Page 1

Model C006

Flavor Dispenser

Operating Instructions

066869--M

8/21/08 (Original Publication)

(Updated 8/16/12)

Page 2

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Fax:

E-mail:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E August, 2008 Taylor (Original Publication)

All rights reserved.

066869-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 Safety 1....................................................

Section 2 To the Installer 3............................................

Installing the Flavor Shot Dispenser 6.....................................

Section 3 Operator Parts Identification 7...............................

Exploded View 7........................................................

Inside Cabinet View 8...................................................

Section 4 Important: To the Operator 10.................................

Power Switch 11.........................................................

Selection Buttons 11.....................................................

Flavor Refill and Level Reset 12...........................................

Service Display Menu 13..................................................

Cleaning Flavors and Liquid Sugar 14......................................

Cleaning All F lavors and Liquid Sugar 15...................................

Prime All Flavors and Liquid Sugar 16......................................

Calibrate Flavors and Liquid Sugar 17......................................

Data Menu 18...........................................................

Cleaning Lockout 18.....................................................

Section 5 Operating Procedures 19.....................................

Assembly and Start Up 19................................................

Cleaning/Sanitizing 19....................................................

Product Tube Removal/Installation 21......................................

Break In Flavor (Product Tube) 23.........................................

Table of Contents Model C006

Page 4

Table of Contents - Page 2

Dispensing Flavor Shots - Hot Beverages 24................................

Dispensing Flavor Shots - Box of Coffee 25.................................

Dispensing Flavor Shots - Iced Coffee 26...................................

Dispensing Flavor Shots - Latté (Hot or Iced) 27.............................

Section 6 Cleaning and Mainten ance 28.................................

Cleaning Procedure 28...................................................

Equipment Cleaning and Maintenance Schedule 28..........................

Section 7 Troubleshooting Guide 29....................................

General Troubleshooting 29...............................................

Section 8 Parts List 31.................................................

Wiring Diagram 33.......................................................

Note: Continuing research results in steady improvements; th erefore, information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are considered to be the o riginal set of in structions.

E August, 2008 Taylor (Original Publication)

(Updated August, 2012)

All rights reserved.

066869-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Model C006 Table of Contents

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 5

Section 1 Safety

We at Taylor are concerned about the safety of the operator when he or she comes in

contact with the dispenser and its parts. Taylor has gone to extreme efforts to design and

manufacture built-in safety features to protect both you and the service technician. As an

example, warning labels have been attached to the dispenser to further point out safety

precautions to the operator.

IMPORTANT-Failuretoadheretothefollowingsafetyprecautionsmayresult

in severe personal injury or death. Failure to comply with these warnings may

damage the machine and its components. Component damage will result in part

replacement expense and service repair expense.

To Operate Safely:

DO NOT operate the dispenser without reading this operator's manual. Failure to

follow this instruction may result in equipment damage, poor dispenser performance,

health hazards, or personal injury.

Per IEC 60335-1 and its part 2 standards, “This appliance is to be used only by

trained personnel. It is not intended for use by children or people with reduced physical,

sensory, or mental capabilities, or lack of experience and knowledge, unless given

supervisionor instruction concerning the use of the appliance by a person responsible for

their safety.”

DO NOT operate the dispenser unlessit is properly grounded. Failure to follow this

instruction may result in electrocution.

Always plug the dispenser into an approved electrical outlet. Do not touch the

dispenser with wet hands. Failure to follow this instruction may result in electrocution.

Do not immerse the dispenser in water. Failure to follow this instruction may result

in electrocution.

Observe the same safety precautions with the dispenser that you would with any

electrical appliance. Failure to follow this instruction may result in electrocution.

Allrepairsmust be performed by aqualified service technicianwiththe mainpower

supply to the dispenser disconnected. Failure to follow this instruction may result in

electrocution. Contact your local authorized Taylor Distributor for service.

120816

Model C006 Safety

1

Page 6

DO NOT operate the dispenser unless all service panels and access doors are

restrainedwithscrews.Failuretofollowthisinstructionmayresultinelectrocution.Contact

your local authorized Taylor Distributor for service.

DO NOT operate the dispenser with larger fuses than specified on the dispenser

data label.

Cleaning and sanitizing schedules are governed by your state or local regulatory

agencies and must be followed accordingly. Please refer to the cleaning section of this

manual for the proper procedure to clean this unit.

This unit has many sharp edges that can cause severe injuries.

DO NOT use a water jet to clean or rinse the dispenser. Failure to follow this

instruction may result in serious electrical shock.

This dispensing unit m ust be placed on a level surface. Use caution when moving

the unit. Failure to comply may cause the unit to tip over, and result in personal injury.

This unit is designed to operate indoors.

DO NOT obstruct air intake and discharge openings: Minimum of 1” (25.4 mm) at the rear

and 4” (102 mm) under the unit for adequate air flow.

NOISE LEVEL: T his unit meets the airborne noise emission standard according to the

applicable European Directive.

If the crossed out wheeled bin symbol is affixed to this product, it signifies that this

product is compliant withthe EU Directive as well as other similar legislation in effect after

August13, 2005. Therefore, it mustbe collectedseparately afterits useis completed,and

cannot be disposed as unsorted municipal waste.

The user is responsible for returning the product to the appropriate collection facility, as

specified by your local code.

For additional information regarding applicable local laws, please contact the municipal

facility and/or local distributor.

Safety Model C006

2

Page 7

Section 2 To the Installer

Overview

TheflavorshotdispenserModelC006dispensesnineflavors,combinationsof flavors,and

liquid sugar products in different volumes. The dispenser is supplied with a cord and

grounding type plug. The dispenser is designed for indoor use only.

Specifications

Capacity: 9 tanks x approximately 1,000 ml.

Weight: approximately 65 lbs. (30 kg.), Crated Weight: 74 lbs. (34 kg.)

Dimensions: 24” D x 8” W x 25” H

Electrical Requirements

Electrical Requirements: 120V, AC, 15 amp., single phase, 60 Hz, supplied with NEMA

cord and plug 5-15P.

The dispenser includes a micro controller and must be operated on grounded electrical

wiring at all times. A qualified technician mustcomplete anyelectrical servicing. Servicing

of the dispenser by unauthorized personnel makes the warranty null and void.

In the United States, this equipment is intended to be installed in accordance with the

National Electrical Code (NEC), ANSI/NFPA 70-1987. In all other areas of the world,

equipment should be installed in accordance with the existing local codes. Please contact

your local authorities. The purpose of the NEC code is the practical safeguarding of

persons and property from hazards arising from the use o f electricity. This code contains

provisions considered necessary for safety. Compliance therewith and proper

maintenance will result in an installation essentially free from hazard!

This unit is provided with an equipotential grounding lug that is to be properly attached

to the rear of the frame by the authorized installer. The installation location is marked by

theequipotentialbonding symbol (5021 of IEC 60417-1) on both theremovable paneland

the equipments frame.

Stationaryapplianceswhicharenotequipped witha powercordand a plugor other device

to disconnect the appliance from the power source must have an all-pole disconnecting

device with a contact gap of at least 3 mm installed in the external installation.

Appliancesthat are permanently connected to fixed wiring and for which leakage currents

may exceed 10 mA,particularlywhen disconnected or not usedfor longperiods, or during

initial installation, shall have protective devices such as a GFI, to protect against the

leakage of current, installed by the authorized personnel to the local codes.

Model C006 To the Installer

3

Page 8

Supply cords used with this unit shall be oil-resistant, sheathed flexible cable not lighter

than ordinary polychloroprene or other equivalent synthetic elastomer-sheathed cord

(Code designation 60245 IEC 57) installed with the proper cord anchorage to relieve

conductors from strain, including twisting, at the terminals and protect theinsulation ofthe

conductors from abrasion.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

CAUTION:THISEQUIPMENTMUSTBEPROPERLYGROUNDED!FAILURETO

DO SO CAN RESULT IN SEVERE PERSONAL INJURY FROM ELECTRICAL SHOCK!

DO NOT attempt any repairs unless the main power supply to the dispenser has

been disconnected.

DO NOT install this equipment in an area where a water jet could be used. Failure

to follow this instruction may r esult in severe personal injury from electrical shock.

To the Installer Model C006

4

Page 9

Air Clearance

Always allow a minimum of 1” (25.4 mm) at the rear and 4” (102 mm) under the unit for

adequate air flow.

Warranty

One year parts and labor, excluding wear items.

CAUTION: Warranty is valid only if required service work is provided by an Authorized

Taylor Service Technician.

Note: Warranty is valid only if the parts are authorized Taylor parts, purchased from an

authorized Taylor Distributor, and the required service work is provided by an authorized

Taylor service technician. Taylor reserves the right to deny warranty claims on equipment

or parts if non-approved parts were installed in the machine, system modifications were

performed beyond factory recommendations, or it is determined that the failure was

caused by neglect or abuse.

IMPORTANT: The unit must be cleaned, primed and calibratedpriorto the first use.

ALL flavors and the sugar must be calibrated at time of start up. It is NOT optional

tocalibrateonlyoneortwoflavors. Ifthese proceduresarenot followed completely, the

CUSTOM (combination) selector button will not operate.

Model C006 To the Installer

5

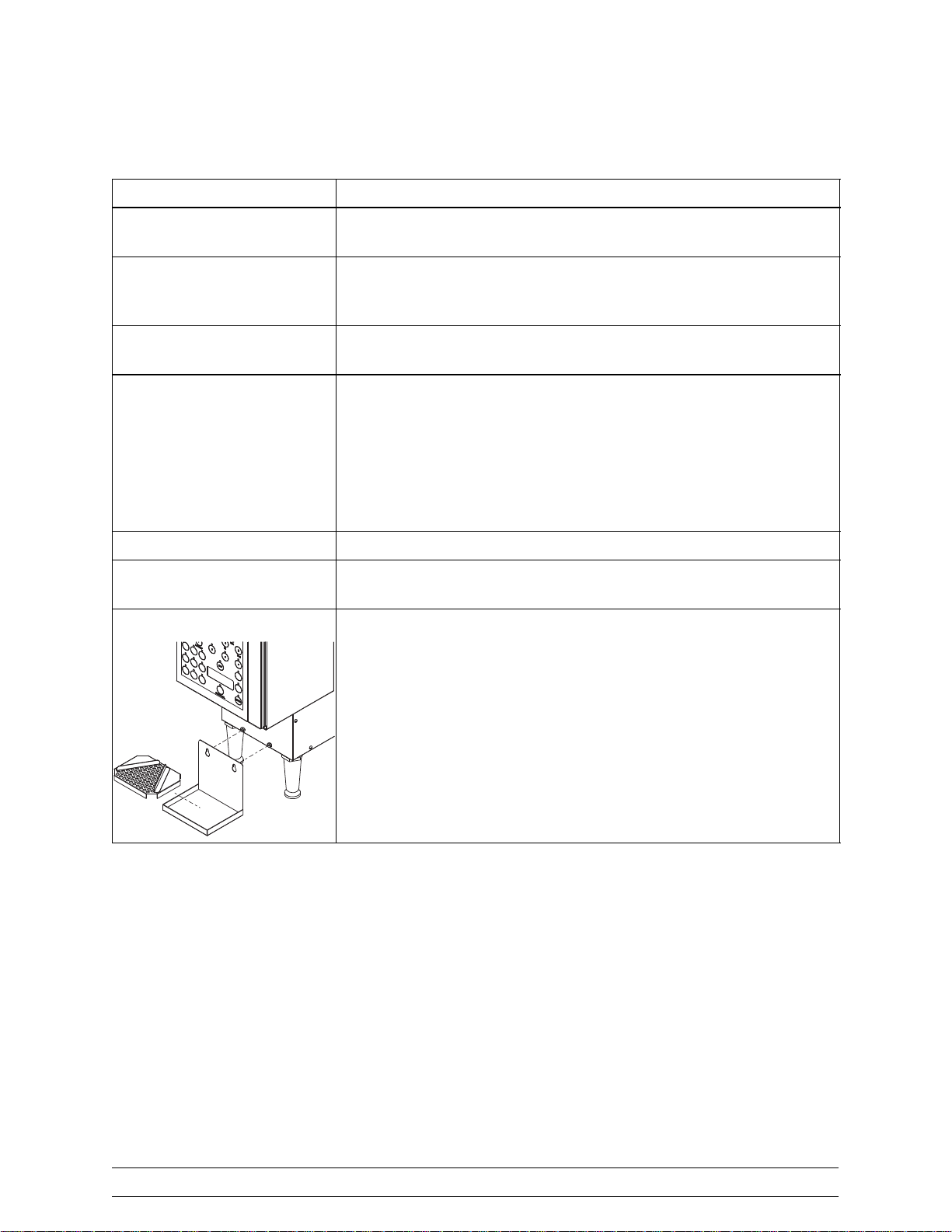

Page 10

Installing the Flavor Shot Dispenser

Step Action

1 Place the flavor shot dispenser where it will best serve

your operation.

2 Make sure that counters, platforms, and shelves are strong

enough to support the weight of the dispenser and full

containers of product (109 lbs. [49 kg.]).

3 Maintain a minimum of 1” (25.4 mm) at the rear and 4”

(102 mm) under the unit for adequate air flow.

4 DO NOT remove the legs from the dispenser or allow

the dispenser to sit d irectly on the counter.

Adequate air flow under the machine is necessary for

proper operation.

Make sure the legs at the four corners of the dispenser are

firmly attached.

Removal of the legs violates the warranty.

5 Make sure the unit is level.

6 Plug the power cord into the proper electrical outlet (NEMA

5-15P).

7 Install the drip tray and the splash shield.

To the Installer Model C006

6

Page 11

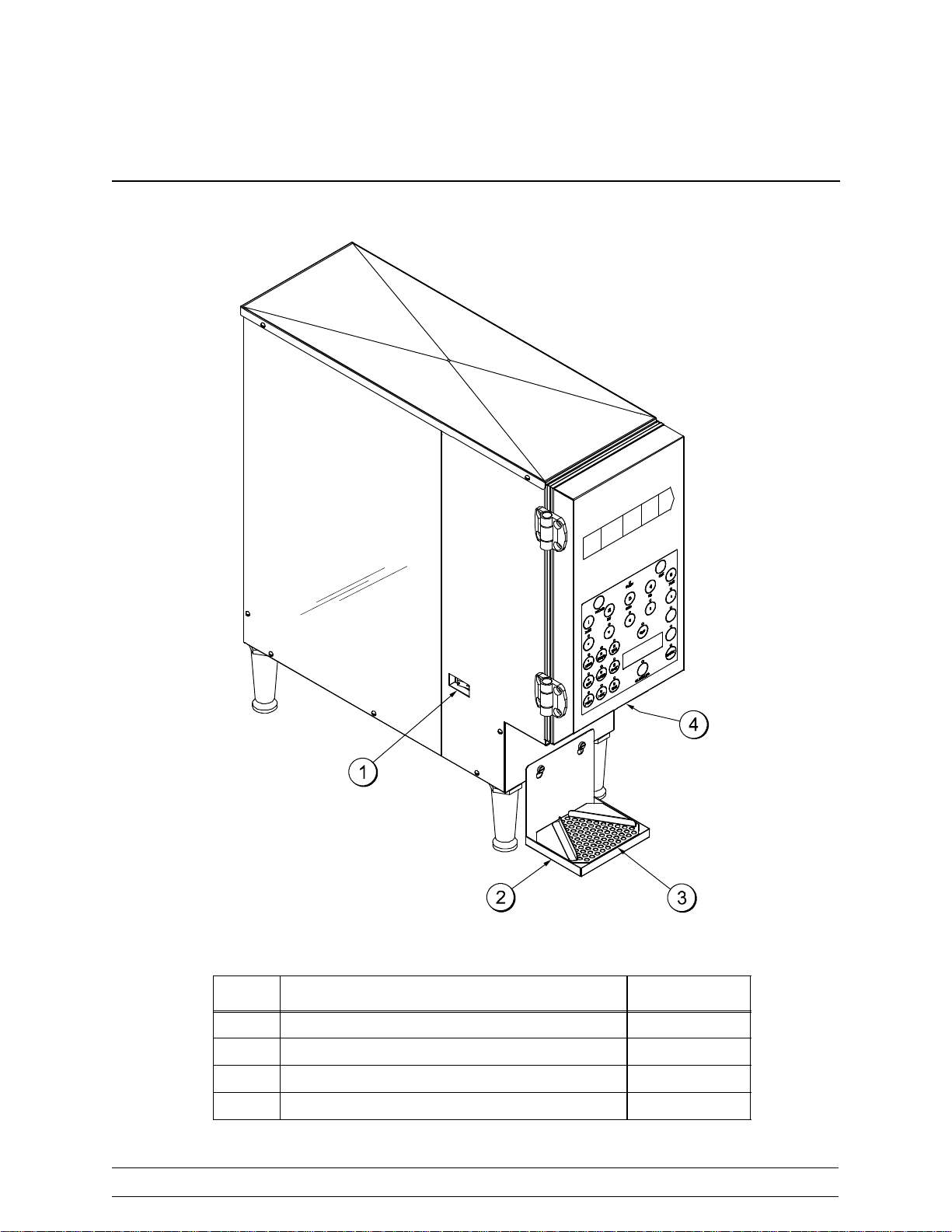

Section 3 Operator Parts Identification

ExplodedView

ITEM DESCRIPTION PART NO.

1 Switch-Rocker (Power Switch) 048093

2 Tray-Drip 058346

3 Shield A.-Splash X59366

4 Tube A.-Outlet X59334

Model C006 Operator Parts Identification

7

Page 12

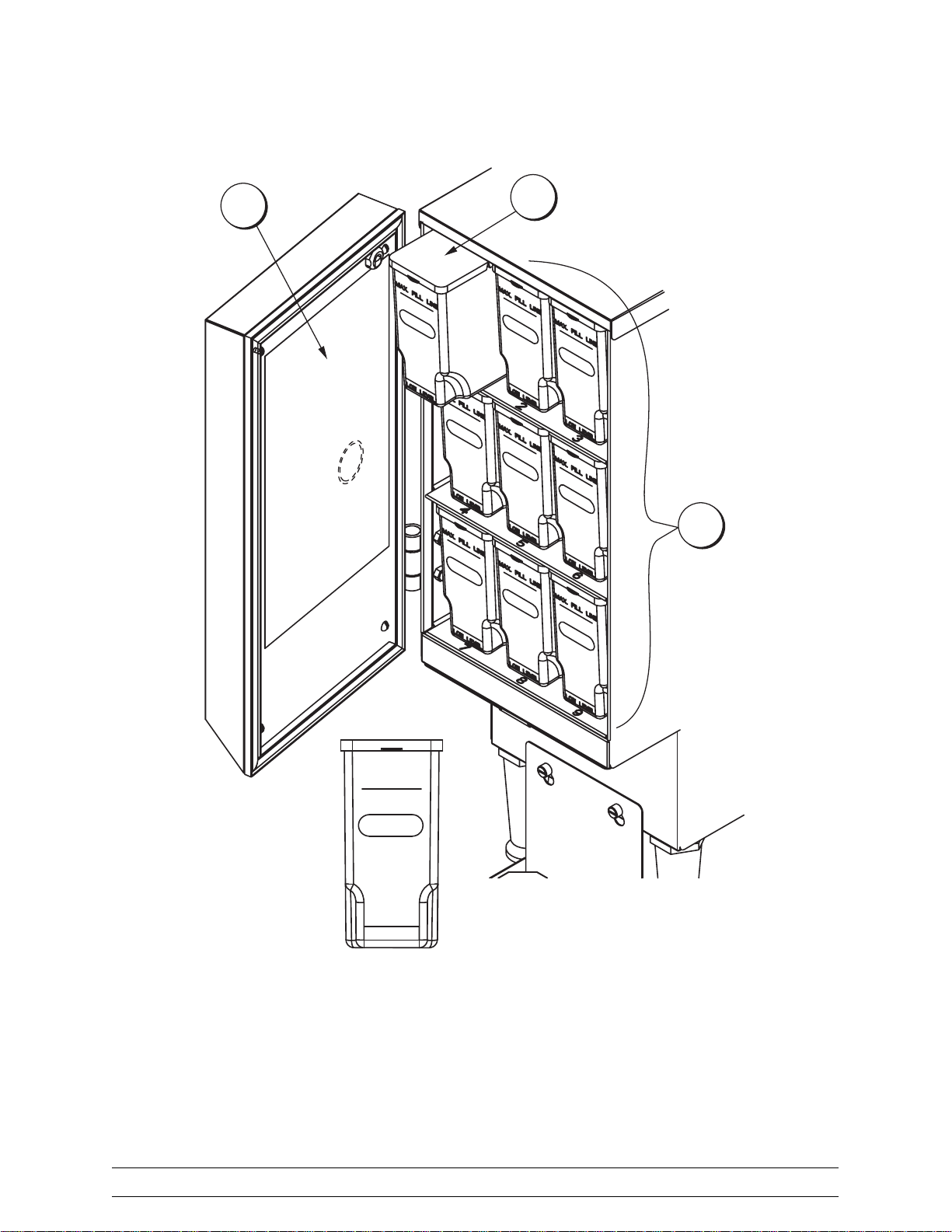

Inside Cabinet View

3

2

1

MAX. FILL LINE

LOW LEVEL

Operator Parts Identification Model C006

8

Page 13

Inside Cabinet View Identification

ITEM DESCRIPTION ABBREVIATION PART NO.

1 Syrup Tank 0622442 Cover-Tank Mix --- 059133

3 Decal-Mag-Instruction --- 059532-TAY

IMPORTANT:

There are nine individual flavor tanks. The tanks must be placed in their

proper locations to correspond with current software and display

characteristics.

All flavors are subject to change at any time.

Model C006 Operator Parts Identification

9

Page 14

Section 4 Important: To the Operator

ITEM DESCRIPTION

1 Power Switch

2 Flavor Buttons

3 Product Buttons / Calibration

4 Size Buttons / Calibration

5 Promo Portion Button

6 Box of Coffee Button

7 Sugar Button

8 Indicator Lights (LED)

9 LCD Screen

10 Clean/Calibrate Button (Service Menu)

11 Preset Combo Buttons

12 Custom Flavor Button

13 Power Indicator (LED)

Important: To the Operator Model C006

10

Page 15

Power Switch

When the unit is plugged into a receptacle and the power switch is placed in the ON

position, the power indicator light will illuminate.The power switch isleft in the ON position

during normal operations.

Selection Buttons

Flavor Shot Buttons

Therearenineflavorshotbuttons. When a particular flavor shotisselected,thelightabove

that button will illuminate.

Note: All flavors are subject to change at any time.

SUG (Sugar) Button

When liquid sugar is selected, the light above that button will illuminate. Press the SUG

button,andthen the appropriate size,to dispense the liquidsugar.Thesugar buttonworks

independently of the flavor shot selections.

Recipe Buttons

When a particular product is selected, the light above that button will illuminate.

ICED COFFEE

LATTÉ/CAP

FUTURE

FUTURE

FUTURE

Size Buttons

When a particular portion size is selected, the product will dispense.

X-SM = Extra Small

SM = Small

MED = Medium

LG = Large

X-LG = Extra Large

PROMO = Promotional or Future

BOX = Box of Coffee

Model C006 Important: To the Operator

11

Page 16

Flavor Refill and Level Reset

Whena MIXLOW condition ispresent, theflavor indicator will flashat 1/2second intervals

and at 1/4 second intervals when a MIX OUT is present. When a MIX OUT condition is

present, that specific flavor will lock out until it is refilled and reset.

Each flavor can be reset individually at the full or low fill level: Full = HI (586 ml) and Low

Fill = LO (195 ml).

Full Level: The operator may reset the level by filling the tank to the fill line and pressing

and holding that specific flavor for 3 seconds. Upon reset, the LED will stop flashing and

will be reset to sense a full tank (HI). The LCD will display “REFILLED HI XX” with the

appropriateflavor (XX)abbreviation indicatedfor 4seconds. The screen willautomatically

return to normal operation.

Low Fill Level: While thescreen is reading “REFILLEDHIXX”,theoperatorcan pressthe

same flavor button to set the control to the “LO” level. The operator may toggle between

HI and LO, but once the flavor button has not been pressed for 4 seconds, the control is

set for that level. T he control will now be in the normal mode of operation.

The control can be reset and refilled prior to a MIX LOW o r MIX OUT condition.

IMPORTANT: Any time a flavor is reset, be sure that th e appropriate tank has been

refilled to the fill line.

Liquid Sugar Refill: When a MIX LOW condition is present, the liquid sugar indicator will

flash at 1/2 second intervals and at 1/4 second intervals when a MIX OUT is present.

Replace the liquid sugar container with a full container and insert the sugar feed tube.

Primethe sugar line by pressing theSUG (liquidsugar) button once andthen pressing the

“Box of Coffee” button once.Reset the refill level by pressing and holding the SUG button

for 3 seconds.

Note: The LED's are above the flavor buttons. The LCD display is under the SUG button.

Important: To the Operator Model C006

12

Page 17

Service Display Menu

TheService Display Menu providesseveral screens to theoperator andtechnicianforsetup, monitoring and evaluation.

To enter the Service Display Menu, press the CLEAN/CALbutton. The screen will prompt

the operator to enter the access code. Use the product size buttons to enter the code as

follows:3 (MED)2 (SM)1 (X-SM).Oncethe ServiceDisplayMenuisentered,thefollowing

screens are available in the order shown. Cycle through the screens by pressing the

CLEAN/CAL button.

1. CLEAN PRESS FLVR = Clean

2. CLEAN ALL <1> = Clean All Tanks

3. PRIME ALL <1> = Prime All Tanks

4. CAL PRESS FLVR = Calibrate (Must be performed at Start-up or unit will not

dispense.)

5. BREAK IN = Break In New Product Tube

6. DATA PRESS PR/FL = Data

To exit the Service Menu, press and hold the CLEAN/CAL button for 3 seconds and

release. Note: The display will read “COFFEE”.

Model C006 Important: To the Operator

13

Page 18

Cleaning Flavors and Liquid Sugar

Clean Menu Screen

The Clean Menu screen allows the operator to clean a maximum of 4 flavors

simultaneously, including the sugar.

Step

Action

1 Press the CLEAN/CAL button. The screen will prompt the

operator to enter the a ccess code. Use the size buttons to

enter the code as follows: 3 (MED) 2 (SM) 1 (X-SM).

2 Upon entry, the screen will read “CLEAN PRESS FLVR”.

3 Press the flavor button(s) to be cleaned (maximum of 3).

The screen will read “CLEANING”, and the LED(s) will

illuminate.

4 The selected flavor(s) will clean simultaneously for 50

seconds. If sugar is selected, it will clean for 50 seconds.

Note: The cleaningoperationfor anyflavor or the sugar can

be stopped by pressing that specific flavor/sugar button

again.

5 Upon completion of the cleaning, the screen will return to

“CLEAN PRESS FLVR”.

6 Empty any remaining sanitizer/cleaner from the tanks prior

to adding the flavor shot product.

7 Press the CLEAN/CAL button to advance within the

Service Menu. Press and hold the CLEAN/CAL button for 4

seconds to exit the Service Menu.

Important: To the Operator Model C006

14

Page 19

Cleaning All Flavors and Liquid Sugar

Clean All Menu Screen

The Clean All Menuscreen allows the operator to clean all the flavors and the liquid sugar

simultaneously.

Step

Action

1 Remove the flavor tanks from the unit.

2 Clean the inside of the unit with a clean, damp cloth.

3 Prepare 4 cleaning containers with an approved 100 PPM

cleaning/sanitizing solution.

4 Place one container on each shelf with the product tubes in

the containers.

5 Place the sugar feed tube in the fourth container.

6 Press the CLEAN/CAL button. The screen will prompt the

operator to enter the a ccess code. Use the size buttons to

enter the code as follows: 3 (MED) 2 (SM) 1 (X-SM).

7 Upon entry, the screen will read “CLEAN PRESS FLVR”.

8 Press the CLEAN/CAL button once to display “CLEAN ALL

<1>”.

9 Press the “1” (X-SM) button.

10 The display will read “CLEANING”.

Flavors 1 - 3 will clean first. When they are complete,

flavors 4 - 6 will clean, followed b y flavors 7 - 9, and then

the sugar. The corresponding LED will illuminate while

each flavor or the sugar is cleaning. (Each flavor and the

sugar will clean for 50 seconds.)

11 Upon completion, the display will return to the “CLEAN ALL

<1>” screen.

12 Empty any remaining sanitizer/cleaner from the tanks prior

to adding the flavor shot product.

13 Press the CLEAN/CAL button to advance within the

Service Menu. Press and hold the CLEAN/CAL button for 4

seconds to exit the Service Menu.

Model C006 Important: To the Operator

15

Page 20

Prime All Flavors and Liquid Sugar

Prime All Men u Screen

The Prime All Menu screen allows the operator to prime all of the flavors, including liquid

sugar, simultaneously. Be sure that every flavor, including liquid sugar, being primed has

been refilled to the fill line indicated on the tank and the control has been reset (refer to

Flavor Refill and Level Reset on page 12.

Step Action

1 Press the CLEAN/CAL button. The screen will prompt the

operator to enter the a ccess code. Use the size buttons to

enter the code as follows: 3 (MED) 2 (SM) 1 (X-SM).

2 Upon entry, the screen will read “CLEAN PRESS FLVR”.

3 Place an empty coffee cup beneath the dispensing spout.

4 Press the CLEAN/CAL button twice to display “PRIME ALL

<1>”.

5 Press the number “1” (X-SM) button.

6 The display will read “PRIMING”.

Flavors 1 - 3 will prime first. When they are complete,

flavors 4 - 6 will prime, followed by 7 - 9, and then the

sugar. The corresponding LED will illuminate while each

flavor or the sugar is priming.

7 Upon completion, the display will read “PRIME ALL <1>”.

8 Press the CLEAN/CAL button to advance within the

Service Menu. Press and hold the CLEAN/CAL button for 4

seconds to exit the Service Menu.

Important: To the Operator Model C006

16

Page 21

Calibrate Flavors and Liquid Sugar

Calibrate Menu Screen

The Calibrate Menu screen allowsthe operator to calibrate and dispensevolume foreach

flavor and liquid sugar. IMPORTANT: Calibration is by weight, NOT volume.

Step

Action

1 Place a scale under the dispensing spout and place an

empty cup on the scale. Reset the scale to “000”.

2 Press the CLEAN/CAL button. The screen will prompt the

operator to enter the a ccess code. Use the size buttons to

enter the code as follows: 3 (MED) 2 (SM) 1 (X-SM).

3 Upon entry, the screen will read “CLEAN PRESS FLVR”.

4 Press the CLEAN/CAL button three times to display “CAL

PRESS FLVR”.

5 Press the flavor in need of calibration. The screen will

read; example: “CAL 100.00 GM”.

6 Check the amount dispensed displayed on the scale

“XXX.X” and enter it onto the dispenser using the numeric

buttons 0-9 listed under the size and recipe buttons.

7 Once the last digit has been entered, press the

CLEAN/CAL button once to return to the CAL PRESS

FLVR screen.

Note: Proper calibration may take more than one attempt.

8 Repeat steps 5 - 7 until the flavor being calibrated is within

± 5% of the 100 grams (95.0 - 105.0 grams).

9 Repeat steps 5 - 8 for all flavors in need of calibration.

IMPORTANT: The unit must be cleaned, primed and calibratedpriorto the first use.

ALL flavors and the sugar must be calibrated at time of start up. It is NOT optional

tocalibrateonlyoneortwoflavors. Ifthese proceduresarenot followed completely, the

CUSTOM (combination) selector button will not operate.

Model C006 Important: To the Operator

17

Page 22

Data Menu

Data Menu Screen

The Data Menu screen allows the operator to view the total number of cycles completed

since the last reset for a product flavor combination.

Step

1 Press the CLEAN/CAL button. The screen will prompt the

operator to enter the a ccess code. Use the size buttons to

enter the code as follows: 3 (MED) 2 (SM) 1 (X-SM).

2 Upon entry, the screen will read “CLEAN PRESS FLVR”.

3 Press the CLEAN/CAL button five times to display “DATA

PRESS PR/FL”. Coffee is the default product and can be

changed by pressing any product button.

4 Press the selected product/flavor combination. The

corresponding flavor and product LED's will illuminate. The

product will be displayed up to 6 characters, a space and

the number of cycles for the flavor/product combination

dispensed from 0 to 65000.

5 To reset the selected product/flavor counter, the operator

should press and hold the flavor button for 4 seconds. The

counter will reset to 0.

6 Press the CLEAN/CAL button to return to the “CLEAN

PRESS FLVR” screen.

7 Press the CLEAN/CAL button to advance within the

Service Menu. Press and hold the CLEAN/CAL button for 4

seconds to exit the Service Menu.

Action

Cleaning Lockout

This unit is manufactured with a 60 day lockout cleaningfeature. To minimize the amount

of product discarded in this process, the CLEAN/CALlight will flash for threedays prior to

the 60th day. At the end of day 60, the unit will lockout (no dispensing allowed) and the

screenwilldisplay“LOCKEDFORCLEAN”.Atthattimeany rem ainingproductinthetanks

must be discarded prior to performing the cleaning process.

Tounlocktheunittheoperatormust clean theunit.Afterthe unitiscleaned,press and hold

the“CLEAN/CAL”button for 4seconds. The screen will display “CLEANED” for 4 seconds

and will clear for nor mal operation.

Important: To the Operator Model C006

18

Page 23

Section 5 Operating Procedures

Assembly and Start Up

Step Action

1 Plug the machine into an approved receptacle. The power

indicator will illuminate on the front of the dispenser.

2 Open the front door to the dispenser.

3 Remove all tanks and lids.

ALWAYS FOLLOW LOCAL HEALTH CODES!

Cleaning/Sanitizing

Step Action

1 Prepare a sink with an approved 100 PPM

cleaning/sanitizing solution (example: Kay-5® or Stera

Sheen®). USE WARM WATER AND FOLLOW THE

MANUFACTURER'S SPECIFICATIONS.

2 Thoroughly wash, rinse, and sanitize all tanks and lids in

the sink.

3 Prepare 3 cleaning containers with an approved 100 PPM

cleaning/sanitizing solution.

4 Place one container on each shelf with product tubes in the

containers.

5 Prepare another cleaning container of cleaning/ sanitizing

solution.

6 Place the sugar feed tube in the cleaning/sanitizing

solution.

7 Press the CLEAN/CAL button. The screen will prompt the

operator to enter the a ccess code. Use the size buttons to

enter the code as follows: 3 (MED) 2 (SM) 1 (X-SM).

8 Upon entry, the screen will read “CLEAN PRESS FLVR”.

9 Press the CLEAN/CAL button once to display “CLEAN ALL

<1>”.

Model C006 Operating Procedures

19

Page 24

Cleaning/Sanitizing (Continued)

Step Action

10 Press the “1” (X-SM) button to begin cleaning. The three

flavors corresponding to the top row of flavor keys will

clean first. Upon completion, the three flavors in the next

row will clean, followed by the three flavors in the last row,

and then the SUG (liquid sugar). The cleaning procedure

will take approximately four minutes.

11 Remove and discard any cleaning/sanitizing solution

remaining in the cleaning containers.

12 Remove the sugar feed tube from the cleaning/sanitizing

solution and allow it to drain.

13 Install the sugar feed tube in the liquid sugar container.

Operating Procedures Model C006

20

Page 25

Product Tube Removal/Installation

Step Action

1 Discard any remaining product in the tank.

2 Wash and rinse the tank and the lid.

3 Fill the tank with clean water to the fill line on the tank.

4 Place a cup under the dispensing spout.

Note: Refer to the “Clean Flavors and Liquid Sugar”

instructions within the Service Menu on page 14.)

5 Activate the flavor selection corresponding to the product

tube in need of replacement. This will pump the water from

the tank and tube.

6 Remove the product tank.

7 Place the dispenser power switch in the OFF position.

8 Unplug the dispenser from the wall receptacle.

9 Remove the right side panel.

10 Carefully open the pump cover.

11 Remove the product tube from the stainless tubes.

12 Install the new product tube onto the stainless steel tubes.

13 Route the product tube through the pump. (Besureto

route the tube properly. The pumps are directional.)

14 Carefully align the product tube, making sure the tube is

centered over the pump rollers.

15 Press down on the tube at both ends to remove slack and

carefully close the pump cover. Make sure there are no

kinks and that the tube stays centered over the rollers.

Model C006 Operating Procedures

21

Page 26

Product Tube Removal/Installation (Continued)

Step Action

16 Follow the Break In Flavor instructions starting on page 23

for the flavor line that was replaced.

17 Refer to Cleaning Flavors and Liquid Sugar on page14.

Note: To minimize or eliminate any mistakes when replacing and installing a new tube,

remove and replace one tube at a time.

Operating Procedures Model C006

22

Page 27

Break In Flavor (Product Tube)

Step Action

1 Prepare a cleaning container with an approved 100 PPM

cleaning/sanitizing solution (example: Kay-5® or Stera

Sheen®). USE WARM WATER AND FOLLOW THE

MANUFACTURER'S SPECIFICATIONS.

2 Remove all three syrup tanks from the shelf containing the

tank with the new product tube.

3 Place the cleaning container on the shelf and insert the

product tubes in the container.

4 Press the CLEAN/CAL button to display the screen that

prompts the operator to enter the access code.

5 Using the size buttons, enter access code: 3 (MED) 2 (SM)

1 (X-SM). Upon entry, the screen will read “CLEAN PRESS

FLVR”.

6 Press the CLEAN/CAL button four times until the screen

displays “BREAK IN FLVR”.

7 Press the appropriate flavor button.

8 The pump will run for 2-1/2 minutes and automatically shut

off.

9 Repeat steps 1, 3, and 7. The pump will run for another

2-1/2 minutes and automatically shut off.

10 Remove and discard any cleaning/sanitizing solution

remaining in the cleaning container.

11 Wipe the interior of the cabinet with a clean, damp cloth.

12 Reinstall the syrup tanks in their appropriate positions.

13 Reprime all three syrup lines as follows: In the standard

operator mode, select the appropriate flavor button and

then the “small” button. Repeat this procedure twice for

each flavor to eliminate air pockets in the line.

14 Calibrate the flavor that received the new product tube.

(See page 17.)

Model C006 Operating Procedures

23

Page 28

Dispensing Flavor Shots - Hot Beverages

To dispense flavor shots for hot beverages (Coffee, Hot Chocolate), follow t h ese

steps:

Step Action

1 Select the appropriate cup for the customer's order.

2 Place the cup under the dispensing spout.

3 Press the flavor button.

Note: If a combination flavor is desired, first press the

CUSTOM button. Then press the desired 2 or 3 flavor

buttons.

4 Press the appropriate cup size button. (Pressing the cup

size button will dispense the flavor shot pr oduct.)

Note: After pressing the flavor button, you have up to three

secondstopressthecupsize.Ifyoudonotpressthecupsize

within three seconds, you must repeat steps 3 and 4.

5 Remove the cup.

Operating Procedures Model C006

24

Page 29

Dispensing Flavor Shots - Box of Coffee

To dispense the flavor shots fo r the box o f coffee, follow these steps:

Step Action

1 Place a small coffee cup under the dispensing spout and

press the flavor button.

2 Press the Box of Coffee button. This will dispense the

proper amount of the flavor shots for the coffee.

3 Place a funnel on the box of coffee. Pour the flavor shots

from the coffee cup into the box of coffee.

4 Fill the box of coffee with 108 oz. of coffee.

Model C006 Operating Procedures

25

Page 30

Dispensing Flavor Shots - Iced Coffee

To dispense the flavor shots f o r Iced Coffee, follow these steps:

Step Action

1 Select the appropriate cup for the customer's order.

2 Fill the cup 2/3 full with ice.

3 Place the cup under the dispensing spout.

4 Press the flavor button.

13497

Note: If a combination flavor is desired, first press the

CUSTOM button. Then press the desired 2 or 3 flavor

buttons.

5 Press the ICE COFF button.

6 Press the appropriate cup size button. (Pressing the cup

size button will dispense the flavor shot pr oduct.)

Operating Procedures Model C006

26

Page 31

Dispensing Flavor Shots - Latté (Hot or Iced)

To dispense the flavor shots fo r Latté drinks, follow these steps:

Step Action

1 Select the appropriate cup for the customer's order.

2 Fill the cup 2/3 full with ice.

Note: Skip this step for hot Latté.

3 Place the cup under the dispensing spout.

4 Press the flavor button.

Note: If a combination flavor is desired, first press the

CUSTOM button. Then press the desired 2 or 3 flavor

buttons.

5 Press the LATTE/CAP button.

6 Press the appropriate cup size button. (Pressing the cup

size button will dispense the flavor shot pr oduct.)

Model C006 Operating Procedures

27

Page 32

Section 6 Cleaning and Maintenance

Cleaning Procedure

ALWAYS FOLLOW LOCAL HEALTH CODES!

To disassemble and clean the unit, the following items will be needed:

S Brushes (provided)

S Cleaner/Sanitizer (example: Kay-5® or Stera Sheen®)

S Single service hand towels

Equipment Cleaning and Maintenance Schedule

Function Procedure Frequency

Initial Flavor Fill Reset the level for each flavor. After cleaning tanks

Flavor Refill Reset the level for each flavor. After adding product to

tanks (full or low fill level)

Prime Prime All. After cleaning tanks

Calibrate Calibrate each flavor. Weekly and after cleaning

tanks.

Wipe the outside of the machine

down with a clean, sanitized towel.

Daily Cleaning

Sixty Day Cleaning

Use a brush to clean the

dispensing spout.

Wash, rinse and dry the drip tray.

Perform a complete machine

breakdown.

Dispose of all existing product.

Wash, rinse, and sanitize tanks.

Daily

Every 60 days.

Perform cleaning procedure.

Reset the cleaning cycle by holding

the Clear/Cal button for 4 seconds.

101005

Cleaning and Maintenance Model C006

28

Page 33

Section 7 Troubleshooting Guide

General Troubleshooting

Problem Probable Cause Remedy

1. Dispenser will not

operate.

2. Dispenser will not

dispense product.

a. Unit is not plugged in. a. Plug the unit into a

receptacle.

b. Power switch is in the

OFF position.

a. There is no product in

the unit; i.e., there is a

MIX OUT condition.

b. The product tube is

obstructed or kinked.

c. The product tube is not

properly aligned over

the pump rollers.

d. Unit is in the 60 day

lockout.

b. Place the power switch

in the ON position. The

power indicator light will

illuminate.

a. Add product to the fill

line and reset (full or

low fill level). Full = HI

(586 ml) and Low Fill =

LO (195 ml).

b. Clear the obstruction or

kink.

c. Realign the product

tube, centering it over

the pump rollers and

removing any slack.

(See page 21.)

d. Clean the unit. Then

press and hold the

CLEAN/CAL button for

4 seconds to reset the

cleaning cycle.

Model C006 Troubleshooting Guide

29

Page 34

Problem Probable Cause Remedy

3. An improper amount of

product is being

dispensed.

a. Incorrect calibration. a. Re-calibrate.

b. The product tube is

obstructed or kinked.

c. The product tube is not

properly aligned over

the pump rollers.

b. Clear the obstruction or

kink.

c. Realign the product

tube, centering it over

the pump rollers and

removing any slack.

(See page 21.)

d. The unit was improperly

reset.

d. Fill the tank to the fill

line and reset (full or

low fill level). Full = HI

(586 ml) and Low Fill =

LO (195 ml).

e. The product tube is

e. Replace the tube.

damaged.

If assistance or service is needed, please co ntact your local Taylor Distributor.

Troubleshooting Guide Model C006

30

Page 35

Section 8 Parts List

UPDATE

REMARKS PARTS

CLASS

QTY. WARR.

NUMBER

DESCRIPTION PART

CONTROL-TOUCH SCREEN W/DECAL 059086-SER 1 103

GASKET-DOOR-FRONT *C006* 062263 1 000

HINGE-DOOR *C006* 059340 1 000

HINGE-DOOR *C006* 059340 2 000

+PLATE A.-HINGE MOUNTING * X59321 2 000

SCREW-10-32X3/8RHM-SS 006749 4 000

SCREW-8-32X3/16SS RHM 017551 4 000

BOARD-CONTROL-FLAVOR SHOT 058542-SER 1 103

BRUSH-DBL END-PUMP & FEED 013072 1 000

BRUSH-DRAW VALVE 1-1/2”OD 014753 1 000

BRUSH-END-DOOR-SPOUT-SS-H 039719 1 000

CABLE-INTERFACE/CONTROL *C006* 059140 1 000 GREY SLEEVE/DOOR

CAP-ULTIMATE SYRUP 053040-WHT 1 000

CORD-POWER-125V-15A-95”L- 042936-12 1 103

COVER-TANK MIX *C006* 059133 9 103

DOOR A.-FRONT *C006* X58578 1 103

+ Available Separately

Model C006 Parts List

31

HARNESS-WIRE-POWER/CTRL *C006 059139 1 103

HARNESS-WIRE-PUMP MOTOR/CTRL *C006 062268 1 103

LABEL-MAG-CONTROL C006 059470- 1 000 FRONT/BLACK FLAVOR SELECT

LEG-4” 3/8-16 STUD-PLASTI 024755 4 103

MOTOR-GEAR 400 RPM 062269-05 10 103

PANEL A.-DOOR *C006* X59089 1 103 FRONT

PANEL-SIDE-RIGHTLOWER *C006 058518 1 103

PANEL A.-LEFT FRONT *C006* X59319 1 103

PANEL-SIDE-LEFT LOWER *C0 058530 1 103

PUMP-PERISTALTIC 3.2MMIDX 058545-1 9 103

PUMP-PERISTALTIC 6.4MMIDX 058545-2 1 103 SUGAR

SHIELD A.-SPLASH *C006* X59366 1 103

SUPPLY-POWER 72W 24DC 059313-12 2 103

SWITCH-ROCKER *370*POWER/ 048093 1 103

TANK-MIX 062244- 1 103

Page 36

UPDATE

REMARKSWARR.

CLASS

QTY.PART

NUMBER

DESCRIPTION PARTS

TANK-MIX 2 *C006* 062244-11 1 103

TANK-MIX 3 *C006* 062244-12 1 103

TRAY-DRIP *C006* 058346 1 103

TUBE A.-OUTLET *C006* X59334 1 103

+ Available Separately

100712

TUBE-PUMP-PERIS-2.4MMIDX2 067120-10 3 000 Length changed from 15” to 10” 1-16-04

TUBE-PUMP-PERIS-2.4MMIDX2 067120-10 3 000 Length changed from 20” to 10” 1-16-04

TUBE-PUMP-PERIS-2.4MMIDX2 067120-10 3 000 Length changed from 25” to 10” 1-16-04

TUBE A.-SUCTION-RIGHT *C006 X59529 3 000 1-16-04 & Up

TUBE A.-SUCTION-MIDDLE *C006 X59530 3 000 1-16-04 & Up

TUBE A.-SUCTION-LEFT *C006 X59531 3 000 1-16-04 & Up

TUBE A.-SYRUP PICK UP X53175 1 103

TUBE-PUMP-PERIS-6.4MMIDX2 059152-60 1 000

Parts List Model C006

32

Page 37

Model C006

059359-12

Rev. 10/10

Loading...

Loading...