Titan 0290008, 0290009 User Manual

Owner’s Manual

Notice d’utilisation Manual del Propietario

Do not use this equipment before reading this manual!

SPEEFLO |

PowrLiner 2850 |

Model Number: |

|

|

|

|

NOTE: This manual contains important |

||

1-gun |

0290008 |

||

warnings and instructions. Please read |

|||

2-gun |

0290009 |

and retain for reference. |

|

|

|

|

0117 • © Titan Tool Inc. All Rights Reserved. Form No. 0290919K

Important Safety Information

Read all safety information before operating the equipment. Save these instructions.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

To reduce the risks of fire or explosion, electrical shock and the injury to persons, read and understand all instructions included in this manual. Be familiar with the controls and proper usage of the equipment.

WARNING: EXPLOSION OR FIRE

Flammable vapors, such as solvent and paint vapors, in work area can ignite or explode.

Prevention:

1.Use equipment only in well ventilated area. Keep a good supply of fresh air moving through the area to keep the air within the spray area free from accumulation of flammable vapors. Keep pump assembly in well ventilated area. Do not spray pump assembly.

2.Do not fill fuel tank while engine is running or hot; shut off engine and allow to cool. Fuel is flammable and can ignite or explode if spilled on a hot surface.

3.Eliminate all ignition sources, such as pilot lights, cigarettes, portable electric lamps and plastic drop cloths (potential static arc).

4.Keep work area free of debris, including solvent, rags and gasoline.

5.Do not plug or unplug power cords, or turn power or light switches on or off when flammable vapors are present.

6.Ground equipment and conductive objects in work area. Make sure grounding chain is in place and reaches the ground.

7.Use only grounded hoses.

8.Hold spray gun firmly to the side of a grounded pail when triggering into pail.

9.If there is static sparking or if you feel a shock, stop operation immediately.

10.Know the contents of the paint and solvents being sprayed. Read all Material Safety Data Sheets (MSDS) and container labels provided with the paints and solvents. Follow the paint and solvent manufacturer’s safety instructions.

11.Do not use a paint or solvent containing halogenated hydrocarbons. Such as chlorine, bleach, mildewcide, methylene chloride and trichloroethane. They are not compatible with aluminum. Contact the coating supplier about compatibility of material with aluminum.

12.Keep a fire extinguisher in work area.

WARNING: Injection injury

A high pressure paint stream produced by this equipment can pierce the skin and underlying tissues, leading to serious injury and possible amputation. See a physician immediately.

Prevention:

1.Do not aim the gun at, or spray any person or animal.

2.Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any part of the body.

3.Always use the nozzle tip guard. Do not spray without the nozzle tip guard in place.

4.Only use a nozzle tip specified by the manufacturer.

5.Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying,

ALWAYS lock gun trigger, shut pump off, and release all pressure before servicing, cleaning tip or guard, or changing tip. Pressure will not be released by turning off the motor. The PRIME/SPRAY valve or pressure bleed valve must be turned to their appropriate positions to relieve system pressure. Refer to PRESSURE RELIEF PROCEDURE described in the pump manual.

6.Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off the unit and relieve the pressure in accordance with the manufacturer’s instructions.

7.High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection occurs, seek medical attention immediately.

8.Check hoses and parts for signs of damage, a leak can inject material into the skin. Inspect hose before each use. Replace any damaged hoses or parts.

9.This system is capable of producing 3300 PSI / 22.8 MPa. Only use replacement parts or accessories that are specified by the manufacturer and that are rated a minimum of 3300 PSI. This includes spray tips, nozzle guards, guns, extensions, fittings, and hose.

10.Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

11.Verify that all connections are secure before operating the unit.

12.Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls. Pressure will not be released by turning off the motor. The PRIME/SPRAY valve or pressure bleed valve must be turned to their appropriate positions to relieve system pressure. Refer to PRESSURE RELIEF PROCEDURE described in the pump manual.

13.Always remove the spray tip before flushing or cleaning the system.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury which can lead to possible amputation. It is important to treat the injury as

soon as possible. DO NOT delay treatment to research toxicity. Toxicity is a concern with some coatings injected directly

into the blood stream. Consultation with a plastic surgeon or reconstructive hand surgeon may be advisable.

WARNING: GENERAL

Can cause severe injury or property damage.

PREVENTION:

1.Always wear appropriate gloves, eye protection, clothing and a respirator or mask when painting. Hazardous vapors

– Paints, solvents, insecticides, and other materials can be harmful if inhaled or come in contact with body. Vapors can cause severe nausea, fainting or poisoning.

2.Do not operate or spray near children. Keep children away from equipment at all times.

3.Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

4.Stay alert and watch what you are doing.

5.Do not operate the unit when fatigued or under the influence of drugs or alcohol.

6.Do not kink or over-bend the hose. Airless hose can develop leaks from wear, kinking and abuse. A leak can inject material into the skin.

English |

2 |

© Titan Tool Inc. All rights reserved. |

|

|

|

Important Safety Information

7.Do not expose the hose to temperatures or pressures in excess of those specified by manufacturer.

8.Do not use the hose as a strength member to pull or lift the equipment.

9.Use lowest possible pressure to flush equipment.

10.Follow all appropriate local, state and national codes governing ventilation, fire prevention and operation.

11.The United States Government Safety Standards have been adopted under the Occupational Safety and Health Act (OSHA). These standards, particularly part 1910 of the General Standards and part 1926 of the Construction Standards should be consulted.

12.Before each use, check all hoses for cuts, leaks, abrasion or bulging of cover. Check for damage or movement of couplings. Immediately replace hose if any of those

conditions exist. Never repair a paint hose. Replace with a conductive high-pressure hose.

13.Do not spray outdoors on windy days.

14.Always unplug cord from outlet before working on equipment (electric models only).

important: Do not lift cart handle when loading or unloading.

Gasoline Engine Safety

The engine exhaust from this unit contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

1.Gas engines are designed to give safe and dependable service if operated according to instructions. Read and understand the engine Owner’s Manual before operating the engine. Failure to do so could result in personal injury or equipment damage.

2.To prevent fire hazards and to provide adequate ventilation, keep the engine at least 1 meter (3 feet) away from buildings and other equipment during operation. Do not place flammable objects close to the engine.

3.Children and pets must be kept away from the area of operation due to a possibility of burns from hot engine components or injury from any equipment the engine may be used to operate.

4.Know how to stop the engine quickly, and understand the operation of all controls. Never permit anyone to operate the engine without proper instructions.

5.Gasoline is extremely flammable and is explosive under certain conditions.

6.Refuel in a well-ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the refueling area or where gasoline is stored.

7.Do not overfill the fuel tank. After refueling, make sure the tank cap is closed properly and securely.

8.Be careful not to spill fuel when refueling. Fuel vapor or spilled fuel may ignite. If any fuel is spilled, make sure the area is dry before starting the engine.

9.Never run the engine in an enclosed or confined area. Exhaust contains poisonous carbon monoxide gas; exposure may cause loss of consciousness and may lead to death.

10.The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Be careful not to touch the muffler while it is hot. To avoid severe burns or fire hazards, let the engine cool before transporting it or storing it indoors.

11.Never ship/transport unit with gasoline in the tank.

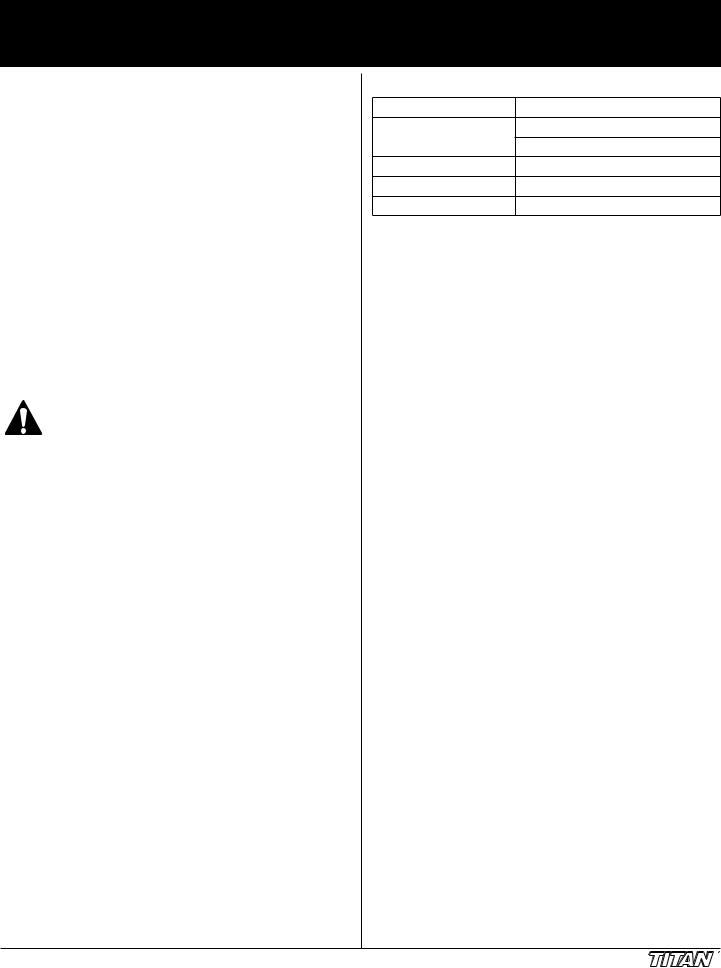

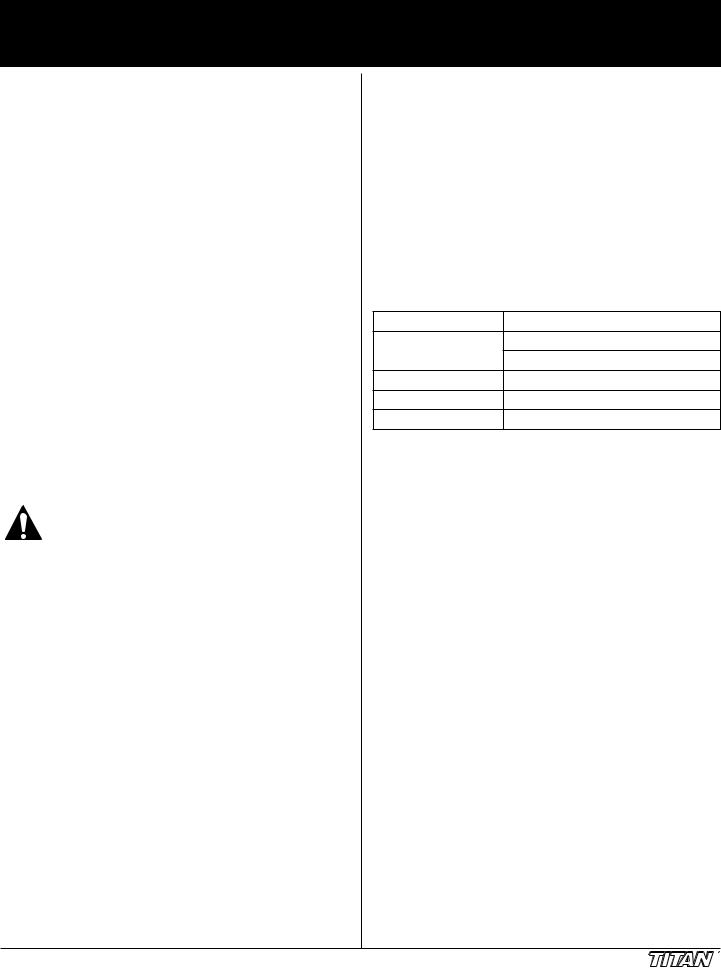

Specifications |

|

|

Gallons per minute (GPM) |

0.85 (3.22 LPM) |

|

Maximum tip sizes |

one gun = 0.030” |

|

|

two guns = 0.021” |

|

Maximum pressure |

3300 PSI (22.8 MPa) |

|

Power |

3.5 HP Honda gas engine |

|

Weight |

138 lbs. (62.6 kg) |

|

Table of Contents |

|

|

Safety Precautions........................................................................... |

|

2 |

Français........................................................................................................... |

|

18 |

Español............................................................................................................ |

|

36 |

General Description......................................................................... |

|

4 |

Trigger Lock..................................................................................................... |

|

4 |

Operation.......................................................................................... |

|

4 |

Fueling.............................................................................................................. |

|

4 |

Setup.................................................................................................................. |

|

5 |

Preparing a New Sprayer............................................................................ |

|

6 |

Preparing to Paint......................................................................................... |

|

7 |

Painting............................................................................................................. |

|

7 |

Operating the Front Caster........................................................................ |

8 |

|

Pressure Relief Procedure.......................................................................... |

8 |

|

Cleanup............................................................................................. |

|

8 |

Cleaning the Spray Tip................................................................................ |

|

9 |

Maintenance..................................................................................... |

|

9 |

General Repair and Service Notes........................................................... |

9 |

|

Maintaining the Engine.............................................................................. |

|

9 |

Adjusting the Trigger Tension.................................................................. |

9 |

|

Replacing the PRIME/SPRAY Valve........................................................ |

10 |

|

Cleaning or Replacing the Filters........................................................... |

10 |

|

Replacing the Pump ON/OFF Switch................................................... |

11 |

|

Replacing the Gears and/or Slider Assembly............................. |

11-12 |

|

Replacing the Transducer........................................................................ |

12 |

|

Servicing the Clutch Assembly........................................................ |

12-14 |

|

Servicing the Fluid Section............................................................... |

15-16 |

|

Troubleshooting............................................................................ |

|

17 |

Parts Listings.................................................................................. |

|

48 |

Main Assembly............................................................................................. |

|

48 |

Drive Assembly............................................................................................ |

|

50 |

Fluid Section Assembly............................................................................. |

|

54 |

Cart Assembly............................................................................................... |

|

56 |

Front Wheel Assembly.............................................................................. |

|

58 |

Gun Holder Assembly................................................................................ |

|

60 |

Brake Assembly............................................................................................ |

|

60 |

Accessories.................................................................................................... |

|

62 |

Limited Warranty........................................................................... |

|

64 |

© Titan Tool Inc. All rights reserved. |

3 |

English |

|

|

|

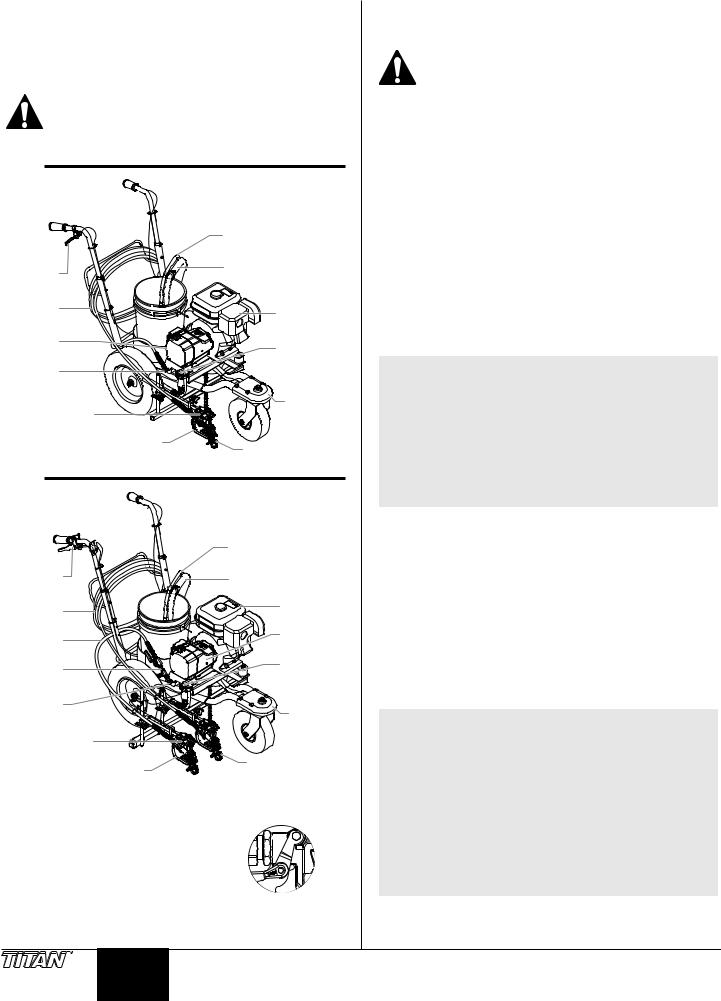

General Description

This airless line striper is a precision power tool used to spray many types of material for many types of applications including parking lots, curbs, and athletic fields. Read and follow this instruction manual carefully for proper operating instructions, maintenance, and safety information.

This equipment produces a fluid stream at extremely high pressure. Read and understand the warnings in the Safety Precautions section at the front of this manual before operating this equipment.

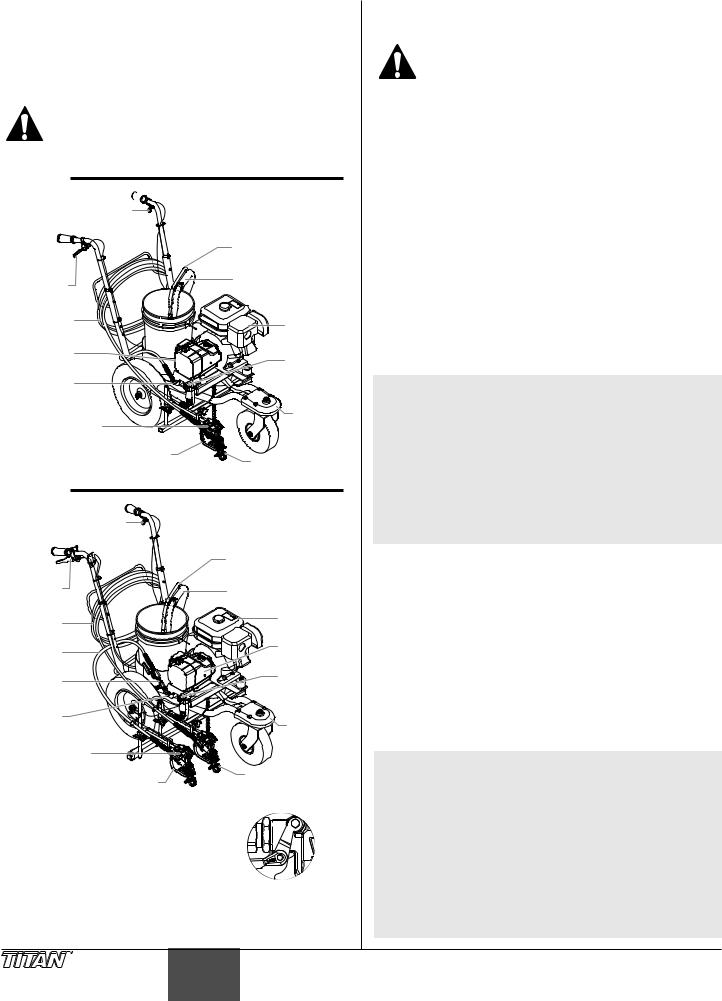

1-Gun

Caster Trigger

|

|

Return Hose |

Gun |

|

Siphon Hose |

|

|

|

Trigger |

|

|

Material |

|

Engine |

Hose |

|

|

|

|

|

Airless |

|

PRIME/ |

Sprayer |

|

|

Outlet |

|

SPRAY |

|

Valve |

|

Fitting |

|

|

|

|

Front |

Gun Holder |

|

Caster |

Assembly |

|

Assembly |

|

Spray Gun |

Tip Assembly |

|

|

2-Gun

Caster Trigger

|

Return Hose |

|

Gun |

Siphon Hose |

|

Trigger |

||

|

||

Material |

Engine |

|

Hose (50’) |

Airless |

|

Material |

||

Sprayer |

||

Hose (6’) |

||

PRIME/ |

||

Valve |

||

SPRAY |

||

Assembly |

||

Valve |

||

|

||

Outlet |

Front |

|

Fitting |

||

|

Caster |

|

Gun Holder |

Assembly |

|

|

||

Assembly (2) |

Tip Assembly (2) |

|

Spray Gun (2) |

||

|

Trigger Lock

Engage the trigger lock whenever the gun is not in use.

To lock the gun, turn the trigger lock forward and slightly down until is stops.

Trigger lock in locked position.

Operation

Fueling (gas engine)

Gasoline is extremely flammable and is explosive under certain conditions.

•ALWAYS turn the engine off before refueling.

•Refuel in a well-ventilated area.

•Do not smoke or allow flames or sparks in the refueling area or where gasoline is stored.

•Do not overfill the fuel tank. After refueling, make sure the tank cap is closed properly and securely.

•Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may ignite. If any fuel is spilled, make sure the area is dry before starting the engine.

•Avoid repeated or prolonged contact with skin or breathing of vapor.

•Keep out of the reach of children.

Fuel Specifications

•Use automotive gasoline that has a pump octane number of

86 or higher, or that has a research octane number of 91 or higher. Use of a lower octane gasoline can cause persistent “pinging” or heavy “spark knock” (a metallic rapping noise) which, if severe, can lead to engine damage.

NOTE: If “spark knock” or “pinging” occurs at a steady engine speed under normal load, change brands of gasoline. If spark knock or pinging persists, consult an authorized dealer of the engine manufacturer. Failure to do so is considered misuse, and damage caused by misuse is not covered by the engine manufacturer’s limited warranty.

Occasionally you may experience light spark knock while operating under heavy loads. This is no cause for concern, it simply means your engine is operating efficiently.

•Unleaded fuel produces fewer engine and spark plug deposits and extends the life of the exhaust system components.

•Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid getting dirt, dust, or water in the fuel tank.

Gasolines Containing Alcohol

If you decide to use a gasoline containing alcohol (gasohol), be sure its octane rating is at least as high as that recommended by the engine manufacturer. There are two types of “gasohol”: one containing ethanol, and the other containing methanol. Do not use gasohol that contains more than 10% ethanol. Do not use gasoline containing methanol (methyl or wood alcohol) that does not also contain co-solvents and corrosion inhibitors for methanol. Never use gasoline containing more than 5% methanol, even if it has cosolvents and corrosion inhibitors.

NOTE: Fuel system damage or engine performance problems resulting from the use of fuels that contain alcohol is not covered under the warranty. The engine manufacturer cannot endorse the use of fuels containing methanol since evidence of their suitability is incomplete at this time.

Before buying gasoline from an unfamiliar station, try to find out if the gasoline contains alcohol. If it does, confirm the type and percentage of alcohol used. If you notice any undesirable operating characteristics while using a gasoline that contains alcohol, or one that you think contains alcohol, switch to a gasoline that you know does not contain alcohol.

English |

4 |

© Titan Tool Inc. All rights reserved. |

Setup

Perform the following procedure before starting the engine of a gaspowered line striper.

NOTE: The PL2850 comes in two versions, a one-gun version and a two-gun version. All information given in this manual applies to both units, except where noted.

1.Ensure that the siphon hose and the return hose are attached and secure.

2.Turn the pressure control knob fully counterclockwise to its lowest pressure setting.

3.Make sure the pump ON/OFF switch is in the OFF position.

4.Fill the fluid section oil cup with approximately one tablespoon of piston seal lubricant (Piston Lube).

important: Never operate unit for more than ten seconds without fluid. Operating this unit without fluid will cause unnecessary wear to the packings.

5.Check the engine oil level. The gasoline engine oil level is determined by the manufacturer. Refer to the engine manufacturer’s service manual (supplied).

6.Close the fuel shut-off lever and fill the gas tank with gasoline. Use only high quality, unleaded gasoline.

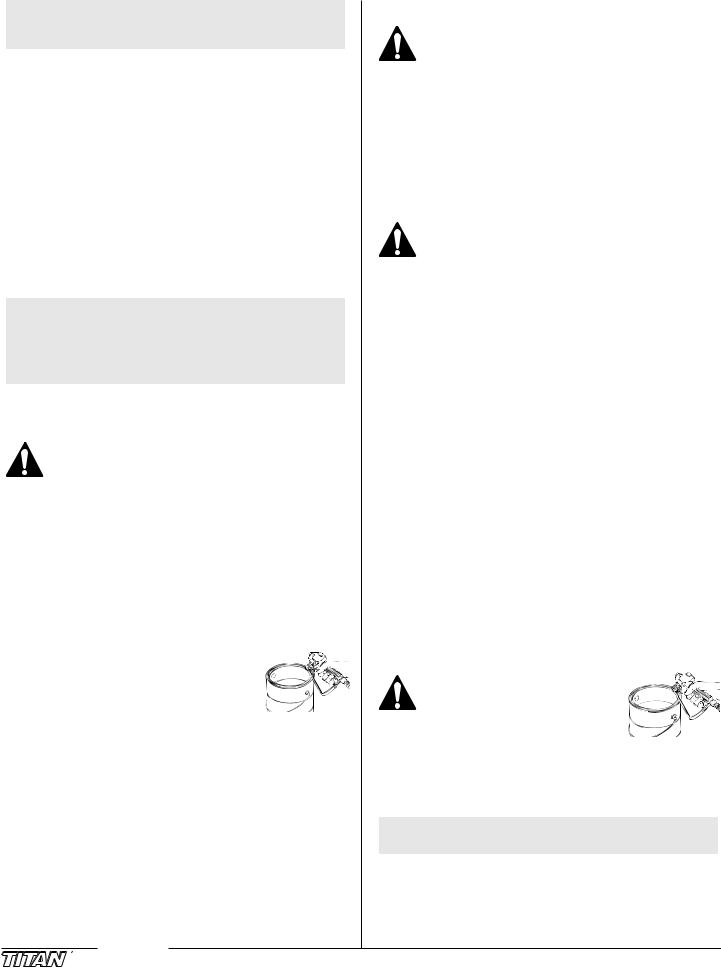

One-Gun Setup

1.Using a wrench, thread the 50’ airless spray hose to the outlet fitting on the sprayer. Tighten securely.

2.Attach an airless spray gun to the spray hose. Using two wrenches (one on the gun and one on the hose), tighten securely.

Two-Gun Setup

1.Using a wrench, thread the valve assembly (with 50’ hose attached) to the outlet fitting on the sprayer. Tighten securely.

2.Using a wrench, thread the 6’ airless spray hose to the top outlet fitting on the valve assembly. Tighten securely.

6’ hose

Valve assembly

50’ hose

Outlet

tting

3.Attach an airless spray gun to each of the spray hoses. Using two wrenches (one on the gun and one on the hose), tighten securely.

NOTE: If you plan on using both guns, make sure the valve handle is in the open position (handle is in line with the 6’ hose)

Valve |

Valve |

closed |

open |

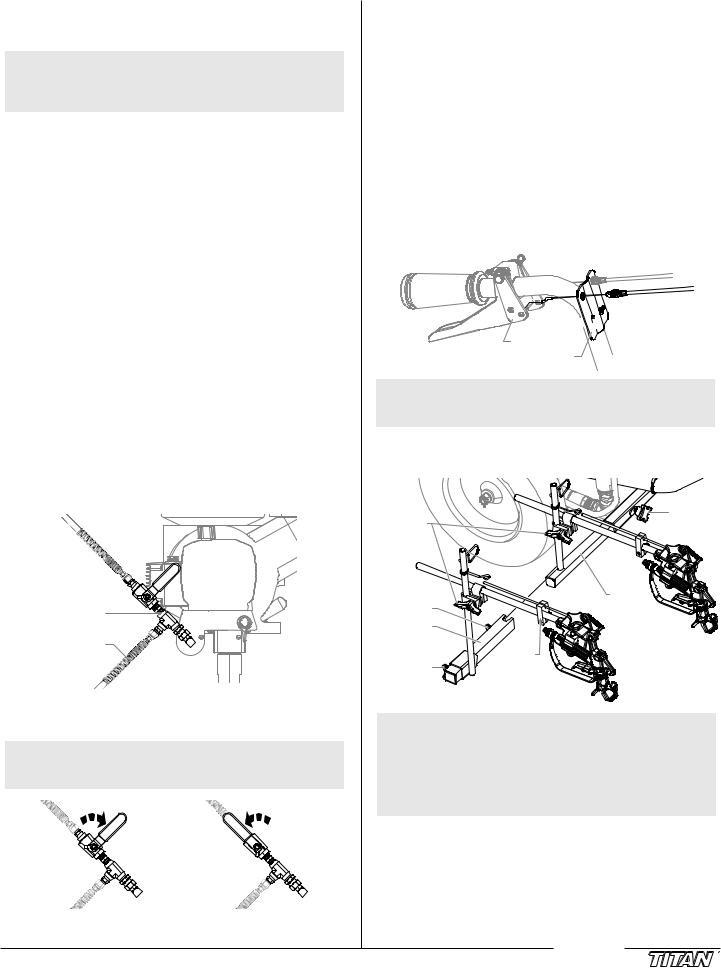

Positioning the spray guns (both units)

1.Loosen the support bar knob and slide the gun support bar to the desired horizontal position. Make sure the gun is far enough away from the cart so that the rear wheel does not track over the fresh spray pattern.

2.2nd Gun Mounting (if equipped) -

a.Slide the 2nd gun support bar assembly over the end of the 1st gun support bar. Secure in place by tightening the 2nd gun support bar knob.

b.Loosen the 2nd gun post knob and slide the post to the desired horizontal position.

c.Run the 2nd gun cable through the block and cable guides, underneath the frame and back towards the cart handle. Use the tie wraps to secure the cable to the frame.

important: Make sure the cable is not touching the tires or interfering with the mobility of the cart in any way.

d.Insert the gun cable assembly into the hole of the control guide until it snaps into place.

e.Attach the hooked end of the cable into the hole of the lever plate.

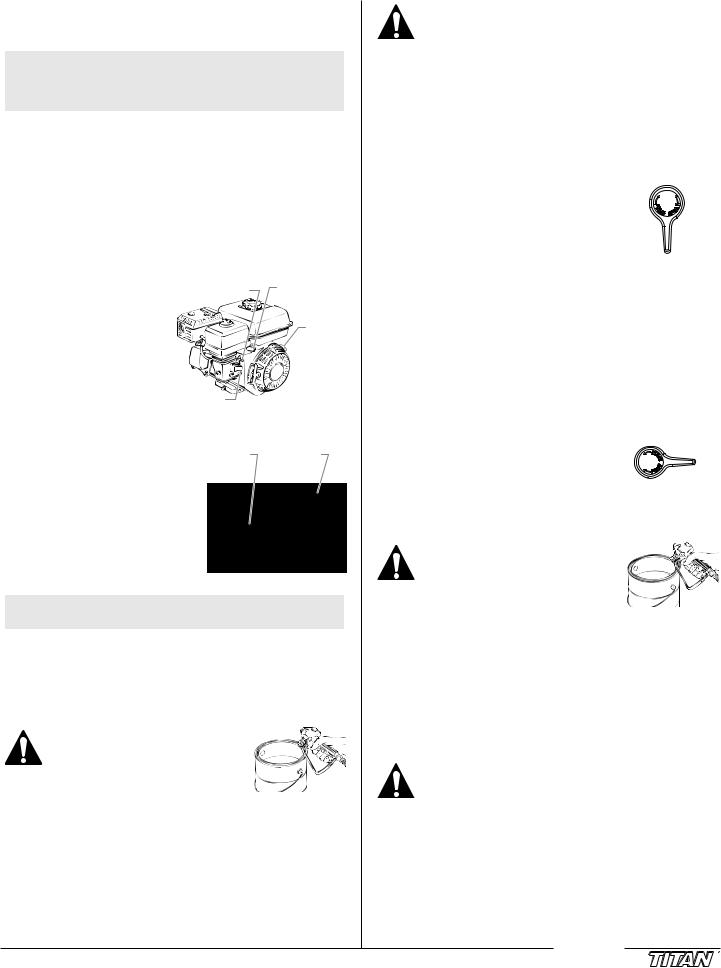

Gun cable

Gun cable

Lever plate

Control guide

NOTE: See the “Adjusting the Trigger Tension” section in order to verify that the cable is installed properly.

3.Loosen the gun riser clamp(s) and slide the spray gun(s) to the desired vertical position(s). A distance of 6” from the tip to the spray surface is a good starting point.

Support Gun riser bar knob

clamps

|

Gun |

Knob |

support |

2nd gun |

bar |

|

|

support bar |

|

2nd gun |

Block |

|

|

post knob |

|

NOTE: The gun support bar and the spray gun(s) can be mounted on either side of the sprayer. Refer to the “Spray Gun Positions” illustration near the back of this manual.

NOTE: The height of the spray gun affects the width of the spray pattern (i.e., the lower the gun, the smaller the line width). Tip size also affects line width.

© Titan Tool Inc. All rights reserved. |

5 |

English |

|

|

|

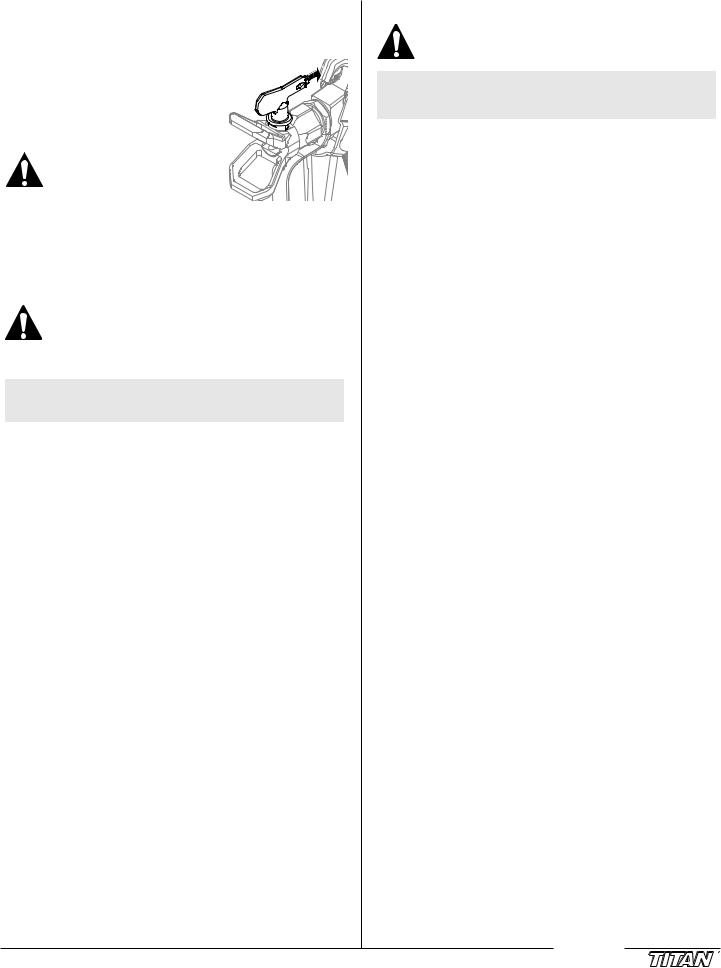

Trigger Selector (Two-Gun units)

1.Set the trigger selector for proper spray gun operation. The gun lever on the right handlebar triggers the gun or guns. The selector on the trigger must be set for the first gun, both guns, or the second gun .

important: Always turn the trigger lock on the spray gun to the locked position before making any adjustments to the trigger selector. Also, release the trigger cable from its block by lifting the cable up and out of the block. There will be a brief triggering of the gun while releasing the trigger cable.

a.First Gun — The first gun position is with the selector in the left position. Push the lever toward the inside of the frame until the pin engages

the left plate.

b.Both Guns — The dual gun position is with the selector

in the center position. Push the lever toward the center position until the pin engages both plates. The pin must engage both plates.

c.Second Gun — The second gun position is with the selector in the right position. Push the lever away from the inside of the frame until the

pin engages the right plate.

Preparing a New Sprayer

If this unit is new, it is shipped with test fluid in the fluid section to prevent corrosion during shipment and storage. This fluid must be thoroughly cleaned out of the system with mineral spirits before you begin spraying.

important: Always keep the trigger lock on the spray gun in the locked position while preparing the system.

1.Place the siphon tube into a container of mineral spirits that has a flash point of 60ºC (140ºF) or above.

2.Place the return hose into a metal waste container.

3.Turn the pressure control knob fully counterclockwise to its lowest pressure setting.

4.Move the PRIME/SPRAY valve to the PRIME position.

5.Move the engine ON/OFF switch to the ON position.

6. Start the engine: |

Choke Lever |

||

a. |

Open the fuel valve |

|

|

|

lever. |

|

|

b. |

Move the throttle lever |

|

|

|

to its middle point. |

|

|

c. |

Close the engine choke |

|

|

|

lever. |

|

|

d. |

Holding the frame |

|

|

|

with one hand, pull the |

|

|

|

starter rope rapidly and |

Fuel Valve |

|

|

firmly. Continue to hold |

||

|

|

Lever |

|

|

the rope as you let it |

|

|

|

|

|

|

|

return. Pull and return |

|

|

|

the rope until the engine starts. |

|

|

7. Turn on the sprayer by moving |

Sprayer |

||

the pump ON/OFF switch to |

|

||

|

ON/OFF |

||

the ON position. |

|

Switch |

|

8.Allow the sprayer to run for 15–30 seconds to flush the test fluid out through the return hose and into the waste container.

9.Turn off the sprayer by moving the pump ON/OFF switch to the OFF position.

Trigger lock in locked position.

PRIME

Throttle

Lever

Engine

ON/OFF

Switch

Starter Rope

Starter Rope

Pressure

Control

Knob

English |

6 |

© Titan Tool Inc. All rights reserved. |

|

|

|

Preparing to Paint

Before painting, it is important to make sure that the fluid in the system is compatible with the paint that is going to be used.

NOTE: Incompatible fluids and paint may cause the valves to become stuck closed, which would require disassembly and cleaning of the sprayer’s fluid section.

important: Always keep the trigger lock on the spray gun in the locked position while preparing the system.

1.Place the siphon tube into a container of the appropriate solvent for the material being sprayed (refer to recommendations of the material manufacturer). An example of the appropriate solvent is water for latex paint.

2.Place the return hose into a metal waste container.

3.Turn the pressure control knob fully counterclockwise to its lowest pressure setting.

4.Move the PRIME/SPRAY valve to the PRIME position.

5.Move the engine ON/OFF switch to the ON position.

6. Start the engine: |

Choke Lever |

|||

a. |

Open the fuel valve |

|||

|

|

|||

|

lever. |

|

|

|

b. |

Move the throttle lever |

|

|

|

|

to its middle point. |

|

|

|

c. |

Close the engine choke |

|

|

|

|

lever. |

|

|

|

d. |

Holding the frame |

|

|

|

|

with one hand, pull the |

|

|

|

|

starter rope rapidly and |

Fuel Valve |

||

|

firmly. Continue to hold |

|||

|

the rope as you let it |

|

Lever |

|

|

return. Pull and return |

|

|

|

|

the rope until the engine starts. |

|

||

7. Turn on the sprayer by moving |

Sprayer |

|||

the pump ON/OFF switch to |

||||

ON/OFF |

||||

the ON position. |

|

Switch |

||

8.Allow the sprayer to run for 15–30 seconds to flush the old solvent out through the return hose and into the metal waste container.

9.Turn off the sprayer by moving the pump ON/OFF switch to the OFF position.

Throttle

Lever

Engine

ON/OFF

Switch

Starter Rope

Starter Rope

Pressure

Control

Knob

NOTE: Make sure that the spray gun does not have a tip or tip guard installed.

10.Move the PRIME/SPRAY valve to the SPRAY position.

11.Turn on the sprayer.

12.Turn the pressure control knob slowly clockwise to increase pressure.

13.Unlock the gun by turning the gun trigger lock to the unlocked position.

Ground the gun by holding it against the edge of the metal container while flushing. Failure to do so may lead to a static electric discharge, which may cause a fire.

14.Trigger the gun into the metal waste container until the old solvent is gone and fresh solvent is coming out of the gun.

15.Lock the gun by turning the gun trigger lock to the locked position.

16.Set down the gun and increase the pressure by turning the pressure control knob slowly clockwise to its highest setting.

17.Check the entire system for leaks. If leaks occur, turn the sprayer off and follow the “Pressure Relief Procedure” in this manual before tightening any fittings or hoses.

20.Follow the “Pressure Relief Procedure” in this manual before changing from solvent to paint.

Be sure to follow the Pressure Relief Procedure when shutting the unit down for any purpose, including servicing or adjusting any part of the spray system, changing or cleaning spray tips, or preparing for cleanup.

Painting

1.Place the siphon tube into a container of paint.

2.Place the return hose into a metal waste container.

3.Turn the pressure control knob fully counterclockwise to its lowest pressure setting.

4.Move the PRIME/SPRAY valve to the PRIME position.

5.Move the engine ON/OFF switch to the

ON position. |

PRIME |

6.Start the engine:

a.Open the fuel valve lever.

b.Move the throttle lever to its middle point.

c.Close the engine choke lever.

d.Holding the frame with one hand, pull the starter rope rapidly and firmly. Continue to hold the rope as you let it return. Pull and return the rope until the engine starts.

7.Turn on the sprayer by moving the pump ON/OFF switch to the ON position.

8.Allow the sprayer to run until paint is coming through the return hose into the metal waste container.

9.Turn off the sprayer by moving the pump ON/OFF switch to the OFF position.

10.Remove the return hose from the waste container and place it in its operating position above the container of paint.

11.Move the PRIME/SPRAY valve to the SPRAY position.

12.Turn on the sprayer.

13.Turn the pressure control knob slowly SPRAY

clockwise to increase pressure.

14.Unlock the gun by turning the gun trigger lock to the unlocked position.

Ground the gun by holding it against the edge of the metal container while flushing. Failure to do so may lead to a static electric discharge, which may cause a fire.

15.Trigger the gun into the metal waste container until all air and solvent is flushed from the spray hose and paint is flowing freely from the gun.

16.Lock the gun by turning the gun trigger lock to the locked position.

17.Turn the pressure control knob fully counterclockwise to its lowest setting.

18.Turn off the sprayer.

19.Attach tip guard and tip to the gun as instructed by the tip guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray without the tip guard in place. Never trigger the gun unless the tip is in either the spray or the unclog position. Always engage the gun trigger lock before removing, replacing or cleaning tip.

20.Turn on the sprayer.

21.Increase the pressure by turning the pressure control knob slowly clockwise. Test the spray pattern and line position on a long piece of roofing felt or cardboard.

a.Adjust the pressure control knob until the spray from the gun is completely atomized. Try to keep the pressure control knob at the lowest setting that maintains good atomization.

© Titan Tool Inc. All rights reserved. |

7 |

English |

|

|

|

NOTE: Turning the pressure up higher than needed to atomize the paint will cause premature tip wear and additional overspray.

b.Check for proper line width and position. If adjustment to the position of the spray gun is required, refer to the “Setup” procedure earlier in this section.

22.Make sure that the spray gun completely shuts off when the gun trigger is released. If adjustment to the trigger tension is required, refer to the “Adjusting the Trigger Tension” procedure.

Operating the Front Caster

The front caster on the cart is designed to track the sprayer in either a straight line or allow free motion. Standing behind the sprayer, the trigger on the left handle of the cart controls the operation of the front caster.

1.To lock the front caster in the straight line position, squeeze then release the caster trigger and move the sprayer forward.

2.To allow free motion of the front caster, squeeze and hold the caster trigger.

NOTE: To lock the front caster in free motion mode, squeeze and hold the caster trigger and then push in the locking button on the side of the trigger. Once the locking button is pushed in, the caster trigger can be released. To release the locking pin, squeeze the caster trigger.

Pressure Relief Procedure

Be sure to follow the Pressure Relief Procedure when shutting the unit down for any purpose, including servicing or adjusting any part of the spray system, changing or cleaning spray nozzles, or preparing for cleanup.

1.Lock the gun by turning the gun trigger lock to the locked position.

2.Turn off the sprayer by moving the pump ON/OFF switch to the OFF position.

3.Turn off the engine by moving the engine ON/OFF switch to the OFF position.

4.Turn the pressure control knob counterclockwise to its lowest setting.

5.Unlock the gun by turning the gun trigger lock to the unlocked position.

6. Hold the metal part of the gun firmly to the side of a metal container to ground the gun and avoid a build up of static electricity.

7. Trigger the gun to remove any pressure that may still be in the hose.

8.Lock the gun by turning the gun trigger lock to the locked position.

9.Move the PRIME/SPRAY valve to the PRIME position.

Cleanup

Special cleanup instructions for use with flammable solvents:

•Always flush spray gun preferably outside and at least one hose length from spray pump.

•If collecting flushed solvents in a one gallon metal container, place it into an empty five gallon container, then flush solvents.

•Area must be free of flammable vapors.

•Follow all cleanup instructions.

Important: The sprayer, hose, and gun should be cleaned thoroughly after daily use. Failure to do so permits material to build up, seriously affecting the performance of the unit.

Always spray at minimum pressure with the gun nozzle tip removed when using mineral spirits or any other solvent to clean the sprayer, hose, or gun. Static electricity buildup may result in a fire or explosion in the presence of flammable vapors.

1.Follow the “Pressure Relief Procedure” found in the Operation section of this manual.

2.Remove the gun tip and tip guard and clean with a brush using the appropriate solvent.

3.Place the siphon tube into a container of the appropriate solvent (refer to recommendations of the material manufacturer). An example of the appropriate solvent is water for latex paint.

4.Place the return hose into a metal waste container.

5.Move the PRIME/SPRAY valve to its PRIME position.

6.Move the engine ON/OFF switch to the ON position and start the engine.

7.Turn on the sprayer by moving the sprayer ON/OFF switch to the ON position.

8.Slowly turn the pressure control knob clockwise to increase the pressure until fluid starts to come out of the return hose.

9.Allow the solvent to circulate through the sprayer and flush the paint out of the return hose into the metal waste container.

10.Turn the pressure control knob fully counterclockwise to its lowest setting.

11.Turn off the sprayer by moving the ON/OFF switch to the OFF position.

12.Move the PRIME/SPRAY valve to its SPRAY position.

13.Turn on the sprayer.

14.Turn the pressure control knob slowly clockwise to increase pressure.

Ground the gun by holding it against the edge of the metal container while flushing. Failure to do so may lead to a static electric discharge, which may cause a fire.

15.Trigger the gun into the metal waste container until the paint is flushed out of the hose and solvent is coming out of the gun.

16.Continue to trigger the spray gun into the waste container until the solvent coming out of the gun is clean.

NOTE: For long-term or cold weather storage, pump mineral sprits through the entire system.

17.Follow the “Pressure Relief Procedure” found in the Operation section of this manual.

18.Store the sprayer in a clean, dry area.

Important: Do not store the unit under pressure.

English |

8 |

© Titan Tool Inc. All rights reserved. |

|

|

|

Cleaning the Spray Tip

1.Flush the gun with solvent immediately after the work is completed.

2.Oil the sliding pins to prevent them from seizing up.

Should the spray tip become clogged, reverse the spray tip with the lever and pull the trigger. Once the obstruction comes out of the spray tip, release the trigger, reverse the spray tip back to the spray pattern setting, and resume spraying.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to clean the tip. The hard

tungsten carbide is brittle and can be chipped.

Maintenance

Before proceeding, follow the Pressure Relief Procedure outlined previously in this manual. Additionally, follow all other warnings to reduce the risk of an injection injury, injury from moving parts or electric shock.

NOTE: All Honda engine work should be performed by a Honda authorized service center.

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

Phillips screwdriver |

3/8” hex wrench |

needle-nose pliers |

5/16” hex wrench |

adjustable wrench |

1/4” hex wrench |

rubber mallet |

3/16” hex wrench |

flat-blade screwdriver |

1/8” hex wrench |

1/2” open-end wrench |

7/8” open-end wrench |

1.Before repairing any part of the sprayer, read the instructions carefully, including all warnings.

Important: Never pull on a wire to disconnect it. Pulling on a wire could loosen the connector from the wire.

2.Test your repair before regular operation of the sprayer to be sure that the problem is corrected. If the sprayer does not operate properly, review the repair procedure to determine if everything was done correctly. Refer to the Troubleshooting section to help identify other possible problems.

3.Make certain that the service area is well ventilated in case solvents are used during cleaning. Always wear protective eyewear while servicing. Additional protective equipment may be required depending on the type of cleaning solvent. Always contact the supplier of solvents for recommendations.

4.If you have any further questions concerning your Titan airless sprayer, call Titan:

Technical Service (U.S.)...................................... 1-800-526-5362

Fax .................................................................. |

1-800-528-4826 |

Maintaining the Engine

When transporting a sprayer with a gas engine, make sure the fuel is shut off.

NOTE: For detailed engine specifications and maintenance, refer to the separate engine manual supplied with this sprayer.

Important Facts Concerning this Sprayer

This gas-powered sprayer contains a clutch that engages when the sprayer is pumping. The sprayer’s pressure control system engages and disengages the clutch to control pressure. To prevent unnecessary wear to the clutch, it is advisable to adjust the engine speed and pressure setting to limit the amount of times the clutch engages and disengages. To reduce clutch wear, refer to the following examples.

Example:

Operating one gun with a .019” tip — reduce the engine speed by adjusting the throttle to a low or medium setting and increase pressure only until the heavy ends of the spray pattern have been eliminated.

Example:

Operating one gun with .025” tip — increase engine speed to a higher setting and increase pressure until the heavy ends of the spray pattern have been eliminated.

Example:

Spraying light-bodied materials at low pressure — to reduce surging at the gun and to decrease clutch wear, reduce the engine speed to idle and reduce pressure until the desired spray pattern is achieved.

Routine Engine Maintenance

Daily

•Check and fill the gas tank.

•After the first 20 hours of operation (or 1 month), drain the oil and refill with clean oil. Check the engine oil level and fill as necessary.

Weekly

•Remove the cover of the air filter and clean the element.

Replace the element if necessary. If operating in an unusually dusty environment, check the filter daily and replace if necessary. (Replacement elements can be purchased from your local Titan dealer.)

•After each 50 hours (or 3 months) of operation: Change the engine oil.

Spark Plug

•Use only a (NKG) BPR6ES plug.

•Gap the plug 0.028” – 0.031” (0.7 - 0.8 mm)

•Make sure to use a spark plug wrench when installing and removing the plug.

© Titan Tool Inc. All rights reserved. |

9 |

English |

|

|

|

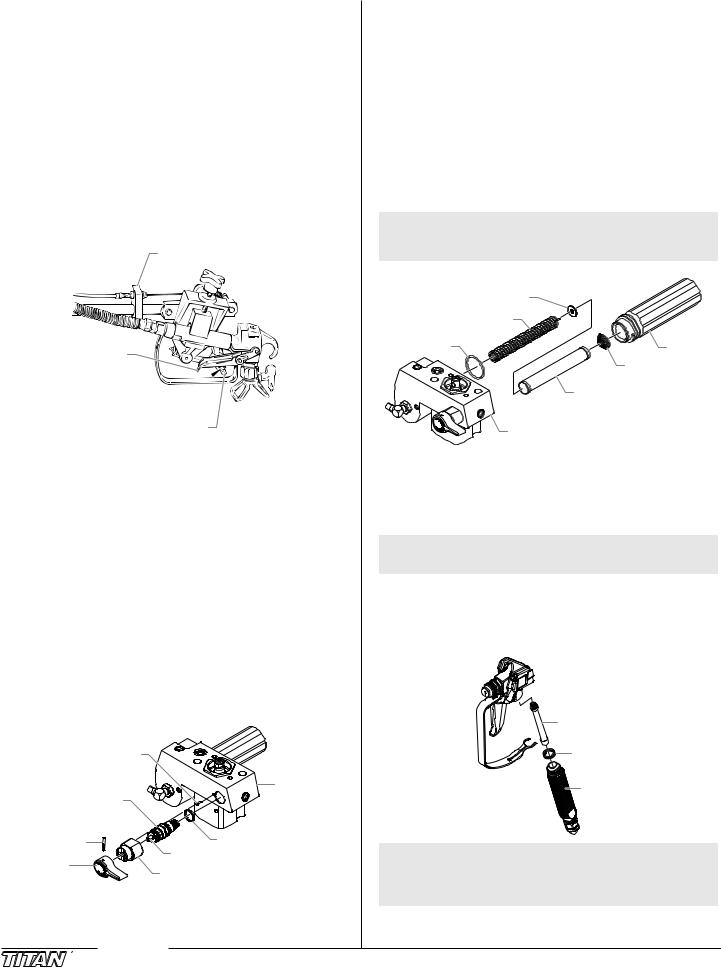

Adjusting the Trigger Tension

Use the following procedure to adjust the spring tension of the trigger lever on the gun holder assembly. The trigger lever pulls and releases the spray gun trigger when operated from the trigger on the cart. The proper tension ensures that the gun will shut off when the gun trigger is released. To ensure proper tension, there should be approximately a 1/32” to 1/16” gap between the trigger lever and the spray gun trigger.

important: Always keep the trigger lock on the spray gun in the locked position while making adjustments to the system.

1.Using a wrench, loosen the bolt on the cable block.

2.Move the cable block in the appropriate direction to create a gap of 1/32” to 1/16” between the trigger lever and spray gun trigger.

a.Slide the cable block toward the gun to increase the gap between the trigger lever and spray gun trigger.

b.Slide the cable block away from the gun to decrease the gap between the trigger lever and spray gun trigger.

Cable Block

(bolt on back)

Spray Gun Trigger

1/32" to 1/16" Gap

Trigger Lever

3.Tighten the set screw securely.

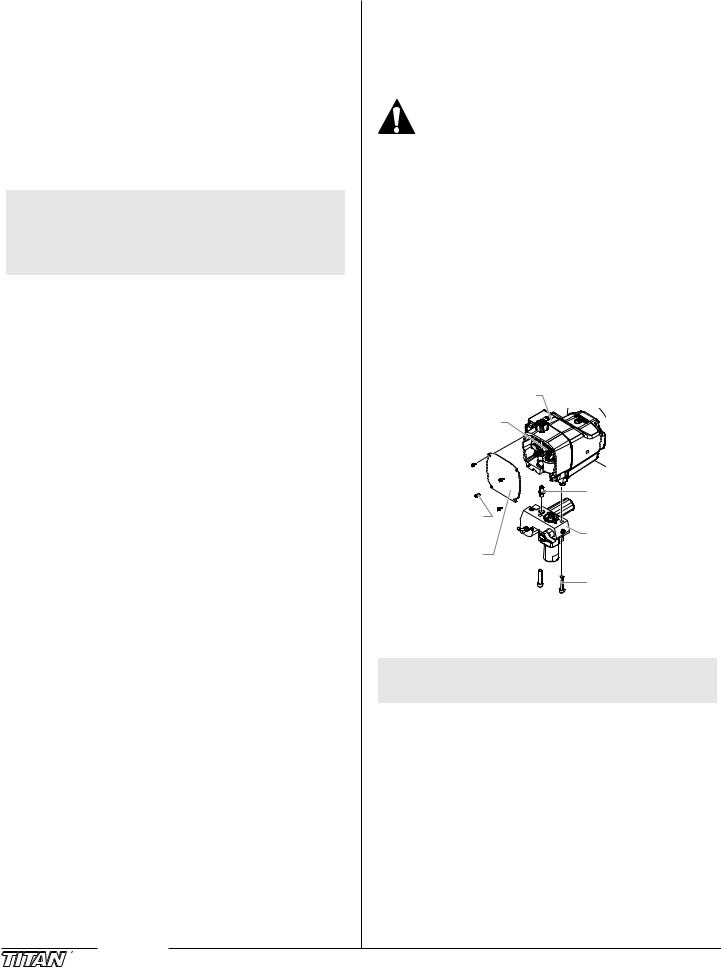

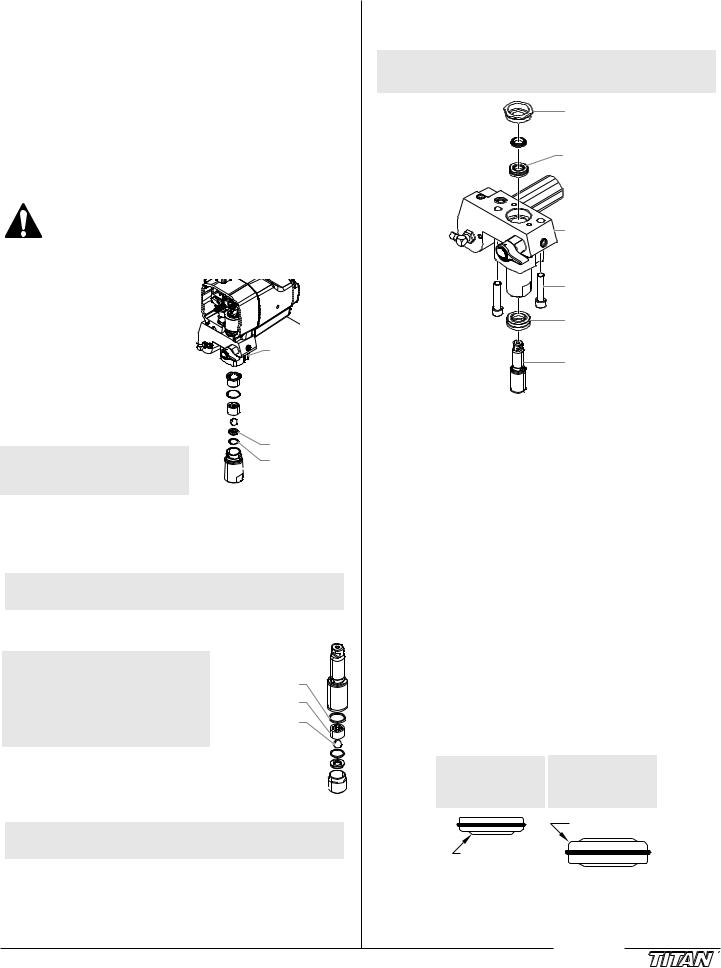

Replacing the prime/spray Valve

Perform the following procedure using PRIME/SPRAY valve replacement kit P/N 800-915 or 700-258.

1.Drive the groove pin out of the valve handle.

2.Remove the valve handle and the cam base.

3.Using a wrench, loosen and remove the valve housing assembly from the pump manifold.

4.Make sure the gasket is in place and thread the new valve housing assembly into the pump manifold. Tighten securely with a wrench.

5.Place the cam base over the valve housing assembly. Lubricate the cam base with grease and line up the cam with the pump manifold using the dowel pin.

6.Line up the hole on the valve stem with the hole in the valve handle.

7.Insert the groove pin into the valve handle and through the valve stem to secure the valve handle in position.

Dowel Pin

Pump

Valve Housing  Manifold

Manifold

Assembly

Groove Pin |

Gasket |

|

Valve |

Valve Stem |

|

Cam Base |

||

Handle |

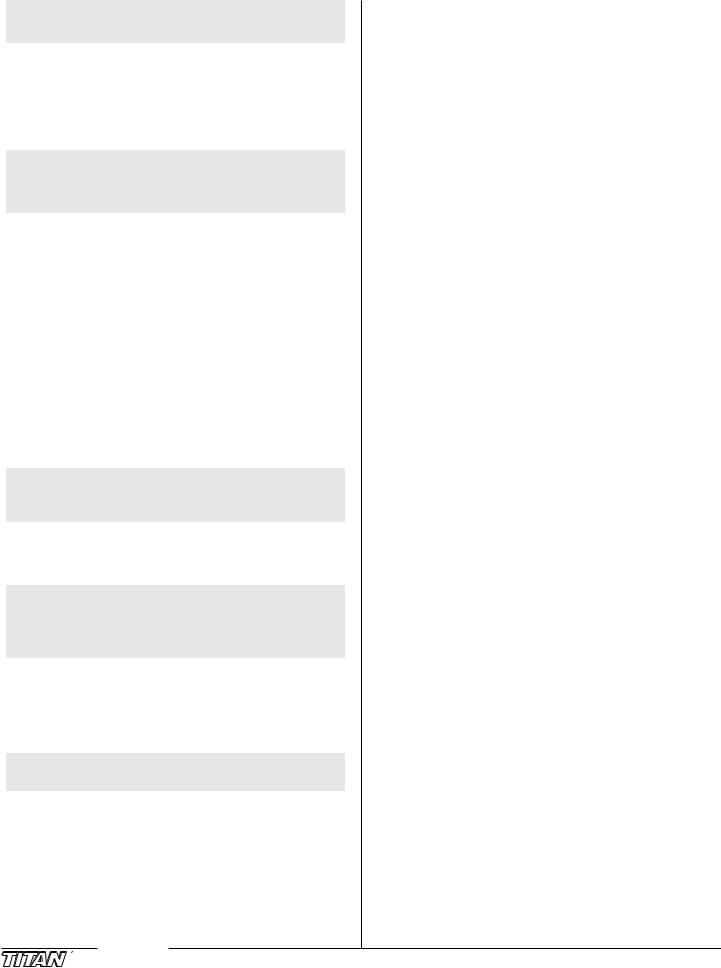

Cleaning or Replacing the Filters

Pump Filter

1.Loosen and remove the filter housing by hand. Pull the filter out of the pump manifold.

2.Slip the filter off of the filter support spring.

3.Inspect the filter. Based on inspection, clean or replace the filter.

4.Inspect the filter seal. Based on inspection, clean or replace the filter seal.

5.Slide the new or cleaned filter over the filter support spring with the adapter in place. Push the filter into the center of the pump manifold.

6.Slide the filter housing over the filter and thread it into the pump manifold until secure.

NOTE: The filter housing should be hand-tightened, but make sure the filter housing is seated fully into the pump manifold.

Adapter |

|

|

Filter Support Spring |

|

|

Filter Seal |

|

Filter |

|

Filter |

Housing |

|

|

|

|

Spring |

|

Filter |

|

|

Pump Manifold |

|

|

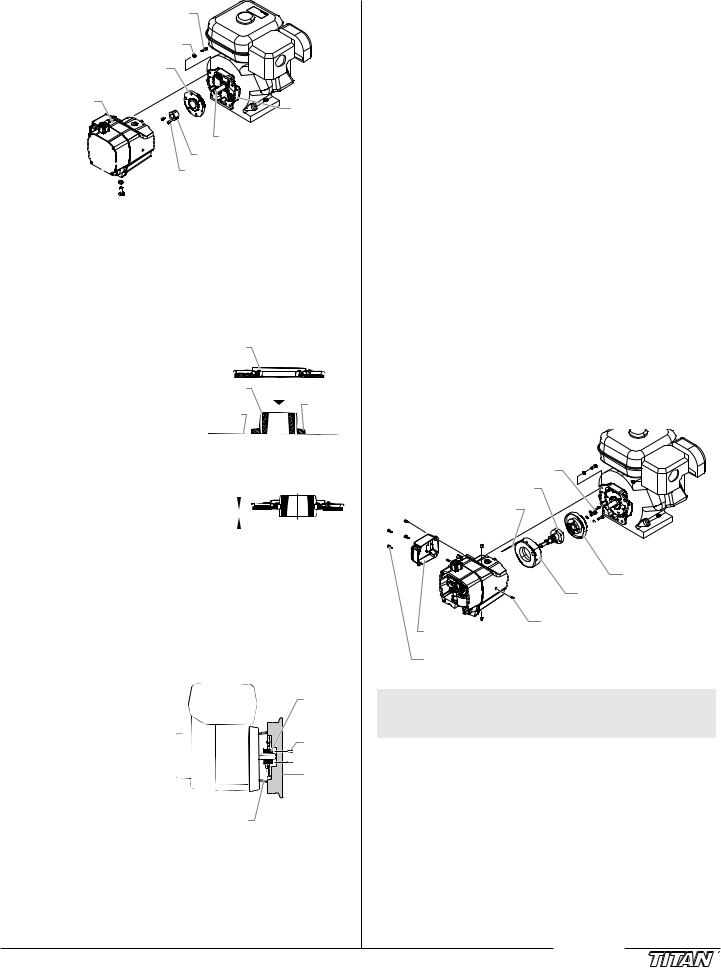

Gun Filter

1.Move the gun trigger lock to the unlocked position.

2.Loosen and remove the handle from the gun body.

3.Turning clockwise, unscrew the filter from the gun body.

NOTE: Left-handed threads require turning the filter clockwise to remove.

4.Turning counterclockwise, screw the new or cleaned filter into the gun body.

5.Make sure the handle seal is in position and thread the handle into the gun body until secure.

6.Move the gun trigger lock to the locked position.

Gun

Gun

Housing

Filter

Handle

Seal

Handle

NOTE: For more detail, part number information, and complete assembly drawings, please see the LX-80II Professional Airless Gun Owner’s Manual (P/N 3132293).

English |

10 |

© Titan Tool Inc. All rights reserved. |

|

|

|

Replacing the Sprayer ON/OFF Switch

1.Perform the Pressure Relief Procedure.

2.Using a Phillips screwdriver, remove the four screws that secure the heat sink assembly to the housing. Carefully remove the heat sink assembly from the housing. Gently move the assembly away from the sprayer and allow the assembly to hang from the housing.

3.Locate the bottom of the sprayer ON/OFF switch inside the housing.

ON/OFF

Switch

Heat Sink

Assembly

Heat Sink

Assembly

Screw

Relay

4.Disconnect the switch wires from the sprayer ON/OFF switch. Remember the locations of each of the two wires (label the wires, if necessary).

5.Depress the mounting tabs on each corner of the sprayer ON/ OFF switch inside the housing and remove the switch through the top of the housing.

6.Snap the new sprayer ON/OFF switch into the switch hole in the housing.

7.Connect the two switch wires to the new sprayer ON/ OFF switch. Make sure the wires are connected to the

corresponding terminals from which they were removed (refer to the labels created earlier in this procedure or the electrical schematic in the Parts List section of this manual).

8.Carefully place the heat sink assembly over the housing taking care not to pinch any wires.

9.Install the four screws that secure the heat sink assembly to the housing. Tighten securely.

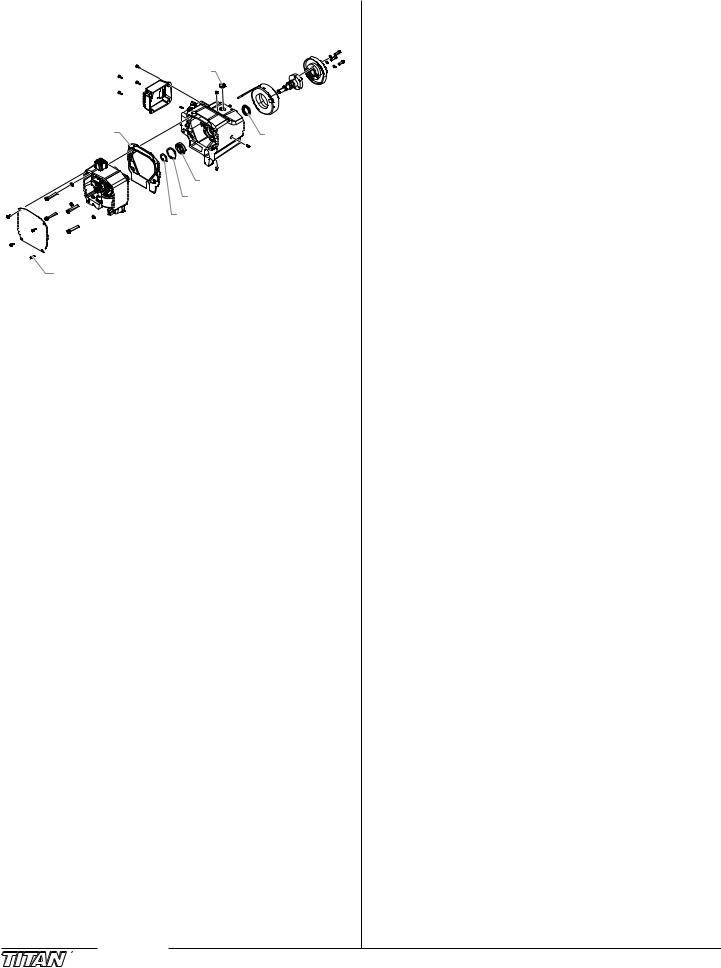

Replacing the Gears and/or Slider Assembly

1.Using a Phillips screwdriver, remove the four front cover screws. Remove the front cover.

2.Start the engine (refer to the procedures in the Operation section of this manual). Turn the pressure control knob clockwise to its maximum pressure setting.

3.Toggle the sprayer ON/OFF switch between the ON and OFF positions in short bursts until the slider assembly and piston stop at the bottom of their stroke (in their lowest position).

4.Turn off the engine and perform the Pressure Relief Procedure.

NOTE: If replacing the slider assembly, the fluid section must be removed from the pump housing.

5.Using a 3/8” hex wrench, remove the two socket screws that secure the fluid section to the pump housing.

6.Pull fluid section housing down approximately 1/2” from the gear box housing to clear the transducer.

Pump |

|

Housing |

|

Slider |

|

Assembly |

|

|

Piston |

Front |

|

Cover |

Fluid |

Screw |

Section |

Front |

Housing |

Cover |

|

Socket |

|

Screw |

|

7.Slide the fluid section housing and piston rod forward until the piston rod is out of the T-slot on the slider assembly.

8.Using a 1/4” hex wrench,remove the four socket screws that secure the pump housing to the gear housing.

Gear Housing

|

Thrust Washer |

|

Output Gear Assembly |

|

Thrust Washer |

Housing Gasket |

|

Pump Housing |

Cylindrical |

|

|

|

Thrust Washer |

|

Crankshaft |

|

Assembly |

|

Thrust |

|

Washer |

Slider Bushing

Slider Assembly

Pump Housing Socket Screw

9.Slide the pump housing away from the gear housing.

10.Remove and clean the housing gasket. Replace if damaged.

11.Slide the crankshaft assembly, with the two thrust washers out from the gear housing side of the pump housing.

12.Remove the output gear assembly with the two thrust washers.

13.Thoroughly clean the crankshaft assembly, the output gear assembly, and all the thrust washers.

14.Inspect all parts for excessive wear and replace if damaged or worn. If the crankshaft or output gear assembly are replaced, replace the corresponding thrust washers as well.

15.Inspect the pinion gear on the end of the drive shaft for wear. Replace if damaged or worn (refer to the “Servicing the Clutch Assembly” procedure in this section).

NOTE: If any of the gears are worn and require replacement, check the grease in the gear housing for metal particles or shavings. Remove the contaminated grease. Replace the grease that has been removed with fresh Lubriplate GR-132 grease.

16.Slide the slider assembly up and out of the slider bushing in the front of the pump housing.

17.Check the parts for wear.

a.If the slider bushing is scored or out of round the pump housing should be replaced.

b.If the slider assembly is scored or the connection between the connecting rod and slider assembly exhibits movement other than pivoting movement, the slider assembly should be replaced. The slider assembly also should be replaced if the connecting rod bearing shows signs of wear.

c.Any parts that will be reused should be cleaned thoroughly, including the connecting rod. Also, clean the crankshaft pin that the connecting rod bearing rides on.

18.Coat the output gear assembly and each side of its thrust washers with fresh Lubriplate GR-132 grease. Place the thrust washers on their proper shaft of the output gear assembly.

19.Lubricate the output gear assembly with fresh Lubriplate GR132 grease. Insert the gear assembly into its bore in the gear housing, gear end first. The teeth on the gear will mate with the teeth on the drive shaft pinion.

20.Generously coat all surfaces of the cylindrical crankshaft assembly thrust washer with fresh Lubriplate GR-132 grease.

21.Slip the flat end of the cylindrical thrust washer behind the gear on the output gear assembly, lining its bore up with the gear housing bearing bore for the crankshaft assembly.

22.Lubricate the crankshaft assembly gear with fresh Lubriplate GR-132 grease. Slide the gear side shaft of the crankshaft through the cylindrical thrust washer and into its bore within the gear housing.

23.Position the pin on the end of the crankshaft towards the bottom of the gear housing (the bottom dead center position).

© Titan Tool Inc. All rights reserved. |

11 |

English |

|

|

|

24.Lubricate both faces of the large crankshaft assembly thrust washer with fresh Lubriplate GR-132 grease. Place the thrust washer onto the crankshaft against the gear.

25.Place the housing gasket over the gear housing dowel pins.

26.Lubricate the outside of the slider assembly and the inside of the slider bushing with oil. Fill the slider cup with Lubriplate 1242 grease (the slider cup is the area on the slider assembly where the connecting rod and slider join and pivot).

27.Insert the slider assembly into the slider bushing.

28.Carefully place the pump housing assembly in front of the gear housing assembly, lining up the gear housing dowel pins with their corresponding holes in the pump housing. Slide the pump housing onto the gear housing until there is no gap between the housings and gasket.

NOTE: While sliding the pump housing into place, the crankshaft pin will begin to protrude from the bearing in the center of the pump housing. Position the slider assembly so that as the crankshaft pin protrudes from the main bearing, it engages the connecting rod bearing.

Important: Do not force the pump housing and gear housing together.

29.Locate the four socket screws and lock washers that secure the pump housing to the gear housing.

30.Using a 1/4” hex wrench, snug and tighten the socket screws in a crossing pattern. Torque to 200–230 in.-lbs.

31.Slide the top of the piston rod into the T-slot on the slider assembly.

32.Position the pump block underneath the gear box housing and push up until it rests against the gear box housing.

33.Insert the two socket screws that secure the fluid section to the pump housing and alternately snug, tighten, and torque the screws to 400-440 in.-lbs.

34.Position the front cover over the pump housing. Secure the front cover using the four front cover screws.

Replacing the Transducer

1.Loosen and remove the four front cover screws. Remove the front cover.

2.Stop the sprayer at the bottom of its stroke so that the piston is at its lowest position.

3.Perform the Pressure Relief Procedure.

Before proceeding, follow the Pressure Relief Procedure outlined previously in this manual. Additionally, follow all other warnings to reduce the risk of an injection injury, injury from moving parts or electric shock.

4.Tilt the sprayer back for easy access to the fluid section.

5.Using a 3/8” hex wrench, loosen and remove the two socket screws.

6.Pull the fluid section down approximately 1/2” from the housing to clear the transducer.

7.Slide the fluid section and piston rod forward until the piston rod is out of the T-slot on the connecting rod.

8.Using a wrench, remove the transducer assembly from the fluid section.

9.Thread the new transducer assembly from the fluid section. Tighten securely with a wrench.

10.Reassemble the pump by reversing steps 1-8.

Important: Make sure the transducer is aligned properly with the hole in the fluid section during reassembly. Improper alignment may cause damage to the transducer O-ring.

Pump

Housing

Slider

Assembly

|

Transducer |

Front |

Assembly |

|

|

Cover |

Fluid |

Screw |

|

Front |

Section |

Housing |

|

Cover |

|

|

Socket |

|

Screw |

Servicing the Clutch Assembly

NOTE: When replacing the clutch armature, the clutch rotor must be replaced also. This will allow for even wear and maximum life on clutch parts.

Removing/Replacing the Clutch Armature Assembly

1.Perform the Pressure Relief Procedure.

2.Locate the wire that exits the rear of the pressure control housing and connects to the wire harness on the engine. Disconnect this wire from its connector at the engine wire harness.

3.Using a 12 point, 5/16” wrench, remove the four screws and lock washers that secure the clutch housing to the gear housing.

4.Using a 9/16” socket, remove the screw that secures the gear housing to the cart.

5.Slide the pump and gear housings away from the engine to disengage them from the clutch housing.

English |

12 |

© Titan Tool Inc. All rights reserved. |

|

|

|

Clutch Housing

Hex Screw

Lock Washer

Clutch Armature

Gear

Housing Clutch

Housing

Engine Shaft

Taper Lock Bushing

Pump Set Screw

Set Screw

Housing

Gear Housing

Screw

6.Locate the clutch armature assembly on the end of the engine shaft. Note the two set screws as well as the unused, threaded hole in the taper lock bushing at the center of the clutch hub.

7.Using an 1/8” hex wrench, remove the two set screws from the taper lock bushing

8.Thread one of the set screws into the unused, threaded hole on the taper lock bushing. As the screw tightens, the bushing will loosen. Once the bushing has loosened enough, slide the clutch armature assembly off the engine shaft.

9. Before replacing the clutch |

|

Clutch |

|

|

|

||||

hub and armature assembly |

Armature |

|

|

|

|||||

the proper “set back” must be |

|

|

|

|

|

|

|

|

|

created. Using the hub set-up |

|

Clutch |

|

|

|

||||

tool (P/N 0555926), create a |

|

|

Hub |

|

|

Set-Up |

|||

|

|

|

|||||||

“set back” of 0.10” between the |

|

|

Flat |

|

|

||||

|

|

|

|

Tool |

|||||

friction surface of the clutch |

|

|

|

|

|||||

Surface |

|

|

|

||||||

armature and the forward face |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

of the clutch hub. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: A new clutch hub and |

|

|

0.10" |

|

|

|

|||

armature assembly will come |

|

|

|

|

|||||

pre-assembled, but the “set |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

back” may not be correct. The |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

“set back” must still be created |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

using the hub set-up tool. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10.To replace the clutch armature assembly , line up the three holes in the taper lock bushing with the three holes in the clutch armature and insert the bushing into the center of the clutch armature.

11.Line up the key on the taper lock bushing with the keyway on the engine shaft and slide the assembly onto the shaft with the holes facing out.

12.Apply blue Loctite to the two set screws and insert the screws into the taper lock bushing. Tighten the set screws only two turns at this time.

13.Using the clutch set-up tool (P/N 0555926), position the clutch armature on

the engine shaft. Hold the tool across the face of the clutch housing so that the center, recessed portion of the tool straddles the clutch armature assembly. Pull the clutch armature assembly towards the tool until the face of the armature is against the tool.

Taper

Lock

Bushing

Set

Screw

Set-Up

Tool

Engine

Clutch

Housing

14.While holding the clutch armature assembly against the tool, use an 1/8” hex wrench and alternately tighten the set screws into the taper lock bushing. Torque to 65–75 in-lbs.

15.Make sure the friction surface of the clutch armature is clean and free from oil or grease.

Removing the Clutch Rotor, Clutch Field, and Drive Shaft

Assembly

1.Follow steps 1–7 in “Removing/Replacing the Clutch Armature Assembly.”

2.Locate the clutch rotor assembly, which will be inside the rear the gear housing. Note the locations of the three socket screws and the two empty, threaded holes on the clutch rotor.

3.Using a 3/16” hex wrench, remove the three socket screws and lock washers that secure the clutch rotor to the drive shaft assembly.

4.Thread two of the socket screws into the empty, threaded holes and tighten alternately. This will push the clutch rotor away from the drive shaft assembly and pinion.

5.Using a Phillips screwdriver, remove the four screws that secure the heat sink assembly to the housing. Carefully remove the heat sink assembly from the housing.

6.Locate the two clutch field wires that pass from the gear housing into the control housing through a hole in the back of the control housing. Remember the wire connection terminals on the relay assembly (label if necessary) and disconnect the wires. Gently move the heat sink assembly away from the housing and rest it on the work surface by the control housing.

7.Locate the four pairs of set screws that secure the clutch field to the gear housing. They are located on the exterior of the gear housing at the 12, 3, 6, and 9 o’clock positions while facing the clutch field end of the gear housing. Using an 1/8” hex wrench, remove the setscrews. Remember the location of the two clutch field wires with respect to the grommet and EPC housing.

8.Carefully slide the clutch field out of the gear housing, keeping the field square to the gear housing so it does not bind.

Clutch Rotor Socket Screw

Drive Shaft Assembly

Clutch Field Wires

Lock

Lock

Washer

Clutch

Clutch Rotor

Field Assembly

Set Screw

Heat Sink

Assembly

Heat Sink

Assembly Screw

NOTE: To remove the drive shaft assembly, the pump housing first must be removed from the gear housing.

9.Using a Phillips screwdriver, remove the four front cover screws. Remove the front cover.

10.Using a 1/4” hex wrench, remove the four socket screws that secure the pump housing to the gear housing.

11.Slide the pump housing away from the gear housing.

12.Remove and clean the housing gasket. Replace if damaged.

13.Locate the drive shaft pinion that is protruding from the front side of the gear housing. Remove the small snap ring that is located on the drive shaft hub in front of the ball bearing that is supporting the drive shaft.

14.From the opposite side of the gear housing (clutch side) slide the drive shaft assembly out of the gear housing.

15.Inspect the grease seal located inside the bore from which the drive shaft was removed. Replace if worn or damaged.

© Titan Tool Inc. All rights reserved. |

13 |

English |

|

|

|

To remove the grease seal, use a flat blade screwdriver to carefully pry the seal from the bore.

16.Clean the inside of the gear housing.

|

Plug |

Housing Gasket |

Grease Seal |

|

Bearing |

|

Snap Ring |

|

Small Snap Ring |

Pump Housing Socket Screw

Pump Housing Socket Screw

Front Cover

Front Cover

Front Cover Screw

Installing the Clutch Rotor Assembly, Clutch Field and Drive Shaft Assembly

1.If the drive shaft grease seal was removed, press a new seal into the bore from which the old seal was removed.

2.From the clutch side of the gear housing, insert the drive shaft assembly into the bore, through the grease seal, and through the ball bearing on the gear side of the gear housing.

3.From the gear side of the gear housing, insert the snap ring into the groove on the drive shaft hub in front of the ball bearing.

4.Place the housing gasket over the gear housing dowel pins.

5.Carefully place the pump housing assembly in front of the gear housing assembly, lining up the gear housing dowel pins with their corresponding holes in the pump housing. Slide the pump housing onto the gear housing until there is no gap between the housings and gasket.

Important: Do not force the pump housing and gear housing together.

6.Locate the four socket screws and lock washers that secure the pump housing to the gear housing.

7.Using a 1/4” hex wrench, snug and tighten the socket screws in a crossing pattern. Torque to 200–230 in.-lbs.

8.Line up the four holes around the outside of the clutch field with the four set screw holes in the gear housing. The clutch field wires should be at approximately the 1 or 2 o’clock position.

9.Route the two clutch field wires through the hole and into the control housing.

10.Carefully slide the clutch field into its bore in the gear housing until it “bottoms out” within the housing. Do not pinch the clutch field wires during installation.

11.Thread one of the pointed set screws into its hole. Using an 1/8” hex wrench, rotate the screw slowly until it contacts the clutch field. Do not tighten the set screw. The tip of the set screw should mate with the drill point hole in the field. Check the clutch field for rotation. If it rotates within its bore, the set screw is not seated within the drill point.

12.When the set screw is properly seated, install the remaining three pointed set screws. Do not tighten the set screws.

13.Using a crossing pattern, tighten each of the pointed setscrews until they are snug. Once all four pointed set screws are snug, use a crossing pattern to tighten and torque the set screws to 70–80 in.-lbs.

Important: It is very important to evenly snug, tighten, and torque the clutch field pointed set screws in a crossing pattern. This ensures the clutch field will stay centered in the gear housing.

15.Line up the three screw holes and dowel pin hole on the clutch rotor with the screw holes and dowel pin on the drive shaft assembly hub. Place the clutch rotor onto the hub.

16.Using a 3/16” hex wrench, thread the three socket screws and lock washers through the clutch rotor and into the drive shaft assembly hub. Evenly snug, tighten, and torque the socket screws to 75–85 in-lbs.

17.Make sure the friction surface of the clutch rotor is clean and free from oil or grease.

18.Locate the two clutch field wires in the control housing. Gently pull the wires fully into the EPC housing so that there is no slack in the gear housing. Connect the wires to their proper terminals on the relay (refer to the labels created earlier in this procedure or the electrical schematic in the Parts List section of this manual).

19.Carefully place the heat sink assembly over the control housing taking care not to pinch any wires.

20.Install the four screws that secure the heat sink assembly to the control housing. Tighten securely.

Mating the Gear Housing and the Clutch Housing

1.Place the gear housing assembly onto the cart in front of the clutch housing. Line up the dowel pins in the gear housing with their corresponding holes in the clutch housing. Slide the gear housing assembly onto the clutch housing until there is no gap between the housings.

2.Thread the four hex screws and lock washers through the clutch housing and into the gear housing.

3.Using a 12 point, 5/16” wrench, snug and tighten the hex screws in a crossing pattern. Torque to 140–155 in.-lbs.

4.Using a 9/16” socket, thread the hex screw that secures the gear housing to the cart through the underside of the cart and into the gear housing. Torque to 100–120 in.-lbs.

5.Connect the wire from the EPC housing to its mating connector on the engine wire harness.

Checking the Clutch Gap

1.Remove the plastic plug from the top of the clutch housing. Look through the port to locate the clutch armature and the clutch rotor.

2.Check the gap between the clutch armature and the clutch rotor using a .016” feeler gauge and a .035” feeler gauge.

a.Insert each feeler gauge through the port and into the gap between the clutch armature and the clutch rotor. The .016” feeler gauge should fit in the gap. The .035” feeler gauge should not fit in the gap.

b.Pull the engine pull cord several times to rotate the clutch armature, checking the gap with each feeler gauge between each pull.

c.If the .016” gauge does not fit or the .035” gauge does fit at any checkpoint, the gap must be readjusted. This is done by relocating the clutch hub and armature assembly on the engine shaft. Refer to the “Removing/Replacing the Clutch Armature Assembly” procedure.

English |

14 |

© Titan Tool Inc. All rights reserved. |

|

|

|

Servicing the Fluid Section

Use the following procedures to service the valves and repack the fluid section.

1.Using a Phillips screwdriver, remove the four front cover screws. Remove the front cover.

2.Start the engine (refer to the procedures in the Operation section of this manual). Turn the pressure control knob clockwise to its maximum pressure setting.

3.Toggle the sprayer ON/OFF switch between the ON and OFF positions in short bursts until the slider assembly and piston rod stop at the bottom of their stroke (in their lowest position).

4.Turn off the engine and perform the Pressure Relief Procedure.

Before proceeding, follow the Pressure Relief Procedure outlined previously in this manual. Additionally, follow all other warnings to reduce the risk of an injection injury, injury from moving parts or electric shock.

Servicing the Valves

The design of the fluid section allows access to the inlet valve and seat

as well as the outlet valve and seat without completely disassembling the fluid section. It is possible that the valves may not seat properly because of debris stuck in the inlet valve seat or outlet valve seat. Use the following instructions to clean the valves and reverse or replace the seats.

NOTE: Keep the sprayer in the upright position for this procedure.

Fluid Section

Housing

Piston Bushing

Piston Bushing

Inlet Valve Seal

Inlet Valve Seal

Inlet Cage

Inlet Cage

Inlet Valve Ball

Inlet Valve Ball

Inlet Valve Seat

PTFE O-Ring

Inlet Valve

Inlet Valve

Housing

1.Using a wrench, loosen and remove the inlet valve housing from the fluid section housing.

2.Clean out any debris in the inlet valve housing and examine the valve housing and seat. If the inlet valve seat is damaged, reverse the seat to the unused side or replace the seat.

NOTE: If the inlet valve seat is reversed or replaced, the inlet valve ball must be replaced.

3.Using a 3/8” hex wrench, loosen and remove the outlet valve retainer from the piston rod.

NOTE: Always service the outlet valve with the piston rod attached to the pump. This will prevent the piston

rod from rotating during disassembly of the outlet valve.

4.Clean out any debris and examine the outlet valve retainer and seat. If the outlet valve seat is damaged, reverse to the unused side or replace the seat.

Piston rod Upper seal

Upper seal

Upper cage

Outlet valve ball

Lower seal

Outlet valve seat

seat

Outlet valve retainer

retainer

NOTE: If the outlet valve seat is reversed or replaced, the outlet valve ball must be replaced.

5.Remove, clean, and inspect the outlet cage and outlet valve ball. Replace if they are worn or damaged.

6.Reassemble the valves by reversing the steps above. Apply blue Loctite (P/N 426-051) to male threads of inlet valve housing and torque to 450-500 in-lbs.

Repacking the Fluid Section

1.Remove the foot valve assembly using the steps in the “Servicing the Valves” procedure above.

NOTE: The outlet valve does not need to be disassembled from the piston rod for this procedure.

Retainer Nut

Piston Guide

Piston Guide

Upper Packing

Assembly

Pump Manifold

Pump

Manifold

Mounting

Screw

Lower Packing

Assembly

Piston Rod

2.Using 3/8” a hex wrench, loosen and remove the two pump block mounting screws.

3.Pull the pump block down approximately 1/2” from the gear box housing.

4.Slide the pump block and piston rod forward until the piston rod is out of the T-slot on the slider assembly.

5.Slide the piston rod out through the bottom of the pump block

6.Loosen and remove the retainer nut and piston guide from the pump block.

7.Remove the upper and lower packings from the pump block.

8.Clean the pump block.

9.Locate the new upper and lower packings and pack the areas between the packing lips with grease. Lubricate the o-rings on the exterior of the packings with grease.

10.Inspect the piston rod for wear and replace if necessary.

11.Insert the upper packing into the top of the pump block with the raised lip on the packing facing down.

12.Insert the piston guide into the retainer nut. Thread the retainer nut into the pump block until it is hand tight.

13.Pre-form the lower packing using the lower packing sizing tool (included in the repacking kit).

14.Insert the lower packing partially into the bottom of the pump block so that the side that has the o-ring closest to the face of the packing faces up.

Install upper packing |

Install lower packing |

with raised lip |

with large beveled |

facing down. |

edge facing up. |

|

Large Beveled Edge |

Raised Lip |

|

15.Push the lower packing into position using the lower packing insertion tool (see Fluid Section Assembly parts list for lower packing insertion tool P/N).

16.Inspect the piston rod for wear and replace if necessary.

© Titan Tool Inc. All rights reserved. |

15 |

English |

|

|

|

NOTE: Coat the piston guide tool and the piston rod with grease before inserting them into the pump block.

17.Place the piston insertion tool (included in the repacking kit) over the top of the piston rod.

18.Insert the piston rod into the bottom of the pump block, through the lower packing, through the upper packing, and out through the retainer nut. Using a rubber mallet, tap the bottom of the piston rod lightly until the piston rod is in position in the pump block.

NOTE: When repacking the fluid section, make sure the raised lip on the bottom of the lower packing is fully outside the packing around the piston rod after insertion of the piston rod.

19.Remove the piston insertion tool from the top of the piston rod.

20.Using a wrench, tighten the retainer nut into the pump block. Torque to 300-360 in. lbs.

21.Slide the top of the piston rod into the T-slot on the slider assembly.

22.Position the pump block underneath the gear box housing and push up until it rests against the gear box housing.

important: Make sure the transducer is aligned properly with the hole in the pump block during reassembly. Improper alignment may cause damage to the transducer gasket.

23.Thread the pump block mounting screws through the pump block and into the gear box housing. Torque to 400-440 in. lbs.

24.Reassemble the inlet valve assembly into the pump block. Apply blue Loctite (P/N 426-051) to male threads of inlet valve housing and torque to 450-500 in-lbs.

NOTE: During reassembly, make sure the o-ring between the pump block and inlet valve housing is lubricated with grease and in position.

25.Reassemble suction set to fluid section. If swivel is removed from the inlet valve housing, add blue Loctite (P/N 426-051) to male threads. Replace the return hose into the clamp on the siphon tube.

NOTE: When adjusting the orientation of the suction tube, use two wrenches: one on the stationary hex of the swivel and one on the movable hex of the swivel. This will keep the inlet valve housing from accidentally being loosened.

26.Thread the return hose into the pump block and tighten securely.

27.Place the front cover on the gear box housing and secure in position using the four front cover screws.