SONY MDS-JA50ES User Manual

MDS-JA50ES

SERVICE MANUAL

Photo: GOLD

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-4A

Base Unit Type MBU-2B

Optical Pick-up Type KMS-210A/J-N

SPECIFICATIONS

US Model

AEP Model

UK Model

MICROFILM

MINIDISC DECK

— 1 —

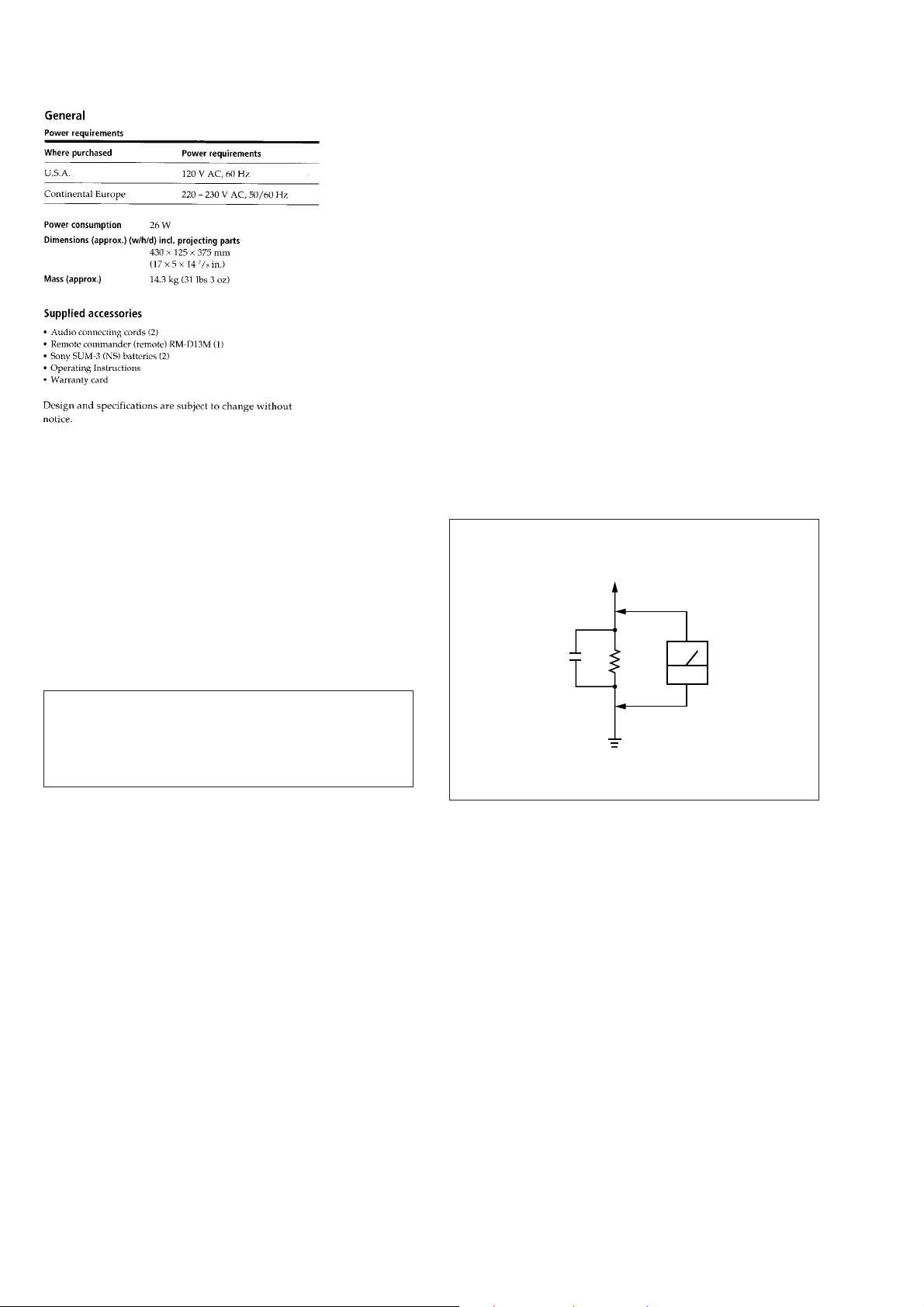

CAUTION

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakag e. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C v oltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the equipment manufacturer.

Discard used batteries according to manufacture’s instructions.

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilakting skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av

apparatfabrikanten.

Brukte batterier katterier kasseres i henhold til fabrikantens

VARNIG

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som rekommenderas

av apparattillverkaren.

Kassera använt batteri enligt gällande föreakrifter.

VAROITUS

Parist voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laite valmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

0.15µF

1.5k

Ω

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

— 2 —

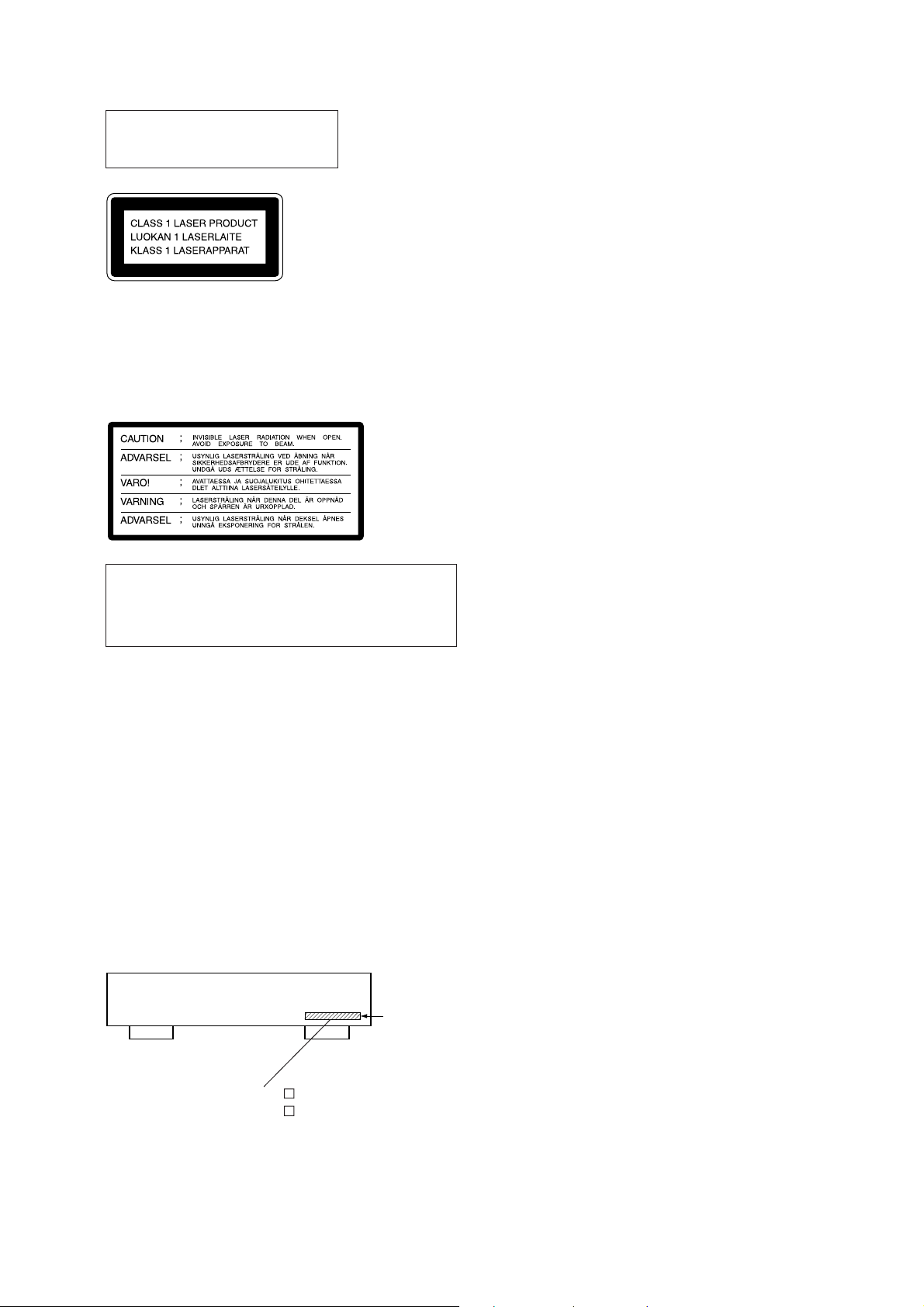

The laser component in this product is

capable of emitting radiation exceeding

the limit for Class 1.

This appliance is classified as a CLASS 1

LASER product. The CLASS 1 LASER

PRODUCT MARKING is located on the

rear exterior.

TABLE OF CONTENTS

1. SERVICING NOTE

.......................................................... 4

2. GENERAL .......................................................................... 7

3. DISASSEMBLY

3-1. Tray Assembly .................................................................... 26

3-2. Bracket (Motor) ASSY ....................................................... 27

3-3. Holder ASSY ...................................................................... 27

3-4. Base Unit.............................................................................28

3-5. HMOT Board and HLIM Board ......................................... 28

4. TEST MODE ..................................................................... 29

The following caution label is located

inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

5. ELECTRICAL ADJUSTMENTS ............................... 32

6. DIAGRAMS

6-1. Brock Diagrams

• BD Section ....................................................................... 37

• Digital Section ................................................................. 39

• Audio Section .................................................................. 41

• Power Section .................................................................. 43

6-2. Circuit Boards Location ...................................................... 44

6-3. Waveforms ......................................................................... 45

6-4. Printed Wiring Board — BD Section —.............................47

6-5. Schematic Diagram — BD Section — ............................... 49

6-6. Schematic Diagram — Digital Section —.......................... 52

6-7. Printed Wiring Board — Digital Section — ....................... 55

6-8. Printed Wiring Board — MD Section —............................ 57

6-9. Schematic Diagram — MD Section — .............................. 58

6-10. Printed Wiring Board — D Out, D Vol Section — .......... 59

6-11. Schematic Diagram — D Out, D Vol Section — ............. 60

6-12. Printed Wiring Board — DA Section — .......................... 61

6-13. Schematic Diagram — DA Section —.............................63

6-14. Printed Wiring Board — AD Section — .......................... 65

6-15. Schematic Diagram — AD Section —.............................67

6-16. Printed Wiring Board — Panel Section —....................... 69

6-17. Schematic Diagram — Panal Section — ......................... 71

6-18. Printed Wiring Board — Power Section — ..................... 73

6-19. Schematic Diagram — Power Section — ........................ 75

6-20. IC Block Diagrams ........................................................... 77

6-21. IC Pin Functions ............................................................... 84

7. EXPLODED VIEWS

7-1. Main Section ..................................................................... 100

7-2. Chassis Section ................................................................. 101

7-3. Front Panel Section 1 ........................................................ 102

7-4. Front Panel Section 2 ........................................................ 103

7-5. Mechanism Section 1 (MDM-4A) .................................... 104

7-6. Mechanism Section 2 (MDM-4A) .................................... 105

7-7. Mechanism Section 3 (MDM-4A) .................................... 106

7-8. Base Unit Section (MBU-2B) ........................................... 107

4-987-511-2 : AEP, UK, German model

4-987-511-3 : US model

8. ELECTRICAL PARTS LIST ...................................... 108

— 3 —

SECTION 1

SERVICING NOTE

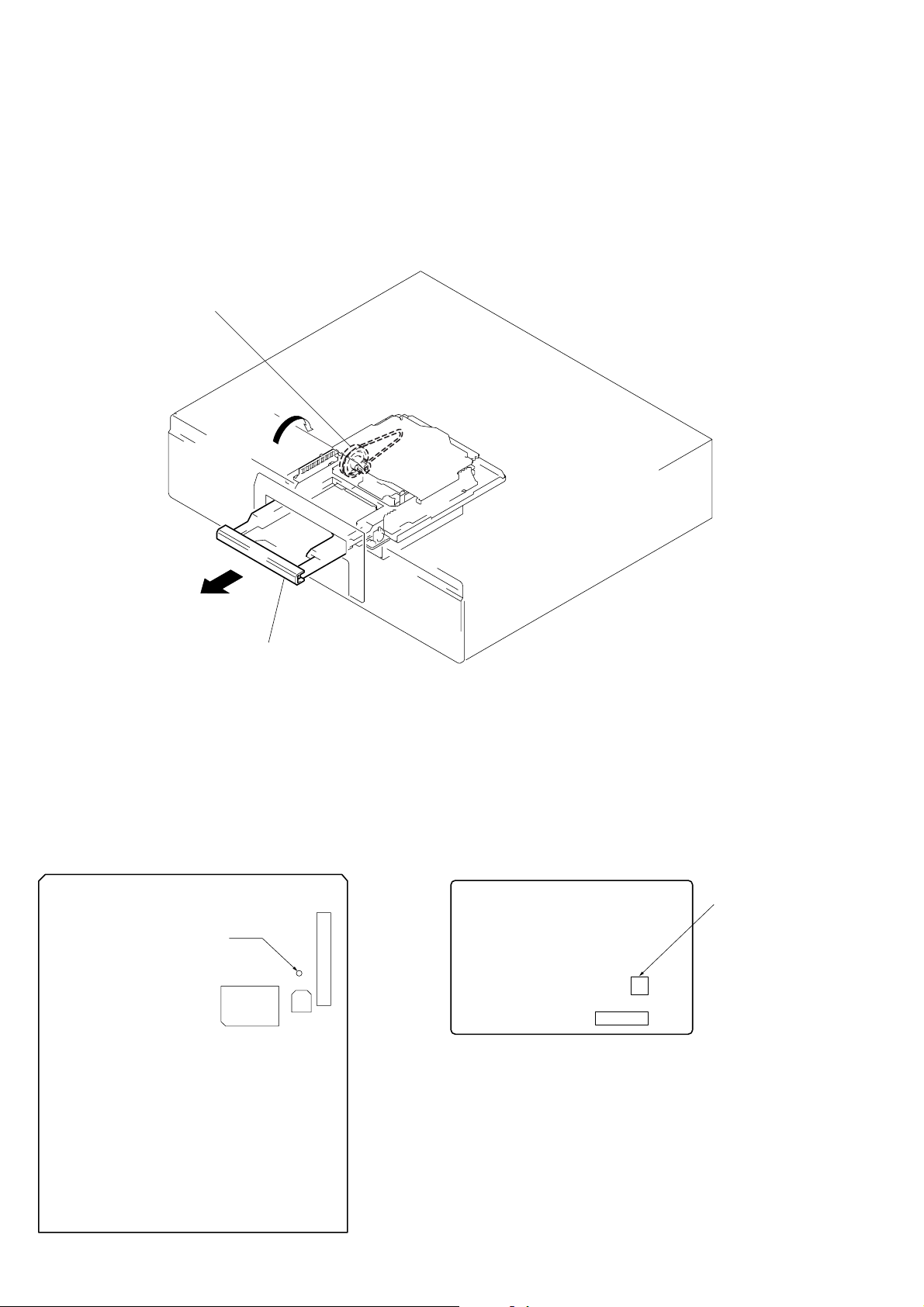

HOW TO OPEN THE DISC TRAY WHEN POWER SWITCH TURNS OFF

1 Remove the fourteen screws (BVTT 3x8) from the bottom plate.

2 Remove the bottom plate.

3 Rotate the pulley gear in the arrow direction A, and open the tray assembly in the arrow direction B.

Pully gear

A

B

Tray assembly

FORCED RESET

The system microprocessor can be reset in the following way.

Use these methods when the unit cannot be operated normally due to the overrunning of the microprocessor, etc.

Method 1:

Set TP (S.RST) of the DIG board to ground momentarily.

[DIG board] (Side A)

CN203

TP

(S.RST)

C206

IC202

Method 2:

Disconnect the power plug, and short-circuit CN905 of the PW board

with a pair of tweezers, etc.

[PW board] (Component Side)

CN901

CN905

(RESET)

— 4 —

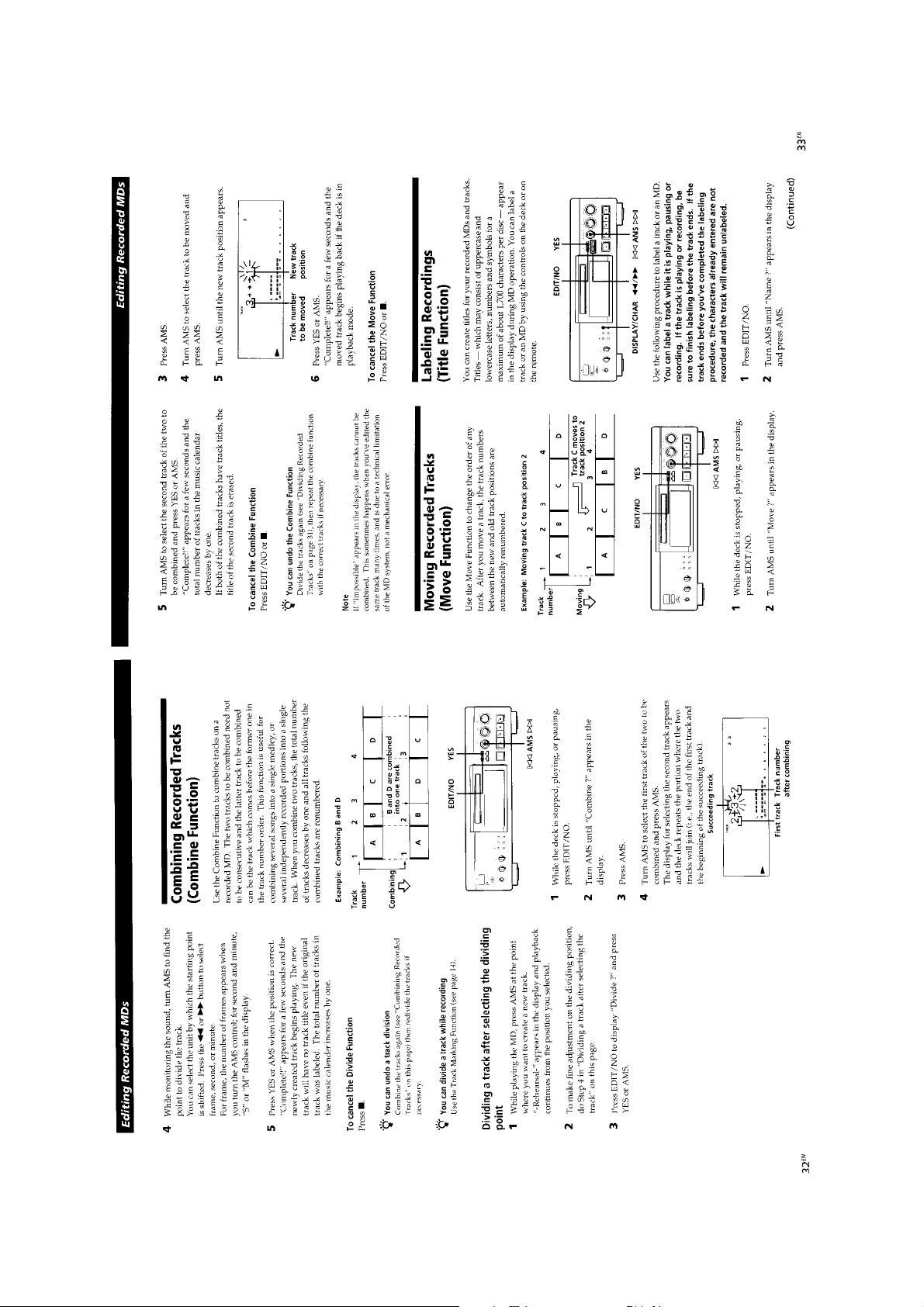

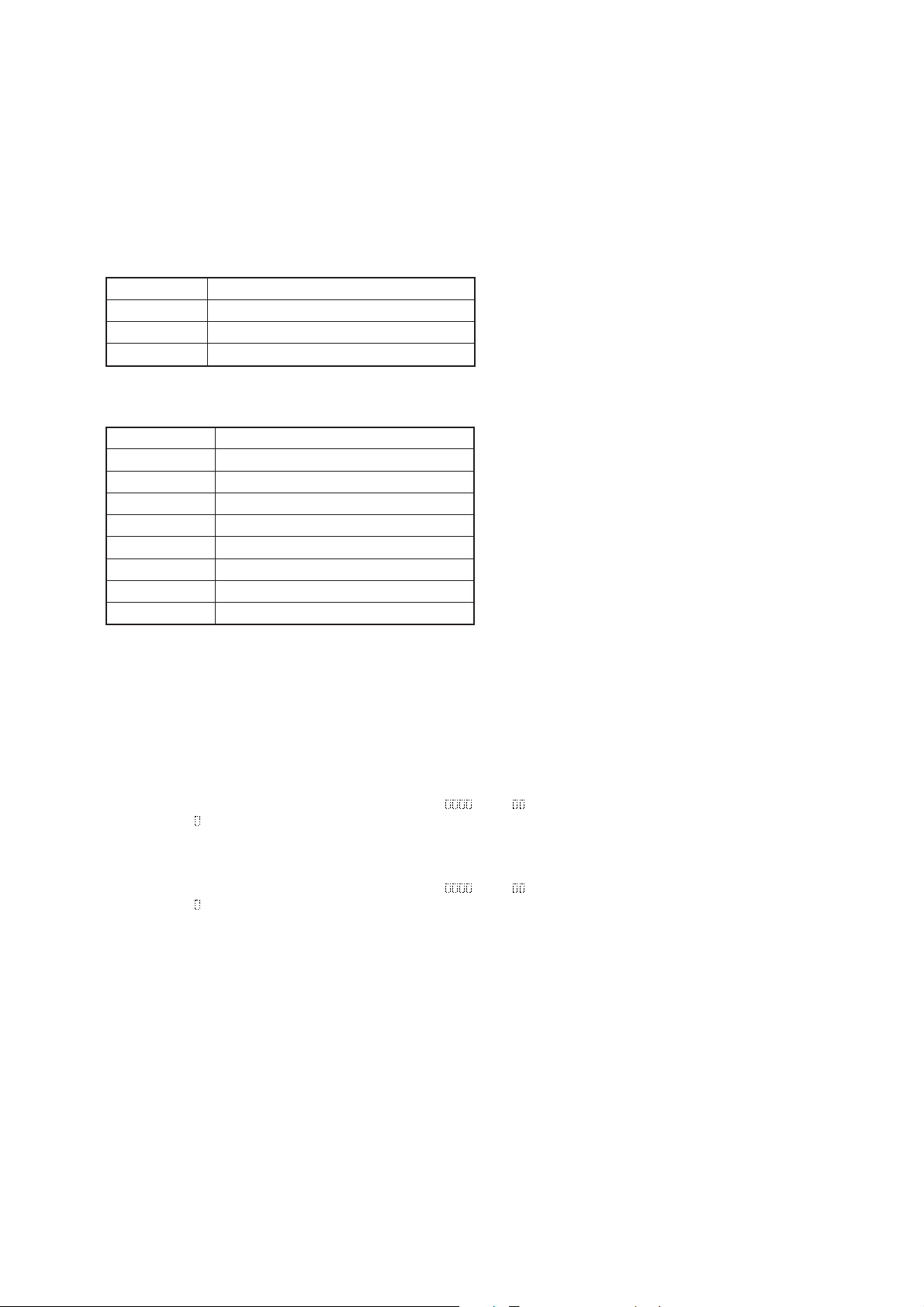

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent display tube.

This is useful for locating the faulty part of the unit.

• The retry cause, number of retries, and number of retry errors are displayed. Each is displayed in hexadecimal number.

Method:

1. Load a recordable disc whose contents can be erased into the unit.

2. Press the p button, §OPEN/CLOSE button, DISPLAY/CHAR button simultaneously.

3. Press the r button, and start recording.

4. The ## value increases with each retry. If an error occurs after a retry, the @@ count will also increase.

5. To exit the test mode, press the TIME button.

Fig. 1 Reading the Test Mode Display

R.T s ∗ ∗ c # # e @@

Fluorescent Display Tube Signs

∗ ∗ : Cause of retry

# # : Number of retries

@@: Number of retry errors

All three displays above are in hexadecimal numbers.

— 5 —

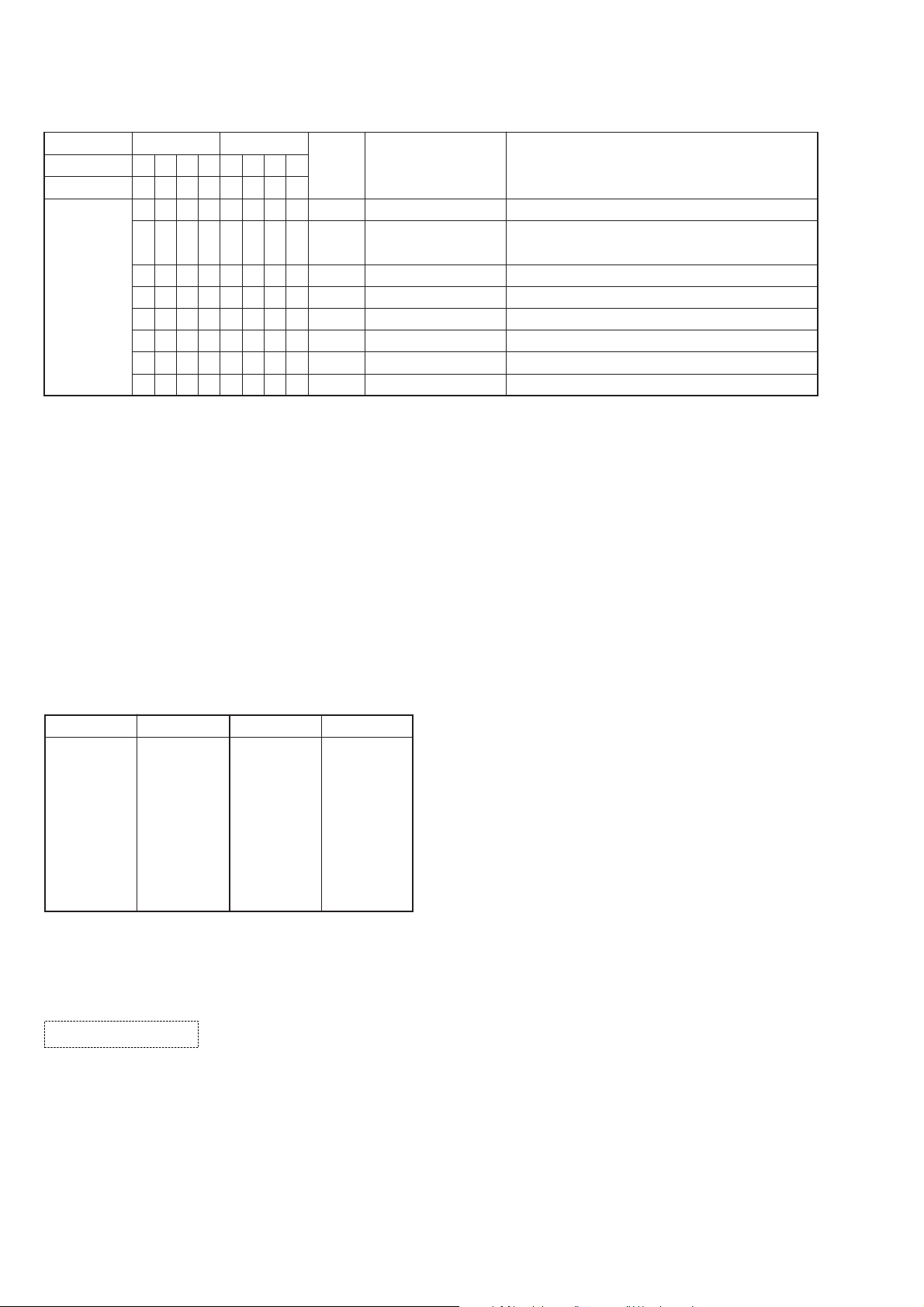

Reading the Retry Cause Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

*1 Some displays are not used depending on the microprocessor version.

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 n b6

Lower bit : 2 = 0010 n b1

In this case, the retry cause is combined of “spindle is slow” and “ader5”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

Cause of Retry Occurring conditions

shock *1

ader5

Discontinuous address

(Not used)

FCS incorrect

IVR rec error

Spindle is slow

Access fault

When more than 3.5 shocks are detected

When ADER was counted more than

five times continuously

When ADIP address is not continuous

(Not used)

When not in focus

When ABCD signal level exceeds the specified range

When spindle rotation is detected as slow

When access operation is not performed normally

When A2 is displayed:

Higher bit : A = 1010 n b7+b5

Lower bit : 2 = 0010 n b1

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

Hexadecimal n Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

Reference:

In this test mode, when the · button is pressed, and the disc is played back, the “PLAYBACK MODE” is set.

The display becomes as shown in Fig. 2. The playback mode is not used in particular during servicing.

44 ¢¢¢¢¢¢ p

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

Fig. 2 Display during Playback Mode

4 : Parts No. (Name of area named on TOC)

¢¢¢¢¢¢ : Address (Physical address on disc)

p : Track mode (Copyright information of each part, information on copyright, etc.)

— 6 —

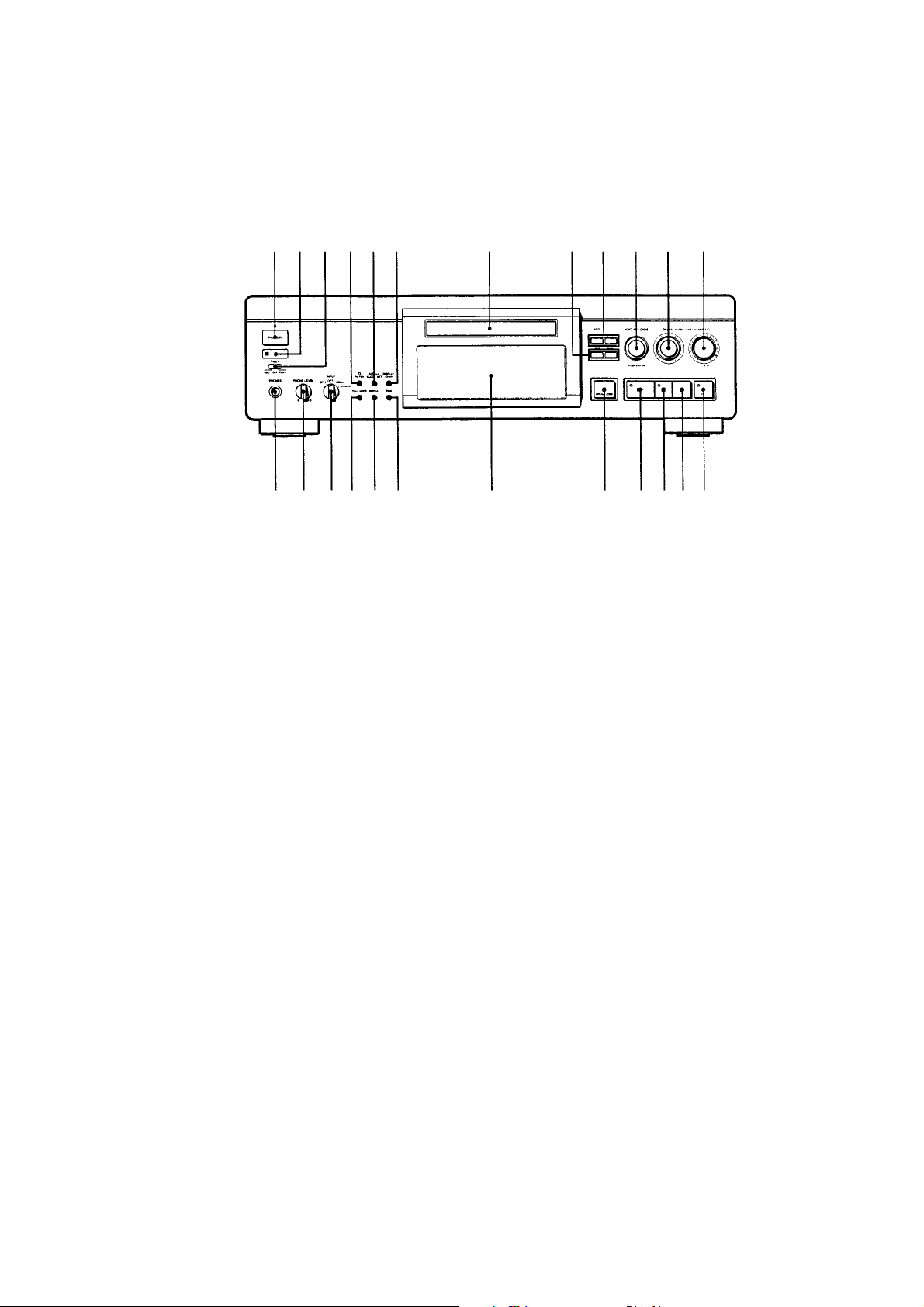

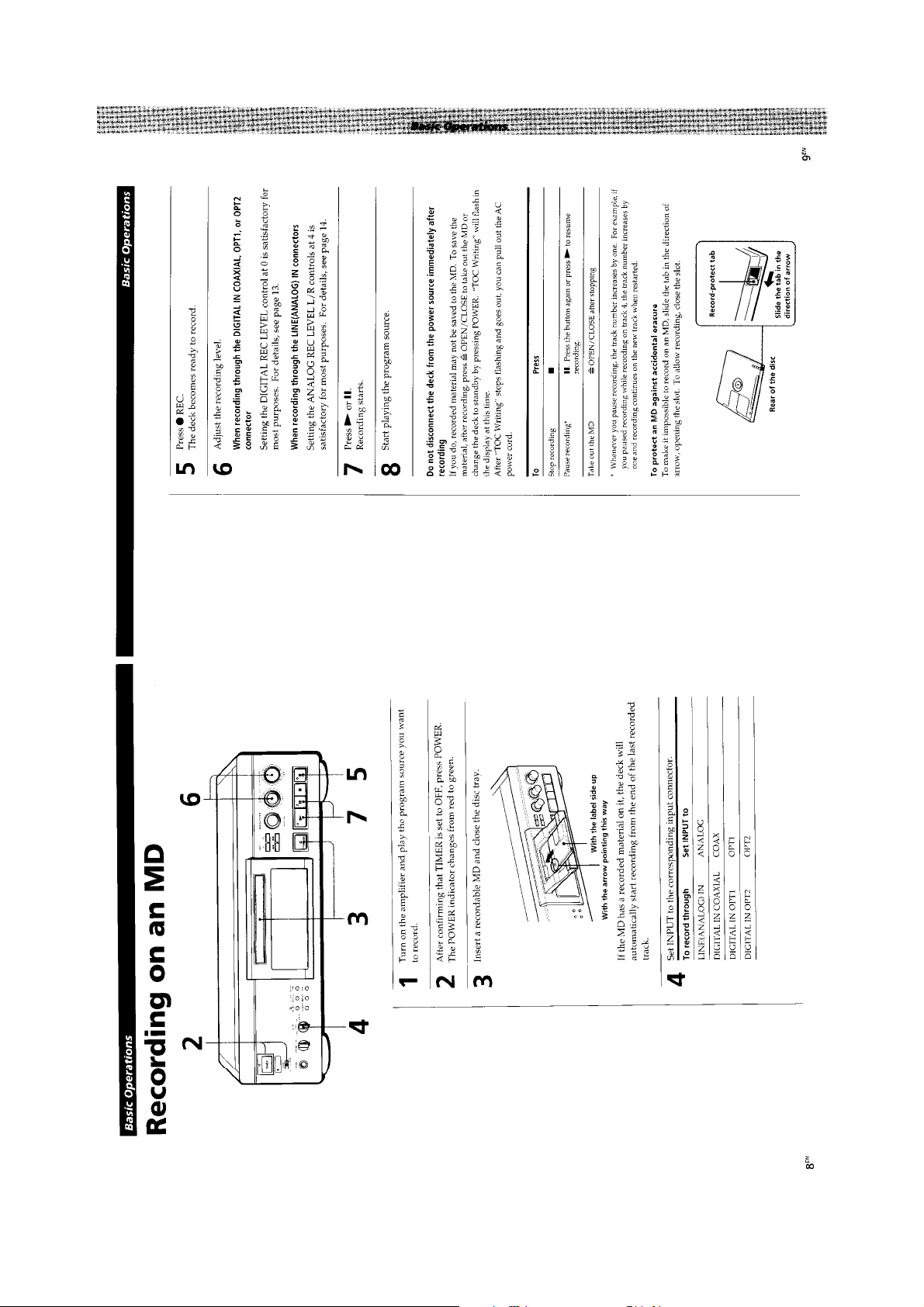

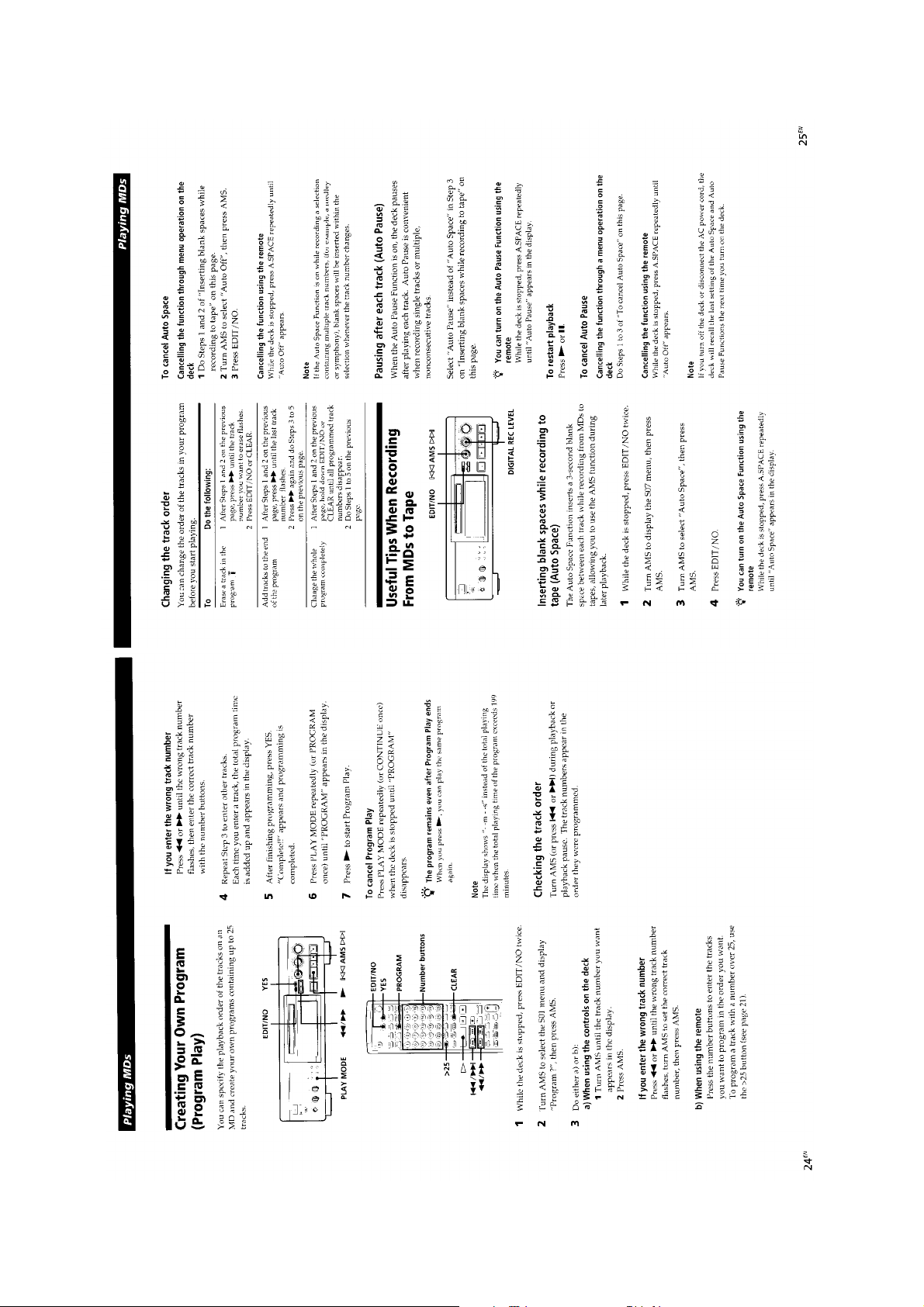

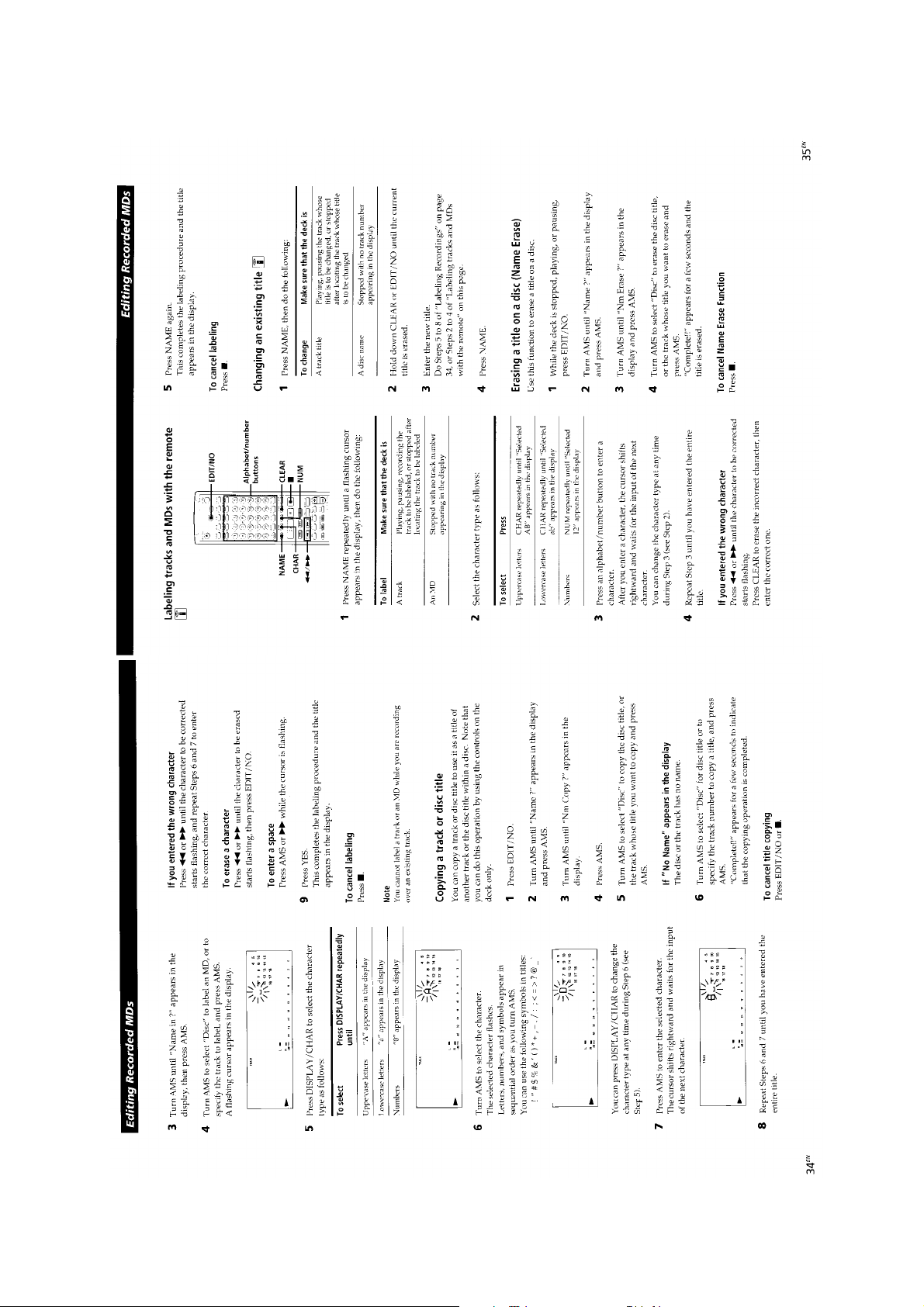

Location of Parts and Controls

SECTION 2

GENERAL

12

@¢

1 POWER switch

2 Remote sensor

3 TIMER switch

4 FILTER button

5 SCROLL/CLOCK SET button

6 DISPLAY/CHAR button

7 Disc tray

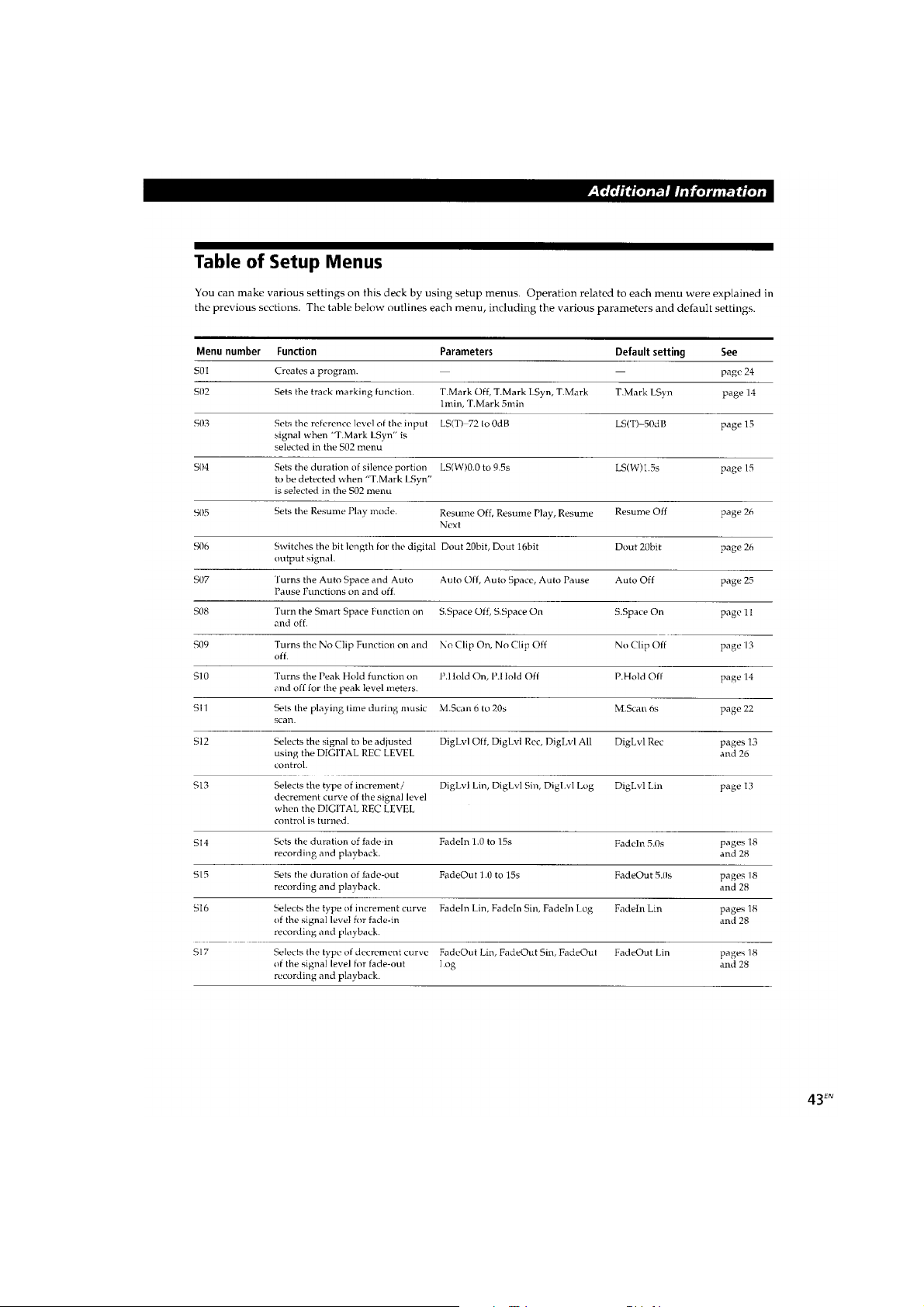

8 0/) (fast backward/fast forward) buttons

9 EDIT/NO /YES buttons

Pressing the EDIT/NO button once, it becomes the edit menu

and the recorded disc can be programmed.

Pressing it twice it becomes the set up menu (page 43), and

various settings are possible.

34567

@£

@™

@¡

@º

890

!•!ª

!º AMS knob

!¡ DIGITAL REC LEVEL knob

!™ ANALOG REC LEVEL L/R knob

!£ r REC (recording) button

!¢ p (stop) button

!∞ P (pause) button

!§ ( (play) button

!¶ § OPEN/CLOSE button

!• Display window

!ª TIME button

@º REPEAT button

@¡ PLAY MODE button

@™ INPUT switch

@£ PHONE LEVEL knob

@¢ PHONES jack

!¶

!§

!¡ !™

!∞

!£!¢

— 7 —

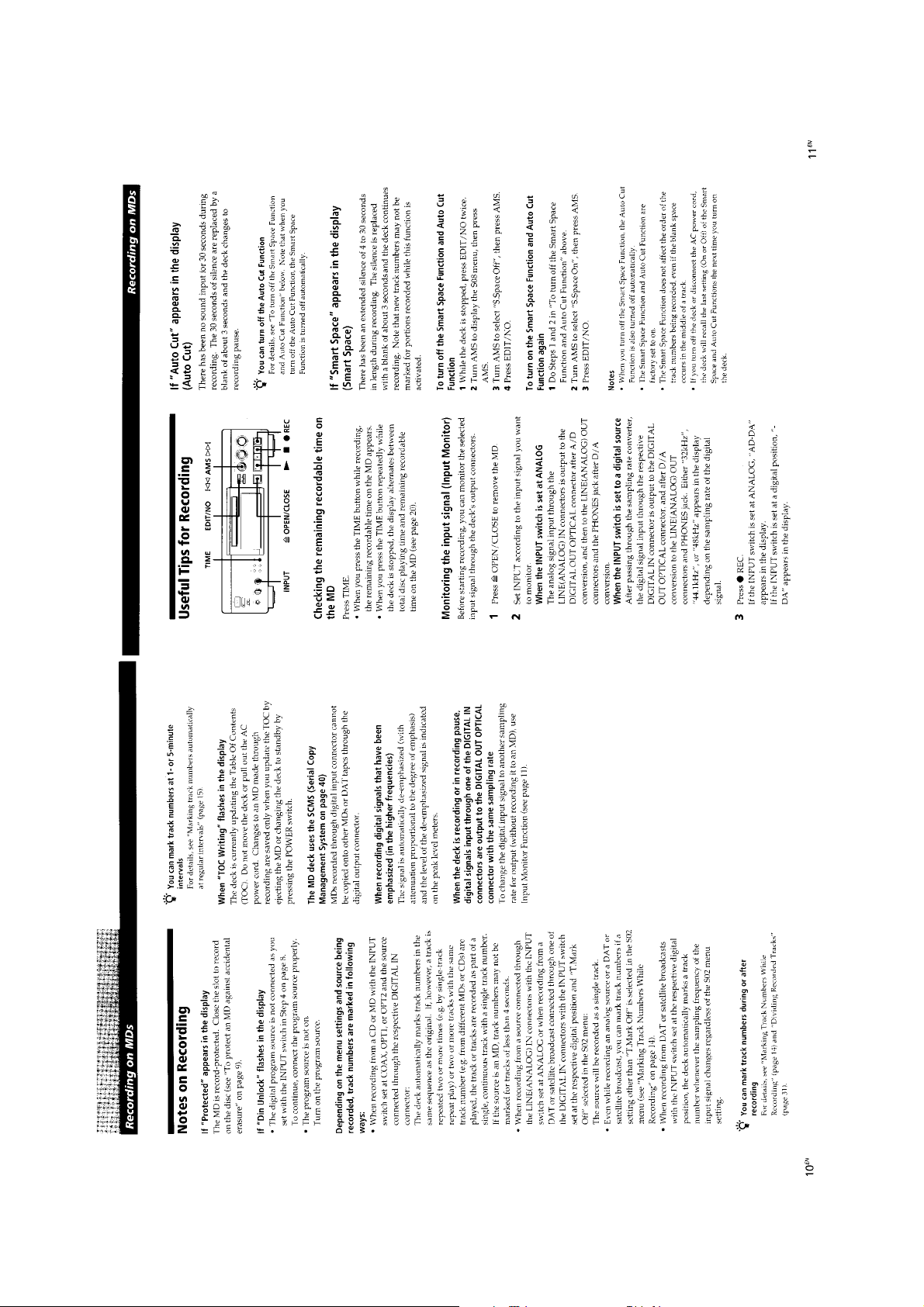

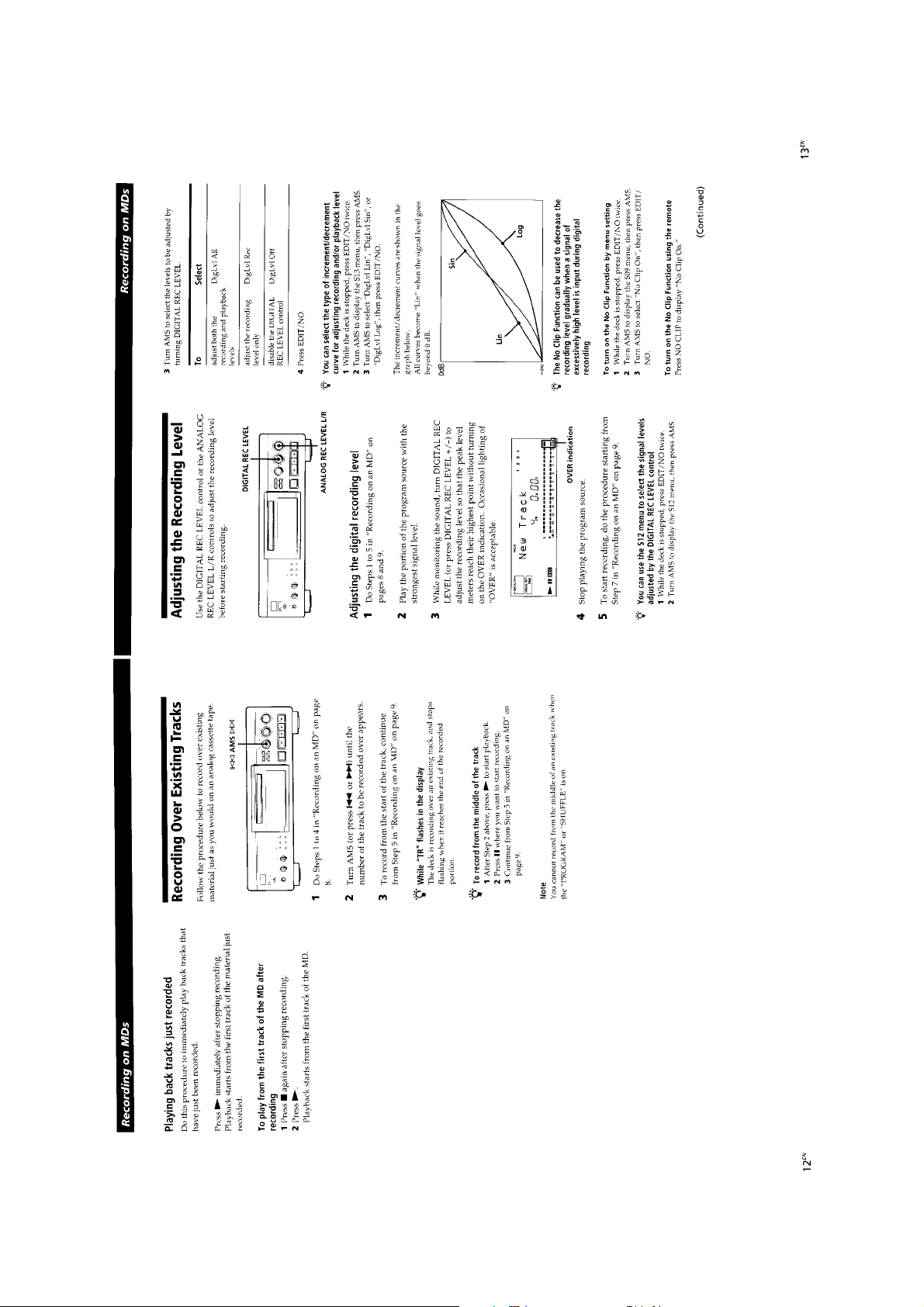

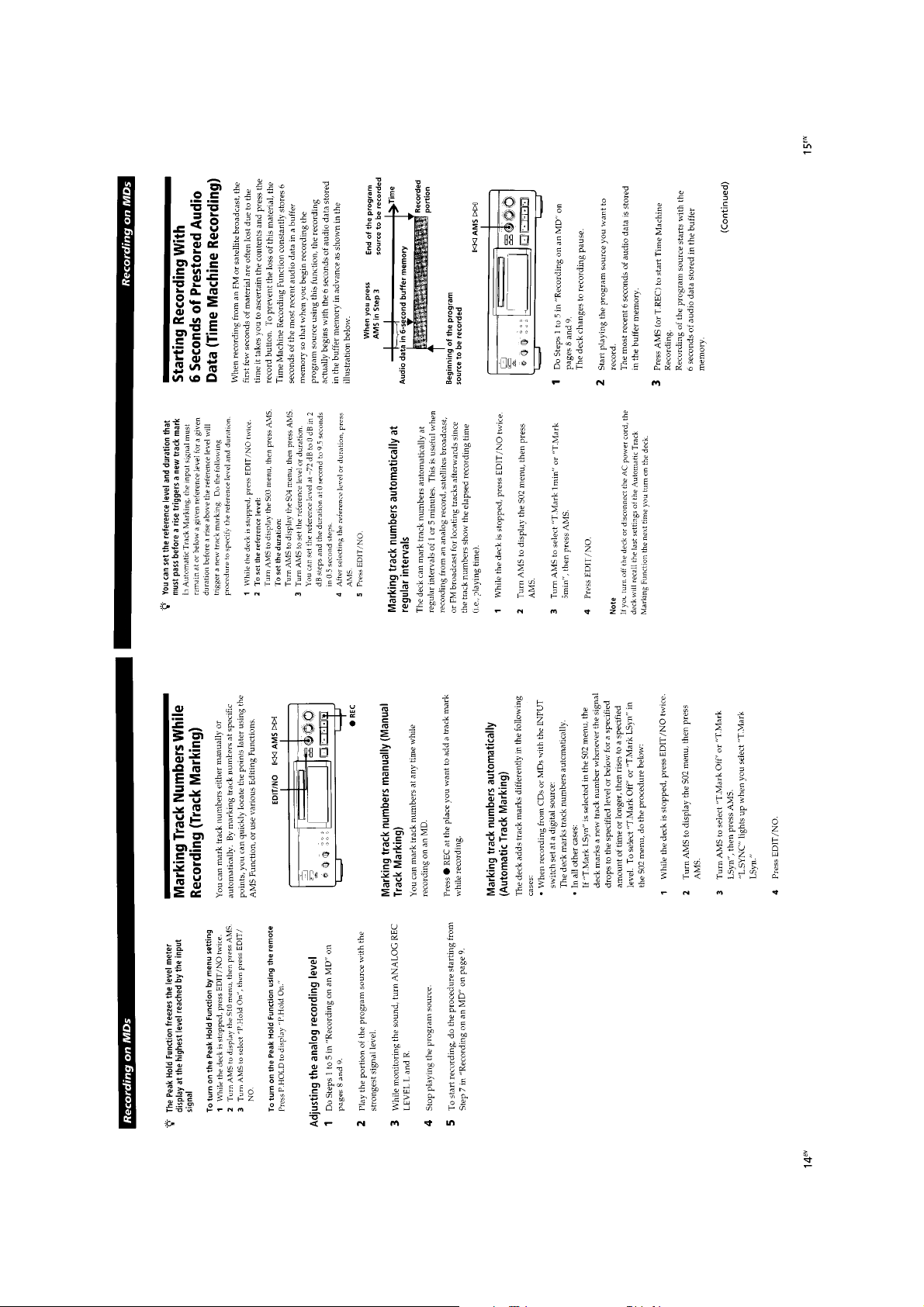

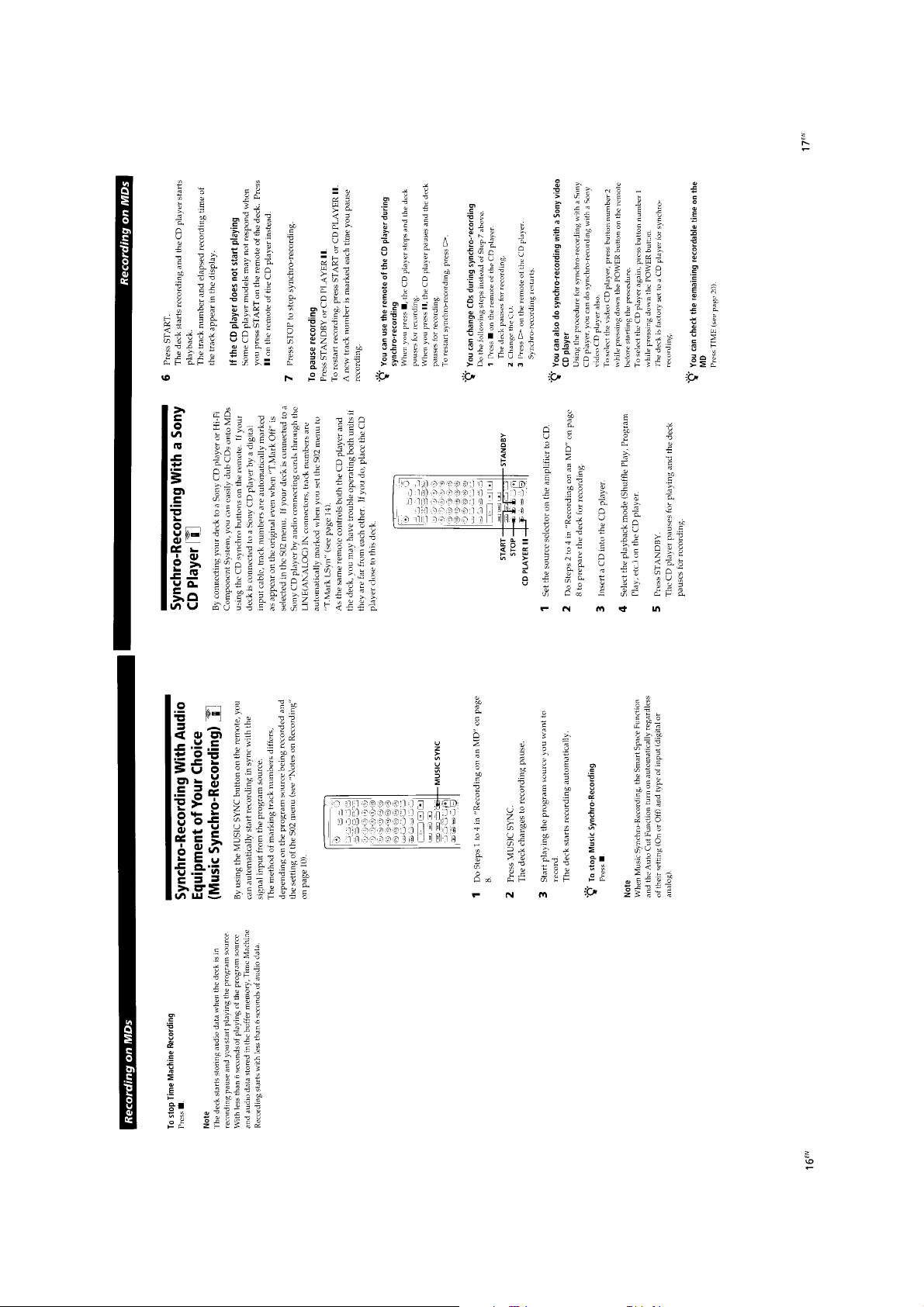

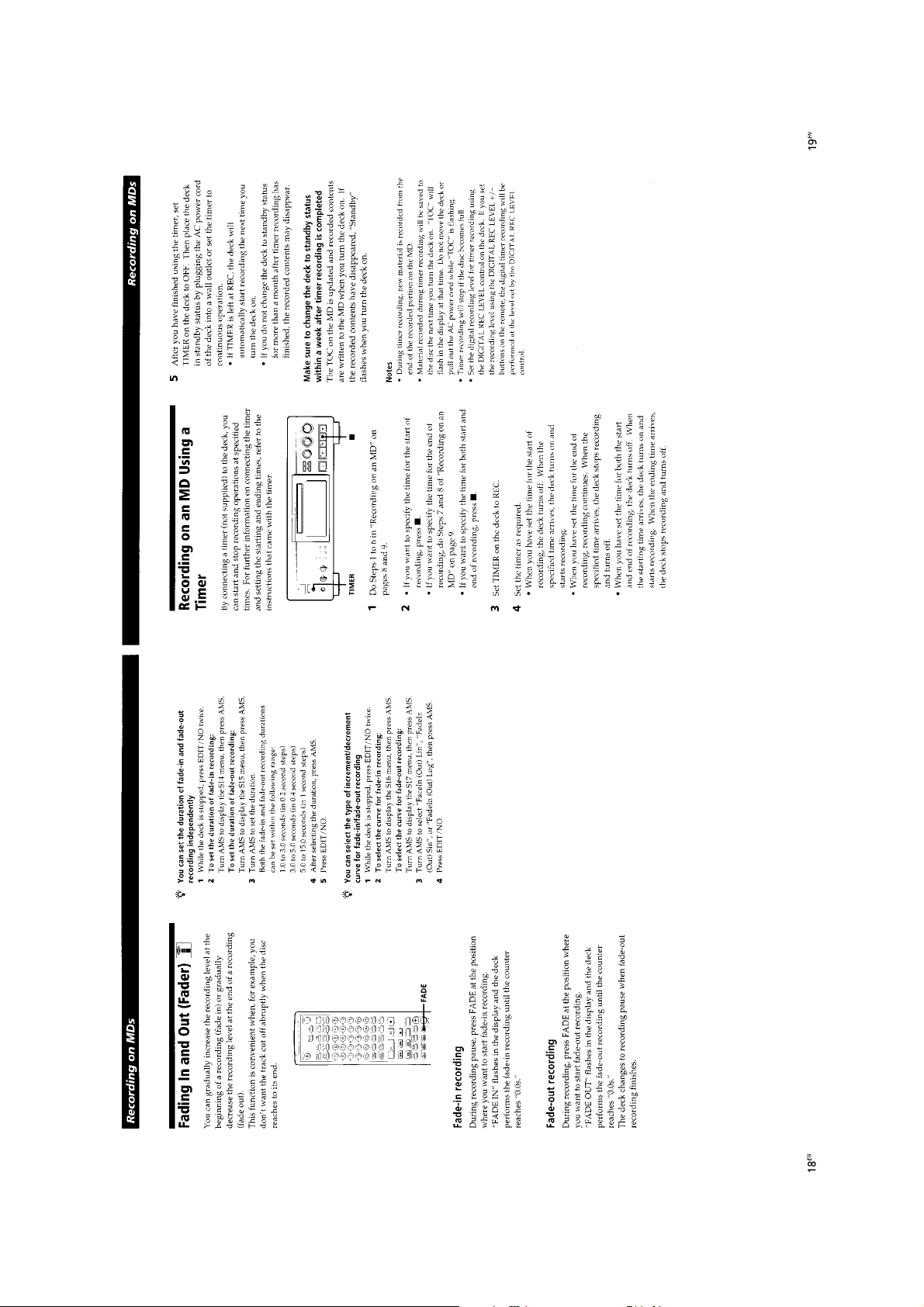

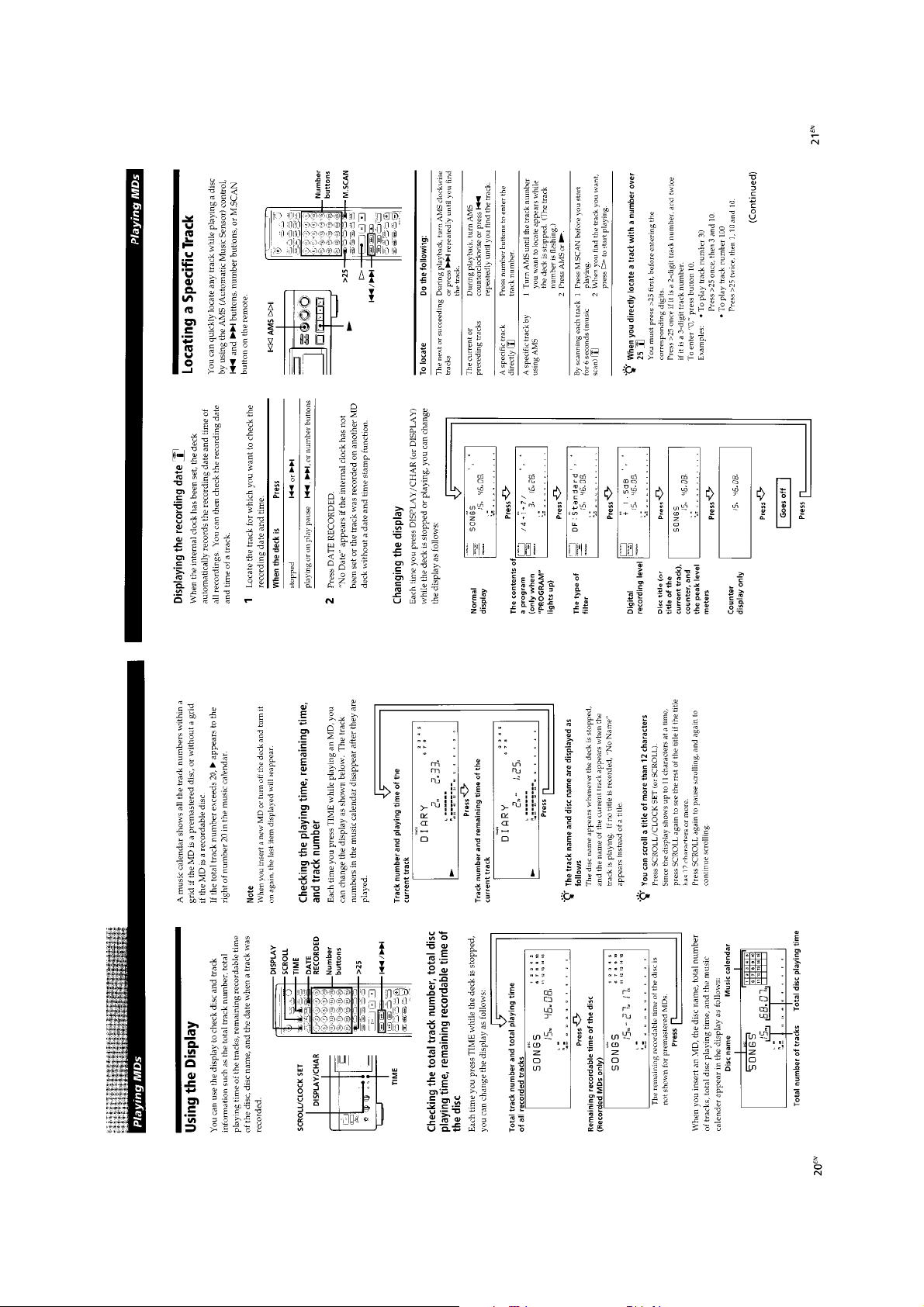

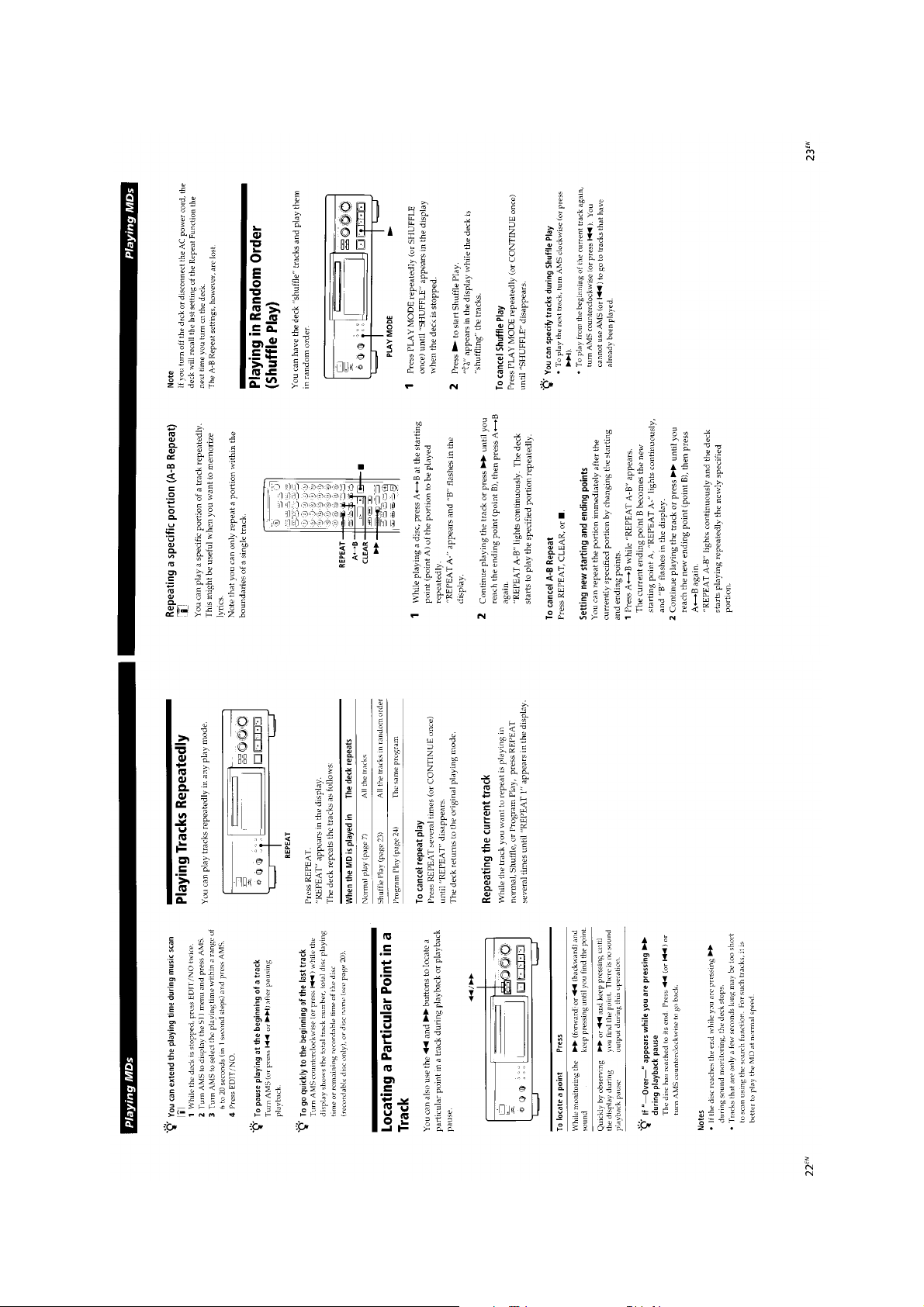

This section is extracted from

instruction manual.

— 8 —

— 9 —

— 10 —

— 11 —

— 12 —

— 13 —

— 14 —

— 15 —

— 16 —

— 17 —

— 18 —

— 19 —

— 20 —

— 21 —

— 22 —

— 23 —

— 24 —

— 25 —

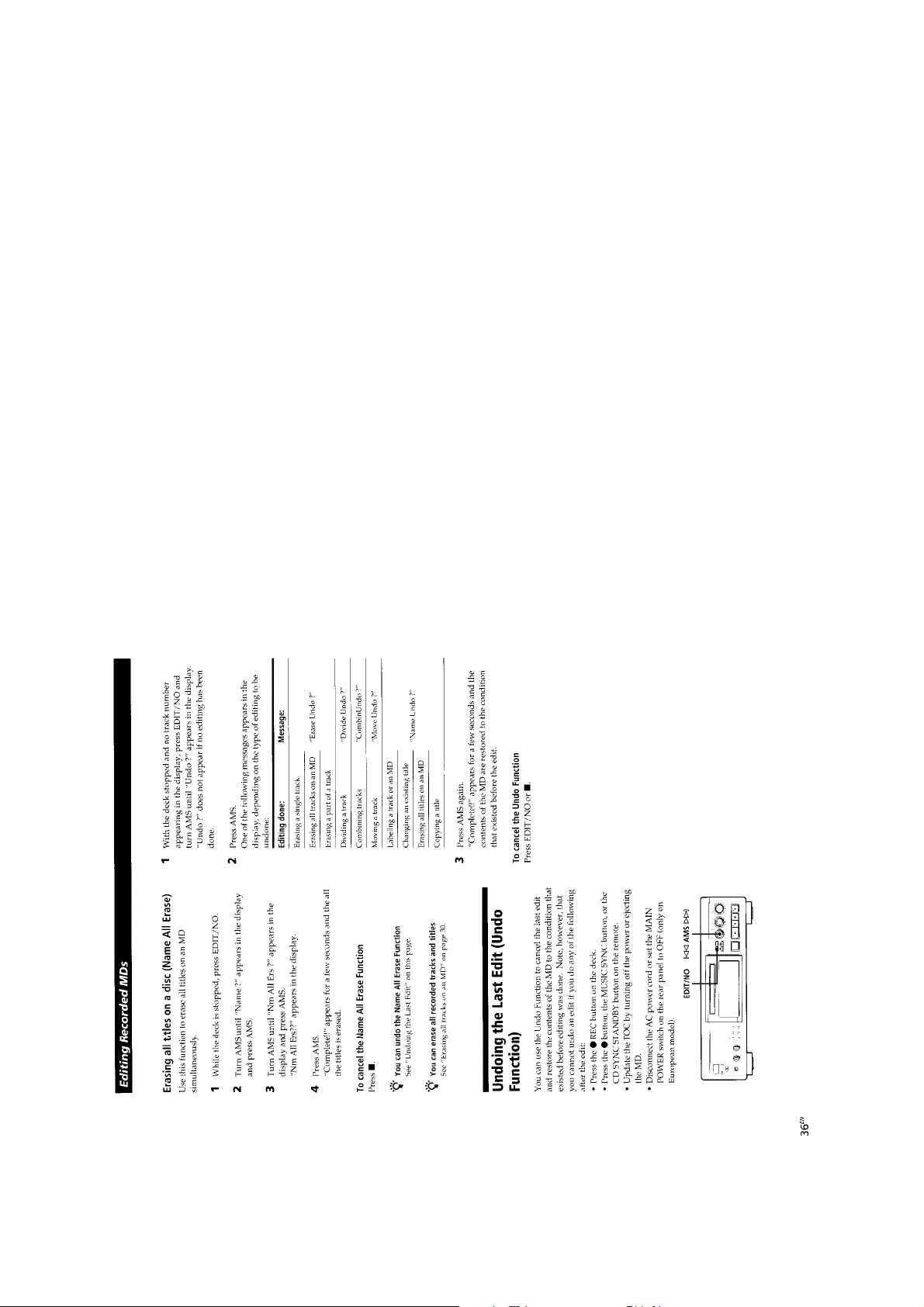

SECTION 3

DISASSEMBLY

Note : Follow Xthe disassembly procedure in the numerical order given.

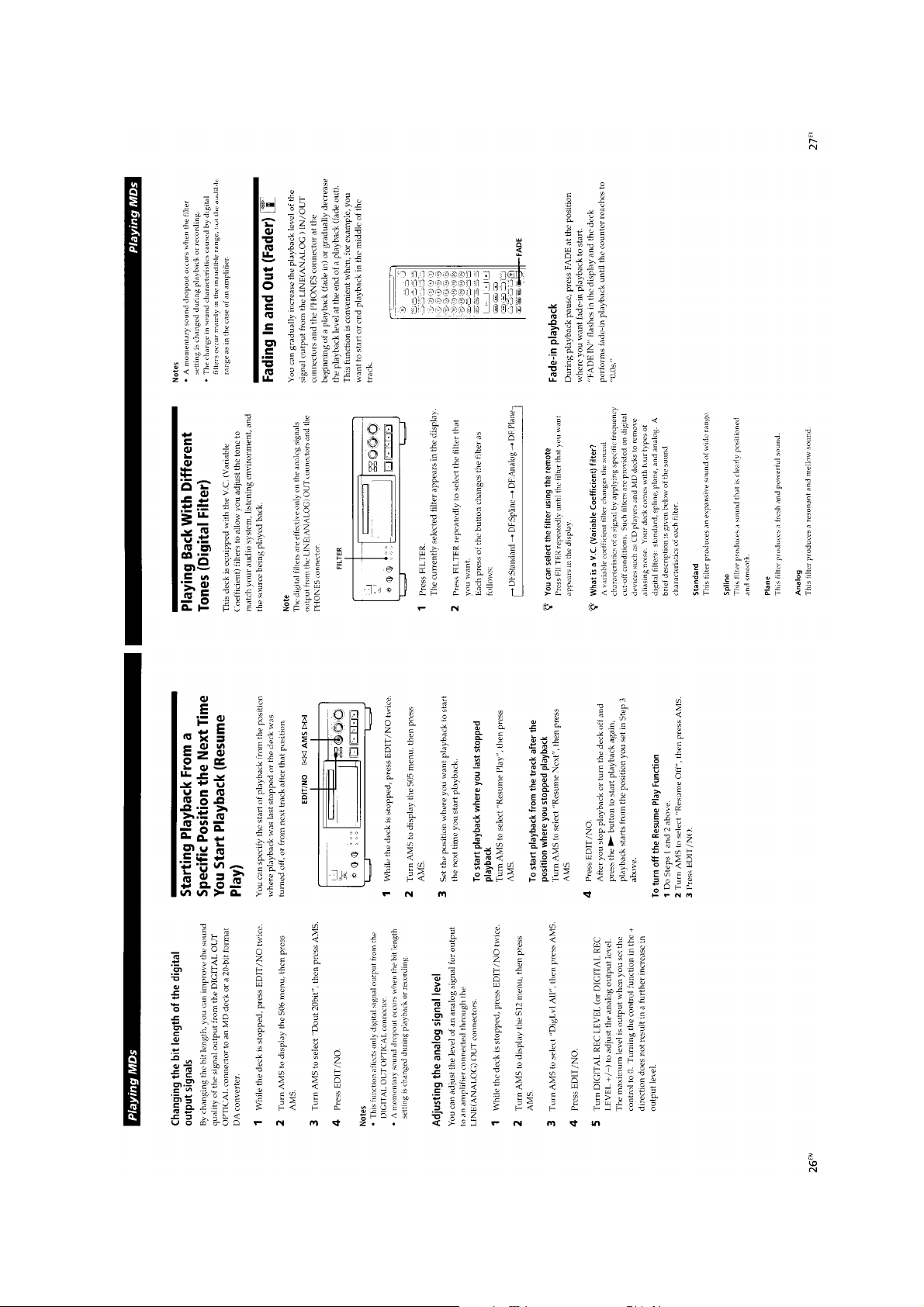

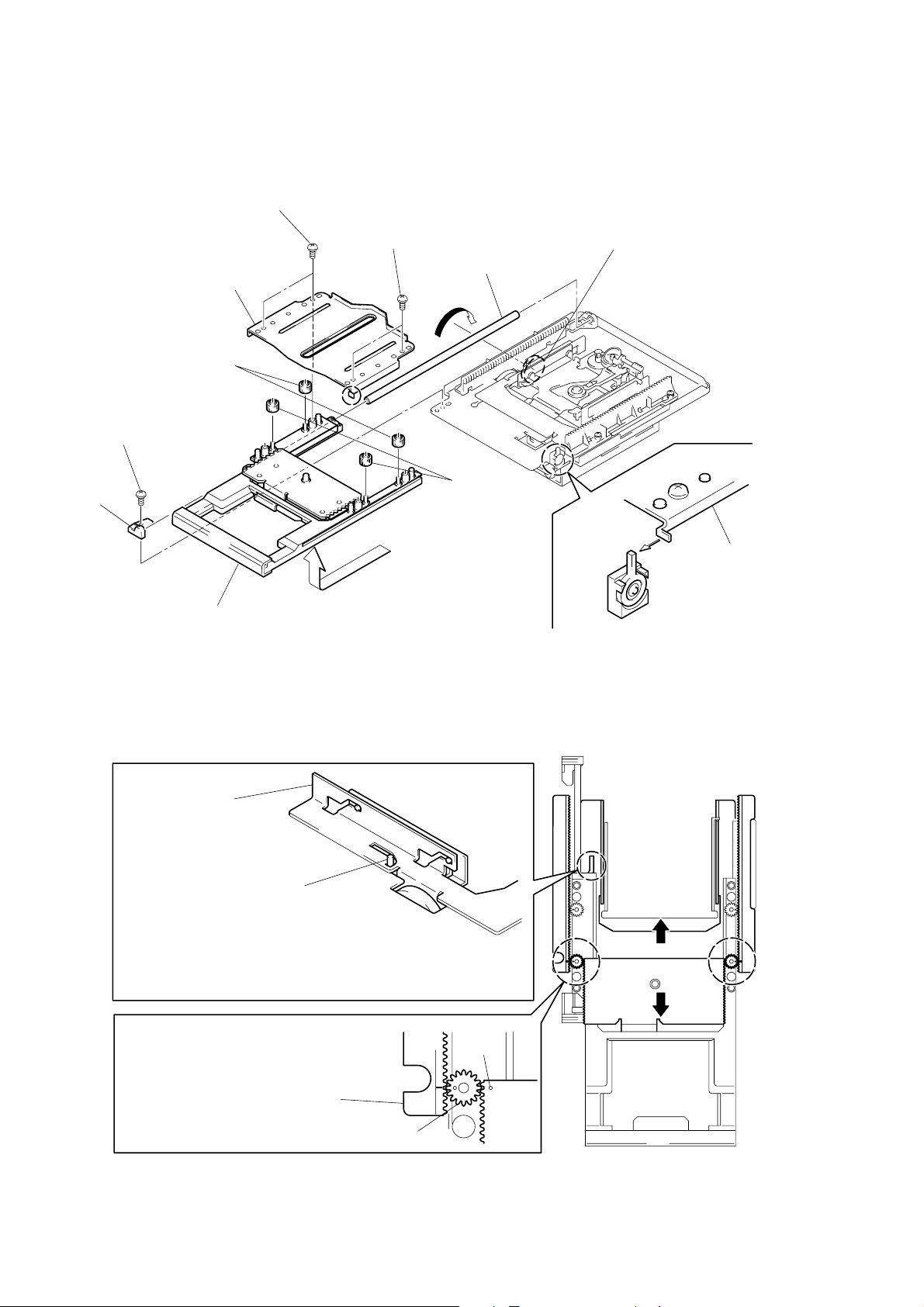

3-1. TRAY ASSEMBL Y

2

Two screws

(BVTP 3x6)

3

Two screws

(BVTP 3x6)

Bracket

4

(TOP)

A

5

Two gear

(Gear 4)

7

Screw

(BVTT 3x6)

8

Stopper

(Shaft A)

9

6

Two gear

(Gear 4)

Shaft

1

Rotate the pulley gear in the arrow

direction

assembly.

A

, and pull out the tray

0

Remove the tray assembly

in the arrow direction

• Precautions on Attaching

(Assemble in the reverse order of removal.)

Slider assembly

When attaching the tray assembly, first move the slider

assembly in the arrow direction

position shown.

Pin

B

B

A

B

and set Pin A at the

Bracket (TOP)

.

Note:

When attaching the bracket (TOP), attach while

pressing the switch as shown in the figure.

B

When attaching gear 4 (two in front), pull the tray

assembly in arrow direction

position racks (L), (R) and (D) as shown in the

figure.

A

completely, and

Rack (L)

A

Hole

Rack (D)

Gear 4

— 26 —

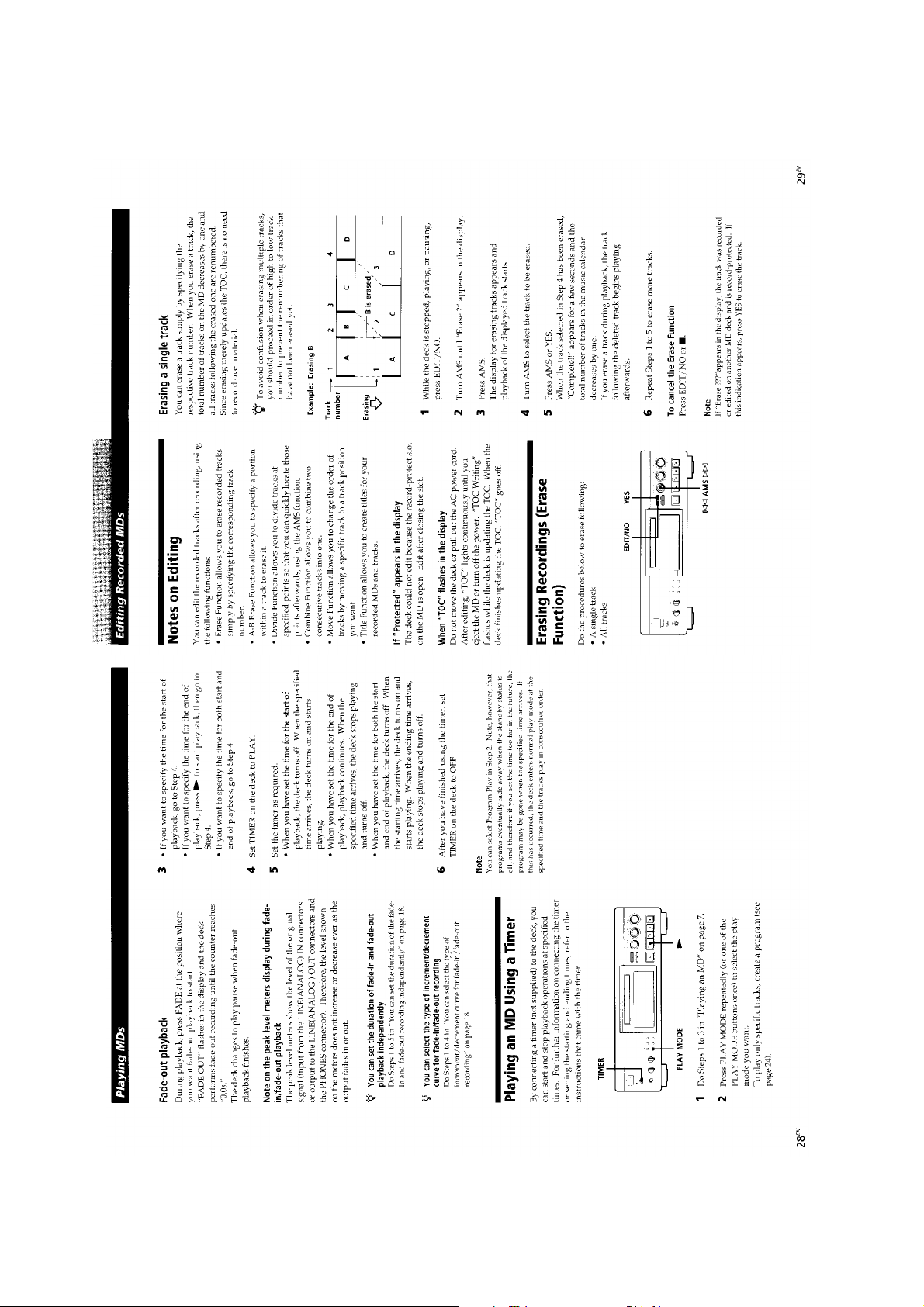

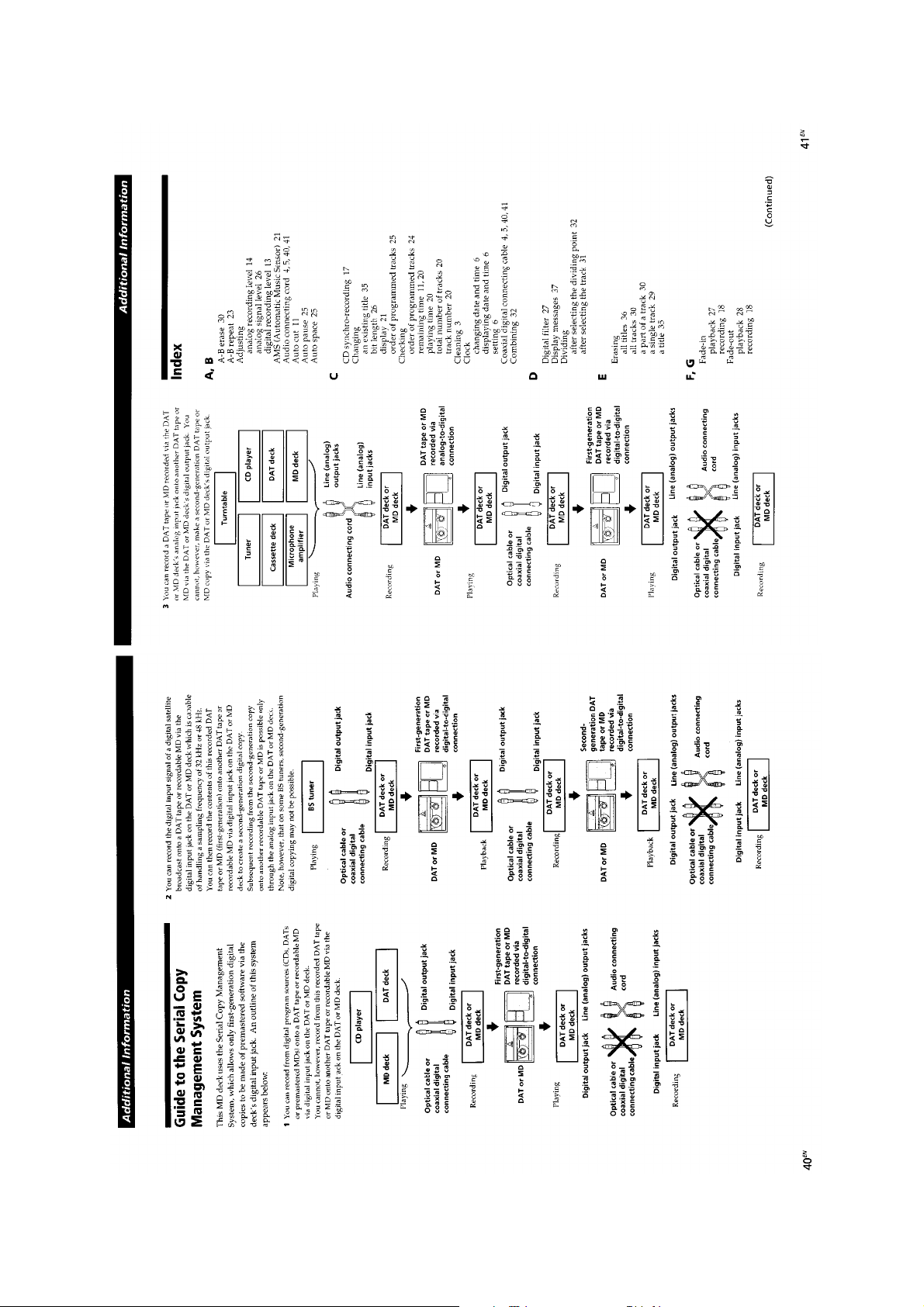

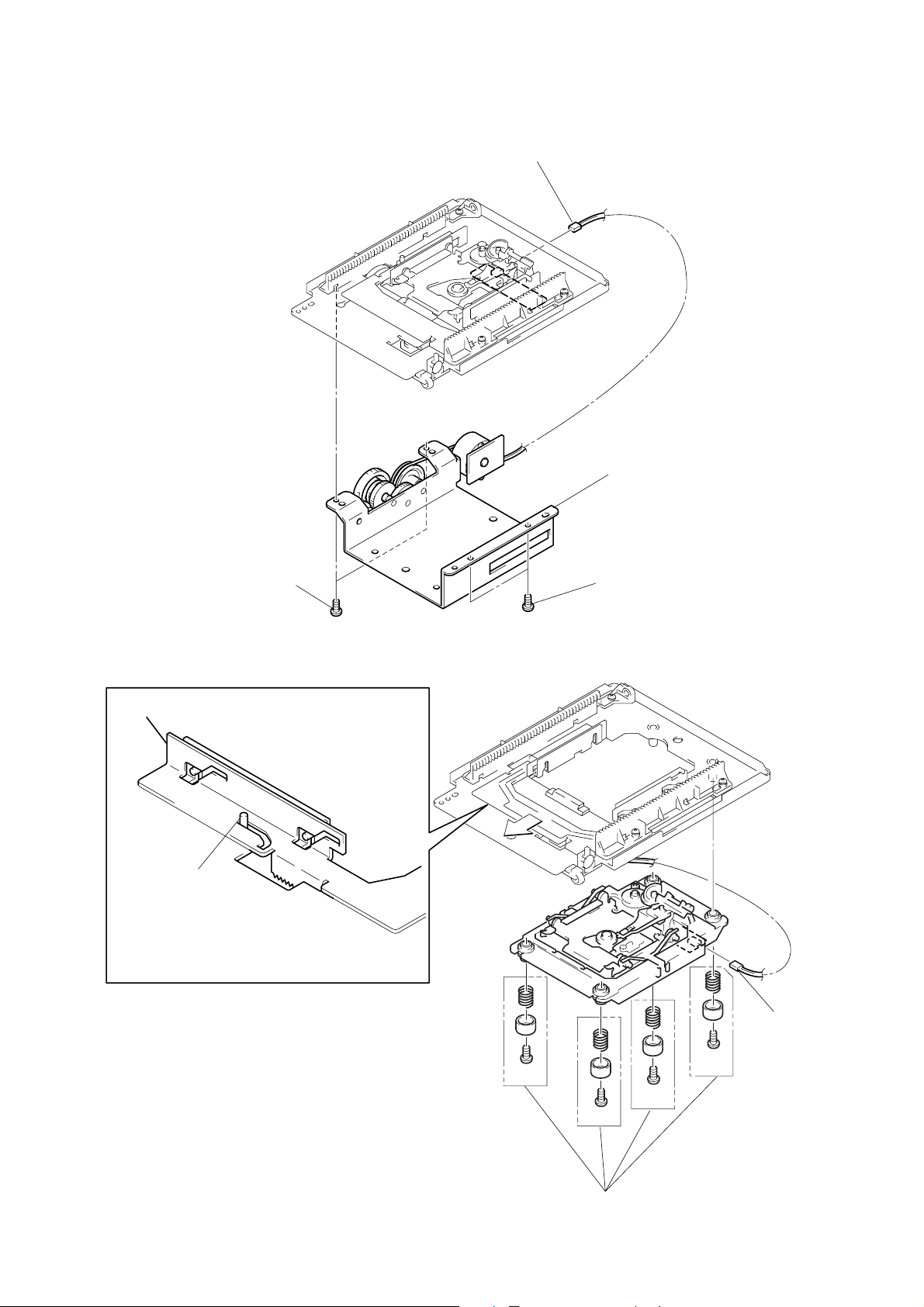

3-2. BRACKET (MOTOR) ASSY

1

Two screws

(BVTT 3x6)

3

Connector (CN198 : HMOT board)

4

Bracket (Motor) assembly

2

Two screws

(BVTT 3x6)

3-3. HOLDER ASSY

Slider assembly

Shaft

A

1

When removing, move the slider assembly

in the arrow direction, and check that shaft

A is at the position shown in the figure.

2

Connector

(CN198 :

HMOT board)

3

Remove the four screws (BVTT 3x6), and

remove the four collars (dampers) and four

compression springs.

— 27 —

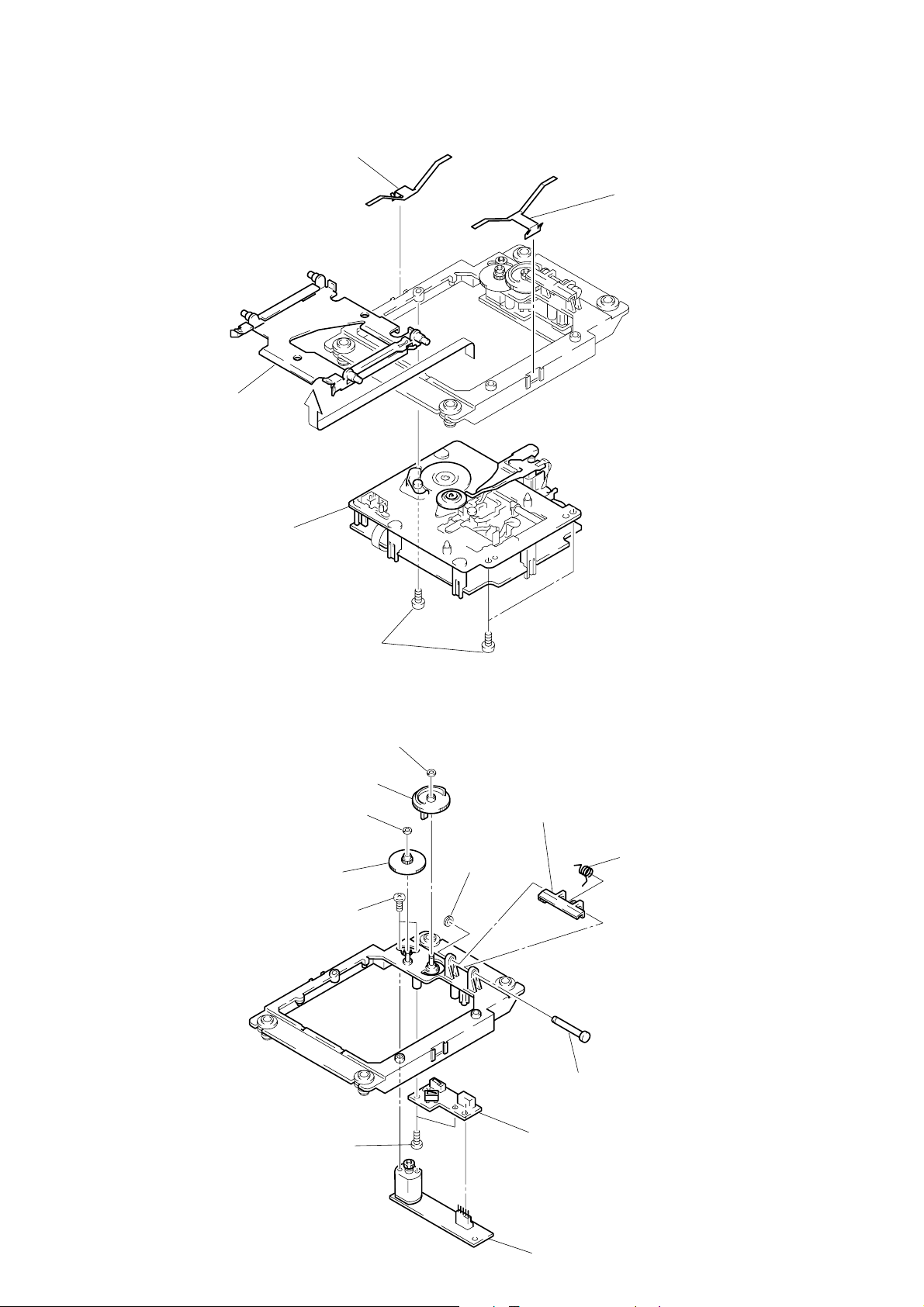

3-4. BASE UNIT

3

Holder assembly

5

Base unit

(MBU-2B)

1

Leaf spring (UDL)

2

Leaf spring (UDR)

4

Three screws

(BVTP 3x6)

3-5. HMOT BOARD AND HLIM BOARD

6

7

Stopper washer

8

Gear (HEAD B)

9

Two screws

(Precision P2x3)

5

Stopper washer

Gear (HEAD C)

1

Stopper

washer

3

Lever (OWH)

2

Shaft (OWH)

4

Torsion spring (OWH)

!¡

Two screws

(PTP 2.6x6)

— 28 —

!™

HLIM board

0

HMOT board

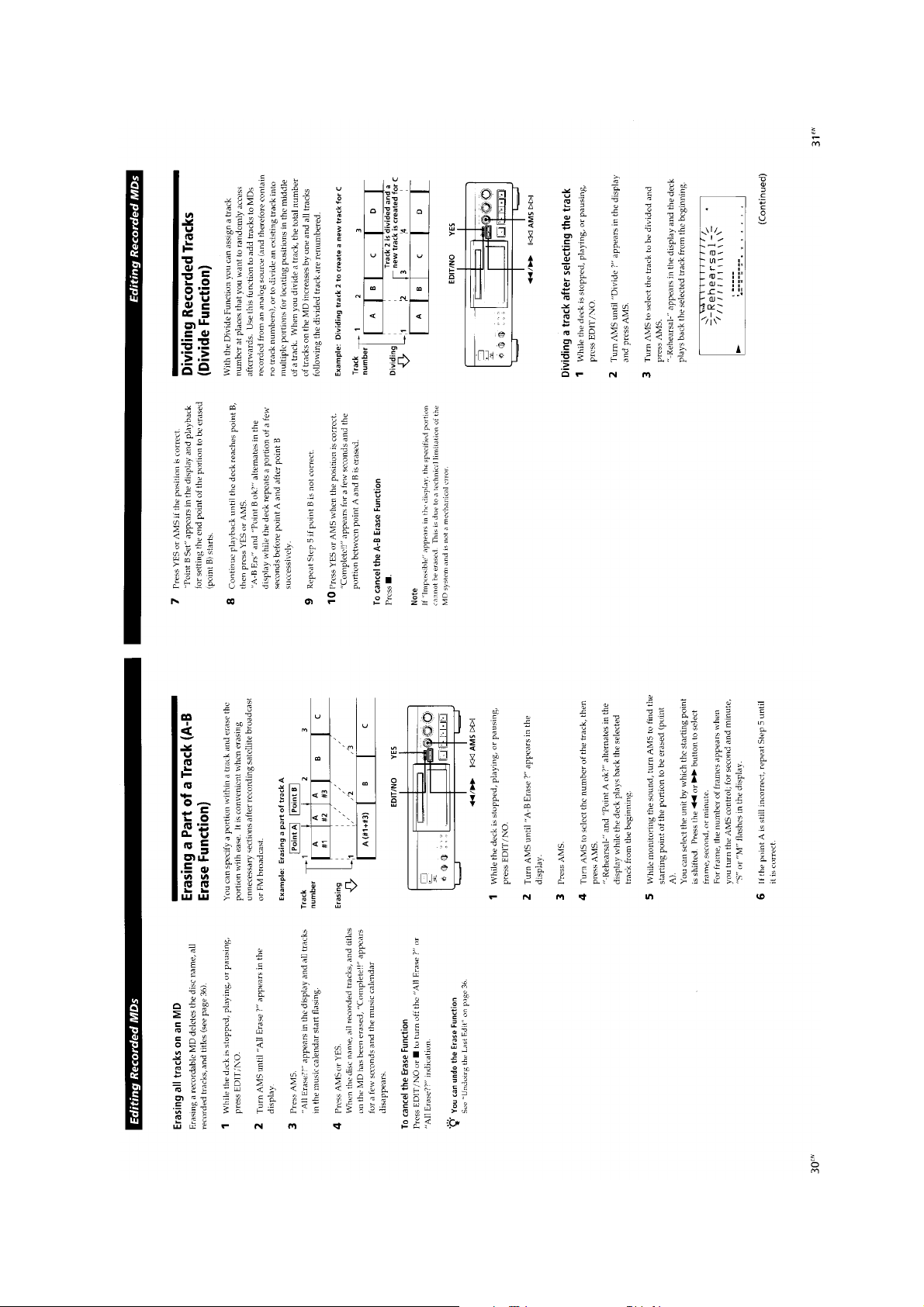

SECTION 4

TEST MODE

4-1. Setting the Test Mode

While pressing the AMS knob, insert the power plug into the power supply inlet, and release the AMS knob.

4-2. Exiting the Test Mode

Press the REPEAT button. Unplug the power plug from an outlet.

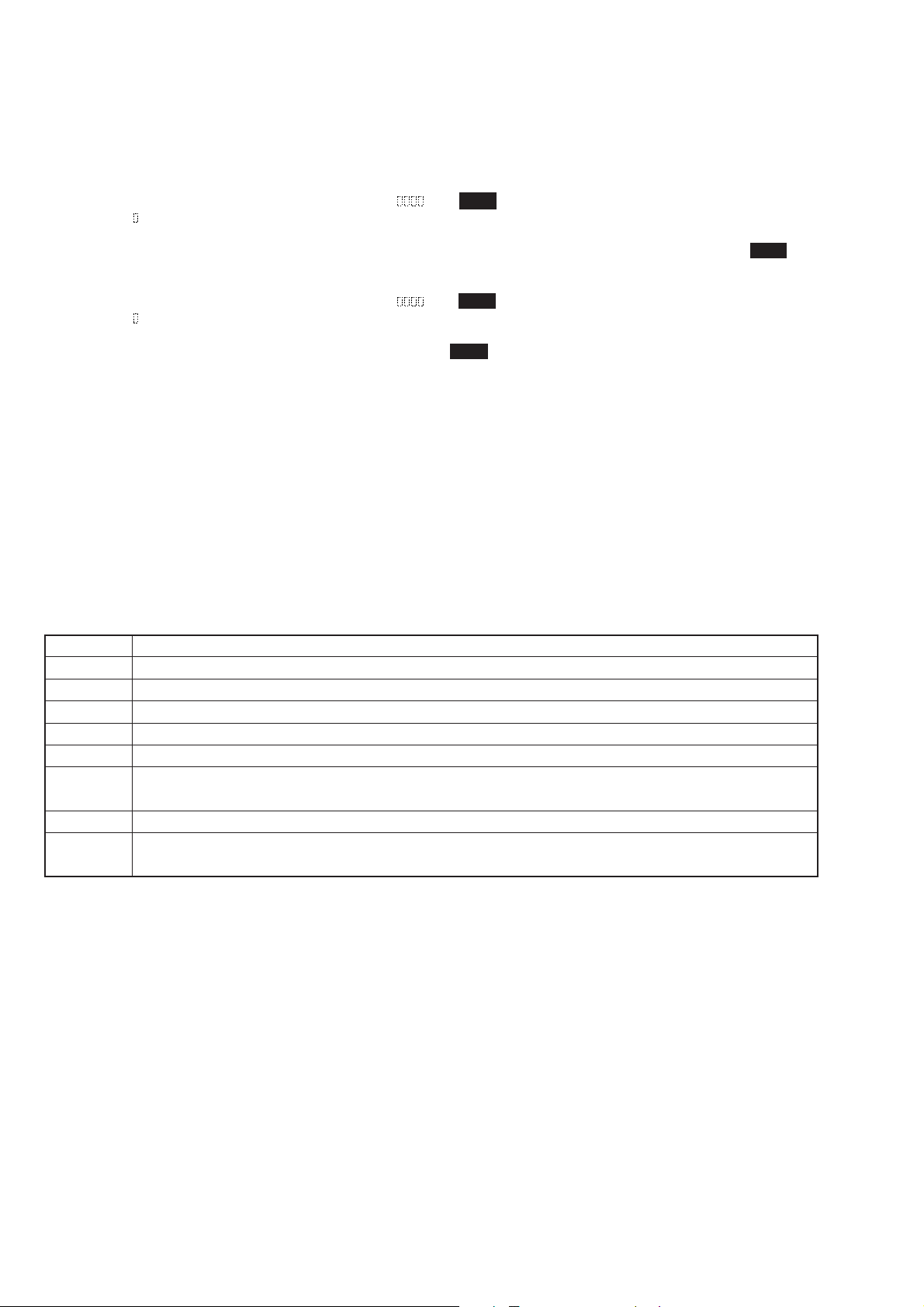

4-3. Basic Operations of the Test Mode

All operations are performed using the AMS knob, YES button, and NO button.

The functions of these buttons are as follows.

Function

AMS knob

YES button

NO button

Changes parameters and modes

Proceeds onto the next step. Finalizes input.

Returns to previous step. Stops operations.

Contents

4-4. Selecting the Test Mode

Eight test modes are selected by turning the AMS knob.

Display

TEMP ADJUS

LDPWR ADJUS

EFBAL ADJUS

FBIAS ADJUS

FBIAS CHECK

CPLAY MODE

CREC MODE

EP MODE

Temperature compensation offset adjustment

Laser power adjustment

Traverse adjustment

Focus bias adjustment

Focus bias check

Continuous playback mode

Continuous recording mode

Non-volatile memory mode *

For detailed description of each adjustment mode, refer to 5. Electrical Adjustments.

If a different adjustment mode has been selected by mistake, press the NO button to exit from it.

* The EP MODE is not used in servicing. If set accidentally, press the NO button immediately to exit it.

4-4-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

1 Set the disc in the unit (either MO or CD).(MO: Recordable disc, CD: Disc for playback only).

2 Rotate the AMS knob and display “CPLAY MODE”.

3 Press the YES button to change the display to “CPLAY IN”.

4 When access completes, the display changes to “C1 =

Note : The “

” displayed are arbitrary numbers.

2. Changing the parts to be played back

1 Press the YES button during continuous playback to change the display to “CPLAY MID”, “CPLAY OUT”.

When pressed another time, the parts to be played back can be changed.

2 When access completes, the display changes to “C1 =

Note : The “

” displayed are arbitrary numbers.

3. Ending the continuous playback mode

1 Press the NO button. The display will change to “CPLAY MODE”.

2 Press the §OPEN/CLOSE button and remove the disc.

Note 1 :The playback start addresses for IN, MID, and OUT are as follows.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

Contents

AD = ”.

AD = ”.

— 29 —

4-4-2. Operating the Continuous Recording Mode

1. Entering the continuous recording mode

1 Set the MO disc in the unit.

2 Rotate the AMS knob and display “CREC MODE”.

3 Press the YES button to change the display to “CREC IN”.

4 When access completes, the display changes to “CREC (

Note : The “

” displayed are arbitrary numbers.

” and REC lights up.

2. Changing the parts to be recorded

1 When the YES button is pressed during continuous recording, the display changes to “CREC MID”, “CREC OUT” and REC goes

off.

When pressed another time, the parts to be recorded can be changed.

2 When access completes, the display changes to “CREC (

Note : The “

” displayed are arbitrary numbers.

” and REC lights up.

3. Ending the continuous recording mode

1 Press the NO button. The display changes to “CREC MODE” and REC goes off.

2 Press the §OPEN/CLOSE button and remove the disc.

Note 1 : The recording start addresses for IN, MID, and OUT are as follows.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

Note 2 : The NO button can be used to stop recording anytime.

Note 3 : During the test mode, the erasing-protection tab will not be detected. Therefore be careful not to set the continuous recording

mode when a disc not to be erased is set in the unit.

Note 4 : Do not perform continuous recording for long periods of time above 5 minutes.

Note 5 : During continuous recording, be careful not to apply vibration.

4-4-3. Non-Volatile Memory Mode

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If set accidentally, press the NO button immediately to exit it.

4-5. Functions of Other buttons

Function

·

p

)

0

r

SCROLL/

CLOCK SET

PLAY MODE

DISPLAY/

CHAR

Sets continuous playback when pressed in the STOP state. When pressed during continuous playback, the tracking servo turns ON/OFF.

Stops continuous playback and continuous recording.

The sled moves to the outer circumference only when this is pressed.

The sled moves to the inner circumference only when this is pressed.

Turns recording ON/OFF when pressed during continuous playback.

Switches between the pit and groove modes when pressed.

Switches the spindle servo mode (CLVS and A).

Switches the display when pressed.Returns to previous step. Stops operations.

Note : The erasing-protection tab is not detected during the test mode. Recording will start regardless of the position of the erasing-protec-

tion tab when the r button is pressed.

Contents

— 30 —

Loading...

Loading...