Page 1

FILE NO. 810-200866GR

SERVICE MANUAL

HDD & DVD Video Recorder

RD-88DTKB

RD-98DTKB

The above models are classified as green products (*1), as indicated by the underlined serial

numbers. This Service Manual describes replacement parts for the green products. When

repairing these green product(s), use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), see the next page.

TOSHIBA CORPORATION 2008

Published in Japan, Jun. 2008 GREEN

Page 2

(*1) GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for recycling

and reuse of Waste Electrical and Electronic Equipment and for the Restriction of the use of

certain Hazardous Substances. From July 1, 2006, the RoHS Directive will prohibit any

marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba Corporation

recognizes environmental protection as a key management tasks, and is doing its utmost to

enhance and improve the quality and scope of its environmental activities. In line with this,

Toshiba proactively promotes Green Procurement, and seeks to purchase and use products,

parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used in

manufacture must also be used as replacement parts.

(*2) LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the consumer

products industry at large to be environmentally responsible. Lead-free solder must be used in the

servicing and repair of this product.

WARNING

This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT !

The melting temperature of lead-free solder is higher than that of leaded solder by 86°F to 104°F

(30°C to 40°C). Use of a soldering iron designed for lead-based solders to repair product made

with lead-free solder may result in damage to the component and or BOARD being soldered.

Great care should be made to ensure high-quality soldering when servicing this product —

especially when soldering large components, through-hole pins, and on BOARDs — as the level

of heat required to melt lead-free solder is high.

Page 3

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

TOSHIBA Equipment. The service procedures recommended by TOSHIBA

and described in this service manual are effective methods of performing

service operations. Some of these service special tools should be used

when and as recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk

of personal injury to service personnel. The possibility exists that improper

service methods may damage the equipment. It also is important to

understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE.

TOSHIBA could not possibly know, evaluate and advice the service trade of

all conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, TOSHIBA has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a

service procedure or tool which is not recommended by TOSHIBA must

first use all precautions thoroughly so that neither his safety nor the safe

operation of the equipment will be jeopardized by the service method

selected.

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

Handling Precautions for HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

Cabinet Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

How to Self-Check and HDD Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

How to Initialize the HDD & DVD Video Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-3

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

Remote Control Key Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

Function Indicator Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

Schematic Diagrams / BOARD’s and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13-1

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

System Control Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15-1

IC Pin Function Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16-1

Lead Identifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17-1

Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18-1

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19-1

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20-1

Manufactured under license from Dolby Laboratories.

Dolby and the double-D symbol are trademarks of Dolby Laboratories.

Page 4

SPECIFICATIONS

1-1-1 E2N72SP

Page 5

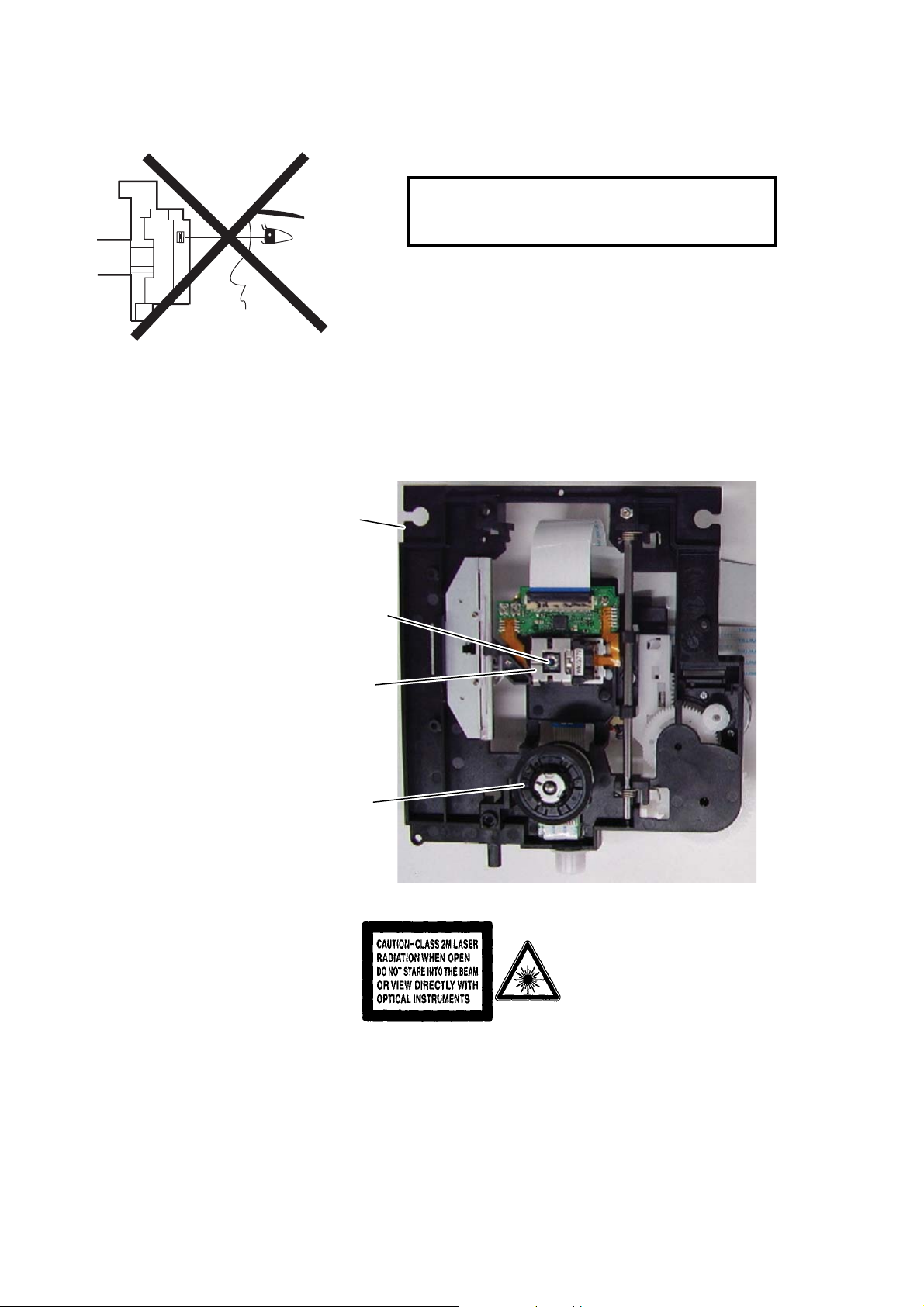

LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

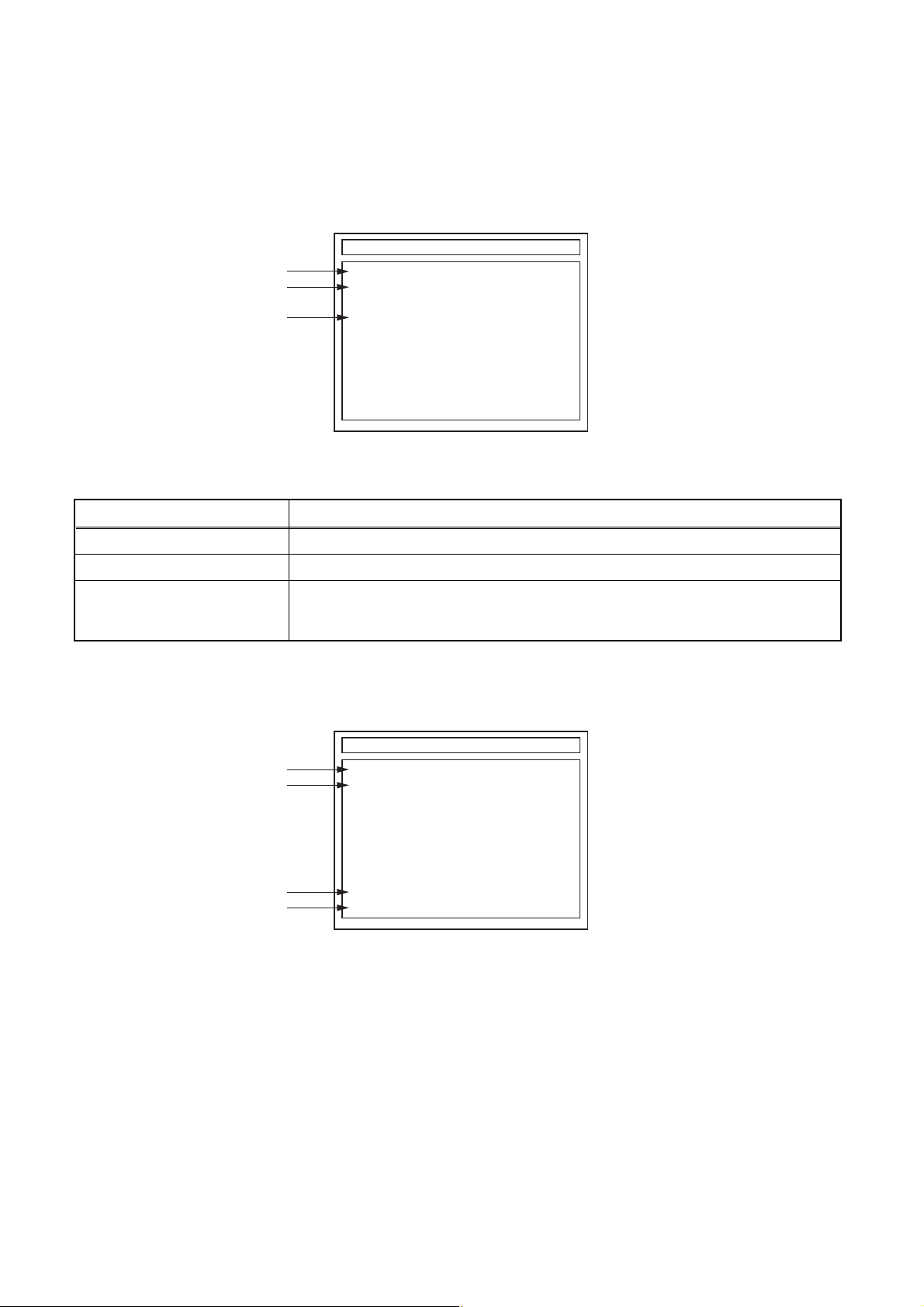

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of DVD mechanism.

1-2-1 HD5PLSP

Page 6

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a ! on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review continuously and new instructions are issued whenever

appropriate. Prior to shipment from the factory, our

products are carefully inspected to confirm with the

recognized product safety and electrical codes of the

countries in which they are to be sold. However, in

order to maintain such compliance, it is equally important to implement the following precautions when a set

is being serviced.

Precautions during Servicing

A. Parts identified by the ! symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1)Wires covered with PVC tubing

2)Double insulated wires

3)High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

L. Be sure to confirm the FAN motor has completely

stopped when disconnecting the AC cord for termination processing is activated during inner P-on

immediately after turning Power off.

1-3-1 DVDP_ISPT

Page 7

Safety Check after Servicing

Examine the area surrounding the repaired location

for damage or deterioration. Observe that screws,

parts, and wires have been returned to their original

positions. Afterwards, do the following tests and confirm the specified values to verify compliance with

safety standards.

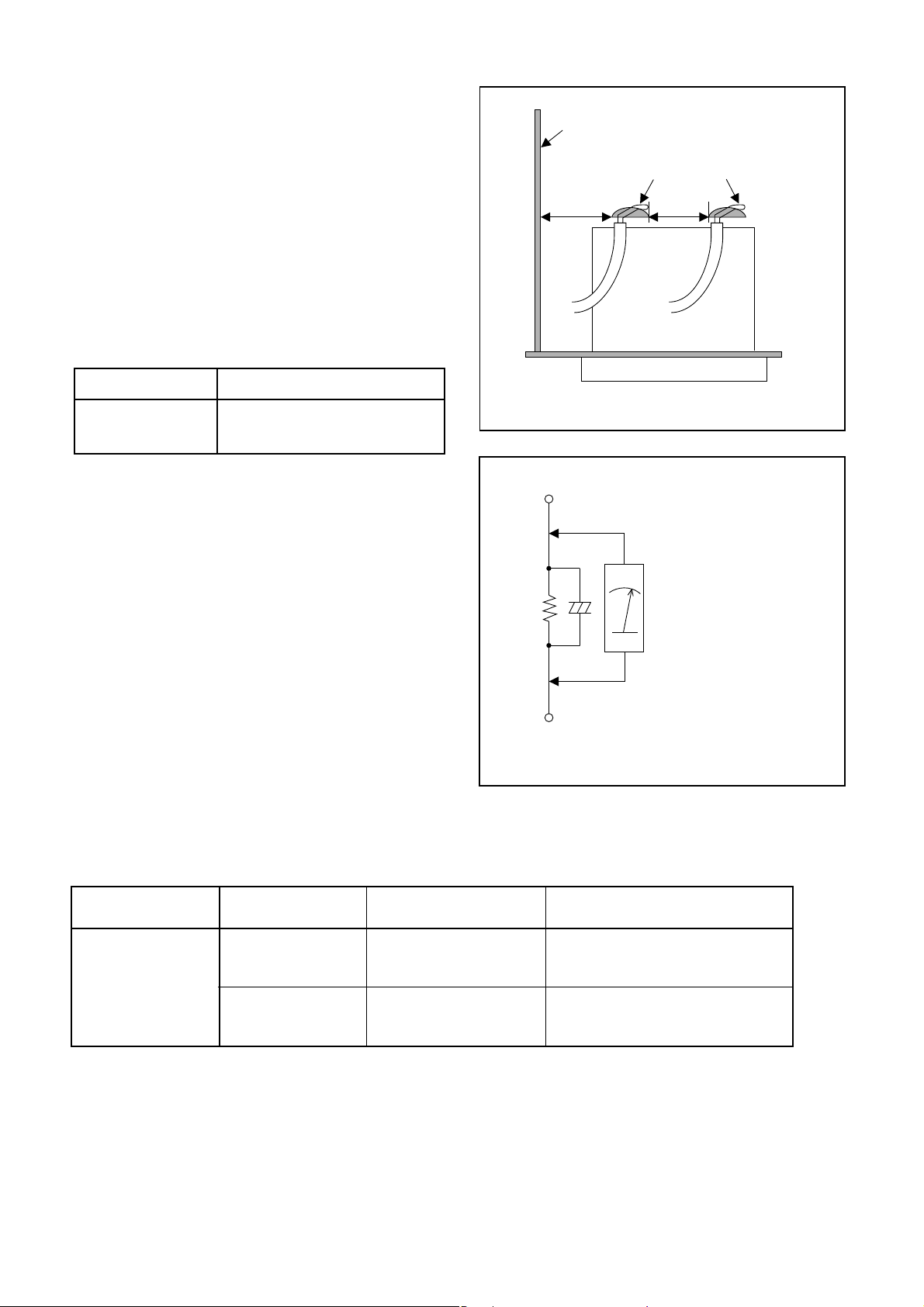

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d), (d’)

230 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

2. Leakage Current Test

≥ 3.2 mm(d)

≥ 6.0 mm(d’)

Chassis or Secondary Conductor

Primary Circuit

d' d

Fig. 1

Exposed Accessible Part

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across the terminals of load

Z. See Fig. 2 and the following table.

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

230 V

2kΩ RES.

Connected in

parallel

50kΩ RES.

Connected in

parallel

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

Z

One side of

B

Power Cord Plug Prongs

One side of power cord plug

AC Voltmeter

(High Impedance)

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

Fig. 2

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

1-3-2 DVDP_ISPT

Page 8

STANDARD NOTES FOR SERVICING

NOTE: BOARD MEANS PRINTED CIRCUIT BOARD.

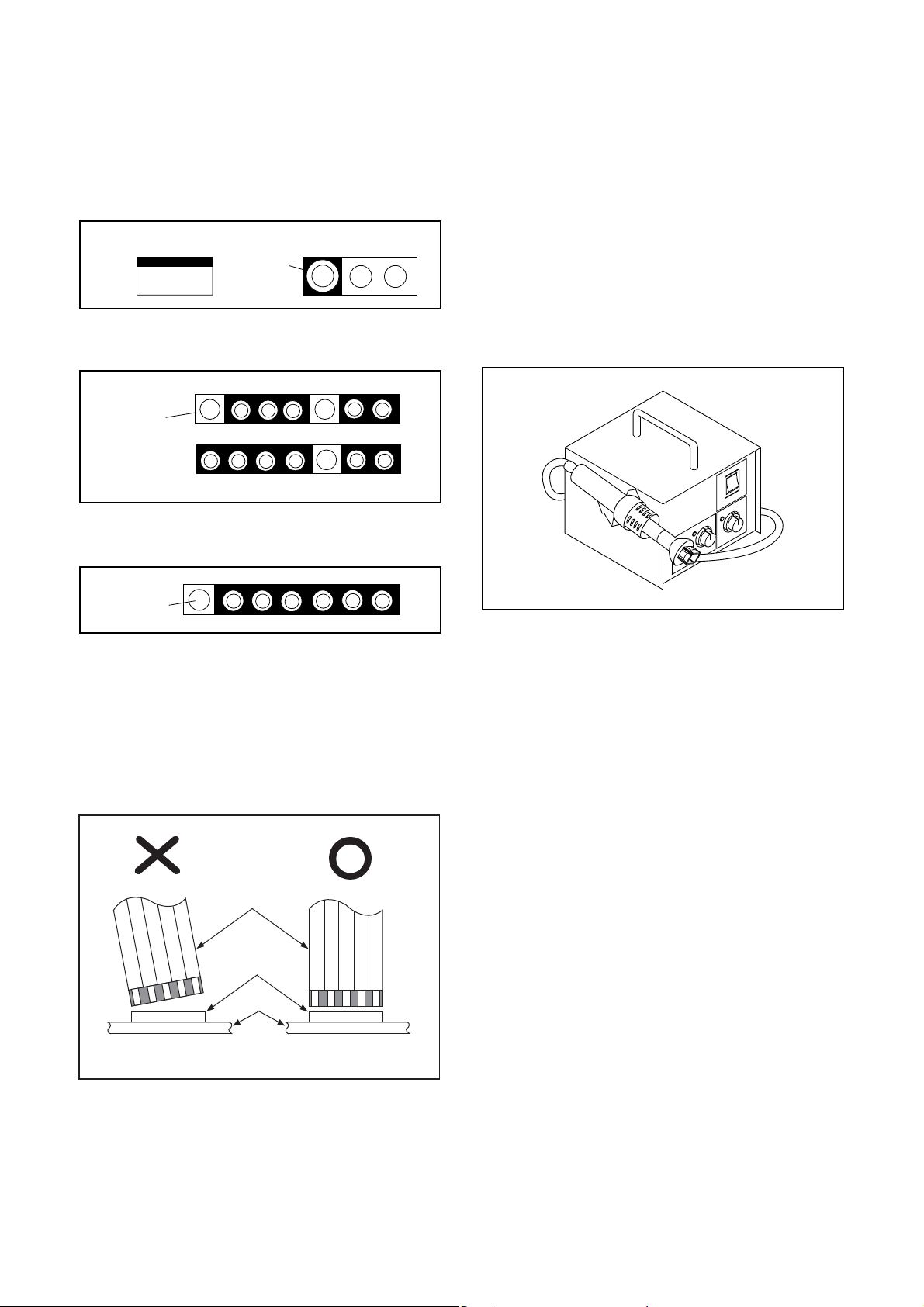

Circuit Board Indications

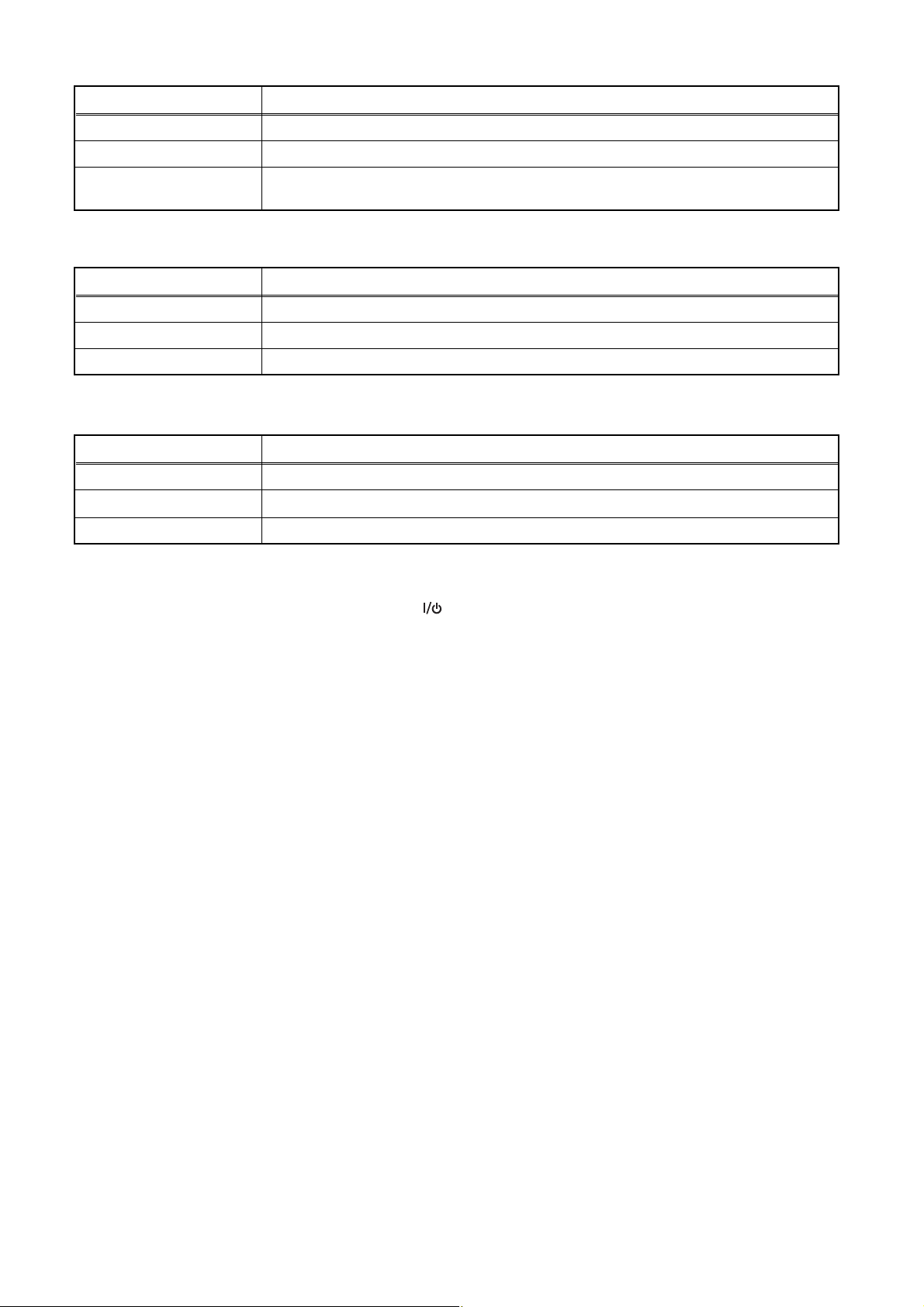

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

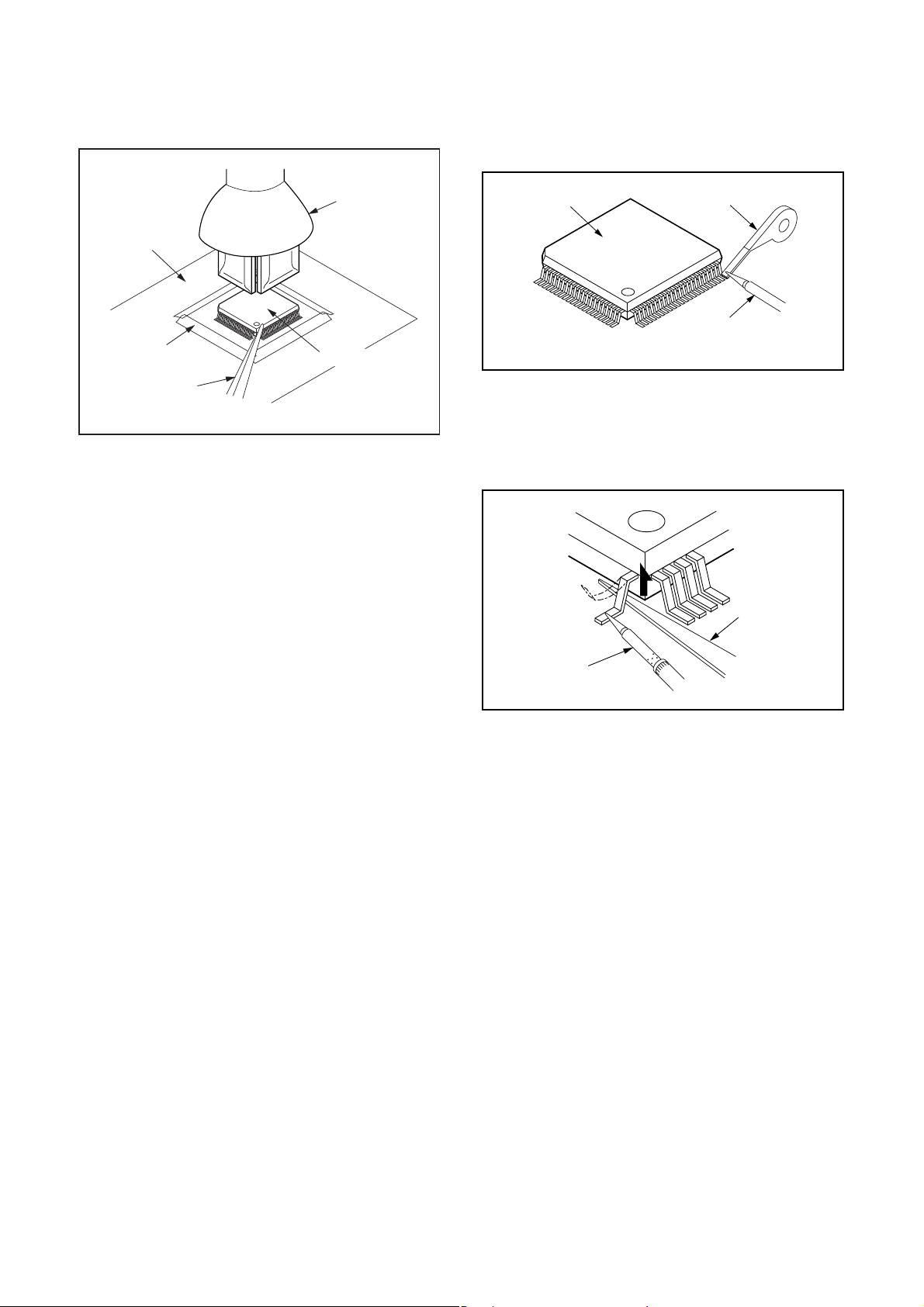

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

BOARD

* Be careful to avoid a short circuit.

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

BOARD; when removing entire flat pack-IC, first

apply soldering iron to center of the flat pack-IC

and heat up. Then remove (glue will be melted).

(Fig. S-1-6)

4. Release the flat pack-IC from the BOARD using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

1-4-1 DVDP_SN

Page 9

3. The flat pack-IC on the BOARD is affixed with

glue, so be careful not to break or damage the foil

of each pin or the solder lands under the IC when

removing it.

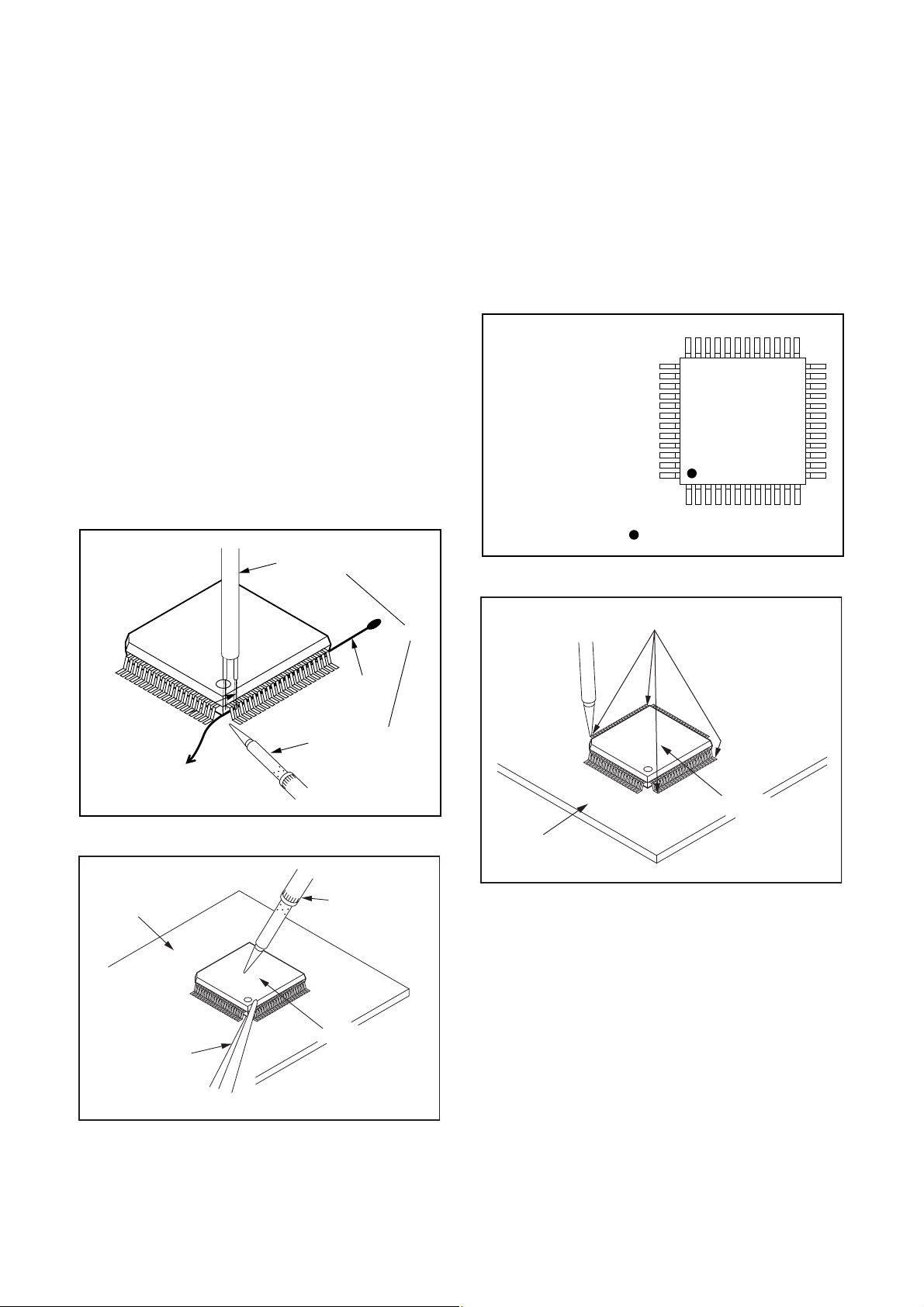

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

BOARD

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

BOARD; when removing entire flat pack-IC, first

apply soldering iron to center of the flat pack-IC

and heat up. Then remove (glue will be melted).

(Fig. S-1-6)

4. Release the flat pack-IC from the BOARD using

tweezers. (Fig. S-1-6)

Fig. S-1-4

1-4-2 DVDP_SN

Page 10

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the BOARD

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

BOARD; when removing entire flat pack-IC, first

apply soldering iron to center of the flat pack-IC

and heat up. Then remove (glue will be melted).

(Fig. S-1-6)

5. Release the flat pack-IC from the BOARD using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the BOARD, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the

BOARD so you can install a replacement flat packIC more easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the BOARD when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

BOARD

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

BOARD

Fig. S-1-8

Fig. S-1-6

1-4-3 DVDP_SN

Page 11

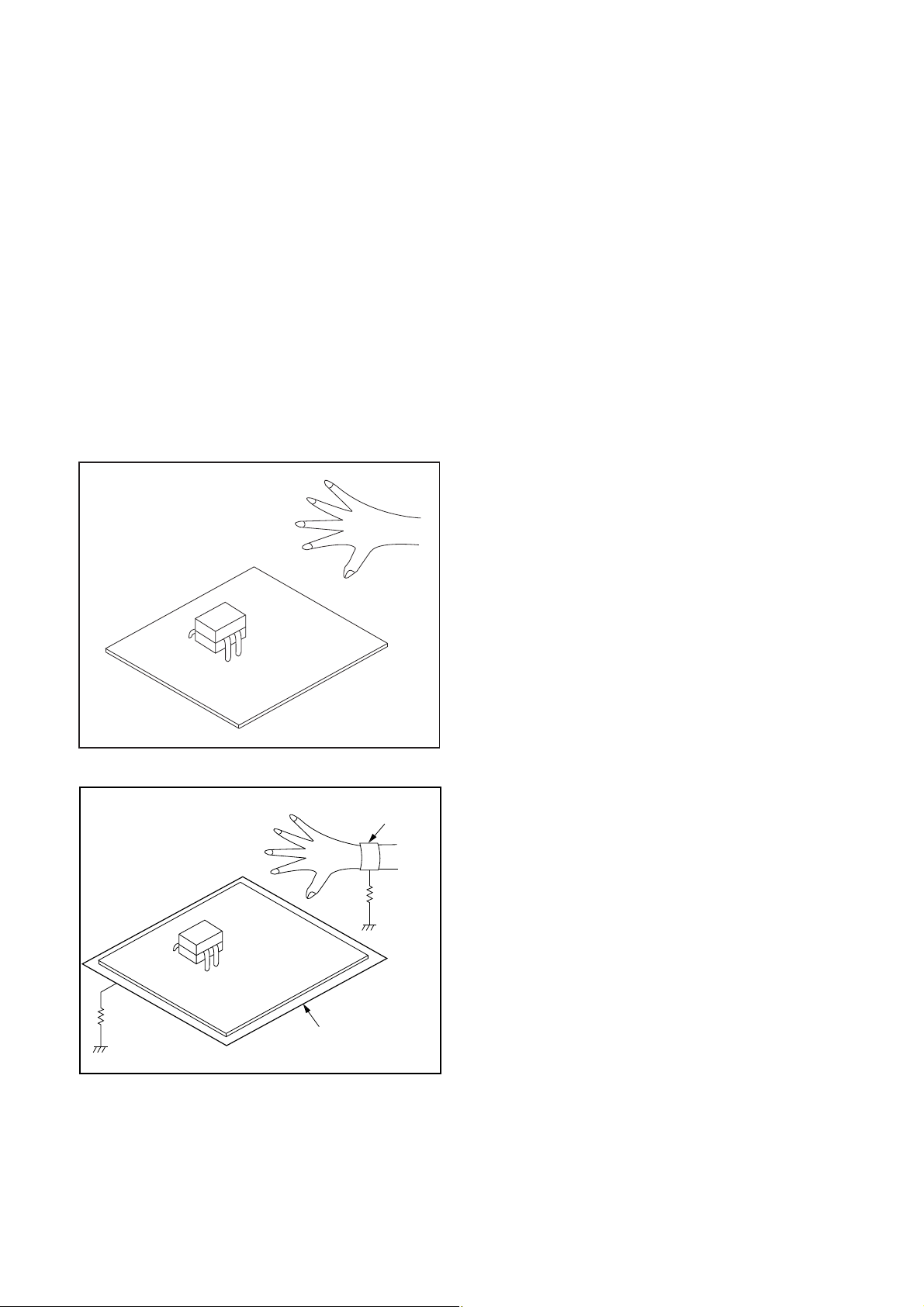

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

BOARD

Grounding Band

1MΩ

BOARD

Conductive Sheet or

Copper Plate

1-4-4 DVDP_SN

Page 12

HANDLING PRECAUTIONS FOR HDD

CAUTION:

1. SHOCK

a. Exposing HDD to shock may be the biggest

damaging factor. Please note that HDD is easily

damaged even if dropped from any height. Be sure

to place HDD on a shock-absorbent mat. Also, be

careful when transporting HDD.

b. Be careful not to subject HDD to any shock when

tightening screws for HDD replacement.

(Tighten screws manually, not with an electric

driver.)

2. MOISTURE

a. Moisture may also be a damaging factor. HDD is

semiclosed style. Sudden changes in ambient

temperature may cause moisture to form. Monitor

temperature and do not allow moisture to form on

the media surface. Also, when opening HDD

package, do so only after package is at ambient

temperature.

b. After replacing HDD, leave it to reach room

temperature (about 2 hours) for preventing dew

internal condensation, and then work necessary

task such as operation check.

4. OTHERS

a. Be careful so as not to do the followings.

Otherwise, HDD might be damaged.

- DO NOT disassemble HDD.

- When handling HDD, be sure to hold both sides

securely.

b. HDD should be stored, packed in the protective

bag, in suitable surroundings (i.e., no extreme

changes in temperature to avoid condensation).

c. When transporting HDD, be sure to use the

exclusive packing case (the replacement HDD

carton).

d. Do not stack HDDs.

e. Do not place vertically because HDD is unstable

and easy to fall.

3. STATIC ELECTRICITY

a. After removing HDD or taking replacement HDD

out of the protective bag (the replacement HDD is

packed in a protective bag), place HDD on a

conductive surface. A grounding band should be

worn when handling.

Grounding Band

Both the conductive surface and grounding band

should be grounded.

b. Make sure that HDD is placed on main unit

completely and then let go of it, when assembling.

c. Do not put HDD on a packing bag. (for preventing

electrostatic damage)

1-5-1 DHD_SN

Page 13

CABINET DISASSEMBLY INSTRUCTIONS

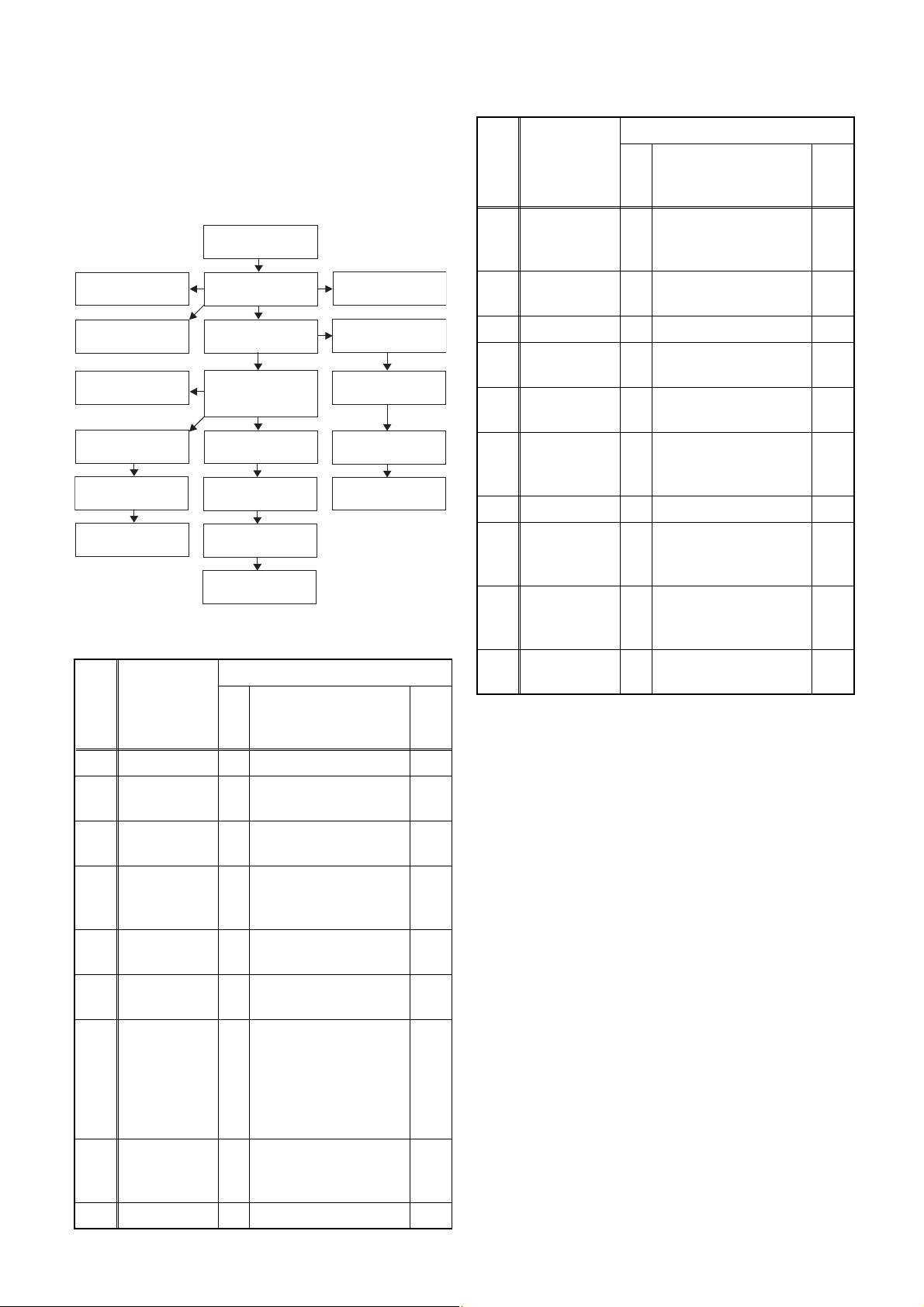

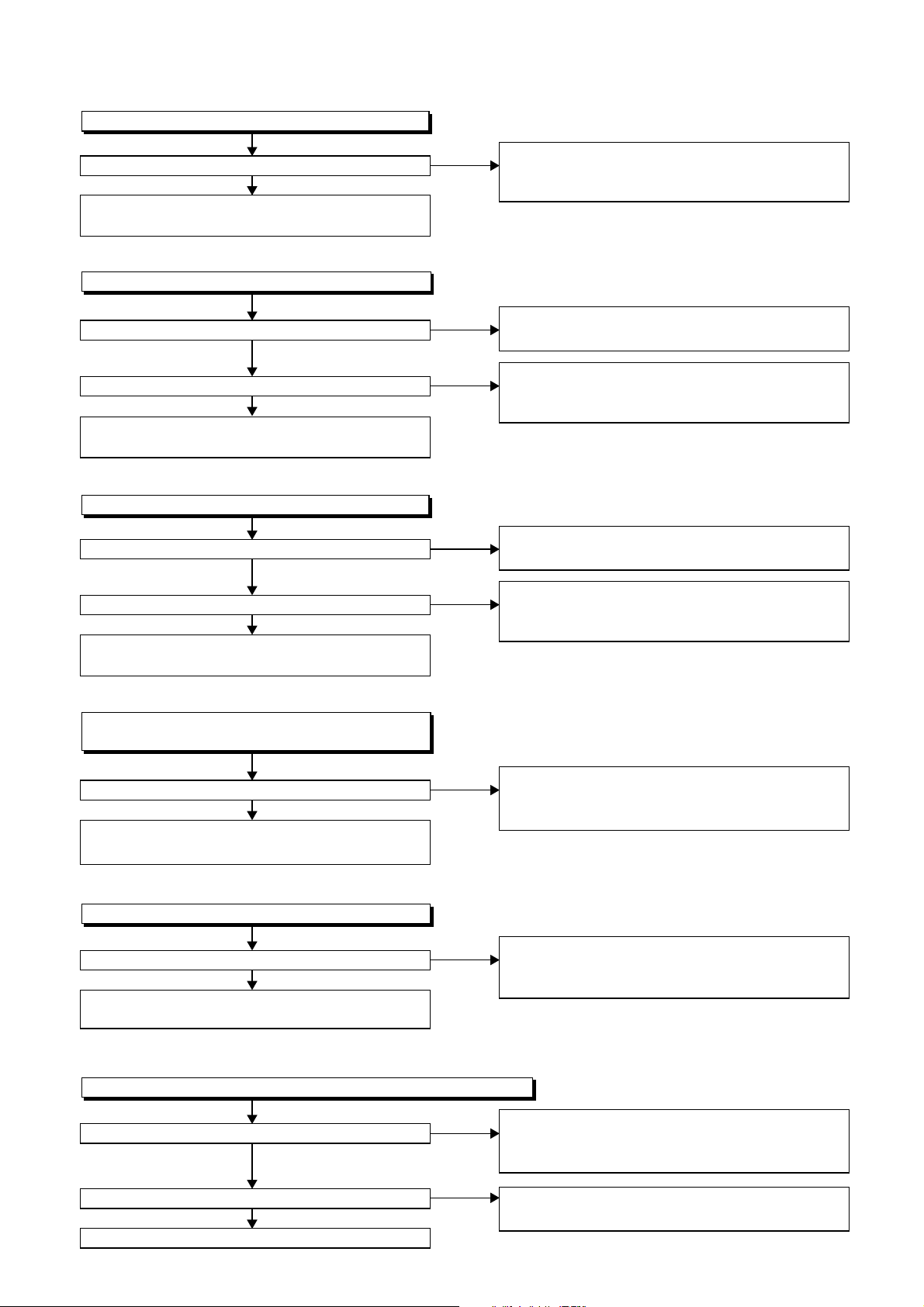

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[1] COVER TOP

[3] BOARD FRONT

[4] BOARD POWER

SWITCH

[8] IEEE 1394

DV-IN CABLE

[12] FAN COVER

[13] MOTOR DC

FAN

[14] PANEL REAR

[2] FRONT

ASSEMBLY

[5] PANEL FRONT

[7] DVD MECHANISM

& DVD/HDD MAIN

BOARD ASSEMBLY

[15] BOARD POWER

SUPPLY

[16] BOARD AV

[17] BOARD DTV

MODULE UNIT

[18] MAIN BOARD

HOLDER

[19] FRONT

BRACKET R

[6] HDD ASSEMBLY

[9] BOARD ATA

[10] HDD BRACKET

[11] HARD DISK

DRIVE

2. Disassembly Method

ID/

LOC.

No.

PART

Fig.

No.

REMOVAL

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

Note

ID/

LOC.

No.

[10]

[11]

PART

HDD

BRACKET

HARD DISK

DRIVE

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

4(S-8),

D5

HDD RUBBER,

RUBBER WASHER

(S-9), HDD PLATE

D5

EARTH

Note

[12] FAN COVER D6 2(S-10) ---

REMOVAL

[13]

[14]

[15]

MOTOR DC

FAN

PA NEL

REAR

BOARD

POWER

SUPPLY

FAN EA RTH,

D6

*CN1601

2(S-11), 2(S-12),

D6

(S-13)

*CN1152, 4(S-14),

D7

POWER HOLDER

[16] BOARD AV D7 5(S-15) ---

BOARD DTV

[17]

MODULE

UNIT

DESOLDER,

D7

MODULE BOARD

HOLDER

MAIN

[18]

BOARD

D7 (S-16) ---

HOLDER

FRONT

[19]

↓

(1)

BRACKET R

↓

(2)

D7 (S-17) ---

↓

(3)

↓

(4)

---

3

---

---

---

---

↓

(5)

[1] COVER TOP D1 8(S-1) ---

[2]

[3]

FRONT

ASSEMBLY

BOARD

FRONT

*CN2204, *5(L-1),

D2

*3(L-2)

D3 *CN3002, 4(S-2A) ---

BOARD

[4]

POWER

D3 (S-2B) ---

SWITCH

PA NE L

[5]

FRONT

HDD

[6]

ASSEMBLY

DVD

MECHANISM

&

[7]

MAIN

BOARD

ASSEMBLY

IEEE 1394

[8]

DV-IN

CABLE

DVD/HDD

D3 ---------- ---

*CN1015, *CN651,

D4

2(S-3A), (S-3B)

(S-4), 4(S-5), (S-6),

*CN101, *CN503,

*CN701, *CN901,

D4

*CNA02, BOARD

SUPPORT/ BOARD

SPACERS

2(S-7), DV PLATE

D4

EARTH

---

---

Note:

1

(1): Identification (location) No. of parts in the figures

(2): Name of the part

(3): Figure Number for reference

(4): Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 7(S-1) = seven Screws (S-1),

5(L-1) = five Locking Tabs (L-1)

(5): Refer to “Reference Notes.”

2

[9] BOARD ATA D5 *CN3001-A ---

1-6-1 E2N70DC

Page 14

Reference Notes

1. Locking Tabs (L-1) ,(L-2) are fragile. Be careful not

to break them.

1-1. Release five Locking Tabs (L-1).

1-2. Release three Locking Tabs (L-2) and

remove the PANEL FRONT.

2. The DVD MECHANISM & DVD/HDD MAIN

BOARD ASSEMBLY is adjusted as a unit at

factory. Therefore, do not disassemble it.

Replace the DVD MECHANISM & DVD/HDD

MAIN BOARD ASSEMBLY as a unit.

3. Whenever you have replaced the Hard Disk Drive,

initialize the Hard Disk Drive. To initialize the Hard

Disk Drive, perform the following.

3-1. To put the HDD & DVD Video Recorder into

the HDD mode, press the [HDD] button on

the remote control unit.

3-2. To put the HDD & DVD Video Recorder into

the self-check mode, after pressing

[VARIABLE SKIP] button, press the [0], [7],

and [9] buttons on the remote control unit in

that order within three seconds.

3-3. Press [ENTER] button. The HDD & DVD

Video Recorder is initialized and the power is

turned off automatically after two seconds.

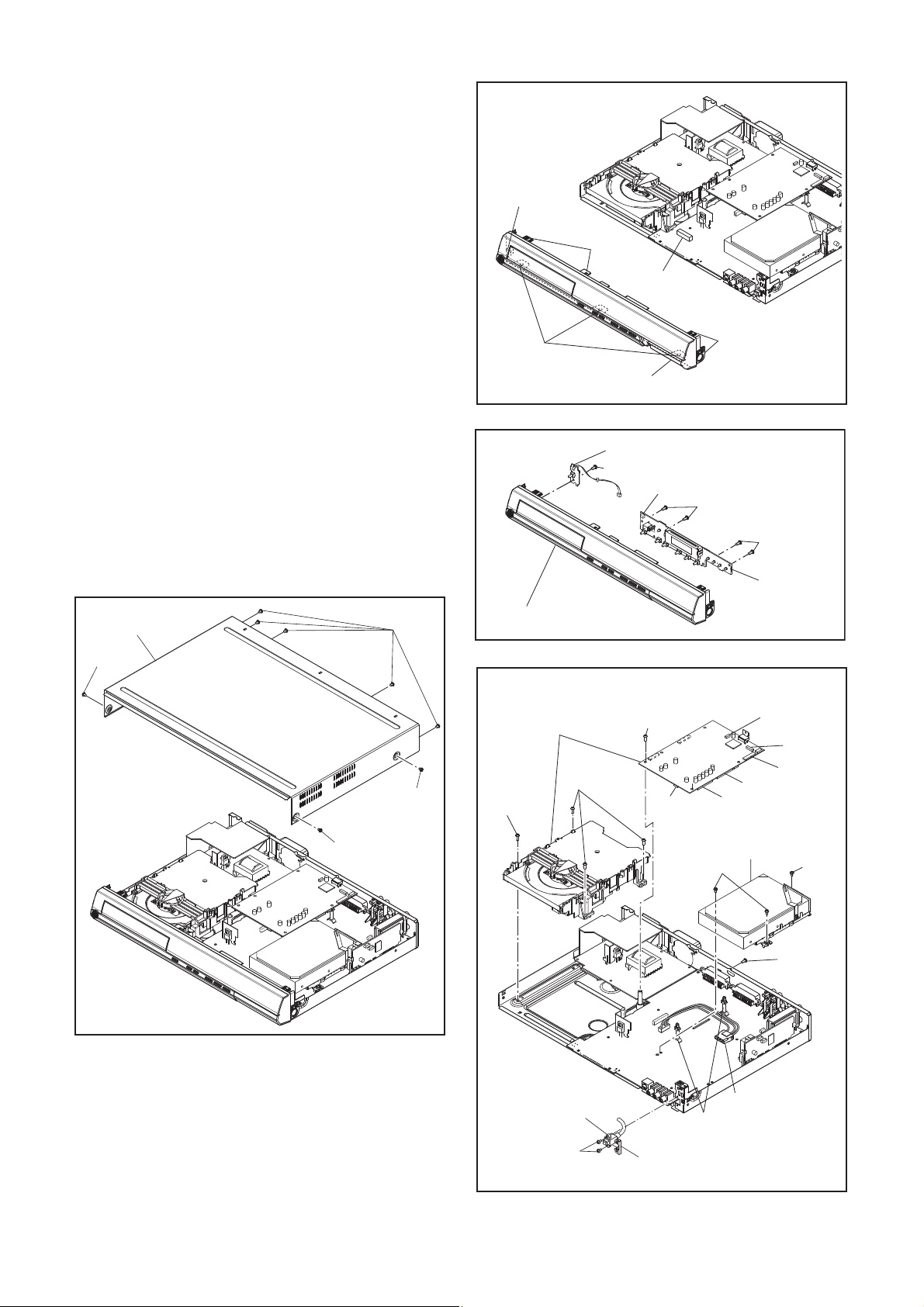

[1] COVER TOP

(S-1)

(L-1)

(L-1)

(L-2)

[2] FRONT ASSEMBLY

[4] BOARD POWER SWITCH

(S-2B)

[5] PANEL FRONT

CN2204

(L-1)

Fig. D2

CN3002

(S-2A)

(S-2A)

[3] BOARD

FRONT

Fig. D3

(S-1)

(S-1)

(S-1)

Fig. D1

[7]

DVD MECHANISM

*

& DVD/HDD MAIN

BOARD ASSEMBLY

(S-5)

(S-5)

[8] IEEE 1394

DV-IN CABLE

(S-7)

See Reference Notes 2.

*

(S-4)

CN901

DV PLATE EARTH

CN101

(S-3A)

CN1015

BOARD SUPPORT

/ BOARD SPACERS

CNA02

CN503

CN651

CN701

[6] HDD

ASSEMBLY

(S-3B)

(S-6)

Fig. D4

1-6-2 E2N70DC

Page 15

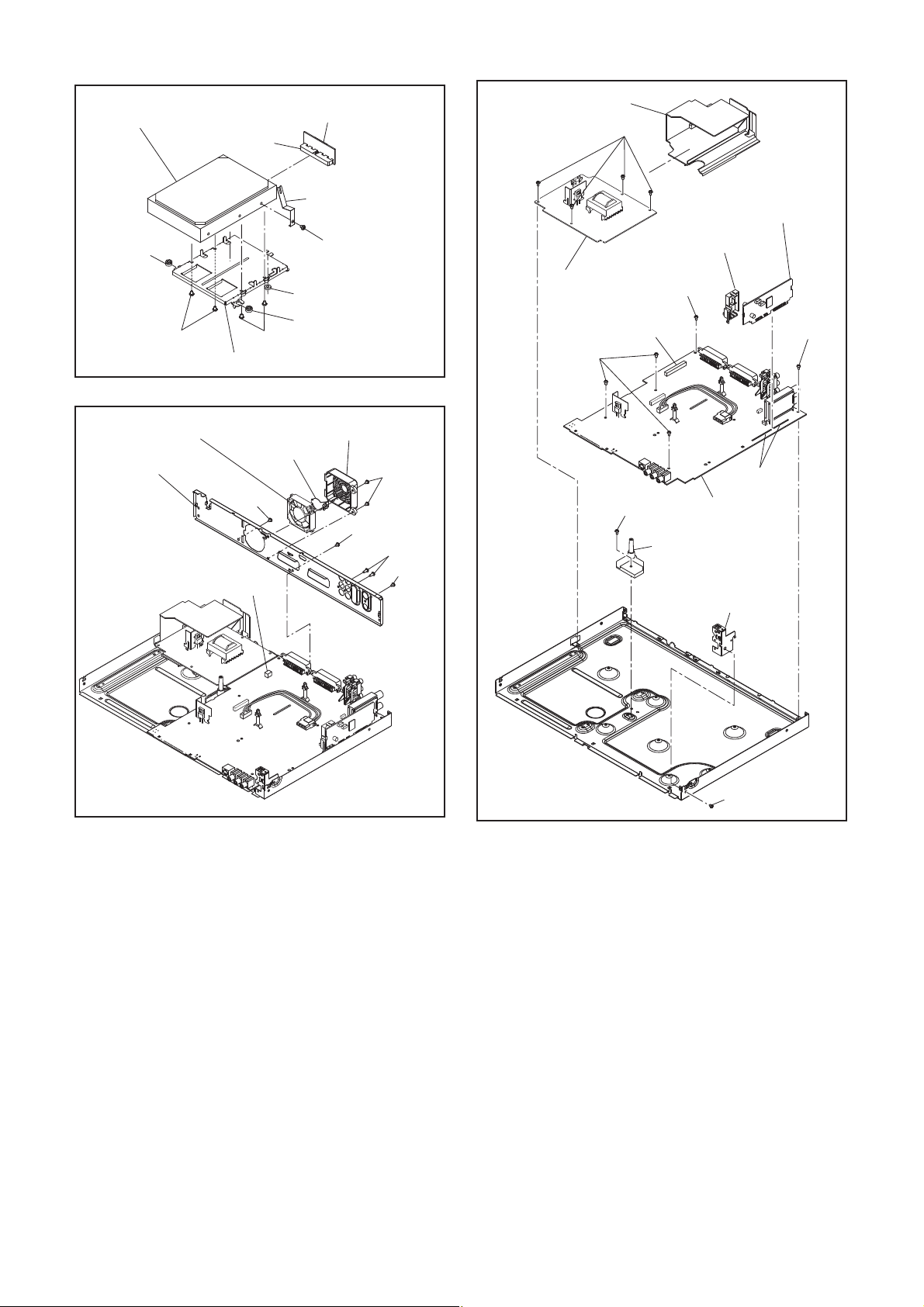

[11] HARD DISK DRIVE

CN3001-A

[9] BOARD ATA

POWER HOLDER

(S-14)

HDD RUBBER

(S-8)

[13] MOTOR DC FAN

[14] PANEL REAR

HDD PLATE EARTH

(S-9)

RUBBER

WASHER

HDD RUBBER

(S-8)

[10] HDD BRACKET

[12] FAN COVER

FAN EARTH

(S-11)

CN1601

(S-11)

Fig. D5

(S-10)

(S-12)

(S-13)

[15] BOARD

POWER SUPPLY

CN1152

(S-15)

(S-16)

[17] BOARD DTV

MODULE UNIT

MODULE BOARD

HOLDER

(S-15)

(S-15)

DESOLDER

[16] BOARD AV

[18] MAIN BOARD

HOLDER

[19] FRONT

BRACKET R

Fig. D6

(S-17)

Fig. D7

1-6-3 E2N70DC

Page 16

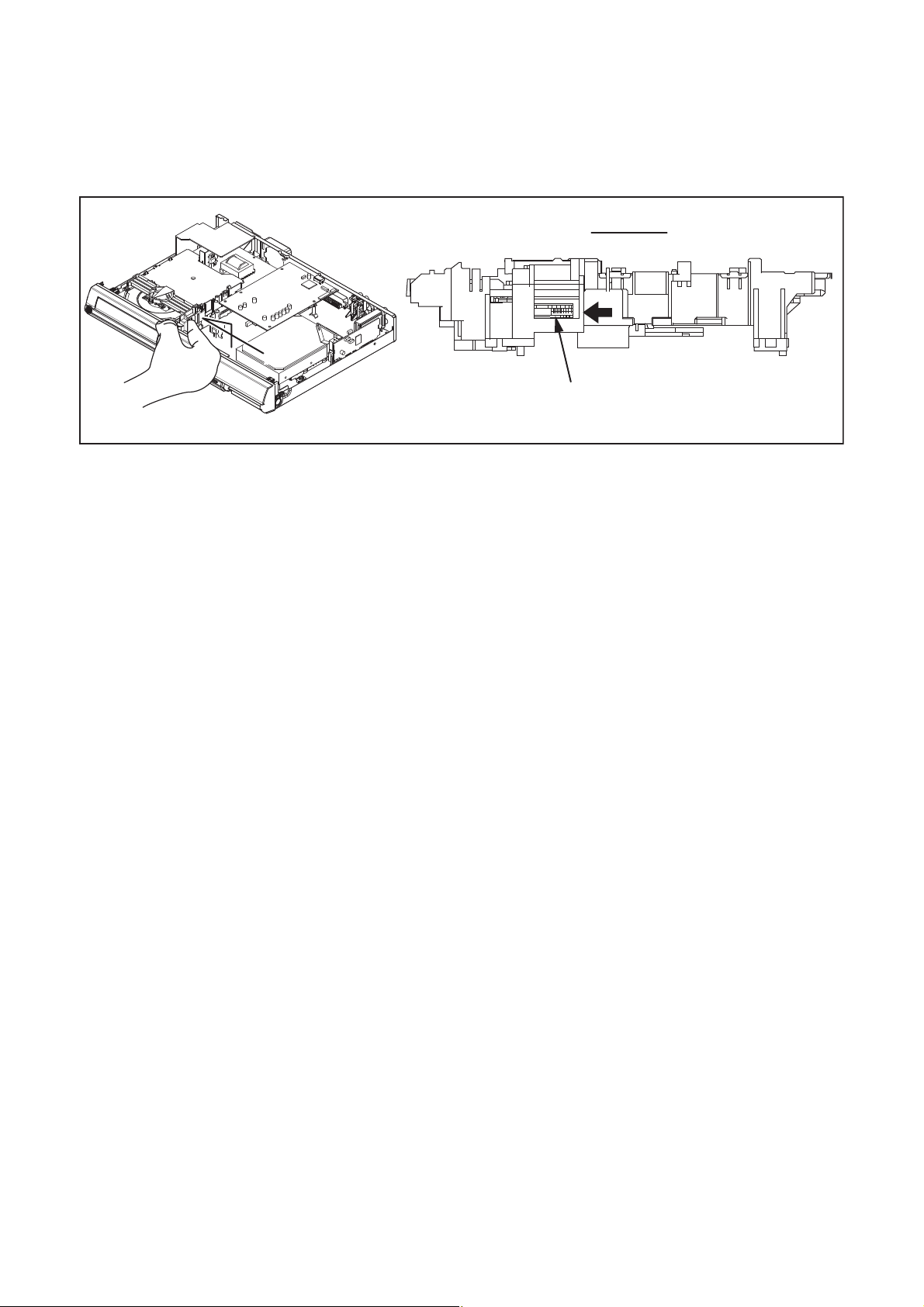

3. How to Eject Manually

Note: When rotating the gear, be careful not to damage the gear.

1. Remove the COVER TOP.

2. Rotate the gear in the direction of the arrow manually as shown below until the tray descends.

3. Pull the tray out manually and remove a disc.

View for A

A

Rotate this gear in

the direction of the arrow

1-6-4 E2N70DC

Page 17

HOW TO SELF-CHECK AND HDD FORMAT

1. Turn on the HDD & DVD Video Recorder.

2. To put the HDD & DVD Video Recorder into the HDD mode, press [HDD] on the remote control unit.

3. To put the HDD & DVD Video Recorder into the self-check mode, after pressing [VARIABLE SKIP] button,

press the [0], [7], and [9] buttons on the remote control unit in that order within three seconds.

Fig. a appears on the screen and all LEDs light.

SELF CHECK

*1

*2

DVD CONNECT STATUS : --

HDD CONNECT STATUS : --

*3

HDD POWER ON HOURS :

POWER OFF : POWER

Fig. a: Self-Check Mode Screen

Table 1: Description of Fig. a

INDICATION DESCRIPTION

DVD CONNECT STATUS (*1) Connecting Condition of DVD(F/E)

HDD CONNECT STATUS (*2) Connecting Condition of HDD

Value of HDD power on hours obtained from S.M.A.R.T. command. (If not obtainable,

HDD POWER ON HOURS (*3)

value of HDD power on hours is “0”.)

Value in parentheses is the factory setting value. (If no setting, the value is “0”.)

4. Upon the self-check completion, Fig. b appears on the screen.

SELF CHECK

*4

*5

DVD CONNECT STATUS : OK

HDD CONNECT STATUS : OK

HDD POWER ON HOURS : 120

*6

*7

HDD FORMAT : ENTER

POWER OFF : POWER

Fig. b: Screen of Finishing Self-Check Mode

1-7-1 E2N70INT

Page 18

Table 2: Indication of DVD self-check (*4)

INDICATION DESCRIPTION

OK Connection of DVD is normal.

NOT FOUND DVD drive cannot be found.

CABLE ERROR

FFC cable (connecting to CN401) between the DVD drive and the DVD/HDD MAIN BOARD

is not connected correctly.

Table 3: Indication of HDD self-check (*5)

INDICATION DESCRIPTION

OK Connection of HDD is normal.

NOT FOUND HDD drive cannot be found.

CABLE ERROR FFC cable between the BOARD ATA and the HDD drive is not connected correctly.

Table 4: Available button in self-check mode

BUTTON DESCRIPTION

ENTER (*6) Format (only when the self-check mode is complete)

STANDBY-ON (*7)

OTHER Not available

Turn the power off

5. When the self-check mode is complete, press [ ] button to turn the power off.

When formatting the HDD & DVD Video Recorder, press [ENTER] button. After two seconds, the power is

turned off automatically.

NOTE: By formatting, “Current Clock” and “HDD Contents” are formatted.

1-7-2 E2N70INT

Page 19

HOW TO INITIALIZE THE

HDD & DVD VIDEO RECORDER

To put the program back at the factory-default, initialize the HDD & DVD Video Recorder as the following

procedure.

1. Turn on the HDD & DVD Video Recorder.

2. To put the HDD & DVD Video Recorder into the HDD mode, press [HDD] on the remote control unit.

3. To put the HDD & DVD Video Recorder into the Version display mode, press [VARIABLE SKIP], [1], [2], and

[3] buttons on the remote control unit in that order within three seconds.

Fig. a appears on the screen.

*1: "

*2: Firmware Version differs depending on the

models, and this indication is one example.

Fig. a Version Display Mode Screen

" differs depending on the models.

*******

F/W VERSION DISP

MODEL NAME :

DVB-T VERSION :

FE VERSION :

BE VERSION :

TT VERSION :

DV UNIQUE ID :

LD ADJUSTMENT :

DISC ADJUSTMENT :

DEFAULT SETTING : ENTER

EXIT : RETURN

*******

*.**

***_***_***

************

*********

******** ********

OK

OK

4. Press [ENTER] button, then the HDD & DVD Video Recorder starts initializing. When the initializing is

completed, the HDD & DVD Video Recorder exits the Version display mode and turns off the power

automatically.

* To move into the Normal mode from the Version display mode, press [RETURN] button on the remote

control unit instead of [ENTER] button.

* When [ ] button is pressed before [ENTER] button is pressed, the HDD & DVD Video Recorder exits the

Version display mode, then the power turns off.

NOTE: By initializing, “Current Clock”, “Setup Changing Item”, “Channel Setup”, “Area Setup” and “Program” are

initialized.

1-7-3 E2N70INT

Page 20

FIRMWARE RENEWAL MODE

1. Turn the power on and remove the disc on the tray.

2. To put the HDD & DVD Video Recorder into

version up mode, press [VARIABLE SKIP], [6], [5],

and [4] buttons on the remote control unit in the

order. Then the tray will open automatically.

Fig. a appears on the screen and Fig. b appears

on the VFD.

* Firmware Version differs depending on the

models, and this indication is one example.

Firm Update Mode

Please insert a disc.

ver. HD5T*****X2G

Current

F/W version

is displayed.

Fig. a Version Up Mode Screen

Fig. b VFD in Version Up Mode

3. Load the disc for version up.

Fig. c appears on the screen. The file on the top is

highlighted as the default.

When there is only one file to exist, Step 4 will

start automatically.

* Firmware Version differs depending on the

models, and this indication is one example.

Firm Update Mode ver. HD5T*****X2G

Disc name

is displayed.

VOL_200707050934

1 HD5T16040X2G

2 HD5T16040X2G

3 HD5T16040X2G

4 HD5T16040X2G

Files included

in the disc are

displayed.

4. Select the firmware version pressing arrow

buttons, then press [ENTER].

Fig. d appears on the screen and Fig. e appears

on the VFD. The HDD & DVD Video Recorder

starts updating.

About VFD indication of Fig. e:

1) When Fig. d is displayed on the screen, “F-UP”

is displayed on the VFD.

2) When “Firmware Updating... XX% Complete.”

is displayed on the screen, “02110” is displayed

on the VFD.

* Firmware Version differs depending on the

models, and this indication is one example.

Firm Update Mode ver. HD5T*****X2G

Firm Update Mode

(*1)

File Loading...

Fig. d Programming Mode Screen

Fig. e VFD in Programming Mode (Example)

The appearance shown in (*1) of Fig. d is

described as follows.

No. Appearance State

1 File Loading... Sending files into the memory

Firmware

2

Updating...

Writing new version data

XX% Complete.

--- Error Failed in updating

1 / 1

Fig. c Update Disc Screen

5. After updating is finished, the tray opens

automatically.

At this time, no button is available.

6. Pull out the AC code once, then insert it again.

1-8-1 E2N72FW

Page 21

How to Verify the Firmware Version

1. Turn the power on.

2. To put the HDD & DVD Video Recorder into HDD

mode, press [HDD] on the remote control unit.

3. To put the HDD & DVD Video Recorder into

version display mode, press [VARIABLE SKIP]

and [1], [2], [3] buttons on the remote control unit

in that order within 3 seconds. Fig. i appears on

the TV screen.

*1: "

*2: Firmware Version differs depending on the

models, and this indication is one example.

Display Contents

" differs depending on the models.

*******

F/W VERSION DISP

MODEL NAME :

DVB-T VERSION :

FE VERSION :

BE VERSION :

TT VERSION :

DV UNIQUE ID :

LD ADJUSTMENT :

DISC ADJUSTMENT :

DEFAULT SETTING : ENTER

EXIT : RETURN

*******

*.**

***_***_***

************

*********

******** ********

OK

OK

Fig. i: Firmware version display

MODEL NAME Model Name

DVB-T

VERSION

DVB-T Module version

FE VERSION Firmware F/E version

BE VERSION Firmware B/E version

TT VERSION Firmware T/T version

DV UNIQUE ID DV Unique ID

LD

ADJUSTMENT

DISC

ADJUSTMENT

LD adjustment progress (done: OK/

not done: --)

Factory adjustment progress (done:

OK/not done: --)

4. Press [RETURN] or [ ] button to turn off.

Note: Be sure to verify the firmware version.

1-8-2 E2N72FW

Page 22

10

14

18

22

26

32

35

39

42

49

53

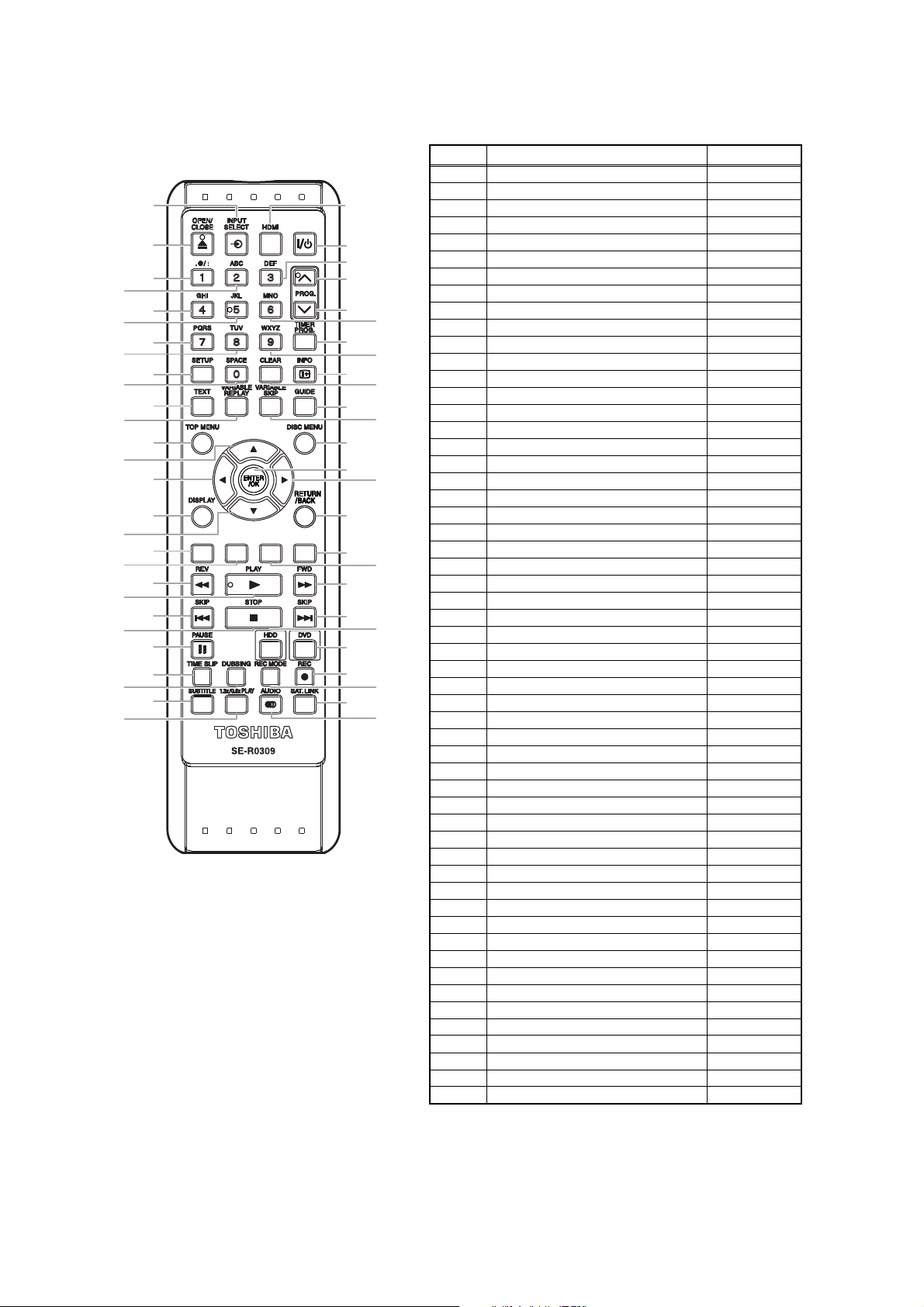

REMOTE CONTROL KEY CODE

NEC Format

Key No. Name Code

1 OPEN/CLOSE 45BC-11

2

1

3

4

7

5

6

9

13

8

12

16

11

15

17

21

20

24

19

23

25

28

31

34

27

29

33

37

30

36

38

41

44

48

40

43

47

51

46

50

52

55

54

2 INPUT SELECT 45BC-0F

3 HDMI 45BC-B0

4 ON/STANDBY 45BC-12

51 45BC-01

62 45BC-02

73 45BC-03

8PROG. UP 45BC-1E

94 45BC-04

10 5 45BC-05

11 6 45BC-06

12 PROG. DOWN 45BC-1F

13 7 45BC-07

14 8 45BC-08

15 9 45BC-09

16 TIMER PROG. 45BC-40

17 SETUP 45BC-52

18 0 45BC-00

19 CLEAR 45BC-53

20 INFO 45BC-3F

21 TEXT 45BC-23

22 VARIABLE REPLAY 45BC-55

23 VARIABLE SKIP 45BC-5B

24 GUIDE 45BC-6D

25 TOP MENU 45BC-D0

26 CURSOR UP 45BC-C0

27 DISC MENU 45BC-D1

28 CURSOR LEFT 45BC-CC

29 ENTER/OK 45BC-44

30 CURSOR RIGHT 45BC-C4

31 DISPLAY 45BC-5A

32 CURSOR DOWN 45BC-C8

33 RETURN/BACK 45BC-D2

34 RED 45BC-2A

35 GREEN 45BC-2B

36 YELLOW 45BC-2C

37 BLUE 45BC-29

38 REV 45BC-98

39 PLAY 45BC-13

40 FWD 45BC-9A

41 SKIP DOWN 45BC-84

42 STOP 45BC-16

43 SKIP UP 45BC-80

44 PAUSE 45BC-17

45 --- ---

46 HDD 45BC-19

47 DVD 45BC-18

48 TIME SLIP 45BC-1A

49 DUBBING 45BC-56

50 REC MODE 45BC-A7

51 REC 45BC-15

52 SUBTITLE 45BC-D5

53 1.3x/0.8x PLAY 45BC-AA

54 AUDIO 45BC-D3

55 SAT.LINK 45BC-1D

1-8-3 E2N72FW

Page 23

NOTE: BOARD MEANS PRINTED CIRCUIT BOARD.

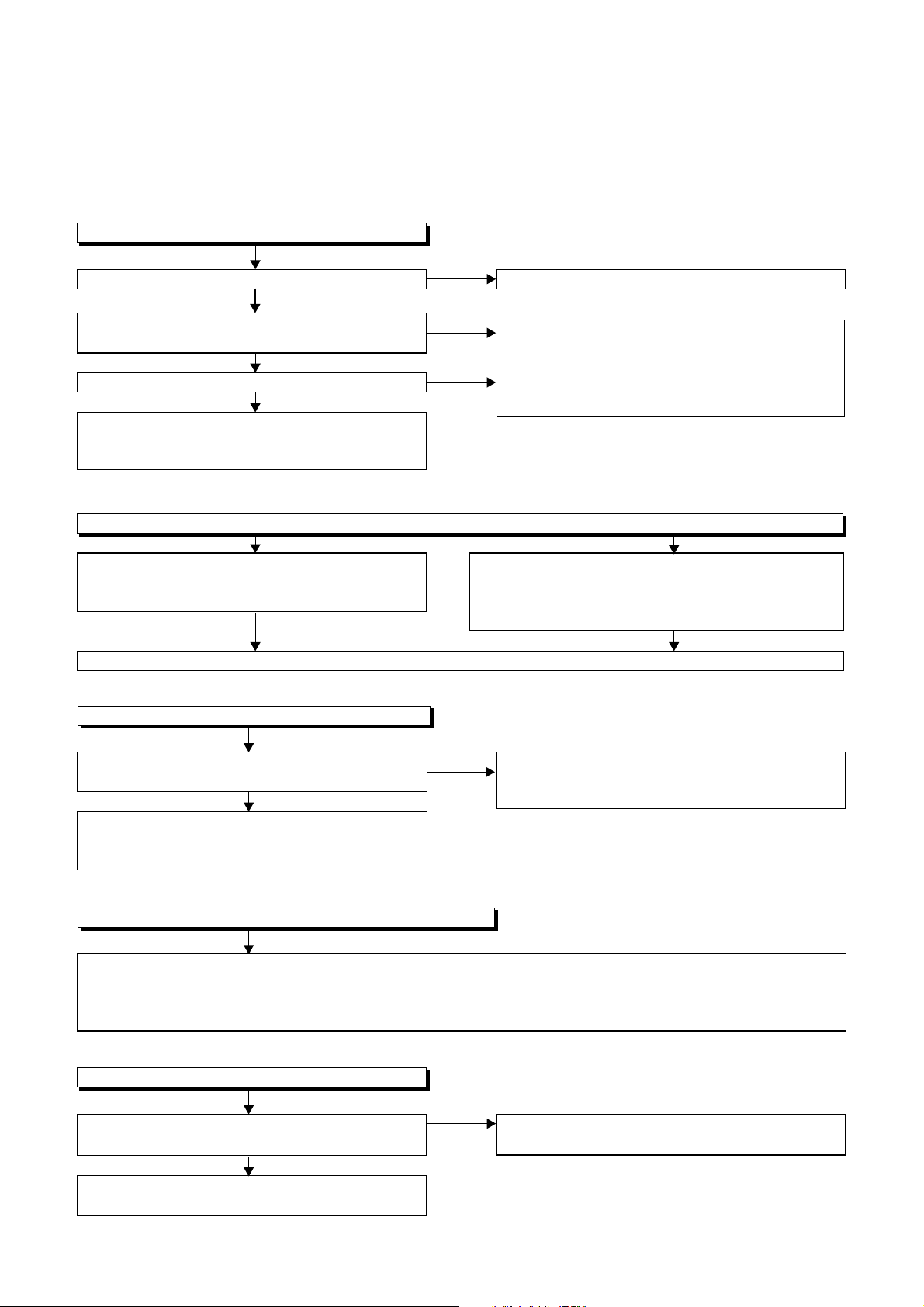

FLOW CHART NO.1

The power cannot be turned on.

TROUBLESHOOTING

Is the fuse normal?

Ye s

Is normal state restored when once unplugged

power cord is plugged again after several seconds.

Ye s

Is the AL+5V(1) line voltage normal?

Ye s

Check each rectifying circuit of secondary circuit

and replace P1 (AV ASSEMBLY) or P5 (BOARD

POWER SUPPLY) if defective.

FLOW CHART NO.2

The fuse blows out.

Check the presence that the primary component

is leaking or shorted and replace P5 (BOARD

POWER SUPPLY) if defective.

After servicing, replace the fuse (F2001).

FLOW CHART NO.3

When the output voltage fluctuates.

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check for lead or short-circuiting of primary

circuit component and replace P5 (BOARD

POWER SUPPLY) it if defective.

(Q2101, Q2102, T2001, D2001, D2002, D2003,

D2004, R2101, R2102, R2103, R2104, R2105)

Check the presence that the rectifying diode or circuit

is shorted in each rectifying circuit of secondary side

and replace P1 (AV ASSEMBLY) or P5 (BOARD

POWER SUPPLY) if defective.

Does the secondary side photo coupler circuit

operate normally?

Ye s

Check the circuit and replace P5 (BOARD

POWER SUPPLY) if defective.

(IC2101, D2111, D2112, D2113)

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is short circuit on the rectifying diode and the circuit in each rectifying circuit of secondary side and

replace P1 (AV ASSEMBLY) or P5 (BOARD POWER SUPPLY)

(D2201, D2202, D2203, D2204, D2205, D2206, D2207, D2208, D2209, D2231, D2232, IC1151, IC1152, IC1751,

Q1015, Q1017, Q1031, Q1154, Q1155, Q1156, Q1159, Q1160, Q1163, Q1251, Q1508, Q1573, Q2201, Q2202, Q2203)

FLOW CHART NO.5

-FL is not outputted.

Is the supply voltage of -30V fed to the anode of

D2201?

Ye s

Check Q1161, Q1162, Q2201 and their periphery,

and replace P1 (AV ASSEMBLY) if defective.

No

No

Check the circuit and replace P5 (BOARD

POWER SUPPLY) if defective.

(IC2101, IC2201, D2212, D2238, D2240)

if defective.

Check D2201 and their periphery, and replace

P5 (BOARD POWER SUPPLY) if defective.

1-9-1 E2N72TR

Page 24

FLOW CHART NO.6

ECO+12V is not outputted.

Is 12V voltage supplied to the emitter of Q1251?

Ye s

Check Q1251, Q1252 and their periphery, and

replace P1 (AV ASSEMBLY) if defective.

FLOW CHART NO.7

AUDIO+10V is not outputted.

Is 12V voltage supplied to the collector of Q1160?

No

Is 12V voltage supplied to the collector of Q2203?

Ye s

Check Q2203, IC2204 and their periphery, and

replace P1 (AV ASSEMBLY) if defective.

FLOW CHART NO.8

AL+9V is not outputted.

Is 12V voltage supplied to the collector of Q1156?

No

Is 13V voltage supplied to the emitter of Q1017?

Ye s

Check Q1017, Q1018 and their periphery, and

replace P1 (AV ASSEMBLY) if defective.

No

Yes Check Q1160, D1162 and their periphery, and

No

Yes Check Q1156, D1156 and their periphery, and

No

Check D2204, D2205, D2212, C2204

and their periphery, and

POWER SUPPLY)

replace P1 (AV ASSEMBLY) if defective.

Check D2204, D2205, D2212, C2204

and their periphery, and replace P5 (BOARD

POWER SUPPLY) if defective.

replace P1 (AV ASSEMBLY) if defective.

Check D2204, D2205, D2212, C2204

and their periphery, and replace P5 (BOARD

POWER SUPPLY) if defective.

replace P5 (BOARD

if defective.

FLOW CHART NO.9

P-ON+5V is not outputted.

(AUDIO+10V is outputted normally.)

Is 5V voltage supplied to the

Check Q1154 and their periphery, and replace

P1 (AV ASSEMBLY) if defective.

FLOW CHART NO.10

EV+32V is not outputted.

Is the supply voltage 37V fed the cathode of D2202

Check D1701 and their periphery and replace

P1 (AV ASSEMBLY) if defective.

FLOW CHART NO.11

AUDIO+5V is not outputted. (AUDIO+10V is outputted normally.)

Is 5V voltage supplied to the collector of Q1163?

collector

Ye s

Ye s

Ye s

of Q1154?

No

No

No

Check D2206, D2207, D2213, C2205, C2216

and their periphery, and replace P5 (BOARD

POWER SUPPLY) if defective.

Check D2202, D2229, C2202 and their periphery,

and replace P5 (BOARD POWER SUPPLY)

if defective.

Check D2206, D2207, D2213, C2205, C2216

and their periphery, and replace P5 (BOARD

POWER SUPPLY) if defective.

Is 6V voltage supplied to the base of Q1163?

Ye s

Replace P1 (AV ASSEMBLY).

No

Check D1163, C1168 and their periphery, and

replace P1 (AV ASSEMBLY) if defective.

1-9-2 E2N72TR

Page 25

FLOW CHART NO.12

SYS+5V is not outputted.

Is 37V voltage supplied to the collector of Q1031?

Ye s

Replace P1 (AV ASSEMBLY).

FLOW CHART NO.13

EV+3.3V is not outputted.

(SYS+5V is outputted normally.)

Is the voltage of approximately 4V supplied to

the base of Q1159?

Ye s

Replace P1 (AV ASSEMBLY).

FLOW CHART NO.14

P-ON+1.8V is not outputted.

Is 2.8V voltage supplied to Pin(1) of IC1151?

Ye s

Replace P1 (AV ASSEMBLY).

No

No

No

Check D2202, D2229, C2202 and their periphery,

and replace P5 (BOARD POWER SUPPLY)

if defective.

Check IC1153 and their periphery, and r

P1 (AV ASSEMBLY)

Check D2203, D2232, D2233, C2203, C2239

and their periphery, and replace P5 (BOARD

POWER SUPPLY) if defective.

if defective.

eplace

FLOW CHART NO.15

P-ON+3.3V is not outputted.

Is 5V voltage supplied to Pin(1) of IC1152?

Ye s

Replace P1 (AV ASSEMBLY).

FLOW CHART NO.16

TUNER+12V is not outputted.

(+32V is outputted normally.)

Is 12V voltage supplied to the collector of Q1573?

Ye s

Is 13V voltage supplied to the base of Q1573?

Ye s

Replace P1 (AV ASSEMBLY)

FLOW CHART NO.17

AL+5V(2) is not outputted.

(AL+9V is outputted normally.)

.

No

No

No

Check D2209, C2217and their periphery, and

replace P5 (BOARD POWER SUPPLY) if defective.

Check D2204, D2205, D2212, C2204

and their periphery, and replace

P5 (BOARD POWER SUPPLY) if defective.

Check Q1571, Q1572 and their periphery,

and

r

eplace P1 (AV ASSEMBLY) if defective.

Is 6V voltage supplied to the base of Q1508?

Ye s

Replace P1 (AV ASSEMBLY)

.

No

Check D1508, C1526 and their periphery, and

r

eplace P1 (AV ASSEMBLY) if defective.

1-9-3 E2N72TR

Page 26

FLOW CHART NO.18

The key operation is not functioning.

Are the contact point and the installation state of

the key switches normal?

Ye s

Is the control voltage normally inputted into

Pin(1, 2) of IC009?

Ye s

Replace P1 (AV ASSEMBLY) or

P2 (DVD MECHANISM & DVD/HDD MAIN

BOARD ASSEMBLY).

FLOW CHART NO.19

No operation is possible from the remote control unit. (

Is 5V voltage supplied to the Pin(3) terminal of

the RE3001 (remote control receiver)?

Ye s

Is the "L" pulse sent out from Pin(1) terminal of

the RE3001 (remote control receiver) when the

remote control unit is activated?

Ye s

Is the "L" pulse signal supplied to the Pin(27) of

IC009?

Ye s

Replace P1 (AV ASSEMBLY) or

P2 (DVD MECHANISM & DVD/HDD MAIN

BOARD ASSEMBLY).

No

Re-install some key switches correctly or

replace P3 (BOARD FRONT) if defective.

No

Check the key switches and their periphery, and

replace P3 (BOARD FRONT) if defective.

3.300

2.479

2.464

1.746

1.730

1.115

1.100

0.484

0.469

0.161

0.146

(V)

Operation is possible from the unit.)

No

Check AL+5V (1) line and replace

P1 (AV ASSEMBLY) if defective.

No

Replace P3 (BOARD FRONT) or replace

remote control unit.

No

Check the line between the RE3001 (remote

control receiver) and the Pin(27) of IC009, and

replace P1 (AV ASSEMBLY) if defective.

KEYTerminal voltage of IC009-1,2 -1

IC009-1

REC

PLAY

STOP

DVD

HDD

KEY-2

IC009-2

----------

-----

OPEN

/CLOSE

-----

-----

POWER

FLOW CHART NO.20

The disc tray cannot be opened and closed. (It can be done using the remote control unit.)

Is the normal control voltage inputted to Pin(2) of

IC009?

Refer to "FLOW CHART NO.18" <The key

No

Replace P3 (BOARD FRONT).

operation is not functioning.>

Ye s

Replace P1 (AV ASSEMBLY) or

P2 (DVD MECHANISM & DVD/HDD MAIN

BOARD ASSEMBLY).

1-9-4 E2N72TR

Page 27

FLOW CHART NO.21

[No Disc] indicated.

Both functions of picture and sound do not operate normally.

Replace the P2 (DVD MECHANISM & DVD/HDD

MAIN BOARD ASSEMBLY).

FLOW CHART NO.22

VIDEO E-E does not appear normally.

Are the video signals inputted to each pin of

IC005?

IC005 VIDEO-IN 1 (AV1)16PIN

IC005 VIDEO-IN (FRONT)14PIN

IC005 Y-IN 1 (FRONT)7PIN

IC005 C-IN 1 (FRONT)9PIN

IC005 VIDEO-IN 2 (AV2)12PIN

IC005 DTV-Y-IN100PIN

IC005 DTV-C-IN1PIN

IC005 TUNER-VIDEO

Are the video signals outputted to each pin of

IC005?

IC005 VIDEO-Y/CVBS-IN61PIN

IC005 VIDEO-C-IN59PIN

Are the video signals outputted to each pin of

CN1201?

CN1201 VIDEO-Y/CVBS-IN20PIN

CN1201 VIDEO-C-IN22PIN

Continued to A on the next page.

20PIN

Ye s

Ye s

Ye s

No

No

No

Check the line between video input terminal and

each pin of IC005, and replace

P1 (AV ASSEMBLY), P6 (BOARD DTV

MODULE UNIT) or TU1751.

IC

005

005

IC

005

IC

005

IC

005

005

IC

005

IC

005

IC

Is 5V voltage supplied to the Pin(27,29,47,63) of IC

Ye s

Replace P1

(AV ASSEMBLY).

Check the line between each pin of IC005 and

each pin of CN1201 and replace P1

(AV ASSEMBLY) if defective.

IC

005

005

IC

→ JK120616PIN

→ JK120114PIN

→ JK12127PIN

→ JK12129PIN

→ JK120712PIN

→ CN1751100PIN

26PIN

→ CN17511PIN

28PIN

→ TU175120PIN

17PIN

Check AL+5V(2) line and

replace P1 (AV ASSEMBLY)

or P5 (BOARD POWER

SUPPLY) if defective.

→ CN120161PIN

→ CN1201 59PIN

VIDEO-IN 1 (AV1)

VIDEO-IN (FRONT)IC

Y-IN 1 (FRONT)

C-IN 1 (FRONT)

VIDEO-IN 2 (AV2)

DTV-Y

DTV-C

TUNER-VIDEO

No

20PIN

22PIN

VIDEO-Y/CVBS-IN

VIDEO-C-IN

005

?

1-9-5 E2N72TR

Page 28

A

Are the video signals outputted to each pin of

CN1201?

CN1201 VIDEO-Y(I/P)-OUT7PIN

CN1201 VIDEO-Y(I)-OUT1PIN

CN1201 VIDEO-Pr/Cr-OUT5PIN

CN1201 VIDEO-Pb/Cb-OUT3PIN

CN1201 VIDEO-C-OUT

Are the video signals shown above inputted into

each pin of IC005?

IC005 VIDEO-Y(I/P)-OUT51PIN

IC005 VIDEO-Y(I)-OUT55PIN

IC005 VIDEO-Pr/Cr-OUT52PIN

IC005 VIDEO-Pb/Cb-OUT53PIN

IC005 VIDEO-C-OUT57PIN

Are the video signals outputted to each pin of

IC005?

IC005 VIDEO-Y40PIN

IC005 VIDEO-Pr/Cr39PIN

IC005 VIDEO-Pb/Cb38PIN

IC005 VIDEO-OUT 1 (AV1)30PIN

IC005 VIDEO-OUT 2 (AV2)22PIN

Are the video signals outputted to the specific

output terminal?

Are the Y, Pb/Cb, Pr/Cr signals outputted to the

COMPONENT OUT terminal (JK1205)?

Are the composite video signals outputted to

the VIDEO OUT (AV1) terminal (JK1206)?

Are the composite video signals outputted to

the VIDEO OUT (AV2) terminal (JK1207)?

9PIN

Ye s

Ye s

Ye s

No

No

No

No

No

No

Replace the P2 (DVD MECHANISM & DVD/HDD

MAIN BOARD ASSEMBLY).

Check the line between each pin of CN1201 and

each pin of IC005, and replace P1 (AV ASSEMBLY)

if defective.

CN1201 → IC

CN1201 → IC

CN1201 → IC

Is 5V voltage supplied to the Pin(27,29,47,63) of IC

Replace P1

(AV ASSEMBLY).

Check the periphery of JK1205 from Pin (38,39,

40) of IC005 and replace P1 (AV ASSEMBLY)

if defective.

Check the periphery of JK1206 from Pin (30) of

IC005 and replace P1 (AV ASSEMBLY) if defective.

Check the periphery of JK1207 from Pin (22) of

IC005 and replace P1 (AV ASSEMBLY) if defective.

7PIN

1PIN 55PIN

5PIN

3PIN

→ IC

9PIN

Ye s

51PIN

005

005

52PIN

005

53PIN

005

005

57PINCN1201

Check AL+5V(2) line and

replace P1 (AV ASSEMBLY)

or P5 (BOARD POWER

SUPPLY) if defective.

VIDEO-Y(I/P)-OUT

VIDEO-Y(I)-OUTCN1201 → IC

VIDEO-Pr/Cr-OUT

VIDEO-Pb/Cb-OUT

VIDEO-C-OUT

005

?

No

1-9-6 E2N72TR

Page 29

FLOW CHART NO.23

Picture does not appear normally.

Set the disc on the disc tray, and playback.

Are the video signals outputted to each pin of

CN1201?

CN1201 VIDEO-Y(I/P)-OUT7PIN

CN1201 VIDEO-Y(I)-OUT1PIN

CN1201 VIDEO-Pr/Cr-OUT5PIN

CN1201 VIDEO-Pb/Cb-OUT3PIN

CN1201 VIDEO-C-OUT

Are the video signals shown above inputted into

each pin of IC005?

IC005 VIDEO-Y(I/P)-OUT51PIN

IC005 VIDEO-Y(I)-OUT55PIN

IC005 VIDEO-Pr/Cr-OUT52PIN

IC005 VIDEO-Pb/Cb-OUT53PIN

IC005 VIDEO-C-OUT57PIN

Are the video signals outputted to each pin of

IC005?

IC005 VIDEO-Y40PIN

IC005 VIDEO-Pr/Cr39PIN

IC005 VIDEO-Pb/Cb38PIN

IC005 VIDEO-OUT 1 (AV1)30PIN

IC005 VIDEO-OUT 2 (AV2)22PIN

Are the video signals outputted to the specific

output terminal?

Are the Y, Pb/Cb, Pr/Cr signals outputted to the

COMPONENT OUT terminal (JK1205)?

Are the composite video signals outputted to

the VIDEO OUT (AV1) terminal (JK1206)?

Are the composite video signals outputted to

the VIDEO OUT (AV2) terminal (JK1207)?

9PIN

Ye s

Ye s

Ye s

No

No

No

No

No

No

Replace the P2 (DVD MECHANISM & DVD/HDD

MAIN BOARD ASSEMBLY).

Check the line between each pin of CN1201 and

each pin of IC005, and replace P1 (AV ASSEMBLY)

if defective.

CN1201 → IC

CN1201 → IC

CN1201 → IC

Is 5V voltage supplied to the Pin(27,29,47,63) of IC

Replace P1

(AV ASSEMBLY).

Check the periphery of JK1205 from Pin (38,39,

40) of IC005 and replace P1 (AV ASSEMBLY)

if defective.

Check the periphery of JK1206 from Pin (30) of

IC005 and replace P1 (AV ASSEMBLY) if defective.

Check the periphery of JK1207 from Pin (22) of

IC005 and replace P1 (AV ASSEMBLY) if defective.

7PIN

1PIN 55PIN

5PIN

3PIN

→ IC

9PIN

Ye s

51PIN

005

005

52PIN

005

53PIN

005

005

57PINCN1201

Check AL+5V(2) line and

replace P1 (AV ASSEMBLY)

or P5 (BOARD POWER

SUPPLY) if defective.

VIDEO-Y(I/P)-OUT

VIDEO-Y(I)-OUTCN1201 → IC

VIDEO-Pr/Cr-OUT

VIDEO-Pb/Cb-OUT

VIDEO-C-OUT

005

?

No

1-9-7 E2N72TR

Page 30

FLOW CHART NO.24

Audio E-E does not appear normally.

Are the audio signals inputted to each pin of

IC005?

IC005 AUDIO-IN1 (AV1)93,94PIN

IC005 AUDIO-IN (FRONT)91,92PIN

IC005 AUDIO-IN2 (AV2)89,90PIN

IC005 DTV-AUDIO-IN81,82PIN

IC005 TUNER-AUDIO84,85PIN

Ye s

No

Check the line between audio input terminal and

each pin of IC005, and replace

P1 (AV ASSEMBLY), P6 (BOARD DTV

MODULE UNIT) or TU1751.

IC

IC

IC

IC

IC

005

005

005

005

005

91,92PIN

81,82PIN

84,85PIN

→

JK120693,94PIN

→

JK1202,

JK1203

→

JK120789,90PIN

→

CN1751

29,30PIN

→

TU1751

6PIN

AUDIO-IN1 (AV1)

AUDIO-IN (FRONT)

AUDIO-IN2 (AV2)

DTV-AUDIO-IN

TUNER-AUDIO

Are the audio signals outputted to Pin(79,80) of

IC005?

Ye s

Are the audio signals outputted to Pin(11,13) of

CN1201?

Ye s

Continued to B on the next page.

No

No

Is 5V voltage supplied to Pin(27, 29, 47, 63) of

IC005? Is 9V voltage supplied to Pin(75) of IC005?

Ye s N o

Replace P1

(AV ASSEMBLY).

Check the line between each pin of IC005 and

each pin of CN1201, and replace

P1 (AV ASSEMBLY) if defective.

IC

005

IC

005

Check the AL+5V(2) , AL+9V

line and replace

P1 (AV ASSEMBLY) or

P5 (BOARD POWER SUPPLY)

if defective.

→

CN1201 13PIN79PIN AUDIO(R)-IN

→

CN1201 11PIN80PIN AUDIO(L)-IN

1-9-8 E2N72TR

Page 31

B

Are the analog audio signals outputted to each pin

of CN1201?

CN1201 17PIN AUDIO (L)-OUT

CN1201 15PIN AUDIO (R)-OUT

Ye s

Are the analog audio signals inputted to each pin

of IC005?

IC005 77PIN AUDIO (L)-OUT

IC005 76PIN AUDIO (R)-OUT

Ye s

Are the analog audio signals outputted to each pin

of IC005?

IC005 73,74PIN AUDIO-OUT 1 (AV1)

IC005 71,72PIN AUDIO-OUT 2 (AV2)

IC005 67,68PIN AUDIO-OUT (REAR)

Ye s

Are the audio signals outputted to the specific

output terminal?

Are the audio signals outputted to the audio

terminal (JK1206)?

Are the audio signals outputted to the audio

terminal (JK1207)?

Are the audio signals outputted to the audio

terminal (JK1204)?

No

No

No

No

No

No

Replace the P2 (DVD MECHANISM & DVD/HDD

MAIN BOARD ASSEMBLY).

Check each line between each pin of CN1201

and each pin of IC005, and replace

P1 (AV ASSEMBLY) if defective.

CN1201 17PIN → IC005 77PIN AUDIO(L)-OUT

CN1201 15PIN → IC005 76PIN AUDIO(R)-OUT

Is 5V voltage supplied to Pin(27, 29, 47, 63) of

IC005? Is 9V voltage supplied to Pin(75) of IC005?

Ye s N o

Replace P1

(AV ASSEMBLY).

Check the periphery between Pin(73,74) of IC005

and the audio terminal (JK1206), and replace

P1 (AV ASSEMBLY) if defective.

Check the periphery between Pin(71,72) of IC005

and the audio terminal (JK1207), and replace

P1 (AV ASSEMBLY) if defective.

Check the periphery between Pin(67,68) of IC005

and the audio terminal (JK1204), and replace

P1 (AV ASSEMBLY) if defective.

Check the AL+5V(2) , AL+9V

line and replace

P1 (AV ASSEMBLY) or

P5 (BOARD POWER SUPPLY)

if defective.

1-9-9 E2N72TR

Page 32

FLOW CHART NO.25

Audio is not outputted during playback.

Set the disc on the disc tray, and playback.

Are the analog audio signals outputted to each pin

of CN1201?

CN1201 17PIN AUDIO (L)-OUT

CN1201 15PIN AUDIO (R)-OUT

Ye s

Are the analog audio signals inputted to each pin

of IC005?

IC005 77PIN AUDIO (L)-OUT

IC005 76PIN AUDIO (R)-OUT

Ye s

Are the analog audio signals outputted to each pin

of IC005?

IC005 73,74PIN AUDIO-OUT 1 (AV1)

IC005 71,72PIN AUDIO-OUT 2 (AV2)

IC005 67,68PIN AUDIO-OUT (REAR)

Ye s

Are the audio signals outputted to the specific

output terminal?

Are the audio signals outputted to the audio

terminal (JK1206)?

Are the audio signals outputted to the audio

terminal (JK1207)?

Are the audio signals outputted to the audio

terminal (JK1204)?

No

No

No

No

No

No

Replace the P2 (DVD MECHANISM & DVD/HDD

MAIN BOARD ASSEMBLY).

Check each line between each pin of CN1201

and each pin of IC005, and replace

P1 (AV ASSEMBLY) if defective.

CN1201 17PIN → IC005 77PIN AUDIO(L)-OUT

CN1201 15PIN → IC005 76PIN AUDIO(R)-OUT

Is 5V voltage supplied to Pin(27, 29, 47, 63) of

IC005? Is 9V voltage supplied to Pin(75) of IC005?

Ye s N o

Replace P1

(AV ASSEMBLY).

Check the periphery between Pin(73,74) of IC005

and the audio terminal (JK1206), and replace

P1 (AV ASSEMBLY) if defective.

Check the periphery between Pin(71,72) of IC005

and the audio terminal (JK1207), and replace

P1 (AV ASSEMBLY) if defective.

Check the periphery between Pin(67,68) of IC005

and the audio terminal (JK1204), and replace

P1 (AV ASSEMBLY) if defective.

Check the AL+5V(2) , AL+9V

line and replace

P1 (AV ASSEMBLY) or

P5 (BOARD POWER SUPPLY)

if defective.

1-9-10 E2N72TR

Page 33

FUNCTION INDICATOR SYMBOLS

Note: If an error occurs, a message with the error number appears on the screen.

Recording Error

Message Solution

Can not record on this disc.

This program is not allowed to

be recorded.

This program is not recordable

in Video mode.

This program is not allowed to

be recorded on this disc.

Disc is full.

(No area for new recording)

You cannot record on this disc as

Power Calibration Area is full.

E35

Insert a recordable disc, and

ensure the disc status satisfies

the recording requirements.

You cannot record copyprohibited programs.

You cannot record copyprohibited programs.

You cannot record cop-y

prohibited programs.

Insert a recordable disc with

enough recording space.

Error message

Error No.

Error

No.

1 An error occurs during data reading.

There is no reply for 15 seconds in Test

2

Unit Ready.

Cannot write the data after trying three

3

times.

4 An error occurs with OPC.

5 During recovery in a record.

An error occurs even if recovery has been

6

tried three times.

7 An error occurs in a format.

8 It cannot start an encode.

NV_PCK/RDI_PCK is not in encoded

9

data.

Encode Pause condition continued for 10

10

minutes.

Encode Pause condition continued in

11

normal REC condition for 10 minutes.

Difference in the address and cannot get

12

Stream ID of RDI/VIDEO.

13 It is a reply that “ATAPI is not readable.”

Cannot write the data after recovering

14

SMALL VMGI.

Cannot write the data after DVD-R

15

Reverse Track.

16 An error occurs in Finalize Close.

17 An error occurs in Rec Stop Close.

18 An error occurs in PCA Full (DVD_R).

19 Safety Stop occurs during editing.

20 High Speed Disc.

21 The disc is not formatted.

22 Disc Error has occurred.

25 During the Macrovision picture input.

26 During the CGMS picture input.

During the CGMS picture input. (Video

27

Format Disc)

During the CGMS picture input. (VR

28

Format Disc that is not compatible with

CPRM.)

30 No available recording space.

Error Description

1-10-1 E2N72FIS

Page 34

Message Solution

Error

No.

Error Description

37 Access to outside of Memory Area.

Can not record on this disc. Repeat the same operation.

38 Sector Address is wrong.

39 BUP writing error of chapter editing.

This program is not recordable

in +VR mode.

You cannot record more than

600 titles on HDD. (The

maximum is 600.)

HDD is full.

You cannot record copyprohibited programs.

45

Delete unnecessary titles. 47

Delete unnecessary titles. 49

During the CGMS picture input (+VR

Format Disc).

The 600 title limit has been reached

(HDD).

The REC key was pushed when HDD

was full.

Delete unnecessary titles. 50 HDD is full during recording.

This Program is not allowed to

be recorded.

Receive PAL/SECAM signal. 51

When you receive signal other than PAL/

SECAM.

If an error occurs during the timer recording, one of the following error numbers (40 to 41) or the above

error messages (error number: 1 to 22, 25 to 28, 30, 37 to 39, 45, 47 and 49 to 51) is displayed on the

recording menu after timer recording.

(Once the screen of the program line is exited, the program line for the error will be cleared.)

(No Error Message is displayed for errors No. 40 ~ 41.)

Timer Programming

Message Solution

Error message is not

displayed.

THU

Error number

Date Start End

'

New Programme

566.

CH

2&%

A program with the error number is grayed out on the timer programming list.

- Set the timer programming

correctly.

- Set the timer programming

Error

No.

40

- Some portion has not been recorded

because of program overlapping.

- Recording did not start at the start time.

Error Description

before the start time.

Turn the power on and set the

clock correctly then set timer

41 Power failed

programming again.

1-10-2 E2N72FIS

Page 35

System Control Block Diagram

BLOCK DIAGRAMS

NOTE: BOARD MEANS PRINTED CIRCUIT BOARD.

TO POWER SUPPLY

BLOCK DIAGRAM

EV+3.3V

SYS+5V

IC106

+1.2V

REGULATOR

AL+2.8V

IC101

(MAIN MICRO CONTROLLER)

RDY

DTV-RXD

DTV-TXD

R25

V25

W26

P22

W25

R22

R23

SYS-RESET

SUB-RXD

SUB-TXD

SUB-SCLK

CLK 27 IN

SYS-RESET

DTV-S-SCLK

DVD/HDD MAIN BOARD

ECO-MODE

1V2CONT

REG-CONT

DTV1.05-CONT

PWR-SW

LOW-POW

B4

L1

A4

Q1504

Q1505

AL+2.8VP-ON+1.2V

CN101 CN1151

111V2CONT

IC107

RESET

2 1

IC501

4 2

X501

27MHz

X'TAL

IC1502

RESET

12

C1511

(BACKUP CAPACITOR)

X1502

8MHz

RESONATOR

X1501

32.768KHz

X'TAL

CN701

27 27SYS-RESET

30 30SUB-RXD

28 28SUB-TXD

26 26SUB-SCLK

29 29RDY

CN503 CN1753

44

DTV-RXD

33

DTV-TXD

22

DTV-SYS-RESET

55

DTV-S-SCLK

CN1201

SW1501

RESET

IC009

(SUB MICRO CONTROLLER)

52

REG-CONT

46

DTV1.05-CONT

53

PWR-SW

17 LOW-POWER

43 ECO-MODE

14

RESET

P-DOWN

30

BUP+3.3V

7

8

XOUT

9

XIN

12

XCOUT

XCIN

11

1V2CONT

26

22

SYS-RESET

19

SUB-RXD

18

SUB-TXD

20

SUB-SCLK

RDY

29

FAN-CONT1

FAN-CONT2

DVD/HDD-AUDIO-MUTE

AUDIO-MUTE

SC-AUDIO-MUTE

DAVN-L

SDA

SCL

DVD-LED 59

HDD-LED

1080p-LED

1080i-LED

720p-LED 56

480p-LED

FL-DIN 48

FL-CLK

FL-STB 49

REMOTE

KEY-1 1

KEY-2

EV+12V

Q1603

15

16

P-ON+5V

Q1751

24

37

38

39

Q1506

33

34

CN2204 CN3001

13 13DVD-LED

12 12HDD-LED

58

54

55

57

50

27

661080p-LED

551080i-LED

44720p-LED

33480p-LED

16 16FL-DIN

15 15FL-CLK

14 14FL-STB

88REMOTE

17 17KEY-1

22KEY-2

2

Q1604

Q1507

Q1601

Q1602

Q1754,1758

SW

Q1757

Q1755,1759

SW

RE3001

REMOTE

SENSOR

Q1756

LEVEL

SHIFTER

LEVEL

SHIFTER

DVD/HDD-AUDIO-MUTE

IC3001 (VFD DRIVER)

28

DIN

1

CLK

2

STB

CN1601

1

FAN-VCC

2

GND

TU-SDA

TU-SCL

TU1751 (TUNER UNIT)

9

SCL

SDA

10

DAVN-L

AUDIO-MUTE

SC-AUDIO-MUTE

1G

23

~

7G

17

a

7

~

h

14

i

16

TO DTV MODULE

BLOCK DIAGRAM

SDA

SCL

TO VIDEO

BLOCK DIAGRAM

TO AUDIO

BLOCK DIAGRAM

SDA

SCL

D3200

D3201

D3202

D3203

D3204

D3205

~

GRID VFD

~

SEGMENT

DVD

HDD

1080p

1080i

720p

480p

FL3001

FAN

EV+3.3V

TO DTV MODULE

BLOCK DIAGRAM

DTV-SYS-RESET

DTV-TXD

DTV-RXD

BOARD AV

1-11-1

SW3001

OPEN

/CLOSE

KEY SWITCH

BOARD FRONT

CN3002

2

POW-SW

CN1064

2

SW3010

POWER

BOARD

POWER SWITCH

E2N72BLS

Page 36

Digital Signal Process Block Diagram

IC101

HARD

DISK

DRIVE

DVD MECHANISM

PICK

-UP

CN3001-A CN3002-A

BOARD ATA

TILT

TRACKING

FOCUS

TRAY OPEN

CN1001

CN652

CN201

CN301

P-ON+3.3V

IC201

RF/

ERROR

AMP

IC301

MOTOR

DRIVER

IC202

OP AMP

IC302

LPC

(MAIN MICRO CONTROLLER/MPEG2 AV CODEC)

BACK-END

FRONT-END

DIGITAL

SIGNAL

PROCESS

DIGITAL

SIGNAL

PROCESS

VIDEO

I/F

U4,W1,W3,

Y2,AA1,AA2

P3,T3,T5,

U2,U3,V1

AUDIO

I/F

VIDEO

ENCODER

D/A

D/A

D/A

D/A

D/A

D/A

D/A

HDMI-SDA

HDMI-SCL

VIDEO-CLOCK

IC701 (VIDEO DECODER)

39-44

N2

P1

M1

N3

M2

D1

D3

R4

K2

K1

N4

Y26

U24

E12

M3

NOTE: BOARD MEANS PRINTED CIRCUIT BOARD.

PB VIDEO SIGNALREC VIDEO SIGNAL PB AUDIO SIGNALREC AUDIO SIGNAL

F2

F1

K5

M5

J3

A5,B5-B7

,C6,C7,

D6,D7

N23

U25

C5

DECODER A/D45-50

DECODER

HDMI-SDA

HDMI-SCL

VIDEO-CLOCK

8

10

13

A/D

PCM-DATA0

PCM-BCK

PCM-LRCK

PCM-SCLK

IC802 (AUDIO A/D CONVERTER)

7

8

9

10

AUDIO A/D

CONVERTER

11

12

6

YC(0-7)

SPDIF

TO HDMI

BLOCK

DIAGRAM

TO HDMI BLOCK

DIAGRAM

L-CH

13

R-CH

14

CN701

VIDEO-Y(I/P)-OUT

VIDEO-Pr/Cr-OUT

VIDEO-Pb/Cb-OUT

VIDEO-Y(I)-OUT

VIDEO-C-OUT

VIDEO-Y/CVBS-IN

VIDEO-C-IN

CN101

SPDIF

CN701

AUDIO(L)-OUT

AUDIO(R)-OUT

DVD/HDD-AUDIO-MUTE

7

5

3

1

9

20

22

3

17

15

18

11AUDIO(L)-IN

13AUDIO(R)-IN

TO VIDEO

BLOCK

DIAGRAM

(CN1201)

TO AUDIO

BLOCK

DIAGRAM

(CN1151)

TO AUDIO

BLOCK

DIAGRAM

(CN1201)

SLED

MOTOR

M

SPINDLE

MOTOR

M

CN1002

BOARD

RELAY

MOTOR

DRIVER

IC104, IC105

(FLASH MEMORY)

FLASH MEMORY

IC102 (DDR2 SDRAM)

DDR SDRAM

DVD/HDD MAIN BOARD

1-11-2

LINK

I/F

AA3

AC2

AB3

AC3

AA4

AE1

AA5

AD1

W5

AC1

IC901 (IEEE1394 I/F)

4

Y5

Y4

5

6

7

8

9

10

11

1

48

2

3

LINK

I/F

RECEIVE

DATA

DECODER

TRANSMIT

DATA

ENCODER

30

29

28

27

CN901

1TPA1P

2TPA1N

4TPB1P

5TPB1N

TO

DV JACK

(W1)

E2N72BLD

Page 37

Video Block Diagram

VIDEO OUT2

VIDEO-G

VIDEO-B

VIDEO-R

TO DIGITAL

SIGNAL

PROCESS

BLOCK

DIAGRAM

(CN701)

VIDEO OUT1

VIDEO-G

VIDEO-B

VIDEO-R

JK1207

19

11

7

15

CN1201

20

VIDEO-Y/CVBS-IN

22 VIDEO-C-IN

7

VIDEO-Y(I/P)-OUT

5

VIDEO-Pr/Cr-OUT

3

VIDEO-Pb/Cb-OUT

1

VIDEO-Y(I)-OUT

9

VIDEO-C-OUT

JK1206

19

11

7

15

VIDEO-Y

-OUT

VIDEO-Pb/Cb

-OUT

VIDEO-Pr/Cr

-OUT

JK1205

(REAR)

Q1853

BUFFER

WF5

WF1

WF4WF2

Q1204

BUFFER

Q1202

BUFFER

Q1201

BUFFER

WF3

(VIDEO SIGNAL PROCESS)IC005

DRIVER FBC

22

48

50

49

61

59

51

52

53

55

57

DRIVER

30

46

DRIVER

44

DRIVER

45

DRIVER

40

DRIVER

38

DRIVER

39

DRIVER

MUTE

MUTE

+

SW

MUTE FBC

SW

SW

SW

SW

LPF

SW

LPF

AGC

GCL

64

65

SW

SW

SW

AGC

NOTE: BOARD MEANS PRINTED CIRCUIT BOARD.

REC VIDEO SIGNAL PB VIDEO SIGNAL

BOARD AV

SW

SW

SW

62

12

16

14

20

100

7

+

1

9

JK1201

(FRONT)

TU1751

(TUNER UNIT)

17

VIDEO OUT

VIDEO-IN

DTV-Y

DTV-C

YC

G G

JK1207

VIDEO

20

IN2

JK1206

VIDEO

20

IN1

TO DTV MODULE

BLOCK DIAGRAM

JK1212

(FRONT)

S-VIDEO

IN

1-11-3

IC1641 (VPS)

16

VPS-V

SDA

IIC

I/F

43

642

7

14

DAVN-L

SCL

DAVN-L

SCL

SDA

TO SYSTEM CONTROL

BLOCK DIAGRAM

E2N72BLV

Page 38

Audio Block Diagram

BOARD AV

TO SYSTEM CONTROL

BLOCK DIAGRAM

WF6

WF7

TO DIGITAL

SIGNAL

PROCESS

BLOCK

DIAGRAM

(CN701)

TO DIGITAL

SIGNAL

PROCESS

BLOCK

DIAGRAM

(CN101)

CN1201

17

AUDIO(L)-OUT

15

AUDIO(R)-OUT

18

DVD/HDD-AUDIO-MUTE

11

AUDIO(L)-IN

13

AUDIO(R)-IN

CN1151

3

SPDIF

SDA

SCL

IC1202

(OP AMP)

6

2

IC1203

OP AMP

(

7

1

OP

AMP

OP

AMP

OP

AMP

OP

AMP

NOTE: BOARD MEANS PRINTED CIRCUIT BOARD.

REC AUDIO SIGNAL PB AUDIO SIGNAL

MUTE-ON

DTV-AUDIO(L)

DTV-AUDIO(R)

2

43

JK1207

JK1206

6

7

AUDIO(L)-IN2

6

AUDIO(R)-IN2

2

AUDIO(L)-OUT2

3

AUDIO(R)-OUT2

1

AUDIO(L)-IN1

6

AUDIO(R)-IN1

2

AUDIO(L)-OUT1

3

AUDIO(R)-OUT1

1

TO DTV MODULE

BLOCK DIAGRAM

TU1751

(TUNER UNIT)

SIF OUT

AUDIO OUT

JK1204

(REAR)

AUDIO(L)

-OUT

AUDIO(R)

-OUT

DIGITAL

AUDIO OUT

(COAXIAL)

JK1202

JK1203

(FRONT)

AUDIO(L)

-IN

(FRONT)

AUDIO(R)

-IN

IC005 (AUDIO SIGNAL PROCESS)

42

IIC

I/F

43

77

7

1

76

SW

SW

)

80

6

2

79

SW

SW

SW

SW

SW

SW

SW

SW

72

71

74

73

68

67

90

94

85

92

82

89

93

84

91

81

DVD/HDD-AUDIO-MUTE

Q1804

MUTE-ON

AUDIO-MUTE

SC-AUDIO-MUTE

Q1801

DRIVE

DRIVE

TO SYSTEM CONTROL

BLOCK DIAGRAM

MUTE-ON

Q1851

Q1805

MUTE-ON

IC001

(IF SIGNAL PROCESS)

31

IF SIGNAL

PROCESS

30

MUTE-ON

Q1806

MUTE-ON

Q1807

Q1802

Q1852

Q1803

BUFFER

1-11-4

E2N72BLA

Page 39

HDMI Block Diagram

NOTE: BOARD MEANS PRINTED CIRCUIT BOARD.

DVD/HDD MAIN BOARD

TO DIGITAL SIGNAL

PROCESS BLOCK

DIAGRAM

HDMI-SCL

HDMI-SDA

PCM-DATA0

SPDIF

PCM-SCLK

PCM-LRCK

PCM-BCK

YC(0-7)

ICA01 (HDMI INTERFACE)

113

IIC

I/F

114

38

43

AUDIO

I/F

33

41

45

81

~

83

VIDEO

I/F

86

~

90

REGISTER

AV

CONTROLLER

REC VIDEO SIGNAL PB VIDEO SIGNAL

AUTHENT

/CATION

KEY

EXCHANGE

HDCP

CIPHER/

ENCRYPTOR

TMDS

ENCODER

DDC

I/F

TMDS

SERIALIZER

REC AUDIO SIGNAL PB AUDIO SIGNAL

QA01,QA02

DRIVE

ICA02

3.3V<-->5V

119

121

120

22

24

18

20

14

16

12

10

CONVERTER

2

3

6

5

+3.3V

19

15

16

10

12

CNA01

HDMI-CONNECTOR

HOT PLUG DETECT

DDC CLOCK

DDC DATA

T.M.D.S DATA2-

3

1

T.M.D.S DATA2+

6

T.M.D.S DATA1-

4

T.M.D.S DATA1+

9

T.M.D.S DATA0-

7