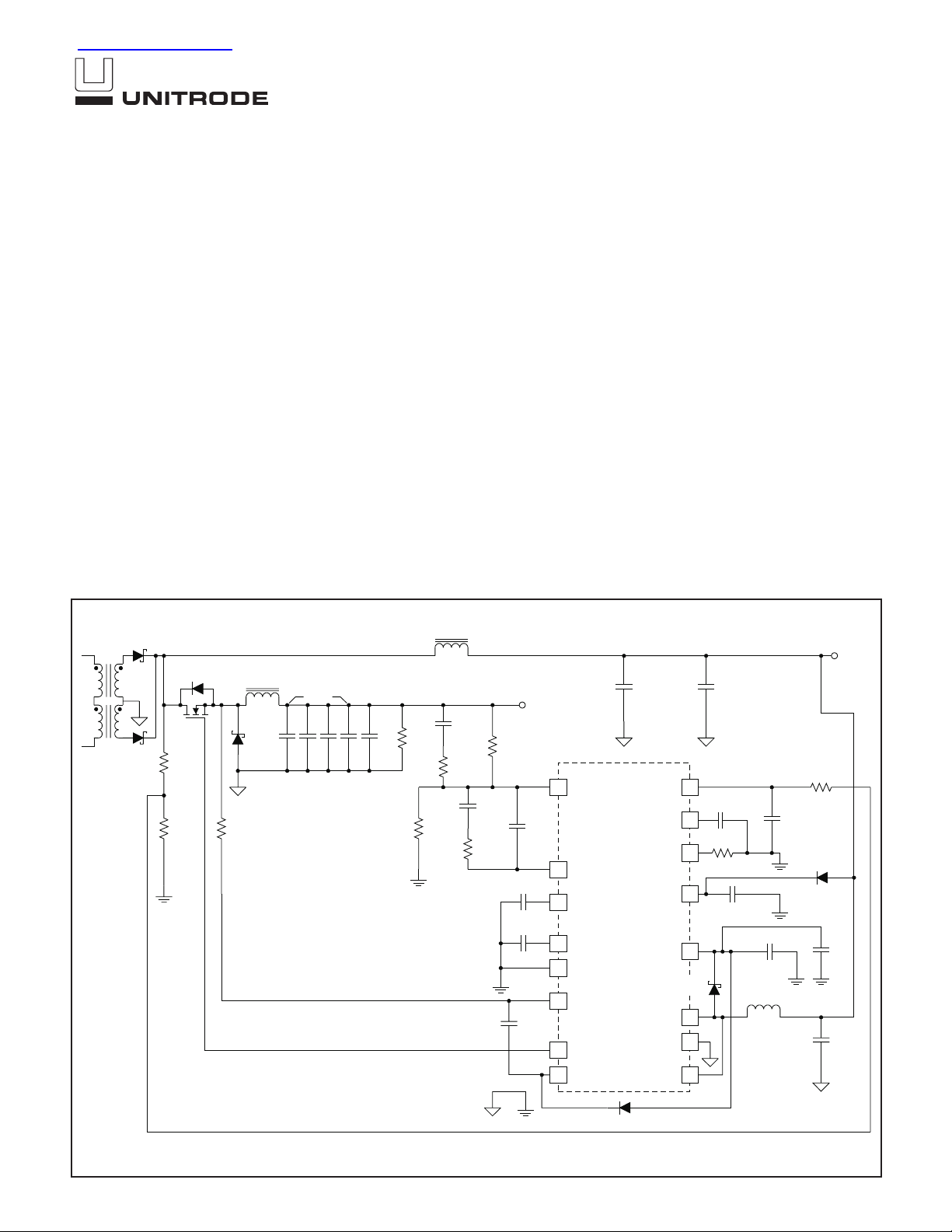

TYPICAL APPLICATION DIAGRAM.

10

170kHz

PUSH-PULL

2

210

IRFR024

4.75kΩ

3.57kΩ 3.3Ω

33µH

COILTRONICS

CSHD

10-45L

390µF

DESCRIPTION

The UC3584 is a low voltage, Secondary Side Synchronous Post Regulator. It is intended to be used for auxiliary output voltage regulation in single

secondary winding, multiple output power supplies (for more details refer

to the Application Section of this Data sheet). The UC3584 is most suited

for systems where the main output is regulated between 5V and 14V. Output voltages regulated by the UC3584 can range from virtually 0V up to

the output voltage of the main output.

Auxiliary output voltage regulation with the UC3584 uses leading edge

modulation making it compatible to primary side peak current or voltage

mode control. The UC3584 clock circuit is synchronized to the switching

frequency utilizing the falling edge of the transformer’s secondary winding

waveform.

7µH

OS-CON

+

3.3V

++++

0.1µF

100Ω

1.5W

24.3kΩ

1500pF

1.33kΩ

3300pF

20kΩ

30.1kΩ

0.1µF

1000pF

1.5µF

AUX

120pF

FB

1

2

COMP

3

SS

4

CDLY

5

GND

SRC

6

OUT

7

VFLT

8

330µF

SYNC

CT

RT

VREG

VCC

BST2

PGND

BST1

16

15

14

13

12

10BQ040

11

10

9

+

220pF

15kΩ

1µF

0.1µF

10µF

+

SOLID

TANTALUM

1kΩ

100pF

1N4148

33µH

COLTRONICS

0.1µF

+

470µF

5V

MAIN

03/99

1N4148

UDG-99062

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20V

V

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . 50V, 30V at 2A

FLT

Supply Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50mA

Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to 20V

SYNC Maximum Sink Current. . . . . . . . . . . . . . . . . . . . . 600µA

PWM Driver, I

PWM Driver, I

Maximum Operating Frequency . . . . . . . . . . . . . . . . . . . . 1MHz

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 300mA

OUT

(Peak). . . . . . . . . . . . . . . . . . . . . . . . . ± 1.5A

OUT

UC1584

UC2584

UC3584

Power Dissipation at T

Storage Temperature . . . . . . . . . . . . . . . . . . . . –65°C to 150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . . –55°C to 150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . . 300°C

Currents are positive into, negative out of specified terminal.

Consult Packaging Section of Databook for thermal limitations

and considerations of packages.

= 60°C . . . . . . . . . . . . . . . . . . . . . . 1W

A

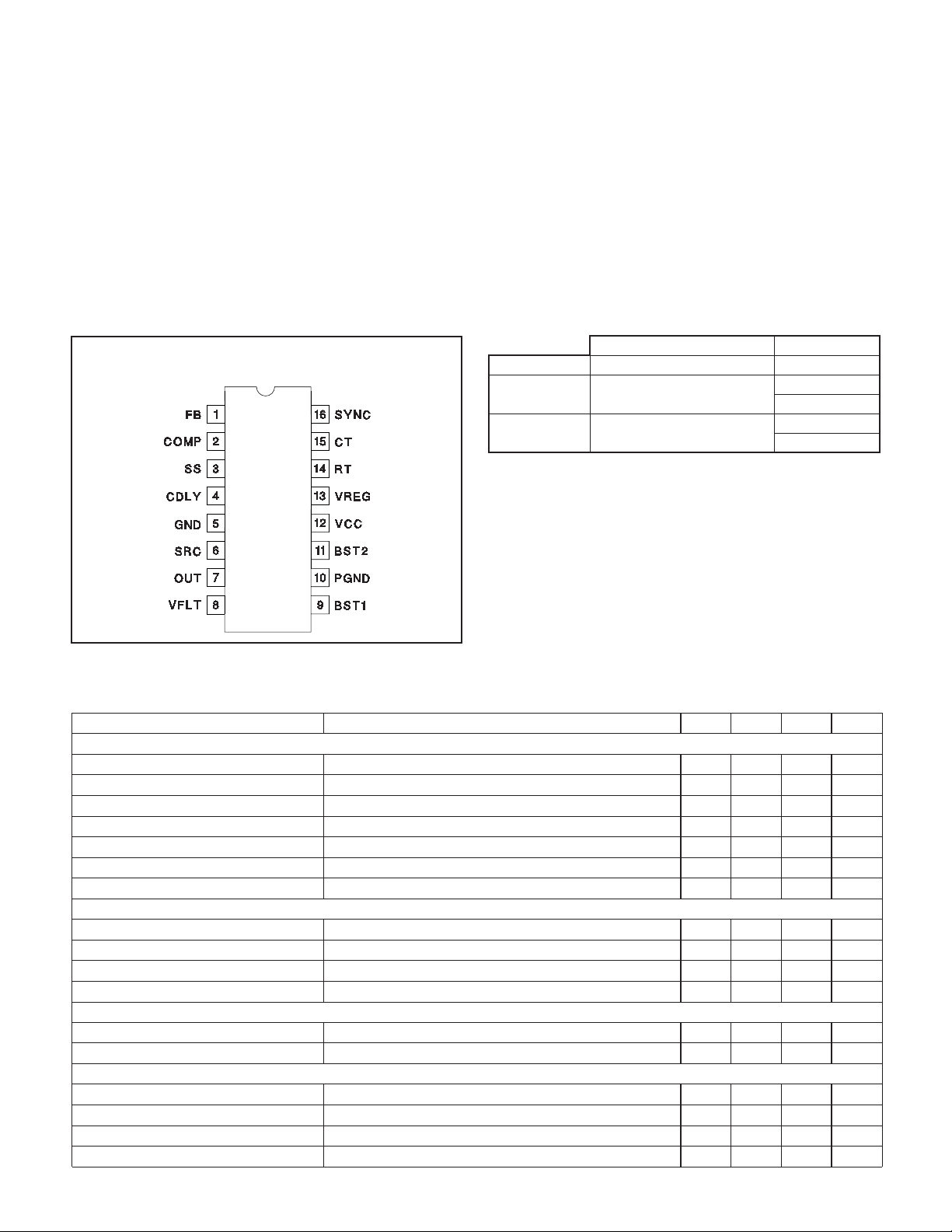

CONNECTION DIAGRAMS

DIL-16, SOIC-16 (Top View)

J, N or DW Packages

ORDERING INFORMATION

TEMPERATURE RANGE PACKAGE

UC1584J –55°C to +125°C CDIP

UC2584DW –40°C to +85°C SOIC-Wide

UC2584N PDIP

UC3584DW 0°C to +70°C SOIC-Wide

UC3584N PDIP

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, T

= 0°C to 70°C for the UC3584, –40°C to 85°C for

A

the UC2584, and –55°C to 125°C for the UC1584, VCC = 15V. TA=TJ.

PARAMETERS TEST CONDITIONS MIN TYPE MAX UNITS

Error Amplifier

FB COMP = FB 1.468 1.5 1.532 V

I

FB

COMP V

COMP V

OL

OH

V

COMP=VFB

FB = 1.6V, I

FB = 1.4V, I

= 200µA 50 400 mV

COMP

= –200µA 5.1 5.5 7 V

COMP

150 300 450 nA

AVOL 60 80 dB

PSRR (COMP) COMP = FB, VCC = 14V to 16V 60 dB

GBW Product F = 100kHz 5 10 MHz

Oscillator

Frequency R

= 3.75k, CT= 400pF, No Synchronization 500 kHz

T

Ramp Low RT= 3.75k, CT= 400pF, No Synchronization 1.75 V

Ramp High RT= 3.75k, CT= 400pF, No Synchronization 3.5 V

Ramp Amplitude RT= 3.75k, CT= 400pF, No Synchronization 1.75 V

PWM

Maximum Duty Cycle COMP = 4.5V 90 %

Minimum Duty Cycle COMP = 0V 0 %

PWM DRIVER

High V

V

SAT

V

Low V

SAT

T

RISE

T

FALL

FLT–VOUT,IOUT

OUT–VSRC,IOUT

Load = 1nF, SRC = 0V, Measure V

Load = 1nF, SRC = 0V, Measure V

= –100mA 2.5 3 V

= 50mA 0.8 2.2 V

1V to 9V 75 100 ns

OUT

9V to 1V 25 100 ns

OUT

2

UC1584

UC2584

UC3584

ELECTRICAL CHARACTERISTICS:

UC2584, and –55°C to 125°C for the UC1584, VCC = 15V. TA=TJ.

PARAMETERS TEST CONDITIONS MIN TYPE MAX UNITS

Soft Start

Charge Current 30 µA

Discharge Current 1mA

SS Delay C

Fault Latch

Charge Current 30 µA

Discharge Current 5mA

Fault Latch Delay CDLY = 500nF 50 ms

UVLO

VCC On 10.5 V

Hysteresis 1.7 V

Regulated Voltage

V

REG

VCC Regulator

VCC Boost inductor connected to 5V 14 15 16 V

I

CC

Unless otherwise specified, TA= 0°C to 70°C for the UC3584, –40°C to 85°C for the

= 500nF 50 ms

SS

I

= 0mA to 1mA 4.8 5.2 V

REG

No Load, Boost Circuitry Inactive 12 40 mA

No Load, Boost Circuitry Active (Note 1) 55 mA

Note 1: Guaranteed by design. Not 100% tested in production.

BLOCK DIAGRAM

UDG-97141

3

PIN DESCRIPTIONS

BST1: Collector of the boost switch. This is the

connection point of the external boost inductor and boost

diode. The boost converter generates the bias supply for

the UC3584 from the regulated 5V output.

BST2: See BST1. BST2 must be connected externally

to BST1 pin.

CDLY: Delay Set. External CDLY capacitor sets the

delay from the time Short Circuit condition is detected

and Fault Condition is asserted.

COMP: Output of the Voltage Error Amplifier.

CT: Connect the Timing Capacitor between CT and GND.

FB: Inverting Input of the Voltage Error Amplifier.

GND: Analog System Ground.

OUT: Output of the floating driver for an external,

N-channel MOSFET.

PGND: Power Ground. This is the reference node for the

boost bias supply regulator. PGND and GND must be

connected externally.

UC1584

UC2584

UC3584

RT: A Timing Resistor connected between RT and GND

sets the discharge current of the timing capacitor.

SRC: Source connection of the floating driver to the

external switch.

SS: Soft Start. An external capacitor is connected

between SS and GND to set the duration of the Soft

Start cycle.

SYNC: Synchronization Pin. The UC3584 is

synchronized from the falling edge of the transformer’s

secondary winding. Voltage must exceed 1V at minimum

input line.

VCC: Bias supply of the chip, approximately 15V. This is

also the output of the boost regulator. The VCC pin must

be decoupled to PGND.

VFLT: Positive rail of the floating driver’s bias supply.

Decouple to SRC using a high frequency (ceramic)

capacitor.

VREG: Output of the internal 5V regulated supply. Must

be decoupled to GND.

APPLICATION INFORMATION

Biasing the UC3584

Bias supply for the UC3584 is generated from the main

output of the power supply by a boost regulator. The inductor, diode and capacitor of the boost converter are external components, while the boost switch is internal to

the chip. The boost converter operates in a burst mode

with a built-in hysteresis of approximately 1V centered at

15V. This is a bang-bang controller and when enabled

has a fixed duty cycle of 75%.

Undervoltage Detection

The UVLO circuit of the UC3584 monitors the voltage on

VCC. During power up and power down, the pulse width

modulator and the output driver are disabled and OUT is

held active low. Operation is enabled when VCC reaches

10.5V. The UVLO circuitry has a built-in hysteresis of

1.7V (10.5V to 8.8V) thus VCC must drop below 8.8V in

order to assert UVLO again.

Precision Reference

An internal precision bandgap reference provides accurate voltages to the error amplifier and other control sections of the IC. A buffered 5V regulated voltage is also

available for external circuitry on the VREG pin. This pin

must be decoupled to the signal GND connection by a

good quality high frequency capacitor.

Oscillator and Trailing Edge Synchronization

The UC3584 is outfitted with a synchronizable oscillator

which also generates a ramp signal across the C

T capac-

itor for the PWM comparator. For easy implementation of

the leading edge pulse width modulation technique, the

oscillator has an inverted ramp waveform as shown in

Fig. 1. The free running oscillator frequency is determined by the timing components, R

T and CT, according

to the following approximate equations:

17..

MAX

8

.

09

C

T

.

()

RC

•

()

TT

R

f

OSC

93

=

T

D

−

1

−ו

28210

=

where

is the timing resistor, its value should be between

R

T

1kΩ and 100kΩ,

CTis the timing capacitor,

is the desired maximum duty cycle, and

D

MAX

is the free running oscillator frequency.

f

OSC

Figure 2 graphically depicts the measured frequency

data.

4

APPLICATION INFORMATION (cont.)

V

SEC

INTERNAL

SYNC PULSE

C

T

COMP

OUT

UC1584

UC2584

UC3584

UDG-99064

Figure 1. Trailing edge synchronization, leading edge modulation.

Edge Modulation

During normal operation the oscillator must be synchronized to the falling edge of the transformer secondary

waveform. Synchronization is achieved by connecting

SYNC to the secondary winding via a resistor divider.

The resistor divider must be chosen to provide a SYNC

pin voltage in excess of 1V at the lowest operating voltage on the transformer secondary winding. The UC3584

will generate a narrow internal synchronization pulse

which will synchronize the oscillator to the switching frequency of the main converter.

PWM and Output Driver

1. VCC within normal range (UVLO is inactive),

2. No fault condition is detected,

3. C

T

During the fast charging time of the C

low.

Ultimately, the output of the PWM circuitry controls the

conduction interval of an external N-channel MOSFET

switch in the power supply. The UC3584 employs an

on-board, floating gate driver circuit to interface to the

external switch. An external capacitor connected between VFLT and SRC acts as a floating power supply for

The UC3584 employs leading edge modulation technique to set the required on time of its output. Leading

1.E+06

edge modulation is preferred for secondary side regulation in multiple output converters to prevent ambiguity in

the primary current waveform. In fact, this is the only feasible technique to preserve compatibility with primary

side peak current mode control.

1.E+05

As Fig. 1 depicts the UC3584 utilizes voltage mode control to regulate output voltage. The output pulse width

(the on-time of the MOSFET switch) is determined on a

FREQUENCY (Hz)

cycle-by-cycle basis by comparing the output of the voltage error amplifier and the ramp waveforms across the

timing capacitor. OUT is asserted when the voltage on

COMP exceeds the voltage on CT. There are three more

1.E+04

1.E+03 1.E+04 1.E+05

conditions which must be satisfied to obtain an active

high on the OUT pin. These conditions are:

Figure 2. Oscillator frequency vs. RTwith CTas a

parameter.

is discharging.

TIMING RESISTOR (Ohms)

1500pF

capacitor is held

T

470pF

1000pF

1200pF

47pF

100pF

220pF

5

APPLICATION INFORMATION (cont.)

the driver during the on-time of the switch. Charge is being replenished to the bootstrap capacitor during the

off-time of the switch through the bootstrap diode connected between VCC and VFLT as shown in the typical

application diagram.

Soft Start

The UC3584 Soft Start circuitry is designed to implement

closed loop startup of the power supply output. During

Soft Start, the reference to the noninverting input of the

error amplifier is controlled by the voltage across the soft

start capacitor on SS. As this voltage rises, it provides an

increasing reference to the error amplifier. Once the soft

start capacitor charges above the 1.5V precision reference of the error amplifier, SS gets disconnected from

the noninverting input of the error amplifier. This technique allows the error amplifier to stay in its linear mode

and to regulate the output voltage of the power supply

according to the gradually increasing reference voltage

on its noninverting input. Further advantage of the closed

loop start up scheme is the absence of output voltage

overshoot during power up of the power supply output.

Fault Detection

Fault Detection feature is implemented to detect excessive overload conditions. Under these conditions the error amplifier output goes high to command the maximum

duty cycle. As soon as the error amplifier’s output exceeds 5V, the fault delay capacitor connected to the

CDLY pin starts charging. If C

reaches 2V before the error amplifier output falls back

capacitor voltage

DLY

UC1584

UC2584

below 5V, a fault condition is declared, the PWM output

is disabled and soft start cycle is initiated. Under persistent fault conditions the UC3584 will continuously cycle

through soft start sequence, attempting to bring the output to its regulated, nominal voltage. The value of C

capacitor should be chosen large enough to delay the

activation of the fault sequence in case of load transients

which can also cause the error amplifier output to go

high temporarily.

Error Amplifier

The Error Amplifier of the UC3584 is used to regulate the

voltage of an auxiliary output in a power supply. The

noninverting input of the error amplifier is connected to

an internal, 1.5V reference. The inverting input (FB pin)

is tied to an output voltage divider. The compensation

network of the negative feedback loop is connected between the amplifier’s output (COMP pin) and FB. The

noninverting input of the error amplifier is also connected

to the SS node through a diode. This arrangement allows

closed loop soft start for the output of a power supply

regulated by the UC3584. Closed loop soft start assures

that the error amplifier is kept in active mode and the output voltage of the converter follows the reference voltage

on its noninverting input as it ramps up (following the SS

node). If a fault condition is detected, SS node gets

pulled to ground, forcing the error amplifier’s reference

low. Consequently, the error amplifier’s output voltage

goes low and duty cycle is reduced.

DLY

UNITRODE CORPORATION

7 CONTINENTALBLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

6

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...