Page 1

HCD-VB5

Main Unit

Amplifier section

The following measured at 220 V AC, 50/60 Hz

DIN power output (rated): 10 + 10 watts

(4 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

12 + 12 watts

(4 ohms at 1 kHz, 10% THD)

The following measured at 240 V AC, 50/60 Hz

DIN power output (rated): 12 + 12 watts

(4 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

15 + 15 watts

(4 ohms at 1 kHz, 10% THD)

Inputs

MD/VIDEO (AUDIO) IN (phono jacks):

voltage 500/250 mV, impedance

47 kilohms

MIC (mini jack): Sensitivity 1 mV, impedance

10 kilohms

Outputs

MD/VIDEO (AUDIO) OUT (phono jack):

voltage 250 mV, impedance

1 kilohm

VIDEO OUT (phono jack):

max. output level 1 Vp-p,

unbalanced, Sync negative, load

impedance 75 ohms

S VIDEO OUT (4-pin/mini-DIN jack):

Y: 1 Vp-p, unbalanced, Sync

negative,

C: 0.286 Vp-p, load impedance

75 ohms

PHONES (stereo minijack):

accepts headphones of 8 ohms or

more.

SPEAKER: accepts impedance of 4 to

16 ohms.

CD DIGITAL OUT OPTICAL:

Optical

VIDEO CD/CD player section

System Compact disc and digital audio and

video system

Laser Semiconductor laser (λ = 780 nm)

Emission duration: continuous

Laser output Max. 44.6 mW*

* This output is the value

measured at a distance of

200 mm from the objective lens

surface on the Optical Pick-up

Block with 7 mm aperture.

Wavelength 780 – 790 nm

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Video color system format

NTSC, PAL

CD DIGITAL OUT OPTICAL

(Square optical connector jack, rear panel)

Wavelength 666 nm

Output Level –18 dBm

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

(50 kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 531 – 1,602 kHz

(with the interval set at 9 kHz)

530 – 1,710 kHz

(with the interval set at 10 kHz)

Antenna AM loop antenna

External antenna terminals

Intermediate frequency 450 kHz

General

Power requirements 110 – 120 V or 220 – 240 V AC,

50/60 Hz

Adjustable with voltage selector

Power consumption 50 watts

Dimensions (w/h/d) Approx. 180 × 130 × 315 mm

incl. projecting parts and controls

Mass Approx. 4.0 kg

Supplied accessories Remote (1)

Size AA (R6) batteries (2)

AM loop antenna (1)

FM lead antenna (1)

Speaker cords (2)

Video cord (1)

Design and specifications are subject to change

without notice.

SERVICE MANUAL

• This set is the Amplifier and VIDEO CD/

CD player section in CMT-VB5.

SPECIFICATIONS

E Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM55C-K6BD37A

Base Unit Name BU-K6BD37A

Optical Pick-up Name KSM-213DCP/Z-NP

MICRO Hi-Fi COMPONENT SYSTEM

Page 2

TABLE OF CONTENTS

1. GENERAL ·········································································· 3

2. DISASSEMBLY ································································ 5

3. SERVICE MODE······························································8

4. ELECTRICAL ADJUSTMENTS ································· 9

5. DIAGRAMS

5-1. BLOCK DIAGRAM –CD SECTION– ······················· 11

–VIDEO SECTION–··················································· 12

–MAIN SECTION– ···················································· 13

–PANEL/POWER SECTION–···································· 14

5-2. Circuit Boards Location ·············································· 15

5-3. Wa veforms ···································································15

5-4. PRINTED WIRING BOARD –BD SECTION–·······16

5-5. SCHEMATIC DIAGRAM –BD SECTION–············ 17

5-6. PRINTED WIRING BOARDS

–MAIN SECTION– ··················································· 18

5-7. SCHEMATIC DIAGRAM

–MAIN SECTION(1/2)– ··········································· 19

5-8. SCHEMATIC DIAGRAM

–MAIN SECTION(2/2)– ··········································· 20

5-9. PRINTED WIRING BOARDS

–POWER SECTION– ················································ 21

5-10. PRINTED WIRING BOARD

–PANEL SECTION– ················································· 22

5-11. SCHEMATIC DIAGRAM

–PANEL SECTION– ················································· 23

5-12. PRINTED WIRING BOARDS

–VIDEO CD SECTION– ·········································· 24

5-13. SCHEMATIC DIAGRAM

–VIDEO CD SECTION(1/2)– ··································· 25

5-14. SCHEMATIC DIAGRAM

–VIDEO CD SECTION(2/2)– ··································· 26

5-15. SCHEMATIC DIAGRAM

–LOADING SECTION–············································27

5-16. PRINTED WIRING BOARDS

–LOADING SECTION–············································27

5-17. IC Pin Function ·························································· 28

5-18. IC Block Diagrams·····················································32

6. EXPLODED VIEWS ................................................... 34

7. ELECTRICAL PARTS LIST ................................... 39

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

2

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

Page 3

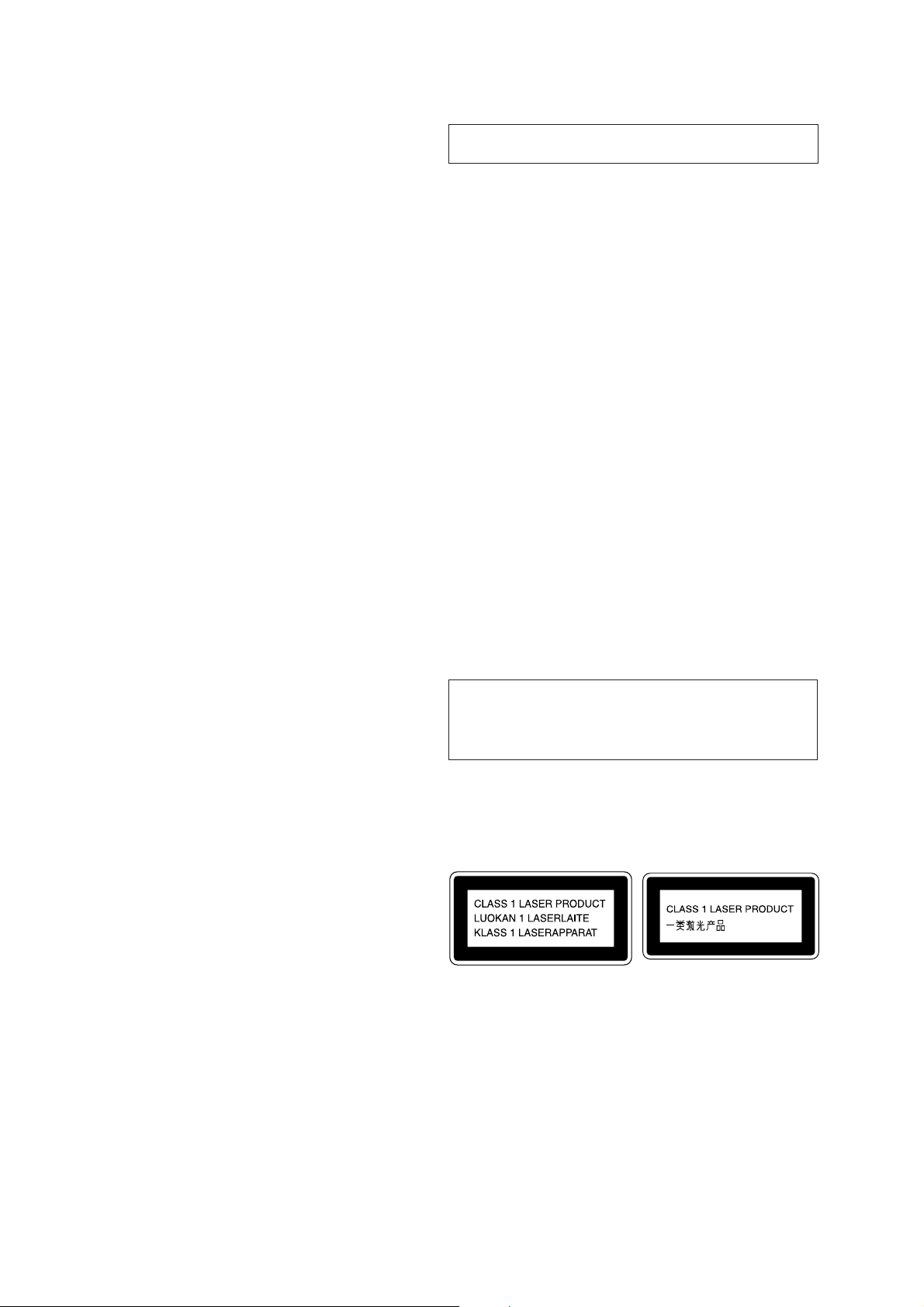

LOCATION OF CONTROLS

– Front Panel –

1

2

3

SECTION 1

GENERAL

654

9

q;

qh qf

qjqk qg

1 ?/1 button

2 DISPLAY button

3 t indicator

4 SELECT button

5 RETURN button

6 TUNER/BAND button

7 7 button

8 FUNCTION button

9 Z button

q; VOLUME knob

qd7qs8qa

qa J L button

qs s button

qd l j button

qf NEXT button

qg PHONES jack

qh PREV button

qj MIC jack

qk MIC VOL knob

3

Page 4

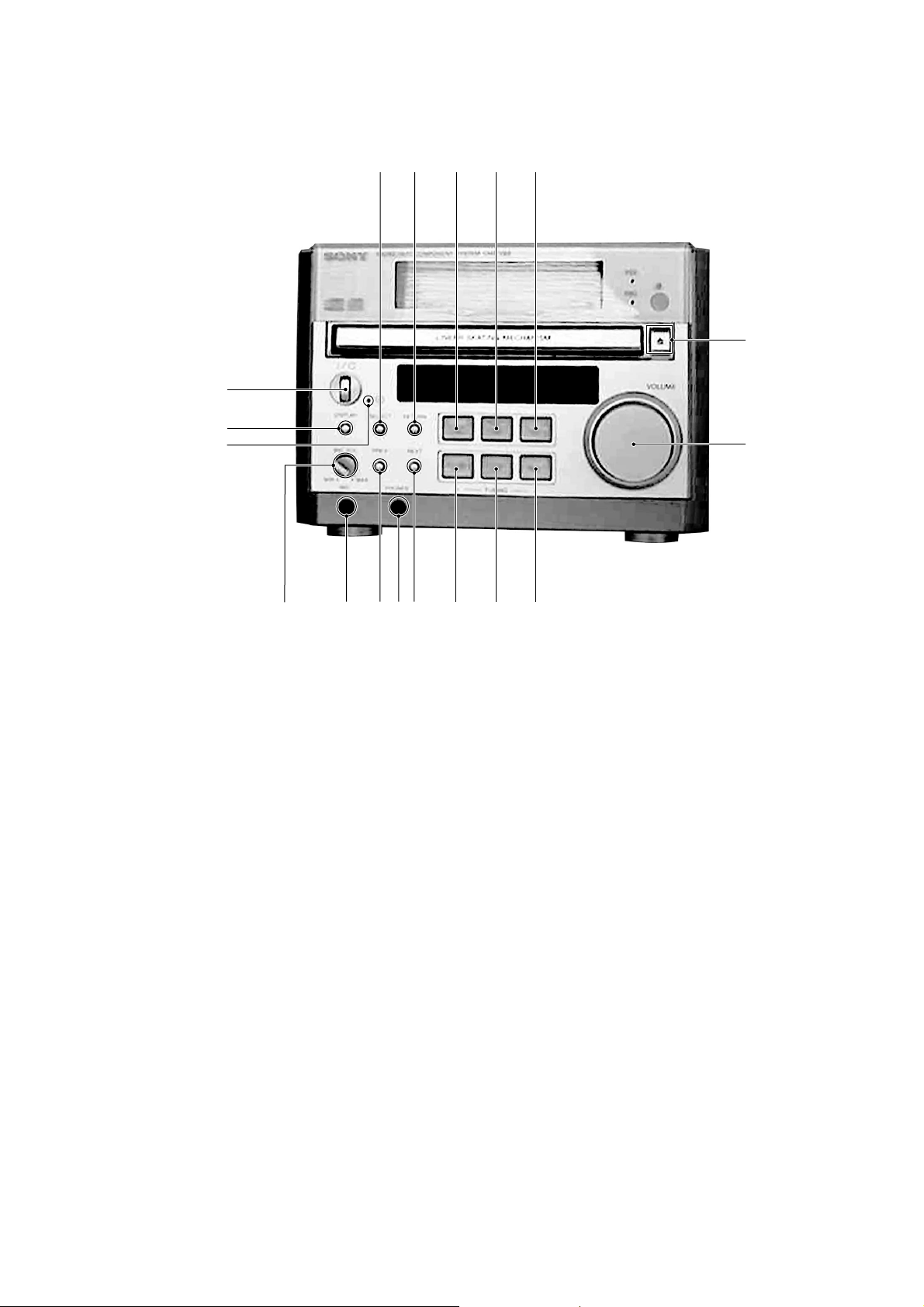

Step 2: Setting the time

You must set the time beforehand to use the timer

functions.

`/1

1

DISPLAY

2

4,6

O

X

H

>

x

3,5

m

1

Turn on the system.

.

Mm

4

4

Press ENTER or M.

The minute indication flashes.

11:00 AM

5

Press ./> to set the minute.

6

Press ENTER.

The clock starts.

If you made a mistake

Press m/M repeatedly until the incorrect item

flashes, then set it again.

To change the preset time

You can change the preset time while the system

is off.

1 Press DISPLAY to display the clock.

2 Press CLOCK/TIMER SET.

3 Repeat steps 3 to 6 of “Setting the time.”

Tips

• The upper dot of the colon flashes for the first 30

seconds, and the lower dot flashes for the last 30

seconds of each minute.

• Each time you press DISPLAY while the system is

off, the display switches between no display and the

clock display.

This section is extracted

from instruction manual.

2

Press CLOCK/TIMER SET.

The clock appears and the hour indication

flashes.

21 :00 AM

3

Press ./> to set the hour.

4

Page 5

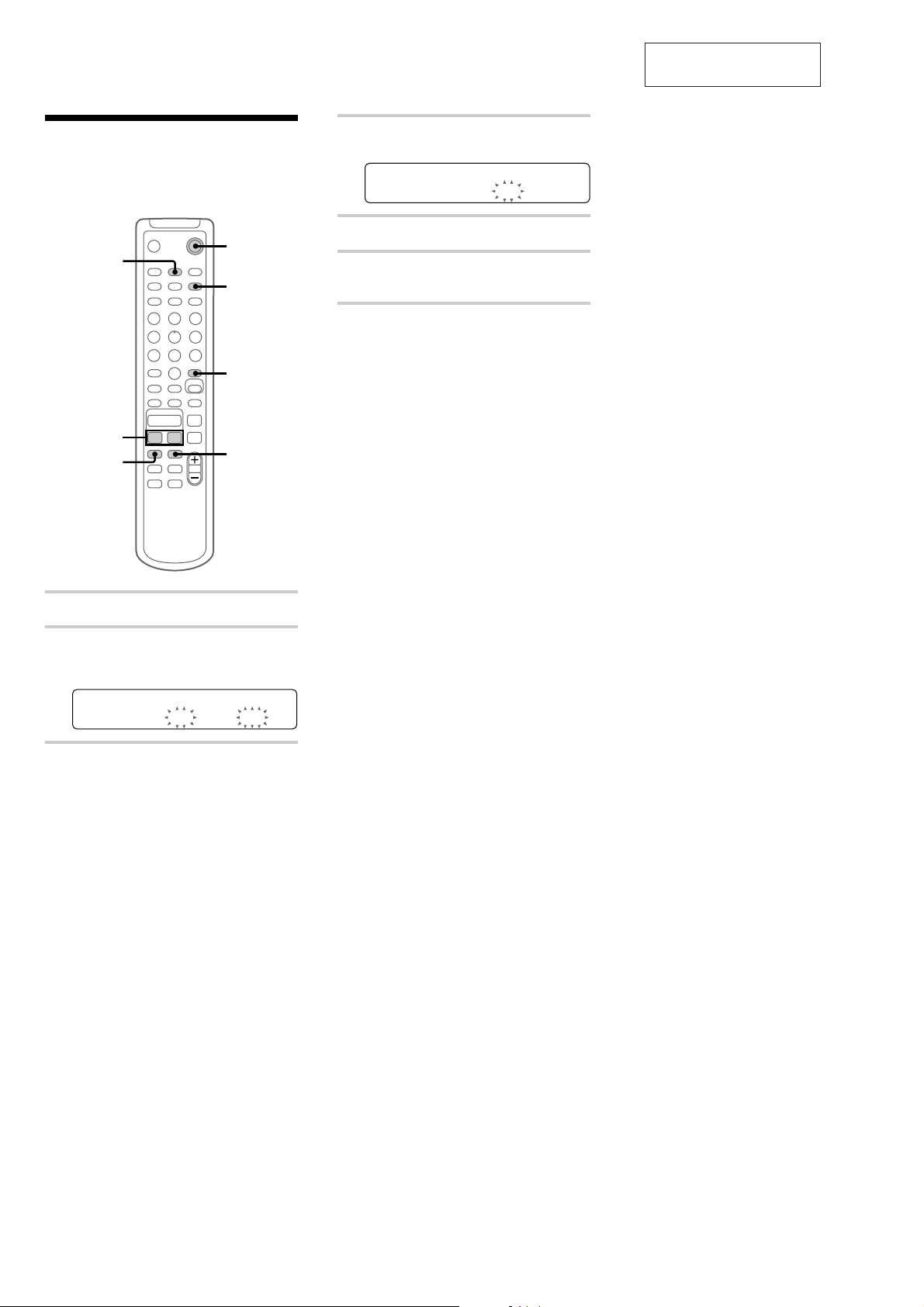

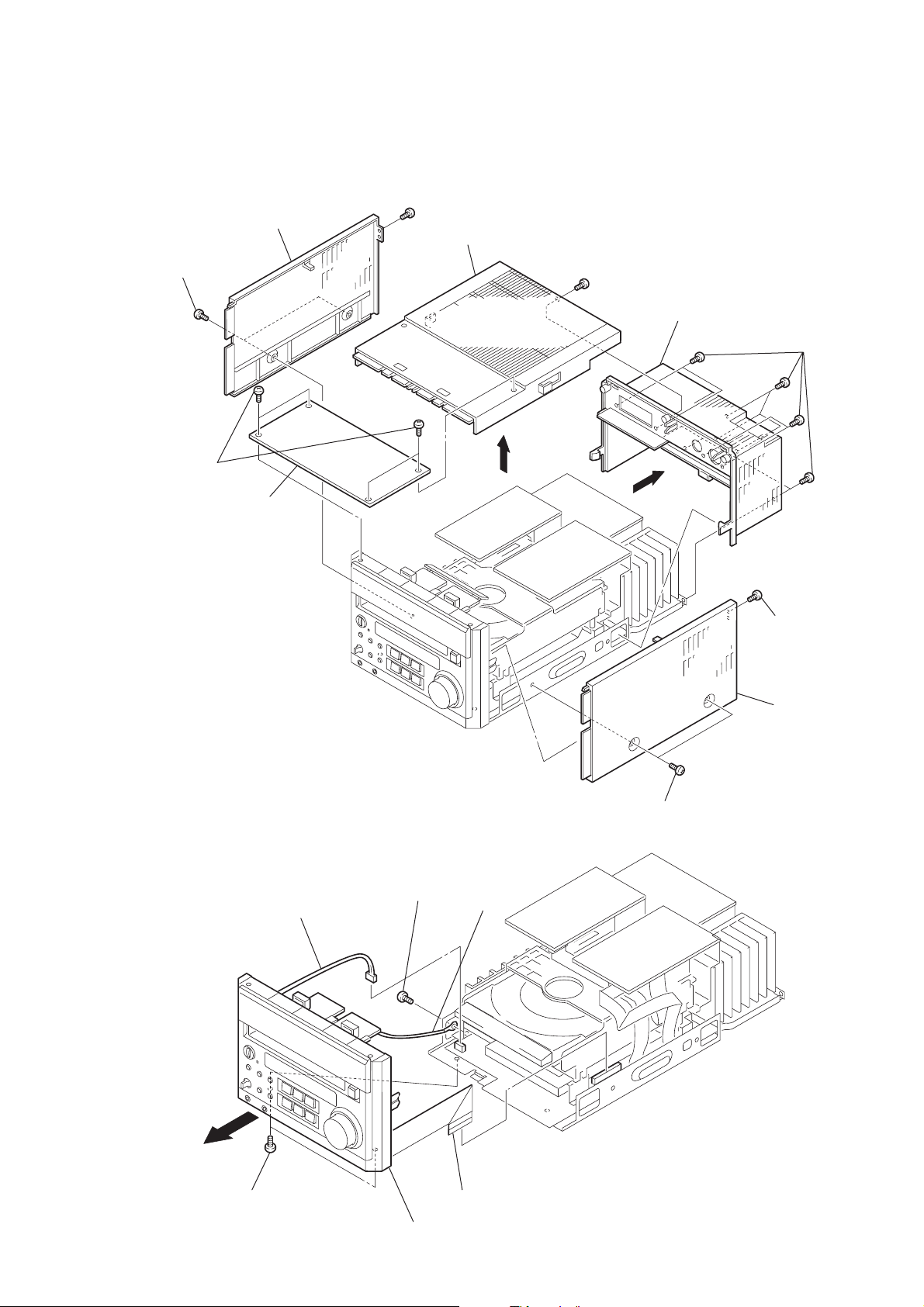

SECTION 2

9

ten screws

(BVTP3

×

10)

q;

one screw

(BVTP3

×

10)

8

case (left)

2

plate top

5

case (right)

qs

back panel

qa

case (top)

6

two case screws

1

four screws

3

two case screws

4

one screw

(BVTP3

×

10)

7

one screw

(BVTP3

×

10)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

2-1. CASE (TOP)

2-2. FRONT PANEL ASSY

2

connector

(CN202)

3

one screw

(BVTP3

×

8)

4

lug

5

two screws

(BVTP3

1

wire (flat type)(23 core)

×

8)

6

front panel assy

(CN441)

5

Page 6

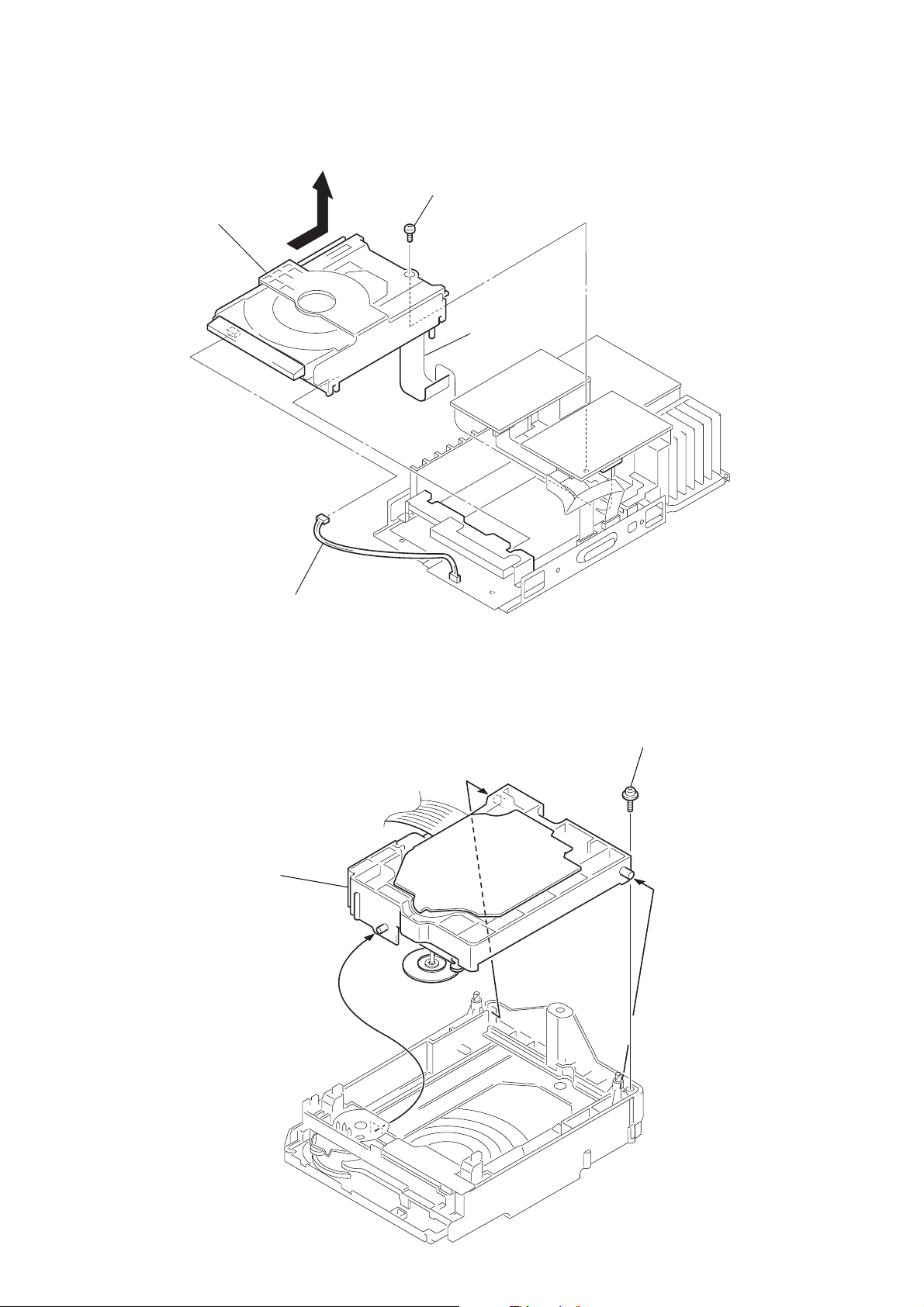

2-3. CD MECHANISM DECK (CDM55C-K6BD37A)

4

CD mechanism deck

(CDM55C-K6BD37A)

3

screw

(BVTP3 × 8)

1

wire (flat type)

(23 core)(CN501)

2

2-4. BASE UNIT (BU-K6BD37A)

2

base unit

(BU-K6BD37A)

connector

(CN1)

1

floating screw

(PTPWHM2.6)

6

Page 7

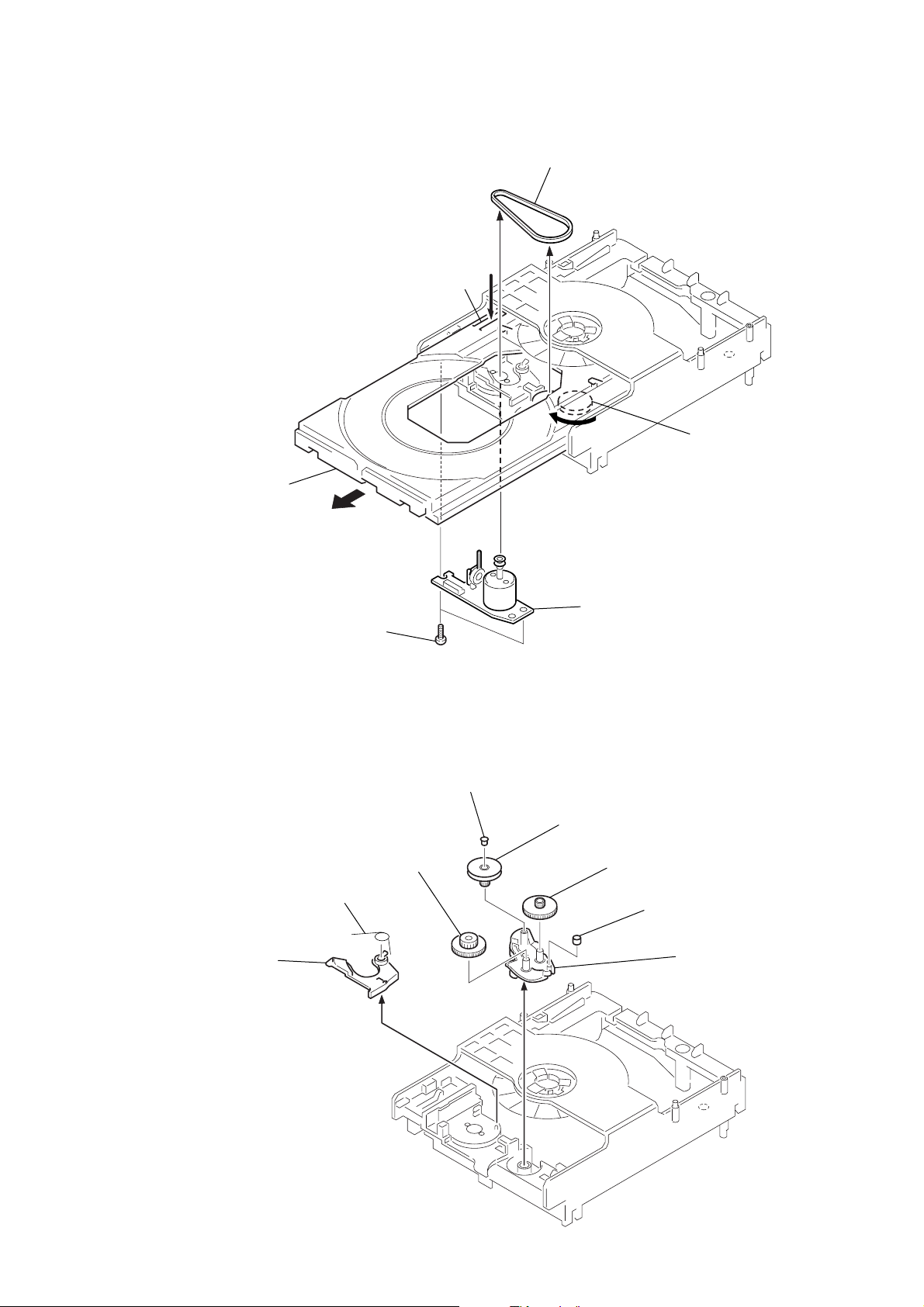

2-5. LOADING BOARD

2

belt (CDM55)

B

3

Pull the tray pushing B.

4

two screws

(BTP2.6

×

6)

5

LOADING board

1

Rotate the gear(B) in

the direction of arrow

A

.

A

)

2-6. CAM (CDM55C-K6BD37A)

1

torsion spring

2

lever (SW)

6

gear (B)

3

spacer (55)

4

pulley (LDG)

5

gear (A)

7

roller

8

cam (CDM55

7

Page 8

SECTION 3

SERVICE MODE

[Panel T est Mode]

Procedure:

1. Set to standby state.

2. Press three buttons of s , ?/1 , and 7 simultaneously.

3. Liquid crystal display and LED are all turned on.

4. Pless Z to enter the version display mode.

5. Press 7 to enter the KEY, VOL, check mode. ( l j

and J L must be pressed for several seconds.)

6. To exit from this mode, press the buttons in the same way as

step 2.

[Cold Reset]

Clears all the memories and starts up the machine again.

Procedure:

1. Set to standby state.

2. Press three b uttons of s , ?/1 , and FUNCTION simultaneously.

[Hot Reset]

Starts up the machine again holding the memory data.

Procedure:

1. Set to standby state.

2. Press three buttons of s , ?/1 , and 7 simultaneously.

8

Page 9

e

TP(TEO)

TP(VC)

BD board

Oscilloscope

Level=1.3 ±0.6 Vp-p

Symmetry

A (DC voltage)

Center of

waveform

B

0 V

1 track jump waveform

Specified level: × 100 = less than ± 22 %

B

A

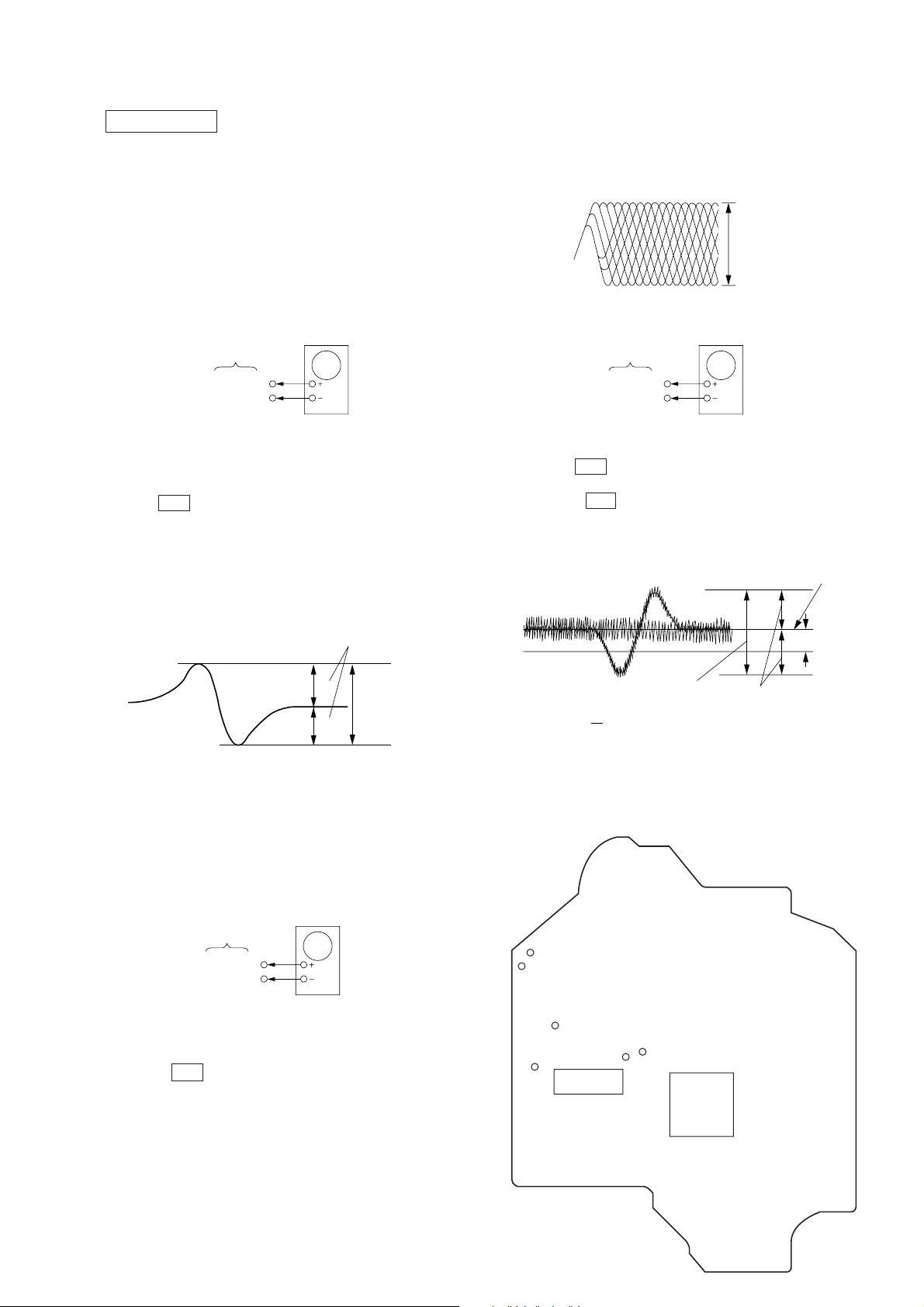

SECTION 4

ELECTRICAL ADJUSTMENTS

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

S-Curve Check

Oscilloscope

BD board

TP(FEO)

TP(VC)

Procedure :

1. Connect oscilloscope to TP (FEO).

2. Connect between TP (FEI) and TP (VC) by lead wire.

3. Connect between TP (AGCCON) and TP (GND) by lead wire.

4. Turn ?/1 button on.

5. Load a disc (YEDS-18) and actuate the focus search. (In

consequence of open and close the disc tray, actuate the focus

search)

6. Confirm that the oscilloscope waveform (S-curve) is

symmetrical between A and B. And confirm peak to peak level

within 4 ±1 Vp-p.

S-curve waveform

Symmetry

Note : Clear RF signal waveform means that the shape “ ◊ ” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

±

Level : 1.45

0.3Vp-p

E-F Balance (1 Track jump) Check

Procedure :

1. Connect oscilloscope to TP (TEO) and TP (VC).

2. Turned ?/1 button on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the 7 button. (Becomes the 1 track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope

waveform.

7. After check, remove the lead wire connected in step 2 and 3.

Note : • Try to measure several times to make sure than the ratio

RF Level Check

Procedure :

1. Connect oscilloscope to TP (RF).

2. Connect between TP (AGCCON) and TP (GND) by lead wire.

3. Turned ?/1 button on.

4. Load a disc (YEDS-18) and playback.

5. Confirm that oscilloscope wavefor m is clear and check RF signal

6. After check, remove the lead wire connected in step 2.

A

Wthin 4

B

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

Oscilloscop

BD board

TP(RF)

TP(VC)

level is correct or not.

±

1Vp-p

6. After check, remove the lead wire connected in step 1.

Adjustment Location:

[BD BOARD] (Conductor Side)

TP (RF)

TP (VC)

TP (AGCCON)

TP (TEO)

IC101

TP

(GND)

TP (FE0)

IC103

9

Page 10

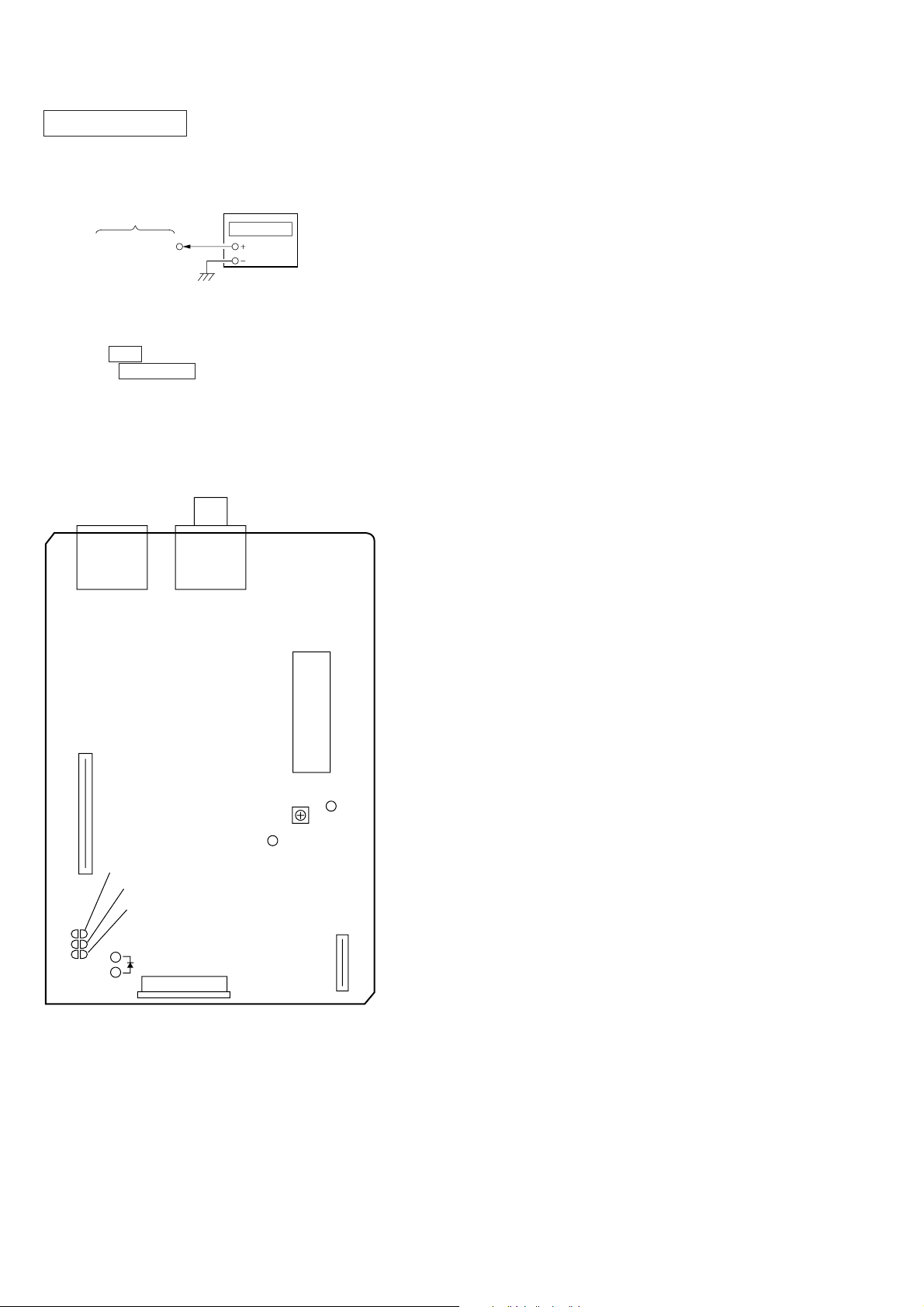

VIDEO SECTION

r

Frequency Adjustment

Connection:

VIDEO board

(27 MHz)

frequency counte

Procedure:

1. Connect the frequency counter to check point of the VIDEO

board.

2. Turned ?/1 button switch on.

3. Press the FUNCTION button to select the CD.

4. Adjust CT503 on the VIDEO board so that the frequency counter

reading 27.0 MHz ± 80 Hz at stop status.

Adjustment Location:

[VIDEO BOARD] (SIDE A)

J301

J302

IC507

CN501

SL503

SL502

SL501

CHECK LED

CN502

(27MHz)

(GND)

CT503

VIDEO

Frequency

Adjustment

CN503

10

Page 11

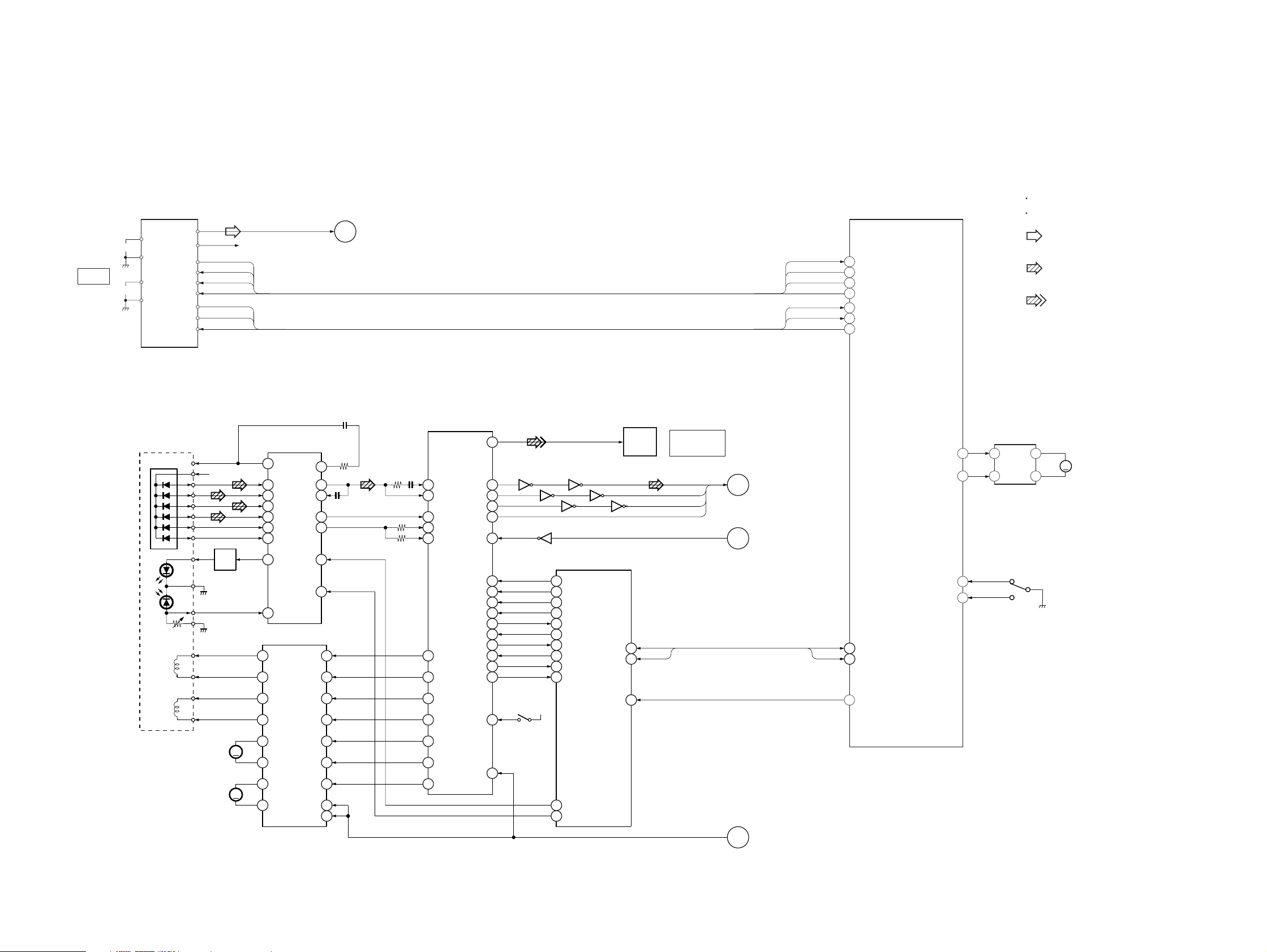

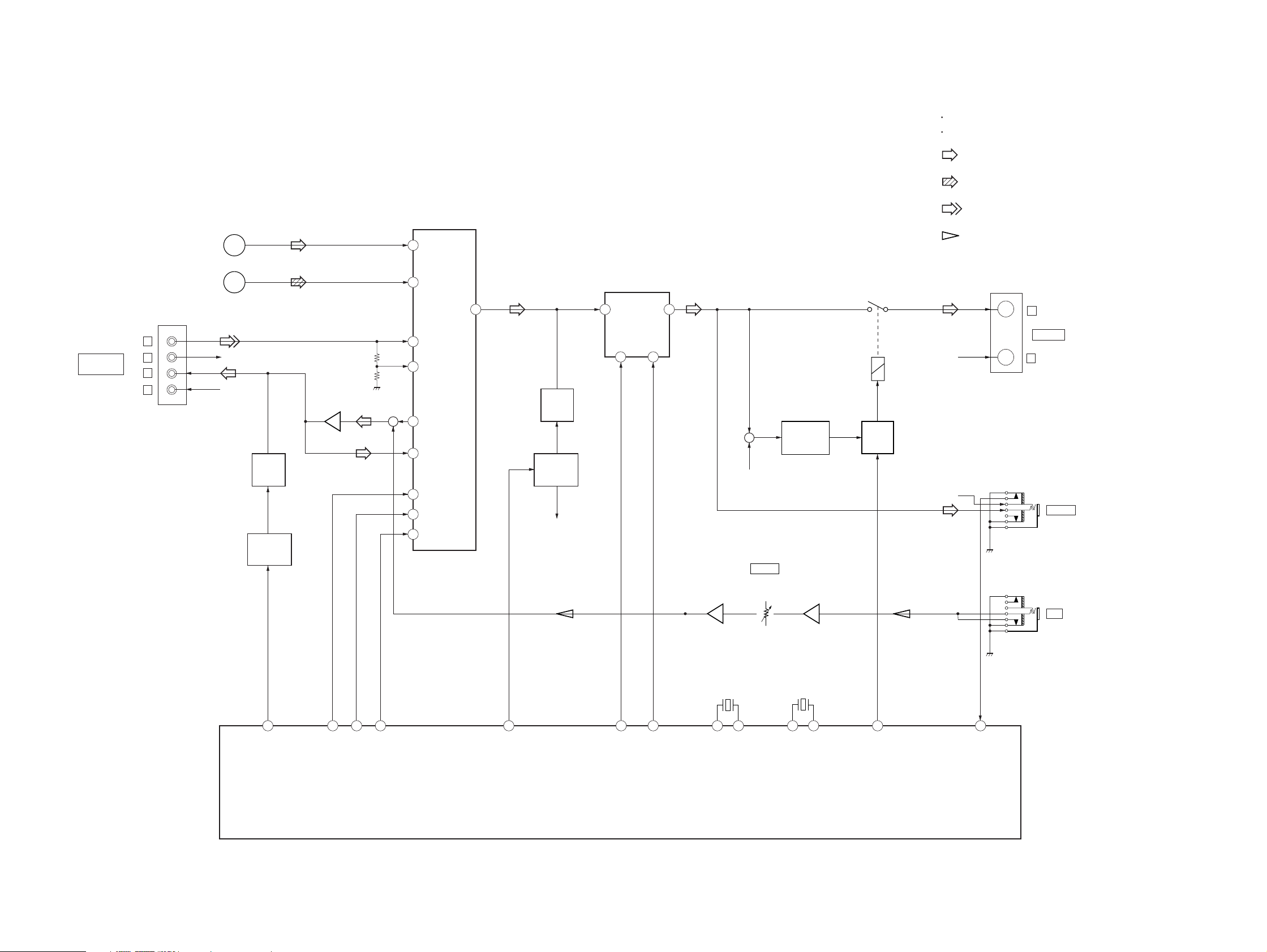

5-1. BLOCK DIAGRAM – CD SECTION –

SECTION 5

HCD-VB5

DIAGRAMS

ANTENNA

TUNER UNIT

ST-L

BLOCK

VR

COIL

COIL

ST-R

ST DOUT

ST DIN

ST CLK

ST CE

TUNED

STEREO

MUTE

VC

A

B

C

D

E

F

LD

GND

PD

F+

F-

T+

T-

FM

AM

OPTICAL PICK-UP

(KSM-213DCP/Z-NP)

FOCUS

TRACKING

16

+5V

DRIVE

M102

SLED

MOTOR

M101

SPINDLE

MOTOR

STDI

STDO

STCK

STCE

TUNED

STEREO

STMT

Q101

LD

IC601 (1/3)

SYSTEM CONTROLLER

54

ST_DIN

53

ST_DOUT

55

ST_CLK

52

ST_CE

51

TUNED

50

STEREO

ST_MUTE

49

IIC_DATA

30

29

59

XRST

LOAD_OUT

LOAD_IN

IN_SW

OPEN_SW

MOTOR DRIVER

5

66

6

67

70

71

TUNER-L

R-CH

IC103

RF AMP

12

VC

5

A

6

B

7

C

8

D

11

E

10

F

3

LD

4

PD

MOTOR/COIL DRIVE

14

VO1(+)

13

VO1(-)

12

VO2(+)

11

VO2(-)

15

VO4(+)

RFE

RFO

LD ON

HOLD SW

IC102

OP1(+)

OP1(-)

OP2(+)

OP2(-)

OP4(+)

15

16

RFI

17

14FE

13TE

22

21

2

3

5

6

27

M

16

17

VO4(-)

VO3(+)

OP4(-)

OP3(-)

26

23

A

MAIN

SECTION

(Page 13)

IC101

DIGITAL SERVO

DIGITAL SIGNAL PROC.

D OUT

50

43

39

41

40

33

34

31

32

29

30

25

RFAC

RFDC

FE

TE

SE

FFDR

FRDR

TFDR

TRDR

SFDR

SRDR

MDP

PCMD

BCLK

DATA

CLOK

XLAT

MUTE

SQSO

SQCK

SENS

SCLK

SCOR

XTSL

XRST

STDI

STDO

STCK

STCE

TUNED

STEREO

STMT

IC101

CD

DIGITAL OUT

OPTICAL

CD DATA

CD BCK

CD LRCK

C2PO

MCLK

B

C

I2C-DATA

I2C-CLK

XRST

VIDEO

SECTION

(Page 12)

VIDEO

SECTION

(Page 12)

I2C.DATA

I2C.CLK

XRESET

DIGITAL

OUT

30

29

12

64

IC501

LEVEL SHIFT

66

67

65LRCK

14C2PO

IC104

S101

LIMIT

IN SW

42

95

DSP DATA

5

DSP CLK

97

DSP LATCH

10

DSP MUTE

36

SUBQ DATA

37

SUBQ CLK

1

SENSE

2

SENSE CLK

18

SCOR

11

CTRL1

A+5V

IC502(1/2)

CD MECHA CONT

71XTAI

4

6

5

3

76

77

7

8

15

69

26SSTP

2

R-ch is omitted due to same as L-ch.

Signal path

: FM

: CD

: CD DIGITAL OUT

IC501

2

OUT1

IN1

IN2

OUT2

10

CLOSE

OPEN

S1

LOADING

SWITCH

M

M103

LOADING

MOTOR

M

18

VO3(-)

STBY1

STBY2

9

20

28

LDON

27

LPH

DEVICE RST

D

VIDEO

SECTION

(Page 12)

1111

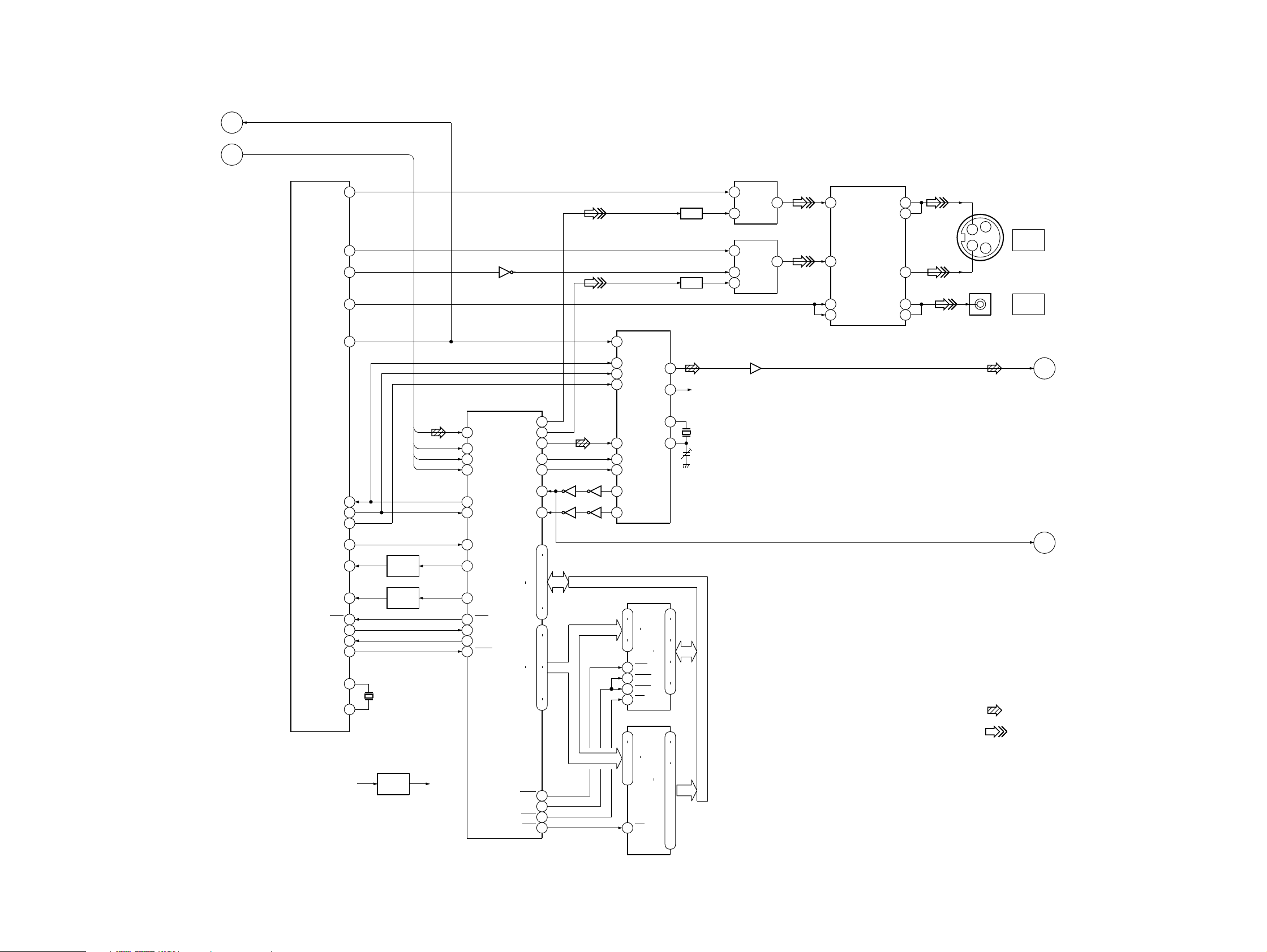

Page 12

HCD-VB5

– VIDEO SECTION –

CD

SECTION

(Page 11)

CD

SECTION

(Page 11)

DEVICE RST

D

CD DATA/CD BCK/CD LRCK/C2PO

B

16

IC502(2/2)

CD MECHA CONT

CHROMA LEVEL

BGP

DEVICE RESET

DATA1 I

DATA1 O

DF LATCH

CLK1

CL680 HINT

CL680 HSEL

CL680 HRDY

680 RESET

XIN

XOUT

26

65V MUTE

77

32

31

22

33

25H SYNC IN

45V SYNC

20

21

23

24

15

13

+5V

IC303

Y AMP

3RESOLUTION

L.P.F

4

Q501

BUFFER

Q502

BUFFER

X501

10MHz

Q531

+3.3V REG

+3.3V

(IC505 VDD)

IC301

11 10

IC505

MPEG VIDEO/AUDIO DEC

VIDEO SIGNAL PROC

4

3

5

6

112

119

117

101

93

114

121

113

60

CD DATA

CD BCK

CD LRCK

CD C2PO

HD OUT

HD IN

HCK

H SYNC

V SYNC

HINT

HSEL

HRDY

RESET

DA DATA

DA LRCK

DA XCLK

Y OUT

C OUT

DA BCK

VCK IN

MD0

MD15

MA0

MA10

RAS0

CAS

MWE

MCE

L.P.F

IC509

DIGITAL FILTER

D/A CONV

10

RSTB

9

MD

V OUT L

V OUT R

IC507

DRAM

A0

A8

RAS

UCAS

LCAS

WE

IC506

A0

A10

CE

DQ1

DQ16

O0

O7

A11

A17

XT1

XT2

ı

14

11

R-CH

1

X503

27MHz

24

2

5

.

7

10

.

31

34

.

36

39

13

15

.

17

21

.

25

.

4

.

28

.

29

.

3

.

2

.

30

8

MC

7

ML

69

75

110

111

108

86

106

10

15

.

17

.

19

.

21

.

23

29

58

56

.

54

.

52

50

.

48

.

46

44

42

40

38

37

IC504

IC504

27MHz

18

DATA

17

BCK

19

LRCK

20

384FSO

4

MCKO

16

19

.

22

26

14

28

29

13

MICROCODE ROM

12

5

.

27

.

26

.

23

22

5

CCT

VIN

IC302

C AMP

TINT

BGP

VIN

L.P.F

IC101

VOUT

1VOUT

6

75

10

8

5

1

2

7

1

8

Y IN

C IN

MUTE A

MUTE B

IC304

VIDEO AMP

C OUT

15Y OUT1

14Y OUT2

9

12MIX OUT1

11MIX OUT2

Y

2

4

3

1

C

J301

S VIDEO

OUT

J302

VIDEO

OUT

CD-L

MCLK

• R-ch is omitted due to same as L-ch.

• Signal Path

: CD

: VIDEO

MAIN

E

SECTION

(Page 13)

CD

C

SECTION

(Page 11)

1212

Page 13

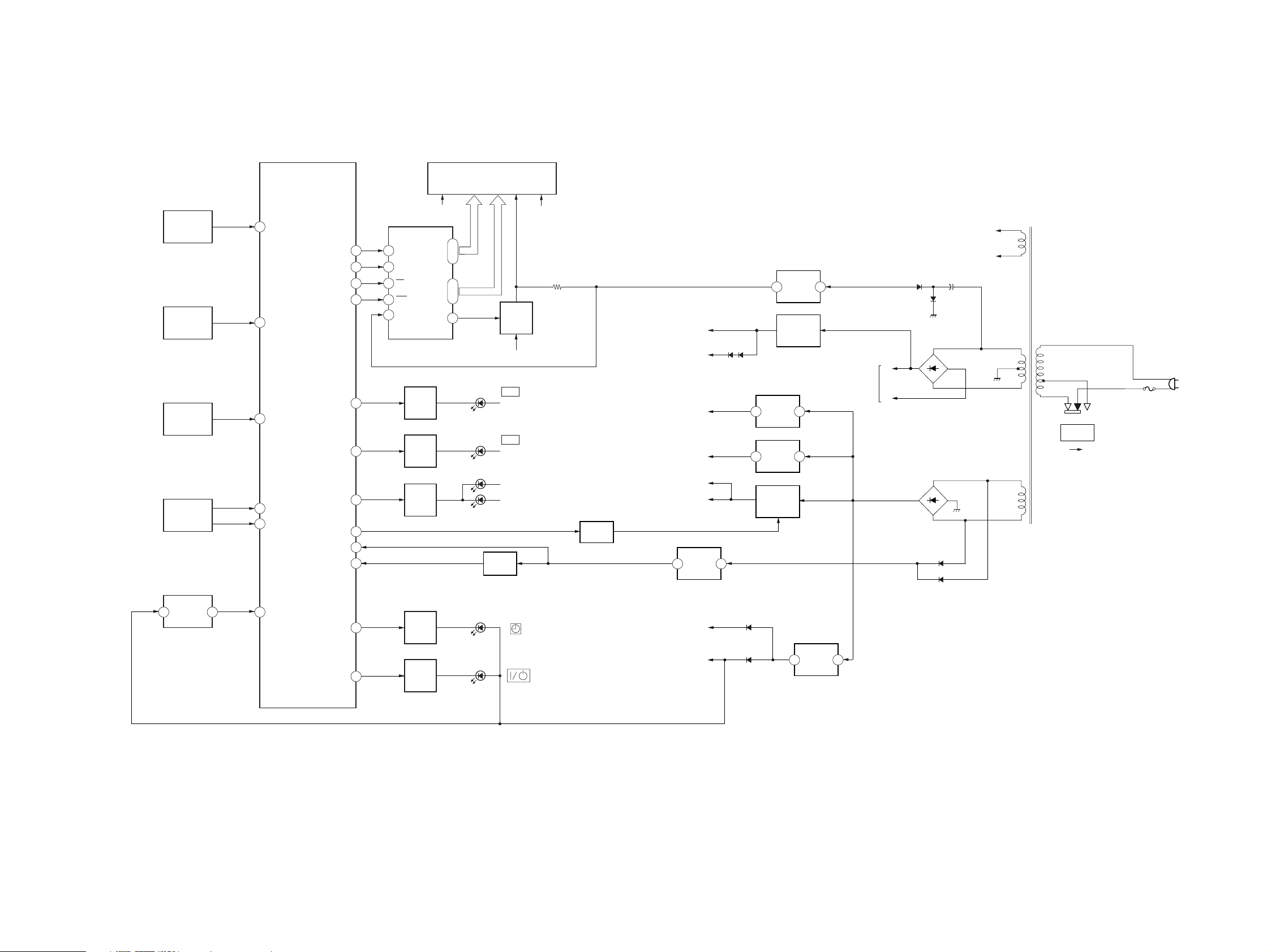

– MAIN SECTION –

HCD-VB5

R-ch is omitted due to same as L-ch.

Signal path

: FM

: CD

MD/VIDEO

(AUDIO)

OUT

IC201

INPUT SELECT

VOLUME/TONE CONTROL

CD

SECTION

(Page 11)

SECTION

(Page 12)

J101

L

IN

R

L

R

VIDEO

R-CH

R-CH

A

E

Q204

MUTE

Q203

BUFFER

1

IC202

AMP

TUNER-L

CD-L

3

L2

13

TUNER

L1

14

CD

5

LOUT

L3

12

VIDEO

L4

11

MD

Q201

MUTE

+

10

LSELO

9

LIN

Q202

BUFFER

1

DI

30

CL

2

CE

R-CH MUTE

IC301

POWER AMP (2CH)

+INA

8

STANDBYA

9 6

OUTA

MUTEA

RY301

3

Q324

RELAY

DRIVER

IC670(2/2)

MIC AMP

+

R-CH

RV701

MIC VOL

Q322,Q323

PROTECTION

DETECT

IC670(1/2)

MIC AMP

R-CH

R-CH

: MD IN

: MIC

J301

+

+

J701

J702

L

SPEAKER

R

PHONES

MIC

X601 X602

38

42

RECOUT_MUTE

16

48

47

VOL_LAT

VOL_CLK

VOL_DATA

27

PRE_MUTE

45

AMP_STANDBY

IC601 (2/3)

SYSTEM CONTROLLER

44

AMP_MUTE

11

10

XCIN

XCOUT

13

15

XIN

XOUT

SPEAKER_RELAY

43

H.PHONE_DETECT

1313

Page 14

HCD-VB5

– PANEL/POWER SECTION –

IC601 (3/3)

SYSTEM CONTROLLER

FLUORESCENT INDICATOR TUBE

FL801

VCC

S812-814

FUNCTION

KEY

S807-811

FUNCTION

KEY

S802-806

FUNCTION

KEY

S801

VOLUME

IC801

REMOTE

CONTROL

RECEIVER

OUT

VF0

IC802

63

62

61

60

56

FL DRIVER

DAT

CLK

CS

RST

VFL

DRIVER

DRIVER

DRIVER

DRIVER

DRIVER

Q801

LED

Q802

LED

Q804

LED

Q806

LED

Q807

LED

S1

S35

G1

G11

G12

5

ı

ı

39

40

ı

ı

50

51

D801

D802

D803-804

Q551

RESET

SWITCH

D805

D806

89

KEY0

35

FL_DATA

FL_CLK

37

36

FL_CS

28

FL_RST

90

KEY1

VCD_LED

AC_CUT

RESET

STBY_LED

23

24

26

5

22

12

40

39

PBC/CDTEXT_LED

91

KEY2

ENC_A

86

ENC_B

87

SIRCS

8832

PANEL_LED

CD_POWER

TIMER_LED

Q805

SWITCH

+5V

PBC

VCD

(BACK LIGHT)

VF1

Q4

BUFFER

TUNER

+10V

IC201

IC202

+5V

+7V

CD A+5V

CD D+5V

IC551

RESET

3 1

(IC601 VCC) +5V

(IC601 VDD) +5V

-VG

3 1

3 1

D551

D552

IC1

+5V

REG

IC2

+7V

REG

Q2-3

+5V

REG

3

IC3

-32V

1

REG

Q1

+10V

REG

IC4

+5.6V

3 1

REG

POWER

AMP

T1

VF0

VF1

D14-15

D2

+B

-B

S1

VOLTAGE

SELECTOR

220-240V 110-120V

D6-9

D55-56

F1

AC

IN

16

+5V(UNSW)

1414

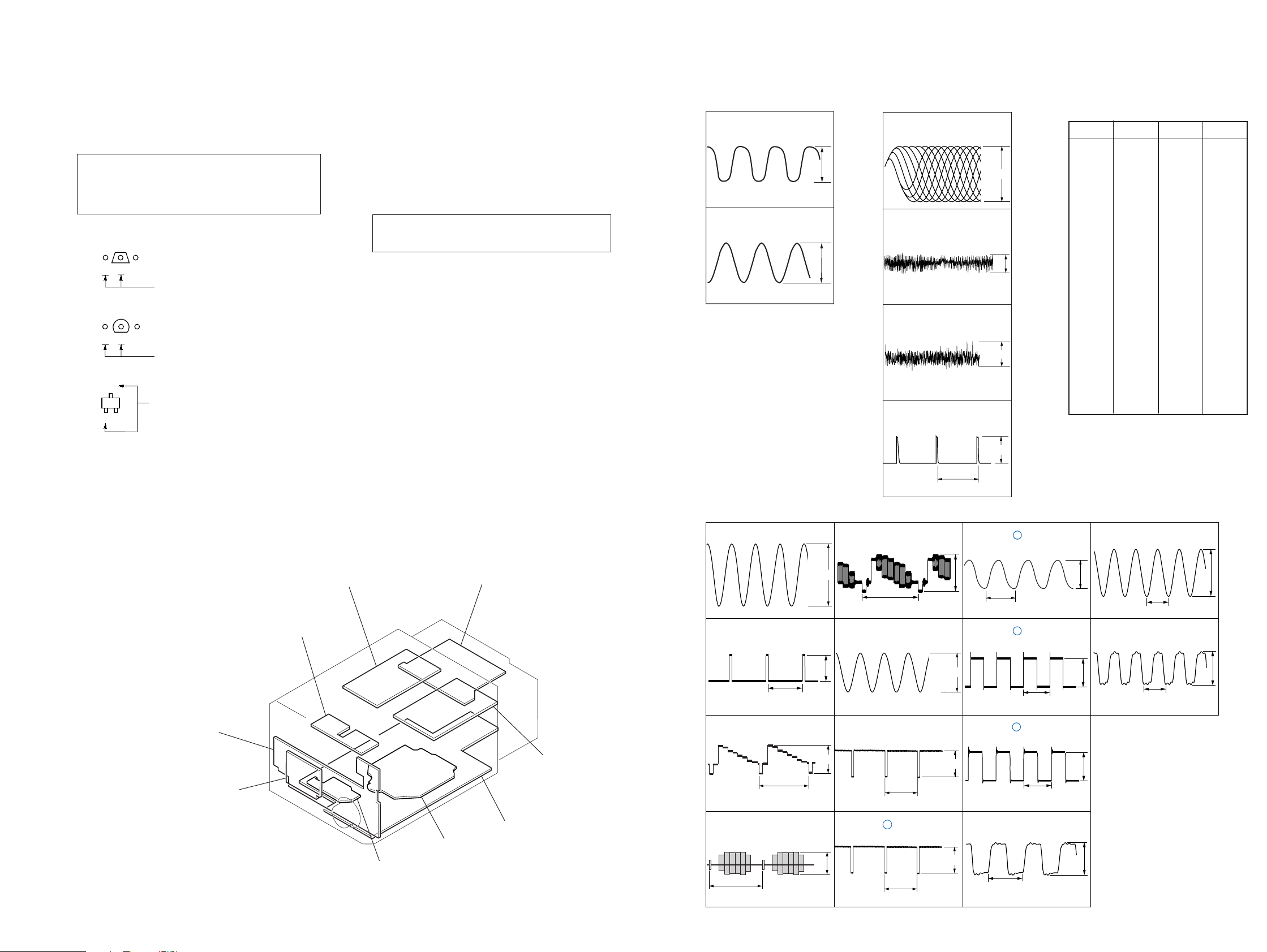

Page 15

HCD-VB5

1 IC601 qa

STOP MODE

3.0Vp-p

32.768kHz

3.4Vp-p

2 IC601 qd

STOP MODE

16MHz

4

J301 3 (COUT)

9

IC505 (VCK-IN)

7

IC505 od (VSYNC)

8

IC505 (HSYNC)

3

J301 4 (YOUT)

1

IC502 qd (XOUT)

37 nsec

4.6 Vp-p

10 MHz

3.5 Vp-p

20 ms

3.2 Vp-p

64 µs

2.0 Vp-p

H

H

2.0 Vp-p

5.4 Vp-p

101

106

2

IC502 wh (BGP)

5

J302 (VIDEO OUT)

6

IC505 ih (DA-XCLK)

3.6 Vp-p

17 MHz

q;

IC505 (DA-LRCK)

108

qa

IC505 (DA-BCK)

111

qs

IC509 w; (384FSO)

qd

IC509 wf (XT2)

qf

IC509 4 (MCKO)

4.5 Vp-p

H

1.3 Vp-p

H

4.5 Vp-p

22.7

µ

s

4.5 Vp-p

472 ns

5.0 Vp-p

59 ns

2.0 Vp-p

37 ns

5.2 Vp-p

37 ns

d

NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

f

•

• b : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Side A) the parts face are indicated.

• Indication of transisitor.

: internal component.

Q

B

CE

These are omitted.

Q

B

CE

These are omitted.

C

Q

B

E

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

Voltage variations may be noted due to normal production tolerances.

no mark : FM

< > : CD

Voltage variations may be noted due to normal production tolerances.

F : TUNER (FM/AM)

L : MD/VIDEO

g : MIC

J : CD PLAY (ANALOG OUT)

c : CD PLAY (DIGITAL OUT)

4

W or less unless otherwise

5-3. Waveforms

– MAIN BOARD –

– BD SECTION –

1

IC101 t;

(RFAC)(CD Play mode)

1.3 Vp-p

2

IC101 ra

(TE)(CD Play mode)

0.5 Vp-p

3

IC101 el

(FE)(CD Play mode)

0.2 Vp-p

4

IC101 wg (MDP)

2.6 Vp-p

• Semiconductor Location

(MAIN BOARD)

Ref. No. Location

D2 D-7

D3 B-8

D4 C-5

D5 C-3

D6 F-7

D7 F-6

D8 E-7

D9 F-7

D10 G-4

D14 D-6

D15 D-6

D16 D-6

D21 G-5

D321 D-10

D501 B-1

D551 F-5

D552 F-5

D553 F-6

D554 G-3

D555 E-6

D556 E-6

D601 D-4

Ref. No. Location

IC1 G-3

IC2 G-6

IC3 E-6

IC4 F-5

IC201 C-3

IC202 C-2

IC301 D-9

IC501 B-1

IC551 G-4

IC601 E-4

Q1 B-8

Q2 G-5

Q3 G-4

Q4 G-4

Q201 C-7

Q202 D-4

Q203 D-4

Q204 D-5

Q251 C-7

Q254 D-5

Q322 D-10

Q323 D-10

Q324 D-10

Q551 G-3

5-2. CIRCUIT BOARDS LOCATION

PANEL board

MIC/PC MIX board

TUNER (FM/AM)

LED board

BACK PANEL board

VIDEO boar

–VIDEO SECTION –

15.1

µ

s

LOADING board

MAIN board

BD board

1515

Page 16

HCD-VB5

5-4. PRINTED WIRING BOARD –BD SECTION–

• Semiconductor

Location

Ref. No. Location

IC101 C-6

IC102 B-5

IC103 C-5

IC104 D-2

Q101 D-3

• See page 15 for Circuit Boards Location.

12

BD BOARD

(SIDE A)

A

B

C162

34567

R210

R152

BD BOARD

Q102

C152

(SIDE B)

C

D

12

(12)

(KSM-213DCP/Z-NP)

C

TO

VIDEO BOARD

(Page 24)

12

(12)

1616

Page 17

HCD-VB5

5-5. SCHEMATIC DIAGRAM –BD SECTION–

• See page 15 for Waveforms.

• See page 32 for IC Block Diagrams.

3

C

25

2.4

2.4

94

1717

Page 18

HCD-VB5

5-6. PRINTED WIRING BOARDS –MAIN SECTION–

• See page 15 for Circuit Boards Location and Semiconductor Location.

D

(Page 22)

VIDEO

(Page 24)

There are a few cases that the part printed on

this diagram isn’t mounted in this model.

(Page 27)

3

3

(Page 21)

(Page 21)

13

1818

Page 19

HCD-VB5

5-7. SCHEMATIC DIAGRAM –MAIN SECTION(1/2)–

• See page 15 for Waveforms.

• See page 28 for IC Pin Function.

PIN FUNCTION

1919

Page 20

HCD-VB5

5-8. SCHEMATIC DIAGRAM –MAIN SECTION(2/2)–

• See page 34 for IC Block Diagrams.

2020

Page 21

HCD-VB5

5-9. PRINTED WIRING BOARDS –POWER SECTION–

• See page 15 for Circuit Boards Location.

There are a few cases that the part printed on

this diagram isn’t mounted in this model.

(Page 18)

VOLTAGE

SELECTOR

110-120V

R

220-240V

901

13

13

(Page 18)

2121

Page 22

HCD-VB5

5-10. PRINTED WIRING BOARD –PANEL SECTION–

• Semiconductor

Location

Ref. No. Location

D801 A-2

D805 C-6

D806 C-7

IC801 A-1

IC802 C-4

Q801 A-1

Q804 D-6

Q805 C-3

Q806 C-6

Q807 C-6

• See page 15 for Circuit Boards Location.

(VCD)

(PBC)

There are a few cases that the part printed on

this diagram isn’t mounted in this model.

3

3

(Page 18)

Z

RETURN

13

SELECT

NEXT

PREV

13

2222

Page 23

5-11. SCHEMATIC DIAGRAM –PANEL SECTION–

HCD-VB5

2323

Page 24

HCD-VB5

5-12. PRINTED WIRING BOARDS –VIDEO CD SECTION–

• See page 15 for Circuit Boards Location.

There are a few cases that the part printed on

this diagram isn’t mounted in this model.

• Semiconductor

Location

Ref. No. Location

D501 C-2

IC101 F-4

IC301 B-9

IC302 B-9

IC303 B-4

IC304 B-7

IC501 D-8

IC502 E-9

IC504 E-4

IC505 C-3

IC506 D-7

IC507 C-4

IC509 E-5

Q501 C-3

Q502 C-2

Q531 C-9

A

B

C

12

345678910

114

87

D

E

F

G

C

TO BD BOARD

(Page 16)

SL503

SL502

SL501

15 1

R554

L503

13

(13)

C560

C562

13

(13)

16

E

(Page 18)

2424

Page 25

HCD-VB5

5-13. SCHEMATIC DIAGRAM – VIDEO CD SECTION (1/2) –

• See page 33 for IC Block Diagrams. • See page 30 for IC Pin Function Description.

PIN FUNCTION

2525

Page 26

HCD-VB5

5-14. SCHEMATIC DIAGRAM – VIDEO CD SECTION (2/2) –

• See page 15 for Waveforms. • See page 33 for IC Block Diagrams.

2626

Page 27

5-15. SCHEMATIC DIAGRAM –LOADING SECTION–

• See page 15 for Waveforms.

S1

LOADING

SWITCH

M103

LOADING

MOTOR

16

5-16. PRINTED WIRING BOARDS –LODING SECTION–

CN1

CLOSE

GND

OPEN

LOAD +

LOAD –

B

TO

MAIN BOARD

(Page 20)

16

TO MAIN

BOARD

(Page 18)

21

21

27

Page 28

5-17. IC Pin Function

• MAIN BOARD IC601 M30622MAA-B04FP (SYSTEM CONTROLLER)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Pin Name

STKPOWER

B-SHUT

SPEAKER RELAY

H.PHONE DETECT

CD-POWER

TA-MUTE

LED

BYTE

CNVss

XCIN

XCOUT

RESET

X0UT

VSS

XIN

VCC

NMI

LED

SCOR

RDS-INT

RDS-DATA

AC-CUT

PBC/CDTEXT LED

VCD LED

CDTEXT LED

PANEL LED

PRE MUTE

FL-RESET

IIC_CLK

IIC_DATA

RXD

SQ-DATA-IN

SQ-CLK

RTS1

FL-DATA

FL-CS

FL-CLK

VOL_CLK

STBY LED

TIMER LED

VSS

RECOUT MUTE

STBY_RELAY

AMP_MUTE

AMP_STANDBY

VDD

VOL_DATA

VOL_CLK

ST-MUTE

STEREO

I/O

I

Not used. OPEN

I

Not used. OPEN

O

FRONT-RELAY ON(H)/OFF(L)

I

HEAD PHONEs detection. Connected (H), Not connected (L).

O

CD-POWER ON(H)/OFF(L)

O

Not used. OPEN

—

Not used. OPEN

—

For switching external data bus wedth

—

For switching precessor mode

I

SUB CLOCK IN

O

SUB CLOCK OUT

—

SYSTEM RESET IN

O

MAIN SYSTEM CLOCK OUT

—

Vss

I

MAIN SYSTEM CLOCK IN(16MHz)

—

POWER SUPPLY(+5V)

I

PULL UP(EVER +5V) CAN’T USE

—

Not used. OPEN

I

CD Q-DATA REQUEST

I

RDS INT

I

RDS DATA

I

AC CUT ON(L)/OFF(H) CHECK

O

CDTEXT LED (RB5) / PBC LED (VB5)

O

VCD_LED

O

Not used. OPEN

O

PANEL_LED

O

TA LINE-MUTE ON(L)/OFF(H)

O

FL RESET

I

IIC SCL

I

IIC SDA

—

Not used. OPEN

O

CD DATA IN

I

Note: SQ CLK : Input when CD-POWER is L

O

Not used. OPEN

O

FL DATA

O

FL CHIP SELECT

O

FL CLK

O

LC75342 LATCH

O

STANDBY LED

O

TIMER LED

—

FLASH VSS

—

FL FILAMENT ON(H)/OFF(L) (for ECO)

—

Not used. OPEN

I

Always O/H when power is OFF except for J, U and CED

I

Always O/H when power is OFF except for J, U and CED

—

FLASH VDD

O

LC75342 DATA

O

LC75342 CLOCK

O

TUNER MUTE

I

STEREO IN(L)/OFF(H)

Description

28

Page 29

Pin No.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Pin Name

TUNED

ST-CE

ST-DOUT

ST-DIN

ST-CLK

SENS

HOLD

XLTAT

XRST

LED

LED

VCC

LED

VSS

AMS-IN

LOAD-OUT

LOAD-IN

B-TRG

CAPM-CNT1

IN SW

OPEN-SW

TC-MUTE

REC/PB/PASS

DOLBY NR

REC-MUTE

BIAS

EQ-H/N

TC-RELAY

ALC

B-PLAY-SW

CD-DATA

CD-CLK

REC-OUT

JOG A

JOG B

ENC A

ENC B

SIRCS

KEY0

KEY1

KEY2

MD REC R

B-HALF

MD REC L

MODEL-IN

AVSS

SPEC-IN

VREF

AVCC

TEST

I/O

I

TUNED IN(L)/OFF(H)

O

TUNER CHIP ENB

O

TUNER DATA OUT

I

TUNER DATA IN

O

TUNER CLOCK

I

From CXP2587 SENS

—

Not used. OPEN

—

Not used. OPEN

O

CD RESET

O

Not used. OPEN

O

Not used. OPEN

—

POWER SUPPLY(+5V)

O

Not used. OPEN

—

Vss

I

Not used. OPEN

O

LOAD OUT

O

LOAD IN

I

Not used. OPEN

I

Not used. OPEN

I

CDM55 IN SW

I

TRAY OPEN switch

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

—

Not used. OPEN

—

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

volume(A)

I

volume(B)

I

remote commander input

I

KEY-line(0)

I

KEY-line(1)

I

KEY-line(2)

I

Not used. OPEN

I

Not used. OPEN

I

Not used. OPEN

I

CMT-RB5(GND) / CMT-VB5(Vdd)

—

Analog ground

I

SPEC IN

—

Analog Reference Voltage

—

Analog Power Supply

O

SOFT CHECK OUT

Description

29

Page 30

• IC502 M30620MCA-A45FP (CD MECHANISM CONTROLLER) (VIDEO BOARD)

Pin No.

Pin No.

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42, 43

42, 43

44

44

45

45

46

46

47

47

48

48

49

49

50

50

51

51

Pin Name

Pin Name

SENSE

SENSE

SENSE CLK

SENSE CLK

RESOLUTION

RESOLUTION

CHROMA LEVEL

CHROMA LEVEL

DSP CLK

DSP CLK

TSENS

TSENS

REMOTE IN

REMOTE IN

BYTE

BYTE

CN VSS

CN VSS

DSP MUTE

DSP MUTE

CTRL1

CTRL1

XRESET

XRESET

XOUT

XOUT

VSS

VSS

XIN

XIN

VCC

VCC

NMI

NMI

SCOR

SCOR

DSENS

DSENS

CL680 HINT

CL680 HINT

CL680 HSEL

CL680 HSEL

DF LATCH

DF LATCH

CL680 HRDY

CL680 HRDY

CL680 RESET

CL680 RESET

H.SYNC IN

H.SYNC IN

BGP

BGP

LPH

LPH

LD ON

LD ON

12C.CLK

12C.CLK

12C.DATA

12C.DATA

DATA1O

DATA1O

DATA1I

DATA1I

CLK1

CLK1

RTS1

RTS1

XVLEVEL.DOWN

XVLEVEL.DOWN

SUBQ DATA

SUBQ DATA

SUBQ CLK

SUBQ CLK

P.ON

P.ON

BUS XRDY

BUS XRDY

BUS

BUS

BUS XHOLD

BUS XHOLD

BUS

BUS

OSD.LANGUAGE

OSD.LANGUAGE

VSYNC

VSYNC

BUS XWRL

BUS XWRL

LO.BOOST

LO.BOOST

AUDIO MUTE

AUDIO MUTE

LOAD OUT

LOAD OUT

LOAD IN

LOAD IN

INSW

INSW

I/O

I/O

I

Internal status (SENSE) signal input from the CXD3008Q (IC101)

I

O

Sense serial data reading clock signal output to the CXD3008Q (IC101)

O

O

Y resolution output

O

O

Chroma level output

O

O

Serial data transfer clock signal output to the CXD3008Q (IC101)

O

O

Not used (open)

O

I

Remote control signal input terminal Not used (open)

I

I

External data bus line byte selection signal input “L”: 16 bit, “H”: 8 bit (fixed at “L”)

I

—

Ground terminal

—

O

Muting on/off control signal output to the CXD3008Q (IC101) “H”: muting on

O

O

Clock selection signal output to the CXD3008Q (IC101) “L”: 16.9344 MHz (double speed), “H”: 33.8688 MHz

O

Reset signal input from the system controller (IC501) “L”: reset

I

I

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

O

Main system clock output terminal (10 MHz)

O

—

Ground terminal

—

I

Main system clock input terminal (10 MHz)

I

—

Power supply terminal (+5V)

—

I

Non-maskable interrupt input terminal (fixed at “H” in this set)

I

I

Subcode sync (S0+S1) detection signal input from the CXD3008Q (IC101)

I

O

Not used (open)

O

I

Interrupt request signal input from the MPEG video/audio decoder (IC505)

I

O

O

O

Serial data latch pulse output to the D/A converter (IC509) “L” active

O

—

—

O

Reset signal output to the MPEG video/audio decoder (IC505) “L”: reset

O

I

Horizontal sync signal input

I

O

Burst gate pulse signal output

O

O

AGC hold signal output

O

O

Laser power selection signal output to the CXA2568M (IC103) “H”: laser on

O

I/O

I2C clock signal from CD mechanism control (IC501).

I/O

I/O

I2C data signal from CD mechanism control (IC501).

I/O

O

Serial data output to the MPEG video/audio decoder (IC506) and D/A converter (IC509)

O

I

Serial data input from the MPEG video/audio decoder (IC506)

I

O

Serial data transfer clock signal output to the MPEG video/audio decoder (IC506) and D/A converter (IC509)

O

O

RTS signal to serial port (check connector).

O

O

Not used (open)

O

I

Sub-code Q data input from the CXD3008Q (IC101)

I

O

Sub-code Q data reading clock signal output to the CXD3008Q (IC101)

O

O

Power on/off control signal output terminal Not used (open)

O

I

Ready signal input terminal Not used (fixed at “H”)

I

O

Not used (open)

O

I

Hold signal input terminal Not used (fixed at “H”)

I

O

Not used (open)

O

I

OSD language select input terminal “H”: English, “L”: China

I

I

Vertical sync signal input

I

O

Bus write signal output.

O

O

Not used (open)

O

O

Audio muting on/off control signal output terminal “L”: muting on Not used (open)

O

O

Loading motor drive signal output terminal Not used (open)

O

O

Loading motor drive signal output terminal Not used (open)

O

I

Disc detection (load in) switch input terminal

I

Description

30

Page 31

Pin No.

52

53

54

55

56

57 to 59

60, 61

62

63

64

65

66 to 72

73

74

75

76

77

78

79

80

81 to 88

89

90 to 92

93

94

95

96

97

98

99

100

Pin Name

OUTSW

MODEL1

MODEL2

TBLL

TBLR

ENC1 to ENC3

VCC

VSS

V.MUTE

A6 to A0

TEST LED

TEST1

TEST2

TEST3

DEVICE RESET

STANDBY

FL CS

FLBLK

D7 to D0

MIC CTRL

KEY1 to KEY3

NT/PAL

MUSIC VOL

DSP DATA

AVSS

DSP LATCH

VREF

AVCC

AMP ON

I/O

I

Disc detection (load out) switch input terminal Not used (fixed at “H”)

—

Not used

—

Not used

—

Not used (open)

—

Not used (open)

—

Not used (open)

—

Not used (open)

—

Power supply terminal (+5V)

—

Not used (open)

—

Ground terminal

O

Video muting on/off control signal output

O

Address signal output for the external device Not used (open)

O

LED drive signal output for the self diagnosis indicator (D502) Normally: “L” (LED on)

I

Setting terminal for the test mode 1 (for VCD check) Normally: fixed at “H” (“L”: test mode)

I

Setting terminal for the test mode 2 (for SERVO check) Normally: fixed at “H” (“L”: test mode)

I

Setting terminal for the test mode 3 Normally: fixed at “H” (“L”: test mode) Not used (fixed at “H”)

O

System reset signal output to the CXD3008Q (IC101), BA5974FP (IC102) and D/A converter (IC509) “L”: reset

O

Standby on/off control signal output terminal Not used (open)

O

Chip select signal output terminal Not used (open)

O

Blank control signal output terminal Not used (open)

I/O

Two-way data bus with the external device Not used (open)

—

Not used.

I

Key input terminal Not used (fixed at “H”)

—

Not used.

—

Not used.

O

Serial data output to the CXD3008Q (IC101)

—

Ground terminal (for A/D conversion)

O

Serial data latch pulse output to the CXD3008Q (IC101)

I

Reference voltage (+5V) input terminal (for A/D conversion)

—

Power supply terminal (+5V) (for A/D conversion)

—

Not used.

Description

31

Page 32

5-18. IC BLOCK DIAGRAMS

IC103 CXA2568M-T6 (BD BOARD)

HOLD

AGCVTH

LD

PD

APC PD AMP

VEE

1

VEE

2

3

4

VREF

VCC

VC

APC LD AMP

VCC

VCC

VCC

24

23

LC/PD

LD_ON

22

HOLD_SW

21

AGCCONT

20

(50%/30%

OFF)

RF_BOT

19

A

5

B

6

RF SUMMING AMP RF_EQ_AMP

VC

VC

VC

VCC

VEE

VEE

C

7

D

8

9

VEE

10

11

VC BUFFER

12

VC

VC

VC

F

E

VC

IC101 CXD3008Q (BD BOARD)

1

VDD

XRST

2

3

MUTE

DATA

DATA

4

5

XLAT

XLAT

CLOK

CLOK

6

SENS

SENS

7

SCLK

8

ATSK

9

10

WFCK

XUGF

11

XPCK

12

GFS

13

C2P0

14

SCOR

15

16

C4M

17

WDCK

18

DVSS

19

COUT

20

MIRR

21

DFCT

22

FDK

PWM1

23

LOCK

24

MDP

25

VC

VEE

VC

ERROR AMP

VC

FOCUS

TRACKING

ERROR AMP

VC

SQCK

SCSY

EXCK

EXCK

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66

CPU

INTERFACE

SERVO

AUTO

SEQUENCER

SERVO

INTERFACE

DIGITAL

PLL

SQSO

XOLT

18

17

16

15

14

13

SOCK

RFTC

RF_1

RFO

RFE

FE

TE

SOUT

XTA0

D/A

INTERFACE

SUB

CODE

PROCESSOR

PWM GENERATOR

FOCUS PWM

GENERATOR

TRACKING PWM

GENERATOR

SLED PWM

GENERATOR

XTSL

XTA1

DVSS2

ERROR

CORRECTOR

32K

RAM

PCMD

BCK

EMPH

EFM

DEMODURATOR

MIRR

DFCT

FOK

SERVO DSP

FOCUS SERVO

TRACKING

SERVO

SLED SERVO

CLOCK

GENERATOR

DIGITAL

DIGITAL

PLL

ASYMMETY

CORRECTOR

A/D

CONVERTER

OUT

OP

AMP

ANALOG

SW

65

LRCK

64

DOUT

63

MD2

62

ASYE

61

60

VPC0

V16M

59

58

57

BIAS

56

DVDD2

55

PCO

FIL1

54

53

FIL0

52

CLTV

51

AVSS1

50

RFAC

49

ASY1

ASY0

48

47

AVDD

46

1GEN

45

AVSS0

44

AD10

RFDC

43

42

CE

TE

41

32

26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

SSTP

FST0

DVDD1

SFDR

SRDR

TFDR

TRDR

FFDR

FRDR

DVSS1

TES1

TES1

FE

VC

SE

Page 33

IC501 LB1641 (MAIN BOARD)

7

1

2

3

4

5

6

8

TINT

GND

V+

BGP

COLOR

V IN

COLOR

OFFSET

H

L

VOUT

HUE ADJ

SATURATION ADJ

(COLOR MAIN)

SATURATION ADJ

(COLOR BURST)

T.S.D O.C.P

MOTOR

DRIVE

FWD/REV/STOP

CONTROL LOGIC

MOTOR

DRIVE

IC302 NJM2255M (VIDEO BOARD)

2 3

1

GND

N.C

14

1 2 3 4 5 6 7

VIDEO

OUTPUT

NOISE

DRIVE

MOTOR

FILTER

GND

N.C

PHASE

LPF

LOWER

LIMITER

(2)

DIFFERENTIATION

13 12 11 10 9 8

5 6 7 8 9 10

4

FWD.IN

N.C

SECONDARY

GAIN ADJ

V +

REV.IN

VIDEO

CONTROL

INPUT

CLAMP

DELAY

INPUT

SWITCH

CONTROL

DIFFERENTIATION

IC304 BA7665FS-E2 (VIDEO BOARD)

VCC 1

LOWER

LIMITER

(1)

N.C

N.C

VCC 2

FREQUENCY

CHARACTERISTIC

CLAMP

SYNC

(

CHIP

DIFFERENTIATION

NOISE

FILTER

MOTOR

COMPENSATION

)

OUTPUT

DRIVE

IC509 PCM1727E-2/T2 (VIDEO BOARD)IC303 NJM2209M (VIDEO BOARD)

PGND

NCKO

SCKO3

RSTB

XT1

VCP

RSV

MC

MC

384fs

MODE

CONTROL

CLOCK MANAGER

•

DUAL PLL

POWER

SUPPLY

DATA INPUT

INTERFACE

8 TIME OVER

SAMPLING DIGITAL

FILTER

•

FUNCTION

CONTROL

AUDIO

OPEN

24

XT2

DGND

23

22

VDD

21

SCKO1

20

SCKO2

19

LRCK

DATA

18

17

BCK

ZERO

16

15

CAP

14

VOUTL

1

2

3

4

5

6

7

ML

8

9

10

MUTEA

INA

GND

GND

GND

N.C.

INB

MUTEB

1

2

3

4

5

6

7

8

CHROMA MUTE

20k

BPZ

MUTE

6dB

6dB

6dB

75Ω

75Ω

75Ω

16

15

14

13

12

11

10

9

VCC1

OUTA1

OUTA2

VCC2

MIXOUT1

MIXOUT2

N.C.

OUTB

VOUTR

AGND

11

12

CONTROL

MULTI LEVEL

∆Σ

MODULATOR

5 LEVEL

DAC

CR LPF

•

OUTPUT

AMP

MULTI LEVEL

∆Σ

MODULATOR

5 LEVEL

DAC

CR LPF

•

OUTPUT

AMP

13

VCA

33

Page 34

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

6-1. CASE(TOP) SECTION

SECTION 6

EXPLODED VIEWS

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

#1

The components identified by mark 0 or

dotted line with mark 0 are critical for safety .

Replace only with part number specified.

3

4

5

#1

#1

6

#1

#1

2

2

#1

1

#1

7

#2

4

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 4-230-227-11 PLATE (TOP), ORNAMENTAL

2 4-230-228-01 SCREW (TOP)

3 4-230-225-01 CASE (LEFT)

4 3-363-099-21 SCREW(CASE 3 TP2)

5 4-230-224-01 CASE (TOP)

6 4-230-222-31 PANEL, BACK

7 4-230-226-01 CASE (RIGHT)

34

Page 35

6-2. FRONT PANEL SECTION

51

52

53

z

C

54

54

54

54

z

A

55

z

B

56

not

supplied

57

Supplied with MAIN board.

z

A : PANEL board

z

B : LED board

z

C : MIC/PC MIX BOARD

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 4-230-213-21 WINDOW (TOP)

52 4-230-202-01 KNOB (MAIN)

53 X-4953-277-1 PANEL SUB ASSY, FRONT

54 4-951-620-01 SCREW (2.6X8), +BVTP

55 4-933-134-11 SCREW (+PTPWH M2.6X8)

56 1-765-343-11 WIRE (FLAT TYPE) (23 CORE)

57 4-230-203-01 KNOB (MIXING)

35

Page 36

6-3. CHASSIS SECTION

Supplied with MAIN board.

z

D : BA CK PANEL board

not supplied

101

CDM55C-K6BD37A

not supplied

#2

#2

107

#2

#3

#4

104

105

102

103

#2

#3

#2

#2

118

not supplied

116

106

#2

120

#2

not supplied

z

113

115

#2

D

#2

not supplied

#2

111

not supplied

T901

not supplied

not supplied

110

108

#2

#2

not supplied

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 4-230-206-01 PANEL, LOADING

102 1-693-488-11 TUNER (FM/AM)

103 1-782-648-11 WIRE (FLAT TYPE) (23 CORE)

104 1-757-266-11 WIRE (FLAT TYPE) (13 CORE)

105 1-769-980-11 WIRE (FLAT TYPE) (13 CORE)

106 3-703-244-00 BUSHING (2104), CORD

107 3-704-515-01 SCREW (BV/RING)

108 A-4475-307-A MAIN BOARD, COMPLETE

109 4-965-822-01 FOOT

#4

110 3-970-608-01 SUMITITE (B3), +BV

* 111 3-743-347-01 COVER, FUSE

* 113 4-374-846-21 COVER, CAPACITOR, CAP TYPE

115 3-531-576-01 RIVET

0 116 1-775-787-41 CORD, POWER

118 1-690-589-31 WIRE (FLAT TYPE) (13 CORE)

120 A-4725-499-A VIDEO BOARD, COMPLETE

0 T901 1-435-653-11 TRANSFORMER, POWER

109

36

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Page 37

6-4. CD MECHANISM DECK SECTION

(CDM55C-K6BD37A)

154

159

161

152

M103

153

157

164

158

155

156

165

160

167

162

151

BU-K6BD37A

163

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

151 4-224-894-11 TRAY (CDM55D)

152 4-220-229-01 LEVER (SW)

153 4-220-239-11 SPRING, TORSION

154 4-221-816-11 BELT (CDM55)

155 4-220-234-01 PULLEY (LDG)

156 4-220-238-01 GEAR (B)

157 4-220-237-01 GEAR (A)

158 4-220-233-01 CAM (CDM55)

159 1-674-336-21 LOADING BOARD

160 4-221-815-01 ROLLER

161 7-685-534-19 SCREW +BTP 2.6X8 TYPE2 N-S

162 X-4953-195-1 PULLEY (AT) ASSY

163 4-985-672-01 SCREW (+PTPWHM2.6), FLOATING

164 4-227-598-01 SPACER (55)

165 1-452-925-21 MAGNET ASSY

167 4-227-236-01 CHASSIS (CDM55C)

M103 A-4672-984-A MOTOR (LD) ASSY (LOADING)

37

Page 38

6-5. BASE UNIT SECTION (BU-K6BD37A)

201

201

202

M101

(include OPTICAL PICK-UP

KSM-213DCP/Z-NP)

201

204

203

205

202

202

201

202

M102

(include OPTICAL PICK-UP

KSM-213DCP/Z-NP)

208

206

206

207

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

201 4-985-672-01 SCREW (+PTPWHM2.6), FLOATING

202 4-227-679-01 INSULATOR (213)

0 203 8-820-116-01 OPTICAL PICK-UP KSM-213DCP/Z-NP

204 A-4725-001-A BD BOARD, COMPLETE

206

205 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

206 4-229-806-01 SPRING (213), COMPRESSION

207 X-4953-169-1 HOLDER (BU) ASSY

208 4-951-620-01 SCREW (2.6X8), +BVTP

206

38

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Page 39

SECTION 7

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

MET AL OXIDE: Metal Oxide-f ilm resistor

F: nonflammable

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

BACK PANEL BOARD

****************

1-533-293-11 FUSE HOLDER

< CAPACITOR >

C101 1-162-282-31 CERAMIC 100PF 10% 50V

C102 1-162-282-31 CERAMIC 100PF 10% 50V

C103 1-104-665-11 ELECT 100uF 20.00% 10V

C105 1-164-159-11 CERAMIC 0.1uF 50V

C107 1-164-159-11 CERAMIC 0.1uF 50V

C108 1-164-159-11 CERAMIC 0.1uF 50V

C151 1-162-282-31 CERAMIC 100PF 10% 50V

C152 1-162-282-31 CERAMIC 100PF 10% 50V

< CONNECTOR >

CN1 1-774-108-11 PIN, CONNECTOR (PC BOARD)

* CN2 1-564-687-11 PIN, CONNECTOR 3P

CN101 1-784-735-11 CONNECTOR, FFC 13P

< FUSE >

0 F1 1-532-500-51 FUSE, CYLINDRICAL (TIME-LAG) 0.63A/250V

< IC >

IC101 8-749-923-04 IC TOTX178 (CD DIGITAL OUT OPTICAL)

< JACK >

J101 1-766-851-11 JACK, PIN 4P (MD/VIDEO(AUDIO))

< RESISTOR >

R101 1-249-417-11 CARBON 1K 5% 1/4W F

R102 1-249-441-11 CARBON 100K 5% 1/4W

R151 1-249-417-11 CARBON 1K 5% 1/4W F

R152 1-249-441-11 CARBON 100K 5% 1/4W

< SWITCH >

0 S1 1-762-753-11 SWITCH, VOLTAGE SELECTION

**************************************************************

• Abbreviation

CND : Canadian model.

G : German model.

EA : Saudi Arabia model.

AUS : Australian model.

SP : Singapore model.

MY : Malaysia model.

AR : Argentine model.

TH : Thai model.

AED : North European model.

MX : Mexican model.

KR : Korean model.

• CAPACITORS:

uF: µF

• COILS

uH: µH

(Supplied with MAIN board)

(VOLTAGE SELECTOR)

• SEMICONDUCTORS

A-4725-001-A BD BOARD, COMPLETE

C101 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C102 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C103 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C105 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C106 1-164-346-11 CERAMIC CHIP 1uF 16V

C107 1-164-346-11 CERAMIC CHIP 1uF 16V

C108 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C109 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C110 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C111 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C112 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C113 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C115 1-126-607-11 ELECT CHIP 47uF 20% 4V

C116 1-126-607-11 ELECT CHIP 47uF 20% 4V

C117 1-126-209-11 ELECT CHIP 100uF 20.00% 4V

C118 1-163-275-11 CERAMIC CHIP 0.001uF 5.00% 50V

C119 1-163-106-00 CERAMIC CHIP 36PF 5.00% 50V

C120 1-109-982-11 CERAMIC CHIP 1uF 10.00% 10V

C121 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C122 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C123 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C124 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C126 1-124-779-00 ELECT CHIP 10uF 20% 16V

C130 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C140 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C141 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C154 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C159 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C161 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C170 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C171 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C180 1-163-137-00 CERAMIC CHIP 680PF 5% 50V

C181 1-163-137-00 CERAMIC CHIP 680PF 5% 50V

C182 1-163-137-00 CERAMIC CHIP 680PF 5% 50V

C183 1-163-137-00 CERAMIC CHIP 680PF 5% 50V

C184 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C185 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C186 1-128-065-11 ELECT CHIP 68uF 20.00% 10V

C187 1-163-038-11 CERAMIC CHIP 0.1uF 25V

BACK PANEL BD

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety .

Replace only with part number specified.

*******************

< CAPACITOR >

39

Page 40

BD LODAINGLED

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< CONNECTOR >

CN101 1-770-706-11 CONNECTOR, FFC/FPC 23P

CN102 1-777-937-11 CONNECTOR, FFC/FPC 16P

< IC >

IC101 8-752-397-42 IC CXD3008Q

IC102 8-759-640-22 IC BA5982FM

IC103 8-752-085-51 IC CXA2568M-T6

IC104 8-759-325-67 IC TC7SH04F(TE85R)

IC104 8-759-398-25 IC TC7SH04F(TE85L)

< COIL >

L101 1-414-234-22 INDUCTOR 0uH

L102 1-410-377-31 INDUCTOR CHIP 4.7uH

MIC/PC MIX

R175 1-216-025-11 RES-CHIP 100 5% 1/10W

R180 1-216-097-11 RES-CHIP 100K 5% 1/10W

R181 1-216-100-00 RES-CHIP 130K 5% 1/10W

R182 1-216-081-00 METAL CHIP 22K 5% 1/10W

R183 1-216-081-00 METAL CHIP 22K 5% 1/10W

R184 1-216-070-00 METAL CHIP 7.5K 5% 1/10W

R185 1-216-070-00 METAL CHIP 7.5K 5% 1/10W

R186 1-216-081-00 METAL CHIP 22K 5% 1/10W

R187 1-216-081-00 METAL CHIP 22K 5% 1/10W

R188 1-216-070-00 METAL CHIP 7.5K 5% 1/10W

R189 1-216-070-00 METAL CHIP 7.5K 5% 1/10W

R190 1-216-081-00 METAL CHIP 22K 5% 1/10W

R191 1-216-081-00 METAL CHIP 22K 5% 1/10W

R192 1-216-070-00 METAL CHIP 7.5K 5% 1/10W

R193 1-216-070-00 METAL CHIP 7.5K 5% 1/10W

< TRANSISTOR >

Q101 8-729-010-08 TRANSISTOR MSB710-R

Q101 8-729-049-31 TRANSISTOR 2SB710-RTX

< RESISTOR >

R101 1-216-077-91 RES-CHIP 15K 5% 1/10W

R102 1-216-097-11 RES-CHIP 100K 5% 1/10W

R103 1-216-077-91 RES-CHIP 15K 5% 1/10W

R104 1-216-085-00 METAL CHIP 33K 5% 1/10W

R105 1-216-073-00 METAL CHIP 10K 5% 1/10W

R106 1-216-049-11 RES-CHIP 1K 5% 1/10W

R107 1-216-073-00 METAL CHIP 10K 5% 1/10W

R108 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R109 1-216-121-11 RES-CHIP 1M 5% 1/10W

R110 1-216-295-11 SHORT 0

R112 1-216-025-11 RES-CHIP 100 5% 1/10W

R123 1-216-073-00 METAL CHIP 10K 5% 1/10W

R124 1-216-097-11 RES-CHIP 100K 5% 1/10W

R125 1-216-033-00 METAL CHIP 220 5% 1/10W

R126 1-216-033-00 METAL CHIP 220 5% 1/10W

R127 1-216-033-00 METAL CHIP 220 5% 1/10W

R131 1-216-033-00 METAL CHIP 220 5% 1/10W

R135 1-216-295-11 SHORT 0

R136 1-216-295-11 SHORT 0

R137 1-216-295-11 SHORT 0

R194 1-216-295-11 SHORT 0

R203 1-216-025-11 RES-CHIP 100 5% 1/10W

R204 1-216-025-11 RES-CHIP 100 5% 1/10W

R205 1-216-025-11 RES-CHIP 100 5% 1/10W

R206 1-216-295-11 SHORT 0

< SWITCH >

S101 1-771-853-11 SWITCH, DETECTION (LIMIT)

**************************************************************

LED BOARD

*********

(Supplied with MAIN board)

< DIODE >

D803 8-719-071-41 DIODE SELS5923C-TP15

D804 8-719-071-41 DIODE SELS5923C-TP15

**************************************************************

1-674-336-21 LOADING BOARD

**************

(Supplied with MAIN board)

< CONNECTOR >

* CN1 1-568-943-11 PIN, CONNECTOR 5P

< SWITCH >

R138 1-216-295-11 SHORT 0

R143 1-216-103-00 METAL CHIP 180K 5% 1/10W

R144 1-216-103-00 METAL CHIP 180K 5% 1/10W

R145 1-216-121-11 RES-CHIP 1M 5% 1/10W

R146 1-216-121-11 RES-CHIP 1M 5% 1/10W

R147 1-216-041-00 METAL CHIP 470 5% 1/10W

R148 1-216-001-00 METAL CHIP 10 5% 1/10W

R149 1-216-003-11 RES-CHIP 12 5% 1/10W

R150 1-216-073-00 METAL CHIP 10K 5% 1/10W

R154 1-216-025-11 RES-CHIP 100 5% 1/10W

R155 1-216-025-11 RES-CHIP 100 5% 1/10W

R156 1-216-025-11 RES-CHIP 100 5% 1/10W

R157 1-216-025-11 RES-CHIP 100 5% 1/10W

R158 1-216-073-00 METAL CHIP 10K 5% 1/10W

R159 1-216-089-11 RES-CHIP 47K 5% 1/10W

R161 1-216-295-11 SHORT 0

R162 1-216-101-00 METAL CHIP 150K 5% 1/10W

R171 1-216-025-11 RES-CHIP 100 5% 1/10W

R172 1-216-025-11 RES-CHIP 100 5% 1/10W

R173 1-216-025-11 RES-CHIP 100 5% 1/10W

40

S1 1-771-799-11 SWITCH, LEVER (SLIDE)(LOADING)

**************************************************************

MIC/PC MIX BOARD

****************

(Supplied with MAIN board)

< CAPACITOR >

C701 1-162-294-31 CERAMIC 0.001uF 10% 50V

C702 1-162-294-31 CERAMIC 0.001uF 10% 50V

C703 1-164-159-11 CERAMIC 0.1uF 50V

C704 1-164-159-11 CERAMIC 0.1uF 50V

C705 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C706 1-124-257-00 ELECT 2.2uF 20% 50V

C707 1-162-294-31 CERAMIC 0.001uF 10% 50V

C708 1-162-294-31 CERAMIC 0.001uF 10% 50V

C709 1-162-302-11 CERAMIC 0.0022uF 20.00% 16V

C710 1-124-261-00 ELECT 10uF 20% 50V

Page 41

MAINMIC/PC MIX

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C711 1-124-261-00 ELECT 10uF 20% 50V

C712 1-162-294-31 CERAMIC 0.001uF 10% 50V

C713 1-162-215-31 CERAMIC 47PF 5% 50V

C714 1-124-261-00 ELECT 10uF 20% 50V

C717 1-124-261-00 ELECT 10uF 20% 50V

C23 1-126-951-11 ELECT 470uF 20.00% 35V

C27 1-126-767-11 ELECT 1000uF 20.00% 16V

C28 1-128-551-11 ELECT 22uF 20.00% 25V

C29 1-126-967-11 ELECT 47uF 20.00% 50V

C30 1-164-159-11 CERAMIC 0.1uF 50V

C718 1-128-057-11 ELECT 330uF 20.00% 6.3V

C719 1-124-254-00 ELECT 0.68uF 20.00% 50V

C751 1-162-294-31 CERAMIC 0.001uF 10% 50V

< IC >

IC670 8-759-634-51 IC M5218AP

IC670 8-759-710-59 IC NJM4580D-D

< JACK >

J701 1-785-569-11 JACK (SMALL TYPE)(PHONES)

J702 1-785-569-11 JACK (SMALL TYPE)(MIC)

< RESISTOR >

R701 1-249-421-11 CARBON 2.2K 5% 1/4W F

R702 1-249-417-11 CARBON 1K 5% 1/4W F

R703 1-249-434-11 CARBON 27K 5% 1/4W

R704 1-249-417-11 CARBON 1K 5% 1/4W F

R705 1-249-434-11 CARBON 27K 5% 1/4W

R706 1-249-424-11 CARBON 3.9K 5% 1/4W F

R707 1-247-881-00 CARBON 120K 5% 1/4W

R708 1-247-807-31 CARBON 100 5% 1/4W

R709 1-249-417-11 CARBON 1K 5% 1/4W F

R710 1-249-417-11 CARBON 1K 5% 1/4W F

R711 1-249-429-11 CARBON 10K 5% 1/4W

C54 1-128-548-11 ELECT 4700uF 20.00% 25V

C201 1-126-964-11 ELECT 10uF 20.00% 50V

C202 1-136-172-00 MYLAR 0.39uF 5.00% 50V

C203 1-136-165-00 MYLAR 0.1uF 5.00% 50V

C204 1-130-476-00 MYLAR 0.0027uF 5% 50V

C205 1-126-960-11 ELECT 1uF 20.00% 50V

C206 1-126-964-11 ELECT 10uF 20.00% 50V

C207 1-126-963-11 ELECT 4.7uF 20.00% 50V

C208 1-162-294-31 CERAMIC 0.001uF 10% 50V

C209 1-126-935-11 ELECT 470uF 20.00% 16V

C210 1-161-494-00 CERAMIC 0.022uF 25V

C211 1-128-551-11 ELECT 22uF 20.00% 25V

C212 1-126-964-11 ELECT 10uF 20.00% 50V

C214 1-107-715-11 ELECT 22uF 20.00% 16V

C215 1-126-963-11 ELECT 4.7uF 20.00% 50V

C216 1-126-963-11 ELECT 4.7uF 20.00% 50V

C217 1-126-963-11 ELECT 4.7uF 20.00% 50V

C218 1-126-964-11 ELECT 10uF 20.00% 50V

C219 1-126-964-11 ELECT 10uF 20.00% 50V

C221 1-162-290-31 CERAMIC 470PF 10% 50V

C251 1-126-964-11 ELECT 10uF 20.00% 50V

C252 1-136-172-00 MYLAR 0.39uF 5.00% 50V

C253 1-136-165-00 MYLAR 0.1uF 5.00% 50V

C254 1-130-476-00 MYLAR 0.0027uF 5% 50V

C255 1-126-960-11 ELECT 1uF 20.00% 50V

< VARIABLE RESISTOR >

RV701 1-225-739-11 RES, VAR CARBON 50K (MIC VOL)

**************************************************************

A-4475-307-A MAIN BOARD, COMPLETE

*********************

7-682-148-01 SCREW+P 3X8

< CAPACITOR >

C2 1-136-165-00 FILM0.1uF 5.00% 50V

C3 1-136-165-00 FILM0.1uF 5.00% 50V

C4 1-128-548-11 ELECT 4700uF 20.00% 25V

C5 1-126-948-11 ELECT 100uF 20.00% 35V

C6 1-161-494-00 CERAMIC 0.022uF 25V

C7 1-126-933-11 ELECT 100uF 20.00% 16V

C8 1-136-165-00 FILM0.1uF 5.00% 50V

C9 1-136-165-00 FILM0.1uF 5.00% 50V

C10 1-126-768-11 ELECT 2200uF 20.00% 16V

C11 1-104-665-11 ELECT 100uF 20.00% 25V

C12 1-104-664-11 ELECT 47uF 20.00% 25V

C13 1-161-494-00 CERAMIC 0.022uF 25V

C15 1-104-664-11 ELECT 47uF 20.00% 25V

C16 1-128-551-11 ELECT 22uF 20.00% 25V

C17 1-104-664-11 ELECT 47uF 20.00% 25V

C256 1-126-964-11 ELECT 10uF 20.00% 50V

C257 1-126-963-11 ELECT 4.7uF 20.00% 50V

C265 1-126-963-11 ELECT 4.7uF 20.00% 50V

C266 1-126-963-11 ELECT 4.7uF 20.00% 50V

C267 1-126-963-11 ELECT 4.7uF 20.00% 50V

C268 1-126-964-11 ELECT 10uF 20.00% 50V

C269 1-126-964-11 ELECT 10uF 20.00% 50V

C271 1-162-290-31 CERAMIC 470PF 10% 50V

C302 1-161-494-00 CERAMIC 0.022uF 25V

C303 1-126-047-71 ELECT 4.7uF 20.00% 50V

C305 1-126-022-11 ELECT 47uF 20.00% 25V

C306 1-162-285-31 CERAMIC 180PF 10% 50V

C307 1-164-159-11 CERAMIC 0.1uF 50V

C308 1-164-159-11 CERAMIC 0.1uF 50V

C309 1-164-159-11 CERAMIC 0.1uF 50V

C310 1-164-159-11 CERAMIC 0.1uF 50V

C314 1-162-219-31 CERAMIC 68PF 5.00% 50V

C321 1-125-972-91 ELECT 100uF 20.00% 16V

C322 1-124-589-11 ELECT 47uF 20% 16V

C323 1-164-159-11 CERAMIC 0.1uF 50V

C352 1-161-494-00 CERAMIC 0.022uF 25V

C353 1-126-047-71 ELECT 4.7uF 20.00% 50V

C355 1-126-022-11 ELECT 47uF 20.00% 25V

C356 1-162-285-31 CERAMIC 180PF 10% 50V

C357 1-164-159-11 CERAMIC 0.1uF 50V

C18 1-128-551-11 ELECT 22uF 20.00% 25V

C19 1-126-965-11 ELECT 22uF 20.00% 50V

C20 1-126-965-11 ELECT 22uF 20.00% 50V

C21 1-126-967-11 ELECT 47uF 20.00% 50V

C22 1-164-159-11 CERAMIC 0.1uF 50V

C358 1-164-159-11 CERAMIC 0.1uF 50V

C359 1-164-159-11 CERAMIC 0.1uF 50V

C360 1-164-159-11 CERAMIC 0.1uF 50V

C364 1-162-219-31 CERAMIC 68PF 5.00% 50V

C411 1-126-935-11 ELECT 470uF 20.00% 6.3V

41

Page 42

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C415 1-164-159-11 CERAMIC 0.1uF 50V

C417 1-126-917-11 ELECT 3300uF 20.00% 6.3V

C418 1-126-928-11 ELECT 3300uF 20.00% 10V

C419 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C431 1-126-935-11 ELECT 470uF 20.00% 16V

C501 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C502 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C503 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C504 1-126-933-11 ELECT 100uF 20.00% 16V

C507 1-126-933-11 ELECT 100uF 20.00% 16V

C551 1-128-836-51 ELECT 2200uF 20% 10V

C552 1-104-664-11 ELECT 47uF 20.00% 16V

C553 1-164-159-11 CERAMIC 0.1uF 50V

C554 1-104-664-11 ELECT 47uF 20.00% 16V

C555 1-164-159-11 CERAMIC 0.1uF 50V

C556 1-164-159-11 CERAMIC 0.1uF 50V

C558 1-126-961-11 ELECT 2.2uF 20.00% 50V

C601 1-162-306-11 CERAMIC 0.01uF 30.00% 16V

C602 1-162-205-31 CERAMIC 18PF 5% 50V

C603 1-162-205-31 CERAMIC 18PF 5% 50V

D556 8-719-911-19 DIODE 1SS119

D601 8-719-911-19 DIODE 1SS119

< GROUND >

EPT1 1-537-770-21 TERMINAL BOARD, GROUND

EPT2 1-537-770-21 TERMINAL BOARD, GROUND

< IC >

IC1 8-759-039-69 IC uPC7805AHF

IC2 8-759-450-49 IC BA07T

IC3 8-759-633-42 IC M5293L

IC4 8-759-450-47 IC BA05T

IC201 8-759-669-03 IC IC LC75342

IC202 8-759-634-51 IC M5218AP

IC301 8-759-333-24 IC LM1876TF

IC501 8-759-822-09 IC LB1641

IC551 8-759-635-63 IC M51943BSL

IC601 8-759-830-99 IC M30622MAA-B04FP

< JACK >

C604 1-161-494-00 CERAMIC 0.022uF 25V

C605 1-161-494-00 CERAMIC 0.022uF 25V

C606 1-161-494-00 CERAMIC 0.022uF 25V

C607 1-161-494-00 CERAMIC 0.022uF 25V

C608 1-162-282-31 CERAMIC 100PF 10% 50V

C609 1-162-282-31 CERAMIC 100PF 10% 50V

C610 1-162-282-31 CERAMIC 100PF 10% 50V

C611 1-126-934-11 ELECT 220uF 20.00% 10V