Sony HCD-FR1, HCD-FR8, HCD-FR9 Service Manual

HCD-FR1/FR8/FR9

SERVICE MANUAL

Ver 1.1 2004.07

PHOTO: HCD-FR1

HCD-FR1/FR8/FR9 are the amplifier, DVD/

SACD and tuner section in DAV-FR1/FR8/FR9.

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS POWER

OUTPUT AND TOTAL HARMONIC

DISTORTION:

With 4 ohm loads, both channels driven, from 20 –

20,000 Hz; rated 75 watts per channel minimum RMS

power, with no more than 0.7 % total harmonic

distortion. (from 250 milli watts to rated outpu t )

Amplifier section (HCD-FR1)

Surround mode Front:

(reference) (with SS-TS20)

music power output Center*:

Amplifier section (HCD-FR8)

Surround mode Front:

(reference) (with SS-TS21)

music power output Center*:

Amplifier section (HCD-FR9)

Surround mode Front:

(reference) (with SS-TS21)

music power output Center*:

110

W +

110

W

W

114

114

114

114

W

110

100

W +

W

114

115

W +

W

(with SS-CT44)

Surround*:

110

(with SS-TS20)

Subwoofer*:

(with SS-WS12)

(with SS-CT33)

Surround*:

114

(with SS-TS20)

Subwoofer*:

(with SS-WS12)

(with SS-CT33)

110

W +

W 2

114

W +

W 2

114

W

×

W

×

W

*Depending on the sound fi eld settings and the source,

there may be no sound output.

Inputs VIDEO/SAT:

Output SURROUND BACK

Phones Accepts low-and high-

Super Audio CD/DVD system

Laser Semiconductor laser

Signal format system NTSC

Frequency response (at 2 CH STEREO mode)

Harmonic distortion Less than 0.03 %

Tuner section

System PLL quartz-locked digital

Surround*:

114

(with SS-TS21)

Subwoofer*:

(with SS-WS12)

Sensitivity: 250 mV/

450 mV

Impedance: 50 kilohms

Voltage: 2V

Impedance: 1 kilohms

impedance headphones.

(Super Audio CD/DVD:

= 650 nm)

(CD: λλ = 780 nm)

Emission duration:

continuous

DVD (PCM): 2 Hz to 22

kHz (±1.0 dB)

CD:2 Hz to 20 kHz (±1.0

dB)

synthesizer system

US Model

HCD-FR1/FR8/FR9

Canadian Model

Model Name Using Similar Mechanism HCD-C770

Mechanism T ype CDM69-DVBU16

Optical Pick-up Name DBU-1

W

114

115

W +

W

FM tuner section

Tuning range 87.5 – 108.0 MHz

×

Antenna (aerial) FM wire antenna (aerial)

2

Antenna (aerial) terminals

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 531 – 1,710 kHz (with the

Antenna (aerial)

Intermediate frequency

Video section

Outputs

General

Power requirements

Power consumption

Dimensions (approx.)

Mass (approx.)

Design and specifications are subject to change

without notice.

(100 kHz step)

75 ohms, un balanced

interval set at 9 kHz)

530 – 1,710 kHz (with the

interval set at 10 kHz)

AM loop antenna (aerial)

450 kHz

Video: 1 Vp-p 75 ohms\

S VIDEO:

Y: 1 Vp-p 75 ohms

C: 0.286 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0. 65 Vp-p

75 ohms

120 V AC, 60 Hz

120 W

430 × 70 × 398 mm

(17 2

(w/h/d) incl . pr ojecting

parts

5.5 kg (12 lb 12 oz)

7

/815 3/4 inches)

××

HCD-FR1

9-879-011-02

2004G16-1

© 2004.07

SACD/DVD RECEIVER

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

HCD-FR1/FR8/FR9

r

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manuf acturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Pr ecision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V A C range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU D ANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

TABLE OF CONTENTS

HCD-FR1/FR8/FR9

1. SERVICING NOTE ................................................... 4

2. GENERAL ................................................................... 5

3. DIAGRAMS

3-1. Printed Wiring Board – RF Board – ................................ 9

3-2. Schematic Diagram – RF Board –................................... 10

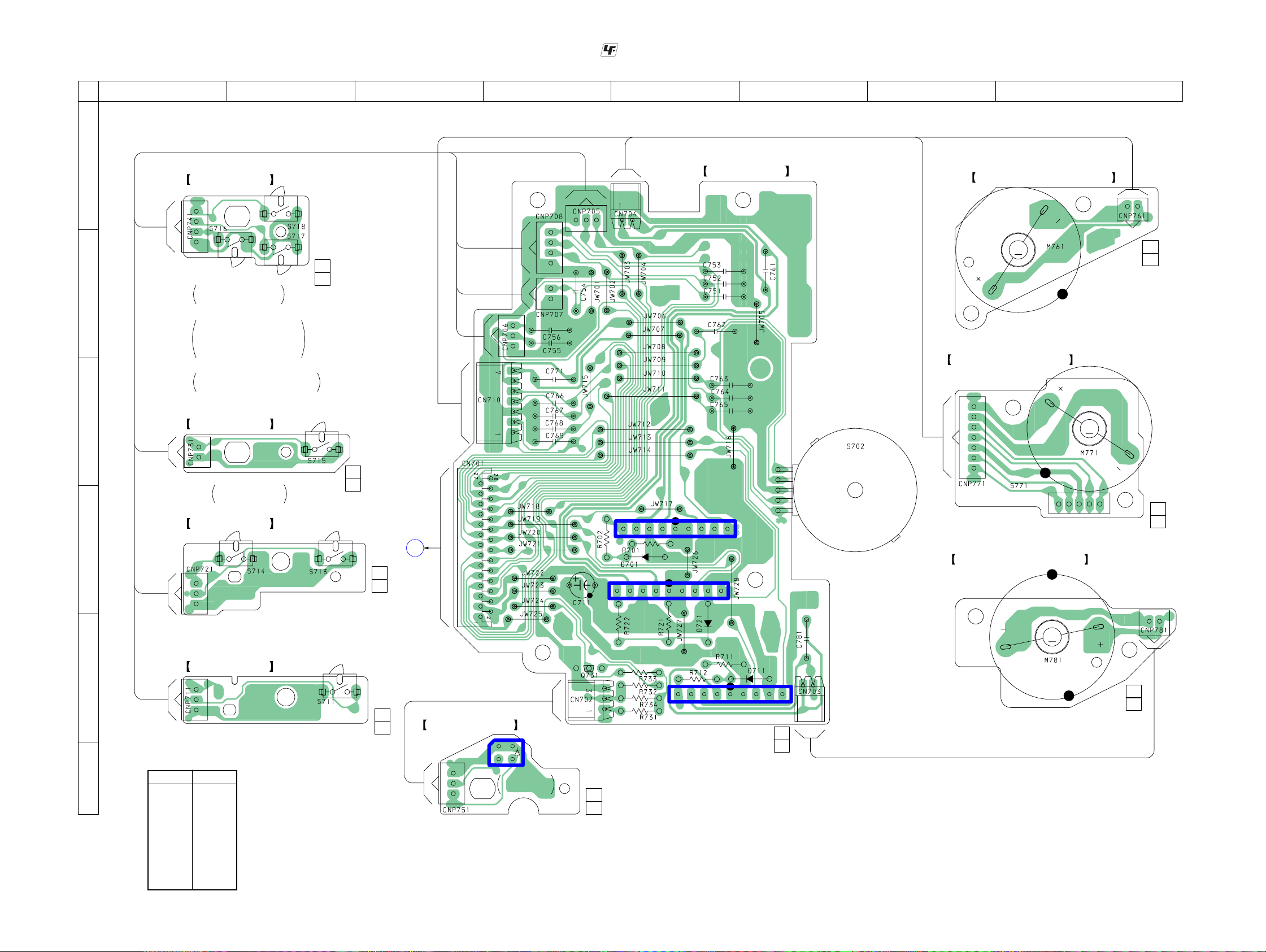

3-3. Printed Wiring Board – RELAY Section –...................... 11

3-4. Schematic Diagram – RELAY Section – ........................ 12

3-5. Printed Wiring Board – DMB08 Board (Side A) – ......... 13

3-6. Printed Wiring Board – DMB08 Board (Side B) – ......... 14

3-7. Schematic Diagram – DMB08 Board (1/10) –................ 15

3-8. Schematic Diagram – DMB08 Board (2/10) –................ 16

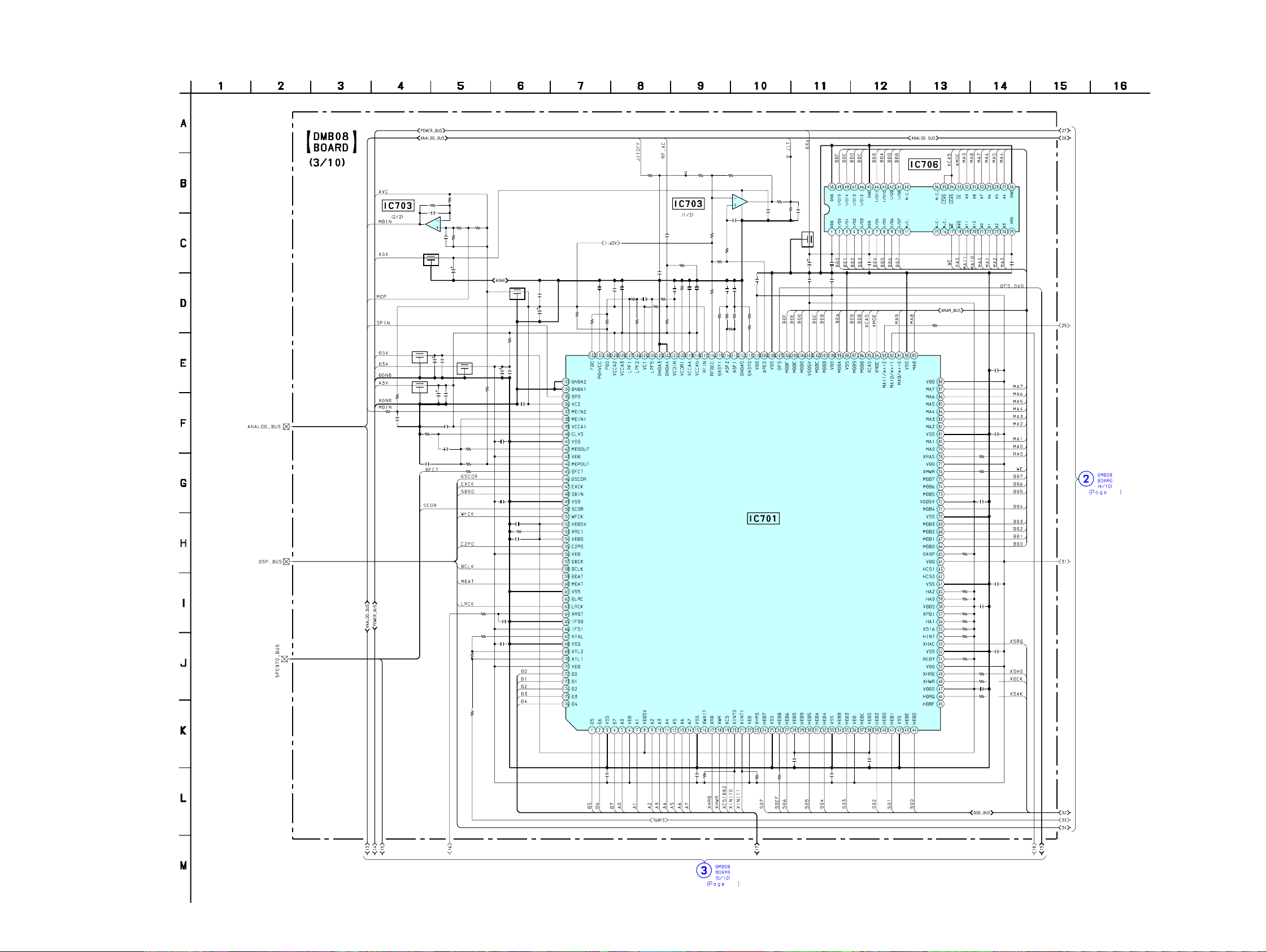

3-9. Schematic Diagram – DMB08 Board (3/10) –................ 17

3-10. Schematic Diagram – DMB08 Board (4/10) –................ 18

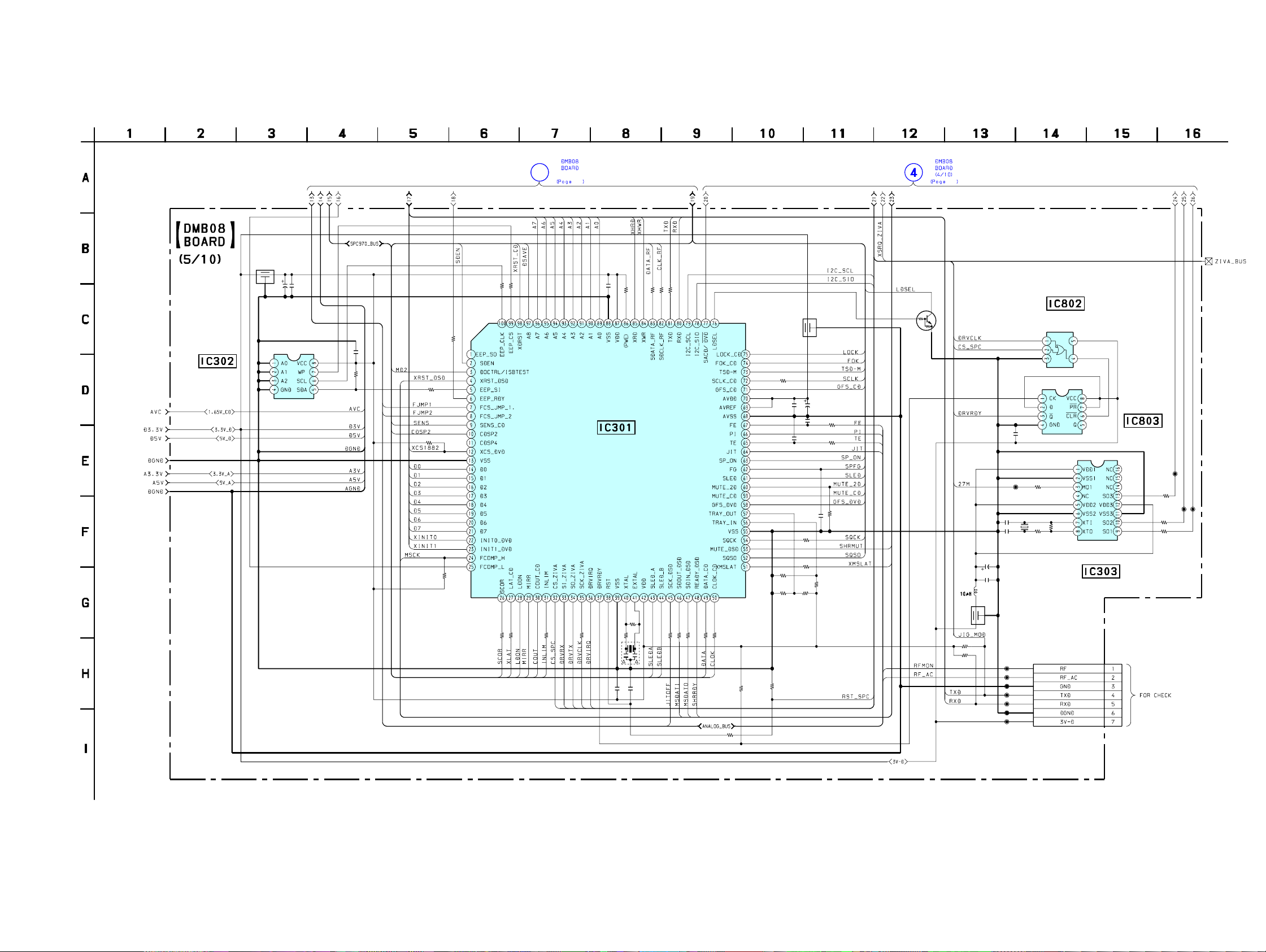

3-11. Schematic Diagram – DMB08 Board (5/10) –................ 19

3-12. Schematic Diagram – DMB08 Board (6/10) –................ 20

3-13. Schematic Diagram – DMB08 Board (7/10) –................ 21

3-14. Schematic Diagram – DMB08 Board (8/10) –................ 22

3-15. Schematic Diagram – DMB08 Board (9/10) –................ 23

3-16. Schematic Diagram – DMB08 Board (10/10) –.............. 24

3-17. Printed Wiring Board – AMP Board (Side A) –.............. 25

3-18. Printed Wiring Board – AMP Board (Side B) – .............. 26

3-19. Schematic Diagram – AMP Board (1/4) – ...................... 27

3-20. Schematic Diagram – AMP Board (2/4) – ...................... 28

3-21. Schematic Diagram – AMP Board (3/4) – ...................... 29

3-22. Schematic Diagram – AMP Board (4/4) – ...................... 30

3-23. Printed Wiring Board – IO Board –................................. 31

3-24. Schematic Diagram – IO Board (1/2) –........................... 32

3-25. Schematic Diagram – IO Board (2/2) –........................... 33

3-26. Printed Wiring Board – DDCON Board –....................... 34

3-27. Schematic Diagram – DDCON Board – ......................... 35

3-28. Printed Wiring Board – FL Board – ................................ 36

3-29. Schematic Diagram – FL Board – ................................... 37

3-30. Printed Wiring Board – SPK Board – ............................. 38

3-31. Schematic Diagram – SPK Board – ................................ 38

3-32. Printed Wiring Board

– POWER/FRONT PANEL Section –............................. 39

3-33. Schematic Diagram

– POWER/FRONT PANEL Section –............................. 40

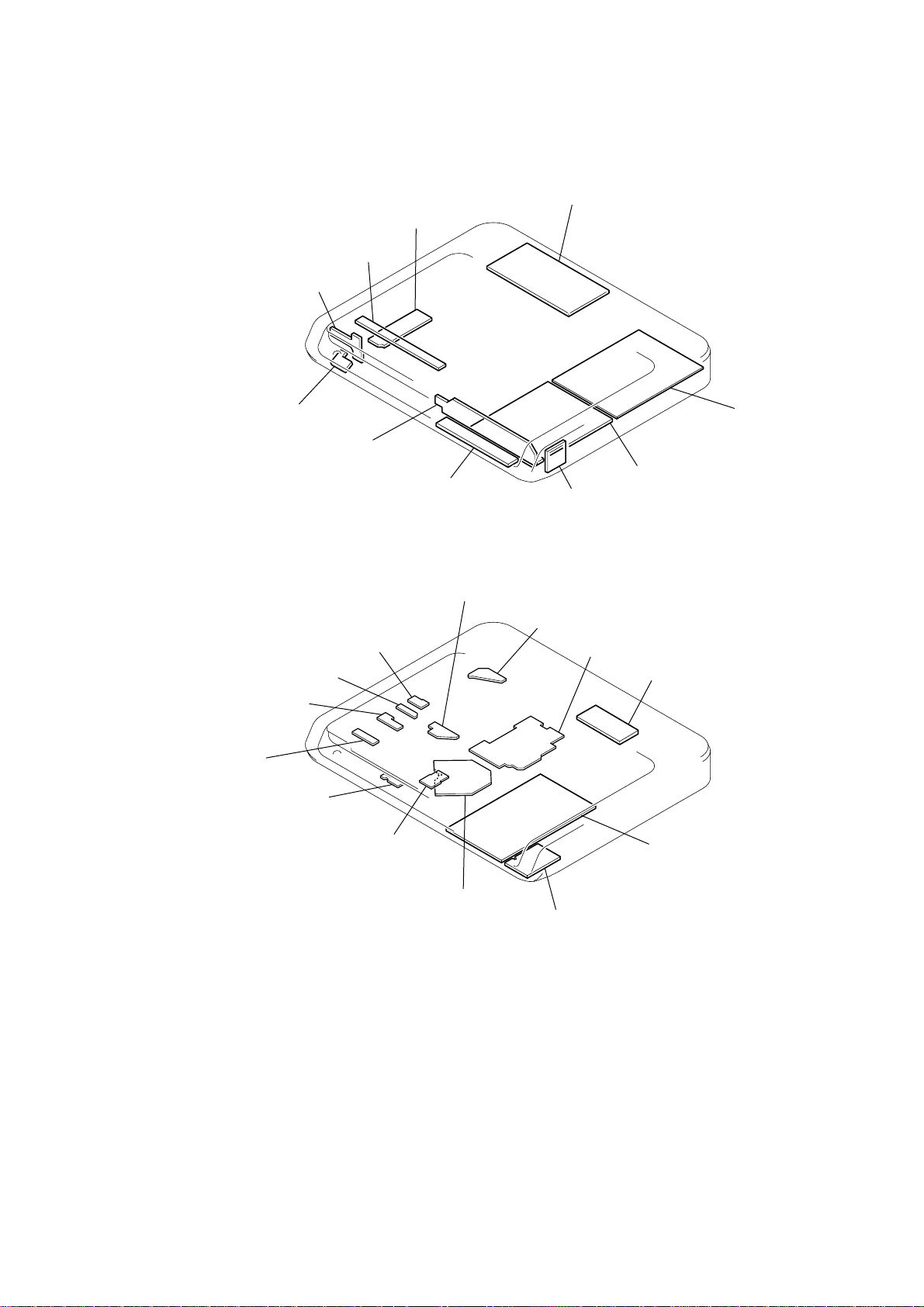

4. EXPLODED VIEWS

4-1. Case Section .................................................................... 41

4-2. Front Panel Section ......................................................... 42

4-3. Chassis Section................................................................ 43

4-4. Mechanism Deck Section-1 (CDM69-DVBU16) ........... 44

4-5. Mechanism Deck Section-2 (CDM69-DVBU16) ........... 45

4-6. Mechanism Deck Section-3 (CDM69-DVBU16) ........... 46

4-7. Mechanism Deck Section-4 (CDM69-DVBU16) ........... 47

4-8. Mechanism Deck Section-5 (CDM69-DVBU16) ........... 48

4-9. Mechanism Deck Section-6 (CDM69-DVBU16) ........... 49

4-10. Optical Pick-up Section (DBU-1) ................................... 50

5. ELECTRICAL PARTS LIST .................................. 51

3

HCD-FR1/FR8/FR9

SECTION 1

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

MODEL IDENTIFICATION

– BACK PANEL –

Part No.

MODEL Part No.

FR1 4-253-916-0[ ]

FR8 4-253-916-1[ ]

FR9 4-253-916-2[ ]

4

SECTION 2

Front Panel

A [/1 (power) switch/STANDBY indicator

(30)

B DISC1-5

Z

(eject)/indicators (30)

C (remote sensor) (13)

D Front panel display (98)

E PHONES (on the side of the system)

jack (30)

F VOLUME +/– (30, 83)

G ./> (31, 33)

H x (stop) (31)

I (play/pause) (30)

J FUNCTION (30, 70, 73)

K Disc slot (30)

GENERAL

HCD-FR1/FR8/FR9

This section is extracted

from instruction manual.

Rear Panel

A SPEAKER jacks (15)

B SURROUND BACK jack (19)

C VIDEO AUDIO IN (L/R) jacks (23)

D COMPO NENT VI DEO OUT jacks (23)

E SAT OPTICA L DIGITAL IN jack (24)

VIDEO

AUDIO IN

SPEAKER

CENTER FRONT LFRONT R

SURR L

WOOFER

WOOFERSURR R

RL

SURROUND

RL

BACK

AUDIO IN

SAT

F AM terminals (21)

G FM 75Ω COAXIAL jack (21)

H MONITOR OUT (VIDEO/S VIDEO) jacks

(23)

I SAT AUDIO IN (L/R) jacks (23)

YP

B/CBPR/CR

COMPOMEMT VIDEO OUT

S VIDEO

(DVD ONLY)

VIDEO

MONITOR OUT

OPTICAL

DIGITAL IN

SAT

AM

FM 75

COAXIAL

5

HCD-FR1/FR8/FR9

Remote

Open the cover.

Note

This remote contro l glows in the dark. How e ve r,

before glowing, the remote must be exposed to light for

awhile.

A DISC SKIP (30, 31)

B DISPLA Y (46, 49, 73)

C SLEEP (75)

D ./>, PRESET –/+ (31, 33, 73, 74)

E H (play) (30, 31, 32, 33, 37, 38, 39, 41,

41, 42, 43)

F DVD TOP MENU/ALBUM– (33, 35, 36)

G C/X/x/c/ENTER (27, 33, 33, 35, 36, 38,

38, 39, 41, 42, 44, 51, 57, 60, 61, 62, 64,

71, 72, 74, 75, 77, 85)

H DVD DISPLAY (35, 36, 38, 41, 42, 44, 49,

50, 51, 60, 61, 62)

I AUTO FORMAT DIRECT (53, 54)

J DSGX (59)

K DVD SETUP (27, 64, 77)

L SUBTITLE (61)

M AUDIO (51)

N ANGLE (60)

O Number buttons (33, 33, 39, 44, 60, 62,

64, 67, 69)

P ENTER

Q TUNER MENU (72, 74)

R TV [/1 (on/standby) (67)

S "/1 (standby) (27, 30, 72, 73)

T SONY TV DIRECT (69)

U TUNER/BAND (72, 73, 74)

V FUNCTION (27, 30, 70, 73, 74)

W m/M// SLOW, TUNING –/+ (37,

43, 72, 73)

X x (stop) (31, 32, 33, 62, 73)

Y X (pause) (31)

Z MUTING (31)

wj DVD MENU/ALBUM+ (33, 35, 36)

wk VOL +/– (31, 73)

wl O RETURN (27, 33, 35, 36, 38, 39, 44,

62, 64, 77)

e; MODE (54, 55)

ea NIGHT MODE (59)

es PLAY MODE (38, 39, 41)

ed REPEAT (39, 42)

ef TV (67, 69)

eg TV/VIDEO (67, 69)

eh TV CH +/– (67, 69)

ej TV VOL +/– (67)

ek AMP MENU (57, 71, 75, 85)

el CLEAR (27, 39, 44)

r; FM MODE (73)

6

• Circuit Boards Location

d

SONY LAMP board

HCD-FR1/FR8/FR9

SECTION 3

DIAGRAMS

IO board

LF board

DISC KEY board

PW KEY board

SW (2) board

SW (1) board

SENSOR board

FL board

SW (3) board

MODE MOTOR board

CONTROL KEY board

ROLLER MOTOR board

SW (4) board

AMP boar

SWITCHING REGLATOR

HP board

STOCKER MOTOR board

RELAY board

SPK board

DMB08 board

RF board

DDCON board

7

HCD-FR1/FR8/FR9

d

d

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note:

The components identified by mark 0 or dotted line with mark 0 are

critical for safety.

Replace only with part

number specified.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

•Voltages and waveforms are dc with respect to ground in

service mode.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

no mark : DVD STOP

•( ) : CD STOP

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

J : CD PLAY

c : DVD PLAY

d : TUNER

L : VIDEO

i : OPTICAL DIGITAL IN

h : VIDEO IN

a : CHROMA

d : Y

r : COMPONENT VIDEO

e : AUX IN

I : SACD PLAY

q : R, G, B

4

W or less unless otherwise

Note:

Les composants identifiés

par une marque 0 sont cr itiques pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

For printed wiring boards.

Note:

• X : parts extracted from the component side.

a

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• Indication of transistor.

: Through hole.

Caution:

Pattern face side: P arts on the pattern face side seen from

(Side A) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side B) the parts face are indicated.

CEB

These are omitte

C

Q

These are omitte

EB

8

HCD-FR1/FR8/FR9

3-1. PRINTED WIRING BOARD — RF BOARD —

1 2 3 4 5 6 7 8 9 10 11 12 13

A

B

E

E

C

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

RF BOARD

(SIDE A)

FLEXIBLE BOARD

OPTICAL PICK-UP

BLOCK

(DBU-1)

RF BOARD

(SIDE B)

D

A

DMB08 BOARD

CN401

(Page 13)

E

F

• Semiconductor

Location

Ref. No.

D001 B-3

D002 B-3

Location

1-684-822-

11

(11)

64 49

1

IC001

16

17 32

48

33

11

1-684-822-

(11)

IC001 D-11

Q001 C-11

Q002 B-11

HCD-FR1/FR8/FR9

99

HCD-FR1/FR8/FR9

3-2. SCHEMATIC DIAGRAM — RF BOARD —

RFMON

(DBU-1)

FLEXIBLE

BOARD

LD GND

DVD LD

INLIM_3V

R026C027C028

C031

12k0.10.1

1000p

0.01

IC001

CXD1881AR

C030

C029

0.01

C032

0.047

JL006

JL003

JL002

JL001

R033

0

330p

0.033

0.033

C036

R034

0.47

C037

C039

C038

N

R

O

IR

D

M

L

10M

C026

C025

0.1

R023

820

C024

JL005

R024

CN001

24P

D

C

RF

GND

VC

VCC

E

A

B

F

N.C

PD

VR

VCC

SW

INLIM

CD LD

FCS+

FCS-

TRK+

TRK-

100

R001

FD+

FD-

TD+

TD-

D

C

RFP

C009

0.1

RFP

A

E

A

B

B

C

F

D

PD FD-

DVD_LD

CD_LD

R041

1k

E

F

D

P

R019 R020

00

JL007

R035

0

R025

100

C019

R022

5600p

220

C017

2200p

C016

0.01

0

22p

22p

22p

22p

5600p

C020

C021

C022

C023

C018

2200p

C015

2200p

C014

2200p

C042

180p

R014

0

R013

0

R012

0

R011

0

R018

0

R017

0

R016

0

R015

0

C008

R021

0.1

JL004

CD/DVD/SACD RF AMP,

FOCUS/TRACKING ERROR AMP

C041

0.1

0.1

0

C040

0.1

C006

C013

22

0.1

10V

C035

0.1

MIRR

PI/CE

TE

FE

SDEN

SDEN

0

R027

0

R028

0

R029

C033 C012

0.1 0.1

R032

100

C034

0.1

C005

22

10V

C049

0.1

DATA_RF

CLK_RF

DATA_RF

CLK_RF

LDON

RFMON

FE

TE

PI/CE

CN002

29P

AGND

RFAC

AGND

AVC

AVC

MIRR

PI

TE

FE

A5V

A5V

SDEN

DATA_RF

CLK_RF

LDON

A3V

RFMON

INLIM

LDSEL

FD+

TD-

TD+

SLB-

SLB+

SLA-

SLA+

FD-

FD+

TD-

TD+

SLEDB-

SLEDB+

SLEDA-

SLEDA+

SPDL-

SPDL+

DMB08 BOARD

(1/10)

CN401

(Page 15)

HCD-FR1/FR8/FR9

CD_LD

C001

R005 R009

IOP2

Q001 Q002

2SB1132-T100-QR 2SB1132-T100-QR

AUTOMATIC POWER

CONTROL

1SS355TE

-17

(FOR DVD)

CN003

9P

SLEDA+

SLEDB+

SLEDB-

SLEDA-

{LIMIT-SW(A)}

LED

{LIMIT-SW(B)}

GND

{LIMIT-SW(B)}

INLIM

SPDL-

SPDL+

SLA+

SLB+

SLB-

SLA-

DVD_LD

R004R003

L001

47µH

C002D001

10

16V

47k 47k

3333

C010

1000p

R006

100

470

6.3V

IOP1

AUTOMATIC POWER

CONTROL

(FOR CD)

1SS355TE

-17

L002

47µH

C004D002

10

16V

C003

R010R008R007

100

4703333

6.3V

C011

1000p

No mark : DVD STOP

1010

HCD-FR1/FR8/FR9

3-3. PRINTED WIRING BOARD — RELAY SECTION —

1 2 3 4 5 6 7 8

A

SW (4) BOARD

4

B

C

3

4

1

S716 (STOCKER IN/OUT)

OFF: The moment disc in/out

from stocker

S717 (DISC POSITION)

In the midst disc is moving between

play position and stocker,

ON: disc is play position side,

OFF: disc is stocker side

S718 (STOCKING)

OFF: In the midst disc is moving between

play position and stocker

SW (3) BOARD

2

1

S715

OFF: When disc out

from play position

1-685-011-

11

(11)

(DISC OUT)

1-685-010-

11

(11)

SW (2) BOARD

D

2

3

1

(ON: Play position (8cm disc only))

(DISC IN (8cm))

S714

1-685-009-

S713

(DISC IN (8/12cm))

(ON: Play position)

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

65 56

1

2

31

4

3

2

3

1

4

1

2

1

1

G

DMB08 BOARD

CN006

11

(Page 13)

(11)

1

IC721

RELAY BOARD

4

3

G

2

1

9

IC701

9

ROTARY ENCODER

(STOCKER POSITION)

STOCKER MOTOR BOARD

M

(STOCKER)

MODE MOTOR BOARD

7

1

ROTARY ENCODER

(MODE)

12G34

ROLLER MOTOR BOARD

M

M

(MODE)

2

1-685-006-

1-685-005-

1

2

11

(11)

11

(11)

1

E

F

HCD-FR1/FR8/FR9

SW (1) BOARD

1

• Semiconductor

Location

Ref. No.

D701 D-5

D711 E-6

D721 E-5

IC701 D-5

IC711 E-5

IC721 D-5

IC751 F-4

Q731 E-4

3

1

Location

(DISC INSERT (8/12cm))

(ON: When disc insert)

1-685-008-

11

(11)

SENSOR BOARD

C

3

1

DETECT SENSOR

KAE

DISC INSERT

IC751

1-685-004-

E

11

(11)

19

IC711

1-685-012-

21

11

(11)

(ROLLER)

1-685-007-

11

(11)

1111

HCD-FR1/FR8/FR9

3-4. SCHEMATIC DIAGRAM — RELAY SECTION —

M781

(ROLLER)

M761

(STOCKER)

IC751

RPR-220

DISC INSERT

DETECT SENSOR

751

CNP751

3P

DIODE DIODE

D SENSE D SENSE

GND

CNP781

2P

MTR RL 1

MTR RL 2

CNP761

2P

MTR ST 2

MTR ST 1

CN702

CN703

CN704

3P

GND

2P

MTR RL 2

MTR RL 1

2P

MTR ST 2

MTR ST 1

C781

0.01

D721

MTZJ-T-77-3.6A

R731

150

R733

R734

15k

R732

1k

OUT2

VREF

R702

100

D701

MTZJ-T-77-4.7B

VREF

OUT2

VCC

RNF

VM

OUT1

R721

680

STOCKER MOTOR

RIN

FIN

GND

RNF

DRIVE

IC721

BA6956AN

OUT1

VM

R701

680

(DISC INSERT(8/12cm))

(ON:WHEN DISC INSERT)

VCC

FIN

MTZJ-T-77-5.1A0.01 100

MODE MOTOR

GND

RIN

DRIVE

IC701

BA6956AN

VM

RNF

OUT1

R711

680

VCC

CNP711 CNP705

GND

SW1-A

SW1-B

VREF

OUT2

R712

100

D711C761 R722

S711

ROLLER MOTOR

FIN

RIN

GND

3P 3P

DRIVE

IC711

BA6956AN

GND

SW1-A

SW1-B

10k

Q731

RT1N141

LEVEL

SHIFT

C754

C711

10

50V

SW1A

SW1B

0.1

C758

0.1

C756

0.1

C751

0.1

C752

0.1

C753

0.1

C764

0.1

C763

0.1

SW3

SW1A

C755

SW1B

0.1

SW2A

SW2B

SW4

SW5A

SW5B

C765

0.1

C762

0.1

P81 D.SENSOR

P92 SW3

P40 SW1-A

P41 SW1-B

P42 SW2-A

P43 SW2-B

P93 SW4

P94 SW5-A

P44 LOD POS

P45 LOD NEG

P46 SLD POS

P47 SLD NEG

P90 ELV POS

P91 ELV NEG

P95 SW5-B

P96 SLD E0

P02 SLD E1

P03 SLD E2

P04 SLD E3

P82 ELV E0

P83 ELV E1

P54 ELV E2

P55 ELV E3

CN701

28P

D+5V

M+12V

M+12V

MGND

MGND

ROTARY ENCODER

(STOCKER POSITION)

S702

G

DMB08 BOARD

(10/10)

CN006

(Page 24)

S713

(DISC IN(8/12cm))

(ON:PLAY POSITION)

S714

(DISC IN(8cm))

(ON:PLAY POSITION(8cm DISC ONLY))

S715

(ON:WHEN DISC OUT FROM PLAY POSITION)

BETWEEN PLAY POSITION AND STOCKER,

ON:DISC IS PLAY POSITION SIDE,

OFF:IN THE MIDST DISC IS MOVING

BETWEEN PLAY POSITION AND STOCKER

(DISC OUT)

S716

(STOCKER IN/OUT)

ON:THE MOMENT DISC IN/OUT

FROM STOCKER

S717

(DISC POSITION)

IN THE MIDST DISC IS MOVING

OFF:DISC IS STOCKER SIDE

S718

(STOCKING)

CNP721 CNP706

3P 3P

GND

SW2-A

SW2-B

CNP731 CNP707

2P 2P

GND

SW3

CNP741 CNP708

4P 4P

GND

SW4

SW5-A

SW5-B

GND

SW2-A

SW2-B

GND

SW3

GND

SW4

SW5-A

SW5-B

SW2A

SW2B

SW5A

SW5B

S771

ROTARY ENCODER

M771

(MODE)

(MODE)

CN710

MTR MD 1

MTR MD 2

7P

E1

E2

GND

E3

E4

C769

0.1

SW3

SW4

C768

0.1

0.1

C767

0.1

C766

C771

0.01

CNP771

7P

E1

E2

GND

E3

E4

MTR MD 1

MTR MD 2

HCD-FR1/FR8/FR9

1212

HCD-FR1/FR8/FR9

3-5. PRINTED WIRING BOARD — DMB08 BOARD (SIDE A) —

12

3456789

A

C002

B

IC901

D

DDCON

BOARD

CN800

(Page 34)

C

FOR

CHECK

IC301

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

RELAY

G

BOARD

CN701

(Page 11)

28

R071

27

CN006

C009

C012

1

2

IC801

IC813

IC612

IC606

IC607

IC605

AMP

BOARD

CN302

(Page 26)

B

C

AMP

BOARD

CN301

(Page 26)

D

E

F

FOR

CHECK

IC402

IC401

IC701

BOARD

A

CN002

(Page 9)

IC206

SWITCHING

REGULATOR

CN8

• Semiconductor

Location

Ref. No.

D900 C-2

RF

F

IO

BOARD

CN201

(Page 31)

E

IO

BOARD

CN601

(Page 31)

D901 C-4

IC206 D-5

IC301 C-2

IC401 D-2

IC402 D-2

IC605 C-8

IC606 C-7

IC607 B-7

IC612 B-6

IC701 D-4

IC801 B-5

IC813 C-4

IC901 B-2

Location

HCD-FR1/FR8/FR9

1313

HCD-FR1/FR8/FR9

3-6. PRINTED WIRING BOARD — DMB08 BOARD (SIDE B) —

12

A

B

IC604

IC005

C

IC004

IC608

D

IC904

IC609

IC601

IC002

E

IC603

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

345678

R076

R081

R058

IC900

IC203

IC215

IC001

IC704

IC205

IC006

IC808

IC303

IC812

FR1/FR8

IC903

FR8/FR9

IC803

IC814

IC802

IC706

IC202

IC501

IC703

IC907

IC302

• Semiconductor

Location

Ref. No.

D902 B-7

D903 B-6

D904 C-7

D907 B-7

IC001 E-3

IC002 D-2

IC004 C-2

IC005 C-2

IC006 E-4

IC202 D-4

IC203 D-3

IC205 D-4

IC215 C-3

IC302 C-7

IC303 C-4

IC501 E-7

IC601 D-2

IC603 E-2

IC604 C-2

IC608 D-2

IC609 D-2

IC703 E-5

IC704 C-4

IC706 D-5

IC802 C-7

IC803 C-6

IC808 B-4

IC812 C-5

IC814 C-5

IC900 B-3

IC903 C-6

IC904 D-1

IC907 B-7

Q301 D-6

Q302 D-3

Q900 B-7

Q901 B-7

Q902 B-7

Q903 B-6

Q906 B-6

Q907 C-7

Q908 B-3

Q909 B-3

Q910 B-3

Q913 B-7

Location

HCD-FR1/FR8/FR9

1414

3-7. SCHEMATIC DIAGRAM — DMB08 BOARD (1/10) —

C404

HCD-FR1/FR8/FR9

FL401

0UH

(2012)

C401

C410

R419

68k

C411

10

0.1

16V

R418

0.1

10k

C402

0.1

10

C406

0.0022

C405

CN401

29P

10

JL544

JL537

JL536

JL535

JL531

JL530

JL529

JL527

JL526

JL525

JL524

JL523

JL522

JL501

JL502

JL500

JL511

JL512

JL509

JL510

JL503

JL504

JL505

JL506

JL507

JL508

10

16V

R414

0

C414

0.01

R428

1k

R433

47k

C415

0.01

R434

47k

R440

R437

2)

(TE

402

IC

3404AV

JM

N

47k

47k

C409

0.0022

R413

10k

R412

10k

C407

10

10V

C408

0.1

C412

0.0022

C413

0.0022

C419

0.047

B

R441

1k

R443

47k

R421

R423

R425

R426

R429

R430

C420

0.0022

C418

R411

0

1k

1k

1k

1k

1k

1k

0.1

1k

R445

1k

R450

C425

0.0022

0.022

C424

B

0

401

R

R451

10k

R420

0

IC401

CXD3068Q

R439

330

C416

10

10V

C417

R442

0.1

10k

R444

B

033

0.0

428

C

0k

k

10

10

33k

7

455

C432

R

44

449

R

C426

0.01

100p

R

C427

0.47

B

B

C433

0.0015

R457

k

1

R446

1M

10k

448

2

R

45

C421

R

0.1

3.3k

C434

C422

10

100p

10V

C423

470k

R453

0.1

1M

FL402

0UH

(2012)

C436C435

0.10.1

HCD-FR1/FR8/FR9

16

1515

HCD-FR1/FR8/FR9

3-8. SCHEMATIC DIAGRAM — DMB08 BOARD (2/10) —

C526

16V

C527

0.1

15

R581

12k

R580

582

10k

R

22

IC501

FAN8035L

R583

10k

33k

C519

0.01

R579

8.2k

C514

0.01

C512

0.01

R532

0

R533

33k

R534

56k

R529

33k

R530 R531

56k 0

R535

0

R592

R525

C509

330p

R536

200k

R522

4.7k

R527

2.2k

10k

R524

10k

R521

100k

R523

10k

R519

100k

R520

10k

C508

0.001

0

R510

R511

150k

150k

C529

0.1

C524

0.1

514

R

R416

0

10k

C525

0.1

C528

47

6.3V

R513

C503

R515

C504

56k

33000p

10k

R512

56k

33000p

C510

0.001

R516 R517

C506

4.7k 2. 2k

330p

HCD-FR1/FR8/FR9

1616

3-9. SCHEMATIC DIAGRAM — DMB08 BOARD (3/10) —

HCD-FR1/FR8/FR9

NJM3404AV(TE2)

R765

22k

R767

47k

IC703(2/2)

FL704

0UH

(2012)

C774

0.0047

FL706

(2012)

(2012)

C718

0.01

B

8

1

7

R

TMC57929PGF

C721

0.1 B

k

0

1

0

0

8

7

R

TP701

R727

3.3k

C728

0.1

R728

B

10k

FL705

0UH

(2012)

F

C727

4

2

10

7

.1

C

10V

0

C723C722

C725

0.01

0.01

B

IC701

-RDP

0.1 F

B

IC706

MSM51V18165F-

60TSKR1

C726

0.1

F

R772

22

C730

0.01

B

C740

0.01

B

R730

22

R731

22

C741

0.01

B

R732

10k

C742

0.01

B

R702

10k

R703

10k

C743

0.01

B

R735

10k

R704

10k

R737

10k

R705

10k

C744

R706

0.01

10k

B

R741

22

R742

22

C745

0.01

B

R743

22

18

TP702

R729

8.2k

R544

R545

100k

100k

C523

0.0015

R541 R540

100k 10k

C521

R538

0.0015

100k

C729

0UH

FL703

0UH

R764

C771

0.047

10

10V

FL701

0UH

(2012)

R701

C777

C780

0.01

10

B

10V

C776

C781

0.1

10

F

10V

C772

0.1

1M

C773

0.47

B

B

R750

10k

680

FL702

0UH

(2012)

R771

C779

2.2k

10

10V

C775

C770

0.01 B

R763

8.2k

R762

22k

R760

0

C767

0.01

B

R778

100k

R799

0

R776

0

C765

0.01

B

R777

0

C706

0.1

F

C702

R707

100

100

4V

B

1

.0

0

8

7

7

C

0.01 B

C769

0.01 B

C768

0.01 B

C766

100p

R708

470k

C709

0.1

C708

0.01

F

C752

0.1

C711

R710

0.01

10k

k

.2

2

R709

1

150k

1

7

R

C715

0.0015

R748

33k

C712

C703

100p

0.1

CH

k

F

0

2

1

k

1

0

.1

7

1

3

0

R

1

7

3

R

1

7

C

k

k

0

3

1

3

4

7

1

4

7

7

R

R

R726R725

1.8k

100k

IC703(1/2)

NJM3404AV(TE2)

C720

0.1

R724

F

.1

0

4

1

7

C

B

1k

R721

33k

C717

R720

0.01

1k

B

k

0

C716

1

0.47

5

B

1

7

R

k

0

k

0

0

0

1

1

0

1

1

9

8

6

1

7

1

7

7

7

R

1

R

7

R

R

HCD-FR1/FR8/FR9

C760

R746

47k

C764

0.01

B

C763

0.01

B

R745

47k

C762

0.01

R744

B

22

0.01

B

C761

0.01

B

19

1717

HCD-FR1/FR8/FR9

3-10. SCHEMATIC DIAGRAM — DMB08 BOARD (4/10) —

(2012)

FL812

POWER-EMIS

(3216)

R808

IC704

TK11125CSCL-G

FL810

0UH

R888

R886

R884

10k

10k

R889

R887

10k

10k

10k

C805

0.01

B

C797

100 4V

C796

0.1

F

C840

10

C843

0.01

10V

B

C848

C841

0.01

10

B

10V

IC808

MSM56V16160F-8TK

-7R1

C854

0.01

B

R804

0

33000p 100

C870 R803

SL812

R882

10k

10k

R885

R883

10k

10k

C842

0.01

B

FL811

POWER-EMIS

SL813

SL811

R805

10k

C815

0.01

B

C871

0.01

B

R842

10k

C865

0.01

B

C867 C866

0.01

B

0.01

B

0UH

IC814

TC7WH157FK

(TE85R)

10

10V

FL807

(2012)

R847

22

C813

0.01

C849

B

0.01

C837

0.01

B

17

IC812

SN74LV245APWR

IC813

SN74LV245APWR

C811

C804

0.01

0.01

B

IC801

CXD2753R

C819

0.01

B

R830

4.7k

C812

0.01

C861

0.01

B

C857

0.01

B

R826

22

R850

22

C855

0.01

B

R849

22

R848

22

R821

22

R822

22

R823

22

R867

0

C856

0.01

B

C803

C802

0.01

HCD-FR1/FR8/FR9

R831

C808

100p

C817 C818

R806

0

0.01

B

0

R829

k

0

8

100

.7

R

4

33k

B

0

1

1

8

C

.0

0

B

7

0

1

8

C

.0

0

0

8

9

3

8

R

0

C839

k

k

2

1

8

0.01

.7

.7

R

4

4

7

B

2

8

R

0.01

B

C838

0.01

B

19

1818

3-11. SCHEMATIC DIAGRAM — DMB08 BOARD (5/10) —

FL301

0UH

(2012)

C302

0.01

B

C301

10

10V

C320

0.01

IC302

BR24L16F-WE2

B

R738

HCD-FR1/FR8/FR9

(3/10)

3

22

22

R304

R303

22

17

C303

0.01

B

22

10k

22

22

R305

R306

R307

R308

FL304

0UH

(2012)

Q301

DTC114EKA

-T146

18

IC802

TC7S32FU(TE85R)

R350

100

R311R312

R361

22

R316

10k

10k

100

R317

100

R318

100

R321

100

R323

IC301

CXP973064-245R

20MHz

X301

0

R324

C307

R325

B

0.01

R333

33k

C304

100

100

100

R326

R327

R328

B

0.01

100

R329

100

R330

R360

R364

4.7k

10k

C311

0.01

B

C309

100p

33000p

R335

10k

R332 R365

10k 100k

C308

C310

100p

22

C312

10

10V

R346

1k

C809

C318

C317

0.01

CL301

12p

X302

27MHz

12p

JL301

JL302

JL303

JL304

JL305

JL306

JL307

R337

100

R366

100k

R344

1k

R363

10k

C316

10 16V

C313

L301

0.1 F

FL303

0UH

(2012)

R359

10k

R353

10k

10k

SN74AHC2G74HDCUR

R355

22

R354

R362

150

1M

CN301

7P

IC803

IC303

SM8707GV -G-E2

R357

R358

R356

68

68

CL304

68

CL303

CL302

HCD-FR1/FR8/FR9

R331

220

1919

HCD-FR1/FR8/FR9

3-12. SCHEMATIC DIAGRAM — DMB08 BOARD (6/10) —

R608

3.3k

600

X

R602

1M

C636

0.1

R625

3.3k

100

R628

100

R631

R639

100

R600

100

6p

5

z

603

H

22p

C

604

88M

C

12.2

0

768

R

R640

100

IC606

LC89056W-E

0

0.1

10

08

6

C

603

R

C648

0.1

R687

1k

0

0

1k

10

10

100

05

6

604

606

607

R

R

R

R

C646

0.01

R642

100

C609

0.1

C612

10

C616

0.1

C626

0.01

100

11

6

R

5.6k

R616

C637

0.01

C652

220

4V

0.1

0.01

634

C

627

33k

C

614

R

R615

4.7k

R623

100

R629

100

R995

4.7k

C644

X601

13.9MHz

0.01

R637

2.2k

R645

1M

R740

R648

C647

0.01

C653

0.01

C650

0.01

R689

33

10k

L602

C632

15p

C629

15p 1k

R994

4.7k

0.01

C641

R634

1k

IC604

IC607

CXD9718BQ

0

C64

C611

0.01

IS61LV6416 -10TLT

5

1

63

C

0.0

1

0.0

1

642

.0

C

0

FL604

C617

0.1

C613

10

0UH

FL603

C643

0UH

C674

220

10

4V

C651

0.01

21

100

R655

100

R658

R659

FL606

0UH

C667

R661

100

C665

0.01

IC612

CXD9742Q

R699

2.2k

C675

0.01

R697

4.7k

R698

10k

C661

0.01

C679

R692

0.01

2.2k

4.7k

691

R

C666

0.01

220

R673

220

R674

220

R675

220

R676

220

R677

100

R672

10

C668

0.01

R688

0

C664

C671

10

0.01

FL607

0UH

C673

0.01

33

100

R662

100

R664

100

R666

100

R667

C670

100 100

0.01

R898

10k

R678R998

C672

0.01

C669

0.01

4.7k4.7k

R996

4.7k

R997

4.7k

R679 R680

C660

0.01

R663

100

00

1

71

6

R

HCD-FR1/FR8/FR9

22

2020

3-13. SCHEMATIC DIAGRAM — DMB08 BOARD (7/10) —

HCD-FR1/FR8/FR9

IC601

IC601

C601

C600

0.1

C602C607

1000.1

FL605

0UH

NJM2391DL1

-26(TE1)

IC605

L600

C638

0.1

C630

10V

L601

10

R621

C631

0.1

100

IC609

PCM1802DBR

C615

5

R622

100

R624

100

C618

R590

0.1

C614

C625

C622

1k

C610

6.3V

150V

150V

10 16V

C620

R739

4.7k

R683

2.2k

47

C619

0.1

10 16V

0.1

R626

1k

1k

R657

R609

470

IC603

NJM2904V(TE2)

R610

2.2k

0.1

C633

R613

4.7k

R618

4.7k

C624

0.1

R612

47k

C628

16V

R619

10

47k

20

R630

470

R627

C639

0.1

IC608

AK4381VT-E2

2.2k

0.1

C657

0.1

C655

100

6.3V

R601

C552

0.1

0

R599

0

22

HCD-FR1/FR8/FR9

2121

HCD-FR1/FR8/FR9

3-14. SCHEMATIC DIAGRAM — DMB08 BOARD (8/10) —

CN900

20

Q908

DTC124EKA

-T146

Q909

DTC124EKA

Q903

8P

C928

0.1

10k

R949

C916

0.1

R932

R685

20MHz

10k

10k

R991

10k

Q900

DTA114EKA

-T146

JW903

0

2SC2712-GL-TE85L

R955

10k

D903

1SS355TE-17

R957

10k

k

0

0

1

9

9

5

3

9

9

R

R

R929

8.2k

X901

R899

10k

R951

10k

k

k

0

0

1

1

8

9

0

0

9

9

R

R

1

0

0

0

0

.0

0

1

1

8

7

3

6

1

9

96

9

C

R

R

k

.2

2

1

1

9

R

-M59-3BA-A

0

0

1

6

2

9

R

k

k

.2

.2

2

2

2

3

1

1

9

9

R

R

IC901

k

k

.3

0

3

1

6

2

3

6

9

9

R

R

k

k

.2

.2

2

2

4

5

C901

1

1

9

9

0.01

R

R

2

0

9

P

T

1

k

0

.0

0

1

1

4

6

1

9

9

C

R

TP904

TP905

R917

R918

820

820

0

0

0

0

0

0

1

1

1

0

0

R906

6

0

1

9

9

W

R

J

1

0

9

P

T

k

0

1

0

6

9

R

R907

1

9

3.3k

3.3k

R

R896

R941

10k

10k

R942

10k

R943

TP903

-T146

R922

10k

10k

R971

47k

4.7k

R933

2.2k

R919

TP900

R944

10k

330p

C905

330p

C906

0.001

C907

DTC124EKA

R992

10k

Q910

-T146

R945

47k

2SC2412K-T

-146-QR

D902

1SS355TE-17

R900

100

R902

100

R954

10k

R904

100

R894

10k

Q901

C909

0.22

R950

47k

R964

100k

C932

0.1

TC74HCT7007AF (EL)

16V

IC907

PST3645NR

0.1

C900

IC900

R901

R903

R905

FB901

0UH

100

100

100

D907

1SS355TE-17

21

FB902

0UH

C927

0.1

C925

0.1

R931

1k

D900

1SR154-400TE-25

D901

1SR154-400TE-25

C911

C910C912

47

0.22

6.3V

R972

10k

R990

2.2k

R895

10k

C926

0.1

5.5V476.3V

HCD-FR1/FR8/FR9

Q902

DTA114EKA-T146

R897

10k

R963

R981

22k

47k

R969

22k:FR8

R935

10k:FR9

no mount:FR1

no mount:FR9

C922

0.1

10k:FR1

47k:FR8

R979

47k

Q913

2SA1037AK

-T146-QR

R980

47k

R978

1k

R977

22k

R986

47k

R985

470k

Q906

2SC2712-GL

-TE85L

R987

47k

R989

C917

0.1

Q907

2SC2712-GL

-TE85L

0

C918

100p

IC903D904

PST3241NL1SS355TE-17

2222

3-15. SCHEMATIC DIAGRAM — DMB08 BOARD (9/10) —

0

R202

R239

47k

BR9040F

B

IC203

C203

0.01

HCD-FR1/FR8/FR9

IC202

HY57V283220T6

R232

R250

R248

C201

4.7k

4.7k

220

R249

4V

4.7k

FB202

0UH

R238

100

R252

4.7k

4.7k

R233

10k

R253

C243

0.01

B

C246

0.01

B

C235

0.01

B

R246

4.7k

4.7k

R245

0

C228

0.01

B

C225

0.1

FB201

0UH

R203

180

0.5%

0UH

R236

C236

1k

1/16W

0.01

0.5%

B

R257

0

R206

0UH

75

75

75

75

75

R207

R262

B

C229

0.01

75

0UH

R259

R263

R264

R208

R209

R258

B

B

C231

C230

0.01

0.01

75

75

0UH

0UH

75

75

R234

R210

R261

R260

R266

R265

C233

0.01

B

C232

0.01

C237

0.01

B

B

C240

0.01

B

C241

0.01

B

C247

0.01

B

C234

0.01

B

C239

0.01

B

C219

0.01

B

C217

0.01

B

C242

0.01

B

C245

0.01

B

C226

0.01

C238

0.01

B

B

C244

0.01 B

C248

0.01 B

CL206

DTC114EKA

XX

IC206

Q302

-T146

1k

R243

FL204

0UH

(2012)

R226

4.7k

R247

4.7k

C255

0.01

C259

0.01

B

C250

0.01

B

R242

10k

1k

R241

R229

33

R230

33

CL803

C264

10

B

CL201

CL202

CL203

CL204

CL205

C261

0.01

B

C265

0.01

B

C266

0.01

B

C268C267

R231

33

0.01

B

0.01

ZIVA5X-C2F

C252

0.01

B

C260

0.01

B

R212

22

C262

0.01

B

R227 R228

R244

R256

4.7k

4.7k

B

C271

0.01

B

33

33

33

33

C269

0.01

B

33

R217

R215

R218

R216

R219

C314 C315

0.01 0.01

C270

33

33

33

33

33

0.01

B

R224

R222

R220

R223

R221

33 33

33

R225

C274

0.01

C251

0.01

B

C319

33p

FL202

(2012)

1k

R255

C249

0.01

B

0UH

B

C253

0.01

C254

10

(2012)

CL801

IC205

MBM29PL32BM90TN

FR

C204

0.01

B

C263

0.01 B

C257

FL203

0UH

C258

0.01

10

B

R213

0

HCD-FR1/FR8/FR9

IC215

SN74ALVTH16841

C356

0.01

0.01

C355

2323

HCD-FR1/FR8/FR9

3-16. SCHEMATIC DIAGRAM — DMB08 BOARD (10/10) —

TP001

TP002

TP003

TP004

TP005

TP006

TP007

TP008

TP009

TP010

TP011

TP012

TP013

TP014

TP015

TP016

TP017

TP019

TP038

TP048

TP018

TP105

TP076

TP023

TP024

TP025

TP026

TP027

TP028

TP029

TP020

TP104

TP021

TP022

TP067

FB001

0UH

R064

1k

FB004

0UH

R043

1k

TP075

TP074

TP062

TP061

TP060

TP059

TP058

TP057

TP056

TP055

TP054

TP053

TP050

FB006

0UH

32

CN002

29P

CN003

15P

33

CN005

17P

35

CN006

12

28P

CN001

CN004

17P

CN008

12P

9P

27

27

TP036

TP035

TP034

TP033

TP032

TP079

TP080

TP081

TP082

TP084

TP083

TP085

TP086

TP088

TP087

TP089

TP090

TP091

TP093

TP092

TP094

TP095

TP097

TP096

TP098

TP099

TP101

TP100

TP102

TP078

R071

0

0.01

C009

0.01

C002

0

0

100

0

R076

R081

R012

R085

IC001

C001

C022

C008

0.1

100

4V

C010

100

0.1

6.3V

IC002

TP103

IC005

C016 C014

0.1 0.1

C011

0.1

1k

1k

R097

1k

R103

R035

470

R038

470

R040

470

R042

470

FB009

R044

R045

R046

R033

R027

R048

R049R891

FL003

0UH

0UH

R892

100

C903

IC904

0.1

R890

100

C018

IC004

C015C017

0.10.1

C020

0.1

220

4V

FB014

0UH

C003

100

IC904

TC7W34FUTE12R

R050

0

R075

0

IC006

C019

0.1

C006

100 16V

FL004

FB010

0UH

C005

0UH

220 4V

FL005

PWR-EMIS

FB011FB012

FL006

0UH

FB013

0UH

C004

47

16V

0UH0UH

R098

470

470

470

470

100

100

100100

R101

1k

FB007FB008

0UH0UH

R019

2.2k

R059FB005

00UH

TP031

TP030

1k

1k

R100

R099

TP037

TP039

TP040

TP041

TP042

TP043

TP044

TP077

TP045

TP046

TP047

TP049

TP052

1k

R104

1k

R102

TP063

TP065

TP064

TP066

TP068

TP070

TP072

TP071

TP073

TP051

HCD-FR1/FR8/FR9

2424

HCD-FR1/FR8/FR9

3-17. PRINTED WIRING BOARD — AMP BOARD (SIDE A) —

12

A

B

• See page 7 for Circuit Boards Location. :Uses unleaded solder.

34567

C

D

E

IC110

IC109

IC305

IC108

IC101IC102IC103IC104IC105IC106IC107

IC301

IC303

22

(22)

• Semiconductor

Location

Ref. No.

IC101 D-6

IC102 D-5

IC103 D-5

IC104 D-4

IC105 D-3

IC106 D-2

IC107 D-1

IC108 E-4

IC109 E-3

IC110 E-2

IC301 E-6

IC303 C-7

IC305 E-5

Q102 B-6

Q104 B-7

Q106 B-4

Q108 B-4

Q110 B-3

Q112 B-3

Q114 B-1

Q301 E-1

Q304 C-1

Location

HCD-FR1/FR8/FR9

F

2525

Loading...

Loading...