Sony MDSMX-101 Service manual

MDS-MX101

SERVICE MANUAL

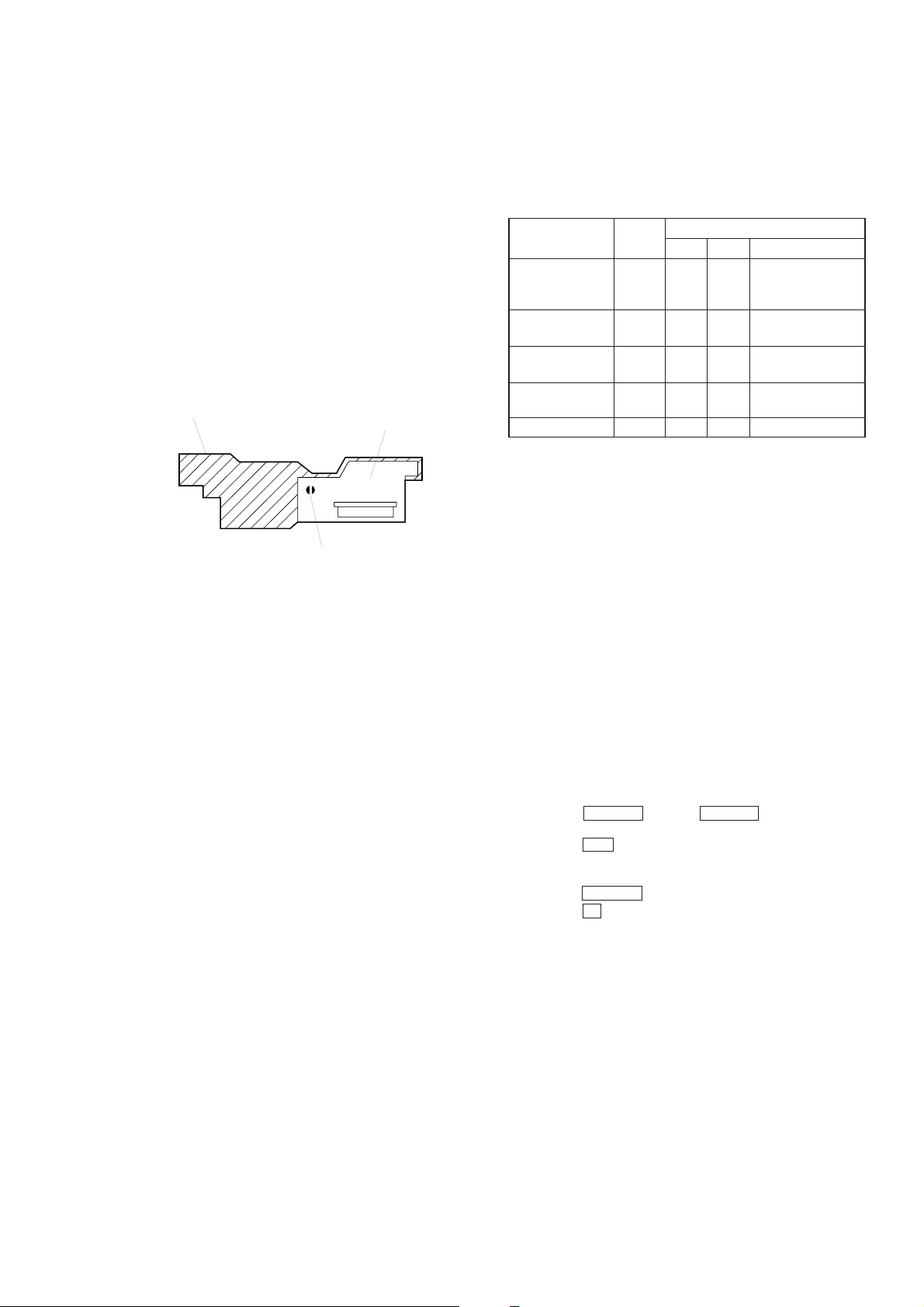

MDS-MX101 is the optional mini disc

deck that can be used only with section

CMT-101.

U.S and foreign patents licensed from Dolby Laboratories Licensing Corporation.

SPECIFICATIONS

AEP Model

UK Model

E Model

Tourist Model

Model Name Using Similar Mechanism MDS-S38

MD Mechanism Type

Optical Pick-up Name KMS-260A/J1N

MDM-3B

System MiniDisc digital audio system

Disc MiniDisc

Laser Semicondu2ctor laser (λ = 780nm)

Laser output power Less than 44.6 µW*

Laser diodo properties Material: GaAIAs

Revolutions (CLV) Approx. 400 rpm to 900 rpm

Error correction Advance Cross

Sampling frequency 44.1 kHz

Modulation system EFM (Eight-to-Fourteen Modulation)

Number of channels 2 stereo channels

Frequency response 5 to 20,000 Hz

Signal-to-noise ratio More than 92 dB (during playback)

Wow and flutter Below measurable limit

DIGITAL IN (MD Square optical connector jack, Optical wave length

OPTICAL IN) input/ 660 nm

DIGITAL OUT (MD

OPTICAL OUT) output

Dimeansions Approx. 142 × 125 × 235 mm (w/h/d) incl.

Mass Approx. 2 kg

Supplied accessory Digital optical cable (1)

*This output is the value measured at a distance of

200 mm from the objective lens surface on the

optical pick-up block with 7 mm aperture.

Interleave Reed Solomon Code (ACIRC)

projecting parts and controls

MICROFILM

MINI DISC DECK

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

TABLE OF CONTENTS

1. SERVICING NOTES

1-1. Check Mode of Fluorescent Indicator Tube,

Buttons, and LED’s ........................................................ 3

1-3. Extension Cable.............................................................. 3

2. GENERAL .................................................................. 4

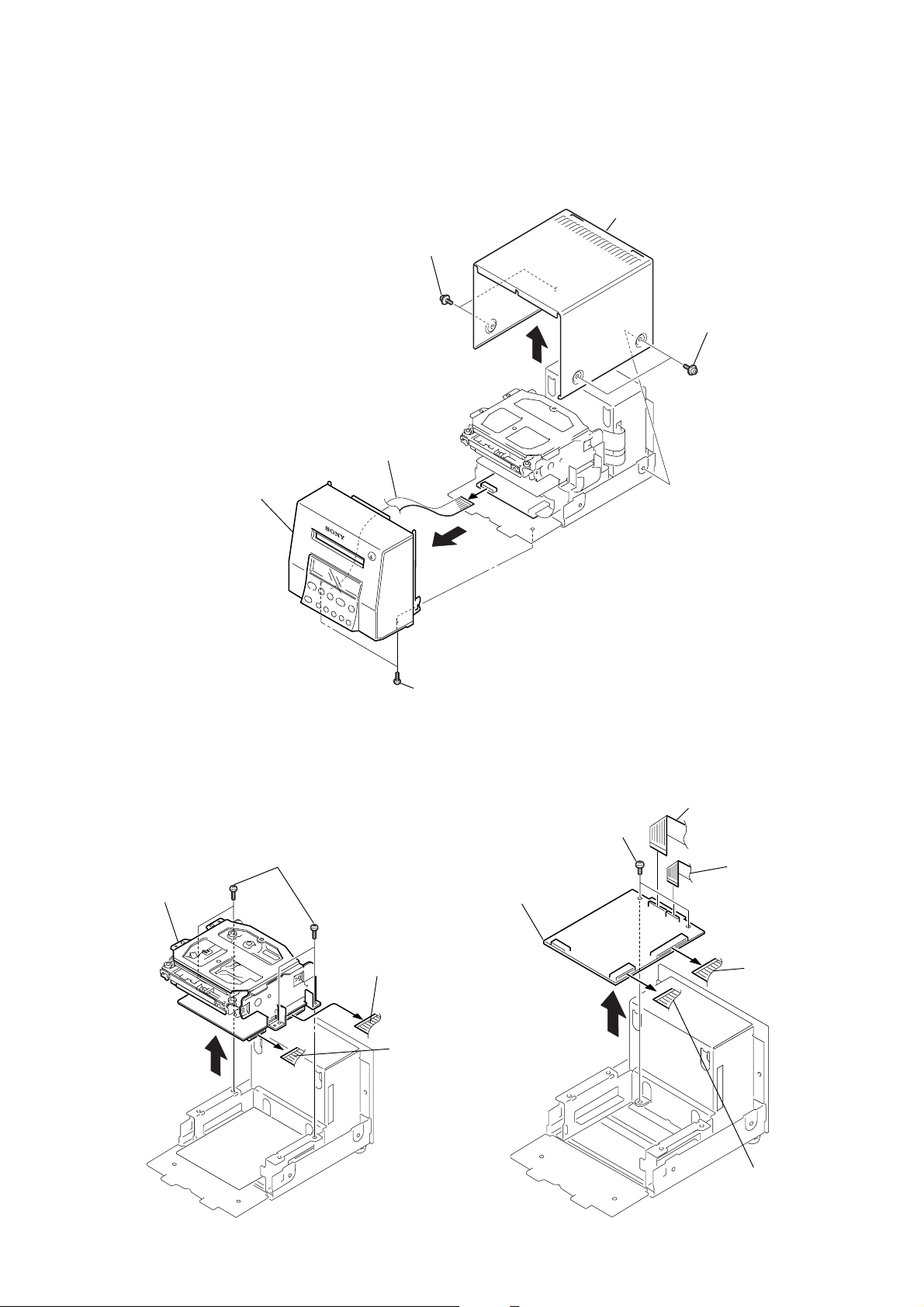

3. DISASSEMBLY

3-1. Cover and Front Panel .................................................... 5

3-2. Mechanism Deck ............................................................ 5

3-3. Digital Board .................................................................. 5

3-4. OPJ Board, Power Board................................................ 6

3-5. Bracket (T), (L) and (R) ................................................. 6

3-6. BD Board........................................................................ 7

3-7. Sub Chassis..................................................................... 7

3-8. Shutter Assembly............................................................ 8

3-9. Over Write Head............................................................. 8

3-10. Slider Complete Assembly ............................................. 9

4. TEST MODE........................................................ 10

5. ELECTRICAL ADJUSTMENTS ......................... 13

6. DIAGRAMS

6-1. Circuit Boards Location ................................................. 18

6-2. Block Diagram ............................................................... 19

6-3. Printed Wiring Boards

– MD Mechanism Deck Section – ................................. 22

6-4. Schematic Diagram

– MD Mechanism Deck Section – ................................. 25

6-5. Schematic Diagram – Digital Section – ......................... 31

6-6. Printed Wiring Boards – Digital Section –..................... 35

6-7. Schematic Diagram – Display Section – ........................ 38

6-8. Printed Wiring Boards – Display Section –.................... 41

6-9. Printed Wiring Boards – Power Section – ...................... 43

6-10. Schematic Diagram – Power Section – .......................... 45

6-11. IC Block Diagrams ......................................................... 47

6-12. IC Pin Functions ............................................................. 49

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

7. EXPLODED VIEWS ................................................ 56

8. ELECTRICAL PARTS LIST ................................. 60

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged

by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instr uctions.

— 2 —

SECTION 1

SERVICING NOTES

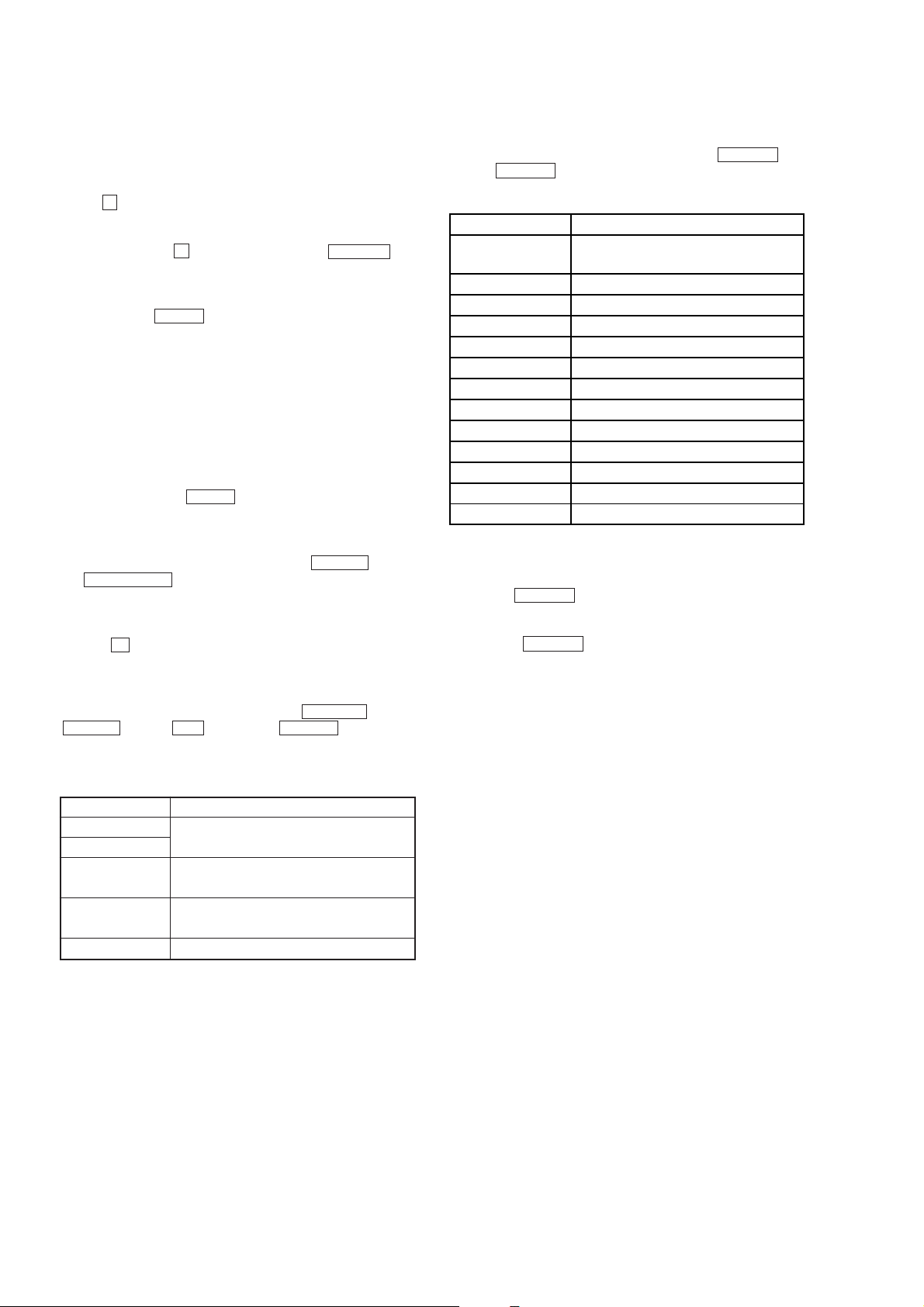

1-1. CHECK MODE OF FLUORESCENT INDICATOR

TUBE, BUTTONS, AND LEDS

Setting the Check Mode:

This mode is activated by inserting the AC power cord of the PFJ1 power supply jig (or HCD-101) into AC w all outlet while pressing

the REC button and the CHARACTER button. When this mode

started, the fluorescent indicator tube and LEDs are all turned on.

1-1-1. Button Check Mode (Key Check)

When the respective buttons (12 buttons are used in total)

are pressed while all tube and LEDs are turned on, the

display area which corresponds to the pressed button, is

turned off. This mode ends by pressing the CD SYNC button

at last.

1-1-2. Fluorescent Indicator Tube Check Mode (Segment

Check)

When the button check mode ends, [Segment Check]

appears and the respective dots of the 12-digit, 5 x 7 segment

fluorescent tube are lit every other dot. This mode ends by

pressing the CD SYNC button at last.

1-1-3. Fluorescent Indicator T ube Check Mode (Scroll Check)

When the segment check ends, [Scroll Check] appears.

When the SCROLL button is pressed, the displayed letter

scrolls to the left one letter after another. When all letters

are scrolled, [end] appears. Press YES button to return to

the normal operating mode.

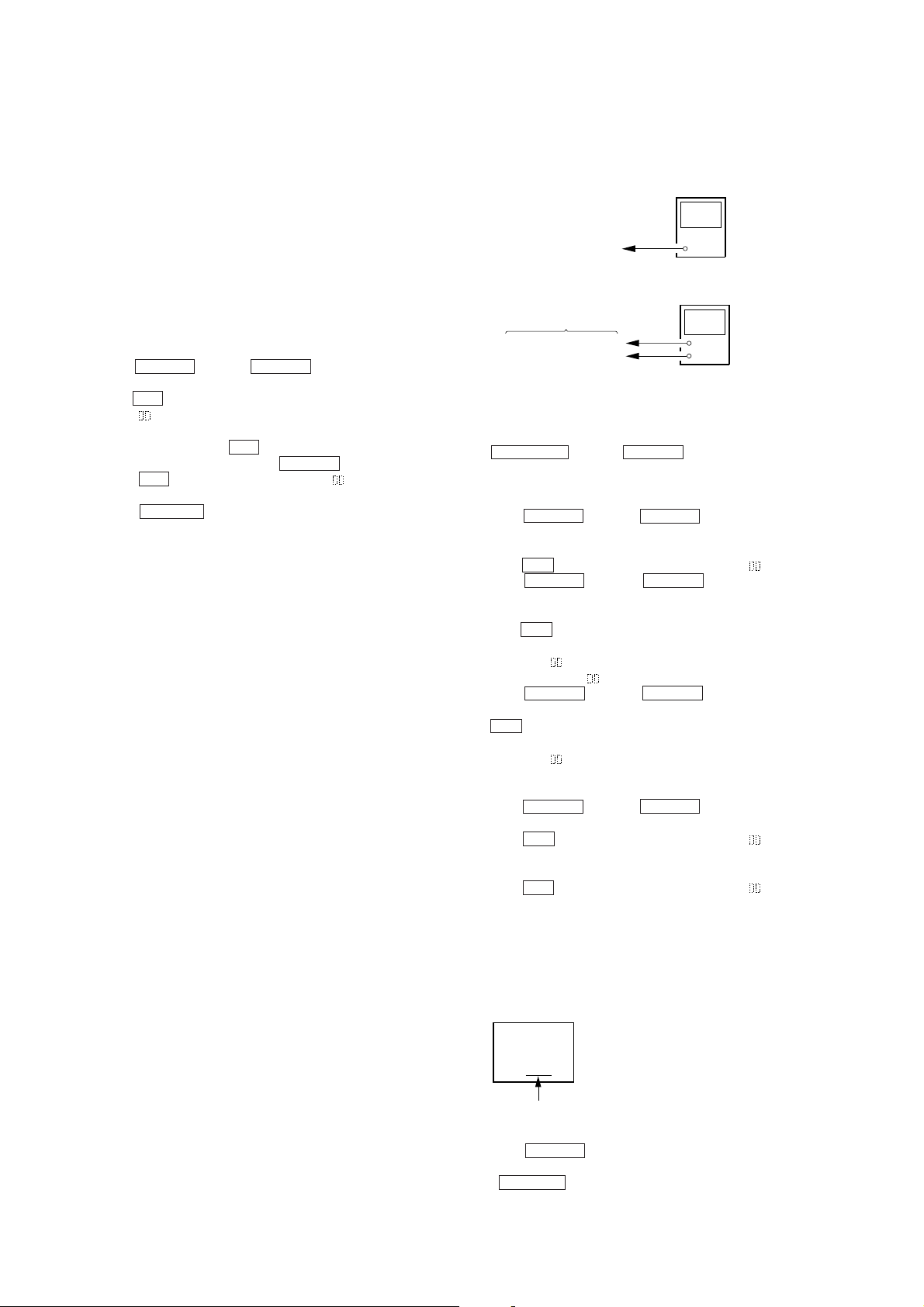

— BD board (Conductor side) —

CN103

Extension Cable

(J-2501-086-A)

CN200

CN102

Extension Cable

(J-2501-103-A)

CN201

— DIGITAL board (Component side) —

1-2. EXTENSION CABLE

The two types of extension cable are available during repair of this

set. The extension cable (part code no. J-2501-086-A) is available

to connect CN103 of the BD board and CN200 of the DIGITAL

board. The extension cable (part code no. J-2501-103-A) is av ailable

to connect CN102 of the BD board and CN201 of the DIGITAL

board.

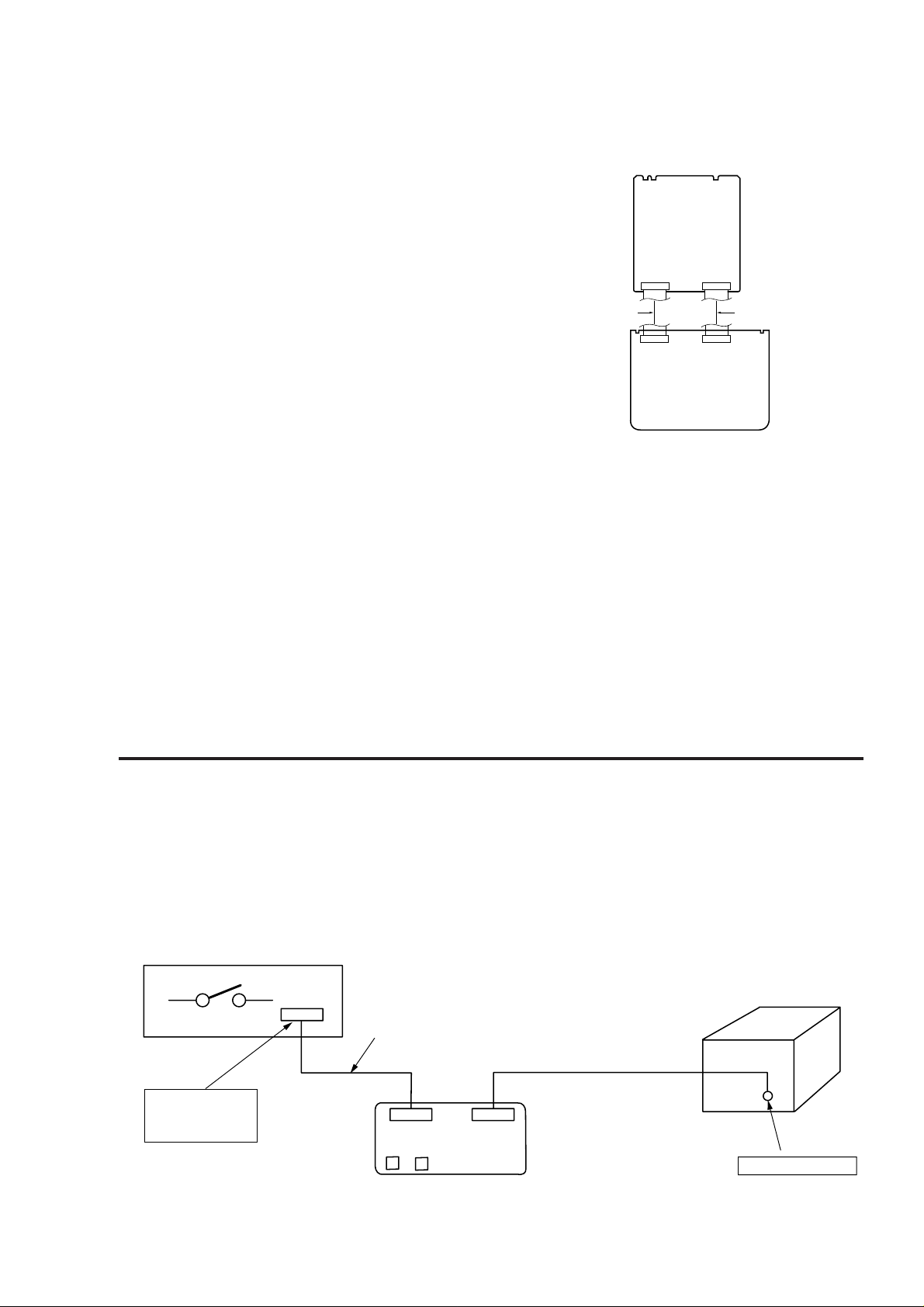

SERVICENG NOTE

• Supplying power during servicing

This equipment cannot operate without using a separate power supply. Connect the machine to the HCD-101. To apply power set the

SYSTEM POWER switch of HCD-101.

When other units are not available use the PFJ-1 power supply jig.

When using the PFJ-1, press the POWER switch of the conversion board to turn on the power.

[Connection Diagram]

PFJ-1

(Power Supply jig)

Set

POWER SW

Connector Cable 17P

(Supplied with set)

FH-E939, 838, 737,

MHC-6600, 5600,

CDP/TC

Power

Function

Conversion Board

(J-2501-144-A)

— 3 —

*

when checking the recording

function of MDS-MX101, select

any function other than MD using

the Function key of the conversion

board before check.

SYSTEM CONTROL

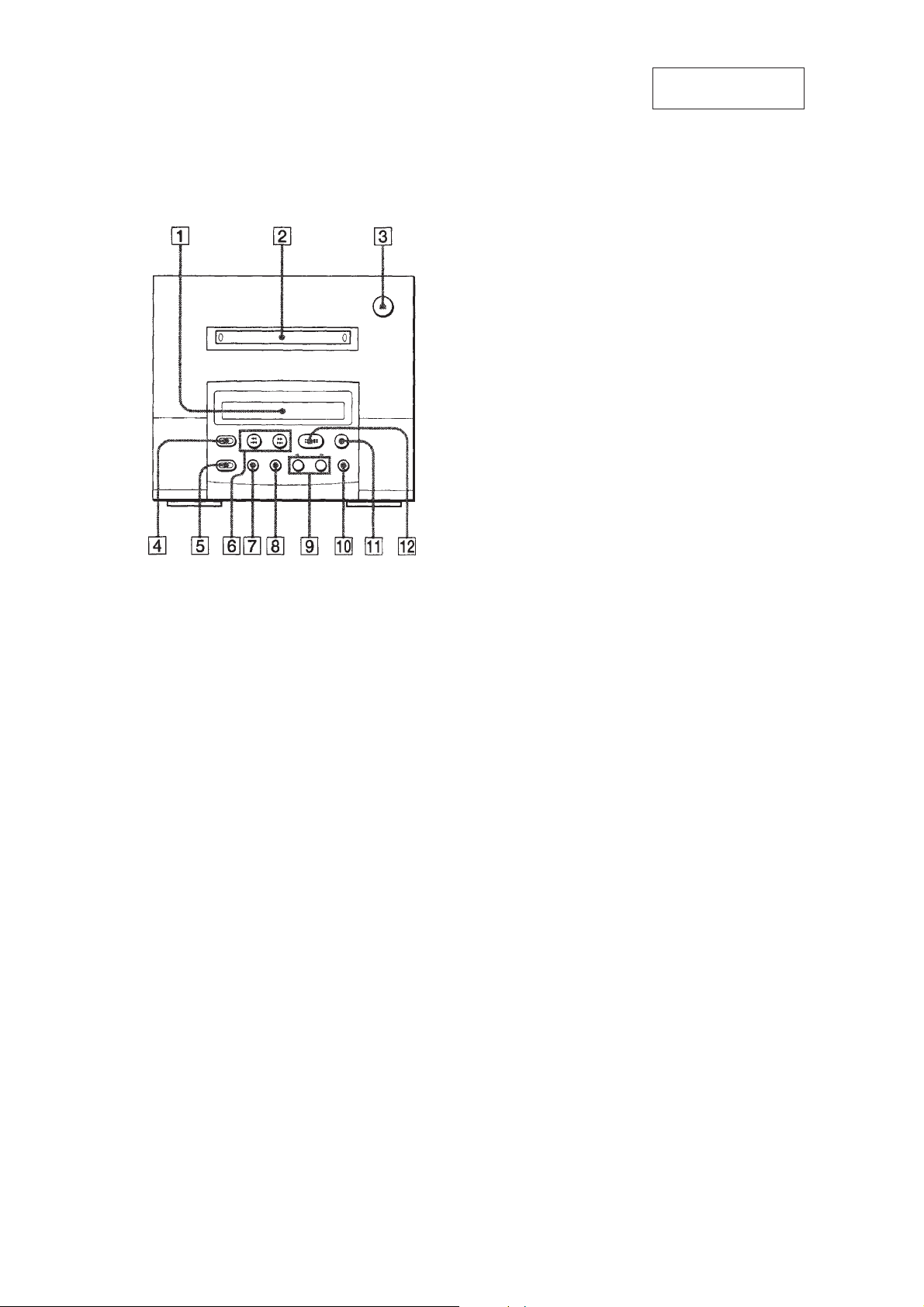

SECTION 2

GENERAL

1 Display window

2 MD slot

3 6 EJECT button

4 r REC button

5 CD SYNC button

6 = 0 (finding a point in a track/

fast backward) button

) + (finding a point in a track/

fast forward) button

7 EDIT/NO button

8 YES button

9 SCROLL button, DISPLAY button/

?CURSOR/ button

0 CHARACTER button

!¡ p (stop) button

!™ ^ (play/pause) button

This section is extracted

from instruction manual.

— 4 —

SECTION 3

)

5

Two screws

(BVTT 3x8)

3

Flat type wire (23Core)

(CN203)

2

Flat type wire (29Core)

(CN201)

1

Flat type wire (19Core)

(CN200)

6

Digital board

4

Flat type wire (13Core)

(CN204)

)

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

3-1. COVER AND FRONT PANEL

1

Two screws (Case)

4

Flac type wire (16Core)

(CN202)

5

Front Panel

2

Cover

1

Two screws (Case

3-2. MECHANISM DECK

1

Four Screws

(BVTT 3x8)

4

Mechanism deck

3

Two screws (BVTP 3x8)

2

Flat type wire (29Core)

(CN102)

3

Flat type wire (19Core

(CN103)

3-3. DIGITAL BOARD

— 5 —

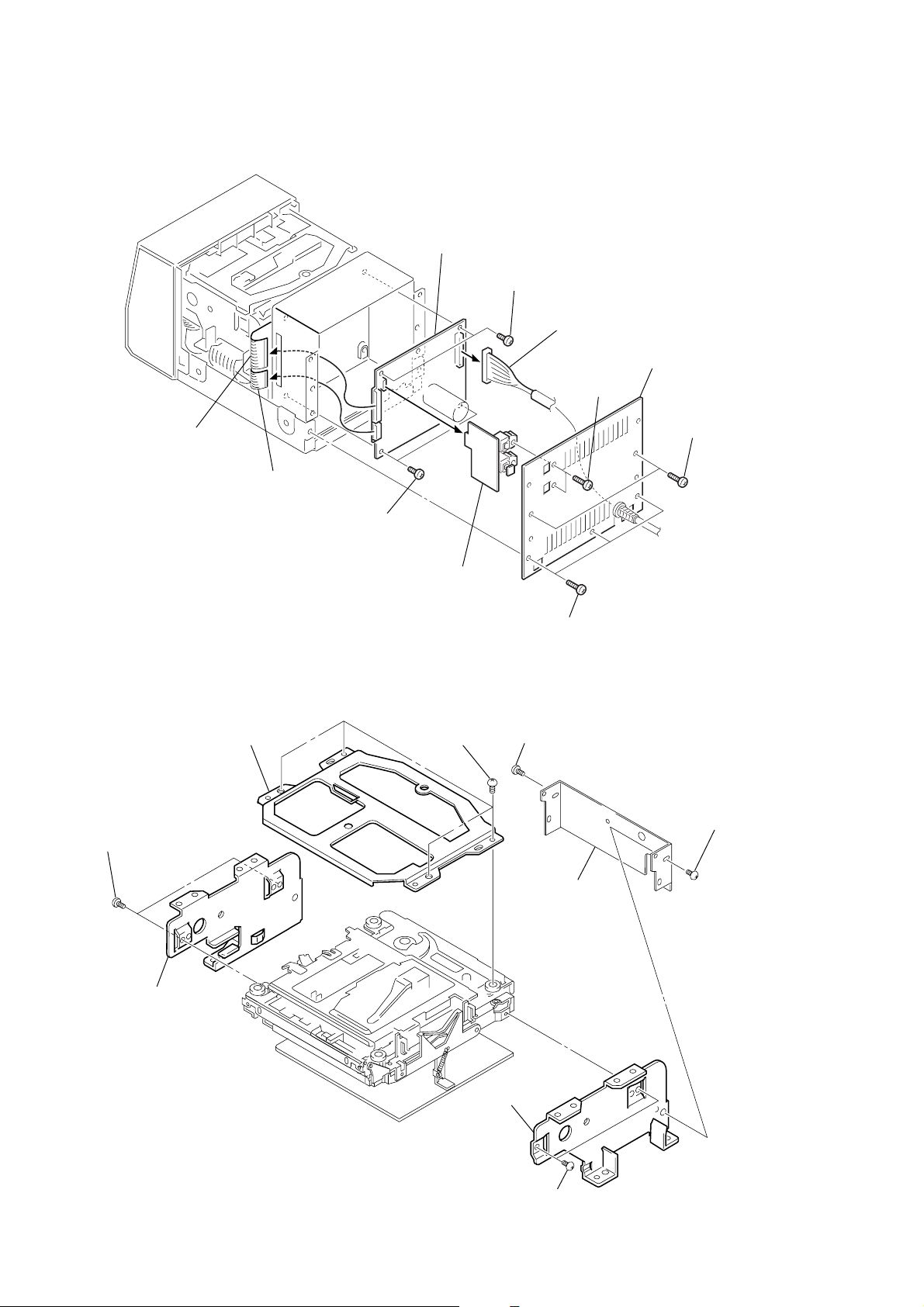

3-4. OPJ BOARD, POWER BOARD

)

6

Flat type wire

(23 Core)

7

Flat type wire

(13 Core)

5

Two screws

(BVTT 3x8)

8

Power board

4

Opj board

5

Two screws

(BVTT 3x8)

3

Cord (with Connector)

(CN102)

1

Two screws

(BVTP 3x8)

2

Back Panel

1

Two screws

(BVTP 3x8)

3-5. BRACKET (T), (L) AND (R)

2

Bracket (T)

6

Two screws

(BVTT 2x3)

7

Bracket (L)

1

Four screws

(BVTT 2x3)

1

Three screws

(BVTP 3x8)

4

Screw (BVTT 2x3)

5

Bracket (joint)

3

Screw (BVTT 2x3

— 6 —

9

Bracket (R)

8

Two screws

(BVTT 2x3)

3-6. BD BOARD

4

OP relay fiexible board

(CN101)

5

BD board

2

Flat type wire (15 Core)

(CN106)

1

Flexible board

(Over write head)

3-7. SUB CHASSIS

1

Two step screws

3

Two insulatores

5

Sub chassis

Part A

2

Two step screws

3

Screw (BVTT 2x4)

4

Two insulatores

Part A

Part A

NG

OK

— 7 —

Take care so that hte part A

may be right position when installing.

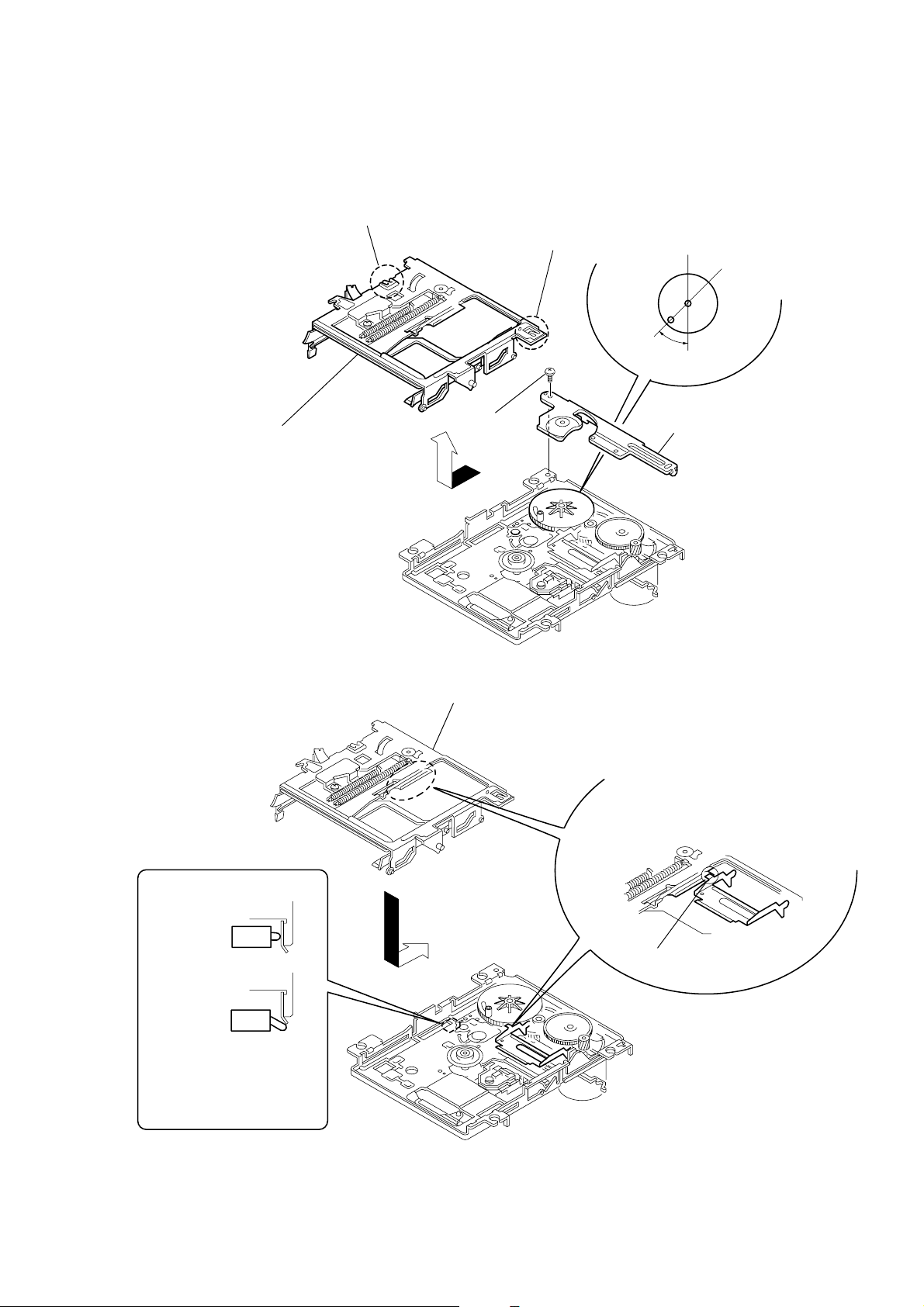

3-8. SHUTTER ASSEMBLY

)

2

Shaft (shutter)

1

Stopper washer

3

Shutter assembly

Shutter assembly

Shaft (lid) B

Hole B

Shaft (shutter) A

Hole A

When installing, install the shaft (shutter)

into the hole A as shown in the figure

before installing the shaft (lid) into the hole B.

3-9. OVER WRITE HEAD

1

Precision screw (P1.7x6

2

Over write head

— 8 —

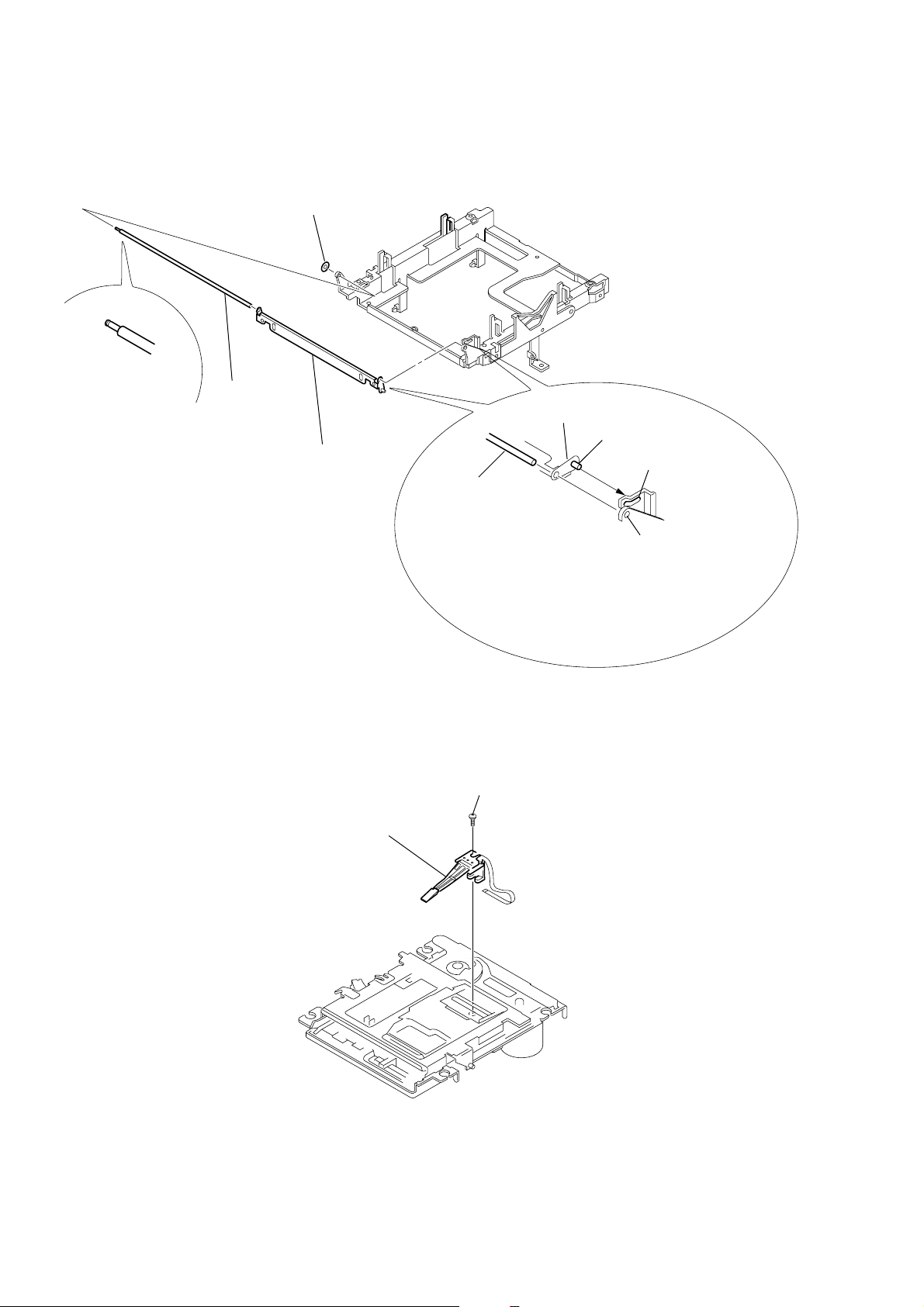

3-10 . SLIDER COMPLETE ASSEMBLY

45

°

OK

NG

3

Set the shaft of Gear (LA) to be at the

position in the figure.

2

Retainer (Gear)

1

Screw

(M1.7x2)

4

Remove the slider complete

assembly in the direction of

arrow with putting out of

two claws.

Claw

Claw

Slider assembly

Install the part A of leever (head up)

to pass over the slider complete assembly.

Part A

Take care not to damage

the detective switch.

• Note for Installation of Slider Complete Assembly

— 9 —

SECTION 4

TEST MODE

4-1. PRECAUTIONS FOR USE OF TEST MODE

1. As loading related operations will be performed regardless of

the test mode operations being performed, be sure to check

that the disc is stopped before setting and removing it. Even if

the 6 button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not

stop rotating. Therefore, it will be ejected while rotating. Be

sure to press the 6 button after pressing the EDIT/NO button and the rotation of disc is stopped.

2. The erasing-protection tab is not detected in the test mode.

Therefore, operating in the recording laser emission mode and

pressing the r REC button, the recorded contents will be

erased regardless of the position of the tab. When using a disc

that is not to be erased in the test mode, be careful not to enter

the continuous recording mode and traverse adjustment mode.

4-1-1. Recording Laser Emission Mode and Operating

Button

1. Continuous recording mode (CREC MODE)

2. Traverse adjustment mode (EFBAL ADJUST)

3. Laser power adjustment mode (LDPWR ADJUST)

4. Laser power check mode (LDPWR CHECK)

5. When pressing the r REC button.

4-2. SETTING THE TEST MODE

With the AC power cord of the PFJ-1 power supply jig (or

HCD-101) removed from AC outlet, press the ) + button

and CHARACTER button simultaneously, and connect the AC

power cord to the AC wall outlet. The test mode is activated.

4-3. RELEASING THE TEST MODE

Press the 6 button, and the power is turned OFF (standby status)

and the set becomes ready for normal operation.

4-5. SELECTING THE TEST MODE

Thirteen test modes are selected by pressing the = 0 button, and ) + button.

Table 4-2.

Display Contents

TEMP ADJUST

LDPWR ADJUST Laser power adjustment

LDPWR CHECK Laser power check

EFBAL ADJUST Traverse (E-F balance) adjustment

FBIAS ADJUST Focus bias adjustment

FBIAS CHECK Focus bias check

CPLAY MODE Continuous playback mode

CREC MODE Continuous recording mode

DETRK CHECK Detrack check

Scurve CHECK S curve check (*1)

EEP MODE Non-volatile memory mode (*1)

MANUAL CMD Manual command transfer mode (*1)

SVDATA READ Data reading out mode (*1)

• For detailed description of each adjustment mode, refer to the

“5. ELECTRICAL ADJUSTMENTS”.

• If a different adjustment mode has been selected by mistake,

press the EDIT/NO button to exit from it.

*1: The Scurve CHECK, EEP MODE, MANUAL CMD and

SVDATA READ are not used in servicing. If set accidentally ,

press the EDIT/NO button immediately to exit it.

Temperature compensation offset

adjustment

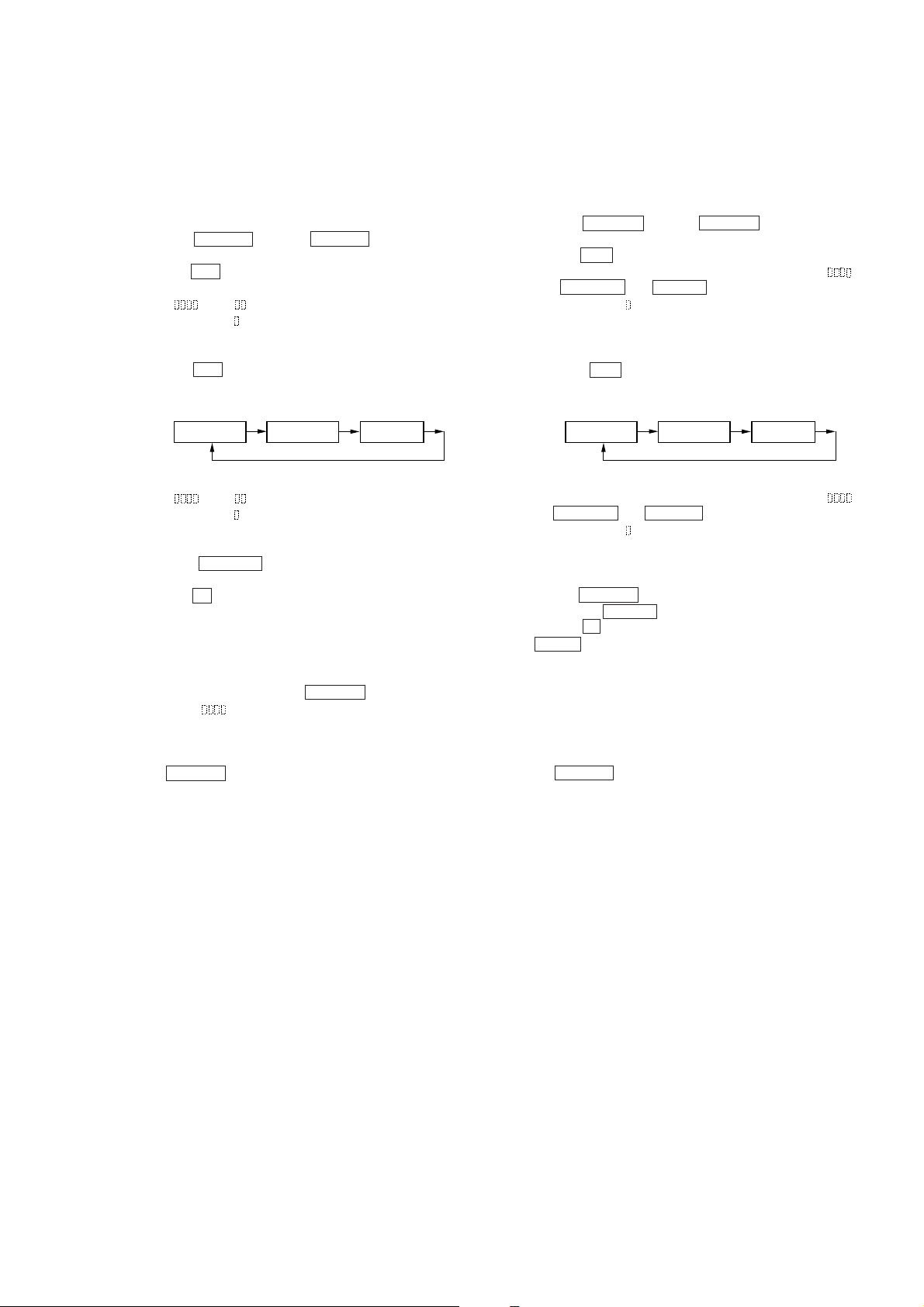

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the =0 button,

) + button, YES button, and EDIT/NO button. The

functions of these buttons are as follows.

Table 4-1.

Button

= 0 button

) + button

YES button

EDIT/NO button

CD SYNC button

Changes parameters and modes.

Proceeds onto the next steps.

Finalizes input.

Returns to previous step.

Stops operations

Confirms the entry.

Function

– 10 –

4-6. OPERATING THE CONTINUOUS PLAYBACK

MODE

4-7. OPERATING THE CONTINUOUS RECORDING

MODE

4-6-1. Entering the Continuous Playback Mode

1. Set the MO or CD disc in the unit. (Whichever recordable discs

or discs for playback only are available.)

2. Press the = 0 button or ) + button and display

“CPLAY MODE”.

3. Press the YES button to change the display to “CPLAY MID”.

4. When access completes, the display changes to

“C1=

Note: The numbers “

4-6-2. Changing the Parts to be Played-back

1. Press the YES button during continuous playback to change

the display as below.

2. When access completes, the display changes to

“C1=

Note: The numbers “

4-6-3. Exitting the Continuous Playback Mode

1. Press the EDIT/NO button. The display will change to

“CPLAY MODE”.

2. Press the 6 button and remove the disc.

Notes:

1. The playback start address for IN, MID, and OUT are as follows.

In case you want to display the address of the playback position on the display, press the DISPLAY button and display

“CPLAY (

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

2. The EDIT/NO button can be used to stop playing anytime.

AD=

CPLAY MID

AD=

”.

” displayed show you error rates and ADER.

CPLAY OUT CPLAY IN

”.

” displayed show you error rates and ADER.

)”.

4-7-1. Entering the Continuous Recording Mode

1. Set the MO disc in the unit.

2. Press the = 0 button or ) + button and display

“CREC MODE”.

3. Press the YES button to change the display to “CREC MID”.

4. When access completes, the display changes to “CREC (

and, SHUFFLE and REPEAT Turn on.

Note:The numbers “

tion address.

4-7-2. Changing the Parts to be Recorded

1. When the YES button is pressed access is completed, the

display changes as below. (See Note 6.)

CREC MID

2. When access completes, the display changes to “CREC (

and SHUFFLE and REPEAT lightup.

Note:The numbers “

tion address.

4-7-3. Ending the Continuous Recording Mode

1. Press the EDIT/NO button. The display will change to “CREC

MODE” and PRESET goes off.

2. Press the 6 button and remove the disc.

( MONO turns on once and turns off immedia Tely.)

Notes:

1. The recording start address for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT : 700h cluster

2. The EDIT/NO button can be used to stop recording anytime.

3. During the test mode, the erasing-protection tab will not be

detected. Therefore be careful not to set the continuous recording mode when a disc not to be erased is set in the unit.

4. Do not perform continuous recording for long periods of time

above 5 minutes.

5. During continuous recording, be careful not to apply vibration.

6. After access is completed, the recorded portions cannot be

moved any more.

” displayed shows you the recording posi-

CREC OUT CREC IN

” displayed shows you the recording posi-

)”

)”

– 11 –

4-8. EEP MODE

This mode reads and writes the contents of the non-volatile

memory. It is not used in servicing.

If set accidentally , press the EDIT/NO button immediately to exit

it.

4-9. FUNCTIONS OF OTHER BUTTONS

Table 4-3.

Button

Function

• Sets continuous playback when pressed in

the STOP state. (servo all on)

^

• When pressed during continuous playback,

the tracking and sled servo turns on/off.

p

CHARACTER

SCROLL

r REC

DISPLAY

6

Stop continuous playback and continuous

recording.

The sled moves to the outer circumference

only when this is pressed.

The sled moves to the inner circumference

only when this is pressed.

Turns recording on/off when pressed during

continuous playback.

Switches the diaplay when pressed.

Disc eject

Note: The erasing-protection tab in not detected during the test

mode. Recording will start regardless of the position of

the erasing-protection tab when the r REC button is

pressed.

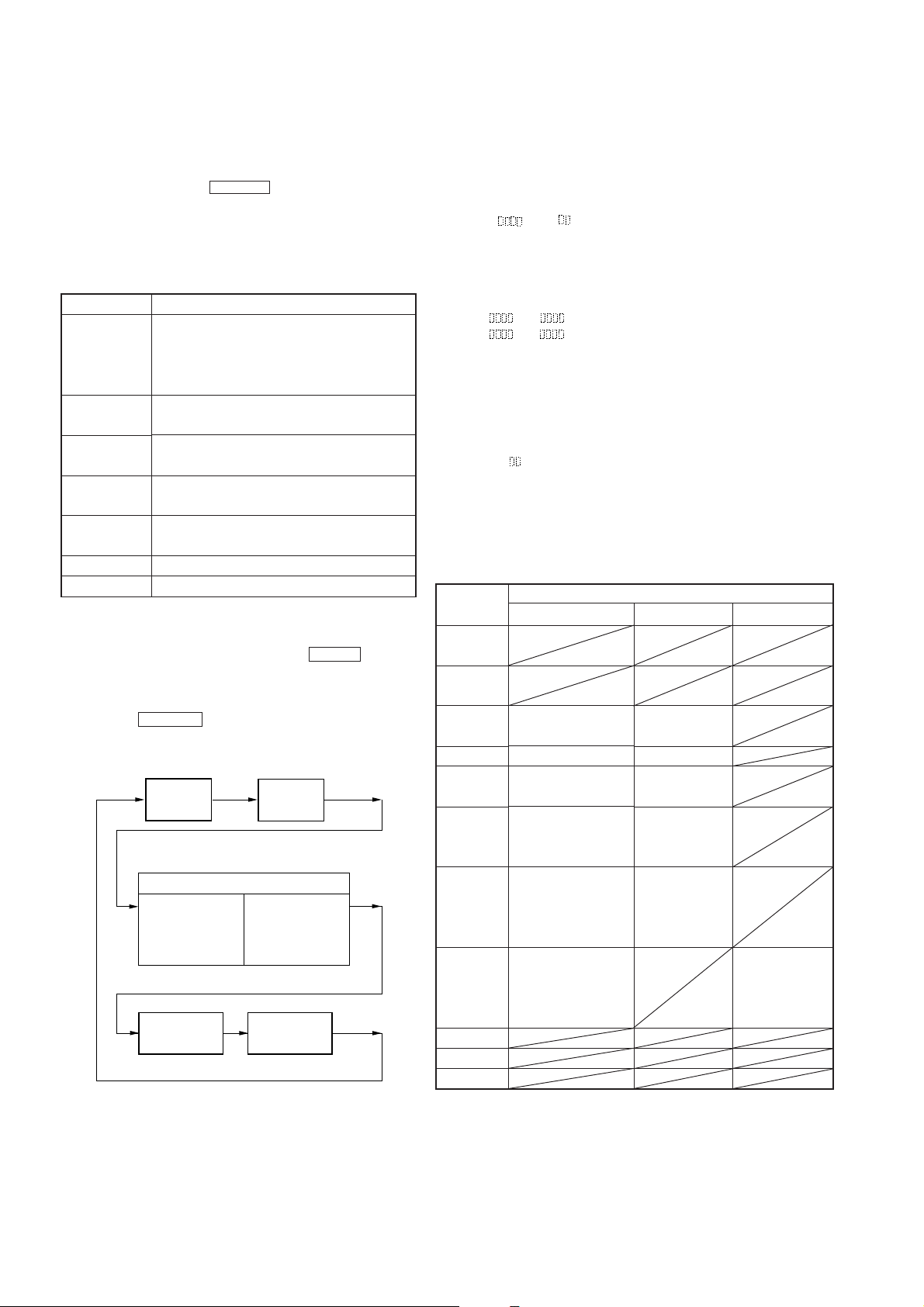

4-10. TEST MODE DISPLAYS

Each time the DISPLAY button pressed, the display changes in

the following order.

Mode

display

Address display

ADIP address

display

(during MO disc

mode)

Auto gain

display

Error rate

display

SUB Q address

display

(during CD disc

mode)

IVR

display

1. MODE display

Displays “TEMP ADJUST”, “CPLAY MODE”, etc..

2. Error rate display

Error rates are displayed as follows.

C1=

AD=

C1= : Indicates C1 error

AD=: Indicates ADER

3. Address display

Address are displayed as follows.

a= (in MO disc)

h=

s= (during CD disc)

h=

h=: Header address

a=: ADIP address

s=: SUB Q address

Note: “—” is displayed when the address cannot be read.

4. Auto gain display

Auto gain are displayed as follows.

AGF=

T=

F= Focus auto gain acquired value

T= Tracking auto gain acquired value

4-11. MEANINGS OF OTHER DISPLAYS

Table 4-4.

Display

indication

1

MONO

SHUFFLE

TRACK

DISC

PROGRAM

REPEAT

REC LEVEL

OVER

D-IN

A-IN

TOC-EDIT

Light On

CLV locked state

Pit mode

High reflection rate disc

Spindle servo

CLV-S

(pill-in mode)

ABCD adjustment

completed

• Focus auto gain

successful

• Tracking auto gain

successful

Contents

Off

CLV unlocked

state

Groove mode

Low reflection

rete disc

Spindle servo

CLV-A

(playback mode)

ABCD adjustment not yet completed

Blinking

• Focus auto gain

successful

• Tracking auto

gain failed

Note: Auto gain display and IVR display are not used in servicing.

– 12 –

SECTION 5

ELECTRICAL ADJUSTMENTS

5-1. PRECAUTIONS FOR CHECKING LASER DI-

ODE EMISSION

To chec k the emission of the laser diode during adjustments, never

view directly from the top as this may lose your eyesight.

5-2. PRECAUTIONS FOR USE OF OPTICAL

PICK-UP (KMS-260A)

As the laser diode in the optical pick-up is easily damaged by

static electricity, solder the laser tap of the flexible board when

using it.

Before disconnecting the connector, desolder first. Before connecting the connector, be careful not to remove the solder. Also

tale adequate measures to prevent damage by static electricity.

Handle the flexible board with care as it breaks easily.

Pick-up

Laser tap

Optical pick-up flexible board

Flexible board

5-3. PRECAUTIONS FOR ADJUSTMENTS

1) When replacing the following parts, perform the adjustments

and checks with ® in the order shown in the following table.

Table 5-1.

Optical

Pick-up

1. Temperature

compensation

offset adjustment

2. Laser power

adjustment

3. Traverse

adjustment

4. Focus bias

adjustment

5. Error rate check

2) Set the test mode when performing adjustments.

After completing the adjustments, exit the test mode.

3) Perform the adjustments in the order shown.

4) Use the following tools and measuring devices.

• Test disc (CD for playback only)

TDYS-1 (part No. 4-963-646-01)

• Laser power meter

LPM-8001 (part No. J-2501-046-A)

• Oscilloscope (Measure after preforming CAL of prove.)

• Digital voltmeter

• Thermometer

5) When observing several signals on the oscilloscope, etc., make

sure that VC and ground do not connect inside the oscilloscope.

(VC and ground will become short-circuited)

IC171 D101 IC101, IC121, IC192

× ®® ®

®®× ®

®®× ®

®®× ®

®®× ®

BD board

5-4. CREATING MO CONTINUOUSLY RECORDED

DISC

* This disc is used in focus bias adjustment and error rate check.

The following describes how to create a MO continuous recording disc.

1. Insert a MO disc (blank disc) commercially available.

2. Press the = 0 button or ) + button and display

“CREC MODE”.

3. Press the YES button and display “CREC MID”.

“CREC (0300)” is displayed for a moment and recording starts.

4. Complete recording within 5 minutes.

5. Press the EDIT/NO button and stop recording.

6. Press the 6 button and remove the MO disc.

The above has been how to create a continuous recording data for

the focus bias adjustment and error rate check.

Note: Be careful not to apply vibration during continuous

recording.

– 13 –

5-5. TEMPERATURE COMPENSATION OFFSET

Optical pick-up

objective lens

laser

power meter

+

–

BD board

digital voltmeter

CN110 pin 5 (I+3V)

CN110 pin

4

(IOP)

ADJUSTMENT

Save the temperature data at that time in the non-volatile memory

as 25°C reference data.

Notes:

1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22 °C to

28 °C. Perform it immediately after the power is turned on

when the internal temperature of the unit is the same as the

ambient temperature of 22 °C to 28 °C.

3. When D101 has been replaced, perform this adjustment after

the temperature of this part has become the ambient temperature.

Adjusting Method:

1. Press the = 0 button or ) + button and display

“TEMP ADJUST”.

2. Press the YES b utton and select the “TEMP ADJUST” mode.

3. “TEMP =

played.

4. To save the data, press the YES button.

When not saving the data, press the EDIT/NO button.

5. When the YES button is pressed, “TEMP=

be displayed for some time, followed by “TEMP ADJUST”.

When the EDIT/NO button is pressed, “TEMP ADJUST”

will be displayed immediately.

Specifications:

The temperature should be within “E0-EF”, “F0-FF”, “00-0F”,

“10-1F” and “20-2F”.

” and the current temperature a data will be dis-

SAVE” will

5-6. LASER POWER ADJUSTMENT

Connection:

Adjusting Method:

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press

the CHARACER button or SCROLL button and move the

optical pick-up.)

Connect the digital voltmeter to CN110 pin 5 (I+3V) and

CN110 pin 4 (IOP) of the BD board.

2. Press the = 0 button or ) + button and display

“LDPWR ADJUST”.

(Laser power: for adjustment)

3. Press the YES button and display “LD 0.9 mW $

4. Press the = 0 button or ) + button so that the

reading of the laser power meter becomes 0.82 to 0.91 mW.

Set the range control on the laser power meter to 10 mW, then

press the YES button to save the adjustment result in the nonvolatile memory.

(“LD SAVE $

5. Then “LD 7.0 mW $

” will be displayed for a moment.)

”will be displayed.

6. Press the = 0 button or ) + button so that the

reading of the laser power meter becomes 6.9 to 7.1 mW, press

the YES button and save the adjustment result in the nonvolatile memory.

(“LD SAVE $

” will be displayed for a moment.)

Note: Do not perform the emission with 7.0 mW more than 15

seconds continuously.

7. Press the = 0 button or ) + button and display

“LDPWR CHECK”.

8. Press the YES button and display “LD 0.9 mW $

Check that the reading of the laser power meter becomes 0.80

to 0.96 mW.

9. Press the YES button and display “LD 7.0 mW $

Check that the reading of the laser power meter and digital

voltmeter satisfy the specified value.

”.

”.

”.

Specification:

Laser power meter reading : 7.0 ± 0.2 mW

Digital voltmeter reading : Optical pick-up displayed value ±10%

(Optical pick-up label)

KMS260A

27X40

B0825

lOP=82.5 mA in this case

lOP (mA) = Digital voltmeter reading (mV)/1 (

10. Press the EDIT/NO button and display “LDPWR CHECK”,

and stop the laser emission.

(The EDIT/NO button is effective at all times to stop the

laser emission.)

– 14 –

Ω

)

Loading...

Loading...