Sony DCR-PC101-101E Service Manual

DCR-PC101/PC101E

RMT-814

SERVICE MANUAL

Ver 1.0 2002. 05

Revision History

Revision History

J MECHANISM

Link

Link

SPECIFICATIONS

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

East European Model

North European Model

Hong Kong Model

Australian Model

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

DCR-PC101

AEP Model

UK Model

Russian Model

DCR-PC101E

E Model

DCR-PC101/PC101E

Chinese Model

DCR-PC101E

Korea Model

DCR-PC101

Tourist Model

DCR-PC101/PC101E

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (992997141.pdf).

• For MECHANISM ADJUSTMENTS, refer to the “DV MECHANICAL ADJUSTMENT MANUAL VI

J MECHANISM ” (9-929-807-11).

• Reference No. search on printed wiring boards is available.

On the BJ-003, VC-284 boards

This service manual provides the information that is premised the circuit board replacement service and not intended repair

inside the BJ-003, VC-284 boards.

Therefore, schematic diagram, printed wiring board, waveforms, mounted parts location and electrical parts list of the BJ-003,

VC-284 boards are not shown.

The following pages are not shown.

Schematic diagram .............................Pages 4-9 to 4-50

Printed wiring board............................Pages 4-73 to 4-80

Waveforms ...........................................

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

Mounted parts location ..................

Electrical parts list.........................Pages 6-11, 6-16 to 6-25

Page 4-98 to 4-100

ADJUSTMENTS

ADJUSTMENTS

REPAIR PARTS LIST

REPAIR PARTS LIST

Page 4-103 to 4-105

DIGITAL VIDEO CAMERA RECORDER

DCR-PC101/PC101E

COVER

COVER

TM

SERIES

SPECIFICATIONS

Video camera

recorder

System

Video recording system

2

rotary heads

Helical scanning system

Audio recording system

2 rotary heads, PCM system

Quantization: 12 bits (Fs 32 kHz,

stereo 1, stereo 2), 16 bits

(Fs 48 kHz, stereo)

Video signal

DCR-PC101:

NTSC color, EIA standards

DCR-PC101E:

PAL color, CCIR standards

Usable cassette

Mini DV cassette with the

mark printed

Tape speed

SP: Approx. 18.81 mm/s

LP: Approx. 12.56 mm/s

Recording/playback time

(using cassette DVM60)

SP: 1 hour

LP: 1.5 hours

Fastforward/rewind time

(using cassette DVM60)

When using the battery pack:

Approx. 2 min. and 30 seconds

When using the AC power

adaptor:

Approx. 1 min. and 45 seconds

Viewfinder

Electric viewfinder (color)

Image device

3.8 mm (1/4.7 type) CCD

(Charge Coupled Device)

Gross: Approx. 1 070 000 pixels

Effective (still):

Approx. 1 000 000 pixels

Effective (moving):

Approx. 690 000 pixels

Lens

Carl Zeiss

Combined power zoom lens

Filter diameter 30 mm. (1 3/16 in.)

10× (Optical), 120× (Digital)

F = 1.8 - 2.0

Focal length

3.7 - 37 mm (5/32 - 1 1/2 in.)

When converted to a 35 mm still

camera

In CAMERA:

50 - 500 mm (2 - 19 3/4 in.)

In MEMORY:

42 - 420 mm (1 11/16 - 16 5/8 in.)

Color temperature

Auto, HOLD (Hold), nIndoor

(3 200K),

Outdoor (5 800K)

Minimum illumination

7 lx (lux) (F 1.8)

0 lx (lux) (in the NightShot mode)*

* Objects unable to be seen due to

the dark can be shot with

infrared lighting.

Input/Output connectors

S video input/output

4-pin mini DIN

Luminance signal: 1 Vp-p,

75 Ω (ohms), unbalanced, sync

negative

Chrominance signal:

DCR-PC101: 0.286 Vp-p

DCR-PC101E: 0.3 Vp-p

75 Ω (ohms), unbalanced

A/V (Audio/Video) input/output

AV MINI JACK, input/output

auto switch

Video signal: 1 Vp-p, 75 Ω (ohms),

unbalanced, sync negative

Audio signal: 327 mV, (at output

impedance more than 47 kΩ

(kilohms) )

Input impedance with more than

47 kΩ (kilohms)

Output impedance with less than

2.2 kΩ (kilohms)

DV input/output

4-pin connector

Headphone jack

Stereo minijack (ø 3.5 mm)

LANC jack

Stereo mini-minijack (ø 2.5 mm)

USB jack

mini-B

MIC jack

Minijack, 0.388 mV low impedance

with 2.5 to 3.0 V DC, output

impedance 6.8 kΩ (kilohms)

(ø 3.5 mm)

Stereo type

LCD screen

Picture

6.2 cm (2.5 type)

50.3 × 37.4 mm (2 × 1 1/2 in.)

Total dot number

211 200 (960 × 220)

General

Power requirements

7.2 V (battery pack)

8.4 V (AC power adaptor)

Average power consumption

(when using the battery pack)

During camera recording using

LCD:

DCR-PC101: 4.0 W

DCR-PC101E: 3.9 W

Viewfinder:

DCR-PC101: 3.3 W

DCR-PC101E: 3.2 W

Operating temperature

0 °C to 40 °C (32 °F to 104 °F)

Storage temperature

–20 °C to +60 °C (–4 °F to +140 °

Dimensions (approx.)

55 × 105 × 99 mm

(2 1/4 × 4 1/4 × 4 in.) (w/h/d)

Mass (approx.)

480 g (1 lb 0 oz)

excluding the battery pack and

cassette

580 g (1 lb 4 oz)

including the battery pack,

NP-FM50, cassette DVM60 and

lens cap

AC power adaptor

Power requirements

100 - 240 V AC, 50/60 Hz

Power consumption

23 W

Output voltage

DC OUT: 8.4 V, 1.5 A during

operation

Operating temperature

0 °C to 40 °C (32 °F to 104 °F)

Storage temperature

–20 °C to +60 °C (–4 °F to +140 °

Dimensions (approx.)

125 × 39 × 62 mm

(5 × 1 9/16 ×2 1/2 in.) (w/h/d)

excluding projecting parts

Mass (approx.)

280 g (9.8 oz)

excluding the power cord

Battery pack

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Capacity

8.5 Wh (1 180 mAh)

Dimensions (approx.)

38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 in.)

(w/h/d)

Mass (approx.)

76 g (2.7 oz)

Type

Lithium ion

F)

“Memory Stick”

Memory

Flash memory

8MB: MSA-8A

Operating voltage

2.7-3.6V

Power consumption

Approx. 45mA during operation

Approx. 130µA in tape recording

standby

Dimensions (approx.)

50 × 2.8 × 21.5 mm

(2 × 1/8 × 7/8 in.) (w/h/d)

Mass (approx.)

4 g (0.14 oz)

Design and specifications are

subject to change without notice.

F)

— 2 —

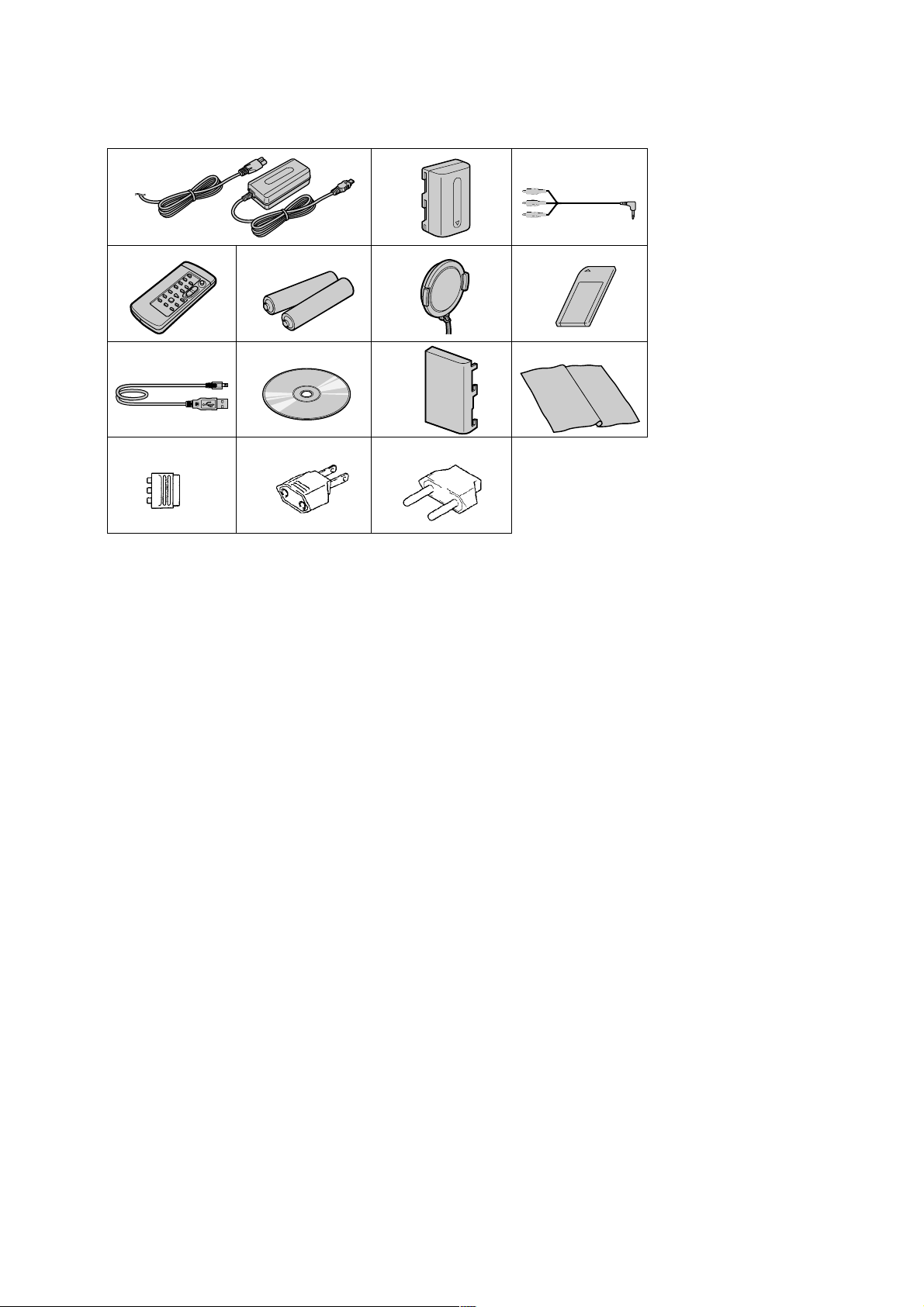

Supplied accessories

DCR-PC101/PC101E

4

8

qs qfqd

1 AC-L10A/L10B/L10C AC power

adaptor (1), Power cord (1)

2 NP-FM50 battery pack (1)

3 A/V connecting cable (1)

4 Wireless Remote Commander (1)

5 Size AA (R6) battery for Remote

Commander (2)

6 Lens cap (1)

7 “Memory Stick” (1)

8 USB cable (1)

5

9

21

6

q;

9 CD-ROM (SPVD-008 USB Driver)

q; Battery terminal cover (1)

qa Cleaning cloth (1)

qs 21-pin adaptor

DCR-PC101: AEP, UK, EE, NE, RU

qd 2-pin conversion adaptor (1)

DCR-PC101E: E, HK/PC101E: E, HK

qf 2-pin conversion adaptor (1)

DCR-PC101: JE/PC101E: JE

3

7

qa

(1)

(1)

— 3 —

DCR-PC101/PC101E

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or eqivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 4 —

DCR-PC101/PC101E

TABLE OF CONTENTS

Section Title Page Section Title Page

1. SERVICE NOTE

1-1. Service Note ····································································1-1

1. Power Supply During Repairs ·········································1-1

2. To Take Out a Cassette when Not Eject (Force Eject) ····1-1

1-2. Self-diagnosis Function ···················································1-2

1. Self-diagnosis Function ···················································1-2

2. Self-diagnosis Display·····················································1-2

3. Service Mode Display ·····················································1-2

4. Self-diagnosis Code Table ···············································1-3

2. DISASSEMBLY

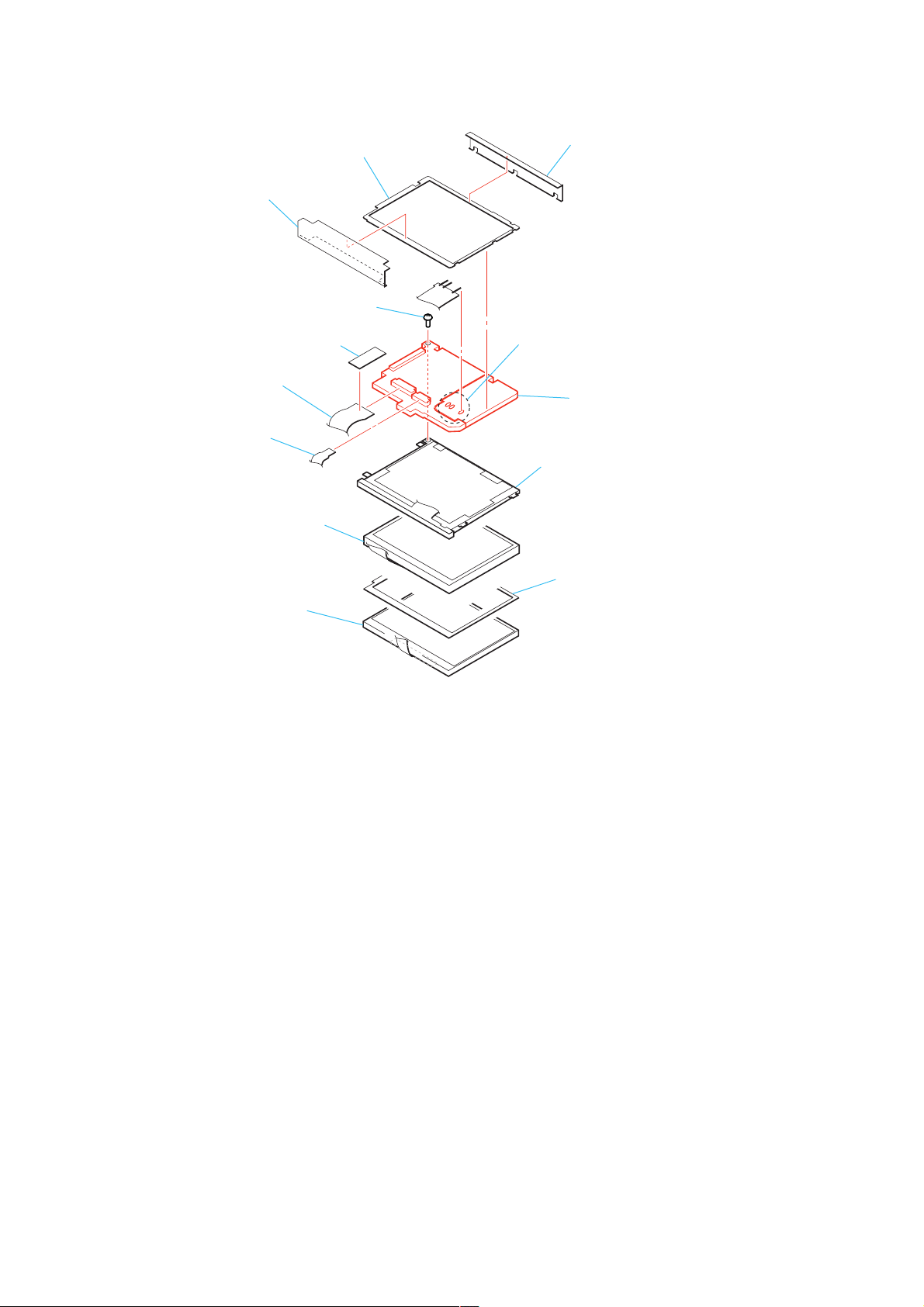

2-1. LCD Cabinet (R) Assembly ············································2-2

LCD Block Service Position ···········································2-2

2-2. Cabinet (R) Block Assembly···········································2-3

2-3. Lens (-EVF) Block Section ·············································2-3

2-4. Lens Block·······································································2-4

2-5. CF-089 Board ··································································2-4

2-6. VC-284 Board ·································································2-5

2-7. Mechanism Deck ·····························································2-5

2-8. Cabinet (G) Assembly ·····················································2-6

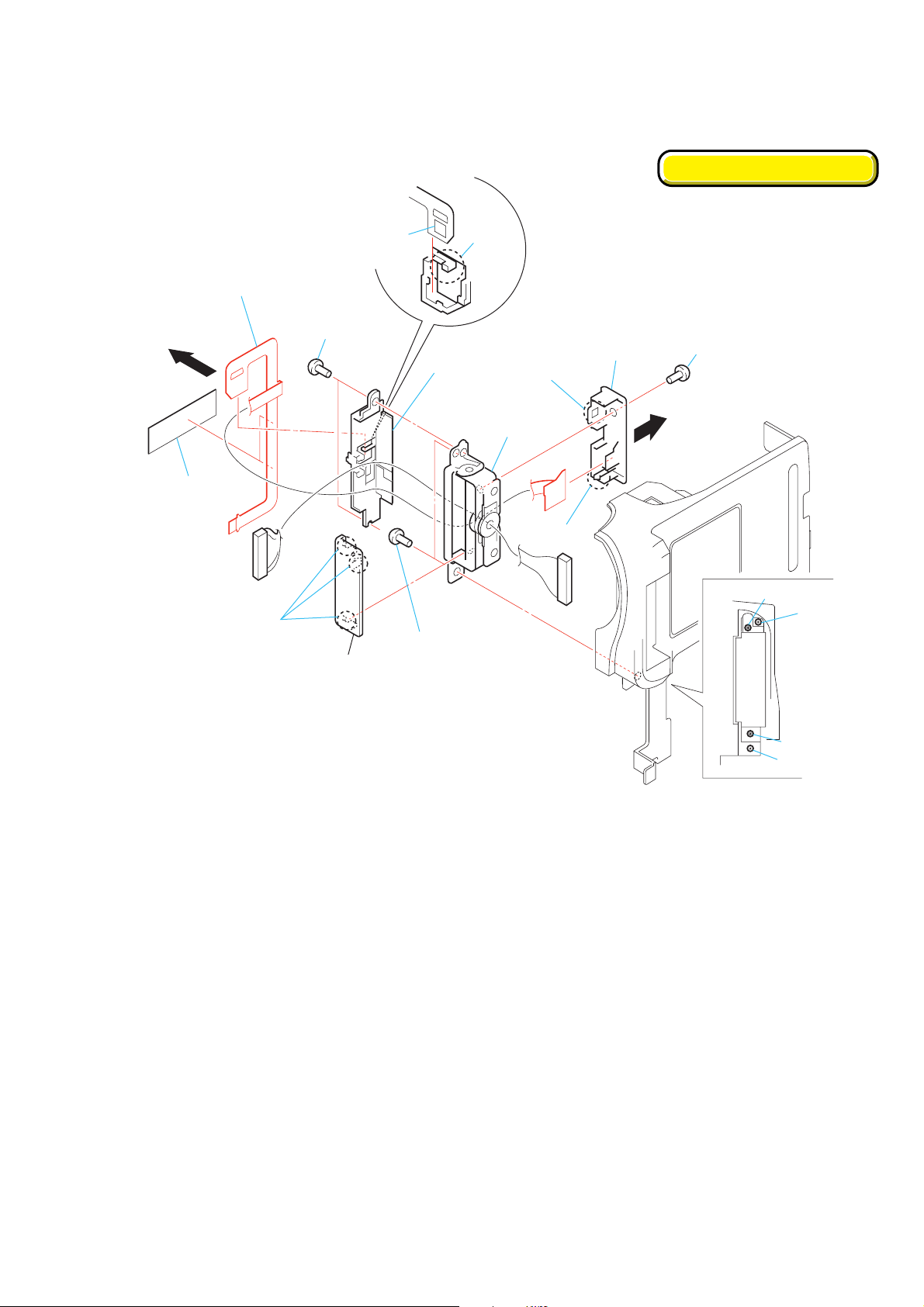

2-9. Control Switch Block (FK-2850) ····································2-7

Note for Installation of Control Switch Block

(FK-2850) ········································································2-7

2-10. Control Switch Block (PS-2850) ·····································2-8

2-11. Cabinet (BT) Block ·························································2-8

2-12. BJ-003 Board ···································································2-9

2-13. LCD Section ····································································2-9

2-14. PD-116 Board ································································ 2-10

2-15. FP-470 Board ································································2-11

Position to Install FP-470 Board When Installing

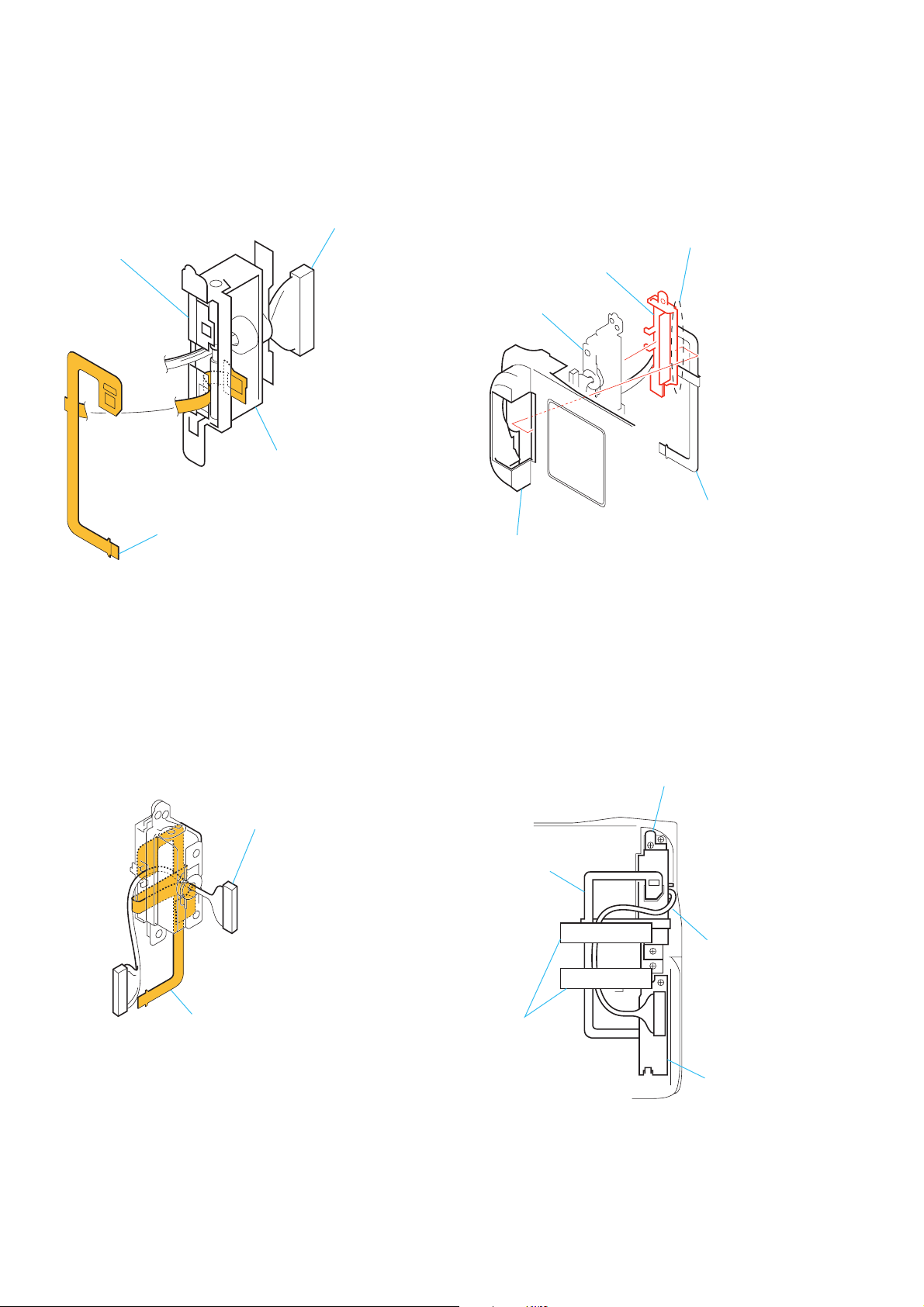

LCD Hinge Assembly, Blind Plate Assembly ···············2-12

Installation of FP-470 Flexible Board,

Harness (PB-051) ··························································2-12

Note for Installation of LCD Hinge Block ····················2-12

Position of Connector Retainer Sheet ···························2-12

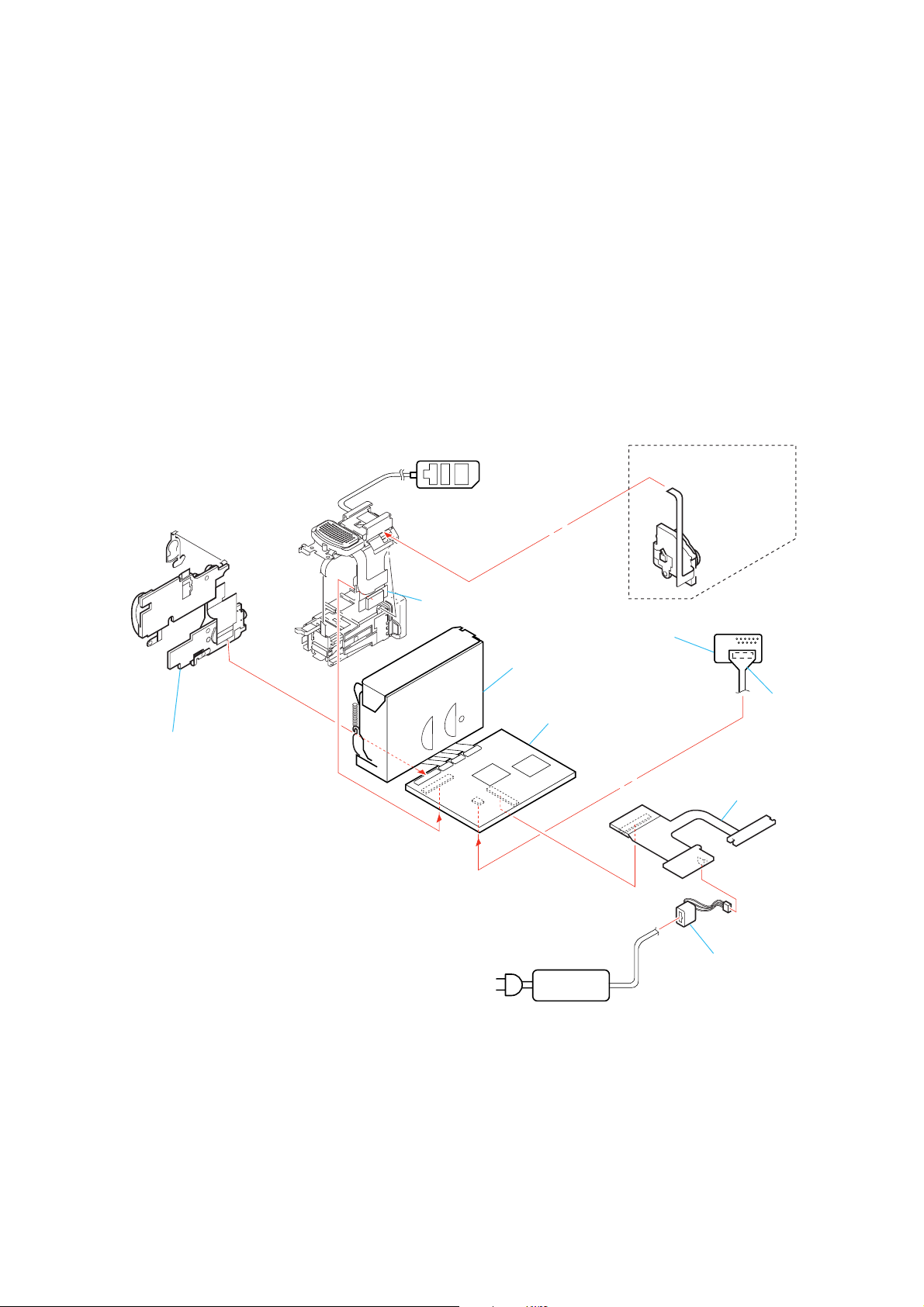

Service Position to Check the VTR Section··················2-13

Service Position to Check the CAMERA Section·········2-14

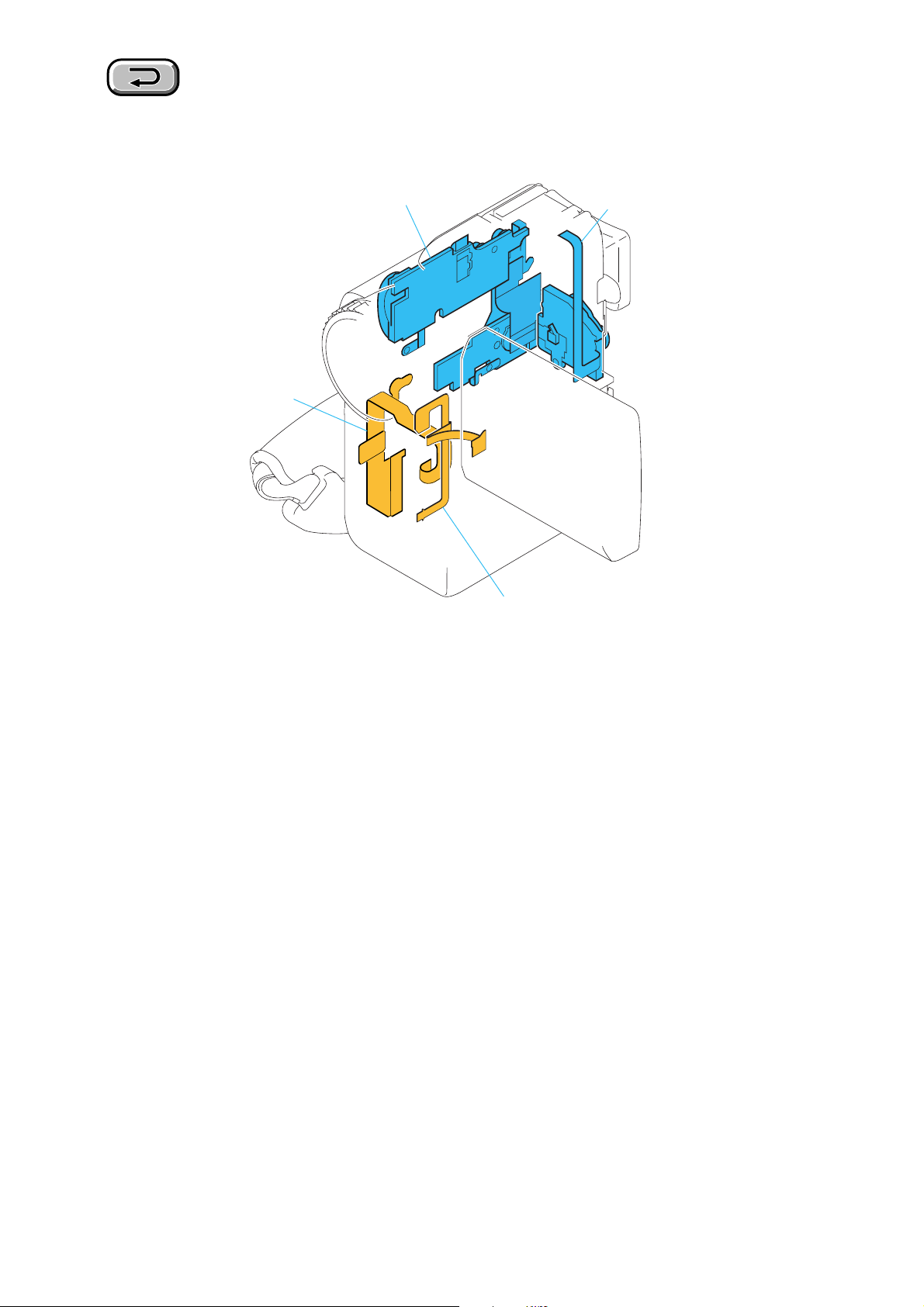

2-16. Flexible Boards Location ··············································2-15

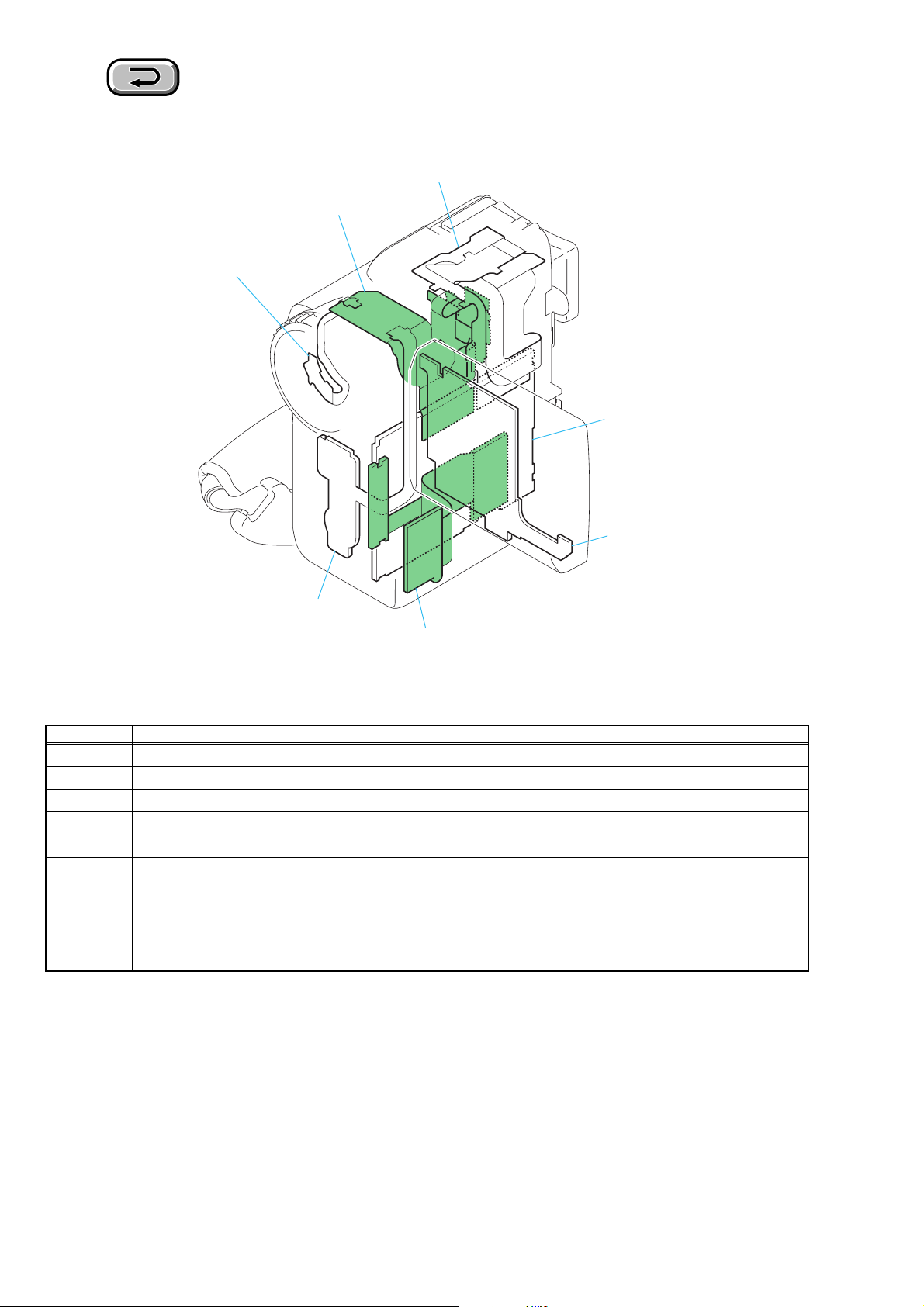

2-17. Circuit Boards Location ················································2-16

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/4)···········································3-1

3-2. Overall Block Diagram (2/4)···········································3-3

3-3. Overall Block Diagram (3/4)···········································3-5

3-4. Overall Block Diagram (4/4)···········································3-7

3-5. Power Block Diagram (1/2)·············································3-9

3-6. Power Block Diagram (2/2)···········································3-11

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagrams

Frame Schematic Diagram (1/2) ·····································4-1

Frame Schematic Diagram (2/2) ·····································4-3

4-2. Schematic Diagrams························································4-5

CF-089(CCD IMAGER) ·················································4-7

PD-166 (1/2)

(LCD DRIVER, TIMING GENERATOR) ···················4-51

PD-166 (2/2) (BACK LIGHT) ······································4-53

ME-020 (1/2) (MIC AMP) ············································4-55

ME-020 (2/2) (EVF, EVF BACK LIGHT, JACK) ········4-57

FP-100, FP-102, FP-228 FLEXIBLE····························4-59

MF-326 (MANUAL FOCUS SENSOR)·······················4-61

NS-014 (REMOTE COMMANDER RECEIVER)·······4-62

CONTROL SWITCH BLOCK (FK-2850) ···················4-63

CONTROL SWITCH BLOCK (PS-2850)···················· 4-65

FP-470 FLEXIBLE ·······················································4-66

4-3. Printed Wiring Boards ···················································4-67

CF-089··········································································· 4-69

PD-166···········································································4-81

ME-020··········································································4-85

FP-100, FP-102, FP-228 FLEXIBLE···························· 4-89

MF-326 ··········································································4-91

NS-014···········································································4-93

4-4. Waveforms·····································································4-97

4-5. Mounted Parts Location ··············································4-102

5. ADJUSTMENTS

Before Starting Adjustment ·······················································5-1

1-1. Adjusting Items when Replacing

Main Parts and Boards ····················································5-2

5-1. Camera Section Adjustments··········································· 5-4

1-1. Preparations before Adjustment (CAMERA Section)·····5-4

1-1-1.List of Service Tools························································5-4

1-1-2.Preparations ·····································································5-5

1-1-3.Precaution ········································································5-7

1-2. Initialization of 8, A, B, C, D, E, F, 1B, 1E,

1F Page Data ···································································5-8

1-2-1.Initialization of A, D Page Data ······································5-9

1. Initializing A, D Page Data··············································5-9

2. Modification of A, D Page Data ······································5-9

3. A Page Table··································································5-10

4. D Page Table··································································5-10

1-2-2.Initialization of 8, C Page Data ·····································5-11

1. Initializing 8, C Page Data ············································5-11

2. Modification of 8, C Page Data. ····································5-11

3. 8 Page Table···································································5-12

4. C Page Table ··································································5-12

1-2-3.Initialization of E, F, 1E, 1F Page Data ························· 5-14

1. Initializing of E, F, 1E, 1F Page Data ····························5-14

2. Modification of E, F, 1E, 1F Page Data·························5-14

3. E Page Table ··································································5-15

4. F Page Table ·································································· 5-16

5. 1E Page Table ································································5-18

6. 1F Page Table ································································ 5-19

1-2-4.Initialization of B, 1B Page Data···································5-20

1. Initializing of B, 1B Page Data ·····································5-20

2. Modification of B, 1B Page Data ··································5-20

3. B Page Table ··································································5-20

4. 1B Page Table ································································5-20

1-3. Camera System Adjustments·········································5-21

1. 66MHz/54MHz Origin Oscillation Adjustment ············5-21

2. Hall Adjustment·····························································5-21

3. MR Adjustment ····························································· 5-22

4. Flange Back Adjustment

(Using the Minipattern Box) ·········································5-23

5. Flange Back Adjustment

(Using the Flange Back Adjustment Chart

and Subject More than 500 m Away) ····························5-24

6. Flange Back Check························································5-25

7. MAX GAIN Adjustment ··············································· 5-25

8. F No. & ND Light Quality Standard Data Input ···········5-26

9. Mechanical Shutter Adjustment ····································5-26

10. Picture Frame Setting ···················································· 5-27

11. Color Reproduction Adjustment····································5-28

12. AWB & LV Standard Data Input ···································5-29

13. Auto White Balance Adjustment ··································· 5-30

14. Auto White Balance Check ···········································5-31

— 5 —

DCR-PC101/PC101E

Section Title Page Section Title Page

15. Steady Shot Check·························································5-32

16. CCD Black Defect Adjustment ·····································5-32

17. CCD Defect Check························································5-33

1-4. Color Electronic Viewfinder System Adjustments ········5-34

1. VCO Adjustment (VC-284 Board)································5-34

2. Back Light Adjustment (VC-284 Board) ······················ 5-35

3. RGB AMP Adjustment (VC-284 Board)·······················5-35

4. Contrast Adjustment (VC-284 Board)···························5-36

5. White Balance Adjustment (VC-284 Board)·················5-36

1-5. LCD System Adjustments ·············································5-37

1. VCO Adjustment (PD-166 Board) ································5-37

2. RGB AMP Adjustment (PD-166 Board) ·······················5-38

3. Black Limit Adjustment (PD-166 Board) ·····················5-38

4. PSIG GRAY Adjustment (PD-166 Board) ····················5-39

5. Contrast Adjustment (PD-166 Board) ···························5-39

6. Center Voltage Adjustment (PD-166 Board) ·················5-40

7. V-COM Adjustment (PD-166 Board)····························5-40

8. White Balance Adjustment (PD-166 Board)················· 5-41

5-2. Mechanism Section Adjustments ··································5-42

2-1. How to Enter Record Mode Without Cassette ··············5-42

2-2. How to Enter Playback Mode Without Cassette ···········5-42

2-3. Tape Path Adjustment····················································5-42

5-3. Video Section Adjustments ···········································5-43

3-1. Preparations before Adjustments···································5-43

3-1-1.Equipment Required······················································ 5-43

3-1-2.Precautions on Adjusting···············································5-44

3-1-3.Adjusting Connectors ····················································5-45

3-1-4.Connecting the Equipment ············································5-45

3-1-5.Alignment T apes····························································5-46

3-1-6.Input/Output Level and Impedance ·······························5-46

3-2. System Control System Adjustments ····························5-47

1. Initialization of 8, A, B, C, D, E, F, 1B, 1E,

1F Page Data ·································································5-47

2. Touch Panel Adjustment················································5-47

3. Node Unique ID No. Input ············································5-48

3-1. Input of Company ID ····················································5-48

3-2. Input of Serial No. ·························································5-48

3-3. Servo and RF System Adjustments ······························5-50

1. CAP FG Duty Adjustment (VC-284 Board) ················· 5-50

2. PLL f0 & LPF f0 Pre-Adjustment (VC-284 Board) ·······5-50

3. Switching Position Adjustment (VC-284 Board)··········5-51

4. AGC Center Level and APC & AEQ Adjustment ·········5-51

4-1. Preparations before Adjustments···································5-51

4-2. AGC Center Level Adjustment (VC-284 Board) ··········5-52

4-3. APC & AEQ Adjustment (VC-284 Board) ··················5-52

5. PLL f0 & LPF f0 Final Adjustment (VC-284 Board)·····5-53

3-4. Video System Adjustments············································5-54

1. Chroma BPF f0 Adjustment (VC-284 Board)················5-54

2. S VIDEO OUT Y Level Adjustment

(VC-284 Board)·····························································5-55

3. S VIDEO OUT Chroma Level Adjustment

(VC-284 Board)·····························································5-55

4. VIDEO OUT Level Check (VC-284 Board)·················5-56

3-5. Audio System Adjustments ···········································5-57

1. Playback Level Check ···················································5-57

2. Overall Level Characteristics Check ·····························5-57

3. Overall Distortion Check···············································5-57

4. Overall Noise Level Check············································ 5-58

5. Overall Separation Check··············································5-58

5-4. Service Mode·································································5-59

4-1. Adjustment Remote Commander ··································5-59

1. Using the Adjustment Remote Commander··················5-59

2. Precautions Upon Using the Adjustment

Remote Commander······················································ 5-59

4-2. Data Process ··································································5-60

4-3. Service Mode·································································5-61

1. Setting the Test Mode ····················································5-61

2. Emergence Memory Address ········································5-61

2-1. C Page Emergence Memory Address ····························5-61

2-2. EMG Code (Emergency Code) ·····································5-62

2-3. MSW Code ····································································5-63

3. Bit Value Discrimination ···············································5-64

4. Jack Check (1) ·······························································5-64

5. Jack Check (2) ·······························································5-64

6. Switch Check·································································5-65

7. Record of Use Check (1) ···············································5-66

8. Record of Use Check (2) ···············································5-66

9. Record of Self-diagnosis Check ····································5-67

6. REPAIR PARTS LIST

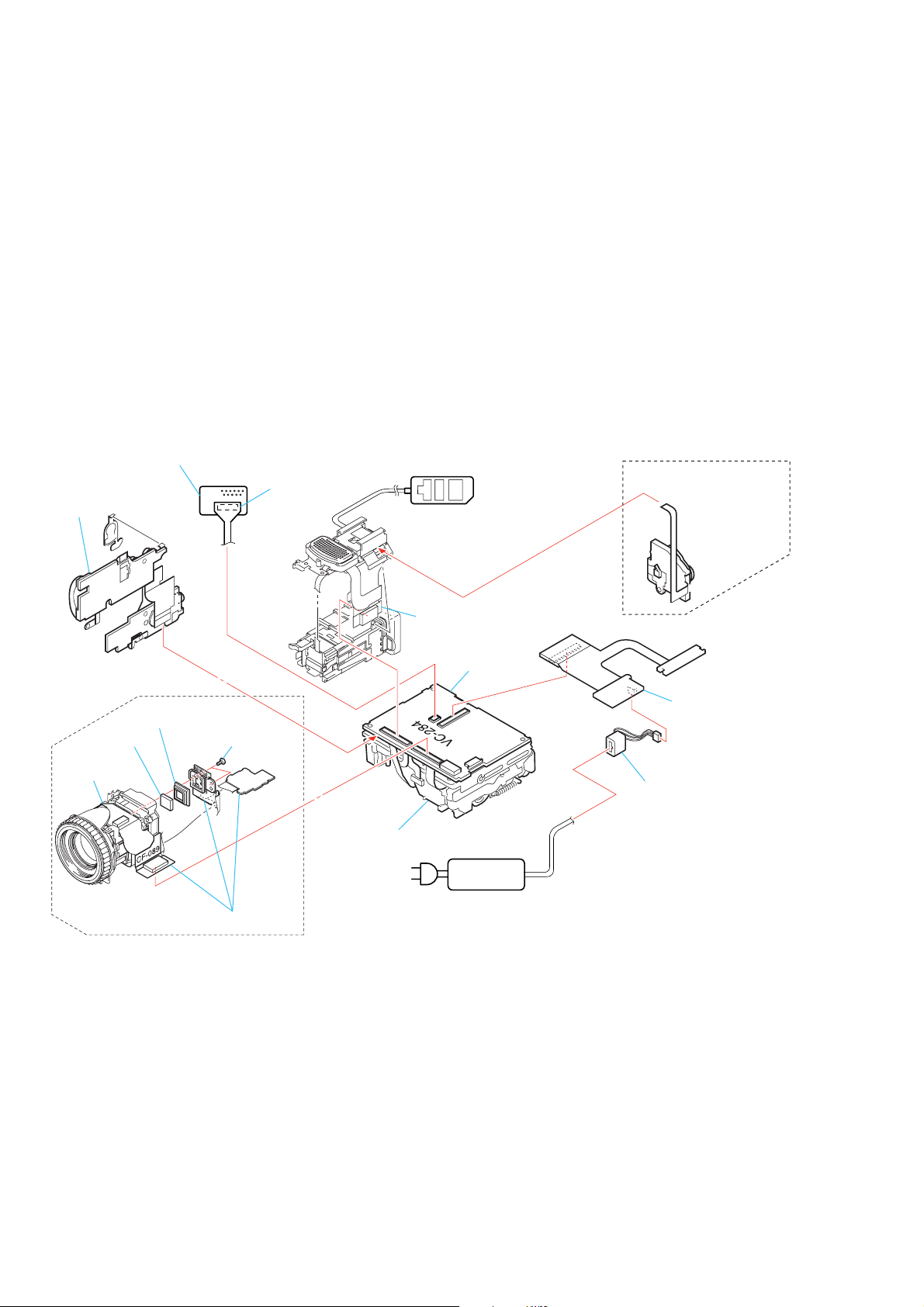

6-1. Exploded Views·······························································6-1

6-1-1.Main Section····································································6-1

6-1-2.Lens Block Section··························································6-2

6-1-3.LCD EVF Block Section ·················································6-3

6-1-4.Cabinet (L) Block Assembly ···········································6-4

6-1-5.Cabinet (BT) Assembly··················································· 6-5

6-1-6.LCD Block Assembly······················································6-6

6-1-7.Overall Mechanism Deck Section (J100)························6-7

6-1-8.LS Chassis Block Assembly············································6-8

6-1-9.Mechanism Chassis Block Assembly······························6-9

6-2. Electrical Parts List ·······················································6-10

* The color reproduction frame is shown on page 179

— 6 —

DCR-PC101/PC101E

COVER

COVER

SECTION 1

SERVICE NOTE

1-1. SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the po wer is shut of f so

that the unit cannot operate.

These following two methods are available to prevent this. Take note of which to use during repairs.

Method 1.

Use the AC power adaptor (AC-L10, AC-VQ800 etc.).

Method 2.

Connect the servicing remote commander RM-95 (J-6082-053-B) to the LANC jack, and set the commander switch to the “ADJ” side.

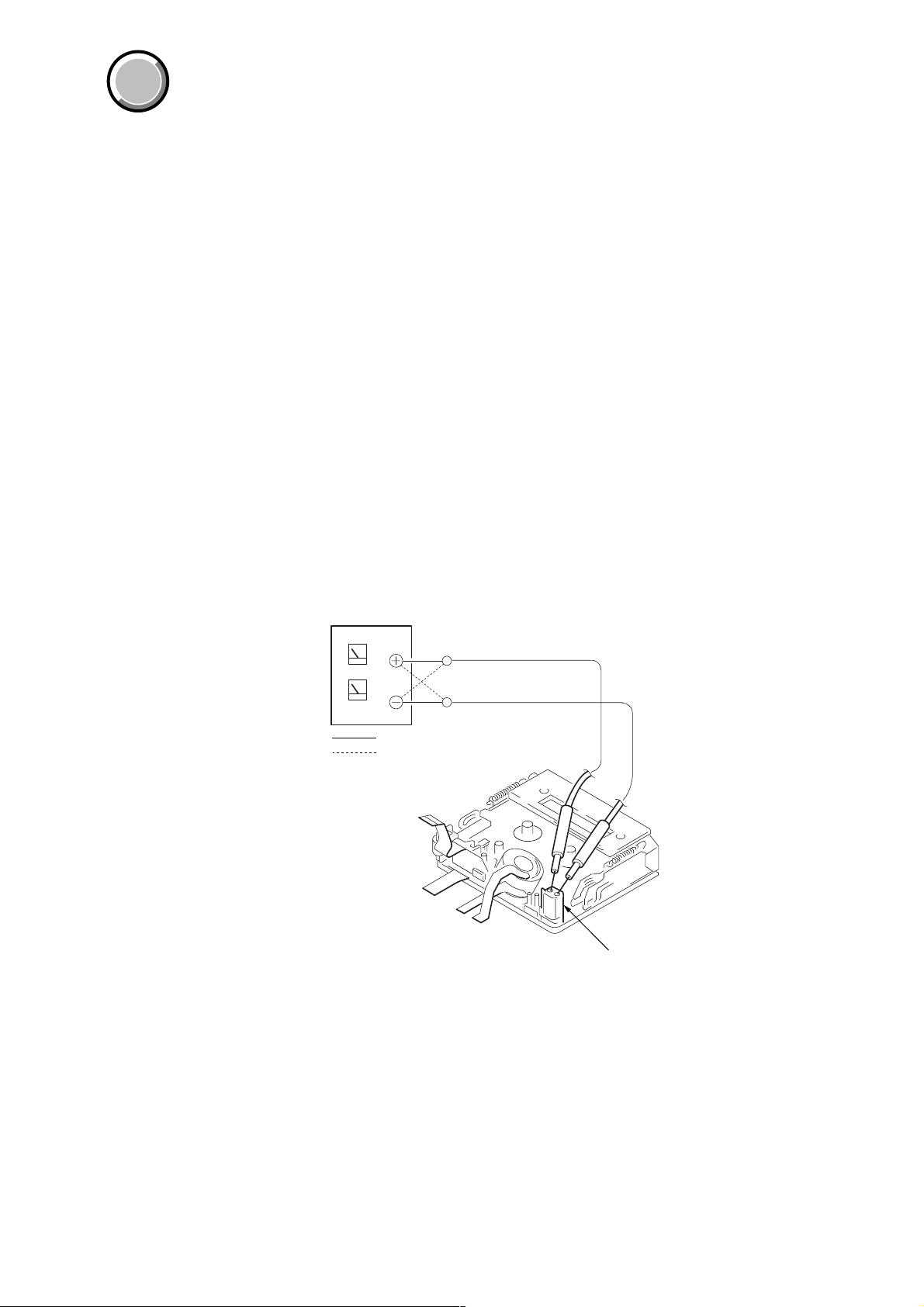

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to 2-2 to remove the cabinet (R) block assembly.

2 Refer to 2-3 to remove the lens (-EVF) block.

3 Refer to 2-6 to remove the VC-284 board.

4 Refer to 2-7 to remove the mechanism deck.

5 Supply +4.5V from the DC power supply to the loading motor and unload with a pressing the cassette compartment.

DC power supply

(+4.5Vdc)

: Unloading

: Loading

Loading motor

1-1

DCR-PC101/PC101E

1-2. SELF-DIAGNOSIS FUNCTION

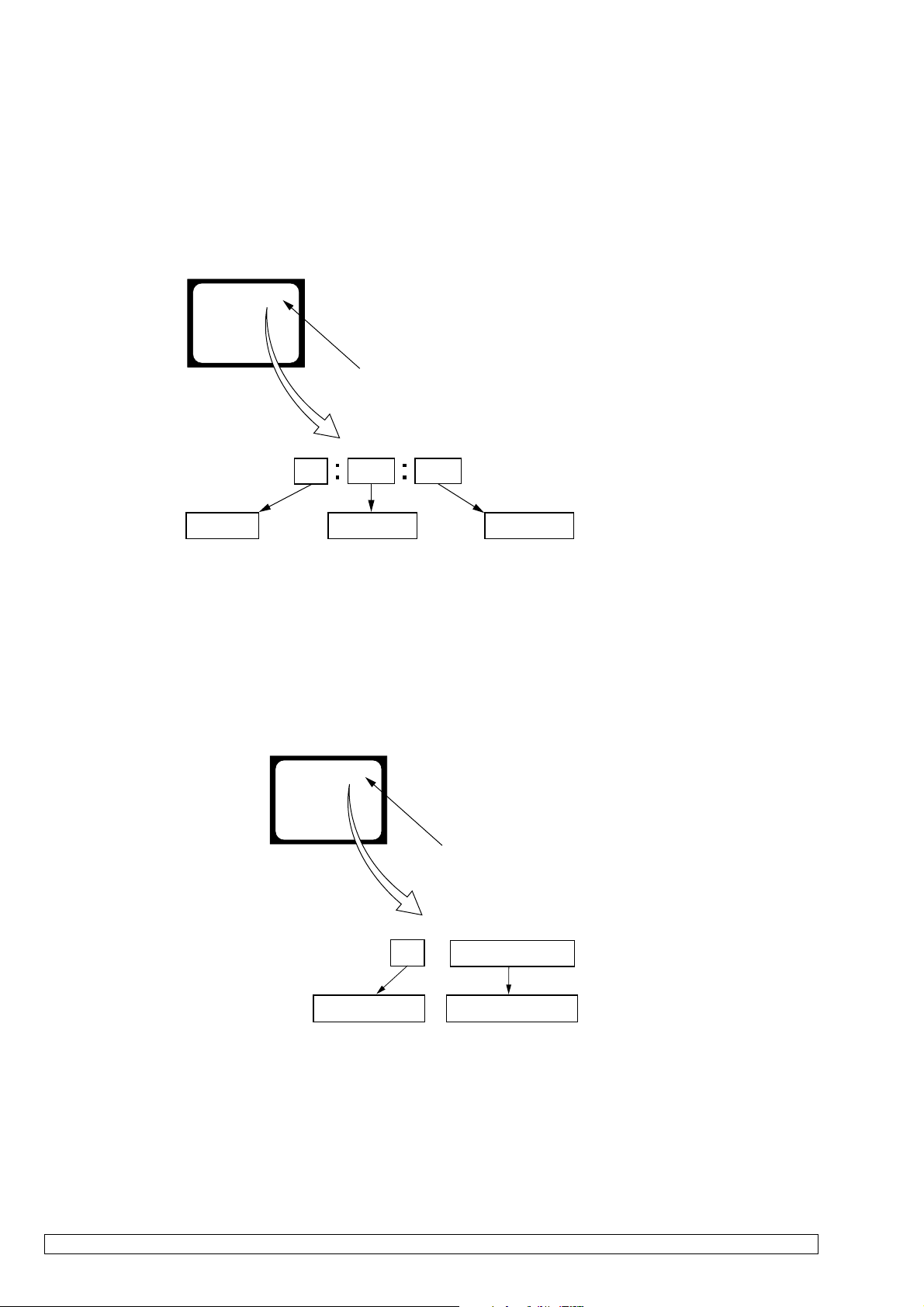

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD

screen what to do. This function consists of two display; selfdiagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen

C : 3 1 : 1 1

Blinks at 3.2Hz

3 1C

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Tu r n o n power again.

Block

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen consists of an alphabet and 4-digit

numbers, which blinks at 3.2 Hz. This 5-character display indicates

the “repaired by:”, “block” in which the problem occurred, and

“detailed code” of the problem.

1 1

Detailed Code

Refer to “4. SELF-DIAGNOSIS CODE TABLE”.

3. SERVICE MODE DISPLAY

The service mode display shows the last self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “BA CK LIGHT” key , set the switch from OFF to “VCR or PLAYER”, and continue pressing the “BACK LIGHT” ke y for

5 seconds continuously. The service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis

codes.

Viewfinder or LCD screen

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

C : 3 1 : 1 1

Self-diagnosis Codes

3-2. Backup No.

The backup No. in the [] indicates the order in which the problem occurred. (If the number of problems which occurred is less than 6, only the

number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

Note: Switching of the backup No. can’t be done.

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will not be erased (reset) when the lithium 3 V supply (NS-014 board BT001) is removed.

1-2

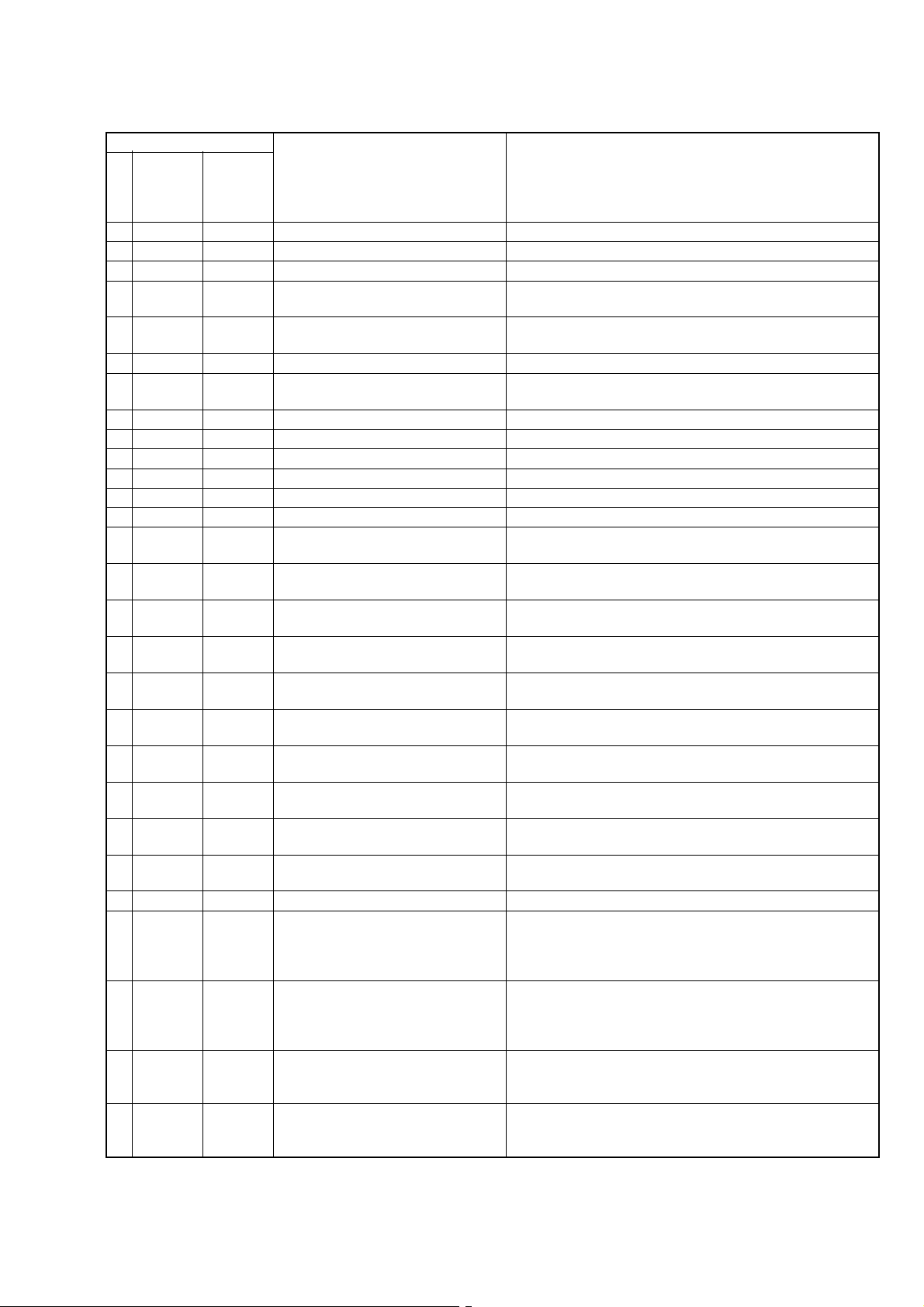

4. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

DCR-PC101/PC101E

Function

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

E

Block

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

20

61

61

62

62

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

00

10

00

01

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

EEPROM data error

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular velocity sensor output

stopped.)

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Initialize A, D page data (EEPROM data).

Inspect the lens block focus MR (Pin ql, w; of CF-089 board CN102)

when focusing is performed when the focus ring is rotated in the

focus manual mode, and the focus motor drive circuit (IC1301 of

VC-284 board) when the focusing is not performed.

Inspect the lens block zoom MR (

CN102

) when zooming is performed when the zoom lens is operated

and the zoom motor drive circuit (IC1301 of VC-284 board) when

zooming is not performed.

Inspect pitch angular velocity sensor (SE201 of CF-089 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE202 of CF-089 board)

peripheral circuits.

Pin 8, 0 of CF-089 board

1-3E

DCR-PC101/PC101E

COVER

COVER

SECTION 2

DISASSEMBLY

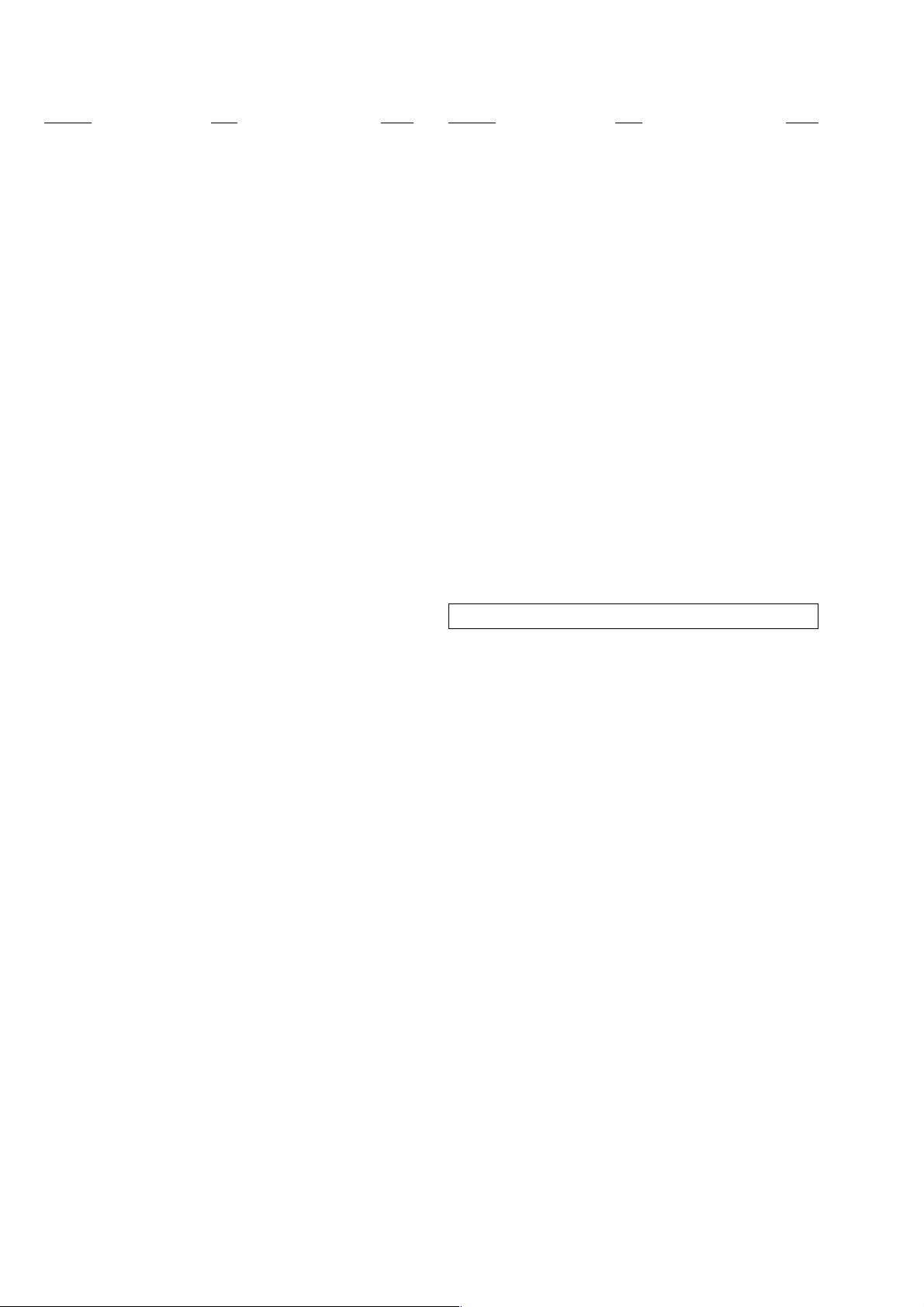

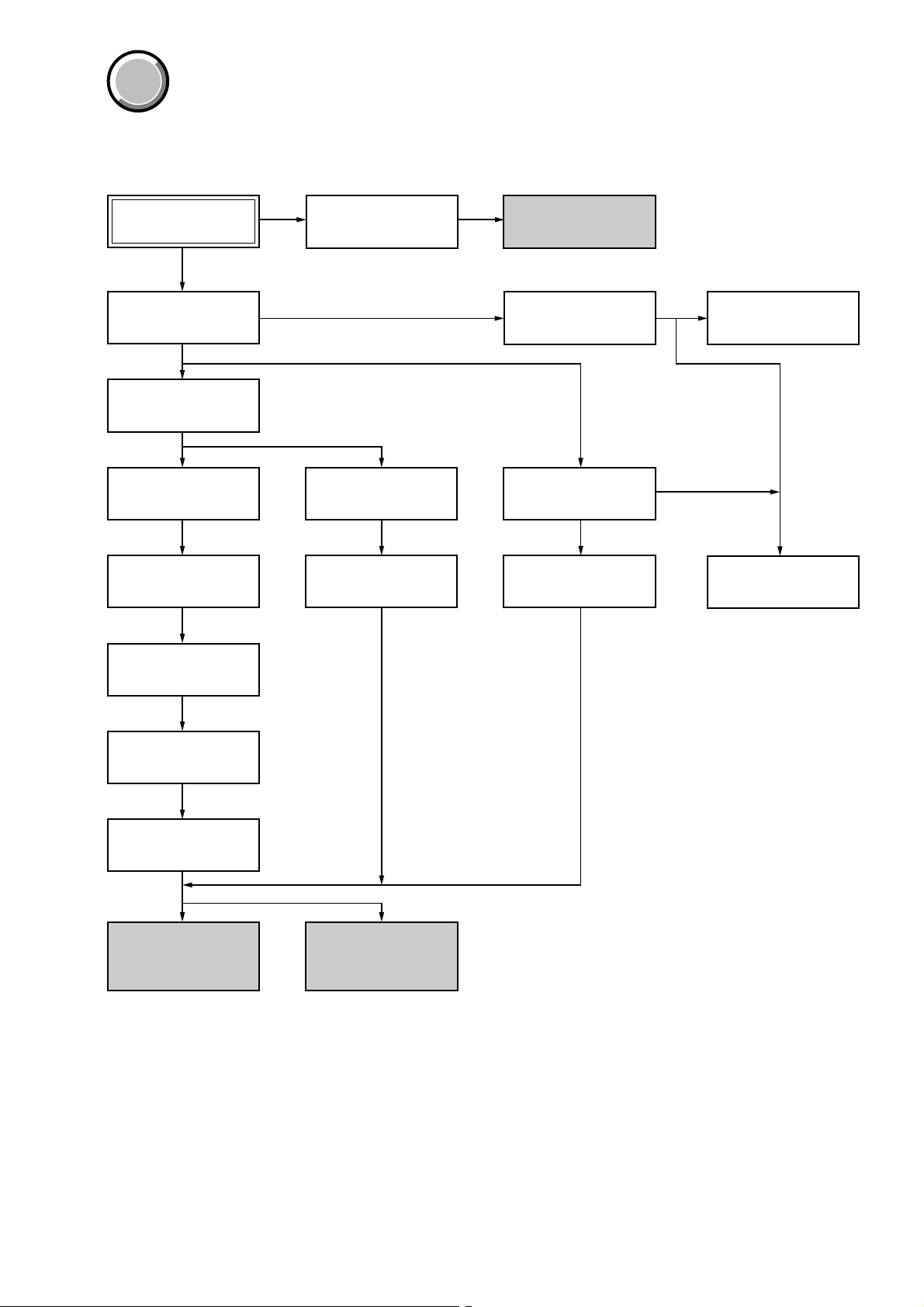

The following flow chart shows the disassembly procedure.

DCR-PC101/

PC101E

2-2. CABINET (R)

BLOCK ASSEMBLY

(Page 2-3)

2-3. LENS (-EVF) BLOCK

SECTION

(Page 2-3)

2-6. VC-284 BOARD

(Page 2-5)

2-1. LCD CABINET (R)

ASSEMBLY

(Page 2-2)

2-4. LENS BLOCK

(Page 2-4)

LCD BLOCK

SERVICE POSITION

(Page 2-2)

2-13. LCD SECTION

(Page 2-9)

2-11. CABINET (BT)

BLOCK

(Page 2-8)

2-14. PD-116 BOARD

(Page 2-10)

2-7. MECHANISM DECK

(Page 2-5)

2-8. CABINET (G)

ASSEMBLY

(Page 2-6)

2-9. CONTROL SWITCH

BLOCK (FK-2850)

(Page 2-7)

2-10. CONTROL SWITCH

BLOCK (PS-2850)

(Page 2-8)

SERVICE POSITION

TO CHECK

THE VTR SECTION

(Page 2-13)

2-5. CF-089 BOARD

(Page 2-4)

SERVICE POSITION

TO CHECK

THE CAMERA SECTION

(Page 2-14)

2-12. BJ-003 BOARD

(Page 2-9)

2-15. FP-470 BOARD

(Page 2-11)

2-1

DCR-PC101/PC101E

NOTE: Follow the disassembly procedure in the numerical order given.

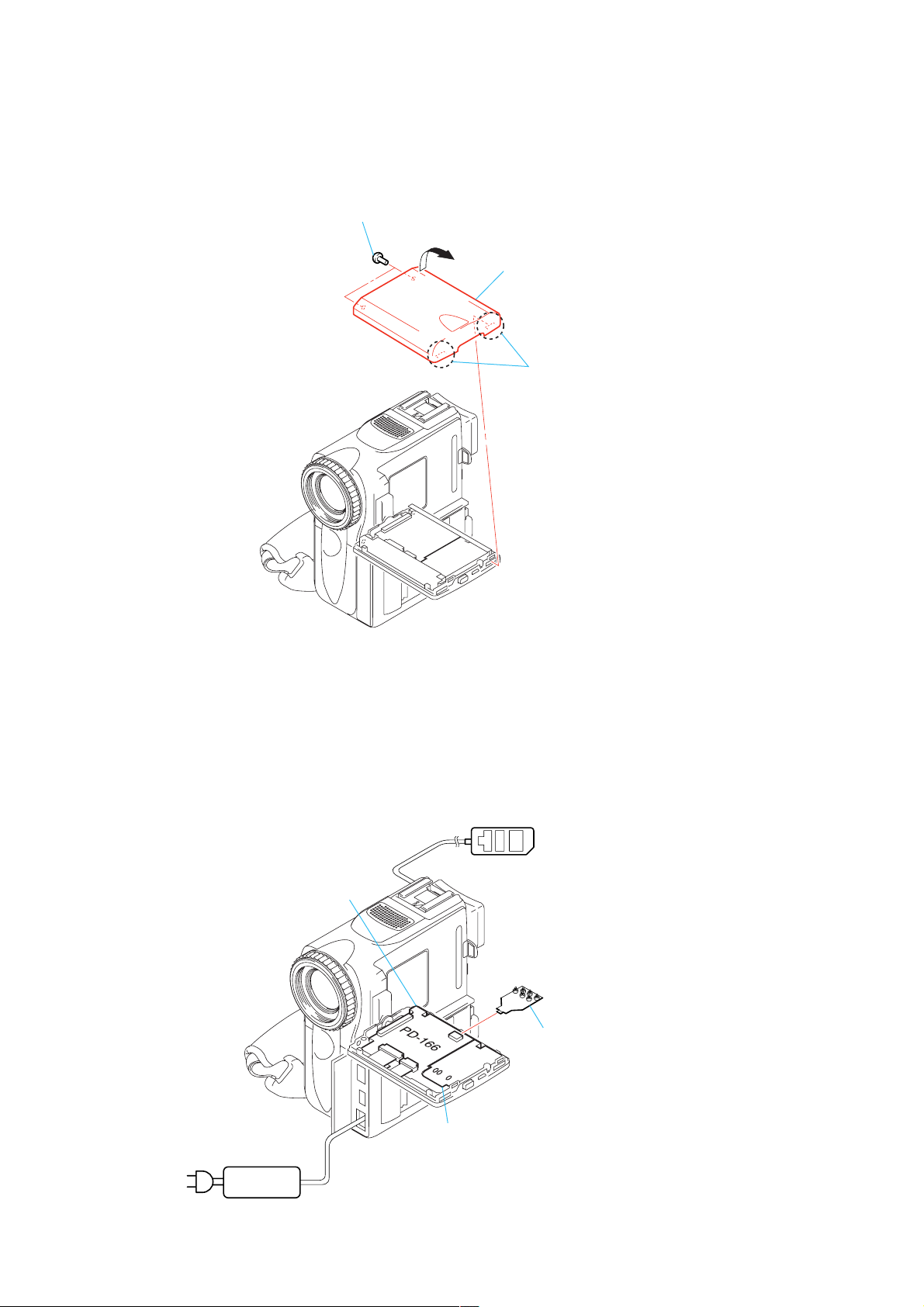

2-1. LCD CABINET (R) ASSEMBLY

1 Two screws

(M1.7)

3 LCD cabinet (R) assembly

2 Two claws

[LCD BLOCK SERVICE POSITION]

PD-166 board

AC IN

AC power

adaptor

Adjustment remote

commander (RM-95)

CPC jig for LCD panel

(J-6082-529-A)

Inverter transformer unit

2-2

DCR-PC101/PC101E

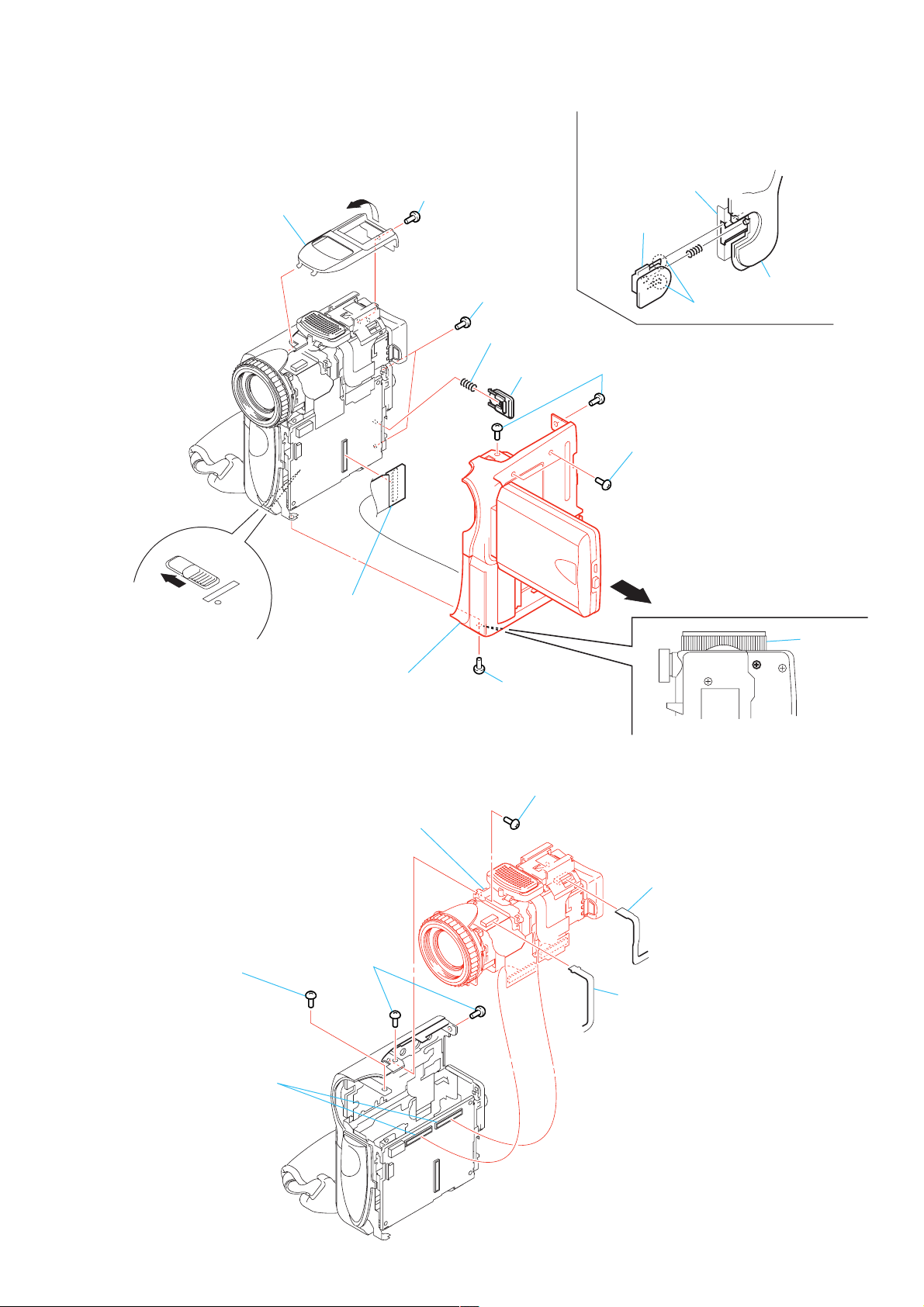

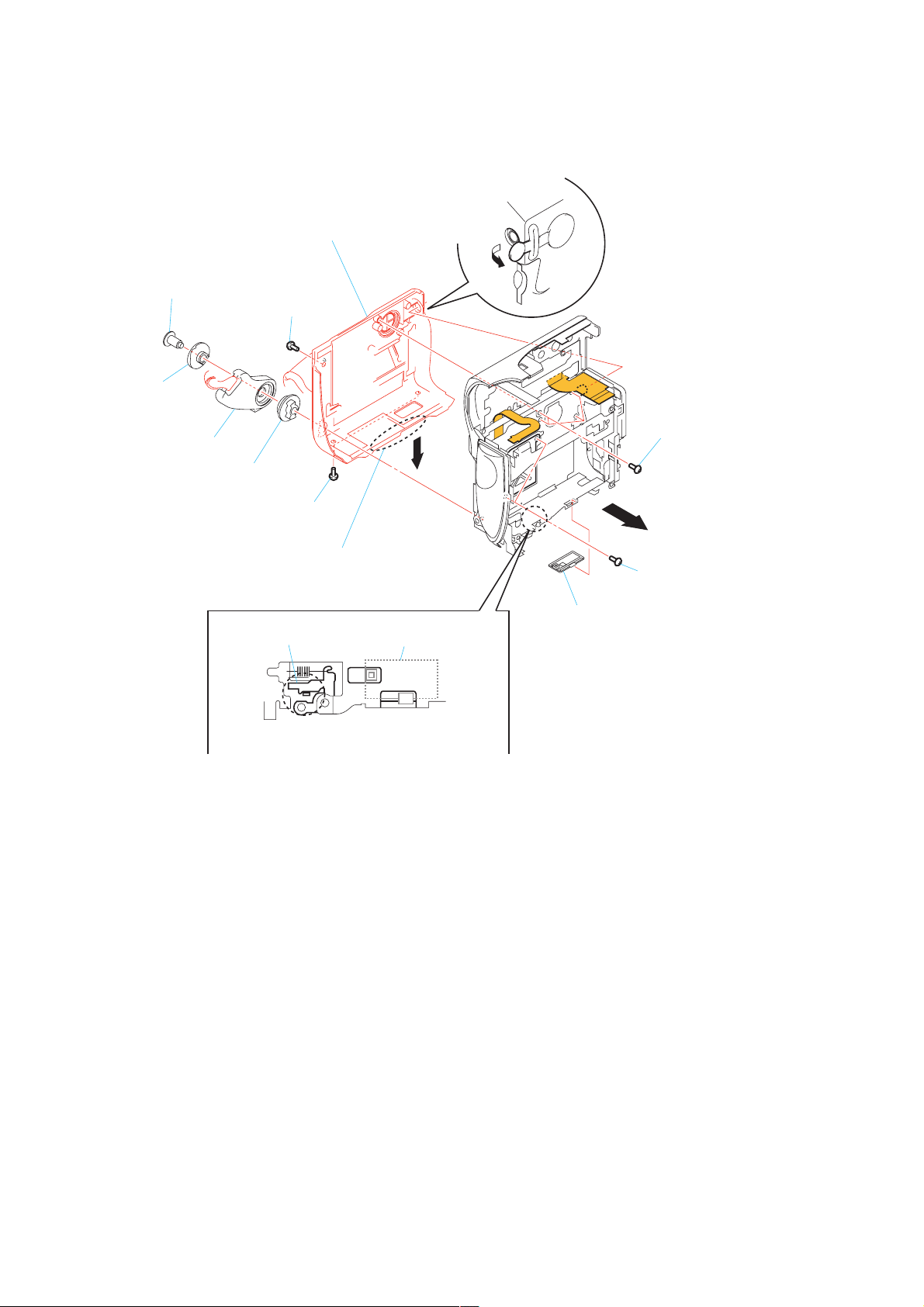

2-2. CABINET (R) BLOCK ASSEMBLY

2 Microphone cover

1 Screw (M1.7)

3 Two screws

(M1.7 × 4)

qs Compression

spring

qa Battery lock

When installing the battery lock,

two claws are met and attached in a slot of the

main frame assembly.

Main frame

assembly

Battery lock

Cabinet (rear)

Two claws

4 Two screw

(M1.7)

5 Two screw

(M1.7)

8 Remove the cabinet (R) block assembly

inthe direction of arrow.

7 Slide the eject knob

9 Connector

(BJ-003 board)

(CN1003)

0 Cabinet (R) block

assembly

2-3. LENS (-EVF) BLOCK SECTION

7 Lens (-EVF) block

section

6 Screw

(M1.7 × 4)

4 Two screws

(M1.7)

Lens section

6 Screw

(M1.7)

— Bottom view —

5 Screw (M1.7)

2 Flexible board

(control switch block (PS-2850))

(CN402)

1 Flexible board (NS-014 board)

(CN104)

3 Two connectors

(CN1010, CN404)

2-3

DCR-PC101/PC101E

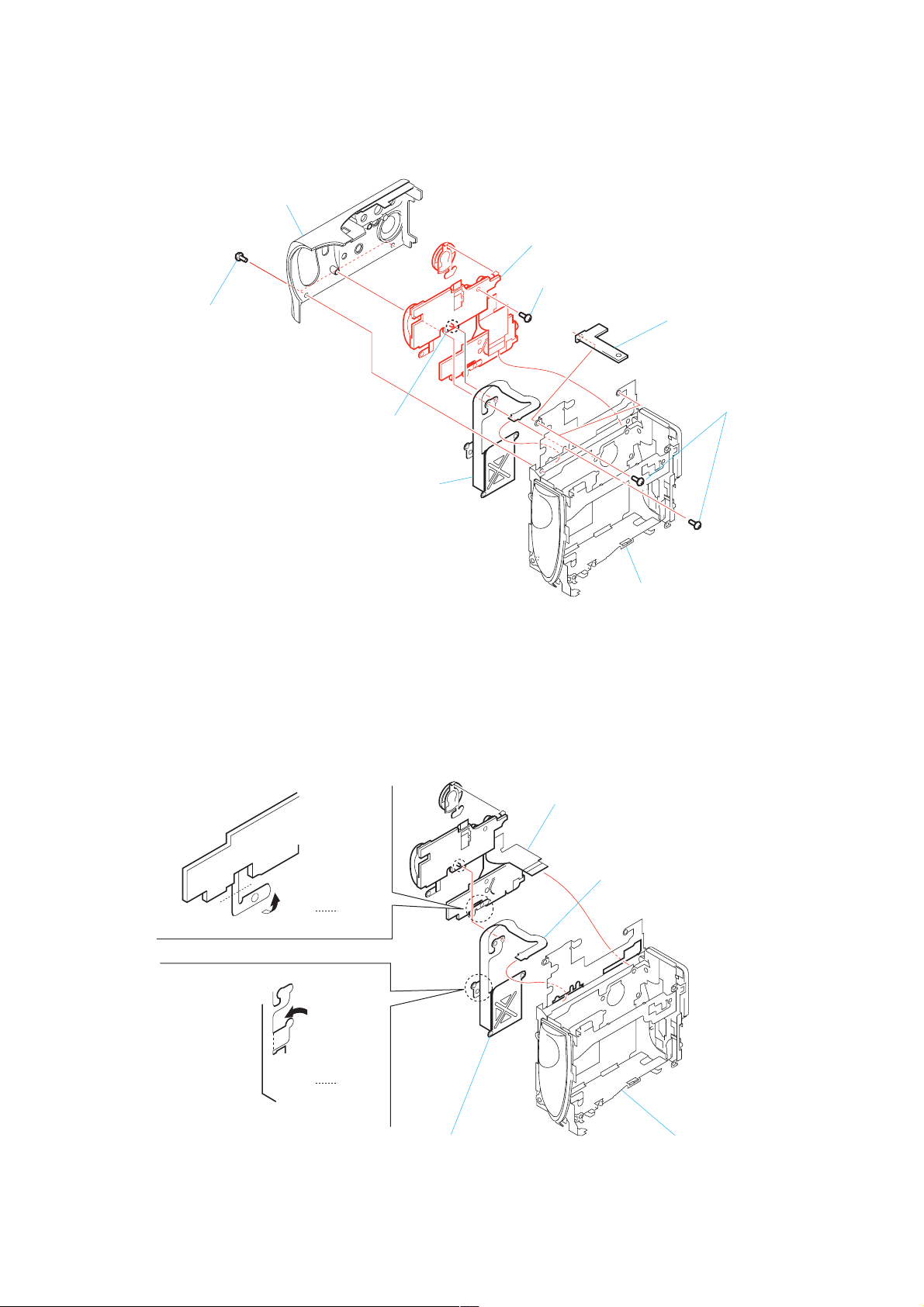

2-4. LENS BLOCK

3 Shoe frame

1 Two claws

9 Lens block

2-5. CF-089 BOARD

1 MF-326 board

(CN103)

6 Screw (M1.7)

2 Screw (M1.7)

8

5 Screw

(M1.7 × 4)

0 CD frame assembly

8 Screw

(M1.7 × 4)

2 Claw

4 Slide the VF lens assembly

A

7 Screw (M1.7)

9 Two screws

(M1.7 × 5)

in the dirrection of arrow A.

6 Two screws

(M1.7)

4 CF-089 board

(upper)

(CN102)

7 CF-089 board

(rear)

qa CF-089 board

(CCD block)

qs Seal rubber (W)

qd Optical filter block

5 Lens flexible board

(CN102)

3 Claw

2-4

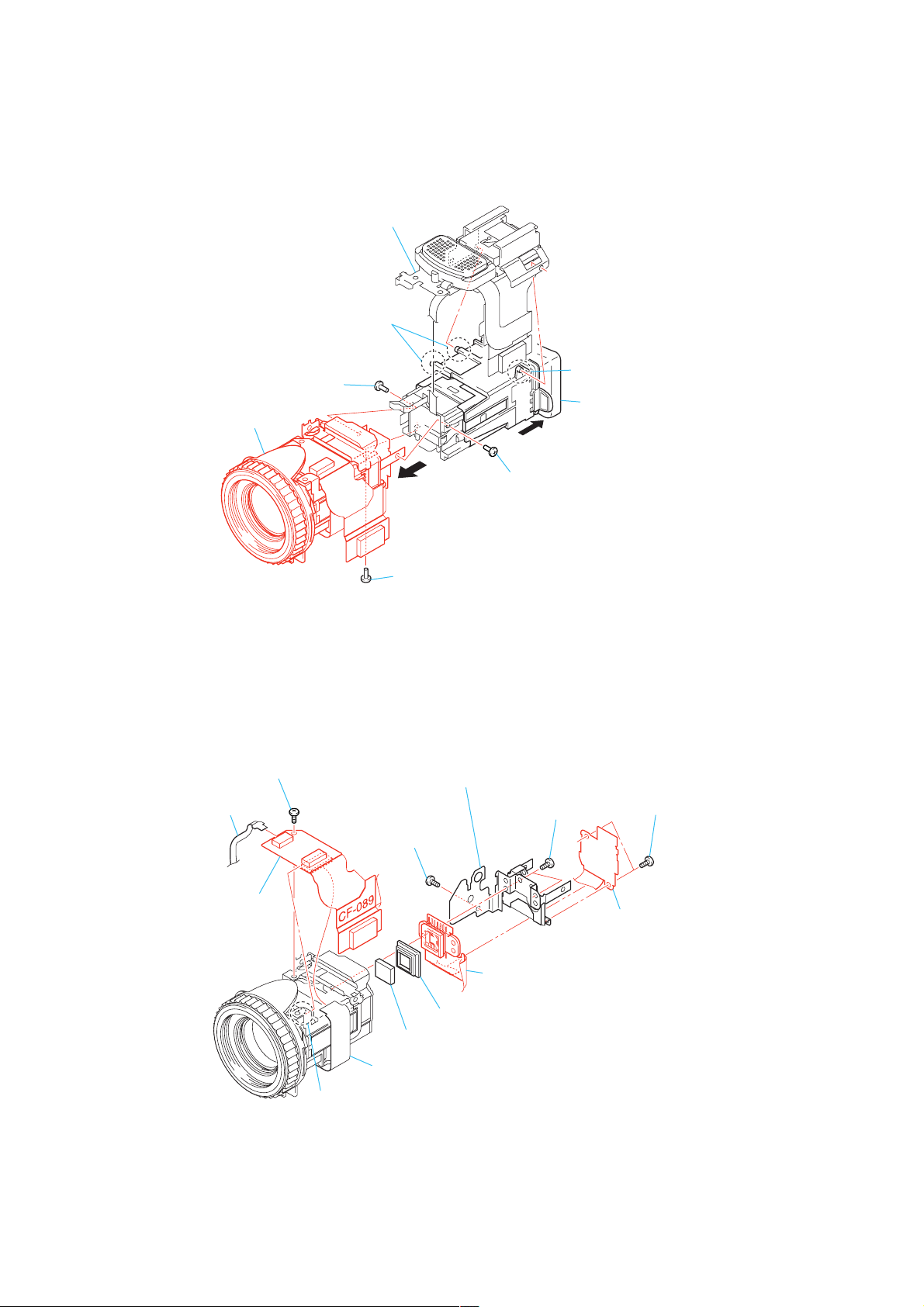

2-6. VC-284 BOARD

5 Flexible board

(CN1008)

6 Flexible board

(CN1007)

7 Flexible board

(CN1901)

DCR-PC101/PC101E

8 Flexible board

(CN1004)

2 Flexible board

(CN1009)

1 Flexible board

2-7. MECHANISM DECK

5 Open the

cabinet (G) assembly.

(CN1005)

9 VC-284 board

4 Remove the VC-284 board

in the direction of arrow.

3 Three screws

(M1.7)

2 Two screws

(M1.4 × 1.5)

4 Slide the eject knob.

1 Heat insulating sheet

3 Two screws

(M1.4 × 1.5)

6 Mechanism deck

2-5

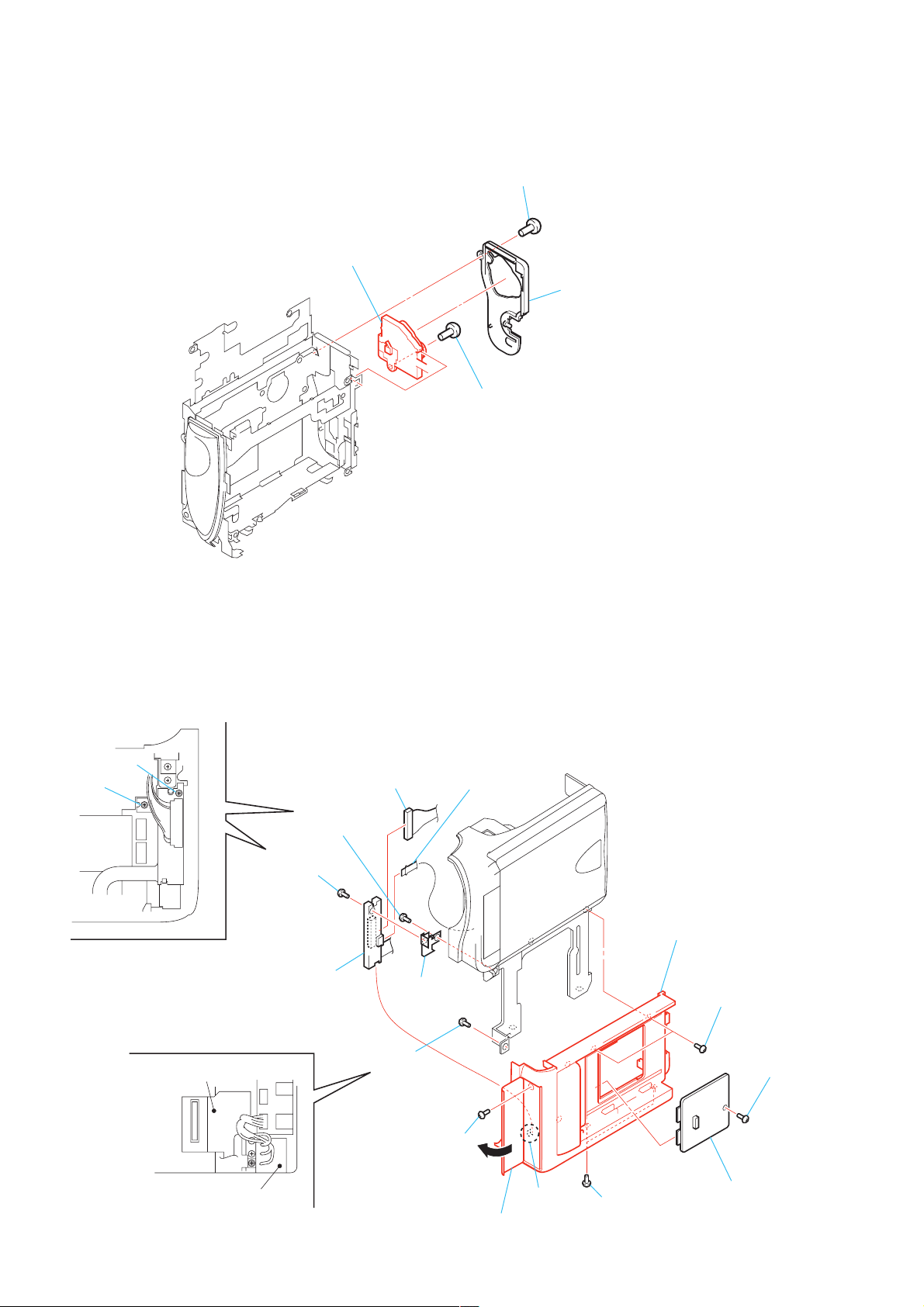

DCR-PC101/PC101E

2-8. CABINET (G) ASSEMBLY

9 Open the jack cover

qd Cabinet (G) assembly

1 Special screw

(M2.6)

2 Sleeve

(front)

3 Hold grip assembly

0 Pull the bottom part of cabinet (G) assembly

in the direction of arrow, and then remove the claw.

4 Sleeve

(rear)

Charge lever

6 Screw

(M1.7)

5 Two screws

(M1.7)

7 Four screws

(M1.7 × 4)

qa

8 Two screws

(M1.7 × 4)

qs Eject knob

Eject knob

When install the eject knob,

charge lever is made into the position of a figure.

Note: Make sure to perform checking of operations

after the installation.

2-6

2-9. CONTROL SWITCH BLOCK (FK-2850)

6 Cabinet (L)

DCR-PC101/PC101E

9 Control switch block

(FK-2850)

5 Screw (M1.7 × 4)

1 Two screws

(M1.7)

7 Boss

8 Memory stick

connector

4 Reinforcement

2 Three screws

(M1.7 × 4)

3 Chassis section

[NOTE FOR INSTALLATION OF CONTROL SWITCH BLOCK (FK-2850)]

: Fold

: Fold

Memory stick connector

block

Pass the cable of the flexible of control switch block

through chassis block.

Pass FP-347 flexible board

through chassis block.

Chassis block

2-7

DCR-PC101/PC101E

2-10. CONTROL SWITCH BLOCK (PS-2850)

4 Control switch block

(PS-2850)

1 Screw (M1.7)

2 Cabinet (rear)

3 Screw (M1.7)

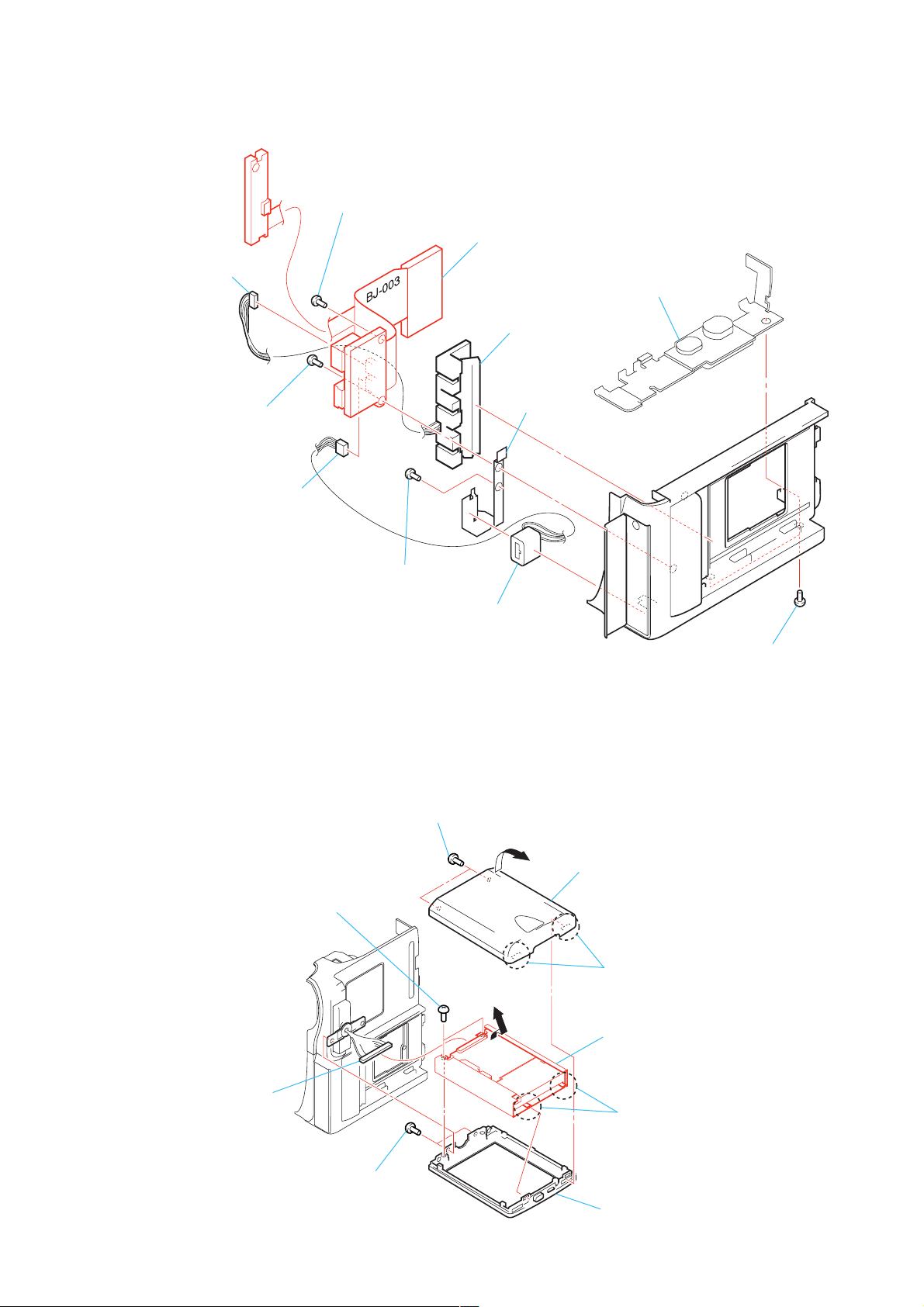

2-11. CABINET (BT) BLOCK

5

qs

5 Screw

(M1.7)

7 Remove the

BJ-003 board

BJ-003 board

qs Screw

(M1.7)

9 Connector

(CN007)

qd DV

qf Screw

(M1.7)

8 FP-470 flexible board

(CN007)

fixed plate

qg Cabinet (BT) block

3 Two screws

(M1.7)

1 Screw

(M1.7)

DC-IN connector

qa Screw

(M1.7)

0 Open the DC-IN lid

2-8

6 Claw

4 Two screws

2 CPC lid

(M1.7 × 4)

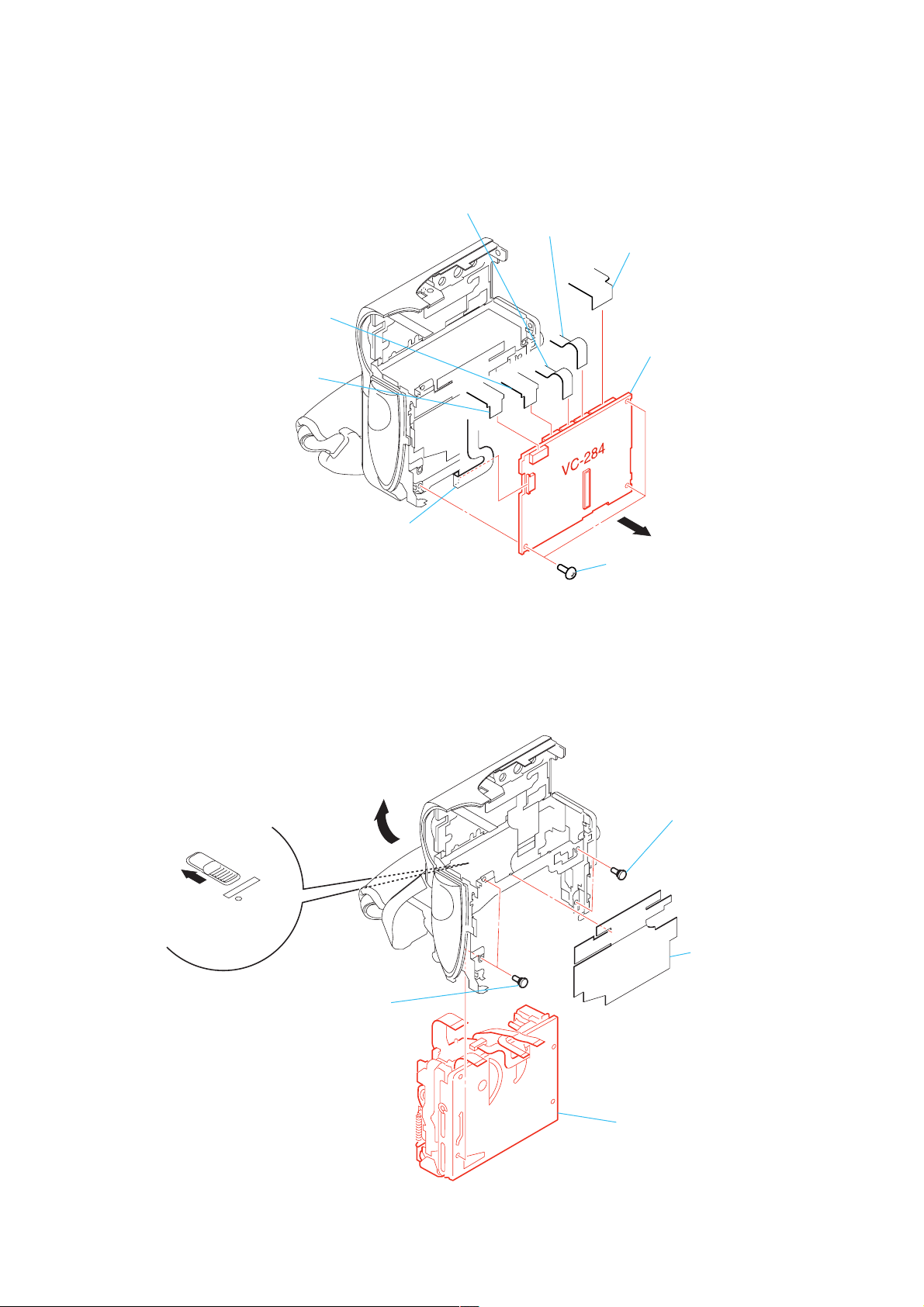

2-12. BJ-003 BOARD

DCR-PC101/PC101E

5 Screw (M1.7 × 4)

3 Connector

(battery terminal

board) (CN001)

7 BJ-003 board

2 Bottom flame section

8 Battery terminal

board

0 BJ frame

6 Screw (M1.7)

4 Connector

(battery terminal

board) (CN002)

9 Screw (M1.7 × 4)

qa Battery terminal

board

1 Two screws

(M1.7)

2-13. LCD SECTION

4 Two screws

7 Connector

(CN801)

1 Two screws

(M1.7)

3 LCD cabinet (R) assembly

(M1.7)

2 Two claws

9 LCD section

6 Two claws

5 Two screws

(M1.7)

8 LCD cabinet (L) assembly

2-9

DCR-PC101/PC101E

2-14. PD-166 BOARD

3 Panel protection sheet

1 Sheet (R)

2 Sheet (T)

qa Screw (M1.7)

8 Flexible board

(LCD) (CN804)

5 Flexible board

(panel (TP-1770))

(CN802)

6 Panel (TP-1770)

4 Tape

9 LCD unit

0 Remove three solders

qd PD-166 board,

inverter transformer block

qs Back light unit

7 Panel spacer

2-10

2-15. FP-470 FLEXIBLE BOARD

DCR-PC101/PC101E

NOTE FOR INSTALLATION

NOTE FOR INSTALLATION

qg FP-470 flexible board

4

1 Two connector

retainer sheet

7 Three claws

S4701

(Panel open)

3 Two screws

(M1.7)

8 Hinge cover

(upper)

5 Claw

6 Blind plate

assembly

qs LCD

2 Two screws

(M1.7 × 4)

0 Claw

hinge assembly

qd Claw

qf Hinge cover

(lower)

9 Screw (M1.7)

qa

3

2

2

3

2-11

DCR-PC101/PC101E

[POSITION TO INSTALL FP-470 BOARD

WHEN INSTALLING LCD HINGE

ASSEMBLY, BLIND PLATE ASSEMBLY]

Harness (PB-051)

Blind plate assembly

LCD hinge assembly

FP-470 flexible board

[NOTE FOR INSTALLATION OF LCD

HINGE BLOCK]

Hook this portion

on the cabinet (R)

to install the blind plate

assembly.

Blind plate assembly

LCD hinge block

FP-470 flexible board

Cabinet (R)

[INSTALLATION OF FP-470 FLEXIBLE

BOARD, HARNESS (PB-051)]

Harness (PB-051)

FP-470 flexible board

[POSITION OF CONNECTOR RETAINER

SHEET]

Hinge block assembly

FP-470

flexible board

Harness (PB-051)

Connector retainer

sheet

BJ-003 board

2-12

DCR-PC101/PC101E

ME-020 board

Adjustment remote

commander (RM-95)

AC power

adaptor

AC IN

Control switch block

(PS-2850) (10P)

Control switch block

(FK-2850)

DC-IN connector

BJ-003 board

VC-284 board

Mechanism deck

CPC-6 flexible jig

(J-6082-370-B)

CPC-6 terminal board jig

(J-6082-371-A)

When exiting the Forced VTR Power ON mode, connect the control

switch block (PS-2850) to the CN402 of ME-020 board. Or,

when ejecting the cassette, connect the control switch block (PS-1770)

to the CN402 of ME-020 board. and press the EJECT switch.

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section

T o check the VTR section, set the VTR to the “Forced VTR po wer ON” mode. (Or , connect the control switch block (PS-2850) to the CN402

of ME-020 board and set the power switch to the “VIDEO” position.)

Operate the VTR function using the adjustment remote commander (with the HOLD switch set in the OFF position).

Setting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 02 and press the P AUSE

button of the adjustment remote commander.

Exiting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, data: 00, and press the PAUSE

button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

2-13

DCR-PC101/PC101E

[SERVICE POSITION TO CHECK THE CAMERA SECTION]

Connection to Check the Camera Section

T o check the camera section, set the camera to the “Forced camera po wer ON” mode. (Or, connect the control switch block (PS-2850) to the

CN-402 of ME-020 board and set the power switch to the “CAMERA” position.)

Operate the camera functions of the zoom and focus using the adjustment remote commander (with the HOLD switch set in the OFF

position).

Setting the “Forced Camera Power ON” mode

1) Select page: O, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 01 and press the PAUSE

button of the adjustment remote commander.

CPC-6 terminal board jig

(J-6082-371-A)

Control switch block

(FK-2850)

Seal rubber

Lens block

Optical filter

block

Two screws

(M1.7 × 5)

CPC-6 flexible jig

(J-6082-370-B)

Exiting the “Forced Camera Power ON” mode

1) Select page: O, address: 01, and set data: 01.

2) Select page: D, address: 10, data: 00, and press the PAUSE

button of the adjustment remote commander.

3) Select page : 0, address: 01, and set data: 00.

When exiting the

Forced Camera Power ON mode,

connect the control switch block (PS-2850)

to the CN402 of ME-020 board.

Adjustment remote

commander (RM-95)

ME-020 board

VC-284 board

Control switch block

(PS-2850) (10P)

BJ-003 board

DC-IN connector

CF-089 board

Mechanism deck

AC IN

2-14

AC power

adaptor

2-16. FLEXIBLE BOARDS LOCATION

DCR-PC101/PC101E

FP-347

Control switch block

(FK-2850)

Control switch block

(PS-2850)

FP-470

2-15

DCR-PC101/PC101E

2-17. CIRCUIT BOARDS LOCATION

CF-089

MF-326

ME-020

VC-284

PD-166

NS-014

BJ-003

Board Name Function

BJ-003 DC IN, DV/USB CONNECTOR

CF-089 CCD IMAGER

ME-020 MIC AMP, EVF, EVF BACK LIGHT, JACK

MF-326 MANUAL FOCUS SENSOR

NS-014 REMOTE COMMANDER RECEIVER

PD-166 LCD DRIVE, BACK LIGHT

VC-284 CAMERA PROCESSOR, LENS DRIVE, MPEG MOVIE/DIGITAL STILL PROCESS,

DV INTERFACE, REC/PB AMP, USB INTERFACE, VIDEO IN/OUT, EVF DRIVE,

MECHA DECK DRIVE, CAMERA/MECHA CONTROL,

HI CONTROL AUDIO IN/OUT, DC/DC CONVERTER

2-16E

COVER

COVER

Link

Link

DCR-PC101/PC101E

3. BLOCK DIAGRAMS

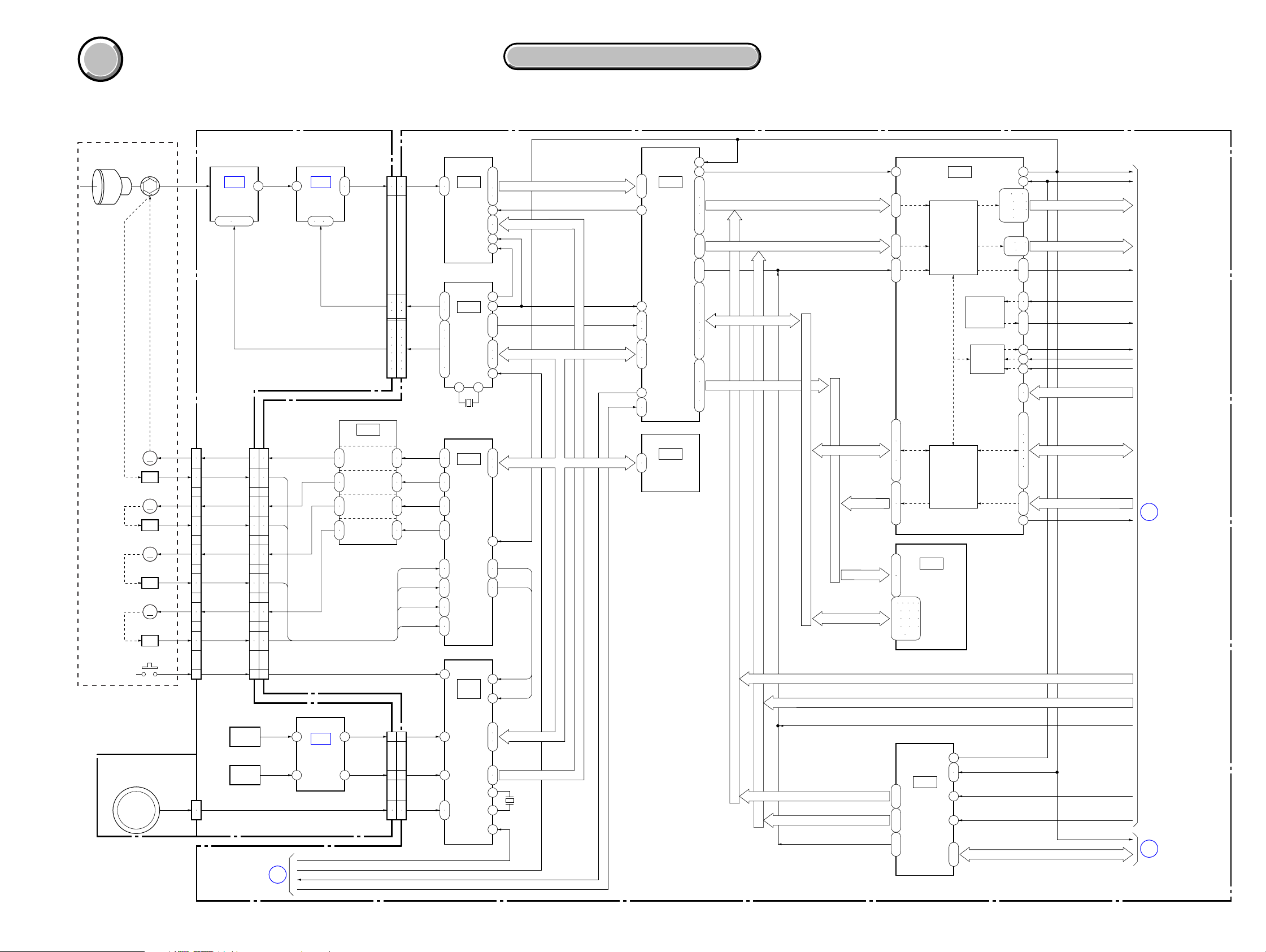

OVERALL BLOCK DIAGRAM (1/4)

OVERALL BLOCK DIAGRAM (1/4)

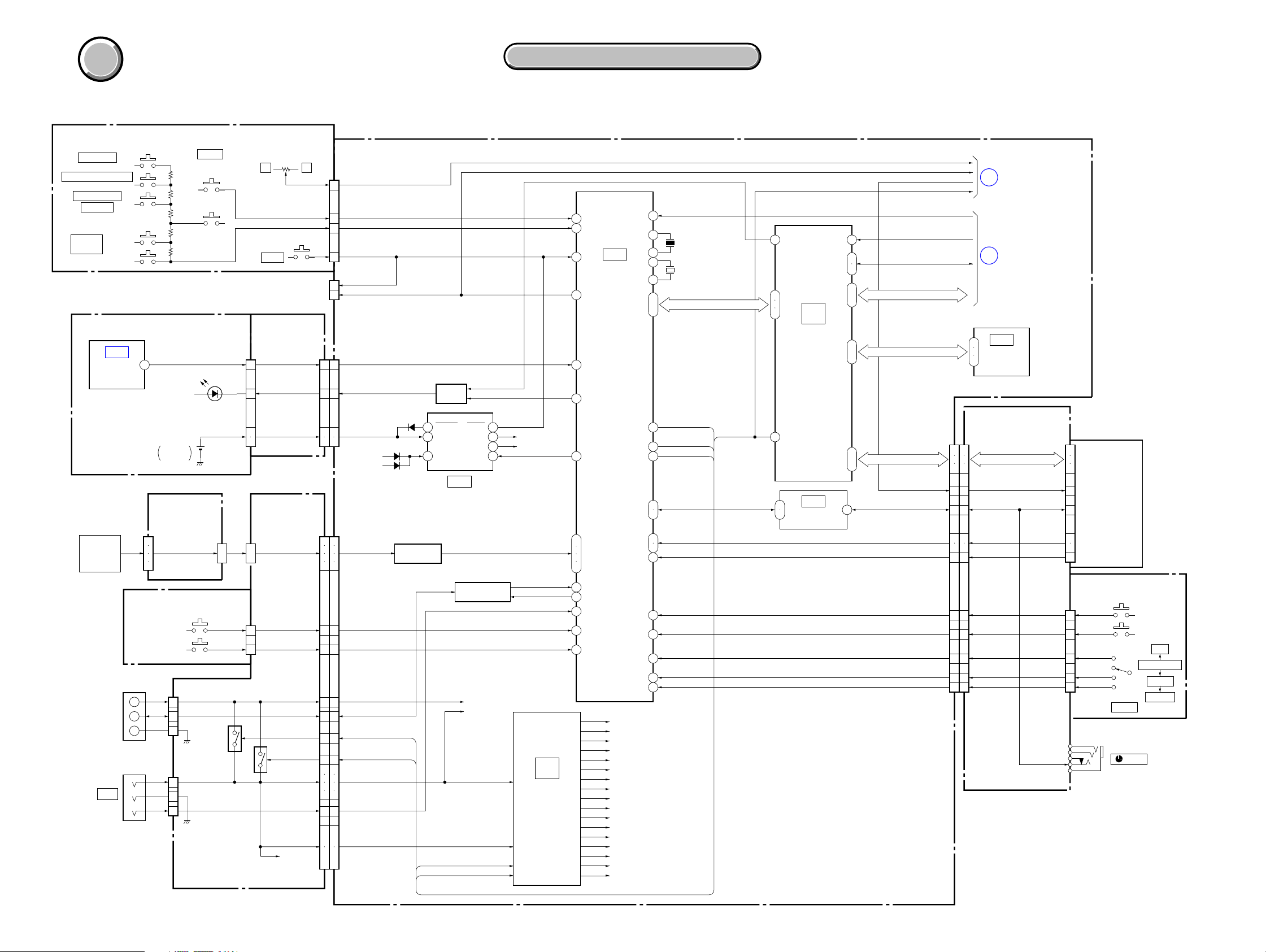

OVERALL BLOCK DIAGRAM (2/4) POWER BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (2/4) POWER BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (3/4) POWER BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (3/4) POWER BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (4/4)

OVERALL BLOCK DIAGRAM (4/4)

DCR-PC101/PC101E

COVER

COVER

SECTION 3

BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/4)

LENS BLOCK

LENS

IRIS

METER

ND FILTER

METER

FOCUS

MOTOR

ZOOM

MOTOR

IRIS

(SHUTTER)

M

H

M

H

M

MR

M

MR

CF-089 BOARD (1/2)

IC301

CCD

IMAGER

1 - 4 10 - 12 1 13 14

CN102

IRIS DRIVE±

3

4

IRIS HALL±

2

6

ND DRIVE±

13

14

ND HALL±

12

16

FOCUS±

26

27

F MR A, B

19

20

ZOOM±

24

25

Z MR A, B

8

10

CCD OUT CCD OUT±

8

CN101

(2/4)

171817

232423

293029

353635

454645

373837

414241

252625

18

24

30

36

46

38

42

26

CN1010

(2/4)

IC305

11

S/H

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-284 BOARD (1/4)

CN101

4

5

SHP, SHD, CLPDM

V1 - V4, RG, H1, H2

IC1301

(3/20)

5

IRIS

19

DRIVE

ND FILTER

7

DRIVE

17

2

FOCUS MOTOR

23

DRIVE

ZOOM MOTOR

4

DRIVE

21

(1/4)

83

85

71

73

84

65

67

68

70

77

79

80

13

14

15

16

9

10

11

12

CN1010

(1/4)

83

85

71

73

84

65

67

68

70

77

79

80

IRIS PWM,

IRIS EN

ND PWM,

ND EN

FC PWM,

FC EN

ZM PWM,

ZM EN

IRIS HALL±

ND HALL±

F MR A, B

Z MR A, B

30

31

A/D CONV.

16

17

22

9

GENERATOR

12

13

40

ı

42

44

30 29

10

11

8

9

ND FILTER

14

CONTROL

15

12

13

44

45

36

37

60

61

52

53

1

ı

IC1502

12

47

AGC,

48

20 65

(1/20)

44

45

16

19

PBLK

21

25

IC1501

33

TIMING

ı

35

(1/20)

1

2

47

6

X1502

66MHz : PC101

54MHz : PC101E

2

IC1304

5

6

FOCUS/

ZOOM/

IRIS/

(3/20)

SPCK

18

HALL AD

26

41

ND HALL

27

40

AD0 - AD13

TG HD,

TG VD,

TG FLD

CAM DD ON

CAM SI, CAM SO, CAM SCKCAM SI, CAM SO, CAM SCK

CLPOB

SH SO, SH SCKSH SO, SH SCK

CHCK

EXT STROBO

XSYS RST

44

ı

57

95

60

61

64

13

15

16

76

163

164

6

7

IC1601

CAMERA

PROCESSOR

(2/20)

IC1801

EVR

(1/20)

SPCK

97

96 177

1

3

169

170

173

175

4

7

8

10

133

137

140

142

145

146

149

154

102

109

114

118

121

ı

ı

ı

ı

ı

ı

ı

ı

ı

IYF Y0 - Y7

IYF C0 - C3

VCK

MDQ0 - MDQ15

MA0 - MA13

IYF Y0 - Y7

IYF C0 - C7

IFI HD, IFI VD, IFI OE

DATA BUS

IYF Y0 - Y7

IYF C0 - C7

IFI HD, IFI VD, IFI OE

MDQ0 - MDQ15

MA0 - MA13

ADDRESS BUS

MA0 - MA13

MDQ0 - MDQ15

76

ı

83

65

ı

72

84

ı

86

153

ı

156

158

ı

160

162

ı

170

128

ı

133

137

ı

144

20

ı

26

29

ı

35

2 4 5 7 8

10 11 13

42 44 45

47 48 50

51 53

MPEG MOVIE

PROCESS

DIGITAL STILL

PROCESS

IC1701

64M bit SDRAM

(4/20)

IC1704

(4/20)

CHARACTER

GENERATOR

AUDIO

99 101

103 106

108 111

113 115

91 93

95 97

74

44

117

ı

119

87

88

120

ı

123

61

62

59

47

48

11

ı

14

16

18

20

22

27

ı

34

2

ı

9

25

VFI HD, VFI VD, VFI OE

VSP SO, XVSP SCK

SPCK

AFCK

VFI Y0 - Y7

VFI C0 - C3

OSD HD, OSD VD

COL 0 - 3

ADAI2

ADAO2

SFD BCK

D0 LK - D15 LK

A16 LK - A23 LK

DSCK

OVERALL (2/4)

2

(PAGE 3-3)

NIGHT SHOT

FILTER DET.

MF-326 BOARD

PH730, 731

MANUAL

FOCUS

SENSOR

CN103

3

4

05

NT SHOT

SE202

YAW

SENSOR

SE201

PITCH

SENSOR

50 5017

OVERALL (4/4)

(PAGE 3-8)

12 18

8 2

MF A, B

ZOOM VR AD

CAM DD ON

EXT STROBO

1

XSYS RST

IC201

YAW/PITCH

SENSOR

AMP

CN101

YS OUT

PS OUT

(3/4)

XNS SW

4 4

3 3

535553

55

CN1010

(3/4)

41

130

129

210

211

IC2501

(1/2)

CAMERA

CONTROL

(15/20)

128

136

135

75

77

78

44

45

1

3

HALL AD

ND HALL

X2501

20MHz

IYF Y0 - Y7

IYF C0 - C3

IFI HD, IFI VD, IFI OE IFI HD, IFI VD, IFI OE

34

31

68

2

34

36

ı

38

IYF Y0 - Y7

IYF C0 - C7

IFI HD, IFI VD, IFI OE

52

59

42

49

36

38

ı

ı

ı

IC2001

VIDEO

A/D CONV.

(11/20)

3-1 3-2

AFCK

SPCK

IYF Y0 - Y7

IYF C0 - C3

Y IN

C IN

SPCK

VD SO, VD SI, VD SCK

OVERALL (3/4)

3

(PAGE 3-5)

DCR-PC101/PC101E

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

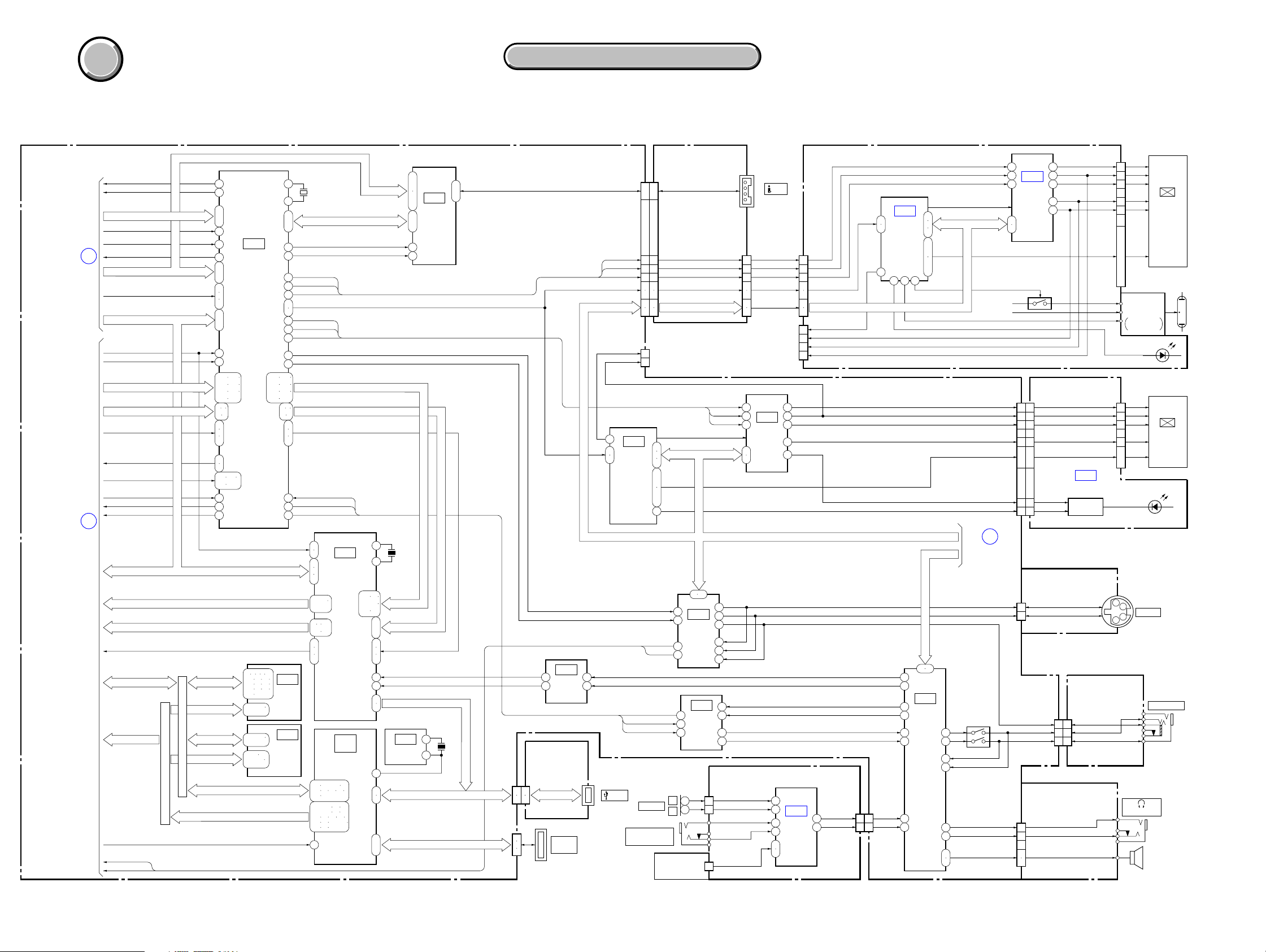

3-2. OVERALL BLOCK DIAGRAM (2/4)

VC-284 BOARD (2/4)

OVERALL (3/4)

OVERALL (1/4)

05

(PAGE 3-5)

(PAGE 3-2)

RECCK

RECDT

ADDT 0 - 5

PBCK

SWP

ATF ERR

4

MC BUS (10)

FRRV, TRRV, TRRT

VSP SO, VSP SI, XVSP SCK

SPCK

AFCK

VFI Y0 - Y7 VFO Y0 - Y7

VFI HD, VFI VD, VFI OE

OSD HD, OSD VD

COL 0 - 3

ADAI2

ADAO2

SFD BCK

2

VSP SO, XVSP SCK VSP SO, VSP SI, XVSP SCK

IYF Y0 - Y7

IYF C0 - C3

IFI HD, IFI VD, IFI OE

D0 LK - D15 LK D0 LK - D15 LK

A16 LK - A23 LK

ADDRESS BUS

DSCK

Y IN

C IN

A1 LK - A14 LK

D0 LK - D15 LK

DATA BUS

A1 LK - A20 LK

99

97

83

ı

88

81

167

79

170

ı

179

152

153

156

159

ı

161

48

196

199 201

203 205

207 211

213 215

1 3

5 7

17

21

23

183

184

190 191

194 195

135

134

127

D0 LK - D15 LK

A1 LK - A20 LK

IC2101

DV SIGNAL

PROCESS

(7/20)

2 4 5 7 8

10 11 13

42 44 45

47 48 50

51 53

20 - 26

29 - 35

29 - 36

38 - 45

1 - 9

16 - 25

48

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

BJ-003 BOARD (1/3) PD-166 BOARD (1/2)

CN005 (1/3)

19

19

ı

ı

22

22

83

83

84

84

85

85

67

67

69

69

72

72

74

74

5

(FOR CHECK)

4

42

45

46

14

ı

18

20

ı

24

8

Y OUT

C OUT

Y IN

C IN

DATA TO SFD

DATA FROM SFD

SFD BCK

STEREO

J402

MIC

(PLUG IN POWER)

INTELLIGENT

ACCESSORY

CN007

PANEL B

PANEL G

PANEL R

PANEL XHD, PANEL XVD

VD SO, VD SCK VD SO, VD SCK

CPC

VD SO, VD SCK, XTG SO

9 10

46

IC4101

7

VIDEO

IN/OUT

(12/20)

36

34

IC4302

8

AUDIO

9

A/D CONV.

D/A CONV.

12

(17/20)

MIC901

MIC UNIT

R

L

SHOE (1/2)

(1/2)

13

12

10

EVF B

46

EVF G

47

EVF R

48

39

40

VD SO, VD SCK

22

14

18

39

48

42

3

2

15

16

ME-020 BOARD (3/4)

CN401

INT MIC R

3

INT MIC L

5

EXT MIC R

EXT MIC L

SHOE MIC L

3

1

2

3

8

DRIVER

(13/20)

200 202

204 206

208 212

214 216

IC3001

16M bit

SDRAM

IC3002

16M bit

MEMORY

138

139

142

ı

145

48

141

PANEL B

71

PANEL R

73

PANEL G

75

PANEL XHD, PANEL XVD

105

106

EVF B

63

EVF R

65

EVF G

67

Y OUT

55

C OUT

59

2 4

VFIO C4 - C7VFI C0 - C3

6 8

18

22

24

DATA TO SFD

133

DATA FROM SFD

132

SFD FCK

127

(6/20)

FLASH

(6/20)

X2101

24.576MHz

33

41

65

82

63

8 - 12

15 - 17

6 7

139 140

18

20

21

DIGITAL STILL

39 41 - 45

47 49 51 52

54 56 - 60

62 - 64 66

68 - 70 72

73 75 76 78

79 81 83 - 88

90 92 93

187

LBUS 0 - 3

TRCK

LCK

IC2301

USB I/F

(10/20)

IC2905

(1/2)

CONTROL

(5/20)

MC BUS (8)

47 48

51 - 54

57 58

25

31

43

ı

46

27

28

42

66

56

79

78

187

239

238

213

ı

215

29

ı

32

34

IC2102

ı

37

DV I/F

42

(8/20)

ı

45

47

79

X2301

48MHz

VFO Y0 - Y7

VFIO C4 - C7

VFO HD, VFO VD, VFO OE

ASDATA

MCLK

USB D±

IC2904

3

XTAL OSC

4

(5/20)

MS DIO, MS BS, MS SCLK

6

ı

9

PANEL XHD, PANEL XVD

IC2302

8

AUDIO

11

A/D CONV.

(10/20)

X2901

48MHz

BJ-003 BOARD

(2/3)

(2/3)

CN005

(2/3)

252625

26

3

5

6

MEMORY

STICK

CN1003

USB D± USB D±

CN1005

CN1003 (1/3)

TPA±, TPB± TPA±, TPB±

PANEL B

PANEL G

PANEL R

PANEL XHD, PANEL XVD

VD SO, VD SCK

CN1006 (1/3)

EVF VCO

EVF VG

2

IC4202

1

TIMING

48

GENERATOR

(13/20)

L IN

3

R IN

2

CN004

(USB)

CN003

(DV)

CPC

(FOR CHECK)

IC4201

LCD

1

35

3

33

36

40

24

22

20

14

35

IC4401

MIC AMP

(1/2)

CN801

(1/2)

1

2

3

13

12

10

8

CN803

4

6

2

1

REC OUT L

REC OUT R

PB IN L

PB IN R

14

22

PSIG

COM

VG

MIC R

MIC L

CN404

(3/4)

S Y I/O

S C I/O

VIDEO I/O

49

49

50

50

1

48

2

CN1001

(3/4)

IC802

TIMING

GENERATOR

(1/2)

62

63

25

23

19

17

49

46

42

45

46

14

ı

18

20

ı

24

48 9

BL ON

PWM

LED ON/OFFHSY

VD SO, VD SCK

VSP SO, VSP SCK

14 15

IC4301

AUDIO

IN/OUT

(17/20)

PANEL B

PANEL G

PANEL R

VD SO, VD SCK, XTG SO

RGT, HCK1, HCK2, HST, WIDE,

PANEL 4.6V

LED DA

LED ON/OFF

5

OVERALL (3/4)

(PAGE 3-5)

CN1004 (1/3)

Q4303, 4304

54

55

53

51

HP R OUT

2

HP L OUT

64

SP±

8

10

46

47

48

39

40

DWN, EN, VCK, VST

UNREG

IC801

LCD

DRIVER

(1/2)

24

22

20

12

27

Q901, 902

ME-020 BOARD (1/4)

CN404 (1/4)CN1001 (1/4)

82

82

838183

81

84 84 16

VST, EVF VCK, STB, EN, DWN,

69

69

RGT, HST, HCK2, HCK1, BLK

ı

ı

78

78

64 64

63 63

CONTROL SWITCH

BLOCK (FK-2850) (1/3)

20

17

CN1001

(2/4)

40 40

393839

CONTROL SWITCH

BLOCK (FK-2850) (2/3)

CN1004

(2/3)

10

12

7

8

B

G

R

COM

IC501

(2/2)

Q501, 503

BACK LIGHT

DRIVE

ME-020 BOARD

(2/4)

CN404

(2/4)

VIDEO I/O

AU LINE I/O L

AU LINE I/O R

38

HP R OUT

HP L OUT

SP±

COM

PSIG

CN804

B

G

R

CN502

3

5

4

23

6

2

7

9

12

13

19

ı

22

INVERTER

TRANSFORMER

UNIT

BACK LIGHT

DRIVE

D901

(STARTER)

13

15

14

3

ı

12

D501, 502

(BACK LIGHT)

Y

S VIDEO

C

J601

(HEAD PHONE)

LCD901

2.5 INCH

LCD UNIT

(BACK LIGHT)

LCD903

COLOR

J602

AUDIO/VIDEO

SP601

SPEAKER

ND901

EVF

UNIT

J401

3-3 3-4

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DCR-PC101/PC101E

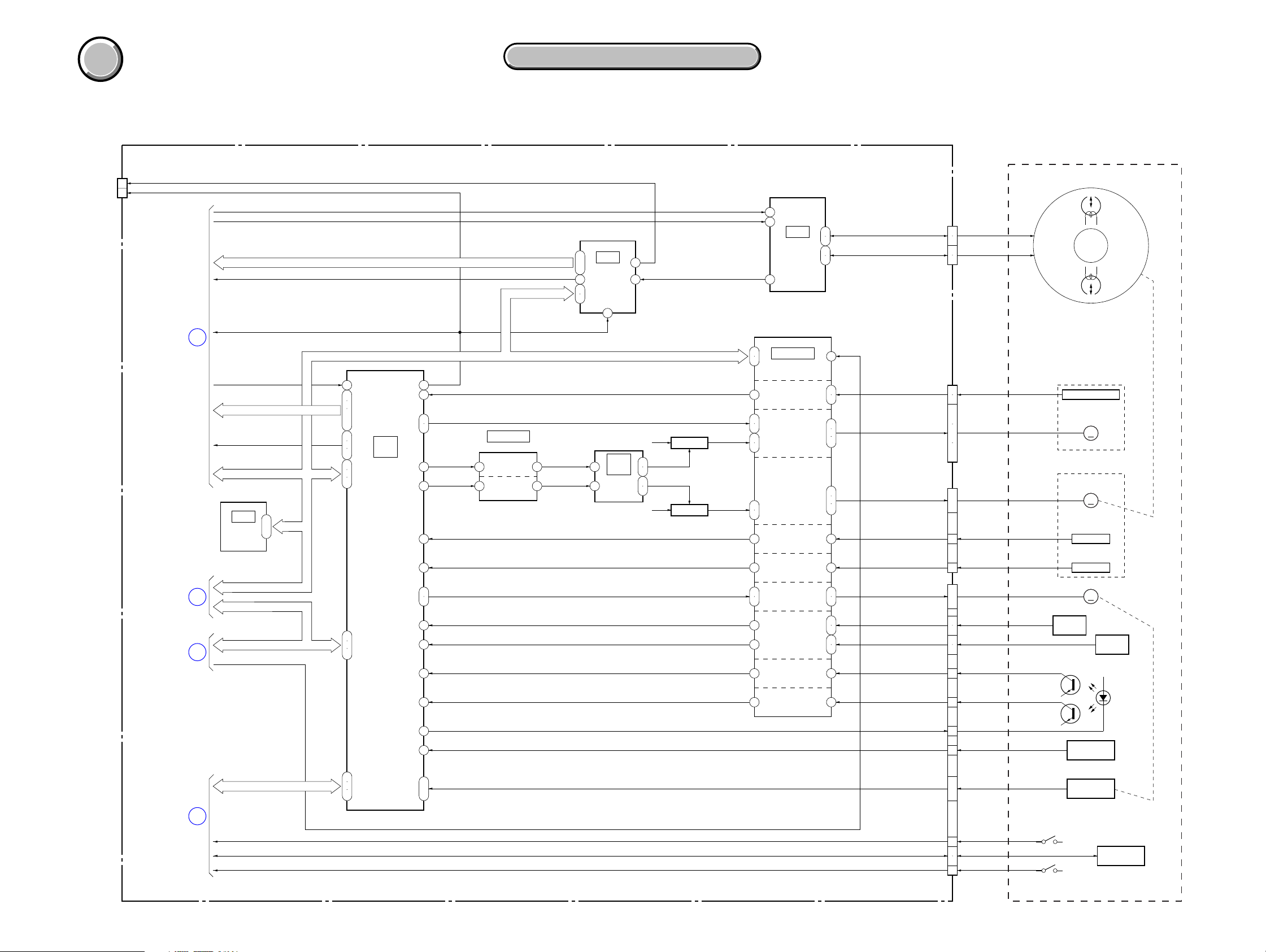

3-3. OVERALL BLOCK DIAGRAM (3/4)

VC-284 BOARD (3/4)

CN1006 (2/3)

RF MON

20

CPC

(FOR CHECK)

SWP

17

OVERALL (2/4)

(PAGE 3-3)

RECCK

RECDT

ADDT 0 - 5

PBCK

SWP SWP

4

ATF ERR

MC BUS (10)

FRRV, TRRV, TRRT

VSP SO, VSP SI, XVSP SCK

IC2502

2

(15/20)

ı

4

EEPROM

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

RECCK

40

RECDT

42

111 164

32

33

45

ı

52

84

IC2501

178

179

67

69

70

(2/2)

MECHA

CONTROL

(15/20)

190

165

166

89

88

197

CAP PWM

DRUM PWM

VSP SO, XVSP SCK

IC2401 (2/2)

(14/20)

(RABI)

41 43

LPF

LPF

44 45

15

IC1901

ADDT 0 - 5

ı

20

PBCK PBYOUT

CAP ERROR

DRUM ERROR

A/D CONV.,

13

22

24

VSP SO, XVSP SCK

CAP FG

CAP ON, CAP FWD

72

78

DRUM FG

EQ,

PLL

(9/20)

31

IC4501

(1/2)

PWM

DRIVE

(18/20)

34

42

UNREG1

26

27

24

25

UNREG1

Q4505, 4516

SWITCHING

SWITCHING

Q4506, 4517

CAP VS

DRUM VS

IC1902

REC/PB AMP

(9/20)

27

36

IC2401 (1/2)

38

(14/20)

CAPSTAN

4

FG AMP

1

80

CAPSTAN

MOTOR

75

DRIVE

77

DRUM

MOTOR

64

DRIVE

67

DRUM

53 52

FG AMP

6

7

1

2

SPCK

35

7

8

74

76

78

63

65

68

ODD

EVEN

FG 1, 2

CAP U, V, W

DRUM U, V, W

DRUM FG SENS

CN1901

CN1009

CN1007

J MECHA DECK

5

6

2

3

22

25

1

ı

4

11

ı

14

17

ı

20

1

ı

6

9

DRUM

M902

CAPSTAN FG

CAPSTAN

MOTOR

MM

M901

DRUM

MOTOR

MM

DRUM FG

OVERALL (2/4)

(PAGE 3-4)

OVERALL (1/4)

(PAGE 3-2)

OVERALL (4/4)

(PAGE 3-8)

5

3

6

VSP SO, XVSP SCK

VD SO, VD SCK

VD SO, VD SI, VD SCK

SPCK

HI SO, HI SI, XHI SCK

REC PROOF

CHIME SDA, CHIME SCK

XCC DOWN

198

13

15

80

82

83

63

65

66

192

193

196

195

180

119

106

ı

108

DRUM PG

LOAD, UNLOAD

TREEL FG

SREEL FG

TAPE END

TAPE TOP

TAPE LED ON

DEW AD

MODE SW A - C

DRUM

50 49

PG AMP

32

LODING MOTOR

33

DRIVE

29

25

21 20

19 20

REEL

FG AMP

TAPE END

DETECT

TAPE TOP

DETECT

69

72

26

27

22

23

DRUM PG SENS

LM±

T REEL±

S REEL±

TAPE END C

TAPE TOP C

CN1008

H902

T REEL

SENSOR

S901

S903

DRUM PG

MM

DEW

SENSOR

S902

MODE

SWITCH

H901

S REEL

SENSOR

TAPE LED

CN901

CASSETTE

MEMORY

M903

LOADING

MOTOR

D901

10

24

ı

27

7

8

4

5

3

1

16

23

19

ı

21

13

11

12

17

Q901

TAPE END

SENSOR

Q902TAPE TOP

SENSOR

REC PROOF

CC DOWN

05

3-5 3-6

DCR-PC101/PC101E

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-4. OVERALL BLOCK DIAGRAM (4/4)

CONTROL SWITCH BLOCK (FK-2850) (3/3)

S608

BACK LIGHT

S607

DISPLAY/TOUCH PANEL

S604

COLOR SLOW S

SUPER NS

S605

(AF/MF)

FOCUS

(INFINITY)

S606

(INFINITY)

PHOTO

S602

(PHOTO FREEZE)

S603

(PHOTO REC)

NS-014 BOARD CF-089 BOARD

IC701

REMOTE

COMMANDER

RECEIVER

4

D702, 703

(NIGHT SHOT)

LITHIUM

BATTERY

BT001

PD-166 BOARD

(2/2)

TP L, TP R

CN801

(2/2)

15

ı

18

TA901

TOUCH

PANEL

CN802

2

3

TP TOP, TP BOT,

5

6

FP-470 FLEXIBLE BOARD

S4702

(PANEL REVERSE)

S4701

(PANEL OPEN)

BT901

BATTERY

TERMINAL

J901

DC IN

+

S

–

CN001

1

2

3

1

2

3

05

CN002

Q001,

002

Q003,

004

RV601

(ZOOM)

W

S601

RESET

(2/2)

CN104

8

4

1

2

BJ-003 BOARD

(3/3)

CN007

(2/2)

15

ı

18

CN006

KEY AD1

3

KEY AD2

5

CPC

(FOR CHECK)

CN101 (4/4)

CN005 (3/3)

P UNREG

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-284 BOARD (3/4)

2

5

4

24

16

9

52

52

62

62

54

54

56

56

65

65

66

66

68

68

70

70

3

3

5

5

62

62

61

61

29

29

31

31

30

30

32

32

34

34

36

36

59

59

2

2

ı

ı

16

16

38

38

ı

ı

56

56

CN1004

(3/3)

ZOOM VR AD

KEY AD0

PHOTO FREEZE

HI XRESET

CN1006 (3/3)

HI XRESET

XINIT

CN1001 (4/4)

SIRCS SIG

NS LED K

BATT LI 3V

VTR UNREG

BATT UNREG

CN1003 (3/3)

KEY AD1

KEY AD2

BATT UNREG

BATT SIG

FAST CHARGE

INIT CHARGE ON

VTR UNREG

BATT XEXT

PRT HEAD UNREG,

SHOE PRT UNREG,

UNREG1, UNREG2

D2702

2

D2701

D2704

3

7

INITIAL RESET, BACK UP VCC

Q1002 - 1004

TOUCH

PANEL I/F

VTR DD ON

CAM DD ON

Q1006, 1009

NS LED

DRIVE

PREEND

RESET

VBAT

VIN CS

VOUT

IC2702

(20/20)

BATTERY CHARGE

DETECTOR

BATT UNREG

VTR UNREG

SIRCS PWM

VRO

Q3101

IR ON

5

8

6

4

EVER 3.0V

VOUT

BATT IN

IC4501

(2/2)

DC/DC CONTROL

(18/20)

59

73

47

41

45

31

34

48

71

72

43

42

74

60

61

6

IC3101

HI CONTROL

(16/20)

MT 4.9V

D 2.8V

D 3.1V

D 1.5V

D 1.9V

A 2.8V

GANDHI 1.5V

A 4.6V

CAM 15V

CAM –7.5V

SW 15V

RP 4.6V

RP 2.8V

AU 2.8V

PANEL/EVF 2.8V

PANEL/EVF 13.5V

PANEL/EVF 4.6V

5

28

29

51

52

23

ı

25

35

FAST CHARGE

37

INIT CHARGE ON

38

39

40

57

58

69

4

3

1

2

7

X3101

10MHz

X3102

32.768kHz

TXD0, RXD0, SCK0

VTR DD ON

CAM DD ON

LANC IN,

LANC OUT

185

190

191

168

10

LANC DRIVER

12

SHOE ID 1, 2

SHOE CONT AD

XVTR MODE SW

XCAM MODE SW

XPHOTO STBY SW

HI CONTROL

X EJECT SW

XS/S SW

T

IC2905

(2/2)

(5/20)

IC2703

(20/20)

ZOOM VR AD

XSYS RST

3730

160

162

199

ı

201

205

ı

207

CHIME SDA, CHIME SCK

HI SO, HI SI, XHI SCK

EEP TXD3, EEP RXD3, EEP SCK3

EXT STROBO

CAM DD ON

XCC DOWN

REC PROOF

1

6

IC2906

2

5

EEPROM

6

(5/20)

ME-020 BOARD (4/4)

CN1001 (4/4) CN404 (4/4)

8

221

ı

HS TXD, HS RXD, HS SCK HS TXD, HS RXD, HS SCK

223

11

LANC SIG

8

10

10

12

12

11 11

31 31 13

797

9

13 13 4

28 28

30 30

27 27

26 26

34 34

OVERALL (1/4)

(PAGE 3-1)

OVERALL (3/4)

(PAGE 3-5)

CN402

8

10

12

7

INTELLIGENT

ACCESSORY

SHOE (2/2)

9

11

CONTROL SWITCH BLOCK

(PS-2850)

8

10

4

5

6

(EJECT)

(START/STOP)

OFF (CHARGE)

S4603

POWER

J403

LANC

S4602

S4601

VCR

CAMERA

MEMORY

3-7 3-8

Loading...

Loading...