Sony MDS-JA555ES User Manual

MDS-JA555ES

SERVICE MANUAL

Photo : GOLD

U.S. and foreign patents licensed from Dolby Laboratories

Licensing Corporation.

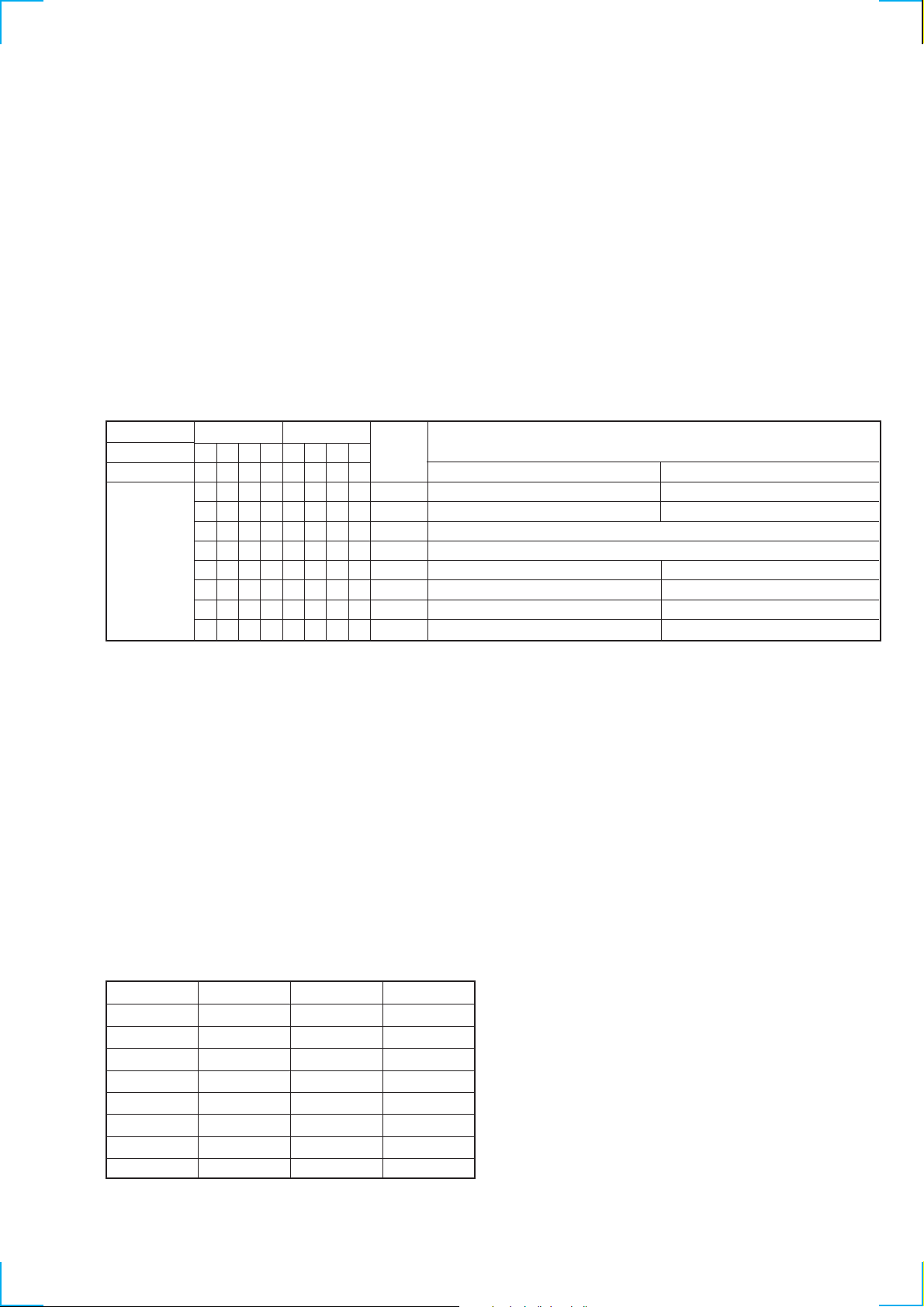

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

Model Name Using Similar Mechanism MDS-JA20ES

MD Mechanism Type MDM-6A

Base Unit Type MBU-5C

Optical Pick-up Type KMS-260B/J1N

System MiniDisc digital audio system

Disc MiniDisc

Laser Semiconductor laser (λ=780 nm)

Emission duration : continuous

Laser output Less than 44.6 µW*

* This output is the value measured at a distance

of 200 mm from the objective lens surface on the

Optical Pick-up Block with 7 mm aperture.

Laser diode properties

Material: GaAlAs

Revolutions (CLV) 400 rpm to 900 rpm

Error correction ACIRC (Advanced Cross Interleave

Reed Solomon Code)

Sampling frequency 44.1 kHz

Coding ATRAC (Adaptive TRansform Acoustic Coding)

Modulation system EFM (Eight-to-Fourteen Modulation)

Number of channels 2 stereo channels

Frequency response 5 Hz to 20,000 Hz ± 0.3 dB

Signal-to-noise ratio Over 105 dB during playback

Wow and flutter Below measurable limit

Inputs

Jack Input Rated Minimum

type impedance input input

LINE Phono

(ANALOG) jacks 47 kΩ 500 mVrms 125 mVrms

IN

DIGITAL Square Optical wave

IN optical length

OPT1 connector 660 nm

jack

DIGITAL Square Optical wave

IN optical length

OPT2 connector 660 nm

jack

DIGITAL Phono 0.5 Vp-p

IN jack 75 Ω ±20%

COAXIAL

— Continued on next page —

MICROFILM

MINIDISC DECK

SAFETY CHECK-OUT

Output

Jack Rated Load

type output impedance

PHONES Stereo phone 28 mW 32 Ω

jacks

LINE(ANALOG) Phono 2 Vrms Over

OUT jacks (at 50 kΩ) 10 kΩ

DIGITAL OUT Square –18 dBm Optical

OPTICAL optical Wave length

connector 660 nm

jack

DIGITAL OUT Phono 0.5 Vp-p 75 Ω

COAXIAL jack (at 75 Ω)

General

Power requirements

Where purchased Power requirements

Continnental Europe and UK 220V – 230V AC, 50/60 Hz

U.S.A. and Canada 120 V AC, 60 Hz

Power consumption 24 W

Dimensions (approx.)(w/h/d) incl. projecting parts and controls

430 × 125.5 × 375.5 mm

(17 × 5 × 13 3/4 in.)

Mass (approx.) 15.3 kg (33 lbs 11 oz)

Supplied accessories

• Audio connecting cords (2)

• Remote commander (remote) RM-D34M (1)

• R6 (size-AA) batteries (2)

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

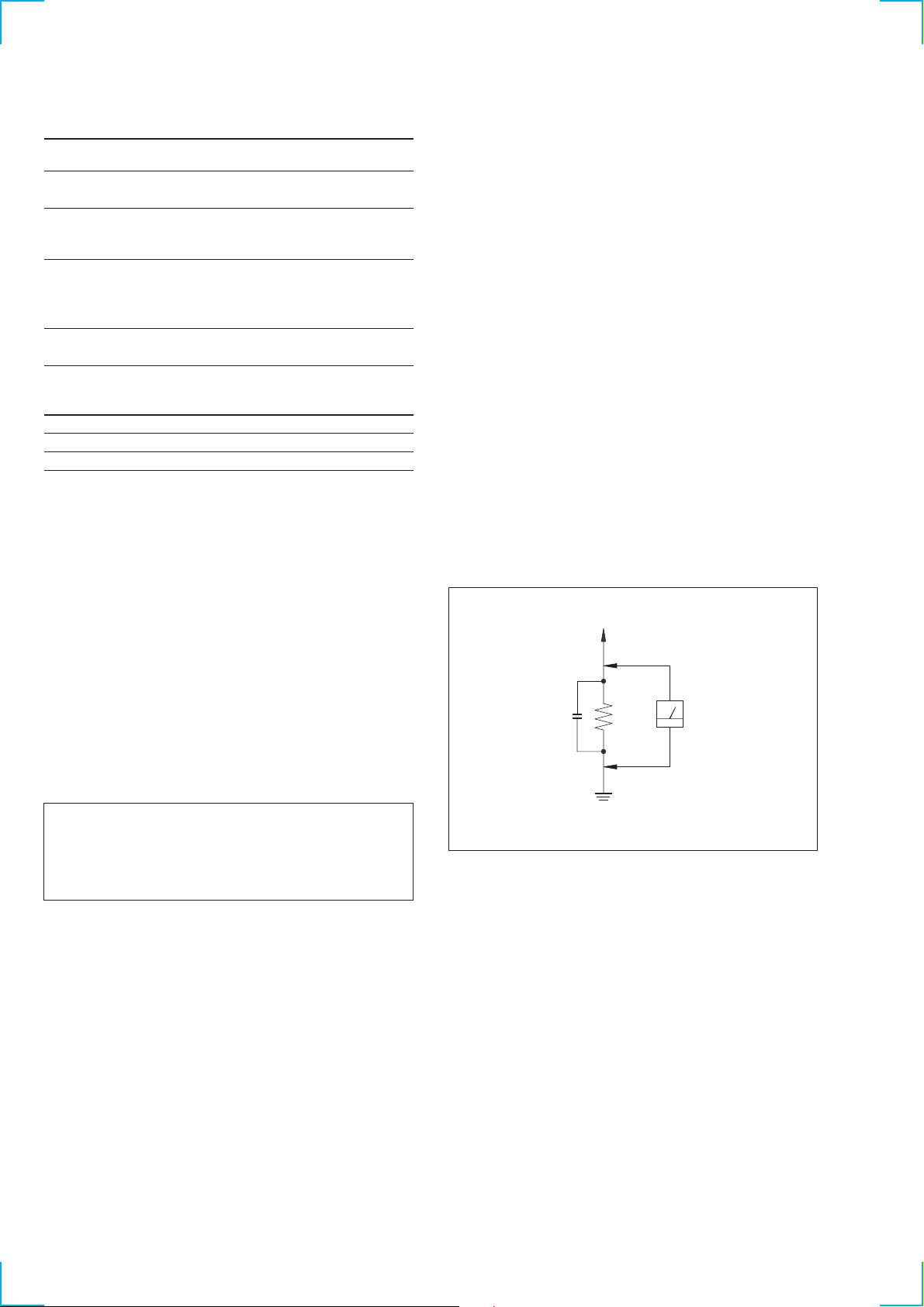

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-volta ge

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

T o Exposed Metal

Parts on Set

Design and specifications are subject to change without notice.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the equipment manufacturer.

Discard used batteries according to manufacture’s instructions.

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilakting skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av

apparatfabrikanten.

Brukte batterier katterier kasseres i henhold til fabrikantens

VARNIG

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som rekommenderas

av apparattillverkaren.

Kassera använt batteri enligt gällande föreakrifter.

VAROITUS

Parist voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laite valmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

AC

µ

F

0.15

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

1.5 k

Ω

Earth Ground

À LA SÉCURITÉ!

Voltmeter

(0.75 V)

2

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

The following caution label is located inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

4-220-300-1 : AEP, UK model

4-220-300-2 : US model

4-220-300-3 : Canadian model

TABLE OF CONTENTS

1. SERVICING NOTE·························································· 6

2. GENERAL ········································································ 12

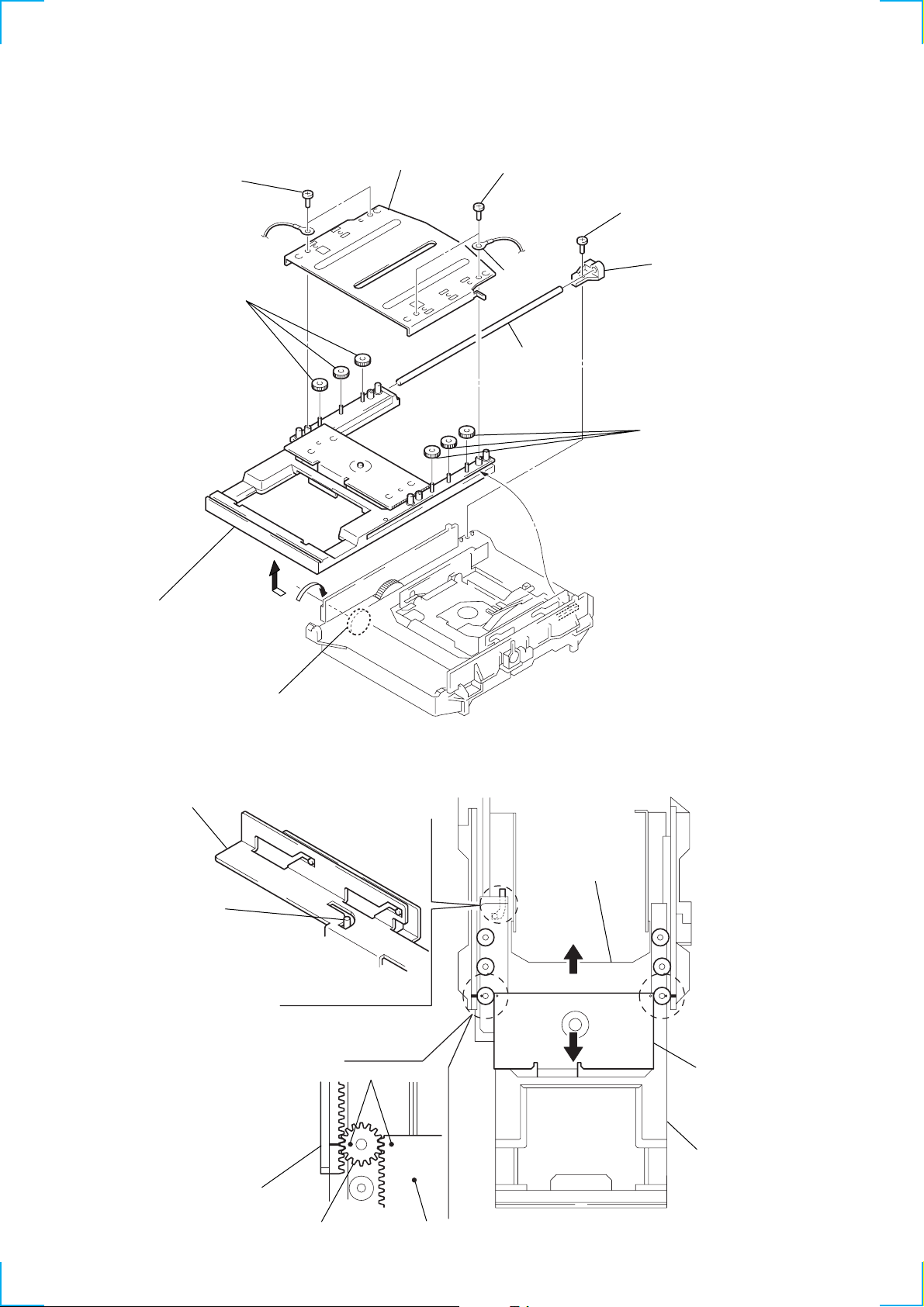

3. DISASSEMBLY

3-1. Case ·················································································· 14

3-2. Loading Panel ··································································· 14

3-3. Front Panel Assembly······················································· 15

3-4. MD Mechanism Deck ······················································ 15

3-5. T ray Assembly·································································· 16

3-6. BU Holder Assembly························································ 17

3-7. Motor (Loading) Assembly (M10) ··································· 17

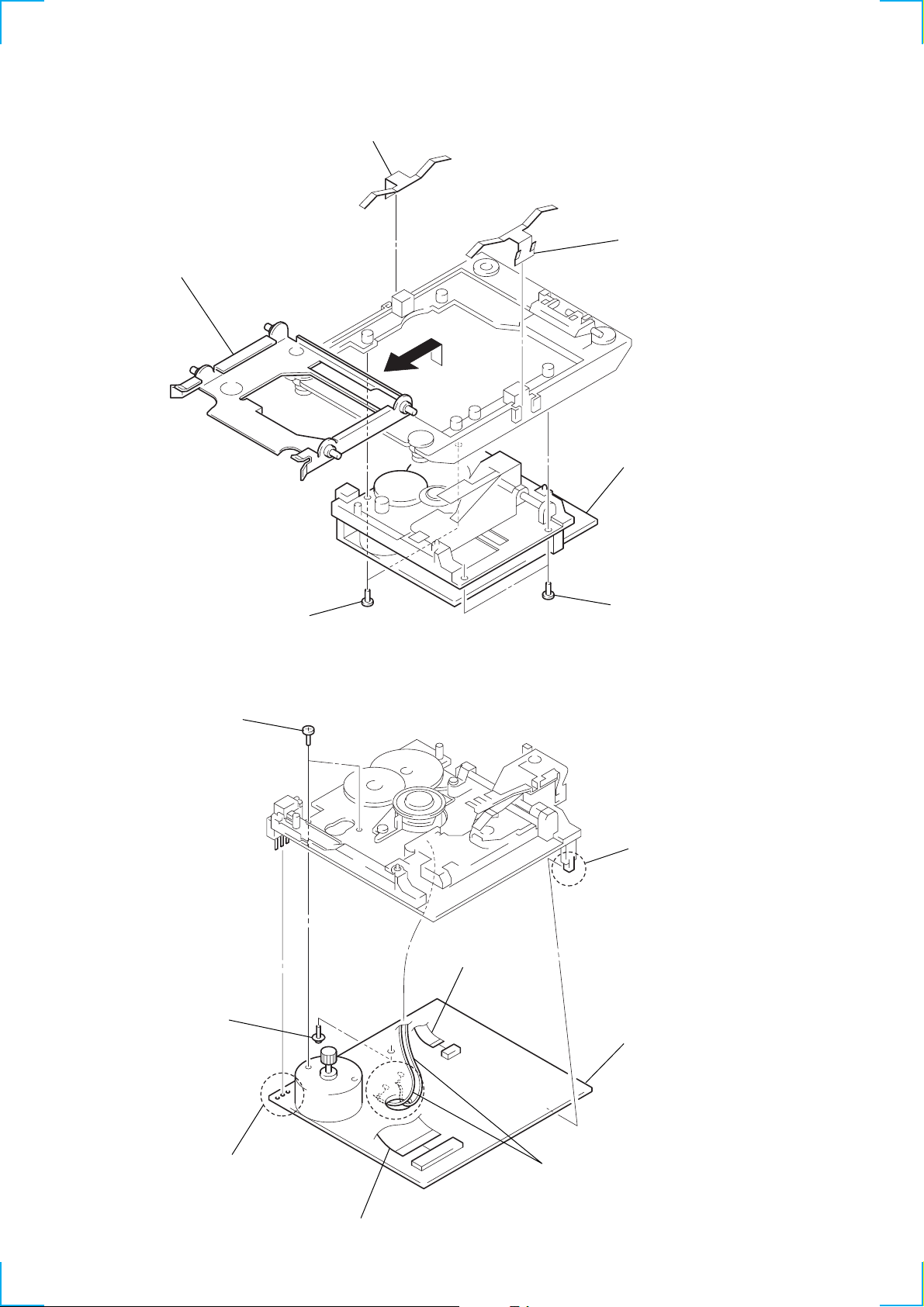

3-8. Base Unit (MBU-5C) ······················································· 18

3-9. BD Board·········································································· 18

3-10. Over Light Head (HP901) ················································ 19

3-11. Mini Disc Device (KMS-260B/JN) ·································· 19

4. TEST MODE ···································································· 20

5. ELECTRICAL ADJUSTMENTS ······························· 25

6. DIAGRAMS

6-1. Block Diagrams

BD Section ······································································· 34

MAIN Section ·································································· 35

Display/Power Supply Section ········································· 36

6-2. Circuit Boards Location ··················································· 37

6-3. Printed Wiring Board BD Section ································· 38

6-4. Schematic Diagram BD (2/1) Section··························· 39

6-5. Schematic Diagram BD (2/1) Section··························· 40

6-6. Schematic Diagram BD Switch Section························ 41

6-7. Printed Wiring Board BD Switch Section····················· 41

6-8. Printed Wiring Board AD Section ································· 42

6-9. Schematic Diagram AD (2/1) Section ··························· 43

6-10. Schematic Diagram AD (2/1) Section ··························· 44

6-11. Schematic Diagram DA (2/1) Section ··························· 45

6-12. Printed Wiring Board DA Section································· 48

6-13. Schematic Diagram DA (2/1) Section ··························· 47

6-14. Printed Wiring Board Digital Section ··························· 48

6-15. Schematic Diagram Digital Section ····························· 50

6-16. Printed Wiring Board AC Section ································· 51

6-17. Schematic Diagram Power Section ······························ 52

6-18. Printed Wiring Board Power Section ···························· 53

6-19. Printed Wiring Board Panel Section······························ 54

6-20. Schematic Diagram Panel Section ································ 55

6-21. IC Block Diagrams ··························································· 57

6-22. IC Pin Functions ······························································· 62

7. EXPLODED VIEWS

7-1. Upper Case Assembly ······················································ 71

7-2. Front Panel Assembly······················································· 72

7-3. Chassis Assembly····························································· 73

7-4. Mechanism Deck Assembly-1 (MDM-6A) ······················ 74

7-5. Mechanism Deck Assembly-2 (MDM-6A) ······················ 75

7-6. Base Unit (MBU-5C) ······················································· 76

8. ELECTRICAL PARTS LIST ······································· 77

3

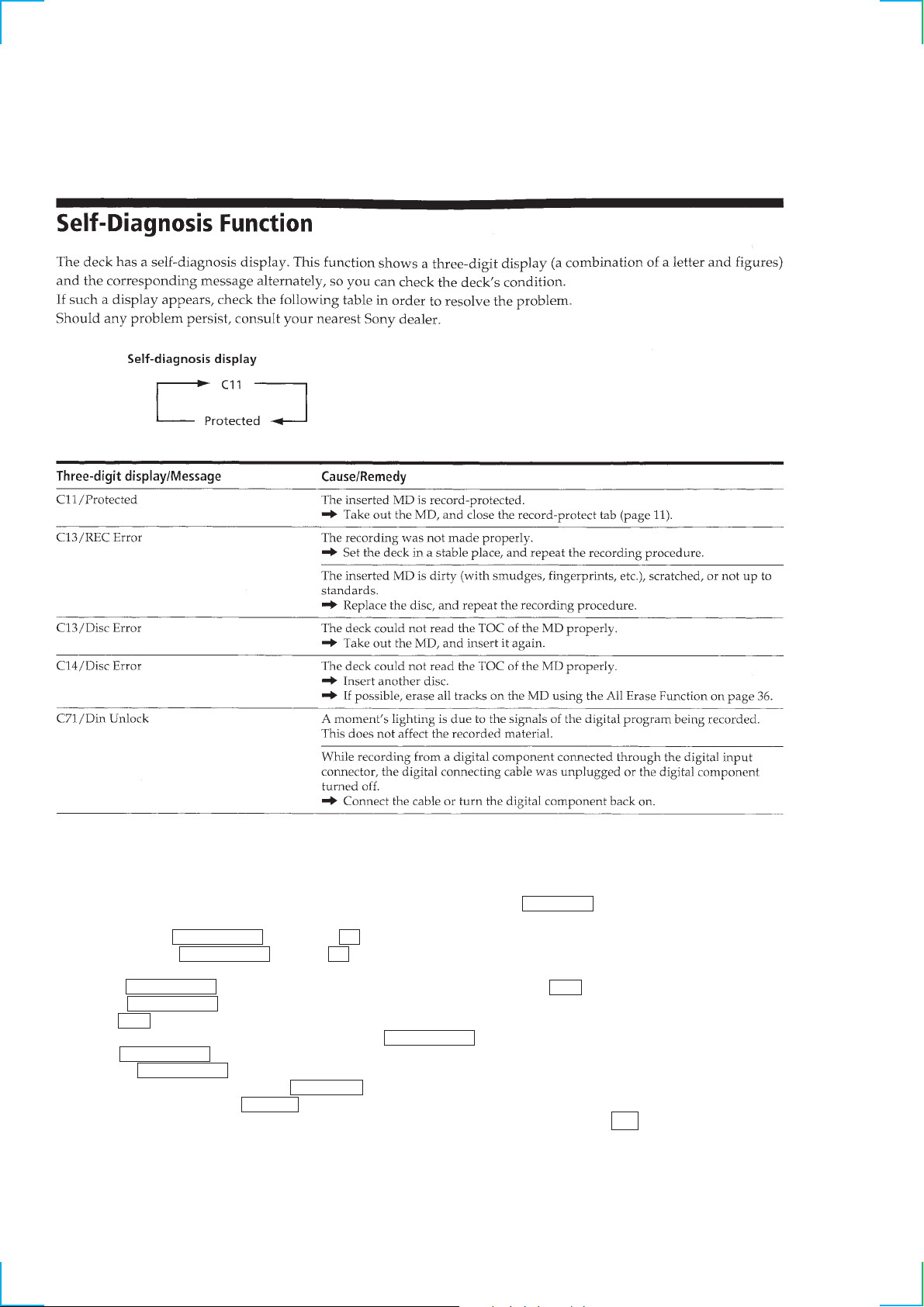

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of the error codes for users and those for service engineers. The error codes for users appear automatically when an error occurs. The error codes for service engineers can be accessed by entering the test mode during servicing and by viewing

the error history display. The error codes for users are shown belo w that are extracted from Operation Manual. For the error codes for service

engineers, refer to the subsequent paragraph “How to Operate the Self-diagnosis Function (Error History Display Mode)”.

How to Operate Self-diagnosis Function (Error History Display Mode)

Note: The self-diagnosis function is performed using the “error history display mode” using the test mode. The following procedure

describes only the minimum required operating procedure to enter the error history mode. Therefore be careful not to enter any other

modes by mistake. If you have entered any other modes by mistake, press the MENU/NO button and exit the mode.

1. While pressing the lAMSL knob and the x button at the same time, connect the A C po wer plug to the wall outlet, then remo ve

your hands from the lAMSL knob and x button at the same time. When the MDS-JA555ES enters the test mode, the message

“[Check]” appears and the STANDBY, PITCH CONTROL, and FILTER LEDs turn on.

2. Rotate the lAMSL knob until the message “Service” appears. Then press the YES button.

3. Rotate the lAMSL knob until the message “ERR DP MODE” appears.

4. Press the YES button to enter the error history mode and the message “total rec” appears.

5. Select the desired item to display or to execute using the lAMSL knob.

6. Press the lAMSL knob to display or execute the selected item.

7. Pressing the lAMSL knob again returns to the display of step 4.

8. To exit the error history mode, press the MENU/NO button. The message “ERR DP MODE” appears to exit the error history mode.

9. To exit the test mode, press the REPEAT button. The test mode display disappears and the PITCH CONTROL and FILTER LEDs are

turned off. The MDS-JA555ES enters the standby state exiting the test mode. While pressing the ?/1 button, turn on the main power .

The message “Initialize” flashes and the MDS-JA555ES is initialized.

4

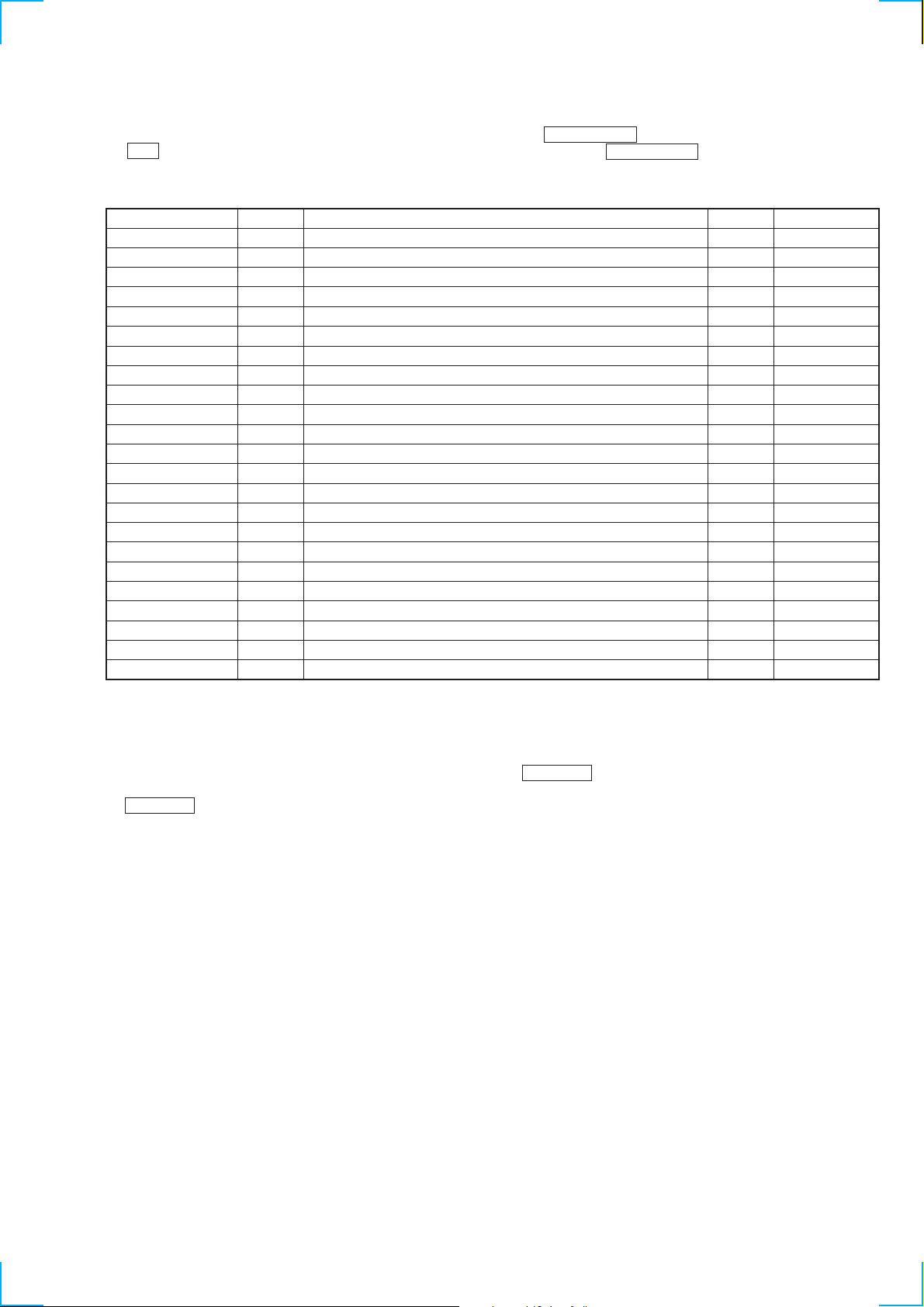

[Displaying Contents of the Error History]

Display on screen

total rec

total play

retry err

total err

err history

er refresh

tm refresh

Contents of error history

Displays the recording time.

The display appears in “r h”. This is the accumulated time when the laser is in the “high power”

operation. This is about 1/4 of the actual recording time. The time is shown in the range of 0h to 65535h in

hexadecimal number.

Displays the playback time.

The display appears in “p h”. This is the accumulated time of actual playback in which pause time is

not counted. The time is shown in the range of 0h to 65535h in hexadecimal number.

Displays the accumulated count of record retry errors and playback retry errors.

The display appears in “r p ”. “r” indicates the record retry error count, and “p” indicates the playback

retry error count. The retry count is shown in the range of 00 to FF in hexadecimal number.

Displays the total error count.

The message “total ” appears. The count is shown in the range of 00 to FF in hexadecimal number.

Displays the error contents from the latest error to the last ten errors.

“0 E@@” appears. The history number is shown in . The smaller number means the newer history. (00 is

the newest error.) The error code is indicated by @@. Refer to the following table for the contents of the error

codes. The error histories can be switched by rotating the lAMSL knob.

This mode is used to delete the histories of “retry err”, “total err”, and “err history”.

Before returning the repaired product to the customer, perform this operation to delete the past error history. To

delete the history, press the lAMSL knob and press the YES button after “er refresh?” appears.

“Complete!” appears for a moment and returns to the ERR DP MODE.

When this mode is executed, be sure to check the following.

• The data have been deleted.

• Perform recording and playback. Check that the mechanism operates normally.

This mode is used to delete the histories of “total rec” and “total play”. These histories are used as reference

when replacing the optical pick-up.

When the optical pick-up is replaced, perform this operation to delete the histories. Press the lAMSL

knob. After “tm refresh?” appears, press the YES button to delete the histories. “Complete!” appears for a

moment and returns to the ERR DP MODE.

When this mode is executed, be sure to check the following.

• The data have been deleted.

• Perform recording and playback and check that the mechanism operates normally.

Error code table

Error code Error contents

E00 No errors

E01 Disc error Cannot read PTOC

(Disc is ejected)

E02 Disc error UTOC error

(Disc is not ejected)

E03 Loading error

E04 Cannot read the address (Out of servo)

Error code Error contents

E05 Out of FOK

E06 Focus does not lock (Out of servo)

E07 Record retry

E08 Record retry error

E09 Playback retry error

(Access error)

E0A Playback retry error (C2 error)

5

SECTION 1

SERVICING NOTE

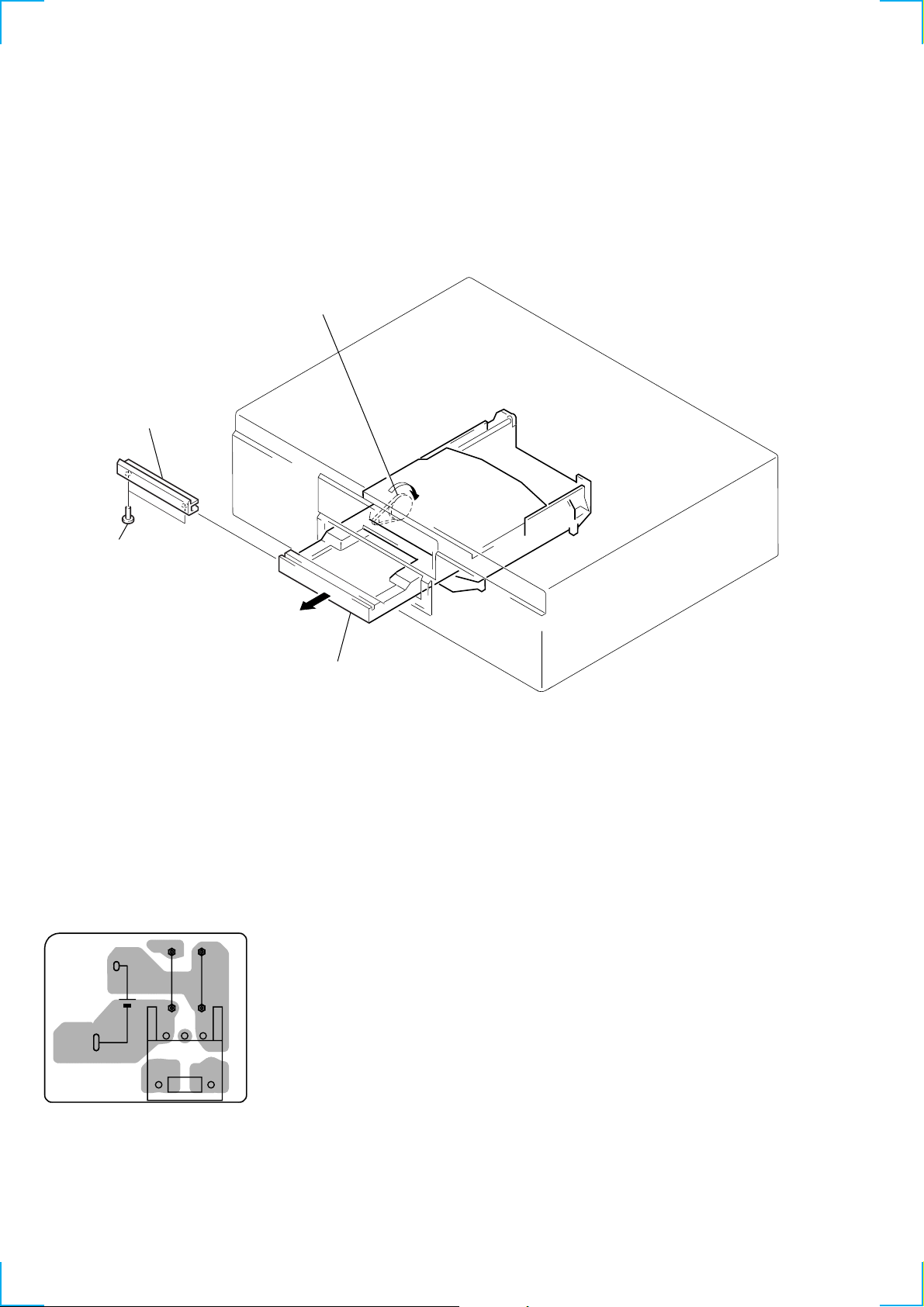

HOW TO OPEN THE DISC TRAY WHEN POWER SWITCH IS TURNED OFF, AND LASER POWER CHECK

1 Remove the 16 screws (BVTT3 x 8) from the bottom plate. (Refer to Section 3 “Disassembly” Loading panel.) (page 14)

2 Remove the bottom plate.

3 Rotate the pully gear in the direction of the arrow A and open the tray in the direction of the arrow B.

4 When checking the laser power, remove beforehand the loading panel by remo ving the two screws (M2.6) and sliding aside the loa ding

panel becouse the cable of the laser power meter can be pinched by the loading panel. (Refer to Section 3 “Disassembly” Loading

panel.) (page 14)

Pulley gear

Remove the Loading panel

A

Two screws

(M2.6)

B

Tray assembly

Forced Reset

Use this function when the MDS-JA555ES cannot be operated normally due to hung-up of the microprocessor.

It is recommended to use this function when you cannot exit the test mode or the retry-cause-display mode, or when the normal operation

cannot be performed after the MDS-JA555ES is disassembled once then re-assembled.

Procedure : Remove the AC power plug from the wall outlet. Short-circuit pin-1 and pin-3 of CN703 on the BT board with a pair of

tweezers or the like, to discharge the back-up battery.

[BT board] (Conductor side)

JW791

JW790

13

BT701

CN703

6

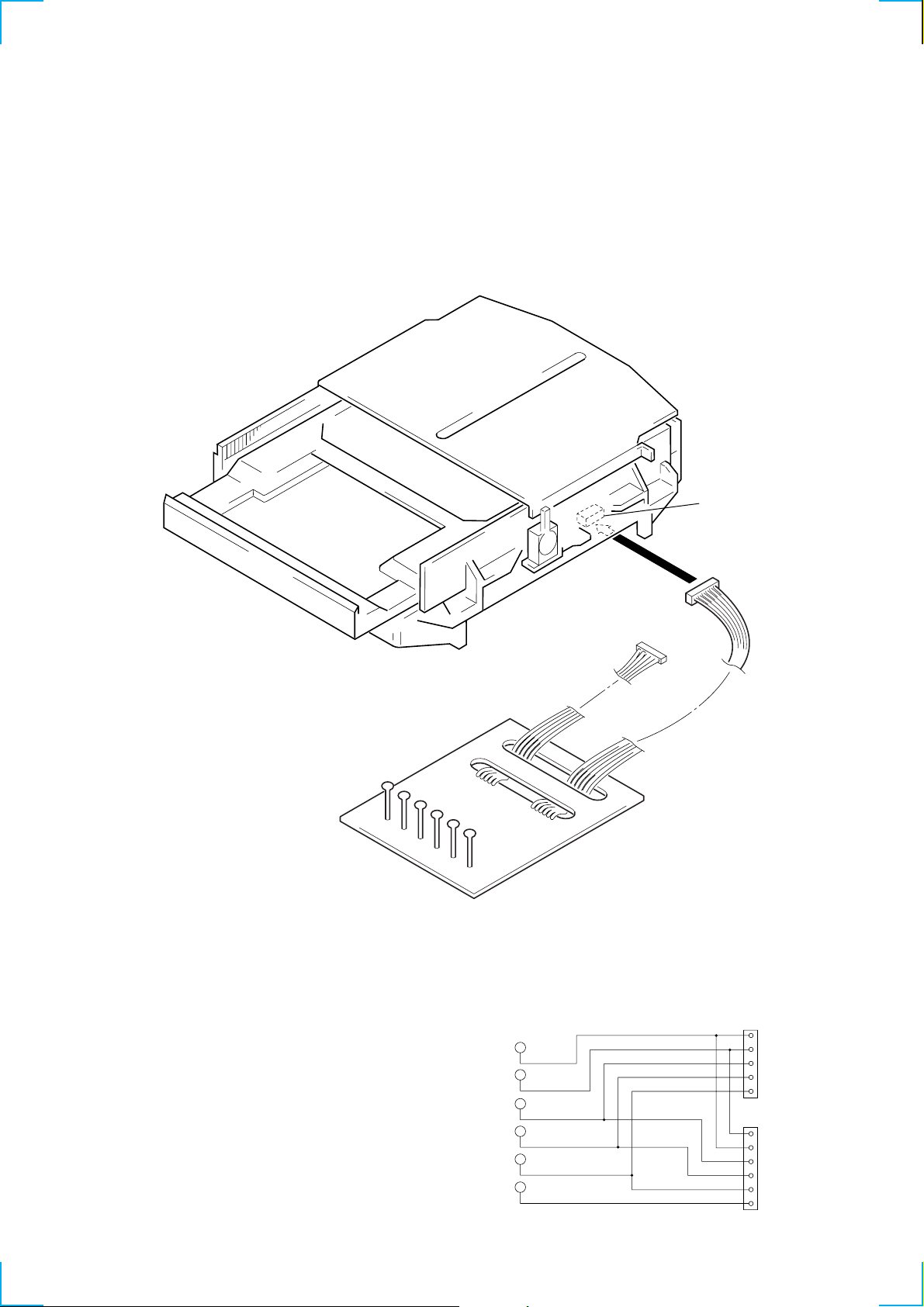

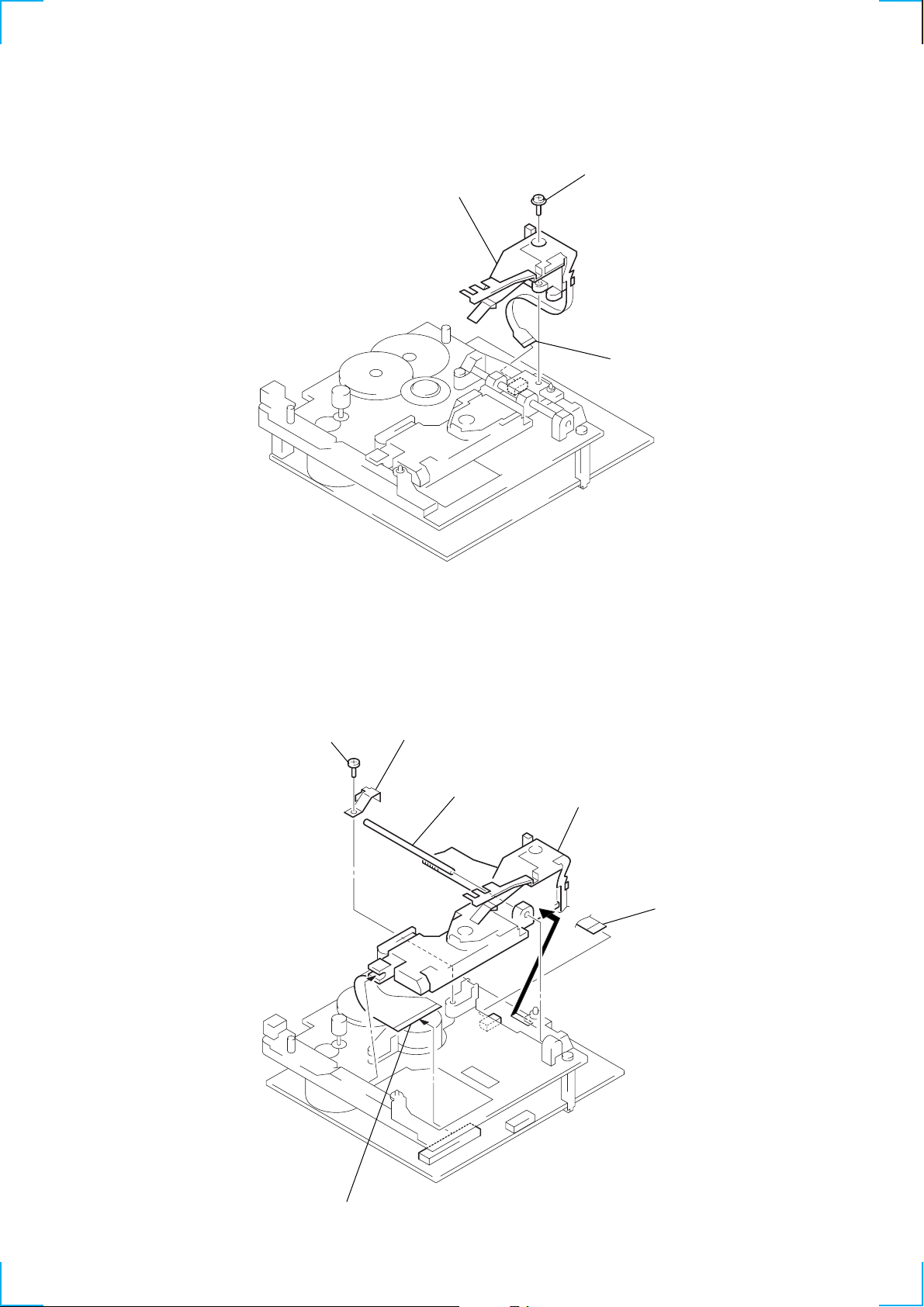

[BD Board Waveform Check Tool]

r

5

6

3

Use of the exclusive tool (J-2501-149-A) is convenient to check the waveforms on the BD board.

GND : Ground terminal

I+3V : For measuring IOP (Checking deterioration of the optical pickup laser)

IOP : For measuring IOP (Checking deterioration of the optical pickup laser)

TEO : TRK error signal (traverse adjustment)

VC : Reference level for when checking signals

RF : RF signal (jitter check)

CN110

6pin connecto

RF

VC

TEO

IOP

I+3V

GND

RF

VC

TEO

5pin connector

Schematic diagram of the connecting tools

1

RF

VC

TEO To MDMIOP

I-3V

5

IOP

I+3V

GND

1

VC

RF

To MDM-

TEO

To MDM-

IOP

I+3V

6

GND

7

[How to Record and Display the IOP Data When Replacing the Optical Pick-up and Non-volatile Memory

(BD Board IC171)]

The IOP data that is indicated on the optical pick-up, can be saved in the non-volatile memory of the MDS-JA555ES. Saving the IOP data in

the memory eliminates the needs to look at the printed value on the label that is attached on the surface of optical pick-up, and enables to vie w

the IOP data on display. When the optical pick-up is replaced or when the non-volatile memory (IC171 on BD board) is replaced, save the

IOP value that is printed on the label on the surface of optical pick-up by the following procedure.

How to Record the IOP Data:

1. While pressing the lAMSL knob and the x button at the same time, connect the A C po wer plug to the wall outlet, then remo ve

your hands from the lAMSL knob and x button at the same time. When the MDS-JA555ES enters the test mode, the message

“[Check]” appears.

2. Rotate the lAMSL knob until the message “Service” appears. Then press the YES button.

3. Rotate the lAMSL knob until the message “lop Write” (C28) appears. Then press the YES button.

4. “Ref=@@@.@” (@ is arbitrary number) appears and the values that can be changed as desired flash.

5. Input the IOP value that is printed on the optical pick-up.

Selection of alphanumeric characters : Rotate the lAMSL knob.

Selection of digit : Press the lAMSL knob.

6. Press the YES button. Then display changes to “Measu= @@@.@” (@ is arbitrary number).

7. The v alue tha t is shown step 6, is the result adjustment and should not be saved. So leave the value of step 6 as it is, and press the YES

button.

8. The message “Complete!” appears for a moment, and the value is saved in the non-volatile memory. The message “Iop Write” appears.

9. Upon completion of data saving, press the REPEAT button.

How to Display the IOP Data:

1. While pressing the lAMSL knob and the x button at the same time, connect the A C po wer plug to the wall outlet, then remo ve

your hands from the lAMSL knob and x button at the same time. When the MDS-JA555ES enters the test mode, the message

“[Check]” appears.

2. Rotate the lAMSL knob until the message “Service” appears. Then press the YES button.

3. Rotate the lAMSL knob until the message “lop Write” (C28) appears. Then press the YES button.

4. The message “@@.@/##.#” appears. The contents that are saved in the non-volatile memory appear.

@@.@ : The IOP value that is printed on optical pick-up

##.# : The IOP value after adjustment

5. To exit the data display, press the lAMSL knob or the MENU/NO button to show the message “Iop Read”. Then press the

REPEAT button.

8

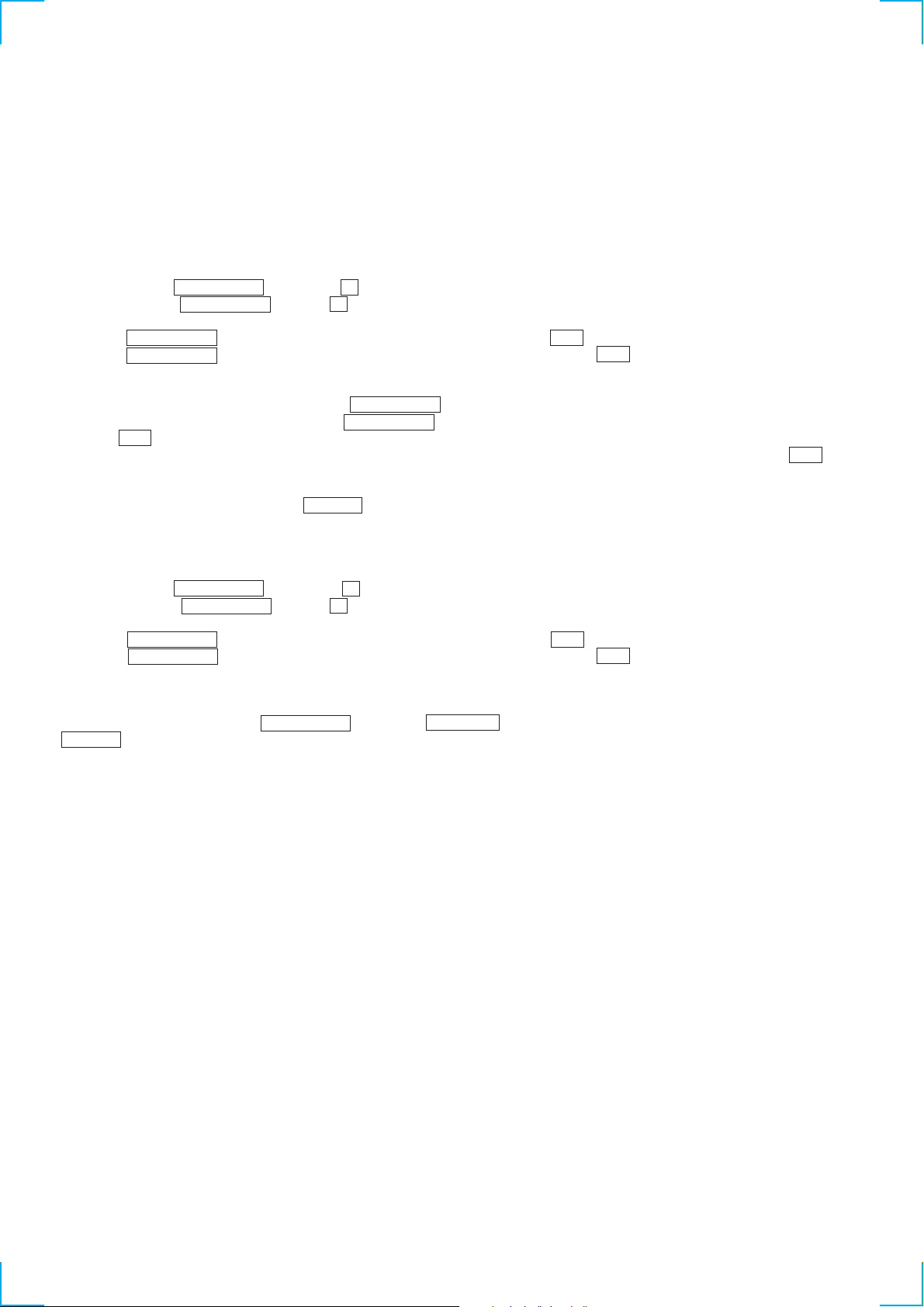

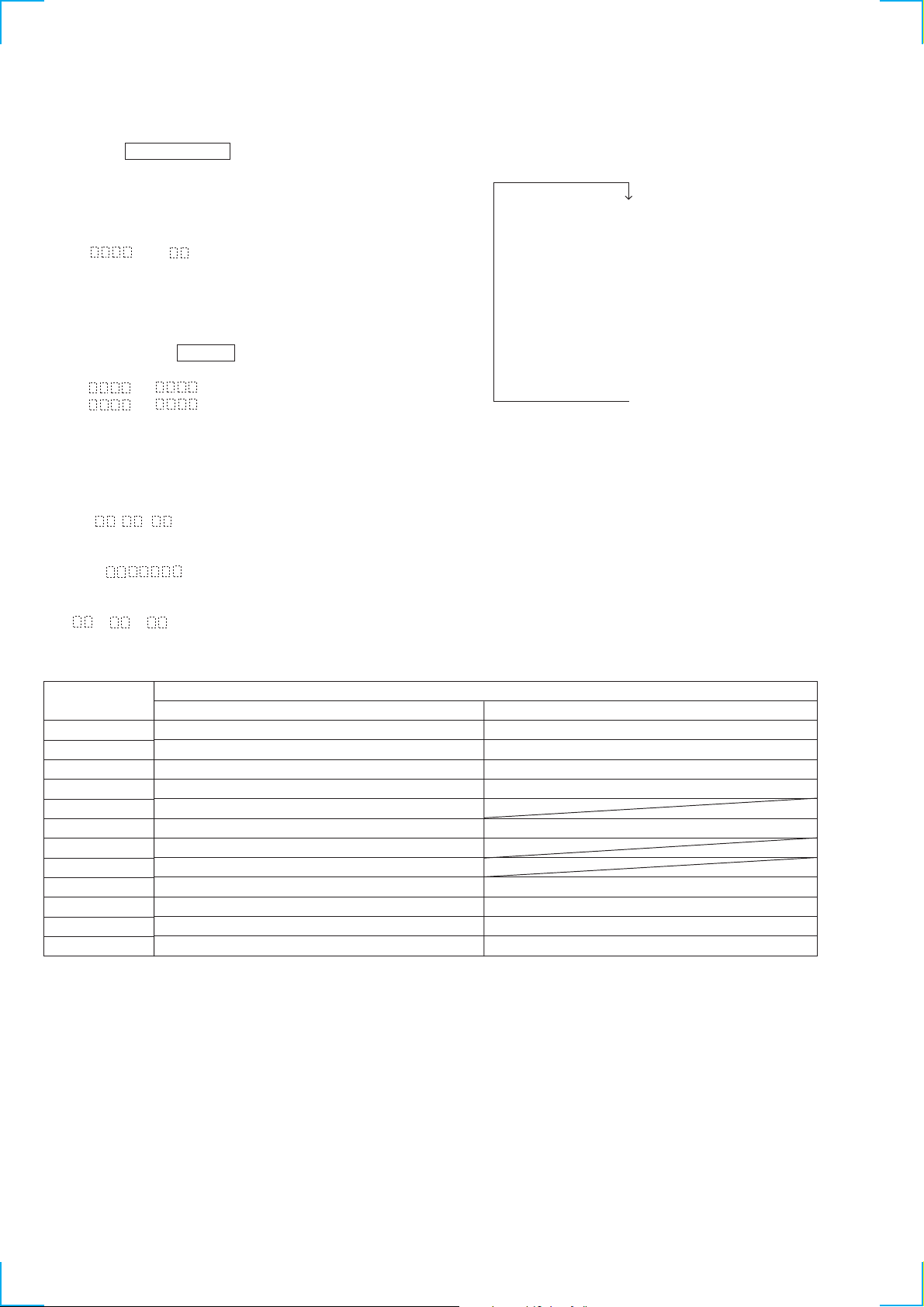

[Checks before Part Replacement and Adjustment]

Cause of faulty can be approximately located by performing the following checks before starting the repair work. Refer to Section “5.

Electrical Adjustment” the check procedure.

Laser power check

(Refer to section 5-6-2, page 27.)

Traverse check

(Refer to section 5-6-3, page 28.)

Focus bias check

(Refer to section 5-6-4, page 29.)

C PLAY check

(Refer to section 5-6-5, page 29.)

Self-recording/playback check

(REC/PLAY)

(Refer to section 5-6-6, page 29.)

Temperature compensation

offset check

(Refer to section 5-6-1, page 27.)

Judgment criterion(NG when the measurement

value is out of the specification value)

• 0.9 mW power

Specification value: 0.84 to 0.92 mW

• 7.0 mW power

Specification value: 6.8 to 7.2 mW

• Iop (when 7 mW)

The Iop value that is shown on the optical

pick-up: +/- 10 mA

• Traverse waveform

Specification value: Offset 10% or less

• Checking the error rate

Specification value: All points of a, b, and c

CI error 220 or less

AD error 2 or less

• Checking the error rate

Specification value:

a. When using the test disc (MDW-74/AU-1)

CI error 80 or less

AD error 2 or less

b. When using the check disc (TDYS-1)

CI error 50 or less

• Checking the error rate in C PLAY

Specification value:

CI error 80 or less

AD error 2 or less

• NG when “T=@@(##)(NG” appears

(@@ and ## are arbitrary numbers.)

Remedial measure in case of NG

• Cleaning the optical pick-up

• Readjustment

• Replacing the optical pick-up

• Replacing the optical pick-up

• Replacing the optical pick-up

• Replacing the optical pick-up

• Replacing the optical pick-up

In case of NG all the time:

• Replacing the overwrite head

• Check disconnection of the circuits around

the overwrite head

In case of intermittent NG:

• Check deformation of overwrite head

• Check mechanism around the sled

• Check disconnection of the circuits around

the D101 (BD board)

• Check signals around the IC101, IC121,

CN102 and CN103 (BD board)

Note: The judgment criterion is shown for the purpose of judging if the performance is acceptable or not. This is not the specification v alue for adjustment.

Use the specification value for adjustment when the MDS-JA555ES is going to be adjusted.

9

[Retry Cause Display Mode]

• In this test mode, the retry causes of the MDS-JA555ES during record and stop modes can be displayed on the fluorescent display tube.

This mode becomes the “track mode” during playback in which the track information is available.

This mode is useful for locating the defective area of the MDS-JA555ES.

• The contents to be displayed are as follows.

During record and stop modes: Retry cause, number of retries, and number of retry errors

During playback mode: Information such as disc types under playing back, position of playback and copyright.

Each information is displayed in hexadecimal number.

Procedure:

1. Load a recordable disc whose contents can be erased, into the MDS-JA555ES.

2. Press the MENU/NO b utton. After the message “Edit Menu” appears on the fluorescent display tube, rotate the lAMSL knob

until the message “All Erase ?” appears.

3. Press the YES button. (Alternately the lAMSL knob can also be pressed.)

4. The message “All Erase ??” appears on the fluorescent display tube. Then the numerals on the music calendar flash.

5. Press the YES button, then the message “Complete !!” appears. Press the x button immediately , and wait for about 15 seconds w hile

keeping pressing the button. (Alternately the lAMSL knob can be pressed instead of YES button.)

6. When the characters “TOC” have disappeared from the fluorescent display tube, remove your hands from the x button.

7. Press the zREC button to enter the record standby mode. Then press the X button to start recording.

8. When you want to enter the “Track mode”, press the N button to start playback.

9. To exit the test mode, press the ?/1 button. The message “TOC” flashes, the MDS-J A555ES enters the standby mode and e xits the test

mode.

Fig. 1 Reading the Test Mode Display (During record and stop modes)

RTs@@c##e**

Display on the fluorescent display tube

@@ : Cause of retry

## : Number of retries

** : Number of retry errors

Fig. 2 Reading the Test Mode Display (During playback)

@@ ####** $$

Display on the fluorescent display tube

@@ : Parts No. (Area name that is given on the TOC)

## : Cluster address (physical address on the disc)

** : Sector

$$ : Track mode (track information such as copyright information of each part, etc.)

How to read the retry cause display:

Lower Bits

Hexadecimal

01

shock

02

ader5

04

Address is not continuous

08

DIN unlock

10

FCS unlock

20

IVR rec error

40

CLV unlock

80

Access fault

Name of retry cause When 1

Hexadecimal

Bit

Binary number

Higher Bits

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

When track jump (shock) is detected

When ADER is counted five times or more continuously

When ADIP address is not continuos

Detects DIN unlock is detected

When focus is unlocked

When signal level of the ABCD signal exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

10

Reading the Display:

Convert the hexadecimal display of each digit into binary display. If more than two causes, they will be added.

Example When 42 is displayed:

Higher bit: 4 = 0100 → b6

Lower bit: 2 = 0010 → b2

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

Example When A2 is displayed:

Higher bit: A = 1010 → b7+b5

Lower bit: 2 = 0010 → b1

In this case, the retry cause is combined of “ACCESS default”, “IVRrec” and “ader5”.

The reading of the track mode display is as follows.

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display of each digit into binary display. The several causes are added and displayed.

Example When 84 is displayed:

Higher bit: 8 = 1000 → b7

Lower bit: 4 = 0100 → b2

This example shows that “Emphasis: OFF”, “Monaural”, “Original”, “Copyright exists” and “Writing is allo wed” because b2 and b7 are 1

while all other bits are 0.

Example When 07 is displayed:

Higher bit: 0 = 0000 → all 0

Lower bit: 7 = 0111 → b0+b1+b2

This example shows that “Emphasis: ON”, “Stereo”, “Original”, “Copyright exists” and “Writing is prohibited” because b0, b1 and b2 are

1 while all other bits are 0.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexadecimal

01

02

04

08

10

20

40

80

When 0 When 1

Emphasis OFF

Monaural

2-bit display, normally 01

01: Normal audio, Other: Invalid

Audio (normal)

Original

Copyright exists

Writing is prohibited

Contents

Emphasis OFF

Stereo

Invalid

Digital copy

No copyright

Writing is allowed

Hexadecimal → Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

11

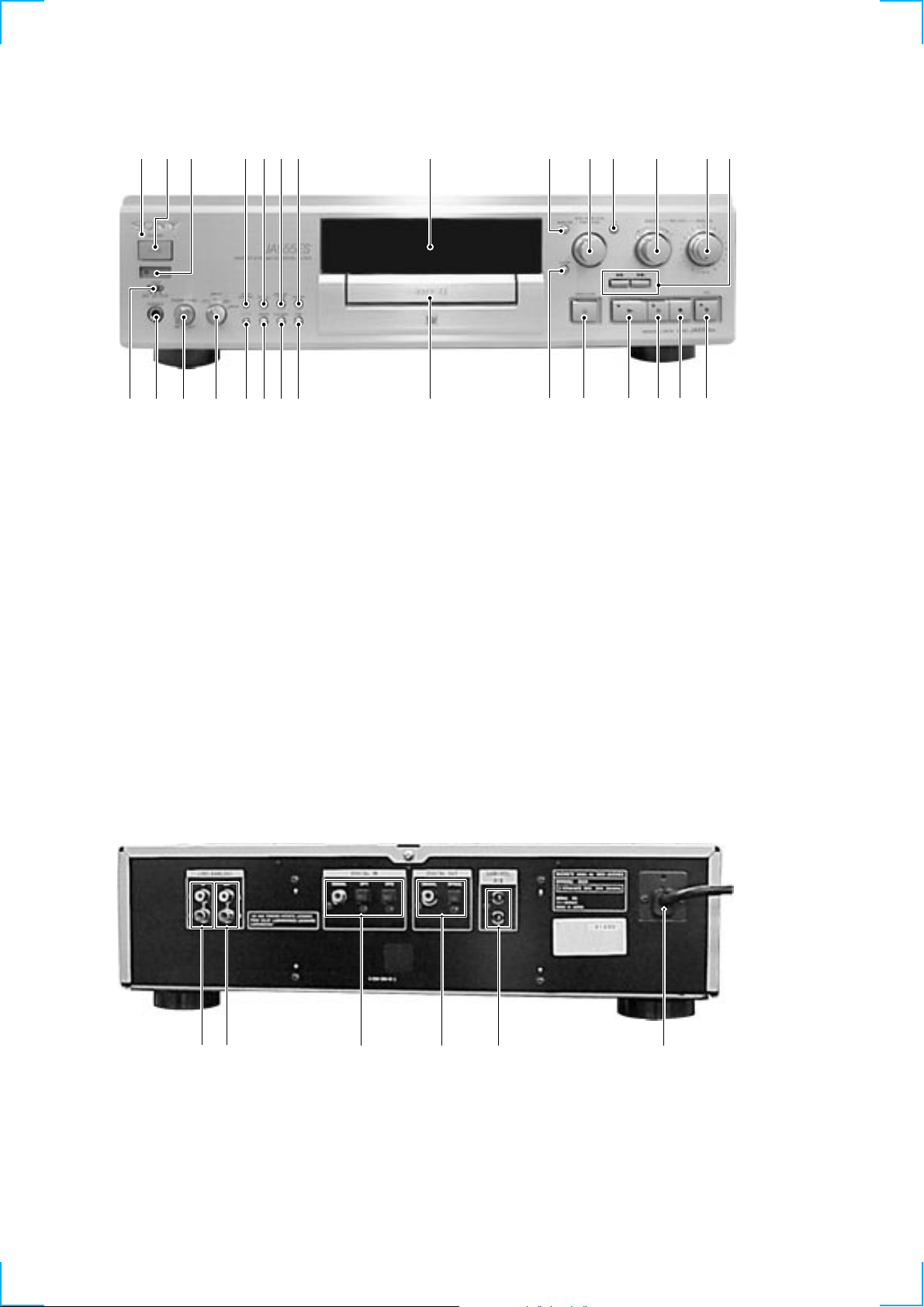

Front Panel

SECTION 2

GENERAL

1 2 3 4 5 6 7 8 9 0 qa qs qd qf

Rear Panel

1 SATNDBY indicator

2 1/u (POWER) button

3 Remote sensor

4 PITCH CONTROL button

5 SCROLL button

6 DISPLAY/CHAR button

7 REPEAT button

8 Display window

9 MENU/NO button

0 l AMS L knob

qa YES button

qs DIGITAL REC LEVEL knob

qd ANALOG REC LEVEL knob

qf 0 ) button

qg z REC button and indicator

wawswdwfwgwhwjwkwl

qh x (STOP) button

qj X (PAUSE) button and indicator

qk N (PLAY) button and indicator

ql A OPEN/CLOSE button

w; CLEAR button

wa Disc Tray

ws TIME button

wd PLAY MODE button

wf FADER button

wg FILTER button

wh INPUT button

wj PHONE LEVEL knob

wk PHONE jack

wl TIMER knob

qgqhqjqkqlw;

12

12 3 4 5 6

1 LINE (ANALOG) IN jack

2 LINE (ANALOG) OUT jack

3 DIGITAL IN (COAXIAL/OPT1/OPT2) jack

4 DIGITAL OUT

(COAXIAL/OPT1/OPT2) jack

5 CONTROL A1 II jack

6 Power Supply cord

This section is extracted

from instruction manual.

13

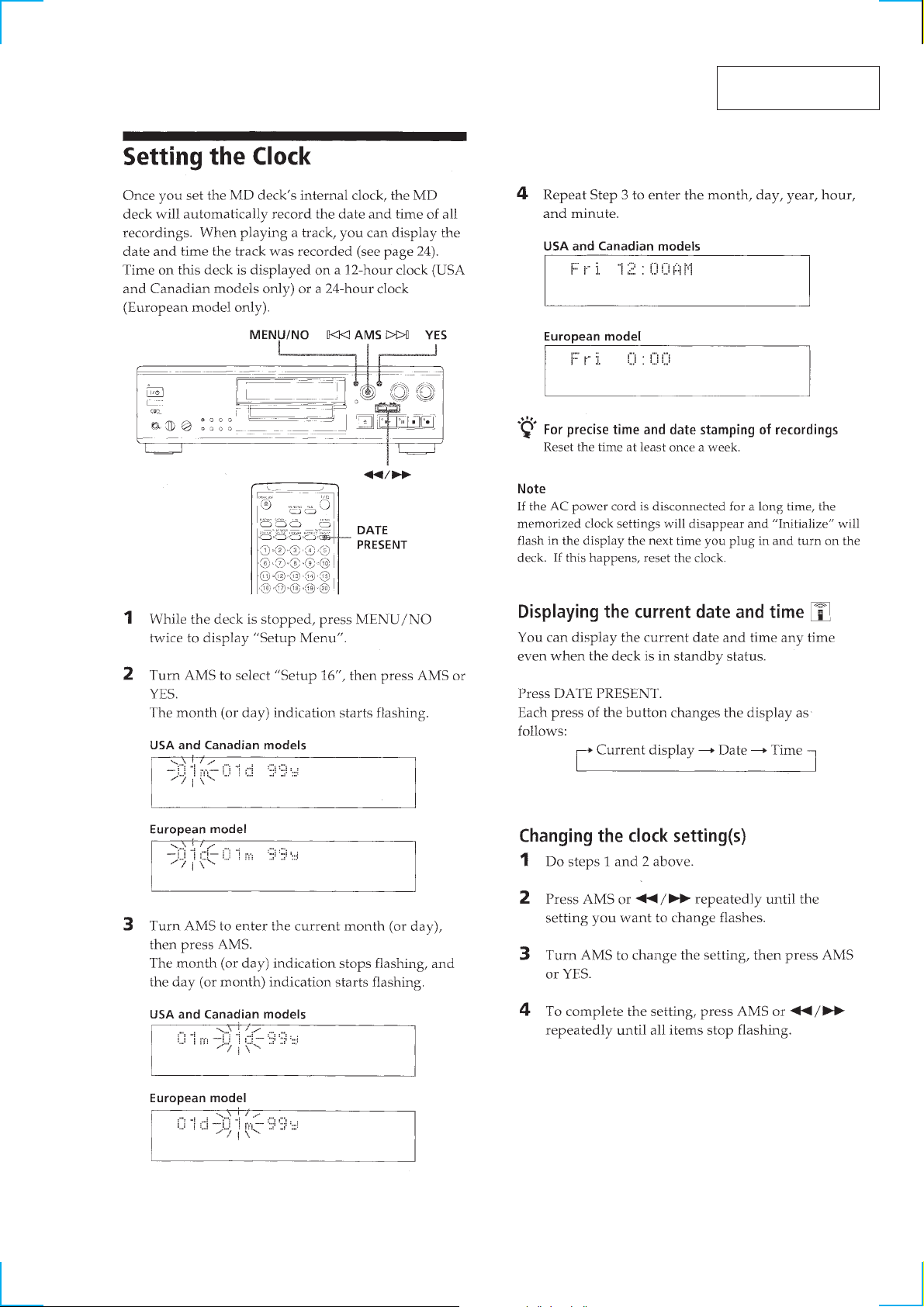

SECTION 3

)

n

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE

1

Two screws

(CASE 3 TP2)

A

3

Remove the upper case

in the direction of the arrow

1

Screw (CASE 3 TP2

A

.

3-2. LOADING PANEL

5

Loading panel

4

Two screws

(M2.6)

Tray assembly

B

2

Open the top cover

A

1

Two screws

(CASE 3 TP2)

3

in the direction of the arrow

and open the tray in the directio

of the arrow B.

2

Rotate the pulley gear

Bottom plate

A

,

14

1

Eight screws

(3

×

8)

1

Six screws

(3

×

8)

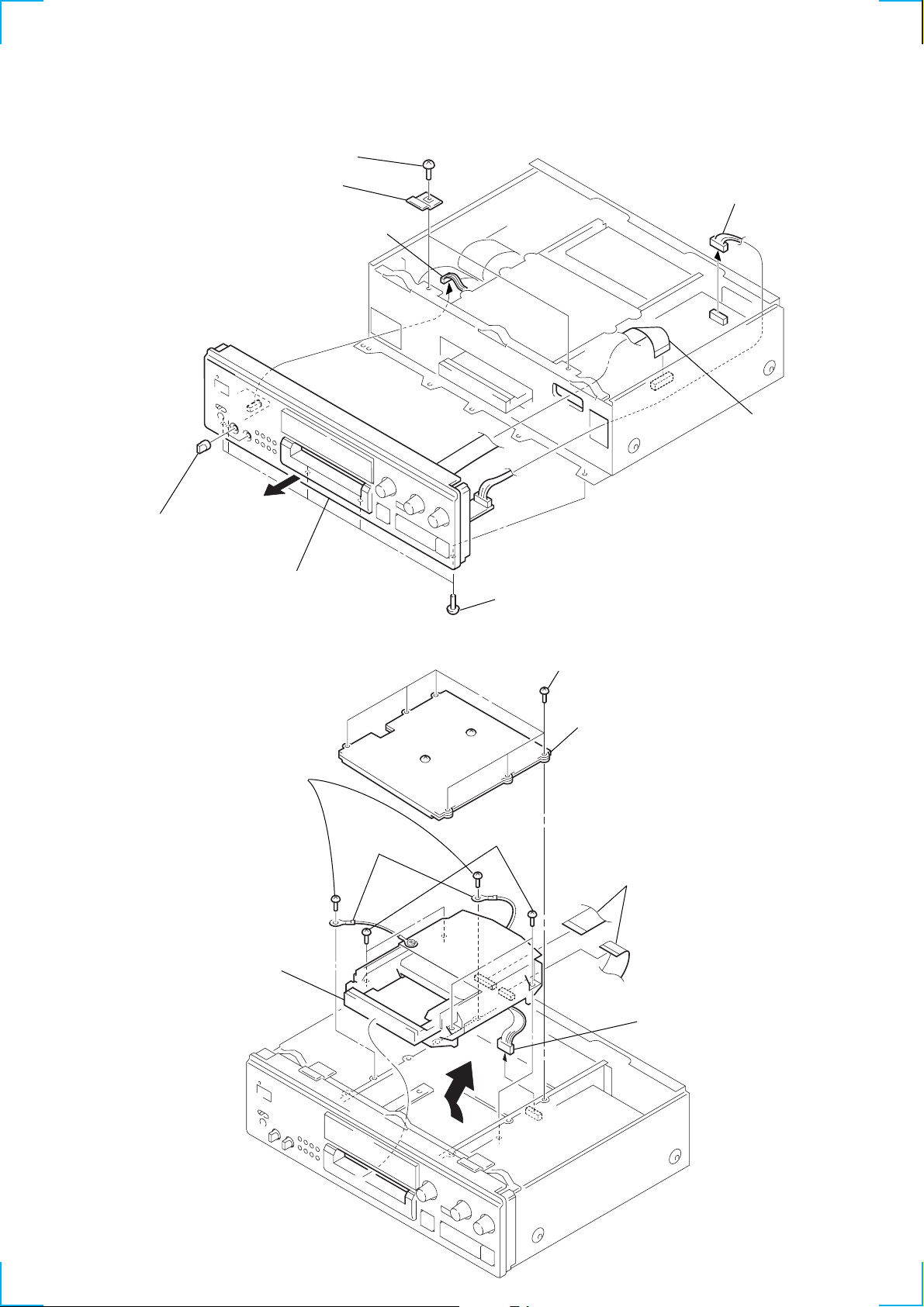

3-3. FRONT PANEL ASSEMBLY

e

6

Three screws

×

8 CU)

Bracket (F)

3

(CN651)

4

Two knobs (VOL)

(BV 3

7

Connector

2

Connector

(CN303)

1

Flat type wir

(CN800)

8

Front panel assembly

3-4. MD MECHANISM DECK

4

Two screws

(BVTT3 × 6)

8

Remove the MD

mechanism deck

in the direction of

the arrow A.

5

Two lug

terminals

5

Five screws

(3

6

Four screws

(BVTT 3 × 6)

×

8)

1

Six screws

(3 × 8)

2

Remove the cover (MDM-T) and

the fixing plate (MDM-T) together.

7

Two flat type wires

(CN102)

(CN102, 103)

(CN103)

3

Connector

(CN202)

A

15

3-5. TRAY ASSEMBLY

)

y

2

Two screws

(BV2.6)

5

Three gears

(top)

4

Bracket (top)

2

Two screws

(BV2.6)

3

8

Lug

Shaft

6

Screw

(BV2.6)

7

5

Three gears (top)

Stopper (shaft B

9

Remove the tray asssembly

in the direction of the arrow

1

Rotate the pully gear in the direction

of the arrow

NOTE FOR INSTALLATION

Slider assembly

Pin

When the tray assembly is attached,

move the slider assembly in the direction

of the arrow B so that the pin is located

in the position as shown above.

Then attach the tray assembly.

B

B

A

and pull the tray assembly.

A

.

Slider assembly

B

When the gears (top) (two gears on the front)

are attached, pull the tray assembly out in the

direction of the arrow

and slider (D) assembly as shown.

A

and align the rack (L)

Rack (L)

16

Gear (top)

Mark

Slider (D) assembly

A

Slider (D) assembl

Tray assembly

3-6. BU HOLDER ASSEMBLY

)

2

Two scews

(BV2.6)

3

Two collars

(damper)

4

Two compression

springs

2

Two scews

(BV2.6)

5

3

Two collars

(damper)

4

Two compression

springs

BU holder assembly

Fig. A

3-7. MOTOR (LOADING) ASSEMBLY (M10)

6

Motor (loading) assembly (M10)

1

Turn the pully gear to align

the slider with of the rib.

(Refer to Fig. A.)

3

Gear assembly

2

Two screws

(BV2.6)

Slider Rib

5

Two screws

×

3)

(B2

4

Belt (loading

1

Connector

(CN14)

17

3-8. BASE UNIT (MBU-5C)

)

3

Remove the holder assembly

in the direction of the arrow

A

1

Leaf spring (UDL)

2

Leaf spring (UDR

.

A

5

Base unit

3-9. BD BOARD

5

4

Two screws

(BV2.6)

Two precision screws

×

2.5)

(+P1.7

4

Tapping screw

(M1.7)

3

Flexible board

(CN104)

4

7

BD board

Two screws

(BV2.6)

6

Claw

18

2

Remove the soldering

from the push switch.

3

Flexible board

(CN101)

1

Remove the soldering of

the lead wires from

the spindle motor assembly.

3-10. OVER LIGHT HEAD (HR901)

d

3

Over light head

(HR901)

2

Screw

(P1.7

×

1

Flexible boar

(CN104)

6)

3-11. MINI DISC DEVICE (KMS-260B/J1N)

2

Screw +B

×

8)

(B2

3

Leaf spring (shaft)

4

Main shaft

5

Remove the mini disc device (KMS-260B/J1N)

in the direction of the arrow

1

Flexible board (CN104)

A

A

.

1

Flexible board (CN101)

19

SECTION 4

TEST MODE

4-1. Precaution on Using the Test Mode

• Be sure to insert and eject a disc after confirming that the disc in the MDS-JA555ES has come to complete stop because the loading

related movements of the mechanism are performed without any relationship with the test mode.

Disc does not stop rotating even through the A button is pressed while disc is rotating in the modes such as continuous playback and

continuous recording. Therefore, the disc is ejected while it is rotating.

Be sure to press the MENU/NO button, then press the A button after a disc has completely stopped of its rotation.

4-1-1. Modes in Which Recording Laser Emits the Light and the Button Operations

• Continuos recording mode (CREC MODE)

• Laser power check mode (LDPWR CHECK)

• Laser power adjustment mode (LDPWR ADJUST)

• Traverse (MO) check (EF MO CHECK)

• Traverse (MO) check (EF MO ADJUST)

• When the zREC button is pressed

4-2. How to Enter the Test Mode

There are two methods to enter the test mode as follows.

Method 1: Connect the power plug to the outlet while pressing the lAMSL knob and x button at the same time, and remove the

lAMSL knob and x button at the same time.

When the unit enters the test mode, “[Check]” appears. The four groups can be switched, ......↔ Check ↔Adjust ↔Service

↔Develop ↔..... , by rotating the lAMSL knob.

Method 2: Connect the power plug to the outlet while pressing the lAMSL knob, and remove the lAMSL knob.

When the unit enters the test mode, “TEMP CHECK” appears. When the test mode is entered using this method, the contents of

check group at method 1 can be performed.

4-3. Exiting the Test Mode

Press the REPEAT button. The display and LEDs of the pitch control and the filter are turned off. The MDS-JA555ES enters the standby

status and exits the test mode.

4-4. Basic Operation of the Test Mode

All operations are performed using the lAMSL knob, YES button, and MENU/NO button.

The functions of these button are as follows.

Function Contents

lAMSL knob Changes parameters and modes

YES button Proceeds onto the next step. Finalize input.

MENU/NO button Returns to previous step. Stops operations.

20

4-5. Selecting the Test Mode

There are 31 types of the test mode. The group can be switched by rotating the lAMSL knob. Select the group to be used and press

the YES button. After each group is entered, each mode can be switched by rotating the lAMSL .

For the selected contents, refer to the “Group” column in the list.

The group S can support all test modes for servicing. Be careful not to select other groups if not necessary.

Display

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

ScurveCHECK

VERIFYMODE

DETRK CHECK

TEMP ADJUS

LDPWR ADJUS

EF MO ADJUS

EF CD ADJUS

FBIAS ADJUS

EEP MODE

ERR DP MODE

ADJ CLEAR

AG Set (MO)

AG Set (CD)

Iop Read

Iop Write

JA555 @@@@@@

CPLAY MODE

CREC MODE

• For detailed description of each adjustment mode, refer to Section 5 “Electrical Adjustments”.

For “ERR DP MODE” (C17), refer to the self-diagnosis function of page 2.

• If a different adjustment mode has been selected by mistake, press the MENU/NO button to exit from it.

• The items marked (×) in the mark are not used in servicing, therefore they are not detailed. . If select these modes accidentally, press the

MENU/NO button immediately to exit from it. If the items marked (!) are selected especially, the unit could be operated wrongly by

rewriting the contents of non-volatile memory. Be careful of it.

No.

C01

C02

C03

C04

C05

C06

C07

C08

C09

C10

C11

C12

C13

C14

C17

C24

C25

C26

C27

C28

C29

C30

C31

Contents

Temperature compensation offset check

Laser power check

Trav erse (MO) check

Traverse (CD) check

Focus bias check

S curve check

Non-volatile memory check

Detrack check

Temperature compensation offset adjustment

Laser power adjustment

Trav erse (MO) adjustment

Traverse (CD) adjustment

Focus bias adjustment

Non-volatile memory control

Error history display, clear

Initialization of non-volatile memory of adjustment value

Auto gain output level adjustment (MO)

Auto gain output level adjustment (CD)

IOP data display

IOP data writing

Version display of microprocessor

Continuous playback mode

Continuos recording mode

Mark

(×)

(×)

(×)

(×) (!)

(*) Group

C : Check A : Adjust

S : Service D : Develop

Group (*)

CS

CS

CS

CS

CS

C

C

C

AS

AS

AS

AS

AS

S

AS

AS

AS

CS

AS

CS

CASD

CASD

D

21

4-5-1. Operating the Continuos Playback Mode

1. Entering the continues playback mode

1)Load the disc into the unit. (recordable disc or disc for playback)

The disc is loaded by pushing the tray.

2)Rotate the lAMSL knob to display “CPLAY MODE” (C30).

3)Press the YES button to change the display to “CPLAY MID”.

4)When access completes, the display changes the display to “C = AD = ”.

Note : The value of the “ ” displayed on the screen indicates error rate and “ADER”.

2. Changing the parts to be played back

1)Press the YES button during continuos playback to change the display as shown and move the played back part.

"CPLAY MID" → "CPLAY OUT" → "CPLAY IN"

2)When access completes, the display changes to “C = AD = ”.

Note : The value of the “ ” displayed on the screen indicates error rate and “ADER”.

3. Ending the continuos playback mode

1) Press the MENU/NO button to change the display to “CPLAY MODE”.

2) Press the A button to eject the disc.

Note1 : The playback start addresses for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT : 700h cluster

Note 2 : When the N button is pressed during the continuos playbac k in order to switch the tracking servo ON and OFF, the message

“SERVO ON” appears without displaying “CPLAY MODE” when the MENU/NO button is pressed to end the continuos

playback mode.

Also when the servo is turned off, the serv o is turned on automatically, the message “SERV O ON” appears and then the mode

ends afterward.

To change the display “SERVO ON” to the normal “mode” display, press the x button.

22

4-5-2. Operating the Continuos Recording Mode (Use this mode for self record/playback check only)

1. Entering the continuos recording mode

1)Load the recordable disc to the unit.

The disc is loaded by pushing the tray.

2)Rotate the lAMSL knob to display “CREC MODE” (C31).

3)Press the YES button to change the display to “CREC MID”.

4)When access completes, the display changes the display to “CREC( ” and illuminates.

Note : The value of the “ ” displayed on the screen indicates the address of the recorded position.

2. Changing the parts to be recorded

1) Press the YES button during continuos playback to change the display as shown and move the played back part. disappear s

during moving.

"CREC MID" → "CREC OUT" → "CREC IN"

REC

REC

2)When access completes, the display changes to “CREC( ” and disappears.

Note : The value of the “ ” displayed on the screen indicates the address of the recorded position.

3. Ending the continuos recording mode

1) Press the MENU/NO button. The display changes to “CREC MODE” and disappears.

2) To eject the disc, press the A button.

Note 1: The playback start addresses for IN, MID, and OUT are as follows.

N : 40h cluster

MID : 300h cluster

OUT : 700h cluster

Note 2: The MENU/NO button can be used to stop recording anytime.

Note 3: Do not perform continuos recording for long periods of time above 5 minutes.

Note 4: During continuos recording, be careful not to apply vibration.

4-5-3. No-Volatile Memory Mode (EEP MODE)

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If selecting this mode accidentally, press the MENU/NO button immediately to exit it.

REC

REC

4-6. Functions of Other Buttons

Function name Main contents

N Sets continuos playback when pressed in the STOP state. When pressed during continuos playback, the tracking

servo turns ON/OFF. *Note

x Stops continuos playback and continuous recording

M The sled moves to the outer circumference only when this is pressed

m The sled moves to the inner circumstance only when this is pressed

SCROLL Switches between the pit and groove modes when pressed

PLAY MODE Switches the spindle servo mode (CLV S ↔ CLV A)

DISPLAY/CHAR Switches the display when pressed

A/OPEN/CLOSE Removes the disc

REPEAT Exits test mode

Note : If the continuos playback mode ends with the tracking servo OFF, the tracking servo is automatically turned on.

When the message “SERVO ON” appears at the end, press the x button to returns to the normal “mode” display.

23

4-7. Test Mode Displays

Each time the DISPLAY/CHAR button is pressed, the display changes in the following order.

1. MODE display

Displays “TEMP CHECK”, “CPLAY MODE”, etc.

2. Error rate display

Error rates are displayed as follows.

C = AD =

C = Indicates CI error

AD = Indicates ADER

3. Address display

Addresses are displayed as follows.

(MO: recordable disc, CD: disc for playback only)

Every pressing of the SCROLL button toggles between the groove display

and the pit display

h = s = (MO pit and CD)

h = a = (MO groove)

h = : Indicates header address

s = : Indicates SUBQ address

a = : Indicates ADIP address

Note: The display “-” appears when the servo is not locked.

4. Auto gain display (not used in servicing)

The auto gain display is shown as follows.

AG= / [

5. Detrack check display (not used in servicing)

The detrack check display is shown as follows.

ADR=

6. IVR display (not used in servicing)

The IVR display is shown as follows.

[ ] [ ] [

Auto gain display (not used in servicing)

Detrack check display (not used in servicing)

IVR display (not used in servicing)

MODE display

↓

Error rate display

↓

Address display

↓

↓

↓

↓

Meaning of Other Displays

Display

H

X

REC

-SYNC

A. SPACE

OVER

B

A-

TRACK

DISC

SLEEP

CLOCK

MODE display Off

During continuos playback (CLV: ON) STOP (CLV:OFF)

Tracking servo OFF Tracking servo ON

Recording mode OFF Recording mode OFF

CLV low speed mode CLV normal mode

ABCD adjustment completed

Tracking offset cancel ON Tracking offset cancel OFF

Tracking auto gain OK

Focus auto gain OK

Pit Groove

High reflection Low reflection

CLV-S CLV-A

CLV LOCK CLV UNLOCK

Contents

24

SECTION 5

ELECTRICAL ADJUSTMENTS

5-1. On Part Replacement and Adjustment

• Perform the checks and adjustments of the MDM and MBU blocks following the procedure below .

The procedure is changed depending on the replaced part.

• Abbreviation

OP : Optical pick-up

•

Temperature compensation

offset check

•

Laser power check

•

Traverse check

•

Focus bias check

•

C PLAY check

•

Self record/playback check

OWH : Overwrite head

OK

NG

Part Replacement and repairing

OWH is replaced ?

NO

Either OP, IC171, IC101, or

IC121 is replaced ?

YES

Initial setting of adjustment value

OP or IC171 is replaced ?

YES

Recording the IOP information

(IOP value that is recorded in OP)

The error occurs by other cause.

Perform the mechanism check of

the sled and spindle system, etc.

YES

NO

NO

Either IC171 or D101 is replaced ?

YES

Temperature compensation offset adjustment

• T ra verse adjustment

• Focus bias adjustment

• Error rate adjustment

• Auto gain adjustment

NO

25

5-2. Precautions for Checking Laser Diode

Emission

T o check the emission of the laser diode during adjustments, ne v er

view directly from the top as this may lose your eye-sight.

5-3. Precautions for Use of Optical Pick-up

(KMS-260B)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap on the flexible board of the optical

pick-up when using it.

Before disconnecting the connector, disorder the laser tap. Be careful

not to remove the solder before connecting the connector . Also take

adequate measures to prevent damage by static electricity. Handle

the flexible board with care as it breaks easily.

Pick-up

Laser tap

Optical pick-up flexible board

Flexible board

5-4. Precautions for Adjustments

1) When replacing the following parts, perform the

adjustments and checks with !! in the order shown in the

following table.

2) Set the test mode when performing the adjustments.

After completing the adjustments, exit the test mode.

Perform the adjustments and checks in “Group S” of the test

mode.

3) Perform the necessary adjustments only in the order given.

4) Use the following tools and measuring devices.

• Check disc (MD) TDYS-1 (Parts No.: 4-963-646-01)

• Test disc (MDW-74/AU-1) (Parts No.: 8-892-341-41)

• Laser power meter LPM-8001 (Parts No.: J-2501-046-A)

Or

• MD laser power meter 8010S (Parts No.: J-2501-145-A)

(Note)

• Oscilloscope (Measure after perform the CAL of the probe.)

• Digital voltmeter

• Thermometer

• T ool for checking wav eform of BD board (Parts No.: J-2501-

149-A)

5) When observing several signals on the oscilloscope, etc., make

sure that VC and ground do not connect inside the oscilloscope.

(VC and ground will become short-circuited.)

6 When checking the waveform, the check can be performed

without soldering by using the tool for checking waveform of

BD board.

(Refer to the Service note (page 6).)

7) Use the tool disc that is free from finger print and dust as they

can affect result of adjustment.

Note: Laser power meter

When the laser power check and adjustment of the electrical

adjustment are performed, using the new MD laser power meter

8010S (J-2501-145-A) instead of the former laser power meter is

recommended.

The procedure of installing the laser meter sensor to the objective

lens of pickup is greatly simplified.

1. Initial setting of

adjustment value

2. Recording IOP

information

(the value that is

written in pick-up)

3. Temperature

compensation offset

adjustment

4. Laser power

adjustment

5. Traverse adjustment

6.

Focus bias adjustment

7.

Error rate adjustment

8. Auto gain output

level adjustment

Optical

pick-up

a

a

×

a

a

a

a

a

IC171

a

a

a

a

a

a

a

a

BD board

IC101,

D101

×

×

a

×

×

×

×

×

IC121

a

×

×

a

a

a

a

a

IC192

×

×

×

a

×

×

×

×

26

5-5. Creating Continuos Recorded Disc

KMS

260B

24391

H0528

(For the checking procedure of

this value, refer to Section 5-8

“Recording and displaying IOP information”.)

IOP = 52.8 mA in this case

IOP (mA) = digital bolt meter reading (mV)/1 (W)

(Optical pick-up label)

• This disc is used in focus bias adjustment and error rate check.

The following describes how to create a continuos recording disc.

1. Load a disc (blank disc) commercially available.

the disc is loaded by pushing the tray.

2. Rotate the lAMSL knob and display “CREC MODE”

(C31).

3. Press the YES button to display “CMEC MID”.

“CREC (0300)” is displayed for a moment and recording starts.

4. Complete recording within 5 minutes.

5. Press the MENU/NO button to stop recording.

6. Press the A button to eject the disc.

The above has been how to create a continuos recording data for

the focus bias adjustment and error rate check.

Note:

• Be careful not to apply vibration during continuos recording.

5-6. Check before Repairing

This check aims at locating the approximate position of cause of

trouble before starting to replace parts using specifications.

For detailed information, refer to [Checks before Part Replacement

and Adjustment] of Service note (page 9).

5-6-1. Temperature Compensation Offset Check

Before adjustment, set the internal temperature and the ambient

temperature are between 22 and 28 °C.

Checking procedure:

1. Rotate the lAMSL knob to display “TEMP CHECK”

(C01).

2. Press the YES button.

3. It is OK when “T=@@(##)[OK” appears. It is NG when

“T=@@(##)[NG” appears. (@@ is the current value. ## is the

value that is written in the non-volatile memory.)

5-6-2. Laser Power Check

Before check:

• Refer to Section 1 “Service note” How to open the disc tray when

power switch is turned off, and laser power check.

• Check the IOP value of optical pick-up. (Refer to Section 5-8

“Recording and displaying IOP information”.)

Connection:

Laser power meter

Optical pick-up

objective lens

Digital voltmeter

BD board

CN110 5-pin (I+3V)

CN110 4-pin (IOP)

Checking procedure:

1. Insert the laser power meter from the disc inlet and set it on the

objective lens of the optical pick-up. (When it cannot be set

properly, press the m button and M button to move the

optical pick-up.)

Connect the digital voltmeter to CN110 5-pin (I+3V) and the

CN110 4-pin (IOP).

2. Rotate the lAMSL knob to display “LDPWR CHECK”

(C02).

3. Press the YES button once to display “LD 0.9mW $ ”.

Confirm that the reading of the laser power meter is 0.84 to

0.92 mW.

4. Press th

e YES button once again to display “LD 7.0mW $ ”.

Confirm that the readings of the laser power meter and digital

bolt meter satisfy the specified value.

Specification:

Laser power meter reading: 7.0 +/- 0.2 mW

Digital bolt meter reading: Optical pick-up displayed value +/- 10 %

5. Press the MENU/NO button to display “LDPWR CHECK”

and stop laser emission.

(The MENU/NO button is effective at all times to stop the

laser emission.)

Note 1 : After step 4, the display of “LD 0.7mW$ ” “LD

6.2mW$ ”, “LD WPcorrection $ ” is switched

every time when pressing the YES button. Operation

is not necessary for these displays.

27

Loading...

Loading...