Page 1

BUILDING and FLYING the

Page 2

INTRODUCTION

It has been suggested for several years that a control line stunter would

make a fine radio controlled model The fairly recent advent of miniaturized

radio control systems has permitted testing this possibility The

Nobler

is ideal for

this conversion because of its airfoil planform and structure

The control line

designed by

George

The radio control version of the

Nobler

is the winningest of all control line stunters It was

Aldrich and has been a

Nobler

Top

Flite

kit

for many

has been the project of Ed Sweeney

years

with considerable technical assistance by Fred Marks Many models were built

in developing the Top Flite

R/C Nobler

kit We think it will follow the

winning ways of its line bound ancestor It opens up a new dimension in precision

RC acrobatics

The airplane has a great airfoil with excellent stability, lift, smooth response,

and gentle stall characteristics Thrust and drag forces are near both center of

pressure and gravity It is a relatively symmetrical aircraft — high thrust

line

high

stabilizer,

air foil This symmetry gives the plane its true neutral stability

deep fuselage

cross

section, and mid wing with symmetrical

It

will hold any

reasonable flying attitude almost indefinitely

BEFORE YOU START—READ THIS!

These

instructions

have

been

carefully

developed after

building

several

prototype models We urge you, in your own interest, not to ignore them Our

aim is to insure that the model goes together in a reasonably quick time

and

without annoying snags

Regardless

of previous modeling experience

follow the directions carefully,

checking them off as you go

Notice the instructions often call for some items to be started before others

are complete This is to allow time for important glue joints to dry properly,

yet not hold up building progress Also in order to help modelers of less experience,

we have tended to the easier jobs first, leaving those requiring more care until

later as skill increases.

Do

not

seperate

parts from die cut sheets

until

you

need

them

This

will

save loss or breakage of some of the small or delicate pieces

We are often asked by less-experienced modelers which glues are best

for model construction The answer to this depends upon the particular job

However this is our normal recommendation For all hardwood to hardwood

or hardwood to balsa joints use white wood glue Titebond is especially good,

as

it

drys

faster than other

white

glues and

is

very

strong

For

balsa

to

balsa

joints regular balsa wood cements are ample for the job although white glue

can be used here too Whichever type you use, remember that excess glue is no

substitute for a well fitting joint Use a minimum of glue at all times, and wipe off

excess glue that squeezes out of joints before it sets hard when set it is difficult

to remove, but if not removed it will spoil the covering job

For joints involving flexible items like foam rubber

R/C equipment packing,

contact cement is the only suitable adhesive this should not be used in construction however because it is not sufficiently strong and is very hard to sand

down

properly

One final word to newcomers to the hobby or modelers of limited ex-

perience Join a club! (You can write to the Academy of Model Aeronautics,

1239 Vermont Avenue N W Washington D C 20005, for the address of

your nearest Club Secretary ) Here you will find indispensable guidance and help

from experienced and friendly fellow modelers should you encounter any small

problem in building or flying this model We at Top Flite will do our best to insure

your success, but it is fair to say that nothing can replace personal help or demon-

stration from a good modeler

1

Page 3

SUB-ASSEMBLIES

To speed building, by cutting down "waiting time," it is recommended that

certain components

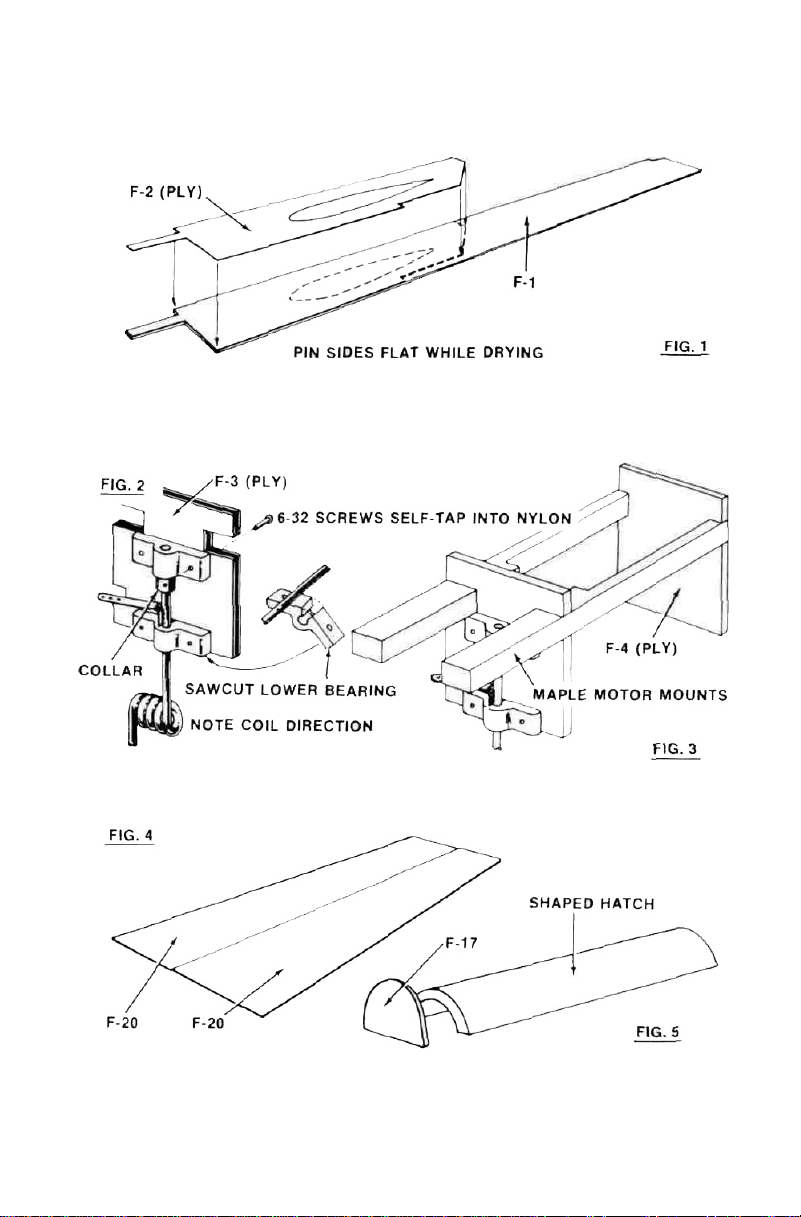

1. Glue

Fig.

1.

be

sub-assembled

F-2 (ply) doublers to F-l

first.

sides — make a left and a right side. See

2. Make sawcut in one nylon nosewheel bearing as shown and snap bearing

over the formed noseleg between the tiller-arm and the coil. Slip the collar over

the leg from the top, followed by the other nylon bearing. Screw the bearings

to 1/4" ply

F-3

using the 6-32 screws provided.

Fig

2 shows assembled unit

3. Glue F-3 and F-4 (ply) to the shaped motor mounts. See

Fig. 3.

4. Glue two F-20 pieces together as in Fig. 4. Use balsa cement for this joint,

Not white glue.

5. Join elevators with l/4"xl/2"x4" hardwood strip.

6. Glue F-17 to one end of shaped hatch block. See

7. Join parts of wing plan to make one-piece plan. Use

Fig. 5.

scotch tape and lots

of care.

2

Page 4

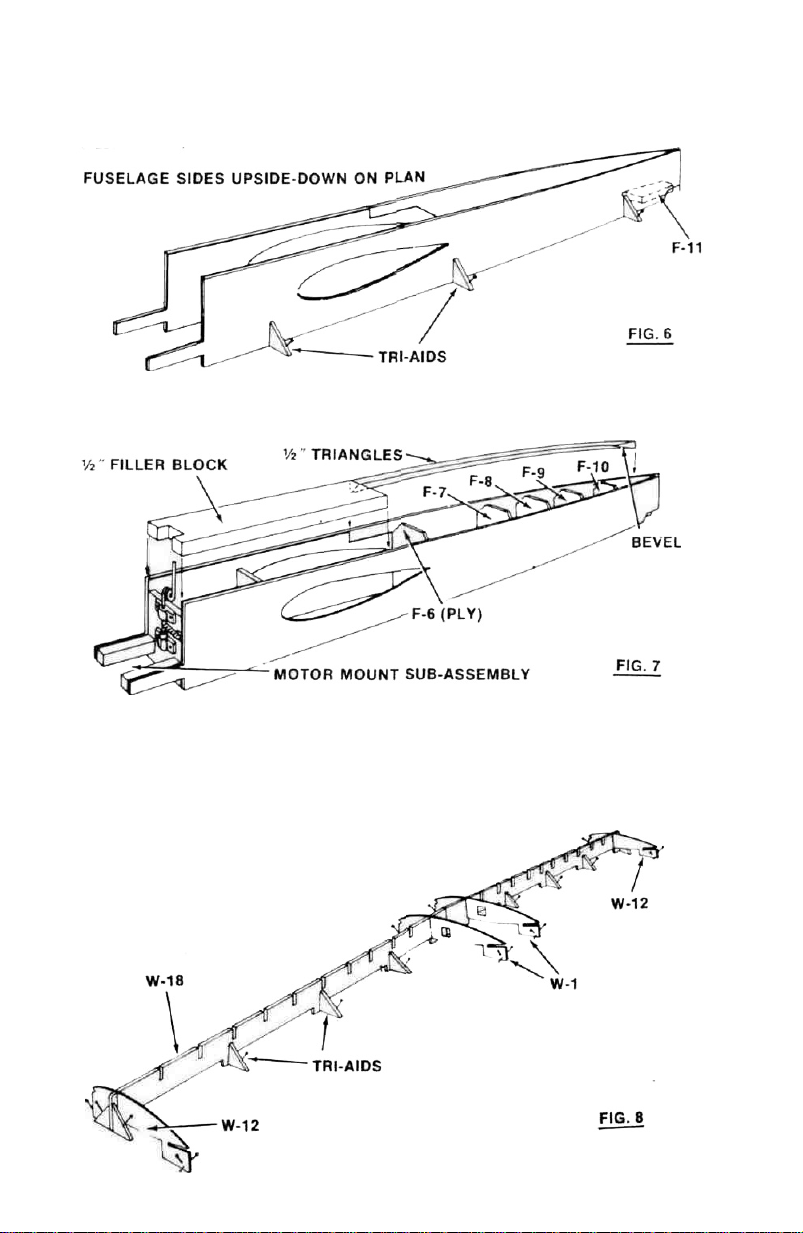

FUSELAGE

8. Pin F-ll in position on top view of fuselage. Pin both fuselage sides over

plan upside-down, and glue to

F-ll.

Use Tri-Aids as shown in

Fig. 6

to keep

sides vertical

9. Glue shaped tail block between sides at rear end. Glue F-6 thru F-10 in place.

10 . Glue motor-mount sub-assembly between sides See Fig. 7. Glue 1/2" x 2-3/4

x 11-7/8" block between sides and to

F-3 and F-4.

11. Glue 1/2" triangular longerons to sides and formers, cutting to scarf-

joint at rear end.

WING

12 Pin Tri-Aids to plan in pairs to support mainspars. Slip spars W-18 between

Tri-Aids

but

do

not

pin

to Tri-Aids or

to

plan.

Glue

spars together

at

center

joints only. See Fig. 8.

3

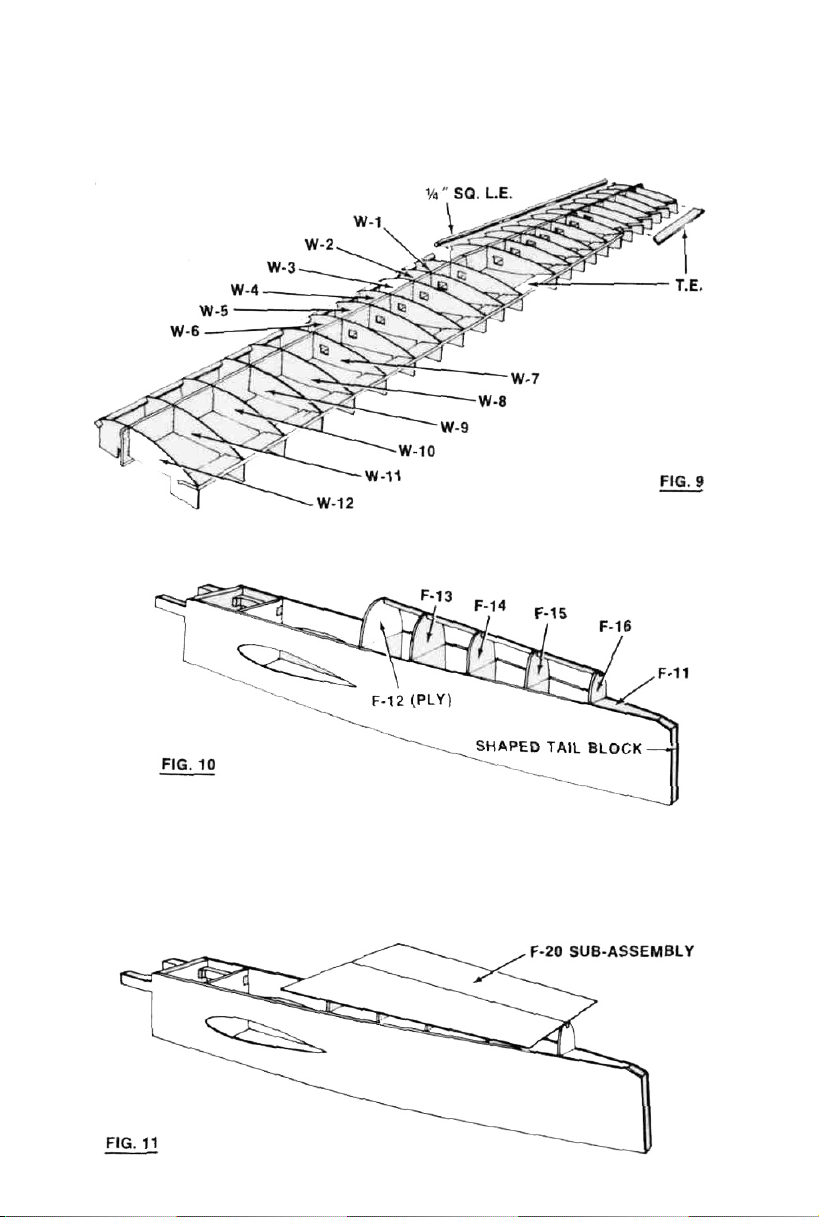

Page 5

13. Slip all ribs

W-l thru W-12

into spars egg-crate fashion.

Do not

glue joints

at this time! Pin all ribs over plan in correct alignment.

14. Glue 1/4" sq. L.E.'s into ribs, glueing center joint well. Slip bottom

sheets into slots in ribs. When satisfied with position, glue to ribs. See

T.E.

Fig. 9.

15. Use weights to hold structure down, making sure that all rib and spar

tabs are contacting table surface on plan properly. Run glue onto all rib-to-spar

joints.

FUSELAGE

16. Remove fuselage from plan. Glue

F-12

(ply) thru

F-16

in place, then 1/4" sq.

stringer. See Fig. 10.

17. Drill hole through F-17 and glue 1/8" dowel into hatch. Pin or tape hatch

in place on fuselage with dowel projecting through F-12. Drill F-18 (ply) with

1/4" drill at punchmark and slip over the dowel. Glue to F-12, making sure not

to get any glue on the dowel itself.

18. Glue the F-20 sub-assembly onto 1/4" sq. stringer centering the joint on

the stringer carefully. See

Fig. 11.

4

Page 6

WING

19. Cut L. E. Sheet doublers from 1/16"x3" sheet and glue in place on wing

from center to

clips or pins to hold L.E. joint while it dries. See

other side to spars and ribs.

W-5

. Glue 1/16" x 3" L. E. sheeting to L. E. first, using spring

Fig. 12.

Then glue and pin

20. Glue upper T.E. sheet in place. Glue in

l/16"x 1/4" rib capping strips.

MARK AND CUT LEVEL WITH TOP OF SIDES

FUSELAGE

21. At this time the rear turtledeck sheeting is attached. Follow the instructions

closely and you will have no trouble:

a) Dampen top of sheeting with water and let soak for a minute or two.

b) Bend sheeting down against formers.. Mark

the sides and trim for exact fit.

c) Run

hold with pins and tape while it dries.

white

glue into formers and sides. Pull sheet down each side and

W-15

and W-17, followed by all

FIG.

13

the sheet where it overlaps

d) Trim front and rear flush with

F-12 and F-16. See Fig. 13.

5

Page 7

22. Glue 1/8" ply patch F-21 into hatch as shown in Fig.

and mount nylon plate. Glue 1/2" x 3/4" x 1-3/8" hardwood block between motor

mounts: drill: and epoxy nylon ball fastener into hole. Adjust for proper fit.

23. Install engine. Glue top cowl block in place. Glue bottom front 3/8" block

to fuselage, then

in place.

24. Glue cowl side blocks in position, center F-19 around engine crankshaft and

glue. Remove engine. Glue servo tray mounts in place.

WING

25. Lift wing from plan. Turn upside-down, remove tabs and repeat instructions

19 and 20 (use parts W-16 and W-17). Glue 1/8" x 1/4" T. E. capping strip in

place. (Fig. 12). Trim and sand excess wood outside of

rib and glue on wingtip blocks.

26. Assemble aileron bellcranks to ply parts W-13. Glue

W-7 and

27. Run 1/16" music wire pushrods through wing ribs and assemble to bell-

cranks. Glue

W-8

F-5

(ply), and

respectively. Glue

W-14's

in position. Do not assemble connecting-links to bellcrank yet.

F-5A

(ply). Glue rear bottom 3/8" shaped block

W-13

in place in wing. See

14.

Drill 3/16" hole

W-12

until flush with

W-19

and

Fig. 15.

W-20

to ribs

FINAL ASSEMBLY

28. Try popping fuselage batch into place. Make any adjustments required

perfect fit.

29. Carve and sand fuselage blocks, cowl and wingtips to sections shown on

plan.

30. Slip metal clips onto main L. G. unit. Hold in position on

holes for mounting screws. Bolt L. G. in place, coating nuts inside with glue.

31. Slip flap horn into wing slots in fuselage sides and push to rear end. Slide

wing into slots and center the wing in the fuselage. It may be necessary to trim

away the front end of the wing slot on one side a little, to achieve this.

32. When satisfied with position, glue wing/fuselage joint using plenty of cement. Fill any oversize holes

carefully.

33. Sand stab and elevators to section and pin stab temporarily on fuselage,

lining up with the wing in front view. Glue tail blocks to fuselage over stab using

the fin temporarily as a 1/4" thick spacer. It will be easier to carve these blocks

to conform to fuselage lines without the stab and fin in place. After carving

blocks, sand fin and rudder to section and glue fin between block, and then glue

stab in place.

34. The R/C equipment is now installed. Screw the aileron servo in place

and hook up to pushrods. Sand ailerons and hinge onto the wing with MonoKote. These hinges are only temporary and will be removed before covering.

Install aileron connecting-links and horns. Check for movement using the radio.

with

vinyl-spackle (from hardware store) and sand

6

F-5 and

for a

drill

Page 8

35 Sand flaps and drill for flap horn (note offset — see plan). Install flaps

and hinge temporarily to wing

36 Mount three servos Make all pushrods as shown on plan Hinge rudder

and elevator Check all controls for free movement

37. Remove engine, R/C gear, landing gear main struts and all control surfaces

This model may be covered with Super MonoKote (follow instructions on

enclosed leaflet closely) or alternatively may be covered and finished using

silk and dope Hinge all control surfaces permanently after covering

38. Install fuel tank receiver, battery, wheels, engine and spinner, and cockpit

canopy Check CG (see plan for correct position) and if necessary move equipment fore or aft to get CG correct

FLYING

With a good 35 to 45-size engine the airspeed is a relatively constant 70

to 80 mph Automatic speed control is an advantage during maneuvering This

is achieved by propeller selection, airfoil, and flying weight of under 6 lbs

The planform of the plan, wing shape with swept leading edge and fuselage

profile provide excellent yaw stability and accurate roll response

The stunt flaps, which will be described later, contribute excellent lateral

stability

A nearly symmetrical plane and neutral stability coupled with efficient

or

large control surfaces produce the Nobler s maneuverability The rudder and

elevator are unusually large for a model airplane The ailerons are reflexing

trailing edge sections with sealed hinge gap giving rapid accurate linear response

with little drag Normal control surface movements are ailerons ± 10 degrees,

elevator ± 15 degrees, and rudder ± 30 degrees The coupled flaps move ±

5 degrees

For many years control line planes have had mechanically coupled flaps

and elevators to give them smoother flight and more lift in sharp corners The

same advantages apply with RC planes Control line models used equal coupled

flap and elevator movement, while the RC models should have much

less

flap

movement than elevator movement This is because of the inferior power/weight

ratio of RC models compared to CL models, and the consequent necessity to hold

down the drag to maintain flying speed

A radio controled model gains other advantages with flaps For example,

with more pitch axis power, we can have a more forward CG location for groovier

flying When deflected downward, the centersection of the wing is operating at

a higher angle of attack than the wing tips ensuring against tip stalling during

high g maneuvers or low speeds With the additional lift of the flaps the plane

needs less rotation about its pitch axis for a given response, thereby causing

less drag speed changes, and showing a smoother flight path The symmetrical

airfoil is, therefore, infinitely variable to obtain optimum performance

When landing or taking off, the flaps allow slower and more stable flight.

Even in gusty or windy weather, the Nobler seems to fly as if on rails The

flaps keep the wings extra stable because the wing tips are flying at a lower

angle of attack while the other features keep it tracking accurately Even though

the flaps are not sharply deflected, they provide a tremendous amount of additional

lift, even at low speeds

The technique of using flaps coupled with the elevator function is relatively

new to RC flying A detailed investigation of the performance with the flaps

and without the flaps has been made At the 1969 DCRC Symposium, Fred Marks

and Ed Sweeney presented a paper describing the technique showing the results

of

tests and experiments with several airplanes To make their findings meaningful,

7

Page 9

a system of in-flight uncoupling of the flap function was devised Maneuvers with

these planes, including of course the RC Nobler, could be made with and

without coupled flaps When uncoupled, the flaps were positioned at neutral

Without question, maneuvers with flaps are smoother, can be tighter, can be

slower, the plane is definitely more stable, and safer The Nobler is a fine

stunt plane without coupled flaps, but like all the other models, it is noticeably

better and more enjoyable with flaps

One finding of the study was that since the coupled flaps offer very little

drag during flare out for landing, the models would generally float in ground

effect With a slow idling engine or with the 10x5 Top Flite and 10x6 Top Flite

or Power Prop on the Noblers, this is no problem, but can be a nuisance

with higher pitch props or a fast idle By uncoupling the flaps, the models

landed as usual at a high sink rate and higher speeds We could also lower

the flaps independently 25 degrees for landing In gusty or windy conditions we

use only 15 degrees deflection for landing Extra flap movement gives higher lift

at slow speeds with adequate drag for precise spot landings This feature is worthwhile if you have a five channel system and five servos.

Uncoupling may be achieved in the transmitter by adding a switch and

potentionmeter in the fifth channel circuit The pot is ganged with or rotated

simultaneously with the elevator stick movement, the switch transfers the fifth

channel control to the ganged pot for coupled flaps and elevator or to the normal

fifth channel control pot for independent flap operation Set linkages in the

transmitter to give the ganged pot one third the rotation of the regular pot.

Now, when ganged, the flap has ± 5 degrees movement, and when operated

independently, it has 25 degrees movement downward See Fig. 16.

ELECTRONIC COUPLING

FIG.

16

Note Flap neutral is at 80°

servo position 0' 80°

is landing flap range,

100° to 60° is coupled

flap range

These leads were originally

wired only to the 5th

channel pot

8

Page 10

Another method to get landing flap operation with a 5 channel system is use

a

linkage

in the plane similar

to

the elevator trim arrangement of reed

control

systems A five servo installation is needed Make a "trim bar" between elevator

and flap servo See FIG. 17. Landing flap mode can be set up with four channel

systems by coupling with the throttle servo, but it has not been proven out yet

MECHANICAL COUPLING

Elev

Elev Servo

Coupling Bar as in reed systems

Trim Bar There are many ways to

accomplish this method

5th Channel Servo

Flap

Note Servo is at 100° position

lor stunting Move toward

0° for landing flap position

FIG.

17

PREPARATION FOR FLYING EXPERT

As mentioned earlier, the control surfaces should have the following movements ailerons ± 10 degrees, elevator ± 15 degrees rudder ± 30 degrees, and

flaps ± 5 degrees. This flap/elevator coupling is the same whether mechanical

or electronic systems are used If landing flap mode is available, the flaps should

go down to 25 degrees.

The Center of Gravity should be measured (without fuel in the tank) at

6 to 7 inches forward of the hinge line on the wing Move the battery pack

around to achieve this Set up the surfaces with transmitter trims in neutral,

then apply up-trim at the transmitter to hold level flight or give a slight climb

Although the engine is well cowled, it is adequately cooled even with a

muffler Have a full fuel tank on the first flights Use a 10 x 5 Top Flite propeller,

after a few flights accomplished, go to a 10x6 Top Flite Power prop

As the model sits level on the ground, a positive rotation is required for

lift-off From grass use a slightly oversized nose wheel to have a positive angle

of attack As an expert flyer, you already know how to trim a model Make

several short flights adjusting the clevises to move the transmitter sticks back

to neutral The model should be adjusted for level hands-off flight upright and

with down trim applied for inverted flight Make these checks at 3/4 throttle

At take-off, propeller slipstream effect gives a left yaw Compensate with

rudder keeping the wings level with ailerons, if necessary Once you have accelerated well past stall speed, the yaw disappears Side thrust can introduce

more problems than it is worth on stunt ships With the

Nobler,

it is easily

accounted for by the effective rudder

When landing, the model is stable and amazingly slow Avoid the floating

in ground effect by closing the throttle during the downwind leg of your landing

approach when the plane is exactly opposite the landing area. Full stall landings

are best.

9

Page 11

PREPARATION FOR FLYING

R/C Nobler

pretty good trainer too

Before going to the flying field, adjust the control surface movements

± 5 degrees on ailerons, ± 10 degrees on elevator,

der.

Set the flaps at a fixed position 25 degrees

settings with transmitter trims at neutral Then before flying, apply full down

trim This compensates for the extra lift from the flaps

Set the Center of Gravity at 7 inches forward of the hinge line on the wing

(with the fuel tank empty) Use a 10x5 Top Flite propeller

Flying hints Hold a bit of up elevator on the stick to make the takeoff, use

full throttle After takeoff throttle back to 1/2 speed and climb in very wide

shallow bank turns to gain altitude Now, trim the

straight flight adjust the elevator trim for level flight if necessary Make slow

gentle movements on the control stick Remember, you must bank into a turn

and when you want to fly straight again, you must bank out of the turn Keep

all banks at less than 10 degrees angle Make wide turns in both directions

The R/C

down If it stalls, it will drop forward Let it drop a few feet then apply a bit

of up elevator to level flight and release the elevator pressure Next time,

before the stall, apply a quick dab of down elevator to prevent the stall

Try a few short power-off glides in the first flight while well up in the sky.

In level flight, throttle back slowly to idle Notice the speed and angle at which

the Nobler glides The model should be slow, verv slightly nose down and steady

To climb up again, open the throttle Repeat the glide and climb several times

Try some gentle turns while gliding If the engine stops unexpectedly, concentrate

on a landing with wings level letting it assume its normal glide speed

It is now time to land It would be nice to land back on the runway,

but don't try too hard to get on the runway Just keep the wings level at touchdown

wherever it is Use the same power off glide as when up high Steer around while

gliding trying to land nearby When the plane gets below 10 feet in an approach,

it is best to land no matter where you are The R/C Nobler is pretty slow in

the glide with flaps down so it will be safe In other words, if you want to try the

landing again, apply full throttle before getting to 10 foot altitude

is a full stunt plane but because of certain features it is a

It is always best to have an expert help you learn to fly.

Nobler

will keep a slow steady stable flying speed with those flaps

NOTICE

and ± 20

down from neutral.

degrees on rud-

ailerons and rudder

for

Do these

for

R/C NOBLER ACROBATICS

The quality of acrobatics depends upon the pilot much more than on the

plane With the Nobler, you will probably enjoy stunting more than with most

other planes This is because of its linear responses, neutral stability, and ability

to fly through smaller maneuvers at slower speeds It has all the ability to win

contests, but winning is up to you

If you are planning on contest work, we suggest you set elevator trim for

slight dive This prevents ballooning after each maneuver and strings out the

rolling maneuvers Very little down elevator is needed during the inverted portions

of the rolls If you are just sport flying, trim for level flight

LOOPS: Enter with full throttle and adjust size for constant flying speed

throughout Big loops or small loops can be done

ROLLS: Use slight down when inverted during consecutive rolls and a bit

more during slow or point rolls

Nobler

does not need top rudder during any rolls.

10

Page 12

WING OVERS: Make the climb at half throttle and do the turn at l/4th

throttle Turns easily either way

CUBAN EIGHTS: In any Cuban eight maneuver use large loops so that

the half rolls can be accurately placed at the intersections, use full aileron for

the

rolls

Ease

off

the

elevator

for fun, try two-point rolls with full top rudder in the Cuban eights

KNIFE EDGE: Enter from level fight and apply rudder simultaneously with

the quarter roll Hold full rudder The Nobler will not drop its nose or loose

altitude If you enter with a climb, the plane will climb throughout

SPINS: Due to the extra stability with flaps, use ailerons in the direction

of the spin The rate of rotation is not fast but can be controled with the ailerons

To regain normal flight release either or both rudder and elevator, recovery is

instant

coming

over

the top before starting the roll Just

LENCHEVICK:

right (or left) turn at 45 degrees climb and bank Use full throttle throughout

While climbing make left (or right) aileron/rudder/up-elevator snap roll so that

the plane is spinning and still going up After one good spin move elevator stick

to down position while maintaining rudder and aileron directions Plane will begin

to tumble a moment later The tumble is not necessarily head-over-tail but

probably diagonal After tumbling which is the desired maneuver, release the

sticks and recover If the stick positions are held, the model will exit the tumble

in an inverted spin

SNAP

left / left combinations but for outside or inverted snaps use left / right or

right / left combinations of rudder and ailerons Precision snaps can also be done

with Nobler, including half snaps

SIDE SLIPS: Rudder is powerful and fuselage offers plenty of side area

so the side slip is effective in checking a landing overshoot In flight,

can do a flat turn by applying full rudder one way and keeping the wings level

with aileron

SQUARE AND TRIANGULAR LOOPS: Because of ths airfoil and flaps,

the

Nobler

and triangles, etc There is no wobbling because of no tip stalling during high lift

demands On the decending side of the square-type maneuvers throttle back

to low speed The corner will be just as sharp as when going up at full

throttle

We wish you all the best of luck with your

ROLLS: Use rudder and aileron together For inside snaps, use

Nobler

is safe in "high G" maneuvers as at corners of square loops, top hat,

Nobler

does it but it takes timing Enter from climbing

will make a wide turn, looks strange, but works.

Nobler.

ED

SWEENEY

FRED

MARKS

you

Top Flite Models recommends that any newcomers to RC model flying

join the AMA (See Page 1 for details) Among the many benefits, the member

will receive a Rule book describing with diagrams the competition maneuvers,

and will be insured against any peisonal liability claim as a result of flying mishaps

mishaps

11

Page 13

The covering with

the built-in finish

MonoKote, acclaimed the greatest advance in covering

and finishing in model building history, will give you a

professional looking

eliminating the usual tedious work of sealing, doping,

sanding and polishing.

MONOKOTE

finish

in a fraction

of

the normal time,

Just lay on MonoKote.

Seal edges with an

electric Iron.

LIGHT ... Is 2/3 lighter than an

equivalent silk and dope finish.

STRONG . . . has a tensile strength of

25,000 Lbs. per Sq. In.

PUNCTURE RESISTANT ... has many

times the tear-strength of silk and

dope finishes, yet should it puncture,

SUPER MONOKOTE

This material has a totally dry adhesive, activated by the heat of an Iron. For

best results use the MonoKote. Sealing iron shown. Recommended for all basic

covering of the model.

Opaque Colon:

REGULAR MONOKOTE

This material has a sticky adhesive and is recommended for trim areas

color scheming, etc. No ironing required; it's just pressed down on

basic covering.

Missile Red

Int. Orange

Piper Yellow

Jet White

Instant, almost Invisible repairs can

be made on the field.

ODORLESS . . . Completely odorless,

eliminates irritating smells and dangerous fumes.

MOISTURE PROOF . . . STAIN PROOF

. . . FADE PROOF . . . FUEL PROOFI

Mustang Alum.

Sky Blue

Insignia Blue

Midnight Black

MONOKOTE

Shrink skin tight

with heat.

Metallics:

Emerald Green

Electric Blue

Transparents:

Solar Red

Sunset Orange

Sunrise Yellow

Sealing

Iron

Page 14

S.

E.

5.

a

Never before has an R/C scale model been

designed with such attention to the most insignificant detail Wing Span 52" Eng 45

to

.60 Kit

RC-13

TAURUS -

NOW includes ailerons & fittings Multi channel

trainer Span 57' Eng 15.45 Kit RC-4

KWIK-FLI III

World and twice Nats winner Designed

by Phil Kraft Span 60 Eng 45 to 61

Includes T A C —Ready made wing fixture

Kit

RC-12

WINNER OF THE

1962 NATIONALS

TAURUS

Most precise and complete R/C kit ever produced.

Span-70 Eng 45 Kit RC 7

TAURUS WING KIT-RC 7W 13.95

/

HEADMASTER

NYLON

THE PROPS OF CHAMPS A size for every flying

requirement TOP FLITES and POWER PROPS

have been used by more NATIONALS and WORLD

CHAMPIONS than any other brand Each prop is

perfectly balanced and aerodynamically designed

for maximum thrust

TOP DAWG

Suitable for escapement, servos galloping ghost,

reeds or even proportional gear TAC construction Wingspan 39 5"—Length 32" Engines 049

15

Kit

No

RC

10

SCHOOLGIRL

One wing or two Span

32 Engines 020 049

Kit

RC

9

SCHOOLMASTER

Single or multi channel

with rudder elevator

and engine control

Span 39 Eng 049 090

Kit

RC

8

Loading...

Loading...