Page 1

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

C007

Item No.

_______________________________

C007

Garnish all your favorite beverages and desserts with freshly

made whipping cream or create your own mousse desserts

with the same equipment. Simply mix the ingredients

together, and pour into the whipping dispenser. Press the

button to serve, with no chemical additives or propellants.

Refrigerated Hopper

Two removable tanks nest inside each other in the hopper:

6.3 qt. (6.0 liter) and 9.5 qt. (9.0 liter). To use the larger

tank, simply remove the smaller one; the smaller tank may be

used alone, or inside the larger one. Refrigerated to maintain

safe product temperatures below 41ºF (5ºC). Electronic

temperature control is adjustable for various product

requirements. Hopper temperature is displayed on electronic

control.

Whipping Action

Refrigerated liquid cream is pumped through a stainless steel

chamber, forcing the cream through multiple paths,

incorporating air and whipping into a light and fluffy topping

or dessert.

Air Pump

Select the lowest number on the adjustment knob for lower

overrun, and adjust to a higher number if a lighter texture is

desired. Compact pump, located above the hopper area,

easily disassembles for cleaning with no tools.

Dispensing

Convenient push-button can be used for two modes of

operation: manual, or timed. For manual operation, just

press and hold until desired quantity is dispensed. For timed

operation, pre-set the dispensing time in the electronic

control for similar portions every serving.

Drip Tray

Clear drip tray and stainless steel holder may be removed as

needed.

Features

Whipped Cream Dispenser

Page 2

C007

C007Whipped Cream Dispenser

Electrical

One dedicated electrical connection is recommended. See the

Electrical chart for the proper electrical requirements. Manufactured

to be cord connected. Consult the international Taylor distributor for

cord & receptacle specifications for 50 Hz. equipment.

Refrigeration System

One, 140 BTU/hr compressor. R134a. (BTUs may vary depending on

compressor used.)

Pump Motor

One, 1/4 HP.

Air Cooled

Minimum Clearance: 4” (100 mm) around all sides. Minimum air

clearances must be met to assure adequate air flow for optimum

performance.

Taylor Company,

A Division of Carrier Commercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Printed in U.S.A.

Weights lbs. kgs.

Net 82 37.2

Crated 104 47.2

cu. ft. cu. m.

Volume 6.2 0.17

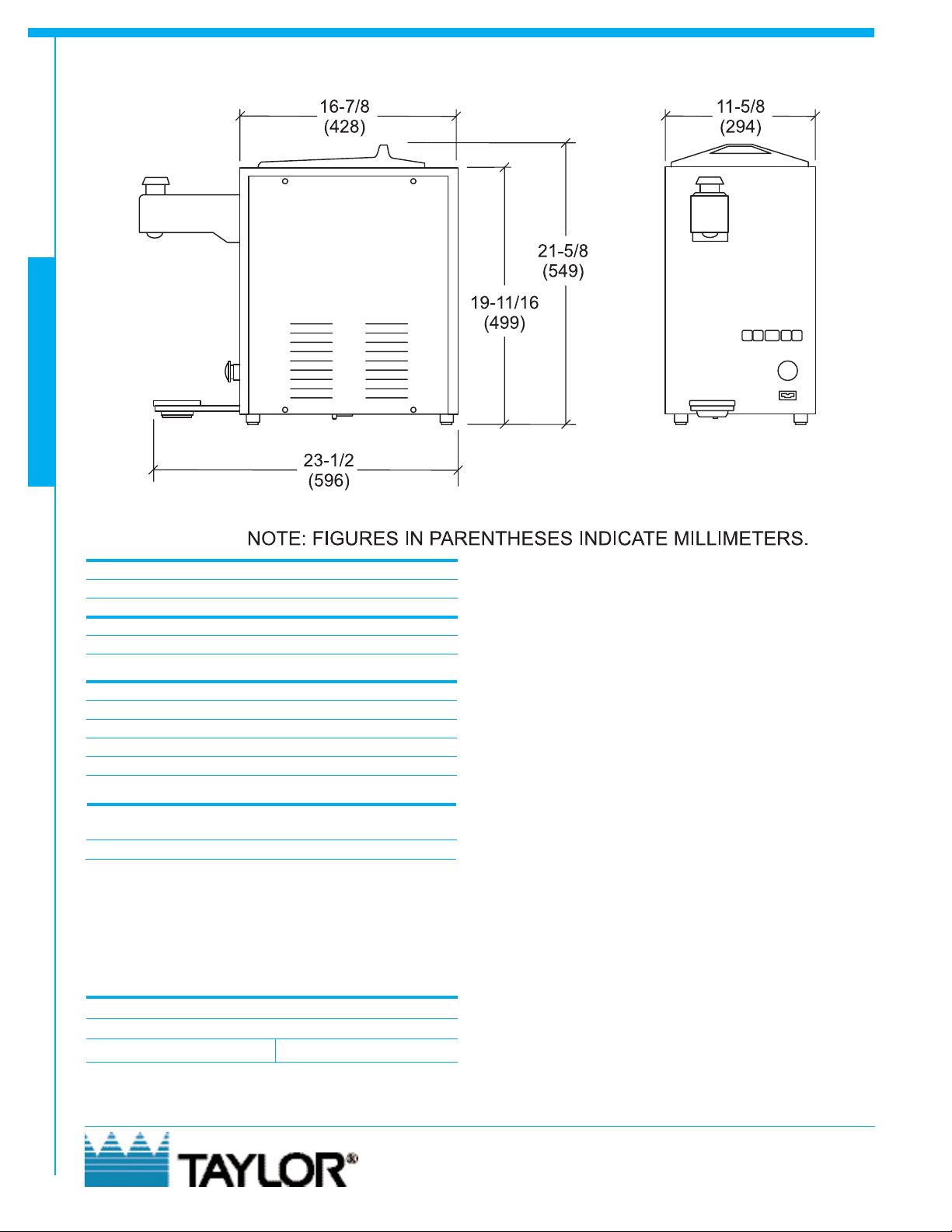

Dimensions in. mm.

Width 11-5/8 294

Depth 23-1/2 596

Height 21-5/8 549

Counter Clearance* 1 25

Mounted on standard feet

Bidding Specs

Electrical: Volt ___________________ Hz__________ ph _________

Neutral: Yes No Cooling: Air Water NA

Options:_________________________________________________

_________________________________________________________

Specifications

063083-ADV

2/09

Accessories

Cleaning rod

O-ring removal tool

Electrical Total Supplied

Amps with NEMA Cord

115/60/1 Air 7.0 5-15P

This unit may be manufactured in other electrical characteristics. Refer to the

local Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

Loading...

Loading...