www.ti.com

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

SYNC

CT

RT

FB1

COMP1

CS1

OUT1

GND

VCC

REF

ENABLE2

FB2

COMP2

CS2

OUT2

PWRGND

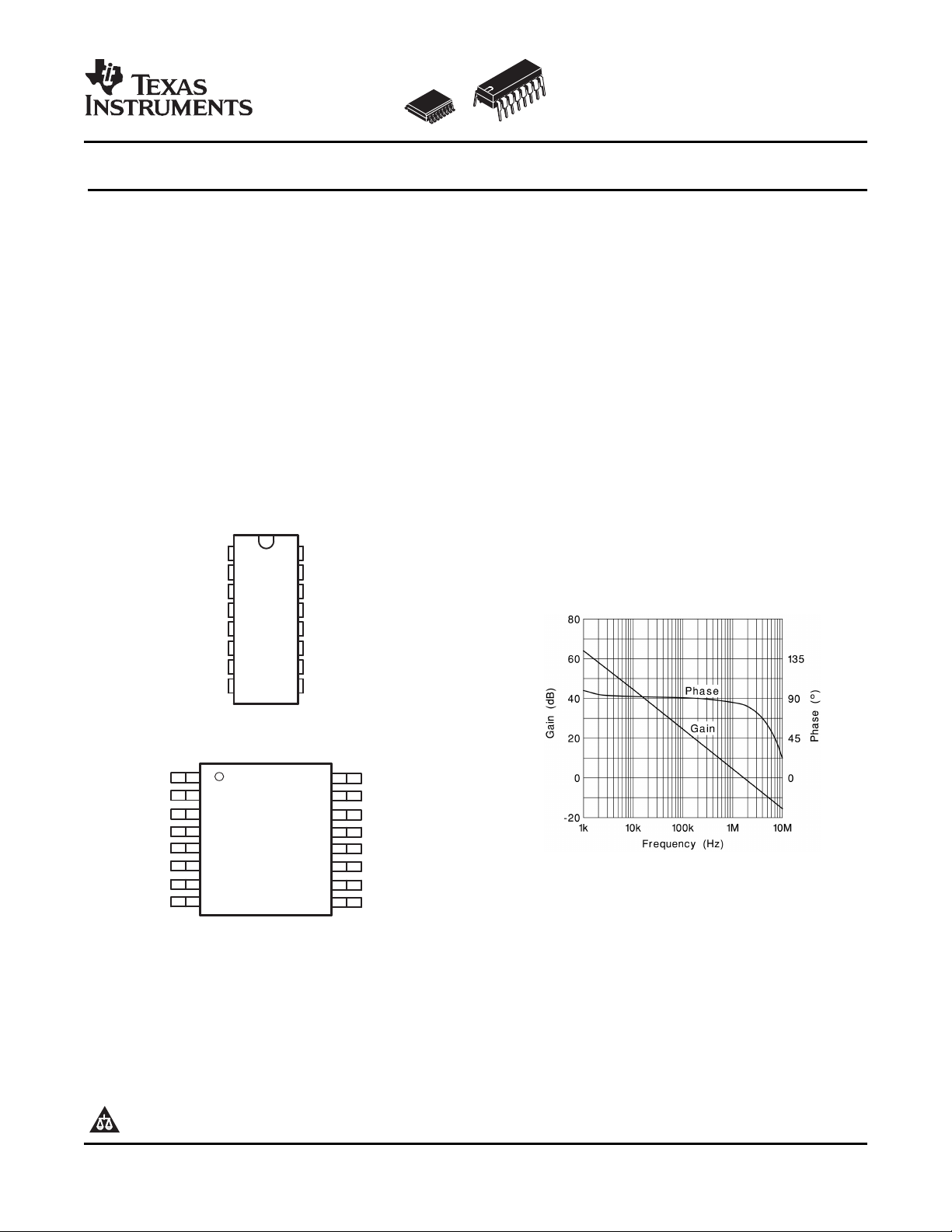

N PACKAGE

(TOP VIEW)

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

SYNC

CT

RT

FB1

COMP1

CS1

OUT1

GND

VCC

REF

ENABLE2

FB2

COMP2

CS2

OUT2

PWRGND

PW PACKAGE

(TOP VIEW)

UCC2810

UCC3810

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

DUAL CHANNEL SYNCHRONIZED CURRENT-MODE PWM

FEATURES DESCRIPTION

• Single Oscillator Synchronizes Two PWMs

• 150-µA Startup Supply Current

• 2-mA Operating Supply Current

• Operation to 1 MHz

• Internal Soft-Start The oscillator’s sawtooth waveform can be used for

• Full-Cycle Fault Restart

• Internal Leading-Edge Blanking of the Current

Sense Signal

• 1-A Totem Pole Outputs

• 75-ns Typical Response from Current Sense

to Output

• 1.5% Tolerance Voltage Reference

The UCC3810 is a high-speed BiCMOS controller

integrating two synchronized pulse width modulators

for use in off-line and dc-to-dc power supplies. The

UCC3810 family provides perfect synchronization

between two PWMs by usin g the same oscillator.

slope compensation if required.

Using a toggle flip-flop to alternate between

modulators, the UCC3810 ensures that one PWM

does not slave, interfere, or otherwise affect the

other PWM. This toggle flip- flop also ensures that

each PWM is limited to 50% maximum duty cycle,

insuring adequate off-time to reset magnetic

elements. This device contains many of the same

elements of the UC3842 current mode controller

family, combined with the enhancements of the

UCC3802. This minimizes power supply parts count.

Enhancements include leading edge blanking of the

current sense signals, full cycle fault restart, CMOS

output drivers, and outputs which remain low even

when the supply voltage is removed.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 1999–2007, Texas Instruments Incorporated

www.ti.com

REF

15

FB115COMP15CS1

6

CS2

11

V

CC

16

Over-Current

Comparator

1.5 V

VCC OK

V

CC

2.5 V

Error

Amp 1

1 V

100 kW

55 kW

12.5 V

Leading

Edge

Blanking

Leading

Edge

Blanking

S Q

R

7

OUT1

Voltage

Ref

REF OK

S

Q

R

S

Q

R

4 V

0.5 V

τ − 5ms

Full Cycle

Soft Start

Error

Amp 2

2.5 V

+

−

55 kW

100 kW

1 V

10

OUT2

35 mA

VDG−92062−1

8

GND

9

PWRGND

14

ENABLES

S

Q

R

R

Oscillator

2

R

TCT

SYNCCOMP2FB2

3211213

UCC2810

UCC3810

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

ORDERING INFORMATION

T

J

–40°C to 85°C UCC2810DW (16) UCC2810N (16)

0°C to 70°C UCC3810DW (16) UCC3810N (16)

(1) All packages are available taped and reeled (indicated by the R suffix on the device type e.g.,

UCC2810JR)

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

V

CC

I

CC

Supply voltage

Supply current 20mA

Output peak current, OUT1, OUT2, 5% duty cycle ±1A

Output energy, OUT1, OUT2, capacitive load 20 µJ 20µJ

Analog inputs, FB1, FB2, CS1, CS2, SYNC –0.3 to 6.3V

T

J

T

stg

Operating junction temperature 150°C

Storage temperature range –65 to 150°C

Lead temperature (soldering, 10 sec) 300°C

(3)

PACKAGED DEVICES

SOP (DW) PDIP (N)

(1) (2)

(1)

UNIT

11V

(1) Currents are positive into, negative out of the specified terminal. All voltages are with respect to GND.

(2) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(3) In normal operation, V

impedance such that the V

is powered through a current-limiting resistor. Absolute maximum of 11 V applies when driven from a low

CC

current does not exceed 20 mA.

CC

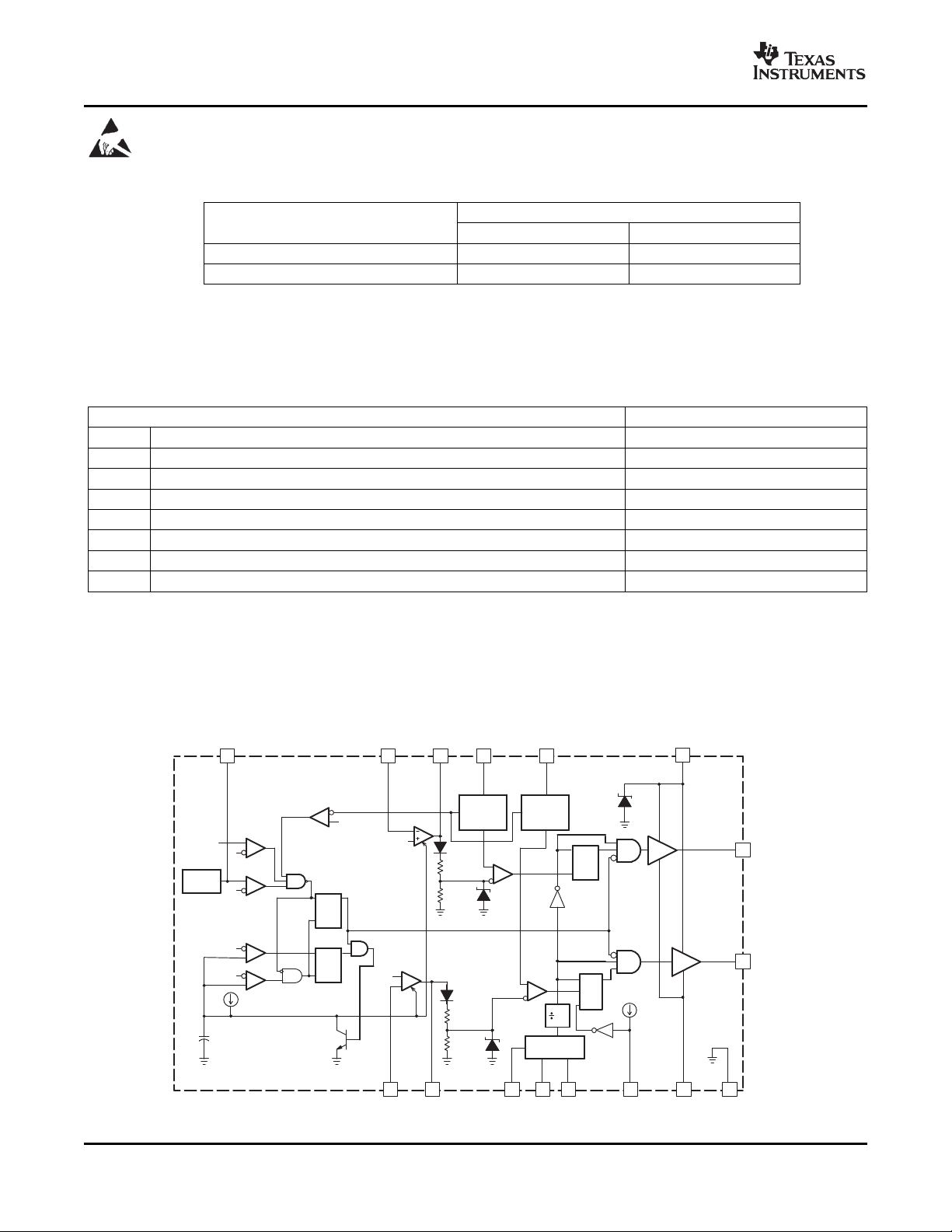

BLOCK DIAGRAM

2

Submit Documentation Feedback

www.ti.com

4

OSC

T T

f

R C=´

COMP

CS

V

A

V

D

=

D

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

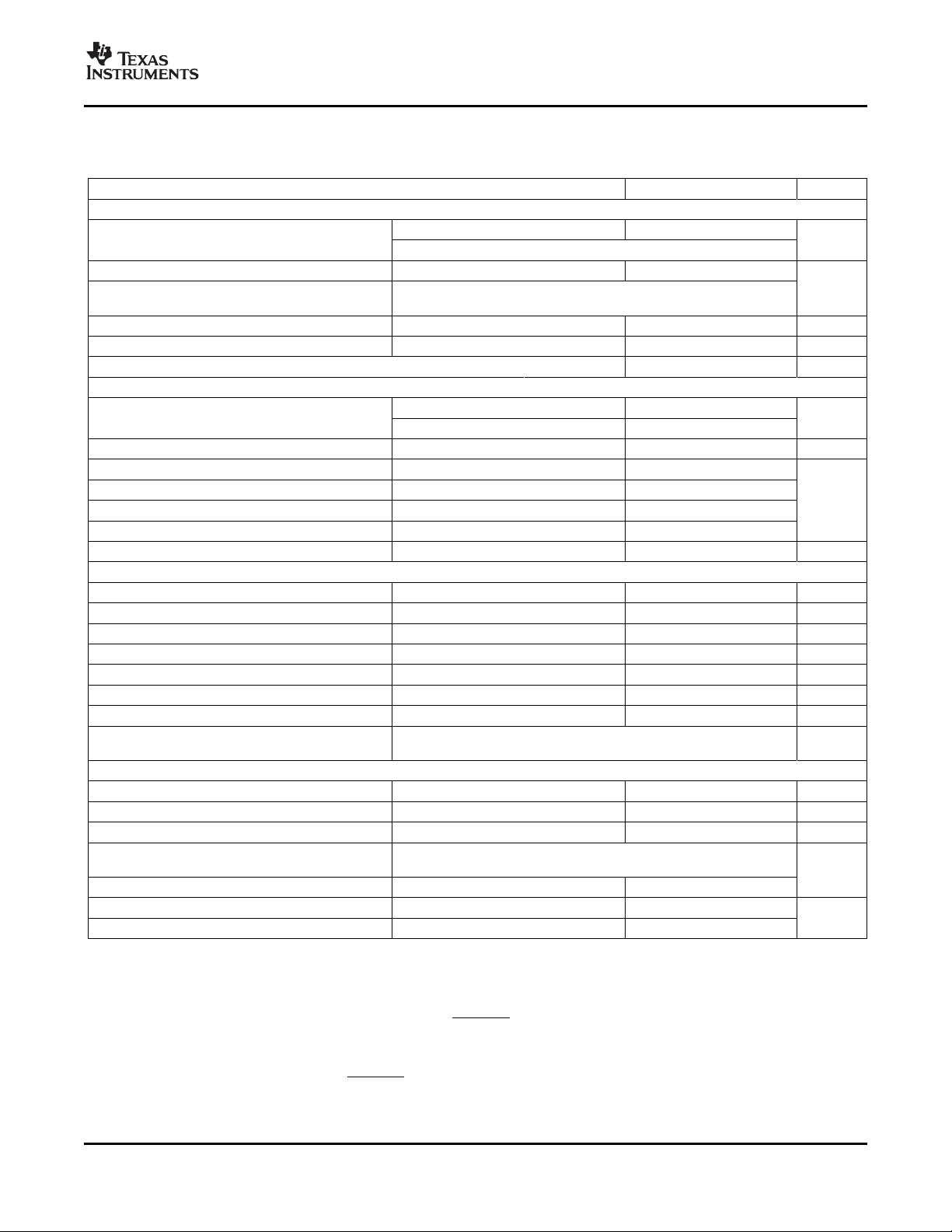

ELECTRICAL CHARACTERISTICS

All parameters are the same for both channels, –40°C ≤ TA≤ 85°C for the UCC2810, 0°C ≤ TA≤ 70°C for the UCC3810,

V

CC

REFERENCE

V

CC

I

O(SC)

OSCILLATOR

f

OSC

ERROR AMPLIFIER

V

FB

I

FB

f

GAIN

I

SINK

I

SRCE

CURRENT SENSE

I

CS

(1)

= 10 V

; RT= 150 k Ω , CT= 120 pF; no load; TA= TJ;(unless otherwise specified)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output voltage V

Load regulation 0 mA ≤ I

Line regulation

Output noise voltage

Long term stability

(2)

(2)

TJ= 25°C 4.925 5.000 5.075

TJ= full range, 0 mA ≤ I

≤ 5 mA 5 30

REF

≤ 5 mA 4.85 5.00 5.10

REF

UVLO stop threshold voltage, 12

0.5 V ≤ V

≤ V

CC

SHUNT

10Hz <f< 10 kHz, TJ= 25°C 235 µV

TA = 125°C, 1000 hours 5 mV

Output short circuit current -8 -25 mA

Oscillator frequency

Temperature stability

(3)

(2)

RT= 30 k Ω , CT= 120 pF 860 980 1100

RT= 150 k Ω , CT= 120 pF 190 220 250

Peak voltage 2.5

Valley voltage 0.05

Peak-to-peak amplitude 2.25 2.45 2.65

SYNC threshold voltage 0.80 1.65 2.20

SYNC input current SYNC = 5 V 30 µA

FB input voltage COMP = 2.5 V 2.44 2.50 2.56 V

FB input bias current ±1 µA

Open loop voltage gain 60 73 dB

Unity gain bandwidth

(2)

Sink current, COMP FB = 2.7 V, COMP = 1 V 0.3 1.4 3.5

Source current, COMP FB = 1.8 V, COMP = 4 V -0.2 -0.5 -0.8 mA

Minimum duty cycle COMP = 0 V 0%

Soft-start rise time, COMP ms

(4)

Gain

Maximum input signal

(5)

FB = 1.8 V, 5

Rise from 0.5 V to (REF – 1.5 V)

1.20 1.55 1.80 V/V

COMP = 5 V 0.9 1.0 1.1 V

Input bias current, CS ±200 nA

Propagation delay time (CS to OUT)

Blank time, CS

(6)

CS steps from 0 V to 1.2 V, 75

COMP = 2.5 V

Overcurrent threshold voltage, CS 1.35 1.55 1.85

COMP-to-CS offset voltage CS = 0 V 0.45 0.90 1.35

UCC2810

UCC3810

mV

kHz

2.5%

V

2 MHz

ns

55

V

(1) For UCC3810, adjust V

(2) Ensured by design. Not production tested.

above the start threshold before setting at 10 V.

CC

(3) Oscillator frequency is twice the output frequency.

(4) Current sense gain A is defined by:

(5) Parameter measured at trip point of latch with FB = 0 V.

, 0 V ≤ V

≤ 0.8 V.

CS

(6) CS blank time is measured as the difference between the minimum non-zero on-time and the CS-to-OUT delay.

Submit Documentation Feedback

3

www.ti.com

UCC2810

UCC3810

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

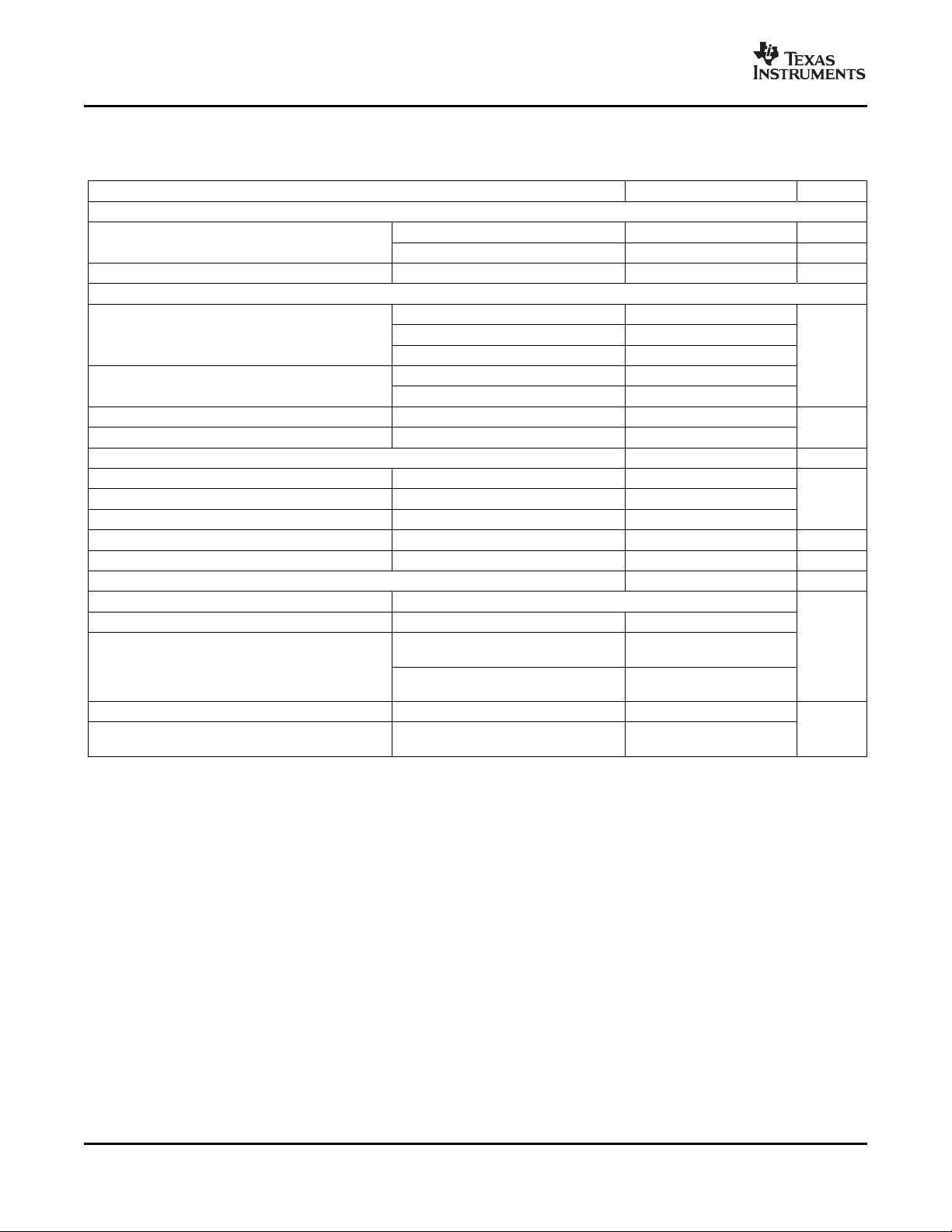

ELECTRICAL CHARACTERISTICS (continued)

All parameters are the same for both channels, –40°C ≤ TA≤ 85°C for the UCC2810, 0°C ≤ TA≤ 70°C for the UCC3810,

V

= 10 V ; RT= 150 k Ω , CT= 120 pF; no load; TA= TJ;(unless otherwise specified)

CC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

PWM

Maximum duty cycle

Minimum on-time CS = 1.2 V, COMP = 5 V 130 ns

OUTPUT

V

V

t

R

t

F

Low-level output voltage I

OL

High-level output voltage (V

OH

Rise time, OUT C

Fall time, OUT C

UNDERVOLTAGE LOCKOUT (UVLO)

Start threshold voltage 9.6 11.3 13.2

Stop threshold voltage 7.1 8.3 9.5 V

Start-to-stop hysteresis 1.7 3.0 4.7

ENABLE2 input bias current ENABLE2 = 0 V -20 -35 -55 µA

ENABLE2 input threshold voltage 0.80 1.53 2.00 V

OVERALL

Startup current V

Operating supply current, outputs off VCC = 10 V, FB = 2.75 V 2 3

Operating supply current, outputs on

VCC internal zener voltage ICC= 10 mA 11.0 12.9 14.0

VCC internal zener voltage minus start 0.4 1.2

threshold voltage

(2)

– OUT)

CC

RT= 150 k Ω , CT= 120 pF 45% 49% 50%

RT= 30 k Ω , CT= 120 pF 40% 45% 48%

I

= 20 mA 0.12 0.42

OUT

= 200 mA 0.48 1.10

OUT

I

= 20 mA, V

OUT

I

= –20 mA 0.15 0.42

OUT

I

= –200 mA 1.2 2.3

OUT

= 1 nF 20 50

OUT

= 1 nF 30 60

OUT

< Start threshold voltage 0.15 0.25

CC

= 0 V 0.7 1.2 V

CC

VCC = 10 V, FB = 0 V, 3.2 5.1

CS = 0 V, RT = 150 k Ω

VCC = 10 V, FB = 0 V, 8.5 14.5

CS = 0 V, RT = 30 k Ω

ns

mA

V

4

Submit Documentation Feedback

www.ti.com

UCC2810

UCC3810

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

DEVICE INFORMATION

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

COMP1 5 O

COMP2 12 O

CS1 6 I Current sense inputs to the PWM comparators. These inputs have leading edge blanking. For

CS2 11 I

CT 2 O

ENABLE2 14 I

FB1 4 I

FB2 13 I

GND 8 – GND and PWRGND. GND and PWRGND must be electrically connected together. However, use

OUT1 7 O The high-current push-pull outputs of the PWM are intended to drive power MOSFET gates

OUT2 10 O

PWRGND 9 –

REF 15 O

RT 3 O

SYNC 1 I part. This pin is edge triggered with TTL thresholds, and requires at least a 10-ns-wide pulse. If

VCC 16 I output stages and the precision reference. Therefore, it is critical that VCC be directly bypassed to

I/O DESCRIPTION

Low impedance output of the error amplifiers.

most applications, no input filtering is required. Leading edge blanking disconnects the CS inputs

from all internal circuits for the first 55 ns of each PWM cycle. When used with very slow diodes or

in other applications where the current sense signal is unusually noisy, a small current-sense R-C

filter may be required.

The timing capacitor of the oscillator. Recommended values of CT are between 100 pF and 1 nF.

Connect the timing capacitor directly across CT and GND.

A logic input which disables PWM 2 when low. This input has no effect on PWM 1. This input is

internally pulled high. In most applications it can be left floating. In unusually noisy applications,

the input should be bypassed with a 1-nF ceramic capacitor. This input has TTL compatible

thresholds.

The high impedance inverting inputs of the error amplifiers.

To separate noise from the critical control circuits, this part has two different ground connections:

care to avoid coupling noise into GND.

through a small resistor. This resistor acts as both a current limiting resistor and as a damping

impedance to minimize ringing and overshoot.

To separate noise from the critical control circuits, this part has two different ground connections:

GND and PWRGND. GND and PWRGND must be electrically connected together.

The output of the 5-V reference. Bypass REF to GND with a ceramic capacitor ≥ 0.01-µF for best

performance.

The oscillator charging current is set by the value of the resistor connected from RT to GND. This

pin is regulated to 1 V, but the actual charging current is 10 V/RT. Recommended values of RT

are between 10 k Ω and 470 k Ω . For a given frequency, higher timing resistors give higher

maximum duty cycle and slightly lower overall power consumption.

This logic input can be used to synchronize the oscillator to a free running oscillator in another

unused, this pin can be grounded, open circuited, or connected to REF.

The power input to the device. This pin supplies current to all functions including the high current

PWRGND with an 0.1-µF ceramic capacitor.

Submit Documentation Feedback

5

www.ti.com

11

CC

T

V

IRD =

Power

Stage

Current

Sense

Resistor

Over−Current

Comparator

1.5 V

−

+

Soft

Start

+

−

Error

Amp

+

−

S

RRQ

From

Oscillator

Gate

Driver

PWM

Latch

PWM

Comparator

OUT

One

Shot

CS

UCC2810

UCC3810

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

APPLICATION INFORMATION

TIMING RESISTOR

Supply current decreases with increased R

For more information, see the detailed oscillator block diagram.

LEADING EDGE BLANKING AND CURRENT SENSE

Figure 1 shows how an external power stage is connected to the UCC3810. The gate of an external power

N-channel MOSFET is connected to OUT through a small current-limiting resistor. For most applications, a 10- Ω

resistor is adequate to limit peak current and also practical at damping resonances between the gate driver and

the MOSFET input reactance. Long gate lead length increases gate capacitance and mandates a higher series

gate resistor to damp the R-L-C tank formed by the lead, the MOSFET input reactance, and the device’s driver

output resistance.

The UCC3810 features internal leading edge blanking of the current-sense signal on both current sense inputs.

The blank time starts when OUT rises and continues for 55 ns. During that 55 ns period, the signal on CS is

ignored. For most PWM applications, this means that the CS input can be connected to the current-sense

resistor as shown in Figure 1 . However, high speed grounding practices and short lead lengths are still required

for good performance.

by the relationship:

T

Figure 1. Detailed Block Diagram

OSCILLATOR

The UCC3810 oscillator generates a sawtooth wave at CT. The sawtooth rise time is set by the resistor from RT

to GND. Since R

higher. The fall time is set by an internal transistor on-resistance of approximately 100 Ω . During the fall time, all

outputs are off and the maximum duty cycle is reduced to below 50%. Larger timing capacitors increase the

discharge time and reduce frequency. However, the percentage maximum duty cycle is only a function of the

timing resistor RT, and the internal 100- Ω discharge resistance.

ERROR AMPLIFIER OUTPUT STAGE

The UCC3810 error amplifiers are operational amplifiers with low-output resistance and high-input resistance.

The output stage of one error amplifier is shown in Figure 3 . This output stage allows the error amplifier output

to swing close to GND and as high as one diode drop below 5 V with little loss in amplifier performance.

6

is biased at 1 V, the current through R

T

Submit Documentation Feedback

is 1 V/R

T

. The actual charging current is 10 times

T

www.ti.com

V

CC

I 10I

1 V

+

−

0.2 V

2.5 V

+

−

+

−

RSQ

One

Shot

SYNC

123

C

T

R

T

R

T

RON 9 100

5 V V

CC

COMP

APPLICATION INFORMATION (continued)

UCC2810

UCC3810

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

Figure 2. Oscillator

Figure 3. Error Amplifier Output Stage

Submit Documentation Feedback

7

www.ti.com

80

60

40

20

0

−20

1 k 10 k 100 k 1 M 10 M

0

45

90

135

Gain

Fhase

Gain − dB

Phase − °

f − Frequency − Hz

1 M

100 k

10 k

10 k 100 k 10 M

Oscillator Frequency − Hz

RT − Timing Resistor − W

1.2

1.15

1.1

1.05

1

0.95

0.9

0.85

0.8

−55 −35 −15 5 25 45 65 85 105 125

Oscillator Frequency − MHz

TA − Temperature − C

50

48

46

44

42

40

10 k 100 k 1 M

Duty Cycle − %

RT − Timing Resistor − W

UCC2810

UCC3810

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

TYPICAL CHARACTERISTICS

ERROR AMPLIFER GAIN AND PHASE OSCILLATOR FREQUENCY

OSCILLATOR FREQUENCY MAXIMUM DUTY CYCLE

vs vs

FREQUENCY TIMING RESISTANCE

Figure 4. Figure 5.

vs vs

TEMPERATURE TIMING RESISTANCE

8

Figure 6. Figure 7.

Submit Documentation Feedback

www.ti.com

10

8

6

4

2

10 k 100 k 1 M

Switching

Outputs Off

I

CC

− Input Current − mA

f − Frequency − Hz

50

48

46

44

42

40

10 k 100 k 1 M

CT = 120 pF

Duty Cycle − %

f − Frequency − Hz

DC

Input

OPTO1

OPTO2

TTL MONITOR

SYNC

HV SUP

ENABLE

5

4

12

13

1

14

3 2 8 9

15

11

10

6

7

16

V

CC

COMP1

FB1

COMP2

FB2

SYNC

ENABLE2

RTCTGND

PWR

GND

OUT1

CS1

OUT2

CS2

REF

0.1 mF

UCC3810

0.1

5

4

6

7

8

1

32

0.1

UC39432

COMP

REF

E/A+

SENSE

V

CC

COLL

I

SET

GND

0.1

5

4

6

7

8

1

32

UC39432

COMP

REF

E/A+

SENSE

V

CC

COLL

I

SET

GND

0.1

VDG−94022

OPTO2

High Voltage Out

(Monitor Raster)

0.1

OPTO1

+12 V OUT

+5 V OUT

SLUS162D – FEBRUARY 1999 – REVISED FEBRUARY 2007

TYPICAL CHARACTERISTICS (continued)

INPUT CURRENT MAXIMUM DUTY CYCLE

vs vs

OSCILLATOR FREQUENCY FREQUENCY

UCC2810

UCC3810

Figure 8. Figure 9.

Figure 10. Typical Application

Submit Documentation Feedback

9

PACKAGE MATERIALS INFORMATION

www.ti.com

TAPE AND REEL INFORMATION

11-Mar-2008

*All dimensions are nominal

Device Package

UCC2810DWTR SOIC DW 16 2000 330.0 16.4 10.85 10.8 2.7 12.0 16.0 Q1

UCC3810DWTR SOIC DW 16 2000 330.0 16.4 10.85 10.8 2.7 12.0 16.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

11-Mar-2008

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

UCC2810DWTR SOIC DW 16 2000 346.0 346.0 33.0

UCC3810DWTR SOIC DW 16 2000 346.0 346.0 33.0

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...