Sony MDSLSA-1 Service manual

MDS-LSA1

g

SERVICE MANUAL

US and foreign patents licensed from Dolby Laboratories

Licensin

Corporation.

SPECIFICATIONS

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-7X2B

Optical Pick-up Type KMS-262A/J1N

System MiniDisc digital audio system

Disc MiniDisc

Laser Semiconductor laser (λ = 780 nm)

Emission duration: continuous

Laser output Less than 44.6 µW

* This output is the value measured

at a distance of 200 mm fr om the

objective lens surface on the Optical

Pick-up Block with 7 mm apertur e.

Laser diode Material: GaAlAs

Revolutions (CLV) 400 rpm to 900 rpm

Error correction ACIRC (Advanced Cr oss Interleave

Reed Solomon Code)

Sampling frequency 44.1 kHz

Coding ATRAC (Adaptive TRansform

Acoustic Coding)/ATRAC3

Modulation system EFM (Eight-to-Fourteen Modulation)

Number of channels 2 stereo channels

Frequency response 5 to 20,000 Hz ±0.3 dB

Signal-to-noise ratio Over 100 dB during playback

Wow and flutter

Below measurable limit

*

Inputs/outputs

i.LINK S200 Jack type: 4-pins to 4-pins

General

Power requirements 230 V AC, 50/60 Hz

Power consumption 18 W

Dimensions (approx.) 430 x 70 x 315 mm (w/h/d) incl.

projecting parts and controls

Mass (approx.) 4.4 kg

Supplied accessories

• i.LINK connecting cable (1)

• Remote commander (remote) (1)

Design and specifications are subject to change without notice.

MINIDISC DECK

1

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for customers which are displayed automatically when errors occur, and error codes which

show the error history in the test mode during servicing. For details on how to view error codes for the customer, refer to the following box

in the instruction manual. For details on how to check error codes during servicing, refer to the following “Procedure for using the Self-

Diagnosis Function (Error History Display Mode)”.

Self-Diagnosis Function

The deck’s self-diagnosis function automatically checks the condition of the MD deck when an error occurs, then issues a

code and an error message on the display . If the code and message alternate, find them in the following table and perform

the indicated countermeasur e. Should the problem persist, consult your nearest Sony dealer .

Code/Message Cause/Remedy

C11/Pr otected The inserted MD is recor d-protected.

C12/Cannot Copy An attempt was made to play a disc that is not compatible with this deck (MD data disc, etc.).

C13/REC Error The recor ding was not made properly .

C13/Read Error The deck could not read the TOC on the MD properly.

C14/T oc Err or The deck could not read the TOC on the MD properly.

C41/Cannot Copy The digitally dubbed material cannot be recorded digitally (page 14).

C71/Din Unlock The sporadic appearance of this message is caused by the digital signal being recor ded. This will not af fect

C78:03/LOOP CONNECT The i.LINK connection is looped.

C78:04/NO SIGNAL The selected component is turned on, but no signal is not output from the component.

C78:11/C78:12/CANNOT LINC

C78:15/BUS FULL The signal bus within the i.LINK configuration is full and no more signals can be output from the deck.

C78:21/NO SIGNAL The deck and the selected component are connected correctly, but no signal from the component is input to

C78:22/NO SIGNAL The format of the input signal is not supported.

C78:23/NO SIGNAL The selected component is not turned on.

C78:31/NO SIGNAL The communication between the deck and the selected component is unstable. Or , the format of the input

C78:32/NEW CONNECT While recor ding, a new component is connected within the i.LINK configuration, or a mains lead or an

E0001/MEMORY NG Ther e is an error in the internal data that the deck needs in order to operate.

E0101/LASER NG Ther e is a problem with the optical pick-up.

, Take out the MD and close the recor d-protect slot (page 13).

, Replace the disc.

, Set the deck in a stable surface, and repeat the recor ding procedure.

The inserted MD is dirty (with smudges, fingerprints, etc.), scratched, or substandard in quality.

, Replace the disc and repeat the recording procedur e.

, Take out the MD and insert it again.

, Insert another disc.

, If possible, erase all the tracks on the MD (page 29).

the recor ding.

While recor ding from a digital component connected through the i.LINK S200 connector , the digital

connecting cable was unplugged or the digital component turned off.

, Connect the cable or turn the digital component back on.

, Check the connection (see page 39).

.

, Check the selected component.

The deck cannot establish a LINC with a component because of an existing LINC between the deck and

another component.

, Cancel the LINC between the deck and the other component.

the deck.

, Check the selected component.

, Verify that the component is on.

signal is not supported.

, Check the condition and the signal format of the selected component.

i.LINK connecting cable of the component within the configuration is connected or disconnected.

, Do not connect or disconnect any mains leads or i.LINK connecting cables during recording. If you do,

recording may not be done corr ectly.

, Consult you nearest Sony dealer.

, Consult you nearest Sony dealer

2

Procedure for using the Self-Diagnosis Function (Error History Display Mode).

Note: Perform the self-diagnosis function in the “error history display mode” in the test mode. The following describes the least required

procedure. Be careful not to enter other modes by mistake. If you set other modes accidentally, press the POWER “X2” button to

exit the mode.

1. While pressing the . button and x button, connect the power plug to the outlet, and release the . button and x button.

When the test mode is set, “[Check]” will be displayed.

2. Press the . or > button and when “[Service]” is displayed, press the 7 button.

3. Press the . or > button and display “Err Display”.

4. Pressing the 7 button sets the error history mode and displays “op rec tm”.

5. Select the contents to be displayed or executed using the . button.

6. Pressing the POWER button will display or execute the contents selected.

7. Pressing the POWER button another time returns to step 4.

8. Pressing the x button displays “Err Display” and exits the error history mode.

9. To exit the test mode, press the POWER “X2” button. The unit sets into the STANDBY state, the disc is ejected, and the test mode ends.

10.If the unit fails to enter STANDBY mode, remove the AC cord from its socket, insert the AC cord into the socket again, turn on the power,

and then check to make sure that the unit has exited from test mode.

NOTE

• The MDS-LSA1 is designed so that a number of functions which may be performed in test mode may be performed by clicking a single

button.

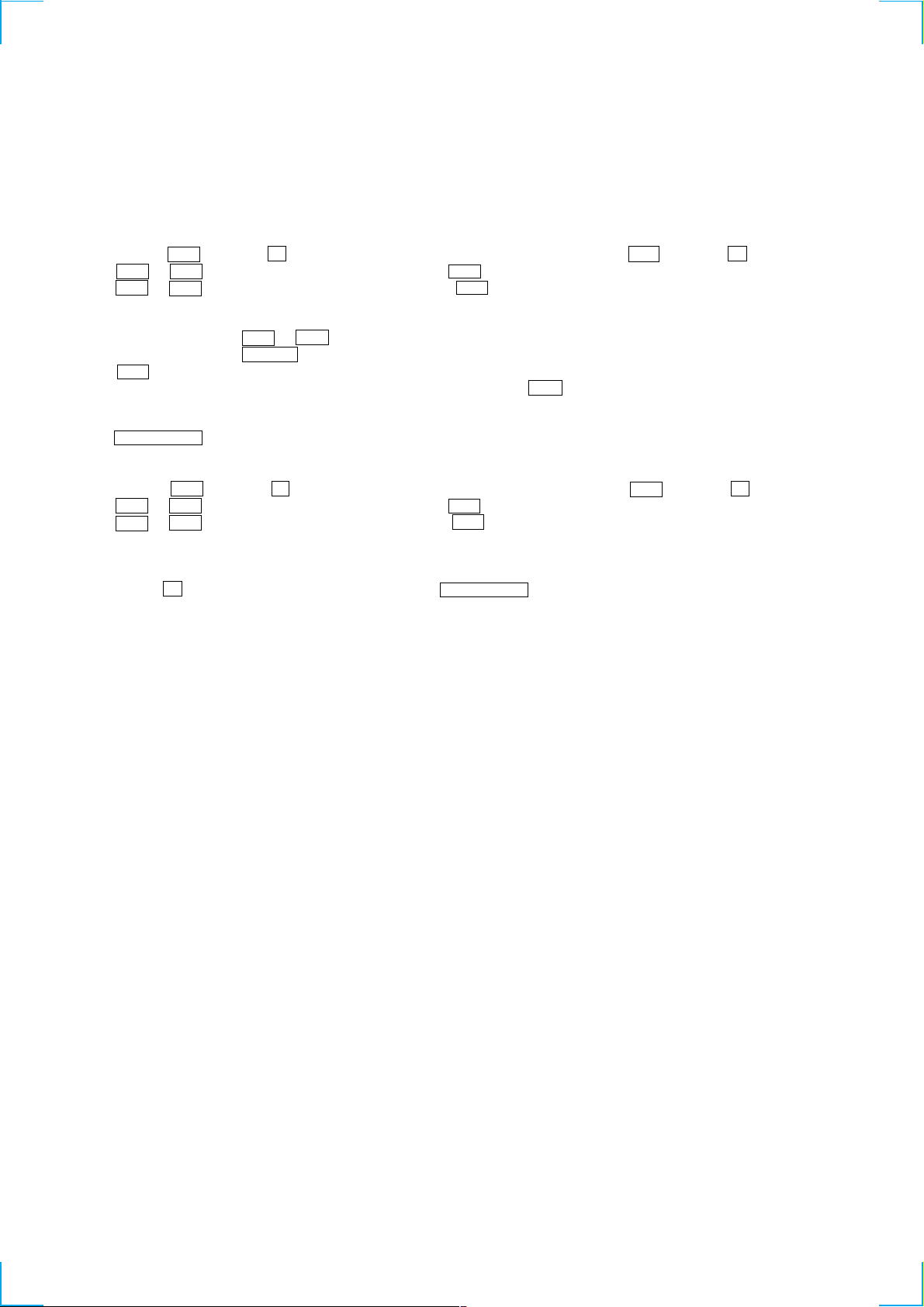

Switching between functions

Pressing the INPUT button causes the display to change as indicated below.

Hidden t “X2”

↑

The functions performed by each button change in accordance with the DISPLAY mode.

Note that the following notation is used herein:

POWER ............. Press the POWER button when HIDDEN.

POWER “X2” .... Press the POWER button while “X2” is lit.

3

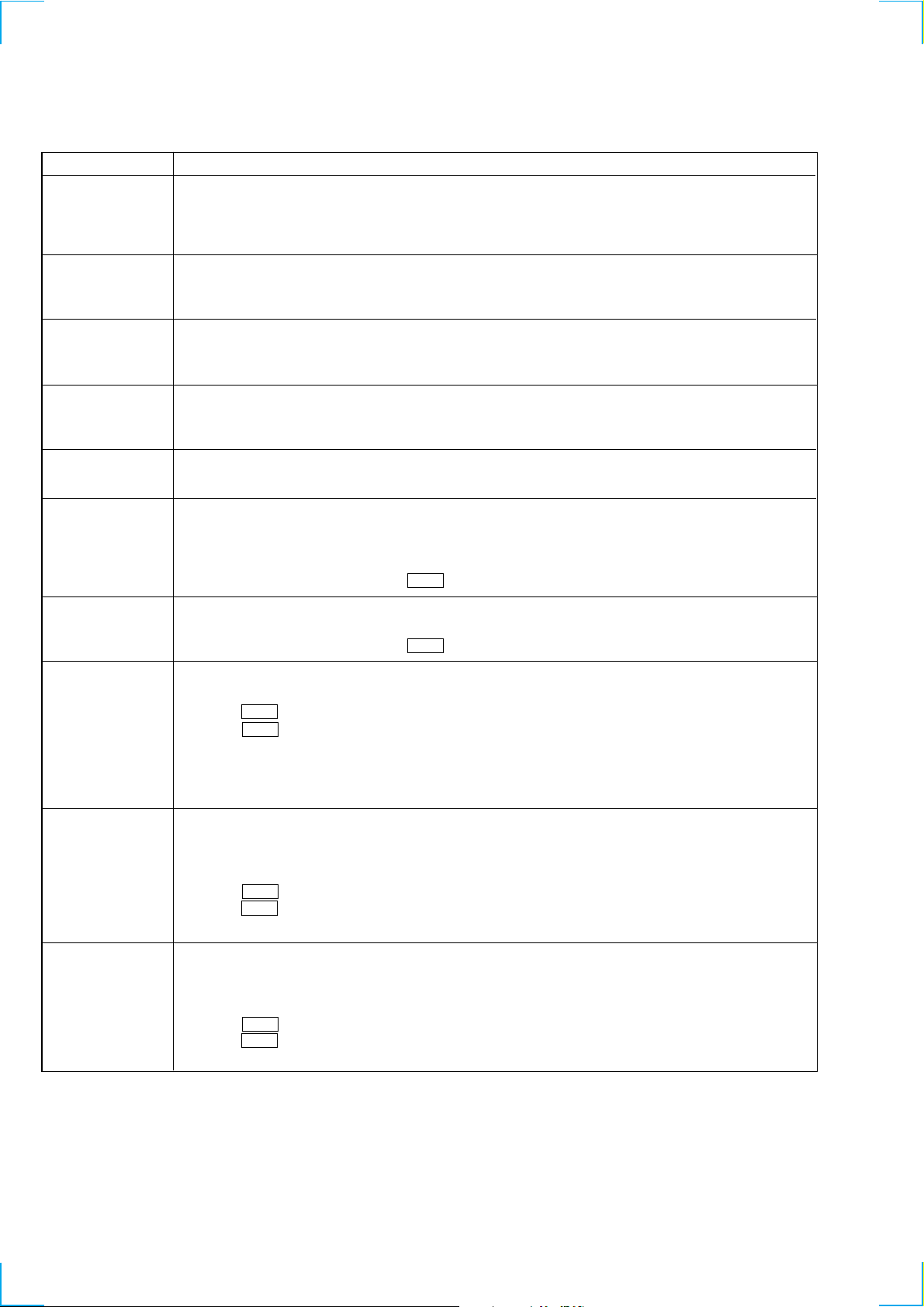

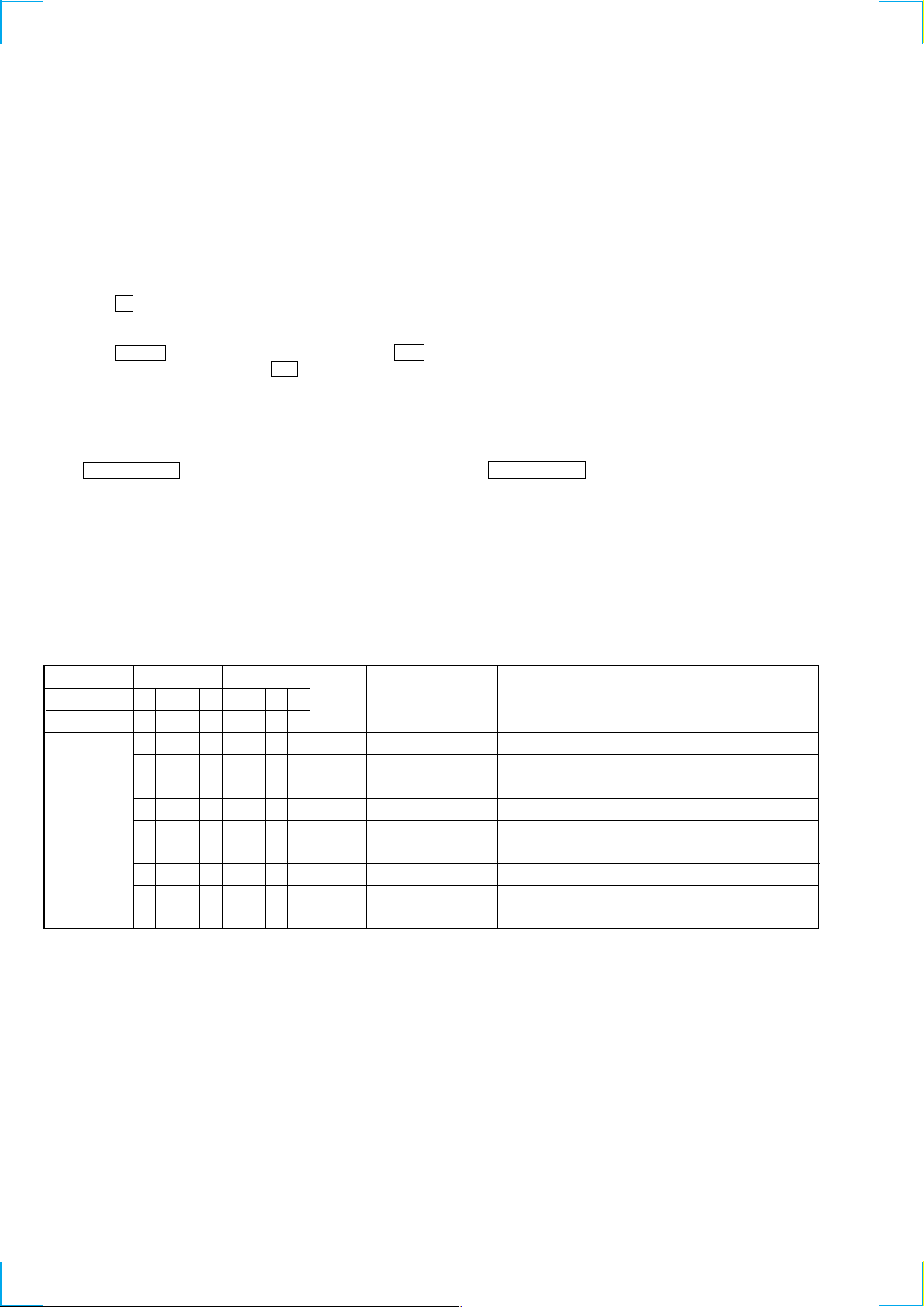

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Selecting the Test Mode

Display

op rec tm

op play tm

spdl rp tm

retry err

total err

err history

retry adrs

History

Displays the total recording time.

When the total recording time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

The display time is the time the laser is set to high power, which is about 1/4 of the actual recording time.

Displays the total playback time.

When the total playback time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

Displays the total rotating time of the spindle motor.

When the total rotating time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

Displays the total number of retry errors during recording and playback

Displays “r xx p yy”. xx is the number of errors during recording. yy is the number of errors during playback.

This is displayed in hexadecimal from 00 to FF.

Displays the total number of errors

Displays “total xx”. This is displayed in hexadecimal from 00 to FF.

Displays the past ten errors.

Displays “0x ErrCd@@”.

X is the history number. The younger the number, the more recent is the history (00 is the latest). @@ is the error

code.

Select the error history number using the . button.

Displays the past five retry addresses.

Displays “xx ADRS yyyy”, xx is the history number, yyyy is the cluster with the retry error.

Select the error history number using the . button.

er refresh

op change

spdl change

Mode for erasing the error and retry address histories

Procedure

1. Press the . button when displayed as “er refresh”.

2. Press the 7 button when the display changes to “er refresh?”.

When “complete!” is displayed, it means erasure has completed.

Be sure to check the following after executing this mode.

*Data has been erased.

*Perform recording and playback, and check that the mechanism is normal.

Mode for erasing the total time of op rec tm, op play tm.

These histories are based on the time of replacement of the optical pick-up. If the optical pick-up has been replaced,

perform this procedure and erase the history.

Procedure

1. Press the . button when displayed as “op change”.

2. Press the 7 button when the display changes to “op change?”.

When “Complete!” is displayed, it means erasure has completed.

Mode for erasing the total spdl rp tm time

These histories are based on the time of replacement of the spindle motor. If the spindle motor has been replaced,

perform this procedure and erase the history.

Procedure

1. Press the . button when displayed as “spdl change”

2. Press the 7 button when the display changes to “spdl change?”

When “Complete!” is displayed, it means erasure has completed.

4

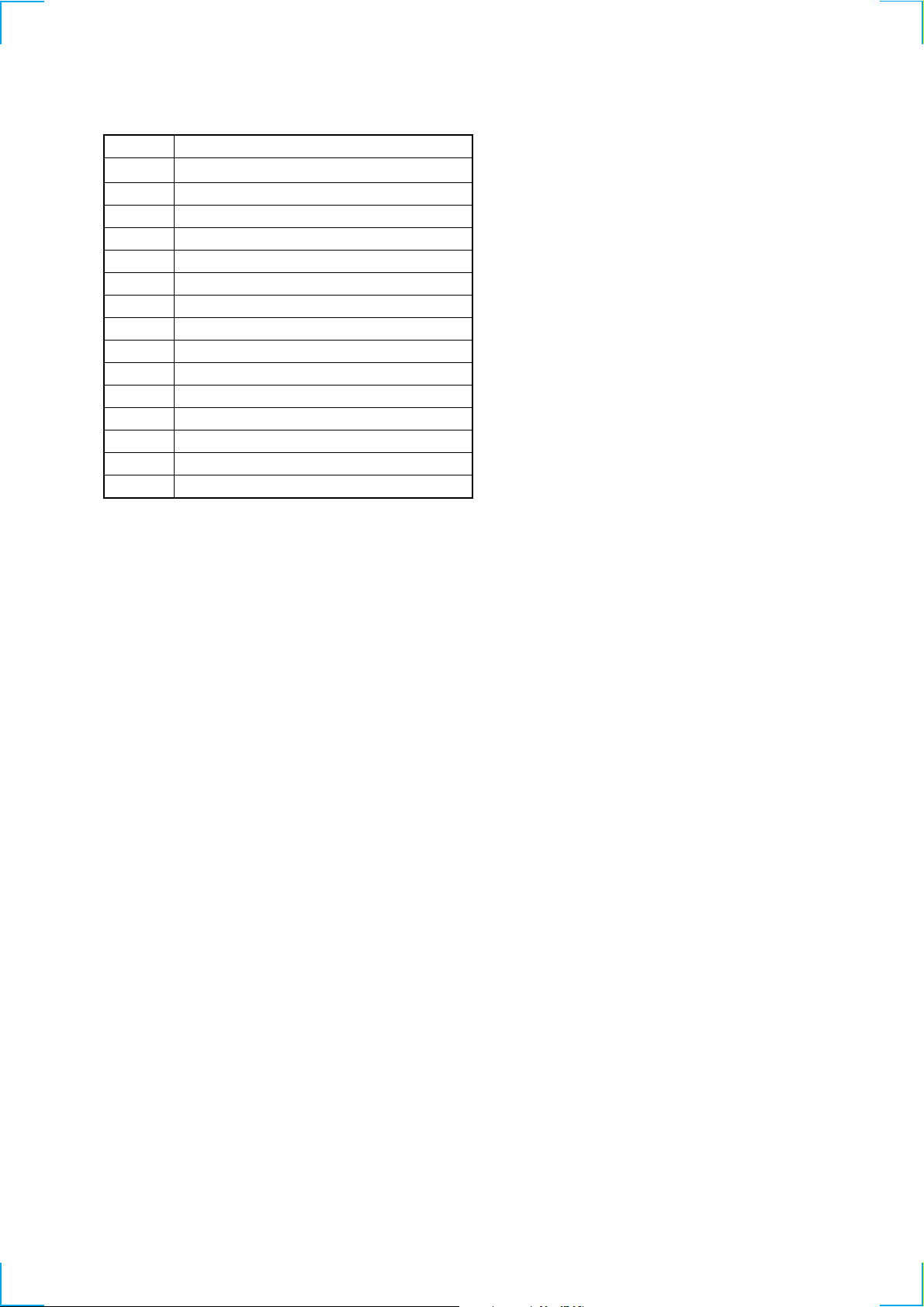

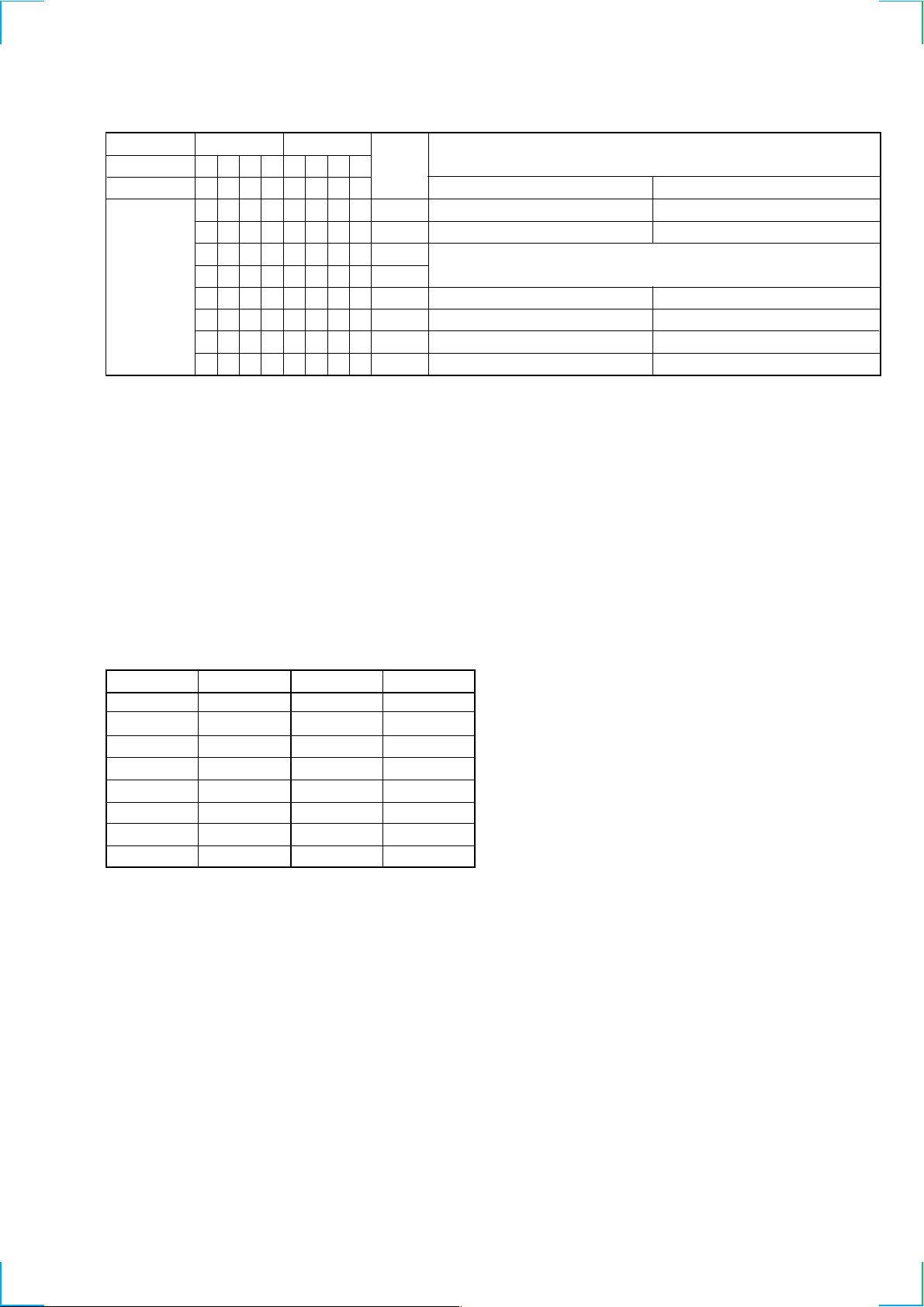

Table of Error Codes

TABLE OF CONTENTS

Error Code

10

12

20

21

22

23

24

30

31

40

41

42

43

50

51

Description

Could not load

Loading switches combined incorrectly

Timed out without reading the top of PTOC

Could read top of PTOC, but detected error

Timed out without accessing UTOC

Timed out without reading UTOC

Error in UTOC

Could not start playback

Error in sector

Retry cause generated during normal recording

Retried in DRAM overflow

Retry occurred during TOC writing

Retry aborted during S.F editing

Other than access processing, and could not read address.

Focus NG occurred and overran.

1. SERVICING NOTES ............................................. 6

2. GENERAL ........................................................................ 12

3. DISASSEMBLY

3-1. Case (Top) ........................................................................... 17

3-2. MD Mechanism Deck ......................................................... 18

3-3. Base (Front) Assy, Panel ..................................................... 18

3-4. Clip Board and Main Board ................................................ 19

3-5. Trans Board ......................................................................... 19

3-6. Holder Assy ......................................................................... 20

3-7. Over Write Head ................................................................. 20

3-8. Optical pick-up (MD) (KMS-262A/J1N) ............................ 21

3-9. BD Board ............................................................................ 21

4. TEST MODE ..................................................................... 22

5. ELECTRICAL ADJUSTMENTS ............................... 30

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................... 41

6-2. Block Diagrams

• BD Section ....................................................................... 42

• Main Section .................................................................... 43

6-3. Printed Wiring Board – BD Section – ................................. 45

6-4. Schematic Diagram – BD Section (1/2) – ........................... 46

6-5. Schematic Diagram – BD Section (2/2) – ........................... 47

6-6. Printed Wiring Board – Main Section (Side A) – ............... 48

6-7. Printed Wiring Board – Main Section (Side B) – ............... 49

6-8. Schematic Diagram – Main Section (1/3) – ........................ 50

6-9. Schematic Diagram – Main Section (2/3) – ........................ 51

6-10. Schematic Diagram – Main Section (3/3) – ..................... 52

6-11. Printed Wiring Board – Power Section – ......................... 53

6-12. Printed Wiring Board – Panel Section – ........................... 54

6-13. Schematic Diagram – Panel Section – ............................. 55

6-14. IC Block Diagrams ........................................................... 56

6-15. IC Pin Functions ............................................................... 59

7. EXPLODED VIEWS

7-1. Panel Section ....................................................................... 70

7-2. Chassis Section ................................................................... 71

7-3. MD Mechanism Section-1 (MDM-7X2B) .......................... 72

7-4. MD Mechanism Section-2 (MDM-7X2B) .......................... 73

8. ELECTRICAL PARTS LIST ........................................ 74

5

SECTION 1

SERVICE NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

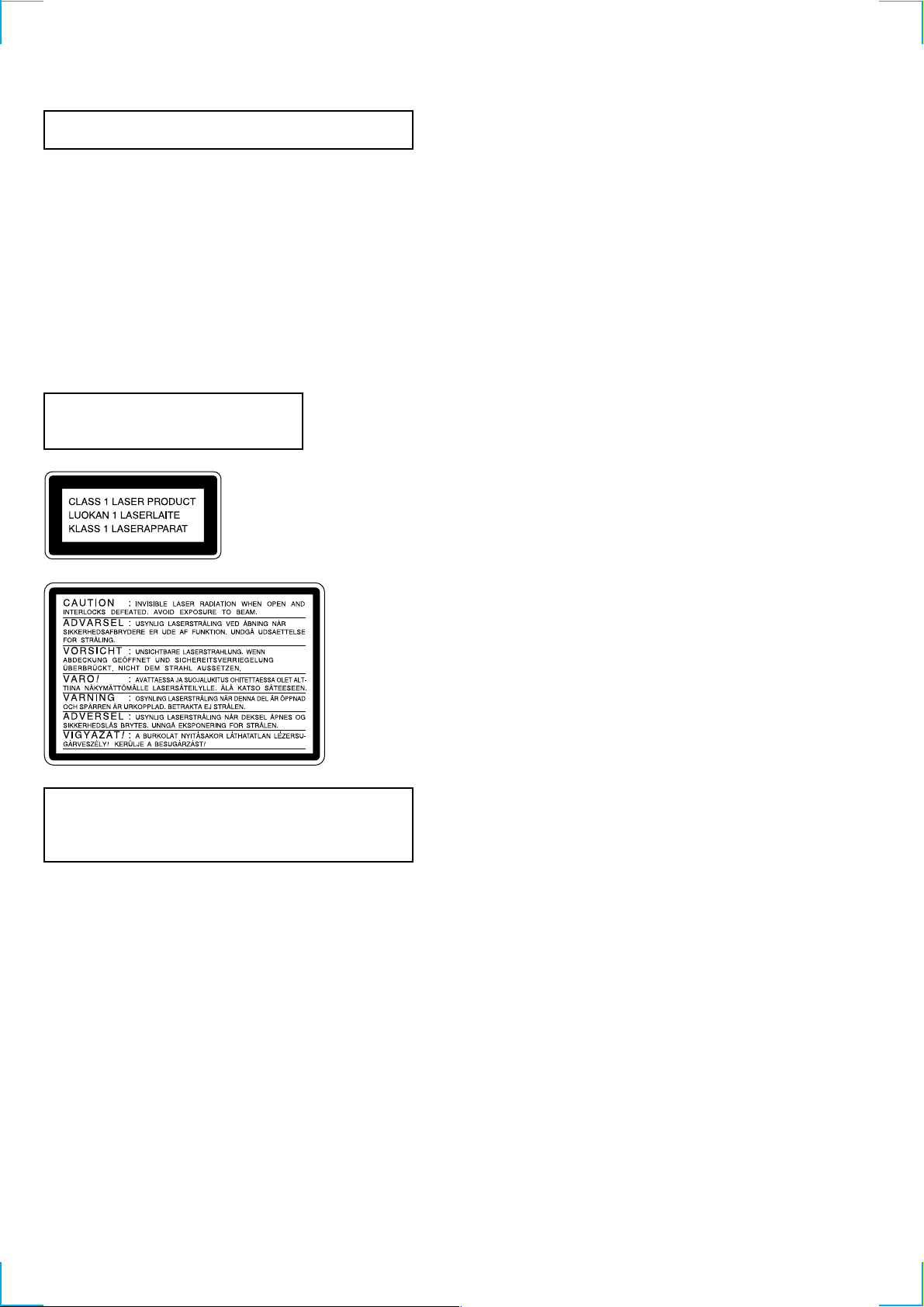

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a

CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT

MARKING is located on the

rear exterior.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

This caution

label is located

inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

6

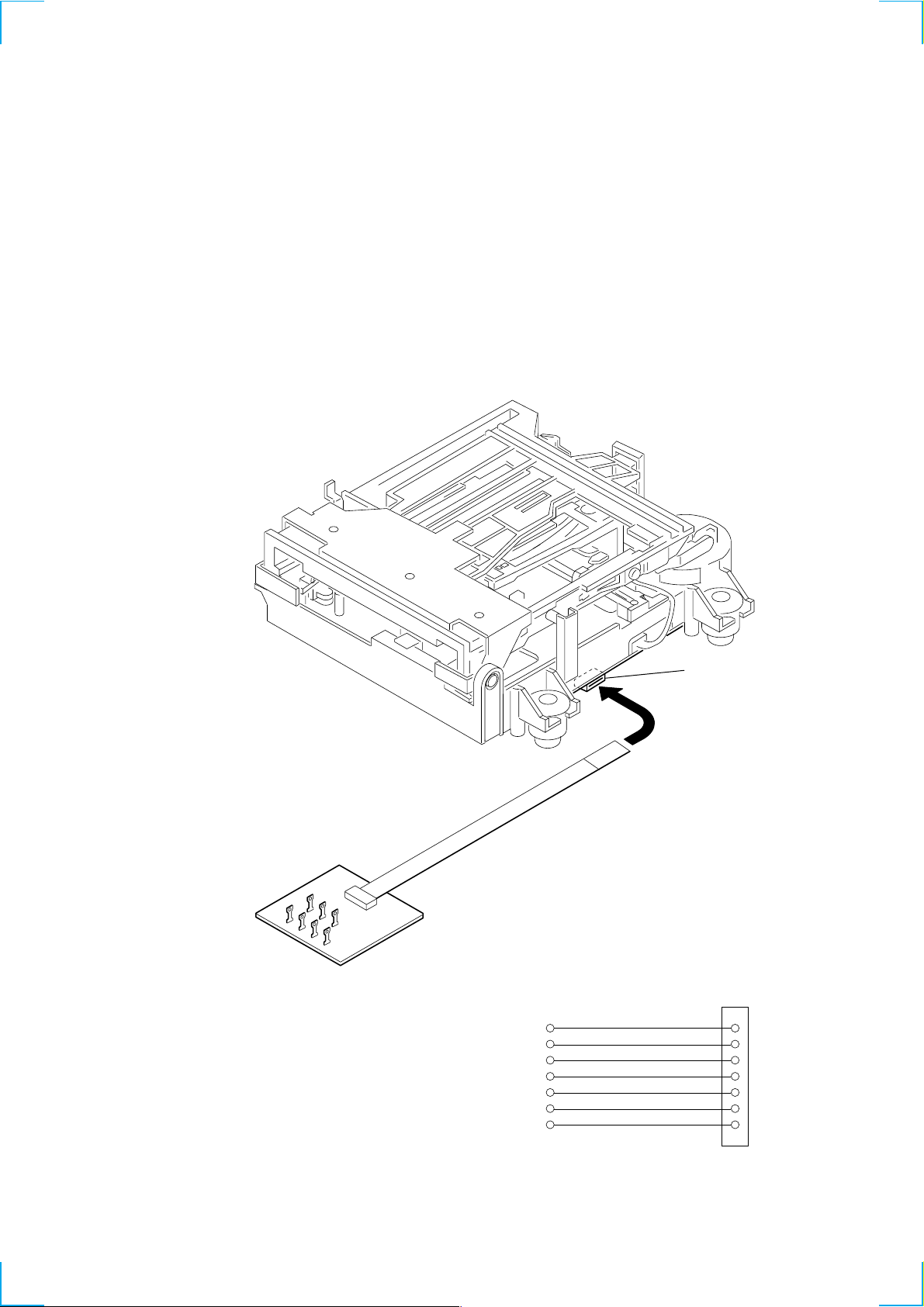

JIG FOR CHECKING BD BOARD WAVEFORM

I+3V

IOP

GND

TE

FE

VC

RF

I+3V

IOP

GND

TE

FE

VC

RF

1

7

for

MDM-7X2B

The special jig (J-2501-196-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

GND : Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TE : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

FE : Focus error signal

I+3V

GND

FE

CN105

IOP

TE

VC

RF

7

IOP DATA RECORDING AND DISPLAY WHEN OPTICAL PICK-UP AND NON-VOLATILE MEMORY (IC195 OF

BD BOARD) ARE REPLACED

The Iop value labeled on the optical pick-up can be recorded in the non-volatile memory. By recording the value, it will eliminate the need

to look at the value on the label of the optical pick-up. When replacing the optical pick-up or non-volatile memory (IC195 of BD board),

record the Iop value on the optical pick-up according to the following procedure.

Record Precedure:

1. While pressing the . button and x button, connect the power plug to the outlet, and release the . button and x button.

2. Press the . or > button to display “[Service]”, and press the 7 button.

3. Press the . or > button to display “Iop Write” , and press the 7 button.

4. The display becomes “Ref=@@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

5. Input the Iop value written on the optical pick-up.

To select the number : Press the . or > button.

To select the digit : Press the POWER button.

6. When the 7 button is pressed, the display becomes “Measu=@@@.@” (@ is an arbitrary number).

7. As the adjustment results are recorded for the 6 value. Leave it as it is and press the 7 button.

8. “Complete!” will be displayed momentarily. The value will be recorded in the non-volatile memory and the display will become “Iop

Write” .

9. Press the POWER “X2” button to complete.

Display Precedure:

1. While pressing the . button and x button, connect the power plug to the outlet, and release the . button and x button.

2. Press the . or > button to display “[Service]”, and press the 7 button.

3. Press the . or > button to display “Iop Read” , and press the 7 button.

4. “@@.@/##.#” is displayed and the recorded contents are displayed.

@@.@ : indicates the Iop value labeled on the optical pick-up.

##.# : indicates the Iop value after adjustment.

5. To end, press the x button to display “Iop Read”. Then press the POWER “X2” button.

8

CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5 Electrical Adjustments”.

• 5-6-2. Laser power check (see page 33)

• 5-6-3. Iop Compare (see page 33)

• 5-6-4. Auto Check (see page 34)

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for

adjustments.

When performing adjustments, use the specified values for adjustments.

FORCED RESET

The system microprocessor can be reset in the following procedure.

Use these procedure when the unit cannot be operated normally due to the overrunning of the microprocessor, etc.

Procedure :

1. Disconnect the short-circuit pin of CN201.

2. Disconnect the AC outlet.

3. After some time, connect AC power plug to the AC outlet again.

4. Connect the short-circuit pin of CN201.

[MAIN BOARD] (SIDE A)

CN201

9

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent indicator tube. During playback, the

“track mode” for obtaining track information will be set.

This is useful for locating the faulty part of the unit.

• The following will be displayed :

During recording and stop : Retry cause, number of retries, and number of retry errors.

During playback : Information such as type of disc played, part played, copyright.

These are displayed in hexadecimal.

Procedure:

1. Press the x button continuously for about 10 seconds.

2. When the mode is set, “RTs 00c 00e 00” is displayed.

3. Set a recortable disc in the unit.

4. Press the z REC button to start recording. Then press the 7 button and start recording.

5. To check the “track mode”, press the 7 button to start play.

6. To exit the test mode, disconnect the power plug from the outlet. If the test mode cannot be exited, refer to “Forced Reset” on page 9.

Fig. 1 Reading the Test Mode Display

(During recording and stop)

(During playback)

RTs@@c##e**

Fluorescent display tube display

@@ : Cause of retry

## : Number of retries

** : Number of retry errors

Fig. 2 Reading the Test Mode Display

Reading the Retry Cause Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

@@ ###** $$

Fluorescent display tube display

@@ : Parts No. (name of area named on TOC)

### : Cluster

** : Sector

$$ : Track mode (Track information such as copyright infor-

Cause of Retry Occurring conditions

shock

ader5

Discontinuous address

DIN unlock

FCS incorrect

IVR rec error

CLV unlock

Access fault

} Address (Physical address on disc)

mation of each part)

When track jump (shock) is detected

When ADER was counted more than five times continu-

ously

When ADIP address is not continuous

When DIN unlock is detected

When not in focus

When ABCD signal level exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 t b6

Lower bit : 2 = 0010 t b1

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

When A2 is displayed:

Higher bit : A = 1010 t b7+b5

Lower bit : 2 = 0010 t b1

The retry cause in this case is combined of “Access fault”, “IVR rec error”, and “ader5”.

10

Reading the Track Mode Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example When 84 is displayed:

Higher bit : 8 = 1000 t b7

Lower bit : 4 = 0100 t b2

In this case, as b2 and b7 are 1 and others are 0, it can be determined that the retry cause is combined of “Emphasis OFF”, “Monaural”,

“Original”, “Copyright exists”, and “Write allowed”.

Example When 07 is displayed:

Higher bit : 0 = 1000 t All 0

Lower bit : 7 = 0111 t b0+b1+b2

In this case, as b0, b1, and b2 are 1 and others are 0, it can be determined that the retry cause is combined of “Emphasis ON”, “Stereo”,

“Original”, “Copyright exists”, and “Write prohibited”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

When 0 When 1

Emphasis OFF

Monaural

This is 2-bit display. Normally 01.

01:Normal audio. Others:Invalid

Audio (Normal)

Original

Copyright

Write prohibited

Details

Emphasis ON

Stereo

Invalid

Digital copy

No copyright

Write allowed

Hexadecimal t Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

11

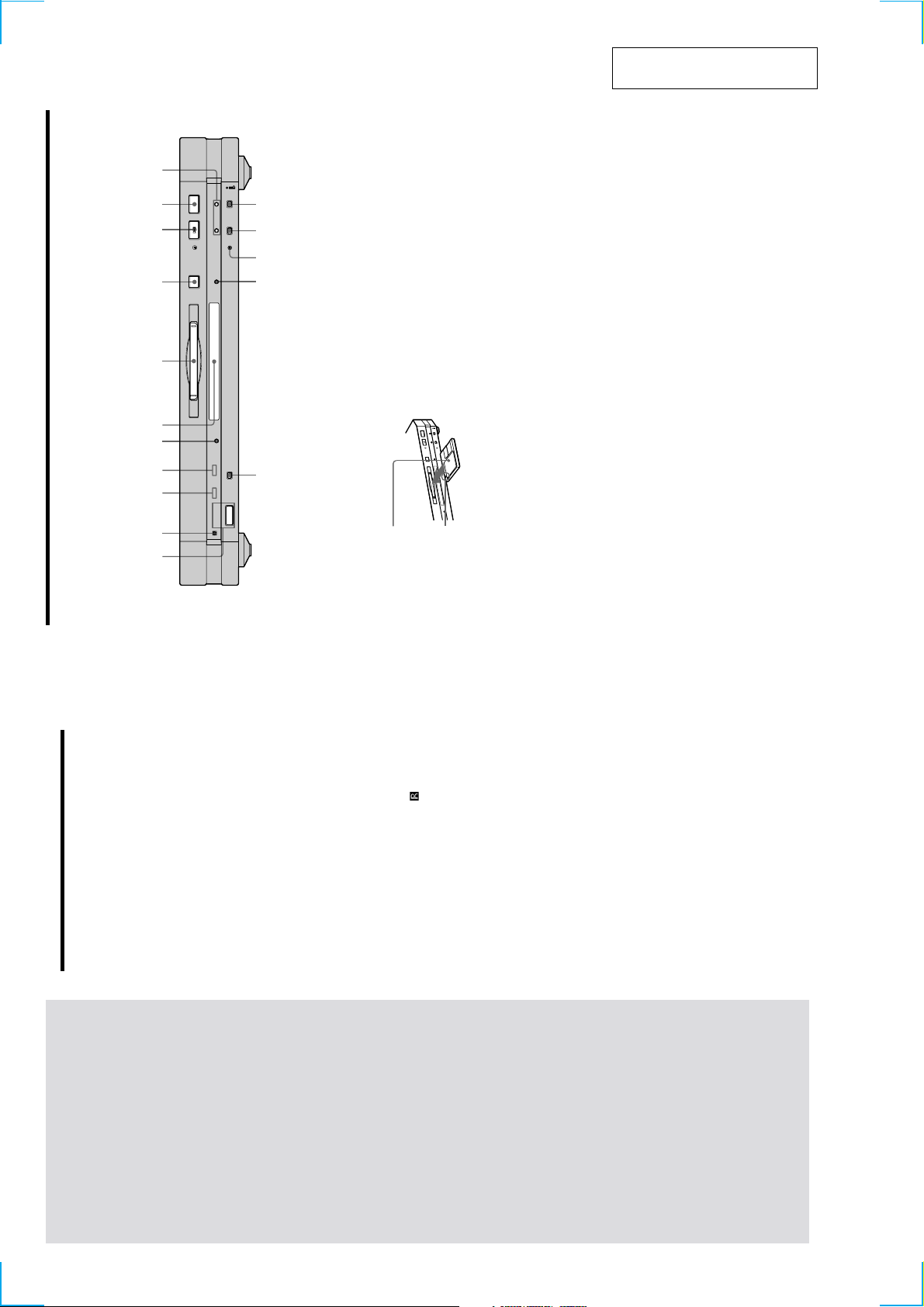

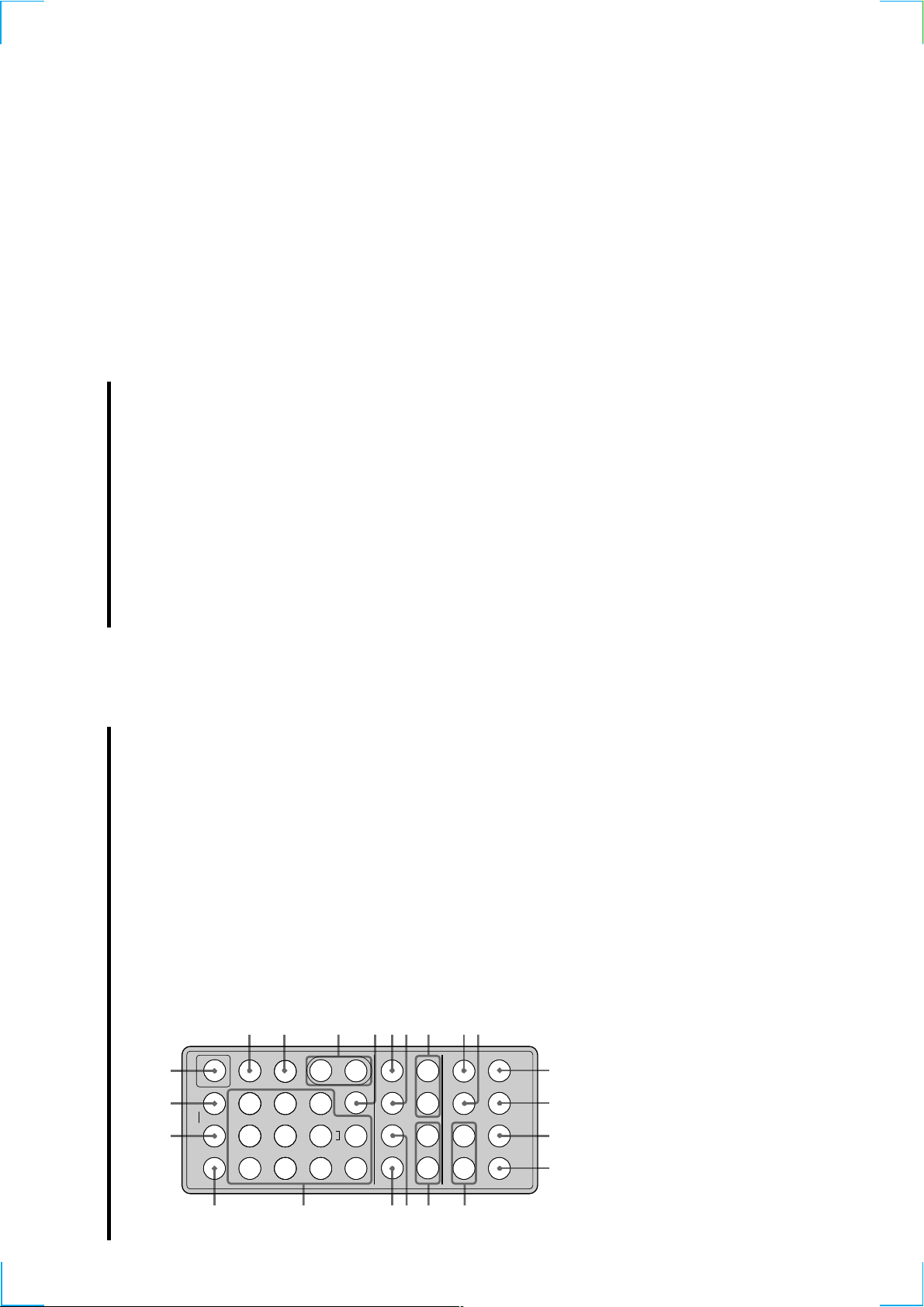

z

x

0qa

. >

HIGH SPEEDCD SYNCHROREC

A

89

DISPLAY REC MODE

456 7

INPUT

qf qd qs

qh qg

qf HIGH SPEED indicator (20)

SECTION 2

GENERAL

Lights up when the deck is in High-speed CD

Synchr o-r ecor ding mode.

Press to select one of the following four r ecording

qg REC MODE button (15)

This section is extracted from

instruction manual.

GB

5

in the display window of the component. Press the

modes: MONO mode (monaural recor ding), stereo

mode (ster eo recor ding), LP2 mode (2 times long

recor ding), and LP4 mode (4 times long recor ding).

Press once to display the selected pr ogramme source.

qh INPUT button (12)

z

x

>

.

A

button again to switch to another programme source.

If the pr ogramme sour ce is either the STR-LSA1 or the

CDP-LSA1, “N N n n” appears momentarily

Front Panel Parts

Descriptions

STANDBY LP H.A.T.S

23

1

?/1

With the arrow

pointing towards

6 Display window (8, 16, 32, 35)

Shows various information. For details, see “Display

Window Descriptions” on page 8.

Press to turn on the deck. When you turn on the deck,

1 ~/1 (power) switch (12, 21)

Insert the MD as illustrated below .

7 MD insertion slot (12, 21)

the STANDBY indicator turns off. When you press the

switch again, the deck turns off and the indicator

With the labelled

side up

) for r emote

lights up.

Point the remote towar ds this sensor (

2 Remote sensor

operations.

3 LP indicator (15)

Lights up when LP2 or LP4 mode is selected, or when

the deck

a track recor ded in LP2 or LP4 mode is being played.

Press to eject the MD.

8 A button (12, 21)

Lights up when the H.A.T.S. function is activated on

the receiver .

4 H.A.T.S. indicator

• P ress when the deck is stopped to start play .

9 HX button (12, 19, 21, 22)

What is the H.A.T.S. function?

z

resume play or r ecor ding.

• P ress during playback to pause play .

• P ress during recor ding to pause recording.

• P ress during playback pause or recording pause to

q; x button (12, 20, 21)

The H.A.T.S. (High-quality digital Audio Transmission

System) function on the receiver causes digital audio signals

output from an MD deck or the recording sour ce (e.g., a CD

player) to be momentarily stor ed in a buffer in the receiver

prior to output. This reduces jitter that sometimes occurs

during digital audio transmission.

Press to stop play or r ecording, or cancel the selected

operation.

5 DISPLAY button (9, 13, 16, 20, 21)

qa ./> buttons (12, 15, 16, 19, 21, 22)

information.

• P ress when the deck is stopped to display disc

Press to locate tracks or select a menu item and a

setting value.

Press to r ecor d on the MD or mark track numbers.

Press to start CD Synchr o-recor ding.

qs REC z button (12, 17)

qd CD SYNCHRO button (19)

ding level.

track being recor ded or recor dable time on the MD.

current track.

of the track curr ently being played in the

pr ogramme.

• P ress during recor ding to display information on the

• P ress during play to display information on the

• P ress during Programme Play to display the number

the recor

• Pr ess during recording or recording pause to adjust

Location and

Function of

Parts

12

This chapter tells you about the

location and function of the various

buttons and contr ols on the front

panel and the supplied remote.

Further details are pr ovided on the

pages indicated in the parentheses.

It also tells you about the information

that appears in the display window .

GB

4

GB

w;

2

wa ws 1

3

4

567

8

9

0

ql

qkqjqh

qg

qdqf qs qa

?/1

.>m M

NX

xz

789

>10

10

/0

123

456

PLAY MODE

ABC

,

–/, DEF DISPLAY

JKLGHI MNO

TUVPQRS WXYZ

SCROLL

YES

MENU/NO

FADER

REC MODE

CLEAR

NAME EDIT/

SELECT

M.SYNC

T.REC

INPUT LEVEL

REPEAT

CLEAR

MD

A

y

B

–

+

1 ~/1 (power) switch (12, 21)

Press to turn on the deck. When you turn on the deck,

the STANDBY indicator on the deck turns off. When

you pr ess the switch again, the deck turns off and the

indicator lights up.

2 DISPLAY button (9, 13, 16, 20, 21, 24)

Press to select the information to be displayed in the

window .

3 SCROLL button (21)

Press to scr oll the name of a track or MD.

4 LEVEL +/– buttons (16)

Press to adjust the recor ding level.

5 INPUT button (12)

Use to select the pr ogramme sour ce to be recorded.

6 z button (12, 17, 19)

Press to r ecor d on the MD or mark track numbers.

7 x button (12, 20, 21)

Press to stop play or recor ding, or cancel the selected

operation.

8 m/M buttons (22, 23, 29, 30, 32)

Press to locate a portion within a track, change the

contents of a pr ogramme, or shift the cursor to the

right.

9 REC MODE button (15)

Press to select one kf the following four recor ding

modes: MONO mode (monaural recor ding), ster eo

mode (ster eo recor ding), LP2 mode (2 times long

recor ding), and LP4 mode (4 times long recor ding).

q; FADER button (36)

Press to perform Fade-in Recor ding or Fade-out

Recor ding.

qa T.REC button (18)

Press to start Time Machine Recording.

qs MUSIC SYNC button (19)

Press to start Music Synchr o-recor ding.

qd CLEAR button (24, 33)

Press to erase a track in the pr ogramme or erase a

character .

qf NAME EDIT/SELECT button (32, 33)

Press to add the name or change the name of a track or

an MD, or to select the type of characters to be input.

GB

7

.

Press to display “Edit Menu” or “Setup Menu.”

YES button (15-17, 19, 24-26, 28-38)

Press to carry out the selected operation.

qg MENU/NO button (15-19, 25, 26, 28-38)

Press to locate tracks, select a menu item and a setting

qh ./> buttons (12, 15-19, 21, 22, 24-26, 28-38)

value, or select the character to be input.

qj X button (12, 20, 21)

Press to pause play or r ecording. Press again to

resume play or recording.

Press to start play .

qk N button (12, 19, 21, 22, 24)

Press to input letters or numbers.

ql Letter/number buttons (22, 24, 32)

Press to select Shuf fle Play or Pr ogramme Play .

w; PLAY MODE button (24)

wa REPEAT CLEAR button (23)

ws AyB button (23)

Press to select Repeat A-B Play

pr ess to resume normal play .

• P ress to play tracks r epeatedly.

• When Repeat All Play or Repeat 1 Play is selected,

13

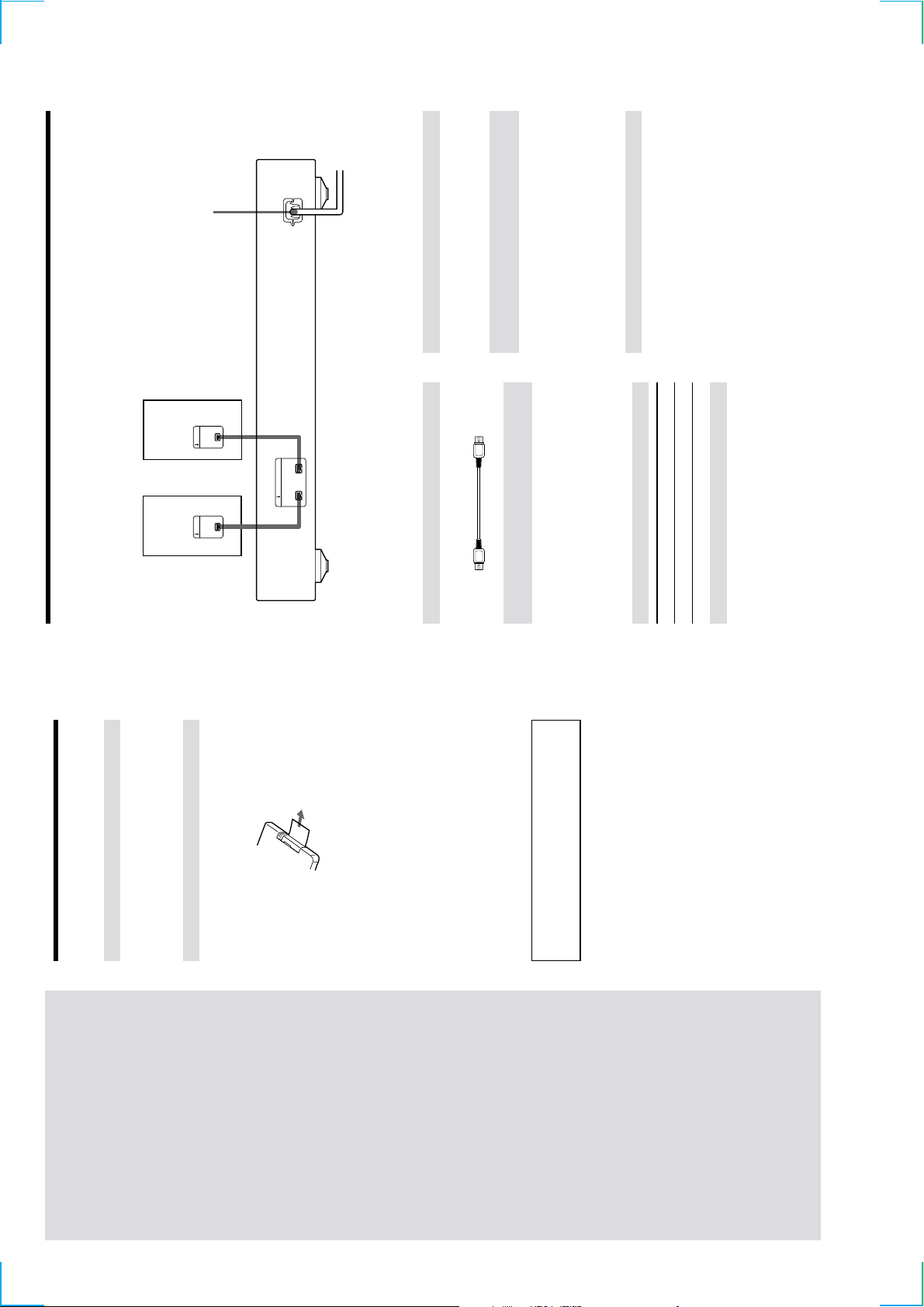

Mains lead

GB

11

CD

Hooking Up the i.LINK Components

About optional i.LINK connecting cables

About i.LINK components to be used in

(4 pins-4 pins).

combination with the MD deck

The following i.LINK components can be used with the

Be sure to use the Sony i.LINK S200 connecting cables

MD deck:

• STR-LSA1 r eceiver

• CDP-LSA1 CD Player

For general information about i.LINK

z

Connecting the mains lead

See “About i.LINK” on page 38.

Connect the mains lead of the deck to a wall outlet.

Note

If you use a timer, connect the mains lead to the outlet of the

timer .

*

player,

etc.

i.LINK S200

v v

i.LINK i.LINK

*

Receiver,

etc.

You can connect the i.LINK components to either i.LINK S200 connector

*

Required cords

i.LINK connecting cables (2) (only one supplied)

Things you should keep in mind while

hooking up the system

any connections.

• Turn off the power to all components befor e making

• Do not connect any mains lead until all the connections

are completed.

noise.

• Be sur e the connections ar e firm to pr event hum and

Jacks for connecting i.LINK components

Connect an To the

Note on i.LINK component hookups

eceiver or CD player , etc. i.LINK S200 connector

If a metal object should fall into the i.LINK S200

connector , short-cir cuiting may occur and damage the

components.

Before You Start the

Hookup

Getting

14

Checking the supplied accessories

This MD deck comes with the following items:

• i.LINK connecting cable (1)

Started

This chapter pr ovides information on

• Remote commander (remote) (1)

the supplied accessories, things you

should keep in mind while hooking

Before using the supplied remote

The supplied r emote alr eady contains a battery . Before

using the remote, pull out the insulating sheet to allow the

up the system, and how to connect

i.LINK components to the MD deck.

Be sur e to r ead this chapter

power to flow from the battery .

connect anything to the deck.

thor oughly befor e you actually

If you don’t use the remote for an extended period of time,

remove the battery to avoid possible damage fr om battery

leakage and corrosion.

When to replace the battery

z

Under normal conditions, the battery should last for about six

months. When the remote no longer operates the deck, replace

To avoid battery leakage

the battery with new kne.

Notes on lithium battery

Should the battery be swallowed, immediately consult a doctor .

battery .

• Keep the lithium battery out of the r each of the children.

• Wipe the battery with a dry cloth to assur e a good contact.

• Be sur e to observe the corr ect polarity when inserting the

short-cir cuit may occur.

WARNING

Battery may explode if mistr eated.

• Do not hold the battery with metallic tweezers, otherwise a

Do not rechar ge, disassemble, or dispose of in fire.

GB

10

B

transfer signals when they ar e turned of f. Refer to the

operation manual of each component to be connected before

you hook them up.

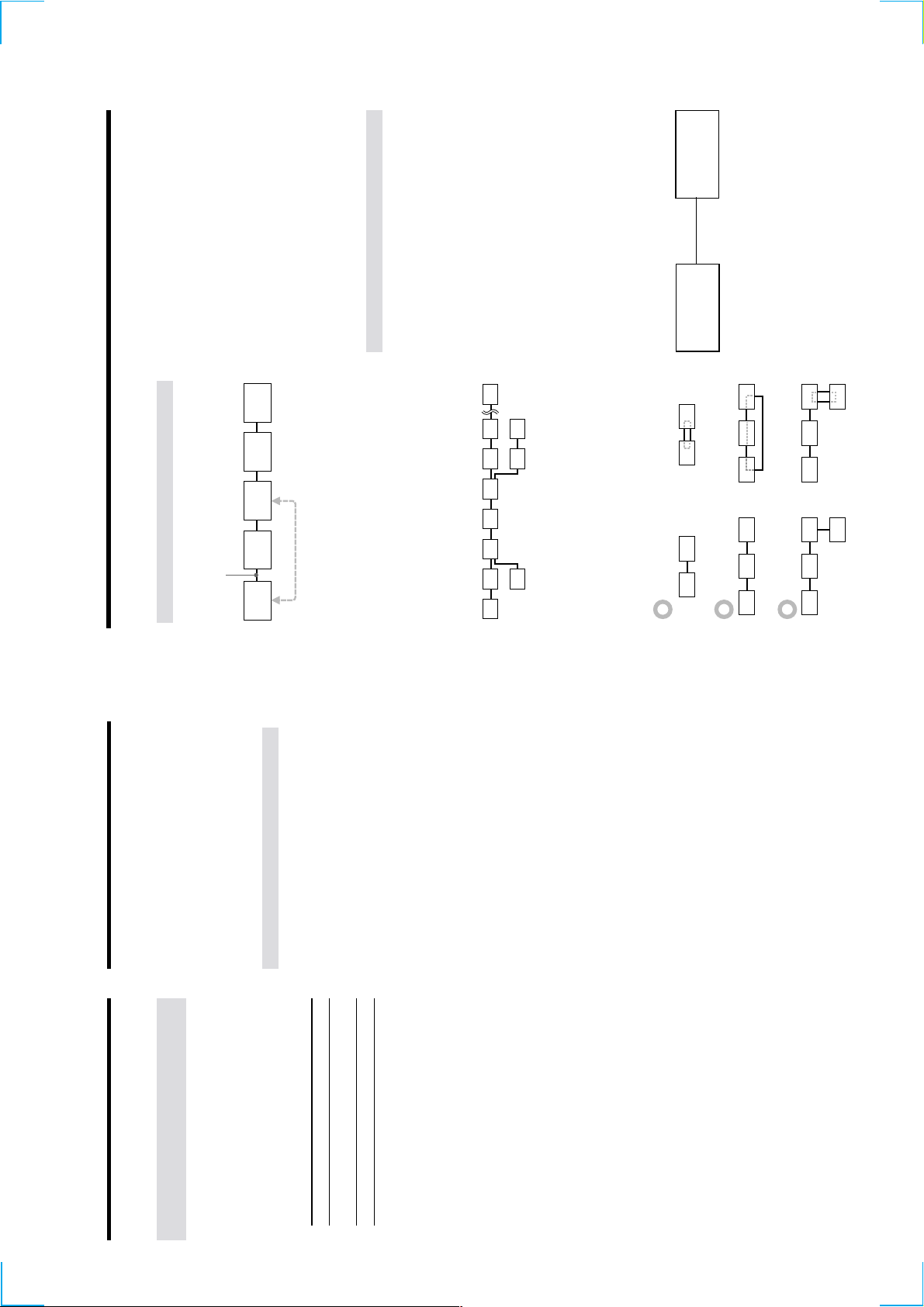

The use of i.LINK cables to connect i.LINK components as

• The maximum transmission rate of an i.LINK component is

shown below is called a “daisy chain” configuration.

i.LINK connecting cable

printed near its i.LINK connector . The indications S100, S200,

Notes

• Some i.LINK components (such as personal computers) do not

i.LINK connections

and S400 refer to maximum transmission rates of 100, 200, or

400 Mbps*, respectively . The actual transmission rate may be

faster or slower , depending on the dif ferences in transmission

i.LINK

component

i.LINK

component

i.LINK

component

i.LINK

component

i.LINK

component

What is Mbps?

rates and specifications among the connected components.

z

“Mbps” is an abbr eviation for megabits per second. It indicates

the amount of data transmitted per second. For example, a rate

Data can be transmitted between any two

components even if they are indirectly connected.

LINC (Logical INterface Connection)

of 200 Mbps means 200 megabits of data are transmitted in one

second.

connectors can serve as a branch point.

Branch connections

• Any i.LINK component with thr ee or mor e i.LINK

• Up to 63 i.LINK components can be connected in a

Before an audio signal can be transmitted between i.LINK

components, a “LINC” must first be established between

the receiving component (of the audio signal) and the

sending component. Establishing a “LINC” means

establishing a logical path for the transmission of digital

audio signals between the two components. Each logical

path has an ID number . Since the component that sends

an audio signal must output the signal to a path, and the

component that receives the signal must input it fr om the

same path, the path must be mutually known by both

components. During the establishment of a LINC, the

following communication occurs between the two i.LINK

components.

BA

C

D

single configuration. However , the maximum number

of components that can be daisy-chained in a single

route is 17 (i.e., a maximum of 16 i.LINK connecting

cables in a row). Each i.LINK cable used in a single

route is called a “hop.” For example, there are 6 hops in

the route between A and C in the illustration below, and

3 hops in the route between A and D.

Each route between A and B; A and C; A and D; B and C; B

and D; and C and D in the illustration above can have 16

Example

A component establishing a LINC with a CD player in

order to receive an audio signal fr om the CD player

hops (i.e., 17 components).

Loop-connection

A signal output fr om one component is transmitted to all

component)

CD player

(sending

1

,2<

from the CD player sends a request and path

information to the CD player to establish a

transmission path for the audio signal.

1 The component that will receive an audio signal

other components. A loop connection should thus be

avoided to pr event the r eturn of a signal to its source.

The component

that receives

Correct Incorrect (looped)

the audio signal

agr eeing to the establishment of a LINC.

2 The CD player r esponds to the component,

The digital audio signal transmission becomes possible

only after the communication described above has

occurr ed and a LINC has been established.

G

39

About i.LINK

Other Settings Using the Setup Menu

This section explains the general specifications and major

featur es of i.LINK. Read this section before doing any

i.LINK-r elated operation.

Turning off the MD deck automatically

(Power Save function)

Note that i.LINK connections and operations may vary ,

You can set so that the MD deck turns off when no

depending on the component. For details regar ding the

connection of i.LINK components to this unit, see

While the deck is stopped, press MENU/NO twice.

operation has been done for five minutes.

1

i.LINK functions

“Hooking Up the i.LINK Components” on page 11.

“Setup Menu” appears in the display .2Press ./> repeatedly until “Powersave On”

appears, then press YES.3Press ./> repeatedly to select the setting,

i.LINK is a serial digital interface that supports the

bidir ectional transmission of audio and video signals,

commands, and even component status information. All

then press YES.

that is needed to hook up i.LINK components are i.LINK

To Select

connecting cables. Audio and video components

connected within an i.LINK configuration can be used to

perform a wide range of operations and data exchanges

(factory setting)

Turn on the Power Save function Powersave On

Turn off the Power Save function Powersave Off

that is sure to expand as the number and variety of i.LINK

components grows.

Since i.LINK allows data to be transmitted fr om one

component to other components to which it is not directly

Press MENU/NO.

4

connected, there is no need to pay attention to connection

order . However , due to dif ferences in characteristics or

specifications, operation of or data exchange with certain

i.LINK components may not be possible, even when they

What is i.LINK?

are connected.

z

i.LINK is a trademark pr oposed by Sony Corporation and

onics Engineers.

accepted by companies throughout the world as an easy-to-

remember name for the IEEE 1394 world standard of the Institute

of Electrical and Electr

GB

38

15

G

Message Meaning

Initialize (flashing) The Setup Menu settings have been lost.

Or the contents recorded by timer have

disappear ed over time and are not be

available for saving to disc, or

Programme Play could not be activated

since the programme has disappeared

over time.

(The message flashes for about four

GB

43

reached its limit (about 1,700 characters).

the i.LINK configuration. This indication

also appears when a mains lead or an

i.LINK connecting cable of the

component within the configuration is

connected or disconnected.

specifying the recording level, resulting

seconds when you turn on the deck by

pr essing +/1.)

Name Full The naming capacity of the MD has

NEW CONNECT A new component is connected within

in no change of recor ding level.

No Change You performed S.F. Edit without

no pr ogramme exists.

pr emaster ed MD.

No Disc Ther e is no MD in the deck.

No Name The track or disc has no name.

No Program!! You tried to start Programme Play when

Premaster ed An attempt was made to recor d on a

number of tracks. You cannot add any

mor e tracks.

ProgramFull The pr ogramme contains the maximum

external device connected to the deck.*While this indication appears, all the

buttons on the deck and the r emote

become inoperable.

the S.F Edit is in progess. You cannot

perform any other operations at this

time.

REMOTE The MD deck is being contr olled by an

S.F Edit! You tried to do another operation while

S.F Edit NOW You pressed +/1 while in S.F Edit

(changing the recording level after

display .

Smart Space The Smart Space function is on (page 16).

Contents) on the MD.

If “REMOTE” appears under other circumstances, turn kff the deck,

then turn it on again.

TOC Reading The deck is checking th e TOC (Table Of

*

recor ding, Fade-in, or Fade-out) mode. If

you turn off the deck while in S.F Edit

mode, any changes that you have made

will not saved pr operly . Finish the

editing and exit S.F Edit mode befor e

turning off the deck. If you wish to turn

off the deck at this time, press +/1 again

while this indication appears in the

Inputs/outputs

i.LINK S200 Jack type: 4-pins to 4-pins

16

eneral

pr ojecting parts and controls

Power consumption 18 W

Dimensions (approx.) 430 × 70 × 315 mm (w/h/d) incl.

Mass (approx.) 4.4 kg

Supplied accessories

See page 10.

US and foreign patents licensed from Dolby Laboratories

Licensing Corporation.

Design and specifications are subject to change without notice.

Display Messages

The following table explains the various messages that

appear in the display . Messages ar e also displayed by the

deck’s Self-Diagnosis function (see page 46).

Power requirements 230 V AC, 50/60 Hz

Message Meaning

Auto Cut The Auto Cut function is on (page 16).

Blank Disc A new (blank) or erased MD has been

inserted.

component. Select another component.

CANNOT LINC You cannot record from the selected

This indication also appears when

communiation err o has occurr ed between

the deck and the selected component

while recor ding. In this case, press x on

the deck to cancel recor ding, and then

start recor ding over again.

copy fr om a digitally dubbed MD (page

14).

pr emaster ed MD, to edit the MD while

Programme or Shuffle Play is selected, or

to change the recor ding level of an MD

recorded in LP2 or LP4 mode.

and the CD player failed during CD

Synchr o-recording.

operation (pages 14 and 31).

after recor ding, Fade-in, or Fade-out)

operation failed because the deck was

moved while the recording was in

pr ogr ess or the MD is damaged or dirty .

Disc Full The MD is full (page 41).

Cannot Copy An attempt was made to make a second

Cannot Edit An attempt was made to edit a

Cannot Synchr o Communication between the MD deck

Impossible The deck cannot do the specified

Incomplete!! S.F Edit (changing the recor ding level

SECTION 3

)

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

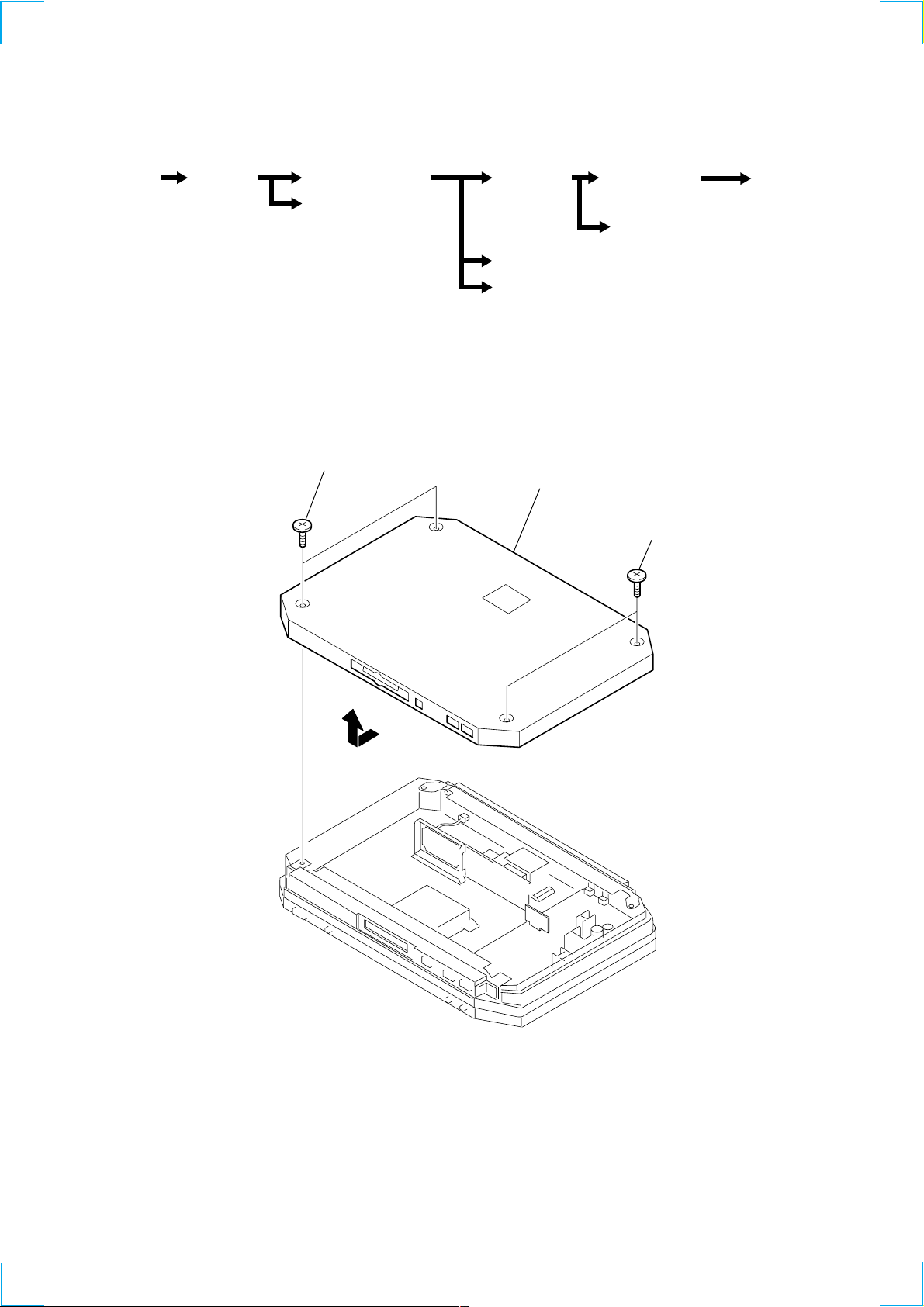

Set Case (Top) MD Mechanism Deck

Base (Front) Assy, Panel

3-1. CASE (TOP)

1 two screws (case)

(Page 18)

(Page 18)

Holder Assy Over Write Head

(Page 20) (Page 20)

BD Board

(Page 21)

Clip Board and Main Board

Trans Board

(Page 19 )

2 case (top)

(Page 19)

1 two screws (case

Optical pick-up

Section (MD)

(Page 21)

3

17

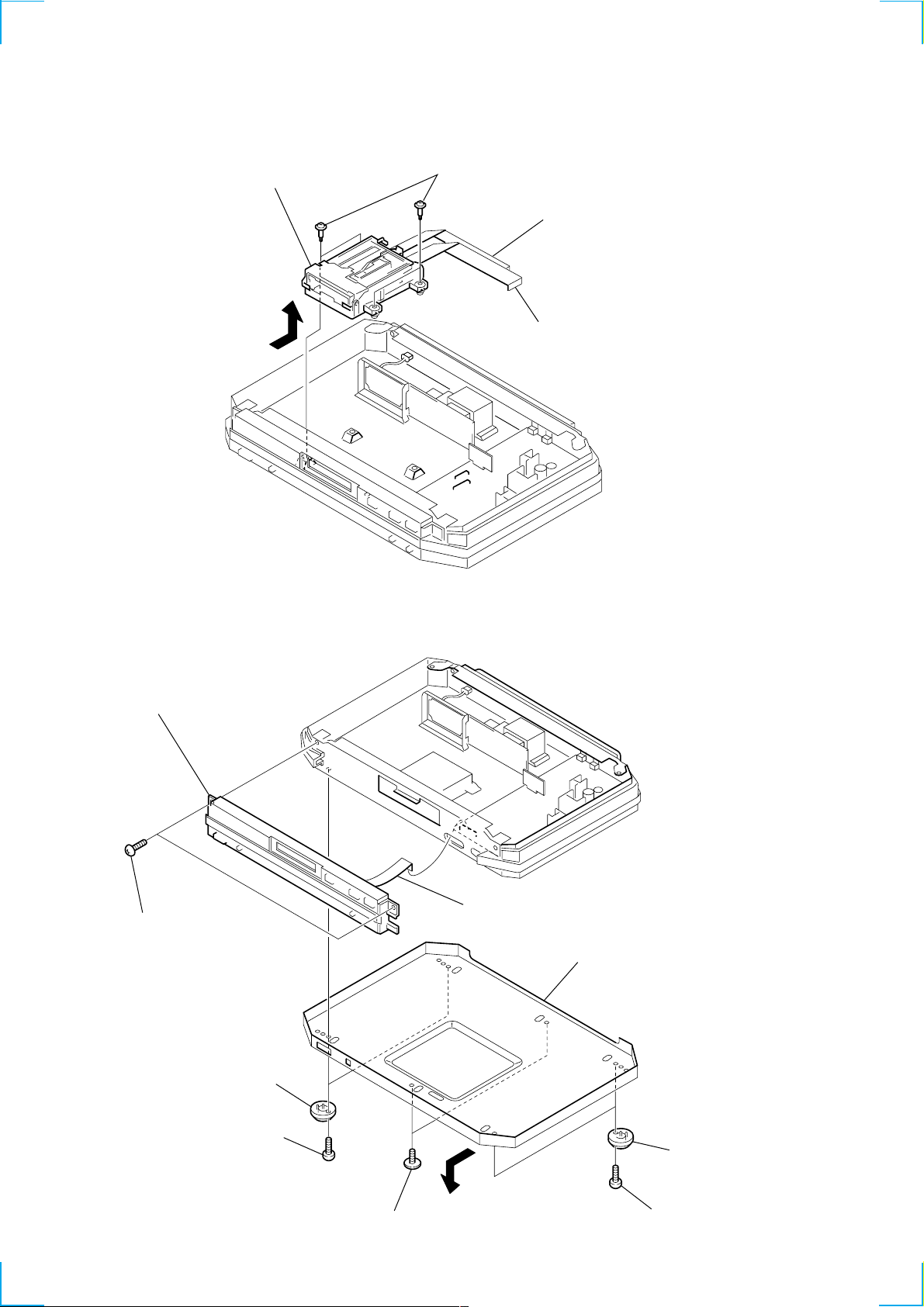

3-2. MD MECHANISM DECK

)

5 MD mechanism deck

4

3 four screws

(BVTTWH M3), STEP

2 flat type wire (23 core)

(CN301)

1 flat type wire (27 core)

(CN302)

3-3. BASE (FRONT) ASSY, PANEL

8 base (front) assy, panel

7 two screws (BVTT 3x6)

6 flat type wire (17 core)

(CN306)

5 case (bottom)

18

2 two foot assy's

1 two screws (BVTT 3x8)

4

3 two screws (TP), flat head

2 two foot assy's

1 two screws (BVTT 3x8

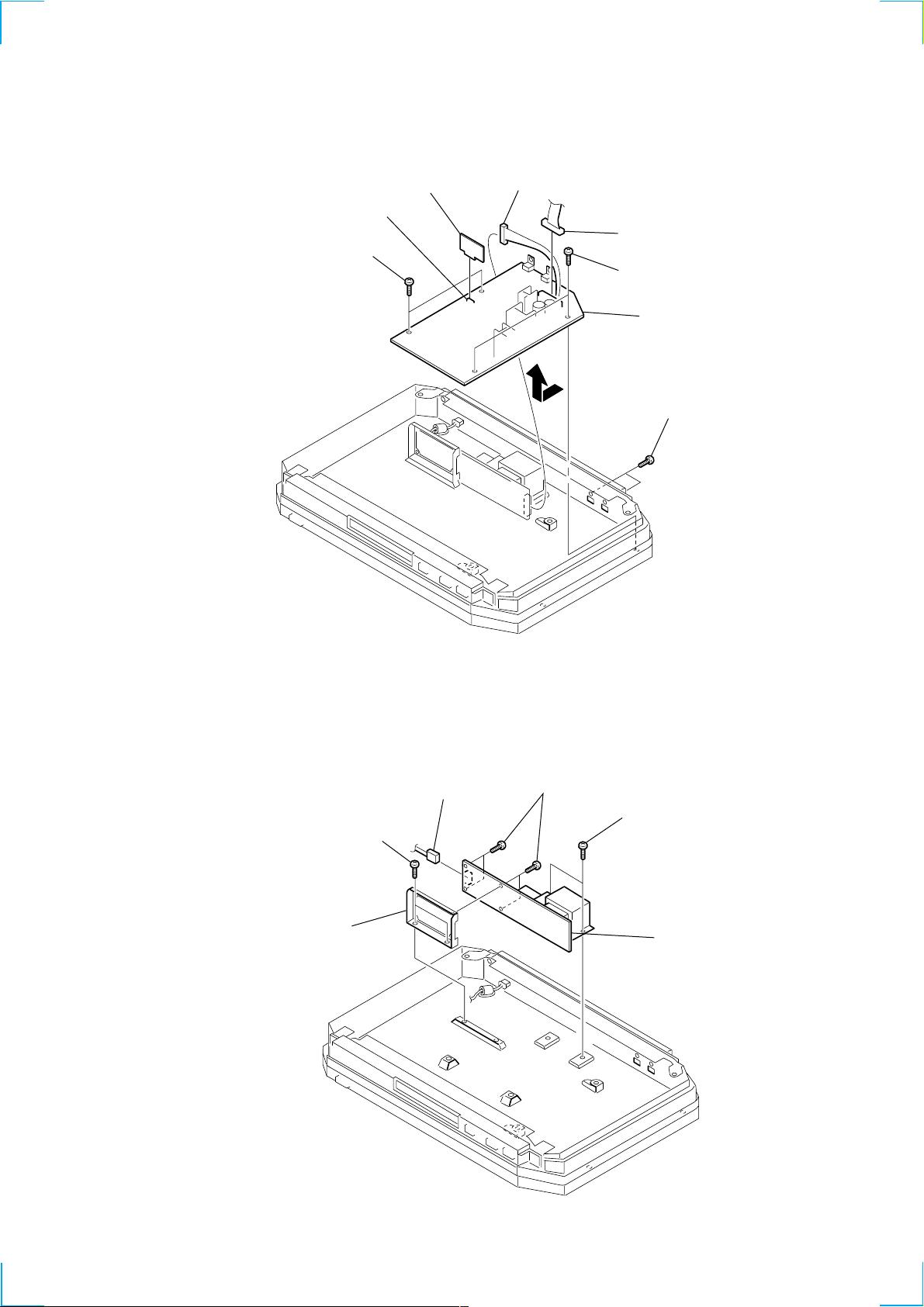

3-4. CLIP BOARD AND MAIN BOARD

)

d

2 CLIP board

1 connector (CN652)

6 two screws

(BVTT 3x6)

4 connector (CN902)

3 connector (CN903)

6 two screws (BVTT 3x6)

8 MAIN board

7

5 two screws (BVTT 2.6x6

3-5. TRANS BOARD

3 two screws

(BVTT 3x6)

5 bracket

(transformer)

1 connector

(CN901)

4 four screws

(BVTT 3x6)

2 two screws

(BVTT 3x6)

6 TRANS boar

19

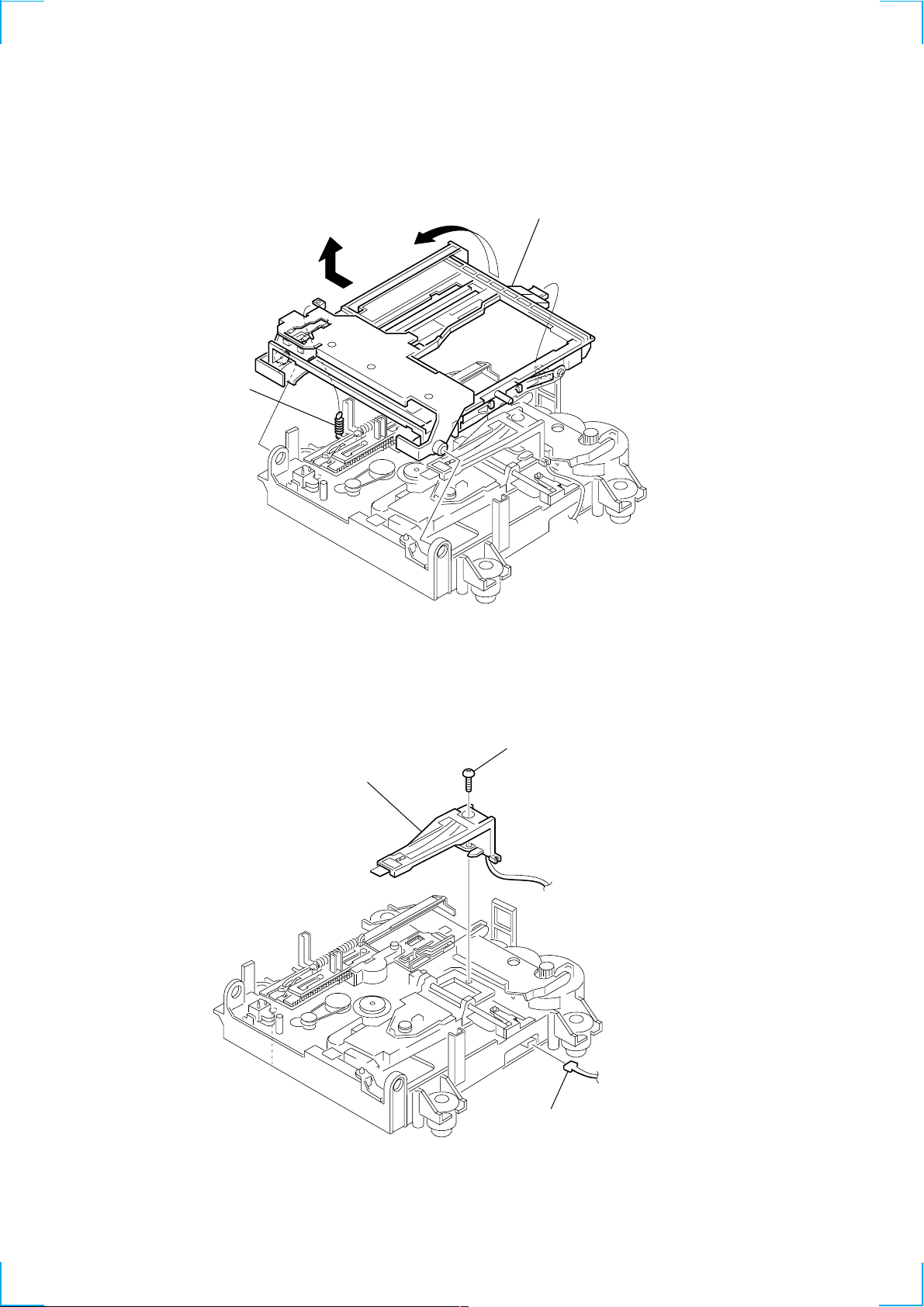

3-6. HOLDER ASSY

1 spring (holder),

tension

4

3

5 holder assy

2

3-7. OVER WRITE HEAD

2 screw (P 1.7x6)

3 over write head

(HR901)

1 connector (CN104)

20

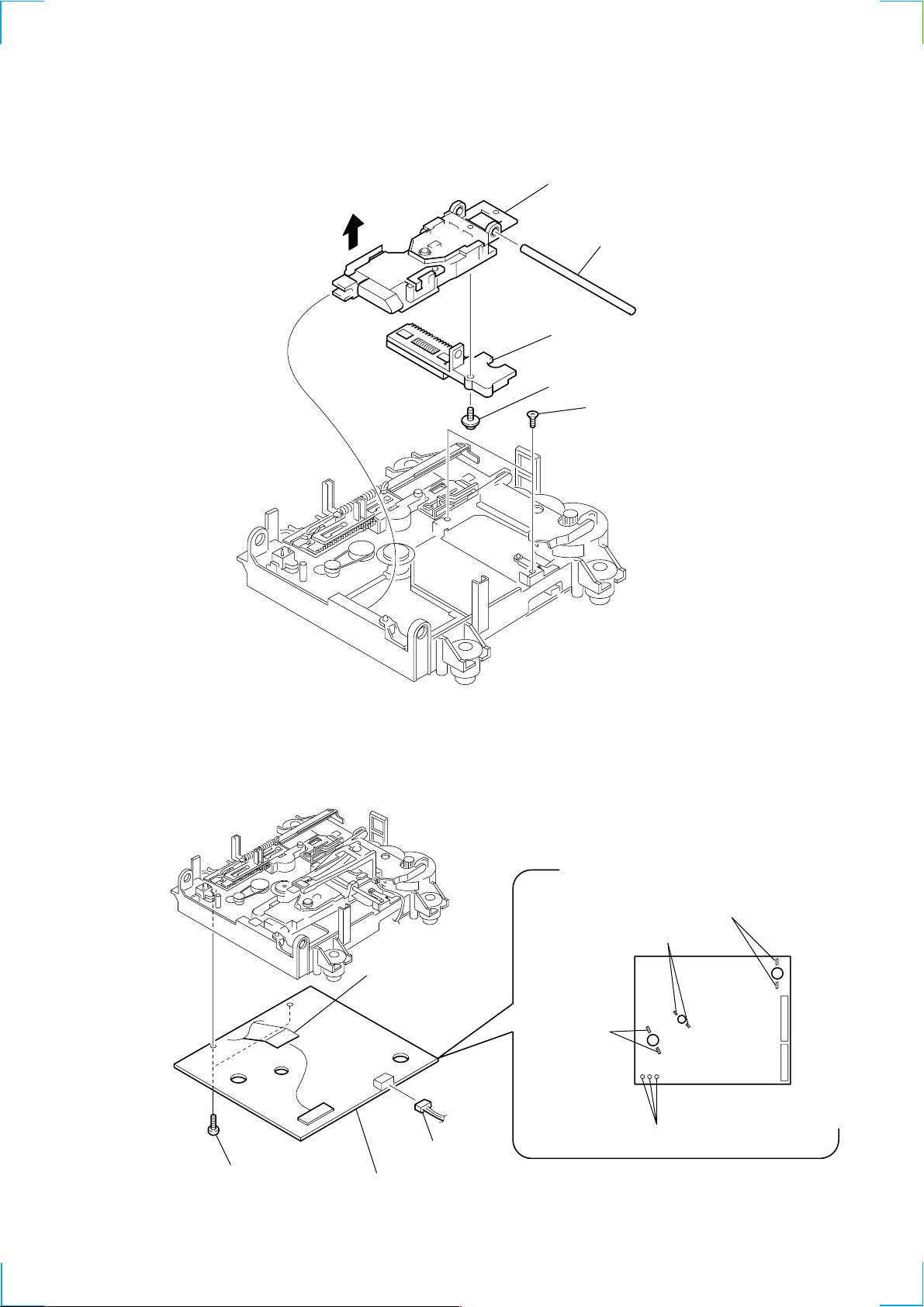

3-8. OPTICAL PICK-UP (MD)

)

(KMS-262A/J1N)

6 optical pick-up

4

5 shaft, main

2 base assy, SL

1 screw (P 1.7x6)

3 two screws (KTP 2x6

3-9. BD BOARD

3 two screws

(BTP 2 × 6)

5 connector

(CN101)

4 BD board

1 connector

(CN104)

2 Remove the solder

(Two portions)

2 Remove the solder

(Two portions)

2 Remove the solder

(Two portions)

M102

M101

M103

S102

2 Remove the solder

(Three portions)

21

SECTION 4

TEST MODE

4-1. PRECAUTIONS FOR USE OF TEST MODE

• As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc

is stopped before setting and removing it.

Even if the A button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not stop

rotating.

Therefore, it will be ejected while rotating.

Be sure to press the A button after pressing the POWER“X2” button and the rotation of disc is stopped.

4-1-1. Recording laser emission mode and operating buttons

• Continuous recording mode (CREC 1MODE)

• Laser power check mode (LDPWR CHECK)

• Laser power adjustment mode (LDPWR ADJUS)

• Iop check (Iop Compare)

• Iop value nonvolatile writing (Iop NV Save)

• Traverse (MO) check (EF MO CHECK)

• Traverse (MO) adjustment (EF MO ADJUS)

• When pressing the z REC button.

4-2. SETTING THE TEST MODE

Procedure : While pressing the . button and x button, connect the power plug to an outlet, and release the . button and x

button.

When the test mode is set, “[Check]” will be displayed. Press the . or > button switches between the following three

groups; ··· y Check y Service y Develop y ···.

NOTE: Do not use the test mode in the [Develop] group.

If used, the unit may not operate normally.

If the [Develop] group is set accidentally, press the x button immediately to exit the [Develop] group.

4-3. EXITING THE TEST MODE

Press the POWER“X2” button. The disc is ejected when loaded, and “Standby” display blinks, and the STANDBY state is set.

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the . or > button, 7 button, and x button.

The functions of these buttons are as follows.

Function name

x button

7 button

. or > button

POWER button*

* NOTE: It dosen’t work in the ease of “X2” mode.

Cancel or move to top hierarchy

Set

Select

Set submenu

Function

22

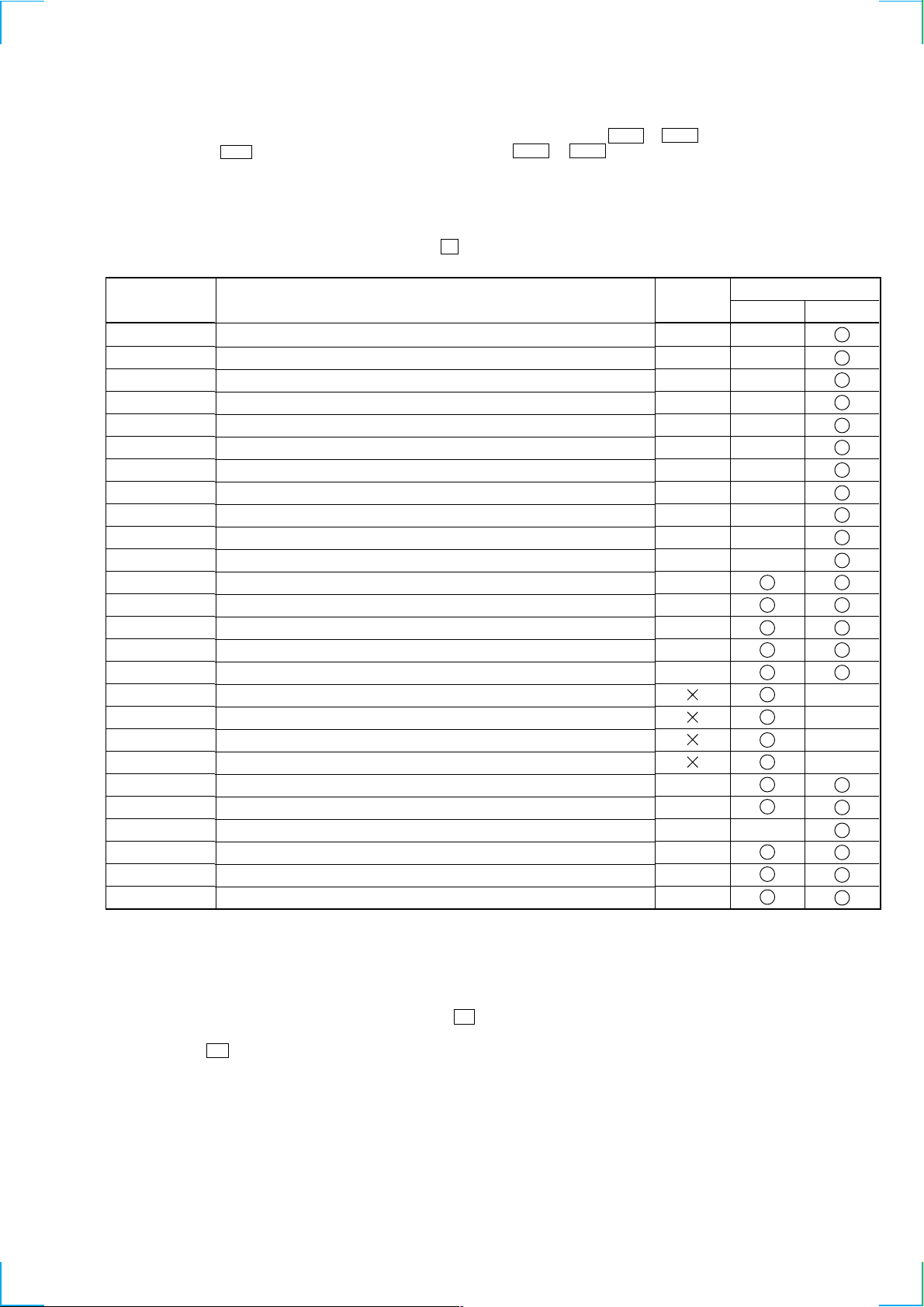

4-5. SELECTING THE TEST MODE

There are 26 types of test modes as shown below. The groups can be switched by press the . or > button. After selecting the group

to be used, press the 7 button. After setting a certain group, press the . or > button switches between these modes.

Refer to “Group” in the table for details selected.

All adjustments and checks during servicing can be performed in the test mode in the Service group.

NOTE: Do not use the test mode in the [Develop] group.

If used, the unit may not operate normally.

If the [Develop] group is set accidentally, press the x button immediately to exit the [Develop] group.

Display

AUTO CHECK

Err Display

TEMP ADJUS

LDPWR ADJUS

Iop Write

Iop NV Save

EF MO ADJUS

EF CD ADJUS

FBIAS ADJUS

AG Set (MO)

AG Set (CD)

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

ScurveCHECK

VERIFYMODE

DETRK CHECK

0920 CHECK

Iop Read

Iop Compare

ADJ CLEAR

INFORMATION

CPLAY2MODE

CREC 2MODE

Details

Automatic self-diagnosis

Error history display, clear

Temperature compensation offset adjustment

Laser power adjustment

Iop data writing

Writes current Iop value in read nonvolatile memory using microprocessor

Traverse (MO) adjustment

Traverse (CD) adjustment

Focus bias adjustment

Focus, tracking gain adjustment (MO)

Focus, tracking gain adjustment (CD)

Temperature compensation offset check

Laser power check

Traverse (MO) check

Traverse (CD) check

Focus bias check

S-curve check

Nonvolatile memory check

Detrack check

Most circumference check

Iop data display

Comparison with initial Iop value written in nonvolatile memory

Initialization of nonvolatile memory for adjustment values

Display of microprocessor version, etc.

Continuous playback mode (CLV2)

Continuous recording mode (CLV2)

Mark

Group

Check Service

• For details of each adjustment mode, refer to “5. Electrical Adjustments”.

For details of “Err Display”, refer to “Self-Diagnosis Function” on page 2.

• If a different mode has been selected by mistake, press the x button to exit that mode.

• Modes with (X) in the Mark column are not used for servicing and therefore are not described in detail. If these modes are set accidentally, press the x button to exit the mode immediately.

23

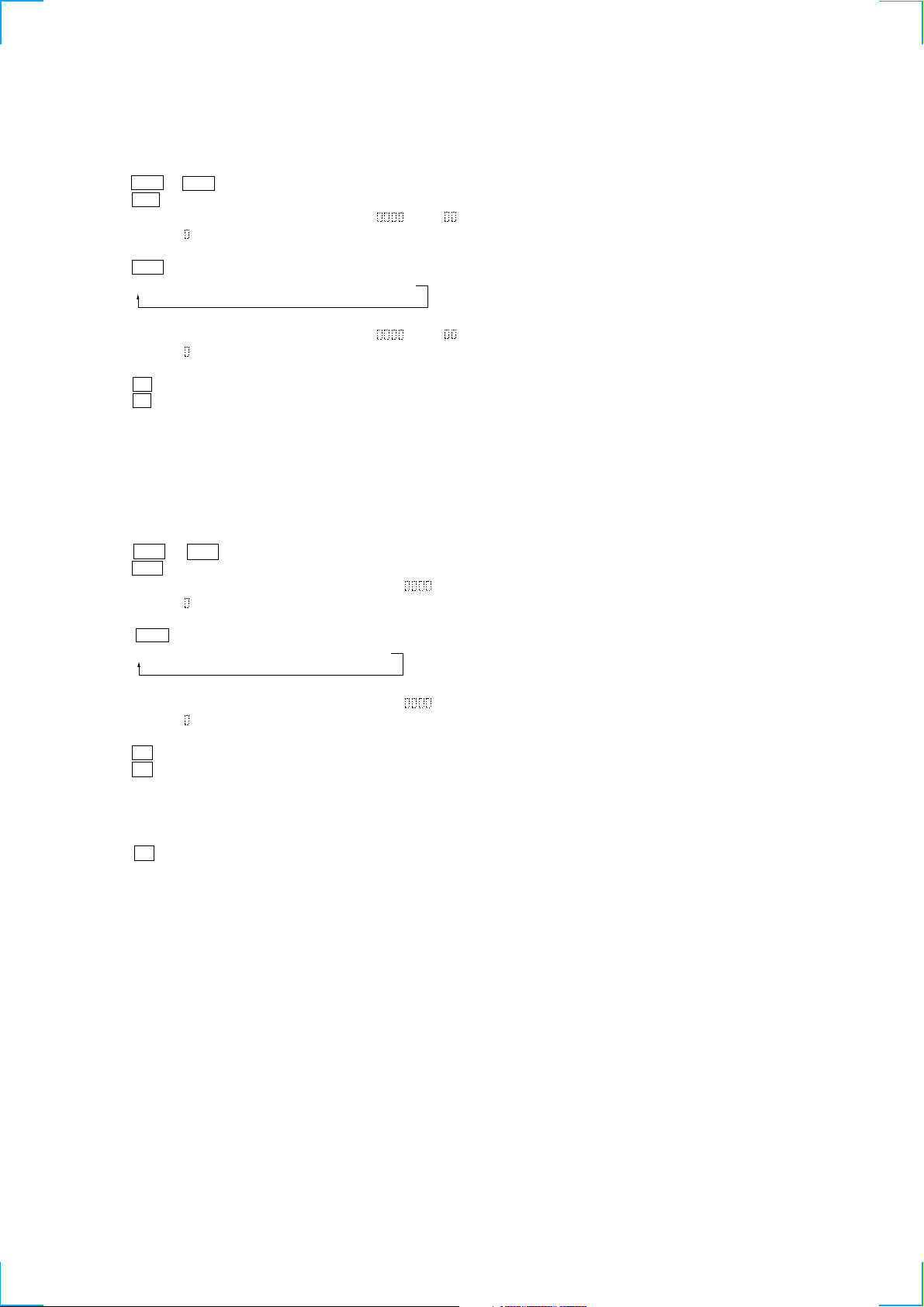

4-5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

1 Set the disc in the unit. (Whichever recordable discs or discs for playback only are available.)

2 Pressthe . or > button and display “CPLAY2MODE”.

3 Press the 7 button to change the display to “CPLAY2MID”.

4 When access completes, the display changes to “C = AD = ”.

Note : The numbers “ ” displayed show you error rates and ADER.

2. Changing the parts to be played back

1 Press the 7 button during continuous playback to change the display as below.

“CPLAY2MID” t “CPLAY2OUT” t “CPLAY2IN”

When pressed another time, the parts to be played back can be moved.

2 When access completes, the display changes to “C = AD = ”.

Note : The numbers “ ” displayed show you error rates and ADER.

3. Ending the continuous playback mode

1 Press the x button. The display will change to “CPLAY2MODE”.

2 Press the A button to remove the disc.

Note : The playback start addresses for IN, MID, and OUT are as follows.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

4-5-2. Operating the Continuous Recording Mode (Use only when performing self-recording/palyback check.)

1. Entering the continuous recording mode

1 Set a recordable disc in the unit.

2 Press the . or > button and display “CREC 2MODE” .

3 Press the 7 button to change the display to “CREC 2MID”.

4 When access completes, the display changes to “CREC 2( )” and REC LED lights up.

Note : The numbers “ ” displayed shows you the recording position addresses.

2. Changing the parts to be recorded

1 When the 7 button is pressed during continuous recording, the display changes as below.

“CREC 2MID” t “CREC 2OUT” t “CREC 2IN”

When pressed another time, the parts to be recorded can be changed. REC LED goes off.

2 When access completes, the display changes to “CREC2 (

Note : The numbers “ ” displayed shows you the recording position addresses.

3. Ending the continuous recording mode

1 Press the x button. The display changes to “CREC 2MODE” and REC LED goes off.

2 Press the A button to remove the disc.

Note 1 : The recording start addresses for IN, MID, and OUT are as follows.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

Note 2 : The x button can be used to stop recording anytime.

Note 3 : Do not perform continuous recording for long periods of time above 5 minutes.

Note 4 : During continuous recording, be careful not to apply vibration.

)” and REC LED lights up.

24

Loading...

Loading...