UCC1839

UCC2839

UCC3839

04/99

FEATURES

• Practical Secondary Side Control of

Isolated Power Supplies

• Provides a Self Regulating Bias

Supply From a High Input Voltage

Using an External N-Channel

Depletion Mode FET

• Onboard Precision, Fixed Gain,

Differential Current Sense Amplifier

• Wide Bandwidth Current Error

Amplifier

• 5V Reference

• High Current, Programmable Gm

Amplifier Optimized to Drive

Opto-couplers

Secondary Side Average Current Mode Controller

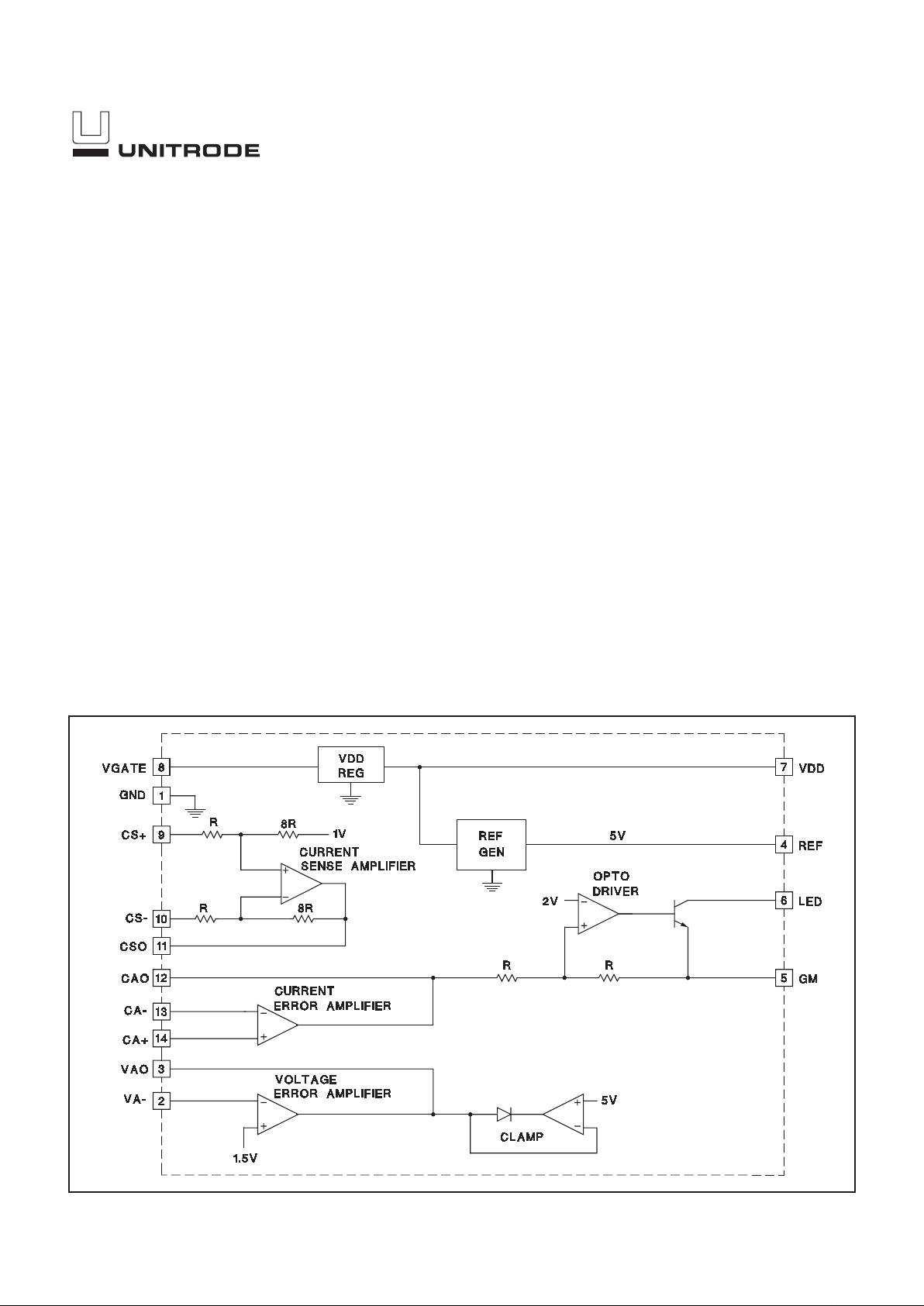

BLOCK DIAGRAM

UDG-97011

DESCRIPTION

The UCC3839 provides the control functions for secondary side average

current mode control in isolated power supplies. Start up, pulse width

modulation and MOSFET drive must be accomplished independently on

the primary side. Communication from secondary to primary side is anticipated through an opto-isolator.

Accordingly, the UCC3839 contains a fixed gain current sense amplifier,

voltage and current error amplifiers, and a Gm type buffer/driver amplifier

for the opto-isolator. Additional housekeeping functions include a precision

5V reference and a bias supply regulator.

Power for the UCC3839 can be generated by peak rectifying the voltage of

the secondary winding of the isolation transformer. From this unregulated

voltage, the UCC3839’s bias supply regulator will generate its own 7.5V

bias supply using an external, N-channel, depletion mode FET.

The UCC3839 can be configured for traditional average current mode control where the output of the voltage error amplifier commands the current

error amplifier. It can also be configured for output voltage regulation with

average current mode short circuit current limiting, employing two parallel

control loops regulating the output voltage and output current independently.

2

UCC1839

UCC2839

UCC3839

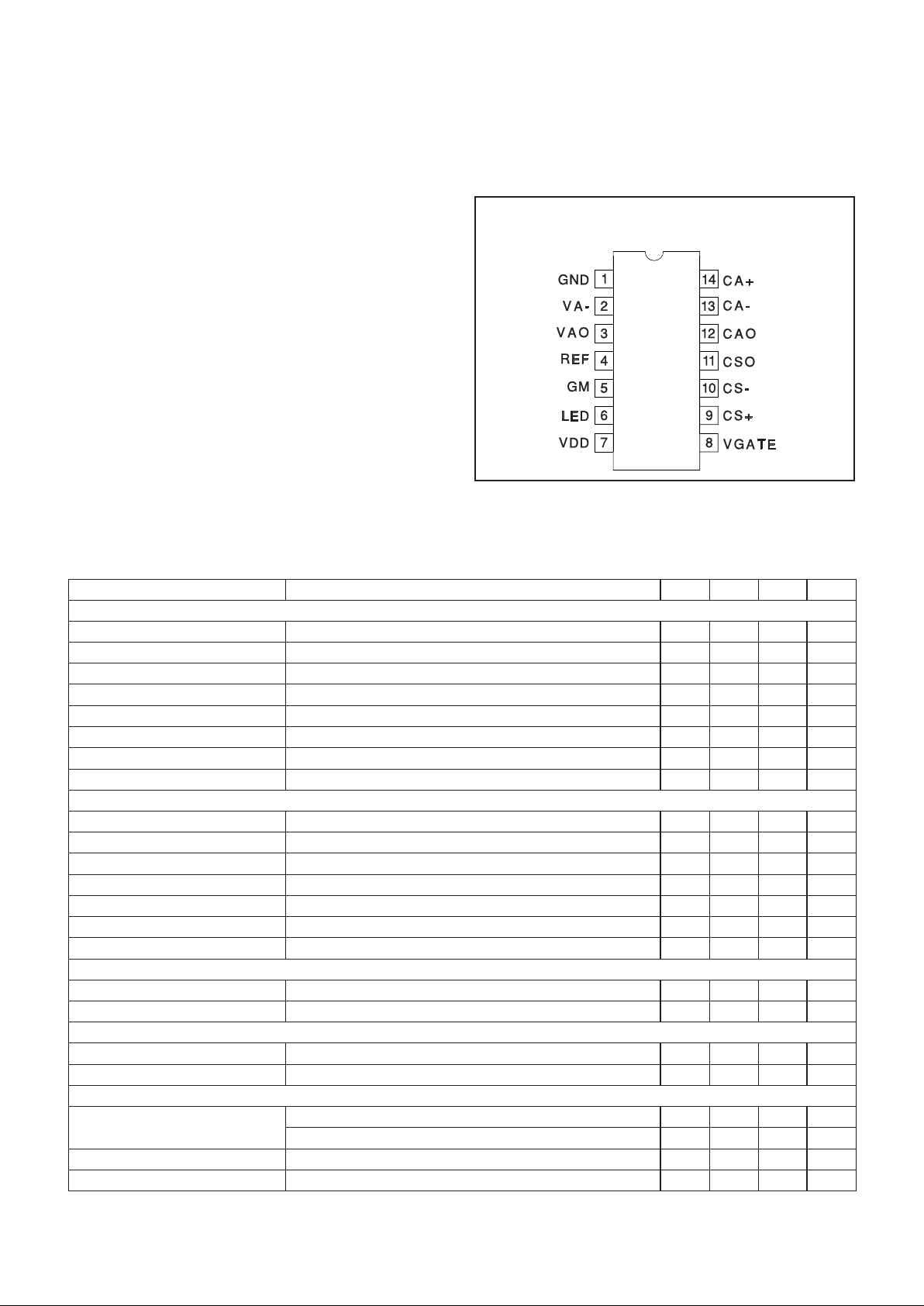

CONNECTION DIAGRAMS

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, 0°C to 70°C for the UCC3839, –40°C to 85° for the

UCC2839 and –55°C to 125°C for the UCC1839. V

LINE

= 10V, RG = 400Ω. TA=TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Error Amplifier

VIO 10 mV

AVOL 60 dB

CMRR V

CM = 0.5V to 5.5V 60 dB

PSRR VLINE = 10V to 20V 60 dB

CAO High CA– = 1V, CA+ = 1.1V, ICAO = –100µA 4.8 7 V

ICAO CA– = 1V, CA+ = 1.1V, CAO = 0.5V –500 –250 µA

CAO Low CA– = 1V, CA+ = 0.9V, ICAO = 500µA 0.2 0.4 V

GBW F = 100kHz, TA = 25°C 3 5 MHz

Voltage Error Amplifier

VA– 1.475 1.5 1.525 V

AVOL 60 dB

PSRR V

LINE = 10V to 20V 60 dB

VAO High IVAO = –100µA to 100µA 4.8 5 5.2 V

IVAO VA– = 1.45V, VAO = 0.5V –500 –250 µA

VAO Low VA– = 1.55V, VAO = 0.5V, IVAO = 500µA 0.2 0.4 V

GBW (Note 1) 3 5 MHz

Current Sense Amplifier

CSO Zero CS+ = CS– = –0.3V to 5.5V, I

CSO = –100µA to 100µA 0.95 1 1.05 V

AV CS+ = 0, CS– = 0mV to –200mV 7.8 8 8.2 V/V

Current Sense Amplifier (cont.)

Slew Rate CS+ = 0, CS– = 0mV to –0.5V 2 4 V/µs

CSO CS+ = –200mV, CS– = –700mV 4.8 5 5.2 V

LED Driver

I

LED LED = 5.5V, CA– = 1V, CA+ = 1.1V, RG = 400 0 10 µA

LED = 5.5V, CA– = 1V, CA+ = 0.9V, RG = 400 9 10 11 mA

Gm LED = 5.5V, CAO = 1V to 3V, RG = 400 2.25 2.5 2.75 mS

Slew Rate CAO = 2V to 2.5V, LED = 400Ω to 5.5V,RG = 400 2 4 V/µs

DIL-14, SOIC-14 (Top View)

J or N Package, D Package

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15V

Supply Current

(LED not connected) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2mA

(LED connected) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14mA

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 15V

Power Dissipation at TA = 60°C

(LED not connected). . . . . . . . . . . . . . . . . . . . . . . . . . 20mW

(LED connected). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55mW

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10sec.) . . . . . . . . . . . . . +300°C

Currents are positive into, negative out of the specified terminal.

Consult Packaging Section of Databook for thermal limitations

and considerations of package.

3

UCC1839

UCC2839

UCC3839

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, 0°C to 70°C for the UCC3839, –40°C to 85° for the

UCC2839 and –55°C to 125°C for the UCC1839. V

LINE

= 10V, RG = 400Ω. TA=TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Precision Reference

REF T

J = 25°C 4.95 5 5.05 V

IREF = 0mA to 1mA, VLINE = 10V to 20V 4.9 5.1 V

VA+/REF 0.298 0.3 0.302 V/V

VDD Regulator

VDD IDD = 0mA to –15mA, V

LINE = 10V to 40V 7 7.5 8 V

IVDD VLINE = 10V to 40V, CA– = 0V, CA+ = 1V, VA– = 2.9V, CS+

= CS– = 0, IREF = 0

1.3 2 mA

Note 1: Guaranteed by design. Not 100% tested in production.

CA–: Current Error Amplifier Negative Input.

CAO: Current Error Amplifier Output. Output source cur-

rent is limited, and output sink current is guaranteed to

be greater than the VAO output source current. Current

loop compensation components are generally connected

to CAO and CA–.

CA+: Current Error Amplifier Positive Input.

CS–: Current Sense Amplifier Negative Input.

CSO: Current Sense Amplifier Output. Internally set gain

V

OUT/VIN = 8 VIN = 0V results in CSO = 1V.

CS+: Current Sense Amplifier Positive Input.

GM: Gm (transconductance) Programming Pin. Resistor

R

GM = 400Ω to GND.

GND: Chip Ground.

LED: Output of LED Driver. Connect LED from VDD pin

to LED.

REF: 5V Precision Reference Buffer Output. Minimum

Decoupling Capacitance = 0.01µF

VA–: Voltage Error Amplifier Negative Input. Voltage Error Amplifier is internally referenced to 1.5V

VAO: Voltage Error Amplifier Output. In a two loop average current mode control configuration, VAO is connected to CA+ and is the current command signal. VAO

is internally clamped not to exceed 5V for short circuit

control. In a single loop voltage mode control configuration with a parallel average short circuit current control

loop, VAO is connected directly to CAO. Output source

current is limited, and output sink current is guaranteed

to be greater than the CAO output source current.

VDD: 7.5V Regulator output. Supply for most of the

chip. Minimum Decoupling Capacitance = 0.01µF

VGATE: External FET Gate Control Voltage.

PIN DESCRIPTIONS

Fig. 1 shows a typical secondary side average current

mode controller configuration using the UCC3839. In this

configuration, output voltage is sensed and regulated by

the voltage error amplifier. Its output, VAO provides the

reference for the current error amplifier at the CA+ pin.

VAO can be connected to CA+ directly or through a resistive divider depending on the particular application requirements.

Average current mode control needs accurate output current information which is provided by a low value current

sense resistor. The voltage proportional to the converter’s output current is sensed and amplified by the

precision current sense amplifier of the chip. The

onboard current sense amplifier has a gain of 8 and is intended for differential sensing of the shunt voltage with a

common mode voltage range from 0V up to 5V. The output of the current sense amplifier, CSO is 1V for zero input which guarantees that the circuit can control currents

down to 0A.

The CSO signal is fed to the CA– input of the current error amplifier through a resistor. The current error amplifier takes the VAO and CSO signals and generates the

error signal for the pulse width modulator.

APPLICATION INFORMATION

4

UCC1839

UCC2839

Figure 1. Secondary side average current mode controller.

UDG-97012

Since the PWM function is located on the primary side of

the power converter the CAO signal must be sent across

the safety isolation boundary. The UCC3839 anticipates

an opto-coupler to provide isolation between primary and

secondary. Therefore, CAO drives a transconductance

amplifier that controls LED current in an opto-isolator.

During start up and when CAO exceeds 4V, the current

in the LED drops to zero. Maximum LED current is obtained during normal operation as CAO reaches its lowest potential. Its value is determined by the programming

resistor value from the GM pin to circuit GND.

An alternative secondary side controller configuration is

introduced in Fig. 2. In this circuit, the voltage and current control loops of the UCC3839 are connected parallel. It can be achieved by connecting the VAO and CAO

pins together. The error amplifier with the lower output

voltage controls the current in the opto-coupler providing

the feedback signal for the PWM section on the primary

side. Voltage regulation is still maintained by the voltage

error amplifier until a user programmable output current

is reached. At this time CAO will take control over the

Gm amplifier and the output current of the converter will

be regulated while the output voltage falls below its nominal value. This current level is set at the CA+ input by a

resistive divider from the 5V reference of the chip.

Since the chip is powered from a peak rectifier which

maintains the bias supply for the UCC3839 even under

short circuit conditions, both of these techniques can be

used to eliminate the short circuit runaway problem in

isolated power supplies using peak current mode control

on the primary side.

APPLICATION INFORMATION (cont.)

5

UCC1839

UCC2839

UCC3839

Figure 3. Typical primary side circuit for use with secondary side average current mode controller.

UDG-97014

UNITRODE CORPORATION

7 CONTINENTALBLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

Figure 2. Voltage mode with average current short circuit limit.

APPLICATION INFORMATION (cont.)

UDG-97014

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...