Sony DSLR-A900 Service Manual

DSLR-A900

RMT-DSLR1

SERVICE MANUAL

Ver. 1.2 2009.07

Revision History

Revision History

Link

Link

SPECIFICATIONS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Japanese Model

PRINTED WIRING BOARDS

SERVICE NOTE

DISASSEMBLY

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

DIGITAL SINGLE LENS REFLEX CAMERA

REPAIR PARTS LIST

DSLR-A900_L2

Sony EMCS Co.

2009G0500-1

© 2009.7

Published by Kohda TEC9-852-609-33

SPECIFICATIONS

Camera

[System]

Camera Type

Lens All of α Lens (except for DT lens*)

* Using a DT lens is not guaranteed because the

corners of the field are darkened and the camera

does not meet the primary AE performance

standard. The APS-C size is automatically

selected.

[Image sensor]

Total pixel number of camera

Effective pixel number of camera

Image format

ISO sensitivity (Recommended exposure index)

[SteadyShot]

System Sensor-Shift mechanism

SteadyShot Compensation capability

[Anti-Dust]

System Charge protection coating on

[Viewfinder]

Type Fixed eye-level system with

Focusing Screen

Frame coverage

Magnification

Eye point Approximately 20 mm from the

Diopter Adjustment

[Auto Focus System]

System TTL phase-detection system, CCD

Ranging point

Sensitivity Range

AF illuminator

Digital Single Lens Reflex Camera

and interchangeable lenses

Approx. 25 720 000 pixels

Approx. 24 610 000 pixels

35 mm (35.9×24.0) CMOS sensor

AUTO, 100 to 6400

Approximately 2.5 to 4 EV decrease

in shutter speed (varies according to

shooting conditions and lens used)

Low-Pass Filter and image

sensor-Shift mechanism

pentaprism

Spherical Acute Matte

(exchangeable, option)

Approx. 1

0.74 × with 50 mm lens at infinity,

–1

–1 m

eyepiece

–3.0 to +1.0 m

line sensors (with center dual

cross-hair sensor, F2.8 sensor)

9 points and 10 supplementary

ranging points

0 to 18 EV (at ISO 100 equivalent)

Approx. 1 to 7 m (3.3 to 23 feet)

–1

[Exposure]

Metering Cell

Metering Range

40-segment honeycomb-pattern SPC

0 to 20 EV (2 to 20 EV with Spot

metering), (at ISO 100 with

F1.4 lens)

[Shutter]

Type Electronically-controlled, vertical-

Speed range 1/8000 second to 30 seconds, bulb

Flash sync speed

traverse, focal-plane type

1/250 second (SteadyShot

deactivated),

1/200 second (SteadyShot activated)

[Recording media]

CompactFlash card (TypeI,II),

Microdrive, “Memory Stick Duo”

[LCD monitor]

LCD panel 7.5 cm (3.0 type) TFT drive

Total number of dots

921 600 (640 × 3 (RGB) × 480) dots

[LCD monitor]

With backlighting

[Power, general]

Used battery pack

Rechargeable battery pack

NP-FM500H

[Others]

PictBridge Compatible

Exif Print Compatible

PRINT Image Matching III

Dimensions Approx. 156.3 × 116.9 × 81.9 mm

Mass Approx.850 g (1 lb 14 oz) (without

Operating temperature

Exif Exif Ver.2.21

USB communication

Compatible

(6 1/4 × 4 5/8 × 3 1/4 inches)

(W/H/D, excluding protrusions)

batteries, memory card and body

accessories)

0 to 40°C (32 to 104°F) (When using

the Microdrive: 5 to 40°C (41 to

104°F))

Hi-Speed USB (USB 2.0 compliant)

BC-VM10 Battery charger

Input rating 100 V – 240 V AC, 50/60 Hz

Output rating

Operating temperature range

Storage temperature range

Maximum dimensions

Mass Approx. 90 g (3.2 oz)

8.4 V DC, 750 mA

0 to 40°C (32 to 104°F)

–20 to +60°C (–4 to +140°F)

Approx. 70 × 25 × 95 mm

(2 7/8 × 1 × 3 3/4 inches) (W/H/D)

Rechargeable battery pack

NP-FM500H

Used battery

Maximum voltage

Nominal voltage

Maximum charge current

Maximum charge voltage

Capacity 11.8 Wh (1 650 mAh)

Maximum dimensions

Mass Approx. 78 g (2.8 oz)

Design and specifications are subject to change

without notice.

Lithium-ion battery

DC 8.4 V

DC 7.2 V

2.0 A

DC 8.4 V

Approx. 38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 inches)

(W/H/D)

DSLR-A900_L2

— 2 —

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. CHEMICALS

Some chemicals used for servicing are highly volatile.

Their evaporation caused by improper management affects your health and environment, and wastes resources.

Manage the chemicals carefully as follows.

• Store chemicals sealed in a specific place to prevent from exposure to high temperature or direct sunlight.

•Avoid dividing chemicals into excessive numbers of small containers to reduce natural evaporation.

•Keep containers sealed to avoid natural evaporation when chemicals are not in use.

•Avoid using chemicals as much as possible. When using chemicals, divide only required amount to a small plate from the container and

use up it.

1-2. EXTERIOR PARTS

Be careful to the following points for plastic parts used in this unit.

• Use a piece of cleaning paper or cleaning cloth for cleaning plastic parts. Avoid using chemicals.

Even if you have to use chemicals to clean heavy dirt, don’t use paint thinner, ketone, nor alcohol.

• Insert the specific screws vertically to the part when installing a plastic part.

Be careful not to tighten screws too much.

1-3. UNLEADED SOLDER

This unit uses unleaded solder.

Boards requiring use of unleaded solder are printed with the lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

Be careful to the following points to solder or unsolder.

• Set the soldering iron tip temperature to 350 °C approximately.

If cannot control temperature, solder/unsolder at high temperature for a short time.

Caution: The printed pattern (copper foil) may peel away if the heated tip is applied for too long, so be careful!

Unleaded solder is more viscous (sticky, less prone to flow) than ordinary solder so use caution not to let solder bridges occur

such as on IC pins, etc.

• Be sure to control soldering iron tips used for unleaded solder and those for leaded solder so they are managed separately. Mixing

unleaded solder and leaded solder will cause detachment phenomenon.

1-4. SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs of deterioration. Point them out to the customer and recommend their

replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 °C during repairing.

• Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or unsoldering.

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

DSLR-A900_L2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

1-1

1-5. METHOD OF EXCHANGING FOCUSING SCREEN

ENGLISH JAPANESE

ENGLISH JAPANESE

1 Remove two claws pushing part A below,

and remove focusing screen holder in the

direction of arrow.

Claw

A

2 Remove focusing screen.

Focusing Screen Holder

Claw

Focusing Screen

3 Confirm whether the point of the focusing

screen holder and the height of front frame

become complete after exchanging boards.

Focusing Screen HolderFront Frame

DSLR-A900_L2

1-2

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. 各種薬品の取り扱いについて

現在使用されている薬品の中には揮発性の高い薬品もあります。

それらを不用意に取り扱い蒸発させてしまうと,環境や健康へ影響を与えたり,資源の無駄使いになります。

各種薬品は,下記の点に注意して取り扱ってください。

・ 保管場所を定め,高温になったり直射日光の当たらない場所に密閉して保管してください。

・ 小分け(ハンドラップ等)する数は必要最小限に留め,容器による自然蒸発を防いでください。

・ 作業に使用しない時は,必ずキャップ等をして自然蒸発を防いでください。

・ 薬品を使用する回数を極力少なくし,使用する場合は使用する量だけ容器より出して受け皿に残さないようにしてくだ

さい。

1-2. 樹脂系部品の取り扱いについて

本機に使用されている樹脂系の部品は,下記の点に注意して取り扱ってください。

・ 清掃には薬品を使用せず,清掃紙や清掃布を使用してください。

やむを得ず汚れがひどくて薬品を使用する場合は,シンナー,ケトン,エーテルは使用しないでください。

・ 各部品の取り付けには指定されたねじを使用し,部品に対して垂直に取り付けてください。

また,ねじを締め付ける時は,無理な力を加えないでください。

1-3. 無鉛半田について

本機には無鉛半田が使用されています。

無鉛半田を使用している基板には,無鉛(LeadFree)を意味するレッドフリーマークがプリントされています。

(注意:基板サイズによっては,無鉛半田を使用していてもレッドフリーマークがプリントされていないものがあります)

:レッドフリーマーク

無鉛半田は,下記の点に注意して使用してください。

・ 半田こてのこて先温度は約350℃に設定してください。

温度調節が無理な場合は,高温短時間で作業を行ってください。

注意: 半田こてを長く当てすぎると,基板のパターン(銅箔)がはがれてしまうことがありますので,注意してくださ

い。また,従来の半田よりも粘性が強いため,IC端子などが半田ブリッジしないように注意してください。

・ 半田こてのこて先は,必ず無鉛半田用と有鉛半田用に分けて管理してください。

無鉛半田と有鉛半田が混在すると剥離現象が発生してしまいます。

DSLR-A900_L2

1-3

ENGLISH JAPANESE

ENGLISH JAPANESE

1-4. SAFETYCHECK-OUT

サービス,点検時には次のことにご注意ください。

1. 注意事項をお守りください。

サービスのとき特に注意を要する個所については,キャビネット,シャーシ,部品などにラベルや捺印で注意事項を表

示しています。これらの注意書き及び取扱説明書等の注意事項を必ずお守りください。

2. 指定部品のご使用を

セットの部品は難燃性や耐電圧など安全上の特性を持ったものとなっています。

従って交換部品は,使用されていたものと同じ特性の部品を使用してください。

特に回路図,部品表に0印で指定されている安全上重要な部品は必ず指定のものをご使用ください。

3. 部品の取付けや配線の引きまわしはもとどおりに

安全上,チューブやテープなどの絶縁材料を使用したり,プリント基板から浮かして取付けた部品があります。

また内部配線は引きまわしやクランパによって発熱部品や高圧部品に接近しないよう配慮されていますので,これらは

必ずもとどおりにしてください。

4. サービス後は安全点検を

サービスのために取外したネジ,部品,配線がもとどおりになっているか,またサービスした個所の周辺を劣化させて

しまったところがないかなどを点検し,安全性が確保されていることを確認してください。

5. チップ部品交換時の注意

・取り外した部品は再使用しないでください。

・タンタルコンデンサのマイナス側は熱に弱いため交換時は注意してください。

6. フレキシブルプリント基板の取扱いについて

・こて先温度を270℃前後にして行なってください。

・同一パターンに何度もコテ先を当てないでください。(3回以内)

・パターンに力が加わらないよう注意してください。

電池の交換は,正しく行わないと破裂する恐れがあり

ます。電池を交換する場合には必ず同じ型名の電池

又は同等品と交換してください。

注意

DSLR-A900_L2

1-4

1-5. 焦点板の交換方法

ENGLISH JAPANESE

ENGLISH JAPANESE

1A部を下に押してつめ2箇所を外し,

矢印方向に焦点板ホルダを外す。

つめ

つめ

A

焦点板ホルダ

2焦点板を外す。

3焦点板を交換したあとは,焦点板ホルダの

先端と前枠との高さが同じになっているか

確認をする。

焦点板ホルダ前枠

焦点板

DSLR-A900_L2

1-5E

NOTE FOR REPAIR

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, don’t pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

• Do not apply excessive load to the gilded flexible board.

SUBSIDIARY MATERIALS

G: Grease

G-15 (J-6082-619-A)

G-85 (J-6082-626-A)

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

DSLR-A900_L2

2-1

2-1. IDENTIFYING PARTS

Rear Cover

- DISASSEMBLY FLOW -

2-2-1. OVERALL SECTION-1

⋅ Side Cover

⋅ Rear Cover

⋅ Top Cover

Top Cover

⋅ TOP-004 Flexible Board

DD-299 Board

⋅ FP-895 Flexible Board

MM-079 Board

⋅ FP-890 Flexible Board

AM-015 Board

MA-453 Flexible Board

Te bure Unit

⋅ Omega Unit

⋅ FP-893 Flexible Board

⋅ FP-894 Flexible Board

2-2-2. MAIN BOARD SECTION

⋅ AM-015 Board

2-2-3. OVERALL SECTION-2

⋅ Te b ure Unit

⋅ Front Cover

2-2-4. SIDE FRAME SECTION

⋅ MA-453 Flexible Board

⋅ Bottom Frame

⋅ Jack Holder

2-2-5. SHUTTER SECTION

⋅ Shutter

⋅ DD-299 Board

2-2-6. BATTERY HOLDER SECTION

⋅ Battery Holder

⋅ MM-079 Board

⋅ GY-009 Flexible Board

Front Cover

AF Assist

Light Block

Battery Holder

⋅ GY-009 Flexible Board

⋅ FP-896 Flexible Board

Shutter

Mirror Box

AF Module

Jack Holder

⋅ FP-898 Flexible Board

Side Cover

2-2-7. MIRROR BOX SECTION (PENTA UNIT)

⋅ AF Module

⋅ Penta Unit

2-2-8. MIRROR BOX SECTION (SUB UNIT-1)

⋅ Iris Ring

⋅ SLLK Contact Piece Unit

⋅ BL Contact Unit

2-2-9. MIRROR BOX SECTION (SUB UNIT-2)

⋅ Mirror Charge Motor Unit

⋅ Aperture Unit

⋅ AF Driving Unit

DSLR-A900_L2

2-2

HELP

EXPLODED VIEW

HELP

2-2. DISASSEMBLY

2-2-1. OVERALL SECTION-1

Follow the disassembly in the numerical order given.

1 Side Cover (1-1 to 1-3)

2 Rear Cover (2-1 to 2-10)

3 Top Cover (3-1 to 3-8)

3 Top Cover

3-2 (#94)

3-8

(Claw)

2-6 (#94)

2-5

(Open)

3-4

3-5 (#94)

3-1

3-3 (#83)

2 Rear Cover

HELP 1 HELP 2

3-6

(#94)

2-10

2-4

(#94)

HARDWARE LIST

2-1

2-2

(#94)

2-3

2-9

(#94)

Body Cap

Main Board

Section

(See Page 2-4)

1 Side Cover

1-2 (Open)

1-3 (#94)

1-1

(Peel off)

3-7 (#94)

DSLR-A900_L2

2-8 (#12)

2-3

2-7 (#94)

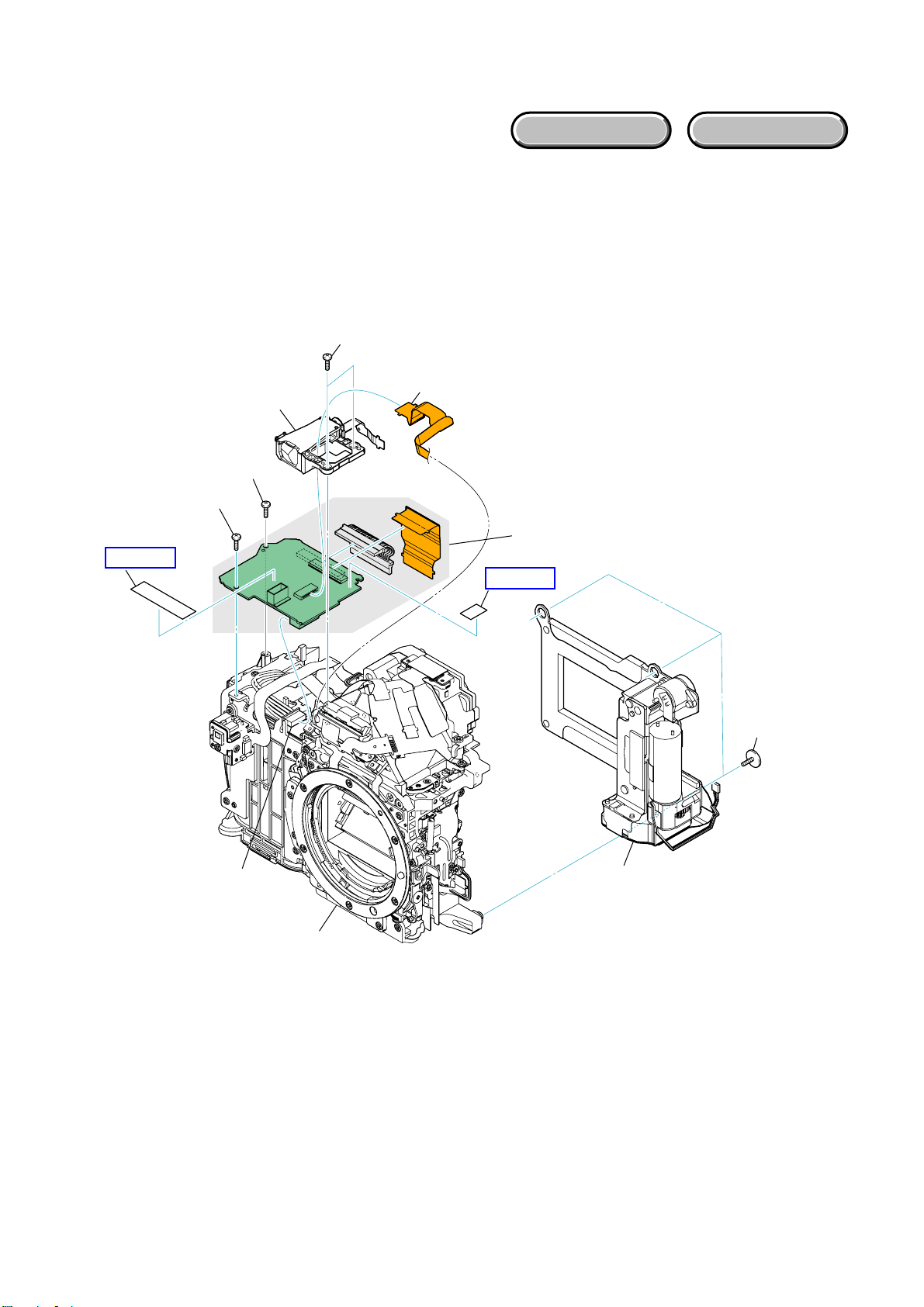

2-2-2. MAIN BOARD SECTION

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 AM-015 Board (1-1 to 1-24)

1 AM-015 Board

1-1 (Open)

HARDWARE LIST

1-4

1-24

(#109)

1-23

(#109)

AM-015

Overall Section-2

(See Page 2-5)

1-5

1-22

1-15

1-16

1-17

1-3

1-2 (#76)

1-18

HELP 5

1-20

1-19

DSLR-A900_L2

1-14

HELP 4

1-111-121-13

HELP 3

1-10

2-4

1-9

1-8

1-7

1-6

1-21

2-2-3. OVERALL SECTION-2

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Te b ure Unit (1-1 to 1-9)

2 Front Cover (2-1 to 2-7)

HARDWARE LIST

1-9 (#59)

1-5 (#59)

2-4 (#83)

2-3

HELP 6

1-7 (#59)

1-6 (#59)

1-1

1-8

1-4

1-2

1-3

(#109)

2-7 (#12)

2 Front Cover

HELP 7

2-5 (#94)

1 Teb ure Unit

HELP 8 G-15

Side Frame Section

(See Page 2-6)

2-6

(#94)

2-2

2-1 (#94)

DSLR-A900_L2

2-5

2-2-4. SIDE FRAME SECTION

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 MA-453 Flexible Board (1-1 to 1-8)

2 Bottom Frame (2-1 to 2-4)

3 Jack Holder (3-1 to 3-4)

3-1

HELP 11

1-7

3-2

HELP 12

1-5

HARDWARE LIST

1-8

1 MA-453 Flexible Board

Shutter Section

(See Page 2-7)

2-4 (#76)

1-2

3-3

HELP 10

1-6

(#109)

1-4

1-1

HELP 9

3 Jack Holder

HELP 15

1-3

HELP 13

HELP 14

3-4 (#76)

DSLR-A900_L2

2 Bottom Frame

2-2 (#109)

2-1 (#109)

2-3 (#76)

2-6

EXPLODED VIEW

2-2-5. SHUTTER SECTION

Follow the disassembly in the numerical order given.

1 Shutter (1-1)

2 DD-299 Board (2-1 to 2-8)

2-1 (#76)

2-3

2-6 (#12)

2-7 (#109)

HARDWARE LIST

2-2

2-5

HELP 17

2-8

Battery Holder Section

(See Page 2-8)

2 DD-299 Board

2-4

HELP 16

1-1 (#91)

1 Shutter

DSLR-A900_L2

2-7

EXPLODED VIEW

2-2-6. BATTERY HOLDER SECTION

1-1 (#76)

1-2 (#76)

3-1

(#109)

2-1 (#109)

2-2 (#76)

2-3

2 MM-079 Board

1 Battery Holder

3 GY-009

Flexible Board

Mirror Box Section

(Penta Unit)

(See Page 2-9)

Follow the disassembly in the numerical order given.

1 Battery Holder (1-1 to 1-2)

2 MM-079 Board (2-1 to 2-3)

3 GY-009 Flexible Board (3-1)

HARDWARE LIST

DSLR-A900_L2

2-8

EXPLODED VIEW

2-2-7. MIRROR BOX SECTION (PENTA UNIT)

Follow the disassembly in the numerical order given.

1 AF Module (1-1 to 1-3)

2 Penta Unit (2-1 to 2-4)

2 Penta Unit

Refer to page 1-2 "1-5. METHOD OF EXCHANGING FOCUSING

2-1

HELP 20

2-2 (#89)

SCREEN" when focusing screen are exchanged.

HARDWARE LIST

2-4

2-3 (#89)

1-3

1 AF Module

HELP 18

Mirror Box Section

(Sub Unit-1)

(See Page 2-10)

DSLR-A900_L2

1-2

1-1 (#149)

HELP 19

2-9

EXPLODED VIEW

Ver. 1.1 2009.01

2-2-8. MIRROR BOX SECTION (SUB UNIT-1)

Follow the disassembly in the numerical order given.

1 Iris Ring (1-1 to 1-15)

2 SLLK Contact Piece Unit (2-1 to 2-8)

3 BL Contact Unit (3-1 to 3-2)

3-1 (#23)

1 Iris Ring

Refer to page 2-13 "2-4. IRIS RING

REMOVAL/INSTALLATION" when

the iris ring is exchanged.

1-7

1-14

3 BL Contact Unit

1-13

1-12

1-10

1-9

2-8 (#23)

HARDWARE LIST

3-2

Mirror Box Section

(Sub Unit-2)

(See Page 2-11)

2 SLLK

Contact

Piece Unit

1-15

2-2

G-85

1-3 (#89)

1-6 (#89)

G-85

1-4 (#89)

2-3

1-2 (#89)

1-5 (#89)

2-4

1-11

1-8

2-5

2-7

HELP 21

2-6

2-1 (#91)

DSLR-A900_L2

1-1 (#89)

2-10

EXPLODED VIEW

2-2-9. MIRROR BOX SECTION (SUB UNIT-2)

Follow the disassembly in the numerical order given.

1 Mirror Charge Motor Unit (1-1 to 1-5)

2 Aperture Unit (2-1 to 2-4)

3 AF Driving Unit (3-1 to 3-5)

HARDWARE LIST

2 Aperture Unit

2-4

HELP 26

1-5 (#23)

1-3

HELP 23

1 Mirror Charge Motor Unit

HELP 24

2-1 (#23)

Refer to page 2-13 "2-5. APERTURE

UNIT INSTALLATION" when the

aperture unit is exchanged.

2-3

HELP 25

2-2

1-2

3-3

3-2 (#23)

3-4 (#23)

1-1

HELP 22

3 AF Driving Unit

3-5

3-1 (#23)

1-4 (#23)

DSLR-A900_L2

2-11

2-3. IMAGER INCLINATION ADJUSTMENT

Checking Method

1. Use the copy stand or place a mirror on the wall, and adjust the accuracy so that the camera is opposed to the mirror.

2. Use the AE master lens as an inspection lens.

3. Obtain the inclination angle with the Photoshop, and perform as follows according to the angle:

• For the angle above ± 0.4 degree, be sure to repair the camera.

• For the angle above ± 0.2 degree and below ± 0.4 degree, repair the camera according to the user's requirement level.

• For the angle below ± 0.2 degree, check again the angle to satisfy the specified value.

Adjusting Method

1. Loosen the fixed screw.

2. Adjust the inclination with the adjusting screw.

• For an image that tilts to the right, rotate the screw clockwise.

• For an image that tilts to the left, rotate the screw counterclockwise.

3. Tighten the fixed screw.

Imager Inclination Adjusting Screw

Fixed Screw

Adjusting Screw

DSLR-A900_L2

2-12

2-4. IRIS RING REMOVAL/INSTALLATION

Removal

Rotate the iris ring clockwise, and remove it at the stop position (iris-in end).

At this time, do not rotate the iris joint gear of the Aperture Unit.

Installation

1. With the Aperture Unit set in the charge position (see "2-6. Aperture Unit Charge Position Setting" ), install it on the front

frame set.

* The Aperture Unit has been set in the charge position, if it is not removed.

However, the iris ring must be in the removed state (where the iris joint gear is not rotated).

2. Install the iris ring with it's a punch mark aligned with a line that connects the iris joint gear shaft and the optical axis center.

Optical Axis Center

Iris Joint Gear Shaft

Punch Mark

Iris Ring

2-5. APERTURE UNIT INSTALLATION

* The Aperture Unit is supplied by being set in the charge position (initial position), but if this position is disordered when the

Aperture Unit is removed, or if the charge position is to be set again, perform as follows.

* Refer to "2-6. Aperture Unit Charge Position Setting" for the confirm method at the charge position.

2-6. APERTURE UNIT CHARGE POSITION SETTING

1. Check that the Aperture Unit is in a free state.

2. After confirming that the Aperture Unit is in a free state, rotate the gear by 3 turns.

3. After rotating the gear by 3 turns, set the Aperture Unit where the holes in the gear and the Aperture Unit coincide. This

position is the charge position.

* Refer to "2-7. Aperture Unit Free Position Setting" for the setting and the confirm method at the free position.

DSLR-A900_L2

2-13

2-7. APERTURE UNIT FREE POSITION SETTING

1. Set the Aperture Unit to a free position once, if the gear was rotated accidentally and the charge position is disordered, or if

the charge position was shifted during disassembly.

In a free state, the edge of this spring

will move up and down about 1 mm if

the gear is moved a little.

In a free state, a hole in the gear almost

coincides with a hole in the Aperture Unit.

Gear rotating

direction to set

the charge position

Gear rotating

direction to make

the unit free

First, check the spring edge position.

As viewed from gear

(Hole in the gear)

If the edge of spring is located downward,

rotate the gear in the arrow direction to

search a free position.

* In a free position, the edge of spring is

located upward.

DSLR-A900_L2

Note: The spring is deformed and cannot

be used if the gear is rotated too

much from a free state.

2-14

2-8. GREASE APPLICATION AREA

Grease uses G-15 (J-6082-619-A).

Chassis Assy Unit

Grease

Grease uses G-85 (J-6082-626-A).

Ring (SP)

Coupler Joint Lever

Grease

DSLR-A900_L2

Grease

2-15

2-9. CLEANING PROCEDURE OF OLPF

<Preparation for Remedy>

If you use the new Jig (J-6082-663-A) below, make sure to clean the CCD Cleaning Jig (Tip) below before using, please.

Note: Protection sheet is for preventing the scratch of a surface on the Jig (Tip).

The protection sheet may be come off the Jig when you take the Jig from a bag, but it is no problem.

Protection Sheet

CCD Cleaning Jig (Tip)

CCD Cleaning Jig

CCD Cleaning Jig (New)

(J-6082-663-A)

<Cleaning Procedure for Tip of CCD Cleaning Jig>

1. Put the two cleaning cloths on a tray like below.

1 Souse the one cleaning cloth in ethyl alcohl.

2 Put the other cleaning cloth on a tray as it is dry.

2. Dab the tip of CCD cleaning jig at the cleaning cloth of 1 5 or 6 times.

* Do not slide the tip from right to left or up and down while dabbing.

3. Dab the tip of CCD cleaning jig at the cleaning cloth of 2 5 or 6 times.

* Do not slide from right to left or up and down while dabbing.

4. Wait until the tip will be dried completely.

1 Souse the cleaning

cloth in ethyl alcohol.

DSLR-A900_L2

2 The dry cleaning cloth.

2-16

<Cleaning Procedure for the OLPF>

1. Clean up the tip of CCD cleaning jig.

2. Set a camera to a cleaning mode.

3. Dab the tip of CCD cleaning jig at the OLPF, and pull up straight.

* Do not slide from right to left or up and down while dabbing.

4. Repeat “3” several times to clean up.

5. According to service manual, check if there is dirt on the CCD.

OLPF

<ATTENTION>

If you cannot remove dirt with remedy above, cleaning by the following jig are used.

Soak a small amount of EE3310 (Liquid cleaner) after wrapping the cleaning cloth (J-6082-636-A) around the cleaning jig (J6082-635-A).

Cleaning Cloth

(J-6082-636-A)

Cut

EE3310

Cleaning Jig

(J-6082-635-A)

DSLR-A900_L2

2-17E

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

HELP 1:

LCD Flexible Board

HELP 2:

Sheet (T)/BL Screen

Sheet (T)

Control Switch Block (JY62300)

Control Switch Block (JY62300)

Back Light Flexible Board

BL Screen

HELP 3:

AF Driving Motor Harness

HELP 4:

AF Driving/Mirror Charge Motor Harness

Mirror Charge Motor Harness

Shutter Motor Harness

Rib Rib Rib

Bottom Frame Sheet

DSLR-A900_L2

HELP 5:

Shutter Motor Harness

Actuator Harness

Actuator Harness

HELP

HELP 6: Synchronise Terminal Harness

Synchronise Terminal Harness

HELP 8: FP-893/FP-894 Flexible Board

FP-894 Flexible Board

Adhesive Tape

FP-893 Flexible Board

FP-894 Flexible Board

HELP 7: Control Switch Block (FS85100)

Control Switch Block

(FS85100)

Claw

FP-893 Flexible Board

HELP 9: SLLK Contact Piece Unit Harness

DSLR-A900_L2

SLLK Contact Piece Unit Harness

HELP

HELP 10:

Bottom Frame Sheet

Bottom Frame Sheet

Bottom Frame Sheet

HELP 13:

BD Tape 1525/DC Jack Harness

DC Jack Harness

Rib

BD Tape 1525

HELP 11:

HELP 12:

Adhesive Sheet

BD Tape 0710/DC Jack Harness

BD Tape 0710

DC Jack Harness

Tape (ASCD)/DC Jack Harness

Tape (ASCD)

HELP 14:

DC Jack Harness

Rib

Rib

DC Jack Harness

DC Jack Harness

DSLR-A900_L2

HELP 15:

FP-898 Flexible Board

FP-898 Flexible Board

Rib

HELP

HELP 16:

BD Tape 0710

BD Tape 0710/Actuator Harness

Actuator Harness

HELP 19:

S Adjustment Screw

S Adjustment Screw

B-50

(J-6082-615-A)

HELP 17:

FP-896 Flexible Board

GY-009 Flexible Board

HELP 18:

Tape (ASCD)/

GY-009/FP-896 Flexible Board

AF Module Flexible Board

Rib

Tape (ASCD)

S Adjustment Screw S Adjustment Screw

HELP 20:

HELP 21:

BD Penta Insulation Sheet

RibScrew

BD Penta Insulation Sheet

Coupler Lever Tension SP

Coupler Lever Tension SP

DSLR-A900_L2

AF Module Flexible Board

Coupler Lever

HELP

HELP 22:

MB Motor Harness Sheet

MB Motor Harness Sheet

HELP 25:

AP Flexible Protection Sheet

AP Flexible Protection Sheet

HELP 23:

MB Flexible Protection Sheet

HELP 24:

Installation Position of Gears

MB Flexible Protection Sheet

Mirror Charge Motor Unit

Boss

Boss

HELP 26:

MB IS-Flexible Protection Sheet

MB IS-Flexible Protection Sheet

Rib

DSLR-A900_L2

OK NG

HELP

Link

Link

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/6)

OVERALL BLOCK DIAGRAM (2/6)

OVERALL BLOCK DIAGRAM (3/6)

OVERALL BLOCK DIAGRAM (4/6)

OVERALL BLOCK DIAGRAM (5/6)

OVERALL BLOCK DIAGRAM (6/6)

POWER BLOCK DIAGRAM (1/6)

POWER BLOCK DIAGRAM (2/6)

POWER BLOCK DIAGRAM (3/6)

POWER BLOCK DIAGRAM (4/6)

POWER BLOCK DIAGRAM (5/6)

POWER BLOCK DIAGRAM (6/6)

DSLR-A900_L2

Loading...

Loading...