Page 1

PRODUCTION SWITCHER

DFS-800

4 DIGITAL VIDEO INPUT BOARD

BKDF-810

2 ANALOG VIDEO INPUT BOARD

BKDF-811

16 INPUT DME BOARD

BKDF-840

4 DIGITAL VIDEO OUTPUT BOARD

BKDF-860

2 ANALOG VIDEO OUTPUT BOARD

BKDF-861

SERVICE MANUAL

1st Edition

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

Attention-when the product is installed in Rack:

1. Prevention against overloading of branch circuit

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

make sure that the rack does not overload the supply

circuit.

2. Providing protective earth

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

confirm that the outlet is provided with a suitable

protective earth connection.

3. Internal air ambient temperature of the rack

When this product is installed in a rack, please make

sure that the internal air ambient temperature of the

rack is within the specified limit of this product.

For safety, do not connect the connector for peripheral

device wiring that might have excessive voltage to the

following port.

: TO CP connector

: TO MU connector

Follow the instructions for the above port.

4. Prevention against achieving hazardous

condition due to uneven mechanical loading

When this product is installed in a rack, please make

sure that the rack does not achieve hazardous

condition due to uneven mechanical loading.

5. Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer

to the specifications of the Operation Manual.

6. When performing the installation, keep the

following space away from walls in order to

obtain proper exhaust and radiation of heat.

Front, Left : 10 cm (4 inches) or more

DFS-800

Page 3

CAUTION

Danger of explosion if battery is incorrectly replaced.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

DFS-800

1 (P)

Page 4

Page 5

Index

Before turning off the power.........................................................................................................................1

1. Specification and Apperance.....................................................................................................................2

1-1. Specification ......................................................................................................................................2

1-1-1. DFS-800 Processor.....................................................................................................................2

1-1-2. DFS-800 Control Panel..............................................................................................................3

1-1-3. BKDF-810..................................................................................................................................4

1-1-4. BKDF-811..................................................................................................................................4

1-1-5. BKDF-860..................................................................................................................................4

1-1-6. BKDF-861..................................................................................................................................5

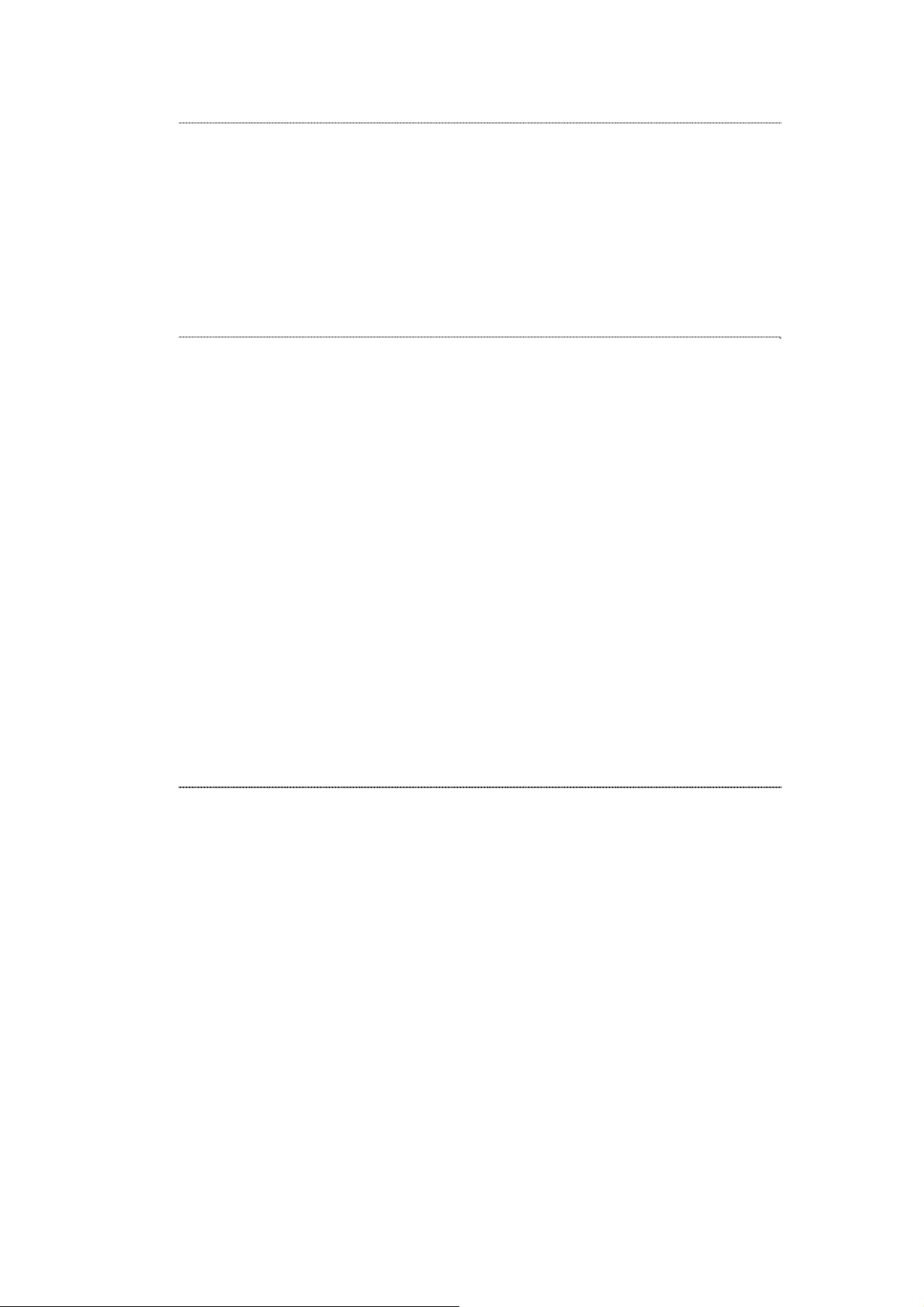

1-2. Appearance.........................................................................................................................................6

1-2-1. DFS-800 Processor.....................................................................................................................6

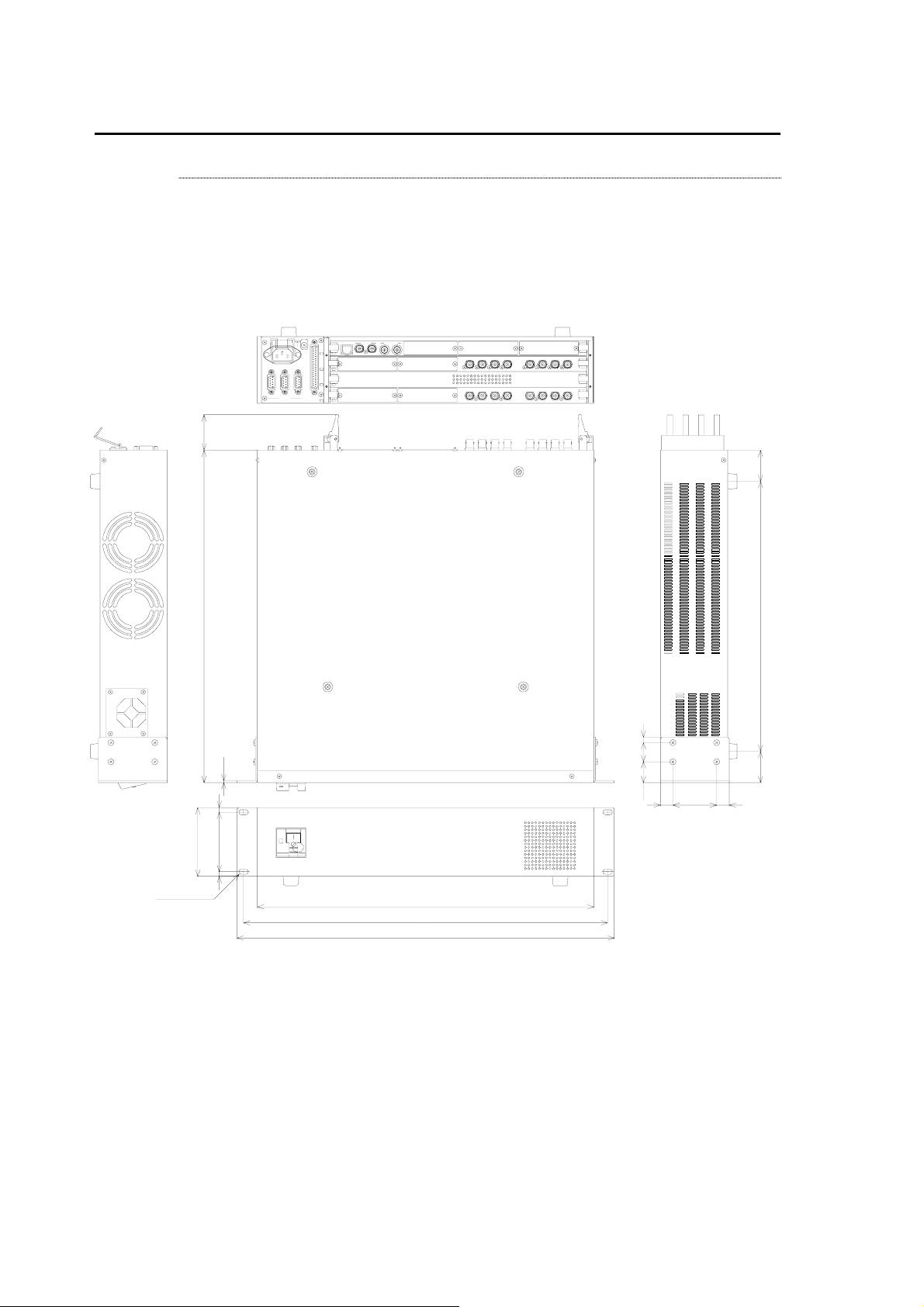

1-2-2. DFS-800 Control Panel..............................................................................................................7

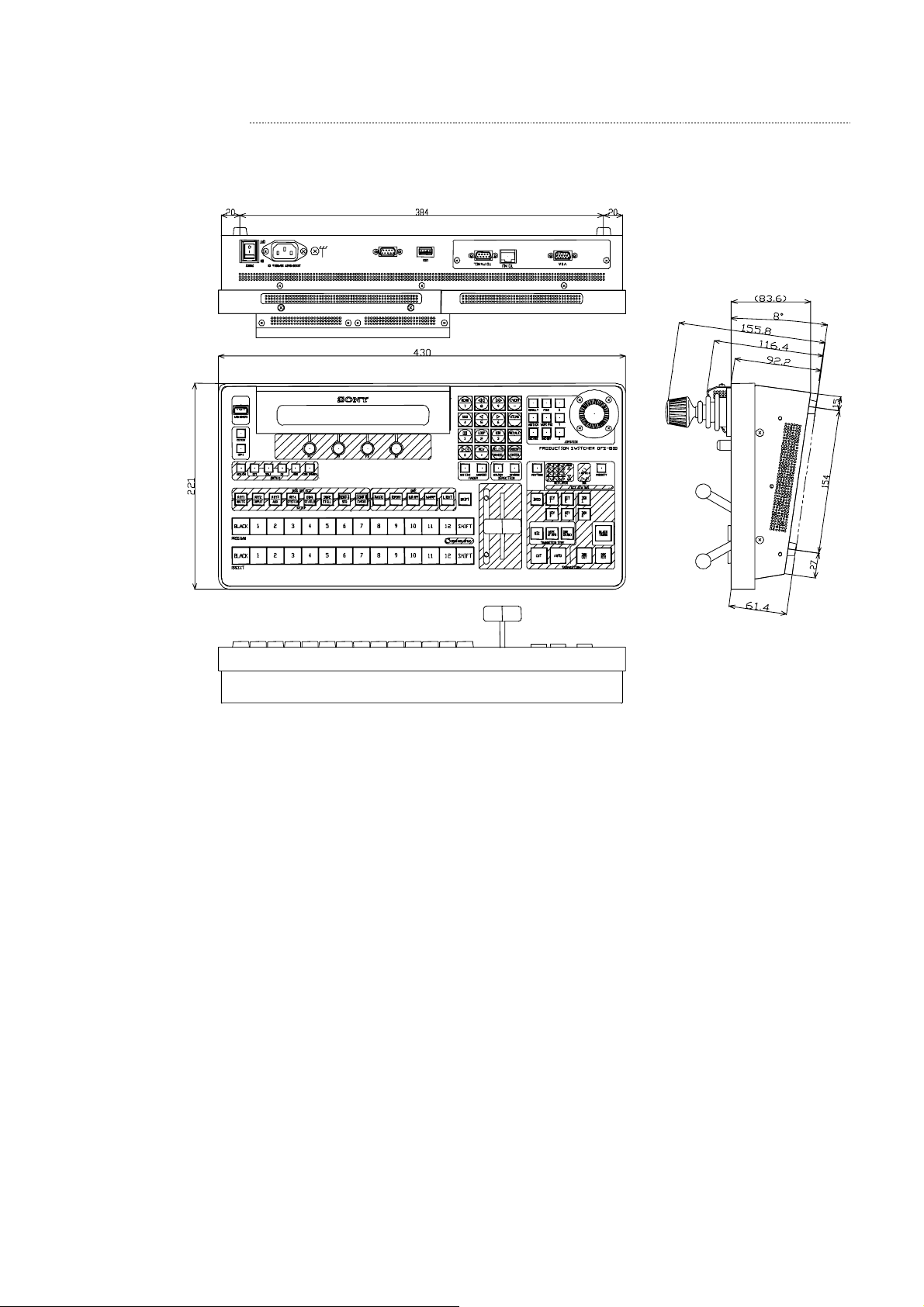

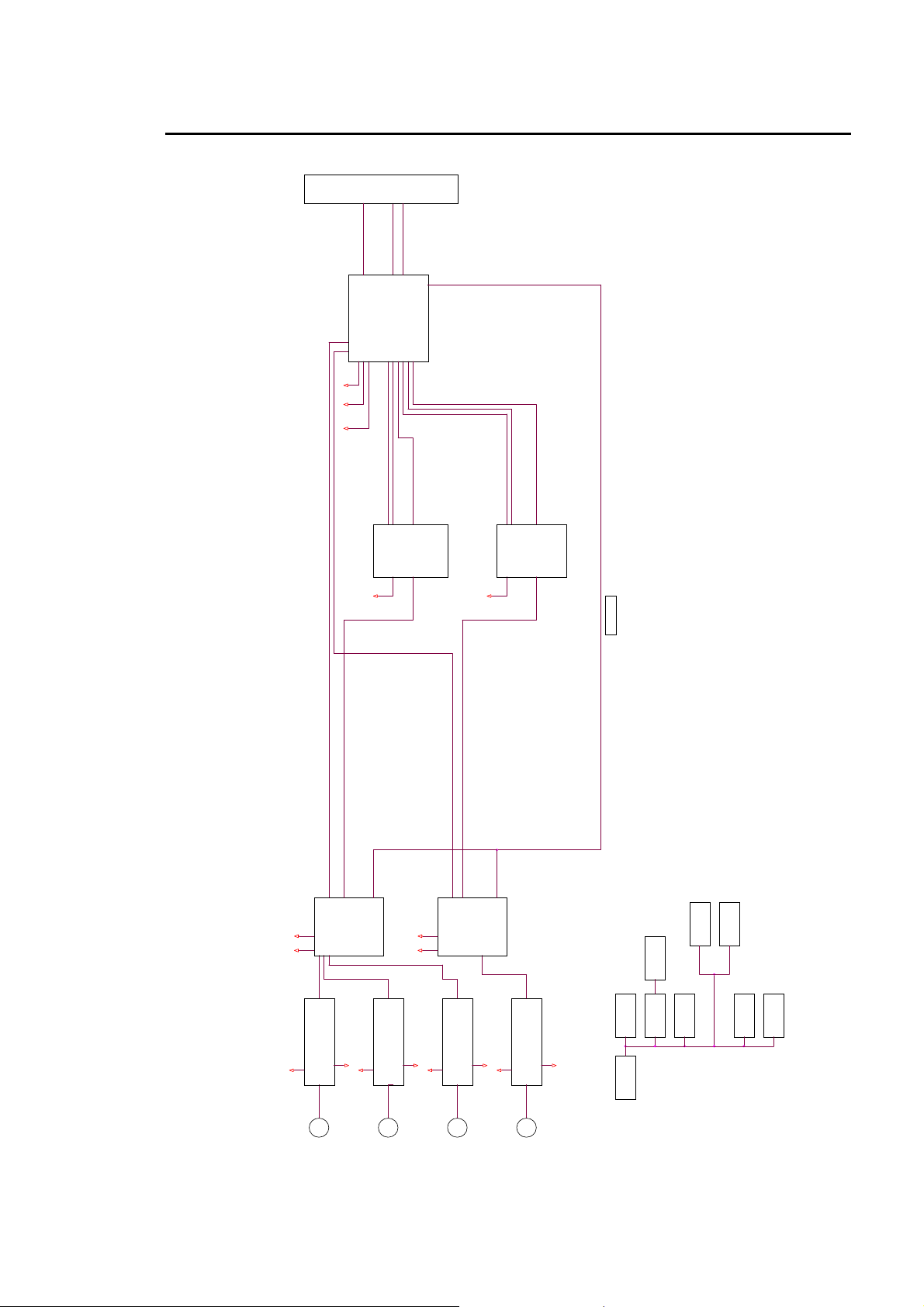

2. Name and Function of Each Block............................................................................................................8

2-1. DFS-800 Processor ............................................................................................................................8

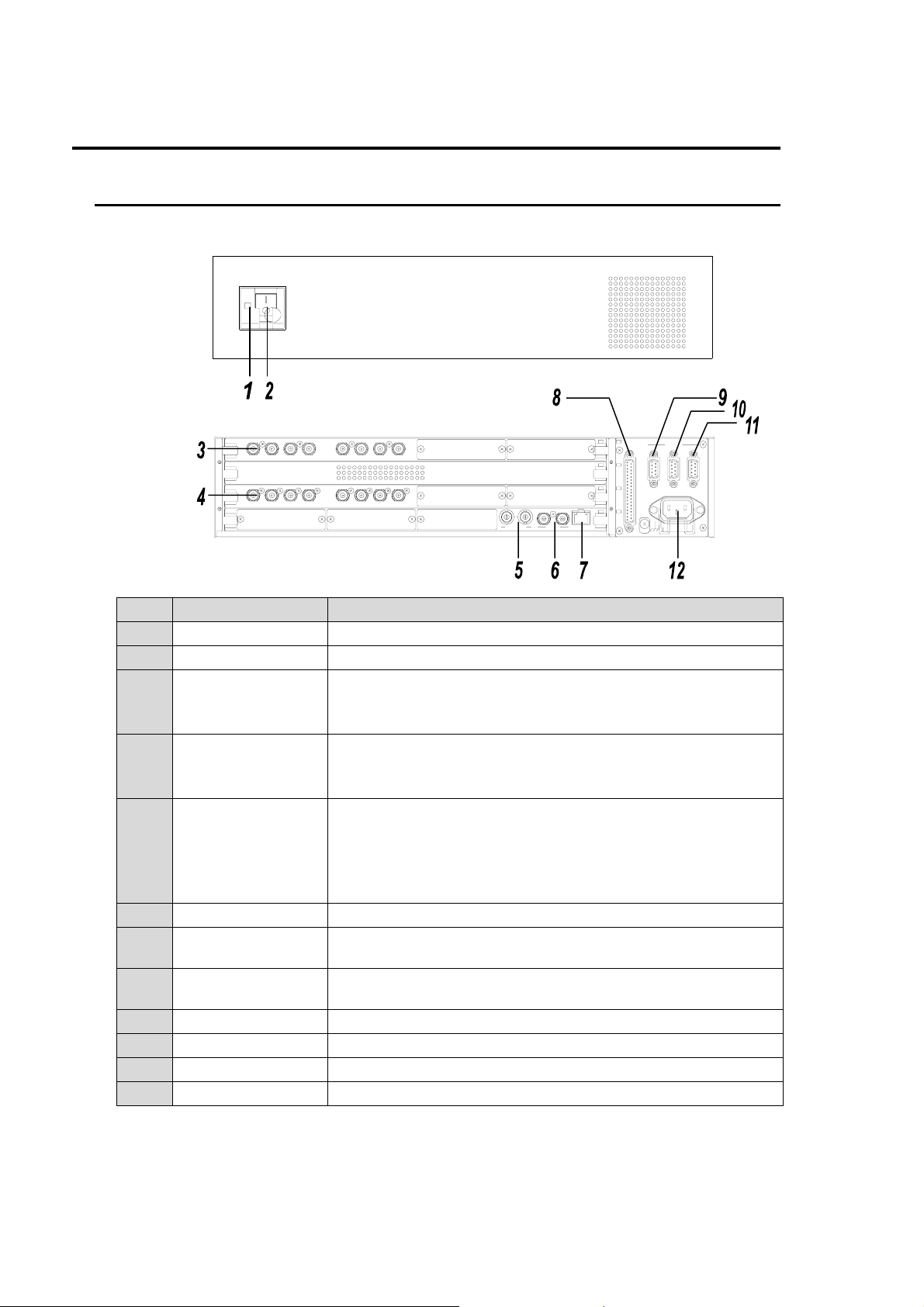

2-2. DFS-800 Control Panel......................................................................................................................9

2-2-1. Control Panel..............................................................................................................................9

2-2-2. Rear Panel ................................................................................................................................10

2-3. Peripheral Interface..........................................................................................................................11

2-4. DFS-800 Board Configuration.........................................................................................................14

3. Connection...............................................................................................................................................15

3-1. Basic Configuration......................................................................................................................... 15

3-2. Option Configuration.......................................................................................................................16

4. Function Block Diagram of Each Board .................................................................................................17

4-1. Function Block Diagram of CPU Board..........................................................................................17

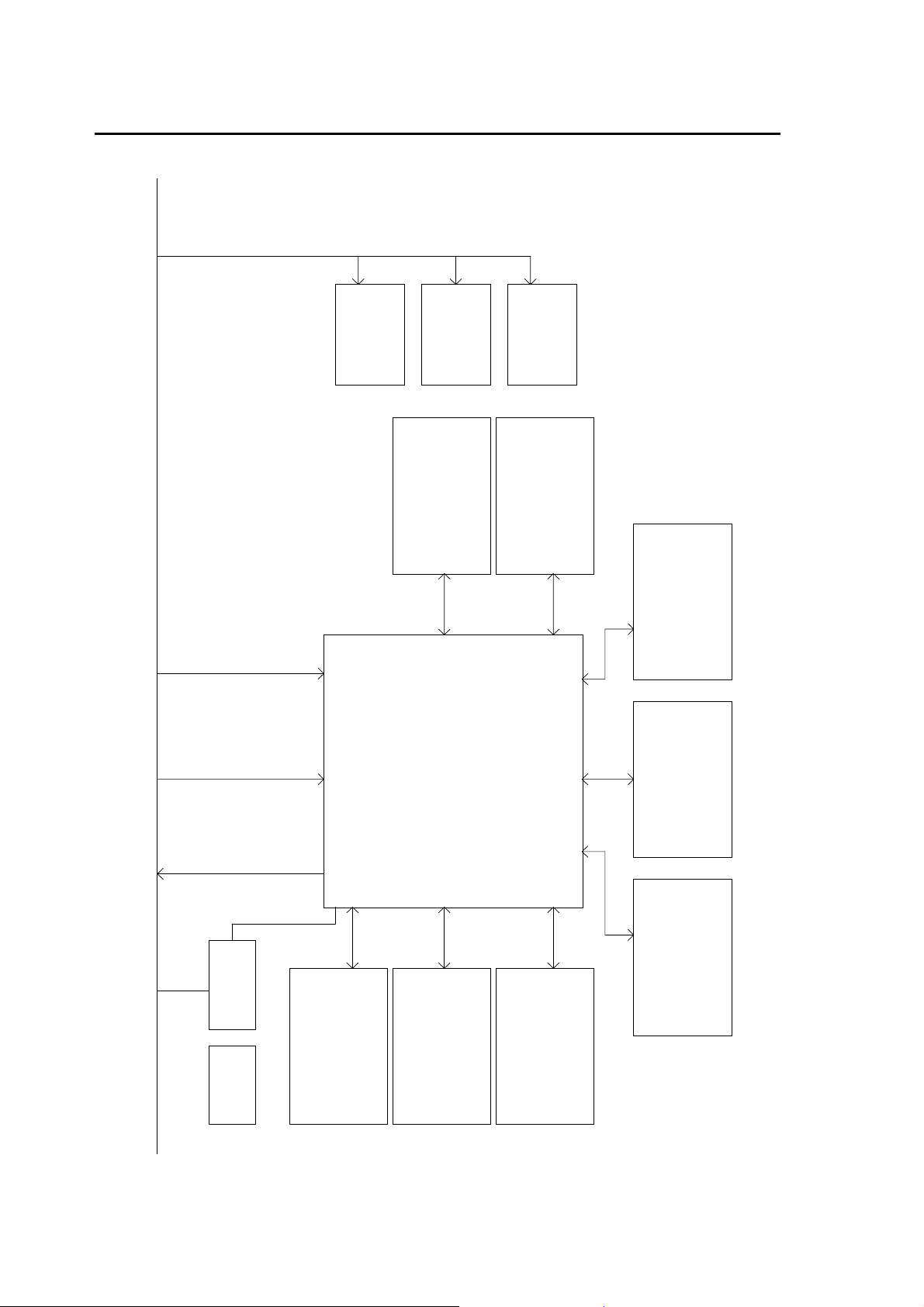

4-2. Function Block Diagram of MAIN Board.......................................................................................18

4-3. Function Block Diagram of GENLOCK Board...............................................................................19

4-4. Function Block Diagram of BKDF-810 Board................................................................................20

4-5. Function Block Diagram of BKDF-811 Board................................................................................21

4-6. Function Block Diagram of BKDF-840 Board................................................................................22

4-7. Function Block Diagram of BKDF-860 Board................................................................................23

4-8. Function Block Diagram of BKDF-861 Board................................................................................24

5. Adjustment Procedure of Each Board......................................................................................................25

5-1. Adjustment of CPU Board ...............................................................................................................25

5-2. Adjustment of MAIN Board ............................................................................................................27

5-3. Adjustment of GENLOCK Board....................................................................................................28

5-4. Adjustment of BKDF-810 Board.....................................................................................................29

5-5. Adjustment of BKDF-811 Board.....................................................................................................30

5-6. Adjustment of BKDF-840 Board.....................................................................................................31

Page 6

5-7. Adjustment of BKDF-860 Board .....................................................................................................32

5-8. Adjustment of BKDF-861 Board .....................................................................................................32

6. Method of Board Replacement/Addition.................................................................................................33

6-1. Removal/Installation of Shield Plate................................................................................................33

6-1-1. Removal of Shield Plate...........................................................................................................33

6-1-2. Installation of Shield Plate........................................................................................................34

6-1-3. Caution on Insertion of Shield Plate.........................................................................................35

6-2. Replacement of CPU Board.............................................................................................................36

6-2-1. Removal of CPU Board............................................................................................................36

6-2-2. Installation of CPU Board........................................................................................................37

6-2-3. Setting.......................................................................................................................................37

6-3. Replacement of MAIN Board..........................................................................................................38

6-3-1. Removal of MAIN Board.........................................................................................................38

6-3-2. Installation of MAIN Board .....................................................................................................39

6-4. Replacement of GENLOCK Board..................................................................................................40

6-4-1. Removal of GENLOCK Board.................................................................................................40

6-4-2. Installation of GENLOCK Board.............................................................................................41

6-5. Replacement/Addition of BKDF-810 Board....................................................................................42

6-5-1. To Begin with...........................................................................................................................42

6-5-2. Removal of BKDF-810 Board..................................................................................................43

6-5-3. Installation of BKDF-810 Board..............................................................................................44

6-5-4. Setting and Confirmation of Operation....................................................................................45

6-6. Replacement/Addition of BKDF-811 ..............................................................................................46

6-6-1. To Begin with...........................................................................................................................46

6-6-2. Removal of BKDF-811 Board..................................................................................................47

6-6-3. Installation of BKDF-811 Board ..............................................................................................48

6-6-4. Setting and Confirmation of Operation....................................................................................49

6-7. Replacement/Addition of BKDF-840 ..............................................................................................50

6-7-1. Removal of BKDF-840 Board..................................................................................................50

6-7-2. Installation of BKDF-840 Board..............................................................................................51

6-7-3. Setting and Confirmation of Operation....................................................................................52

6-7-4. Positioning Drawing for affixing the rubber ............................................................................52

6-8. Replacement/Addition of BKDF-860 Board....................................................................................53

6-8-1. To Begin with...........................................................................................................................53

6-8-2. Removal of BKDF-860 Board..................................................................................................54

6-8-3. Installation of BKDF-860 Board..............................................................................................55

6-8-4. Confirmation of Operation.......................................................................................................55

6-9. Replacement/Addition of BKDF-861 Board....................................................................................56

6-9-1. To Begin with...........................................................................................................................56

6-9-2. Removal of BKDF-861 Board..................................................................................................57

6-9-3. Installation of BKDF-861 Board..............................................................................................58

6-9-4. Confirmation of Operation.......................................................................................................59

Page 7

7. Update of Firmware/Software.................................................................................................................60

7-1. Procedure of Version Confirmation .................................................................................................60

7-1-1. Confirmation of GUI Version...................................................................................................60

7-1-2. Confirmation of CPU1 Version................................................................................................60

7-2. Update Procedure.............................................................................................................................61

7-3. Update of GUI Software..................................................................................................................62

7-4. Update of Board Firmware ..............................................................................................................62

8. FAQ・Troubleshooting...........................................................................................................................63

8-1. Trouble at Startup.............................................................................................................................63

8-2. Trouble related to Input and Output.................................................................................................64

8-3. Trouble after Board Addition/Replacement.....................................................................................65

8-4. Trouble related to Updating.............................................................................................................65

8-5. Trouble related to Function..............................................................................................................66

9. Error Code Table .....................................................................................................................................67

10. Replacement Parts for Mainteance........................................................................................................68

10-1. List of Replacement Parts for Maintenance ...................................................................................68

10-2. Replacement of DFS-800 Processor Parts.....................................................................................69

10-2-1. Removal of Front Panel.......................................................................................................... 69

10-2-2. Removal of Top Cover ...........................................................................................................69

10-2-3. Replacement of Power Unit ...................................................................................................70

10-2-4. Replacement of Fan................................................................................................................74

10-3. Replacement of DFS-800 Control Panel Parts...............................................................................77

10-3-1. Removal of Control Panel......................................................................................................77

10-3-2. Replacement of Power Supply...............................................................................................78

10-3-3. Replacement of Flash Memory ..............................................................................................80

10-3-4. Replacement of Button Cell...................................................................................................81

Page 8

Page 9

Before turning off the power

Before turning off the DFS-800 Processor, shut down in the manner below.

1) Confirm that the USB is not accessed.

2) Press the F1 knob and F4 knob simultaneously. Then, the display on the panel changes as shown

below.

Shutdown?

3) Press the F2 knob. ( To cancel the shutdow, press the F3 knob.)

4) When the F2 knpb is pressed, the shutdown begins. When the DFS-800 Processor is normally

shut down, the display on the panel changes as shown below.

Shutdown…OK!

5) Turn off the power of Control Panel and then the power of Processor.

F2: OK F3: CANCEL

Caution

Before turning off the power, be sure to shut down. If the power is turned off before

shut-down, the present panel setting cannot be saved. Therefore, the system is not

normally terminated and the re-startup may fail.

When the system is normally shut down, the previous panel setting can be restored at

the startup.

1

Page 10

1. Specification and Apperance

1-1. Specification

1-1-1. DFS-800 Processor

Television System 525/60, 625/50

Signal Process Method Digital Component 4:2:2 4 ( key ) 10 bits

Quantization Y: 10 bits, C: 10 bits, Key: 10 bits

Video Input SD SDI 270Mpbs, 75Ω, 8 inputs ( Expandable up to 16 inputs ), BNC

Sync Signal Input BB: 0.429 Vp-p ( NTSC ) or 0.45 Vp-p ( PAL ),

75Ω or loop-through, 1 input, BNC

Video Output SD SDI 270Mpbs, 75Ω, 8 outputs ( Program 2 outputs, Preview,

Clean 1 output each , Auxiliary 4 outputs ) ( Expandable up to 16 outputs ),

BNC

Sync Signal Output BB: 0.429 Vp-p ( NTSC ) or 0.45 Vp-p ( PAL ), 75Ω, 2 utputs, BNC

I/O Delay 1H (minimum delay) – 4 frames

Interface

TO OU

( To control panel ):

RS-422: D-sub 9-pin ( female ), 2 ports

EDITOR D-sub 9-pin ( female ), 1 port

REMOTE: D-sub 37-pin ( female ), 1 port ( 8-pin input/24-pin output )

Operating Temperture 5°C - 40°C

Operating Humidity 30% - 90% ( No dropwise )

Power Source 100VAC-240VAC, 50/60Hz

Current Consumption 1.9A - 0.9A

Maximun In-rush

Current

Weight About 15kg

Dimensions 430 ( W ) x 425( D ) x 88 ( H ) mm, EIA 2RU

Ethernet, 10/100BASE-TX, RJ-45; 1 port

(1) Power ON, current probe method: 60A ( 240V )

(2) Hot switching inrush current, measured in accordance with European

standard EN55103-1: 20A ( 230V )

Consumed Parts Cooling Fan: x1 at front side Replacement: every 4 years

x2 at rear side Replacement: every 4 years

2

Page 11

1-1-2. DFS-800 Control Panel

USB

( Control Panel )

Interface

TO PANEL D-sub 9-pin ( female ), 1 port

TO MU (To switcher) Ethernet 10/100BASE-TX, RJ-45, 1 port

VGA VGA OUT, D-sub 15-pin ( female )

USB: USB1.1, A type ( female ), 1 port

Operating Temperature 5°C - 40°C

Operating Humidity 30% - 90% ( No dropwise )

Power Source 100VAC-240VAC, 50/60Hz

Current Consumption 0.5A - 0.2A

Maximum In-rush

Current

Weight About 5kg

USB1.1, A type ( female ), 1 port

For USB memory stick ( Up to 2GB ).

(1) Power ON, current probe method: 40A ( 240V )

(2) Hot switching inrush current, measured in accordance with European

standard EN55103-1: 10A ( 230V )

Dimenstions 430 ( W ) x 221 ( D ) x 117 ( H ) mm

3

Page 12

1-1-3. BKDF-810

Television System 525/60, 625/50

Video Input SD SDI 270Mpbs, 75Ω, 4 inputs, BNC

I/O Delay 1 Frame ( When FS is used )

1-1-4. BKDF-811

Television System 525/60, 625/50

Video Input Analog Composite 2 inputs or

Analog Composite and Analog Component 1 input each

Analog Composite: 1.0V ( p-p ) 75Ω BNC

Analog Component

Y: 1.0V ( p-p ) 75Ω BNC

B-Y, R-Y: 0.486V ( p-p ) ( SMPTE Level, 7.5% Setup )

0.525V ( p-p ) ( SMPTE Level, 0% Setup )

0.700V ( p-p ) ( Betacam Level, 7.5% Setup )

0.757V ( p-p ) ( Betacam Level, 0% Setup )

Phase Control ±8 Pixcels

I/O Delay 1 Frame ( The FS is always turned on. )

1-1-5. BKDF-860

Television System 525/60, 625/50

Video Input SD SDI 270Mpbs, 75Ω, 4 outputs, BNC

4

Page 13

1-1-6. BKDF-861

Television System 525/60, 625/50

Video Output Analog Composite 2 outputs or

Analog Composite and Analog Component 1 output each

Analog Composite: 1.0V ( p-p ) 75Ω BNC

Analog Component Y,B-Y,R-Y

Y: 1.0V ( p-p ) 75Ω BNC

B-Y, R-Y: 0.486V ( p-p ) ( SMPTE Level, 7.5% Setup )

0.525V ( p-p ) ( SMPTE Level, 0% Setup )

0.700V ( p-p ) ( Betacam Level, 7.5% Setup )

0.757V ( p-p ) ( Betacam Level, 0% Setup )

Analog Component GBR

G, B, R: 1.0V ( p-p ) 75Ω BNC

Characterristics

At Analog Composite Output:

Frequency

Chatacteristics

S/N Ratio

DG/DP

K Factor

HV Tilt

Residual Jitter

At Analog Component Y,B-Y,R-Y output:

Frequency

Characteristics

S/N Ratio

Linearity

K Factor

Phase difference

between Y/B-Y/R-Y

100kHz - 4.2MHz: ±0.5dB,

4.2MHz - 5MHz: within -1dB,

Over 5MHz: Descending characteristics

60dB ( Excluding quantizing noise )

1%/1°

1%

1%

±15ns

100kHz - 4.2MHz: ±0.5dB,

4.2MHz - 5MHz: within -1dB,

Over 5MHz: Descending characteristics

60dB ( Excluding quantizing noise )

2%

1%

10ns

At nalog Component GBR output:

Frequency

Chatacteristics

S/N Ratio

K Factor

100kHz - 5MHz: ±0.5dB,

Over 5MHz: Descending characteristics

60dB ( Excluding quantizing noise )

1%

5

Page 14

1-2. Appearance

1-2-1. DFS-800 Processor

( In mm. )

U

O

T

B

B

I

K

N

C

O

L

O

U

4

I

N

z

H

/

0

0

5

6

V

0

4

O

T

R

I

D

E

2

2

2

4

-

S

45

4

2

-

0

0

1

C

A

3

3

2

2

1

R

E

T

M

O

E

R

1

1

N

O

E

T

G

1

2

8

7

6

5

4

X

4

U

A

3

U

X

A

X

2

U

A

X

U

1

A

N

A

E

L

C

V

I

D

E

O

I

N

3

2

1

V

I

D

T

E

O

U

O

V

E

R

P

2

M

G

P

1

M

G

P

425

2x2-6.4x12

t2.3

26.5 24.5 7

DFS-800

PRODUCTION SWITCHE R

88

ON

OFF

16 56 16

6766

430

465

482

40 345 40

6

Page 15

1-2-2. DFS-800 Control Panel

( In mm. )

7

Page 16

2. Name and Function of Each Block

2-1. DFS-800 Processor

Front Panel

Rear Panel

No. Name Function

1 POWER LAMP When turning on the power, the POWER lamp lights green.

2 POWER SWITCH Power switch of DFS-800

3 VIDEO OUT

4 VIDEO INPUT

5 GENLOCK IN

6 REF OUT Connector for sync signal output 2 outputs

7 TO CP

8 REMOTE

9 RS-422 -1 Connector for RS-422 control D-sub 9-pin ( female )

10 RS-422 -2 Connector for RS-422 control D-sub 9-pin ( female )

11 RS-422 - EDITOR Connector for editor control D-sub 9-pin ( female )

12 AC IN For power input Feed AC100V - 240V.

ON

OFF

E

R

E

X

U

A

P

V

2

1

G

P

M

V

I

D

E

O

O

U

T

1

V

I

D

E

O

I

N

L

C

A

N

M

G

P

3

4

2

X

U

A

1

2

A

A

U

3

X

U

4

X

7

5

8

6

2

1

N

T

K

C

N

B

E

O

B

G

I

O

L

U

SD SDI Digital Video output

2 programs, 1 preview, 1 clean and 4 auxiliaries are provided for

standard output. 8 auxiliary outputs can be added.

SD SDI Digital Video output

8 inputs are provided for standard input. 8 inputs can be added as

an option.

Connector for inputting the external sync signal ( black burst )

When a signal is fed to one connector, the other connector becomes

automatically the loop through connector.

When desiring no loop through, terminate the other connector with

75Ω.

Connector for connecting the Control Panel ( RJ-45,

10Base-T/100Base-TX ).

Connector for inputting GPI, connector for outputting GPI/Tally

D-sub 37-pin ( female )

DFS-800

PRODUCTION SWITCHER

1

1

E

O

M

T

E

R

S

R

4

2

2

E

I

D

1

T

R

O

2

2

2

3

3

4

4

U

O

T

O

I

z

N

0

H

V

/

A

6

0

0

0

-

C

5

1

2

4

0

8

Page 17

2-2. DFS-800 Control Panel

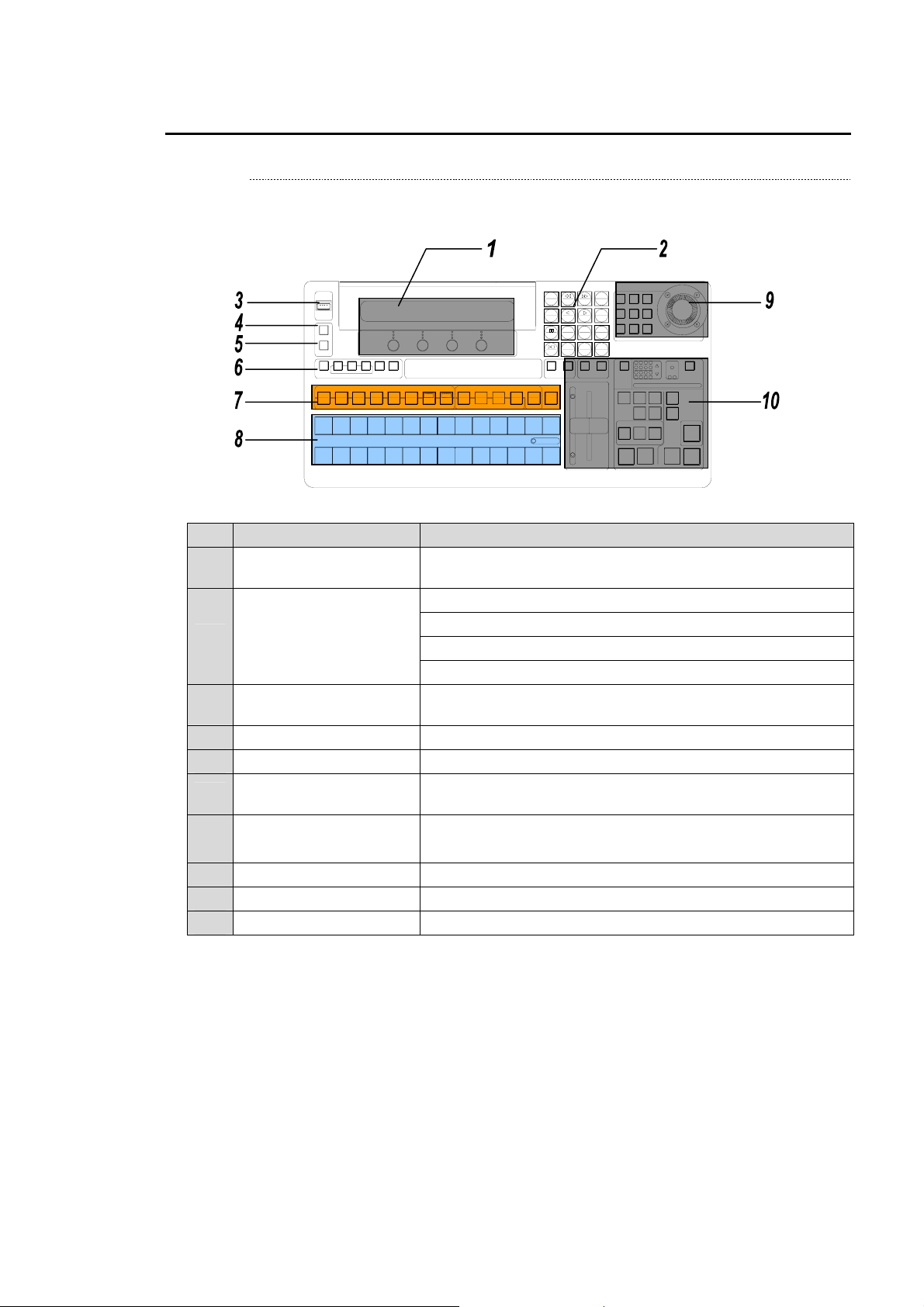

2-2-1. Control Panel

The configuration of each part of control panel is as follows.

PROGRAM

PRESET

USB MEMORY

BLACK

BLACK

EDITOR

GPI

KEY ON

KEY1

MATTE

EXT SELF CK EDGE SHADOWMASK

KEYER

BUS SELECT

KEY3

KEY2

INPUT SYSTEM

AUX

2

1

2

1

F3 F4F2F1

PRODUCTION SWITCHER

DME

BORDERBASIC

COMB B

COMB A

DSK2

DSK1

KEY4

STATUS

SETUP

443

3

EVENT

SEQ

STILL

7

6

5

7

6

5

SUB EFF

8

10109

8

9

No. Name Function

Display panel and menu

1

control

2 digits display panel for menu and control knpb for menu

setting

Operation mode select button of menu, event and sequence

2 Keypad and mode button

Used for input/change of menu.

Used for save/call of event.

Used for save/replay of sequence.

3 USB Memory

Used for save/read of data. ( exclusive for USB flash memory,

up to 2GB, USB 1.1 or 2.0 )

4 EDITOR button Used for ON/OFF editor control.

5 GPI button Used for ON/OFF of GPI IN control.

6 Keyer section

Used for keyer setup. ( Settings of keyer signal, type

selection,mask, edge and shadow )

WARP LIGHT

11

MENU

SEQ

4

1

SEQ LINK

SHIFT

SHIFT

121211

COMBINER SETU P

SHIFT

8 97

65

RECALL

LOOP DIR

23

INSERT

DELETE

NEW

CANCEL

.0

FADER LIMIT NOR/REV REVERSE PREV TRANS

FADER DIRECTION

EVENT

FINE

X

DEFAULT

STORE

WIPE POSAUTO CK

Y

Z

DME POS DME ROT

JOYSTICK

DFS-800

CUT

1

WIPE

(FAM)

TRANSITION TYPE

PRODUCTION SWITCHER

HIGH

321

2434

1 OVER 2

PRIOR ITY

4321

21

LOW1 234

KEY LAYER

DSK

KEY STATUS

DSK

KEY

KEY

1

2

1

DSK

KEY

KEY

2

4

3

DME

BLACK

TRANS

(NAM)

DSK

TRANSITION

DSK

CUT

MIX

AUTO

ENTER

BKGD

MIX

BUS SELECT、SETUP、

7

DME section

Selects a bus and displays menu.

8 M/E bus Selects the background video.

9 Joystick block Used for menu operation and auto chroma key setting.

10 Transition block Executes the transitions of background and key.

9

Page 18

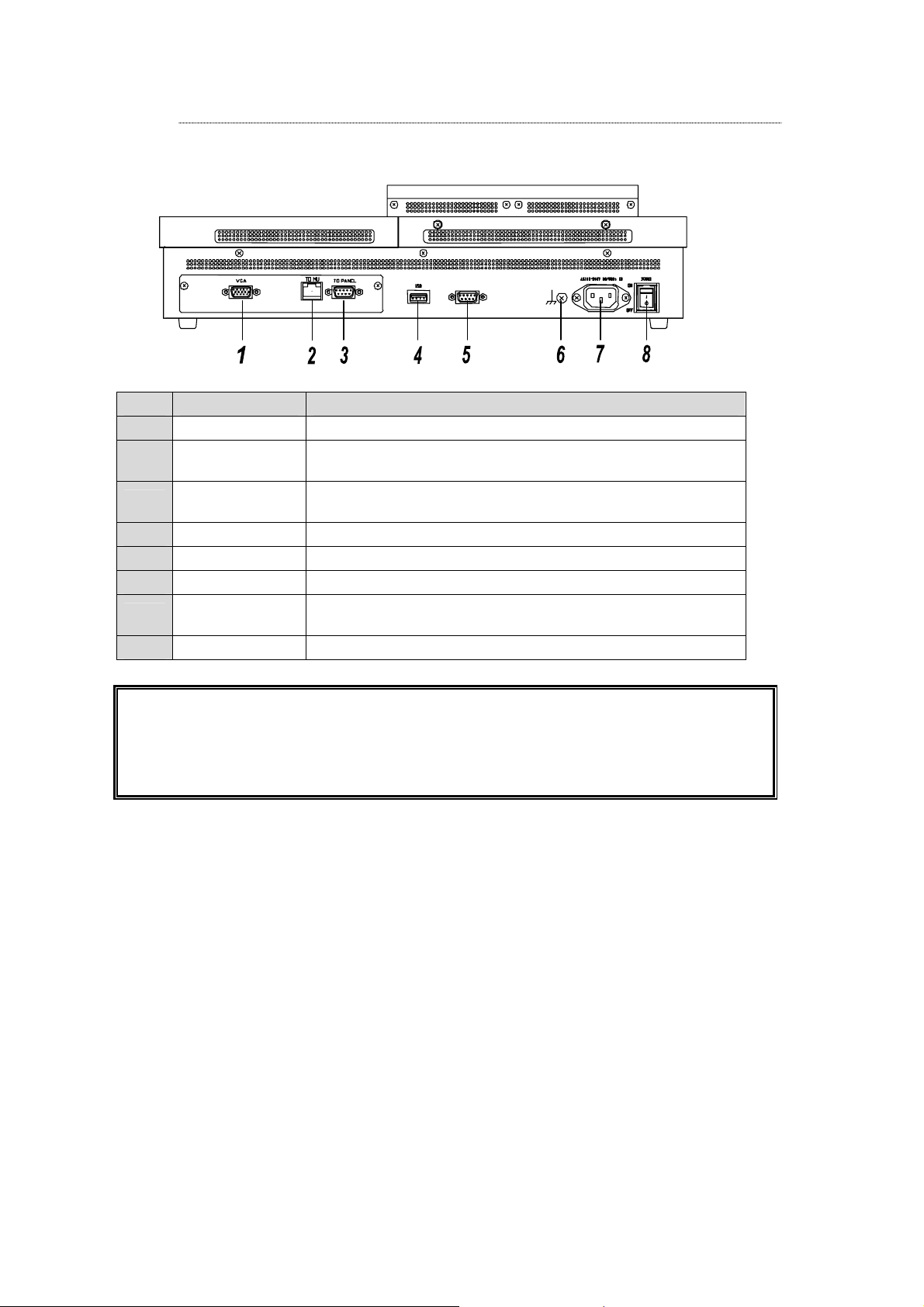

2-2-2. Rear Panel

The configuration of rear panel of control panel is as follows.

No. Name Function

1 VGA Cconnect the LCD monitor.

2 TO MU

3 TO PANEL

4 USB Connect the USB flash memory. ( Up to 2GB, USB 1.1 or 2.0 )

5 ― Not used

6 Ground For safety, connect it to the ground.

7 AC IN

8 Power Switch Power switch of control panel

Connect the Processor. ( RJ-45, 10Base-T/100Base-TX,

category5, cross cable )

Connect the touch panel LCD.

( RS232C, D-sub 9-pin (female ) )

Using the supplied power cord, supply the AC power.

( AC100V-240V 50/60Hz ).

Caution

The USB port is exclusively for connecting the mouse or USB flash memory. Other

USB drive equipment cannot be recognized. Insert the USB memory stick either in

the USB memory drive on the control panel or USB memory drive on the rear panel.

Do not insert in both of them at the same time.

10

Page 19

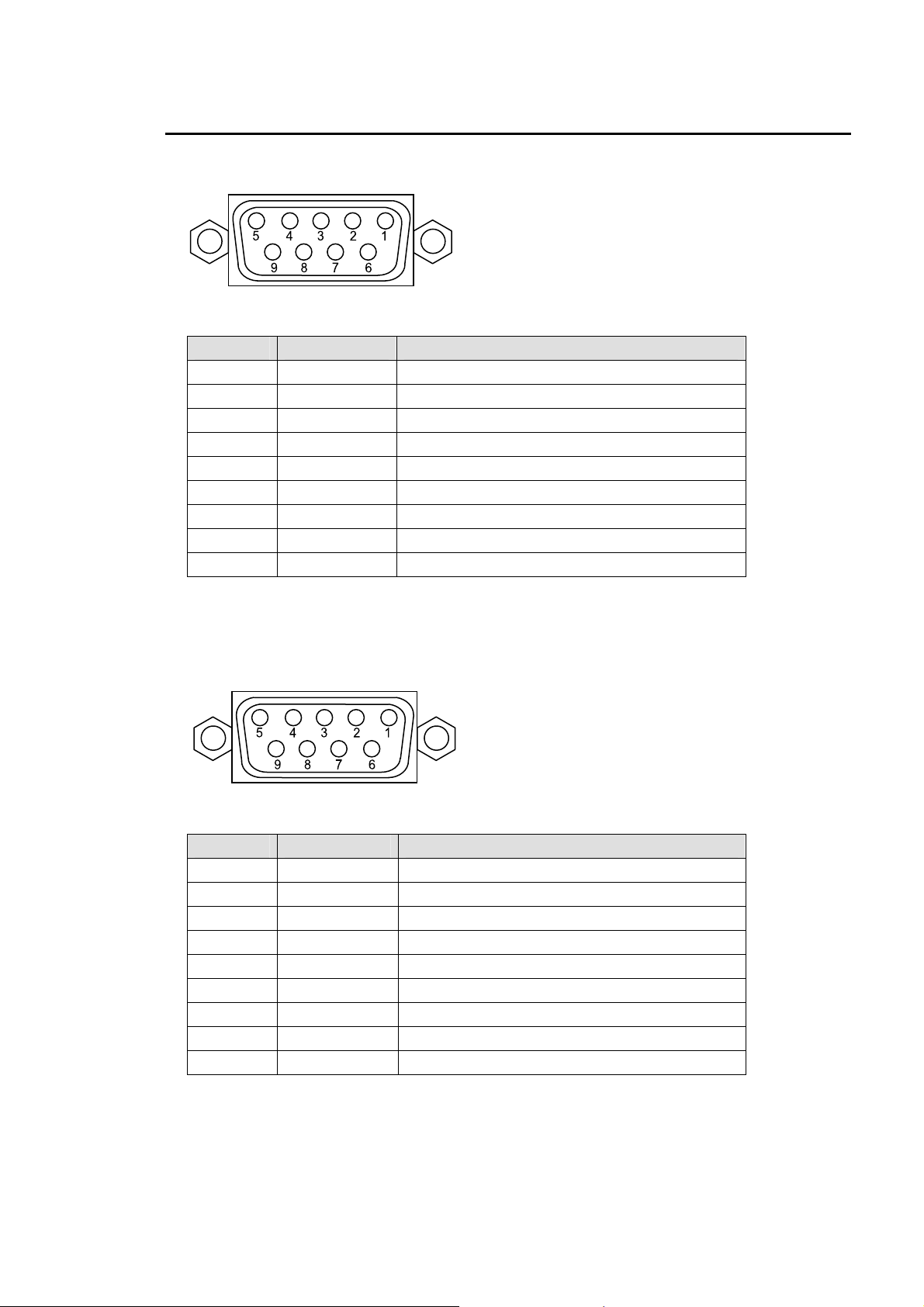

2-3. Peripheral Interface

EDITOR CONNECTOR

Pin Assignment Table ( D-sub 9-pin, female )

Pin No. Signal Name Content

1 FG Frame Ground

2 T- Data Send ( - )

3 R+ Data Receive ( + )

4 SG Signal Ground

5 - Not used

6 SG Signal Ground

7 T+ Data Send ( + )

8 R- Data Receive ( - )

9 FG Frame Ground

Cable Connector: D-sub 9-pin connector ( male ), Inch screws are used.

RS-422 (1) (2) Connector

Pin Assignment Table ( D-sub 9-pin, female )

Pin No. Signal Name Content

1 FG Frame Ground

2 R- Data Receive ( - )

3 T+ Data Send ( + )

4 SG Signal Ground

5 - Not used

6 SG Signal Ground

7 R+ Data Receive ( + )

8 T- Data Send ( - )

9 FG Frame Ground

Cable Connector: D-sub 9-pin connector ( male ), Inch screws are used.

11

Page 20

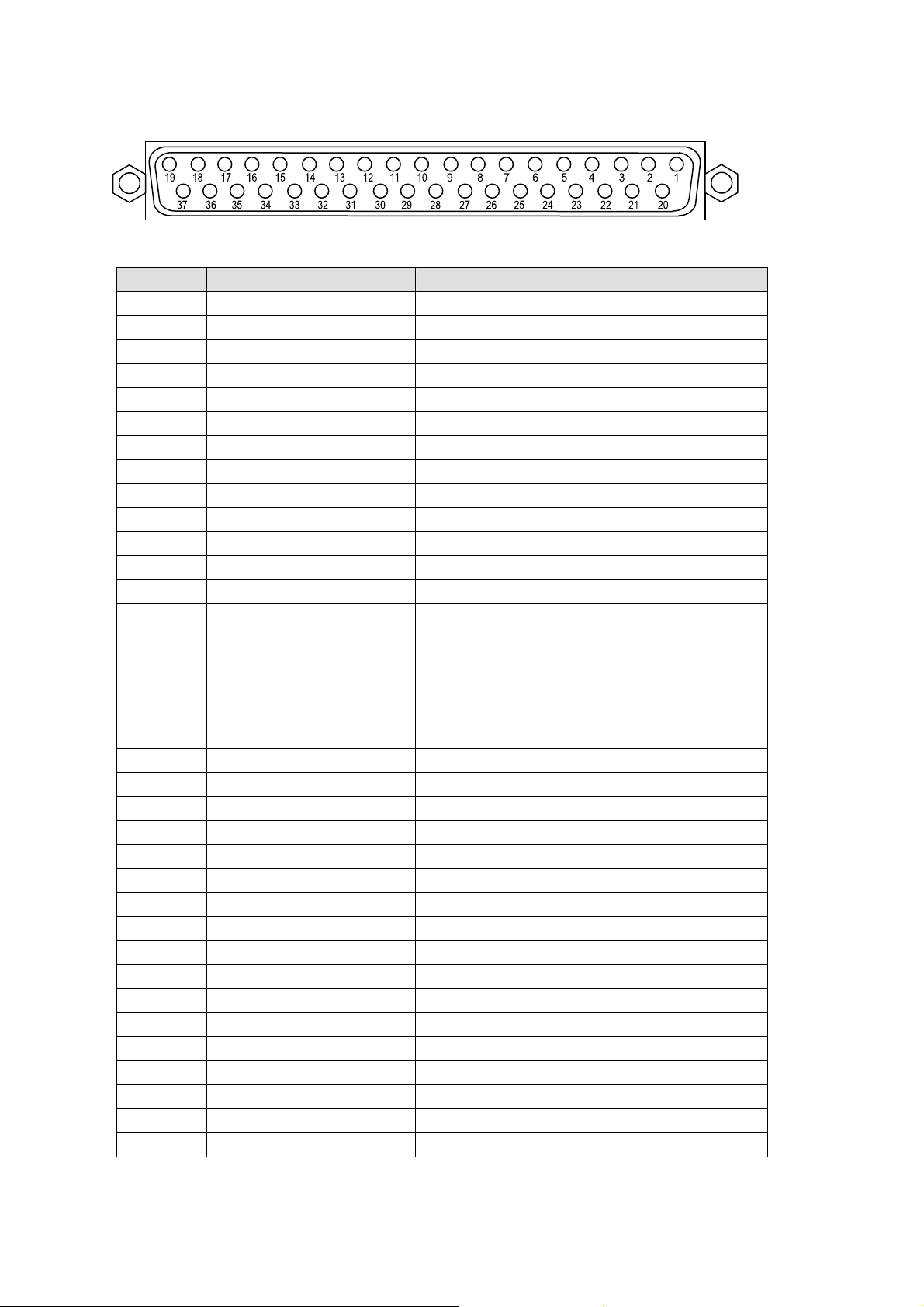

REMOTE Connector

Pin Assignment Table ( D-sub 37-pin, female )

Pin No. Pin Function Default Setting

1 Tally Output 1 RedTallyInput01

2 Tally Output 2 RedTallyInput02

3 Tally Output 3 RedTallyInput03

4 Tally Output 4 RedTallyInput04

5 Tally Output 5 RedTallyInput05

6 Tally Output 6 RedTallyInput06

7 Tally Output 7 RedTallyInput07

8 Tally Output 8 RedTallyInput08

9 Tally Output 9 GreenTallyInput01

10 Tally Output 10 GreenTallyInput02

11 Tally Output 11 GreenTallyInput03

12 Tally Output 12 GreenTallyInput04

13 Tally Output 13 GreenTallyInput05

14 Tally Output 14 GreenTallyInput06

15 Tally Output 15 GreenTallyInput07

16 Tally Output 16 GreenTallyInput08

17 +5V

18 +5V

19 +5V

20 Tally Output 17 None

21 Tally Output 18 None

22 Tally Output 19 None

23 Tally Output 20 None

24 Tally Output 21 None

25 Tally Output 22 None

26 Tally Output 23 None

27 Tally Output 24 None

28-29 GND

30 GPI 1 PGMAutoTrans

31 GPI 2 PGMCutTrans

32 GPI 3 DSKAutoTrans< Mix >

33 GPI 4 DSKCutTrans

34 GPI 5 PGMMixType

35 GPI 6 PGMWipeType

36 GPI 7 PGMDMEType

37 GPI 8 BlackTrans

12

Page 21

Cable Connector

D-sub 37-pin ( male ), Inch screws are used. Maximum load current DC 0.1A

Pin Free assignment

The table shown on the previous page shows the setting of pin assignment at ex-factory. They

can be changed on the menu.

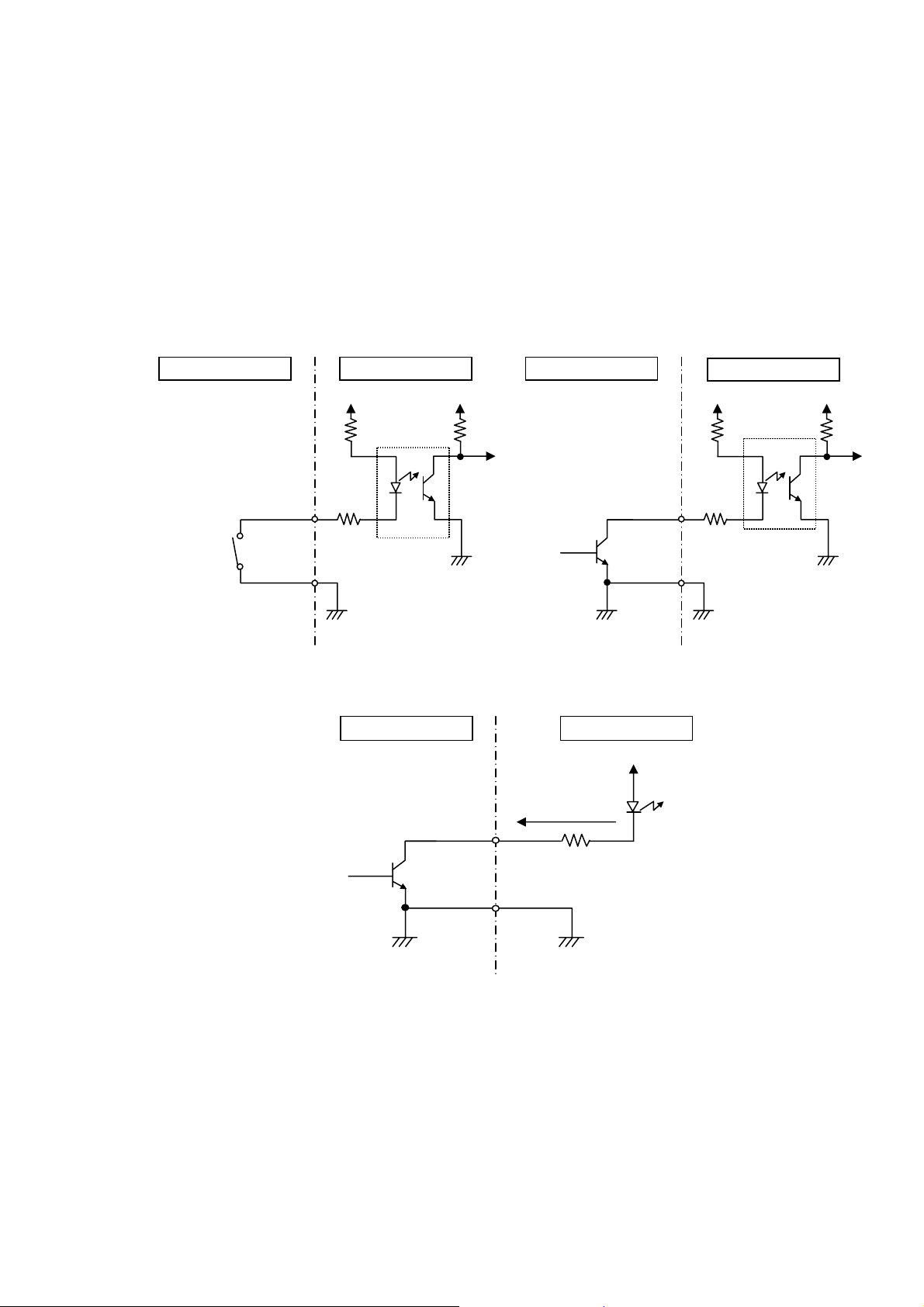

GPI Input Circuit

Switch or Relay

External Equipment

Tally Output Circuit

DFS-800

DFS-800

Open Collector

External Equipment

VCCVCC

External Equipment

Maximum voltage:

30V

Maximum load

current

100mA

DFS-800

VCCVCC

13

Page 22

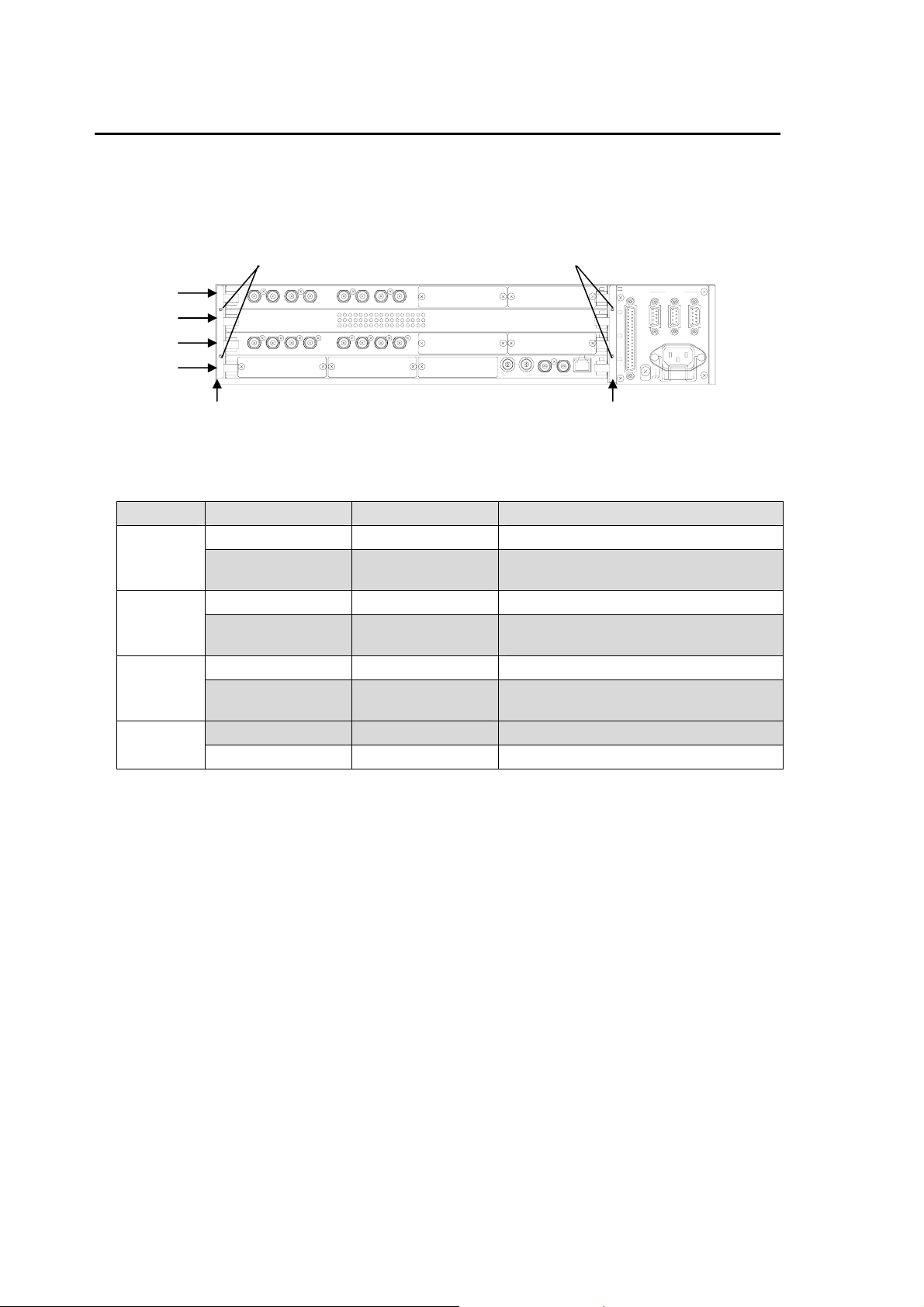

2-4. DFS-800 Board Configuration

r

w

The board configuration of DFS-800 rear panel is shown in the figure below and on the table. Each

board is fixed with the retainer. To draw out the board from the unit, remove the retainers and then

draw out the board.

1

2

3

4

Configuration of Rear Panel Card of DFS-800 (From top slot to down slot)

Slot Standard/Option Card Content

1

2

3

4

*1 For expansion of option input, refer to [ 6-5. Replacement/Addition of BKDF-810 board ]

and [ 6-6. Replacement/Addition of BKDF-811 board ]. For expansion of option output,

refer to [ 6-8. Replacement/Addition of BKDF-860 board ] and [ 6-9.

Replacement/Addition of BKDF-861 board ].

Screw Scre

M

P

V

2

1

M

G

P

G

P

E

V

I

D

E

O

O

U

V

I

D

E

O

I

N

R

T

3

1

2

U

A

L

C

A

N

E

7

5

4

8

6

2

1

T

N

U

B

B

I

O

K

C

O

L

N

E

G

1

1

E

R

O

M

T

2

2

3

3

4

4

U

O

T

O

4

X

A

U

X

U

A

3

X

U

1

2

A

X

Retainer Retaine

Standard BKDF-860 Standard SD-SDI 1-8 Output

Option

BKDF-860 /

BKDF-861

2 cards are expandable. ( *1 )

Standard MAIN MAIN card

Option BKDF-840

Input DME card

( Pre-combiner )

Standard BKDF-810 Standard SD-SDI 1-8 Input

Option

BKDF-810 /

BKDF-811

2 cards are expandable. ( *1 )

Option BKDF-811 2 cards are expandable. ( *1 )

Standard CPU CPU card

4

2

2

-

S

E

R

1

2

E

0

H

/

6

z

0

0

-

5

2

4

0

V

0

C

1

A

R

O

I

D

T

N

I

14

Page 23

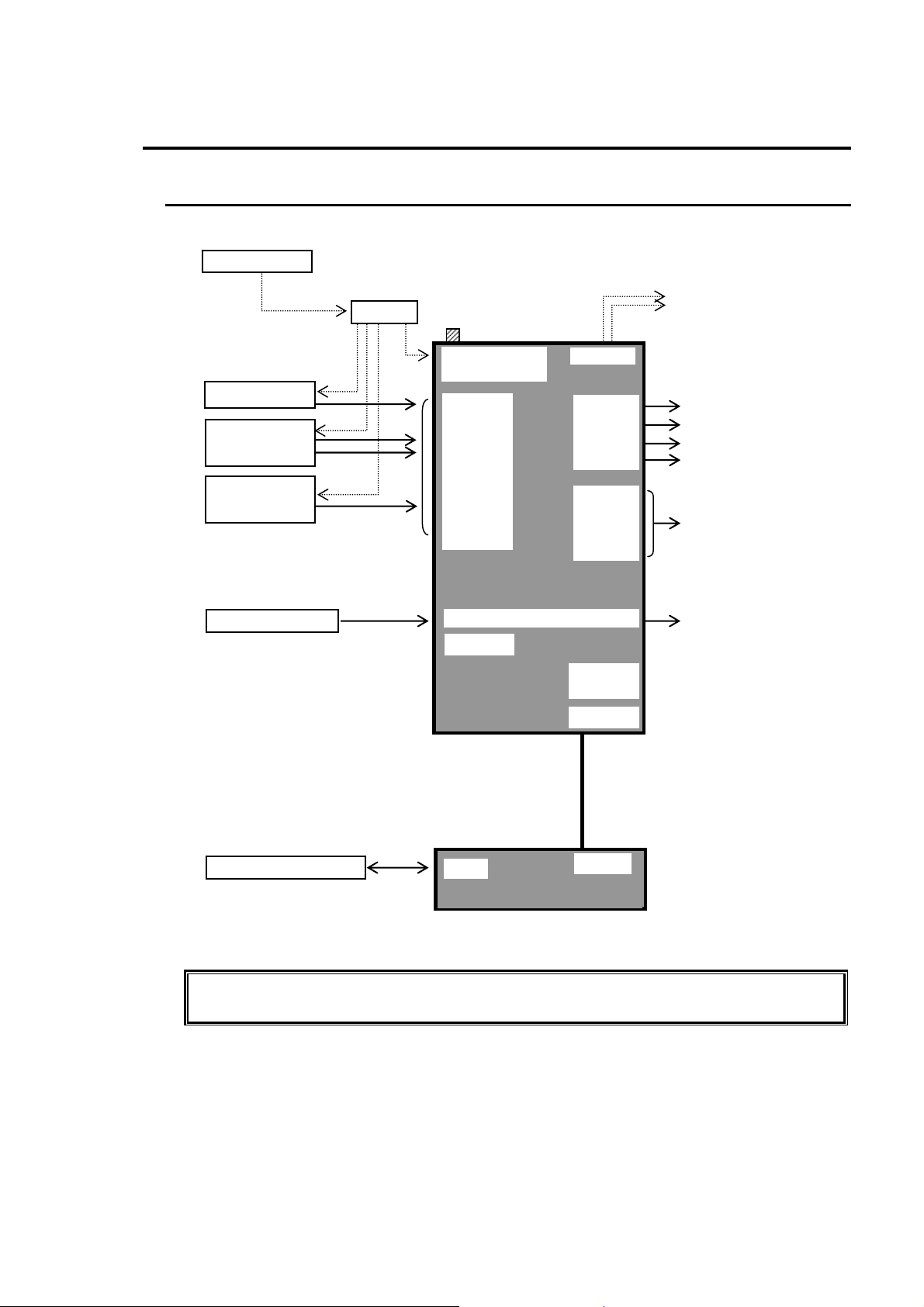

3. Connection

(

)

3-1. Basic Configuration

TSG

VDA

Camera

Character

Generator

Digital Video

Database

GPI Controller

USB Flash Memory

(75ohm terminator)

GENLOCK IN

(w/ loop-through

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 8

REF OUT

REF OUT

CLEAN

DFS-800 Processor

30-37) REMOTE (1-27

EDITOR

RS-422 1

RS-422 2

TO OU

USB

TO MU

DFS-800 Control Panel

Reference outputs

PGM 1

PGM 2

PREV

AUX1

AUX2

AUX3

AUX4

Supplied LAN Cable

PGM1 output

PGM2 output

PREV output

CLEAN output

AUX outputs

(Free assign)

Tally outputs

Caution

Connect to the Control Panel with the supplied control cable (10m) or ( LAN

crosscable, category 5, RJ-45 ).

15

Page 24

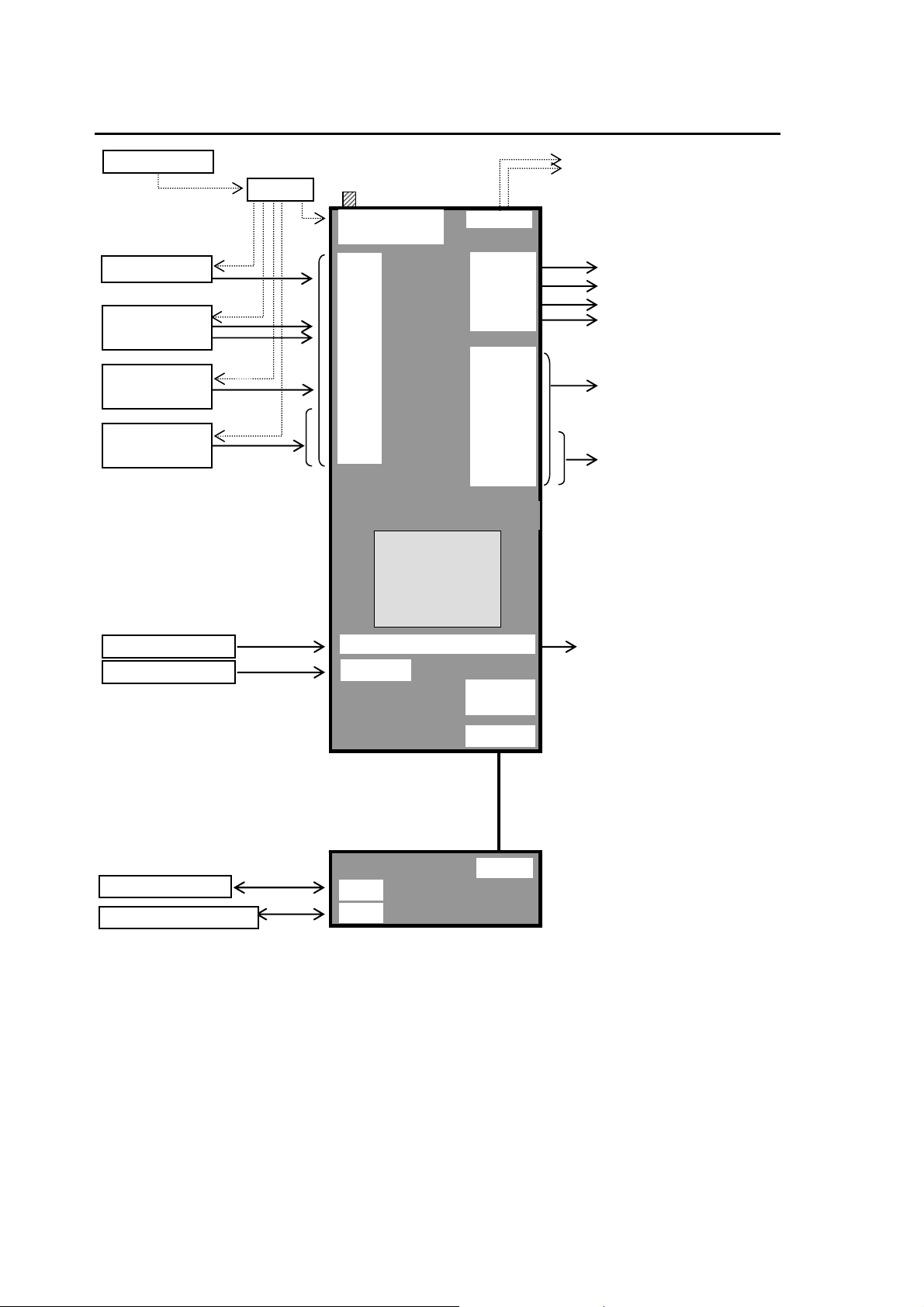

3-2. Option Configuration

TSG

Camera

Character

Generator

Digital Video

Database

Analog Video

Database

GPI Controller

Editor, etc

SVGA Display

USB Flash Memory

VDA

(75ohm terminator)

GENLOCK IN

(w/ loop-through

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 8

IN 9

|

IN 16

DFS-800 Processor

(30-37) REMOTE (1-27)

EDITOR

Supplied LAN Cable

VGA

USB

REF OUT

BKDF-810

BKDF-811

BKDF-860

BKDF-861

BKDF-840

RS-422 1

RS-422 2

TO OU

DFS-800

PGM 1

REF OUT

PGM 2

PREV

CLEAN

AUX1

AUX2

AUX3

AUX4

AUX5

I

AUX12

TO MU

Reference outputs

PGM1 output

PGM2 output

PREV output

CLEAN output

AUX outputs

(SD-SDI)

AUX outputs

(Analog)

Tally outputs

16

Page 25

4. Function Block Diagram of Each Board

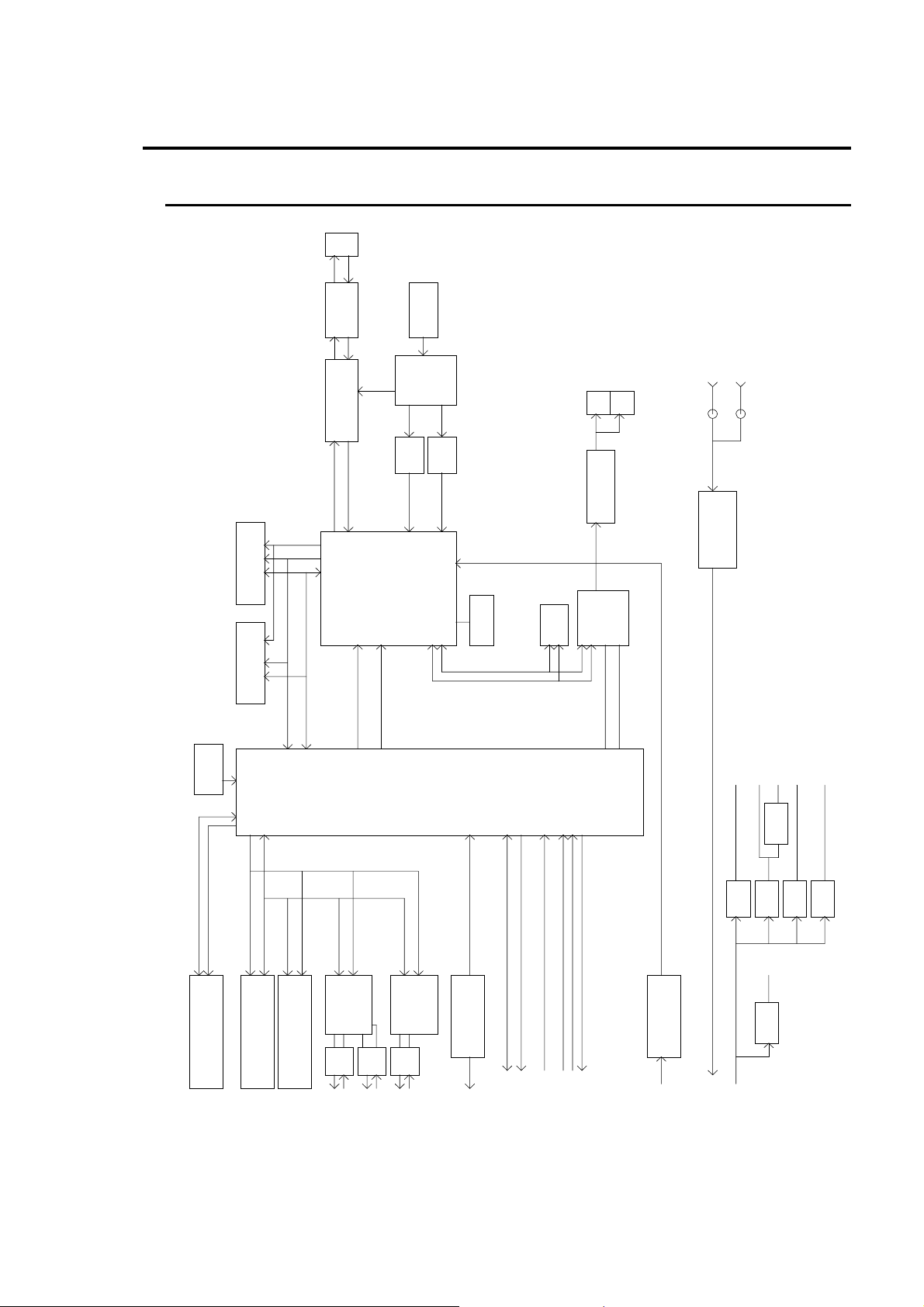

4-1. Function Block Diagram of CPU Board

SDRAM IC52

EDS1232AATA

133MHz

133MHz

Address Bus 22bits

SDRAM IC51

EDS1232AATA

133MHz

RJ45

IC30

PULSE TRANS

Ethernet Physical

IC29

M2 Interface TX

DATA Bus 64bits

BEL FUSE

25MHz

INTEL LXT971C

M2 Interface RX

DSP IC3

TMS320DM642

Crystal

Clock Buffer

25MHz

PLL

IC19

ICS511M

50MHz

IC18

TQC73DCP

IC21

IDT5V2310

25MHz

PLL

133MHz

I2C CLK

I2C DATA

IC19

ICS511M

JTAG I/F

DSP emulator

EEPROM

IC24

24LC16B

BB OUT

LEVEL & PEDESTAL

IC28,IC62,IC27

AD8091,AD8092

ENCODER

IC26

ADV7176A

CN1

BCJ-BPLH2P

75 Ohme COAX CABLE

CN8

BCJ-BPLH2P

CN9

BCJ-BPLH2P

Differential Signal

Driver

IC58,IC59

AD8132

75 Ohme COAX CABLE

ConfigROM

XCF02S-VOG20

I2C CLK

I2C DATA

Dangle CD

(I2C BUS EEPROM)

FPGA Xilinx

XC2S300E-7FG456C

IC33

Peripheral Data Bus 8bits

Peripheral Address Bus 26bits

Serial I/F

29LV128‚l

IC57

*NOT USED NOW

RS485

FLASH MEMORY

29LV128‚l

IC53

FLASH MEMORY

Multiplexed intrrupt signal

Video intrrupt signal

ADDRESS DECODER

I2C I/F

TARNSACTION BUS

Serial I/F

IC40

RS485

Driver

IC43

To Mother BD

Controller

RS485

Driver

Controller

TL16C752B

Driver

IC41

TL16C752B

IC45

IC44

24bits

GPO

IC38,IC38,IC39,IC42

ULN2003ANS

Transaction BUS 32bits

24bits

To Mother BD

ENC_BB 16bits

H SYNC/FELED/BLANKING

8bits

FAN ALARM 3bits

Frame Pulse from Genlock CD

POWER ALARM 1bit

Transaction BUS Device select (Each FPGA has a CS)

POWER LED CONTROL 2bits

To Mother BD

GPI

IC35,IC36

TLP280-4

8bits

From Mother BD

+3.3V

+2.5V

+1.4V

+5.0V

-5.0V

IC49

LP3965EMP

IC56

LM2660M

IC50

LT1764A

IC48

LP3966ES

IC46

LP3966ES

+1.8V

P1

Differential analog video signal go to the Genclock CD

To Mother BD

AXH005AOX

+5.25V

From Mother BD

17

Page 26

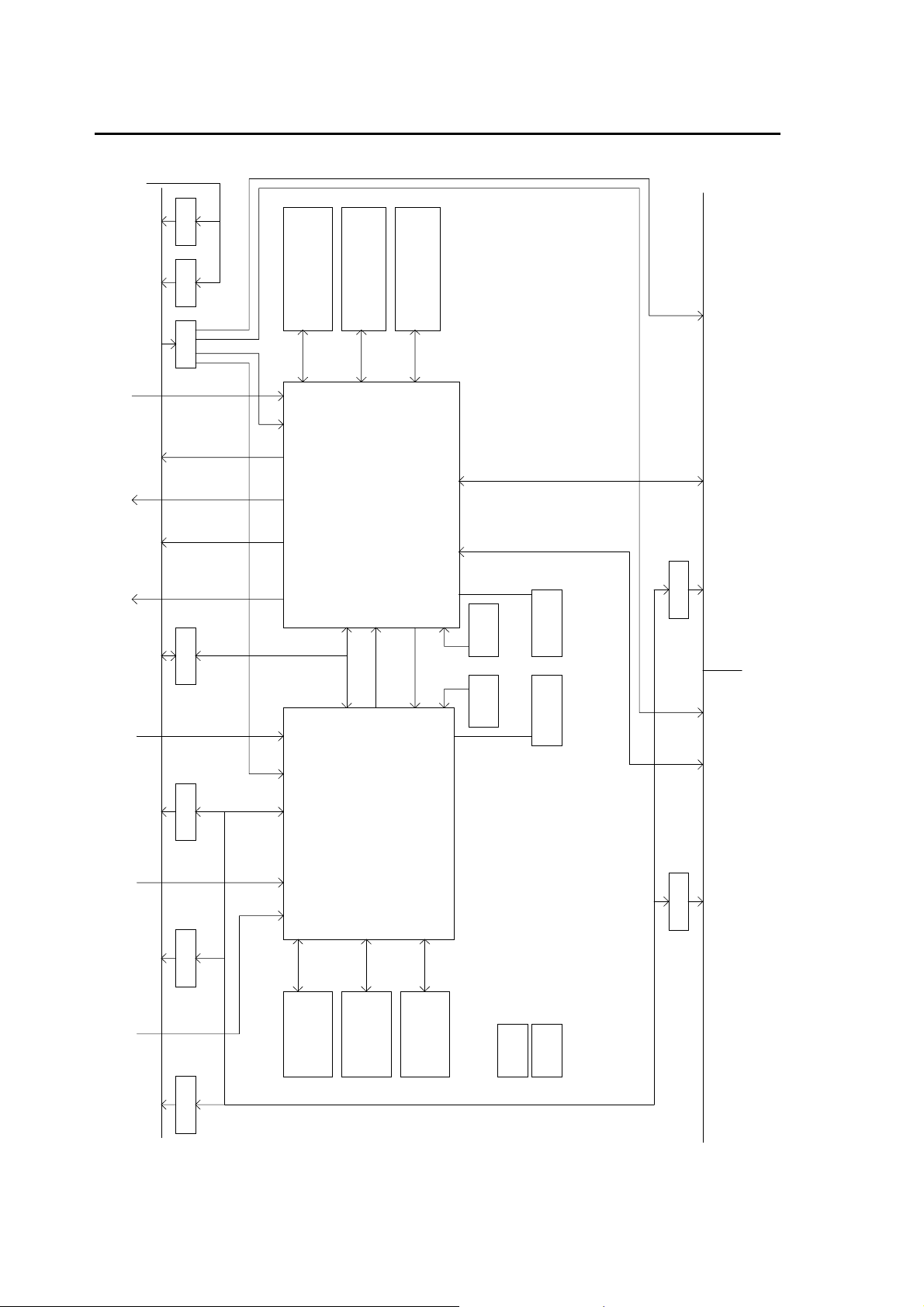

4-2. Function Block Diagram of MAIN Board

Transaction BUS

Clock IN 33MHz

To Mother Board

Pixel Clock 27MHz

From Genlock CD

VIDEO IN(Slot4)

LVDS 162MHz DDR

VIDEO OUT(Slot4)

VIDEO OUT(Slot3)

LVDS 162MHz DDR

VIDEO OUT(Slot2)

VIDEO OUT(Slot1)

LVDS 162MHz DDR

IC5IC7IC6

5V2310 5V2310 5V2310

LVDS 162MHz DDR

LVDS 162MHz DDR

IC15

IC18

Transaction BUS

Clock Distribution

33MHz

IC24

IC26

8ch Delay

IC25

PGM/PRV/DSK1/DSK2

KEY1/KEY2/KEY3/KEY4

Switcher Chip

M/E

KEYER

IC28

IC27

6ch Trail Store

DSK

IC29

INPUT DVE Filed Delay

Still Store

Caputure/Load

Key Delay for Edge

Chromakey

WIPE Generator

Mask Generator

Edge Generator

Still Store Controller

Trail

paint

Color Corrector

SDRAM Controller

P5P4

DC/DC

+5V to +1.5V

CORE POWER

MAIN CD(E02886-1)

Cofiguration ROMCofiguration ROM

IC43

IC44

LVC16245LVC16245

VIDEO IN/OUT

LVDS 162MHz DDR

*Write Only*

Transaction BUS

32bits 2.5V LVCMOS

Transaction BUS

32bits 2.5V LVCMOS

VIDEO IN(Slot3)

LVDS 162MHz DDR

IC14

*Write Only**Write Only**Write Only*

Transaction BUS

32bits 2.5V CMOS

VIDEO IN(Slot2)

LVDS 162MHz DDR

IC13

Transaction BUS

32bits 2.5V CMOS

VIDEO IN(Slot1)

LVDS 162MHz DDR

IC45

Transaction BUS

32bits 2.5V CMOS

IC17

LVC16245LVC16245

IC49

IC46

LVC16245 LVC16245

IC35

IC38

IC30 IC19

DVE ch1

DVE ch3

DVE Border

Warp Engin

Lighting

Effects Chip

IC36

IC39

DVE ch2

DVE ch5

IC37

IC40

DVE ch3

DVE ch6

DC/DC

+5V to +1.5V

CORE POWER

P2

DC/DC

+5V to +3.3V

I/O POWER

IC33 IC22

P3

DC/DC

+5V to +2.5V

I/O POWER

IC41

IC42

VIDEO IN/OUT

LVDS 162MHz DDR

DVE-SUB CD(E02882-1) DVE-SUB CD(E02882-1)

*Write Only*

Transaction BUS

32bits 2.5V LVCMOS

18

Page 27

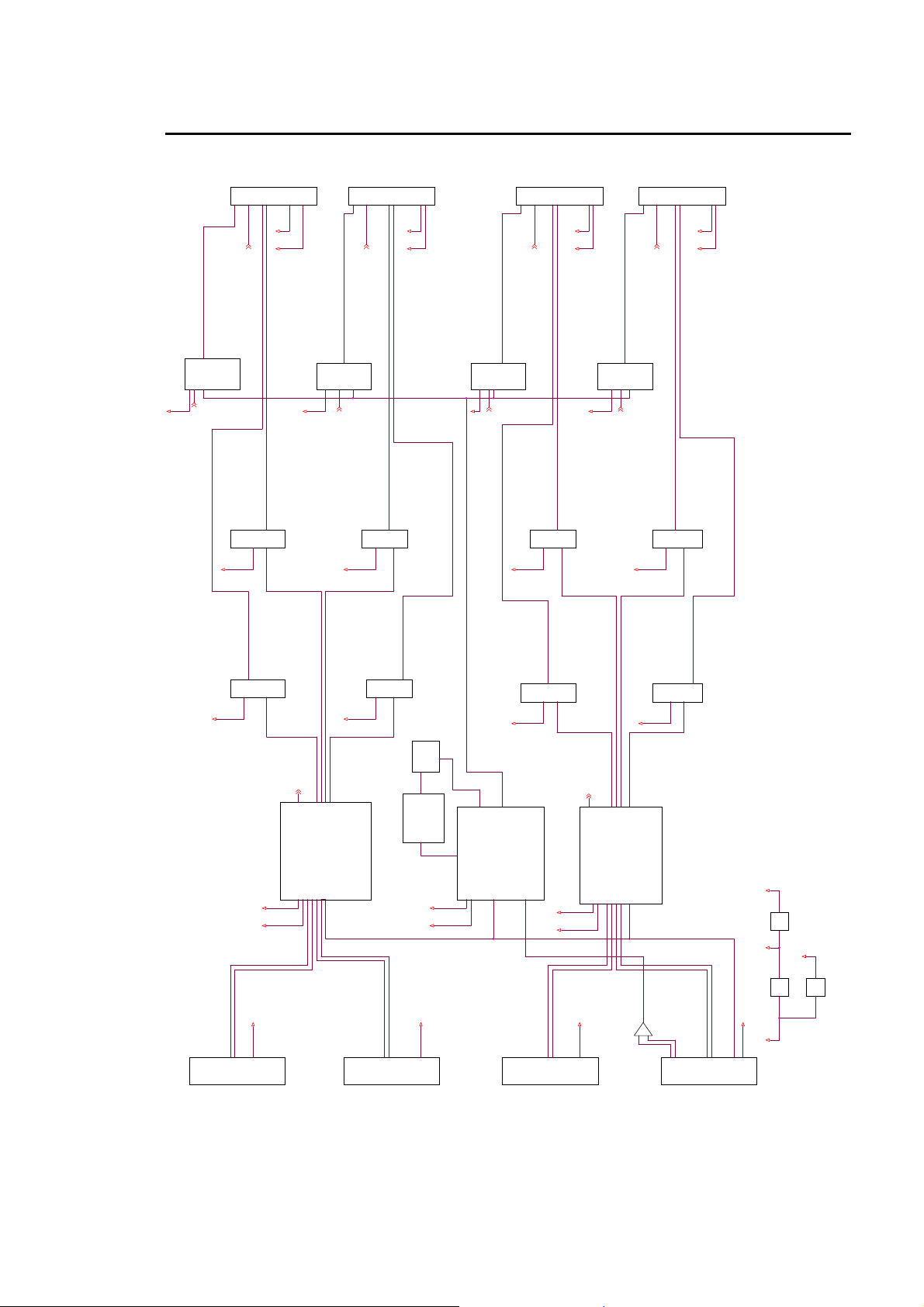

4-3. Function Block Diagram of GENLOCK Board

CN7

+3.3_SDI +3.3_SDI +3.3_SDI +3.3_SDI

+5V_PS +5V_PS +5V_PS +5V_PS

IIC_CLK,IIC_DATA,

PCB_ST

MH_SYNC-VA,MF_SYNC-VA,MV_SYNC-VA

CF_SYNC-VA,LVDS_RST-RA,FIFO_RST-A

FIFO_EN-A,NCS-A,SCLK-A,SDIN-A

DS1A_N:4bit

DS1A_P:4bit

DS0A_N:4bit

DS0A_P:4bit

IC11

LVCH16245

+3.3V +3.3V +3.3V +3.3V

CF_SYNC,LVDS_RST,

FIFO_EN-AB,NCS,

SCLK,SDIN

IC8

DS90CR217

+3.3V +3.3V

VO2-A:10bit

VO3-A:10bit

CN8

IIC_CLK,IIC_DATA,

PCB_ST

MH_SYNC-VA,MF_SYNC-VA,MV_SYNC-VA

CF_SYNC-VA,LVDS_RST-RA,FIFO_RST-A

FIFO_EN-A,NCS-A,SCLK-A,SDIN-A

IC12

LVCH16245

CF_SYNC,LVDS_RST,

FIFO_EN-AB,NCS,

SCLK,SDIN

IC10

DS90CR217

DS0B_N:4bit

DS1B_N:4bit

DS1B_P:4bit

VO2-B:10bit

VO3-B:10bit

DS0B_P:4bit

IC18

LVCH16245

CN9

IIC_CLK,IIC_DATA,

PCB_ST

MH_SYNC-VA,MF_SYNC-VA,MV_SYNC-VA

CF_SYNC-VA,LVDS_RST-RA,FIFO_RST-A

FIFO_EN-A,NCS-A,SCLK-A,SDIN-A

DS1C_N:4bit

DS1C_P:4bit

DS0C_N:4bit

DS0C_P:4bit

CF_SYNC,LVDS_RST,

FIFO_EN-AB,NCS,

SCLK,SDIN

IC15

DS90CR217

VO2-A:10bit

VO3-A:10bit

CN10

IIC_CLK,IIC_DATA,

MH_SYNC-VA,MF_SYNC-VA,MV_SYNC-VA

CF_SYNC-VA,LVDS_RST-RA,FIFO_RST-A

FIFO_EN-A,NCS-A,SCLK-A,SDIN-A

IC19

LVCH16245

CF_SYNC,LVDS_RST,

FIFO_EN-AB,NCS,

SCLK,SDIN

IC17

DS90CR217

+3.3V+3.3V

PCB_ST

DS1D_N:4bit

DS1D_P:4bit

DS0D_N:4bit

VO2-B:10bit

VO3-B:10bit

DS0D_P:4bit

IC7

+3.3V

CN1

To Mother Board

IC9

SCLK,SDIN

DS90CR217

+3.3V

VO0-B:10bit

VO1-B:10bit

IC34

IC31 HD64F7045

+3.3VD

+2.5VD

LVDS:162MHz

LVDS:162MHz

VOD-B_N:4bit

VOD-B_P:4bit

CN2

MH_SYNC,MF_SYNC,MV_SYNC

IC29

EP1K100FC

IC14

DS90CR217

+3.3V +3.3V

CN3

VO0-C:10bit

IC4

+3.3VD

+2.5VD

LVDS:162MHz

LVDS:162MHz

VOD-C_P:4bit

VOD-C_N:4bit

XC3S400

CF_SYNC,LVDS_RST,

FIFO_EN-AB,NCS,

SCLK,SDIN

IC16

DS90CR217

VO0-D:10bit

LVDS:162MHz

VOD-D_N:4bit

CN4

DS90CR217

VO0-A:10bit

VO1-A:10bit

CF_SYNC,LVDS_RST,

FIFO_EN-AB,NCS,

IC1

XC3S400

+3.3VD

+2.5VD

LVDS:162MHz

LVDS:162MHz

+5V_PS +5V_PS +5V_PS +5V_PS

VOD-A_P:4bit

VOD-A_N:4bit

ADM:32bit

LVDS:162MHz

VOD-D_P:4bit

+2.5VD

+3.3VD

+5V_PS

IC42

LP3965EMP

P1

AXH005AOX

+3.3_SDI

P3

AXH005AOX

19

Page 28

4-4. Function Block Diagram of BKDF-810 Board

CONNECTOR

( 8071 )

FPGA

[LVDS_CLK]

[LVDS_DATA]

( XC3S1500 )

CN8

IC102 = CLOCK BUFFER ( 74LVC245 )

[ADM_DATA]

[ADM_CTRL]

[LVDS_FRM]

IC11

FUNCTION

- VIDEO PROCESS ( BEFORE FRAME MEMORY )

> LUMINANCE GAIN

> CHROMINANCE GAIN

> LUMINANCE SETUP

> HUE CONTROL

> WHITE CLIP

> BLACK CLIP

> CHROMINANCE CLIP

[ADM_CLK]

IC22

[ADM_CLK2]

- LINE MEMORY ( USE MINIMUM DELAY MODE ONLY)

- FRAME SYNCHRONIZER CONTROLER

- VIDEO FREEZE CONTROLER( FRAME , ODD , EVEN )

- AUTO VIDEO FREEZE CONTROLER

- STILL STORE CONTROLER

[FVH]

[VSD-RCTRL]

[VSD-DATA]

[VD-WCTRL]

[VD-DATA3]

[VSC-RCTRL]

[VSC-DATA]

[VC-WCTRL]

[VC-DATA3]

[VSB-RCTRL]

[VSB-DATA]

[VB-WCTRL]

[VB-DATA3]

[VSA-RCTRL]

[VSA-DATA]

[VA-WCTRL]

[VA-DATA3]

IC27

FRAME

FIFO

MEMORY

[ADM_CLK2]

[ADM_CTRL]

IC14, 15, 101

[CONFIG]

IC29

[JTAG_OUT]

[JTAG_IN]

CONFIG ROM

FRAME

FIFO

MEMORY

IC28

FRAME

FIFO

[SYS_CLK]

[SYS_CLK2]

MEMORY

X2

[DBG_CLK]

IC16, 17, 18, 19, 20, 21

SYSTEM CLOCK DRIVERS

[SYS_CLK_D]

[SYS_CLK2]

[SYS_CLK2]

[SYS_CLK2]

[SYS_CLK2]

FRAME

FIFO

MEMORY

IC30

[VB-CLK2]

[VA-DATA2]

[VA-CLK2]

IC6

[VA-DATA]

IC23

[VB-CLK]

[VB-EQ]

IC2

SDI Input B

IC22

IC22, 23, 24, 25 = CLOCK BUFFER ( PI6CV304 )

IC6, 8, 9, 10 = DATA BUFFER ( 74LVCH16245 )

[VA-CLK]

SDI INDEPENDENT CLOCK

QUAD DESERIALIZER

( CYV15G0404RB )

[VA-EQ]

Equalizer

( GS9064 )

IC1

SDI Input A

SDI Input

[VB-DATA2]

IC8

[VB-DATA]

IC5

[VC-CLK2]

IC24

[VC-CLK]

[VC-DATA2]

[VC-DATA]

[VC-EQ]

IC3

SDI Input C

= field pulse + vertical pulse + horizontal pulse[FVH]

= 27MHz SYSTEM CLOCK[SYS_CLK]

= 27MHz CLOCK ( DEBUG CLOCK )[DBG_CLK]

[VD-CLK2]

= 27MHz DIFFERENTIAL SYSTEM CLOCK [ delayed 0.87 - 1.695ns ][SYS_CLK_D]

= 27MHz SYSTEM CLOCK [ delayed 2.335 - 4.91ns ][SYS_CLK2]

= CPU_CHIPSELECT & CPU_READY[ADM_CTRL]

= FPGA CONFIG DATA[CONFIG]

= 33MHz CPU_DATA_CLK

= 33MHz CPU_DATA_CLK [ delayed 16ns ]

[ADM_CLK2]

[ADM_CLK]

[ADM_DATA] = 33MHz CPU_DATA

= JTAG TDO FOR CPU WRITE CONFIG ROM

= JTAG TDI & TMS FOR CPU WRITE CONFIG ROM

[JTAG_OUT]

[JTAG_IN]

[VD-DATA2]

[VD-CLK2]

IC9

IC25

[VD-CLK]

IC10

[VD-DATA]

[VD-EQ]

IC4

SDI Input D

[VA-CLK2]

= 27MHz PIX_CLK

= 270MHz DIFFERENTIAL (Equalizer out)

[V*-EQ]

[V*-CLK]

"*" is video channel name [ A, B, C, D ]

[VB-CLK2]

= 4BIT FRAME MEMORY WRITE CONTROL DATA (synchronus PIX_CLK)[V*-WCTRL]

= 27MHz 10BIT DESCRAMBLE VIDEO DATA (synchronus PIX_CLK)

= BUFFERED 27MHz 10BIT SCRAMBLE VIDEO DATA (synchronus PIX_CLK)

[ delayed 1-4ns ]

= 27MHz BUFFERED PIX_CLK [ delayed 1-3ns ][V*-CLK2]

= 27MHz 10BIT SCRAMBLE VIDEO DATA (synchronus PIX_CLK)

[V*-DATA]

[V*-DATA3]

[V*-DATA2]

[VC-CLK2]

= 162MHz DDR 5 pair video data 162MHZ1 pair clock + 1 pair frame[LVDS_DATA]

= 4BIT FRAME MEMORY READ CONTROL DATA (synchronus SYS_CLK)[VS*-RCTRL]

= 162MHz 1 pair frame[LVDS_FRM]

= 162MHz 1 pair clock[LVDS_CLK]

[VS*-DATA] = 27MHz 10BIT DESCRAMBLE VIDEO DATA (synchronus SYS_CLK)

20

Page 29

4-5. Function Block Diagram of BKDF-811 Board

CN8

DSP_DATA:32bit

SYSYEM_CLK

5pair

LVDS,162MHz

FPGA

VCC0

VCCAUX,VCC0

VCCINT

+3.3V

+2.5V

+1.2V_core

VA_FM_RD:10bit

IC27

MS81V26000-12TB

+3.3V +3.3V

VA_FM_WD:10bit

S_CLK

CH1

VA_FM_CLK

IC11

XC3S1500-4FGG456C

VB_FM_RD:10bit

VB_FM_WD:10bit

S_CLK

CH2

VB_FM_CLK

SDA,SCLK

IC28

MS81V26000-12TB

I2C BUS

DV_1:10bit

SDA,SCLK

+1.8V

+3.3V

ADV7189

DECORDER1

DV_2:10it

SDA,SCLK

+1.8V

+3.3V

ADV7189

DECORDER2

+1.8VA

+1.8VD

+2.5V+3.3VA

+5.0VA

Input Amp Filter

+5V

Input Amp Filter

-5V

+5V

Input Amp Filter

-5V

+5V

Input Amp Filter

-5V

+5V

-5V

+3.3VD

+1.2VCORE

-5.0VA

+5.2V

21

Page 30

4-6. Function Block Diagram of BKDF-840 Board

+5V

To Main Card

DC/DC P4

BSV-H

+5V to +1.5V

DC/DC P2

AXH005AOX

+5V to +2.5V

I/O POWER

(XILINX LVDS &

Configuration)

DC/DC P5

BSV-H

+5V to +3.3V

I/O & SRAM POWER

CORE POWER

*Write Only*

Transaction BUS

32bits 2.5V LVCMOS

VIDEO IN 17ch

LVDS 162MHz DDR

VIDEO OUT 4ch

LVDS 162MHz DDR

IC5 & IC7

Synchronous SRAM

Synchronous SRAM

CY7C1372D

Input DVE 16ch & Pre-Combiner

XC2VP30-5FF1152

IC1

CY7C1372D

IC6 & IC8

Synchronous SRAM

CY7C1372D

Synchronous SRAM

CY7C1372D

IC9 & IC11IC10 & IC12

JTAG CHAIN

for update FGPA data

REG IC21

Cofiguration ROM

XCF16VOG48

IC4

3.3V to 1.8V

to XCF16( IC4 )

CY7C1372D

IC18 & IC20

Synchronous SRAM

Synchronous SRAM

CY7C1372D

22

IC17 & IC19

Synchronous SRAM

CY7C1372D

IC14 & IC16

Synchronous SRAM

CY7C1372D

IC13 & IC15

Page 31

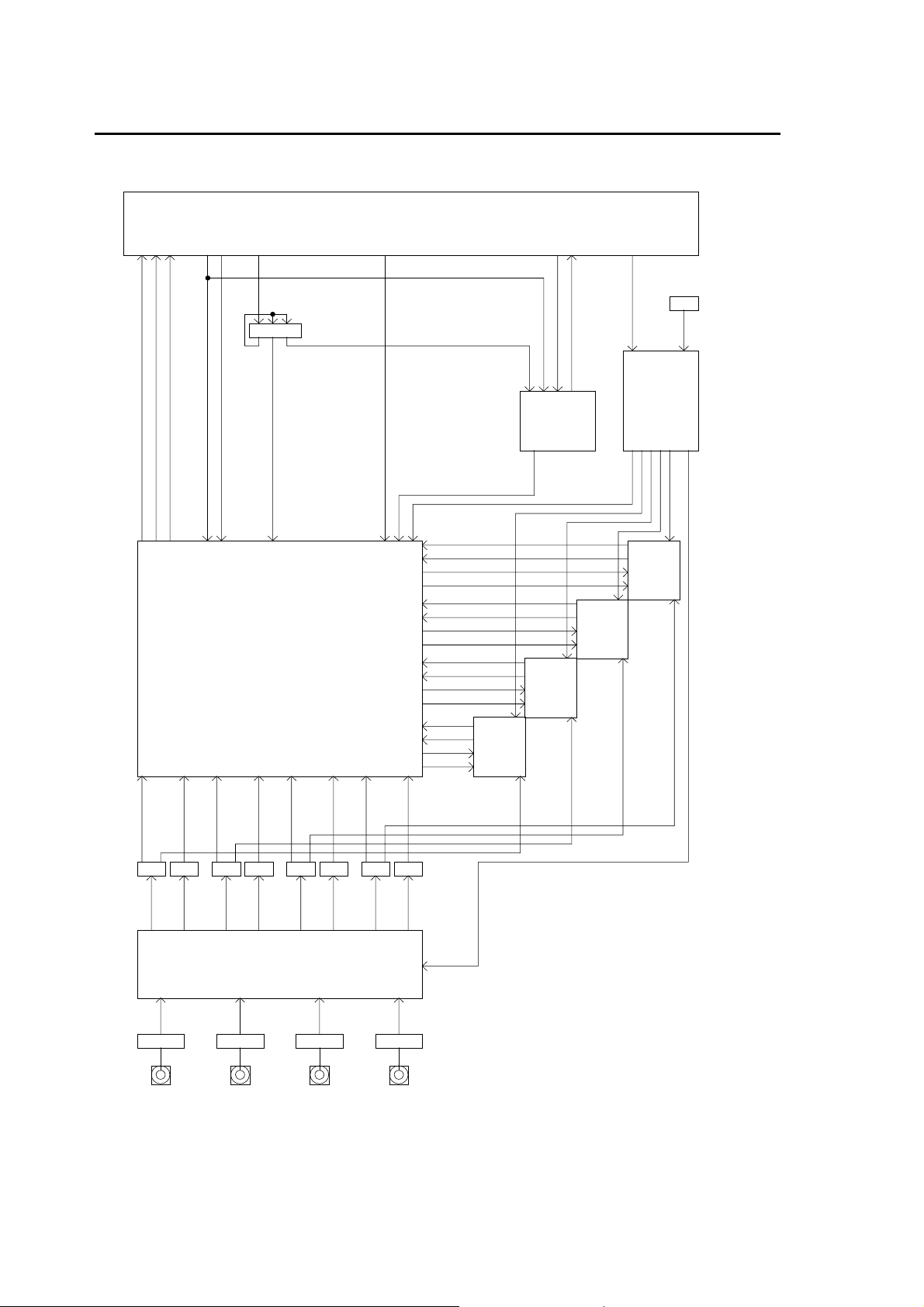

4-7. Function Block Diagram of BKDF-860 Board

IC14

GS9068

SDD_N

SDI_OUT4

+1.8VD_C

SDD_P

+3.3VD

IC12

GS9068

SDC_N

SDI_OUT3

SDC_P

NRST_AB,NCS_AB,SCLK_AB,SDIN_AB,

H-SYNC_AB,V-SYNC_AB,F-SYNC_AB,

FIFO-EN_AB

IC11

GS9092

IC10

GS9068

SDI_OUT2

+3.3VD

+1.8VD_A

IC8

GS9068

SDI_OUT1

SDA_P

SDA_N

IC7

GS9092

NRST_CD,NCS_CD,SCLK_CD,SDIN_CD,

H-SYNC_CD,V-SYNC_CD,F-SYNC_CD,

FIFO-EN_CD

+3.3VD

+3.3V_LVDS

+3.3VD

+1.8VD_D

IC3

DS90CR21BAMTD

VDD_:10bit

VDC_:10bit

DS1_N:4bit

DS1_P:4bit

IC13

GS9092

NRST_AB,NCS_AB,SCLK_AB,SDIN_AB,

H-SYNC_AB,V-SYNC_AB,F-SYNC_AB,

FIFO-EN_AB

IC1

DS90CR21BAMTD

+3.3V_LVDS

CN1

To Genlock Card

VDB_:10bit

VDA_:10bit

DS0_N:4bit

DS0_P:4bit

+5V

+3.3VD

+1.8VD_B

SDB_N

SDB_P

IC9

GS9092

NRST_CD,NCS_CD,SCLK_CD,SDIN_CD,

H-SYNC_CD,V-SYNC_CD,F-SYNC_CD,

FIFO-EN_CD

NRST_AB,NCS_AB,SCLK_AB,SDIN_AB,

H-SYNC_AB,V-SYNC_AB,F-SYNC_AB,

FIFO-EN_AB

IC2

LVCH16245

+3.3VD+3.3VD

ANRESET,ANCS,ASCLK,ASDIN,AMH-SYNC,

AMV-SYNC,AMF-SYNC,AFIFO-EN

+1.8V_C

+1.8VD +1.8VD

NRST_CD,NCS_CD,SCLK_CD,SDIN_CD,

H-SYNC_CD,V-SYNC_CD,F-SYNC_CD,

FIFO-EN_CD

+1.8VD

IC4

+3.3VD

L11

+1.8V_B

+1.8VD

+1.8V_A

+1.8VD

LP3965EMP

+3.3_LVDS

+3.3VD

+1.8V_D

SAGND_C

L12

L7

L3

L1

L8

L4

L2

L15

SAGND_B

SAGND_ALVDS_GND

SAGND_D

L16

23

Page 32

4-8. Function Block Diagram of BKDF-861 Board

Pb / G

Composite1 / Y / R

Pr / B

Composite2

AD8180

low pass filter

Video Encorder

CH1

Analog Devices

ADV7321

offset voltage

pedestal fix & low pass filter

cntroll signal (for video encorder & AD8180)

pedestal fix & low pass filter

10bits 27MHz

low pass filter

Video Encorder

CH1

Analog Devices

ADV7321

10bits 27MHz

I2C BUS

IC2

DS90CR218

LVDS 162MHz 4 paires 10 controll signals multiplexed

LVDS 162MHz 4paires 2 video channnel multiplexed

24

IC3

DS90CR218

+5.2V

+3.3V

+2.5V

LP3965EMP

LT1175

-6.0V

Page 33

5. Adjustment Procedure of Each Board

5-1. Adjustment of CPU Board

Default Setting of DIP switches and Jumpers on the BKDF-810 Board

SW1 ( Zone on board: J4 )

Setting at ex-factory

Depending on the option configuration, the setting differs.

In case of standard configuration ( without option ), all of bits are set to OFF.

Content of Setting

Referring to the table below, set to meet the option installation.

For location of each slot, refer to the figure on the next page.

SW No Content of Setting

1

2

3

4

5

6

7

8 OFF: Install nothing in the slot DS1.

ON: Install the BKDF-810 or BKDF-811 in the slot A.

OFF: Install nothing in the slot A.

ON: Install the BKDF-810 or BKDF-811 in the slot B.

OFF: Install nothing in the slot B.

ON: Install the BKDF-811 in the slot C.

OFF: Install nothing in the slot C.

ON: Install the BKDF-811 in the slot D.

OFF: Install nothing in the slot D.

ON: Install the BKDF-811 in the slot A.

OFF: Install the BKDF-810 or nothing in the slot A.

ON: Install the BKDF-811 in the slot B.

OFF: Install the BKDF-810 or nothing in the slot B.

ON: Install the BKDF-840 in the slot DS2.

OFF: Install nothing in the slot DS2.

SW1JP3 JP4 SW2

25

Page 34

DS1

Slot C

Slot A

Slot D

DS2

Slot B

SW2 ( Zone on board: N1 )

Setting at ex-factory

All of bits: OFF

Content of Setting

No need to change the setting. Use the factory setting as is.

JP3 ( Zone on board:E3 )

Setting at ex-factory

MAIN Board

Slot DS2

BKDF-840

1 2 3 4 5 6 7 8

Short-circuit pins 1 and 2 with jumper plug.

Content of Setting

No need to change the setting. Use the factory setting as is.

JP4 (Zone on board:L1)

Setting at ex-factory

Short-circuit pins 1 and 2 with jumper plug.

Content of Setting

No need to change the setting. Use the factory setting as is.

26

Page 35

5-2. Adjustment of MAIN Board

Default Setting of DIP switches on the MAIN Board

SW2 SW1

SW1 ( Zone on board:K1 )

Setting at ex-factory

ON: 1,2,3,8, OFF: 4,5,6,7

Content of Setting

No need to change the setting. Use the factory setting as is.

SW2 ( Zone on board:J1 )

Setting at ex-factory

ON: 1,2,3,8, OFF: 4,5,6,7

Content of Setting

No need to change the setting. Use the factory setting as is.

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

27

Page 36

5-3. Adjustment of GENLOCK Board

Default Setting of DIP switches on the GENLOCK Board ( E03012-1 and later )

S1 ( Zone on board: K2 )

Setting at ex-factory

ON: 3,4,5,6,7,8, OFF: 1,2

Content of Setting

No need to change the setting. Use the factory setting as is.

S2 ( Zone on board: N6 )

Setting at ex-factory

All of bits: OFF

Content of Setting

No need to change the setting. Use the factory setting as is.

S1 S2 S3

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

S3 ( Zone on board: W3 )

Setting at ex-factory

ON: 1,2,6,7, OFF: 3,4,5,8

Content of Setting

No need to change the setting. Use the factory setting as is.

28

1 2 3 4 5 6 7 8

Page 37

5-4. Adjustment of BKDF-810 Board

Default Setting of DIP switches on the BKDF-810 Board

S1 ( Zone on board: Q2 )

Setting at ex-factory

ON: 1,2,3,4, OFF: 5,6,7,8

Content of Setting

No need to change the setting. Use the factory setting as is.

S2 ( Zone on board: D1 )

Setting at ex-factory

ON: 2,3,4, OFF: 1,5,6,7,8

Content of Setting

No need to change the setting. Use the factory setting as is.

S1 S2

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

29

Page 38

5-5. Adjustment of BKDF-811 Board

Default Setting of DIP switch on the BKDF-811 Board

S1 ( Zone on board:P5 )

Setting at ex-factory

ON: 4, OFF: 1,2,3,5,6,7,8

Content of Setting

No need to change the setting. Use the factory setting as is.

S1

1 2 3

4 5 6

7

8

ON

30

Page 39

5-6. Adjustment of BKDF-840 Board

Default Setting of DIP switch on the BKDF-840 Board

SW1

SW1 ( Zone on board: B7 )

Setting at ex-factory

ON: 1,2,3,8, OFF: 4,5,6,7

Content of Setting

No need to change the setting. Use the factory setting as is.

1 2 3 4 5 6 7 8

31

Page 40

5-7. Adjustment of BKDF-860 Board

No setting item

5-8. Adjustment of BKDF-861 Board

No setting item

32

Page 41

w

6. Method of Board Replacement/Addition

6-1. Removal/Installation of Shield Plate

In this section, the method of removal and installation of shield plate required when replacing/adding

each board is explained.

6-1-1. Removal of Shield Plate

1) Referring to the figure below, unscrew four screws ( 3×6mm ) and remove the retainer fixing

the board in the slot.

DFS-800 Rear Panel

1

2

3

4

2) Remove the shield plate from the slot where the target board is installed.

From top to bottom, slots are named 1 to 4. For board in each slot, refer to the table below.

When removing the shield plate, widen the black handles and draw the shield plate toward you.

Screw Scre

G

P

M

P

2

1

M

G

P

E

R

V

L

C

A

N

V

I

D

E

O

O

U

T

1

V

I

D

E

O

I

N

E

3

4

2

2

A

X

U

A

1

5

A

U

X

U

A

3

X

U

4

X

8

6

7

1

N

O

K

C

N

B

E

O

B

G

I

L

1

2

3

2

4

T

U

U

O

T

O

Retainer Retainer

Slot Board

Slot 1 GENLOCK, BKDF-860, BKDF-861

Slot 2 MAIN, BKDF-840

Slot 3 BKDF-810, BKDF-811

Slot 4 CPU, BKDF-811

1

E

R

O

M

T

S

E

R

4

2

2

-

1

T

2

E

R

O

I

D

2

3

4

0

H

/

6

I

z

0

N

5

V

0

0

-

C

1

2

4

0

A

33

Page 42

r

r

6-1-2. Installation of Shield Plate

1) Return the shield plate to the original slot. When returning the shield plate, hook the claws of

black handles to the unit and turn the handles inwards.

2) Install the retainers removed in [ 6-1-1. Removal of Shield Plate ] and tighten them with screws.

Screw Screw

E

R

E

X

M

G

P

V

I

D

E

O

O

U

T

1

V

I

D

E

O

I

N

Retaine

P

V

2

1

M

G

P

3

2

U

A

X

U

L

C

4

A

A

N

1

5

4

X

2

A

A

U

3

X

U

7

8

6

1

N

T

K

C

N

B

E

O

B

G

I

O

L

U

2

1

2

3

4

U

O

T

O

Retaine

1

R

2

3

4

S

E

R

O

4

M

E

2

2

-

T

R

O

I

D

T

2

E

1

0

H

V

/

6

I

z

0

0

-

N

5

2

4

0

0

C

1

A

Caution

When installing the shield plates of slot 1 and slot 2, they may not be installed.

In this case, refer to [ 6-1-3. Caution on Insertion of Shield Plate ] and install them

34

Page 43

6-1-3. Caution on Insertion of Shield Plate

Shield Plate of Slot1

When removing the shield plate of slot 1 alone and returning it in the original slot, the shield plate

may not be inserted.

In this case, insert it in the following procedure.

1) Remove the shield plate of slot 2.

With this, the pressure to the shield plate of slot 1 from the bottom is released.

2) Loosen the screw fixing the top cover.

With this, the top cover can be lifted upward.

3) While holding down the shield plate of slot 1 from the top, insert it.

4) Tighten the screw fixing the top cover.

Screw

Shield Plate of Slot 2

When the BKDF-840 board is already installed, if the shield plate of slot 2 is inserted, the heat sink

on the BKDF-840 board may touch the shield plate of slot 1.

In this case, lift the shield plate of slot 1 and insert the shield plate of slot 2.

Lift up the slot 1.

Slot 1

Slot 2

Insert the shield plate.

35

Page 44

6-2. Replacement of CPU Board

Install the CPU board in the 4th slot of DFS-800 from the top. To install the CPU board, remove the

shield plate of slot 4 from the rear of DFS-800 and insert the CPU board in the slot.

For removal and installation of shield plate, refer to [ 6-1. Removal/Installation of Shield Plate ].

6-2-1. Removal of CPU Board

1) Referring to the figure below, unscrew 4 screws fixing the CPU board to the shield palte.

( W SEMS screw 3×6mm 4 locations )

2) Unscrew one screw fixing the shield plate and BNC connector.

( Binding screw 2.6×6mm 1 location )

3) While sliding the CPU board, remove the CPU board from the shield plate

36

Page 45

6-2-2. Installation of CPU Board

1) Install the CPU board, aligning the BNC connector of CPU board with the hole on the shield

plate.

2) Fix the shield plate and BNC connector with the binding screw ( 2.6×6mm ).

3) Fix the CPU board to the shield plate with four W SEMS screws ( 3×6mm ).

6-2-3. Setting

Referring to [ 5-1. Adjustment of CPU board ], set the DIP switch to meet the option configuration.

37

Page 46

6-3. Replacement of MAIN Board

Install the MAIN board in the 2nd slot of DFS-800 from the top. To install the MAIN board, remove

the shield plate of slot 2 from the rear of DFS-800 and insert the MAIN board in the slot.

For removal and installation of shield plate, refer to [ 6-1. Removal/Installation of Shield Plate ].

6-3-1. Removal of MAIN Board

1) Referring to the figure below, unscrew 6 screws fixing the Main board to the shield palte.

( W SEMS screw 3×6mm 6 locations )

2) If the BKDF-840 is installed, remove the MAIN board from the shield plate, sliding the MAIN

board.

MAIN CARD

Slot 2

BKDF-840

38

Page 47

6-3-2. Installation of MAIN Board

1) Before installing the board, check the DIP switch setting. Referring to [ 5-2. Adjustment of

MAIN Board ], set the DIP switch.

2) Aligning the screw holes with the screw holes on the shield plate, install the MAIN board.

If the BKDF-840 board is installed, slide the MAIN board and connect the connector.

3) Fix the MAIN board to the shield plate with six W SEMS screws ( 3×6mm ).

MAIN CARD

Slot 2

BKDF-840

39

Page 48

6-4. Replacement of GENLOCK Board

Install the GENLOCK board in the 1st slot of DFS-800 from the top. To install the GENLOCK board,

remove the shield plate of slot 1 from the rear of DFS-800 and insert the GENLOCK board in the

slot.

For removal and installation of shield plate, refer to [ 6-1. Removal/Installation of Shield Plate ].

6-4-1. Removal of GENLOCK Board

1) Referring to the figure below, unscrew six screws fixing the GENLOCK board to

the shield plate. ( 3×6mm W SEMS screw 6 locations )

2) Referring to the figure below, remove the GENLOCK board from the shield plate while

sliding slowly the GENLOCK board. Finally remove the he GENLOCK board completely.

Do not remove the GENLOCK board and option board together. When removing, the

Caution

Protrusion

strong force is required and the GENLOCK board is suddenly removed. At this

moment, The components mounted on the back side of board may hit the

protorusions, resulting in damage.

GENLOCK Board

Protrusion

Shied plate

40

Page 49

6-4-2. Installation of GENLOCK Board

1) Before installing the board, check the DIP switch setting. Referring to [ 5-3. Adjustment of

GENLOCK Board ], set the DIP switch.

2) Sliding the GENLOCK board with caution, install the GENLOCK board to the shield plate.

Engage the GENLOCK board firmly.

3) Fix the GENLOCK board to the shield plate with 6 screws ( 3×6mm W SEMS ) removed in

[ 6-4-1. Removal of GENLOCK Board ].

GENLOCK CD

Shield Plate

41

Page 50

6-5. Replacement/Addition of BKDF-810 Board

Install the BKDF-810 board in the 3rd slot of DFS-800 from the top. To install the GENLOCK board,

remove the shield plate of slot 3 from the rear of DFS-800 and insert the BKDF-810 board in the

slot.

For removal and installation of shield plate, refer to [ 6-1. Removal/Installation of Shield Plate ].

6-5-1. To Begin with

For input board of DFS-800, the BKDF-810 and BKDF-811 can be used. Refer to the

combination list of input board and installation slocation below and install the board in the

appropriate slot. After changing the configuration, be sure to set the DIP switch.

Combination List of Input Board and Installation Location

BKDF-810

BKDF-810

BKDF-810

BKDF-810

BKDF-810

BKDF-810

BKDF-810

BKDF-810

BKDF-810

Slot S

Slot C

Slot S'

Slot D

Slot A Slot B

DFS-800 Rear Location of Slot

Slot

Standard Option

S S' A B C D Digital Analog To tal

( 1-4 )

( 1-4 )

( 1-4 )

( 1-4 )

( 1-4 )

( 1-4 )

( 1-4 )

( 1-4 )

( 1-4 )

BKDF-810

( 5-8 )

BKDF-810

( 5-8 )

BKDF-810

( 5-8 )

BKDF-810

( 5-8 )

BKDF-810

( 5-8 )

BKDF-810

( 5-8 )

BKDF-810

( 5-8 )

BKDF-810

( 5-8 )

BKDF-810

( 5-8 )

- - - - SDI x 8 AI x 0 8

BKDF-811

( 9,10 )

BKDF-811

( 9,10 )

BKDF-811

( 9,10 )

BKDF-811

( 9,10 )

BKDF-810

( 9-12 )

BKDF-810

( 9-12 )

BKDF-810

( 9-12 )

BKDF-810

( 9-12 )

- - - SDI x 8 AI x 2 10

BKDF-811

( 11,12 )

BKDF-811

( 11,12 )

BKDF-811

( 11,12 )

- - - SDI x 12 AI x 0 12

-

-

BKDF-810

( 13-16 )

- - SDI x 8 AI x 4 12

BKDF-811

( 13,14 )

BKDF-811

( 13,14 )

BKDF-811

( 13,14 )

BKDF-811

( 13,14 )

- - SDI x 16 AI x 0 16

- SDI x 8 AI x 6 14

BKDF-811

( 15,16 )

- SDI x 12 AI x 2 14

BKDF-811

( 15,16 )

Number of input

SDI x 8 AI x 8 16

SDI x 12 AI x 4 16

42

Page 51

6-5-2. Removal of BKDF-810 Board

1) Referring to the figure below, unscrew 4 screws fixing the BKDF-810 board to the shield plate.

( W SEMS screw 3×6mm 4 locations )

2) Unscrew 4 screws fixing the shield plate and BNC connector.

( Binding screw 2.6×6mm 4 locations )

3) Sliding the BKDF-810 board, remove the BKDF-810 board from the shield plate.

43

Page 52

6-5-3. Installation of BKDF-810 Board

1) Before installing the board, check the DIP switch setting. Referring to [ 5-4. Adjustment of

BKDF-810 Board ], set the DIP switch.

2) Referring to the combination list on page 42, confirm the slot to be installed.

3) When installing newly the BKDF-810 board, unscrew 2 screws (3x6mm ) at both sides of blank

panel on the rear panel of shield plate and remove the blank panel.

4) Aligning the holes on the shield plate with BNC connectors on the BKDF-810 board, install the

BKDF-810 board. First, fix the shield plate and BNC connectors with 4 binding screws

(2.6×6mm). At this moment, be careful not to dislocate the screw holes.

5) Fix the BKDF-810 board to the shield plate with 4 W SEMS screws ( 3×6mm ).

44

Page 53

6-5-4. Setting and Confirmation of Operation

Referring to [ 5-1. Adjustment of CPU Board ], set SW1 to meet the input board configuration.

Turn on the power and display [ STATUS ]. Then, confirm that the BKDF-810 board is recognized.

And confirm that the input extended can be selected.

45

Page 54

6-6. Replacement/Addition of BKDF-811

Install the BKDF-811 board in the 3rd slot or 4th slot of DFS-800 from the top. To install the

BKDF-811 board, remove the shield plate of slot 3 or slot 4 from the rear of DFS-800 and insert the

BKDF-811 board in the slot.

For removal and installation of shield plate, refer to [ 6-1. Removal/Installation of Shield Plate ].

6-6-1. To Begin with

For input board of DFS-800, the BKDF-810 and BKDF-811 can be used. Refer to the

combination list of input board and installation slot on page 42, and install the board in the

appropriate slot. After changing the configuration, be sure to set the setting of DIP switch on the

CPU board.

When using two composite inputs of the analog input board, use two connectors at both ends.

When using Y, B-Y, R-Y, use three connectors from the left side. The type of signal is displayed

on the ornamental panel.

46

Page 55

Y

6-6-2. Removal of BKDF-811 Board

1) Referring to the figure below, unscrew four screws fixing the BKDF-811 board to the shield

plate. ( W SEMS screw 3×6mm 4 locations )

2) Unscrew four screws fixing the shield plte and BNC connector.

( Binding screw 2.6×6mm 4 locations )

3) Sliding the BKDF-811 board, remove the BKDF-811 board from the shield plate.

Ornamental Panel

COMP/Y B-

R-Y COMP

47

Page 56

6-6-3. Installation of BKDF-811 Board

1) Before installing the BKDF-811 board, check the DIP switch setting.

Referring to [ 5-5. Adjustment of BKDF-811 Board ], set the DIP switch.

2) Referring to the combination list on page 42, confirm the slot to be installed.

3) Affix the input number seal to the ornamental panel to identify the input number to be extended.

Example: In case of installing the analog input board to In09 and In10

COMP/Y B-Y R-Y COMP

9 10

4) When adding newly the BKDF-811 board, unscrew two screw ( 3 x 6mm ) at both side of blank

panel on the rear of shield panel and remove the blank panel.

48

Page 57

5) Aligning the holes on the shield plate with the BNC connectors on the analog input board,

install the BKDF-811 board. First, fix the shield plate and BNC connectors with four binding

screws ( 2.6×6mm ). At this moment, be careful not to dislocate the screw holes on the board.

Ornamental panel

6) Fix the board to the shield plate with four W SEMS screws ( 3×6mm ).

Installation in slot 3

COMP/Y B-Y R-Y COMP

COMP/Y B-Y R-Y COMP

Installation in slot 4

6-6-4. Setting and Confirmation of Operation

Referring to [ 5-1.Adjustment of CPU Board ], set the DIP switch SW1 to meet the

configuration of input board.

Turn on the power and disply [ STATUS ]. Then, confirm that the BKDF-811 board is

recognized. And confirm that the input extended can be selected.

49

Page 58

r

r

6-7. Replacement/Addition of BKDF-840

Install the BKDF-840 board in the 2nd slot ( slot 2 ) of DFS-800 from the top. To install the

BKDF-840 board, remove the shield plate of slot 2 from the rear of DFS-800 and install the

BKDF-840 board in the slot.

For removal/installation of shield plate, refer to [ 6-1. Removal/Installation of Shield Plate ].

6-7-1. Removal of BKDF-840 Board