TEAC PLD-200-V Service manual

PPLL--DD220000VV

SERVICE MANUAL

VCR/DVD HOME THEATER SYSTEM

Effective : September, 2003 S-0000A

CAUTION

●

£ Parts marked with this sign are safety critical components. They

must be replaced with identical components - refer to the appropriate

parts list and ensure exact replacement.

●

Before returning appliance to the customer, make leakage-current or

resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit.

CONTENTS

SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

DISASSEMBLY

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・6

PRINCIPAL PARTS LOCATION

・・・・・・・・・・・・・・・・・・・・・・・・・・7

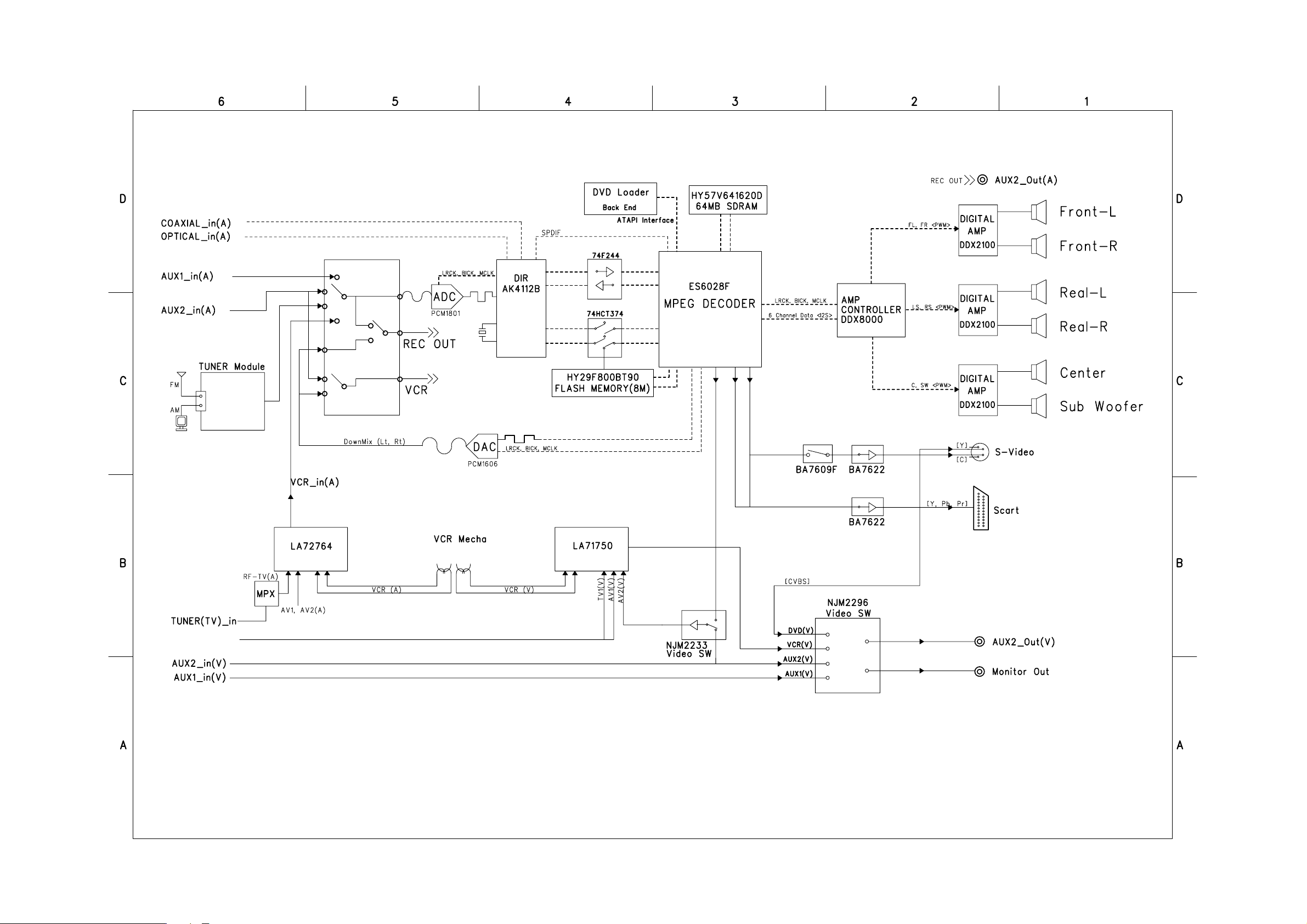

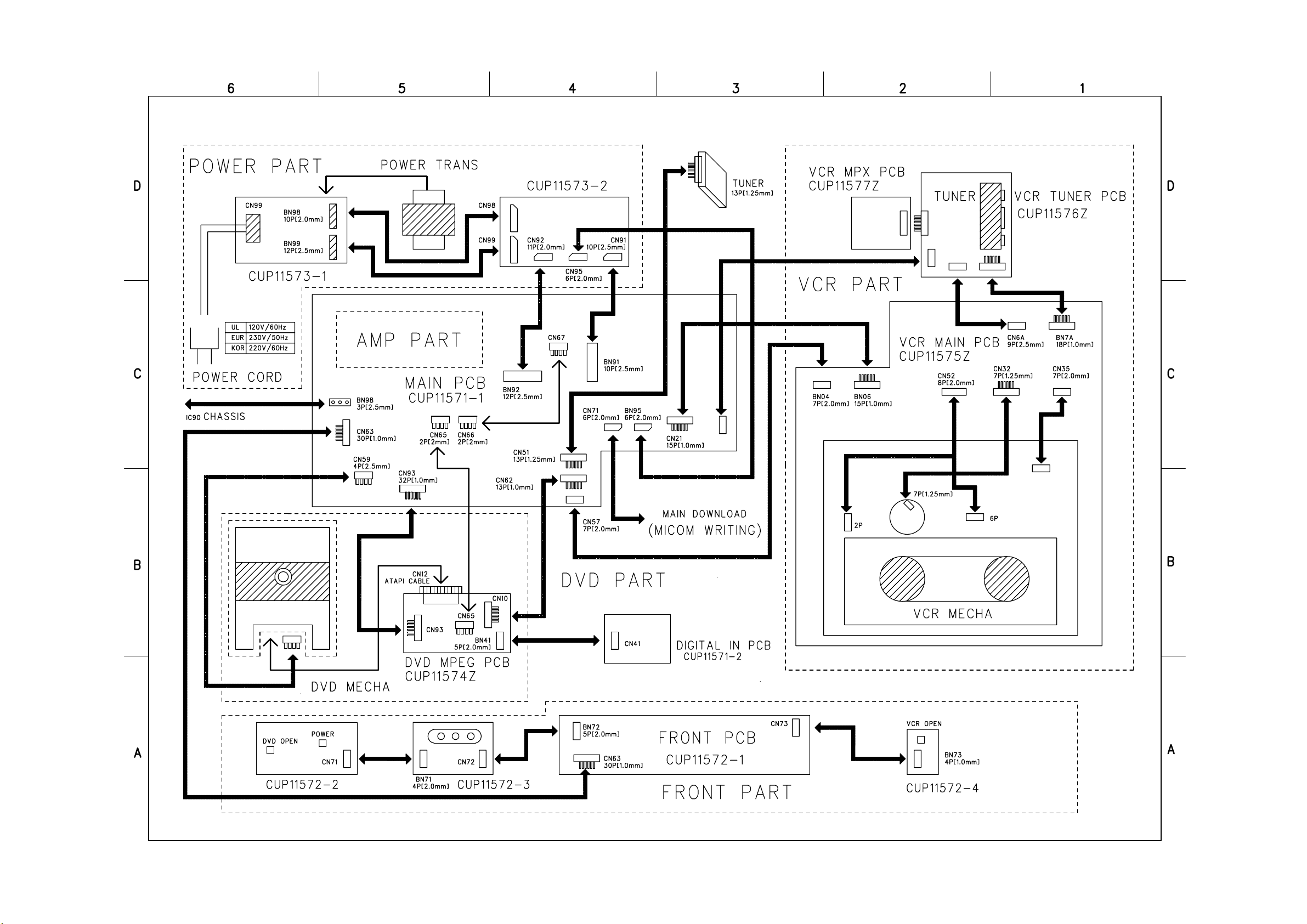

BLOCK DIAGRAM

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・9

TROUBLE SHOOTING

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・11

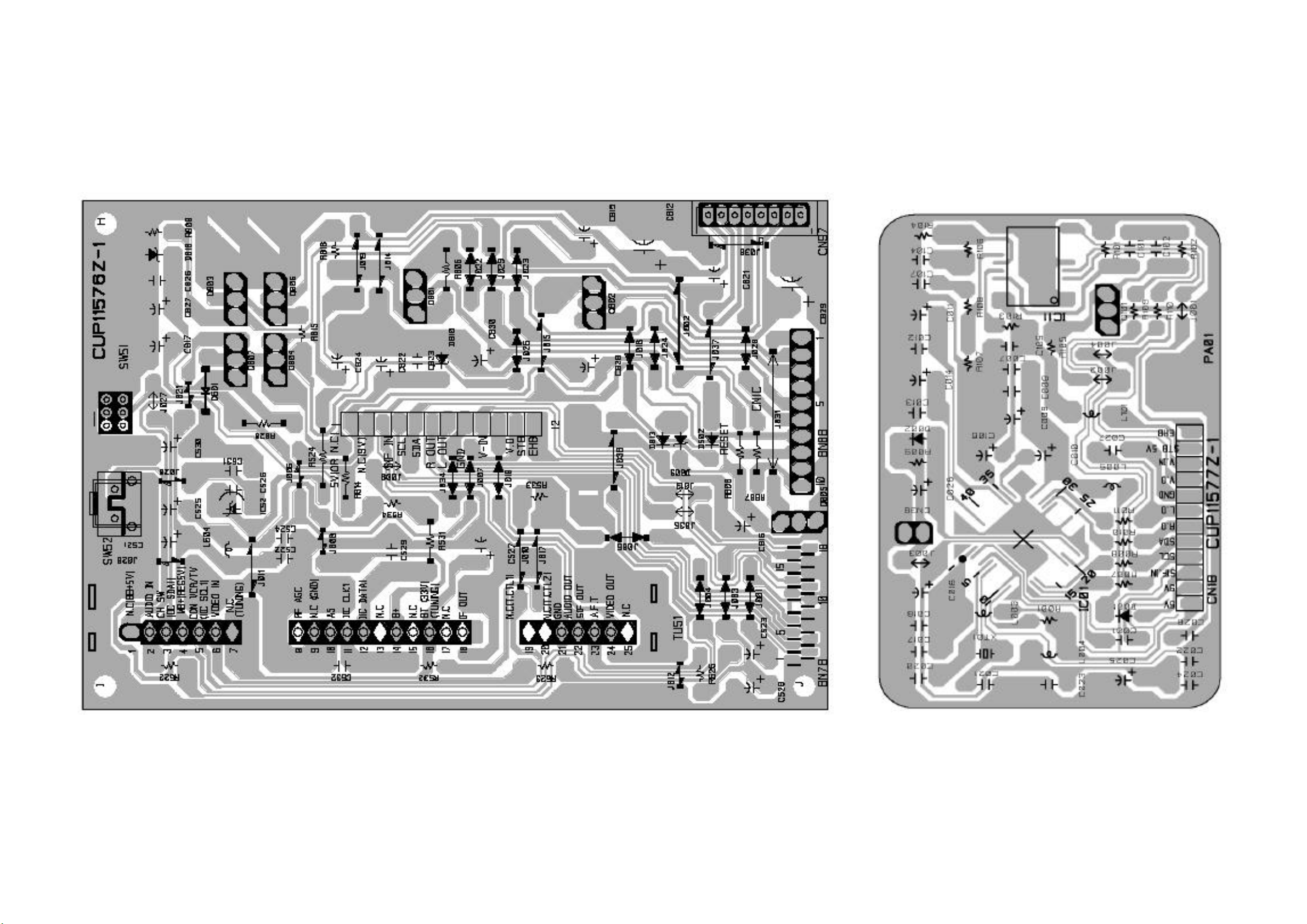

PRINTED CIRCUIT BOARDS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・15

WIRING DIAGRAM

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・29

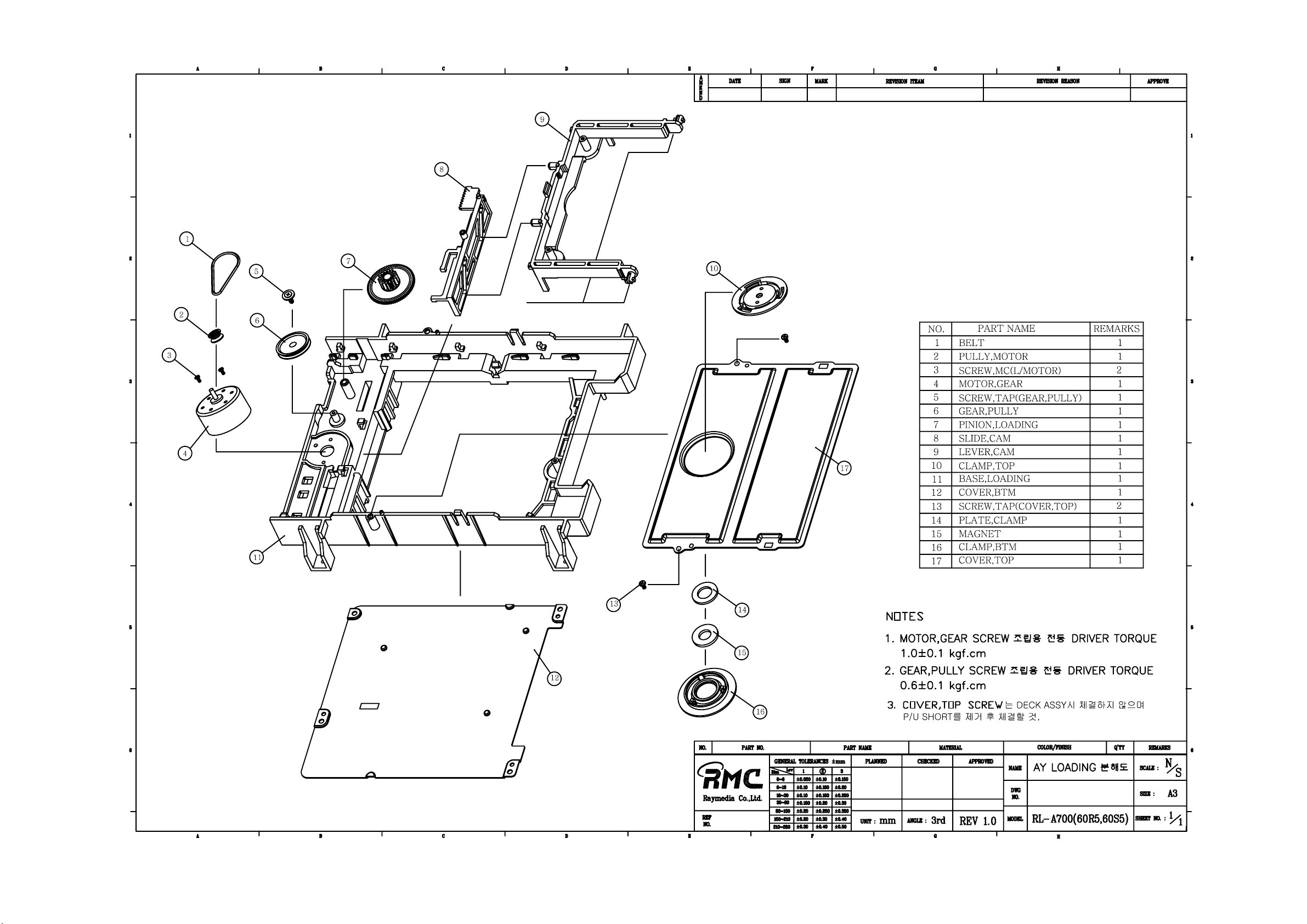

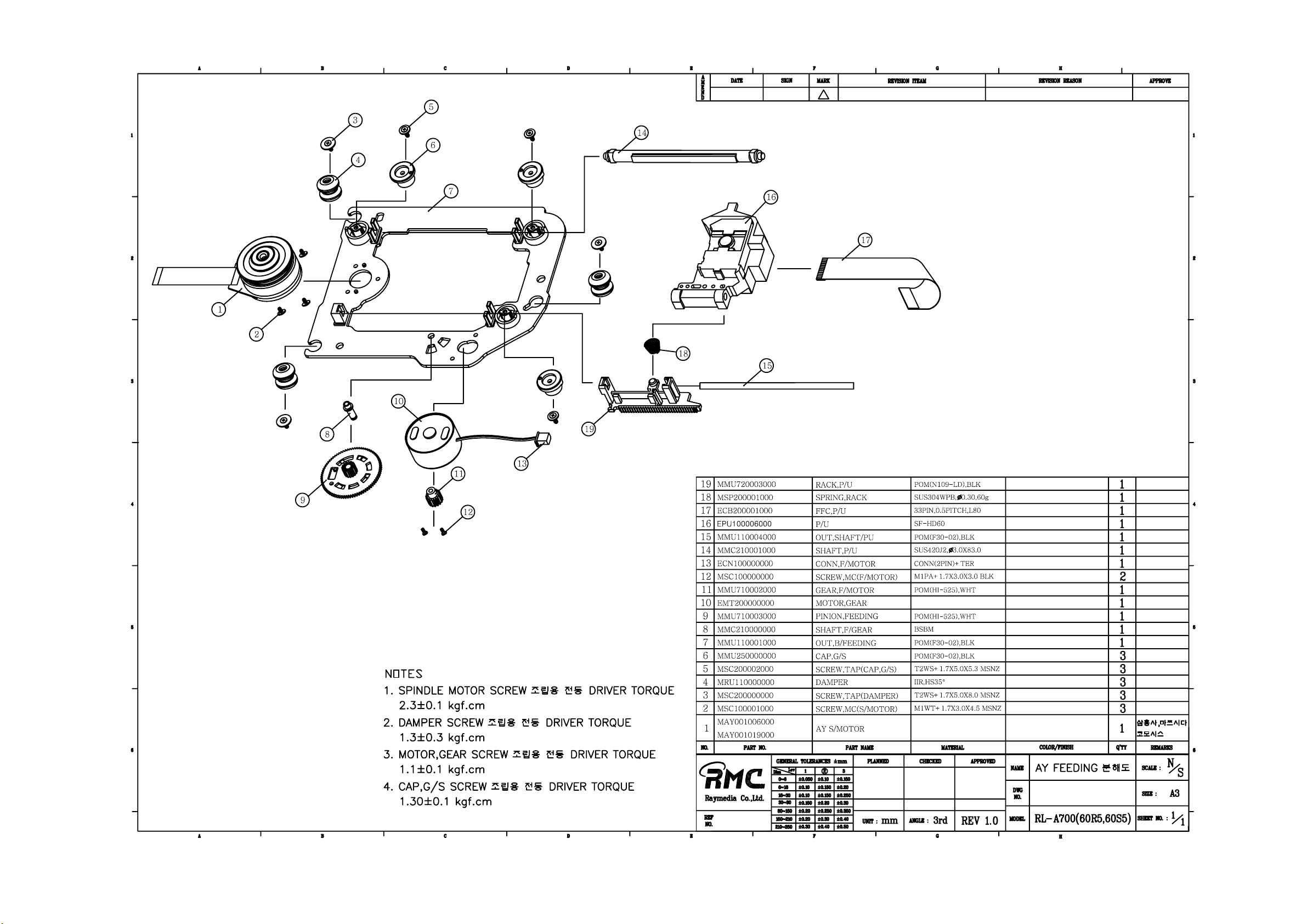

EXPLODED VIEW

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・31

ELECTRICAL PARTS LIST

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・43

IC INTERNAL DIAGRAMS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・88

IC AND TRANSISTOR VOLTAGE CHART

・・・・・・・・・・・・・131

SCHEMATIC DIAGRAMS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・141

ADJUSTMENT METHOD

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・155

2

SPECIFICATIONS

AMPLIFIER Section

Output Power (6 ohms, 1KHz, 1% T.H.D) : Stereo

Front L/R (2 Channel Driven) 45W x 2ch

Output Power (6 ohms, 1KHz, 1% T.H.D)

Front L/R (2 Channel Driven) 45W x 2ch

Center (1 Channel Driven) 45W x 1ch

Rear L/R (2 Channel Driven) 45W x 2ch

Subwoofer (1 Channel Driven) 45W x 1ch

S/N Ratio (IHF-A Weighted)

1 Channel Driven >65dB

Frequency Response

Front L/R (Large) 120~20KHz (-3dB point)

Center (Large) 120~20KHz (-3dB point)

Rear L/R (Large) 120~7KHz (-3dB point)

Subwoofer 10~150Hz (-3dB point)

Tone Control

Bass (100Hz) ±6dB

Treble (10KHz) ±6dB

Input Sensitivity

Stereo (1KHz) 260mV~360mV

CH Separation

Stereo (1KHz) > 50dB

FM TUNER Setion

Frequency Range 87.5~108 MHz

Sensitivity

Mono 8uV/m, EMF

Distortion

Mono 0.5%

Stereo

1%

S/N Ratio

Mono 65dB

Stereo

60dB

DVD Section (TDV-540)

Composite Output Level 1.0V (p-p), 75ohm

S-Video Y-Output Level 1.0V (p-p), 75ohm

S-Video C-Output Level 280mV (p-p), 75ohm

VCR (audio) Section [Hi-Fi]

Output Level

Audio -8dBm (E.E) -8±2dBm

Distortion (T.H.D)

Audio -8dBm (SP) 1.0 %

Audio -8dBm (LP/SLP) 1.5

%

S/N Ration

Audio -8dBm (E.E) 50 %

Audio -8dBm (SP) 55

%

Audio -8dBm (LP/SLP) 55

%

VCR (video) Section

E.E Video Level 1.0±0.2V

SRP SYNC Level 0.3±0.03V

SRP BURST Level 0.3±0.03V

SRP Video Level 1.0±0.2V

GENERAL

Power Consumption

110W

Weight (Main unit) 9.42Kg

Dimension (WxHxD) 430x107x422

NOTE: Design and specifications are subject to change and improvement without notice

3

SAFETY PRECAUTIONS

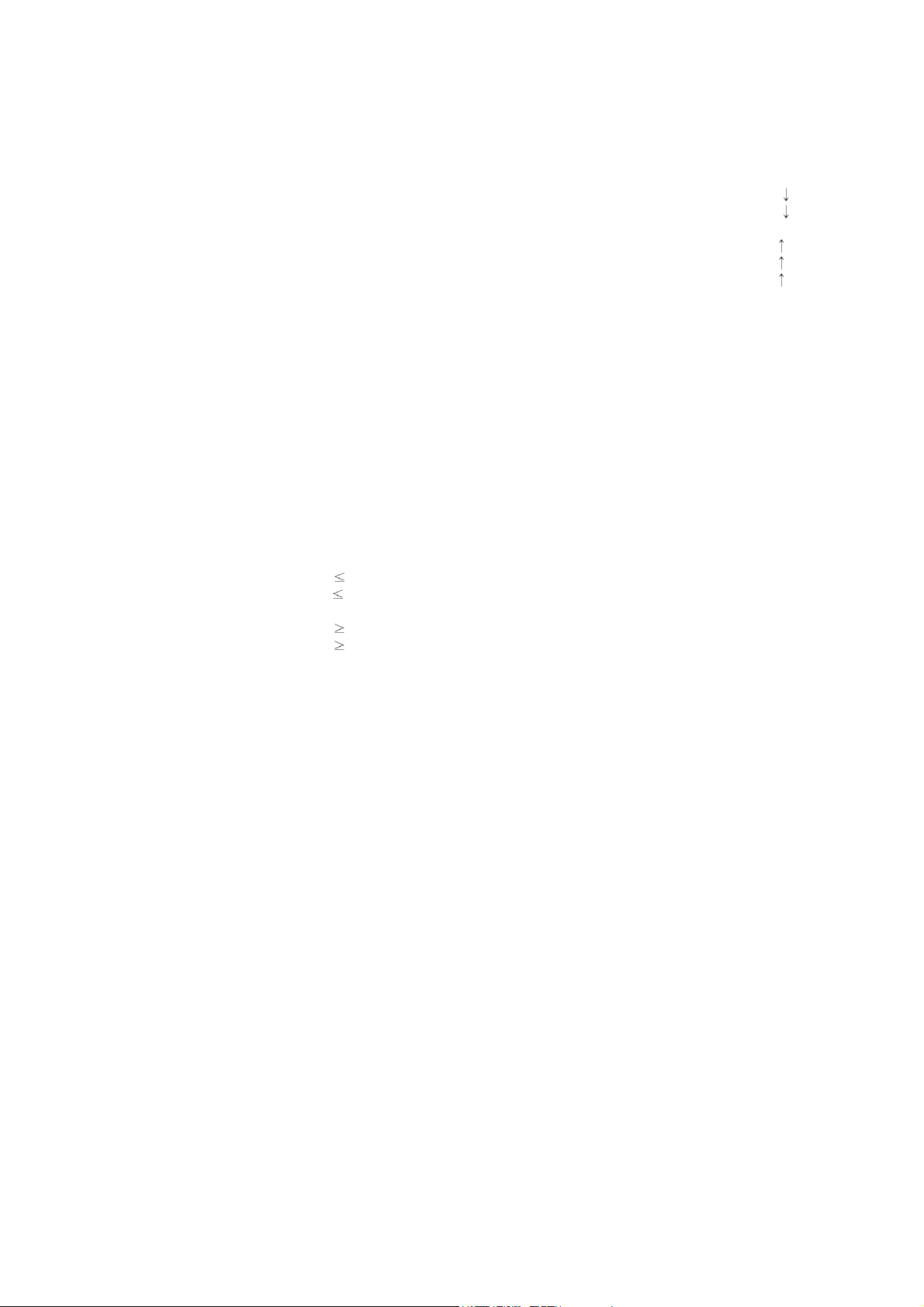

The following check should be performed for the continued

protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

between the earth ground and all exposed metal parts of the

appliance (input/output terminals, screwheads, metal

overlays, control shaft, etc.). Plug the AC line cord of the

appliance directly into a 120V AC 60Hz outlet and turn the

AC power switch on. Any current measured must not exceed

0.5mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A

POTENTIAL SHOCK HAZARD AND MUST BE

CORRECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

AC Leakage Test

4

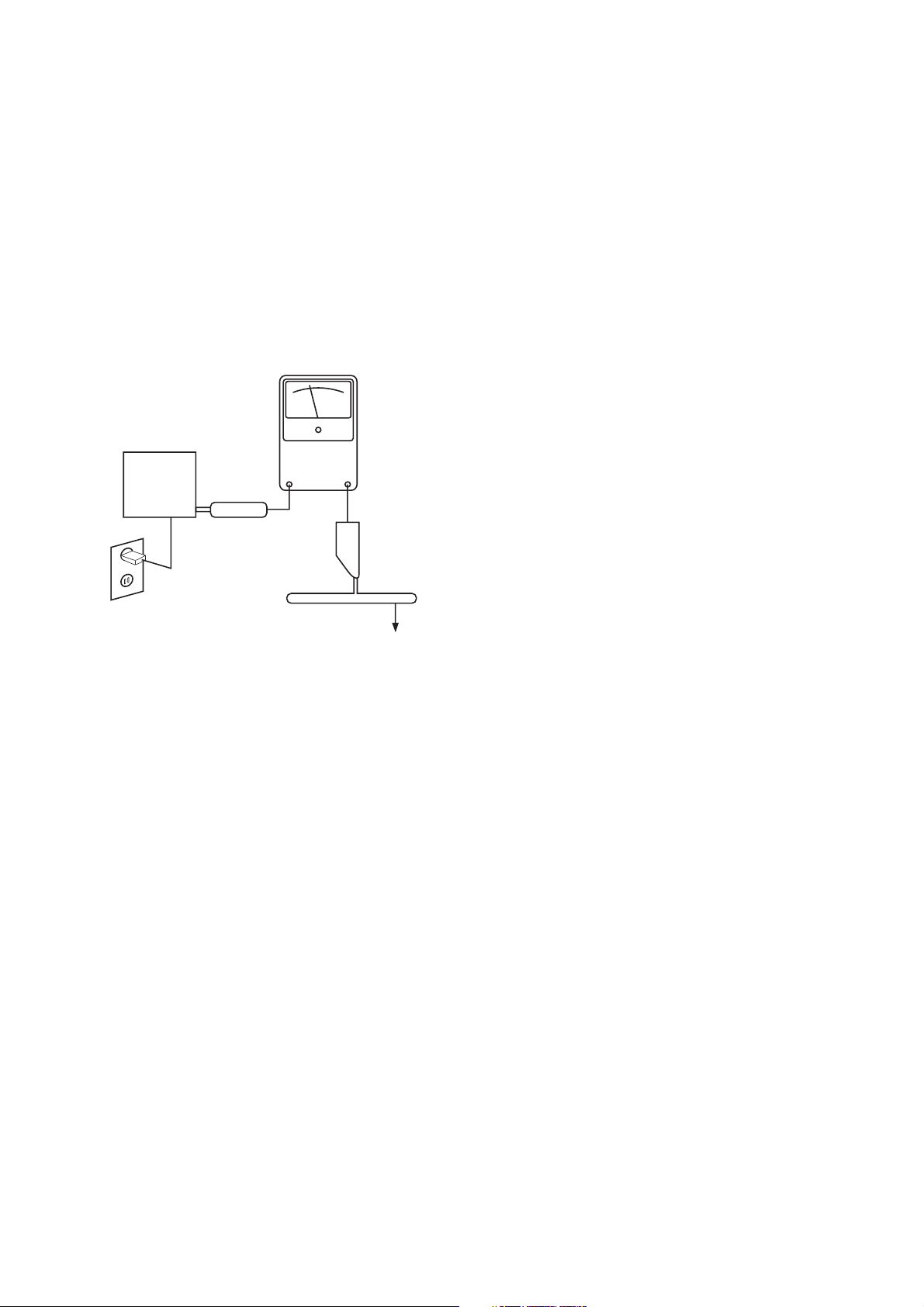

LASER BEAM SAFETY PRECAUTIONS

CLASS 1 LASER PRODUCT

DANGER

INVISIBLE LASER RADIATION

AVOID DIRECT EXPOSURE TO BEAM

This Receiver uses a pickup that emits a laser beam.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep your eyes

at least 1 foot away from the pickup lens when the diode is turned on. Do not look directly at the laser beam.

Caution: Use of controls and adjustments, or doing procedures other than those specified herein, may result in hazardous

radiation exposure.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

Laser Beam Radiation

5

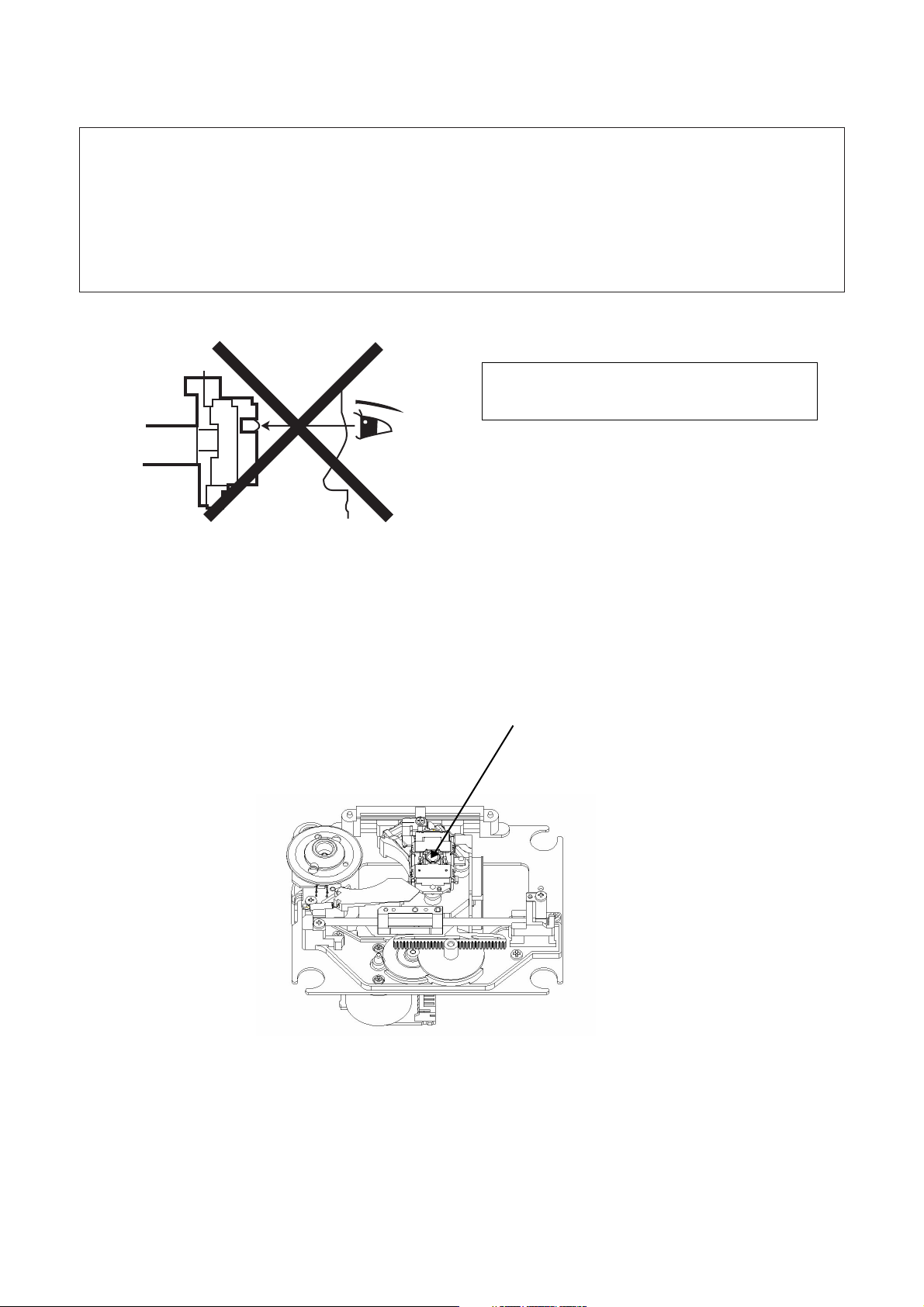

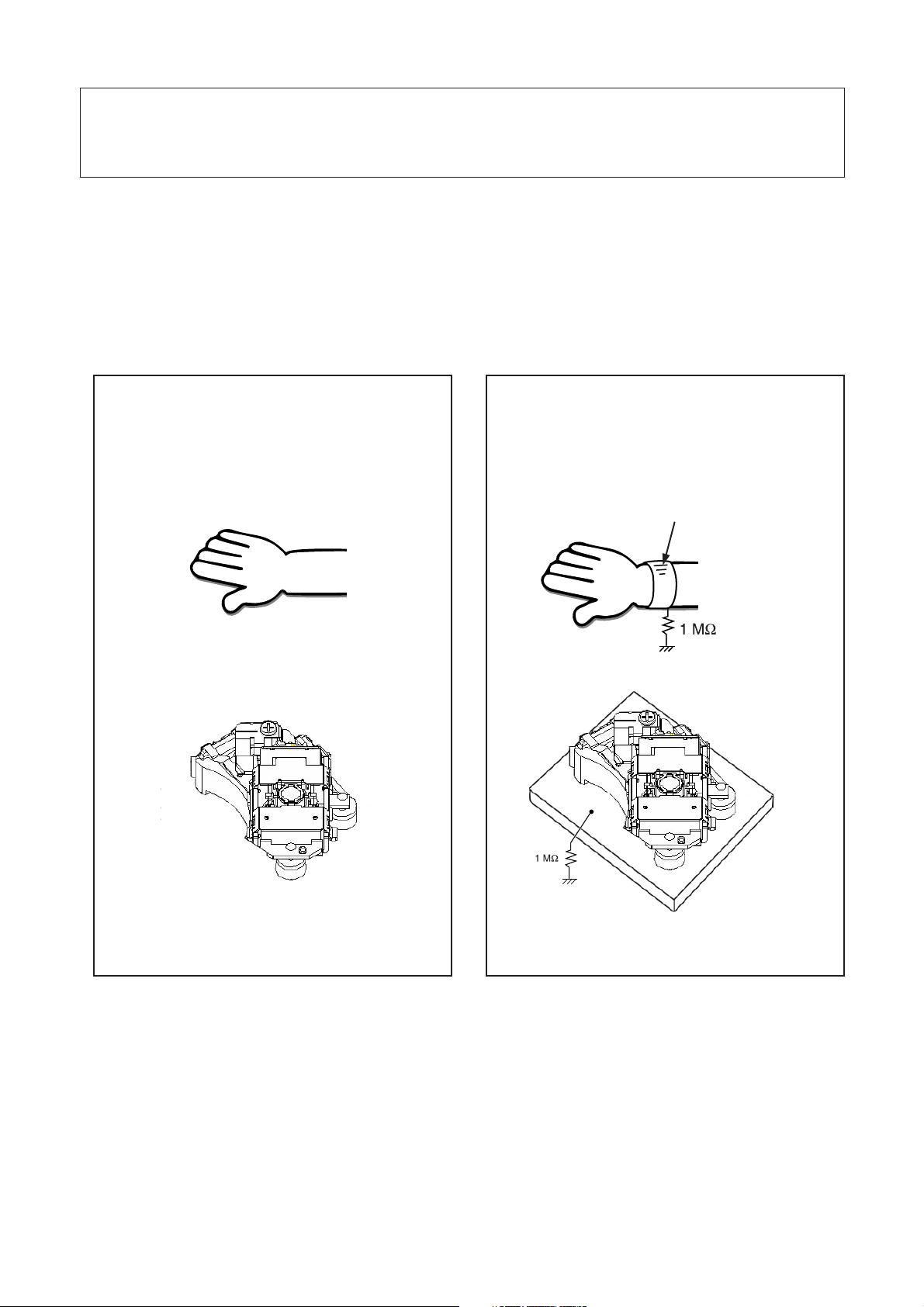

HANDLING LASER PICKUP

The laser diode in the optical system of this receiver can be damaged by electrostatic discharge from clothes,

body, etc. Proper electrostatic grounding for service personnel is required during servicing.

BEFORE REPAIRING THE DVD MECHANISM

a. Human Body Grounding:

Many of the components used in this compact disc player, including the laser pickup, are sensitive to electrostatic

discharge.

Service personnel should be grounded with an electrostatic armband (1M ohm).

Caution: Static charge on clothing does not escape through a body grounding wristband. Be careful not to contact the

pickup or electrical components with your clothing.

b. Workbench and Tool Grounding:

A properly-grounded electroconductive plate (1 M ohm) or metal sheet should be fitted to the workbench surface.

Tools and instruments (soldering irons, scopes, etc.) should be grounded to prevent AC leakage.

c. Make two standard ESD solder bridges on the Laser optic PC Board

Before disassembly of mechanism or disconnect any cables in it, make two standard ESD solder bridges on the laser

optic PC Board.

INCORRECT

CORRECT

Ground conductive wristband

for body

6

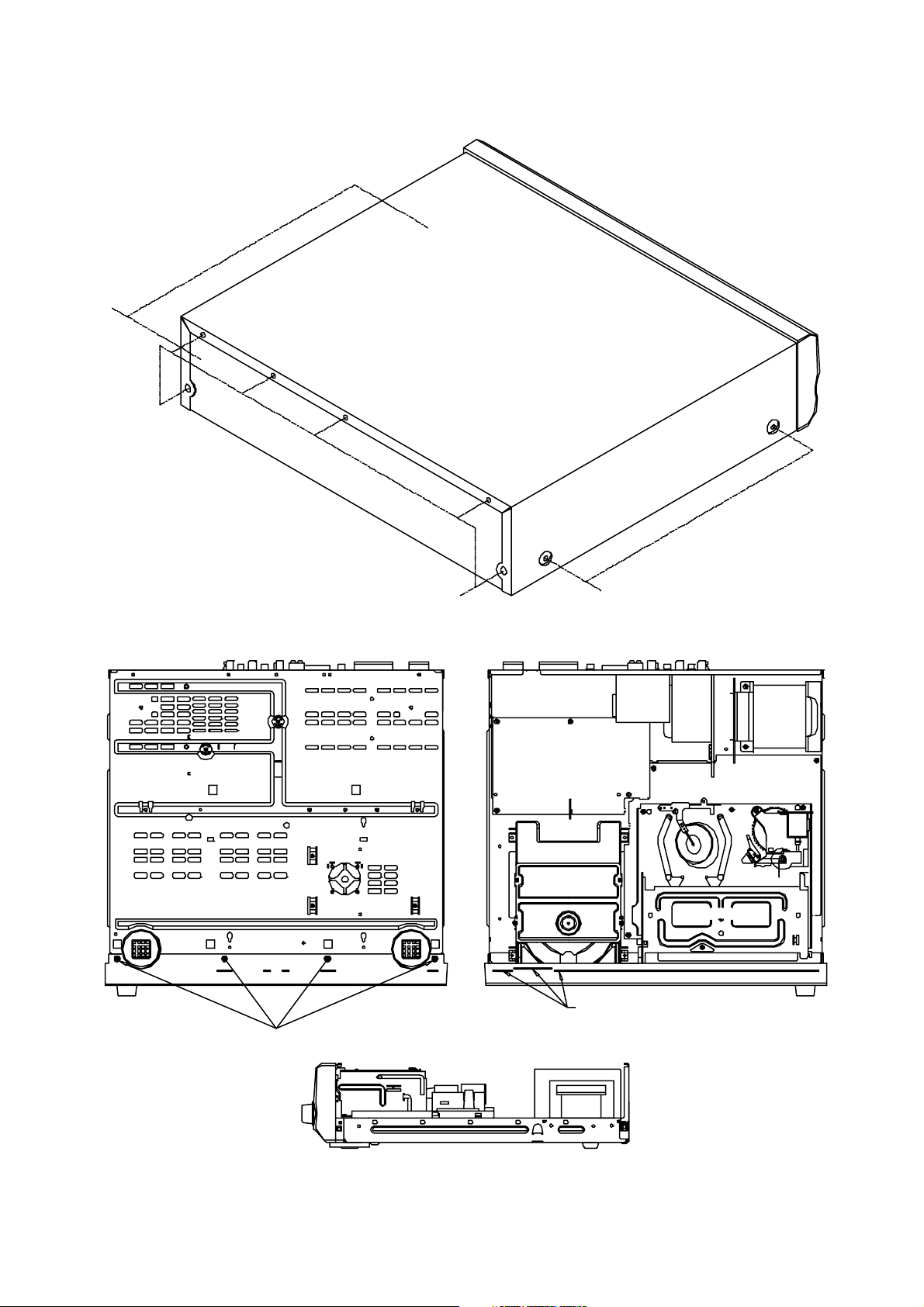

SCREW

SCREW

SCREWSCREW

MAIN PCB

POWER PCB

RADIO

TUNER

TV

TUNER

TRANS

FORMER

VCR MAIN PCB

FRONT PCB

1) REMOVAL OF TOP COVER

2) REMOVAL OF FRONT PANEL

DVD MECHANISM

VCR MECHANISM

DISASSEMBLY

7

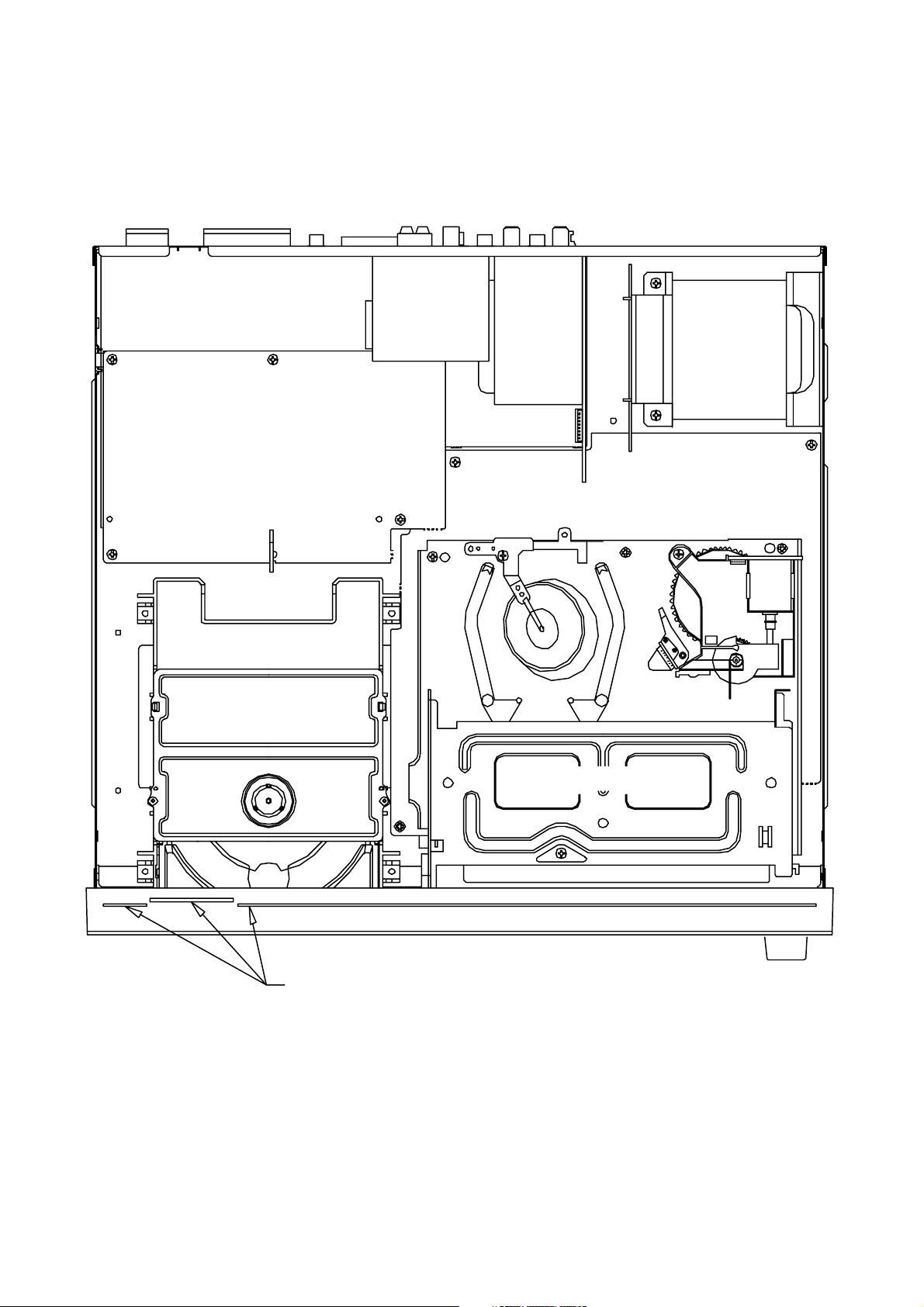

MAIN PCB

POWER PCB

RADIO

TUNER

TV

TUNER

TRANS

FORMER

VCR MAIN PCB

FRONT PCB

DVD MECHANISM

VCR MECHANISM

PRINCIPAL PARTS LOCATION

BLOCK DIAGRAM

9 10

11

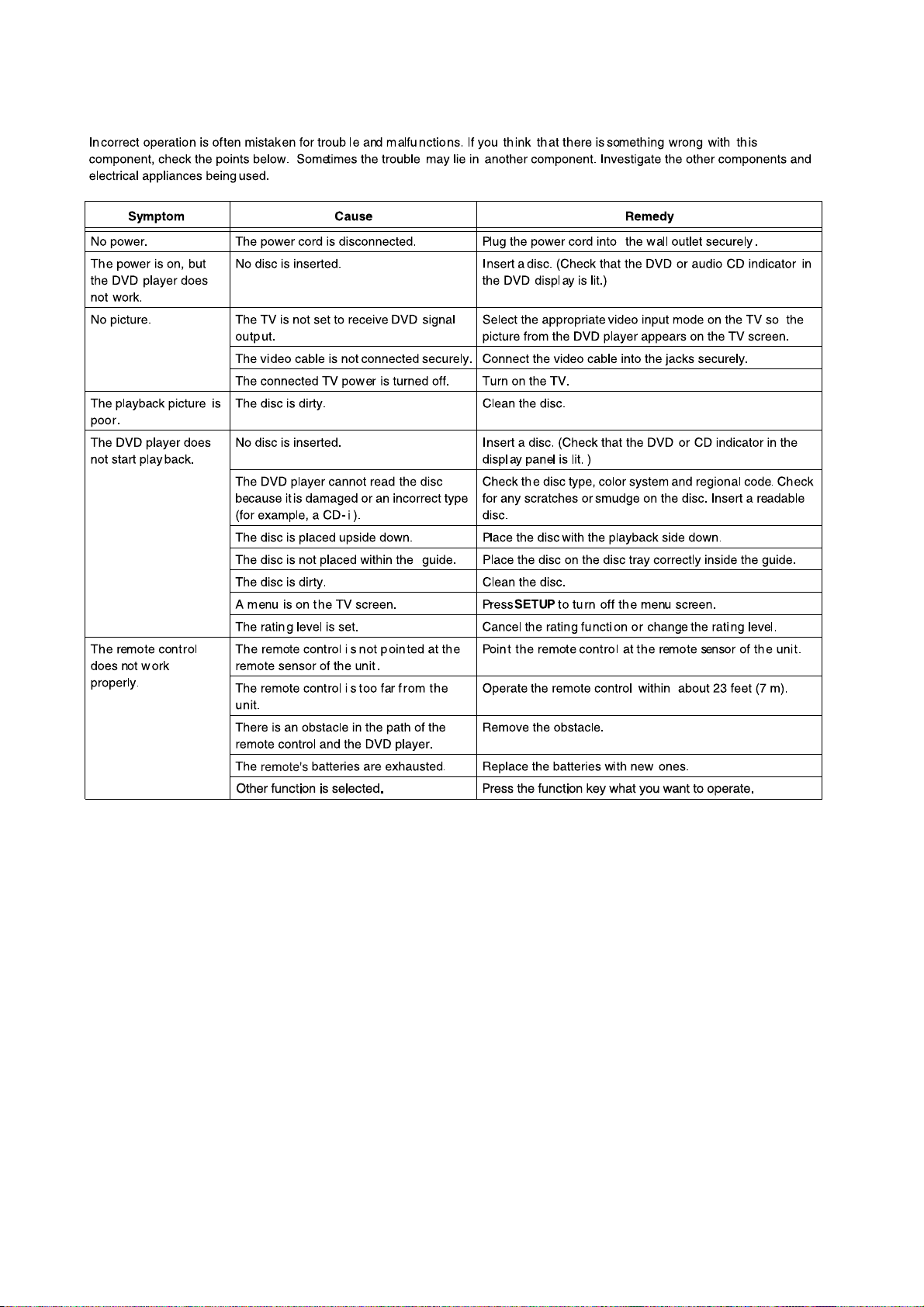

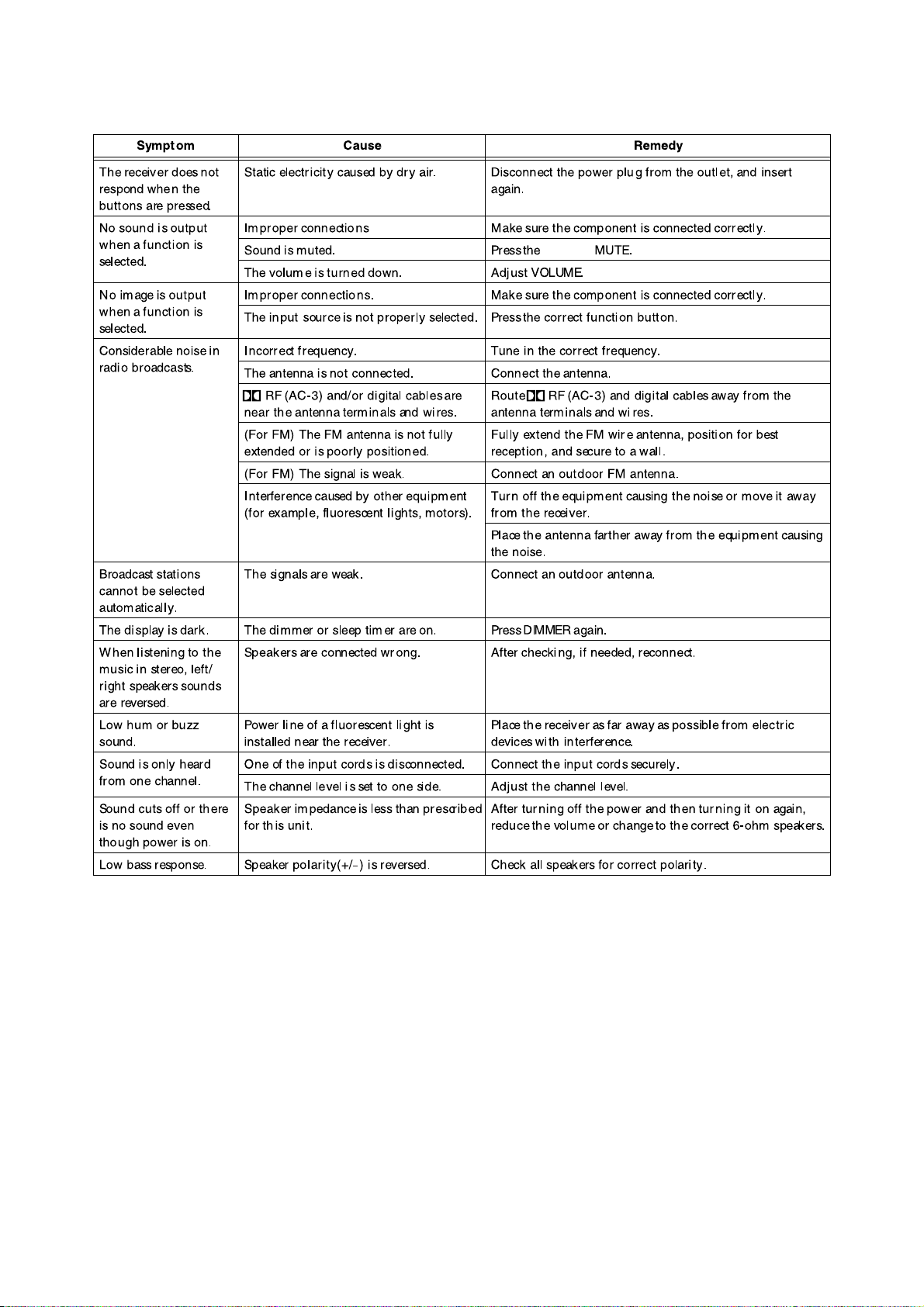

TROUBLE SHOOTING

12

remote’s

13

TEST MODE

TEST Mode shows the infomation as follows.

I. Back End Version (It is to express each Buyer, each model, and version number.)

II. Front End Version (It is to display the Mecha Fimware version number.)

III. Back End Build time (It can be used to seperate each B/E firmware version by the day.)

IV. Region No.(It is only to display region code.)

[operation]

To enter the first state of test mode, first open DISC. (Press OPEN key.)

then, press key on the remote unit as follows.

[CLEAR] - [2] - [5] - [8] -[0] - [CLEAR]

If you press key correctly, you will see the message below.

BE VER MODEL No. - (I : B/E version)

FE VER 61-500101 - (II : F/E version)

BUILD TIME 20030510B - (III : B/E bulid time)

REGION xx - (IV : Region Number)

<B/E Firmware update> : Function 2

The update is done with CD-R. (When the firmware is changed, the updated firmware will be provided by Anam on CD-R)

Put the DISC in at the first state of service mode and then press the PRGM key on the remote unit.

Updating will begin as follows.

ERASE -> WRITE -> DONE

You'll see the update sequence on the TV screen.

ERASE >>>>>>>>>>>>

WRITE >>>>>>>>>>>>

DONE

When the TV screen's display goes off, turn the POWER OFF.

Turn the POWER ON and then DO EEPROM CLEAR.

<F/E Firmware update> : Function 3

The update is done with CD-R. (When the firmware is changed, the updated firmware will be provided by Anam on CD-R)

- Put the disc on OPEN at normal operation mode.

- Press PLAY on the remote.

- After about 30 seconds, DVD door will be open.

- Turn the power off.

- Turn the power on and open DISC

- Remove the disc.

Note: F/E update method has another method. It is that you can update in the normal mode, same

sequence, same method. Updating in the normal mode is recommandable because of updating

during the short time. In this case, you must confirm the F/E firmware version.

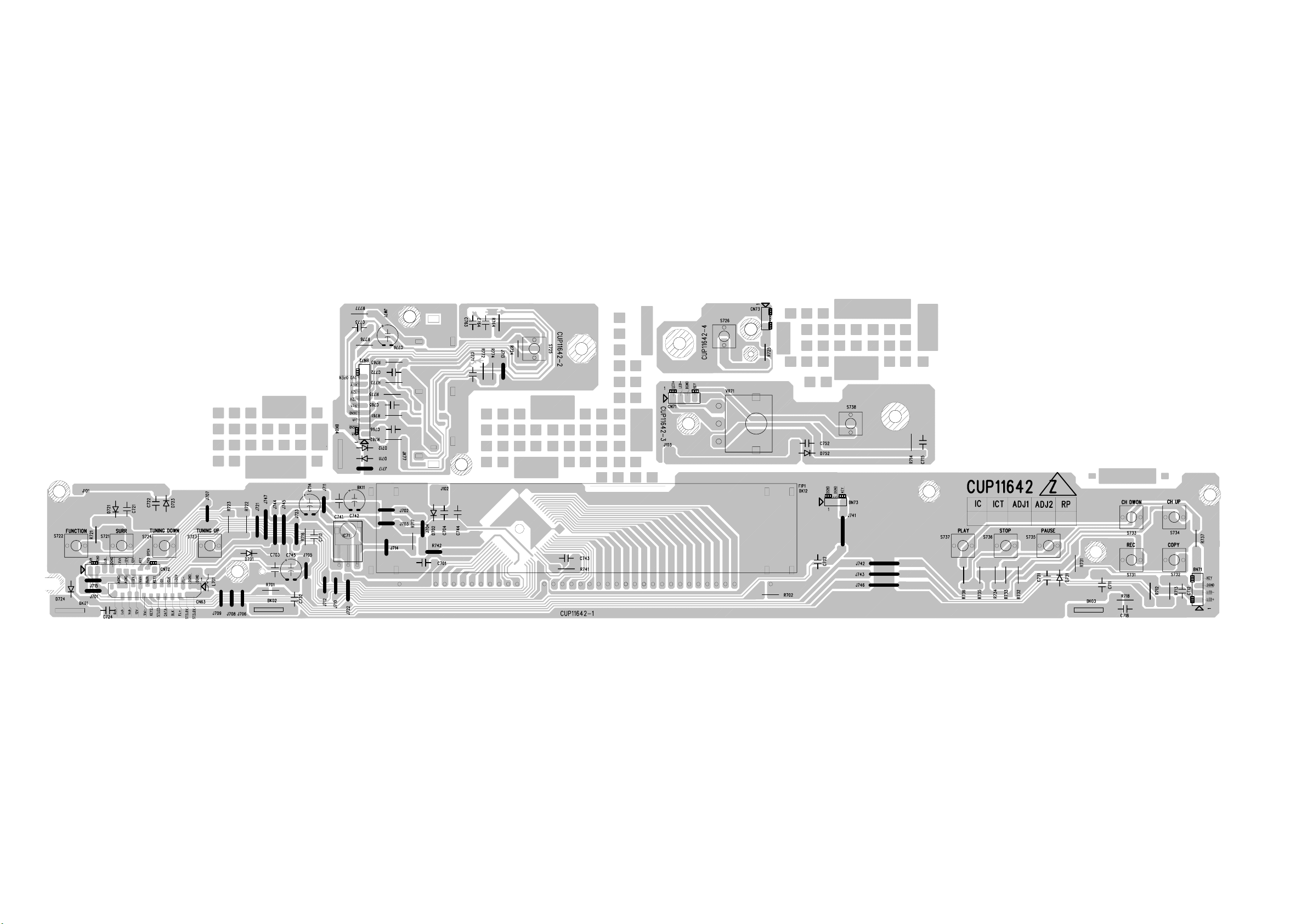

PRINTED CIRCUIT BOARDS

FRONT BOARD

CUP11642Z

15 16

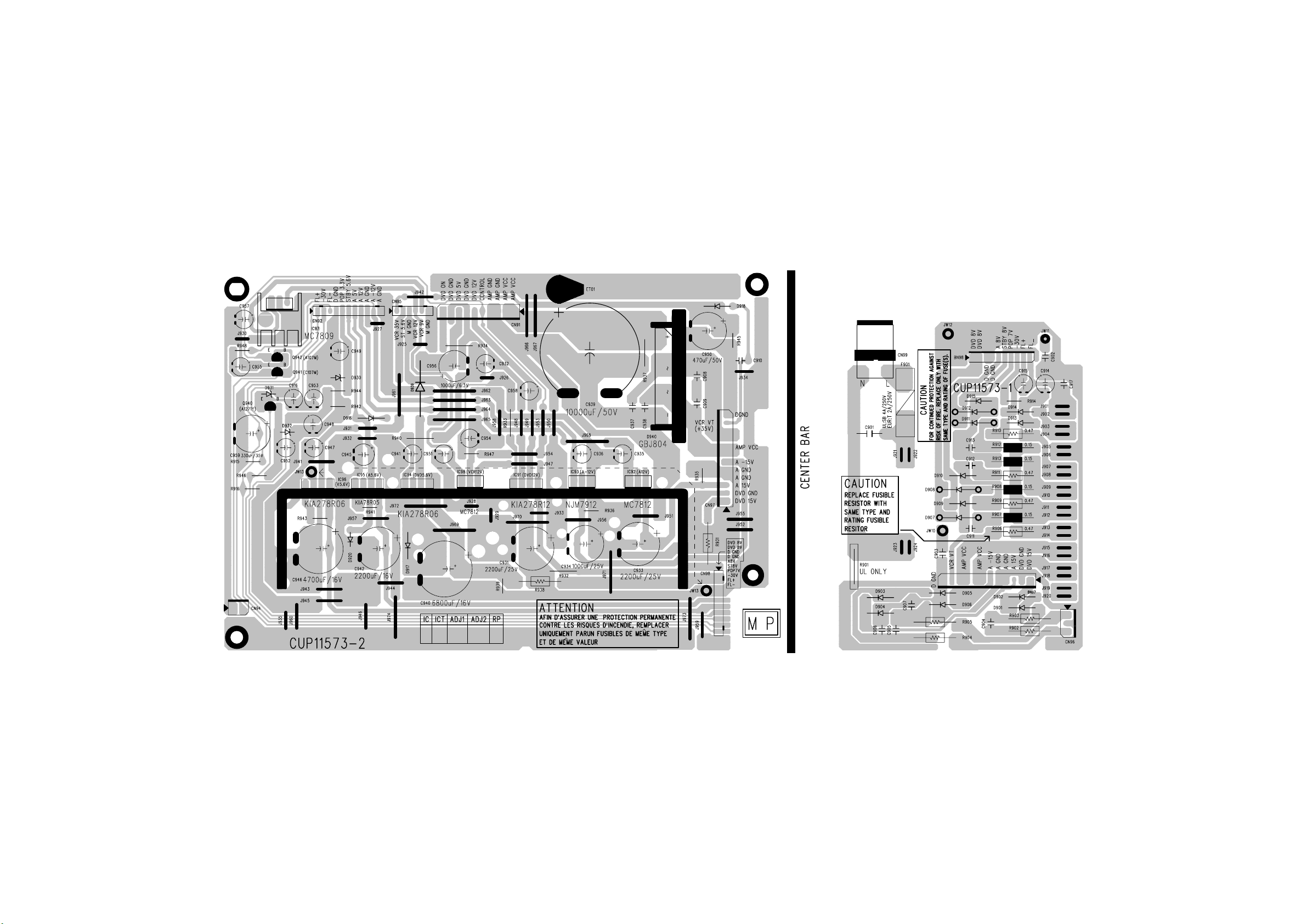

POWER BOARD

CUP11573Z

17 18

TOP VIEW

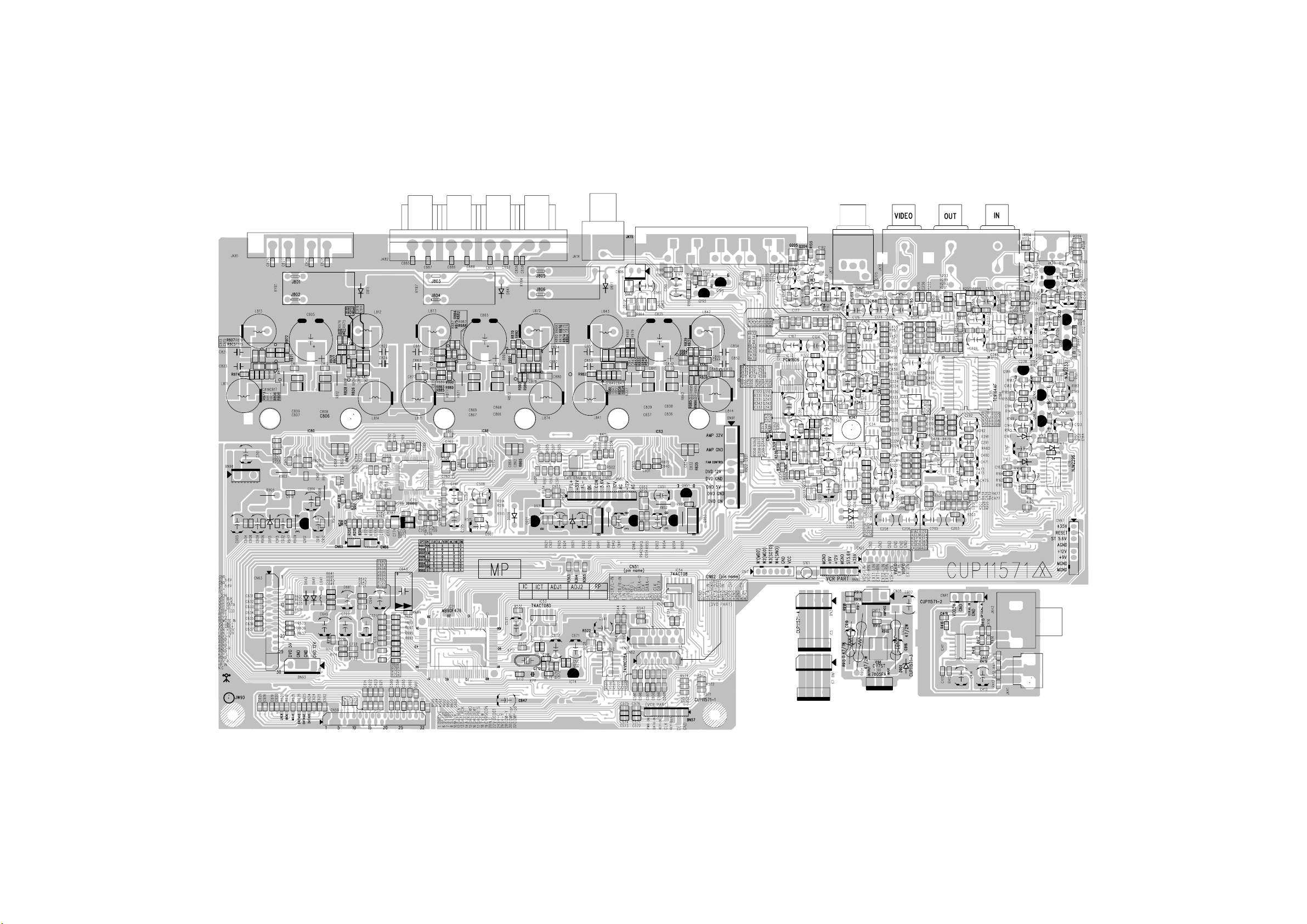

MAIN BOARD

CUP11571Z

19 20

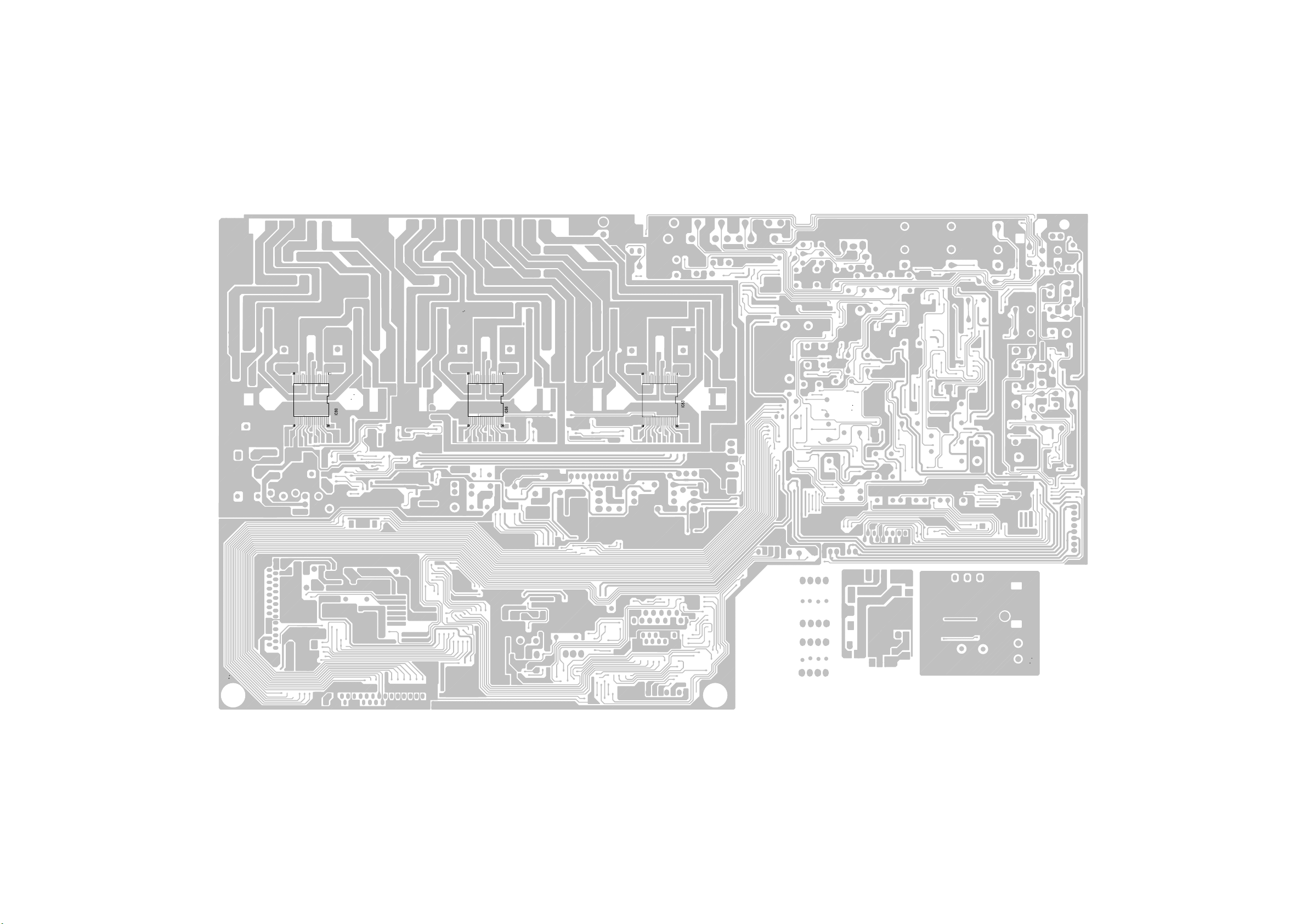

MAIN BOARD

CUP11571Z

BOTTOM VIEW

21 22

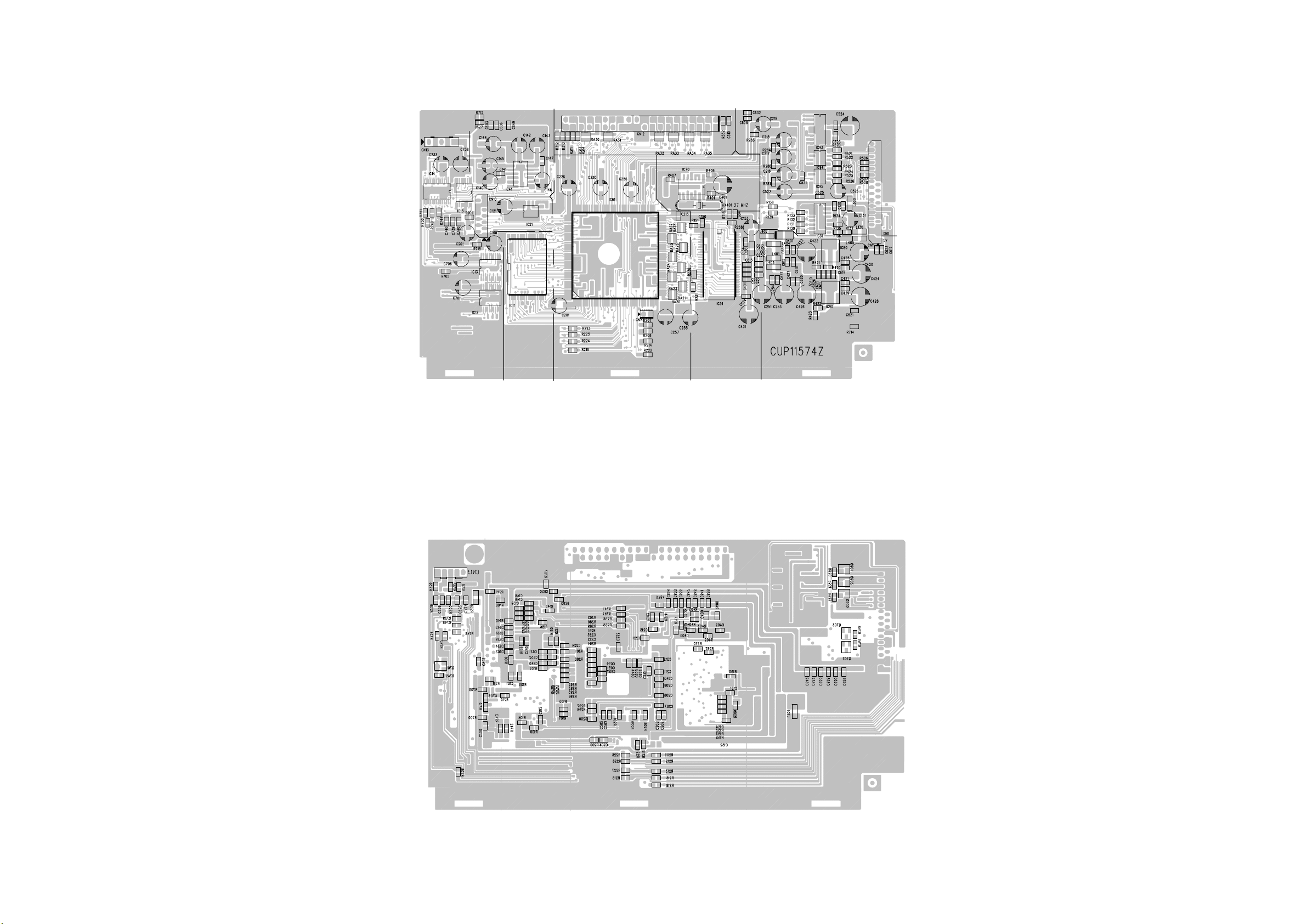

TOP VIEW

MPEG BOARD

CUP11574Z

BOTTOM VIEW

23 24

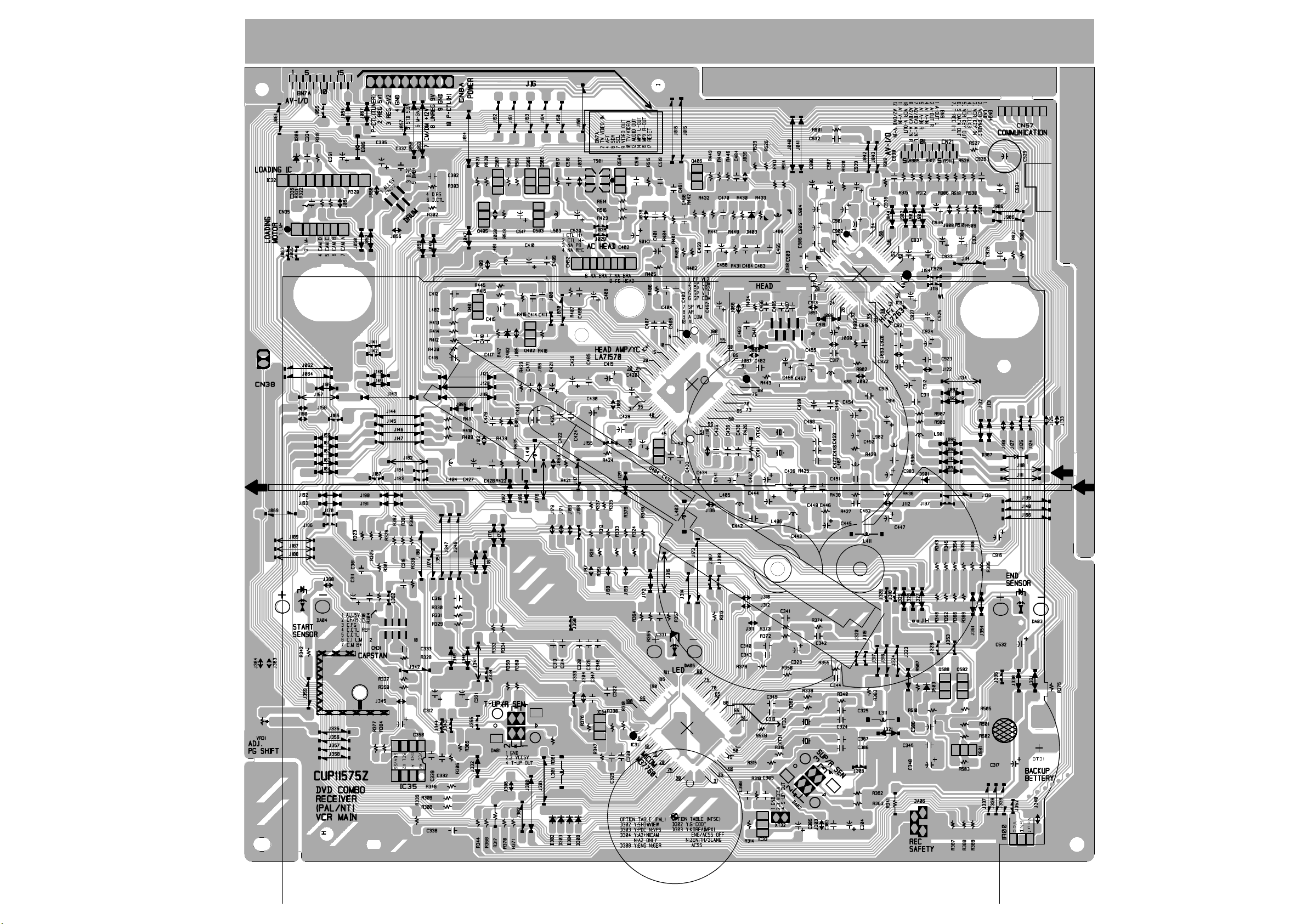

VCR MAIN BOARD

CUP11575Z

25 26 24

VCR TUNER BOARD VCR MPX BOARD

CUP11577ZCUP11576Z

27 28

WIRING DIAGRAM

29 30

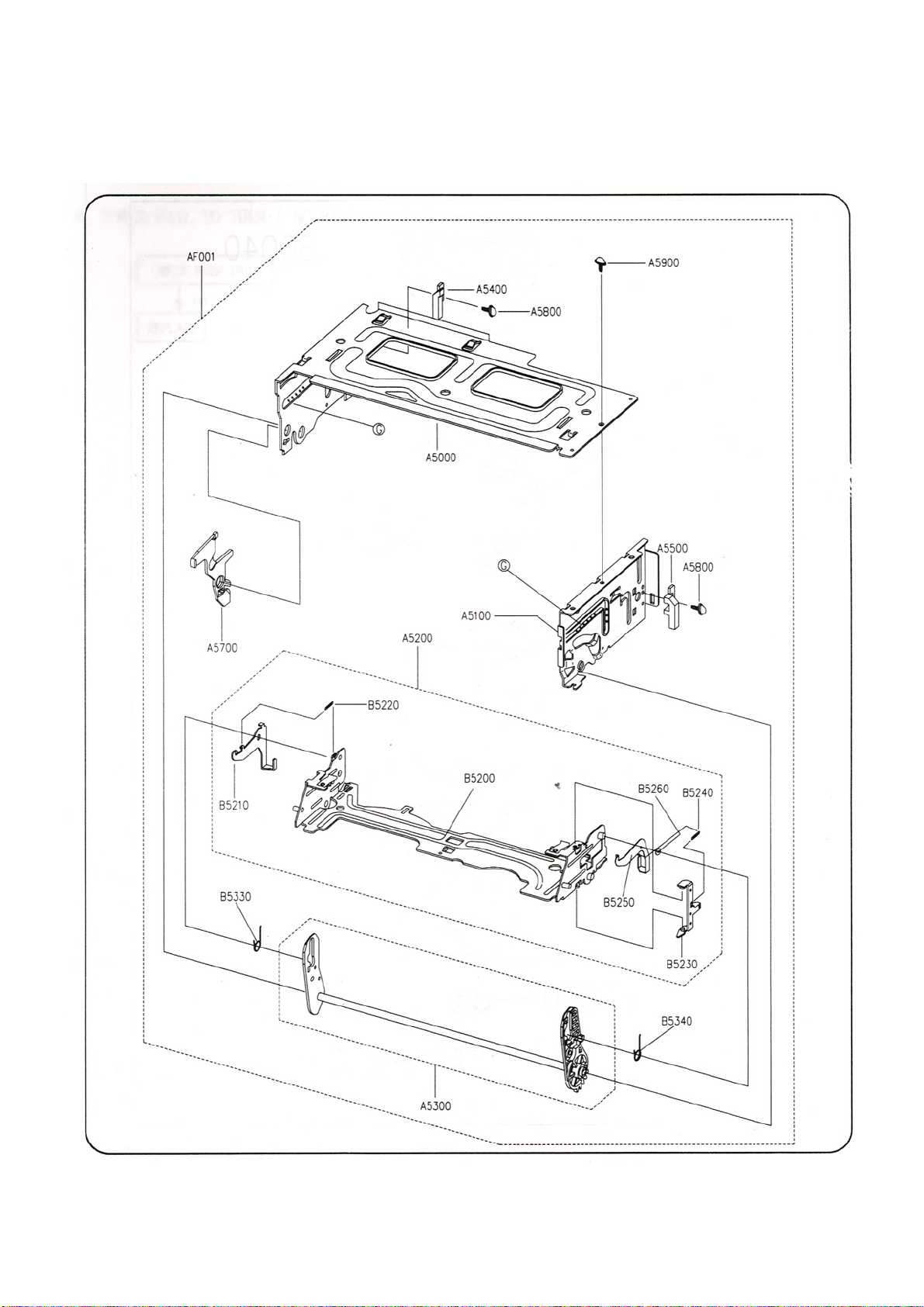

EXPLODED VIEW

31 32

A700-60R5 (DVD MECHANISM) EXPLODED VIEW 1

33 34

A700-60R5 (DVD MECHANISM) EXPLODED VIEW 2

35 36

38

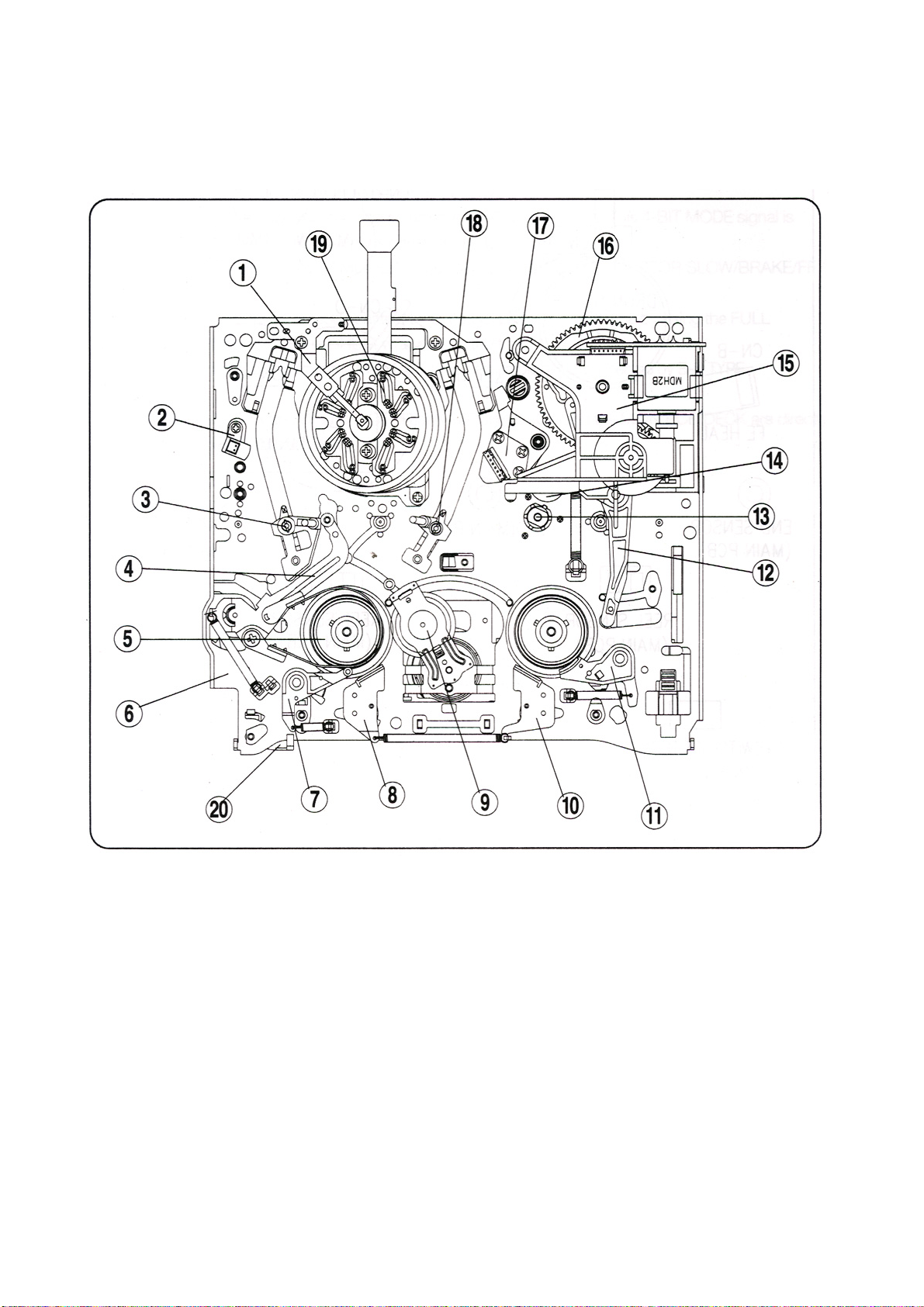

K-30 (VCR MECHANISM) ASSEMBLING DIAGRAM

A. TOP VIEW

1. EARTH BRKT ASS’Y 11. T-SUB BRAKE ASS’Y

2. FE HEAD 12. RELAY LEVERL

3. S SLANT POLE ASS’Y 13. CAPSTAN MOTOR

4. TENSION BEND ASS’Y 14. PINCH LEVEL TOTAL ASS’Y

5. REEL TABLE 15. L/C BRKT TOTAL ASS’Y

6. MAIN BASE ASS’Y 16. CAM GEAR

7. S SUB BRAKE ASS’Y 17. AC HEAD TOTAL ASS’Y

8. S MAIN BRAKE ASS’Y 18. T SLANT POLE ASS’Y

9. IDLER PLATE TOTAL ASS’Y 19. DRUM TOTAL ASS’Y

10. T MAIN BRAKE ASS’Y 20. RECORD SAFETY LEVEL

39

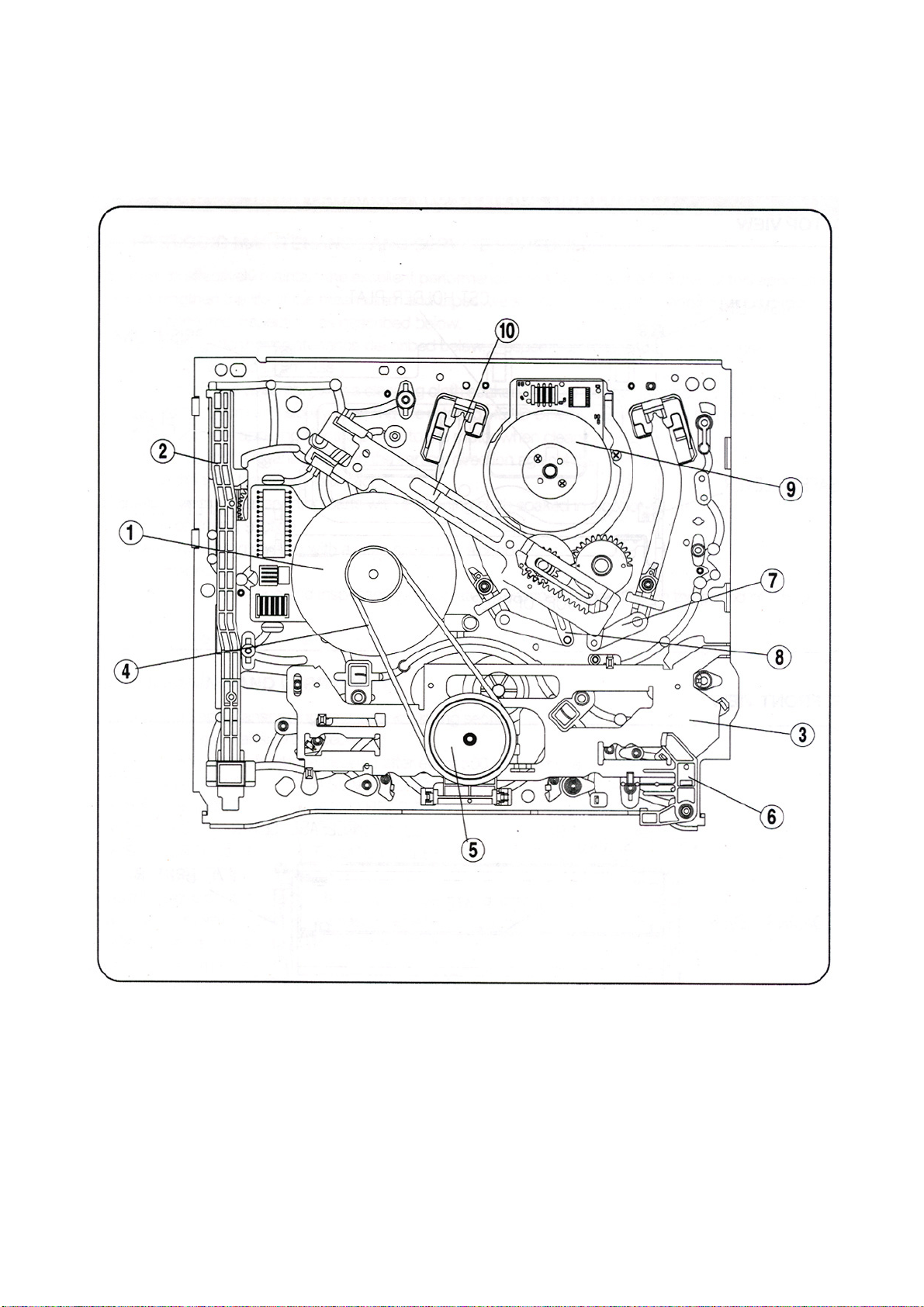

B. BOTTOM VIEW

1. CAPSTAN MOTOR 6. RECPRD SAFETY LEVER

2. F/L RACK 7. L LOADING ASS’Y

3. CONNECT PLATE 8. R LOADING ASS’Y

4. REEL BELT 9. DRUM TOTAL ASS’Y

5. REEL GEAR TOTAL ASS’Y 10. LOADING RACK ASS’Y

40

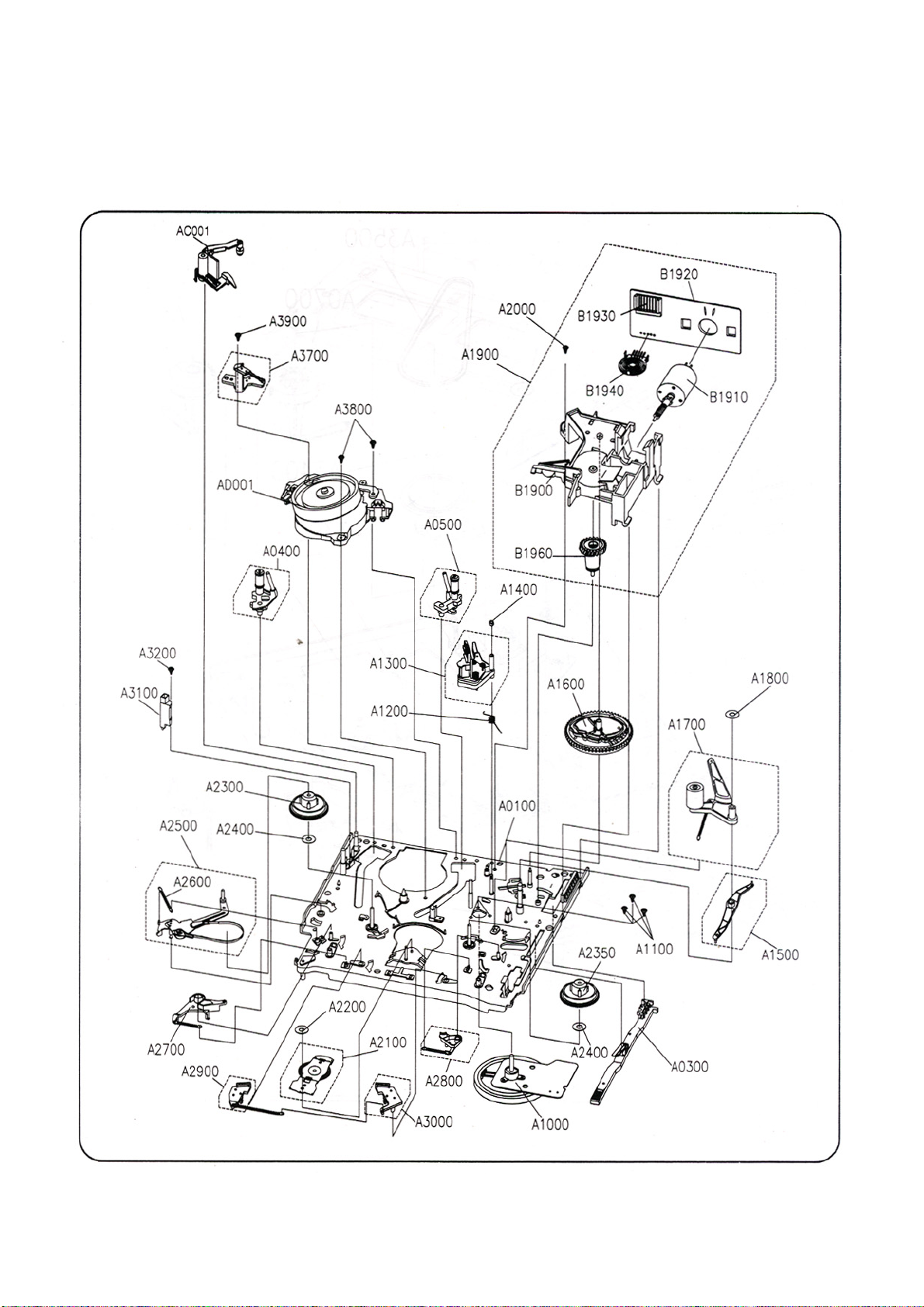

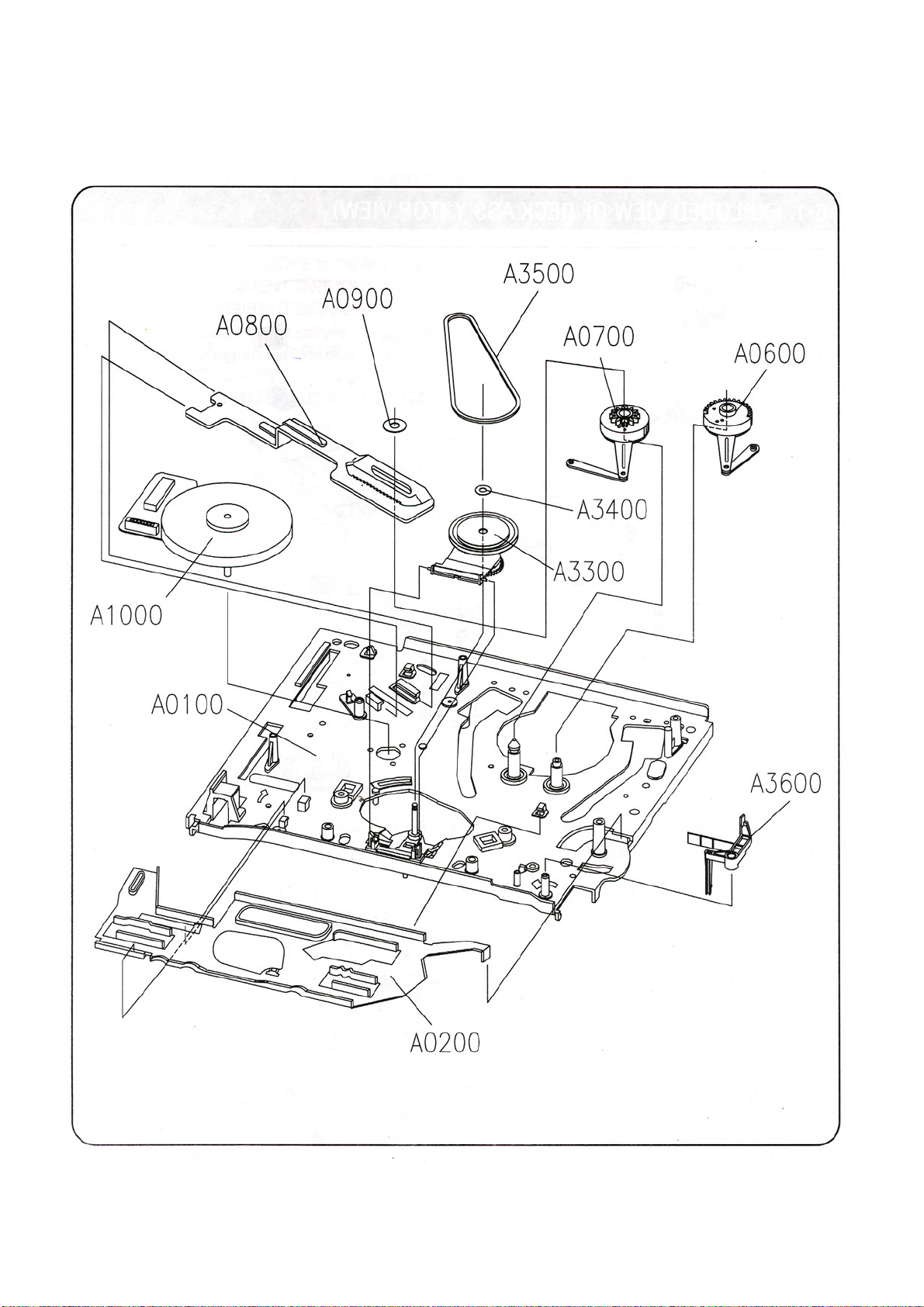

K-30 (VCR MECHANISM) EXPLODED VIEW

A. TOP VIEW

41

B. BOTTOM VIEW

42

K-30 (VCR MECHANISM) EXPLODED VIEW OF P/L ASS'Y

43

RESISTORS AND CAPACITORS

IMPORTANT SAFETY NOTICE

Numbering System of Resistor

Example

Numbering System of Capacitor

Example

RESISTORS AND CAPACITORS

RESISTORS AND CAPACITORS

RESISTORS AND CAPACITORS

Notes.

* Circuit No's first character indicates kinds of part type.

C : Capacitors

R : Resistors

D : Diode

J : Jumper

L : Coil

Q : Transistors

S : Switch

BK : Bracket

JK : Jack

IC : Integrated Circuit

X : Crystal

BD : Bead

* Components identified by ! Mark have special characteristics important for safety.

* When replacing any of these components, use only manufacture's specified parts.

* The unit of resistance is OHM ( )

K=1000( ), M=1000(K )

* The unit of capacitance is MICROFARAD (uF )

-6

P=10

uF

CRD 25 F J 101 HCKR 1H 101 K B

Type Wattage Shape Tolerance Value Type Voltage ValueTolerance Pecularity

Resistor Type Wattage Tolerance Tolerance

K(C/H)RD : Carbon 20 : 1/5W F : 1%

K(C/H)RG : Metal Oxide 25 : 1/4W J : 5% HCB : Ceramic 0J : 6.3V 1H : 50V DC C : 0.25pF

50 : 1/2W K : 10% CCC : Ceramic 1A : 10V 1 : 125V DC G : 2%

1 : 1W CCK : Ceramic 1C: 16V KC : 400V AC J : 5%

K(C/H)RG : Metal Cement 2 : 2W HCQI : Polyester 1E : 25V K : 10%

3 : 3W HCQP : Polypropyene 1H : 50V Z : +80%, -20%

K(H)RJ : Carbon. CHIP 10 : 1/10W HCQS : Polystyrol 1V : 35V

14 : 1/4W HCUS : Ceramic

ELECTRICAL PARTS LIST

Capacitor Type

HCEA : ELECT

HCEA : ELECT.CHIP

Voltage

HCEA Type

Other

44

DVD PART

DVD PART

SEQ. PART NO. DESCRIPTION SPECIFICATION

C701 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C702 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C703 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C704 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C711 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C712 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C713 HCBS1H220JT CAP , CERAMIC 22UF 50V J

C714 HCEA1CKS470T CAP , ELECT 47UF 16V

C715 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C718 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C721 HCBS1H221KBT CAP , CERAMIC 220PF 50V K

C722 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C723 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C724 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C731 HCBS1H221KBT CAP , CERAMIC 220PF 50V K

C732 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C741 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C742 HCEA1HKS4R7T CAP , ELECT 4.7UF 50V

C743 HCBS1H220JT CAP , CERAMIC 22UF 50V J

C744 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C745 HCEA1CKS101T CAP , ELECT 100UF 16V

C752 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C763 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C764 HCBS1H103ZFT CAP , CERAMIC 0.01UF 50V Z

C765 HCBS1H101KBT CAP , CERAMIC 100PF 50V K

C766 HCBS1H101KBT CAP , CERAMIC 100PF 50V K

C771 HCBS1H101KBT CAP , CERAMIC 100PF 50V K

C772 HCBS1H101KBT CAP , CERAMIC 100PF 50V K

C773 HCBS1H181KBT CAP , CERAMIC 180PF 50V K

C776 HCEA1CKS101T CAP , ELECT 100UF 16V

D701 HVD1SS133MT DIODE 1SS133T-77

D702 HVD1SS133MT DIODE 1SS133T-77

D721 HVD1SS133MT DIODE 1SS133T-77

D722 HVD1SS133MT DIODE 1SS133T-77

D723 HVD1SS133MT DIODE 1SS133T-77

D724 HVD1SS133MT DIODE 1SS133T-77

D731 HVD1SS133MT DIODE 1SS133T-77

D752 HVD1SS133MT DIODE 1SS133T-77

J701 C3A206 WIRE , COPPER SN95/PB5,0.6

J702 C3A206 WIRE , COPPER SN95/PB5,0.6

J703 C3A206 WIRE , COPPER SN95/PB5,0.6

J704 C3A206 WIRE , COPPER SN95/PB5,0.6

J705 C3A206 WIRE , COPPER SN95/PB5,0.6

J706 C3A206 WIRE , COPPER SN95/PB5,0.6

J707 C3A206 WIRE , COPPER SN95/PB5,0.6

REMARKS

COP11572B FRONT PCB ASS'Y ADV R-7100

CIP11572B FRONT PCB AUTO ASS'Y ADV R-7100

CUP11572Z PCB , FRONT ADV R-7100

45

SEQ. PART NO. DESCRIPTION SPECIFICATION

J708 C3A206 WIRE , COPPER SN95/PB5,0.6

J709 C3A206 WIRE , COPPER SN95/PB5,0.6

J710 C3A206 WIRE , COPPER SN95/PB5,0.6

J711 C3A206 WIRE , COPPER SN95/PB5,0.6

J721 C3A206 WIRE , COPPER SN95/PB5,0.6

J722 C3A206 WIRE , COPPER SN95/PB5,0.6

J723 C3A206 WIRE , COPPER SN95/PB5,0.6

J724 C3A206 WIRE , COPPER SN95/PB5,0.6

J741 C3A206 WIRE , COPPER SN95/PB5,0.6

J742 C3A206 WIRE , COPPER SN95/PB5,0.6

J743 C3A206 WIRE , COPPER SN95/PB5,0.6

J744 C3A206 WIRE , COPPER SN95/PB5,0.6

J745 C3A206 WIRE , COPPER SN95/PB5,0.6

J746 C3A206 WIRE , COPPER SN95/PB5,0.6

J747 C3A206 WIRE , COPPER SN95/PB5,0.6

J748 C3A206 WIRE , COPPER SN95/PB5,0.6

J749 C3A206 WIRE , COPPER SN95/PB5,0.6

J750 C3A206 WIRE , COPPER SN95/PB5,0.6

J761 C3A206 WIRE , COPPER SN95/PB5,0.6

J762 C3A206 WIRE , COPPER SN95/PB5,0.6

J763 C3A206 WIRE , COPPER SN95/PB5,0.6

J781 C3A206 WIRE , COPPER SN95/PB5,0.6

L701 HLQ02C100KT COIL , AXAIL 10UHK

Q711 HVTKRC107MT T.R KRC107M

R711 CRD20TJ331T RES , CARBON 330OHM 1/5W J

R712 CRD20TJ102T RES , CARBON 1KOHM 1/5W J

R713 CRD20TJ102T RES , CARBON 1KOHM 1/5W J

R714 C3A206 WIRE , COPPER SN95/PB5,0.6

R716 CRD20TJ333T RES , CARBON 33KOHM 1/5W J

R717 CRD20TJ100T RES , CARBON 10OHM 1/5W J

R718 CRD20TJ100T RES , CARBON 10OHM 1/5W J

R721 CRD20TJ102T RES , CARBON 1KOHM 1/5W J

R722 CRD20TJ152T RES , CARBON 1.5KOHM 1/5W J

R723 CRD20TJ182T RES , CARBON 1.8KOHM 1/5W J

R724 CRD20TJ272T RES , CARBON 2.7KOHM 1/5W J

R725 CRD20TJ332T RES , CARBON 3.3KOHM 1/5W J

R731 CRD20TJ102T RES , CARBON 1KOHM 1/5W J

R732 CRD20TJ152T RES , CARBON 1.5KOHM 1/5W J

R733 CRD20TJ182T RES , CARBON 1.8KOHM 1/5W J

R734 CRD20TJ272T RES , CARBON 2.7KOHM 1/5W J

R735 CRD20TJ332T RES , CARBON 3.3KOHM 1/5W J

R736 CRD20TJ562T RES , CARBON 5.6KOHM 1/5W J

R737 CRD20TJ752T RES , CARBON 7.5KOHM 1/5W J

R741 CRD20TJ562T RES , CARBON 5.6KOHM 1/5W J

R761 CRD20TJ221T RES , CARBON 220OHM 1/5W J

R762 CRD20TJ221T RES , CARBON 220OHM 1/5W J

R763 CRD20TJ101T RES , CARBON 100OHM 1/5W J

R764 CRD20TJ101T RES , CARBON 100OHM 1/5W J

R772 CRD20TJ471T RES , CARBON 470OHM 1/5W J

R773 CRD20TJ471T RES , CARBON 470OHM 1/5W J

REMARKS

Loading...

Loading...