Page 1

Model C005

Refrigerated Dairy Dispenser

Operating Instructions

067852--M

7/23/09

Page 2

Complete this page for quick reference when service is required:

r

Taylor Distributor:

Address:

Phone:

Fax:

E-mail:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E July, 2009 Taylo

All rights reserved.

067852-M

Taylor Company

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 Safety 1....................................................

Section 2 To the Installer 3............................................

Installing the Dairy Dispenser 5...........................................

Section 3 Operator Parts Identification 6...............................

Section 4 Important: To the Operator 7.................................

Power Switch 8.........................................................

Product Level Reset Button 8.............................................

Temperature Adjustment 9...............................................

Product Temperature Indicator 9..........................................

Indicator Lights 9.......................................................

Cappuccino and Latté Selections 10........................................

Clean/Lockout Feature 10.................................................

Product Selection 10.....................................................

Calibration 11...........................................................

Section 5 Operating Procedures 12.....................................

Starting the Dispenser 12.................................................

Set Up Tanks 13.........................................................

Assembly and Start Up 14................................................

Dispensing Product 16....................................................

Recipe Settings 19.......................................................

Model C005 Table of Contents

Page 4

Table of Contents - Page 2

Section 6 Cleaning and Main ten ance 20.................................

Cleaning Procedure 20...................................................

Disassembly/Cleaning 20.................................................

Equipment Cleaning and Maintenance Schedule 22..........................

Section 7 Troubleshooting Guide 23....................................

General Troubleshooting 23...............................................

Section 8 Parts List 25.................................................

Wiring Diagram 28.......................................................

Note: Continuing research results in steady improvements; therefore,information

in this manual is subject to change without notice.

E July, 2009 Taylor

All rights reserved.

067852--M

Taylor Company

The word T aylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Table of Contents Model C005

Page 5

Section 1 Safety

We at Taylor are concerned about the safety of the operator when he or she comes in

contact with the dispenser and its parts. Taylor has gone to extreme efforts to design and

manufacture built-in safety features to protect both you and the service technician. As an

example, warning labels have been attached to the dispenser to further point out safety

precautions to the operator.

IMPORTANT-F ailu re to adhereto thefo llo wingsafetyprecautions mayresult

in severe personal injury or death. Failure to comply with these warnings may

damage the machine and its components. Component damage will result in part

replacement expense and service repair expense.

To Op erate Safely:

DO NOT operate the dispenser without reading this operator's manual. Failure to

follow this instruction may result in equipment damage, poor dispenser performance,

health hazards, or personal injury.

DO NOT operatethedispenser unless itisproperly grounded. Failure to followthis

instruction may result in electrocution.

Always plug the dispenser into an approved electrical outlet. Do not touch the

dispenser with wet hands. Failure to follow this instruction may result in electrocution.

Do not immerse the dispenser in water. Failure to follow this instruction may result

in electrocution.

Observe the same safety precautions with the dispenser that you would with any

electrical appliance. Failure to follow this instruction may result in electrocution.

Allrepairs mustbe performedbya qualifiedservicetechnicianwiththemain power

supply to the dispenser disconnected. Failure to follow this instruction may result in

electrocution. Contact your local authorized Taylor Distributor for service.

DO NOT operate the dispenser unless all service panels and access doors are

restrainedwithscrews. Failuretofollowthisinstructionmay resultinelectrocution.Contact

your local authorized Taylor Distributor for service.

Model C005 Safety

1

Page 6

This dispensing unit must be placed on a level surface. Use caution when moving

the unit. Failure to comply may cause the unit to tip over, and result in personal injury.

DO NOT obstructairintakeand discharge openings: Minimum of 1” (25.4 mm) at ther ear

and 4” (102 mm) under the unit for adequate air flow across the condenser.

NOISE LEVEL: T his unit meets the airborne noise emission standard according to the

applicable European Directive.

If the crossed out wheeled bin symbol is affixed to this product, it signifies thatthis

product iscompliant with the EUDirectiveas well as other similar legislationin effect after

August13,2005. Therefore, itmust be collectedseparately after itsuse is completed,and

cannot be disposed as unsorted municipal waste.

The user is responsible for returning the product to the appropriate collection facility, as

specified by your local code.

For additional information regarding applicable local laws, please contact the municipal

facility and/or local distributor.

Safety Model C005

2

Page 7

Section 2 To the Installer

Overview

The dairydispenser Model C005dispensesthree productsin different volumesfor coffee,

cappuccino, and latté products. The dispenser issupplied with a cord and grounding type

plug.

Specifications

Capacity: 2 tanks x 1.5 gallons (whole milk, skim milk), 1 tank x 2.5 gallons (cream)

Weight: 95 lbs., Crated Weight: 101 lbs.

Dimensions: 25” D x 12-1/2” W x 27” H

Electrical Requirements

ElectricalRequirements:120V, AC, 15 amp., single phase, 60 mHz, supplied with NEMA

cord and plug 5-15P.

The dispenser includes a micro controller and must be operated on grounded electrical

wiring at all times. A qualified technician must complete any electrical servicing. Servicing

of the dispenser by unauthorized personnel makes the warranty null and void.

It is recommended that this dispenser be plugged into an electrical surge protector,

selected by a qualified service technician, for added protection against power surges,

which could damage an electrical/electronics component. An electrical surge event may

cause the unit to shut down. Such an event would require service by a qualified service

technician if the dispenser was not adequately protected.

In the United States, this equipment is intended to be installed in accordance with the

National Electrical Code (NEC), ANSI/NFPA 70-1987. In all other areas of the world,

equipment shouldbe installed in accordancewiththe existing localcodes.Pleasecontact

your local authorities. The purpose of the NEC code is the practical safeguarding of

persons and property from hazards arising from the use of electricity. This code contains

provisions considered necessary for safety. Compliance therewith and proper

maintenance will result in an installation essentially free from hazard!

FOLLOW YOUR LOCAL ELECTRICAL CODES!

CAUTION:THIS EQUIPMENTMUSTBE PROPERLYGROUNDED!FAILURETO

DO SO CAN RESULT IN SEVERE PERSONAL INJURY FROM ELECTRICAL SHOCK!

Model C005 To the Installer

3

Page 8

Air Clearance

Always allow a minimum of 1” (25.4 mm) at the rear and 4” (102 mm) under the unit for

adequate air flow across the condenser.

Refrigeration Servicing

The temperature is set at the factory to maintain the product within the range of 35_Fto

41_F(1.7_Cto5.0_C).

Warranty

One year on parts and labor, excluding wear items.

CAUTION: Warranty is valid only if required service work is provided by an Authorized

Taylor Service Technician.

Note: Taylor reserves the right to deny warranty claims on equipment or parts if a

non-approved refrigerant was installed in the machine, system m odifications were

performed beyond factory recommendations, or it is determined that the failure was

caused by neglect or abuse.

Compressor Warranty Disclaimer

The refrigeration compressor on this machine is warranted for one year. However, dueto

the Montreal Protocol and the U.S. Clean Air Act Amendments of 1990, many new

refrigerants are being tested and developed, thus seeking their way into the service

industry.Some ofthese newrefrigerantsare beingadvertised asdrop-in replacementsfor

numerous applications. It should be noted that, in the event of ordinary service to this

machine'srefrigerationsystem, onlythe refrigerantspecified onthe affixeddata plate

shouldbe used.The unauthorized useof alternate refrigerantswill voidyourcompressor

warranty. It will be the owner's responsibility to make this fact known to any technician he

employs.

It should also be noted that Taylor does not warrant the refrigerant used in its equipment.

For example,ifthe refrigerant islostduring the course ofordinaryservice to thismachine,

Taylor has no obligation to either supply or provide its replacement either at billable or

unbillable terms.

Taylor will continue to monitor the industry and test new alternates as they are being

developed. Should a new alternate prove, through our testing, that it would be accepted

as a drop-in replacement, then the above disclaimer would become null and void. To find

out thecurrentstatus of an alternaterefrigerant as it relates toyour compressor warranty,

call the local Taylor Distributor. Be prepared to provide the Model/Serial Number of the

freezer in question.

To the Installer Model C005

4

Page 9

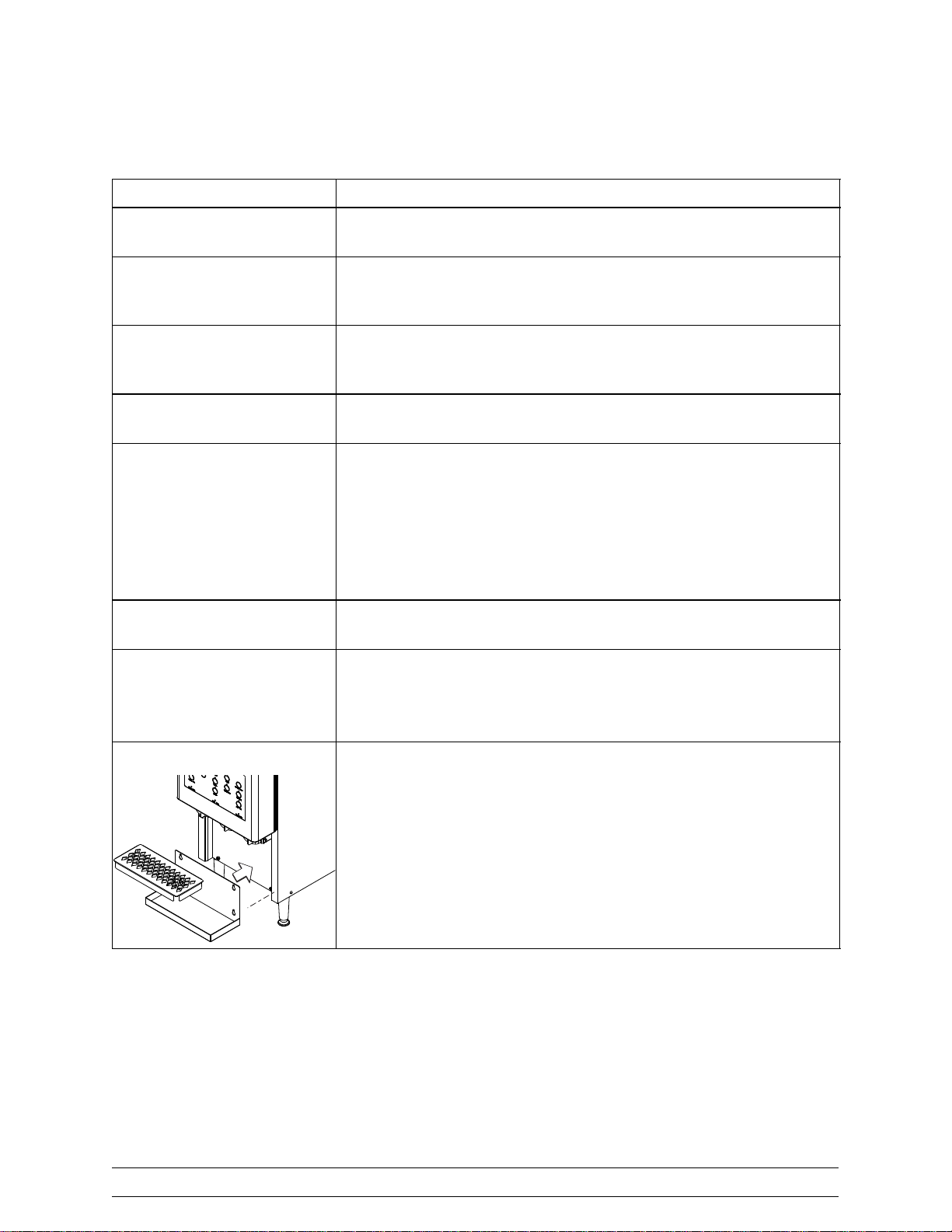

Installing the Dairy Dispenser

Step Action

1 Place the dairy dispenser where it will best serve your

operation.

2 Make sure that counters, platforms, and shelves are strong

enough to support the weight of the dispenser and full

containers of product ( 139 lbs. [63 kg.]).

3 Maintain a minimum of 1” (25.4 mm) at the rear and 4”

(102 mm) under the unit for adequate air flow across the

condenser.

4 Place the dispenser at a convenient height for the operator

to access the keys and cups.

5 DO NOT remove the legs from the dispenser or allow

the dispenser to sit directly on the counter.

Adequate air flow under the machine is necessary for

proper operation.

Make sure the legs at the four corners of the dispenser are

firmly attached.

Removal of the legs violates the warranty.

6 Make sure the unit is level. (Adjust the legs to ensure the

dispenser is level and does not rock on the counter.)

7 Plug the power cord into the proper electrical outlet (NEMA

5-15P).

Allow the unit to run for twenty minutes prior to filling

with product.

8 Install the drip tray and the splash shield.

Model C005 To the Installer

5

Page 10

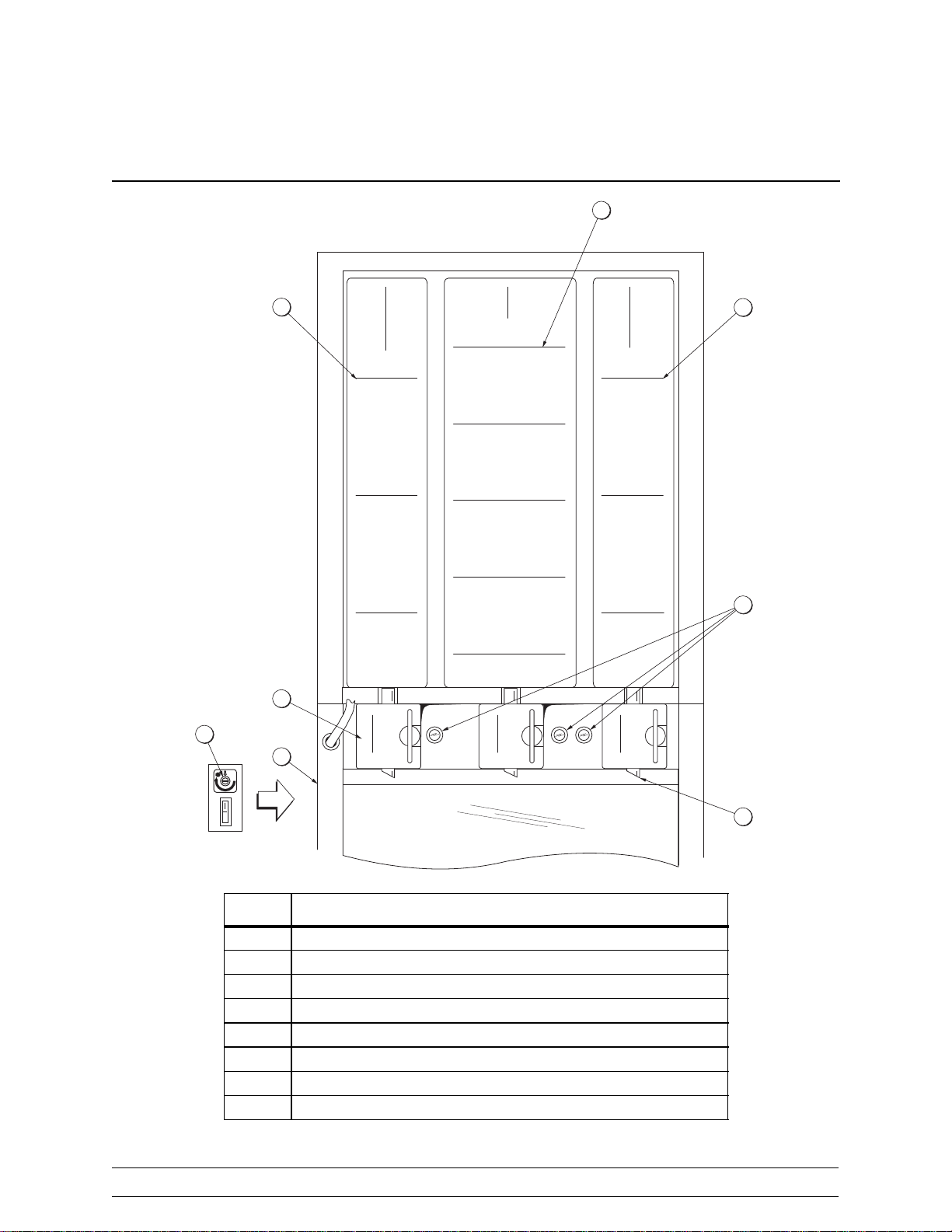

Section 3 Operator Parts Identification

0

B

A

C

5

3

FULL

3

FULLFULL

4

CREAMWHOLE MILK SKIM MILK

2

3

2

2

1

1

F

1

D

H

G

E

ITEM DESCRIPTION

A PRODUCT TANK 1-1/2 GAL (WHOLE MILK)

B PRODUCT TANK 2-1/2 GAL (CREAM)

C PRODUCT TANK 1-1/2 GAL (SKIM MILK)

D PRODUCT DISPENSING VALVE DOOR

E DISPENSING TUBE

F RESET BUTTONS

G POWER SWITCH

H TEMPERATURE ADJUSTMENT (± 2 DEGREES)

Operator Parts Identification Model C005

6

Page 11

Section 4 Important: To the Operator

ITEM DESCRIPTION

1 EXTRA PORTIONKEY (1/2 OZ.)

2 PORTION SIZE KEYS

3 1ST RECIPE MODIFIER SELECT KEY

4 1ST RECIPE MODIFIER SELECT INDICATOR

5 2ND RECIPE MODIFIER SELECT KEY

6 2ND RECIPE MODIFIER SELECT INDICATOR

7 3RD RECIPE MODIFIER (LATTÉ) SELECT KEY

8 3RD RECIPE MODIFIER (LATTÉ) SELECT INDICATOR

9 4TH RECIPE MODIFIER (CAPPUCCINO) SELECT KEY

10 4TH RECIPE MODIFIER (CAPPUCCINO) SELECT INDICATOR

11 5TH RECIPE MODIFIER SELECT KEY

12 5TH RECIPE MODIFIER SELECT INDICATOR

13 PRODUCT SELECT KEYS

14 PRODUCT SELECT/MIX LOW INDICATORS

15 PRODUCT CONTAINER “CLEAN” INDICATORS

16 POWER INDICATOR

17 PRODUCT LEVEL INDICATOR

18 PRODUCT TEMPERATURE INDICATOR

Model C005 Important: To the Operator

7

Page 12

Power Switch

The power switch is located on the left side of the unit. When the unit is plugged into a

receptacle and the power switch is placed in the ON position, the powerindicator light will

illuminate. The cabinet will start cooling and the control is powered up. The power switch

is left in the ON position during normal operations.

Product Level Reset Button

Eachproduct tank hasaseparate resetbutton.The reset buttonsarelocated next toeach

product dispensing valve door. These buttons are used to reset the control when a

particulartank isrefilled, andtoinstructthecontrolof thelevel ofmix inthe particulartank.

Each tank can b e refilled, reset and cleaned independently of each other.

The product tanks must be filled to the half gallon increments indicated on the tanks. The

operator hasthree product level optionswhen filling theWHOLEand SKIMmilk tanks: 1/2

gallon, 1 gallon, or 1-1/2 gallons. The operator has five product level options when filling

the CREAM tank: 1/2 gallon, 1 gallon, 1-1/2 gallons, 2 gallons, and 2-1/2 gallons.

When each product tank is refilled, the operator must press the corresponding product

level reset button to match the fill level. The product level selected is displayed on the

productlevelindicatoronthefrontpaneldisplay.Theindicatorcorresponds tothe filllevels

as noted below.

WHOLE and SKIM Milk

Product Tank Levels

Level 3 = 1-1/2 Gallons

Level 2 = 1 Gallon

Level 1 = 1/2 Gallon

IMPORTANT: The operator must ensure that the level of product/dairy in the tank

corresponds to the number shown on the product level indicator. FAILURE TO

FOLLOW THIS INSTRUCTION WILL RESULT IN INCORRECT PORTIONING!

Theproductlevel indicator hasan automatic time-out feature.Theindicator display willgo

blank if approximately 6 seconds pass between presses of the reset button. The product

level indicator automatically starts the level sequence over again if the reset button is

pressed two more times after the lowest number has been reached.

Note: Don't press the reset button unless the tank has been refilled or the tank has been

cleaned.

Product Tank Levels

Level 5 = 2-1/2 Gallons

Level 4 = 2 Gallons

Level 3 = 1-1/2 Gallons

Level 2 = 1 Gallon

Level 1 = 1/2 Gallon

CREAM

Important: To the Operator Model C005

8

Page 13

Temperature Adjustment

The temperature is set at the factory to maintain the product within the range of 35_Fto

41_F(1.7_Cto5.0_C). The oper ator has the capability to make a slight adjustment (± 2_)

to the cabinet temperature. (Note: The product temperature must NOT exceed

41_F / 5.0_C). The temperature adjustment screw is located above the power switch.

Before a temperature adjustment is made, make sure the product temperature has been

tested several times throughout the day (24 hour minimum).

Product Temperature Indicator

The product temperature indicator displays the product temperature.

(IMPORTANT: Allow the unit to operate for three or more hours before comparing the

product temperature to the display.)

Indicator Lights

Power

This light will illuminate when power is supplied to the unit, and the power switch is in the

“ON” position.

3rd Recipe Modifier Key (from left side) - Latté

This light will illuminate when a Latté drink is selected.

4th Recipe Modifier Key (from left side) - Cappuccino

This light will illuminate when a Cappuccino drink is selected.

5th Recipe Modifier Key (from left side)

This light will illuminate when a drink is selected.

Whole Milk

This light will illuminate when whole milk is selected.

Cream

This light will illuminate when cream is selected.

Skim Milk

This light will illuminate when skim milk is selected.

Product Low Level

Eachproduct lightalso servesas theproduct “LOW”light.Whenthecontrol sensesa“low”

condition (approximately 30 oz. until empty) for a particular product, the corresponding

light will flash.

Model C005 Important: To the Operator

9

Page 14

Product Out Level

Eachproductlightalso servesastheproduct “OUT”light.Whenthe controlsensesan“out”

conditionfor aparticular product,thecor respondinglight willilluminate andproduct willnot

dispense.

Clean

Each product container has its own “CLEAN” indicator light. Each product container has

to be removed for cleaning at least every 72 hours. Otherwise, that particular product will

lockout and not dispense product.

Cappuccino and Latté Selections

These are the 3rd and 4th recipe modifier keys, located in the center row of the display.

Note: The Cream product is not an option with these two beverages.

Clean/Lockout Feature

To assure that NSF food safety standards are adhered to, a 72 hour lockout feature is

provided. To minimize the amount of product discarded in this process, the following two

features have been added:

1. The “CLEAN” light associated with each product tank will begin to flash 68 hours

after the last cleaning (four hours prior to the lockout).

2. Each product tank will have its own lockout interval. This allows cleaning of

individual product tanks.

To reset the 72 hour lockout feature:

S Place the power switch in the ON position.

S Open the dispensing door.

S Discard the remaining product.

S Clean the tank, lid, and funnel.

S Install a new product tube.

Product Selection

Recipe Base Select

Thebase selectionforthe 5threcipemodifierkeyisactivatedbya mountedswitch,located

inside the lower front of the unit.

Toggle Switch Position: UP = Coffee Base (Default):

- Small = 4 oz., Medium = 6 oz., Large = 8 oz.,

Toggle Switch Position: DOWN = Neutral Base:

- Small = 3 oz., Medium = 4.5 oz., Large = 6 oz.

When the unit leaves the factory, the base selected is the coffee base (toggle switch is in

the UP position). This is indicated by the green indicator light which illuminates when the

5th recipe modifier key is selected.

Important: To the Operator Model C005

10

Page 15

To change to the neutral base, perform the following steps:

1. Place the power switch in the OFF position.

2. Unplug the unit from the wall receptacle.

3. Remove the lower front control panel.

4. Flip the toggle switch to the DOWN position.

5. Install the lower front control panel.

6. Plug the unit into the wall receptacle.

7. Place the power switch in the ON position.

The unit is now set for the neutral base product. This state is indicated by the amber

indicator light which illuminates when the 5th recipe modifier key is selected.

Calibration

Tools Needed: scale (grams and/or ounces) and small coffee cups

IMPORTANT: Calib ration is by weight, not volume.

Before starting calibration, the dispenser should be sanitized and NEW tubes installed,

prior toaddingthe product. The dispensermusthave the product(s) to be calibrated reset

totheir highestfilllevels.The dispensermust notbeinamixlow, mixout,lock outwarning,

or lock out condition.

1. Place the power switch in the ON position.

2. Press and hold the EXTRA key for approximately 4 seconds. The letters “CA” will

be displayed for 5 seconds. This indicates that the machine is in the Calibration

mode. When the “CA" disappears, the calibration process can begin.

3. Place a small coffee cup under the spout to be calibrated.

4. Select the product (beverage type, if applicable) and the size to be calibrated.

The p roduct or beverage indicator will illuminate.

5. Press the WHOLE MILK reset button.

6. Measure the amount dispensed (+/- 10%) compared to the recipe.

Note: Ifcalibrationis required,presstheSKIMreset buttonto increasethe amount.Press

theCREAMreset buttonto decreasetheamount. Thedisplaywill increment ordecrement

with each button press. Each press of the button counts as approximately 2 grams.

7. If adjustments were made, place the small coffee cup under the spout and press

the WHOLE MILK reset button.

8. Measure the amount dispensed.

9. Press and hold the EXTRA key for approximately 5 seconds and release. The

letters “DN” (done) will appear on the display for approximately 5 seconds.

10. The display will go blank and the unit is r eturned to normal operation.

Model C005 Important: To the Operator

11

Page 16

Section 5 Operating Procedures

We begin our instructions at the point where the parts are disassembled and laid out.

The following steps will explain how to clean, sanitize, assemble and install the

components for the product dispenser.

If youaredisassembling the unitforthe first time or need informationto getto this starting

point in our instructions, turn to page 20, “Disassembly” and start there.

Starting the Dispenser

Step Action

1 Make sure the unit is plugged into a receptacle. Place the

power switch in the “ON” position.

2 The machine is powered when plugged into a receptacle

and the power indicator light is illuminated.

3 Allow the machine to refrigerate for 20 minutes before

loading product. The unit must maintain the compartment

temperature between 35_Fto41_F(1.6_Cto5.0_C).

Operating Procedures Model C005

12

Page 17

Set Up Tanks

Step Action

1 Prepare the 3 compartment sink with an approved 100

2 Thoroughly wash, rinse, sanitize and air dry all tanks, lids,

3 Install the dispensing tubes onto the product tank's

PPM cleaning/sanitizing solution (example: Kay-5r). USE

WARM WATER AND FOLLOW THE MANUFACTURER'S

SPECIFICATIONS.

and funnels.

adaptors/spouts.

Model C005 Operating Procedures

13

Page 18

Assembly and Start Up

Step Action

1 With the compartment door open, open the product

2 With sanitized hands and/or clean gloves on, install the

dispensing valve doors.

product tank, tank covers, tank funnels and dispensing

tubes. (Be sure the tanks are placed in their appropriate

locations.)

3 Close the product dispensing valve doors onto the

dispensing tubes.

Push and turn the key clockwise to “Close/Lock” the

dispensing valve door in place.

4 Close the compartment door.

Operating Procedures Model C005

14

Page 19

Assembly and Start Up (Continued)

Step Action

5 Install the drip tray and the splash shield.

6 Fill each product tank through the lid/funnel with the

appropriate product and proper amount.

7 Label each tank with a 72 hour shelf life.

8 Push the reset button the appropriate number of times to

indicate the fill level for each product. The product indicator

light will stay illuminated for 6 seconds.

The reset display indicator will indicate the number of 1/2

gallons selected in each tank. (Example: Level 5 = 2-1/2

gallons, Level 4 = 2 gallons, Level 3 = 1-1/2 gallons,

Level 2 = 1 gallon, Level 1 = 1/2 gallon.)

Model C005 Operating Procedures

15

Page 20

Dispensing Product

Theproductand volumeto bedispensed areselected bypressingthekeysontheselector

keypad on the compartment door.

To dispense product, follow these steps:

Step Action

1 Place a cup under the appropriate dispensing tube and

press the product key (Whole Milk, Cream or Skim Milk) to

be dispensed.

2 Select the type of beverage. If no selection is made, the

unit will default to “Hot or Iced Coffee” recipes.

Operating Procedures Model C005

16

Page 21

Step Action

3 Press the portion size key to be dispensed (S, M, L, or XL).

(Note: XL is not a valid selection for the 5th recipe modifier

key.)

4 Remove the cup.

Model C005 Operating Procedures

17

Page 22

If additional product is desired, follow these steps:

Step Action

1 Press the product key (Whole Milk, Cream or Skim Milk).

2 Press the “Extra” key.

1/2 oz. of product selected will be dispensed.

Operating Procedures Model C005

18

Page 23

Recipe Settings

Recipe Modifier Key Extra Small Medium Large Extra

Large

None (Defaults to Coffee) 0.5 1 1.5 2 2.5

1(Future)

2(Future)

3 (Whole or Skim, No Cream) 0.5 6 9 12 14

4 (Whole or Skim, No Cream) 0.5 4 6 8 10

5 (Toggle Switch Up) 2 4 6 8

5 (Toggle Switch Down) 2 3 4.5 6

Note: The recipe modifier keys are the unlabeled keys located in the center row of the

display. The modifier keys 1 - 5 are counted from left to right.

Model C005 Operating Procedures

19

Page 24

Section 6 Cleaning and Maintenance

Cleaning Procedure

ALWAYS FOLLOW LOCAL HEALTH CODES!

To disassemble and clean the unit, the following items will be needed:

S Brushes (provided) - 1 tank brush, 1 tank spout brush, 1 valve brush

S Cleaner/Sanitizer (example: Kay-5r)

S Sanitizer spray bottle (provided)

S Single service hand towels

Disassembly/Cleaning

Step Action

1

2 Open the compartment door.

3 Open the product dispensing valve door. Allow the product

to empty into a container and discard the remaining

product.

4 Repeat Step 3 for the remaining two product tanks.

5 Take the product tanks, product tank covers, tank funnels,

and the drip tray (if applicable) to the 3 compartment sink

for cleaning.

PLACE THE POWER SWITCH IN THE

“OFF” POSITION. Failure to follow this

instruction may result in electrocution.

Cleaning and Maintenance Model C005

20

Page 25

Disassembly (Continued)

Step Action

6 Prepare the 3 compartment sink with an approved 100

7 Remove the dispensing tubes from the product tanks, and

8 Thoroughly brush clean all disassembled parts. Make sure

9 Rinse and place all parts in the cleaning/sanitizing solution

PPM cleaning/sanitizing solution (example: Kay-5r). USE

WARM WATER AND FOLLOW THE MANUFACTURER'S

SPECIFICATIONS.

discard. (Note: dispensing tubes must be discarded at

least every 72 hours.)

all product film is removed.

for one minute.

10 Place all cleaned parts on a clean, dry surface to air dry.

11 With an approved cleaning/sanitizing solution in the

sanitizer spray bottle and a small valve brush, thoroughly

spray and brush clean the plunger spout area and the

product dispensing valve door.

12 With a single service hand towel, wipe down the interior

and exterior of the dispenser.

Model C005 Cleaning and Maintenance

21

Page 26

Equipment Cleaning and Maintenance Schedule

Frequency Equipment Procedure

Every 4 hours Dairy Verify that the product temperatures are

between 35_Fto41_F(1.7_Cto5.0_C).

Every four hours, dispense a small amount

(approx. 2 oz.) of dairy product into a coffee

cup and check the temperature with an

approved Atkins thermometer. Repeat the

process for all three dairy products (whole

milk, cream and skim milk).

Every 24 hours Exterior of

machine

Wipe down the exterior of the machine.

IMPORTANT: Due to the function of the

control, always wipe the d isp lay panel from

top to bottom.

Every 72 hours Tank Wash, rinse, sanitize, and air dry all tanks, lids

and funnels.

Discard used dispensing tubes. Never

reuse dispensing tubes.

Keep a supply of dispensing tubes on hand.

Every 72 hours Plunger spout

area and

product

dispensing

valve door

With an approved cleaning/sanitizing solution

in the sanitizer spray bottle and a small valve

brush, thoroughly spray and brush clean the

plunger spout area and the product

dispensing valve door.

Every 72 hours All Dairy All products in the tank have a maximum shelf

life of 72 hours.

When cleaning the product tanks, discard

the used dispensing tubes and all

remaining dairy product in the tanks.

Every 72 hours Dispensing

Replace all used tubes every 72 hours.

tubes

Every 72 hours Refrigerated

product

compartment

Use a sanitized single service hand towel to

wipe the inside of the product compartment

until all condensation is removed and the

compartment is clean.

Cleaning and Maintenance Model C005

22

Page 27

Section 7 Troubleshooting Guide

General Troubleshooting

Problem Probable Cause Remedy

1. Dispenser will not

operate.

2. Dispenser will not

refrigerate.

3. Dispenser will not

dispense product.

a. Unit is not plugged in. a. Plug unit into

receptacle.

b. Power switch is in the

OFF position.

a. Unit is not plugged in. a. Plug unit into

b. Power switch is in the

OFF position.

a. No product is in the

unit.

b. The dispensing tube is

obstructed or kinked.

c. 72 hour lockout. c. Clean the unit, per

b. Place the power switch

in the ON position. The

power indicator light will

illuminate.

receptacle.

b. Place the power switch

in the ON position. The

power indicator light will

illuminate.

a. Add product to the unit.

b. Clear the obstruction or

kink.

instructions.

4. Frost builds up on the

inside of the cabinet.

5. Improper amount of

product is being

dispensed.

Model C005 Troubleshooting Guide

a. Door is open too often. a. Adjust fill levels

properly.

b. Door gasket is not

sealing.

a. The wrong product was

placed in the tank.

b. Check product

temperature.

23

b. Call service technician.

a. Make sure the

appropriate product is in

the tank.

b. Product added to the

dispenser must be

below 41°F (5.0°C).

Page 28

General Troubleshooting (Continued)

Problem Probable Cause Remedy

5. Improper amount of

product is being

c. Unit was reset

improperly.

dispensed. (Cont'd.)

d. Dispensing tube is not

centered in spout.

e. Dispensing tube is

restricted.

6. Actuator valve is sticky. a. Product is on the

actuator valve solenoid.

b. Faulty actuator valve

solenoid.

7. Product temperature is

too warm.

a. Compartment door is

open too often.

b. Warm product was

placed in the dispenser.

c. Add product and reset

the unit properly.

d. Align the tube properly

or replace the tube.

e. Clear dispensing tube

of restriction.

a. Clean the valve area

with cleaning/sanitizing

solution and a brush.

b. Call service technician.

a. Adjust fill levels properly

so tanks do not need

frequent re filling.

b. Product added to the

dispenser must be

below 41°F (5.0°C).

c. Compartment door

c. Call service technician.

gasket is not sealing.

d. Cabinet temperature is

d. Call service technician.

set too warm.

8. Dispenser is leaking

product.

9. Dispensing door will not

latch.

a. Dispensing tube is not

centered in spout.

b. The valve door was not

shut properly.

a. Dispensing tube is not

centered in spout.

a. Align the tube properly

or replace the tube.

b. Make sur e the valve

door is shut properly.

a. Align the tube properly

or replace the tube.

Note: Note:If theabovesuggestions don'tresolve the problem,pleasecontact yourlocal

Taylor Service Company.

Troubleshooting Guide Model C005

24

Page 29

Section 8 Parts List

UPDATE

REMARKS PARTS

CLASS

QTY. WARR.

NUMBER

DESCRIPTION PART

FASTENER A. *C005* 1/4 TURN X57070 3 103

HARNESS-WIRE *C005* LO VOLT #1 057350 1 103

HINGE-DOOR-DISPENSING *C005* 055877 3 103

RETAINER-PUSH ON *C005* 056797 3 103

SCREW-10-32X1/2FLAT HD-SS 043074 3 000

ACTUATOR-24 VOLT-1/4-20 *C005* 056511-03 3 103 SOLENOID

+ MARKER-WIRE #1 018520 1 000

+ MARKER-WIRE #2 018521 1 000

+ MARKER-WIRE #3 018522 1 000

+ PLUNGER-ACTUATOR-DISPENSER 055889 3 103

+ SPACER-5/16-18 UNC *C005* 057845 3 000

+ SPRING-COMP.ACTUATOR *C005* 055888 3 000

BLOCK A.-DISPENSING *C005* X56502 1 103

BOTTLE-WASH-PLASTIC 044818 1 000

BRUSHWITHRING 058643 1 000

BRUSH-SET CREAMER 058642 1 000

COMPRESSOR PL50F 055613-12 1 103

+ CAPACITOR-START 80UF/220V 055953 1 103

+ RELAY-START-COMPRESSOR-PL50F 055954 1 103

CONDENSER-AC 9X8 -2 ROW 029797 1 103

CORD-POWER-125V-15A-95”L-SO 042936-12 1 103

COVER-MIX TANK-NARROW *C005* 058078 2 103 K3051747/UP

COVER-MIX TANK-WIDE *C005* 058079 1 103 K3051747/UP

DEFLECTOR-AIR/WATER-BASEPAN 056540 1 103

DIAGRAM-WIRING *C005* 056850-12 1 000

DOOR A.-CREAMER *C005* X55892 1 103 K2048437/UP

+ GASKET-DOOR-FOAM C005 R70023 1.5' 000 REPLACES 057841

+ HINGE-CABINETDOOR *C005* 056447 2 103

DOOR A.-CAPTIVE SCREW *C005* X55879 3 103

+ Available Separately

Model C005 Parts List

25

SWITCH-PUSHBUTTON-SPST MOM 056702 3 103

DRYER-CAP. TUBE .021 ID X 9FT 055522 1 000

FAN-EVAPORATOR 3000RPM 105CFM 028534-12 1 103

Page 30

UPDATE

REMARKSWARR.

CLASS

QTY.PART

NUMBER

DESCRIPTION PARTS

FILTER-CORCOM 6EH1 040140-001 1 103

FUNNEL-MIX TANK-NARROW *C005* 058080 2 103 K3051747/UP

FUNNEL-MIX TANK-WIDE *C005* 058081 1 103 K3051747/UP

HARNESS-COFFEE-COOLATTA LOVOLT 058484 1 103 J6 TO LOCKOUT

HARNESS-WIRE *C005* HI VOLT 057349 1 103 J2 TO RESETS

+ Available Separately

HARNESS-WIRE *C005* LO VOLT #2 057351 1 103 J5 Control board to Actuator Solenoids/Relay

HOOK-MAGNETIC 058644 1 103 XXX

INDICATOR-DIGITAL TEMP-SOLAR 056615 1 103 DOOR

+ SCREW-6X1/2 TYPE A-SS-TRUSS HD 022427 2 000

LABEL-OPERATION 065669 1 000

LABEL-INST-FILLDAIRY 065670 1 000

LEG-4” 3/8-16 STUD 036397 4 103

OVERLAY-CONTROL 065629 1 000

PANEL-FRONT-CONTROL *C005* 055914 1 103 UPPER

PANEL-FRONT-CONTROL-CREAMER 056531 1 103 LOWER

PANEL-REAR *C005* 055915 1 103

PCB A.-CONTROL *C005* CREAMER X57838-SER 1 103 K3025267/UP

CHIP-SOFTWARE *C005* CREAMER X40822 1 103

PCB A.-CONTROL-CREAMER X57839-SER 1 103

POTENTIOMETER A. *C005* X57071 1 103 FINE TEMP CONTROL ADJUSTMENT

RELAY-DPDT-24VDC-25A@208/308V 054703-05 1 103 FAN MOTOR & COMPRESSOR

SANITIZER KAY-5 125 PACKETS 041082 1 000

SHIELD-SPLASH *C005* 055920 1 103

SWITCH-ROCKER *370*POWER/LIGHT 048093 1 103

TANK-MIX-1.5 GAL *C005* 057969 2 103 K3051747/UP

TANK-MIX-2.5 GAL *C005* 057968 1 103 K3051747/UP

TRANS.-100VA 120/208/240 PRI 079800 1 103

TRAY-DRIP-SS *C005* 055919 1 103

+ SCREW-SHOULDER 10-32X3/8X.078 057386 2 000

TUBE-DISPENSING *C005* 056579 1 000

VALVE-ACCESS-1/4 MFLX1/4 S-90 047016 1 103

Parts List Model C005

26

Page 31

UPDATE

REMARKSWARR.

CLASS

QTY.PART

NUMBER

DESCRIPTION PARTS

+ CAPACITOR-START 60UF-220/275V 047703 1 103

COMPRESSOR PL35G 055187-27 1 512 220-240V 50HZ 1PH

+ RELAY-START-COMPRESSOR-PL35G 055358 1 103

220-240V 50 HZ 1PH

+ Available Separately

DIAGRAM-WIRING *C005* 056850-40 1 000 220-240V 50HZ 1PH

KIT A.-MOTOR-FAN X62253-27 1 103 220-240V 50HZ 1PH

INSTRUCTION-WEEEEND OF LIFE 064371-INS

Model C005 Parts List

27

Page 32

Model C005

056850--12

Rev . 7/09

Loading...

Loading...