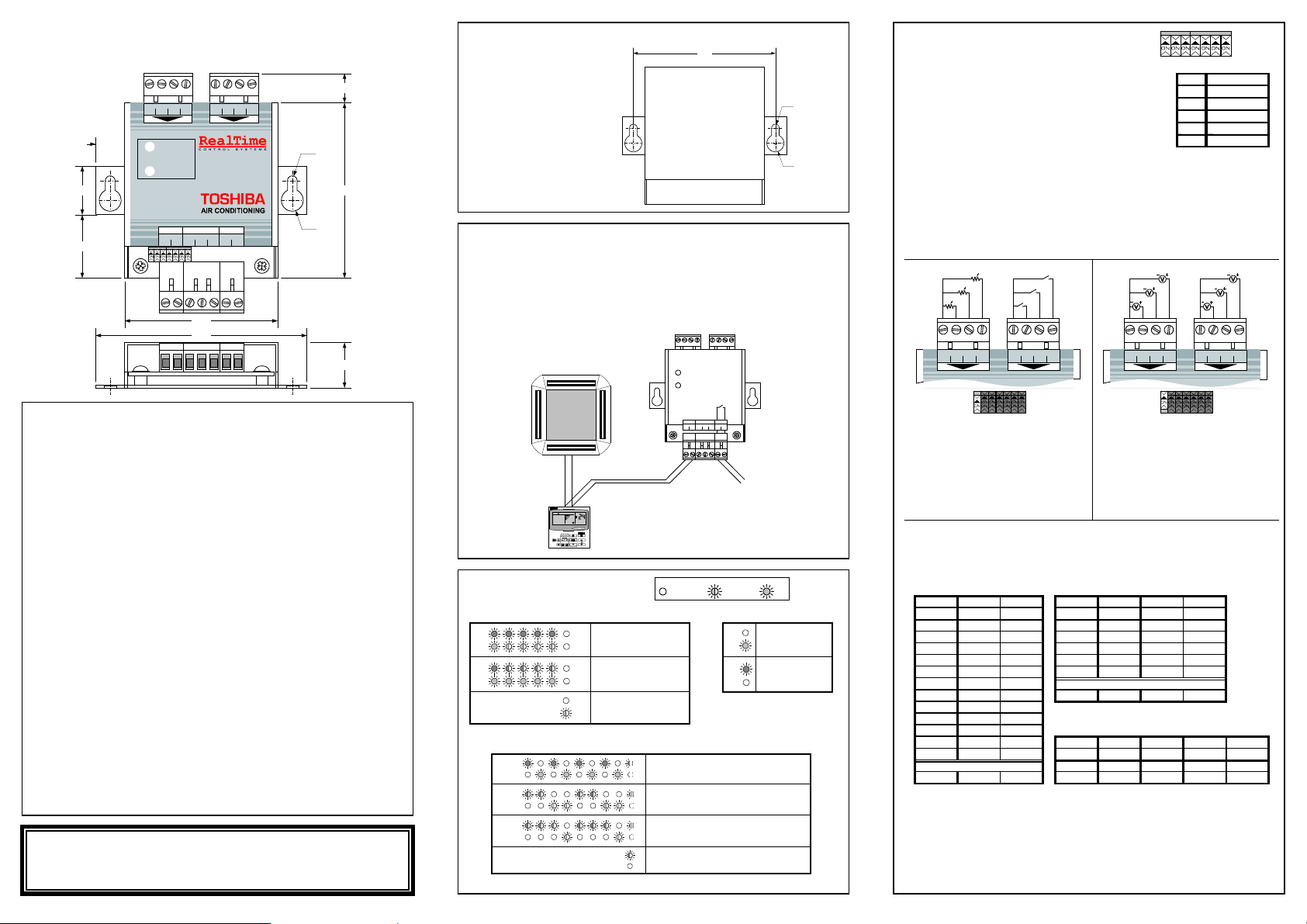

Toshiba RBC-FDP2-BMS-PE INSTALLATION MANUAL

RBC-FDP2-BMS-PE Interface

A/B connect to the Toshiba TCC-NET. TCC-NET installation should follow

R

G

Fanspeed

23

4.6k

Ω

5.1

Default

>=10k

Ω

Installation and Operating Instructions

12.00

S1S2S3 S4S5S6

0V 0V

13.00

20.00

26.00

ALL DIMENSIONS IN MM NOT TO SCALE

FDP2 Description

The FDP2-BMS is a monitoring and control interface for the Toshiba Digital

Inverter and SMMS range of air-conditioners.

Fault Reporting

The FDP2-BMS Interface detects all indoor and outdoor faults occurring in

TCC-NET compatible Toshiba air-conditioners and reports them by closing

relay contacts R1-R2. The FDP2-BMS is connected on the TCC-NET

network with or without a standard remote controller and detects any faults

that can be displayed on the controller for up to 8 units. Red and Green

LEDs Indicate Fault/No Fault state.

Control Functions

HARDWIRED CONTROL. Unit control can be achieved through resistance

inputs using potentiometer and volt-free contact inputs.

BMS INTEGRATION. Unit control can be achieved through 1-10V voltage

inputs integrated with BMS control outputs.

GROUP CONTROL. Multiple FDP2 Interfaces can be connected to form

large groups of units.

CUSTOM CONTROL. FDP2 interfaces can be supplied in custom

configurations to suit specific applications.

CONFIGURATION. The FDP2 has a number of standard configurations that

can be set using switches SW1 to SW7.

Warnings and Cautions

Do not exceed the specified fault relay ratings

Fault

No Fault

FDP2-BMS

Control Interface

TCC-NET D-BUS RELAY

ABD1D2R1

ON

SW1 SW7

ON

RealTime Control Systems Ltd

FDP2 Model 9410-2-A6

63.00

87.00

Ø 4.00

72.00

R2C

Ø 9.00

18.60

Mounting

The FDP2 should be

mounted using the

keyhole mounting

points as indicated in

the adjacent diagram.

The FDP2 can be

mounted horizontally

or vertically.

75.00

Ø 4.00

Ø 9.00

Basic Cable Installation

Cabling should be a minimum 0.75mm2 throughout. Terminals TCC-NET

Toshiba installation specifications. Terminals R1-R2 connect to fault

monitoring or indication equipment according to the specified rating of the

relay. The FDP2 is powered from the TCC-NET and requires no extra power

supply.

Indoor Unit

TCC-NET D-BUS RELAY

ABD1D2R1

R2C

A

B

LED Functionality

Normal Operation

R

G

R

G

R

G

Error Conditions

R

G

R

G

R

G

TCC-NET

Key:

Power-Up sequence

Factory Configuration

Power-Up sequence

Custom Configuration

TCC-NET Holdoff. After

power-up and during

unit configuration

Device configuration error

No unit master found on TCC-Net

D-BUS Communications timeout

Duplicate D-BUS Address detected

To fault monitoring

FLASHINGOFF ON

R

No Fault State

G

R

Unit Fault

G

FDP2-BMS Standard Operation

SW1 SW7

The FDP2-BMS Inputs S1 to S6 allow individual

control of various unit operating parameters. Each

input corresponds to a specific unit setting shown

in the table to the right. If an input is left

unconnected then the corresponding setting will

remain at a preset value.

ON

FDP2 Configuration Switches

S1

S2 Fanspeed

S3

S4

S5 On/Off

S6

ON

Setpoint

Mode

Louvre

Local unlock

S1 to S6 cables should be 0.5 to 1.0 mm2 multi-stranded screened twisted

pair. The screen should be earthed at one end only. The maximum

distance from the FDP2 to the input source is 200m.

The configuration switch SW1 changes the inputs S1 to S6 between

Resistance and Voltage modes.

Resistance Mode Voltage Mode

S3

S2

S1

S1S2S3 S4S5S60V 0V

RESISTANCE MODE

With SW1 OFF the inputs S1 to S6

operate in Resistance Mode, unit

operation can be controlled by

connecting fixed or variable

resistors to inputs S1 to S3 and

latching switch inputs to inputs S4

to S6.

S6

S5

S4

S3

S2

S1

S1S2S3 S4S5S60V 0V

VOLTAGE MODE

S6

S5

S4

With SW1 ON inputs S1 to S6

operate in Voltage Mode. Voltage

ranges between 1V and 10V can

be used to modulate each input.

This mode is designed for

interfacing the FDP2-BMS to BMS

voltage outputs.

Each control input has a defined control range under voltage and

resistance mode as outlined in the following tables. Default settings are

applied if the input remains unconnected. These are indicated in the table

by the symbol .

Resistance

S1

Setpoint

18

19

20

21

22

24

25

26

27

28

29

Default OFF OFF LOCK

21

Resistances should be within +/-250 ohms of the quoted value. Open circuit is R>200kΩ.

Voltages should be within +/- 0.25V of the quoted value. Open circuit for V<1V.

Under open circuit conditions the input will revert to its default value.

S1 in resistance mode is designed to be operated using a linear 10kΩ variable resistance.

It is recommended that volt-free contacts or switch mechanisms connected to S4, S5 and S6 have gold

plated contacts to ensure a low resistance circuit when the switch is made.

Voltage S2 S3

/Ohms

ΩΩΩΩ

<=0.4kΩ

1.3k

2.1kΩ

2.9kΩ

3.8k

5.4k

6.3k

7.1k

7.9kΩ

8.8k

9.6kΩ

>200kΩ

V

1.4 AUTO HEAT

2.1 HIGH COOL

Ω

2.9

3.6 LOW DRY

4.4

Ω

5.9

Ω

6.6

Ω

7.4

Ω

8.1

8.9

Ω

>=9.6

<1.0

MED FAN

LOW AUTO

AUTO AUTO

S4 S5 S6

Louvre On/Off Local

ON ON UNLOCK

Mode

Resistance

/Ohms

ΩΩΩΩ

<=1kΩ

2.2k

Ω

3.3kΩ

4.7kΩ

6.8k

Ω

>200k

Ω

Voltage

V

1.75

3.25

4.75

6.25

>=7.75

<1.0

Resistance

ΩΩΩΩ/Ohms

<1kΩ

Voltage

V

<3.5

>6.5

9670-0 FDP2-BMS Installation & Operating Instructions issue 1.14.05 Copyright © RealTime Control Systems Limited.

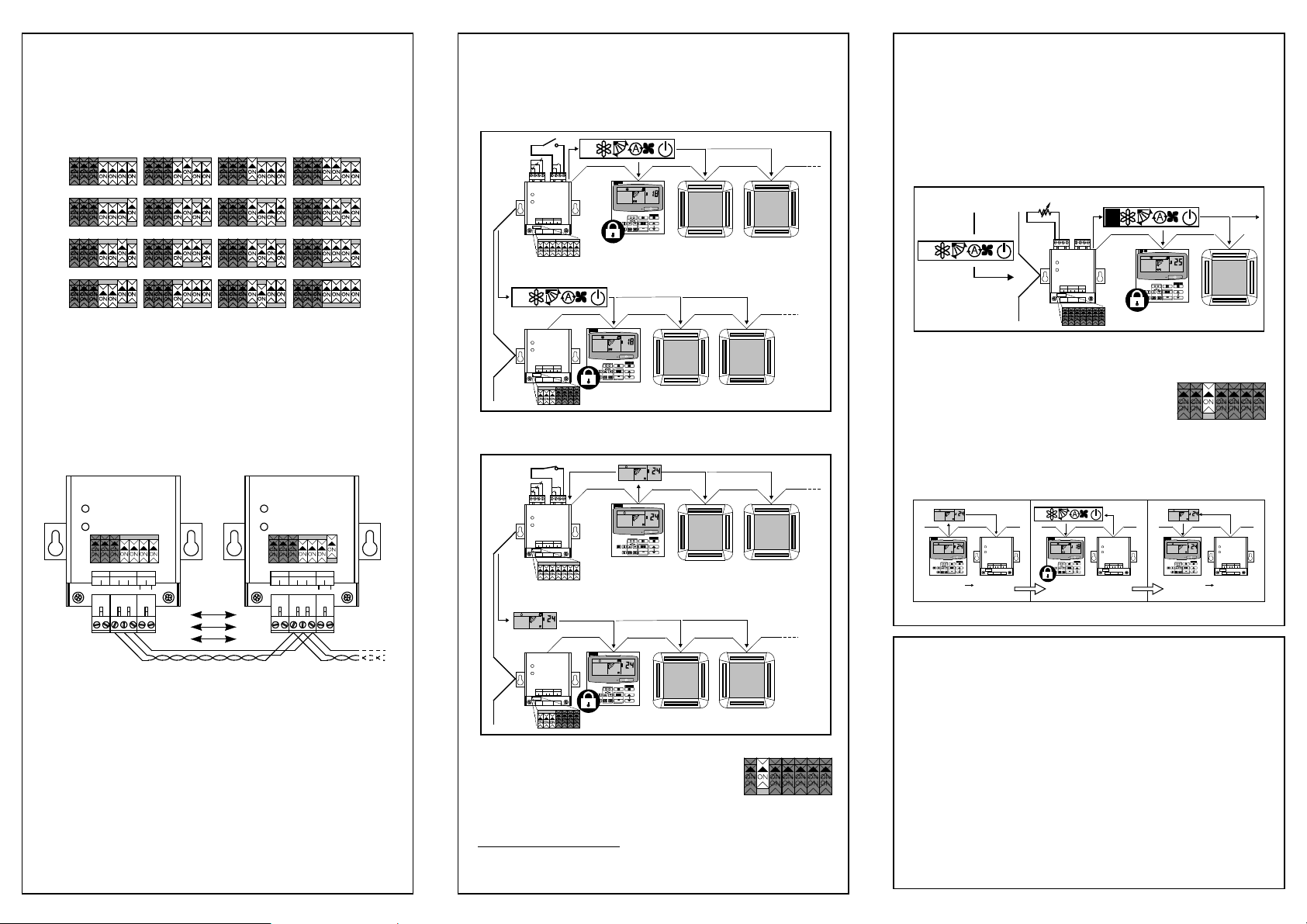

FDP2-BMS Advanced Operation

ADDRESSING

The FDP2 has the facility to create control groups using multiple FDP2s

connected together on the D-Bus network. In standard configuration up

to 16 FDP2 devices can be connected together. Each FDP2 is assigned

a D-Bus address using the configuration switches SW4 to SW7. Unit

addresses are shown below.

ADDRESS 0

ADDRESS 1

ADDRESS 2

ADDRESS 3

Address 0 is the FDP2 MASTER address. Address 1 to 15 are FDP2

SLAVE addresses that can be used to create large control groups.

NETWORK INSTALLATION

The D-Bus network requires a twisted pair cable connecting terminals

D1 and D2 on each FDP2 as shown below. Terminal D1 must be

connected to all other D1 terminals. Terminal D2 must be connected to

all other D2 terminals. In addition the common terminal C on all devices

must be connected together. If a shielded cable is used then the shield

can be used for this purpose. The network must be installed as a point

to point BUS configuration, Star and Ring connections must NOT be

used.

ADDRESS 0

ADDRESS 4

ADDRESS 5

ADDRESS 6

ADDRESS 7

ADDRESS 8

ADDRESS 9

ADDRESS 10

ADDRESS 11

ADDRESS 12

ADDRESS 13

ADDRESS 14

ADDRESS 15

ADDRESS 1

FDP2-BMS Group Control

Connecting additional FDP2-BMS or FDP2-F controllers as slaves allows

larger groups of units to be controlled from the master.

With S6 open (LOCKED) units operate to the settings S1 to S5 from the

FDP2-BMS master.

S6

18

D-BUS

16 FDP2 max

With S6 closed (UNLOCKED) the remote controller on the master FDP2 is

unlocked and all slaves operate to the master remote controller settings.

S6

18

Address 0 (MASTER)

Address 1-15 (SLAVE)

8 Units max

8 Units max

8 Units max

FDP2-BMS Slave Input Control

With no inputs connected the FDP2-BMS slave will duplicate the settings

of the FDP2 master. If one or more slave inputs S1 to S6 are connected

then each input on the slave will override the corresponding value sent

from the master. For example if S1 on a slave is connected, then the units

attached to the slave will be sent the local S1 setpoint rather than the

master setpoint. Similarly slave inputs S2 and S3 will override the

corresponding values from the master. If an ON signal is applied to inputs

S4 to S6 then this will override an OFF value sent from the master. The

example below shows a setpoint override on a slave.

From MASTER

S1=25oC

18

25

18

D-BUS

Address 1-15 (SLAVE)

Local Restore Mode SW3

SW3 enables Local Restore Mode on master and

slave FDP2-BMS. In this mode the remote

controller settings are saved when the FDP2 enters

central/locked operation. When the remote

controller returns to local operation the saved

settings are restored to the remote controller.

When operating in this mode, a 15 second delay will occur when

unlocking the keypad to allow the previous user settings to be restored.

Local Restore operation is shown in the following figure.

18

USER RESTORE

TCC-NET D-BUS RELAY

ABD1D2R1

R2C

D1 D1

D2 D2

C C

TCC-NET D-BUS RELAY

ABD1D2R1

R2C

SPECIFICATION

Use solid or stranded 24awg shielded or unshielded twisted pair to

Cat3, Cat4 or Cat5 specification. Use a twisted pair for connections

D1,D2 and an extra core for connection C.

NETWORK LENGTH

Standard installation for total network distances of up to 500m can be

achieved following the basic daisy-chaining method showed in the

above diagram. Network layout should follow a point-to-point

connection, ‘T’ and star connections are not supported.

Address 0 (MASTER)

8 Units max

D-BUS

16 FDP2 max

Address 1-15 (SLAVE)

The switch SW2 on the master allows remote

controllers on slave units to be unlocked. With

SW2 ON on the master FDP2-BMS, slave remote

controllers will unlock when the master remote

controller unlocks

NOTE ON FDP2-F SLAVE OPERATION: FDP2-F interfaces can be used as slaves to FDP2-BMS

interfaces, however the duty/standby mode available in the FDP2-F will no longer operate.

UNLOCK SLAVES

LOCAL CENTRAL

Save User Settings

CENTRAL CONTROL

Use FDP2 Settings

Functional Specification

Electrical Environmental

18V DC from TCC-NET

Power

Relay

<1VA

1A, 24VAC max

1A, 30VDC max

Mechanical

Dimensions

Mounting

Casing

Weight

Connectors

H72 x W87 x D19 mm

Two keyhole mounting

flanges

Zinc coated mild steel

80g

Rising clamp to 0.75mm

cable

2

TemperatureSupply

Storage

Operation

Humidity

Protection

EMC Emissions

EMC Immunity

Inputs

Voltage Mode

Resistance Mode

CENTRAL LOCAL

Restore User Settings

-10oC to 50oC

0oC to 50oC

0-90% RH

non-condensing

IP30

EN61000-6-1

EN61000-6-3

S1..S6 0..10VDC <1mA

S1..S5 5V, 1mA

S6 5V, 10mA

Loading...

Loading...