Page 1

1

Operator Manual

Betriebsanleitung

Guide de lopérateur

WARNING

U Drive 25

U Drive 25

SERIAL NO. 1001 TO CURRENT

Manual del operador

operating instructions before performing maintenance on or operating any

All personnel shall carefully read, understand and follow all safety rules, and

UpRight aerial work platform.

Refer to page 2 for the English language version of this Operator Manual.

WARNUNG

AVERTISSEMENT

Wartungsarbeiten ausführen oder diese in Betrieb nehmen.

sécurité avant dentretenir ou dutiliser une plate-forme élévatrice UpRight.

Tout le personnel doit lire attentivement et respecter toutes les consignes de

Reportez-vous à la page 11 pour la version française de ce guide de lopérateur.

Alle Bediener müssen die Sicherheitsregeln und Bedienungsanleitungen gründlich

durchlesen, verstehen und befolgen, bevor sie an irgendeiner UpRight-Hocharbeitsbühne

Bezüglich der deutschsprachigen Ausgabe dieser Betriebsanleitung siehe Seite 20.

ADVERTENCIA

seguridad, las instrucciones de operación antes de efectuar trabajos de

mantenimiento o manejar cualquier plataforma aérea de trabajo UpRight.

Todo el personal debe leer atentamente, entender y respetar todas las reglas de

Referirse a la página 29 para la versión en español de este manual del operador.

7/99 K

069316-020

FOR MORE INFORMATION

Tel.: (800) 926-5438 or (209) 891-5200

Fax: (209) 896-9012

1775 Park St., Selma, CA 93662

Tel: (353) 1-285-3333

Fax: (353) 1-284-0015

USA

EUROPE

Pottery Road, Dun Laoire, Ireland

Pour de plus amples informations

É.-U.

Téléphone : (800) 926-5438 ou (209) 891-5200

Télécopieur : (209) 896-9012

1775 Park St., Selma, CA 93662

Téléphone : (353) 1-285-3333

Télécopieur : (353) 1-284-0015

Pottery Road, Dun Laoire, Irlande

EUROPE

Tel.: (800) 926-5438 oder (209) 891-5200

Fax: (209) 896-9012

1775 Park St., Selma, CA 93662

Tel.: (353) 1-285-3333

Fax: (353) 1-284-0015

Für weitere Informationen

USA

EUROPA

Pottery Road, Dun Laoire, Irland

Para obtener más información

Tel.: (800) 926-5438 ó (209) 891-5200

Fax: (209) 896-9012

EE.UU.

1775 Park St., Selma, CA 93662

Tel.: (353) 1-285-3333

EUROPA

Fax: (353) 1-284-0015

Pottery Road, Dun Laoire, Irlanda

44

Page 2

43

NOTES:

the UpRight Lift with

NEVER attempt to push

people or materials on

platform elevated.

the platform or with the

NEVER elevate platform without

first leveling the base.

NOTE: The placement and movement of the machine with the platform raised is

permitted on smooth, firm surfaces with sufficient load carrying capacity only, the

inclination of which shall not exceed 1.0 degrees.

Section

English Language

SAFETY RULES

NEVER elevate

platform unless all

four (4) outriggers

have been properly

installed. All wheels or

Climbing up on the railing of the platform,

standing on or stepping from the platform

onto buildings, steel or prefab concrete

structures, etc., is prohibited.

NOT INSULATED.

THIS MACHINE IS

screwjacks must be in

solid contact with a firm

surface before the

platform is elevated.

Use of the Aerial Work Platform: This aerial work platform is intended to lift one person and his tools as well as the

material used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings,

cranes, roof structures, buildings, etc.). All other uses of the aerial work platform are prohibited.

MACHINE must be driven only on smooth level floor surface.

This aerial work platform is not insulated! For this reason it is imperative to keep a safe distance from live parts of

electrical equipment.

To extend the height or the range by placing ladders, scaffolds or similar devices on the platform is prohibited.

NEVER attach overhanging loads to the platform or increase the platform size.

Exceeding the specified permissible maximum load of 159 kg (350 lbs) or the presence of more than one person on the

platform is prohibited.

LOOK up, down and around for overhead obstructions and electrical conductors.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial platform and in its

working range.

NEVER use outriggers from one model on another model.

Dismantling the folding entry railing or other railing components is prohibited! Always make certain that the entry

folding rail is closed and securely locked!

It is prohibited to keep the entry folding rail in an open position (e.g. held open with tie straps) when the platform is

raised!

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, damaged control or

power cables and loose wire connections.

The use and operation of the aerial work platform as a lifting tool (lifting of loads from below upwards or from up high on

down) is prohibited!

NEVER recharge battery near sparks or open flame. Batteries that are being charged emit highly explosive hydrogen

gas.

AFTER USE secure the work platform against unauthorized use by turning key switch off and removing key.

Modifications to the aerial work platform are prohibited or permissible only by the approval of UpRight.

The attachment or the use of components not manufactured or supplied by UpRight is prohibited!

NEVER use machine as a welding ground. Welding ground must be attached to same structural element which is being

repaired.

2

Page 3

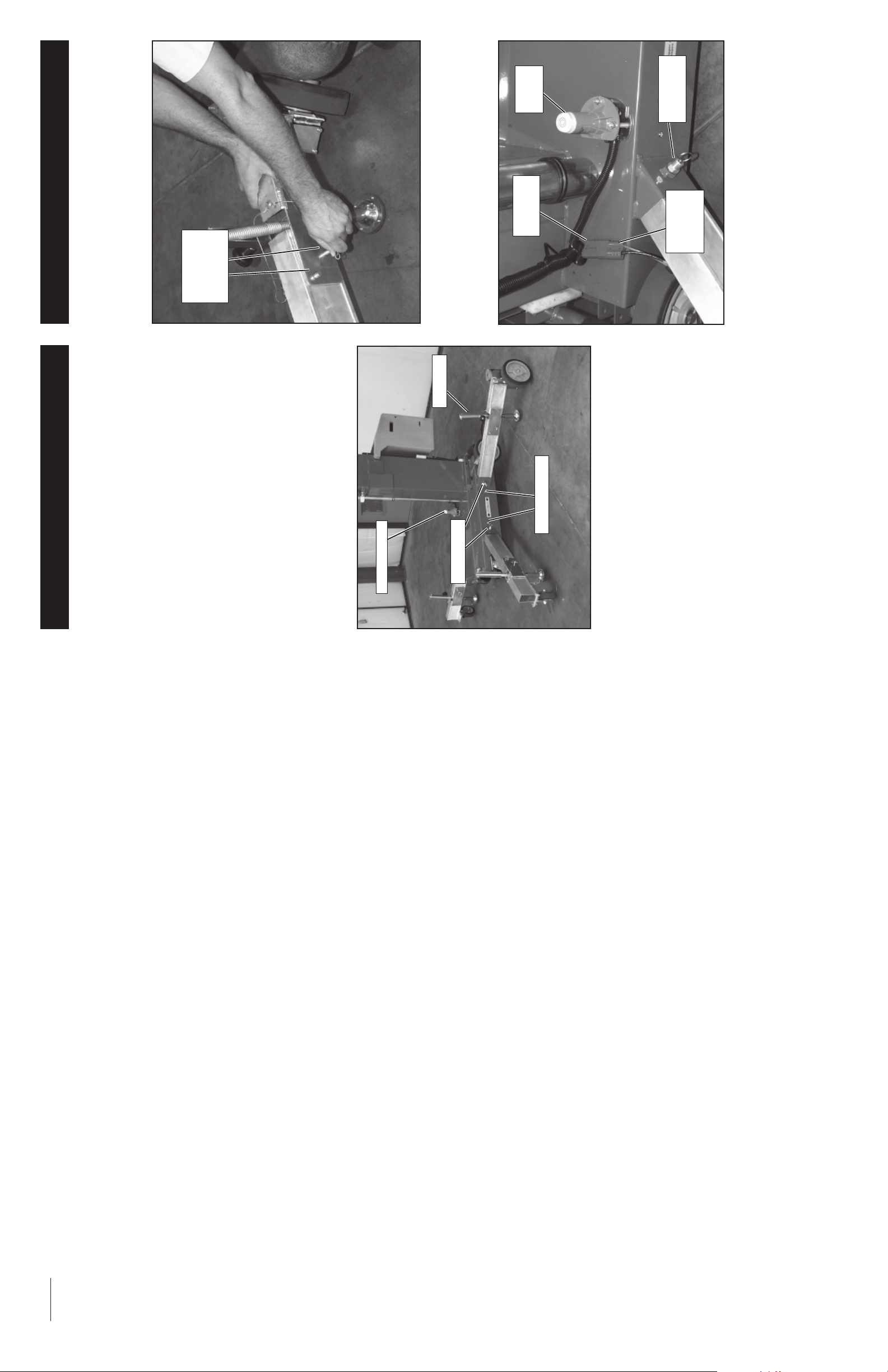

Wheel Installation

screwjacks clockwise until wheels can be

installed.

wheels in place using pins provided.

1. After outriggers have been installed, turn

2. Install rear wheels into rear outriggers. Pin

pins

Wheel

connecting

Figure 2: Installing wheels

3. Plug connector from rear wheels into connector

Level

Sensor

Base

Connector

from chassis wiring.

Lock Pin

Outrigger

Rear

Wheel

Connector

3

Figure 3: Connecting rear wheel cables

Outrigger Installation

on sides of mast.

1. Remove the outriggers from storage locations

2. Insert into outrigger socket in base (Figure 1).

outrigger. Pull outward on outrigger to ensure

engagement.

3. Push in until locking pin engages hole in end of

Make sure all four (4) locking pins are engaged.

level on the base by adjusting the screwjacks at

4. Repeat the above steps for all other outriggers.

5. Level the base, centering the bubble in the orbit

the end of each outrigger (Figure 1). DO NOT

release the tension on an outrigger, by turning

Level Sensor

counterclockwise, to level base.

IMPORTANT: All four (4) screwjack pads must be

in solid contact with a firm surface and each outrig-

ger indicator light must be lit before the platform is

elevated.

Screwjack

Locking Pin

Indicator Light

Figure 1: Installing outriggers

NOTES:

42

Page 4

41

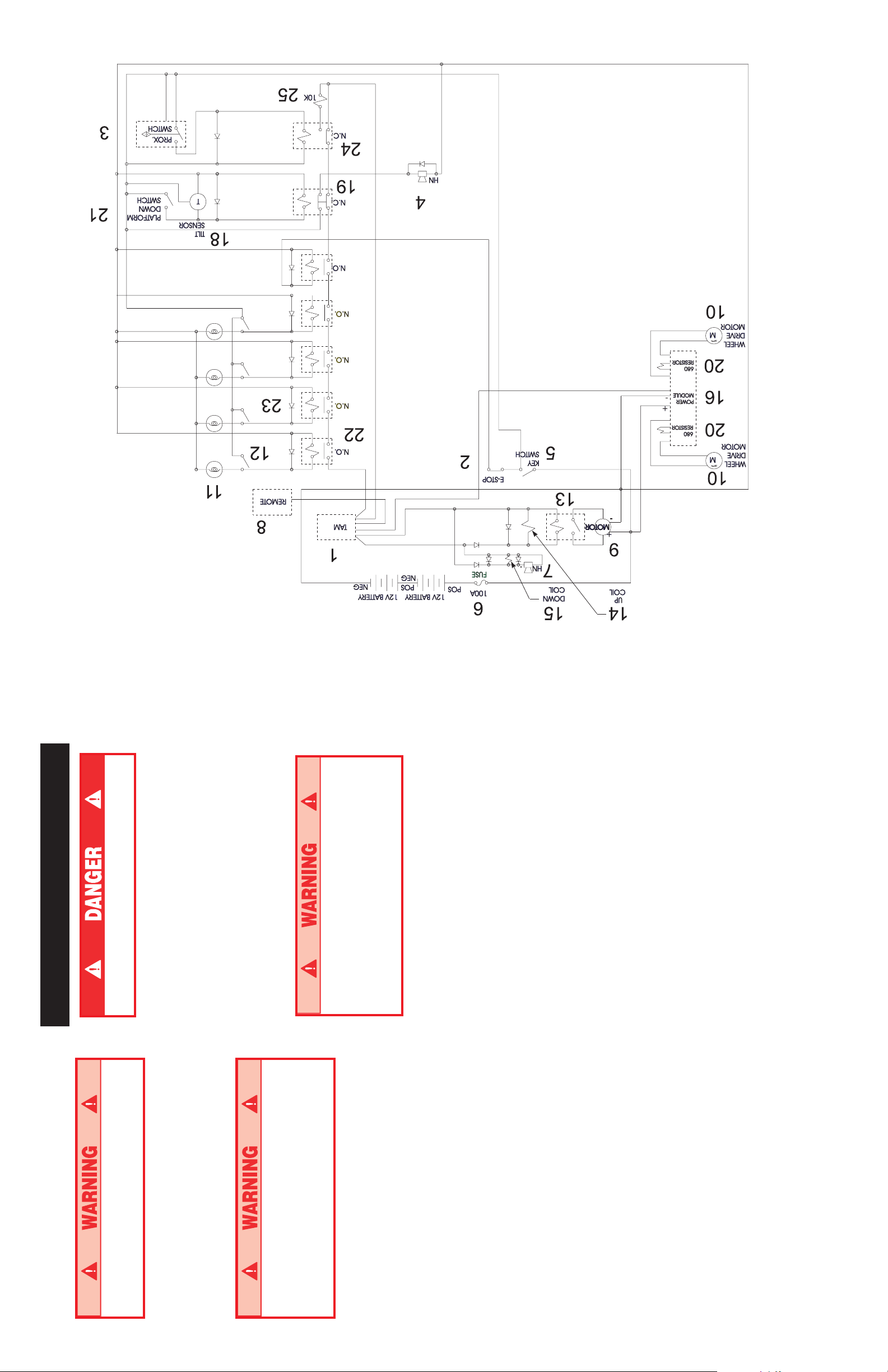

U-Drive 25 Electrical Schematic - 069304-000

Pre-Operation & Safety Test

using pins provided.

4. Install front wheels. Pin front wheels in place

NEVER perform this test from the platform.

1. On a solid level surface, install outriggers and

BE SURE all wheels are securely attached.

Pull on wheels to check for loose pins.

5. Lower screwjacks (turn counterclockwise) until

wheels.

hydraulic tank and check for proper hydraulic oil

2. Lower platform completely. Remove fill cap on

wheels are resting on ground. Be sure

screwjacks are high enough to avoid inter-

level.

ference with the ground when machine is

driven.

pushing level sensor out of alignment. Listen for

3. Activate lift function on platform controller while

DO NOT use a machine that elevates when

level sensor is off of level or tension has

been released on an outrigger. Remove

machine from service and repair before

audible tilt alarm.

4. Platform should not elevate.

DO NOT use machine if screwjack limiting

tubes have been removed. Remove ma-

chine from service and repair before

using.

IMPORTANT: All four wheels must be in solid

using.

contact with the ground and each outrigger indica-

tor light must be lit before the machine is operated.

straps. Check for missing or loose parts.

5. Release level sensor and fully elevate platform.

6. Visually inspect elevating assembly, chains and

lowering alarm.

for proper operation. To close Emergency

Lowering Valve, turn the knob until it snaps

7. Partially lower platform and listen for audible

8. Turn Emergency Lowering Valve knob to check

back in.

4

Page 5

5

8. Push ON/OFF button. Green LED will blink.

9. Adjust Drive/Lift and High/Low switches for

desired operation.

ahead or back to move or raise machine.

10.Holding Enable button down, push joystick

NOTE: Move joystick right or left while driving

forward or backwards to turn machine. Machine

will only drive at high speed when platform is

fully lowered.

NOTE: High/Low switch affects drive speed

only. Lift/Lower speed is constant.

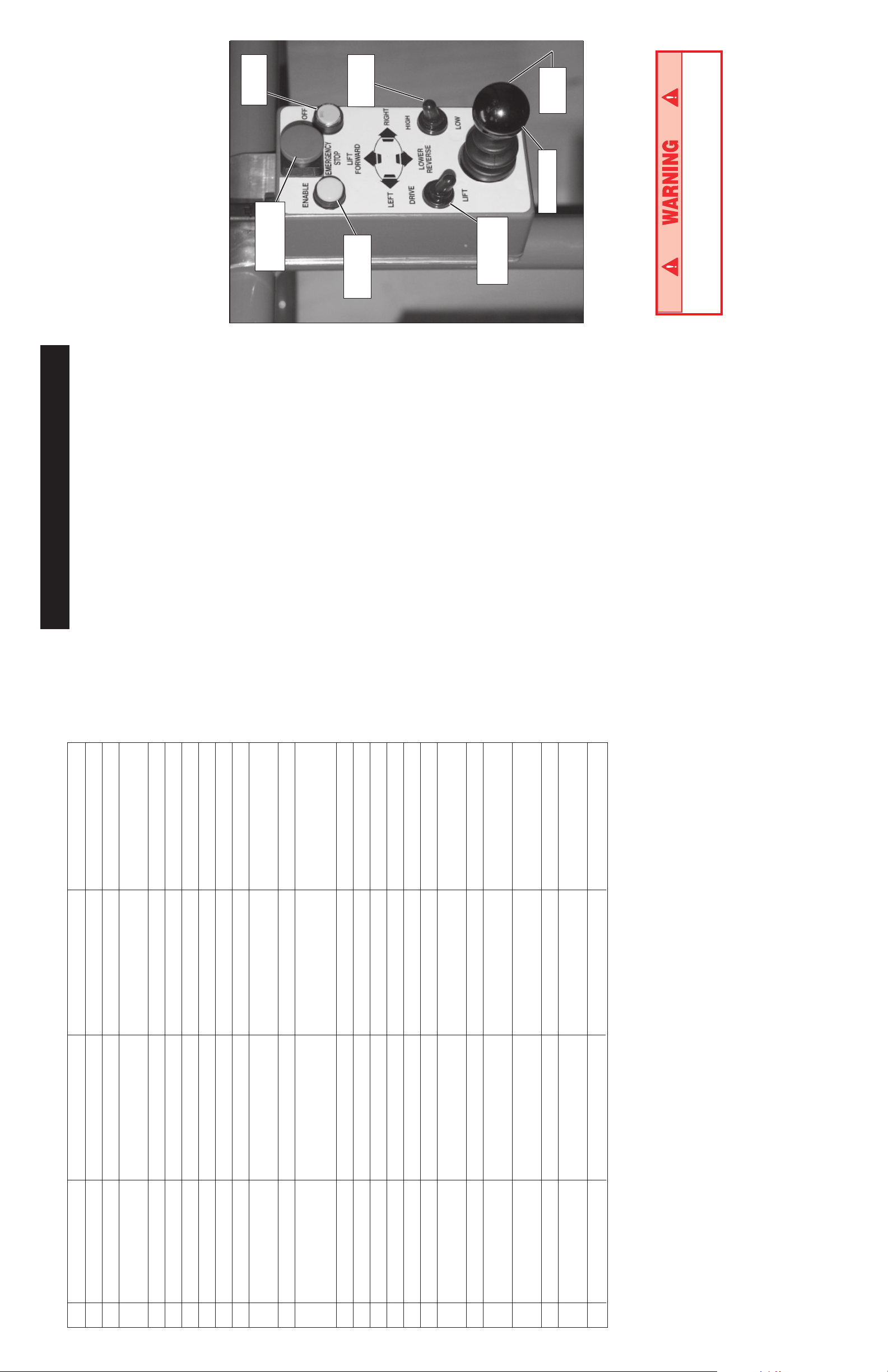

Button

ON/OFF

Emergency

Stop Button

Switch

High/Low

Button

Enable

Switch

Drive/Lift

Horn

Button

Joystick

Figure 4: Platform Controls

IMPORTANT: Machine is designed to travel on

smooth flat surfaces only.

If the platform should fail to lower, NEVER

climb down the mast.

before lowering the platform.

11. Check that the area below the platform is clear

turning Key Switch to OFF and removing key.

12. After use, secure unit from unauthorized use by

Operation Using Wheels

this machine.

The operator has been thoroughly trained on

Before operating the machine, be sure that:

follows this Operator Manual and the Scaffold

The operator has read, fully understands, and

Industry Association's MANUAL OF

RESPONSIBILITIES.

outriggers and wheels properly installed and

machine has passed the Safety Interlock

Test (page 6).

The unit has been properly set up with all

NOTE: Platform will not elevate unless all four

outriggers and wheels are properly installed

with wheels firmly in contact with floor and

each outrigger indicator lamp lit.

de las ruedas

1. Check for external damage to the mast.

2. Turn Key to ON, Key Switch is located on the left

side of the mast (Figure 4).

located on the left side of the mast, to turn switch

ON.

3. Pull out on Lower Emergency Stop Button,

before elevating the platform.

IMPORTANT: In the event of an emergency

push the button in to cut power to all controls.

4. Check that the area above the platform is clear

Enter the platform.

5. Release latch and raise upper half of cage.

platform making sure latch is engaged.

6. Lower upper half of the cage after entering

platform control panel.

7. Pull out on Emergency Stop Button, located on

de proximité

U-Drive 25 Electrical Schematic - 069304-000

ENGLISH FRANÇAIS GERMAN SPANISH

1 Control Module Module de commande Steuermodul Módulo de control

2 E-Stop Arrêt darrêt durgence Notaustaster Parada de emergencia

3 Proximity Switch Commutateur Näherungsschalter Interruptor de proximidad

4 Tilt Alarm Alarme dinclinason Neigungswarnung Alarma de inclinación

5 Key Switch Interrupteur à clé Schlüsselschalter Interruptor de la llave

6 100A fuse Fusible, 100A Sicherung 100 A Fusible de 100 AMP

7 Down Alarm Alarme, abaissée Senkwarnung Alarma abajo

8 Platform Module Module de la plate-forme Plattformmodul Módulo de la plataforma

9 Motor Moteur Motor Motor

10 Motor, Wheel Drive Moteur, roues motrices Motor, Radantrieb Motor, accionamiento

Interlock chement solidaire, Hilfsstützensperre Enclavamiento

11 Lamp, Indicator Témoin lumineux Kontrolleuchte Lámpara, indicador

12 Switch, Outrigger Interrupteur denclen- Schalter, Interruptor, Estabilizador

stabilisateurs

13 Relay, Motor Relais, moteur Relais, Motor Relé, motor

14 Coil, Up Bobinage, élév. Spule, aufwärts Bobina, elevación

15 Coil, Down Bobinage, abaiss. Spule, abwärts Bobina, descenso

16 Power Module Bloc de puissance Antriebseinheit Módulo de alimentación

17 Battery Batterie Batterie Batería

18 Level Sensor Capteur de niveau Niveausensor Sensor de nivel

19 Relay Contact Contact de relais Relaiskontakt (Öffner) Contacto del relé

plate-forme de la plataforma

Normally Closed normalement fermé normalmente cerrado

20 Resistor (680) Résistance (680) Widerstand (680) Resistencia (680)

21 Platform Down Switch Interrupteur dabaiss., Plattform-Absenkschalter Interruptor de descenso

Normally Open normalement ouvert Normalmente abierto

22 Relay Contact Contact de relais Relaiskontakt (Schließer) Contacto de relé

23 Diode Diode Diode Diodo

24 Relay Contact Contact de relais Relaiskontakt (Öffner) Contacto del relé

Normally Closed normalement fermé normalmente cerrado

25 Resistor (10K) Résistance (10K) Widerstand (10K) Resistencia (10K)

40

Page 6

39

NOTES:

under cover.

AFTER USE EACH DAY

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably

3. Secure against vandals, children or unautho-

If the platform should fail to lower, NEVER

climb down the mast.

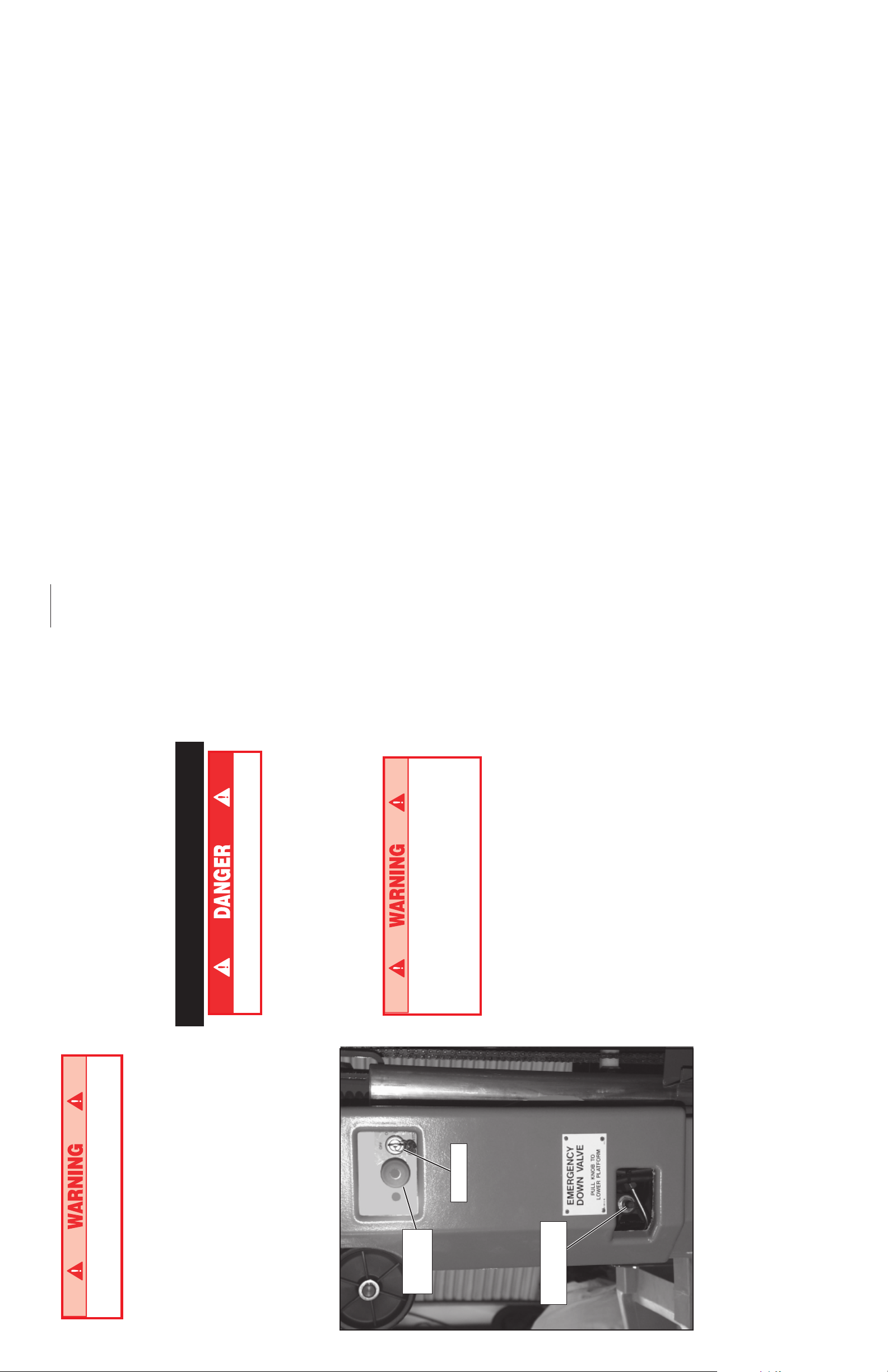

EMERGENCY LOWERING

rized operation by turning the Key Switch to

OFF and removing the key.

Ask a person on the ground to open the Emer-

gency Lowering Valve to lower the platform. This

valve is located through a cutout in the power unit

Safety Interlock Test

cover on the left side of the mast.

1. Pull the knob out and turn one quarter turn

either direction to open the Emergency Lower-

ing Valve.

NEVER perform this test from the platform.

the knob until it snaps back in.

2. To close the Emergency Lowering Valve, turn

base using screwjacks.

1. Properly install all four (4) outriggers and level

2. Release the tension on one (1) outrigger by

NOTE: Once the platform is fully lowered, be

certain that the Emergency Lowering Valve is

closed again. The platform will not elevate if the

turning the screwjack counterclockwise, until the

indicator lamp is no longer lit.

Emergency Lowering Valve is open.

3. Activate lift switch on side of mast to elevate the

DO NOT use a machine that elevates when

tension has been released on an outrigger.

Remove machine from service and repair

platform. Platform should not elevate.

Emergency

Stop Button

before using.

Key Switch

repeat step 2 with another outrigger.

4. Re-level the base with all four (4) outriggers then

have been tested.

5. Repeat steps 2 , 3 & 4 until all four (4) outriggers

Figure 5: Base Controls

Emergency

Lowering Valve

6

Page 7

If the platform should fail to lower, NEVER

climb down the mast.

EMERGENCY LOWERING

Ask a person on the ground to open the Emer-

gency Lowering Valve to lower the platform. This

valve is located through a cutout in the power unit

cover on the left side of the mast (Figure 5).

/4 turn to open the

1

1. Pull the knob out and turn

Emergency Lowering Valve.

2. To close the Emergency Lowering Valve, turn

the knob until it snaps back in.

Once the platform is fully lowered, be certain that

the Emergency Lowering Valve is closed again.

The platform will not elevate if the Emergency

Lowering Valve is open.

AFTER USE EACH DAY

under cover.

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably

rized operation by turning the Key Switch to

OFF and remove the key.

3. Secure against vandals, children or unautho-

Battery Maintenance

Hazard of explosive gas mixture. Keep

sparks, flame and smoking materials away

from battery.

Always wear safety glasses when working

with batteries.

Battery fluid is highly corrosive. Rinse away

any spilled fluid thoroughly with clean water.

Always replace battery with UpRight battery

or manufacturer approved replacement

weighing at least 23.6 kg (52 lbs.) each.

Check battery fluid level daily, especially if

work platform is being used in a warm, dry

climate.

in.) above

8

/

3

If electrolyte level is less than 10 mm (

plates add distilled water only. DO NOT use tap

water with high mineral content, it will shorten

battery life.

Keep terminals and tops of batteries clean.

Refer to the Service Manual to extend battery life

and for complete service instructions.

7

Outriggers Only

Operation Using

this machine.

follows this Operator Manual and the Scaffold

Industry Association's MANUAL OF

RESPONSIBILITIES.

The operator has been thoroughly trained on

The operator has read, fully understands, and

Before operating the machine, insure that:

(4) outriggers properly installed and the base

leveled, and the machine has passed the

Safety Interlock Test.

The unit has been properly set up with all four

bomba/motor

Note: Platform will not elevate unless all four

outriggers are properly installed with screwjack

pads firmly in contact with floor and each

outrigger indicator lamp lit.

1. Check for external damage to the mast.

2. Turn Key to ON, Key Switch is located on the left

side of the mast (Figure 5).

located on the left side of the mast, to turn switch

ON. In the event of an emergency push the

3. Pull out on Lower Emergency Stop Button,

button in to cut power to all controls.

lifting up on the upper half of the cage.

4. Enter the platform by releasing the latch and

platform making sure latch is engaged.

5. Lower upper half of the cage after entering

before elevating the platform.

6. Check that the area above the platform is clear

7. Pull out on Emergency Stop Button, located on

platform control panel. In the event of an emer-

gency push the button in to cut power to all

controls.

8. Push ON/OFF button. Green LED will blink.

9. Adjust Drive/Lift switch to Lift position.

ahead to raise machine.

10.Holding Enable button down, push joystick

NOTE: High/Low switch affects drive speed

only. Lift/Lower speed is constant.

before lowering the platform.

11.Check that the area below the platform is clear

turning Key Switch to OFF and remove key.

12.After use, secure unit from unauthorized use by

retour de retorno

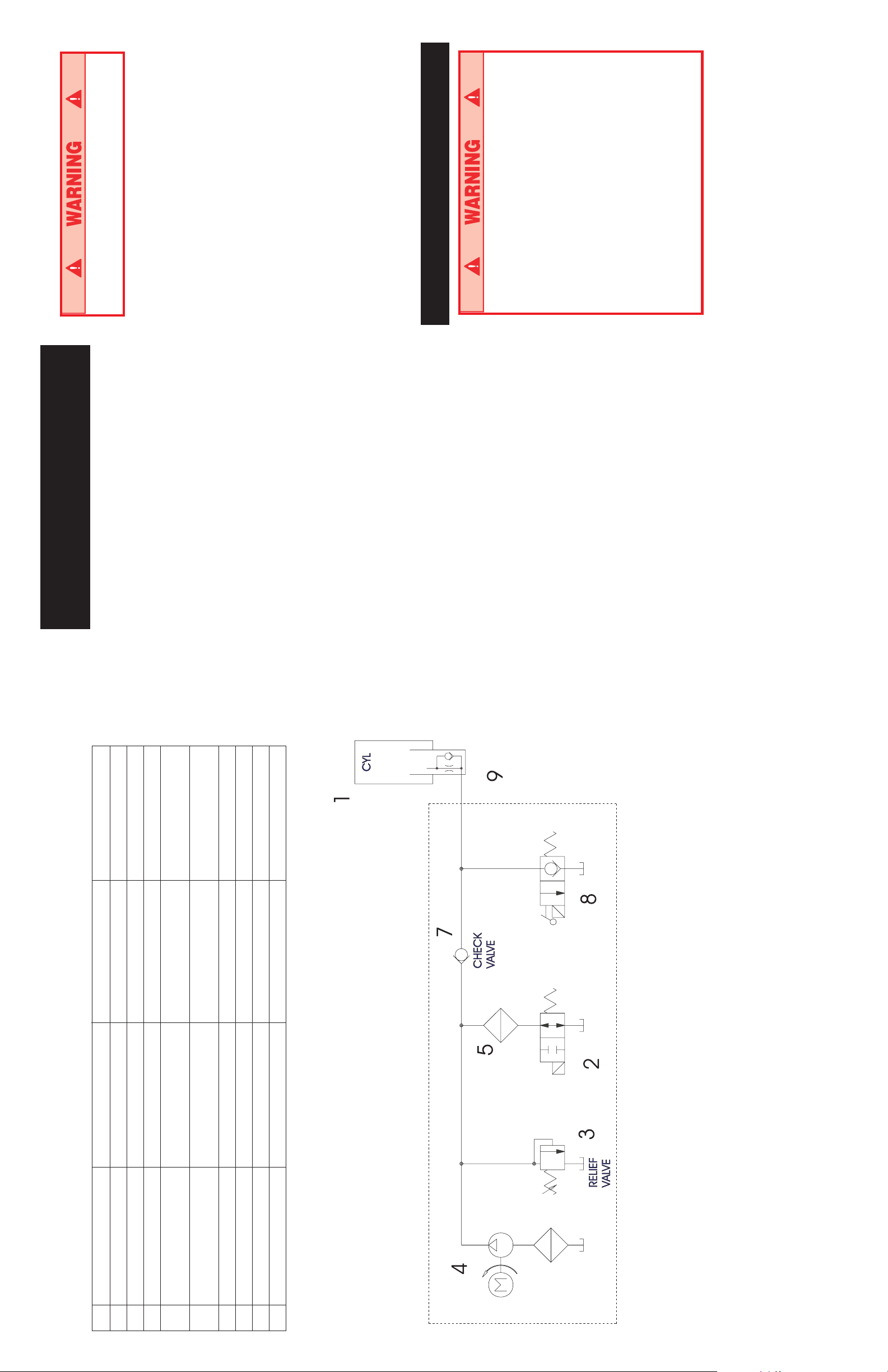

U-Drive 25 Hydraulic Schematic - 068011-000

ENGLISH FRANCAIS GERMAN SPANISH

1 Lift Cylinder Vérin de levage Hubzylinder Cilindro de elevación

2 Bypass Valve Soupape de dérivation Umgehungsventil Válvula de derivación

3 Relief Valve Soupape de décharge Überdruckventil Válvula de alivio

4 Return Line Filter Filtre de canalisation de Rücklauffilter Filtro de la línea

5 Motor/Pump Unit Unité de moteur/pompe Motor-Pumpeneinheit Unidad de la

6 Tank Filter Filtre de réservoir Tankfilter Filtro del depósito

7 Check Valve Clapet de non-retour Rückschlagventil Válvula de comprobación

8 Lift Valve Soupape de levage Hubventil Válvula de elevación

9 Orifice Orifice Drosselblende Orificio

38

Page 8

50 HR 125 HR. 500 HR.

MENSUAL C/3 MESES ANUAL

37

Especificaciones*

ITEM U DRIVE 25

Altura plataforma

Máximo 7,62 m (25 pies)

Mínimo 38 cm (15 pulg.)

Capacidad de la plataforma 159 kg (350 lbs.)

Dimensiones guardada

Alto 1,98 m (79 pulg.)

Ancho 84 cm (29 pulg.)

Largo 1,24 m (49 pulg.)

Superficie de apoyo (sólo gatos de rosca)

Ancho/Largo 1,5 m (59 pulg.)/1,42 m (56 pulg.)

Superficie de apoyo (con ruedas instaladas)

Ancho/Largo 2,1 m (80,5 pulg.)/1,9 m (75 pulg.)

Peso total 409,6 kg (903 lbs.)

Caja de la batería 42,9 kg (94,5 lbs.)

Altura de la baranda 1,1 m (43,5 pulg.)

Altura de barra punta pie 152 mm (6 pulg.)

60 Amp/hr., Peso mín. 23,6 kg (52 lbs.)

Voltaje sistema

Fuente de electricidad CC 2 baterías de 12 volt, grupo 22

60 Hz o 220 volts, corriente alterna, 50 Hz

Alimenta 5 amp, 24 volts, corriente continua

Cargador de batería 120 volts, corriente alterna,

Máxima presión hidráulica del sistema 165 bar (2400 psi)

Velocidad de desplazamiento 0,2 Km/h / 2 MPH

Velocidad de elevación 22 seg.

Inclinación máxima 1 grado

Fuerza máxima del viento 5 escala Beaufort (10,1 m/sec.)

*Las especificaciones pueden cambiarse sin aviso previo.

Cumple o supera los requisitos de las directivas CE y GS sobre

maquinaria.

DIARO O O O

X

Loading

MANTENIMIENTO DE RUTINA

Utilice la siguiente tabla como guía para mantenimiento de rutina. Consulte el Manual de servicio para obtener

OPERACIÓN DE MANTENIMENTO INTERVALO

instrucciones completas sobre serviio de mantenimiento.

Verifique la exactitud del nivel de la burbuja X

Revise la operación de los mecanismos de enganche del estabilizador X

Revise el nivel del fluido de la batería y cargue la batería (modelos CD solamente) X

Verifique que no existan etiquetas dañadas, descoloridas o faltantes y cámbielas X

Revise la condición del cable de control X

Verifique que el ensamblado del mástil no esté doblado, rajado o le falten remaches X

Revise la operación del chasis y del interruptor de parada de emergencia

de la plataforma X

Revise la operación de la válvula de bajada de emergencia X

Verifique que las ruedecillas no presenten daños X

Revise el nivel de fluido hidráulico X

Verifique que la cabina y los sujetadores de soporte de la

cabina tengan el par de torsión adecuado X

Revise y ajuste la tensión de las correas de secuencia X

Lubrique las cadenas de elevación y las roldanas X

Cambie el fluido hidráulico (ISO #46) X

Compruebe las ruedas tractoras para ver si hay piezas sueltas,

perdidas o desgastadas

remove the battery box from the rear of the

machine (Figure 7).

1. Disconnect the plug from the battery box and

BATTERY CHARGING

Charge batteries at end of each work shift or

sooner if batteries have been discharged.

The battery box is heavy, 42.9 kg

Charge battery in a well ventilated area.

Do not charge battery when the work

(94.5 lbs.), lift properly (or have someone

help you) to prevent back injury.

platform is in an area containing sparks or

flames.

Permanent damage to battery will result if not

Make sure loader fully engages tailgate or

vehicle bed.

immediately recharged after discharging.

Keep charger dry.

1. Check battery fluid level. If electrolyte level is

2. Raise the loader support bracket and engage

in.) above plates add

8

/

3

lower than 10 mm (

the retaining pin in the top hole of the loader

distilled water only.

channel (Figure 7).

2. Verify charger voltage switch is set to 12 volts.

3. Connect extension cord (1.5 mm² (12 ga.)

with the gravity hook.

3. Secure the loader to the loader support bracket

4. Position the unit so the back of the machine

conductor minimum and 15 m (50 ft.) in length

maximum) to charger plug.

comes in contact with the vehicle bed or tail-

gate.

Connect extension cord to properly grounded

outlet of proper voltage and frequency.

4. Set charger control to Conventional setting.

down until it comes into contact with the vehicle

5. Release the gravity hook and slide the loader

Charger ammeter should indicate charge rate.

5. When battery is fully charged, charger automati-

bed or tailgate. Then reposition the loader

support bracket so the retaining pin is in the

cally turns itself off. Disconnect extension cord.

first available hole above the loader.

6. Release the locking pin and pull the handle out

until the locking pin engages the hole in the end

of the handle (Figure 8).

pivot, until the unit rotates to a horizontal posi-

7. Lift up on the handle, using the loader as a

Charger Control

Charger

tion in the vehicle bed (Figure 9).

the vehicle bed. The machine will slide on the

loader until the rear wheels are on the bed. The

unit may then be rolled on the rear wheels and

upper casters.

sure the locking pin engages the handle.

8. Push the base of the unit towards the front of

9. Return the handle to the stored position, making

Battery Box Plug

Figure 6: Battery Box

8

Page 9

until the locking pin engages the hole in the end

of the handle.

UNLOADING

1. Unsecure the unit.

2. Release the locking pin and pull the handle out

3. Roll the unit back until the rear wheels are off

the edge of the tailgate or vehicle bed.

4. Pull downward on the handle, allowing the unit

to slide on the loader. As the unit stops sliding

on the loader, it will pivot on the loader to an

upright position. Gradually counterbalance the

units weight by applying an upward force on the

handle. This allows the unit to settle gently on

the wheels, avoiding undue impact on the unit.

sure the locking pin engages the handle.

5. Return the handle to the stored position, making

box plug making certain it is fully engaged.

6. Replace the battery and reconnect the battery

9

Figure 9: Tilting machine onto or off of a vehicle

10.Secure unit with suitable strength rope or tie

straps using forklift pockets located under the

base of the unit and upper caster axle.

To prevent damage to the mast assembly,

do not place rope or tie straps across the

mast assembly when securing the unit for

transportation.

DO NOT overtighten the rope or tie straps,

damage to the machine will result.

Retaining Pin

Loader Channel

Tailgate

Bracket

Loader Support

T-handle

Loader

Locking Pin

Figure 8: Handle positioning

Figure 7: Loader in load position

Gravity Hook

traseras estén fuera de la punta de la compuerta

trasera o de la plataforma del vehículo.

3. Haga rodar la unidad hasta que las ruedas

4. Tire de la palanca hacia abajo, permitiendo que la

unidad se deslice en la cargadora. Cuando la

unidad ya no se deslice en la cargadora, pivotará

en la cargadora a una posición vertical. Gradual-

mente equilibre el peso de la unidad tirando de la

palanca hacia arriba. Esto permitirá que la unidad

se establezca sobre las ruedas delicadamente y

se evita un impacto excesivo en la unidad.

miento, asegurándose de que el pasador traba

enganche en la palanca.

5. Coloque la palanca en la posición de almacena-

6. Cambie la batería, vuelva a conectar la toma de la

caja de la batería y asegúrese de que esté

completamente colocada.

trasera

retención

Pasador de

Abrazadera de

soporte de la

cargadora

Compuerta

Cargadora

Palanca en

forma de T

o fuera del mismo

Figura 9: Inclinar la máquina en un vehículo

seguridad

Pasador de

Para evitar daños al ensamblado del mástil,

no coloque la soga o las correas de amarre

en el ensamblado del mástil al asegurar la

unidad para su transporte.

NO ajuste la soga o las correas de amarre en

exceso, ya que se puede dañar la máquina.

DESCARGA

1. Desasegure la unidad.

2. Quite el pasador traba y tire de la palanca hacia

afuera hasta que el pasador traba se enganche

en el orificio del extremo de la palanca.

cargadora

Canal de la

gravedad

Gancho de

Figura 8: Colocación de la palanca

Figura 7: Cargadora en posición de carga

36

Page 10

Carga

quite la caja de la batería de la parte trasera de la

1. Desconecte la toma de la caja de la batería y

máquina (figura 7).

La caja de la batería es pesada, 42,9 kg

(94,5 lbs.), levántela apropiadamente (o haga

que alguien lo ayude) para evitar lesiones en

la espalda.

Asegúrese de que la cargadora esté

enganchada a la compuerta trasera o a la

plataforma del vehículo.

2 Levante la abrazadera de apoyo de la cargadora y

coloque el pasador de retención en el orificio

superior del canal de la cargadora (figura 7).

de la cargadora con el gancho de gravedad.

3. Asegure la cargadora a la abrazadera de soporte

de la máquina toque la plataforma del vehículo o

la compuerta trasera.

4. Coloque la unidad de modo que la parte trasera

dora hacia abajo hasta que toque la plataforma

del vehículo o la compuerta trasera. Luego vuelva

5. Suelte el gancho de gravedad y deslice la carga-

a colocar la abrazadera de soporte de la

cargadora de modo que el pasador de retención

se encuentre en el primer orificio disponible

sobre la cargadora.

afuera hasta que el pasador traba se enganche

en el orificio del extremo de la palanca (figura 8).

6. Quite el pasador traba y tire de la palanca hacia

pivote, hasta que la unidad rote a la posición

7. Levante la palanca, utilizando la cargadora como

horizontal en la plataforma del vehículo (figura 9).

delantera de la plataforma del vehículo. La

8. Empuje la base de la unidad hacia la parte

máquina se deslizará en la unidad de la cargado-

ra hasta que las ruedas traseras se encuentren en

la plataforma. La unidad puede rodar sobre las

ruedas traseras y las ruedecillas delanteras.

almacenamiento y asegúrese de que el pasador

traba se enganche en la palanca.

9. Vuelva a colocar la palanca a la posición de

resistente o correas de amarre. Emplee las

cavidades para horquillas de carretilla elevadora

situadas bajo la base de la unidad y el eje de

pivotamiento superior.

10.Asegure la unidad con una soga suficientemente

35

CARGA DE LA BATERÍA

Cargue las baterías al final de cada turno de trabajo

o antes si las baterías se descargan.

Cargue las baterías en un área bien ventilada.

No cambie las baterías cuando la plataforma

de trabajo se encuentra en un área en donde

pueden haber chispas o llamas.

Si no se recargan las baterías inmediatamente

luego de la descarga, se pueden producir

daños permanentes.

Mantenga el cargador seco.

pulg.) por

8

/

3

del electrólito es menor a 10 mm (

1. Revise el nivel del fluido de la batería. Si el nivel

encima de las placas, agregue agua destilada

solamente.

voltaje esté colocado en 12 voltios.

2. Verifique que el interruptor del cargador de

mínimo conductor y 15 m (50 pies) de longitud

3. Conecte la correa de extensión 1,5 mm² (12 ga.)

máxima) a la toma del cargador.

Conecte la correa de extensión a una salida a

tierra de voltaje y frecuencia apropiados.

Mando del cargador

Cargador

de la batería

Toma de la caja

Figura 6: Caja de batería

4. Sitúe el mando del cargador en la posición

Convencional. El amperímetro del cargador

debe indicar el régimen de carga.

5. Cuando la batería este completamente cargada,

el cargador se apagará automáticamente.

Desconecte el cable prolongador.

U DRIVE 25

7.62 m (25 ft.)

38 cm (15 in.)

159 kg (350 lbs.)

1.98 m (79 in.)

74 cm (29 in.)

1.24 m (49 in.)

Specifications*

ITEM

Minimum

Platform Capacity

Stored Dimensions

Vertical Height

Width

Platform Height

Maximum

Depth

1.5 m (59 in.)/1.42 m (56 in.)

2.1 m (80.5 in.)/1.9 m (75 in.)

Footprint (screw jacks only)

Width/Length

Footprint (wheels attached)

Width/Length

152 mm (6 in.)

1.1 m (43.5 in.)

42.9 kg (94.5 lbs.)

409.6 kg (903 lbs.)

Weight-overall

Battery Box

Guardrail Height

Toe Board Height

System Voltage

2-12 Volt Battery, Grp. 22

60 Amp/Hrs., Min. Wt. 152 mm (52 lbs.)

DC Electric Power Source

Output: 5 Amps, 24 Volts D.C.

120 VAC 60 Hz or 220 VAC 50 Hz

Battery Charger

165 bar (2400 PSI)

Maximum Hydraulic System

Pressure

22 Seconds

0.2Km/h / 2 MPH

Drive Speed

Raising Speed

1 Degree

Beaufort 5 (10.1 m/sec)

Maximum Slope

Maximum Wind Force

*Specifications subject to change without notice. Meets or exceeds

all applicable CE & GS Machinery Directive Requirements.

50 HRS. 125 HRS. 500 HRS.

MONTHLY 3 MONTHS YEARLY

DAILY OR OR OR

ROUTINE SERVICE

SERVICE OPERATION INTERVAL

Use the following table as a guide for routine maintenance, refer to Service Manual for complete service

instructions.

Check bubble level accuracy X

Check operation of outrigger interlocks X

Check battery fluid level and charge battery (D.C. models only) X

Check for peeling, faded or missing labels & replace X

Check condition of control cable X

Inspect mast assembly for bends, cracks or loose rivets X

Check chassis and platform emergency stop switch operation X

Check emergency lowering valve operation X

Check casters for damage X

Check hydraulic fluid level X

Check cage and cage support fasteners for proper torque X

Inspect and adjust sequence straps slack X

Lubricate lift chains and sheaves X

Change hydraulic fluid (ISO #46) X

Check drive wheels for loose, missing or worn parts X

10

Page 11

élévatrice UpRight

pousser la plate-forme

NE JAMAIS tenter de

lorsque la plate-forme

est élevée ou que des

personnes ou de

léquipement sy

trouvent.

NE JAMAIS élever la plate-

forme sans avoir dabord

mis la base de la machine à

lhorizontale.

11

NOTA : La mise en place et le déplacement de lengin, plate-forme élevée, ne

sont permis que sur des surfaces solides et lisses, dune capacité portante

suffisante et dont la pente ne doit pas dépasser 1,0 degré.

RÈGLES DE SÉCURITÉ

Version française

Il est interdit de monter ou de se tenir debout

sur les garde-corps de la plate-forme, ou de se

servir de la plate-forme pour monter sur des

bâtiments, des structures dacier ou de béton

préfabriqué, etc.

CETTE MACHINE

NE JAMAIS élever la

plate-forme sans que

les quatre (4)

stabilisateurs ne

soient solidement

fixés en place. Avant

de lélever, sassurer

que tous les pieds

réglables à vis des

stabilisateurs sappuient

fermement contre une surface

solide.

N'EST PAS ISOLÉE.

Utilisation de la plate-forme élévatrice de travail : Cette plate-forme élévatrice de travail est conçue pour lever une (1) personne et ses outils, ainsi

que le matériel utilisé pour la tâche à accomplir. Elle est conçue pour permettre lexécution de tâches et de travaux de réparation et dassemblage

en des endroits surélevés (plafonds, ponts roulants, structures de toit, bâtiments, etc.). Il est interdit dutiliser la plate-forme élévatrice de travail

à quelque autre fin que ce soit.

La MACHINE ne doit être utilisée que sur des surfaces de plancher lisses et planes.

Cette plate-forme élévatrice de travail nest pas isolée ! Il est donc capital de garder une distance sécuritaire entre la plate-forme de travail

et toute partie sous tension déquipement électrique.

Il est interdit de tenter daugmenter la portée ou la hauteur de la machine en plaçant sur la plate-forme des échelles, des échafaudages ou autres

dispositifs semblables.

NE JAMAIS agrandir la surface de la plate-forme ni y fixer une charge qui en excède la surface.

Il est interdit dexcéder la charge maximale admissible prescrite de 159 kg (350 lb), et la présence de plus dune (1) personne à bord de la plate-

forme est également interdite.

REGARDER en haut, en bas et tout autour de la machine afin de sassurer quil ny a aucun conducteur électrique ou autre obstacle aux alentours.

Il est interdit de contourner tout dispositif de sécurité; cela met en danger la vie de la personne embarquée sur la plate-forme et celle de toute

personne se trouvant dans lespace de travail de cette machine.

NE JAMAIS utiliser sur une machine des stabilisateurs destinés à un autre modèle.

Il est interdit de démonter les garde-corps dentrée rabattables ou tout autre composant des garde-corps! Toujours sassurer que le garde-corps

dentrée rabattable est bien fermé et verrouillé solidement !

Il est interdit de maintenir le garde-corps dentrée en position ouverte (p. ex., au moyen de courroies darrimage) lorsque la plate-forme est

élevée.

VÉRIFIER la machine de fond en comble en sassurant que toutes les soudures et tous les câbles électriques ou de commande sont en bon état,

que toutes les pièces de fixation sont bien serrées et quaucune delles ne manque, que le circuit hydraulique ne présente aucune fuite et que

tous les fils électriques sont bien branchés.

Il est interdit dutiliser et de faire fonctionner la plate-forme élévatrice de travail comme outil de levage (pour lever des charges par en dessous

ou pour abaisser des charges à partir du dessus de celle-ci) !

NE JAMAIS recharger la batterie daccumulateurs près dune flamme nue ou dune source détincelles : au moment du rechargement, les

batteries dégagent de lhydrogène gazeux hautement explosif.

APRÈS AVOIR UTILISÉ la plate-forme élévatrice, tourner linterrupteur à clé à la position darrêt (« OFF »), puis retirer celle-ci afin de prévenir

lutilisation de la plate-forme par toute personne non autorisée.

Toute modification à la plate-forme élévatrice de travail est interdite, à moins quelle ne soit approuvée au préalable par UpRight.

Il est interdit de fixer à la plate-forme élévatrice de travail, ou dutiliser avec celle-ci, des composants non fabriqués ou fournis par UpRight.

NE JAMAIS utiliser cette machine comme masse de soudage. La masse de soudage doit être reliée à lélément structural même qui fait lobjet

de la réparation.

En caso de que la plataforma no baje,

JAMÁS descienda por el mástil.

BAJADA DE EMERGENCIA

Pídale a alguien que se encuentre en el piso que

abra la válvula de bajada de emergencia para bajar

la plataforma. Esta válvula se encuentra a través de

un disyuntor en la tapa de la unidad de energía del

lado izquierdo del mástil (figura 5).

de vuelta

4

/

1

1. Tire de la perilla hacia afuera y gírela

para abrir la válvula de bajada de emergencia.

gire la perilla hasta que se vuelva para adentro.

2. Para cerrar la válvula de bajada de emergencia,

Una vez que la plataforma se encuentre completa-

mente abajo, asegúrese de que la válvula de bajada

de emergencia esté cerrada nuevamente. La plata-

forma no se elevará si la válvula de bajada de

emergencia está abierta.

DESPUÉS DE CADA USO DIARIO

abajo.

preferencia bajo techo.

1. Cerciórese de que la plataforma esté totalmente

2. Estacione la máquina en piso horizontal, de

vándalos o personas no autorizadas, gire el

3. Para que la máquina no sea operada por niños,

interruptor de la llave a la posición OFF

(apagado) y quite la llave.

Mantenimiento de la batería

Peligro de mezcla de gases explosiva.

Mantenga la batería lejos de chispas, llamas o

de cigarrillos.

Cuando trabaje con baterías, use siempre

anteojos de seguridad.

Los electrólitos son muy corrosivos. Lave bien

los derrames con agua limpia.

Use siempre baterías UpRight de repuesto o

aquellas aprobadas por el fabricante como

tales y que pesen 23,6 kg (52 lbs.) c/u.

pulg.) del

8

/

3

Inspeccione el nivel de electrólito diariamente,

especialmente si la plataforma de trabajo se

usa en un clima seco y cálido.

Si el electrólito está a menos de 10 mm (

tope de las placas agregue sólo agua destilada. NO

use agua potable con alto contenido de

minerales para no acortar la vida de la batería.

Mantenga los terminales y las baterías limpias.

Consulte en el Manual de mantenimiento como

incrementar la vida de la batería y las instrucciones

completas de mantenimiento.

Utilización con los

estabilizadores solamente

El operador ha recibido una formación adecuada

Antes de utilizar la máquina, compruebe lo siguiente:

sobre esta máquina.

(MANUAL OF RESPONSIBILITIES) de la Scaffold

Industry Association (asociación profesional del

sector de los andamiajes), y comprende plenamente

y pone en práctica su contenido.

El operador ha leído el Manual de responsabilidades

cuatro (4) estabilizadores se han instalado

La unidad se ha configurado correctamente, los

debidamente, la base está nivelada y la máquina ha

superado la prueba de enclavamiento de seguridad.

Nota: La plataforma no se elevará a menos que los

cuatro estabilizadores se encuentren correctamente

instalados y que los apoyos de los gatos estén en

contacto con el suelo y las luces indicadoras de

todos los estabilizadores estén encendidas.

1. Verifique que el mástil no presente daños externos.

2. Gire la llave a la posición de ON (encendido), el

interruptor de la llave está ubicado del lado izquierdo

del mástil (figura 5).

3. Tire del botón de parada de emergencia inferior

hacia afuera, ubicado del lado izquierdo del mástil,

para colocar el interruptor en la posición de ON

(encendido). En caso de emergencia presione el

botón hacia adentro para suspender la energía a

todos los controles.

levantando la mitad superior de la jaula.

4. Suba a la plataforma liberando el seguro y

la jaula y compruebe que el seguro está echado.

5. Una vez en la plataforma, baje la mitad superior de

plataforma esté libre de obstáculos antes de elevar

6. Verifique que el área que se encuentra arriba de la

la plataforma.

afuera, ubicado en el panel de control de la

plataforma. En caso de emergencia, presione el

7. Tire del botón de parada de emergencia hacia

botón hacia adentro para suspender la energía a

todos los controles.

LED verde quedará intermitente.

la posición de elevación.

8. Pulse el botón ON/OFF (encendido/apagado). El

9. Sitúe el interruptor de desplazamiento/elevación en

hacia delante la palanca para elevar la máquina.

10.Manteniendo pulsado el botón de activación, empuje

NOTA: El interruptor de máximo/mínimo solamente

varía la velocidad de desplazamiento. La velocidad

de elevación/descenso es constante.

11.Verifique que el área que se encuentra debajo de la

plataforma esté libre de obstáculos antes de bajar la

plataforma.

12.Luego del uso, asegúrese de que la unidad no sea

utilizada sin autorización girando el interruptor de la

llave a la posición OFF (apagado) y quite la llave.

34

Page 12

abajo.

DESPUÉS DE CADA USO DIARIO

1. Cerciórese de que la plataforma esté totalmente

2. Estacione la máquina en piso horizontal, de

preferencia bajo techo.

3. Para que la máquina no sea operada por niños,

vándalos o personas no autorizadas, gire el

interruptor de la llave a la posición OFF

(apagado) y quite la llave.

Prueba de seguridad del

mecanismo de enganche

JAMÁS realice esta prueba desde la

plataforma.

1. Instale correctamente los cuatro (4)

estabilizadores y nivele la base mediante los

gatos.

2. Destense un (1) estabilizador girando en el gato

en sentido antihorario, hasta que se apague la luz

indicadora.

3. Active interruptor de elevación, situado en el

lateral del mástil, para elevar la plataforma. La

plataforma no debería elevarse.

NO utilice una máquina que se eleva una vez

aliviada la tensión en un estabilizador. Retire

la máquina del servicio y repárela antes

de utilizarla.

estabilizadores y luego repita el paso 2 con otro

4. Vuelva a nivelar la base con los cuatro (4)

estabilizador.

estabilizadores hayan sido probados.

5. Repita los pasos 2, 3 y 4 hasta que los cuatro (4)

33

En caso de que la plataforma no baje,

JAMÁS descienda por el mástil.

BAJADA DE EMERGENCIA

Pídale a alguien que se encuentre en el piso que

abra la válvula de bajada de emergencia para bajar

la plataforma. Esta válvula se encuentra a través de

un disyuntor en la tapa de la unidad de energía del

lado izquierdo del mástil.

de vuelta

4

/

1

1. Tire de la perilla hacia afuera y gírela

para abrir la válvula de bajada de emergencia.

gire la perilla hasta que se vuelva para adentro.

2. Para cerrar la válvula de bajada de emergencia,

NOTA: Una vez que la plataforma se encuentre

completamente abajo, asegúrese de que la

válvula de bajada de emergencia esté cerrada

nuevamente. La plataforma no se elevará si la

válvula de bajada de emergencia está abierta.

Botón de

parada de

emergencia

de la llave

Interruptor

bajada de

Válvula de

emergencia

Figura 5: Controles de la base

Pose des roues

pieds à vis réglables dans le sens horaire jusquà

1. Une fois les stabilisateurs installés, tourner les

ce que les roues puissent être montées.

arrière. Goupiller les roues en place au moyen

2. Installer les roues arrière dans les stabilisateurs

des goupilles fournies à cet effet.

Goupilles de

connexion de roues

Figure 2 : Pose des roues

3. Brancher le connecteur des roues arrière dans le

connecteur du câblage du châssis.

Capteur

de niveau

de la base

Connecteur

blocage de

Goupille de

stabilisateur

arrière

de roue

Connecteur

de roues arrière

Figure 3 : Connexion des câbles

Pose des stabilisateurs

rangement, situés sur les côtés du mât.

destinées, à la base de la machine (figure 1).

jusquà ce que la goupille de blocage sengage

dans le trou de lextrémité du stabilisateur. Tirer

sur le stabilisateur afin de sassurer quil est bien

1. Retirer les stabilisateurs de leurs espaces de

2. Les insérer dans les emboîtures qui leur sont

3. Rentrer à fond le stabilisateur dans lemboîture,

engagé en place.

4. Mettre en place tous les autres stabilisateurs en

observant la marche à suivre ci-dessus. Sassurer

que les quatre (4) goupilles de blocage sont

toutes bien engagées dans leurs trous respectifs.

laire centrée) en réglant la longueur des pieds à

vis situés à lextrémité de chaque stabilisateur

5. Mettre la base de niveau (bulle du niveau globu-

(figure 1). NE PAS relâcher la pression exercée

sur lun ou lautre des stabilisateurs, en tournant

le pied à vis dans le sens antihoraire, pour mettre

la base de niveau.

IMPORTANT : Avant délever la plate-forme,

sassurer que les quatre (4) pieds réglables à vis

portent fermement sur une surface solide et que le

témoin lumineux de chaque stabilisateur est allumé.

Capteur de niveau

Pied à vis réglable

Témoin lumineux

Figure 1 : Pose des stabilisateurs

Goupille de blocage

12

Page 13

Essai préliminaire de

sécurité et dutilisation

NE JAMAIS effectuer cet essai à partir de la

plate-forme.

stabilisateur et les roues.

1. Sur une surface solide et de niveau, installer les

bouchon de remplissage du réservoir hydrauli-

2. Abaisser la plate-forme complètement. Enlever le

que, et vérifier si le niveau de liquide hydraulique

est approprié.

la plate-forme tout en poussant le capteur de

3. Actionner la fonction de levage du contrôleur de

niveau pour le désaligner. Prêter loreille pour

entendre lalarme sonore de détecteur dinclinai-

son.

4. La plate-forme ne devrait pas sélever.

NE PAS utiliser une machine qui effectue

une élévation lorsque le capteur de niveau

est désaligné ou que la pression a été

relâchée sur un stabilisateur. Retirer du

service la machine, et la faire réparer

avant de la réutiliser.

ment la plate-forme.

5. Relâcher le capteur de niveau et lever complète-

tion, des chaînes et des courroies. Vérifier si des

composants ont du jeu ou manquent.

6. Faire une inspection visuelle du dispositif déléva-

loreille pour entendre lalarme sonore dabaisse-

ment.

7. Abaisser partiellement la plate-forme, et prêter

de secours pour vérifier le bon fonctionnement du

dispositif. Pour fermer la soupape dabaissement

de secours, tourner le bouton jusquà ce quil

senclenche de lui-même en place.

8. Actionner le bouton de la soupape dabaissement

13

roues avant au moyen des goupilles fournies.

4. Installer les roues avant. Goupiller en place les

SASSURER que toutes les roues sont

montées de façon bien assujettie. Tirer sur

les roues pour détecter toute goupille qui a

du jeu.

5. Abaisser les pieds réglable à vis (tourner dans le

sens antihoraire) jusquà ce que les roues repo-

sent au sol. Sassurer que les pieds réglables à

vis sont suffisamment élevés pour éviter toute

interférence avec le sol lorsque la machine sera

conduite.

apagado

Botón de encendido/

NE PAS utiliser la machine si les tubes

limiteurs des pieds réglables ont été enlevés.

Retirer du service la machine, et la faire

réparer avant de la réutiliser.

Interruptor de

máximo/mínimo

IMPORTANT : La plate-forme peut être utilisée

seulement si les quatre (4) pieds réglables à vis

portent fermement sur le sol et si le témoin lumineux

de chaque stabilisateur est allumé.

bocina

Botón de la

Palanca

NOTA: Para girar la máquina, mueva la palanca

hacia la derecha o la izquierda mientras está

avanzando o retrocediendo. La máquina sólo

se desplazará a alta velocidad cuando la

Utilización con la ruedas

Antes de utilizar la máquina, compruebe lo siguiente:

plataforma esté completamente bajada.

NOTA: El interruptor de máximo/mínimo

solamente varía la velocidad de desplazamiento.

La velocidad de elevación/descenso es

constante.

sobre esta máquina.

bilidades (MANUAL OF RESPONSIBILITIES) de

la Scaffold Industry Association (asociación

El operador ha recibido una formación adecuada

El operador ha leído el Manual de responsa-

IMPORTANTE: La máquina está diseñada para

desplazarse solamente en superficies

profesional del sector de los andamiajes), y

comprende plenamente y pone en práctica su

contenido.

horizontales lisas.

estabilizadores y las ruedas se han instalado

La unidad se ha configurado correctamente, los

debidamente y la máquina ha superado la prueba

de enclavamiento de seguridad (pág. 33).

de emergencia

Botón de parada

Nota: La plataforma no se elevará a menos que

los estabilizadores y las ruedas se encuentren

correctamente instalados y que los apoyos de los

gatos estén en contacto con el suelo y las luces

indicadoras de todos los estabilizadores estén

encendidas.

Botón de

activación

interruptor de la llave está ubicado del lado

1. Verifique que el mástil no presente daños externos.

2. Gire la llave a la posición de ON (encendido), el

izquierdo del mástil (figura 4).

hacia afuera, ubicado del lado izquierdo del

mástil, para colocar el interruptor en la posición

3. Tire del botón de parada de emergencia inferior

elevación

Interruptor de

desplazamiento/

de ON (encendido).

IMPORTANTE: En caso de emergencia presione

el botón hacia adentro para suspender la energía

a todos los controles

la plataforma esté libre de obstáculos antes de

4. Verifique que el área que se encuentra arriba de

Figura 4: Controles de la plataforma

elevar la plataforma.

jaula. Suba a la plataforma.

5. Libere el seguro y levante la mitad superior de la

de la jaula y compruebe que el seguro está

echado.

6. Una vez en la plataforma, baje la mitad superior

En caso de que la plataforma no baje,

afuera, ubicado en el panel de control de la

7. Tire del botón de parada de emergencia hacia

JAMÁS descienda por el mástil.

plataforma.

la plataforma esté libre de obstáculos antes de

11.Verifique que el área que se encuentra debajo de

LED verde quedará intermitente.

8. Pulse el botón ON/OFF (encendido/apagado). El

bajar la plataforma.

12.Luego del uso, asegúrese de que la unidad no

elevación y máximo/mínimo para obtener el

funcionamiento deseado.

9. Ajuste los interruptores de desplazamiento/

la llave.

sea utilizada sin autorización girando el interrup-

tor de la llave a la posición OFF (apagado) y quite

empuje la palanca hacia delante o hacia atrás

para desplazar o elevar la máquina.

10. Manteniendo pulsado el botón de activación,

32

Page 14

al funcionamiento

JAMÁS realice esta prueba desde la

plataforma.

Prueba de seguridad previa

estabilizadores y las ruedas.

1. En una superficie nivelada y resistente, instale los

2. Baje la plataforma completamente. Retire el

tapón de llenado del depósito hidráulico y com-

pruebe si el nivel de aceite hidráulico es correcto.

3. En el control de la plataforma, active la función de

elevación al mismo tiempo que desalínea el

sensor de nivel. Debe escuchar la alarma acústi-

ca de inclinación.

4. La plataforma no debe elevarse.

NO utilice una máquina que se eleve con el

sensor de nivel desealineado o con un

estabilizador que haya perdido tensión.

Retire la máquina del servicio y repárela

antes de utilizarla.

la plataforma.

ción, las cadenas y las correas. Compruebe si se

han perdido o aflojado piezas.

5. Suelte el sensor de nivel y eleve completamente

6. Inspeccione visualmente el conjunto de eleva-

alarma acústica de descenso.

7. Baje parcialmente la plataforma. Debe oír la

8. Gire la perilla de la válvula de bajada de

emergenciapara verificar su apropiada operación.

Para cerrar la válvula de bajada de emergencia,

gire la perilla que se vuelva para adentro hasta.

31

pasadores suministrados.

4. Instale las ruedas delanteras. Fíjelas mediante los

ASEGÚRESE de que todas las ruedas están

correctamente instaladas. Tire de ellas para

comprobar si hay pasadores flojos.

antihorario) hasta que las ruedas se apoyen en el

suelo. Asegúrese de que los gatos están a una

5. Haga bajar los gatos (girándolos en sentido

altura suficiente para que no rocen con el suelo

cuando se desplace la máquina.

NO utilice la máquina si se han retirado los

Bouton de

marche-arrêt

tubos de tope de los gatos de rosca. Retire la

máquina del servicio y repárela antes de

utilizarla.

IMPORTANTE: Las cuatro ruedas deben estar

Sélecteur de

firmemente asentadas en el suelo y las luces

indicadoras de los estabilizadores han de estar

encendidas antes de elevar la plataforma.

mode haut/bas

sonore

Bouton de

lavertisseur

Levier de

commande

tion, pousser le levier de commande ou le

ramener en arrière, pour faire avancer ou lever la

10.Tout en maintenant enfoncé le bouton de valida-

machine.

NOTA : Pour faire virer la machine en mode de

translation vers lavant ou vers larrière, déplacer

le levier de commande vers la droite ou vers la

gauche, selon le cas. La machine ne peut

avancer à grande vitesse que si la plate-forme est

complètement abaissée.

NOTA : Le sélecteur de mode haut/bas influe sur

la vitesse de translation seulement. La vitesse

Bouton darrêt

délévation/dabaissement demeure constante.

durgence

validation

Bouton de

mode de

Sélecteur de

fonctionnement

de la plate-forme

Figure 4 : Tableau de commandes

IMPORTANT : Cette machine est conçue pour se

déplacer sur des surfaces planes et lisses

seulement.

Lorsque la plate-forme ne sabaisse pas, NE

JAMAIS descendre par le mât.

ny a aucun obstacle en dessous.

11. Avant dabaisser la plate-forme, sassurer quil

tourner linterrupteur à clé à la position « OFF »,

puis le retirer afin de prévenir lutilisation de la

plate-forme par toute personne non autorisée.

12. Après avoir utilisé la plate-forme élévatrice,

avec les roues

Utilisation de la machine

Lopérateur a reçu une formation pratique com-

Avant dutiliser la machine, sassurer que :

plète lui permettant dutiliser cette machine.

Lopérateur a lu, comprend à fond et observe les

directives et recommandations du présent Guide

de lopérateur et du MANUAL OF RESPONSIBI-

LITIES de la Scaffold Industry Association.

La machine a été correctement préparée pour

utilisation, les stabilisateurs et roues étant fixés

solidement, et a subi avec succès lessai du

dispositif de sécurité (page 15).

NOTA : La plate-forme sélèvera seulement si les

quatre (4) stabilisateurs et roues portent

fermement sur une surface solide et si le témoin

lumineux de chaque stabilisateur est allumé.

endommagées.

mât (figure 4), tourner linterrupteur à clé à la

position « ON ».

1. Sassurer que les surfaces du mât ne sont pas

2. Au tableau de commandes du côté gauche du

3. Toujours du côté gauche du mât, tirer sur le

bouton darrêt durgence inférieur pour le régler à

la position « ON ».

IMPORTANT: En cas durgence, rentrer le bouton

pour couper le courant à lensemble des

commandes.

aucun obstacle au-dessus de la machine.

4. Avant délever la plate-forme, sassurer quil ny a

supérieure de la nacelle.

5. Déclencher le loquet, puis soulever la moitié

supérieure de la nacelle, et limmobiliser au

moyen du loquet de verrouillage.

6. Une fois sur la plate-forme, abaisser la moitié

sur le bouton darrêt durgence.

7. Au tableau de commandes de la plate-forme, tirer

8. Appuyer sur le bouton de marche-arrêt (« ON/

OFF »). La DÉL verte clignotera.

et de mode haut/bas selon lutilisation voulue.

9. Régler les sélecteurs de mode de fonctionnement

14

Page 15

APRÈS UTILISATION, TOUS

LES JOURS

préférablement à labri.

1. Abaisser complètement la plate-forme.

2. Stationner la machine sur une surface plane,

3. Tourner linterrupteur à clé à la position darrêt

« OFF », puis retirer celle-ci afin de prévenir

lutilisation de la plate-forme par des vandales,

des enfants ou toute personne non autorisée.

sécurité

Essai du dispositif de

NE JAMAIS effectuer cet essai à partir de la

plate-forme.

1. Poser correctement les quatre (4) stabilisateurs,

et mettre la base de niveau, au moyen des pieds

réglables à vis.

2. Relâcher la pression exercée sur lun (1) des

stabilisateurs en tournant le pied réglable à vis

dans le sens antihoraire, jusquà ce que le témoin

lumineux séteigne.

La plate-forme ne devrait pas sélever.

3. Actionner linterrupteur de levage du côté du mât.

NE PAS utiliser une machine dont la plate-

forme sélève lorsque la pression a été

relâchée à lun des stabilisateurs. Retirer du

service une telle machine, et la faire

réparer.

(4) stabilisateurs, et répéter létape 2 avec un

4. Remettre la base de niveau, au moyen des quatre

autre stabilisateur.

quatre (4) stabilisateurs aient été vérifiés.

5. Répéter les étapes 2, 3 et 4 jusquà ce que les

15

Lorsque la plate-forme ne sabaisse pas,

ABAISSEMENT DURGENCE

NE JAMAIS descendre par le mât.

Demander à une personne qui se trouve au sol

douvrir la soupape dabaissement de secours.

Située du côté gauche du mât, dans une ouverture

ménagée dans le panneau de fermeture du bloc de

puissance, cette soupape permet dabaisser la plate-

forme.

1. Ouvrir la soupape dabaissement de secours en

de

4

/

1

tirant sur son bouton et en le tournant de

tour.

ce quil revienne dun coup sec à sa position

dorigine.

2. Pour fermer la soupape, tourner le bouton jusquà

à clé

Interrupteur

Soupape

durgence

Bouton darrêt

NOTA : Une fois la plate-forme abaissée, veiller à

refermer la soupape dabaissement de secours :

la 3te-forme ne sélèvera pas tant que cette

soupape ne sera pas fermée.

de secours

dabaissement

Figure 5 : Commandes de base

Instalación de las ruedas

gatos en sentido horario hasta que sea posible

1. Una vez instalados los estabilizadores, gire los

instalar las ruedas.

traseros. Fíjelas mediante los pasadores suminis-

trados.

2. Instale las ruedas traseras en los estabilizadores

Pasadores de

las ruedas

sujeción de

Figura 2: Instalación de las ruedas

3. Enchufe el conector de las ruedas traseras en el

conector del cableado del chasis.

Sensor

Conector

Gato

de nivel

de la base

Pasador de

estabilizador

seguridad del

las ruedas

Conector de

traseras

de las ruedas traseras

Figura 3: Conexión de los cables

estabilizadores

Instalación de los

almacenamiento en los laterales del mástil.

(figura 1).

1. Retire los estabilizadores de sus posiciones de

2. Introduzca el conector del estabilizador en la base

3. Presione hasta que el pasador de seguridad

encaje en el orificio del extremo del estabilizador.

Tire hacia fuera del estabilizador para asegurar

que encaje correctamente.

estabilizadores restantes. Cerciórese de que los

4. Repita los pasos anteriores con los

cuatro (4) han encajado correctamente.

circular instalado en ella. Para ello, ajuste de los

gatos situados en el extremo de los

estabilizadores (Figura 1). NO destense ningún

5. Nivele la base centrando la burbuja del nivel

estabilizador, girando en sentido antihorario, para

nivelar la base.

IMPORTANTE: Las cuatro (4) planchas de los gatos

deben estar firmemente asentadas en una superficie

resistente, y las luces indicadoras de los

estabilizadores han de estar encendidas antes de

elevar la plataforma.

Sensor

de nivel

seguridad

Pasador de

Luz indicadora

Figura 1: Instalación de los estabilizadores

30

Page 16

elevador de Upright con

JAMÁS intente mover el

con la plataforma

elevada.

sobre la plataforma o

personas o materiales

JAMÁS eleve la plataforma

sin antes nivelar la base.

29

NOTA: Solamente se puede colocar y desplazar la máquina con la plataforma

elevada en superficias lisas y firmes con suficiente resistencia y cuya inclinación no

exceda de 1,0 grados.

Versión

en español

REGLAS DE SEGURIDAD

JAMÁS eleve la

plataforma a menos que

se hayan instalado los

cuatro (4)

estabilizadores. Todos

los apoyos del gato del

estabilizador deben

estar en contacto con

una superficie firme

antes de que la

plataforma sea elevada.

Está prohibido subirse a las barandillas de la plataforma o

permanecer de pie sobre ellas, y también acceder a la

plataforma desde edificios, estructuras de acero u hormigón

ESTÁ AISLADA.

LA MÁQUINA NO

prefabricado, etc. está prohibido.

Utilización de la plataforma de trabajo aérea: Esta plataforma está pensada para elevar una persona, sus herramientas y el

material necesario para realizar los trabajos. Se ha diseñado para llevar a cabo tareas de reparación y montaje en lugares

elevados (techos, grúas, estructuras de tejados, edificios, etc.). Está prohibido destinar la plataforma a otras aplicaciones.

LA MÁQUINA solamente debe accionarse en un terreno llano y horizontal.

La plataforma de trabajo aérea no está aislada. Por este motivo, es esencial mantenerse a una distancia de seguridad de

las piezas con corriente de los equipos eléctricos.

Está prohibido ampliar la altura o el radio de acción de la plataforma colocando en ella escaleras, andamios o dispositivos

similares.

JAMÁS coloque cargas colgantes a la plataforma o aumente el tamaño de la misma.

Está prohibido sobrepasar la carga máxima especificada, 159 kg (350 lbs), y también que suba a la plataforma más de una

persona.

MIRE hacia arriba, abajo y alrededores para detectar obstáculos aéreos y conductores eléctricos.

Desactivar cualquier equipo de seguridad está prohibido y supone un peligro para las personas que se encuentran en la

plataforma aérea o en su zona de trabajo.

JAMÁS utilice los estabilizadores de un modelo en otro.

Desmontar la barandilla plegable de acceso o cualesquiera otros componentes de las barandillas está prohibido. Asegúrese

siempre de que la barandilla plegable de acceso está cerrada y con el seguro echado.

Está prohibido mantener abierta la barandilla plegable de acceso (por ejemplo, mantenerla abierta mediante correas) con la

plataforma elevada.

REVISE la máquina detenidamente y asegúrese de que no existan piezas soldadas rajadas, elementos de montaje flojos o

faltantes, fugas hidráulicas, controles o cables eléctricos dañados y conexiones eléctricas flojas.

Utilizar la plataforma de trabajo aérea como herramienta de elevación (para subir o bajar cargas) está prohibido.

JAMÁS cargue la batería donde hayan chispas o llamas. Las baterías en carga emiten hidrógeno gaseoso, que es altamente

explosivo.

DESPUÉS DE USAR, asegure la plataforma de trabajo girando el interruptor de la llave a la posición OFF (apagado) y quite la

UpRight.

Introducir modificaciones en la plataforma de trabajo aérea está prohibido o requiere obligatoriamente la aprobación de

Incorporar o utilizar componentes no fabricados o suministrados por UpRight está prohibido.

llave para evitar usos no autorizados.

JAMÁS utilice la máquina como zona de soldadura. La zona de soldadura debe encontrarse en el mismo elemento estructural

que se está reparando.

Lorsque la plate-forme ne sabaisse pas, NE

JAMAIS descendre par le mât.

ABAISSEMENT DURGENCE

Demander à une personne au sol douvrir la soupape

dabaissement de secours. Située du côté gauche du

mât (figure 5), dans une ouverture ménagée dans le

1

panneau de fermeture du bloc de puissance, cette

soupape permet dabaisser la plate-forme.

1. Ouvrir la soupape dabaissement de secours en tirant

de tour.

4

/

sur son bouton et en le tournant de

2. Pour fermer la soupape dabaissement de secours,

tourner le bouton jusquà ce quil revienne dun

coup sec à sa position dorigine.

po), ajouter de leau distillée

8

/

3

Entretien des batteries

Risque démanations gazeuses explosives. Tenir

les batteries à lécart de toute source détincelles

ou de flammes et de toute matière fumante.

Ne jamais manipuler les batteries sans porter de

lunettes de sécurité.

Lélectrolyte est un liquide très corrosif. Éliminer

toute trace de liquide déversé par les batteries en

rinçant à grande eau claire.

Toujours remplacer les batteries par des batteries

UpRight ou de rechange homologuée par le

fabricant et pesant au moins 23,6 kg (52 lb)

chacune.

Vérifier le niveau délectrolyte tous les jours,

surtout lorsque la plate-forme de travail est utilisée

préférablement à labri.

« OFF », puis retirer celle-ci afin de prévenir

lutilisation de la plate-forme par des vandales, des

enfants et toute personne non autorisée.

Une fois la plate-forme abaissée, veiller à refermer la

soupape dabaissement de secours : la plate-forme ne

sélèvera pas tant que cette soupape ne sera pas

fermée.

APRÈS UTILISATION, TOUS LES JOURS

1. Abaisser complètement la plate-forme.

2. Stationner la machine sur une surface plane,

3. Tourner linterrupteur à clé à la position darrêt

par temps sec et chaud.

Si lélectrolyte ne recouvre pas les plaques des batteries

dau moins 10 mm (

seulement. NE PAS utiliser de leau de robinet à haute

teneur en minéraux, sinon la vie utile des batteries sera

raccourcie.

Garder les bornes et le dessus des batteries propres.

Le manuel dentretien contient les marches à suivre

détaillées pour entretenir les batteries et leur assurer une

longue vie utile.

seulement

avec les stabilisateurs

Utilisation de la machine

Lopérateur a reçu une formation pratique complète

Avant dutiliser la machine, sassurer que :

lui permettant dutiliser cette machine.

directives et recommandations du présent Guide de

lopérateur et du MANUAL OF RESPONSIBI-

LITIES de la Scaffold Industry Association.

Lopérateur a lu, comprend à fond et observe les

utilisation, les quatre (4) stabilisateurs étant fixés

La machine a été correctement préparée pour

solidement, et a subi avec succès lessai du

dispositif de sécurité.

Nota : La plate-forme sélèvera seulement si les

quatre (4) pieds réglables à vis portent fermement

contre le sol et si le témoin lumineux de chaque

endommagées.

stabilisateur est allumé.

1. Sassurer que les surfaces du mât ne sont pas

(figure 5), tourner linterrupteur à clé à la position

2. Au tableau de commandes du côté gauche du mât

« ON ».

darrêt durgence inférieur pour le régler à la position

« ON ». En cas durgence, rentrer le bouton pour

3. Toujours du côté gauche du mât, tirer sur le bouton

couper le courant à lensemble des commandes.

loquet, puis soulever la moitié supérieure de la

nacelle.

4. Pour monter sur la plate-forme, déclencher le

supérieure de la nacelle, et limmobiliser au moyen

du loquet de verrouillage.

5. Une fois sur la plate-forme, abaisser la moitié

aucun obstacle au-dessus de la machine.

6. Avant délever la plate-forme, sassurer quil ny a

sur le bouton darrêt durgence. En cas durgence,

rentrer le bouton pour couper le courant à

7. Au tableau de commandes de la plate-forme, tirer

lensemble des commandes.

OFF »). La DÉL verte clignotera.

8. Appuyer sur le bouton de marche-arrêt (« ON/

9. Régler le sélecteur de mode de fonctionnement à la

position de levage.

10.Tout en maintenant enfoncé le bouton de validation,

pousser le levier de commande en avant pour faire

lever la plate-forme.

NOTA : Le sélecteur de mode haut/bas influe sur la

vitesse de translation seulement. La vitesse

délévation/dabaissement demeure constante.

11.Avant dabaisser la plate-forme, sassurer quil ny a

aucun obstacle en dessous.

linterrupteur à clé à la position « OFF », puis retirer

12.Après avoir utilisé la plate-forme élévatrice, tourner

celle-ci afin de prévenir lutilisation de la plate-forme

par toute personne non autorisée.

16

Page 17

Chargement

des batteries après en avoir débranché le câble

(figure 7).

1. À larrière de la machine, déposer le caisson

Le caisson des batteries, qui pèse 42,9 kg

(94,5 lb), est lourd. Il faut donc veiller à le

17

soulever comme il se doit, de manière à

prévenir toute blessure au dos (ou le

soulever à deux).

Sassurer que le dispositif de chargement

sappuie fermement contre le plateau du

véhicule ou sa porte à rabattement arrière,

sur toute sa longueur.

chargement, puis insérer sa goupille de retenue

2. Lever la ferrure de support du dispositif de

dans le trou supérieur de la glissière (figure 7).

3. Au moyen du crochet de suspension, accrocher

le dispositif de chargement à la ferrure de sup-

port.

fasse contact avec le plateau du véhicule ou sa

porte à rabattement arrière.

4. Positionner la machine de façon à ce que larrière

5. Décrocher le crochet de suspension et faire

glisser le dispositif de chargement vers le bas,

jusquà ce quil entre en contact avec le plateau

du véhicule ou sa porte à rabattement arrière.

Changer ensuite la position de la ferrure de

support, de manière à pouvoir insérer la goupille

dessus du dispositif de chargement.

de retenue dans le premier trou qui est libre au-

tirer sur celle-ci jusquà ce que la goupille sen-

6. Libérer la goupille de blocage de la poignée, et

gage dans le trou situé à lextrémité de la poignée

(figure 8).

7. En se servant du dispositif de chargement

comme point darticulation, tirer vers le haut sur la

poignée, jusquà ce que la machine bascule et se

mette en position horizontale sur le plateau du

véhicule (figure 9).

poussant sur sa base. Elle glissera le long du

dispositif de chargement jusquà ce que les roues

arrière reposent sur le plateau. On peut alors

déplacer la machine en la faisant rouler sur ses

roues arrière et roulettes supérieures.

en sassurant que sa goupille de blocage sen-

gage dans le trou qui lui destiné.

8. Déplacer la machine vers lavant du plateau en

9. Remettre la poignée en position de rangement,

RECHARGE DES BATTERIES

Charger les batteries à la fin de chaque quart de

travail, ou dès quelles se déchargent.

Charger les batteries dans un endroit bien

ventilé.

Ne pas charger les batteries lorsque la plate-

forme de travail est dans une zone contenant

des sources détincelles ou de flammes.

Le fait de ne pas recharger immédiatement

les batteries une fois quelles sont à plat les

endommagera de façon permanente.

Tenir le chargeur de batteries au sec.

des batteries

po), ajouter de

8

/

3

Fiche du caisson

chargeur

Commande du

Figure 6 : Caisson des batteries

leau distillée propre seulement.

volts.

1,5 mm² (calibre 12) au moins, dune longueur ne

dépassant pas 15 m (50 pi).

Brancher lautre extrémité de la rallonge à une

prise électrique dune tension et dune fréquence

appropriées.

normale « Conventional ». Lampèremètre du

chargeur devrait afficher lintensité de la charge.

gées, le chargeur se met automatiquement hors

5. Lorsque les batteries sont complètement rechar-

circuit. Débrancher le câble de rallonge.

Chargeur

lélectrolyte ne recouvre pas les plaques des

batteries dau moins 10 mm (

2. Régler le sélecteur de tension du chargeur sur 12

1. Vérifier le niveau délectrolyte des batteries. Si

3. Relier au chargeur une rallonge à conducteur de

4. Régler la commande du chargeur à la position