Page 1

MDS-JB940

SERVICE MANUAL

U.S and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

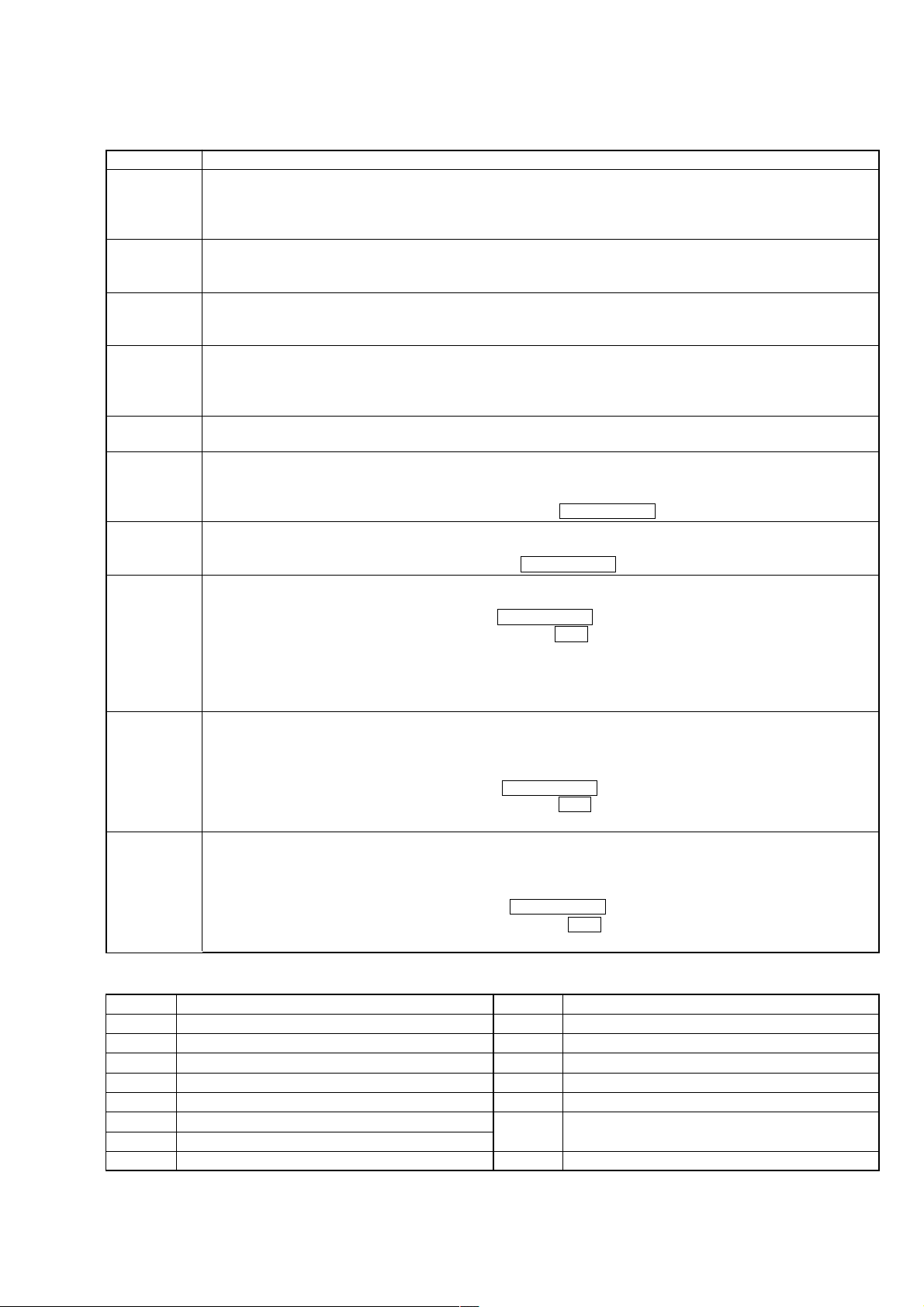

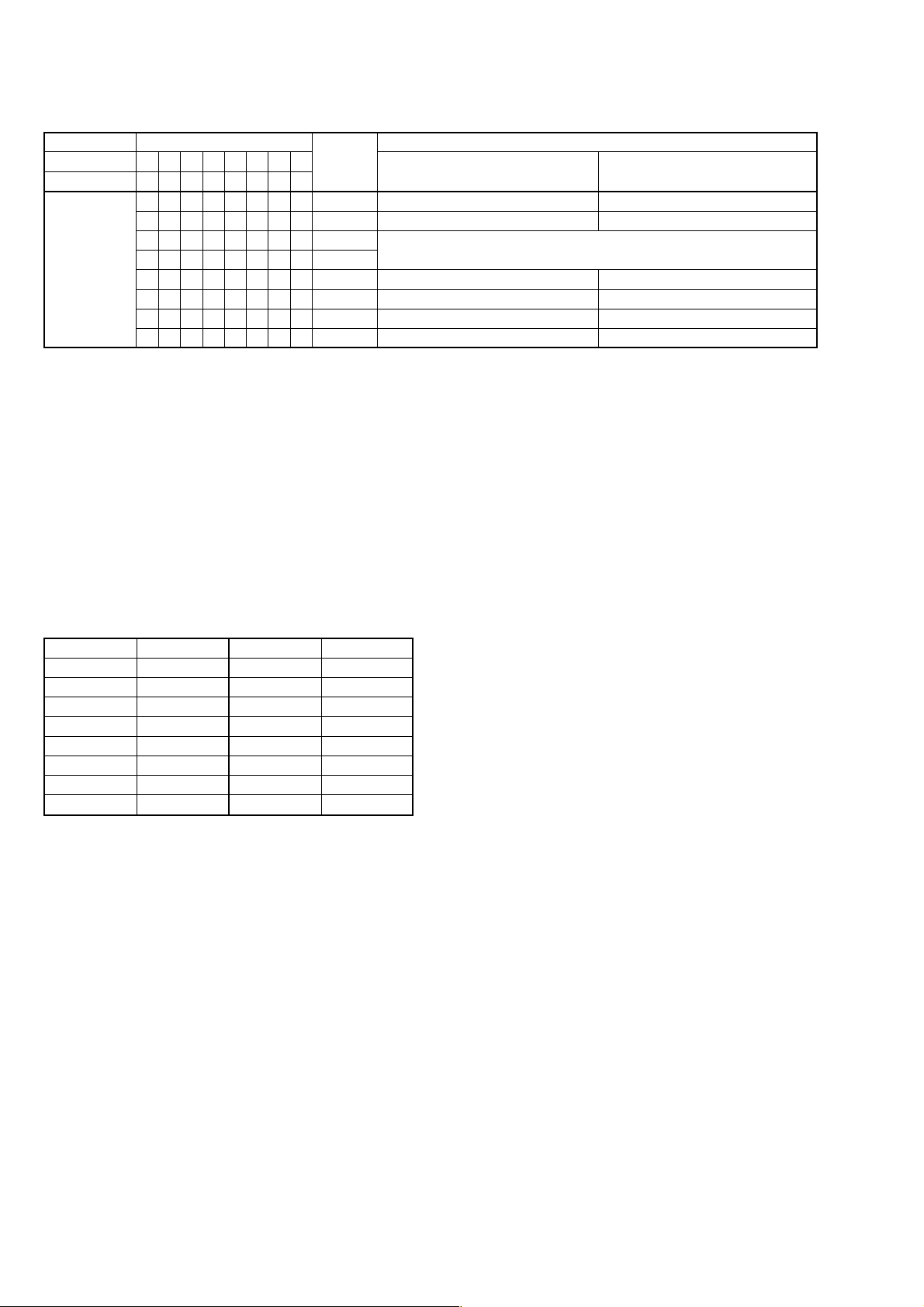

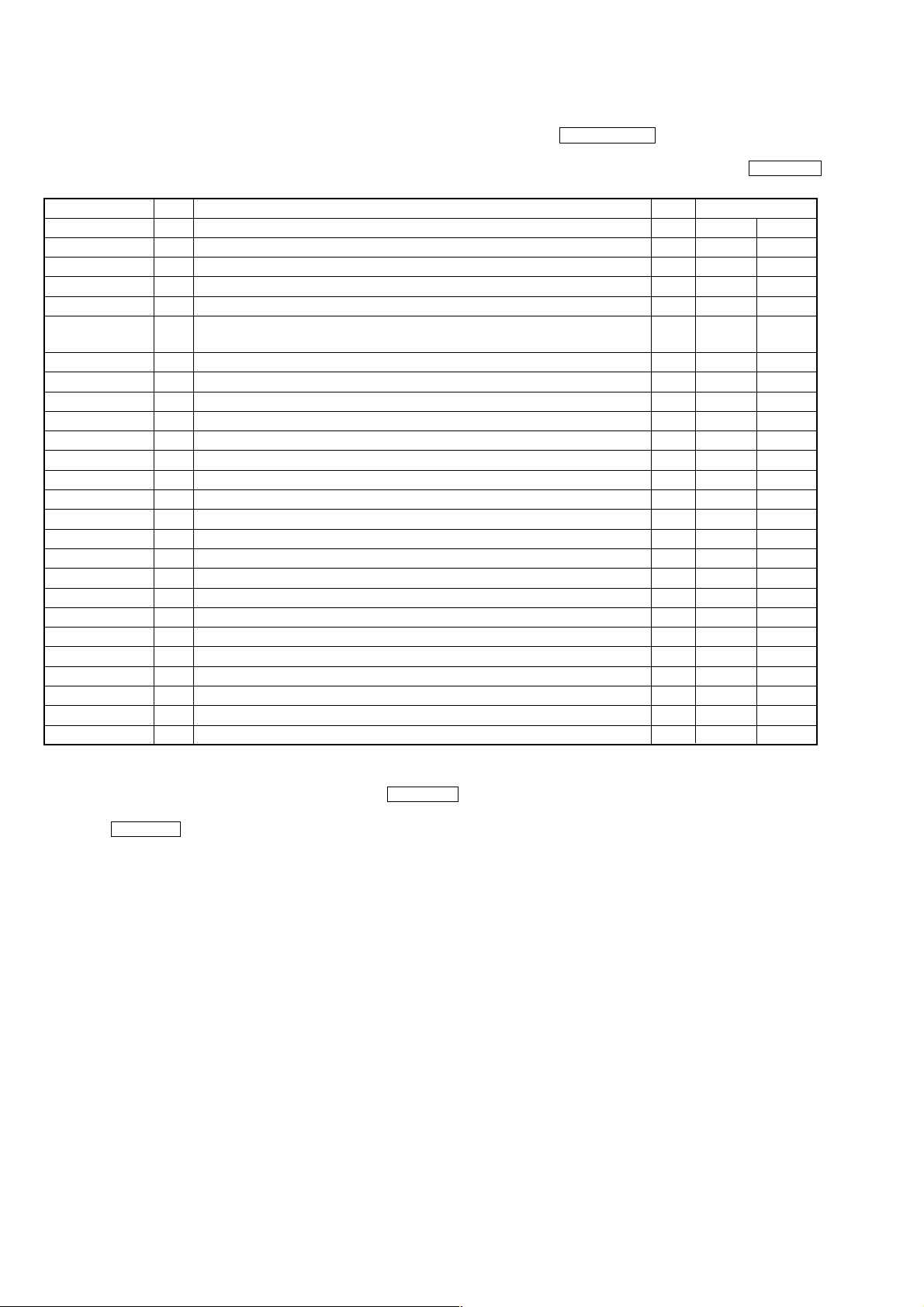

SPECIFICATIONS

System

Disc

Laser

Laser output

Laser diode

Revolutions (CLV)

Error correction

Sampling frequency

Coding

Modulation system

Number of channels

Frequency response

Signal-to-noise ratio

Wow and flutter

Inputs

ANALOG IN

MiniDisc digital audio system

MiniDisc

Semiconductor laser (λ = 780 nm)

Emission duration: continuous

MAX 44.6 µW

1) This output is the value

Material: GaAlAs

400 rpm to 900 rpm

ACIRC (Advanced Cross Interleave

Reed Solomon Code)

44.1 kHz

ATRAC (Adaptive TRansform

Acoustic Coding)/ATRAC 3

EFM (Eight-to-Fourteen

Modulation)

2 stereo channels

5 to 20,000 Hz ±0.3 dB

Over 100 dB during pla y

Below measurable limit

Jack type: phono

Impedance: 47 kilohms

Rated input: 500 mVrms

Minimum input: 125 mVrms

1)

measured at a distance of

200 mm from the objective lens

surface on the Opt ical Pick-up

Block with 7 mm aperture.

DIGITAL OPTICAL IN1

DIGITAL OPTICAL IN2

DIGITAL COAXIAL IN

Outputs

PHONES

ANALOG OUT

DIGITAL OPTICAL OUT

DIGITAL COAXIAL OUT

Connector type: square optical

Impedance: 660 nm (optical wave

length)

Connector type: square optical

Impedance: 660 nm (optical wave

length)

Jack type: phono

Impedance: 75 ohms

Rated input: 0.5 Vp-p, ±20 %

Jack type: stereo phone

Rated output: 28 mW

Load impedance: 32 ohms

Jack type: phono

Rated output: 2 Vrms (at 50

kilohms)

Load impedance: over 10 kilohms

Connector type: square optical

Rated output: –18 dBm

Load impedance: 660 nm (opti cal

wave length)

Jack type: phono

Rated output: 0.5 Vp-p (at 75 ohms)

Load impedance: 75 ohm s

US Model

Canadian Model

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-7A

Optical Pick-up Name KMS-260B/J1N

General

Power requirements

Where purchased Power requirements

U.S.A. and Canada 120 V AC, 60 Hz

Europe 230 V AC, 50/60 Hz

Power consumption

Dimensions (approx. )

Mass (approx.)

Supplied accessories

This MD deck comes with the following items:

Audio connecting cords (2)

Optical cable (1)

Remote commander (remote) (1)

R6 (size-AA) batteries (2)

US and foreign patents licensed from Dolby Labora t ories.

Design and specifications are subject to change without

notice.

18 W

430 × 111 × 286 mm (17 × 4

3

/8 in.) (w/h/d) incl. projecting

11

parts and controls

5.3 kg (11 lbs 11 oz)

3

/8 ×

MINIDISC DECK

Page 2

TABLE OF CONTENTS

SAFETY CHECK-OUT

SELF-DIAGNOSIS FUNCTION ········································ 4

1. SERVICE NOTE ······························································· 6

2. GENERAL ········································································ 11

3. DISASSEMBLY ······························································ 14

4. TEST MODE··································································· 17

5. ELECTRICAL ADJUSTMENTS······························ 22

6. DIAGRAMS

6-1. Block Diagram MAIN Section································ 31

6-2. Block Diagram DISPLAY/POWER Section ··········· 32

6-3. Note for Printed Wiring Boards and

Schematic Diagrams···················································· 33

6-4. Circuit Board Location ················································ 33

6-5. Waveforms··································································· 34

6-6. Printed Wiring Board BD Board ····························· 35

6-7. Schematic Diagram BD Board (1/2) ······················· 36

6-8. Schematic Diagram BD Board (2/2) ······················· 37

6-9. Printed Wiring Board HP Board/KEY Board·········· 38

6-10.Schematic Diagram HP Board/KEY Board ············ 38

6-11.Schematic Diagram MAIN Board (1/3) ·················· 39

6-12.Schematic Diagram MAIN Board (2/3) ·················· 40

6-13.Schematic Diagram MAIN Board (3/3) ·················· 41

6-14.Printed Wiring Board MAIN Board (Side A) ·········· 42

6-15.Printed Wiring Board MAIN Board (Side B)·········· 43

6-16.Printed Wiring Board PANEL Section ···················· 44

6-17.Schematic Diagram PANEL Section······················· 45

6-18.Schematic Diagram AC Board ································ 46

6-19.Printed Wiring Board AC Board······························ 47

6-20.IC Block Diagrams ······················································ 48

6-21.IC Pin Function Description ········································ 53

7. EXPLODED VIEWS ······················································ 60

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

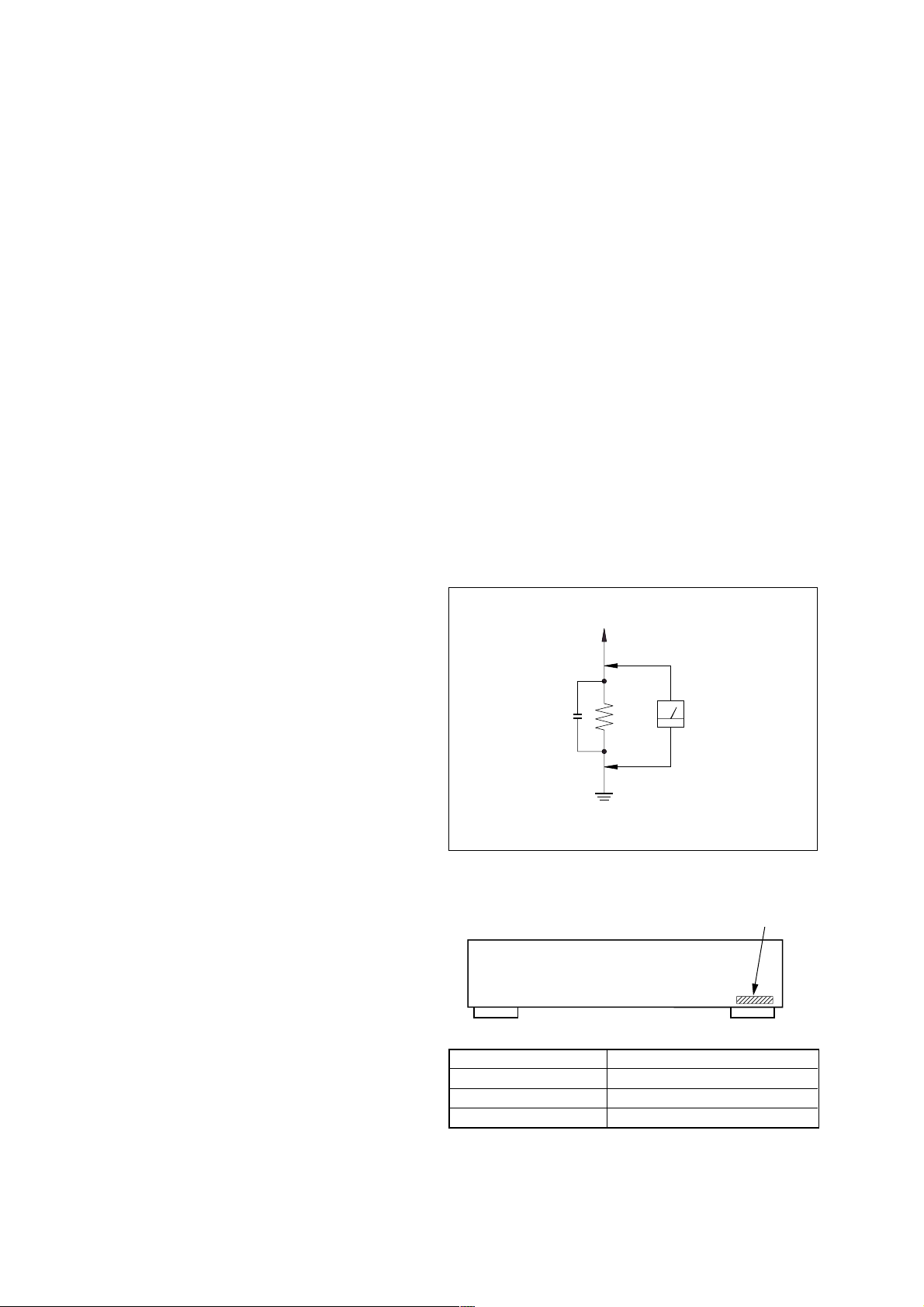

LEAKAGE

The A C leakag e from any exposed metal part to earth g round and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

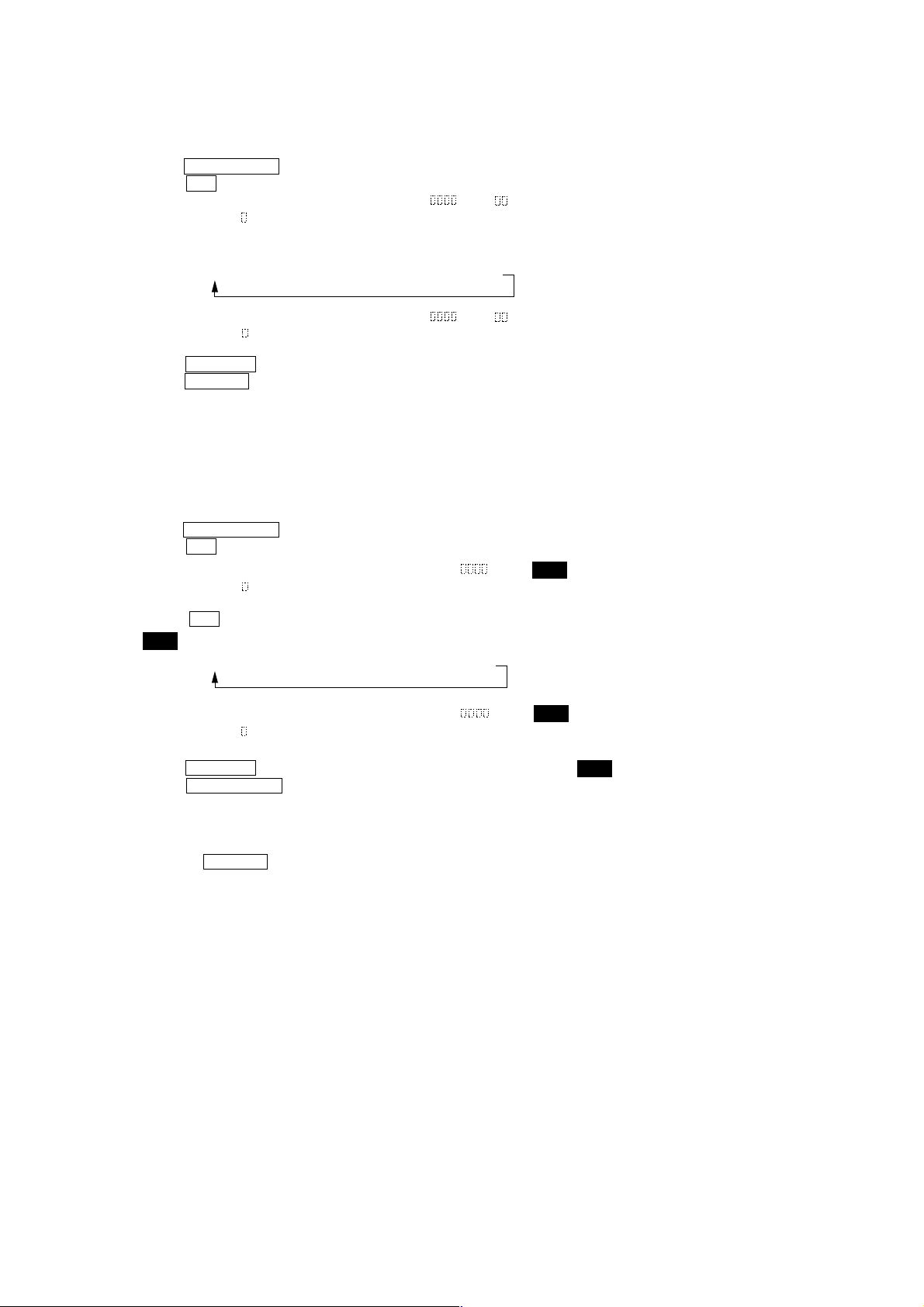

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated A C voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

T o Exposed Metal

Parts on Set

AC

0.15 µF

1.5 kΩ

Voltmeter

(0.75 V)

8. ELECTRICAL PARTS LIST ······································· 64

Earth Ground

Fig. A. Using an A C v oltmeter to check A C leakage.

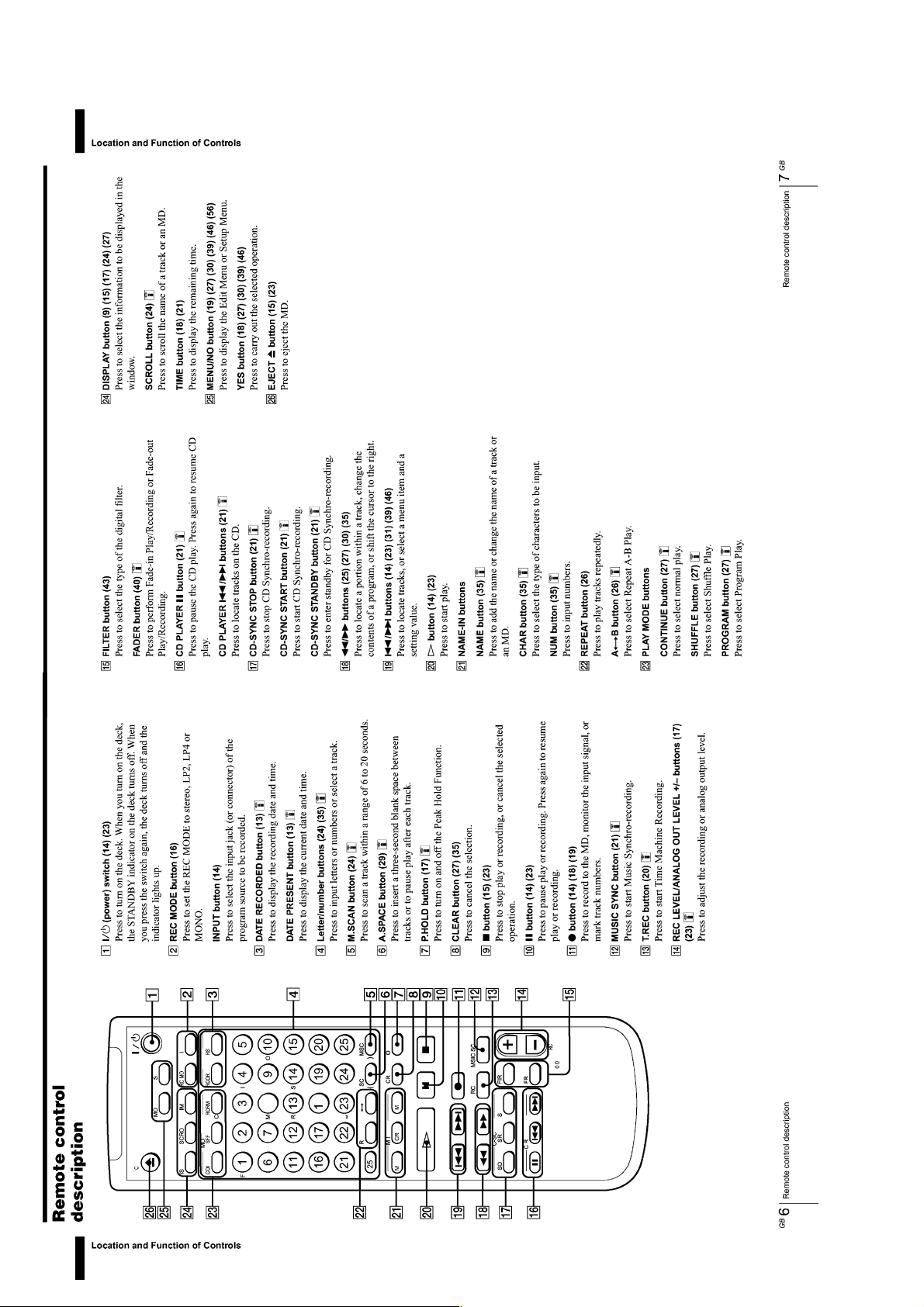

MODEL IDENTIFICATION

— BACK PANEL —

Model

AEP, UK models

Canadian model

US model

4-228-507-0s

4-228-507-1s

4-228-507-2s

Part No.

Part No.

2

Page 3

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laitev almistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

The following caution label is located inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Nev er reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

3

Page 4

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for customers which are displayed automatically when errors occur, and error codes whic h

show the error history in the test mode during servicing. For details on how to view error codes for the customer, r efer to the following box

in the instruction manual. For details on how to check error codes during servicing, refer to the following “Procedure for using the Self-

Diagnosis Function (Error History Display Mode)”.

The deck’s self-diagnosis function automatically checks the condition of the MD dec k when an error occurs, then issues a three- or fi ve-digit

code and an error message on the display. If the code and message alternate, find them in the following table and perform the indicated

countermeasure. Should the problem persist, consult your nearest Sony dealer.

Three- or fivedigit code/

Message

C11/Protected

C12/Cannot Copy

C13/REC Error

C13/Read Error

C14/To c Error

C41/Cannot Copy

Cause/Remedy

The inserted MD is record-protected.

Take out the MD and close the recordprotect slot (page 15).

You tried to record a CD with a format

that the external device connected t o the

deck does not support, such as CD-ROM

or video CD.

Remove the disc and insert a music

CD.

The recording was not made properly.

Set the deck in a stable surface, and

repeat the recording procedure.

The inserted MD is dirty (with smudges,

fingerprints, etc.), scratched, or

substandard in quality.

Replace the disc and repeat the

recording procedure.

The deck could not read the TOC on the

MD properly.

Take out the MD and insert it again.

The deck could not read the TOC on the

MD properly.

Insert another disc.

If possible, erase all the tracks on the

MD (page 32).

The sound source is a copy of

commercially available music software, or

you tried to record a CD-R (Recordable

CD).

The Serial Copy Management System

prevents making a digital copy

(page 52). Yo u cannot record a CD-R.

Three- or fivedigit code/

Message

C71/Din Unlock

E0001/

MEMORY NG

E0101/

LASER NG

Cause/Remedy

The sporadic appearance of this message

is caused by the digital signal being

recorded. This will not affect the

recording.

While recording from a dig ital c ompon ent

connected through the DIGIT AL IN

connector, the digital connecti ng cable

was unplugged or the digital compon e nt

turned off.

Connect the cable or turn the digital

component back on .

There is an error in the internal data that

the deck needs in order to operate.

Consult your nearest Sony dealer.

There is a problem with the optical

pickup.

The optical pickup may have failed.

Consult your nearest Sony dealer.

PROCEDURE FOR USING THE SELF-DIAGNOSIS FUNCTION (ERROR HISTORY DISPLAY MODE)

Note: Perform the self-diagnosis function in the “error history display mode” in the test mode. The following describes the least required procedure. Be

careful not to enter other modes by mistake. If you set other modes accidentally, press the MENU/NO button to exit the mode.

1. While pressing the l AMS L knob and x button, connect the power plug to the outlet, and release the l AMS L knob and

x button. When the test mode is set “[Check]” is displayed.

2. Turn the l AMS L knob and when “[Service]” is displayed, press the YES button.

3. Turn the l AMS L knob to display “Err Display”.

4. Press the YES button to sets the error history mode and displays “op rec tm”.

5. Select the contents to be displayed or executed using the l AMS L knob.

6. Press the l AMS L knob to display or execute the contents selected.

7. Press the l AMS L knob another time to return to step 4.

8. Press the MENU/NO button to display “Err Display” and release the error history mode.

9. To release the test mode, press the REPEAT button. The unit sets into the STANDBY state and the test mode ends.

4

Page 5

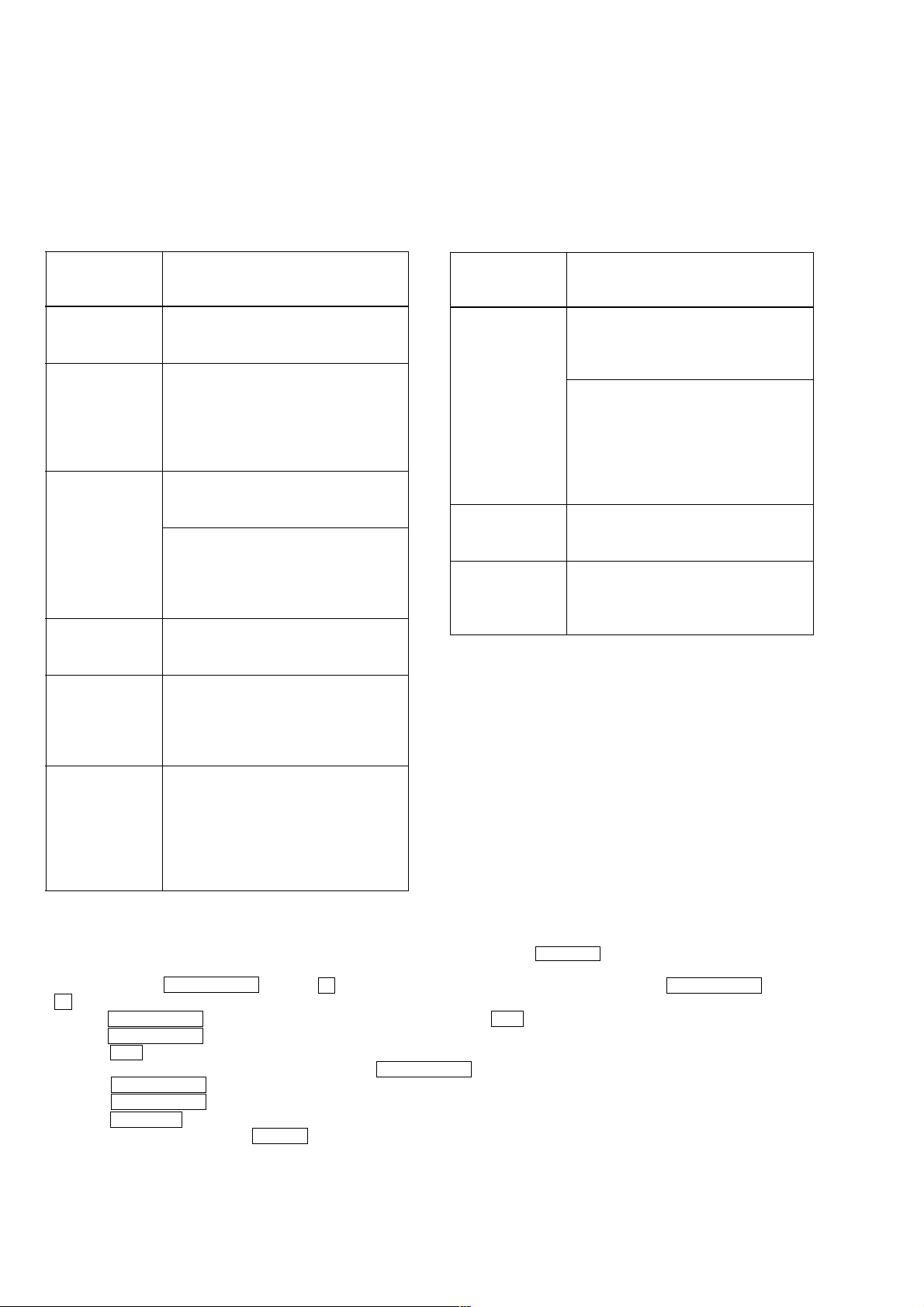

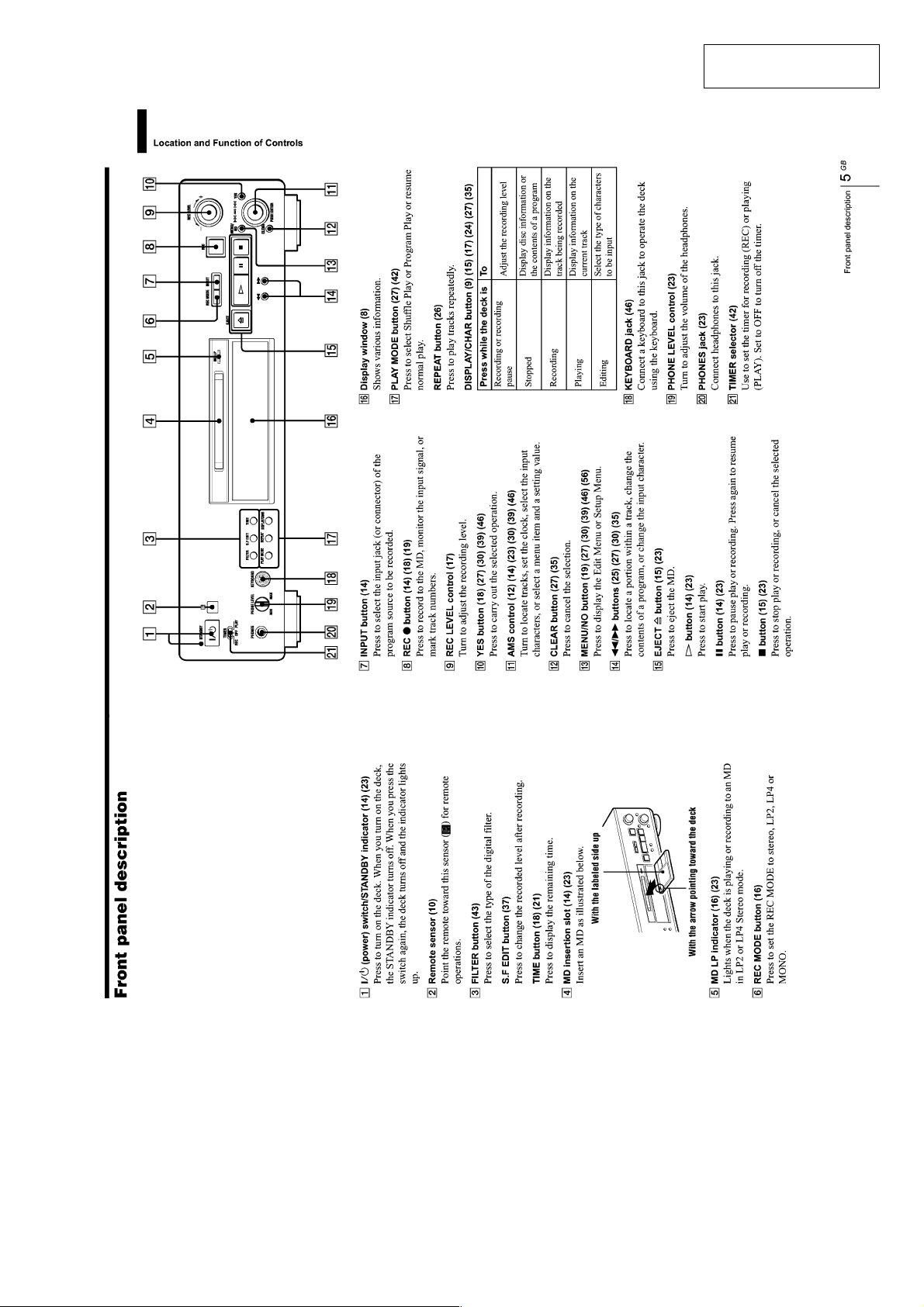

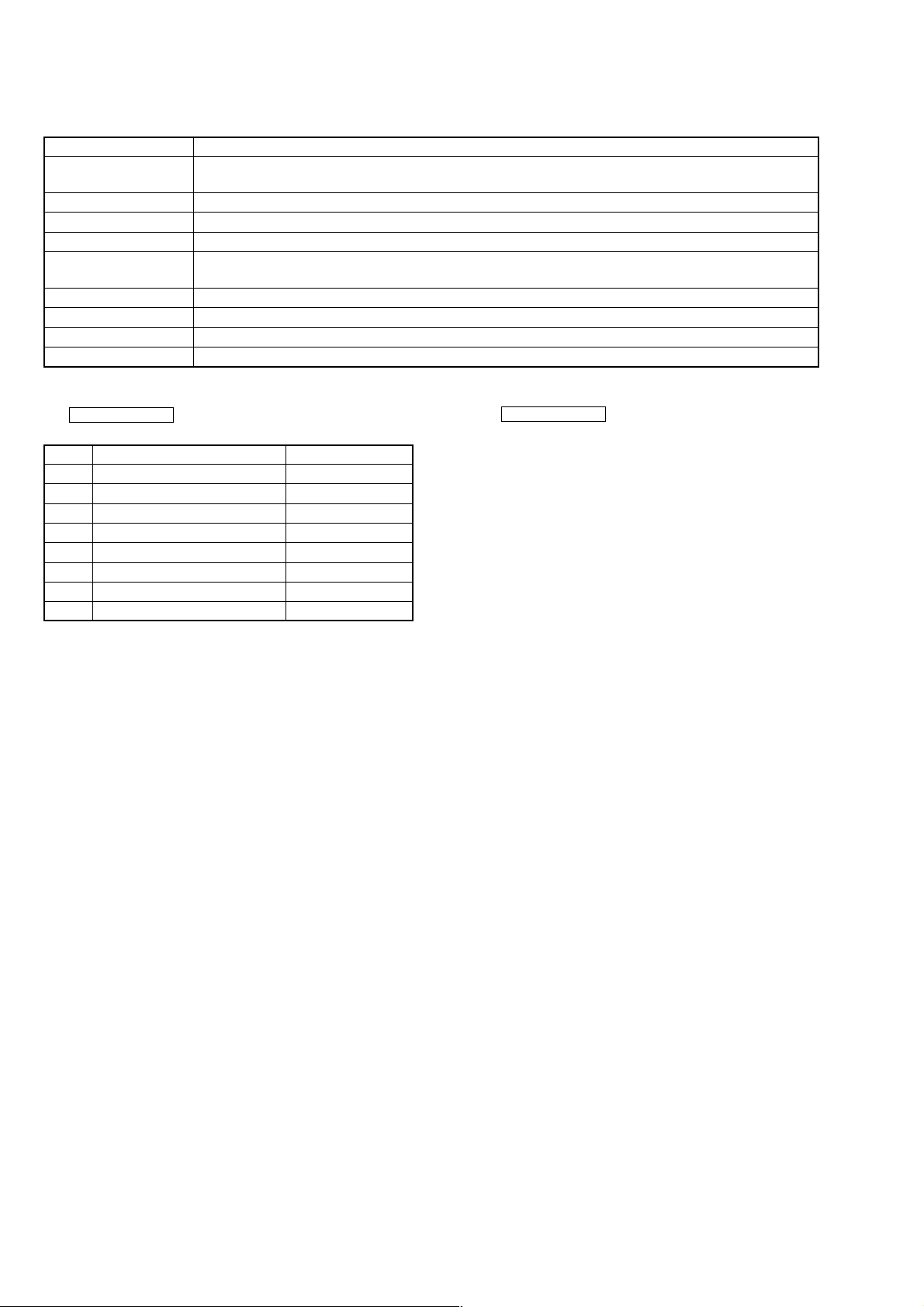

[ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS]

Display

op rec tm

op play tm

spdl rp tm

retry err

total err

err history

retry adrs

er refresh

op change

spdl change

Details of History

Displays the total recording time.

When the total recording time is one minute or longer, displays the time and minute.

When the total recording time is less than one minute, displays “Under 1 min”.

The displayed time is about 1/4 of the actual recording time when the laser is set to the high power state.

Displays the total playback time.

When the total playback time is one minute or longer, displays the time and minute.

When the total playback time is less than one minute, displays “Under 1 min”.

Displays the total time when the spindle motor rotates.

When the total rotation time is one minute or longer, displays the time and minute.

When the total rotation time is less than one minute, displays “Under 1 min”.

Displays the total number of retries during recording and number of retry errors during playback.

Displayed as “r xx p yy”. “xx” indicates the number of retries during recording, “yy” indicates the number of retry

errors during playback.

The numbers are displayed in hexadecimal from 00 to FF.

Displays the total number of errors.

Displayed as “total xx”. The number is displayed in hexadecimal from 00 to FF.

Displays the last ten errors.

Displayed as “0x ErrCd@@”.

“x” indicates the history number. A smaller number indicates a more recent error (00 is the latest). @@ indicates the

error code. The error history number is selected by turning the l AMS L knob.

Displays the last five retry addresses.

Displayed as “xx ADRS yyyy”. “xx” indicates the history number. “yyyy” indicates the cluster where the retry

occurred. The history number is selected by turning the l AMS L knob.

Mode which erases the error history and the retry address history

[Operation procedure]

1 When “er refresh” is displayed, press the l AMS L knob.

2 After the display changes to “er refresh?”, press the YES button.

The “Complete!” message indicates that the operation has ended.

After executing this mode, be sure to check the following:

• The data has been erased.

• The mechanism runs normally when recording and playback are performed.

Mode which erases the total time of “op rec tm” and “op play tm”

These histories are used as a guideline for the time to replace the optical pick-up. After replacing the optical pick-up,

perform this operation to erase the history.

[Operation procedure]

1 When “op change” is displayed, press the l AMS L knob.

2 After the display changes to “op change?”, press the YES button.

The “Complete!” message indicates that the operation has ended.

Mode which erases the total time of “spdl rp tm”

The history is used as a guideline for the time to replace the spindle motor. After replacing the spindle motor, perform

this operation to erase the history.

[Operation procedure]

1 When “spdl change” is displayed, press the l AMS L knob.

2 After the display changes to “spdl change?”, press the YES button.

The “Complete!” message indicates that the operation has ended.

Table of Error Codes

Error Code

10

12

20

21

22

23

24

30

Loading error

The combination of loading switches is not acceptable.

Time out. The beginning of PTOC cannot be read.

Contents error. The beginning of PTOC can be read.

Time out. Access to UTOC failed.

Time out. UTOC cannot be read.

Contents error of UTOC

Playback start error

Details of Error

Error Code

31

40

41

42

43

50

51

Details of Error

There is an abnormality in the sector contents.

An error caused a retry during continuous recording.

Retry was executed due to DRAM overflow.

Retry was executed during TOC writing.

S.F Edit was aborted due to retry.

Address cannot be read although access processing is

not in progress.

Runaway due to focus NG

5

Page 6

SECTION 1

7

SERVICE NOTE

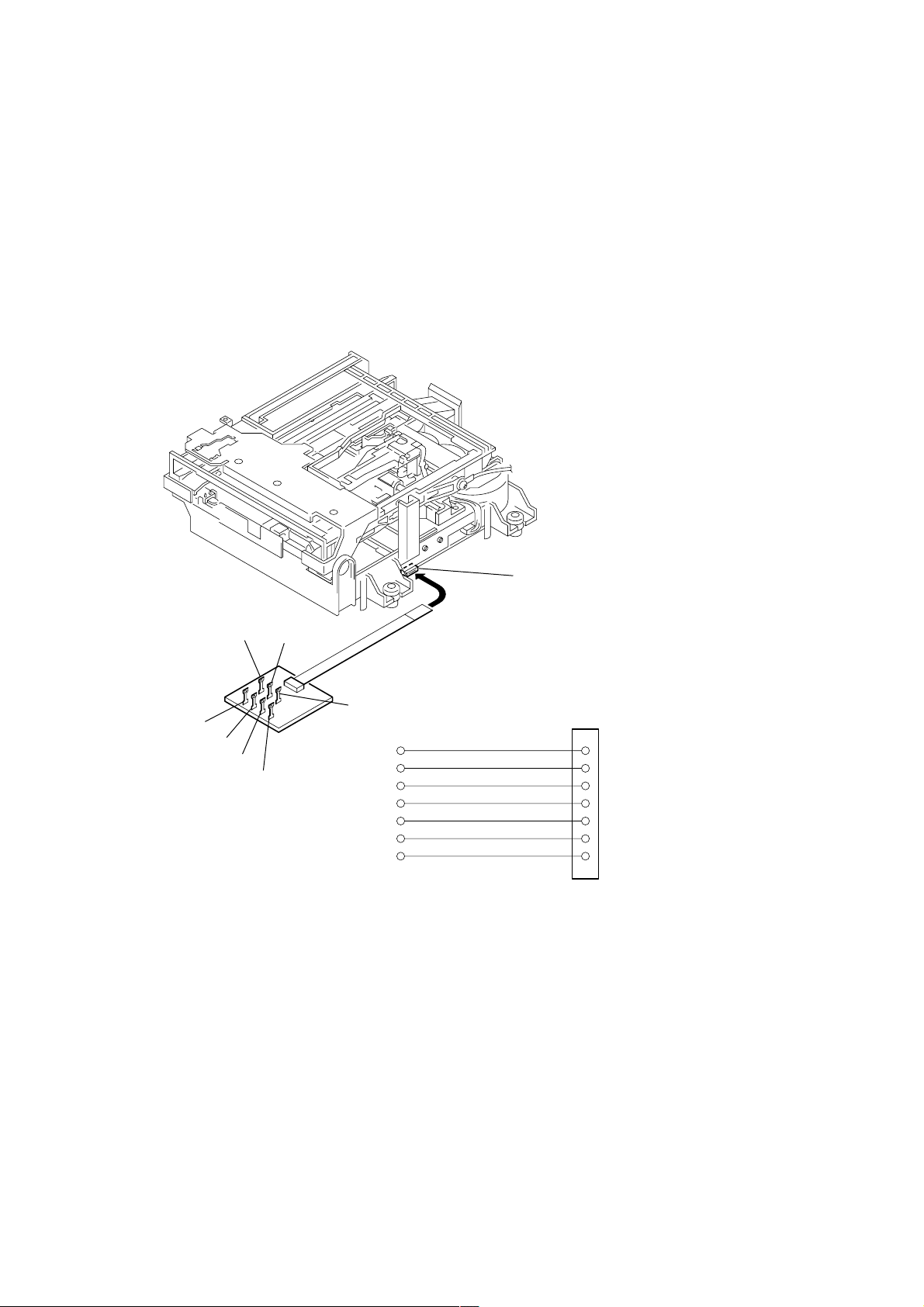

JIG FOR CHECKING BD BOARD WAVEFORM

The special jig (J-2501-196-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

GND : Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TEO : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

FE : FOCUS error

Mechanism deck

I+3V

GND

IOP

FE

RF

TE

VC

I+3V

IOP

GND

TE

FE

VC

RF

CN105

1

I+3V

IOP

GND

for

TE

MDM-

FE

VC

RF

7

6

Page 7

IOP DATA RECORDING AND DISPLAY WHEN OPTICAL PICK-UP AND

NON-VOLATILE MEMORY (IC195 OF BD BOARD) ARE REPLACED

The IOP value labeled on the optical pick-up can be recorded in the non-volatile memory. By recording the value, it will eliminate the need

to look at the value on the optical pick-up label. When replacing the optical pick-up or non-v olatile memory (IC195 of BD board), record the

IOP value on the optical pick-up according to the following procedure.

Record Procedure:

1. While pressing the l AMS L knob and x button, connect the power plug to the outlet, and release the l AMS L knob

and x button.

2. Turn the l AMS L knob to display “[Service]”, and press the YES button.

3. Turn the l AMS L knob to display “lop Write” (C28), and press the YES button.

4. The display becomes “Ref=@@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

5. Input the IOP value written on the optical pick-up label.

To select the number : Turn the l AMS L knob.

To select the digit : Press the l AMS L knob.

6. When the YES button is pressed, the display becomes “Measu=@@@.@” (@ is an arbitrary number).

7. As the adjustment results are recorded for the 6 value. Leave it as it is and press the YES button.

8. “Complete!” will be displayed momentarily. The value will be recorded in the non-volatile memory and the display will become “Iop

Write”.

9. Press the FILTER button to complete.

Display Procedure:

1. While pressing the l AMS L knob and x button, connect the power plug to the outlet, and release the l AMS L knob

and x button.

2. Turn the l AMS L knob to display “[Service]”, and press the YES button.

3. Turn the l AMS L knob to display “lop Read” (C27).

4. “@@.@/##.#” is displayed and the recorded contents are displayed.

@@.@ : indicates the IOP value on the optical pick-up label.

##.# : indicates the IOP value after adjustment

5. To end, press the l AMS L knob or MENU/NO button to display “Iop Read”. Then press the FILTER button.

7

Page 8

CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5. Electrical Adjustments”.

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

Laser power check

(See page 25)

Temp check

(See page 25)

Note: The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for adjustments.

When performing adjustments, use the specified values for adjustments.

• 0.9 mW power

Specified value : 0.84 to 0.92 mW

• 7.0 mW power

Specified value : 6.8 to 7.2 mW

lop (at 7mW)

• Labeled on the optical pickup

Iop value ± 10mA

• Unsatisfactory if displayed as T=@@ (##) [NG”

NG

(@@, ## are both arbitrary numbers)

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Check for disconnection of the circuits around

D101 (BD board)

• Check the signals around IC101, IC151, CN102,

CN103 (BD board)

Measure if unsatisfactory:

8

Page 9

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent indicator tube. During playback, the

“track mode” for obtaining track information will be set.

This is useful for locating the faulty part of the unit.

• The following will be displayed :

During recording and stop : Retry cause, number of retries, and number of retry errors.

During playback : Information such as type of disc played, part played, copyright.

These are displayed in hexadecimal.

Procedure:

1. Procedure 1: Press the x button continuously for about 10 seconds.

Procedure 2: Press the LEVEL/DISPLAY/CHAR button while pressing the x button and MENU/NO button.

2. When the mode is set, “RTs 00c 00e 000” is displayed.

3. Press the z REC button to start recording. Then press the X button and start recording.

4. To check the “track mode”, press the H button to start play.

5. To exit the test mode, press the ?/1 button, and turn OFF the power. When “TOC” disappears, disconnect the power plug from the

outlet.

Fig. 1 Reading the Test Mode Display

(During recording and stop)

RTs@@c##e

Fluorescent indicator tube display

@@ : Cause of retry

## : Number of retries

: Number of retry errors

**

Reading the Retry Cause Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

**

Hexa-

decimal

01

02

04

08

10

20

40

80

Cause of

Retry

shock

ader5

Discontinuous address

DIN unlock

FCS incorrect

IVR rec error

CLV unlock

Access fault

Fig. 2 Reading the Test Mode Display

(During playback)

@@ ###

Fluorescent indicator tube display

@@ : Parts No. (name of area named on TOC)

## : Cluster

: Sector

**

$$ : Track mode (Track information such as

copyright information of each part)

When track jump (shock) is detected

When ADER was counted more than five times

continuously

When ADIP address is not continuous

When DIN unlock is detected

When not in focus

When ABCD signal level exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

Address

Occurring conditions

**

$$

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 t b6

Lower bit : 2 = 0010 t b1

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

When A2 is displayed:

Higher bit : A = 1010 t b7+b5

Lower bit : 2 = 0010 t b1

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

9

Page 10

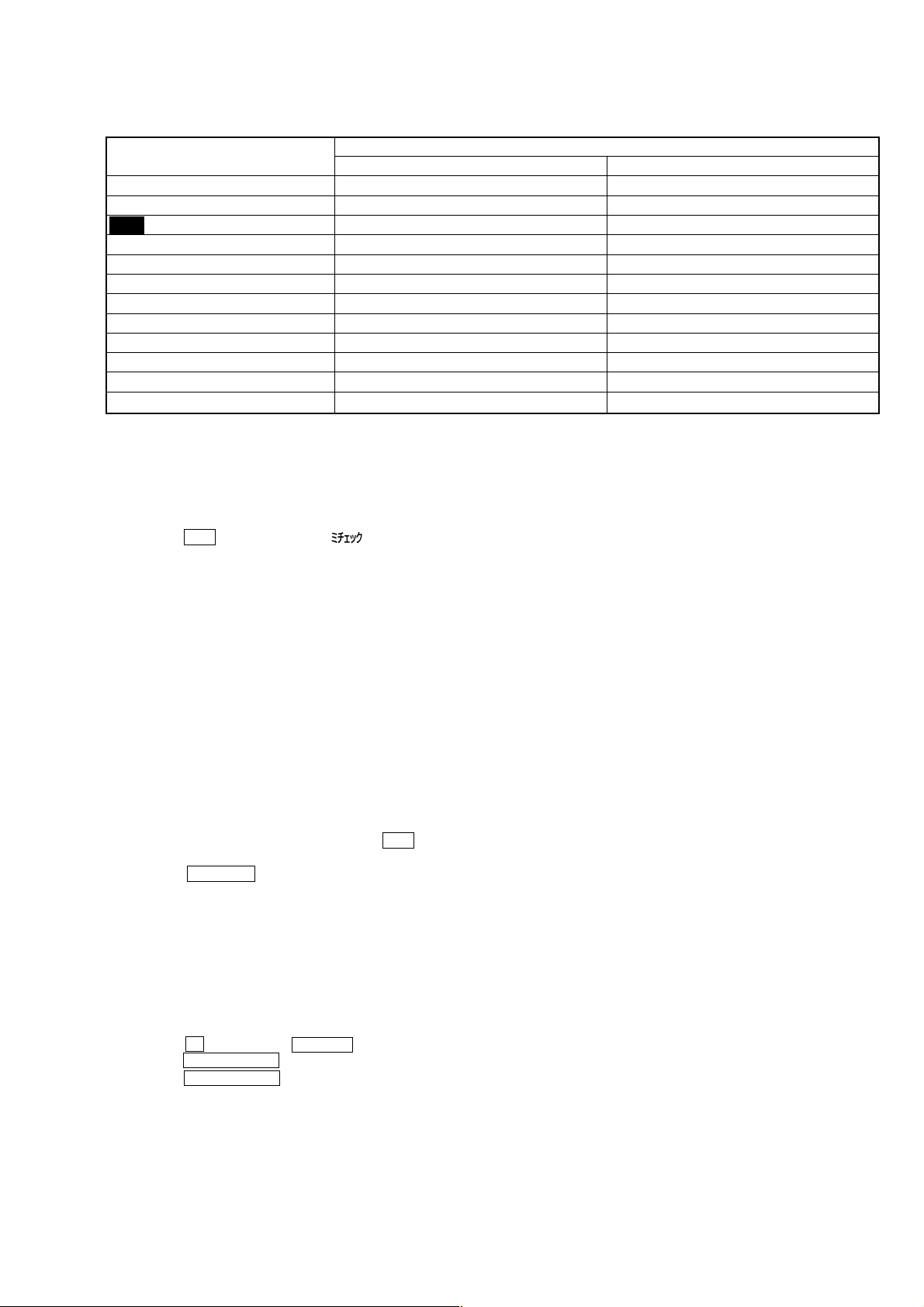

Reading the Retry Cause Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example When 84 is displayed:

Higher bit : 8 = 1000 t b7

Lower bit : 4 = 0100 t b2

In this case, as b2 and b7 are 1 and others are 0, it can be determined that the retry cause is combined of “emphasis OFF”, “monaural”,

“original”, “copyright exists”, and “write allowed”.

Example When 07 is displayed:

Higher bit : 0 = 1000 t All 0

Lower bit : 7 = 0111 t b0+b1+b2

In this case, as b0, b1, and b2 are 1 and others are 0, it can be determined that the retry cause is combined of “emphasis ON”, “stereo”,

“original”, “copyright exists”, and “write prohibited”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

When 0

Emphasis OFF

Monaural

This is 2-bit display. Normally 01.

01:Normal audio. Others:Invalid

Audio (Normal)

Original

Copyright

Write prohibited

Details

When 1

Emphasis ON

Stereo

Invalid

Digital copy

No copyright

Write allowed

Hexadecimal t Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0 0000 8 1000

1 0001 9 1001

2 0010 A 1010

3 0011 B 1011

4 0100 C 1100

5 0101 D 1101

6 0110 E 1110

7 0111 F 1111

10

Page 11

SECTION 2

GENERAL

This section is extracted

from instruction manual.

11

Page 12

121314

Page 13

Page 14

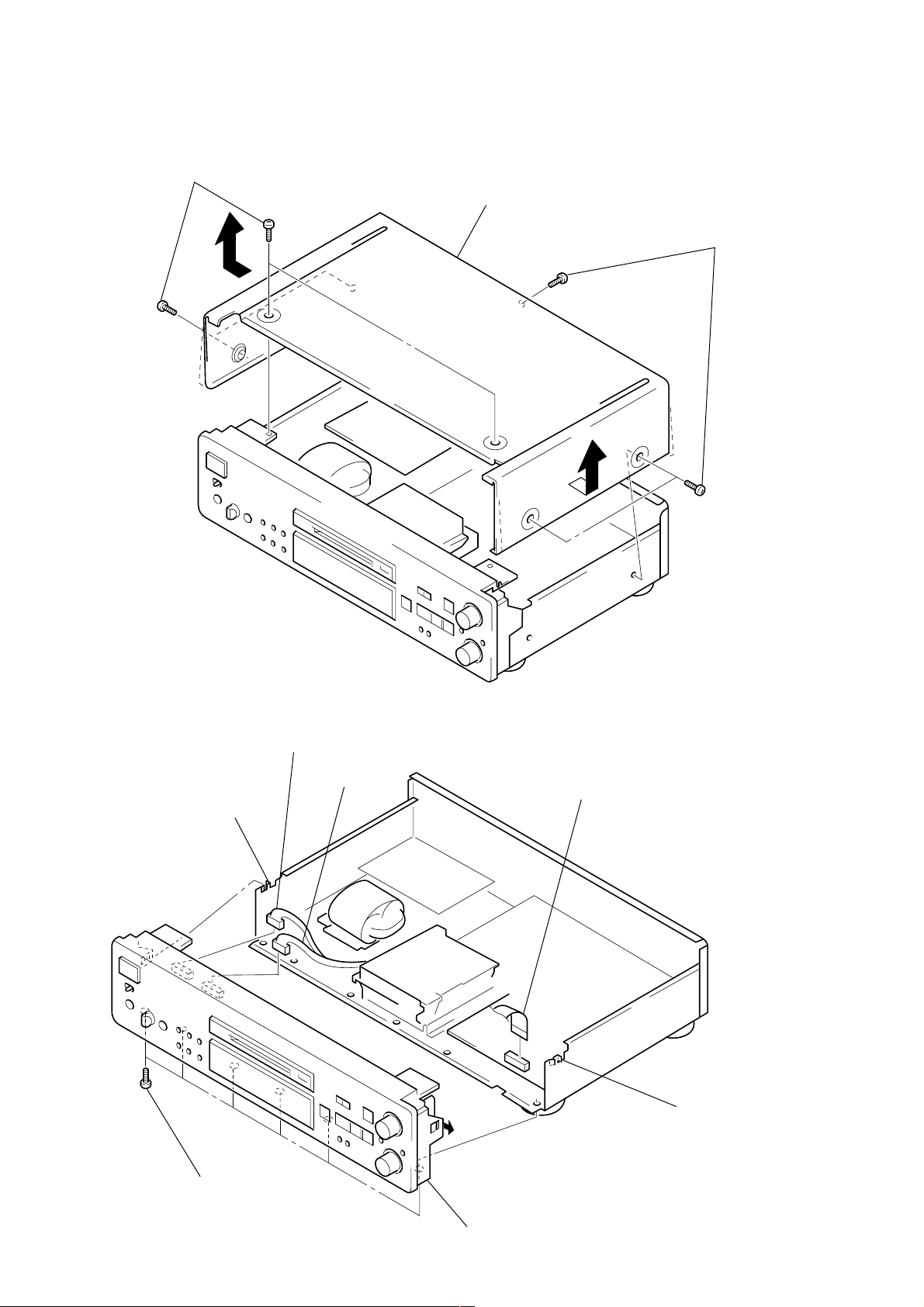

SECTION 3

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE (4095269)

1 Four screws (Screw (TP), flat head)

3 Case (4095269)

2 Three screws

(Screw (TP), flat head)

3-2. FRONT PANEL SECTION

2 Connector

Claw

(CN801)

1 Connector

(CN800)

3 Wire (flat type)(19 core)(CN2)

Claw

4 Six screws

(BVTP3 × 8)

5 Front panel section

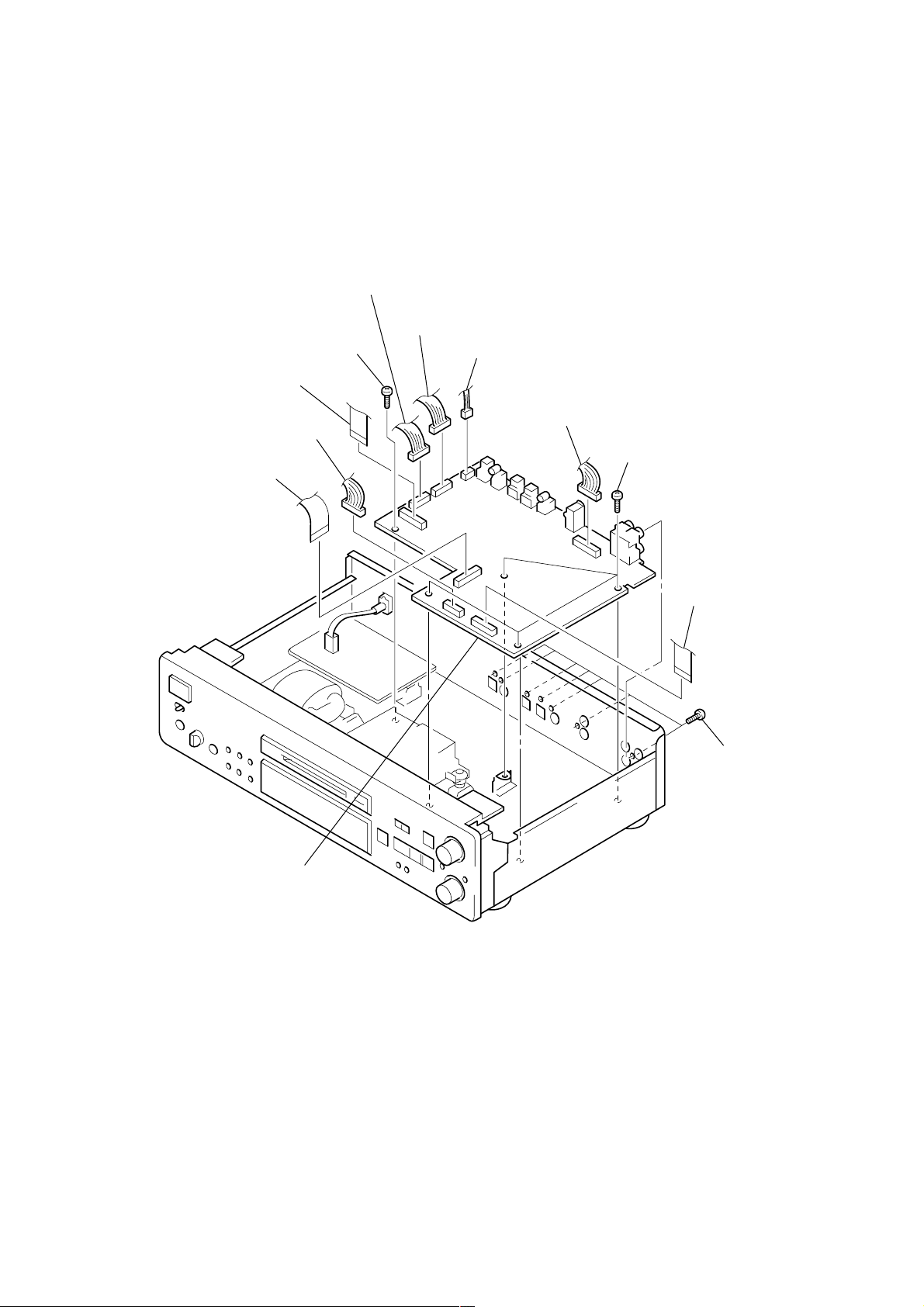

Page 15

3-3. AU BOARD

8 Wire (flat type) (23 core)

7 Wire (flat type) (27 core)

(CN12)

(CN11)

9 Screw

(BVTP 3 × 8)

6 Connector

(CN700)

5 Connector

(CN401)

4 Connector

(CN403)

3 Connector

(CN404)

2 Connector

(CN200)

q; Four screws

(BVTP 3 × 8)

qs AU board

1 Wire (flat type) (19 core)

(CN2)

qa Seven screws

(BVTP 3 × 8)

15

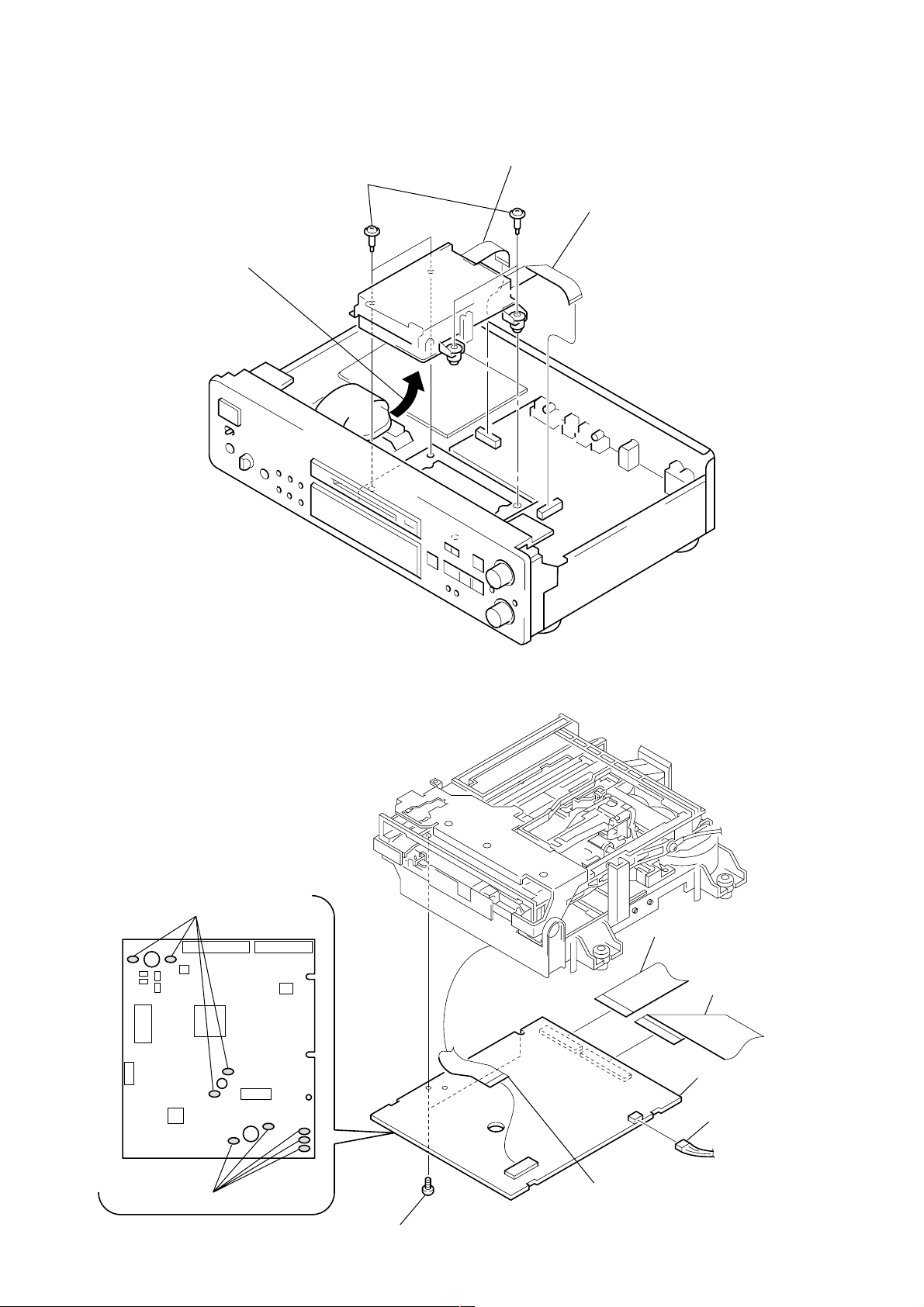

Page 16

3-4. MECHANISM DECK (MDM-7A)

)

)

4 Remove the mechanism deck

(MDM-7A) to direction of the arrow.

2 Wire (flat type)(23 core)(CN11)

3 Four step screws

(BVTTWH M3)

1 Wire (flat type) (27 core

(CN12)

3-5. BD BOARD

5 Remove the solder (four portions)

1 Wire (flat type)(23 core)

2 Wire (flat type

(27 core)

7 BD board

3 Connector

(CN104)

16

4 Remove the solder (five portions)

8 Flexible board (CN104)

6 Two screws (BTP 2 × 6)

Page 17

SECTION 4

TEST MODE

4-1. PRECAUTIONS FOR USE OF TEST MODE

• As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc is

stopped before setting and removing it.

Even if the EJECT A b utton is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not

stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the EJECT A button after pressing the MENU/NO button and the rotation of disc is stopped.

4-1-1. Recording laser emission mode

• Continuous recording mode (CREC 1 MODE)

• Laser power check mode (LDPWR CHECK)

• Laser power adjustment mode (LDPWR ADJUS)

• IOP check (Iop compare)

• IOP value non-volatile writing (Iop NV Save)

• Traverse (MO) check (EF MO CHECK)

• Traverse (MO) adjustment (EF MO ADJUS)

• When pressing the REC z button.

4-2. SETTING THE TEST MODE

The following are two methods of entering the test mode.

Procedure 1: While pressing the l AMS L knob and x button, connect the power plug to an outlet, and release the l AMS L

knob and x button.

When the test mode is set, “[Check]” will be displayed. T urn the l AMS L knob switches between the following three

groups; ···y [Check] y [Service] y [Develop] y ···.

Procedure 2: While pressing the l AMS L knob, connect the power plug to the outlet and release the l AMS L knob.

When the test mode is set, “TEMP CHECK” will be displayed. By setting the test mode using this method, only the “Check”

group of method 1 can be executed.

4-3. RELEASING THE TEST MODE

Press the REPEAT button. The test mode is released and the unit sets into the STANDBY state.

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the l AMS L knob, YES button, and MENU/NO button.

The functions of these buttons are as follows.

Function name

MENU/NO button

YES button

l AMS L knob (right and left)

l AMS L knob (push)

Cancels or moves to the next level up in the hierarchy.

Establishes.

Selects.

Establishes the sub menu.

Function

17

Page 18

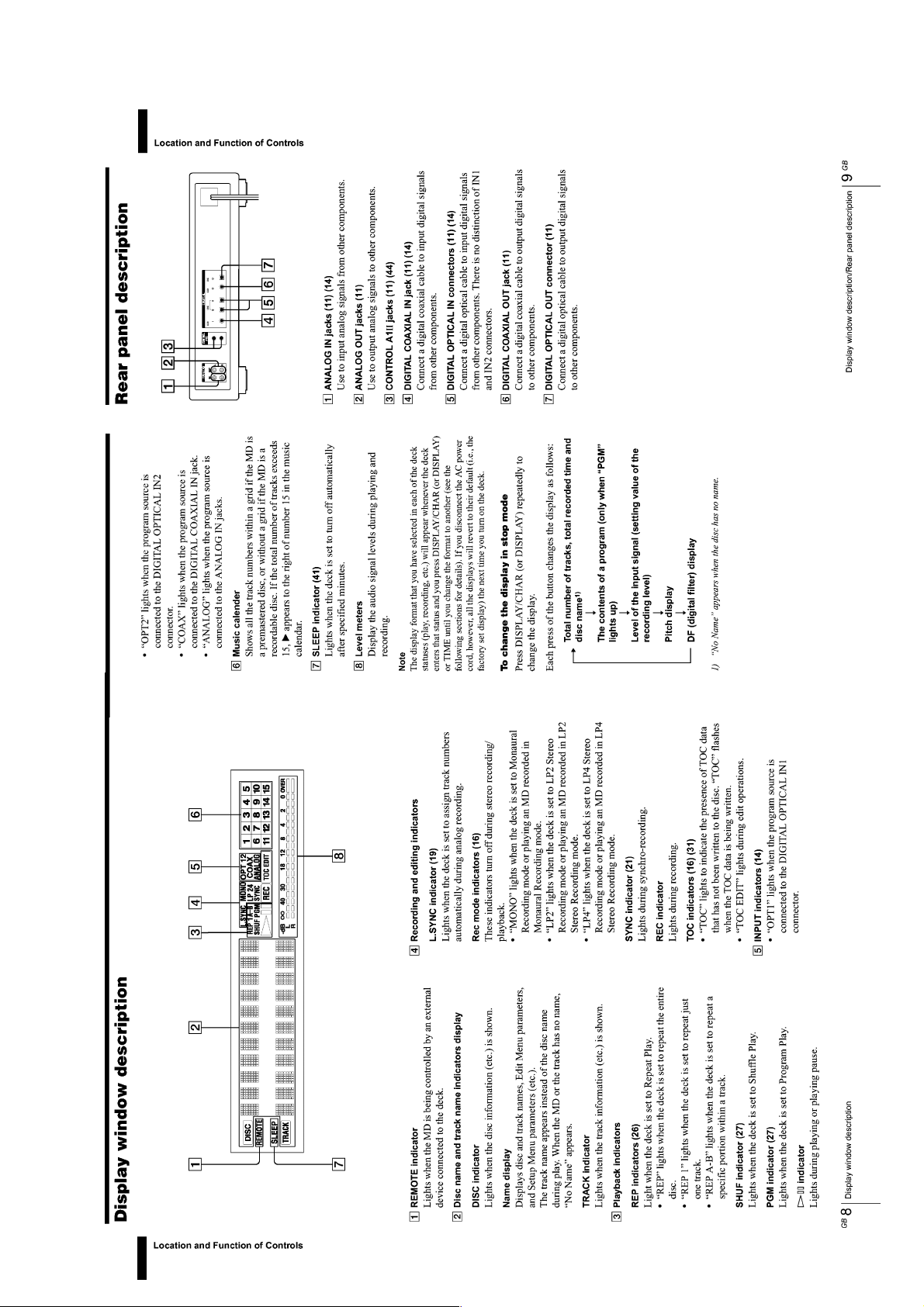

4-5. SELECTING THE TEST MODE

There are 25 types of test mode as shown below. The groups can be switched by turning the l AMS L knob.

All of the service adjustments and checks can be performed in the test modes of Service group.

There is also the Develop group, but it is not used for service. If the Develop group is set by mistake, immediately press the MENU/NO

button to release the group.

Display

AUTO CHECK

Err Display

TEMP ADJUS

LDPWR ADJUS

Iop Write

Iop NV Save

EF MO ADJUS

EF CD ADJUS

FBIAS ADJUS

AG Set (MO)

AG Set (CD)

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

ScurveCHECK

VERIFYMODE

DETRK CHECK

0920 CHECK

Iop Read

Iop Compare

ADJ CLEAR

INFORMATION

CPLAY 1 MODE

CREC 1 MODE

No.

C01

Auto self-diagnosis

C02

Error history display/delete

C03

Temperature compensation offset adjustment

C04

Laser power adjustment

C05

IOP data writing

C06

The current IOP value is read by the microprocessor and written into nonvolatile memory.

C07

Traverse (MO) check

C08

Traverse (CD) check

C09

Focus bias adjustment

C10

Focus tracking gain adjustment (MO)

C11

Focus tracking gain adjustment (CD)

C12

Temperature compensation offset check

C13

Laser power check

C14

Traverse (MO) check

C15

Traverse (CD) check

C16

Focus bias check

C17

S-curve check

C18

Non-volatile memory check

C19

Detrack check

C25

Outermost circumference check

C26

IOP data display

C27

Comparison with initial IOP value written in non-volatile memory

C28

Initialization of adjustment value in non-volatile memory

C31

Display of version of microprocessor, etc.

C34

Continuous playback mode

C35

Continuous recording mode

Contents

GroupMark

Check

×

×

×

×

Service

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

• For details of each adjustment mode, refer to “5. Electrical Adjustments” on page 22.

• For details of “Err Display” (C02), refer to “Self-Diagnosis Function” on page 4.

• If a different mode has been selected by mistake, press the MENU/NO button to release that mode.

• Modes with (×) in the Mark column are not used for servicing and therefore are not described in detail. If these modes are set accidentally,

press the MENU/NO button to release the mode immediately. Be especially careful not to use a test mode of Develop the unit will not

operate normally.

18

Page 19

4-5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

1) Set the disc in the unit. (Whichever recordable discs or discs for playback only are available.)

2) Turn the l AMS L knob and display “CPLAY 1 MODE” (C35).

3) Press the YES button to change the display to “CPLAY 1 MID”.

4) When access completes, the display changes to “C = AD = ”.

Note: The numbers “ ” displayed show you error rates and “ADER”.

2. Changing the parts to be played back

1) Press the YES button during continuous playback to change the display as below. The parts to be played back can be moved.

“CPLAY 1 MID” t “CPLAY 1 OUT” t “CPLAY 1 IN”

2) When access completes, the display changes to “C = AD = ”.

Note: The numbers “ ” displayed show you error rates and “ADER”.

3. Ending the continuous playback mode

1) Press the MENU/NO button. The display will change to “CPLAY 1 MODE”.

2) Press the EJECT A button and take out the disc.

Note: The playback start addresses for IN, MID, and OUT are as follows.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

4-5-2. Operating the Continuous Recording Mode (Use only when performing self-recording/palyback check.)

1. Entering the continuous recording mode

1) Set a recordable disc in the unit.

2) Turn the l AMS L knob and display “CREC 1 MODE” (C34).

3) Press the YES button to change the display to “CREC 1 MID”.

4) When access completes, the display changes to “CREC 1 (

Note: The numbers “ ” displayed shows you the recording position addresses.

” and “

REC

” lights up.

2. Changing the parts to be recorded

1) When the YES b utton is pressed during continuous r ecording, the display changes as below. The parts to be recorded can be changed.

“

” goes off during movement.

REC

“CPLAY 1 MID” t “CPLAY 1 OUT” t “CREC 1 IN”

2) When access completes, the display changes to “CREC 1 ( ” and “

Note: The numbers “ ” displayed shows you the recording position addresses.

REC

3. Ending the continuous recording mode

1) Press the MENU/NO button. The display changes to “CREC 1 MODE” and “

2) Press the l AMS L button and take out the disc.

Note 1: The recording start addresses for IN, MID, and OUT are as follows.

Note 2: The MENU/NO button can be used to stop recording anytime.

Note 3: Do not perform continuous recording for long periods of time above 5 minutes.

Note 4: During continuous recording, be careful not to apply vibration.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

” lights up.

” goes off.

REC

19

Page 20

4-6. FUNCTIONS OF OTHER BUTTONS

Function

PLAY

STOP

FF

FR

REC MODE

(other models/SF EDIT/SCROLL)

PLAY MODE

DISPLAY

EJECT

POWER/REPEAT

Sets continuous playback when pressed in the STOP state. When pressed during continuous playback, the

tracking servo turns ON/OFF.

Stops continuous playback and continuous recording.

The sled moves to the outer circumference only when this is pressed.

The sled moves to the inner circumference only when this is pressed.

Switches between the pit and groove modes when pressed.

Switches the spindle servo mode (CLV-S y CLV-A).

Switches the displayed contents each time the button is pressed

Ejects the disc

Releases the test mode

Contents

4-7. TEST MODE DISPLAYS

The DISPLAY/CHAR button is used to change the display mode. Each time the DISPLA Y/CHAR button is pr essed, the display changes

in the following order.

Order

1

Mode display

2

Error rate display

3

Address display

4

Auto gain display

5

Detrack display

6

IVR display

7

Display of C1 error and jitter

8

Display of AD error and jitter

Details

Display

CPLAY (xxxx

C=xxxxAD=xx

hxxxx sxxxx

AG=xx/xx[xx]

ADR=xx#0000

[xx][xx][xx]

Jxxxx Cxxxx

Jxxxx AD=xx

When C-PLAY or C-REC starts, the display is forcibly switched to one of “2” as the initial mode.

Supplementary explanations of each display

1. Mode display

A display such as “TEMP ADJUST” or “CPLAY 1 MODE” appears.

2. Error rate display

The error rate is displayed as shown below.

C=xxxxAD=xx

C= indicates C1 error, AD= indicates ADER.

3. Address display

The address is displayed as shown below.

h=xxxx s=xxxx (pit of recordable disc and playback-only disc)

h=xxxx a=xxxx (groove of recordable disc)

h= indicates header address, s= indicates SUBQ address, a= indicates ADIP address.

* If the address cannot be read, “-” appears.

Displays other than the above are not used for service.

20

Page 21

4-8. MEANINGS OF OTHER DISPLAYS

Display

N

X

REC

SYNC (other models/TOC EDIT)

L. SYNC (other models/A.SPACE)

OVER

B/1 (REP portion)

A-REP

TRACK/(LP)4/calender frame

DISC/LP2

SLEEP/SHUF

MONO

When Lit

Servo ON

Tracking servo OFF

Recording mode ON

CLV low speed mode

ABCD adjustment completed

Tracking offset cancel ON

Tracking auto gain OK

Focus auto gain OK

Pit

High reflection

CLV-S

CLV LOCK

Contents

When Off

Servo OFF

Tracking servo ON

Recording mode OFF

CLV normal mode

Tracking offset cancel OFF

Groove

Low reflection

CLV-A

CLV UNLOCK

4-9. AUTO DIAGNOSIS FUNCTION

This test mode automatically performs C-REC and C-PLAY and checks mainly the characteristics of the optical pick-up. To ex ecute the test

mode, first check the laser power and perform AUTO CHECK after Iop Compare.

[Operation Procedure]

1. Press the YES b utton. If “LDPWR

perform Iop Compare. Then, repeat this step.

2. If there is a disc in the mechanism deck, the disc is forcibly ejected.

After “DISC IN” appears, load a recordable test disc (MDW-74/GA-1).

3. When the disc is loaded in step 2, the check automatically starts.

4. While “XX CHECK” is displayed, the check of the item shown in “XX” is in progress.

After “06 check” is complete, eject the disc loaded in step 2. When “DISC IN” appears, load the TDYS-1 check disc (MD).

5. After the disc loaded in step 4 is loaded, the check automatically restarts from “07 CHECK”.

6. After the check of item 12 is complete, “OK” or “NG” appears. When all items are OK, “CHECK ALL OK” appears. If e ven one of t he

items failed, “NG: xxxx” appears.

” appears, which means the laser power has not been checked, first check the laser po wer and

When “CHECK ALL OK” appears, there is no problem in the optical pick-up. Check the operations of the spindle motor, sled motor, etc.

If “NG: xxxx” appears, there is an abnormality in the optical pick-up. Replace the optical pick-up.

4-10. INFORMATION

The version of the software is displayed.

[Operation Procedure]

1. When “INFORMATION” appears, press the YES button.

2. The version of the software is displayed.

3. Press the MENU/NO button to end this mode.

4-11. MEASURE WHEN “MEMORY NG” APPEARS

If there is an abnormality in the data of the non-volatile memory , “E001” or “MEMORY NG” appears so that the MD mechanism deck does

not continue to be operated. If either of these messages appears, immediately enter the test mode and perform the following operation.

[Operation Procedure]

1. Enter the test mode. (Refer to Section 4-2.)

2. Normally, the test mode selection display appears. If there is an abnormality in the non-volatile memory, the message “INIT EEP?”

appears.

3. Press the x button and the EJECT A button at the same time.

4. Turn the l AMS L knob to select “MDM-7A”.

5. Press the l AMS L knob. After the non-volatile memory is re written, the mode returns to the normal test mode and the test mode

selection display appears.

21

Page 22

SECTION 5

ELECTRICAL ADJUSTMENTS

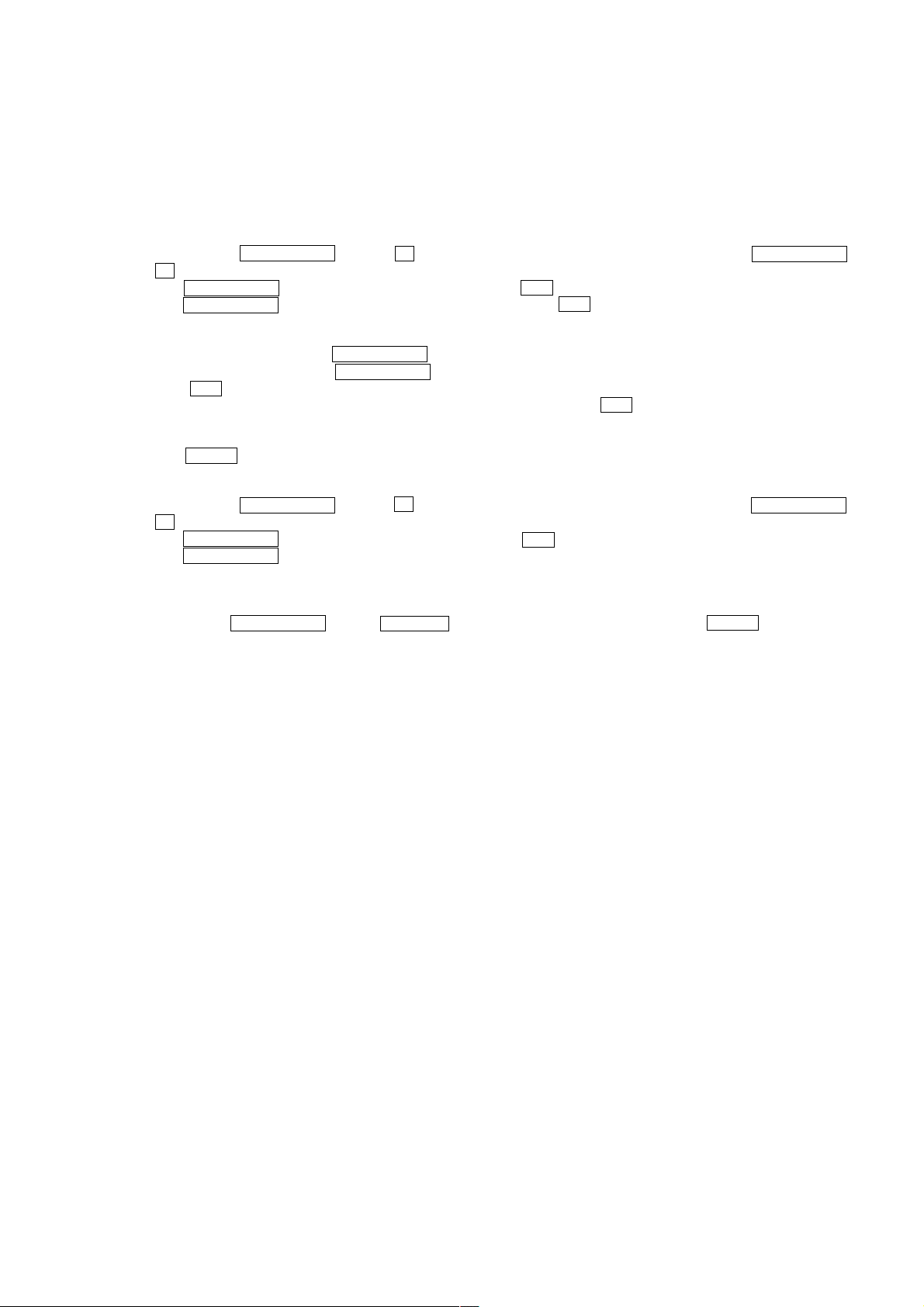

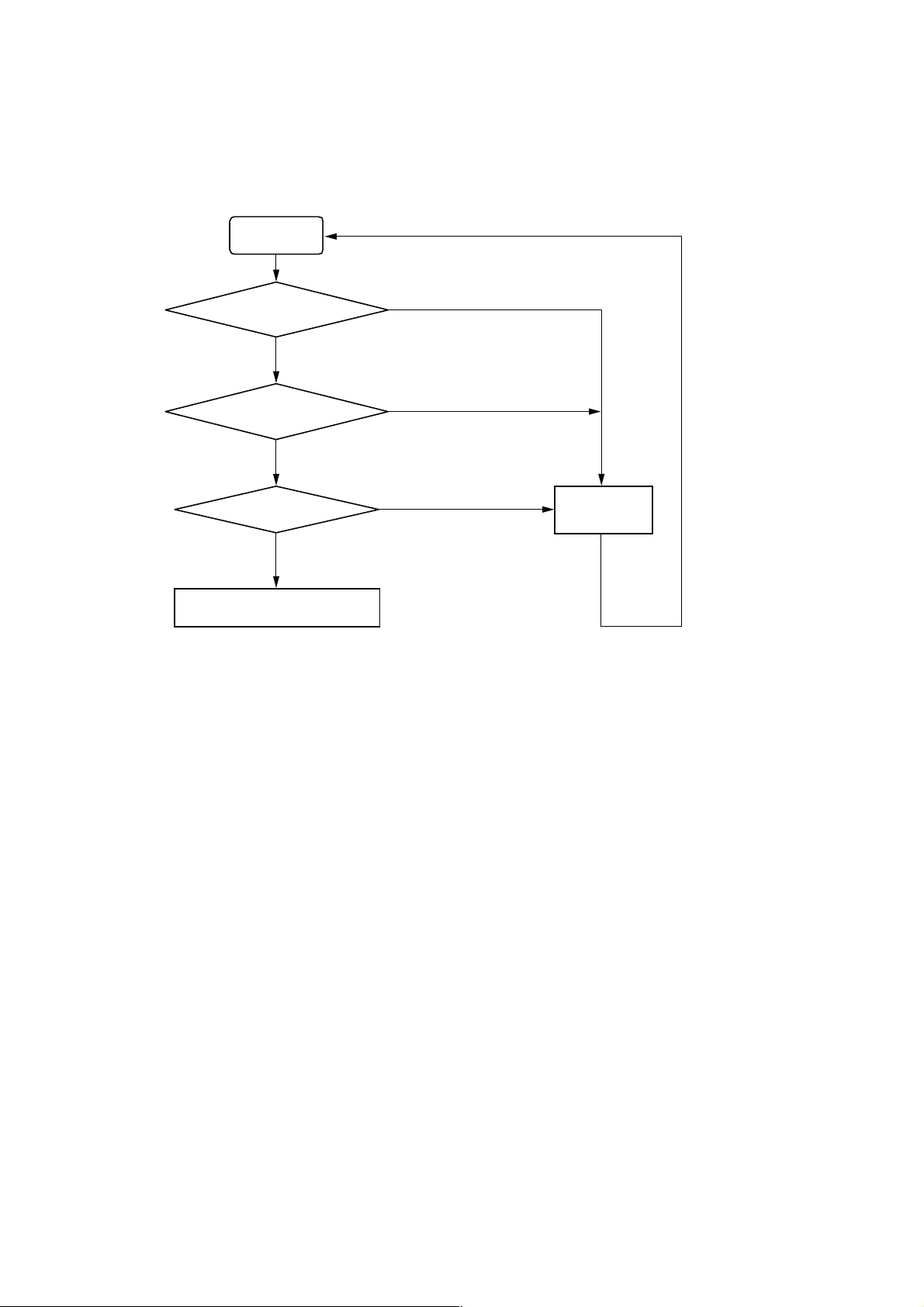

5-1. PARTS REPLACEMENT AND ADJUSTMENT

If a defect such as dropout caused by the OP is found, check the following.

Check Procedure Before Replacement

Start

Laser power check

OK

Iop Compare

OK

AUTO CHECK

OK

Mechanism check of sled, etc.

Other cause is likely.

NG

NG

NG

Replace the OP

or replace the

MDM.

22

Page 23

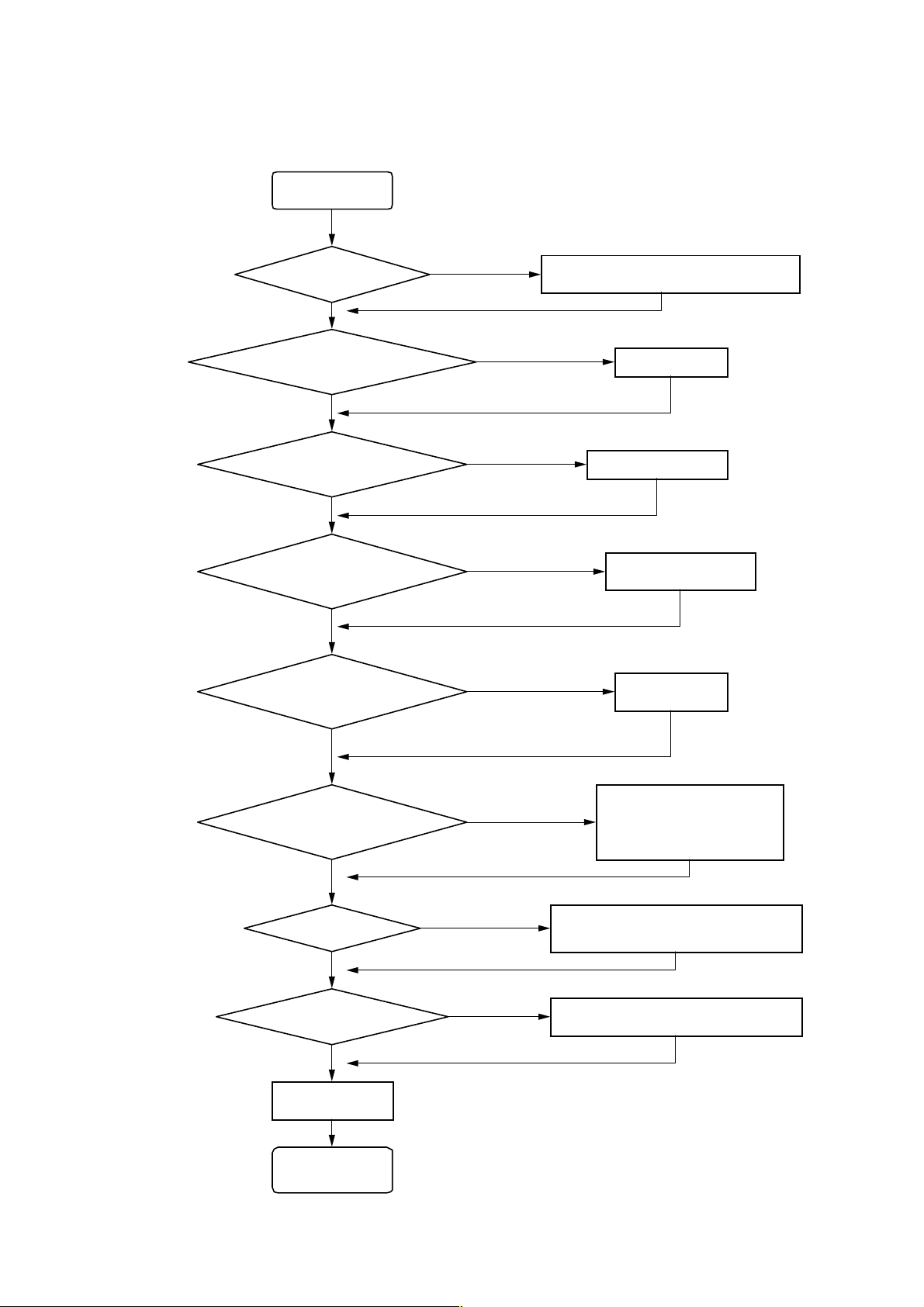

Flow During Adjustment

Start

Replace IC195.

Replace either OP or IC195. ADJ CLEAR

Replace either IC101, IC195 or D101.

Replace either OP, IC190 or IC195.

Replace either

OP, IC102, IC190 or IC195.

YES

YES

YES

YES

YES

After turning on the power again, initialize

EEPROM.

TEMP ADJUST

LDPWR ADJUST

Iop NV Save

Replace either

OP, IC101, IC151 or IC195.

YES

Replace the OP.

Replace the spindle motor. spdl change in Err Display mode

AUTO CHECK

End adjustment.

YES

YES

EF MO, CD ADJUST

FBIAS ADJUST

AG SET (MO), (CD)

op change in Err Display mode

Iop Write

23

Page 24

5-2. PRECAUTIONS FOR CHECKING LASER

d

DIODE EMISSION

T o c heck the emission of the laser diode during adjustments, ne v er

view directly from the top as this may lose your eye-sight.

5-3. PRECAUTIONS FOR USE OF OPTICAL

PICK-UP (KMS-260B)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap of the flexible board of the optical

pick-up when using it.

Before disconnecting the connector, desolder f irst. Before connecting

the connector, be careful not to remove the solder . Also take adequate

measures to prevent damage by static electricity . Handle the flexible

board with care as it breaks easily.

Pick-up

Laser tap

Flexible boar

Optical pick-up flexible board

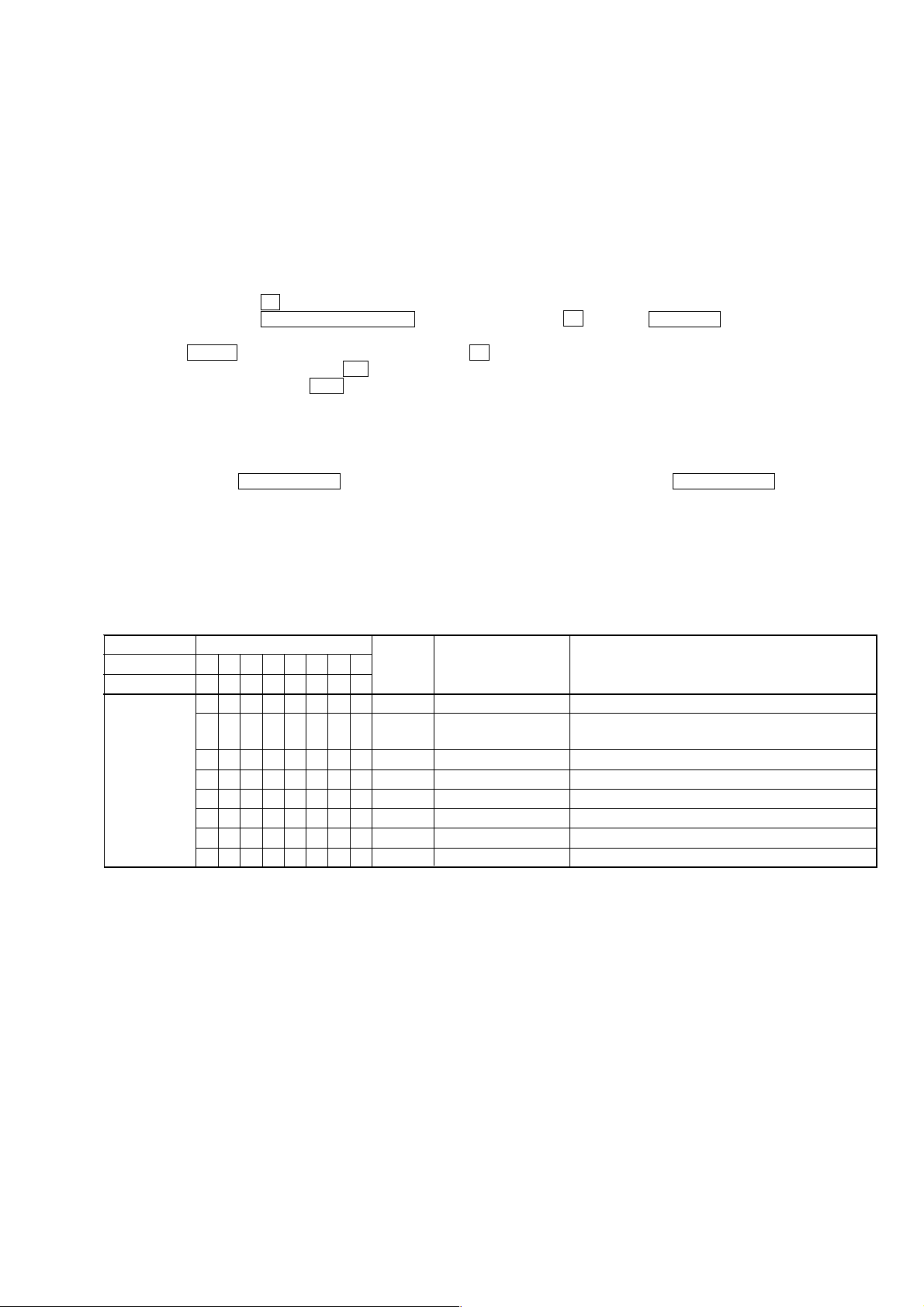

5-4. PRECAUTIONS FOR ADJUSTMENTS

1. When replacing the following parts, perform the adjustments

and checks with a in the order shown in the following table.

Replacement parts

Optical

IC101

IC102

IC151

IC190

IC195

D101

a

×

a

×

a

a

a

×

a

×

a

×

a

×

a

×

a

×

Initial setting of

adjustment value

Recording of

Iop information

TEMP

CHECK

Laser power

adjustment

Iop NV Save

Traverse

adjustment

Focus bias

adjustment

Auto gain

adjustment

AUTO

CHECK

Pick-up

a

a

×

a

a

a

a

a

a

×

×

×

×

×

×

×

×

a

×

×

×

×

×

×

a

×

a

×

a

a

×

a

×

a

×

a

×

a

×

a

×

a

×

a

a

4. Use the following tools and measuring devices.

• Check Disc (MD) TDYS-1

(Part No. 4-963-646-01)

• Test Disc (MDW-74/GA-1) (Part No. 4-229-747-01)

• Laser power meter LPM-8001 (Part No. J-2501-046-A)

or

• MD Laser power meter 8010S (Part No. J-2501-145-A)

• Oscilloscope (Measure after performing CAL of prove)

• Digital voltmeter

• Thermometer

• Jig for checking BD board waveform

(Part No. : J-2501-196-A for MDM-7A)

5. When observing several signals on the oscilloscope, etc.,

make sure that VC and ground do not connect inside the

oscilloscope.

(VC and ground will become short-circuited)

6. Using the above jig enables the waveform to be check ed without

the need to solder.

(Refer to Servicing Notes on page 6)

7. As the disc used will affect the adjustment results, make sure

that no dusts nor fingerprints are attached to it.

Laser power meter

When performing laser power checks and adjustment (electrical

adjustment), use of the new MD laser power meter 8010S (Part No.

J-2501-145-A) instead of the conventional laser power meter is

convenient.

It sharply reduces the time and trouble to set the laser power meter

sensor onto the objective lens of optical pick-up.

5-5. CREATING CONTINUOUSLY-RECORDED

DISC

* This disc is used in focus bias adjustment and MO error rate check.

The following describes how to create an MO continuous recording

disc.

1. Insert a disc (MDW-74/GA-1)(blank disc) commercially

available.

2. Turn the l AMS L knob and display “CREC 1 MODE”

(C35).

3. Press the YES button again to display “CREC 1 MID”.

Display “CREC (0300)” and start to recording.

(Complete recording within 5 minutes.)

4. Press the MENU/NO button and stop recording .

5. Press the EJECT A button and remove the disc.

The above has been how to create a continuous recorded data for

the focus bias adjustment and MO error rate check.

Note: Be careful not to apply vibration during continuous recording.

2. Set the test mode when performing adjustments.

After completing the adjustments, release the test mode.

3. Perform only the adjustments to be needed in the order shown.

24

Page 25

5-6. CHECK PRIOR TO REPAIRS

r

r

)

These checks are performed before replacing parts to determine the

faulty locations.

5-6-1. TEMP CHECK

When performing adjustments, set the internal temperature and room

temperature of 22 °C to 28 °C. Accurate checks are not possible

because the temperature of the IC and diode, etc. rises as time goes

by after the power is turned on. If the check is performed in this

state, wait for some minutes and perform the check again.

Checking Procedure:

1. Turn the l AMS L knob to display “TEMP CHECK”

(C12).

2. Press the YES button.

3. “T=@@(##) [OK” should be displayed. If “T=@@ (##) [NG”

is displayed, it means that the results are bad.

(@@ indicates the current value set, and ## indicates the value

written in the non-volatile memory)

5-6-2. Laser Power Check

Before checking, check the IOP value of the optical pick-up.

(Refer to 5-8. Recording and Displaying IOP Information)

Connection :

Optical pick-up

objective lens

BD board

CN105 pin 1 (I +3V)

CN105 pin 2 (IOP)

Checking Procedure:

1. Load the laser power meter into the disc inlet and set it on the

objective lens of the optical pick-up. (When it cannot be set

properly, press the m button or M button to move the

optical pick-up)

Connect the digital voltmeter to CN105 pin 1 (I+3V) and

CN105 pin 2 (IOP) on the BD board.

2. Then, turn the l AMS L knob to display “LDPWR

CHECK” (C13).

3. Press the YES button once to display “LD 0.9 mW $

Check that the laser power meter satisfy the specified value.

Specified value:

Laser power meter reading: 0.84 to 0.92 mW

4. Press the YES button once more to display “LD 7.0 mW $

”. Check that the laser power meter and digital voltmeter

satisfy the specified value.

Specified V alue:

Laser power meter reading : 7.0 ± 0.2 mW

Digital voltmeter reading : Value on the optical pick-up label

±10%

(Optical pick-up label)

Laser

power mete

Digital voltmete

+

–

5. Press the MENU/NO button to display “LDPWR CHECK”

and stop the laser emission.

(The MENU/NO button is effective a t all times to stop the

laser emission)

Note: After step 4, each time the YES button is pressed, the display will

be switched “LD 0.7 mW $

$ ”. Nothing needs to be performed here.

”, “LD 6.2 mW $ ”, and “LD Wp

5-6-3. Iop Compare

The current IOP value when 7 mW laser power is output and the

reference IOP value (normally, the value when shipped from the

factory) written in the non-volatile memory are compared and the

degree of increase or decrease is shown as a percentage.

Note: Do the following operation when the temperature of the optical

pick-up is almost the same as room temperature.

Operation Procedure:

1. Turn the l AMS L knob to display “Iop Compare”.

2. Press the YES button to start measurement.

3. After the measurement is complete, the display changes to

“±xx% yy”. “xx” indicates the degree of increase or decrease.

OK or NG is shown in “yy”, which indicates whether the

increase or decrease is acceptable.

4. Press the MENU/NO button to end Iop Compare.

5-6-4. AUTO CHECK

This test mode automatically performs C-REC and C-PLAY and

checks mainly the characteristics of the optical pick-up. T o ex ecute

the test mode, first check the laser power and perform AUTO

CHECK after Iop Compare.

Operation Procedure:

1. Press the YES button. If “LDPWR

means the laser power has not been checked, first check the

laser power and perform Iop Compare. Then, repeat this step.

2. If there is a disc in the mechanism deck, the disc is forcibly

ejected. After “DISC IN” appears, load a recordable test disc

(MDW-74/GA-1).

3. When the disc is loaded in step 2, the check automatically starts.

4. While “XX CHECK” is displayed, the check of the item shown

in “XX” is in progress.

After “06 check” is complete, eject the disc loaded in step 2.

When “DISC IN” appears, load the TD YS-1 check disc (MD).

5. After the disc is loaded, the check automatically restarts from

”.

“07 CHECK”.

6. After the check of item 12 is complete, “OK” or “NG” appears.

When all items are OK, “CHECK ALL OK” appears. If even

one of the items failed, “NG: xxxx” appears.

When “CHECK ALL OK” appears, there is no problem in the optical

pick-up, Check the operations of the spindle motor, sled motor , etc.

If “NG: xxxx” appears, there is an abnormality in the optical pickup. Replace the optical pick-up.

” appears, which

KMS-260B

27X40

B0825

lOP = 82.5 mA in this case

lOP (mA) = Digital voltmeter reading (mV)/1 (Ω

25

Page 26

5-6-5. Other Checks

All of the following check modes have already been check ed in the

section “ AUTO CHECK”. Therefore, normally do not check them.

1. T raverse Check

Connection :

Oscilloscope

(DC range)

BD board

CN105 pin 4 (TE)

CN105 pin 6 (VC)

+

–

V: 0.1 V/div

H: 10 ms/div

Checking Procedure:

1. Connect an oscilloscope to CN105 pin 4 (TE) and CN105

pin 6 (VC) on the BD board.

2. Load a recordable disc (MDW-74/GA-1).

3. Press the M button to move the optical pick-up outside the

pit.

4. Turn the l AMS L knob to display “EF MO

CHECK”(C14).

5. Press the YES button to display “EFB = MO-R”.

6. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not turn the l AMS L

knob.

Tra verse Wa veform

A

VC

B

Specified value : Below 10% offset value

Offset value (%) = × 100

IA – BI

2 (A + B)

7. Press the YES button to display “EFB = MO-W”.

8. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not turn the l AMS L

knob.

Tra verse Wa veform

A

VC

B

Specified value : Below 10% offset value

11. Press the YES button to display “EF MO CHECK”

The disc stops rotating automatically.

12. Press the EJECT A button and take out the disc.

13. Load the check disc (MD) TDYS-1.

14. Turn the l AMS L knob and display “EF CD CHECK”

(C15).

15. Press the YES button to display “EFB = CD”. Ser vo is

imposed automatically.

16. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not turn the l AMSL

knob.

Tra verse Wa veform

A

VC

B

Specified value : Below 10% offset value

17. Press the YES button to display “EF CD CHECK”.

18. Press the EJECT A button and tak e out the test disc (TDYS-

1).

2. Focus Bias Check

Change the focus bias and check the focus tolerance amount.

Checking Procedure :

1. Load the recorded test disk (MDW-74/GA-1).

(Refer to “5-5. Creating Continuously-Recorded Disc”.)

2. Turn the l AMS L knob to display “CPLAY 1 MODE”

(C34).

3. Press the YES button to display “CPLAY 1MID”.

4. Press the MENU/NO button when “C =

AD = ” is

displayed.

5. Turn the l AMS L knob to display “FBIAS CHECK”

(C16).

6. Press the YES button to display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate the

focus bias value.

Check that the C1 error is below 20 and ADER is below 2.

7. Press the YES button to display “ / b = ”.

Check that the C1 error is about 100 and ADER is below 2.

8. Press the YES button to display “ / a = ”.

Check that the C1 error is about 100 and ADER is below 2.

9. Press the MENU/NO button, then press the EJECT A button

and take out the test disc.

9. Press the YES button to display “EFB = MO-P”.

Then, the optical pick-up moves to the pit area automatically

and servo is imposed.

10. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not turn the l AMS L

knob.

Tra verse Wa veform

A

VC

B

Specified value : Below 10% offset value

26

Page 27

3. C PLAY Checking

a. MO Error Rate Check

Checking Procedure :

1. Load the recorded test disk (MDW-74/GA-1).

(Refer to “5-5. Creating Continuously-Recorded Disc”.)

2. Turn the l AMS L knob to display “CPLA Y 1 MODE”

(C34).

3. Press the YES button to display “CPLAY 1 MID”.

4. The display changes to “C = AD = ”.

5. If the C1 error rate is below 20, check that ADER is 00.

6. Press the MENU/NO button to stop playback, then press the

EJECT A button and take out the test disc.

b. CD Error Rate Check

Checking Procedure :

1. Load the check disc (MD) TDYS-1.

2. Turn the l AMS L knob to display “CPLA Y 1 MODE”

(C34).

3. Press the YES button twice to display “CPLAY 1 MID”.

4. The display changes to “C = AD = ”.

5. Check that the C1 error rate is below 20.

6. Press the MENU/NO button to stop playback, then press the

EJECT A button and take out the check disc.

4. Self-Recording/playback Check

• Create a continuous recording disc using the unit to be repaired

and check the error rate.

1. Load a recordable test disc (MDW-74/GA-1).

2. Turn the l AMS L knob to display “CREC 1 MODE”

(C34).

3. Press the YES button to display “CREC 1 MID”.

4. REC z lights and “CREC(@@@@” (@@@@ indicates the

address.). Then recording starts.

5. About one minute later, press the MENU/NO button to stop

the continuous recording.

6. Turn the l AMS L knob to display “CPLA Y 1 MODE”

(C34).

7. Press the YES button to display “CPLAY 1 MID”.

8. The display changes to “C1 =

AD = ”.

9. Check that the C1 error rate is below 20 and ADER is belo w 2.

10. Press the MENU/NO button to stop playback and press the

EJECT A button to remove the disc.

5-8. RECORDING AND DISPLAYING THE IOP

INFORMATION

The IOP data can be recorded in the non-volatile memory . The IOP

value on the optical pick-up label and the IOP value after the

adjustment will be recorded. Recording these data eliminates the

need to read the label on the optical pick-up.

Recording Procedure :

1. Turn the l AMS L knob to display “Iop Write” (C05),

and press the YES button.

2. The display becomes Ref=@@@/@ (@ is an arbitrary number)

and the numbers which can be changed will blink.

3. Input the IOP value on the optical pick-up label.

To select the number : Turn the l AMSL knob.

To select the digit : Press the l AMS L knob

4. When the YES button is pressed, the display becomes

“Measu=@@@.@” (@ is an arbitrary number).

5. As the adjustment results are recorded for the 6 value. Leave it

as it is and press the YES button.

6. “Complete!” will be displayed momentarily. The value will be

recorded in the non-volatile memory and the display will

become “Iop Write”.

Display Procedure :

1. Turn the l AMS L knob to display “Iop Read”(C26).

2. “@@.@/##.#” is displayed and the recorded contents are

displayed.

@@.@ indicates the IOP value on the optical pick-up label.

##.# indicates the IOP value after adjustment

3. To end, press the l AMS L button or MENU/NO

button to display “Iop Read”.

5-9. TEMPERATURE COMPENSATION OFFSET

ADJUSTMENT

Save the temperature data at that time in the non-volatile memory

as 25 ˚C reference data.

Note: 1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22 ˚C to

28 ˚C. Perform it immediately after the power is turned on when

the internal temperature of the unit is the same as the ambient

temperature of 22 ˚C to 28 ˚C.

3. When D101 has been replaced, perform this adjustment after

the temperature of this part has become the ambient temperature.

5-7. INITIAL SETTING OF ADJUSTMENT VALUE

Note: Mode which sets the adjustment results recorded in the non-volatile

memory to the initial setting value. However the results of the

temperature compensation offset adjustment will not change to the

initial setting value.

If initial setting is performed, perform all adjustments again

excluding the temperature compensation offset adjustment.

For details of the initial setting, refer to “5-4. Precautions for

Adjustments” and execute the initial setting before the adjustment

as required.

Setting Procedure :

1. Turn the l AMS L knob to display “ADJ CLEAR”

(C28).

2. Press the YES button. “Complete!” will be displayed

momentarily and initial setting will be executed, after which

“ADJ CLEAR” will be displayed.

Adjusting Procedure :

1. Turn the l AMS L knob to display “TEMP ADJUS”

(C03).

2. Press the YES button to select the “TEMP ADJUS” mode.

3. “TEMP = [OK” and the current temperature data will be

displayed.

4. To save the data, press the YES button.

When not saving the data, press the MENU/NO button.

5. When the YES button is pressed, “TEMP = SAVE” will be

displayed and turned back to “TEMP ADJUS” display then.

When the MENU/NO button is pressed, “TEMP ADJUS”

will be displayed immediately.

Specified V alue :

The “TEMP =

” should be within “E0 - EF”, “F0 - FF”, “00 -

0F”, “10 - 1F” and “20 - 2F”.

27

Page 28

5-10. LASER POWER ADJUSTMENT

r

r

)

Check the IOP value of the optical pick-up before adjustments.

(Refer to 5-8. Recording and Displaying IOP Information)

Connection :

Optical pick-up

objective lens

BD board

CN105 pin 1 (I +3V)

CN105 pin 2 (IOP)

Adjusting Procedure :

1. Load the laser power meter into the disc inlet and set it on the

objective lens of the optical pick-up. (When it cannot be set

properly, press the m button or M button to move the

optical pick-up)

Connect the digital voltmeter to CN105 pin 1 (I+3V) and

CN105 pin 2 (IOP) on the BD board.

2. Turn the l AMS L knob to display “LDPWR ADJUS”

(C04).

3. Press the YES button once to display “LD 0.9 mW $ ”.

4. Turn the l AMS L knob so that the reading of the laser

power meter becomes 0.85 to 0.91 mW . Pr ess the YES button

after setting the range knob of the laser power meter, and sa v e

the adjustment results in the non-volatile memory . (“LD SAVE

$ ” will be displayed for a moment)

5. Then “LD 7.0 mW $

” will be displayed.

6. Turn the l AMS L knob so that the reading of the laser

power meter becomes 6.9 to 7.1 mW, press the YES button to

save it. (“LD SAVE $ ” will be displayed for a moment)

Note: Do not perform the emission with 7.0 mW more than 15 seconds

continuously.

7. Then, turn the l AMS L knob to display “LDPWR

CHECK” (C13).

8. Press the YES button once to display “LD 0.9 mW $ ”.

Check that the reading of the laser power meter become 0.85

to 0.91 mW.

9. Press the YES button once more to display “LD 7.0 mW $

”. Check that the reading the laser power meter and digital

voltmeter satisfy the specified value.

Note down the digital voltmeter reading value.

Laser

power mete

Digital voltmete

+

–

12. Press the YES button. When the display becomes

Ref=@@@.@ (@ is an arbitrary number), press the YES

button to display “Measu=@@@.@” (@ is an arbitrary

number).

13. The numbers which can be changed will blink. Input the Iop

value noted down at step 9.

To select the number : Turn the l AMS L knob.

To select the digit : Press the l AMS L knob.

14. When the YES button is pressed, “Complete!” will be

displayed momentarily. The v alue will be recorded in the nonvolatile memory and the display will become “Iop Write”.

Note: After step 4, each time the YES button is pressed, the display will

be switched “LD 0.7 mW $ ”, “LD 6.2 mW $ ”, and “LD Wp

$ ”. Nothing needs to be performed here.

5-11. Iop NV Save

Write the reference value in the non-volatile memory for “Iop

Comparer”. Do not perform this operation other than when

performing the laser power adjustment while replacing the OP, etc.

and when replacing IC102 as the reference value is rewritten.

Otherwise, deterioration judgment of the OP is wrong.

Note: Perform this operation when the temperature of the optical pick-up

is almost same as the room temperature.

Operation Procedure:

1. Turn the l AMS L knob to display “Iop NV Save”

(C06).

2. Press the YES button to display “Iop [stop]”.

3. After the display changes to “Iop=xxsave?”, press the YES

button.

4. “Complete!” is displayed momentarily and the display changes

to “Iop 7.0mW”.

5. After the display changes to “Iop=yysave?”, press the YES

button.

6. The “Complete!” message indicates that the operation has

ended.

Specified Value:

Laser power meter reading : 7.0 ± 0.2 mW

Digital voltmeter reading : Value on the optical pick-up label

±10%

(Optical pick-up label)

KMS-260B

27X40

B0825

lOP = 82.5 mA in this case

lOP (mA) = Digital voltmeter reading (mV)/1 (Ω

10. Press the MENU/NO button to display “LDPWR CHECK”

and stop the laser emission.

(The MENU/NO button is effective at all times to stop the

laser emission.)

11. Turn the l AMS L knob to display “Iop Write”(C05).

28

Page 29

5-12. TRAVERSE ADJUSTMENT

Connection:

Oscilloscope

(DC range)

BD board

CN105 pin 4 (TE)

CN105 pin 6 (VC)

Adjusting Procedure:

1. Connect an oscilloscope to CN105 pin 4 (TE) and CN105

pin 6 (VC) on the BD board.

2. Load a recordable test disc (MDW-74/GA-1).

3. Press the M button to move the optical pick-up outside the

pit.

4. Turn the l AMS L knob to display “EF MO ADJUS”

(C07).

5. Press the YES button to display “EFB = MO-R”.

6. Turn the l AMS L knob so that the waveform of the

oscilloscope becomes the specified value.

(When the l AMS L knob is turned, the of “EFB=

MO-R” changes and the waveform changes.) In this

adjustment, waveform v aries at intervals of approx. 2%. Adjust

the waveform so that the specified v alue is satisfied as much as

possible.

T raverse W aveform

VC

Specification A = B

+

–

V: 0.1 V/div

H: 10 ms/div

A

B

11. Turn the l AMS L knob until the waveform of the

oscilloscope moves closer to the specified value.

In this adjustment, waveform varies at interv als of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

T raverse Wa veform

A

VC

B

Specification A = B

12. Press the YES button, and save the adjustment results in the

non-volatile memory. (“EFB = SAV” will be displayed for

a moment.)

Next “EF MO ADJUS” is displayed. The disc stops rotating

automatically.

13. Press the EJECT A button and take out the disc.

14. Load the check disc (MD) TDYS-1.

15. Turn the l AMS L knob to display “EF CD ADJUS”

(C08).

16. Press the YES button to display “EFB = CD”. Servo is

imposed automatically.

17. Turn the l AMS L knob so that the waveform of the

oscilloscope moves closer to the specified value.

In this adjustment, waveform varies at interv als of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

T raverse Wa veform

7. Press the YES button and sa ve the result of adjustment to the

non-volatile memory (“EFB = SAV” will be displayed for a

moment. Then “EFB = MO-W” will be displayed).

8. Turn the l AMS L knob so that the waveform of the

oscilloscope becomes the specified value.

(When the l AMS L knob is turned, the of “EFB-

MO-W” changes and the waveform changes.) In this

adjustment, waveform v aries at intervals of approx. 2%. Adjust

the waveform so that the specified v alue is satisfied as much as

possible.

T raverse W aveform

A

VC

B

Specification A = B

9. Press the YES button, and save the adjustment results in the

non-volatile memory. (“EFB = SAV” will be displayed for

a moment)

10. “EFB = MO-P” will be displayed.

The optical pick-up moves to the pit area automatically and

servo is imposed.

A

VC

B

Specification A = B

18. Press the YES button, display “EFB = SAV” for a moment

and save the adjustment results in the non-volatile memory.

Next “EF CD ADJUS” will be displayed.

19. Press the EJECT A button and take out the test disc TD YS-1.

29

Page 30

5-13. FOCUS BIAS ADJUSTMENT

Adjusting Procedure :

1. Load the continuously-recorded disc (MDW-74/GA-1).

(Refer to “5-5. Creating Continuously-Recorded Disc”)

2. Turn the l AMS L knob to display “CPLA Y 1 MODE”

(C34).

3. Press the YES button to display “CPLAY 1 MID”.

4. Press the MENU/NO button when “C = AD = ” is

displayed.

5. Turn the l AMS L knob to display “FBIAS ADJUS”

(C09).

6. Press the YES button to display “ / a = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [a =] indicate the

focus bias value.

7. Turn the l AMS L knob clockwise and find the focus

bias value at which the C1 error rate becomes about 200.

8. Press the YES button to display “ / b = ”.

9. Turn the l AMS L knob counterclockwise and find

the focus bias value at which the C1 error rate becomes about

200. The C1 error rate must be almost same as the value set at

step 7.

10. Press the YES button to display “ / c = ”.

11. Check that the C1 error rate is below 20 and ADER is 00. Then

press the YES button.

12. If the “( )” in “ - - ( )” is above 20, press the YES

button.

If below 20, press the MENU/NO button and repeat the

adjustment from step 2.

13. Press the EJECT A button and take out the disc.

Note 1:The relation between the C1 error and focus bias is as shown in the

following figure. Find points A and B in the follo wing figure using

the above adjustment. The focal point position C is automatically

calculated from points A and B.

Note 2:As the C1 error rate changes, perform the adjustment using the

average value.

5-14. ERROR RATE CHECK

5-14-1. CD Error Rate Check

Checking Procedure :

1. Load the check disc (MD) TDYS-1.

2. Turn the l AMS L knob and display “CPLAY 1

MODE” (C34).

3. Press the YES button and display “CPLAY 1 MID”.

4. The display changes to “C = AD = ”.

5. Check that the C1 error rate is below 20.

6. Press the MENU/NO button to stop playback, then press the

EJECT A button and take out the check disc.

5-14-2. MO Error Rate Check

Checking Procedure :

1. Load the continuously-recorded disc (MDW -74/GA-1). (Refer

to “5. Creating Continuously-Recorded Disc”)

2. Turn the l AMS L knob to display “CPLA Y 1 MODE”

(C34).

3. Press the YES button to display “CPLAY 1 MID”.

4. The display changes to “C1 = AD = ”.

5. If the C1 error rate is below 20, check that ADER is 00.

6. Press the MENU/NO button to stop playback, then press the

EJECT A button and take out the test disc.

5-15. FOCUS BIAS CHECK

Change the focus bias and check the focus tolerance amount.

Checking Procedure :

1. Load the continuously-recorded disc (MDW -74/GA-1). (Refer

to “5. Creating Continuously-Recorded Disc”)

2. Turn the l AMS L knob to display “CPLAY 1 MODE”

(C34).

3. Press the YES button twice to display “CPLAY 1 MID”.

4. Press the MENU/NO button when “C = AD = ” is

displayed.

5. Turn the l AMS L knob to display “FBIAS CHECK”

(C16).

6. Press the YES button to display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate the

focus bias value.

Check that the C1 error is below 20 and ADER is below 2.

7. Press the YES button and display “ / b = ”.

Check that the C1 error is about 100 and ADER is below 2.

8. Press the YES button and display “ / a = ”.

Check that the C1 error is about 100 and ADER is below 2

9. Press the MENU/NO button, then press the EJECT A button

and take out the disc.

Note: If the C1 error rate and ADER are above other than the specified

value at points a (step 8. in the above) or b (step 7. in the above),

the focus bias adjustment may not have been carried out properly.

Perform the adjustment from the beginning again.

5-16. AUTO GAIN CONTROL OUTPUT LEVEL

ADJUSTMENT

Be sure to perform this adjustment when the optical pick-up is

replaced.

If the adjustment results becomes “Adjust NG!”, the optical pickup may be faulty or the servo system circuits may be abnormal.

5-16-1. CD Auto Gain Control Output Level Adjustment

Adjusting Procedure :

1. Load the check disc (MD) TDYS-1.

2. Turn the l AMS L knob to display “AG Set (CD)”

(C11).

3. When the YES button is pressed, the adjustment will be

performed automatically.

“Complete!!” will then be displayed momentarily when the

value is recorded in the non-volatile memory, after which the

display changes to “AG Set (CD)”.

4. Press the EJECT A button and take out the check disc.

5-16-2. MO Auto Gain Control Output Le vel Adjustment

Adjusting Procedure :

1. Load the test disc (MDW-74/GA-1).

2. Turn the l AMS L knob to display “AG Set (MO)”

(C10).

3. When the YES button is pressed, the adjustment will be

performed automatically.

“Complete!!” will then be displayed momentarily when the

value is recorded in the non-volatile memory, after which the

display changes to “AG Set (MO)”.

4. Press the EJECT A button and take out the test disc.

30

Page 31

6-1. BLOCK DIAGRAM MAIN Section

SECTION 6

MDS-JB940

DIAGRAMS

HR901

OVER WRITE

HEAD

OPTICAL PICK-UP BLOCK

(KMS-260B/J1N)

DETECTOR

I J

HF

MODULE

LD

PD

FOCUS

TRACKING

16

LASER ON

DIODE

2-AXIS

DEVICE

F

CB

AD

E

COIL

COIL

OVER WRITE

HEAD DRIVE

Q181,182

K

VCC

VC

I

J

F

B

A

E

D

C

ILCC

PD

VR

FCS+

FCS

TRK+

TRK

MOD

OVER WRITE

HEAD DRIVE

A+3V

VC

AUTOMATIC

POWER

CONTROL

Q121,122

LASER ON

SWITCH

Q101

IC181

M901

SPINDLE

MOTOR

M902

SLED

MOTOR

HF MODULE

SWITCH

Q131-134

SPINDLE/SLED MOTOR DRIVE,

FOCUS/TRACKING COIL DRIVE

OUT 4F

6

M

OUT 4R

8

OUT 2F

27

M

OUT 2R

25

OUT 1F

21

OUT 1R

23

OUT 3F

12

OUT 3R

10

WRPWM

MOD

1

2

9

5

4

8

7

6

11

10

RF AMP

I

J

F

B

A

E

D

C

APC

PD

SPINDLE

TRACKING

WAVEFORM

SHAPPER

IC101

IC152

MOTOR

DRIVE

SLED

MOTOR

DRIVE

FOCUS

COIL

DRIVE

COIL

DRIVE

IC102

ADFG

FOCNT

SWDT

SCLK

XLAT

APCREF