Page 1

查询DRV593供应商

www.ti.com

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

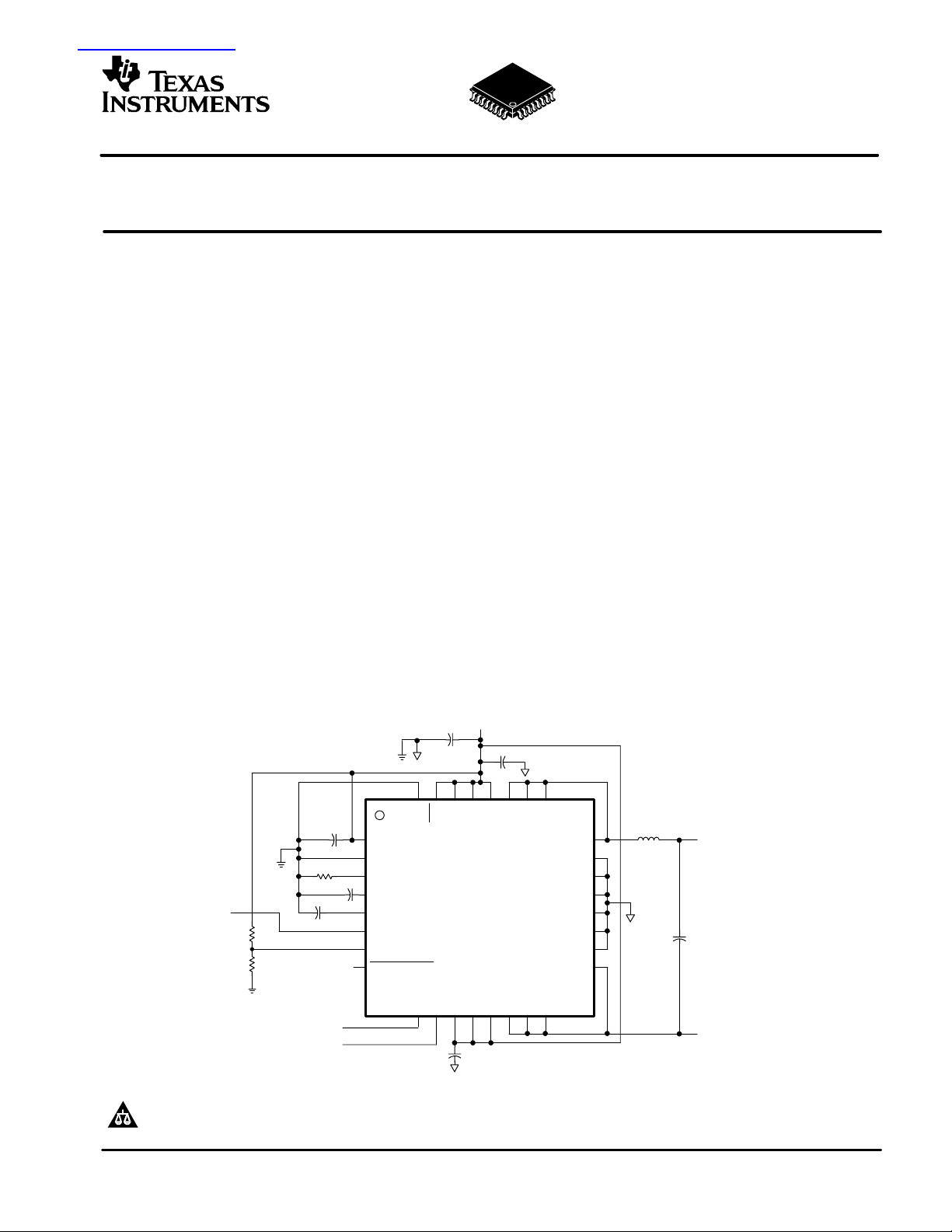

±3−A HIGH−EFFICIENCY PWM POWER DRIVER

DRV593

DRV594

FEATURES

D Operation Reduces Output Filter Size and

Cost by 50% Compared to DRV591

D ±3-A Maximum Output Current

D Low Supply Voltage Operation: 2.8 V to 5.5 V

D High Efficiency Generates Less Heat

D Overcurrent and Thermal Protection

D Fault Indicators for Overcurrent, Thermal and

Undervoltage Conditions

D Two Selectable Switching Frequencies

D Internal or External Clock Sync

D PWM Scheme Optimized for EMI

D 9×9 mm PowerPAD Quad Flatpack Package

APPLICATIONS

D Thermoelectric Cooler (TEC) Driver

D Laser Diode Biasing

DESCRIPTION

The DRV593 and DRV594 are high-efficiency,

high-current power amplifiers ideal for driving a wide

variety of thermoelectric cooler elements in systems

powered from 2.8 V to 5.5 V. The operation of the device

requires only one inductor and capacitor for the output

filter, saving significant printed-circuit board area.

Pulse-width modulation (PWM) operation and low output

stage on-resistance significantly decrease power

dissipation in the amplifier.

The DRV593 and DRV594 are internally protected against

thermal and current overloads. Logic-level fault indicators

signal when the junction temperature has reached

approximately 115°C to allow for system-level shutdown

before the amplifier’s internal thermal shutdown circuitry

activates. The fault indicators also signal when an

overcurrent event has occurred. If the overcurrent circuitry

is tripped, the devices automatically reset (see application

information section for more details).

The PWM switching frequency may be set to 500 kHz or

100 kHz depending on system requirements. To eliminate

external components, the gain is fixed at 2.3 V/V for the

DRV593. For the DRV594, the gain is fixed at 14.5 V/V.

V

DD

1 µF

120 kΩ

DC Control

Voltage

1 kΩ

1 kΩ

Shutdown Control

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of TexasInstruments

semiconductor products and disclaimers thereto appears at the end of this data sheet.

PowerPAD is a trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date. Products

conform to specifications per the terms of Texas Instruments standard warranty.

Production processing does not necessarily include testing of all parameters.

220 pF

1 µF

FAULT1

FAULT0

AVDD

AGND (Connect to PowerPAD)

ROSC

COSC

AREF

IN+

IN-INSHUTDOWN

10 µF

FREQ

FAULT1

PVDD

INT/EXT

DRV593

DRV594

FAULT0

PVDD

1 µF

PVDD

PVDD

1 µF

PWM

PVDD

PVDD

H/C

PWM

H/C

PWM

PGND

PGND

PGND

PGND

PGND

PGND

H/C

PWM

H/C

10 µH

Copyright 2002, Texas Instruments Incorporated

To TEC or Laser

Diode Anode

10 µF

To TEC or Laser

Diode Cathode

Page 2

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

www.ti.com

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

ORDERING INFORMATION

T

A

-40°C to 85°C

(1)

This package is available taped and reeled. To order this

packaging option, add an R suffix to the part number (e.g.,

PowerPAD QUAD FLATPACK

(VFP)

DRV593VFP

DRV594VFP

(1)

(1)

DRV593VFPR or DRV594VFPR).

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range unless otherwise noted

Supply voltage, AVDD, PVDD -0.3 V to 5.5 V

Input voltage, V

I

Output current, IO (FAULT0, FAULT1) 1 mA

Continuous total power dissipation See Dissipation Rating Table

Operating free-air temperature range, T

Operating junction temperature range, T

Storage temperature range, T

(1)

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only , and

stg

A

J

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability .

(1)

DRV593, DRV594

-0.3 V to VDD + 0.3 V

-40°C to 85°C

-40°C to 150°C

-65°C to 165°C

RECOMMENDED OPERATING CONDITIONS

MIN MAX UNIT

Supply voltage, AVDD

High-level input voltage, V

Low-level input voltage, V

Operating free-air temperature, T

PVDD

,

2.8

5.5

IH

IL

A

FREQ, INT/EXT, SHUTDOWN, COSC

FREQ, INT/EXT, SHUTDOWN, COSC

-40

2

0.8

85

V

V

V

°C

PACKAGE DISSIPATION RATINGS

PACKAGE

Θ

JA

(°C/W)

Θ

JC

(°C/W)

(1)

VFP 29.4 1.2 4.1 W

(1)

This data was taken using 2 oz trace and copper pad that is

soldered directly to a JEDEC standard 4-layer 3 in× 3 in PCB.

2

T

A

POWER RATING

= 25°C

Page 3

DRV593

VDD = 5 V, IO = 4 A

VDD = 3.3 V, IO = 4 A

www.ti.com

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

ELECTRICAL CHARACTERISTICS

over operating free-air temperature range unless otherwise noted

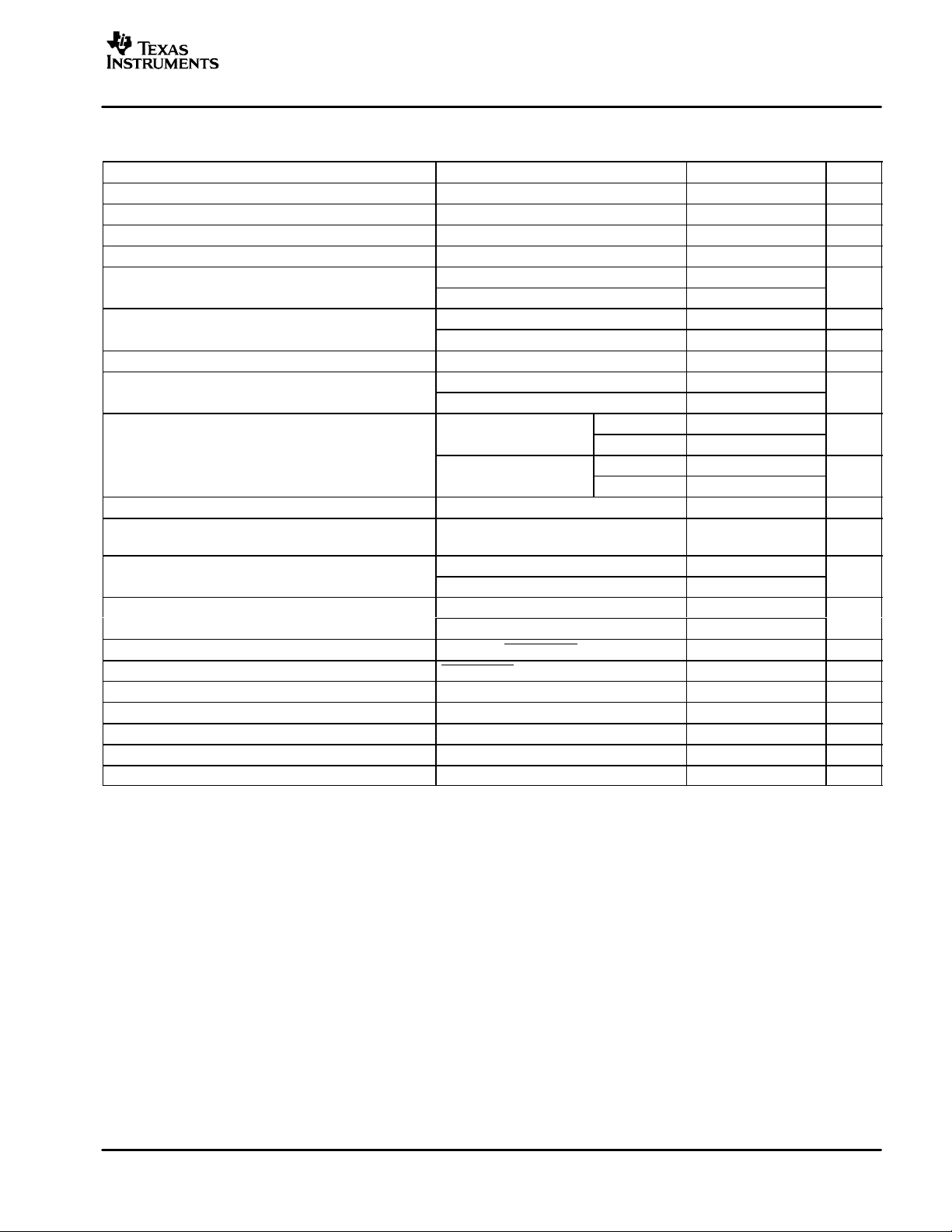

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

|VOO| Output offset voltage (measured differentially) VI = VDD/2, IO = 0 A 14 100 mV

|IIH| High-level input current VDD = 5.5V , VI = V

|IIL| Low-level input current VDD = 5.5V , VI = 0 V 1 µA

V

n

V

ICM

A

v

Integrated output noise voltage f = <1 Hz to 10 kHz 40 µV

Common-mode voltage range

Closed-loop voltage gain

VDD = 5 V 1.2 3.8

VDD = 3.3 V 1.2 2.1

DRV593 2.1 2.3 2.6 V/V

DRV594 13.7 14.5 15.3 V/V

Full power bandwidth 60 kHz

V

O

Voltage output (measured dif ferentially)

IO = ±1 A, r

IO = ±3 A, r

VDD = 5 V , IO = 4 A,

= 65 mΩ, VDD = 5 V 4.87

ds(on)

= 65 mΩ, VDD = 5 V 4.61

ds(on)

,

TA = 25°C

r

DS(on)

Drain-source on-state resistance

VDD = 3.3 V , IO = 4 A,

,

TA = 25°C

Maximum continuous current output 3 A

I

q

I

q(SD)

Status flag output pins (FAULT0, FAULT1)

Fault active (open drain output)

External clock frequency range

Quiescent current

Quiescent current in shutdown mode VDD = 5 V, SHUTDOWN = 0.8 V 0 40 80 µA

Sinking 200 µA 0.1 V

For 500 kHz operation 225 250 300

For 100 kHz operation 45 50 55

VDD = 5 V , No load or filter 4 12

VDD = 3.3 V , No load or filter 2.5 8

Output resistance in shutdown SHUTDOWN = 0.8 V 1 2 kΩ

Power-on threshold 1.7 2.8 V

Power-off threshold 1.6 2.6 V

Thermal trip point FAULT0 active 115 °C

Thermal shutdown Power off 150 °C

Z

I

Input impedance (IN+, IN-) 100 kΩ

DD

High side 25 60 95

Low side 25 65 95

High side 25 80 140

Low side 25 90 140

DRV594

1 µA

V

V

mΩ

mΩ

kHz

mA

3

Page 4

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

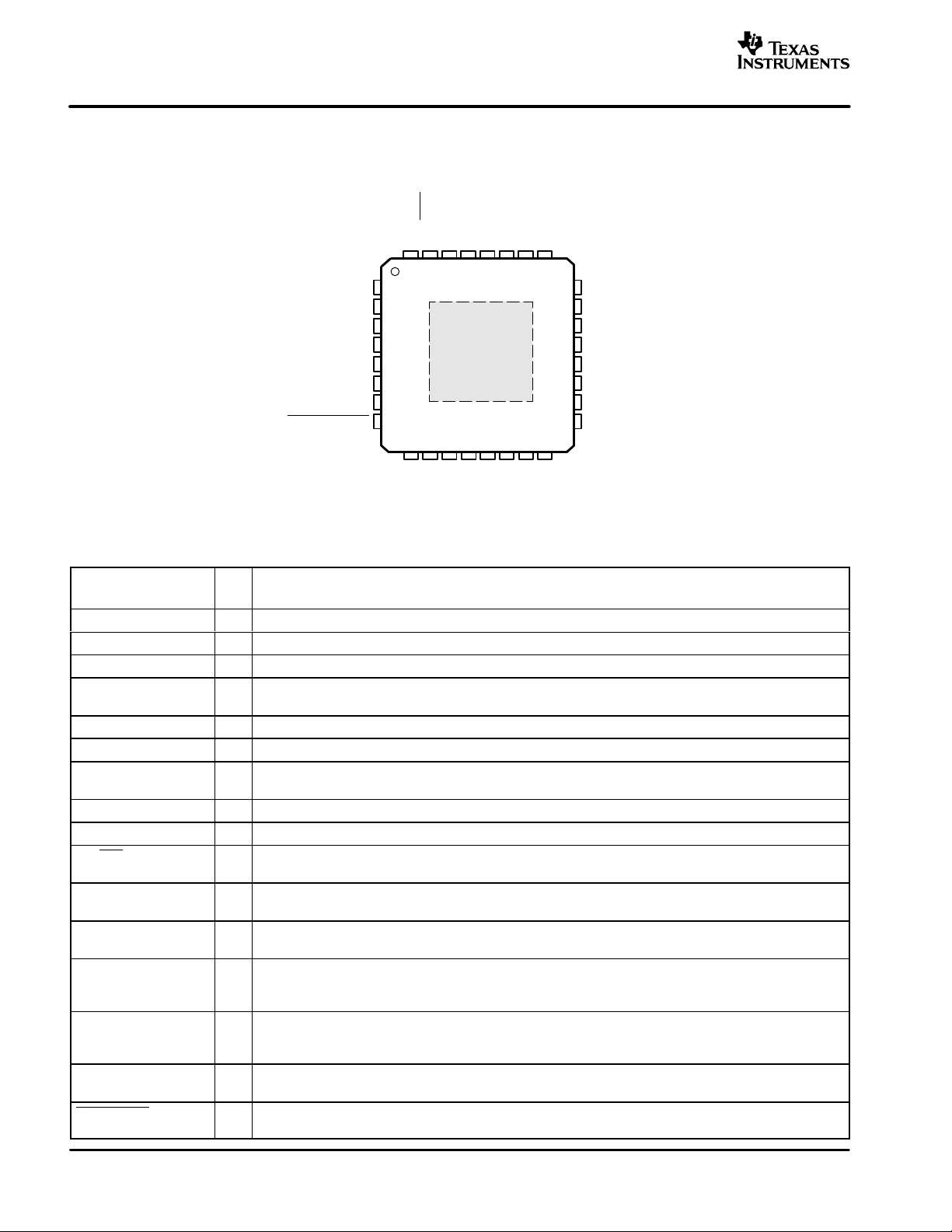

PIN ASSIGNMENTS

www.ti.com

VFP PACKAGE

(TOP VIEW)

AVDD

AGND

ROSC

COSC

AREF

IN+

IN-

SHUTDOWN

PVDD

FREQ

INT/EXT

PVDD

PVDD

31 30 29 28 27

32 26

1

2

3

4

5

6

7

8

PowerPAD

910

11 12 13 14 15

PVDD

FAULT1

FAULT0

PVDD

PVDD

PWM

PWM

H/C

H/C

PWM

25

16

H/C

24

23

22

21

20

19

18

17

PWM

PGND

PGND

PGND

PGND

PGND

PGND

H/C

Terminal Functions

TERMINAL

NAME NO.

AGND 2 Analog ground

AREF 5 O Connect 1 µF capacitor to ground for AREF voltage filtering

AVDD 1 I Analog power supply

COSC 4 I Connect capacitor to ground to set oscillation frequency (220 pF for 500 kHz, 1 nF for 100 kHz) when the internal

FAULT0 10 O Fault flag 0, low when active open drain output (see application information)

FAULT1 9 O Fault flag 1, low when active open drain output (see application information)

FREQ 32 I

IN- 7 I Negative differential input

IN+ 6 I Positive differential input

INT/EXT 31 I Selects the internal oscillator when a TTL logic high is applied to this terminal; selects the use of an external oscil-

H/C 14, 15,

16, 17

PWM 24, 25,

26, 27

PGND 18, 19,

20, 21,

22, 23

PVDD 11, 12,

13, 28,

29, 30

ROSC 3 I Connect 120-kΩ resistor to AGND to set oscillation frequency (either 500 kHz or 100 kHz). Not needed if an

SHUTDOWN 8 I Places the amplifier in shutdown mode when a TTL logic low is applied to this terminal; places the amplifier

I/O DESCRIPTION

oscillator is selected; connect clock signal when an external oscillator is used

Selects 500 kHz switching frequency when a TTL logic low is applied to this terminal; selects 100 kHz switching

frequency when a TTL logic high is applied

lator when a TTL logic low is applied to this terminal

O Direction control output for heat and cool modes (4 pins)

O PWM output for voltage magnitude (4 pins)

High-current ground (6 pins)

I High-current power supply (6 pins)

external clock is used.

in normal operation when a TTL logic high is applied

4

Page 5

www.ti.com

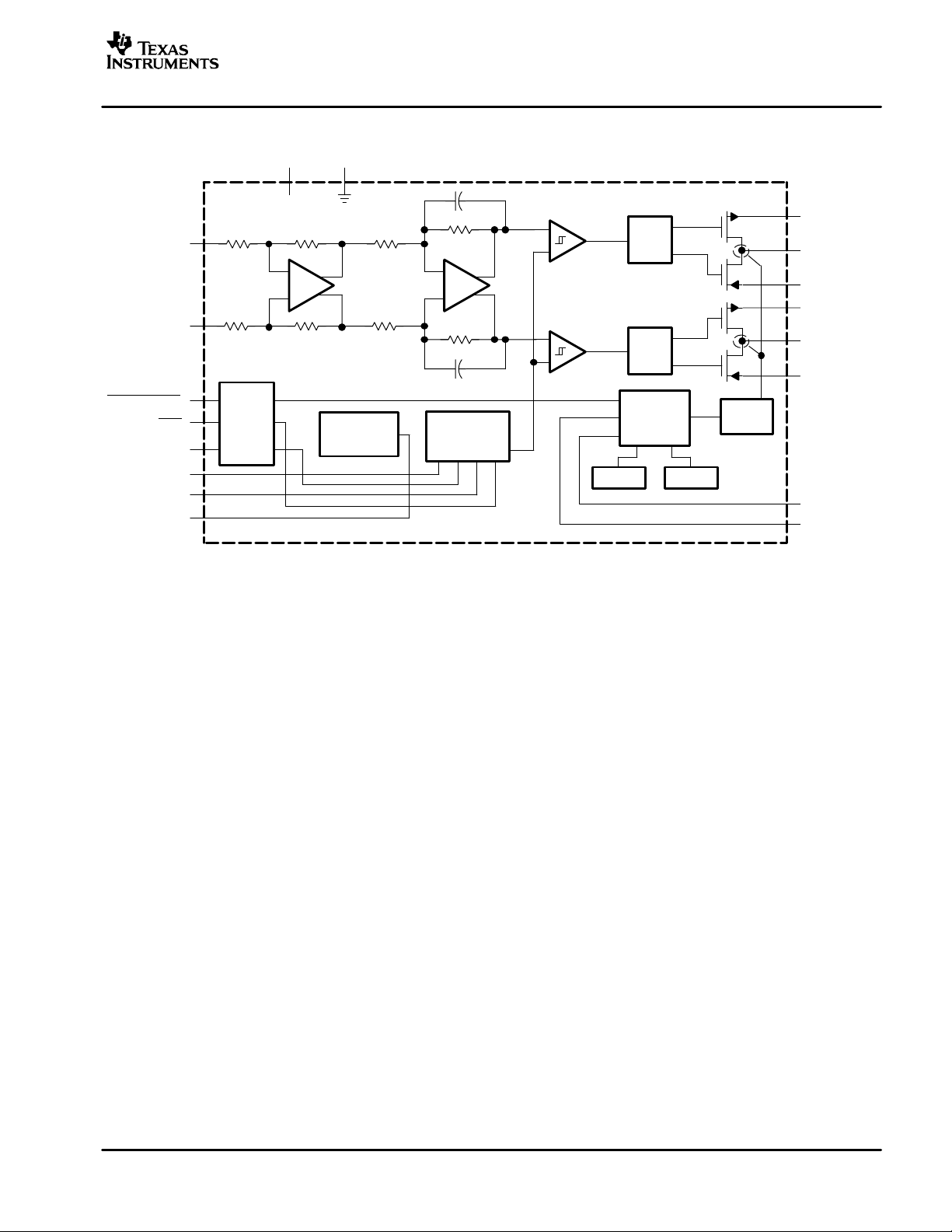

FUNCTIONAL BLOCK DIAGRAM

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

IN-

IN+

SHUTDOWN

INT/EXT

FREQ

COSC

ROSC

AREF

R

R

TTL

Input

Buffer

AVDD

AVDD

AGND

2.3 ×R (DRV593)

14.5 x R (DRV594)

_

+

_

+

2.3 ×R (DRV593)

14.5 x R (DRV594)

Biases

References

and

_

+

_

+

Ramp

Generator

+

_

+

_

Thermal VDDok

Gate

Drive

Gate

Drive

Start-Up

Protection

Logic

PVDD

H/C

PGND

PVDD

PWM

PGND

OC

Detect

FAULT0

FAULT1

5

Page 6

DRV593

)

r

DS(on)

Drain source on state resistance

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

TYPICAL CHARACTERISTICS

TABLE OF GRAPHS

Efficiency vs Load resistance 2, 3

vs Supply voltage 4

r

DS(on

I

q

PSRR Power supply rejection ratio vs Frequency 8, 9

I

O

V

IO

Drain-source on-state resistance

Supply current vs Supply voltage 7

Closed loop response 12, 13

Maximum output current

Input offset voltage Common-mode input voltage 16, 17

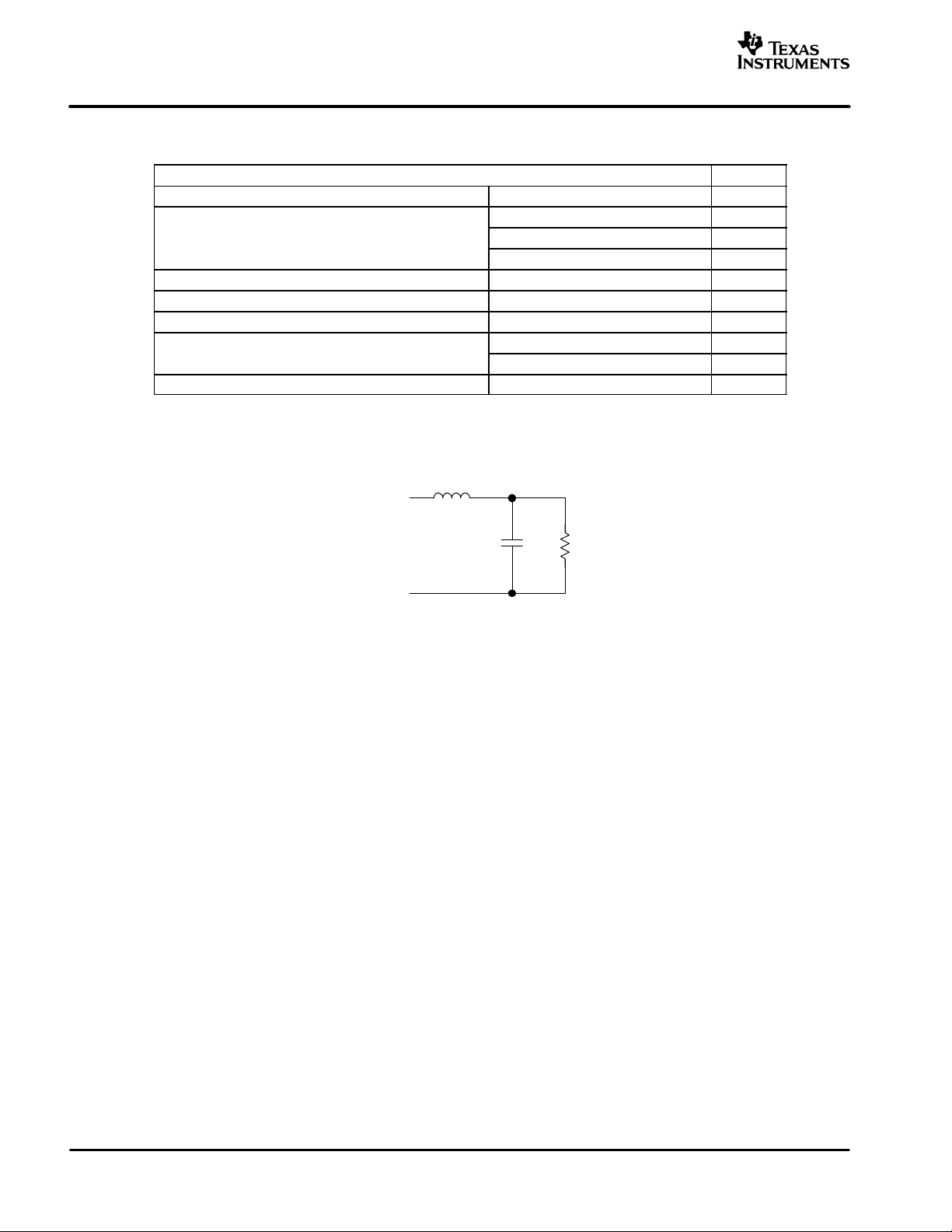

TEST SETUP FOR GRAPHS

The LC output filter used in Figures 2, 3, 8, and 9 is shown below.

L1

PWM

vs Free-air temperature 5

vs Free-air temperature 6

vs Output voltage 14

vs Ambient temperature 15

www.ti.com

FIGURE

C1

H/C

L1 = 10 µH (part number: CDRH104R, manufacturer: Sumida)

C1 = 10 µF (part number: ECJ-4YB1C106K, manufacturer: Panasonic)

R

L

Figure 1. LC Output Filter

6

Page 7

www.ti.com

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

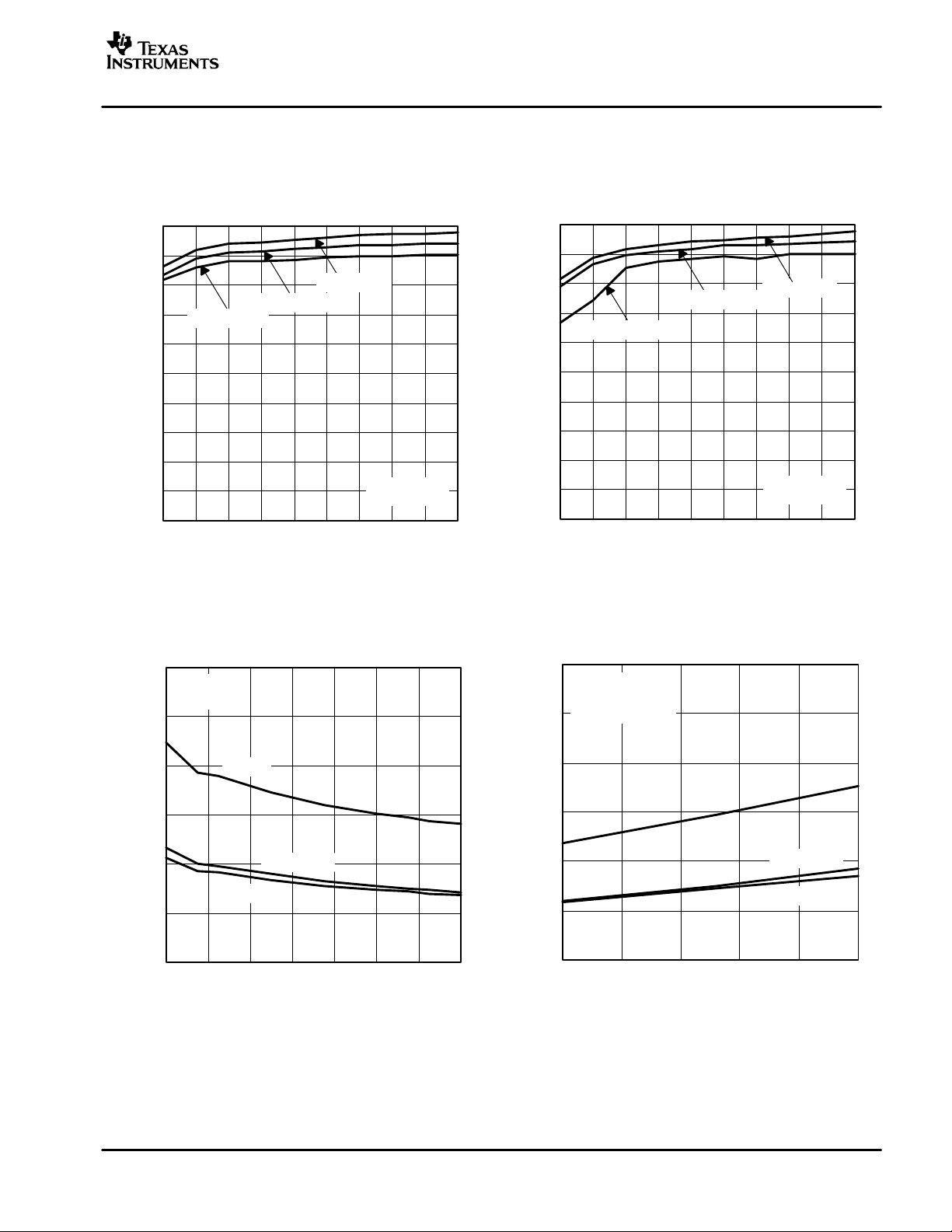

TYPICAL CHARACTERISTICS

EFFICIENCY

vs

LOAD RESISTANCE

100

90

80

70

60

50

40

Efficiency - %

30

20

10

PO = 0.5 W

0

12345678910

PO = 1 W

RL - Load Resistance - Ω

PO = 2 W

VDD = 5 V

fS = 500 kHz

Figure 2

DRAIN-SOURCE ON-STATE RESISTANCE

vs

SUPPLY VOLTAGE

300

IO = 1 A

TA = 25°C

250

EFFICIENCY

vs

LOAD RESISTANCE

100

90

80

70

60

50

40

Efficiency - %

30

20

10

0

PO = 0.25 W

12345678910

RL - Load Resistance - Ω

PO = 0.5 W

PO = 1 W

VDD = 3.3 V

fS = 500 kHz

Figure 3

DRAIN-SOURCE ON-STATE RESISTANCE

vs

FREE-AIR TEMPERATURE

300

VDD = 5 V

IO = 1 A

VFP Package

250

200

150

100

50

- Drain-Source On-State Resistance - mΩ

DS(on)

r

0

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

Total

Low Side

High Side

VDD - Supply Voltage - V

Figure 4

200

Total

150

100

50

- Drain-Source On-State Resistance - mΩ

DS(on)

r

0

-40 -15 10 35 60 85

TA - Free-Air Temperature - °C

Figure 5

Low Side

High Side

7

Page 8

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

TYPICAL CHARACTERISTICS

www.ti.com

DRAIN-SOURCE ON-STATE RESISTANCE

vs

FREE-AIR TEMPERATURE

300

VDD = 3.3 V

IO = 1 A

VFP Package

250

Total

200

150

Low Side

100

High Side

50

- Drain-Source On-State Resistance - mΩ

DS(on)

r

0

-40 -15 10 35 60 85

TA - Free-Air Temperature - °C

Figure 6

SUPPLY CURRENT

vs

SUPPLY VOLTAGE

10

No Load

9

8

7

6

5

4

3

- Supply Current - mA

q

I

2

1

0

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

VDD - Supply Voltage - V

Figure 7

POWER SUPPLY REJECTION RATIO

vs

FREQUENCY

-20

VDD = 5 V

fS = 500 kHz

-30

RL = 1 Ω

V

= 100 mV

ripple

-40

-50

-60

-70

PSRR - Power Supply Rejection Ratio - dB

-80

10 100 1k 10k 100k

pp

f - Frequency - Hz

Figure 8

POWER SUPPLY REJECTION RATIO

vs

FREQUENCY

-20

VDD = 3.3 V

fS = 500 kHz

-30

RL = 1 Ω

V

= 100 mV

ripple

-40

-50

-60

-70

PSRR - Power Supply Rejection Ratio - dB

-80

10 100 1k 10k 100k

pp

f - Frequency - Hz

Figure 9

8

Page 9

www.ti.com

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

TYPICAL CHARACTERISTICS

DRV593

CLOSED LOOP RESPONSE

4

Phase

3

Gain

2

Gain - V/V

1

VDD = 5 V

No Load

0

10 100 1k 10k 100k

f - Frequency - Hz

Figure 10

DRV593

CLOSED LOOP RESPONSE

4

Phase

3

Gain

2

Gain - V/V

1

VDD = 3.3 V

No Load

0

10 100 1k 10k 100k

f - Frequency - Hz

Figure 12

10

0

-10

-20

-30

-40

-50

-60

-70

-80

10

0

-10

-20

-30

-40

-50

-60

-70

-80

DRV594

CLOSED LOOP RESPONSE

16

14

12

Phase

10

8

Phase - °

Gain - V/V

6

4

VDD = 5 V

2

No Load

0

10 100 1 k 10 k 100 k

f - Frequency - Hz

Figure 11

DRV594

CLOSED LOOP RESPONSE

16

14

12

Phase

10

°

8

Phase -

Gain - V/V

6

4

VDD = 3.3 V

2

No Load

0

10 100 1 k 10 k 100 k

f - Frequency - Hz

Figure 13

Gain

Gain

10

0

-10

-20

-30

Phase - °

-40

-50

-60

-70

10

0

-10

-20

-30

Phase - °

-40

-50

-60

-70

9

Page 10

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

TYPICAL CHARACTERISTICS

www.ti.com

MAXIMUM OUTPUT CURRENT

vs

OUTPUT VOLTAGE

3.5

3

TJ = 100°C

2.5

2

1.5

1

- Maximum Output Current - A

O

I

0.5

0

012345

TJ = 125°C

VO - Output Voltage - V

TJ = 85°C

VDD = 5 V

TA = 25°C

VFP Package

Figure 14

INPUT OFFSET VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

10

VDD = 5 V

No Load

9

MAXIMUM OUTPUT CURRENT

vs

AMBIENT TEMPERATURE

3.5

3

2.5

2

1.5

1

- Maximum Output Current - A

O

I

0.5

TJ ≤ 125°C

VFP Package

0

-40-30-20-100 10203040506070 80

TA - Ambient Temperature - °C

Figure 15

INPUT OFFSET VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

20

VDD = 3.3 V

No Load

19

10

8

7

6

5

4

3

- Input Offset Voltage - mV

IO

V

2

1

0

1.2 1.6 2.0 2.4 2.8 3.2 3.6 3.8

VIC - Common-Mode Input Voltage - V

Figure 16

18

17

16

15

14

13

- Input Offset Voltage - mV

IO

V

12

11

10

1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1

VIC - Common-Mode Input Voltage - V

Figure 17

Page 11

www.ti.com

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

APPLICATION INFORMATION

PULSE-WIDTH MODULATION SCHEME FOR DRV593 AND DRV594

The pulse-width modulation scheme implemented in the DRV593 and DRV594 eliminates one-half of the full output

filter previously required for PWM drivers. The DRV593 and DRV594 require only one inductor and capacitor for the

output filter. The H/C outputs determine the direction of the current and do not switch back and forth. The PWM outputs

switch to produce a voltage across the load that is proportional to the input control voltage.

COOLING MODE

Figure 18 shows the DRV593 and DRV594 in cooling mode. The H/C outputs (pins 14-17) are at ground and the

PWM outputs (pins 24-27) create a voltage across the load that is proportional to the input voltage.

The differential voltage across the load is determined using equation (1) and the duty cycle using equation (2). The

differential voltage is defined as the voltage measured after the filter on the PWM output relative to the H/C output.

DRV593

DRV594

V

D +

Load

A

v

+ D V

ǒ

V

IN)–VIN–

V

DD

DD

Ǔ

where

D duty cycle of the PWM signal

A

V

V

V

Gain of DRV593/594 (DRV593: 2.3 V/V, DRV594: 14.5 V/V)

v

Positive input terminal of the DRV593/594

IN+

Negative input terminal of the DRV593/594

IN -

Power supply voltage

DD

For example, a 50% duty cycle, shown in Figure 18, results in 2.5 V across the load for V

VDD

PWM

0

VDD

DD

(1)

(2)

= 5 V.

H/C

VDD/2

Load

Voltage

0

VDD

0

Figure 18. Cooling Mode

11

Page 12

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

HEATING MODE

Figure 19 shows the DRV593 and DRV594 in heating mode. The H/C output is at VDD and the PWM output is

proportional to the voltage across the load.

The differential voltage across the load is determined using equation (3). The variables are the same as used

previously for equations (1) and (2).

www.ti.com

V

+ –(1–D) V

Load

DD

(3)

For example, a 50% duty cycle, shown in Figure 19, results in -2.5 V across the load for VDD = 5 V. The differential

voltage across the load is defined as the voltage measured after the filter on the PWM output relative to the H/C output.

VDD

PWM

0

VDD

H/C

0

Load

Voltage

0

-VDD/2

12

-VDD

Figure 19. Heating Mode

Page 13

www.ti.com

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

HEAT/COOL TRANSITION

As the device transitions from cooling to heating, the duty cycle of the PWM outputs decrease to a small value and

the H/C outputs remains at ground. When the device transitions to heating mode, the H/C outputs change from zero

volts to VDD and the PWM outputs change to a high duty cycle. The direction of the current flow is reversed, but a

low voltage is maintained across the load. The duty cycle decreases as the part is put further into heating mode to

drive more current through the load. Figure 20 illustrates the transition from cooling to heating.

ZERO-CROSSING REGION

When the differential output voltage is near zero, the control logic in the DRV593 and DRV594 causes the outputs

to change between heating and cooling modes. There are two possible states for the PWM and H/C outputs to obtain

zero volts differentially: both outputs can be at VDD or both outputs can be at ground. Therefore, random noise causes

the outputs to change between the two states when the two input voltages are equal. The outputs switch from zero

to VDD, although not at a fixed frequency rate. Some of the pulses may be wider than others, but the two outputs

(PWM and H/C) track each other to provide zero differential voltage. These uneven pulse widths can increase the

switching noise during the zero-crossing condition.

To avoid this phenomenon, hysteresis should be implemented in the control loop to prevent the device from operating

within this region. Although planning for operation during the zero-crossing is important, the normal operating points

for the DRV593 and DRV594 are outside of this region. For laser temperature/wavelength regulation, the zero volts

output condition is only a concern when the laser temperature or wavelength, relative to the ambient temperature,

requires no heating or cooling from the TEC element.

DRV593

DRV594

PWM

H/C

VDD

VDD

VDD

IN +

IN -

0

0

0

Figure 20. Transition From Cooling to Heating

13

Page 14

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

www.ti.com

V

DD

1 µF

PVDD

PVDD

1 µF

PWM

PVDD

PVDD

H/C

PWM

H/C

PWM

PGND

PGND

PGND

PGND

PGND

PGND

H/C

PWM

H/C

10 µH

To TEC or Laser

Diode Anode

10 µF

To TEC or Laser

Diode Cathode

DC Control

Voltage

1 kΩ

1 kΩ

Shutdown Control

1 µF

220 pF

1 µF

FAULT1

FAULT0

120 kΩ

10 µF

PVDD

AVDD

AGND (Connect to PowerPAD)

ROSC

COSC

AREF

IN+

IN-IN-

SHUTDOWN

FREQ

FAULT1

INT/EXT

DRV593

DRV594

FAULT0

PVDD

Figure 21. Typical Application Circuit

OUTPUT FILTER CONSIDERATIONS

TEC element manufacturers provide electrical specifications for maximum dc current and maximum output

voltage for each particular element. The maximum ripple current, however, is typically only recommended to

be less than 10% with no reference to the frequency components of the current. The maximum temperature

differential across the element, which decreases as ripple current increases, may be calculated with the

following equation:

ǒ

1 ) N

1

DT

2

max

Ǔ

DT +

(4)

where

∆T = actual temperature differential

∆T

= maximum temperature differential (specified by manufacturer)

max

N = ratio of ripple current to dc current

According to this relationship, a 10% ripple current reduces the maximum temperature differential by 1%. An

LC network may be used to filter the current flowing to the TEC to reduce the amount of ripple and, more

importantly, protect the rest of the system from any electromagnetic interference (EMI).

FILTER COMPONENT SELECTION

The LC filter, which may be designed from two different perspectives, both described below, helps estimate the

overall performance of the system. The filter should be designed for the worst-case conditions during operation,

which is typically when the differential output is at 50% duty cycle. The following section serves as a starting

point for the design, and any calculations should be confirmed with a prototype circuit in the lab.

Any filter should always be placed as close as possible to the DRV593 and DRV594 to reduce EMI.

L

PWM

C

H/C

Figure 22. LC Output Filter

14

TEC

R

Page 15

www.ti.com

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

LC FILTER IN THE FREQUENCY DOMAIN

The transfer function for a second-order low-pass filter (Figures 17 and 18) is shown in equation (5):

DRV593

DRV594

HLP(jw) +

w

ǒ

–

w

w0+

For the DRV593 and DRV594, the differential output switching frequency is typically selected to be 500 kHz.

The resonant frequency for the filter is typically chosen to be at least one order of magnitude lower than the

switching frequency. equation (5) may then be simplified to give the following magnitude equation (6). These

equations assume the use of the filter in Figure 22.

Ť

If L=10 µH and C=10 µF, the cutoff frequency is 15.9 kHz, which corresponds to –60 dB of attenuation at the

500 kHz switching frequency. For VDD = 5 V, the amount of ripple voltage at the TEC element is approximately

5 mV.

The average TEC element has a resistance of 1.5 Ω, so the ripple current through the TEC is approximately

3.4 mA. At the 3-A maximum output current of the DRV593 and DRV594, this 5.4 mA corresponds to 0.11%

ripple current, causing less than 0.0001% reduction of the maximum temperature differential of the TEC

element (see equation 4).

1

Ǹ

LC

Q + quality factor

w + DRV593 or DRV594 switching frequency

H

LPŤdB

f

fs+ 500 kHz (DRV593 or DRV594 switching frequency)

+

o

+ –40 log

1

Ǹ

2p LC

1

2

Ǔ

0

)

jw

1

) 1

w

Q

0

f

s

ǒ

Ǔ

f

o

(5)

(6)

LC FILTER IN THE TIME DOMAIN

The ripple current of an inductor may be calculated using equation (7):

ǒ

VO–V

DI

+

L

D + duty cycle (0.5 worst case)

Ts+ 1ńfs+ 1ń500 kHz

For VO = 5 V, V

ripple current flows through the TEC element, however, the properties of the filter capacitor must be considered.

For relatively small capacitors (less than 22 µF) with very low equivalent series resistance (ESR, less than

10 mΩ), such as ceramic capacitors, the following equation (8) may be used to estimate the ripple voltage on

the capacitor due to the change in charge:

DV

= 2.5 V, and L = 10 µH, the inductor ripple current is 250 mA. To calculate how much of that

TEC

2

p

+

C

2

D + duty cycle

fs+ 500 kHz

f

+

o

2p LC

ǒ

1–D

1

Ǹ

TEC

L

Ǔ

DT

s

2

f

o

Ǔ

ǒ

Ǔ

V

TEC

f

s

(7)

(8)

15

Page 16

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

For L = 10 µH and C = 10 µF, the cutoff frequency, fo, is 15.9 kHz. For worst case duty cycle of 0.5 and

=2.5 V, the ripple voltage on the capacitors is 6.2 mV. The ripple current may be calculated by dividing the

V

TEC

ripple voltage by the TEC resistance of 1.5 Ω, resulting in a ripple current through the TEC element of 4.1 mA.

Note that this is similar to the value calculated using the frequency domain approach.

For larger capacitors (greater than 22 µF) with relatively high ESR (greater than 100 mΩ), such as electrolytic

capacitors, the ESR dominates over the charging/discharging of the capacitor. The following simple

equation (9) may be used to estimate the ripple voltage:

www.ti.com

DVC+ DIL R

DIL+ inductor ripple current

R

+ filter capacitor ESR

ESR

ESR

For a 100 µF electrolytic capacitor, an ESR of 0.1 Ω is common. If the 10 µH inductor is used, delivering 250 mA

of ripple current to the capacitor (as calculated above), then the ripple voltage is 25 mV. This is over ten times

that of the 10 µF ceramic capacitor, as ceramic capacitors typically have negligible ESR.

SWITCHING FREQUENCY CONFIGURATION: OSCILLATOR COMPONENTS R

OSC

AND C

AND FREQ OPERATION

The onboard ramp generator requires an external resistor and capacitor to set the oscillation frequency. The

frequency may be either 500 kHz or 100 kHz by selecting the proper capacitor value and by holding the FREQ

pin either low (500 kHz) or high (100 kHz). Table 1 shows the values required and FREQ pin configuration for

each switching frequency.

Table 1. Frequency Configuration Options

SWITCHING FREQUENCY R

500 kHz 120 kΩ 220 pF LOW (GND)

100 kHz 120 kΩ 1 nF HIGH (VDD)

For proper operation, the resistor R

should have 1% tolerance while capacitor C

OSC

OSC

type with 10% tolerance. Both components should be grounded to AGND, which should be connected to PGND

at a single point, typically where power and ground are physically connected to the printed-circuit board.

C

OSC

FREQ

should be a ceramic

OSC

(9)

OSC

EXTERNAL CLOCKING OPERATION

To synchronize the switching to an external clock signal, pull the INT/EXT terminal low, and drive the clock signal

into the COSC terminal. This clock signal must be from 10% to 90% duty cycle and meet the voltage

requirements specified in the electrical specifications table. Since the DRV593 and DRV594 include an internal

frequency doubler, the external clock signal must be approximately 250 kHz. Deviations from the 250 kHz clock

frequency are allowed and are specified in the electrical characteristic table. The resistor connected from ROSC

to ground may be omitted from the circuit in this mode of operation—the source is disconnected internally.

INPUT CONFIGURATION: DIFFERENTIAL AND SINGLE-ENDED

If a differential input is used, it should be biased around the midrail of the DRV593 or DRV594 and must not

exceed the common-mode input range of the input stage (see the operating characteristics at the beginning

of the data sheet).

The most common configuration employs a single-ended input. The unused input should be tied to VDD/2, which

may be simply accomplished with a resistive voltage divider. For the best performance, the resistor values

chosen should be at least 100 times lower than the input resistance of the DRV593 or DRV594. This prevents

the bias voltage at the unused input from shifting when the signal input is applied. A small ceramic capacitor

should also be placed from the input to ground to filter noise and keep the voltage stable. An op amp configured

as a buffer may also be used to set the voltage at the unused input.

16

Page 17

www.ti.com

FIXED INTERNAL GAIN

The differential output voltage may be calculated using equation (10):

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

VO+ V

AV is the voltage gain, which is fixed internally at 2.3 V/V for DRV593 and 14.5 V/V for DRV594. The maximum

and minimum ratings are provided in the electrical specification table at the beginning of the data sheet.

OUT)–VOUT–

+ A

ǒ

V

v

IN)–VIN–

Ǔ

POWER SUPPLY DECOUPLING

To reduce the effects of high-frequency transients or spikes, a small ceramic capacitor, typically 0.1 µF to 1 µF,

should be placed as close to each set of PVDD pins of the DRV593 and DRV594 as possible. For bulk

decoupling, a 1 0 µF to 100 µF tantalum or aluminum electrolytic capacitor should be placed relatively close to

the DRV593 and DRV594.

AREF CAPACITOR

The AREF terminal is the output of an internal mid-rail voltage regulator used for the onboard oscillator and ramp

generator. The regulator may not be used to provide power to any additional circuitry. A 1 µF ceramic capacitor

must be connected from AREF to AGND for stability (see oscillator components above for AGND connection

information).

SHUTDOWN OPERATION

The DRV593 and DRV594 include a shutdown mode that disables the outputs and places the device in a low

supply current state. The SHUTDOWN pin may be controlled with a TTL logic signal. When SHUTDOWN is

held high, the device operates normally. When SHUTDOWN is held low, the device is placed in shutdown. The

SHUTDOWN pin must not be left floating. If the shutdown feature is unused, the pin may be connected to VDD.

(10)

FAULT REPORTING

The DRV593 and DRV594 include circuitry to sense three faults:

D Overcurrent

D Undervoltage

D Overtemperature

These three fault conditions are decoded via the FAULT1 and FAULT0 terminals. Internally, these are

open-drain outputs, so an external pullup resistor of 5 kΩ or greater is required.

Table 2. Fault Indicators

FAULT1 FAULT0

0 0 Overcurrent

1 0 Undervoltage

0 1 Overtemperature

1 1 Normal operation

The overcurrent fault is reported when the output current exceeds four amps. As soon as the condition is

sensed, the overcurrent fault is set and the outputs go into a high-impedance state for approximately 3 µs to

5 µs (500 kHz operation). After 3 µs to 5 µs, the outputs are re-enabled. If the overcurrent condition has ended,

the fault is cleared and the device resumes normal operation. If the overcurrent condition still exists, the above

sequence repeats.

The undervoltage fault is reported when the operating voltage is reduced below 2.8 V . This fault is not latched,

so as soon as the power supply recovers, the fault is cleared and normal operation resumes. During the

undervoltage condition, the outputs go into a high-impedance state to prevent overdissipation due to increased

r

.

DS(on)

17

Page 18

DRV593

DRV594

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

The overtemperature fault is reported when the junction temperature exceeds 115°C. The device continues

operating normally until the junction temperature reaches 150°C, at which point the IC is disabled to prevent

permanent damage from occurring. The system’s controller must reduce the power demanded from the

DRV593 o r D R V594 once the overtemperature flag is set, or else the device switches of f when it reaches 150°C.

This fault is not latched; once the junction temperature drops below 115°C, the fault is cleared, and normal

operation resumes.

POWER DISSIPATION AND MAXIMUM AMBIENT TEMPERATURE

Though the DRV593 and DRV594 are much more efficient than traditional linear solutions, the power drop

across the on-resistance of the output transistors does generate some heat in the package, which may be

calculated as shown in equation (11):

www.ti.com

I

OUT

ǒ

2

Ǔ

r

DS(on), total

θ

P

JA

DISS

Ǔ

P

DISS

For example, at the maximum output current of 3 A through a total on-resistance of 130 mΩ (at TJ = 25°C),

the power dissipated in the package is 1.17 W.

Calculate the maximum ambient temperature using equation (12):

TA+ T

+

ǒ

*

J

PRINTED-CIRCUIT BOARD (PCB) LAYOUT CONSIDERATIONS

Since the DRV593 and DRV594 are high-current switching devices, a few guidelines for the layout of the

printed-circuit board (PCB) must be considered:

1. Grounding. Analog ground (AGND) and power ground (PGND) must be kept separated, ideally back to

where the power supply physically connects to the PCB, minimally back to the bulk decoupling capacitor

(10 µF ceramic minimum). Furthermore, the PowerPAD ground connection should be made to AGND, not

PGND. Ground planes are not recommended for AGND or PGND, traces should be used to route the

currents. Wide traces (100 mils) should be used for PGND while narrow traces (15 mils) should be used

for AGND.

2. Power supply decoupling. A small 0.1 µF to 1 µF ceramic capacitor should be placed as close to each

set of PVDD pins as possible, connecting from PVDD to PGND. A 0.1 µF to 1 µF ceramic capacitor should

also be placed close to the AVDD pin, connecting from AVDD to AGND. A bulk decoupling capacitor of at

least 10 µF, preferably ceramic, should be placed close to the DRV593 or DRV594, from PVDD to PGND.

If power supply lines are long, additional decoupling may be required.

(11)

(12)

3. Power and output traces. The power and output traces should be sized to handle the desired maximum

output current. The output traces should be kept as short as possible to reduce EMI, i.e., the output filter

should be placed as close to the DRV593 or DRV594 outputs as possible.

4. PowerPAD. The DRV593 and DRV594 in the Quad Flatpack package use TI’s PowerPAD technology to

enhance the thermal performance. The PowerPAD is physically connected to the substrate of the DRV593

and DRV594 silicon, which is connected to AGND. The PowerPAD ground connection should therefore be

kept separate from PGND as described above. The pad underneath the AGND pin may be connected

underneath the device to the PowerPAD ground connection for ease of routing. For additional information

on PowerPAD PCB layout, refer to the PowerPAD Thermally Enhanced Package application note,

SLMA002.

5. Thermal performance. For proper thermal performance, the PowerPAD must be soldered down to a

thermal land, as described in the PowerPAD Thermally Enhanced Package application note, SLMA002.

In addition, at high current levels (greater than 2 A) or high ambient temperatures (greater than 25°C), an

internal plane may be used for heat sinking. The vias under the PowerPAD should make a solid connection,

and the plane should not be tied to ground except through the PowerPAD connection, as described above.

18

Page 19

DRV593

www.ti.com

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

MECHANICAL DATA

VFP (S-PQFP-G32) PowerPAD PLASTIC QUAD FLATPACK

DRV594

25

32

1,45

1,35

0,80

24

0,45

0,30

17

16

9

1

5,60 TYP

7,20

SQ

6,80

9,20

SQ

8,80

8

0,22

M

Thermal Pad

(See Note D)

0,05 MIN

0,13 NOM

Gage Plane

0,25

0°-7°

1,60 MAX

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MS-026

PowerPAD is a trademark of Texas Instruments.

Seating Plane

0,10

0,75

0,45

4200791/A 04/00

19

Page 20

PACKAGE OPTION ADDENDUM

www.ti.com

4-Mar-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

DRV593VFP ACTIVE HLQFP VFP 32 250 None CU NIPDAU Level-1-235C-UNLIM

DRV593VFPR ACTIVE HLQFP VFP 32 1000 None CU NIPDAU Level-1-235C-UNLIM

DRV594VFP ACTIVE HLQFP VFP 32 250 None CU NIPDAU Level-1-235C-UNLIM

DRV594VFPR ACTIVE HLQFP VFP 32 1000 None CU NIPDAU Level-1-235C-UNLIM

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - May not be currently available - please check http://www.ti.com/productcontent for the latest availability information and additional

product content details.

None: Not yet available Lead (Pb-Free).

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean "Pb-Free" and in addition, uses package materials that do not contain halogens,

including bromine (Br) or antimony (Sb) above 0.1% of total product weight.

(2)

Lead/Ball Finish MSL Peak Temp

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDECindustry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 21

Page 22

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...