HCD-V3900/V5900

SERVICE MANUAL

• This set is the tuner, deck,Video CD and

amplifier section in LBT-V3900/V5900.

Manufactured under license from Dolby Laboratories

Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks

of Dolby Laboratories Licensing Corporation.

Photo : HCD-V5900

CD CD Mechanism Type CDM37L-5BD21AL

Section Base Unit Name BU-5BD21AL

Tape deck Model Name Using Similar Mechanism HCD-V4800

Section T ape Transport Mechanism T ype TCM-220WR2

E Model

Model Name Using Similar Mechanism HCD-V4800

Optical Pick-up Name KSS-213D/Q-NP

Amplifier section

(HCD-V3900)

The following measured at AC 120/240 V, 50 Hz

DIN power output (Rated)

100 + 100 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (Reference)

120 + 120 watts

(6 ohms at 1 kHz, 10 % THD)

The following measured at AC 220 V, 50 Hz

DIN power output (Rated)

90 + 90 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (Reference)

105 + 105 watts

(6 ohms at 1 kHz, 10 % THD)

Peak music power output (Reference)

1,500 watts

(HCD-V5900)

The following measured at AC 120/240 V, 50 Hz

DIN power output (Rated)

120 + 120 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (Reference)

140 + 140 watts

(6 ohms at 1 kHz, 10 % THD)

The following measured at AC 220 V, 50 Hz

DIN power output (Rated)

110 + 110 watts

(6 ohms at 1 kHz, DIN)

SPECIFICATIONS

Continuous RMS power output (Reference)

130 + 130 watts

(6 ohms at 1 kHz, 10 % THD)

Peak music power output (Reference)

2,000 watts

Inputs

PHONO IN (phono jacks):

sensitivity 3 mV,

impedance 47 kilohms

VIDEO (AUDIO) IN (phono jacks):

sensitivity 250 mV,

impedance 47 kilohms

MIX MIC (phono jack):

sensitivity 1 mV,

impedance 10 kilohms

Outputs

VIDEO (AUDIO) OUT (phono jacks):

voltage 250 mV, impedance 1 kilohm

VIDEO (phono jack):

max. output level 1 Vp-p, unbalanced,

Sync negative, load impedance 75 ohms

S-VIDEO (4-pin/mini-DIN jack):

Y: 1 Vp-p, unbalanced, Sync negative

C: 0.286 Vp-p, load impedance 75 ohms

PHONES (stereo phone jack):

accepts headphones of 8 ohms or more

COMPACT HI-FI STEREO SYSTEM

SPEAKER:

accepts impedance of 6 to 16 ohms

Video CD/CD player section

System Compact disc digital audio and video

system

Laser Semiconductor laser (= 780 nm)

Emission

duration: continuous

Laser output

Max. 44.6 µW*

* This output is the value measured at a

distance of 200 mm from the objective

lens surface on the Optical Pick-up Block

with 7 mm aperture.

Wavelength

780 – 790 nm

Frequency response

2 Hz – 20 kHz (±0.5 dB)

Signal-to-noise ratio

More than 90 dB

Dynamic range

More than 90 dB

Video Color system format:

NTSC, PAL

— Continued on next page —

MICROFILM

Tape player section

Recording system

4-track 2-channel stereo

Frequency response (DOLBY NR OFF)

60 – 13,000 Hz (±3 dB), using a Sony TYPE I cassette

60 – 14,000 Hz (±3 dB), using a Sony TYPE II cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

87.5 – 108.0 MHz (50 kHz step)

Antenna

FM wire antenna

Antenna terminals

75 ohm unbalanced

Intermediate frequency

10.7 MHz

AM tuner section

Tuning range

531 – 1,602 MHz (with the tuning interval set at 9 kHz)

530 – 1,710 MHz (with the tuning interval set at 10 kHz)

Antenna

AM loop antenna, External antenna terminals

Intermediate frequency

450 kHz

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

General

Power requirements 110 – 120 V or 220 – 240 V AC, 50/60 Hz

adjustable with voltage selector

Power consumption (HCD-V3900) 245 watts

(HCD-V5900) 255 watts

Dimensions (w/h/d) Approx. 355 × 425 × 435 mm incl.

projecting parts and controls

Mass (HCD-V3900) Approx. 16.3 kg

(HCD-V5900) Approx. 16.8 kg

Supplied accessories AM loop antenna (1)

Remote (1)

RM-SV808S (LBT-V3900)

RM-SV4800S (LBT-V5900)

Size AA batteries (2)

FM wire antenna (1)

Speaker cords (2)

Video cable (1)

Design and specifications are subject to change without notice.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

The following caution label is located inside the unit.

— 2 —

TABLE OF CONTENTS

SERVICING NOTES

1. GENERAL ······································································ 4

2. DISASSEMBLY ····························································· 7

3. TEST MODE ·······························································15

4. MECHANICAL ADJUSTMENTS ························· 18

5. ELECTRICAL ADJUSTMENTS

DECK Section ··································································· 18

CD Section········································································· 21

VIDEO Section ··································································22

6. DIAGRAMS

6-1. Block Diagram — BD Section — ····································· 23

6-2. Block Diagram — VIDEO Section — ······························ 25

6-3. Block Diagram — MAIN Section — ································ 27

6-4. Circuit Board Location ······················································ 29

6-5. Schematic Diagram — BD Section — ······························ 31

6-6. Printed Wiring Board — BD Section — ··························· 33

6-7. Schematic Diagram — CD MOTOR Section —··············· 35

6-8. Printed Wiring Board — CD MOTOR Section —············ 37

6-9. Schematic Diagram — AUDIO Section —·······················39

6-10.Printed Wiring Board — AUDIO Section — ···················· 41

6-11.Printed Wiring Board — MAIN Section — ······················ 43

6-12.Schematic Diagram — MAIN Section (1/3) — ················ 45

6-13.Schematic Diagram — MAIN Section (2/3) — ················ 47

6-14.Schematic Diagram — MAIN Section (3/3) — ················ 49

6-15.Printed Wiring Board — VIDEO Section — ···················· 51

6-16.Schematic Diagram — VIDEO Section (1/3) — ·············· 53

6-17.Schematic Diagram — VIDEO Section (2/3) — ·············· 55

6-18.Schematic Diagram — VIDEO Section (3/3) — ·············· 57

6-19.Schematic Diagram — PANEL Section — ······················· 59

6-20.Printed Wiring Board — PANEL Section — ···················· 61

6-21.Schematic Diagram — VIDEO OUT Section — ·············· 63

6-22.Printed Wiring Board — VIDEO OUT Section — ··········· 65

6-23.Schematic Diagram — AMP KEY CONTROL Section —67

6-24.Printed Wiring Board

— AMP/KEY CONTROL Section —·······························69

6-25.Schematic Diagram — POWER Section —······················ 71

6-26.Printed Wiring Board — POWER Section —··················· 73

6-27.IC Pin Function Description ·············································· 74

6-28.IC Block Diagrams ···························································· 83

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveforms is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

7. EXPLODED VIEWS ·················································88

8. ELECTRICAL PARTS LIST ··································97

— 3 —

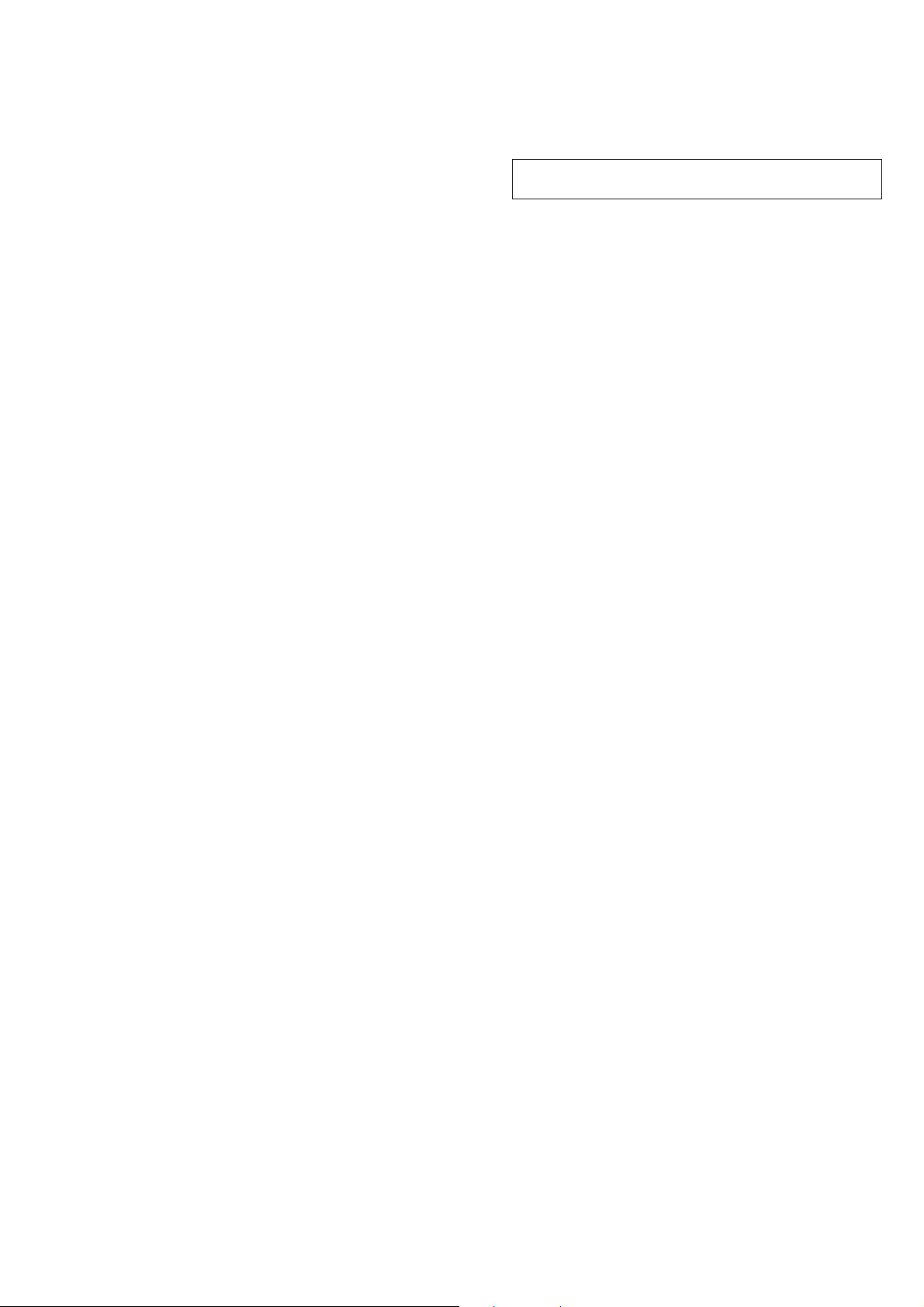

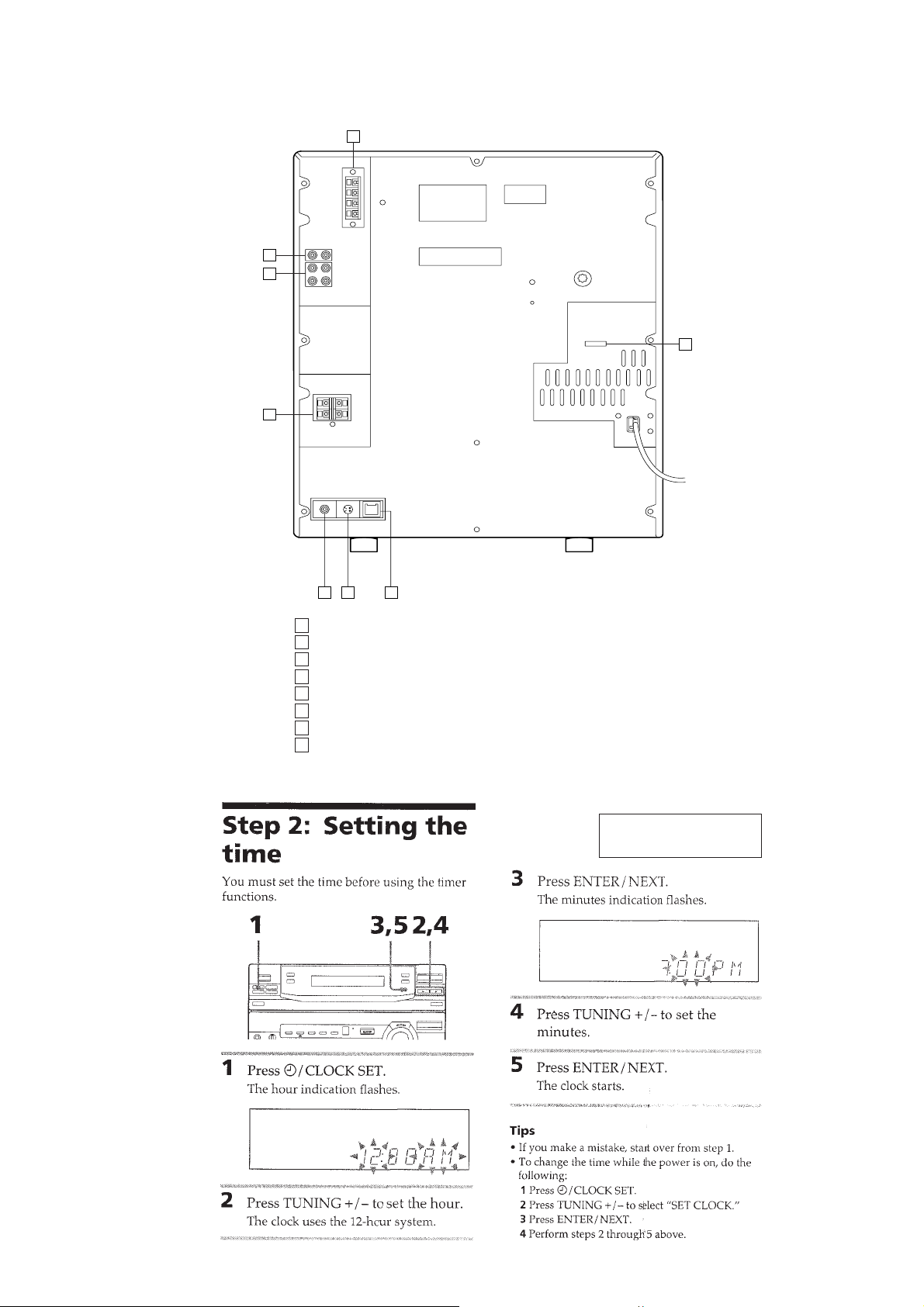

– FRONT PANEL –

SECTION 1

GENERAL

$¢

%ª ^º

%¶ %•

%§

%¢ %∞

%£

%¡ %™

$ª$• %º

$§

$¶

$∞

$£

$™

$¡

$º

123 4 67

A

5

B

89

!¡

!™

!£ !¢

!∞

!§

!¶

!•

!ª @º

@¡ @™ @£

@¢ @∞

@§ @¶

@ª #º

#¡ #™ #£

@•

A

1 1/u button

2 DISPLAY/DEMO button

3 SPECTRUM ANALYZER button

4 ENTER/NEXT button

5 TUNER MEMORY button

6 TUNING MODE button

7 TUNER/BAND button

8 TUNING – button

9 TUNING + button

!¡ STEREO/MONO button

!™ EFFECT button

!£ GROOVE button

!¢ FUNCTION button

!∞ VOLUME knob

!§ SUPER WOOFER button

!¶ SUPER W MODE

!• GEQ button

!ª DECK B ª (play) button

@º DECK B · (play) button

@¡ DECK B p (stop) button

@™ DECK B 0 (backward) button

@£ DECK B ) (forward) button

@¢ DECK B P (pause) button

@∞ DECK B r REC button

^¡ ^™ ^£ ^¢

^• ^∞

^¶ ^§

@§ H SPEED DUB button

@¶ CD SYNC button

@• DECK B 6 EJECT button

@ª CD 6 OPEN button

#º CD · (play) button

#¡ DISK SKIP button

#™ CD P (pause) button

#£ CD p (stop) button

#¢ CD ) (forward) button

#∞ ≠ AMS ± knob

#§ CD 0 (backward) button

#¶ CD FLASH button

#• CD LOOP button

#ª CD NON-STOP button

$º DISC 1 button

$¡ DISC 2 button

$™ DISC 3 button

$£ DISC 4 button

$¢ DISC 5 button

$∞ DECK A 6 EJECT button

$§ DIRECTION button

$¶ DOLBY NR button

$• DECK A p (stop) button

$ª DECK A 0 (backward) button

#¢

#∞#§#• #¶#ª

&™ ^ª

B

&¡

&º

%º DECK A ) (forward) button

%¡ DECK A ª (play) button

%™ DECK A · (play) button

%£ PHONES jack

%¢ MIC1, MIC2 jack

%∞ MIC LEVEL, ECHO LEVEL knobs

%§ SLEEP button

%¶ DAILY 1 button

%• DAILY 2 button

%ª t / CLOCK SET button

^º REC button

^¡ WAVE button

^™ SURROUND button

^£ P FILE MEMORY button

^¢ GEQ CONTROL button

^∞ ENTER button

^§ KEY CONTROL (n) button

^¶ KEY CONTROL (˜) button

^• KARAOKE PON/MPX button

^ª PLAY MODE button

&º REPEAT button

&¡ EDIT button

&™ 1/ALL DISCS button

— 4 —

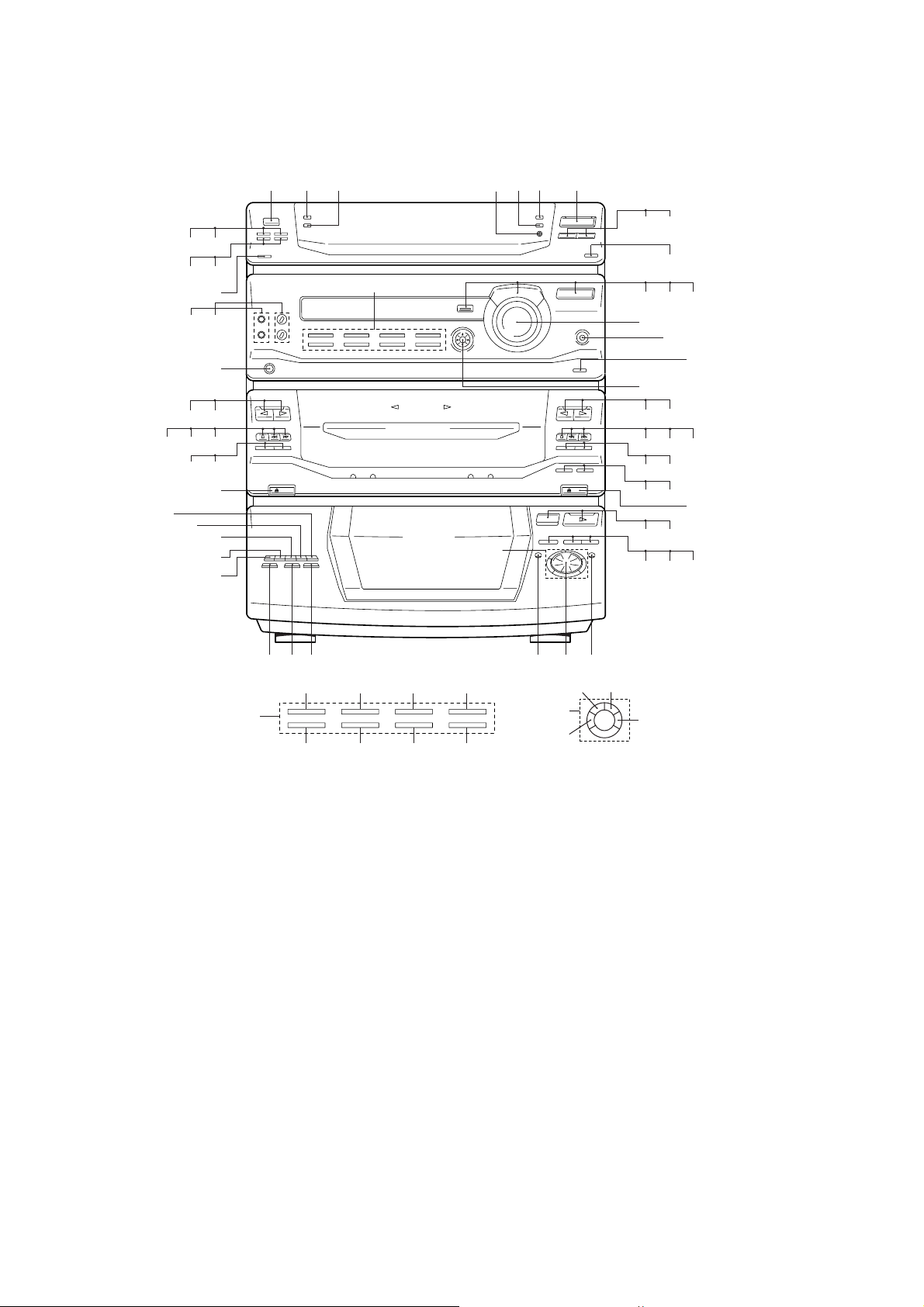

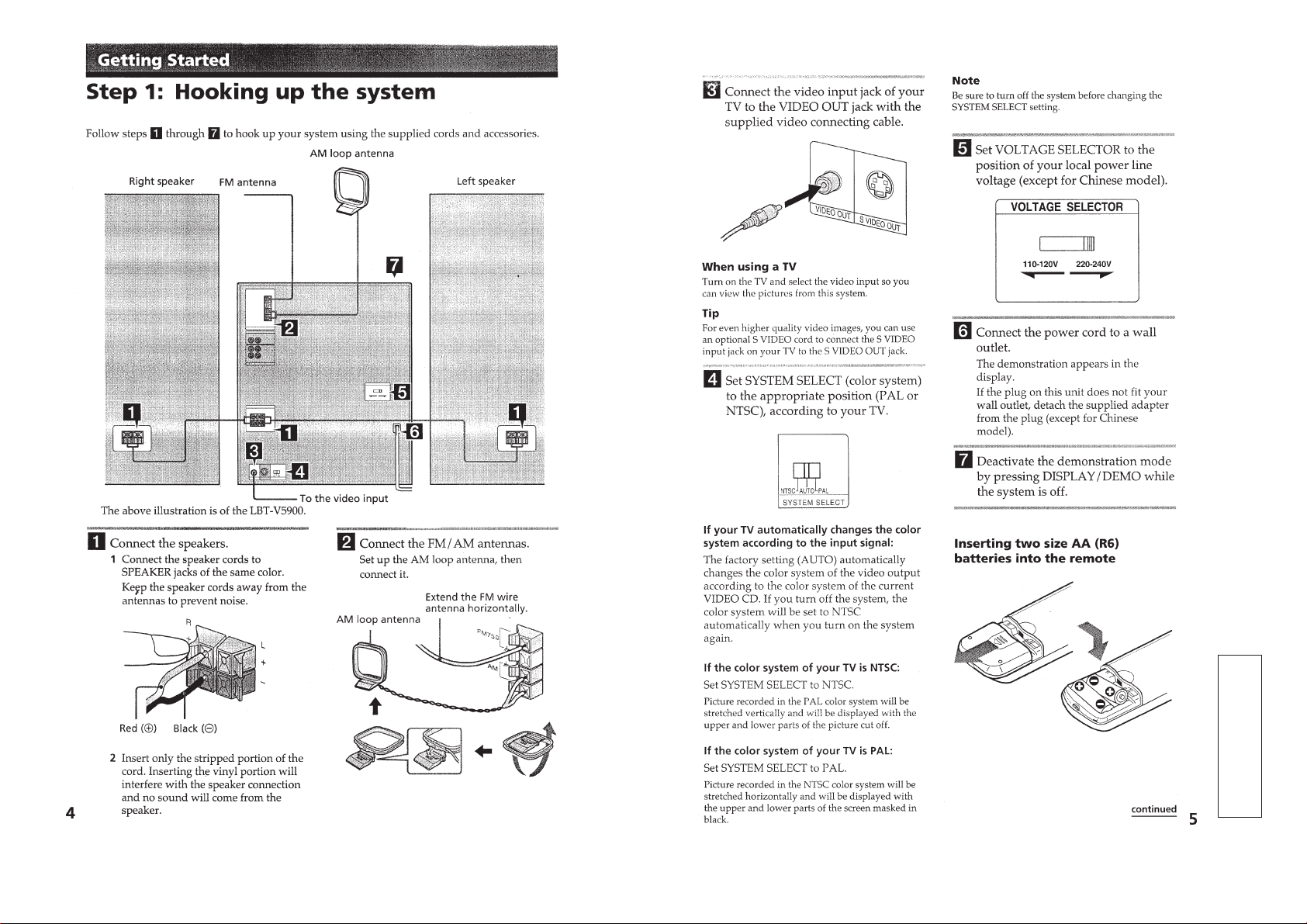

– BACK PANEL –

⁄‚⁄

⁄‚fl

⁄‚fi

⁄‚‹

⁄‚‹

IN

OUT

⁄⁄‚ ⁄‚·

⁄‚°

⁄‚⁄ ANTENNA terminal

⁄‚¤ VOLTAGE SELECTOR switch (E, AR model)

⁄‚‹ SPEAKER terminal

⁄‚fi VIDEO (AUDIO) jack

⁄‚fl PHONO jack

⁄‚° SYSTEM SELECT

⁄‚· S VIDEO OUT

⁄⁄‚ VIDEO OUT

⁄‚¤

— 5 —

This section is extracted

from instruction manual.

— 6 —

from instruction manual.

This section is extracted

)

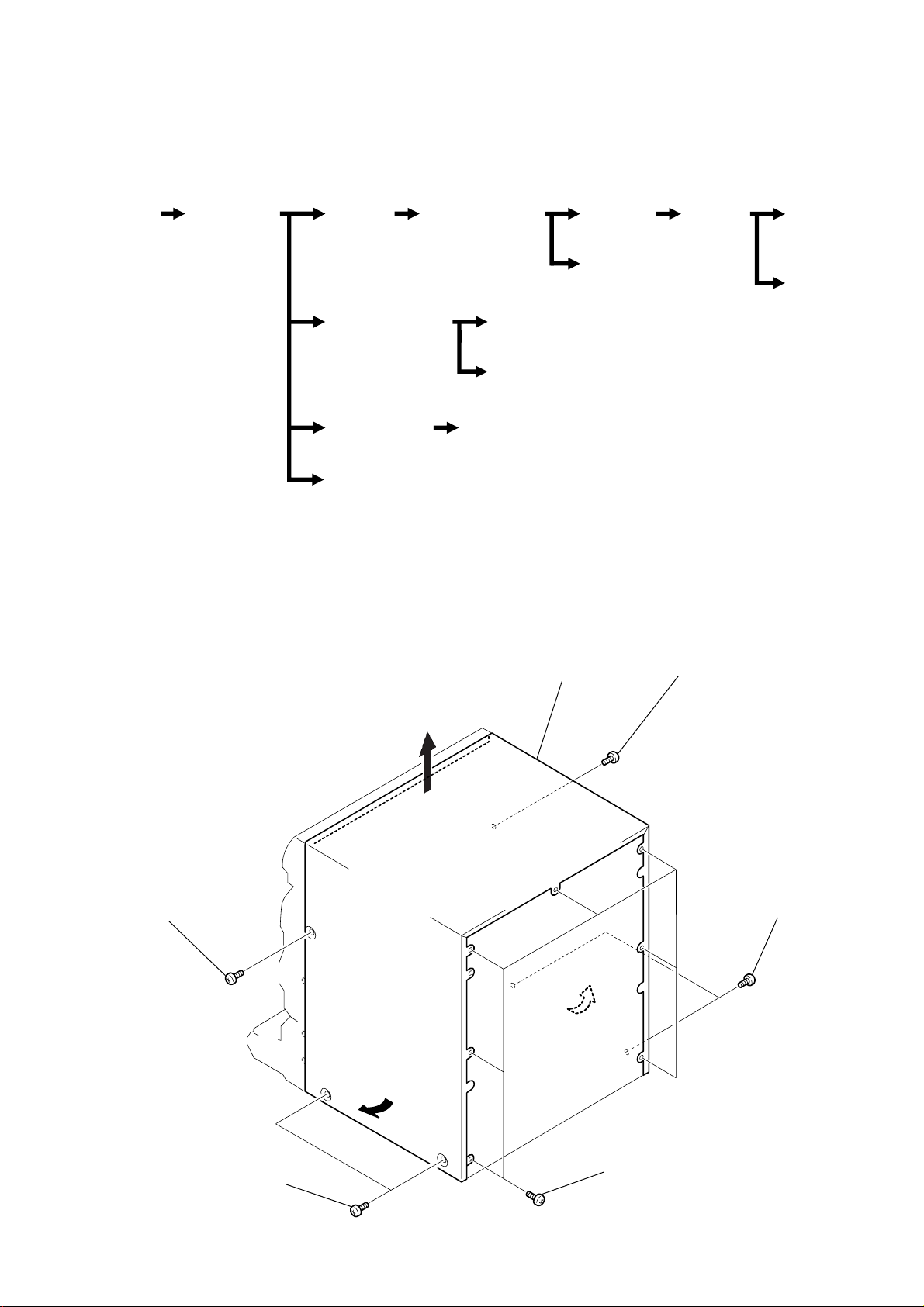

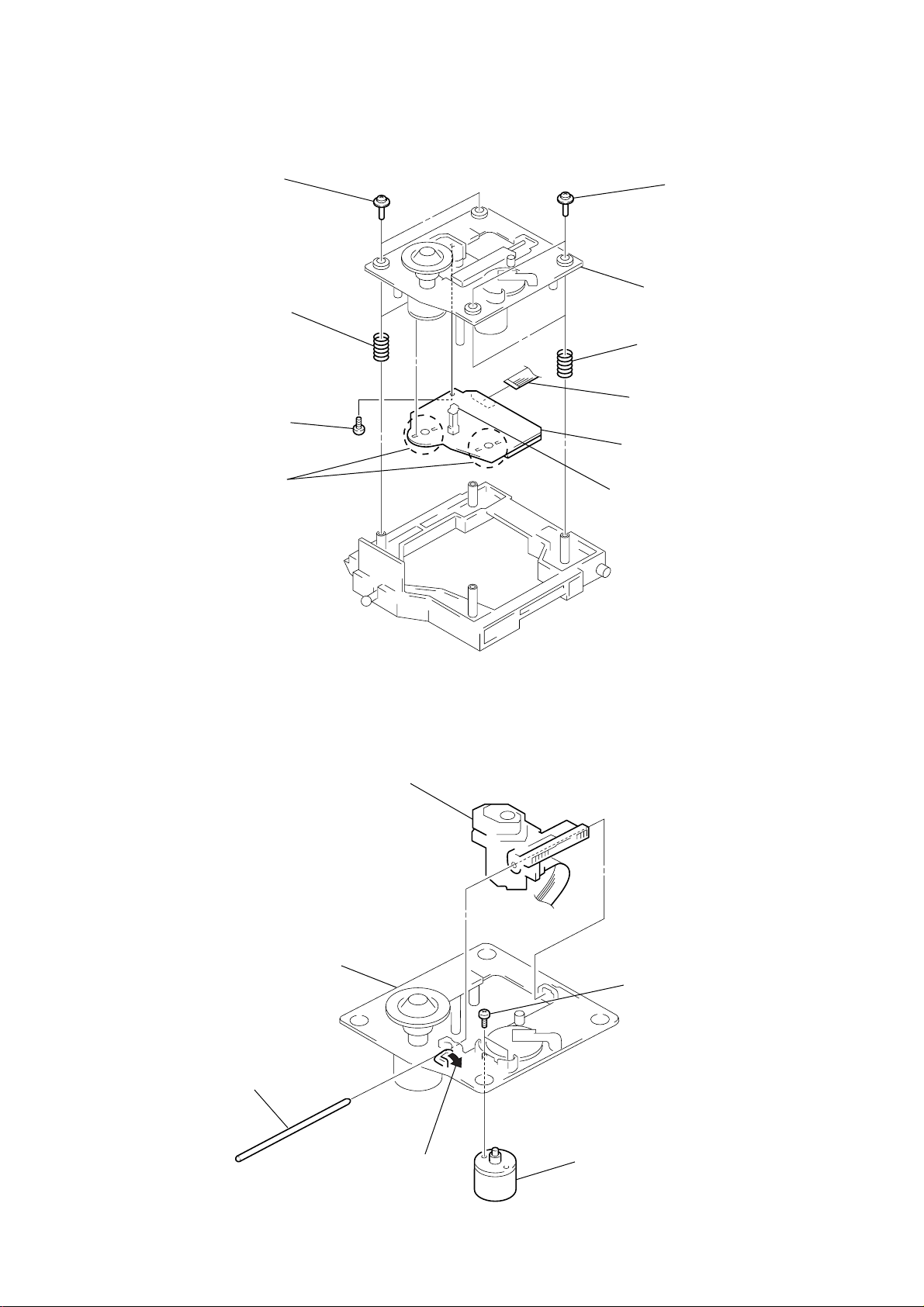

• This set can be disassembled in the order shown below.

SECTION 2

DISASSEMBLY

CASE

(Page 7)

Note: Follow the disassembly procedure in the numerical order given.

FRONT PANEL

SECTION

(Page 8)

MAIN

SECTION

(Page 9)

TAPE MECHANISM

DECK SECTION

(TCM-220WR2)

(Page 10)

CD LID ASS’Y

SECTION

(Page 11)

MAIN BOARD

(Page 8)

CD MECHANISM

DECK SECTION

(CDM37L-5BD21AL)

(Page 9)

PANEL (A)/(B)

SUB ASS’Y

(Page 11)

2-1. CASE

BASE UNIT

(BU-5BD21AL)

(Page 12)

DISC TABLE

(Page 12)

CAPSTAN MOTOR (M1)

(Page 14)

CASSETTE

LID ASS’Y

(Page 10)

3

case

BD BOARD

(Page 13)

1

screw

(case 3 TP2)

OPTICAL

PICK-UP

(KSS-213D/Q-NP)

(Page 13)

SLED

MOTOR (M102),

SPINDLE

MOTOR (M101)

(Page 13)

1

screw

(case 3 TP2)

1

two screws

(case 3 point)

— 7 —

2

seven screws

(BVTT 3

1

two screws

(case 3 point

×

6)

)

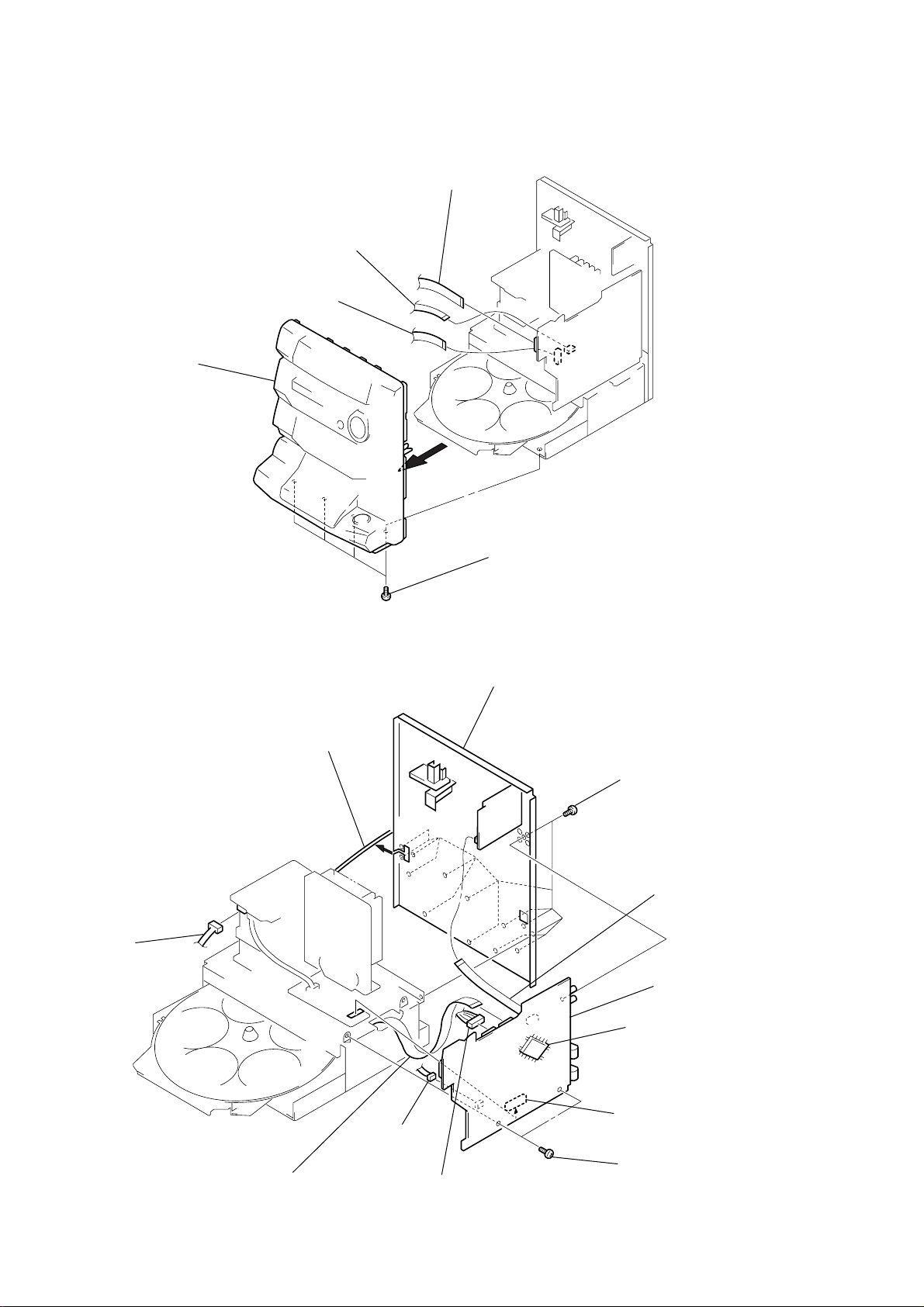

2-2. FRONT PANEL SECTION

1

3

front panel section

1

flat wire (11 core)

(CN206)

flat wire (21 core)

(CN205)

1

flat wire (17 core)

(CN102)

2

four screws

(BVTP 3 × 8)

2-3. MAIN BOARD

5

connector

(CN901)

3

power cord

4

back panel

2

fourteen screws

(BVTP 3

1

flat wire (13 core

(CN1)

8

MAIN board

IC201

×

8)

5

flat wire (13 core)

(CN202)

1

connector

(CN106)

5

connector

(CN203)

— 8 —

7

connector

(CN101)

6

two screws

(BVTP 3

×

8)

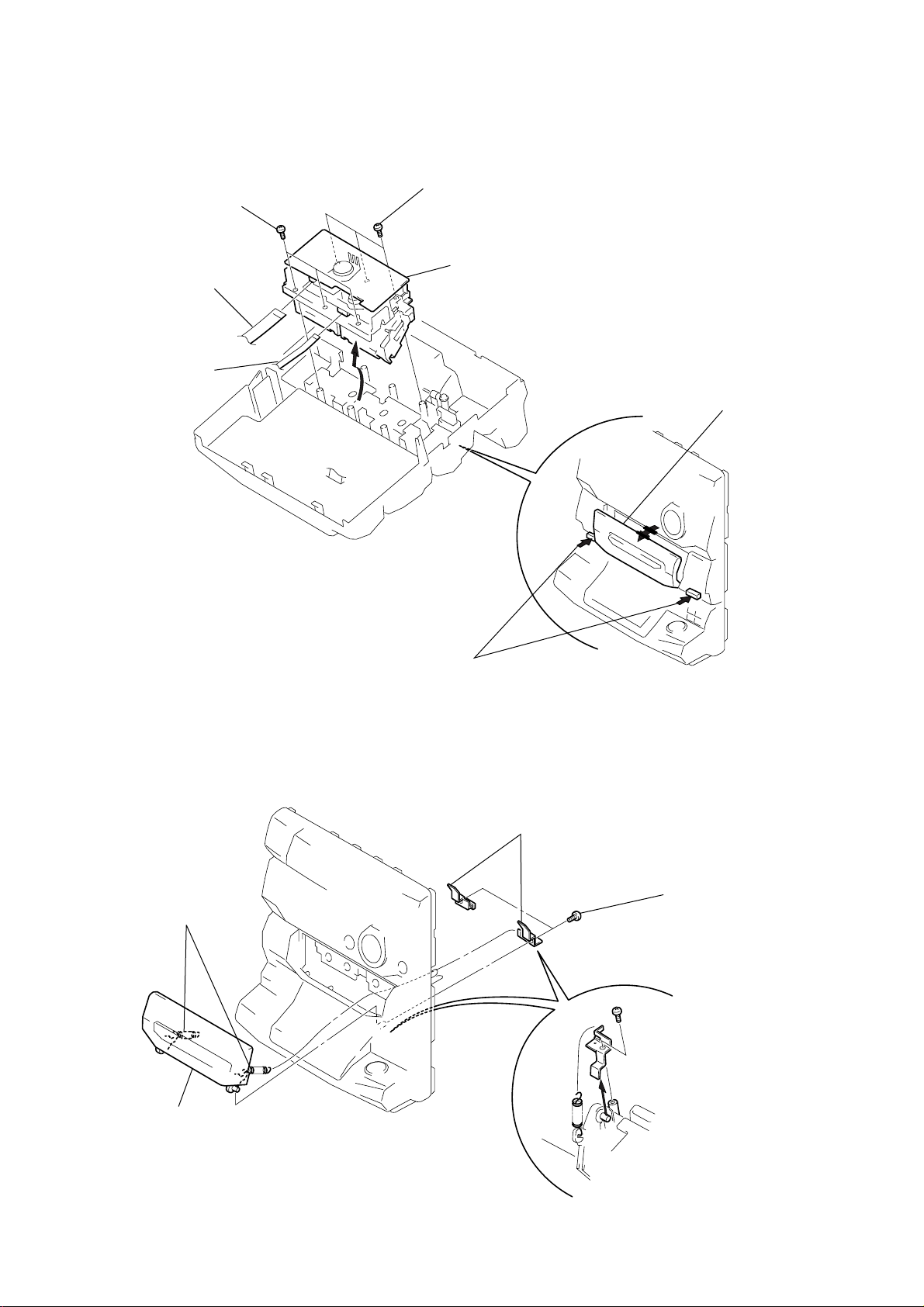

2-4. MAIN SECTION

)

3

two screws

(BVTP 3

×

8)

2

connector

(CN203)

1

flat wire (13 core)

(CN202)

4

main section

3

eight screws

(BVTP 3

3

two screws

(BVTP 3

×

8

×

8)

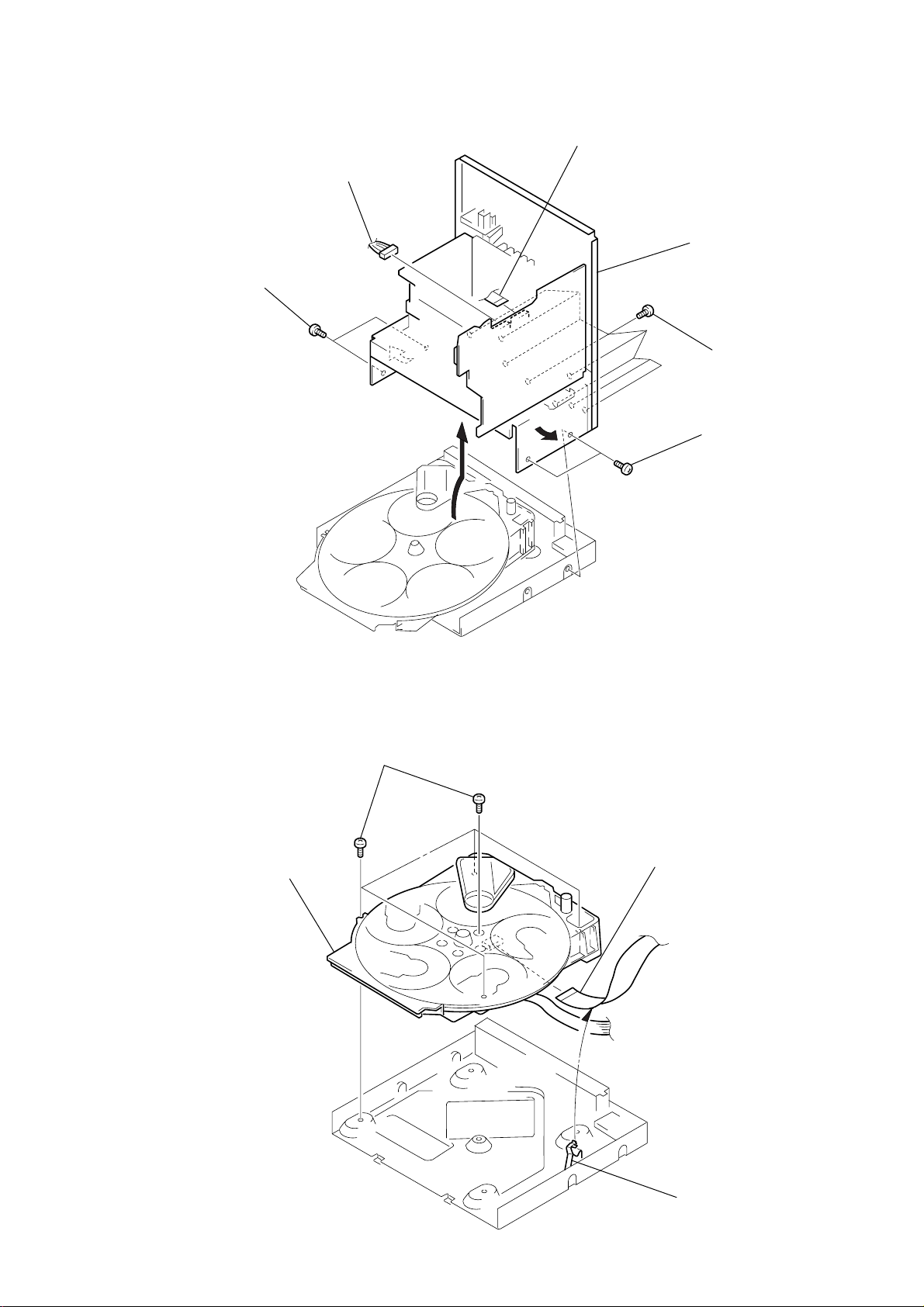

2-5. CD MECHANISM DECK SECTION (CDM37L-5BD21AL)

2

five screws

(BVTP 3 × 8)

3

CD mechanism

deck section

(CDM37A-5BD21AL)

4

flat wire (29 core)

(CN101)

— 9 —

1

Open the clamp.

2-6. TAPE MECHANSM DECK SECTION (TCM-220WR2)

)

4

4

three screws

(BVTP 2.6

3

flat wire (21 core)

(CN601)

3

flat wore (11 core)

(CN1001)

×

8)

A

three screws

(BVTP 2.6

×

8)

5

Remove the tape mechanism

deck section (TCM-220WR2)

to derection of the arrow

A

.

2

Open the

cassette lids.

2-7. CASSETTE LID ASS’Y

1

two springs

4

cassette lid ass y

1

Push the

two buttons.

3

two brackets

2

two screws

(BVTP 2.6 × 8

— 10 —

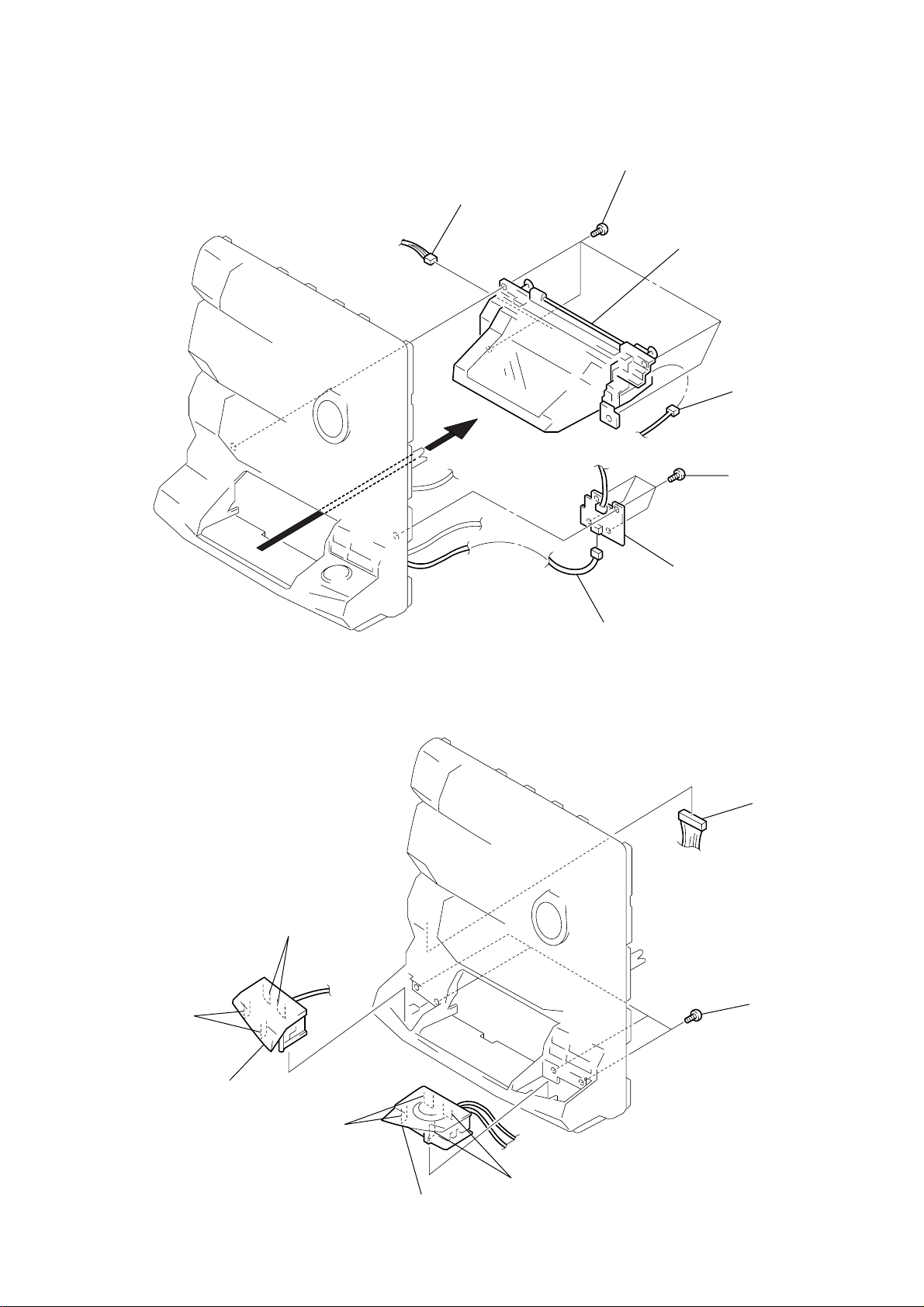

2-8. CD LID ASS’Y SECTION

)

)

5

connector

(CN671)

6

four screws

(BVTP 2.6

×

8)

7

CD lid ass y

4

connector

(CN661)

2

four screws

(BVTP 2.6

×

8

2-9. PANEL (A) / (B) SUB ASS’Y

3

two claws

3

two claws

1

connector

(CN642)

3

CD-B1 SW board

1

connector

(CN612)

2

four screws

(BVTP 2.6 × 8

4

panel (A) sub ass y

5

two claws

6

panel (B) sub ass y

— 11 —

5

two claws

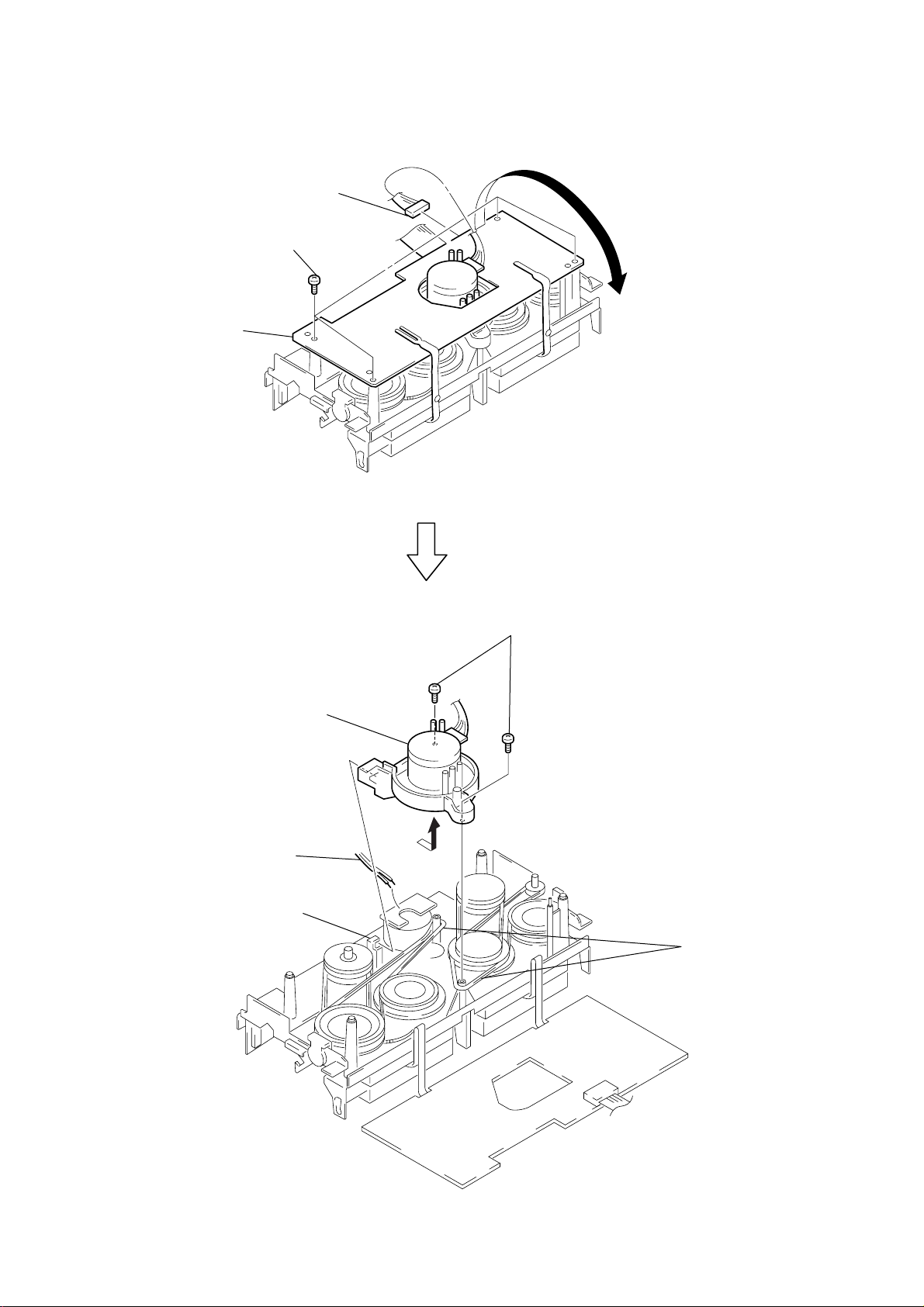

2-10. BASE UNIT (BU-5BD21AL)

e

3

base unit

(BU-5BD21AL)

2

2-11. DISC TABLE

Note:

When the disc table is installed, adjust the positions

of roller cam amd mark ( as shown in the figure, then

set to the groove of disc table.

A

boss

1

screw

(BVTP 3 × 8)

2

bracket (BU)

1

screw

(BVTP 3 × 8)

1

yoke bracket

3

step screw

4

disc tabl

— 12 —

A

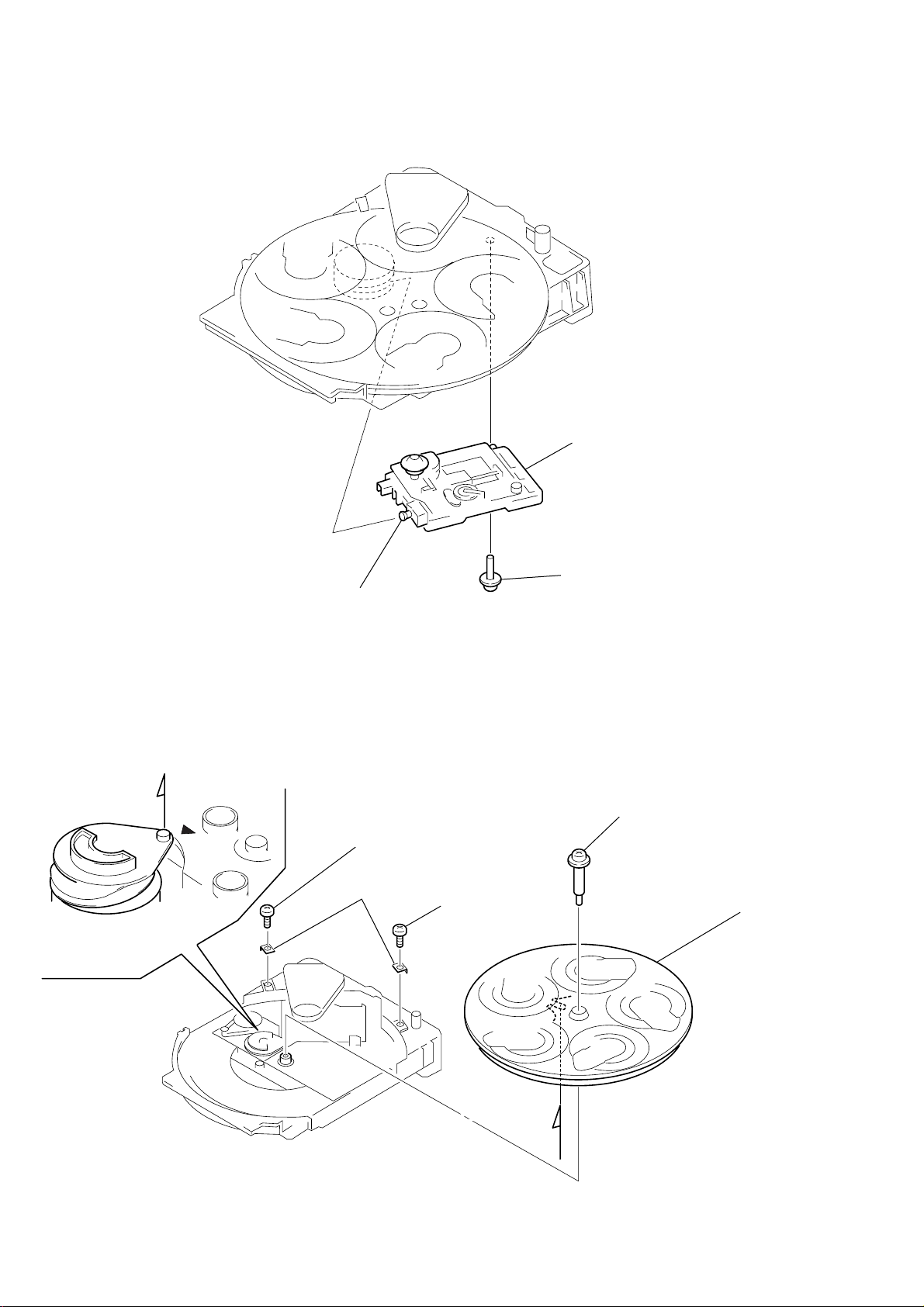

2-12. BD BOARD

)

1

two screws

(PTPWH M2.6

3

two springs

5

screw

(BVTP 2.6

6

×

6)

2

3

two springs

4

flat wire (16 core)

7

(S101)

(CN102)

BD board

×

8)

Removal

four solders. limit switch

1

two screws

(PTPWH M2.6

optical pick-up

section

×

6

2-13. OPTICAL PICK-UP (KSS-213D/Q-NP), SLED MOTOR (M102), SPINDLE MOTOR (M101)

3

optical pick-up (KSS-213D/Q-NP)

6

spindle motor

2

sled shaft

(M101)

1

claw

5

4

two screws

(P2

sled motor

(M102)

×

3)

— 13 —

2-14. CAPSTAN MOTOR (M1)

2

3

Removal the AUDIO board

to direction of the arrow A.

1

connector

(CN651)

four screws

(BTP 2.6

×

4)

A

7

Removal the capstan motor (M1)

to direction of the arrow B.

4

Break the soldering

of motor lead.

6

claw

B

5

two screws

(BTP 2.6

×

8)

8

Hang two belts.

— 14 —

SECTION 3

TEST MODE

MC COLD RESET

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press three buttons GROOVE , ENTER/NEXT , and

DISC 1 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

CD DELIVERY MODE

• This mode moves the pick-up to the position durable to vibration.

Use this mode when returning the set to the customer after repair.

Procedure:

1. Press 1/u button to turn the set ON.

2. Press PLAY MODE button and 1/u button simultaneously.

3. A message “LOCK” is displayed on the fluorescent indicator

tube, and the CD delivery mode is set.

MC HOT RESET

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power

cord is plugged in and out.

Procedure:

1. Press three buttons GROOVE , ENTER/NEXT , and

DISC 2 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

SLED SERVO MODE

• This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pick-up.

Procedure:

1. Select the function “CD”.

2. Press three buttons GROOVE , ENTER/NEXT , and

CD FLASH simultaneously.

3. The Sled Servo mode is selected, if “CD” is blinking on the

fluorescent indicator tube.

4. With the CD in stop status, press ) button in CD section to

move the pick-up to outside track, or 0 button to inside track.

5. To exit from this mode, perform as follows:

1) Move the pick-up to the most inside track.

2) Press three buttons in the same manner as step 2.

Note:

• Always move the pick-up to most inside track when exiting

from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can

be chipped.

CHANGE-OVER OF AM TUNER STEP BETWEEN 9 kHz

AND 10 kHz

• A step of AM channels can be changed over between 9 kHz and

10 kHz.

Procedure:

1. Press 1/u button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND

button to select the BAND “AM”.

3. Press 1/u button to turn the set OFF.

4. Press ENTER/NEXT and 1/u buttons simultaneously, and

the display of fluorescent indicator tube changes to “AM 9 k

STEP” or “AM 10 k STEP”, and thus the channel step is changed

over.

Be sure not to change with carelessness.

LED AND FLUORESCENT INDICA TOR TUBE ALL LIT, KEY

CHECK MODE

Procedure:

1. Press three buttons GROOVE , ENTER/NEXT , and

DISC 3 simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

Press DISC 2 button, and the key check mode is activated.

3. In the key check mode, the fluorescent indicator tube displays

“K 1 J0 V0”. Each time a button is pressed, “K”value increases.

However, once a button is pressed, it is no longer taken into

account.

“J” value increases like 1, 2, 3 ... if rotating JOG dial knob in

“clock wise” direction, or it decreases like 0, 9, 8 ... if rotating

in “counter clock wise” direction.

“V” value increases like 1, 2, 3 ... if rotating VOLUME knob

in “+” direction, or it decreases like 0, 9, 8 ... if rotating in “–”

direction.

4. To exit from this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

SELF-DIAGNOSIS

This model has the self-diagnosis function for the video and audio

decoder sections.

Immediately after the power on, the self-diagnosis function searches

each operation of IC’s around the mechanism controller (IC701).

The LED (D701) on the VIDEO board indicates their results.

LED (D701) INDICATION SYMPTOM

Light No error

1 time blinking (Repeatedly) External RAM (S-RAM) error

(IC751)

2 times blinking (Repeatedly) Video decoder section error

(IC201)

3 times blinking (Repeatedly) Video RAM (D-RAM) error

(IC251)

4 times blinking (Repeatedly) Audio decoder section error

(IC201)

[VIDEO BOARD] (SIDE-A)

— 15 —

IC701

D701

IC771

IC201

IC901

VERSION CHECK MODE

Procedure:

1. Press three buttons GROOVE , ENTER/NEXT , and DISC 3

simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

Press DISC 1 button, and the version check mode is activated.

3. In the version check mode, the fluorescent indicator tube displays

version information as follows.

SPEC ASIA-2←

Press DISC 1 ↓

MC F/V V1.3

Press DISC 1 ↓ Press

VC F/V V1.4 DISC 1

Press DISC 1 ↓

GC S-V V1.0

Press DISC 1 ↓

LBT 715 VCD

4. T o exit from this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

AGING MODE

This mode can be used for operation check of CD section and tape

deck section.

• If an error occurred:

The aging operation stops.

• If no error occurs:

The aging operation continues repeatedly.

1. Aging Mode in CD Section

1-1. Operating Method of Aging Mode

1. Set discs in DISC 1 and DISC 3 trays.

2. Select the function “CD”.

3. Press three buttons GROOVE , ENTER/NEXT ,

and DISC 5 simultaneously.

4. The aging mode is activated, if a changer mark on the

fluorescent indicator tube is blinking.

5. In the aging mode, the aging is executed in a sequence given

in “1-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

6. To exit from the aging mode, press 1/u button to turn the

set OFF.

• If a button other than buttons In CD section is pressed during

aging, the aging in the CD section is finished.

• To execute aging to the tape deck section successively,

press · button in the deck A.

“AGING” is displayed on the fluorescent indicator tube. (For

the aging in tape deck, see “2. Aging Mode in Tape Deck

Section”.

1-2. Operation during aging Mode

In the aging mode, the program is executed in the following

sequence.

1. The disc tray turns to select a disc. (For a disc selection

sequence, see Section 1-3.)

2. TOC of disc is read.

3. The pick-up accesses to the last track.

4. Steps 1 through 3 are repeated.

1-3. Disc Selection Sequence

• During the aging mode, discs are selected in the following

sequence:

Disc 1 → Disc 3

↑ ↓

Disc 3 ← Disc 1

2. Aging Mode in Tape Deck Section

2-1. Operating Method of Aging Mode

1. Load a commercially available 10-minute tape into the decks

A and B respectively.

(If a 10-minute tape is not available, another tape may be

used but a cycle time will be longer.)

2. Select the function “TAPE”.

3. Rewind tapes in advance by pressing 0 button

respectively on decks A and B.

4. Press three buttons GROOVE , ENTER/NEXT ,

and DISC 5 simultaneously.

5. Press · button on deck A. (This button triggers the aging

mode.)

6. The aging mode is activated if “AGING A” is displayed on

the fluorescent indicator tube.

7. In the aging mode, the aging is executed in a sequence given

in “2-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

8. T o exit from the aging mode, press 1/u button to turn the

set OFF.

2-2. Operation during Aging Mode

In the aging mode, the program is executed in the following

sequence.

1. A tape on FWD side is played for one minute.

2. PAUSE STOP is made.

3. Recording is made for 3 minutes. (For the deck not having

the record function, the play is executed. In this case, ·

LED does not light up.)

4. FF is executed up to the end of tape.

5. A tape is reversed, and the tape on REV side is played for

one minute.

6. PAUSE STOP is made.

7. Recording is made for 3 minutes. (For the deck not having

the record function, the play is executed. In this case, ª

LED does not light up.)

8. FF is executed up to the end of tape.

9. Steps 1 through 8 are executed for the other deck.

10. Steps 1 through 9 are repeated unless an alarm occurred.

2-3. Deck Selection Sequence

• During the aging mode, decks are selected in the following

sequence:

Deck A (FWD) → Deck A (REV)

↑ ↓

Deck B (REV) ← Deck B (FWD)

— 16 —

VIDEO CD COLOR BAR MODE

On this mode, the data of the color bar signal as a picture signal and

the 1 kHz sine wave signal as a sound signal are output by the

mechanism controller (IC701) for the video CD signal check. When

measurement of the voltage and waveform on the VIDEO board,

perform it in this mode.

For reference, the color bar signal can be observed at J9001 (VIDEO

OUT) and the sound signal can be observed at J101 (VIDEO

(AUDIO) OUT) using an oscilloscope.

Procedure:

1. Turned power switch on.

2. Press the FUNCTION button to select the CD.

3. Connect the SL701 on the VIDEO board with solder.

4. After measuring, remove the soldering installed.

oscilloscope

E-F BALANCE MODE

Refer to the SECTION 6 ELECTRICAL ADJUSTMENTS page

21.

Procedure:

1. Turned power switch on.

2. Press the FUNCTION button to select the CD.

3. Connect the SL701 and SL703 on the VIDEO board with solder.

4. Press the · button in playback.

5. Press the REPEAT button, the tracking servo and sledding

servo are turned on or off.

6. When the servo is off, the counter on front panel will not be

changed.

7. After measuring, remove the soldering installed.

set

B

A

C

75

Ω

J9001 (VIDEO OUT)

H

+

–

A = 0.9 to 1.1 Vp-p

B = 0.678 to 0.75 Vp-p

C = 0.214 to 0.328 Vp-p

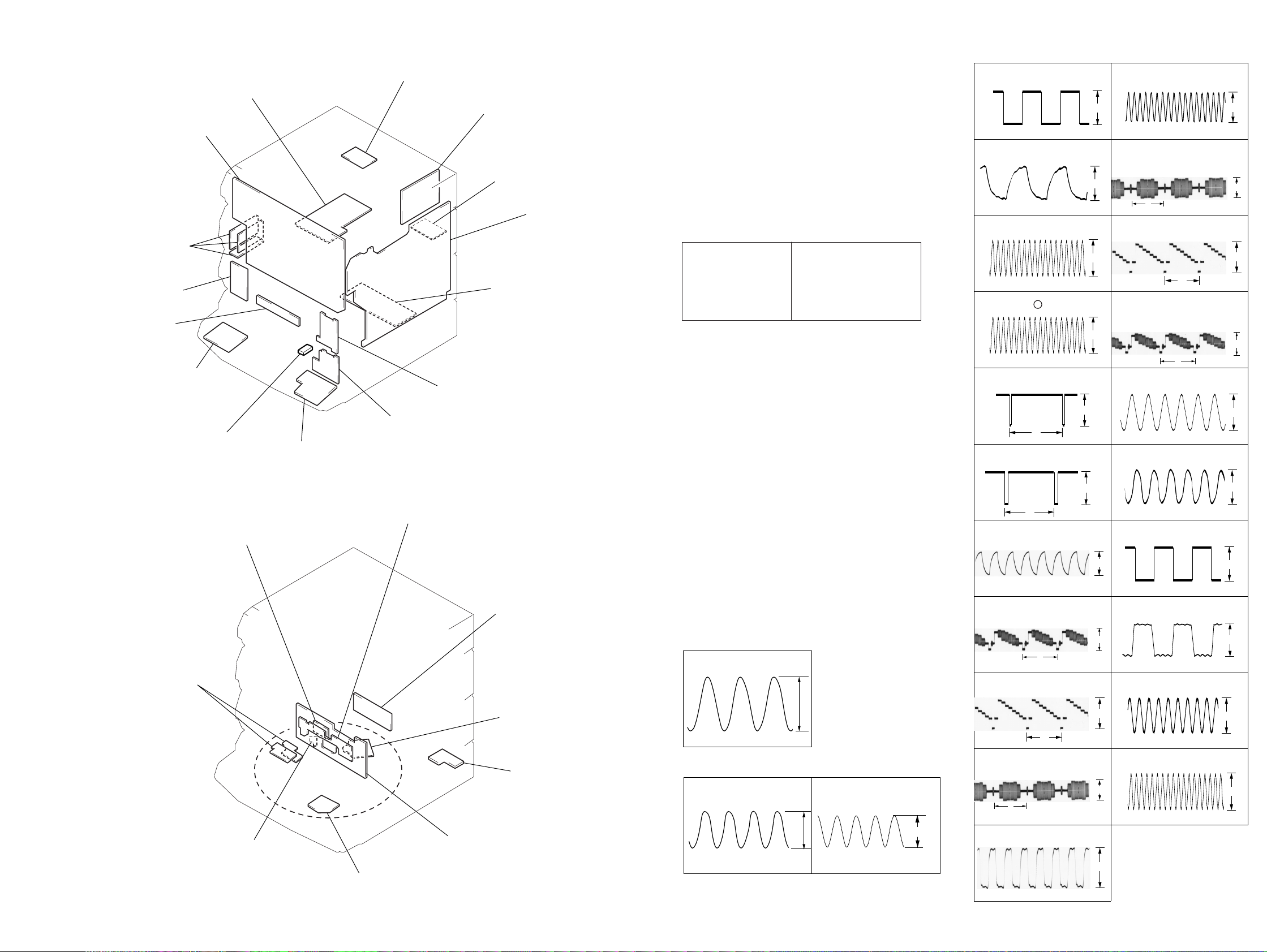

Fig. 1 Video CD Color Bar Signal Output from J9001

(VIDEO OUT)

[VIDEO BOARD] (SIDE-B)

SL703

SL702

SL701

IC751

IC251

— 17 —

SECTION 4

r

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

• Torque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension (0.026 – 0.082 oz•inch)

Reverse CQ-102RC

Reverse

Back Tension (0.026 – 0.082 oz•inch)

FF, REW CQ-201B

CQ-102C

CQ-102RC

36 to 61g•cm

(0.50 – 0.84 oz•inch)

2 to 6g•cm

36 to 61g•cm

(0.50 – 0.84 oz•inch)

2 to 6g•cm

61 to 143g•cm

(0.85 – 1.98 oz•inch)

DECK SECTION

0 dB=0.775 V

1. Demagnetize the record/playback head with a head

demagnetizer. (Do not bring the head demagnetizer close to

the erase head.)

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and Rch.

7. Switches and controls should be set as follows unless otherwise

specified.

8. Set to test mode. (Press key switch same time

GROOVE ENTER/NEXT and DISC 4 buttons.)

To exit from the test mode, press the 1/u button.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Level Adjustment

• T ape Tension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A more than 100 g (3.53 oz)

Reverse CQ-403R more than 100 g (3.53 oz)

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note: Perform this adjustments f or both dec ks .

Procedure:

1. Mode: Playback (FWD)

test tape

P-4-A100

(10 kHz, –10 dB)

set

MAIN board

CN207

3

(L-CH)

pin

1

(R-CH)

pin

MAIN board

CN207

pin

2

(GND)

level mete

+

–

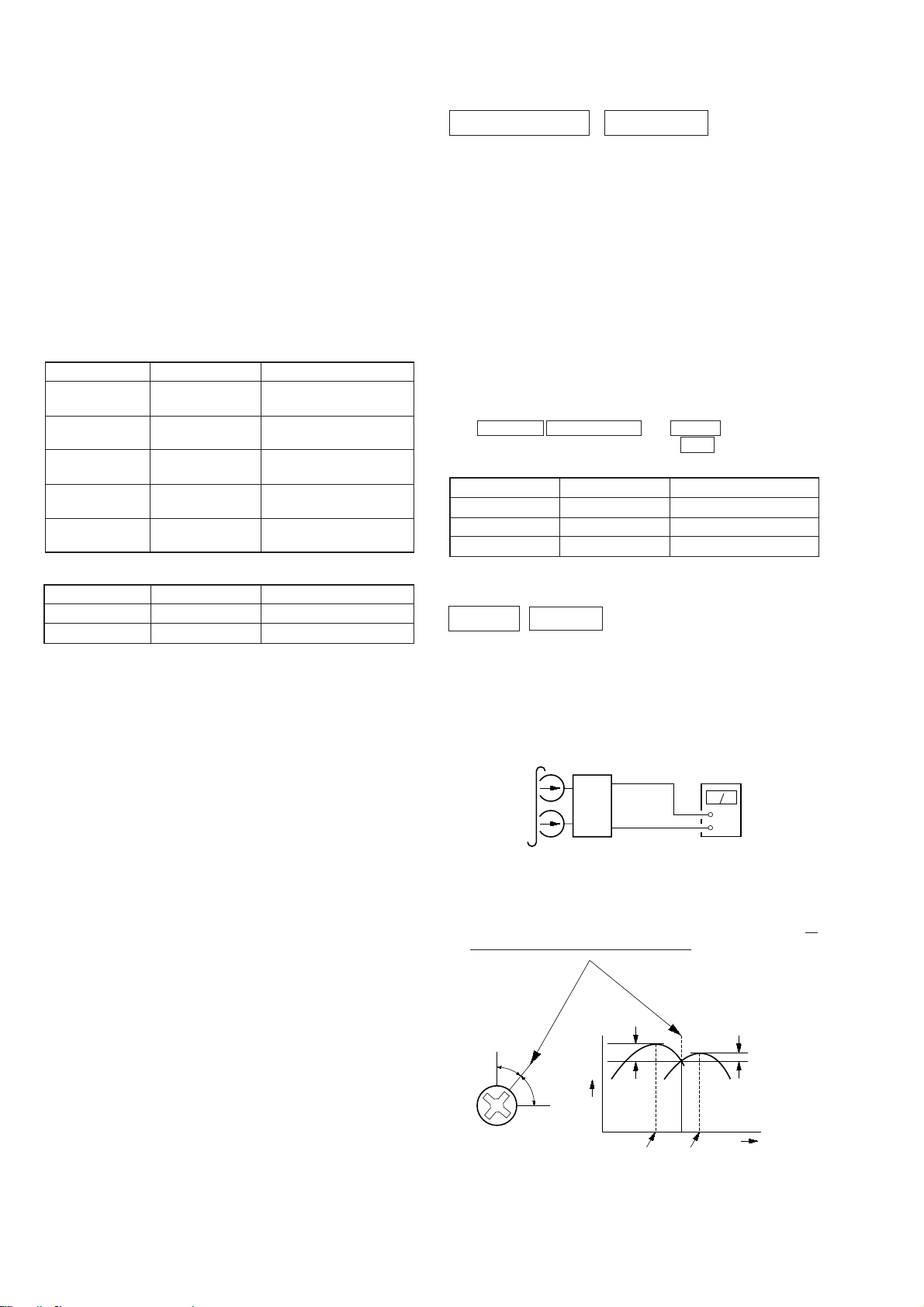

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so

that outputs match within 1 dB of peak.

output

level

within

1 dB

within

1 dB

L-CH

peak

R-CH

Screw

position

peak

L-CH

peak

R-CH

peak

Screw

position

— 18 —

3. Mode: Playback (FWD)

e

e

+

–

set

test tape

P-4-L300

(315 Hz, 0 dB)

MAIN board

CN207 (pin

3

: L-CH)

(pin

1

: R-CH)

level meter

test tape

P-4-A100

(10 kHz, –10 dB)

set

pin

waveform of oscilloscope

in phase 45°90°135°180

MAIN board

CN207

pin

pin 2 (GND)

1

(R-CH)

good

3

(L-CH)

oscilloscop

V

wrong

Tape Speed Adjustment DECK A

Note: Start the Tape Speed adjustment as below after setting to the test

mode.

In the test mode, the tape speed is high during press the

H SPEED DUB button.

Procedure:

H

1. Turn the power switch on.

2. Press the GROOVE button, ENTER/NEXT button and

DISC 4 button simultaneously.

To exit from the test mode, press the 1/u button.

Mode: Playback (FWD)

test tape

WS-48B

(3 kHz, 0 dB)

°

set

frequency counter

+

–

4. Repeat steps 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location : Playback Head (Deck A)

Record/Playback Head (Deck B)

revers

forward

MAIN board

CN207 (pin

(pin

3

: L-CH)

1

:R-CH)

1. Insert the WS-48B into the deck A and the blank tape into the

deck B.

2. Press the r REC button and · button on the deck B. Then

the deck B is at recording mode.

3. Set the deck A to playback mode.

4. Press the H SPEED DUB button in playback mode.

Then at high speed mode.

5. Adjust RV652 on the AUDIO board so that frequency counter

reads 6,000 ± 180 Hz.

6. Press the H SPEED DUB button.

Then at normal speed mode.

7. Adjust R V651 on the AUDIO board so that frequency counter

reads 3,000 ± 90 Hz.

8. Frequency difference between deck A and deck B the beginning

of the tape should be within ± 1.5 %.

Adjustment Location: AUDIO board (See page 20)

Sample Value of Wow and Flutter: 0.3% or less W.RMS

(WS-48B)

Playback level Adjustment DECK A DECK B

Procedure:

Mode: Playback (FWD)

Deck A is RV311 (L-CH) and RV411 (R-CH), Deck B is RV301

(L-CH) and RV401 (R-CH) so that adjustment within adjustment

level as follows.

Adjustment Level:

CN207 PB level: 301.5 to 338.3 mV (– 8.2 to – 7.2 dB) level

difference between the channels: within ± 0.5 dB

Adjustment Location: AUDIO board (See page 20)

— 19 —

Record bias Current Adjustment DECK B

r

r

5

Procedure:

1. Mode: Record

Adjustment and Connection Location:

[AUDIO BOARD] (Conductor Side)

pin 6 (L-CH) of IC1501 on the MAIN board.

pin

#¶

(R-CH) of IC1501 on the MAIN board.

1) 315 Hz

2) 10 kHz

AF OSC

attenuator

pin 2 (GND) of CN207 on the MAIN board.

50 mV (–23.8 dB)

Ω

600

set

blank tape

CS-123

2. Mode: Playback

recorded

portion

set

MAIN board

CN207 (pin

(pin

3

1

: L-CH)

: R-CH)

level mete

+

–

Confirm playback the signal recorded in step 1 become adjustable

limits as follows.

If these levels do not adjustable limits, adjustment the RV341 (LCH) and R V441 (R-CH) on the AUDIO board to repeat steps 1 and

2.

Adjustable limits: Playback output of 315 Hz to playback

output of 10 kHz: ±0.5 dB

Adjustment Location: AUDIO board

Record Level Adjustment DECK B

Procedure:

1. Mode: Record

pin

6

(L-CH) of IC1501 on the MAIN board.

pin

#¶

(R-CH) of IC1501 on the MAIN board.

AF OSC

315 Hz, 50 mV (–23.8 dB)

Ω

attenuator

600

blank tape

CS-123

set

RECORD

BAIS

L

RV301

RV401®R

PB LEVEL

[MAIN BOARD] (Component Side)

R

®

L

RV441RV341

– DECK B –

IC201

IC301

TAPE SPEED

(NORMAL)

RV651

®

PB

LEVEL

1

CN207

RECORD LEVEL

– DECK A –

RV1501

21 1

3

IC1501

22 42

RV1551

(HIGH)

RV652

RV311

L

RV411

R

®

®

®

CN20

pin

2

(GND) of CN207 on the MAIN board.

2. Mode: Playback

recorded

portion

set

MAIN board

CN207 (pin

(pin

3

1

: L-CH)

: R-CH)

level mete

+

–

Confirm playback the signal recorded in step 1 become adjustable

limits as follows.

If these levels do not adjustable limits, adjustment the RV1501 (LCH) and R V1551 (R-CH) on the MAIN board to repeat steps 1 and

2.

Adjustable limits:

CN207 PB level: 47.3 to 53.1 mV (–24.3 to –23.3 dB)

Adjustment Location: MAIN board

— 20 —

HCD-V3900/V5900

e

e

e

e

+

–

TP (PLCK)

BD board

frequency counter

r

CD SECTION

Notes:

1. CD block basically constructed to operate without adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (Part No.: 3-702-101-01) unless otherwise indicated.

3. Use the oscilloscope with more than 10 MΩ impedance.

4. Clean an object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

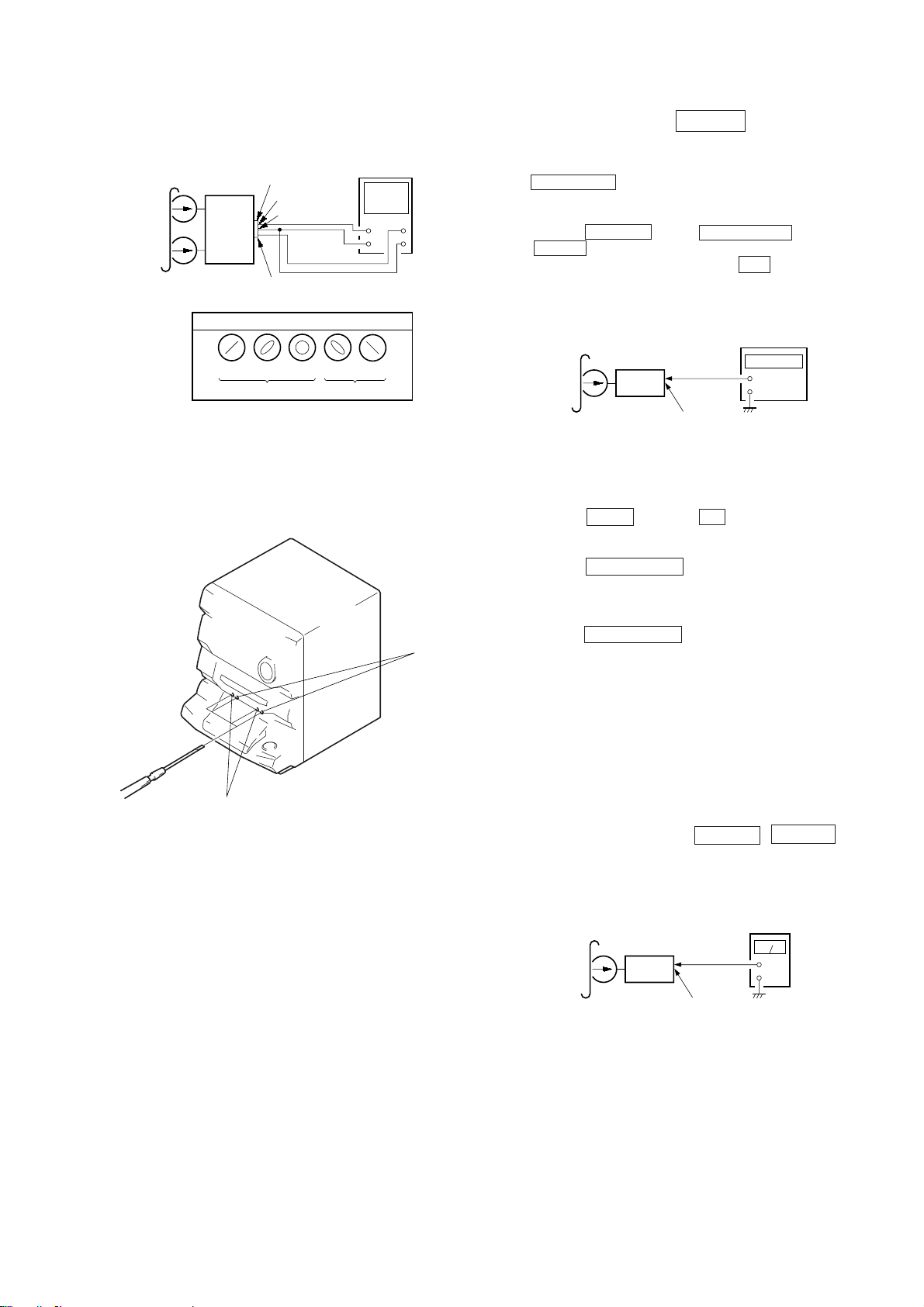

S-Curve Check

Connection:

oscilloscop

BD board

TP (FE)

TP (VC)

+

–

Procedure:

1. Connect the oscilloscope to TP (FE) and TP (VC) on BD board.

2. Connect the TP (FEI) and TP (VC) with lead wire.

3. Turned power switch on.

4. Put disc (YEDS-18) in and turned power switch on again and

actuate the focus search.

5. Confirm that the oscilloscope waveform (S-curve) is

symmetrical between A and B. And confirm peak to peak level

within 3.0 ± 1.0 Vp-p.

S-curve waveform

symmetry

A

within 3.0

B

±

1.0 Vp-p

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

(with the 10: 1 prob

in use)

level: 1.3 Vp-p

+0.25

–0.20

When observing the eye pattern, set the oscilloscope for AC range

and raise vertical sensitivity.

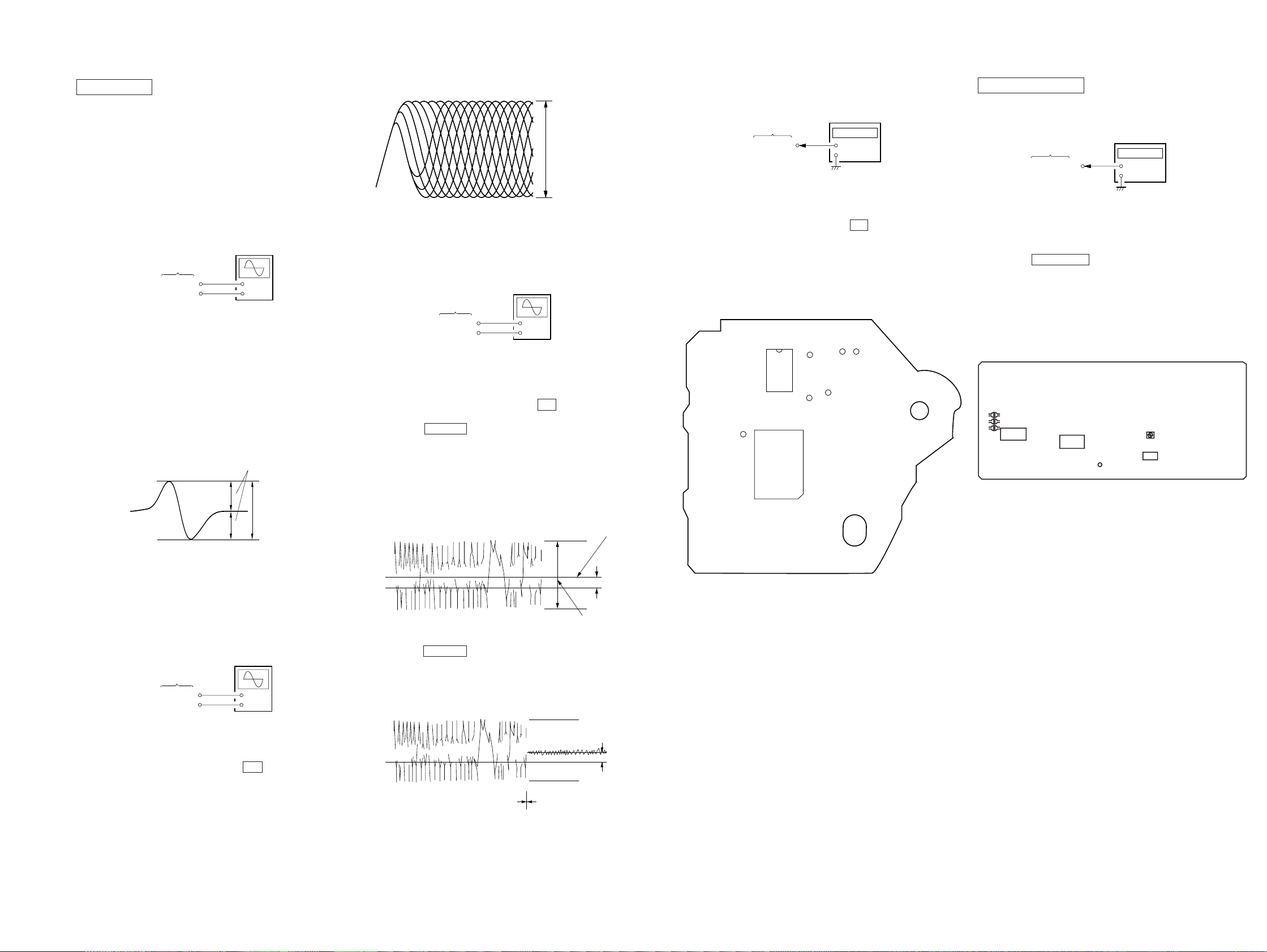

E-F Balance (Traverse) Check

Connection:

oscilloscop

(DC range)

BD board

TP (TE)

TP (VC)

+

–

Procedure:

1. Connect the oscilloscope to TP (TE) and TP (VC) on BD board.

2. Turned power switch on.

3. Connect the SL702 and SL703 on the VIDEO board with solder.

4. Put disc (YEDS-18) in and press the · button, and play the

number five track.

5. Press the REPEA T button. (The tracking servo and the sledding

servo are turned off.)

6. Confirm that the level B of the oscilloscope’s waveform and

the A (DC voltage) of the center of the traverse waveform.

Confirm the following:

A/B × 100 = less than ±22 %

Traverse waveform

Center of the waveform

RF PLL Free-run Frequency Check

Connection:

Procedure:

1. Connect the frquency counter to TP (PLCK) on the BD board.

2. Turned power switch on.

3. Put disc (YEDS-18) in and press the · button, and play the

number five track.

4. Confirm that the reading on frequency counter is 4.3218 MHz.

Connection Location:

[BD BOARD] (SIDE-A)

(FEI)

(FE)

(TE)

(PLCK)

IC103

IC101

(RF)

(VC)

VIDEO SECTION

Frequency Adjustment

Connection:

VIDEO board

TP410 (DCLK)

Procedure:

1. Connect the frequency counter to TP410 (DCLK) on VIDEO

board.

2. Turned power switch on.

3. Press the FUNCTION button to select the CD.

4. Adjust CT401 on the VIDEO board so that the frequency counter

reading 13.5 MHz ± 40 Hz at stop status.

Adjustment Location:

[VIDEO BOARD] (SIDE-B)

frequency counte

+

–

CT401

TP410

(DCLK)

IC402

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure that the ratio of A : B

or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness

to obtain best waveform.

RF Level Check

Connection:

oscilloscop

(AC range)

BD board

TP (RF)

TP (VC)

+

–

Procedure:

1. Connect the oscilloscope to TP (RF) and TP (VC) on BD board.

2. Turned power switch on. (stop mode)

3. Put disc (YEDS-18) in and press the · button.

4. Confirm that the oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “≈” can be clearly

distinguished at the center of the waveform.

B

0V

A (DC voltage)

level: 1.3 ± 0.6 Vp-p

7. Press the REPEA T button. (The tracking servo and the sledding

servo are turned on.) Confirm that the C (DC voltage) is almost

equal to the A (DC voltage) is step 6.

Traverse waveform

0 V

Tracking servo

Sled servo

OFF

Tracking servo

Sled servo

ON

C (DC

voltage)

8. After check, remove the soldering installed in step 3.

— 21 — — 22 —

HCD-V3900/V5900

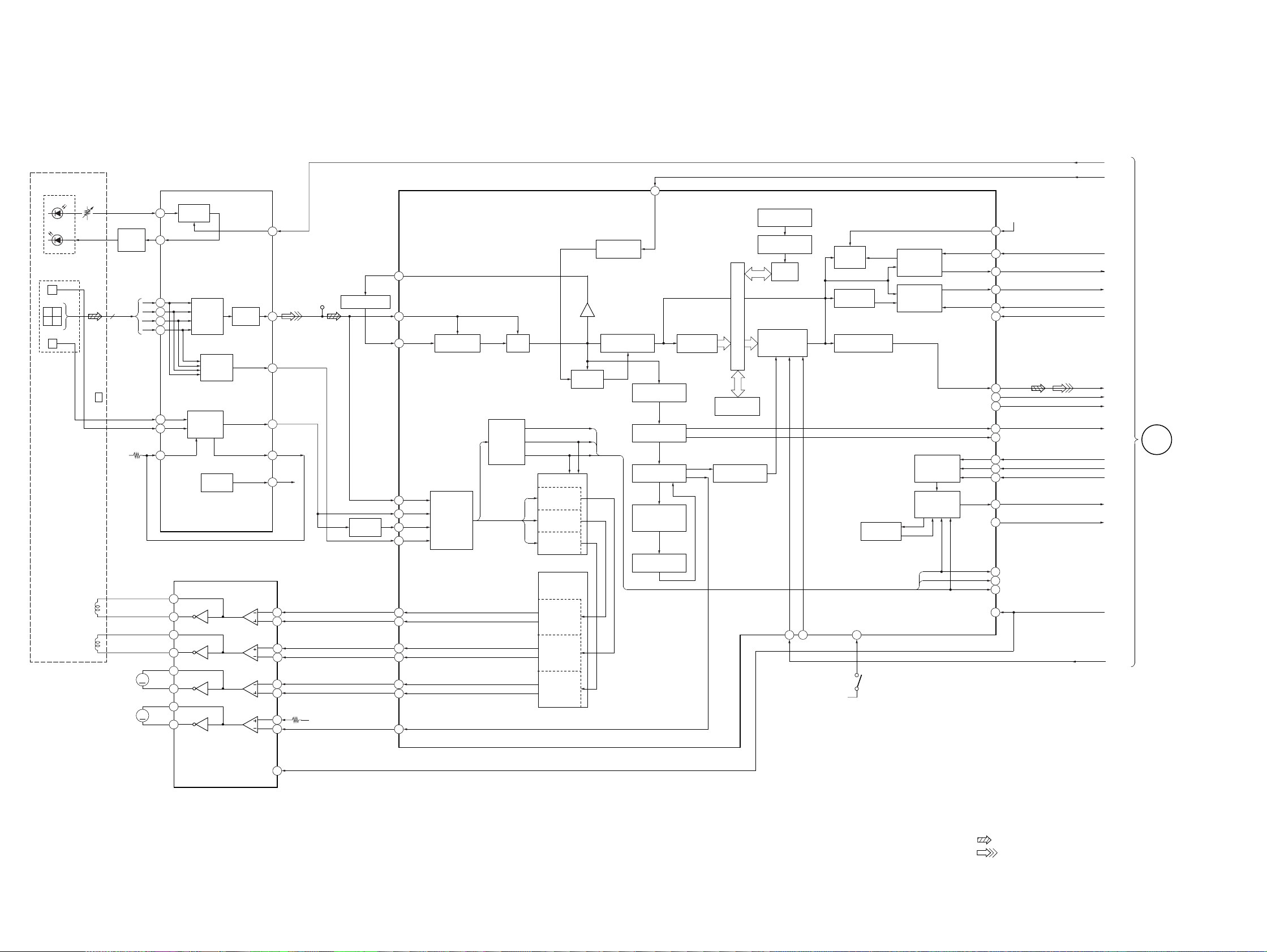

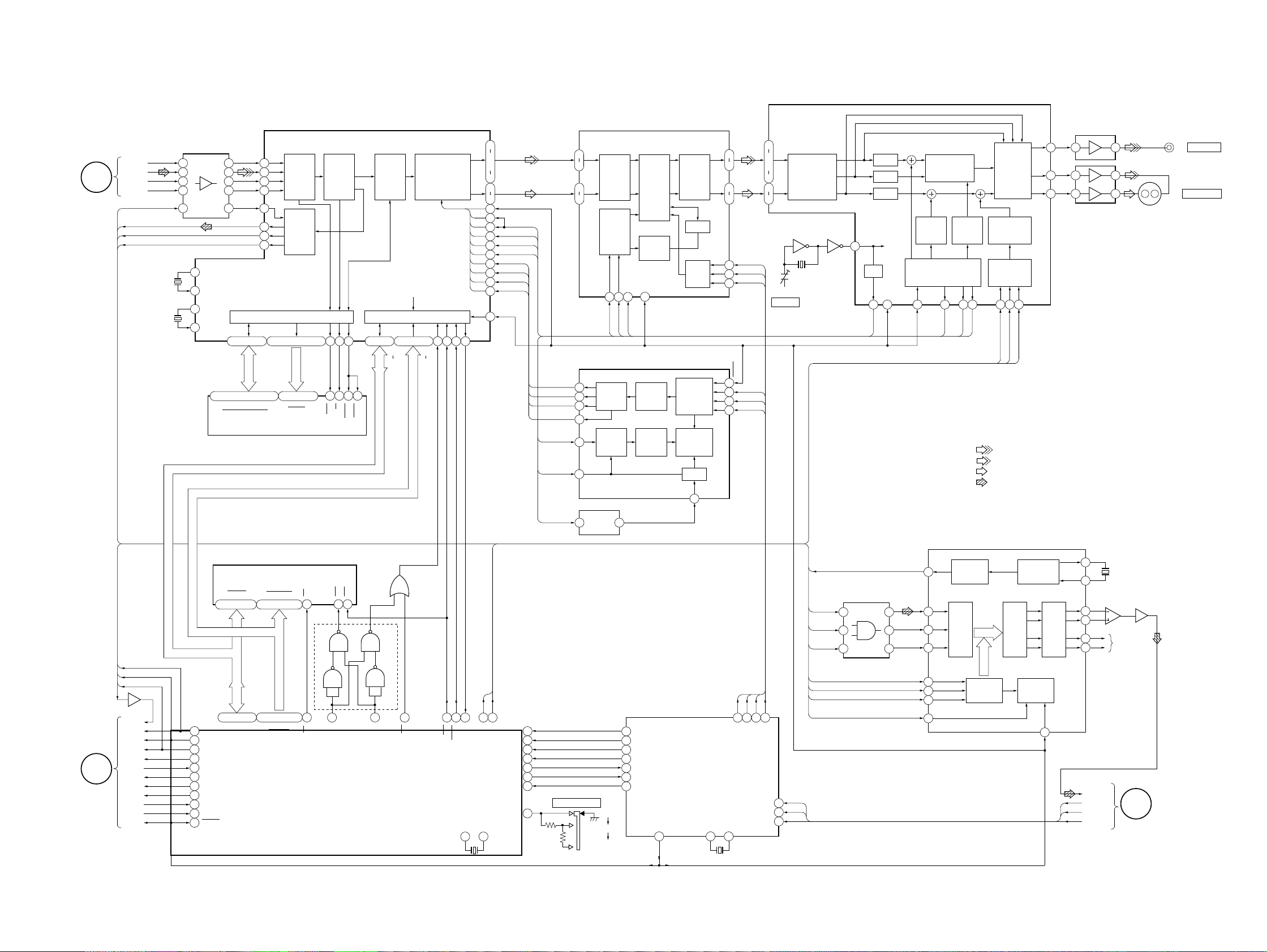

6-1. BLOCK DIAGRAM – BD SECTION –

SECTION 6

DIAGRAMS

OPTICAL PICK-UP

BLOCK (KSS-213D/Q-NP)

LASER

DIODE

PD

DETECTOR

E

AC

BD

F

LD

TRACKING

COIL

FOCUS

COIL

LD

POWER

1

4

VC

M102

SLED

MOTOR

M101

SPINDLE

MOTOR

LD

DRIVE

Q101

RF AMP

IC103

APC LD

2

AMP

RF FQ

AMP

19

RF

INTEGRATOR

16

15

13

1110

VC

12

INTE-

GRATOR

4

5

19

20

10

9

23

24

VC

1

3

4

5

6

8

9

T+

T–

F+

16

F–

17

13

M

12

27

M

26

RF

SUMMING

AMP

FOCUS

ERROR

AMP

TRACKING

ERROR

AMP

VC

BUFFER

FOCUS/TRACKING COIL DRIVE

SPINDLE/SLED MOTOR DRIVE

IC102

1

2

DIGITAL SERVO

DIGITAL SIGNAL PROCESSOR

IC101

ASY0

39

RF AC

36

ASY1

RF DC

TE

SE

FE

TFDR

TRDR

FFDR

FRDR

SRDR

SFDR

MDP

ASYMMETRY

CORRECTION

A/D

CONVERTER

38

26

27

28

29

4

6

8

10

2

100

96

MIRR

DFCT

FOK

DETECTOR

MIX

FOK

DFCT

MIRR

SERVO DSP

FOCUS

SERVO

TRACKING

SERVO

SLED

SERVO

PWM

GENERATOR

TRACKING

PWM

GENERATOR

FOCUS

PWM

GENERATOR

SLED

PWM

GENERATOR

DIGITAL

PLL

CLOCK

GENERATOR

EFM

DEMODULATOR

62

XTAL

SYNC

PROTECTOR

TIMING

GENERATOR 1

CLV SERVO

PROCESSOR

1B TIMS

OVERSAMPLING

FILTER

NOISE

SHAPER

REGISTER

DATA BUS

ERROR

CORRECTOR

TIMING

GENERATOR 2

PRIORITY

EMCODER

ADDRESS

GENERATOR

32K

RAM

D/A

DATA

PROCESSOR

MUTE

79 54

GFS

DIGITAL

OUT

PEAK

DETECTOR

SERIAL/PARALLEL

PROCESSOR

INTERFACE

S STOP

99

SWITCH

+5V

SERVO

S101

LIMIT

SUBCODE

P-W

PROCESSOR

SUBCODE

Q

PROCESSOR

INTERFACE

SEQUENCER

CPU

SERVO

AUTO

MD2

EXCK

SBSO

SUBQ

SQCK

SCLK

DATA

LRCK

BCLK

SCOR

WFCK

DATA

XLT

CLK

SENS

C2PO

FOK

DFCT

MIRR

XRST

+5V

70

76

75

77

78

83

46

45

47

74

73

86

87

88

80

56

93

92

91

81

LDON

384FS

EXCK

SUBQ

SUBQ

SQCK

SCLK

ADATA

LRCK

BCLK

SCOR

DATA

XLT

CLK

SENS

C2PO

XRST

AMUTE

B

VIDEO

SECTION

(Page 25 )

15MUTE

16

• SIGNAL PATH

: CD

: VIDEO

— 23 — — 24 —

6-2. BLOCK DIAGRAM – VIDEO SECTION –

BUFFER

IC501 (1/2)

B

CD

SECTION

(Page 24)

IC501

(2/2)

B

CD

SECTION

(Page 24)

16

BCK

ADATA

LRCK

C2PO

384FS

ADATA

LRCK

BCLK

28.63636MHz

45.1584MHz

DATA

CLK

AMUTE

384FS

416

384FS

DATA

CLK

AMUTE

SQCK

SUBQ

SCLK

XLT

LDON

SCOR

SENS

XRST

X202

X201

9

8

7

6

5

XTL0O

2

XTL01

3

106

XTL2O

107

XTL2I

73

DATA

78

CLK

74

AMUTE

11

SQCK

10

SUBQ

77

SCLK

XLT

76

75

LDON

71

SCOR

62

SENS

RESET

48

11

12

13

14

15

2–5 7–10 35–38 40–43

•

DQ1

I/O1

38–43 46–55•

•

•11–13 15–19

D0

112

111

110

109

103

100

101

102

D-RAM INTERFACE

17–21 23 24 32 33••••

•

A0

I/O8

2–10 21 23–25

22–29 • 31–3513 – 20

A0

D7

18–21 24–28•

DQ16

D-RAM

IC251

S-RAM

IC751

••

CD-ROM

DECODER

MPEG

AUDIO

DECODER

A0

A12

A12

MPEG DECODER

IC201

7–13 16

LCAS

UCAS

IC772

WE

XTCS

6

54

3

12

40

IC701

MPEG

VIDEO

DECODER

EACH CIRCUIT BLOCK

•

IC771

A17

POSTPROCESSOR

SYNC GENERATOR

HOST INTERFACE

•

120

119

•

D0

D7

AS

5 6

•

A0

A3

MPEG

SYSTEM

DECODER

34

3735

301516 31

W

A8

RAS

CE1

OE

55

RD

272022

8

10 9

11

12

13

41 54 56 43 70 7 8

A18

MECHA CONTROL

VIDEO

&

XHCS

XWR

WR

XHDT

WAIT

117115116114

XHIRQ

Y

C

XHIRQ

EXTAL

71

73

•

76

80

63

70

97

95

92

93

94

89

56

57

58

59

118

DF-XLAT

VDAC-XLAT

XTAL

5251

X701

10MHz

XSGRST

HSYNC

VSYNC

FID

DCLK

XOSDEN

OSD B

OSD G

OSD R

XRST

CLOCK

GENERATOR

IC272

CMD0

CMD1

CMD2

CMD3

SACK

QINT

MREQ

NPIN

Y0-Y7

C0-C7

1

2

3

4

5

6

72

64

OSD B

OSD G

OSD R

XOSDEN

VSYNC

HSYNC

DCLK

SYSTEM SELECT

18

Y

11

27

C

20

18

17

16

15

19

20

CK 1/2 Q

1 5

S9001

RGB-YUV

CONV.

TIMING

GEN.

98 10097

HSYNC

OUTPUT

CONT.

SYNC

CONT.

PAL

AUTO

NTSC

NOISE REDUCTION

REDUSER

MEMORY

DCLKI

93

VSYNC

DCLK

VIDEO

RAM

DATA

34

CMD0

35

CMD1

36

CMD2

37

CMD3

44

SACK

18

QINT

MREQ

43

IC301

NOISE

CONT.

XRST

OSD

IC271

SEL.

6.75MHz

CD-XRST

YUV-RGB

CONV.

DRAM

IF

DATA INPUT

SHIFT

RESISTOR

DISPLAY

POSITION

CONT.

OSC

8

IIC INTERFACE

IC901

HCD-V3900/V5900

10BIT VIDEO D/A CONVERTER

IC401

VIDEO AMP

IC451

&

INTER-

49 504859 60625557 51

CLK

V

Y

C

VDAC-XLAT

24

29325

5 7

3

7

3

4

1

60

67

51

58

29

30

31

4

3

2

1

NR-XCS

MCLK

MDATA

RESET

MDATA

OS-XLAT

MCLK

9

6

•

4

1

18

11

CT401

13.5MHZ

DEMPX, LEVEL

TRANSLATOR

&

INTERPOLTATOR

CLOCK GENARATOR

IC402

56

4

3

X401

27MHz

HSYNC

Y, C/Y, U, V

SELECTOR

POLATOR

CLOSED

CAPTION

ENCODER

SIO & I2O-BUS

CONT.

DATA

LPF

LPF

DELAY

56

1/2

XRST

DCLK

MODULATOR

SYNC

SLOPE

GEN.

SYNC GEN.

TIMING CONT.

XVRST

SUB

CARRIER

GEN.

&

FID

VSYNC

• R CH: Same as L ch

• SIGNAL PATH

: VIDEO

: Y

: CHROMA

: CD

DIGITAL FILTER & D/A CONVERTER

384FS

BUFFER

ADATA

LRCK

BCLK

DATA

CLK

DF-XLAT

68494847

MCLK

MDATA

NR-XCS

OS-XLAT

15

RESET

55

IIC-DATA

56

X2

IIC-CLK

X1

111052

X901

5MHz

AMUTE

XRST

IC181

13

4

1

11

6

3

11

12

10

TIMING

6

CIRCUIT

INPUT PLM

3

4

5

2

MODE

IC101

D/A

CONV.

CLOCK

GENERATOR

MUTE

CIRCUIT

INT

1

21

22

27

25

16

18

L CH

XRST

IIC-DATA

IIC-CLK

X101

33.8688MHz

ACTIVE LPF

IC102

R CH

A

MAIN

SECTION

(Page 27)

J9001

VIDEO OUT

J9002

S VIDEO OUT

— 25 — — 26 —

HCD-V3900/V5900

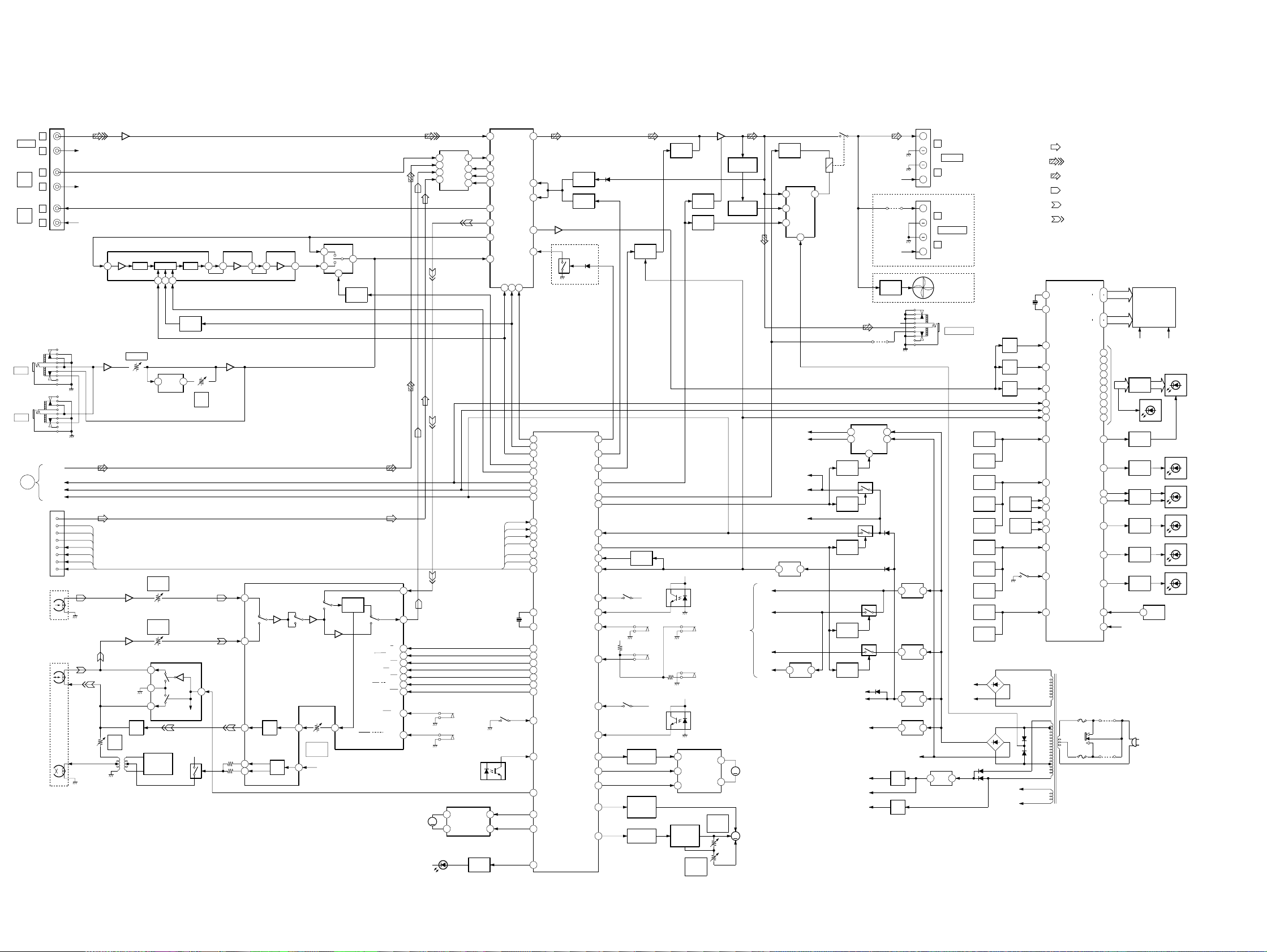

6-3. BLOCK DIAGRAM – MAIN SECTION –

PHONO

VIDEO

REC

OUT

J761

MIC 1

J762

MIC 2

VIDEO

SECTION

(Page26)

IN

A

ST BLOCK

(A DECK)

(B DECK)

TO

PB

HEAD

REC/PB

HEAD

ERASE

HEAD

L

R

L

R

L

R

CD L CH

IIC DATA

16

IIC CLK

XRST

CN201

HRPE101

J101

HP101

TU L CH

ST DOUT

TUNED

STEREO

ST MUTE

ST DATA

ST CLK

ST CE

R CH

R CH

R CH

22

MIC AMP

IC760

IC101

KEY CONTROL

LPF1

RV341

REC

BIAS

IC501

RV760

MIC VOL

PB EQ

AMP

IC611

PB EQ

AMP

IC601

C331,L331

BIAS

TRAP

EQALIZER/VOLUME

IC201

69

OUT 2

DET

DET

IC202

TABLE

IC201

IN2B

71

IN2A

13

28

10A

PORT A

29

9B

PORT B

30

PORT C

6

61

REC 2B

62

REC 2A

65

KEY OUT 2

64

KEY IN 2

1

IN2

9

IN1

LED

DRIVE

Q201

SELECTOR

IC102

12

OUT

V L

14

CD

15

TC

11

ST

C

IC502

5

A7.5V

4

3

10

SWITCH

Q502

REC

6

DOLBY

B

DOL

PB

PB A/B

NORM/HIGH

BIAS ON/OFF

RM ON/OFF

NR ON/OFF

REC PB/PASS

LM ON/OFF

A120/70

8

12

14

16

17

18

19

20

13

15

M201

TABLE

MOTOR

D201

(DISC No.)

S1005

A CrO2

S1008

B CrO2

SENSOR

MOTOR DRIVE

OUT2

3

M

OUT1

7

9

PAS

NORM/CROM/METAL

15

REC

70

PB

120

10

RV1501

REC(L)

LEVEL

22

4

26 18

MIC AMP

IC760

LPF2

11

25

24

A/D

LOGIC

D/A

7 8 9

STORBE

CLOCK

DATA

SWITCH

Q501

DIGITAL

81

ECHO

IC761

RV761

ECHO

LEVEL

RV311

PB(L)

LEVEL

RV301

PB(L)

LEVEL

IC602

REC/PB SWITCH

1

2

3

Q621,622

R CH

BIAS

OSC

+7.5V

Q623

2

4

17 16

A

B

NORM

CROM

MIX

IC1501

DOLBY NR/REC EQ AMP

REC

EQ

BIAS

SW

S201

UP SW

33

X101

5MHz

BUF IN2

DATA

ST DOUT

TUNED

STEREO

ST MUTE

ST DAYA

ST CLK

ST CE

BB12

BB22

CLOCK32LATCH

34

38

41

40

45F OUT2

39

3

45

44

5

4

55

56

57

66

69

70

72

67

65

68

11

10

87

88

89

90

91

92

93

77

76

96

61

60

62

LATCH

COM CLK

COM DATA

K CON ON

K CON LAT

IIC DATA

IIC CLK

XRST

ST DOUT

TUNED

STEREO

ST MUTE

ST DAYA

ST CLK

ST CE

X1

X2

PB A/B

EQ H/N

BIAS

REC MUTE

NR ON/OFF

R/P PASS

TC MUTE

UP SW

T SENS

TC RELAY

TBL R

TBL L

TRAY LED

SPEANA

IC231

V5900 ONLY

Q201

MAIN CONTROL

IC301

A PLAY SW

B PLAY SW

CAP M ON/OFF

FEED

BACK

Q203

DBFB

SWITCH

Q202

D309

SW F CON

DBFB H/L

TA MUTE

XRST

CD POWER

AC CUT

A SHUT

A HALF SW

B HALF SW

B SHUT

TRG LOW

B TRG

A TRG

CAP M H/L

D291

MUTE

CONT

Q231,232

99

2

1

100STK MUTE

6F RELAY

98POWER

57

46

15RESET

20

94

26

97

28

95

27

85

84

83

86

82

+5V

S1001

A PLAY

S1002

B PLAY

RESET

SWITCH

Q301

S1004

A HALF

S1007

B HALF

SWITCH

Q1534,1535

CAPSTAN

MOTOR

SWITCH

Q1531,1532

SWITCH

Q1533

+5V

+5V

MUTE

Q204

+5V

+5V

4

VZ

6

IN2

IN1

5

SPEED

CONTROL

Q651

STANDBY

SWITCH

Q283

RELAY

SWITCH

Q281

Q1001

ROTATION

DET A

S1006

REC A

S1009

REC B

Q1002

ROTATION

DET B

IC1502

TRIGGER

MOTOR DRIVE

RV651

TAPE

SPEED

(NOMAL)

POWER AMP

OUT1

OUT2

RV652

TAPE

SPEED

(HIGH)

IC801

TM131

+

IC9001

IC9002

-11.5V

REG

REG

IC903

REG

IC902

REG

L

FRONT

R

+

TM132

+

L

SURROUND

R

+

V3900 ONLY

FAN

V5900 ONLY

J760

HEADPHONS

LOW

FREQ

HIGH

FREQ

MID

FREQ

S601-608

FUNCTION

KEY

S651-659

FUNCTION

KEY

S609-615

FUNCTION

KEY

S676-679

FUNCTION

S681-686

FUNCTION

S616-618

FUNCTION

S641-647

FUNCTION

13

S661-666

FUNCTION

S619-626,628-633

FUNCTION

S667-671

FUNCTION

+B

-B

D906

D907

+5V

13

+5V

13

+5V

13

+7V

13

IC904

+12V

REG

-32V

KEY

KEY

KEY

KEY

KEY

KEY

KEY

D901

D902-905

VOLUME

S701

JOG

S711

F1

F2

RELAY

DRIVE

M2

MOTOR

M1

D+5V

(UNSW)

D+5V

(SW)

A+5V

(SW)

+3.3V

Q141,142

2

PROTECTOR

1

7

RESET

IC302

IC281

AC OFF

A+7.5V

A-7.5V

+5V

(UNSW)

DVDD

RDS

D+5V

IC801

+3.3V

REG

RY141

R-CH

6

4

R-CH

FAN

DRIVE

Q191,192

R-CH

IC901

1

VCC

+7.5V

VDD

D+5V

ST +10V

Q905

Q901

Q9001

Q9003

VP

2

VEE

9

EN

4

D901

D303

D914

Q903

+10V

REG

REG

Q904

10

POWER

CONT

Q907

POWER

CONT

Q906

POWER

CONT

Q902

13

POWER

CONT

Q9002

POWER

13

CONT

Q9004

µCOM D+5V

CD M+7V

(UNSW)

TC M+12V

OVER LOAD

SENSOR

Q801

OVER LOAD

DET

Q282

TO

MPEG

2

TRIGGER

M

10

CAPSTAN

M

MOTOR

X601

8MHz

S691

DOOR

• RCH Same as L CH

• Signal Path

DISPLAY CONTROL

8

XOUT

9

XIN

36

SPEANA 1

37

SPEANA 2

38

L+R

24

DATA

23

CLOCK

10

RESET

27

KEY1

28

KEY2

20

VOL A

34

VOL B

22

JOG A

35

JOG B

29

KEY3

21

DOOR SW

30

KEY4

KEY4

T901

T901

: FM

: PHONO

: CD

: PB (DECK A)

: PB (DECK B)

: REC (DECK B)

IC601

SEG1

SEG21

GR15

LED11

LED12

LED13

LED SELECT

LED15

LED16

LED17

F901

S901

F902

GR1

LED7

LED8

LED4

LED4

LED5

LED6

57

77

42

56

79LED1

80LED2

1LED3

2LED4

5

6

14

15

16

17

25

2

3

4

18

19

31

33SIRCS

78VKK

LED3

VP

FLOURESCENT

INDICATOR TUBE

VF1

LED

DRIVE

Q604-612

SELECT

SWITCH

Q601-603

LED

DRIVE

Q618

LED

DRIVE

Q619,621

LED

DRIVE

Q614

LED

DRIVE

Q617

LED

DRIVE

Q620

2

AC

IN

D646

FL601

SIRCS

IC602

VF2

D611-625,627

D645,647

D635-638

D631,632

D641,642

D643,644

— 27 — — 28 —

HCD-V3900/V5900

T

T

1 IC301 !º (X2)

2 IC301 !¢ (XT1)

5.6Vp-p

5MHz

2.3 Vp-p

32.768 kHz

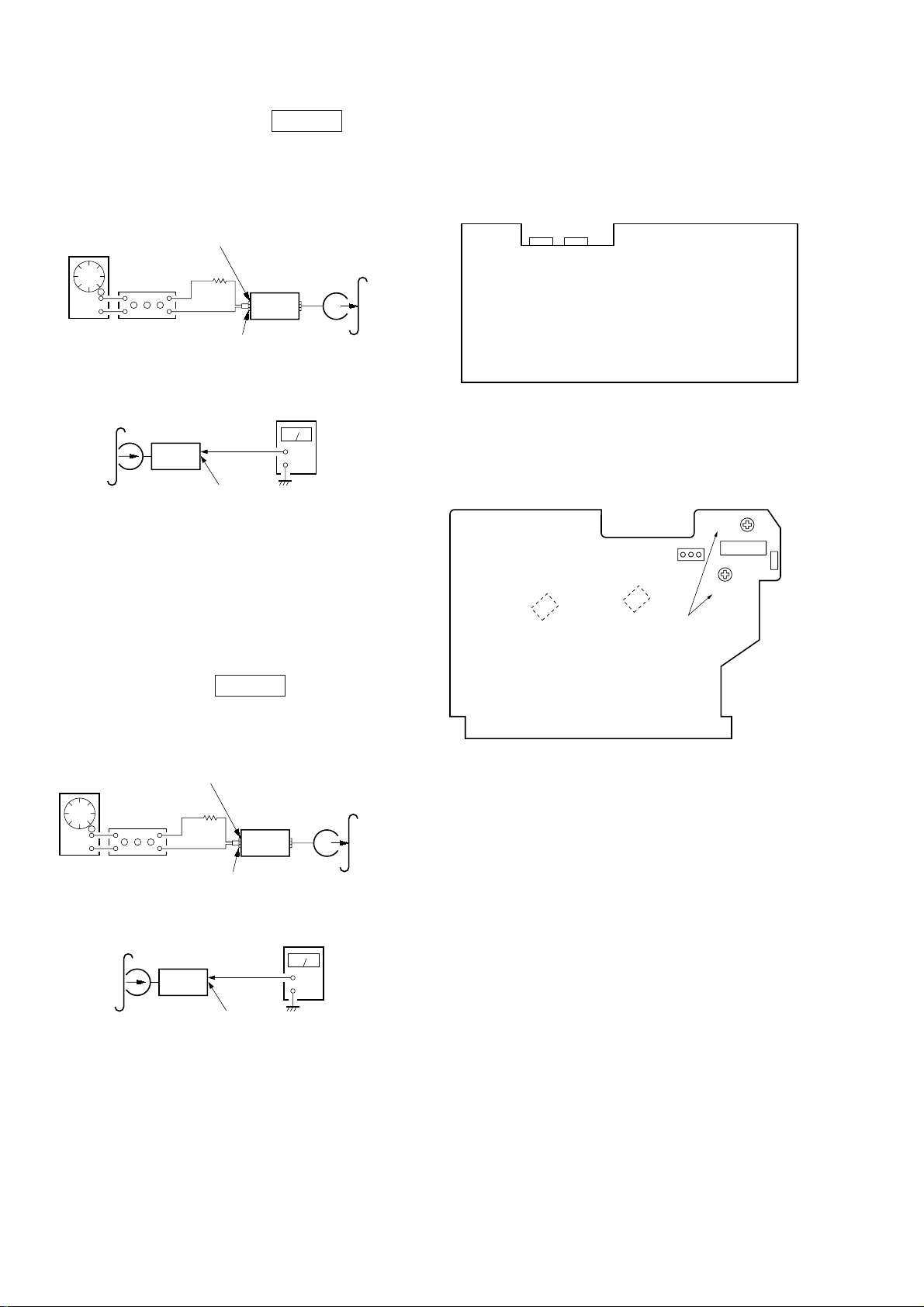

6-4. CIRCUIT BOARDS LOCATION

TRANS board

PANEL board

HP/MIC board

TC-A SW

board

LED board

CD-A SW board

DOOR SW board

MOTOR board

CD-B2 SW board

VIDEO POWER board

TC-B SW board

CD-B1 SW board

LEAF SWITCH

board

ENCAPSULATED COMPONEN

(FM/AM TUNER UNIT)

KEY-CON board

MAIN board

AMP board

VIDEO board

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this necessary note is printed in each

block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

¢

•

: internal component.

• 2 : nonflammable resistor.

• 1 : fusible resistor.

• C : panel designation.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

g : VIDEO/MD

E : PB (DECK A)

d : PB (DECK B)

G : REC (DECK B)

J : CD

I : PHONO

For printed wiring boards.

Note:

• X : parts extracted from the component side.

®

•

•

• b : Pattern from the side which enables seeing.

: Through hole.

¢

: internal component.

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

– VIDEO SECTION –

1

TP115 LRCK

44.1kHz

2

TP117 BCLK

2.11MHz

3

IC201 2 XLT0O

28.63636MHz

4

5

6

7

8

106

IC201 XLT2O

45MHz

IC201 (£ VSYNC

V

IC201 (™ HSYNC

H

IC271 8 OSCIN

6.75MHz

IC401 @¢ COMPO

4.8Vp-p

4.5Vp-p

4Vp-p

4Vp-p

4.8Vp-p

4.8Vp-p

!™

!£

(TP453 COUT)

!¢

!∞

(TP451 VOUT)

!§

!¶

!•

4.4Vp-p

!ª

TP409 27M

5Vp-p

27MHz

CN 103 5 COUT

0.9Vp-p

H

TP452 YOUT

1.3Vp-p

H

CN103 1 VOUT

0.9Vp-p

H

IC701 %¡ EXTAL

5Vp-p

10MHz

IC901 !º X2

5.4Vp-p

5MHz

TP104 LRCK

4.8Vp-p

44.1kHz

TP102 BCLK

CD MOTOR board

TABLE SENSOR board

• Wavef orm

– DISPLAY SECTION –

1

IC601 8 (X-OUT)

9

BD board

VIDEO OU

8MHz

– MAIN SECTION –

4Vp-p

!º

board

AUDIO board

!¡

BD LED board

— 29 — — 30 —

H

IC401 @ª YOUT

H

IC401 #™ COUT

H

TP410 DCLK

13.5MHz

0.9Vp-p

0.9Vp-p

0.3Vp-p

3.7Vp-p

@º

@¡

4.8Vp-p

2.11MHz

TP101 384FS

1.3Vp-p

16.9MHz

IC101 @¡ XOUT

4Vp-p

33.8MHz

HCD-V3900/V5900

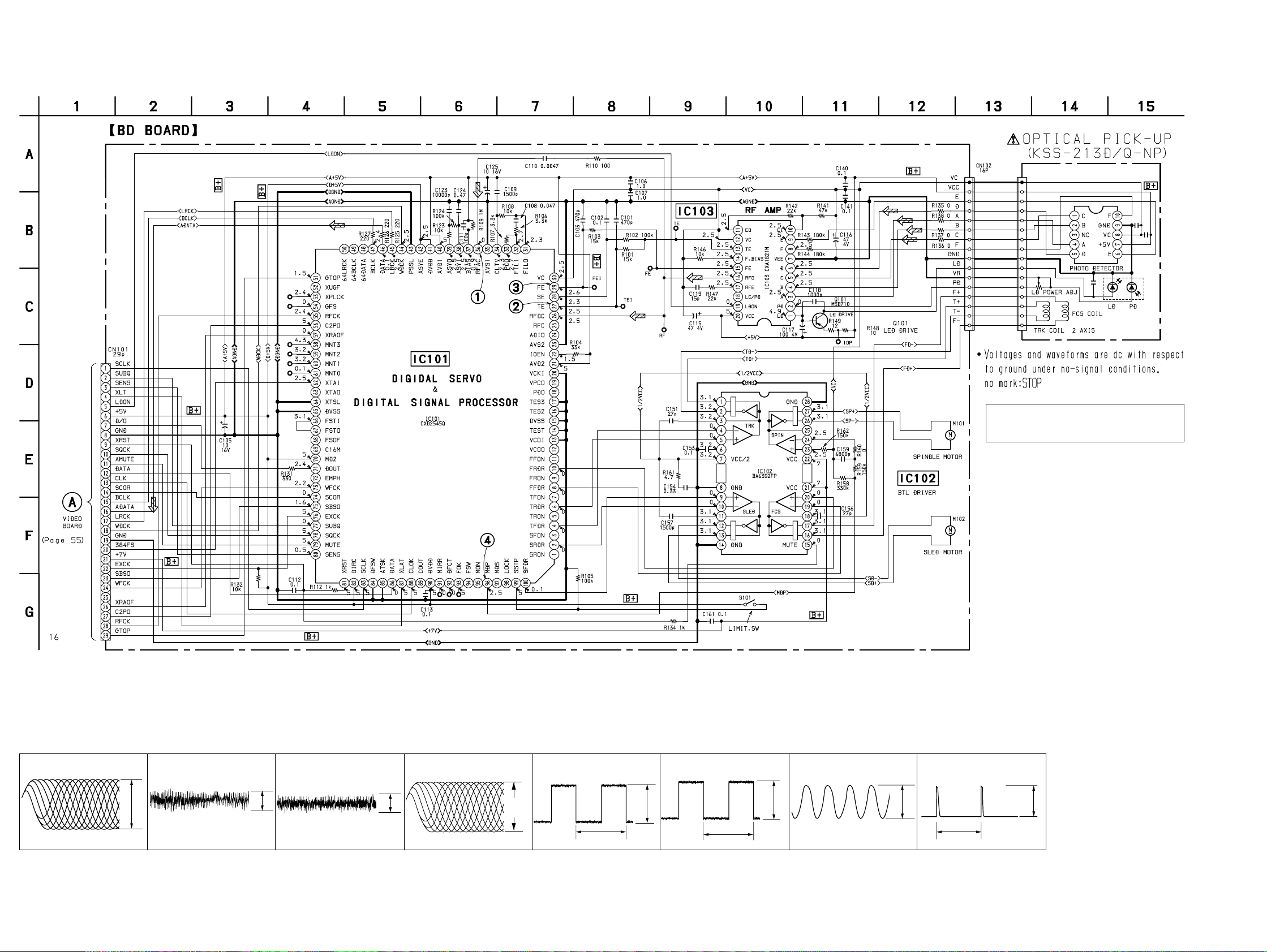

6-5. SCHEMATIC DIAGRAM – BD SECTION – • See page 83 for IC Block Diagrams.

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

• Waveform

1 IC101 @§ (RFDC)

Approx. 1.3Vp-p

2 IC101 @¶ (TEI)

(PLAY MODE)

Approx. 0.5Vp-p

3 IC101 @ª (FE)

(PLAY MODE)

Approx. 0.2Vp-p

4 IC101 #§ (RFAC)

5 IC101 $∞ (LRCK)

+0.25

1.3

–0.20

Vp-p

22.7 µsec

5.2Vp-p

6 IC101 $¶ (BCLK)

5.2Vp-p

474 nsec

7 IC101 ^™ (XTAI)

16.9344MHz

5.2Vp-p

— 31 — — 32 —

8 IC103 (§ (MDP)

2.4Vp-p

7.5 µsec

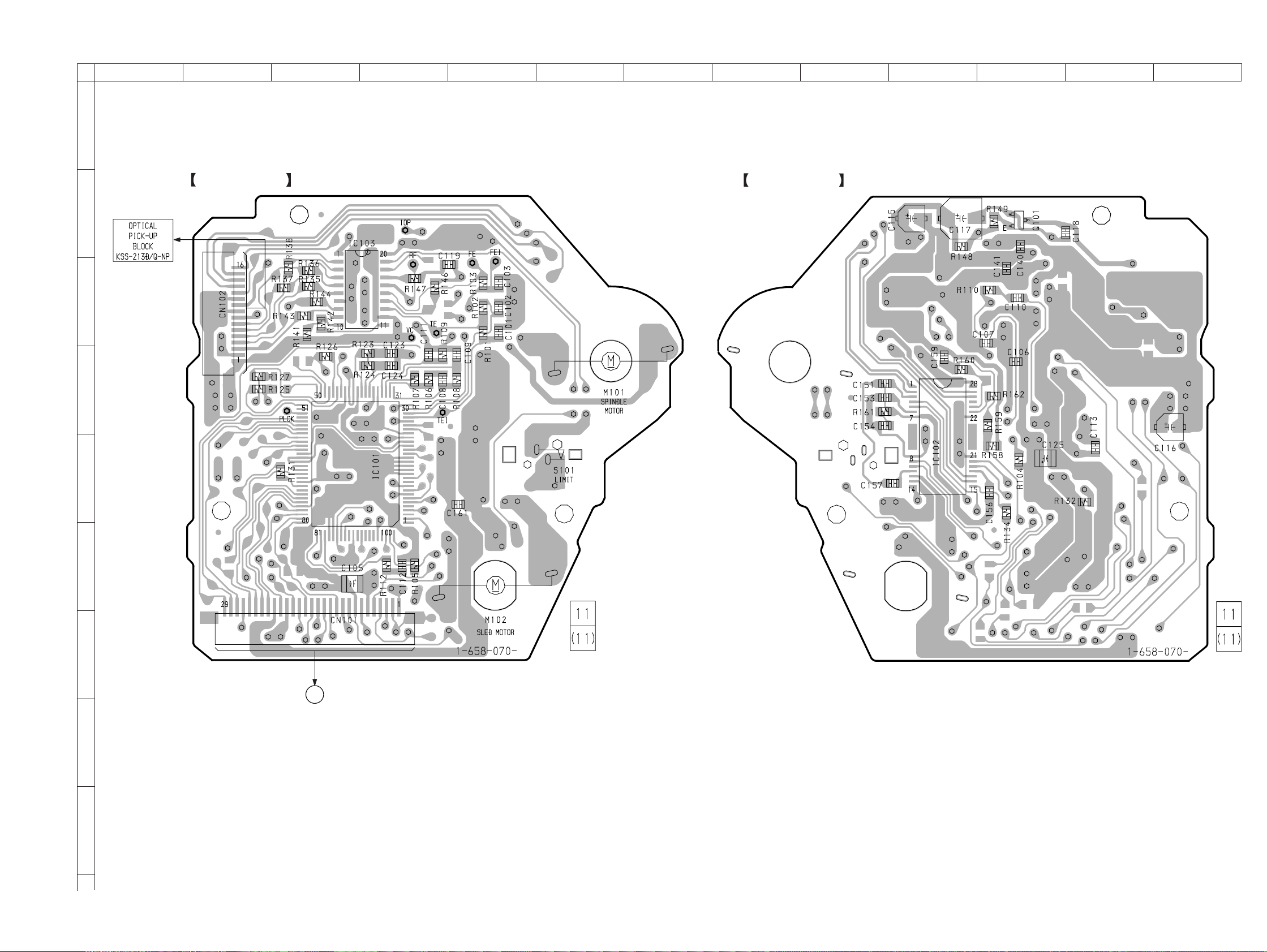

6-6. PRINTED WIRING BOARD – BD SECTION – • See page 29 for Circuit Board Location.

HCD-V3900/V5900

A

B

C

D

12

BD BOARD

(SIDE A)

345678910111213

BD BOARD

(SIDE B)

E

F

G

H

16

A

TO

VIDEO

(Page 51)

I

— 33 —

— 34 —

Loading...

Loading...