Page 1

INSTRUCTION MANUAL

LASER SCANNER

GLS-1000

SERIES

64650 90070

Page 2

Page 3

FOREWORD

Thank you for purchasing the TOPCON Laser Scanner, GLS-1000 series.

For the best performance of the instruments, please carefully read these instructions

and keep them in a convenient location for future reference.

1

Page 4

General Handling Precautions

Before starting work or operation, be sure to check that the instrument is

functioning correctly with normal performance.

Using the instrument on rainy days

It may not be possible to use the instrument if there are water drops on the glass of the

windows.

It is also not possible to scan wet objects.

Horizontally rotating part (head)

Do not turn the head with your hands while the power is ON. If it has been turned by force, turn

the power ON again.

Waterproof property

The instrument is designed based on the International Standard IPX2, therefore it can

withstand light rain. However, in case of heavy rain, there is no guarantee that the instrument

will be protected from waterdrops.

Setting the instrument on a tripod

When mounting the instrument on a tripod, use a wooden tripod.

Do not use a metallic tripod.

Installing the tribrach

If the tribrach is installed incorrectly, the measuring precision could be effected. Occasionally

check the adjusting screws on the tribrach. Make sure the base fixing lever is locked and the

base fixing screws are tightened.

Guarding the instrument against shocks

When transporting the instrument, provide some protection to minimize risk of shocks. Heavy

shocks may cause the measurement to be faulty.

Exposing the instrument to extreme heat.

Do not leave the instrument in extreme heat for longer than necessary. It could adversely

affect its performance.

Sudden changes of temperature

Any sudden change of temperature to the instrument may result in a reduction of measuring

distance range, i.e when taking the instrument out from a heated vehicle. Let instrument

acclimate itself to ambient temperature.

Battery level check

Confirm battery level remaining before operating.

Battery use

Always use four batteries as one set, and operate the instrument with batteries that have been

charged and discharged the same number of times. Do not mix old and new batteries, or

batteries that have been charged and discharged a different number of times.

Taking the battery out

It is recommended not to take the battery out during the power is on. Please do your

assembling or taking the battery out after the power is off.Refer to Chapter 4.5 “Replacing the

Battery” if you need to replace the batteries during scanning.

External power source

Use only recommended batteries or external power source. Use of batteries or an external

power source not recommended by us may result in equipment failure.

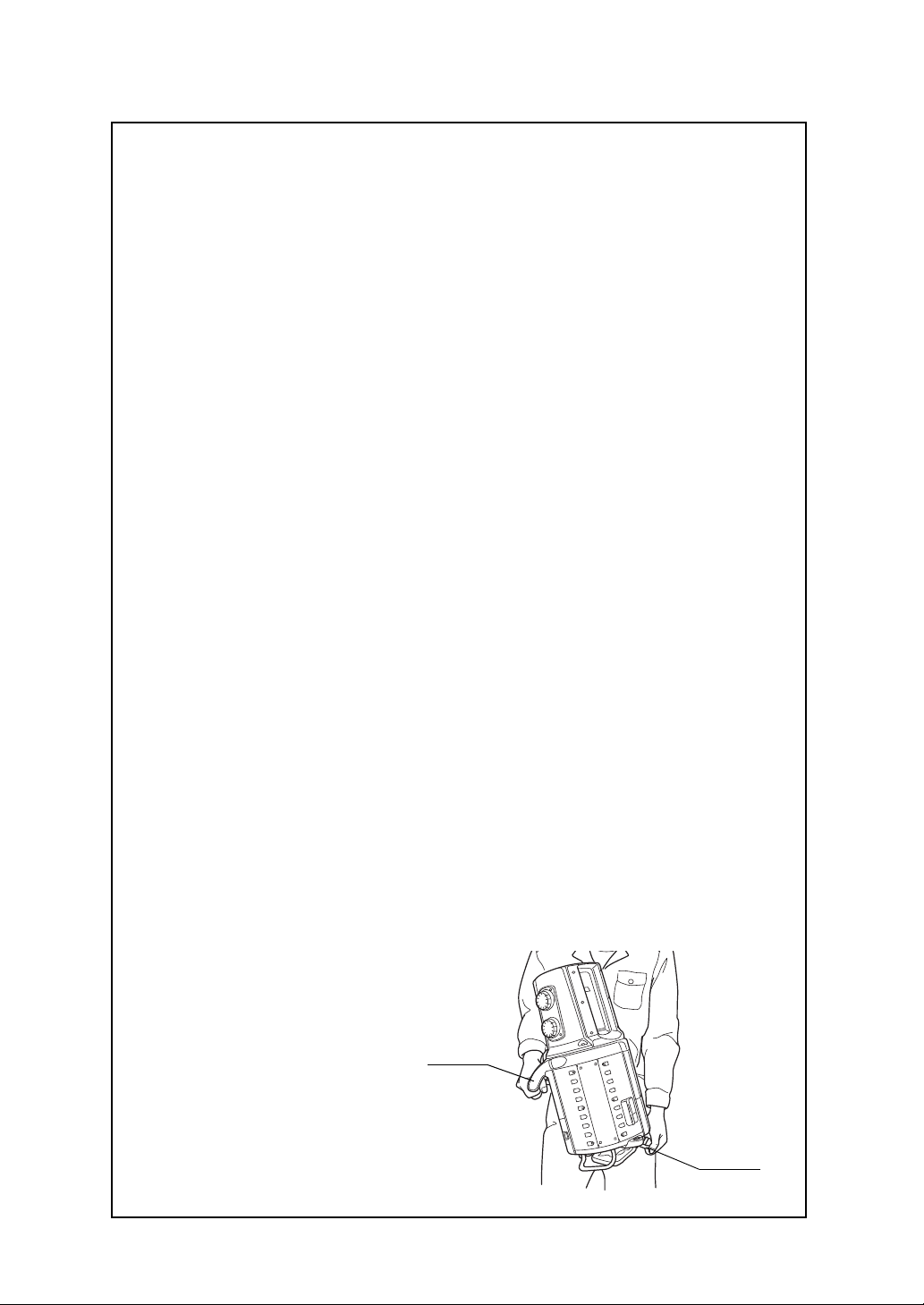

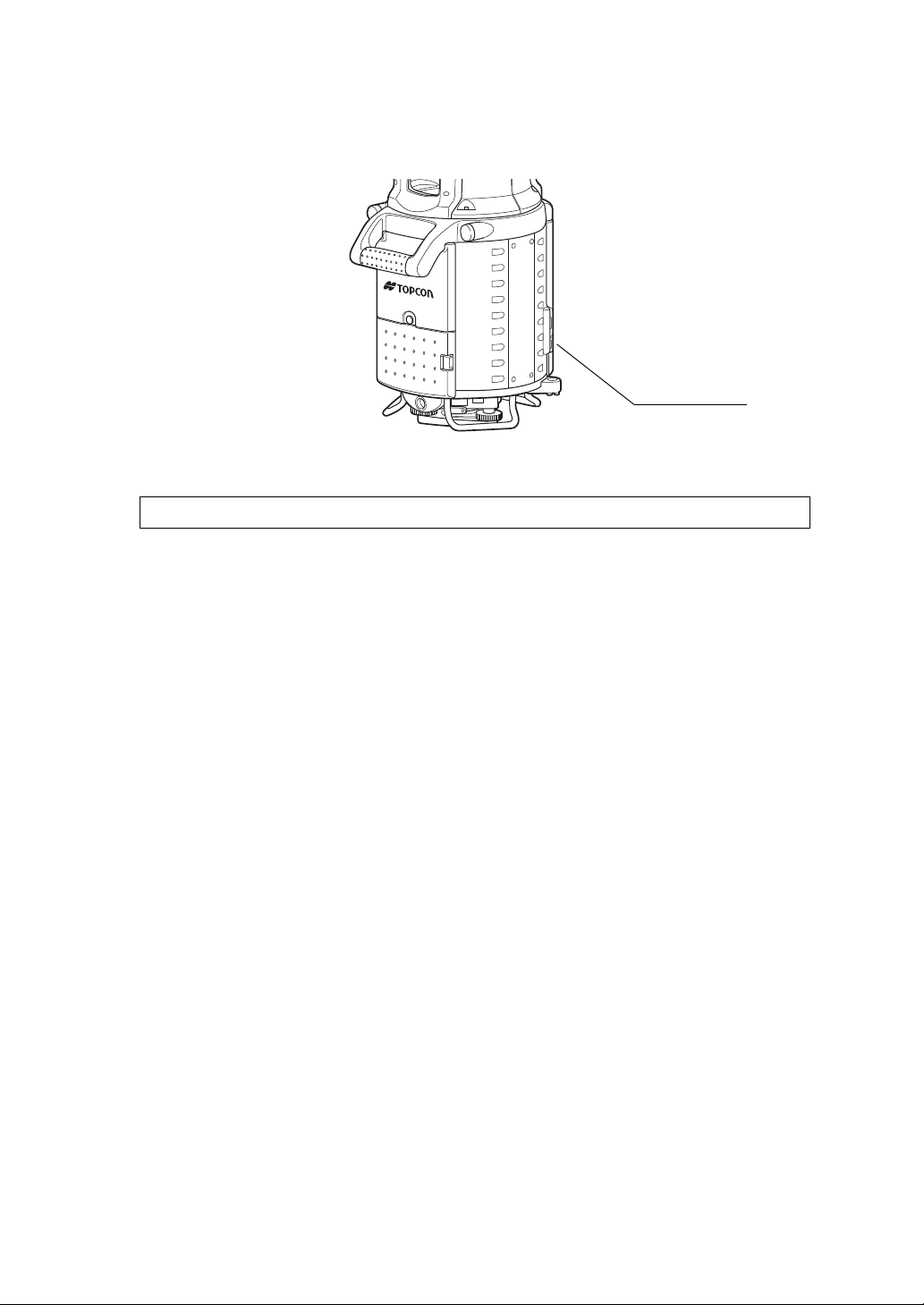

Carrying the instrument

Because this instrument is heavy,

make sure to carry it carefully using

both the handle and the handgrip.

There is a possibility that the

instrument may topple and fall

resulting in possible injury. Incorrect

lifting posture may also result in

hurting your back.

Handle

Handgrip

2

Page 5

Display for Safe Use

WARNING

CAUTION

In order to encourage the safe use of products and prevent any danger to the operator and others or

damage to properties, important warnings are put on the products and inserted in the instruction

manuals.

We suggest that everyone understand the meaning of the following displays and icons before reading

the “Safety Cautions” and text.

Display Meaning

Ignoring or disregard of this display may lead to the danger of death or

serious injury.

Ignoring or disregard of this display may lead to personal injury or physical damage.

• Injury refers to hurt, burn, electric shock, etc.

• Physical damage refers to extensive damage to buildings or equipment and furniture.

Safety Cautions

WARNING

• There is a risk of fire, electric shock or physical harm if you attempt to disassemble or repair

the instrument yourself.

This is only to be carried out by TOPCON or an authorized dealer, only!

• High temperature may cause fire.

Do not cover the charger while it is charging.

• Risk of fire or electric shock.

Do not use damaged power cable, plug and socket.

• Risk of fire or electric shock.

Do not use a wet battery or charger.

• May ignite explosively.

Never use an instrument near flammable gas, liquid matter, and do not use in a coal mine.

• Battery can cause explosion or injury.

Do not dispose in fire or heat.

• Risk of fire or electric shock.

Do not use any power voltage except the one given on manufacturers instructions.

• Battery can cause outbreak of fire.

Do not use any other type of charger other than the one specified.

• Risk of fire or electric shock.

Do not use an AC cable incompatible with the power supply voltage in use.

• Because this instrument is heavy, make sure to carry it carefully using both the handle and

the handgrip.

There is a possibility that the instrument may topple and fall resulting in possible injury, and incorrect lifting posture

may also result in hurting your back.

• The short circuit of a battery can cause a fire.

Do not short circuit battery when storing it.

3

Page 6

CAUTION

• Use of controls or adjustment or performance of procedures other than those specified herein may result in hazardous radiation exposure.

• Risk of injury by overturn the carrying case.

Do not stand or sit on the carrying cases.

• Please note that the tips of tripod can be hazardous, be aware of this when setting up or carrying the tripod.

• Risk of injury by falling down the instrument or case.

Do not use a carrying case with a damaged which grips or casters.

• Do not allow skin or clothing to come into contact with acid from the batteries, if this does occur then wash off with

copious amounts of water and seek medical advice.

• Ensure that you mount the Tribrach correctly, failing to do so may result in injury if the tribrach were to fall over.

• It could be dangerous if the instrument falls over, please check that you fix the instrument to the tripod correctly.

• Risk of injury by falling down a tripod and an instrument.

Always check that the screws of tripod are tightened.

• The appliance is not intended for use by young children or infirm persons without supervision.

Young children should be supervised to ensure that they do not play with the appliance.

User

1)This product is for professional use only!

The user is required to be a qualified surveyor or have a good knowledge of surveying, in order to

understand the user and safety instructions, before operating, inspecting or adjusting.

2)Wear the required protectors (safety shoes, helmet, etc.) when operating.

Exceptions from Responsibility

1)The user of this product is expected to follow all operating instructions and make periodic checks of the

product’s performance.

2)The manufacturer, or its representatives, assumes no responsibility for results of a faulty or intentional

usage or misuse including any direct, indirect, consequential damage, and loss of profits.

3)The manufacturer, or its representatives, assumes no responsibility for consequential damage, and

loss of profits by any disaster, (an earthquake, storms, floods etc.).

A fire, accident, or an act of a third party and/or a usage any other usual conditions.

4)The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of profits

due to a change of data, loss of data, an interruption of business etc., caused by using the product or

an unusable product.

5)The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of profits

caused by usage except for explained in the user manual.

6)The manufacturer, or its representatives, assumes no responsibility for damage caused by wrong

movement, or action due to connecting with other products.

4

Page 7

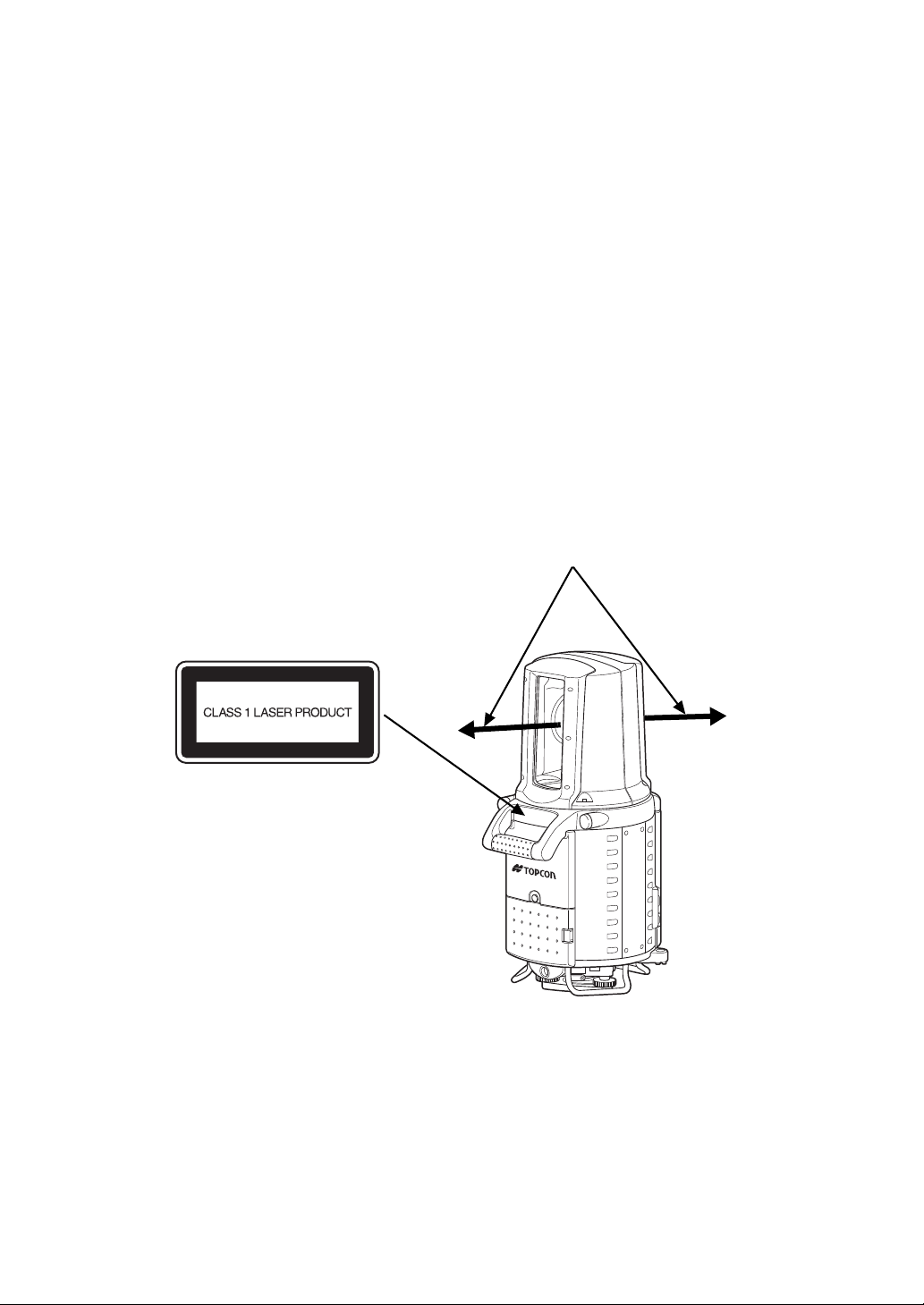

Laser Safety

Explanatory Label

(Only for U.S.A.)

Laser aperture

Laser beam comes out from here.

The GLS-1000 series emits an invisible laser beam when the power is turned ON.

The GLS-1000 series are manufactured and sold in accordance with "Performance Standards for LightEmitting Products" (FDA/BRH 21 CFR 1040) or "Radiation Safety of Laser Products, Equipment

Classification, Requirements and User`s Guide" (IEC Publication 60825-1) provided on the safety

standard for laser beam.

"Complies with FDA performance standards for laser products except for deviations pursuant to Laser

Notice No. 50, dated (July 26, 2001)"

As per the said standard, the GLS-1000 series is classified as "Class 1 Laser Products".

In case of any failure, do not disassemble the instrument. Contact TOPCON or your TOPCON dealer.

Labels

Find the labels which describes the caution and safety about the laser beam as follows in GLS-1000

series.

We request you to replace it one anytime the caution labels are damaged or lost and paste a new one

at the same place. You can get the labels from Topcon or your dealer.

5

Page 8

Contents

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Display for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Exceptions from Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Standard Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Attaching/removing casters on the carrying case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1 NOMENCLATURE AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Operating Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 Preparations before Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

3 Overview of Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1 Procedure for Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Display and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Screen Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4 PREPARATION FOR MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.1 Detach/Attach of Tribrach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Mount the Instrument to the Tripod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.1 Leveling and Centering the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Power Switch Key ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.4 Battery Power Remaining Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.5 Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.6 How to Collimate to a Target. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.7 How to Enter Alphanumeric Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.7.1 Switching between Numerical Input Mode and Alphabetical Input Mode . . . . . . 4-9

4.8 Target . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.8.1 Selecting the Target Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.8.2 Assembling the Target . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

5 Instrument Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Settings by the Star Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Star Key Screen Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 Tilt Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.3 Zoom Control (Zoom setting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.4 Camera Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.5 Contrast Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.6 Backlight Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.7 Setting Example Using the Star Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2 Using the Setting Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.1 Setting Menu Screen Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.2 Network Settings (when the instrument is used connected to a PC) . . . . . . . . . . 5-5

5.2.3 Editing the SD Card Data (data management) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.2.4 Setting the Temperature and Atmospheric Pressure . . . . . . . . . . . . . . . . . . . . . 5-10

5.2.5 Displaying the Last Calibration Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.2.6 Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.2.7 Changing the Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.2.8 Adjusting the Tilt Sensor Installation Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

6 Project Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.1 Creating a New Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 Selecting from Existing Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6

Page 9

7 Station Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.1 Creating a New Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2 Selecting from Existing Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3 Setting the Occupied Point Name and the Backsight Point Name . . . . . . . . . . . . . . . . 7-4

8 Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Target Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2 3D Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.1 Scanning Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.2 Setting the Scanning Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.3 Performing 3D Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

9 Charging the Internal Power Source (BT-65Q) . . . . . . . . . . . . . . . . . . .9-1

10 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

11 SPECIAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

12 ERROR DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

13 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

7

Page 10

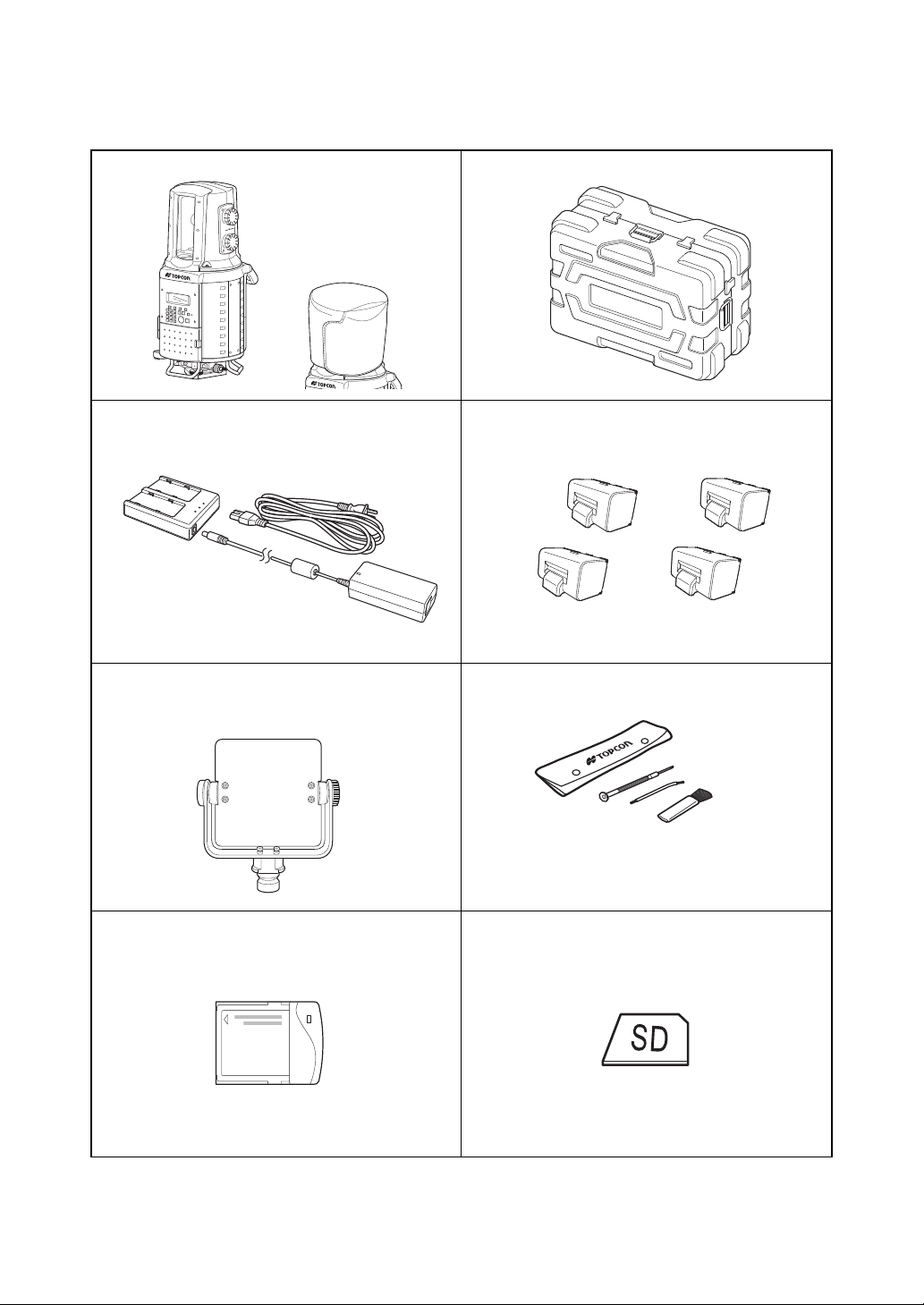

Standard Components

The numerical value in parentheses shows the quantity.

GLS-1000 with head cover(1) Plastic carrying case [Casters included](1)

Battery charger BC-30D(2)

[Charger(2), AC/DC Converter AD-12(2), AC-Cable(2)]

Target board [small](1)

Attach a [M (middle)] or [S (small)] target sheet

(magnet type).

Wireless LAN card(1) SD card(1)

Battery BT-65Q(4)

Tool kit with case(1)

[ rod pin(2), screwdriver(1), cleaning brush(1) ]

8

Page 11

USB cable F-25(1) Silicon cloth(1)

Attachment

Removal

If you cannot remove casters by pulling them with your

hand, use commercially available tools sold in stores.

Target sheet [Magnet type] : Middle(1), Small(1) Target sheet : Middle(10), Small(5)

Instruction manual(1)

Make sure that all of the above items are with the instrument when purchased.

Attaching/removing casters on the carrying case

At the time of purchase, casters are stored inside the case. Remove them from the case and attach as

necessary.

9

Page 12

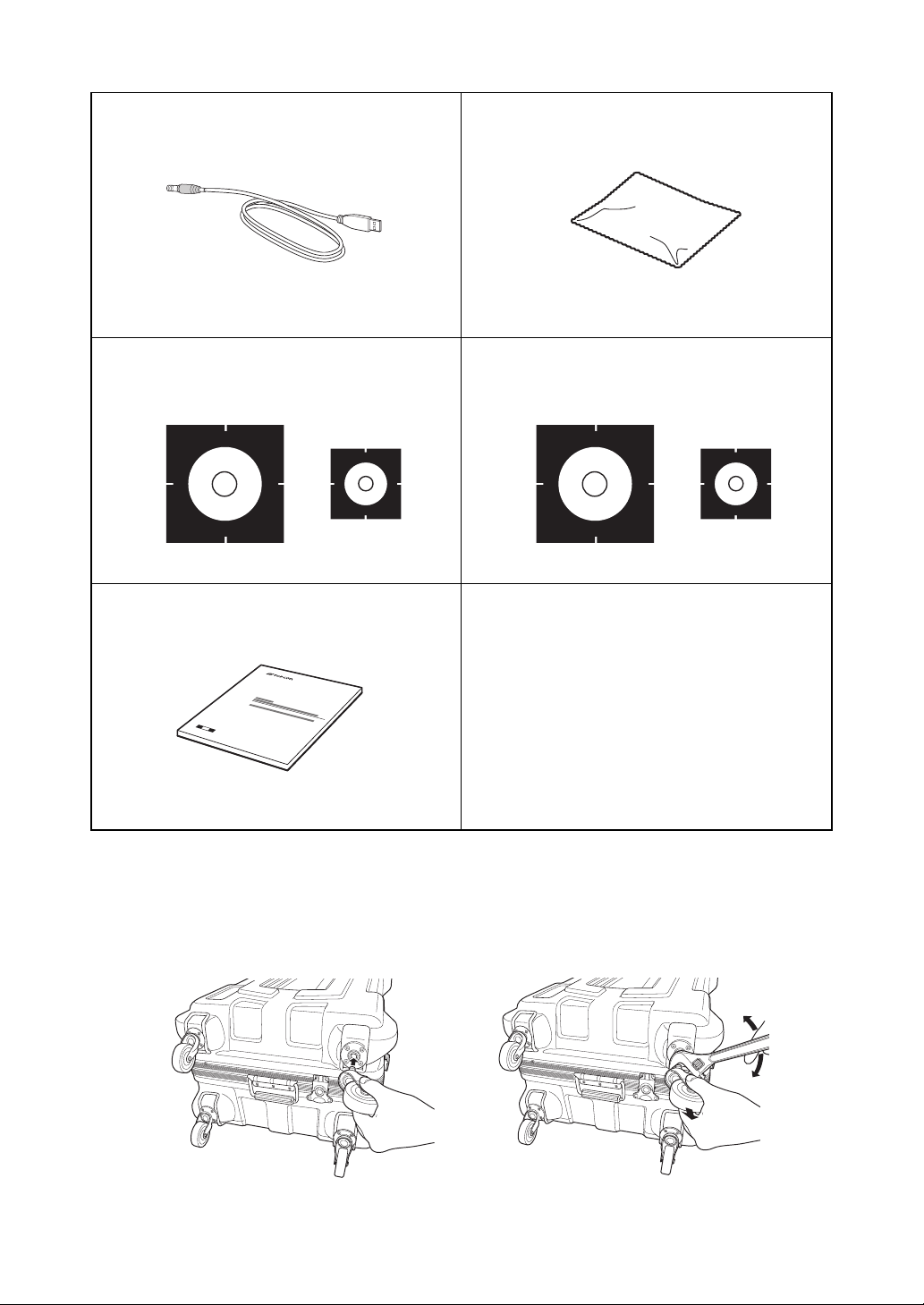

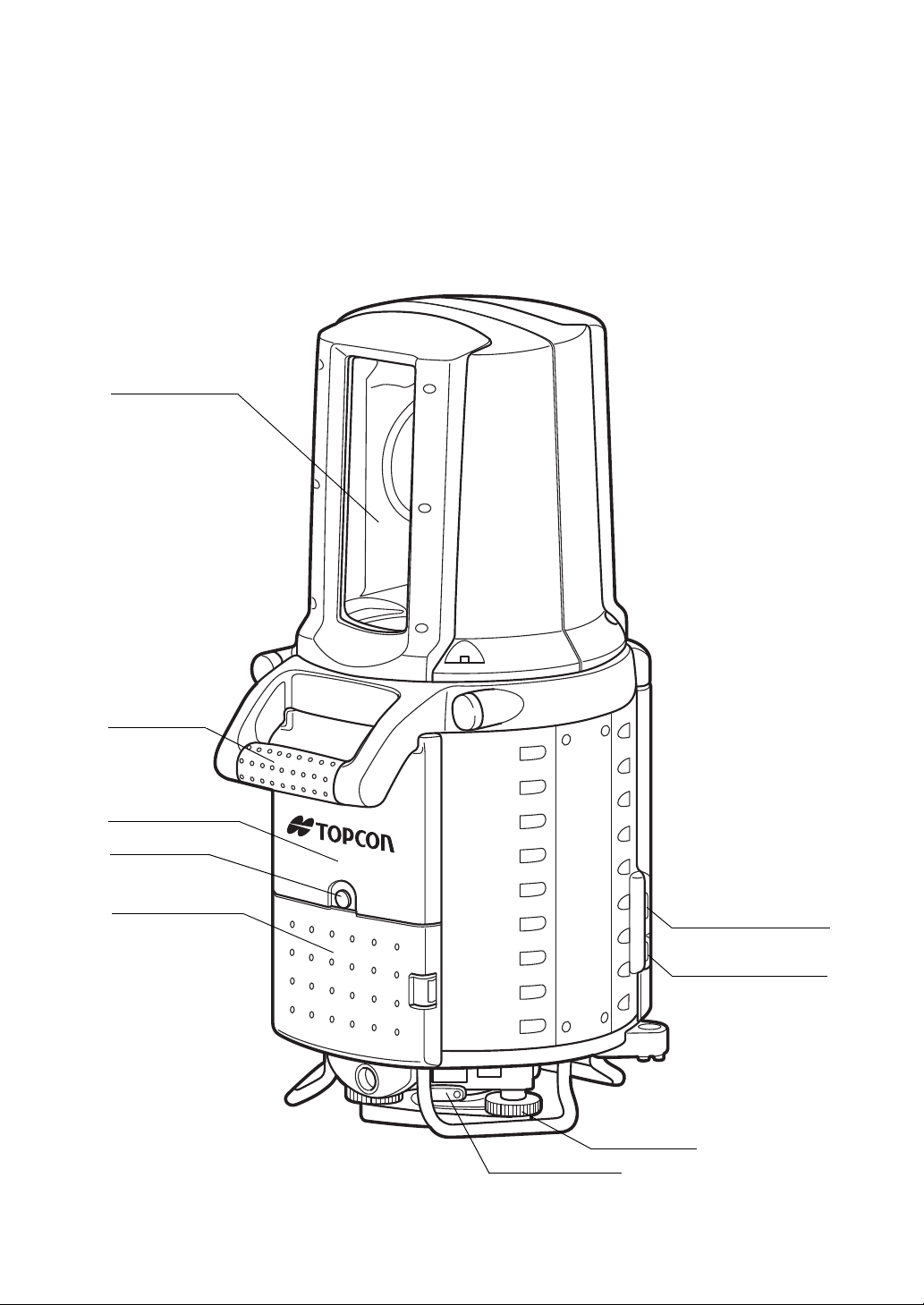

1 NOMENCLATURE AND FUNCTIONS

Instrument

center mark

Tribrach

Display

Circular level

Adjustment screw

for circular level

Battery cover lever

Battery cover

Vertical jog

Horizontal jog

Operation key

Collimating window

Handle

Optical plummet

telescope

Battery connector

Horizontally rotating part

(head)

1.1 Nomenclature

1 NOMENCLATURE AND FUNCTIONS

1-1

Page 13

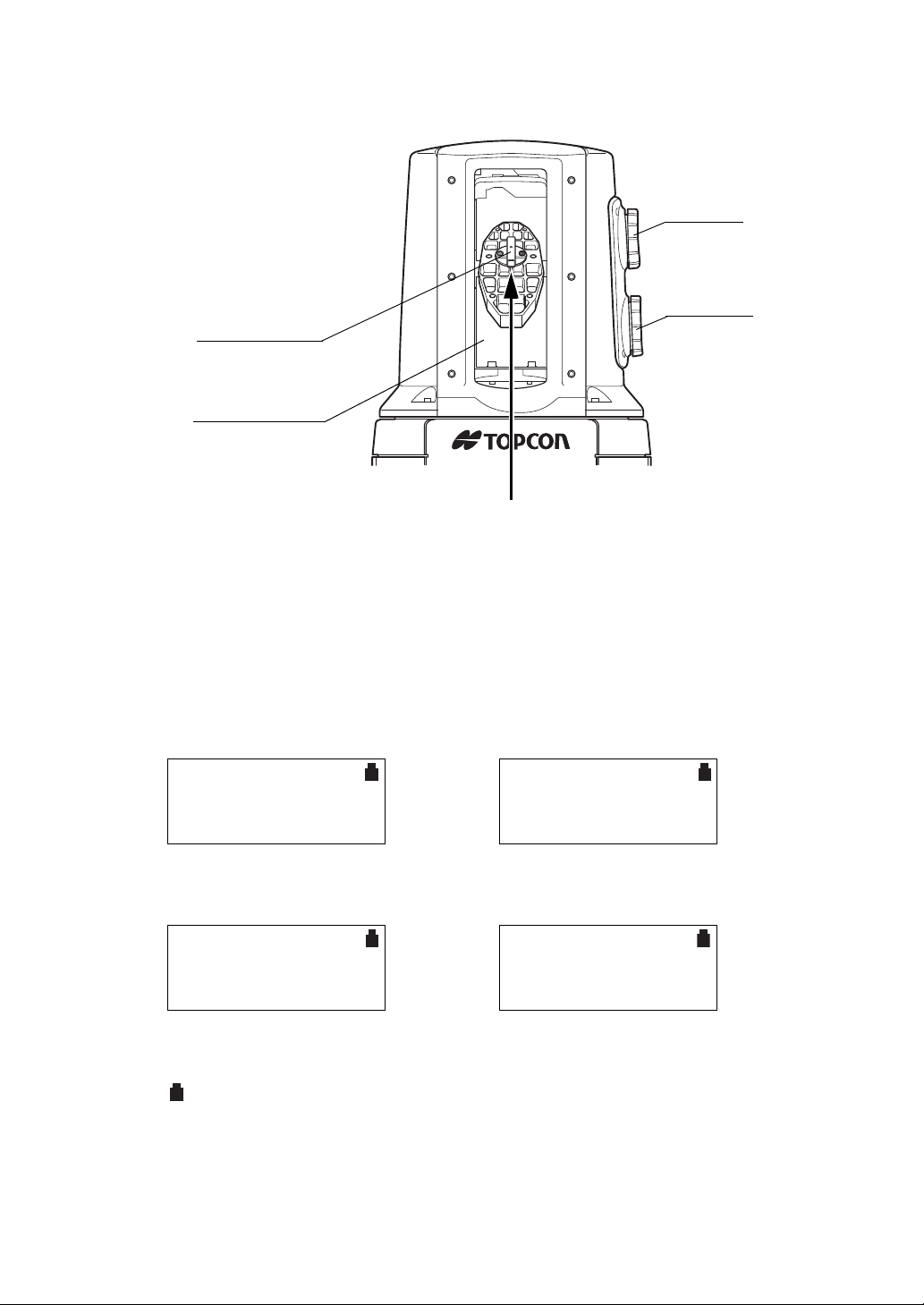

USB memory cannot be

used.

I/O cards cannot be used.

Handgrip

Tribrach fixing lever

Leveling screw

Window

SD card slot

Cover screw

Wireless LAN cover

USB connector

Back battery cover

1 NOMENCLATURE AND FUNCTIONS

1-2

Page 14

1 NOMENCLATURE AND FUNCTIONS

Sighting collimator

Collimating window

Vertical jog

Horizontal jog

Collimate from here

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

SCAN MENU

F1 3D SCANNING

F2 TARGET SCANNING

PROJECT MENU

F1 NEW PROJECT

F2 SELECT PROJECT

Refer to Chapter 4.4 “Battery Power

Remaining Display”.

:Battery power remaining mark

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/3

↓

↑

1.2 Display

z Display

The display uses a character-type LCD which has 4 lines and 20 characters per line.

z Contrast and Illumination

The contrast and illumination of display window are adjusted. See 5.1 “Settings by the Star Key”.

z Example

STATION MENU SCAN MENU

PROJECT MENU SETTING MENU

1-3

Page 15

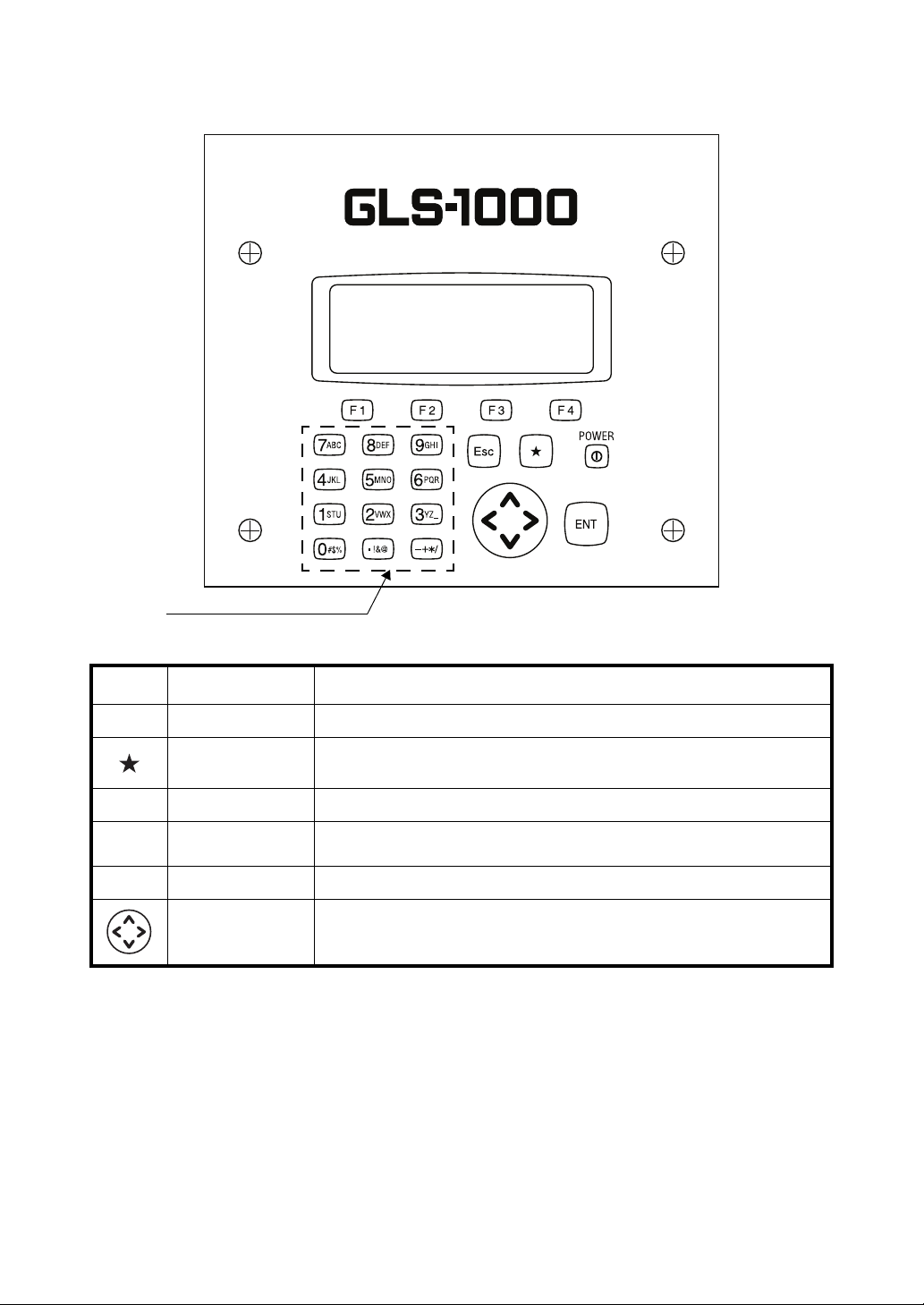

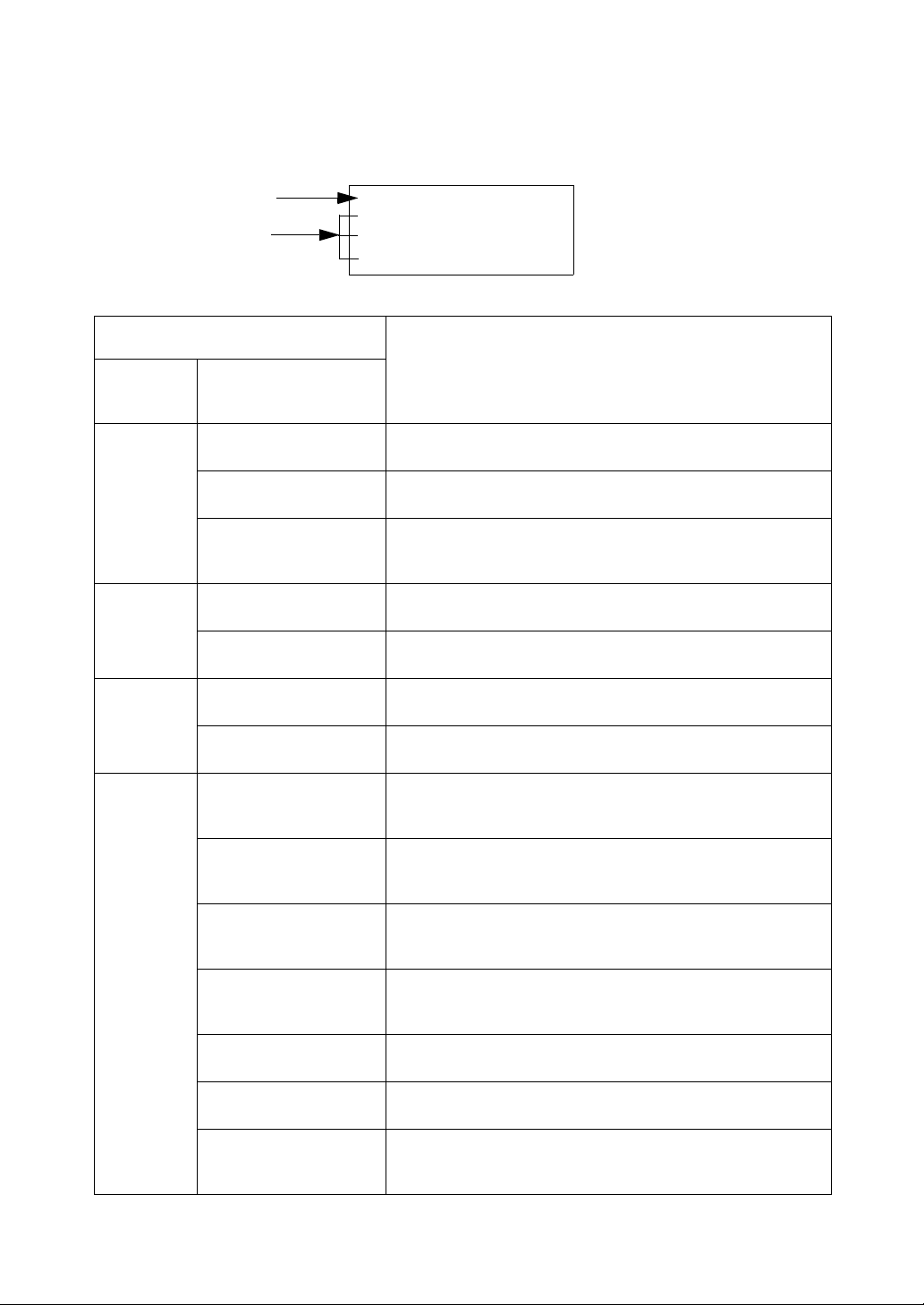

1.3 Operating Key

Alphanumeric characters key

1 NOMENCLATURE AND FUNCTIONS

Keys Name of Key Function

POWER Power source key ON/OFF of power source

Star key

ESC Escape key Returning to the previous display.

F1–F4

ENT Enter key Press at the end of inputting values.

Soft key

(Function key)

Cursor key Moves the selected item or the cursor laterally and vertically.

Star key mode is used for each presetting or displaying.

To select function of Star key, see Chapter 5.1 “Settings by the Star Key” .

Responds to the message displayed.

1-4

Page 16

2 Preparations before Use

1.

Inserting a wireless LAN card (when the instrument is used

connected to a PC)

Cover screw

Wireless LAN cover

LAN port

2 Preparations before Use

The following are the preparation procedures before use.

It is necessary to insert a wireless LAN card for wireless communication between the instrument and

the PC.

Insert a wireless LAN card after purchasing the instrument.

1 Use a coin to remove the cover screw.

2 Remove the wireless LAN cover.

3 Insert a wireless LAN card.

4 Replace the wireless LAN cover.

5 Replace the cover screw.

2-1

Page 17

2 Preparations before Use

2.

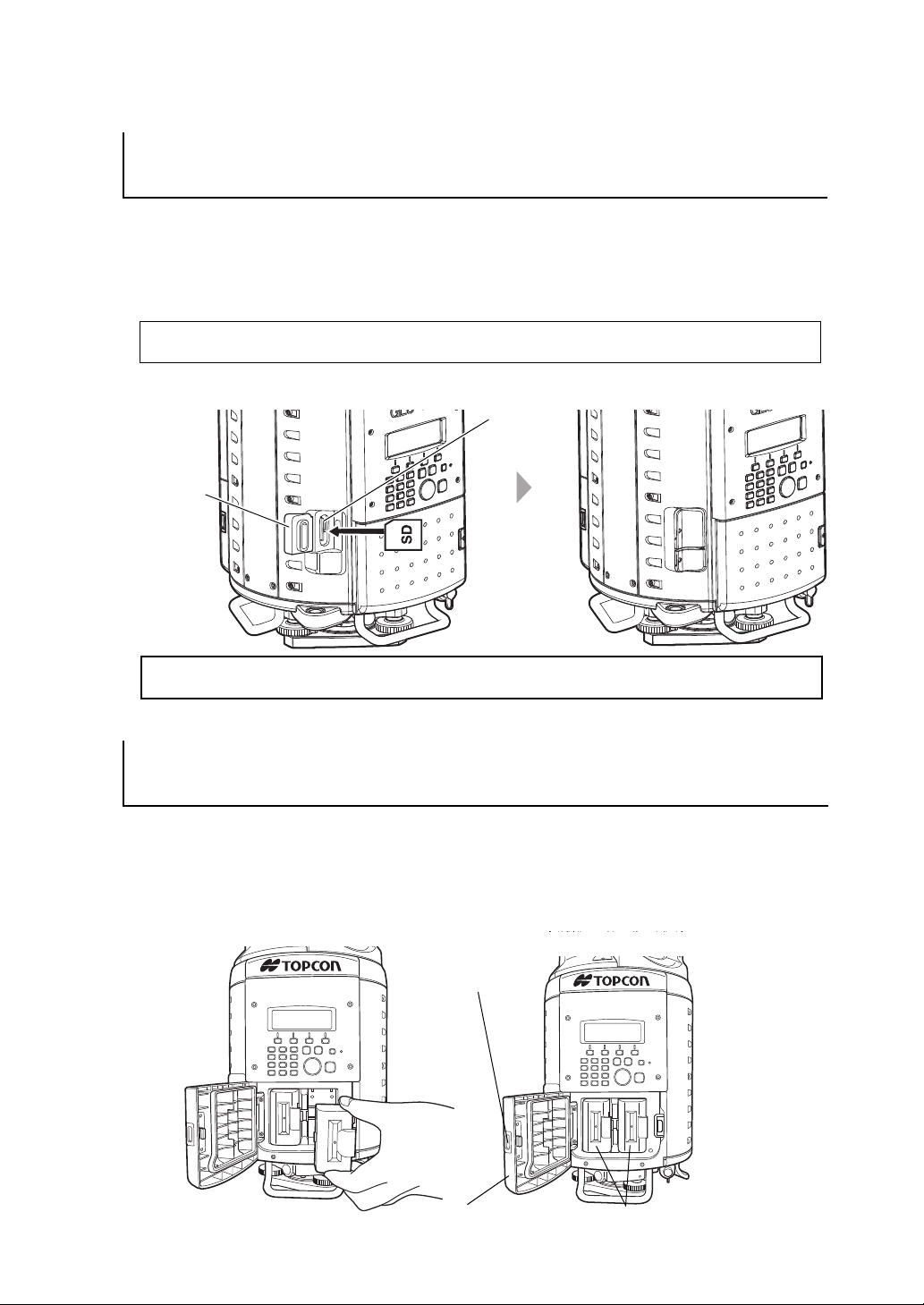

Inserting an SD card (when the instrument is used alone (stand alone))

Please make sure you have the front and back of the SD card facing correctly when inserting into

the card slot.

Card slot

cover

Card slot

When [SCANNING IN PROGRESS] and [PAUSING] is being displayed, do not remove the SD card.

Otherwise, the data may be destroyed.

3.

Connecting to a power source

Battery cover lever

Battery cover

BT-65Q

All of the data including project, station information, and scanning data will be recorded on the SD card.

Make sure to insert an SD card before scanning.

1 Open the card slot cover.

2 Insert a SD card to the card slot..

3 Close the card slot cover.

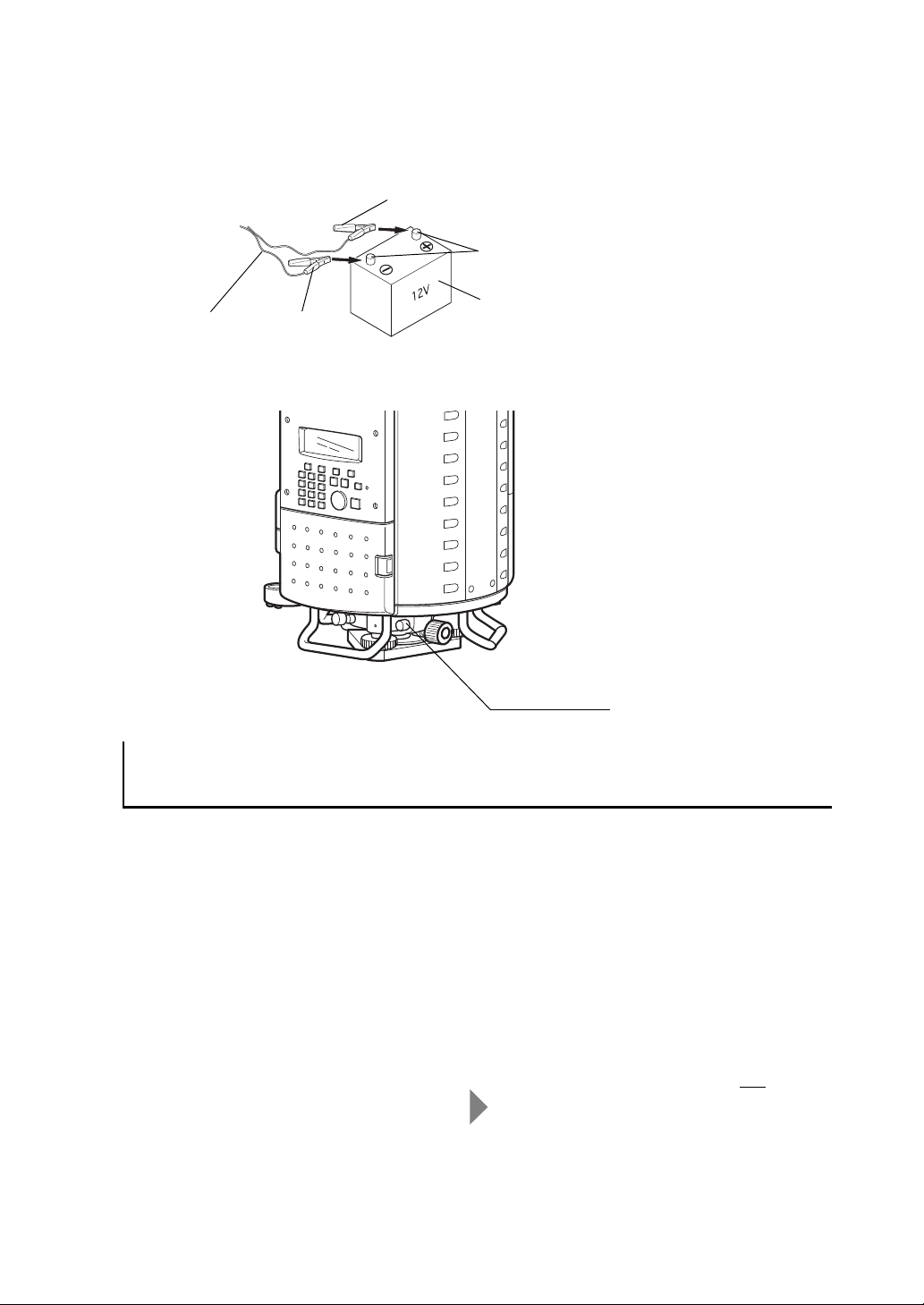

z When using the internal BT-65Q power source

1

Open the battery cover, and place four batteries in the instrument.

2 Shut the battery cover until click sound can be heard.

2-2

Page 18

2 Preparations before Use

External battery

Battery terminal

Red clip (+)

Black clip (-)

PC-21

Battery connector

4.

Network Settings (when the instrument is used connected to a PC)

[Initial setting of the instrument at shipping]

IP address : 192.168.0.1

SUBNET address : 255.255.255.0

SSID : gls1000

Refer to Chapter 5.2.2 “Network Settings (when the instrument is used connected to a PC)” for PC

settings.

If you want to change the IP address, subnet address, or SSID of the instrument, Refer to Chapter

5.2.2 “Network Settings (when the instrument is used connected to a PC)”

[Example of the setting on the user's PC]

IP address* : 192.168.0.240

SUBNET address : 255.255.255.0

SSID : gls1000

* "240" at the end of the IP address is

arbitrarily-specified.

z When using an external power source

1

Connect the clips of the external power source cable (PC-21) to the terminals of the external power

source (12V, commercially available).

2 Connect the external power source cable (PC-21) to the battery connector.

Use one of the following methods to connect the instrument to the PC.

z Connection via Wireless LAN cards

Network setting is necessary if the instrument is connected to the PC via wireless LAN cards. After

purchasing the instrument, make sure the IP address, subnet address, and SSID of this instrument

correspond to those of the PC.

1 Move to the network setting screen.

Refer to Chapter 5.2.2 “Network Settings (when the instrument is used connected to a PC)”

2 Match the PC setting with the instrument setting.

2-3

Page 19

2 Preparations before Use

USB connector

USB connector is for connection to PC, and USB memory cannot be connected.

z Connection via USB cable

1 Connect a USB cable(F-25) to the USB connector.

The USB connection is automatically recognized and [PC CONTROL MODE] is displayed.

2-4

Page 20

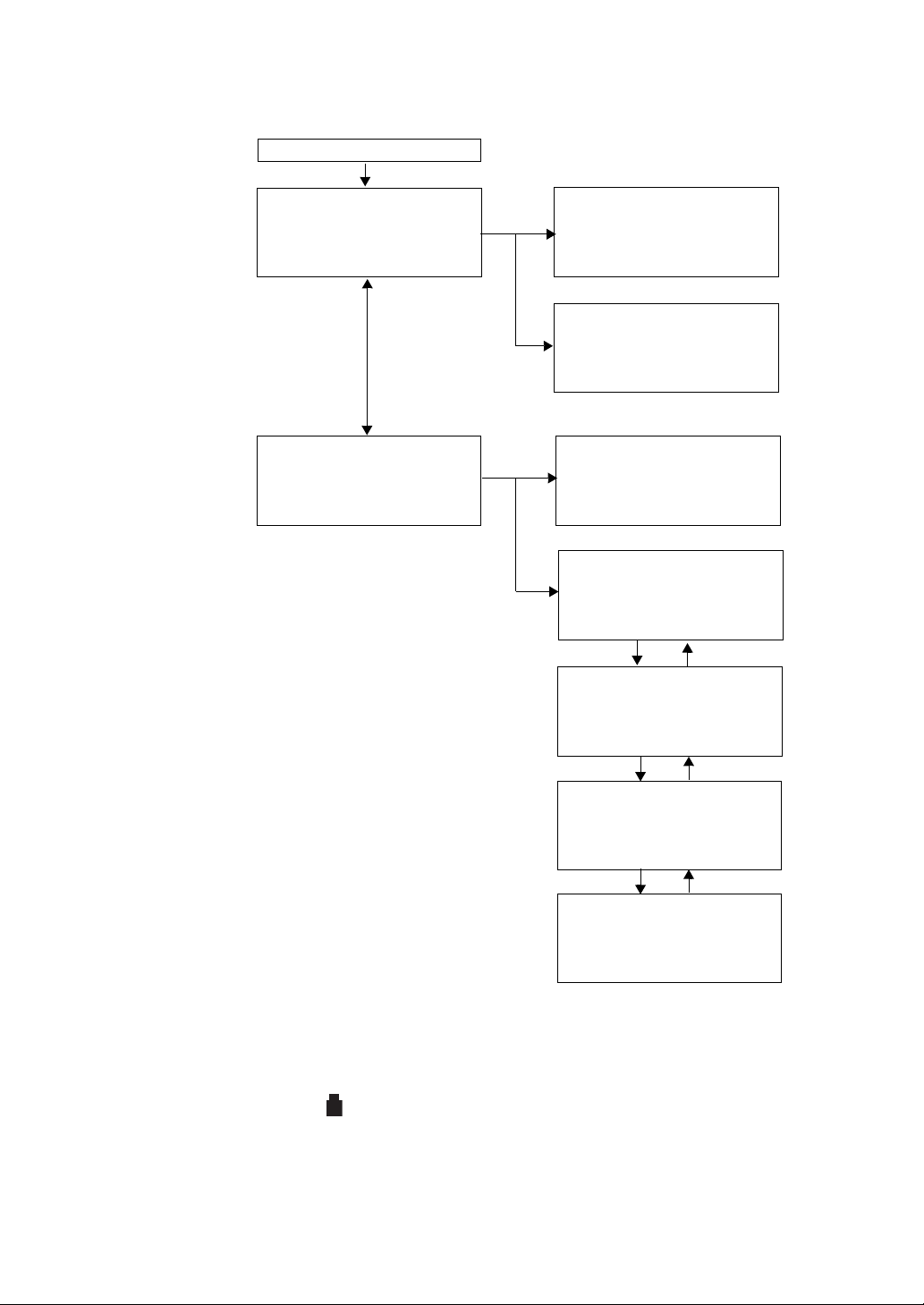

3 Overview of Scanning

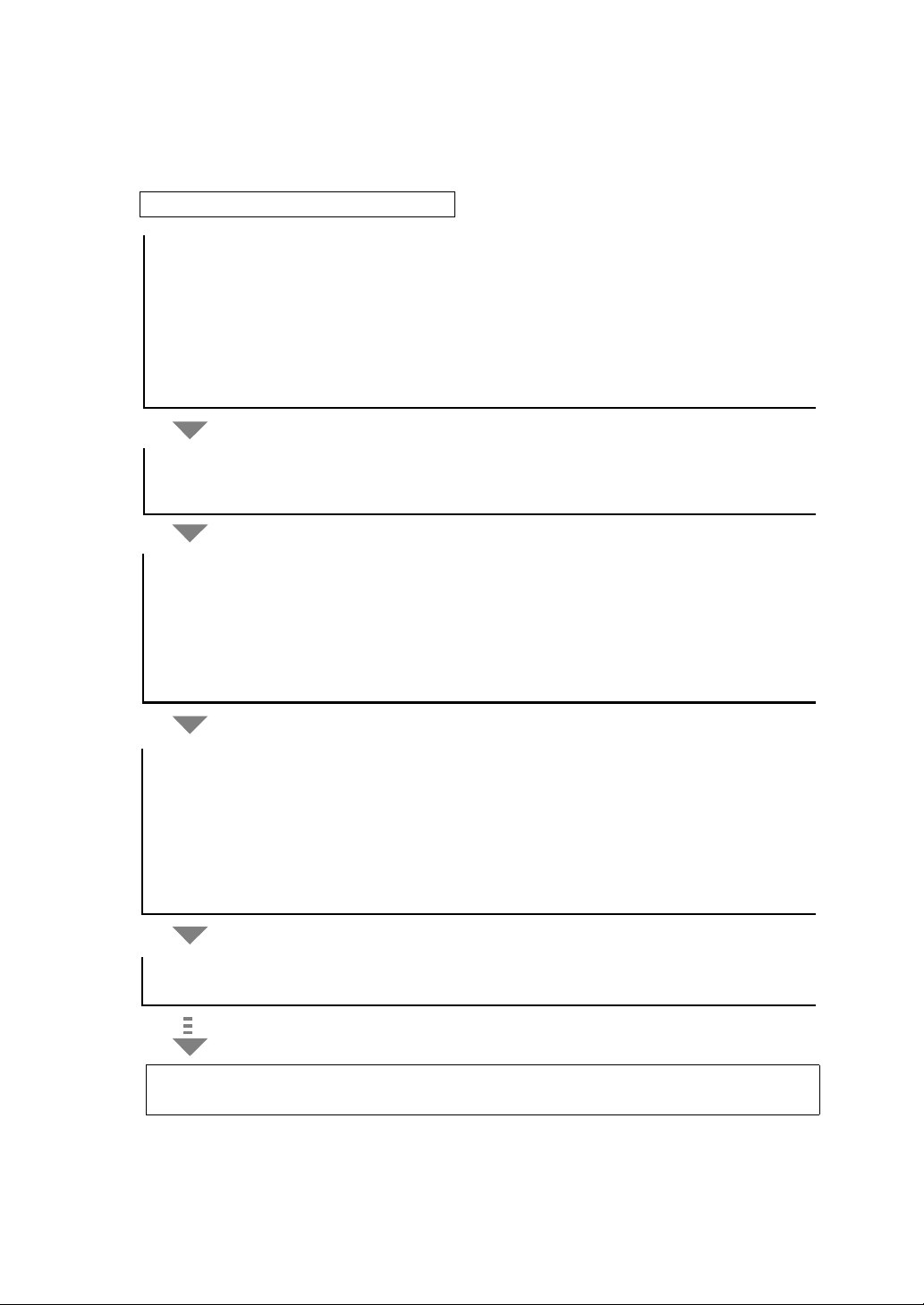

Scanning

Setting the stations

Setting the project

1

. Scan the target.

2

. Perform the 3D scanning.

1

. Set the backsight point name and the occupied point name.

2

. Turn the power ON.

1

. Mount and level the instrument.

Scanning Preparation

Turning the power OFF

When scanning another target within the same project, move the instrument to the next station

and repeat the procedures above.

Refer to Chapter 4.2 “Mount the Instrument to the Tripod”.

Refer to Chapter 4.3 “Power Switch Key ON”.

Refer to Chapter 6 “Project Settings”.

Refer to Chapter 7 “Station Setting”.

Refer to Chapter 7.3 “Setting the Occupied Point Name and the Backsight Point Name”.

Refer to Chapter 8 “Scanning”.

Refer to Chapter 8.1 “Target Scanning”.

Refer to Chapter 8.2 “3D Scanning”.

z When the instrument is used alone

2

. Scan the backsight point.

3.1 Procedure for Scanning

The following are the procedures for scanning.

3 Overview of Scanning

3-1

Page 21

3 Overview of Scanning

Using the PC, enter settings and perform the scanning

2

. Turn the power ON.

1

. Mount and level the instrument.

Scanning Preparation

Turning the power OFF

When scanning another target within the same project, move the instrument to the next station

and repeat the procedures above.

Refer to Chapter 4.2 “Mount the Instrument to the Tripod”.

Refer to Chapter 4.3 “Power Switch Key ON”.

z When the instrument is used connected to a PC

Refer to the Instruction Manual for Scan Master.

3-2

Page 22

3.2 Display and Functions

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

Main Menu

Sub Menu

Display

The following are examples of the displays and its functions.

Display

3 Overview of Scanning

Main

Menu

STATION

MENU

SCAN

MENU

PROJECT

MENU

SETTING

MENU

Sub

Menu

NEW STATION

SELECT STATION

OCC/BS SETTING

3D SCANNING

TARGET SCANNING

NEW PROJECT

SELECT PROJECT

NETWORK SETTING

DATA MANAGE

TEMP.&PRES. SET

LAST CALIB. DATE

TIME ADJUST

UNIT SET

TILT 0 ADJUST

Function

Set a new station.

Refer to Chapter 7.1 “Creating a New Station”.

Select an existing station.

Refer to Chapter 7.2 “Selecting from Existing Stations”.

Set the backsight point name and the occupied point name.

Refer to Chapter 7.3 “Setting the Occupied Point Name and the

Backsight Point Name”.

Perform a 3D scanning of the designated area.

Refer to Chapter 8.2 “3D Scanning”.

Scan the target.

Refer to Chapter 8.1 “Target Scanning”.

Set a new project.

Refer to Chapter 6.1 “Creating a New Project”.

Select an existing project.

Refer to Chapter 6.2 “Selecting from Existing Projects”.

Set the network.

Refer to Chapter 5.2.2 “Network Settings (when the instrument is

used connected to a PC)”.

Edit the data.

Refer to Chapter 5.2.3 “Editing the SD Card Data (data

management)”.

Set the temperature and air pressure.

Refer to Chapter 5.2.4 “Setting the Temperature and

Atmospheric Pressure”.

Display the last calibration date.

Refer to Chapter 5.2.5 “Displaying the Last Calibration Date and

Time”.

Set the time.

Refer to Chapter 5.2.6 “Setting the Date and Time”.

Set the units.

Refer to Chapter 5.2.7 “Changing the Units”.

Adjust the tilt sensor installation error.

Refer to Chapter 5.2.8 “Adjusting the Tilt Sensor Installation

Error”.

3-3

Page 23

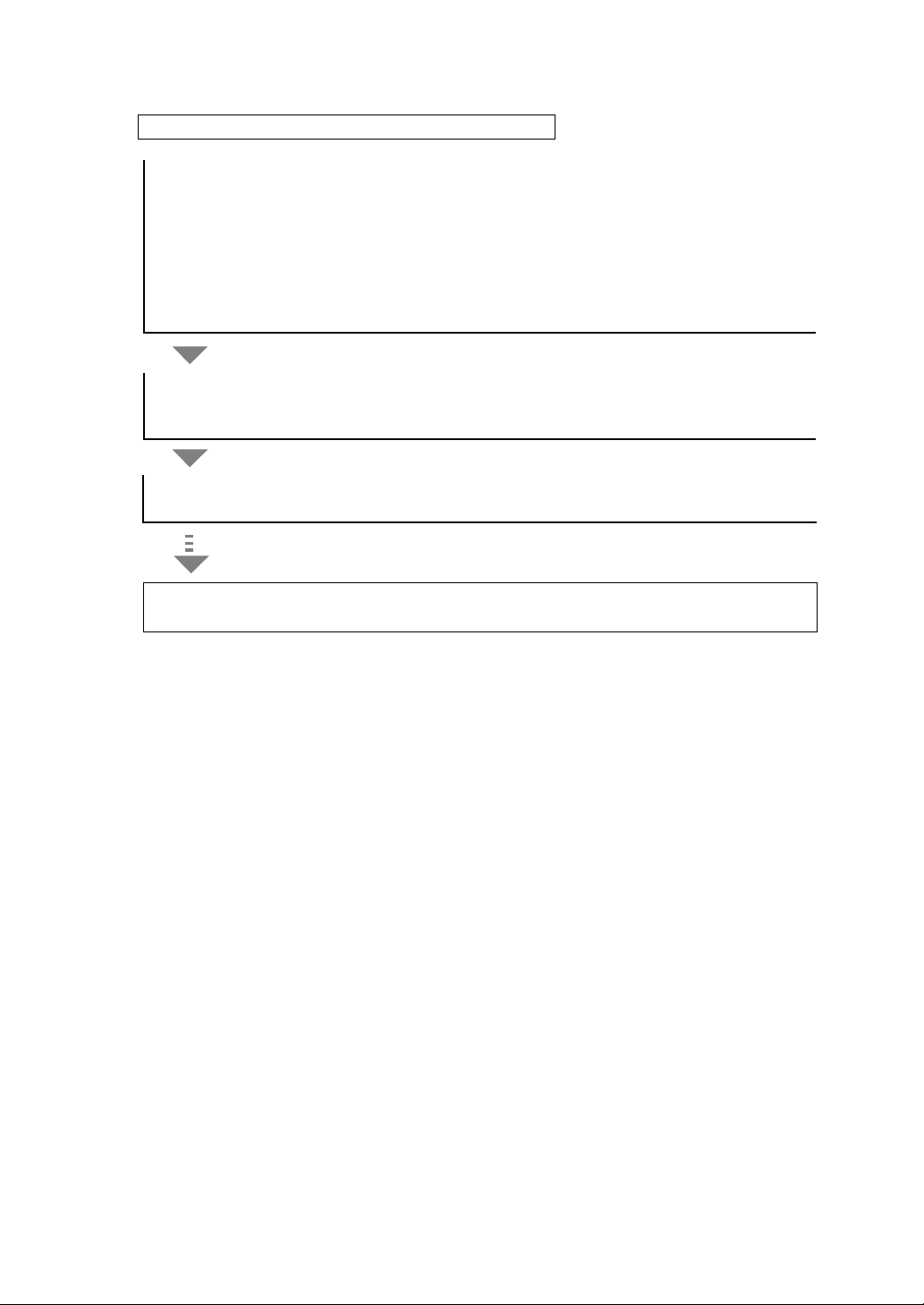

3.3 Screen Flowchart

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SCAN MENU

F1 3D SCANNING

F2 TARGET SCANNING

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

F1

F2

F1

Press the power key

: Battery marks omitted

F3

PROJECT MENU

F1 NEW PROJECT

F2 SELECT PROJECT

F2

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/4

↓

SETTING MENU

F1 TEMP.&PRES. SET

F2 LAST CALIB. DATE

P2/4

↓

↑

SETTING MENU

F1 TIME ADJUST

F2 UNIT SET

P3/4

↓

↑

F3

F4

ESC key : Returning to the previous display.

First page

Second page

Second page

Third page

First page

F3

F4

SETTING MENU

F1 TILT 0 ADJUST

P4/4

↑

Fourth page

F3

F4

3 Overview of Scanning

3-4

Page 24

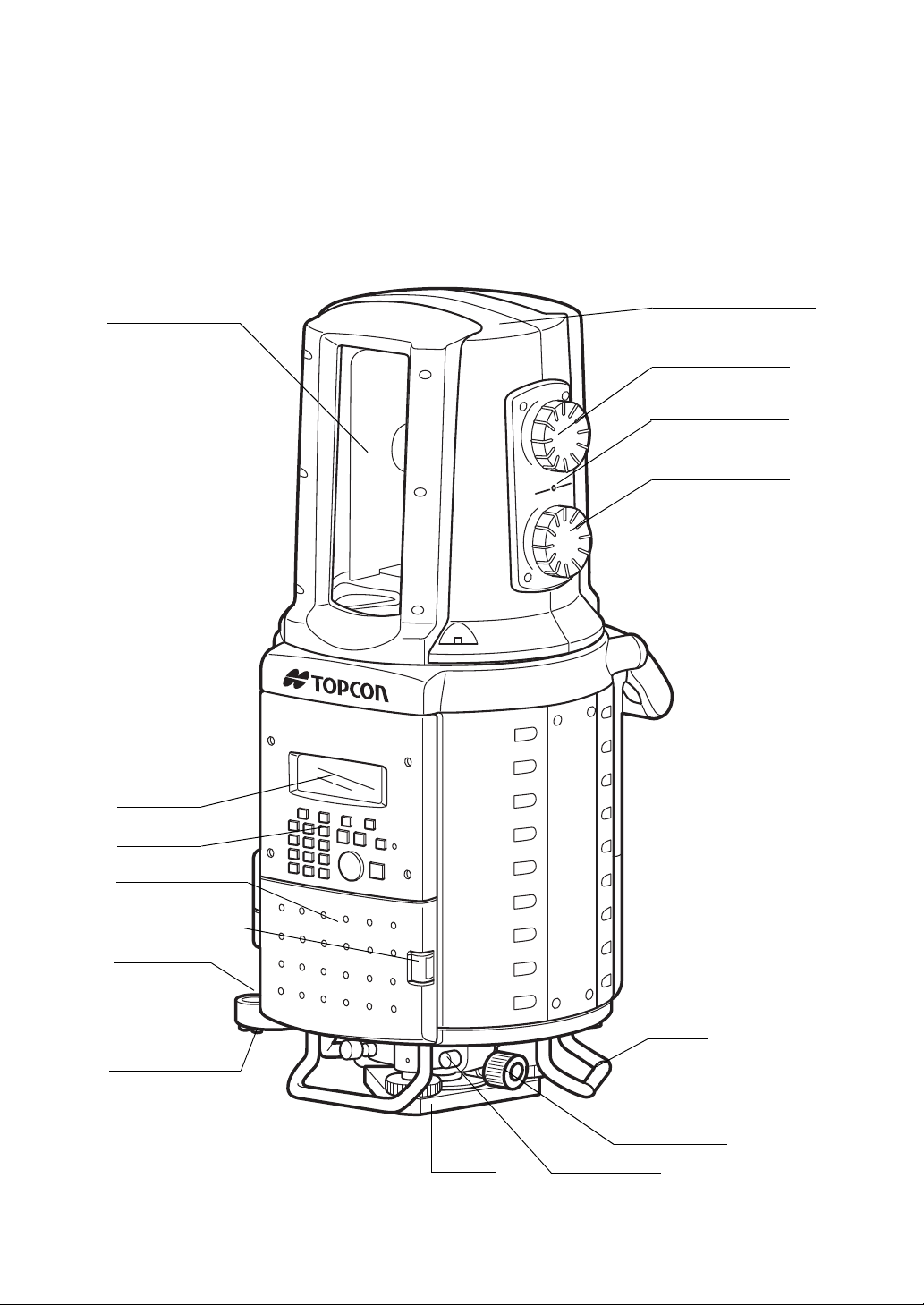

4 PREPARATION FOR MEASUREMENT

Securing screw

Tribrach fixing lever

Tribrach alignment groove

Tribrach fixing screw

Tribrach circular level

Optical plummet telescope

Alignment piece

Tribrach alignment groove

4 PREPARATION FOR MEASUREMENT

When attaching the instrument on a tripod, first attach only the tribrach on the tripod, then attach the

instrument after leveling and centering.

4.1 Detach/Attach of Tribrach

The instrument is easily detached or attached to the tribrach.

z Detachment

1 Loosen the tribrach fixing screw.

2 Loosen the tribrach fixing lever by turning counterclockwise.

(When the tribrach fixing lever securing screws are screwed in, use the driver provided in the

package to loosen.)

3 Lift the instrument straight upwards and off.

z Attachment

1 Coincide the white alignment piece on the lower part of the instrument with the tribrach alignment

groove.

2 Tighten the tribrach fixing lever firmly by turning clockwise.

3 Tighten the tribrach fixing screw.

z Locking the tribrach fixing lever

1 The tribrach fixing lever can be locked from being moved accidentally.

This is useful if the upper instrument section is not being detached very often. Simply tighten the

securing screw on the fixing lever with the accessory screw driver.

4-1

Page 25

4 PREPARATION FOR MEASUREMENT

Leveling

screw A

Leveling screw C

Leveling screw B

Tribrach circular level

Point

Center mark

4.2 Mount the Instrument to the Tripod

First, mount the tribrach to the tripod. Roughly level and center the tribrach.

Next, mount the instrument to the tribrach. Level and center the instrument precisely.

Level and center the instrument precisely to insure the best performance.

Use tripods with a tripod screw of 5/8 in. diameter and 11 threads per inch, such as the Type E

TOPCON wide-frame wooden tripod. Do not use a metallic tripod.

4.2.1 Leveling and Centering the Instrument

1

Setting up the Tripod

1) First, extend the extension legs to suitable lengths and tighten the screws on their midsections.

2) Remove the tribrach from the instrument, and place the tribrach carefully on the tripod head.

3) Loosen the tripod screw and slide the instrument. When the instrument is directly above the point,

lightly tighten the tripod screw.

2 Roughly Leveling the Tribrach by Using the Tribrach circular level

1) Turn the leveling screws A and B and adjust the bubble to stay at the top or bottom of the circular

level.

2) Turn the leveling screw C to bring the bubble to the center of the tribrach circular level.

3 Centering by Using the Optical Plummet Telescope

1) Adjust the eyepiece of the optical plummet telescope to your eyesight.

2) Slide the instrument by loosening the tripod screw, place the point on the center mark, and then

tighten the tripod screw.

Try to keep the tribrach from rotating when sliding it so as to minimize the dislocation of the bubble.

3) Repeat step 2 and 3 if necessary.

4-2

Page 26

4 PREPARATION FOR MEASUREMENT

Circular level

TILT SETTING [ON]

X :+0°01'02"

Y :-0°04'05"

ON OFF

4 Mounting the instrument on the tribrach

1) Mount the instrument on the tribrach and tighten the tribrach fixing lever and the tribrach fixing

screw.

Refer to Chapter 4.1 “Detach/Attach of Tribrach”.

5 Leveling the instrument using the circular level on the instrument

1) Level the instrument as in procedure 2 using the circular level on the instrument.

6 Completely Leveling the Instrument by Using the Tilt Sensor of the Instrument

1) Turn the power ON.

2) After initialization of the instrument is complete, turn the tilt sensor ON, and wait until inclination of

the instrument is shown on the display.

Refer to Chapter 5.1.7 “Setting Example Using the Star Key”.

4-3

Page 27

4 PREPARATION FOR MEASUREMENT

Collimating window

Tribrach

Horizontal jog

Leveling screw A

Leveling screw B

TILT SETTING [ON]

X :+0°03'45"

Y : 0°00'00"

ON OFF

Leveling screw C

TILT SETTING [ON]

X : 0°00'00"

Y :+0°00'06"

ON OFF

3) Use the horizontal jog to turn the instrument as shown in the figure. Make the collimating window

parallel to the line connecting the leveling screws A and B of the tribrach (or make a random choice

of any two).

4) Turn the leveling screws A and B, and adjust the Y-inclination on the display to ±6' or less.

5) Turn the leveling screw C, and adjust the X-inclination on the display to ±6' or less.

4-4

Page 28

4 PREPARATION FOR MEASUREMENT

TILT SETTING [ON]

X :+0°00'08"

Y :+0°00'06"

ON OFF

NOTE:

Since the level may change slightly while

scanning, we recommend leveling the

instrument as precisely as possible.

Notes on the Tribrach:

Note that the angle measuring precision may be effected directly if the tribrach has

not been installed firmly.

1 If there is any slack between the leveling screws and the base, loosen

the set screw of the holding ring and tighten the holding ring with

adjusting pin, until it is properly adjusted. Re-tighten the set screw on

completing the adjustment.

Leveling screw

Holding ring

Set screw

6) Use the horizontal jog to make sure the X and Y inclinations are ±6' or less (within the calibration

range of the tilt sensor), regardless of the direction the collimating window faces.

Leveling of the instrument is complete.

7 Checking centering

1) Re-check the centering with an optical plummet telescope. If there is misalignment, adjust the

instrument to align.

2) Repeat the above described steps 6-7 until both leveling and centering are matched.

4-5

Page 29

4.3 Power Switch Key ON

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

Battery power remaining display

Project name display

Station name display

TOPCON LASER SCANNER

Version 1.00

WARMING UP NOW

TOPCON LASER SCANNER

PROJECT: pr-1

STATION: st-1

PLEASE WAIT..

It takes 3 minutes after the power has been

switched ON to initialize the instrument and

warm up the laser.

Do not turn the head or operate any keys

while the head and mirror are turning.

Note:

Do not turn the head with your hands while the power is ON.

If it has been turned by force, turn the power ON again.

TOPCON LASER SCANNER

[CALIBRATING] display

[CALIBRATING] will be displayed on the screen once every 20 minutes or when ambient

temperature fluctuates during operation. When displayed, distance measurement is being

adjusted internally. Please wait for the display to disappear.

1 Press the power key.

4 PREPARATION FOR MEASUREMENT

4-6

Page 30

4 PREPARATION FOR MEASUREMENT

Measurement is possible.

The power is poor. Please replace

with fully charged batteries.

Measurement is impossible.Please

replace with fully charged batteries.

4.4 Battery Power Remaining Display

Battery power remaining display indicates the power condition.

Note: 1 The battery operating time will vary depending on the environmental conditions such as

ambient temperature, charging time, the number of times of charging and discharging

etc. It is recommended for safety to charge the battery beforehand or to prepare spare

full charged batteries.

2 For general usage of the battery, Refer to Chapter 9 “Charging the Internal Power

Source (BT-65Q)”.

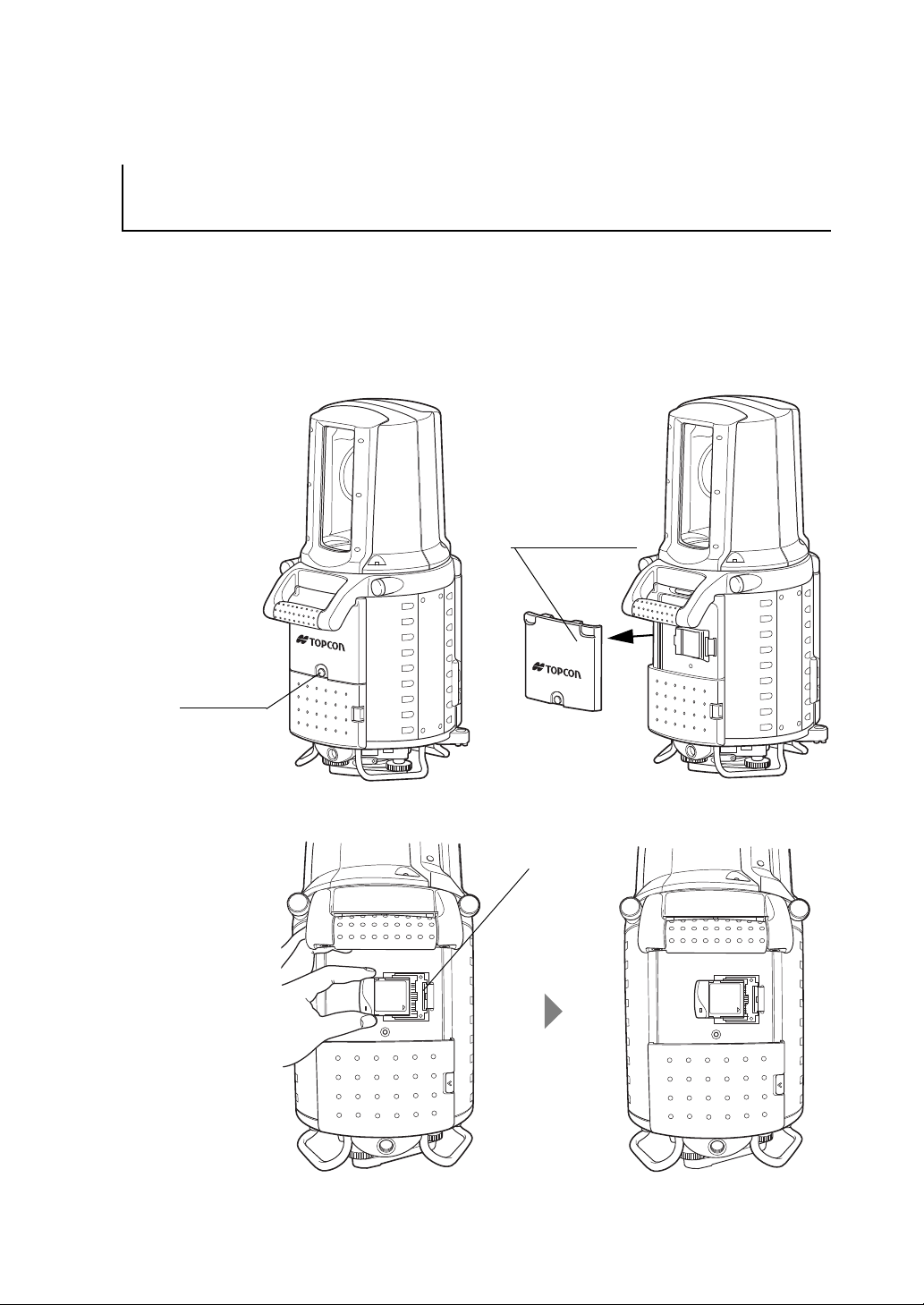

4.5 Replacing the Battery

Replace all (4) batteries with fully charged batteries when replacing the internal batteries.

z How to replace the batteries without turning the instrument's power switch OFF

If the battery power becomes low while scanning, replace the batteries by following the below steps.

The scanning can be continued.

1 Press the F2 key (stop) while scanning. The scanning will pause.

2 Open the front battery cover, and replace 2 batteries.

3 Close the front battery cover.

4 Open the back battery cover, and replace 2 batteries.

5 Close the back battery cover.

6 Press the F1 key (start) to resume scanning.

4-7

Page 31

4 PREPARATION FOR MEASUREMENT

Sighting collimator

Collimating window

Vertic al j og

Horizontal jog

Collimate from here

Sighting collimator

Target

4.6 How to Collimate to a Target.

1 From the collimating window, use the vertical and horizontal jogs to set the sighting collimator

approximately on the target.

2 Look into the sighting collimator.

3 Use the vertical and horizontal jogs to adjust the peak of the triangle inside the sighting collimator to

the target.

4-8

Page 32

4 PREPARATION FOR MEASUREMENT

Alphanumeric characters key

OCC/BS SETTING

INPUT OCC NAME

[ ]

ALPH <-

Numerical input mode

Cursor key

[F1] [F2] [F3] [F4]

Soft keys

Soft key

The Soft Key message is displayed at the bottom line

of display. The functions are according to the displayed

message.

Letters that can be entered:

All alphabets (small letter) a to z, Numeric 0 to 9,

'_', '!', '@', '&', '-', '#', '$', '%'can be entered.

'+' cannot be entered.

Number of characters that can be entered: up to 8

<- [F3] or Cursor key []

Press the [F3] or Cursor key [ ] to delete an entry.

ALPHA [F1] key

Press the [F1] key to enter alphabetical input mode.

OCC/BS SETTING

INPUT OCC NAME

[ ]

ALPH <-

NUME [F1] key

Press the [F1] key to enter numerical input mode.

OCC/BS SETTING

INPUT OCC NAME

[ ]

NUME <-

[F1]

Alphabetical input mode

4.7.1 Switching between Numerical Input Mode and Alphabetical Input Mode

4.7 How to Enter Alphanumeric Characters

When entering the station, instrument height, backpoint, etc., you can enter alphanumeric (small

letters) characters.

4-9

Page 33

[Example setting] Occupied point name : [a-1]

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2 DOWN

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

OCC/BS SETTING

INPUT OCC NAME

[ ]

NUME <-

OCC/BS SETTING

INPUT OCC NAME

[a ]

NUME <-

OCC/BS SETTING

INPUT OCC NAME

[a- ]

NUME <-

OCC/BS SETTING

INPUT OCC NAME

[a- ]

ALPH <-

OCC/BS SETTING

INPUT OCC NAME

[a-1 ]

ALPH <-

OCC/BS SETTING

INST HEIGHT INPUT

[ ]

NUME <-

Operating procedure Operation Display

4 PREPARATION FOR MEASUREMENT

1 Press the [F1](STATION MENU) key.

2 Press the [F3](OCC/BS SETTING) key.

3 Press the [7] key to select “a”.

4 Press the [-+*/] key to select “-”.

5 Press the [F1](NUME) key.

The instrument switches to numerical input mode.

6 Press the [1] key to select “1”.

[F1]

[F3]

[7]

[-+*/]

[F1]

[1]

7 Press the [ENT] key.

Occupied point name is set.

z When you want to delete an entry, press the [F3] or Cursor key [ ]. Then the entry will be deleted.

[ENT]

4-10

Page 34

4 PREPARATION FOR MEASUREMENT

Tribrach fixing lever

Prism adapter (Sold separately)

Alignment piece

Tribrach (Sold separately)

Settlement

screw

Center mark

Target board

Target sheet

Center mark

4.8 Target

4.8.1 Selecting the Target Sheet

Select the target sheet (large, medium, small) based on the distance to the object being scanned.

(Target sheet (large) is sold separately)

Target sheet

Large 50-200

Middle 10-100

Small 2-50

Distance to the object

being scanned (m)

4.8.2 Assembling the Target

1

Coincide the alignment piece on the lower part of the prism-adapter with the tribrach alignment

groove.

2 Tighten the tribrach fixing lever firmly by turning clockwise.

3 Install the target board in the arrow point as shown in the illustration.

4 Tighten the settlement screw surely.

5 Put the magnetic target sheet on the target board.

At this point, adjust the center marks (4) of the target sheet and the target board exactly.

4-11

Page 35

5 Instrument Settings

F1 TILT [ON ]

F2 ZOOM COTROL

P1/3

↓

Press the star key

TILT SETTING [ON]

X :+0°01'02"

Y :-0°04'05"

ON OFF

ZOOM CONTROL

SELECT DISTANCE

F1 UNDER 50M

F2 OVER 50M

F 1

F2

F1 CAMERA [HIGH]

2/3

↓

↑

F3

F1 CONTRAST [ 5 ]

F2 BACKLIGHT [ON :5]

3/3

↑

CAMERA SETTING

F1 HIGH MODE

F2 MIDDLE MODE

F1

CONTRAST ADJUST

LEVEL 6

↑

↓

BACKLIGHT ADJ

F1 : ON [OFF : 9]

F2 : OFF

F3 : LEVEL

F1

F2

F4

First page

Second page

Third page

F3

F4

5.1 Settings by the Star Key

z Items to be set by the star key

Display Function

5 Instrument Settings

TILT SETTING

ZOOM CONTROL

CAMERA SETTING

CONTRAST ADJUST

BACKLIGHT ADJ

Set the tilt sensor ON/OFF.

Choose the best optical zoom system setting for the scanning.

Set the image quality mode of the camera.

Adjust the contrast of the display.

Adjust the backlight of the display.

5.1.1 Star Key Screen Flowchart

5-1

Page 36

5 Instrument Settings

Zenith

Standing

axis

Inclination of the standing

axis in the X direction

Zenith

Inclination of the standing

axis in the Y direction

Trunnion axis

Horizontal

Standing axis

5.1.2 Tilt Setting

When the auto tilt correction function of the vertical and horizontal angles is turned ON, the 2-axis tilt

sensor is activated, and tilts in vertical and horizontal angles due to inclination of the standing axis will

be corrected automatically.

To ensure precise scanning, use the instrument with the auto tilt correction ON. If the tilt is out of

automatic compensation range, [TILT OVER] display will appear on the screen. In such case, level the

instrument. When the tilt comes into the automatic compensation range after the leveling, the screen

will automatically return to the display before the [TILT OVER] display.

z GLS-1000 compensates both the vertical angle and the horizontal angle readings due to inclination

of the standing axis in the X and Y directions.

z The display of Vertical or Horizontal angle is unstable when instrument is on an unstable stage or a

windy day. You can turn off the auto tilt correction function of V/H angle in this case.

5.1.3 Zoom Control (Zoom setting)

The zoom control function is used to select the best optical zoom system based on the scanning

distance, scanning precision, and scanning time. The GLS-1000 is equipped with three types of optical

zoom systems and the ability to change the size of the beam spot according to the scanning object,

which allows you the choice of obtaining a highly precise three-dimensional data or a quick scan.

Select the following two items below according to the scanning conditions.

Selection item (1)

UNDER 50m

OVER 50m

Selection item (2)

NORMAL Use one optical zoom system. Scanning time is quickest.

FINE Use two optical zoom systems which measure with high precision.

SFINE Select the optimum use of three optical zoom systems which measure

The setting will become invalid when the power is turned off. Please set the scanning mode each time

the instrument is used for measurement.

Select when the distance between the instrument and the scanning

object is 50 m or less.

Select when the distance between the instrument and the scanning

object is over 50 m.

Scanning time is about twice that of NORMAL mode.

with the highest accuracy. Scanning time is three times that of

NORMAL mode.

5-2

Page 37

5 Instrument Settings

F1 TILT [ON ]

F2 ZOOM COTROL

P1/3

↓

TILT SETTING [ON]

X :+0°01'02"

Y :-0°04'05"

ON OFF

TILT SETTING [OFF]

ON OFF

F1 TILT [OFF]

F2 ZOOM COTROL

P1/3

↓

5.1.4 Camera Setting

When scanning, the internal camera automatically takes pictures of the entire scanning area, and

keeps the data in the image file (if [SCAN+IMG] or [IMAGE] has been selected. Refer to Chapter 8.2.2

“Setting the Scanning Density”.)

Several photographs are taken in order to cover the entire scanning area. As the scanning area

becomes larger, number of photographs taken will increase.

Also, as the quality of the image becomes higher, the file size will increase. Select the image quality

based on your needs.

Selection item

HIGH MODE High image(1600x1200 pixels) quality mode, large file size

MIDDLE MODE Standard image(800x600 pixels) quality mode, small file size

5.1.5 Contrast Adjust

Adjust the contrast of the display according to the surrounding conditions. The contrast range is from 1

[light] to 10 [dark].

5.1.6 Backlight Adjust

Use the backlight when the display is difficult to read; for example at dusk or when you are inside a

tunnel. There is a switch to keep the backlight always ON or always OFF. When selecting the backlight

is always ON, the brightness can be adjusted. The range is from 1 [dark] to 10 [light].

5.1.7 Setting Example Using the Star Key

Example: set the tilt sensor OFF

Operating procedure Operation Display

1 Press the [ ] key.

2 Press [F1] key.

3 Press the [F2] key.

4 Press the [F4] key.

[]

[F1]

[F2]

[F4]

5-3

Page 38

5.2 Using the Setting Menu

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/4

↓

NETWORK SETTING

→ IP :192.168.1.0

SUB:255.255.255.0

P1/2 EDIT

↑

↓

DATA MANAGE(PRO)

→ pr-1

pr-2

OPEN

↑

↓

EDIT

F 1

F2

SETTING MENU

F1 TEMP.&PRES. SET

F2 LAST CALIB. DATE

P2/4

↓

↑

F3

SETTING MENU

F1 TIME ADJUST

F2 UNIT SET

P3/4

↓

↑

TEMP.&PRES. SET

→TMP. 20.0 °C

PRES. 1017.0 hPa

EDIT

↓

LAST CALIB. DATE

2008/04/28

F1

F2

TIME ADJUST

→DATE 2008/12/24

TIME 22:00

EDIT

↓

UNIT SET

→TEMP.&PRES

ANGLE

P1/2

↑

↓

EDIT

F1

F2

F4

F3

F4

UNIT SET

→DISTANCE

FEET

P2/2

↑

↓

EDIT

F3

F4

First page

Second page

Third page

SETTING MENU

F1 TILT 0 ADJUST

P4/4

↑

Fourth page

F3

F4

z Selection items in the setting menu

Display Function

NETWORK SETTING

DATA MANAGE

TEMP.&PRES. SET

LAST CALIB. DATE

TIME ADJUST

UNIT SET

TILT 0 ADJUST

5.2.1 Setting Menu Screen Flowchart

Set the network.

Edit the data on the SD card.

Set the temperature and air pressure.

Display the date of the last calibration.

Set the date and time.

Set the scanning units.

Adjust the tilt sensor installation error.

5 Instrument Settings

5-4

Page 39

5 Instrument Settings

The IP address, subnet address, and SSID can be entered on the PC and the GLS-1000.

If a wireless connection is used, make sure the addresses on the PC and the GLS-1000

corresponds.

[Initial setting of the instrument at shipping]

IP address : 192.168.0.1

SUBNET address : 255.255.255.0

SSID : gls1000

[Example of the setting on the user's PC]

IP address* : 192.168.0.240

SUBNET address : 255.255.255.0

SSID : gls1000

* "240" at the end of the IP address is

arbitrarily-specified.

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/4

↓

↑

NETWORK SETTING

→IP:

SUB:

P1/2 EDIT

↑

↓

5.2.2 Network Settings (when the instrument is used connected to a PC)

You can connect the instrument to a PC either using a wireless LAN connection with a wireless LAN

card, or through a USB cable. Here we describe how to select one of the connections, and connect via

wireless LAN.

Selectable networks and selection items

Wireless LAN

: IP address

(ID numbers assigned to the individual PC and the GLS-1000)

: SUBNET address

(Numbers identifying the network that connects the PC and the GLS-1000)

:SSID

(Identifier assigned to the PC and the GLS-1000 in order to prevent crossed

signals. Up to 15 characters can be used.)

USB

: No setting is necessary to connect the USB cable and PC.

(It is automatically recognized.)

[Example]

z GLS-1000 settings

Operating procedure Operation Display

1 Press F3 (

main menu.

↓

) key to display the second page of the

2 Press the [F2](SETTING MENU) key to select

SETTING MENU.

[F3]

[F2]

3 Press the [F1](NETWORK SETTING) key to

select NETWORK SETTING.

5-5

[F1]

Page 40

5 Instrument Settings

NETWORK SETTING

INPUT IP ADDRESS

[ ]

<-

NETWORK SETTING

INPUT IP ADDRESS

[192.168.0.1 ]

<-

NETWORK SETTING

IP:192.168.0.1

→SUB:

P1/2 EDIT

↑

↓

NETWORK SETTING

INPUT SUBNET ADDRESS

[255.255.255.0 ]

<-

NETWORK SETTING

SSID:

P2/2 EDIT

↑

↓

NETWORK SETTING

INPUT SSID

[ ]

NUME <-

NETWORK SETTING

INPUT SSID

[gls1000 ]

NUME <-

NETWORK SETTING

SSID: gls1000

P2/2 EDIT

↑

↓

NETWORK SETTING

WLAN AdHoc SET!

PRESS ENT KEY

4 Press the [F2](EDIT) key to edit IP address.

5 Input IP address [192.168.0.1].

6 Press the [ENT] key.

Press the [F4] key and move the curser to

SUBNET.

7 Input SUBNET address [255.255.255.0].

8 Press the [ENT] key.

Press the [F4] key and move the page to SSID.

9 Press the [F2](EDIT) key to edit SSID.

[F2]

Input

IP

address

[ENT]

[F4]

Input

SUBNET

address

[ENT]

[F4]

[F2]

10 Input SSID [gls1000].

11 Press the [ENT] key.

12 Press the [ENT] key.

WLAN AdHoc is set.

Input

SSID

[ENT]

[ENT]

5-6

Page 41

5 Instrument Settings

Make sure to check before deleting folders.

Once a folder is deleted, all the data under the directory will be deleted.

z Data management operation

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/3

↓

↑

DATA MANAGE(PRO)

→ pr-1

pr-2

OPEN

↑ ↓

EDIT

F2

z PC settings (for Windows XP)

Following are the procedures to set the IP address, subnet address, and SSID on the PC.

1 Click [Start] → [Control Panel] → [Network Connections] → [Wireless Network Connection]

2 Right-click [Wireless Network Connection] and select [Properties]. [Wireless Network Connection

Properties] will be displayed.

3 Select [Wireless Network] tab.

4 Select [Add], displayed under [Preferred networks].

5 Click [Association] tab in [Wireless Network Connection Properties]

6 Set the following

Network name → gls1000

Network authentication → Open

Data encryption → Disabled

7 Select [Advanced] under [Preferred networks].

8 Select [Computer-to-computer (ad hoc) networks only] under [Network to access].

9 Enter the IP address, subnet address, and SSID.

Settings are complete.

5.2.3 Editing the SD Card Data (data management)

You can delete or rename the folders on the SD card.

Data that can be renamed or deleted : Project data

: Station data

: 3D scan data

: Target data

5-7

Page 42

5 Instrument Settings

Project1

Station1

Statio n2

3D Scan1

3D Scan2

3D Scan3

3D Scan4

Project1 (Directory)

Station1 (Directory)

3D Scan1 (Directory)

Target Scan1 (Directory)

Station information file (sta file format)

Point cloud file of back sight (clt file format)

Project information file (.prj)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

3D Scan2 (Directory)

Station2 (Directory)

Station information file (sta file format)

Point cloud file of back sight (clt file format)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

Project2 (Directory)

Station21 (Directory)

Station information file (sta file format)

Point cloud file of back sight (clt file format)

Project information file (.prj)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

Point cloud file (clr file format)

JPEG file e.g) 0001.jpg,0002.jpg

Angle file e.g) 0001.ang,0002.ang

3D Scan3 (Directory)

3D Scan4 (Directory)

Point cloud file (clt file format)

3d coordinate file(trg file format)

Tilt orientation file e.g) 0001.tor,0002.tor

z Data structure in an SD card

SD card data is saved under the following directory structure.

An object should be 3D scanned several times from multiple positions, and the results should be kept

together as a single project.

5-8

Page 43

z Renaming folders

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/3

↓

↑

DATA MANAGE(PRO)

→ pr-1

pr-2

OPEN

↑ ↓

EDIT

DATA MANAGE(STA)

→ st-1

st-2

OPEN

↑ ↓

EDIT

DATA MANAGE(STA)

st-1

F1 RENAME

F2 DELETE

DATA MANAGE(STA)

INPUT STATION NAME

[st-1 ]

NUME SPC <-

DATA MANAGE(STA)

INPUT STATION NAME

[st-9 ]

NUME SPC <-

DATA MANAGE(PRO)

→ pr-1

pr-2

OPEN

↑ ↓

EDIT

Refer to the below when deleting or renaming folders

[Example] Rename station [st-1] --> [st-9]

Operating procedure Operation Display

5 Instrument Settings

1 Press the [F3](

the main menu.

↓

)key to display the second page of

2 Press the [F2](SETTING MENU) key to select the

menu.

3 Press the [F2](DATA MANAGE) key to select the

DATA MANAGE.

The projects list will be shown.

4 Choose the project file (Project containing the

station you want to rename) by pressing the [F2]

(

↑

) or [F3] (↓) key

5 Press the [F1](OPEN) key to open the project file.

The stations list will be showen.

6 Choose the station file (you want to rename) by

pressing the [F2] (

↑

) key or the [F3] (↓) key.

7 Press the [F4](EDIT) key.

8 Press the [F1](RENAME) key.

[F3]

[F2]

[F2]

[F2]or[F3]

[F1]

[F2]or[F3]

[F4]

[F1]

9 Press the [F3] (<-) key to move the curser.

10 Rename the station name.

[ST-1] --> [ST-9]

11 Press the [ENT] key.

The station name has been changed.

[F3]

Rename

[ENT]

5-9

Page 44

5 Instrument Settings

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/3

↓

↑

SETTING MENU

F1 TEMP.&PRES. SET

F2 LAST CALIB. DATE

P2/3

↓

↑

TEMP.&PRES. SET

→TMP. 20.0 °C

PRES. 1017.0 hPa

EDIT

↓

TEMP.&PRES. SET

INPUT TMP.

[20.0]

<-

TEMP.&PRES. SET

INPUT TMP.

[22.5

]

<-

TEMP.&PRES. SET

→TMP. 22.5 °C

PRES. 1017.0 hPa

EDIT

↓

5.2.4 Setting the Temperature and Atmospheric Pressure

In order to calibrate the scanning data, enter the temperature and atmospheric pressure at the time of

scanning.

Setting range

Temperature : -10°C to +50°C (0.1°C step) (Factory preset: +20°C)

: -14°F to +122°F (0.1°F step) (Factory preset: 1013.3hPa)

Pressure : 560hPa to 1066.0hPa (0.1hPa step)

: 420mmHg to 800mmHg (0.1mmHg step)

: 16.5inHg to 31.5inHg (0.1inHg step)

Example: Entering a temperature of 22.5°C.

Operating procedure Operation Display

1 Press the [F3] (

of the main menu.

↓

) key to display the second page

2 Press the [F2](SETTING MENU) key.

3 Press the [F3] (

↓

) key to display the second page.

4 Press the [F1](TEMP.&PRES. SET) key.

5 Press the [F2](EDIT) key.

6 Press the [F3] (<-) key to move the curser.

7 Input a temperature. [22.5°C]

[F3]

[F2]

[F3]

[F1]

[F2]

[F3]

Input a

tempera-

ture.

8 Press the [ENT] key.

[ENT]

5-10

Page 45

5 Instrument Settings

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/3

↓

↑

SETTING MENU

F1 TEMP.&PRES. SET

F2 LAST CALIB. DATE

P2/3

↓

↑

LAST CALIB. DATE

2008/04/28

PRESS ENT KEY

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/3

↓

↑

SETTING MENU

F1 TIME ADJUST

F2 UNIT SET

P3/3

↓

5.2.5 Displaying the Last Calibration Date and Time

The GLS-1000 can display the date and time of the last calibration (precision calibration of scanning

distance and scanning angle).

It is recommended that precision calibration be performed within one year after the last calibration.

Operating procedure Operation Display

1 Press the [F3] (

of the main menu.

↓

) key to display the second page

2 Press the [F2](SETTING MENU) key.

3 Press the [F3] (

↓

) key to display the second page.

4 Press the [F2](LAST CALIB. DATE) key.

5.2.6 Setting the Date and Time

Enter the date and time in order to record the date of the scanning.

Example: Date: 2008 01 01 Time 22:30

Operating procedure Operation Display

[F3]

[F2]

[F3]

[F2]

1 Press the [F3] (

of the main menu.

2 Press the [F2](SETTING MENU) key.

3 Press the [F3] (

page.

↓

) key to display the second page

↓

) key twice to display the third

[F3]

[F2]

[F3]

[F3]

5-11

Page 46

5 Instrument Settings

TIME ADJUST

→ DATE 2007/12/24

TIME 22:00

EDIT

↓

TIME ADJUST

INPUT DATE

[20080101]

NUME SPC <-

TIME ADJUST

→ DATE 2008/01/01

TIME 22:00

EDIT

↓

TIME ADJUST

DATE 2008/01/01

→ TIME 22:00

EDIT

↓

TIME ADJUST

INPUT TIME

[2230]

NUME SPC <-

TIME ADJUST

→ DATE 2008/01/01

TIME 22:30

EDIT

↓

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/4

↓

↑

4 Press the [F1](TIME ADJUST) key.

5 Press the [F2](EDIT) key.

6 Press the [F3] (<-) key to move the curser.

7 Input date.(20080101)

8 Press the [ENT] key.

9 Press the [F4](

↓

) key.

10 Press the [F2](EDIT) key.

11 Press the [F3] (<-) key to move the curser.

12 Input time.(2230)

13 Press the [ENT] key.

[F1]

[F2]

[F3]

Input date

[ENT]

[F4]

[F2]

[F3]

Input time

5.2.7 Changing the Units

Select the units for temperature, angle, and distance.

Units that can be selected

Temperature : °C / °F

Angle : DEG / GON / MIL

Distance : METER / FEET / US SURVE / INTERNATIONAL

[Example] Changing the Distance unit to METER

1 Press the [F3](

2 Press the [F2](SETTING MENU) key.

Operating procedure Operation Display

↓

) key.

[F3]

[F2]

5-12

Page 47

5 Instrument Settings

SETTING MENU

F1 TIME ADJUST

F2 UNIT SET

P3/4

↑

UNIT SET

→TEMP.&PRES

ANGLE

P1/2

↑

↓

EDIT

UNIT SET

→DISTANCE

FEET

P2/2

↑

↓

EDIT

UNIT SET

DISTANCE [ft+in]

F1:METER F2:FEET

F3:FEET+INCH SET

UNIT SET

DISTANCE [mt]

F1:METER F2:FEET

F3:FEET+INCH SET

UNIT SET

→DISTANCE

METER

P2/2

↑

↓

EDIT

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

SETTING MENU

F1 NETWORK SETTING

F2 DATA MANAGE

P1/4

↓

↑

SETTING MENU

F1 TILT 0 ADJUST

P4/4

↑

3 Press the [F3](

page P3/3.

↓

) key twice to turn to the menu

4 Press the [F2](UNIT SET) key.

5 Press the [F3](

↓

) key.

6 Press the [F4](EDIT) key.

7 Press the [F1](METER) key to select “METER”.

8 Press the [F4](SET) key.

[F3]

[F3]

[F2]

[F3]

[F4]

[F1]

[F4]

5.2.8 Adjusting the Tilt Sensor Installation Error

Calibrate tilt sensor 0 datum.

1 Press the [F3] (

of the main menu.

2 Press the [F2](SETTING MENU) key.

3 Press the [F3] (

page.

Operating procedure Operation Display

↓

) key to display the second page

↓

) key 3 times to display the fourth

[F3]

[F2]

[F3]

[F3]

[F3]

5-13

Page 48

5 Instrument Settings

TILT 0 ADJUST

X :+0°00'25"

Y :+0°00'20"

START

TILT 0 ADJUST

PROCESSING..

PLEASE WAIT..

TILT 0 ADJUST

SET!

PRESS ENT KEY

4 Press the [F1](TILT 0 ADJUST) key.

5 Turn the leveling screw to level the unit to within

30".

6 Press the [F4](START) key.

Begin the calibration of tilt sensor 0 datum.

When [TILT OVER] is displayed while calibrating,

press the [ENT] key and level the unit once again.

[F1]

[F4]

5-14

Page 49

6 Project Settings

Station1

Station2

Station3

Station4

Project1

pt01

pt02

pt03

pt04

pt05

pt06

pt04

pt05

pt06

Ta rg e t

The GLS-1000 scans an object from several directions. All the scanned data are managed and stored

as one project.

The station information of each scanning is stored inside the same project.

Create a new project when you scan a new object.

If you continue scanning for the same project or control the existing data, select from the existing

projects.

6 Project Settings

6-1

Page 50

Project data is saved on the SD card.

Project1 (Directory)

Station1 (Directory)

3D Scan1 (Directory)

Target Scan1 (Directory)

Station information file (sta file format)

Point cloud file of back sight (clt file format)

Project information file (.prj)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

3D Scan2 (Directory)

Point cloud file (clr file format)

JPEG file e.g) 0001.jpg,0002.jpg

Angle file e.g) 0001.ang,0002.ang

Tilt orientation file e.g) 0001.tor,0002.tor

F3

z Project menu operation

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

PROJECT MENU

F1 NEW PROJECT

F2 SELECT PROJECT

F1

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

PROJECT MENU

F1 NEW PROJECT

F2 SELECT PROJECT

NEW PROJECT

INPUT PROJECT NAME

[ ]

NUME <-

6 Project Settings

6.1 Creating a New Project

[Example] Project name: p03

1 Press the [F3] (

of the main menu.

2 Press the [F1](PROJECT MENU) key.

3 Press the [F1](NEW PROJECT) key to input the

project name.

Operating procedure Operation Display

↓

) key to display the second page

6-2

[F3]

[F1]

[F1]

Page 51

6 Project Settings

NEW PROJECT

INPUT PROJECT NAME

[p03 ]

NUME <-

PROJECT MENU

F1 NEW PROJECT

F2 SELECT PROJECT

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

SELECT MENU

F1 PROJECT MENU

F2 SETTING MENU

P2/2

↑

PROJECT MENU

F1 NEW PROJECT

F2 SELECT PROJECT

SELECT PROJECT

→ p01

p02

↑

↓

SELECT

SELECT PROJECT

p01

→ p02

↑

↓

SELECT

PROJECT MENU

F1 NEW PROJECT

F2 SELECT PROJECT

4 Input project name [p03].

5 Press the [ENT] key.

Project "p03" is set.

6.2 Selecting from Existing Projects

[Example] Select project name: p02

Operating procedure Operation Display

1 Press the [F3] (

of the main menu.

2 Press the [F1](PROJECT MENU) key.

↓

) key to display the second page

Input

project

name

[ENT]

[F3]

[F1]

3 Press the [F2](SELECT PROJECT) key.

4 Select the project [p02] by pressing the [F2] or [F3]

key.

5 Press the [F4](SELECT) key.

Project "p02" is selected.

[F2]

[F2] or [F3]

[F4]

6-3

Page 52

7 Station Setting

Station1

Backpoint1

Station1

Project1 (Directory)

Station1 (Directory)

3D Scan1 (Directory)

Target Scan1 (Directory)

Station information file (sta file format)

Point cloud file of back sight (clt file format)

Project information file (.prj)

3D coordinate of back sight (trg file format)

Camera orientation/calibration data (binEXT file format)

3D Scan2 (Directory)

Point cloud file (clr file format)

JPEG file e.g) 0001.jpg,0002.jpg

Angle file e.g) 0001.ang,0002.ang

Tilt orientation file e.g) 0001.tor,0002.tor

Data related to the scanning (occupied point name, backsight point name, target data, 3D data, etc.)

are stored in the station.

Create a new station when moving to another station to scan the object.

To continue scanning from the same station, or to control existing data, select from the existing stations.

7 Station Setting

Station data is saved on the SD card.

7-1

Page 53

7 Station Setting

F1

F2

F1

z Station menu operation

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

NEW STATION

INPUT STATION NAME

[ ]

NUME <-

SELECT STATION

→ st-1

st-2

↑

↓

SELECT

OCC/BS SETTING

INPUT OCC NAME

[ ]

NUME <-

F3

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

NEW STATION

INPUT STATION NAME

[ ]

NUME <-

NEW STATION

INPUT STATION NAME

[st-4 ]

NUME <-

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

7.1 Creating a New Station

[Example] Station name: st-4

Operating procedure Operation Display

1 Press the [F1](STATION MENU) key to select the

station menu.

2 Press the [F1](NEW STATION) key.

3 Input station name [st-4].

4 Press the [ENT] key.

Station "st-4" is set.

[F1]

[F1]

Input

station

name

[ENT]

7-2

Page 54

7.2 Selecting from Existing Stations

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

SELECT STATION

→ st-1

st-2

↑

↓

SELECT

SELECT PROJECT

st-1

→ st-2

↑

↓

SELECT

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

[Example] Select station name: st-2

Operating procedure Operation Display

7 Station Setting

1 Press the [F1](STATION MENU) key to select the

station menu.

2 Press the [F2](SELECT STATION) key.

3 Select the station [st-2] by pressing the [F2] or [F3]

key.

4 Press the [F4](SELECT) key.

Station "st-2" is selected.

[F1]

[F2]

[F2] or [F3]

[F4]

7-3

Page 55

7 Station Setting

z The only target you can use is Topcon target sheets.

z The target sheet to use differs depending on the scanning distance. Refer to Chapter 4.8.1

“Selecting the Target Sheet”.

SELECT MENU

F1 STATION MENU

F2 SCAN MENU

P1/2

↓

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

OCC/BS SETTING

INPUT OCC NAME

[ ]

NUME <-

OCC/BS SETTING

INPUT OCC NAME

[a-1 ]

NUME <-

OCC/BS SETTING

INPUT HEIGHT

[ ]

NUME <-

OCC/BS SETTING

INPUT HEIGHT

[1.5 ]

NUME <-

OCC/BS SETTING

INPUT BS NAME

[ ]

NUME <-

7.3 Setting the Occupied Point Name and the Backsight Point Name

The occupied point name and backsight point name must be set in order to obtain the coordinates of

the scanning object relative to a known point.

Enter the occupied point name, instrument height, backsight point name, and target name. Collimate

the backsight point.

Start the target scanning, and record the backsight point data.

[Example] Use the following settings.

Occupied point name : a-1

Instrument height : 1.5m (Entry range: -999.999m-999.999m)

Backsight point name : b-1

Target name : t-1

Operating procedure Operation Display

1 Press the [F1](STATION MENU) key to select the

station menu.

2 Press the [F3](OCC/BS SETTING) key to input the

occupied point name.

3 Input the occupied point name [a-1].

[F1]

[F3]

Input

occupied

point name

4 Press the [ENT] key.

5 Input instrument height [1.5m].

Input unit is meters (m).

6 Press the [ENT] key.

7-4

[ENT]

Input

instrument

height

[ENT]

Page 56

7 Station Setting

OCC/BS SETTING

INPUT BS NAME

[b-1 ]

ALPH <-

OCC/BS SETTING

AREA SELECT

AIM TO TARGET

AND PRESS ENT KEY

OCC/BS SETTING

SCANNING IN PROGRESS

REMAIN 10S

PAUSE STOP

OCC/BS SETTING

FINISHED

PRESS ENT KEY

OCC/BS SETTING

PLEASE PEEP TARGET

F1 FINISH F2 REVOKE

F3 SCAN AGAIN

STATION MENU

F1 NEW STATION

F2 SELECT STATION

F3 OCC/BS SETTING

TILT OVER

PRESS ENT KEY

TARGET SCANNING

SCAN START

PRESS ENT KEY

ENT

After leveling the instrument,

press the [ENT] key.

7 Input backsight point name [b-1].

8 Press the [ENT] key.

9 Collimate to the center of backpoint target by

using Horizontal/Vertical jog.

10 Press the [ENT] key.

Scanning of the backsight point will start.

REMAIN: remaining time of the scan

11 When scanning of the backsight point is correctly

completed, an end message will be displayed.

Then, press the [ENT] key. *1) *2)

Input

backsight

point name

[ENT]

Collimate to

a target

[ENT]

[ENT]

12 The mirror will rotate toward the backsight point.

Look into the sighting collimator and confirm the

position of the backsight point that was scanned.

When the backsight point is correctly collimated,

select the F1 (FINISH) key.

When the backsight point is not correctly

collimated, there is a possibility of a reflecting

object other than the target being scanned. Select

either the F2 (REVOKE) or F3 (SCAN AGAIN) key

and redo.

The backsight point name and the occupied point

name are set.

*1) If the instrument is tilted 10' or more, the screen

shown below will be displayed.

[F1]

7-5

Page 57

7 Station Setting

DEVIATION IS LARGE!!

ANG_DEV : 14.5asec

DIST_DEV: 12mm

OK NG RETRY

TARGET SCANNING

FINISHED

PRESS ENT KEY

SCAN MENU

F1 3D SCANNING

F2 TARGET SCANNING

TARGET SCANNING

AREA SELECT

AIM TO TARGET

AND PRESS ENT KEY

F1

F2

F3

*2) If the scan result exceeds the following conditions, the screen below will be displayed.