Sony MDSJE-480 Service manual

MDS-JE480

SERVICE MANUAL

Ver. 1.3 2005.11

US and foreign patents licensed form Dolby Laboratories

Licensing Corporation.

SPECIFICATIONS

System MiniDisc digital audio system

Disc MiniDisc

Laser Semiconductor laser

Laser output MAX 44.6 µW

1) This output is the value measured at a distance of

200mm from the objective lens surface on the

Optical Pick-up Block with 7 mm aperture.

Laser diode Material: GaAlAs

Revolutions (CLV) 400 rpm to 900 rpm

Error correction ACIRC (Advanced Cross

Sampling frequency 44.1 kHz

Coding ATRAC (Adaptive

Modulation system EFM (Eight-to-Fourteen

Number of channels 2 stereo channels

Frequency response 5 to 20,000 Hz ±0.5 dB

Signal-to-noise ratio Over 96 dB during play

Wow and flutter Below measurable limit

Inputs

ANALOG IN Jack type: phono

(λ = 780 nm) Emission

duration: continuous

Interleave Reed Solomon Code)

Transform Acoustic Coding)/

ATRAC 3

Modulation)

during play

Impedance: 47 kilohms

Rated input: 500 mVrms

Minimum input: 125 mVrms

1)

US Model

AEP Model

UK Model

Model Name Using Similar Mechanism MDS-JE470

MD Mechanism Type MDM-7S1A

Optical Pick-up Type KMS-260B/260E

DIGITAL OPTICAL IN Connector type: square optical

Impedance: 660 nm

(optical wave length)

Outputs

ANALOG OUT Jack type: phono

Rated output: 2 Vrms (at 50 kilohms)

Load impedance: over 10 kilohms

General

Power requirements

US model: 120 V AC, 60Hz

European model: 230 V AC, 50/60Hz

Power consumption 14 W (0.5 W in standby mode)

Dimensions (approx.) 430 x 95 x 285 mm

(w/h/d) incl. projecting

parts and controls

Mass (approx.) 3.0 kg

Supplied accessories

Audio connecting cords (2)

Optical cable (1)

Remote commander (remote) (1)

R6 (size-AA) batteries (2)

Design and specifications are subject to change without notice.

9-873-964-04

2005K02-1

© 2005.11

MINIDISC DECK

Sony Corporation

Home Audio Division

Published by Sony Engineering Corporation

MDS-JE480

Ver 1.1 2003.04

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microampers).

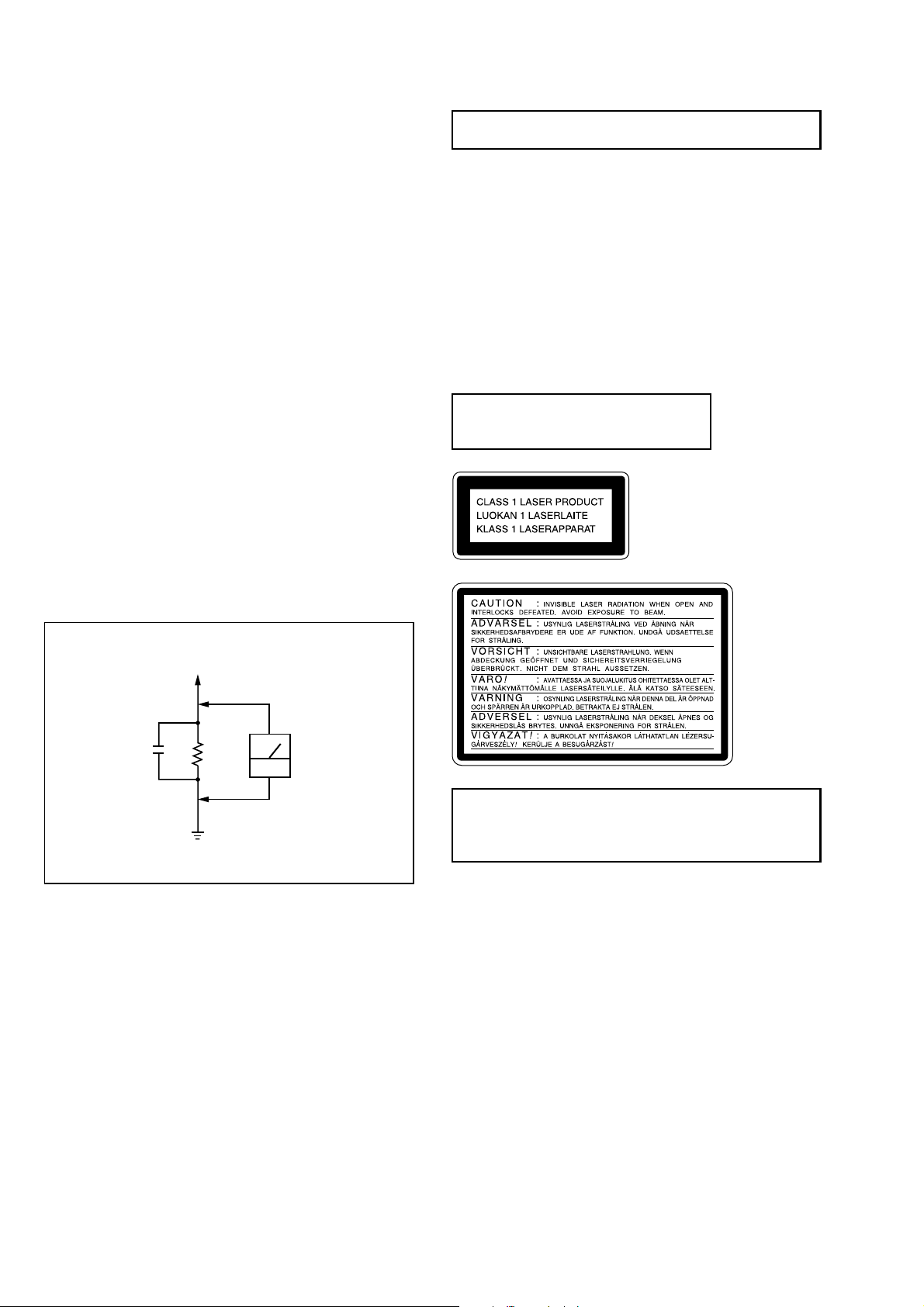

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a

CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT

MARKING is located on the

rear exterior.

This caution

label is located

inside the unit.

0.15µF

1.5kΩ

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

MDS-JE480

Self-diagnosis function

The deck’s self-diagnosis function automatically checks

the condition of the MD deck when an error occurs, then

issues a three- or five-digit code and an error message on

the display. If the code and message alternate, find them in

the following table and perform the indicated

countermeasure. Should the problem persist, consult your

nearest Sony dealer.

Three- or fivedigit code/

Message

Cause/Remedy

C11/Protected

,

Ta ke out the MD and close the recordprotect slot.

C12/Cannot Copy

You tried to record a CD with a format

that the external device connected to the

deck does not support, such as CD-ROM

or video CD.

,

Remove the disc and insert a music

CD.

C13/REC Error

,

Set the deck in a stable surface, and

repeat the recording procedure.

The inserted MD is dirty (with smudges,

fingerprints, etc.), scratched, or

substandard in quality.

,

Replace the disc and repeat the

recording procedure.

C13/Read Error

,

Ta ke out the MD and insert it again.

C14/Toc Error

,

Insert another disc.

,

If possible, erase all the tracks on the

MD.

C41/Cannot Copy

The sound source is a copy of

commercially available music software, or

you tried to record a CD-R (Recordable

CD).

,

The Serial Copy Management System

prevents making a digital copy

.

Yo u cannot record a CD-R.

C71/Din Unlock

The sporadic appearance of this message

is caused by the digital signal being

recorded. This will not affect the

recording.

While recording from a digital component

connected through the DIGITAL IN

connector, the digital connecting cable

was unplugged or the digital component

turned off.

,

Connect the cable or turn the digital

component back on.

E0001/

MEMORY NG

There is an error in the internal data that

the deck needs in order to operate.

,

Consult your nearest Sony dealer.

E010

E0201

LOADING NG

1/

LASER NG

There is a problem with the optical

pickup.

,

The optical pick-up may have failed.

Consult your nearest Sony dealer.

Three- or fivedigit code/

Message

Cause/Remedy

There is a problem with the loading.

,The loading may have failed. Consult

your nearest Sony dealer.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

VARNING

VAROITUS

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for customers which are displayed automatically when errors occur, and error codes which

show the error history in the test mode during servicing. For details on how to view error codes for the customer, refer to the following box

in the instruction manual. For details on how to check error codes during servicing, refer to the following “Procedure for using the SelfDiagnosis Function (Error History Display Mode)”.

Procedure for using the Self-Diagnosis Function (Error History Display Mode).

Note: Perform the self-diagnosis function in the “error history display mode” in the test mode. The following describes the least required

procedure. Be careful not to enter other modes by mistake. If you set other modes accidentally, press the MENU/NO button to exit

the mode.

3

MDS-JE480

1. While pressing the lAMSL knob and x button, connect the power plug to the outlet, and release the lAMSL knob and

x button.

When the test mode is set, “[Check]” will be displayed.

2. Rotate the lAMSL knob and when “[Service]” is displayed, press the YES button.

3. Rotate the lAMSL knob and display “Err Display”.

4. Pressing the YES button sets the error history mode and displays “op rec tm”.

5. Select the contents to be displayed or executed using the lAMSL knob.

6. Pressing the lAMSL knob will display or execute the contents selected.

7. Pressing the lAMSL knob another time returns to step 4.

8. Pressing the MENU/NO button displays “Err Display” and exits the error history mode.

9. To exit the test mode, press the REPEAT button. The unit sets into the STANDBY state, the disc is ejected, and the test mode ends.

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Selecting the Test Mode

Display

op rec tm

op play tm

spdl rp tm

retry err

total err

err history

retry adrs

History

Displays the total recording time.

When the total recording time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

The display time is the time the laser is set to high power, which is about 1/4 of the actual recording time.

Displays the total playback time.

When the total playback time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

Displays the total rotating time of the spindle motor.

When the total rotating time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

Displays the total number of retry errors during recording and playback

Displays “r xx p yy”. xx is the number of errors during recording. yy is the number of errors during playback.

This is displayed in hexadecimal from 00 to FF.

Displays the total number of errors

Displays “total xx”. This is displayed in hexadecimal from 00 to FF.

Displays the past ten errors.

Displays “0x ErrCd@@”.

X is the history number. The younger the number, the more recent is the history (00 is the latest). @@ is the error

code.

Select the error history number using the lAMSL knob.

Displays the past five retry addresses.

Displays “xx ADRS yyyy”, xx is the history number, yyyy is the cluster with the retry error.

Select the error history number using the lAMSL knob.

er refresh

tm change

op change

4

Mode for erasing the error and retry address histories

Procedure

1. Press the lAMSL knob when displayed as “er refresh”.

2. Press the YES button when the display changes to “er refresh?”.

When “complete!” is displayed, it means erasure has completed.

Be sure to check the following after executing this mode.

*Data has been erased.

*Perform recording and playback, and check that the mechanism is normal.

Mode for erasing the total time of recording and playback

Procedure

1. Press the lAMSL knob when displayed as “tm refresh”.

2. Press the YES button when the display changes to “tm refresh?”.

When “complete!” is displayed, it means erasure has completed.

Mode for erasing the total time of op rec tm, op play tm.

These histories are based on the time of replacement of the optical pickup. If the optical pick-up has been replaced,

perform this procedure and erase the history.

Procedure

1. Press the lAMSL

2. Press the YES button when the display changes to “op chang?”.

When “Complete!” is displayed, it means erasure has completed.

knob when displayed as “op change”.

MDS-JE480

Ver. 1.3

Display

spdl change

Table of Error Codes

Error Code

10

12

20

21

22

23

24

30

31

40

41

42

43

50

51

Could not load

Loading switches combined incorrectly

Timed out without reading the top of PTOC

Could read top of PTOC, but detected error

Timed out without accessing UTOC

Timed out without reading UTOC

Error in UTOC

Could not start playback

Error in sector

Retry cause generated during normal recording

Retried in DRAM overflow

Retry occurred during TOC writing

Retry aborted during S.F editing

Other than access processing, and could not read address.

Focus NG occurred and overran.

History

Mode for erasing the total spdl rp tm time

These histories are based on the time of replacement of the spindle motor. If the spindle motor has been replaced,

perform this procedure and erase the history.

Procedure

1. Press the lAMSL knob when displayed as “spdl change”

2. Press the YES button when the display changes to “spdl chang?”

When “Complete!” is displayed, it means erasure has completed.

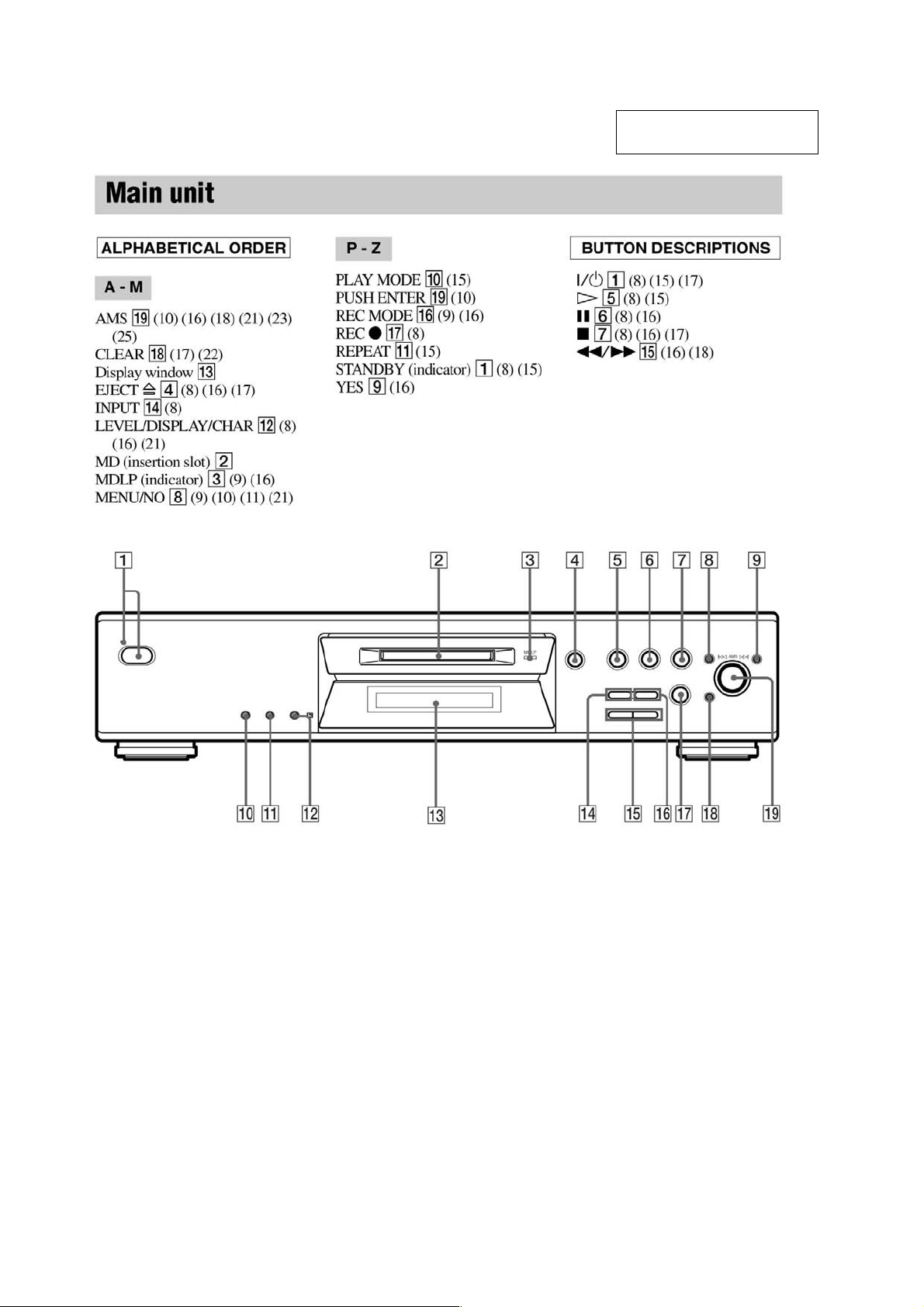

TABLE OF CONTENTS

Description

1. SERVICING NOTES ........................................................ 6

2. GENERAL ........................................................................ 12

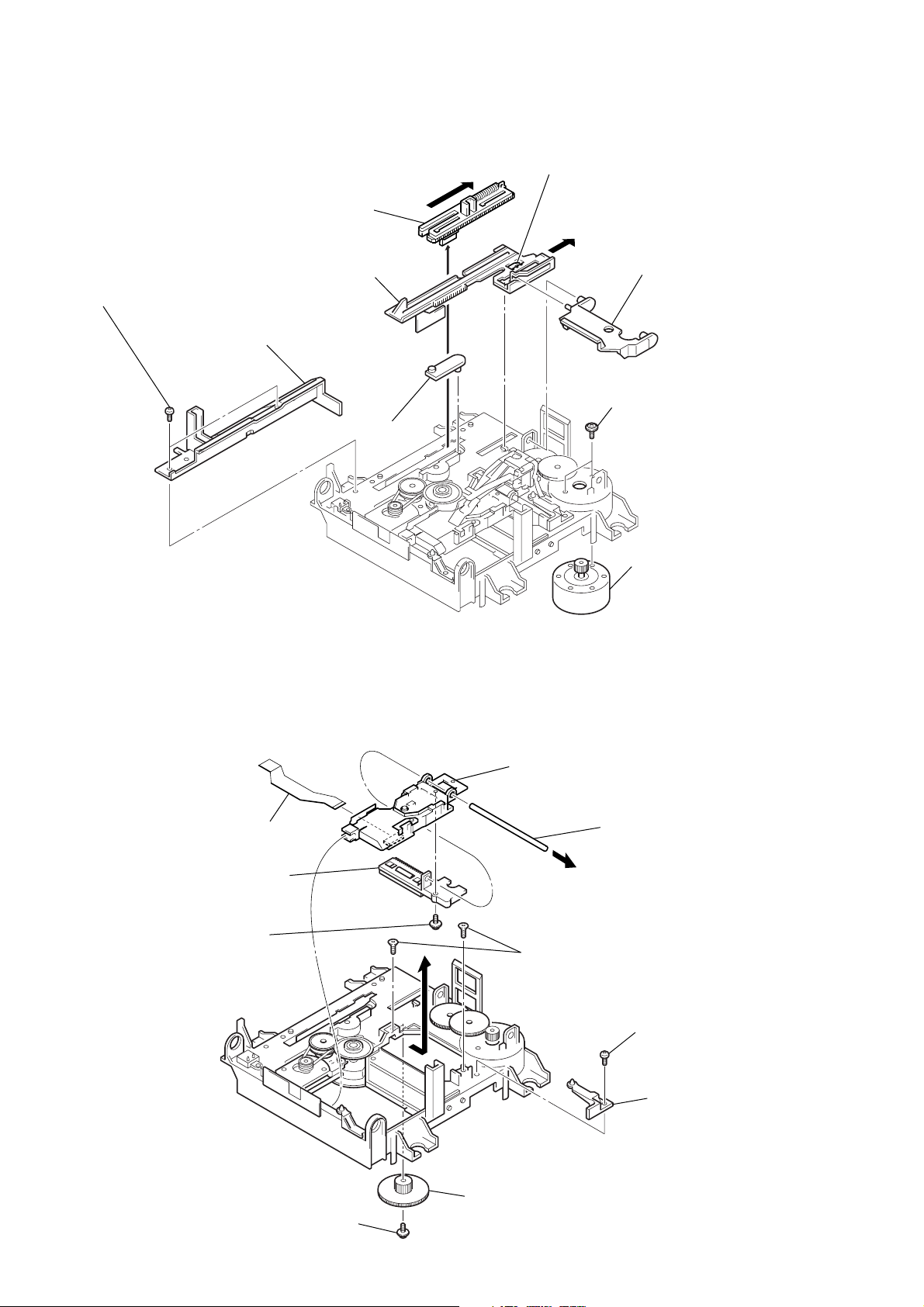

3. DISASSEMBLY

3-1. Disassembly flow .............................................................. 13

3-2. Upper Case (408226) ........................................................ 14

3-3. Front Panel Section ........................................................... 14

3-4. Main Board ....................................................................... 15

3-5. PT Board ........................................................................... 15

3-6. Mechanism Deck Section ( MDM-7S1A) ........................ 16

3-7. Over Light Head (HR901), BD Board .............................. 16

3-8. Holder Assy ....................................................................... 17

3-9. Loading Motor Assy (M103) ............................................ 17

3-10. Sled Motor Assy (M102), Slider ....................................... 18

3-11. Optical Pick-up.................................................................. 18

3-12. Spindle Motor Assy (M101) ............................................. 19

4. TEST MODE ......................................................................20

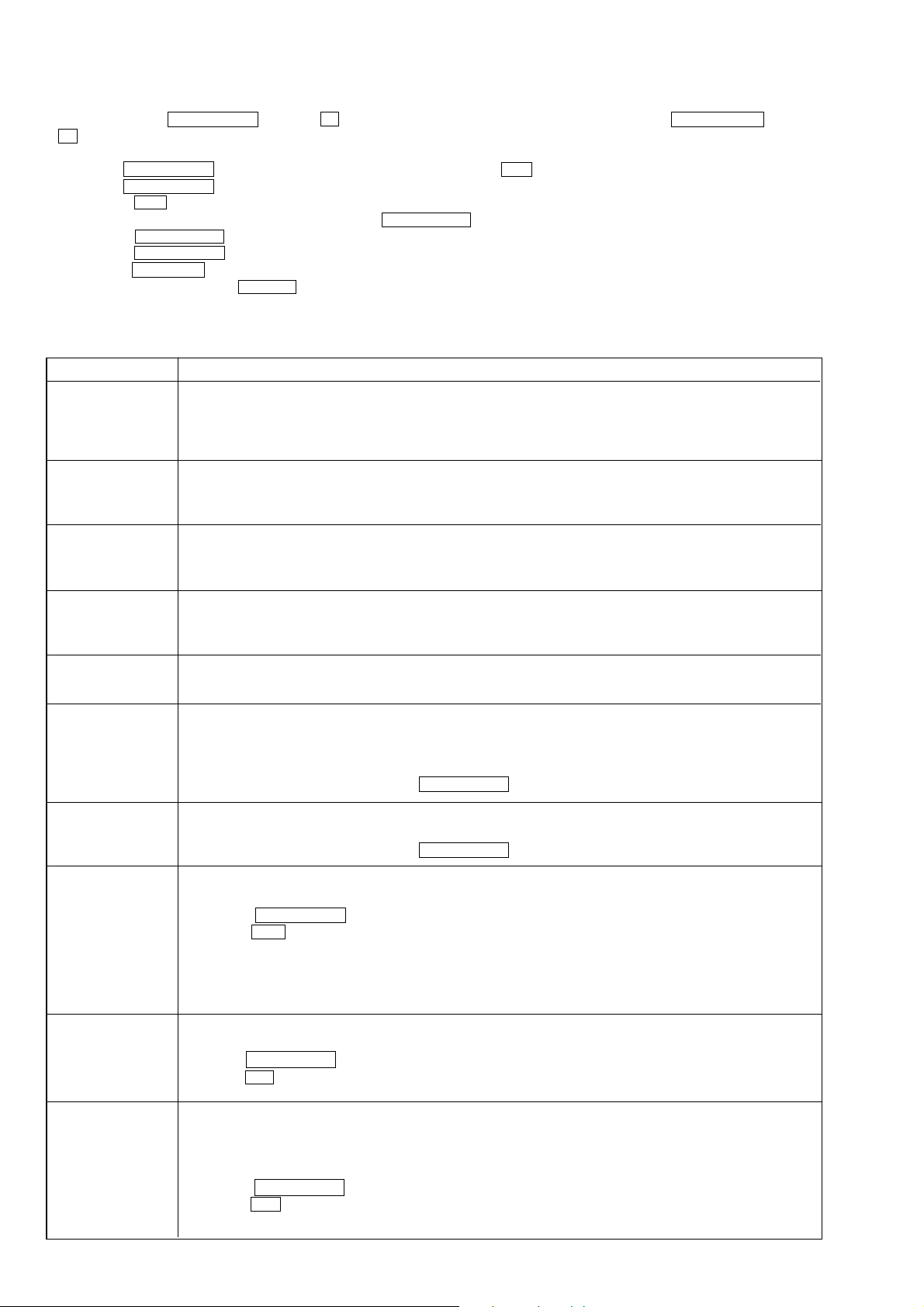

MODEL IDENTIFICATION

— BACK PANEL —

MODEL

US model

AEP and Russian models

UK model

Par t No.

PARTS No.

4-238-633-0s

4-238-633-5s

4-238-633-6s

5. ELECTRICAL ADJUSTMENTS ............................... 25

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................... 36

6-2. Block Diagrams

• BD Section ....................................................................... 38

• Main Section .................................................................... 39

6-3. Printed Wiring Board – BD Board – ................................... 40

6-4. Schematic Diagram – BD Section (1/2) – ........................... 41

6-5. Schematic Diagram – BD Section (2/2) – ........................... 42

6-6. Schematic Diagram – Main Section (1/2) – ........................ 43

6-7. Schematic Diagram – Main Section (2/2) – ........................ 44

6-8. Printed Wiring Board – Main Section – ............................. 45

6-9. Printed Wiring Board – Display Section – .......................... 46

6-10. Schematic Diagram – Display Section – .......................... 47

6-11. Printed Wiring Board – Power Section – ......................... 48

6-12. Schematic Diagram – Power Section – ............................ 48

6-13. IC Pin Function Discription ............................................ 49

6-14. IC Block Diagrams ........................................................... 55

7. EXPLODED VIEWS

7-1. Chassis Section ................................................................... 58

7-2. Front Panel Section ............................................................. 59

7-3. Mechanism Section-1 (MDM-7S1A) ................................. 60

7-4. Mechanism Section-2 (MDM-7S1A) ................................. 61

8. ELECTRICAL PARTS LIST ........................................ 62

5

MDS-JE480

A

SECTION 1

SERVICE NOTES

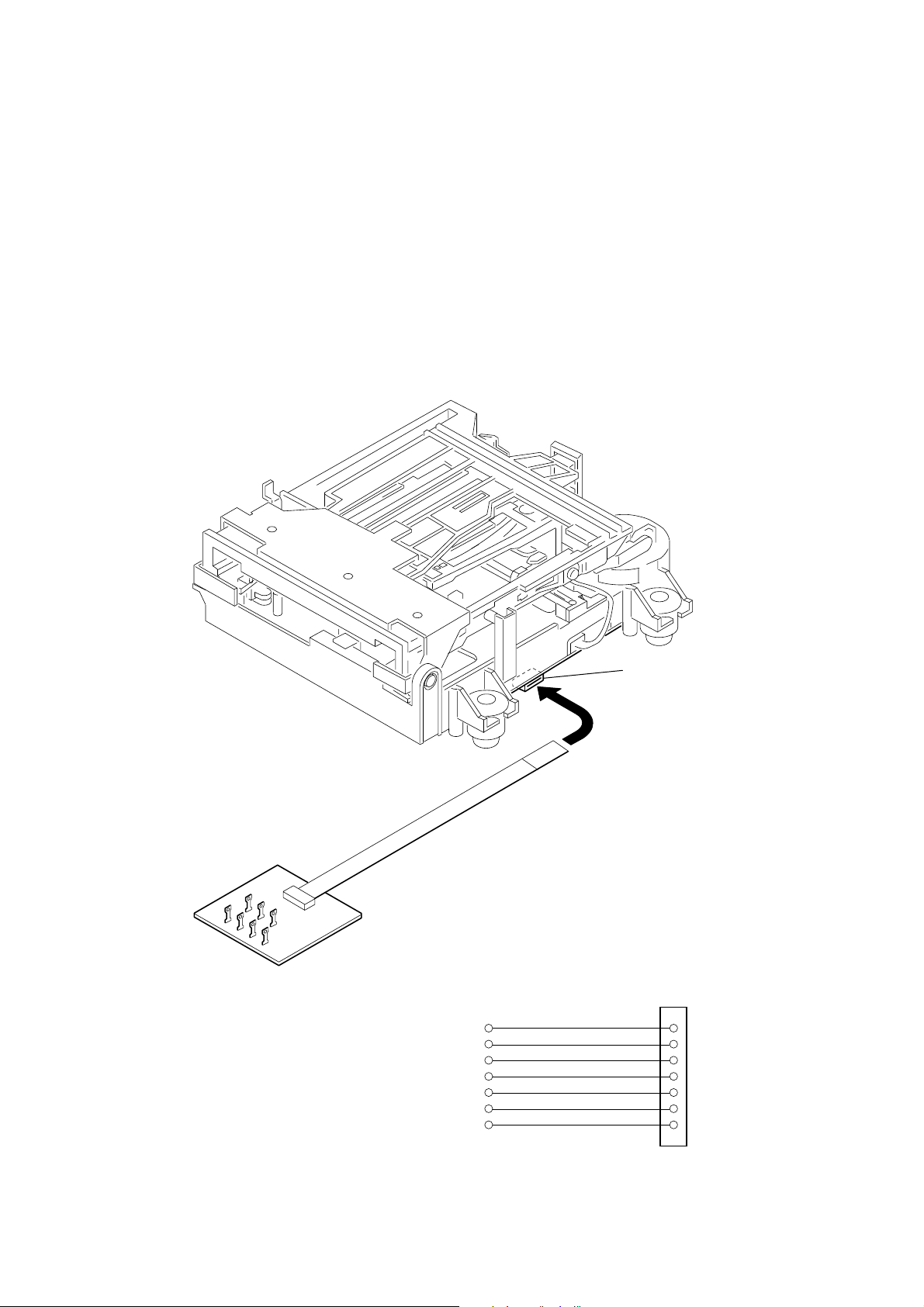

JIG FOR CHECKING BD BOARD WAVEFORM

The special jig (J-2501-196-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

GND : Ground

I+3V : For measuring Iop (Check the deterioration of the optical pick-up laser)

Iop : For measuring Iop (Check the deterioration of the optical pick-up laser)

TE : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

FE : Focus error signal

I+3V

GND

FE

RF

Iop

TE

VC

I+3V

Iop

GND

TE

FE

VC

RF

CN105

1

I+3V

Iop

GND

TE

FE

VC

RF

7

for

MDM-7S1

6

MDS-JE480

Iop DATA RECORDING AND DISPLAY WHEN OPTICAL PICK-UP AND NON-VOLATILE MEMORY (IC195 OF

BD BOARD) ARE REPLACED

The Iop value labeled on the optical pick-up can be recorded in the non-volatile memory. By recording the value, it will eliminate the need

to look at the value on the label of the optical pick-up. When replacing the optical pick-up or non-volatile memory (IC195 of BD board),

record the Iop value on the optical pick-up according to the following procedure.

Record Procedure:

1. While pressing the l AMS L knob and x button, connect the power plug to the outlet, and release the l AMS L knob and

x button.

2. Rotate the l AMS L knob to display “[Service]”, and press the YES button.

3. Rotate the l AMS L knob to display “Iop Write” (C05), and press the YES button.

4. The display becomes “Ref=@@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

5. Input the Iop value written on the optical pick-up.

To select the number : Rotate the l AMS L knob.

To select the digit : Press the l AMS L knob.

6. When the YES button is pressed, the display becomes “Measu=@@@.@” (@ is an arbitrary number).

7. As the adjustment results are recorded for the 6 value. Leave it as it is and press the YES button.

8. “Complete!” will be displayed momentarily. The value will be recorded in the non-volatile memory and the display will become “Iop

Write”.

9. Press the REPEAT button to complete.

Display Procedure:

1. While pressing the l AMS L knob and x button, connect the power plug to the outlet, and release the l AMS L knob and

x button.

2. Rotate the l AMS L knob to display “[Service]”, and press the YES button.

3. Rotate the l AMS L knob to display “Iop Read” (C26).

4. “@@.@/##.#” is displayed and the recorded contents are displayed.

@@.@ : indicates the Iop value labeled on the optical pick-up.

##.# : indicates the Iop value after adjustment

5. To end, press the l AMS L button or MENU/NO button to display “Iop Read”. Then press the REPEAT button.

7

MDS-JE480

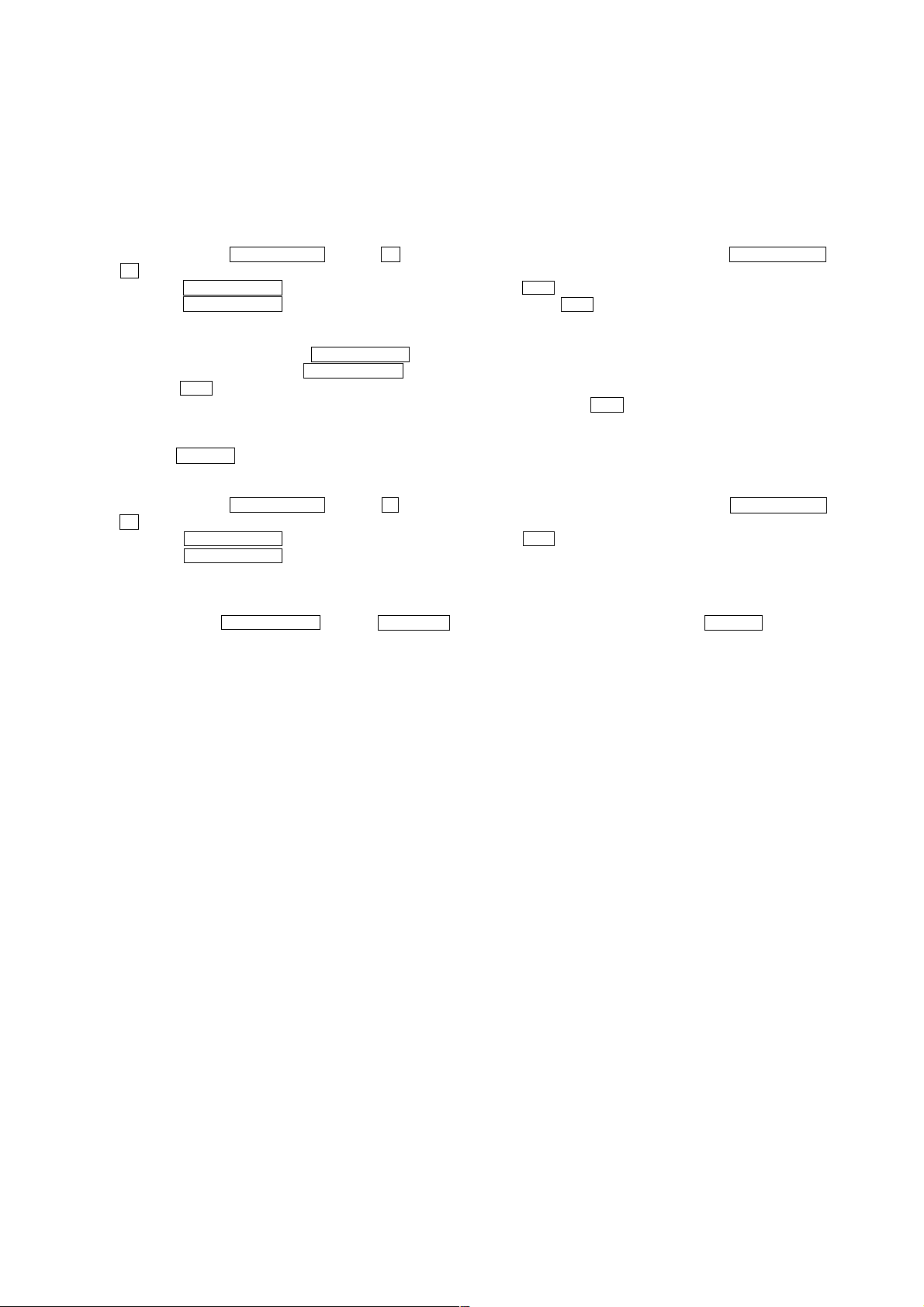

OPTICAL PICK-UP BLOCK TYPE DISCRIMINATION

There are two types of the optical pick-up block in this model.

These are compatible except for the laser power.

Check the type of the optical pick-up block before replacement.

Ajdust following items after replacing the optical pick-up block.

• 5-6-2. Laser Power Check (See page 28)

• 5-10. LASER POWER ADJUSTMENT (See page 31)

Differences

KMS-260B KMS-260E

Color of the adhesive agent at PDIC portion Pink White

Form of FPC retainer plate Close the hole on SL base Not close the hole on SL base

APC variable resistor Small volume (2 type)

Fig. B type is for repair.

• Abbreviation

260B: KMS-260B model

260E: KMS-260E model

Big variable resistor (3 type) and chip resistor (Fig. A)

Small variable resistor (2 type) and chip resistor (Fig. B)

Hold on SL base

Adhesive agent at

PDIC portion

KSN-260B

FPC retainer plate

APC variable

resistor

Hold on SL base

Adhesive agent at

PDIC portion

KSN-260E

FPC retainer plate

(Fig A)

CHIP

3 type variable

resistor

(Fig B)

CHIP

2 type variable

resistor

8

MDS-JE480

CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5 Electrical Adjustments”.

• 5-6-2. Laser power check (see page 28)

• 5-6-3. Iop Compare (see page 28)

• 5-6-4. Auto Check (see page 29)

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for

adjustments.

When performing adjustments, use the specified values for adjustments.

FORCED RESET

The system microprocessor can be reset in the following procedure.

Use these procedure when the unit cannot be operated normally due to the overrunning of the microprocessor, etc.

Procedure :

Remove the short-pin attached to CN406, and then attach it again.

[MAIN BOARD] (Component Side)

CN406

9

MDS-JE480

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent indicator tube. During playback, the

“track mode” for obtaining track information will be set.

This is useful for locating the faulty part of the unit.

• The following will be displayed :

During recording and stop : Retry cause, number of retries, and number of retry errors.

During playback : Information such as type of disc played, part played, copyright.

These are displayed in hexadecimal.

Procedure:

1. Insert the recordable disc.

2. Press MENU/NO button to display “Edit Menu” on the fluorescent display.

3. Turn l AMS L button to display “All Erase?” on the fluorescent display.

4. Press YES button to display “All Erase??” on the fluorescent display.

5. Press YES button, “Complete!” is displayed on the fluorescent display and it turns off immediately.

6. Procedure 1: Press the x button continuously for about 10 seconds.

Procedure 2: Press the LEVEL/DISPLAY/CHAR button while pressing the x button and MENU/NO button.

7. When the mode is set, “RTs 00c 00e 000” is displayed.

8. Press the z REC button to start recording. Then press the X button and start recording.

9. To check the “track mode”, press the H button to start play.

10.To exit the test mode, press the @/1 button, and turn OFF the power . When “T OC” disappears, disconnect the power plug from the outlet.

If the test mode cannot be exited, refer to “Forced Reset” on page 9.

Fig. 1 Reading the Test Mode Display

(During recording and stop)

RTs@@c##e***

Fluorescent display tube display

@@ : Cause of retry

## : Number of retries

*** : Number of retry errors

Reading the Retry Cause Display

Lower Bits

Hexadecimal

Bit

Binary

Higher Bits

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

Fig. 2 Reading the Test Mode Display

(During playback)

@@###**$$

Fluorescent display tube display

@@ : Parts No. (name of area named on TOC)

### : Cluster

** : Sector

$$ : Track mode (Track information such as copyright infor-

Cause of Retry Occurring conditions

shock

ader5

Discontinuous address

DIN unlock

FCS incorrect

IVR rec error

CLV unlock

Access fault

} Address (Physical address on disc)

mation of each part)

When track jump (shock) is detected

When ADER was counted more than five times continuously

When ADIP address is not continuous

When DIN unlock is detected

When not in focus

When ABCD signal level exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

10

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 t b6

Lower bit : 2 = 0010 t b1

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

When A2 is displayed:

Higher bit : A = 1010 t b7+b5

Lower bit : 2 = 0010 t b2

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

Reading the Track Mode Display

Hexadecimal

Bit

Binary

Higher Bits Lower Bits

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

When 0 When 1

Emphasis OFF

Monaural

This is 2-bit display. Normally 01.

01:Normal audio. Others:Invalid

Audio (Normal)

Original

Copyright

Write prohibited

Details

MDS-JE480

Emphasis ON

Stereo

Invalid

Digital copy

No copyright

Write allowed

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example When 84 is displayed:

Higher bit : 8 = 1000 t b7

Lower bit : 4 = 0100 t b2

In this case, as b2 and b7 are 1 and others are 0, it can be determined that the retry cause is combined of “emphasis OFF”, “monaural”,

“original”, “copyright exists”, and “write allowed”.

Example When 07 is displayed:

Higher bit : 0 = 1000 t All 0

Lower bit : 7 = 0111 t b0+b1+b2

In this case, as b0, b1, and b2 are 1 and others are 0, it can be determined that the retry cause is combined of “emphasis ON”, “stereo”,

“original”, “copyright exists”, and “write prohibited”.

Hexadecimal t Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

11

MDS-JE480

SECTION 2

GENERAL

This section is extracted from

instruction manual.

12

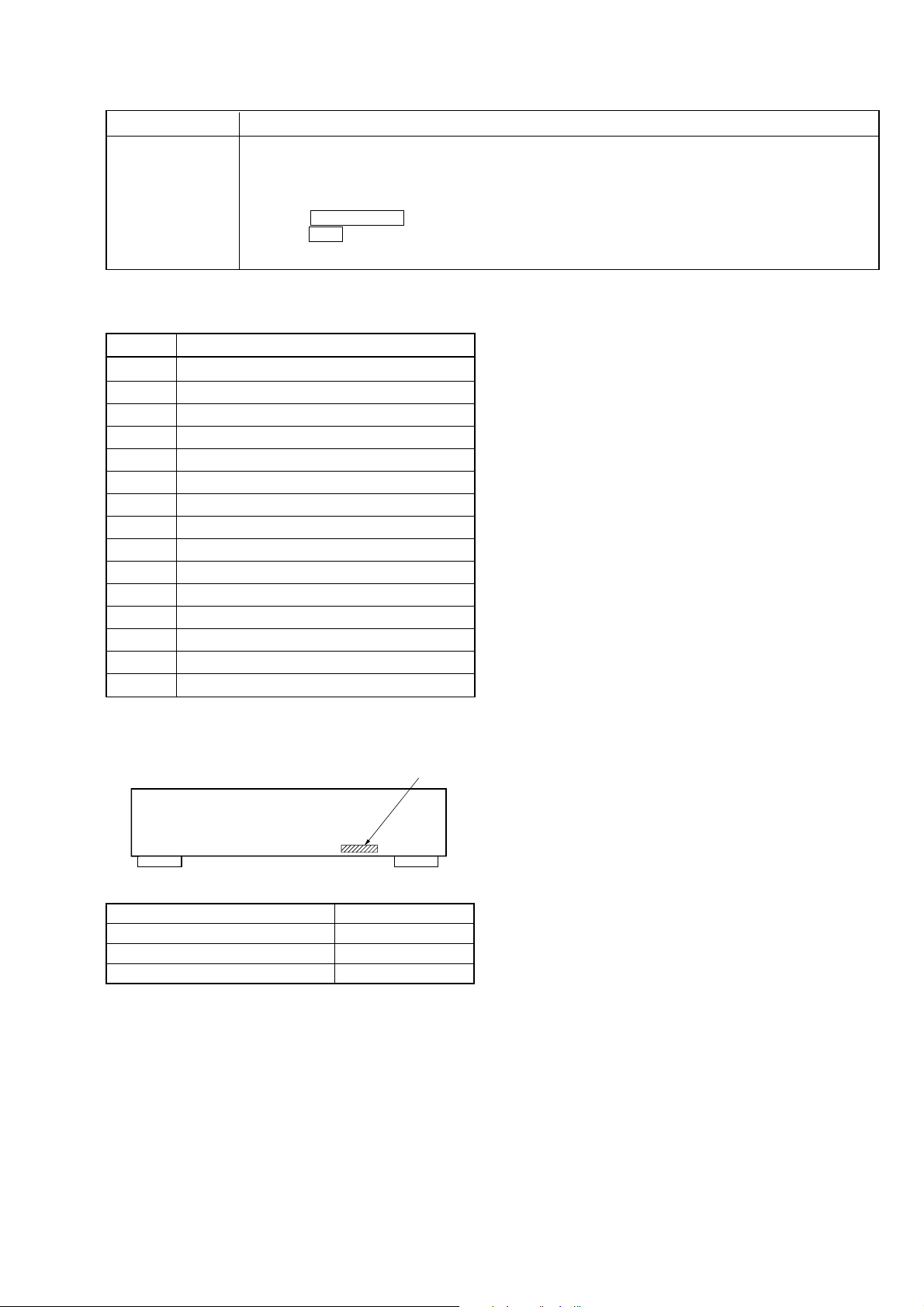

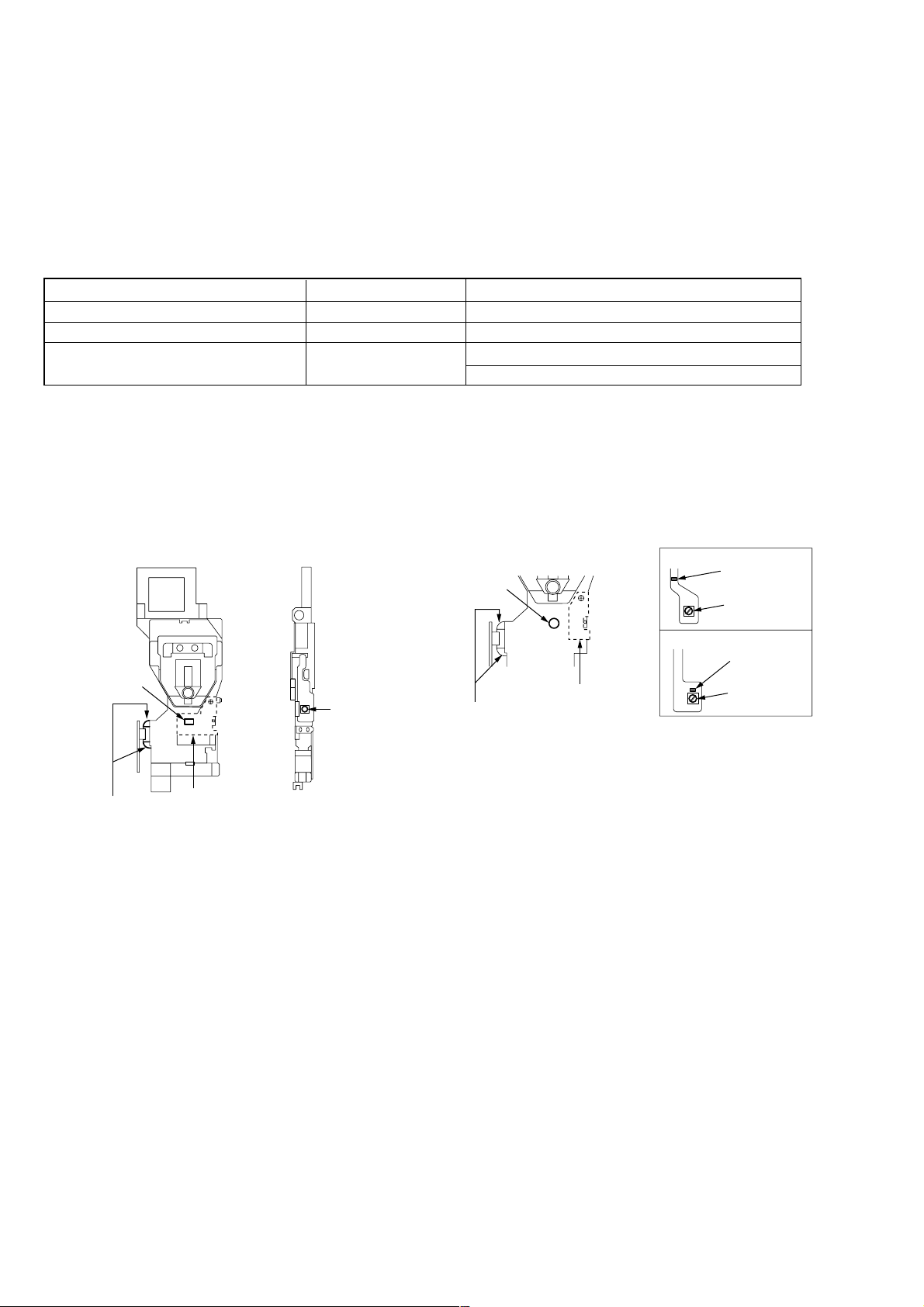

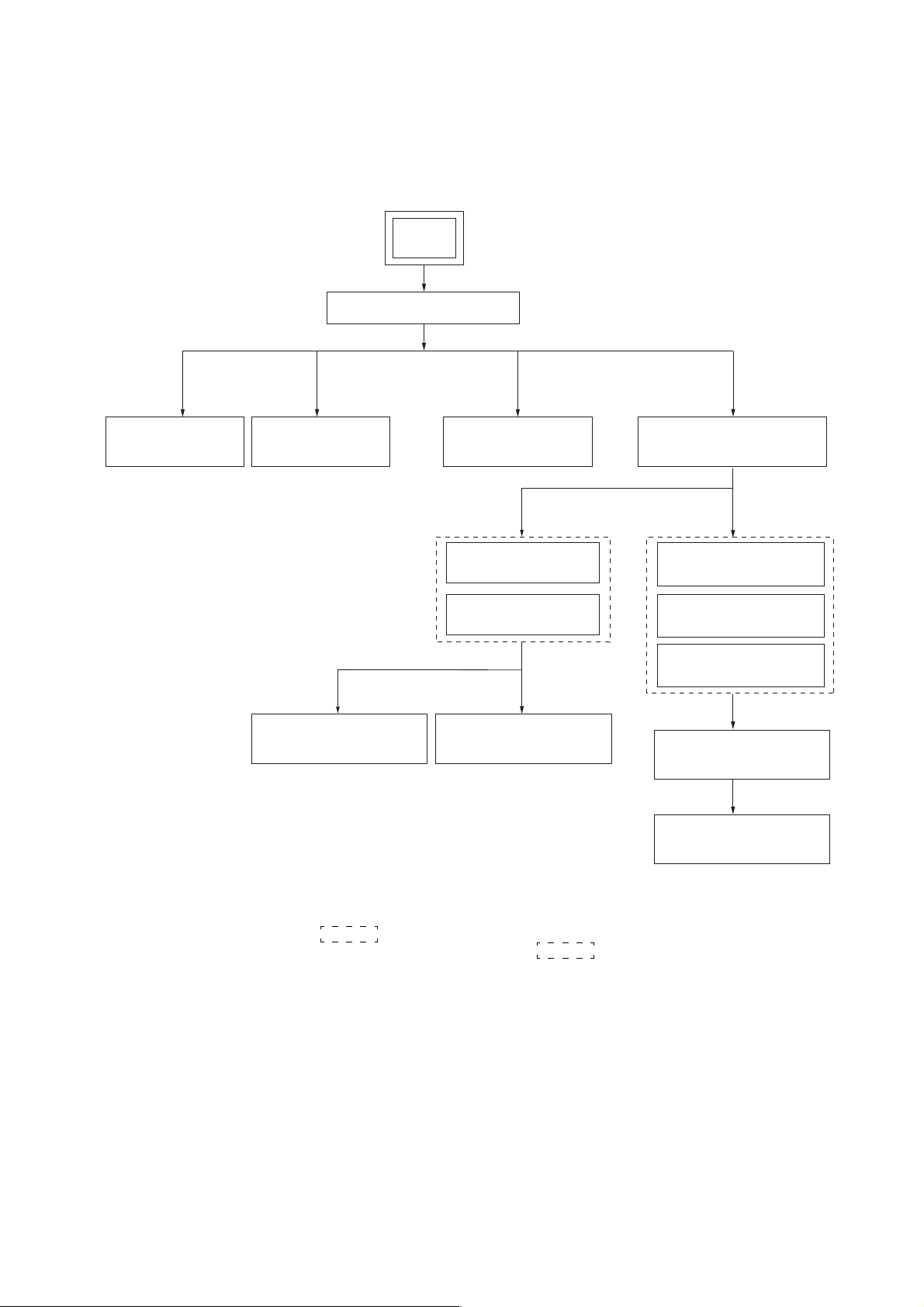

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2 UPPER CASE (408226)

MDS-JE480

SECTION 3

DISASSEMBLY

3-3 FRONT PANEL

SECTION

3-4 MAIN BOARD

3-10 SLED MOTOR

ASSY (M102)

3-5 PT BOARD

3-7 BD BOARD

3-8 HOLDER ASSY

3-9 LOADING MOTOR

ASSY (M103)

3-6 MECHANISM DECK

SECTION (MDM-7S1A)

3-7 OVER LIGHT HEAD

(HR901)

3-7 BD BOARD

3-8 HOLDER ASSY

3-11 OPTICAL PICK-UP

(KMS-260B/260E)

3-12 SPINDLE MOTOR

ASSY (M101)

Note 1: The processes enclosed with , remove in the any order.

Note 2: You cannot go to the next process until every process enclosed with has done.

13

MDS-JE480

)

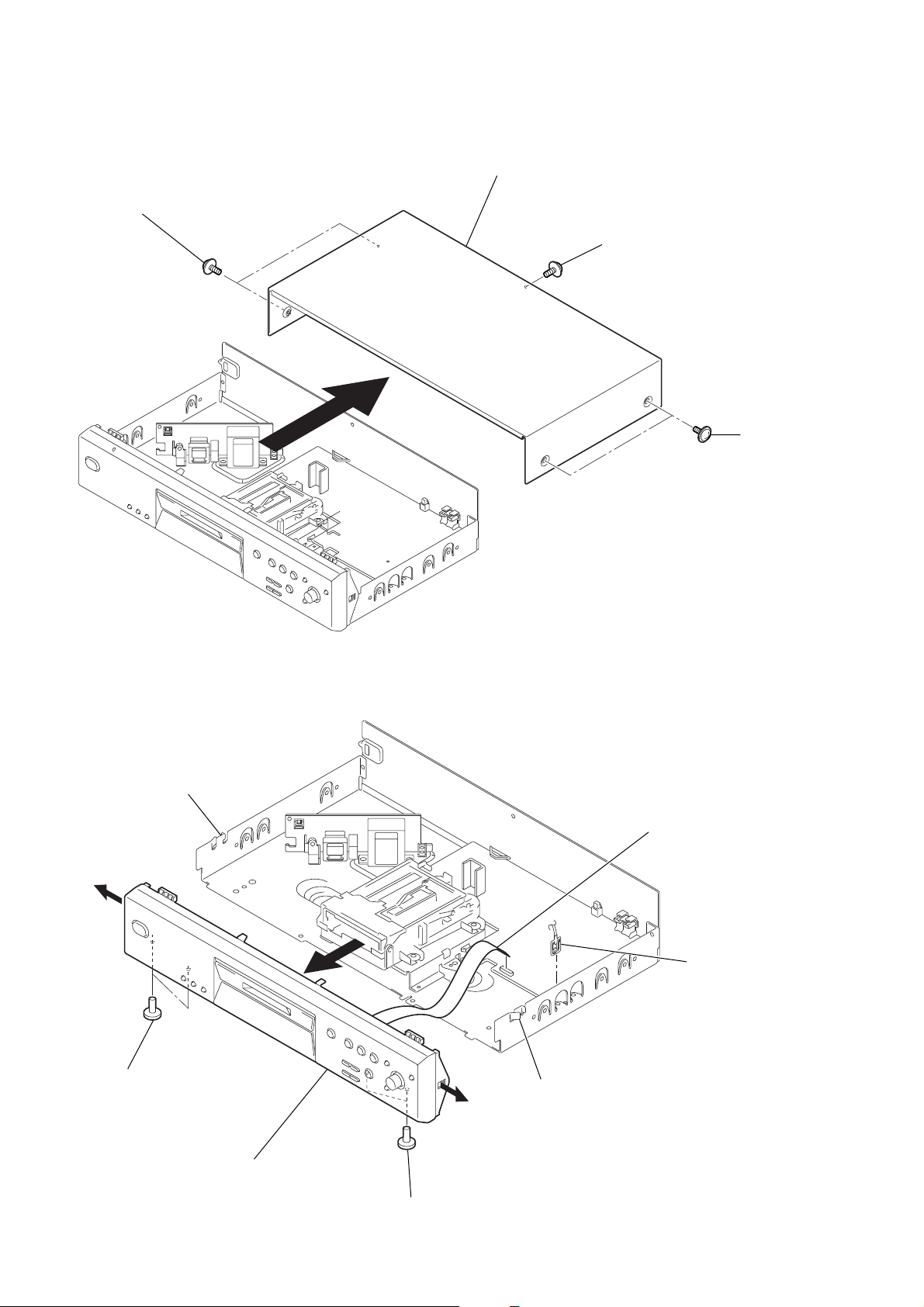

3-2. UPPER CASE (408226)

1

Two screws

(CASE 3TP2)

2

Case (408226)

1

Screw

(CASE 3TP2)

1

Two screws

(CASE 3TP2

3-3. FRONT PANEL SECTION

4

Claw

5

3

Two screws

(+BVTP3x8)

6

5

4

Claw

1

Wire (flat type) (CN3)

2

Lead with connector

14

7

Front panel

3

Two screws

(+BVTP3x8)

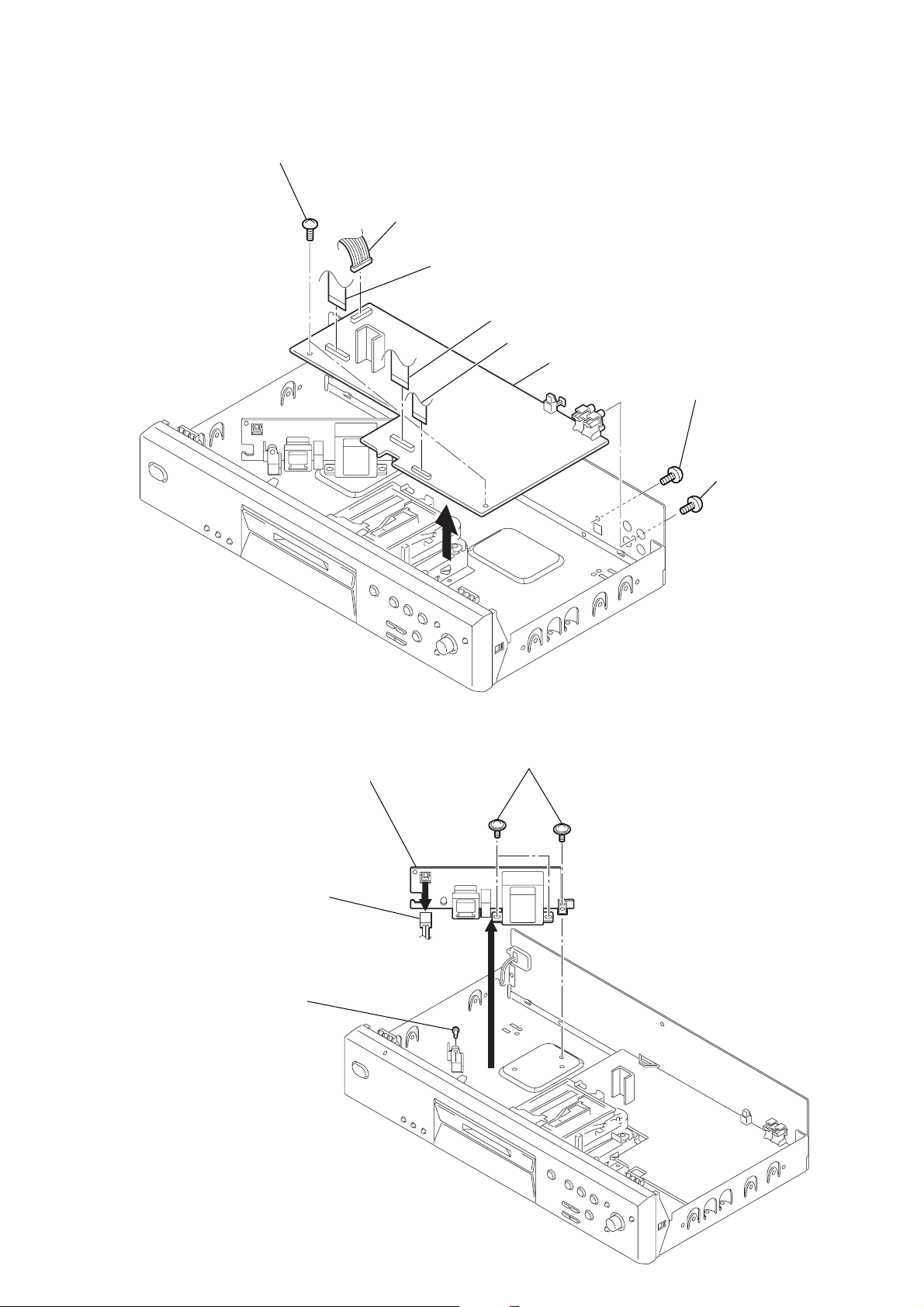

3-4. MAIN BOARD

7

Two screws

(+BVTP3x8)

4

Connector (CN400)

2

Wire (flat type) (CN1)

1

Wire (flat type) (CN2)

3

Wire (flat type) (CN3)

8

MAIN board

5

Screw

(+BVTP3x8)

6

Screw (+BVTP3x8)

MDS-JE480

3-5. PT BOARD

1

2

Connector (CN900)

Nylon rivet (dia 3)

4

PT board

3

Three screws

(+PTTWH M3)

15

MDS-JE480

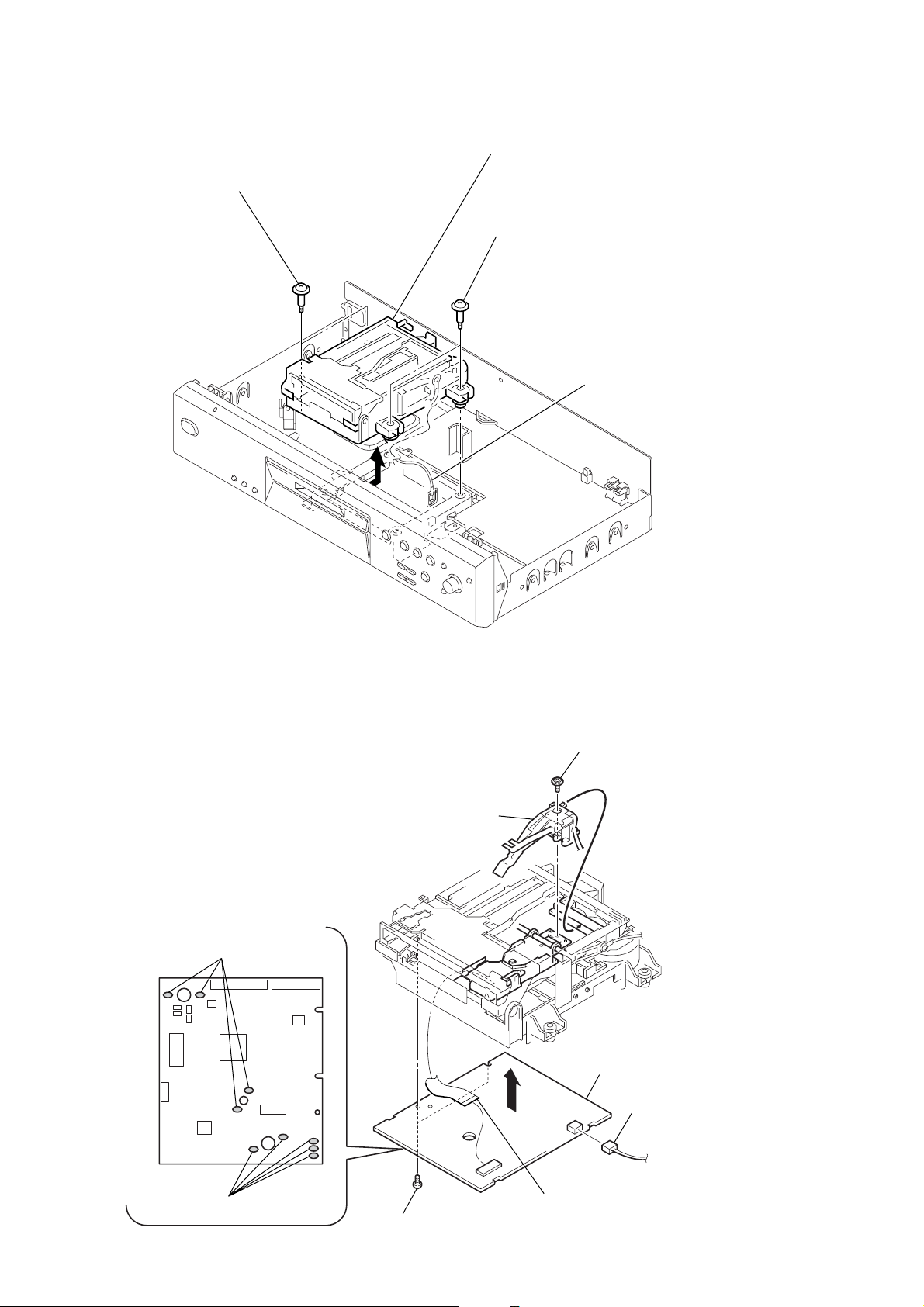

r

)

3-6. MECHANISM DECK SECTION (MDM-7S1A)

2

Two step screws

(+BVTTWH M3)

3

Mechanism deck (MDM-7S1A)

2

Two step screws

(+BVTTWH M3)

1

Lead with connecto

3-7. OVER LIGHT HEAD (HR901), BD BOARD

Note 1: If you disconnect the connector (CN104), you can remove the

BD board without removing the over write head (HR901).

Note 2: Be careful to handle the over write head (HR901) because it is

easy to be damaged.

3

Over light head (HR901)

5

Remove the solder (four portion)

7

2

Screw (P1.7X6)

9

BD board

1

Connector (CN104

16

4

Remove the solder (five portion)

6

Two screws (BTP2X6)

8

FLEXIBLE board (CN101)

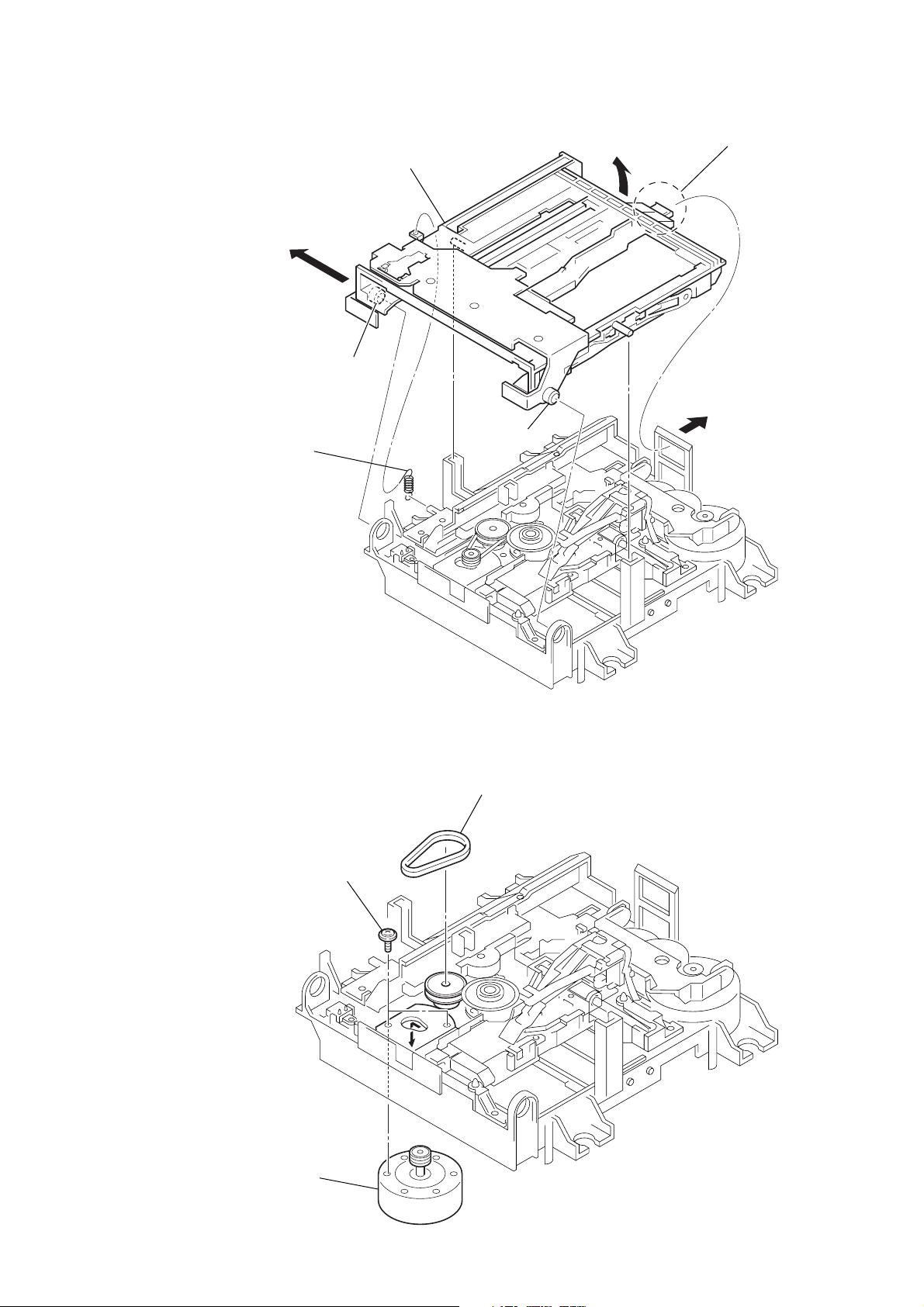

3-8. HOLDER ASSY

1

Tension spring (holder)

5

7

Holder Assy

6

Boss

6

Boss

4

2

MDS-JE480

3

Claw

3-9. LOADING MOTOR ASSY (M103)

2

Two screws (PWH1.7x2.5)

3

1

Belt (loading)

4

Loading motor Assy (M103)

17

MDS-JE480

d

)

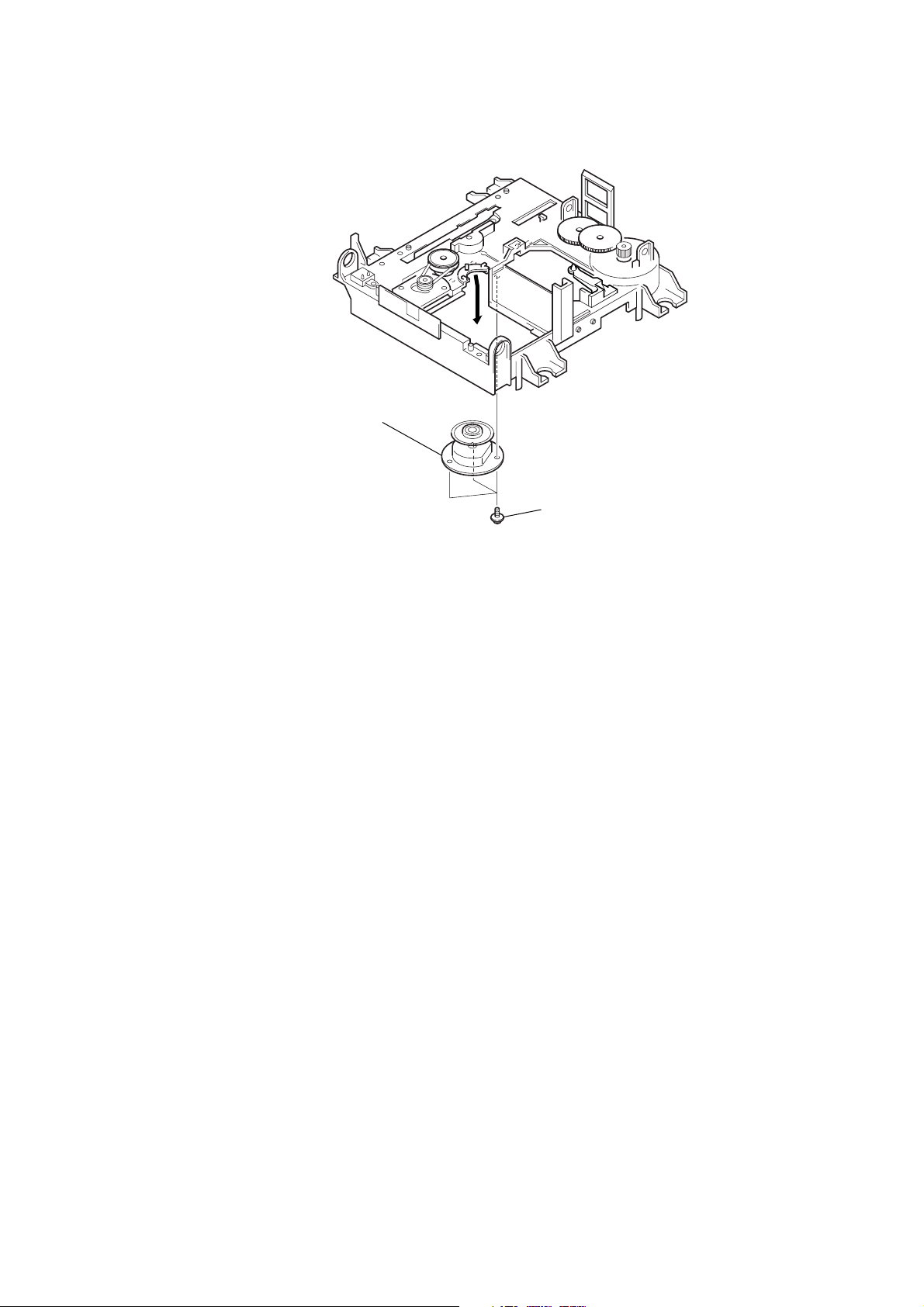

3-10. SLED MOTOR ASSY (M102), SLIDER

4

Slider (EJ)

3

Remove the claw.

5

Shift the slider in the arrow

direction.

A

1

Two screws (BTP2X6)

3-11. OPTICAL PICK-UP

2

Guide (L)

6

Slider

7

Lever (CHG)

A

8

Lever (head)

9

Two screws

(PWH1.7X2.5)

0

Motor Assy, sle

(M102)

1

FLEXIBLE board

0

9

Screw (P1.7X6)

2

SL base

Screw (M1.7), tapping

8

qa

Optical pick-up

(KMS-260B/260E)

6

3

Gear (SD)

7

Main shaft

Two screws (K2X6)

4

Screw (BTP2X6

5

Base (BU-A)

18

g

3-12. SPINDLE MOTOR ASSY (M101)

3

Spindle motor Assy (M101)

MDS-JE480

2

1

Three screws (M1.7), tappin

19

MDS-JE480

SECTION 4

TEST MODE

4-1. PRECAUTIONS FOR USE OF TEST MODE

• As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc

is stopped before setting and removing it.

Even if the A EJECT button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will

not stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the A EJECT button after pressing the MENU/NO button and the rotation of disc is stopped.

4-1-1. Recording laser emission mode and operating buttons

• Continuous recording mode (CREC 1MODE) (C35)

• Laser power check mode (LDPWR CHECK) (C13)

• Laser power adjustment mode (LDPWR ADJUST) (C04)

• Iop check (Iop Compare) (C27)

• Iop value nonvolatile writing (Iop NV Save) (C06)

• Traverse (MO) check (EF MO CHECK) (C14)

• Traverse (MO) adjustment (EF MO ADJUST) (C07)

• When pressing the z REC button.

4-2. SETTING THE TEST MODE

The following are two methods of entering the test mode.

Procedure 1:While pressing the l AMS L knob and x button, connect the power plug to an outlet, and release the l AMS L

knob and x button.

When the test mode is set, “[Check]” will be displayed. Rotating the l AMS L knob switches between the following

three groups; ··· y Check y Service y Develop y ···.

Procedure 2:While pressing the l AMS L knob, connect the power plug to the outlet and release the l AMS L knob.

When the test mode is set, “TEMP CHECK” will be displayed. By setting the test mode using this method, only the “Check”

group of method 1 can be executed.

NOTE: Do not use the test mode in the [Develop] group.

If used, the unit may not operate normally.

If the [Develop] group is set accidentally, press the MENU/NO button immediately to exit the [Develop] group.

4-3. EXITING THE TEST MODE

Press the REPEAT button. The disc is ejected when loaded, and “Standby” display blinks, and the STANDBY state is set.

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the l AMS L knob, YES button, and MENU/NO button.

The functions of these buttons are as follows.

Function name

MENU/NO button

YES button

AMS

knob

Left or Right

Push

Cancel or move to top hierarchy

Set

Select

Set submenu

Function

20

MDS-JE480

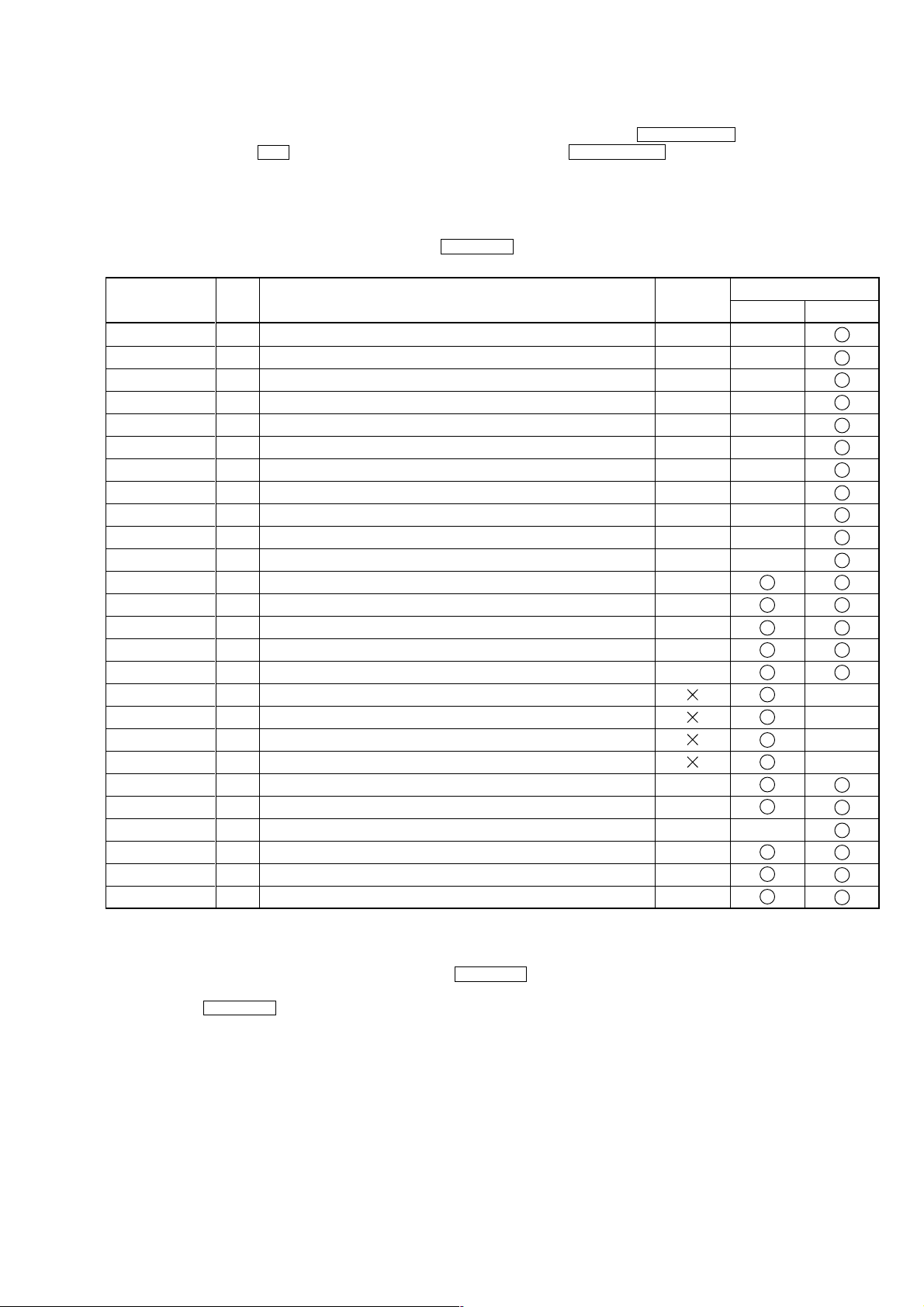

4-5. SELECTING THE TEST MODE

There are 25 types of test modes as shown below. The groups can be switched by rotating the l AMS L knob. After selecting the

group to be used, press the YES button. After setting a certain group, rotating the l AMS L knob switches between these modes.

Refer to “Group” in the table for details selected.

All adjustments and checks during servicing can be performed in the test mode in the Service group.

NOTE: Do not use the test mode in the [Develop] group.

If used, the unit may not operate normally.

If the [Develop] group is set accidentally, press the MENU/NO button immediately to exit the [Develop] group.

Display

AUTO CHECK

Err Display

TEMP ADJUST

LDPWR ADJUST

Iop Write

Iop NV Save

EF MO ADJUST

EF CD ADJUST

FBIAS ADJUST

AG Set (MO)

AG Set (CD)

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

ScurveCHECK

VERIFYMODE

DETRK CHECK

0920 CHECK

Iop Read

Iop Compare

ADJ CLEAR

INFORMATION

CPLAY1MODE

CREC 1MODE

No.

Automatic self-diagnosis

C01

Error history display, clear

C02

Temperature compensation offset adjustment

C03

Laser power adjustment

C04

Iop data writing

C05

Writes current Iop value in read nonvolatile memory using microprocessor

C06

Traverse (MO) adjustment

C07

Traverse (CD) adjustment

C08

Focus bias adjustment

C09

Focus, tracking gain adjustment (MO)

C10

Focus, tracking gain adjustment (CD)

C11

Temperature compensation offset check

C12

Laser power check

C13

Traverse (MO) check

C14

Traverse (CD) check

C15

Focus bias check

C16

S-curve check

C17

Nonvolatile memory check

C18

Detrack check

C19

Most circumference check

C25

Iop data display

C26

Comparison with initial Iop value written in nonvolatile memory

C27

Initialization of nonvolatile memory for adjustment values

C28

Display of microprocessor version, etc.

C31

Continuous playback mode

C34

Continuous recording mode

C35

Details

Mark

Group

Check Service

• For details of each adjustment mode, refer to “5. Electrical Adjustments”.

For details of “Err Display”, refer to “Self-Diagnosis Function” on page 3.

• If a different mode has been selected by mistake, press the MENU/NO button to exit that mode.

• Modes with (X) in the Mark column are not used for servicing and therefore are not described in detail. If these modes are set accidentally, press the MENU/NO button to exit the mode immediately.

21

Loading...

Loading...