Titan PL4950, PL8950, PL6950 User Manual

GB D |

F |

|

|

Operating manual |

|

|

|

Betriebsanleitung............ |

p. 26 |

PowrLiner |

|

Mode d’emploi |

p. 52 |

||

|

Airless high-pressure spraying unit

Airless Hochdruck-Spritzgerät

Groupe de projection à haute pression

Model 0290019 (PL4950)

Model 0290010 (PL6950)

Model 0290011 (PL8950)

Edition 9 / 2014 |

0290 944C |

Ausgabe |

|

Original Operating Manual |

GB |

Warning!

1

2

Attention: Danger of injury by injection!

Airless units develop extremely high spraying pressures.

Never put your fingers, hands or any other parts of the body into the spray jet!

Never point the spray gun at yourself, other persons or animals. Never use the spray gun without safety guard.

Do not treat a spraying injury as a harmless cut. In case of injury to the skin through coating materials or solvents, consult a doctor immediately for quick and expert treatment. Inform the doctor about the coating material or solvent used.

The operating instructions state that the following points must always be observed before starting up:

1.Faulty units must not be used.

2.Secure Titan spray gun using the safety catch on the trigger.

3.Ensure that the unit is properly earthed.

4.Check allowable operating pressure of high-pressure hose and spray gun.

5.Check all connections for leaks.

3 |

The instructions regarding regular cleaning and maintenance of |

the unit must be strictly observed. |

|

Before any work is done on the unit or for every break in work the |

|

|

following rules must be observed: |

1. Release the pressure from spray gun and hose.

2. Secure the Titan spray gun using the safety catch on the trigger. 3. Switch off unit.

Be safety conscious!

2 |

PowrLiner |

GB

Contents

Contents |

|

|

|

|

Page |

1. |

Safety regulations for Airless spraying |

...................................... 2 |

1.1 |

Explanation of symbols used............................................................... |

2 |

1.2 |

Electrical safety......................................................................................... |

3 |

1.3 |

Gasoline engine safety........................................................................... |

4 |

1.4 |

Fueling (gas engine)............................................................................... |

4 |

2. |

General view of application............................................................. |

5 |

2.1 |

Application................................................................................................. |

5 |

2.2 |

Coating materials..................................................................................... |

5 |

3. |

Description of unit................................................................................ |

5 |

3.1 |

Airless process........................................................................................... |

5 |

3.2 |

Functioning of the unit.......................................................................... |

5 |

3.3 |

System diagram - gasoline PL units.................................................. |

6 |

3.4 |

Technical data for PL units.................................................................... |

7 |

3.5 |

Airless Spray Tip Recommendation Chart...................................... |

7 |

4. |

Operation.................................................................................................. |

8 |

4.1 |

Setup............................................................................................................ |

8 |

4.2 |

Preparing a new sprayer........................................................................ |

9 |

4.3 |

Preparing to paint.................................................................................. |

10 |

4.4 |

Painting..................................................................................................... |

10 |

4.5 |

Pressure relief procedure.................................................................... |

11 |

4.6 |

Operating the Front Caster................................................................ |

11 |

5. |

Cleanup.................................................................................................... |

12 |

5.1Special cleanup instructions for use with

|

flammable solvents............................................................................... |

12 |

5.2 |

Cleaning the sprayer............................................................................. |

12 |

5.3 |

Cleaning a clogged tip......................................................................... |

12 |

6. |

Maintenance.......................................................................................... |

13 |

6.1 |

Daily maintenance................................................................................. |

13 |

6.2 |

Maintaining the filter assembly........................................................ |

13 |

6.3 |

Maintaining the hydraulic system................................................... |

14 |

6.4 |

Maintaining the fluid section............................................................. |

14 |

6.5 |

Basic engine maintenance................................................................. |

15 |

6.6 |

Replacing the motor brushes (120V electric convertokit)...... |

15 |

6.7 |

Adjusting the Tracking of the Front Caster.................................. |

16 |

6.8 |

Replacing the belt.................................................................................. |

17 |

6.9 |

Servicing the hydraulic motor........................................................... |

18 |

6.10 Servicing the fluid section.................................................................. |

20 |

|

6.11 |

SAE O-ring fitting installation............................................................ |

22 |

|

|

Page |

7. |

Troubleshooting.................................................................................. |

23 |

7.1 |

Airless gun................................................................................................ |

23 |

7.2 |

Fluid section............................................................................................. |

23 |

7.3 |

Hydraulic motors.................................................................................... |

24 |

7.4 |

Spray patterns......................................................................................... |

25 |

Accessories and spare parts......................................................................... |

78 |

|

Spare parts list for the main assembly.................................................. |

78/79 |

|

Spare parts list for the cart assembly I................................................... |

80/81 |

|

Spare parts list for the cart assembly II................................................. |

82/83 |

|

Spare parts list for the hydraulic system.............................................. |

84/85 |

|

Spare parts list for the hydraulic motor................................................ |

86/87 |

|

Spare parts list for the fluid section • PL4950..................................... |

88/89 |

|

Spare parts list for the fluid section • PL6950 / PL8950................... |

90/91 |

|

Spare parts list for gas convertokit................................................................ |

92 |

|

Spare parts list for belt guard assembly...................................................... |

93 |

|

Spare parts list for the high-pressure filter.......................................... |

94/95 |

|

Spare parts list for bleed hose assembly with valve............................... |

96 |

|

Spare parts list for bleed valve........................................................................ |

97 |

|

Spare parts list for siphon hose assembly................................................... |

98 |

|

Spare parts list for caster assembly............................................................... |

98 |

|

Spare parts list for second gun assembly.................................................... |

99 |

|

Installing the Second Gun Assembly........................................... |

100/101 |

|

Connection diagram (PL4950).................................................................. |

102 |

|

Connection diagram (PL6950/8950)...................................................... |

103 |

|

Accessories for PL units................................................................................ |

104 |

|

SC-6 Striping Tip Chart..................................................................................... |

105 |

|

Spare parts list for electric convertokit (120V)........................................ |

107 |

|

Warranty.............................................................................................................. |

108 |

|

PowrLiner |

1 |

GB

Safety precautions

1.Safety regulations for Airless spraying

1.1Explanation of symbols used

This manual contains information that must be read and understood before using the equipment. When you come to an area that has one of the following symbols, pay particular attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause serious injury or loss of life. Important safety information will follow.

This symbol indicates a potential hazard to you or to the equipment. Important information that

Attention |

tells how to prevent damage to the equipment or |

how to avoid causes of minor injuries will follow. |

|

|

|

|

Danger of skin injection |

Danger of fire from solvent and paint fumes

Danger of explosion from solvent, paint fumes and incompatible materials

Danger of injury from inhalation of harmful

|

vapors |

i |

Notes give important information which should |

be given special attention. |

HAZARD: Injection injury

A high pressure stream produced by this equipment can pierce the skin and underlying tissues, leading to serious injury and possible amputation.

Do not treat a spraying injury as a harmless cut. In case of injury to the skin through coating materials or solvents, consult a doctor immediately for quick and expert treatment. Inform the doctor about the coating material or solvent used.

PREVENTION:

•NEVER aim the gun at any part of the body.

•NEVER allow any part of the body to touch the fluid stream. DO NOT allow body to touch a leak in the fluid hose.

•NEVER put your hand in front of the gun. Gloves will not provide protection against an injection injury.

•ALWAYS lock the gun trigger, shut the fluid pump off and release all pressure before servicing, cleaning the tip guard, changing tips, or leaving unattended. Pressure will not be released by turning off the engine. The PRIME/SPRAY valve or pressure bleed valve must be turned to their appropriate positions to relieve system pressure.

•ALWAYS keep tip guard in place while spraying. The tip guard provides some protection but is mainly a warning device.

•ALWAYS remove the spray tip before flushing or cleaning the system.

•NEVER use a spray gun without a working trigger lock and trigger guard in place.

•All accessories must be rated at or above the maximum operating pressure range of the sprayer. This includes spray tips, guns, extensions, and hose.

HAZARD: High Pressure Hose

The paint hose can develop leaks from wear, kinking and abuse. A leak can inject material into the skin. Inspect the hose before each use.

PREVENTION:

•Avoid sharp bending or kinking of the high-pressure hose. The smallest bending radius amounts to about 20 cm.

•Do not drive over the high-pressure hose. Protect against sharp objects and edges.

•Replace any damaged high-pressure hose immediately.

•Never repair defective high-pressure hoses yourself!

•Electrostatic charging of spray guns and the high-pressure hose is discharged through the high-pressure hose. For this reason the electric resistance between the connections of the high-pressure hose must be equal to or lower than 1MΩ.

•For reasons of function, safety and durability use only original

Titan high-pressure hoses.

•Before each use, check all hoses for cuts, leaks, abrasion or bulging of cover. Check for damage or movement of couplings. Immediately replace the hose if any of these conditions exist. Never repair a paint hose. Replace it with another earthed high-pressure hose.

•Make sure power cord, air hose and spray hoses are routed in such a manner to minimize slip, trip and fall hazard.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Severe injury and/or property damage can occur.

PREVENTION:

•Do not use materials with a flashpoint below 38º C (100º F).

Flashpoint is the temperature at which a fluid can produce enough vapors to ignite.

•Do not use the unit in work places which are covered by the explosion protection regulations.

•Provide extensive exhaust and fresh air introduction to keep the air within the spray area free from accumulation of flammable vapors.

•Avoid all ignition sources such as static electricity sparks, electrical appliances, flames, pilot lights, hot objects, and sparks from connecting and disconnecting power cords or working light switches.

•Do not smoke in spray area.

•Place sprayer sufficient distance from the spray object in a well ventilated area (add more hose if necessary). Flammable vapors are often heavier than air. Floor area must be extremely well ventilated. The pump contains arcing parts that emit sparks and can ignite vapors.

•The equipment and objects in and around the spray area must be properly grounded to prevent static sparks.

•Use only conductive or earthed high pressure fluid hose. Gun must be earthed through hose connections.

•Power cord must be connected to a grounded circuit (electric units only).

•Always flush unit into separate metal container, at low pump pressure, with spray tip removed. Hold gun firmly against side of container to ground container and prevent static sparks.

2 |

PowrLiner |

GB

|

|

|

|

Safety precautions |

|

• Follow material and solvent manufacturer’s warnings and |

1.2 |

Electric Safety |

|||

instructions. Be familiar with the coating material’s MSDS |

Electric models must be earthed. In the event of an electrical short |

||||

sheet and technical information to ensure safe use. |

|||||

• Use lowest possible pressure to flush equipment. |

circuit, earthing reduces the risk of electric shock by providing an |

||||

escape wire for the electric current. This product is equipped with |

|||||

• When cleaning the unit with solvents, the solvent should |

|||||

a cord having an earthing wire with an appropriate earthing plug. |

|||||

never be sprayed or pumped back into a container with a |

Connection to the mains only through a special feed point, e.g. |

||||

small opening (bunghole). An explosive gas/air mixture can |

through an error protection insallation with INF < 30 mA. |

||||

arise. The container must be earthed. |

|

|

|

||

|

|

|

|

DANGER — Work or repairs at the electrical |

|

|

|

|

|

equipment may only be carried out by a skilled |

|

|

HAZARD: HAZARDOUS VAPORS |

|

|

electrician. No liability is assumed for incorrect |

|

|

|

|

installation. Switch the unit off. Before all repair |

||

|

Paints, solvents, and other materials can be harmful |

|

|

work, unplug the power plug from the outlet. |

|

|

if inhaled or come in contact with body. Vapors can |

Danger of short-circuits caused by water ingressing into the electrical |

|||

|

cause severe nausea, fainting, or poisoning. |

||||

|

|

equipment. Never spray down the unit with high-pressure or high- |

|||

PREVENTION: |

pressure steam cleaners. |

|

•Wear respiratory protection when spraying. Read all instructions supplied with the mask to be sure it will provide the necessary protection.

•All local regulations regarding protection against hazardous vapors must be observed.

•Wear protective eyewear.

•Protective clothing, gloves and possibly skin protection cream are necessary for the protection of the skin. Observe the regulations of the manufacturer concerning coating materials, solvents and cleaning agents in preparation, processing and cleaning units.

HAZARD: GENERAL

This product can cause severe injury or property damage.

Work or repairs at the electrical equipment:

These may only be carried out by a skilled electrician. No liability is assumed for incorrect installation.

Operating Temperature

This equipment will operate correctly in its intended ambient, at a minimum between +10°C and +40°C.

Relative Humidity

The equipment will operate correctly within an environment at 50% RH, +40°C. Higher RH may be allowed at lower temperatures.

Measures shall be taken by the Purchaser to avoid the harmful effects of occasional condensation.

Altitude

This equipment will operate correctly up to 2100 m above mean sea level.

PREVENTION:

•Follow all appropriate local, state, and national codes governing ventilation, fire prevention, and operation.

•Pulling the trigger causes a recoil force to the hand that is holding the spray gun. The recoil force of the spray gun is particularly powerful when the tip has been removed and a high pressure has been set on the airless pump. When

cleaning without a spray tip, set the pressure control knob to the lowest pressure.

•Use only manufacturer authorized parts. User assumes all risks and liabilities when using parts that do not meet the minimum specifications and safety devices of the pump manufacturer.

•ALWAYS follow the material manufacturer’s instructions for safe handling of paint and solvents.

•Clean up all material and solvent spills immediately to prevent slip hazard.

•Wear ear protection. This unit can produce noise levels above

85 dB(A).

•Never leave this equipment unattended. Keep away from children or anyone not familiar with the operation of airless equipment.

•Do not spray on windy days.

•The device and all related liquids (i.e. hydraulic oil) must be disposed of in an environmentally friendly way.

Transportation and Storage

This equipment will withstand, or has been protected against, transportation and storage temperatures of -25°C to +55°C and for short periods up to +70°C.

It has been packaged to prevent damage from the effects of normal humidity, vibration and shock.

PowrLiner |

3 |

GB

Safety precautions

1.3 |

Gasoline Engine Safety |

1.4 |

Fueling (gas engine) |

1.Gas engines are designed to give safe and dependable service if operated according to instructions. Read and understand the engine manufacturer’s Owner’s Manual before operating the engine. Failure to do so could result in personal injury or equipment damage.

2.To prevent fire hazards and to provide adequate ventilation, keep the engine at least 1 meter (3 feet) away from buildings and other equipment during operation. Do not place flammable objects close to the engine.

3.People who are not operating the device must stay away from the area of operation due to a possibility of burns from hot engine components or injury from any equipment the engine may be used to operate.

4.Know how to stop the engine quickly, and understand the operation of all controls. Never permit anyone to operate the engine without proper instructions.

5.Gasoline is extremely flammable and is explosive under certain conditions.

6.Refuel in a well-ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the refueling area or where gasoline is stored.

7.Do not overfill the fuel tank. After refueling, make sure the tank cap is closed properly and securely.

8.Be careful not to spill fuel when refueling. Fuel vapor or spilled fuel may ignite. If any fuel is spilled, make sure the area is dry before starting the engine.

9.Never run the engine in an enclosed or confined area. Exhaust contains poisonous carbon monoxide gas; exposure may cause loss of consciousness and may lead to death.

10.The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Be careful not to touch the muffler while it is hot. To avoid severe burns or fire hazards, let the engine cool before transporting it or storing it indoors.

11.Never ship/transport sprayer with gasoline in the tank.

DO NOT use this equipment to spray water or acid.

Do not lift by cart handle when loading or unloading. Attention Device is very heavy. Three-person lift is required.

Gasoline is extremely flammable and is explosive under certain conditions.

Fuel Specifications

•Use automotive gasoline that has a pump octane number of

86 or higher, or that has a research octane number of 91 or higher. Use of a lower octane gasoline can cause persistent

“pinging” or heavy “spark knock” (a metallic rapping noise) which, if severe, can lead to engine damage.

i |

If “spark knock” or “pinging” occurs at a steady |

engine speed under normal load, change brands of |

|

gasoline. If spark knock or pinging persists, consult |

|

|

an authorized dealer of the engine manufacturer. |

|

Failure to do so is considered misuse, and damage |

|

caused by misuse is not covered by the engine |

|

manufacturer’s limited warranty. |

|

Occasionally you may experience light spark knock |

|

while operating under heavy loads. This is no |

|

cause for concern, it simply means your engine is |

|

operating efficiently. |

|

|

•Unleaded fuel produces fewer engine and spark plug deposits and extends the life of the exhaust system components.

•Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid getting dirt, dust, or water in the fuel tank.

Gasolines Containing Alcohol

If you decide to use a gasoline containing alcohol (gasohol), be sure its octane rating is at least as high as that recommended by the engine manufacturer. There are two types of “gasohol”: one containing ethanol, and the other containing methanol. Do not use gasohol that contains more than 10% ethanol. Do not use gasoline containing methanol (methyl or wood alcohol) that does not also contain co-solvents and corrosion inhibitors for methanol. Never use gasoline containing more than 5% methanol, even if it has cosolvents and corrosion inhibitors.

Fuel system damage or engine performance

i problems resulting from the use of fuels that contain alcohol is not covered under the warranty. The engine manufacturer cannot endorse the use of fuels containing methanol since evidence of their suitability is incomplete at this time.

Before buying gasoline from an unfamiliar station, try to find out if the gasoline contains alcohol. If it does, confirm the type and percentage of alcohol used. If you notice any undesirable operating characteristics while using a gasoline that contains alcohol, or one that you think contains alcohol, switch to a gasoline that you know does not contain alcohol.

4 |

PowrLiner |

|

GB |

General view of application |

Description of unit |

2.General view of application

2.1Application

This airless line striper is a precision power tool used to spray many types of material for many types of applications including parking lots, curbs, and athletic fields. Read and follow this instruction manual carefully for proper operating instructions, maintenance, and safety information.

2.2Coating materials

Processible coating materials

i |

Pay attention to the Airless quality of the coating |

materials to be processed. |

Latex paint, dispersion paints, fire protection and thick film materials, zinc dust and micaceous iron ore paints, Airless spray primer, sprayable glue, anti-corrosive agents, thick coating materials and bitumen-like coating materials.

No other materials should be used for spraying without Titan’s approval.

Filtering

In spite of the high-pressure filter, filtering of the coating material is to be recommended in general (except when processing airless joint filler).

Stir coating material before commencement of work.

i |

Make sure when stirring with motor-driven agitators |

that no air bubbles are stirred in. Air bubbles disturb |

|

when spraying and can, in fact, lead to interruption |

|

|

of operation. |

|

|

Viscosity

It is possible to work with high-viscosity coating materials with the devices.

If highly viscous coating materials cannot be sucked up, they must be diluted in accordance with the manufacturer’s instruction.

Two-component coating material

The appropriate processing time must be adhered to exactly. Within this time rinse through and clean the unit meticulously with the appropriate cleaning agents.

Coating materials with sharp-edged additional materials

These have a strong wear and tear effect on valves, high-pressure hose, spray gun and tip. The durability of these parts can be reduced appreciably through this.

3.Description of unit

3.1Airless process

The main area of application are thick layers of highly viscous coating material for large areas and a high consumption of material.

A piston pump takes in the coating material by suction and conveys it to the tip. Pressed through the tip at a pressure of up to a maximum of 227 bar (22.7 MPa), the coating material is atomised. This high pressure has the effect of micro fine atomisation of the coating material.

As no air is used in this process, it is described as an AIRLESS process.

This method of spraying has the advantages of finest atomisation, cloudless operation and a smooth, bubble-free surface. As well as these, the advantages of the speed of work and convenience must be mentioned.

3.2Functioning of the unit

The following section contains a brief description of the technical construction for better understanding of the function.

TITAN PowrLiner (PL) are high-pressure spraying units driven by either a gasoline engine or electric motor.

The gasoline engine or electric motor (fig. 1, item 1) drives the hydraulic pump (3) by means of a V-belt which is under the belt cover

(2). Hydraulic oil flows to the hydraulic motor (4) and then moves the piston up and down in the material feed pump (5).

The inlet valve is opened automatically by the upwards movement of the piston. The outlet valve is opened when the piston moves downward.

The coating material flows under high pressure through the highpressure hose to the spray gun. When the coating material exits from the tip it atomises.

The pressure control valve (6) controls the volume and the operating pressure of the coating material.

4 |

5 |

6 |

3 |

1 |

2 |

PowrLiner |

5 |

GB

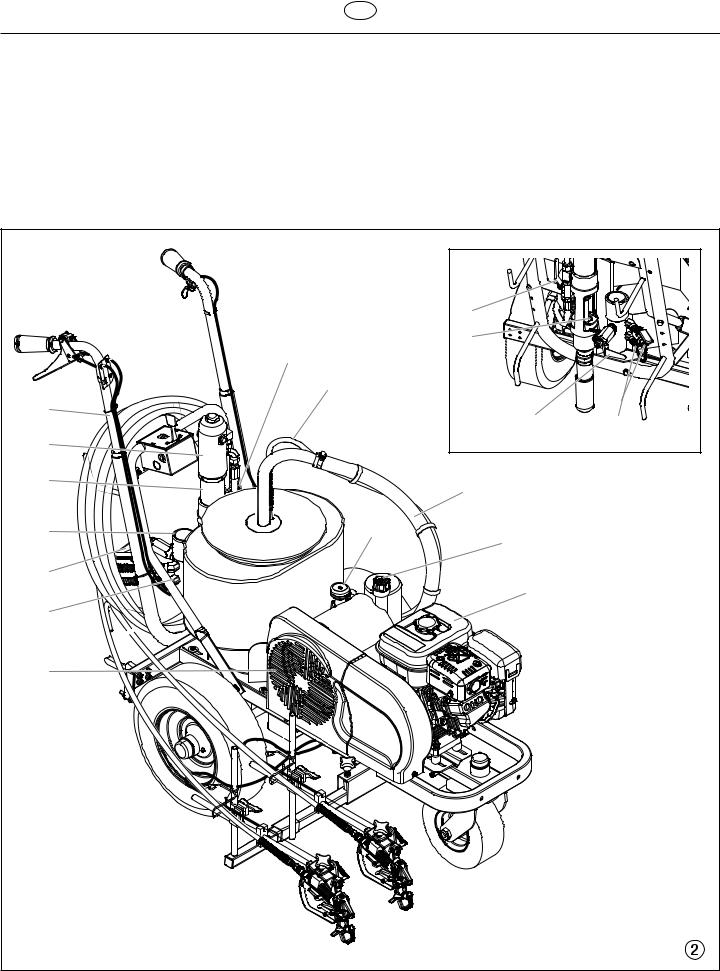

3.3System diagram - gasoline PL units

7 High-pressure hose outlet

8 V-belt under the belt cover

9 Ball valve: horizontal position – hydraulic motor switched off vertical position – hydraulic motor switched on

4 |

Pressure control knob |

10 |

Bleed hose |

|

5 |

High-pressure filter |

|||

11 |

Suction tube |

|||

6 |

Relief valve handle: Turn left for circulation k |

|||

12 |

Oil measuring stick |

|||

|

Turn right for spray p |

|||

|

13 |

Gasoline engine |

||

|

|

|

|

|

9 |

|

|

9 |

|

3 |

|

|

|

|

|

|

|

|

10 |

|

|

1 |

|

|

6 |

7 |

|

|

|

||

2 |

|

|

|

|

3 |

|

|

11 |

|

|

|

|

|

|

5 |

|

4 |

12 |

|

|

|

|

||

|

|

|

|

|

6 |

|

|

13 |

|

|

|

|

|

|

7 |

|

|

|

|

8 |

|

|

|

|

|

|

6 |

|

PowrLiner |

GB

Description of unit

3.4Technical data for PL units

|

|

|

PL4950 |

PL6950 |

PL8950 |

|

|

|

|

||

Gasoline engine, power |

169cc, 5.7 Hp |

211cc, 7.0 Hp (electric start) |

211cc, 7.0 Hp (electric start) |

||

|

|

|

|

|

|

Fuel Capacity |

|

0.95 US gal (3.60 l) |

0.95 US gal (3.60 l) |

0.95 US gal (3.60 l) |

|

|

|

|

|

||

Max. operating pressure |

22.7 MPa (227 bar, 3300 PSI) |

22.7 MPa (227 bar, 3300 PSI) |

22.7 MPa (227 bar, 3300 PSI) |

||

|

|

|

|

||

Max. sound pressure level |

92 dB (A)* |

92 dB (A)* |

98 dB (A)* |

||

|

|

|

|

||

Max. size of tip with |

1-gun |

0.037” – 0.94 mm |

0.050” – 1.27 mm |

0.054” – 1.37 mm |

|

a spray gun |

|

|

|

|

|

|

2-gun |

0.028” – 0.71 mm |

0.033” – 0.84 mm |

0.038” – 0.96 mm |

|

|

|

||||

|

|

|

|

|

|

Max. volume flow |

|

1.5 gal (5.7 l)/min |

2.25 gal (8.5 l)/min |

2.5 gal (9.5 l)/min |

|

|

|

|

|

|

|

Weight |

|

302 lbs (137 kg) |

308 lbs (140 kg) |

313 lbs (142 kg) |

|

|

|

|

|

|

|

Max. viscosity |

|

50.000 mPa·s |

50.000 mPa·s |

65.000 mPa·s |

|

|

|

|

|

|

|

Dimensions L x W x H |

|

59” x 27” x 40” |

59” x 27” x 40” |

59” x 27” x 40” |

|

|

|

|

(150 cm x 69 cm x 102 cm) |

(150 cm x 69 cm x 102 cm) |

(150 cm x 69 cm x 102 cm) |

|

|

|

|

||

Max. temperature of the |

109ºF (43° C) |

109ºF (43° C) |

109ºF (43° C) |

||

coating material |

|

||||

|

|

|

|

||

Filter insert (standard |

|

50 mesh, 18 in2 |

50 mesh, 18 in2 |

50 mesh, 18 in2 |

|

equipment) |

|

||||

|

|

|

|

||

Hydraulic oil filling quantity |

5.9 l (1.56 gal) CoolFlo |

5.9 l (1.56 gal) CoolFlo |

5.9 l (1.56 gal) CoolFlo |

||

|

|

|

|

|

|

Max. tire pressure |

|

0.2 MPa (2 bar, 30 PSI) |

0.2 MPa (2 bar, 30 PSI) |

0.2 MPa (2 bar, 30 PSI) |

|

|

|

|

|

||

Special high-pressure hose |

DN 6 mm, 15 m (50’ x 1/4”), |

DN 6 mm, 15 m (50’ x 1/4”), |

DN 6 mm, 15 m (50’ x 1/4”), |

||

|

|

|

connection thread NPSM 1/4 |

connection thread NPSM 1/4 |

connection thread NPSM 1/4 |

* Place of measurement: 1 m distance from unit and 1.60 m above reverberant floor, 120 bar (12 MPa) operating pressure.

3.5Airless Spray Tip Recommendation Chart

Viscosity |

Filter Mesh |

Coating |

Orifice Range |

Synergy™ (Fine Finish) |

|

|

|

|

|

Light |

100-150 |

Varnishes |

.009 - .011 |

.008 - .010 |

|

|

Lacquer Finishes (clear) |

.009 - .011 |

.008 - .010 |

|

|

Sanding Sealers |

.009 - .011 |

.008 - .010 |

|

|

Shellac (clear) |

.009 - .013 |

.008 - .012 |

|

|

Transparent Stain |

.011 - .013 |

.010 - .012 |

|

|

Water Sealers (clear) |

.011 - .013 |

.010 - .012 |

|

|

|

|

|

Medium |

60-100 |

Solid Stains |

.013 - .015 |

|

|

|

Exterior House Paints |

.013 - .017 |

|

|

|

Interior Wall Paints |

.013 - .017 |

|

|

|

Interior & Exterior Primers |

.017 - .019 |

|

|

|

|

|

|

Heavy |

30-60 |

Commercial Grade |

|

|

|

|

Architectural Coatings |

.017 - .019 |

|

|

|

Interior Wall Paints |

.017 - .019 |

|

|

|

Interior Wall Primers |

.017 - .019 |

|

|

|

Dry Fall (quick dry) |

.019 - .023 |

|

|

|

One Coat, Primer-Finish Paints |

.019 - .023 |

|

|

|

|

|

|

Extra Heavy |

0 |

Elastomerics |

.021 - .031 |

|

|

|

Pigmented Waterproofers |

.021 - .027 |

|

|

|

Block Filler |

.025 - .031 |

|

|

|

|

|

|

Orifice sizes recommended on this chart are based on fan widths between 8 inches (20 cm) and 12 inches (30 cm)

PowrLiner |

7 |

GB

Operation

4.Operation

This equipment produces a fluid stream at extremely high pressure. Read and understand the warnings in the Safety Precautions section at the front of this manual before operating this equipment.

4.1Setup

1.Make sure the siphon hose (fig. 4, 1) is connected to the fluid section (2) and the bleed hose (3) is connected to the bleed valve (4). They each have factory installed PTFE tape on the male end of the hoses and should be wrench tight.

4 |

2 |

|

|

|

3 |

1

2.Install the gun support bar.

iThe spray gun, hose, and cables are mounted to the gun support bar at the factory.

a.Loosen the support bar clamps on each side of the cart.

b.Slide the gun support bar through the cart.

c.Tighten the support bar clamps to secure the gun support bar in position.

i |

The gun support bar and the spray gun(s) can be |

mounted on either side of the sprayer. |

3.Position the first spray gun.

a. Disengage the trigger cable from the tensioning clamp.

Always disengage the trigger cable from the tensioning clamp before making any adjustments to

Attention the spray gun position.

b.Loosen the support bar clamps and slide the gun support bar to the desired horizontal position.

c.Loosen the gun riser clamp and slide the spray gun to the desired vertical position.

The height of the spray gun affects the width of the i spray pattern (i.e., the lower the gun, the smaller the

line width). Tip size also affects line width.

4.Install the second gun assembly, if desired. Refer to the installation instructions for the second gun assembly in the Spare Parts List section of this manual (p. 100/101).

5.Set the trigger selector for proper spray gun operation. The right handlebar triggers the gun or guns. The selector on the trigger must be set for the first gun, both guns, or the second gun .

|

Always turn the trigger lock on the spray gun to the |

|

locked position before making any adjustments to |

Attention |

the trigger selector. Also, release the trigger cable |

from its block by lifting the cable up and out of the |

|

|

block. There will be a brief triggering of the gun |

|

while releasing the trigger cable. |

|

|

a.First Gun — The first gun position is with the selector in the left position. Push the lever toward the inside of the frame until the pin engages the left plate.

b.Both Guns — The dual gun position is with the selector in the center position. Push the lever toward the center position until the pin engages both plates. The pin must engage both plates.

c.Second Gun — The second gun position is with the selector in the right position. Push the lever away from the inside of the frame until the pin engages the right plate.

A

A  B C

B C

6.Fill the oil cup 1/2 full with Piston Lube (P/N 314-480). This extends packing life.

Piston Lube prevents increased wear and tear to the packings.

Attention

7.Check the hydraulic fluid level daily before starting the sprayer. The hydraulic fluid level should be at the “Full” mark on the dipstick. Refer to the Maintenance section of this manual for hydraulic system maintenance instructions.

Use of Titan’s Coolflo™ Hydraulic Fluid (P/N 430-361) is mandatory in the hydraulic system. Do not use

any other hydraulic fluid. Use of any other hydraulic

Attention fluid may seriously damage the hydraulic system and will void the warranty.

8.For gas models, check the engine oil level daily before starting the sprayer. The gasoline engine oil level is determined by the engine manufacturer. Refer to the engine manufacturer’s service manual supplied with this sprayer.

8 |

PowrLiner |

GB

|

|

|

|

Operation |

9. |

For electric models, use a 20 amp service outlet. Always |

4.2 |

Preparing a New Sprayer |

|

|

locate the electric model within 10 to 15 feet of the service |

If this unit is new, it is shipped with test fluid in the fluid section to |

||

|

outlet. Use a short electric cable and a long paint hose. Any |

|||

|

extension cord will create some voltage drop. If an extension |

prevent corrosion during shipment and storage. This fluid must be |

||

|

cord is necessary, use only a grounded 3-wire #12 extension |

thoroughly cleaned out of the system with mineral spirits before you |

||

|

cord. |

begin spraying. |

||

10. |

Make sure the sprayer is earthed. All sprayers are equipped |

|

|

|

|

|

|

||

|

with a earthing lug. An earthing cable (not supplied) should |

|

|

Always keep the trigger lock on the spray gun in the |

|

be used to connect the sprayer to a true earth ground. |

|

|

|

|

Check your local electrical regulations for detailed earthing |

Attention |

locked position while preparing the system. |

|

|

instructions. |

|

||

|

Proper earthing is important. This applies to both |

1. |

Place the siphon tube into a container of mineral spirits. |

|

|

2. |

Place the bleed hose into a metal waste container. |

||

|

gas and electric powered models. The passage of |

|||

|

3. Turn the pressure control knob fully counterclockwise to its |

|||

|

some materials through the nylon fluid hose will |

|||

|

build up a static electric charge, which if discharged, |

|

lowest pressure setting (fig 7, 1). |

|

|

could ignite solvent vapors present and create an |

4. Open the hydraulic shut-off valve (2) located on the hydraulic |

||

|

explosion. |

|

pressure hose. The handle should be in line with the hose. |

|

11.Strain all paints with a nylon strainer to ensure trouble free operation and freedom from frequent cleaning of the inlet screen and gun filter.

12.Make sure the spray area is well ventilated to prevent hazardous operation with volatile solvents or exhaust fumes.

5.Open the bleed valve (3) by turning it fully counterclockwise.

2 |

1 |

3 |

|

6.Start the engine or turn on the electric motor. a. To start the gas engine (fig. 8),

•move the fuel valve lever (2) to the open position,

•move the throttle lever (3) to its middle point,

•move the choke lever (4) to the closed position for a cold engine or to the open position for a warm engine,

•turn the engine switch (1) to the ON position, and

•pull the starter rope (5) briskly until the engine starts or turn and hold the electric starter key towards “Start” until the engine starts (PL6950/8950 only)

b.To start the electric motor, move the ON/OFF switch to the ON position.

4 3

1

1

2

5

5

7.Turn the pressure control knob (fig. 7, 1) clockwise approximately 1/3 of the way down to increase pressure until the sprayer cycles evenly and solvent flows freely from the bleed hose.

8.Allow the sprayer to run for 15–30 seconds to flush the test fluid out through the bleed hose and into the waste container.

9.Turn off the sprayer.

a.To turn off the gas engine,

•set the pressure to minimum by turning the pressure control knob fully counterclockwise,

•move the throttle lever to the slow position, and

•turn the engine switch to the OFF position.

PowrLiner |

9 |

GB

Operation

b.To turn off the electric motor,

•set the pressure to minimum by turning the pressure control knob fully counterclockwise,

•move the ON/OFF switch to the OFF position.

4.3Preparing to Paint

Before painting, it is important to make sure that the fluid in the system is compatible with the paint that is going to be used.

i |

Incompatible fluids and paint may cause the valves |

to become stuck closed, which would require |

|

disassembly and cleaning of the sprayer’s fluid |

|

|

section. |

|

|

Always keep the trigger lock on the spray gun in the Attention locked position while preparing the system.

1.Place the siphon tube into a container of the appropriate solvent for the material being sprayed.

iIf you are spraying a water-based latex, flush with warm, clean water. If you are using any other material, check with the material manufacturer for a compatible solvent.

2.Place the bleed hose into a metal waste container.

3.Turn the pressure control knob fully counterclockwise to its lowest pressure setting (fig 7, 1).

4.Open the hydraulic shut-off valve (2) located on the hydraulic pressure hose. The handle should be in line with the hose.

5.Open the bleed valve (3) by turning it fully counterclockwise.

6.Start the engine or turn on the electric motor.

a.To start the gas engine (fig. 8),

•move the fuel valve lever (2) to the open position,

•move the throttle lever (3) to its middle point,

•move the choke lever (4) to the closed position for a cold engine or to the open position for a warm engine,

•turn the engine switch (1) to the ON position, and

•pull the starter rope (5) briskly until the engine starts or turn and hold the electric starter key towards “Start” until the engine starts (PL6950/8950 only)

b.To start the electric motor, move the ON/OFF switch to the ON position.

7.Turn the pressure control knob (1) clockwise approximately 1/3 of the way down to increase pressure until the sprayer cycles evenly and solvent flows freely from the bleed hose.

8.Allow the sprayer to run for 15–30 seconds to flush the test fluid out through the bleed hose and into the waste container.

9.Turn off the sprayer.

a.To turn off the gas engine,

•set the pressure to minimum by turning the pressure control knob fully counterclockwise,

•move the throttle lever to the slow position, and

•turn the engine switch to the OFF position.

b.To turn off the electric motor,

•set the pressure to minimum by turning the pressure control knob fully counterclockwise,

•move the ON/OFF switch to the OFF position.

iMake sure that the spray gun does not have a tip or tip guard installed.

10.Close the bleed valve by turning it fully clockwise.

11.Start the engine or turn on the electric motor.

12.Turn the pressure control knob clockwise approximately 1/3 of the way down to increase pressure.

13.Unlock the gun by turning the gun trigger lock to the unlocked position.

Earth the gun by holding it against the edge of the metal container while flushing. Failure to do so may lead to a static electric discharge, which may cause a fire.

14.Trigger the gun into the metal waste container until the old solvent is gone and fresh solvent is coming out of the gun.

15.Lock the gun by turning the gun trigger lock to the locked position (fig 10).

16.Set down the gun and increase the pressure by turning the pressure control knob slowly clockwise to its highest setting.

17.Check the entire system for leaks. If leaks occur, turn the sprayer off and follow the “Pressure Relief Procedure” in this manual before tightening any fittings or hoses.

18.Follow the “Pressure Relief Procedure” (section 4.5) in this manual before changing from solvent to paint.

Be sure to follow the Pressure Relief Procedure when shutting the unit down for any purpose, including servicing or adjusting any part of the spray system, changing or cleaning spray tips, or preparing for cleanup.

4.4Painting

1.Place the siphon hose into a container of paint.

2.Place the bleed hose into a metal waste container.

3.Turn the pressure control knob fully counterclockwise to its lowest pressure setting (fig 7, 1).

4.Open the hydraulic shut-off valve (2) located on the hydraulic pressure hose. The handle should be in line with the hose.

5.Open the bleed valve (3) by turning it fully counterclockwise.

6.Start the engine or turn on the electric motor.

a.To start the gas engine (fig. 8),

•move the fuel valve lever (2) to the open position,

•move the throttle lever (3) to its middle point,

•move the choke lever (4) to the closed position for a cold engine or to the open position for a warm engine,

•turn the engine switch (1) to the ON position, and

10 |

PowrLiner |

GB

|

|

|

|

|

|

Operation |

|

|

• |

pull the starter rope (5) briskly until the engine starts or turn |

4.5 |

|

Pressure Relief Procedure |

||

|

|

and hold the electric starter key towards “Start” until the engine |

|

|

|

|

|

|

|

starts (PL6950/8950 only) |

|

|

|

|

|

|

|

|

|

|

Be sure to follow the Pressure Relief Procedure when |

||

|

b. To start the electric motor, move the ON/OFF switch to the ON |

|

|

|

|||

|

|

position. |

|

|

|

shutting the unit down for any purpose, including |

|

7. |

Turn the pressure control knob (1) clockwise approximately |

|

|

|

servicing or adjusting any part of the spray system, |

||

|

|

1/3 of the way down to increase pressure until the sprayer |

|

|

|

changing or cleaning spray nozzles, or preparing for |

|

|

|

cycles evenly and solvent flows freely from the bleed hose. |

|

|

|

cleanup. |

|

8. |

Turn off the sprayer. |

1. |

Lock the spray gun by turning the gun trigger lock to the |

||||

|

a. |

To turn off the gas engine, |

|||||

|

|

|

locked position. |

||||

|

• set the pressure to minimum by turning the pressure control |

|

|

||||

|

2. |

Turn off the sprayer. |

|||||

|

|

knob fully counterclockwise, |

|||||

|

|

|

a. |

To turn off the gas engine, |

|||

|

• move the throttle lever to the slow position, and |

|

|||||

|

|

• set the pressure to minimum by turning the pressure control |

|||||

|

• turn the engine switch to the OFF position. |

|

|||||

|

|

|

knob fully counterclockwise, |

||||

|

b. |

To turn off the electric motor, |

|

|

|||

|

|

• move the throttle lever to the slow position, and |

|||||

|

• set the pressure to minimum by turning the pressure control |

|

|||||

|

|

• turn the engine switch to the OFF position. |

|||||

|

|

knob fully counterclockwise, |

|

||||

|

|

|

b. |

To turn off the electric motor, |

|||

|

• move the ON/OFF switch to the OFF position. |

|

|||||

|

|

• set the pressure to minimum by turning the pressure control |

|||||

9. |

|

Remove the bleed hose from the waste container and place it |

|

||||

|

|

|

knob fully counterclockwise, |

||||

|

|

into the container of paint. |

|

|

|||

|

|

|

• move the ON/OFF switch to the OFF position. |

||||

10. |

Close the bleed valve by turning it fully clockwise. |

|

|||||

3. |

Close the hydraulic shut-off valve on the hydraulic pressure |

||||||

11. Start the engine or turn on the electric motor. |

|||||||

|

|

hose. |

|||||

12. |

|

Turn the pressure control knob clockwise approximately 1/3 |

4. |

|

Unlock the gun by turning the gun trigger lock to the |

||

|

|

of the way down to increase pressure. |

|

|

unlocked position. |

||

13. |

|

Unlock the gun by turning the gun trigger lock to the |

5. |

|

Hold the metal part of the gun firmly to the side of a metal |

||

|

|

unlocked position. |

|

|

waste container to earth the gun and avoid a build up of static |

||

|

|

|

|

|

electricity. |

||

Earth the gun by holding it against the edge of the metal container while flushing. Failure to do so may lead to a static electric discharge, which may cause

afire.

14.Trigger the gun into the metal waste container until all air and solvent is flushed from the spray hose and paint is flowing freely from the gun.

15.Lock the gun by turning the gun trigger lock to the locked position (fig 10).

16.Turn off the sprayer.

17.Attach tip guard and tip to the gun as instructed by the tip guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray without the tip guard in place. Never trigger the gun unless the tip is in either the spray or the unclog position. Always engage the gun trigger lock before removing, replacing or cleaning tip.

18.Start the engine or turn on the electric motor.

19.Increase the pressure by turning the pressure control knob slowly clockwise and test the spray pattern on a piece of cardboard. Adjust the pressure control knob until the spray from the gun is completely atomized.

iTurning the pressure up higher than needed to atomize the paint will cause premature tip wear and additional overspray.

6.Trigger the gun to remove any pressure that may still be in the hose.

7.Lock the gun by turning the gun trigger lock to the locked position.

8.Place the bleed hose into the metal waste container.

9.Open the bleed valve by turning it fully counterclockwise.

4.6Operating the Front Caster

The front caster on the cart is designed to track the sprayer in either a straight line or allow free motion. Standing behind the sprayer, the trigger on the left handle of the cart controls the operation of the front caster.

1.To lock the front caster in the straight line position, squeeze then release the caster trigger and move the sprayer forward.

2.To allow free motion of the front caster, squeeze and hold the caster trigger.

PowrLiner |

11 |

GB

Cleanup

5.Cleanup

The sprayer, hose, and gun should be cleaned thoroughly after daily use. Failure to do so permits material to build up, seriously affecting the

Attention performance of the unit.

Always spray at minimum pressure with the gun nozzle tip removed when using mineral spirits or any other solvent to clean the sprayer, hose, or gun. Static electricity buildup may result in a fire or explosion in the presence of flammable vapors.

5.1Special cleanup instructions for use with flammable solvents

•Always flush spray gun preferably outside and at least one hose length from spray pump.

•If collecting flushed solvents in a one gallon metal container, place it into an empty five gallon container, then flush solvents.

•Area must be free of flammable vapors.

•Follow all cleanup instructions.

Earth the gun by holding it against the edge of the metal container while flushing. Failure to do so may lead to a static electric discharge, which may cause

a fire.

13.Trigger the gun into the metal waste container until the paint is flushed out of the hose and solvent is coming out of the gun.

14.Continue to trigger the spray gun into the waste container until the solvent coming out of the gun is clean.

iFor long-term or cold weather storage, pump mineral sprits through the entire system.

15.Follow the “Pressure Relief Procedure” found in the Operation section of this manual.

16.Store the sprayer in a clean, dry area.

Do not store the sprayer under pressure.

Attention

5.3Cleaning a Clogged Tip

5.2Cleaning the sprayer

1.Follow the “Pressure Relief Procedure” found in the Operation section of this manual, section 4.5.

2.Remove the gun tip and tip guard and clean with a brush using the appropriate solvent.

3.Place the siphon tube into a container of the appropriate solvent.

Use only compatible solvents when cleaning out oil based enamels, lacquers, coal tar, and

epoxies. Check with the fluid manufacturer for the Attention recommended solvent.

epoxies. Check with the fluid manufacturer for the Attention recommended solvent.

4.Place the bleed hose into a metal waste container.

5.Set the pressure to minimum by turning the pressure control knob (1) fully counterclockwise.

6.Open the hydraulic shut-off valve located on the hydraulic pressure hose (2). The handle should be in line with the hose.

7.Open the bleed valve (3) by rotating the bleed valve handle fully counterclockwise.

2 |

1 |

3 |

|

8.Start the engine or turn on the electric motor.

9.Allow the solvent to circulate through the sprayer and flush the paint out of the bleed hose into the metal waste container.

10.Turn off the sprayer.

11.Close the bleed valve by rotating the bleed valve handle fully clockwise.

12.Start the engine or turn on the electric motor.

1.Follow the “Pressure Relief Procedure” in the Operation section of this manual.

2.If the tip clogs, rotate the tip handle 180° until the arrow on the handle is facing the opposite of the spray direction and the handle clicks in the reverse position.

3.Trigger the gun once so that the pressure can blow the clog out. NEVER use the tip in the reverse position for more than ONE trigger pull at a time. This procedure can be repeated until the tip is free of clogging.

The flow from the spray tip is at very high pressure. Contact with any body part may be dangerous. Do not place finger on gun outlet. Do not point the gun at any person. Never operate the spray gun without the proper tip guard.

12 |

PowrLiner |

GB

Maintenance

6.Maintenance

Before proceeding, follow the Pressure Relief Procedure outlined previously in this manual. Additionally, follow all other warnings to reduce the risk of an injection injury, injury from moving parts or electric shock. Always unplug the sprayer before servicing!

6.1Daily Maintenance

Two daily procedures are required for routine operator maintenance on this sprayer:

A.Lubricating the upper packings.

B.Cleaning the filter screen

A)Lubricating the Upper Packings

1.Clean out the paint that has seeped past the upper packings into the packing oil reservoir (fig. 13, item 1) above the fluid section.

2.Fill the packing oil reservoir 1/2 full with Piston Lube (P/N 314-

480)supplied by the factory. This will extend packing life.

1

iDo not over-fill the reservoir so that it overflows and drips into the paint.

B)Cleaning the Filter Screen

1.The filter screen will clog and must be cleaned at least once a day.

2.Loosen the hex nut (fig. 14, item 1) that secures the filter screen to the siphon tube.

3.Remove the filter screen (2) from the bottom of the siphon tube.

4.Clean thoroughly with the appropriate solvent.

1

2

6.2Maintaining the Filter Assembly

Clean the filter regularly. Dirty or clogged filters can greatly reduce filtering ability and cause a number of system problems including poor spray patterns, clogged spray tips, etc.

Cleaning (Fig. 15)

To clean the filter, perform the following procedure.

1.Follow the “Pressure Relief Procedure” found in the Operation section of this manual.

2.Remove the filter cap assembly (1) and spring (2).

3.Pull the filter element with ball straight (3) out of the filter body (4).

4.Clean inside the filter body, filter element with ball, and filter cap assembly using the appropriate solvent.

iUse care in handling parts as dirt, debris, scratches, or nicks may prevent o-rings or gaskets from sealing.

This filter element filters from the inside out. Be sure to clean the filter element thoroughly on the inside. Soak in solvent to loosen hardened paint or replace.

1

2

3

7

8

5  6

6

4

Inspection (Fig. 15)

Inspect all parts of the filter assembly before reassembly.

1.Inspect the ball inside the filter element. If the ball has pressure cuts or scratches, replace the filter element.

a.If the ball is cut, remove the PTFE o-ring (5) using an o-ring pick and remove the carbide seat (6).

b.Check the seat for nicks or grooves. If the seat is damaged, replace.

iRemoval of the PTFE o-ring will damage the o-ring and require replacement.

2.Remove the spring (2) from the spring guide on the filter cap.

a.Measure the length of the spring uncompressed. If it measures less than 3/4” from end to end, replace.

b.Push the spring back onto the spring guide until it “snaps” back into position.

3.Inspect the two PTFE gaskets (7,8) and the PTFE o-ring (5) for deformity, nicks, or cuts. Replace, if needed.

iThe PTFE gaskets, PTFE o-ring, and spring are packaged in Filter Service Kit P/N 930-050.

PowrLiner |

13 |

GB

Maintenance

Reassembly (Fig. 15)

After cleaning and inspecting all parts, reassemble the filter.

1.Place the carbide seat (6) into the filter body (4). Make sure the beveled side of the seat is facing up.

2.Place the PTFE o-ring (5) into the groove on the outer diameter of the carbide seat (6).

3.Place the filter element with ball (3) into the filter body (4).

iThe top and bottom of the filter element with ball are identical.

4.Push the spring (2) back onto the spring guide of the filter cap

(1)until it “snaps” back into position, if not already done.

5.Place the thin PTFE gasket (8) onto the step at the top of the filter body (4).

6.Place the thick PTFE gasket (7) onto the top of the thin gasket

7.Tighten the filter cap assembly (1) onto the filter body (4).

1

2

3

7

8

5  6

6

4

6.3Maintaining the Hydraulic System

Use of Titan’s Coolflo™ Hydraulic Fluid is mandatory in the PowrLiner hydraulic system. Do not use any

other hydraulic fluid. Use of any other hydraulic

Attention fluid may seriously damage the hydraulic system and will void the warranty.

1.Check the hydraulic fluid daily. It should be at the “Full” mark (fig. 16, item 1) on the dipstick (2). If it is low, add only

Titan Coolflo™ Hydraulic Fluid (P/N 430-361). Never add or change hydraulic fluid except in a clean, dust-free area. Contamination of the hydraulic fluid will shorten hydraulic pump life and may void warranty.

2

1

3

3

2.Change the hydraulic fluid every twelve months. Drain the old fluid from the tank and fill with 6.25 quarts of hydraulic fluid. Start the sprayer at just enough pressure to operate the fluid section. Run the sprayer at this low pressure for at least 5 minutes. This removes air from the system. Check the fluid level after this procedure. Do not over-fill.

iWhen replacing the hydraulic filter (3) during a fluid change, it may be necessary to add up to one additional quart of hydraulic fluid.

3.The hydraulic system has an external, replaceable hydraulic filter. Change the filter every twelve months.

4.The hydraulic pump should not be serviced in the field. If service on the hydraulic pump is required, it must be returned to Titan.

6.4Maintaining the Fluid Section

If the sprayer is going to be out of service for an extended period of time, it is recommended that following cleanup, a kerosene and oil mixture be introduced as a preservative. Packings may tend to dry out from lack of use. This is particularly true of the upper packing set for which upper packing lubricant Piston Lube (P/N 314-480) is recommended in normal usage.

If the sprayer has been out of service for an extended period of time, it may be necessary to prime the pump with solvent. It is extremely important that the threads on the siphon hose coupling are properly sealed. Any air leakage will produce erratic operation of the sprayer and may damage the system. The up and the down strokes should be approximately equal in time (one should not be faster than the other). A fast up or down stroke may indicate air in the system or malfunctioning valve or seats (see the Troubleshooting section).

14 |

PowrLiner |

GB

Maintenance

6.5Basic Engine Maintenance (gas engine)

•For detailed engine maintenance and technical specifications refer to the separate gasoline engine manual.

•All service to the engine should be performed by a dealer authorized by the engine manufacturer.

•Use a premium quality motor oil. 10W30 is recommended for general all temperature use. Other viscosities may be required in other climates.

•Use only a (NGK) BR-6HS (PL4950), or (NGK) BP6ES / BPR6E spark plug (PL6950/PL8950). Gap the plug to 0.028 to 0.031 In. (0.7 to 0.8 mm) Always use a spark plug wrench.

Daily

1.Check engine oil level, and fill as necessary.

2.Check gasoline level, and fill as necessary.

Always follow the fueling procedure outlined earlier in this manual.

First 20 Hours

1.Change engine oil.

Every 100 Hours

1.Change engine oil.

2.Clean the sediment cup.

3.Clean and re-gap the spark plug.

4.Clean the spark arrestor.

Weekly

1.Remove the air filter cover and clean the element. In very dusty environments, check the filter daily. Replace the element as needed. Replacement elements can be purchased from your local engine manufacturer dealer.

Engine Operation and Service

1.Clean and oil air filter pad on gasoline engine every 25 hours or once weekly. Do not permit the air intake screen around the fly wheel of the gas engine to load up with paint or trash. Clean it regularly. The service life and efficiency of the gas engine model depends upon keeping the gasoline engine running properly. Change the oil in the engine every 100 hours. Failure to observe this may result in engine overheating. Consult the engine manufacturer’s service manual provided.

2.To conserve fuel, service life, and efficiency of the sprayer, always operate the gasoline engine at the lowest RPM at which it runs smoothly without laboring and delivers the amount required for the particular painting operation. Higher RPM does not produce higher working pressure. The gasoline engine is connected to the hydraulic pump by a pulley combination designed to produce full paint delivery at maximum RPM.

3.The warranty on gasoline engines or electric motors is limited to the original manufacturer.

6.6Replacing the Motor Brushes (optional 120V electric motor, PL4950 only)

The 120V electric Convertokit is available for separate purchase.

Perform this procedure using Motor Brush Kit P/N 978-050. The kit consists of two brushes, two springs, and two clips.

i |

Brushes should be replaced when they are worn to |

less than 1/2 inch. Check and replace both brushes |

|

at the same time. |

|

|

|

1.Remove both inspection covers (1) on the motor.

1

2.Push in the spring clip (2) to unhook it, then pull it out.

3.Loosen the terminal screw (3). Pull the brush lead (4) away, but leave the motor lead in place. Remove the brush and spring.

3

4

4

2

2

4.Inspect the commutator (5) for burning, excessive pitting or gouging. A black color on the commutator is normal.

5

5.Install the new brush (6) so its lead slides in the long slot of the brush holder (7). Push the terminal under the terminal screw washer (8). Ensure the motor lead is still connected at the screw. Tighten the screw.

PowrLiner |

15 |

GB

Maintenance

6.Place the spring (9) on the brush (6) as shown above. Push in and hook the spring clip (2). Repeat this procedure for the other side.

6

8

7

9

9

2

2

7.Reinstall both inspection covers.

If electric motor overloads and stops running, IMMEDIATELY turn the motor off and follow the Pressure Relief Procedure in the Cleanup

section of this manual. Wait until the motor cools (approximately 30 minutes). Then push in the bubble top, manual reset button, turn the motor on and pressurize the system.

6.7Adjusting the Tracking of the Front Caster

The front caster is set by the factory to track in a straight line. Use the following procedure if adjustment the caster becomes necessary.

1.Loosen the two hex screws (1) in the top of the caster mounting bracket (2).

2.Turn the caster mounting bracket (2) slightly in the desired direction.

iThe front caster locking pin must be engaged during tracking adjustment.

3.Tighten the two hex screws (1).

4.Check the tracking of the front caster (3). If the caster does not track straight, repeat the above procedure.

2

1

3

16 |

PowrLiner |

GB

Maintenance

6.8Replacing the Belt (Fig. 22)

|

Before replacing the belt on your unit, make sure |

|

you have performed the “Pressure Relief Procedure” |

|

as illustrated in the Operation section of this manual. |

|

DO NOT attempt this repair while the unit is running. |

|

|

i |

The graphics below show a unit with a gas engine. |

All instructions given in this section will apply to |

|

both gas engine models and electric motor models |

|

|

except where noted. |

|

|

1.Loosen the bolt (1) on the front of the belt guard. Lift open the front end of the belt guard (2) so that the front end of the belt (3) is exposed.

2.Gently lift the front end of the gas engine / electric motor. This will loosen the tension on the belt and make it easier to remove.

PINCH HAZARD. Make sure your fingers remain clear of the gas engine / electric motor mounting plate.

BURN HAZARD. Make sure the gas engine has had time to sufficiently cool before touching it.

3.While the gas engine / electric motor is lifted up, remove the belt from the front (4) and rear (5) pulleys.

4.Install the new belt:

a.Insert the belt into the fixed section of the belt guard (6). Loop the belt over the rear pulley (5) until the belt engages the pulley groove.

b.Gently lift the front end of the gas engine / electric motor.

c.With the front end of the gas engine / electric motor lifted, loop the other end of the belt around the front pulley (4).

d.Gently set the the gas engine / electric motor down. The weight of the gas engine / electric motor will create tension in the belt and prevent it from coming off.

Make sure the belt is not pinched or twisted in any way once you have set the gas engine / electric

Attention motor back into place.

e.Close the belt guard (2) and tighten the belt guard bolt (1).

|

1 |

|

2 |

6 |

3 |

5 |

4 |

PowrLiner |

17 |

Maintenance |

|

GB |

|

|

|

|

|

||

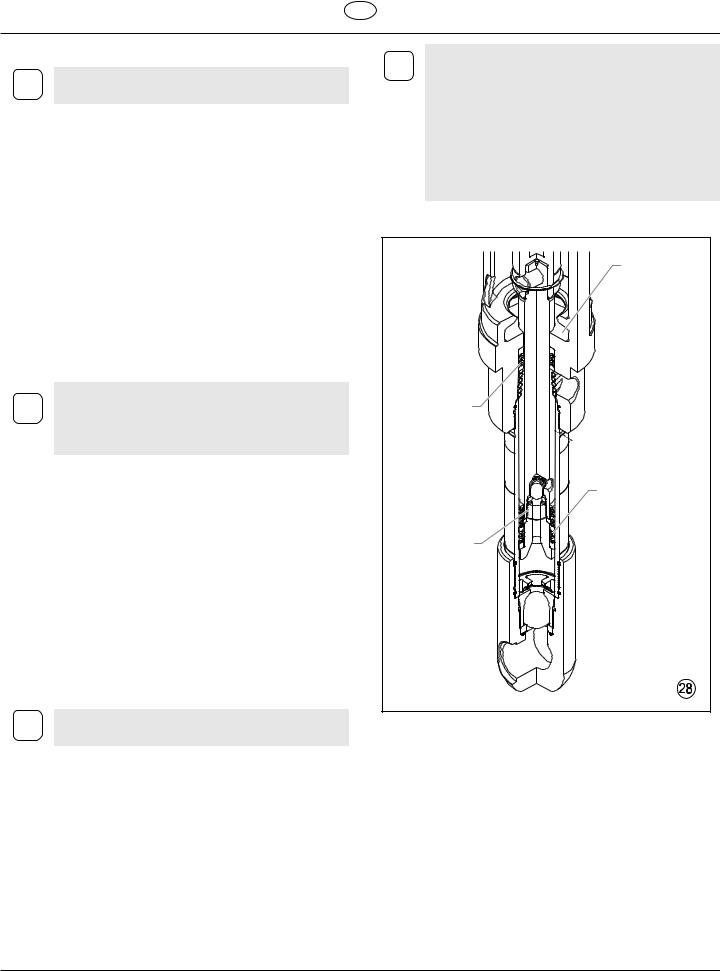

6.9 |

Servicing the Hydraulic Motor (Fig. 23) |

|

i |

Refer to the ”SAE O-Ring Fitting Installation” |

|

|

|

||

|

|

|

procedure at the end of this section for installation |

|

|

|

|

|

instructions for item 22. |

1 |

|

21 |

Perform this procedure using the necessary parts from Motor Service |

|

2 |

|

|||

|

|

Kit — Minor (P/N 235-050). If the hydraulic motor is operable, start |

||

3 |

|

|

||

|

|

the machine and jog the piston rod (19) into its top position. |

||

4 |

|

22 |

i |

Servicing of the hydraulic motor should be carried |

5 |

|

|

out in a clean, dust free area only. Any dust or |

|

6 |

|

|

metallic particles left in the motor or entering it on |

|

7 |

|

|

|

reassembly may damage the critical parts and affect |

|

|

|

|

its service life and warranty. All parts should be |

8 |

|

23 |

|

inspected for absolute cleanliness. |

|

|

|

Disassembling the Hydraulic Motor |

|

|

|

|

1. |

Disconnect the pressure hose assembly (B) from the elbow |

9 |

20 |

24 |

|

(34 and 35 in Hydraulic System parts list) on the back of the |

|

hydraulic pump. |

|||

|

|

25 |

2. |

Remove the two mounting screws and two lock washers that |

|

|

|

|

attach the motor/pump assembly to the pump support on the |

|

|

|

|

cart. |

10 |

(A) |

|

3. |

Place the motor/pump assembly in a vise, holding it securely |

|

|

|

by the motor/pump block (31). |

|

|

|

|

|

|

|

21 |

|

4. |

Remove cylinder head plug (1). |

|

|

|

5. |

Loosen lock ring (28) with a spanner wrench and unthread |

|

|

|

|

tube retaining nut on tee (24). Loosen tube retaining nut on |

|

|

|

|

elbow (22). Slide the nut down. Push motor tube (23) into tee |

11 |

|

|

|

(24) far enough to clear elbow (22). Slowly unthread cylinder |

|

|

|

|

head (8) and Iift it just high enough above the cylinder (29) to |

12 |

|

26 |

|

reach the valve rod assembly (18) with vise grip pliers. |

|

|

6. |

The piston rod (19) should be near the top of its stroke for |

|

|

|

|

||

13 |

|

|

|

disassembly. It may be necessary to use a wood or nylon driver |

14 |

|

|

|

to push the piston rod up to its top position. |

|

|

7. |

Grip the valve rod securely with vise grip pliers and then |

|

15 |

(B) |

|

remove the FlexLoc nut (3) from the top of the valve rod |

|

|

assembly (18). Be careful that spool (10) does not fall. The |

|||

16 |

|

28 |

|

cylinder head (8) can now be lifted off. Unthread the cylinder |

|

29 |

|

(29) from the motor/pump block (31). |

|

|

|

|

||

17 |

|

|

|

|

|

|

i |

An extra lock ring (28) can be used to jam the two |

|

|

|

|

||

|

9 |

|

lock rings together on the cylinder and a pipe |

|

|

|

wrench can be used to unthread the cylinder (29) |

||

18 |

|

30 |

|

from the motor/pump block. |

|

|

|

||

|

|

|

|

|

|

|

|

8. |

To remove the connecting pin (Fig. 24, 1), slide the retaining |

|

|

|

|

ring (2) down with a small screwdriver, and then push the |

|

|

|

|

connecting pin out. |

|

|

31 |

|

|

|

|

|

|

1 |

19 |

|

|

|

2 |

|

|

|

|

|

|

|

|

9. |

Remove the piston rod assembly from the motor/pump block |

|

|

|

|

(31). |

|

|

|

10. |

Remove rod seal (30), being extremely careful not to scratch |

|

|

|

|

the seal groove in the motor/pump block (31). |

|

|

|

11. |

Place the piston retainer screw (14) on the piston rod assembly |

|

|

|

|

in a vise. Slide a long bar through the hole at the base of the |

|

|

|

|

piston rod for leverage, and unthread the piston rod from the |

|

|

|

|

piston retainer screw. |

|

|

|

12. |

Remove piston (19) and lift out valve rod assembly (18). |

18 |

PowrLiner |

GB

Maintenance

13.Remove piston seal (16) and o-ring (17).

14.Remove trip retainers (4), trip springs (6), and balls (7) from cylinder head (8). Remove o-rings (5) from trip retainers.

15.Remove retaining ring (13) and sleeve retainer (12). Gently tap spool/sleeve set (10) out of cylinder head (8) using a wood or nylon rod.

16.Inspect piston rod (19) and cylinder (29) for wear, scratches, and dents. Replace if damaged.

17.Inspect spool valve (10) for wear. Replace if necessary. spool valve should move smoothly and freely with no force by holding in a vertical position. If it does not, it can cause the motor to stall.

rod pass through the top of the spool/sleeve set (10). The valve rod threads must be clean and free of oil. Place one drop of blue Loctite on threads of flex lock nut (3) and thread nut onto valve rod to full tight position (do not over-tighten) while holding valve rod below with vise grip pliers.

13.Thread cylinder head (8) down onto the cylinder (29) and then back off just enough to reassemble hydraulic fittings and motor tube (23). Tighten lock ring with spanner wrench to hold cylinder head in position.