Sony DES-51 Service manual

D-ES51/ES55

SERVICE MANUAL

Ver 1.1 1998. 07

Photo: D-ES55

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-2801AAA

Optical Pick-Up Name DAX-01A2

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of 200 mm from the

objective lens surface on the optial pick-up block with 7 mm

aperture.)

Error correction

Sony Super Strategy Cross Interleave Reed Solomon Code

D-A conversion

1-bit quartz time-axis control

Frequency response

20 – 20,000 Hz dB (measured by EIAJ CP-307)

Output (at 4.5 V input level)

Headphones (stereo minijack)

15 mW + 15 mW at 16 ohms

+1

–2

General

Power requirements

For the area code of the model you purchased, check the upper left

side of the bar code on the package.

• Sony BP-DM10 Rechargeable battery:

2.4 V DC, Ni-Cd, 650 mAh

• Two LR6 (size AA) batteries: 3 V DC

• AC power adaptor (DC IN 4.5 V jack):

US, Canadian, E92 model: 120 V, 60 Hz

AEP, French, E13 model: 220 – 230 V, 50/60 Hz

UK model: 230 – 240 V, 50 Hz

Australian model: 240 V, 50 Hz

Dimensions (w/h/d) (without projecting parts and controls)

Approx. 138.3 × 34.3 × 145.8 mm

(51/2 × 13/8 × 53/4 in.)

Mass (without rechargeable batteries)

Approx. 312 g (11.1oz)

Operating temperature

5˚C – 35˚C (41˚F – 95˚F)

— Continued on next page —

MICROFILM

COMPACT DISC COMPACT PLAYER

Supplied accessories

For the area code of the model you purchased, check the upper left side

of the bar code on the package.

D-ES51

AC power adaptor (1)

AC plug adaptor (1)*

Stereo headphones (1)

* Supplied with E13 model

D-ES55

AC power adaptor (1)

AC plug adaptor (1)*

Stereo headphones (1)

Rechargeable batteries (1)**

* Supplied with E13 model

**Supplied with US model only

Design and specifications are subject to change without notice.

• Abbreviation

E13: 220 – 230 V AC area

E92: 120 V AC area

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY ......................................................... 7

4. SERVICE MODE...................................................... 10

5. ELECTRICAL ADJUSTMENTS......................... 11

6. DIAGRAMS

6-1. Block Diagram ................................................................ 13

6-2. Printed Wiring Boards .................................................... 17

6-3. Schematic Diagram ......................................................... 21

6-4. IC Pin Function Description ........................................... 33

7. EXPLODED VIEWS ................................................ 35

8. ELECTRICAL PARTS LIST ............................... 38

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

– 2 –

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Befor Replacing the Optical Pick-Up Block

Please be sure to check thoroughly the parameters as par the “Optical Pick-Up Block Checking Procedures” (Part No.: 9-960-027-

11) issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

• FOK output: IC501 !™ pin

When checking FOK, remov the lead wire to disc motor.

• S curve P-to-P value: 0.6 - 1.8 Vp-p IC501 #¡ pin

When checking S curve P-to-P value, remove the lead wire to

disc motor.

• RF signal P-to-P value: 0.8 - 1.2 Vp-p

• Traverse signal P-to-P value: 1.2 Vp-p

• The repairing grating holder is impossible.

Precautions for Checking Emission of Laser Diode

Laser light of the equipment is focused by the object lens in the

optical pick-up so that the light focuses on the reflection surface

of the disc. Therefore, be sure to keep your eyes more then 30 cm

apart from the object lens when you check the emission of laser

diode.

Laser Diode Checking Methods

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper panel is closed while turning

ON the S801 (push switch type).

The following two checking methods for the laser diode are operable.

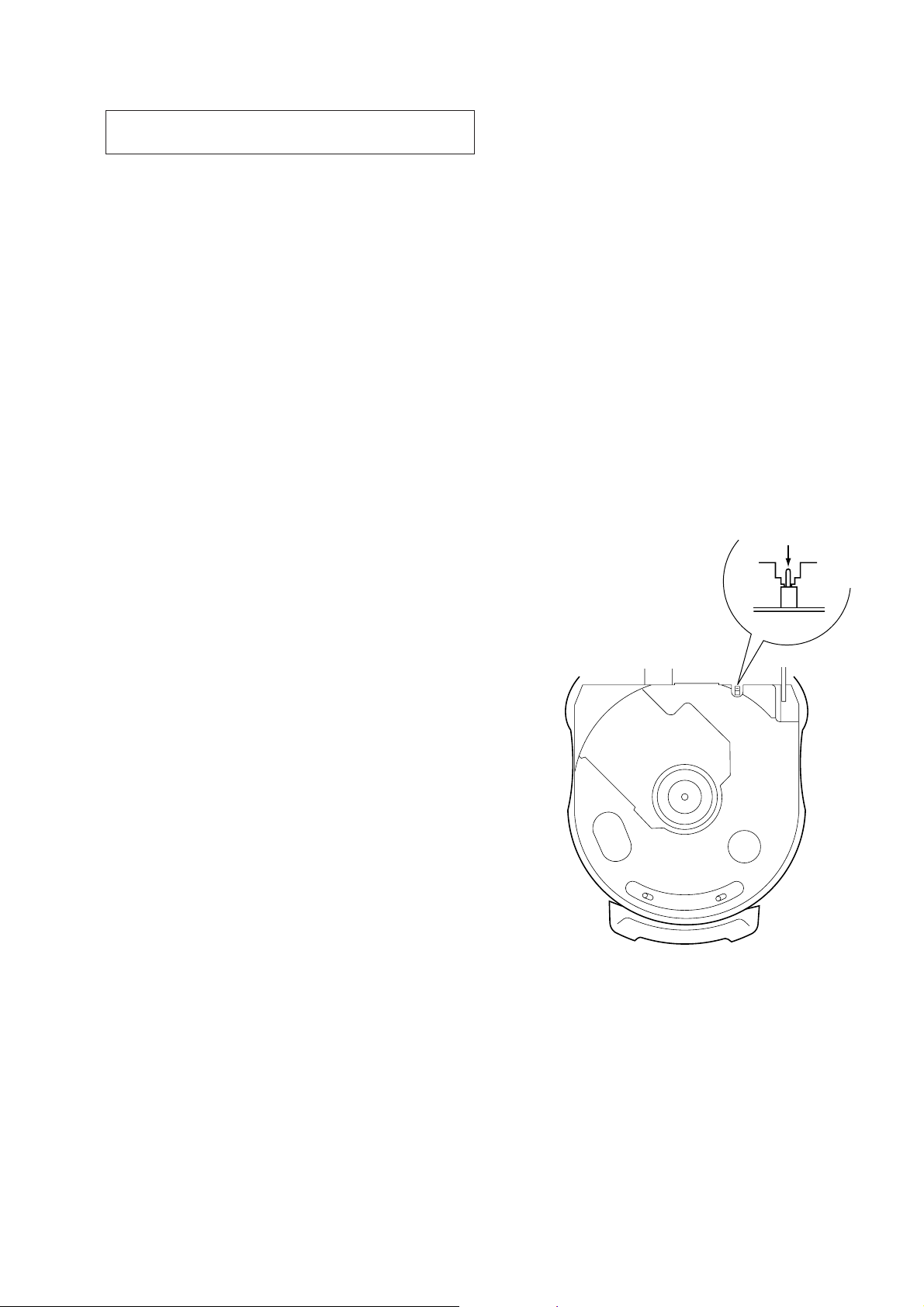

• Method (In the service mode or normal operation):

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. Push the S801 as shown in Fig. 1.

3. Press the ^ key.

4. Check the object lens for confirming normal emission of the

laser diode. If not emitting, there is a trouble in the automatic

power control circuit or the optical pick-up.

During normal operation, the laser diode is turned ON about

2.5 seconds for focus searching.

S801

– 3 –

Fig. 1 Method to push the S801

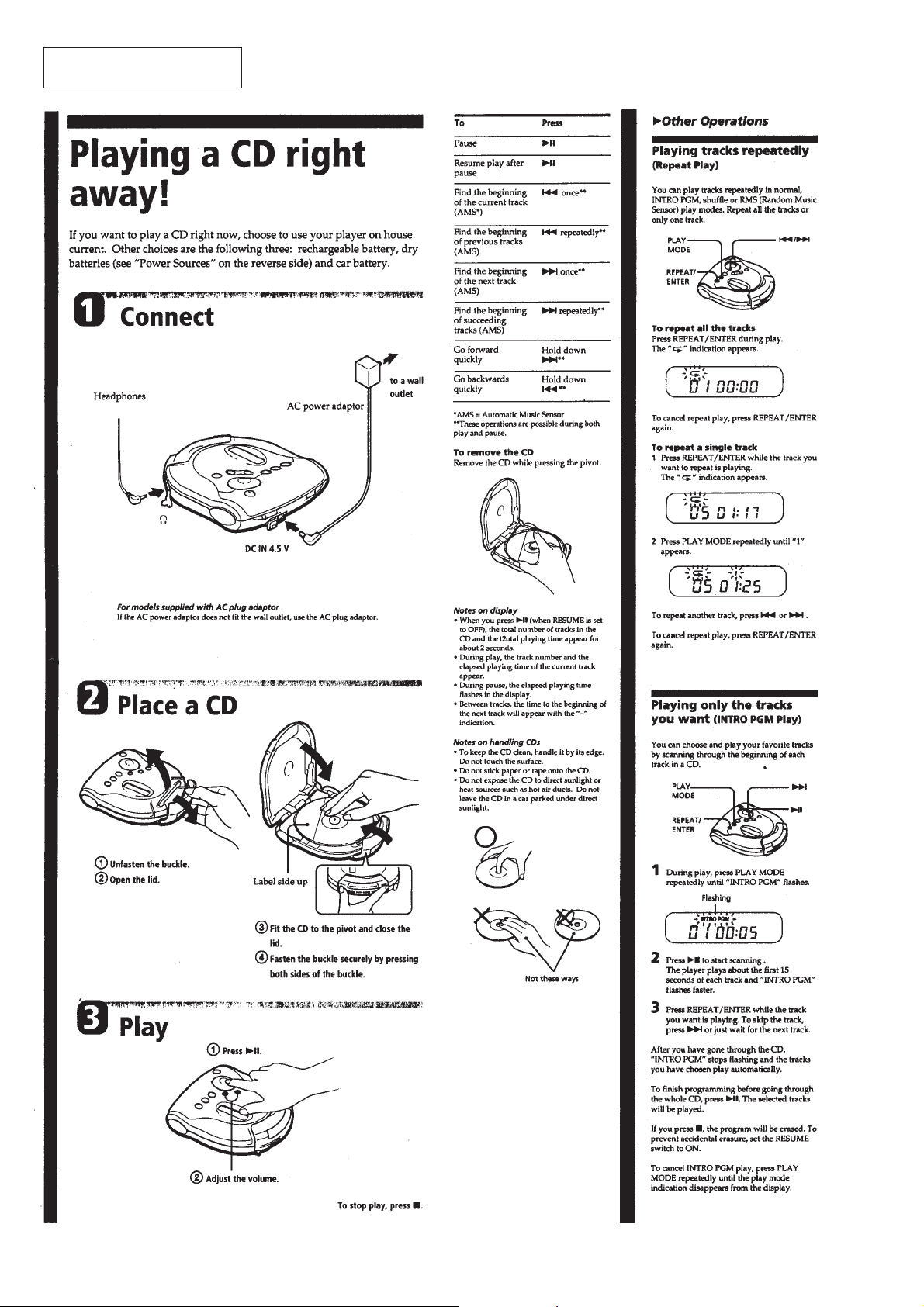

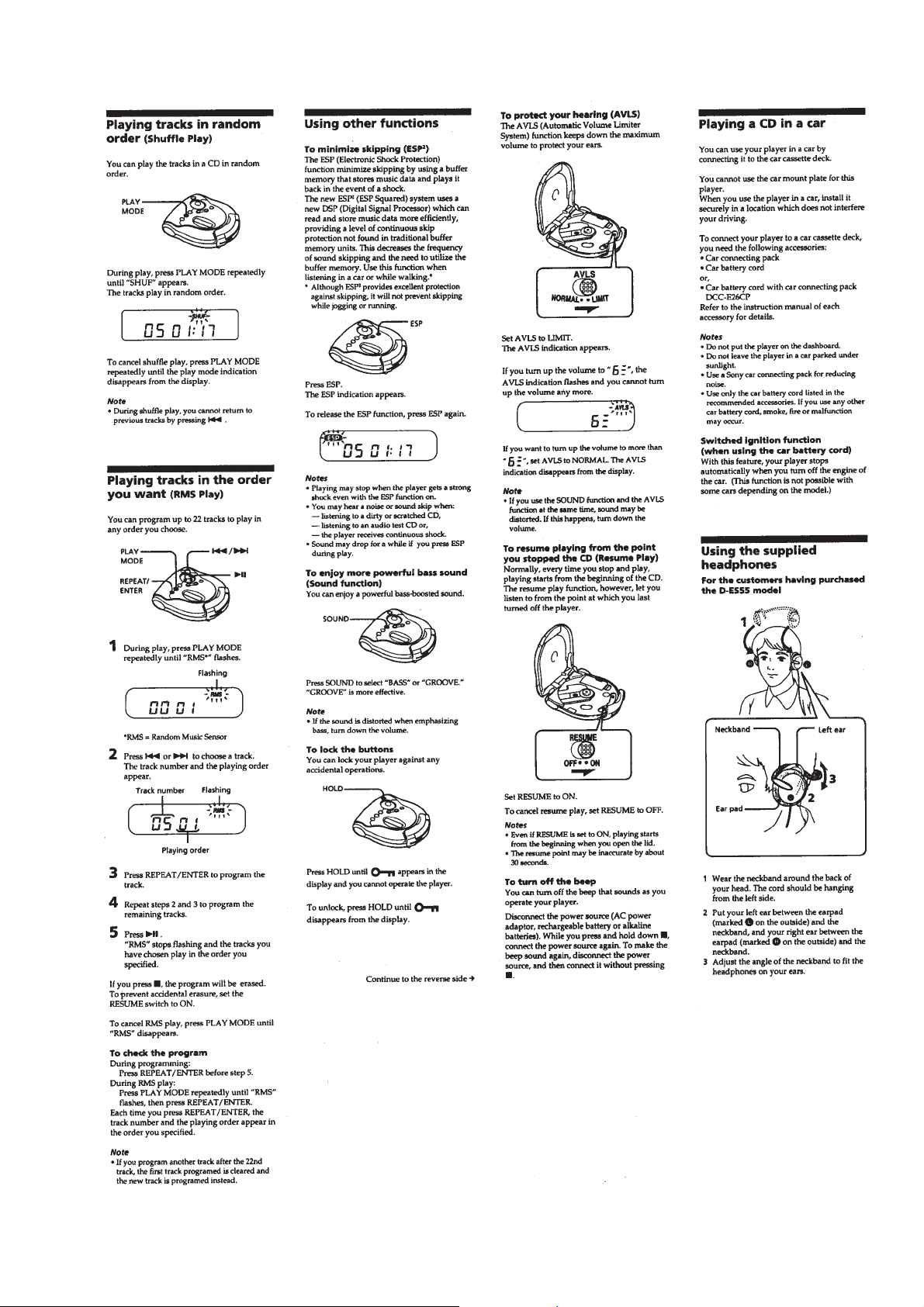

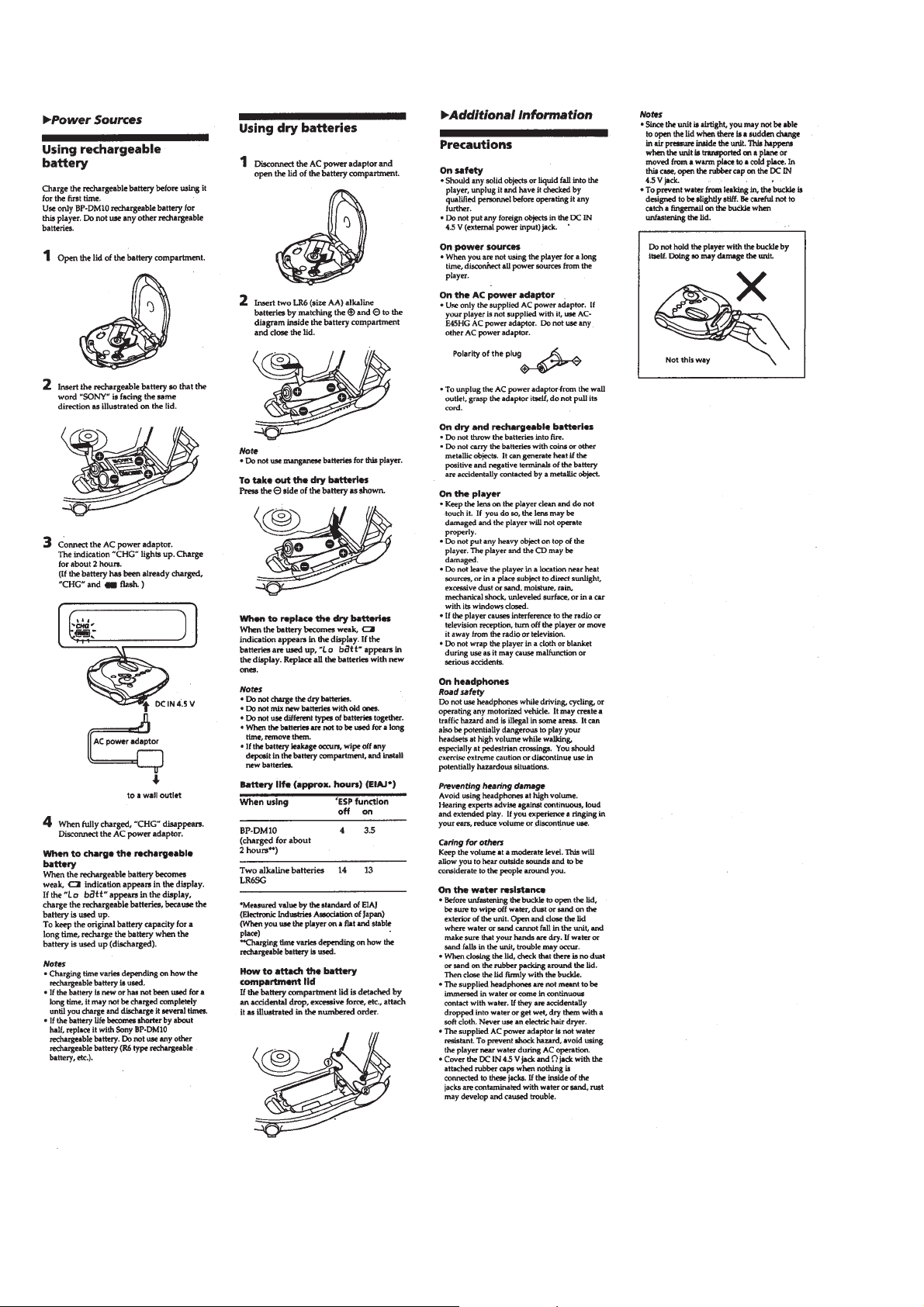

This section is extracted from

instruction manual.

SECTION 2

GENERAL

– 4 –

– 5 –

– 6 –

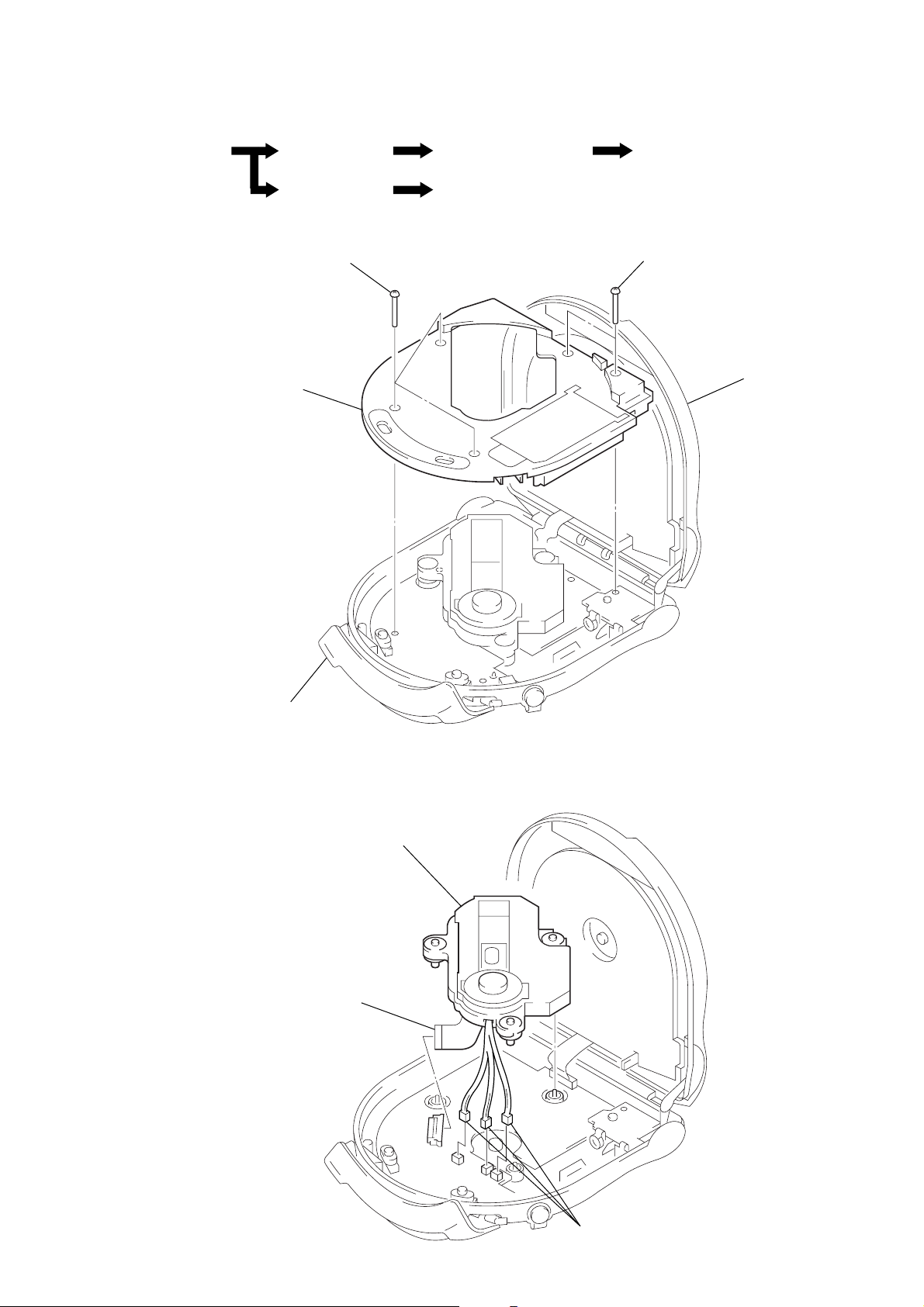

DISASSEMBLY

• This set can be disassembled in the order shown below.

SECTION 3

SET CHASSIS ASS’Y

SWITCH UNIT

Note: Follow the disassembly procedure in the numerical order given.

3

CHASSIS ASS’Y

4

chassis ass’y

three screws

CD MECHANISM DECK

(CDM-2801AAA)

UPPER LID ASS’Y

MAIN/POWER BOARD

3

two screws

2

Open the upper lid.

1

Open the buckle.

CD MECHANISM DECK

(CDM-2801AAA)

2

slide flexible board

(CN501)

3

CD mechanism deck

(CDM-2801AAA)

– 7 –

1

three connectors

(CN503-505)

MAIN / POWER BOARD

d

6

two knobs (AVLS)

7

MAIN board

4

flexible board

(CN801)

1

connector

(CN401)

2

screw

(B2)

3

POWER board

SWITCH UNIT

1

three screws

(B1.7)

2

cover (upper lid)

3

switch unit

5

Open the HP jack packing.

4

flexible boar

1

four screws

(B1.7)

– 8 –

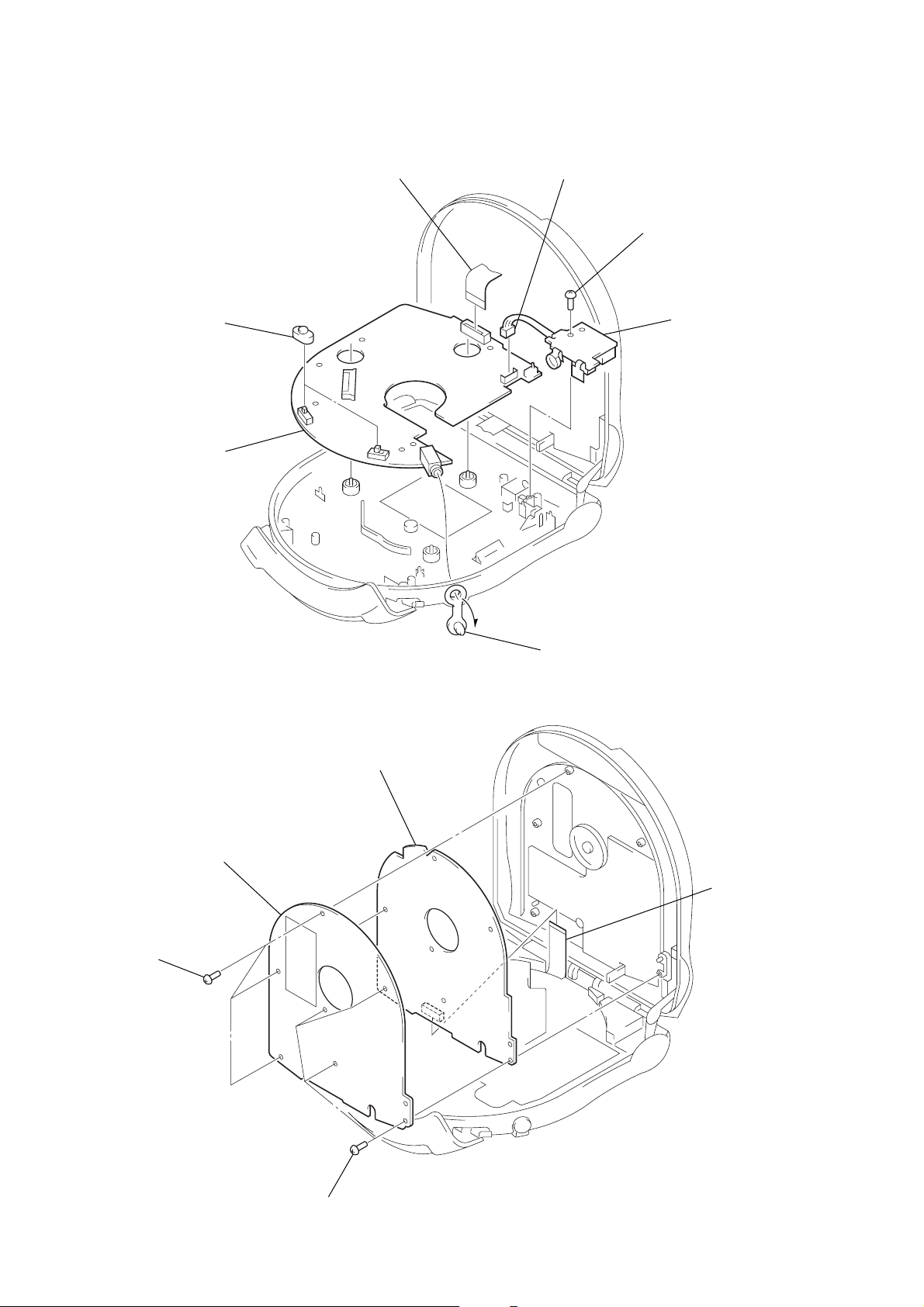

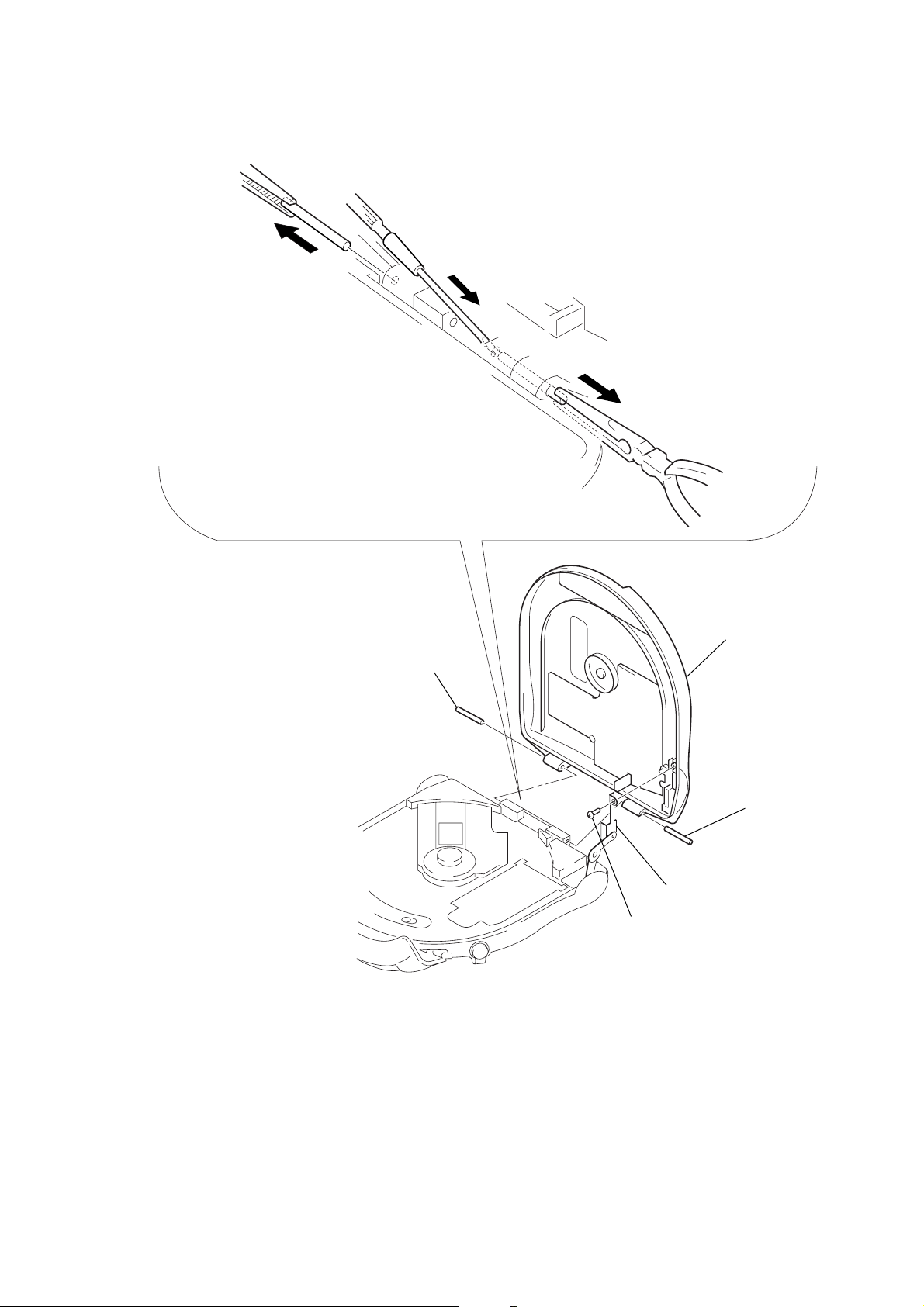

UPPER LID ASS’Y

5

Pull the shaft out through

3

and 4.

steps

3

Push the end face of shaft using

a precision screwdriver, etc.

4

When the shaft edge comes out,

pull it out with long-nose pliers, etc.

shaft

1

2

screw

(B2)

6

upper lid ass’y

shaft

click arm ass’y

– 9 –

SECTION 4

SERVICE MODE

Service Mode (Service program)

The equipment is provided with a service program built in the

microcomputer, like conventional models.

Service program operation methods are described in the following.

p

(STOP)

All servos are turned OFF

=

(FR)

The optical pick-up

is moved inwardly

HOLD OFF → ON

Be sure to turn OFF

the HOLD switch

(If ON, all the LCD

indication and

LED are light up)

+

(FF)

The optical pick-up

is moved outwardly

^

(PLAY/PAUSE)

Focus is tuned ON to

effect draw-in mode

4. By pressing the ^ key , focus is turned ON from focus searching while entering CLV-S (draw-in mode).

Without disc, focus searching is repeated continuously.

5. By pressing the PLAY MODE key, tracking servo, sled servo

and CLV-A (servo in PLAY) are turned ON.

6. When 4. an 5. are performed, playing begins. No muting is

ON in the service mode.

7. By pressing the p key, all servos (focus, tracking and sled)

are turned OFF . Ho we ver, the disc motor revolv es for a while

by inertia.

• Step 3 (Resetting of service mode)

1. Be sure to disconnect the external power supply and remove

the solder bridge at the TEST terminals connected before in

setting.

2. The set thus becomes available for normal operation.

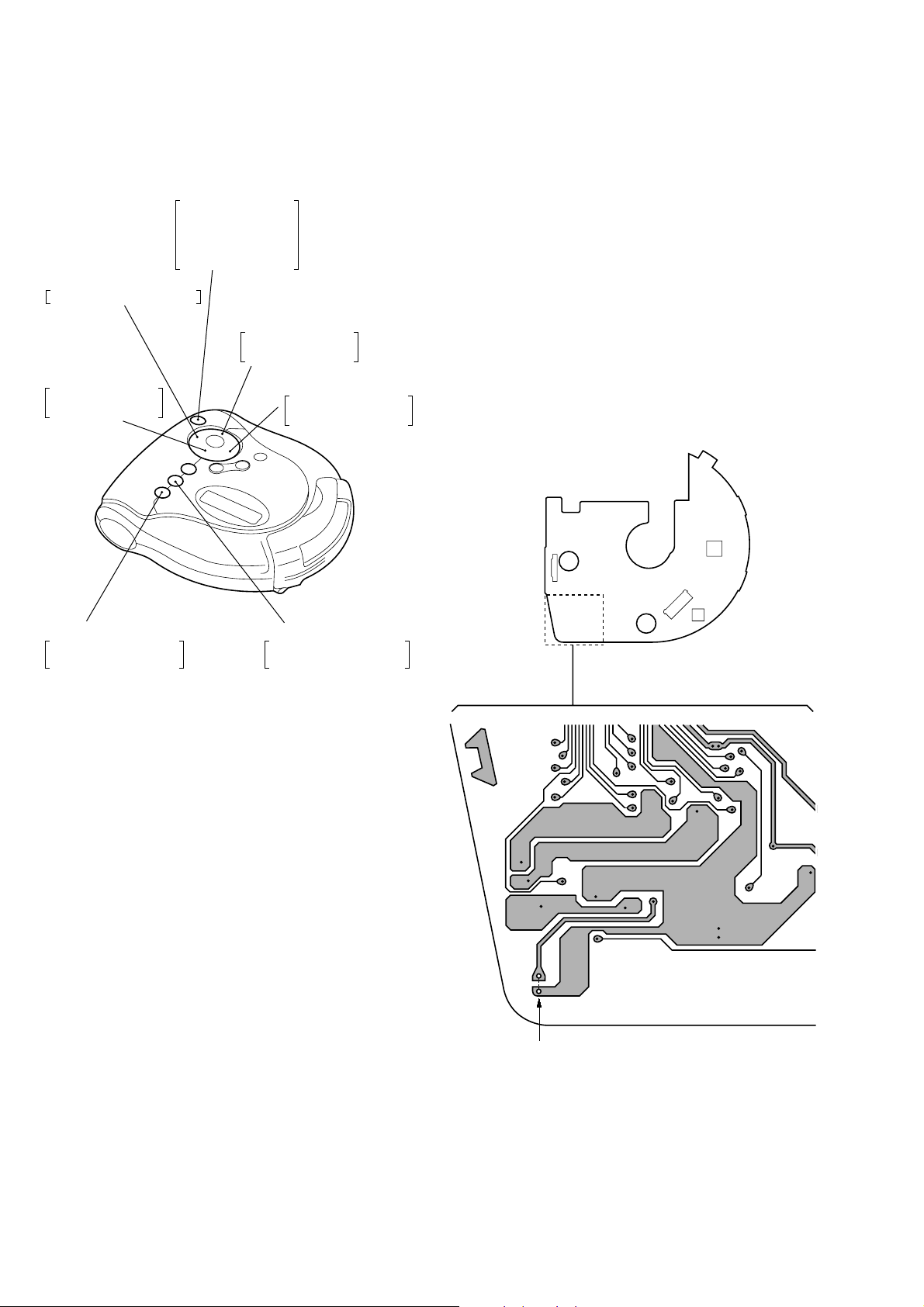

– MAIN BOARD – (Side A)

REPEAT/ENTER

Tracking gain-up mode

while pressing

PLAY MODE

Tracking servo and sled

servo are turned ON

Descriptions in [ ] indicate major operations in the service

mode. For more information, see Step 2.

Fig. 1 Layout of each key

• Step 1 (Service mode setting methods)

1. Turn OFF the HOLD switch with external power supply disconnected (power is not applied to the set).

2. Solder across the TEST terminals (TAP807) (pin %¢, IC801

(TEST) is grounded).

3. Connect an external power supply.

Thus, the set is switched to the service mode.

• Step 2 (Operation in the service mode)

1. Once the service mode is effected, the LCD displays 5 indications each of which is repeatedly displayed.

However, the following operations can be activated even if

LCD indication is effected.

2. By pressing the + or = key, the optical pick-up is movable inwardly or outwardly . Howev er, if this is acti vated, tracking servo and sled servo are turned OFF, so it can be turned

ON by pressing the PLAY MODE key if required.

3. By pressing the REPEAT/ENTER key, the tracking gain-up

mode becomes active.

TAP807

(TEST)

Fig. 2 Location of Test terminal

– 10 –

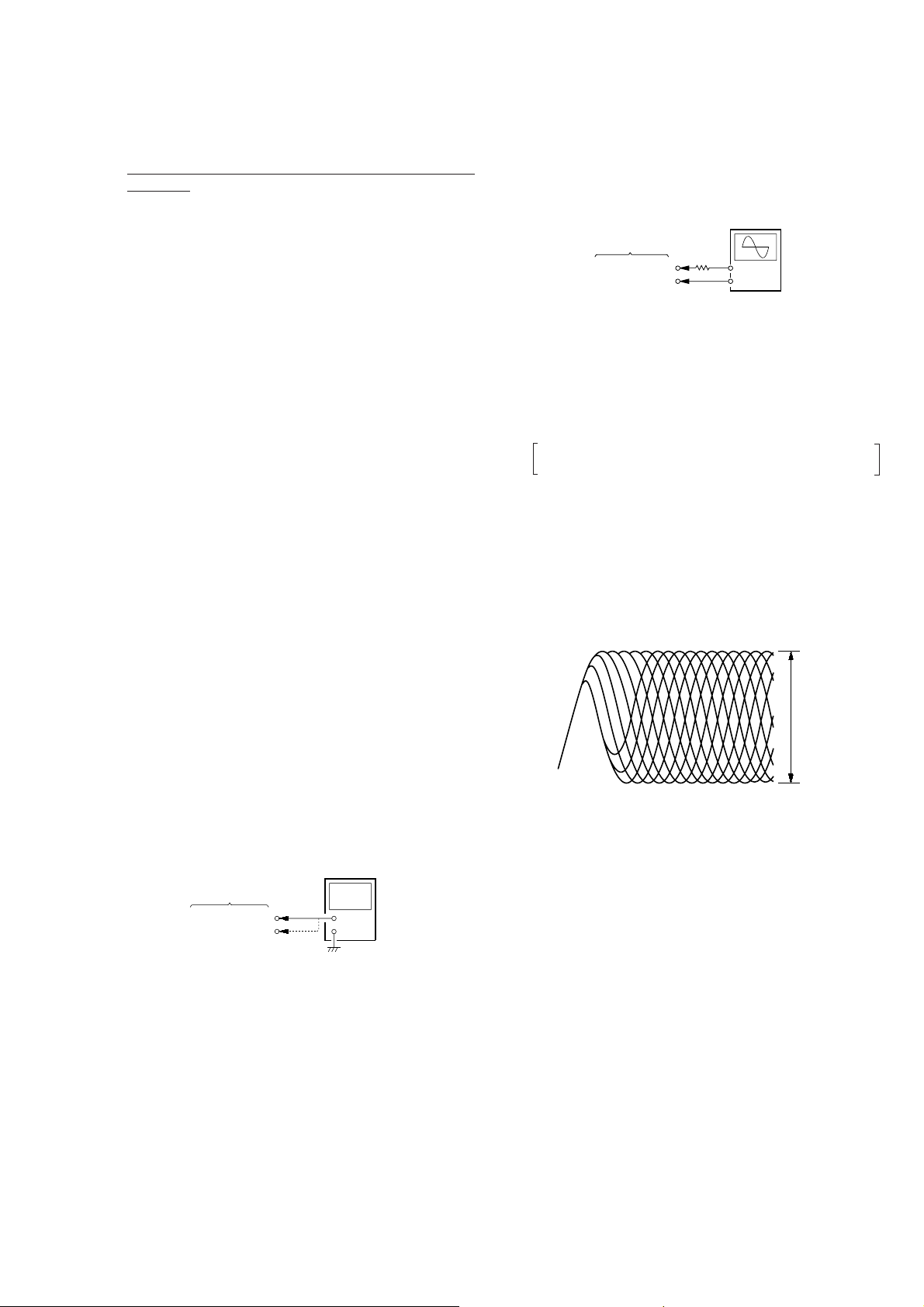

SECTION 5

oscilloscope

(AC range)

+

–

MAIN board

TP522 (RFO)

TP520 (VC)

(See page 13)

2 k

Ω

RF level

1.0 V

+ 0.2

–0 .15

ELECTRICAL ADJUSTMENTS

Precautions for Adjustment

1. Before beginning adjustment, set the equipment to service

mode.

After the completion of adjustment, be sure to reset the service mode.

For more information, see “Service Mode (service program) ”

on page 10.

2. Perform adjustments in the order given.

3. Use YEDS-18 disc (Part No.: 3-702-101-01) unless otherwise

indicated.

4. Power supply voltage requirement: DC2.5 V in battery terminal

VOLUME knob : Minimum

SOUND switch : OFF

RESUME switch : OFF

ESP switch : OFF

AVLS switch : NORMAL

HOLD switch : OFF

Before Beginning Adjustment

Set the equipment to service mode (See page 10) and check the

following. If there is an error, repair the equipment.

• Checking of the sled motor

1. Disengage the buckles and open the upper panel.

2. Press the + and = keys and check that the optical pickup can move smoothly without sluggishness or abnormal noise

in innermost periphery n outermost periphery n innermost

periphery

+ : The optical pick-up moves outwardly.

=: The optical pick-up moves inwardly.

• Checking of focus searching

1. Disengage the buckles and open the upper panel.

2. Press the ^ key. (Focus searching operation is activated

continuously.)

3. Check the object lens of the optical pick-up for smooth up/

down motion without sluggishness or abnormal noise.

4. Press the p key.

Check that focus searching operation is deactivated. If not,

again press the p key slightly longer.

+B V oltage Adjustment

Adjustment Procedure:

digital voltmeter

(DC range)

MAIN board

TP401 (VCC)

TP427 (VCPU)

+

–

Focus bias Check

Condition:

• Hold the set in horizontal state.

Check Procedure:

1. Set the equipment to service mode stop state. (See page 10.)

2. Connect the oscilloscope to the test point TP522 (RFO) of the

MAIN board.

3. Move the optical pick-up to the center by pressing the +

and = keys.

4. Put the disc (YEDS-18).

5. Press the ^ key.

From focus searching, focus is turned ON while entering

CLV drawing-in mode. Tracking and sled are tur ned OFF.

6. Press the PLA Y MODE key . (Both tracking and sled are turned

ON.)

7. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape (≈) in the

center of the waveform can be clearly distinguished.

RF SIGNAL REFERENCE W A VEFORM (EYE PATTERN)

VOLT/DIV : 200 mV (With the 10:1 probe in use)

TIME/DIV : 500 ns

To watch the eye pattern, set the oscilloscope to AC range and

increase the vertical sensitivity of the oscilloscope for easy watching.

8. Stop revolving of the disc motor by pressing the p key.

9. After the completion of adjustment, reset service mode. (See

page 10.)

Check Location: MAIN Board (See page 13.)

(See page 13)

1. Set the equipment to service mode stop state. (See page 10.)

2. Connect the digital voltmeter to TP401 (VCC) of the MAIN

board.

3. Adjust RV401 on the MAIN board so tha t the reading on digital voltmeter goes 2.73-2.77 V.

4. Connect the digital voltmeter to TP427 (VCPU) on the MAIN

board, and confirm that a reading of digital voltmeter is 2.97-

3.07 V.

5. After the completion of adjustment, reset service mode. (See

page 10.)

Adjustment Location: MAIN board (See page 13.)

– 11 –

Loading...

Loading...