Page 1

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

D Low Supply-Voltage Range, 1.8 V to 3.6 V

D Ultralow-Power Consumption:

− Active Mode: 200 μA at 1 MHz, 2.2 V

− Standby Mode: 0.7 μA

− Off Mode (RAM Retention): 0.1 μA

D Five Power-Saving Modes

D Wake-Up From Standby Mode in Less

Than 6 μs

D Frequency-Locked Loop, FLL+

D 16-Bit RISC Architecture, 125-ns

Instruction Cycle Time

D Scan IF for Background Water, Heat, and

Gas Volume Measurement

D 16-Bit Timer_A With Three

Capture/Compare Registers

D 16-Bit Timer_A With Five

Capture/Compare Registers

D Integrated LCD Driver for Up to

96 Segments

D On-Chip Comparator

D Serial Onboard Programming,

No External Programming Voltage Needed

Programmable Code Protection by Security

Fuse

D Brownout Detector

D Supply Voltage Supervisor/Monitor With

Programmable Level Detection

D Bootstrap Loader in Flash Devices

D Family Members Include:

− MSP430FW423:

8KB + 256B Flash Memory,

256B RAM

− MSP430FW425:

16KB + 256B Flash Memory,

512B RAM

− MSP430FW427:

32KB + 256B Flash Memory,

1KB RAM

D Available in 64-Pin Quad Flat Pack (QFP)

D For Complete Module Descriptions, Refer

to the MSP430x4xx Family User’s Guide,

Literature Number SLAU056

description

The Texas Instruments MSP430 family of ultralow-power microcontrollers consists of several devices featuring

different sets of peripherals targeted for various applications. The architecture, combined with five low power

modes, is optimized to achieve extended battery life in portable measurement applications. The device features

a powerful 16-bit RISC CPU, 16-bit registers, and constant generators that contribute to maximum code

efficiency. The digitally controlled oscillator (DCO) allows wake-up from low-power modes to active mode in less

than 6 μs.

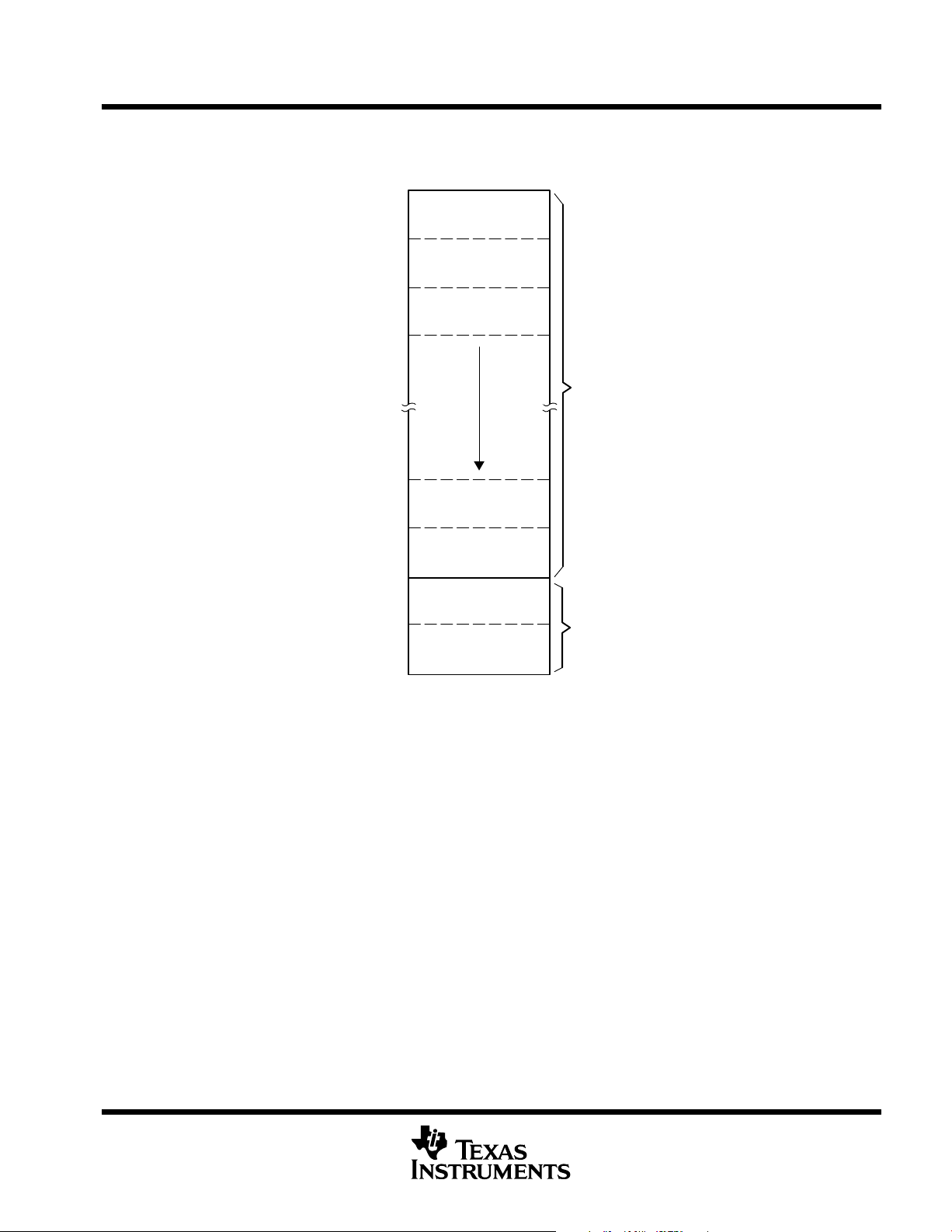

The MSP430xW42x series are microcontroller configurations with two built-in 16-bit timers, a comparator,

96 LCD segment drive capability, a scan interface, and 48 I/O pins.

Typical applications include sensor systems that capture analog signals, convert them to digital values, and

process the data and transmit them to a host system. The comparator and timers make the configurations ideal

for gas, heat, and water meters, industrial meters, counter applications, handheld meters, etc.

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage. ESD damage can range

from subtle performance degradation to complete device failure. Precision integrated circuits may be more susceptible to damage

because very small parametric changes could cause the device not to meet its published specifications. These devices have limited

built-in ESD protection.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright © 2007, Texas Instruments Incorporated

1

Page 2

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

T

A

−40°C to 85°C

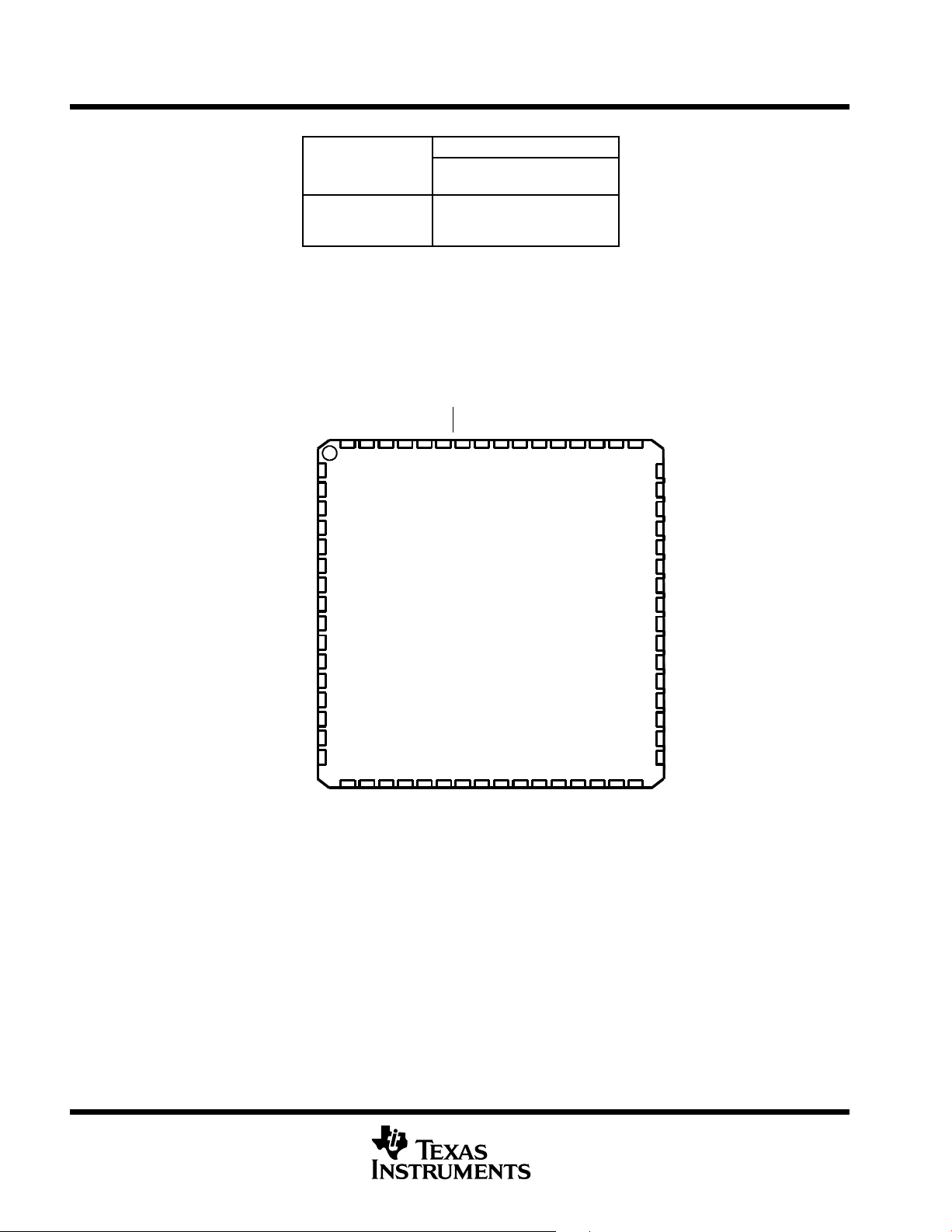

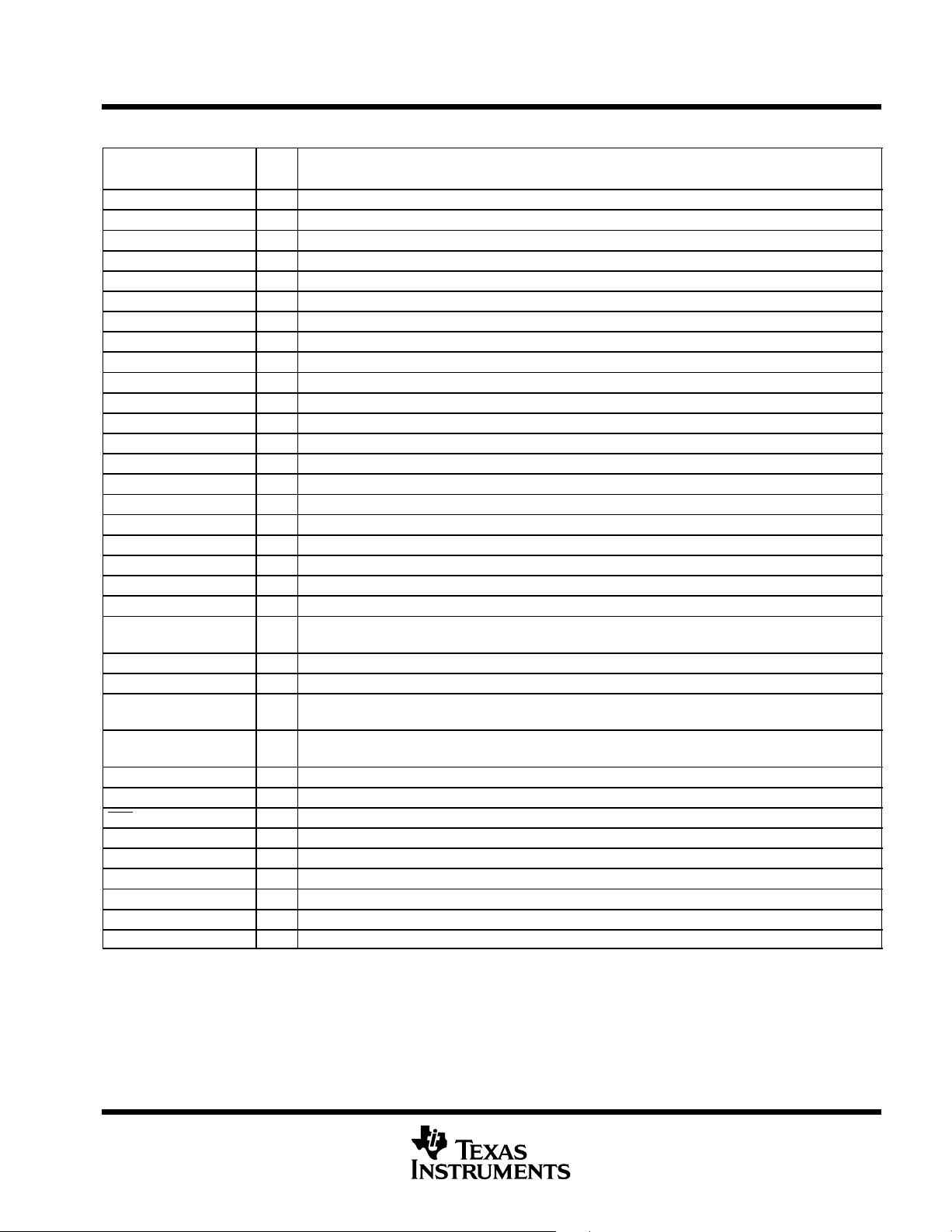

pin designation, MSP430xW42x

AVCCDVSSAV

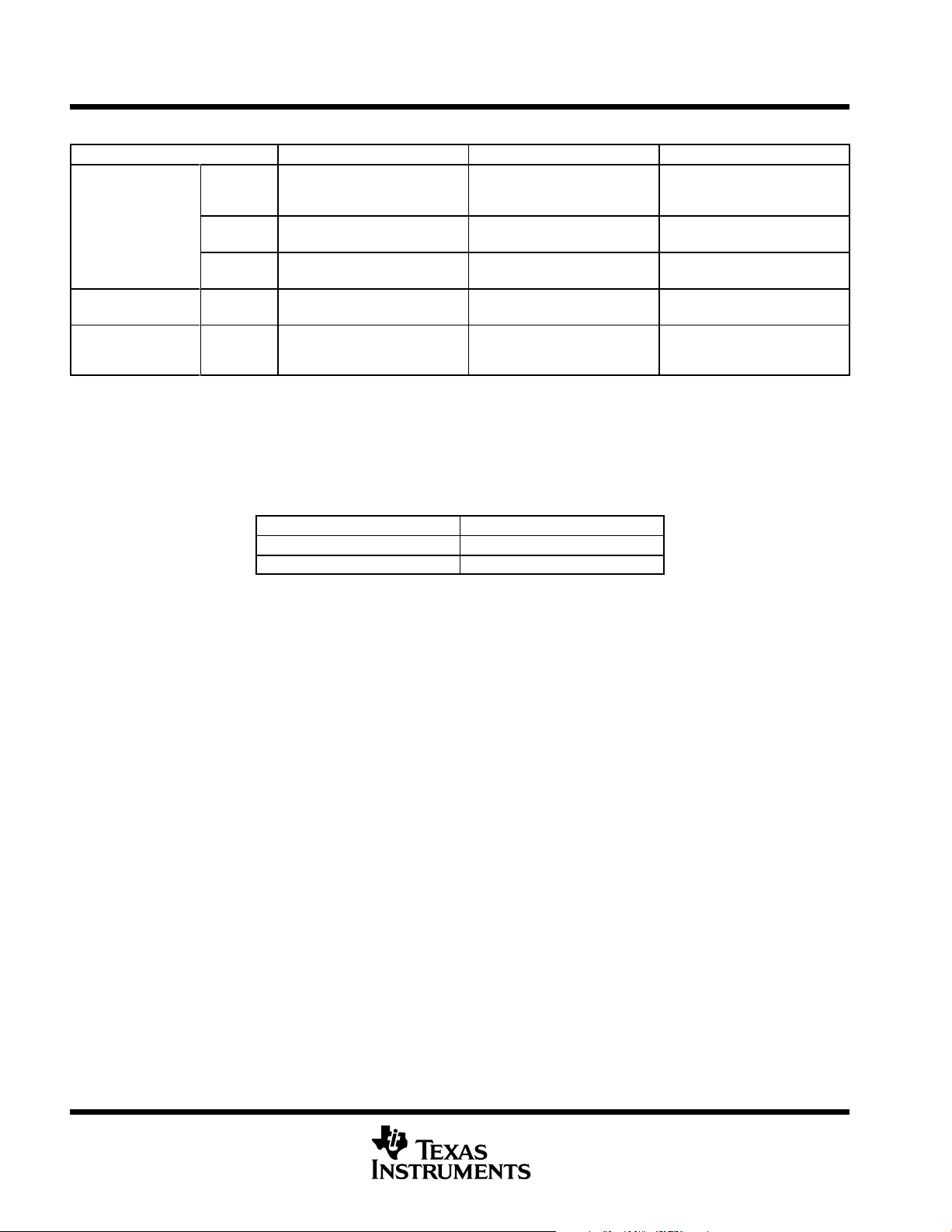

AVAILABLE OPTIONS

PACKAGED DEVICES

PLASTIC 64-PIN QFP

MSP430FW423IPM

MSP430FW425IPM

MSP430FW427IPM

SS

P6.2/SIFCH2

P6.1/SIFCH1

P6.0/SIFCH0

RST/NMI

TCK

TMS

(PM)

TDI/TCLK

TDO/TDI

P1.0/TA0.0

P1.1/TA0.0/MCLK

P1.2/TA0.1

P1.3/TA1.0/SVSOUT

P1.4/TA1.0

DV

CC

P6.3/SIFCH3/SIFCAOUT

P6.4/SIFCI0

P6.5/SIFCI1

P6.6/SIFCI2/SIFDACOUT

P6.7/SIFCI3/SVSIN

SIFCI

XIN

XOUT

SIFVSS

SIFCOM

P5.1/S0

P5.0/S1

P4.7/S2

P4.6/S3

P4.5/S4

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

P4.4/S5

P4.3/S6

P4.2/S7

P4.1/S8

P4.0/S9

MSP430xW42x

P3.7/S10

P3.6/S11

P3.5/S12

P3.4/S13

P3.3/S14

P3.2/S15

P3.1/S16

P3.0/S17

P2.7/SIFCLKG/S18

P1.5/TA0CLK/ACLK

48

P1.6/CA0

47

P1.7/CA1

46

P2.0/TA0.2

45

P2.1/TA1.1

44

P5.7/R33

43

P5.6/R23

42

P5.5/R13

41

40

R03

39

P5.4/COM3

38

P5.3/COM2

37

P5.2/COM1

36

COM0

35

P2.2/TA1.2/S23

P2.3/TA1.3/S22

34

33

P2.4/TA1.4/S21

P2.6/CAOUT/S19

P2.5/TA1CLK/S20

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 3

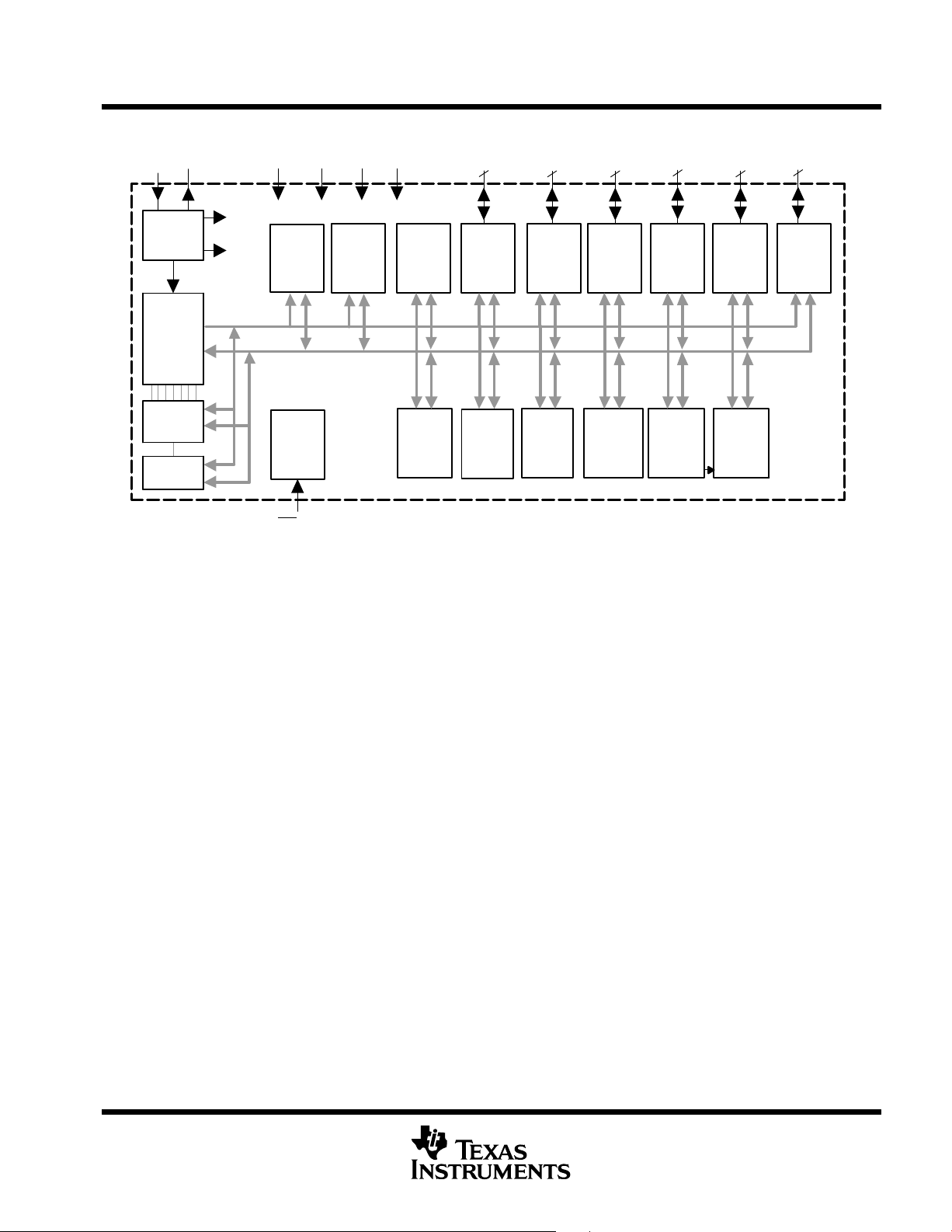

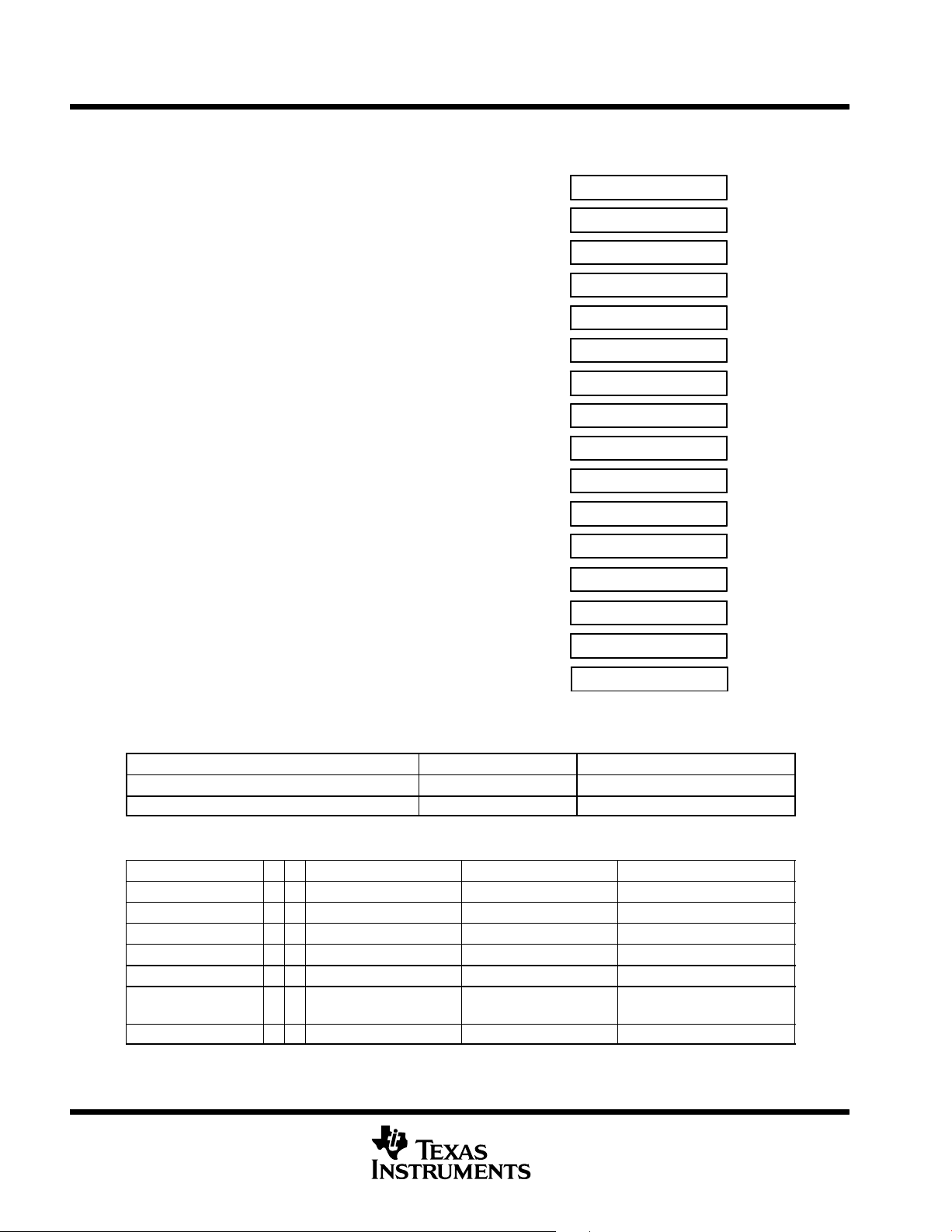

functional block diagram

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

XOUT

XIN

Oscillator

FLL+

MCLK

8 MHz

CPU

incl. 16

Registers

Emulation

Module

JTAG

Interface

DVCCDVSSAVCCAV

ACLK

MAB

MDB

Flash

32KB

16KB

8KB

POR/

Multilevel

SVS/

Brownout

RST/NMI

SMCLK

RAM

1KB

512B

256B

SS

Scan IF

Watchdog

Timer

WDT

15/16-Bit

P1

8

Port 1

8 I/O

Interrupt

Capability

Timer0_A3

3 CC Reg

P2

Port 2

8 I/O

Interrupt

Capability

Timer1_A5

5 CC Reg

8

P3

8

Port 3

8 I/O

Comparator_

A

P4

Port 4

8 I/O

Basic

Timer 1

1 Interrupt

Vector

8

Segments

1,2,3,4 MUX

f

LCD

P5

Port 5

8 I/O

LCD

96

P6

8

8

Port 6

8 I/O

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

Page 4

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

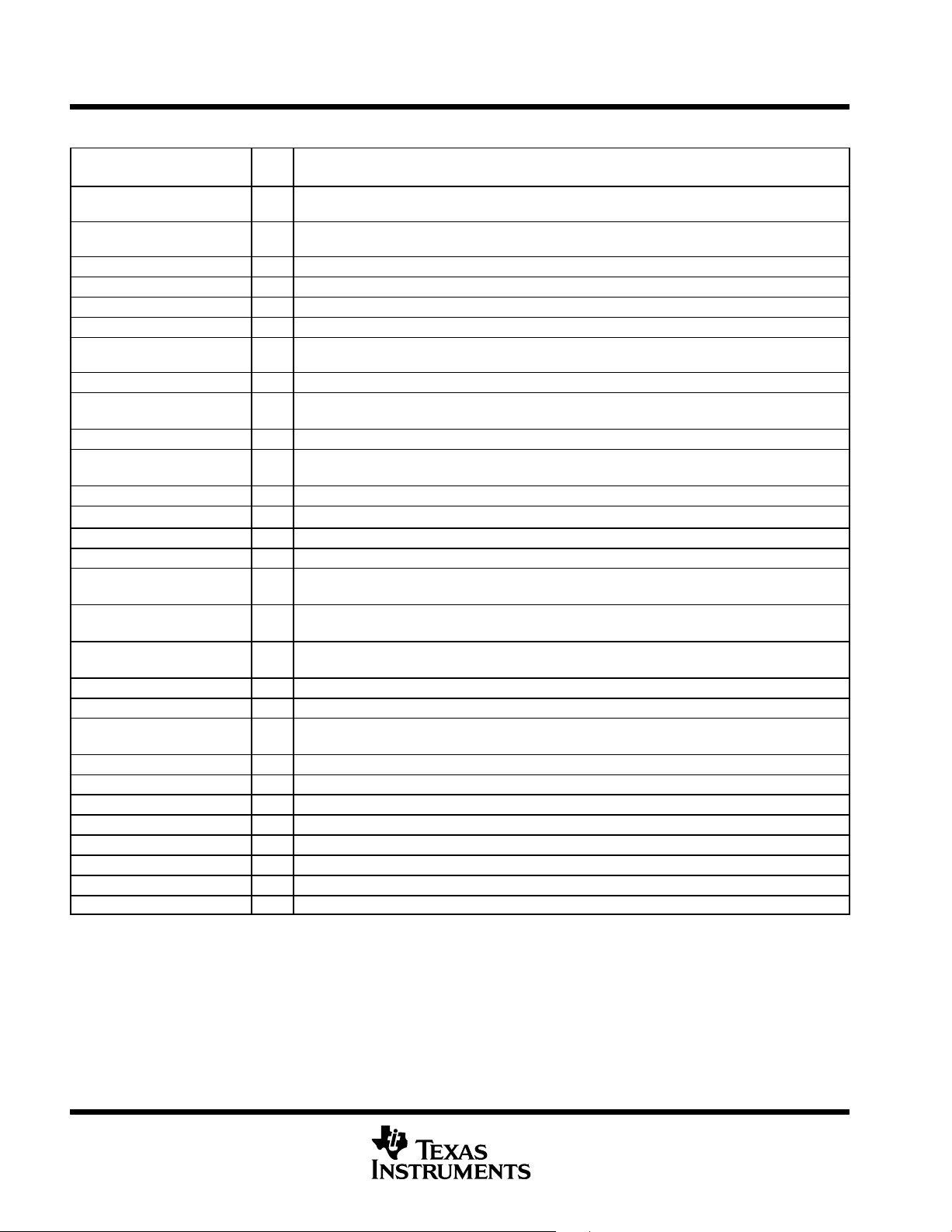

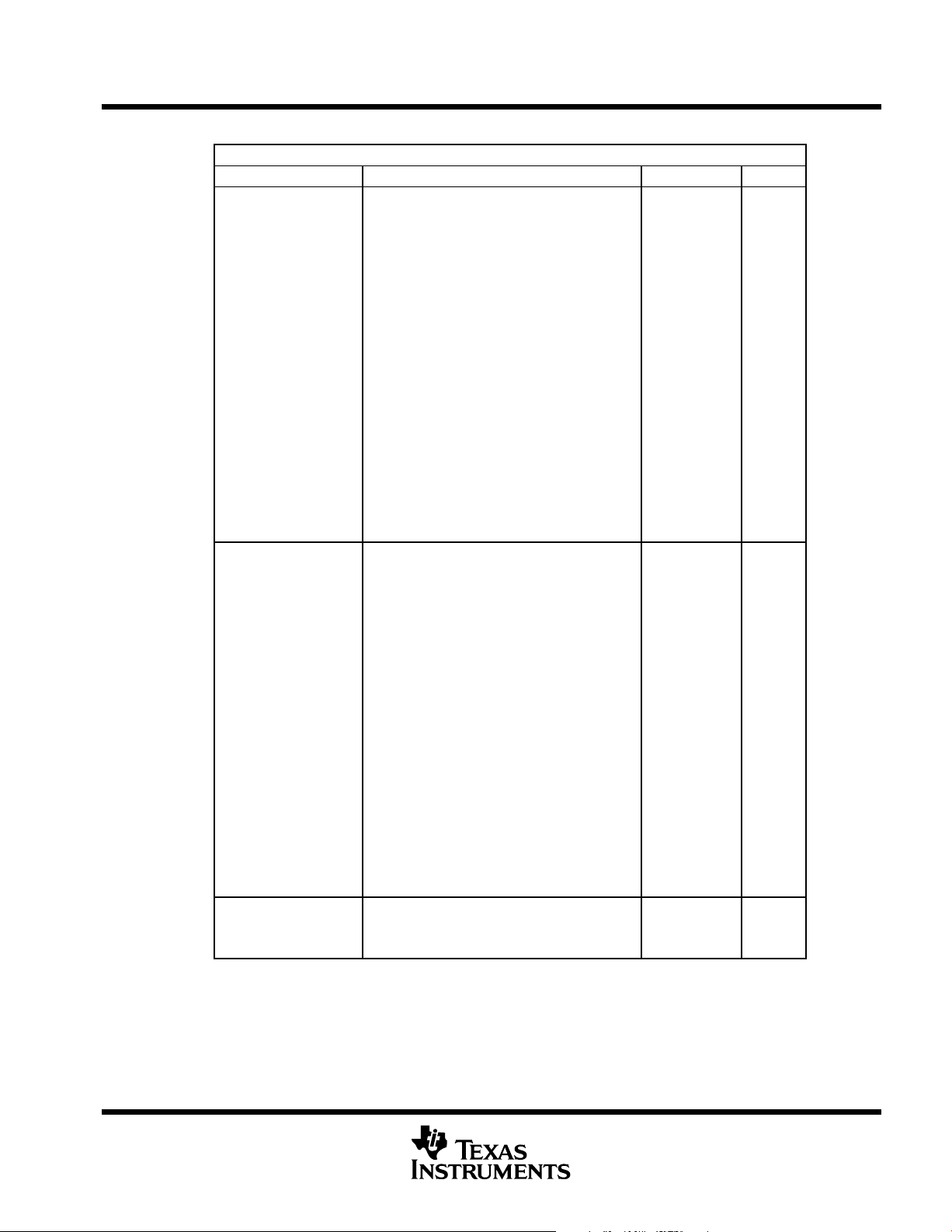

Terminal Functions

TERMINAL

NAME NO.

AV

CC

AV

SS

DV

CC

DV

SS

SIFVSS 10 Scan IF AFE reference supply voltage.

P1.0/TA0.0 53 I/O General-purpose digital I/O/Timer0_A. Capture: CCI0A input, compare: Out0 output/BSL transmit

P1.1/TA0.0/MCLK 52 I/O General-purpose digital I/O/Timer0_A. Capture: CCI0B input/MCLK output/BSL receive

P1.2/TA0.1 51 I/O General-purpose digital I/O/Timer0_A, capture: CCI1A input, compare: Out1 output

P1.3/TA1.0/

SVSOUT

P1.4/TA1.0 49 I/O General-purpose digital I/O/Timer1_A, capture: CCI0A input, compare: Out0 output

P1.5/TA0CLK/

ACLK

P1.6/CA0 47 I/O General-purpose digital I/O/Comparator_A input

P1.7/CA1 46 I/O General-purpose digital I/O/Comparator_A input

P2.0/TA0.2 45 I/O General-purpose digital I/O/Timer0_A, capture: CCI2A input, compare: Out2 output

P2.1/TA1.1 44 I/O General-purpose digital I/O/Timer0_A, capture: CCI1A input, compare: Out1 output

P2.2/TA1.2/S23 35 I/O General-purpose digital I/O/Timer1_A, capture: CCI2A input, compare: Out2 output/LCD segment

P2.3/TA1.3/S22 34 I/O General-purpose digital I/O/Timer1_A, capture: CCI3A input, compare: Out3 output/LCD segment

P2.4/TA1.4/S21 33 I/O General-purpose digital I/O/Timer1_A, capture: CCI4A input, compare: Out4 output/LCD segment

P2.5/TA1CLK/S20 32 I/O General-purpose digital I/O/input of Timer1_A clock/LCD segment output 20 (see Note)

P2.6/CAOUT/S19 31 I/O General-purpose digital I/O/Comparator_A output/LCD segment output 19 (see Note)

P2.7/SIFCLKG/

S18

P3.0/S17 29 I/O General-purpose digital I/O/ LCD segment output 17 (see Note)

P3.1/S16 28 I/O General-purpose digital I/O/ LCD segment output 16 (see Note)

P3.2/S15 27 I/O General-purpose digital I/O/ LCD segment output 15 (see Note)

P3.3/S14 26 I/O General-purpose digital I/O/ LCD segment output 14 (see Note)

P3.4/S13 25 I/O General-purpose digital I/O/LCD segment output 13 (see Note)

P3.5/S12 24 I/O General-purpose digital I/O/LCD segment output 12 (see Note)

P3.6/S11 23 I/O General-purpose digital I/O/LCD segment output 11 (see Note)

P3.7/S10 22 I/O General-purpose digital I/O/LCD segment output 10 (see Note)

NOTE: LCD function selected automatically when applicable LCD module control bits are set, not with PxSEL bits.

64 Analog supply voltage, positive terminal. Supplies SVS, brownout, oscillator, comparator_A, scan IF

62 Analog supply voltage, negative terminal. Supplies SVS, brownout, oscillator, comparator_A, scan IF

63 Digital supply voltage, negative terminal.

50 I/O General-purpose digital I/O/Timer1_A, capture: CCI0B input/SVS: output of SVS comparator

48 I/O General-purpose digital I/O/input of Timer0_A clock/output of ACLK

30 I/O General-purpose digital I/O/Scan IF, signal SIFCLKG from internal clock generator/LCD segment

I/O

AFE, port 6, and LCD resistive divider circuitry; must not power up prior to DV

AFE. and port 6. Must be externally connected to DV

1 Digital supply voltage, positive terminal.

Note: TA0.0 is only an input on this pin.

Note: TA1.0 is only an input on this pin.

output 23 (see Note)

output 22 (see Note)

output 21 (see Note)

output 18 (see Note)

DESCRIPTION

SS

.

CC

. Internally connected to DVSS.

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 5

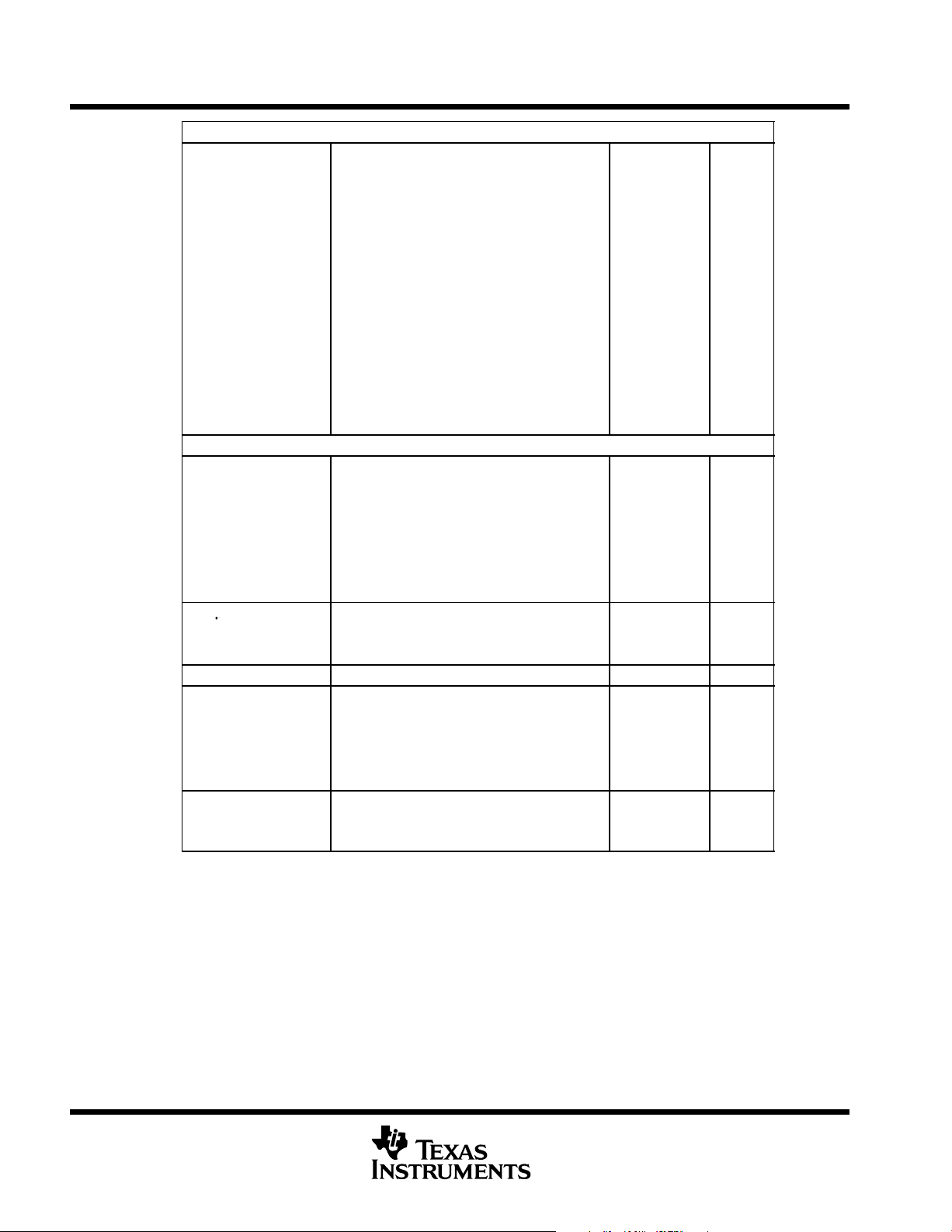

MIXED SIGNAL MICROCONTROLLER

Terminal Functions (Continued)

MSP430xW42x

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

TERMINAL

NAME NO.

P4.0/S9 21 I/O General-purpose digital I/O/LCD segment output 9 (see Note)

P4.1/S8 20 I/O General-purpose digital I/O/LCD segment output 8 (see Note)

P4.2/S7 19 I/O General-purpose digital I/O/LCD segment output 7 (see Note)

P4.3/S6 18 I/O General-purpose digital I/O/LCD segment output 6 (see Note)

P4.4/S5 17 I/O General-purpose digital I/O/LCD segment output 5 (see Note)

P4.5/S4 16 I/O General-purpose digital I/O/LCD segment output 4 (see Note)

P4.6/S3 15 I/O General-purpose digital I/O/LCD segment output 3 (see Note)

P4.7/S2 14 I/O General-purpose digital I/O/LCD segment output 2 (see Note)

P5.0/S1 13 I/O General-purpose digital I/O/LCD segment output 1 (see Note)

P5.1/S0 12 I/O General-purpose digital I/O/LCD segment output 0 (see Note)

COM0 36 O Common output. COM0−3 are used for LCD backplanes

P5.2/COM1 37 I/O General-purpose digital I/O/common output. COM0−3 are used for LCD backplanes

P5.3/COM2 38 I/O General-purpose digital I/O/common output. COM0−3 are used for LCD backplanes

P5.4/COM3 39 I/O General-purpose digital I/O/common output. COM0−3 are used for LCD backplanes

R03 40 I Input port of fourth positive (lowest) analog LCD level (V5)

P5.5/R13 41 I/O General-purpose digital I/O/input port of third most positive analog LCD level (V4 or V3)

P5.6/R23 42 I/O General-purpose digital I/O/input port of second most positive analog LCD level (V2)

P5.7/R33 43 I/O General-purpose digital I/O/output port of most positive analog LCD level (V1)

P6.0/SIFCH0 59 I/O General-purpose digital I/O/Scan IF, channel 0 sensor excitation output and signal input

P6.1/SIFCH1 60 I/O General-purpose digital I/O/Scan IF, channel 1 sensor excitation output and signal input

P6.2/SIFCH2 61 I/O General-purpose digital I/O/Scan IF, channel 2 sensor excitation output and signal input

P6.3/SIFCH3/

SIFCAOUT

P6.4/SIFCI0 3 I/O General-purpose digital I/O/Scan IF, channel 0 signal input to comparator

P6.5/SIFCI1 4 I/O General-purpose digital I/O/Scan IF, channel 1 signal input to comparator

P6.6/SIFCI2/

SIFDACOUT

P6.7/

SIFCI3/SVSIN

SIFCI 7 I Scan IF input to Comparator.

SIFCOM 11 O Common termination for Scan IF sensors.

RST/NMI 58 I Reset input or nonmaskable interrupt input port.

TCK 57 I Test clock. TCK is the clock input port for device programming and test.

TDI/TCLK 55 I Test data input or test clock input. The device protection fuse is connected to TDI/TCLK.

TDO/TDI 54 I/O Test data output port. TDO/TDI data output or programming data input terminal.

TMS 56 I Test mode select. TMS is used as an input port for device programming and test.

XIN 8 I Input port for crystal oscillator XT1. Standard or watch crystals can be connected.

XOUT 9 O Output terminal of crystal oscillator XT1.

NOTE: LCD function selected automatically when applicable LCD module control bits are set, not with PxSEL bits.

I/O

2 I/O General-purpose digital I/O/Scan IF, channel 3 sensor excitation output and signal input/Scan IF

comparator output

5 I/O General-purpose digital I/O/Scan IF, channel 2 signal input to comparator/10-bit DAC output

6 I/O General-purpose digital I/O/Scan IF, channel 3 signal input to comparator/SVS, analog input

DESCRIPTION

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

Page 6

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

short-form description

CPU

The MSP430 CPU has a 16-bit RISC architecture

that is highly transparent to the application. All

operations, other than program-flow instructions,

are performed as register operations in

conjunction with seven addressing modes for

source operand and four addressing modes for

destination operand.

The CPU is integrated with 16 registers that

provide reduced instruction execution time. The

register-to-register operation execution time is

one cycle of the CPU clock.

Four of the registers, R0 to R3, are dedicated as

program counter, stack pointer, status register,

and constant generator respectively. The

remaining registers are general-purpose

registers.

Peripherals are connected to the CPU using data,

address, and control buses, and can be handled

with all instructions.

instruction set

The instruction set consists of 51 instructions with

three formats and seven address modes. Each

instruction can operate on word and byte data.

Table 1 shows examples of the three types of

instruction formats; the address modes are listed

in Table 2.

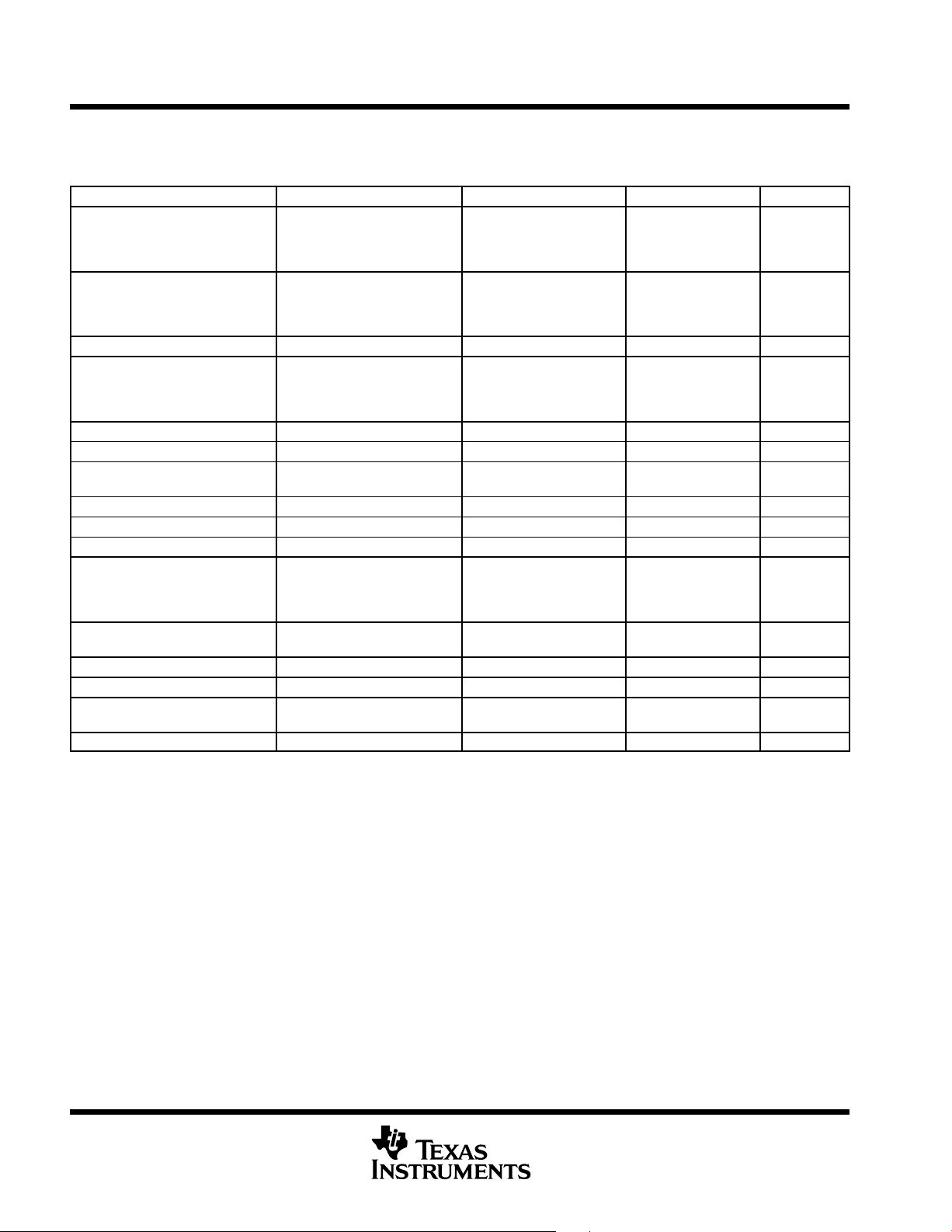

Program Counter

Stack Pointer

Status Register

Constant Generator

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

General-Purpose Register

PC/R0

SP/R1

SR/CG1/R2

CG2/R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

Table 1. Instruction Word Formats

Dual operands, source-destination e.g. ADD R4,R5 R4 + R5 −−−> R5

Single operands, destination only e.g. CALL R8 PC −−>(TOS), R8−−> PC

Relative jump, un/conditional e.g. JNE Jump-on-equal bit = 0

Table 2. Address Mode Descriptions

ADDRESS MODE S D SYNTAX EXAMPLE OPERATION

Register D

Indexed D D MOV X(Rn),Y(Rm) MOV 2(R5),6(R6) M(2+R5)−−> M(6+R6)

Symbolic (PC relative) D D MOV EDE,TONI M(EDE) −−> M(TONI)

Absolute D D MOV &MEM,&TCDAT M(MEM) −−> M(TCDAT)

Indirect D MOV @Rn,Y(Rm) MOV @R10,Tab(R6) M(R10) −−> M(Tab+R6)

Indirect

autoincrement

Immediate D MOV #X,TONI MOV #45,TONI #45 −−> M(TONI)

NOTE: S = source D = destination

D

D MOV @Rn+,Rm MOV @R10+,R11

MOV Rs,Rd MOV R10,R11 R10 −−> R11

M(R10) −−> R11

R10 + 2−−> R10

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 7

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

operating modes

The MSP430 has one active mode and five software selectable low-power modes of operation. An interrupt

event can wake up the device from any of the five low-power modes, service the request and restore back to

the low-power mode on return from the interrupt program.

The following six operating modes can be configured by software:

D Active mode (AM)

− All clocks are active

D Low-power mode 0 (LPM0)

− CPU is disabled

ACLK and SMCLK remain active, MCLK is available to modules

FLL+ loop control remains active

D Low-power mode 1 (LPM1)

− CPU is disabled

ACLK and SMCLK remain active, MCLK is available to modules

FLL+ loop control is disabled

D Low-power mode 2 (LPM2)

− CPU is disabled

MCLK, FLL+ loop control, and DCOCLK are disabled

DCO’s dc-generator remains enabled

ACLK remains active

D Low-power mode 3 (LPM3)

− CPU is disabled

MCLK, FLL+ loop control, and DCOCLK are disabled

DCO’s dc-generator is disabled

ACLK remains active

D Low-power mode 4 (LPM4)

− CPU is disabled

ACLK is disabled

MCLK, FLL+ loop control, and DCOCLK are disabled

DCO’s dc-generator is disabled

Crystal oscillator is stopped

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

Page 8

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

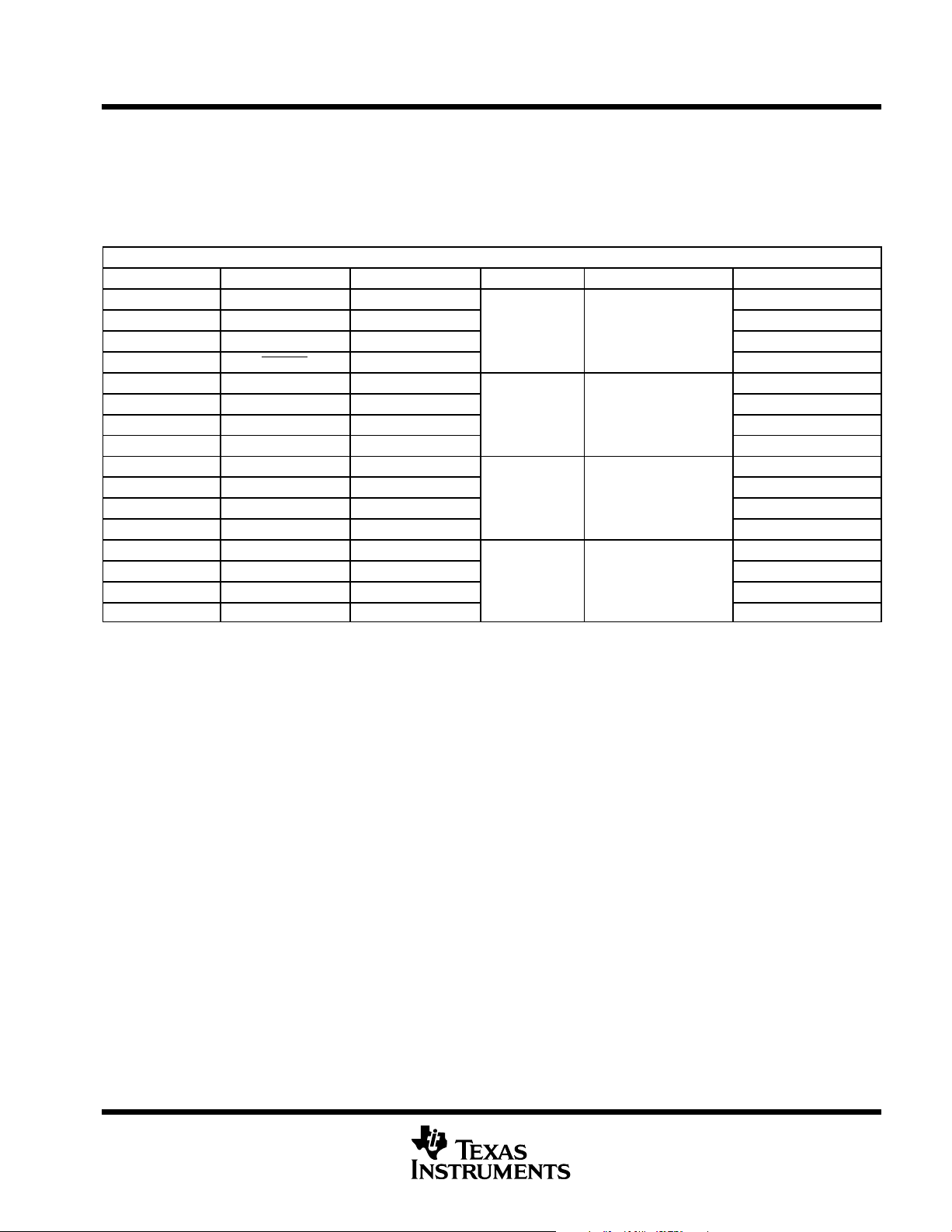

interrupt vector addresses

The interrupt vectors and the power-up starting address are located in the address range 0FFFFh − 0FFE0h.

The vector contains the 16-bit address of the appropriate interrupt-handler instruction sequence.

INTERRUPT SOURCE INTERRUPT FLAG SYSTEM INTERRUPT WORD ADDRESS PRIORITY

Power-up

External Reset

Watchdog

Flash memory

NMI

Oscillator Fault

Flash memory access violation

Timer1_A5 TA1CCR0 CCIFG (see Note 2) Maskable 0FFFAh 13

Timer1_A5

Comparator_A CMPAIFG Maskable 0FFF6h 11

Watchdog Timer WDTIFG Maskable 0FFF4h 10

Scan IF SIFIFG0 to SIFIFG6

Timer0_A3 TA0CCR0 CCIFG (see Note 2) Maskable 0FFECh 6

Timer0_A3

I/O port P1

(eight flags)

I/O port P2

(eight flags)

Basic Timer1 BTIFG Maskable 0FFE0h 0, lowest

NOTES: 1. Multiple source flags

2. Interrupt flags are located in the module.

3. (Non)maskable: the individual interrupt-enable bit can disable an interrupt event, but the general interrupt-enable cannot.

WDTIFG

KEYV

(see Note 1)

NMIIFG

OFIFG

ACCVIFG

(see Notes 1 & 3)

TA1CCR1 CCIFG to

TA1CCR4 CCIFG,

TA1CTL TAIFG

(see Notes 1 & 2)

(See Note 1)

TA0CCR1 CCIFG,

TA0CCR2 CCIFG,

TA0CTL TAIFG

(see Notes 1 & 2)

P1IFG.0 to P1IFG.7

(see Notes 1 & 2)

P2IFG.0 to P2IFG.7

(see Notes 1 & 2)

Reset 0FFFEh 15, highest

(Non)maskable

(Non)maskable

(Non)maskable

Maskable 0FFF8h 12

Maskable 0FFF2h 9

Maskable 0FFEAh 5

Maskable 0FFE8h 4

Maskable 0FFE2h 1

0FFFCh 14

0FFF0h 8

0FFEEh 7

0FFE6h 3

0FFE4h 2

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 9

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

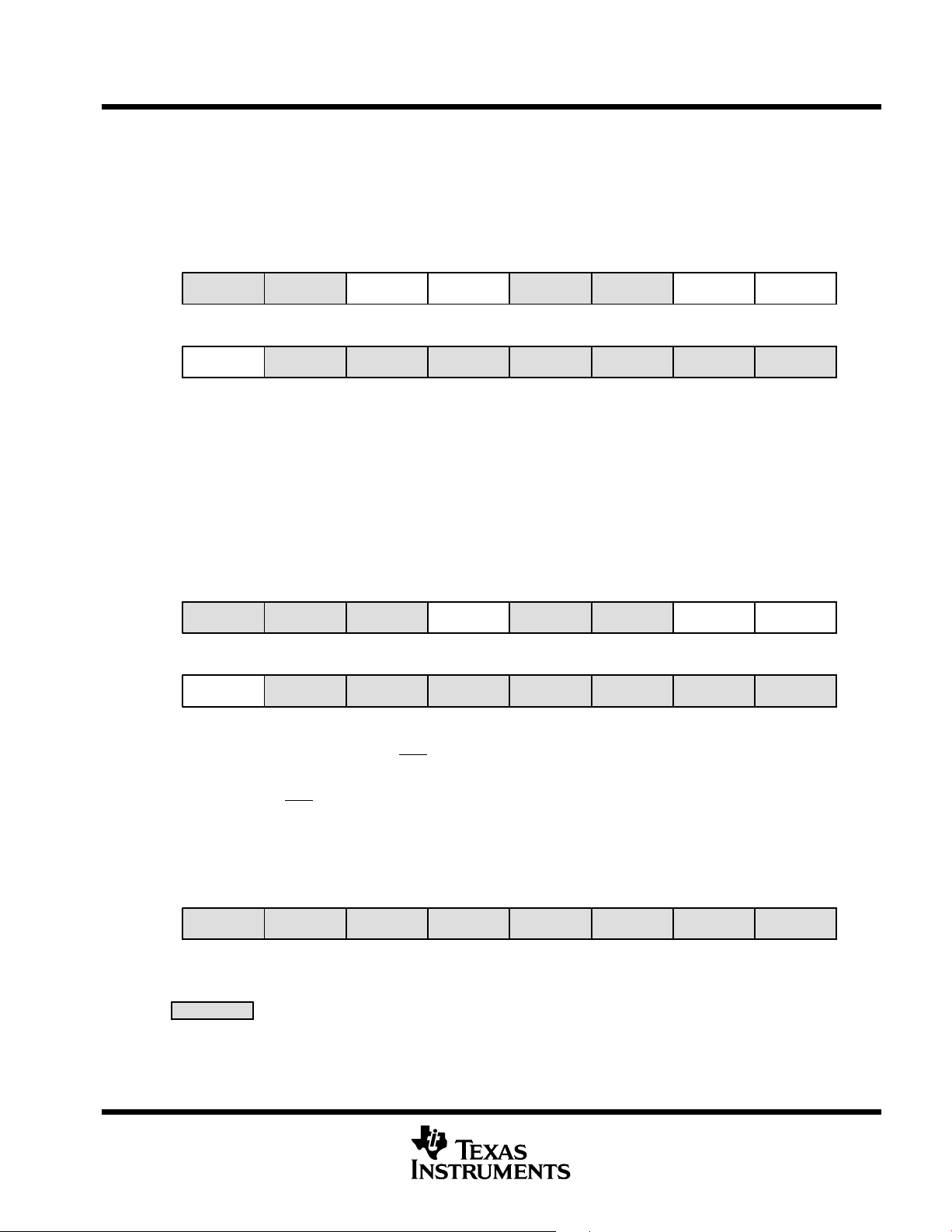

special function registers

Most interrupt and module enable bits are collected into the lowest address space. Special function register bits

that are not allocated to a functional purpose are not physically present in the device. Simple software access

is provided with this arrangement.

interrupt enable 1 and 2

Address

00h ACCVIE NMIIE

Address

01h BTIE

7654 0

rw-0

7654 0321

rw-0

rw-0 rw-0 rw-0

321

OFIE WDTIE

WDTIE: Watchdog-timer interrupt enable. Inactive if watchdog mode is selected. Active if watchdog timer is

configured in interval timer mode.

OFIE: Oscillator-fault-interrupt enable

NMIIE: Nonmaskable-interrupt enable

ACCVIE: Flash access violation interrupt enable

BTIE: Basic Timer1 interrupt enable

interrupt flag register 1 and 2

Address

02h NMIIFG

Address

03h BTIFG

7654 0

rw-0 rw-1 rw-(0)

7654 0321

rw-0

321

OFIFG WDTIFG

WDTIFG: Set on watchdog-timer overflow (in watchdog mode) or security key violation. Reset with VCC power-up,

or a reset condition at the RST

/NMI pin in reset mode.

OFIFG: Flag set on oscillator fault

NMIIFG: Set via RST

/NMI pin

BTIFG: Basic Timer1 interrupt flag

module enable registers 1 and 2

Address

04h/05h

Legend: rw:

rw-0,1:

rw-(0,1):

7654 0321

Bit Can Be Read and Written

Bit Can Be Read and Written. It Is Reset or Set by PUC.

Bit Can Be Read and Written. It Is Reset or Set by POR.

SFR Bit Not Present in Device

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

Page 10

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

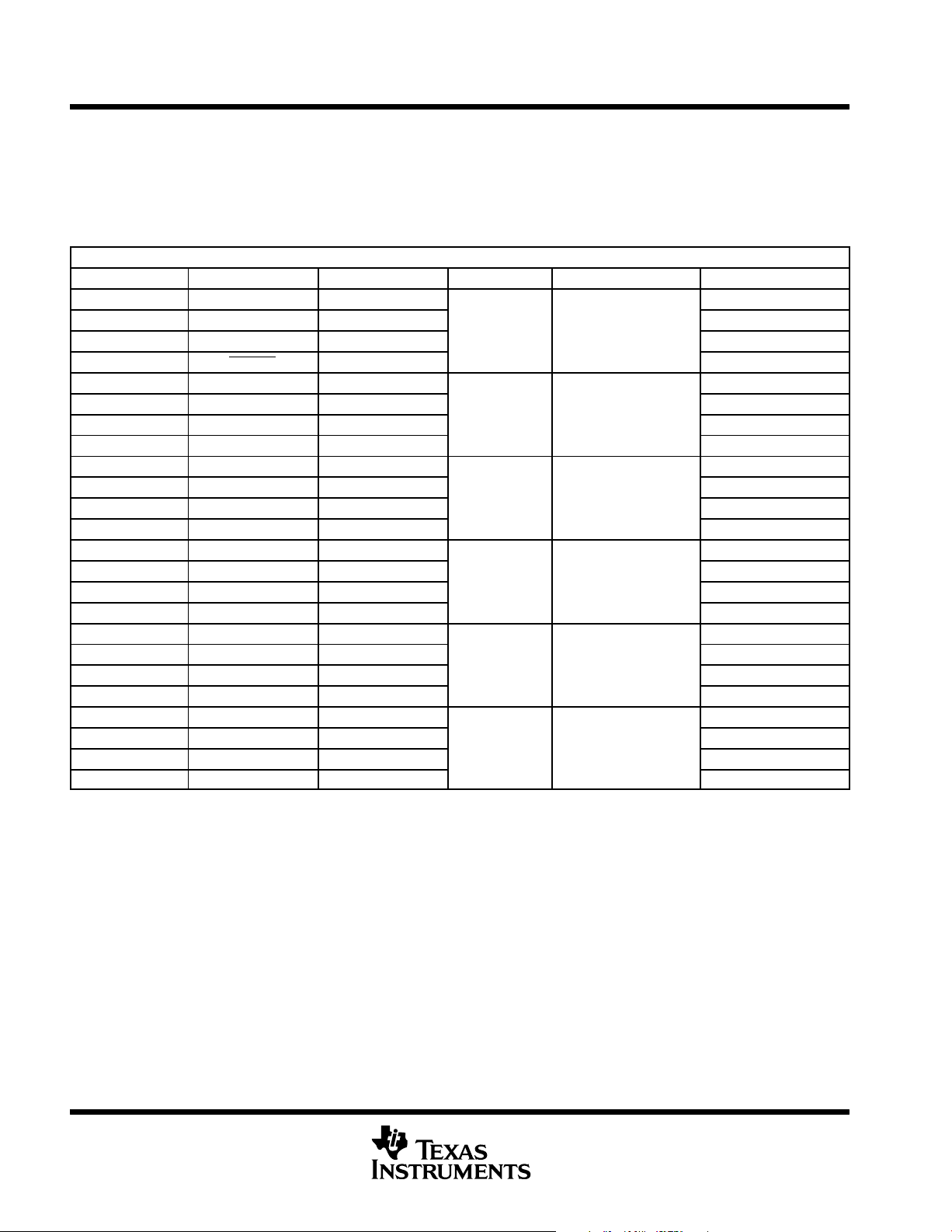

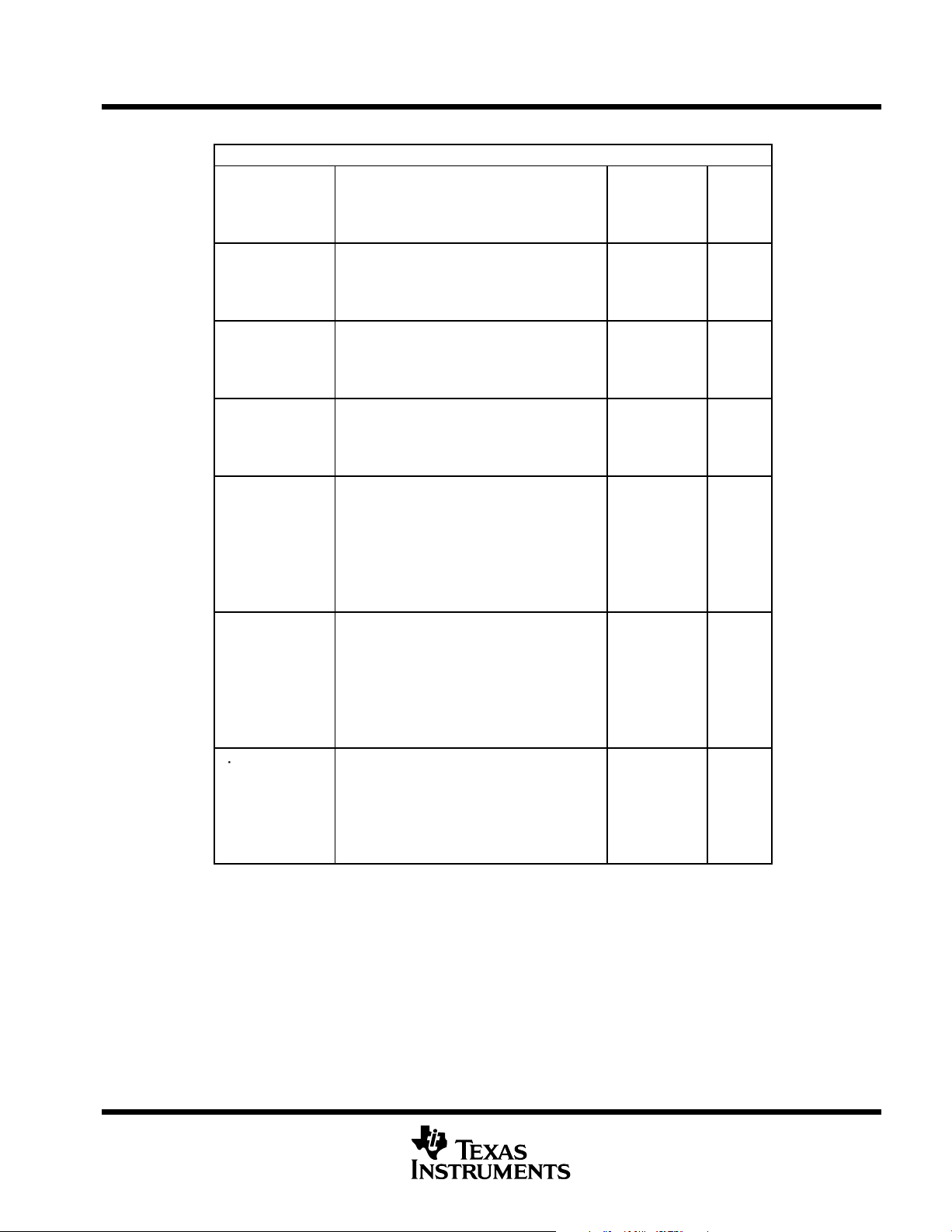

memory organization

MSP430FW423 MSP430FW425 MSP430FW427

Memory

Interrupt vector

Code memory

Information memory Size 256 Byte

Boot memory Size 1KB

RAM Size 256 Byte

Peripherals 16-bit

bootstrap loader (BSL)

The MSP430 bootstrap loader (BSL) enables users to program the flash memory or RAM using a UART serial

interface. Access to the MSP430 memory via the BSL is protected by user-defined password. For complete

description of the features of the BSL and its implementation, see the Application report Features of the MSP430

Bootstrap Loader, Literature Number SLAA089.

Size

Flash

Flash

8-bit

8-bit SFR

8KB

0FFFFh − 0FFE0h

0FFFFh − 0E000h

010FFh − 01000h

0FFFh − 0C00h

02FFh − 0200h

01FFh − 0100h

0FFh − 010h

0Fh − 00h

16KB

0FFFFh − 0FFE0h

0FFFFh − 0C000h

256 Byte

010FFh − 01000h

1KB

0FFFh − 0C00h

512 Byte

03FFh − 0200h

01FFh − 0100h

0FFh − 010h

0Fh − 00h

32KB

0FFFFh − 0FFE0h

0FFFFh − 08000h

256 Byte

010FFh − 01000h

1KB

0FFFh − 0C00h

1KB

05FFh − 0200h

01FFh − 0100h

0FFh − 010h

0Fh − 00h

BSL Function PM Package Pins

Data Transmit 53 - P1.0

Data Receive 52 - P1.1

flash memory

The flash memory can be programmed via the JTAG port, the bootstrap loader, or in-system by the CPU. The

CPU can perform single-byte and single-word writes to the flash memory. Features of the flash memory include:

D Flash memory has n segments of main memory and two segments of information memory (A and B) of 128

bytes each. Each segment in main memory is 512 bytes in size.

D Segments 0 to n may be erased in one step, or each segment may be individually erased.

D Segments A and B can be erased individually, or as a group with segments 0−n.

Segments A and B are also called information memory.

D New devices may have some bytes programmed in the information memory (needed for test during

manufacturing). The user should perform an erase of the information memory prior to the first use.

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 11

flash memory (continued)

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

8KB

0FFFFh

0FE00h

0FDFFh

0FC00h

0FBFFh

0FA00h

0F9FFh

0E400h

0E3FFh

0E200h

0E1FFh

0E000h

010FFh

01080h

0107Fh

01000h

16KB

0FFFFh

0FE00h

0FDFFh

0FC00h

0FBFFh

0FA00h

0F9FFh

0C400h

0C3FFh

0C200h

0C1FFh

0C000h

010FFh

01080h

0107Fh

01000h

32KB

0FFFFh

0FE00h

0FDFFh

0FC00h

0FBFFh

0FA00h

0F9FFh

08400h

083FFh

08200h

081FFh

08000h

010FFh

01080h

0107Fh

01000h

Segment 0

With Interrupt Vectors

Segment 1

Segment 2

Main Memory

Segment n−1

Segment n

Segment A

Information Memory

Segment B

peripherals

Peripherals are connected to the CPU through data, address, and control busses and can be handled using

all instructions. For complete module descriptions, refer to the MSP430x4xx Family User’s Guide, literature

number SLAU056.

oscillator and system clock

The clock system in the MSP430xW42x family of devices is supported by the FLL+ module that includes support

for a 32768-Hz watch crystal oscillator, an internal digitally-controlled oscillator (DCO) and a high frequency

crystal oscillator. The FLL+ clock module is designed to meet the requirements of both low system cost and

low-power consumption. The FLL+ features a digital frequency locked loop (FLL) hardware which in conjunction

with a digital modulator stabilizes the DCO frequency to a programmable multiple of the watch crystal frequency.

The internal DCO provides a fast turn-on clock source and stabilizes in less than 6 μs. The FLL+ module

provides the following clock signals:

D Auxiliary clock (ACLK), sourced from a 32768-Hz watch crystal or a high frequency crystal.

D Main clock (MCLK), the system clock used by the CPU.

D Sub-Main clock (SMCLK), the sub-system clock used by the peripheral modules.

D ACLK/n, the buffered output of ACLK, ACLK/2, ACLK/4, or ACLK/8.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

Page 12

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

brownout, supply voltage supervisor

The brownout circuit is implemented to provide the proper internal reset signal to the device during power on

and power off. The supply voltage supervisor (SVS) circuitry detects if the supply voltage drops below a user

selectable level and supports both supply voltage supervision (the device is automatically reset) and supply

voltage monitoring (SVM, the device is not automatically reset).

The CPU begins code execution after the brownout circuit releases the device reset. However, V

have ramped to V

reaches V

CC(min)

. If desired, the SVS circuit can be used to determine when VCC reaches V

at that time. The user must insure the default FLL+ settings are not changed until V

CC(min)

CC(min)

digital I/O

There are six 8-bit I/O ports implemented—ports P1 through P6:

D All individual I/O bits are independently programmable.

D Any combination of input, output, and interrupt conditions is possible.

D Edge-selectable interrupt input capability for all the eight bits of ports P1 and P2.

D Read/write access to port-control registers is supported by all instructions.

Basic Timer1

The Basic Timer1 has two independent 8-bit timers which can be cascaded to form a 16-bit timer/counter. Both

timers can be read and written by software. The Basic Timer1 can be used to generate periodic interrupts and

clock for the LCD module.

LCD drive

The LCD driver generates the segment and common signals required to drive an LCD display. The LCD

controller has dedicated data memory to hold segment drive information. Common and segment signals are

generated as defined by the mode. Static, 2-MUX, 3-MUX, and 4-MUX LCDs are supported by this peripheral.

watchdog timer

may not

CC

.

CC

The primary function of the watchdog timer (WDT) module is to perform a controlled system restart after a

software problem occurs. If the selected time interval expires, a system reset is generated. If the watchdog

function is not needed in an application, the module can be configured as an interval timer and can generate

interrupts at selected time intervals.

comparator_A

The primary function of the comparator_A module is to support precision slope analog−to−digital conversions,

battery−voltage supervision, and monitoring of external analog signals.

scan IF

The scan interface is used to measure linear or rotational motion and supports LC and resistive sensors such

as GMR sensors. The scan IF incorporates a V

up to four sensors.

/2 generator, a comparator, and a 10-bit DAC and supports

CC

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 13

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

timer0_A3

Timer0_A3 is a 16-bit timer/counter with three capture/compare registers. Timer0_A3 can support multiple

capture/compares, PWM outputs, and interval timing. Timer0_A3 also has extensive interrupt capabilities.

Interrupts may be generated from the counter on overflow conditions and from each of the capture/compare

registers.

Timer0_A3 Signal Connections

Input Pin Number Device Input Signal Module Input Name Module Block Module Output Signal Output Pin Number

48 - P1.5 TA0CLK TACLK

ACLK ACLK

SMCLK SMCLK

48 - P1.5 TA0CLK INCLK

53 - P1.0 TA0.0 CCI0A

52 - P1.1 TA0.0 CCI0B

DV

SS

DV

CC

51 - P1.2 TA0.1 CCI1A

CAOUT (internal) CCI1B

DV

SS

DV

CC

45 - P2.0 TA0.2 CCI2A

ACLK (internal) CCI2B

DV

SS

DV

CC

GND

V

CC

GND

V

CC

GND

V

CC

Timer NA

53 - P1.0

CCR0 TA0.0

51 - P1.2

CCR1 TA0.1

45 - P2.0

CCR2 TA0.2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

13

Page 14

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

timer1_A5

Timer1_A5 is a 16-bit timer/counter with five capture/compare registers. Timer1_A5 can support multiple

capture/compares, PWM outputs, and interval timing. Timer1_A5 also has extensive interrupt capabilities.

Interrupts may be generated from the counter on overflow conditions and from each of the capture/compare

registers.

Timer1_A5 Signal Connections

Input Pin Number Device Input Signal Module Input Name Module Block Module Output Signal Output Pin Number

32 - P2.5 TA1CLK TACLK

ACLK ACLK

SMCLK SMCLK

32 - P2.5 TA1CLK INCLK

49 - P1.4 TA1.0 CCI0A

50 - P1.3 TA1.0 CCI0B

DV

DV

SS

CC

GND

V

CC

44 - P2.1 TA1.1 CCI1A

CAOUT (internal) CCI1B

DV

DV

SS

CC

GND

V

CC

35 - P2.2 TA1.2 CCI2A

SIFO0sig (internal) CCI2B

DV

DV

SS

CC

GND

V

CC

34 - P2.3 TA1.3 CCI3A

SIFO1sig (internal) CCI3B

DV

DV

SS

CC

GND

V

CC

33 - P2.4 TA1.4 CCI4A

SIFO2sig (internal) CCI4B

DV

DV

SS

CC

GND

V

CC

Timer NA

49 - P1.4

CCR0 TA1.0

44 - P2.1

CCR1 TA1.1

35 - P2.2

CCR2 TA1.2

34 - P2.3

CCR3 TA1.3

33 - P2.4

CCR4 TA1.4

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 15

peripheral file map

Watchdog Watchdog Timer control WDTCTL 0120h

Timer1_A5

Timer0_A3

Flash

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

PERIPHERALS WITH WORD ACCESS

_

_

Timer1_A interrupt vector TA1IV 011Eh

Timer1_A control TA1CTL 0180h

Capture/compare control 0 TA1CCTL0 0182h

Capture/compare control 1 TA1CCTL1 0184h

Capture/compare control 2 TA1CCTL2 0186h

Capture/compare control 3 TA1CCTL3 0188h

Capture/compare control 4 TA1CCTL4 018Ah

Reserved 018Ch

Reserved 018Eh

Timer1_A register TA1R 0190h

Capture/compare register 0 TA1CCR0 0192h

Capture/compare register 1 TA1CCR1 0194h

Capture/compare register 2 TA1CCR2 0196h

Capture/compare register 3 TA1CCR3 0198h

Capture/compare register 4 TA1CCR4 019Ah

Reserved 019Ch

Reserved 019Eh

Timer0_A interrupt vector TA0IV 012Eh

Timer0_A control TA0CTL0 0160h

Capture/compare control 0 TA0CCTL0 0162h

Capture/compare control 1 TA0CCTL1 0164h

Capture/compare control 2 TA0CCTL2 0166h

Reserved 0168h

Reserved 016Ah

Reserved 016Ch

Reserved 016Eh

Timer0_A register TA0R 0170h

Capture/compare register 0 TA0CCR0 0172h

Capture/compare register 1 TA0CCR1 0174h

Capture/compare register 2 TA0CCR2 0176h

Reserved 0178h

Reserved 017Ah

Reserved 017Ch

Reserved 017Eh

Flash control 3 FCTL3 012Ch

Flash control 2 FCTL2 012Ah

Flash control 1 FCTL1 0128h

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

15

Page 16

MSP430xW42x

p

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

PERIPHERALS WITH WORD ACCESS (CONTINUED)

Scan IF

LCD

Comparator_A

Brownout, SVS SVS control register SVSCTL 056h

FLL+ Clock

Basic Timer1

_

SIF timing state machine 23 SIFTSM23 01FEh

: : :

SIF timing state machine 0 SIFTSM0 01D0h

SIF DAC register 7 SIFDACR7 01CEh

: : :

SIF DAC register 0 SIFDACR0 01C0h

SIF control register 5 SIFCTL5 01BEh

SIF control register 4 SIFCTL4 01BCh

SIF control register 3 SIFCTL3 01BAh

SIF control register 2 SIFCTL2 01B8h

SIF control register 1 SIFCTL1 01B6h

SIF processing state machine vector SIFPSMV 01B4h

SIF counter CNT1/2 SIFCNT 01B2h

Reserved SIFDEBUG 01B0h

PERIPHERALS WITH BYTE ACCESS

LCD memory 20 LCDM20 0A4h

: : :

LCD memory 16 LCDM16 0A0h

LCD memory 15 LCDM15 09Fh

: : :

LCD memory 1 LCDM1 091h

LCD control and mode LCDCTL 090h

Comparator_A port disable CAPD 05Bh

Comparator_A control 2 CACTL2 05Ah

Comparator_A control 1 CACTL1 059h

FLL+ Control 1 FLL_CTL1 054h

FLL+ Control 0 FLL_CTL0 053h

System clock frequency control SCFQCTL 052h

System clock frequency integrator SCFI1 051h

System clock frequency integrator SCFI0 050h

BT counter 2 BTCNT2 047h

BT counter 1 BTCNT1 046h

BT control BTCTL 040h

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 17

peripheral file map (continued)

p

Port P6

Port P5

Port P4

Port P3

Port P2

Port P1

Special Functions

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

PERIPHERALS WITH BYTE ACCESS (CONTINUED)

Port P6 selection P6SEL 037h

Port P6 direction P6DIR 036h

Port P6 output P6OUT 035h

Port P6 input P6IN 034h

Port P5 selection P5SEL 033h

Port P5 direction P5DIR 032h

Port P5 output P5OUT 031h

Port P5 input P5IN 030h

Port P4 selection P4SEL 01Fh

Port P4 direction P4DIR 01Eh

Port P4 output P4OUT 01Dh

Port P4 input P4IN 01Ch

Port P3 selection P3SEL 01Bh

Port P3 direction P3DIR 01Ah

Port P3 output P3OUT 019h

Port P3 input P3IN 018h

Port P2 selection P2SEL 02Eh

Port P2 interrupt enable P2IE 02Dh

Port P2 interrupt-edge select P2IES 02Ch

Port P2 interrupt flag P2IFG 02Bh

Port P2 direction P2DIR 02Ah

Port P2 output P2OUT 029h

Port P2 input P2IN 028h

Port P1 selection P1SEL 026h

Port P1 interrupt enable P1IE 025h

Port P1 interrupt-edge select P1IES 024h

Port P1 interrupt flag P1IFG 023h

Port P1 direction P1DIR 022h

Port P1 output P1OUT 021h

Port P1 input P1IN 020h

SFR module enable 2 ME2 005h

SFR module enable 1 ME1 004h

SFR interrupt flag 2 IFG2 003h

SFR interrupt flag 1 IFG1 002h

SFR interrupt enable 2 IE2 001h

SFR interrupt enable 1 IE1 000h

absolute maximum ratings

†

Voltage applied at VCC to VSS −0.3 V to + 4.1 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage applied to any pin (see Note) −0.3 V to V

CC

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diode current at any device terminal . ±2 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature (unprogrammed device) −55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature (programmed device) −40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE: All voltages referenced to V

applied to the TDI/TCLK pin when blowing the JTAG fuse.

. The JTAG fuse-blow voltage, VFB, is allowed to exceed the absolute maximum rating. The voltage is

SS

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

17

Page 18

MSP430xW42x

(

3)

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

recommended operating conditions

PARAMETER MIN NOM MAX UNITS

Supply voltage during program execution (see Note 1),

V

(AVCC = DVCC = VCC)

CC

Supply voltage during program execution, SVS enabled, PORON = 1

(see Note 1 and Note 2), V

(AVCC = DVCC = VCC)

CC

Supply voltage during programming flash memory (see Note 1),

V

(AVCC = DVCC = VCC)

CC

Supply voltage, V

Operating free-air temperature range, T

(AVSS = DVSS = VSS) 0 0 V

SS

A

LF selected, XTS_FLL=0 Watch crystal 32768 Hz

LFXT1 crystal frequency, f

see Note

(LFXT1)

XT1 selected, XTS_FLL=1 Ceramic resonator 450 8000 kHz

XT1 selected, XTS_FLL=1 Crystal 1000 8000 kHz

Processor frequency (signal MCLK), f

(System)

NOTES: 1. It is recommended to power AVCC and DVCC from the same source. A maximum difference of 0.3 V betweeen AVCC and DVCC can

be tolerated during power up and operation.

2. The minimum operating supply voltage is defined according to the trip point where POR is going active by decreasing supply voltage.

POR is going inactive when the supply voltage is raised above minimum supply voltage plus the hysteresis of the SVS circuitry.

3. In LF mode, the LFXT1 oscillator requires a watch crystal. In XT1 mode, LFXT1 accepts a ceramic resonator or a crystal.

MSP430xW42x 1.8 3.6 V

MSP430xW42x 2.0 3.6 V

MSP430FW42x 2.7 3.6 V

MSP430xW42x −40 85 °C

VCC = 1.8 V DC 4.15

VCC = 3.6 V DC 8

MHz

f (MHz)

Supply Voltage Range

During Programming of

the Flash Memory

8 MHz

Supply Voltage Range During

Program Execution

4.15 MHz

− Maximum Processor Frequency − MHz

(System)

f

1.8 V 3.6 V

2.7 V 3 V

VCC − Supply Voltage − V

Figure 1. Maximum Frequency vs Supply Voltage

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 19

MSP430xW42x

(

)

(

)

(

)

f

(MCLK)

f

(SMCLK)

f

(DCO)

MHz

(

)

(

)

(

)

f

(MCLK)

f

(SMCLK)

f

(DCO)

MHz

V

CC

2.2 V

Low power mode, (LPM3)

()

V

CC

V

(

)

I

(LPM4)

Low power mode, (LPM4) (see Note 3)

V

CC

2.2 V/3 V

μA

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted)

supply current into AVCC + DVCC excluding external current, (see Note 1)

PARAMETER TEST CONDITIONS MIN NOM MAX UNIT

Active mode,

I

(AM)

= f

f

=

MCLK

= 32,768 Hz, XTS_FLL = 0

f

(ACLK)

SMCLK

= f

=

DCO

= 1 MHz,

= 1

,

= −40°C to 85°C

T

A

(FW42x: Program executes in flash)

Low-power mode, (LPM0)

I

(LPM0)

= f

f

=

MCLK

= 32,768 Hz, XTS_FLL = 0

f

(ACLK)

SMCLK

= f

=

DCO

= 1 MHz,

= 1

,

= −40°C to 85°C

T

A

FN_8=FN_4=FN_3=FN_2=0 (see Note 3)

I

(LPM2)

Low-power mode, (LPM2) (see Note 3) TA = −40°C to 85°C

TA = −40°C 0.95 1.4

TA = −10°C 0.8 1.3

TA = 25°C

TA = 60°C

T

= 85°C 1.6 2.3

I

(LPM3)

Low-power mode, (LPM3)

(see Note 2 and Note 3)

A

= −40°C 1.1 1.7

T

A

TA = −10°C 1.0 1.6

TA = 25°C

TA = 60°C

TA = 85°C 2.0 2.6

TA = −40°C 0.1 0.5

= 25°C

I

LPM4

Low-power mode, (LPM4) (see Note 3)

T

A

TA = 85°C

NOTES: 1. All inputs are tied to 0 V or VCC. Outputs do not source or sink any current. The current consumption is measured with active Basic

Timer1 and LCD (ACLK selected).

The current consumption of the Comparator_A and the SVS module are specified in the respective sections.

2. The LPM3 currents are characterized with a KDS Daishinku DT−38 (6 pF) crystal.

3. Current for brownout included.

VCC = 2.2 V 200 250

VCC = 3 V 300 350

VCC = 2.2 V 57 70

VCC = 3 V 92 100

VCC = 2.2 V 11 14

VCC = 3 V 17 22

VCC = 2.2 V

0.7 1.2

0.95 1.4

VCC = 3 V

3

0.9 1.5

1.1 1.7

VCC = 2.2 V/3 V

0.1 0.5

0.8 2.5

μA

μA

μA

μA

μA

current consumption of active mode versus system frequency

I

= I

(AM)

(AM) [1 MHz]

current consumption of active mode versus supply voltage

I

= I

(AM)

(AM) [3 V]

× f

(System) [MHz]

+ 140 μA/V × (VCC – 3 V)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

19

Page 20

MSP430xW42x

(int)

pg

for the interrupt flag, (see Note 1)

Timer_A clock frequency

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

Schmitt-trigger inputs − Ports P1, P2, P3, P4, P5, and P6; RST/NMI; JTAG: TCK, TMS, TDI/TCLK

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IT+

V

IT−

V

hys

Positive-going input threshold voltage

Negative-going input threshold voltage

Input voltage hysteresis (V

IT+

− V

IT−

)

inputs Px.x, TAx.x

PARAMETER TEST CONDITIONS V

t

(int)

t

(cap)

f

(TAext)

f

(TAint)

External interrupt timing

Timer_A, capture timing TAx.x

Timer_A clock frequency

externally applied to pin

Timer_A clock frequency SMCLK or ACLK signal selected

NOTES: 1. The external signal sets the interrupt flag every time the minimum t

trigger signals shorter than t

MCLK cycles.

Port P1, P2: P1.x to P2.x, External trigger signal

TAxCLK, INCLK

. Both the cycle and timing specifications must be met to ensure the flag is set. t

(int)

t

= t

(H)

(L)

VCC = 2.2 V 1.1 1.5

= 3 V 1.5 1.9

V

CC

VCC = 2.2 V 0.4 0.9

= 3 V 0.9 1.3

V

CC

VCC = 2.2 V 0.3 1.1

VCC = 3 V 0.45 1

CC

MIN TYP MAX UNIT

2.2 V/3 V 1.5 cycle

2.2 V 62

3 V 50

2.2 V 62

3 V 50

2.2 V 8

3 V 10

2.2 V 8

3 V 10

cycle and time parameters are met. It may be set even with

(int)

is measured in

(int)

V

V

V

ns

ns

MHz

MHz

leakage current − Ports P1, P2, P3, P4, P5, and P6 (see Note 1)

PARAMETER TEST CONDITIONS MIN NOM MAX UNIT

I

lkg(Px.x)

NOTES: 1. The leakage current is measured with VSS or VCC applied to the corresponding pin(s), unless otherwise noted.

Leakage current Port Px Port x: V

2. The port pin must be selected as an input.

(see Note 2) VCC = 2.2 V/3 V ±50 nA

(Px.x)

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 21

MSP430xW42x

C

L

P1.1/TA0.0/MCLK

P1.5/TA0CLK/ACLK

C

L

pF

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

outputs − Ports P1, P2, P3, P4, P5, and P6

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

High-level output voltage

OH

V

Low-level output voltage

OL

NOTES: 1. The maximum total current, I

specified voltage drop.

2. The maximum total current, I

specified voltage drop.

output frequency

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

Px.y

f

ACLK,

f

MCLK,

f

SMCLK

t

Xdc

(1 ≤ x ≤ 6, 0 ≤ y ≤ 7)

P1.1/TA0.0/MCLK,

,

P1.5/TA0CLK/ACLK

Duty cycle of output frequency

I

OH(max)

I

OH(max)

I

OH(max)

I

OH(max)

I

OL(max)

I

OL(max)

I

OL(max)

I

OL(max)

OH(max)

OH(max)

= −1.5 mA, V

= −6 mA, V

= −1.5 mA, V

= −6 mA, V

= 1.5 mA, V

= 6 mA, V

= 1.5 mA, V

= 6 mA, V

and I

OL(max),

and I

OL(max),

CL = 20 pF,

= 20 pF,

I

= ± 1.5mA

L

= 20 pF

C

L

C

= 20 pF

20

L

VCC = 2.2 V / 3 V

P1.1/TA0.0/MCLK,

CL = 20 pF,

V

= 2.2 V / 3 V

CC

= 2.2 V, See Note 1 VCC−0.25 V

CC

= 2.2 V, See Note 2 VCC−0.6 V

CC

= 3 V, See Note 1 VCC−0.25 V

CC

= 3 V, See Note 2 VCC−0.6 V

CC

= 2.2 V, See Note 1 V

CC

= 2.2 V, See Note 2 V

CC

= 3 V, See Note 1 V

CC

= 3 V, See Note 2 V

CC

SS

SS

SS

SS

CC

CC

CC

CC

VSS+0.25

VSS+0.6

VSS+0.25

VSS+0.6

V

V

for all outputs combined, should not exceed ±12 mA to satisfy the maximum

for all outputs combined, should not exceed ±24 mA to satisfy the maximum

V

= 2.2 V DC 10

CC

V

= 3 V DC 12

CC

V

= 2.2 V 8

CC

V

= 3 V 12

CC

f

= f

ACLK

,

f

= f

ACLK

f

= f

ACLK

f

MCLK

f

MCLK

= f

= f

LFXT1

LFXT1

LFXT1/n

LFXT1/n

DCOCLK

= f

= f

XT1

LF

40% 60%

30% 70%

50%−

15 ns

50%−

15 ns

50%

50%

50%

50%+

15 ns

50%+

15 ns

MHz

MHz

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

21

Page 22

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

outputs − Ports P1, P2, P3, P4, P5, and P6 (continued)

TYPICAL LOW-LEVEL OUTPUT CURRENT

vs

LOW-LEVEL OUTPUT VOLTAGE

25

VCC = 2.2 V

P2.4

20

15

10

5

− Typical Low-Level Output Current − mA

OL

I

0

0.0 0.5 1.0 1.5 2.0 2.5

VOL − Low-Level Output Voltage − V

TA = 25°C

TA = 85°C

Figure 2

TYPICAL HIGH-LEVEL OUTPUT CURRENT

vs

HIGH-LEVEL OUTPUT VOLTAGE

0

VCC = 2.2 V

P2.4

TYPICAL LOW-LEVEL OUTPUT CURRENT

vs

LOW-LEVEL OUTPUT VOLTAGE

40

VCC = 3 V

P2.4

35

30

25

20

15

10

5

− Typical Low-Level Output Current − mA

OL

I

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

VOL − Low-Level Output Voltage − V

TA = 85°C

Figure 3

TYPICAL HIGH-LEVEL OUTPUT CURRENT

vs

HIGH-LEVEL OUTPUT VOLTAGE

0

VCC = 3 V

−5

P2.4

TA = 25°C

−5

−10

−15

−20

− Typical High-Level Output Current − mA

OH

I

−25

TA = 85°C

TA = 25°C

0.0 0.5 1.0 1.5 2.0 2.5

VOH − High-Level Output Voltage − V

Figure 4

NOTE: One output loaded at a time

22

−10

−15

−20

−25

−30

−35

TA = 85°C

−40

− Typical High-Level Output Current − mA

−45

OH

I

−50

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TA = 25°C

VOH − High-Level Output Voltage − V

Figure 5

Page 23

MSP430xW42x

)

t

d(LPM3)

Delay time

V

CC

2.2 V/3 V

μs

pg

Segment line

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

wake-up LPM3

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f = 1 MHz 6

±20

±20

±20

− 0.1

− 0.1

− 0.1

+ 0.1

6

μs

6

V

nA

V

t

d(LPM3

Delay time

f = 2 MHz

V

CC

= 2.2 V/3 V

f = 3 MHz

RAM (see Note 1)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VRAMh CPU halted (see Note 1) 1.6 V

NOTES: 1. This parameter defines the minimum supply voltage when the data in the program memory RAM remain unchanged. No program

execution should take place during this supply voltage condition.

LCD

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

(33)

V

(23)

V

(13)

V

(33) −

I

(R03)

I

(R13)

I

(R23)

V

(Sxx0)

V

(Sxx1)

V

(Sxx2)

V

(Sxx3)

Analog voltage

V

(03)

Input leakage

Segment line

voltage

Voltage at P5.7/R33 2.5 VCC +0.2

Voltage at P5.6/R23

Voltage at P5.5/R13

VCC = 3 V

(V33−V03) × 2/3 + V

(V

(33)−V(03)

) × 1/3 + V

03

(03)

Voltage at R33/R03 2.5 VCC +0.2

R03 = V

SS

P5.5/R13 = VCC/3

P5.6/R23 = 2 × VCC/3

I

= −3 μA, VCC = 3 V

(Sxx)

No load at all

segment and

common lines,

V

= 3 V

CC

V

(03)

V

(13)

V(

23)

V(

33)

V

(03)

V

(13)

V

(23)

V

(33)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

23

Page 24

MSP430xW42x

(See Figure 6 and

T

A

25 C

T

A

25 C

T

A

25 C

T

A

25 C

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

Comparator_A (see Note 1)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

(CC)

I

(Refladder/RefDiode)

CAON = 1, CARSEL = 0, CAREF = 0

CAON = 1, CARSEL = 0,

CAREF = 1/2/3,

No load at P1.6/CA0 and P1.7/CA1

VCC = 2.2 V 25 40

VCC = 3 V 45 60

VCC = 2.2 V 30 50

VCC = 3 V 45 71

μA

μA

V

(Ref025)

V

(Ref050)

V

(RefVT)

V

(IC)

V

(offset)

V

hys

Voltage @ 0.25 VCCnode

V

CC

Voltage @ 0.5 VCCnode

V

CC

(See Figure 6 and

Figure 7)

Common-mode input

voltage range

Offset voltage See Note 2 VCC = 2.2 V/3 V −30 30 mV

Input hysteresis CAON = 1 VCC = 2.2 V / 3 V 0 0.7 1.4 mV

PCA0 = 1, CARSEL = 1, CAREF = 1,

No load at P1.6/CA0 and P1.7/CA1

PCA0 = 1, CARSEL = 1, CAREF = 2,

No load at P1.6/CA0 and P1.7/CA1

PCA0 = 1, CARSEL = 1, CAREF = 3,

No load at P1.6/CA0 and P1.7/CA1;

= 85°C

T

A

CAON = 1 VCC = 2. 2V/3 V 0 VCC−1.0 V

TA = 25°C,

=

,

Overdrive 10 mV, without filter: CAF = 0

t

(response LH)

TA = 25°C

=

Overdrive 10 mV, with filter: CAF = 1

TA = 25°C

=

Overdrive 10 mV, without filter: CAF = 0

t

(response HL)

TA = 25°C,

=

,

Overdrive 10 mV, with filter: CAF = 1

NOTES: 1. The leakage current for the Comparator_A terminals is identical to I

2. The input offset voltage can be cancelled by using the CAEX bit to invert the Comparator_A inputs on successive measurements.

The two successive measurements are then summed together.

VCC = 2.2 V / 3 V 0.23 0.24 0.25

VCC = 2.2V / 3 V 0.47 0.48 0.50

VCC = 2.2 V 390 480 540

VCC = 3.0 V 400 490 550

VCC = 2.2 V 130 210 300

VCC = 3 V 80 150 240

VCC = 2.2 V 1.4 1.9 3.4

VCC = 3 V 0.9 1.5 2.6

VCC = 2.2 V 130 210 300

VCC = 3 V 80 150 240

VCC = 2.2 V 1.4 1.9 3.4

VCC = 3.0 V 0.9 1.5 2.6

specification.

lkg(Px.x)

mV

ns

μs

ns

μs

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 25

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

REFERENCE VOLTAGE

vs

FREE-AIR TEMPERATURE

650

600

Typical

550

500

− Reference Voltage − mV

(RefVT)

450

V

400

−45 −25 −5 15 35 55 75 95

TA − Free-Air Temperature − °C

Figure 6

V

0 V

CC

1

0

CAON

+

V+

_

V−

VCC = 3 V

REFERENCE VOLTAGE

vs

FREE-AIR TEMPERATURE

650

VCC = 2.2 V

600

Typical

550

500

− Reference Voltage − mV

(RefVT)

450

V

400

−45 −25 −5 15 35 55 75 95

TA − Free-Air Temperature − °C

Figure 7

CAF

Low Pass Filter

0

1

0

1

To Internal

Modules

CAOUT

τ ≈ 2 μs

Figure 8. Block Diagram of Comparator_A Module

V

CAOUT

V−

400 mV

V+

Overdrive

t

(response)

Figure 9. Overdrive Definition

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Set CAIFG

Flag

25

Page 26

MSP430xW42x

B

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

POR brownout, reset (see Notes 1 and 2)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

d(BOR)

V

CC(start)

V

(B_IT−)

V

hys(B_IT−)

t

(reset)

rownout

dVCC/dt ≤ 3 V/s (see Figure 10) 0.7 × V

dVCC/dt ≤ 3 V/s (see Figure 10, Figure 11, Figure 12) 1.71 V

dVCC/dt ≤ 3 V/s (see Figure 10) 70 130 180 mV

Pulse length needed at RST/NMI pin to accepted reset internally,

V

= 2.2 V/3 V

CC

2 μs

NOTES: 1. The current consumption of the brownout module is already included in the ICC current consumption data. The voltage level

V

+ V

(B_IT−)

hys(B_IT−)

2. During power up, the CPU begins code execution following a period of t

settings must not be changed until V

is ≤ 1.8 V.

CC

≥ V

CC(min)

, where V

after VCC = V

d(BOR)

is the minimum supply voltage for the desired operating

CC(min)

(B_IT−)

+ V

hys(B_IT−)

frequency. See the MSP430x4xx Family User’s Guide (SLAU056) for more information on the brownout/SVS circuit.

V

CC

2000 μs

(B_IT−)

. The default FLL+

V

2

1.5

1

(drop) − V

CC

V

0.5

V

hys(B_IT−)

V

(B_IT−)

V

CC(start)

1

0

Figure 10. POR/Brownout Reset (BOR) vs Supply Voltage

V = 3 V

cc

Typical Conditions

t

d(BOR)

V

CC(drop)

V

3 V

CC

t

pw

0

26

0.001 1 1000

tpw − Pulse Width − μst

Figure 11. V

CC(drop)

Level With a Square Voltage Drop to Generate a POR/Brownout Signal

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1 ns 1 ns

− Pulse Width − μs

pw

Page 27

MSP430xW42x

)

V

hys(SVS_IT−)

V

V

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

V

2

V = 3 V

cc

Typical Conditions

1.5

1

(drop) − V

CC

0.5

V

0

0.001 1 1000

tpw − Pulse Width − μs

V

CC(drop)

CC

3 V

t

pw

t

= t

f

r

t

f

t

r

tpw − Pulse Width − μs

Figure 12. V

CC(drop)

Level With a Triangle Voltage Drop to Generate a POR/Brownout Signal

SVS (supply voltage supervisor/monitor) (See Notes 1 and 2)

PARAMETER TEST CONDITIONS MIN NOM MAX UNIT

t

d(SVSR)

t

d(SVSon)

t

settle

V

(SVSstart)

V

hys(SVS_IT−

(SVS_IT−)

I

CC(SVS)

(see Note 1)

†

The recommended operating voltage range is limited to 3.6 V.

‡

t

is the settling time that the comparator o/p needs to have a stable level after VLD is switched VLD ≠ 0 to a different VLD value somewhere

settle

between 2 and 15. The overdrive is assumed to be > 50 mV.

NOTES: 1. The current consumption of the SVS module is not included in the I

2. The SVS is not active at power up.

dVCC/dt > 30 V/ms (see Figure 13) 5 150 μs

dVCC/dt ≤ 30 V/ms 2000 μs

SVSon, switch from VLD=0 to VLD ≠ 0, VCC = 3 V 20 150 μs

‡

VLD ≠ 0

12 μs

VLD ≠ 0, VCC/dt ≤ 3 V/s (see Figure 13) 1.55 1.7 V

VLD = 1 70 120 155 mV

VCC/dt ≤ 3 V/s (see Figure 13)

VCC/dt ≤ 3 V/s (see Figure 13), external voltage applied

on SVSIN

V

VLD = 2 .. 14

(SVS_IT−)

x 0.004

VLD = 15 4.4 10.4 mV

V

(SVS_IT−)

x 0.008

VLD = 1 1.8 1.9 2.05

VLD = 2 1.94 2.1 2.25

VLD = 3 2.05 2.2 2.37

VLD = 4 2.14 2.3 2.48

VLD = 5 2.24 2.4 2.6

VLD = 6 2.33 2.5 2.71

VCC/dt ≤ 3 V/s (see Figure 13)

VLD = 7 2.46 2.65 2.86

VLD = 8 2.58 2.8 3

VLD = 9 2.69 2.9 3.13

VLD = 10 2.83 3.05 3.29

VLD = 11 2.94 3.2 3.42

3.99

†

†

†

VCC/dt ≤ 3 V/s (see Figure 13), external voltage applied

on SVSIN

VLD = 12 3.11 3.35 3.61

VLD = 13 3.24 3.5 3.76

VLD = 14 3.43 3.7

†

VLD = 15 1.1 1.2 1.3

VLD ≠ 0, VCC = 2.2 V/3 V 10 15 μA

current consumption data.

CC

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

27

Page 28

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

V

V

(SVS_IT−)

V

(SVSstart)

V

(B_IT−)

V

CC(start)

Brownout

SVS out

Set POR

CC

Software Sets VLD>0:SVS is Active

V

hys(SVS_IT−)

V

hys(B_IT−)

Brownout

Region

Brownout

Region

1

0

t

d(BOR)

1

0

1

SVS Circuit is Active From VLD > to VCC < V

t

d(SVSon)

(B_IT−)

t

d(SVSR)

t

d(BOR)

Undefined

0

Figure 13. SVS Reset (SVSR) vs Supply Voltage

V

CC

3 V

t

pw

2

Rectangular Drop

1.5

− V

1

CC(drop)

V

0.5

0

1 10 1000

Figure 14. V

CC(drop)

V

Triangular Drop

CC(drop)

1 ns 1 ns

V

CC

t

pw

3 V

100

t

− Pulse Width − μs

pw

V

CC(drop)

t

= t

f

r

t

f

t

r

t − Pulse Width − μs

With a Square Voltage Drop and a Triangle Voltage Drop to Generate an SVS Signal

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 29

MSP430xW42x

Step size between adjacent DCO taps:

(DCO)

Temperature drift, N

(DCO)

01Eh, FN_8=FN_4=FN_3=FN_2=0

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

DCO

PARAMETER TEST CONDITIONS V

N

=01Eh, FN_8=FN_4=FN_3=FN_2=0, D = 2, DCOPLUS= 0,

f

(DCOCLK)

f

(DCO=2)

f

(DCO=27)

f

(DCO=2)

f

(DCO=27)

f

(DCO=2)

f

(DCO=27)

f

(DCO=2)

f

(DCO=27)

f

(DCO=2)

f

(DCO=27)

S

n

D

t

D

V

(DCO)

f

= 32.738 kHz

Crystal

FN_8=FN_4=FN_3=FN_2=0 , DCOPLUS = 1

FN_8=FN_4=FN_3=FN_2=0, DCOPLUS = 1

FN_8=FN_4=FN_3=0, FN_2=1; DCOPLUS = 1

FN_8=FN_4=FN_3=0, FN_2=1; DCOPLUS = 1

FN_8=FN_4=0, FN_3= 1, FN_2=x; DCOPLUS = 1

FN_8=FN_4=0, FN_3= 1, FN_2=x;, DCOPLUS = 1

FN_8=0, FN_4= 1, FN_3= FN_2=x; DCOPLUS = 1

FN_8=0, FN_4=1, FN_3= FN_2=x; DCOPLUS = 1

FN_8=1, FN_4=FN_3=FN_2=x; DCOPLUS = 1

FN_8=1,FN_4=FN_3=FN_2=x,DCOPLUS = 1

Step size between adjacent DCO taps:

Sn = f

DCO(Tap n+1)

Temperature drift, N

/ f

DCO(Tap n)

(see Figure 16 for taps 21 to 27)

= 01Eh, FN_8=FN_4=FN_3=FN_2=0

=

D = 2, DCOPLUS = 0

Drift with VCC variation, N

= 01Eh, FN_8=FN_4=FN_3=FN_2=0

(DCO)

D = 2, DCOPLUS = 0

1 < TAP ≤ 20 1.06 1.11

CC

2.2 V/3 V 1 MHz

2.2 V 0.3 0.65 1.25

2.2 V 2.5 5.6 10.5

2.2 V 0.7 1.3 2.3

2.2 V 5.7 10.8 18

2.2 V 1.2 2 3

2.2 V 9 15.5 25

2.2 V 1.8 2.8 4.2

2.2 V 13.5 21.5 33

2.2 V 2.8 4.2 6.2

2.2 V 21 32 46

TAP = 27 1.07 1.17

2.2 V –0.2 –0.3 –0.4

2.2 V/3 V 0 5 15 %/V

MIN TYP MAX UNIT

3 V 0.3 0.7 1.3

3 V 2.7 6.1 11.3

3 V 0.8 1.5 2.5

3 V 6.5 12.1 20

3 V 1.3 2.2 3.5

3 V 10.3 17.9 28.5

3 V 2.1 3.4 5.2

3 V 16 26.6 41

3 V 4.2 6.3 9.2

3 V 30 46 70

3 V –0.2 –0.3 –0.4

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

%/_C

f

(DCO)

f

(DCO3V)

1.0

1.8 3.02.4 3.6

Figure 15. DCO Frequency vs Supply Voltage VCC and vs Ambient Temperature

f

(DCO)

f

(DCO205C)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1.0

20 6040 85

0−20−400

TA − °CVCC − V

29

Page 30

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

1.17

(DCO)

f

- Stepsize Ratio between DCO Taps

n

S

1.11

1.07

1.06

Max

Min

12720

DCO Tap

Figure 16. DCO Tap Step Size

Legend

Tolerance at Tap 27

DCO Frequency

Adjusted by Bits

9

2

to 25 in SCFI1 {N

Tolerance at Tap 2

{DCO}

}

30

FN_2=0

FN_3=0

FN_4=0

FN_8=0

Overlapping DCO Ranges:

Uninterrupted Frequency Range

FN_2=1

FN_3=0

FN_4=0

FN_8=0

FN_2=x

FN_3=1

FN_4=0

FN_8=0

FN_2=x

FN_3=x

FN_4=1

FN_8=0

FN_2=x

FN_3=x

FN_4=x

FN_8=1

Figure 17. Five Overlapping DCO Ranges Controlled by FN_x Bits

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 31

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

crystal oscillator, LFXT1 oscillator (see Notes 1 and 2)

PARAMETER TEST CONDITIONS V

CC

OSCCAPx = 0h 2.2 V/3 V 0

C

XIN

Integrated load capacitance

OSCCAPx = 1h 2.2 V/3 V 10

OSCCAPx = 2h

2.2 V/3 V 14

OSCCAPx = 3h 2.2 V/3 V 18

OSCCAPx = 0h 2.2 V/3 V 0

C

XOUT

Integrated load capacitance

OSCCAPx = 1h 2.2 V/3 V 10

OSCCAPx = 2h

2.2 V/3 V 14

OSCCAPx = 3h 2.2 V/3 V 18

V

IL

V

IH

Input levels at XIN see Note 3 2.2 V/3 V

NOTES: 1. The parasitic capacitance from the package and board may be estimated to be 2pF. The effective load capacitor for the crystal is

(C

XIN

x C

XOUT

) / (C

XIN

+ C

). It is independent of XTS_FLL.

XOUT

2. To improve EMI on the low-power LFXT1 oscillator, particularly in the LF mode (32 kHz), the following guidelines must be

observe:

• Keep as short a trace as possible between the ’xW42x and the crystal.

• Design a good ground plane around oscillator pins.

• Prevent crosstalk from other clock or data lines into oscillator pins XIN and XOUT.

• Avoid running PCB traces underneath or adjacent to XIN an XOUT pins.

• Use assembly materials and praxis to avoid any parasitic load on the oscillator XIN and XOUT pins.

• If conformal coating is used, ensure that it does not induce capacitive/resistive leakage between the oscillator pins.

• Do not route the XOUT line to the JTAG header to support the serial programming adapter as shown in other documentation.

This signal is no longer required for the serial programming adapter.

3. Applies only when using an external logic-level clock source. XTS_FLL must be set. Not applicable when using a crystal or resonator.

4. External capacitance is recommended for precision real-time clock applications; OSCCAPx = 0h.

MIN TYP MAX UNIT

V

0.8×V

SS

CC

0.2×V

V

CC

CC

pF

pF

V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

31

Page 32

MSP430xW42x

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

Scan IF, port drive, port timing

PARAMETER TEST CONDITIONS V

Voltage drop due to

V

OL(SIFCHx)

excitation transistor’s

on−resistance.

I

= 2.0 mA, SIFTEN = 1 3 V 0.3 V

(SIFCHx)

(see Figure 18)

Voltage drop due to

V

OH(SIFCHx)

(see Note 1)

damping transistor’s

on−resistance.

I

= −200 μA, SIFTEN = 1 3 V 0.1 V

(SIFCHx)

(see Figure 18)

V

OL(SIFCOM)

I

SIFCHx(tri-state)

Δt

t

:

dSIFCH

wEx(tsm)−twSIFCH

(see Figure 18)

Change of pulse width

of internal signal

SIFEX(tsm) to pulse

width at pin SIFCHx

I

V

= 3 mA, SIFSH = 1 2.2 V/3 V 0 0.1 V

(SIFCOM)

= 0 V to AVCC, port function

(SIFCHx)

disabled, SIFSH = 1

I

= 3 mA,

(SIFCHx)

t

Ex(SIFCHx)

= 500 ns ±20%

NOTE: 1. SIFCOM=1.5V , supplied externally. (See Figure 19).

CC

3 V −50 50 nA

2.2 V/3 V −20 20 ns

MIN TYP MAX UNIT

t

Ex(SIFCHx)

SIFEX(tsm)

P6.x/SIFCH.x

t

SIFCH(x)

Figure 18. P6.x/SIFCHx timing, SIFCHx function selected

SIFCOM

V

OH(SIFCHx)

I

(SIFCHx)

Damping

Transistor

P6.x/SIFCH.x

V

OL(SIFCHx)

Excitation

Transistor

Figure 19. Voltage drop due to on-resistance

32

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 33

MSP430xW42x

g

g

generator operating

C

L

SIFCOM pin = 470 nF ±20%

ms

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

Scan IF, sample capacitor/Ri timing

PARAMETER TEST CONDITIONS V

C

SHC(SIFCHx)

Ri

(SIFCHx)

t

Hold

(See Note 1)

Sample capacitance

at SIFCHx pin

Serial input resistance

at the SIFCHx pin

SIFEx(tsm) = 1, SIFSH = 1 2.2 V/3 V 5 7 pF

SIFEx(tsm) = 1, SIFSH = 1 2.2 V/3 V 1.5 3 kΩ

Maximum hold time ΔV

< 3 mV 62 μs

sample

NOTES: 1. The sampled voltage at the sample capacitance varies less than 3 mV (ΔV

after t

, the sampled voltage may be any other value.

Hold

2. The minimum sampling time (7.6 x tau for 1/2 LSB accuracy) with maximum C

t

sample(min)

~ 7.6 x C

SHC(SIFCHx)

x (Ri

(SIFCHx)

+ Ri

(source)

) with Ri

(source)

Scan IF, VCC/2 generator

PARAMETER TEST CONDITIONS V

AV

CC

AI

CC

f

refresh(SIFCOM)

Analog supply

voltage

Scan IF VCC/2

enerator operatin

supply current into

AV

terminal

CC

VCC/2 refresh

frequency

AVCC = DVCC (connected together)

AV

= DVSS (connected together)

SS

at

C

at SIFCOM pin = 470 nF ±20%,

f

refresh(SIFCOM)

=32768 Hz

Source clock = ACLK

,

CC

) during the hold time t

sample

SHC(SIFCHx)

estimated at 3 kΩ, t

CC

2.2 V 250 350

3 V 370 450

2.2 V/3 V

MIN TYP MAX UNIT

If the voltage is sampled

Hold.

and Ri

sample(min)

(SIFCHx)

= 319 ns.

and Ri

(source)

is

MIN TYP MAX UNIT

2.2 3.6 V

nA

30 32.768 kHz

V

(SIFCOM)

I

source(SIFCOM)

I

sink(SIFCOM)

t

recovery(SIFCOM)

t

on(SIFCOM)

t

VccSettle(SIFCOM)

(See Note 1)

Output voltage at

pin SIFCOM

SIFCOM source

current (see Note 2

and Figure 20)

SIFCOM sink

current (see Note 2

and Figure 20)

Time to recover

from Voltage Drop

on Load

Time to reach 98%

after V

CC/

2 is

switched on

Settling time to

±V

/512 (2 LSB)

CC

after AVCC voltage

change

CL at SIFCOM pin = 470 nF ±20%,

I_Load = 1μA

I

= I

Load1

I

= 3 mA, t

Load2

C

at SIFCOM pin = 470 nF ±20%

L

LOAD3

= 0 mA

load(on)

= 500nS,

CL at SIFCOM pin = 470 nF ±20%

f

refresh(SIFCOM)

= 32768 Hz

SIFEN =1, SIFVCC2 =1, SIFSH =0,

AV

CC

f

refresh(SIFCOM)

= AV

−100 mV

CC

= 32768 Hz

AVCC = AVCC + 100mV

f

refresh(SIFCOM)

= 32768 Hz

AVCC/2 −

.05

AVCC/2

AVCC/2 +

.05

2.2 V −500

3 V −900

2.2 V 150

3 V 180

2.2 V/3 V 30 μs

2.2 V/3 V

1.7 6 ms

2.2 V/3 V 80

2.2 V/3 V 3

NOTES: 1. The settling time after an AVCC voltage change is the time to for the voltage at pin SIFCOM to settle to AVCC/2 ± 2LSB.

2. The sink and source currents are a function of the voltage at the pin SIFCOM. The maximum currents are reached if SIFCOM is

shorted to GND or V

. Due to the topology of the output section (refer to Figure 20) the VCC/2 generator can source relatively large

CC

currents but can sink only small currents.

V

μA

nA

ms

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

33

Page 34

MSP430xW42x

p

y

operating supply

C

L

SIFCOM pin = 470 nF ±20%

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

V

CC

VCC/2

I

Source(SIFCOM)

SIFCOM

I

Sink(SIFCOM)

Figure 20. P6.x/SIFCHx timing, SIFCHx function selected

Scan IF, 10-bit DAC (See Note 1)

AV

AI

CC

CC

PARAMETER TEST CONDITIONS V

Analog supply voltage

AVCC = DVCC (connected together)

AV

= DVSS (connected together)

SS

Scan IF 10-bit DAC

o

erating suppl

current into AV

CC

at

f

refresh(SIFCOM)

= 32768 Hz

,

CL at SIFCOM pin = 470 nF ±20%,

terminal

CC

2.2 V 23 45

3 V 33 60

Resolution 10 bit

R

= 1000 MΩ,

INL

DNL

E

ZS

E

G

R

O

t

on(SIFDAC)

t

Settle(SIFDAC)

L

C

= 20 pF

L

R

= 1000 MΩ,

L

C

= 20 pF

L

2.2 V/3 V ±2 ±5 LSB

2.2 V/3 V ±1 LSB

Zero Scale Error 2.2 V/3 V ±10 mV

Gain Error 2.2 V/3 V 0.6 %

Output resistance 25 50 kΩ

On time after AVCC of

SIFDAC is switched on

Settling time

V

− V

+SIFCA

SIFDAC code = 1C0h → 240h

V

SIFDAC(240h)

SIFDAC code = 240h → 1C0h,

V

SIFDAC(1C0h)

= ±6 mV 2.2 V/3 V 2.0 μs

SIFDAC

− V

− V

+SIFCA

+SIFCA

= +6 mV

= −6 mV

2.2 V/3 V 2.0 μs

2.2 V/3 V 2.0 μs

NOTES: 1. The SIFDAC operates from AVCC and SIFVSS. All parameters are based on these references.

MIN TYP MAX UNIT

2.2 3.6 V

μA

34

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 35

MSP430xW42x

Scan IF oscillator at

Scan IF oscillator at

Scan IF oscillator at

MIXED SIGNAL MICROCONTROLLER

SLAS383B − OCTOBER 2003 − REVISED JUNE 2007

electrical characteristics over recommended operating free-air temperature (unless otherwise

noted) (continued)

Scan IF, Comparator

AV

CC

AI

CC

V

IC

V

Offset

dV

/dT

Offset

dV

/dV

Offset

V

hys

t

on(SIFCA)

t

Settle(SIFCA)

PARAMETER TEST CONDITIONS V

Analog supply voltage

AVCC = DVCC (connected together)

AV