Page 1

Model BC12

Razzle Blender

Operating Instructions

067802-M

7/24/09 (Original Publication)

Updated 9/21/10

Page 2

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Fax:

E-mail:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E July, 2009 Taylor (Original Publication)

(Updated September, 2010)

All rights reserved.

067802-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 To the Installer 1............................................

Electrical Connections 1.................................................

Section 2 To the Operator 2...........................................

Warranty on Taylor Blenders 2...........................................

Section 3 Safety 3....................................................

Section 4 Operator Parts Identification 6...............................

Section 5 Important: To the Operator 8.................................

BC 12 8...............................................................

ON/OFF Power Switch 9.................................................

Switch Rod (Actuator) 9.................................................

Agitator 9..............................................................

Pulse/Rinse Switch 9....................................................

Program Dial 10.........................................................

Reset Switch 10.........................................................

Splash Guard 10.........................................................

Section 6 Operating Procedures 11.....................................

Mixing Instructions 11....................................................

Pulse Switch Operation 13................................................

Model BC12 Table of Contents

Page 4

Table of Contents - Page 2

Daily Cleaning 14........................................................

Sanitizing 15............................................................

Permanent Agitator Cleaning and Sanitizing 15..............................

Section 7 Parts List 16.................................................

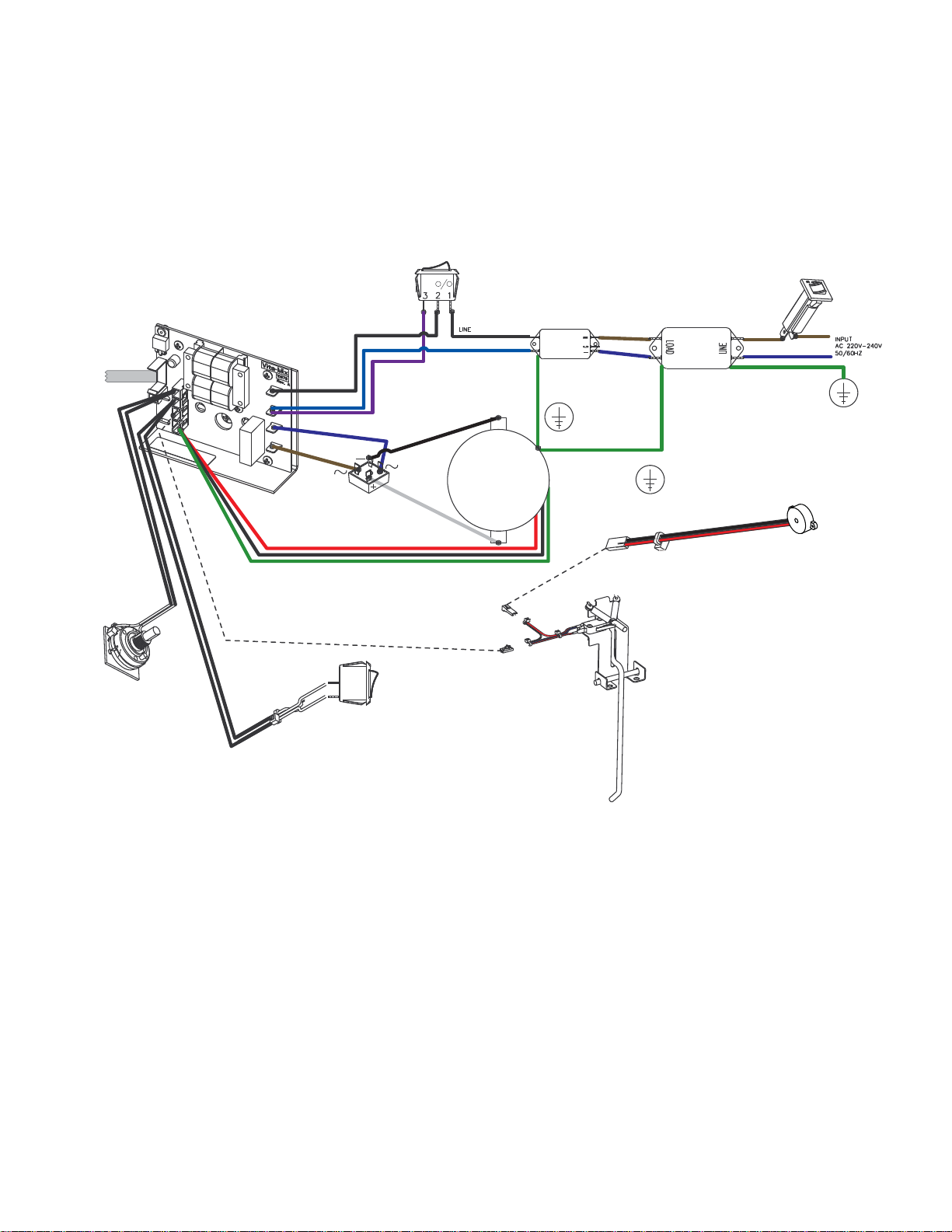

Wiring Diagram 18.......................................................

Note: Continuin g research results in steady improvements; therefore, information

in this manual is subject to change without notice.

E July, 2009 Taylor (Original Publication)

(Updated September, 2010)

All rights reserved.

067802-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Table of Contents Model BC12

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 5

Section 1 To the Installer

This machine is designed for indoor use only.

DO NOT installthemachineinanarea

where a water jet could be used to clean or rinse the

machine. Failure to follow this instruction may result

in serious electrical shock.

Electrical Connections

In the United States, this equipment is intended to

be installed in accordance with the National

Electrical Code (NEC), ANSI/NFPA 70-1987. The

purpose of the NEC code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

Each unit requires one power supply. Check the

data labels on the unit for fuse, wire ampacity and

electrical specifications. Refer to the wiring diagram

for proper power connections.

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not lighter than

ordinary polychloroprene or other equivalent

synthetic elastomer-sheathed cord (Code

designation 60245 IEC 57) installed with the proper

cord anchorage to relieve conductors from strain,

including twisting, at the terminals and protect the

insulation of the conductors from abrasion.

Model BC12 To the Installer

1

Page 6

Section 2 To the Operator

The blender you have purchased has been carefully

engineered and manufactured to give you

dependable operation. Mixing various candies,

cookies, fruits, nuts, liquid flavors, and other food

items into dairy slush or neutral slush has made

unlimited flavor combinations and product textures

available.

The development of counter blenders has made this

unlimited resource available to even very small retail

outlets and to those facilities where counter space is

limited.

The blender, when properly operated and cared for,

will produce a consistent, quality product. Like all

mechanical products, it will require cleaning and

maintenance. A minimum amount of care and

attention is necessary if the operating procedures

outlined in this manual are followed closely.

This Operator's Manual should be read before

operating or performing any maintenance on your

equipment. In the event that you should require

technical assistance, please contact your local

authorized Taylor Distributor.

Note: Warranty is valid only if the parts are

authorized Taylor parts, purchased from an

authorized Taylor Distributor, and the required

service work is provided by an authorized Taylor

service technician. Taylor reserves the right to deny

warranty claims on equipment or parts if

non-approved parts or refrigerant were installed in

the machine, system modifications were performed

beyond factory recommendations, or it is determined

that the failure was caused by neglect or abuse.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

NSF approvals of this unit was obtained by the

Vita-Mix Corporation, 8615 Usher Road, Cleveland,

Ohio 44138.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code. For additional information regarding

applicable local laws, please contact the municipal

facility and/or local distributor.

Warranty on Taylor Blenders

Caution: Warrantyisvalidonly if the parts are

authorized Taylor parts, purchased from an

authorized Taylor Distributor, and the required

service work is provided by an authorized Taylor

service technician.

Warranty Terms

This warranty covers only defects in material

and workmanship under normal use and service.

The Taylor Distributor will replace those

components that become defective as follows:

S Three year warranty on parts from the

date of installation of blender.

S One year warranty on labor from the

date of installation of blender.

Not included are the following items:

S External power cords and electrical

grounding.

S Wear items: mixing agitator, agitator

shaft extension, switch rod (actuator),

switch rod seal, splash shield, and foot

pedal.

S Replacements required because of

operator misuse as defined below, fire

or other casualty, normal wear or

deterioration.

Misuse includes the owner's failure to handle

parts properly, resulting in breakage. Misuse is

also defined as allowing unauthorized service

agents to attempt repairs on units.

For validation of warranty, this unit must be

registered at Taylor within thirty (30) days of

installation.

101021

2

Model BC12To the Operator

Page 7

Section 3 Safety

Taylor is concerned about the safety of the operator

when he or she comes in contact with the blender

and its parts. Taylor has gone to extreme efforts to

provide built-in safety features to protect both you

and the service technician. As an example, warning

labels have been attached to the unit to further point

out safety precautions to the operator.

IMPORTANT - Failure to adhere to the

following safety precautions may result in

severe personal injury or death. Failure to

comply with these warnings may damage the

machine and its components. Component

damage will result in part replacement expense

and service repair expense. SAVE THESE

INSTRUCTIONS FOR FUTURE REFERENCE

To Operate Safely:

DO NOT operate the unit without reading

this operator's manual. Failure to follow this

instruction may result in equipment damage, poor

performance, health hazards, or personal injury.

S DO NOT operate the unit unless it is

properly grounded.

S DO NOT operate the unit with larger fuses

than specified on the data label.

S DO NOT attempt any repairs unless the

main power supply to the unit has been

disconnected. Note: Contact your local

authorized Taylor Distributor for service.

S DO NOT use this appliance outdoors.

S DO NOT operate this appliance if the power

cord is damaged.

S DO NOT let the power cord hang over the

edge of the table or counter.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

DO NOT use a water jet to clean or rinse

the unit. Failure to follow these instructions may

result in serious electrical shock.

Model BC12 Safety

Failure to follow these instructions may result in

electrocution. Contact your local authorized Taylor

Distributor for service.

3

Page 8

S DO NOT allow children or untrained

personnel to operate this machine.

S DO NOT operate the unit unless all service

panels and access doors are restrained with

screws.

S AVOID contact with the agitator shaft and

other moving parts.

S Make sure the splash guard is installed prior

to operating the appliance.

S DO NOT disassemble or install parts unless

the control switch is in the “OFF” position.

S Always use the foot pedal guard, and avoid

accidental use of the foot pedal. When using

the foot pedal, make sure the appliance is

located where accidental contact with the

pedal is not likely. When the blender is not

in use, place the front switch in the “OFF”

position to avoid accidental use of the pedal.

(Note: Some international units are not

equipped with this feature.)

Failure to follow these instructions may result in

severe personal injury from hazardous moving parts.

DO NOT operate this appliance if it

malfunctions or is damaged in any way. Failure to

follow this instruction may result in injury or

component damage.

DO NOT use attachments not

recommended or sold by Taylor. Doing so may

cause fire, electric shock, injury, or equipment

damage.

Make sure the blender is sitting or mounted

solidly on a sturdy surface during operation. Failure

to comply may result in injury or equipment damage.

WARNING!

Some consumers are highly allergic to peanuts,

peanut oil, and peanut dust. In some severe

cases, peanut allergy reactionscan cause death.

When blending product with peanuts, make sure

excess product is cleaned fromthe agitator shaft

to eliminate the fear of product carryover.

DO NOT allow the power cord to hang over

the edge of the counter or touch hot surfaces.

Failure to comply may result in an electrical fire or

serious electrical shock.

4

Model BC12Safety

Page 9

Notes:

Model BC12 Safety

5

Page 10

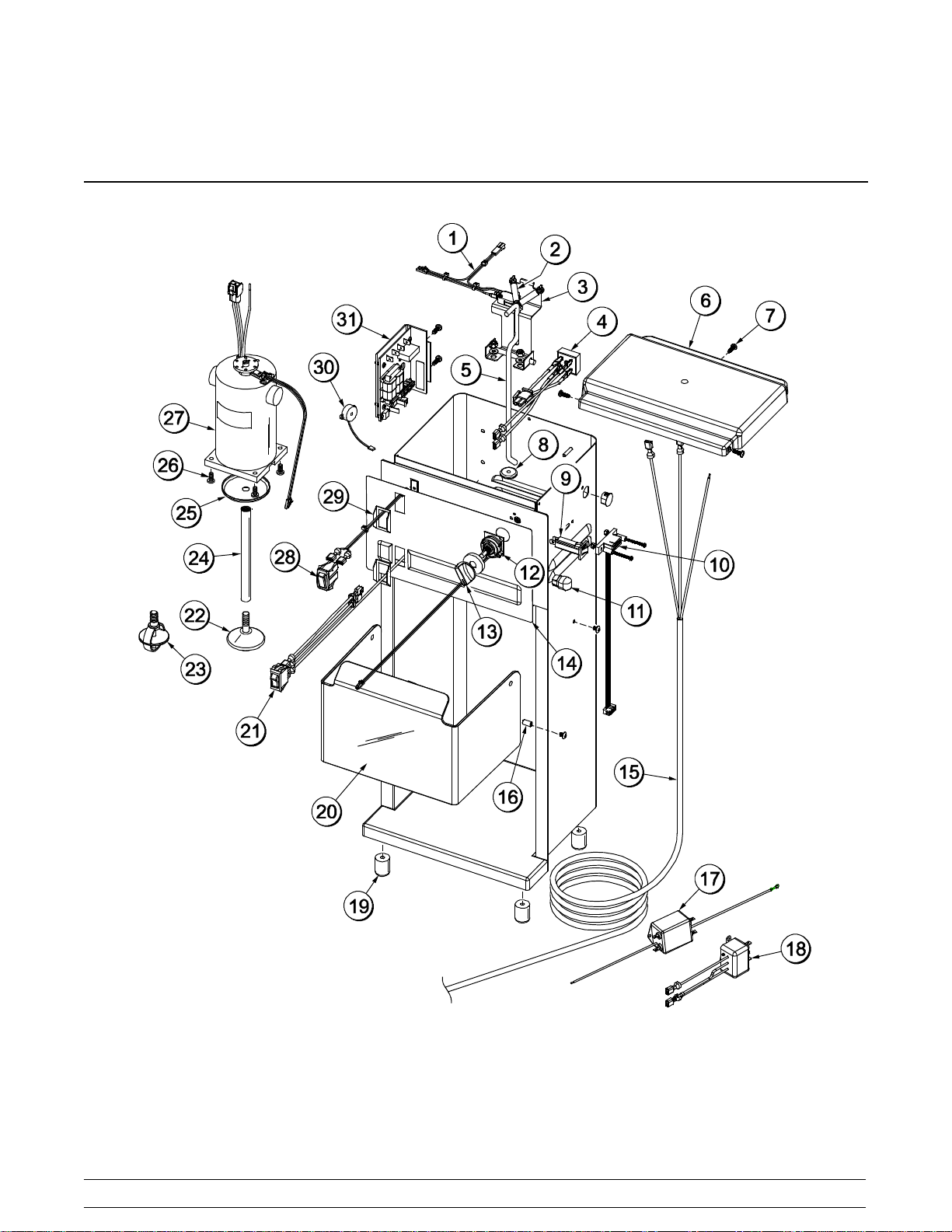

Section 4 Operator Parts Identification

BC12

Figure 1

6

Model BC12Operator Parts Identification

Page 11

BC12 Parts Identification

ITEM DESCRIPTION PART NO.

1 SWITCH-ROD-SNAP ACTION 067650

2 SPRING-SWITCH ROD*BC12* 067648

3 ROD A.-SWITCH*BC12* 067647

4 BRIDGE-RECTIFIERW/WIRES 067646

5 ROD-SWITCH*BC12* 067649

6 CAP-MIXER 051484

7 SCREW-MIXER-RETAINERCAP 051487

8 SEAL-SWITCH ROD*BC12* 067651

9 BREAKER-CIRCUIT-MIXER-2A 067637

10 CABLE-MEMORY*BC12* 067654

11 RELIEF-STRAIN-MIXER-R ANGL 067636

12 SWITCH-SELECTOR-CONTROL 067634

13 KNOB-CONTROL-SPEED*BC12* 067635

14 DECAL-DEC-RAZZLE*BC12* 067645

15 CORD-POWER-120V*BC12* 067640

16 PIN-PIVOT-SPLASH GUARD

W/SCREWS

17 FILTER-EMI*BC12* 067655

18 SUPPRESSOR-SURGE*BC12* 067656

067642

ITEM DESCRIPTION PART NO.

19 FOOT A.-MIXER-PLUGGED 051500

20 GUARD-SPLASH*BC12* 067638

21 SWITCH-ROCKER-LIGHTED 067643-40

22 AGITATOR-CONE*BC10*BC12* 067549

23 AGITATOR-MIXER-PERM

(GLOBE) (OPTIONAL)

24 SHAFT-AGITATOR-EXTENSION 051495

25 SLINGER-MIXER 051494

26 SCREW-MIXER-MOTORMTG 051493

27 MOTOR A.-ADVANCE*BC12* 067632-40

28 SWITCH-PUSHBUTTON-MOM 054699

29 GUARD-SWITCH*BC12* 067652

30 ALARM-AUDIBLE

W/MOUNT*BC12*

31 BOARD-CONTROL-UNIVERSAL 067633

* ADAPTOR-PLUG-JAPAN*BC12* 067657

* KIT-PROGRAM

SOFTWARE*BC12*

* KIT-PROGRAMCHIP*BC12* 067658

*NOT SHOWN

051497

067660

067659

100921

Model BC12 Operator Parts Identification

7

Page 12

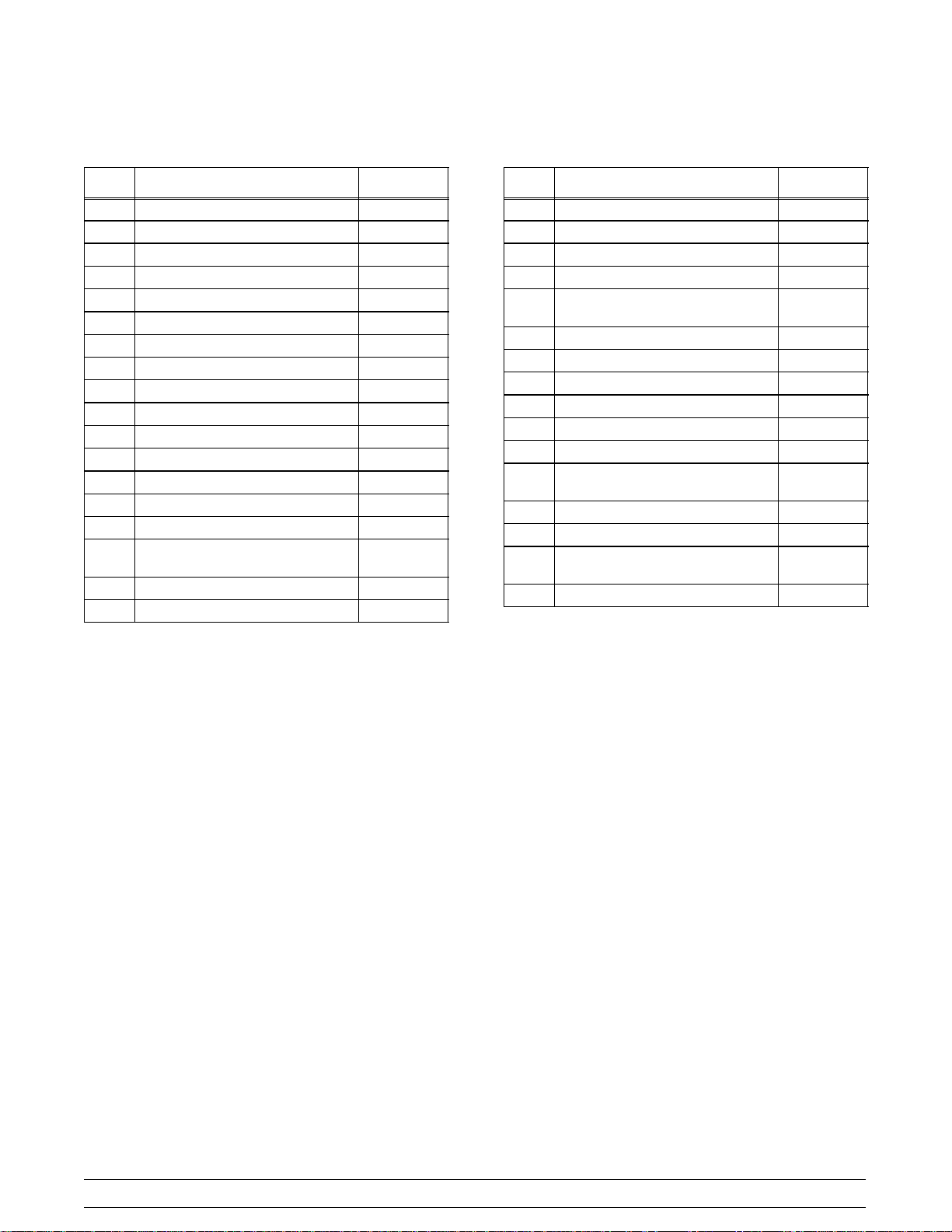

Section 5 Important: To the Operator

BC12

ITEM DESCRIPTION

1 PULSE/RINSE SWITCH

2 POWER SWITCH

3 PROGRAM DIAL

4 RESET SWITCH

5 POWER CORD

6 PROGRAMMING PORT

091020

Figure 2

8

The BC12 blender is pre-programmed with one

blending option and a pulse switch.

Model BC12Important: To the Operator

Page 13

ON/OFF Power Switch

The power switch is located on the front of the

machine. The power switch controls the power to

the machine. The switch illuminates when placed in

the ON position. Shut the power switch off at night

and whenever the machine will be left unattended.

Figure 3

Agitator

When the switch rod (actuator) is pushed, the

agitator spins and mixes the product and other

ingredients.

Figure 5

The agitator is manufactured from FDA and NSF

approved, food safe material.

Note: The agitator and shaft must be cleaned

between servings as product carryover will

occur. (See page 15.)

Switch Rod (Actuator)

The switch rod (actuator) starts the agitator and

begins a blending cycle. Push the switch rod to

activate a program setting. The machine shuts off

automatically at the end of the program setting.

Figure 4

Pulse/Rinse Switch

The pulse/rinse switch starts the agitator and can be

used to quickly refresh product or rinse the agitator

between servings. Press and hold the switch to

activate the agitator. The agitator will stop as soon

as the pulse switch is released.

Figure 6

Model BC12 Important: To the Operator

9

Page 14

Program Dial

Splash Guard

The program dial allows the operator to select a

number of pre-programmed settings. The machine

will shut off automatically at the end of the program.

Figure 7

Reset Switch

The reset switch is located above the power switch

on the front panel. The reset switch protects the

motor from an overload condition. If an overload

occurs, the reset mechanism will trip. To properly

reset the unit, wait a short period of time to allow the

motor to cool. Press the reset switch and resume

operation.

The splash guard catches product thrown from the

agitator and shields the operator during mixing.

Figure 9

Figure 8

10

Model BC12Important: To the Operator

Page 15

Section 6 Operating Procedures

Mixing Instructions

Make sure your hands are clean and sanitized

before performing these steps.

Step 1

Fill a serving cup with product (dairy slush or neutral

slush).

Figure 10

Step 2

Add “mix-in” ingredients such as liquid flavoring,

candy, cookies, fruit, or other condiments.

Step 4

Select the desired setting on the dial.

Figure 12

Step 5

Holding the cup securely from the side, reach under

the splash guard. Move the cup under the agitator

and lift up so the agitator touches the bottom of the

cup.

Step 3

Place the power switch in the ON position.

Figure 11

Model BC12 Operating Procedures

11

Figure 13

091020

Page 16

Step 6

While holding the cup securely in your hand, use

your fingers to push the switch rod (actuator),

located behind the agitator, to activate a

programmed blending cycle.

Figure 14

Notes:

S If the cup is hard to hold, either move the

agitator into the mix more slowly or start

with softer product. Do not continue to

operate the mixer if the cup is too hard to

hold.

S The agitator is designed to reduce the

possibility of damage when contacting a

paper cup. However, the agitator should not

be forced or held solidly against the side or

bottom of the cup. The hard product agitator

is specially designed to mix the product

aggressively and thoroughly, so use a cup

holder or a sturdy cup to prevent the agitator

from going through the side of the cup.

Step 8

Swirl the cup around the agitator to produce a

pleasing product appearance and to avoid leaving a

hole in the center of the mixture. Before removing

the cup, allow the excess mixture to be thrown off

the agitator and caught by the cup.

Step 7

Using a swirling motion, gradually move the cup up

and down around the spinning agitator and

completely around all sides of the cup. (If the

product is hard, this should be done slowly.)

The agitator will do some chipping and breaking of

the solids. However, it is not intended to completely

pulverize ingredients. Solid chunks are expected to

be evident in the finished product.

The machine shuts off automatically at the end of

the programmed cycle. When the program is within

4 seconds of completion, a tone will sound, so

preparation can begin to remove the cup from the

agitator. The tone gets progressively faster to

indicate that the program cycle is almost complete

and the machine will shut off. This allows the

operator the opportunity to spin off excess product

from the agitator.

Step 9

Place the power switch in the OFF position when the

machine is not in use.

100921

Figure 15

12

Figure 16

Model BC12Operating Procedures

Page 17

Pulse Switch Operation

Make sure your hands are clean and sanitized

before performing these steps.

Step 1

Place the power switch in the ON position.

Figure 17

Step 3

Press the pulse switch to start the agitator.

Figure 19

Step 4

With a swirling motion, gradually move the cup up

and down over the spinning agitator and completely

around all sides of the cup. Swirl the cup around the

agitator to produce a pleasing product appearance

and to avoid leaving a hole in the center of the

mixture.

Step 2

Hold the cup under the agitator and lift up, so the

agitator touches the bottom of the cup.

Figure 18

Figure 20

Step 5

Before removing the cup, allow excess mixture to be

thrown off the agitator and be caught by the cup or

lid/collar.

091020

Model BC12 Operating Procedures

13

Page 18

Step 6

Release the switch to stop the agitator.

Figure 21

Daily Cleaning

Step 3

Remove the splash guard by squeezing the sides

until it is clear of the top pivot pins and then pulling it

out. Take it to the sink for cleaning and sanitizing.

Figure 22

Step 4

Wash the splash guard in the approved cleaning

solution.

Taylor recommends daily cleaning and

sanitizing.

ALWAYS FOLLOW LOCAL HEALTH CODES

Step 1

Prepare a sink with an approved cleaning solution

(examples: Kay-5r or Stera-Sheenr). USE HOT

WATER (110_F/43_C) AND FOLLOW THE

MANUFACTURER'S SPECIFICATIONS. Do not

use a solution that contains ammonia and avoid

placing components in a dishwasher.

Step 2

Disconnect power from the wall

receptacle before performing the following

steps. Failure to comply may result in electrical

shock.

Step 5

Wipe clean all stainless steel surfaces with an

approved, non-abrasive commercial cleaner. This

includes the mixer, dispenser, and organizer

surfaces.

Step 6

Clean sticky switches with a clean cloth, dampened

with cleaning solution. Clean around the edges of

the switch paddles until they function freely. Work

the switches back and forth a few times to loosen

any dried residue under the switch. Dry the switches

withasoftcottoncloth.

Note: Leaving the switches sticky will damage or

burn them out.

WARNING: Do not spray water or other

liquid around the motor chamber. Do not use

excess liquid around the switches, motor protector,

power cords, or cord entry hole. Make certain all

areas in and around the motor are dry before

connecting power to the wall receptacle. Failure to

comply may cause equipment damage or

personal injury due to electric shock.

14

Model BC12Operating Procedures

Page 19

Sanitizing

Taylor recommends daily cleaning and

sanitizing.

Step 1

Prepare a sink with an approved sanitizing solution

(examples: Kay-5r or Stera-Sheenr). USE HOT

WATER (110_F/43_C) AND FOLLOW THE

MANUFACTURER'S SPECIFICATIONS.

Step 3

Submerge the agitator in the cleaning solution, all

the way to the bottom of the motor chamber. Place

the power switch in the ON position. Allow the

agitator to run for about 15 seconds. Repeat this

step several times. Make certain all portions of the

agitator and shaft have been submerged in the

cleaning solution.

Step 2

Repeat Steps 4 - 5 of the cleaning procedure, using

the sanitizing solution.

Step 3

Install the splash guard by squeezing the sides and

placing it onto the top pivot pins.

Step 4

Repeat the sanitizing procedures at the start of the

day.

ALWAYS FOLLOW LOCAL HEALTH CODES

Agitator Cleaning and Sanitizing

Step 1

Remove the splash guard by squeezing the sides

until it clears the top pivot pins and then pull the

guard out.

Step 2

Prepare a durable container with an approved cleaning solution (example: Kay-5r or Stera-Sheenr).

USE HOT WATER (110_F/43_C) AND FOLLOW

THE MANUFACTURER'S SPECIFICATIONS. Do

not use a solution that contains ammonia.

Note: The container must be deep enough to

submerge the entire agitator and shaft.

WARNING: Never try to wipe clean the

agitator while it is active. Failure to follow these

instructions can lead to severe personal injury from

hazardous moving parts, or damage to the unit.

Step 4

Repeat Step 3, using cool, clean water.

Step 5

Prepare a durable container with an approved sanitizing solution (example: Kay-5r or Stera-Sheenr).

USE HOT WATER (110_F/43_C) AND FOLLOW

THE MANUFACTURER'S SPECIFICATIONS. Do

not use a solution that contains ammonia.

Step 6

Repeat Step 3, using the sanitizing solution. Allow

the agitator to run for a minimum of two minutes.

Step 7

Re-install the splash guard by squeezing the sides

and placing it onto the top pivot pins.

Step 8

Repeat the sanitizing procedures at the start of the

day.

ALWAYS FOLLOW LOCAL HEALTH CODES

100921

Model BC12 Operating Procedures

15

Page 20

Section 7 Parts List

REMARKS

CLASS

QTY. WARR.

NUMBER

DESCRIPTION PART

+SCREW-MIXER-RETAINERCAP 051487 3 000

+ADAPTOR-PLUG-JAPAN*BC12* 067657 * 103 *OPTIONAL

ALARM-AUDIBLE W/MOUNT *BC12* 067660 1 103

AGITATOR-CONE*BC10*BC12* 067549 1 000 DISC

AGITATOR-MIXER-PERMSOFT SERVE (GLOBE) 051497 * 000 OPTIONAL

BOARD-CONTROL-UNIVERSAL*B 067633 1 103

BREAKER-CIRCUIT-MIXER-2 A 067637 1 103

BRIDGE-RECTIFIERW/WIRES* 067646 1 103

CABLE-MEMORY*BC12* 067654 1 103

CAP-MIXER 051484 1 103 HOOD

CORD-POWER-120V*BC12* 067640 1 103

FILTER-EMI*BC12* 067655 1 000

FOOT A.-MIXER-PLUGGED 051500 4 000

GUARD-SPLASH*BC12* 067638 1 000 CLEAR PLASTIC

KIT-PROGRAM SOFTWARE*BC12* 067659 1 000

KIT-PROGRAM CHIP*BC12* 067658 1 000

LIGHT-INDICATOR-LED*BC12* 067644 * 000 *USED PRIOR TO 067660 ALARM-AUDIBLE

100921

Parts List Model BC12

16

MOTOR A.-ADVANCE*BC12* 067632-12 1 103 115V

MOTOR A.-ADVANCE*BC12* 067632-40 1 103 220-240V

+SCREW-MIXER-MOTOR MOUNTING 051493 4 000

+GUARD-SWITCH*BC12* 067652 1 000

PIN-PIVOT-SPLASHGUARD*BC 067642 1 000 SET 4-PINS & 4-SCREWS

RELIEF-STRAIN-MIXER-R ANG 067636 1 000

SHAFT-AGITATOR-EXTENSION- 051495 1 000

SLINGER-MIXER 051494 1 000 BETWEEN SHAFT & MOTOR

SUPPRESSOR-SURGE*BC12* 067656 1 103

SWITCH-PUSHBUTTON-MOM 054699 1 000

SWITCH-ROCKER-LIGHTED*BC12* 067643-12 1 103 115V

SWITCH-ROCKER-LIGHTED*BC1 067643-40 1 103 220-240V

SWITCH-ROD-SNAP ACTION*BC 067650 1 103

Page 21

CLASS

QTY.PART

NUMBER

DESCRIPTION REMARKSWARR.

+ROD A.-SWITCH*BC12* 067647 1 103

Model BC12

+ROD-SWITCH*BC12* 067649 1 000

+SEAL-SWITCH ROD*BC12* 067651 1 000

+SPRING-SWITCH ROD*BC12* 067648 1 000

SWITCH-SELECTOR-CONTROL*B 067634 1 103

KNOB-CONTROL-SPEED*BC12* 067635 1 103

17

100921

Parts List

Page 22

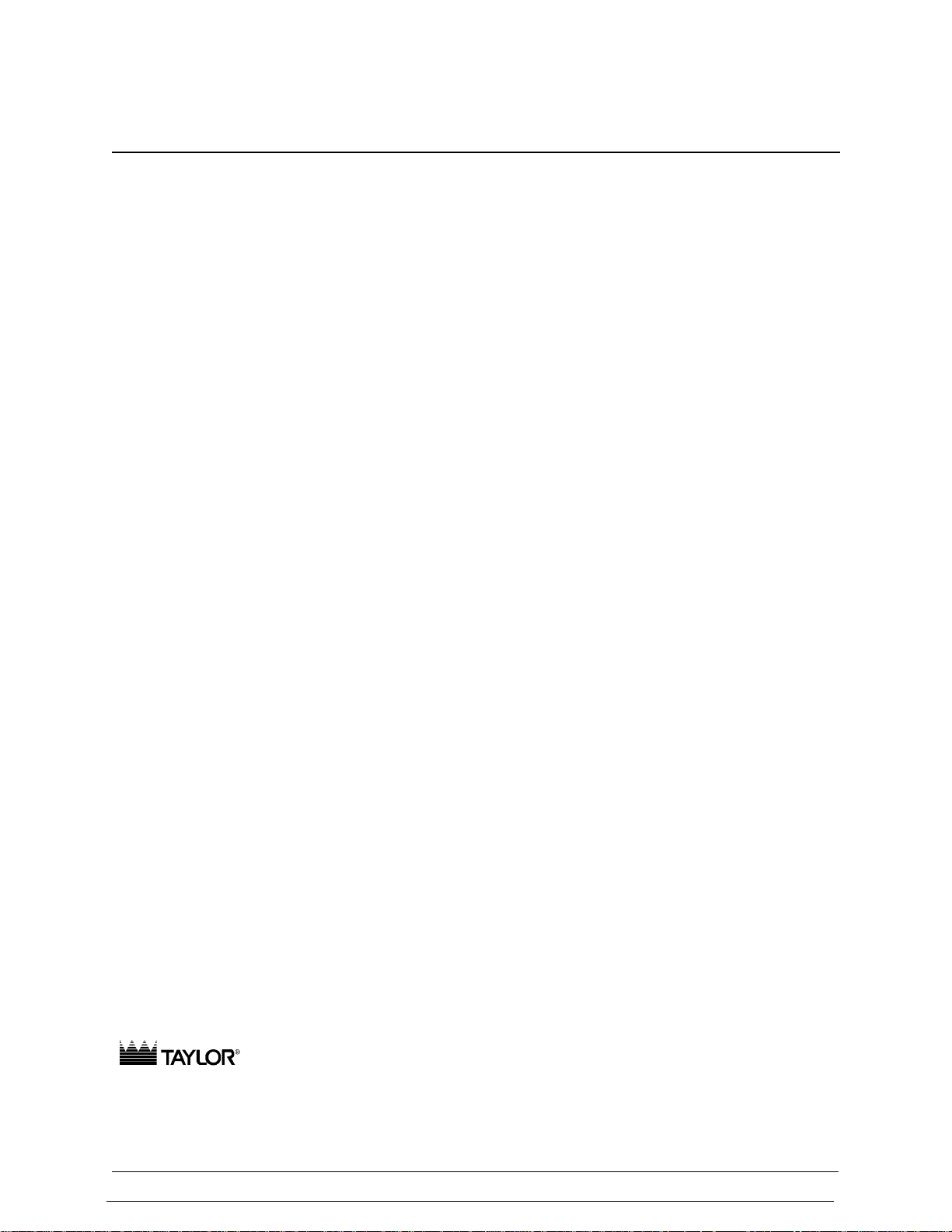

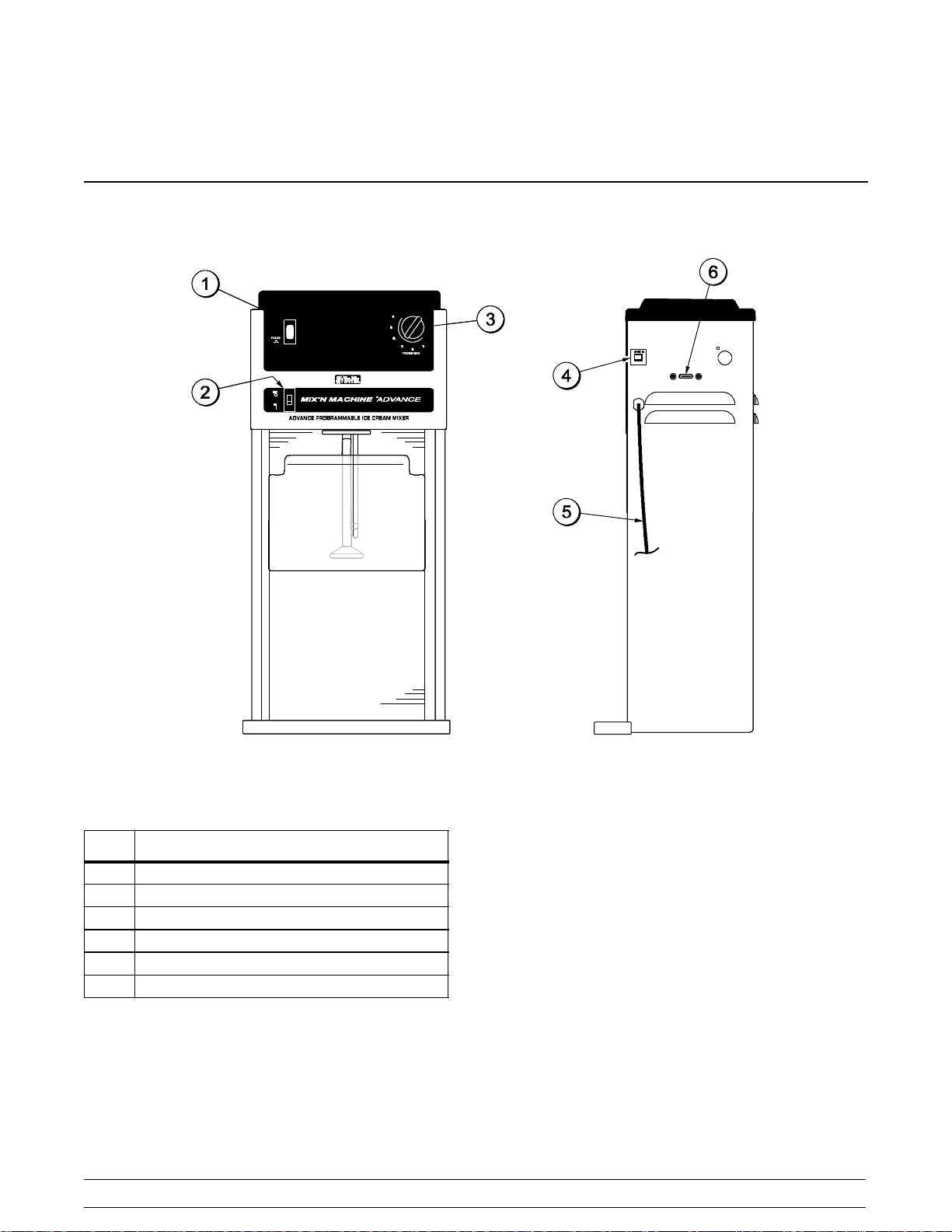

Wiring Diagram

y

TO

PROGRAMMING

PORT

LIT SWITCH

SURGE

SUPPRESSOR

GROUND

RFI

FILTER

2A

CIRCUIT

BREAKER

GROUND

PROGRAM

SELECTOR

SWITCH

(SAFETY

LOW

VOLTAGE)

HALL EFFECT SENSOR -

NON-CONTACT

PULSE

SWITCH

(SAFETY

LOW

VOLTAGE)

DC PM MOTOR

220V-240V

50/60 HZ

PM - DC

GROUND

Model BC12

Wiring Diagram

For Training Purposes Onl

2009hz0528

INITIATE

SWITCH

(SAFETY

LOW

VOLTAGE)

Loading...

Loading...