Sony HVR-M10C, HVR-M10E, HVR-M10J, HVR-M10U, HVR-M10N Service Manual

...

HVR-M10C/M10E/M10J

SERVICE MANUAL

M10N/M10P/M10U

RMT-843

HVR-M10U

US Model

Canadian Model

Ver. 1.5 2006. 10

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Link

Link

SPECIFICATIONS

SPECIFICATIONS

SERVICE NOTE

SERVICE NOTE

Photo : HVR-M10E

BLOCK DIAGRAMS

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

HVR-M10E

AEP Model

HVR-M10C

Chinese Model

HVR-M10N/M10P

E Model

HVR-M10J

Japanese Model

Z (Z311) MECHANISM

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

REPAIR PARTS LIST

REPAIR PARTS LIST

DISASSEMBLY

DISASSEMBLY

• INSTRUCTION MANUAL is shown at the end of this document.

• Reference number search on printed wiring boards is available.

• TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

SCHEMATIC DIAGRAMS ADJUSTMENT

SCHEMATIC DIAGRAMS

DIGITAL HD VIDEOCASSETTE RECORDER

ADJUSTMENT

HVR-M10C/M10E/M10J/M10N/M10P/M10U

9-876-852-11

Sony EMCS Co.

2006J1600-1

©2006.10

Published by Kohda TEC

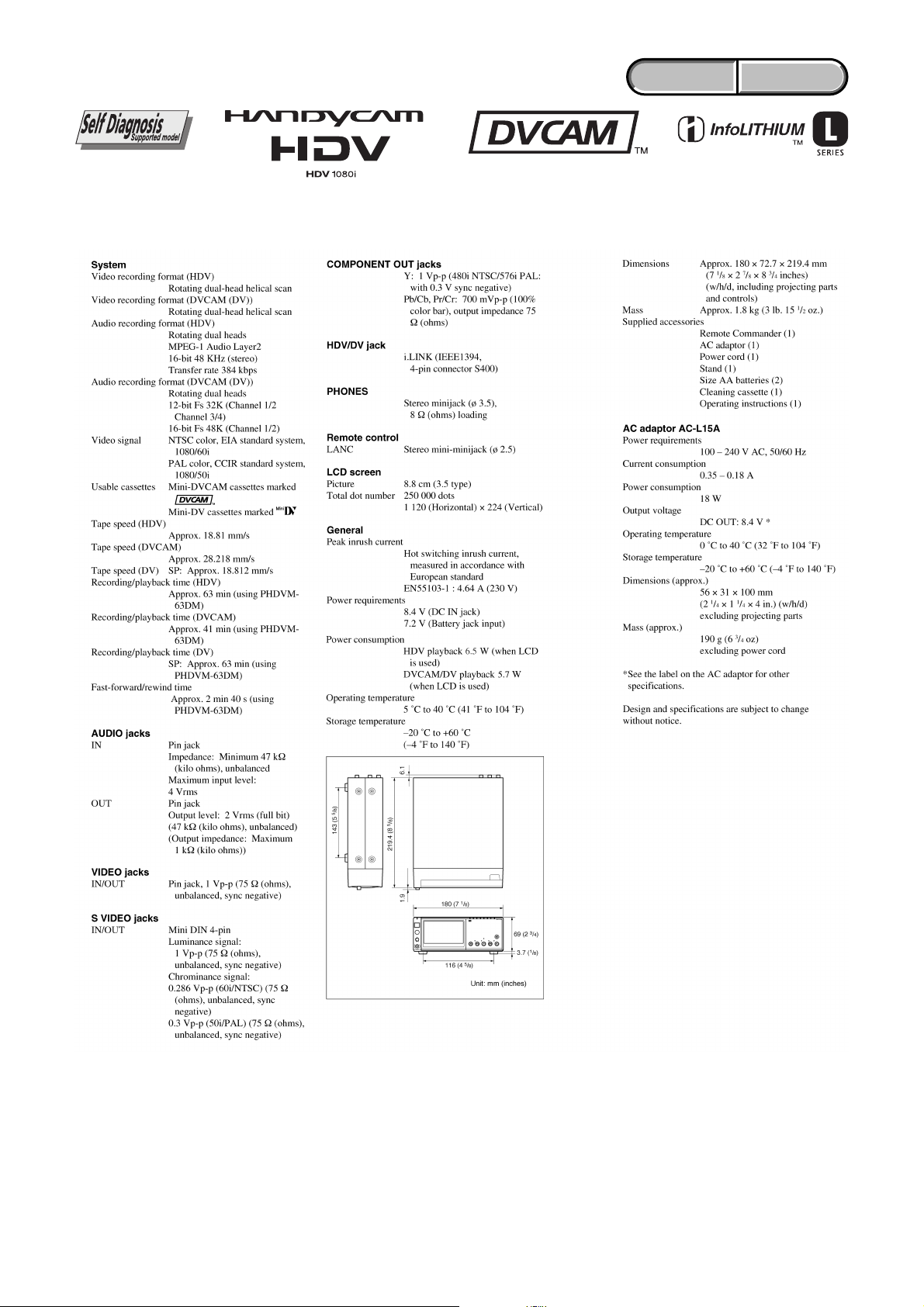

SPECIFICATIONS

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-M10C/M10E/M10J/M10N/M10P/M10U

— 2 —

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-M10C/M10E/M10J/M10N/M10P/M10U

— 3 —

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

ENGLISH JAPANESE

ENGLISH JAPANESE

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

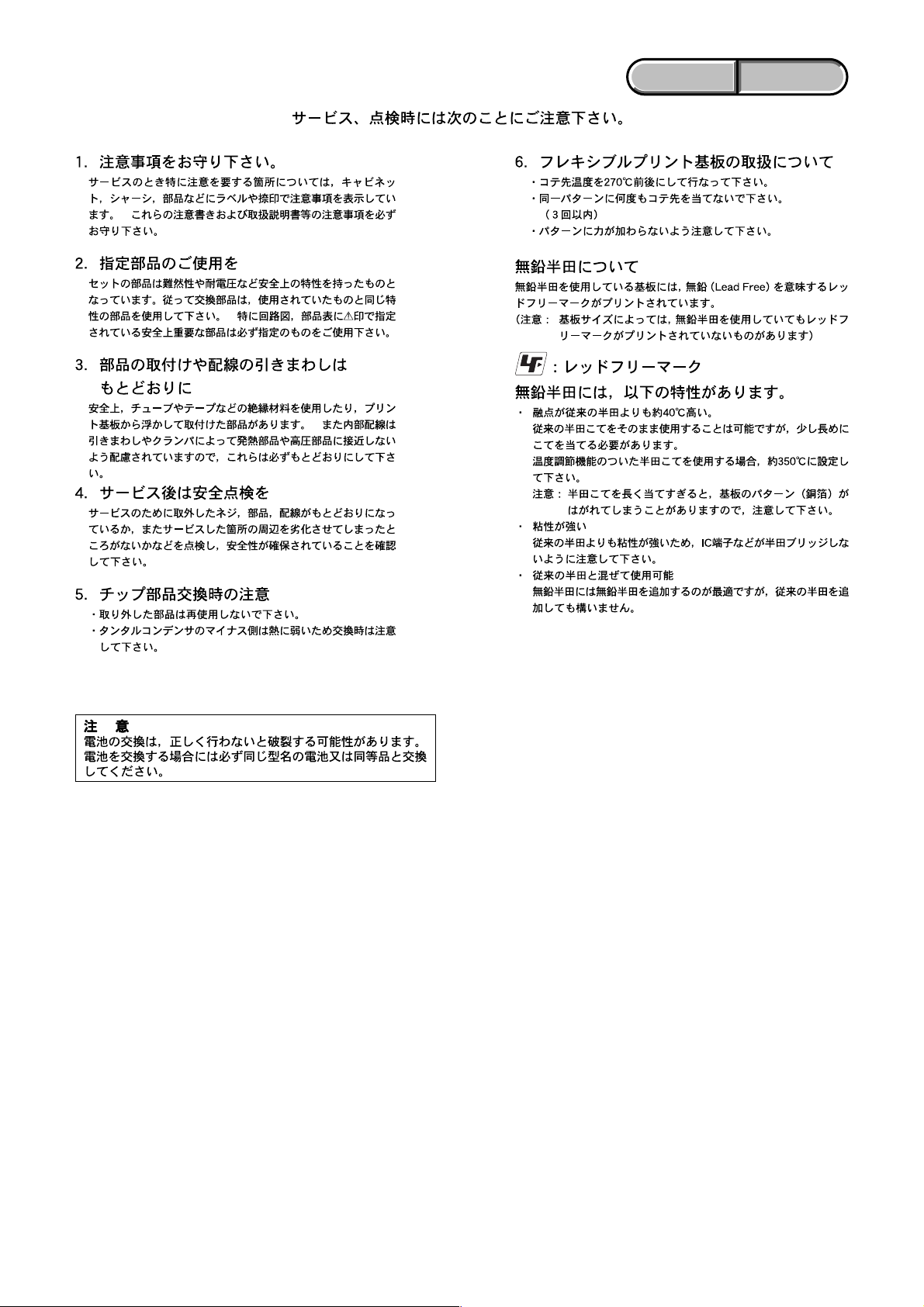

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

HVR-M10C/M10E/M10J/M10N/M10P/M10U

— 4 —

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-M10C/M10E/M10J/M10N/M10P/M10U

— 5 —

TABLE OF CONTENTS

1. SERVICE NOTE

1-1. SER VICE NOTE ····························································· 1-1

1. NOTE FOR REPAIR ······················································· 1-1

2. POWER SUPPLY DURING REPAIRS··························1-2

3. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) ····························································· 1-2

1-2. SELF-DIAGNOSIS FUNCTION····································1-3

1. SELF-DIAGNOSIS FUNCTION···································· 1-3

2. SELF-DIAGNOSIS DISPLAY ·······································1-3

3. SELF-DIAGNOSIS CODE TABLE································ 1-4

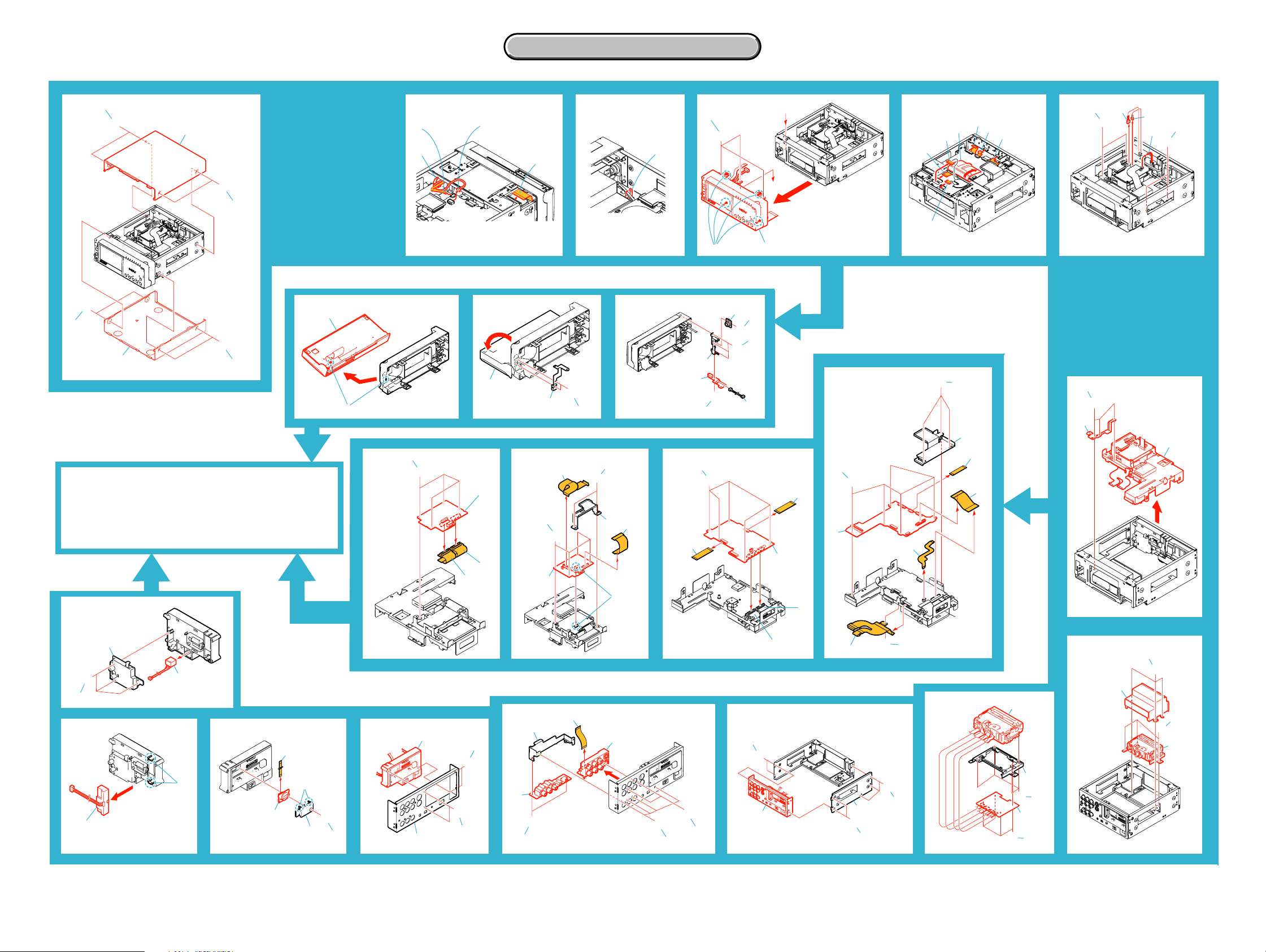

2. DISASSEMBLY

2-1. DISASSEMBLY ······························································ 2-1

2-2. SERVICE POSITION ·····················································2-7

2-3. CIRCUIT BOARDS LOCATION ································· 2-10

2-4. FLEXIBLE BOARDS LOCATION ······························2-11

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/5) ···························3-1

3-2. OVERALL BLOCK DIAGRAM (2/5) ···························3-3

3-3. OVERALL BLOCK DIAGRAM (3/5) ···························3-5

3-4. OVERALL BLOCK DIAGRAM (4/5) ···························3-7

3-5. OVERALL BLOCK DIAGRAM (5/5) ···························3-9

3-6. POWER BLOCK DIAGRAM (1/4)······························ 3-11

3-7. POWER BLOCK DIAGRAM (2/4)······························ 3-13

3-8. POWER BLOCK DIAGRAM (3/4)······························ 3-15

3-9. POWER BLOCK DIAGRAM (4/4)······························ 3-17

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME PRINTED WIRING BOARD (1/2)··················4-1

FRAME PRINTED WIRING BOARD (2/2)·················· 4-3

4-2. SCHEMATIC DIAGRAMS

• FP-230 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS····························4-7

• FP-971 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS····························4-9

• FP-976 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS··························4-11

• FP-977 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS··························4-13

• HP-139 (HP JACK)

SCHEMATIC DIAGRAMS··························4-16

• JL-001 (JACK)

SCHEMATIC DIAGRAMS··························4-15

• FP-090 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS··························4-16

• FP-096 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS··························4-16

• JU-001 (AV IN JA CK)

SCHEMATIC DIAGRAMS··························4-17

• FP-095 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS··························4-18

• LI-073 (BATTERY)

SCHEMATIC DIAGRAMS··························4-17

• MR-048 (1/2) (REC/PB RF AMP)

SCHEMATIC DIAGRAMS··························4-19

• MR-048 (2/2) (DRUM/CAPSTAN/LOADING MOTOR

DRIVE)

SCHEMATIC DIAGRAMS··························4-21

• PD-222 (LCD DRIVER, TIMING GENERATOR)

SCHEMATIC DIAGRAMS··························4-23

• PW-129 (REMOTE COMMANDER RECEIVER)

SCHEMATIC DIAGRAMS··························4-25

• SW-436 (FUNCTION PANEL)

SCHEMATIC DIAGRAMS··························4-27

• VA-120 (1/4) (CONNECTOR)

SCHEMATIC DIAGRAMS ··························4-29

• FP-088 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS ··························4-29

• FP-089 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAMS ··························4-29

• FFC-093 (RELAY)

SCHEMATIC DIAGRAMS ··························4-30

• VA-120 (2/4) (VIDEO IN/OUT)

SCHEMATIC DIAGRAMS ··························4-31

• VA-120 (3/4) (VIDEO AMP)

SCHEMATIC DIAGRAMS ··························4-33

• VA-120 (4/4) (AUDIO IN/OUT)

SCHEMATIC DIAGRAMS ··························4-35

• DA-033 (DC/DC CONVERTER)

SCHEMATIC DIAGRAMS ··························4-37

• DB-018 (1/2) (DC IN, CHARGE)

SCHEMATIC DIAGRAMS ··························4-39

• DB-018 (2/2) (DC/DC CONVERTER)

SCHEMATIC DIAGRAMS ··························4-41

• VC-367 (1/16) (BASE BAND PROCESS)

SCHEMATIC DIAGRAMS ··························4-43

• VC-367 (2/16) (OSD, D3 FILTER)

SCHEMATIC DIAGRAMS ··························4-45

• VC-367 (3/16) (HDV SIGNAL/RF SIGNAL PROCESS)

SCHEMATIC DIAGRAMS ··························4-47

• VC-367 (4/16) (HDV VIDEO DECODER)

SCHEMATIC DIAGRAMS ··························4-49

• VC-367 (5/16) (64MBIT Y/C-SDRAM)

SCHEMATIC DIAGRAMS ··························4-51

• VC-367 (6/16) (ILINK INTERFACE)

SCHEMATIC DIAGRAMS ··························4-53

• VC-367 (7/16) (DV/RF SIGNAL PROCESS)

SCHEMATIC DIAGRAMS ··························4-55

• VC-367 (8/16) (VIDEO A/D CONV.)

SCHEMATIC DIAGRAMS ··························4-57

• VC-367 (9/16) (HDV AUDIO SIGNAL PROCESS)

SCHEMATIC DIAGRAMS ··························4-59

• VC-367 (10/16) (AUDIO INPUT SELECT, AUDIO

CONVERTER)

SCHEMATIC DIAGRAMS ··························4-61

• VC-367 (11/16) (DS CONTROL)

SCHEMATIC DIAGRAMS ··························4-63

• VC-367 (12/16) (FRONT CONTROL)

SCHEMATIC DIAGRAMS ··························4-65

• VC-367 (13/16) (LSI CONTROL)

SCHEMATIC DIAGRAMS ··························4-67

• VC-367 (14/16) (MECHA CONTROL)

SCHEMATIC DIAGRAMS ··························4-69

• VC-367 (15/16) (CONNECTOR-1)

SCHEMATIC DIAGRAMS ··························4-71

• VC-367 (16/16) (CONNECTOR-2)

SCHEMATIC DIAGRAMS ··························4-73

• FP-228/FP-467/FP-826 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-75

4-3. PRINTED WIRING BOARDS

• FP-230 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-79

• FP-971 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-81

• FP-976 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-81

• FP-977 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-83

• HP-139 (HP JACK)

PRINTED WIRING BOARD ·······················4-83

HVR-M10C/M10E/M10J/M10N/M10P/M10U

— 6 —

• JL-001 (JACK)

PRINTED WIRING BOARD ·······················4-85

• FP-090 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-85

• JU-001 (AV IN JA CK)

PRINTED WIRING BOARD ·······················4-87

• FP-095 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-89

• LI-073 (BATTERY)

PRINTED WIRING BOARD ·······················4-89

• MR-048 (REC/PB RF AMP, DRUM/CAPSTAN/

LOADING MOTOR DRIVE)

PRINTED WIRING BOARD ·······················4-91

• PD-222 (LCD DRIVER, TIMING GENERATOR)

PRINTED WIRING BOARD ·······················4-95

• PW-129 (REMOTE COMMANDER RECEIVER)

PRINTED WIRING BOARD ·······················4-99

• SW-436 (FUNCTION PANEL)

PRINTED WIRING BOARD ·····················4-101

• VA-120 (CONNECTOR, VIDEO IN/OUT, VIDEO AMP,

AUDIO IN/OUT)

PRINTED WIRING BOARD ·····················4-105

• FP-088 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·····················4-109

• FP-089 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·····················4-109

• DA-033 (DC/DC CONVERTER)

PRINTED WIRING BOARD ·····················4-113

• DB-018 (DC IN, CHARGE, DC/DC CONVERTER)

PRINTED WIRING BOARD ·····················4-115

• VC-367 (BASE BAND PROCESS, OSD, D3 FILTER,

HDV SIGNAL/RF SIGNAL PROCESS, HDV VIDEO

DECODER, 64MBIT Y/C-SDRAM, ILINK INTERFACE,

DV/RF SIGN AL PROCESS, VIDEO A/D CONV., HDV

AUDIO SIGNAL PROCESS, AUDIO INPUT SELECT ,

AUDIO CONVERTER, DS CONTROL, FRONT

CONTROL, LSI CONTROL, MECHA CONTROL,

CONNECTOR-1, CONNECTOR-2)

PRINTED WIRING BOARD ·····················4-119

• FP-228/FP-467/FP-826 FLEXIBLE

PRINTED WIRING BOARD ·····················4-123

4-4. WAVEFORMS ····························································4-125

4-5. MOUNTED PARTS LOCATION ······························· 4-128

5. REPAIR PARTS LIST

5-1-1.OVERALL SECTION····················································· 5-3

5-1-2.FRONT PANEL SECTION ············································· 5-4

5-1-3.CONTROL PANEL SECTION ·······································5-5

5-1-4.MAIN FRAME SECTION-1 ··········································5-6

5-1-5.MAIN FRAME SECTION-2 ··········································5-7

5-1-6.REAR PANEL SECTION··············································· 5-8

5-1-7.MECHANISM DECK OVERALL (Z311) ·····················5-9

5-1-8.LS CHASSIS BLOCK ASSEMBLY·····························5-10

5-1-9.MECHANICAL CHASSIS BLOCK ASSEMBLY·······5-11

Checking supplied accessories ················································ 5-12

5-2. ELECTRICAL PARTS LIST ········································ 5-14

6. ADJUSTMENTS

1. Before starting adjustment··············································· 6-1

1-1.

Adjusting items when replacing main parts and boards···

6-1. MECHANISM SECTION ADJUSTMENT····················6-3

1-1. Preparations for Check, Adjustment and Replacement of

Mechanism Block····························································6-3

1-1-1.Cassette Compartment Assy, Damper Assy ····················6-3

1-2. Periodic Inspection and Maintenance

6-2

1-2-1.Rotary Drum Cleaning ···················································· 6-4

1-2-2.Tape Path System Cleaning (Refer to Fig. 6-1-2.) ·········· 6-4

1-2-3.Periodic Inspection List ··················································· 6-5

1-2-4.Mode Selector II Operating Procedure····························6-6

2-4-1.Introduction ····································································· 6-6

2-4-2.Operation ·········································································6-7

2-4-3.Mechanism Status (Position) Transition Table Using

Mode Selector II ······························································ 6-9

2-4-4.Battery Alarm Indication ·················································6-9

1-3. Check, Adjustment and Replacement of

Mechanical Parts ··························································· 6-10

1-3-1.Flowchart of Replacement of Mechanical Parts············ 6-10

1-3-2.Drum··············································································6-11

1-3-3.Cassette Compartment Assy··········································6-13

1-3-4.TG7 Support ··································································6-14

1-3-5.Motor Holder Block Assy and L Motor Block Assy ····· 6-15

1-3-6.MIC Terminal (MIC902)···············································6-16

1-3-7.LED (D901)···································································6-17

1-3-8.Retainer Plate ································································6-18

1-3-9.T Reel Table Assy·························································· 6-19

1-3-10. Brake (S) and Release Rack (S)·································· 6-20

1-3-11. Band Adjuster, S Reel Table Assy and

TG2 Arm Block Assy ·················································6-21

1-3-12. ULE Brake Assy ·························································6-22

1-3-13. Cassette Positioning (S) ·············································· 6-23

1-3-14. TG7 Arm Block Assy and Pinch Arm Assy ················ 6-24

1-3-15. TG7 ·············································································6-25

1-3-16. Gooseneck Gear Assy ················································· 6-26

1-3-17. LS Guide Retainer and LS Cam Plate ························ 6-27

1-3-18. LS Chassis Block Assy and

Mechanical Chassis Block Assy································· 6-28

1-3-19. Brake (T) Block Assy ·················································6-30

1-3-20. END Sensor (Q901)····················································6-31

1-3-21. TOP Sensor (Q902)·····················································6-32

1-3-22. C-IN Switch (S903), S Reel Sensor (H901) and

T Reel Sensor (H902)····················································6-33

1-3-23. Guide Rail ··································································· 6-34

1-3-24. Conversion Gear ·························································6-35

1-3-25. Coaster (S) Block Assy and

Coaster (T) Block Assy ··············································6-36

1-3-26. TG5 Roller Assy and GL Gear (T) ····························· 6-37

1-3-27. TG2 Cam Plate Assy (N) ············································ 6-38

1-3-28. LS Arm Assy ·······························································6-39

1-3-29. M Slider Assy (1)························································ 6-40

1-3-30. M Slider Assy (2)························································ 6-41

1-3-31. EJ Arm ········································································6-42

1-3-32. Cam Gear and GL Driving·········································· 6-43

1-3-33. Rotary Encoder (S902) ··············································· 6-44

1-3-34. FP-228 Flexible Board (DEW SENSOR) and

FP-467 Flexible Board ··············································· 6-45

1-4. Adjustment ···································································· 6-46

1-4-1.FWD Position Adjustment·············································6-46

1-4-2.Reel Torque Check ························································6-46

1-4-3.LS Cam Plate Position Adjustment ·······························6-47

1-4-4.Tape Path Adjustment···················································· 6-48

6-2. VIDEO SECTION ADJUSTMENT································6-4

2-1. PREPARATIONS BEFORE ADJUSTMENTS ············ 6-52

2-1-1.Equipment to Required··················································6-52

2-1-2.Precautions on Adjusting··············································· 6-53

2-1-3.Adjusting Connectors ····················································6-54

2-1-4.Connecting the Equipment ············································6-54

2-1-5.Alignment Tapes···························································· 6-55

2-1-6.Input/Output Level and Impedance ······························· 6-55

2-2. INITIALIZATION OF 8, 9, A, B, C, D, 13, 18, 1A,

1B, 1C, 1D PAGE DATA···············································6-56

2-2-1.INITIALIZATION OF A, B, D, 1A, 1B PAGE DATA··6-56

1. Initializing the A, B, D, 1A, 1B Page Data ···················6-56

HVR-M10C/M10E/M10J/M10N/M10P/M10U

— 7 —

2. Modification of A, B, D, 1A, 1B Page Data··················6-56

3. A Page Table ·································································· 6-56

4. B Page Table ··································································6-57

5. D Page Table ·································································· 6-57

6. 1A Page Table ································································ 6-57

7. 1B Page Table ································································6-57

2-2-2.

INITIALIZATION OF 8, C, 13, 18, 1C PAGE DATA ···

1. Initializing the 8, C, 13, 18, 1C Page Data ···················· 6-58

2. Modification of 8, C, 13, 18, 1C Page Data ··················6-58

3. 8 Page Table ···································································6-59

4. C Page Table ··································································6-59

5. 13 Page Table································································· 6-60

6. 18 Page Table································································· 6-61

7. 1C Page Table ································································6-61

2-2-3.INITIALIZATION OF 9, 1D PAGE DATA ·················· 6-62

1. Initializing the 9, 1D Page Data ···································· 6-62

2. Modification of 9, 1D Page Data··································· 6-62

3. 9 Page Table ···································································6-62

4. 1D Page Table ································································ 6-62

2-3. SYSTEM CONTROL SYSTEM ADJUSTMENT ········ 6-63

1. Serial No. Input ····························································· 6-63

2-4. SERVO AND RF SYSTEM ADJUSTMENT ···············6-65

1. Cap FG Duty Adjustment (VC-367 board) ···················6-65

2. Switching Position Adjustment (VC-367 board)···········6-65

3. Error Rate Check ···························································6-66

3-1. Preparations before adjustments····································6-66

3-2. Error Rate Check ···························································6-66

3-3. Processing after Completing Adjustments ···················· 6-66

2-5. VIDEO SYSTEM ADJUSTMENTS····························· 6-67

1. Origin Oscillation Check (VC-367 board) ····················6-67

2. S VIDEO OUT Y Level Adjustment (VC-367 board)··· 6-68

3. S VIDEO OUT Chroma Level Adjustment

(VC-367 board) ····························································· 6-68

4. VIDEO OUT Y, Chroma Level Check

(VC-367 board) ····························································· 6-69

5. COMPONENT OUTPUT Level Adjustment

(VC-367 board) ····························································· 6-70

6. E-E Level Check (VC-367 board)································· 6-71

2-6. AUDIO SYSTEM ADJUSTMENTS ···························· 6-72

1. Playback Level Check ···················································6-73

2. Overall Level Characteristics Check ····························· 6-73

3. E-E Audio Level Check ·················································6-73

2-7. LCD SYSTEM ADJUSTMENT ···································6-74

1. LCD Automatic Adjustment (PD-222 board) ················ 6-74

2. Contrast Adjustment (HD) (PD-222 board) ··················6-75

3. V COM Adjustment (PD-222 board) ····························6-75

4. Sample Hold Phase Adjustment (PD-222 board)·········· 6-76

5. Transmissive Mode White Balance Adjustment

(PD-222 board)······························································ 6-76

6. Reflective Mode White Balance Adjustment

(PD-222 board)······························································ 6-77

6-3. SER VICE MODE·························································· 6-78

3-1. ADJUSTMENT REMOTE COMMANDER ················ 6-78

1. Using the adjustment remote commander ····················· 6-78

2. Precautions upon using the adjustment remote

commander ····································································6-78

3-2. DATA PROCESS··························································· 6-79

3-3. SER VICE MODE·························································· 6-80

1. Setting the Test Mode ···················································· 6-80

2. Emergence Memory Address (Mechanism section)······6-80

2-1. EMG Code (Emergency Code) ····································· 6-80

2-2. MSW Code ···································································· 6-81

3. Bit value discrimination ················································ 6-82

4. Switch check (1) ···························································· 6-82

5. Switch check (2) ···························································· 6-82

6. Switch check (5) ···························································· 6-83

7. LED check ····································································· 6-83

6-58

8. Record of Use check (1) ················································ 6-84

9. Record of Use check (2) ················································ 6-84

10. Record of Self-diagnosis check ····································· 6-85

SELF-DIAGNOSIS CODE TABLE········································6-86

HVR-M10C/M10E/M10J/M10N/M10P/M10U

— 8 —

1. SERVICE NOTE

1-1. SERVICE NOTE

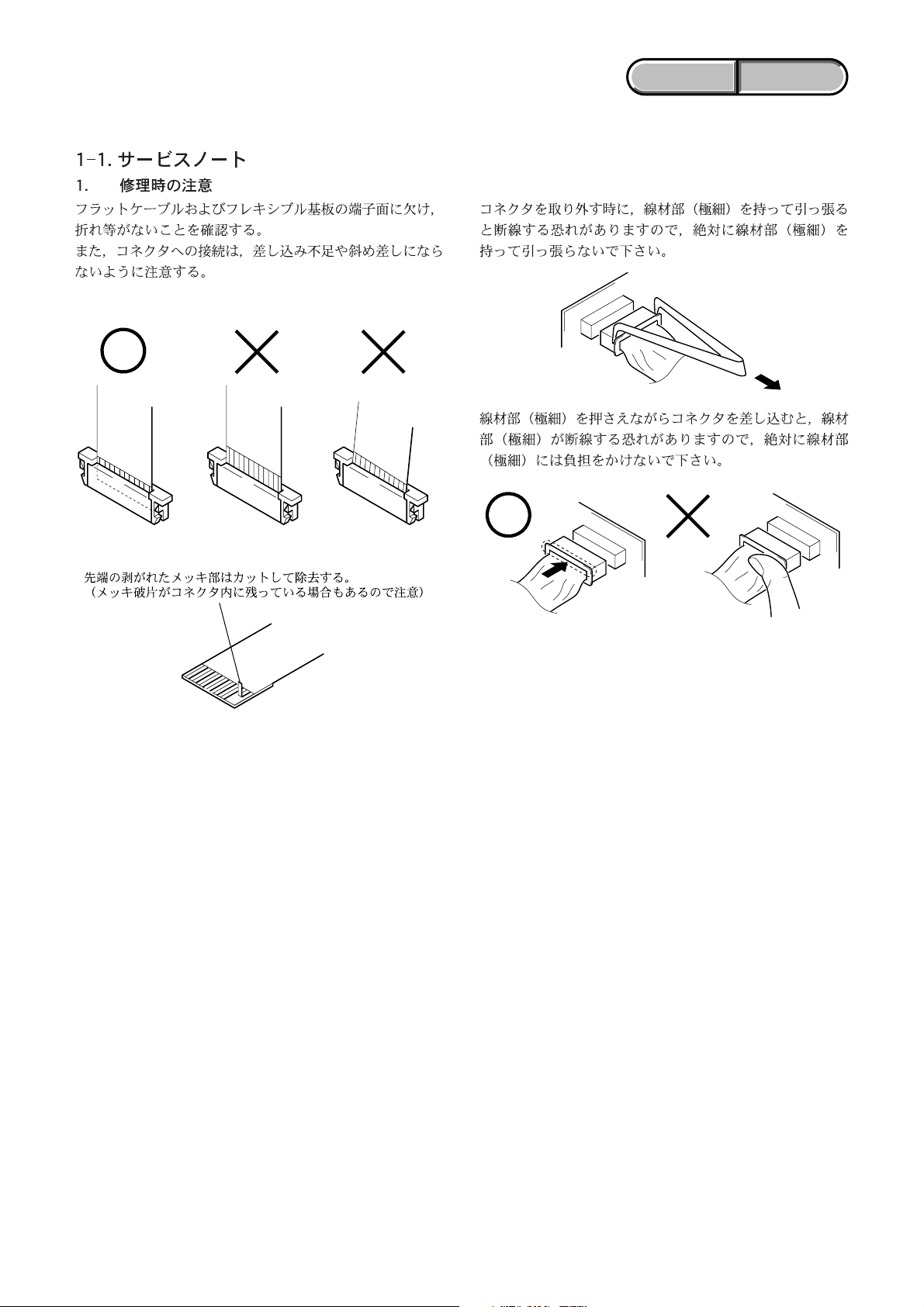

1. NOTE FOR REPAIR

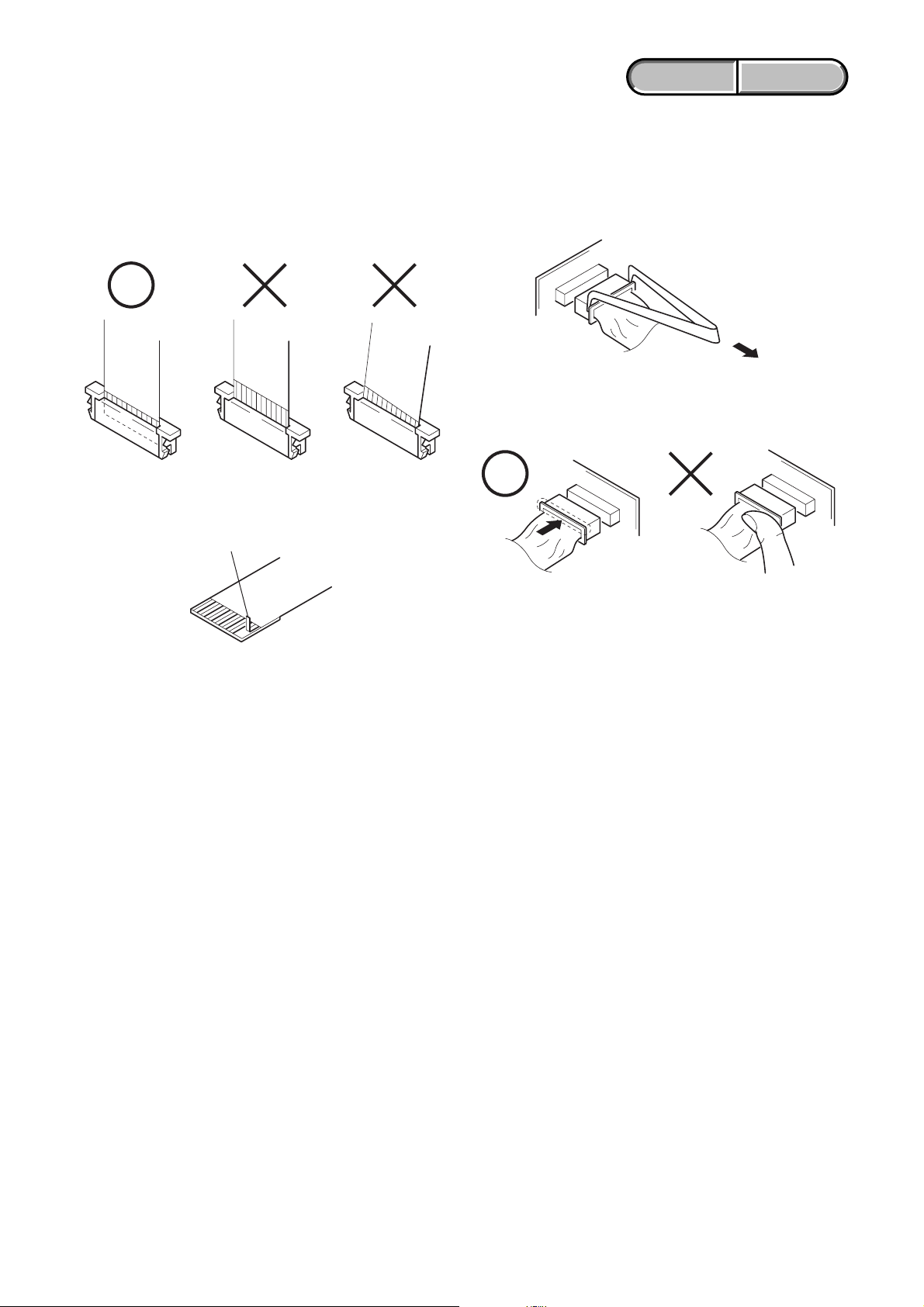

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

ENGLISH JAPANESE

ENGLISH JAPANESE

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1-1

ENGLISH JAPANESE

ENGLISH JAPANESE

2. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V),

the power is shut off so that the unit cannot operate.

This following two methods are available to prevent this.Take note of which to use during repairs.

Method 1.

Use the AC power adaptor.

Method 2.

Connect the servicing remote commander RM-95 (J-6082-053-B) to the LANC jack,and set the commander switch to the “ADJ” side.

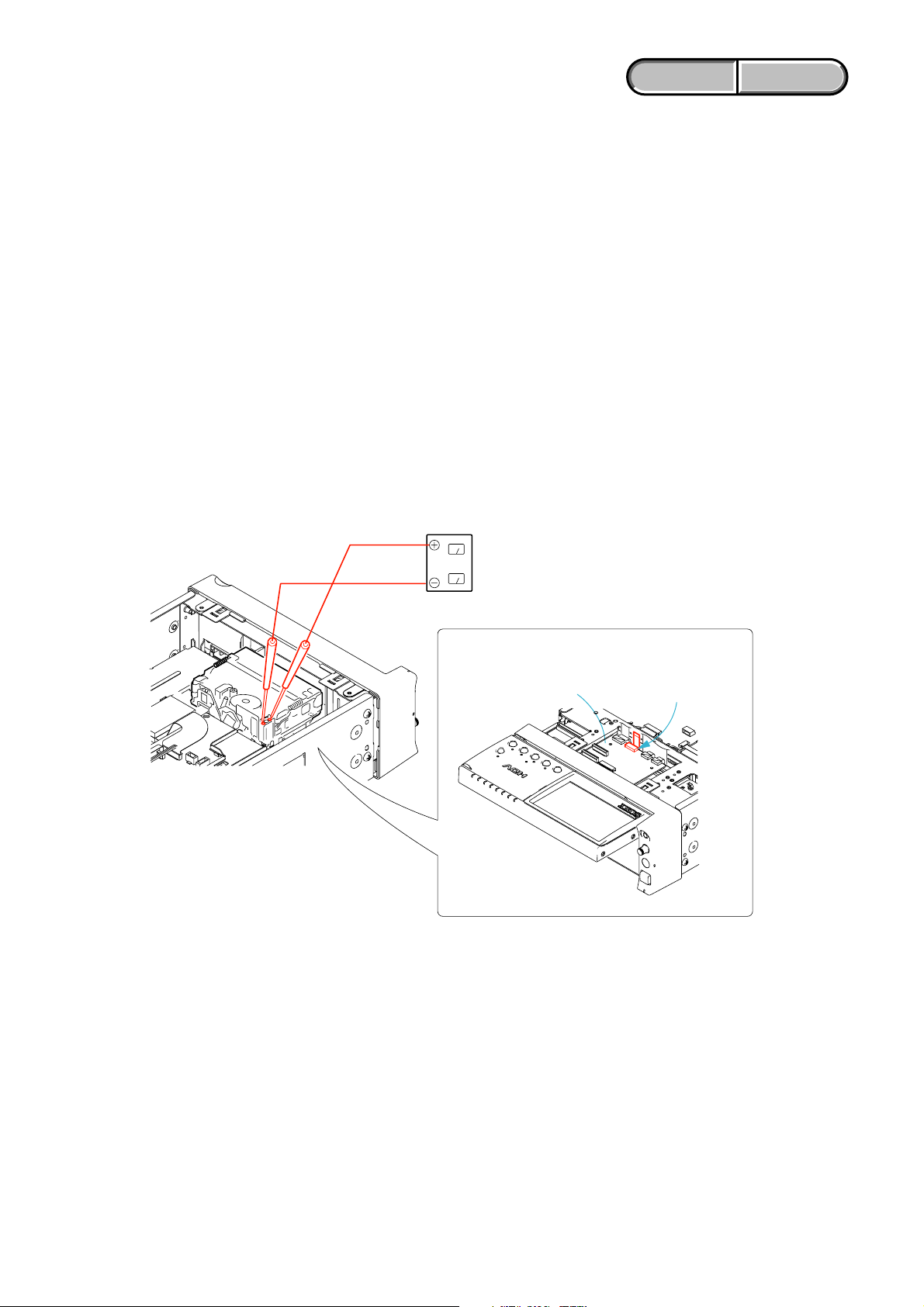

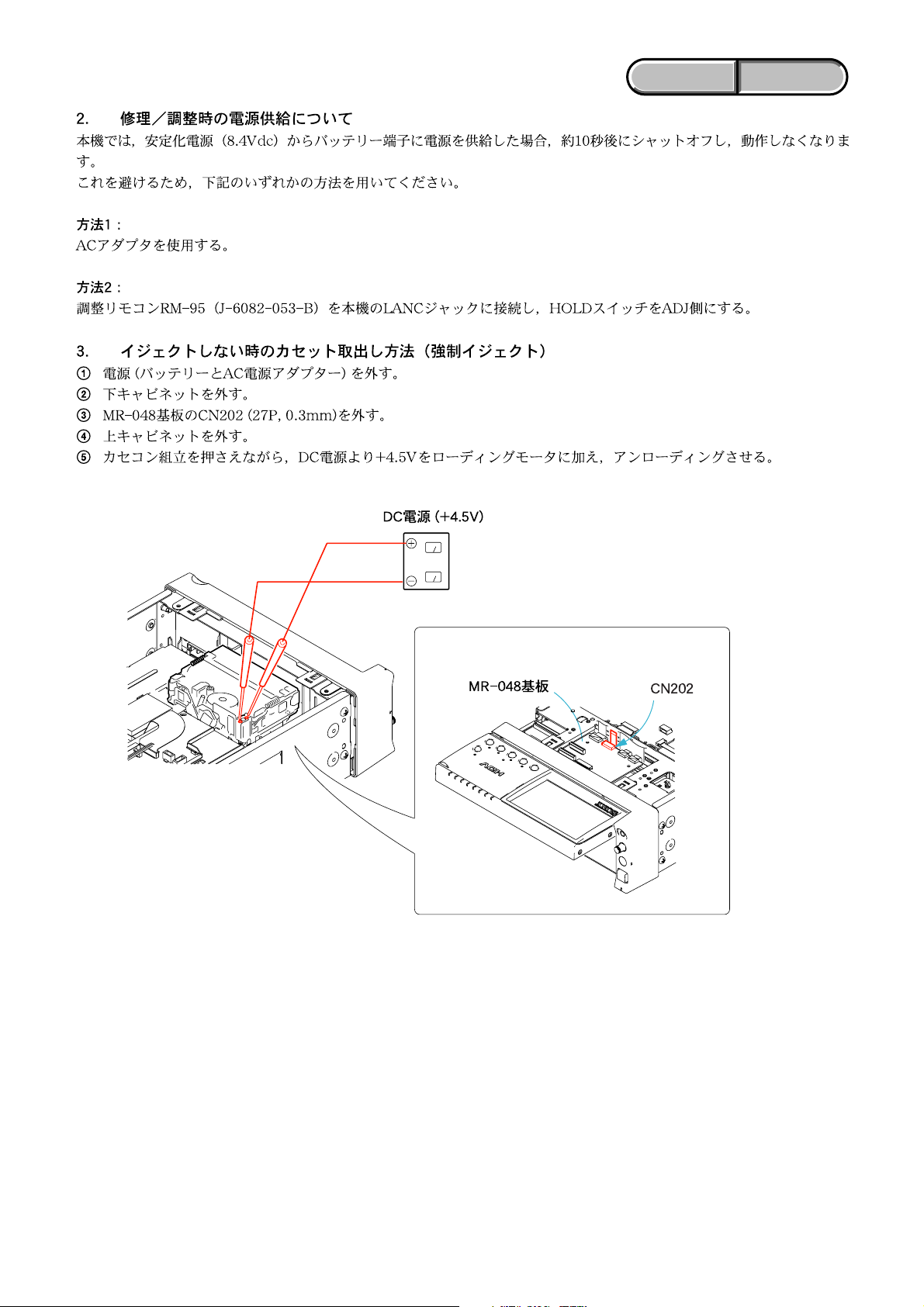

3. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Remove the power supply (Battery and AC power adaptor).

2 Remove the bottom cabinet.

3 Disconnect the CN202 (27P, 0.3mm) of MR-048 board.

4 Remove the top cabinet.

5 Supply +4.5V from the DC power supply to the loading motor and unload with pressing the cassette compartment.

DC power supply

(+ 4.5V)

MR-048 board

CN202

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1-2

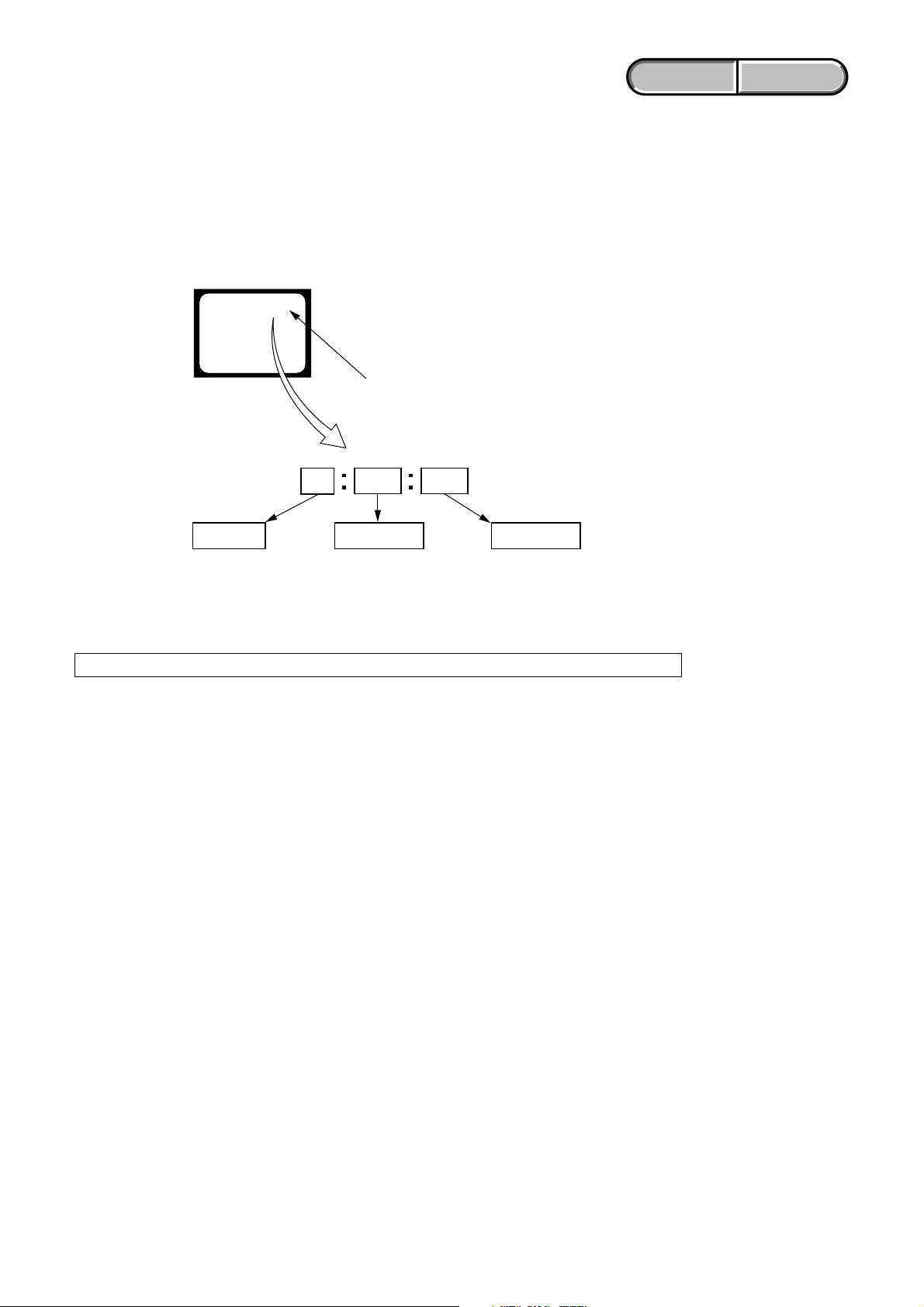

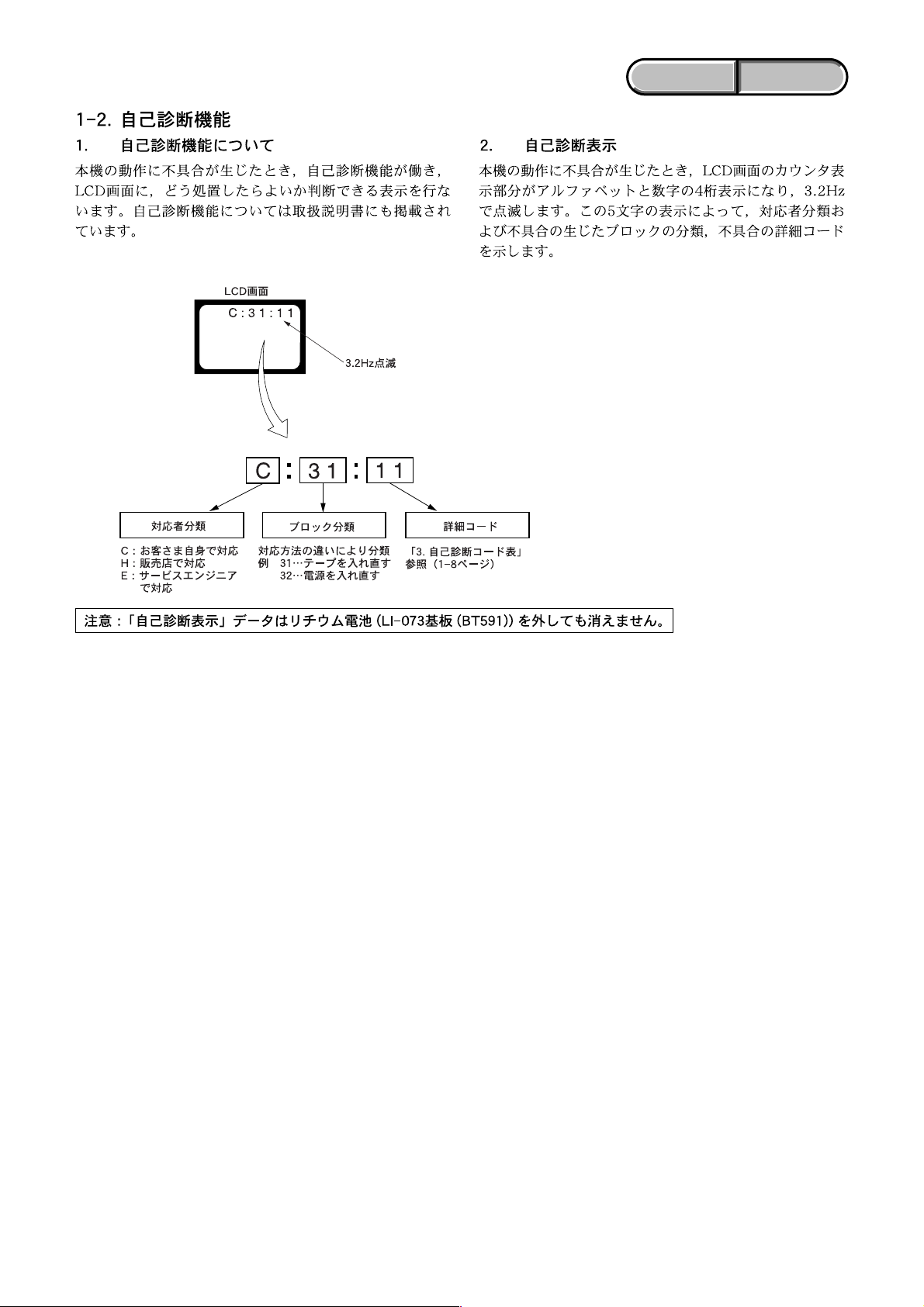

1-2. SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the LCD screen what to do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

LCD screen

C : 3 1 : 1 1

Blinks at 3.2Hz

ENGLISH JAPANESE

ENGLISH JAPANESE

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of

the LCD screen consists of an alphabet and 4-digit number, which

blinks at 3.2Hz. This 5-character display indicates the “repaired

by:”, “block” in which the problem occurred, and “detailed code”

of the problem.

3 1C

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Note: The self-diagnosis display data will be kept even if the lithium battery (BT591 of LI-073 board) is removed.

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

Block

1 1

Detailed Code

Refer to page 1-4.

Self-diagnosis Code Table.

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1-3

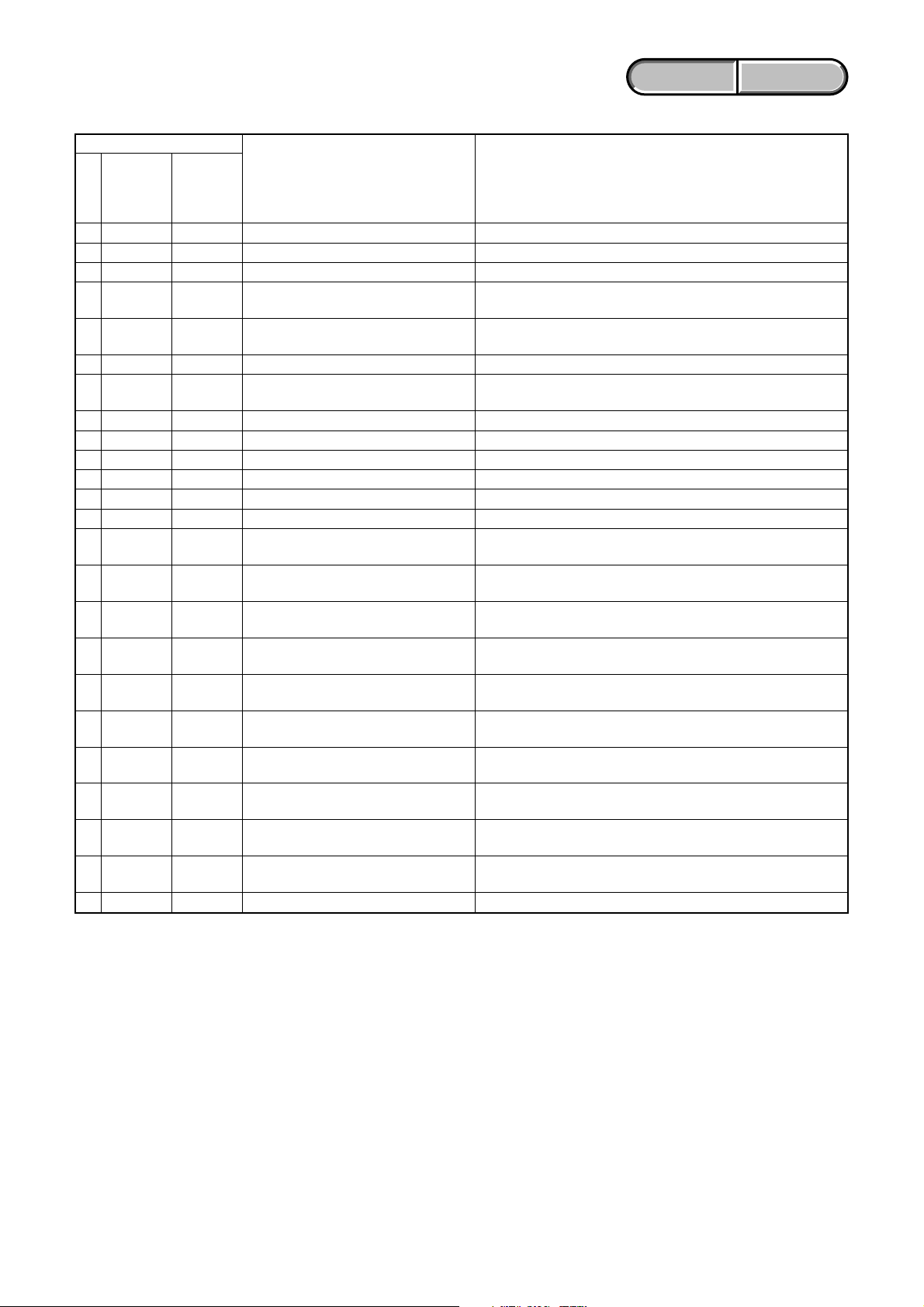

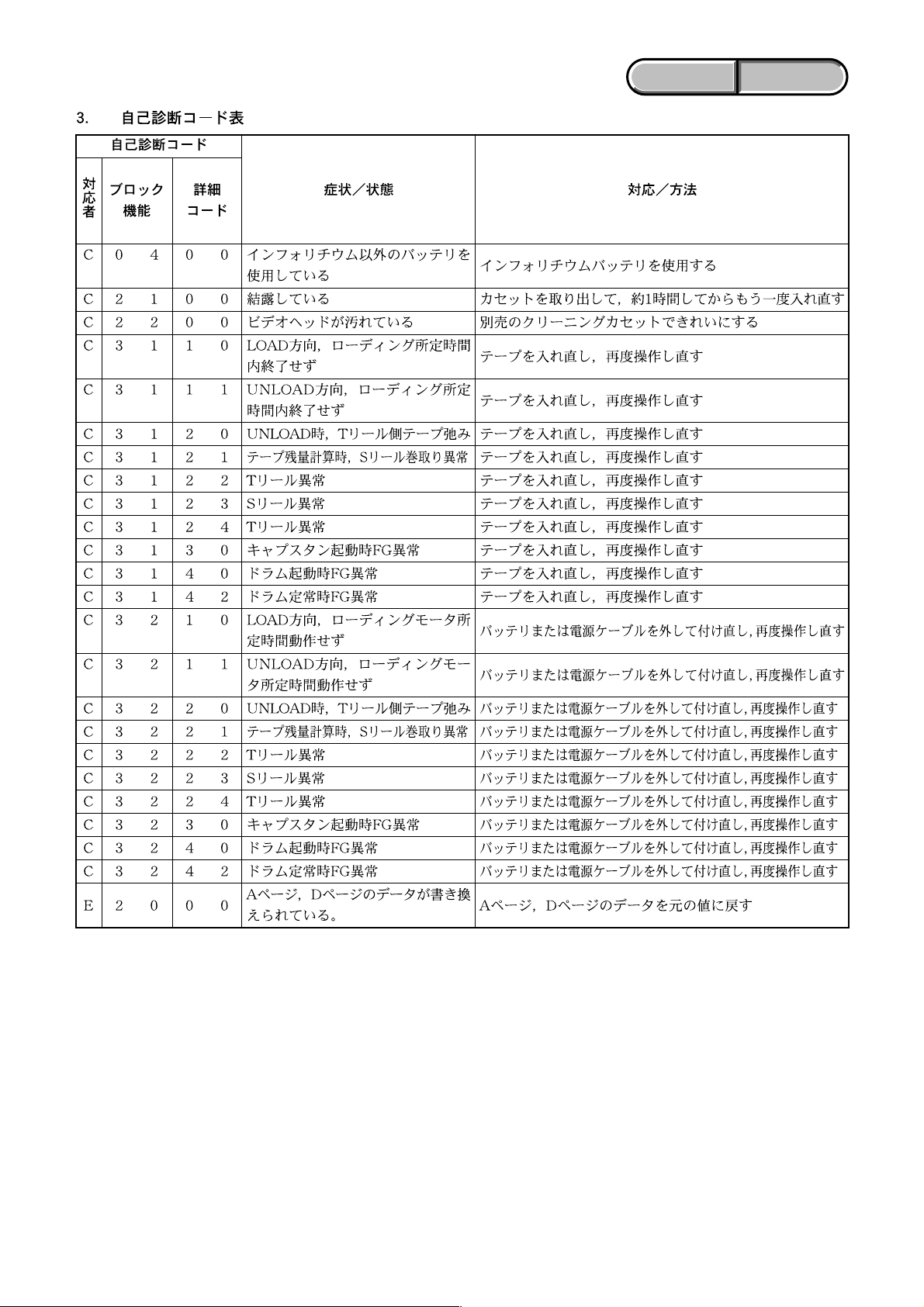

3. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Function

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

Block

04

21

22

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

20

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Data on A page or D page are rewriten.

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Make data A page and D page correct value.

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1-4

1. SERVICE NOTE

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1-5

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1-6

ENGLISH JAPANESE

ENGLISH JAPANESE

✂✂

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1-7

ENGLISH JAPANESE

ENGLISH JAPANESE

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1-8E

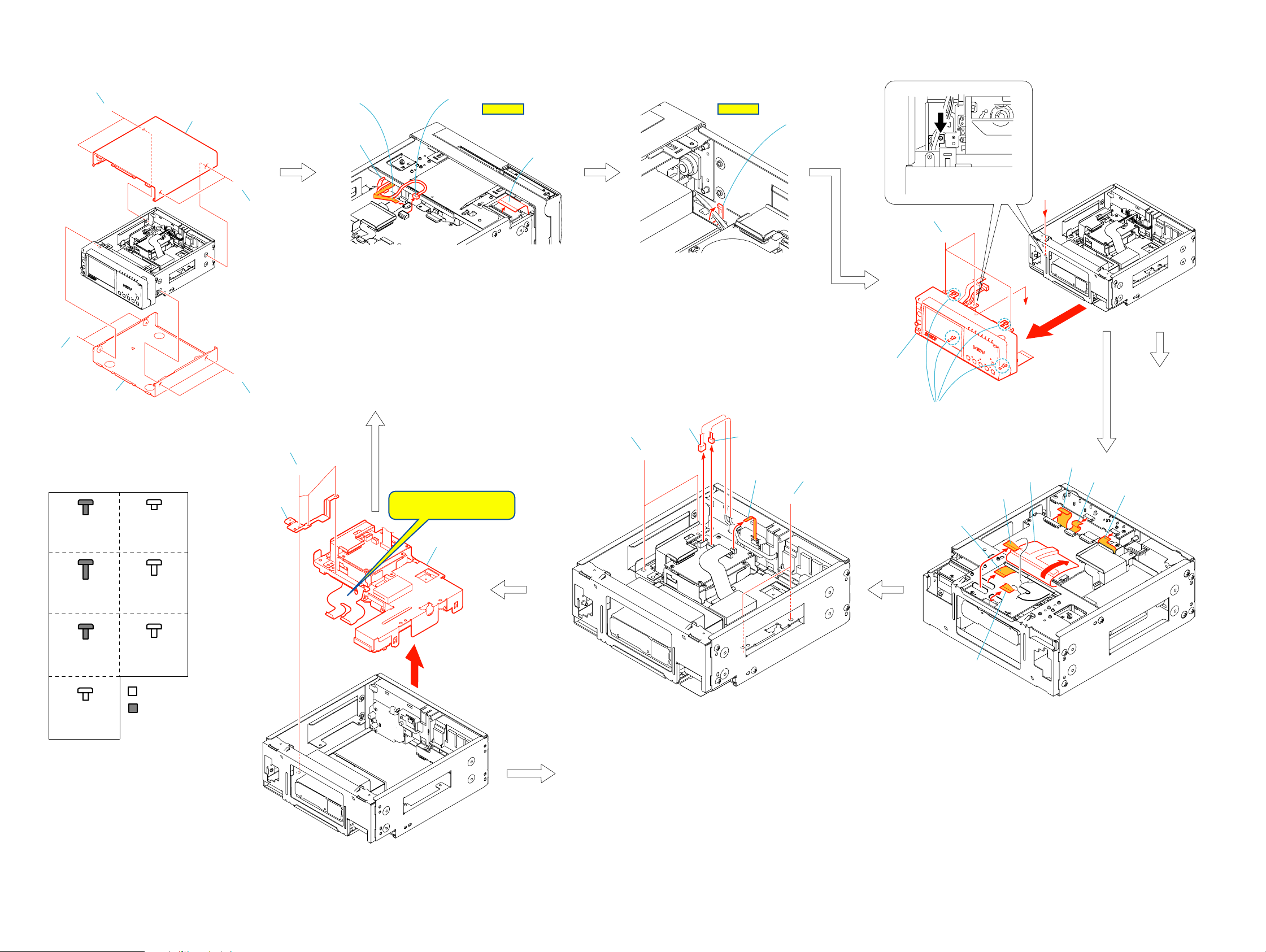

2. DISASSEMBLY

The following flow chart shows the disassembly procedure.

2-1. DISASSEMBLY

2

A

5

A

Screw

M3x6

2-059-756-01

C

A

6

Two screws (M3×6)

1

2

Two screws (M3×6)

3

Cabinet (upper)

4

Two screws (M3×6)

5

Two screws (M3×6)

6

Cabinet (lower)

B

M1.4x1.5

3-059-718-01

D

Screw

3

A

1

A

4

1

I

2

2

1

1

Open the clamper

2

FFC-094 Flexible flat cable (8P)

3

Harness (HP-146)

4

FFC-093 Flexible flat cable (50P)

Main frame section-1 (See page 2-3)

A

1

Three screws (M2x3) silver

2

Ground plate (HP)

3

Main frame section

Note:

Be very careful not to

damage the flexible board.

3

Ver 1.2 2005. 09

3

HELP 01 HELP 02

1

4

a

1

I

1

Open the clamper

a

3

B

Front panel section

2

4

2

3

D

1

5

D

1

Three screws (M2x3) silver

2

Four claws

3

Front panel section

7

1

3

4

(See page 2-5)

6

5

Screw

M3x8

3-077-331-41

Screw

M3x6

3-077-331-21

EF

Tapping screw

M2x5

3-080-206-21

I

Screw

M2x3

3-080-202-21

Screw

M2x5

7-681-000-00

Silver

Black

C

Main frame section-2 (See page 2-5)

1

FFC-095 Flexible flat cable (6P)

2

Battery terminal board (4P)

3

DC-IN connector (3P)

4

Two screws (M3x6) silver

5

Two screws (M3x6) silver

2

1

Peel the sheet (SW-VA)

2

FP-230 flexible board (22P)

3

FP-230 flexible board (30P)

4

FP-098 flexible board (28P)

5

FP-090 flexible board (10P)

6

FP-096 flexible board (12P)

7

FP-095 flexible board (28P)

HVR-M10C/M10E/M10J/M10N/M10P/M10U

2-1 2-2

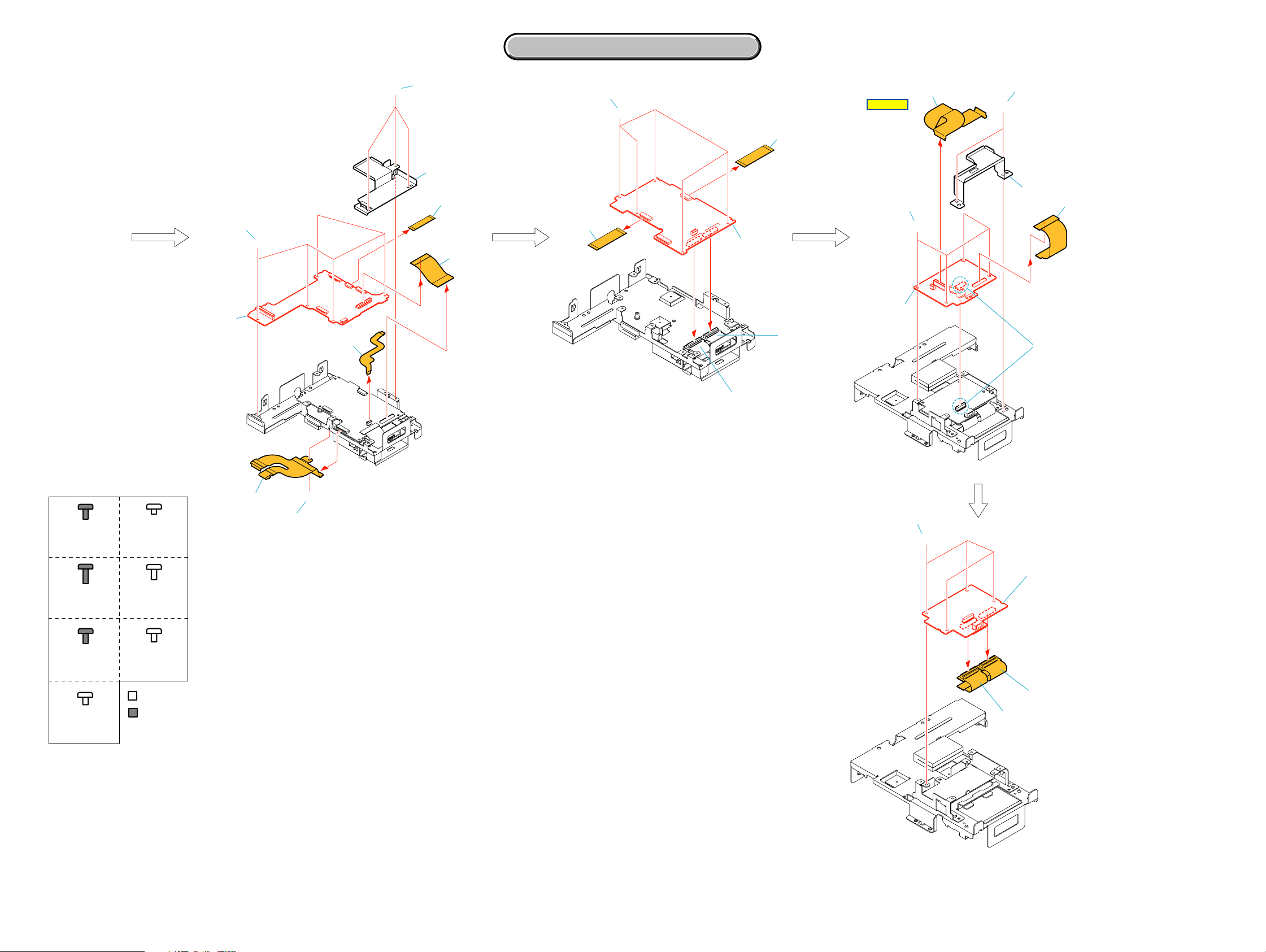

2. DISASSEMBLY

2. DISASSEMBLY

Ver 1.1 2005. 05

3

1

Screw (M2x3) silver

2

FP-230 flexible board (51P)

3

Three screws (M2x3) silver

4

VC connector retainer

5

FP-971 flexible board (100P),(100P)

6

FP-096 flexible board (12P)

7

FP-090 flexible board (10P)

8

Five screws (M2x3) silver

9

VA-120 board

A

8

I

I

4

6

5

3

I

1

HELP 03

VC-367

2

6

VA-120

9

4

VC-367

7

1

FP-089 flexible board (33P)

2

FP-088 flexible board (39P)

3

Five screws (M2x3) silver

4

FP-976 flexible board (80P)

5

FP-976 flexible board (80P)

6

VC-367 board

5

1

5

I

DB-018

7

DA-033

I

2

1

FP-098 flexible board (28P)

2

Two screws (M2x3) silver

3

DB connector retainer

4

FP-977 flexible board (100P)

5

Four screws (M2x3) silver

6

Board to board connector (28P)

7

DB-018 board

3

4

6

A

Screw

M3x6

2-059-756-01

C

Screw

M3x8

3-077-331-41

B

Screw

M1.4x1.5

3-059-718-01

D

Screw

M3x6

3-077-331-21

EF

Tapping screw

M2x5

3-080-206-21

I

Screw

M2x3

3-080-202-21

Screw

M2x5

7-681-000-00

Silver

Black

2

I

1

1

I

1

4

DA-033

3

2

Four screws (M2x3) silver

2

FP-976 flexible board (80P)

3

FP-976 flexible board (80P)

4

DA-033 board

HVR-M10C/M10E/M10J/M10N/M10P/M10U

2-3 2-4

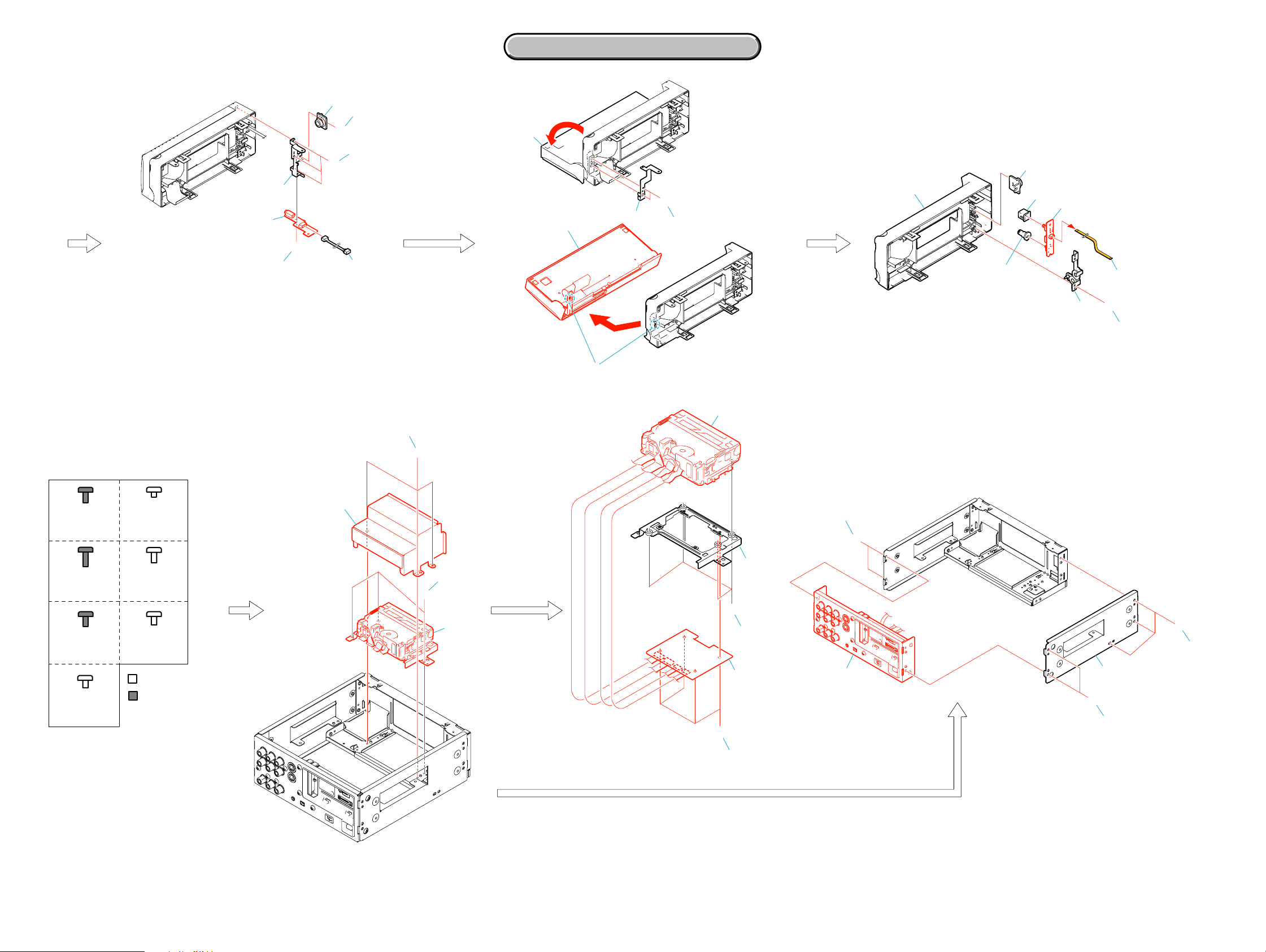

2. DISASSEMBLY

2. DISASSEMBLY

3

2

F

4

1

E

6

7

B

Harness (HP-146)

1

2

Screw (M2x5) silver

3

Damper

4

Three tapping screws (M2x5) black

5

Screw (M2x3) silver

6

Front sub chassis

7

HP-139 board

I

5

1

a

1

Lean the control panel section

in the direction of an arrow a .

2

Two tapping screws (M2x5) black

3

Ground plate (R)

4

Dowel

5

E

3

5

b

4

2

Remove the control panel section

in the direction of an arrow b .

4

3

6

7

1

Tapping screw (M2x5) black

2

Fulcrum plate (front L)

3

Damper

4

Front panel assembly

5

FFC-094 Flexible flat cable (8P)

6

(Power) button

7

(HP VOL) knob

8

PW-129 board

8

5

2

E

1

A

Screw

M3x6

2-059-756-01

C

Screw

M3x8

3-077-331-41

B

Screw

M1.4x1.5

3-059-718-01

D

Screw

M3x6

3-077-331-21

EF

Tapping screw

M2x5

3-080-206-21

I

Screw

M2x3

3-080-202-21

Screw

M2x5

7-681-000-00

Silver

Black

1

Three screws (M2x3) silver

2

Cover (MD)

3

Three screws (M2x3) silver

4

Mechanism deck,

MD frame assembly

1

1

I

2

Four screws (M2x3) silver

2

MR-048 board

3

Four screws (M1.4x1.5) silver

4

MD frame assembly

5

Mechanism deck

5

1

Three screws (M3x6) silver

2

Two screws (M3x6) silver

3

Side plate (L)

4

Two screws (M3x6) silver

5

Rear panel section

4

D

4

3

I

C

4

MR-048

B

3

2

5

3

D

1

D

2

I

HVR-M10C/M10E/M10J/M10N/M10P/M10U

1

2-5 2-6

2-2. SERVICE POSITION

2. DISASSEMBLY

2. DISASSEMBLY

2

A

3

A

1

A

5

A

6

4

[SERVICE POSITION TO

CHECK THE VTR SECTION]

Connection to Check the

VTR Section (page 2-9)

2

3

1

I

1

4

4

a

1

2

3

2

F

4

a

7

1

6

3

4

a

2

3

5

2

4

D

3

5

1

D

E

6

b

3

1

I

DA-033

1

E

3

2

1

4

5

I

2

3

4

I

3

2

DB-018

7

6

DA-033

7

I

5

3

I

1

8

I

1

I

3

1

I

2

4

6

5

3

VA-120

VC-367

9

2

6

4

7

VC-367

2

E

1

2

2

1

HVR-M10C/M10E/M10J/M10N/M10P/M10U

5

2

I

1

1

I

2

1

4

4

1

C

2

5

E

3

1

3

C

2

6

3

4

D

D

D

3

1

2

7

I

5

C

2

4

C

5

5

3

I

4

4

3

B

M

R

-0

4

8

2

1

I

2-7 2-8

2. DISASSEMBLY

2. DISASSEMBLY

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section

To check the VTR section, set the VTR to the "Forced VTR power ON" mode.

Operate the VTR functions using the adjustment remote commander

(with the HOLD switch set in the OFF position).

Setting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 0, address: 10, and set data: 00.

3) Select page: A, address: 10, set data: 02, and press

the PAUSE button of the adjustment remote commander.

Exiting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 0, address: 10, and set data: 00.

3) Select page: A, address: 10, set data: 00, and press the

PAUSE button of the adjustment remote commander.

4) Select page: 0, address: 01, and set data: 00.

*1: Only in the following cases, it is necessary to connect these flexible cables.

1) When ejecting the cassette.

2) When using the LCD block.

3) When changing the menu settings.

4) When checking the audio systems.

CPC-8 jig

(J-6082-388-A)

FP-098 flexible

board (28P)

Mechanism deck

FP-977 flexible

board (100P)

CN201

CN101

CN103

CN107

DB-018

CN205

CN104

AC IN

DC-IN connector

CN206

Extension cable (28P)

(J-6082-566-A)

AC power

adaptor

DC-IN

Monitor TV

CN0102

CN0103

FP-098 flexible

board (28P)

CN203

CN202

CN201

CN104

MR-048

FP-230 flexible

board (51P)

CN0101

FP-230 flexible

board (22P)

FP-230 flexible

board (30P)

1*

FFC-093 Flexible flat cable (50P)

CN0007

FP-977 flexible

board (100P)

CN0003

CN0005

CN0001

CN2007

DA-033

FP-976 flexible

board (80P)

1*

CN0008

CN2005

VA-120

VA-120 board

CN2008

DA-033 board

CN0002

VC-367 board

VC-367

CN0004

CN2001

CN2000

CN2006

1*

CN801

CN901

JL-001 board

Adjustment remote

commander (RM-95)

FP-095 flexible board (30P)

FP-096 flexible board (12P)

Video

out jack

JU-001 board

HVR-M10C/M10E/M10J/M10N/M10P/M10U

2-9

2-3. CIRCUIT BOARDS LOCATION

2. DISASSEMBLY

2. DISASSEMBLY

PW-129

HP-139

VA-120

MR-048

PD-222

FP-977

DB-018

FP-976

LI-073

DA-033

JU-001

JL-001

VC-367

SW-436

NAME FUNCTION

DA-033

DB-018

FP-971

FP-976

FP-977

HP-139

JL-001

JU-001

LI-073

MR-048

PD-222

PW-129

SW-436

VA-120

VC-367

DC/DC CONVERTER

DC IN, CHARGE, DC/DC CONVERTER

RELAY

RELAY

RELAY

HP JACK

JACK

AV IN JACK

BATTERY

REC/PB RF AMP, DRUM/CAPSTAN/LOADING MOTOR DRIVE

LCD DRIVER, TIMING GENERATOR

REMOTE COMMANDER RECEIVER

FUNCTION PANEL

CONNECTOR, VIDEO IN/OUT, VIDEO AMP, AUDIO IN/OUT

BASE BAND PROCESS, OSD, D3 FILTER, HDV SIGNAL/RF SIGNAL PROCESS,

HDV VIDEO DECODER, 64MBIT Y/C-SDRAM, ILINK INTERFACE, DV/RF SIGNAL PROCESS

VIDEO A/D CONV., HDV AUDIO SIGNAL PROCESS, AUDIO INPUT SELECT,

AUDIO CONVERTER, DS CONTROL, FRONT CONTROL, LSI CONTROL,

MECHA CONTROL, CONNECTOR-1, CONNECTOR-2

FP-976

FP-971

HVR-M10C/M10E/M10J/M10N/M10P/M10U

2-10

2. DISASSEMBLY

5

2. DISASSEMBLY

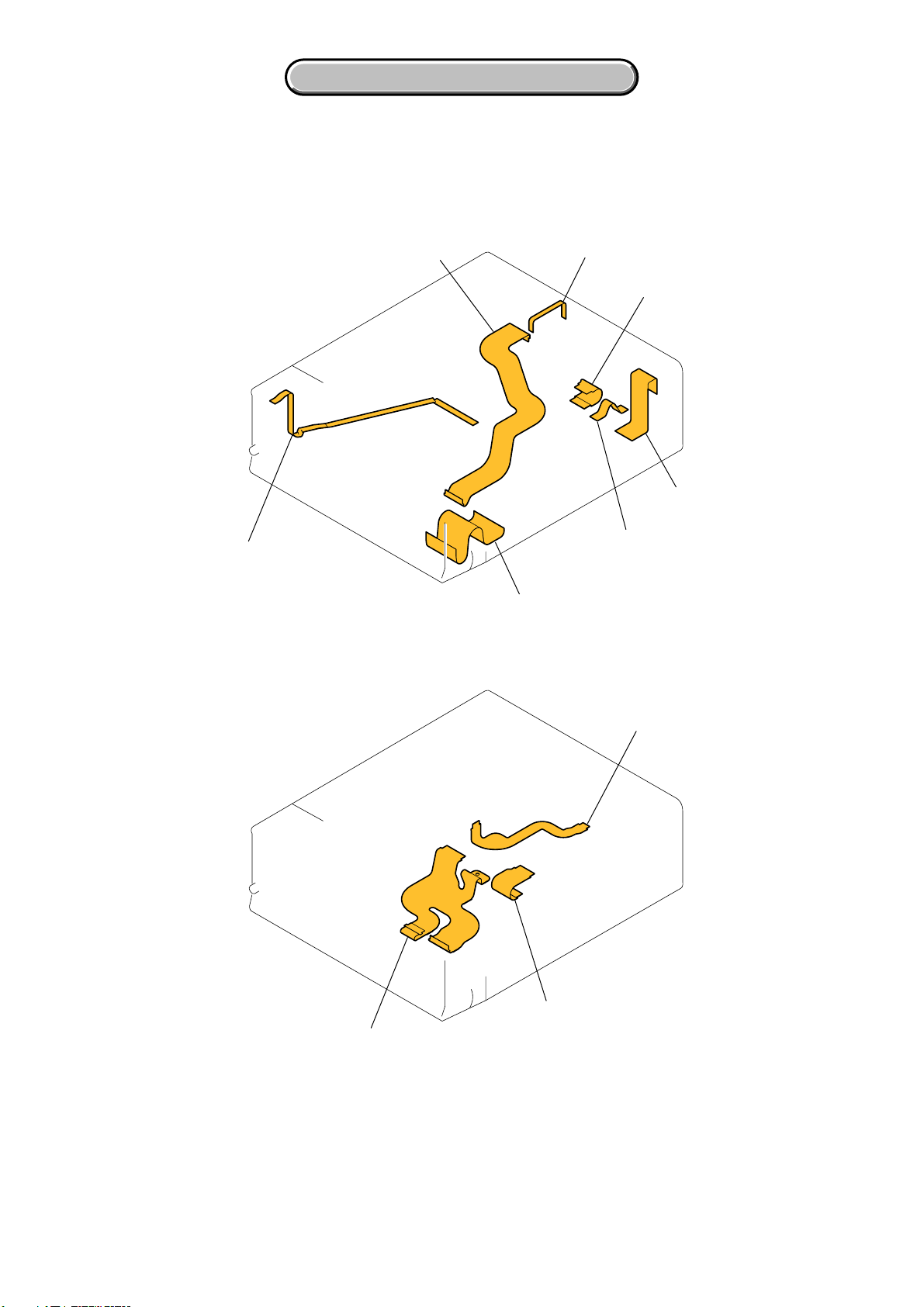

2-4. FLEXIBLE BOARDS LOCATION

The flexible boards contained in the mechanism deck and lens block are not shown.

FFC-094

FP-098

FFC-095

FP-089

FP-09

FP-096

FFC-093

FP-230

FP-090

FP-088

HVR-M10C/M10E/M10J/M10N/M10P/M10U

2-11E

HELP

)

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

HELP 01

FC-094 Flexible flat cable (8P)

Clamper

Harness (HP-146)

HELP 02

HELP 03

Harness (HP-146)

Main frame section

FC-094 Flexible flat cable (8P

Clamper

FP-098 flexible board

HVR-M10C/M10E/M10J/M10N/M10P/M10U

HELP

Link

Link

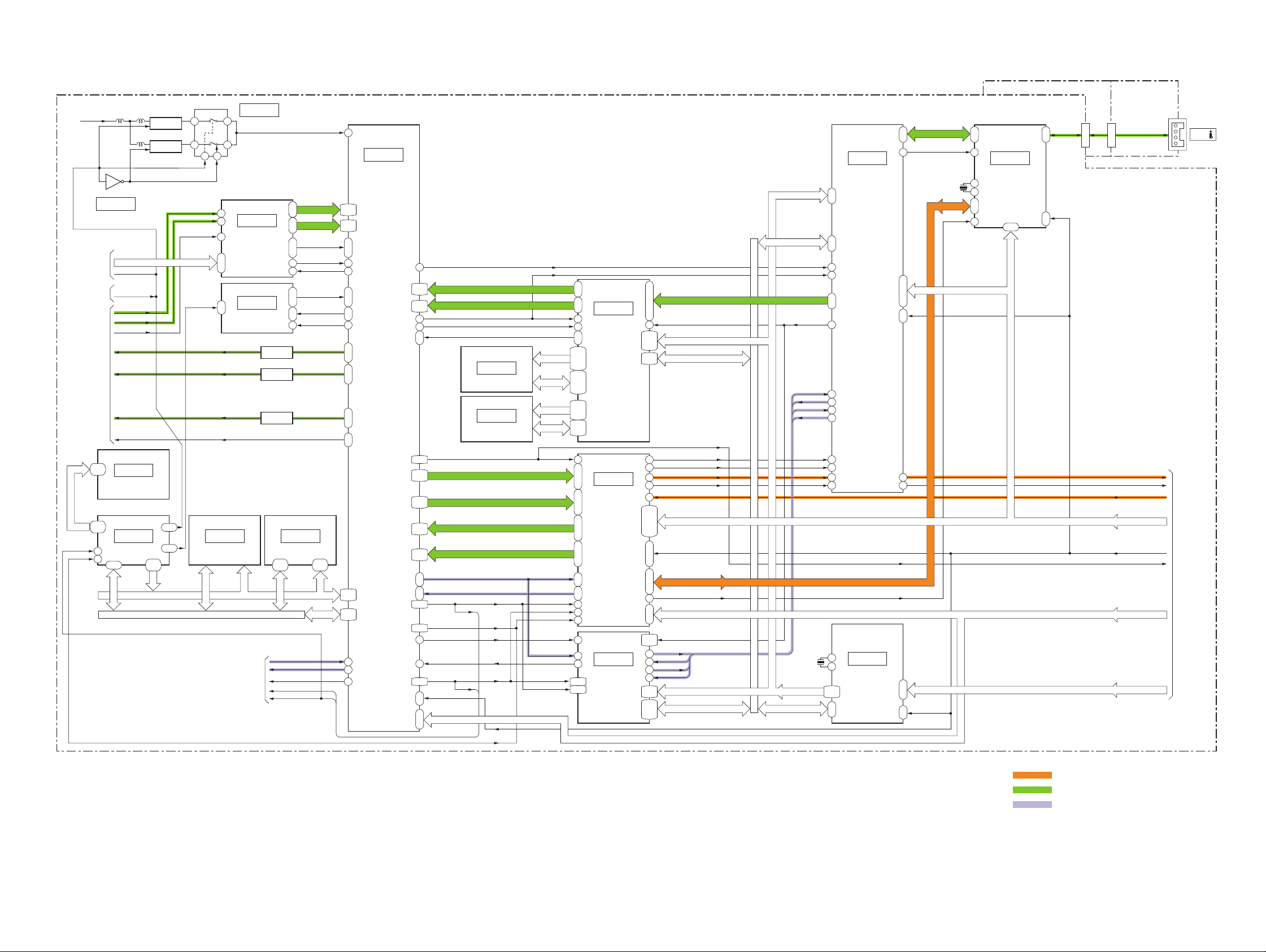

3. BLOCK DIAGRAMS

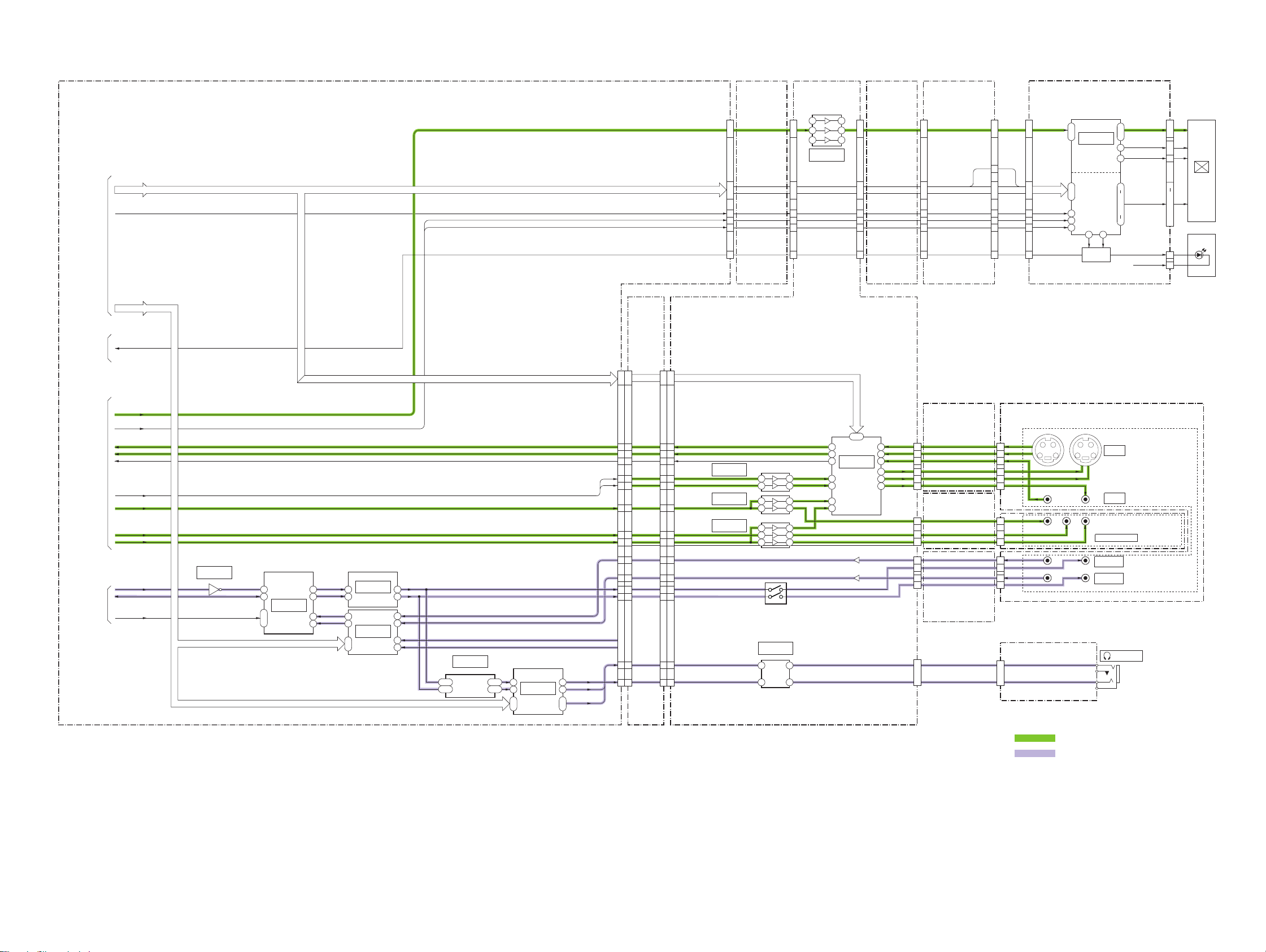

OVERALL BLOCK DIAGRAM (1/5)

OVERALL BLOCK DIAGRAM (1/5)

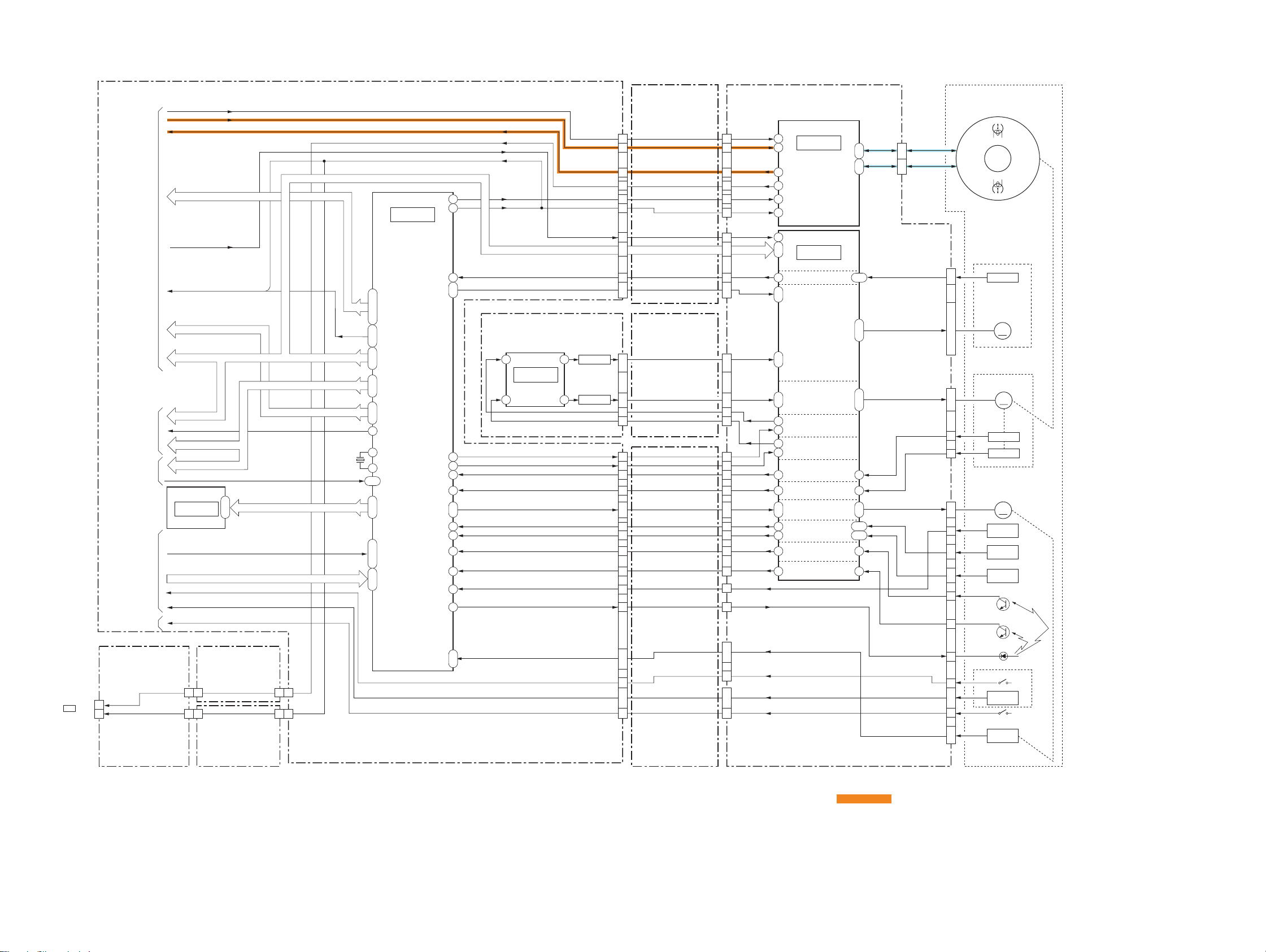

OVERALL BLOCK DIAGRAM (2/5)

OVERALL BLOCK DIAGRAM (2/5)

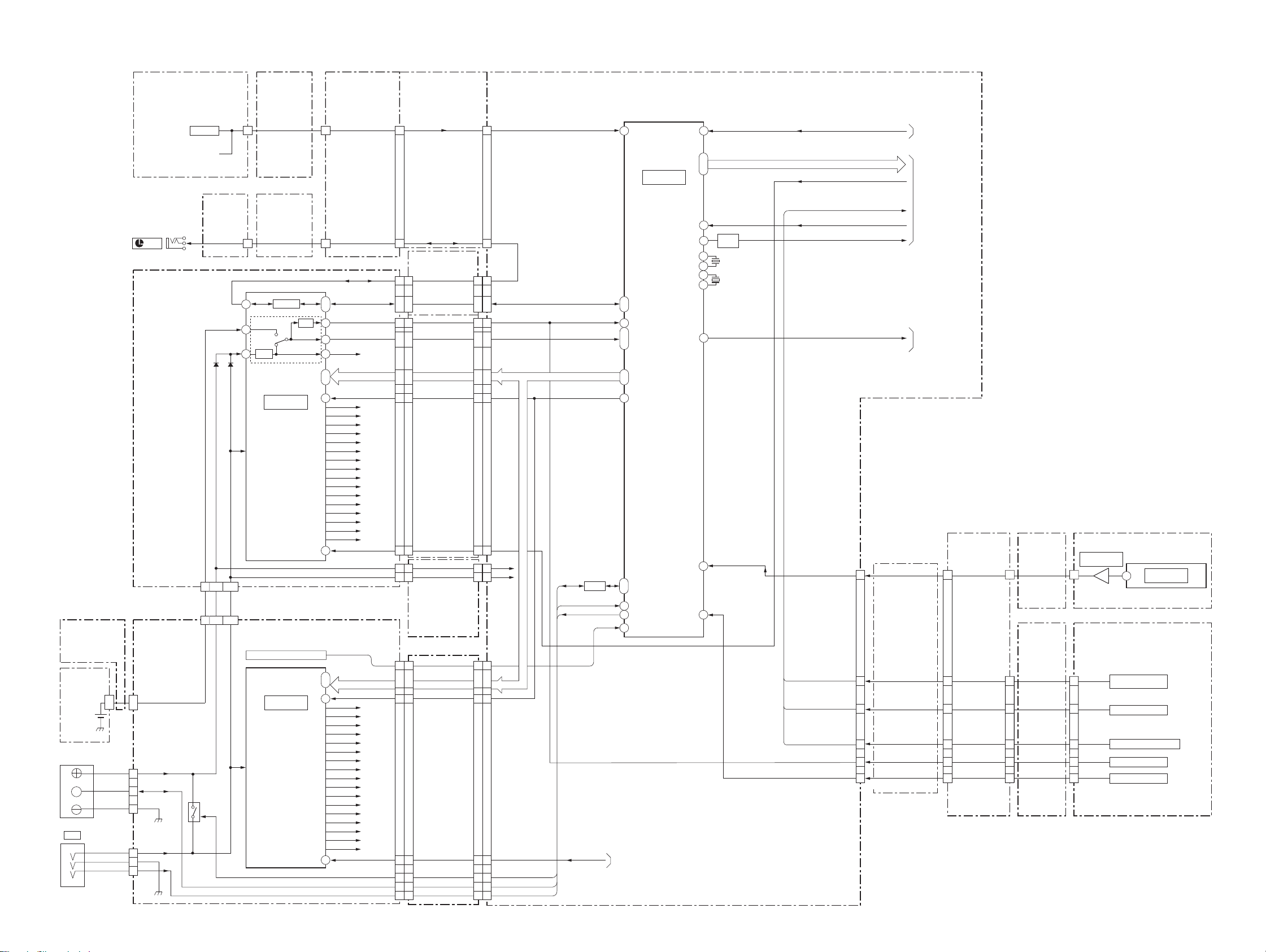

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (3/5)

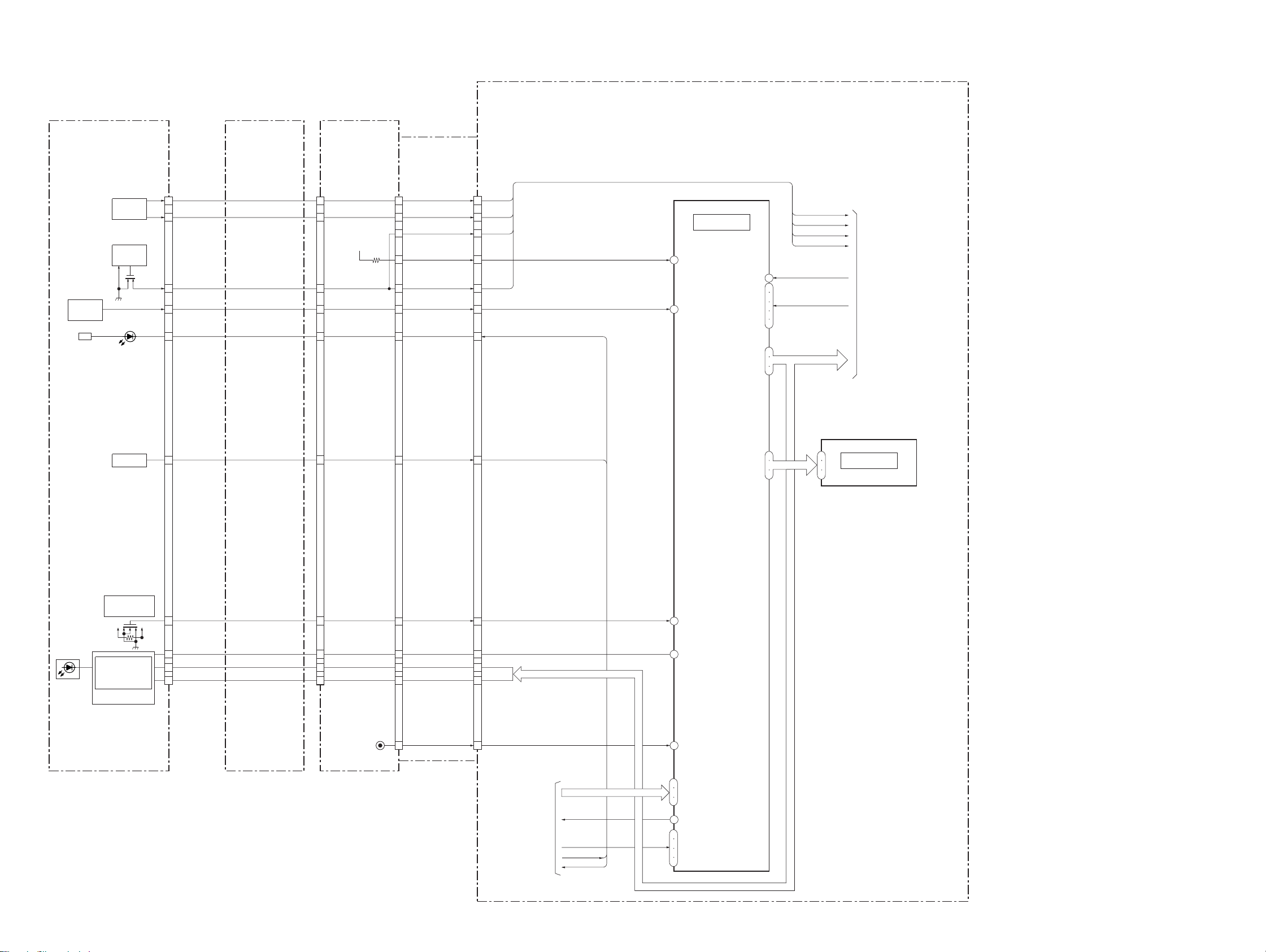

OVERALL BLOCK DIAGRAM (5/5)

OVERALL BLOCK DIAGRAM (5/5)

POWER BLOCK DIAGRAM (1/4)

POWER BLOCK DIAGRAM (1/4)

POWER BLOCK DIAGRAM (2/4)

POWER BLOCK DIAGRAM (2/4)

POWER BLOCK DIAGRAM (3/4)

POWER BLOCK DIAGRAM (3/4)

POWER BLOCK DIAGRAM (4/4)OVERALL BLOCK DIAGRAM (4/5)

POWER BLOCK DIAGRAM (4/4)OVERALL BLOCK DIAGRAM (4/5)

HVR-M10C/M10E/M10J/M10N/M10P/M10U

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/5)

6

2

6

25

64

•

66

•

63

3

•

1

FLASH

TO

OVERALL

BLOCK DIAGRAM

(2/5)

(PAGE 3-3)

(1/16)

IC2023

VCO

(8/16)

IC5001

VIDEO

A/D

CONV.

(2/16)

IC2101

OSD

Q2119-2121

Q2110-2112

LPF

Q2116-2117

BUFF

Q2113-2115

BUFF

IC8003

D0-D15 A1-A14

20-26

29-35

VC-367 BOARD (1/5)

D 2.28 V

NTSC/XPAL DET

(1/16)

IC2022

TO

OVERALL

1

BLOCK DIAGRAM

q;

2

(3/5)

(PAGE 3-5)

TO

OVERALL

BLOCK DIAGRAM

(4/5)

(PAGE 3-8)

TO

OVERALL

BLOCK DIAGRAM

(2/5)

(PAGE 3-3)

CKFSO

DSCK VM

103-105

235,236

NTSC/XPAL DET

NTSC/XPAL DET

Y

C

CK

YO

PRO

PBO

EVGR

EVBL

PLRE

PLGR

PLBL

XPHD

XPVD

(11/16)

1-3

5,6

IC8002

EEPROM

(11/16)

IC8009

D0-D15

16-35

CONTROL

DS

124

123

(1/2)

A1-A22

291-304

1-32

X2020

55.631MHz

X2021

55.687MHz

100,102

1 2

5

37

Y

C

CK

VD SO,SI,SCK

OSD SO

XOSD SCK

129

(11/16) (11/16)

IC8001

MEMORY

D0-D15 A1-A21

A1-A22

D0-D15

6

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SPCKO

132

(1/16)

IC2021

BASE BAND

PROCESS

59

59

|

|

52

52

49

|

42

38

•

37

•

36

34

68

17

•

16

•

14

20

•

19

8

16Mbit

SDRAM

AUIN11

ADAO1

CK256FSO

CK64FSO

CKFSO

VFIY0-VFIY7

VFIC0-VFIC7

VFI HD

VFI VD

VFI OE

AFCK

CK13MFO

COLH1

COLH2

COLH3

HOSDHD

HOSDVD

CK14MFO

20-26

29-35

26-29

264-267

30-38

273-276

262

•

25

•

263

24

17

315

•

85

•

317

313

•

80

81

Y

PR

75

PB

•

79

•

77

EVGR

EVBL

72

•

74

PLRE

PLGR

68

PLBL

•

69

•

67

XPHD

XPVD

64

•

56

222-234

A2-A19

442-452

8-15

D0-D15

245-252

193

423

186

332

107-110

339-342

102-105

334-338

189

111

DHD

DFD

115

•

344

VY[0]-VY[7]

VC[0]-VC[7]

(5/16)

IC3201

Y SDRAM

(5/16)

IC3202

C SDRAM

22,20

45,46

283,285

43,44

281,282

53,290

291,292

51,52

288,289

187,188

55,54

195,198

418

•

197

419

•

201

17

419

254

255

257

•

258

•

19

RYO0-RYO3,DEHD,DEVD,DEFLD,SGOUT

RCO0-RCO3,EDHD,EDVD,EDFLD,FRMREF

RYI0-RYI3,DE0-DE3

RCI0-RCI3,DE4-DE7

ADATAIN0

ADATAIN1

ADATAOUT0

ADATAOUT1

CK64FSO

DSCK VM

AUIN21 AUIN21

FRRV

TRRT

VSP SO,SI,SCK

269

256

289

272

CK27MFO1

291

CK DENEBO2

252

287

286

42,44

47-49

52-55

A0-A10

61,64

3-24

33-35

58,59

D0-D31

68-90

123-124

134-137

A0-A10

144-147

151

92-118

148,150

D0-D31

155-176

VCK

143 86

119

162

120

163

121

122

123

166

124

125

168

127

167

126

CK64FSO

CKFSO

DSCK VM

CK13MFOCK13MFO

ADATAIN0

CKFSOCKFSO

43,73

CK64FSO

41,71

(20/25)

|

(4/16)

|

IC3001

HDV

VIDEO

DECORDER

•

66

61

(7/16)

•

•

IC4001

•

70

71

13

72

14

73

21

78

15

97

45

74

DV

SIGNAL

•

PROCESS

•

RF

•

SIGNAL

PROCESS

•

•

•

•

•

•

•

•

(9/16)

IC7001

HDV

AUDIO

SIGNAL

PROCESS

215

225

223

221

BS[0]-BS[7]

220

231

227

224

DJCLK

226

191,218

193-201

HADR[0]-HADR[13]

204-207

210-213

179-189

HDAT[0]-HDAT[7]

192

VIT DT

VIT CK

30

CREC DT

45

CREC CK

41

RF IN RF IN

139

107

54

•

•

189

152

•

•

153

55

MC BUS MC BUS

•

•

109

190

•

•

192

155

SWP

FRRV

60

TRRT

•

TRRV

58

•

112

•

111

149

•

186

•

LBUS0-LBUS3

150

•

187

TRCK0

104

114

•

157

VSP SO,SI,SCK

•

3

AUIN21

38,42

48,49

AUDAL

59

AUDAO

35

AUENI

60

AUENO

47

62,18

HADR[0]-HADR[3] HADR[0]-HADR[13]

39,46

58,69

81,95

HDAT[0]-HDAT[7] HDAT[0]-HDAT[7]

120,124

135,6

HADR[0]-HADR[7]

HDAT[0]-HDAT[7]

FLD27MFFLD27MF

CK27MFO1

CREC DT

CREC CK

X8601

20MHz

AUDAL

AUDAO

AUENI

AUENO

DJCLK

VIT DT

VIT CK

FP-090 FLEXIBLE BOARD

JL-001

BOARD(1/3)

FRRV

TRRT

TRRV

CN901

HDV/DV

SWP

VCK

3

TO

OVERALL

BLOCK DIAGRAM

(3/5)

(PAGE 3-5)

TPA

CN0009

NTPA

5

187

PD10-PD17

|

(3/16)

IC2502

HDV

SIGNAL

PROCESS

HDV

RF SIGNAL

241

PROCESS

|

251

256

|

266

7

1

11

|

23

10

276

279

277

281

71

72

73

74

197

185 87

LBUS0-LBUS3

204

|

207

MC BUS

213

|

224

FRRV

TRRT

235

229

REC DT

80

REC CK

82

24.576MHz

X3501

TRCK0

PCLK1

77

|

85

(6/16)

IC3501

iLINK

INTERFACE

149

150

95

|

98

104

51-64

TPB

139

NTPB

|

136

FRRV

TRRT

105

108

4

•

•

6

2

•

•

4

6

•

•

3

8

CN902

REC DT

REC CK

VSP SO,SI,SCK

(13/16)

1

IC8601

3

LSI

CONTROL

44-37

33-28

52

|

45

66

•

65

VSP2 SO,SI,SCK

•

63

FRRV

204

TRRT

•

203

VSP2 SO,SI,SCK

16

HVR-M10C/M10E/M10J/M10N/M10P/M10U

VIDEO/AUDIO SIGNAL

VIDEO SIGNAL

AUDIO SIGNAL

3-1 3-2

3-2. OVERALL BLOCK DIAGRAM (2/5)

Ver 1.1 2005. 05

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-367 BOARD(2/5)

TO

OVERALL

BLOCK DIAGRAM

(3/5)

(PAGE 3-5)

TO

OVERALL

BLOCK DIAGRAM

(4/5)

(PAGE 3-8)

TO

OVERALL

BLOCK DIAGRAM

(1/5)

(PAGE 3-1)

TO

OVERALL

BLOCK DIAGRAM

(1/5)

(PAGE 3-1)

16

4

5

2

6

VD SO,SI,SCK

XCS LCD

VSP SO,SCK

BL CONT

PLRE

PLGR

PLBL

XPHD

XPVD

Y

C

CK

EVGR

EVBL

YO

PRO

PBO

ADAO1

AUIN11

CKFSO

CK64FSO

CK256FSO

IC7119

2

VD SO,SI,SCK

FP-088

(FLEXIBLE

BOARD)

CN0008

PLRE

PLGR

3

•

PLBL

2

•

1

11

•

12

•

9

XCS LCD XCS LCD

10

XPHD

14

XPVD

13

15

VA-120 BOARD

(1/4)

3

•

2

10 8

•

1

12 14

12

•

VD SCK,SO,SI

14

•

15

13

PANEL HD

17

PANEL VD

16

BL CONT

18

5 7

IC2204

RGB DRIVE

FFC-093

(FLEXIBLE

BOARD)

CN2008CN2007 CN402CN401

30

•

28

•

26

36

•

40

•

42

38

44

43

45

SW-436 BOARD

(1/3)

30

•

28

•

26

36

•

40

•

42

38

44

43

45

PD-222 BOARD

LCD901

4

5

3

23

COLOR

1

LCD UNIT

6

22

19

•

13

•

12

•

8

•

7

•

2

LED901

BACK

LIGHT

3

1

11

12

10

14

13

15

3

•

2

•

1

•

•

9

VD SO,SI,SCK

CN601

PANEL R,G,B

EXTDA

19

20

21

23

25

35

32

15

14

4

2

BL LO

VR,VG,VB

COM

PSIG

VST,VCK,EN,DWN,

WIDE,HST,HCK2,

HCK1,RGT

BL ANODE

BL CATHODE

CN603

CN604

40

39

38

IC601

RGB DRIVE

48

•

47

•

46

TIMING

GENERATOR

45

43

42

31 28

BL ON

BACK LIGHT

DRIVE

Q601-604

20

•

21

•

22

SCK

14

11

•

12

13

9

10

8

FP-971

FLEXIBLE

BOARD

VD SO,SCK

1

1

2

2

1

1

2

2

VD SO,SCK

CN0002 CN710CN711 CN2005

JU-001 BOARDFP-095

FLEXIBLE

BOARD(1/2)

4

10

28

1

7

25

CN2001 CN801

12

7

9

CN2000

13

16

19

22

CN2001

SY IN

SC IN

VIDEO IN

SY OUT

SC OUT

VIDEO OUT

FP-096 FLEXIBLE

BOARD

Y

PR

PB

AU IN L

AU OUT L

AU IN R

AU OUT R

FP-095

27

21

1

30

24

4

1

6

4

17

14

11

8

CN801(2/2)

(1/2)

FLEXIBLE

BOARD(2/2)

HP-139 BOARD

HP R

4

HP L

1

CN2002 CN701

4

1

CN901

HP R

HP L

18

18

17

17

16

16

303430

34

LNO Y

23

23

LNO PR

26

26

LNO PB

27

27

XLR LINE1

82

82

(10/16)

CH1

(10/16)

AUDIO

A/D CONV.

D/A CONV.

26

27

5

3

VSP SO,SCK

CH2

CH1

CH2

4

13

14

11

12

15

IC7115

6

2

41

39

29

30

(10/16)

IC7113

LINE OUT

GAINUP

(10/16)

IC7114

AUDIO INPUT

SELECT

L OUT

R OUT

VSP SO,SCK

(10/16)

13

3

A AV OUT L

A AV OUT R

A LINE L

A LINE R

EXT MIC L

EXT MIC R

B4

A5

E5

E1

(10/16)

IC7120

SPEAKER AMP

HEADPHONE AMP

HP CH1

D6

HP CH2

B6

SP+

B2

SP-

D2

7

1

6

11

3

8

IC7501

SELECTOR

CH 1

B4

CH 2

A5

83

97

98

75 75

73

83

97

98

73

XLR LINE2

AUDIO OUT L

AUDIO OUT R

HP CH2

HP CH1

18

16

23

26

27

97

98

73

17

303430

828382

Y,OUT

18

C,OUT

17

CK

16

34

23

26

27

83

97

98

7575

73

EVGR

EVBL

YO

PRO

PBO

LINE AU L

LINE AU R

IC2203

IC2200

IC2201

(3/4)

12

10

(3/4)

5

10

(3/4)

12 14

10

5

IC2300

10 13

5 2

Q2314,2315

EVR

IN A OUT A

IN B OUT B

14

8

7

14

8

7

(4/4)

34

36

26

44

5

46

7

910

(3/4)

IC2201

VIDEO

IN/OUT

AGC

ACC

Q2309

Q2308

39

48

42

18

14

22

J801

YC

G

G

YC

S VIDEO

IN-OUT

G

G

J801

VIDEO

IN-OUT

JL-001 BOARD(2/3)

J901

COMPONENT OUT

AUDIO CH 1/3

IN-OUT

AUDIO CH 2/4

IN-OUT

J701

(HEADPHONES)

HVR-M10C/M10E/M10J/M10N/M10P/M10U

VIDEO SIGNAL

AUDIO SIGNAL

3-3 3-4

3-3. OVERALL BLOCK DIAGRAM (3/5)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CPC

(FOR ADJUSTMENT)

VC-367 BOARD (3/5)

TO

OVERALL

3

BLOCK DIAGRAM

(1/5)

(PAGE 3-2)

TO

OVERALL

4

BLOCK DIAGRAM

(2/5)

(PAGE 3-3)

TO

OVERALL

1

BLOCK DIAGRAM

(1/5)

(PAGE 3-1)

TO

OVERALL

7

BLOCK DIAGRAM

(5/5)

(PAGE 3-10)

TO

OVERALL

8

BLOCK DIAGRAM

(4/5)

(PAGE 3-8)

DA-033 BOARD

(2/3)

RF MON

13

SWP

CN107

16

REC CK

REC DT

RF IN

SWP

MC BUS

VCK

SWP,FRRV,TRRT,TRRV

VSP2 SO,SI,SCK

VSP SO,SI,SCK

VD SO,SCK

VSP SO,SCK

XCS_LCD

VD SO,SI,SCK

VD SO,SI,SCK

NTSC/XPAL DET

(14/16)

IC8802

EEPROM

REC LEVEL VOL CH1

REC LEVEL VOL CH2

MANUAL REC CH1

MANUAL REC CH2

HI SO,SI,SCK

REC PROOF

CHIME SDA,CHIME SCK,CHIME VDD

XCC DOWN

5

•

2

EEP SO,SI,SCK

•

6

FP-976 (1)

(FLEXIBLE

BOARD)(3/4)

CN101 CN0003

535353

5315

CN761

CN103

CN760CN761

535353

53

CN0005

CN760

FP-976 (2)

(FLEXIBLE

BOARD)(2/4)

X8801

20MHz

FRRV

TRRT

TRRV

117

178

179

111

113

114

52

|

45

33

|

30

•

•

69

•

70

•

67

82

•

83

•

80

73

•

74

•

71

38

1

3

86

•

87

•

84

•

•

56

•

57

63

•

65

•

68

IC8801

XCS_LCD

NTSC/XPAL

(14/16)

MECHA

CONTROL

CONT1

172

SWP

164

CAP FG

190

CAP ON,CAP FWD

165

•

166

CAP PWM

89

DRUM PWM

88

DRUM FG

197

DRUM PG

198

LOAD,UNLOAD

15

•

13

T REEL FG

192

S REEL FG

193

TAPE END

196

TAPE TOP

195

DEW DET

119

TAPE LED ON

180

106

MODE SW A-MODE SW C

|

108

VSP SO,SCK

DB-018 BOARD (1/2)

H6

(2/2)

G11

IC201

(1/2)

PWM

DRIVE

J6

G8

Q218

SWITCHING

Q219

SWITCHING

CAP ERROR

DRUM ERROR

CN0007

CN0007

CN206

48

51

40

38

44

43

13

17

•

15

3

1

•

2

14

|

12

11

•

10

15

16

19

21

24

23

9

•

10

7

6

5

4

36

26

34

|

32

31

30

|

28

27

FP-230

(FLEXIBLE

BOARD)(1/2)

FP-098

(FLEXIBLE

BOARD)

FP-230

(FLEXIBLE

BOARD)(2/2)

MR-048 BOARD

CN102

REC CK

5

2

13

15

9

10

CN103

18

14

•

16

28

30

•

29

CN0101

15

|

17

18

DRUM VS

•

19

14

13

CN103

12

10

7

8

22

•

21

24

25

26

27

CN102

17

CN103

5

CN102

19

|

21

22

CN103

1

|

3

4

44

REC DT

46

RF IN

35

RF MON

30

CONT1

39

SWP

38

VCK

35

38

•

36

CAP FG

4

CAP ON

CAP FWD

80

•

1

75

CAP VS

•

77

64

•

67

43

41

45

44

53

50

32

•

33

29

25

21 20

19 18

(1/2)

IC0101

REC/PB

AMP

(2/2)

IC201

CAPSTAN

FG AMP

CAPSTAN

MOTOR

DRIVE

DRUM

MOTOR

DRIVE

CAP

PWM

LPF

DRUM

PWM

LPF

DRUM

FG

AMP

DRUM

PG

AMP

LOADING

MOTOR

DRIVE

REEL

FG

AMP

TAPE

END

DETECT

TAPE

TOP

DETECT

26•27

22•23

Z MECHA DECK

(MDX-Z311)

CN104

10

•

9

4

•

3

7•8

74

•

76

•

78

63

•

65

•

68

52

49

69

•

72

ODD

EVEN

T REEL +,–

S REEL +,–

6

•

5

9

•

8

FG 1,2

CAP U,V,W

DRUM U,V,W

LM +,–

CN203

CN201

CN202

DEW AD

XCC DOWN

DRUM

M903

22

•

25

20

|

17

•

4

|

1

•

11

|

14

5

|

10

1

2

1

|

4

5

26

•

25

22

•

23

20

11

18

12

13

|

15

17

7

|

9

CAPSTAN FG

CAPSTAN

MOTOR

M

M901

DRUM

MOTOR

M

DRUM FG

DRUM PG

M902

LOADING

MOTOR

M

DEW

SENSOR

H902

T REEL

SENSOR

H901

S REEL

SENSOR

Q901

TAPE END SENSOR

Q902

TAPE TOP SENSOR

D901

TAPE LED

MIC902

REC PROOF

4PIN

CONNECTOR

S903

C. C. DOWN

MODE

SWITCH

S902

HVR-M10C/M10E/M10J/M10N/M10P/M10U

VIDEO/AUDIO SIGNAL

3-5 3-6

3-4. OVERALL BLOCK DIAGRAM (4/5)

PW-129 BOARD(1/2)

S602

POWER ON

VTR ON SW

JL-001

BOARD

J931

LANC

(3/3)

DA-033 BOARD

(3/3)

CN104

8 19,20 11-18

FFC-095

FLEXIBLE

DB-018

BOARD (2/2)

8 19,20 11-18

FLAT CABLE

LI-073

16

BOARD

BT591

LITHIUM

BATTERY

(SECONDARY)

BT901

BATTERY

TERMINAL

S

J901

DC IN

CN501

CN207

1

5

VBATT

•

•

2

6

CN204

1

3

4

CN203

1

2

3

Q307,

Q304

HVR-M10C/M10E/M10J/M10N/M10P/M10U

VBATT

CN901

K2

D2

C1

CN205

5

12

LANC SIG

FFC-094

FLEXIBLE

BOARD

FP-096

FLEXIBLE

BOARD

LANC I/O

3V REG

IC101

DC/DC

CONVERTER

RESET

LANC I/O

NTSC/PAL SELECT SW

(2/2)

IC201

DC/DC

CONVERTER

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VA-120

BOARD (3/4)

FP-971

(FLEXIBLE

VC-367 BOARD (4/5)

BOARD)(2/2)

LANC SIG

RESET

CN2005

CN2003

XVTR ON SW

4

CN2000

LANC SIG

1

LANC OUT

LANC IN

L3

•

K3

HI XRESET

A3

VOUT

D3

C2

E2

•

E3

D1

G1

EVER 3.0V

FR EVER SO,SCK FR EVER SO,SCK

VTR DD ON

A 1.5V

CAM 1.5V

D1 1.5V

D 1.2V

D 1.9V

A 4.6V

AU 4.6V

D 3.1V

D1 2.8V

A1 2.8V

CAM 5.1V

RP 4.6V

CAM -7.5V

EP 13.5V

A -2.8V

CAM 15V

CAM DD ON

BATT UNREG

VTR UNREG

CN710 CN0002

63

47

FP-976 (2)

11

11

5

5

•

•

3

3

39

39

47

47

•

•

49

49

31

31

•

•

29

29

33

33

(FLEXIBLE

BOARD)(3/4)

CN761

CN761

CN103

CN101

FP-976 (1)

(FLEXIBLE

BOARD)

(3/3)

35

35

CN103 CN0005

CN761

50

50

48

48

FP-976 (2)

(FLEXIBLE

BOARD)

(4/4)

CN760

CN760

CN760

CN711

CN0008

SIRCS SIG FRONT

XCC DOWN

TXD,RXD,SCK

CAM DD ON

KEY AD0 VM

KEY AD1 VM

KEY AD2 VM

XEJECT SW

CHARGE LED

NTSC/XPAL DET

30

FP-088

(FLEXIBLE

63

1 5

XVTR ON SW

(12/16)

XCC DOWN

SI

SO

SCK

23

•

24

•

25

IC8301

FRONT

CONTROL

XEJECT SW

4

Q8308

LED

SIRCS SIG

X TAL

X TAL

9

DRIVE

X 0A

52

X8302

32.768KHz

51

X 1A

29

X8301

10MHz

28

46

41

47

CN0005

11

11

5

5

•

•

3

3

CN0003

39

39

47

47

•

•

49

49

31

31

•

•

29

29

33

33

35

35

504850

48

BATT SIG

40

•

39

73

14

•

53

•

62

20

•

21

35

Q8307

42

I/F

•

43

77

37 6

75

LANC OUT

LANC IN

XRESET

VCC

HI EVER SO

HI EVER SCK

VTR DD ON

IB SO

IB SI

BATT/XEXT

FAST CHARGE

INIT NTSC/XPAL

XCHARGE LED

NTSC/PAL OUT

XBATT INFO SW

BOARD)

CN201 CN0001

CN771

80 80

6

E2

•

E3

FR EVER SO,SCK

VTR DD ON

D1

(2/2)

L9

BL CONT

D2 1.5V

D 1.0V

CAM 2.5V

D 2.5V

CAM 3.6V

CAM 2.8V

EP 2.8V

RP 2.8V

D2 2.8V

A2 2.8V

AU 4.9V

EVF 4.9V

MT 4.9V

AU 8V

RP 13.5V

BL HIV

BL LO

FAST CHARGE

BATT SIG

BATT/XEXT

6

•

•

4

4

8

8

20

20

14

14

12

12

22

22

FP-977

(FLEXIBLE

BOARD)

CN770

80 80

6

•

4

8

20

14

12

22

(2/2)

6

•

4

8

20

14

12

22

BL CONT

TO

OVERALL

BLOCK DIAGRAM

(2/5)

(PAGE 3-3)

5

KEY AD0 VM

KEY AD1 VM

KEY AD2 VM

HI RESET

XBATT INFO SW

27

26

25

24

23

3-7 3-8

TO

OVERALL

BLOCK DIAGRAM

(3/5)

(PAGE 3-5)

TO

OVERALL

BLOCK DIAGRAM

(5/5)

(PAGE 3-9)

TO

OVERALL

BLOCK DIAGRAM

(1/5)

(PAGE 3-1)

8

9

q;

37

33

32

31

30

29

VA-120

BOARD

(2/4)

KEY AD0 VM

KEY AD1 VM

KEY AD2 VM

HI XRESET

XBATT INFO SW

7

9

8

7

16

4

CN2008CN2007 CN401

FFC-094

FLEXIBLE

BOARD

FFC-093

FLEXIBLE

BOARD

KEY AD0 VM

KEY AD1 VM

KEY AD2 VM

XRESET

BATT INFO

Ver 1.1 2005. 05

PW-129 BOARD (2/2)

IC601

2

CN601CN2003

SW-436 BOARD(2/3)

9

8

7

16

4

41.2

S001-S005

STOP,PB,REW,FF

S011-013

LCD BRIGHT +/-,PAUSE

S021-S024

REC,INDEX,AUDIO DUB,TC/U-BIT

S111

S112

DISPLAY/BATT INFO

1

LCD ON/OFF

RESET

IC602

3-5. OVERALL BLOCK DIAGRAM (5/5)

Ver 1.1 2005. 05

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-367 BOARD (5/5)

SW-436

BOARD(3/3)

S041-S045

EXEL,MENU

MENU+MENU-

STATUS

D110

CHG

RV001,002

AUDIO REC

LEVEL

S110

AUDIO LEVEL

MANUAL/AUTO

S113

DOOR OPEN

FFC-093

FLEXIBLE

BOARD

VA-120(4/4)

BOARD

FP-089

(FLEXBLE

BOARD)

CN2006CN2008CN401

11

12

14

6

23

2

11

12

D2 2.8V

14

6

23

2

REC LEVEL VOL CH1 CN0004

2

REC LEVEL VOL CH2

4

MANUAL REC CH2

8

KEY AD7 VM

24 20

MANUAL REC CH1

7

KEY AD4 VM

21

CHARGE LED

39

XEJECT SW

11

2

4

7

137

6

17

33

9

143

KEY AD7 VM

KEY AD4 VM

(11/16)

IC8009

HI CONTROL (2/2)

REC PROOF

CHIME SDA

CHIME SCK

CHIME AD0

CHIME AD1

CHIME AD2

HI SO

HI SI

XHI SCK

EEP TXD

EEP RXD

EEP SCK

REC LEVEL VOL CH1

REC LEVEL VOL CH2

MANUAL REC CH1

MANUAL REC CH2

HI SO, SI, SCK

HI SO, SI, SCK

REC PROOF

CHIME SDA

CHIME SCK

CHIME VDD

5

2

6

7

(11/16)

IC8002

EEPROM

TO OVERALL

BLOCK DIAGRAM (3/5)

(PAGE 3-5)

234

246

247

134

135

136

97

98

99

103

104

105

S061

INPUT SELECT

VIDEO-S VIDEO-HDV/DV

D001-D013

IC003

IC004

LED DRIVE

22

20

18

HVR-M10C/M10E/M10J/M10N/M10P/M10U

KEY AD6 VM

CL2001

23

30

29

28

22

XCS CAM COM

XHI SCK

HI SO

KEY AD5 VM

55

22

20

18

19

25

24

23

18

TO

OVER ALL

9

BLOCK DIAGRAM

(4/5)

(PAGE 3-8)

HI SO, SCK

CAM DO ON

KEY ADO VM

KEY AD1 VM

KEY AD2 VM

KEY AD3 VM

XCHARGE LED

XEJECT SW

TXD, RXD, SCK

145

269

144

93

94

95

131

139

140

141

142

KEY AD6 VM

XCS FKAMERA

KEY AD5 VM

TXD

RXD

SCK

CAM DD ON

KEY AD0 VM

KEY AD1 VM

KEY AD2 VM

KEY AD3 VM

3-9 3-10

Loading...

Loading...