Page 1

GLS-2000

SERIES

LASER SCANNER

INSTRUCTION MANUAL

64652 90261

Page 2

i

HOW TO READ THIS MANUAL

Thank you for selecting the TOPCON instrument.

• Please read this instruction manual carefully, before using this product.

• The specifications and general appearance of the instrument are subject to change without prior notice

and without obligation by TOPCON CORPORATION and may differ from those appearing in this

manual.

• The content of this manual is subject to change without notice.

• Some of the diagrams shown in this manual may be simplified for easier understanding.

• This manual is protected by copyright and all rights are reserved by TOPCON CORPORATION.

• Except as permitted by Copyright law, this manual may not be copied, and no part of this manual may

be reproduced in any form or by any means.

This manual may not be modified, adapted or otherwise used for the production of derivative works.

Symbols

The following conventions are used in this manual.

: Indicates precautions and important items which should be read before operations.

: Indicates the chapter title to refer to for additional information.

: Indicates supplementary explanation.

[OK] etc. : Indicates buttons on the display.

Notes regarding manual style

• All company and product names featured in this manual are trademarks or registered trademarks of

each respective organization.

Li-ion

S Li-ion

Page 3

ii

CONTENTS

1. PRECAUTIONS FOR SAFE OPERATION .............................................. 1

2. PRECAUTIONS ....................................................................................... 3

3. LASER SAFETY INFORMATION ............................................................ 6

4. PRODUCT OUTLINE............................................................................... 8

4.1 Parts of the Instrument .................................................................. 8

4.2 Operating Keys ........................................................................... 10

4.3 Display and Functions of the Main Menu .................................... 11

4.4 Flow of the Screens .................................................................... 12

5. PREPARATIONS BEFORE USE........................................................... 13

5.1 Inserting an SD memory card and Installing the Battery ............. 13

5.2 Connecting the External Power Source ...................................... 16

5.3 Overview of Scanning Procedure ................................................ 17

6. PREPARATION FOR MEASUREMENT................................................ 18

6.1 Detaching / attaching the Handle ................................................ 18

6.2 Detaching / attaching the Tribrach .............................................. 18

6.3 Power ON/OFF ...........................................................................19

6.4 Setting Up the Instrument ........................................................... 21

6.5 Using the SD Card ...................................................................... 23

6.6 Battery Power Remaining Display ............................................... 24

6.7 Replacing the Batteries during the power is ON ......................... 25

6.8 Entering Numeric and Alphabetic Characters ............................. 26

6.9 Preparing the Target .................................................................... 27

Assembling the target .................................................................. 27

7. INSTRUMENT SETTINGS..................................................................... 29

7.1 Setting the Tilt Sensor ON/OFF .................................................. 29

7.2 Camera Settings (Angle of view and Resolution) ........................ 31

7.3 Settings for Scanning Conditions ................................................ 32

7.4 Measuring Distance to the Target Measurement Object ............. 35

8. FLOW OF THE CONFIGURATION SCREEN ....................................... 37

8.1 Setting Temperature and Atmospheric Pressure ........................ 39

8.2 Setting the Prism Constant and Flash Light ................................ 40

8.3 Setting the Date and Time ........................................................... 41

8.4 Displaying the Last Calibration Date ........................................... 42

8.5 Adjusting the Brightness of the Display Section .......................... 43

8.6 Setting the Volume ...................................................................... 44

8.7 Selecting the Unit ........................................................................ 45

8.8 Selecting the Coordinate System ................................................ 46

8.9 Handling the Coordinate Point File ............................................. 47

Import the coordinate point file .................................................... 47

Conditions to create the CSV file (coordinate point file) .............. 47

8.10 Data structure in the SD card ...................................................... 50

9. STATION SETTINGS............................................................................. 51

9.1 Creating a New Station ............................................................... 52

Page 4

iii

CONTENTS

9.2 Setting the Point Name (Occupied point and Backsight point) .. 53

When using the known point ........................................................ 53

Importing the point name (Occupied point or Backsight point) .... 57

10. MEASURING (SCANNING) ................................................................... 59

10.1 Target Scanning .......................................................................... 60

Recommended search width setting ............................................ 63

Setting the target height ............................................................... 63

10.2 3D Scanning ................................................................................ 64

Scanning range ............................................................................ 64

Performing 3D range setting scanning ........................................ 65

Performing 3D whole circumference scanning ............................ 68

10.3 View the Data on the SD Card .................................................... 70

11. CHECKS AND ADJUSTMENTS ............................................................ 71

11.1 Circular Level Adjustment ........................................................... 71

11.2 Tilt Sensor Calibration ................................................................. 72

11.3 Aligning the Laser Plummet Beam with the Instrument Center ... 73

11.4 Aligning the Center of the Instrument and that of the Image ....... 75

12. BATTERY CHARGING .......................................................................... 77

12.1 Battery Charging ......................................................................... 77

13. HOW TO STORE ................................................................................... 79

14. OPTIONAL ACCESSORIES .................................................................. 80

15. WARNING AND ERROR MESSAGES .................................................. 81

15.1 Error ............................................................................................81

15.2 Warning ....................................................................................... 82

16. SPECIFICATIONS ................................................................................. 84

17. REGULATIONS ..................................................................................... 87

Page 5

1

1. PRECAUTIONS FOR SAFE OPERATION

For the safe use of the product and prevention of injury to operators and other persons as well as

prevention of property damage, items which should be observed are indicated by an exclamation point

within a triangle used with WARNING and CAUTION statements in this instruction manual.

The definitions of the indications are listed below. Be sure you understand them before reading the

manual’s main text.

Definition of Indication

General

WARNING

Ignoring this indication and making an operation error could possibly result in death

or serious injury to the operator.

CAUTION

Ignoring this indication and making an operation error could possibly result in

personal injury or property damage.

This symbol indicates items for which caution (hazard warnings inclusive) is urged. Specific

details are printed in or near the symbol.

This symbol indicates items which are prohibited. Specific details are printed in or near the

symbol.

This symbol indicates items which must always be performed. Specific details are printed in

or near the symbol.

Warning

Do not use the unit in areas exposed to high amounts of dust or ash, in areas where there is

inadequate ventilation, or near combustible materials. An explosion could occur.

Do not perform disassembly or rebuilding. Fire, electric shock, burns, or hazardous radiation

exposure could result.

Because this instrument is heavy, make sure to carry it carefully using both the handle and

the side handle. There is a possibility that the instrument may topple and fall resulting in

possible injury, and incorrect lifting posture may also result in hurting your back.

When securing the instrument in the carrying case make sure that all catches, including the

side catches, are closed. Failure to do so could result in the instrument falling out while being

carried, causing injury.

When scanning the target with the flash light while the instrument is set to use the prism,

please pay attention to the surroundings before doing so. When the target scanning is started

with the flash light while the instrument is set to use the prism, a white spot beam will be

emitted from the scanner unit to detect the position of the prism. This spot beam may

decrease a driver or pedestrian's vision temporarily if it hits the eye and may cause a serious

accident.

Secure handle to main unit. Failure to properly secure the handle could result in the unit falling

off while being carried, causing injury.

Caution

Do not use the carrying case as a footstool. The case is slippery and unstable so a person

could slip and fall off it.

Do not place the instrument in a case with a damaged catch, belt or handle. The case or

instrument could be dropped and cause injury.

Do not touch the instrument while the motor is in operation. Injury could result.

Page 6

2

1. PRECAUTIONS FOR SAFE OPERATION

Power Supply

Tripod

Do not touch the scanner section during high-speed rotation. Injury could result.

Tighten the adjustment tribrach clamp securely. Failure to properly secure the clamp could

result in the tribrach falling off while being carried, causing injury.

Warning

Do not short circuit. Heat or ignition could result.

Do not place articles such as clothing on the battery charger while charging batteries. Sparks

could be induced, leading to fire.

Do not use voltage other than the specified power supply voltage. Fire or electrical shock

could result.

Do not use batteries other than those designated. An explosion could occur, or abnormal heat

generated, leading to fire.

Do not use damaged power cords, plugs or loose outlets. Fire or electric shock could result.

Do not use power cords other than those designated. Fire could result.

Use only the specified battery charger to recharge batteries. Other chargers may be of

different voltage rating or polarity, causing sparking which could lead to fire or burns.

Do not use the battery or charger for any other equipment or purpose. Fire or burns caused

by ignition could result.

Do not heat or throw batteries or chargers into fire. An explosion could occur, resulting in

injury.

To prevent shorting of the battery in storage, apply insulating tape or equivalent to the

terminals. Otherwise shorting could occur resulting in fire or burns.

Do not use batteries or the battery charger if wet. Resultant shorting could lead to fire or burns.

Do not connect or disconnect power supply plugs with wet hands. Electric shock could result.

Caution

Do not touch liquid leaking from batteries. Harmful chemicals could cause burns or blisters.

Caution

When mounting the instrument to the tripod, tighten the centering screw securely. Failure to

tighten the screw properly could result in the instrument falling off the tripod, causing injury.

Tighten securely the leg fixing screws of the tripod on which the instrument is mounted.

Failure to tighten the screws could result in the tripod collapsing, causing injury.

Do not carry the tripod with the tripod shoes pointed at other persons. A person could be

injured if struck by the tripod shoes.

Keep hands and feet away from the tripod shoes when fixing the tripod in the ground. A hand

or foot stab wound could result.

Tighten the leg fixing screws securely before carrying the tripod. Failure to tighten the screws

could lead to the tripod legs extending, causing injury.

Page 7

3

2. PRECAUTIONS

Charging Battery

• Be sure to charge the battery within the charging temperature range.

Charging temperature range: 0 to 40°C

Warranty policy for Battery

• Battery is an expendable item. The decline in retained capacity depending on the repeated charging/

discharging cycle is out of warranty.

Precautions concerning water and dust resistance

The instrument conforms to IP54 specifications for waterproofing and dust resistance when battery cover,

connector cap and the Wide-angle camera lens cap of the instrument and are closed.

• Be sure to correctly attach the connector caps to protect the instrument from moisture and dust particles

when the connector is not in use.

• Make sure that moisture or dust particles do not come in contact with the terminal or connectors.

Operating the instrument with moisture or dust on the terminal or connectors may cause damage to the

instrument.

• Make sure that the inside of the carrying case and the instrument are dry before closing the case. If

moisture is trapped inside the case, it may cause the instrument to rust.

• If there is a crack or deformation in the rubber packing for the battery cover, stop using and replace the

packing.

• To retain the waterproof property, it is recommended that you replace the rubber packing once every

two years. To replace the packing, contact your local sales dealer.

The Lithium Battery

• The lithium battery is used to maintain the Calendar & Clock function. It can back up data for

approximately 5 years of normal use and storage (Temperature = 20°, humidity = about 50%), but its

lifetime may be shorter depending on circumstances.

The Levelling Base

• Always use the levelling base provided.

If the tribrach is installed incorrectly, the measuring precision could be effected. Occasionally check the

adjusting screws on the tribrach. Make sure the base fixing lever is locked and the base fixing screws

are tightened.

Tripod

• When mounting the instrument on a tripod, use a wooden tripod.

Do not use a metallic tripod.

Heat Release

• To prevent malfunction caused by a temperature rise inside this instrument, heat vents are provided to

release heat. Do not cover the vents when in use. When installing this instrument, keep the vents away

from a wall.

Heat vents

Heat vents

Page 8

4

2. PRECAUTIONS

Removing the instrument

• When removing the instrument from the case, hold by the handle and side handle and pick it up while

keeping it level.

Other precautions

• Effect of water drops

It may not be possible to measure if there are water drops on the glass of the scanner unit. Wipe off

moisture completely. A wet object may not be measured.

• When raining or snowing

When it is raining, snowing or foggy outside, please do not use the instrument to measure objects. Water

drops and snowflakes will be recognized as 3D data.

• Horizontally rotating part

Do not turn the horizontally rotating part and the scanner unit with your hands while the power is ON.

If it has been turned by force, turn the power ON again. (Except when collimating)

• Guarding the instrument against shocks

When transporting the instrument, provide some protection to minimize risk of shocks. Heavy shocks

may cause the measurement to be faulty.

• Sudden changes of temperature

Any sudden change of temperature to the instrument may result in a reduction of measuring distance

range, i.e when taking the instrument out from a heated vehicle. Let instrument acclimate itself to

ambient temperature.

• Direct sunlight

Do not expose the instrument to direct sunlight for extended periods of time. When left in the sun for

long periods, performance may be adversely affected, or if the inner temperature of the instrument may

rise to an abnormally high level, the instrument may fail to operate.

When measurements must be made in locations exposed to the sun and require high precision, protect

from direct sunlight by using a sunshade for the instrument and tripod.

• Battery level check

Confirm battery level remaining before operating.

• Battery use

Always use four batteries as one set, and operate the instrument with batteries that have been charged

and discharged the same number of times. Do not mix old and new batteries, or batteries that have been

charged and discharged a different number of times.

• Taking the battery out

It is recommended not to take the battery out during the power is on. Doing so may cause loss of data.

Please do your assembling or taking the battery out after the power is off. Refer to Chapter “Replacing

the Batteries during the power is ON” on page 25 if you need to replace the batteries during the power

is on.

Side handle

Handle

Page 9

5

2. PRECAUTIONS

Maintenance

• Wipe off moisture completely if the instrument gets wet during survey work.

• Always clean the instrument before returning it to the case. The scanner unit, wide-angle camera lens

and laser plummet window, etc. require special care. First, dust it off with the lens brush to remove tiny

particles. Then, after providing a little condensation by breathing on the lens, wipe it with the wiping

cloth.

• If the display is dirty, carefully wipe it with a soft, dry cloth. To clean other parts of the instrument or the

carrying case, lightly moisten a soft cloth in a mild detergent solution. Wring out excess water until the

cloth is slightly damp, then carefully wipe the surface of the unit. Do not use any alkaline cleaning

solutions, alcohol, or any other organic solvents on the instrument or display.

• Store the instrument in a dry room where the temperature remains fairly constant.

• Check the tripod for loose fit and loose screws.

• If a foreign object is thought to be in the rotation section or the screw section of this instrument, or if a

trace of water droplets or mold is found on the scanner unit, or the reflecting prism of the scanner,

contact your local dealer.

• When the instrument is not used for a long time, check it at least once every 3 months.

• When removing the instrument from the carrying case, never pull it out by force. The empty carrying

case should be closed to protect it from moisture.

• Check the instrument for proper adjustment periodically to maintain the instrument accuracy.

Exporting this product (Relating EAR)

• This product is equipped with the parts/units, and contains software/technology, which are subject to the

EAR (Export Administration Regulations). Depending on countries you wish to export or bring the

product to, a US export license may be required. In such a case, it is your responsibility to obtain the

license. The countries requiring the license as of May 2013 are shown below. Please consult the Export

Administration Regulations as they are subject to change.

North Korea

Iran

Syria

Sudan

Cuba

URL for the EAR of the US: http://www.bis.doc.gov/policiesandregulations/ear/index.htm

User

• This product is for professional use only!

The user is required to be a qualified surveyor or have a good knowledge of surveying, in order to

understand the user and safety instructions, before operating, inspecting or adjusting.

• Wear the required protectors (safety shoes, helmet, etc.) when operating.

Exceptions from responsibility

• The user of this product is expected to follow all operating instructions and make periodic checks

(hardware only) of the product’s performance.

• The manufacturer, or its representatives, assumes no responsibility for results of faulty or intentional

usage or misuse including any direct, indirect, consequential damage, or loss of profits.

• The manufacturer, or its representatives, assumes no responsibility for consequential damage, or loss

of profits due to any natural disaster, (earthquake, storms, floods etc.), fire, accident, or an act of a third

party and/or usage under unusual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage (change of data,

loss of data, loss of profits, an interruption of business etc.) caused by use of the product or an unusable

product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of profits

caused by usage different to that explained in the operator’s manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by incorrect

operation, or action resulting from connecting to other products.

Page 10

6

3. LASER SAFETY INFORMATION

This instrument emits a laser beam while scanning or using a laser plummet.

The instrument is classified as the following class of Laser Product according to IEC Standard

Publication 60825-1 Ed.2.0: 2007 and United States Government Code of Federal Regulation FDA

CDRH 21CFR Part 1040.10 and 1040.11 (Complies with FDA performance standards for laser

products except for deviations pursuant to Laser Notice No.50, dated June 24, 2007.)

Laser class of each mode is as follows.

Warning

• Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

• Never intentionally point the laser beam at another person. The laser beam is injurious to the eyes and

skin. If an eye injury is caused by exposure to the laser beam, seek immediate medical attention from

a licensed ophthalmologist.

• Do not look directly into the laser beam. Doing so could cause permanent eye damage.

• Do not stare at the laser beam. Doing so could cause permanent eye damage.

• Never look at the laser beam through a telescope, binoculars or other optical instruments. Doing so

could cause permanent eye damage.

Caution

• Perform checks at start of work and periodic checks and adjustments with the laser beam emitted under

normal conditions.

• When the instrument is not being used, turn off the power.

• When disposing of the instrument, destroy the battery connector so that the laser beam cannot be

emitted.

Device Laser class

Scanner unit

Range mode

(“Detail” / ”High Speed” / ”Standard“ / ”Close“ is selected.)

Class 3R

Range mode (“Low Power“ is selected.) Class 1M

Laser pointer Class 3R

Laser Plummet Class 3R

Laser beam

emitted from here

Page 11

7

3. LASER SAFETY INFORMATION

• Avoid setting the instrument at heights at which the path of the laser may strike pedestrians or drivers

at head height. Operate the instrument with due caution to avoid injuries that may be caused by the

visible laser beam unintentionally striking a person in the eye.

• Only those who have received training as per the following items shall use this product.

• Read this manual for usage procedures for this product.

• Hazardous protection procedures (read "LASER SAFETY INFORMATION")

• Requisite protective gear (read "LASER SAFETY INFORMATION")

• Accident reporting procedures (stipulate procedures beforehand for transporting the injured and

contacting physicians in case there are laser-induced injuries).

• Persons working within the range of the laser beam are advised to wear eye protection which

corresponds to the laser wavelength of the instrument being used.

• Areas in which the laser is used should be posted with a standard laser warning sign.

• When using the laser-pointer function, be sure to turn OFF the output laser after distance measurement

is completed.

Page 12

8

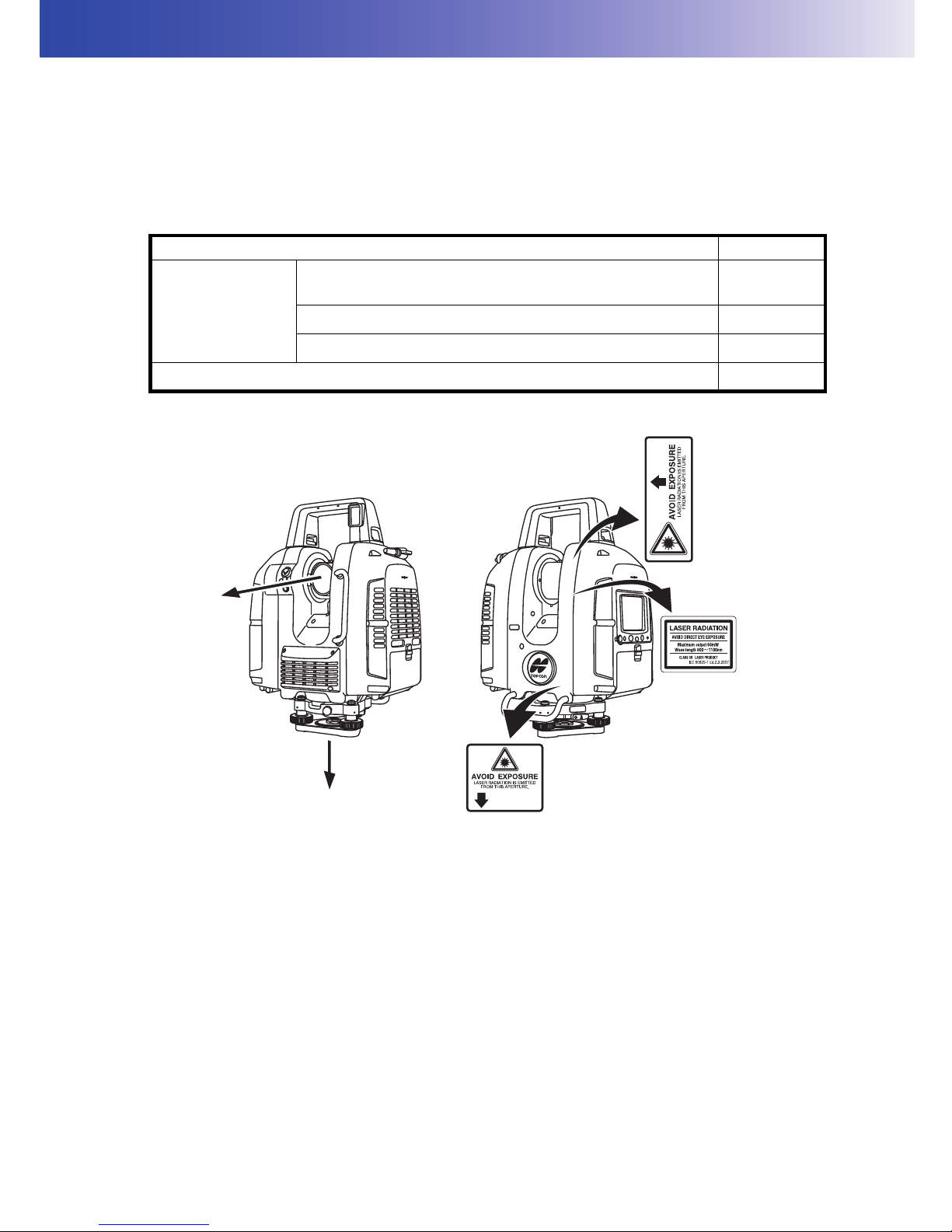

4. PRODUCT OUTLINE

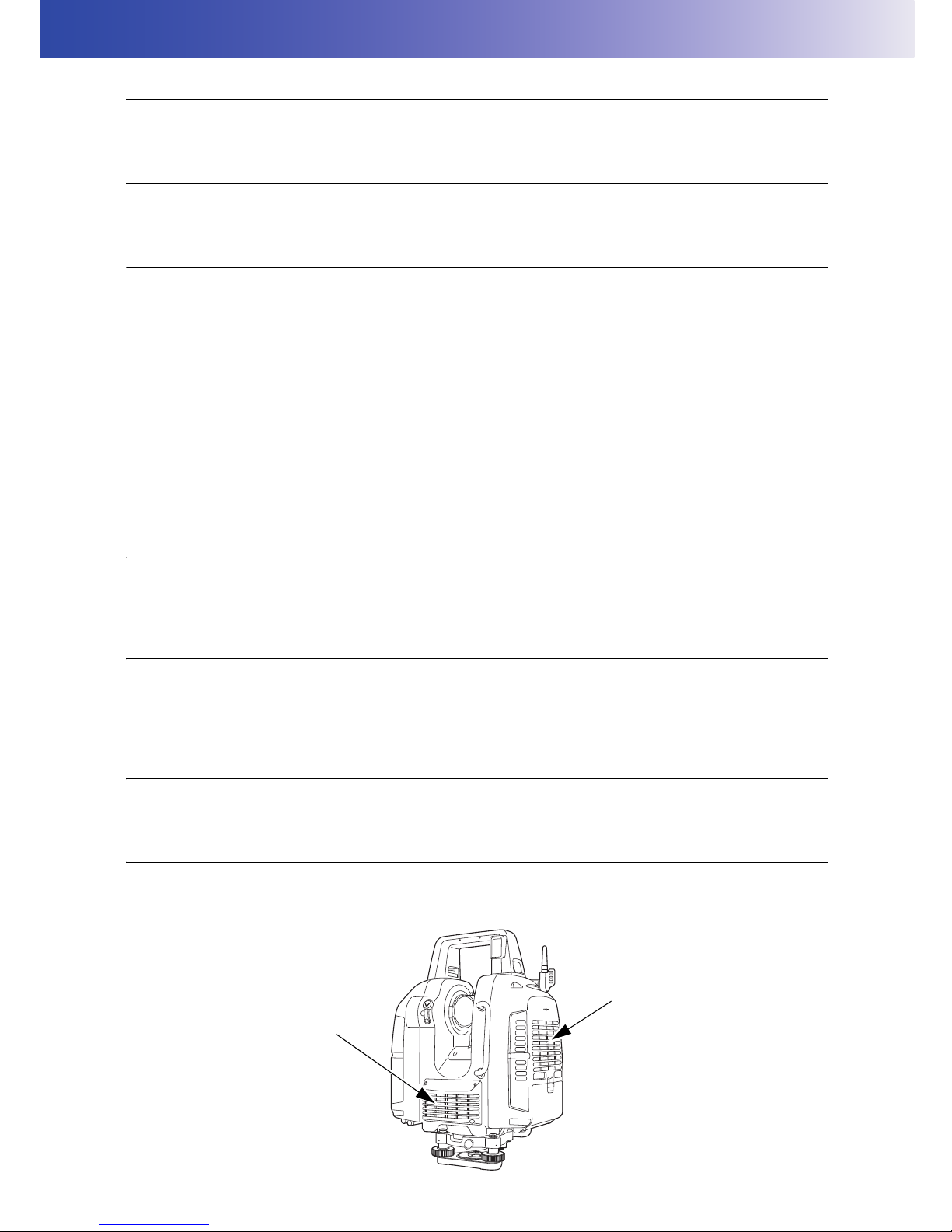

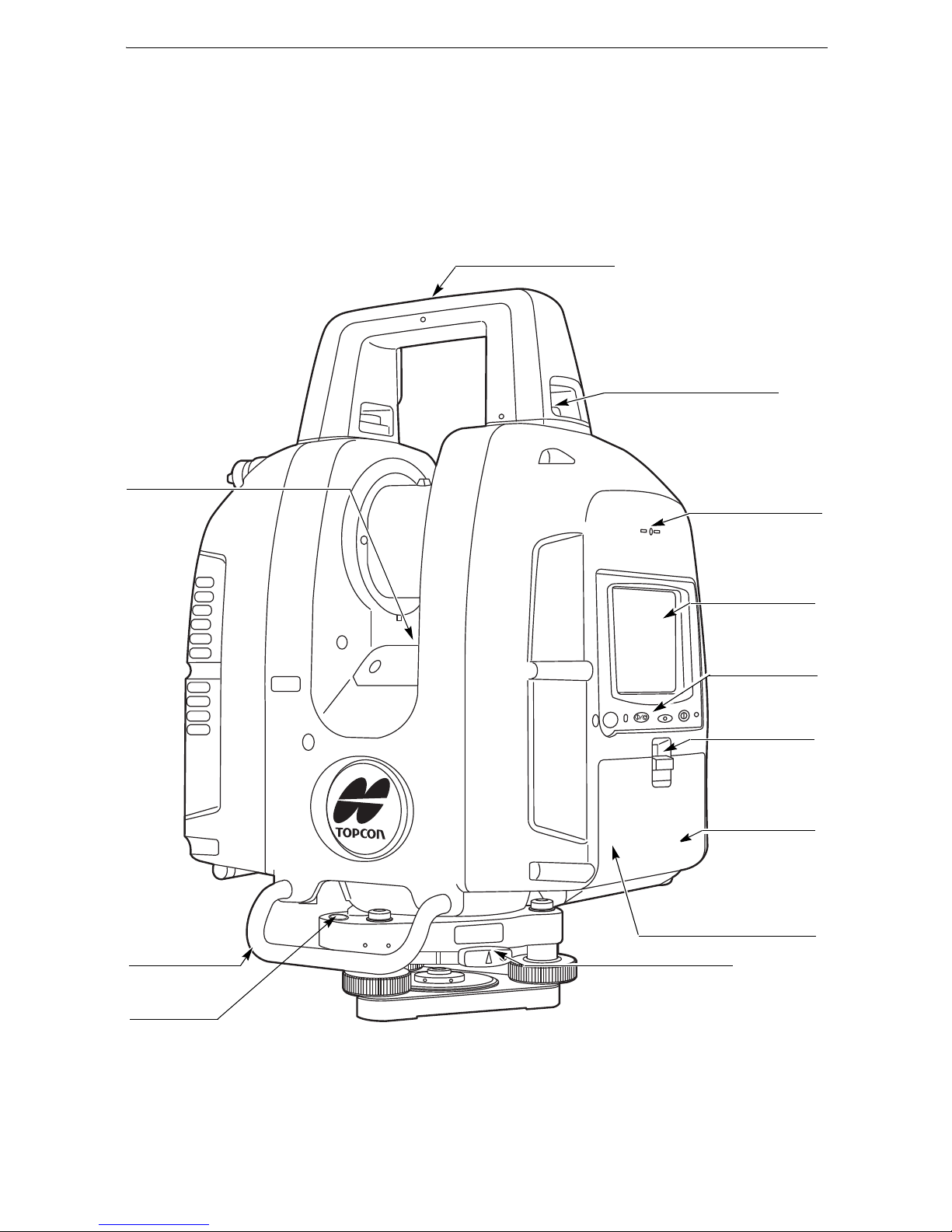

4.1 Parts of the Instrument

Side handle

Battery

cover lever

Wide-angle camera

(with lens cap)

Levelling base locking screw

Battery

cover Left

Battery connector

Leveling screw

Handle

Scanner unit (laser aperture)

and

Camera (telescope)

Heat vents

Stylus (pen)

Instrument

height mark

Heat vents

Sighting collimator

Page 13

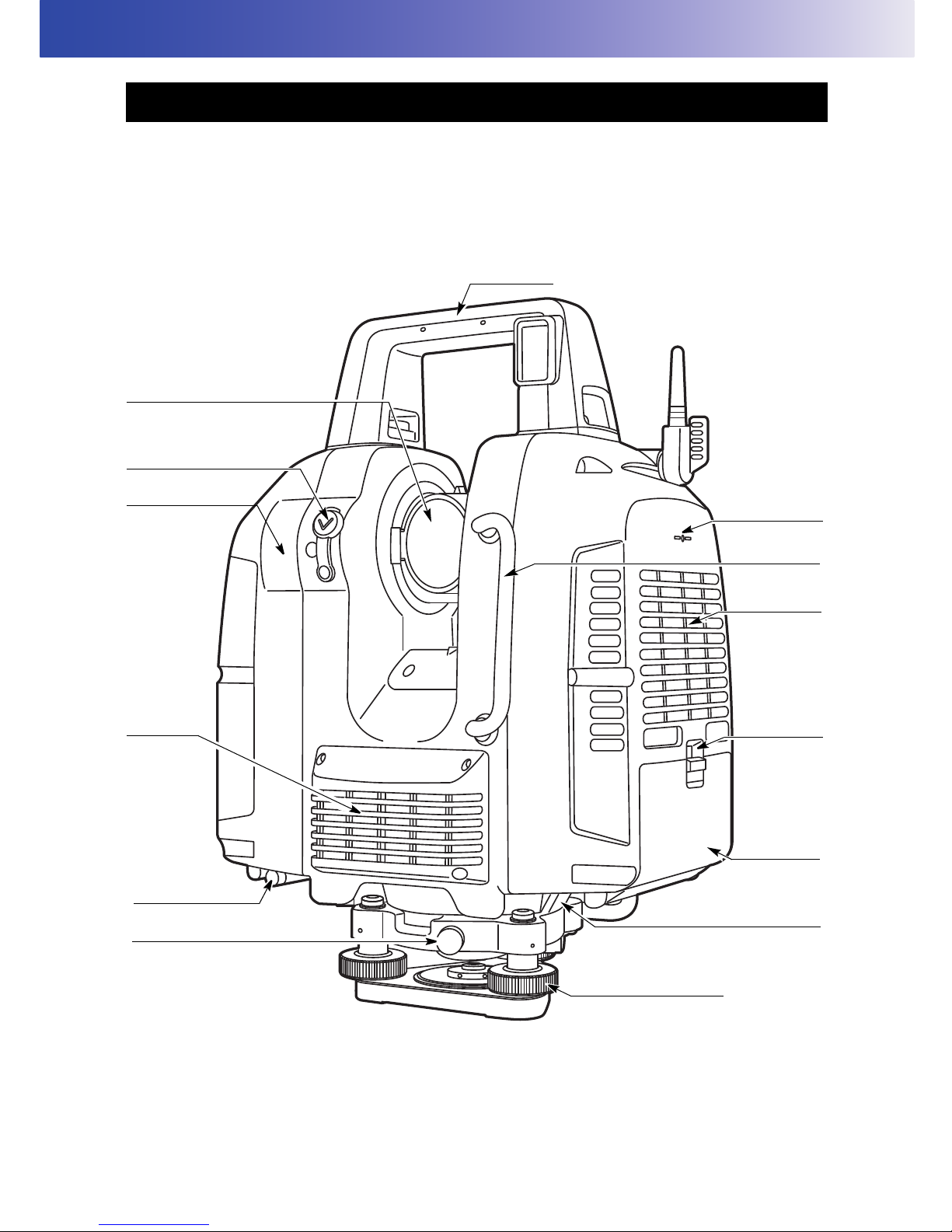

9

4. PRODUCT OUTLINE

Display

Operation key

Battery cover

lever

Battery cover

Right

Tribrach fixing lever

Side handle

Instrument height

mark

Handle locking screw

Card slot

(inside of a battery cover)

Circular level

Laser plummet

window

Instrument center mark

Page 14

10

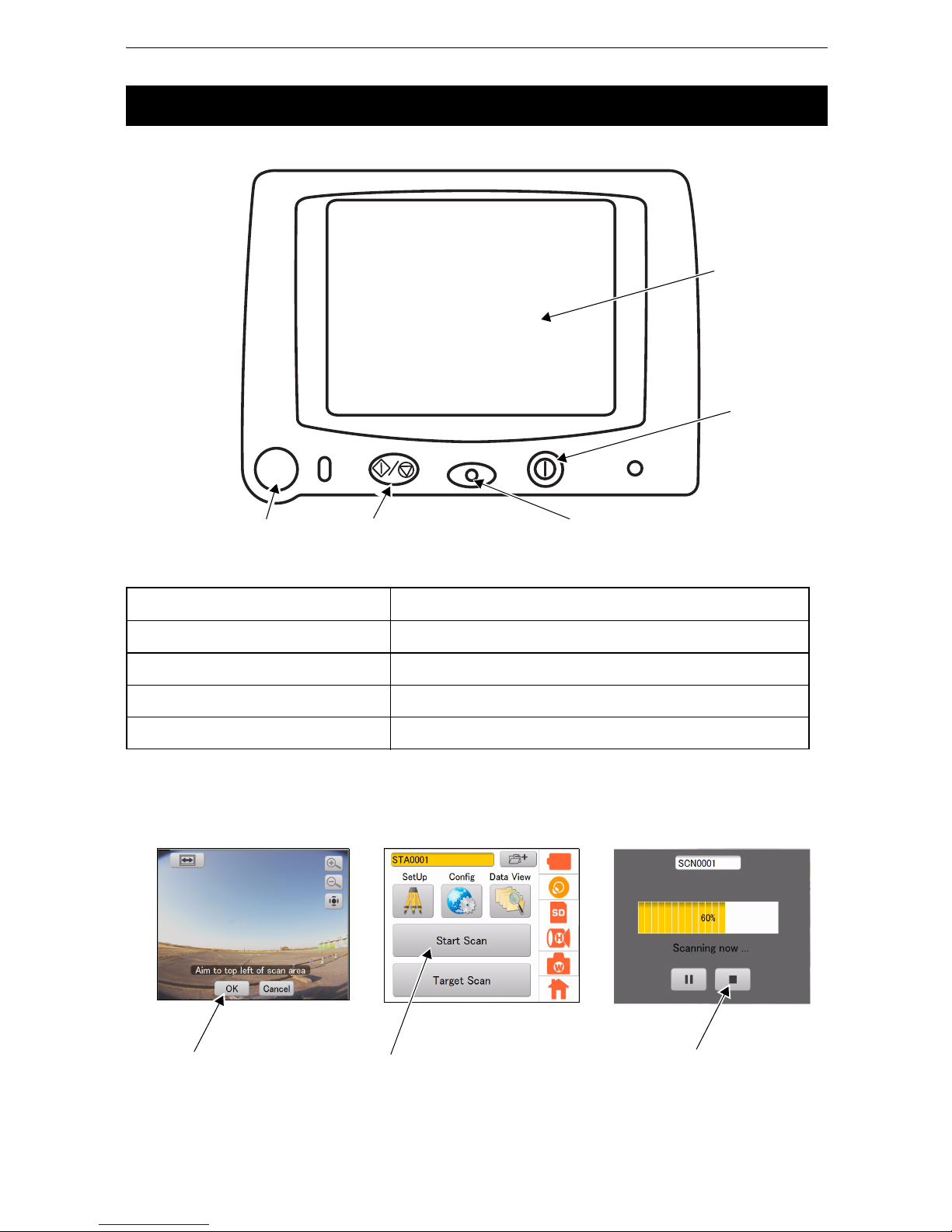

4. PRODUCT OUTLINE

The operating keys on the side of the instrument are as follows:

• The buttons in the screens below provide the same functions as the keys listed in the table above.

4.2 Operating Keys

Key / Indicator name Function

Collimating Position Setting key Sets the collimating position.

Start/Stop Scan key Starts or stops scanning.

Power key Turns the power ON and OFF.

Power Indicator Lighting up in orange when the power is turned ON.

Collimating Position Setting key Start/Stop Scan key

Power key

Screen

Power Indicator

Start Scan button

Scan Stop key

Collimating Position Setting key

Page 15

11

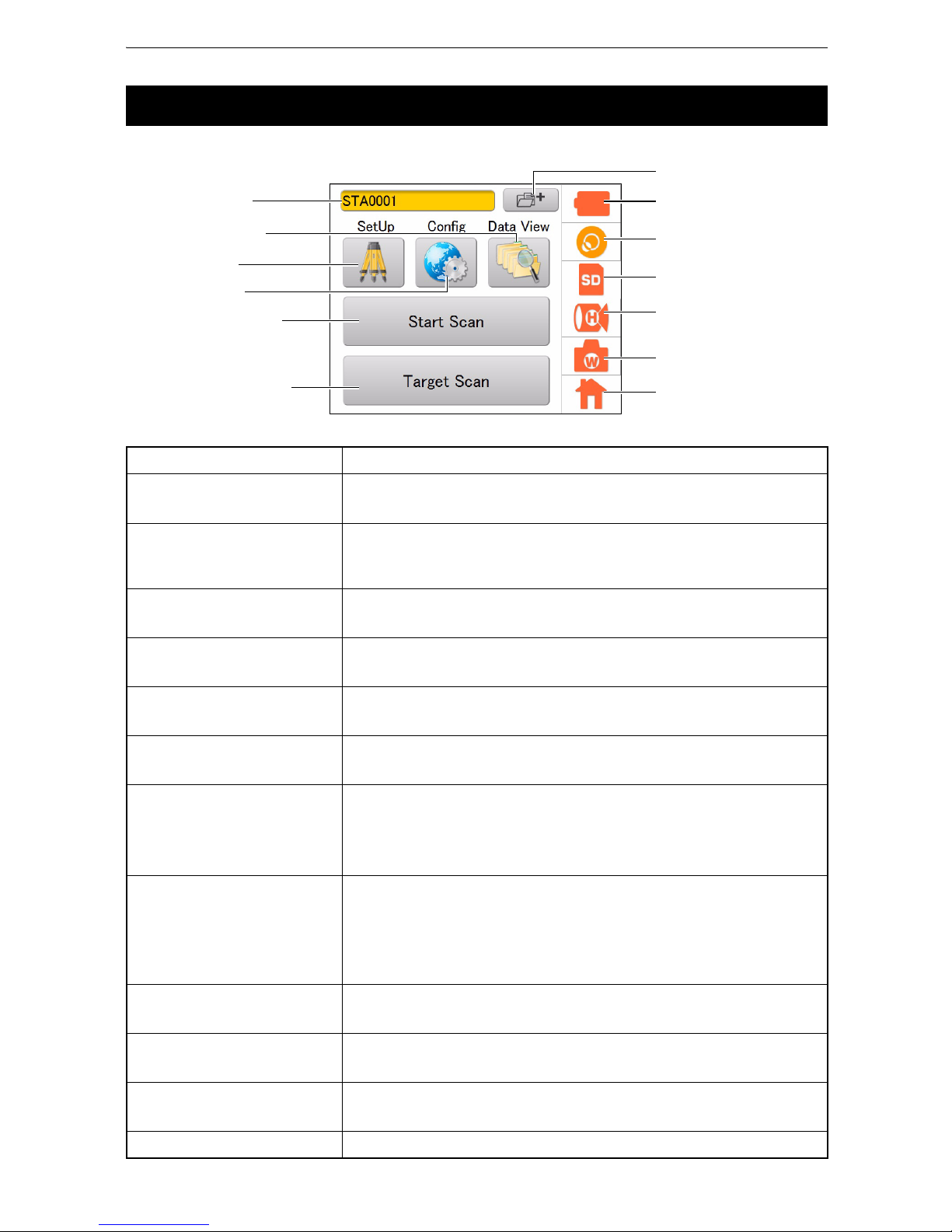

4. PRODUCT OUTLINE

Icons for frequently used functions and various setting modes are displayed on the main menu.

4.3 Display and Functions of the Main Menu

Name of the button / icon Function(s)

Station Setting button

Sets a new station name.

“9. STATION SETTINGS”

SetUp icon

Enters the SetUp mode to set the occupied point name and the

backsight point name.

“9.2 Setting the Point Name (Occupied point and Backsight point)”

Config icon

Enters the Config mode to configure various settings.

“8. FLOW OF THE CONFIGURATION SCREEN”

Data View icon

Enters the Data View mode.

“8.10 Data structure in the SD card”

Start Scan button

Starts Scanning.

“10.2 3D Scanning”

Target Scan button

Scans the target.

“10.1 Target Scanning”

Battery icon

Displays the remaining battery life. Also, use it to replace the batteries

while scanning.

“6.6 Battery Power Remaining Display”

“6.7 Replacing the Batteries during the power is ON”

Tilt Setting icon

Displays the electronic circular level.

Switches the tilt, ON or OFF.

“7.1 Setting the Tilt Sensor ON/OFF”

Adjusts the tilt sensor installation error.

“11.2 Tilt Sensor Calibration”

SD Card icon

Displays the detail of the SD card usage.

“6.5 Using the SD Card”

Scan Setting icon

Sets the conditions of scanning.

“10.2 3D Scanning”

Camera Setting icon

Sets the built-in camera

“7.2 Camera Settings (Angle of view and Resolution)”

Home icon Displays the main menu.

Battery icon

Tilt Setting icon

SD Card icon

Scan Setting icon

Camera Setting icon

Home icon

Data View icon

Config icon

Start Scan button

Target Scan button

SetUp icon

Main Menu

Station Setting button

Station name

Page 16

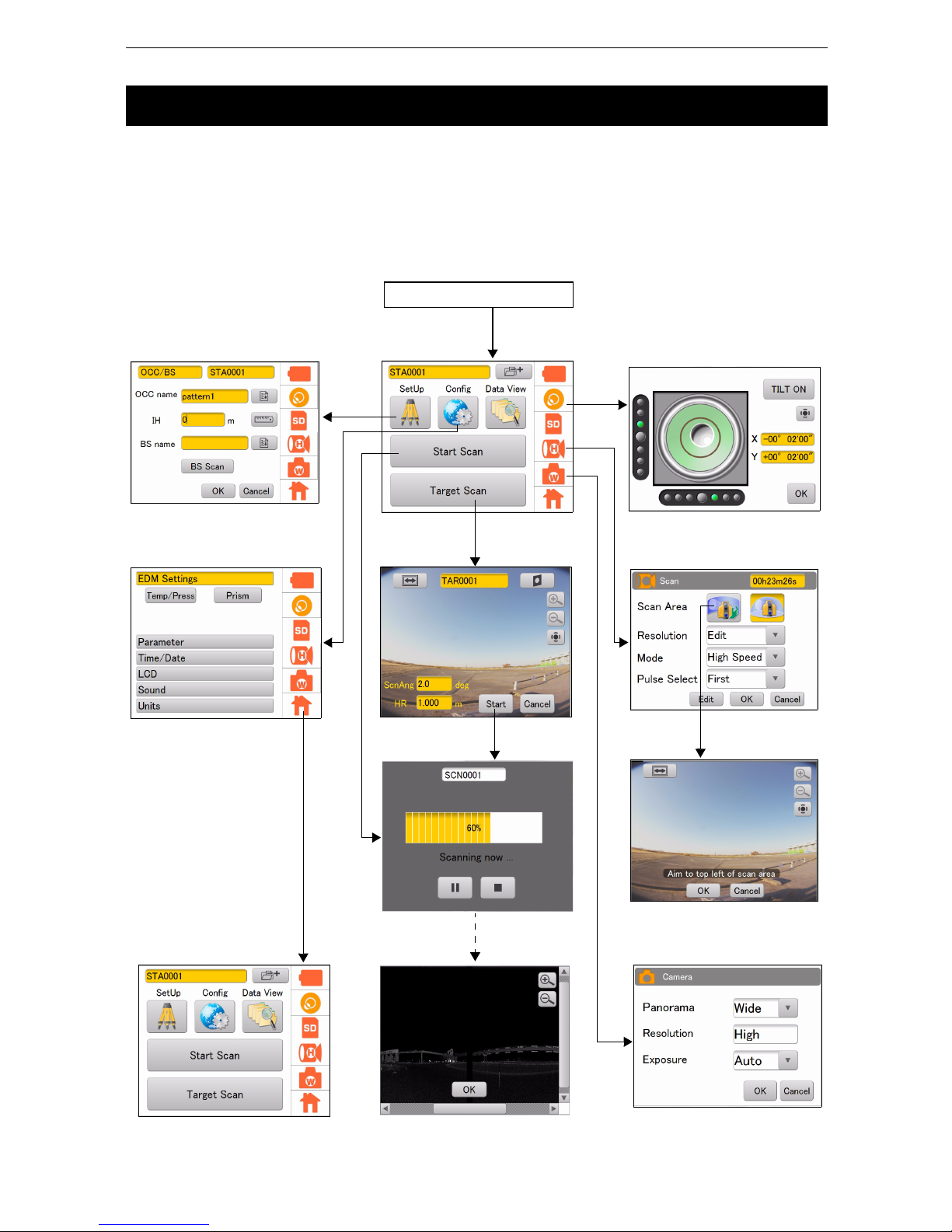

12

4. PRODUCT OUTLINE

The following illustrates the main flow of the screens.

Use a stylus pen to operate the screen.

• Do not scratch or use any sharp objects other than a stylus pen on the screen face.

4.4 Flow of the Screens

Power ON

Main Menu

Scan Setting Screen

Camera Setting Screen

Config Screen

Tilt Setting Screen

SetUp Screen

Main Menu

Page 17

13

5. PREPARATIONS BEFORE USE

• The station information and the measured data are stored in the SD memory card. Make sure that the

SD memory card is inserted before measuring.

• When using a coordinate point that is already known, make sure that the data (coordinate point file

(CSV file), etc.) is stored in the SD card.

• Use an SD card with the speed at 6MB/sec or faster, or an SDHC card of Class 6 or higher. SD cards

of Class 4 or lower cannot be used.

• Use the supplied battery (BDC70) for the instrument.

• See “12. BATTERY CHARGING” on how to charge the batteries.

• Do not break the projection (Open/Close sensor) inside the battery cover. Be careful not to pinch your

finger.

• Make sure that no water drop or dust gets inside the instrument when setting or removing the batteries.

• When storing the batteries, remove the batteries from the instrument or the charger.

• The batteries are chemical products that use a chemical reaction and have a limited life expectancy.

Even if the batteries are not used, they deteriorate over time and the capacity decreases. If the service

lives of the properly charged batteries are shortened, purchase new ones, as the batteries have come

to the end of their useful service life.

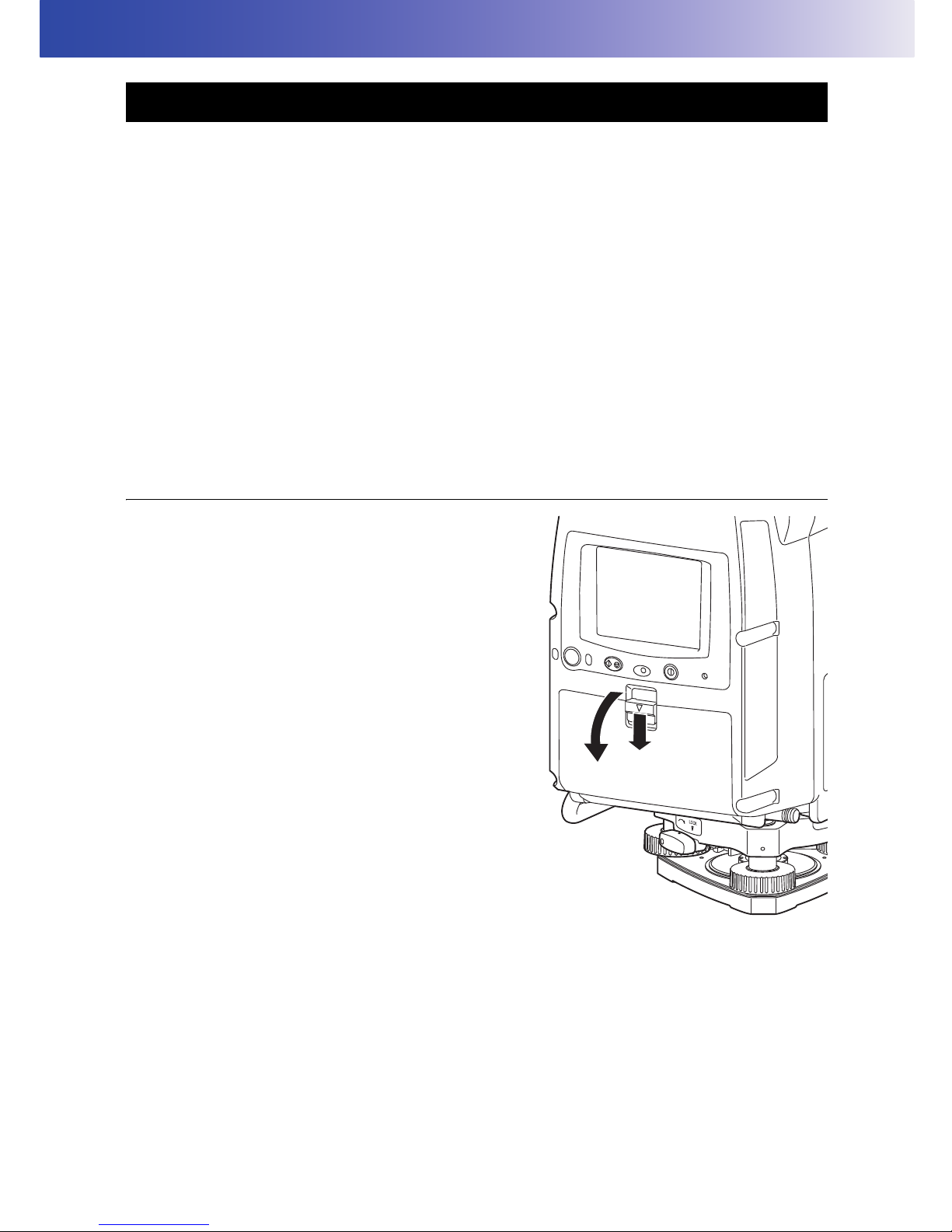

PROCEDURE

1. Slide down the lever on the battery cover (Right)

to open.

5.1 Inserting an SD memory card and Installing the Battery

Page 18

14

5. PREPARATIONS BEFORE USE

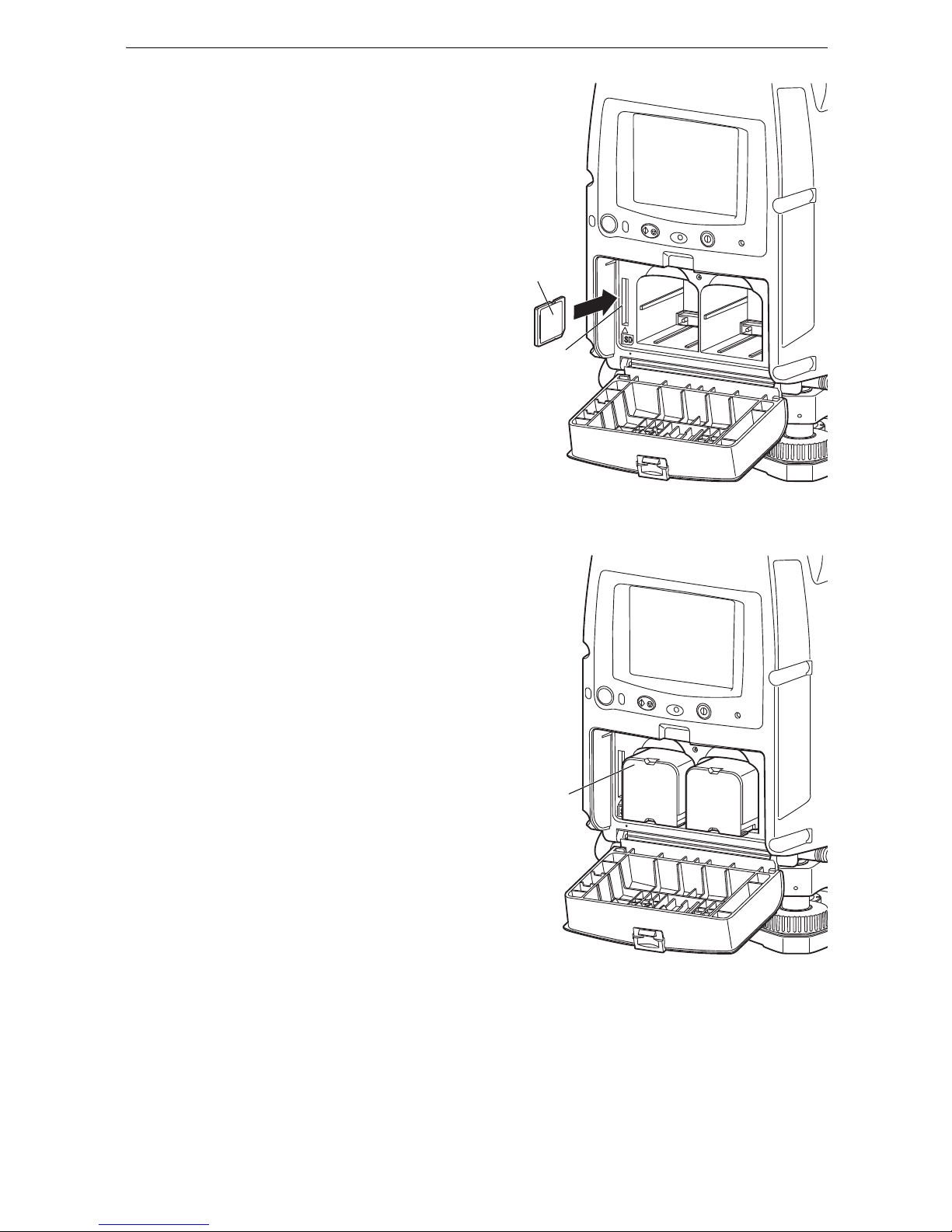

2. Insert a SD card to the card slot.

• Please make sure you have the front and back of

the SD card facing correctly when inserting into the

card slot.

• When removing the SD card, press the center of

the card slowly. Pressing the edge of the card may

cause the card to eject strongly.

• While a progress bar displays, do not remove the

SD card.

Otherwise, the data may be destroyed.

3. Checking the terminal side on the battery, insert

two batteries as shown.

4. Close the battery

cover (Right).

Make sure it clicks.

SD card

Card slot

Battery

Page 19

15

5. PREPARATIONS BEFORE USE

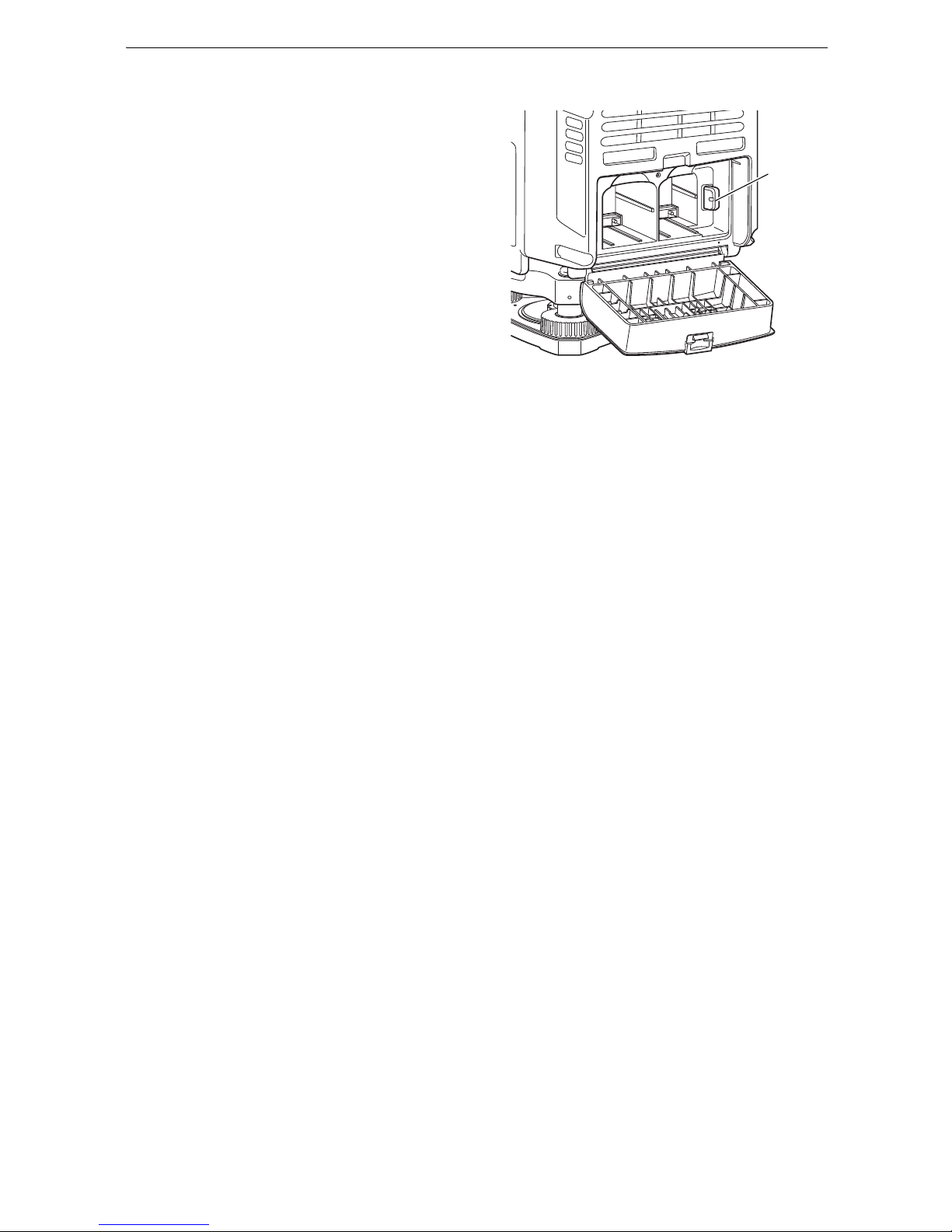

5. Open the battery cover (left).

6. Similarly, Install two batteries.

• Never remove the backup memory in the battery

cover (Left).

7. Close the battery cover (Left). A click is heard

when the cover is secure.

Backup

memory

Page 20

16

5. PREPARATIONS BEFORE USE

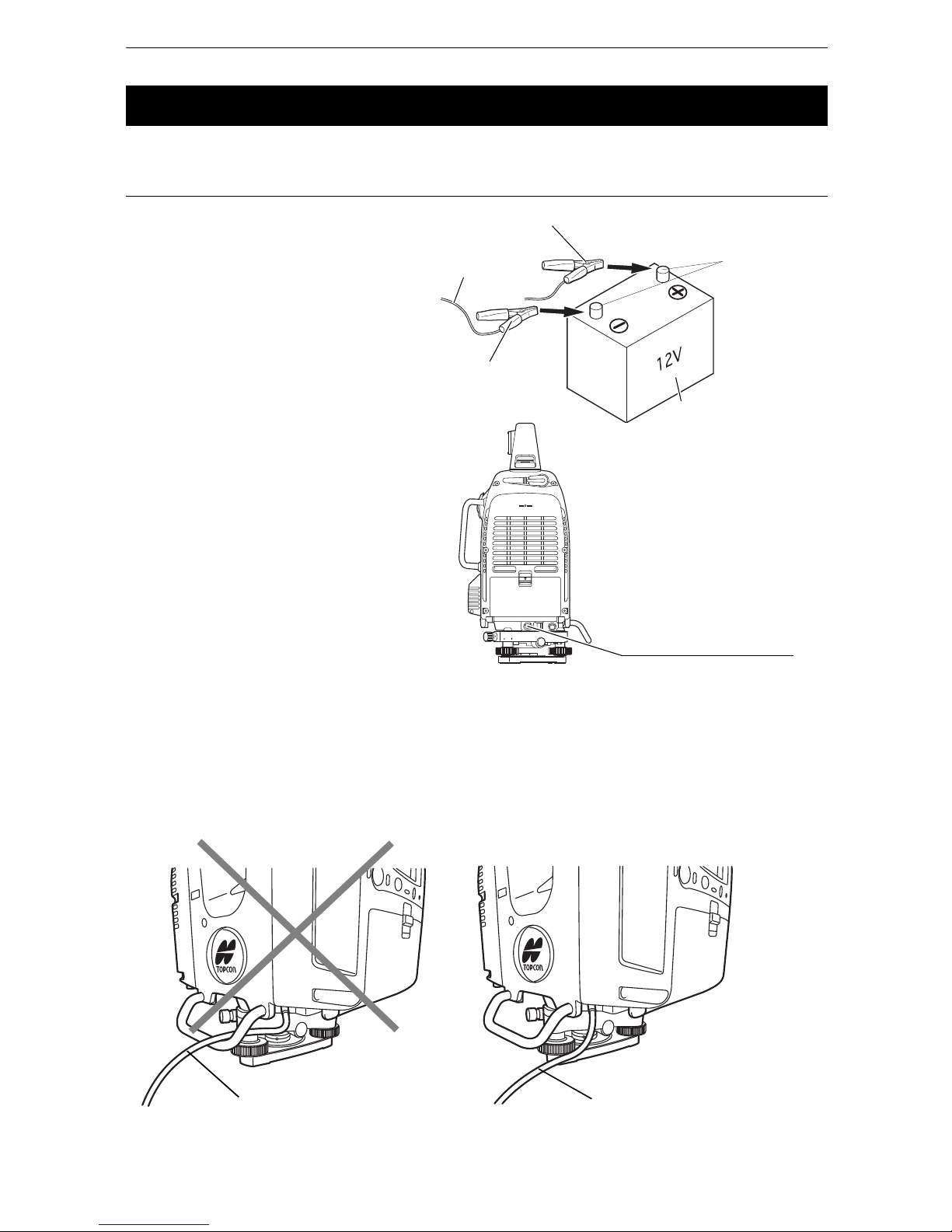

Use the external power source if necessary.

PROCEDURE Connect the external power source

1. Connect the clip of the external

power cable PC-26 (Sold separately)

to a terminal of commercial external

power source.

2. Connect the external power cable

PC-26 to the power source

connector.

• The GLS-2000 automatically starts by connecting the external power source without the batteries

(BDC70) in the instrument.

• Make sure to close the connector cap of the power source connector when an external power source

is not being used.

• When connecting the power cable to the power source connector, place the power cable outside the

side handle as shown below. If the power cable is inside the side handle, it may be disconnected due

to the instrument’s rotation. Rotate the instrument before turning the power on to make sure that it does

not hit the power cable.

5.2 Connecting the External Power Source

PC-26

Red clip (+)

Black clip (-)

External power source

Terminal

Power source connector

Power cable is inside the

side handle.

Power cable is outside the

side handle.

Page 21

17

5. PREPARATIONS BEFORE USE

The following describes the overview of scanning procedure:

5.3 Overview of Scanning Procedure

Scan

Set the station, the occupied point and the backsight point

1. Scan the target.

2. Perform a 3D scanning.

1. Set the station.

2. Turn the power ON.

1. Install the instrument.

Prepare for scanning

Turn the power OFF

“6.4 Setting Up the Instrument”

“6.3 Power ON/OFF”

“9.1 Creating a New Station”

“9.2 Setting the Point Name (Occupied point and Backsight point)”

“10. MEASURING (SCANNING)”

“10.1 Target Scanning”

“10.2 3D Scanning”

2. Set the occupied point name and the backsight point name, and then scan

the backsight point.

3. Set up this instrument.

“7. INSTRUMENT SETTINGS”

1. Turn the power OFF.

“6.3 Power ON/OFF”

“8.9 Handling the Coordinate Point File”

Page 22

18

6. PREPARATION FOR MEASUREMENT

The carrying handle can be removed from the instrument. To remove it, loosen the 2 handle rocking

screws.

• Remove the handle when scanning around the zenith or the whole circumference.

• To remove the handle, hold both sides of the handle and lift it straight above. If you hold the handle by

one hand or incline it, the terminal attached on the handle may be damaged.

• When using the instrument with the handle detached, pay careful attention that no water or dust has

adhered to the terminal.

To attach the handle, position and align the handle and then tighten up the handle locking screws. (Two

points need to be screwed.)

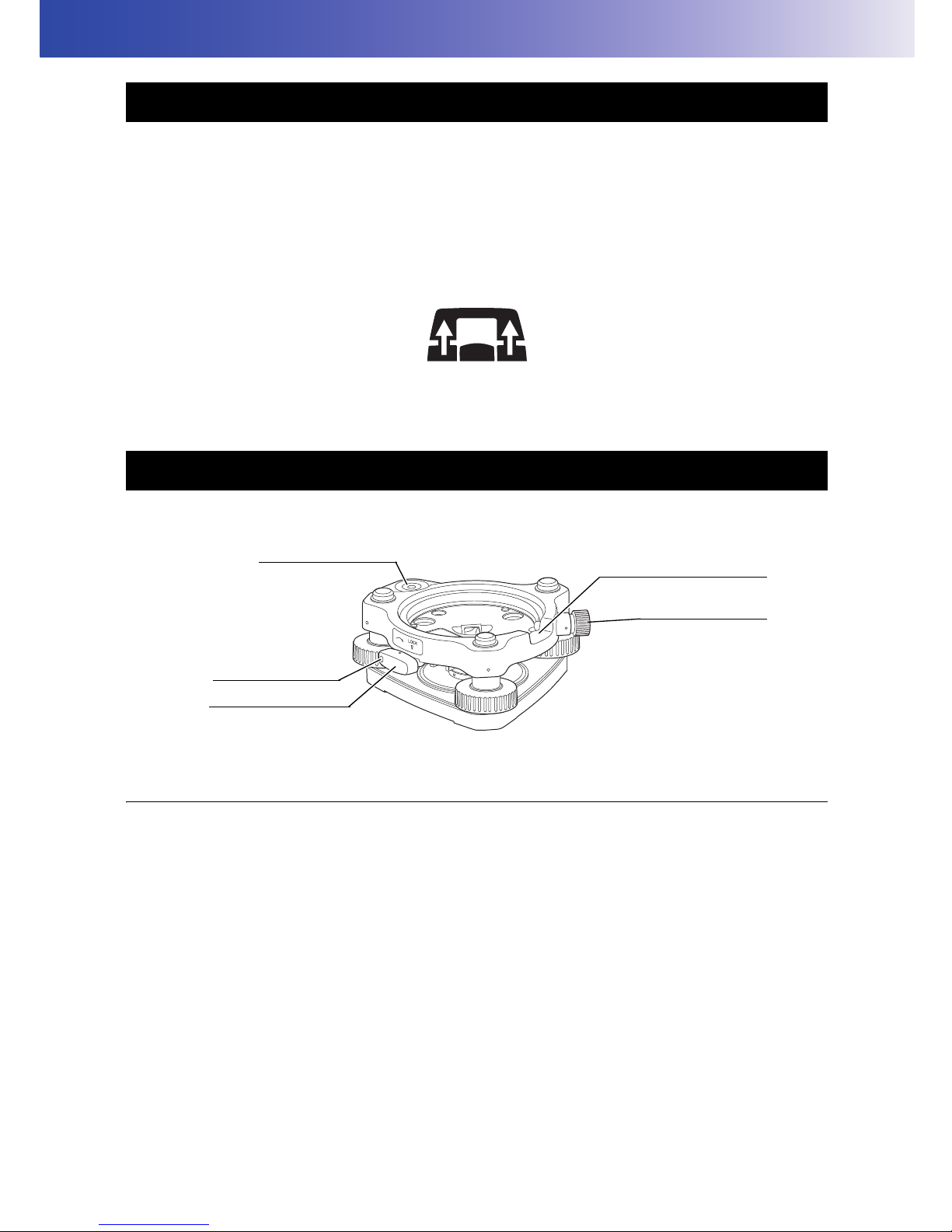

The instrument is easily detached or attached to the tribrach.

PROCEDURE Detaching the instrument from the levelling base

1. Loosen the levelling base locking screw by

turning 2 or 3 rotations in the counterclockwise

direction.

2. Turn the tribrach clamp counterclockwise to

loosen. (When the tribrach fixing lever securing

screws are screwed in, use the driver provided in

the package to loosen.)

3. Lift the instrument to detach.

6.1 Detaching / attaching the Handle

6.2 Detaching / attaching the Tribrach

Securing screw

Tribrach fixing lever

Tribrach alignment groove

Tribrach fixing screw

Tribrach circular level

Page 23

19

6. PREPARATION FOR MEASUREMENT

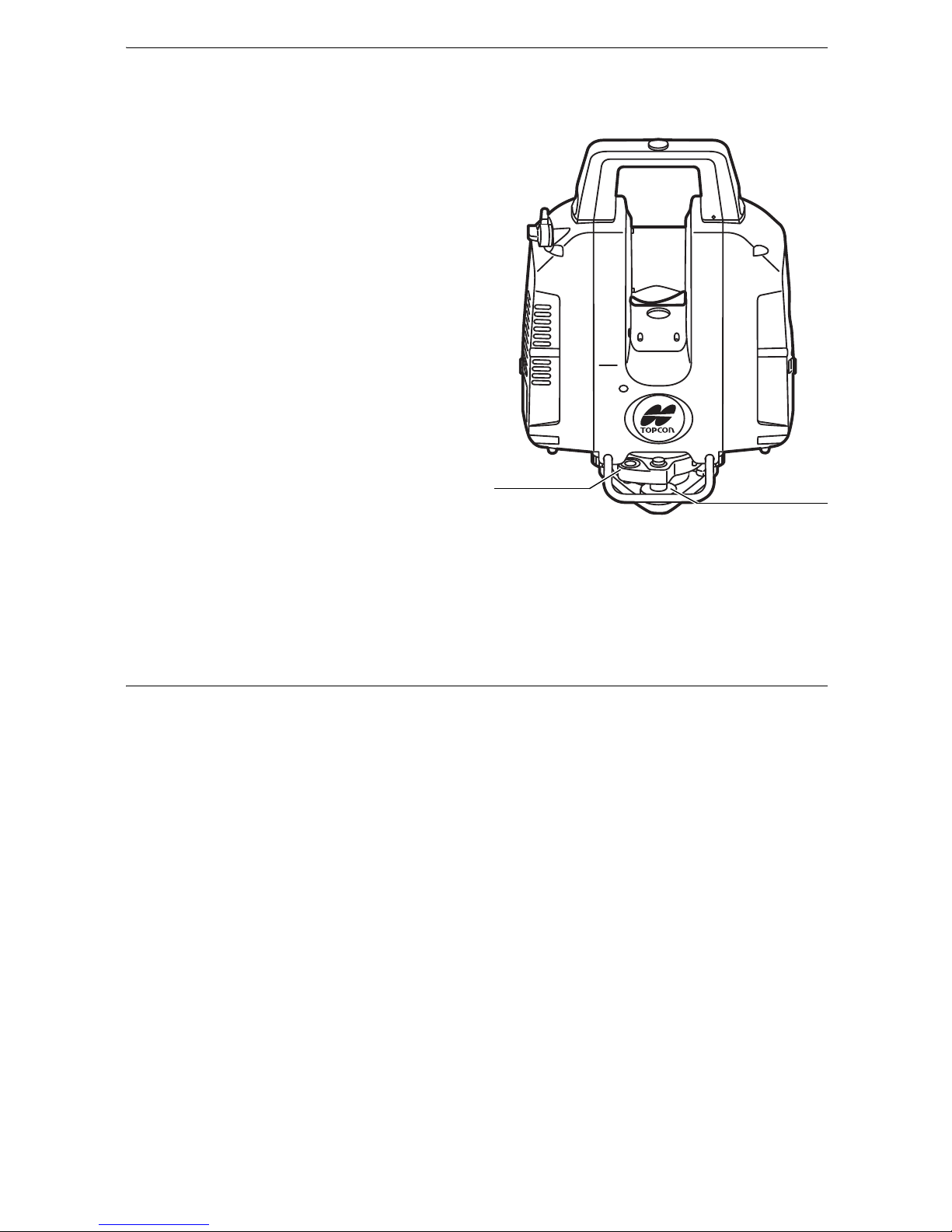

PROCEDURE Attaching the instrument to the levelling base

1. Check that the tribrach fixing screw has been

loosened.

2. Align the alignment piece and the tribrach

alignment groove and lower the instrument onto

the levelling base.

3. Turn the tribrach fixing lever clockwise to tighten.

4. Turn the tribrach fixing screw clockwise to

tighten.

• Locking the tribrach fixing lever

The tribrach fixing lever can be locked from being moved accidentally. This is useful if the upper

instrument section is not being detached very often. Simply tighten the securing screw on the fixing

lever with the accessory screw driver.

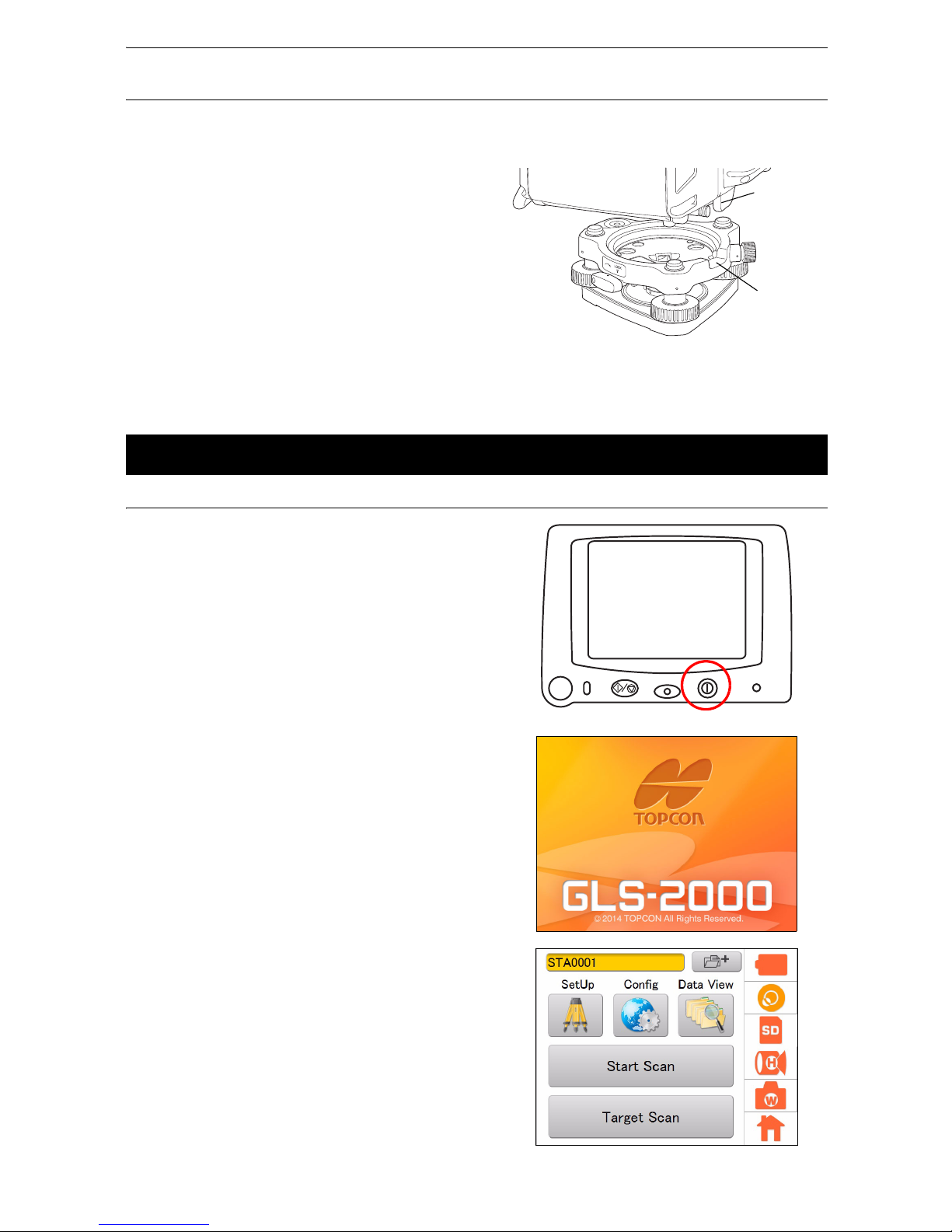

PROCEDURE Power ON

1. Press the power key located on the right side of

the instrument.

After the power Indicator turned on, a startup

screen will be displayed.

• It takes approximately 3 minutes after the power

has been switched ON to initialize the instrument

and warm up the laser.

Do not turn the instrument with your hands or

operate any keys while the instrument is turning.

The main menu will appear.

• If [TILT OVER] is displayed, this instrument is

inclining beyond the tilt angle compensation

range. Level this instrument using the tilt sensor.

“6.4 Setting Up the Instrument”

6.3 Power ON/OFF

Alignment

piece

Tribrach

alignment

groove

Main menu

Page 24

20

6. PREPARATION FOR MEASUREMENT

• Internal Calibration

In order to maintain its precision, the instrument will automatically perform internal calibration. The

internal calibration will take approximately 2 minutes.

Confirm that, after the setup is finished, the

positional relationship between the instrument

and the tribrach will be as shown in the figure

here.

• Do not turn the head or the scanner unit with your

hands while the power is ON. If it has been turned

by force, turn the power ON again. (Except when

collimating)

PROCEDURE Power OFF

1. Press and hold (about 2 seconds) the power key

located on the right side of the instrument.

The power is switched off.

Leveling screw

Circular level

Page 25

21

6. PREPARATION FOR MEASUREMENT

• Level and center the instrument precisely. Level and center the instrument precisely to insure the best

performance.

• Use tripods with a tripod screw of 5/8 in. diameter and 11 threads per inch, such as the Type E TOPCON

wide-frame wooden tripod. Do not use a metallic tripod.

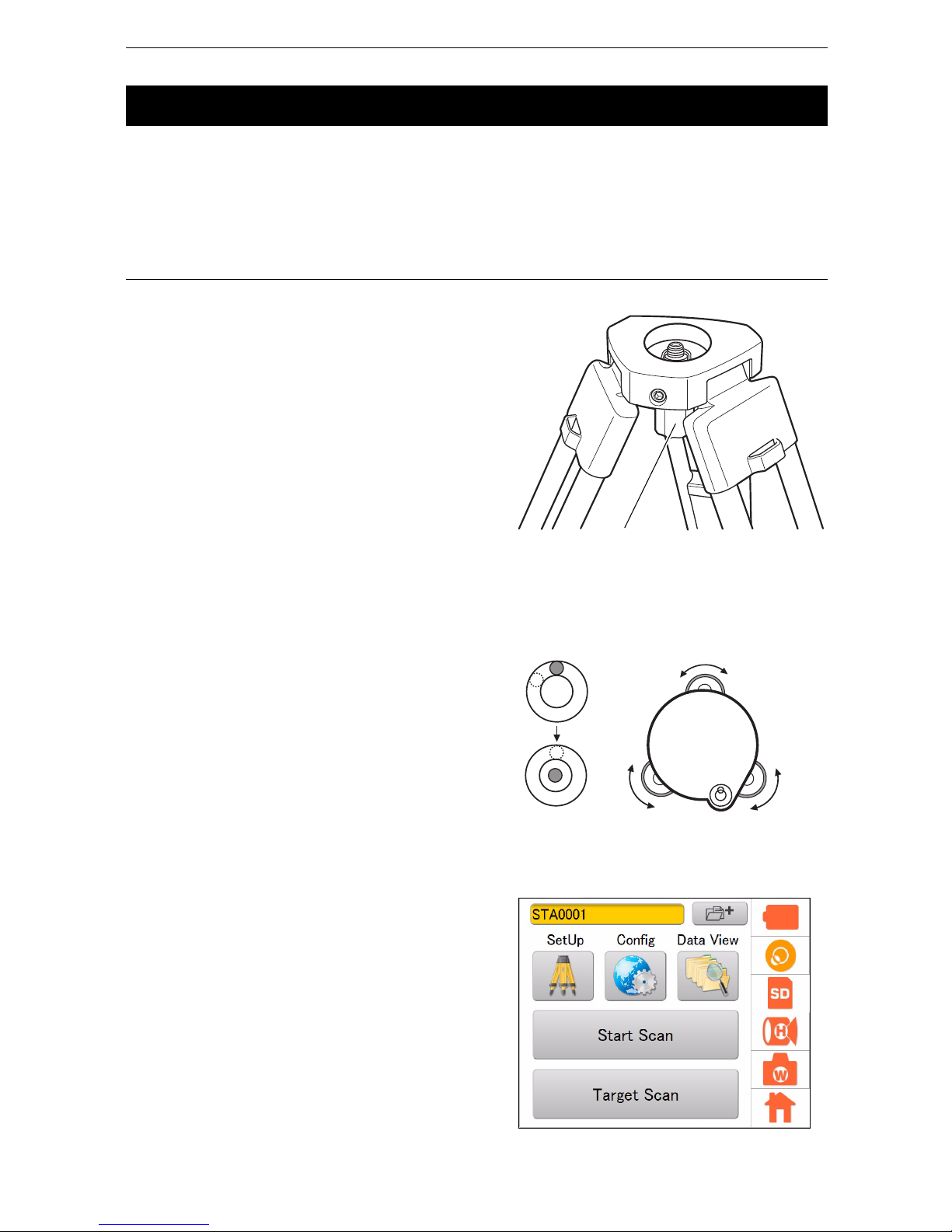

PROCEDURE Leveling and Centering the Instrument

1. Setting up the Tripod

First, extend the extension legs to suitable

lengths and tighten the screws on their

midsections.

2. Place the instrument on the tripod head.

Place the instrument on the tripod head, lightly

tighten the centering screw.

Slide the instrument by loosening the centering

screw, place the point over the survey point, and

then tighten the centering screw.

3. Roughly Leveling the Tribrach by Using the

Tribrach circular level

Turn the leveling screws A and B and adjust the

bubble to stay at the top or bottom of the circular

level.

Turn the leveling screw C to bring the bubble to

the center of the tribrach circular level.

4. Centering with the Laser Plummet

Turn the power of this instrument ON.

Press the Tilt Setting icon.

6.4 Setting Up the Instrument

Centering screw

Leveling screw A

Leveling screw B

Leveling screw C

Tribrach circular level

Page 26

22

6. PREPARATION FOR MEASUREMENT

The electronic circular level is displayed.

Press , and then the laser plummet beam

will

be emitted from the bottom of the instrument.

“” indicates the bubble in circular level.

The line within the electronic circular level is set

at ±6'. The amount of dislocation will not be

displayed when the bubble is beyond the line.

Center “” in the circular level using foot screws.

Slide the instrument by loosening the centering

screw, place the point on the survey point, and

then tighten the centering screw.

Try to keep the instrument from rotating when

sliding it so as to minimize the dislocation of the

bubble.

Repeat step 3 and 4 if necessary.

5. Press [OK] after centering.

: Laser plummet beam is lit.

: Laser plummet beam is off.

Page 27

23

6. PREPARATION FOR MEASUREMENT

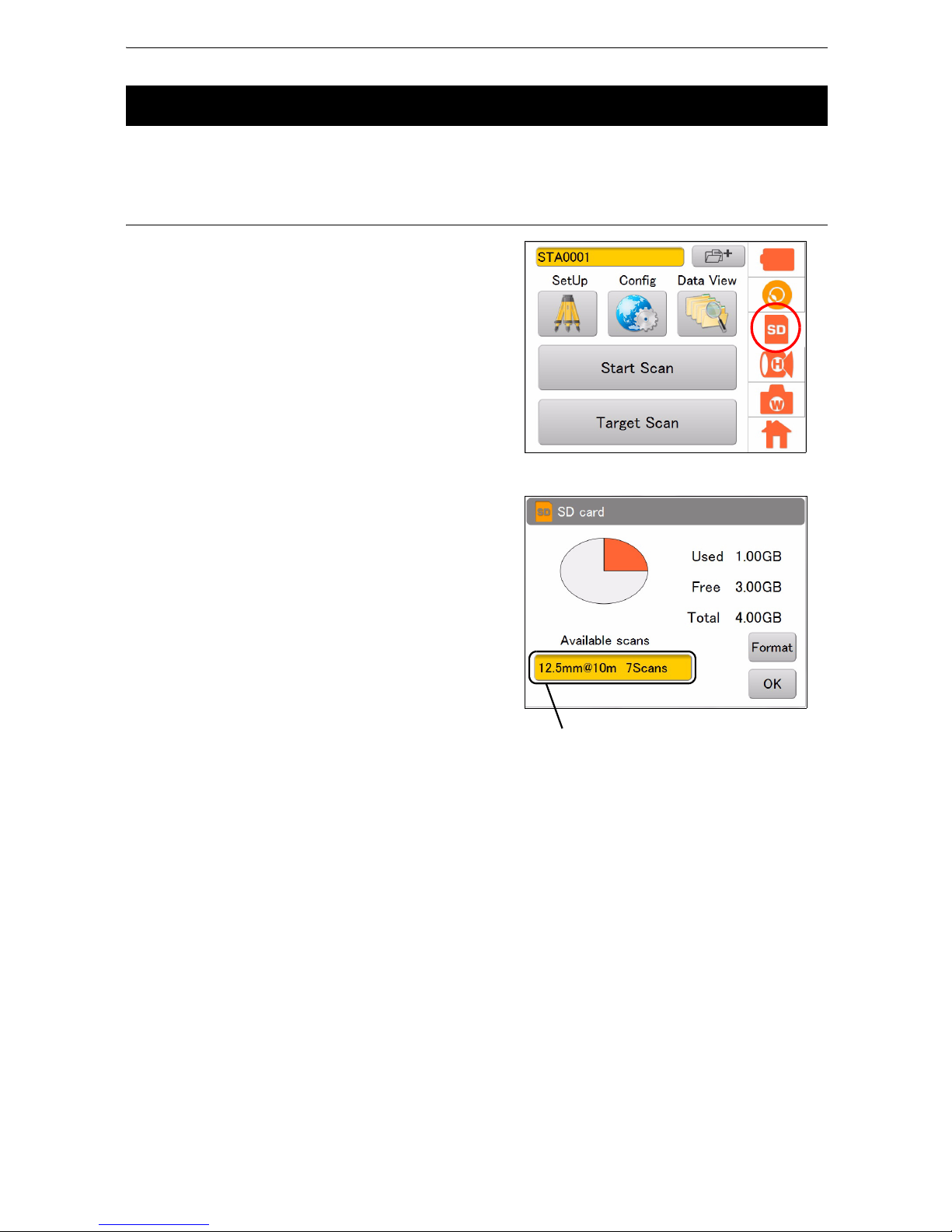

Tap the SD Card icon to check the detail of the SD card usage.

PROCEDURE

1. Press the SD Card icon.

The confirmation window will appear.

Press [Format] to format the SD card.

Press [OK] in the confirmation message window

to start the format.

The time required to format an SD card depends

on the volume of the SD card.

2. Press [OK] to return to the main menu.

• Note that when the card is formatted, all files in the card are deleted and cannot be used.

6.5 Using the SD Card

It means that there are seven scans worth of

memory available when the scanning is to be

done within the set scanning range at a

resolution of 12.5mm@10m.

Page 28

24

6. PREPARATION FOR MEASUREMENT

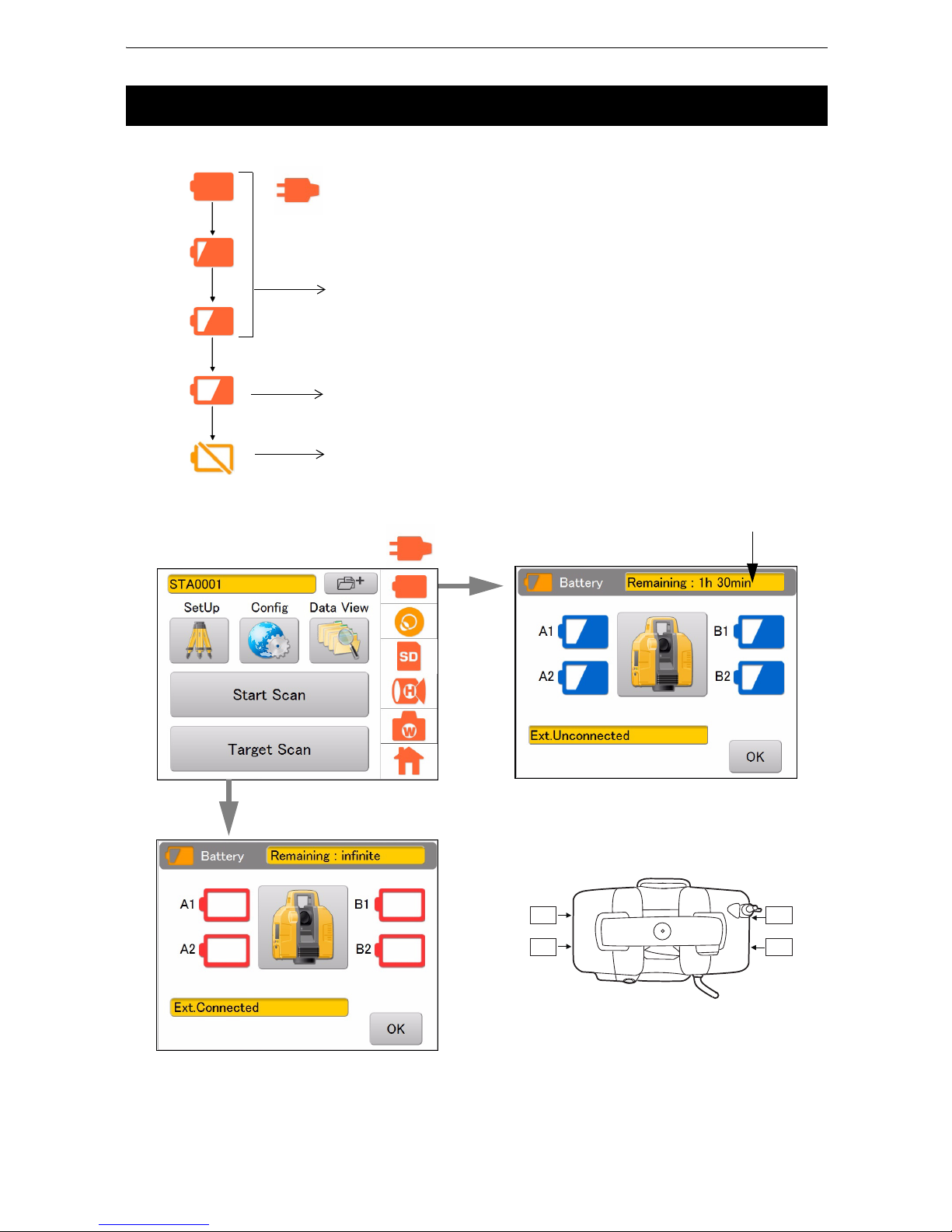

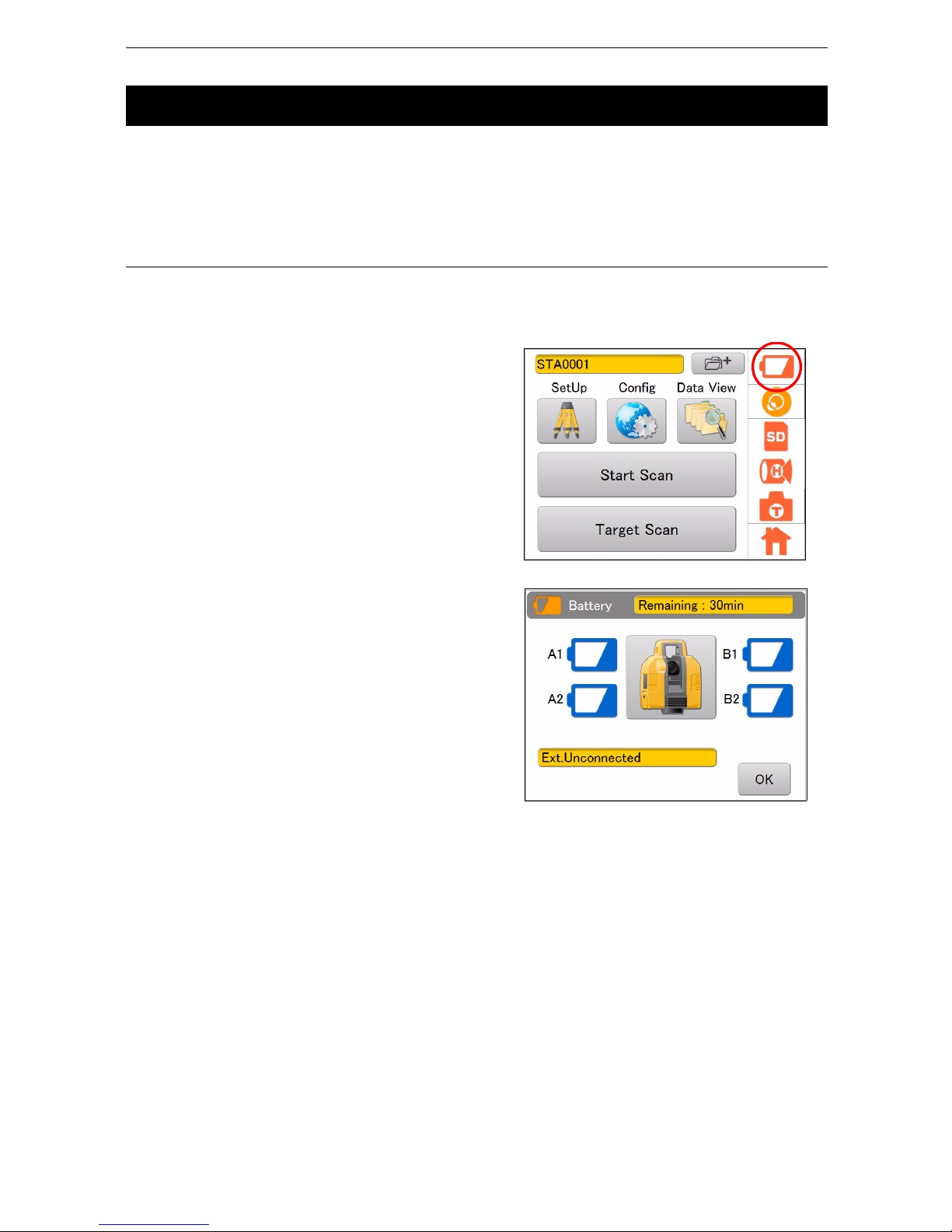

Battery power remaining display indicates the power condition.

Press the Battery icon to display the remaining battery time.

• The battery operating time will vary depending on the environmental conditions such as ambient

temperature, charging time, the number of times of charging and discharging etc. It is recommended for

safety to charge the battery beforehand or to prepare spare full charged batteries.

“12. BATTERY CHARGING”

6.6 Battery Power Remaining Display

Measurement is possible.

The power is poor. Please replace with fully

charged batteries.

Measurement is impossible.

Please replace with fully charged batteries.

( : When using external power source)

• The remaining battery level will not be displayed when an external

power source is used.

B1A1

A2

B2

Remaining battery time

Position of each battery

(Top View)

( : When using external power source)

When using external power source

Page 29

25

6. PREPARATION FOR MEASUREMENT

• When replacing the built-in batteries, replace all four batteries with fully charged batteries.

• Replace two batteries at a time: Replace A1 and A2 batteries first, and then B1 and B2 batteries, all with

fully charged ones.

“ Position of each battery” on page 24

PROCEDURE

If the battery power becomes low during the power is ON, replace the batteries by following the instruction

below to continue the scanning:

1. Press the Battery icon.

The remaining battery level will be displayed.

2. Open the right-side battery cover to replace two

batteries.

3. Close the right-side battery cover.

Confirm that both A1 and A2 batteries are

recognized and that the battery level has

increased.

4. Similarly, open the left-side battery cover to

replace two batteries.

5. Close the left-side battery cover.

Confirm that both B1 and B2 batteries are

recognized and that the battery level has

increased.

6. Press [OK].

6.7 Replacing the Batteries during the power is ON

Page 30

26

6. PREPARATION FOR MEASUREMENT

Numerical, uppercase, and lowercase alphabetic characters can be entered when entering a station, an

instrument height, or a backpoint.

The function of a keyboard is as follows.

Characters that can be entered

6.8 Entering Numeric and Alphabetic Characters

Items to enter characters Characters that can be entered Number of characters

• Target name

• Station name

• Occupied point name

• Backsight point name

• Alphabet : a to z, A to Z

• Numeric characters: 0 to 9

• Symbols (“*”, “:“, “/“, “?“ are disabled)

8 characters or less

When entering

capital letters

When entering

lower case letters

When entering

alphabetic characters

When entering

numeric characters

or symbols

Deletes the letter on the left side

switch

Inputted characters

Cancel the input data

Determines the selection

Page 31

27

6. PREPARATION FOR MEASUREMENT

Use the target or (single) prism when performing “target scanning”.

• Be sure to use the target sheets for the GLS-2000/1500 manufactured by TOPCON.

• Select the target sheet (large, medium, small) based on the distance to the object being scanned.

(Target sheet (large / medium) is sold separately)

Assembling the target

• Refer to the instruction manual of the prism in use for its assembling.

PROCEDURE

1. Attach the alignment piece of the prism adaptor

(sold separately) to the tribrach (sold separately),

according to the position shown in the figure

here.

2. Tighten the tribrach fixing lever firmly by turning

clockwise.

6.9 Preparing the Target

Distance to the

scanning target (m)

Target sheet Size (m)

50-200 Large 0.12

10-100 Middle 0.06

2-50 Small 0.03

Prism-adapter

Alignment piece

Tribrach

Tribrach fixing lever

Page 32

28

6. PREPARATION FOR MEASUREMENT

3. Install the target board (Sold separately) as

shown in the illustration.

Tighten the settlement screw surely.

4. Put the magnetic target sheet on the target

board. At this point, adjust the center marks (4)

of the target sheet and the target board exactly.

Settlement

screw

Center mark

Target board

Target sheet

Center mark

Page 33

29

7. INSTRUMENT SETTINGS

Settings for this instrument are set through main menu icons and settings mode (“8. FLOW OF THE

CONFIGURATION SCREEN”).

When the auto tilt correction function for the vertical and horizontal angles is turned ON, the 2-axis tilt

sensor is activated, automatically compensating errors in vertical and horizontal angles due to inclination

of the standing axis.

To ensure precise measurement, set the auto tilt correction [Tilt] to ON. If the error is out of the automatic

compensation range, [TILT OVER] will be displayed. In such a case, level this instrument. The screen

appearing before [TILT OVER] was displayed will appear again when the tilt enters the automatic

compensation range after the leveling.

• This instrument automatically compensates errors in the vertical and horizontal angles by detecting the

inclination of the standing axis of the instrument towards the X, Y directions.

• Indication of the inclination of the X, Y directions may not be consistent when this instrument is mounted

on an unstable stand or when the wind is strong. In such a case, stop the auto tilt correction for the

vertical and horizontal angles to operate.

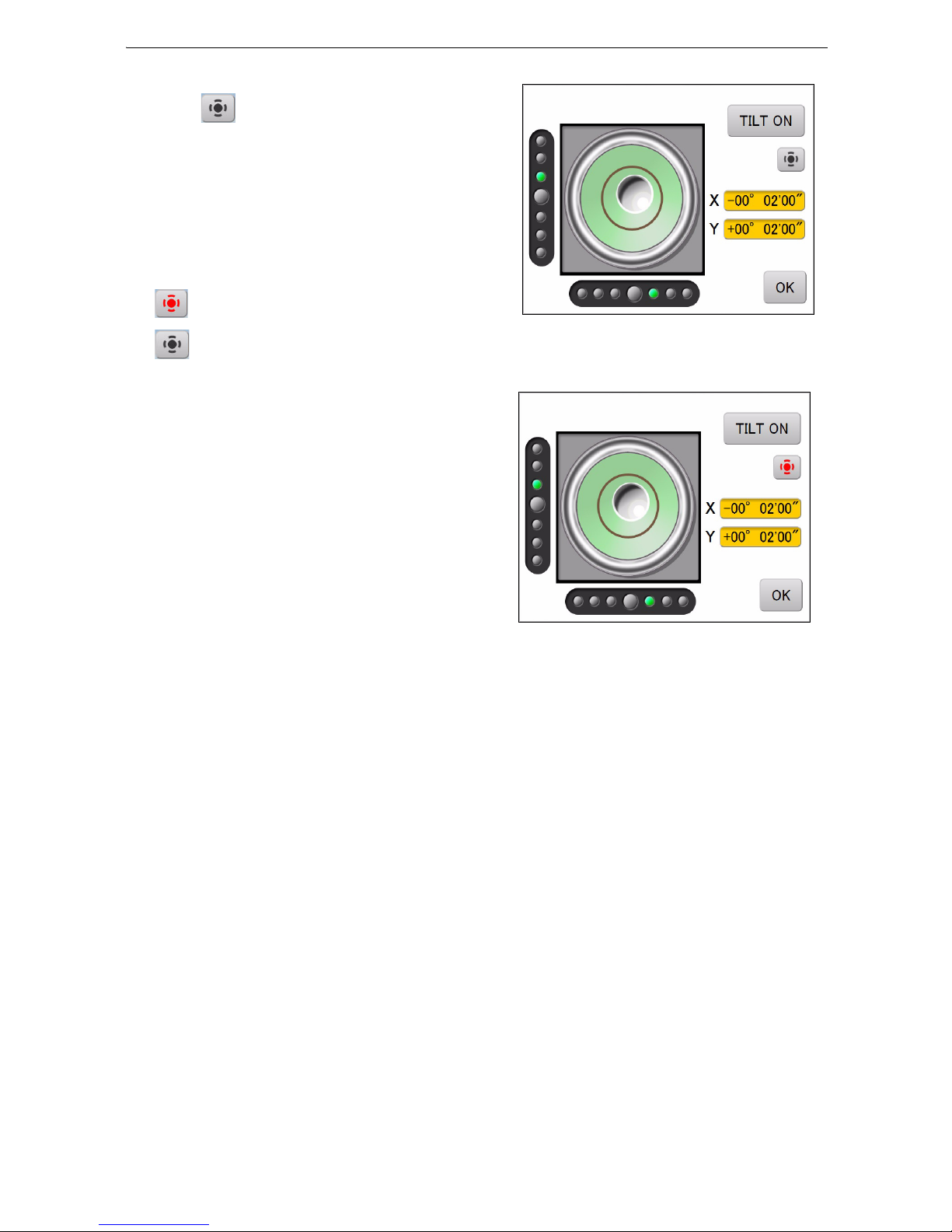

PROCEDURE Setting example: Tilt ON to OFF

1. Press the Tilt Setting icon.

7.1 Setting the Tilt Sensor ON/OFF

Verticality

Standing axis

Inclination of the

standing axis towards X

direction

Verticality

Inclination of the standing

axis towards Y direction

Trunnion axis

Horizontal

Standing axis

Page 34

30

7. INSTRUMENT SETTINGS

2. Press [TILT ON.]

The tilt is set to OFF.

The line within the electronic circular level is set

at ±6'. The amount of dislocation will not be

displayed when the bubble is beyond the line.

3. Press [OK.]

The Tilt Setting icon is switched OFF ( ).

: OK (It is correctable by using the tilt

correction function.)

: NG (It is not correctable by using the

correction function.)

: OFF (The tilt correction function is turned

off.)

Page 35

31

7. INSTRUMENT SETTINGS

The built-in camera automatically takes photographs of the entire scanning range and saves the

photograph data in the image file when scanning. (when selecting “Wide” or “Tele”)

The photograph data of the entire scanning range consists of several photographs. As the scanning area

becomes wider, the number of photographs taken will increase.

Also, as the resolution becomes finer, the file size will increase. Set the resolution as needed.

1. Press the Camera Setting icon.

• The Camera Setting icon displayed in the status

screen shows the selective condition of the

Panorama selected.

2. Select “Panorama,” “Resolution,” “Exposure,”

and press [OK.]

Setting items and each selection

(*: Factory default)

(1) Panorama: Wide* / Tele / OFF

• Remove the Wide-angle camera lens cap of the instrument when selecting “Wide".

(2) Resolution: Low / Normal / High*

(When selecting “Wide” for the “Panorama” camera setting: “High”

only)

(3) Exposure: Auto* / Manual

7.2 Camera Settings (Angle of view and Resolution)

Panorama Angle of view

Wide

Diagonal 170°

Te le

8.9° (V) × 11.9° (H)

OFF

No image data

Resolution Number of pixels

Low

480 (V) × 640 (H)

Normal

960 (V) × 1280 (H)

High

1920 (V) × 2560 (H)

Exposure Exposure value

Auto

The exposure value will be automatically determined by the signal level of

the center of the scanning range.

Manual

The exposure value can be adjusted on the exposure adjust screen at the

start of the scanning.

: Wide

: Tele

: OFF

Page 36

32

7. INSTRUMENT SETTINGS

By changing the scanning settings, measurement that suits the purpose can be carried out.

Resolution can be selected from the predetermined resolutions or by entering the desired resolution.

1. Press the Scan Setting icon.

• The Scan Setting icon displayed in the status screen

shows the selective condition of the range mode.

2. Select “Scan Area,” “Resolution,” “Mode,”

“Pulse Select,” and press [OK.]

(1) Scanning range

Range setting scanning or Whole circumference scanning can be selected.

“Scanning range” on page 64

(2) Resolution (a predetermined value)

Select a predetermined resolution listed below:

50mm@10m, 25mm@10m, 12.5mm@10m, 6.3mm@10m, 3.1mm@10m, Edit

“50mm@10 m” means “a measurement accuracy of 50mm in pitch at a position of 10 m ahead”.

For the range of measurement distance and the accuracy of measurement, see the following table.

*1) Range varies depending on weather conditions or stability of the atmosphere.

7.3 Settings for Scanning Conditions

Range of

measurement *1)

Reflectivity

Range mode

Detail

High

Speed

Low

Power

Standard

Close

9% reflection----40m

18% reflection 40m 90m 90m 150m -

90% reflection 100m 210m 210m 350m -

: Detail

: High Speed

: Low Power

: Standard

: Close

Range mode

Pulse Select

Resolution

(a predetermined value)

Scanning range

Resolution

(a desired value)

Estimated time for scanning

Page 37

33

7. INSTRUMENT SETTINGS

(3) Resolution (a desired value)

The horizontal and vertical start point angle, end point angle and measurement pitch can be set to

a desired value. (Set the start point angle and end point angle in the scan range setting screen

(

P. 65).)

Setting the measurement pitch

Enter the vertical or horizontal measurement pitch settings within the scanning range by using one

of the following three methods. Each value is linked.

mm : Enter the pitch between scanning points

pts : Enter the total number of scanning points

deg : Enter the angle between scanning points

When entering the space between the two measurement points in millimeters, enter or measure

the distance to the target beforehand.

About the angle of the starting point and the end point

The angle which is set within the scanning range will be displayed.

The angle will be H : -180~0, V : -135~-45 when whole circumference scanning is to be done.

Unit of measurement pitch:

mm/deg/pts

Start point angle

End point angle

Measurement pitch

Horizontal

Vertical

Distance measurement

Select “Edit”

Press [Edit]

“7.4 Measuring

Distance to the Target

Measurement Object”

Page 38

34

7. INSTRUMENT SETTINGS

(4) Range mode

Range mode settings are as follows.

Detail / High Speed / Low Power / Standard / Close

Please refer to the following for details.

The number of measured data may vary depending on the measurement distance or the selected

range mode in the circumstances noted below.

• In the case where the incident angle of the distance measurement laser toward the target

measurement object was narrow.

• In the case where the target was measured by using objects that have a multiple reflection effect

such as a mirror.

• In the case where a highly reflective object located close and facing toward the instrument is

measured.

(5) Pulse select

When the target measurement objects are in the foreground and background as shown below, the

distance of either object can be measured by changing the pulse selection.

• Depending on the reflection ratio of or the distance between the target measurement objects, it

might not be possible to measure the target even by switching from first to last or vice versa.

Range mode Cycle of light emission Laser class Distance

Detail 120 KHz Laser class 3R Up to 100 m

High Speed 120 KHz Laser class 3R Up to 210 m

Low Power 48 KHz Laser class 1M Up to 210 m

Standard 60 KHz Laser class 3R Up to 350 m

Close 120KHz Laser class 3R Up to 40 m

Pulse Select : First

Pulse Select : Last

Target measurement

object (foreground)

Target measurement

object (background)

GLS-2000

Top View

Distance finder laser

Page 39

35

7. INSTRUMENT SETTINGS

An overall distance to the target measurement object that is required when setting the resolution (a

desired value) of the scanning parameter in millimeters will be measured as indicated below. (The

distance is not required when using the unit of points or degrees.)

PROCEDURE

1. Press the Scan Setting icon.

2. Select “Edit” in “Resolution”, and then press

[Edit].

3. Press .

7.4 Measuring Distance to the Target Measurement Object

Page 40

36

7. INSTRUMENT SETTINGS

4. Press to switch the camera to "Tele"

and tap the target measurement object.

“Explanation of the buttons” on page 61

The instrument will automatically turn to the

target measurement object which will be

displayed around the middle of the screen.

While doing this, the horizontally rotating part

and the turn of the scanner unit will be locked.

To unlock, turn the horizontally rotating part or

the scanner unit manually.

5. Press [Meas].

6. The scanning distance is displayed. (20.1m)

Press [OK].

• This function confirms rough distance and is not for measuring accurate distance to the target.

• Do not use a prism or a target sheet in this measurement.

Page 41

37

8. FLOW OF THE CONFIGURATION SCREEN

Press the Config icon to enter the Config mode.

The following illustrates the flow of the configuration screen.

[Parameter]

[Temp / Press]

[Prism]

[Tilt 0 Set]

[PC offset]

[PL offset]

Press the Config icon.

[EDM Settings]

Page 42

38

8. FLOW OF THE CONFIGURATION SCREEN

[Back Light]

[LCD ]

[Sound]

[Units]

[Unit]

[Coord]

[Sound]

[Time / Date]

[Calib Date]

[Time / Date]

Page 43

39

8. FLOW OF THE CONFIGURATION SCREEN

To compensate the measured data, enter the temperature and atmospheric pressure during the

measurement.

PROCEDURE

1. Press the Config icon.

2. Press [EDM Settings].

3. Press [Temp/Press].

4. Enter the temperature and atmospheric

pressure, and then press [OK].

Temperature:

-10 °C to + 50 °C (increments of 0.1 °C)

(Default setting: +20 °C)

Atmospheric pressure:

560 hPa to 1066.0 hPa (increments of 0.1 hPa)

(Default setting: 1013.0 hPa)

8.1 Setting Temperature and Atmospheric Pressure

Page 44

40

8. FLOW OF THE CONFIGURATION SCREEN

Set the prism constant to be used and the flash light.

PROCEDURE

1. Press the Config icon.

2. Press [EDM Settings].

3. Press [Prism].

4. Enter the prism constant, choose ON/OFF of

the flash light, and then press [OK].

When the target scanning is started after the

flash light is set to “ON” and the instrument is set

to use the prism, a white spot beam will be

emitted from the scanner unit to detect the

position of the prism.

Prism Constant : -99 mm to

+

99 mm

(Default setting: 0 mm)

Flashlight : ON/OFF

(Default setting: OFF)

8.2 Setting the Prism Constant and Flash Light

Page 45

41

8. FLOW OF THE CONFIGURATION SCREEN

Set the date and time to record the date in the measurement data.

[Setting example] Date: July 11, 2014 Time: 12:00

PROCEDURE

1. Press the Config icon.

2. Press [Time/Date].

3. Press [Time/Date].

4. Tap the value that you want to change, and use

the up and down arrows to set the date and

time, and press [OK].

8.3 Setting the Date and Time

Page 46

42

8. FLOW OF THE CONFIGURATION SCREEN

The date of the last calibration (precision calibration of measurement distance and angle) can be

displayed.

We recommend performing the precision calibration again within one year from the last calibration date.

PROCEDURE

1. Press the Config icon.

2. Select [Time/Date].

3. Select [Calib Date].

4. Press [OK].

The last calibration date will be displayed.

8.4 Displaying the Last Calibration Date

Page 47

43

8. FLOW OF THE CONFIGURATION SCREEN

Use the backlight if it is hard to look at the display section in the evening or in a tunnel.

The level of backlight brightness can be adjusted from OFF to 10.

PROCEDURE

1. Press the Config icon.

2. Press [LCD].

3. Press [Back Light].

4. Adjust the brightness using the slider, and then

press [OK].

8.5 Adjusting the Brightness of the Display Section

Page 48

44

8. FLOW OF THE CONFIGURATION SCREEN

The volume of the sound which can be heard from this instrument can be adjusted as follows.

PROCEDURE

1. Press the Config icon.

2. Press [Sound].

3. Press [Sound].

4. Adjust the volume with a slider, and then press

[OK].

8.6 Setting the Volume

Page 49

45

8. FLOW OF THE CONFIGURATION SCREEN

Select the units as follows.

PROCEDURE

1. Press the Config icon.

2. Press [Units].

3. Press [Unit].

4. Select the units for “Temperature,” “Pressure,”

“Distance,” and “Angle.”

Items set and options (* : Factory setting)

Temperature:

celsius* / fahrenheit

Pressure : hPa* / mmHg / inHg

Distance :

m* / ft (us) / ft (NT)

Angle :

deg* / gon

8.7 Selecting the Unit

Page 50

46

8. FLOW OF THE CONFIGURATION SCREEN

Select the coordinate system (ENH or NEH) as follows.

PROCEDURE

1. Press the Config icon.

2. Press [Units].

3. Press [Coord].

4. Select the coordinate system (ENH* or NEH),

and then press [OK].

* Factory setting

8.8 Selecting the Coordinate System

Page 51

47

8. FLOW OF THE CONFIGURATION SCREEN

Import the coordinate point file

The coordinate point name and the coordinate value described in CSV file format can be imported into the

instrument via the SD card. The occupied point name and the occupied point coordinate or the backsight

point name and the backsight point coordinate can be selected from the imported coordinate list.

The imported coordinate list is retained even after turning OFF the instrument.

Conditions to create the CSV file (coordinate point file)

Create the CSV file in accordance with the following conditions.

Example of creating a CSV file

1. Enter the name of the coordinate point and E, N, and H (X, Y, and Z) in a text file.

2. Change the extension to CSV or enter the name of the coordinate point and E, N, and H

(X, Y, and Z) in a file such as Microsoft Excel's.

3. Change the format of the file to CSV when saving it.

8.9 Handling the Coordinate Point File

Items Conditions for creation

CSV file

A CSV file is comma delimited, and records fields in the following order:

coordinate point name, E, N, H (X, Y, Z).

Example

pt-01,1105.494,1069.231,6.6,

pt-02,1110.989,1088.461,7.2,

pt-03,1116.483,1107.691,7.8,

Save the CSV file in the highest hierarchy in the SD card. If the file is saved in

any lower hierarchy, it cannot be imported.

Up to 250 coordinate points can be imported. (Up to 250 coordinate points are

registered.)

They are read with the coordinate system.

Always use “***.csv” for the file extension. (Case insensitive)

Point name

Use up to eight characters for the coordinate point name. (For a long string, up

to eight characters are automatically imported, and the ninth and subsequent

characters cannot be imported. As a consequence, multiple identical coordinate

point names may exist.)

Coordinate

value

Express the coordinate value within the range of ±99999999.999 m.

(A coordinate value that exceeds the range cannot be imported.)

Page 52

48

8. FLOW OF THE CONFIGURATION SCREEN

PROCEDURE How to import a CSV file (coordinate file) in the SD card

1. Press the SetUp icon.

2. Press of the “OCC name” or “BS name“

window.

3. Press [List Import].

4. Select the CSV file you wish to import, and then

press [OK].

The CSV file has been imported.

• The data of the coordinate point that is already

imported into the instrument will be erased when

the data of the coordinate point in another CSV

file is added.

Page 53

49

8. FLOW OF THE CONFIGURATION SCREEN

PROCEDURE How to delete the coordinate list

1. Press the SetUp icon.

2. Press of the “OCC name” or “BS name“

window.

3. Press [List Clear] to delete the coordinate list.

The coordinate list will be deleted.

• The coordinate list stored in the instrument will be

erased. However, the coordinate list stored on an

SD card will not be affected. Thus, it is possible to

read the coordinate list again from the SD card.

Page 54

50

8. FLOW OF THE CONFIGURATION SCREEN

Save data in the SD card with the following hierarchy structure.

Within the area where the instrument is set, it is possible to extract and measure a certain target.

Select the measurement range to measure the target.

Data configuration example

8.10 Data structure in the SD card

Station

STA0001

STA0002

SCN 0001

SCN 0002

SCN0003

SCN0004

STA0001 (Station data folder)

SCN0001 (Scan data folder)

TAR0001 (Target data folder)

Station information file (sta file format)

Point cloud file of back sight (clt file format)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

SCN0002 (Scan data folder)

STA0002

Station information file (sta file format)

Point cloud file of back sight (clt file format)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

STA0021

Station information file (sta file format)

Point cloud file of back sight (clt file format)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

SCN0003

SCN0004

Point cloud file (clr file format)

JPEG file e.g) 0000.jpg,0001.jpg

Angle file e.g) 0000.ang,0001.ang

Point cloud file (clt file format)

3d coordinate file (trg file format)

Tilt orientation file e.g) 0000.tor,0001.tor

BMP file

Kinematics parameter file e.g) 0000.kin,0001.kin

Page 55

51

9. STATION SETTINGS

Data related to measurement, such as an occupied point name, a backsight point name, target data, and

3D data, are stored in the station.

• When setting (moving) the instrument, create a new station.

Station data are stored in the SD card.

Backsight point 1

Occupied point 1

Station

STA0001 (Station data folder)

SCN0001(Scan data folder)

TAR0001 (Target data folder)

Station information file (sta file format)

Point cloud file of back sight (clt file format)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

SCN0002 (Scan data folder)

Point cloud file (clr file format)

JPEG file e.g) 0000.jpg,0001.jpg

Angle file e.g) 0000.ang,0001.ang

Tilt orientation file e.g) 0000.tor,0001.tor

BMP file e.g) 0000.ang,0001.ang

Kinematics parameter file e.g) 0000.kin,0001.kin

Page 56

52

9. STATION SETTINGS

[Configuration example] Set the station name as [STA0002].

“6.8 Entering Numeric and Alphabetic Characters”

PROCEDURE

1. Press .

2. Enter the station name (Example: “STA0002”),

and then press [Ent] to create the station.

“Station0002” is set.

9.1 Creating a New Station

Page 57

53

9. STATION SETTINGS

The setting of the occupied point name and the backsight point name is required in order to correlate the

known point promptly when the coordinates of the measurement target is transformed during a postprocessing.

When using the known point

By selecting the occupied point name and the backsight point name from the imported coordinated list,

the data of the occupied point name, backsight point name and the coordination can be stored to be used

in a post-processing. Perform target scanning on the backsight point after selecting the occupied point

name and the backsight point name from the coordinate list.

For the import method of coordinate lists,

“8.9 Handling the Coordinate Point File”

For target scanning,

“10.1 Target Scanning”

PROCEDURE Setting the occupied point name

1. Press the SetUp icon.

2. Press of the “OCC name” window to

display the coordinate list.

3. Select a coordinate point that you want to set as

the occupied point from the coordinate points

list, and then press [OK].

The occupied point name and its coordinate will

be stored.

At this point, if you want to change the occupied

point name read from the coordinate file, tap on

the input-editor of the occupied point name and

enter a different occupied point name.

9.2 Setting the Point Name (Occupied point and Backsight

point)

Page 58

54

9. STATION SETTINGS

4. Press .

(Instrument height (IH) can also be entered

directly.)

5. Press to display an image of the survey

point.

• In this case, the laser plummet does not turn on.

6. As shown in the image to the right, place the

target for instrument height on the survey point.

7. Press [Meas].

The instrument height will be entered automatically.

• If [Meas] is pressed in step 5, the instrument height

will be measured without displaying the survey point.

(The screen shown in step 8)

Target for measuring

instrument height

Survey point

Page 59

55

9. STATION SETTINGS

8. Press next to the backsight point (BS)

name, and then select the backsight point name

and the coordinate in the same manner as the

occupied point.

At this point, if you want to change the backsight

point name read from the coordinate file, tap the

input-editor of the backsight point name and

enter a different backsight point name.

9. Press [BS Scan].

The image will be displayed.

10.Enter the backsight point name (BS0002) in the

input-editor on top of the screen.

For details of setting “ScnAng” and “HR”,

“10.1 Target Scanning”

11. Press to switch the camera to "Tele"

and tap the target at the backsight point.

“Explanation of the buttons” on page 61

The instrument will automatically turn to the

object which will be displayed around the middle

of the screen. While doing this, the horizontally

rotating part and the turn of the scanner unit will

be locked. To unlock, turn the horizontally

rotating part or the scanner unit manually.

12.Press [Start], Start/Stop scan key or collimating

position setting key.

• Sometimes “Internal calibration Please wait ...” is

displayed.

• When is pressed, it will take a while to stop.

Page 60

56

9. STATION SETTINGS

Scanning results will be displayed.

13.Press [OK].

The instrument height, the backsight point

name, and the backsight coordinate will be

stored.

Press [OK] in the confirmation message window.

• Only the prism or the target sheet for Topcon's GLS-

2000/1500 can be used as the target.

• The target sheet used varies depending on the

scanning distance. (

“6.9 Preparing the Target”)

Page 61

57

9. STATION SETTINGS

Importing the point name (Occupied point or Backsight point)

After entering the occupied point name and the backsight point name, perform target scanning on the

backsight point. When calculating with a PC after measuring, it is possible to set the coordinates of the

occupied point and the backsight point.

[Configuration example] Configure the settings as follows:

Occupied point name : OCC-1

Instrument height : 1.5m (depending on the measurement result)

Backsight point name : BACK-1

PROCEDURE

1. Press the SetUp icon.

2. Tap on the occupied point name

input-editor, and

then enter the occupied point name.

3. Press , and then press [Meas] to

measure the instrument height.

(Instrument height (IH) can also be entered

directly.)

4. Enter the backsight point in the same manner

as the occupied point name.

5. Press [BS Scan].

The image will be displayed.

Page 62

58

9. STATION SETTINGS

6. Press to switch the camera to "Tele"

and tap the target at the backsight point.

“Explanation of the buttons” on page 61

The instrument will automatically turn to the

object which will be displayed around the middle

of the screen. While doing this, the horizontally

rotating part and the turn of the scanner unit will

be locked. To unlock, turn the horizontally

rotating part or the scanner unit manually.

7. Press [Start], Start/Stop scan key or collimating

position setting key.

• Sometimes “Internal calibration Please wait ...” is

displayed.

• When is pressed, it will take a while to stop.

Scanning results will be displayed.

8. Press [OK].

The instrument height, the backsight point

name, and the backsight point coordinate will be

stored.

Page 63

59

10. MEASURING (SCANNING)

There are two types of scanning: target scanning that only measures the target, and 3D scanning that

obtains 3D data.

Scanned data will be saved in the Station folder in the SD card.

Target scanning

Perform target scanning to measure the target placed within the range of 3D scanning. This

target scanning data is used to align 3D scanning data from multiple instrument points by postprocessing.

Target scanning provides the coordinate data on which the target is centered.

3D scanning

Perform 3D scanning to obtain the 3D data.

First, determine the scanning range, and then set parameters for the resolution of scanning.

• The name of the folder will be the same as that of the station which has been set.

STA0001 (Station data folder)

SCN0001 (Scan data folder)

Station information file (sta file format)

Point cloud file of back sight (clt file format)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

Point cloud file (clr file format)

JPEG file e.g) 0001.jpg,0002.jpg

Angle file e.g) 0001.ang,0002.ang

Tilt orientation file e.g) 0001.tor,0002.tor

BMP file e.g) 0000.ang,0001.ang

Kinematics parameter file e.g) 0000.kin,0001.kin

TAR0001 (Target data folder)

Point cloud file (clt file format)

3d coordinate file (trg file format)

Page 64

60

10. MEASURING (SCANNING)

Target scanning must be performed to align the positional information of multiple 3D scanning data to

perform post-processing of data.

Thus, the target must be placed in a position that can be seen from the position of the next station. To

measure the object, place the target near the scanning target or stick the target directly on the scanning

target.

• Only the prism or the target sheet for Topcon's GLS-2000/1500 can be used as the target.

• To align the positional information of the data, at least three sets of common target scanned data are

required. Place the target on three or more positions that can be collimated from each station.

• 3D data cannot be obtained from the positions where the target sheet is stuck. Avoid sticking the sheet

on an important scanning position.

• Do not stick the target sheet in a straight line. Secure a wide range for 3D scanning to stick target sheets

evenly.

• The target sheet used varies depending on the scanning distance. (

“6.9 Preparing the Target”)

[Configuration example] Scan from target pt01 to pt06

Target height of pt01: 1 m (Input range: -999.999m~999.999m)

PROCEDURE

1. Press the Target Scan button.

10.1 Target Scanning

pt03

pt02

pt01

pt04

pt05

pt06

Page 65

61

10. MEASURING (SCANNING)

2. Press to switch the camera to "Tele"

and tap the target (pt01).

“Explanation of the buttons” on page 61

The instrument will automatically turn to the object

which will be displayed around the middle of the

screen. While doing this, the horizontally rotating

part and the turn of the scanner unit will be locked.

To unlock, turn the horizontally rotating part or the

scanner unit manually.

3. Enter “Target name”, “ScnAng”, and “HR”, and

then press [Start], Start/Stop scan key or

collimating position setting key.

Example: Target name : pt01

ScanAng : 2°

HR : 1 m

“Recommended search width setting” on page 63

“Setting the target height” on page 63

• Make sure to select the target ( / ) according to the target object.

Target scanning is in progress.

• Sometimes “Internal calibration Please wait ...” is

displayed.

• When is pressed, it will take a while to

stop.

Target name

/ : Zoom in or out of the image (Effective only when using the telescopic camera)

When using the

wide-angle camera

When using the

telescopic camera

When using the prism

When using the target sheet

When the laser pointer

is turned ON

When the laser pointer

is turned OFF

switch

Explanation of the buttons

Page 66

62

10. MEASURING (SCANNING)

4. The scanning results will be displayed. Check

the scanning range, and then press [OK].

You will return to the main menu.

5. Similarly, perform steps 1 to 4 until the

completion of target scanning the target “pt06.”

Page 67

63

10. MEASURING (SCANNING)

Recommended search width setting

• Select the search width that meets your usage condition.

• Type of target

Setting the target height

Coordinate points on the ground can be registered (combining multiple sets of scanned data) as

the tie point (the connecting point) by entering the target height.

Set the target height as follows:

Distance to the

scanning target (m)

Search width

(degrees)

Target sheet

2-5 2.5 Small

5-10 1.0 Small

10-20 1.0 Small, medium

20-50 0.5 Small, medium, large

50-100 0.5 Medium, large

100-200 0.5 Large

Target

Distance to the

scanning target (m)

Size (m)