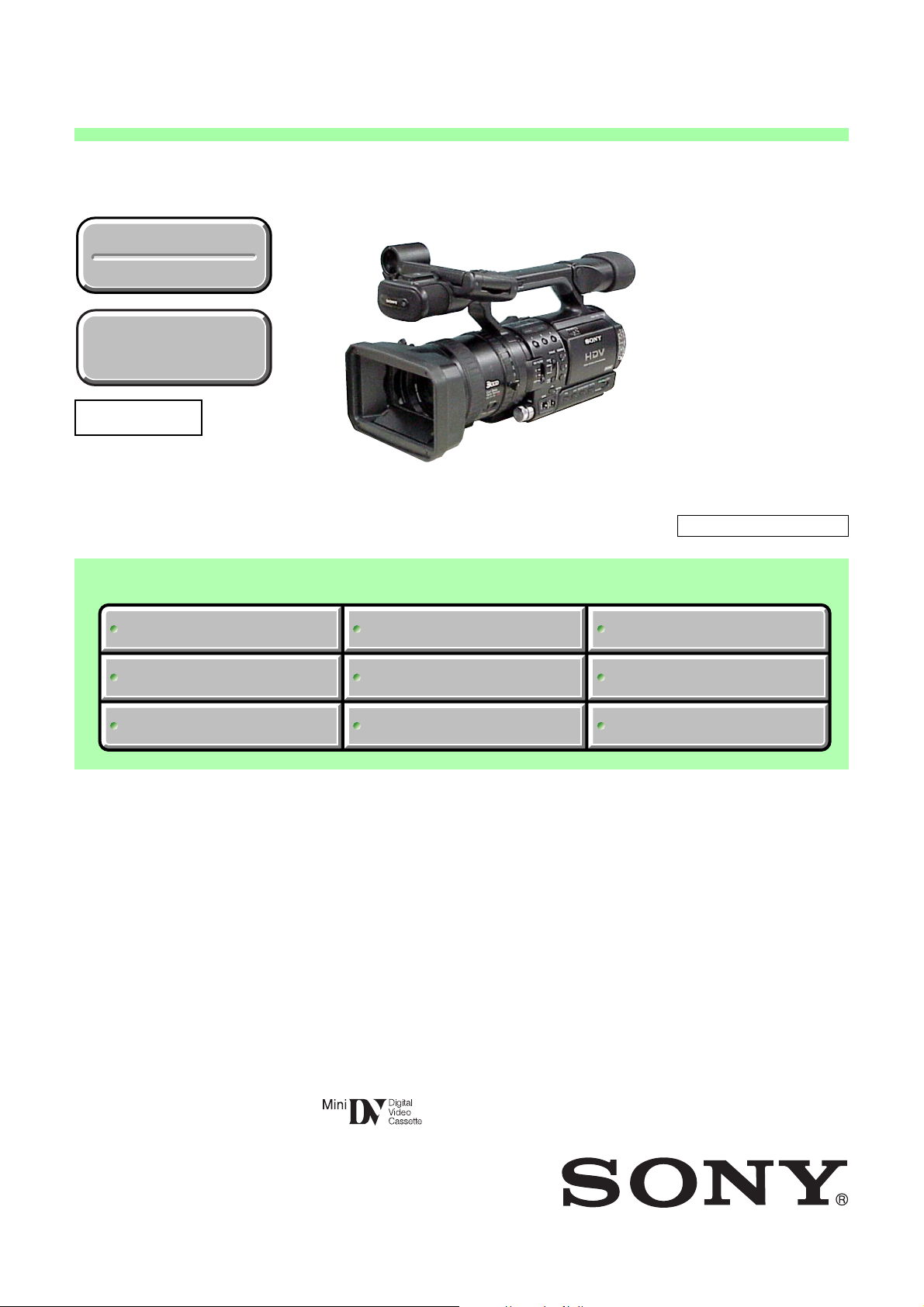

Sony HVR Z1J, HVR-Z1U, HVR-Z1N, HVR-Z1E, HVR-Z1P Service Manual

...

SERVICE MANUAL

HVR-Z1J/Z1U/Z1N/

Z1E/Z1P/Z1C

RMT-841

HVR-Z1U

US Model

Canadian Model

Ver. 1.9 2008.09

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Revised-1

Replace the previously issued

SERVICE MANUAL 9-876-853-11

with this Manual.

Link

Link

SPECIFICATIONS

SPECIFICATIONS

SERVICE NOTE

SERVICE NOTE

BLOCK DIAGRAMS

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

HVR-Z1E

AEP Model

HVR-Z1C

Chinese Model

HVR-Z1N/Z1P

E Model

HVR-Z1J

Japanese Model

Z (Z311) MECHANISM

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

REPAIR PARTS LIST

REPAIR PARTS LIST

DISASSEMBLY

DISASSEMBLY

• INSTRUCTION MANUAL is shown at the end of this document.

• Reference number search on printed wiring boards is available.

• TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

SCHEMATIC DIAGRAMS ADJUSTMENT

SCHEMATIC DIAGRAMS

DIGITAL VIDEO CAMERA RECORDER

ADJUSTMENT

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

9-876-853-12

Sony EMCS Co.

2008I0800-1

©2008.09

Published by Kohda TEC

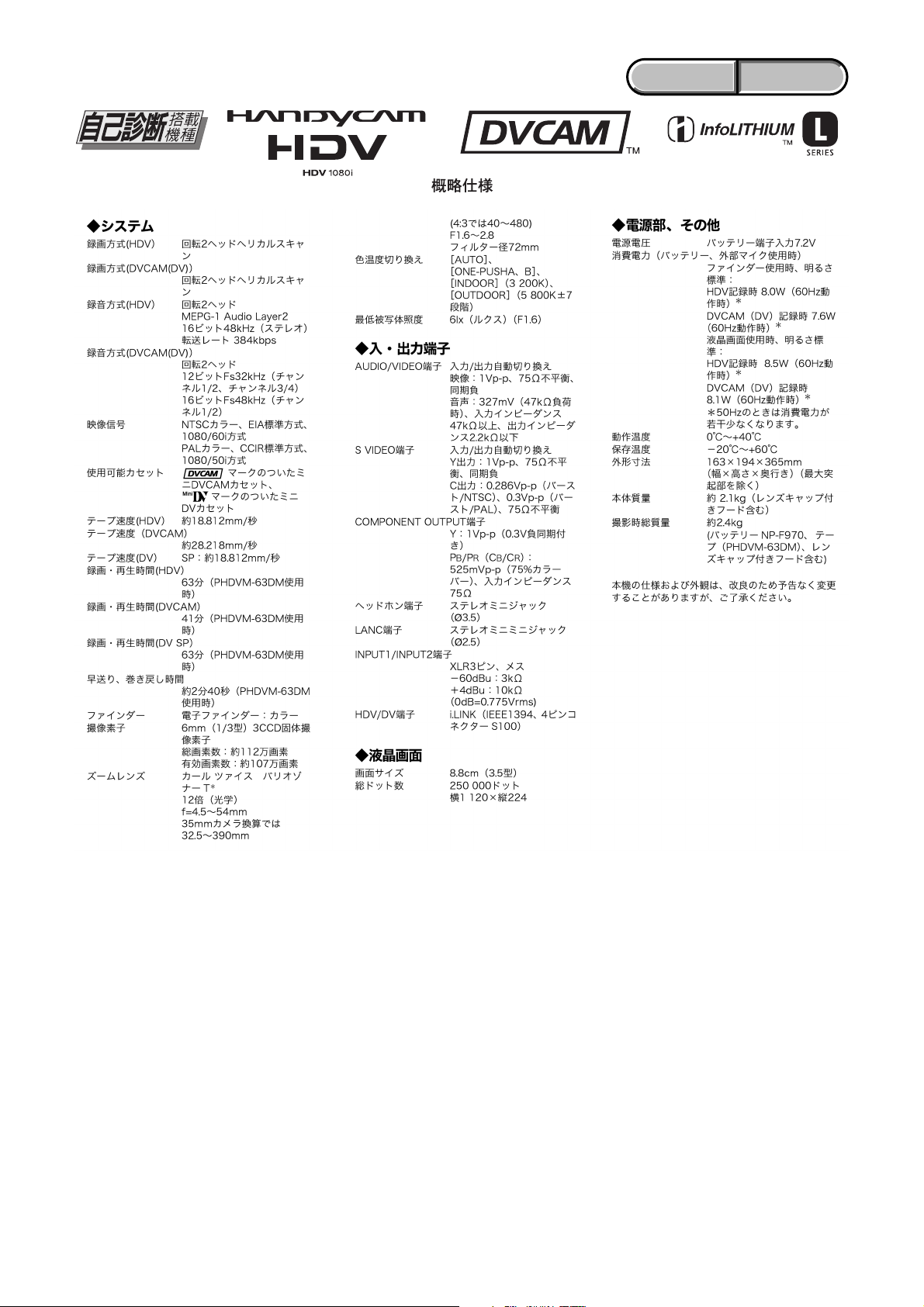

SPECIFICATIONS

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

— 2 —

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

— 3 —

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

ENGLISH JAPANESE

ENGLISH JAPANESE

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

— 4 —

サービス,点検時には次のことにご注意下さい。

ENGLISH JAPANESE

ENGLISH JAPANESE

1. 注意事項をお守りください。

サービスのとき特に注意を要する個所については,

キャビネット,シャーシ,部品などにラベルや捺印で

注意事項を表示しています。これらの注意書き及び取

扱説明書等の注意事項を必ずお守り下さい。

2. 指定部品のご使用を

セットの部品は難燃性や耐電圧など安全上の特性を

持ったものとなっています。従って交換部品は,使用

されていたものと同じ特性の部品を使用して下さい。

特に回路図,部品表に0印で指定されている安全上重要

な部品は必ず指定のものをご使用下さい。

3. 部品の取付けや配線の引きまわしはもとどおりに

安全上,チューブやテープなどの絶縁材料を使用した

り,プリント基板から浮かして取付けた部品がありま

す。また内部配線は引きまわしやクランパによって発

熱部品や高圧部品に接近しないよう配慮されています

ので,これらは必ずもとどおりにして下さい。

4. サービス後は安全点検を

サービスのために取外したネジ,部品,配線がもとど

おりになっているか,またサービスした個所の周辺を

劣化させてしまったところがないかなどを点検し,安

全性が確保されていることを確認して下さい。

5. チップ部品交換時の注意

• 取外した部品は再使用しないで下さい。

• タンタルコンデンサのマイナス側は熱に弱いため交

換時は注意して下さい。

6. フレキシブルプリント基板の取扱いについて

• コテ先温度を270℃前後にして行なって下さい。

• 同一パターンに何度もコテ先を当てないで下さい。

(3回以内)

• パターンに力が加わらないよう注意して下さい。

7. 無鉛半田について

無鉛半田を使用している基板には,無鉛(Lead Free)を

意味するレッドフリーマークがプリントされています。

(注意:基板サイズによっては,無鉛半田を使用して

いてもレッドフリーマークがプリントされて

いないものがあります)

:レッドフリーマーク

無鉛半田には,以下の特性があります。

• 融点が従来の半田よりも約40℃高い。

従来の半田こてをそのまま使用することは可能です

が,少し長めにこてを当てる必要があります。

温度調節機能のついた半田こてを使用する場合,約

350℃に設定して下さい。

注意: 半田こてを長く当てすぎると,基板のパター

ン(銅箔)がはがれてしまうことがあります

ので,注意して下さい。

• 粘性が強い

従来の半田よりも粘性が強いため,IC端子などが半田

ブリッジしないように注意して下さい。

• 従来の半田と混ぜて使用可能

無鉛半田には無鉛半田を追加するのが最適ですが,

従来の半田を追加しても構いません。

電池の交換は,正しく行わないと破裂する恐れがあり

ます。電池を交換する場合には必ず同じ型名の電池

又は同等品と交換してください。

注意

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

— 5 —

TABLE OF CONTENTS

1. SERVICE NOTE

1-1. SERVICE NOTE ·····························································1-1

1. NOTE FOR REPAIR ·······················································1-1

2. POWER SUPPLY DURING REPAIRS··························1-2

3. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) ·····························································1-2

1-2. SELF-DIAGNOSIS FUNCTION····································1-3

1. SELF-DIAGNOSIS FUNCTION····································1-3

2. SELF-DIAGNOSIS DISPLAY ·······································1-3

3. SELF-DIAGNOSIS CODE TABLE································1-4

2. DISASSEMBLY

2-1. DISASSEMBLY ······························································2-1

2-2. SERVICE POSITION ·····················································2-7

2-3. CIRCUIT BOARDS LOCATION ·································2-10

2-4. FLEXIBLE BOARDS LOCATION ······························2-12

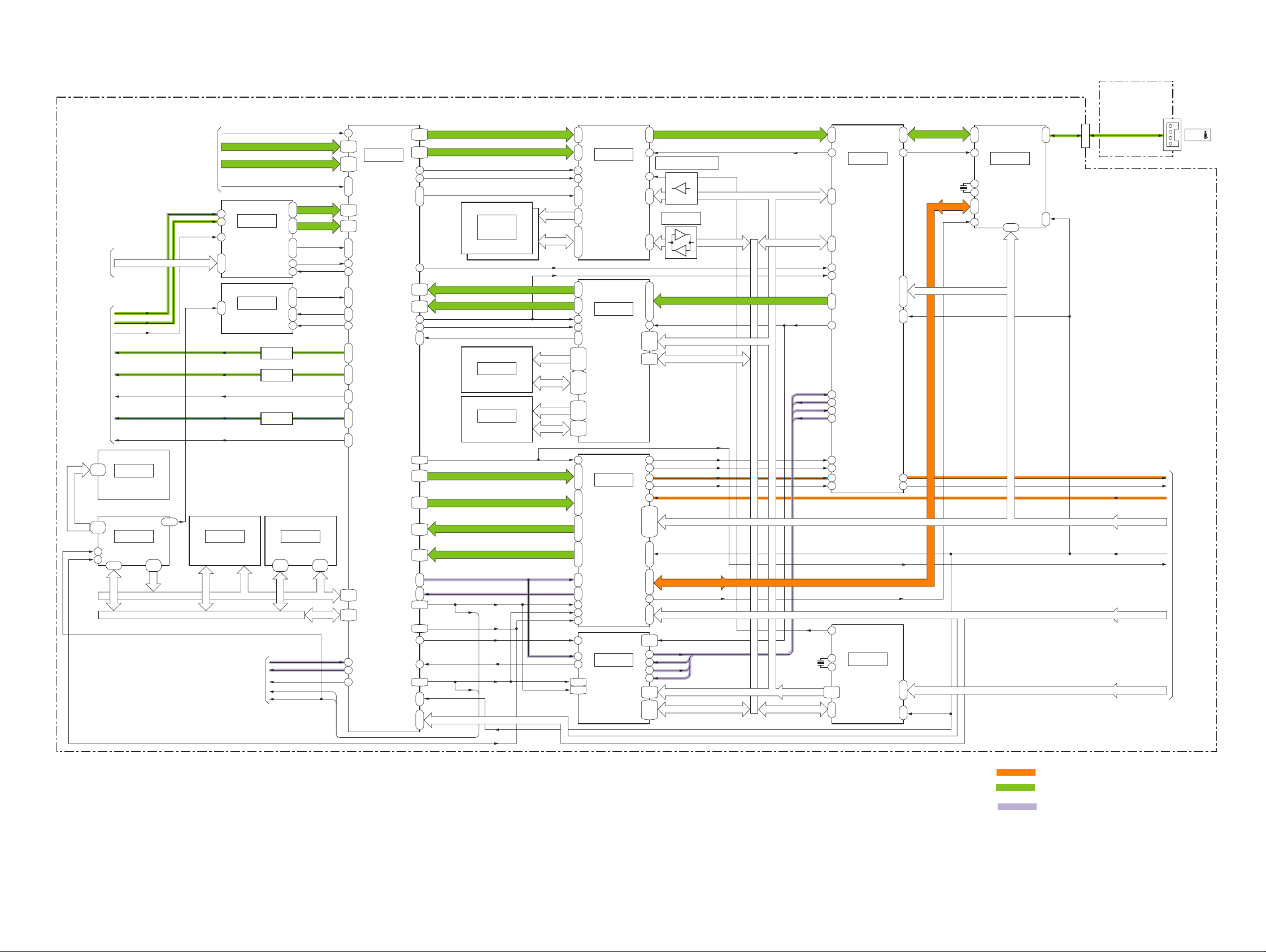

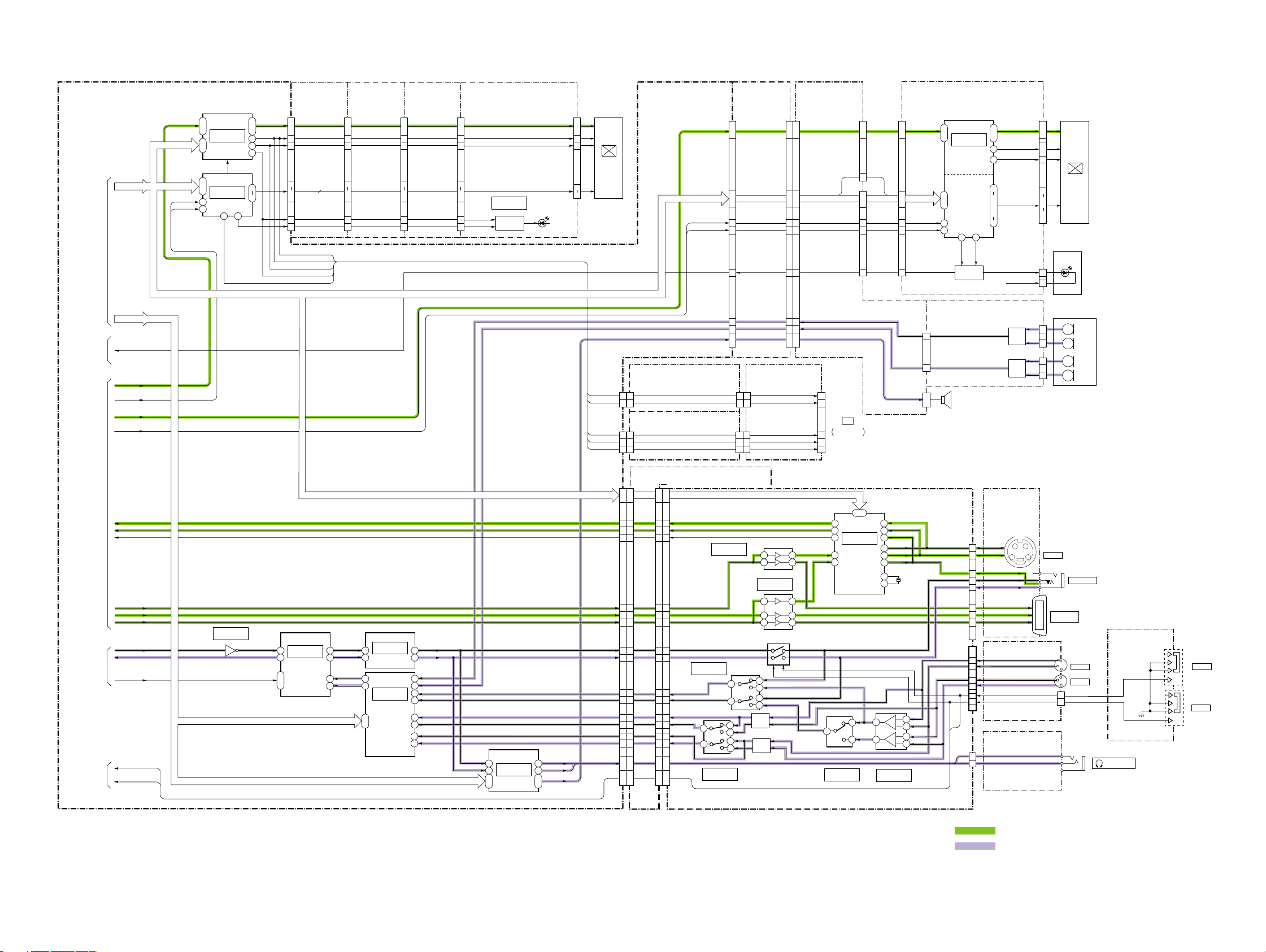

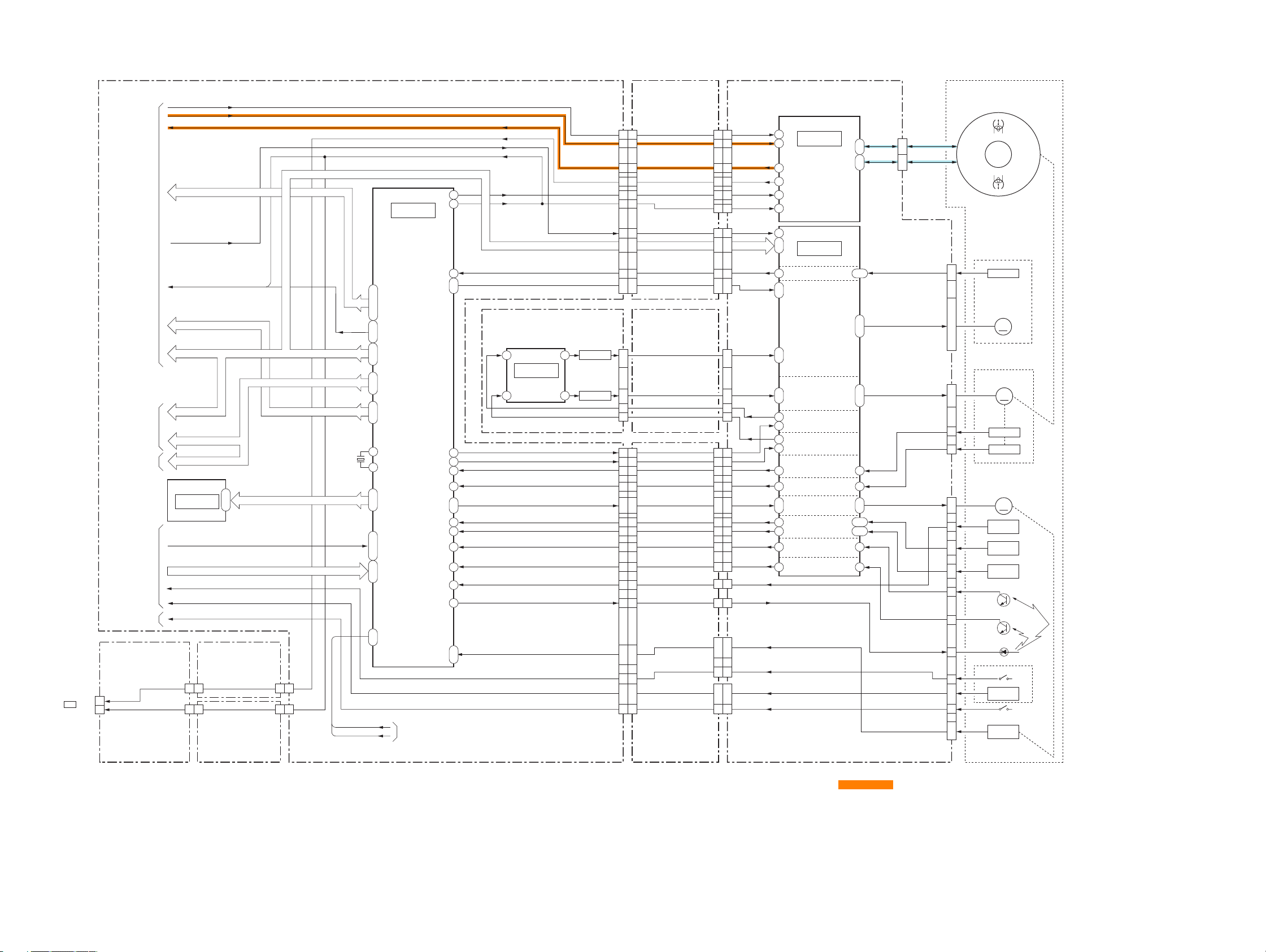

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/6) ···························3-1

3-2. OVERALL BLOCK DIAGRAM (2/6) ···························3-3

3-3. OVERALL BLOCK DIAGRAM (3/6) ···························3-5

3-4. OVERALL BLOCK DIAGRAM (4/6) ···························3-7

3-5. OVERALL BLOCK DIAGRAM (5/6) ···························3-9

3-6. OVERALL BLOCK DIAGRAM (6/6) ·························3-11

3-7. POWER BLOCK DIAGRAM (1/4)······························3-13

3-8. POWER BLOCK DIAGRAM (2/4)······························3-15

3-9. POWER BLOCK DIAGRAM (3/4)······························3-17

3-10. POWER BLOCK DIAGRAM (4/4)······························3-19

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME PRINTED WIRING BOARD (1/2)··················4-1

FRAME PRINTED WIRING BOARD (2/2)··················4-3

4-2. SCHEMATIC DIAGRAMS

• CK-143 (FUNCTION KEY)

SCHEMATIC DIAGRAMS····························4-7

• FP-962 FLEXIBLE BOARD (IRIS DIAL)

SCHEMATIC DIAGRAM ······························4-7

• FP-963 FLEXIBLE BOARD (WB/GAIN SW)

SCHEMATIC DIAGRAM ······························4-7

• FP-965 FLEXIBLE BOARD (LID SW)

SCHEMATIC DIAGRAM ······························4-7

• FK-090 (VTR FUNCTION KEY)

SCHEMATIC DIAGRAM ······························4-9

• FP-959 FLEXIBLE BOARD (BATTERY)

SCHEMATIC DIAGRAM ···························· 4-11

• FP-960 FLEXIBLE BOARD (MIC SELECT)

SCHEMATIC DIAGRAM ···························· 4-11

• FP-961 FLEXIBLE BOARD (FUNCTION KEY, TALLY)

SCHEMATIC DIAGRAM ···························· 4-12

• FP-964 FLEXIBLE BOARD (DV TERMINAL)

SCHEMATIC DIAGRAM ···························· 4-11

• FP-971 FLEXIBLE BOARD (RELAY)

SCHEMATIC DIAGRAM ···························· 4-13

• FP-972 FLEXIBLE BOARD (RELAY)

SCHEMATIC DIAGRAM ···························· 4-15

• FP-978 FLEXIBLE BOARD (MIC TERMINAL)

SCHEMATIC DIAGRAM ···························· 4-15

• FP-974 FLEXIBLE BOARD (RELAY)

SCHEMATIC DIAGRAM ···························· 4-17

• FP-976 FLEXIBLE BOARD (RELAY)

SCHEMATIC DIAGRAM ···························· 4-19

• FP-977 FLEXIBLE BOARD (RELAY)

SCHEMATIC DIAGRAM ···························· 4-21

• FP-980 FLEXIBLE BOARD (RELAY, REAR IR)

SCHEMATIC DIAGRAM ···························· 4-23

• CONTROL SWITCH BLOCK (ZS5610)

SCHEMATIC DIAGRAM ···························· 4-23

• FP-975 FLEXIBLE BOARD (RELAY)

SCHEMATIC DIAGRAM ···························· 4-24

• FP-981 FLEXIBLE BOARD (RELAY)

SCHEMATIC DIAGRAM ···························· 4-25

• IF-122 (RELAY)

SCHEMATIC DIAGRAM ···························· 4-27

• FP-967 FLEXIBLE BOARD (MR SENSOR)

SCHEMATIC DIAGRAM ···························· 4-27

• SW-433 (PANEL REV)

SCHEMATIC DIAGRAM ···························· 4-28

• JK-275 (JACK)

SCHEMATIC DIAGRAM ···························· 4-29

• LB-106 (EVF BACK LIGHT)

SCHEMATIC DIAGRAM ···························· 4-31

• MA-431 (INT MIC AMP)

SCHEMATIC DIAGRAM ···························· 4-33

• MK-017 (FUNCTION KEY)

SCHEMATIC DIAGRAM ···························· 4-35

• FP-966 FLEXIBLE BOARD (AUTO LOCK)

SCHEMATIC DIAGRAM ···························· 4-36

• CONTROL SWITCH BLOCK (VV91010)

SCHEMATIC DIAGRAM ···························· 4-36

• MR-048 (1/2) (REC/PB RF AMP)

SCHEMATIC DIAGRAM ···························· 4-37

• MR-048 (2/2) (DRUM/CAPSTAN/LOADING MOTOR

DRIVE)

SCHEMATIC DIAGRAM ···························· 4-39

• PD-222 (LCD DRIVER, TIMING GENERATOR)

SCHEMATIC DIAGRAM ···························· 4-41

• SE-150 (PITCH/YAW SENSOR AMP)

SCHEMATIC DIAGRAM ···························· 4-43

• VA-119 (1/4) (AUDIO IN/OUT)

SCHEMATIC DIAGRAM ···························· 4-45

• VA-119 (2/4) (VIDEO IN/OUT)

SCHEMATIC DIAGRAM ···························· 4-47

• VA-119 (3/4) (Y. PB. PR. OUT AMP)

SCHEMATIC DIAGRAM ···························· 4-49

• VA-119 (4/4) (XLR INPUT)

SCHEMATIC DIAGRAM ···························· 4-51

• CONTROL SWITCH BLOCK (CF5610)

SCHEMATIC DIAGRAM ···························· 4-53

• CONTROL SWITCH BLOCK (PS5610)

SCHEMATIC DIAGRAM ···························· 4-54

• CD-522 (R.G.B-CH CCD IMAGER, S/H, AGC)

SCHEMATIC DIAGRAM ···························· 4-55

• DA-033 (DC/DC CONVERTER)

SCHEMATIC DIAGRAM ···························· 4-57

• DB-018 (1/2) (DC IN, CHARGE)

SCHEMATIC DIAGRAM ···························· 4-59

• DB-018 (2/2) (DC/DC CONVERTER)

SCHEMATIC DIAGRAM ···························· 4-61

• VC-367 (1/25) (CCD RF IN)

SCHEMATIC DIAGRAM ···························· 4-63

• VC-367 (2/25) (R.G.B-CH AGC, A/D CONV., TIMING

GENERATOR)

SCHEMATIC DIAGRAM ···························· 4-65

• VC-367 (3/25) (CAMERA RGB PROCESS)

SCHEMATIC DIAGRAM ···························· 4-67

• VC-367 (4/25) (LENS DRIVE)

SCHEMATIC DIAGRAM ···························· 4-69

• VC-367 (5/25) (LENS DRIVE CONTROL)

SCHEMATIC DIAGRAM ···························· 4-71

• VC-367 (6/25) (CAMERA CONTROL)

SCHEMATIC DIAGRAM ···························· 4-73

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

— 6 —

• VC-367 (7/25) (BASE BAND PROCESS)

SCHEMATIC DIAGRAM ···························· 4-75

• VC-367 (8/25) (OSD, D3 FILTER)

SCHEMATIC DIAGRAM ···························· 4-77

• VC-367 (9/25) (HDV VIDEO ENCODER)

SCHEMATIC DIAGRAM ···························· 4-79

• VC-367 (10/25) (64MBIT SDRAM (L/U))

SCHEMATIC DIAGRAM ···························· 4-81

• VC-367 (11/25) (HDV SIGNAL/RF SIGNAL PROCESS)

SCHEMATIC DIAGRAM ···························· 4-83

• VC-367 (12/25) (HDV VIDEO DECODER)

SCHEMATIC DIAGRAM ···························· 4-85

• VC-367 (13/25) (64MBIT Y/C-SDRAM)

SCHEMATIC DIAGRAM ···························· 4-87

• VC-367 (14/25) (I LINK INTERFACE)

SCHEMATIC DIAGRAM ···························· 4-89

• VC-367 (15/25) (DV/RF SIGNAL PROCESS)

SCHEMATIC DIAGRAM ···························· 4-91

• VC-367 (16/25) (VIDEO A/D CONV.)

SCHEMATIC DIAGRAM ···························· 4-93

• VC-367 (17/25) (EVF RGB DRIVER, TIMING

GENERATOR)

SCHEMATIC DIAGRAM ···························· 4-95

• VC-367 (18/25) (HDV AUDIO SIGNAL PROCESS)

SCHEMATIC DIAGRAM ···························· 4-97

• VC-367 (19/25) (AUDIO INPUT SELECT, AUDIO

CONVERTOR)

SCHEMATIC DIAGRAM ···························· 4-99

• VC-367 (20/25) (DS CONTROL)

SCHEMATIC DIAGRAM ·························· 4-101

• VC-367 (21/25) (FRONT CONTROL)

SCHEMATIC DIAGRAM ·························· 4-103

• VC-367 (22/25) (LSI CONTROL)

SCHEMATIC DIAGRAM ·························· 4-105

• VC-367 (23/25) (MECHA CONTROL)

SCHEMATIC DIAGRAM ·························· 4-107

• VC-367 (24/25) (CONNECTOR-1)

SCHEMATIC DIAGRAM ·························· 4-109

• VC-367 (25/25) (CONNECTOR-2)

SCHEMATIC DIAGRAM ·························· 4-111

• FP-228/467/826 FLEXIBLE BOARD

SCHEMATIC DIAGRAM ·························· 4-113

4-3. PRINTED WIRING BOARDS

• CK-143 (FUNCTION KEY)

PRINTED WIRING BOARD ····················· 4-119

• FK-090 (VTR FUNCTION KEY)

PRINTED WIRING BOARD ····················· 4-121

• FP-959 FLEXIBLE (BATTERY)

PRINTED WIRING BOARD ····················· 4-121

• FP-960 FLEXIBLE (MIC SELECT)

PRINTED WIRING BOARD ····················· 4-122

• FP-964 FLEXIBLE (DV TERMINAL)

PRINTED WIRING BOARD ····················· 4-123

• FP-971 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ····················· 4-123

• FP-967 FLEXIBLE (MR SENSOR)

PRINTED WIRING BOARD ····················· 4-124

• FP-975 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ····················· 4-124

• FP-978 FLEXIBLE (MIC TERMINAL)

PRINTED WIRING BOARD ····················· 4-125

• FP-980 FLEXIBLE (RELAY, REAR IR)

PRINTED WIRING BOARD ····················· 4-125

• FP-981 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ····················· 4-127

• FP-977 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ····················· 4-127

• FP-976 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ····················· 4-128

• IF-122 (RELAY)

PRINTED WIRING BOARD ····················· 4-129

• JK-275 (JACK)

PRINTED WIRING BOARD ····················· 4-131

• FP-972 FLEXIBLE BOARD (RELAY)

PRINTED WIRING BOARD ····················· 4-131

• LB-106 (EVF BACK LIGHT)

PRINTED WIRING BOARD ····················· 4-133

• FP-974 FLEXIBLE BOARD (RELAY)

PRINTED WIRING BOARD ····················· 4-133

• MA-431 (INT MIC AMP)

PRINTED WIRING BOARD ····················· 4-135

• MK-017 (FUNCTION KEY)

PRINTED WIRING BOARD ····················· 4-137

• FP-228/467/826 FLEXIBLE

PRINTED WIRING BOARD ····················· 4-137

• MR-048 (REC/PB RF AMP, DRUM/CAPSTAN/

LOADING MOTOR DRIVE)

PRINTED WIRING BOARD ····················· 4-139

• PD-222 (LCD DRIVER, TIMING GENERATOR)

PRINTED WIRING BOARD ····················· 4-143

• SE-150 (PITCH/YAW SENSOR AMP)

PRINTED WIRING BOARD ····················· 4-147

• SW-433 (PANEL REV)

PRINTED WIRING BOARD ····················· 4-147

• VA-119 (AUDIO IN/OUT, VIDEO IN/OUT, Y. PB. PR.

OUT AMP)

PRINTED WIRING BOARD ····················· 4-149

• CD-522 (R.G.B-CH CCD IMAGER, S/H, AGC)

PRINTED WIRING BOARD ····················· 4-153

• DA-033 (DC/DC CONVERTER)

PRINTED WIRING BOARD ····················· 4-157

• DB-018 (DC IN, CHARGE, DC/DC CONVERTER)

PRINTED WIRING BOARD ····················· 4-161

• VC-367 (CCD RF IN, R.G.B-CH AGC, A/D CONV.,

TIMING GENERATOR, CAMERA RGB PROCESS,

LENS DRIVE, LENS DRIVE CONTROL, CAMERA

CONTROL, BASE BAND PROCESS, OSD, D3 FILTER,

HDV VIDEO ENCODER, 64MBIT SDRAM (L/U),

HDV SIGNAL/RF SIGNAL PROCESS, HDV VIDEO

DECODER, 64MBIT Y/C-SDRAM, I LINK

INTERFACE, DV/RF SIGNAL PROCESS, VIDEO A/D

CONV., EVF RGB DRIVER, TIMING GENERATOR,

HDV AUDIO SIGNAL PROCESS, AUDIO INPUT

SELECT, AUDIO CONVERTOR, DS CONTROL,

FRONT CONTROL, LSI CONTROL, MECHA

CONTROL, CONNECTOR-1, CONNECTOR-2)

PRINTED WIRING BOARD ····················· 4-165

4-4. WAVEFORMS ····························································4-169

4-5. MOUNTED PARTS LOCATION ······························· 4-173

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································ 5-3

5-1-1.OVERALL SECTION····················································· 5-3

5-1-2.CABINET (R) SECTION-1 ············································ 5-4

5-1-3.CABINET (R) SECTION-2 ············································ 5-5

5-1-4.CABINET (L) SECTION ················································ 5-6

5-1-5.HANDLE SECTION-1 ··················································· 5-7

5-1-6.HANDLE SECTION-2 ··················································· 5-8

5-1-7.LCD SECTION ······························································· 5-9

5-1-8.EVF SECTION ······························································ 5-10

5-1-9.CENTER SECTION ······················································ 5-11

5-1-10. MAIN BOARD SECTION (VA, VC, DA, DB) ··········5-12

5-1-11. LENS SECTION ························································ 5-13

5-1-12. TERMINAL CABINET SECTION···························· 5-14

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

— 7 —

5-1-13. BATTERY SECTION AND DV SECTION ···············5-15

5-1-14. MECHANISM DECK OVERALL (Z311) ················ 5-16

5-1-15. LS CHASSIS BLOCK ASSEMBLY ·························· 5-17

5-1-16. MECHANICAL CHASSIS BLOCK ASSEMBLY ···· 5-18

Checking supplied accessories. ··············································· 5-19

5-2. ELECTRICAL PARTS LIST ········································ 5-21

6. ADJUSTMENT

1. Before starting adjustment ··············································· 6-1

1-1. Adjusting items when replacing main parts and boards. ··· 6-2

6-1. CAMERA SECTION ADJUSTMENT ··························· 6-4

1-1. PREPARATIONS BEFORE ADJUSTMENT

(CAMERA SECTION) ··················································· 6-4

1-1-1.List of Service Tools ························································6-4

1-1-2.Preparations ·····································································6-6

1-1-3.Precaution ········································································6-8

1. Setting the Switch ···························································· 6-8

2. Order of Adjustments ······················································ 6-8

3. Subjects ··········································································· 6-8

1-2. INITIALIZATION OF 8, 9, A, B, C, D, E, F, 13, 14, 18,

19, 1A, 1B, 1C, 1D, 1E, 1F PAGE DATA ·······················6-9

1-2-1.INITIALIZATION OF A, B, D, 1A, 1B PAGE DATA···· 6-9

1. Initializing the A, B, D, 1A, 1B Page Data ····················· 6-9

2. Modification of A, B, D, 1A, 1B Page Data ···················· 6-9

3. A Page Table ····································································6-9

4. B Page Table ·································································· 6-10

5. D Page Table ··································································6-10

6. 1A Page Table ································································6-10

7. 1B Page Table ································································ 6-10

1-2-2.INITIALIZATION OF 8, C, 13, 18, 1C PAGE DATA ···· 6-11

1. Initializing the 8, C, 13, 18, 1C Page Data ····················6-11

2. Modification of 8, C, 13, 18, 1C Page Data ·················· 6-11

3. 8 Page Table ··································································· 6-12

4. C Page Table ·································································· 6-13

5. 13 Page Table ································································· 6-14

6. 18 Page Table ································································· 6-14

7. 1C Page Table ································································ 6-15

1-2-3.INITIALIZATION OF 9, 1D PAGE DATA ·················· 6-16

1. Initializing the 9, 1D Page Data ···································· 6-16

2. Modification of 9, 1D Page Data ··································· 6-16

3. 9 Page Table ··································································· 6-16

4. 1D Page Table ································································6-16

1-2-4.

INITIALIZATION OF E, F, 14, 19, 1E, 1F PAGE DATA ··

1. Initializing the E, F, 14, 19, 1E, 1F Page Data ·············· 6-17

2. Modification of E, F, 14, 19, 1E, 1F Page Data ············· 6-18

3. E Page Table (NTSC (60i) & PAL (50i) modes) ··········· 6-18

4. F Page Table (NTSC (60i) & PAL (50i) modes) ···········6-19

5. 14 Page Table (NTSC (60i) & PAL (50i) modes) ········· 6-20

6. 19 Page Table (NTSC (60i) & PAL (50i) modes) ········· 6-21

7. 1E Page Table (NTSC (60i) & PAL (50i) modes) ········· 6-21

8. 1F Page Table (NTSC (60i) & PAL (50i) modes) ·········6-22

1-3. CAMERA SYSTEM ADJUSTMENTS ························ 6-23

1. Origin Oscillation Check (NTSC (60i) & PAL (50i) modes)

(VC-367 board) ····························································· 6-24

2. HALL Adjustment (NTSC (60i) mode) ························ 6-25

3. MR Adjustment (NTSC (60i) mode) ····························· 6-26

4. Focus Ring Adjustment (NTSC (60i) mode)················· 6-27

5. Zoom Ring Adjustment (NTSC (60i) mode)················· 6-27

5-1. Zoom Ring Adjustment (1)············································ 6-27

5-2. Zoom Ring Adjustment (2)············································ 6-28

6. Flange Back Adjustment (NTSC (60i) mode) ··············· 6-29

6-1. Flange Back Adjustment (Using Minipattern Box or Flange

Back Adjustment Jig) ···················································· 6-29

6-2. Flange Back Adjustment (Using Flange Back Adjustment

Chart and Subject More Than 500m Away) ·················· 6-30

6-2-1.Flange Back Adjustment (1) ·········································· 6-30

6-2-2.Flange Back Adjustment (2) ·········································· 6-30

6-17

7. Flange Back Check (NTSC (60i) mode) ······················· 6-31

8. HALL Adjustment (PAL (50i) mode) ··························· 6-32

9. MR Adjustment (PAL (50i) mode) ································6-33

10. Focus Ring & Zoom Ring Adjustment

(PAL (50i) mode) ·························································· 6-33

11. Flange Back Adjustment (PAL (50i) mode) ··················6-34

12. Flange Back Check (PAL (50i) mode) ·························· 6-34

13. Picture Frame Setting

(NTSC (60i) & PAL (50i) modes) ································· 6-35

14. Auto White Balance Standard Data Input

(NTSC (60i) & PAL (50i) modes) ································· 6-36

14-1. Auto White Balance Standard Data Input ND OFF ······· 6-36

14-2. Auto White Balance Standard Data Input ND 1 ············ 6-36

14-3. Auto White Balance Standard Data Input ND 2

(NTSC (60i) & PAL (50i) modes) ································· 6-37

15. MAX GAIN Adjustment

(NTSC (60i) & PAL (50i) modes) ································· 6-37

16. LV Standard Data Input

(NTSC (60i) & PAL (50i) modes) ································· 6-38

17. Auto White Balance Adjustment

(NTSC (60i) & PAL (50i) modes) ································· 6-38

17-1. Auto White Balance Adjustment ND OFF ····················6-38

17-2. Auto White Balance Adjustment ND 1 ························· 6-39

17-3. Auto White Balance Adjustment ND 2 ························· 6-39

18. Color Reproduction Adjustment

(NTSC (60i) & PAL (50i) modes) ································· 6-40

18-1. Color Reproduction Adjustment ND OFF····················· 6-40

18-2. Color Reproduction Adjustment ND 1 ·························· 6-41

18-3. Color Reproduction Adjustment ND 2 ·························· 6-41

19. White Balance Check

(NTSC (60i) & PAL (50i) modes) ································· 6-42

19-1. White Balance Check ND OFF ·····································6-42

19-2. White Balance Check ND 1 ·········································· 6-43

19-3. White Balance Check ND 2 ·········································· 6-45

20. Color Reproduction Check HD STD γ

(NTSC (60i) & PAL (50i) modes) ································· 6-45

20-1. Color Reproduction Check ND OFF HD STD γ ··········· 6-45

20-2. Color Reproduction Check ND 1 HD STD γ ················· 6-46

20-3. Color Reproduction Check ND 2 HD STD γ ················ 6-46

21. Color Reproduction Check HD CINE γ

(NTSC (60i) & PAL (50i) modes) ································· 6-47

21-1. Color Reproduction Check ND OFF HD CINE γ ·········· 6-47

21-2. Color Reproduction Check ND 1 HD CINE γ ···············6-48

21-3. Color Reproduction Check ND 2 HD CINE γ ···············6-48

22. Color Reproduction Check SD STD γ

(NTSC (60i) & PAL (50i) modes) ································· 6-49

22-1. Color Reproduction Check ND OFF SD STD γ ···········6-49

22-2. Color Reproduction Check ND 1 SD STD γ·················· 6-50

22-3. Color Reproduction Check ND 2 SD STD γ·················· 6-50

23. Color Reproduction Check SD CINE γ

(NTSC (60i) & PAL (50i) modes) ································· 6-51

23-1. Color Reproduction Check ND OFF SD CINE γ ·········· 6-51

23-2. Color Reproduction Check ND 1 SD CINE γ ················ 6-52

23-3. Color Reproduction Check ND 2 SD CINE γ ················ 6-52

24. PSD Sensor Gain Adjustment

(NTSC (60i) & PAL (50i) modes) ································· 6-53

24-1. PSD Sensor Gain Adjustment (NTSC (60i) mode) (1) ···· 6-53

24-2. PSD Sensor Gain Adjustment (NTSC (60i) mode) (2) ···· 6-54

24-3. PSD Sensor Gain Adjustment (PAL (50i) mode) ·········· 6-55

25. Angular Velocity Sensor Sensitivity Adjustment

(NTSC (60i) & PAL (50i) modes) ································· 6-56

25-1. Angular Velocity Sensor Sensitivity Adjustment

(NTSC (60i) mode) ·······················································6-56

25-2. Angular Velocity Sensor Sensitivity Adjustment ··········· 6-57

1-4. COLOR ELECTRONIC VIEWFINDER SYSTEM

ADJUSTMENT ·····························································6-58

1. VCO Adjustment (VC-367 board) ································ 6-58

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

— 8 —

2. Backlight Adjustment (VC-367 board) ························· 6-59

3. PSIG Level Adjustment (VC-367 board) ······················ 6-59

4. VCOM Level Adjustment (VC-367 board) ··················· 6-60

5. RGB AMP Adjustment (VC-367 board) ······················ 6-60

6. Contrast Adjustment (VC-367 board) ··························· 6-61

7. White Balance Adjustment (VC-367 board) ·················6-61

1-5. LCD SYSTEM ADJUSTMENT ···································6-62

1. LCD Automatic Adjustment (PD-222 board) ················6-62

2. Contrast Adjustment (HD) (PD-222 board) ·················· 6-63

3. V COM Adjustment (PD-222 board) ···························· 6-63

4. Sample Hold Phase Adjustment

(PD-222 board) ······························································6-64

5. Transmissive Mode White Balance Adjustment

(PD-222 board) ······························································6-64

6. Reflective Mode White Balance Adjustment

(PD-222 board) ······························································6-65

6-2. MECHANISM SECTION ADJUSTMENT·················· 6-66

2-1. Preparations for Check, Adjustment and Replacement of

Mechanism Block ·························································· 6-66

2-1-1.Cassette Compartment Assy, Damper Assy ··················6-66

2-2. Periodic Inspection and Maintenance

2-2-1.Rotary Drum Cleaning ·················································· 6-67

2-2-2.Tape Path System Cleaning (Refer to Fig. 6-2-2.) ········ 6-67

2-2-3.Periodic Inspection List ·················································6-68

2-2-4.Mode Selector II Operating Procedure ·························· 6-69

2-4-1.Introduction ··································································· 6-69

2-4-2.Operation ·······································································6-70

2-4-3.Mechanism Status (Position) Transition Table Using

Mode Selector II ····························································6-72

2-4-4.Battery Alarm Indication ··············································· 6-70

2-3. Check, Adjustment and Replacement of

Mechanical Parts ··························································· 6-73

2-3-1.Flowchart of Replacement of Mechanical Parts ············ 6-73

2-3-2.Drum ·············································································· 6-75

2-3-3.Cassette Compartment Assy ·········································· 6-76

2-3-4.TG7 Support ··································································6-77

2-3-5.Motor Holder Block Assy and L Motor Block Assy ····· 6-78

2-3-6.MIC Terminal (MIC902) ···············································6-79

2-3-7.LED (D901) ··································································· 6-80

2-3-8.Retainer Plate ································································6-81

2-3-9.T Reel Table Assy ··························································6-82

2-3-10. Brake (S) and Release Rack (S) ·································· 6-83

2-3-11. Band Adjuster, S Reel Table Assy and

TG2 Arm Block Assy ················································· 6-84

2-3-12. ULE Brake Assy ························································· 6-85

2-3-13. Cassette Positioning (S) ··············································6-86

2-3-14. TG7 Arm Block Assy and Pinch Arm Assy ················6-87

2-3-15. TG7 ············································································· 6-88

2-3-16. Gooseneck Gear Assy ·················································6-89

2-3-17. LS Guide Retainer and LS Cam Plate ························ 6-90

2-3-18. LS Chassis Block Assy and

Mechanical Chassis Block Assy ································· 6-91

2-3-19. Brake (T) Block Assy ················································· 6-93

2-3-20. END Sensor (Q901) ···················································· 6-94

2-3-21. TOP Sensor (Q902)·····················································6-95

2-3-22. C-IN Switch (S903), S Reel Sensor (H901) and

T Reel Sensor (H902) ····················································6-96

2-3-23. Guide Rail ···································································6-97

2-3-24. Conversion Gear ························································· 6-98

2-3-25. Coaster (S) Block Assy and

Coaster (T) Block Assy ·············································· 6-99

2-3-26. TG5 Roller Assy and GL Gear (T) ··························· 6-100

2-3-27. TG2 Cam Plate Assy (N) ·········································· 6-101

2-3-28. LS Arm Assy ····························································· 6-102

2-3-29. M Slider Assy (1) ······················································ 6-103

2-3-30. M Slider Assy (2) ······················································ 6-104

2-3-31. EJ Arm ······································································ 6-105

2-3-32. Cam Gear and GL Driving········································ 6-106

2-3-33. Rotary Encoder (S902) ············································· 6-107

2-3-34. FP-228 Flexible Board (DEW SENSOR) and

FP-467 Flexible Board ············································· 6-108

2-4. Adjustment ·································································· 6-109

2-4-1.FWD Position Adjustment···········································6-109

2-4-2.Reel Torque Check ······················································ 6-109

2-4-3.LS Cam Plate Position Adjustment ·····························6-110

2-4-4.Tape Path Adjustment ·················································· 6-111

6-3. VIDEO SECTION ADJUSTMENT···························· 6-115

3-1. PREPARATIONS BEFORE ADJUSTMENTS ·········· 6-115

3-1-1.Equipment to Required ················································ 6-115

3-1-2.Precautions on Adjusting ············································· 6-116

3-1-3.Adjusting Connectors ··················································6-117

3-1-4.Connecting the Equipment ·········································· 6-117

3-1-5.Alignment Tapes ··························································6-118

3-1-6.Input/Output Level and Impedance ·····························6-118

3-2. SYSTEM CONTROL SYSTEM ADJUSTMENT ······6-119

1. Initialization of 8, 9, A, B, C, D, E, F, 13, 14, 18, 19, 1A,

1B, 1C, 1D, 1E, 1F Page Data ····································· 6-119

2. Serial No. Input ··························································· 6-119

3-3. SERVO AND RF SYSTEM ADJUSTMENT ·············6-121

1. Cap FG Duty Adjustment (VC-367 Board)················· 6-121

2. Switching Position Adjustment (VC-367 Board) ········ 6-121

3. Error Rate Check ·························································6-122

3-1. Preparations before adjustments ·································· 6-122

3-2. Error Rate Check ·························································6-122

3-3. Processing after Completing Adjustments ·················· 6-122

3-4. VIDEO SYSTEM ADJUSTMENTS··························· 6-123

1.

S VIDEO OUT Y Level Adjustment (VC-367 Board) ···

2. S VIDEO OUT Chroma Level Adjustment

(VC-367 Board) ··························································· 6-124

3. VIDEO OUT Y, Chroma Level Check

(VC-367 Board) ··························································· 6-125

4. COMPONENT OUTPUT Level Adjustment

(VC-367 Board) ··························································· 6-126

3-5. AUDIO SYSTEM ADJUSTMENTS ·························· 6-127

1. Playback Level Check ·················································6-128

2. Overall Level Characteristics Check ···························6-128

3. Camera E-E Audio Level Check (1) ···························· 6-128

4. Camera E-E Audio Level Check (2) ···························· 6-128

6-4. SERVICE MODE ························································ 6-129

4-1. ADJUSTMENT REMOTE COMMANDER ··············6-129

1. Using the adjustment remote commander ···················6-129

2. Precautions upon using ················································ 6-129

the adjustment remote commander ······························ 6-129

4-2. DATA PROCESS························································· 6-130

4-3. SERVICE MODE ························································ 6-131

1. Setting the Test Mode ··················································6-131

2. Emergence Memory Address (Mechanism section) ···· 6-131

2-1. EMG Code (Emergency Code) ··································· 6-131

2-2. MSW Code ··································································6-132

3. Bit value discrimination ·············································· 6-133

4. Switch check (1) ··························································6-133

5. Switch check (2) ··························································6-133

6. Switch check (3) ··························································6-133

7. Switch check (4) ··························································6-134

8. Switch check (5) ··························································6-134

9. LED check ···································································6-135

10. Record of Use check (1) ··············································6-135

11. Record of Use check (2) ··············································6-135

12. Record of Self-diagnosis check ···································6-136

SELF-DIAGNOSIS CODE TABLE ······································ 6-137

* Color reproduction frame is shown on page 6-138, 139.

6-124

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

— 9 —

1. SERVICE NOTE

1-1. SERVICE NOTE

1. NOTE FOR REPAIR

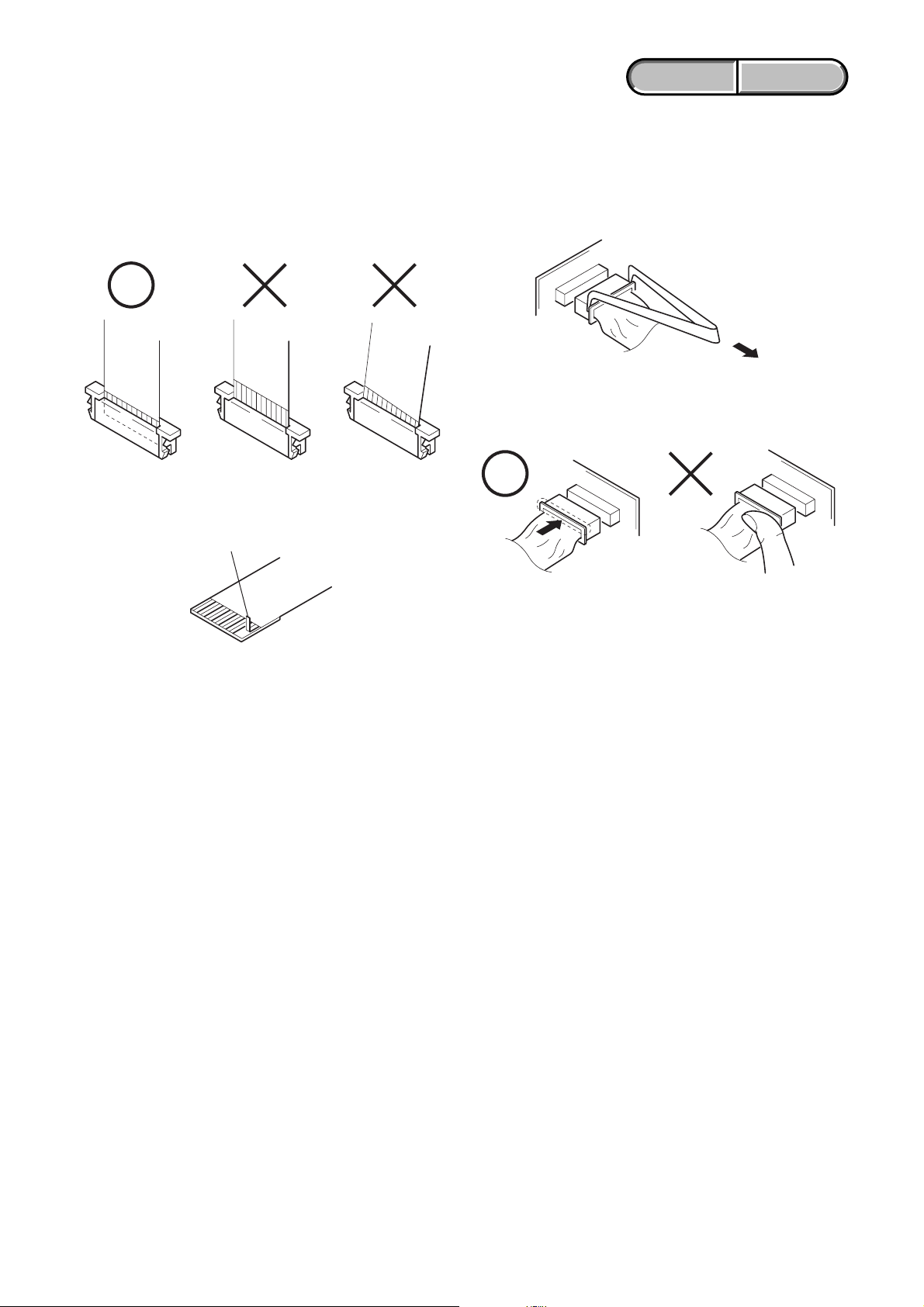

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

ENGLISH JAPANESE

ENGLISH JAPANESE

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

1-1

Ver. 1.7 2007. 10

ENGLISH JAPANESE

ENGLISH JAPANESE

2. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the power is shut off so

that the unit cannot operate.

This following three methods are available to prevent this. Take note of which to use during repairs.

Method 1:

Use the AC adapter and the connecting cord that are supplied with the equipment.

Method 2:

When you want to supply the power from a regulated power supply unit to the BATTERY terminal of this equipment, connect the adjustment

remote commander RM-95 (J-6082-053-B) to the LANC terminal of this equipment. Then set the HOLD switch to the ADJ position.

Method 3:

Note: The Method 3 should be used only during repair. Do not use the Method 3 during the ordinary operation.

Connect a usable AC adapter: AC-L10 or AC-L15. (There are type A and type B. Both types can be used.)

1. Set the MIC PHANTOM switch to OFF. (Power consumption should be minimal because AC adapter has the limited capacity.)

2. Remove the DC IN cover and connect the AC adapter.

3. Connect the adjustment remote commander RM-95 (J-6082-053-B) to the LANC terminal of this equipment, and set the HOLD switch

to the ADJ position. Turn on the power of the camera.

4. When the data are set as described below, the equipment can be operated on the AC adapter even if you unplug the adjustment remote

commander.

1)Select page: 0, address: 01, and set data: 01.

2)Select page: 0, address: 10, and set data: 00.

3)Select page: D, address: 23, set data: AF, and press the PAUSE button of the adjustment remote commander.

5. Be sure to return the data setup to the original setup as shown below upon completion of the adjustment.

1)Select page: 0, address: 01, and set data: 01.

2)Select page: 0, address: 10, and set data: 00.

3)Select page: D, address: 23, set data: FF, and press the PAUSE button of the adjustment remote commander.

4)Select page: 0, address: 01, and set data: 00.

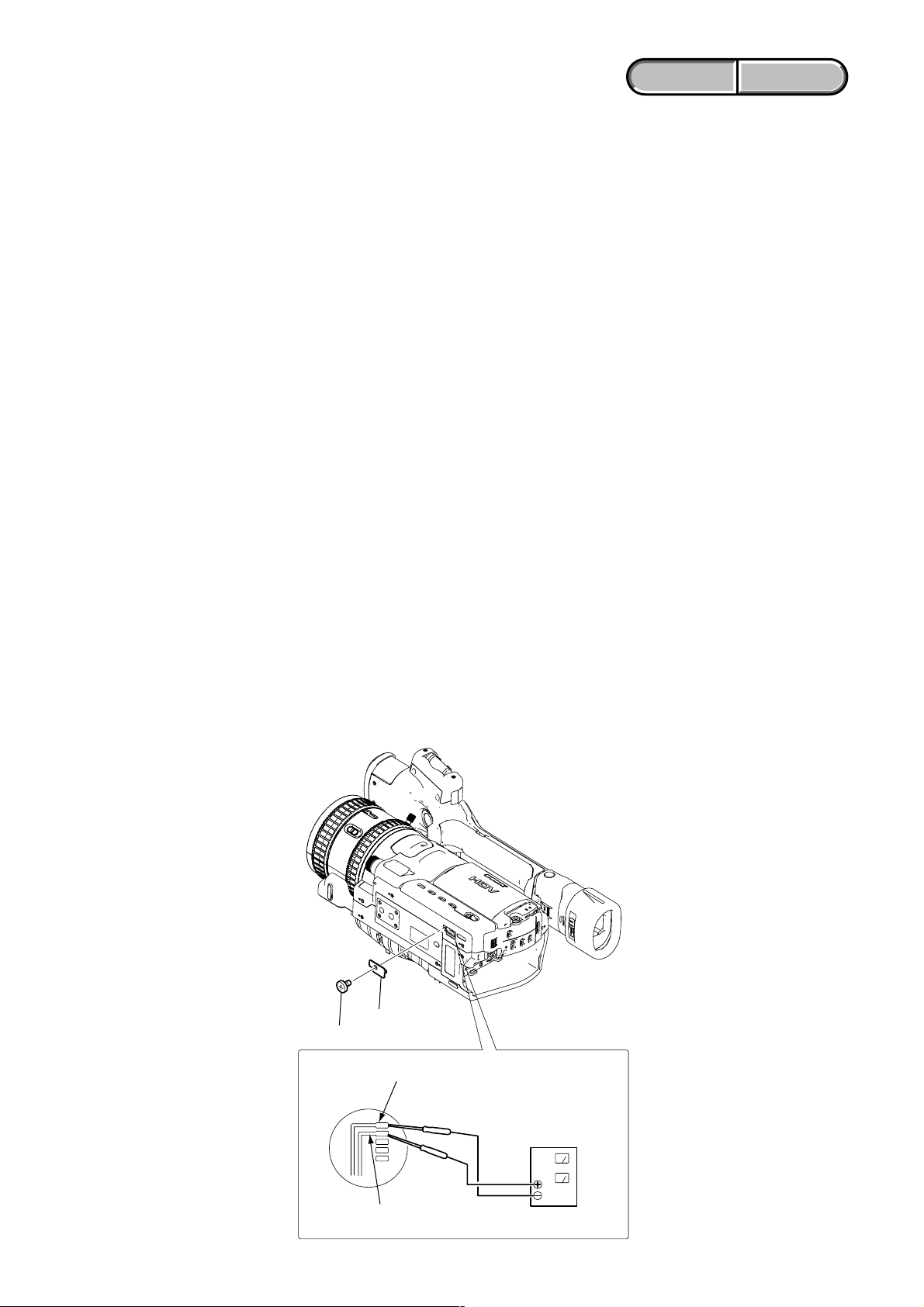

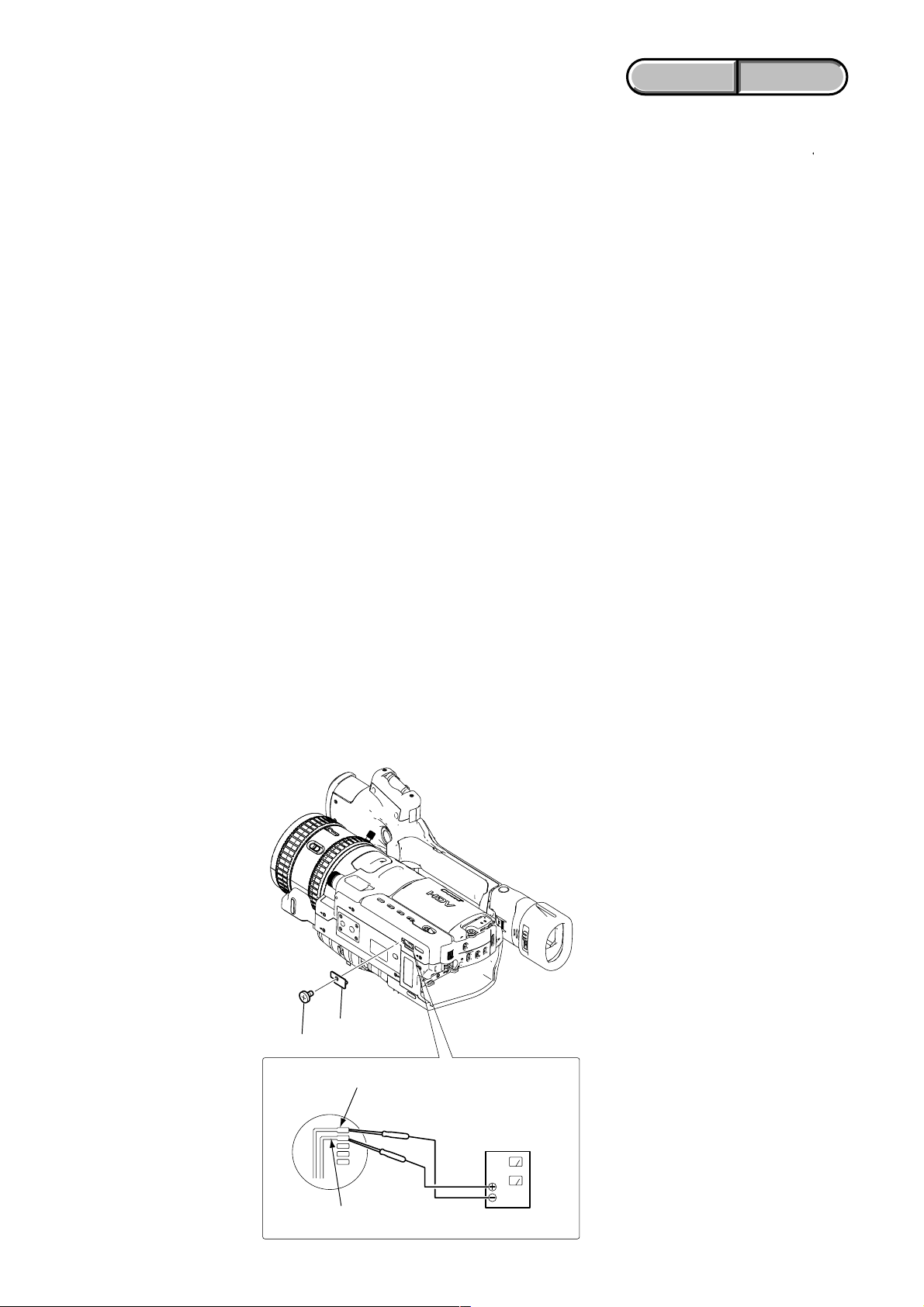

3. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Remove the power supply (Battery and AC power adaptor).

2 Open the cassette lid.

3 Remove the MD lid.

4 Supply +4.5V between the LM UNLOAD terminal and the LM LOAD terminal from the DC power supply and unload the cassete.

MD lid

Screw (M2x4)

LM load

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

DC power supply

(+4.5V)

LM unload

1-2

1-2. SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION

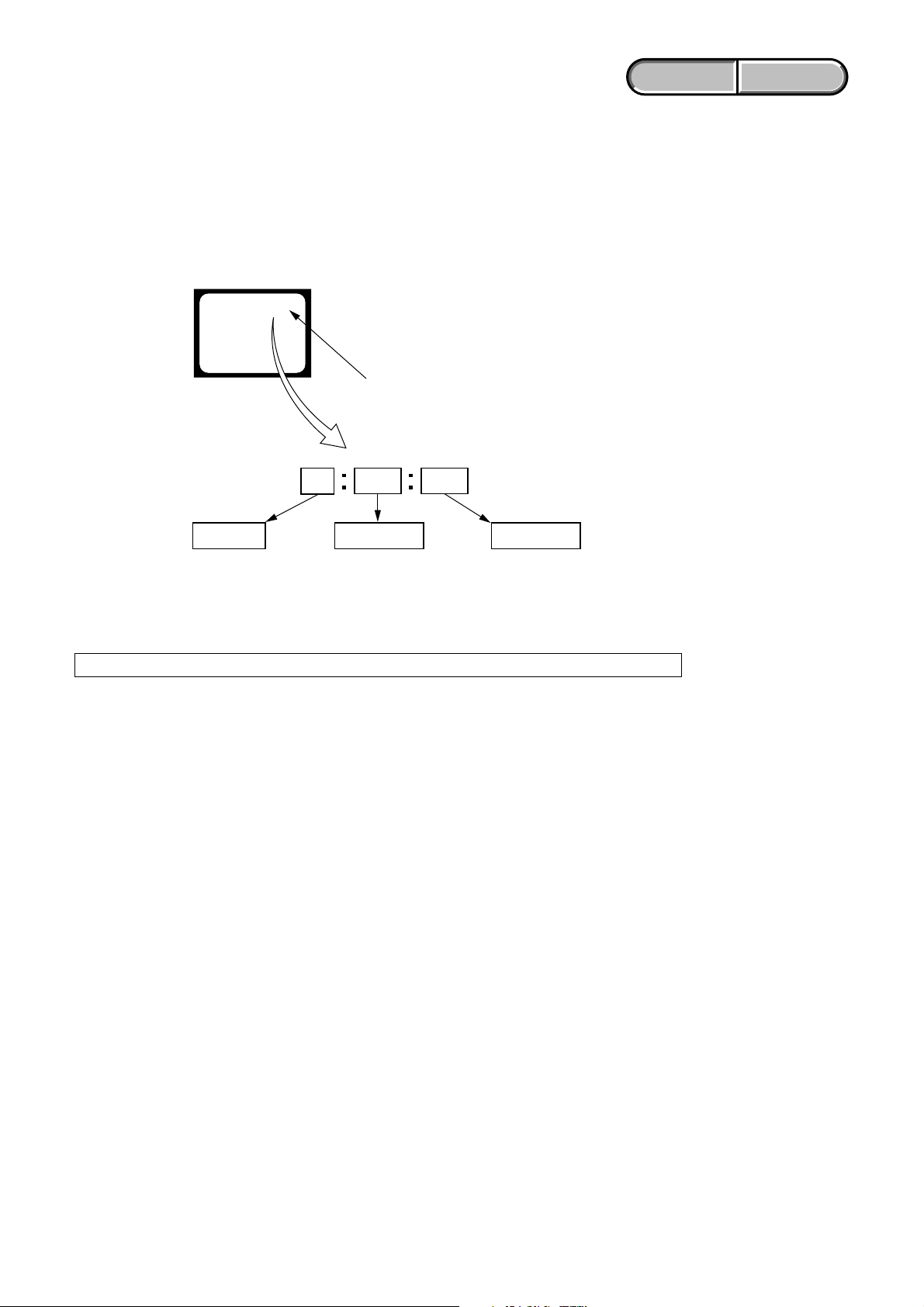

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder, or LCD

screen what to do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

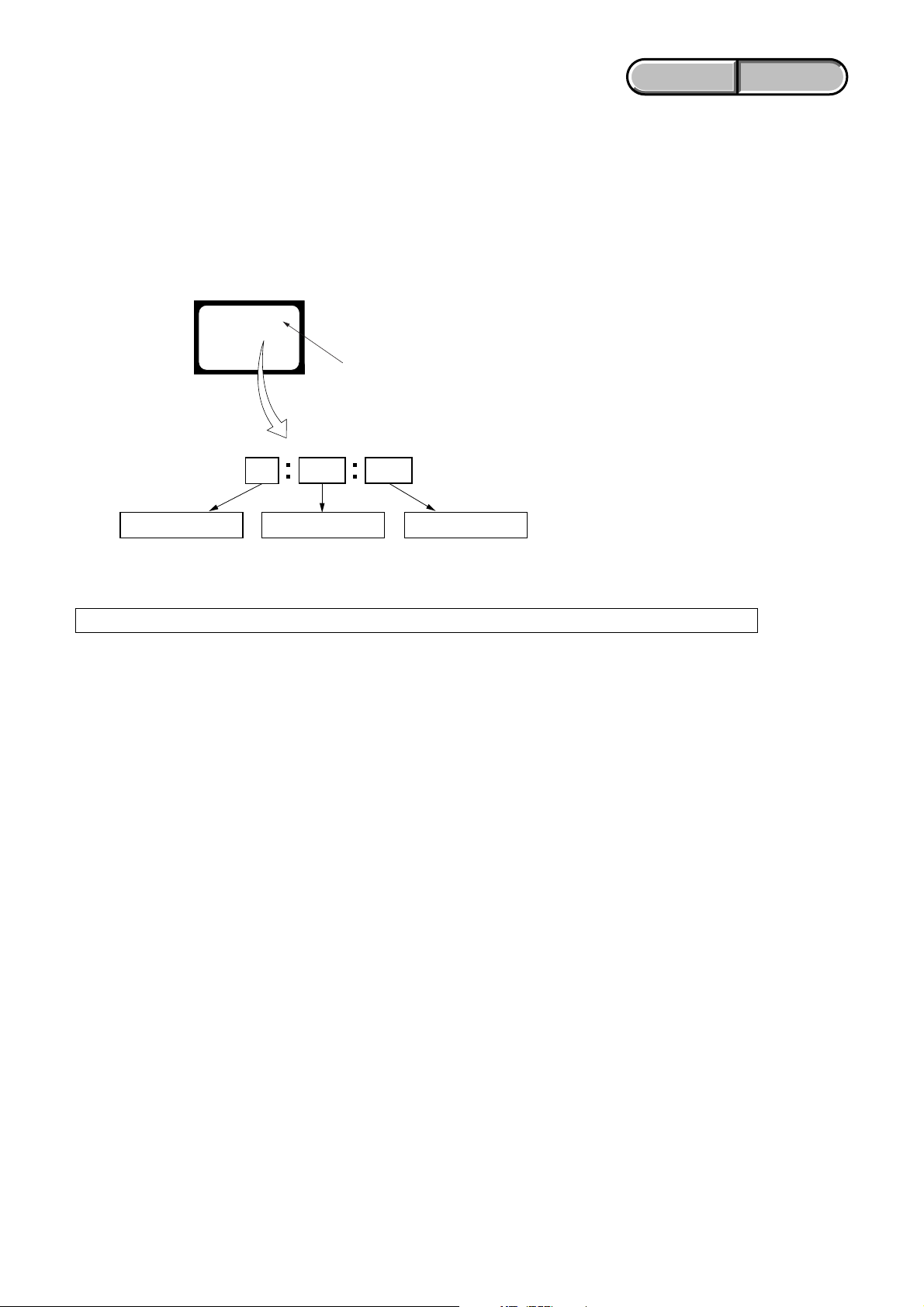

Viewfinder or LCD screen

C : 3 1 : 1 1

Blinks at 3.2Hz

ENGLISH JAPANESE

ENGLISH JAPANESE

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen consists of an alphabet and 4-digit number ,

which blinks at 3.2Hz. This 5-character display indicates the

“repaired by:”, “block” in which the problem occurred, and “detailed

code” of the problem.

3 1C

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Note: The self-diagnosis display data will be kept even if the lithium battery (BT591 of FP-959 flexible) is removed.

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

Block

1 1

Detailed Code

Refer to page 1-4.

Self-diagnosis Code Table.

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

1-3

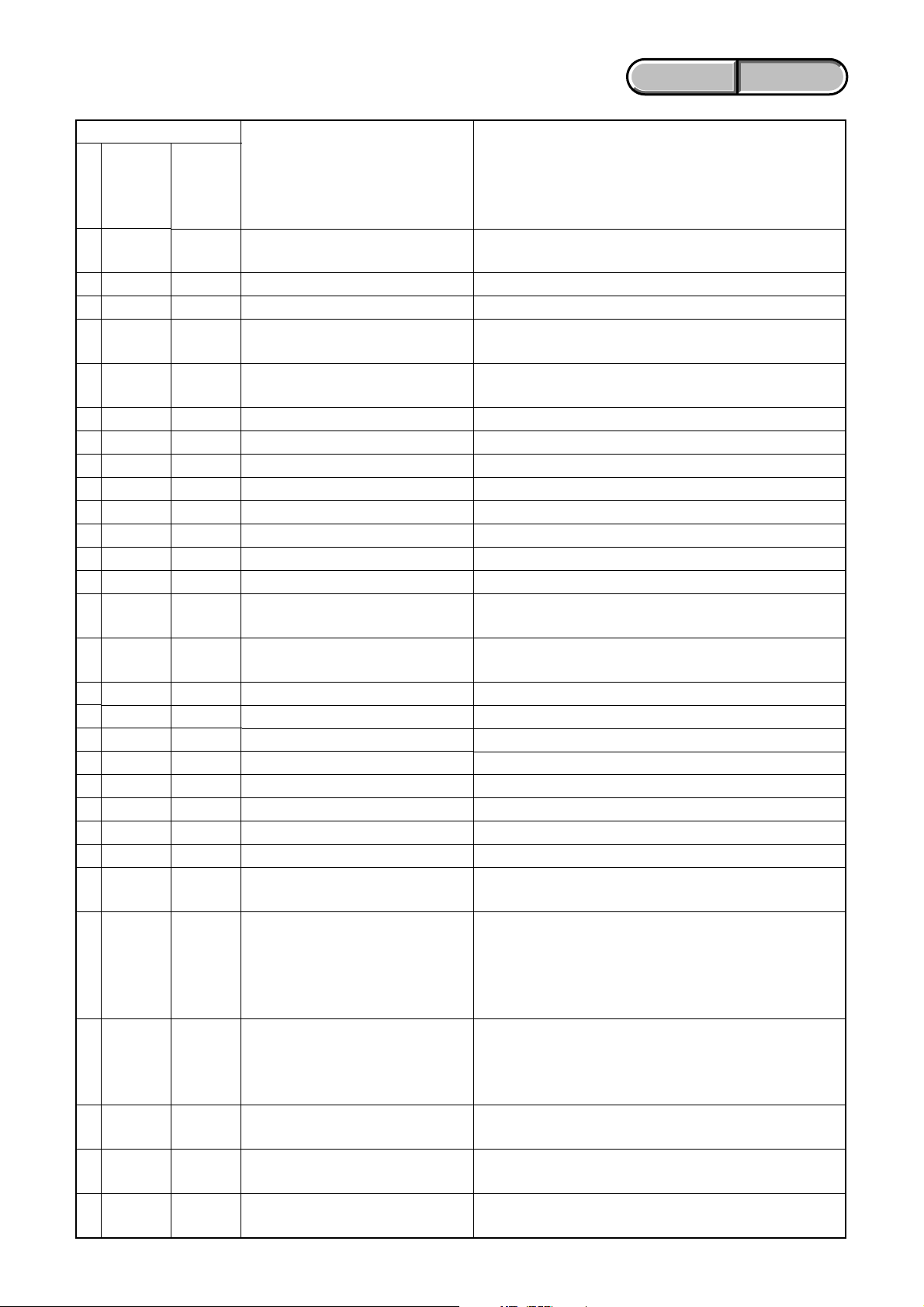

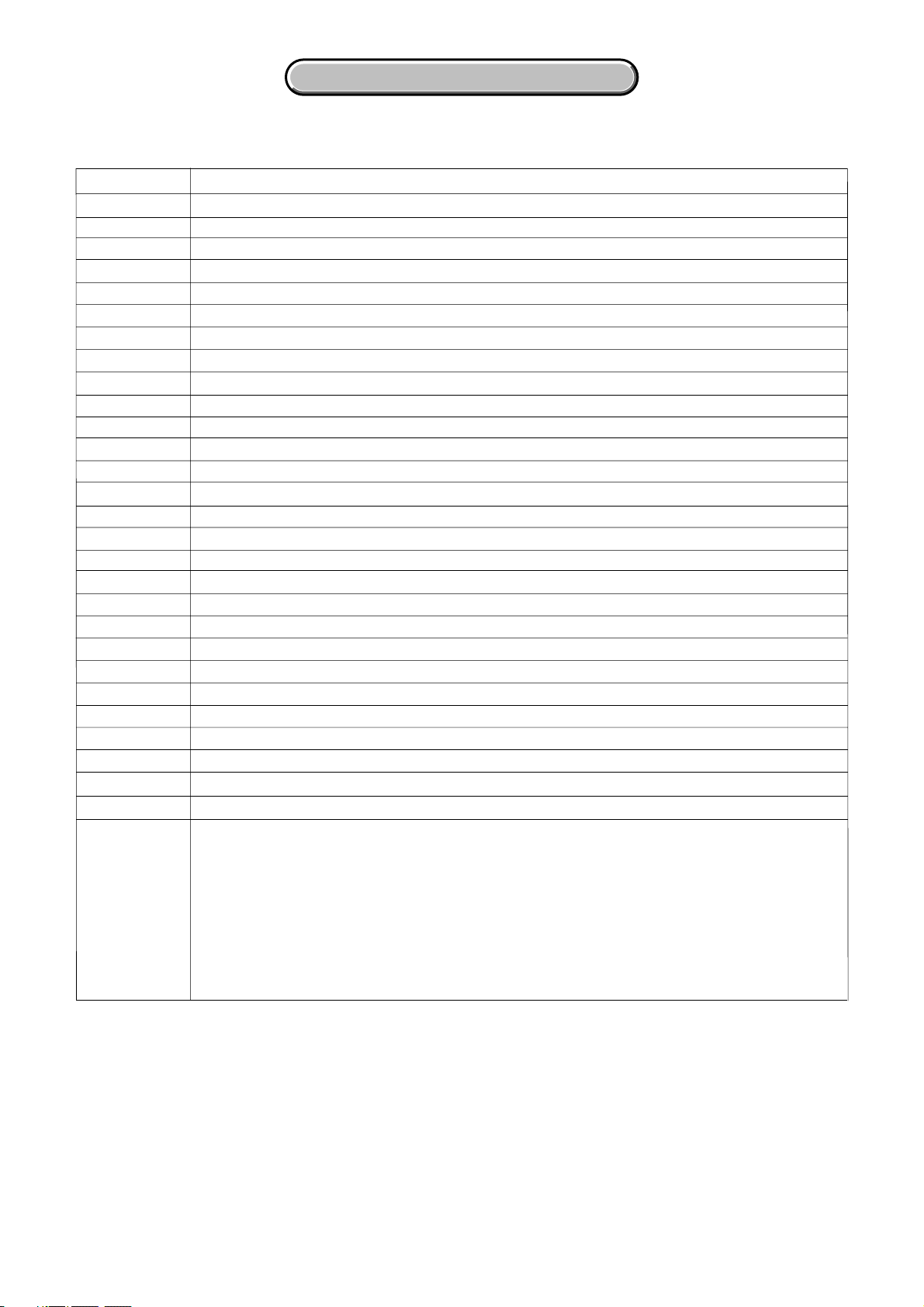

3. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Function

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

E

E

Block

04

21

22

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

20

61

61

61

62

62

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

00

10

11

00

01

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Data on A page or D page are rewriten.

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

The abnormalities in initialization of the

focus lens and the abnormalities in

initialization of the zoom lens occurred

simultaneously.

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular velocity sensor output

stopped.)

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Make data A page and D page correct value.

Inspect the lens block focus MR sensor (Pin qd, qf of CN1501 of

VC-367 board) when focusing is performed when the focus ring is

rotated in the focus manual mode, and the focus motor drive circuit

(IC1702 of VC-367 board) when the focusing is not performed.

Inspect the lens block zoom MR sensor (

VC-367 board

is operated and the zoom motor drive circuit (IC1702 of VC-367

board) when zooming is not performed.

Check whether the flexible board of the lens is broken, and check

whether it is inserted imperfectly. If there is no problem in the

flexible board, inspect the focus/zoom motor drive circuit (IC1702

of VC-367 board).

Inspect pitch angular velocity sensor (SE401 of SE-150 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE402 of SE-150 board)

peripheral circuits.

) when zooming is performed when the zoom switch

Pin ra, rs of CN1501 of

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

1-4

SECTION 1

る

を

SERVICE NOTE

1-1. サービスノート

1. 修理時の注意

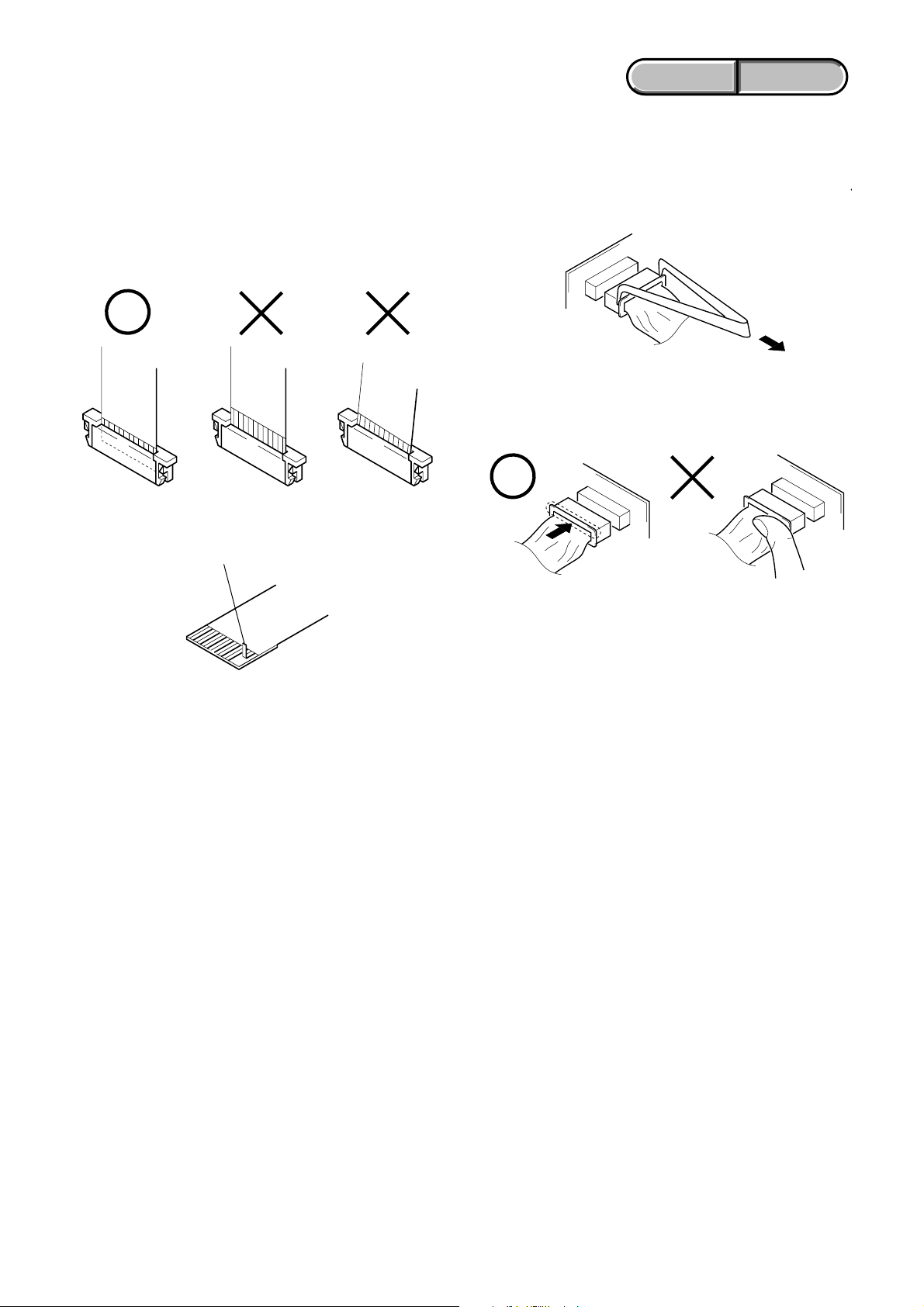

フラットケーブルおよびフレキシブル基板の端子面に欠け,

折れ等がないことを確認する。

また,コネクタへの接続は,差し込み不足や斜め差しになら

ないように注意する。

ENGLISH JAPANESE

ENGLISH JAPANESE

コネクタを取り外す時に,線材部(極細)を持って引っ張

と断線する恐れがありますので,絶対に線材部(極細)

持って引っ張らないで下さい。

線材部(極細)を押えながらコネクタを差し込むと,線材

部(極細)が断線する恐れがありますので,絶対に線材部

(極細)には負担をかけないで下さい。

先端が剥がれたメッキ部はカットして除去する。

(メッキ破片がコネクタ内に残っている場合もあるので注意)

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

1-5

り

Ver. 1.7 2007. 10

ENGLISH JAPANESE

ENGLISH JAPANESE

2. 修理/調整時の電源供給について

本機では、安定化電源(8.4Vdc)からバッテリー端子に電源を供給した場合、約10秒後にシャットオフし、動作しなくな

ます。

これを避けるため、下記のいずれかの方法を用いてください。

方法1:

本機付属のACアダプタと接続コードを使用する。

方法2:

安定化電源からバッテリー端子に電源を供給する場合は、調整リモコンRM-95(J-6082-053-B)を本気のLANC端子に接続

し、HOLDスイッチをADJ側にする。

方法3:

注意:この操作は修理時のみの対応方法です。一般動作時には使用しないで下さい。

使用可能なACアダプタ:AC-L10、L15(A、Bタイプあり。いずれも使用可)

1.MICPHANTOMスイッチをOFFにする。(ACアダプタ容量の余裕がないので消費電力を最小にする必要がある。)

2.DCINカバーをはずしACアダプタを接続する。

3.本機のLANC端子に調整リモコンRM-95(J-6082-053-B)を接続してADJ側に設定、カメラ電源を入れる。

4.下記のようにデータを設定すれば、調整リモコンを抜いてもACアダプタを使用して動作可能です。

1)ページ:0、アドレス:01、データ:01にセット

2)ページ:0、アドレス:10、データ:00にセット

3)ページ:D、アドレス:23、データ:AFにセットし調整リモコンのPAUSEボタンを押す。

5.調整後下記のようにデータ設定を必ず元の状態に戻す。

1)ページ:0、アドレス:01、データ:01にセット

2)ページ:0、アドレス:10、データ:00にセット

3)ページ:D、アドレス:23、データ:FFにセットし調整リモコンの PAUSE ボタンを押す。

4)ページ:0、アドレス:01、データ:00にセットする。

3. イジェクトしない時のカセット取出し方法(強制イジェクト)

1 電源(バッテリーとAC電源アダプター)を外す。

2 カセット蓋を開く。

3 MD蓋を外す。

4 DC電源より+4.5VをLMUNLOAD端子とLMLOAD端子の間に加え、アンローディングさせる。

ねじ (M2X4)

MD 蓋

LM LOAD 端子

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

DC 電源

(+4.5V)

LM UNLOAD 端子

1-6

1-2. 自己診断機能

っ

1. 自己診断機能について

本機の動作に不具合が生じたとき,自己診断機能が働き,

ビューファインダまたはLCD画面に,どう処置したらよいか

判断できる表示を行ないます。自己診断機能については取扱

説明書にも掲載されています。

ビューファインダまたはLCD画面

C : 3 1 : 1 1

3.2Hz点滅

ENGLISH JAPANESE

ENGLISH JAPANESE

2. 自己診断表示

本機の動作に不具合が生じたとき,ビューファインダまたは

LCD画面のカウンタ表示部分がアルファベットと数字の4桁

表示になり,3.2Hzで点滅します。この5文字の表示によ

て,対応者分類および不具合の生じたブロックの分類,不具

合の詳細コードを示します。

1 1

詳細コード

「3. 自己診断コード表」

参照(1-8ページ)

対応者分類

C:お客さま自身で対応

H:販売店で対応

E:サービスエンジニア

で対応

3 1C

ブロック分類

対応方法の違いにより分類

例 31…テープを入れ直す

32…電源を入れ直す

注意:「自己診断表示」データはリチウム電池 (FP-959フレキシブル基板 (BT591)) を外しても消えません。

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

1-7

3. 自己診断コード表

自己診断コード

対

応

者

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

E

ブロック

機能

04

21

22

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

20

61

61

61

62

62

詳細

コード

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

00

10

11

00

01

症状/状態

インフォリチウム以外のバッテリを

使用している

結露している

ビデオヘッドが汚れている

LOAD方向,ローディング所定時間

内終了せず

UNLOAD方向,ローディング所定

時間内終了せず

UNLOAD時,Tリール側テープ弛み

テープ残量計算時,Sリール巻取り異常

Tリール異常

Sリール異常

Tリール異常

キャプスタン起動時FG異常

ドラム起動時FG異常

ドラム定常時FG異常

LOAD方向,ローディングモータ所

定時間動作せず

UNLOAD方向,ローディングモー

タ所定時間動作せず

UNLOAD時,Tリール側テープ弛み

テープ残量計算時,Sリール巻取り異常

Tリール異常

Sリール異常

Tリール異常

キャプスタン起動時FG異常

ドラム起動時FG異常

ドラム定常時FG異常

Aページ,Dページのデータが書き換

えられている。

フォーカスが合いにくい

(フォーカスの初期化ができない)

ズーム動作の異常(ズームレンズの

初期化ができない)

フォーカスレンズ初期化異常、

ズームレンズ初期化異常の同時発生

手振れ補正が効きにくい

(PITCH角速度センサ出力張り付き)

手振れ補正が効きにくい

(YAW角速度センサ出力張り付き)

ENGLISH JAPANESE

ENGLISH JAPANESE

対応/方法

インフォリチウムバッテリを使用する

カセットを取り出して,約1時間してからもう一度入れ直す

別売のクリーニングカセットできれいにする

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

テープを入れ直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す

Aページ,Dページのデータを元の値に戻す

フォーカス手動モードでフォーカスリングを回した時,

フォーカス動作をすればレンズブロックのフォーカスMRセ

ンサ(VC-367基板CN1501qd,qfピンを点検。フォーカス動

作をしなければフォーカスモータドライブ回路(VC-367基

板IC1702)を点検

ズームレバーを操作した時,ズーム動作をすればレンズブ

ロックのズームMRセンサ(VC-367基板CN1501 ra,rsピ

ン)を点検。ズーム動作をしなければズームモータドライブ

回路(VC-367基板IC1702)を点検

フレキ切れ、半挿しを点検。問題なければフォーカス、

ズームモータドライブ回路 (VC-367基板IC1702) を点検。

PITCH角速度センサ(SE-150基板SE401)周辺回路点検

YAW角速度センサ(SE-150基板SE402)周辺回路点検

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

1-8E

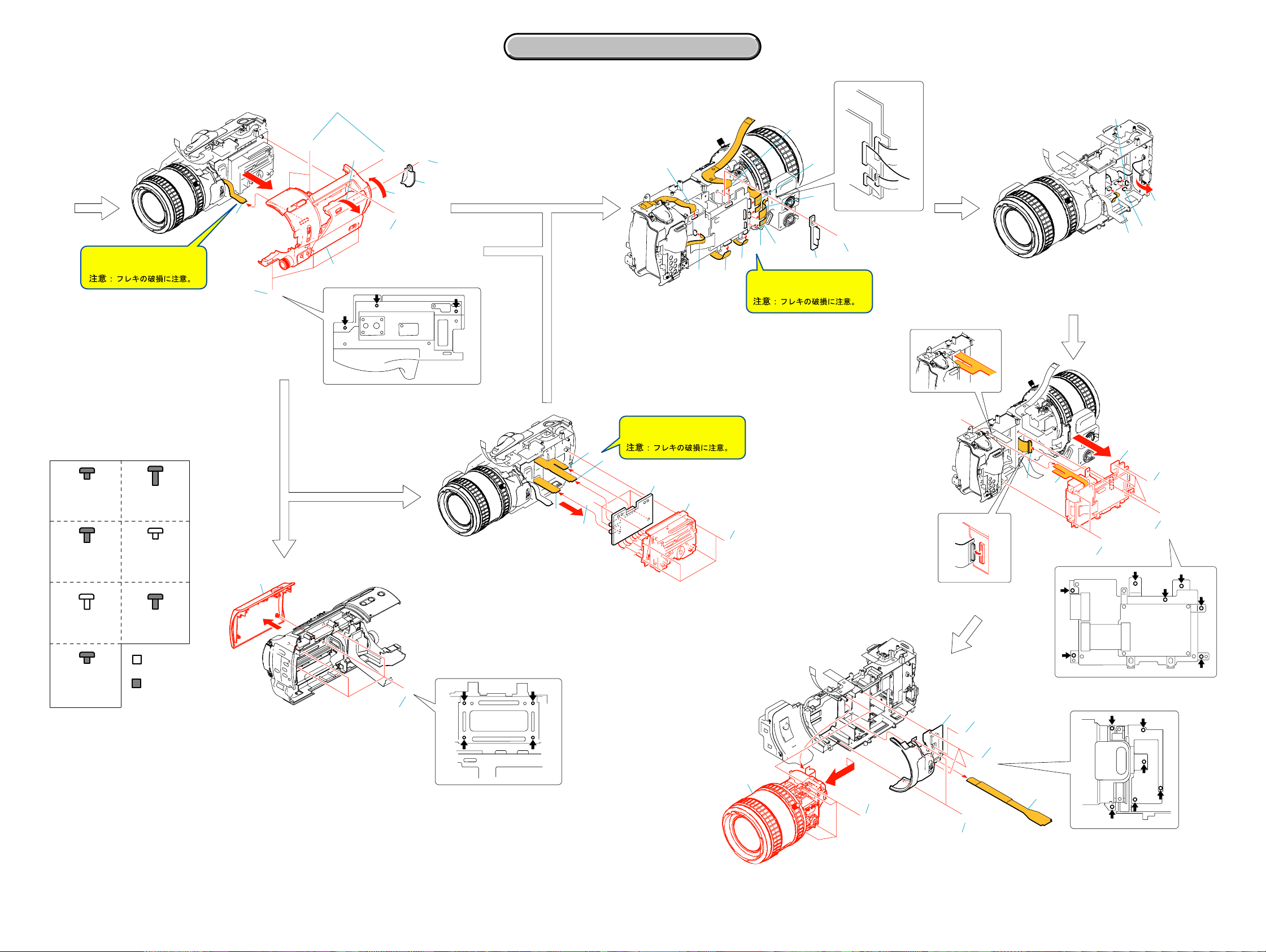

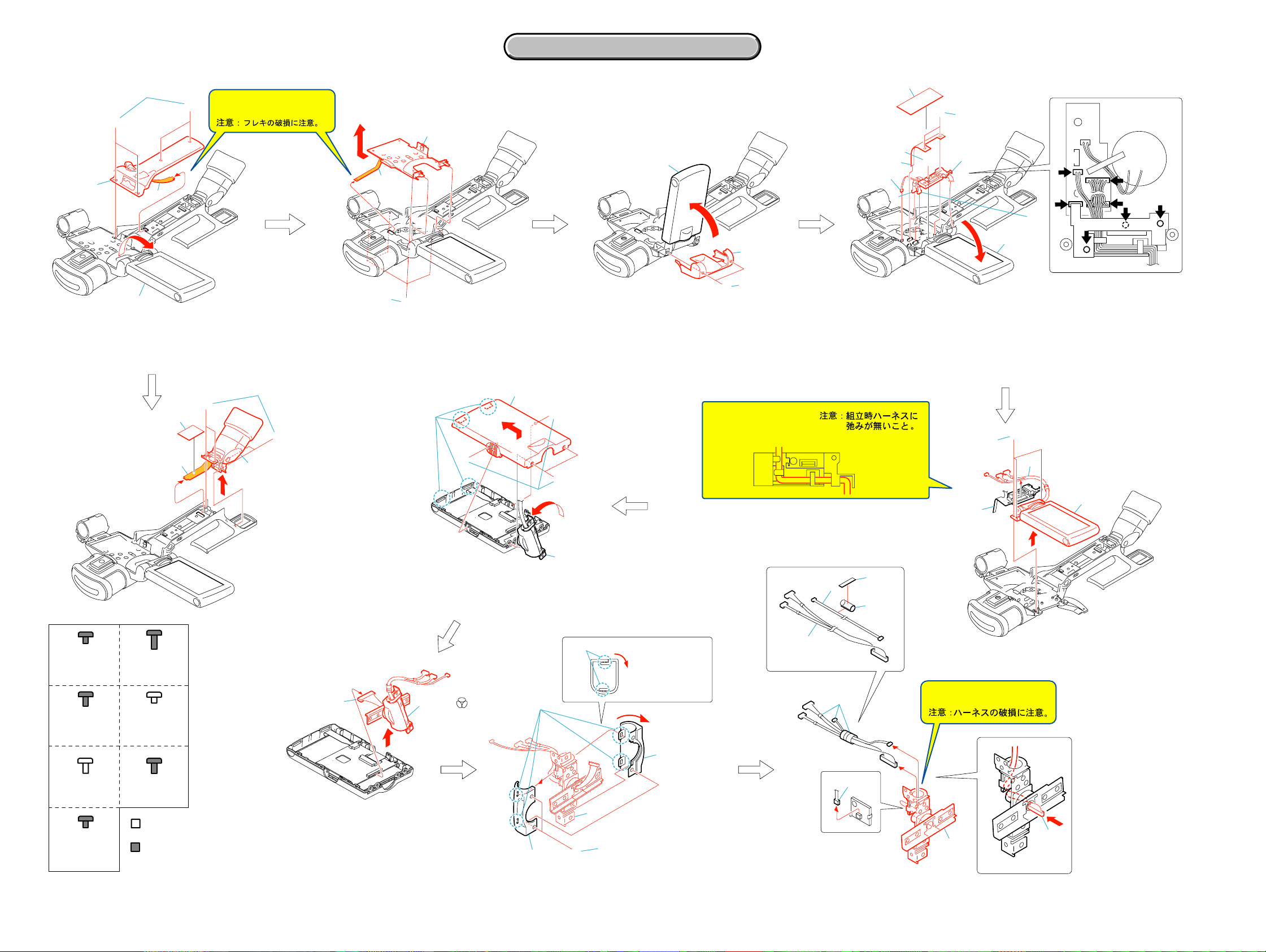

The following flow chart shows the disassembly procedure.

2-1. DISASSEMBLY

B

2. DISASSEMBLY

C

1

7

6

1

Turn over the EVF section in

the direction of the arrow.

2

Two screws (M2x4) black

3

Remove the handle cabinet

(Rear) assembly in the direction

of the arrow.

2

8

4

FP-980 flexible board (40P)

5

Screw (M2x6) black

6

Push

7

Handle cabinet (Front)

8

FP-981 flexible board (40P)

1

5

2

Handle section

(See page 2-5, 2-6)

B

2

4

A

cabinet (R) section,

3

1

Four bolts (M2.6x5) black

2

Handle section

A

Lens section (See page 2-3)

A

Screw

M2x4

3-080-203-31

C

Bolt

M2.6x5

3-061-062-11

B

Screw

M2x6

3-080-203-51

D

Screw

M2x3

3-080-202-21

EF

A

Screw

M2x5

3-080-202-41

G

3

7

1

Screw

M2.6x4

7-627-556-37

Tipping screw

M2x5

3-080-206-21

Silver

Black

1

b

3

1

Open the grip belt.

2

Remove the grip belt

in the direction of the arrow a.

3

Remove the grip belt

in the direction of the arrow b.

a

1

Note:

Be very careful not to

a

2

Slide the knob to unlock.

1

2

Remove the VF rear cabinet

assembly in the direction of the arrow a.

damage the flexible board.

1

Open the grip belt.

2

Remove the grip belt

in the direction of the arrow a.

3

Three screws (M2x4) black

4

Three screws (M2x4) black

5

Two screws (M2x4) black

6

Control switch block

(PS5610) (18P)

7

Remove the cabinet (L) section

in the direction of the arrow b.

VA-119

b

Lens section

Front side

of unit

B

(See page 2-3)

a

6

A

A

5

4

2

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

2-1 2-2

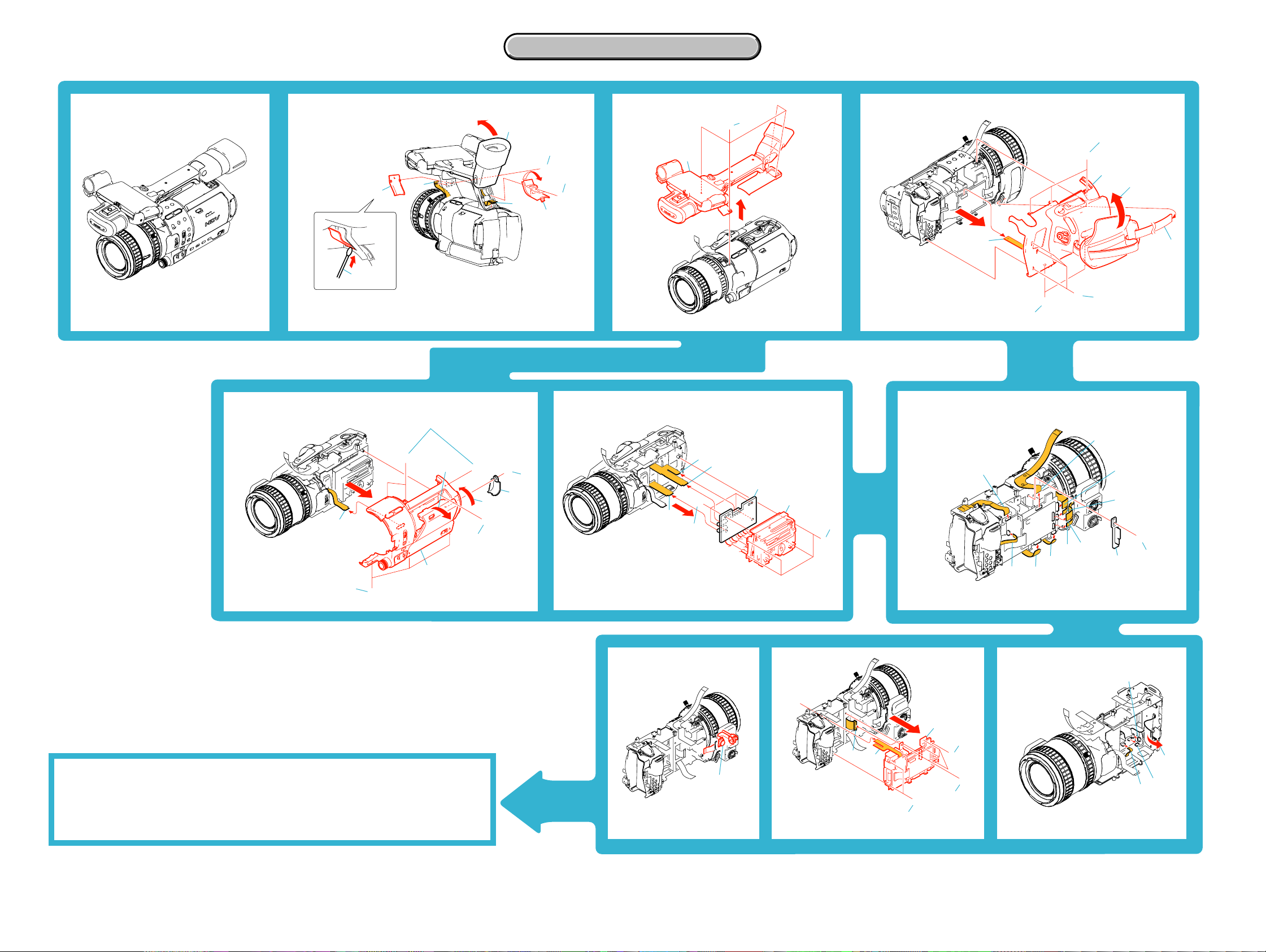

2. DISASSEMBLY

2. DISASSEMBLY

A

Note:

Be very careful not to

damage the flexible board.

1

Open the cassette lid assembly.

2

Screw (M2x4) black

3

Close the cassette lid assembly.

4

Screw (M2x6) black

5

Cover (DCIN)

6

Three screws (M2x4) black

A

Screw

M2x4

3-080-203-31

C

Bolt

M2.6x5

3-061-062-11

B

Screw

M2x6

3-080-203-51

D

Screw

M2x3

3-080-202-21

EF

Screw

M2x5

3-080-202-41

Tipping screw

M2x5

3-080-206-21

a

8

7

A

7

Three screws (M2x4) black

8

FP-972 flexible board (32P)

9

Remove the cabinet (R) section

in the direction of the arrow a.

2

A

6

1

1

A

B

4

5

3

4

qa

0

VC-367

VA- 119

4

1

A

2

B

9

1

FP-981 flexible board (39P)

2

Screw (M2x4) black

3

Holder (CCD connector)

4

FP-975 flexible board (39P)

5

FP-964 flexible board (10P)

6

FP-972 flexible board (33P)

Note:

Be very careful not to

damage the flexible board.

3

2

6

D

4

5

1

Four screws (M2x3) silver

2

FP-974 flexible board (30P)

3

FP-974 flexible board (22P)

4

FP-985 flexible board (28P)

5

Four screws (M2x3) silver

6

MR-048 board

7

Mechanism deck, MD chassis assembly

MR-048

VA-119

9

8

5

7

7

6

Note:

Be very careful not to

damage the flexible board.

7

From lens flexible (10P)

8

FP-978 flexible board (10P)

9

From JK-275 board (22P)

0

From lens flexible (27P)

qa

From lens flexible (51P)

1

D

A

2

3

1

Screw (M2x5) silver

2

Four screws (M2x3) silver

3

Two screws (M2x3) silver

4

From CD-522 board (100P)

5

FP-974 flexible board

6

VC-367 board, VA-119 board,

Heat sink (VC) assembly, etc

1

Peel off the sheet (EMI DC harness) sheet .

2

FP-959 flexible board (6P)

3

DC-IN connector (3P)

4

Battery terminal board (4P)

4

5

VA-119

D

3

3

2

6

1

E

D

2

G

Screw

M2.6x4

7-627-556-37

Silver

Black

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

1

Four screws (M2x3) silver

2

Cassette lid assembly

2-3 2-4

1

Screw (M2x5) silver

2

D

1

Three screws (M2x5) silver

3

Two screws (M2x5) silver

4

FP-972 flexible board

5

Cabinet (R (Lens)) assembly,

Protection cushion (FP)

6

Four screws (M2x5) silver

7

Lens section

5

1

E

2

E

7

4

E

6

E

3

2. DISASSEMBLY

2. DISASSEMBLY

2

A

A

4

1

Open the LCD section in the direction of the arrow.

2

Four screws (M2x4) black

3

Control switch block (ZS-5610) (6p)

4

Handle cabinet (Upper) assembly,

Control switch block (ZS-5610)

1

Peel off the harness fixed tape.

2

FP-984 flexible board (33P)

3

Four screws (M2x3) silver

4

EVF section

3

1

1

2

Note:

Be very careful not to

damage the flexible board.

3

D

D

4

3

2

1

F

1

Four tipping screws (M2x5) black

2

Flexible flat cable (FDM-009) (10P)

3

Handle panel cabinet assembly,

FK-090 board, etc.

3

A

2

A

3

5

4

1

6

A

7

9

6

4

8

3

7

8

3

5

1

3

2

A

1

1

Close the LCD section in the direction of the arrow.

2

Two screws (M2x4) black

3

Hinge cover (Lower)

4

Note:

b

A

upon assembling

Route the wire of the

harnesses without slack.

Open the LCD section in

the direction of the arrow a.

2

Peel off the protection sheet

(FP-967).

3

Two screws (M2x4) black

4

FP-967 board (6P)

5

Screw (M2x4) black

a

6

Harness (SW-116) (2P)

7

Harness (PD-226) (12P)

8

Harness (PD-226) (10P)

9

Harness guide. etc.

1

Harness (PD-226), Harness (SW-116)

2

G

3

1

FP-967 board, Harness guide

3

Three screws (M2.6x4) silver

4

LCD section

@

A

2

P

D

-22

6

a

2

4

A

Screw

M2x4

3-080-203-31

C

Bolt

M2.6x5

3-061-062-11

B

Screw

M2x6

3-080-203-51

D

Screw

M2x3

3-080-202-21

EF

Screw

M2x5

3-080-202-41

G

Screw

M2.6x4

7-627-556-37

Tipping screw

M2x5

3-080-206-21

Silver

Black

1

Turn over the hinge section in the

direction of the arrow a.

2

Four screws (M2x4) black

2

P

D

-2

2

6

1

Hinge section, Harness (PD-226),

Harness (SW-116)

2

Harness (PD-226) (22P)

1

1

3

Two claws

4

Remove the p cabinet (C) assembly in

the direction of the arrow b.

Two claws

Remove the Hinge

cover (Rear) in the

direction of the arrow.

2

5

3

A

1

4

1

Two screws (M2x4) black

2

Two claws

3

Hinge cover (Front)

4

Hinge cover (Rear)

5

Hinge section, Harness (PD-226),

Harness (SW-116)

8

7

5

6

Note:

Be very careful not to

3

2

damage the harnesses.

4

1

Remove the harness (PD-226)

in the direction of the arrow.

2

Harness (SW-116) (2P)

3

Harness (PD-226),

Harness (SW-116), Harness clamp

4

Hinge section

5

1

Tape (W)

6

Harness clamp

7

Harness (PD-226)

8

Harness (SW-116)

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

2-5 2-6

2-2. SERVICE POSITION

2. DISASSEMBLY

2. DISASSEMBLY

1

1

5

2

B

7

6

8

4

2

A

3

C

VA- 119

b

3

A

7

1

a

6

A

A

5

4

2

6

A

1

A

a

8

9

7

A

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section (page 2-9)

1

3

D

5

JK-275 board

2

6

7

MR-048

1

D

6

4

5

9

-11

A

V

E

4

VA- 119

9

8

5

1

7

6

D

2

B

4

5

3

4

A

2

qa

0

A

2

3

4

1

3

2

D

3

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

2-7 2-8

n

Ver. 1.7 2007. 10

2. DISASSEMBLY

2. DISASSEMBLY

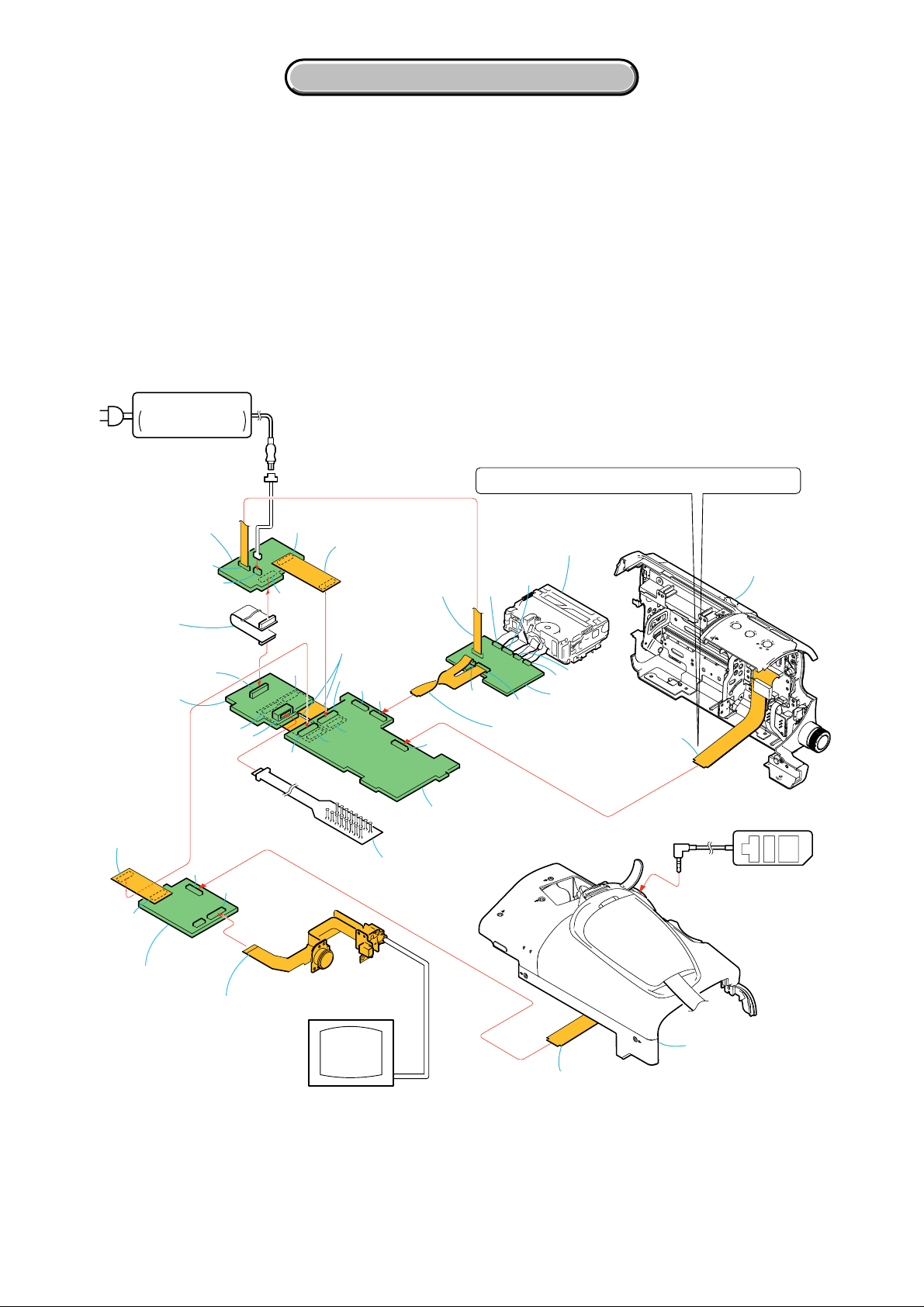

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section

To check the VTR section, set the VTR to the "Forced VTR power ON" mode.

Power off the MIC PHANTOM switch.(Need to miniminze the power consumption as AC adapter capacity is limited.)

Operate the VTR functions using the adjustment remote commander

(with the HOLD switch set in the OFF position).

Note: This operation is not effected in the normal operation, and is effected only repairing.

Setting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 0, address: 10, and set data: 00.

3) Select page: D, address: 23, set data: AF, and press

the PAUSE button of the adjustment remote commander.

AC power adaptor

AC-L10A/L10B or

AC IN

Extension cable (28P)

(J-6082-566-A)

AC-L15A/L15B

DB-018 board

DA-033 board

CN206

CN203

CN104

DC-IN

CN101

CN107

DC-IN jack

CN201

DB-018

CN205

CN103

DA-033

CN0002

FP-977 flexible board

(100P)

FP-985 flexible

board (28P)

FP-976 flexible board

(80P)

CN0001

CN6001

CN0007

CN0005

CN0003

VC-367

CN0004

Exiting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 0, address: 10, and set data: 00.

3) Select page: D, address: 23, set data: FF, and press the

PAUSE button of the adjustment remote commander.

4) Select page: 0, address: 01, and set data: 00.

(To eject a cassette, connect the cabinet (R) assembly.)

Mechanism deck

Cabinet (R) sectio

CN203

MR-048

CN103

FP-974 flexible

board (51P)

CN202

CN102

CN201

CN104

MR-048 board

FP-972 flexible

board (33P)

FP-971 flexible

board (100P)

VA-119

CN2004

VA-119 board

CN2007

CN2006

JK-275 board

(22P)

JK-275

CPC-8 jig

(J-6082-388-A)

Audio/Video jack

Monitor TV

VC-367 board

Adjustment remote

commander (RM-95)

LANC jack

Cabinet (L) section

Contron switch block (PS5610) (18P)

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

2-9

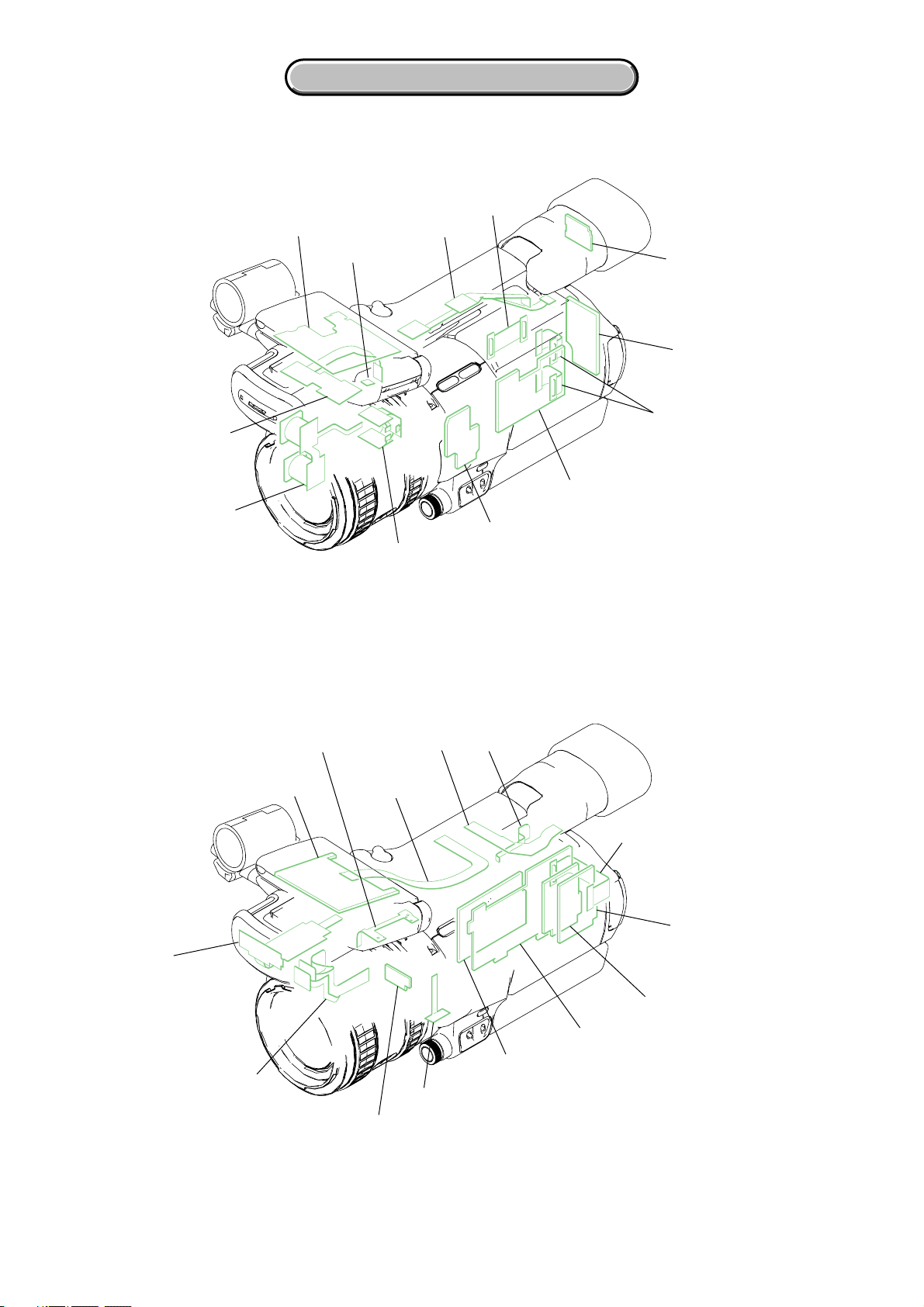

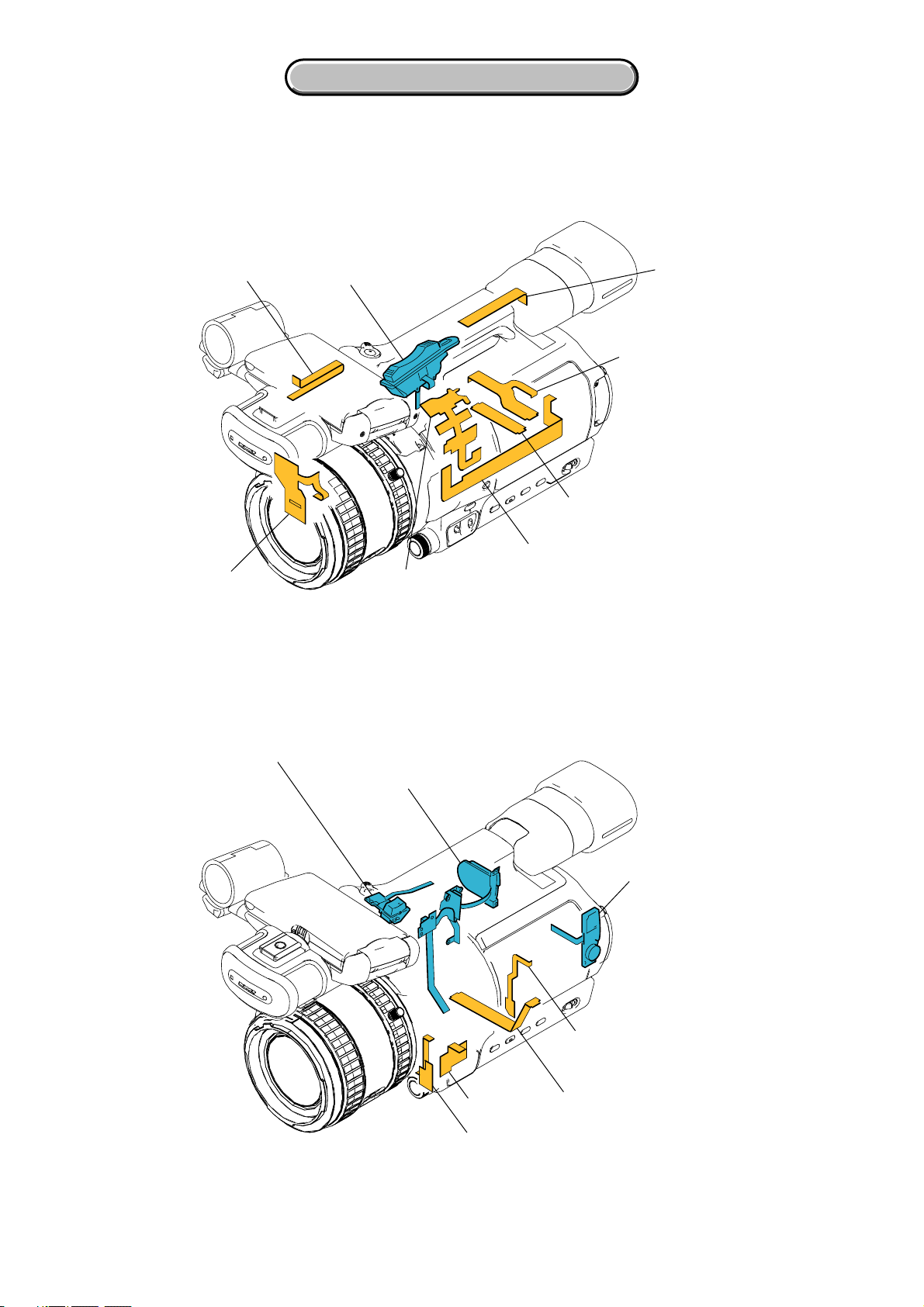

2-3. CIRCUIT BOARDS LOCATION

7

FK-090

SW-433

IF-122

FP-978

2. DISASSEMBLY

2. DISASSEMBLY

FP-971

FP-980

CK-143

CD-522

LB-106

MK-01

FP-976

MR-048

MA-431

JK-275

FP-967

PD-222

FP-981

SE-150

FP-975

FP-959

FP-964

FP-977

DB-018

DA-033

VC-367

VA-119

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

2-10

2. DISASSEMBLY

2. DISASSEMBLY

NAME

CD-522

CK-143

DA-033

DB-018

FK-090

FP-959

FP-964

FP-967

FP-971

FP-975

FP-976

FP-978

FP-980

FP-981

IF-122

JK-275

LB-106

MA-431

MK-017

MR-048

PD-222

SE-150

SW-433

VA-119

VC-367

FUNCTION

R.G.B-CH CCD IMAGER, S/H, AGC

FUNCTION KEY

DC/DC CONVERTER

DC IN, CHARGE, DC/DC CONVERTER

VTR FUNCTION KEY

BATTERY

MIC SELECTFP-960

DV TERMINAL

MR SENSOR

RELAY

RELAYFP-972

RELAYFP-974

RELAY

RELAYFP-977

RELAY

MIC TERMINAL

RELAY, REAR IR

RELAY

RELAY

JACK

EVF BACK LIGHT

INT MIC AMP

FUNCTION KEY

REC/PB RF AMP, DRUM/CAPSTAN/LOADING MOTOR DRIVE

LCD DRIVER, TIMING GENERATOR

PITCH/YAM SENSOR AMP

PANEL REV

AUDIO IN /OUT, VIDEO IN/OUT, Y.PB.PR OUT AMP, XLR INPUT

CCD RF IN, R.G.B-CH AGC, A/D CONV, TIMING GENERATOR, CAMERA RGB PROCESS,

LENS DRIVE, LENS DRIVE CONTROL, CAMERA CONTROL, BASE BAND PROCESS,

OSD, D3 FILTER, HDV VIDEO ENCODER, 64MBIT SDRAM (L/U),

HDV SIGNAL/RF SIGNAL PROCESS, HDV VIDEO DECODER, 64MBIT Y/C-SDRAM,

ILINK, INTERFACE, DV/RF SIGNAL PROCESS, VIDEO A/D CONV., EVF RGB DRIVER,

TIMING GENERATOR, HDV AUDIO SIGNAL PROCESS, AUDIO INPUT SELECT,

AUDIO CONVERTER, D3 CONTROL, FRONT CONTROL, LSI CONTROL,

MECHA CONTROL, CONNECTOR-1, CONNECTOR-2

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

2-11

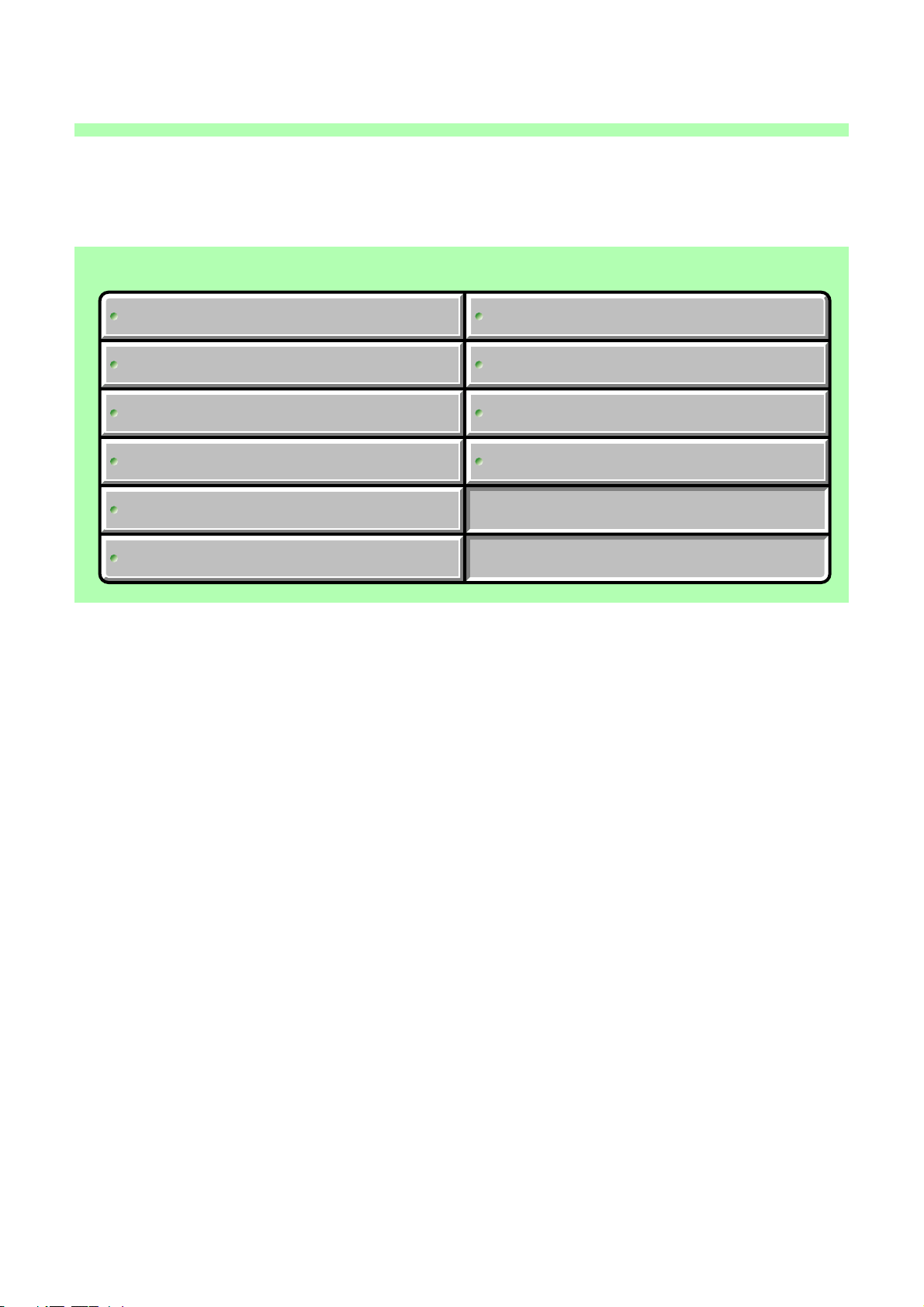

2. DISASSEMBLY

2. DISASSEMBLY

2-4. FLEXIBLE BOARDS LOCATION

The flexible boards contained in the mechanism deck and lens block are not shown.

CONTROL SWITCH BLOCK

FDM-009

(CF5610)

FP-984

FP-974

FP-985

FP-960

CONTROL SWITCH BLOCK

(ZS-5610)

CONTROL SWITCH BLOCK

(PS5610)

FP-966

FP-961

CONTROL SWITCH BLOCK

(VV91010)

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

FP-963

FP-962

2-12E

FP-965

FP-972

Link

Link

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/6)

OVERALL BLOCK DIAGRAM (1/6)

OVERALL BLOCK DIAGRAM (2/6)

OVERALL BLOCK DIAGRAM (2/6)

OVERALL BLOCK DIAGRAM (3/6)

OVERALL BLOCK DIAGRAM (3/6)

OVERALL BLOCK DIAGRAM (5/6)

OVERALL BLOCK DIAGRAM (5/6)

OVERALL BLOCK DIAGRAM (6/6)

OVERALL BLOCK DIAGRAM (6/6)

POWER BLOCK DIAGRAM (1/4)

POWER BLOCK DIAGRAM (1/4)

POWER BLOCK DIAGRAM (2/4)

POWER BLOCK DIAGRAM (2/4)

POWER BLOCK DIAGRAM (3/4)

POWER BLOCK DIAGRAM (3/4)

POWER BLOCK DIAGRAM (4/4)OVERALL BLOCK DIAGRAM (4/6)

POWER BLOCK DIAGRAM (4/4)OVERALL BLOCK DIAGRAM (4/6)

HVR-Z1J/Z1U/Z1N/Z1E/Z1P/Z1C

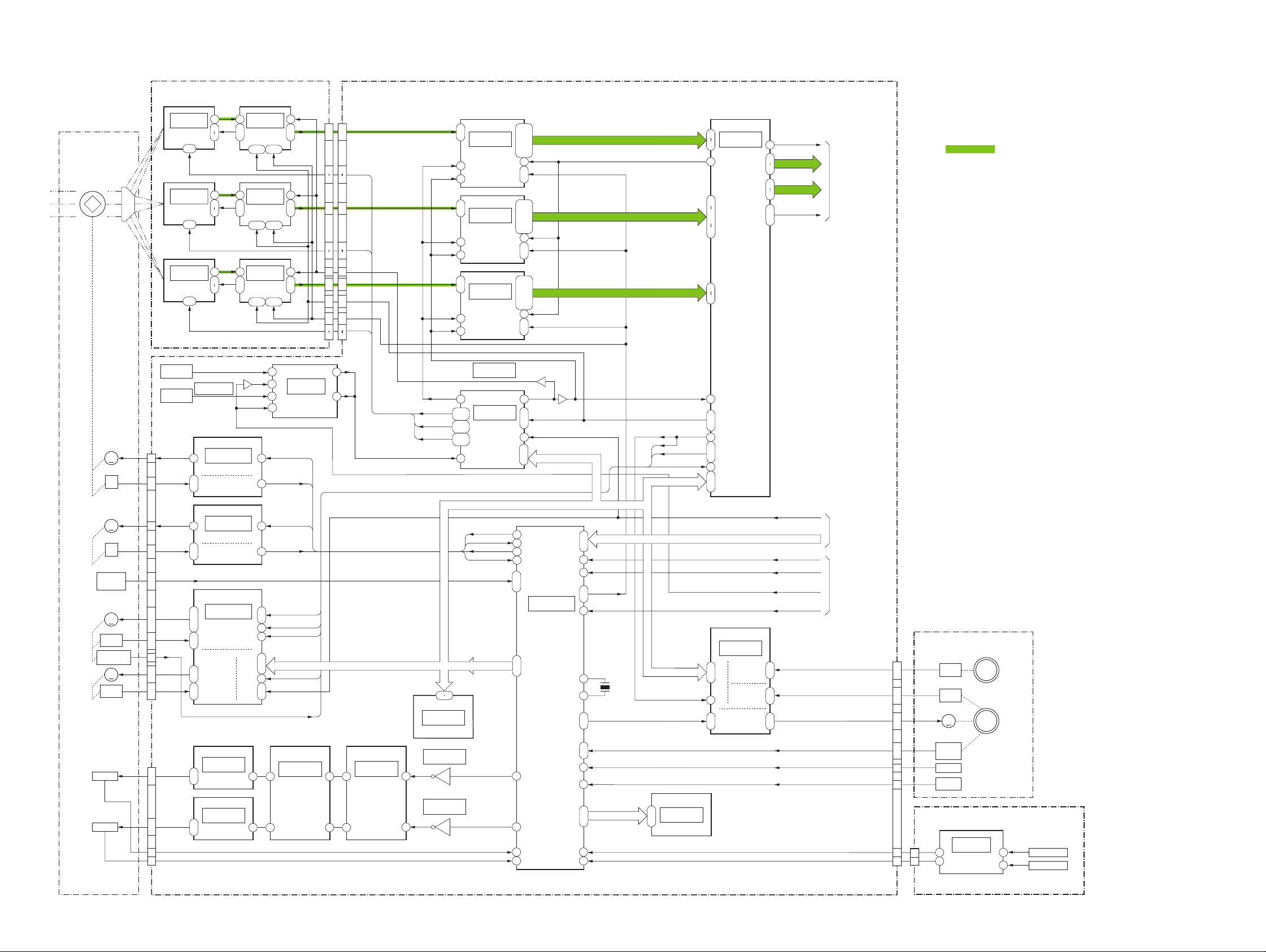

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/6)

CD-522 BOARD VC-367 BOARD(1/6)

CCD OUT

8

10

13

CCD OUT

8

10

13

CCD OUT

8

10

13

(2/25)

(4/25)

IC1504

IRIS DRIVE

IRIS

HALL AMP

A8

IC104

J7

D9

B-CH S/H

E9

RGB

H1B

H2B

RGR

H1R

H2R

RGR

H1R

H2R

A8

J7

D9

E9

A8

J7

D9

E9

TG VD

TG VD

TG VD

J4,G5

IC105

R-CH S/H

J4,G5

IC106

G-CH S/H

J4,G5

4

3

14

H1,J2

H1,J2

H1,J2

5

3

1

7

SO GCAM

SCK GCAM

SO GCAM

SCK GCAM

SO GCAM

SCK GCAM

A2

OE2

A1

OE1

IRIS PWM

I HALL AD

LENS BLOCK

(1/2)

DICHROIC

IRIS

IRIS

METER

PRISM

M

IC101

B-CH

CCD IMAGER

4-1

V1B-V4B TG HD

IC102

R-CH

CCD IMAGER

4-1

V1R-V4R TG HD

IC103

G-CH

CCD IMAGER

4-1

V1G-V4G TG HD

X1101

81MHz

OSC

X1102

IC1102

80.91908MHz

OSC

CN1501

I DRIVE-

I HALL+

I HALL-

1

9

12

28

H

24

22

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CHCK

F1

C1

B1

CHCK

F1

C1

B1

CHCK

F1

C1

B1

CN101

(2/25)

IC1103

SELECTOR

424042

52

4

6

626162

636463

262326

B2

B1

CN1001

9090

9292

7171

7474

40

6767

7070

CHCK1

52

4

6

TG HD

TG VD

61

64

23

6

2

CDS+B

CDS-B

CDS+R

CDS-R

CDS+G

CDS-G

PBCLK

CHCK2

PBCLK

CHCK2

PBCLK

CHCK2

PBCLK

V1B-V4B

V1R-V4R

V1G-V4G

(2/25) (3/25)

F9

E9

IC1104

A/D CONV.

G5

J5

(2/25)

F9

E9

IC1105

A/D CONV.

G5

J5

(2/25)

F9

E9

IC1106

A/D CONV.

G5

J5

IC1107

C8

B4 A5

IC1101

C4

B5

F2 E2

E1

E3

GENERATOR

B6 B7

A7

A8

J2

B-CH

AGC

R-CH

AGC

G-CH

AGC

(2/25)

TIMING

A2 B1

C1

D1 D3

E1 E3

F1 F3

G1 G3

H1 J2

A2 B1

C1

D1 D3

E1 E3

F1 F3

G1 G3

H1 J2

A2 B1

C1

D1 D3

E1 E3

F1 F3

G1 G3

H1 J2

(2/25)

CHCK1

C3

J8

A6

A5

C3

J8

A6

A5

C3

J8

A6

A5

J5

10

9

8

G1

C2

A1

C1

CLPOB

SO GCAM

SCK GCAM

CLPOB

SO GCAM

SCK GCAM

CLPOB

SO GCAM

SCK GCAM

71

TG HD

TG VD

TG FLD

CAM DD ON

CAM,SO,SI,SCK

325

BIL0-13

RIL0-13

GIL0-13

ZM RST SENS

CAM,SO,SI,SCK

CLPOB

CHCK2

TG HD

TG VD

TG FLD

SPCK

EN1

DIR1A

DIR1B

141

124

310

103

95

68

62

41

22

306

314

315

316

192

188

189

190

187

300

303

301

IC1301

CAMERA

RGB

PROCESS

169

151

142

165

154

175

174

173

SIRCKO

YO2-9

CO2-9

CAM HD

CAM VD

CAM FLD

1

TO

OVERALL

BLOCK DIAGRAM

(2/6)

(PAGE 3-3)

VIDEO SIGNAL

CL IRIS

METER

ZOOM

MOTOR

FOCUS

MOTOR

ACTIVE

LENS ACTUATOR

M

ND FILTER

SWITCH

M

MR

ZOOM RESET

SENSOR

M

MR

PITCH

H

38

33

35

7

8

9

3

2

4

1

42

41

47

17

18

13

14

6

7

CL DRIVE-

CL HALL+

CL HALL-

ND SW1

ND SW2

ND SW3

ZOOM A+

ZOOM AZOOM BZOOM B+

Z MR A

Z MR B

ZM RST SENS

FOCUS+

FOCUS-

F MR A

F MR B

1

9

12

K6

L4

F1

G3

E12

E10

F3

E3

B1

C4

1

7

IC1505

CL IRIS DRIVE

CL IRIS

HALL AMP

(5/25)

IC1702

ZOOM

MOTOR

DRIVE

FOCUS

MOTOR

DRIVE

(4/25)

IC1501

PITCH DRIVE

(4/25)

YAW

16

5

4

9

2

CN1503

1

7

IC1502

YAW DRIVE

CL IRIS PWM

3

CL HALL AD

14

L9

EN1

K9

DIR1A

M9

DIR1B

J9

J11

K11

H12

SPCK

K12

L10

CAM DD ON

L11

67

(6/25)

IC1903

EVR

(4/25) (4/25)

IC1503

6

7

PRE DRIVE

IC1506

6

7

LPF

3

IC1507

42

IC1508

2

8

9

8

12

42

CAM,SO,SI,SCKCAM,SO,SI,SCK

(4/25)

PITCH PWM

(4/25)

YAW PWM

PITCH POS AD

YAW POS AD

IRIS PWM

I HALL AD

CL IRIS PWM

CL HALL AD

ND SW1

ND SW2

ND SW3

94

128

98

142

176

175

41

77

78

75

95

96

131

132

(6/25)

IC1902

CAMERA

CONTROL

66

HI,SO,SI,SCK HI,SO,SI,SCK

65

63

ZOOM VR AD

135

H ZOOM AD

138

SO GCAM

73

SCK GCAM

71

ZM SPD SEL

139

(5/25)

IC1701

ZOOM

RING

DRIVE

FOCUS

RING MR

INPUT

ZOOM

RING MR

INPUT

(6/25)

EEPROM

SPCK

J11

K11

H12

K12

L8

M8

X1901

20MHz

1

3

RNGMT EN

184

RNGMT PWM

91

210

211

136

49

69

SO,SI,SCK

70

67

129

130

5

2

6

CAM,SO,SI,SCK

IC1901

(4/25)

CAM DD ON

TO

OVERALL

2

BLOCK DIAGRAM

(6/6)

3

(PAGE 3-12)

TO

OVERALL

BLOCK DIAGRAM

(5/6)

(PAGE 3-10)

ZOOM VR AD

H ZOOM AD

NTSC/XPAL DET

ZM SPD SEL

LENS BLOCK(2/2)

F RING MR A

B1

F RING MR B

C4

ZM RING MR A

E12

ZM RING MR B

E10

ZOOM RING+

L6

ZOOM RING-

L7

T END SENS