Page 1

KP-44PX2/44PX2U

PROJECTION TV

RM-938

SERVICE MANUAL

MODEL

KP-44PX2

COMMANDER DEST CHASSIS NO.

RM-938 AEP SCC-Q85C-A

MODEL

KP-44PX2U

AE-6X

COMMANDER DEST CHASSIS NO.

RM-938 UK SCC-Q84G-A

CHASSIS

KP-44PX2

RM-938

- 1 -

Page 2

KP-44PX2/44PX2U

RM-938

TABLE OF CONTENTS

Section Title Page Section Title Page

Specifications ...................................................... 3

Connectors .......................................................... 4

1. SELF DIAGNOSIS FUNCTION

1-1. AE-6X Self Diagnostic Software ....................... 5

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Rear Board Removal .......................................... 15

3-2. Main Bracket Block Removal ............................ 15

3-3. Service Position ................................................. 15

3-4. Front Panel Removal ......................................... 15

3-5. Resistor Assembly (Focus Pack) Removal ....... 16

3-6. H1 and H3 Board Removal ................................ 16

3-7. Beznet Block Removal ....................................... 17

3-8. High Voltage Cable Removal and Installation .... 17

3-9. AP and D Board Removal .................................. 17

3-10. Terminal Board Removal .................................... 18

3-11. G Board Removal ............................................... 18

3-12. A Board Removal ............................................... 19

3-13. Chassis Block Removal ...................................... 19

3-14. Picture Tube Removal ......................................... 19

4. SET-UP ADJUSTMENTS

4-1. Screen Voltage Adjustment

(Rough Alignment) ............................................ 20

4-2. Screen (G2) Adjustment .................................... 20

4-3. Focus Rough Adjustment .................................. 20

4-4. Deflection Yoke Tilt Adjustment ........................ 20

4-5. 2-Pole Magnet Adjustment ................................. 21

4-6. 4-Pole Magnet Adjustment ................................. 21

4-7. Green, Red and Blue Focus Adjustment ............ 21

5. SAFETY RELATED ADJUSTMENT

5-1. HV Hold-Down Adjustment ............................. 22

6. ELECTRICAL ADJUSTMENTS

6-1. Adjustments with Commander ........................... 23

6-1-1. How to Select Each Mode .............................. 23

6-1-2. Programming the Remote Commander

for Operation in Service Mode ....................... 23

6-1-3. Setting the TV into Service Mode .................. 23

6-1-4. Screen Display for Service Menu .................. 24

6-1-5. Service List (Projector Engine) ...................... 25

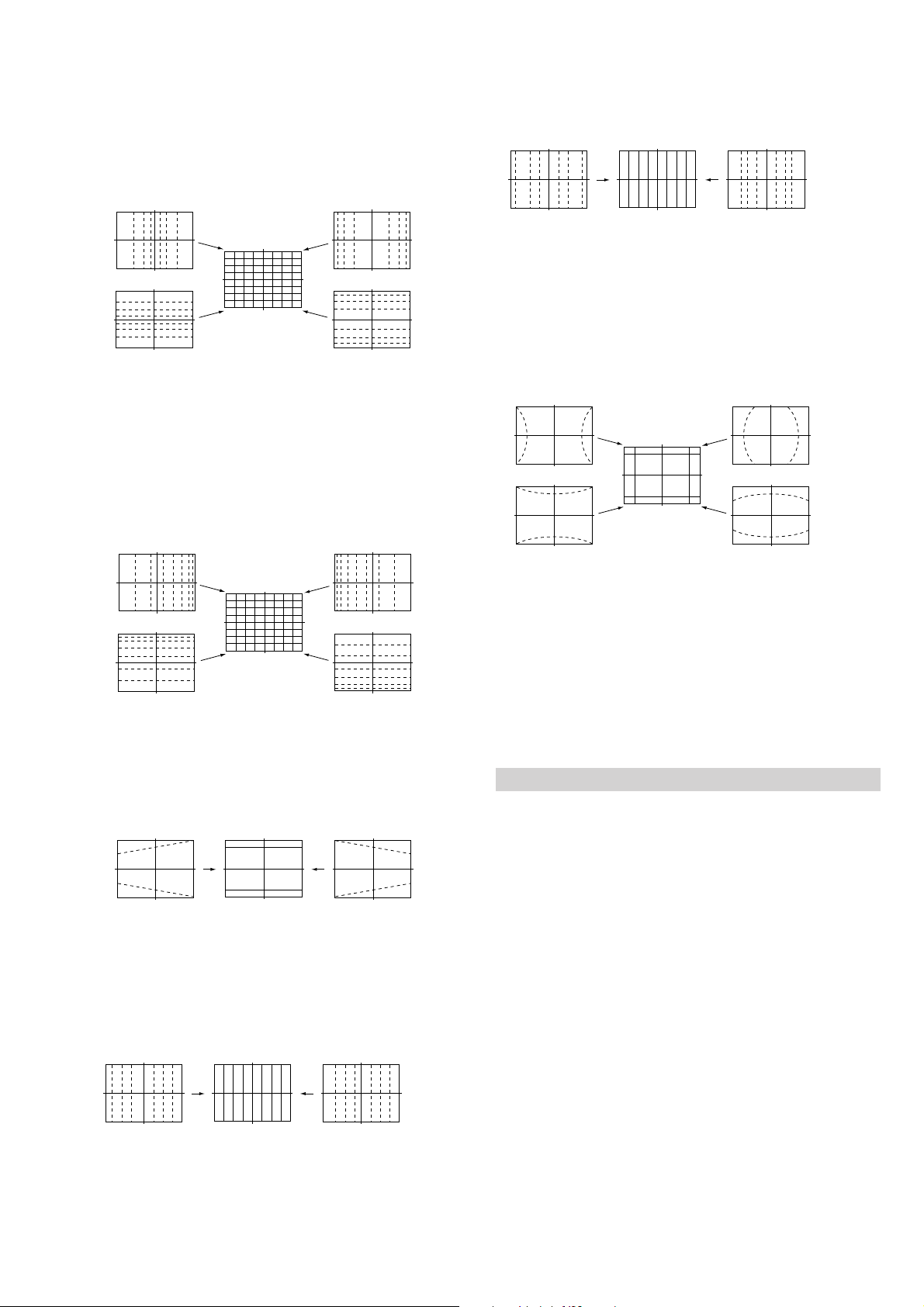

6-2. Registration Adjustment ................................................ 27

6-2-1. Setup for Adjustment ..................................... 27

6-2-2. Main Deflection Adjustment .......................... 27

6-2-3. Operation Method for

Projector Engine Mode ................................... 28

6-2-4. Projector Engine Adjustment

(Sub Deflection Adjustment) .......................... 29

6-3. Auto Convergence Offset ................................... 31

6-4. White Balance Adjustment .................................. 31

6-5. Sub Bright Adjustment ....................................... 31

6-6. Sub Color Adjustment ........................................ 31

6-7. Auto Convergence Error Code List .................... 32

6-8. Test-Test Mode ................................................... 33

7. DIAGRAMS

7-1. Block Diagrams .................................................. 35

7-2. Circuit Boards Location ...................................... 40

7-3. Schematic Diagrams and Printed Wiring

Boards ................................................................. 40

A Board Schematic Diagram (1/2) .................... 41

A Board Schematic Diagram (2/2) ................... 42

A Printed Wiring Board .................................... 43

AP Board Schematic Diagram ............................ 45

AP Printed Wiring Board ................................. 49

D Board Schematic Diagram .............................. 46

D Printed Wiring Board .................................... 50

G Board Schematic Diagram .............................. 52

G Printed Wiring Board .................................... 51

M2 Board Schematic Diagram ............................ 53

M2 Printed Wiring Board ................................. 54

CB, ZB, H1 and H3 Board

Schematic Diagrams ........................................... 55

CB, ZB, H1 and H3 Printed Wiring Boards .... 54

CG, ZG and H2 Board Schematic Diagrams ..... 56

CG, ZG and H2 Printed Wiring Boards ........... 57

CR and ZR Board Schematic Diagrams ............. 58

CR and ZR Printed Wiring Boards ................... 57

7-5. Semiconductors .................................................. 59

7-6. IC Block Diagrams ............................................. 62

8. EXPLODED VIEWS

8-1. Screen and Cover Block ................................... 65

8-2. Control Panel and Cabinet Block ........................ 66

8-3. Main Bracket Block ............................................ 67

8-4. Picture Tube Block ............................................. 68

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

CAUTION

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR THE

CARBON PAINTED ON THE CRT, AFTER REMOVAL OF THE

ANODE CAP.

WARNING !!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE WORK TO AVOID POSSIBLE SHOCK HAZARD

DUE TO LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS

DIRECTLY CONNECTED TO THE POWER LINE.

9. ELECTRICAL PARTS LIST .................................. 69

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

- 2 -

ON

Page 3

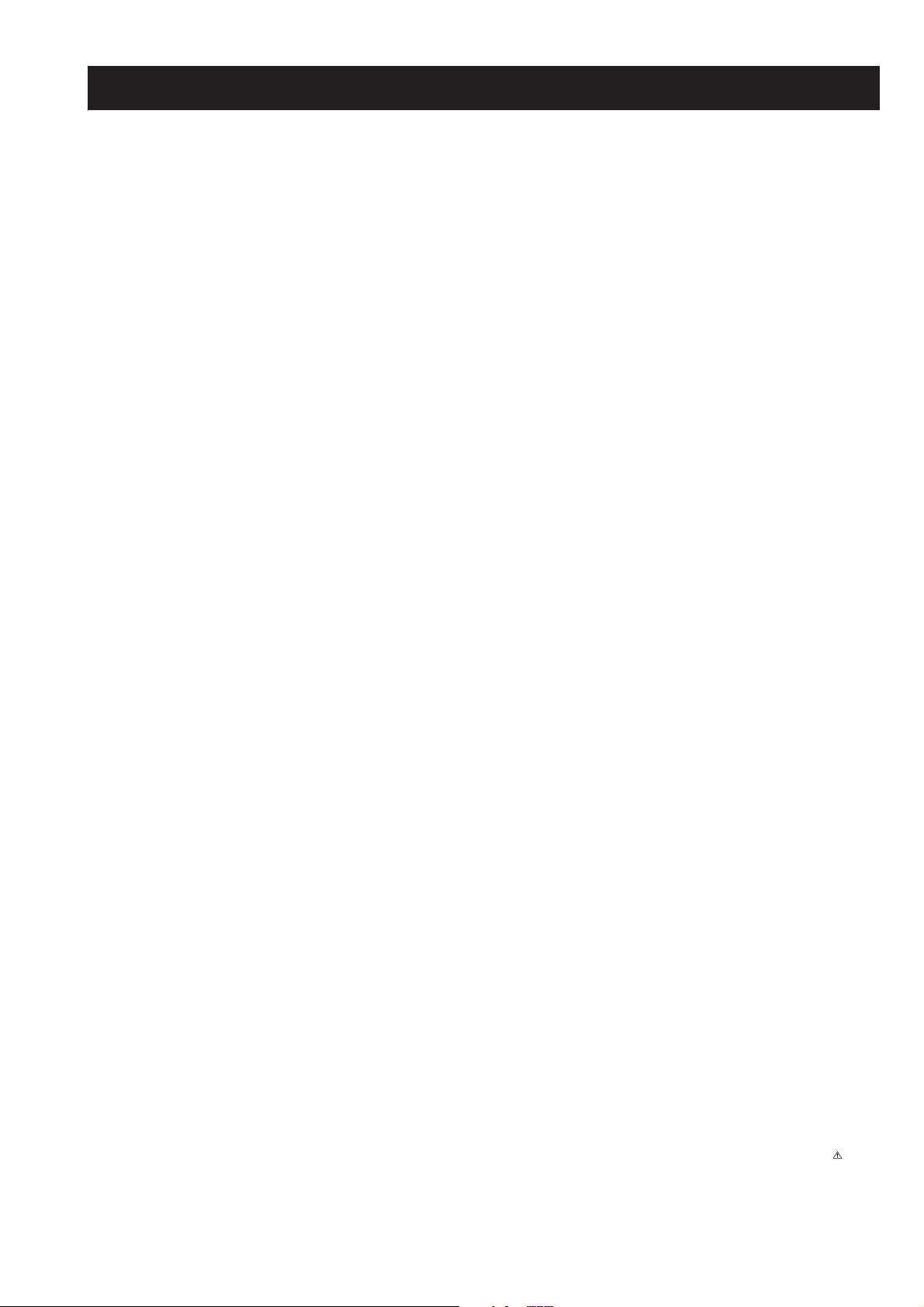

LEDOMMETI metsySnoisiveleT metsySoeretS egarevoClennahC metsySroloC

How to replace the fuse.

Open the fuse compartment with

a screwdriver blade and replace

the fuse.

FUSE

21-10R,21-20E:FHV

Q-B,01-20F:L

21-1R:K/D

AL,I,K/D,H/G/B

UI oeretSMACIN96-12B

MACIN/NAMREG

oeretS

96-12E:FHU

96-210:L

96-12R:K/D

96-12B:I

02S-1S:VTELBAC

14S-12S:REPYH

KP-44PX2/44PX2U

RM-938

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

eziSerutciPdetcejorP

rotcennocoruEnip-12:1

)dradnatsCELENEC(

rotcennocoruEnip-12:2

rotcennocoruEnip-12:3

skcaJonohPoiduArofelbairavsrotcennoCtuptuO

kcajenohpdaeHkcajinimoerets

stupnioiduAskcajonohp

stupnioediVskcajonohp

tupnioediVSNIDnip4

)sehcni44(mc011xorppA

derusaemerutcipmc011xorppA(

)yllanogaid

]RAER[slanimreTtuptuO/tupnI snoitacificepSlareneG

.slangisoediVdnaoiduArofstupnI

.BGRrofstupnI

oiduAdnaoediVVTfostuptuO

.slangis

.slangisoediVdnaoiduArofstupnI

.BGRrofstupnI

.slangisoiduAdnaoediVVTfostuptuO

)tuOrotinoM(

.slangisoediVdnaoiduArofstupnI

)elbatceleS(

.oediVSrofstupnI

kniLVA

slangiS

]EDIS[slanimreTtuptuO/tupnI lortnoCderarfnI:metsySlortnoCetomeR

tuptuodnuoS

rekaepstfeLdnathgiR)SMR(W51x2)rewoPcisuM(W03x2

stnemeriuqeRrewoPV042-022

noitpmusnoCrewoPW522

snoisnemiDmm645x1611x7901xorppA

thgieWgk46xorppA

seirosseccAdeilppuS

serutaeFrehtO

stnemeriuqerrewoP

)1(rednammoCetomeR839-MR

)2(yrettab6RdetangisedCEI

esioNotuA,RND,FCD,sulPlatigiDzH001

,ezeerFerutciP,txeteleT,PIP,noitcudeR

PSD,EBB,ybloDlautriV

cdV3

noitangisedCEIseirettab2

)AAezis(6R

.ecitontuohtiwegnahcottcejbuserasnoitacificepsdnangiseD

metI

bmoClaPFFOFFO

PIPFFOFFO

1tracSNONO

2tracSNONO

3tracSNONO

4tracSFFOFFO

rotcejorPNONO

G/BmroNNOFFO

ImroNNONO

K/DmroNNOFFO

SUAmroNFFOFFO

LmroNNOFFO

TASmroNFFOFFO

MmroNFFOFFO

txeteleTNONO

emaNledoM

ytiroirPBGRNONO

xoBrefooWFFOFFO

)4(nitnorFNONO

oeretSmaciNNONO

2XP44-PK U2XP44-PK

WARNING (UK Models only)

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of 5 AMP rating. Should the fuse need to be

replaced, use a 5 AMP FUSE approved by ASTA to BS 1362, ie one

that carries the

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT SUITABLE FOR THE OUTLET SOCKETS IN YOUR HOME, IT SHOULD

BE CUT OFF AND AN APPROPRIATE PLUG FITTED. THE PLUG

SEVERED FROM THE MAINS LEAD MUST BE DESTROYED AS A

PLUG WITH BARED WIRES IS DANGEROUS IF ENGAGED IN A

LIVE SOCKET.

When an alternative type of plug is used, it should be fitted with a

5 AMP FUSE, otherwise the circuit should be protected by a 5 AMP

FUSE at the distribution board.

- 3 -

ASA

T

mark.

Page 4

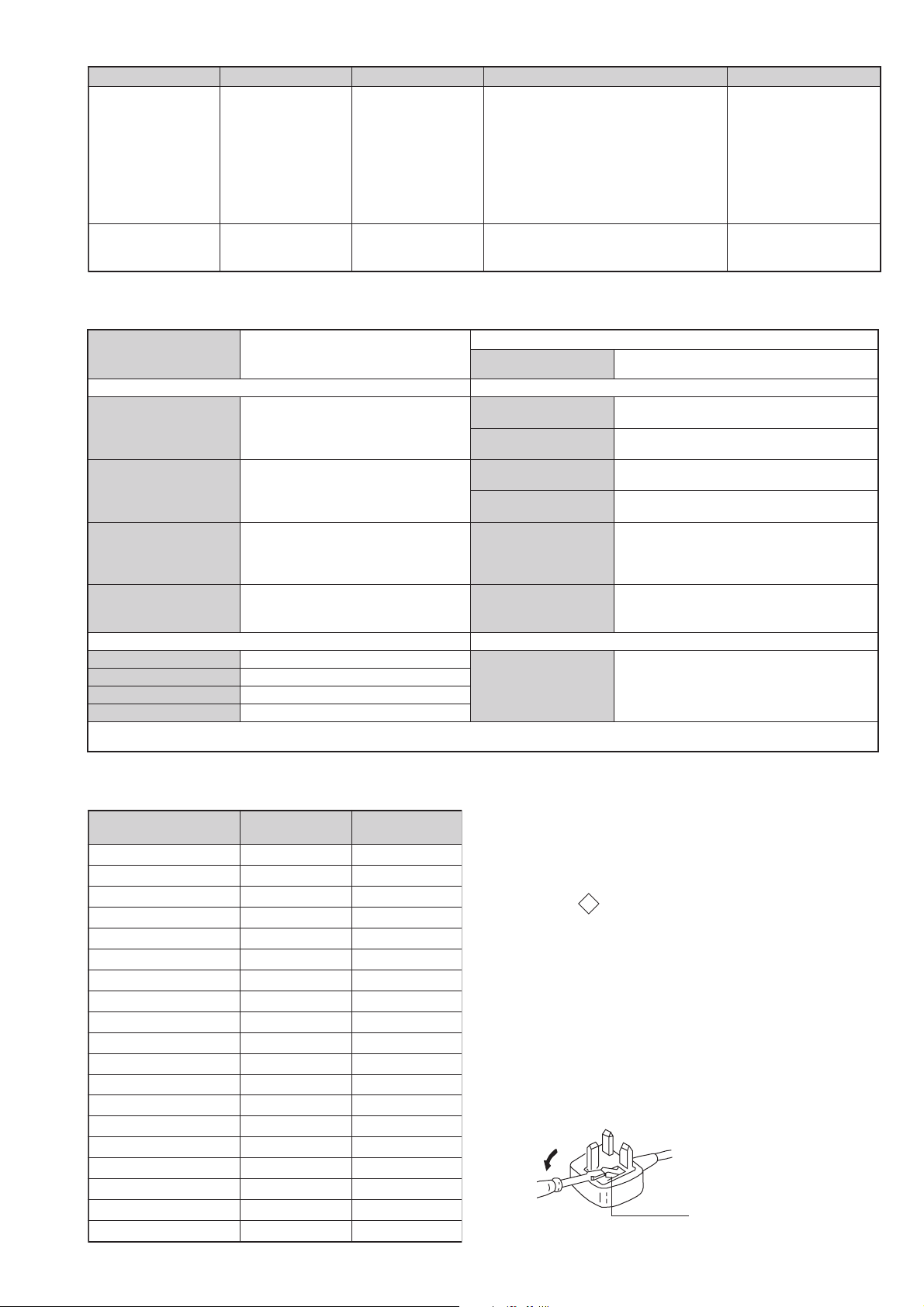

21 pin connector

KP-44PX2/44PX2U

RM-938

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

8

6

4

2

Pin No 1 2 4 Signal Signal level

1 Audio output B

2

3

4 Ground (audio)

5 Ground (blue)

6 Audio input A

7 Blue input 0.7 +/- 3dB, 75 ohms positive

8 Function select

9 Ground (green)

10 Open

11 Green Green signal : 0.7 +/- 3dB, 75 ohms,

12 Open

13 Ground (red)

14 Ground (blanking)

15

16 Blanking input

17 Ground (video

18 Ground (video

19 Video output 1V +/- 3dB, 75ohms, positive sync 0.3V

20

21 Common ground

3

(right)

Audio input B

(right)

Audio output A

(left)

(left)

(AV control)

_ _ Red input 0.7 +/- 3dB, 75 ohms, positive

_ (S signal Chroma

input)

(Ys signal)

output)

input)

_ _ Video input 1V +/- 3dB, 75ohms, positive sync 0.3V

_ Video input

Y (S signal)

(plug, shield)

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

High state (9.5-12V) : Part mode

Low state (0-2V) : TV mode

Input impedence : More than 10K ohms

Input capacitance : Less than 2nF

positive

0.3 +/- 3dB, 75 ohms, positive

High state (1-3V) Low state (0-0.4V)

Input impedence : 75 ohms

(-3+10dB)

(-3+10dB)

1V +/- 3dB, 75ohms, positive sync 0.3V

(-3+10dB)

Connected Not Connected (open) * at 20Hz - 20kHz

Rear Connection Panel Front Connection Panel

niP

oN

S-Video

socket

1dnuorG-

2dnuorG-

3tupni)langisS(Y,mho57Bd3-/+V1

4tupni)langisS(CBd3-/+V3.0

langiS leveLlangiS

noitarugifnocniptekcosoediVS

V3.0.cnySevitisop

Bd01+3-

evitisop,mho57

.cnyS

- 4 -

Page 5

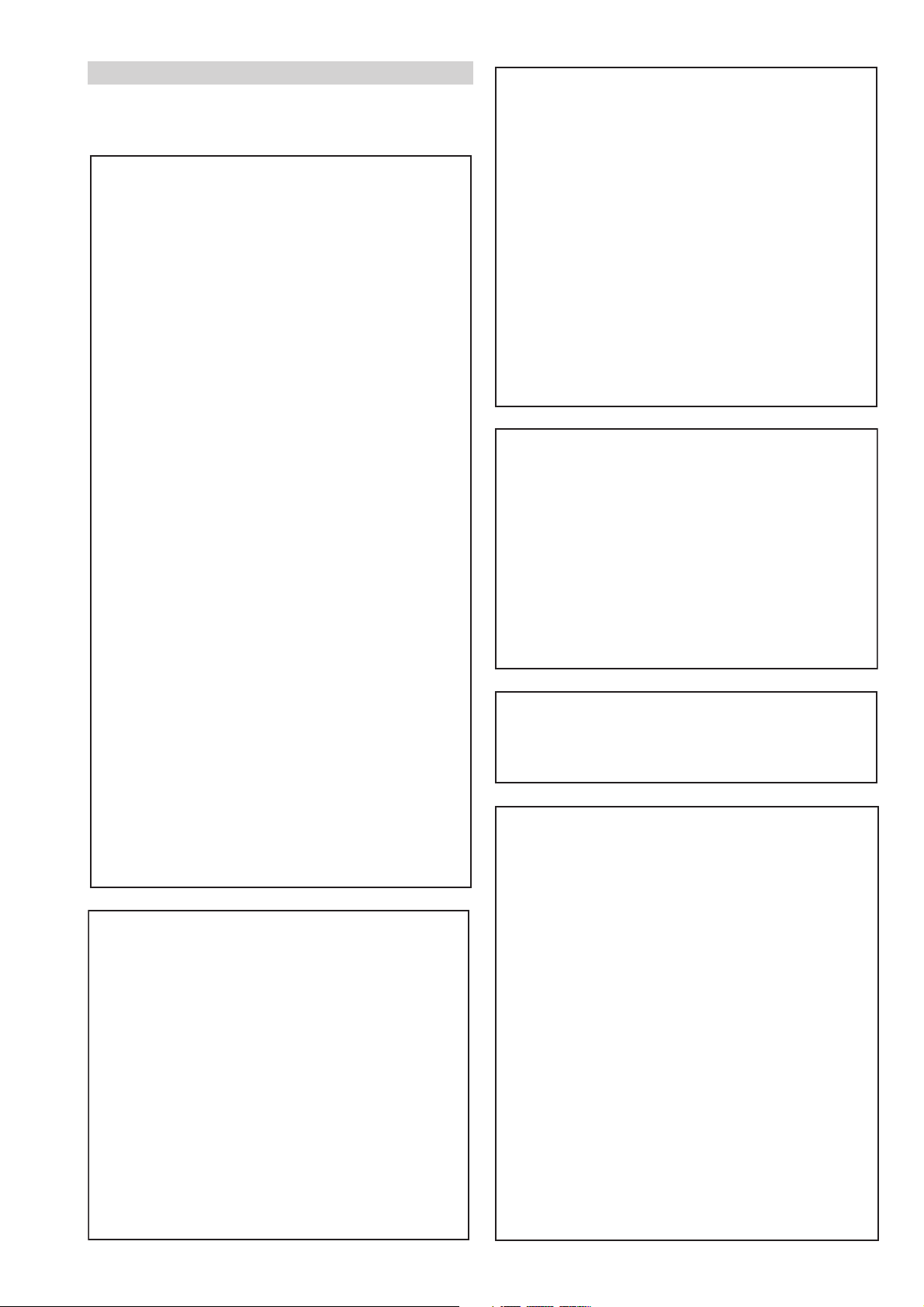

KP-44PX2/44PX2U

RM-938

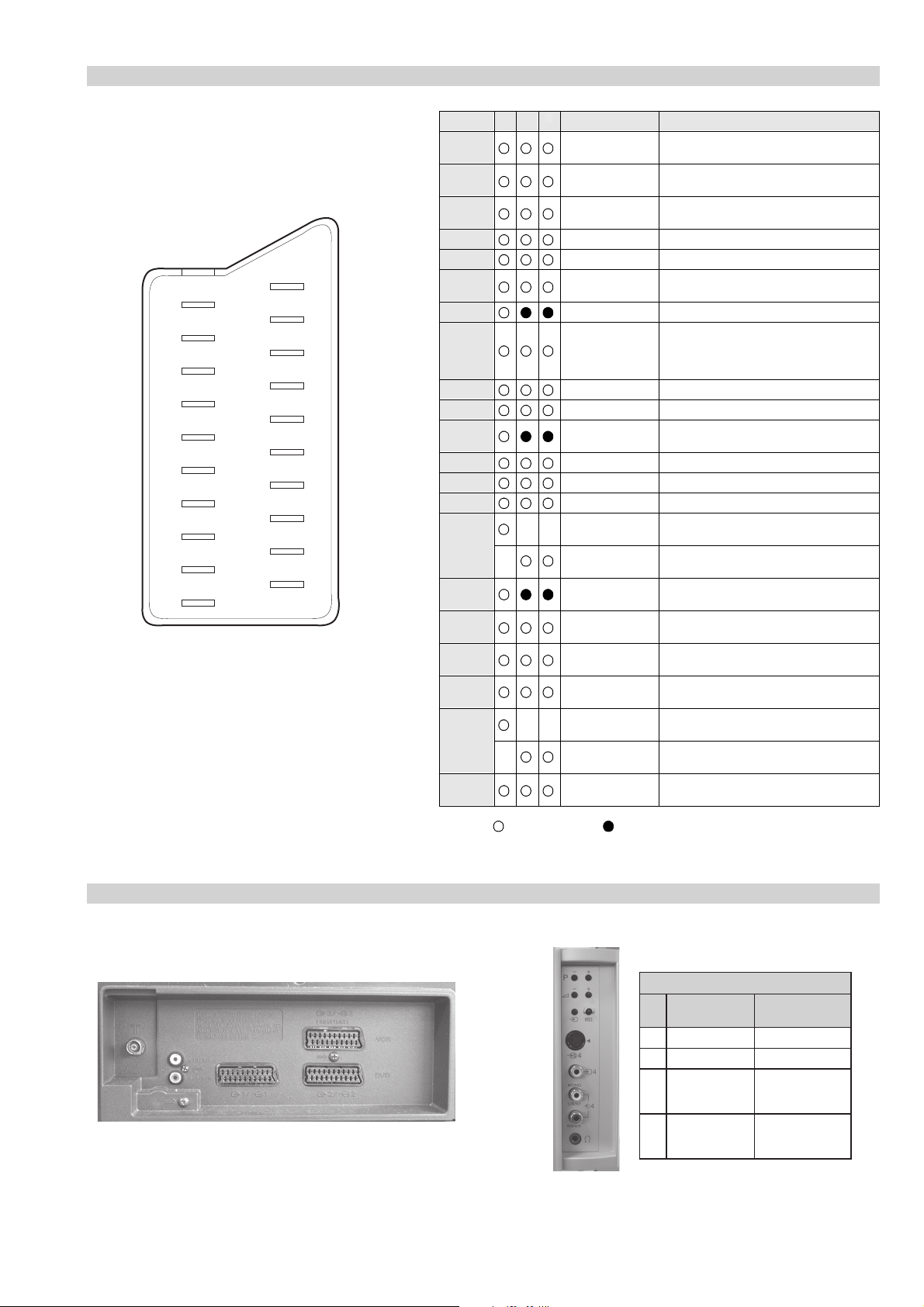

SECTION 1 SELF DIAGNOSIS FUNCTION

1-1. AE-6X Self Diagnostic Software

The identification of errors within the AE-6X chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with a continuous

flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant

device number will be displayed through the LED (Series of flashes which must be counted) See table 1, non fatal errors are reported using this

method.

Each time the software detects an error it is stored within the NVM. See Table 2.

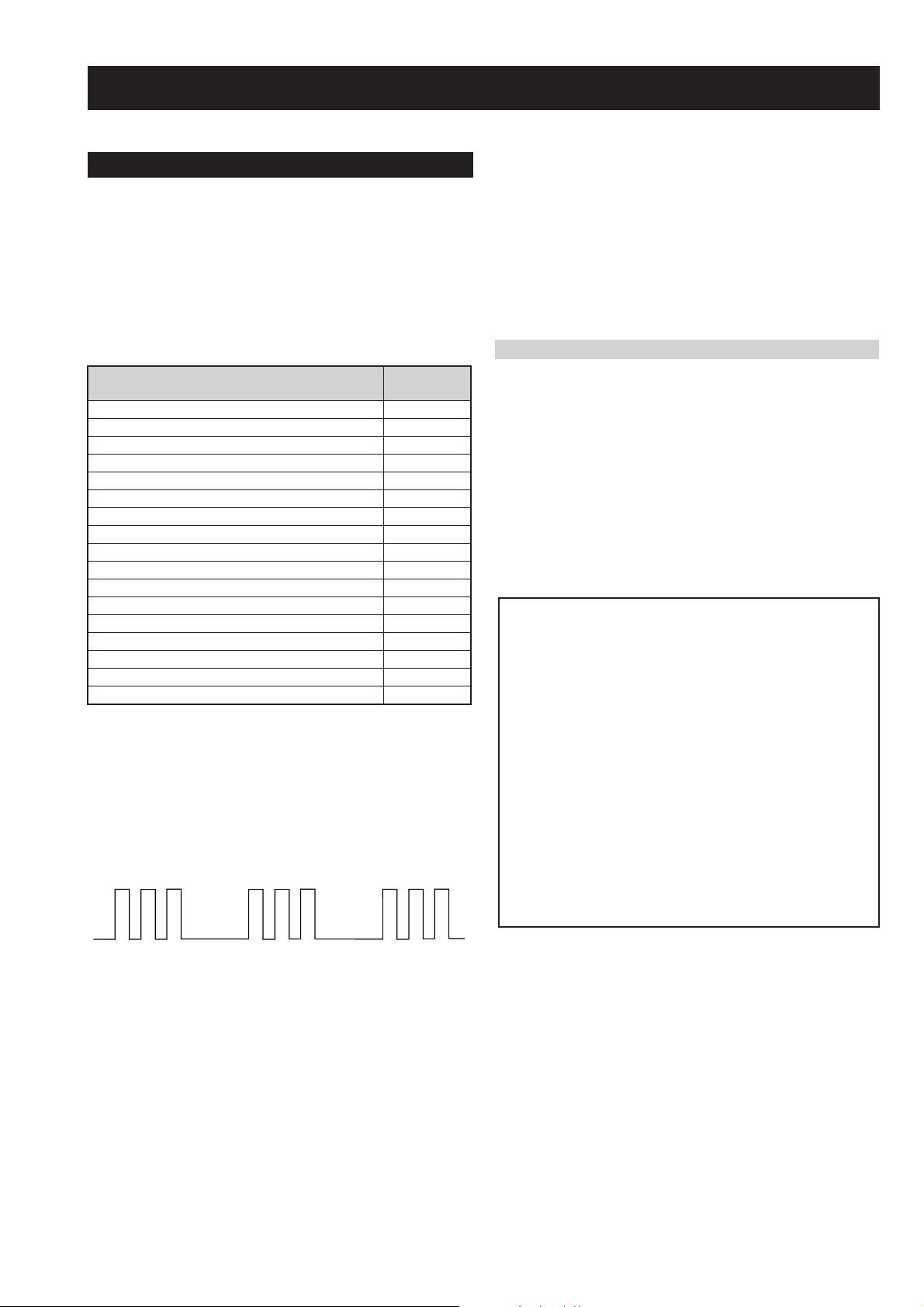

Table 1

egasseMrorrE

rorreoN00

devreseR10

)noitcetorPtnerruCrevO(PCO20

noitcetorPegatloVrevO30

cnySlacitreVoN40

norewoptarorrERKI50

norewoptaegdelwonkcasubCIIonMVN70

noitcetorPlatnoziroH80

norewoptaegdelwonkcaonrenuT90

rorrErossecorPdnuoS01

devreseR11

rorrEetarnacS21

rorrECAD31

rorrEdnekcaB41

rorrEecnegrevnoCcimanyD51

rorrEPIP61

Flash Timing Example : e.g. error number 3

StBy LED

ON ON ON

OFF

OFF

norewoptawolsenilatadro/dnakcolcsubCII60

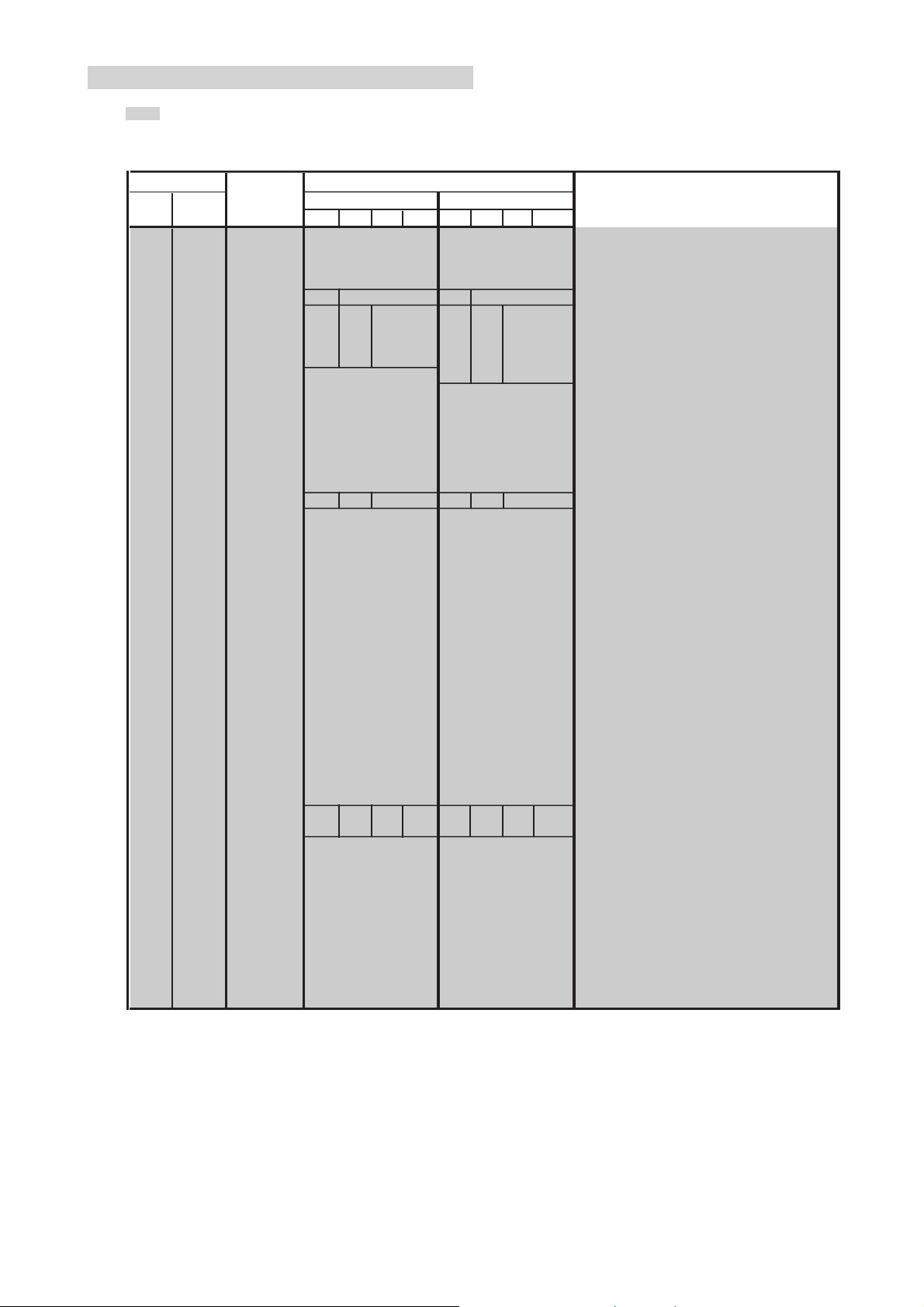

How to enter into Table 2

DEL

edoC

1. Turn on the main power switch of the TV set.

2. Program Remote Commander for Operation in Service

Mode. [See Page 23].

3. Press ‘VIDEO’ ‘VIDEO’ > ‘MENU’ on the Remote

Commander.

4. Using the Remote Commander, Scroll to the ‘Error Menu’

item using the down arrow key, then press the right arrow

key.

5. The following table will be displayed indicating the error

count.

Table 2

UNEMRORRE

20E

30E

40E

50E

60E

70E

80E

90E

01E

11E

21E

31E

41E

51E

61E

SRUOH

SETUNIM

PCO

PVO

CNYSV

RKI

CII

MVN

TORPH

RENUT

PDNUOS

ETARNACS

CAD

DNEKCAB

-

PIP

EMITGNIKROW

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

41

7

Note: To clear the error count data press ‘80’ on the Remote

commander.

- 5 -

Page 6

Language

English

Norge

Français

Italiano

Nederlans

Select Language: Confirm: OK

Language

English

Norge

Français

Italiano

Nederlans

Select Language: Confirm: OK

Language

English

Norge

Français

Italiano

Nederlans

Select Language: Confirm: OK

Country

Sverige

Norge-Italia

Schweiz/Suisse/Svizzera

Select Language: Confirm: OK

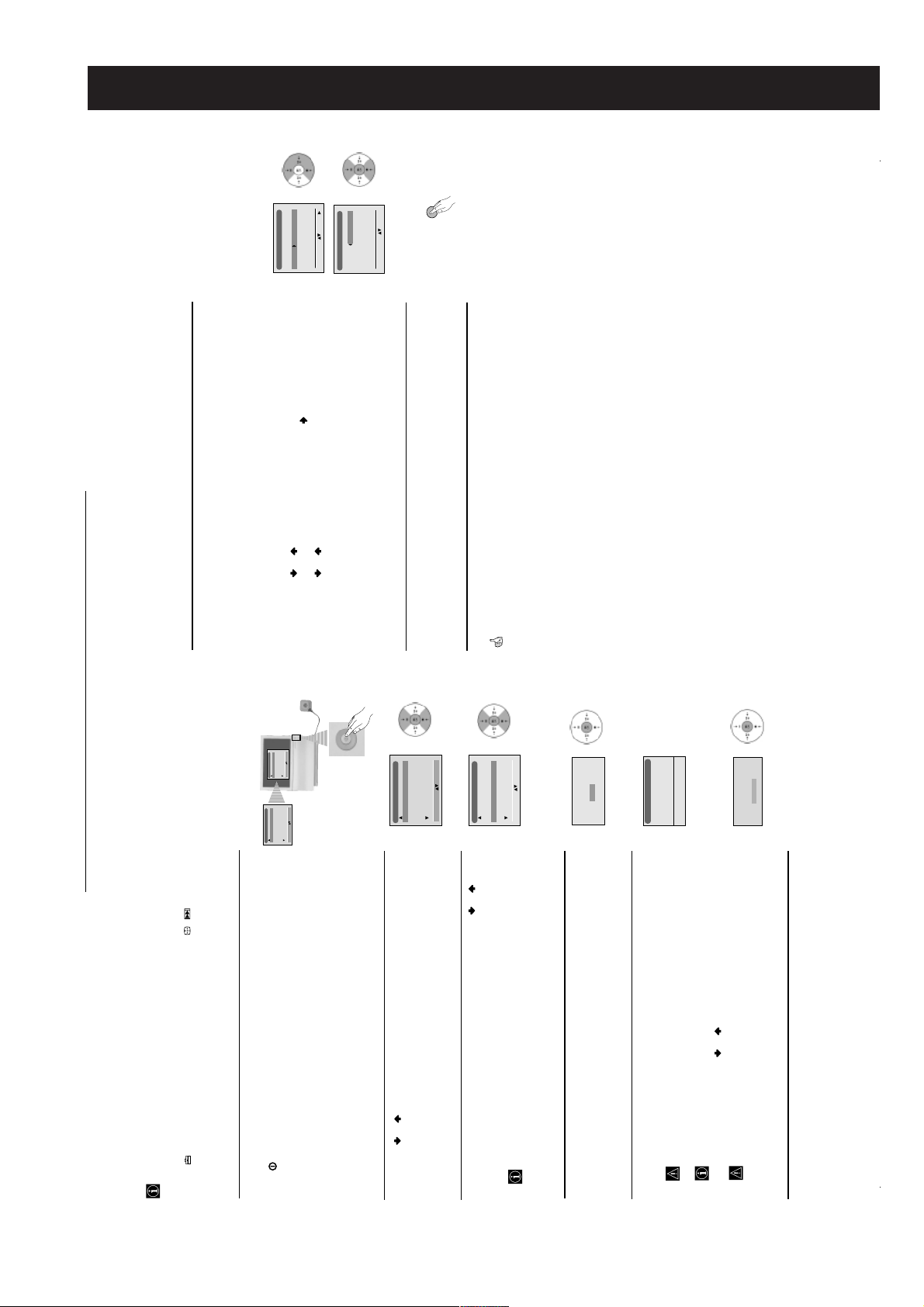

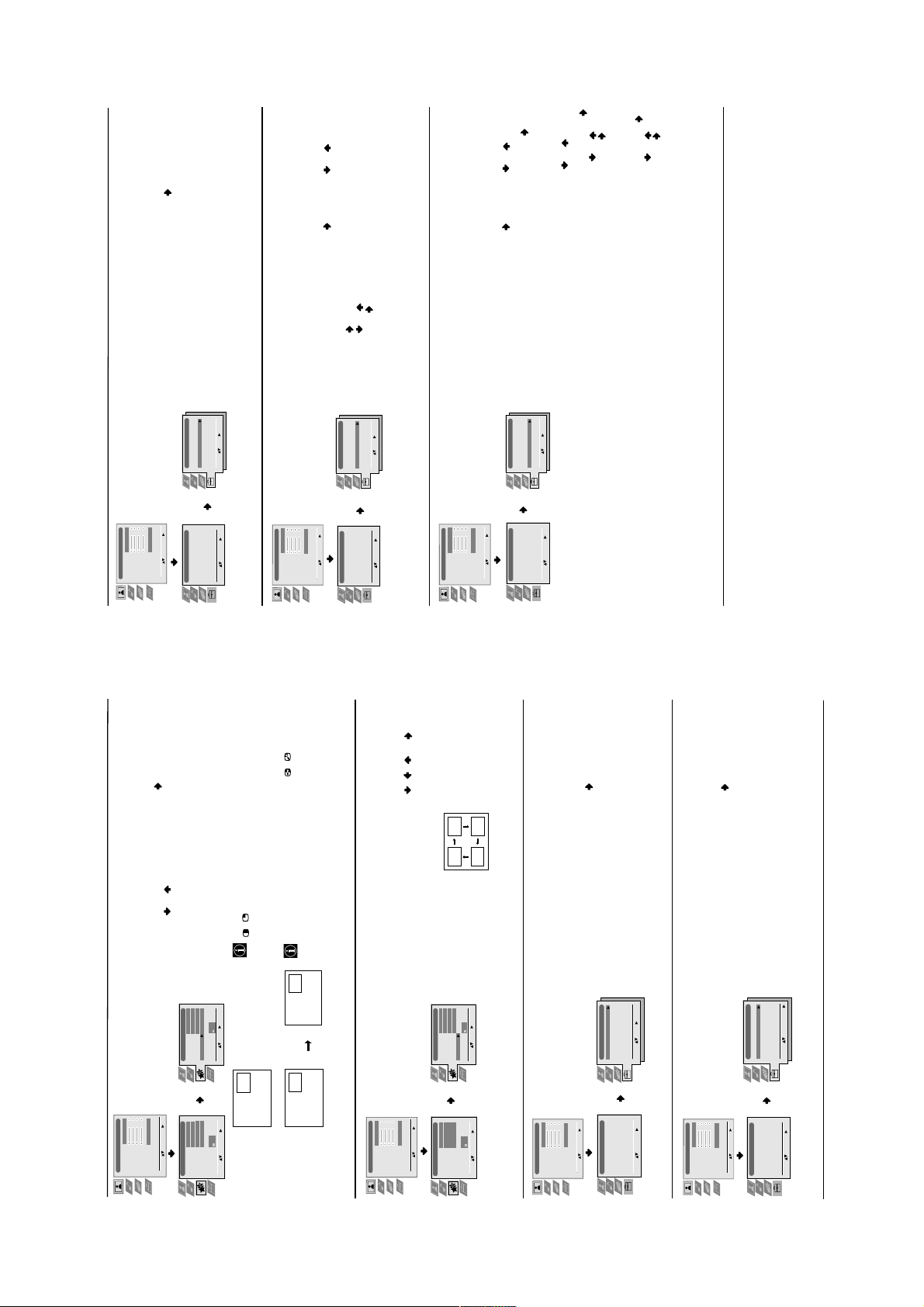

SECTION 2 GENERAL

Programme Sorting

Programme:

01 TVE2

02 TVE

03 ANT3

Select Channel Confirm:

04 TELE5

05 C+

06 C44

Programme Sorting

Programme:

01 TVE2 41 TVE

02 TVE

03 ANT3

Select new position Move: OK

04 TELE5

05 C+

06 C44

GB

9

MENU

First Time Operation

Broadcast) you wish to rearrange, then press the button.

If you wish to keep the broadcast channels in the tuned order, go to step 7.

automatically appears on the screen enabling you to change the order in which the

After all available channels are captured and stored, the Programme Sorting menu

If you wish to store the channels in a different order:

channels appear on the screen.

a)

b)

6

The operating instructions mentioned here are partial abstracts

from the Operating Instruction Manual. The page numbers of

the Operating Instruction Manual remain as in the manual.

selected channel (TV Broadcast), then press OK.

1 Press the or button to select the programme number with the channel (TV

2 Press the or button to select the new programme number position for your

3 Repeat steps b)1 and b)2 if you wish to change the order of the other channels.

Press the MENU button to remove the menu from the screen.

7

Your projection TV is now ready for use.

No

Yes

automatic tuning?

Do you want to start

OK button to select Yes.

1

B/G

C 01

Auto Tuning

Programme:

Channel:

System

Searching...

Confirm

No channel found

Please connect aerial

continued...

select “-” instead of a country.

recommend to select Russia country in the case that your own country does not

appear in the list.

• If the country in which you want to use the TV se does not appear in the list,

• In order to avoid wrong teletext characters for Cyrillic languages we

The first time you switch on your TV, a sequence of menu screens appear on the TV enabling you to: 1) choose the language

However, if you need to change any of these settings at a later date, you can do that by selecting the appropriate option in

of the menu screen, 2) choose the country in which you wish to operate the TV, 3) search and store all available channels (TV

Broadcast) and 4) change the order in which the channels (TV Broadcast) appear on the screen.

the (Set Up menu) or by pressing the Auto Start Up Button / on the TV set.

Switching On the Projection TV and Automatically Tuning

Connect the Projection TV plug to the mains socket (220-240V AC, 50Hz)

The first time that the TV set is connected, it is usually turned on. If the TV is off, press

The first time you switch on the TV, a Language menu displays automatically on the

the on/off button on the TV set to turn on the TV.

TV screen.

1

Press the or button on the remote control to select the language, then press the

OK button to confirm your selection. From now on all the menus will appear in the

selected language.

2

button to confirm your selection.

The Country menu appears automatically on the TV screen. Press the or button

to select the country in which you will operate the TV set, then press the OK

3

– 6 –

The Auto Tuning menu appears on the screen. Press the

4

any buttons, otherwise automatic tuning will not be completed.

system). In this case, the TV Broadcaster sends a menu in which you can select

In some countries the TV Broadcaster installs the channels automatically (ACI

The projection TV starts to automatically search and store all available broadcast

This procedure could take some minutes. Please be patient and do not press

channels for you.

5

again.

appears automatically on the screen asking you to connect the aerial. Please

connect the aerial (see page 7) and press OK. The auto tuning process will start

your city by pressing the or button and OK to store the channels.

If no channels were found during the auto tuning process then a new menu

First Time Operation

8

Page 7

GB

11

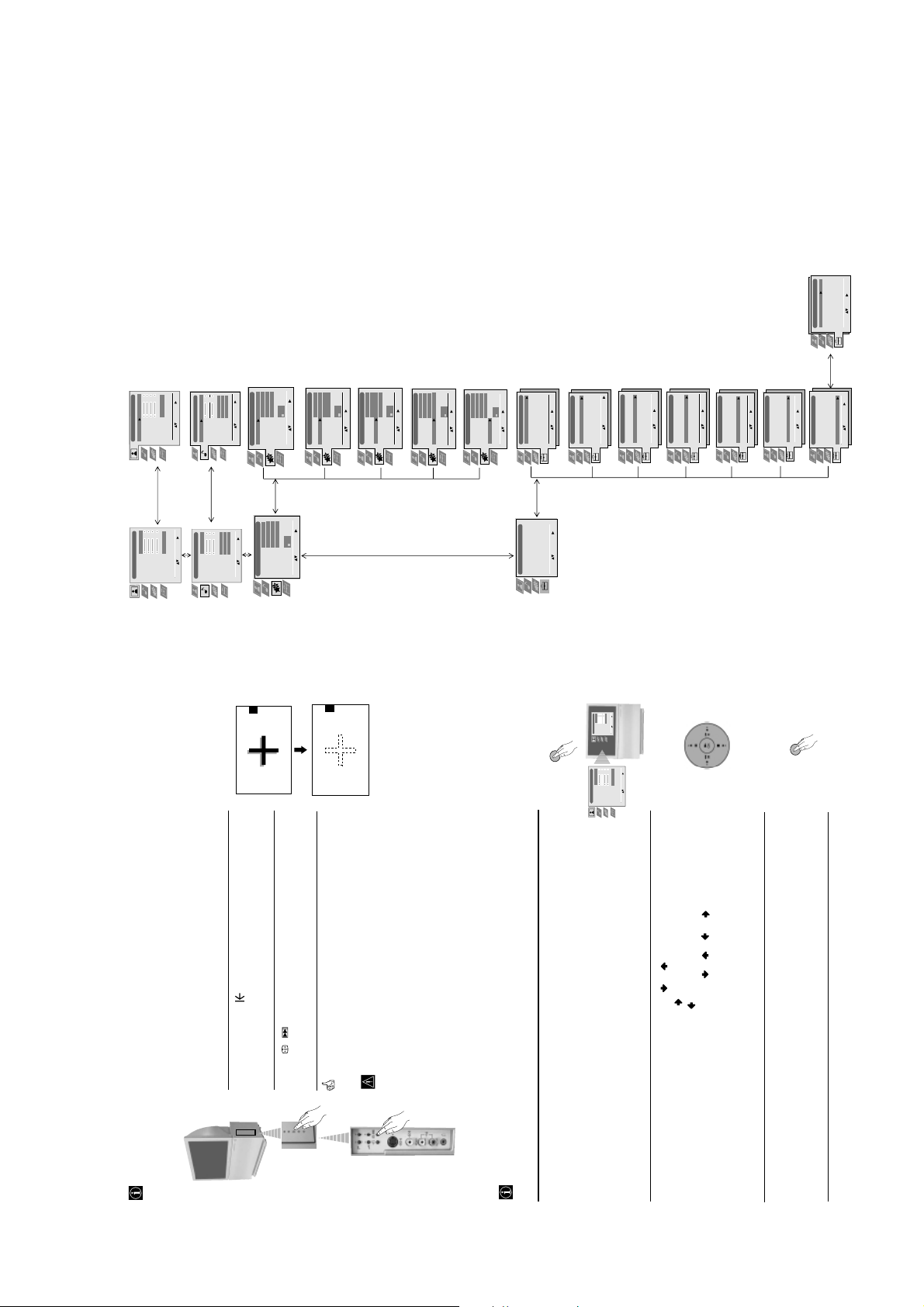

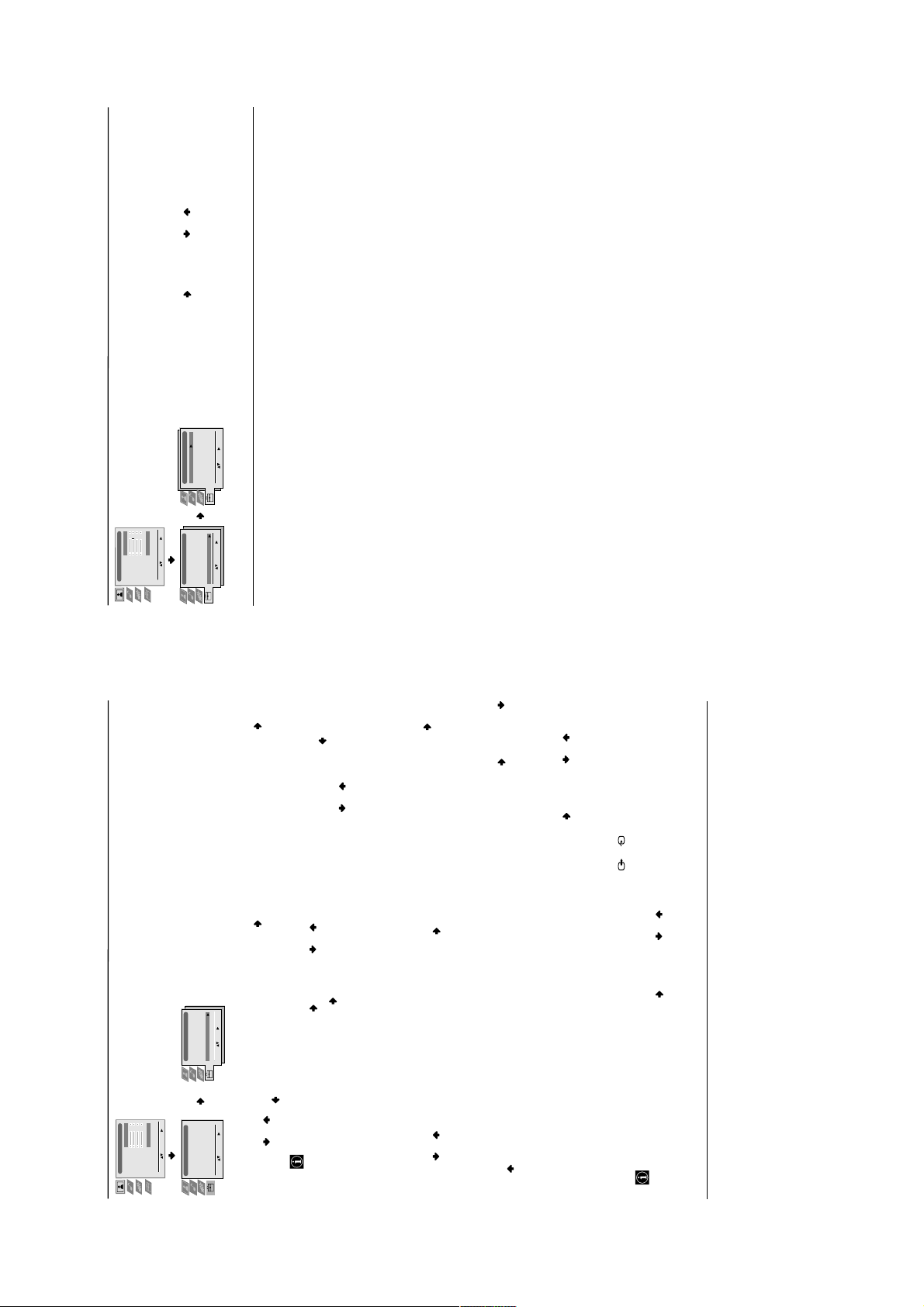

Menu System

Refer to the section "RGB Centring"

on page 17.

0

Enter:

Select:

Detail Set Up

RGB Centring

Personal

Picture Adjustment

Picture Mode

Contrast

Personal

Picture Adjustment

Picture Mode

Contrast

Refer to the section "Picture Adjustment”, on page 12.

AUTO

Brightness

Colour

Sharpness

Reset

Noise Reduction

AUTO

Brightness

Colour

Sharpness

Reset

Noise Reduction

Select: Enter:

Select: Enter Menu:

Natural

Sound Adjustment

Effect

Treble

Bass

Natural

Sound Adjustment

Effect

Treble

Bass

Refer to the section "Sound Adjustment”, on page 12.

Off

On

Stereo

Select: Enter:

Balance

Reset

Dual Sound

Auto Volume

TV Speakers

Off

On

Stereo

Select: Enter Menu:

Balance

Reset

Dual Sound

Auto Volume

TV Speakers

Features

Off

Sleep Timer

Features

On

AUTO

Auto Format

AV3 Output

On

Off

Sleep Timer

Auto Format

Refer to the section "Sleep Timer" on page 13.

AV1

PIP Input

AUTO

AV3 Output

PIP Position

PIP Input

Refer to the section "Auto Format" on page 13.

On

Off

AV1

AUTO

Features

Sleep Timer

Auto Format

AV3 Output

PIP Input

Select: Enter:

AV1

Select: Enter Menu:

PIP Position

Refer to the section "AV3 Output" on page 13.

On

Off

AV1

AUTO

Features

Sleep Timer

Auto Format

AV3 Output

PIP Position

PIP Input

Select: Enter:

On Screen display Menus Guide

PIP Position

Refer to the section "PIP Input" on page 14.

On

Off

AV1

AUTO

Features

Sleep Timer

Auto Format

AV3 Output

PIP Input

Select: Enter:

Refer to the section "PIP Position" on page 14.

On

Off

AV1

AUTO

Features

Sleep Timer

Auto Format

AV3 Output

PIP Input

PIP Position

PIP Position

Select: Enter:

Select: Enter:

Refer to the section "Language/Country" on page 14.

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Auto Tuning

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Auto Tuning

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Set Up

Set Up

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Refer to the section "Auto Tuning" on page 14.

Refer to the section "Programme Sorting" on page 15.

Reset

Select: Enter Menu:

AUTO

Noise Reduction

Set Up

Select: Enter Menu:

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Enter:

Select:

Manual Programme Preset

Detail Set Up

Enter:

Select:

Detail Set Up

Enter Menu:

Enter Menu:

Enter Menu:

Select:

Select:

Select:

Detail Set Up

MENU

Start Auto Tuning:

Select:

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

AUTO

Personal

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Personal

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Set Up

Language/Country

Auto Tuning

Programme Sorting

Refer to the section "Programme Labels" on page 15.

Refer to the section "AV Preset" on page 15.

Enter:

Select:

Set Up

Language/Country

Auto Tuning

Programme Sorting

AV Preset

Manual Programme Preset

Detail Set Up

Programme Labels

Programme Labels

Refer to the section "Manual Programme Preset" on page 16.

Enter:

Select:

AV Preset

Manual Programme Preset

Detail Set Up

Enter:

Enter Menu:

Enter Menu:

Enter Menu:

Select:

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Auto Tuning

Auto Tuning

Set Up

Set Up

Set Up

Language/Country

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Select:

Select:

Select:

MENU

• the input signal is weak.

• the screen is exposed to spotlights or direct sunlight.

• you watch the teletext broadcast.

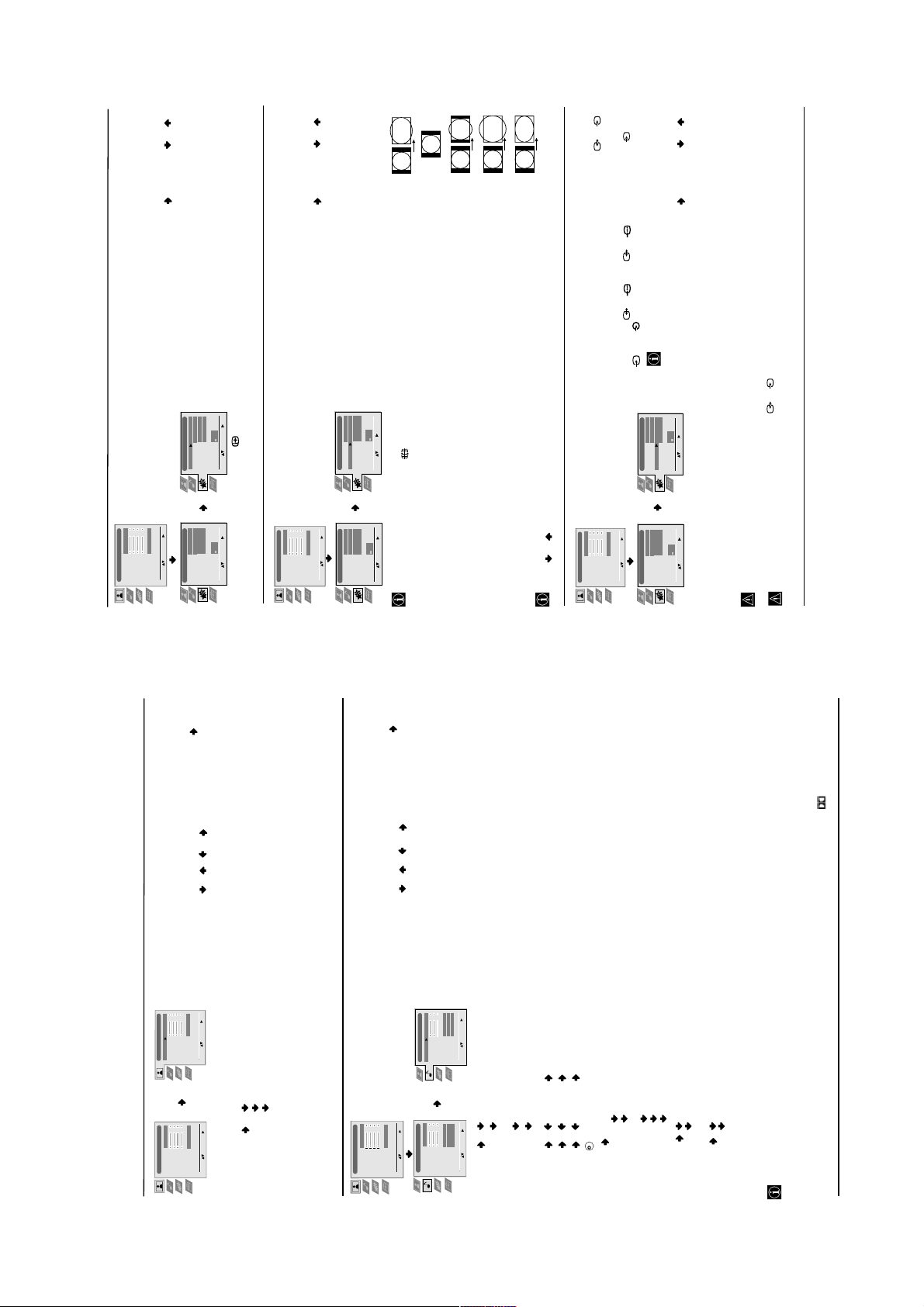

The Auto Convergence function does not work when:

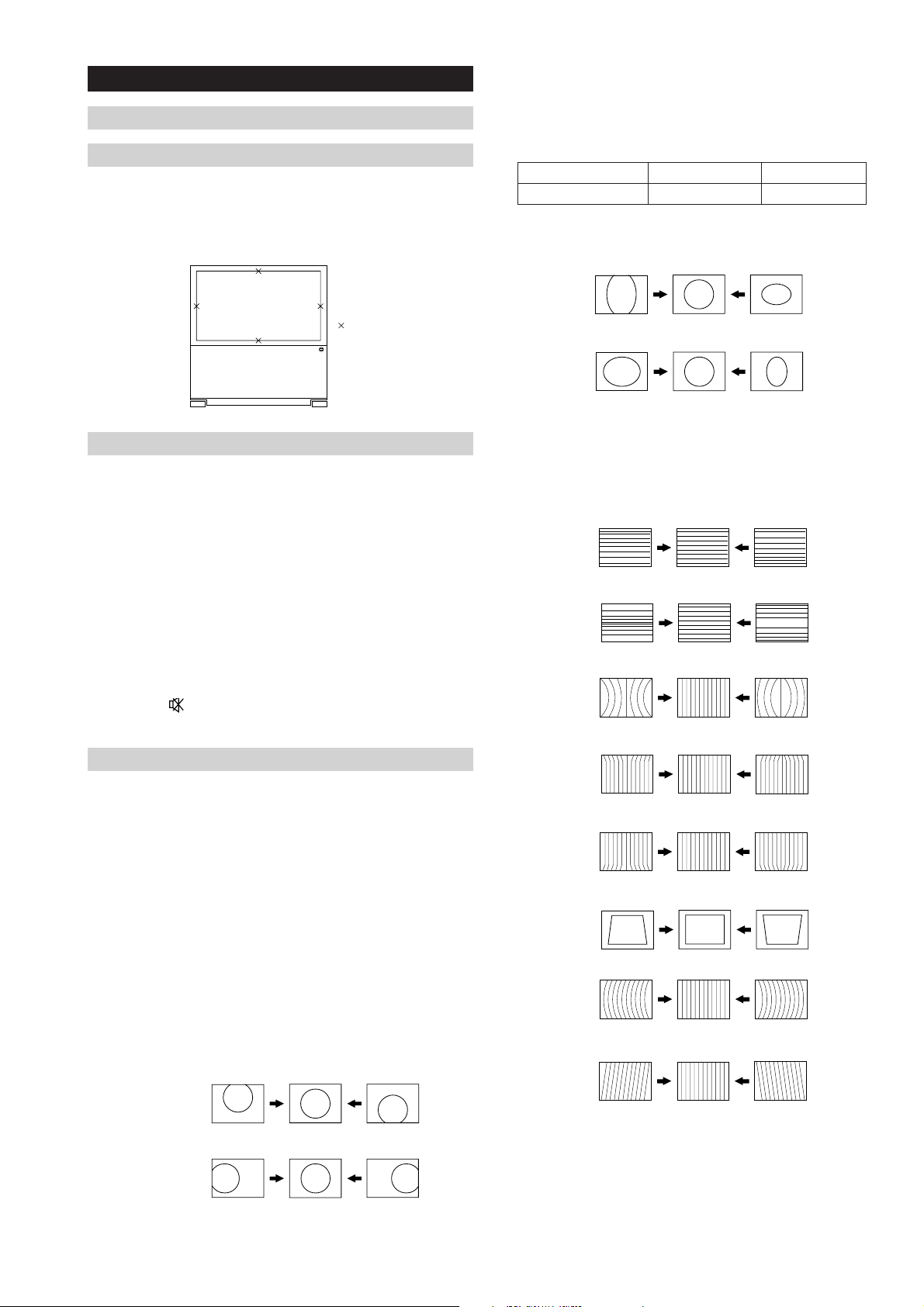

The Auto Convergence function works for about 10 seconds. When the white

Press on the mark , on the right side of the projection TV.

Auto converge the Red, Green, and

Blue Lines

Due to the earth’s magnetism, the picture might become undefined and you could see different colours on the outlines of

the images.

In that case, proceed as follows.

Press / button.

1

2

cross disappears from the screen, your projection TV is ready for use.

Adjusting Colour Registration (Convergence)

• you watch NexTView.

• no signal is input.

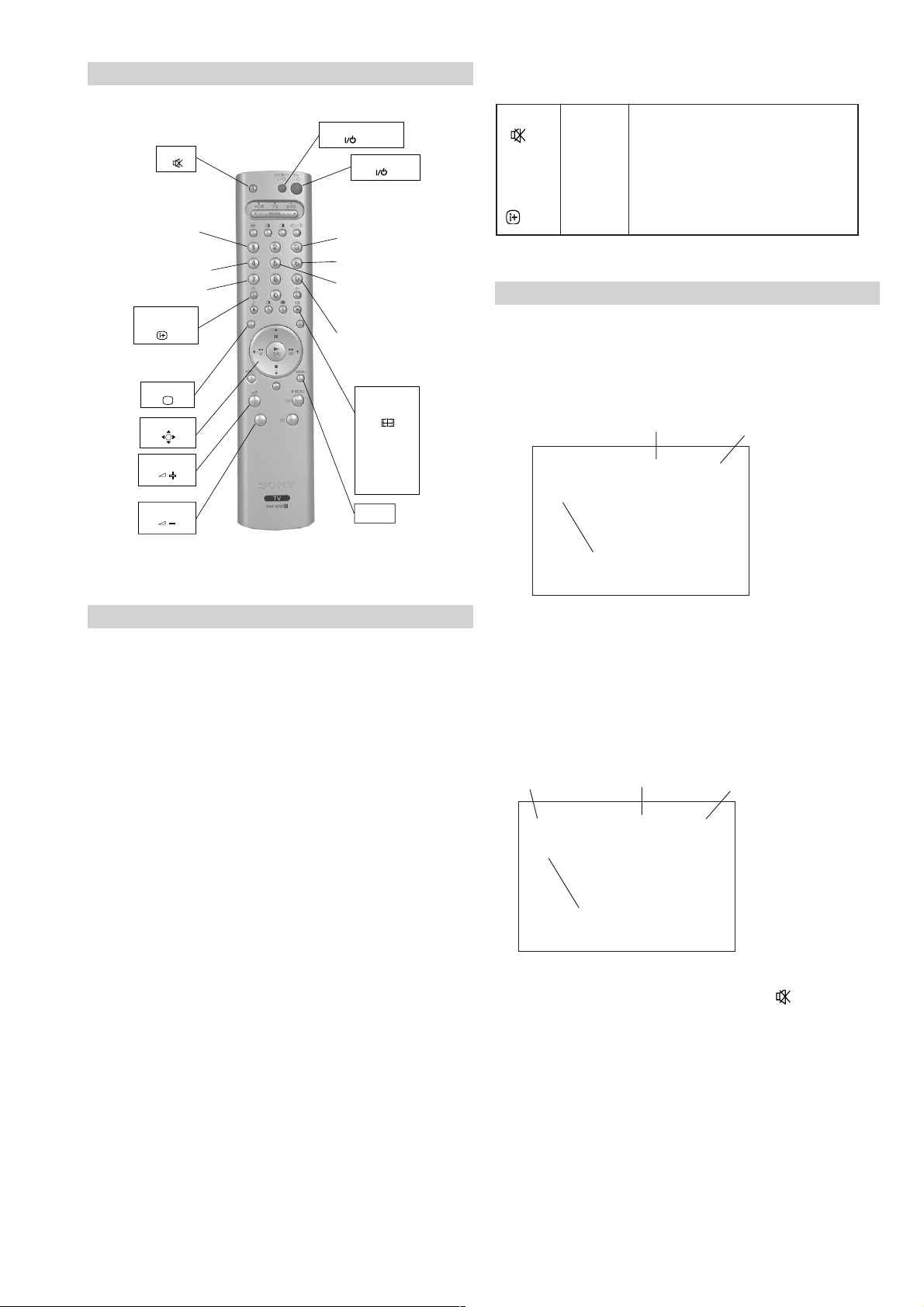

Your projection TV uses an on-screen menu system to guide you through the operations. Use the following buttons on the

Introducing and Using the Menu system

– 7 –

Remote Control to operate the menu system:

Press the MENU button to switch the first level menu on.

1

• To highlight the desired menu or option, press or .

2

• To enter the selected menu or option, press .

• To return to the last menu or option, press .

• To alter the settings of your selected option, press //or.

• To confirm and store your selection, press OK.

Press the MENU button to remove the menu from the screen.

3

First Time Operation - Menu System

10

Page 8

AUTO FORMAT

The “Auto Format” option in the “Features” menu allows you to

To do this: after selecting the option, press . Then press or to

automatically change the aspect ratio of the screen.

select On (if you wish the TV set to automatically switch the screen

format according to the broadcast signal) or Off (if you wish to keep

SLEEP TIMER

The “Sleep Timer” option in the “Features” menu allows you to

select a time period for the TV to switch itself automatically into the

standby mode.

To do this: after selecting the option press , then press or to

set the time period delay (max. of 4 hours).

On

Off

AV1

AUTO

your preference). Finally press OK to store.

On

Off

Features

Sleep Timer

Auto Format

On

Off

AUTO

Personal

Features

Select: Enter:

Sleep Timer

Auto Format

AV3 Output

PIP Input

PIP Position

On

Off

AV1

AUTO

AUTO

Personal

AUTO

AV3 Output

AUTO

GB

S

S

Smart

4:3

14:9

Zoom

Wide

necessary.

If your VCR supports Smartlink, this procedure is not

4 and 4.

To do this: after selecting the option, press . Then press or to

select the desired output signal: TV, AV1, AV2, AV4, YC4 or

AUTO

AV3 Output

AUTO

AUTO.

S

AV1

PIP Input

PIP Position

Select: Enter:

AV1

so that you can record from this Scart any signal coming from the

projection TV or from an external equipment connected to the Scart

AV3 OUTPUT

AV1

PIP Input

PIP Position

Select: Enter:

AV1

connectors 1/ 1 or 2/ 2 or side connectors 4 or

The “AV3 Output” option in the “Features” menu allows you to

select the source to be output from the Scart connector 3/ 3

On

Off

Features

Sleep Timer

Auto Format

On

Off

AUTO

Personal

13

continued...

Menu System

Select: Enter Menu:

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Level 1 Level 2 Level 3 / Function

PICTURE ADJUSTMENT

• While watching the TV, you can press the button on the remote control to display the time remaining.

• One minute before the projection TV switches itself into standby mode, the time remaining is displayed on the TV screen automatically.

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Features

Select: Enter Menu:

Sleep Timer

Auto Format

AV3 Output

PIP Input

PIP Position

The “Picture Adjustment” menu allows you to alter the picture

adjustments.

To do this: after selecting the item you want to alter press , then

press repeatedly / / or to adjust it and finally press OK

to store the new adjustment.

AUTO

Personal

Sharpness

Reset

Noise Reduction

Select: Enter Menu:

Features

Select: Enter Menu:

Sleep Timer

Auto Format

AV3 Output

PIP Input

PIP Position

Even if you have selected “On” or “Off” in the “Auto Format” option, you can always modify the

format of the screen by pressing repeatedly on the remote control to select one of the following

SOUND ADJUSTMENT

The “Sound Adjustment” menu allows you to alter the sound

adjustments.

To do this: after selecting the item you want to alter, press . Then

press repeatedly / / or to adjust it and finally press OK

Smart: Imitation of wide screen effect for 4:3 broadcast.

4:3: Conventional 4:3 picture size, full picture information.

14:9: Compromise between 4:3 and 16:9 picture size.

Zoom: Widescreen format for letterbox movies.

Wide: For 16:9 broadcast. Full picture information.

formats:

In “Smart”, “Zoom” and “14:9” modes, parts of the top and bottom of the screen are cut off.

Press or to adjust the position of the image on the screen (e.g. to read subtitles).

to store the new adjustment.

Off

On

Stereo

Natural

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Select: Enter Menu:

Features

Sleep Timer

Auto Format

AV3 Output

Select: Enter Menu:

PIP Input

PIP Position

the “AV3 Output” to “AUTO” or “TV” for correct unscrambling.

If you select “AUTO”, the output signal will always be the same one that is displayed on the screen.

If you have connected a decoder to the Scart 3/ 3 or to a VCR connected to this Scart, please remember to change back

continued...

Select: Enter:

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

AUTO

Personal

Select: Enter Menu:

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Level 1 Level 2 Level 3 / Function

Menu Guide

Select: Enter:

Sound Adjustment

Effect

Treble

Bass

Balance

Reset

Dual Sound

Auto Volume

TV Speakers

intelligibility and musical realism.

Personal (for individual settings).

Movie (for films).

Off

On

Select: Enter Menu:

Natural

Sound Adjustment

Effect

Treble

Stereo

Select: Enter Menu:

Bass

Balance

Reset

Dual Sound

Auto Volume

TV Speakers

Effect Natural: Enhances clarity, detail and presence of sound by using “BBE High Definition Sound system”*.

Dolby**V: Dolby Virtual, simulates the sound effect of “Dolby Surround Pro Logic”.

Off: Flat response.

Dynamic: “BBE High Definition Sound system”* intensifies clarity and presence of sound for better

Treble Less More

Bass Less More

AUTO

Personal

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Picture Mode Live (for live broadcast programmes, DVD and Digital Set Top Box receivers).

• This menu also allows you to customise the picture mode based on the programme you are watching:

• Brightness, Colour and Sharpness can only be altered if “Personal” mode is selected.

select “Off” instead of “AUTO”.

• The Noise Reduction option is set to AUTO to automatically reduce the picture noise visible in the broadcast signal. To cancel this function,

• Hue is only available for NTSC colour signal (e.g: USA video tapes).

• Select Reset and press OK to reset the picture to the factory preset levels.

– 8 –

Mono.

Stereo.

Mono (for mono channel if available).

(e.g. in the case of advertisements).

A (for channel 1).

B (for channel 2).

On: volume level of the channels will stay the same, independent of the broadcast signal

Off:to listen to the TV from an external amplifier connected to the audio outputs on the rear of the projection

• For a bilingual broadcast:

K

TV Speakers On: to listen to the TV from the set speakers.

Balance Left Right

Reset Resets the sound to the factory preset levels.

Dual Sound • For a stereo broadcast:

Auto Volume Off: volume level changes according to the broadcast signal.

TV set.

when the broadcast audio signal is Dolby Surround encoded. The sound effect can also be improved by connecting a suitable external

amplifier (for details refer to “Connecting to external audio Equipment” on page 21).

U.S. Patent No. 4,638,258 and No. 4,482,866. The word “BBE” and BBE Symbol are trademarks of BBE Sound, Inc.

* The “BBE High Definition Sound system” is manufactured by Sony Corporation under license from BBE Sound, Inc. It is covered by

• If you are listening to the TV through headphones, the “Effect” option will automatically be switched to “Off”.

• If you select “Dolby Virtual” on the “Effect” option, the “Auto Volume” option will automatically be switched to “Off” and vice versa.

Laboratories.

**Manufactured under license from Dolby Laboratories. “Dolby”, “Pro Logic” and the double-D symbol are trademarks of Dolby

** This TV has been designed to create the “Dolby Surround” sound effect by simulating the sound of four speakers with two speakers,

Menu System

12

Page 9

to change the order in which the channels (TV Broadcast) appear on

the screen.

To do this: after selecting the option, press and then proceed in

the same way as in step 6 b) of the section “Switching On the

PROGRAMME SORTING

The “Programme Sorting” option in the “Set Up” menu allows you

Projection TV and Automatically Tuning” on page 9.

PROGRAMME LABELS

The “Programme Labels” option in the “Set Up” menu allows you

the programme number with the channel you wish to name.

to name a channel using up to five characters (letters or numbers).

To do this:

1 After selecting the option, press , then press or to select

GB

press or to select a letter or number (select “-“ for a blank),

then press to confirm this character. Select the other four

characters in the same way. Finally press OK to store.

2 Press . With the first element of the Label column highlighted,

AV PRESET

The “AV Preset” option in the “Set Up” menu allows you to

designate a name to the external equipment you have connected to

the input sockets of this projection TV.

To do this:

GAME, CAM, DVD, VIDEO or SAT), press or to select

the desired label and finally press OK to store.

Then with the first element highlighted, press or to

b) If you want to set a different label, select Edit and press .

a) If you want to use one of the 6 predefined label (CABLE,

the input source you wish to name (AV1, AV2 and AV3 are for

the rear Scarts and AV4 for side connectors). Then press .

1 After selecting the option, press , then press or to select

2 A label automatically appears in the label column:

Then with the first element highlighted, press or to

select a letter, number or “-“ for a blank, then press to

confirm this character. Select the other four characters in the

same way and finally press OK to store.

b) If you want to set a different label, select Edit and press .

15

continued...

Menu System

select a letter, number or “-“ for a blank, then press to

confirm this character. Select the other four characters in the

same way and finally press OK to store.

AUTO

Personal

Select: Enter Menu:

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Level 1 Level 2 Level 3 / Function

Set Up

Set Up

Set Up

Set Up

Language/Country

Auto Tuning

Auto Tuning

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Enter:

Select:

Enter Menu:

Enter Menu:

Enter Menu:

Select:

Select:

Select:

Personal

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

AUTO

Noise Reduction

Select: Enter Menu:

Set Up

Language/Country

Auto Tuning

Auto Tuning

Set Up

Set Up

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Enter:

Select:

Enter Menu:

Enter Menu:

Enter Menu:

Select:

Select:

Select:

Personal

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

AUTO

Noise Reduction

Select: Enter Menu:

Set Up

Language/Country

Auto Tuning

Auto Tuning

Set Up

Set Up

Set Up

Language/Country

Auto Tuning

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Enter:

Select:

Enter Menu:

Enter Menu:

Enter Menu:

Select:

Select:

Select:

continued...

PIP INPUT

The “PIP Input” option in the “Features” menu allows you to select

To do this: after selecting the option, press . Then press

the source you want to watch in the “PIP” screen.

AUTO

Personal

Select: Enter Menu:

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Level 1 Level 2 Level 3 / Function

repeatedly or to select the desired source AV1, AV2, AV3,

AV4 or TV. Finally press OK to store.

On

Off

AV1

AUTO

Features

Sleep Timer

Auto Format

AV3 Output

PIP Input

PIP Position

Select: Enter:

On

Off

AV1

AUTO

Features

Select: Enter Menu:

Sleep Timer

Auto Format

AV3 Output

PIP Input

PIP Position

/ button on the remote control.

To watch the “PIP” screen with the selected source, press the

You can swap the screens by pressing the / button on the

remote control.

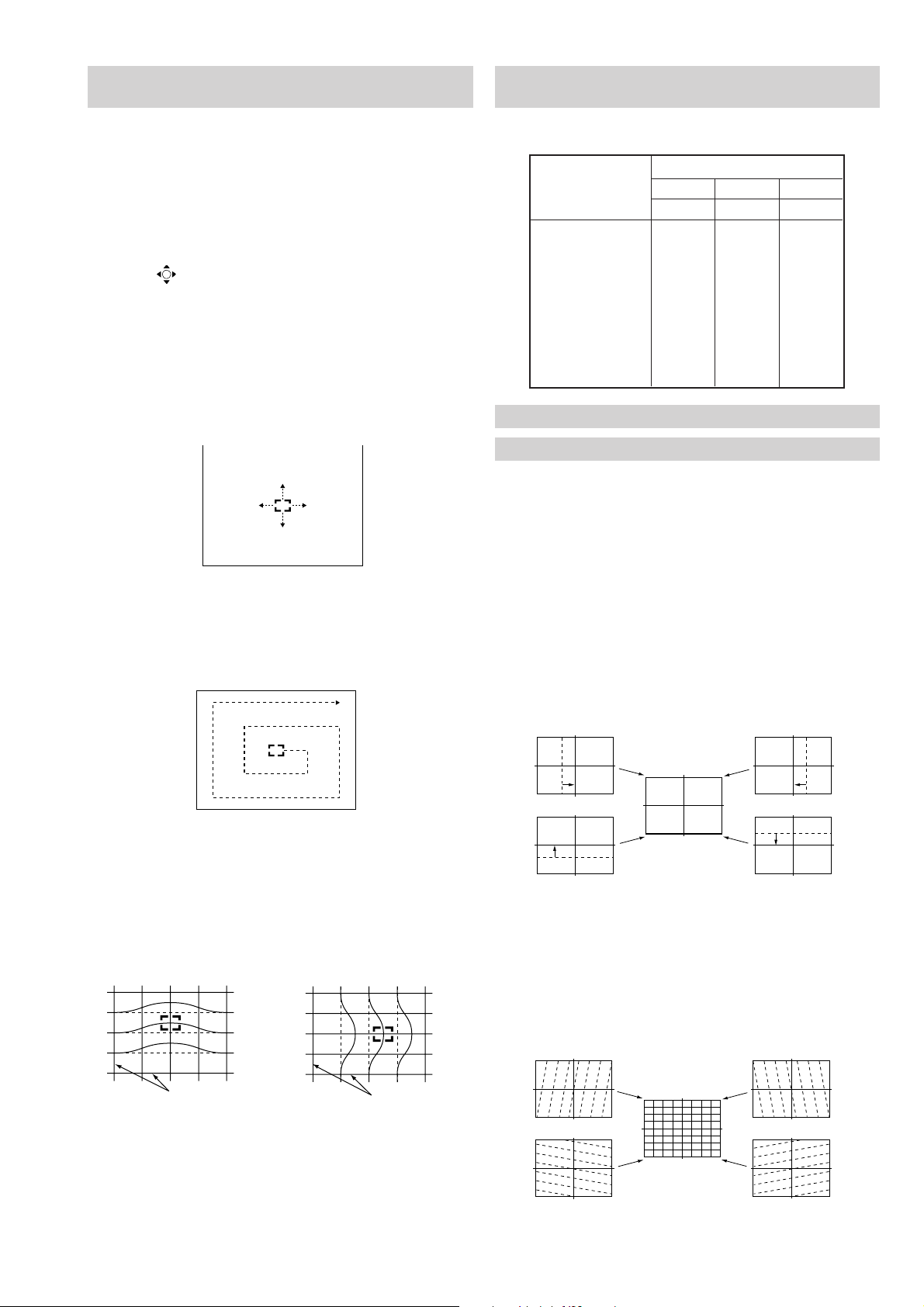

PIP POSITION

The “PIP Position” option in the “Features” menu allows you to

change the position of the “PIP” screen within the main screen.

A

BB

B

B

A

A

Personal

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

To do this: after selecting the option press , , or to select

AUTO

Select: Enter Menu:

Noise Reduction

the desired position. Finally press OK to store.

Off

Features

Sleep Timer

Off

Features

Sleep Timer

On

AUTO

Auto Format

AV3 Output

On

AUTO

Auto Format

AV3 Output

AV1

PIP Input

AV1

PIP Input

PIP Position

PIP Position

– 9 –

Select: Enter:

Select: Enter Menu:

LANGUAGE/COUNTRY

The “Language/Country” option in the “Set Up” menu allows you

to select the language that the menus are displayed in. It also allows

you to select the country in which you wish to operate the projection

TV set.

To do this: after selecting the option, press and then proceed in

the same way as in steps 2 and 3 of the section “Switching On the

Personal

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

AUTO

Noise Reduction

Select: Enter Menu:

Projection TV and Automatically Tuning” on page 8.

Set Up

Language/Country

Auto Tuning

Auto Tuning

Programme Sorting

Auto Tuning

Programme Sorting

Set Up

Set Up

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Select NexTView

AV Preset

Manual Set Up

Select NexTView

AV Preset

Manual Set Up

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Detail Set Up

Enter:

Select:

Enter Menu:

Enter Menu:

Enter Menu:

Select:

Select:

Select:

AUTO TUNING

The “Auto Tuning” option in the “Set Up” menu allows you to

automatically search for and store all available TV channels.

To do this: after selecting the option, press and then proceed in

the same way as in the steps 4 and 5 of the section “Switching On the

Projection TV and Automatically Tuning” on page 8.

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AUTO

Personal

Select: Enter Menu:

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Auto Tuning

Auto Tuning

Set Up

Set Up

Set Up

Language/Country

Programme Sorting

Select NexTView

Programme Sorting

Select NexTView

Auto Tuning

Programme Sorting

AV Preset

Manual Programme Preset

Detail Set Up

AV Preset

Manual Set Up

AV Preset

Manual Set Up

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Start Auto Tuning:

Select:

Enter Menu:

Enter Menu:

Enter Menu:

Select:

Select:

Select:

Menu System

14

Page 10

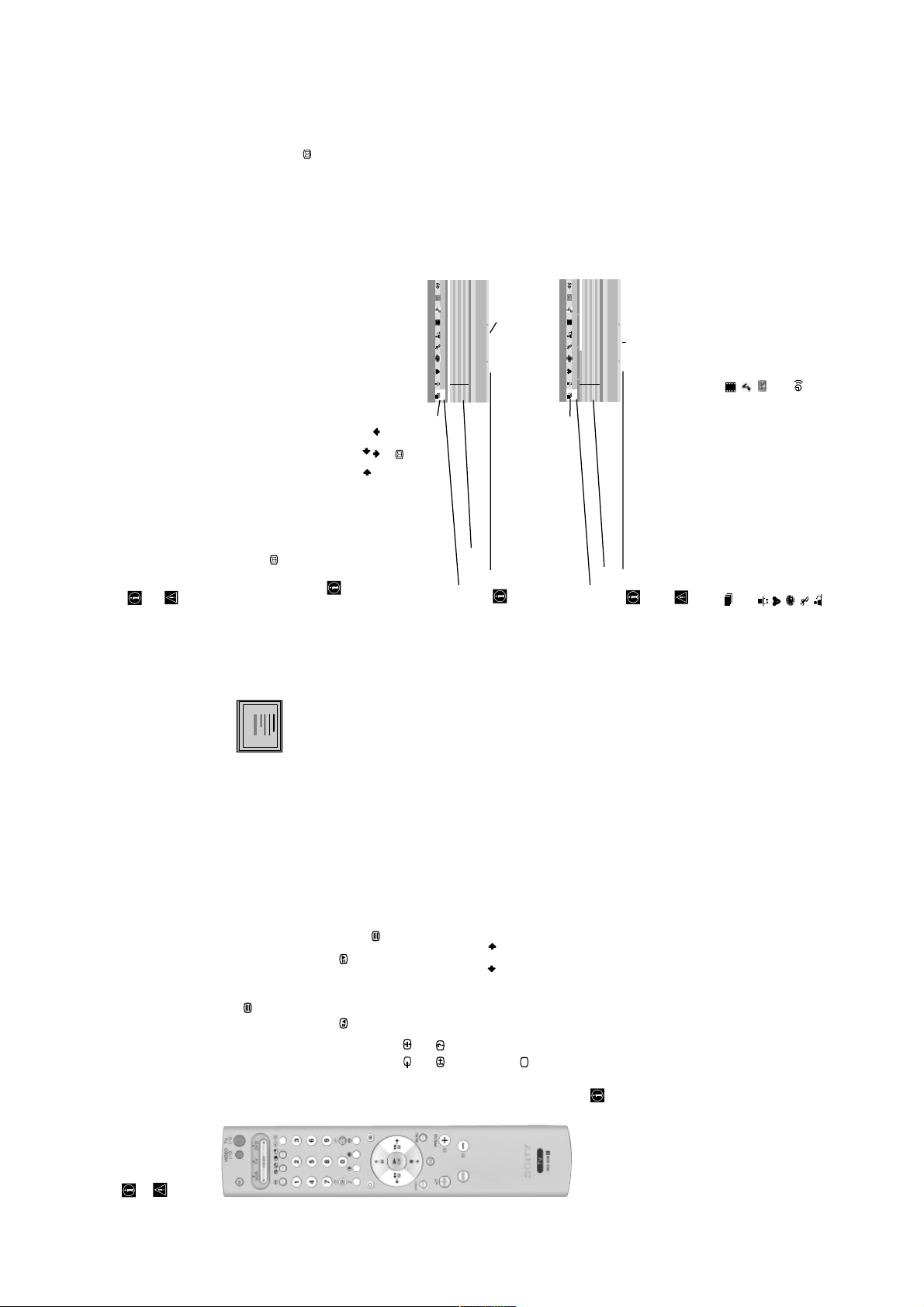

RGB CENTRING

When connecting an RGB source, such as a “PlayStation”, you may

need to readjust the horizontal position of the picture. If this is the

case, you can adjust it through the “RGB Centring” option in the

“Detail Set Up”.

To do this: while watching an RGB source select the “RGB Centring”

option and press . Then press or to adjust the centre of the

picture between –10 and +10. Finally press OK to confirm and store.

0

Enter:

Select:

Detail Set Up

RGB Centring

AUTO

Personal

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Select: Enter Menu:

Auto Tuning

Auto Tuning

Set Up

Set Up

Set Up

Language/Country

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Enter Menu:

Enter Menu:

Enter Menu:

Select:

Select:

Select:

Level 1 Level 2 Level 3 / Function

GB

17

Menu System

MANUAL PROGRAMME PRESET

The “Manual Programme Preset” option in the “Set Up” menu

allows you to:

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

AUTO

Personal

Select: Enter Menu:

Picture Adjustment

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Auto Tuning

Programme Sorting

Select NexTView

Auto Tuning

Programme Sorting

Select NexTView

Set Up

Set Up

Set Up

Language/Country

Auto Tuning

Programme Sorting

Programme Labels

Level 1 Level 2 Level 3 / Function

Enter:

Select:

AV Preset

Manual Programme Preset

Detail Set Up

Enter Menu:

Enter Menu:

Enter Menu:

Press or to select which programme number you want to preset the channel on (for VCR, select programme number

AV Preset

Manual Set Up

AV Preset

Manual Set Up

AV Preset

Manual Programme Preset

Detail Set Up

Select:

Select:

Select:

“0”). Then press .

2 The following option is only available depending on the country you have selected in the “Language/Country” menu.

1 After selecting the ”Manual Programme Preset” option, press then with Programme option highlighted press .

Preset channels or the VCR channel one by one to the programme order of your choice. To do this:

a)

TV Broadcast or the channel of the VCR signal. If you do not know the channel number, press or to search for it. When

you tune the desired channel, press OK twice to store.

After selecting the System option, press . Then press or to select the TV Broadcast system (B/G for western

European countries, D/K for eastern European countries, L for France or I for United Kingdom). Then press .

3 After selecting the Channel option, press . Then press the number buttons to enter directly the channel number of the

Label a channel using up to five characters.

To do this: highlighting the Programme option, press the PROG +/- button to select the programme number with the channel

Repeat all the above steps to tune and store more channels.

b)

Fine tune the broadcast reception. Normally the automatic fine tuning (AFT) will give the best possible picture, however you

press or to select a letter, number or “-“ for a blank. Press to confirm this character. Select the other four characters in

the same way. After selecting all the characters, press OK twice to store.

you wish to name. When the programme you want to name appears on the screen, select the Label option and press . Next

To do this: while watching the channel (TV Broadcast) you wish to fine tune, select the AFT option and press . Next press

can manually fine tune the TV to obtain a better picture reception in case the picture is distorted.

or to adjust the fine tuning between -15 and +15. Finally press OK twice to store.

c)

continued...

S

This option is only available depending on the country you have selected in the “Language/Country” menu.

Skip any unwanted programme numbers when they are selected with the PROG +/- buttons.

d)

To cancel this function afterwards, select “No” instead of “Yes” in the step above.

To do this: highlighting the Programme option, press the PROG +/- button to select the programme number you want to skip.

When the programme you want to skip appears on the screen, select the Skip option and press . Next press or to select

View and record scrambled channels when using a decoder connected to Scart 3/ 3 directly or through a VCR.

Yes. Finally press OK twice to confirm and store.

e)

To cancel this function afterwards, select “Off” instead of “On” in the step above.

To do this: select the Decoder option and press . Next press or to select On. Finally press OK twice to confirm and

store.

Menu System

16

– 10 –

Page 11

GB

19

NexTView

Star Wars

|

Euro Sports

Euronews

|

Euro Sports

07

07

06

05

04

03

02

01

Sun 7 : 07 : 01

Sat

Fri

Thu

Wed

Tue

Mon

Songs from the shows

Weather forecast informati

A1 news magazine

Arts show

00 : 30

01 : 30

05 : 30

06 : 30

TV1

TV2

TV3

TV4

Oclock news

Weather forecast informati

A1 news magazine

Arts show

07 : 30

08 : 30

09 : 30

10 : 30

TV5

TV6

TV7

TV8

Remind*:

If you wish to be reminded when the selected programme is

broadcast, press the green button on the remote control. At the

Record Remind

Songs from the shows

TV1 00:30 - 01:30 Thursday 04

Programme description

Sun 9 : 15 : 0 3

time that the programme should be broadcast a reminder

message is displayed on the TV.

Mike's show

Magazine

|

|

Euro Sports

06

Sat

Fantasy film

Songs from the shows

05

Fri

|

|

04

Thu

03

Wed

9 : 00 9 : 30 10 : 00

Magazine

Weather Forecast

Euronews

02

Tue

TV1

TV2

TV3

01

Mon

Home Shopping Europe

News | Arts show

TV4

TV5

Larry King's live |

Euro magazine |

Home Shopping Europe |

TV6

TV7

TV8

Remind*:

If you wish to be reminded when the selected programme is broadcast, press

the green button on the remote control. At the time that the programme

should be broadcast a reminder message is displayed on the TV.

Record Remind

Songs from the shows

TV1 00:30 - 01:30 Thursday 04

Programme description

In case the NexTView provider sends information of more than 8

shows you the list with all the programmes (maximum 5 programmes)

broadcast channels, you can select 8 of them to create your personal list.

music

movies

channel selection:

that you have selected to be reminded about.

remind list:

*

button on the remote control to watch the “Programme List” interface (see fig. 1).

Whilst you are watching TV, and after more than 50% of NexTView data is available (100% data may not be available

Whilst you are watching TV, and after the indication “NexTView” (coloured white) is displayed on the screen, press the

depending on the area) the indication “NexTView” (coloured black) is displayed on the screen. Press the button on

“Programme List” interface:

NexTView is an on-screen electronic programme guide, providing you with programme information for different

When looking for information you can search by theme (sports, art, etc...) or date.

If wrong characters appear when viewing NexTView, use the menu system to enter the “Language/Country” menu (see page

broadcasters.

(depending on availability of service).

NexTView

*

14) and select the same language as the NexTView is broadcasted.

Displaying NexTView

a)

Select a broadcast channel providing a NexTView service. In this case the indication “NexTView” is displayed as soon as data

To see NexTView service you have two different types of NexTView interface. These depend on the % of available data:

is available.

1

2

25

98

25

98

25

98

25

98

25

98

25

98

25

98

25

98

101

153

153

101

153

101

153

101

153

101

153

101

153

101

153

101

TELETEXT

TELETEXT

TELETEXT

TELETEXT

TELETEXT

TELETEXT

TELETEXT

TELETEXT

Index

Programme

News

Sport

Weather

Index

Programme

News

Sport

Weather

Index

Programme

News

Sport

Weather

Index

Programme

News

Sport

Weather

Index

Programme

News

Sport

Weather

Index

Programme

News

Sport

Weather

Index

Programme

News

Sport

Weather

Index

Programme

News

Sport

Weather

the remote control to watch the “Overview” interface (see fig. 2).

b) “Overview” interface:

the screen. Once you have entered the service, the % of data will not increase.

As soon as you enter the NexTView service the % of NexTView data available will be shown in the bottom left corner of

• moving to right or left press or .

• moving up or downwards, press or .

• confirming a selection, press OK.

To navigate through NexTView:

To switch NexTView off, press the button on the remote control.

3

4

Icons for different themes (see the “Icons’ key” section

below)

“Programme List” interface (fig. 1):

This function only works if you have connected a VCR which supports

SmartLink and Timer Programming feature.

Record*:

Date

Programme list

are watching a TV channel which is not a NexTView provider.

”Record” and “Remind” options will be shown on the screen as soon as a programme has been selected, but they will not be shown if you

”Record” and “Remind” will not be available if the programme that you have selected has already started.

*

This function only works if you have connected a VCR which

If you wish to record the selected programme, press the red button on

the remote control.

“Overview” interface (fig. 2):

Icons for different themes (see the “Icons’ key” section

below)

Date

supports SmartLink and Timer Programming feature.

Overview

Record*:

If you wish to record the selected programme, press the

*

full selection list:

red button on the remote control.

Icons’ key:

All the programme information is listed by time

and broadcast channels order.

entertainment

children

arts

sports

news

If this is the case, input another page number

Input 3 digits for the page number, using the numbered buttons.

• If you make a mistake, retype the correct page number.

• If the counter on the screen continues searching, it is because the page is not available.

Press PROG + ( ) or PROG - ().

Whilst you are viewing teletext, press . Press it again to cancel teletext mode.

Press / . Press it again to cancel the freeze.

Press / . Press it again to conceal the information.

wish to view, press .

After selecting the TV channel which carries the teletext service you

To switch on Teletext :

To select a Teletext page:

automatically decreases notoriously to avoid any damage to the picture tube. Press any button of the remote control to

gives you information on how to use the service. To operate teletext, use the remote control buttons as indicated below.

Teletext is an information service transmitted by most TV stations. The index page of the teletext service (usually page 100)

reset the brightness level.

•Teletext errors may occur if you use a channel (TV Broadcast) with a weak signal.

•After 5 minutes viewing the same teletext page and without any button being pressed, the brightness level of the picture

To access the next or preceding page:

To superimpose teletext on to the TV:

To freeze a teletext page:

A teletext page may consist of several sub pages. In this case the page number that appears on the

To reveal concealed information (e.g: answer to a quiz):

To select a sub page:

Press .

upper left corner will change from white to green and one or more arrows will appear next to the page

number. Repeatedly press the or buttons on the remote control to watch the desired sub page.

To Switch Off Teletext:

Teletext

– 11 –

Fastext service lets you access Teletext pages with one button push.

When you are in Teletext mode and Fastext is broadcast, a colour coded menu appears at the bottom

of the teletext page. Press the appropriate coloured button (red, green, yellow or blue) to access

the page corresponding to your menu choice.

Fastext

Teletext

18

Page 12

GB

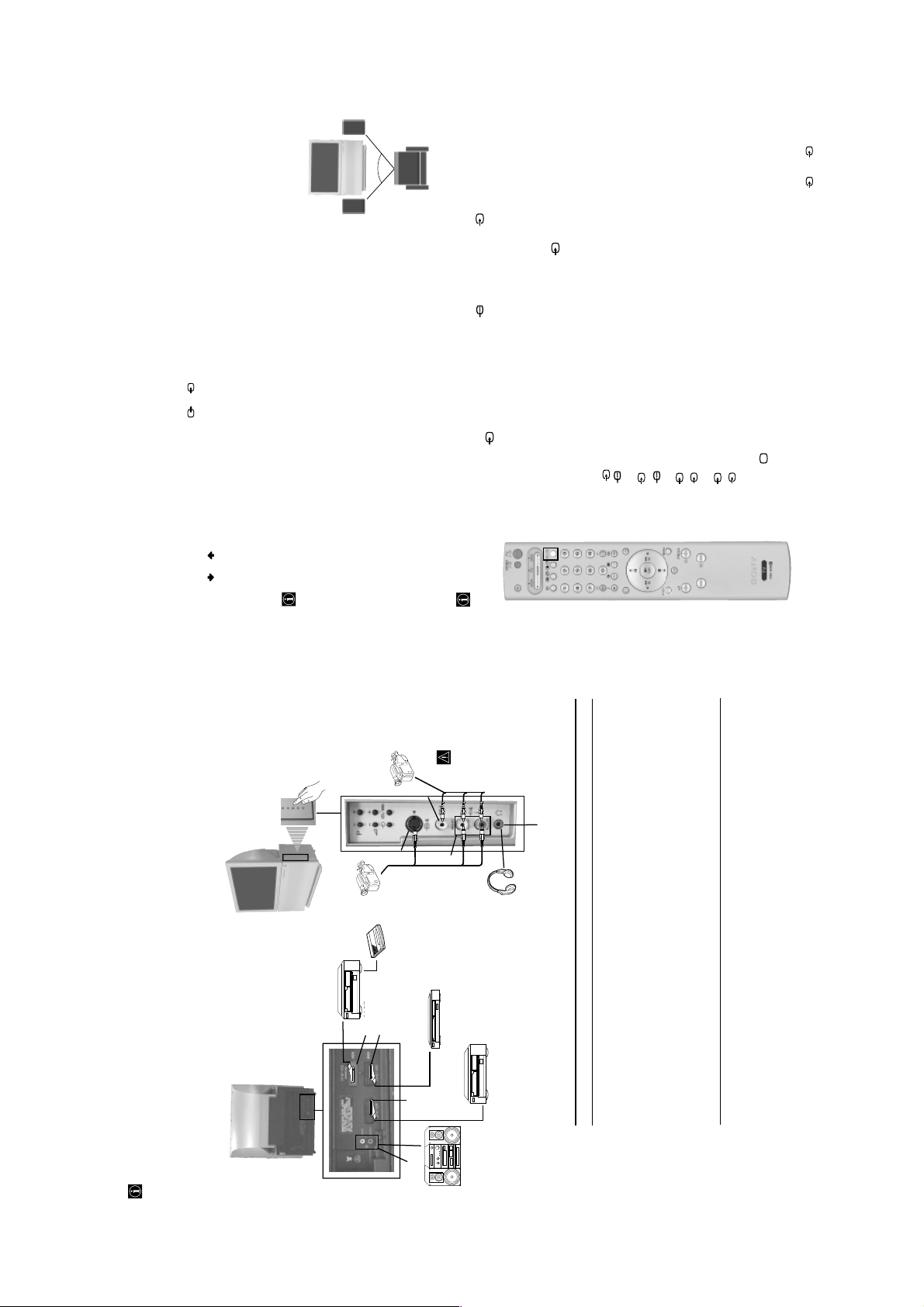

21

Hi-Fi

Right

speaker

S

~50°

Your sitting position

Left

Hi-Fi

speaker

1/ 1. Press the button on the remote control

Y

S

source has been connected.

source has been connected.

Video source has been connected.

G. This symbol appears only if an S Video source has been connected.

2 • RGB input signal through the Scart connector C. This symbol appears only if an RGB

3 • S Video Input signal through the Scart connector D. This symbol appears only if an S

2 • Audio / video input signal through the Scart connector C.

Symbol Input Signals

Connect your equipment to the designated projection TV socket, as it is indicated on the previous

Switch on the connected equipment.

To watch the picture of the connected equipment, press the button repeatedly until the

page.

1

2

3

1 • Audio / video input signal through the Scart connector B

correct input symbol appears on the screen.

3 • Audio/video input signal through the Scart connector D.

4 • S Video Input signal through the front S Video input jack E and Audio signal through

4 • Video input signal through the phono socket F and Audio input signal through G.

S

S

Press button on the remote control to return to the normal TV picture.

For mono equipment

4

Additional Information

Connect the phono plug to the L/G/S/I socket on the side of the TV and select 4 or 4 input

signal using the instructions above. Finally, refer to the “Sound Adjustment” section of this manual

and select “Dual Sound” “A” on the sound menu screen.

bass settings can be modified through the “Sound Adjustment” menu.

Audio level of the external speakers can be modified by pressing the volume buttons on the remote control. Also treble and

Additional Information when connecting equipment

Connecting a VCR

We recommend you connect your VCR to the D socket using a scart lead. If you do not have a scart lead, use the “Manual

Programme Preset” section on page 16 to tune in the channel of the VCR test signal to TV programme number “0”. Also refer to

your VCR instruction manual to get the VCR test signal.

If your video supports SmartLink please refer to the "SmartLink" section of this instruction manual on page 22.

If you have connected a decoder to the Scart 3/ 3 D or through a VCR connected to this Scart:

Select the “Manual Programme Preset” option in the “Set Up” menu and after entering in the “Decoder**” option, select “On” (by

using or ). Repeat this option for each scrambled signal.

**This option is only available depending on the country you have selected in the “Language/Country” menu.

Connecting to external Audio Equipment:

Plug in your Hi-Fi equipment to the audio output sockets A if you wish to amplify the audio output from projection TV. Next ,

using the menu system, select the “Sound Adjustment” menu and set the “TV Speakers” to “Off”.

To enjoy “Dolby Virtual” sound effect through your Hi-Fi equipment:

Place the speakers of your equipment in front of your listening position and beside the

projection TV set but keeping a distance of 50 cm between each speaker and the

projection TV set.

Then by using the menu system, select the menu “Sound Adjustment”. Next select

“Dolby V” on the “Effect” option.

8mm/Hi8/

DVC

camcorder

E

S VHS/Hi8

DVC

camcorder

Decoder

In order to get the input signal of a connected equipment onto the TV screen, you need to select the symbol of the

Using Optional Equipment

picture

distortion:

To avoid

F

G

1 • RGB input signal through the Scart connector B. This symbol appears only if an RGB

connector to which you have connected the device.

e. g. : Your VCR is connected to the connector with the symbol

repeatedly until you see the symbol 1 on the screen.

equipment

connectors

connect

to E and F

at the same

Do not

time.

H

Available output signal

Audio signal.

Video/audio from TV tuner.

Video/audio displayed on TV screen (monitor out).

Video/audio from selected source.

No output.

No output.

No output.

continued...

Audio signal to headphones.

VCR

VCR

C

D

Using the following instructions, you can connect a wide range of optional equipment to your projection TV.

DVD

B

A

Connecting Optional Equipment

– 12 –

Hi-fi

VCR

Acceptable input signal

A No inputs

B Audio/video and RGB signal

C Audio/video and RGB signal

D Audio/video and S video signal

E S Video signal

F Video signal

G Audio signal

H No input

Additional Information

20

Page 13

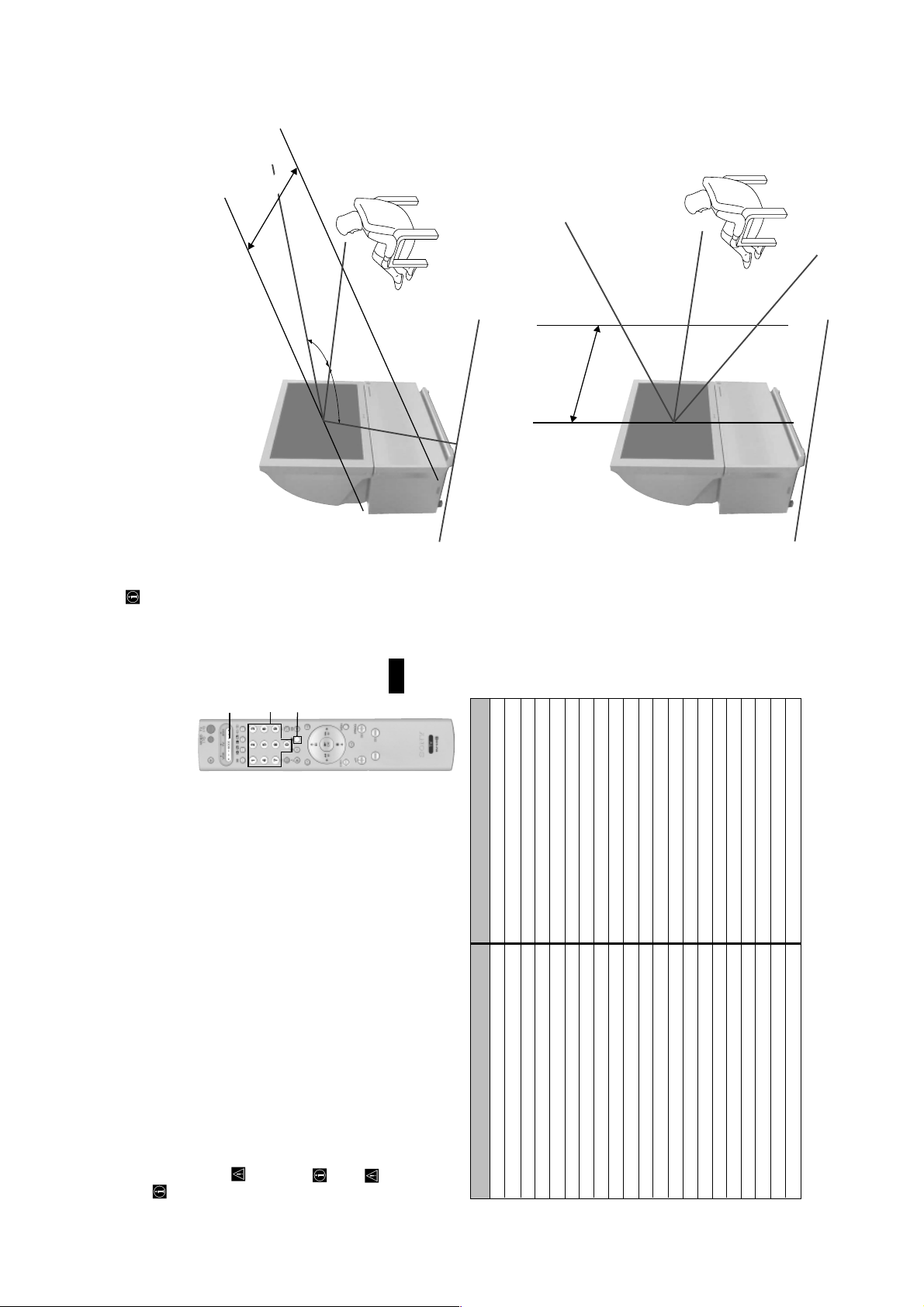

2

1

3

minimum distance 1.7 m

60º

(Optimum viewing position)

(Optimum viewing position)

60º

below.

For the best picture quality, try to position the projection TV so that you can view the screen from within the areas shown

Optimum Viewing Area

Horizontal viewing area

Vertical viewing area

GB

minimum distance 1.7 m

20º

20º

Additional Information

24

23

Additional Information

the correct code set or try the next code listed against the brand.

your brand of DVD or VCR please repeat the above steps. A small label is added inside the

battery door to allow you to record your brand codes.

• If your device is not working or some of the functions do not work please check that you entered

• Your brand codes may be lost if weak batteries are not replaced within a few minutes. To reset

more than one code, enter the first code number.

• Before you start, look up the 3 digit code for your brand of DVD or VCR from the list below. On those brands that have

• Sony will endeavour to update the software according to market changes. Therefore, please refer to code table included

Remote Control Configuration for VCR/DVD

In it’s default condition this remote control will operate the basic functions of this Sony TV, Sony DVDs and most Sony VCRs. To

control VCRs and DVDs of other manufacturers (and some Sony VCR models), please complete the following steps:

If Media Selector is on TV position, code numbers will not be stored.

with the remote control for latest code set.

or DVD) is lit.

Press the Media Selector button on the remote control repeatedly until the required green light (VCR

1

Before the green light goes out, press and hold the yellow button for approximately 6 seconds until the

2

If your selected code is entered correctly, all three green lights will be lit momentarily.

green light starts flashing.

Whilst the green light is flashing, enter all three digits of the code for your brand of VCR or DVD using

the number buttons on the remote control.

3

Turn on your VCR or DVD and check that the main functions work.

4

• Not all brands are covered and not all models of every brand may be covered.

VCR Brand List DVD Brand List

Brand Code Brand Code

SONY (VHS) 301, 302, 303, 308, 309 SONY 001

SONY (BETA) 303, 307, 310 AIWA 021

SONY (DV) 304, 305, 306 DENON 018, 027, 020, 002

AIWA 325, 331, 351 GRUNDIG 009, 028, 023, 024, 016, 003

AKAI 326, 329, 330 HITACHI 025, 026, 015, 004

DAEWOO 342, 343 JVC 006, 017

GRUNDIG 358, 355, 360, 361, 320, 351 KENWOOD 008

HITACHI 327, 333, 334 LG 015, 014

JVC 314, 315, 322, 344, 352, 353, 354, 348, 349 LOEWE 009, 028, 023, 024, 016, 003

LG 332, 338 MATSUI 013, 016

LOEWE 358, 355, 360, 361, 320, 351 ONKYO 022

MATSUI 356, 357 PANASONIC 018, 027, 020, 002

ORION 328 PHILIPS 009, 028, 023, 024, 016, 003

PANASONIC 321, 323 PIONEER 004

PHILIPS 311, 312, 313, 316, 317, 318, 358, 359 SAMSUNG 011, 014

SAMSUNG 339, 340, 341, 345 SANYO 007

SANYO 335, 336 SHARP 019, 027

SHARP 324 THOMSON 012

THOMSON 319, 350 TOSHIBA 003

TOSHIBA 337 YAMAHA 018, 027, 020, 002

– 13 –

Page 14

return to the factory settings.

Solution

• Check the aerial connection.

• Plug the TV in and press the button on the front of the projection TV.

• If the standby indicator is on, press TV button on the remote control.

remote control until the correct input symbol is displayed on the screen.

• Using the menu system, select the “Picture Adjustment” menu and select “Reset” to

• Check that the optional equipment is on and press the button repeatedly on the

• Press the + button on the remote control.

return to factory settings.

desired channel.

Registration (Convergence)” section on page 10.

• Check that “TV Speakers” is “On” in the “Sound Adjustment” menu.

• Check that headphones are not connected.

• Using the menu system, select the “Picture Adjustment” menu and select “Reset” to

• This is not a malfunction. Press the number buttons on the remote control to select the

Tuning (AFT) to obtain better picture reception.

• Adjust the colour registration. For more details, please refer to “Adjusting Colour

• Using the menu system, select the “Manual Programme Preset” menu and adjust Fine

Adjustment” menu and select “Auto” to reduce the noise in the picture.

option and set “AV3 Output” to “TV”.

• Using the menu system, select the “Noise Reduction” option in the “Picture

• Using the menu system, select the “Features” menu. Then enter to “Detail Set Up”

TV.

• Check that the Decoder is not connected on the scart 2/ 2.

• Turn off any equipment connected to the Scart connector on the rear of the projection

country in which you operate the projection TV set. For Cyrillic languages, we

recommend to select Russia country in the case that your own country does not

appear in the list.

the same language that NexTView is broadcast in.

any button being pressed, the projection TV automatically decreases the brightness

level to avoid any damage to the picture tube. To reset the brightness level, press any

button of the remote control.

(VCR, TV or DVD).

has been set correctly. Enter the necessary code set as explained in the “Remote

• Using the menu system, enter to the “Language/Country” menu and select the

• Use the menu system to enter the “Language/Country” menu (see page 14) and select

• This is not a malfunction. After 5 minutes viewing the same teletext page and without

Control Configuration for VCR/DVD” chapter on page 23.

• Check that the Media Selector on the remote control is set to the device you are using

• If the remote control does not operate the VCR or DVD even when the Media Selector

• Replace the batteries.

• Contact your nearest Sony service centre.

Here are some simple solutions to problems which may affect the picture and sound.

Problem

No picture (screen is dark) and no sound.

Poor or no picture (screen is dark), but good

sound.

No picture or no menu information from

equipment connected to the Scart connector.

Good picture, no sound.

No colour on colour programmes.

When you switch on the TV the last channel

you were watching before switching the TV

off does not appear.

Undefined picture with different colour on

the outlines of the images.

Troubleshooting

Noisy picture when viewing a TV channel.

GB

2 x 30 W (music power)

2 x 15 W (RMS)

Sound Output:

Power Consumption:

225 W

Standby Power Consumption:

< 0.7 W

Dimensions (w x h x d) :

approx. 1100 x 1160 x 536 mm.

Weight:

approx. 61 Kg.

Accessories supplied:

1 Remote Control (RM-938)

2 Batteries (IEC designated, AA size)

TEXT memory).

Other features:

•Digital Comb Filter (High resolution).

•100 Hz picture, Digital Plus.

•Teletext, Fastext, TOPtext (250 page

•NICAM.

•Sleep Timer.

•SmartLink (direct link between your

S

3/ 3.

No unscrambling or unstable picture whilst

viewing a scrambled channel with a decoder

connected through the Scart connector

Distorted picture when changing

programmes or selecting teletext.

Wrong characters appear when viewing

teletext.

Wrong characters appear when viewing

NexTView.

projection TV set and a compatible VCR.

For more information on SmartLink,

please refer to the Instruction Manual of

your VCR).

•TV system autodetection.

•Dolby Virtual.

•BBE.

•PIP.

•Auto Format.

•ACI (Auto Channel Installation).

Brightness level of the picture is notoriously

decreased when viewing a teletext page.

Remote control does not function.

The standby indicator on the projection

TV flashes.

If you continue to experience problems, have your projection TV serviced by qualified personnel.

Never open the casing yourself.

Additional Information

26

25

Additional Information

TV system:

Depending on your country selection:

B/G/H, D/K, L, I

Colour system:

PAL

Specifications

SECAM, NTSC 3.58, 4.43 (only Video In)

Channel Coverage:

VHF: E2-E12

UHF: E21-E69

CATV: S1-S20

HYPER: S21-S41

D/K: R1-R12, R21-R69

L: F-2F-10, B-Q, F21-F69

including audio/video input, RGB input, TV

audio/video output.

including audio / video input, RGB input,

monitor audio/video output.

1/ 1 21-pin scart connector (CENELEC standard)

I: UHF B21-B69

Projected picture size:

44” (approx. 112 cm. measured diagonally)

2/ 2 21-pin Scart connector (CENELEC standard)

Rear Terminals

including audio / video input, S video input,

interface.

S

4 S Video input – 4 pin DIN

4 video input – phono jack

audio outputs (Left/Right) - phono jacks

(SMARTLINK)

selectable audio / video output and Smartlink

3/ 3 21-pin Scart connector (CENELEC standard)

4 audio input – phono jacks

S

Side Terminals

headphones jack

– 14 –

Design and specifications are subject to change without notice.

Ecological Paper - Totally Chlorine Free

Page 15

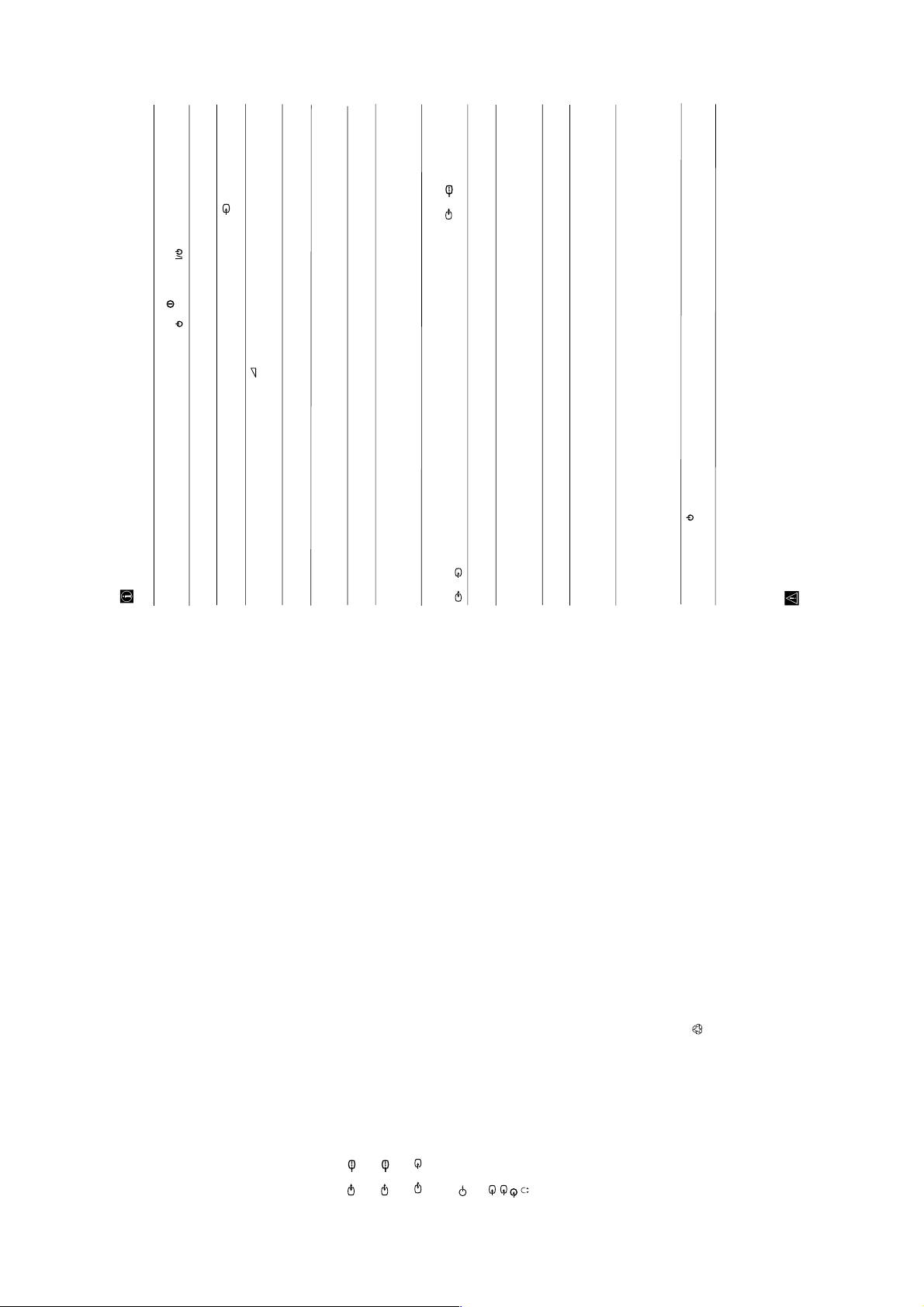

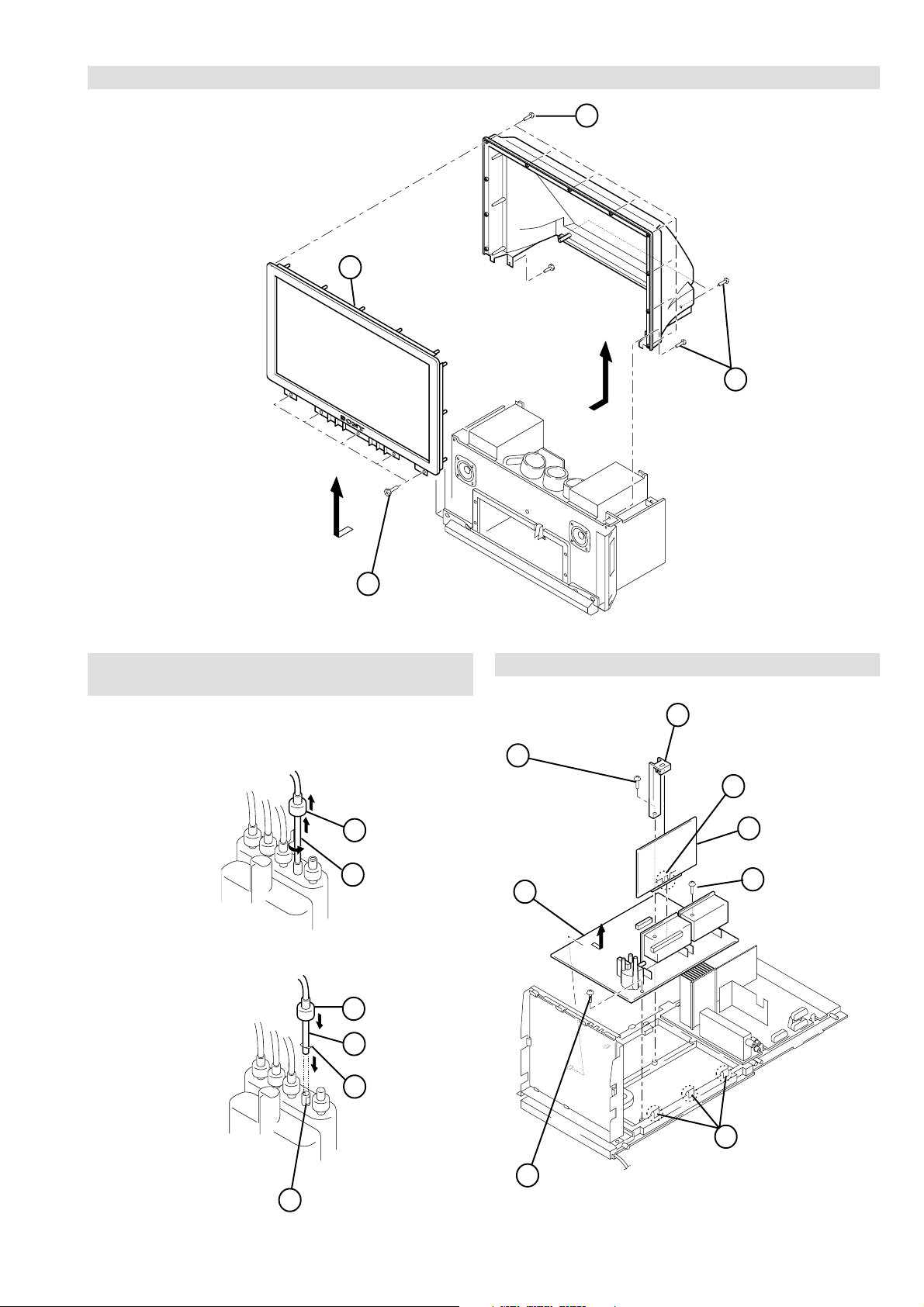

SECTION 3 DISASSEMBLY

KP-44PX2/44PX2U

RM-938

3-1. REAR BOARD REMOVAL

2

Rear board

3-2. MAIN BRACKET BLOCK REMOVAL

Light shield

3

board

2

Two screws

(Hexagon head)

3-3. SERVICE POSITION

1

Twelve screws

(Hexagon head)

Main bracket block

1

3-4. FRONT PANEL REMOVAL

1

Main bracket block

– 15 –

1

Front Panel

2

Two screws

(Hexagon head)

Page 16

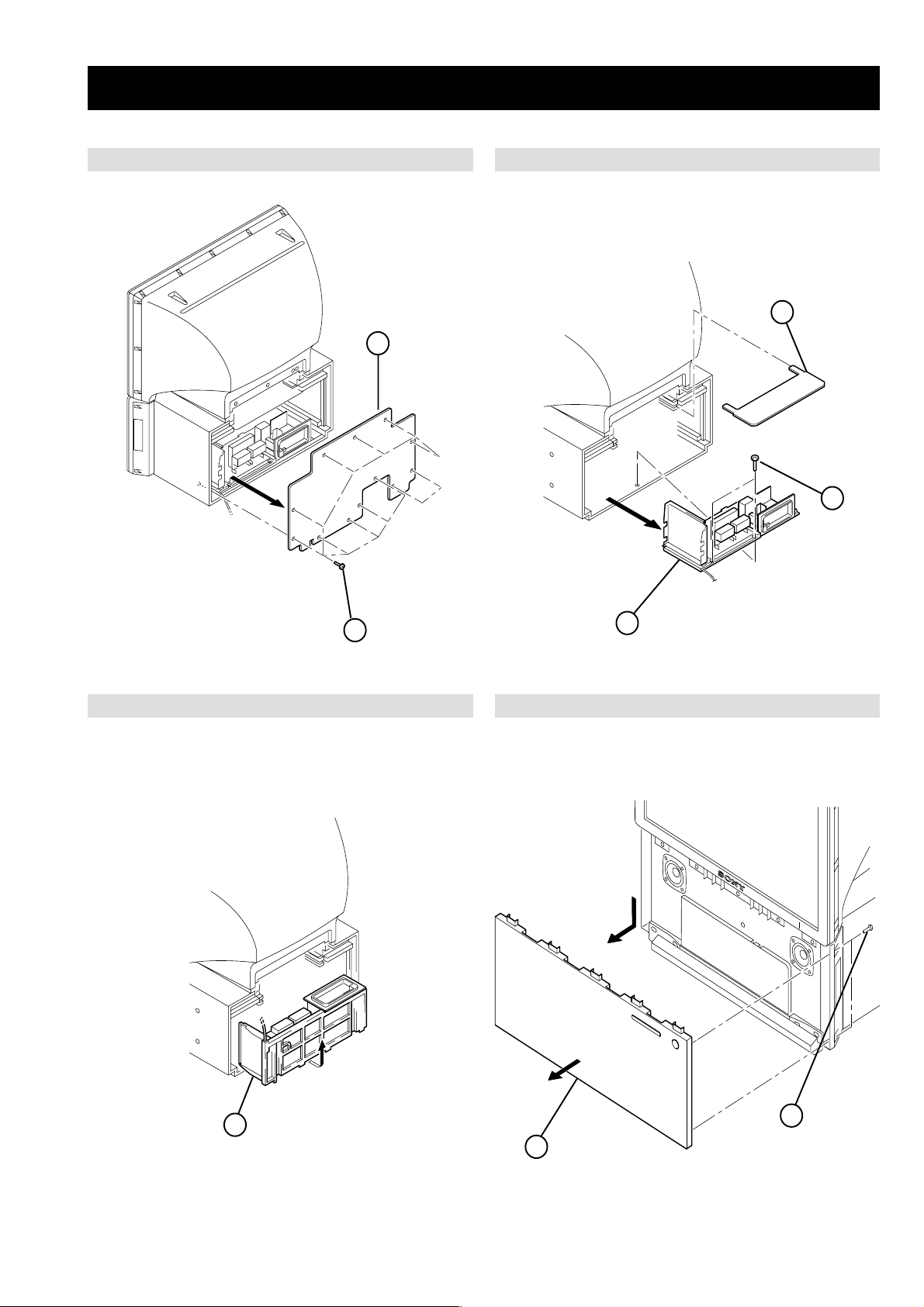

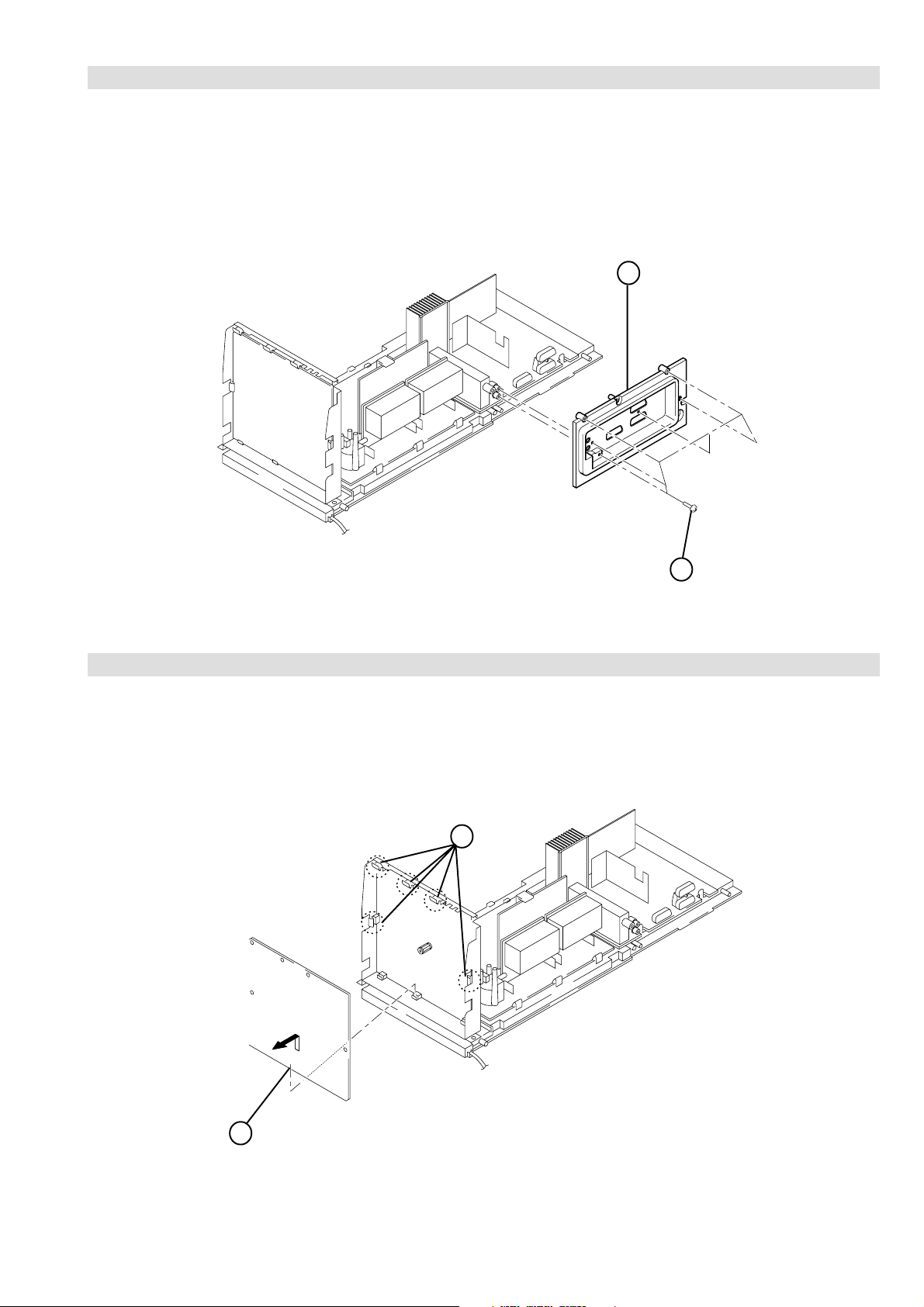

3-5. RESISTOR ASSEMBLY (FOCUS PACK) REMOVAL

KP-44PX2/44PX2U

RM-938

3

Front board

4

Four screws

(Hexagon head)

3-6. H1 AND H3 BOARD REMOVAL

Screw

2

(+BVTP 4x16)

1

Resistor assembly

(Focus pack)

3

Front panel

– 16 –

2

H1 board

1 H3 board

Page 17

3-7. BEZNET BLOCK REMOVAL

2

Beznet block

Eleven screws

1

(+BVTP 4x16)

KP-44PX2/44PX2U

RM-938

4

Four screws

(Hexagon head)

3

Five screws

(Hexagon head)

3-8. HIGH-VOLTAGE CABLE REMOVAL AND

INSTALLATION

(1) Removal

Rubber cap

1

HV cable

2

turn 90

(2) Installation

Rubber cap

1

3-9. AP AND D BOARD REMOVAL

Printed circuit

1

Six screws

(+BVTP 3x12)

2

D board

3

board support

6 AP board

Claw7

Screw

4

(+BVTP 3x12)

4

Gutter

2

HV cable

3

Hook

– 17 –

Screw

4

(+BVTP 3x12)

5

Three claws

Page 18

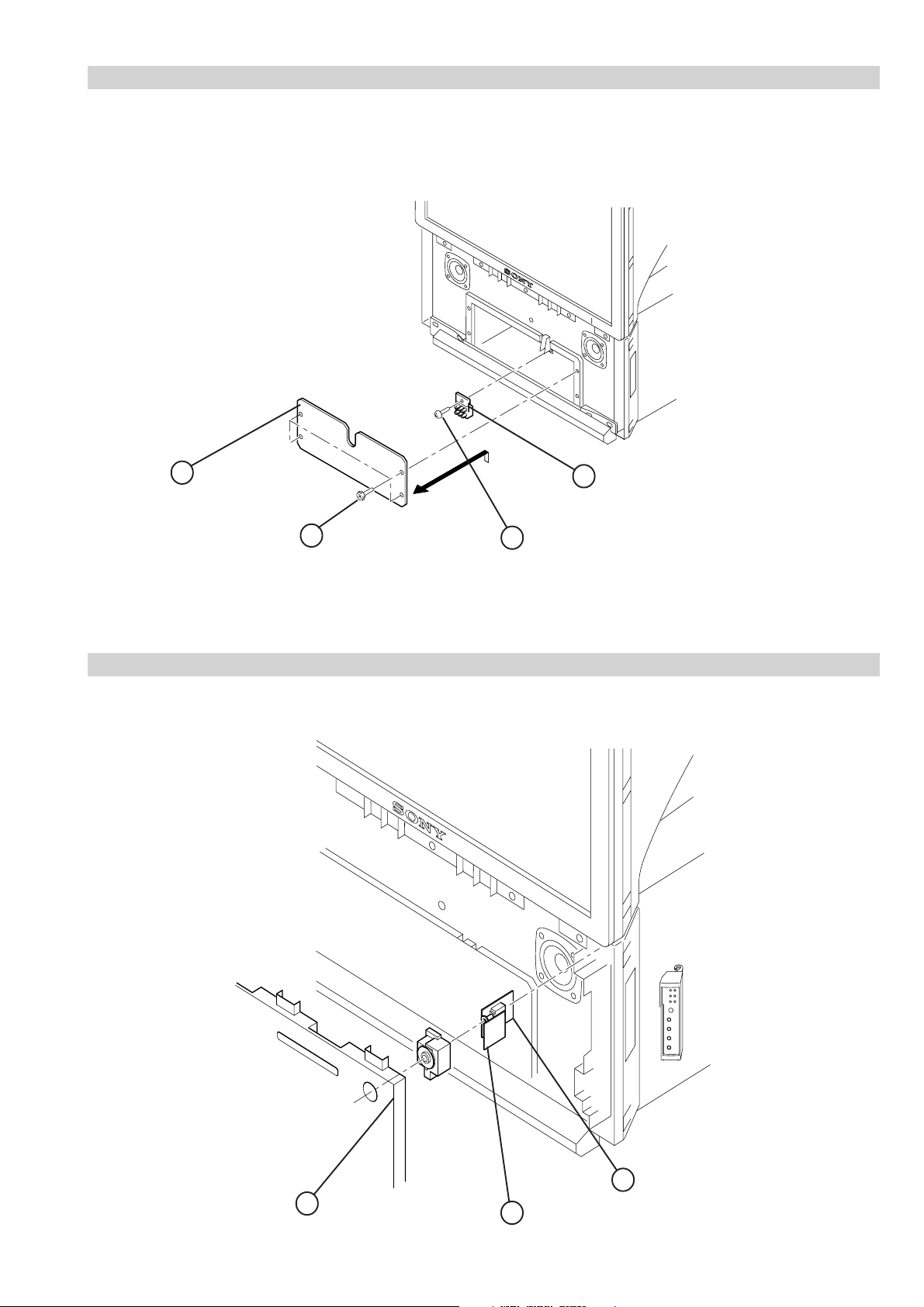

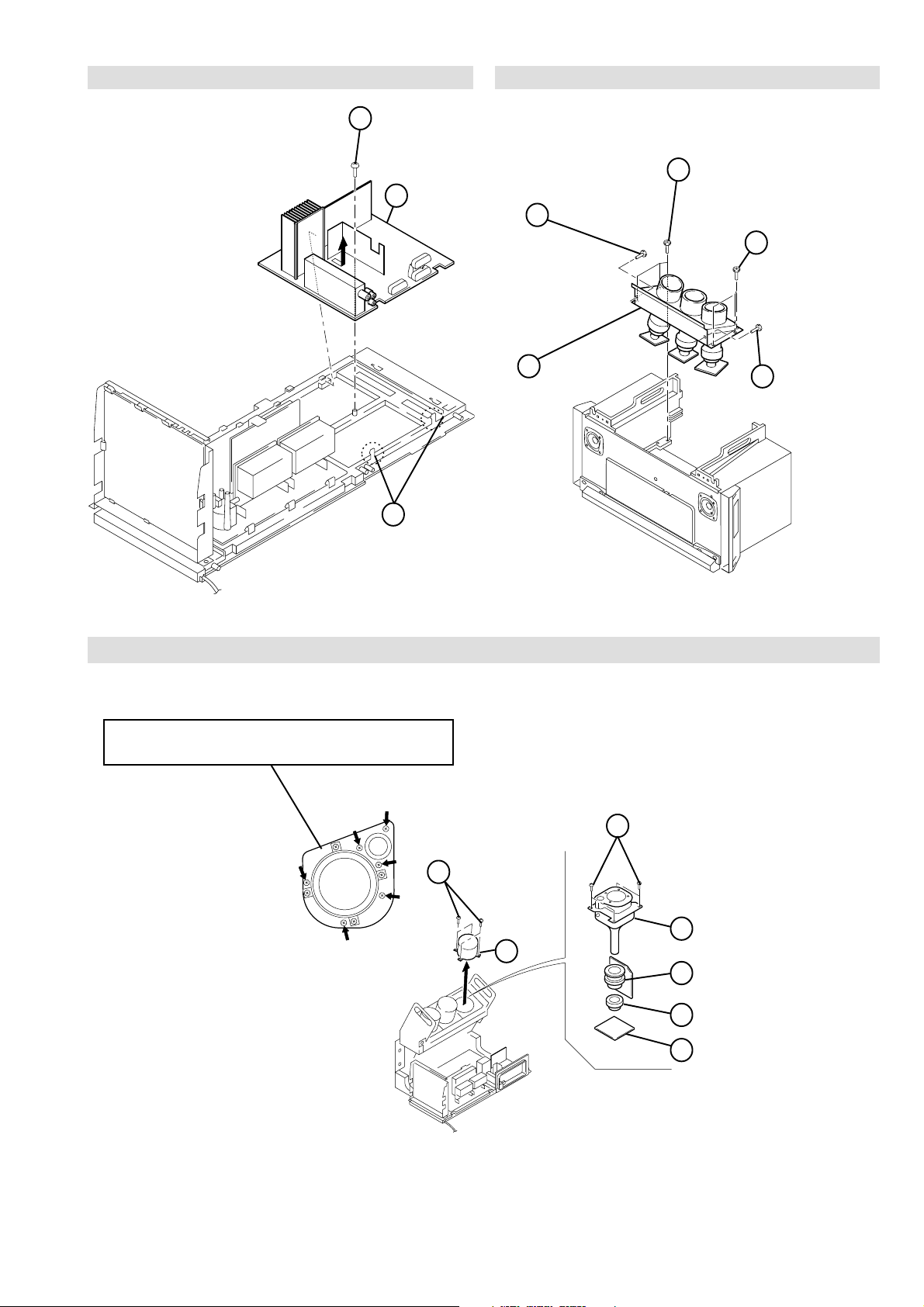

3-10. TERMINAL BOARD REMOVAL

2

Terminal board

KP-44PX2/44PX2U

RM-938

3-11. G BOARD REMOVAL

1

Five claws

Six screws

1

(BVTP 4x16)

2 G board

– 18 –

Page 19

3-12. A BOARD REMOVAL

Screw

1

(+BVTP 3x12)

2

A board

KP-44PX2/44PX2U

3-13. CHASSIS BLOCK REMOVAL

Three screws

2

Screw

(Hexagon head)

3

4

Chassis block

(Hexagon head)

Two screws

1

(Hexagon head)

Screw

3

(Hexagon head)

RM-938

3

3-14. PICTURE TUBE REMOVAL

Removing the arrow-marked screw is strictly inhibited.

If removed, it may cause liquid spill.

Two claws

Four screws

1

(+BTVP 4x16)

Four screws

7

(+BTVP 4x16)

6

Picture tube

2

Lens

5

Deflection yolk

– 19 –

4

Neck assembly

3

CR board

Page 20

SECTION 4 SET-UP ADJUSTMENTS

KP-44PX2/44PX2U

RM-938

4-1. SCREEN VOLTAGE ADJUSTMENT

(ROUGH ALIGNMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the focus pack all the way to the left

and then gradually turn it to the right until the point where

you can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

RG

RG

B

SCREEN

B

FOCUS

Focus Pack

Fig. 4-1

4-2. SCREEN (G2) ADJUSTMENT

1. Turn on the power of the set.

2. Select VIDEO1 mode without signals.

3. Supply DC 175 ±0.5 V from external power supply to

TP7103 (KR), TP7203 (KG) or TP7303 (KB) of CR board,

CG board and CB board.

4. Adjust red, green and blue screen voltage, with SCREEN

VR on the focus packuntil retraceline disappears .

5. Rotate the green lens and align to obtain the best lens

focus at the center area.

6. Rotate the green focus VR on the focus pack and align to

obtain the best electrical focus in the top right corner.

7. Perform the same alignment for red and blue lenses and

electric focus.

8. Fix lens screw.

A

Minimize both A and B.

Lens

Fig. 4-3

B

Fig. 4-4

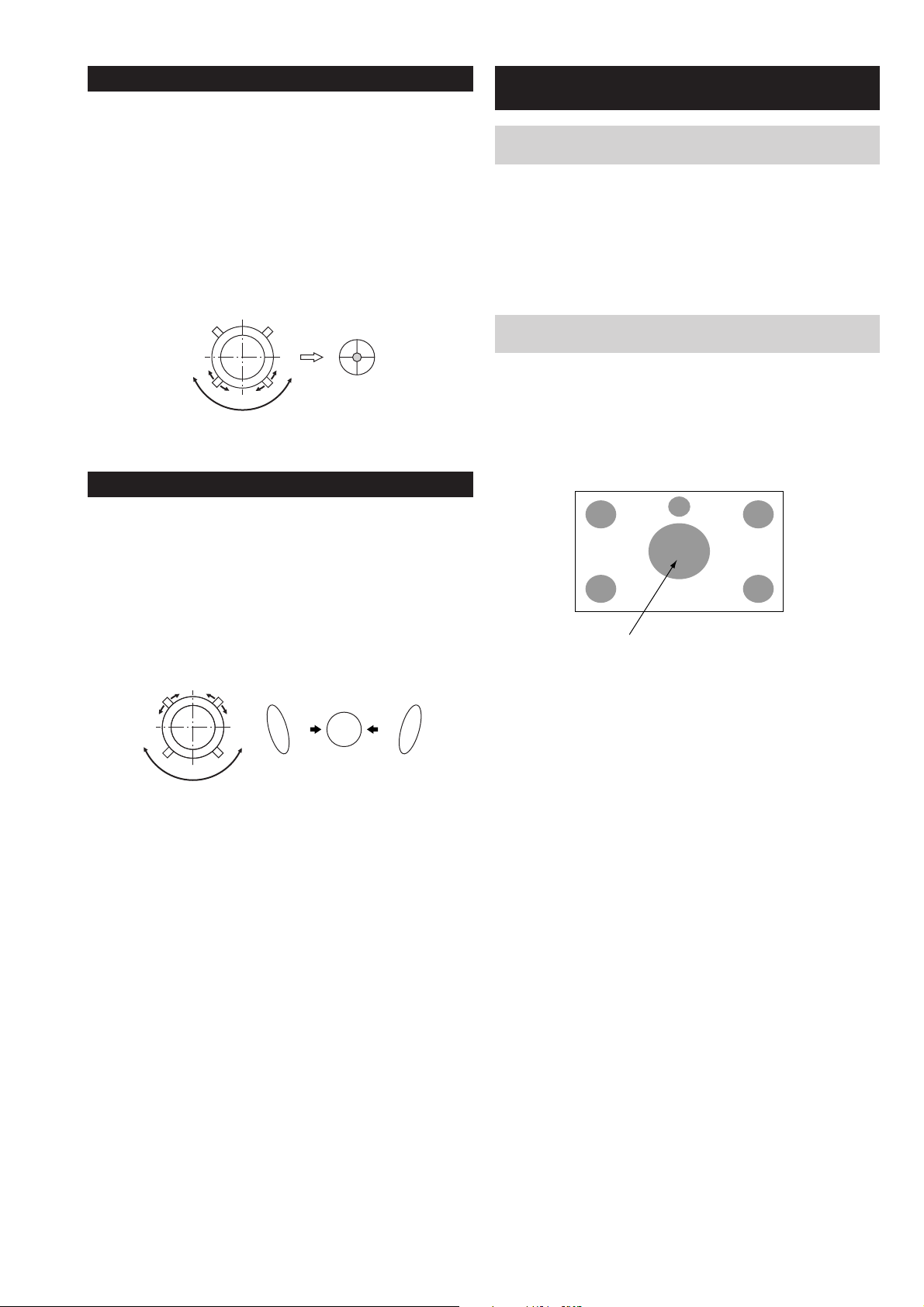

4-4. DEFLECTION YOKE TILT ADJUSTMENT

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the

green color.

3. Loosen the deflection yoke set screw and align the tilt of

the Deflection yoke so that the bars at the center of

the monoscope pattern are horizontal.

4. After aligning the deflection yoke, fasten it securely to

the funnel-shaped portion (neck) of the CRT.