Sony MDSJE-320 Service manual

MDS-JE320

SERVICE MANUAL

Ver. 1.1 2004. 12

Model Name Using Similar Mechanism MDS-JE510

MD Mechanism Type MDM-3GC

Optical Pick-up Type KMS-260A/J1NP

SPECIFICATIONS

US Model

Canadian Model

AEP Model

9-922-894-12

2004L16-1

© 2004.12

MINIDISC DECK

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the equipment manufacturer.

Discard used batteries according to manufacture’s instructions.

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilakting skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av

apparatfabrikanten.

Brukte batterier katterier kasseres i henhold til fabrikantens

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

VARNIG

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som rekommenderas

av apparattillverkaren.

Kassera använt batteri enligt gällande föreakrifter.

VAROITUS

Parist voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laite valmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

This caution label is located inside the unit.

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

— 2 —

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT . NE REMPLA CER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

SAFETY CHECK-OUT

TABLE OF CONTENTS

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

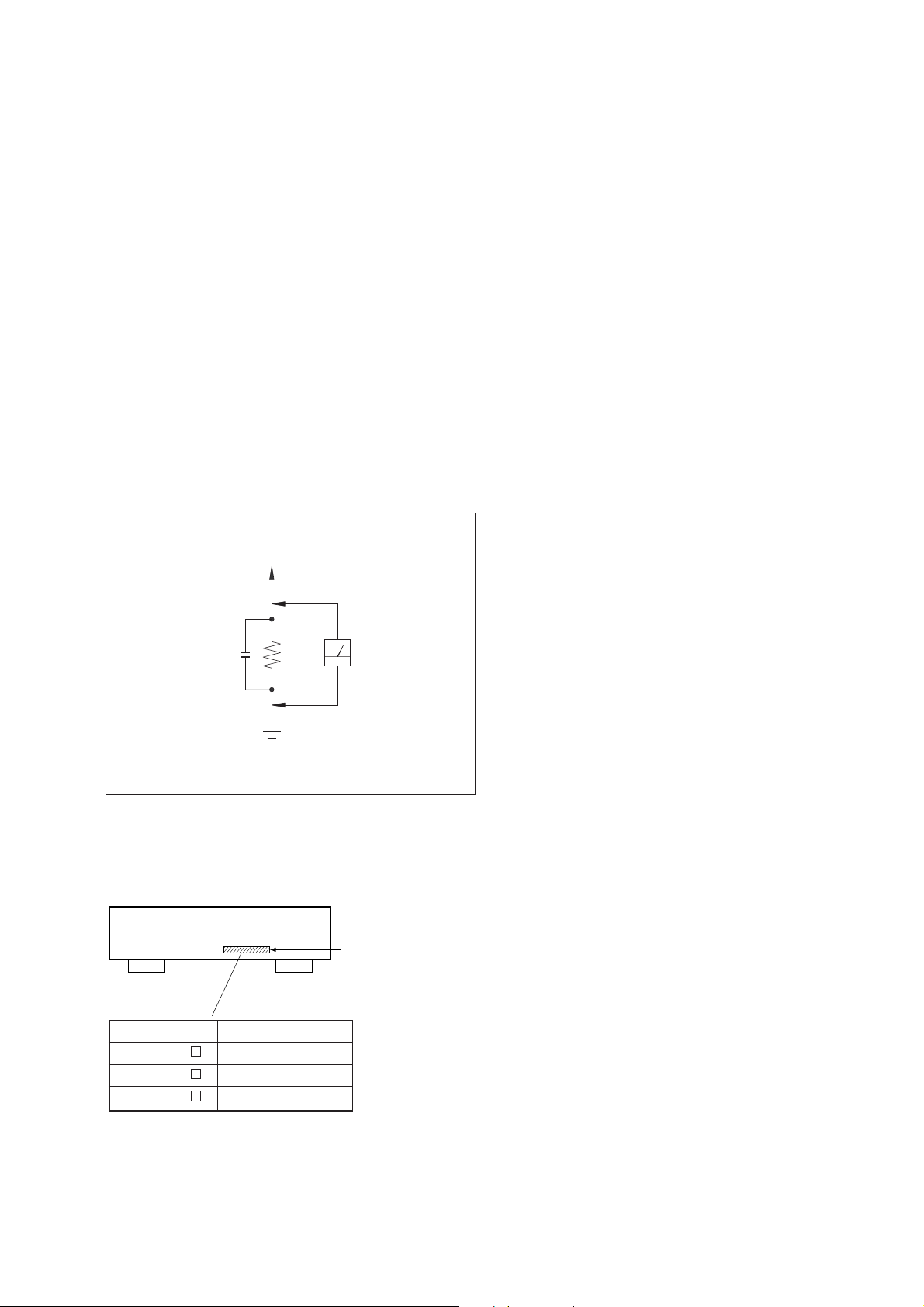

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated A C voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate lo w-v olta ge

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

T o Exposed Metal

Parts on Set

AC

0.15

µ

F

Fig. A. Using an A C v oltmeter to check A C leakage.

1.5 k

Ω

Earth Ground

Voltmeter

(0.75 V)

1. SERVICING NOTE .......................................................... 5

2. GENERAL ..........................................................................8

3. DISASSEMBLY

3-1. Case and Front Panel Assembly ...................................... 9

3-2. Bracket (T), (L) and (R)..................................................9

3-3. BD Board ...................................................................... 10

3-4. SUB Chassis ................................................................. 10

3-5. Shutter Assembly .......................................................... 11

3-6. Over Write Head ........................................................... 11

3-7. Slider Complete Assembly............................................ 12

4. TEST MODE ..................................................................... 13

5. ELECTRICAL ADJUSTMENTS ...............................16

6. DIAGRAMS

6-1. Brock Diagrams

• BD Section .......................................................................21

• Main Section .................................................................... 23

6-2. Circuit Boards Location................................................25

6-3. Printed Wiring Board — BD Section — ......................27

6-4. Schematic Diagram — BD Section (1/2) — ................ 29

6-5. Schematic Diagram — BD Section (2/2) — ................ 31

6-6. Printed Wiring Board — Main Section —.................... 33

6-7. Schematic Diagram — Main Section (1/3) —.............. 35

6-8. Schematic Diagram — Main Section (2/3) —.............. 37

6-9. Schematic Diagram — Main Section (3/3) —.............. 39

6-10. Printed Wiring Board — Display Section — .............. 41

6-11. Schematic Diagram — Display Section — ................43

6-12. Printed Wiring Board — Switch Section — ...............45

6-13. Schematic Diagram — Switch Section —.................. 47

6-14. IC Brock Diagrams — BD Section—......................... 49

6-15. IC Pin Functions .........................................................54

7. EXPLODED VIEWS

7-1. Main Section ................................................................. 63

7-2. Front Panel Section ....................................................... 64

7-3. Mechanism Deck Section (1) (MDM-3GC) ................. 65

7-4. Mechanism Deck Section (2) (MDM-3GC) ................. 66

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

4-990-651-1

4-990-651-4

4-990-651-5

US model

Canadian model

AEP model

8. ELECTRICAL PARTS LIST ........................................ 67

Parts No.

Model

— 3 —

[SELF-DIAGNOSIS FUNCTION]

C11

Protected

Self-diagnosis display

The self-diagnosis function consists of error codes for users which are displayed automatically when errors occur, and error codes which show the error

history in the test mode during servicing.For detail on how to view error codes for users, refer to the following box in the instruction manual.

Self-Diagnosis Function

The deck has a self-diagnosis display. This function shows a three-digit display (a combination of a letter and figures)

and the corresponding message alternately, so you can check the deck’s condition. If such a display appears, check the

following table in order to resolve the problem. Should any problem persist, consult your nearest Sony dealer.

Three-digit display/Message Cause/Remedy

C11/Protected The inserted MD is record-protected.

C13/REC Error The recording was not made properly.

C13/Disc Error The deck could not read the TOC of the MD properly.

C14/Disc Error The deck could not read the TOC of the MD properly.

C71/Din Unlock A moment’s lighting is due to the signals of the digital program being recorded.

/Take out the MD, and close the record-protect tab (page 9.)

/Set the deck in a stable place, and repeat the recording procedure.

The inserted MD is dirty (with smudges, fingerprints, etc.) scratched, or not up to standards.

/Replace the disc, and repeat the recording procedure.

/Take out the MD, and insert it again.

/Insert another disc.

/If possible, erase all tracks on the MD using the All Erase Function on page 28.

This does not affect the recorded material.

While recording from a digital component connected through the digital input connector,

the digital connecting cable was unplugged or the digital component turned off.

/Connect the cable or turn the digital component back on.

— 4 —

SECTION 1

SERVICING NOTE

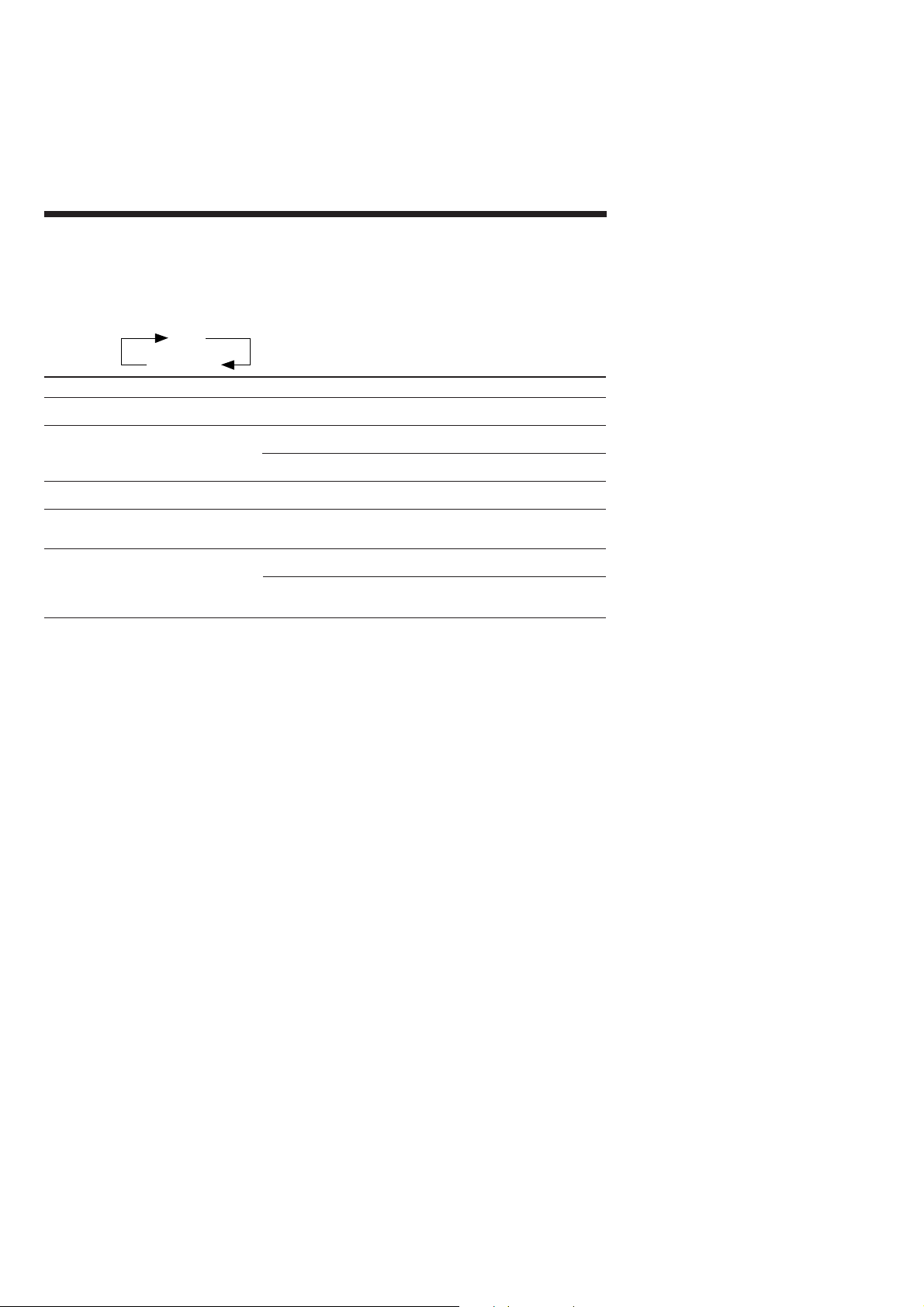

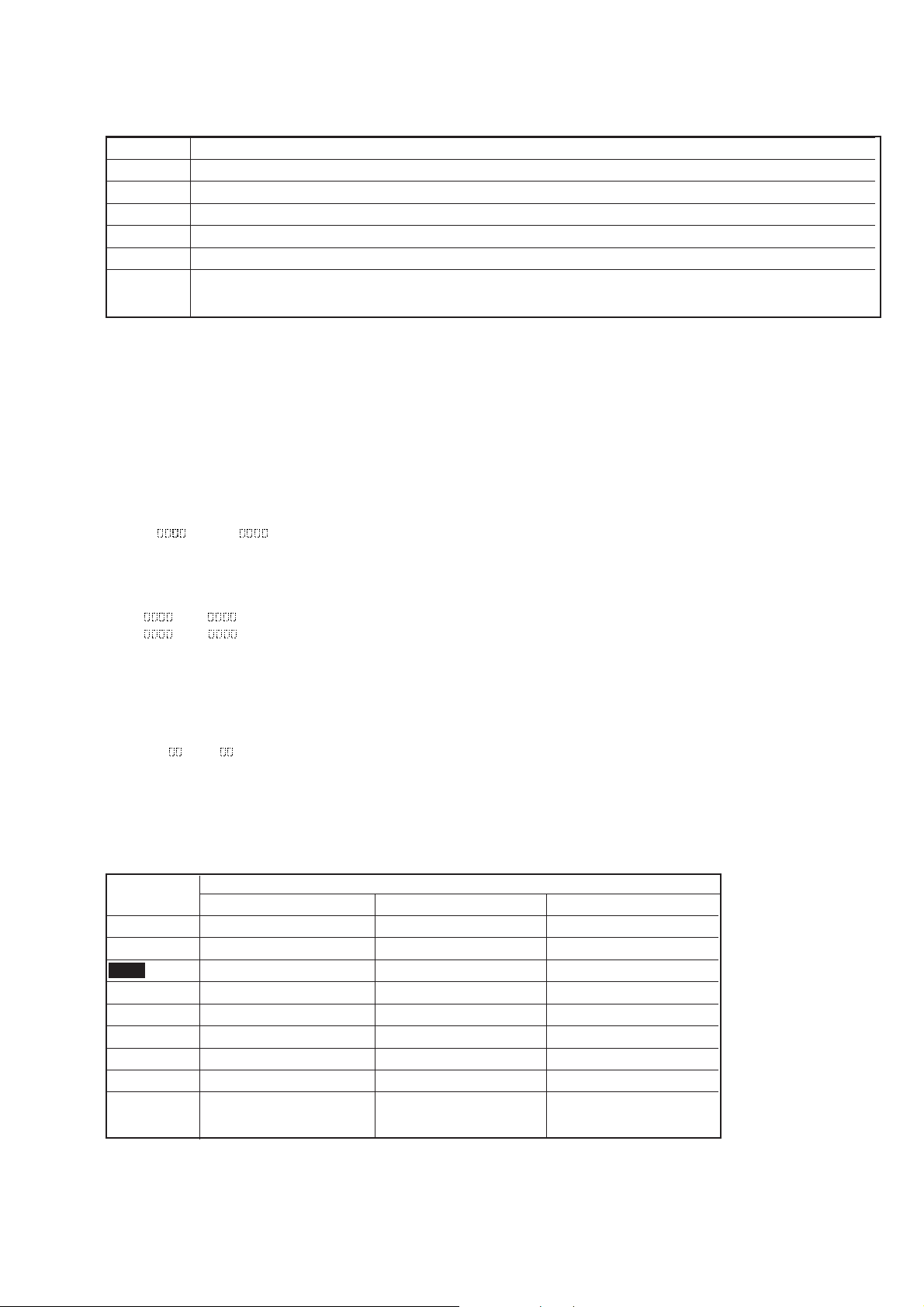

JIG FOR CHECKING BD BOARD WAVEFORM

The special jig (J-2501-124-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TEO : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

RF

VC

TEO

IOP

I + 3V

Jig

(J-2501-124-A)

CN110

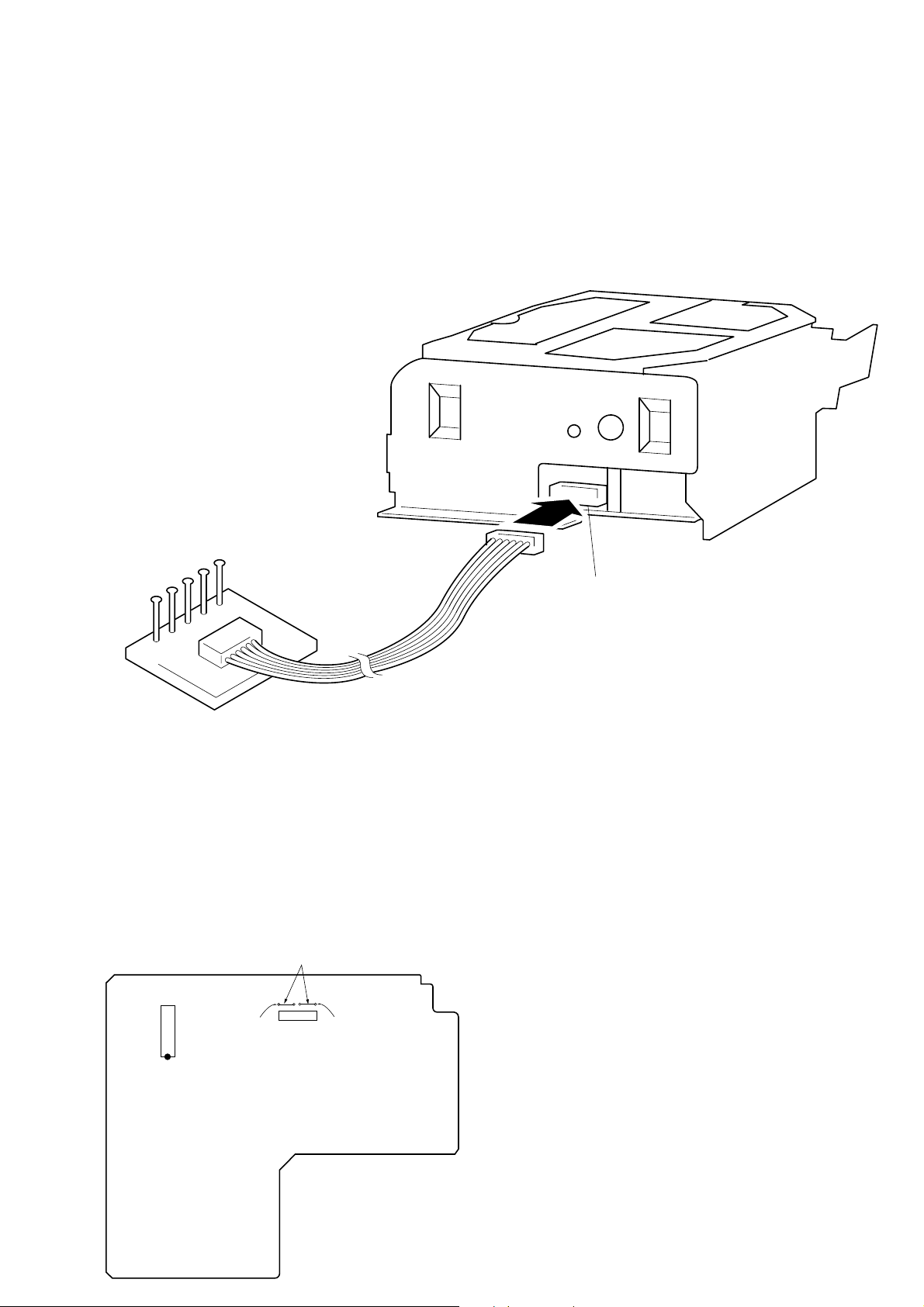

FORCED RESET

The system microprocessor can be reset in the following way.

Use these methods when the unit cannot be operated normally due to the overrunning of the microprocessor, etc.

Method :

Disconnect the power plug, short-circuit jumper wire of JW70 and JW181.

[MAIN BOARD] (Component Side)

Jumper wire

Mechanism deck

IC301

BT301

JW181JW70

— 5 —

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent display tube.

This is useful for locating the faulty part of the unit.

• The data amount stored in DRAM, number of retries, and retry cause are displayed. Each is displayed in hexadecimal number.

• The display of the DRAM data amount enables data reading, accumulation, ejection, and writing to be performed smoothly. If writing is

not smooth, data may decrease considerably.

Method:

1. Load a recordable disc whose contents can be erased into the unit.

2. Press the EDIT/NO button several times to display “All Erase?” on the fluorescent display tube.

3. Press the YES button.

4. When “All Erase??” is displayed on the fluorescent display tube, the numbers on the music calendar will start blinking.

5. Press the YES button to display “Complete”, and press the p button immediately and continue pressing for about 10 seconds.

6. When the “TOC” displayed on the fluorescent display tube goes off, release the p button.

7. Press the r REC and · PLAY buttons to start recording.

8. Press the DISPLAY/CHAR button to display the test mode (Fig. 1), and check the display.

9. The Rt value increases with each retry . If an error occurs after a retry, “Retry Error” will be displayed, and the number of retries counted

will be set back to 0.

10. T o exit the test mode, press the 1/u b utton. T urn OFF the po wer , and after “TOC” disappears, disconnect the po wer plug from the outlet.

Fig. 1 Reading the Test Mode Display

Fluorescent Display Tube Signs

SC @@ Rt # # ∗ ∗

@@ : Displays the DRAM memory amount when at all times.

# # : Displays the number of retries. When a retry error occurs, the number will be set back to 0.

* * : Cause of retry

All three displays above are in hexadecimal numbers.

— 6 —

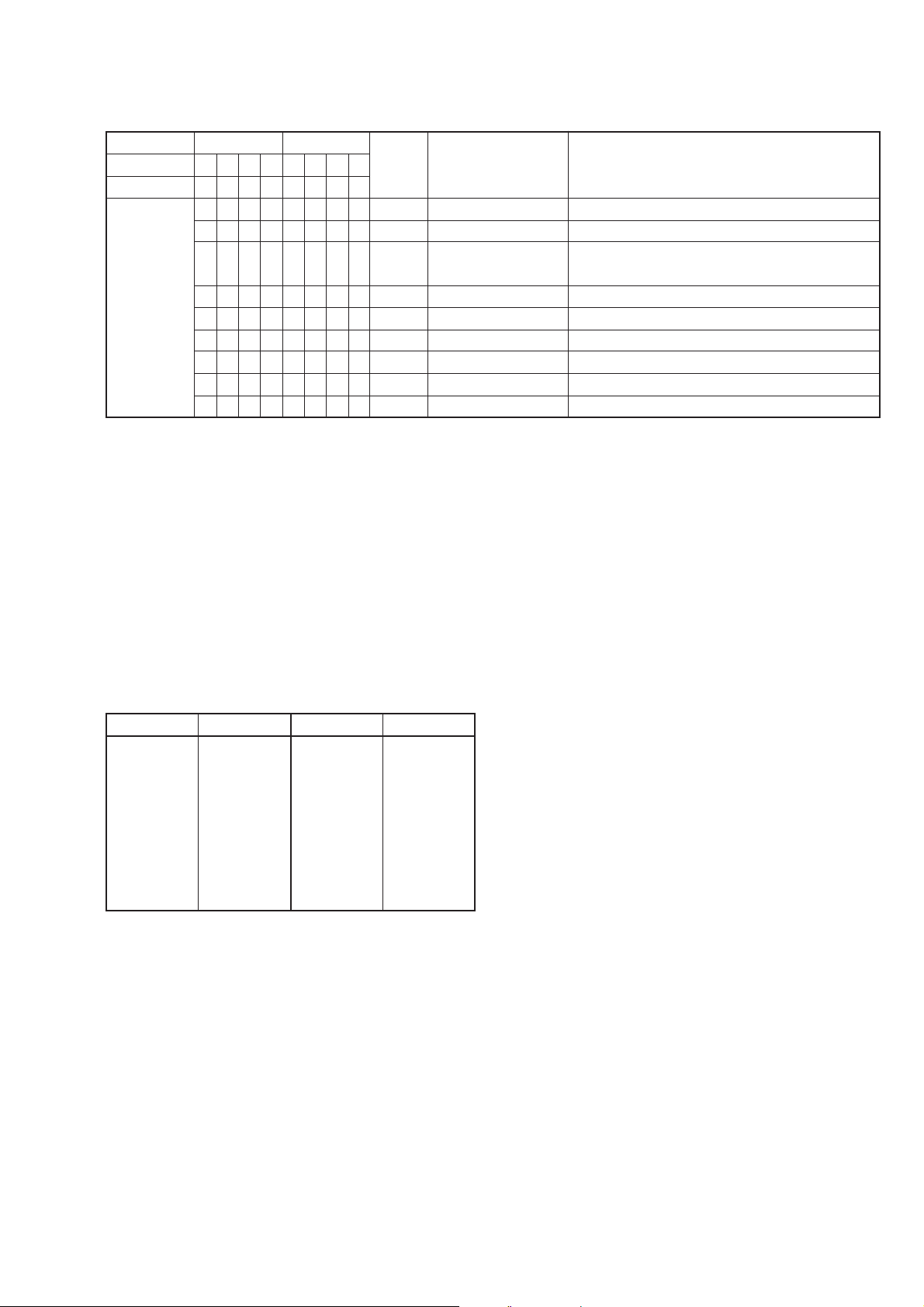

Reading the Retry Cause Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 n b6

Lower bit : 2 = 0010 n b1

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000000

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

00

01

02

04

08

10

20

40

80

Cause of Retry Occurring conditions

Spindle is slow

(Not used)

ader5

Discontinuous address

(Not used)

FCS incorrect

IVR rec error

CLV unlock

Access fault

When spindle rotation is detected as slow

(Not used)

When ADER was counted more than

five times continuously

When ADIP address is not continuous

(Not used)

When not in focus

When ABCD signal level exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

When A2 is displayed:

Higher bit : A = 1010 n b7+b5

Lower bit : 2 = 0010 n b1

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

Hexadecimal n Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

— 7 —

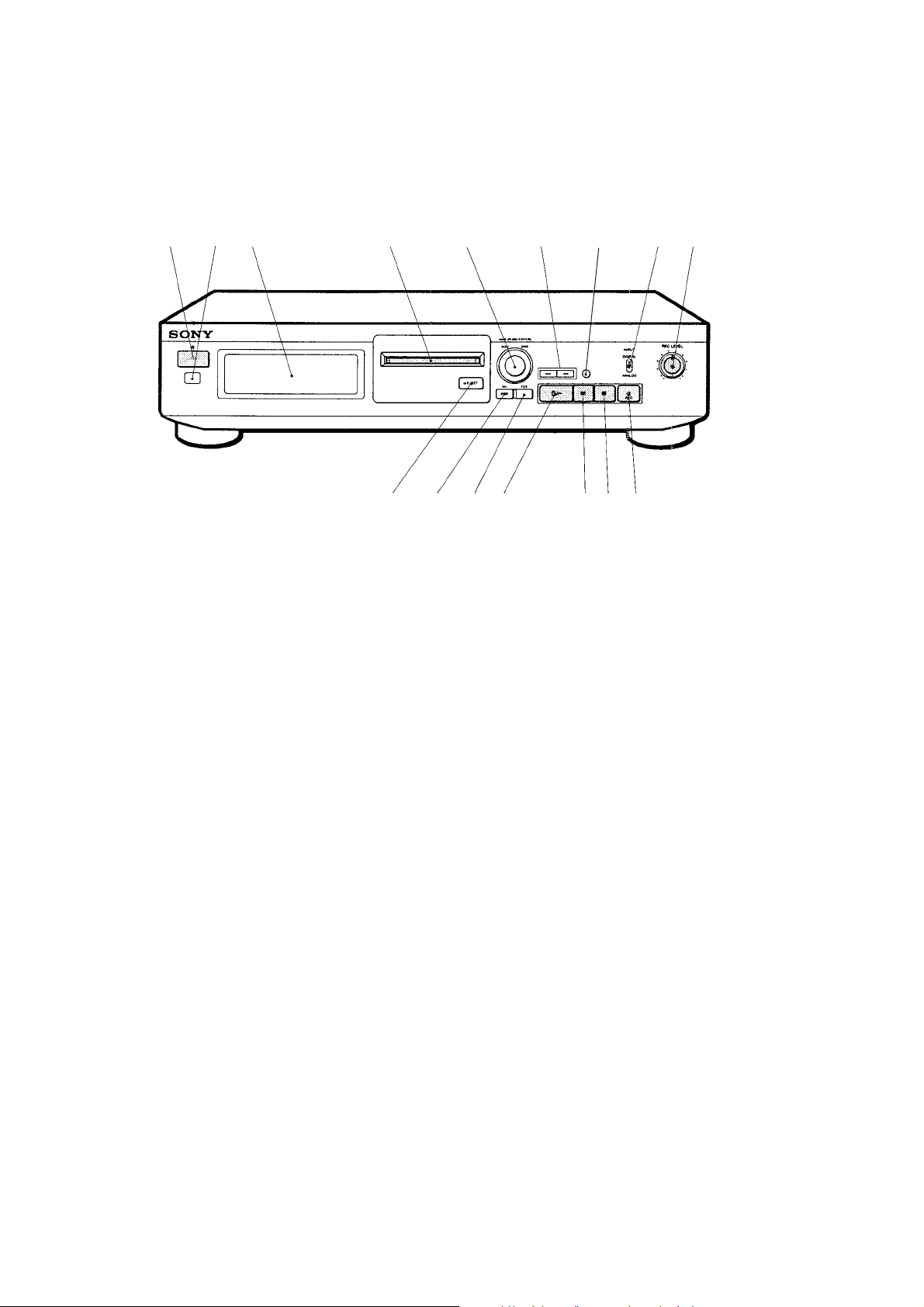

Location of Parts and Controls

23

1

SECTION 2

GENERAL

456 8

7

9

1 1/u (Power) switch

2 Remote sensor

3 Display window

4 Disc compartment

5 AMS knob

6 0/) buttons

7 DISPLAY/CHAR button

8 INPUT switch

!ª

!• !¶ !§

9 REC LEVEL knob

!£ r REC (recording) button

!¢ p (stop) button

!∞ P (pause) button

!§ · (play) button

!¶ YES button

!• EDIT/NO button

!ª § EJECT button

!∞ !¢ !£

— 8 —

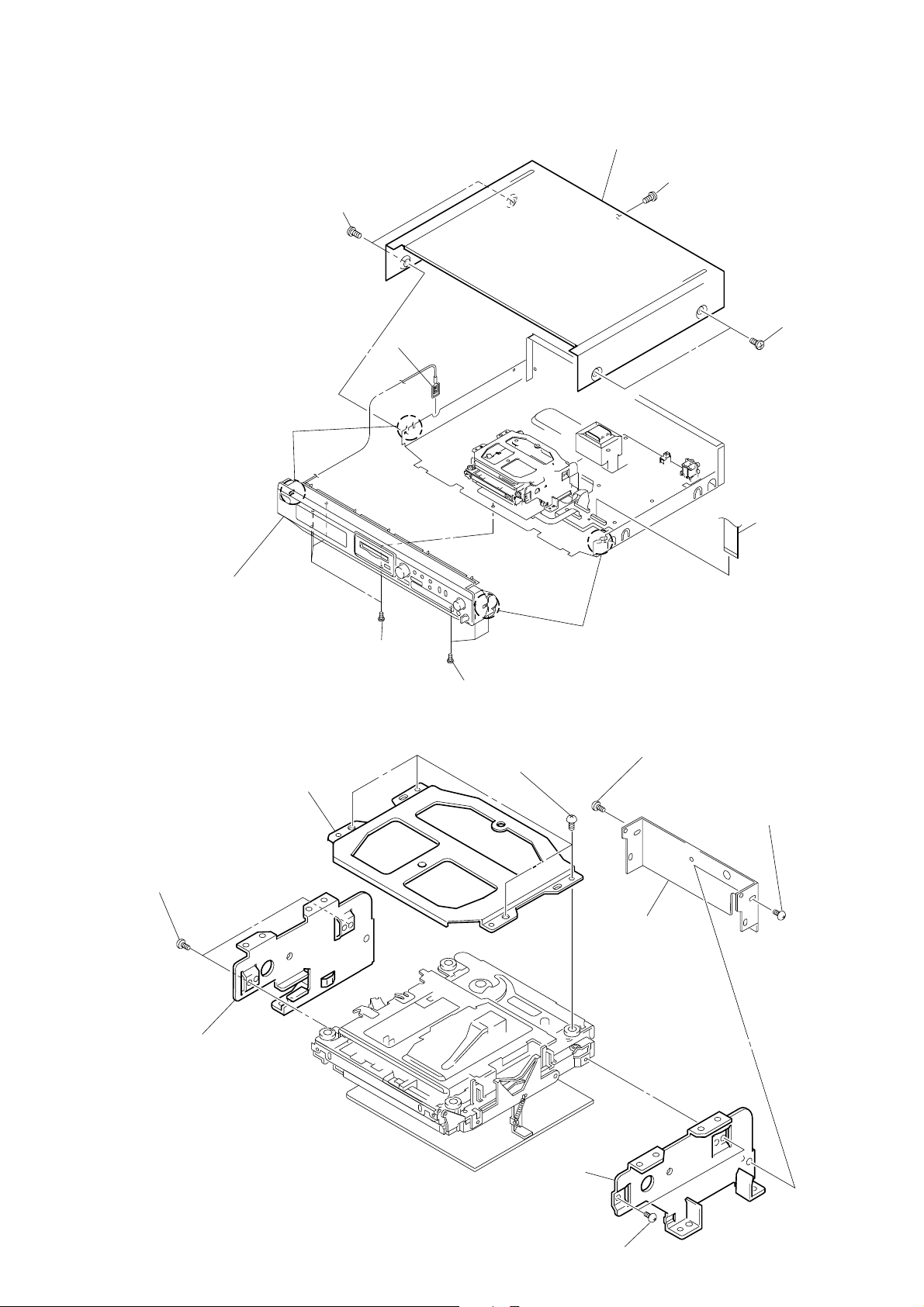

SECTION 3

4

Case

3

Screw

(case 3 TP 2)

2

T wo screws

(Case 3 TP 2)

6

Flat type wire

(CN303)

claw

8

Four screws

(BVTP3

×

8)

9

Remove the front panel assembly

releasing two claws.

claw

1

T wo screws

(Case 3 TP 2)

7

Three screws

(BVTP3

×

8)

5

Ground terminal

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE AND FRONT PANEL ASSEMBLY

3-2. BRACKET (T), (L) AND (R)

6

T wo screws

(BVTT2

×

3)

7

Bracket (L)

2

Bracket (T)

1

Four screws

(BVTT2

×

3)

5

Bracket (joint)

9

Bracket (R)

4

Screw (BVTT2×3)

3

Screw (BVTT2×3)

8

— 9 —

T wo screws

(BVTT2

×

3)

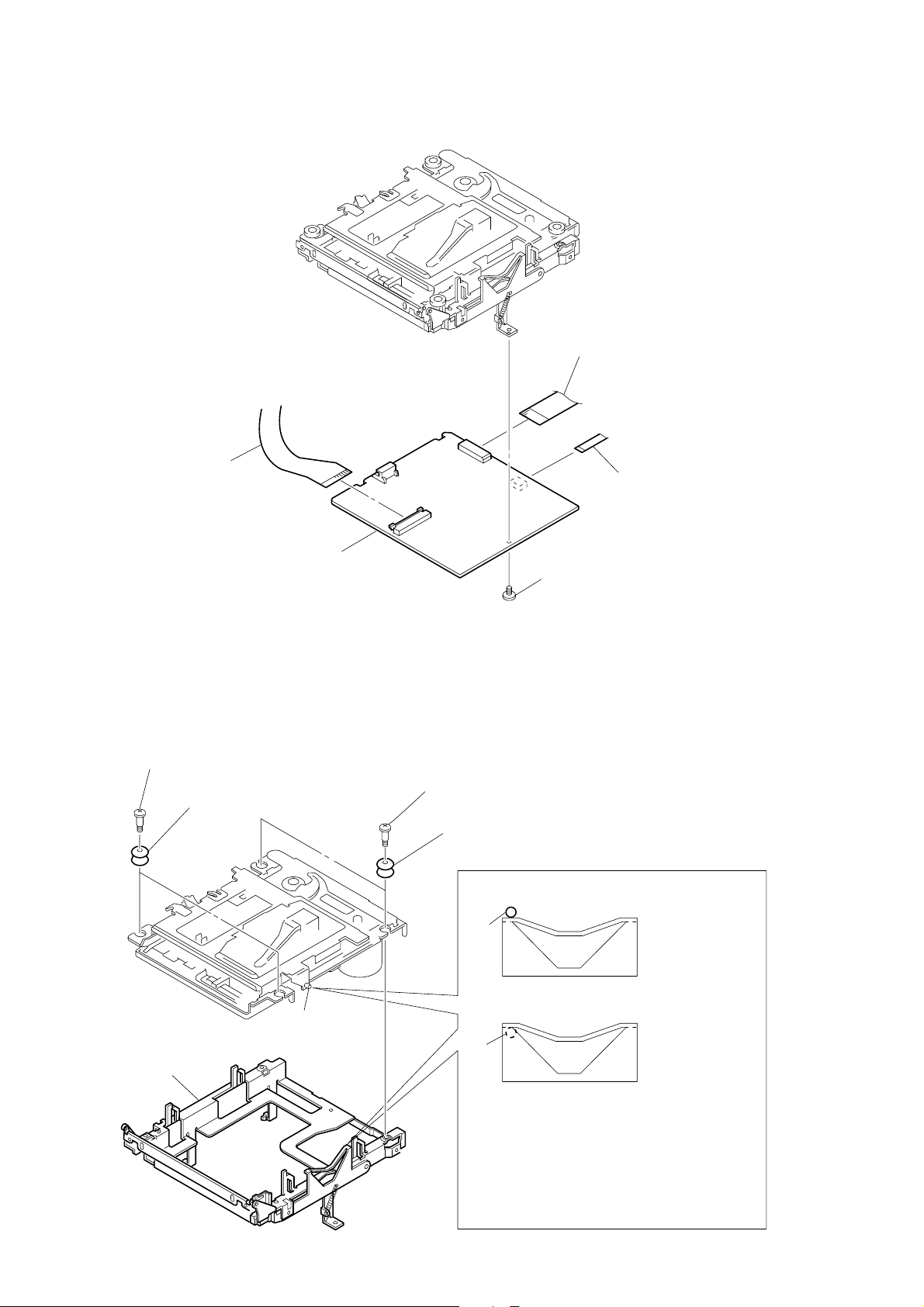

3-3. BD BOARD

)

4

OP relay flexible board

5

BD board

2

Flat type wire (15 core)

1

(Over write head

3

Screw (BVTT2×4)

Flexible board

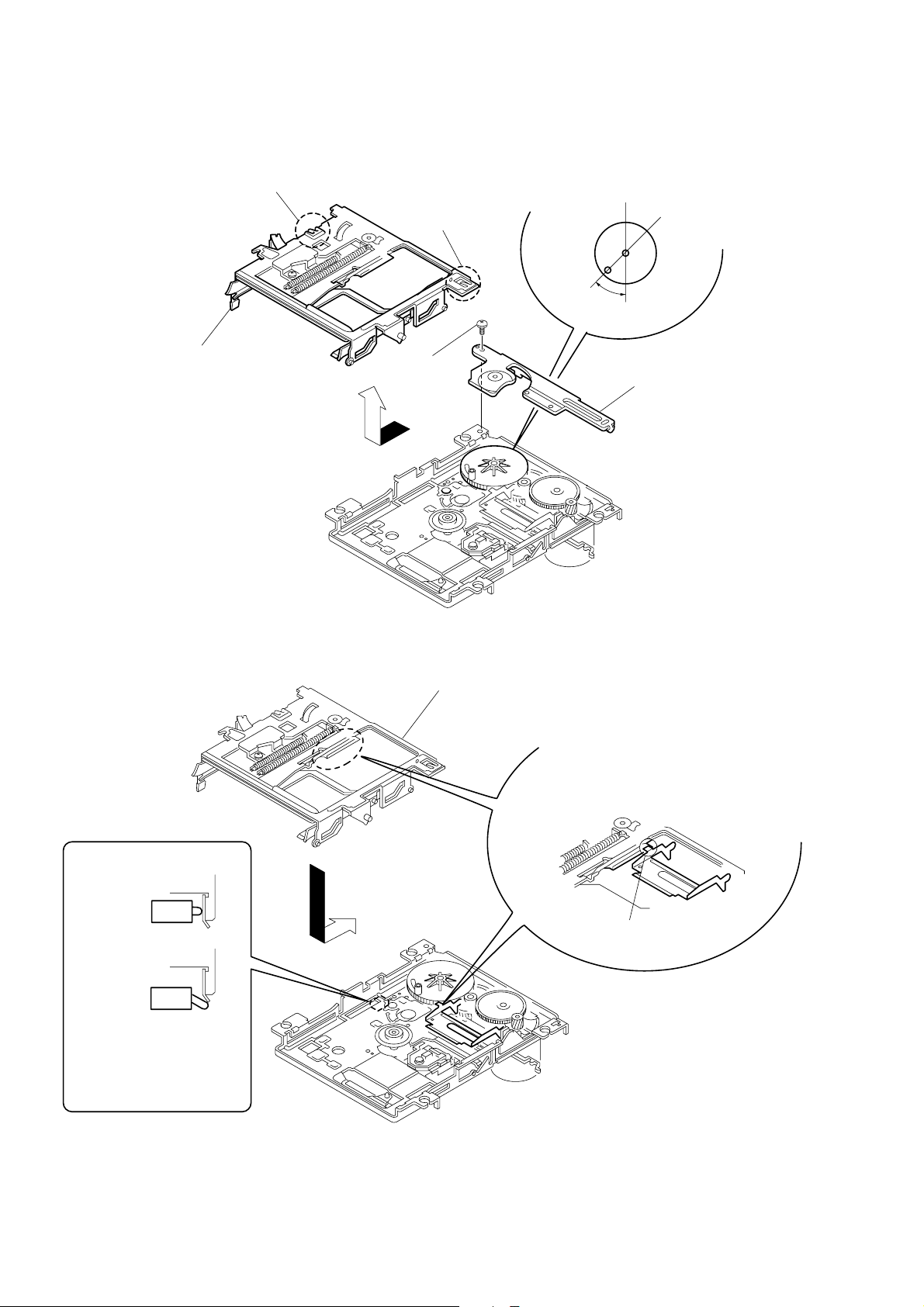

3-4. SUB CHASSIS

1

Two step screws

5

Sub chassis

3

T wo insulators

Part A

2

Two step screws

4

T wo insulators

Part A

Part A

NG

OK

— 10 —

Take care so that the part A

may be right position when installing.

3-5. SHUTTER ASSEMBLY

1

Stepper washer

2

Shaft (shutter)

3-6. OVER WRITE HEAD

3

Shutter assembly

Shutter assembly

Shaft (shutter)

Shaft (lid)

Hole B

Hole A

When installing, install the shaft

(shutter) into the hole A as shown

in the figure before installing the

shaft (lid) into the hole B.

1

Precision screw (P1.7×6)

2

Over write head

— 11 —

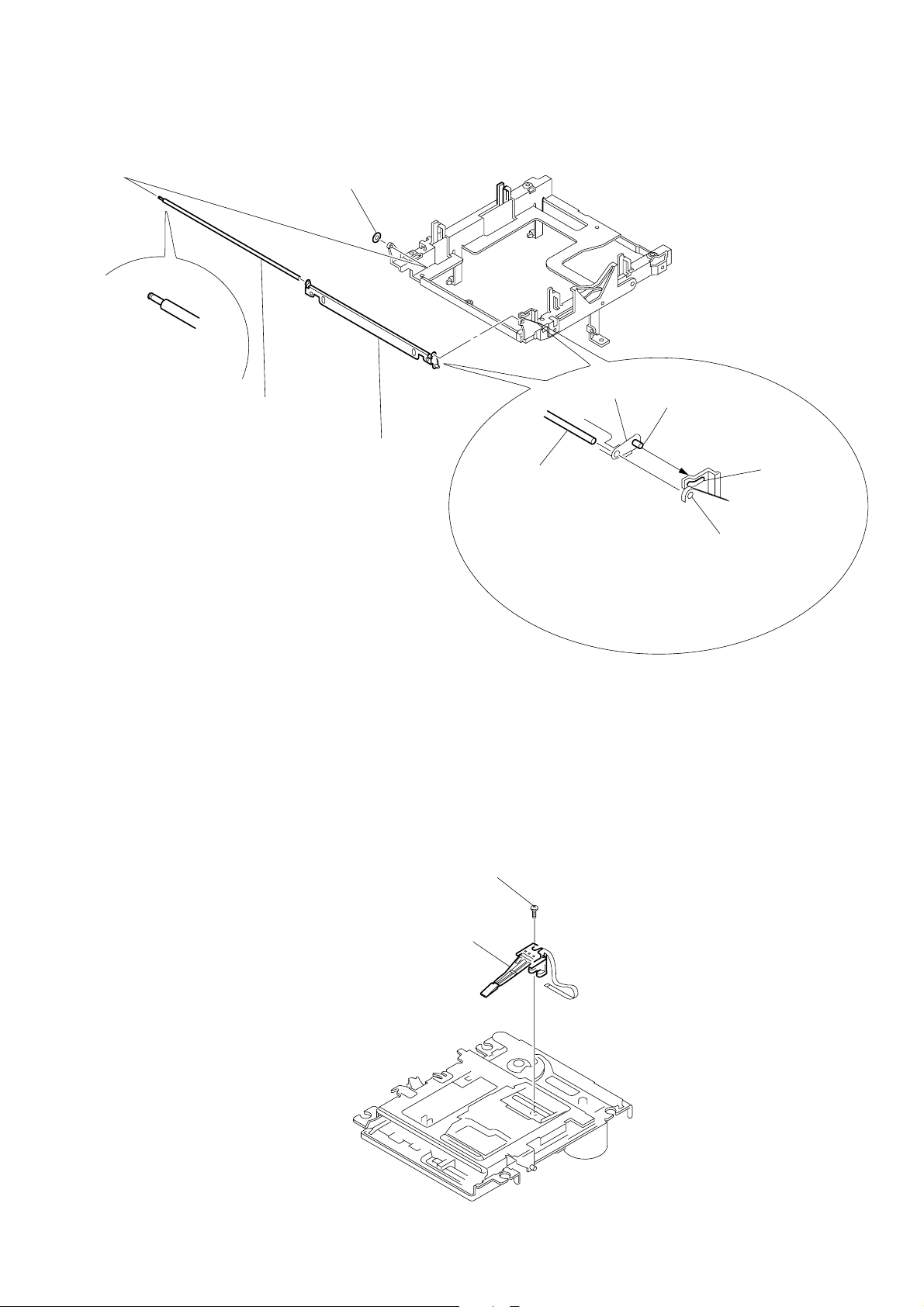

3-7. SLIDER COMPLETE ASSEMBLY

claw

4

Remove the slider complete assembly

in the direction of arrow with putting

out of two claws.

claw

1

Screw

(M1.7

3

Set the shaft of Gear (LA) to be at the

position in the figure.

45

°

×

2)

2

Retainer (gear)

• Note for Installation of Slider Complete Assembly

OK

NG

Take care not to damage

the detective switch.

Slider assembly

Install the part A of lever (head up)

to pass over the slider complete assembly.

Part A

— 12 —

SECTION 4

TEST MODE

4-1. PRECAUTIONS FOR USE OF TEST MODE

1 As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc is

stopped before setting and removing it.

Even if the §EJECT button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not

stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the §EJECT button after pressing the EDIT/NO button and the rotation of disc is stopped.

2 The erasing-protection tab is not detected in the test mode. Therefore, operating in the recording laser emission mode and pressing the

rREC button, the recorded contents will be erased regardless of the position of the tab . When using a disc that is not to be er ased in the

test mode, be careful not to enter the continuous recording mode and traverse adjustment mode.

4-1-1. Recording laser emission mode and operating buttons

1. Continuous recording mode (CREC MODE)

2. Traverse adjustment mode (EFBAL ADJUST)

3. Laser power adjustment mode (LDPWR ADJUST)

4. Laser power check mode (LDPWR CHECK)

5. When pressing the rREC button.

4-2. SETTING THE TEST MODE

While pressing the AMS knob, insert the power plug into the power supply outlet, and release the AMS knob.

4-3. EXITING THE TEST MODE

When the 1/u button is pressed, it becomes in the STANDBY mode. Or unplug the power plug from an outlet.

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the AMS knob, YES button, and EDIT/NO button.

The functions of these buttons are as follows.

Function name

AMS knob

YES button

EDIT/NO button

Changes parameters and modes

Proceeds onto the next step. Finalizes input.

Returns to previous step. Stops operations.

Function

4-5. SELECTING THE TEST MODE

Thirteen test modes are selected by turning the AMS knob.

Display

TEMP ADJUST

LDPWR ADJUST

LDPWR CHECK

EFBAL ADJUST

FBIAS ADJUST

FBIAS CHECK

CPLAY MODE

CREC MODE

DETRK CHECK

S curve CHECK

EEP MODE

MANUAL CMD

SVDATA READ

Temperature compensation offset adjustment

Laser power adjustment

Laser power check

Traverse adjustment

Focus bias adjustment

Focus bias check

Continuous playback mode

Continuous recording mode

Detrack check

S curve check ∗

Non-volatile memory mode ∗

Manual command transfer mode ∗

Data reading out mode ∗

Contents

For detailed description of each adjustment mode, refer to “5. Electrical Adjustments”.

If a different adjustment mode has been selected by mistake, press the EDIT/NO button to exit from this mode.

* The EEP MODE, S curve CHECK, MANU AL CMD and SVD AT A READ are not used in servicing. If set accidentally , press the EDIT/NO

button immediately to exit this mode.

— 13 —

4-5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

1 Set the disc in the unit. (Whichever recordable discs or discs for playback only are available.)

2 Rotate the AMS knob and display “CPLAY MODE”.

3 Press the YES button to change the display to “CPLAY MID”.

4 When access completes, the display changes to “C1 = AD = ”.

Note : The numbers “ ” displayed show you error rates and ADER.

2. Changing the parts to be played back

1 Press the YES button during continuous playback to change the display as below.

“CPLAY MID” n “CPLAY OUT”n “CPLAY IN”

4

When pressed another time, the parts to be played back can be moved.

2 When access completes, the display changes to “C1 = AD = ”.

Note : The numbers “ ” displayed show you error rates and ADER.

3. Ending the continuous playback mode

1 Press the EDIT/NO button. The display will change to “CPLAY MODE”.

2 Press the §EJECT button to remove the disc.

Note : The playback start addresses for IN, MID, and OUT are as follows. In case you w ant to display the address of the playback position

on the display, press the DISPLAY/CHAR button and display “CPLAY ( )”.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

4-5-2. Operating the Continuous Recording Mode

1. Entering the continuous recording mode

1 Set a recordable disc in the unit. (Refer to Note 3)

2 Rotate the AMS knob and display “CREC MODE”.

3 Press the YES button to change the display to “CREC MID”.

4 When access completes, the display changes to “CREC ( )” and REC lights up.

Note : The numbers “ ” displayed shows you the recording position addresses.

2. Changing the parts to be recorded

1 When the YES button is pressed during continuous recording, the display changes as below.

“CPLAY MID” n “CPLAY OUT”n “CPLAY IN”

4

When pressed another time, the parts to be recorded can be changed. REC goes off.

2 When access completes, the display changes to “CREC (

)” and REC lights up.

Note : The numbers “ ” displayed shows you the recording position addresses.

3. Ending the continuous recording mode

1 Press the EDIT/NO button. The display changes to “CREC MODE” and REC goes off.

2 Press the §EJECT button to remove the disc.

Note 1 : The recording start addresses for IN, MID, and OUT are as follows.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

Note 2 :The EDIT/NO button can be used to stop recording anytime.

Note 3 :During the test mode, the erasing-protection tab will not be detected. Therefore be careful not to set the continuous recording

mode when a disc not to be erased is set in the unit.

Note 4 :Do not perform continuous recording for long periods of time above 5 minutes.

Note 5 :During continuous recording, be careful not to apply vibration.

4-5-3. Non-Volatile Memory Mode

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If set accidentally, press the EDIT/NO button immediately to exit it.

— 14 —

4-6. FUNCTIONS OF OTHER BUTTONS

Function

·

p

)

0

r REC

DISPLAY/

CHAR

Sets continuous playback when pressed in the STOP state. When pressed during continuous playback, the tracking servo turns ON/OFF.

Stops continuous playback and continuous recording.

The sled moves to the outer circumference only when this is pressed.

The sled moves to the inner circumference only when this is pressed.

Turns recording ON/OFF when pressed during continuous playback.

Switches the display when pressed.Returns to previous step. Stops operations.

Contents

Note : The erasing-protection tab is not detected during the test mode. Recording will start regardless of the position of the erasing-protection

tab when the r REC button is pressed.

4-7. TEST MODE DISPLAYS

Each time the DISPLAY/CHAR button is pressed, the display changes in the following order.

MODE displaynError rate displaynAddress displaynAuto gain displaynIVR display

The auto gain display and the IVR display are not used for servicing.

1. MODE display

Displays “TEMP ADJUST”, “CPLAY MODE”, etc.

2. Error rate display

Error rates are displayed as follows.

C1 =

C1 = : Indicates C1 error

AD= : Indicates ADER

3. Address display

Addresses are displayed as follows. (MO : Recordable disc, CD : Disc for playback only)

h= s = (MO pit and CD)

h= a = (MO groove)

h= : Header address

s = : SUBQ address

a = : ADIP address

* “_” is displayed when the address cannot be read.

4. Auto gain display

Auto gains are displayed as follows.

AG F = T =

F= Focus auto gain collection value.

T= Tracking auto gain collection value.

AD =

4-8. MEANINGS OF OTHER DISPLAYS

Display

”

P

REC

CLOCK

TRACK

DISC

DA TE

A. SPACE

A – B

During continuous playback

Tracking servo OFF

Recording mode ON

CLV LOCK

Pit

High reflection

CLV-S

ABCD adjustment completed

Focus auto gain successful

Tracking auto gain successful

Light Off Blinking

Contents

STOP

Tracking servo ON

Recording mode OFF

CLV UNLOCK

Groove

Low reflection

CLV-A

Focus auto gain successful

Tracking auto gain failed

— 15 —

SECTION 5

ELECTRICAL ADJUSTMENTS

5-1. PRECAUTIONS FOR CHECKING LASER

DIODE EMISSINON

T o check the emission of the laser diode dur ing adjustments, never

view directly from the top as this may lose your eye-sight.

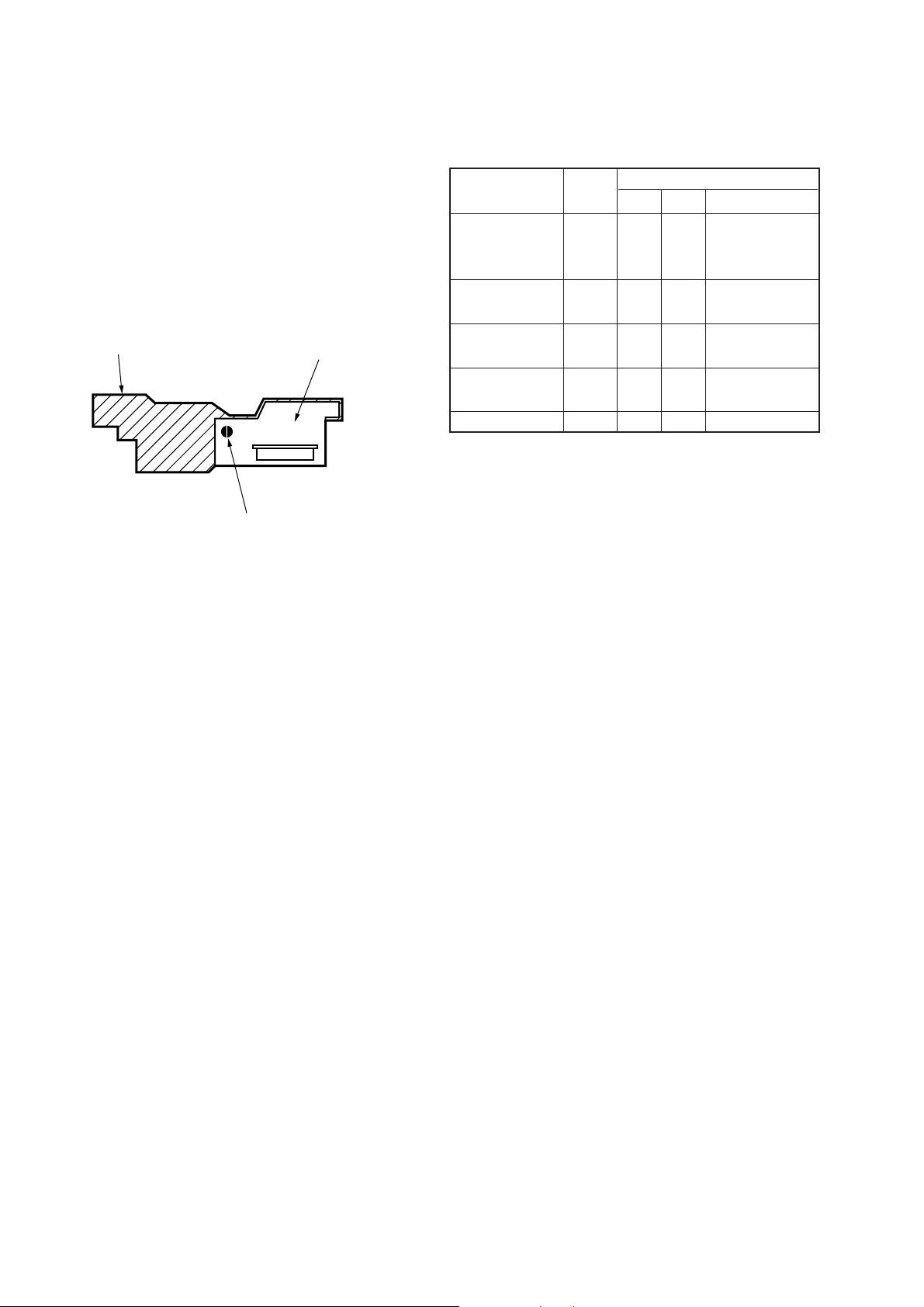

5-2. PRECAUTIONS FOR USE OF OPTICAL PICK-

UP (KMS-260A)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap of the flexible board when using it.

Before disconnecting the connector, desolder f irst. Before connecting

the connector, be careful not to remov e the solder. Also take adequate

measures to prevent damage by static electricity . Handle the flexible

board with care as it breaks easily.

pick-up

laser tap

Optical pick-up flexible board

flexible board

1.Temperature

compensation

offset adjustment

2. Laser power

adjustment

3. Traverse

adjustment

4. Focus bias

adjustment

5. Error rate check

Optical

Pick-up

G

¬

¬

¬

¬

¬

¬

¬

¬

¬

BD Board

IC101, IC121, IC192D101IC171

¬

G

G

G

G

¬

¬

¬

¬

¬

5-3. PRECAUTIONS FOR ADJUSTMENTS

1) When replacing the following parts, perform the adjustments

and checks with ¬ in the order shown in the following table.

2) Set the test mode when performing adjustments.

After completing the adjustments, exit the test mode.

3) Perform the adjustments in the order shown.

4) Use the following tools and measuring devices.

• Check Disc (MD) TDYS-1

(Parts No. 4-963-646-01)

• Laser power meter LPM-8001 (Parts No. J-2501-046-A)

• Oscilloscope (Measure after performing CAL of prove.)

• Digital voltmeter

• Thermometer

• Jig for checking BD board waveform

(Parts No. : J-2501-124-A)

5) When observing several signals on the oscilloscope, etc.,

make sure that VC and ground do not connect inside the

oscilloscope.

(VC and ground will become short-circuited.)

6) Using the above jig enables the wav eform to be checked without

the need to solder.

(Refer to Servicing Note on page 4.)

Note :When performing laser power checks and adjustment

5-4. CREATING CONTINUOUSLY RECORDED DISC

• This disc is used in focus bias adjustment and error rate check.

1. Insert a disc (blank disc) commercially available.

2. Rotate the AMS knob and display “CREC MODE”.

3. Press the YES button again to display “CREC MID”.

4. Complete recording within 5 minutes.

5. Press the EDIT/NO button and stop recording .

6. Press the §EJECT button and remove the disc.

The above has been how to create a continuous recorded data for the

focus bias adjustment and error rate check.

Note :

• Be careful not to apply vibration during continuous recording.

— 16 —

(electrical adjustment), use of the new MD laser power meter

8010S (J-2501-145-A) instead of the conventional laser po wer

meter is convenient.

It sharply reduces the time and trouble to set the laser power

meter sensor onto the objective lens of the pick-up.

The following describes how to create a continuous recording disc.

Display “CREC (0300)” and start to recording.

5-5. TEMPERATURE COMPENSATION OFFSET

ADJUTMENT

Save the temperature data at that time in the non-volatile memory

as 25 ˚C reference data.

Note :

1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22 ˚C

to 28 ˚C. Perform it immediately after the power is turned on

when the internal temperature of the unit is the same as the

ambient temperature of 22 ˚C to 28 ˚C.

3. When D101 has been replaced, perform this adjustment after

the temperature of this part has become the ambient

temperature.

Adjusting Method :

1. Rotate the AMS knob and display “TEMP ADJUST”.

2. Press the YES button and select the “TEMP ADJUST” mode.

3. “TEMP = ” and the current temperature data will be

displayed.

4. To save the data, press the YES button.

When not saving the data, press the EDIT/NO button.

5. When the YES button is pressed, “TEMP = SAVE” will be

displayed and turned back to “TEMP ADJUST” display then.

When the EDIT/NO button is pressed, “TEMP ADJUST” will

be displayed immediatelly.

Specified Value :

The “TEMP = ” should be within “E0 - EF”, “F0 - FF”, “00 0F”, “10 - 1F” and “20 - 2F”.

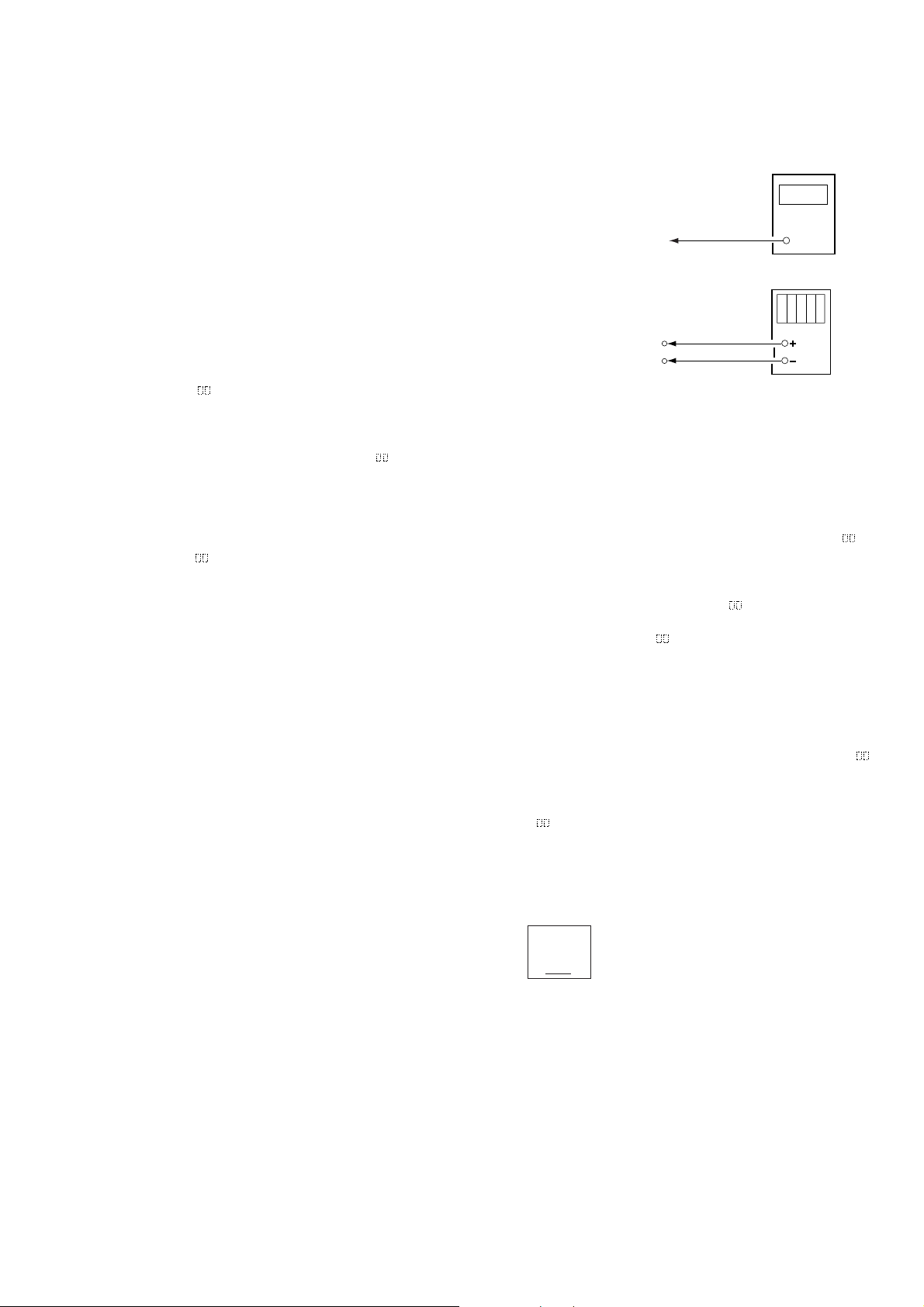

5-6. LASER POWER ADJUSTMENT

Connection :

Laser power

meter

Optical pick-up

objective lens

Digital volt meter

BD board

CN110 pin 5 (I+3V)

CN110 pin 4 (IOP)

Adjusting Method :

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, pr ess the 0 button

or ) button to move the optical pick-up.)

Connect the digital volt meter to CN110 pin 5 (I+3V) and

CN110 pin 4 (IOP).

2. Rotate the AMS knob and display “LDPWR ADJUST”.

(Laser power : For adjustment)

3. Press the YES button once and display “LD 0.9 mW $ ”.

4. Rotate the AMS knob so that the reading of the laser power

meter becomes 0.86 to 0.92 mW. Press the YES button after

setting the range knob of the laser power meter, and save the

adjustment results. (“LD SAVE $ ” will be displayed for a

moment.)

5. Then “LD 7.0 mW $ ” will be displayed.

6. Rotate the AMS knob so that the reading of the laser power

meter becomes 6.9 to 7.1 mW, press the YES button and save

it.

Note : Do not perform the emission with 7.0 mW more than 15

seconds continuously.

7. Then, rotate the AMS knob and display “LDPWR CHECK”.

8. Press the YES button once and display “LD 0.9 mW $ ”.

Check that the reading of the laser power meter become 0.85

to 0.91 mW.

9. Press the YES button once more and display “LD 7.0 mW $

”. Check that the reading the laser power meter and digital

volt meter satisfy the specified value.

Specified Value :

Laser power meter reading : 7.0 ± 0.1 mW

Digital voltmeter reading : Optical pick-up displayed value ± 10%

10. Press the EDIT/NO button and display “LDPWR CHECK” and

— 17 —

KMS

260A

27X40

B0825

N

Iop = 82.5 mA in this case

Iop (mA) = Digital voltmeter reading (mV)/1 (Ω)

(Optical pick-up label)

stop the laser emission.

(The EDIT/NO button is effective at all times to stop the laser

emission.)

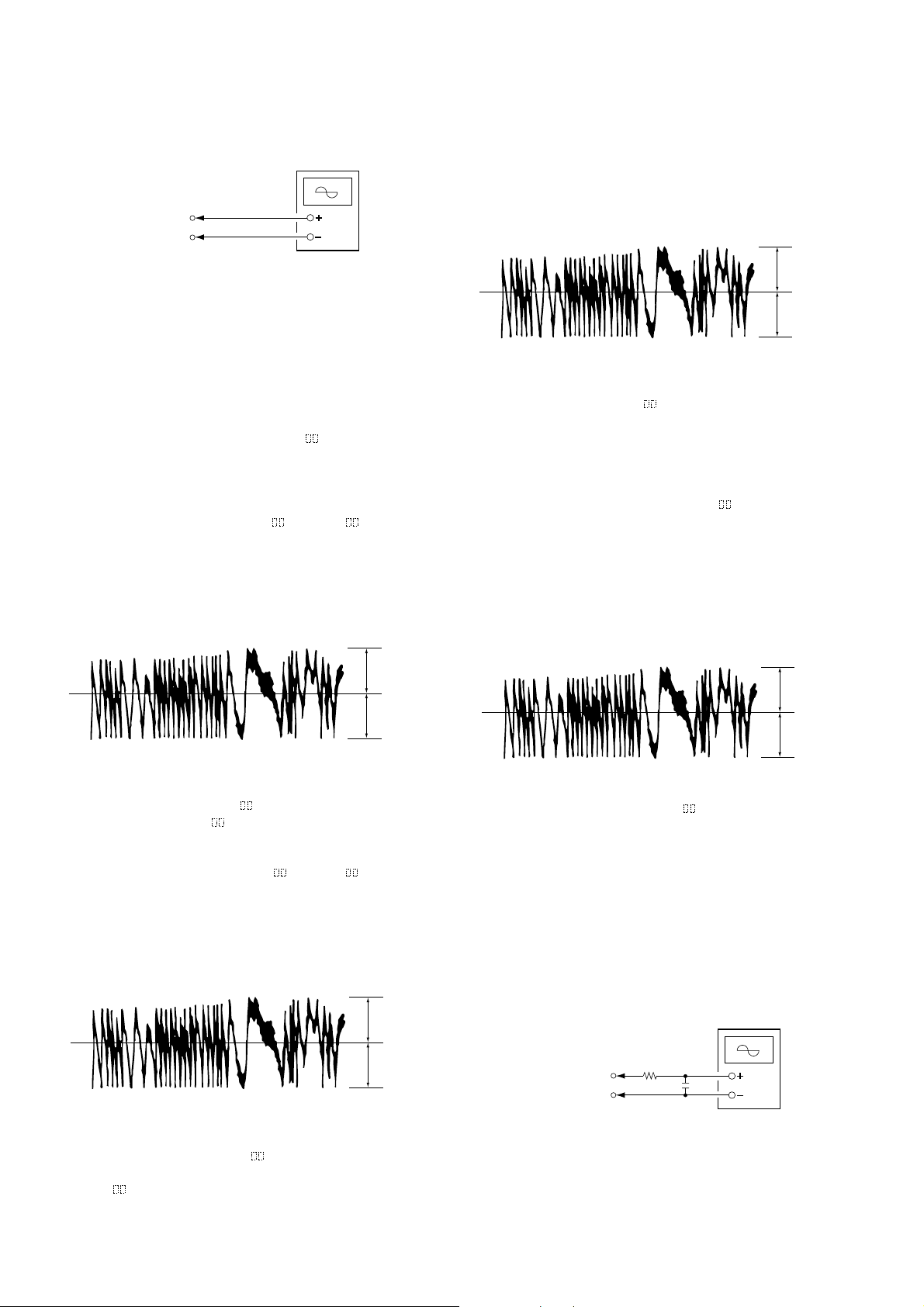

5-7. TRA VERSE ADJUSTMENT

Connection :

BD board

3

CN110 pin

CN110 pin 2 (VC)

(TEO)

Oscilloscope

11. Rotate the AMS knob until the waveform of the oscilloscope

moves closer to the specified value.

In this adjustment, waveform v aries at interv als of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

(Traverse Wa vef orm)

V : 0.5 V/div

H : 10 ms/div

Input : DC mode

Adjusting method :

1. Connect an oscilloscope to CN110 pin 3 (TEO) and CN110

pin 2 (VC) of the BD board.

2. Load a disc (any available on the market). (Refer to Note 1.)

3. Press the 0 button or ) button and move the optical pickup outside the pit.

4. Rotate the AMS knob and display “EFBAL ADJUST”.

5. Press the YES button and display “EFB = MO-R”.

(Laser power READ power/Focus servo ON/tracking servo

OFF/spindle (S) servo ON)

6. Rotate the AMS knob so that the waveform of the oscilloscope

becomes the specified value.

(When the AMS knob is rotated, the of “EFB= ” changes

and the waveform changes.) In this adjustment, wa veform varies

at intervals of approx. 2%. Adjust the waveform so that the

specified value is satisfied as much as possible.

(Read power traverse adjustment)

(Traverse Wa v eform)

A

VC

B

Specification A = B

7. Press the YES button and save the result of adjustment to the

non-volatile memory (“EFB = SAVE” will be displayed for

a moment. Then “EFB = MO-W” will be displayed).

8. Rotate the AMS knob so that the waveform of the oscilloscope

becomes the specified value.

(When the AMS knob is rotated, the of “EFB- ” changes

and the waveform changes.) In this adjustment, wa veform varies

at intervals of approx. 2%. Adjust the waveform so that the

specified value is satisfied as much as possible.

(Write power traverse adjustment)

(Traverse Wa v eform)

A

VC

B

Specification A = B

12. Press the YES button, and save the adjustment results in the

non-volatile memory . (“EFB = SA VE” will be display ed for

a moment.)

Next “EFBAL CD” is displayed. The disc stops rotating

automatically.

13. Press the §EJECT button and remove the disc.

14. Load the check disc (MD) TDYS-1.

15. Press the YES button and display “EFB = CD”. Servo is

imposed automatically.

16. Rotate the AMS knob so that the waveform of the oscilloscope

moves closer to the specified value.

In this adjustment, waveform v aries at interv als of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

(Traverse Wa vef orm)

A

VC

B

Specification A = B

17. Press the YES button, display “EFB = SAVE” for a moment

and save the adjustment results in the non-volatile memory.

Next “EFBAL ADJUST” will be displayed.

18. Press the §EJECT button and remove the c heck disc (MD)

TDYS-1.

Note 1 : MO reading data will be erased during if a recorded disc is

used in this adjustment.

Note 2 : If the traverse waveform is not clear, connect the

oscilloscope as shown in the following figur e so that it can

be seen more clearly.

A

VC

B

Specification A = B

9. Press the YES button, and save the adjustment results in the

non-volatile memory. (“EFB = SAVE” will be displayed

for a moment.)

10. “EFB = MO-P”. will be displayed.

The optical pick-up moves to the pit area automatically and

servo is imposed.

— 18 —

CN110 pin 3 (TEO)

BD board

CN110 pin 2 (VC)

330 k

Oscilloscope

Ω

10pF

Loading...

Loading...