Page 1

OPERATOR'S

MANUAL

Model BC10/BW11

Razzle Blenders

Original Operating Instructions

052544-M 2/1/01 (Original Publication)

(Updated 9/15/14)

Page 2

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E 2001 Carrier Commercial Refrigeration, Inc.

052544- M

Any unauthorized reproduction, disclosure, or distribution of copies by any person of any portion of this work may be

a violation of Copyright Law of the United States of America and other countries, could result in the awarding of Statutory

Damages of up to $250,000 (17 USC 504) for infringement, and may result in further civil and criminal penalties.

All rights reserved.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 To the Installer 1............................................

Installer Safety 1........................................................

Site Preparation 1.......................................................

Electrical Connections 2.................................................

Foot Pedal Instructions 2................................................

Section 2 To the Operator 3...........................................

Section 3 Safety 4....................................................

Section 4 Operator Parts Ident ificatio n 6...............................

BC10 - Standard Unit 6.................................................

BC10 - Unit Equipped With Timer 8.......................................

BW11 - Standard Unit 10.................................................

Accessories 12..........................................................

Optional Dispensers 13...................................................

Optional Large Candy Dispenser Canister Assembly (X53638- 1) 18...........

Optional Small Candy Dispenser Canister Assembly (X53638- 2) 19............

Section 5 Important: To the Operator 20.................................

On/Off Switch 20.........................................................

Start Switch (Timer Equipped Units, Only) 20................................

Foot Pedal 20...........................................................

Reset Switch 20.........................................................

Splash Guard 21.........................................................

Motor 21................................................................

Agitators 21.............................................................

Candy Dispenser Canisters 22.............................................

Table of Contents Models BC10/BW11

Page 4

Table of Contents - Page 2

Section 6 Operating Procedures 23.....................................

Mixing Instructions 23....................................................

Daily Cleaning 25........................................................

Sanitizing 26............................................................

Section 7 Limited Warranty on Equipment 27............................

Wiring Diagram 29.......................................................

Note: Continuing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are con sid ered to be th e original set of in struction s.

E 2001 Carrier Commercial Refrigeration, Inc. (Original Publication)

Updated September, 2014

052544- M

Any unauthorized reproduction, disclosure, or distribution of copies by any person of any portion of this work

may be a violation of Copyright Law of the United States of America and other countries, could result in the

awarding of Statutory Damages of up to $250,000 (17 USC 504) for infringement, and may result in further

civil and criminal penalties.

All rights reserved.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Models BC10/BW11 Table of Contents

Page 5

Section 1 To the Installer

The following information has been included in the

manual as safety and regulatory guidelines. For

complete installation instructions, please see the

Installation Checklist.

Installer Safety

In all areas of the world, equipment should be

installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor equipment.

S Only authorized Taylor service personnel

should perform installation and repairs on the

equipment.

S Authorized service personnel must ensure

that the proper PPE is available and worn

when required during installation and service.

S Authorized service personnel must remove all

metal jewelry , rings, and watches before

working on electrical equipment.

Site Preparation

Review the area where the unit will be installed before

uncrating the unit. Make sure that all possible hazards

to the user and the equipment have been addressed.

For IndoorUse Only: This unit is designed to operate

indoors, under normal ambient temperatures of

70_-75_F(21_-24_C). The unit has successfully per-

formed in high ambient temperatures of 104_(40_C) at

reduced capacities.

This unit must NOT be installed in an area

where a water jet or hose can be used. NEVER use a

water jet or hose to rinse or clean the unit. Failure to

follow this instruction may result in electrocution.

This unit must be installed on a level surface

to avoid the hazard of tipping. Extreme care should be

taken in moving this equipment for any reason. Failure

to comply may result in personal injury or equipment

damage.

Uncrate the unit and inspect it for damage. Report any

damage to your Taylor Distributor.

The main power supply(s) to the machine

must be disconnected prior to performing any repairs.

Failure to follow this instruction may result in personal

injury or death from electrical shock or hazardous

moving parts as well as poor performance or damage

to the equipment.

Note:Allrepairsmustbeperformedbyan

authorized Taylor Service Technician.

This unit has many sharp edges that can

cause severe injuries.

This piece of equipment is made in the USA and has

USA sizes of hardware. All metric conversions are

approximate and vary in size.

140106

Models BC10/BW11 To the Installer

1

Page 6

Electrical Connections

In the United States, this equipment is intended to be

installed in accordance with the National Electrical

Code (NEC), ANSI/NFPA 70- 1987. The purpose of

the NEC code is the practical safeguarding of persons

and property from hazards arising from the use of

electricity. This code contains provisions considered

necessary for safety. Compliance therewith and

proper maintenance will result in an installation

essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

Each unit requires one power supply for each data

label on the unit. Check the data label(s) on the unit for

branch circuit overcurrent protection or fuse, circuit

ampacity, and other electrical specifications. Refer to

the wiring diagram provided inside of the electrical box

for proper power connections.

S Stationary appliances which are not equipped

with a power cord and a plug or other device

to disconnect the appliance from the power

source must have an all- pole disconnecting

device with a contact gap of at least 3 mm

installed in the external installation.

S Appliances that are permanently connected to

fixed wiring and for which leakage currents

may exceed 10 mA, particularly when

disconnected or not used for long periods, or

during initial installation, shall have protective

devices such as a GFI, to protect against the

leakage of current, installed by the authorized

personnel to the local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord

(Code designation 60245 IEC 57) installed

with the proper cord anchorage to relieve

conductors from strain, including twisting, at

the terminals and protect the insulation of the

conductors from abrasion.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualified person, in order to

avoid a hazard.

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECT RI CAL SHOCK!

This equipment is provided with a grounding lug

that is to be properly attached to the rear of the frame

by the authorized installer. The installation location is

marked by the equipotential bonding symbol (5021 of

IEC 60417- 1) on the removable panel and the frame.

130419

Foot Pedal Instructions

The foot pedal is an optional accessory on units not

equipped with a timer. To use the foot pedal to control

the mixer, connect the foot pedal to a grounded wall

outlet. Plug the mixer cord into the back of the foot

pedal plug. In this mode, both the On/Off switch and

the foot pedal must be activated. Leave the On/Off

switch in the ON position when you wish to use the foot

control. Make sure the foot control is kept where it will

not be activated accidentally . The foot guard is an

additional design feature which helps prevent

accidental use of the foot pedal.

2

Models BC10/BW11To the Installer

Page 7

Section 2 To the Operator

The mixer you have purchased has been carefully

engineered and manufactured to give you dependable

operation. Mixing various candies, cookies, fruits,

nuts, liquid flavors, and other food items into ice cream

or frozen yogurt has made unlimited flavor

combinations and product textures available.

The development of counter and wall mount mixers

have made this unlimited resource available to even

very small retail outlets and to those facilities where

counter space is limited.

The mixer, when properly operated and cared for, will

produce a consistent, quality product. Like all

mechanical products, it will require cleaning and

maintenance. A minimum amount of care and

attention is necessary if the operating procedures

outlined in this manual are followed closely .

This Operator’s Manual should be read

before operating or performing any maintenance on

your equipment. In the event that you should require

technical assistance, please contact your local

authorized Taylor Distributor.

Note: Your Taylor warranty is valid only if the parts are

authorized Taylor parts, purchased from the local

authorized Taylor Distributor, and only if all required

service work is provided by an authorized Taylor

service technician. Taylor reserves the right to deny

warranty claims on units or parts if non- Taylor

approved parts or incorrect refrigerant were installed

in the unit, system modifications were performed

beyond factory recommendations, or it is determined

that the failure was caused by abuse, misuse, neglect,

or failure to follow all operating instructions. For full

details of your Taylor Warranty, please see the Limited

Warranty section in this manual.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

NSF approvals of the Models BC10 and BW11 were

obtained by the Vita- Mix Corporation, 8615 Usher

Road, Cleveland, Ohio 44138.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other similar

legislation in effect after August 13, 2005. Therefore,

it must be collected separately after its use is

completed, and cannot be disposed as unsorted

municipal waste.

The user is responsible for returning the product to the

appropriate collection facility, as specified by your local

code. For additional information regarding applicable

local laws, please contact the municipal facility and/or

local distributor.

140106

Models BC10/BW11 To the Operator

3

Page 8

Section 3 Safety

Taylor is concerned about the safety of the operator

when he or she comes in contact with the blender and

its parts. Taylor has gone to extreme efforts to provide

built- in safety features to protect both you and the

service technician. As an example, warning labels

have been attached to the unit to further point out

safety precautions to the operator.

IMPORTANT - Failure to adh ere to the

following safety precautions may result in severe

personal injury or death. Failure to comply with

these warnings may damage the machine and its

components. Component damage will result in

part replacement expense and service repair

expense. SAVE THESE INSTRUCTIONS FOR

FUTURE REFERENCE

unit. Failure to follow these instructions may result in

serious electrical shock.

DO NOT use a water jet to clean or rinse the

S DO NOT operate the unit unless it is properly

grounded.

S DO NOT operate the unit with larger fuses

than specified on the data label.

S All repairs must be performed by an

authorized Taylor service technician.

To Operate Safely:

DO NOT operate the unit without reading

this operator’s manual. Failure to follow this instruction

may result in equipment damage, poor performance,

health hazards, or personal injury.

This appliance is to be used only by trained

personnel. It is not intended for use by children or

people with reduced physical, sensory, or mental

capabilities, or lack of experience and knowledge,

unless given supervision or instruction concerning the

use of the appliance by a person responsible for their

safety. Children should be supervised to ensure that

they do not play with the appliance.

This unit is provided with an equipotential

grounding lug that is to be properly attached to the rear

of the frame by the authorized installer. The installation

location is marked by the equipotential bonding

symbol (5021 of IEC 60417-1) on both the removable

panel and the frame.

S The main power supplies to machine must be

disconnected prior to performing repairs.

S Cord Connected Units: Only Taylor authorized

service technicians or licensed electricians

may install a plug or replacement cord on

these units.

S DO NOT operate this appliance if the power

cord is damaged.

S DO NOT use this appliance outdoors.

S Stationary appliances which are not equipped

with a power cord and a plug or another device

to disconnect the appliance from the power

source must have an all-pole disconnecting

device with a contact gap of at least 3 mm

installed in the external installation.

S Appliances that are permanently connected to

fixed wiring and for which leakage currents

may exceed 10 mA, particularly when

disconnected or not used for long periods, or

during initial installation, shall have protective

devices such as a GFI, to protect against the

leakage of current, installed by the authorized

personnel to the local codes.

130419

4

Models BC10/BW11Safety

Page 9

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or other

equivalent synthetic elastomer- sheathed

cord (Code designation 60245 IEC 57)

installed with the proper cord anchorage to

relieve conductors from strain, including

twisting, at the terminals and protect the

insulation of the conductors from abrasion.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualified person, in order to

avoid a hazard.

Failure to follow these instructions may result in

electrocution. Contact your local authorized Taylor

Distributor for service.

S DO NOT allow children or untrained personnel

to operate this machine.

S DO NOT operate the unit unless all service

panels and access doors are restrained with

screws.

S AVOID contact with the agitator shaft and

other moving parts.

S Make sure the splash guard is installed prior

to operating the appliance.

S DO NOT disassemble or install parts unless

the On/Off switch is in the OFF position.

S If unit is equipped with a foot pedal, always

use the foot pedal guard. Avoid accidental use

of the foot pedal. When using the foot pedal,

make sure the appliance is located where

accidental contact with the pedal is not likely .

When the mixer is not in use, place the front

switch in the OFF position to avoid accidental

use of the pedal.

Failure to follow these instructions may result in severe

personal injury from hazardous moving parts.

DO NOT operate this appliance if it

malfunctions or is damaged in any way. Failure to

follow this instruction may result in injury or component

damage.

Cleaning and sanitizing schedules are

governed by your Federal, State, or local regulatory

agencies and must be followed accordingly. Please

refer to the cleaning section of this manual for the

proper procedure to clean this unit.

DO NOT use attachments not recommended

or sold by Taylor. Doing so may cause fire, electric

shock, injury, or equipment damage.

Make sure the mixer is sitting or mounted

solidly on a sturdy surface during operation. Failure to

comply may result in injury or equipment damage.

WARNING!

Some consumers are highly allergic to

peanuts, peanut oil, and peanut dust. In

some severe cases, peanut allergy

reactions can cause death. When

blending product with peanuts, make

sure excess product is cleaned from the

agitator shaft to eliminate the fear of

product carryover.

NOISE LEVEL: Airborne noise emission does not

DO NOT allow the power cord to hang over

the edge of the counter or touch hot surfaces. Failure

to comply may result in an electrical fire.

Models BC10/BW11 Safety

exceed 78 dB(A) when measured at a distance of 1.0

meter from the surface of the machine and at a height

of 1.6 meters from the floor.

130515

5

Page 10

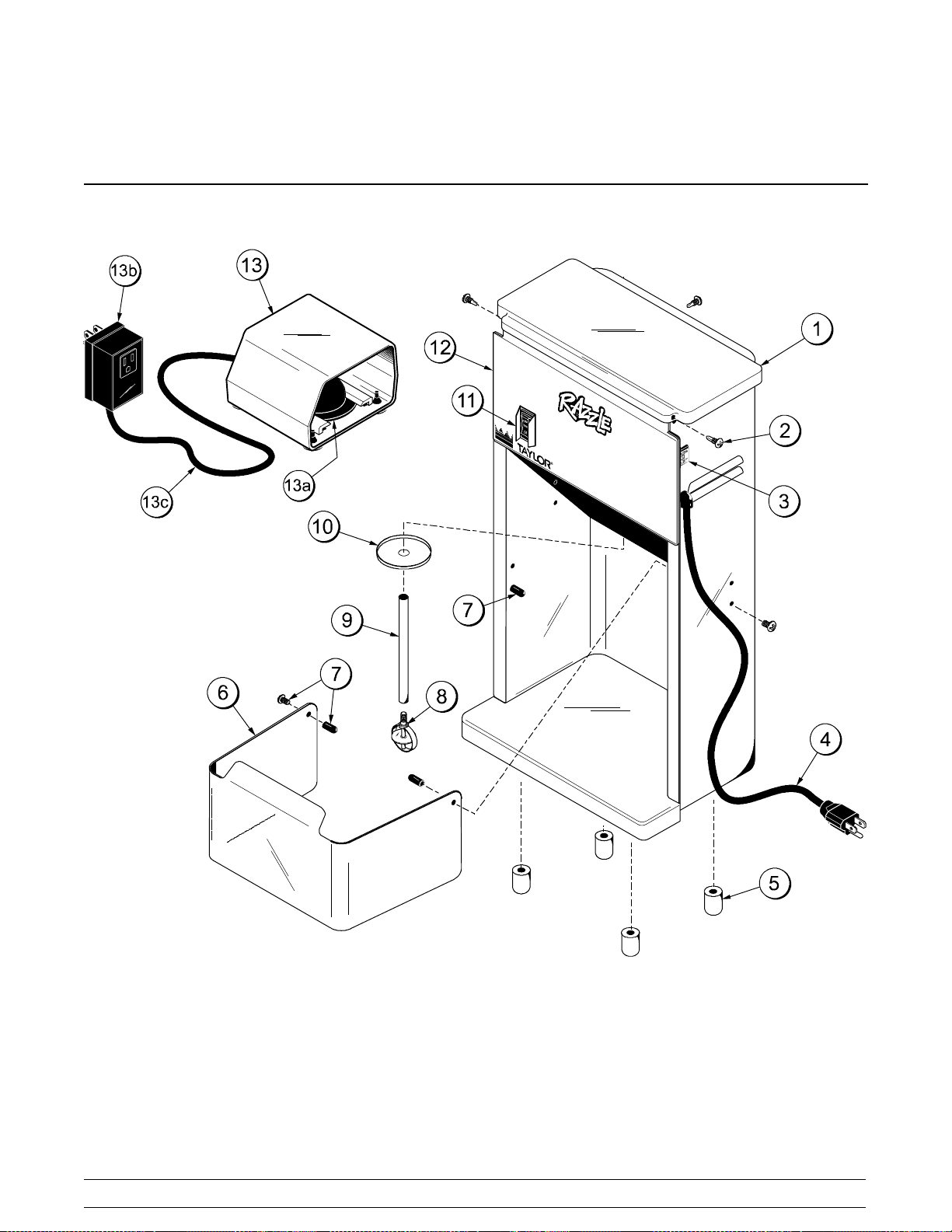

Section 4 Operator Parts Identification

BC10 - Standard Unit

130524

6

Models BC10/BW11Operator Parts Identification

Page 11

BC10 Standard Unit - Exploded View Parts Identification

ITEM DESCRIPTION PART NO.

1 CAP- MIXER 051484

2 SCREW- MIXER- RETAINER

CAP

BREAKER- CIRCUIT- MIXER3A- 120V

3

BREAKER- CIRCUIT- MIXER- 5A

- 220/240V

4 CORD- MIXER- 18/3

GROUNDED W/PLUG

5 FOOT A.- MIXER- PLUGGED-

PKG OF 4

6 GUARD - SPLASH- MIXER 051499

7 PIVOT PIN&SCREW*PKG OF 4* 051507

8 AGITATOR- MIXER- PERM SOFT 051497

9 SHAFT- MIXER- AGITATOR- EXT

- PERMANENT

051487

051489

051490

051491

051500

051495

ITEM DESCRIPTION PART NO.

10 SLINGER- MIXER 051494

11 SWITCH- ROCKER- MIXER 051488

12 LABEL- MIXER- COUNTER-

RAZZLE

PEDAL- FOOT - MIXER- 120V 052451

13

PEDAL- FOOT - MIXER- 220V 053192

13a TRANSMITTER FOOT PEDAL 052451- 1

CONTROLLER- FOOT PEDAL115V

13b

SWITCH- PRESSURE- FOOT

PEDAL- 220

13c TUBE - AIR - FOOT PEDAL 052451- 3

052250

052451- 2

053192- 1

130524

Models BC10/BW11 Operator Parts Identification

7

Page 12

BC10 - Unit Equipped With Timer

130529

8

Models BC10/BW11Operator Parts Identification

Page 13

BC10 Unit Equipped With Timer - Exploded View Parts Identification

ITEM DESCRIPTION PART NO.

1 CAP- MIXER 051484

2 SCREW- MIXER- RETAINER

CAP

3 BREAKER- CIRCUIT- MIXER- 5A

220/240V

4 FOOT A.- MIXER- PLUGGED-

PKG OF 4

5 GUARD- SPLASH- MIXER 051499

6 PIVOT PIN&SCREW*PKG OF 4 051507

051487

051490

051500

ITEM DESCRIPTION PART NO.

7 SHAFT- DRIVEN SPINNER-

MIXER

8 SLINGER- MIXER 051494

9 SWITCH- ROCKER- LIGHTED 067643- 40

10 LABEL- MIXER- COUNTER-

RAZZLE

11 SWITCH- PUSHBUTTON-

MOMENTARY (START BUTTON)

051436

052250

054699

130524

Models BC10/BW11 Operator Parts Identification

9

Page 14

BW11 - Standard Unit

130524

10

Models BC10/BW11Operator Parts Identification

Page 15

BW11 Standard Unit - Exploded View Parts Identification

ITEM DESCRIPTION PART NO.

1 COVER- MIXER- TOP WALL MT 051516

2 LABEL- MIXER- WALL- FRONT/

SIDE - 3

BREAKER- CIRCUIT- MIXER- 3A

120V

3

BREAKER- CIRCUIT- MIXER- 5A

220/240V

4 SWITCH- ROCKER- MIXER 051488

5 BUSHING- MIXER- TRAVEL ROD 051522

6 GUARD- SPLASH- MIXER- CUP-

WALL MOUNT

7 SLINGER- MIXER 051494

8 SHAFT- MIXER- AGITATOR - EXT

- WALL MOUNT

052251

051489

051490

051518

051520

ITEM DESCRIPTION PART NO.

9 AGITATOR- MIXER- PERM SOFT

SERVE

10 KIT- DRIP PAN- BW11 052429

PEDAL- FOOT - MIXER- 120V 052451

11

PEDAL- FOOT - MIXER- 220V 053192

11a TRANSMITTER- FOOT PEDAL 052451- 1

CONTROLLER- FOOT

PEDAL- 115V

11b

SWITCH- PRESSURE- FOOT

PEDAL- 220V

11c TUBE- AIR- FOOT PEDAL 052451 - 3

12 CORD- MIXER- 18/3

GROUNDED W/PLUG

051497

052451- 2

053192- 1

051491

139524

Models BC10/BW11 Operator Parts Identification

11

Page 16

Accessories

ITEM DESCRIPTION PART NO.

1 ORGANIZER A.- CUP/LID X52080

1a INSERT- SPOON BIN 052113

1b COLUMN- LID DISPENSER 052084

1c SCREW- 1/4 X 1 HEX HEAD 052139

CUP 12 OZ RAZZLE 1000/CS 051967

2

CUP 16 OZ RAZZLE 1000/CS 051968

3 LID RAZZLE CLEAR DOME

1200/CS

051969

131010

ITEM DESCRIPTION PART NO.

4 COLLAR- PLASTIC 051750

5 KIT- DRIP PAN 052429

6a SHAFT- DRIVEN SPOON

MIXER

6b AGITATOR - MIXER-

PERMANENT SOFT SERVE

*6c AGITATOR- MIXER-

PERMANENT HARD SERVE

*NOT SHOWN

12

Models BC10/BW11Operator Parts Identification

051436

051497

051498

Page 17

Optional Dispensers

X52037- 1

Item Description Part No.

Dispenser A.-2 Large - 2 Small X52037-1

1 Bracket A.-Wall Mount X52035

2 Canister A.-Large (2) X53638-1

3 Canister A.-Small (2) X53638-2

4 Kit A.-Dispenser-WallMount X52039

4a Screw-10-24 x 2 Sltd Pan Hd SS 051443

4b Anchor-Toggle Wing Zinc Plated 051444

4c* Template-Dispenser-Wall Mount 052041-T

*Not Shown

X52037- 2

Item Description Part No.

Dispenser A.-4 Small (WallMt.)

1 Bracket A.-Wall Mount X52035

2 Canister A.-Small (4) X53638-2

3 Kit A.-Dispenser-WallMount X52039

3a Screw-10-24 x 2 Sltd Pan Hd SS 051443

3b Anchor-Toggle Wing Zinc Plated 051444

3c* Template-Dispenser-Wall Mount 052041-T

*Not Shown

X52037-2

X52078- 1

Item Description Part No.

Dispenser A.- 2 Small

(Wall/Counter Mount)

1 Bracket A.- Wall/Counter Mt. X51414

2 Canister A.-Small(2) X53638- 2

3 Kit A.- Dispenser- Wall/Counter Mt. X51441

3a Screw-10-24x2SltdPanHd(3) 051443

3b Anchor - Toggle Wing Zinc (3) 051444

3c* Template- Dispenser- Wall Mt. 051415 - T

*Not Shown

X52078- 1

Models BC10/BW11 Operator Parts Identification

13

Page 18

Optional Dispensers (Cont’d.)

X52078- 2

Item Description Part No.

Dispenser A.-2 Large

(Wall/Counter Mount)

1 Bracket A.-Wall/CounterMt. X51414

2 CanisterA.-Large (2) X53638-1

3 Kit A.-Dispenser-Wall/CounterMt. X51441

3a Screw-10-24x2SltdPanHd(3) 051443

3b Anchor- Toggle Wing Zinc (3) 051444

3c* Template- Dispenser- Wall Mt. 051415- T

*Not Shown

X52078-2

X52566- 1

Item Description Part No.

Dispenser A.-2 Large - 2 Small

(Hood/Counter/WallMount)

1 Bracket A.-Hood Mount X52559

2 Bracket A.-Splitback X52556

3 Bracket A.-Counter/WallMt. (2) X52618

4 Canister A.-Small (2) X53638-1

5 Canister A.-Large (2) X53638-2

6 Kit A.-Dispenser-Counter/Wall Mt X52567

6a Screw-10-24 x 2 Sltd Pan Hd (6) 051443

6b Anchor-Toggle Wing Zinc (6) 051444

6c Collar-Holding (8) 046551

6d Screw-10-32 x 1/2 Oval Hd (8) 001251

7 Tray A.-Hood Mount (2) X53773

8* Instruction-Dispenser X52566-INS

*Not Shown

X52566-1

14

Models BC10/BW11Operator Parts Identification

Page 19

Optional Dispensers (Cont’d.)

X52566- 2

Item Description Part No.

Dispenser A.-4 Small

(Hood/Counter/WallMount)

1 Bracket A.-Hood Mount X52559

2 Bracket A.-Splitback (2) X52556

3 Bracket A.-Counter/WallMt (2) X52618

4 Canister A.-Small (4) X53638-2

5 Tray A.-Hood Mount (2) X53773

6 Kit A.-Dispenser-Counter/Wall Mt X52567

6a Screw-10-24 x 2 Sltd Pan Hd (6) 051443

6b Anchor-Toggle Wing Zinc (6) 051444

6c Collar-Holding (8) 046551

6d Screw-10-32 x 1/2 Oval Hd-NP (8) 001251

7* Instruction-Dispenser X52566-INS

*Not Shown

X52566-2

X52566- 3

Item Description Part No.

Dispenser A.-4 Large

(Hood/Counter/WallMount)

1 Bracket A.-Hood Mount X52559

2 Bracket A.-Splitback (2) X52556

3 Bracket A.-Counter/WallMt (2) X52618

4 Canister A.-Large (4) X53638-1

5 Tray A.-Hood Mount (2) X53773

6 Kit A.-Dispenser-Counter/Wall Mt X52567

6a Screw-10-24 x 2 Sltd Pan Hd (6) 051443

6b Anchor-Toggle Wing Zinc (6) 051444

6c Collar-Holding (8) 046551

6d Screw-10-32 x 1/2 Oval Hd (8) 001251

7* Instruction-Dispenser X52566-INS

*Not Shown

X52566-3

Models BC10/BW11 Operator Parts Identification

15

Page 20

Optional Dispensers (Cont’d.)

X52566- 5

Item Description Part No.

Dispenser A.-2 Large

(Hood Mount Only)

1 Canister A.-Large (2) X53638-1

2 Bracket A.-Splitback (1) X52556

3 Bracket A.-Hood Mount X52559

4 Kit A.-Dispenser-Counter/Wall Mt X52567-4

4a Screw-10-32 x 1/2 Oval Hd (8) 001251

4b Collar-Holding (8) 046551

5 Tray A.-Hood Mount X53773

6* Instruction-Dispenser X52566-INS

*Not Shown

X52566-5

X53407- 1

Item Description Part No.

Dispenser A.-2 Small -Vertical

(WallMount Only)

1 Kit A.-Vertical Wall Mount X53460

2 Canister A.-Small (2) X53638-2

3 Kit A.-Vertical Wall Mount X53461

3a Screw-10-24 x 2 Sltd Pan Hd (3) 051443

3b Anchor-Toggle Wing Zinc (3) 051444

3c* Template-Dispenser-Wall Mt. 053462-T

*Not Shown

X53407-1

16

Models BC10/BW11Operator Parts Identification

Page 21

Optional Dispensers (Cont’d.)

X53492- 1

Item Description Part No.

Dispenser A.-1 Large - Vertical

(WallMount Only)

1 Canister A.-Large (1) X53638-1

2 Bracket A.-Vertical Wall Mount X53488

3 Kit A.-Dispenser-WallMount X53490

3a Screw-10-24 x 2 Sldt Pan Hd (3) 051443

3b Anchor-Toggle Wing Zinc (3) 051444

Template-Single Canister-WallMt 053491-T

3c*

*Not Shown

X53492-1

X53492- 2

Item Description Part No.

Dispenser A.-1 Small - Vertical

(WallMount Only)

1 Canister A.-Small (1) X53638-2

2 Bracket A.-Vertical Wall Mount X53488

3 Kit A.-Dispenser-WallMount X53490

3a Screw-10-24 x 2 Sldt Pan Hd (3) 051443

3b Anchor-Toggle Wing Zinc (3) 051444

Template-Single Canister-WallMt 053491-T

3c*

*Not Shown

X53492-2

Models BC10/BW11 Operator Parts Identification

17

Page 22

Optional Large Candy Dispenser Canister Assembly (X53638- 1)

ITEM DESCRIPTION PART NO.

1 CANISTER A.- LARGE CANDY DISP. X53638- 1

1a COVER- CANDY DISPENSER- LARGE 052032- 1

1b SHAFT A.- LONG W/AGITATORS X53530- 1

1c PLATE- ANTI- ROTATION INS. W/POST 053581

ITEM DESCRIPTION PART NO.

1d PUCK A.- CANDY DISPENSER X52027

1e CANISTER- CANDY DISPENSER- LG. 052033- 1

1f KNOB A.- CANDY DISPENSER X51564

18

Models BC10/BW11Operator Parts Identification

Page 23

Optional Small Candy Dispenser Canister Assembly (X53638- 2)

ITEM DESCRIPTION PART NO.

2 CANISTER A.- SM. CANDY DISP. (2) X53638- 2

2a COVER- CANDY DISPENSER- SMALL 052032- 2

2b SHAFT A.- SHORT W/AGITATORS X53530- 2

2c PLATE- ANTI- ROTATION INS. W/POST 053581

Models BC10/BW11 Operator Parts Identification

ITEM DESCRIPTION PART NO.

2d PUCK A.- CANDY DISPENSER X52027

2e CANISTER- CANDY DISPENSER- SM. 052033- 2

2f KNOB A.- CANDY DISPENSER X51564

19

Page 24

Section 5 Important: To the Operator

On/Off Switch

The On/Off switch is a rocker switch located on the

front of the machine. It controls the power to the

machine.

Units Not Equipped With Foot Pedal or Timer: The

On/Off switch is used to activate the agitator for

blending.

Foot Pedal or Timer Equipped Units: The On/Off

switch is placed in the ON position to ready the

machine for blending. The switch is placedin theOFF

position at the endof the dayorwhenever themachine

will be left unattended.

Foot Pedal

Standard units may be equipped with an optional foot

pedal. The foot pedal allows hands- free activation of

the agitator and allows the operator to use both hands

to mix the product. Press and hold the switch to

activate the agitator. Release the switch to stop the

agitator.

Figure 2

Reset Switch

Figure 1

Start Switch

(Timer Equipped Units, Only)

The Start switch (Momentary Pushbutton Switch) is

located on the front of the machine above the On/Off

switch. With the On/Off switch in the ON position,

pressing the Start switch activates the agitator and

beginsa pre-set timedblending cycle. Theagitator will

stop automatically at the end of the blending cycle.

The Model BC10 reset switch is located on right side

panel. The Model BW11 reset switch is located on the

front panel. The reset switch protects the motor from

an overload condition. If an overload occurs, the reset

mechanism will trip. To properly reset the unit, place

the On/Off switch in the OFF position. Allow the motor

to cool down for a few minutes. Press the reset switch.

Place the On/Off switch in the ON position and resume

operation.

Figure 3

20

Models BC10/BW11Important: To the Operator

Page 25

Splash Guard

Agitators

Permanent Agitator

The splash guard functions as a built- in cup limiter

which protects the cups from agitator penetration. The

splash guard also helps keep the inside of the housing

clean.

The splash guard for the Model BC10 (counter- top)

slides up and down on stainless steel rods. The splash

guard for the Model BW11 (wall mount) rotates upward

for easy operation.

Figure 4

Material: NSF accepted Acetal

The non- metal permanent agitator can be carefully

pushed up against the inside of the paper or plastic

cups with no damage to the cup.

IMPORTANT: The shaft must be cleaned between

servings as product carryover will occur.

(See page 26 for cleaning instructions.)

Figure 5

Removable Spoon Agitator

Material: NSF accepted Eastman Tritant

The non- metal single serve agitator/spoon clips onto

the machine for mixing and removal for use as a

serving spoon. The spoon agitator increases the

speed of service and prevents flavors, colorings, and

potential allergens from being transferred from serving

to serving, while not damaging paper or plastic cups

during processing.

Motor

The motor features a heavy duty, ball bearing induction

motor and does not use brushes, belts, couplings, or

gears. This design reduces power consumption, heat,

noise, and wear. The motor maintains an optimal

speed of 3,485 RPM to maintain product consistency.

Models BC10/BW11 Important: To the Operator

21

Figure 6

Page 26

Candy Dispenser Canisters

Canister Care and L o catio n

The canisters contain the candy toppings. The

operator dispenses the toppings by use of the

dispenser handle.

Candy Care

Most candies have a tendency to “clump” or “cluster”

under various conditions. This can lead to broken

dispensing pucks if excessive pressure is required to

move the handle.

S Store candies in the proper ambient

conditions according to the manufacturer’s

directions. Avoid excessively hot and humid

locations.

S Avoid opening a bag of candy if the entire

contents cannot be poured into the canister. If

this cannot be avoided, be sure to fold the bag

opening over and reseal it with a bag clip.

Store it in a cool, dry place until needed again.

S Rotate the candy stock to use the oldest

candy first (First in- First- out).

S Before opening a new bag of candy, check to

see if it contains large clumps by slightly

squeezing the bag. If clumps exist, gently

break them apart with your fingers prior to

opening the bag.

S Avoid mounting canisters near heat, humidity,

or hot air discharges. These conditions can

promote clumping and difficult dispensing of

candies.

S Always keep candies protected from the open

ambience by having the lids properly installed

on top of the canisters when candies are

present.

S When canisters are not cleaned daily, candy

dust and powers begin to congeal and will

cause excessive pressure to be exerted in

order to dispense candies. This additional

pressure can cause the pucks to break.

S Avoid “slamming” the dispensing handle back

and forth when dispensing candies. This can

cause the puck to break.

S Do not apply undue force on the handle to

make the puck move. If a “lock up” condition

occurs, empty the dispenser of candies.

Disassemble, clean and thoroughly dry the

dispenser according to cleaning instructions.

Eliminate clusters and clumps before refilling

the canister.

S When reassembling the canister, take care

not to over- tighten the handle into the “puck

bushing”. After the handle has been screwed

into the puck bushing, check tightness by

unscrewing it slightly to be sure it requires little

effort to unscrew. Then reseat it.

030103

22

Models BC10/BW11Important: To the Operator

Page 27

Section 6 Operating Procedures

Mixing Instructions

IMPORTANT: Make sure your hands are clean and

sanitized before performing these steps.

Step 1

Fill a serving cup with soft serve product and install the

plastic domed lid.

Figure 7

Step 2

Add “mix- in” ingredients such as liquid flavoring,

candy, cookies, fruit, or other condiments.

Figure 9

Step 3

For units using the spoon agitator, slide the agitator

onto the agitator shaft until it snaps into place.

Figure 10

Step 4

Hold the cup securely in your hands (from the side, not

Figure 8

Models BC10/BW11 Operating Procedures

from the bottom) and move the cup under the agitator.

23

Page 28

Step 5

Position the cup so the agitator makes slight contact

with the bottom of the cup.

Figure 11

Step 6

Activate the agitator. Follow the instructions below

based on the specific model:

Step 9

Before removing the cup completely, hold the top edge

of the cup near the spinning agitator to allow excess

mixture to be projected into the cup or the mix- through

collar.

Step 10

Deactivate the agitator. Follow the instructions below

based on the specific model:

Standard Unit Without Foot Pedal: Place the

On/Off switch in the OFF position.

Standard Units With Foot Pedal: Release the

foot pedal.

Unit Equipped With Timer: The machine stops

automatically at the end of the blending cycle.

Step 11

Serve the product. If using spoon agitator, remove the

spoon from the agitator shaft. Serve the product with

the spoon in the cup.

Standard Unit Without Foot Pedal: Place the

On/Off switch in the ON position.

Standard Unit With Foot Pedal: With the On/Off

switch in the ON position, step on the foot pedal

switch.

Unit Equipped With Timer: With the On/Off

switch in the ON position, press the Start switch.

Step 7

Using a circular motion, work the cup upward and over

the spinning agitator.

Note: Agitation will chip and break down solids. It is

not intended to completely pulverize ingredients. Solid

chunks should be evident in the finished product.

CAUTION: Both the permanent agitator and the spoon

agitator are designed to withstand reasonable contact

with the spinning agitator shaft. However, it should not

be forced or held solidly against the side or bottom of

the cup. This may cause damage to the cup or

components.

Note: Spoon agitators should be used only once.

Step 12

Permanent Agitators, Only: Prepare a durable

square or rectangular container, filling it to within 1 inch

(30 mm) from the top with an approved cleaning

solution. The container must be deep enough to

submerge the entire agitator and shaft. USE WARM

WATER (110_F/43_C) AND FOLLOW THE MANUFACTURER’S SPECIFICATIONS. Do not use a

solution that contains ammonia.

Submerge the agitator in the cleaning solution all the

way to the bottom of the motor chamber. Activate the

agitator and allow it to run for about 15 seconds.

Repeat this step several times, making certain all

portions of the agitator and shaft have been

submerged in the cleaning solution.

Repeat this step using cool, clean water instead of

cleaning solution.

Step 8

After about 10 seconds have elapsed, slowly remove

the cup by “swirling” it around the agitator. This will

create an effect that is pleasing to the eye and avoids

leaving a hole in the center of the product.

130620

WARNING: Never try to wipe clean the

agitator while it is active. Failure to follow these

instructions can lead to severe personal injury

from hazardous moving parts, or damage to the

unit.

24

Models BC10/BW11Operating Procedures

Page 29

Daily Cleaning

Step 7

Discard any remaining topping.

Taylor recommends daily cleaning.

ALWAYS FOLLOW LOCAL HEALTH CODES

Step 1

Prepare a sink with an approved cleaning/sanitizing

solution with an active chlorine concentrate of 100 200 PPM (parts per million). USE W ARM WATER

(110_F/43_C) AND FOLLOW THE MANUFACTURER’S SPECIFICATIONS. Do not use a solution

that contains ammonia and avoid placing components

in a dishwasher.

Note: Follow label directions, as too STRONG of a

solution can cause parts damage, while too MILD of a

solution will not provide adequate cleaning. Make sure

all brushes provided with the freezer are available for

brush cleaning.

Step 2

Disconnect power from the wall

receptacle. Failure to comply may result in

electrical shock.

Step 3

Remove the splash guard.

Wall mount units only (BW11): Remove the sliding

splash guard cup by squeezing the travel rods together

and sliding the guard downward. Take the cup to the

sink for cleaning.

Step 4

Wash the splash guard in the approved cleaning

solution.

Step 5

Using a single service towel moistened with the

cleaning solution, wipe clean the travel rods and the

agitator shaft.

CAUTION: DO NOT REMOVE THE TRAVEL RODS

FROM THE UNIT.

Step 6

Remove the dispenser from the bracket by tilting it

toward you and lifting upward.

Step 8

Remove the cover, shaft, dispensing plate, and

dispensing puck. Unscrew the handle from the

dispensing puck.

Step 9

Check all parts for cracks and damage, especially the

puck. Replace damaged parts immediately.

Step 10

Wash all plastic parts in the approved cleaning

solution. CAUTION: PLASTIC PARTS ARE NOT

DISHWASHER SAFE! HAND WASH ONLY!

Step 11

Re- assemble the dispenser. Make sure the

dispensing puck is placed in the canister with the

counterbore face down and the threaded insert facing

the slot.

Note: Parts must be dry prior to assembling and

refilling them with mix ingredients.

Step 12

Screw the handle through the slot and into the metal

insert in the dispensing puck. Place the dispensing

plate on top of the dispensing puck.

Step 13

Position the shaft through the plate and into the slot in

the dispensing puck. Make certain the shaft is properly

seated.

Step 14

Install the dispenser. Place the dispenser on the wall

bracket with the locating pin facing the holding bracket.

The dispenser must be tilted toward the operator to

clear the handle. Insert the pin into the hole in the

bracket.

Note: When loading the dispenser with product, keep

powder away from the top of the shaft. Fill the canister

only within one inch of the top. Do not overfill the

canister.

080221

Models BC10/BW11 Operating Procedures

25

Page 30

Step 15

Wipe clean all stainless steel surfaces with an

approved, non- abrasive commercial cleaner. This

includes the mixer, dispenser, and organizer surfaces.

WARNING: Do not spray water or other

liquid around the motor chamber. Do not use

excess liquid around the switch, motor protector,

power cords, or cord entry orifice. Make certain all

areas in and around the motor are dry before

connecting power to the wall receptacle. Failure to

comply may cause equipment damage or

personal injury due to electric shock.

Step 16

When foot pedal cleaning is required, disconnect it and

wipe it with a damp single service towel. Make sure the

foot pedal is thoroughly dry before re- connecting it to

the unit.

CAUTION: The foot pedal should be kept

dry. Do not leave it on the floor during mopping.

Failure to comply may result in electrical shock.

Permanent Agitator Cleaning

Step 1

Prepare a durable container with an approved

cleaning/sanitizing solution with an active chlorine

concentrate of 100 - 200 PPM (parts per million). USE

WARM WATER (110_F/43_C) AND FOLLOW THE

MANUFACTURER’S SPECIFICATIONS. Do not use

a solution that contains ammonia.

Note: The container must be deep enough to

submerge the entire agitator and shaft.

Step 2

Submerge the agitator in the cleaning solution, all the

way to the bottom of the motor chamber. Activate the

agitator and alllow it to run for about 15 seconds.

Repeat this step several times, making certain all

portions of the agitator and shaft have been

submerged in the cleaning solution.

WARNING: Never try to wipe clean the

agitator while it is active. Failure to follow these

instructions can lead to severe personal injury

from hazardous moving parts, or damage to the

unit.

Step 3

Repeat Step 2 using cool, clean water instead of

cleaning solution.

Sanitizing

Step 1

Repeat all steps of the cleaning procedure using an

approved cleaning/sanitizing solution with an active

chlorine concentrate of 100 - 200 PPM (parts per

million). USE WARM WATER (110_F/43_C) AND

FOLLOW THE MANUFACTURER’S SPECIFICATIONS.

Step 2

Reinstall the splash guard.

Step 3

Repeat the sanitizing procedures at the start of the

day.

ALWAYS FOLLOW LOCAL HEALTH CODES

080221

26

Models BC10/BW11Operating Procedures

Page 31

Section 7 Limited Warranty on Equipment

TAYLOR COMPANY LIMITED WARRANTY ON BLENDERS

Taylor Company, a division of Carrier Commercial Refrigeration, Inc. (“Taylor”) is pleased to provide this limited

warranty on new equipment available from Taylor (the “Product”) to the original purchaser only.

LIMITED WARRANTY

Taylor warrants the Product against failure due to defect in materials or workmanship under normal use and

service as follows. All warranty periods begin on the date of original Product installation. If a part fails due to

defect during the applicable warranty period, Taylor, through an authorized Taylor distributor or service agency,

will provide a new or re- manufactured part, at Taylor’s option, to replace the failed defective part at no charge for

the part. Except as otherwise stated herein, these are Taylor’s exclusive obligations under this limited warranty for

a Product failure. This limited warranty is subject to all provisions, conditions, limitations and exclusions listed

below and on the reverse (if any) of this document.

Product

Blenders One (1) year

In addition, during the one (1) year period commencing on the date of original installation of blenders, Taylor will

also provide, through an authorized Taylor distributor or service agency, all service needed to replace the failed

defective part at no charge for the service. Local sales and use taxes may still apply and will be charged

accordingly.

Except as otherwise stated herein, these are Taylor’s exclusive obligations under this limited warranty for a

Product failure. This limited warranty is subject to all provisions, conditions, limitations and exclusions listed below

and on the reverse (if any) of this document.

LIMITED WARRANTY CONDITIONS

1. This limited warranty is valid only if the Product is registered with Taylor within thirty (30) days of installation.

2. This limited warranty is valid only if the Product is installed and all required service work on the Product is

performed by an authorized Taylor distributor or service agency, and only if genuine, new Taylor parts are

used.

3. Installation, use, care, and maintenance must be normal and in accordance with all instructions contained in

the Taylor Operator’s Manual.

4. Defective parts must be returned to the authorized Taylor distributor or service agency for credit.

LIMITED WARRANTY EXCEPTIONS

This limited warranty does not

cover:

Limited Warranty Period

1. Except as otherwise specifically set forth in this limited warranty, labor or other costs incurred for diagnosing,

repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new

Products.

2. Normal maintenance, cleaning and lubrication as outlined in the Taylor Operator’s Manual.

3. Replacement of wear items designated as Class “000” parts in the Taylor Operator’s Manual.

4. External hoses, electrical power supplies, and machine grounding.

5. Parts not supplied or designated by Taylor, or damages resulting from their use.

6. Return trips or waiting time required because a service technician is prevented from beginning warranty

service work promptly upon arrival.

140106

Models BC10/BW11 Limited Warranty on Equipment

27

Page 32

7. Failure, damage or repairs due to faulty installation, misapplication, abuse, no or improper servicing,

unauthorized alteration or improper operation or use as indicated in the Taylor Operator’s Manual, including

but not limited to the failure to use proper assembly and cleaning techniques, tools, or approved cleaning

supplies.

8. Failure, damage or repairs due to theft, vandalism, wind, rain, flood, high water, water, lightning, earthquake

or any other natural disaster, fire, corrosive environments, insect or rodent infestation, or other casualty,

accident or condition beyond the reasonable control of Taylor; operation above or below the electrical or

water supply specification of the Product; or components repaired or altered in any way so as, in the

judgment of the Manufacturer, to adversely affect performance, or normal wear or deterioration.

9. Any Product purchased over the Internet.

10. Failure to start due to voltage conditions, blown fuses, open circuit breakers, or damages due to the

inadequacy or interruption of electrical service.

1 1. Electricity or fuel costs, or increases in electricity or fuel costs from any reason whatsoever.

12. ANY SPECIAL, INDIRECT OR CONSEQUENTIAL PROPERTY OR COMMERCIAL DAMAGE OF ANY

NATURE WHATSOEVER. Some jurisdictions do not allow the exclusion of incidental or consequential

damages, so this limitation may not apply to you.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from

jurisdiction to jurisdiction.

LIMITA TION OF WARRANTY

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, CONDITIONS

AND/OR REMEDIES UNDER THE LAW, INCLUDING ANY IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE ORIGINAL OWNER’S SOLE

REMEDY WITH RESPECT TO ANY PRODUCTS SHALL BE REPAIR OR REPLACEMENT OF DEFECTIVE

COMPONENTS UNDER THE TERMS OF THIS LIMITED WARRANTY. ALL RIGHTS TO CONSEQUENTIAL

OR INCIDENTAL DAMAGES (INCLUDING CLAIMS FOR LOST SALES, LOST PROFITS, PRODUCT LOSS,

PROPERTY DAMAGES OR SERVICE EXPENSES) ARE EXPRESSLY EXCLUDED. THE EXPRESS

WARRANTIES MADE IN THIS LIMITED WARRANTY MAY NOT BE AL TERED, ENLARGED, OR CHANGED

BY ANY DISTRIBUTOR, DEALER, OR OTHER PERSON, WHATSOEVER.

LEGAL REMEDIES

The owner must notify Taylor in writing, by certified or registered letter to the following address, of any defect or

complaint with the Product, stating the defect or complaint and a specific request for repair, replacement, or other

correction of the Product under warranty, mailed at least thirty (30) days before pursuing any legal rights or

remedies.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072, USA

28

Models BC10/BW11Limited Warranty on Equipment

Page 33

Wiring Diagram

Models BC10/BW11

29

Wiring Diagram

Loading...

Loading...