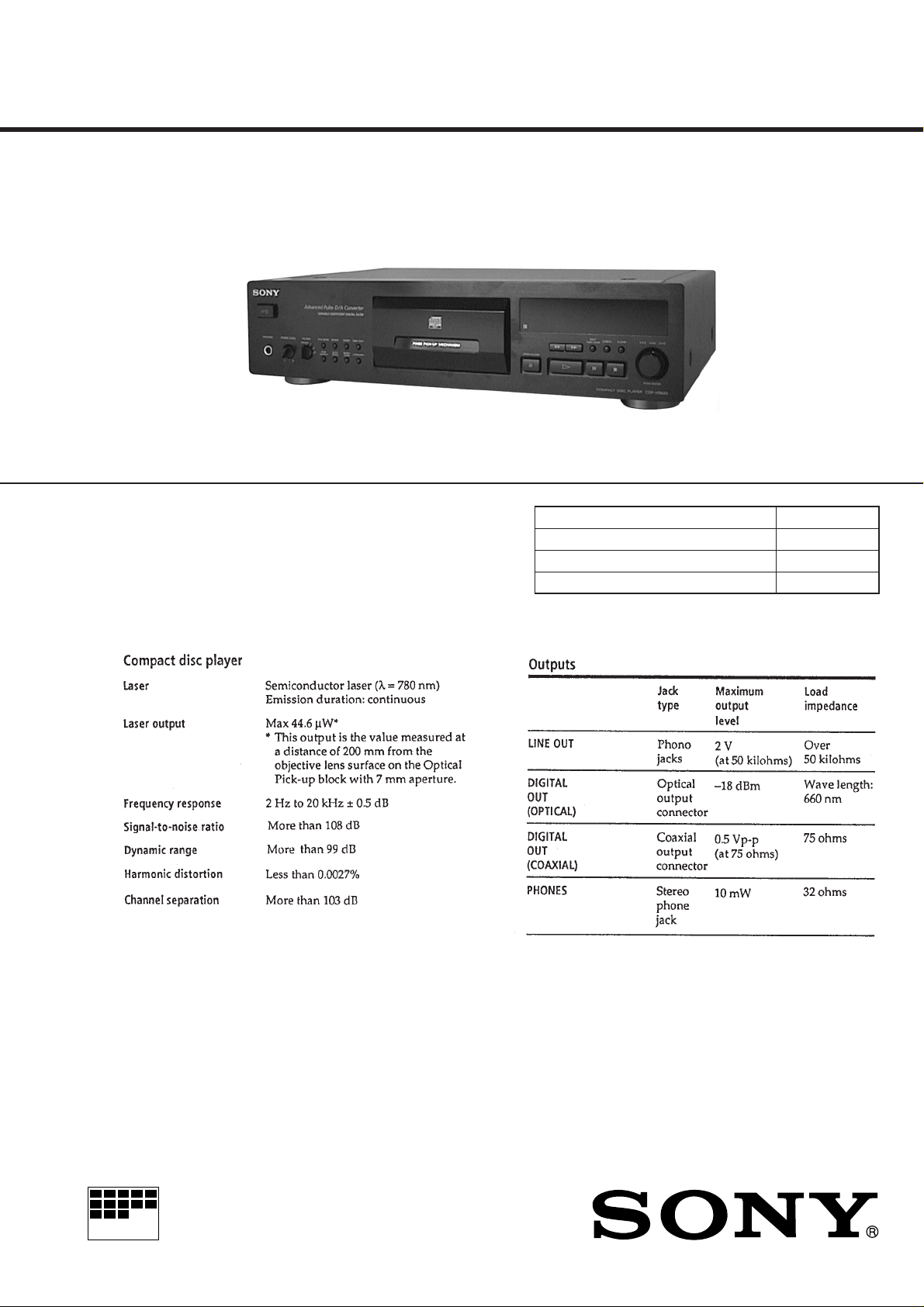

CDP-XB820

SERVICE MANUAL

SPECIFICATIONS

AEP Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM36-14E

Base Unit Type BU-14E

Optical Pick-up Type KSS-213B/F-NP

MICROFILM

– Continued on next page –

COMPACT DISC PLAYER

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 6

3. DISASSEMBLY ......................................................... 7

4. TEST MODE

4-1. AF ADJ Mode ................................................................. 9

4-2. ADJ Mode ....................................................................... 10

4-3. CLV-S Mode.................................................................... 10

4-4. AGING Mode.................................................................. 11

5. ELECTRICAL BLOCK CHECKING ................ 12

6. DIAGRAMS

6-1. IC Pin Function Description ........................................... 14

6-2. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 16

6-3. Printed Wiring Board – BD Section – ............................ 19

6-4. Schematic Diagram – BD Section – ............................... 21

6-5. Printed Wiring Boards

– OPTICAL PICK-UP/MOTOR Section – .................... 23

6-6. Schematic Diagram

– OPTICAL PICK-UP/MOTOR Section – .................... 24

6-7. Printed Wiring Board – MAIN Section –....................... 25

6-8. Schematic Diagram – MAIN Section (1/2) –................. 27

6-9. Schematic Diagram – MAIN Section (2/2) –................. 29

6-10. Printed Wiring Boards – POWER Section – .................. 31

6-11. Schematic Diagram – POWER Section – ...................... 33

6-12. Printed Wiring Boards – PANEL Section – ................... 35

6-13. Schematic Diagram – PANEL Section –........................ 37

7. EXPLODED VIEWS ................................................ 42

8. ELECTRICAL PARTS LIST ............................... 46

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

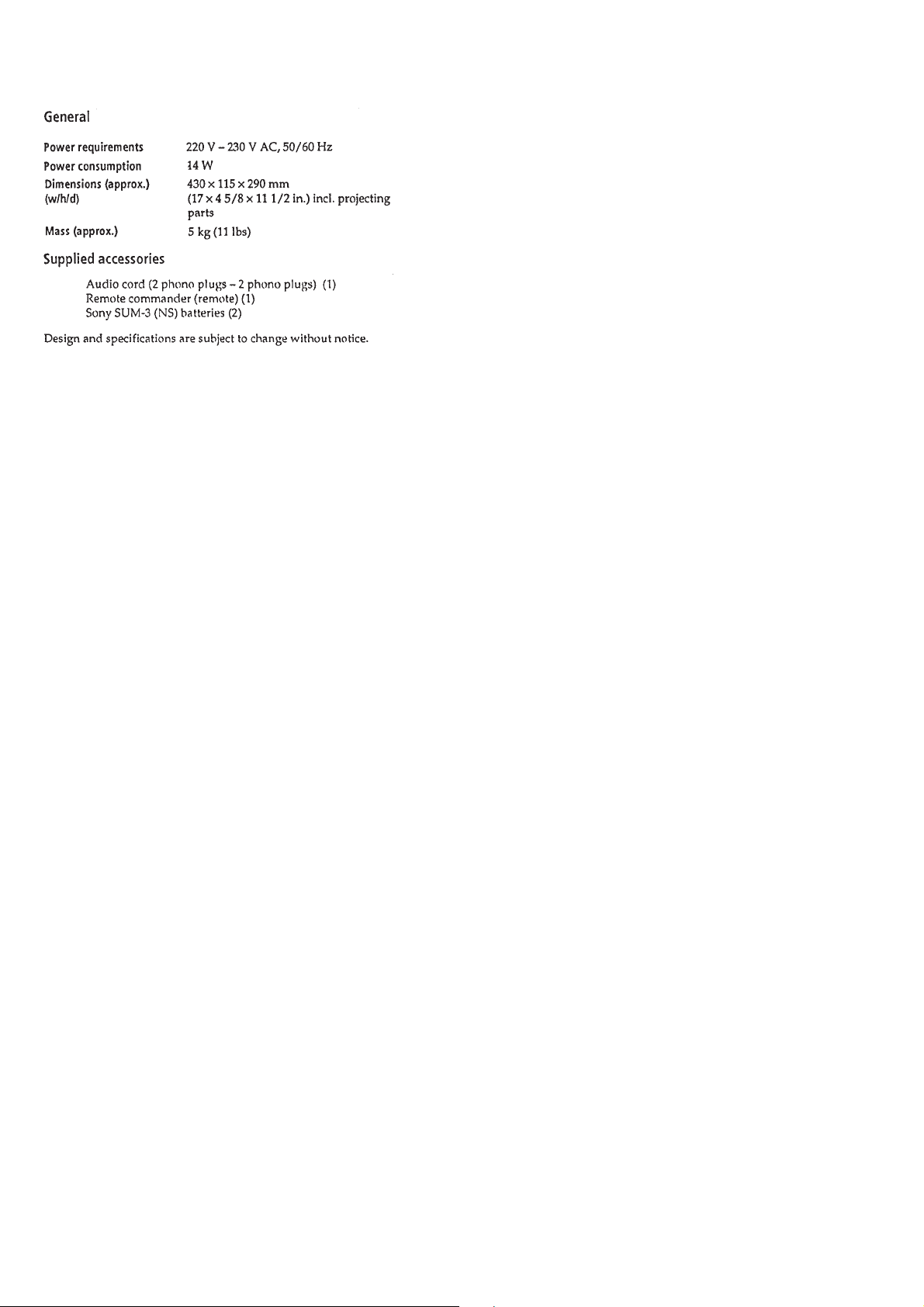

HOW TO OPEN THE DISC TRAY WHEN POWER

SWITCH TURNS OFF

Insert a tapering driver into the aperture of he unit bottom, and

turn in the direction of arrow (to OUT direction).

DISC REMOVAL PROCEDURE (at POWER OFF)

1. Remove the case. (Refer to page 7.)

2. Push the slide cam in the direction of the arrow A.

3. Draw out the loading panel in the direction of the arrow B by

hand, and remove a disk.

slide cam

A

”B

loading panel

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

– 3 –

CD-TEXT TEST DISC

This unit is able to display the test data (character information) written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:4-989-366-01) is used for checking the display.

To check, perform the following procedure.

Checking Method:

1. Turn ON the power, set the disc to the disc table with the “test disc” label facing up, and chuck the disc.

2. Press the · button and play back the disc.

3. The following will be displayed on the fluorescent indicator tube.

Display : 1KHZ 0DB

4. Rotating [AMS] knob, select the track. The text data of each track will be displayed.

For details of the displayed contents for each track, refer to “Table 1 : CD-TEXT TEST DISC TEXT Data Contents” and “Table 2 : CDTEXT TEST DISC Recorded Contents and Display”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling it. For

details, refer to “Table 2 : CD-TEXT DISC Recorded Contents and Display”.

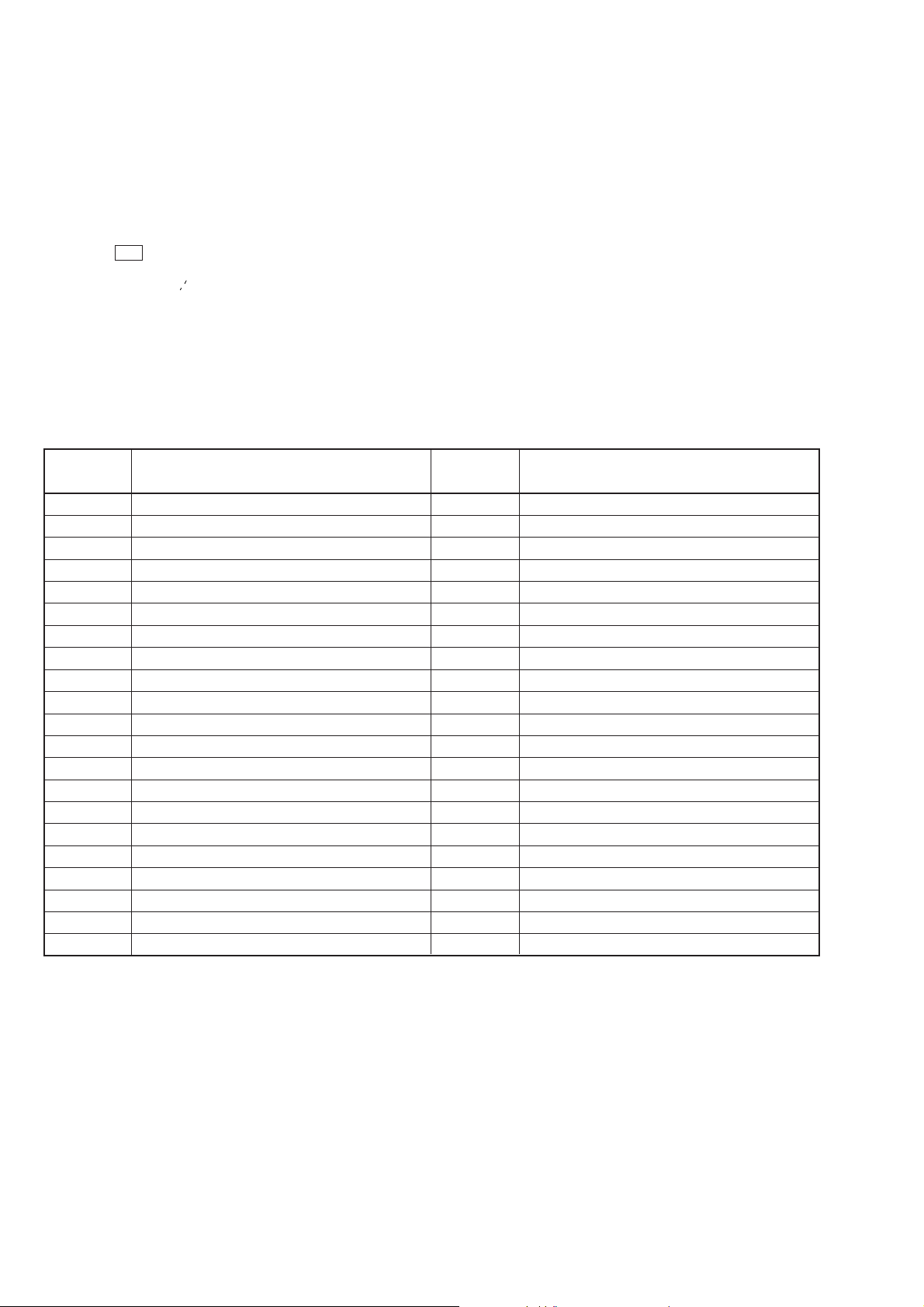

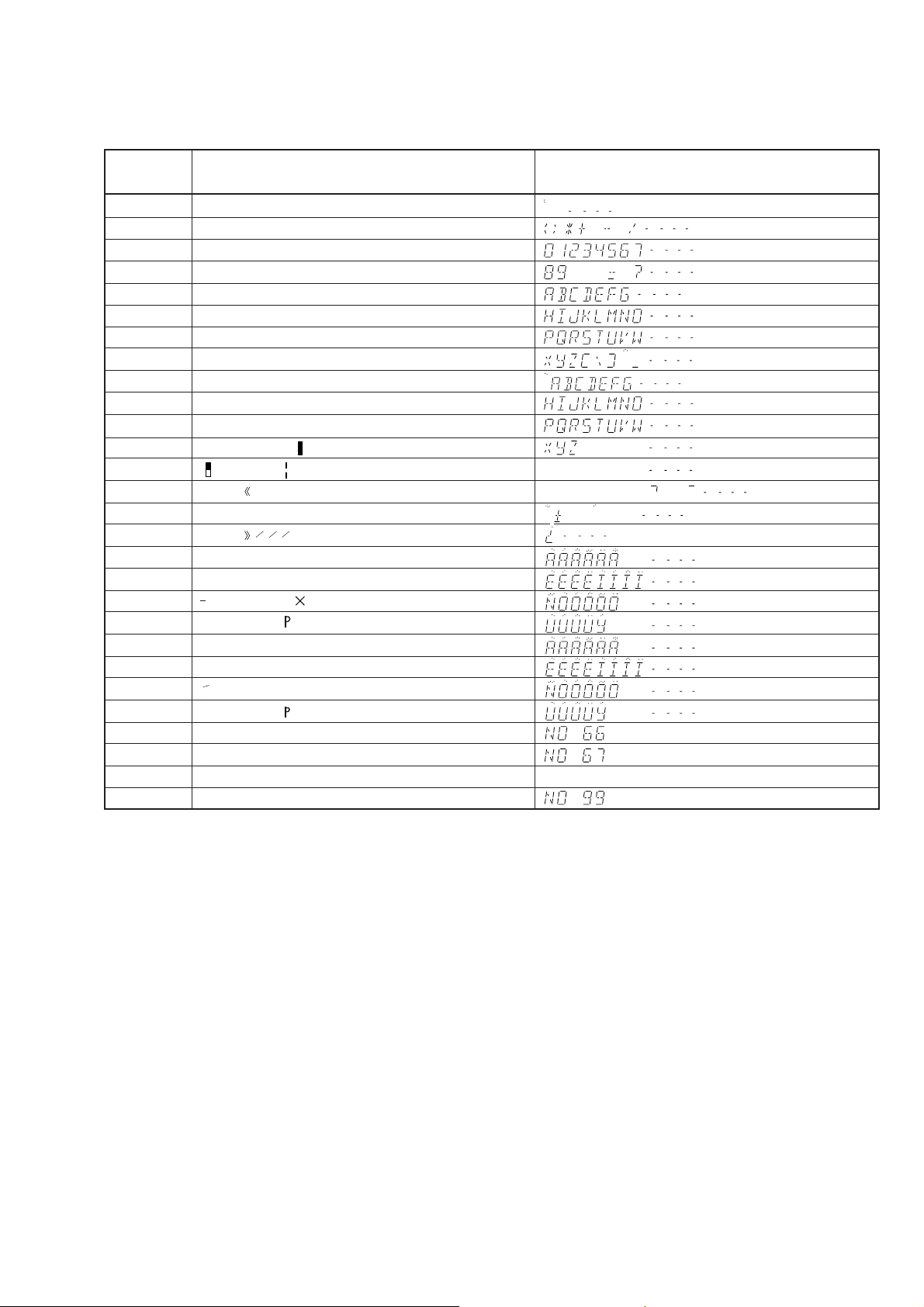

Table 1 : CD-TEXT TEST DISC TEXT Data Contents (TRACKS No. 1 to 41:Normal Characters)

TRACK

≠

No.

1 1kHz/0dB/L&R 22 1kHz/-90dB/L&R

2 20Hz/0dB/L&R 23 Infinity Zero w/o emphasis//L&R

3 40Hz/0dB/L&R 24 Infinity Zero with emphasis//L&R

4 100Hz/0dB/L&R 25 400Hz+7kHz(4:1)/0dB/L&R

5 200Hz/0dB/L&R 26 400Hz+7kHz(4:1)/-10dB/L&R

6 500Hz/0dB/L&R 27 19kHz+20kHz(1:1)/0dB/L&R

7 1kHz/0dB/L&R 28 19kHz+20kHz(1:1)/-10dB/L&R

8 5kHz/0dB/L&R 29 100Hz/0dB/L*

9 7kHz/0dB/L&R 30 1kHz/0dB/L*

10 10kHz/0dB/L&R 31 10kHz/0dB/L*

11 16kHz/0dB/L&R 32 20kHz/0dB/L*

12 18kHz/0dB/L&R 33 100Hz/0dB/R*

13 20kHz/0dB/L&R 34 1kHz/0dB/R*

14 1kHz/0dB/L&R 35 10kHz/0dB/R*

15 1kHz/-1dB/L&R 36 20kHz/0dB/R*

16 1kHz/-3dB/L&R 37 100Hz Squer Wave//L&R

17 1kHz/-6dB/L&R 38 1kHz Squer Wave//L&R

18 1kHz/-10dB/L&R 39 1kHz w/emphasis/-0.37dB/L&R

19 1kHz/-20dB/L&R 40 5kHz w/emphasis/-4.53dB/L&R

20 1kHz/-60dB/L&R 41 16kHz w/emphasis/-9.04dB/L&R

21 1kHz/-80dB/L&R

±

Displayed Contents

TRACK

No.

Displayed Contents

NOTE: The contents of Track No. 1 to 41 are the same as those of the current TEST DISC-their titles are displayed.

– 4 –

Table 2: CD-TEXT TEST DISC Recorded Contents and Display

(In this unit, some special characters cannot be displayed. This is no a fault.)

TRACK

No.

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

to

99

Recorded contents

! ” # $ %& ´ (21h to 27h)1kHz 0dB L&R

( ) + , – . / (28h to 2Fh)

*

01234567 (30h to 37Fh)

8 9 : ; < = > ? (38h to 3Fh)

@A B C D E F G (40h to 47Fh)

H I J K L MNO (48h to 4Fh)

P QR S T U VW (50h to 57Fh)

X Y Z [ ¥ ] ^ _ (58h to 5Fh)

a b c d e f g (60h to 67Fh)

′

h i j k l m n o (68h to 6Fh)

p q r s t u v w (70h to 77Fh)

xyz{ I }

~

(78h to 7Fh)

i¢£¤¥ § (A0h to A7h) 8859-1

¬

≥ C ª

•±23

1

º ¿ (B8h to BFh)

†

–

PR

µ ¶ • (B0h to B7h)

′

14123

(A8h to AFh)

4

АБВГДЕЖЗ (C0h to C7Fh)

ИЙКЛМНОП (C8h to CFh)

D СТУФХЦ

ШЩЪЫЬY

˙

(D0h to D7Fh)

Я (D8h to DFh)

абвгдежз (E0h to E7Fh)

ийклмноп (E8h to FFh)

∂ стуфхц÷ (F0h to F7Fh)

шщъыьy

ÿ (F8h to FFFh)

´

No.66

No.67

to

No.99

Display

to

– 5 –

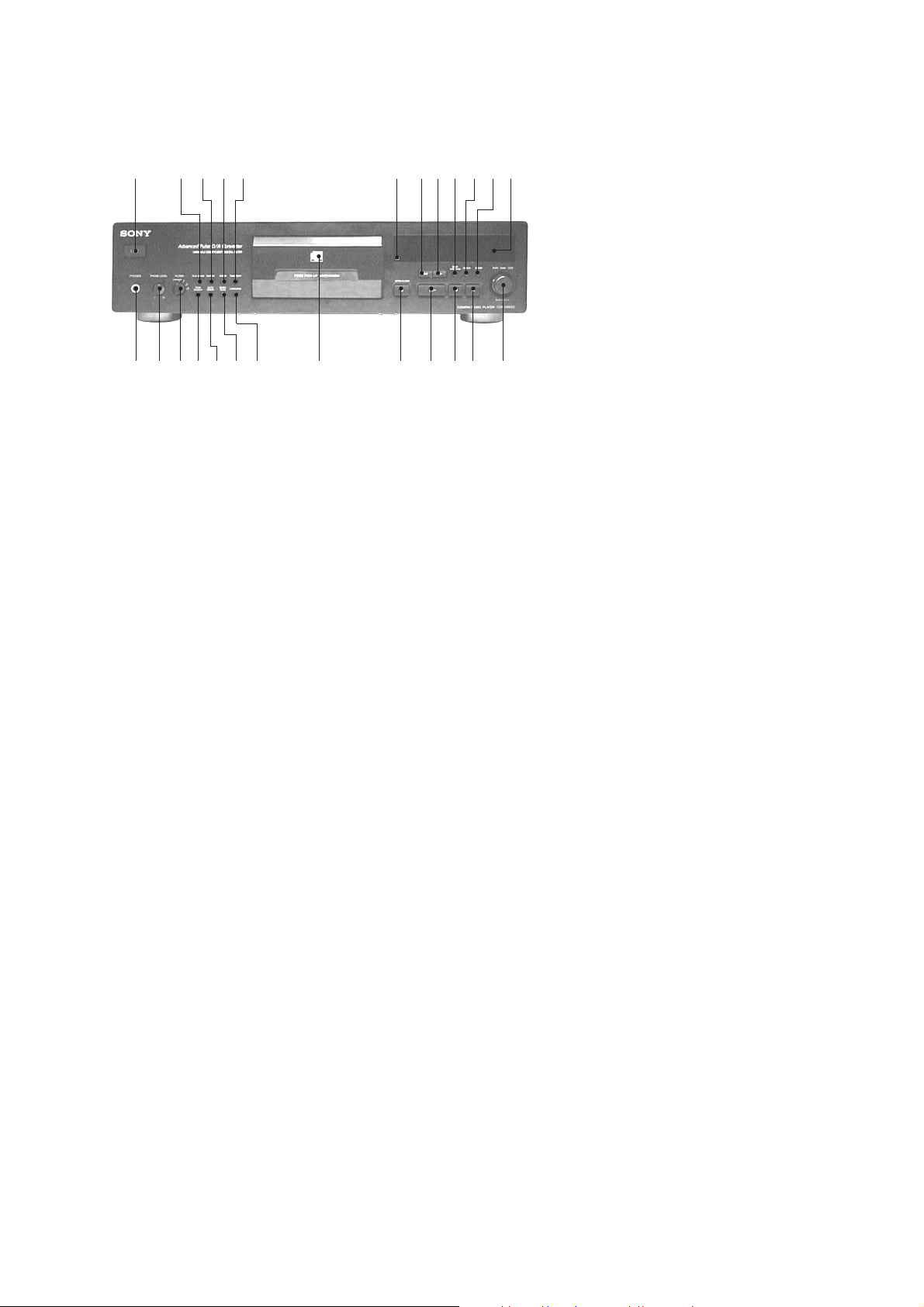

• LOCATION OF CONTROLS

SECTION 2

GENERAL

1 432 5 6

!£ !¢ !∞!§ !¶ !• !ª @º @¡ @™ @£@¢ @∞

1 U (power) button

2 PLAY MODE button

3 REPEAT button

4 FADER button

5 TIME TEXT button

6 Remote sensor

7 0 button

8 ) button

9 EDIT/TIME FADER button

0 CHECK button

!¡ CLEAR button

!™ Fluorescent indicator tube

!£ PHONES jack

!¢ PHONE LEVEL knob

!∞ FILTER knob

!§ PEAK SEARCH button

!¶ AUTO SPACE button

!• MUSIC SCAN button

!ª LANGUAGE button

@º Disc tray

@¡ § OPEN/CLOSE button

@™ · button

@£ P button

@¢ p button

@∞ ≠ AMS ±, PUSH ENTER knob

78

9 0 !¡!™

– 6 –

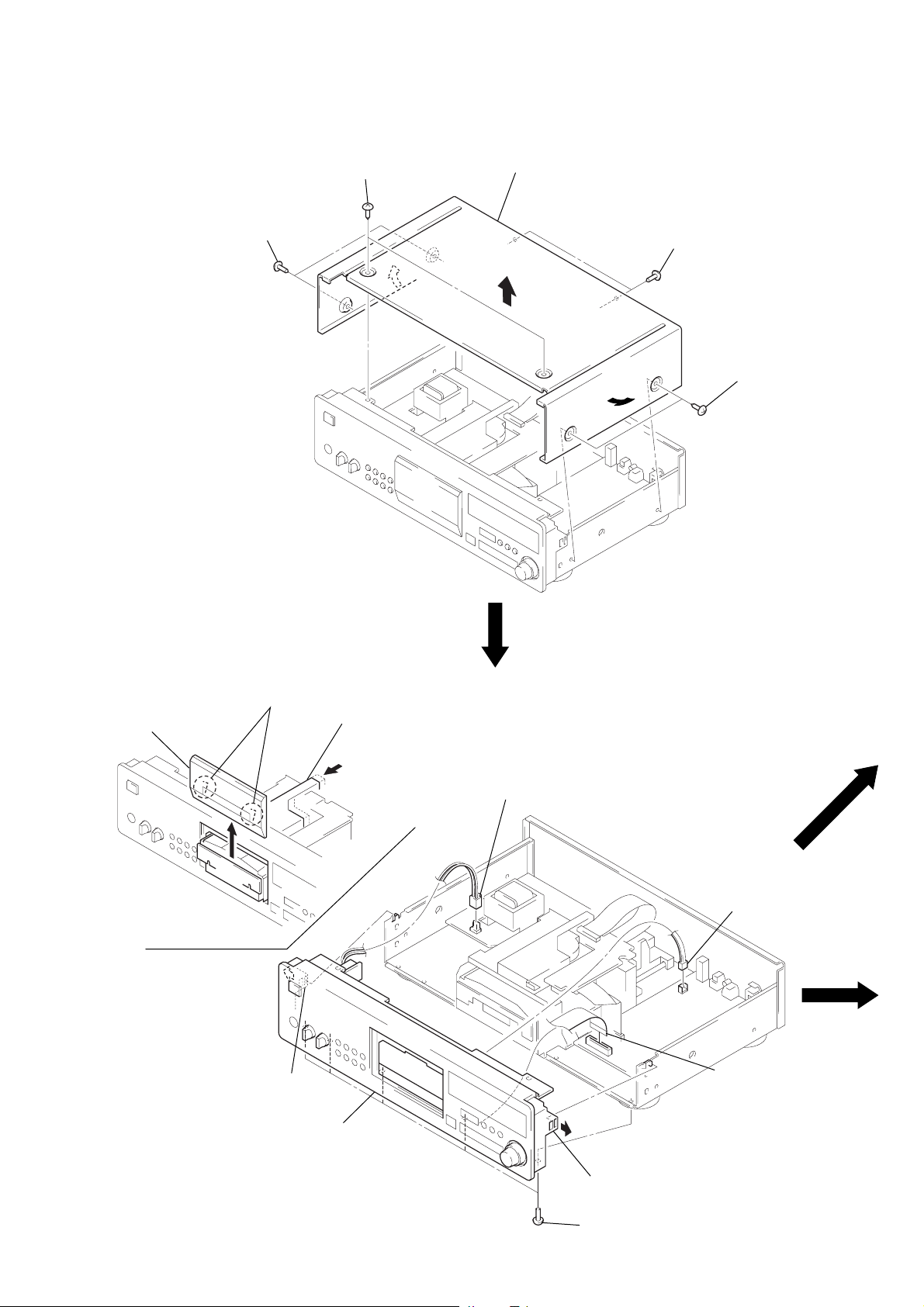

SECTION 3

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

2

two screws

(case 3TP2)

2

two screws

(case 3TP2)

3

case

1

two screws

(BV/RING)

2

two screws

(case 3TP2)

FRONT PANEL SECTION

2

two claws

3

loading panel ass’y

8

claw

1

Push the slide cam

in the direction of the arrow

A

4

connector

(CN903)

A

.

5

connector

(CN351)

6

flat wire (25 core

(CN302)

9

front panel section

– 7 –

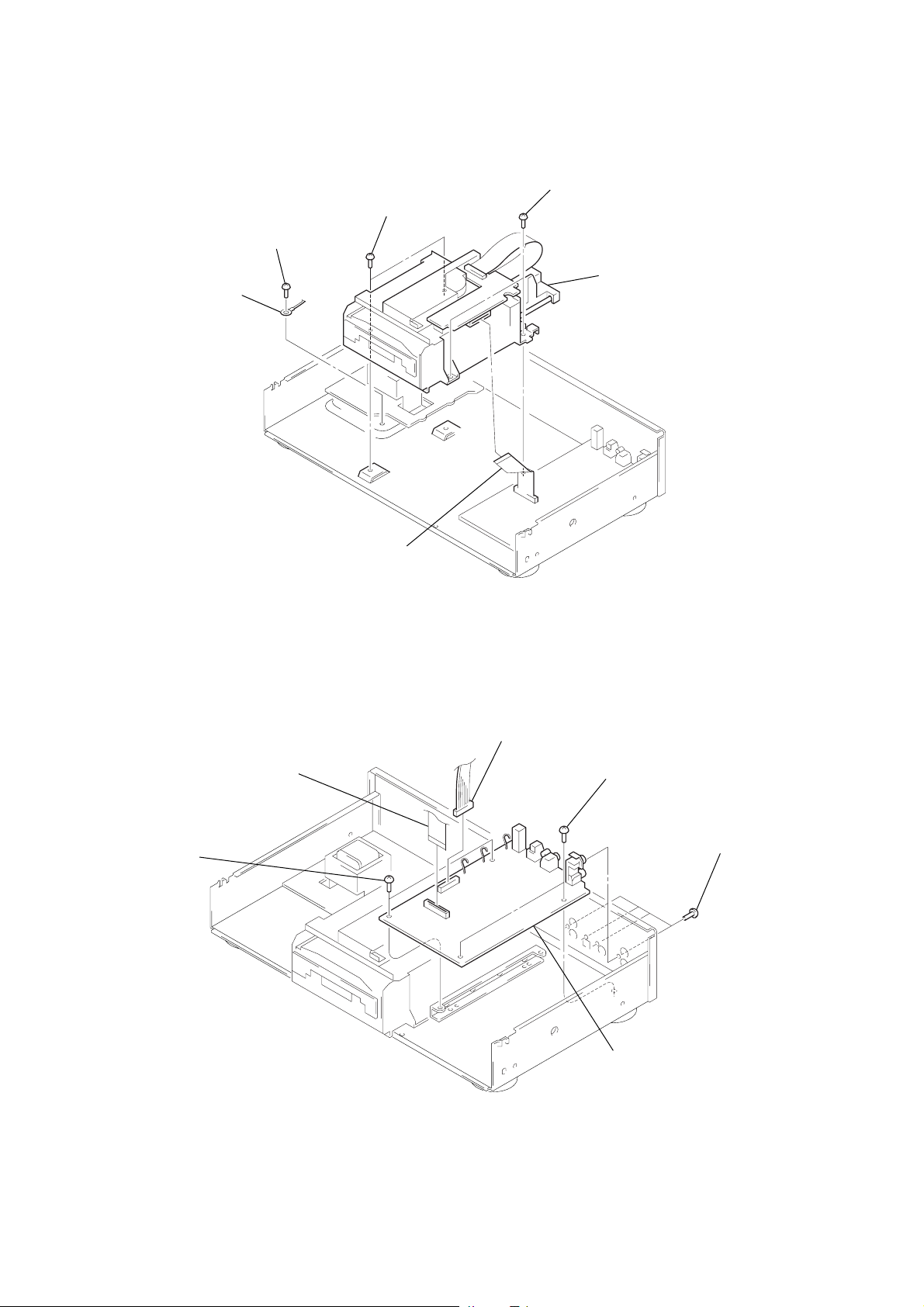

8

claw

7

five screws

(BV3

×

8)

MECHANISM DECK (CDM36-14E)

k

2

screw

(BVTP3

3

lug

1

4

two screws

(BVTP3

×

8)

flat wire (23 core)

(CN301)

4

two screws

×

8)

(BVTP3

×

8)

5

mechanism dec

(CDM36-14E)

MAIN BOARD

4

two screws

(BVTP 3

2

connector

(CN951)

4

1

flat wire (23 core)

(CN301)

×

8)

two screws

(BVTP 3

5

main board

×

8)

3

four screws

(BV/RING)

– 8 –

SECTION 4

TEST MODE

4-1. AF ADJ MODE

The following checks can be performed in the AF ADJ mode, which

is set by connecting the TP2 (AF ADJ : JW96) terminal on MAIN

board to the Ground and turning on the power.

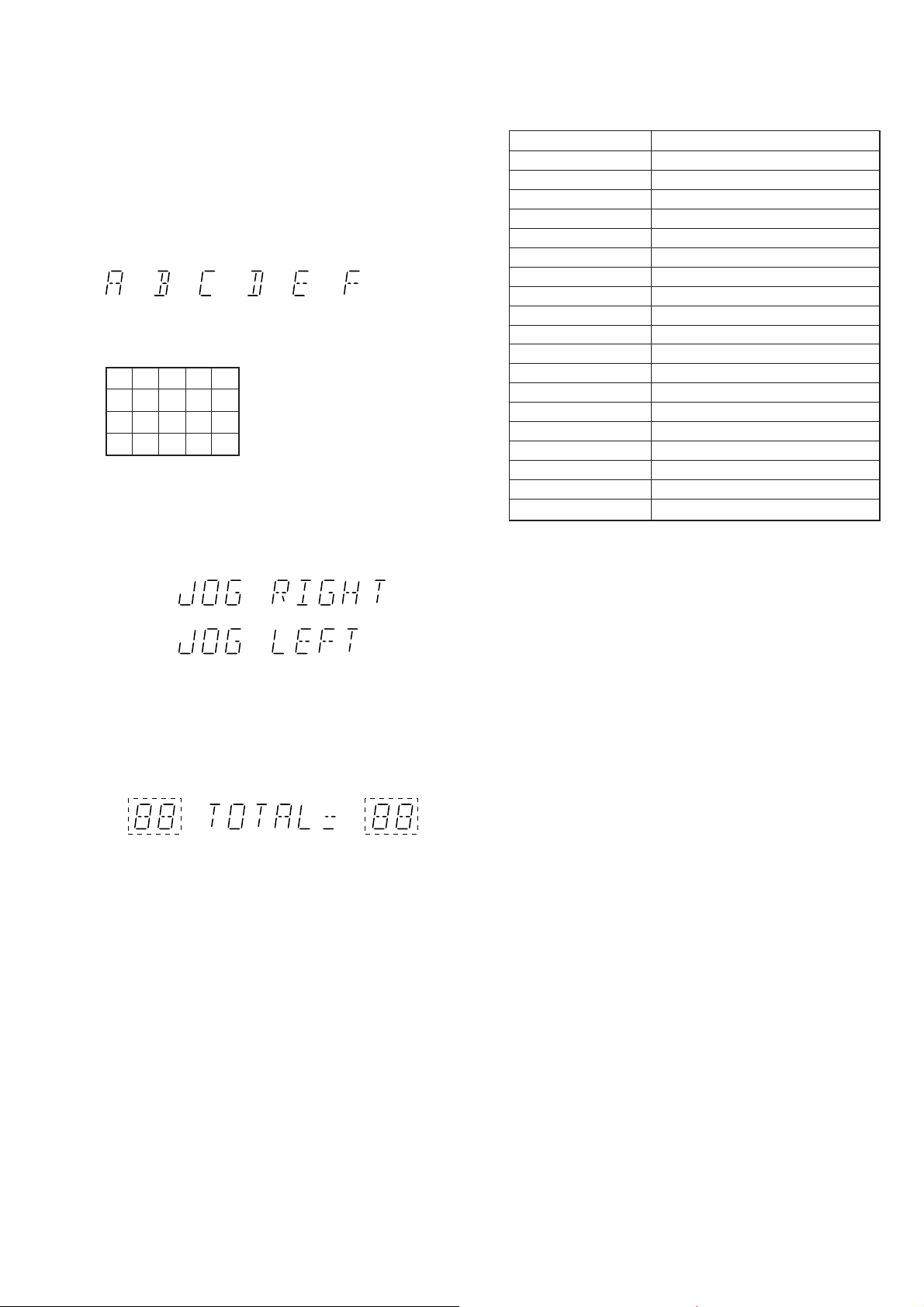

• FL tube check

After all segments light up, when the · button is pressed, the

following will be displayed. (Partial lighting 1)

(Partial lighting 1)

When the p button is pressed, the following will be displayed.

(partial lighting 2)

24

6810

12 14

16 18 20

When the OPEN/CLOSE § button is pressed, all will light up

again.

When the ≠ AMS ± knob is rotated, the following

will be displayed. (partial lighting 3)

(Partial lighting 2)

Buttons and Corresponding Button Numbers

Button Button Number or Display

LANGUAGE 0

MUSIC SCAN 1

AUT O S PAC E 2

PEAK SEARCH 3

PLAY MODE 4

REPEAT 5

FADER 6

TIME/TEXT 7

0 8

) 9

EDIT/TIME FADE 10

CHECK 11

CLEAR 12

P 18

PUSH ENTER 20

OPEN/CLOSE § All lit

PLAY · Partial lighting 1

STOP p Partial lighting 2

≠ AMS ± Partial lighting 3

“FILTER-STD/1/2/3” is displayed on the FL tube when the

FILTER switch is pressed.

Rightward:

Lefrward:

(Partial lighting 3)

• Key check

All buttons have corresponding b utton numbers. When a button is

pressed, the counter will count up and display the button’s number. Ho wever , the counter will only count to “18”. It will not count

for buttons already pressed once, but will display the button’ s number.

Â

Display of counting

Display of button number

Â

• Remote commander check

“REMOCON PLA Y” is displayed on the FL tube when the PLAY

button on the remote commander is pressed.

All go off when the other buttons a pressed.

• Audio check

• Initial setting of digital filter and release of mute.

• When the TP2 (AF ADJ) terminal on MAIN board is set to HIGH

(VDD), emphasis turns on. When set to LOW (GND), it turns

off.

– 9 –

4-2. ADJ MODE

The following operations are performed in the ADJ mode, which

is set by connecting the TP1 (ADJ : JW98) terminal to the Ground

and turning on the power.

• During playback, there is no problem even if the GFS is continuously LOW.

• High speed search is prohibited during access.

• During playback, the gain of focus servo and spindle servo does

not decrease.

• Servo related manual operations and measurement can be

performed.

(For details of operations, refer to Table of Key Operrations in

ADJ Mode.)

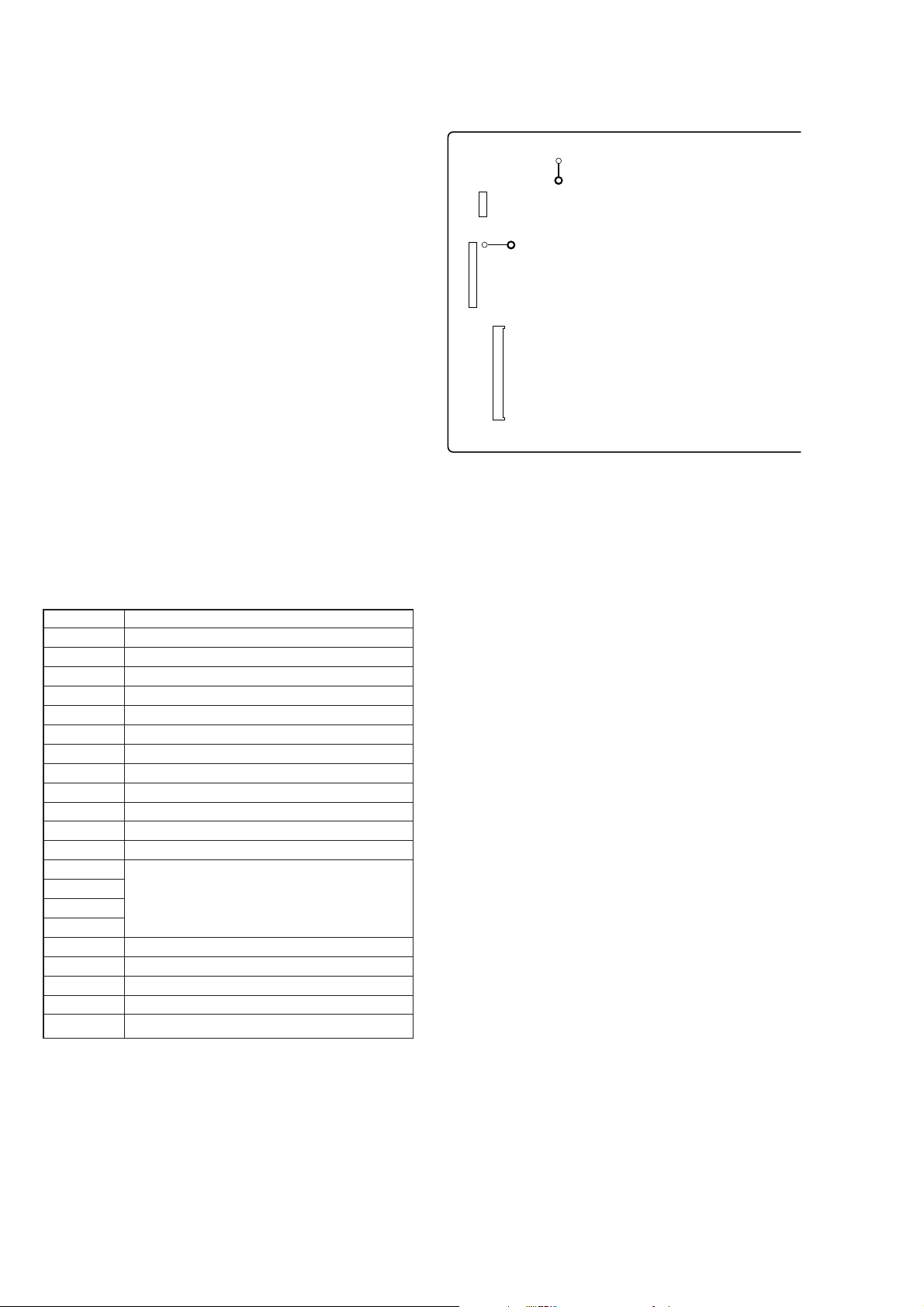

[ MAIN BOARD ] – Conductor Side –

JW096

IC930

TP2

(AFADJ)

JW098

TP1

(ADJ)

IC302

4-3. CLV-S MODE

The spindle servo for playback sets into the CLV-S mode when

the TP2 (AF ADJ) terminal is connected to Ground after turning on

the power.

T ABLE OF BUTTON OPERATIONS IN ADJ MODE

The jitter value display mode can be set after the all-music

remaining number mode using the [TIME/TEXT] button.

The functions of the number buttons are shown in the following

table.

FUNCTIONS OF NUMBER BUTTONS

(With the attached remote commander)

Button Function

1 Focus bias up

2 Focus bias aliasing (upper, middle, lower) display

3 Focus bias (best point, jitter value) display

4 Tracking servo, sled servo off

5 Tracking gain up

6 Focus bias down

7 Focus bias readjustment

8 Focus bias 00 point

9 Tracking servo, sled servo on

10 Tracking gain normal

11 S-Curve mode (play mode only)

12 Eccentric mode

13

14

15

16

17 Tracking gain initialize

18 Offset display (TE), EF, Bias

19 Offset display (VC, FE, RF)

20 Auto gain (FCS, TRK)

CLR key (Error Rate, RFCK, GFS) selection

Reserved for BD

CN302

– 10 –

4-4. AGING MODE

1. How to Enter AGING Mode

Aging method 1

(When using the aging mode remote controller (J-2501-123-A)):

1) Pess the U button and turn ON the power.

2) Set the disc on the tray.

3) Press the [AGINGSTART] button of the aging remote control-

ler.

4) Aging starts and the message shown in Fig. 1 is displayed on the

fluorescent display tube.

5) To end, press the U button.

Aging method 2 (When no aging mode remote controller):

1) Turn on the power of the set, and insert any disc.

2) Press three buttons of [MUSICSCAN], [ªOPEN/CLOSEº],

and p simultaneously, and the set goes in the AGING mode.

3) Performing the aging for a while, confirm that “ERROR” is not

displayed on the fluorescent display tube.

2. How to Exit from AGING Mode

Turn off the Power, and normal operation becomes ready.

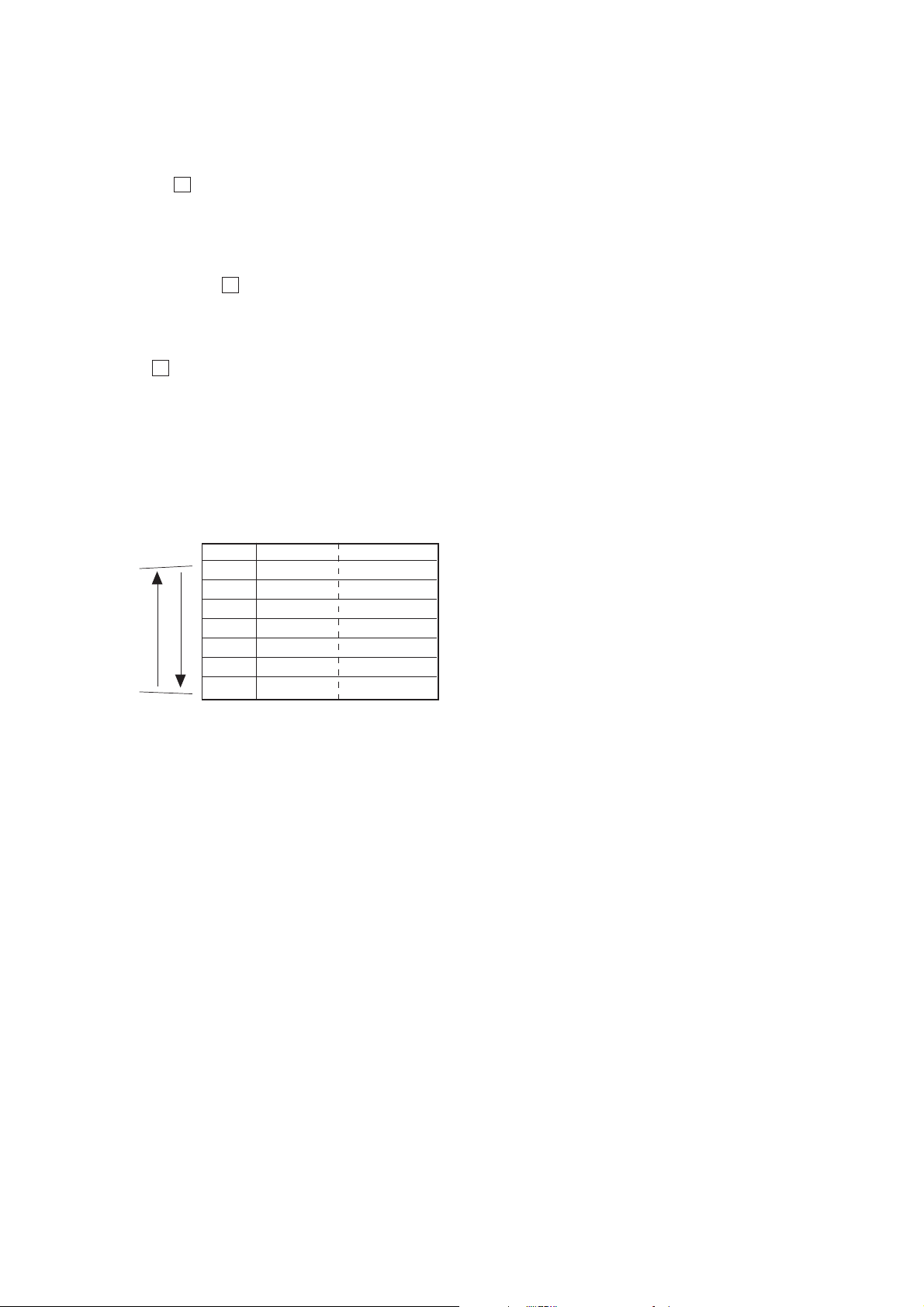

3. Operation sequence in AGING Mode.

Contents of AGING mode

Display Operation

1 AGING-0 loading IN

2 AGING-1 Toc read

3 AGING-2 last access

4 AGING-3 last play

5 AGING-4 first access

6 AGING-5 first play

7 AGING-6 loading OUT

§

Fig. 1

*: In case of a failure

A faulty operation mode No. such as “ERROR-3’’ is blinking.

*: During aging, the keys on the set and the remote control A1 are

not accepted.

*: To quit the aging, turn of the power of the set.

– 11 –

SECTION 5

V

)

ELECTRICAL BLOCK CHECKING

Note:

1. CD Block is basically designed to operate without adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

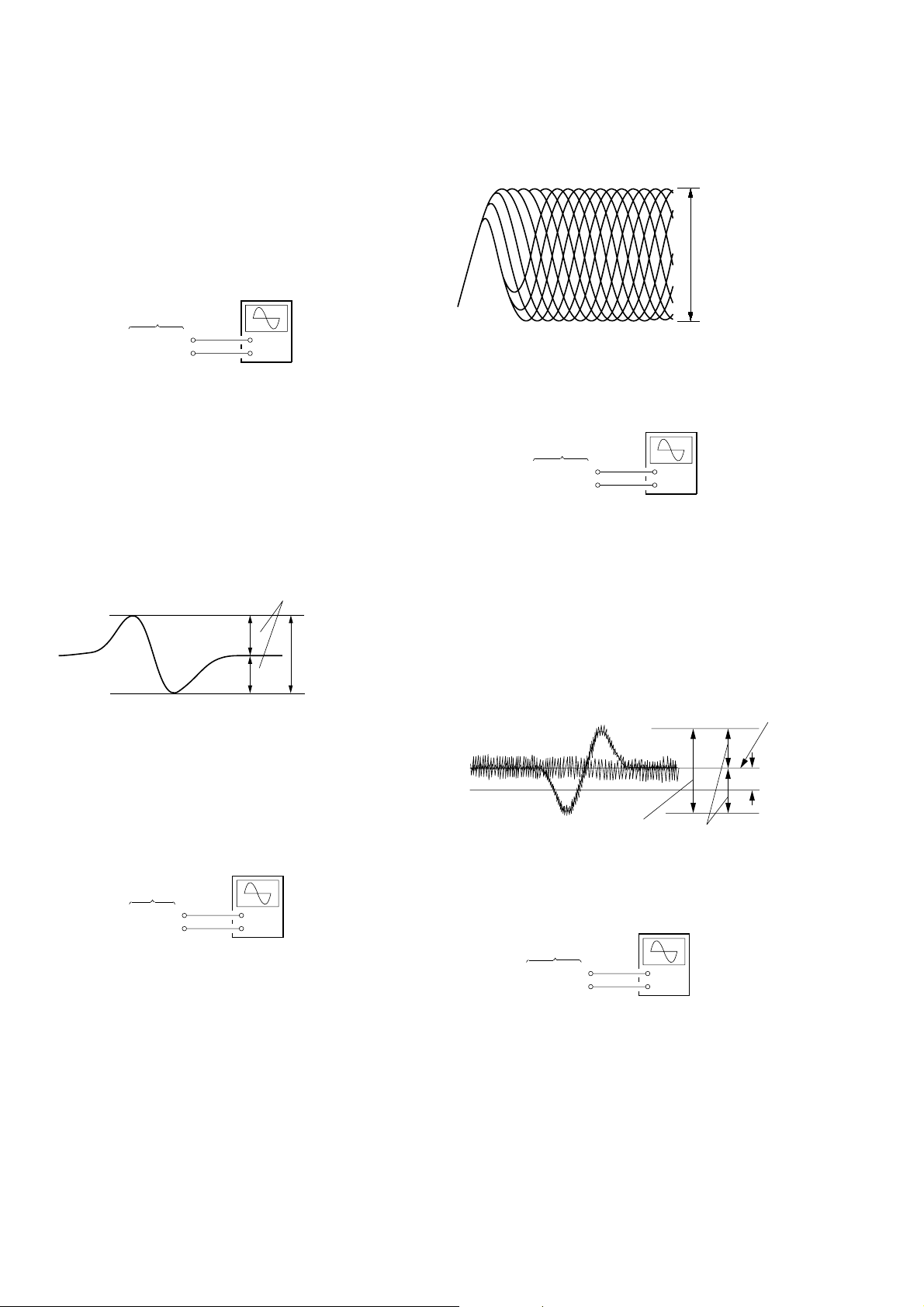

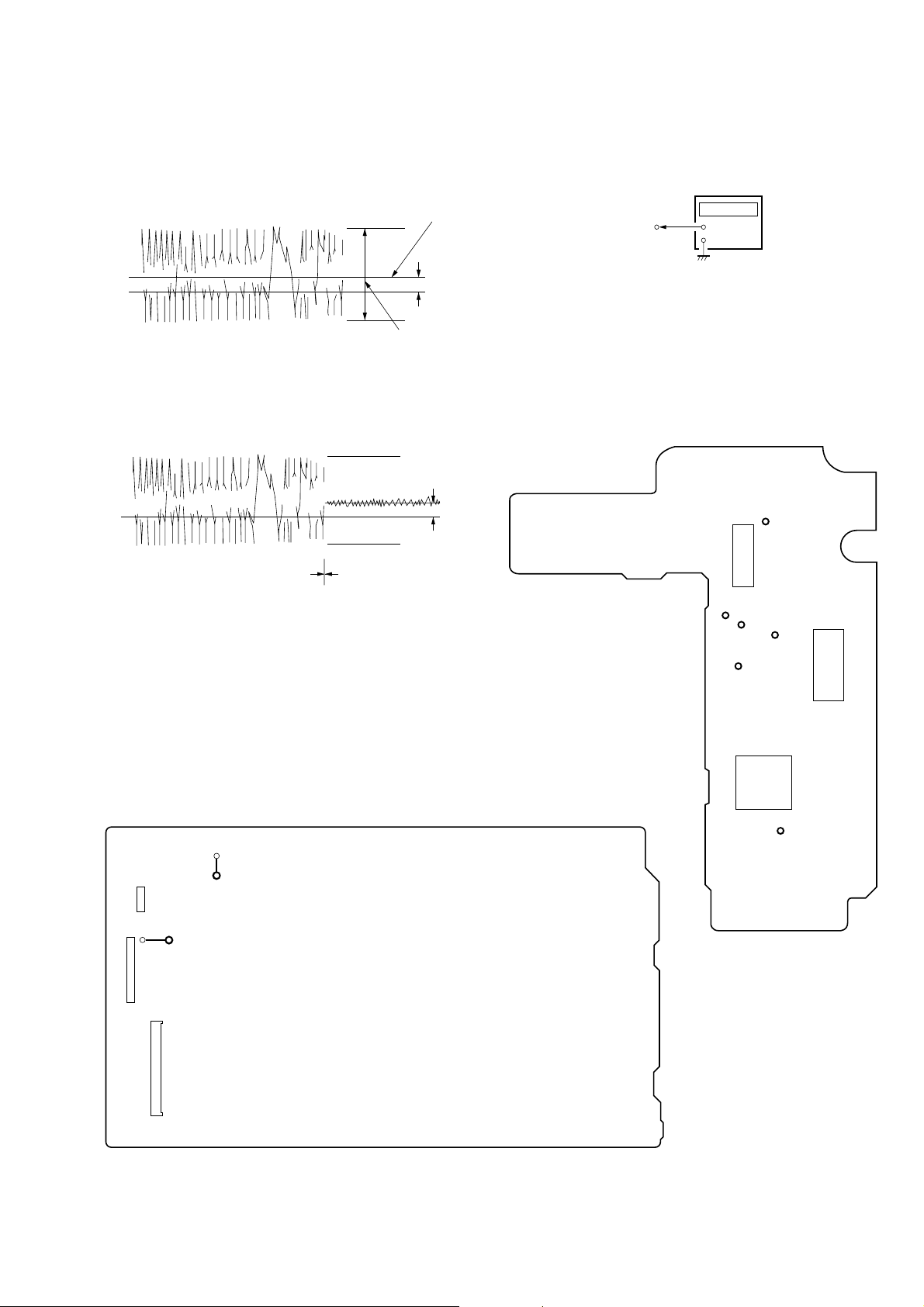

S Curve Check

Connection:

oscilloscope

BD board

TP2 (FE)

TP (VC)

+

–

Procedure :

1. Connect oscilloscope to test point TP2 (FE) on BD board.

2. Connect between test point TP3 (FEI) and TP (VC) by lead wire.

3. Turn ON the power.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 3±1

Vp-p.

S-curve waveform

symmetry

A

B

within 3

±

1 Vp-p

6. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio of A : B

or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

Note: A clear RF signal waveform means that the shape “≈” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 m

TIME/DIV: 500 ns

level: 1.2

±

0.2 Vp-p

E-F Balance (1 Track Jump) Check

(Without remote commander)

Connection:

oscilloscope

(DC range)

BD board

TP4 (TE)

TP (VC)

+

–

Procedure :

1. Connect oscilloscpe to test point TP4 (TE) on BD board.

2. Turn ON the power.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (Pause)” button. (Becomes the 1 track jump mode)

5. Check the level B of the oscilliscope's waveform and the A (DC

voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 22%

1 track jump waveform

Center of the waveform

B

0 V

A (DC voltage

RF Level Check

Connection:

oscilloscope

BD board

TP1 (RF)

TP (VC)

+

–

Procedure :

1. Connect oscilloscope to test point TP1 (RF) on BD board.

2. Turn ON the power.

3. Put disc (YEDS-18) in to play the number five track.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

level: 1.3 ± 0.6 Vp-p

symmetry

E-F Balance Check (With remote commander)

Connection:

oscilloscope

(DC range)

BD board

TP4 (TE)

TP (VC)

+

–

Procedure :

1. Connect the test point TP1 (ADJ : JW98) on MAIN board to the

ground with a lead wire on MAIN board.

2. Connect oscilloscpe to test point TP4 (TE) on BD board.

3. Turn ON the power to set the ADJ mode.

4. Put disc (YEDS-18) in to play the number five track.

5. Press the “4” button. (The tracking servo and the sledding servo

are turned OFF.)

– 12 –

6. Check the lev el B of the oscilliscope's wa v eform and the A (DC

)

r

voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 22%

Traverse waveform

Center of the waveform

B

RF PLL Free-run Frequency Check

Procedure :

1. Connect frequency counter to test point (MNT1) with lead wire.

frequency counte

BD board

TP9 (MNT1)

+

–

0 V

A (DC voltage)

level: 1.3

±

0.6 Vp-p

7. Press the “9” button. (The tracking serv o and sledding servo are

turned ON.) Confirm the C (DC voltage) is almost equal to the A

(DC voltage) is step 6.

Traverse waveform

0 V

Tracking servo

Sledding servo

OFF

Tracking servo

Sledding servo

ON

8. Disconnect the lead wire of TP1 (ADJ : JW98) connected in

step 1.

C (DC

voltage

2. Turn ON the power.

3. Put the disc (YEDS-18) in to play the number five track.

Confirm that reading on frequency counter is 4.3218MHz.

Adjustment Location :

[ BD BOARD ] — Side A —

TP

IC103

TP4

(TE)

TP2

(FE)

TP1

(RF)

(VC)

TP3

(FEI)

IC102

[ MAIN BOARD ] – Conductor Side –

JW096

IC930

TP2

(AFADJ)

JW098

TP1

(ADJ)

IC302

CN302

IC101

TP9

(MNT1)

– 13 –

SECTION 6

DIAGRAMS

6-1. IC PIN FUNCTION DESCRIPTION

• DISP BOARD IC801 CXP82832-009Q (SYSTEM CONTROLLER/FL DRIVER)

Pin No. Pin Name I/O Function

1, 2

3

4

5 SCOR

6, 7

8

9

10, 11

12

13

14

15

16

17

18

19

20

21

22 CLK O

23

24

25

26

27

28 AVREF I

29

30

31

32

33

34

35

13G, 14G O Grid drive signal output to the fluorescent indicator tube (FL801) “H”: goes on

NC — Not used (fixed at “H”)

+5V — Power supply terminal (+5V)

Subcode sync (S0+S1) detection signal input from the CXD2585Q (IC101) in BD section

I

“H” active

GND — Ground terminal

RMIN I Sircs signal input from the remote control receiver (IC802) “L” active

GND — Ground terminal

OPEN O Not used (open)

LDOUT O

LDIN

SENSE I Internal status monitor input from the CXD2585Q (IC101) in BD section

XLT O Serial data latch pulse output to the CXD2585Q (IC101) in BD section “L” active

DMUTE O

PRGLT O Serial data latch pulse output to the D/A converter (IC301) “L” active

SENSOR IN I Stabilizer detect sensor input terminal (fixed at “L” in this set)

BUSOUT O Sircs remote control signal output for the CONTROL A1 “H” active

BUSIN I Sircs remote control signal input for the CONTROL A1 “L” active

SENSOR SW I Stabilizer detect sensor switch input terminal “H” active Not used (open)

LDON O Laser on/off control signal output to the CXA2568M (IC103) “H”: laser on

DATA

SQCK

SUBQ

+5V — Power supply terminal (+5V)

KEY0 I

KEY1 I

KEY2 I

FILTER.SW I FILTER switch (S860) input terminal (A/D input)

ADJ/AFADJ I

LOADSW I Loading in/out detect switch (S152 and S153) input terminal

MODEL.SEL1 I Destination setting terminal (fixed at “H”)

Motor control signal (load out direction) output to the loading motor driver (IC302)

“H” active *1

Motor control signal (load in direction) output to the loading motor driver (IC302)

O

“H” active *1

Digital muting on/off control signal output to the CXD2585Q (IC101) and D/A converter (IC301)

“L”: muting on

Serial data transfer clock signal output to the CXD2585Q (IC101) in BD section “L” active

O

Serial data output to the CXD2585Q (IC101) in BD section

Subcode Q data reading clock signal output to the CXD2585Q (IC101) in BD section

O

“L” active

I

Subcode Q data input from the CXD2585Q (IC101) in BD section

Reference voltage (+5V) input terminal (for A/D converter)

Key input terminal (A/D input) S851 to S858 (LANGUAGE, MUSIC SCAN, AUTO SPACE,

PEAK SEARCH, PLAY MODE, REPEAT, FADER, TIME/TEXT keys input)

Key input terminal (A/D input) S801 to S805 and S810 (CLEAR, CHECK, EDIT/TIME FADE,

0, ), PUSH ENTER keys input)

Key input terminal (A/D input)

S806 to S810 (§ OPEN/CLOSE, ·, P, p, ≠ AMS ± keys input)

Input terminal for the CD test mode setting

“L”: ADJ mode, center voltage: AFADJ mode, normally: “H”

*1 Loading motor (M903) control

Operation

Terminal

LDOUT (pin !™)

LDIN (pin !£)

IN OUT BRAKE RUN IDLE

“L” “H” “H” “L”

“H” “L” “H” “L”

– 14 –

Pin No. Pin Name I/O Function

36

37 AVSS

38

39

40

41

42

43

44

45

46

47

48

49 to 66

67 to 87

88

89

90 to 100

MODEL.SEL2 I Destination setting terminal (fixed at “L”)

— Ground terminal (for A/D converter)

System reset signal input from the reset signal generator (IC930) “L”: reset

RST

EXTAL I Main system clock input terminal (8 MHz)

XTAL O Main system clock output terminal (8 MHz)

VSS — Ground terminal

TX O Sub system clock output terminal Not used (open)

TEX I Sub system clock input terminal Not used (fixed at “L”)

VDD (+5V) — Power supply terminal (+5V)

VFDP (–30V) — Power supply terminal (–30V) (for FL drive)

XSEL O Not used (open)

REINIT O Not used (open)

RFGF O Laser power hold control signal output to the CXA2568M (IC103) “H”: hold on

OPEN O Not used (open)

S21 to S1 O Segment drive signal output to the fluorescent indicator tube (FL801) “H”: goes on

1G O Grid drive signal output to the fluorescent indicator tube (FL801) “H”: goes on

VDD (+5V) — Power supply terminal (+5V)

2G to 12G O Grid drive signal output to the fluorescent indicator tube (FL801) “H”: goes on

I

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

– 15 –

6-2. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

: internal component.

4

W or less unless otherwise

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark ! or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• V : B– Line.

• Voltages and wa vef orms are dc with respect to ground in

playback mode.

no mark : PLAY

• Voltages are taken with a VOM (Input impedance 10 M Ω).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD

c : digital out

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

®

•

: Through hole.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

• Indication of transistor.

C

Q

B

E

These are omitted.

Q

B

CE

These are omitted.

– 16 –

• Circuit Boards Location

AC SW board

HP board

VC SELECT board

TRANS board

BD board

LOADING board

SLED board

MAIN board

KEY board

SPINDLE board

DISP board

– 17 –

• Wavef orms

– BD Board –

1 IC103 !§ (RFO) (PLAY MODE)

500 mV/DIV, 1 µs/DIV

2 IC101 $¡ (TE) (PLAY MODE)

200 mV/DIV, 1 µs/DIV

3 IC101 #ª (FE) (PLAY MODE)

100 mV/DIV, 500 ns/DIV

1.2 ± 0.2 Vp-p

Approx.

570 mVp-p

6 IC101 0 (WFCK)

2 V/DIV, 100 µs/DIV

µ

s

136

7 IC101!™ (XPCK)

2 V/DIV, 100 ns/DIV

230 ns

5.8 Vp-p

6.6 Vp-p

4 IC101^∞ (LRCK)

2 V/DIV, 10 µs/DIV

22.8

5 IC101 ^¶ (BCLK)

2 V/DIV, 200 ns/DIV

– MAIN Board –

Approx.

240 mVp-p

5.8 Vp-p

1 IC301 @• (XOUT)

2 V/DIV, 20 ns/DIV

3.4 Vp-p

45 MHz

– DISP Board –

1 IC801 #ª (EXTAL)

2 V/DIV, 50 ns/DIV

µ

s

4.2 Vp-p

472

5.8 Vp-p

µ

s

8 MHz

– 18 –

CDP-XB820

6-3. PRINTED WIRING BOARD – BD Section – • See page 17 for Circuit Boards Location.

(Page 23)

(Page 23)

• Semiconductor

Location

Ref. No. Location

D101 E-4

IC101 D-3

IC102 C-4

IC103 B-3

Q101 A-3

Q102 A-3

(Page 25)

– 19 –

– 20 –

6-4. SCHEMATIC DIAGRAM – BD Section – • See page 18 for Waveforms. • See page 39 and 40 for IC Block Diagrams.

CDP-XB820

(Page 24)

(Page 27)

(Page 24)

– 21 –

– 22 –

CDP-XB820

6-5. PRINTED WIRING BO ARDS – OPTICAL PICK-UP / MO TOR Section –

• See page 17 for Circuit Boards Location.

(Page 20)

6-6. SCHEMATIC DIAGRAM – OPTICAL PICK-UP / MOTOR Section –

(Page 23)

(Page 22)

(Page 23)

(Page 20)

(Page 22)

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

– 23 –

– 24 –

6-7. PRINTED WIRING BOARD – MAIN Section – • See page 17 for Circuit Boards Location.

CDP-XB820

(Page 36)

• Semiconductor Location

Ref. No. Location

D301 C-1

D303 D-5

D304 D-6

D305 E-6

D381 E-8

D909 B-3

D910 C-7

D911 D-3

D912 C-3

IC301 B-4

IC302 C-1

Ref. No. Location

IC303 D-6

IC371 D-8

IC391 D-8

IC401 A-6

IC501 B-6

IC901 D-4

IC902 D-4

IC903 D-4

IC904 D-3

IC905 C-3

IC930 A-1

Ref. No. Location

Q301 D-5

Q381 E-8

Q401 A-8

Q402 A-8

Q404 D-5

Q405 D-7

Q501 B-8

Q502 B-8

Q504 E-5

Q505 D-6

Q901 C-4

Q902 E-3

(Page 20)

(Page 31)

(Page 26)

(Page 26)

– 25 –

– 26 –

CDP-XB820

6-8. SCHEMATIC DIAGRAM – MAIN Section (1/2) – • See page 18 for Waveform. • See page 41 for IC Block Diagrams.

(Page 21)

(Page 38)

(Page 29)

– 27 –

– 28 –

6-9. SCHEMATIC DIAGRAM – MAIN Section (2/2) –

CDP-XB820

(Page 33)

(Page 28)

– 29 –

– 30 –

CDP-XB820

6-10. PRINTED WIRING BOARDS – POWER Section – • See page 17 for Circuit Boards Location.

(Page 25)

(Page 31)

– 31 –

(Page 32)

– 32 –

6-11. SCHEMATIC DIAGRAM – POWER Section –

CDP-XB820

(Page 30)

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

– 33 –

– 34 –

CDP-XB820

6-12. PRINTED WIRING BOARDS – PANEL Section – • See page 17 for Circuit Boards Location.

(Page 35)

(Page 36)

(Page 25)

– 35 –

– 36 –

6-13. SCHEMATIC DIAGRAM – PANEL Section – • See page 18 for Waveform.

CDP-XB820

(Page 27)

– 37 –

– 38 –

• IC Block Diagrams

– BD BOARD –

IC101 CDX2585Q

EXCK

SCSY

SBSO

80

79 77

78

1

DVDD0

2

XRST

MUTE

3

4

DATA

5

XLAT

CLOCK

SENS

SCLK

ATSK

WFCK

XUGF

6

7

8

9

10

11

CPU

Interface

SQCK

76

SQSO

XOLT

7475 73

SOCK

SOUT

D/A

Interface

Sub Code

Processor

Sequencer

Servo

Auto

Error

Corrector

XTAO

72

XTAI

70

71

Clock

Generator

EFM

demodurator

DVSS2

69

XTSL

32K

RAM

68

EMPH

67

BCK

66 65

LRCK

PCMD

Digital

PLL

Asymmetry

Corrector

DOUT

64

Digital

OUT

63

MD2

ASYE

62 61

DVDD2

60

59

58

57

56

55

54

53

52

51

50

49

VPCO

V16M

VCTL

BIAS

AVDD1

PCO

FILI

FILO

CLTV

AVSS1

RFAC

ASYI

XPCK

GFS

V2PO

SCOR

C4M

WDCK

DVSS0

COUT

MIRR

12

48

13

Digital

2423

PWMI

25 26

LOCK

CLV

MDP

27

SSTP

28

FETO

29

SFDR

DVDD1

30

31

11

SRDR

PWM GENERATOR

FORCUS PWM

TRACKING PWM

32

33 34

11

FFDR

TFDR

TRDR

GENERATOR

GENERATOR

SLED PWM

GENERATOR

FRDR

SIGNAL PROCESSOR BLOCK

SERVO BLOCK

SERVO DSP

FOCUS SERVO

TRACKING

SERVO

SLED SERVO

OPAmp

A/D

TEST

TES1

Analog SW

38 39 40

VC

Converter

35 36 37

DVSS1

FE

SE

14

15

16

17

18

19

20

SERVO

Interface

MIRR

DFCT

FOK

21

22

FOK

DFCT

47

46

45

44

43

42

41

ASYO

AVDD0

IGEN

AVSSO

ADIO

RFDC

CE

TE

– 39 –

IC103 CXA2568M-T6

HOLD

AGC VTH

VEE

+

–

VC

VCC

APC LD AMP

50µA

+

–

+

–

VEE

RF SUMMING AMP

VC

+

–

FOCUS ERROR AMP

+

–

VCC

+

–

VCC

VC

+

–

VC

RF EQ AMP

+

–

+

–

1

VEE

2

LD

3

4

PD

5

A

6

B

C

7

D

8

9

VC

10

F

APC PD AMP

+

–

+

–

VEE

–

+

VC

VEE

VC

+

–

24

23

22

21

20

19

18

17

16

15

14

VCC

LC/PD

LD ON

HOLD SW

AGC CONT

RF BOT

RFTC

RF I

RF O

RFE

FE

–

+

VC BUFFER

VC

–

+

VC

+

–

VEE

VCC

E

11

VC

VC

12

VC

TRACKING

ERROR AMP

TE

13

– 40 –

– MAIN Board –

IC301 CXD8735N

INVO

BCKI

DATA1

LRCKI

INIT

ATT

SHIFT

LATCH

SYSM

DVSS1

DVDD1

CKCTL

MUTE

SYNC

VSUB

AVDDL1

L1(–)

L1(+)

AVSSL1

1

2

3

4

5

6

7

8

9

10

NU

11

NU

12

13

14

NU

15

16

17

18

19

20

21

22

S/P

MODE

ATT

IIR

ATT

IIR

3rd order

NOISE

SHAPER

REGISTER

3rd order

NOISE

SHAPER

Buffer(–) PLM-L1

Buffer(+)

OVERFLOW DETECTER OR

FIR1

FIR1

FIR2

FIR4

OVERFLOW DETECTER

FIR2

FIR4

L.I.P

DITHER

L.I.P

X0.75

X0.75

FIR3

FIR3

ATT

ATT

PLM-R1

CLOCK

GENERATOR

D/F

TIMNG

Buffer(–)

Buffer(+)

CIRCUIT

CLOCK

MUTE

CIRCUIT

“0” DETECT

BUFFER

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

INVI

TEST

128FsO

DINIT

OVFLAG

MUTEL

MUTER

NU

64FSI

MCKIN

DVSS1

DVDD1

DVDD2

256FSO

CKVdd

LVCKO

64FSO

DVSS2

AVDDR1

R1(–)

R1(+)

AVSSR2

23

AVSSL2

L2(+)

L2(–)

AVDDL2

XVDD

XVDD

24

25

26

27

28

Buffer(+)

Buffer(–)

1024Fs-CLOCK

BUFFER

PML-L2

IC302 LB1641

T.S.D O.C.P

MOTOR

DRIVE

FWD/REV/STOP

CONTROL LOGIC

2 3

1

GND

DRIVE

MOTOR

NOISE

FILTER

5 6 7 8 9 10

4

VCC 1

FWD.IN

REV.IN

CLAMP

VCC 2

MOTOR

NOISE

FILTER

DRIVE

PLM-R2

DRIVE

MOTOR

Buffer(+)

Buffer(–)

IC930 M51957AL

–

+

1.25V

1 2

VDD

3

IN

GND

AVSSR2

34

R2(+)

33

R2(–)

32

31

AVDDR2

30

XVSS

29

XIN

4

DL

5

OUT

– 41 –

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) FRONT PANEL SECTION

10

10

9

8

supplied

with J601

supplied

with RV601

15

26

7

6

5

12

not supplied

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

12

11

28

27

10

10

16

10

17

18

19

10

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

13

29

14

28

12

27

4

24

3

#1

2

Ref. No. Part No. Description Remark

1 3-703-685-21 SCREW (+BV 3X8)

2 4-996-687-51 KNOB (AMS)

3 X-4949-457-1 PANEL ASSY, LOADING

4 4-950-189-01 KNOB (A) (VOL)

5 4-942-568-41 EMBLEM (NO.5), SONY

6 4-997-199-21 PANEL, FRONT

7 4-997-200-01 BASE (L), PANEL

8 4-998-790-01 KNOB, POWER (U)

* 9 1-668-768-11 AC SW BOARD

10 4-951-620-01 SCREW (2.6X8), +BVTP

* 11 1-668-767-11 HP BOARD

12 4-210-291-01 SCREW (CASE 3 TP2)

* 13 4-997-138-01 CASE (4095269)

14 3-704-515-21 SCREW (BV/RING)

* 15 1-668-769-11 VC SELECT BOARD

25

1

21

20

22

23

Ref. No. Part No. Description Remark

* 16 1-668-766-11 KEY BOARD

17 4-997-211-01 BUTTON (MODE)

18 4-997-202-11 BASE (M1), PANEL

* 19 A-4699-984-A DISP BOARD, COMPLETE

20 1-773-216-11 WIRE (FLAT TYPE) (25 CORE)

21 4-997-213-01 BUTTON (F.R) (0, ))

22 X-4949-458-1 BASE (R) ASSY, PANEL

23 4-997-210-01 PLATE, INDICATION

24 4-948-469-01 SPRING, RING

25 3-354-981-11 SPRING (SUS), RING

26 3-840-486-12 CUSHION, SPEAKER

27 4-949-302-21 WASHER

28 4-959-077-01 DAMPER

* 29 4-962-329-01 DAMPER

– 42 –

(2) CHASSIS SECTION

54

T901

#1

55

54

53

CDM36-14E

not

supplied

#1

#4

not

supplied

#1

#4

57

58

not

supplied

#1

56

62

59

61

60

61

61

52

51

not

#2

Ref. No. Part No. Description Remark

51 4-984-485-01 CUSHION (FOOT)

52 X-4949-523-1 FOOT ASSY (F50180S)

* 53 1-668-765-11 TRANS BOARD

54 4-886-821-11 SCREW, S TIGHT, +PTTWH 3X6

* 55 A-4699-998-A BD BOARD, COMPLETE

56 1-783-699-11 WIRE (FLAT TYPE) (23 CORE)

* 57 A-4699-983-A MAIN BOARD, COMPLETE

supplied

#1

#1

52

51

#2

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark

58 1-500-386-11 FILTER, CLAMP (FERRITE CORE)

59 4-966-267-11 BUSHING (FBS001), CORD

* 60 4-997-214-21 PANEL, BACK

61 3-704-515-21 SCREW (BV/RING)

! 62 1-575-651-21 CORD, POWER

! T901 1-431-715-11 TRANSFORMER, POWER

– 43 –

(3) MECHANISM DECK SECTION

(CDM36-14E)

#1

108

102

#1

106

BU-14E

106

106

101

103

#1

not supplied

#1

#1

not supplied

112

not

supplied

109

107

113

not

supplied

110

not supplied

#1

M903

111

not

supplied

104

105

Ref. No. Part No. Description Remark

101 1-452-820-11 MAGNET (ASSY)

* 102 4-977-902-01 PANEL (DRAWER)

* 103 4-977-894-01 HOLDER (AP)

* 104 4-977-889-01 PLATE (BU), GROUND

* 105 4-977-888-01 SHAFT

106 4-948-503-01 SPRING (BU), COMPRESSION

107 4-977-897-01 GEAR

* 108 4-977-893-01 CAM, SLIDE

not

supplied

114

not supplied

Ref. No. Part No. Description Remark

109 4-977-896-01 PULLEY

110 4-968-905-01 BELT (CDM)

* 111 1-658-710-11 LOADING BOARD

* 112 4-977-891-01 PLATE, GROUND

113 4-977-898-01 LEVER (SWING)

* 114 4-977-892-01 BEARING

M903 A-4660-968-A MOTOR ASSY (LOADING)

– 44 –

(4) BASE UNIT SECTION

(BU-14E)

160

155

151

152

156

153

154

169

M902

157

161

169

162

not

supplied

not

supplied

163

159

M901

#4

158

not

supplied

not

supplied

164

163

168

165

Ref. No. Part No. Description Remark

151 4-977-925-01 SPRING (SLIDE BASE), COMPRESSION

152 4-977-926-01 RACK, SLIDE

153 4-977-915-02 CAP, CENTERING

154 4-977-927-02 SPRING (CENTERING), COMPRESSION

155 4-977-923-01 SHAFT, SLED

* 156 1-658-708-11 SPINDLE BOARD

157 1-775-990-11 WIRE (FLAT TYPE) (5 CORE)

* 158 4-977-928-01 SPRING (SPINDLE), LEAF

159 4-977-921-01 GEAR (B), FLAT

!160 8-848-379-31 OPTICAL PICK-UP KSS-213B/F-RP

161 1-775-991-11 WIRE (FLAT TYPE) (16 CORE)

166

167

167

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark

* 162 4-993-919-01 SPRING (A) (OP), LEAF

163 4-951-940-01 INSULATOR (BU)

* 164 4-977-918-01 BASE (OUTSERT)

165 4-977-920-01 GEAR (C), FLAT

* 166 1-658-709-11 SLED BOARD

167 4-951-620-01 SCREW (2.6X8), +BVTP

168 1-776-998-11 WIRE (FLAT TYPE) (21 CORE)

169 2-279-715-01 RIVET, NYLON

M901 X-4947-303-1 MOTOR ASSY (SLED)

M902 X-4950-385-1 MOTOR ASSY (SPINDLE)

– 45 –

AC SW BD

SECTION 8

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark

* 1-668-768-11 AC SW BOARD

************

< CAPACITOR >

! C610 1-113-924-11 CERAMIC 0.0047uF 20% 250V

< CONNECTOR >

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

Ref. No. Part No. Description Remark

C128 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C129 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C132 1-164-346-11 CERAMIC CHIP 1uF 16V

C140 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C141 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C151 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C152 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

CN610 1-690-123-21 REED (WITH CONNECTOR) (2 CORE)

< SWITCH >

! S610 1-572-267-51 SWITCH, PUSH (AC POWER) (1 KEY)

(U (POWER))

************************************************************

* A-4699-998-A BD BOARD, COMPLETE

*******************

< CAPACITOR >

C101 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C102 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C103 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C104 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C105 1-135-155-21 TANTALUM CHIP 4.7uF 10% 16V

C108 1-163-035-00 CERAMIC CHIP 0.047uF 50V

C109 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C110 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C111 1-163-021-00 CERAMIC CHIP 0.01uF 10% 50V

C112 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C113 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C116 1-126-209-11 ELECT CHIP 100uF 20% 4V

C117 1-126-209-11 ELECT CHIP 100uF 20% 4V

C118 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C119 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C120 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C121 1-163-021-00 CERAMIC CHIP 0.01uF 10% 50V

C122 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C123 1-163-021-00 CERAMIC CHIP 0.01uF 10% 50V

C124 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C125 1-104-851-11 TANTALUM CHIP 10uF 20% 10V

C126 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C127 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C153 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C154 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C155 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C156 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C157 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C158 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C159 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C160 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C161 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C162 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C171 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C172 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C173 1-163-021-00 CERAMIC CHIP 0.01uF 10% 50V

< CONNECTOR >

CN101 1-770-072-11 CONNECTOR, (LIF(NON-ZIF)) FFC23P

CN102 1-750-753-11 CONNECTOR, FFC/FPC 21P

CN103 1-774-653-21 PIN, CONNECTOR (PC BOARD) 3P

< DIODE >

D101 8-719-016-74 DIODE 1SS352

< IC >

IC101 8-752-389-34 IC CXD2585Q

IC102 8-759-071-79 IC BA6297AFP

IC103 8-752-085-51 IC CXA2568M-T6

< COIL >

L101 1-414-234-11 INDUCTOR CHIP 0uH

< TRANSISTOR >

Q101 8-729-010-08 TRANSISTOR MSB710-R

Q102 8-729-010-08 TRANSISTOR MSB710-R

– 46 –

BD DISP

Ref. No. Part No. Description Remark

< RESISTOR >

R101 1-216-077-00 METAL CHIP 15K 5% 1/10W

R102 1-216-097-00 RES,CHIP 100K 5% 1/10W

R103 1-216-077-00 METAL CHIP 15K 5% 1/10W

R104 1-216-085-00 METAL CHIP 33K 5% 1/10W

R105 1-216-097-00 RES,CHIP 100K 5% 1/10W

R106 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R107 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R108 1-216-073-00 METAL CHIP 10K 5% 1/10W

R109 1-216-121-00 RES,CHIP 1M 5% 1/10W

R110 1-216-025-00 RES,CHIP 100 5% 1/10W

R112 1-216-049-11 RES,CHIP 1K 5% 1/10W

R113 1-216-073-00 METAL CHIP 10K 5% 1/10W

R114 1-216-073-00 METAL CHIP 10K 5% 1/10W

R117 1-216-073-00 METAL CHIP 10K 5% 1/10W

R118 1-216-073-00 METAL CHIP 10K 5% 1/10W

R121 1-216-073-00 METAL CHIP 10K 5% 1/10W

R122 1-216-073-00 METAL CHIP 10K 5% 1/10W

R123 1-216-073-00 METAL CHIP 10K 5% 1/10W

R124 1-216-097-00 RES,CHIP 100K 5% 1/10W

R125 1-216-037-00 METAL CHIP 330 5% 1/10W

R126 1-216-037-00 METAL CHIP 330 5% 1/10W

R127 1-216-037-00 METAL CHIP 330 5% 1/10W

R128 1-216-295-00 SHORT 0

R129 1-216-295-00 SHORT 0

R131 1-216-037-00 METAL CHIP 330 5% 1/10W

R132 1-216-295-00 SHORT 0

R133 1-216-049-11 RES,CHIP 1K 5% 1/10W

R134 1-216-049-11 RES,CHIP 1K 5% 1/10W

R135 1-216-295-00 SHORT 0

R136 1-216-295-00 SHORT 0

R137 1-216-295-00 SHORT 0

R138 1-216-295-00 SHORT 0

R139 1-216-089-00 RES,CHIP 47K 5% 1/10W

R143 1-216-103-00 METAL CHIP 180K 5% 1/10W

R144 1-216-103-00 METAL CHIP 180K 5% 1/10W

Ref. No. Part No. Description Remark

R173 1-216-073-00 METAL CHIP 10K 5% 1/10W

R174 1-216-073-00 METAL CHIP 10K 5% 1/10W

R175 1-216-073-00 METAL CHIP 10K 5% 1/10W

R176 1-216-073-00 METAL CHIP 10K 5% 1/10W

R177 1-216-025-00 RES,CHIP 100 5% 1/10W

R181 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R182 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R183 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R184 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

< SWITCH >

S152 1-762-010-11 SWITCH, LEVER (LOADING IN)

S153 1-762-010-11 SWITCH, LEVER (LOADING OUT)

************************************************************

* A-4699-984-A DISP BOARD, COMPLETE

********************

* 4-997-495-01 GUIDE (FL)

< CAPACITOR >

C802 1-164-159-21 CERAMIC 0.1uF 50V

C803 1-164-159-21 CERAMIC 0.1uF 50V

C804 1-126-177-11 ELECT 100uF 20% 10V

C807 1-126-177-11 ELECT 100uF 20% 10V

< CONNECTOR >

* CN801 1-568-841-11 SOCKET, CONNECTOR 25P

< FLUORESCENT INDICATOR TUBE >

FL801 1-517-740-11 INDICATOR TUBE, FLUORESCENT

< IC >

IC801 8-752-888-75 IC CXP82832-009Q

IC802 8-749-014-66 IC NJL56H400A

< TRANSISTOR >

R145 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R147 1-216-081-00 METAL CHIP 22K 5% 1/10W

R148 1-216-001-00 METAL CHIP 10 5% 1/10W

R149 1-216-003-11 RES,CHIP 12 5% 1/10W

R150 1-216-121-00 RES,CHIP 1M 5% 1/10W

R151 1-216-073-00 METAL CHIP 10K 5% 1/10W

R152 1-216-073-00 METAL CHIP 10K 5% 1/10W

R153 1-216-073-00 METAL CHIP 10K 5% 1/10W

R154 1-216-073-00 METAL CHIP 10K 5% 1/10W

R155 1-216-073-00 METAL CHIP 10K 5% 1/10W

R156 1-216-073-00 METAL CHIP 10K 5% 1/10W

R157 1-216-105-00 RES,CHIP 220K 5% 1/10W

R158 1-216-105-00 RES,CHIP 220K 5% 1/10W

R159 1-216-101-00 METAL CHIP 150K 5% 1/10W

R160 1-216-097-00 RES,CHIP 100K 5% 1/10W

R161 1-216-308-00 METAL CHIP 4.7 5% 1/10W

R162 1-216-113-00 METAL CHIP 470K 5% 1/10W

R163 1-216-105-00 RES,CHIP 220K 5% 1/10W

R168 1-216-121-00 RES,CHIP 1M 5% 1/10W

R171 1-216-073-00 METAL CHIP 10K 5% 1/10W

R172 1-216-073-00 METAL CHIP 10K 5% 1/10W

Q801 8-729-029-66 TRANSISTOR DTC114ESA

Q802 8-729-029-66 TRANSISTOR DTC114ESA

< RESISTOR >

R801 1-249-415-11 CARBON 680 5% 1/4W

R802 1-249-417-11 CARBON 1K 5% 1/4W

R803 1-249-419-11 CARBON 1.5K 5% 1/4W

R804 1-249-421-11 CARBON 2.2K 5% 1/4W

R805 1-247-843-11 CARBON 3.3K 5% 1/4W

R806 1-249-415-11 CARBON 680 5% 1/4W

R807 1-249-417-11 CARBON 1K 5% 1/4W

R808 1-249-419-11 CARBON 1.5K 5% 1/4W

R809 1-249-421-11 CARBON 2.2K 5% 1/4W

R810 1-247-843-11 CARBON 3.3K 5% 1/4W

R811 1-249-427-11 CARBON 6.8K 5% 1/4W

R812 1-249-427-11 CARBON 6.8K 5% 1/4W

R813 1-249-427-11 CARBON 6.8K 5% 1/4W

R814 1-249-427-11 CARBON 6.8K 5% 1/4W

R816 1-249-427-11 CARBON 6.8K 5% 1/4W

R819 1-249-429-11 CARBON 10K 5% 1/4W

R820 1-249-441-11 CARBON 100K 5% 1/4W

– 47 –

DISP HP KEY LO ADING MAIN

Ref. No. Part No. Description Remark

R821 1-249-441-11 CARBON 100K 5% 1/4W

R822 1-247-807-31 CARBON 100 5% 1/4W

R823 1-247-807-31 CARBON 100 5% 1/4W

R824 1-249-417-11 CARBON 1K 5% 1/4W

R825 1-249-429-11 CARBON 10K 5% 1/4W

R826 1-249-429-11 CARBON 10K 5% 1/4W

R827 1-249-429-11 CARBON 10K 5% 1/4W

< SWITCH >

S801 1-554-303-21 SWITCH, TACTILE (CLEAR)

S802 1-554-303-21 SWITCH, TACTILE (CHECK)

S803 1-554-303-21 SWITCH, TACTILE (EDIT/TIME FADER)

S804 1-554-303-21 SWITCH, TACTILE (0)

S805 1-554-303-21 SWITCH, TACTILE ())

S806 1-554-303-21 SWITCH, TACTILE (§ OPEN/CLOSE)

S807 1-554-303-21 SWITCH, TACTILE (·)

S808 1-554-303-21 SWITCH, TACTILE (P)

S809 1-554-303-21 SWITCH, TACTILE (p)

S810 1-475-543-11 ENCODER, ROTARY

(≠ AMS ±, PUSH ENTER)

< VIBRATOR >

X801 1-579-125-11 VIBRATOR, CERAMIC (8MHz)

************************************************************

* 1-668-767-11 HP BOARD

*********

* 4-962-201-01 PLATE (HP), GROUND

< CAPACITOR >

C601 1-162-294-31 CERAMIC 0.001uF 10% 50V

C602 1-164-159-21 CERAMIC 0.1uF 50V

C603 1-162-294-31 CERAMIC 0.001uF 10% 50V

C604 1-164-159-21 CERAMIC 0.1uF 50V

< JACK >

J601 1-750-162-61 JACK (LARGE TYPE) (PHONES)

Ref. No. Part No. Description Remark

R857 1-249-429-11 CARBON 10K 5% 1/4W

< SWITCH >

S851 1-554-303-21 SWITCH, TACTILE (LANGUAGE)

S852 1-554-303-21 SWITCH, TACTILE (MUSIC SCAN)

S853 1-554-303-21 SWITCH, TACTILE (AUTO SPACE)

S854 1-554-303-21 SWITCH, TACTILE (PEAK SEARCH)

S855 1-554-303-21 SWITCH, TACTILE (PLAE MODE)

S856 1-554-303-21 SWITCH, TACTILE (REPEAT)

S857 1-554-303-21 SWITCH, TACTILE (FADER)

S858 1-554-303-21 SWITCH, TACTILE (TIME/TEXT)

************************************************************

* 1-658-710-11 LOADING BOARD

**************

************************************************************

* A-4699-983-A MAIN BOARD, COMPLETE

*********************

* 3-309-144-21 HEAT SINK

7-685-871-01 SCREW +BVTT 3X6 (S)

< CAPACITOR >

C301 1-136-850-11 FILM 0.1uF 5% 63V

C302 1-161-494-00 CERAMIC 0.022uF 25V

C303 1-162-306-11 CERAMIC 0.01uF 20% 16V

C304 1-161-494-00 CERAMIC 0.022uF 25V

C305 1-126-767-11 ELECT 1000uF 20% 16V

C307 1-164-159-21 CERAMIC 0.1uF 50V

C308 1-162-290-31 CERAMIC 470PF 10% 50V

C309 1-162-282-31 CERAMIC 100PF 10% 50V

C310 1-126-026-11 ELECT 470uF 20% 25V

C311 1-136-850-11 FILM 0.1uF 5% 63V

C312 1-102-945-00 CERAMIC 8.0PF 0.5PF 50V

C313 1-102-945-00 CERAMIC 8.0PF 0.5PF 50V

C314 1-126-051-11 ELECT 47uF 20% 50V

C315 1-126-026-11 ELECT 470uF 20% 25V

C316 1-126-026-11 ELECT 470uF 20% 25V

< COIL >

L601 1-424-122-11 FILTER, NOISE

L602 1-424-122-11 FILTER, NOISE

L603 1-424-122-11 FILTER, NOISE

L604 1-410-397-21 FERRITE BEAD INDUCTOR

< VARIABLE RESISTOR >

RV601 1-223-926-11 RES, VAR, CARBON 1K/1K (PHONE LEVEL)

************************************************************

* 1-668-766-11 KEY BOARD

**********

< RESISTOR >

R851 1-249-415-11 CARBON 680 5% 1/4W

R852 1-249-417-11 CARBON 1K 5% 1/4W

R853 1-249-419-11 CARBON 1.5K 5% 1/4W

R854 1-249-421-11 CARBON 2.2K 5% 1/4W

R855 1-247-843-11 CARBON 3.3K 5% 1/4W

R856 1-249-427-11 CARBON 6.8K 5% 1/4W

– 48 –

C317 1-162-208-31 CERAMIC 24PF 5% 50V

C321 1-128-201-11 ELECT 100uF 20% 50V

C322 1-136-851-11 FILM 0.2uF 5% 63V

C323 1-124-700-11 ELECT 330uF 20% 25V

C326 1-136-850-11 FILM 0.1uF 5% 63V

C327 1-136-850-11 FILM 0.1uF 5% 63V

C333 1-136-850-11 FILM 0.1uF 5% 63V

C335 1-124-910-11 ELECT 47uF 20% 50V

C336 1-124-910-11 ELECT 47uF 20% 50V

C337 1-126-023-11 ELECT 100uF 20% 25V

C338 1-136-850-11 FILM 0.1uF 5% 63V

C361 1-161-494-00 CERAMIC 0.022uF 25V

C362 1-161-494-00 CERAMIC 0.022uF 25V

C363 1-162-294-31 CERAMIC 0.001uF 10% 50V

C364 1-164-159-21 CERAMIC 0.1uF 50V

C371 1-164-159-21 CERAMIC 0.1uF 50V

C373 1-126-009-81 ELECT 100uF 20% 16V

C374 1-164-159-21 CERAMIC 0.1uF 50V

C375 1-161-494-00 CERAMIC 0.022uF 25V

C376 1-164-159-21 CERAMIC 0.1uF 50V

MAIN

Ref. No. Part No. Description Remark

C381 1-161-494-00 CERAMIC 0.022uF 25V

C391 1-124-994-11 ELECT 100uF 20% 10V

C392 1-164-159-21 CERAMIC 0.1uF 50V

C394 1-164-159-21 CERAMIC 0.1uF 50V

C404 1-126-023-11 ELECT 100uF 20% 25V

C405 1-136-850-11 FILM 0.1uF 5% 63V

C406 1-136-850-11 FILM 0.1uF 5% 63V

C408 1-136-808-11 FILM 100PF 5% 100V

C410 1-102-816-00 CERAMIC 120PF 5% 50V

C411 1-102-816-00 CERAMIC 120PF 5% 50V

C412 1-106-343-00 MYLAR 1000PF 5% 200V

C413 1-130-484-00 MYLAR 0.012uF 5% 50V

C414 1-136-850-11 FILM 0.1uF 5% 63V

C415 1-128-201-11 ELECT 100uF 20% 50V

C504 1-126-023-11 ELECT 100uF 20% 25V

C505 1-136-850-11 FILM 0.1uF 5% 63V

C506 1-136-850-11 FILM 0.1uF 5% 63V

C508 1-136-808-11 FILM 100PF 5% 100V

C510 1-102-816-00 CERAMIC 120PF 5% 50V

C511 1-102-816-00 CERAMIC 120PF 5% 50V

C512 1-106-343-00 MYLAR 1000PF 5% 200V

C513 1-130-484-00 MYLAR 0.012uF 5% 50V

C514 1-136-850-11 FILM 0.1uF 5% 63V

C515 1-128-201-11 ELECT 100uF 20% 50V

C911 1-126-023-11 ELECT 100uF 20% 25V

C912 1-126-023-11 ELECT 100uF 20% 25V

C913 1-124-700-11 ELECT 330uF 20% 25V

C914 1-124-700-11 ELECT 330uF 20% 25V

C915 1-124-556-11 ELECT 2200uF 20% 16V

C917 1-126-024-11 ELECT 220uF 20% 16V

C919 1-126-023-11 ELECT 100uF 20% 25V

C920 1-126-049-11 ELECT 22uF 20% 50V

C921 1-136-850-11 FILM 0.1uF 5% 63V

C925 1-126-049-11 ELECT 22uF 20% 50V

C930 1-162-294-31 CERAMIC 0.001uF 10% 50V

C931 1-126-962-11 ELECT 3.3uF 20% 50V

C932 1-164-159-21 CERAMIC 0.1uF 50V

C933 1-161-494-00 CERAMIC 0.022uF 25V

< CONNECTOR >

* CN301 1-568-839-11 SOCKET, CONNECTOR 23P

* CN302 1-568-841-11 SOCKET, CONNECTOR 25P

CN351 1-506-468-11 PIN, CONNECTOR 3P

CN951 1-766-270-11 PIN, CONNECTOR (PC BOARD) 8P

Ref. No. Part No. Description Remark

EB602 1-537-770-21 TERMINAL BOARD, GROUND

< IC >

IC301 8-759-527-07 IC CXD8735N

IC302 8-759-822-09 IC LB1641

IC303 8-759-710-59 IC NJM4580D-D

IC371 8-759-242-70 IC TC7WU04F

IC391 8-749-921-12 IC GP1F32T (DIGITAL OUT OPTICAL)

IC401 8-759-712-02 IC NJM2114D

IC501 8-759-712-02 IC NJM2114D

IC901 8-759-604-86 IC M5F7807L

IC902 8-759-604-90 IC M5F7907L

IC903 8-759-231-53 IC TA7805S

IC904 8-759-604-86 IC M5F7807L

IC905 8-759-710-59 IC NJM4580D-D

IC930 8-759-636-16 IC M51957AL

< JACK >

J301 1-774-727-11 JACK, PIN 2P (LINE OUT)

J371 1-784-689-11 JACK, PIN 1P (DIGITAL OUT COAXIAL)

J381 1-774-726-11 JACK (S-LINK CONTROL A1)

< COIL >

L301 1-410-322-11 INDUCTOR 3.3uH

L302 1-410-322-11 INDUCTOR 3.3uH

L303 1-410-503-11 INDUCTOR 3.3uH

L321 1-424-122-11 FILTER, NOISE

L331 1-424-122-11 FILTER, NOISE

L371 1-410-322-11 INDUCTOR 3.3uH

L391 1-410-322-11 INDUCTOR 3.3uH

L401 1-412-473-21 INDUCTOR 0uH

L501 1-412-473-21 INDUCTOR 0uH

< TRANSISTOR >

Q301 8-729-029-56 TRANSISTOR DTA144ESA

Q381 8-729-119-78 TRANSISTOR 2SC403SP-51

Q401 8-729-231-55 TRANSISTOR 2SC2878-AB

Q402 8-729-231-55 TRANSISTOR 2SC2878-AB

Q404 8-729-029-56 TRANSISTOR DTA144ESA

Q405 8-729-141-30 TRANSISTOR 2SC3623A-LK

Q501 8-729-231-55 TRANSISTOR 2SC2878-AB

Q502 8-729-231-55 TRANSISTOR 2SC2878-AB

Q504 8-729-029-56 TRANSISTOR DTA144ESA

Q505 8-729-141-30 TRANSISTOR 2SC3623A-LK

< DIODE >

D301 8-719-921-40 DIODE MTZJ-4.7C

D303 8-719-991-33 DIODE 1SS133T-77

D304 8-719-991-33 DIODE 1SS133T-77

D305 8-719-991-33 DIODE 1SS133T-77

D381 8-719-991-33 DIODE 1SS133T-77

D909 8-719-115-38 DIODE RD5.1JS-T1B2

D910 8-719-210-21 DIODE 11EQS04

D911 8-719-991-33 DIODE 1SS133T-77

D912 8-719-991-33 DIODE 1SS133T-77

< GROUND TERMINAL >

EB601 1-537-770-21 TERMINAL BOARD, GROUND

Q901 8-729-104-18 TRANSISTOR 2SC3514-Q

Q902 8-729-140-96 TRANSISTOR 2SD774-34

< RESISTOR >

R301 1-249-417-11 CARBON 1K 5% 1/4W

R303 1-249-417-11 CARBON 1K 5% 1/4W

R304 1-249-401-11 CARBON 47 5% 1/4W

R305 1-249-429-11 CARBON 10K 5% 1/4W

R306 1-249-441-11 CARBON 100K 5% 1/4W

R308 1-249-429-11 CARBON 10K 5% 1/4W

R312 1-249-417-11 CARBON 1K 5% 1/4W

R313 1-247-815-91 CARBON 220 5% 1/4W

R314 1-247-843-11 CARBON 3.3K 5% 1/4W

R315 1-247-807-31 CARBON 100 5% 1/4W

– 49 –

MAIN SLED SPINDLE TRANS

Ref. No. Part No. Description Remark

R316 1-249-419-11 CARBON 1.5K 5% 1/4W

R317 1-249-441-11 CARBON 100K 5% 1/4W

R318 1-249-429-11 CARBON 10K 5% 1/4W

R319 1-249-429-11 CARBON 10K 5% 1/4W

R320 1-247-807-31 CARBON 100 5% 1/4W

R372 1-247-807-31 CARBON 100 5% 1/4W

R373 1-249-403-11 CARBON 68 5% 1/4W

R375 1-249-417-11 CARBON 1K 5% 1/4W

R376 1-247-807-31 CARBON 100 5% 1/4W

R381 1-249-425-11 CARBON 4.7K 5% 1/4W

R382 1-249-429-11 CARBON 10K 5% 1/4W

R383 1-249-393-11 CARBON 10 5% 1/4W

R401 1-259-464-11 CARBON 33K 5% 1/6W

R402 1-259-464-11 CARBON 33K 5% 1/6W

R403 1-259-464-11 CARBON 33K 5% 1/6W

R404 1-259-464-11 CARBON 33K 5% 1/6W

R405 1-259-458-11 CARBON 18K 5% 1/6W

R406 1-259-458-11 CARBON 18K 5% 1/6W

R407 1-259-461-11 CARBON 24K 5% 1/6W

R408 1-259-461-11 CARBON 24K 5% 1/6W

R409 1-259-427-81 CARBON 910 5% 1/6W

R410 1-259-434-11 CARBON 1.8K 5% 1/6W

R411 1-259-488-11 CARBON 330K 5% 1/6W

R412 1-259-422-11 CARBON 560 5% 1/6W

R413 1-259-404-11 CARBON 100 5% 1/6W

R417 1-249-421-11 CARBON 2.2K 5% 1/4W

R418 1-249-441-11 CARBON 100K 5% 1/4W

R419 1-249-421-11 CARBON 2.2K 5% 1/4W

R420 1-259-423-81 CARBON 620 5% 1/6W

R421 1-249-421-11 CARBON 2.2K 5% 1/4W

Ref. No. Part No. Description Remark

R555 1-249-402-11 CARBON 56 5% 1/4W

R902 1-249-421-11 CARBON 2.2K 5% 1/4W

R903 1-249-436-11 CARBON 39K 5% 1/4W

R904 1-249-425-11 CARBON 4.7K 5% 1/4W

R905 1-247-807-31 CARBON 100 5% 1/4W

R906 1-249-417-11 CARBON 1K 5% 1/4W

R907 1-249-417-11 CARBON 1K 5% 1/4W

R930 1-249-436-11 CARBON 39K 5% 1/4W

R931 1-249-431-11 CARBON 15K 5% 1/4W

R932 1-247-843-11 CARBON 3.3K 5% 1/4W

< COIL >

T371 1-409-594-11 COIL (WITH CORE)

< VIBRATOR >

X301 1-760-955-11 VIBRATOR, CRYSTAL (45MHz)

************************************************************

* 1-658-709-11 SLED BOARD

***********

< CONNECTOR >

CN104 1-774-380-11 CONNECTOR, FFC/FPC 16P

CN105 1-568-838-11 SOCKET, CONNECTOR 21P

* CN106 1-750-737-11 CONNECTOR, FFC/FPC 5P

************************************************************

* 1-658-708-11 SPINDLE BOARD

**************

< CONNECTOR >

R451 1-249-435-11 CARBON 33K 5% 1/4W

R452 1-249-435-11 CARBON 33K 5% 1/4W

R453 1-249-429-11 CARBON 10K 5% 1/4W

R454 1-249-435-11 CARBON 33K 5% 1/4W

R455 1-249-402-11 CARBON 56 5% 1/4W

R501 1-259-464-11 CARBON 33K 5% 1/6W

R502 1-259-464-11 CARBON 33K 5% 1/6W

R503 1-259-464-11 CARBON 33K 5% 1/6W

R504 1-259-464-11 CARBON 33K 5% 1/6W

R505 1-259-458-11 CARBON 18K 5% 1/6W

R506 1-259-458-11 CARBON 18K 5% 1/6W

R507 1-259-461-11 CARBON 24K 5% 1/6W

R508 1-259-461-11 CARBON 24K 5% 1/6W

R509 1-259-427-81 CARBON 910 5% 1/6W

R510 1-259-434-11 CARBON 1.8K 5% 1/6W

R511 1-259-488-11 CARBON 330K 5% 1/6W

R512 1-259-422-11 CARBON 560 5% 1/6W

R513 1-259-404-11 CARBON 100 5% 1/6W

R517 1-249-421-11 CARBON 2.2K 5% 1/4W

R518 1-249-441-11 CARBON 100K 5% 1/4W

R519 1-249-421-11 CARBON 2.2K 5% 1/4W

R520 1-259-423-81 CARBON 620 5% 1/6W

R521 1-249-421-11 CARBON 2.2K 5% 1/4W

R551 1-249-435-11 CARBON 33K 5% 1/4W

R552 1-249-435-11 CARBON 33K 5% 1/4W

R553 1-249-429-11 CARBON 10K 5% 1/4W

R554 1-249-435-11 CARBON 33K 5% 1/4W

* CN107 1-568-848-11 SOCKET, CONNECTOR 5P

< SWITCH >

S151 1-571-958-11 SWITCH, PUSH (1 KEY) (LIMIT)

************************************************************

* 1-668-765-11 TRANS BOARD

************

* 4-962-200-01 PLATE (TR), GROUND

< CAPACITOR >

C901 1-126-017-11 ELECT 6800uF 20% 16V

C902 1-124-689-11 ELECT 1000uF 20% 16V

C903 1-128-198-11 ELECT 22uF 20% 63V

C904 1-126-052-11 ELECT 100uF 20% 16V

C905 1-136-802-11 FILM 0.015uF 5% 100V

C906 1-136-850-11 FILM 0.1uF 5% 63V

C907 1-136-850-11 FILM 0.1uF 5% 63V

C908 1-136-165-00 FILM 0.1uF 5% 50V

! C909 1-113-924-11 CERAMIC 0.0047uF 20% 250V

! C910 1-113-924-11 CERAMIC 0.0047uF 20% 250V

C922 1-124-907-11 ELECT 10uF 20% 50V

C923 1-136-165-00 FILM 0.1uF 5% 50V

C924 1-162-306-11 CERAMIC 0.01uF 20% 16V

C990 1-164-159-21 CERAMIC 0.1uF 50V

C991 1-164-159-21 CERAMIC 0.1uF 50V

– 50 –

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

TRANS VC SELECT

Ref. No. Part No. Description Remark

C992 1-164-159-21 CERAMIC 0.1uF 50V

C995 1-136-165-00 FILM 0.1uF 5% 50V

C996 1-136-165-00 FILM 0.1uF 5% 50V

C998 1-136-850-11 FILM 0.1uF 5% 63V

< CONNECTOR >

CN901 1-580-230-11 PIN, CONNECTOR (PC BOARD) 2P

CN903 1-564-321-00 PIN, CONNECTOR 2P

< DIODE >

D901 8-719-210-21 DIODE 11EQS04

D902 8-719-210-21 DIODE 11EQS04

D903 8-719-210-21 DIODE 11EQS04

D904 8-719-210-21 DIODE 11EQS04

D905 8-719-200-82 DIODE 11ES2

D906 8-719-991-33 DIODE 1SS133T-77

D907 8-719-991-33 DIODE 1SS133T-77

D908 8-719-921-40 DIODE MTZJ-4.7C

D921 8-719-982-22 DIODE MTZJ-30D

D922 8-719-109-85 DIODE RD5.1ES-B2

< COIL >

! L901 1-421-915-11 COIL, LINE FILTER

L991 1-410-322-11 INDUCTOR 3.3uH

L992 1-410-322-11 INDUCTOR 3.3uH

L993 1-410-322-11 INDUCTOR 3.3uH

L994 1-410-322-11 INDUCTOR 3.3uH

L997 1-412-473-21 INDUCTOR 0uH

< TRANSISTOR >

Q921 8-729-041-38 TRANSISTOR 2SB1241TV2Q

< RESISTOR >

R901 1-249-411-11 CARBON 330 5% 1/4W

R921 1-247-843-11 CARBON 3.3K 5% 1/4W

R922 1-247-843-11 CARBON 3.3K 5% 1/4W

R923 1-247-807-31 CARBON 100 5% 1/4W

R925 1-247-807-31 CARBON 100 5% 1/4W

Ref. No. Part No. Description Remark

MISCELLANEOUS

**************

20 1-773-216-11 WIRE (FLAT TYPE) (25 CORE)

56 1-783-699-11 WIRE (FLAT TYPE) (23 CORE)

58 1-500-386-11 FILTER, CLAMP (FERRITE CORE)

! 62 1-575-651-21 CORD, POWER

101 1-452-820-11 MAGNET (ASSY)

157 1-775-990-11 WIRE (FLAT TYPE) (5 CORE)

! 160 8-848-379-31 OPTICAL PICK-UP KSS-213B/F-RP

161 1-775-991-11 WIRE (FLAT TYPE) (16 CORE)

168 1-776-998-11 WIRE (FLAT TYPE) (21 CORE)

M901 X-4947-303-1 MOTOR ASSY (SLED)

M902 X-4950-385-1 MOTOR ASSY (SPINDLE)

M903 A-4660-968-A MOTOR ASSY (LOADING)

! T901 1-431-715-11 TRANSFORMER, POWER

************************************************************

**************

HARDWARE LIST

**************

#1 7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

#2 7-685-885-09 SCREW +BVTT 4X16 (S)

#3 7-627-852-07 SCREW, PRECISION +P 1.7X2.5

#4 7-685-871-01 SCREW +BVTP 3X6

************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

1-473-720-11 REMOTE COMMANDER (RM-DX50)

1-590-925-31 CORD, CONNECTION (AUDIO 100cm)

3-810-765-72 MANUAL, COMMONNESS INSTRUCTION

(ENGLISH, FRENCH, GERMAN, SPANISH,

DUTCH, ITALIAN, PORTUGUESE)

3-861-844-11 MANUAL, INSTRUCTION

(ENGLISH, FRENCH, SPANISH)

3-861-844-21 MANUAL, INSTRUCTION

(GERMAN, DUTCH, ITALIAN, PORTUGUESE)

4-983-956-01 COVER, BATTERY (for RM-DX50)

R926 1-249-441-11 CARBON 100K 5% 1/4W

! R927 1-212-873-11 FUSIBLE 47 5% 1/4W F

< TRANSFORMER >

! T901 1-431-715-11 TRANSFORMER, POWER

************************************************************

* 1-668-769-11 VC SELECT BOARD

***************

< RESISTOR >

R861 1-249-415-11 CARBON 680 5% 1/4W

R862 1-249-417-11 CARBON 1K 5% 1/4W

R863 1-249-419-11 CARBON 1.5K 5% 1/4W

< SWITCH >

S860 1-771-312-11 SWITCH, ROTARY (FILTER)

************************************************************

– 51 –

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

CDP-XB820

Sony Corporation

Home A&V Products Company9-922-850-11

– 52 –

Printed in Hungary © 1998. 6

98F057541-1

Published by Quality Assurance Dept.

(Shibaura)

Loading...

Loading...