Sony RHTG-2000 Service manual

RHT-G2000

SERVICE MANUAL

Ver. 1.0 2005.08

This system incorporates Dolby* Digital and Pro Logic Surround and

the DTS** Digital Surround System.

* Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are trademarks of Dolby Laboratories.

** “DTS” and “DTS Digital Surround” are registered trademarks of Digital Theater Systems,

Inc.

SPECIFICATIONS

US Model

Canadian Model

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION:

With 4 ohm loads, both channels driven, from 200 – 20,000 Hz; rated

40 watts per channel minimum RMS power, with no more than 0.7 %

total harmonic distortion from 250 milli watts to rated output.

Amplifier section

Surround mode (reference) power output

*

Depending on the sound field settings and the source, there may

be no sound output.

Inputs (Analog)

TV, SAT, DVD,

VIDEO 1, VIDEO 2 Sensitivity: 610 mV

Inputs (Digital)

TV, SAT, DVD, VIDEO 1,

VIDEO 2 (Coaxial) Impedance: 75 ohms

Tuner section

System PLL quartz-locked digital synthesizer

FM tuner section

Tuning range 87.5 – 108.0 MHz (100 kHz step)

Antenna FM wire antenna

Antenna terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 530 – 1,710 kHz

Front: 100 W + 100 W 4 ohms

Center*: 100 W 4 ohms

Surround*: 100 W + 100 W 4 ohms

Subwoofer*: 200 W 2 ohms

Impedance: 25 kilohms

system

(with the interval set at 10 kHz)

531 – 1,710 kHz

(with the interval set at 9 kHz)

Antenna AM loop antenna

Intermediate frequency 450 kHz

Video section

Inputs/Outputs Video: 1 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0.7 Vp-p 75 ohms

Accepts 480i/480p/720p/1080i

Speakers

Front

Speaker system Bass reflex, magnetically shielded

Speaker unit 65 mm (2 5/8 inches) cone type

Center

Speaker system Bass reflex, magnetically shielded

Speaker unit 65 mm (2 5/8 inches) cone type

Surround

Speaker system Bass reflex, magnetically shielded

Speaker unit 65 mm (2 5/8 inches) cone type × 2

Subwoofer

Speaker system Bass reflex, magnetically shielded

Speaker unit 160 mm (6 3/8 inches) cone type × 2

– Continued on next page –

THEATRE STAND SYSTEM

9-879-844-01

2005H02-1

© 2005.08

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

RHT-G2000

General

Power requirements 120 V AC, 60 Hz

Power consumption On: 120 W

Standby: 0.3 W

(at the Standby Mode)

Dimensions (approx.) 1,570 × 500 × 570 mm

(61 7/8 × 19 3/4 × 22 1/2 inches) (w/h/d)

incl. projecting parts

Mass (approx.) 79 kg (174 lb 3 oz)

Supplied accessories AM loop antenna (1)

FM wire antenna (1)

Input Box (4)

System cable (4)

Optical cable (1)

Video cord (blue/green/red) (1)

Video cord (yellow) (1)

Remote commander (remote) (1)

Size AA (R6) batteries (2)

Operating Instructions (1)

Quick Setup Guide (card) (1)

Rated impedance (external SP) 4 ~ 16 ohms

A

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

B

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

C

damaged by heat.

B

C

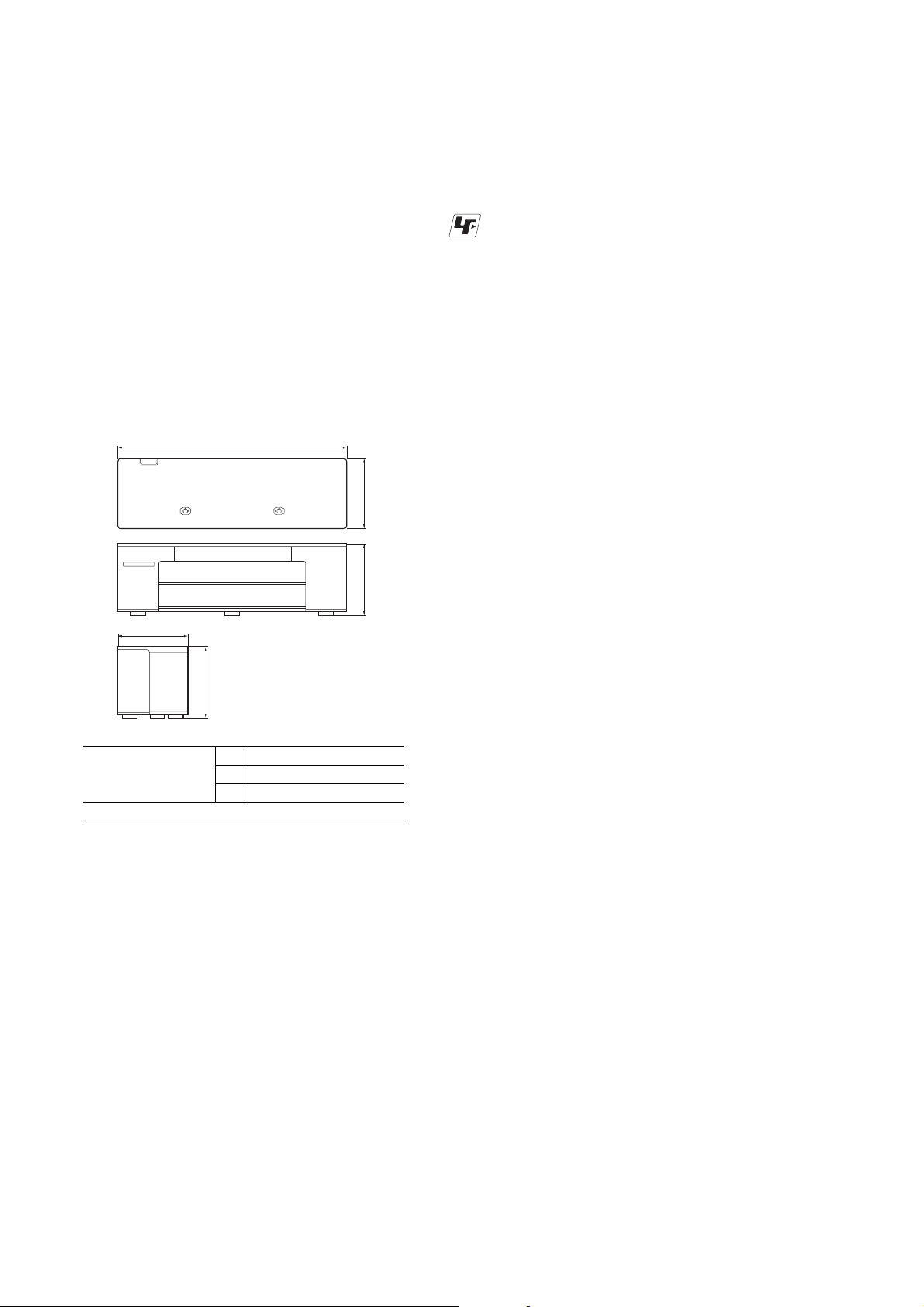

Dimensions:

mm (inch)

Weight: kg (oz) 79 (174 lb 3 oz)

Design and specifications are subject to change without notice.

A 1,570 (61 7/8)

B 500 (19

C 500 (19

3

/4)

3

/4)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

2

RHT-G2000

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

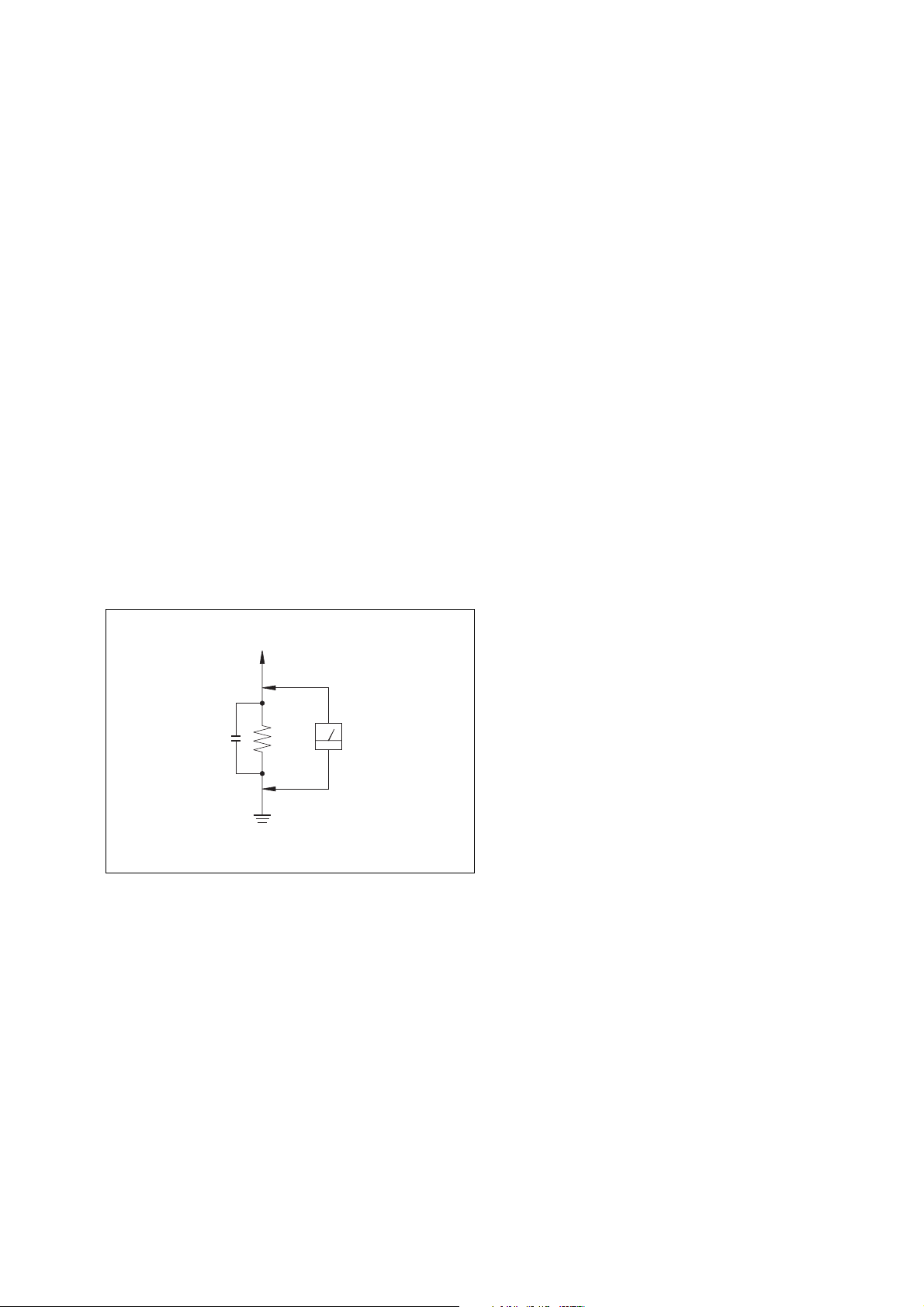

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Par ts on Set

TABLE OF CONTENTS

1. GENERAL ................................................................... 4

2. DISASSEMBLY

2-1. AMP Assy ........................................................................ 6

3. TEST MODE ............................................................... 7

4. DIAGRAMS ................................................................. 8

4-1. Block Diagram – Video Section – .................................. 9

– DSP Section – ............................................................... 10

– Audio Section – ............................................................ 11

– Power Section – ............................................................ 12

4-2. Printed Wiring Board – MAIN Board (Side A) –........... 13

4-3. Printed Wiring Board – MAIN Board (Side B) – ........... 14

4-4. Schematic Diagram – MAIN Board (1/8) – ................... 15

4-5. Schematic Diagram – MAIN Board (2/8) – ................... 16

4-6. Schematic Diagram – MAIN Board (3/8) – ................... 17

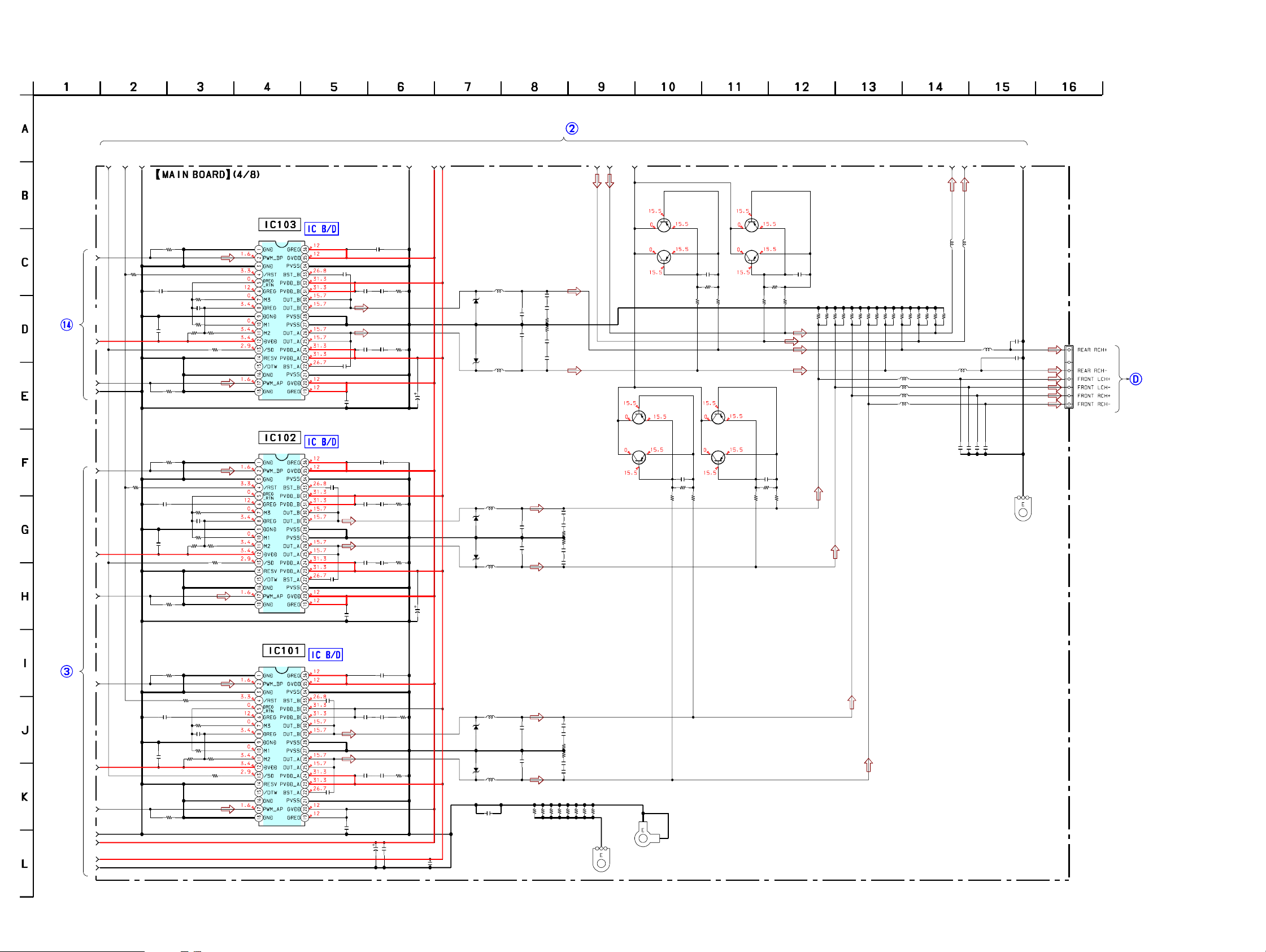

4-7. Schematic Diagram – MAIN Board (4/8) – ................... 18

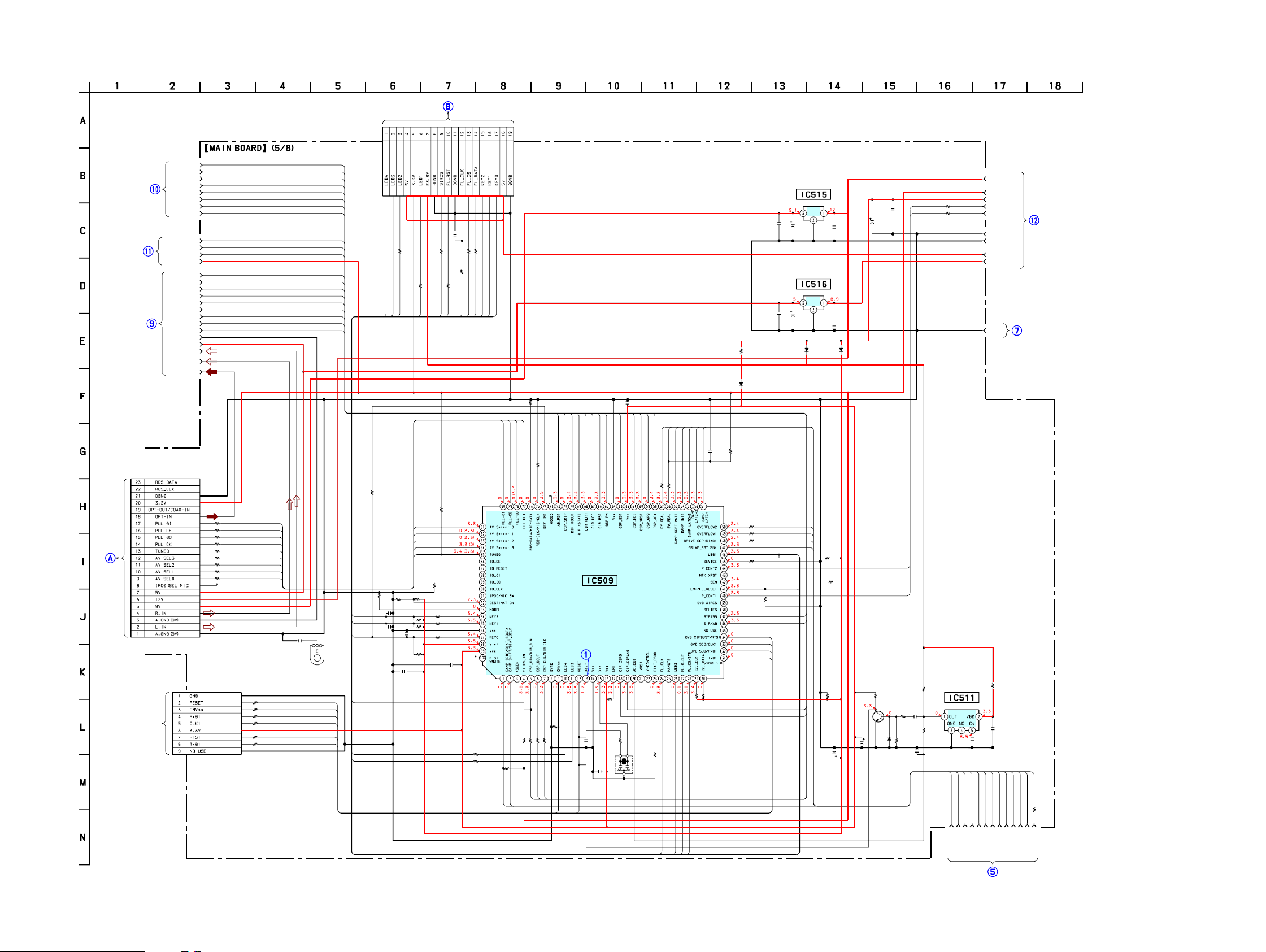

4-8. Schematic Diagram – MAIN Board (5/8) – ................... 19

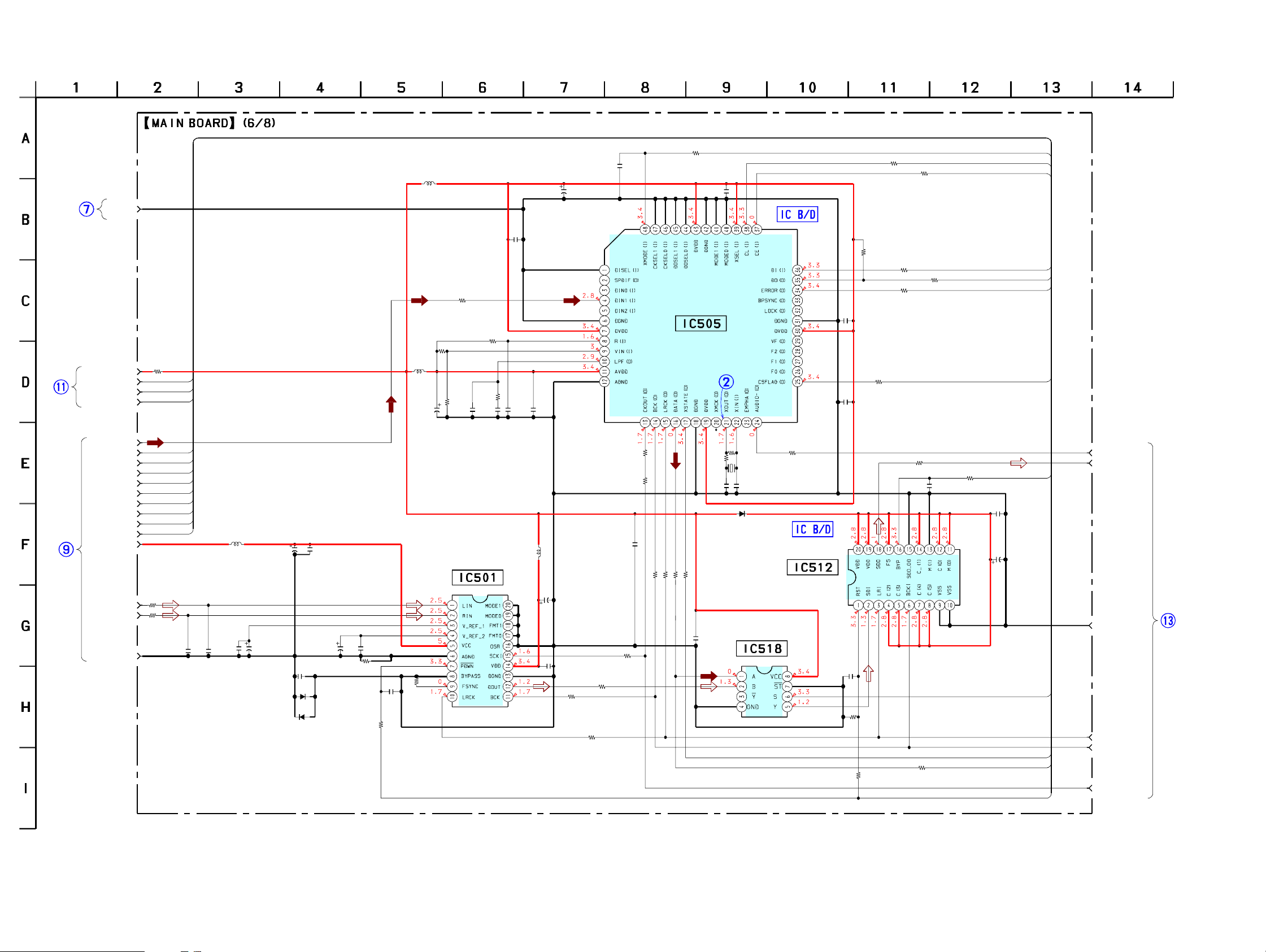

4-9. Schematic Diagram – MAIN Board (6/8) – ................... 20

4-10. Schematic Diagram – MAIN Board (7/8) – ................... 21

4-11. Schematic Diagram – MAIN Board (8/8) – ................... 22

4-12. Printed Wiring Board – IO Board (Side A) – ................. 23

4-13. Printed Wiring Board – IO Board (Side B) – ................. 24

4-14. Schematic Diagram – IO Board – .................................. 25

4-15. Printed Wiring Board – Panel Section (Side A) – .......... 26

4-16. Printed Wiring Board – Panel Section (Side B) – .......... 27

4-17. Schematic Diagram – Panel Section – ........................... 28

4-18. Printed Wiring Board – In/Out/Power Section – ............ 29

4-19. Schematic Diagram – In/Out/Power Section – ............... 30

4-20. Printed Wiring Board – Input Box Section – ................. 31

4-21. Schematic Diagram – Input Box Section – .................... 32

AC

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 kΩ

Earth Ground

Voltmeter

(0.75 V)

5. EXPLODED VIEWS

5-1. Grille Frame Section ....................................................... 42

5-2. Panel Section ................................................................... 43

5-3. Speaker Section ............................................................... 44

5-4. Amp Section-1 ................................................................. 45

5-5. Amp Section-2 ................................................................. 46

5-6. Amp Section-3 ................................................................. 47

5-7. Input Box Section ............................................................ 48

6. ELECTRICAL PARTS LIST .................................. 49

3

RHT-G2000

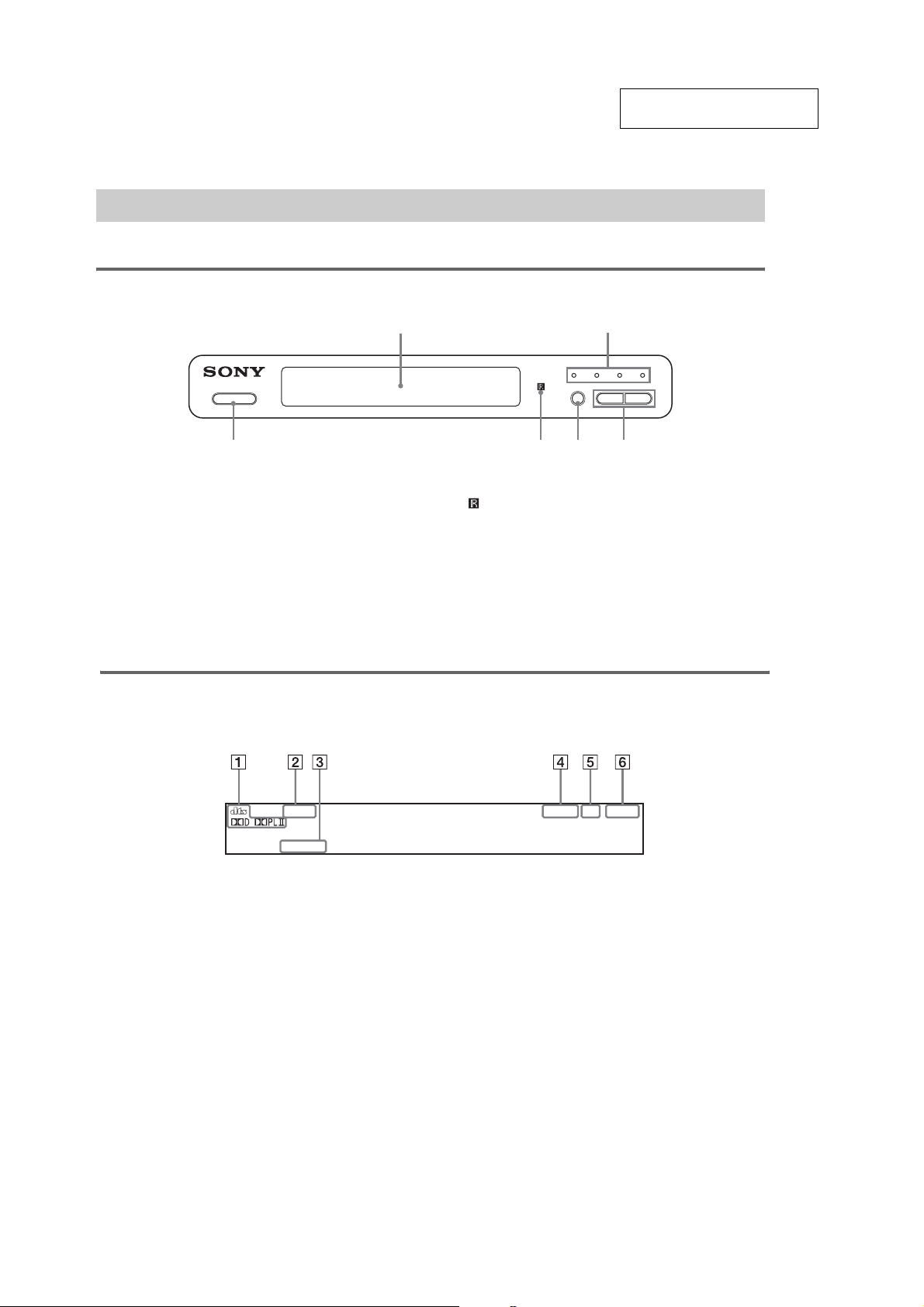

LOCATING THE CONTROLS

Index to Parts and Controls

For more information, refer to the pages indicated in parentheses.

Front panel

A Front panel display

B Sound field indicator

C VOLUME +/–

?/1

6

SECTION 1

GENERAL

1

D INPUT SELECTOR

E (remote sensor)

F "/1 (on/standby)

This section is extracted from

instruction manual.

2

4 35

Front panel display

About the indications in the front panel display

SLEEP

A/V SYNC

A Current surround format

B Lights up in SLEEP mode.

C Lights up when A/V SYNC is functioning.

TUNED ST MONO

D Lights up when a radio station is tuned.

E Lights up when a stereo broadcast is tuned.

F Lights up when listening to the radio in monaural

effect.

4

RHT-G2000

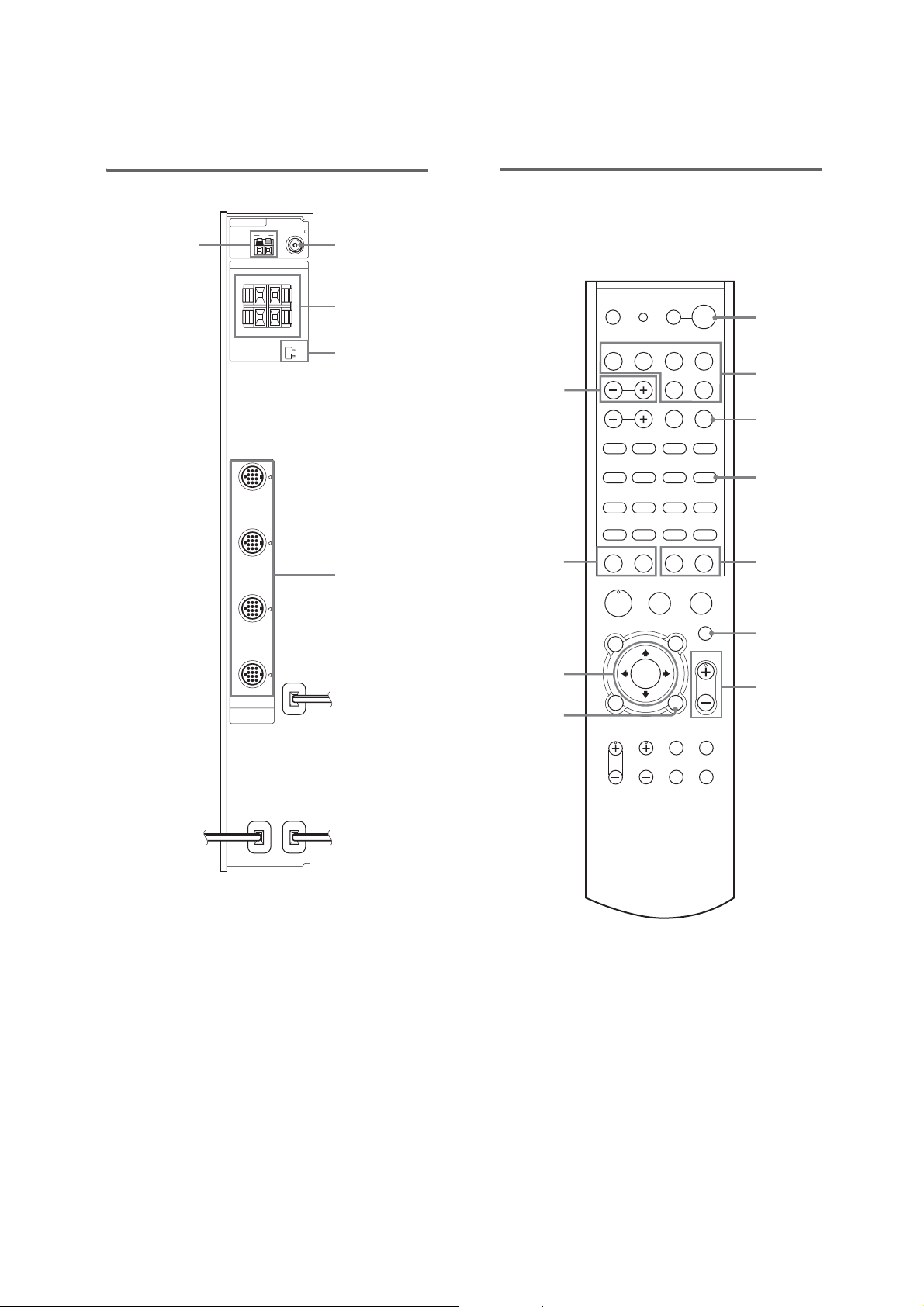

Rear panel

5

ANTENNA

AM

SPEAKERS

+

L

R

+

SURROUND

SAT

DVD

VIDEO 1

VIDEO 2

AUDIO VIDEO

INPUT

-

-

COAXIAL

FM

MODE

Remote control

Here describes the buttons for amplifier operation only. See

75

1

L

2

R

5.1CH

3

FRONT

4

page 12 for the buttons for operation of the connected

components.

TV ?/1 AV ?/1

RM SETUP

?/1

P

1

SYSTEM STANDBY

VIDEO1 VIDEO2 TV DVD

2

qa

SOUND FIELD TUNER/BAND

CH/DISC SKIP SLEEP

SAT

AMP

MENU

3

13

0

2

46

5

7

89

- TUNING + - PRESET +

Mm.

H

TOP MENU/

GUIDE

X

AV MENU

12/SET>10/110/10

ENTERCLEAR

FM MODE

AUDIO

TUNER MENU

SUBTITLE

ANGLE

-

>

x

MUTING

VOLUME

4

5

6

9

7

8

O

RETURN/EXIT

TV VOL TV CH

DISPLAY

TV/

VIDEO

ANT

A COAXIAL FM 75Ω jack

B SPEAKER TERMINALS For Real 5.1 mode

C 5.1CH/FRONT mode switch

D AUDIO VIDEO INPUT jacks

E AM terminal

JUMPWIDE

A "/1 (on/standby)

B Input buttons

C AMP MENU

D TUNER MENU

E PRESET +/–

F MUTING

G VOLUME +/–

The VOLUME + button has a tactile dot.*

H DISPLAY (19)

I C/X/x/c/ENTER

J TUNING +/–

K SOUND FIELD +/–

*Use the tactile dot as a reference when operating the system.

5

RHT-G2000

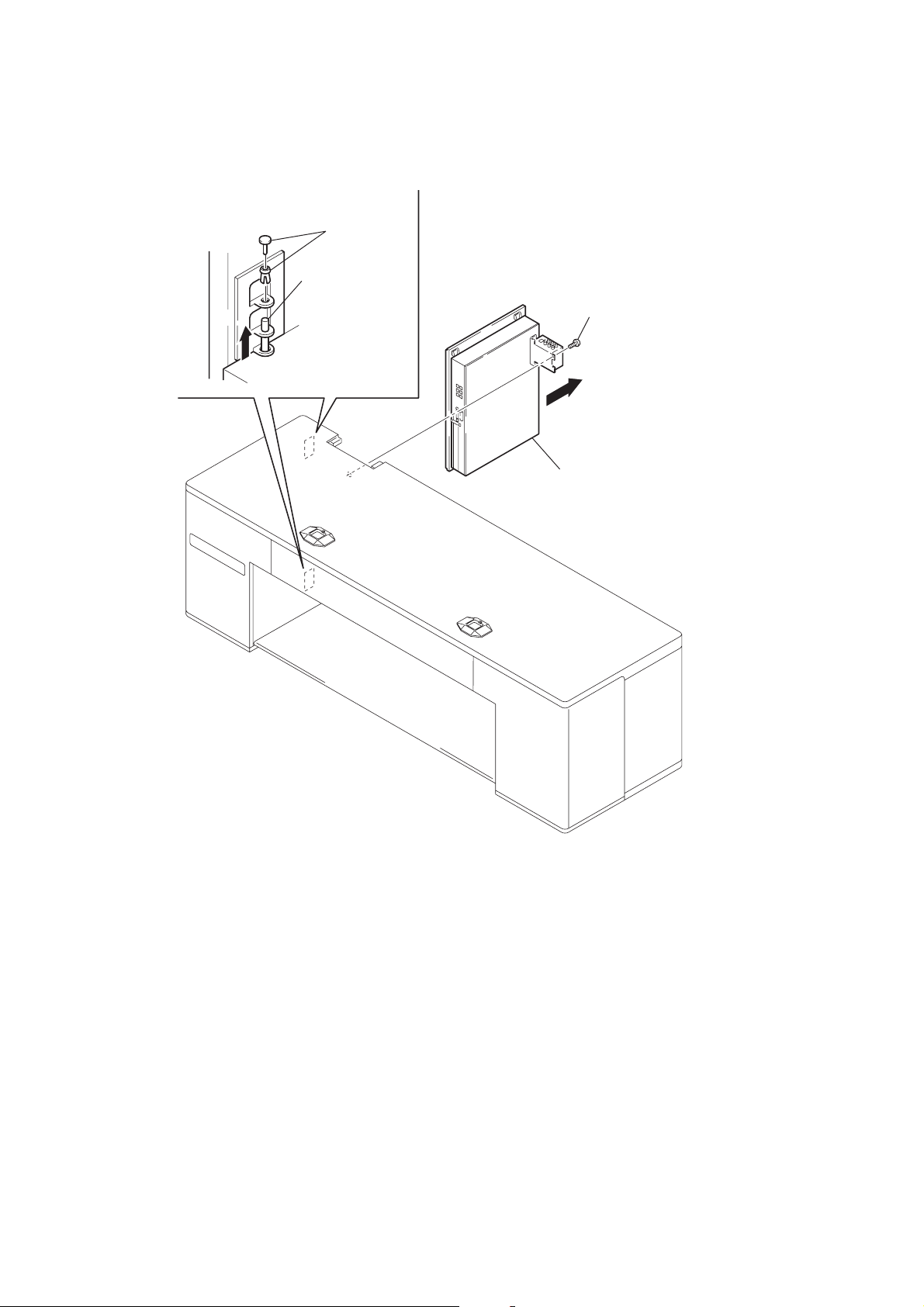

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

2-1. AMP ASSY

2

two rivets

3

two shafts (lock)

1

screw

(wood +R4.1X16)

4

5

AMP assy

6

SECTION 3

TEST MODE

RHT-G2000

1. Starting Test Mode

• Please start the test mode by the following procedure when

you execute “Volume Test’’ or “Panel Test’’.

Procedure:

1. Press the `/1 button to turn the power on.

2. Press two buttons of INPUT SELECTOR and VOLUME +

at the same time for five seconds.

3. After “TEST MENU” displays it, “COMMON” is blinking.

2. Cold Reset

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customers.

Procedure:

1. Press the `/1 button to turn the power on.

2. Press three buttons of `/1 , INPUT SELECTOR and

VOLUME – simultaneously.

3. When this button is operated, display as “COLD RESET” for

a while and all of the settings are reset.

3. AM Step Change

•A step of AM channels can be changed over between 9 kHz

and 10 kHz.

Procedure:

1. Press `/1 button to turn the power on.

2. Press the FUNCTION button to select “AM”.

3. Press `/1 button to turn the power off.

4. Press two buttons `/1 and INPUT SELECTOR at the same

time, and the display changes to “AM 9k Step” or “AM 10k

Step”, and thus the channel step is changed over.

5-3. Version Check

Procedure:

1. Press the VOLUME + button with all segment lit, and

“RACK” is displayed.

2. Whenever VOLUME + button is pressed, the category is

displayed in the way below.

t RACK t NA t MC t SYS t UI t ST t TA t TM

3. When the INPUT SELECTOR button is pressed when each

category is displayed, the version of the category is displayed.

4. To exit this mode, press the `/1 button.

4. Volume Test

Procedure:

1. Enter the test mode.

2. Press the INPUT SELECTOR button, and “DVD” is

displayed.

3. Press the VOLUME – button, and “VOLUME MIN” is

displayed for second times.

4. Press the VOLUME + button, and “VOLUME MAX” is

displayed for second times.

5. When the `/1 button is pressed twice, the test mode is

released. At that time, cold reset is done as for the set.

5. Panel Test

• This mode is used to check the display, key and software

version.

5-1. Display Check

Procedure:

1. Enter the test mode.

2. Press the VOLUME + button, and “PANEL” is blinking.

3. Press the INPUT SELECTOR button, and all segments turn

on.

5-2. Key Test

Procedure:

1. Press the VOLUME – button with all segment lit, and “K0”

is displayed.

2. It is displayed every time one of four kinds of buttons ( `/1 ,

INPUT SELECTOR , VOLUME – and VOLUME + ) is

pressed as “K1”, “K2”, “K3”, and “K4”.

3. To exit this mode, press the `/1 button.

7

RHT-G2000

SECTION 4

DIAGRAMS

• Note for Printed Wiring Boards and Schematic Diagrams

Note on Schematic Diagrams.

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

•%: indicates tolerance.

• f : internal tolerance.

• 2 : nonflammable resistor.

• C : panel designation.

Note:

The components identified

by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part

number specified.

• A : B+ Line.

•Voltages and waveforms are dc with respect to ground under nosignal conditions.

no mark : DVD

( ) : FM

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

d : TUNER

f : DIGITAL IN

E : Y

r : COMPONENT VIDEO

L : VIDEO

4

W or less unless otherwise

Note:

Les composants identifiés

par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

Note on Printed Wiring Boards.

• X : parts extracted from the component side

• Y : parts extracted from the conductor side

• a : Through hole

• : Pattern from the side which enables seeing

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

•Waverforms

1

IC509 qd (XOUT)

202 ns

1 V/DIV, 100 ns/DIV

2

IC505 wa (XOUT)

81.3 ns

1 V/DIV, 20 ns/DIV

8

3.1 Vp-p

4.2 Vp-p

3

IC506 qs (MCLK2)

71.9 ns

1 V/DIV, 20 ns/DIV

4

IC108 rk (XFSOIN)

20.2 ns

0.5 V/DIV, 20 ns/DIV

4.2 Vp-p

1.8 Vp-p

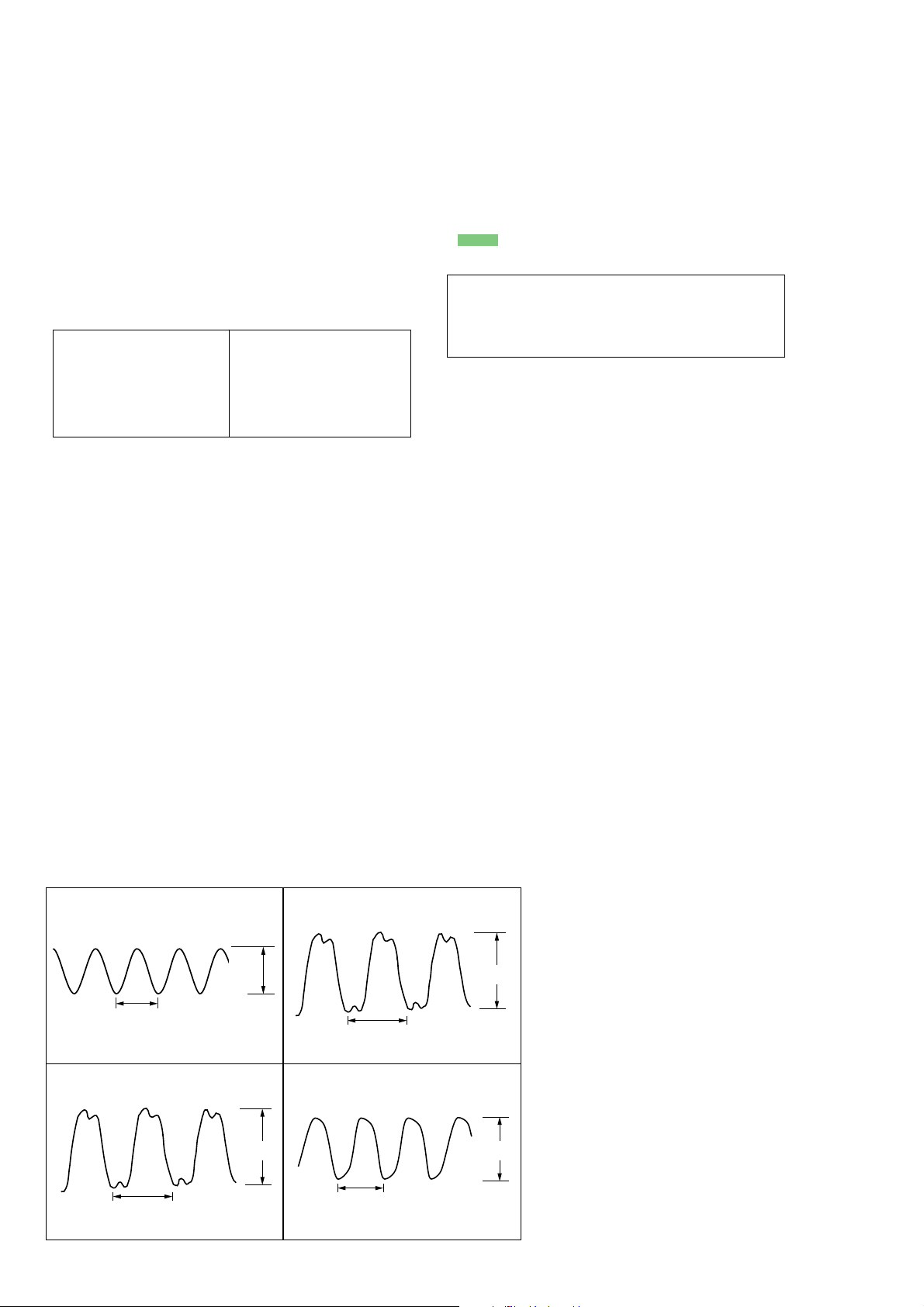

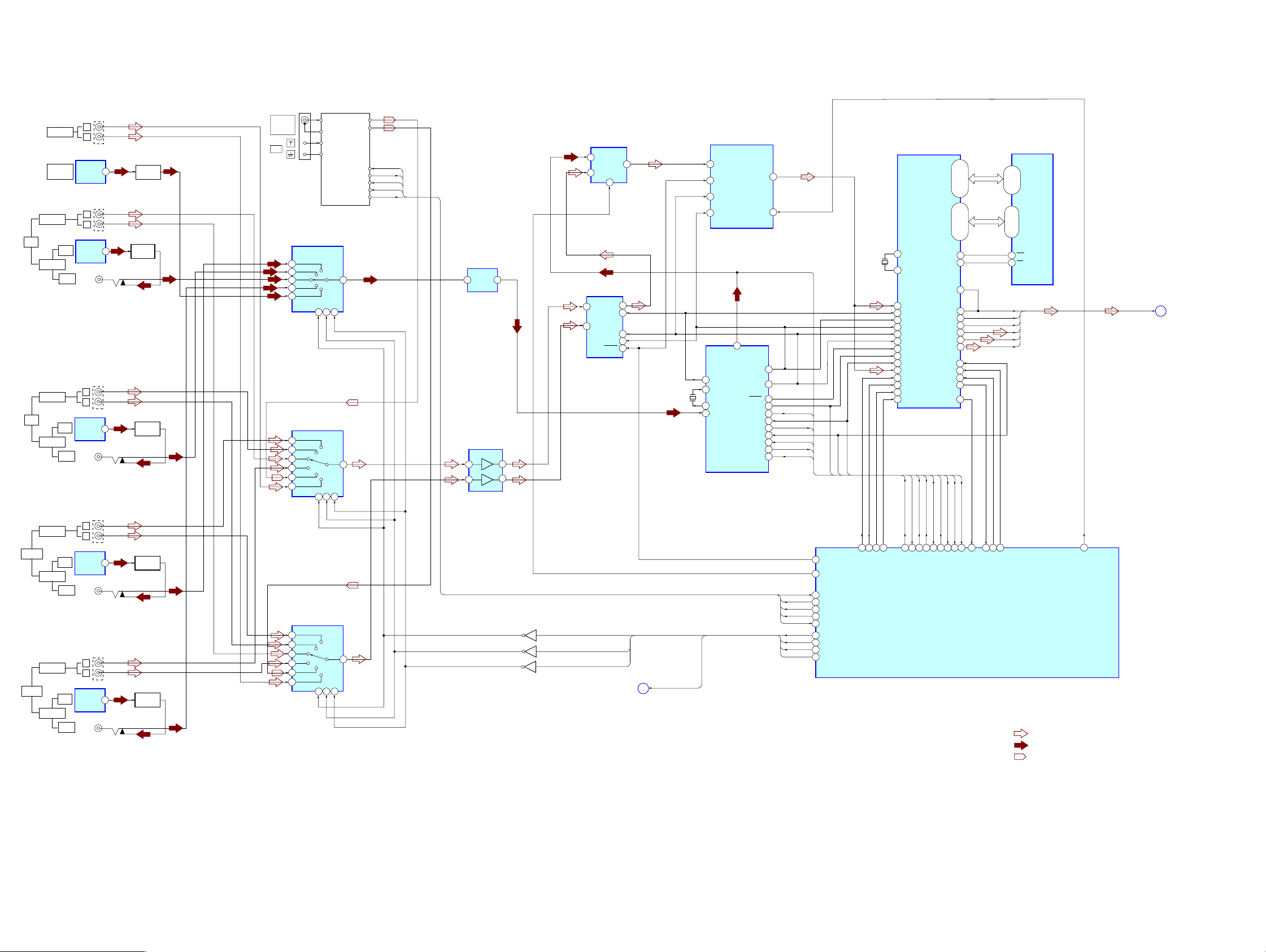

4-1. BLOCK DIAGRAM –VIDEO SECTION–

J101 (1/2)

Y

CB

CR

COMPOSITE

J101 (1/2)

Y

CB

CR

COMPOSITE

SAT

DVD

B/CB

P

R/CR

P

VIDEO IN

B/CB

P

R/CR

P

VIDEO IN

Y

/B-Y

/R-Y

Y

/B-Y

/R-Y

7

IN1

9

IN2

14

IN3

16

IN4

IC202

VIDEO SWITCH

1 24

OUT OUT

CTL2

CTL1

CTL3

12

83

AV_SEL2

AV_SEL0

AV_SEL1

AV_SEL2

AV_SEL0

AV_SEL1

VIDEO AMP

IN

IC203

P_SAVE

1

AV_SEL3

J101 (1/2)

VIDEO OUT

Y

B/CB

/B-Y

P

R/CR

/R-Y

P

COMPONENT

VIDEO OUT

AV SEL0-3

B

RHT-G2000

DSP

SECTION

(Page 10)

VIDEO 1

VIDEO 2

B/CB

P

R/CR

P

VIDEO IN

VIDEO IN

/B-Y

/R-Y

Y

J101 (1/2)

J101 (1/2)

Y

CB

CR

COMPOSITE

COMPOSITE

1

3

5

8

10

12

17

15

13

Q205

23242

PS

SW1

IC201

VIDEO AMP

4

SW2

22

20

• Signal Path

: VIDEO

: Y

: COMPONENT VIDEO

RHT-G2000

99

RHT-G2000

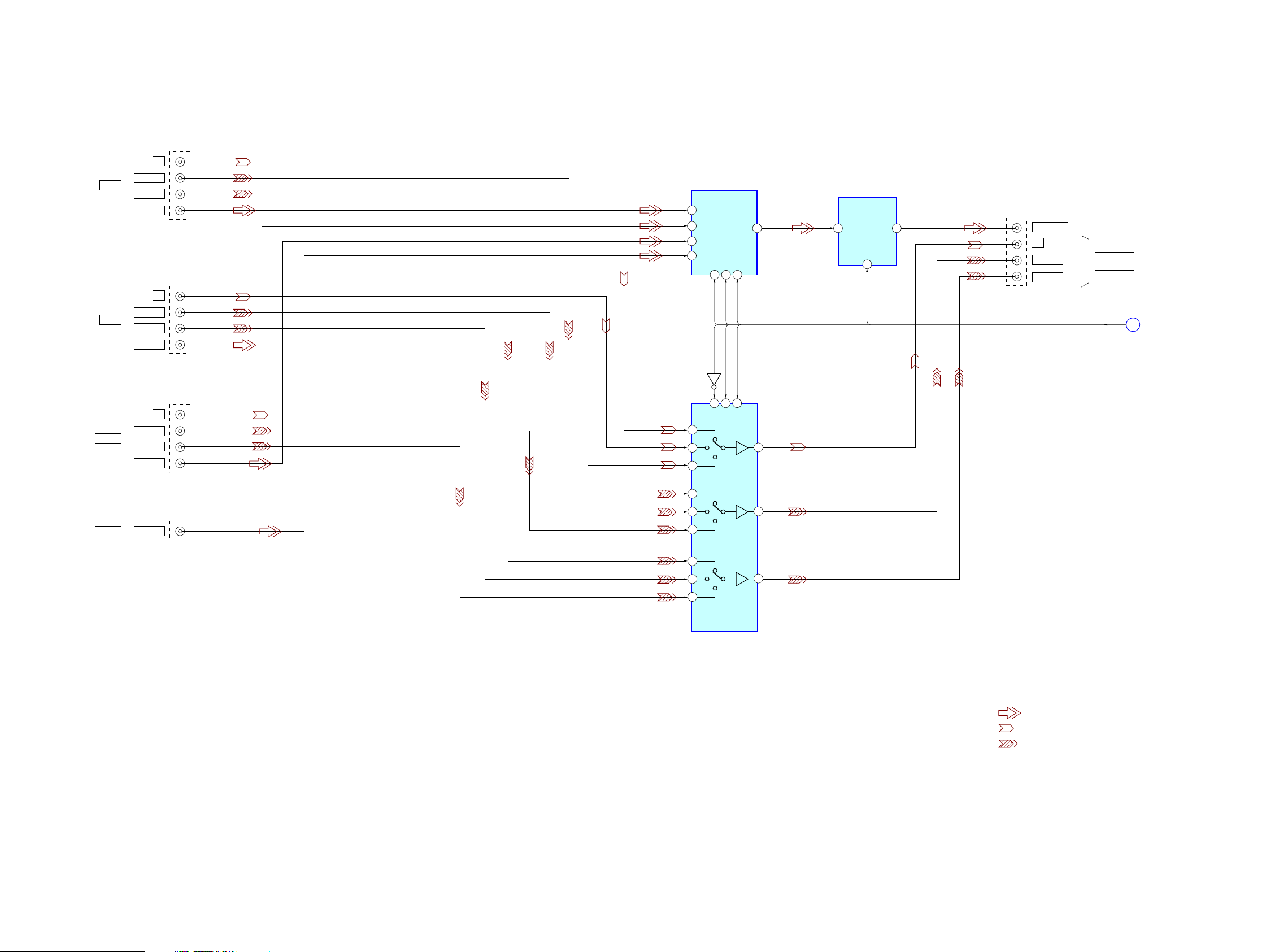

–DSP SECTION–

SAT

DVD

VIDEO 1

VIDEO 2

ANALOG IN

OPTICAL IN

DIGITAL

ANALOG IN

DIGITAL IN

ANALOG IN

DIGITAL IN

ANALOG IN

DIGITAL IN

ANALOG IN

DIGITAL IN

OPT

COAX

OPT

COAX

OPT

COAX

OPT

COAX

J101(2/2)

L

R

IC101

OPTICAL

RECEIVER

J101(2/2)

L

R

IC101

OPTICAL

RECEIVER

J101(2/2)

L

R

IC101

OPTICAL

RECEIVER

J101(2/2)

L

R

IC101

OPTICAL

RECEIVER

J101(2/2)

L

R

IC101

OPTICAL

RECEIVER

J102

J102

J102

J102

COAXIAL

FM

75Ω

AM

1

1

1

1

1

BUFFER

Q101

BUFFER

Q101

BUFFER

Q101

BUFFER

Q101

BUFFER

Q101

1

2

4

12

15

1

2

4

12

13

15

1

2

4

12

13

15

FM ANT

GND

AM ANT

GND

IC204

SPDIF INPUT

SELECTOR

CBA

9 10 11

IC206

AUDIO INPUT

SELECTOR L-CH

CBA

9 10 11

IC205

AUDIO INPUT

SELECT R-CH

CBA

9 10 11

FM/AM TUNER UNIT

L-CH

R-CH

CLK

TUNED

3

3

3

IC518

SELCTOR

1

A

5

TUDI

DI

TUDO

DO

TUCLK

TCE

CE

TUNED

IC210

1

2

WAVE

SHAPER

IC209

AMP

1

3

7

5

Q202

Q203

Q204

2

B

IC501

A/D CONVERTER

1

LIN

DOUT

2

RIN

LRCK

PDWN

AV_SEL2

AV_SEL1

AV_SEL0

S

6

SCKI

BCK

Y

12

15

10

11

7

VIDEO

SECTION

(Page 9)

X500

12.288MHz

AV_SEL0-3

B

DIGITAL AUDIO DELAY

2

SDI

1

RST

3

LRI

6

BCKI

13 CKOUT

22

XIN

21

XOUT

4

DIN1

DIGITAL AUDIO

IC512

16

DATA

IC505

INTERFACE

LRCK

AUDIO

ERROR

XSTATE

CSFLAG

XMODE

IC506

DIGITAL AUDIO

PROCESSOR

72-75

18

SDO

16

BYP

9

DSP PM

DSP BST

113

DSP GP9

MCLK1

12

MCLK2

30

SDI2

22

KFSIO

17

BCKI1

29

BCKI2

28

LRCKI2

15

LRCKI1

69

GP8

59

EXLOCK

33

HDIN

18

SDI1

2

XRST

PM

56

BS T

68

GP9

DIN

5

DSP DIN/DIR DIN

DIR_DO

DIR_CLK

70

7

DIR HDOUT

X501

DIR_CLK

DIR_RERR

13.90MHz

DIN

65

60 5963

DSP XRST

DIR_ZERO

14

BCK

15

24

34

XSTATE

17

36

DI

DIR_D0

35

DO

DIR_CLK

38

CL

DIR_HCE

37

CE

CS FLAG

25

DIR_RST

48

72

AD RST

36

DIR/AD

TUDO

TUDI

TUCLK

TCE

TUNED

AV SEL0

AV SEL1

AV SEL2

AV SEL3

78

80

77

79

85

81

82

83

84

PLL_DO

PLL_DI

PLL_CLK

PLL_CE

TUNED

AV select0

AV select1

AV select2

AV select3

D0-D15

A0-A15

WEO

CS0

GPIO

LRCKO

BCKO

SCKOUT

SD01

SD02

SD03

HCLK

GP12

HCS

HD OUT

HACN

XSTATE

CSFLAG

DIR_HCE

DIR_RST

67

69

66

19

DIR HCE

DIR RST

DIR XSTATE

DSP CLK/DIR CLK

SYSTEM CONTROLLER

77-80

98,99

102-105

107,108

64-66

82-85

92-97

109,110

112

45 17

44 6

67

19

20

14

23

24

25

34

37

36

35

32

DIR_ZERO

DIR_RERR

58

6

68

18

DSP ACK

DIR ZERO

DIR RERR

DIR CSFLAG

DSP DOUT

IC509 (1/3)

61

LRCKO

BCKO

MCKO

71

DSP HCE

DSP SKIP

7-10

13-16

29-32

35-38

44-42

27-24

21-18

IC507

SD-RAM

D0 – D15

5-1

A0 – A15

WE

CS

D1 - D3, MCKO,

BCKO, LRCKO

D1

D3

D2

37

BYPASS

A

AUDIO

SECTION

(Page 11)

• Signal Path

: AUDIO

: DIGITAL IN

: TUNER

RHT-G2000

1010

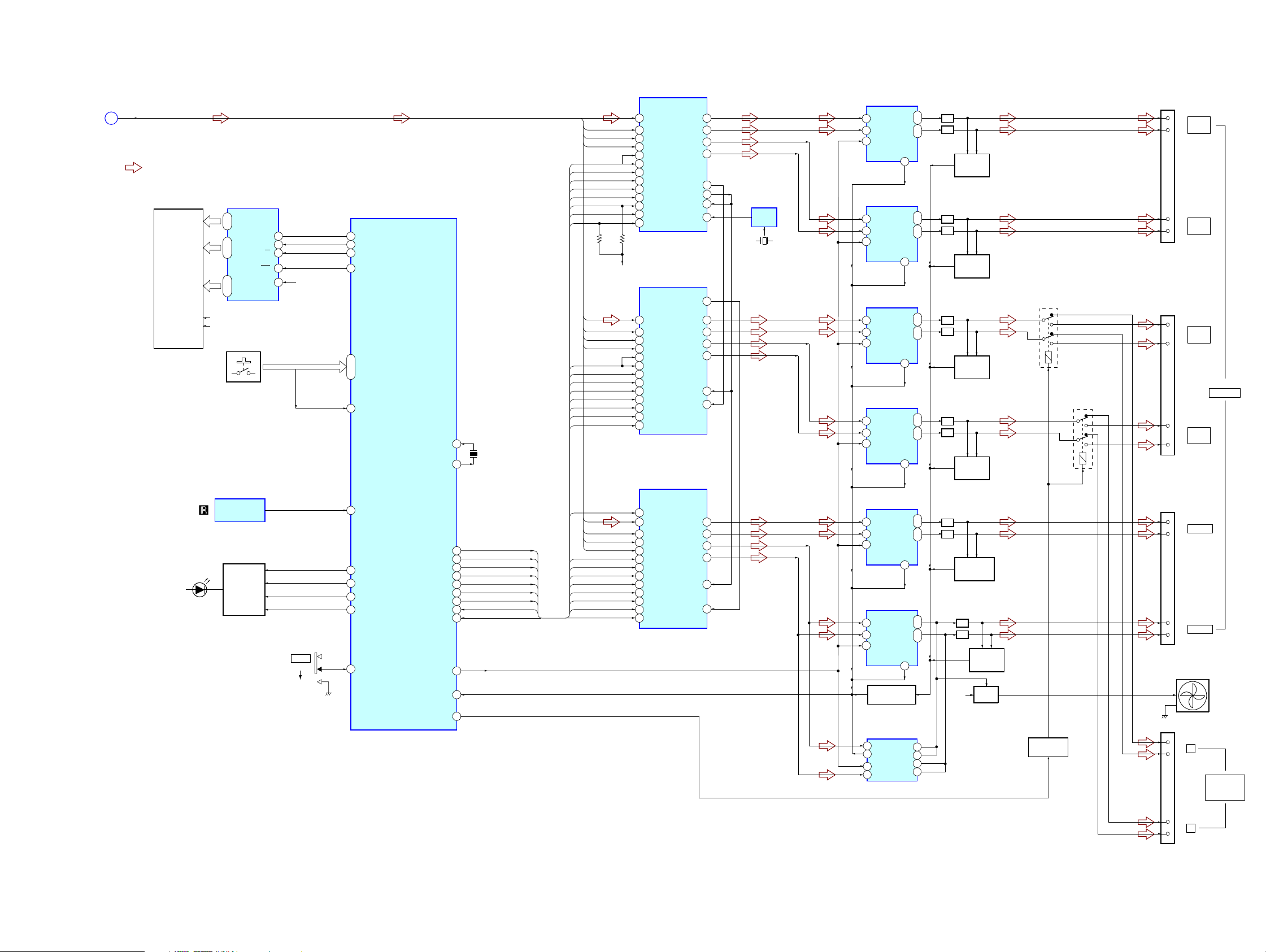

– AUDIO SECTION–

D1 – D3, MCKO,

DSP

SECTION

(Page 10)

BCKO, LRCKO

A

• Signal Path

: AUDIO

FL841

FLUORESCENT

INDICATOR TUBE

S801 – S804

D806 - D809

FL DRIVER

3, 4

AD1, 2

5 – 39

S1 – S35

40 – 50

G1 – G11

F1

F2

IC801

REMOTE CONTROL

RECEIVER

Q811 - Q814

LED

DRIVE

IC842

DAT

CLK

RST

VFL

RHT-G2000

IC108

STREAM PROCESSOR

D1

MCKO

BCKO

LRCKO

OVF

SCDT

SHIFT

LAT1

INIT

IC509 (2/3)

SYSTEM CONTROLLER

63

62

61

CS

60

56

VFL

KEY0

S851

MODE

FRONT

5.1CH

27

24

28

41

97,95,94

74

4

10

11

26

46

56

FL DATA

FL CLK

FL CS/STB

FL RESET

KEY0 – KEY2

KEY INT

SIRCS–IN

LED4

LED3

LED2

LED1

SW_REAL

Xout

DAMP SCDT

DAMP SHIFT

DAMP LAT1

DAMP LAT2

DAMP LAT3

DAMP INIT

DAMP SOFT MUTE

OVERFLOW1

OVERFLOW2

DRIVE RST

DRIVE OCP

RY REAL

13

X502

Xin

5MHz

15

1

2

51

52

53

54

55

49

50

47

48

57

SCDT

SHIFT

LAT1

LAT2

LAT3

INIT

SOFTMUTE

OVF

OVF2

NSPMUTE

SOFTMUTE

PGMUTE

D2

MCKO

BCKO

LRCK

OVF

SCDT

SHIFT

LAT2

INIT

NSPMUTE

SOFTMUTE

PGMUTE

PGMUTE

D3

MCKO

BCKO

LRCKO

OVF

SCDT

SHIFT

LAT3

INIT

NSPMUTE

SOFTMUTE

OVF2

AMP +3.3V

31

DATA

36

XFSIIN

30

BCK

29

LRCK

25

FLAGL OVF

24

OVF FLAGR

21

SCDT

22

SCSHIFT

23

SCLATCH

27

INIT

18

NSPMUTE

19

SOFTMUTE

20

PGMUTE

IC109

STREAM PROCESSOR

31

DATA

36

XFSIIN

30

BCK

29

LRCK

25

FLAGL OVF

24

OVF FLAGR

21

SCDT

22

SCSHIFT

23

SCLATCH

27

INIT

18

NSPMUTE

19

SOFTMUTE

20

PGMUTE

IC110

STREAM PROCESSOR

20

PGMUTE

31

DATA

36

XFSIIN

30

BCK

29

LRCK

25

FLAGL OVF

21

SCDT

22

SCSHIFT

23

SCLATCH

27

INIT

18

NSPMUTE

SOFTMUTE

19

OVF FLAGR

24

OUTR1

OUTR2

OUTL1

OUTL2

XFS0OUT

FSOCKO

FS0I

XFS0IN

XFS0OUT

OUTR1

OUTR2

OUTL1

OUTL2

FS0I

XFS0IN

OUTR1

OUTR2

OUTL1

OUTL2

FS0I

XFS0IN

6

4

11

9

14

37

38

48

14

6

4

11

9

38

48

6

4

11

9

38

48

R

R

L

L

IC305

OSC

X450

49.152MHz

SR

SR

SL

SL

C

C

WF

WF

IC101

POWER DRIVER

2

PWMBP

17

PWMAP

RESET

4

IC102

POWER DRIVER

2

PWMBP

17

PWMAP

RESET

4

IC103

POWER DRIVER

2

PWMBP

17

PWMAP

RESET

4

IC104

POWER DRIVER

2

PWMBP

17

PWMAP

RESET

4

IC105

POWER DRIVER

2

PWMBP

17

PWMAP

RESET

4

IC106

POWER DRIVER

2

PWMBP

17

PWMAP

RESET

4

Q301

PROTECT DETECT

IC107

POWER DRIVER

2

PWMBP

13

SD

4

RESET

17

PWMAP

OUTB

OUTA

OUTB

OUTA

OUTB

OUTA

OUTB

OUTA

OUTB

OUTA

OUTB

OUTA

OUTB

OUTA

29

LPF

30

25

LPF

26

SD

13

29

30

25

26

SD

13

29

30

25

26

SD

13

29

30

25

26

SD

13

29

30

25

26

SD

13

29

30

25

26

SD

13

29

30

25

26

Q101, 102

DC

DETECT

LPF

LPF

Q103, 104

DC

DETECT

RY852

LPF

LPF

Q105, 106

DC

DETECT

RY851

LPF

LPF

Q107, 108

DC

DETECT

LPF

LPF

Q109, 110

DC

DETECT

LPF

LPF

Q111, 112

DC

DETECT

FAN

+12V

DRIVE

Q302-304

Q851

RELAY DRIVE

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

FRONT

R

FRONT

L

SURR

R

SURR

L

CENTER

WOOFER

FAN

R

TM851

SPEAKERS

TM852

EXTERNAL

SPEAKERS

SURROUND

RHT-G2000

(+)

L

(–)

1111

RHT-G2000

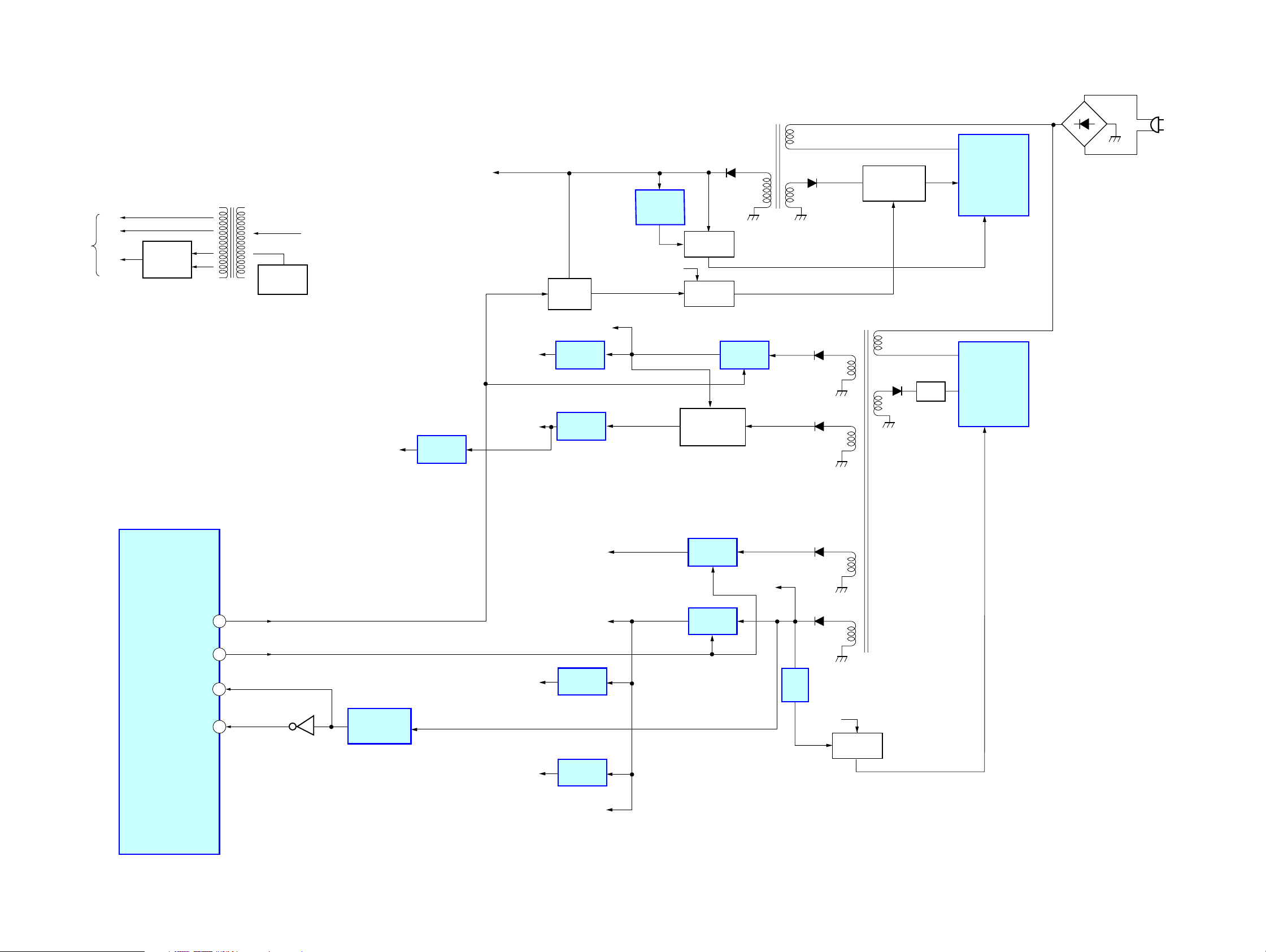

–POWER SECTION–

TO FLUORESCENT

INDICATOR TUBE

VFL

T901

TRANSFORMER(MAIN)

D931

DC/DC

CONVERTER

T801

F1

F2

RECT

D801,802

D804,805

OSC

Q801

+5V

+3.3V

IC207

+3.3V REG

+31.5V

Q943,947

+9V

+5V

POWER

CONTROL

IC515

+9V REG

IC516

+5V REG

+12V

IC931

VOLTAGE

DETECT

E4V

PC901

PHOTO

COUPLER

PC903

PHOTO

COUPLER

IC941

+12V REG

Q945

+8V

SWITCH

D905

T902

TRANSFORMER (SUB)

D941

D944

Q901

POWER

ON/OFF

D922

Q921

REG

IC901

AC/DC

CONVERTER

IC921

AC/DC

CONVERTER

D901

AC IN

IC509 (3/3)

SYSTEM CONTROLLER

+5V

44P CONT2

40P CONT1

20AC_CUT

Q506

12RESET

IC511

RESET

+1.8V

+1.8V

+3.3V

IC303

+1.8V REG

IC508

+1.8V REG

AMP +3.3V

IC942

+5V REG

E 4V

IC943

+3.3V REG

D942

D943

IC951

VOLTAGE

DETECT

E 4V

PC902

PHOTO

COUPLER

RHT-G2000

1212

RHT-G2000

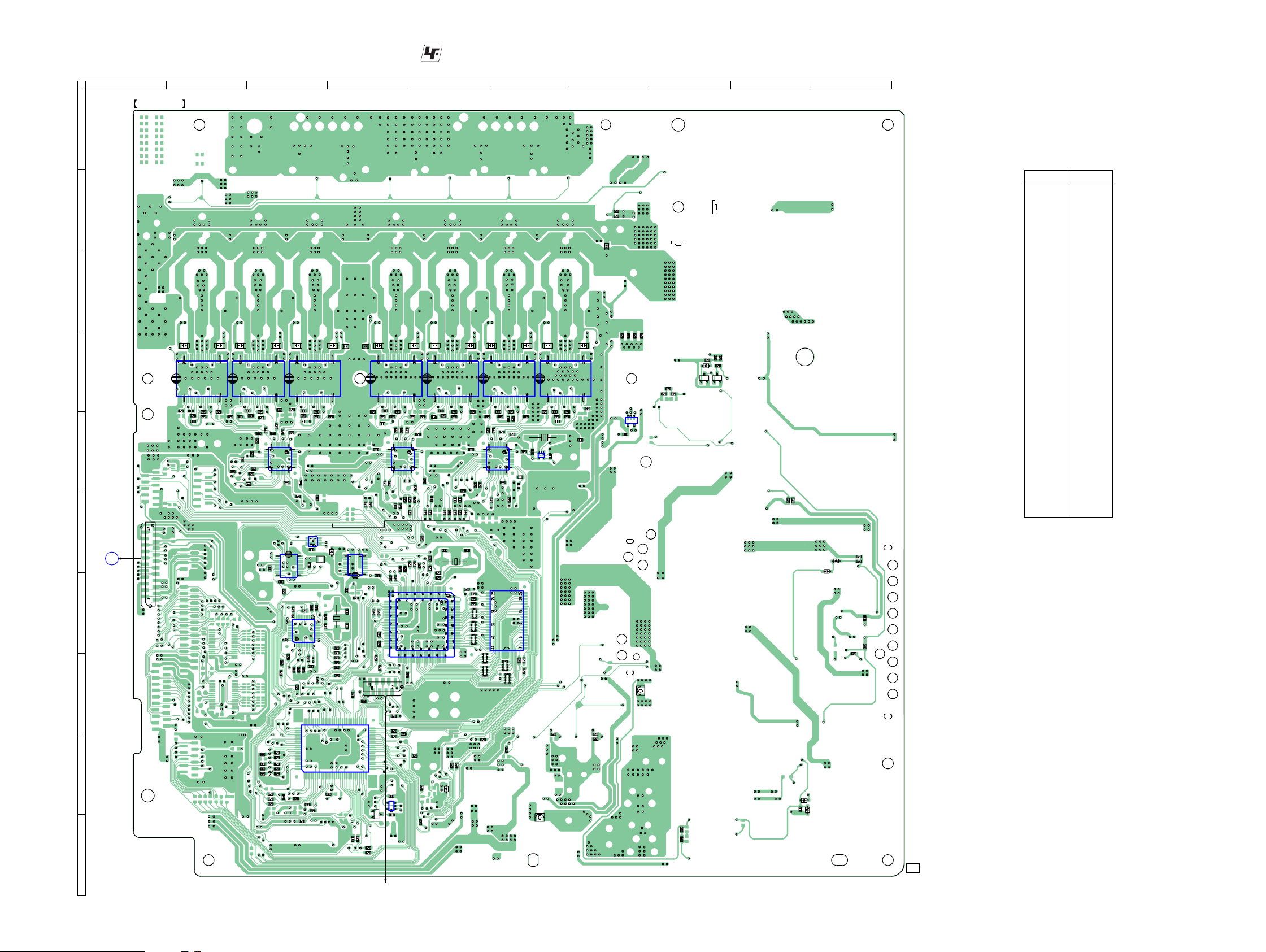

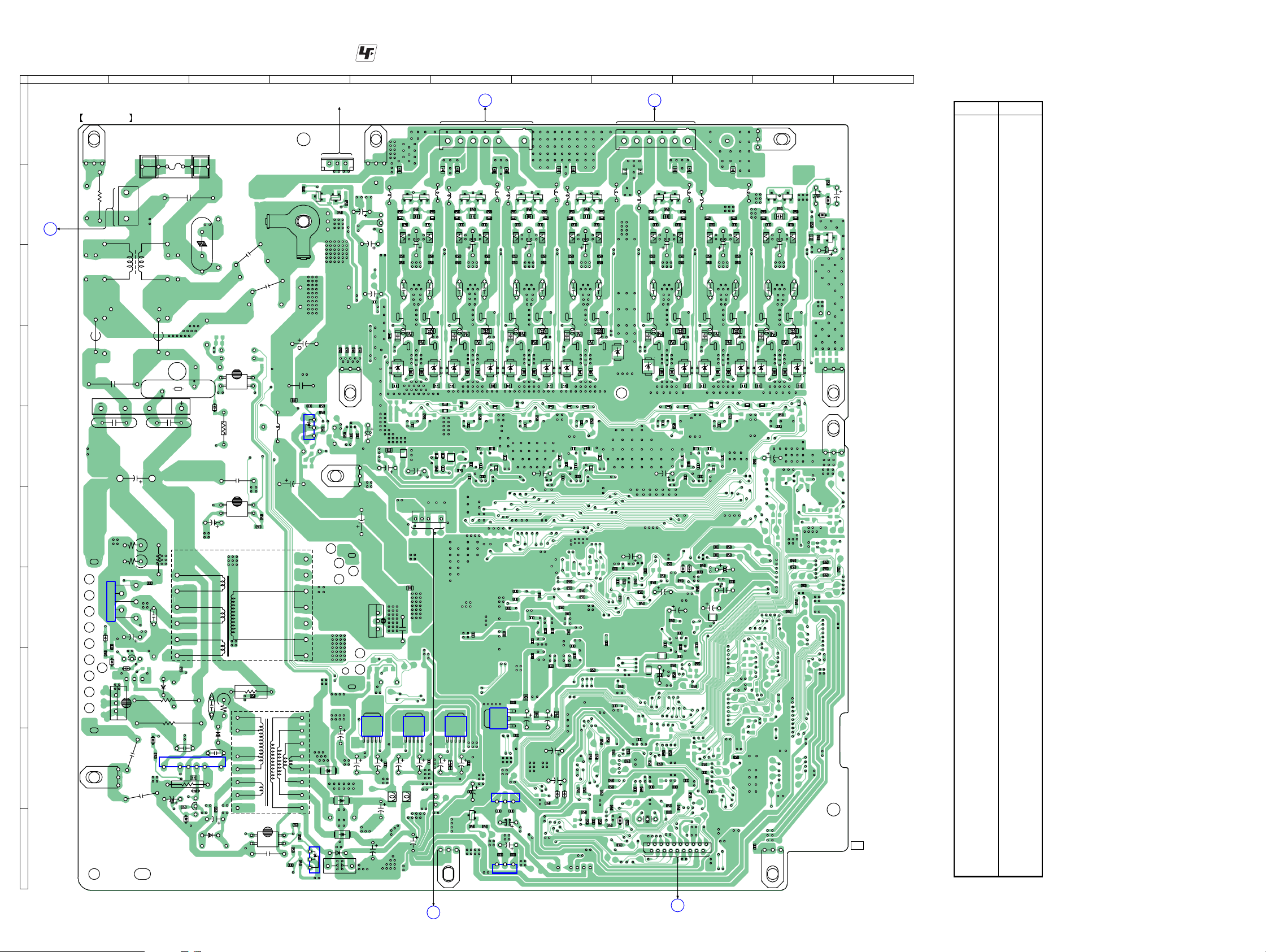

4-2. PRINTED WIRING BOARD – MAIN BOARD (SIDE A) –

A

B

C

D

E

F

G

H

I

J

RHT-G2000

A

IO

BOARD

(Page 24)

1

MAIN BOARD (SIDE A)

C274

R120

R167

CN507

IC107

C218

C147

R147

R157

:Uses unleaded solder.

2

3 4 5 6 7

• See page 33 for Circuit Boards Location.

8

9 10

• Semiconductor

Location

C273

R128

R319

R119

C146

C272

R316

R612

IC106

C200

R166

R384

R347

R317

R353

R792

R616

R614

R156

R723

R724

R731

R146

R345

C271

R383

R480

IC110

C512

IC505

R790

R118

R381

R382

R326

R356

IC501

C524

R508

R527

R519

R577

R789

R117

R596

R705

R380

R543

100

R791

R706

C210

C515

R516

R517

C543

R528

81

R628

IC105

C199

C145

R379

IC518

C528

C546

R558

80

1

R726

R328

R504

R556

R145

R165

R155

C406

C545

C209

L504

R526

R540

R542

R544

R537

IC509

R728

R116

R531

R532

D507

C506

R713

X500

C105

R302

R551

R573

R300

C533

R745

C608

C114

R115

R312

R351

IC512

R534

C534

R541

R756

51

30

C208

R164

C144

IC109

R303

R304

R545

R572

R580

R578

50

31

E

R608

R620

R707

PROGRAM

WRITER

R329

R310

R306

R522

R597

Q506

C198

R308

5

FOR

R318

4

IC104

R144

R154

R378

C403

R554

R552

R575

R624

R750

R748

C589

C587

C207

R377

R327

R344

R314

R563

CN510

IC511

3

1

R114

R376

R354

R305

R565

R564

IC506

R749

R611

R375

R313

R567

R582

R739

R625

R113

R357

R315

R311

R568

C143

R324

C206

C190

R560

IC103

R163

C405

C531

FB509

R559

R569

Ref. No.

D503 I-5

R424

R428

D507 F-4

D914 F-10

D915 F-10

D925 I-10

D926 I-10

C350

D932 D-8

IC101 D-7

IC102 D-6

IC103 D-5

IC104 D-4

IC105 D-3

R475

R474

R473

IC101

R946

3

C374

R472

4

1

IC303

5

L941

R932

R965

R931

R951

D932

R952

R938

Q947

R937

R940

R949

E

E

Q943

R910

R909

R911

R919

D915

D914

C911

R907

R918

D925

D926

C923

1-867-397-

11

C204

C205

C203

C202

C201

IC102

C189

R346

R675

R111

R374

R348

RB504

RB503

R355

R162

R373

R323

IC507

RB502

R372

R941

R142

C142

RB501

R371

R393

R321

R358

R505

R143

R112

R153

R325

IC108

R322

C404

C402

C532

X501

R525

R515

R507

R506

RB506

RB507

RB505

R703

R704

D503

R110

R152

R396

R320

R518

R109

X450

3

4

IC305

R520

L947

C188

R141

R108

R151

R161

C141

C119

1

C381

5

R943

R948

IC106 D-3

IC107 D-2

IC108 E-5

IC109 E-4

IC110 E-3

IC303 D-7

IC305 E-6

IC501 F-3

IC505 G-3

IC506 G-5

IC507 G-6

IC509 I-4

IC511 I-4

IC512 F-4

IC518 F-3

Q506 J-4

Q943 D-8

Q947 D-8

Location

1313

RHT-G2000

4-3. PRINTED WIRING BOARD – MAIN BOARD (SIDE B) –

1

A

MAIN BOARD (SIDE B)

EB901

R902

B

2

F901

FH901

C901

CN901

G

ACIN

BOARD

(Page 29)

C902

C918

IC901

D907

R906

D913

EB902

C907

D906

R913

A

K

C913

R912

D908

2

4

LF901

C903

D901

C909

1

3

5

Q901

E

IC921

C912

C908

FB901

D910

R925

C924

8

C920

R914

C906

D905

R926

TH901

C910

R905

R903

R904

C905

6

C929

E

R923

D924

C

FB902

D

E

F

G

H

I

J

3 4 5 6 7

3

L931

C936

C939

R427

C937

CN304

C934

Q304

EP909

E

EB911

FH902

D909

VDR901

PC903

C963

C964

R908

IC931

TRANSFORMER

C921

D921

C925

3

R927

D923

Q921

C938

PC901

T901

MAIN POWER

R921

1

R922

C922

D922

R934

R967

R968

R935

T902

SUB POWER

TRANSFORMER

PC902

C928

C952

C933

R956

R954

D943

D942

R955

R953

IC951

RHT-G2000

R933

R936

R939

DC FAN

Q302

E

R426

C953

C940

R479

R400

D941

:Uses unleaded solder.

EB908

1

R478

EB903

R429

D944

C307

C367

R477

C368

C932

Q303

C248

C366

R476

C371

IC943

1

C948

C375

A

K

A

C946

FB301

C329

D931

C944

C101

5

C949

E

L101

C281

C251

R490

R459

R179

R401

C161

C955

L942

R211

C211

L301

C945

C275

Q101

R361

L121

R191

D101

C151

C380

C935

IC942

1

L945

C941

E

C391

CN301

4

C931

R201

C131

Q102

5

C947

R489

C191

R458

C181

R241

R402

E

C111

R131

R171

E

C261

C171

C954

6

C276

L111

C283

C282

R221

C221

L131

D201

C384

R394

1

C942

SPOUT

BOARD

(Page 29)

R403

C252

R457

R488

C212

C162

C102

L302

C383

C303

C382

IC941

1

D945

C525

L102

Q103

R212

C943

Q945

D102

R132

5

C277

R362

L122

R192

C152

R957

EB904

E

C392

R202

C132

C304

C302

C310

Q104

C557

C951

D

E

R404

R456

C192

R487

C182

C112

R242

C305

C301

C309

IC508

C603

E

R958

C597

(Page 29)

C278

L112

C284

C262

R222

C222

L132

C172

R172

IC516

1

C598

1

IC515

SPOUT

BOARD

C285

C253

R464

R463

D202

C103

C308

C573

C558

• See page 33 for Circuit Boards Location.

8

SPOUT

BOARD

C

(Page 29)

R405

C163

C568

C569

C602

CN303

C299

Q105

L103

R213

C213

D103

R133

C306

C549

3

3

L123

R193

C561

3

C601

C596

C595

1

R363

C393

C153

1

E

R203

C133

C332

C527

C555

C559

FB511

C567

Q106

R406

R460

C193

R491

C183

R243

C564

FB512

R609

E

C263

L133

C113

R561

C552

C563

C286

C173

R173

C582

L113

R223

C223

C298

C287

R461

R492

D203

C313

R548

R566

C254

D104

C104

C551

C562

C580

D505

L104

C164

R134

C319

R538

R407

R214

C214

C314

C312

D506

C318

R547

C540

Q107

L124

R194

C554

C556

C560

R765

R678

C297

C394

C154

R174

C315

R204

C134

C311

E

R549

R546

R581

R764

R364

R762

R673

Q108

C194

R244

C317

C184

R763

C583

E

C264

R462

R493

L134

C507

R761

R662

R601

R408

C288

C174

C316

C577

R730

R514

R659

R224

C224

C856

R760

R746

L114

C508

R729

R657

6

C296

R574

R741

C510

R583

D504

D204

R530

R562

R743

L105

R409

C289

C762

R775

C255

R450

R481

D105

R533

R510

C875

C335

X502

19

C165

R511

L503

L502

R717

C268

R215

C215

C509

R524

C716

Q109

R539

R512

C542

R521

C539

R774

C712

CN302

R365

C395

C195

L125

R195

C155

R135

C536

C544

C269

Q110

E

R205

C135

C529

R557

R721

C799

R709

1414

C185

R245

R650

C530

C535

R718

CN509

B

9 10 11

1

EB906

L115

E

R410

C290

C265

R451

R482

L135

C175

C115

R175

C322

C328

D510

C541

R555

C798

R719

R550

BOARD

(Page 27)

R225

C225

C323

C321

CNV

D205

C327

C279

C106

D509

R553

R452

R483

C166

C324

C565

C511

C538

R627

R216

C216

C320

R660

R529

C571

C570

L106

D106

R136

C575

1

C291

R196

C136

R755

C572

C256

L126

C156

C326

C517

C518

L501

R206

C526

C325

C186

R453

C196

R484

R246

R605

R604

C280

C292

C116

C513

C266

L136

C176

D206

R176

C514

R702

L116

R226

C226

R411

C293

C107

R309

C701

C167

R137

C257

C217

D107

EB905

Q111

C120

R217

L127

R197

E

C396

C157

R207

Q112

R366

R247

C137

C197

R595

R591

C187

R586

E

C267

R227

L137

R585

R412

C294

C227

C177

D207

C117

R177

R587

C372

R139

C385

R395

EB907

R594

R590

R589

1-867-397-

R431

D304

E

R430

D303

EB910

C158

Q301

R588

C377

• Semiconductor

Location

Ref. No.

D101 D-5

D102 D-6

D103 D-7

D104 D-7

D105 D-8

D106 D-9

D107 D-10

D201 D-6

D202 D-6

D203 D-7

D204 D-8

D205 D-9

D206 D-9

D207 D-10

D303 B-10

D304 B-10

D504 J-8

D505 I-7

D506 I-7

D509 F-9

D510 F-9

D901 D-2

D905 H-2

D906 D-2

D907 G-1

D908 H-2

D909 E-3

D910 I-2

D913 H-1

D921 I-3

D922 J-3

D923 I-3

D924 J-2

D931 G-5

D941 J-4

D942 I-4

D943 I-4

D944 J-5

D945 I-6

IC508 I-6

IC515 J-6

IC516 I-6

IC901 G-2

IC921 I-2

IC931 E-4

IC941 H-6

IC942 H-5

IC943 H-5

IC951 I-4

PC901 F-3

PC902 I-3

PC903 B-3

Q101 B-5

Q102 B-5

Q103 B-6

Q104 B-6

Q105 B-7

Q106 B-7

Q107 B-7

Q108 B-8

Q109 B-8

Q110 B-9

Q111 B-10

Q112 B-10

Q301 B-11

Q302 B-4

Q303 B-5

Q304 B-4

11

Q901 H-2

Q921 I-3

Q945 J-6

Location

RHT-G2000

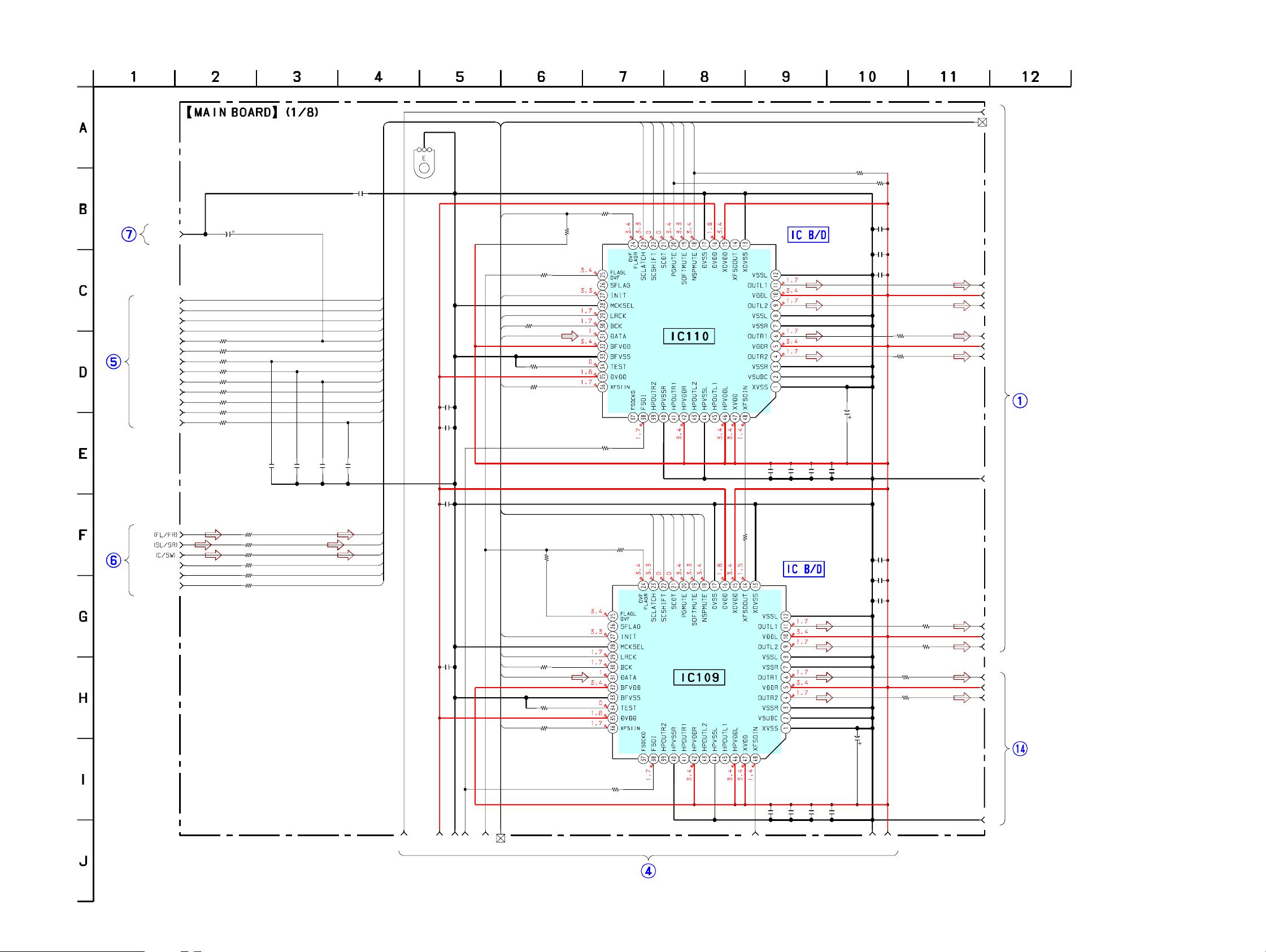

4-4. SCHEMATIC DIAGRAM – MAIN BOARD (1/8) –

MAIN

BOARD

(5/8)

(Page 19)

MAIN

BOARD

(7/8)

(Page 21)

MAIN

BOARD

(5/8)

(Page 19)

MAIN

BOARD

(6/8)

(Page 20)

MAIN

BOARD

(8/8)

(Page 22)

D-GND

RY_REAL

SW_REAL

OVF2

OVF1

DIAG

RESET

LAT3

LAT2

LAT1

SHIFT

SCDT

SOFT_MUTE

NS_INIT

C120

47

35V

R309

R308

R306

R305

R304

R303

R302

R351

R300

100

100

100

100

100

100

100

100

100

C402

100p

C403

100p

C404

100p

C406

0.0047

RY_REAL

SW_REAL

OVF2

OVF

RESET

LAT3

LAT2

LAT1

SHIFT

SCDT

SOFT MUTE

INIT

C405

0.001

• See page 35 for IC Block Diagrams.

EB907

OVF2

INIT

LRCK

BCK

SD

C326

0.1

C328

0.1

DATA3

SCK

R356

33

R316

470

R353

R319

R326

10k

100

11

10

UTE

LAT3

SCDT

SHIFT

PGM

NSP MUTE

SOFT MUTE

R317

470

IC110

CXD9843AR

STREAM

PROCESSOR

0

R328

0

C327

0.1

C320

0.1

C321C322

0.1

0.1

C335

47

35V

R345

10k

R347

10k

C325

0.1

C324

0.1

C323

0.1

R380

560

R379

560

12

13

14

15

16

17

MAIN

BOARD

(2/8)

(Page 16)

18

MAIN

BOARD

(7/8)

(Page 21)

D1

D2

D3

BCKO

LRCKO

MCKO

R310

R311

R312

R313

R314

R315

100

100

100

0

100

0

DATA1

DATA2

DATA3

BCK

LRCK

SCK

C317

0.1

C319

0.1

INIT

LRCK

BCK

DATA2

SCK

R357

33

R344

470

R354

R327

LAT2

SCDT

R318

470

100

0

R324

0

SHIFT

IC109

CXD9843AR

STREAM

PROCESSOR

PGMUTE

SOFT MUTE

NSP MUTE

R329

0

C311

0.1

C312

0.1

C313

0.1

C318

0.1

C332

47

35V

C316

0.1

C315

0.1

C314

0.1

R376

R375

560

560

R378

560

R377

560

19

20

21

22

23

24

MAIN

BOARD

(4/8)

(Page 18)

25

RHT-G2000

9

1

2

6

MAIN

BOARD

(3/8)

(Page 17)

5

4

3

7

8

1515

RHT-G2000

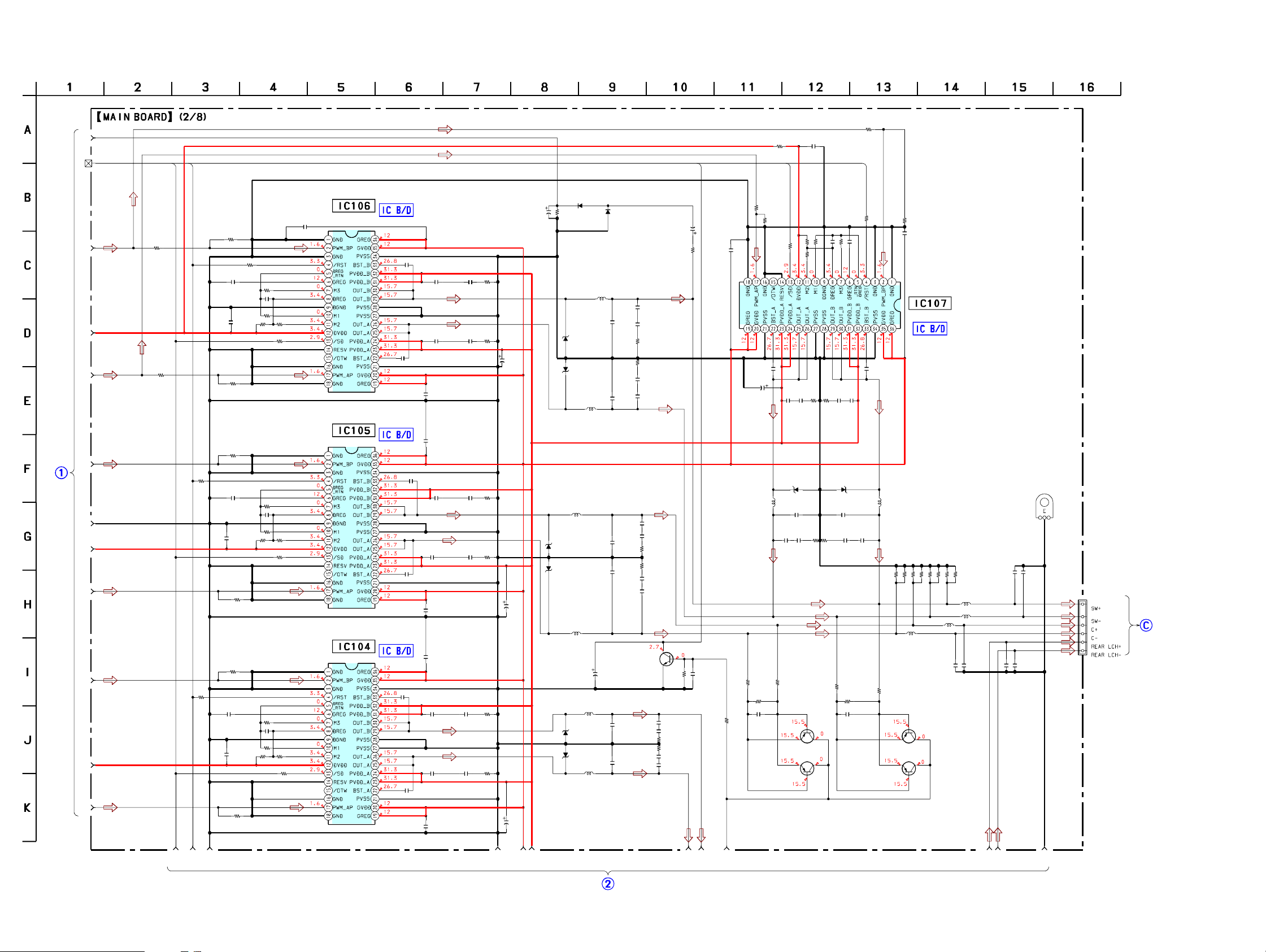

4-5. SCHEMATIC DIAGRAM – MAIN BOARD (2/8) –

11

10

12

13

14

R382

560

R381

560

SD

RESET

R119

22k

C200

R176

0.1

0

0

R166

0.1

C146

0

R156

C136

R246

0.1

R118

22k

100

R146

R136

• See page 34 for IC Block Diagrams.

IC106

CXD9775M

C116

POWER DRIVER

1

C186

0.033

C272

0.22

C156

0.033

C271

0.22

C106

1

0

0

IC105

CXD9775M

C176

0.22

C166

0.22

R206

3.3

R196

3.3

C196

2200

35V

C372

50V

R384

560

C137

R480

SD

D304

1SS355TE-17

1

R431

100k

D206

P6SMB39AT3

D106

P6SMB39AT3

L126

10uH

L136

10uH

C226

1

D303

1SS355TE-17

R226

2.7

R216

2.7

C216

1

C292

0.0022

C266

0.0022

C256

0.0022

C291

0.0022

C377

50V

R430

10k

10

C107

R383

560

R128

C157

0.033

C197

2200

22k

R137

35V

1

0.1

0

SD

0

100

R157

R247

0

0

R147

C273

R197

C167

0.22

R207

3.3

3.3

0.22

0.1

C147

C177

0.22

0

R167

C274

0.22

0.1

C218

RESET

R177

0.033

0

C187

R120

22k

C117

1

IC107

CXD9775M

POWER DRIVER

MAIN

BOARD

(1/8)

(Page 15)

R117

22k

15

18

16

17

19

20

21

R175

R174

0

C199

0.1

0

R165

0.1

C145

C135

0.1

0

C134

0.1

C198

0.1

R115

22k

C144

R116

22k

R114

22k

R155

R164

R154

R245

100

R244

100

0

R145

R135

0

0.1

0

R144

R134

POWER DRIVER

0

0

IC104

CXD9775M

POWER DRIVER

0

0

C155

0.033

C184

0.033

C154

0.033

C185

0.033

C209

0.22

C208

0.22

C207

0.22

C115

C210

0.22

C105

C114

C104

1

D107

P6SMB39AT3

R409

100k

L127

R365

100k

C395

2.2

2SA1235-F

R205

C175

3.3

0.22

L135

10uH

C225

L125

10uH

C158

47

10V

L134

10uH

D204

P6SMB39AT3

D104

P6SMB39AT3

L124

10uH

C215

1

1

PROTECT DETECT

R195

C165

3.3

0.22

C195

2200

C174

0.22

C164

0.22

35V

R204

3.3

R194

3.3

C194

2200

35V

1

1

1

D205

P6SMB39AT3

D105

P6SMB39AT3

C265

0.0022

C255

0.0022

Q301

2SC1623-L5L6

C224

1

C264

0.0022

C254

C214

0.0022

1

C290

0.0022

R225

2.7

R215

2.7

C289

0.0022

R395

100k

C288

0.0022

R224

2.7

R214

2.7

C287

0.0022

C385

2.2

R139

0

10uH

Q109

C293

0.0022

R410

100k

C217

1

C257

0.0022

Q110

2SA1235-F

R217

2.7

D207

P6SMB39AT3

C227

R227

2.7

0.0022

R411

100k

C267

R366

100k

C396

1

10

C294

0.0022

2SA1235-F

Q111

L137

10uH

R412

100k

10k

10k

R450

R481

Q112

2SA1235-F

10k

R482

L105

10k

R451

10k

R483

10k

10k

R452

R484

0uH

Q109-112

DC DETECT

10k

R453

L115

0.01

C268

0.01

C269

L116

L106

0uH

0uH

0uH

0.01

C296

0.01

C280

0.01

C297

0.01

C279

EB908

CN302

6P

SPOUT

BOARD

(Page 30)

RHT-G2000

36

37

38

41

39

40

MAIN

BOARD

(4/8)

(Page 18)

43

42

44

45

46

47

1616

RHT-G2000

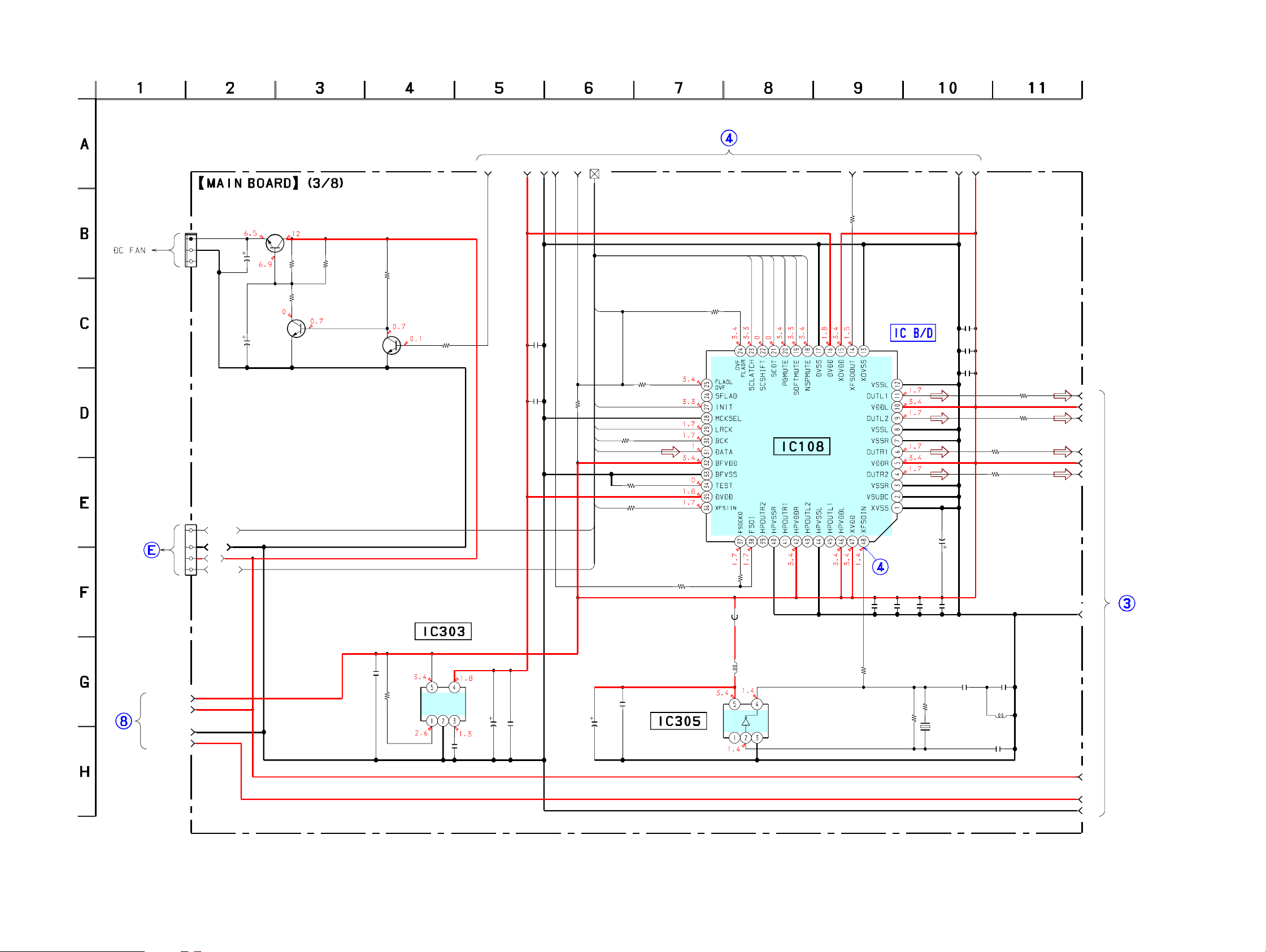

4-6. SCHEMATIC DIAGRAM – MAIN BOARD (3/8) –

SPOUT

BOARD

(Page 30)

CN301

4P

CN304

3P-EH

RY_REAL

PGND

12V

SW

C307

50V

_REAL

1

Q303

2SD1616A-K

R429

1.2k

C248

47

16V

R428

2.2k

Q302-304

FAN DRIVE

R424

1.5k

Q302

2SC1623-L5L6

• See page 8 for Waveforms. • See page 35 for IC Block Diagrams.

6

5

OVF

R348

470

INIT

LRCK

R355

BCK

DATA1

R323

SCK

R358

33

R426

10k

Q304

2SC1623-L5L6

R427

10k

1

C308

0.1

C310

0.1

RY_REAL

SW_REAL

2

3

4

R322

10k

100

MAIN

BOARD

(1/8)

(Page 15)

9

7

R325

0

LAT1

SCDT

SHIFT

PGMUTE

R346

470

0

R320

0

R321

0

NSP MUTE

SOFT MUTE

IC108

CXD9843AR

STREAM

PROCESSOR

C329

47

35V

8

C306

0.1

C305

0.1

C304

0.1

R374

R372

560

R371

560

560

R373

560

26

27

28

29

30

31

RHT-G2000

MAIN

BOARD

(8/8)

(Page 22)

AMP_3.3V

AMP_12V

P-GND

31.5V

C368

1

TK11118CSCL-G

R400

100k

IC303

+1.8V REG

C371

0.001

C375

100

16V

C374

0.01

C380

220

10V

C381

0.01

IC305

SN74AHC1GU04DCKR

OSC

FB301

0UH

L301

10uH

1717

C309

0.1

R393

C301

C302

0.1

C303

0.1

C382

0.001

R396

100

X450

49.152MHz

L302

1uH

C384

5p

C383

10p

0.1

22

R394

1M

32

33

34

35

MAIN

BOARD

(4/8)

(Page 18)

RHT-G2000

4-7. SCHEMATIC DIAGRAM – MAIN BOARD (4/8) –

38

37

36

IC103

CXD9775M

0

0

0

0

POWER DRIVER

IC102

CXD9775M

POWER DRIVER

IC101

CXD9775M

MAIN

BOARD

(1/8)

(Page 15)

R113

22k

22

23

24

25

26

27

28

R173

R172

0

C190

0.1

R163

0

0.1

C143

C133

R153

C189

0.1

C142

R112

22k

R111

22k

R110

22k

R162

R152

R243

100

R242

100

0

R143

R133

0

0.1

0

R142

R132

0.1

0

C132

0.1

• See page 34 for IC Block Diagrams.

41

39

40

C113

1

C183

C182

0.033

C152

0.033

0.033

C103

C102

C153

0.033

1

1

C206

0.22

C205

0.22

C204

0.22

C203

0.22

C173

0.22

C163

0.22

C112

C172

0.22

C162

0.22

R203

3.3

R193

3.3

C193

2200

35V

1

R202

3.3

R192

3.3

C192

2200

35V

D203

P6SMB39AT3

D103

P6SMB39AT3

D202

P6SMB39AT3

D102

P6SMB39AT3

L132

10uH

L122

10uH

L133

10uH

L123

10uH

C223

C213

C222

C212

MAIN

BOARD

(2/8)

(Page 16)

EB906

47

C298

0.01

C299

0.01

CN303

7P

SPOUT

BOARD

(Page 30)

45

L114

0uH

10k

493

R

10k

R462

L103

0uH

0.01

C278

46

L104

0.01

C277

0uH

0.01

C276

L113

0uH

0.01

C275

43

42

C286

0.0022

C263

0.0022

R223

2.7

1

R213

2.7

1

1

1

C285

0.0022

R222

2.7

R212

2.7

C253

0.0022

C284

0.0022

C283

0.0022

Q101-104

DC DETECT

C262

0.0022

C252

0.0022

44

2SA1235TP-1EF

2SA1235TP-1EF

Q101

2SA1235TP-1EF

Q105

Q102

R401

100k

Q106

2SA1235TP-1EF

C393

R363

R405

100k

100k

C391

2.2

R402

R361

100k

100k

2.2

R406

100k

2SA1235TP-1EF

Q103

2SA1235TP-1EF

Q107

2SA1235TP-1EF

R407

100k

Q104

C392

R403

R362

100k

100k

Q108

2SA1235TP-1EF

R364

R408

100k

100k

2.2

R404

100k

C394

2.2

Q105-108

DC DETECT

10k

10k

487

R456

R

10k

R457

10k

R488

10k

R489

10k

R458

10k

10k

463

490

459

R

R

R

10k

10k

10k

64

492

461

460

R

R491

R

R

R4

0uH

L112

0uH

L102

L111

0uH

0uH

L101

0k

1

10k

10k

MAIN

BOARD

(3/8)

(Page 17)

RHT-G2000

R109

22k

29

R171

0.1

R151

0

0

0

R141

R131

C188

0.1

R161

C141

C131

R241

0.1

R108

22k

100

30

31

32

33

34

35

POWER DRIVER

0

0

C181

0.033

C151

0.033

220

C101

C366

1

C202

0.22

C201

0.22

16V

C111

1

C171

0.22

C161

0.22

C367

R201

3.3

R191

3.3

0.1

C350

0.1

D201

P6SMB39AT3

D101

P6SMB39AT3

C119

100p

L131

10uH

L121

10uH

C221

C211

C282

0.0022

C261

1

0.0022

R221

2.7

R211

C251

2.7

0.0022

1

0

R472

0

R473

0

R474

0

R475

C281

0.0022

0

R476

0

R477

0

R478

0

R479

EP909

EB911

1818

RHT-G2000

4-8. SCHEMATIC DIAGRAM – MAIN BOARD (5/8) –

SKIP

DSP_DO

DSP_BST

DSP_PM

DSP_XRST

DSP_HCE

D_CLK

DIR_RST

DIR_ZERO

DIR_XSTAE

CSFLAG

HDOUT

DIR_HCE

AD_RST

BYPASS

DIR/AD

GP9

ACK

DIN

ERR

(Page 21)

MAIN

BOARD

(6/8)

(Page 20)

MAIN

BOARD

(7/8)

(Page 21)

MAIN

BOARD

(6/8)

(Page 20)

MAIN

BOARD

(7/8)

DSP_SKIP

DSP_DO

DSP_BST

DSP_GP9

DSP_PM

DSP_ACK

DSP_XRST

DSP_HCE

DSP/DIR_DIN

DSP/DIR_CLK

DIR_RERR

D3.3V

DIR_RST

DIR_ZERO

DIR_XSTAE

DIR_CSFLAG

DIR_DO

DIR_HCE

AD_RST

BYPASS

DIR/AD

A-GND

OPT-IN

A5V

LIN

RIN

• See page 8 for Waveforms. • See page 39 for IC Pin Function Description.

CNV

BOARD

(Page 28)

CN509

19P

100

100

R706

LED4

LED3

LED2

R625

R628

100

1k

100

LED1

SIRCS

C608

100p

R608

R707

FL_RST

R601

R620

100

100

KEY2

KEY1

FL_CS

FL_DATA

KEY0

R718

C762

10k

0.1

FL_CLK

R609

0

C595

D505

1SS355TE-17

0.1

C602

0.1

1SS355TE-17

D503

TA7809LS

+9V REG.

C596

47

35V

TA7805LS

+5V REG.

C601

47

35V

IC515

IC516

C597

C598

12V

3.3V

E4V

1k

C525

C603

100

D506

1SS355TE-17

10V

1

1

P-CONT1

P-CONT2

0.1

R704

R703

P.CONT1

1k

P.CONT2

MAIN

BOARD

(1/8)

(Page 15)

MAIN

BOARD

(7/8)

(Page 21)

MAIN

BOARD

(8/8)

(Page 22)

MAIN

BOARD

(6/8)

(Page 20)

MAIN

BOARD

(8/8)

(Page 22)

GND_EB903

AGND

D.DCON5V

M-8V

D-GND

IO

BOARD

(Page 25)

FOR PROGRAM WRITER

CN507

23P

CN510

8P

R595

R591

R594

R590

R589

R588

R587

R586

R585

ERR

SKIP

HDOUT

100

R723

DIN

100

100

R731

R724

D_CLK

DSP_DO

R721

10k

AD_RST

10k

R709

CNVSS

PLL_DI

PLL_DO

PLL_CE

PLL_CLK

R774

1k

R524

10k

SEL0

SEL1

SEL2

SEL3

TUNED

R614

R612

10k

R792

R702

22k

R789

R790

10k

R791

10k

C799

10k

100

100

100

0.1

10k

R719

R705

10k

SCDT

SHIFT

R726

R728

1k

1k

100

PLL_DI

100

PLL_CE

100

PLL_DO

100

PLL_CLK

1k

TUNED

100

SEL3

100

SEL2

100

SEL1

100

R765

R764

R763

R762

R761

R760

SEL0

C701

0.1

EB905

100

100

100

100

100

100

RESET

CNVSS

SOD/RXD1

SCO/CLK1

BUSY/RTS1

SID/TXD1

KEY2

KEY1

KEY0

SIRCS

LED4

LED3

R577

C571

R596

1k

47k

C572

0.1

R616

0.1

C570

0.1

C798

0.1

DSP_PM

DIR_RST

DIR_HCE

DIR_XSTAE

IC509

M30622MEP-A52FPUO

SYSTEM CONTROLLER

R717

10k

R713

C712

0.1

C716

0.1

RESET

0

DSP_BST

X502

5MHz

DSP_HCE

DSP_XRST

R739

47k

GP9

ACK

LAT2

LAT3

LAT1

C856

4.7k

R730

4.7k

R624

0.1

10k

R750

1k

R749

1k

R748

1k

OVERFLOW2

OVERFLOW1

DIAG

EN

C582

100

10V

R746

47k

R514

R743

1k

P-CONT2

10k

P-CONT1

R673

10k

R775

IC511

PST3629NR

RESET

47k

NS_INIT

SOFT_MUTE

SCDT

SHIFT

C587

0.22

LAT1

LAT2

LAT3

R678

C589

0.1

EN

0

DIAG

SW_REAL

OVERFLOW1

OVERFLOW2

RY_REAL

R675

100

C580

2200

R657

47k

2SC1623-L5L6

1SS355TE-17

Q506

INVERTER

D504

R662

C583

0.22

47k

R659

100k

C875

0.01

R611

R741

BUSY/RTS1

SCO/CLK1

SOD/RXD1

SID/TXD1

10k

47k

FL_RST

BYPASS

DIR/AD

CSFLAG

DIR_ZERO

LED1

RY_REAL

1k

100

R756

R745

FL_CLK

SW_REAL

SOFT_MUTE

LED2

NS_INIT

FL_DATA

FL_CS

R729

RHT-G2000

LAT3

LAT2

LAT1

DIAG

OVF2

MAIN

BOARD

(1/8)

(Page 15)

RESET

OVF1

RY_REAL

SW_REAL

NS_INIT

SOFT_MUTE

SCDT

SHIFT

1919

RHT-G2000

4-9. SCHEMATIC DIAGRAM – MAIN BOARD (6/8) –

D-GND

MAIN

BOARD

(1/8)

(Page 15)

MAIN

BOARD

(7/8)

(Page 21)

(Page 19)

(Page 21)

MAIN

BOARD

(5/8)

MAIN

BOARD

(7/8)

MAIN

BOARD

(5/8)

(Page 19)

MAIN

BOARD

(5/8)

(Page 19)

MAIN

BOARD

(8/8)

(Page 22)

DSP/DIR_CLK

DSP/DIR_DIN

DIR_CSFLAG

D3.3V

DIR_RERR

OPT-IN

DIR/AD

BYPASS

DIR_ZERO

DIR_RST

AD_RST

DIR_HCE

DIR_DO

DIR_XSTAE

A5V

LIN

RIN

A-GND

R538

0

DIR_ZERO

DIR_XSTAE

R604

470

R605

470

D_CLK

ERR

DIR/AD

BYPASS

DIR_RST

AD_RST

DIR_HCE

DIR_DO

CSFLAG

DIN

C575

0.01

C565

0.01

C514

0.1

L501

10uH

C518

10

50V

C511

0.001

D510

1SS355TE-17

D509

1SS355TE-17

C526

47

35V

• See page 8 for Waveforms. • See page 35, 36 for IC Block Diagrams.

C524

0.1

C517

10

50V

R660

C541

0.01

C539

0.1

0

C542

220

10V

C529

50V

C528

0.1

10

L503

0

R627

100

R557

4.7k

L502

10uH

C544

10

50V

C513

0.1

0

R650

C512

0

0.01

R508

100

R555

5.6k

R556

100

R558

33k

C545

C546

0.01

IC501

PCM1803DBR

A/D CONVERTER

C543

0.01

0.1

L504

R511

100

R510

100

C538

0.01

R512

100

C506

0.01

R529

100

R544

100

R534

100

100

R542

100

R541

R543

100

IC505

LC89056W-E

DIGITAL AUDIO

INTERFACE

100

100

R537

R540

C515

0.01

C535

0.1

R532

1k

C534

12p

1SS355TE-17

R531

1M

12.288MHz

C533

12p

D507

TC7WH157FU

SELECTOR

X500

IC518

(TE12R)

R526

3.3k

IC512

NJU26902VM1-TE2

DIGITAL AUDIO

DELAY

C508

0.01

R530

10k

C530

0.1

C536

0.1

R521

R562

100

10k

R504

100

R528

100

R516

100

R519

100

R533

R527

100

R551

1k

R517

100

220

C509

R539

0.01

100

DIR_RST

D_CLK

DIR_HCE

DIR_DO

ERR

CSFLAG

BYPASS

C507

0.1

C510

10

50V

DIR/AD

DIR_XSTAE

DIR_ZERO

AD_RST

DIN

DIR_AUDIO

SDI1

GND

LRCKI2

BCKI2

KFSIO

MAIN

BOARD

(7/8)

(Page 21)

RHT-G2000

2020

Loading...

Loading...