Sony DCR-TRV255E, DCR-TRV260, DCR-TRV265, DCR-TRV265E Service manual

DCR-TRV255E/TRV260/TRV265/TRV265E

SERVICE MANUAL

Ver 1.3 2005.07

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

RMT-830

US Model

Canadian Model

DCR-TRV260

AEP Model

UK Model

East European Model

North European Model

DCR-TRV255E/TRV265E

E Model

DCR-TRV260/TRV265/TRV265E

Australian Model

DCR-TRV265E

M2200 MECHANISM

Link

Link

SPECIFICATIONS

SPECIFICATIONS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

NTSC MODEL: DCR-TRV260/TRV265

PAL MODEL: DCR-TRV255E/TRV265E

•For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (987629251.pdf).

•For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (987629241.pdf).

•For MECHANISM ADJUSTMENTS, refer to the “8mm Video MECHANICAL ADJUSTMENT MANUAL IX

M2000 MECHANISM ” (9-929-861-11).

• Reference No. search on printed wiring boards is available.

•Table for differences of function of each model.

•TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

•When the machine needs to be repaired, make sure to follow the items of “LCD TYPE CHECK”.

• Changing the data is needs when IC4501 is replaced, make sure to follow the items of “CHANGE OF IC4501”.

• HELP: Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

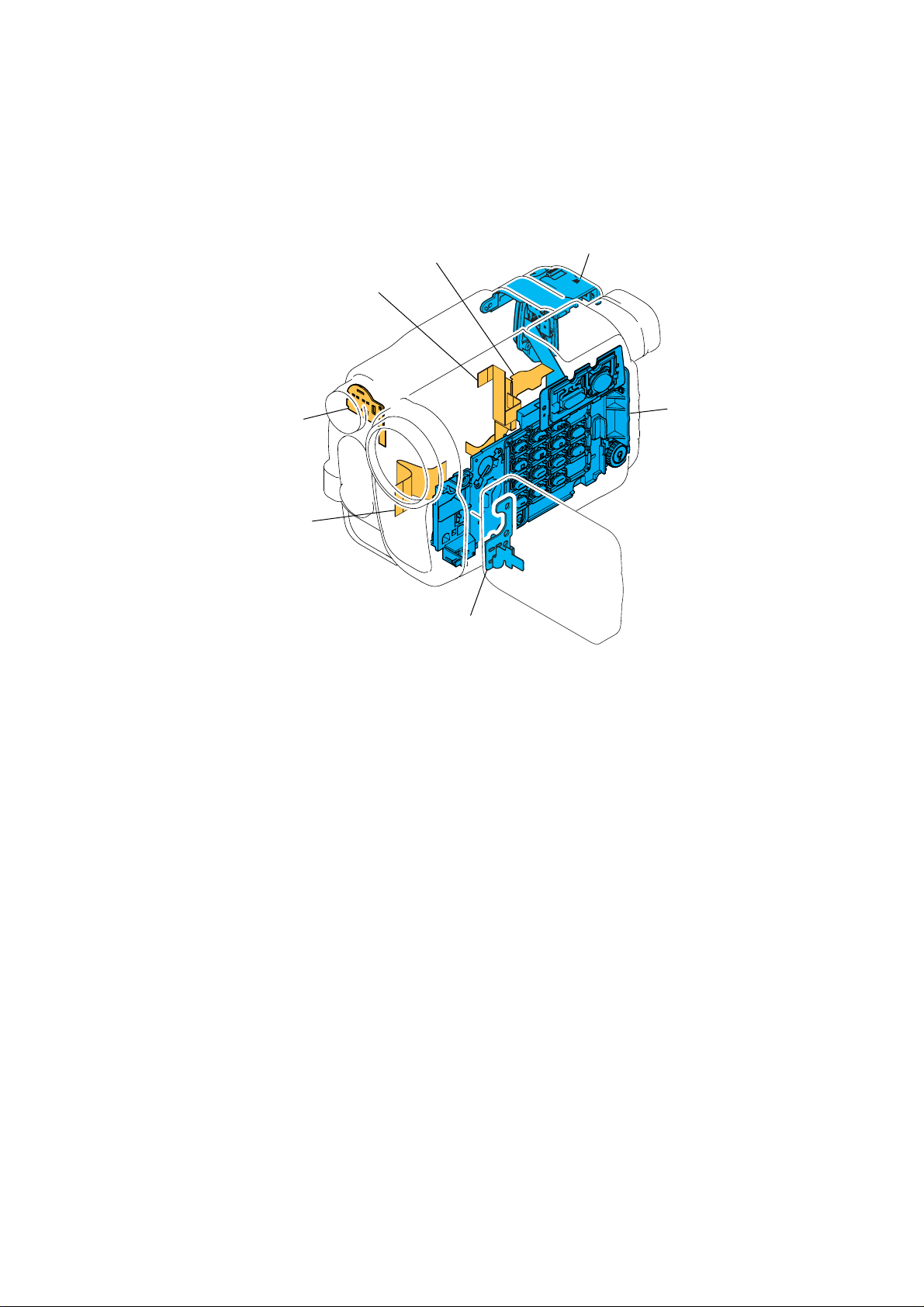

Photo: DCR-TRV265

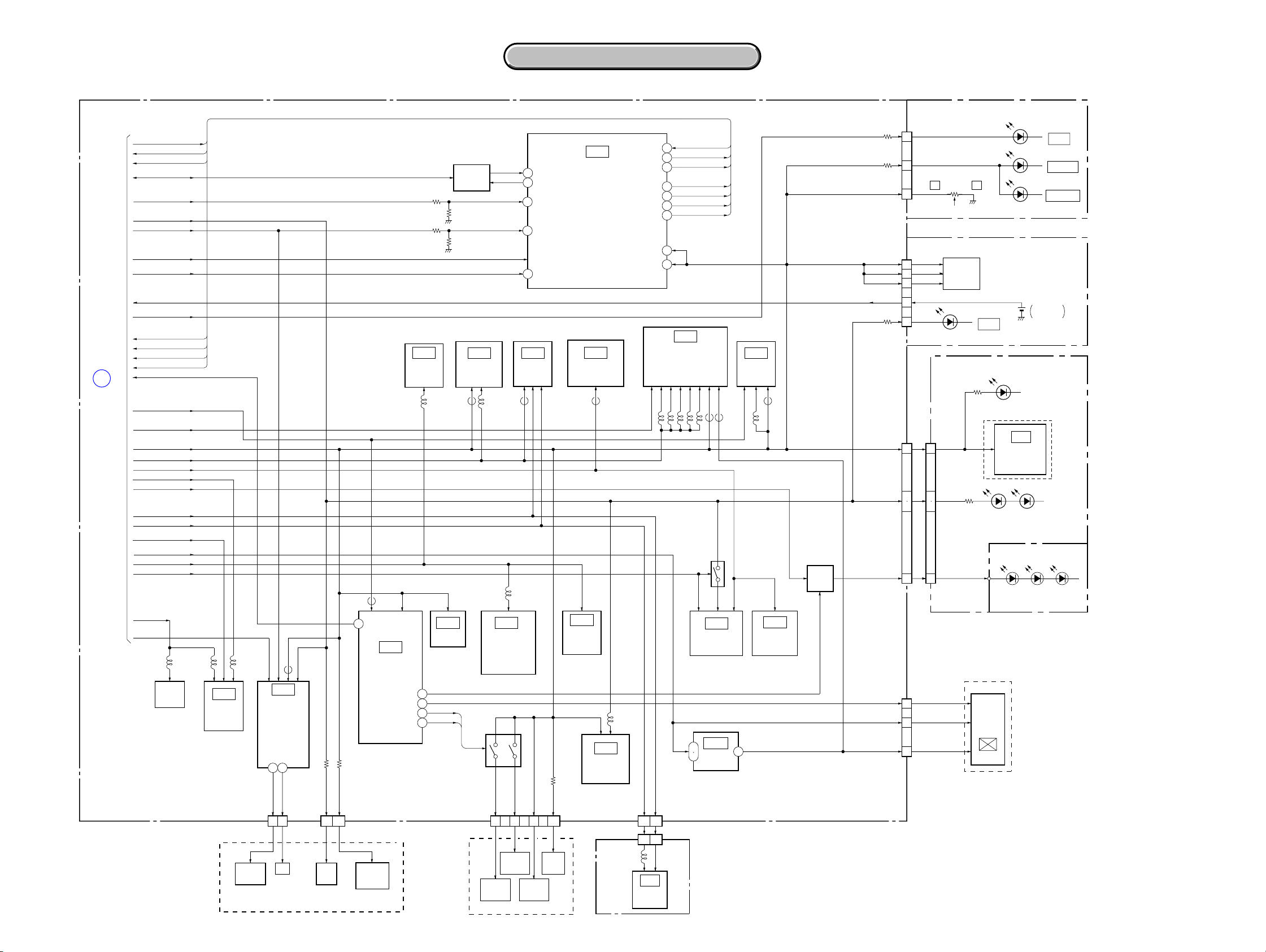

BLOCK DIAGRAMS

BLOCK DIAGRAMS

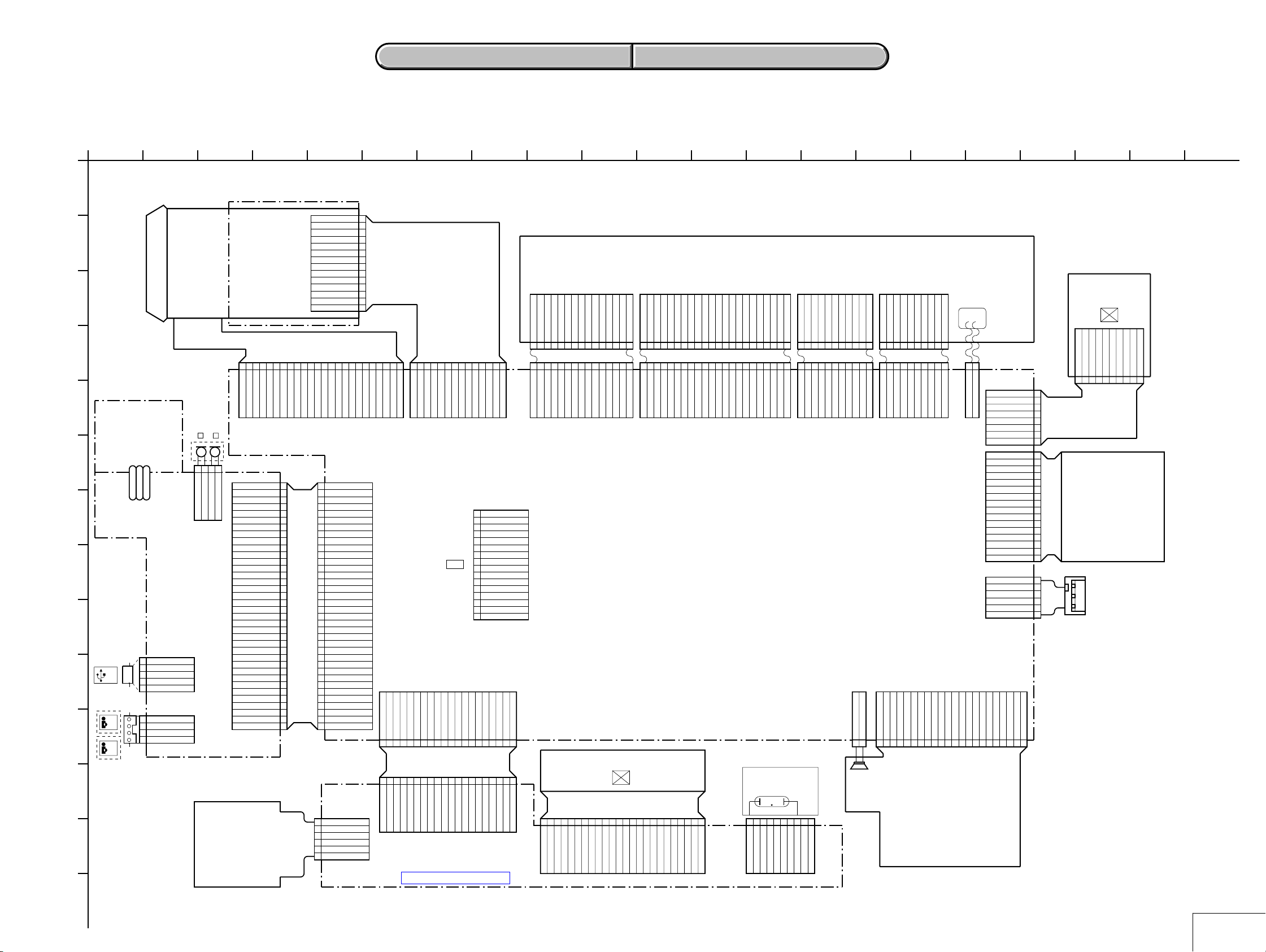

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

REPAIR PARTS LIST

REPAIR PARTS LIST

DCR-TRV265/TRV265E

Tourist Model

VIDEO CAMERA RECORDER

DCR-TRV255E/TRV260/TRV265/TRV265E

S

SPECIFICATIONS

TM

SERIE

Video camera recorder

System

Video recording system

2 rotary heads, Helical scanning system

Audio recording system

Rotary heads, PCM system

Quantization: 12 bits (Fs 32 kH z, ster eo 1,

stereo 2), 16 bits (Fs 48 kHz, stereo)

Video signal

DCR-TRV260/265:

NTSC color, EIA standards

DCR-TRV255E/265E:

PA L c o lor, CCIR standards

Usable cassette

8 mm video format cassette

Tape speed

DCR-TRV260/265:

SP: Approx. 28.67 mm/s

LP: Approx. 19.11 mm/s

DCR-TRV255E/265E:

SP: Approx. 28.70 mm/s

LP: Approx. 19.13 mm/s

Recording/playback time

DCR-TRV260/265:

(using 120 min. Digital8 video cassette)

DCR-TRV255E/265E:

(using 90 min. Digital8 video cassette)

1 h

SP:

LP: 1 h 30 min

Fast forward/rewind time

DCR-TRV260/265:

(using 120 min. Digital8 video cassette)

DCR-TRV255E/265E:

(using 90 min. Digital8 video cassette)

Approx. 5 min

Viewfinder

Electric vie wfi nder (monochrome )

Image device

3.0 mm (1/6 type) CCD (Charge Coupled

Device)

DCR-TRV260/265:

Gross: Approx. 460 000 pixels

Effective: Approx. 290 000 pixels

DCR-TRV255E/265E:

Gross: Approx. 540 000 pixels

Effective: Approx. 350 000 pixels

Lens

Combined power zoom lens

Filter diameter: 37 mm (1 1/2 in.)

20 × (Optical), 990 × (Digital)

F=1.6 - 2.4

Focal length

2.5 - 50 mm (1/8 - 2 in.)

When converted to a 35 mm still camera

42 - 840 mm (1 11/16 - 33 1/8 in.)

Color temperature

Auto

Minimum illumi n ation

4 lx (lux) (F 1.6)

0 lx (lux) (in the NightShot plus mode)*

*Objects unable to be seen due to the dark can be

shot with infrared lighting.

Input/Output connectors

S video output

4-pin mini DIN

Luminance signal: 1 Vp-p, 75 Ω (ohms),

unbalanced

Chrominance signal:

DCR-TRV260/265: 0.286 Vp-p

DCR-TRV255E/265E: 0.3 Vp-p

75 Ω (ohms), unbalanced

Audio/Video output

AV M I NIJACK

Video signal: 1 Vp-p, 75 Ω: (ohms),

unbalanced, sync negative

Audio signal: 327 mV (at output impedance

more than 47 kΩ: (kilohms)), Output

impedance with less than 2.2 kΩ: (kilohms)

Stereo minijack (ø 3.5 mm)

DV input/output

DCR-TRV260/265/265E:

4-pin connector

DV ou tput

DCR-TRV255E:

4-pin connector

USB jack

mini-B

LCD screen

Picture

6.2 cm (2.5 type)

Total dot number

123 200 (560 × 220)

General

Power requirements

DC 7.2 V (battery pack)

DC 8.4 V (AC Adaptor)

Average power consumption (when using the

battery pack)

During camera recording using viewfin der

2.5 W

During camera recording using L CD

3.4 W

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

-20°C to + 60°C (-4°F to + 140°F)

Dimensions (approx.)

85 × 98 × 151 mm (3 3/8 × 3 7/8 × 6 in.) (w/h/

d)

Mass (Approx.)

780 g (1 lb 11 oz) main unit only

890 g (1 lb 15 oz) including the

NP-FM30 rechargeable battery pack, Digital8

cassette, lens cap, and shoulder strap

Supplied accessories

AC Adaptor (1)

Power cord (1)

Lens cap (1)

Shoulder strap (1)

Wireless Remote Commander (1)

RMT-830: (DCR-TRV265/265E)

A/V connecting cable (1)

USB cable (1)

Rechargeable battery pack NP-FM30 (1)

CD-ROM “SPVD-012 USB Driver” (1)

21-pin adaptor (1)

: (AEP, UK, EE, NE)

Camera Operating Guide (1)

Computer Application Guide (1)

See page 5-22.

AC Adaptor AC-L15A/L15B

Power requirements

AC 100 - 240 V, 50/60 Hz

Current consumption

0.35 - 0.18 A

Power consumption

18 W

Output voltage

DC 8.4 V, 1.5 A

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

-20°C to + 60°C (-4°F to + 140°F)

Dimensions (approx.)

56 × 31 × 100 mm (2 1/4 × 1 1/4 × 4 in.) (w/h/

d) excluding the projecting parts

Mass (approx.)

190 g (6.7 oz) excluding the ma ins lea d

Rechargeable battery pack (NP-FM30)

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Capacity

5.0 Wh (700 mAh)

Dimensions (approx.)

38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 in.) (w/h/d)

Mass (approx.)

65 g (2.3 oz)

Operating temperature

0°C to 40°C (32°F to 104°F)

Type

Lithium ion

Design and specification s are subj ect to cha nge

without notice

— 2 —

DCR-TRV255E/TRV260/TRV265/TRV265E

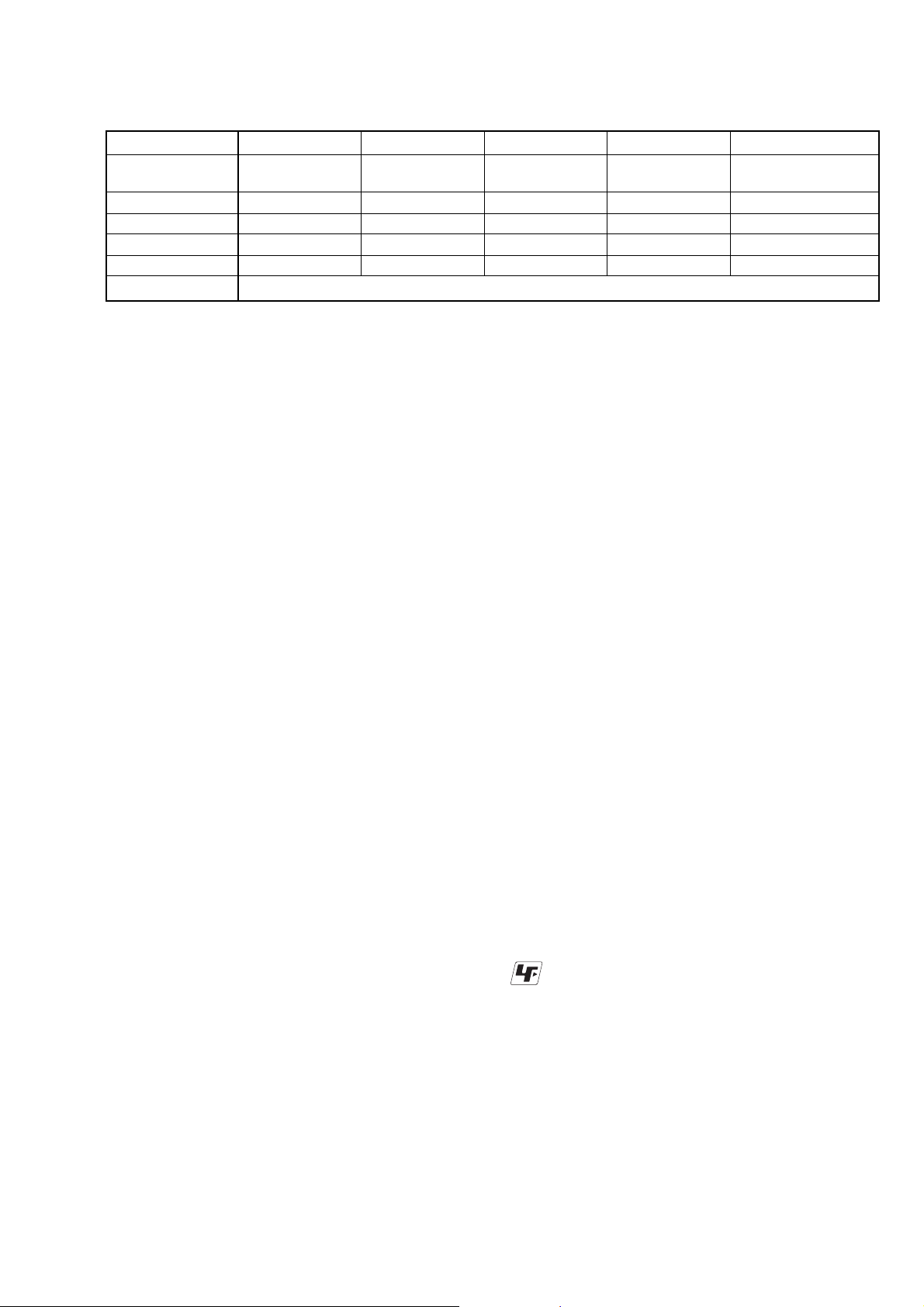

Table for differences of function

Model DCR-TRV255E DCR-TRV260 DCR-TRV265 DCR-TRV265E Remark

Destination AEP, UK, EE, NE US, CND, E E, JE

Remote commander ✕✕aa

Color system PAL NTSC NTSC PAL

VTR Rec ✕ aaaa: with REC button

DV interface DV OUT DV IN/OUT DV IN/OUT DV IN/OUT

LCD type Please refer to page 1-3 to discriminate the type of LCD (TYPE C or TYPE S).

•Abbreviation

AUS: Australian model

CND: Canadian model

EE : East European model

JE : Tourist model

NE : North European model

AEP, UK, EE, NE,

E, AUS, JE

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

DCR-TRV255E/TRV260/TRV265/TRV265E

TABLE OF CONTENTS

Section Title Page Section Title Page

1. SERVICE NOTE

1-1. Note for Repair ································································1-1

1-2. Power Supply During Repairs ·········································1-1

1-3. To Take Out a Cassette when not Eject (Force Eject) ·····1-2

1-4. LCD T ype Check·····························································1-3

1-5. Self-diagnosis Function···················································1-4

1-5-1.Self-diagnosis Function ··················································· 1-4

1-5-2.Self-diagnosis Display·····················································1-4

1-5-3.Service Mode Display ·····················································1-4

1-5-4.Self-diagnosis Code Table ··············································· 1-5

1-6. Change of IC4501 ···························································1-6

2. DISASSEMBLY

2-1. Flow Chart·······································································2-1

2-2. Mechanism Deck Service Position··································2-3

2-3. LCD Service Position ······················································2-5

2-4. Circuit Boards Location ·················································· 2-6

2-5. Flexible Boards Location ················································ 2-7

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/5)··········································· 3-1

3-2. Overall Block Diagram (2/5)··········································· 3-3

3-3. Overall Block Diagram (3/5)··········································· 3-5

3-4. Overall Block Diagram (4/5)··········································· 3-7

3-5. Overall Block Diagram (5/5)··········································· 3-9

3-6. Power Block Diagram (1/2)···········································3-11

3-7. Power Block Diagram (2/2)···········································3-13

5. REPAIR PARTS LIST

5-1. Exploded V iews ····························································5-2

5-1-1. Overall Assembly··························································5-2

5-1-2. Front Panel Block ·························································5-3

5-1-3. Lens Block ····································································5-4

5-1-4. LCD Block ····································································5-5

5-1-5. Cabinet R Block ····························································5-6

5-1-6. EVF Block ····································································5-7

5-1-7. Battery Panel Block ······················································ 5-8

5-1-8. MD Frame Block ·························································· 5-9

5-1-9. Cassette Compartment Assembly, Drum Assembly ···5-10

5-1-10. LS Chassis Block Assembly ·······································5-11

5-1-11. Mechanical Chassis Block Assembly-1 ······················5-12

5-1-12. Mechanical Chassis Block Assembly-2 ······················5-13

5-2. Electrical Parts List ·····················································5-14

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram ··············································4-1

4-2. Schematic Diagrams························································4-5

CD-471 (CCD IMAGER)················································4-7

VC-344 (1/10)

(A/D CONVERTER, TIMING GENERATOR)··············4-9

VC-344 (2/10)

(DV SIGNAL PROCESS, LENS CONTROL,

STEADYSHOT, DV INTERFACE, VIDEO OUT) ······4-11

VC-344 (3/10) (LENS DRIVE) ····································4-13

VC-344 (4/10) (REC/PB AMP) ····································4-15

VC-344 (5/10) (SERVO) ···············································4-17

VC-344 (6/10) (CAMERA/MECHA CONTROL) ·······4-19

VC-344 (7/10) (HI CONTROL)····································4-21

VC-344 (8/10) (AUDIO PROCESS)·····························4-23

VC-344 (9/10) (DC CONTROL) ··································4-25

VC-344 (10/10) (CONNECTOR) ·································4-27

PD-204 (LCD DRIVER, BACKLIGHT DRIVE)········· 4-29

SI-041 (JACK)·······························································4-31

FP-792 FLEXIBLE ·······················································4-31

FP-228, FP-299, FP-300, FP-301, FP-302, FP-802

FLEXIBLE ····································································4-33

SS-5100, PR-5100 (CONTROL KEY BLOCK)··········· 4-34

CF-5100 (CONTROL KEY BLOCK)···························4-35

4-3. Printed Wiring Boards ···················································4-39

CD-471 ··········································································4-41

VC-344 ··········································································4-43

PD-204···········································································4-47

SI-041, FP-792 FLEXIBLE ··········································4-49

FP-228, FP-299, FP-300, FP-301, FP-302, FP-802

FLEXIBLE ····································································4-51

4-4. Mounted Parts Location ················································ 4-53

— 4 —

1-1. NOTE FOR REPAIR

When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

DCR-TRV255E/TRV260/TRV265/TRV265E

SECTION 1

SERVICE NOTE

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

When remove a connector, don’t pull at wire of connector.

It is possible that a wire is snapped.

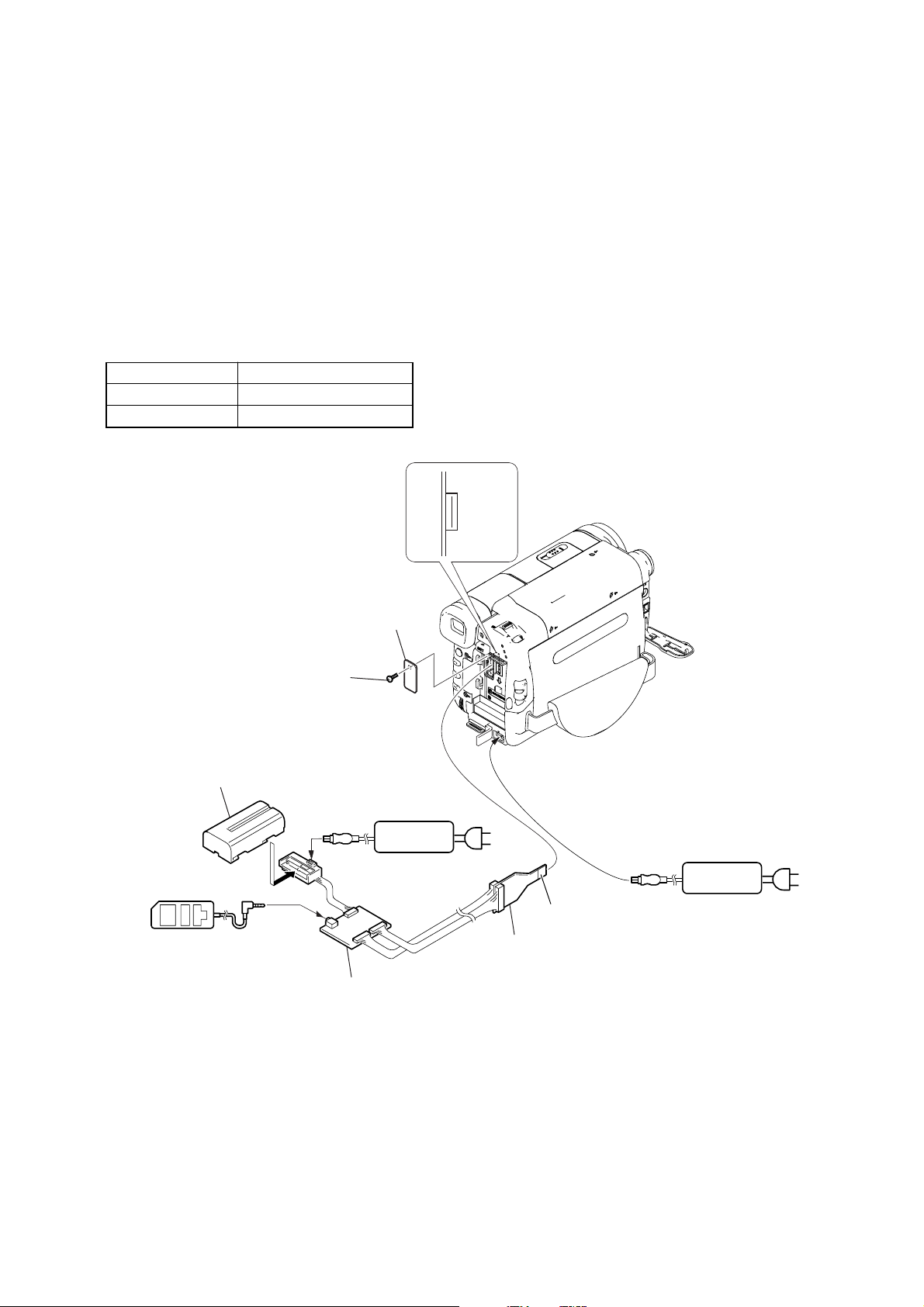

1-2. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the po wer is shut of f so

that the unit cannot operate.

The following method is available to prevent this.

Method 1.

Use the AC power adaptor (AC-L10, AC-VQ800 etc.).

1-1

DCR-TRV255E/TRV260/TRV265/TRV265E

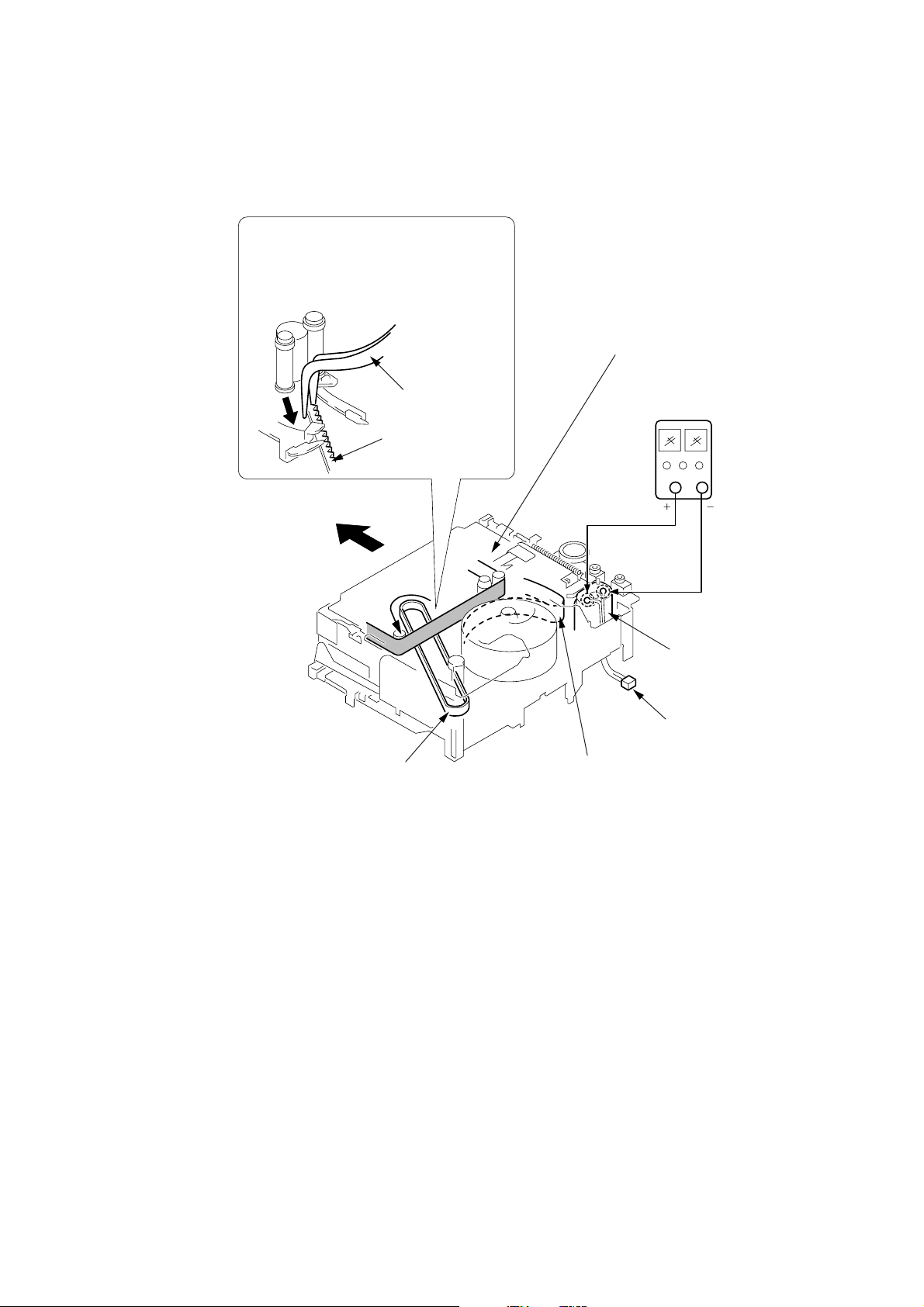

1-3. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to “SECTION 2. DISASSEMBLY” to remove the mechanism deck block.

2 Disconnect CN2401 (2P) of VC-344 board.

3 Add +5V from the DC POWER SUPPLY and unload with a pressing the cassette compartment.

4 Pull the timing belt in the direction of

arrow A with a pincette while pressing

the cassette compartment (take care

not to damage) to adjust the bending

of a tape.

Press the cassette compartment not to

rise the cassette compartment

5 Let go your hold the cassette

compartment and rise the cassette

compartment to take out a cassette.

A

Timing belt

A

Timing belt

Pincette

[DC power supply]

(+5V)

Loading motor

Disconnect CN2401

of VC-344 board.

Adjust the bending of a tape

1-2

DCR-TRV255E/TRV260/TRV265/TRV265E

1-4. LCD TYPE CHECK

The LCD type can be checked with data value by connecting the adjustment remote commander.

Note: About PD-204 board and LCD module, discriminate LCD type on the machine, and replace the same type.

Preparations:

1) Connect the equipment for adjustments according to Fig. 1.

2) Connect the adjustment remote commander to VC-344 board CN1011 via I/F unit for LANC control (J-6082-521-A) and CPC jig

connector (J-6082-539-A).

To operate the adjustment remote commander, connect the A C po wer adaptor to the DC IN jack of I/F unit for LANC control, or connect

the L series Info-LITHIUM battery to the battery terminal of I/F unit for LANC control.

Checking method:

1) Select page: 3, address: CC.

2) By checking the data value of display data, the type of LCD can be discriminated.

Data LCD type

64 to 67 TYPE C

40 to 43 TYPE S

CN1011

1

Screw (M2)

L serices Info

LITHIUM battery (7.2Vdc)

LANC jack

Adjustment

remote commander (RM-95)

CPC lid

AC adaptor

16

AC IN

Conductor side

CPC jig connector

(J-6082-539-A)

AC adaptor

AC IN

I/F unit for LANC control

(J-6082-521-A)

1-3

DCR-TRV255E/TRV260/TRV265/TRV265E

1-5. SELF-DIAGNOSIS FUNCTION

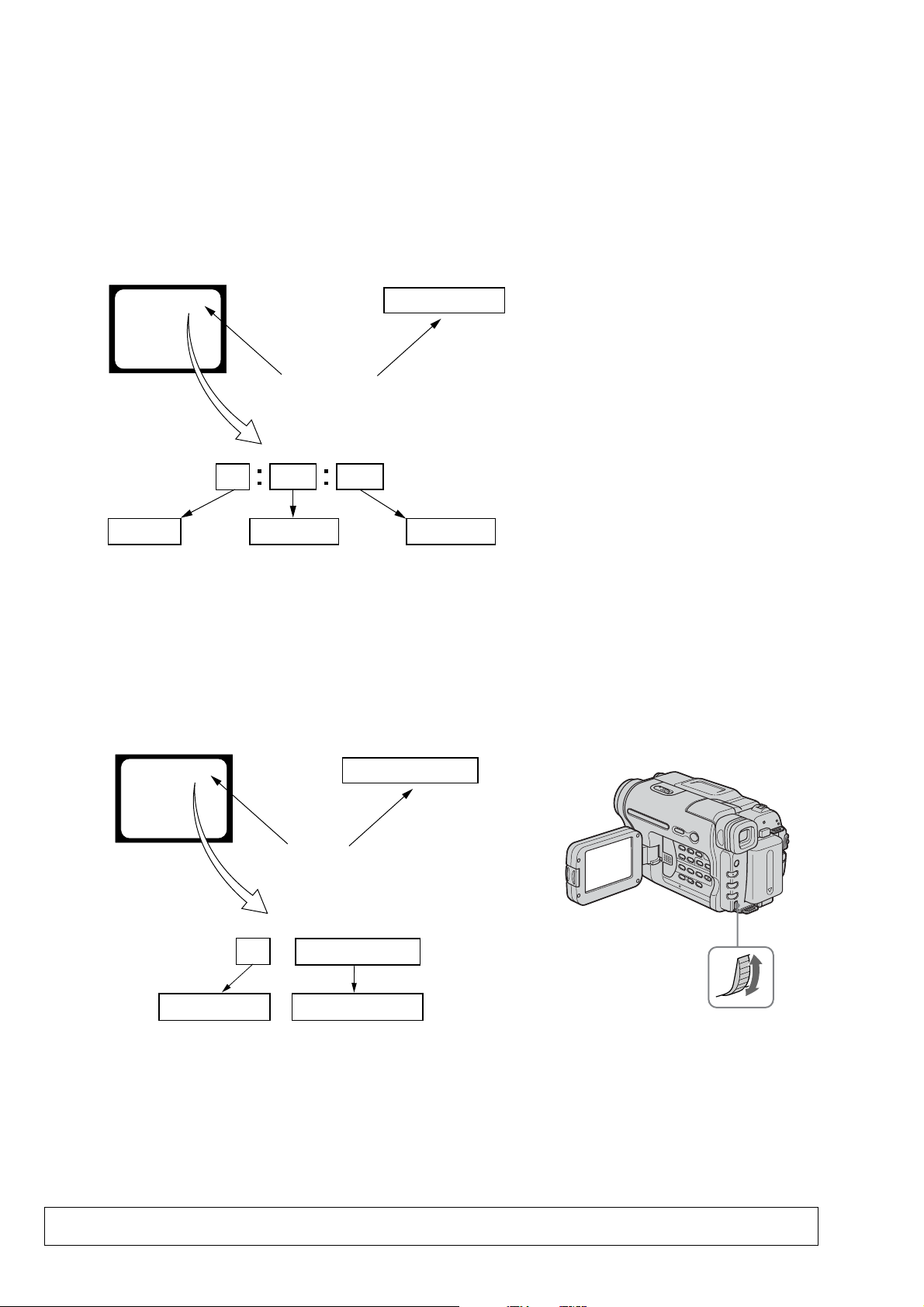

1-5-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or Display

window what to do. This function consists of two display; selfdiagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder Display window

C : 3 1 : 1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Blinks at 3.2Hz

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Tur n o n power again.

3 1

Block

1 1

C : 3 1 : 11

Refer to “1-5-4. Self-diagnosis Code Table”.

1-5-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or Display window shows a 4-digit display consisting

of an alphabet and numbers, which blinks at 3.2 Hz. This 5-character

display indicates the “repaired by:”, “block” in which the problem

occurred, and “detailed code” of the problem.

Detailed Code

1-5-3. Service Mode Display

The service mode display shows up to six self-diagnosis codes shown in the past.

1. Display Method

While pressing the “STOP” key, set the switch from OFF to “ON”, and continue pressing the “STOP” key for 5 seconds continuously. The

service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder

[3] C : 3 1 : 1 1

[3]

Backup No.

Order of previous errors

Lights up

C : 3 1 : 1 1

Self-diagnosis Codes

Display window

3 C : 3 1 : 11

Control Dial

2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [3] : Occurred third time [5] : Occurred fifth time

[2] : Occurred second time [4] : Occurred fourth time [6] : Occurred the last time

3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will not be erased (reset), when the lithium battery (CONTROL KEY BLOCK (CF-

5100): BT001) is removed.

1-4

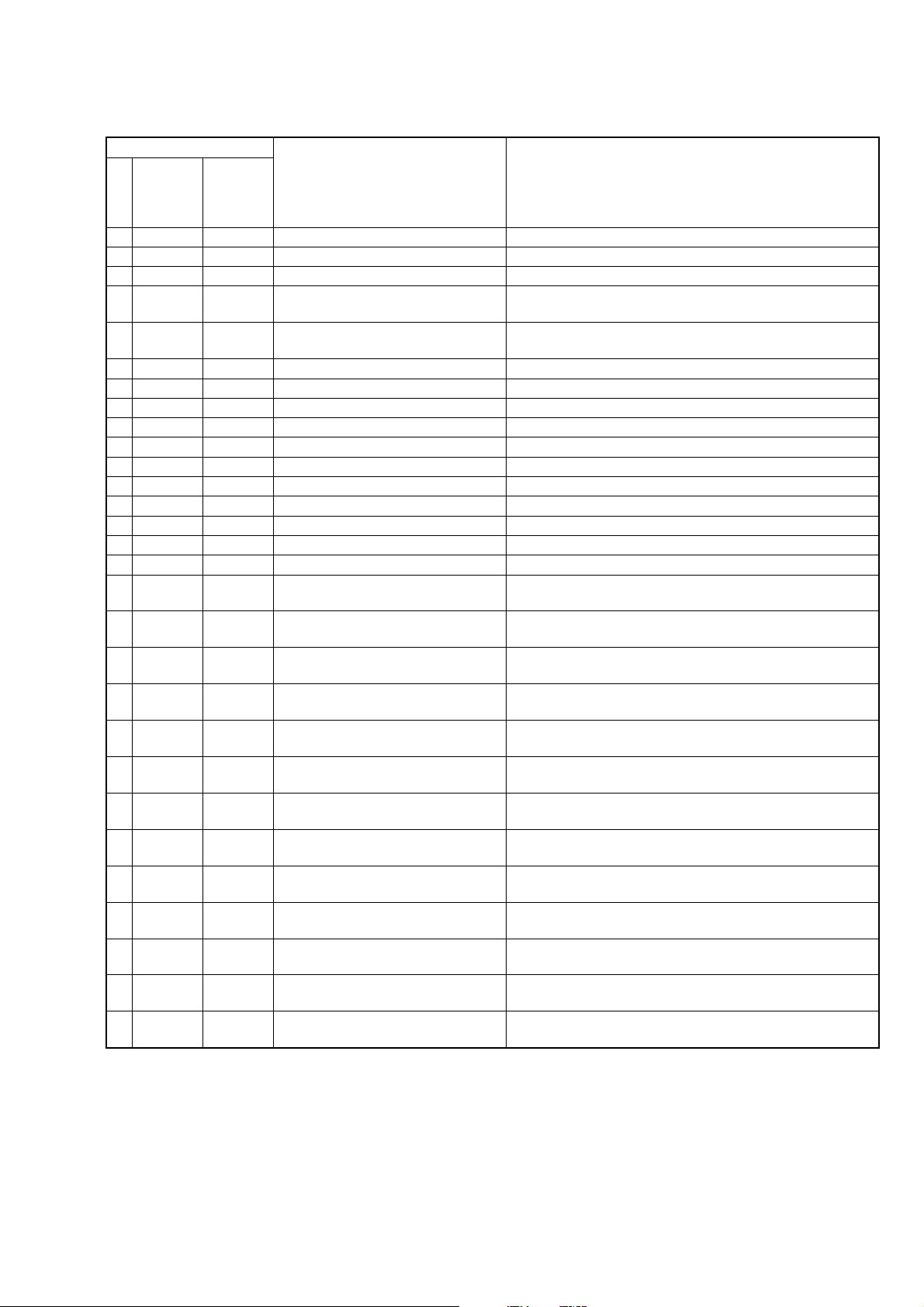

1-5-4. Self-diagnosis Code Table

Self-diagnosis Code

DCR-TRV255E/TRV260/TRV265/TRV265E

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Block

Function

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

32

32

Detailed

Code

00

00

00

10

11

20

21

22

23

30

31

40

41

42

43

44

10

11

20

21

22

23

30

31

40

41

42

43

44

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

S reel

side tape slacking when unloading

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum operations.

PG fault during normal drum operations.

Phase fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

S reel side tape slacking when

unloading.

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan

operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum

operations.

PG fault during normal drum

operations.

Phase fault during normal drum

operations.

Correction

Use the InfoLITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

1-5

DCR-TRV255E/TRV260/TRV265/TRV265E

Self-diagnosis Code

Repaired by:

E

E

Block

Function

61

61

Detailed

Code

00

10

Symptom/State

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

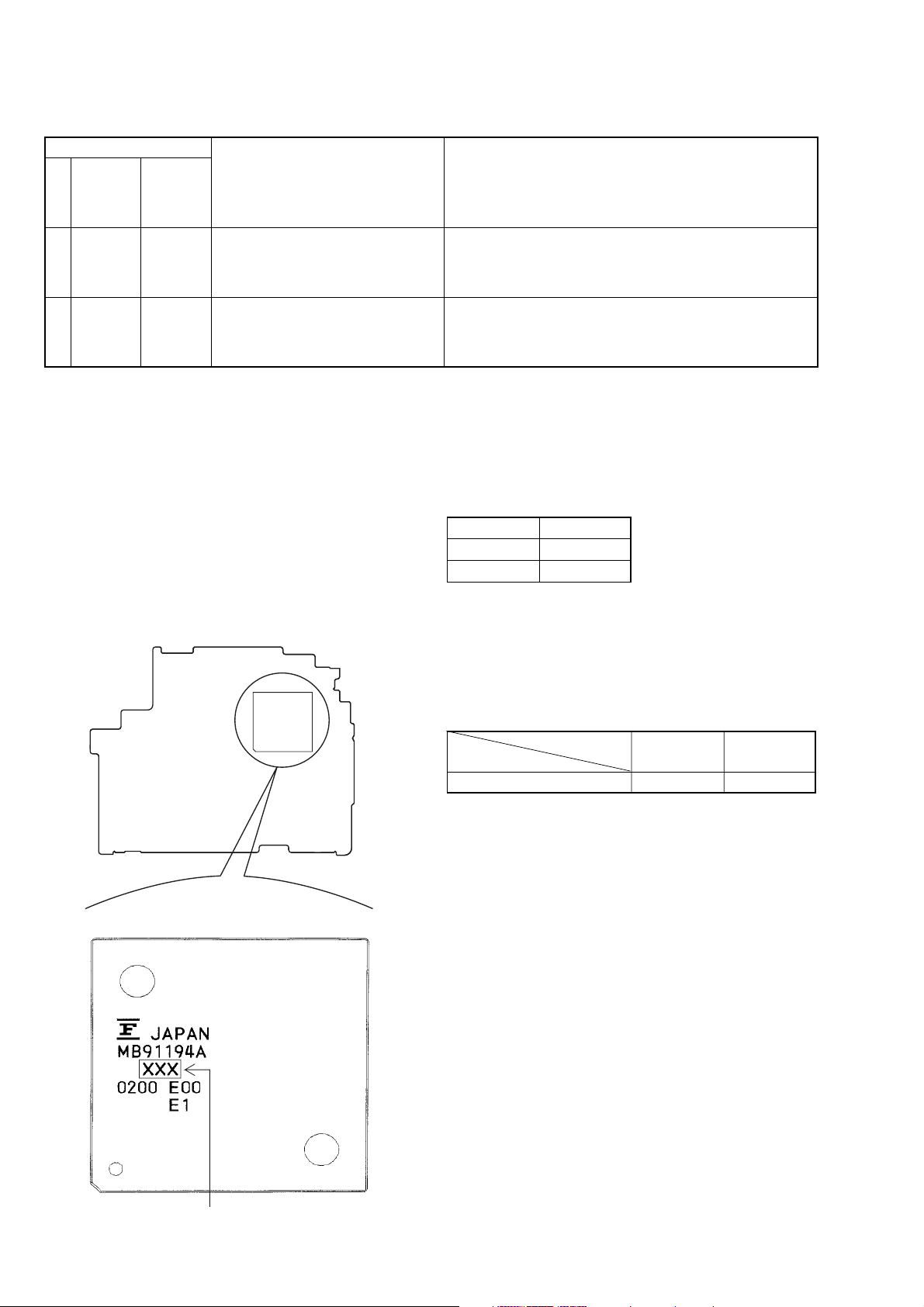

1-6. CHANGE OF IC4501

Due to the change of IC4501 (mechanism control), there are two

types of versions A and B

The EEPROM data are different according to respective versions.

Also, the IC4501 version can be checked by a discrimination method

by the model name or by the adjusting remote commander.

Note 1: Changing the version does not make any changes in

schematic diagrams and the rest.

Note 2: Make it sure to confirm the version after replacing IC4501.

1. Discrimination method by the model name of

IC4501 (mechanism control)

VC-344 BOARD (SIDE A)

IC4501

Correction

Inspect the lens block focus reset sensor (Pin qs of CN1551 of

VC-344 board) when focusing is performed when the control dial

is rotated in the focus manual mode and the focus motor drive circuit

(IC1553 of VC-344 board) when the focusing is not performed.

Inspect the lens block zoom reset sensor (Pin qg of CN1551 of

VC-344 board) when zooming is performed when the zoom switch

is operated and the zoom motor drive circuit (IC1553 of VC-344

board) when zooming is not performed.

2. Discrimination method by adjusting remote

commander

Version check method:

1) Select page: 3, and address: FF.

2) The version of IC4501 can be checked from the displayed data.

Data Version

01 A

02 B

Data change method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 1C, and input the data in the following table.

Note: To write in the non-volatile memory (EEPROM), press the

PAUSE button of the adjustment remote commander each

time to set the data.

3) Select page: 0, address: 01, and set data: 00.

Version

Address

D0 40 42

AB

154 : A

155 : B

1-6E

DCR-TRV255E/TRV260/TRV265/TRV265E

SECTION 2

DISASSEMBLY

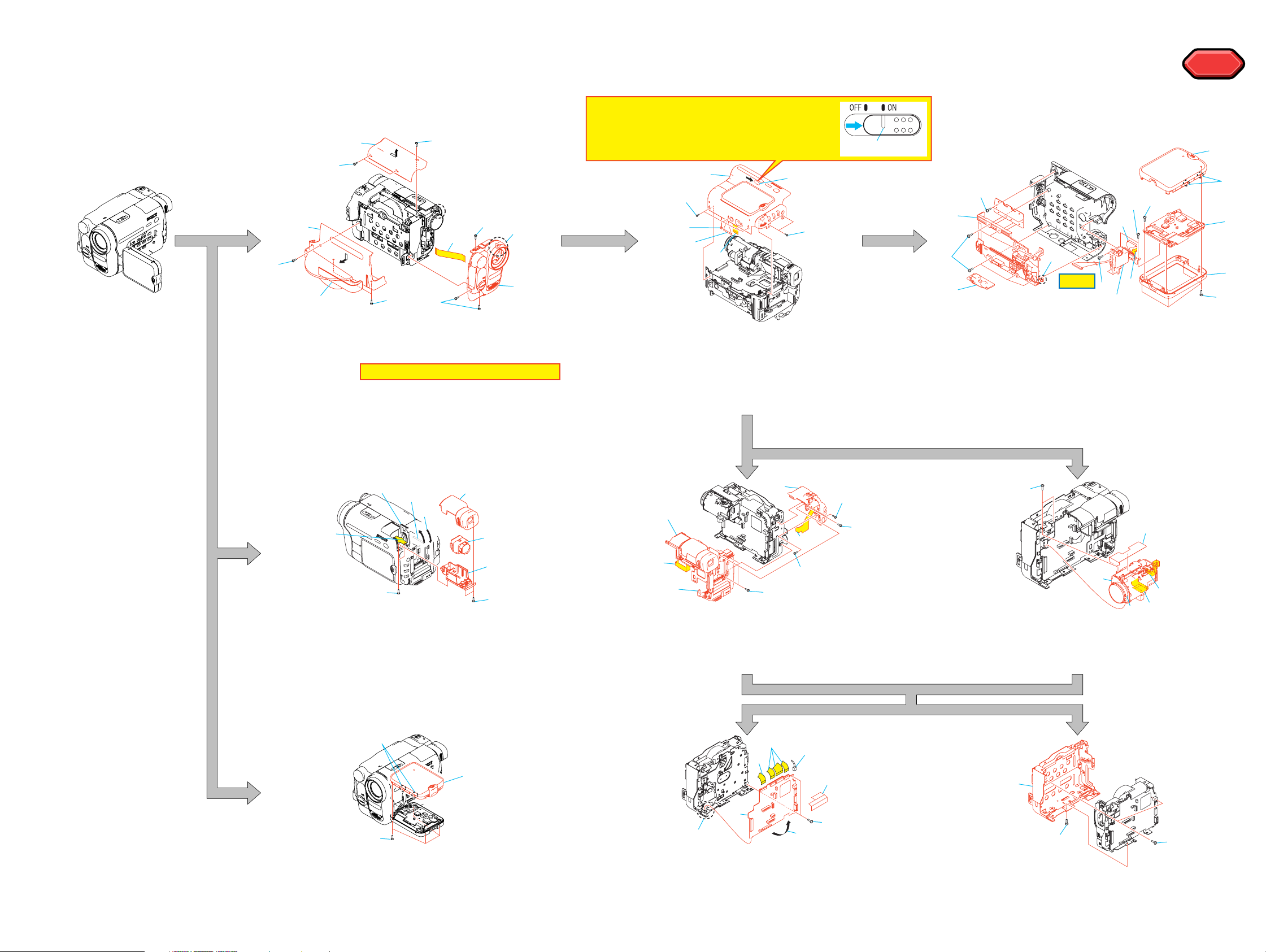

2-1. FLOW CHART

The following flow chart shows the disassembly procedure.

1

5

4

3

1 Lock ace

2 Cabi (upper)

3 Grip belt

4 Lock ace

5 Cabi (L)

x3

x3

2

4

6 Lock ace

1

6

9

6

x3

7 Claw

8 Front panel

Note: Flexible board is connected.

9 FP-796: CN754, CN1001

7

8

Note: When you remove Cabinet (R) Block,

or when you assembly, please slide

NS knob to the position of "ON".

3

1

6

5

4

1 Lock ace

x6

2

1

2 NS knob to the position of "ON".

3 Cabi (R)

4 VC-344: CN1007

5 VC-344: CN1003

6 VC-344: CN1008

NS knob

3

2

5

1

1 Tripod Screw

2 Tapping P2

3 Tapping P2

4 Claw

5 CF-5100

6 Tapping P2

7 Claw

8 P Cabi (C)

x2

4

q;

9

qd

HELP

9 Tapping P2

x2

q; Tapping P2

x6

qa P Cabi (M)

qg

qs

qh

x2

x1

qs PD-204: CN6005

qd PD-204: CN6001

qf PD-204, LCD901, ND901

x4

qg Tapping P2

x4

qh Hinge assy

HELP

HELP

8

7

qf

qa

6

4

7

2

1 Lift up the EVF.

2 Tapping P2

x4

3 Down the EVF.

4 EVF block

2

1

3

5

8

6

2

5 EVF Cabi (upper)

6 EVF Cabi (lower)

7 FP-797: LCD902

8 EVF lens

3

4

1

2

1 VC-344: CN1013

2 VC-344: CN4001

3 Lock ace

x3

4 EVF/Battely panel block

7

8

5

6

3

7

3

5 VC-344: CN1009

6 Tapping P2

7 Lock ace

x1

8 SS-5100

2

3

1

x1

4

6

1 VC-344: CN1501

2 VC-344: CN1551

3 Lens sheet

2

3

1

2

5

4 Lock ace

x2

5 Boss

6 Lens LSV-820A

1

1 Tapping P2

2 Claw

x2

3 P Cabi (C)

2-1 2-2

x4

8

5

1 VF blind sheet

2 VC-344: CN2403, CN2404, CN3201

3 VC-344: CN2401

4 Screw (M1.7)

x2

4

6

5 Claw

6 Open the VC-344.

7 VC-344: CN2402

8 VC-344

1

1 Screw (M1.7)

2 CS frame

1

x3

DCR-TRV255E/TRV260/TRV265/TRV265E

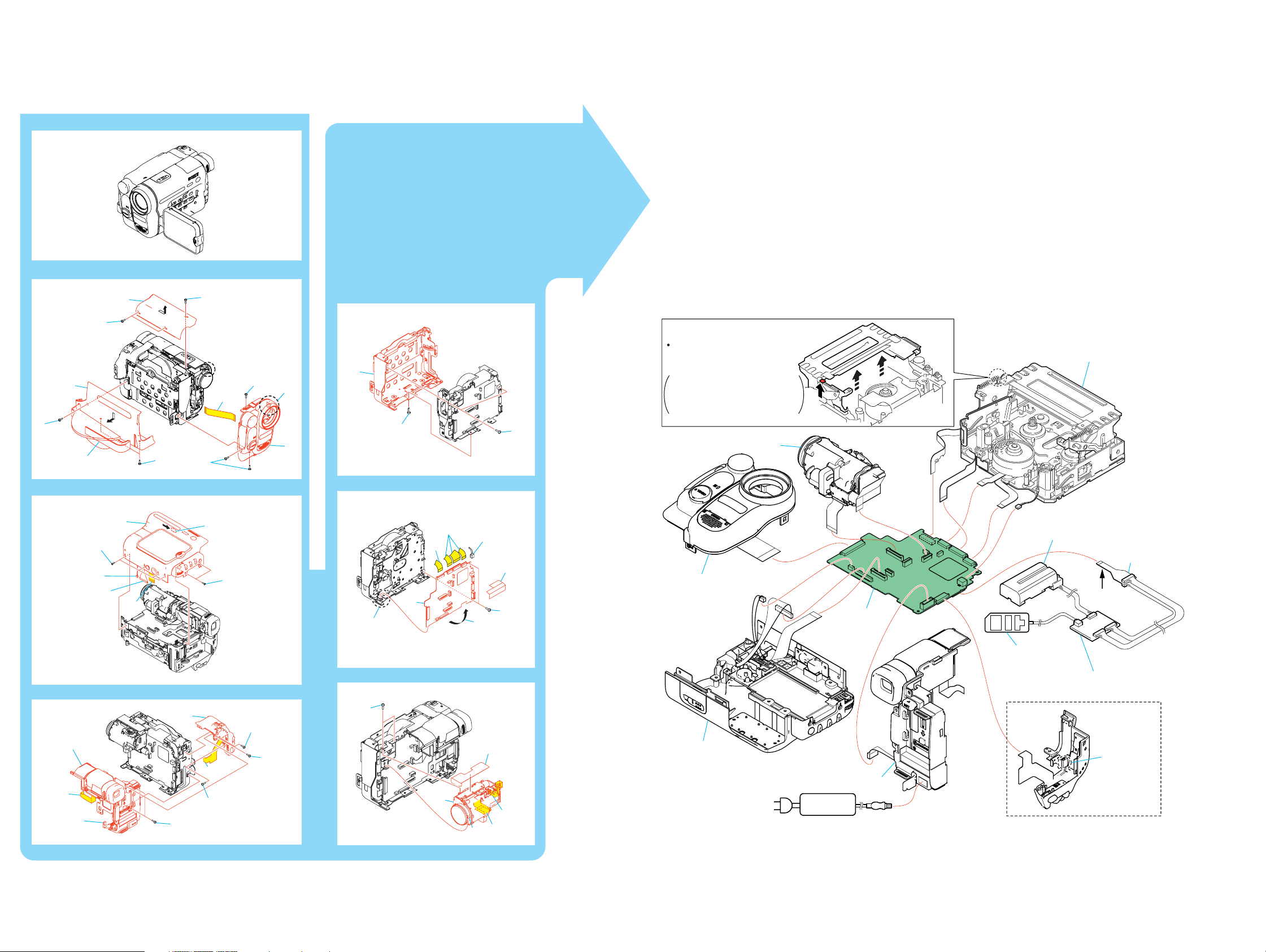

2-2. MECHANISM DECK SERVICE POSITION

Connection to Check the Mechanism deck

To check the mechanism deck, set the Camera or VTR to the "Forced power ON" mode. (Or, connect the control key

block (SS-5100) to the CN1009 of VC-344 board and set the power switch to the "CAMERA" or "PLAY/edit" position.)

Operate the Camera functions of the zoom and focus, the VTR function using the adjustment remote commander

(with the HOLD switch set in the OFF position).

4

5

3

1

2

4

6

1

9

6

7

8

2

1

1

Setting the "Forced Camera Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 02 and

press the PAUSE button of the adjustment remote

commander.

Setting the "Forced VTR Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 02 and

press the PAUSE button of the adjustment remote

commander.

How to move up the cassette

compartment manually

Press the cassette compartment

in the direction of the arrow A

to move it up in the direction of

the arrow B.

Lens block

A

B

Exiting the "Forced Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, data: 00, and press the PAUSE

button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

Mechanism deck

1

4

2

1

6

5

3

4

3

8

2

5

6

1

7

3

4

5

8

7

6

2

5

6

3

3

2

1

4

1

Front panel block

Cabinet R block

EVF block/

Battery panel block assembly

AC IN

AC adaptor

VC-344 board

Info lithium battery

(L series)

CPC jig connector

(J-6082-539-A)

Contacting

surface

Adjustment remote

commander (RM-95)

I/F unit for LANC control

(J-6082-521-A)

Eject switch

Control key block

(SS-5100)

When exiting the "Forced Power ON" mode, connect the control

key block (SS-5100) to the CN1009 of VC-344 board. Or, when

ejecting the cassette, connect the control key block (SS-5100) to

the CN1009 of VC-344 board. and press the Eject switch.

2-3 2-4

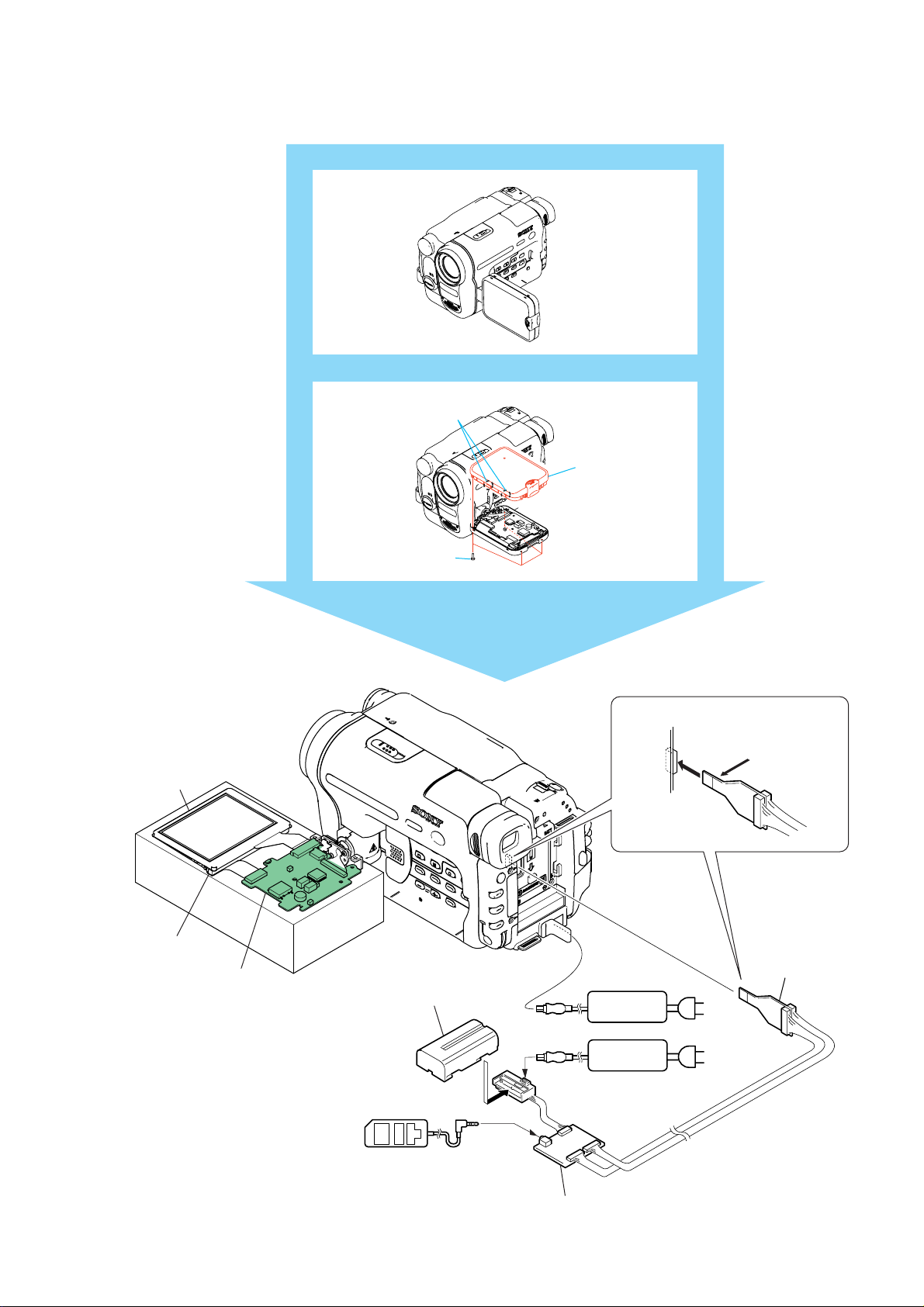

2-3. LCD SERVICE POSITION

AC adaptor

AC IN

AC adaptor

I/F unit for LANC control

(J-6082-521-A)

CPC jig connector

(J-6082-539-A)

CPC jig connector

L serices Info

LITHIUM battery (7.2Vdc)

LCD panel

PD-204 board

Back light unit

Adjustment

remote commander (RM-95)

Conductor side

CN1011

1

16

LANC jack

AC IN

2

1

3

DCR-TRV255E/TRV260/TRV265/TRV265E

2-5

DCR-TRV255E/TRV260/TRV265/TRV265E

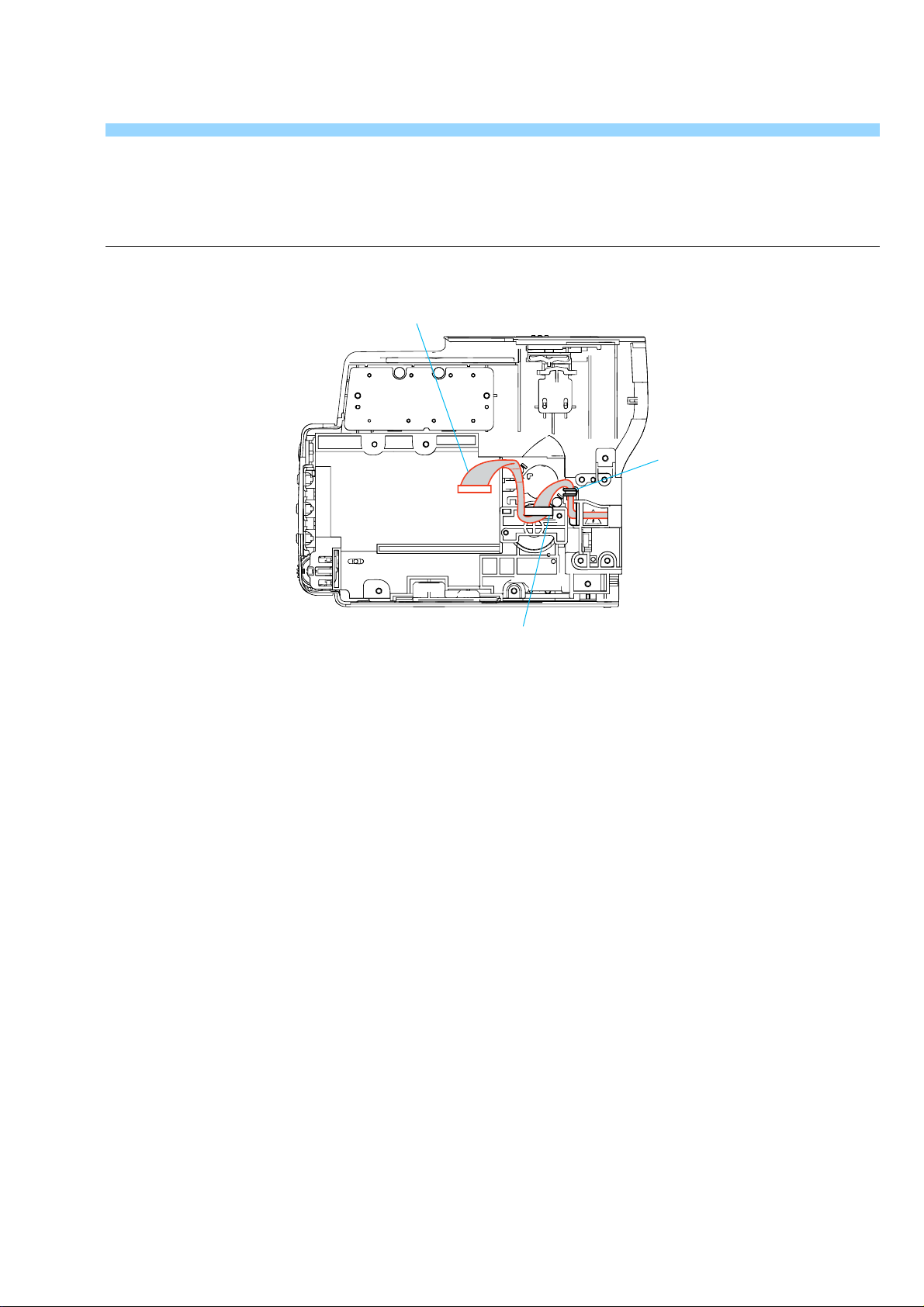

2-4. CIRCUIT BOARDS LOCATION

VC-344

SI-041

CD-471

PD-204

Board Name Function

CD-471 CCD IMAGER

VC-344 A/D CONVERTER, TIMING GENERATOR, DV SIGNAL PROCESS, LENS

CONTROL, STEADYSHOT, DV INTERFACE, VIDEO OUT, LENS DRIVE,

REC/PB AMP, SERVO, CAMERA/MECHA CONTROL, HI CONTROL,

AUDIO PROCESS, DC CONTROL, CONNECTOR

PD-204 LCD DRIVE, BACKLIGHT DRIVE

SI-041 JACK

2-6

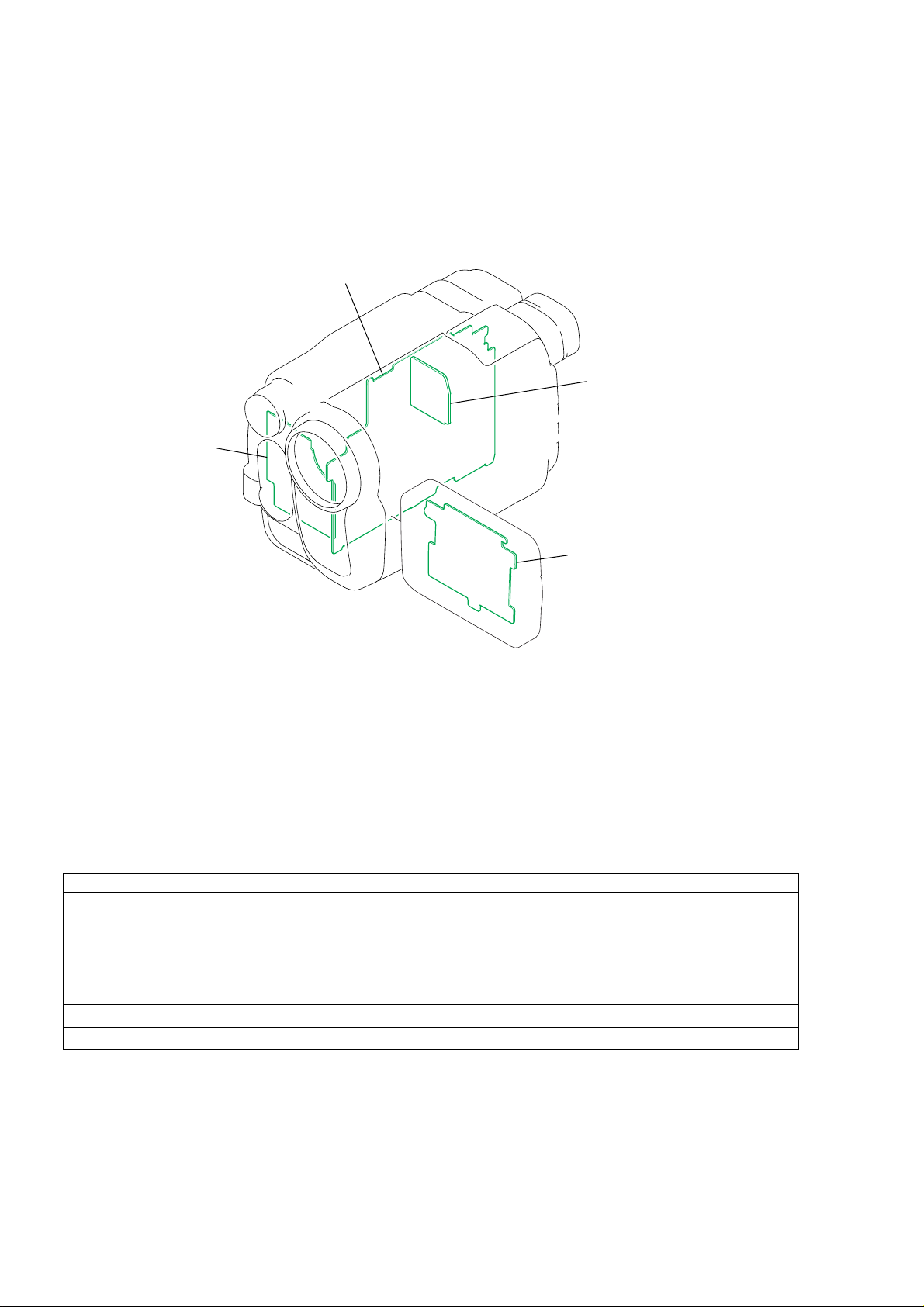

2-5. FLEXIBLE BOARDS LOCATION

DCR-TRV255E/TRV260/TRV265/TRV265E

FP-792

FP-796

FFC-005

FP-797

PR-5100

SS-5100

CF-5100

2-7E

DCR-TRV255E/TRV260/TRV265/TRV265E

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

Harness (PD-124)

Claw

Claw

Note: Close the LCD panel, when you work.

HELP

Link

Link

DCR-TRV255E/TRV260/TRV265/TRV265E

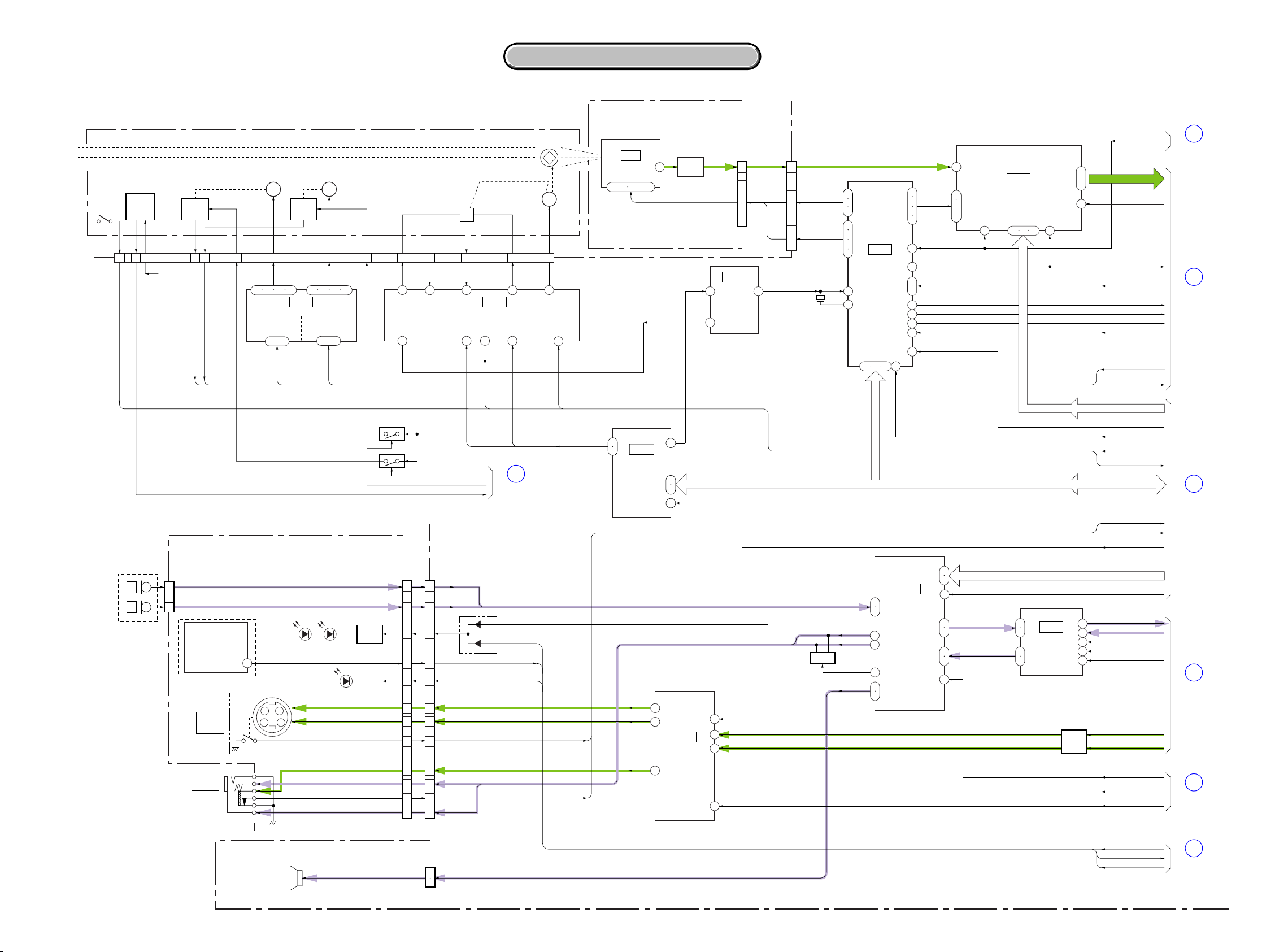

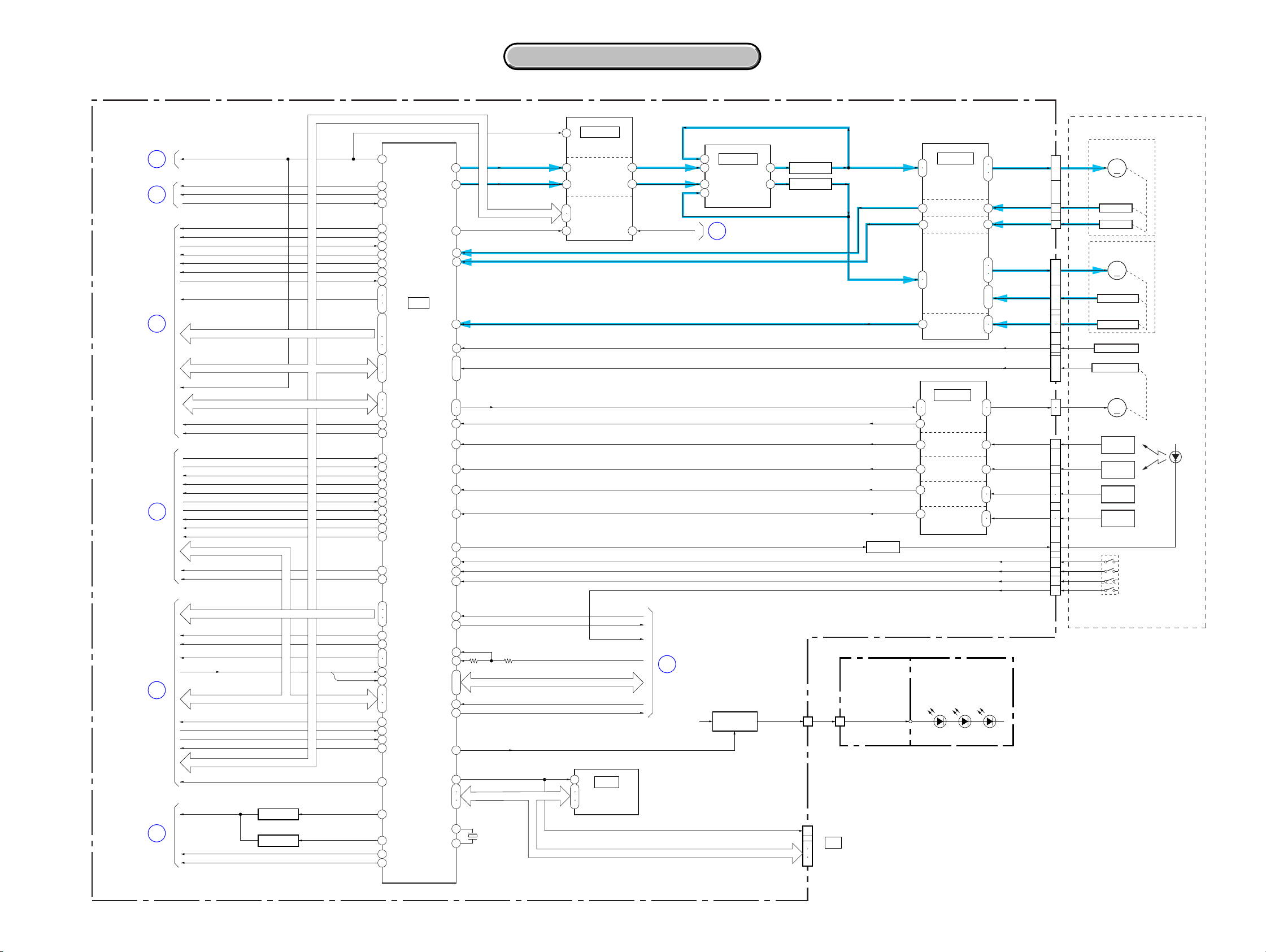

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/5)

OVERALL BLOCK DIAGRAM (1/5)

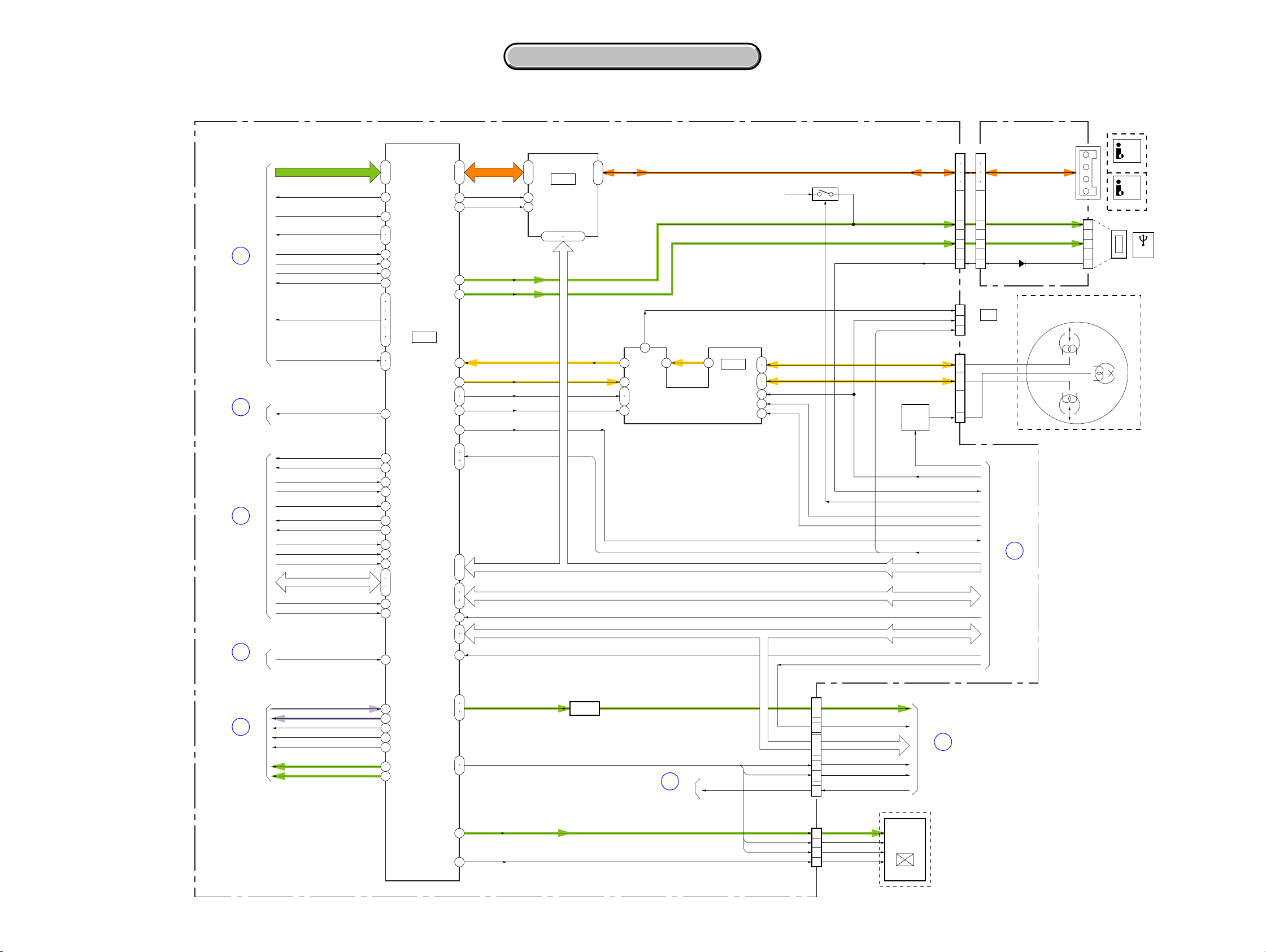

OVERALL BLOCK DIAGRAM (2/5)

OVERALL BLOCK DIAGRAM (2/5)

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (4/5)

OVERALL BLOCK DIAGRAM (4/5)

OVERALL BLOCK DIAGRAM (5/5)

OVERALL BLOCK DIAGRAM (5/5)

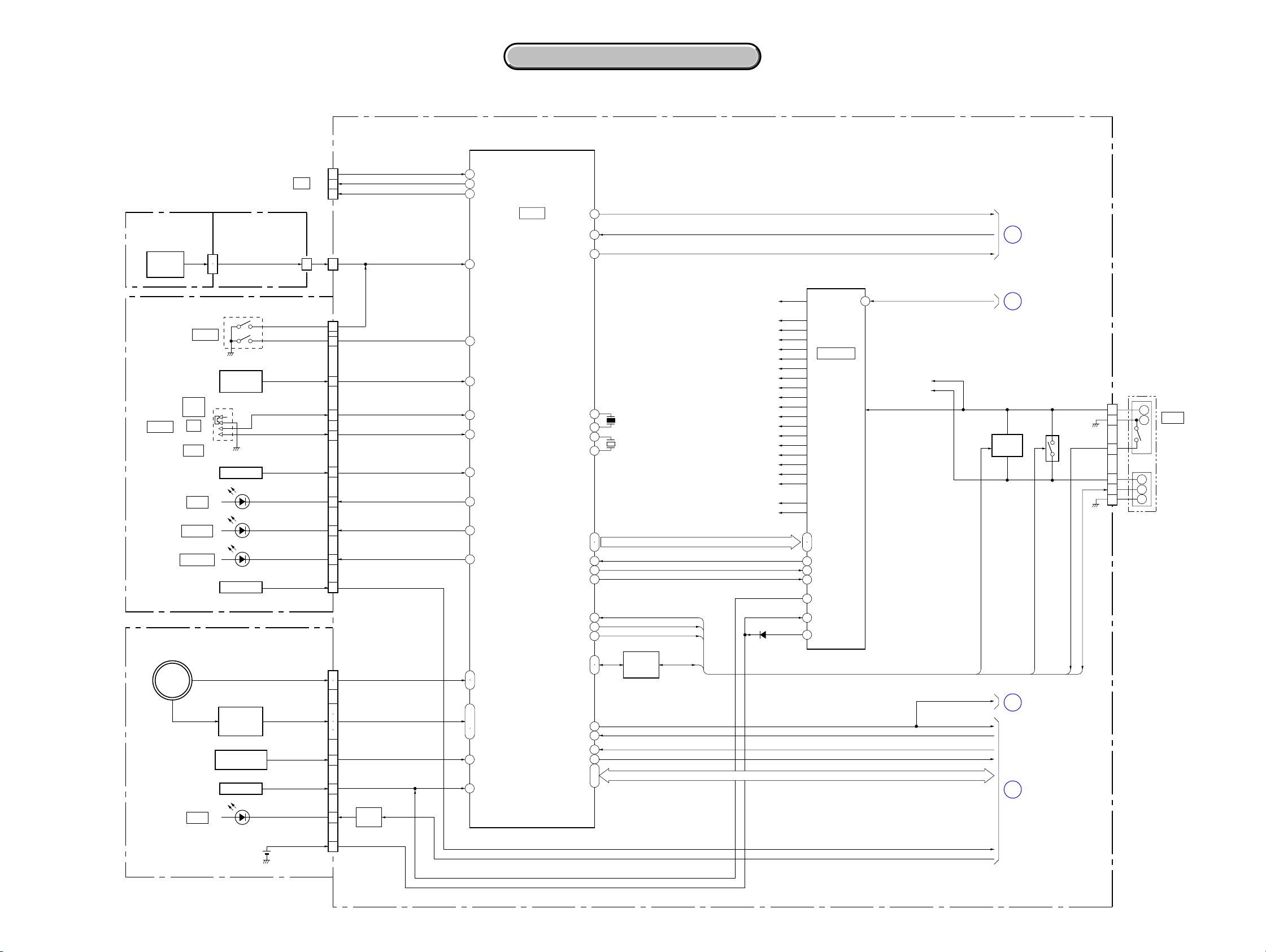

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (2/2)

POWER BLOCK DIAGRAM (2/2)

DCR-TRV255E/TRV260/TRV265/TRV265E

SECTION 3

BLOCK DIAGRAMS

3-1. O VERALL BLOCK DIAGRAM (1/5)

LENS ASSY

ZOOM MOTOR

NIGHT

SHOT

CN1551

LENS

TEMP

SENSOR

5 15 12 21 19

17 18

TEMP

IR SWITCH

XNS SW

D 2.8V

ZOOM

SENSOR

FC SENS OUT

ZM SENS OUT

ZM RST

FC RST

MM MM

10 – 7

ZM SENSE

VCC

5717 19 24

ZOOM

MOTOR

DRIVE

13 – 16

SI-041 BOARD (1/3)

FOCUS

SENSOR

ZOOM

A,B,XA,XB

IC1553

(3/10)

LD EN1

LD DIR1A

LD DIR1B

FOCUS MOTOR

1 – 4

FOCUS

MOTOR

DRIVE

9 – 12

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CD-471 BOARD VC-344 BOARD (1/4)

FOCUS

A,B,XA,XB

21 23

LD EN0

LD DIR0A

LD DIR0B

1316

FC SENSE

VCC

Q1555 (1/2)

IRIS

BIAS(+)

1

HALL

BIAS

HALL

REF

Q1555 (2/2)

2322

IRIS

HALL(+)

2

HALL

OFFSET

D 2.8V

ZM RST LED

LENS TEMP AD

H

IRIS

HALL(-)

5

HALL

AMP

6

FC RST LED

IC1552

(3/10)

73

HALL

AD

OVERALL (3/5)

(PAGE 3-5)

20

14

HALL

GAIN

12

IRIS

BIAS(-)

HALL

GAIN

7

IRIS

IRIS

METER

MM

IRIS DRIVE(-)

8

IRIS

DRIVE

10

IRIS PWM,

IRIS COM

HALL OFFSET,

HALL GAIN

IC951

CCD

IMAGER

1 – 4 12 – 14

3

IC1601

2

EVR

(D/A CONVERTER)

(3/10)

7

HALL REF

1

6

7

8

Q951

BUFFER

DA STRB

CN951 CN1501

1

7

5

1

11

14

IC1554

(3/10)

XTAL AMP

HALL REG

ı

9

ı

V1-V4,RG,H1,H2

CAM SO, CAM SCK

FREQ TUNE

7

14

6

ı

8

1

ı

4

CCD OUT

RG, H1, H2

V1 – V4

X1501

27MHz

18

21

22

25

26

28

31

4

5

IC1501

TIMING

GENERATOR

(1/10)

35 3738

CLPDM,

PBLK,

1

XSHP,

2

XSHD

15

16

XRST VTR

40

VCK VCK

12

44

45

34

41

48

36

CAM DD ON

42

39

XCS TG

CAM SI, CAM SO, CAM SCK

30

S/H, AGC, A/D CONVERTER

19

21

ı

23

43

IC1502

(1/10)

46 4847

2

ı

11

20

16

CAM SI, CAM SO, CAM SCK

XRST VTR

AD0-AD9

FE CLPOB

TG AHD, TG AVD

TG ZSG1

TG ZV1

TG ID

TG VGAT

LD EN0,EN1,

LD DIR0A,B,

LD DIR1A,B,

FC RST, ZM RST

CS CH, CH SO, CH SCK

CAM DD ON

XCS TG

IRIS PWM, IRIS COM

HALL AD, XNS SW

DA STRB

AV JACK IN

XS JACK IN

VOUT ON

1

OVERALL (3/5)

(PAGE 3-5)

2

OVERALL (2/5)

(PAGE 3-3)

3

OVERALL (3/5)

(PAGE 3-5)

MIC901

L

R

CN753

INT MIC L

1

INT MIC R

3

TRV265/TRV265E

A/V OUT

IC751

REMOTE

COMMANDER

RECEIVER

J751

S VIDEO

OUT

J752

1

(IR EMITTER)

CONTROL KEY BLOCK (CF-5100) (1/2)

SP901

SPEAKER

05

D753, 754

D759

(TALLY)

Y

C

XS JACK IN

V

L

AV JACK IN

R

CN754 (1/3)

Q751

LED

DRIVE

XSIRCS SIG

33

32 5

20

23

25 10

13

11

12

15

18

19

17

CN1001 (1/3)

4

17

14

24

26

25

22

19

18

20

CN1008

1

2

SP+, –

D1009

L

R

IR_ON

SIRCS PWM

SIRCS SIG

XF TALLY LED

XS JACK IN

AV JACK IN

2

VSP SO, XVSP SCK

IC5401

L, R

L

R

Q5401, 5403

Y

11

C

5

IC6501

Y/C MIX

BUFFER

V

(2/10)

6

13

Y Y OUT

14

C C OUT

1

3

MUTE

POWER MUTE

SP+,–

AUDIO

42

PROCESS

46

(8/10)

27

26

25

7

9

3

4

56

58

62

64

13

REC OUT L, R

PB IN L, R

3

2

15

16

IC5402

A/D, D/A

CONVERTER

(8/10)

Q3308

BUFFER

8

9

12

10

11

VSP SO, XVSP SCK

XCS IC 5401

DATA TO SFD

DATA FROM SFD

SFD BCK

SFD LRCK

SFD FCK

BEEP

IR ON

SDC ON

SIRCS PWM

SIRCS SIG

XF TALLY LED

4

OVERALL (2/5)

(PAGE 3-3)

5

OVERALL (3/5)

(PAGE 3-5)

6

OVERALL (4/5)

(PAGE 3-8)

A : VIDEO SIGNAL

A : AUDIO SIGNAL

3-1 3-2

DCR-TRV255E/TRV260/TRV265/TRV265E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-2. O VERALL BLOCK DIAGRAM (2/5)

VC-344 BOARD (2/4)

199

AD0-AD9

FE CLPOB

VCK

TG AHD, TG AVD

2

OVERALL (1/5)

(PAGE 3-2)

8

OVERALL (3/5)

(PAGE 3-6)

9

OVERALL (3/5)

(PAGE 3-5)

10

OVERALL (4/5)

(PAGE 3-8)

4

OVERALL (1/5)

(PAGE 3-2)

05

TG ZSG1

TG ZV1

TG ID

TG VGAT

LD EN0, EN1,

LD DIR0A, B,

LD DIR1A, B

FC RST, ZM RST

SPCK

VFO VD

VFO OE

DRP

SWP

XUSB EN

VREF

LINE OUT VD

XCS VFD

XCS SFD

XCS IC3301

CAM SI, CAM SO, CAM SCK

CAM XCE

XIRQ GEMINI

OSD V

DATA TO SFD

DATA FROM SFD

SFD BCK

SFD LRCK

SFD FCK

Y OUT

C OUT

ı

208

209

216

4

3

214

215

212

213

5

6

8

9

11

12

14

15

141

42

43

161

162

129

181

182

187

188

189

196

195

194

193

197

192

63

64

68

67

69

110

113

IC3301

DV SIGNAL

PROCESS,

D/A CONVERTER,

LENS CONTROL,

STEADYSHOT

(2/10)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

TPA+, –,

Q3303

BUFFER

6

ı

9

TPB+, –

RF MON

30

35 28

46

40

42

44

OVERALL (4/5)

(PAGE 3-8)

13

PB Y OUT

2796

BL CONT

IC3201

REC/PB

AMP

(4/10)

USB 3.3V

3

4

10

9

38

37

43

PANEL HD

PANEL VD

PANEL HD

PANEL VD

RF SWP

SW PS

ALL PS

CN1003

(1/2)

CN1013

Q3307

5

ı

7

10

11

ı

VD SO, VD SI, VD SCK

13

9

8

4

6

5

4

2

VIDEO IN

H SYNC

V SYNC

NSLEEP

154

ı

L BUS0-3

157

TRCKO

143

24M

159

USB D+

126

USB D–

127

RF IN

REC DT

77

REC A1, A2

75

76

REC CK

78

ATF LATCH

163

180

FRRV,TRRV,TRRT

179

178

167

MC BUS

ı

176

185

184

VSP SO, VSP SI, XVSP SCK

178

XRST VTR

190

18

VD SO, VD SCK

20

XCS VD

19

119

PANEL R, G, B PANEL R, G, B

121

123

131

PANEL HD, VD

130

BW Y

116

EVF DD ON

117

45

ı

42

47

79

IC3302

DV INTERFACE

(2/10)

29-32 34-37

MC BUS

XCS LCD DA

C-SYNC/XHD

PANEL XVD

BL CONT

Q3202, 3204, 3205

VSP SO, VSP SI, XVSP SCK

EVF BLOCK

LCD902

B/W

LCD UNIT

CN1001

(2/3)

USB D+

USB D–

USB DET

CN1011

(1/3)

RF MON

RF SWP

FRRV

CN3201

ODD (SP1)

EVEN (SP2)

FLYING

ERAE

OSC

USB DET

XUSB ON

ATF LATCH

FRRV, TRRV, TRRT

MC BUS

XRST VTR

VD SO, VD SI, VD SCK

XCS LCD

12

OVERALL (5/5)

(PAGE 3-9)

28

29

31

32

35

34

36

9

5

2

5

4

7

8

11

XFE ON

RF SWP

SW PS

ALL PS

XCS VD

SI-041 BOARD (2/3)

CN754

(2/3)

5

6

8

9

CN752

2

3

D755

1

D+

D–

VCC

M2200 MECHA DECK (1/2)

CPC

(FOR CHECK)

VIDEO HEAD

11

OVERALL (3/5)

(PAGE 3-5)

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/AUDIO SIGNAL

A : VIDEO/AUDIO/SERVO SIGNAL

SP1

SP2

CN751

TRV260/

TRV265/

DV

(OUT)

TRV265E

TRV255E

DV

(USB)

(IN/OUT)

3

2

1

CH

FLYING

ERASE

CH

3-3 3-4

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DCR-TRV255E/TRV260/TRV265/TRV265E

3-3. O VERALL BLOCK DIAGRAM (3/5)

VC-344 BOARD (3/4)

OVERALL (1/5)

(PAGE 3-2)

OVERALL (1/5)

(PAGE 3-1)

OVERALL (2/5)

(PAGE 3-4)

OVERALL (2/5)

(PAGE 3-3)

OVERALL (1/5)

(PAGE 3-2)

OVERALL (1/5)

(PAGE 3-2)

11

1

7

9

3

5

XRST VTR

ZM RST LED

FC RST LED

LENS TEMP AD

XFE ON

RF SWP

USB DET

XUSB ON

SW PS

ALL PS

ATF LATCH

FRRV, TRRV, TRRT

MC BUS

VSP SO, VSP SI, XVSP SCK

XRST VTR

VD SO, VD SI, VD SCK

XCS VD

XCS LCD

VFO VD

VFO OE

DRP

SWP

XUSB EN

VREF

LINE OUT VD

XCS VFD

XCS SFD

XCS IC 3301

CAM SI, CAM SO, CAM SCK

CAM XCE

XIRQ GEMINI

CS CH, CH SO, CH SCK

CAM DD ON

XCS TG

IRIS PWM, IRIS COM

HALL AD, XNS SW

CAM SI, CAM SO, CAM SCK

DA STRB

AV JACK IN

XS JACK IN

VOUT ON

VSP SO, XVSP SCK

XCS IC 5401

BEEP

IR ON

SDC ON

Q4502

MODULATOR

Q4501

MODULATOR

MELODY ENV

MELODY CARR

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

(5/10)

IC2401 (3/3)

XNS SW

HALL AD

34

100

55

57

127

170

172

113

131

29

28

162

23

179

IC4501

178

CAMERA/

45

MECHA

ı

CONTROL

52

(6/10)

32

33

69

70

67

82

83

80

61

38

203

68

163

164

132

204

201

155

215

97

161

208

62

73

71

173

20

94

95

187

128

78

77

75

59

185

186

26

43

98

202

194

209

88

89

197

198

190

119

106

ı

108

15

13

138

31

30

192

193

180

110

109

120

214

181

8

9

63

ı

66

135

169

91

10

87

86

84

3

1

DRUM PWM

CAP PWM

VSP SO, XVSP SCK

XCS IC 2401

DRUM FG

DRUM PG

CAP FG

DEW AD

MODE SW A-C

LOAD

UNLOAD

LM LIM DET

TAPE END

TAPE TOP

T REEL FG

S REEL FG

TAPE LED ON

REC PROOF

ME SW

HI8 MP SW

IC 5001 SO, IC 5001 SI, IC 5001 SCK, XCS IC 5001

V LIGHT PWM

XCS EEP

EEP SI, EEP SO, EEP SCK

X4501

20MHz

44

41

38

36

3716

1

2

5

6

XCS EEP

EEP SI, EEP SO, EEP SCK

LPF

SERIAL

INTERFACE

XCC DOWN

XSYS RST

ZOOM VR AD

CUSTOM LED ON

IC4502

EEPROM

(6/10)

OSD V

SYS V

45

43

35

DRUM ERROR

CAP ERROR

SPCK

14

IN7 (VL 16V)

OVERALL (4/5)

(PAGE 3-8)

(9/10)

25

IC1301 (1/2)

6

DRUM/CAPSTAN

PWM

9

DRIVE

24

OVERALL (2/5)

8

(PAGE 3-3)

Q1001

VIDEO LIGHT

DRIVE

EEP SI, EEP SO, EEP SCK

62

61

XCS EEP

SWITCHING

SWITCHING

CN1001

(3/3)

CN1011

(2/3)

Q1310

Q1309

TAPE LED ON

1 36

16

1

(FOR CHECK)

14

15

CN754(3/3)

CPC

DRUM VS

DRUM FG

DRUM PG

CAP VS

CAP FG

UNLOAD

LM LIM DET

TAPE END

TAPE TOP

T REEL FG

S REEL FG

Q2401

LED DRIVE

SI-041 BOARD

(3/3)

LND754

VL+

64

67

53

50

75

77

4

LOAD,

32

33

31

21 20

19

29

25

FP-792 FLEXIBLE

(5/10)

IC2401 (1/3)

DRUM

MOTOR

DRIVE

FG AMP

PG AMP

CAPSTAN

MOTOR

DRIVE

FG AMP

(5/10)

IC2401 (2/3)

LOADING

MOTOR

DRIVE

TAPE END

DETECT

TAPE TOP

DETECT

T REEL

FG AMP

S REEL

FG AMP

D001 – 003

(VIDEO LIGHT)

63

65

68

52

49

74

76

78

10

ı

15

7

8

69

72

18

26

27

22

23

DRUM U, V, W

CAP U, V, W

HU1, 2

HV1, 2

HW1, 2

FG1, 2

DEW AD

MODE SW A-C

LM (+) , LM (–)

TAPE END (C)

TAPE TOP (C)

T REEL (+) , (–)

S REEL (+) , (–)

TAPE LED (K)

REC PROOF

ME SW

HI8 MP SW

XCC DOWN

CN2402

FG

PG

CN2403

CN2401

CN2404

M2200 MECHA DECK (2/2)

M901

10

ı

5

3

1

14

ı

9

7

ı

2

18

16

22

21

ı

19

2

1

2

1

9

10

7

6

3

13

12

14

15

DRUM MOTOR

M

DRUM FG

DRUM PG

M902

CAPSTAN MOTOR

M

HU, HV, HW

CAPSTAN FG

DEW SENSOR

S901

MODE SWITCH

M903

LOADING MOTOR

M

Q002

TAPE END

SENSOR

Q001

TAPE TOP

SENSOR

T REEL

SENSOR

S REEL

SENSOR

S001

S002

A : SERVO SIGNAL

H001

H002

REC PROOF

ME/MP

HI8 MP

C. C. LOCK

D001

TAPE

LED

05

3-5 3-6

DCR-TRV255E/TRV260/TRV265/TRV265E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-4. OVERALL BLOCK DIAGRAM (4/5)

VC-344 BOARD (4/4)

CN1011

(3/3)

12

11

13

CN1003

(2/2)

20

20

CN1009

14

15

1

4

3

16

6

8

9

12

CN1007

19

20

5

14

18

16

6

22

Q1002

LED

9

DRIVE

1

2

PD-204 BOARD (1/2)CONTROL KEY

CN6005

AD5

BLOCK (PR-5100)

S601

PANEL

REVERSE

SW

CONTROL KEY BLOCK (SS-5100)

S003

PHOTO

S001

START/STOP

SW

(CHG)

S004

POWER

OFF

ON

>

MODE

D004

CHG

D002

CAMERA

D001

PLAY/EDIT

S002

EJECT SW

RV001

ZOOM VR

CONTROL KEY BLOCK (CF-5100) (2/2)

S024

SEL/PUSH

EXEC

DIAL

MENU EXEC

D002

EASY

FUNCTION

SW

S001

DISP/

BATT INFO SW

S002

RESET SW

DIAL A, B

CPC

(FOR CHECK)

CN6001

(1/2)

PHOTO

XPHOTO FREEZE XPHOTO FREEZE

XS/S SW

XPOWERSW

XMODE SW

XEJECT SW

XCHARGE LED

XCAM LED

XVTR LED

ZOOM VR

KEY AD0 – KEY AD3

XCUSTOM LED ON

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

LANC IN

LANC OUT

XLANC POWER ON

KEY AD5

KEY AD7

XPOWER SW

XMODE SW

XEJECT SW

XCHARGE LED

XCAM LED

XVTR LED

ZOOM VR AD

DIAL A, B

KEY AD0 – KEY AD3

XBATT INFO SW

XRESET

39

40

8

IC5001

HI CONTROL

(7/10)

67

6

69

1

2

4

12

11

9

79

80

59

ı

61

65

3

73

45

41

10

29

28

52

51

20

21

31

35

49

74

37

38

43

42

19

32

47

23

26

X5001

10MHz

X5002

32.768kHz

Q5001

BATTERY

CHARGE

DETECTOR

5

ı

IC 5001 SO, IC 5001 SI, IC 5001 SCK, XCS IC 5001 IC 5001 SO, IC 5001 SI, IC 5001 SCK, XCS IC 5001

SIRCS PWM

SIRCS SIG

XF TALLY LED

BL REG

D 1.5V

D 1.9V

A 2.8V

D 2.8V

AU 2.8V

EP 2.8V

RP 2.8V

A 4.6V

AU 4.6V

EP 4.6V

RP 4.6V

RP 6V

MT 5V

VL 16V

CAM –7.5V

CAM 15V

EP 13.5V

PANEL –15.3V

EVER 3.0V

VOUT

HI EVER SO, HI EVER SCK

BATT IN

VTR DD ON

XCS DD

XRESET

BATT/XEXT

FAST CHARGE

INIT CHARGE ON

BATT SIG

OSD V

SYS V SYS V

XCC DOWN

XSYS RST

D1301

VBAT

REG 3V

DC CONTROL,

27

28

44

38

26

45

39

40

IC1301 (2/2)

RESET

(9/10)

14

VTR UNREG

BATT UNREG

SIRCS PWM

SIRCS SIG

XF TALLY LED

BL CONT

OSD V

OSD V

XCC DOWN

XSYS RST

OVERALL (1/5)

6

(PAGE 3-2)

OVERALL (2/5)

13

(PAGE 3-4)

Q4003, 4004 Q4001, 4002

CHARGE

CONTROL

10

14

FAST CHARGE

OVERALL (2/5)

(PAGE 3-3)

OVERALL (3/5)

(PAGE 3-6)

INIT CHARGE ON

BATT/XEXT

BATT SIG

CN4001

BT901

4

+

–

+

S

–

DC IN

BATTERY

TERMINAL

3

2

6

5

1

BT001

LITHIUM

BATTERY

05

3

LI 3V

ZOOM VR AD

CUSTOM LED ON

XRESET

LI 3V

ZOOM VR AD

CUSTOM LED ON

3-7 3-8

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DCR-TRV255E/TRV260/TRV265/TRV265E

3-5. O VERALL BLOCK DIAGRAM (5/5)

PD-204 BOARD (2/2)

CN6001

(2/2)

PANEL R, PANEL G, PANEL BPANEL R, PANEL G, PANEL B

7

ı

5

OVERALL (2/5)

(PAGE 3-4)

12

XCS LCD DA

VD SO, VD SI, VD SCK VD SO, VD SI, VD SCK

C-SYNC/XHD

PANEL XVD

BL CONT BL CONT

10

11

ı

13

9

8

4

XCS LCD DA

C-SYNC/XHD

PANEL XVD

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

TYPE C/S: Please refer to page 1-3

to discriminate the type of LCD.

NOTE: CN6004 Pin Name A/B

A: TYPE C MODEL

B: TYPE S MODEL

CN6004

40

ı

38

IC6001

45

46

48

43

42

28

LCD

DRIVER

ı

2–6

14–16

29

32–35

19

ı

21

23

N.C./SPC, GRES/EX1, GPCK/MO1, GSRT/MO2,

STBYB/PSG,RESET/EX2, VBC/CLS, STBYB/RES,

SRT/PSS1, OE/PSS2, CLR/CTR, MCLK/CLD, HCNT/SPD

T6001, Q6002

INVERTER

BL REG

BL DET

30

TRANSFORMER

BACKLIGHT

DRIBE

D6004

VR, VG, VB

VCOM

BL HIGH

BL LOW

CN6003

19

ı

21

11

5

ı

10

12

ı

18

10

3

LCD901

2.5 INCH

COLOR

LCD UNIT

ND901

BACKLIGHT

05

A : VIDEO SIGNAL

3-9 3-10

DCR-TRV255E/TRV260/TRV265/TRV265E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-6. POWER BLOCK DIAGRAM (1/2)

VC-344 BOARD (1/2)

CN4001

6

5

1

4

2

3

05

Q4003, 4004

CHARGE

CONTROL

Q4001, 4002

CDET

36

VIN

43

VCC0

56

VCC1

55

DC CONTROL, RESET

VREF

37

DTC6

1

RT

30

DC IN

BT901

BATTERY

TERMINAL

+

S

–

+

–

BATT UNREG

BATT SIG

BATT GND

ACV UNREG

BATT/XEXT

ACV GND

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

BATT SIG

BATT/XEXT

INIT CHARGE ON

FAST CHARGE

VOUT

SEL

CS

VBAT

REG 3V

VRO

RST

LD

DIN

CLK

CTL1

IC1301

(9/10)

VR

OUT2

+INE2

OUT1

OUT3

IN3

OUT7

–INE7

OUT4

IN4

F002

D1306

Q1316, 1318, 1320

5V REG

L1311

L1310

L1319

L1317

L1318

L1320

Q1302, 1312, 1313

+15V REG

L1308

L1309

L1314

L1313

L1315

L1312

L1316

1

5

Q1301, 1303

13.5V REG

Q1304, 1314

–7.5V REG

IC1302

6V REG

(9/10)

Q1324, 1325

–15.3V REG

Q1315, 1317

1.9V REG

BL REG

4

F003

F004

BL REG UNREG

F001

VTR UNREG

42

32

44

39

40

41

29

26

27

28

38

34

58

21IN2

14

57

20IN1

59

22

63

2

60

23

D1301

Q1308

SWITCHING

BL CONT

D1302

Q1306

SWITCHING

Q1305

SWITCHING

Q1307

SWITCHING

L1301

L1304

L1302

L1305

L1303

Q1311

SWITCHING

D1303

D1305

FAST CHARGE

INIT CHARGE ON

BATT/XEXT

BATT SIG

BATT UNREG

MT 5V

VTR UNREG

V OUT

BATT IN

LI 3V

EVER 3.0V

XCS DD

HI EVER SO

HI EVER SCK

VTR DD ON

CAM DD ON

D 1.9V

D 1.5V

D 2.8V

A 2.8V

AU 2.8V

RP 2.8V

IN7 (VL 16V)

CAM –7.5V

CAM 15V

RP 6.0V

EP 4.6V

A 4.6V

AU 4.6V

RP 4.6V

EP 13.5V

CN1003

PANEL 2.8V

PANEL 4.6V

BL REG

PANEL –15.3V

PANEL 13.5V

BL CONT

A

POWER(2/2)

(PAGE 3-13)

17

18

2

16

19

4

TYPE C/S: Please refer to page 1-3 to descriminate the type of LCD.

PD- 204 BOARD

TYPE C

L6004

L6001

28

L6004

L6001

FB6001

IC6001

LCD DRIVER

FB6001

IC6001

LCD DRIVER

T6001, Q6002

INVERTER

TRANSFORMER

BACKLIGHT

DRIVE

18

16

19

17

4

2

BL REG

CN6001

PANEL 4.6V

PANEL –15.3V

PANEL 13.5V

PANEL 2.8V

BL CONT

TYPE S

PANEL 4.6V

PANEL –15.3V

PANEL 13.5V

PANEL 2.8V

BL CONT

L6002 L6003

R6026

R6019

R6020

Q6004, 6005,

6008, 6009

2428

BL HIGH

R6031

CN6004

VSH

VGL

VGH

VDD

VDD

CN6004

VSH5V

VGL

VGH

VSH3V

CN6003

LCD901

24

3

2.5INCH

1

COLOR

23

LCD UNIT

4

LCD901

24

3

2.5INCH

1

COLOR

23

LCD UNIT

ND901

10

BACK

LIGHT

3-11 3-12

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DCR-TRV255E/TRV260/TRV265/TRV265E

3-7. POWER BLOCK DIAGRAM (2/2)

VC-344 BOARD (2/2)

BATT/XEXT

FAST CHARGE

INIT CHARGE ON

BATT SIG

BATT UNREG

MT 5V

VTR UNREG

VOUT

BATT IN

LI 3V

EVER 3.0V EVER 3.0V

XCS DD

HI EVER SO

HI EVER SCK

VTR DD ON

A

POWER (1/2)

(PAGE 3-12)

CAM DD ON

D 1.9V

D 1.5V

D 2.8V

A 2.8V

AU 2.8V

RP 2.8V

IN7 (VL 16V)

CAM –7.5V

CAM 15V

RP 6.0V

EP 4.6V

A 4.6V

AU 4.6V

RP 4.6V

EP 13.5V

L3203

FLYING

ERASE

OSC

Q3202, 3204, 3205

L3202

IC3201

REC/PB

(4/10)

AMP

L3201

FB2401

IC2401

LOADING/

DRUM/

CAPSTAN

MOTOR

DRIVE

(5/10)

VMR

VH

3

17

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CHARGE LED VDD

BATT/XEXT

74

37

INIT CHARGE ON

38

35

20

21

33

56

IC3301

D/A CONVERTER,

LENS CONTROL,

STEADYSHOT

(2/10)

L3307

L3313

L3320

L3310

Q5408

AUDIO PROCESS

1

5

L3305

FB3303

IC5401

(8/10)

IC1001

3.3V REG

(10/10)

FB3301

4

D 2.8V

LI 3V

IC3302

DV

INTERFACE

(2/10)

IN7 (VL 16V)

CONVERTER

L3321

FB3302

IC5402

A/D, D/A

(8/10)

V LIGHT PWM

MODE LED VDD

CUSTOM LED VDD

USB 3.3V

Q1001

VIDEO

LIGHT

DRIVE

IN7 (VL 16V)

FB4501

CAM DD ON

173

CAMERA/MECHA

V LIGHT PWM

D 1.5V

D 1.9V

D 2.8V

A 2.8V

AU 2.8V

MT 5V

CAM –7.5V

CAM 15V

EP 4.6V

A 4.6V

AU 4.6V

IC4501

CONTROL

(6/10)

EVF DD ON

IC6501

Y/C MIX

BUFFER

(2/10)

L6501

91

173

55ZM RST LED

57FC RST LED

IC4502

EEPROM

(6/10)

Q5001

BATTERY

CHARGE

DETECTOR

S/H, AGC,

A/D CONVETER

43

42

54

55

31

IC1502 IC1501

(1/10)

FB1504

L1553

HALL BIAS/GAIN

Q1555

L1501

IC1552

IRIS DRIVE,

CONTROL,

HALL AMP

(3/10)

TIMING

GENERATOR

(1/10)

FB1501

IB SI

IB SO

BATT SENSE

ACV SENSE

BATT IN

IC5001

HI CONTROL

(7/10)

IC1601

EVR

(D/A CONVERTER)

(3/10)

FB1601

IC1554

XTAL AMP,

HALL REG

(3/10)

IC1553

FOCUS/ZOOM

MOTOR DRIVE

(3/10)

BATT/EXT

FAST CHARGE

INIT CHARGE

VTR DD ON

XCS DD 49

HI EVER SO

HI EVER SCK

XHI DS HELP

VTR DD SENSE

L1551

DV SIGNAL PROCESS,

CN1009

D 2.8V

CN1007

D 2.8V

D 2.8V

D 2.8V

LI 3V

CN1001

D 2.8V

MT 5V

CN1013

EVF DD ON

EP 4.6V

3.3V

CONTROL KEY BLOCK (SS-5100)

5

10

RV001

WT

11

(ZOOM)

CONTROL KEY BLOCK (CF-5100)

17

15

4

3

7

FUNCTION

SWITCH

D002

EASY

SI-041 BOARD

CN754

13

24

15

16

MT 5V

21

22

COMMANDER

FP-792 FLEXIBLE

LND754

VL+

1

36

EVF BLOCK

NSLEEP

2

EVF 4.6V

3

3.3V

1

LCD902

B/W

LCD

UNIT

D759

(TALLY)

TRV265/265E

IC751

REMOTE

RECEIVER

D001 – 003

(VIDEO LIGHT)

CAMERA

PLAY/EDIT

BT001

LITHIUM

BATTERY

(IR EMITTER)

D004

CHG

D002

D001

D753, 754

FG VCC

VH+

05

CAPSTAN

FG

17 8

CN2404CN2403

HE

SENSOR VCC

TAPE LED (A)

4 8

TAPE

LED

D001

T REEL,

S REEL,

SENSOR

H001,002

CN1551

FC SENSE

VCC

FOCUS

SENSOR

M2200 MECHA DECK

ZM SENSE

VCC

ZOOM

SENSOR

TEMP

SENSOR

LENS BLOCK

TEMP

18 241613

IRIS

METER

CD-471

BOARD

CAM 15V

1210

L951

IC951

CCD

IMAGER

CAM –7.5V

CN1501

35

CN951

IRIS DRIVE(+)

3-13 3-14E

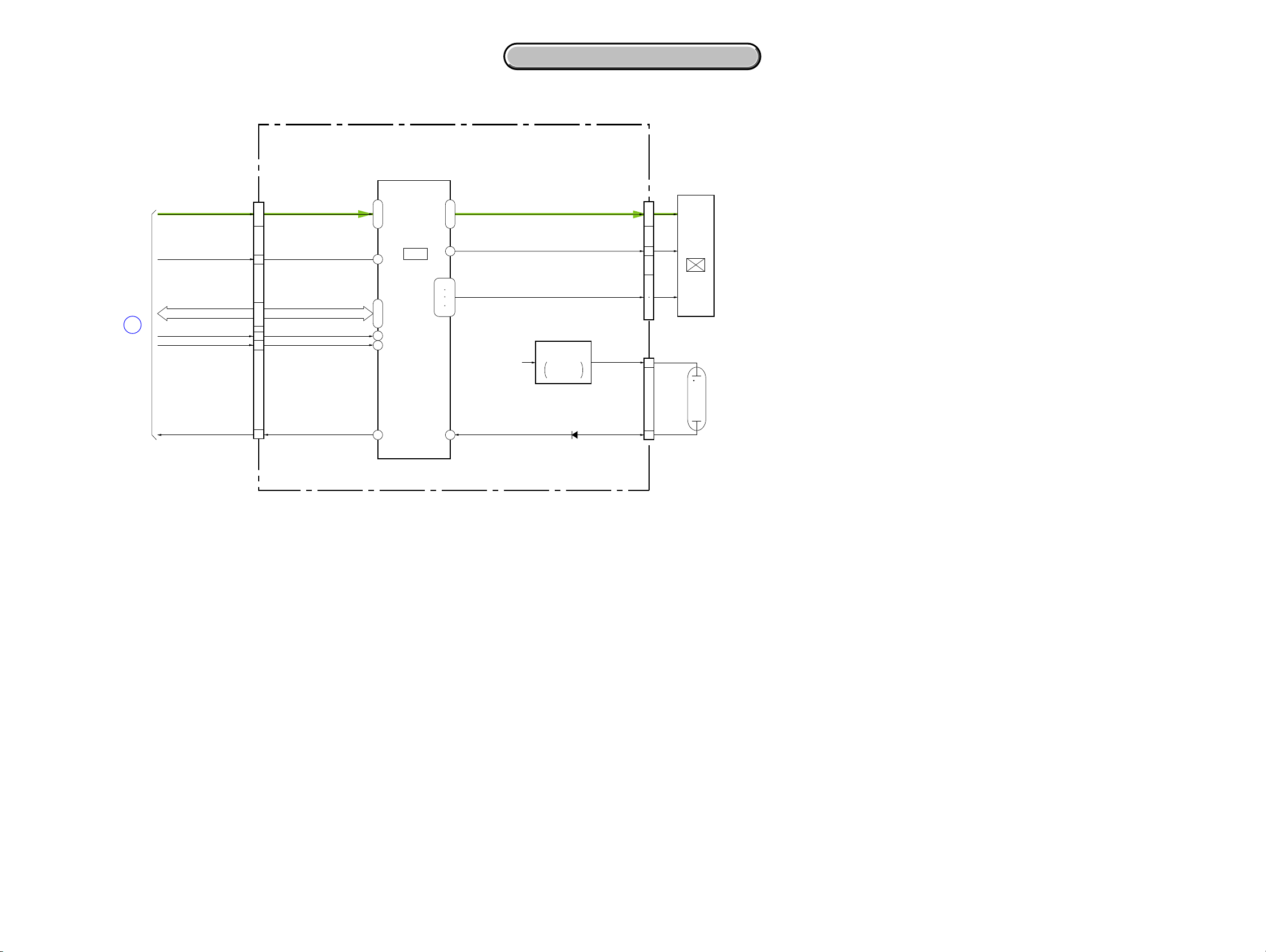

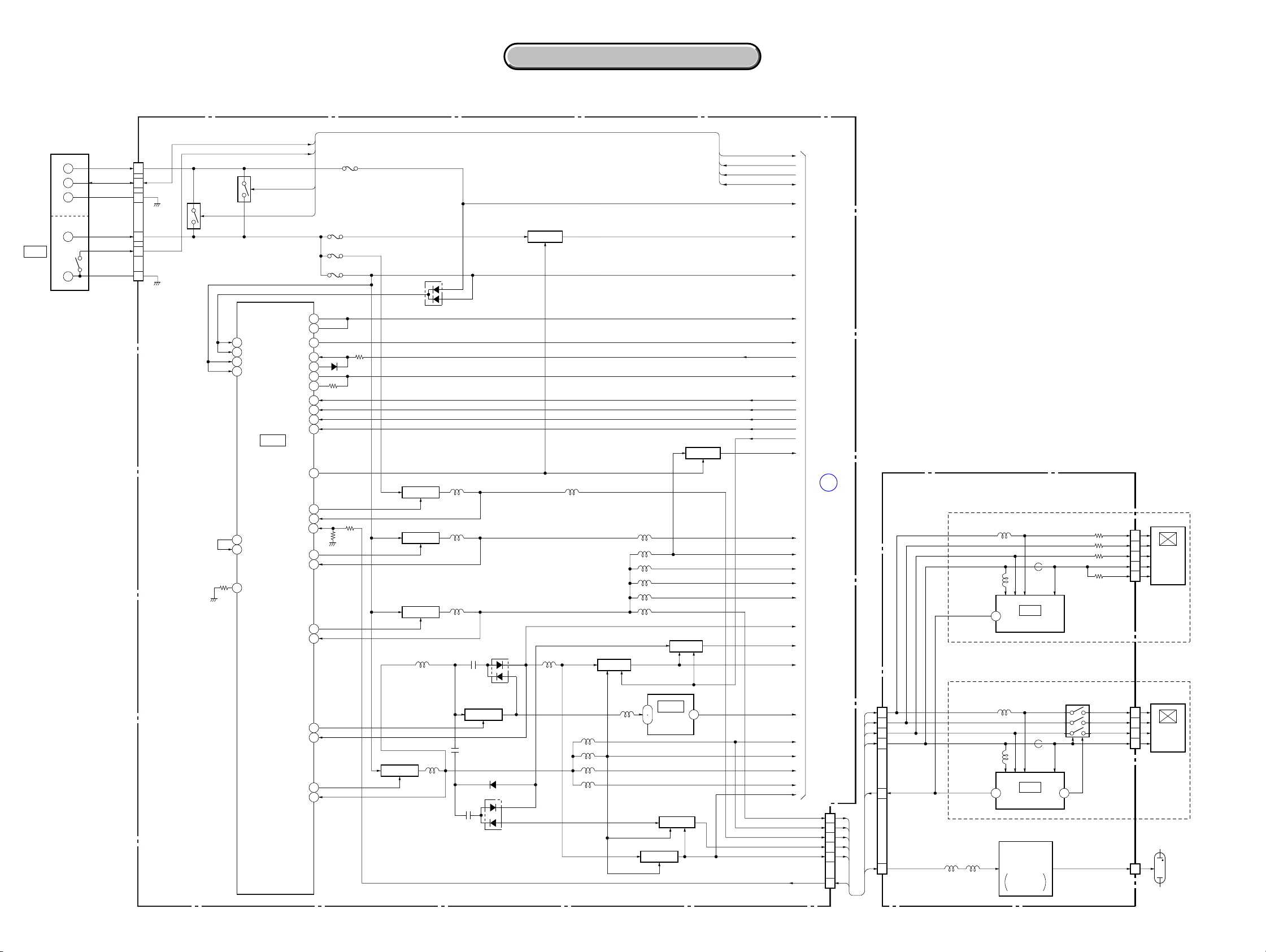

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAMS

SECTION 4

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

DCR-TRV255E/TRV260/TRV265/TRV265E

1

FRAME SCHEMATIC DIAGRAM

A

2 10

B

LENS

C

D

E

FP-792

FLEXIBLE

MIC901

MICROPHONE

R

BOARD

F

VL+

REG_GND

REG_GND

LND757

LND754

G

LND763

H

4P

CN753

4

GND

GND

INT_MIC_R

SI-041

1 VCC

2D-

3D+

4ID

5GND

CN751

1NTPB

2 TPB

3NTPA

4 TPA

BOARD

5PCN752

4P

I

(USB)

J

TRV255E

DV

OUT

K

DV

TRV260

/TRV265/TRV265E

L

CONTROL

M

(PR-5100)

N

05

34 1814

CD-471

BOARDBLOCK

L

123

INT_MIC_L

24PCN1551

IRIS_HALL(+)

IRIS_DRIVE(+)

XF_TALLY_LED

XSIRCS_SIG

SIRCS_PWM/IR_DRV_EN

INT_MIC_R

IRIS_BIAS(+)

IRIS_HALL(-)

CN754

MIC_GND

MIC_GND

INT_MIC_L

VREF1

VREF2

A_2.8V

A_2.8V

D_2.8V

MT_5V

MT_5V

AV_JACK_IN

AUDIO_L_I/O

AUDIO_R_I/O

REG_GND

VIDEO_I/O

REG_GND

S_Y_I/O

XS_JACK_IN

S_C_I/O

REG_GND

REG_GND

REG_GND

USB_D-

USB_D+

USB_DET

IRIS_BIAS(-)

36P

VL+

LIA1

LIA2

NTPA

TPA

TPB

NTPB

TEMP

IRIS_DRIVE(-)

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TEMP

KEY

BLOCK

5 12

CN951

14P

14

V4

13

V3

12

V2

11

V1

10

GND

9

H2

8

LENS_DET

ZM_SENSE_VCC

ZM_SENSE_OUT

FP-796 FLEXIBLE

6

5

4

3

2

1

FC_SENSE_VCC

FC_SENSE_OUT

CN1001

VL+

1

2

MIC_GND

MIC_GND

3

4

INT_MIC_L

5

INT_MIC_R

6

VREF1

LIA1

7

8

LIA2

VREF2

9

A_2.8V

10

A_2.8V

11

XF_TALLY_LED

12

D_2.8V

13

XSIRCS_SIG

14

MT_5V

15

MT_5V

16

SIRCS_PWM/IR_DRV_EN

17

AV_JACK_IN

18

AUDIO_L_I/O

19

AUDIO_R_I/O

20

REG_GND

21

VIDEO_I/O

22

REG_GND

23

S_Y_I/O

24

XS_JACK_IN

25

S_C_I/O

26

REG_GND

27

NTPA

28

TPA

29

REG_GND

30

TPB

31

NTPB

32

REG_GND

33

USB_D-

34

USB_D+

35

USB_DET

36

SE_GND

SE_GND

N.C.

N.C.

PANEL_REV

PANEL_REV

CAM_-7.5V

GND

CAM_15V

CCD_OUT

101112131415161718192021222324

ZOOM_A

36P

6PCN6005

GND

VSHT

GND

ZOOM_B

H1

RG

ZOOM_XB

7

6

5

4

3

2

1

ZOOM_XA

IR_SWITCH

FOCUS_A

IR_SWITCH

20P

CN1003

20P

CN6001

AD5

AD5

FOCUS_B

PANEL_13.5V

PANEL_13.5V

FFC-005

FLEXIBLE

FLAT CABLE

FOCUS_XB

PANEL_4.6V

PANEL_4.6V

123456789

FOCUS_XA

PANEL_2.8V

PANEL_2.8V

14PCN1501

CCD_OUT

PANEL_-15.3V

PANEL_-15.3V

GND

REG_GND

REG_GND

CAM_-7.5V

PANEL_HOLD

VD_SI(HDO)

VD_SI(HDO)

PANEL_HOLD

1011121314

VSHT

CAM_15V

(FOR CHECK)

VD_SO

VD_SCK

PD-124

HARNESS

VD_SO

VD_SCK

GND

CPC

XCS_LCD_DA

1011121314151617181920

1011121314151617181920

XCS_LCD_DA

PD-204

BOARD

When the machine needs to be repaired,please refer to

page 1-3 to discriminate the type of LCD(TYPE C or TYPE S).

C-SYNC/XHD

PANEL_XVD

9

8

8

9

PANEL_XVD

C-SYNC/XHD

H2RGH1

GND

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PANEL_R

PANEL_R

16PCN1011

XCS_EEP

EEP_SI

EEP_SO

XLANC_PWR_ON

LANC_IN

LANC_OUT

REG_GND

PB_RF

REG_GND

REC_RF

REG_GND

SWP_DIR

CAP_FG

BPF_MONI

PB_RF

EEP_SCK

PANEL_G

PANEL_B

PANEL_B

PANEL_G

V3V1V2

BL_CONT

BL_CONT

BL_GND

BL_GND

123456789

V4

SE_GND

BL_REG

1234567

1234567

BL_REG

SE_GND

9

TAPE_TOP(C)

TAPE_LED(A)

TAPE_END(C)

S_REEL(-)

REG_GNDREG_GND

TAPE_LED(K)

123456789

15P

CN2404

TAPE_TOP(C)

S_REEL(-)

TAPE_LED(K)

TAPE_LED(A)

TAPE_END(C)

123456789

24P

VGL/VGL

VSS/GND

VGH/VGH

VDD/VGLAC

CN6004

N.C./SPS

S_REEL(+)

SENSOR_VCC

T_REEL(+)

T_REEL(-)

ME/MP

HALL_COM

HI8_MP

REC_PROOF

FP

1011121314

ME/MP

HI8_MP

T_REEL(-)

T_REEL(+)

S_REEL(+)

HALL_COM

SENSOR_VCC

REC_PROOF

VC-344 BOARD

LCD901

2.5INCH

COLOR

LCD UNIT

101112131415161718192021222324

GSRT/MO2

RESET/EX2

STBYB/PSG

VBC/CLS

VCOM/VCOM

GRES/EX1

GPCK/MO1

11 15

M2200 MECHANISM DECK

C_LOCK_SW

15

C_LOCK_SW

SRT/PSS1

STBYB/RES

22P

CN2403

DEW

DEW

OE/PSS2

M-SW(A)

M-SW(B)

M-SW(A)

M-SW(B)

CLR/CTR

MCLK/CLD

CN6004 Pin Name A/BNote:

A:

TYPE C MODEL

B: TYPE S MODEL

M-SW(C)

M-SW(C)

HCNT/SPD

FG VCC

FG1

FG1

FG VCC

VR/VR

VG/VG

CAP_W

CAP_W

CAP_U

REG_GND

CAP_U

CAP_V

FG2

FP

CAP_U

VSH/VSH5V

VDD/VSH3V

CAP_U

CAP_W

CAP_W

10111213141516171819202122

CAP_V

FG2

REG_GND

VB/VB

VSS/GND

13 17

CAP_V

CAP_V

HU1

HV1

HU2

HV2

VH+

HV1

HV2

VH+

HU2

HU1

ND901

BACKLIGHT

10

N.C

N.C

10PCN6003

BL_HIGH

FE(X)

VH-

HW1

HW2

123456789

11

11PCN3201

VH-

HW2

HW1

FE(X)

N.C

N.C

N.C

N.C

BL_LOW

4-1 4-2

1916678

20

21

EVF BLOCK

LCD902

B/W

LCD

UNIT

LM

SP2(X)

GND

FP

GND

XEVEN(SP2Y)

SP1(X)

SP1(Y)

YODD(SP1X)

XODD(SP1Y)

2PCN1008

SPEAKER

GND

GND

GND

123456789

GND

GND

GND

22PCN1007

SP(+)

SP(-)

1

2

SP901

U

V

V

U

W

W

FP

10

V

V

U

U

W

10P

CN2402

REG_GND

123456789

W

KEY_AD0

LI_3V

BATT_INFO

D_2.8V

CUSTOM_LED_VDD

N.C

COM

PG

FG

FG-PG_COM

1

2

123456789

2P

FG

PG

COM

FG-PG_COM

N.C

XCUSTOM_LED_ON

REG_GND

10111213141516171819202122

XMS_LED

N.C

LM(+)

CN2401

MS_LED_VDD

KEY_AD1

LM(-)

D_2.8V

KEY_AD3

D_2.8V

CN1009

XPOWER_SW

CHARGE_LED_VDD

XCHARGE_LED

MODE_LED_VDD

XPHOTO_FREEZE

ACV_UNREG

BATT_UNREG

KEY_AD2

DIAL_A

XS/S_SW

REG_GND

XMODE_SW

XCAM_LED

XVTR_LED

ZOOM_VR

REG_GND

KEY_AD5

XEJECT_SW

BATT_GND

BATT/XEXT

ACV_GND

BATT_SIG

DIAL_B

N.C

D_2.8V

REG_GND

16P

6PCN4001

XRESET

NC

NC

8PCN1013

13.3V

2NSLEEP

3EVF_4.6V

4HSYNC

5VSYNC

6VIDEO_IN

7DIG_GND

8ANA_GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

10

FP-797

FLEXIBLE

CONTROL

KEY

BLOCK

(SS-5100)

BT901

BATTERY

TERMINAL

3.3V3NSLEEP4EVF_4.6V5HSYNC6VSYNC7VIDEO_IN8DIG_GND9ANA_GND

1

2

GND

FE(Y)

SP2(Y)

10

GND

FE(Y)

YEVEN(SP2X)

CONTROL

KEY

123456789

LED

LED_GND

BLOCK

(CF-5100)

FRAME

Loading...

Loading...